Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62 results about "Surface breakdown" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

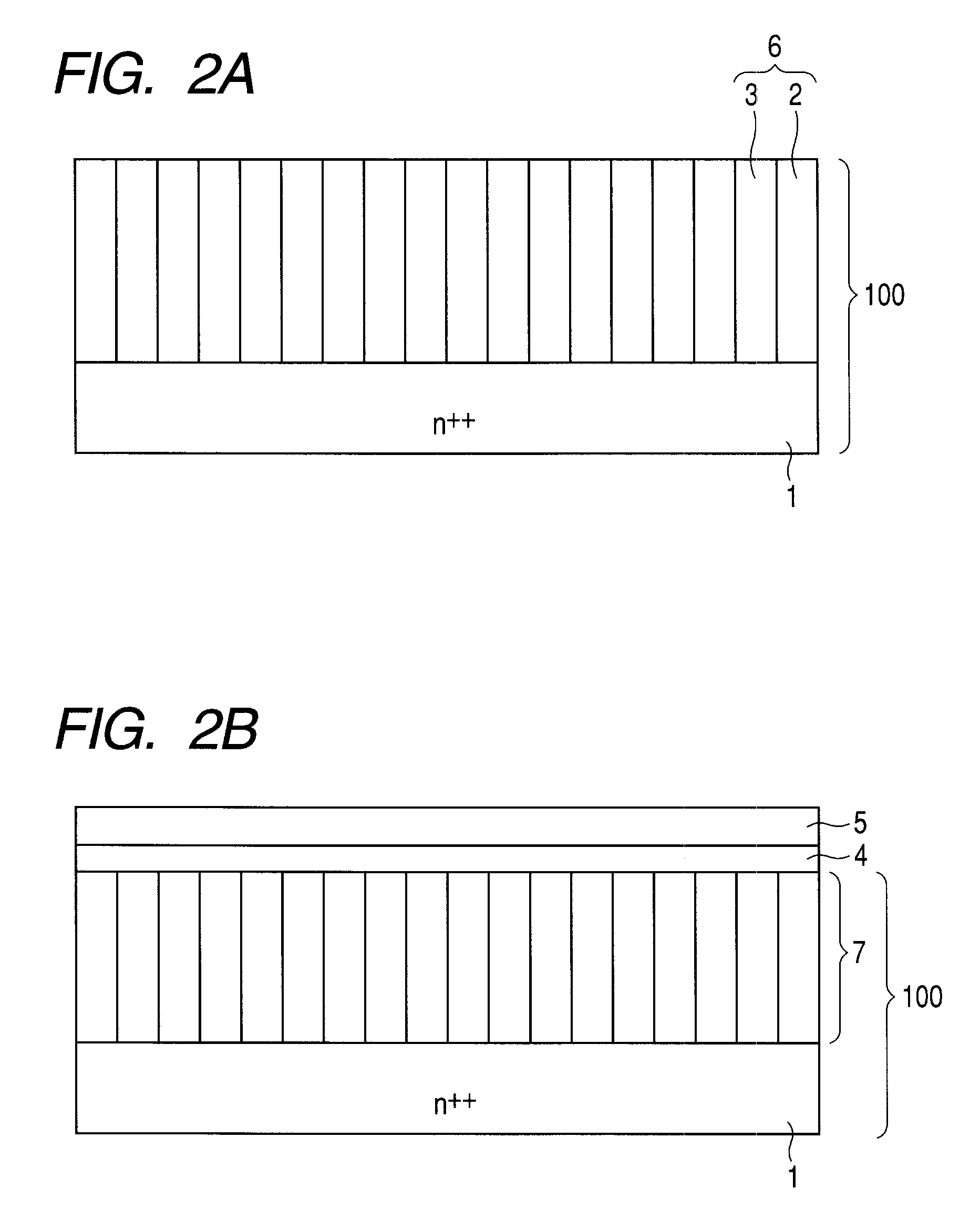

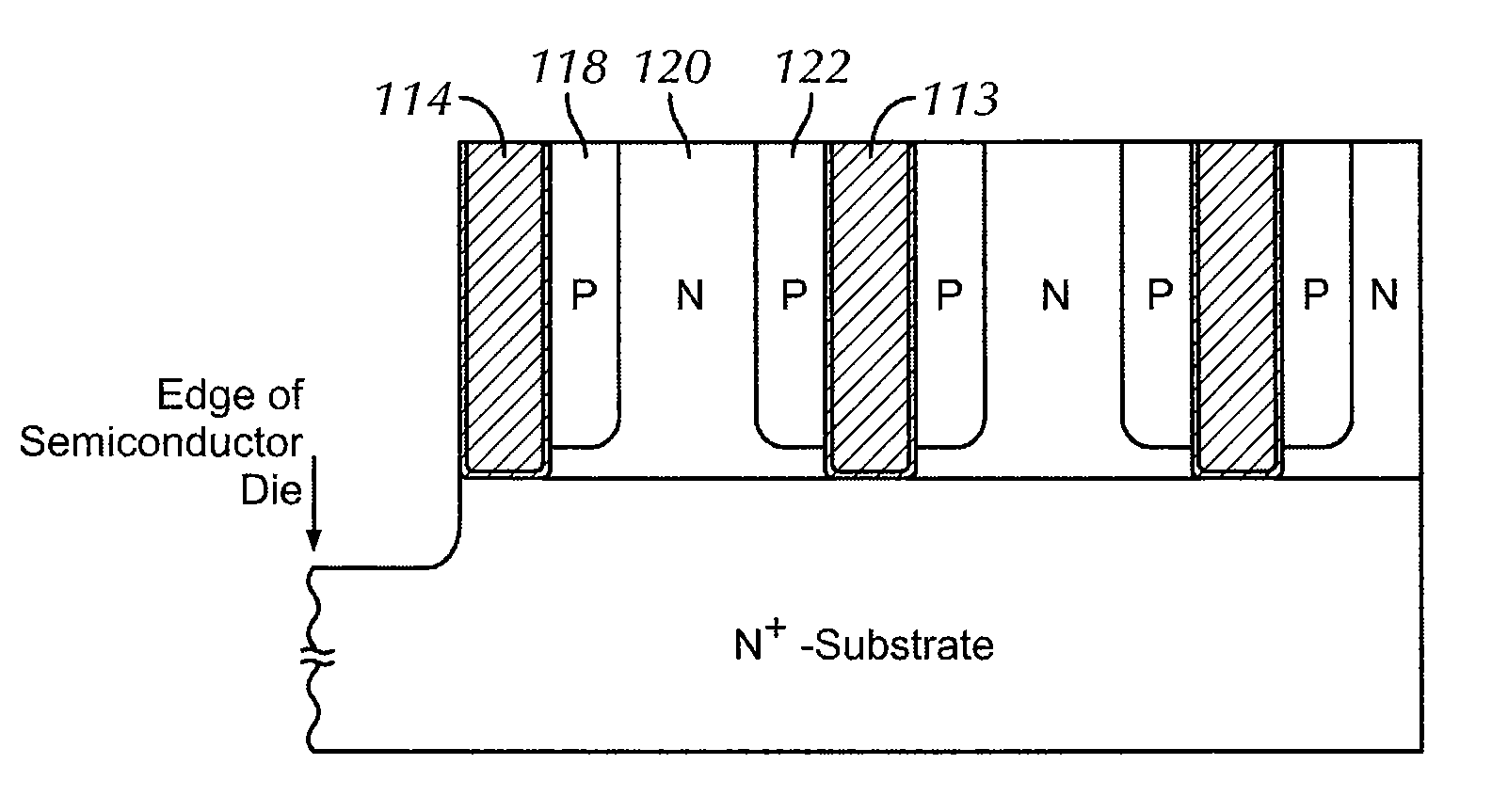

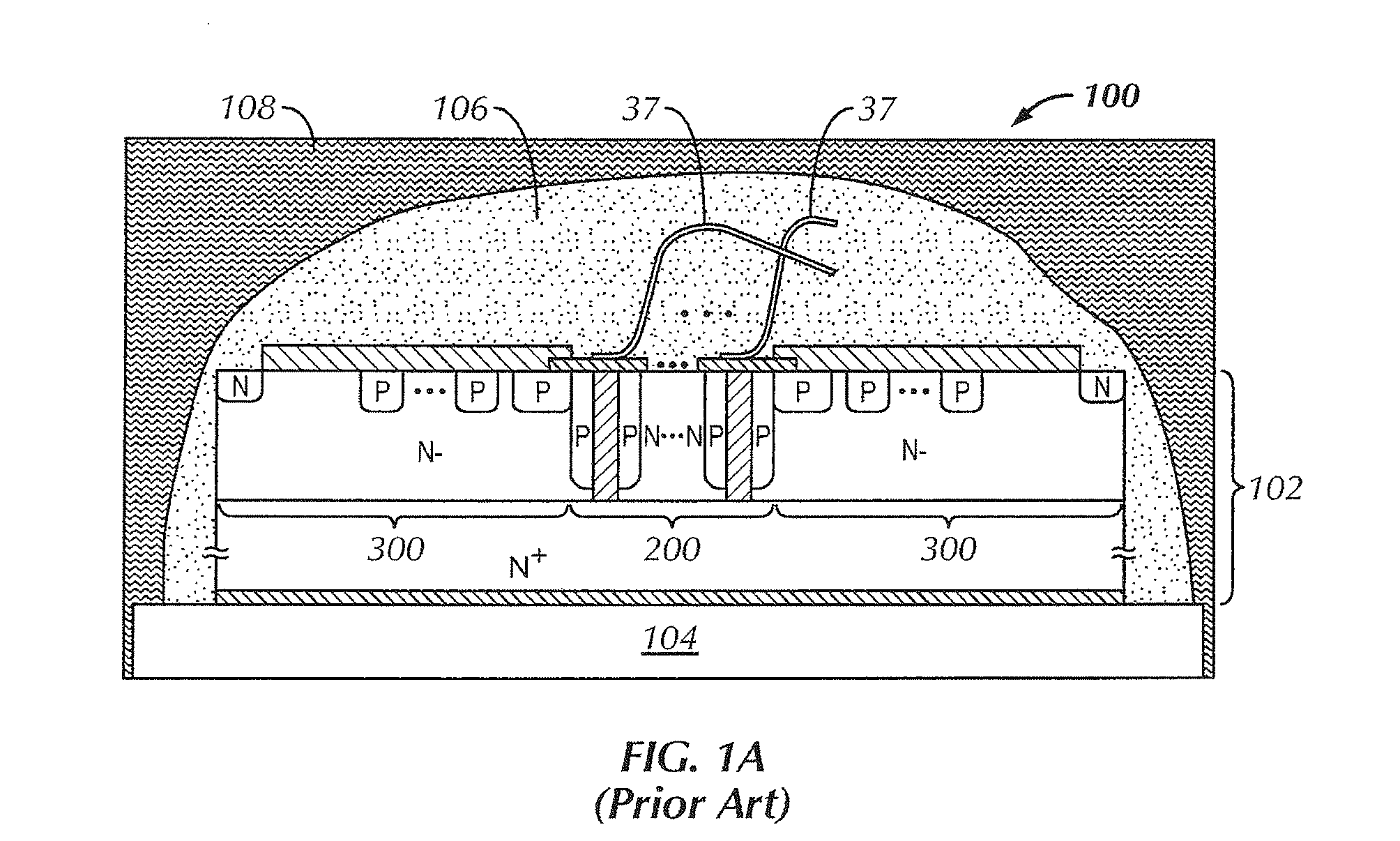

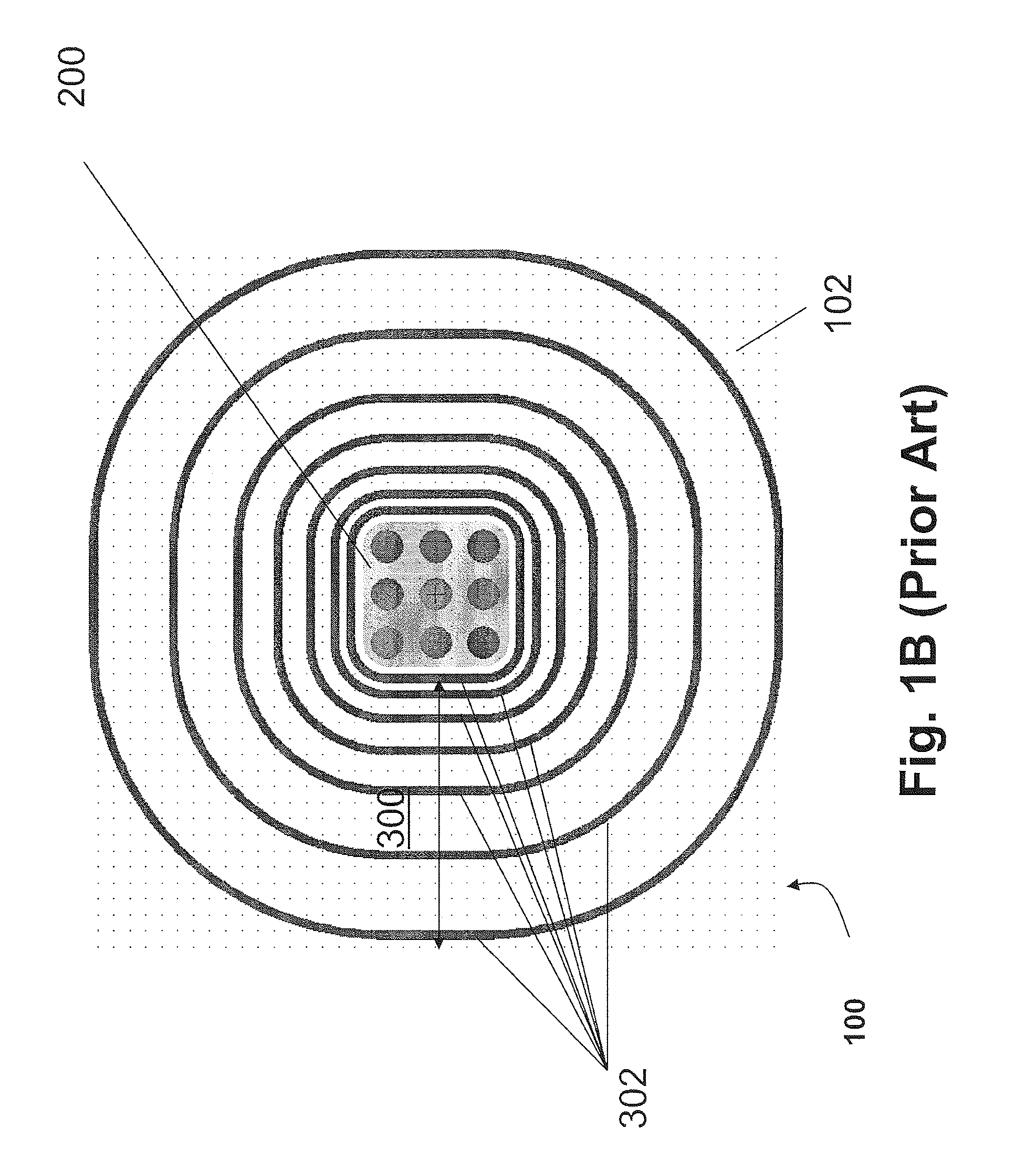

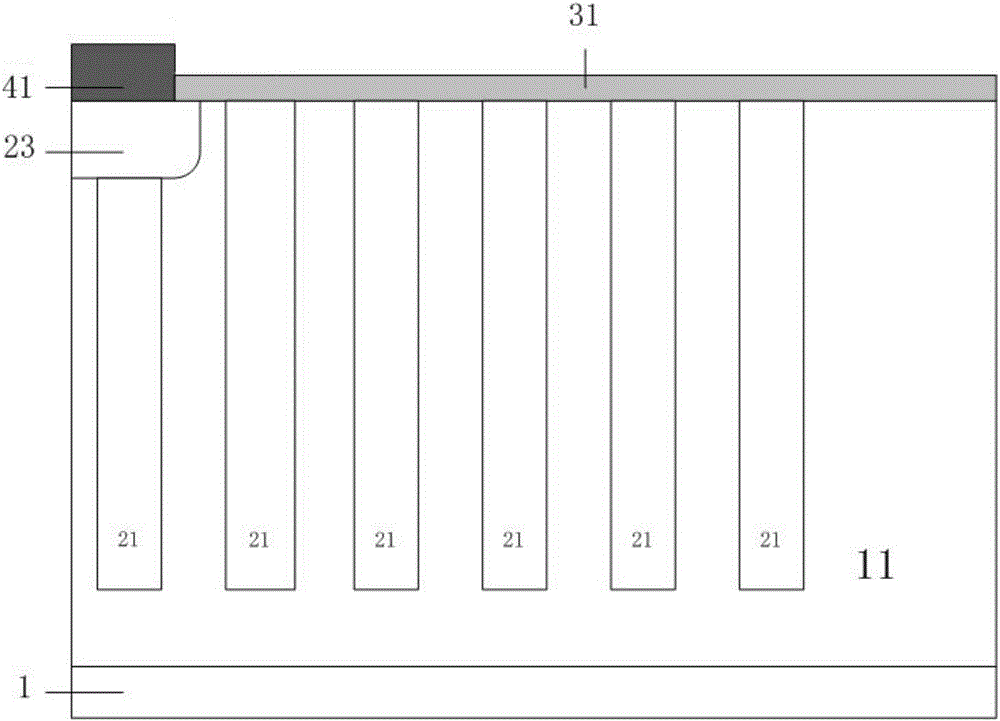

Superjunction device having a dielectric termination and methods for manufacturing the device

InactiveUS20090179298A1Avoid voltage breakdownSolid-state devicesSemiconductor/solid-state device manufacturingDielectricDevice material

A superjunction semiconductor device is provided having at least one column of a first conductivity type and at least one column of a second conductivity type extending from a first main surface of a semiconductor substrate toward a second main surface of the semiconductor substrate opposed to the first main surface. The at least one column of the second conductivity type has a first sidewall surface proximate the at least one column of the first conductivity type and a second sidewall surface opposed to the first sidewall surface. A termination structure is proximate the second sidewall surface of the at least one column of the second conductivity type. The termination structure includes a layer of dielectric of an effective thickness and consumes about 0% of the surface area of the first main surface. Methods for manufacturing superjunction semiconductor devices and for preventing surface breakdown are also provided.

Owner:ICEMOS TECH

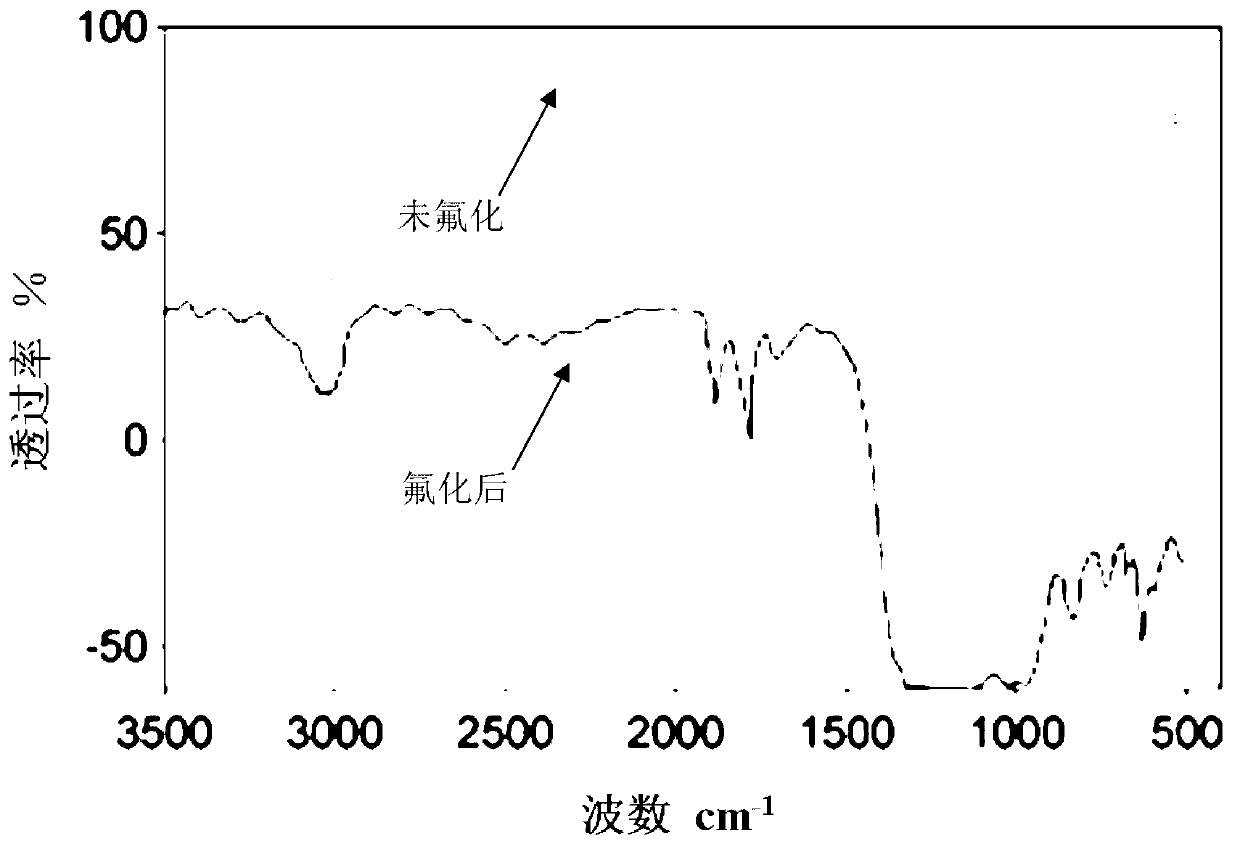

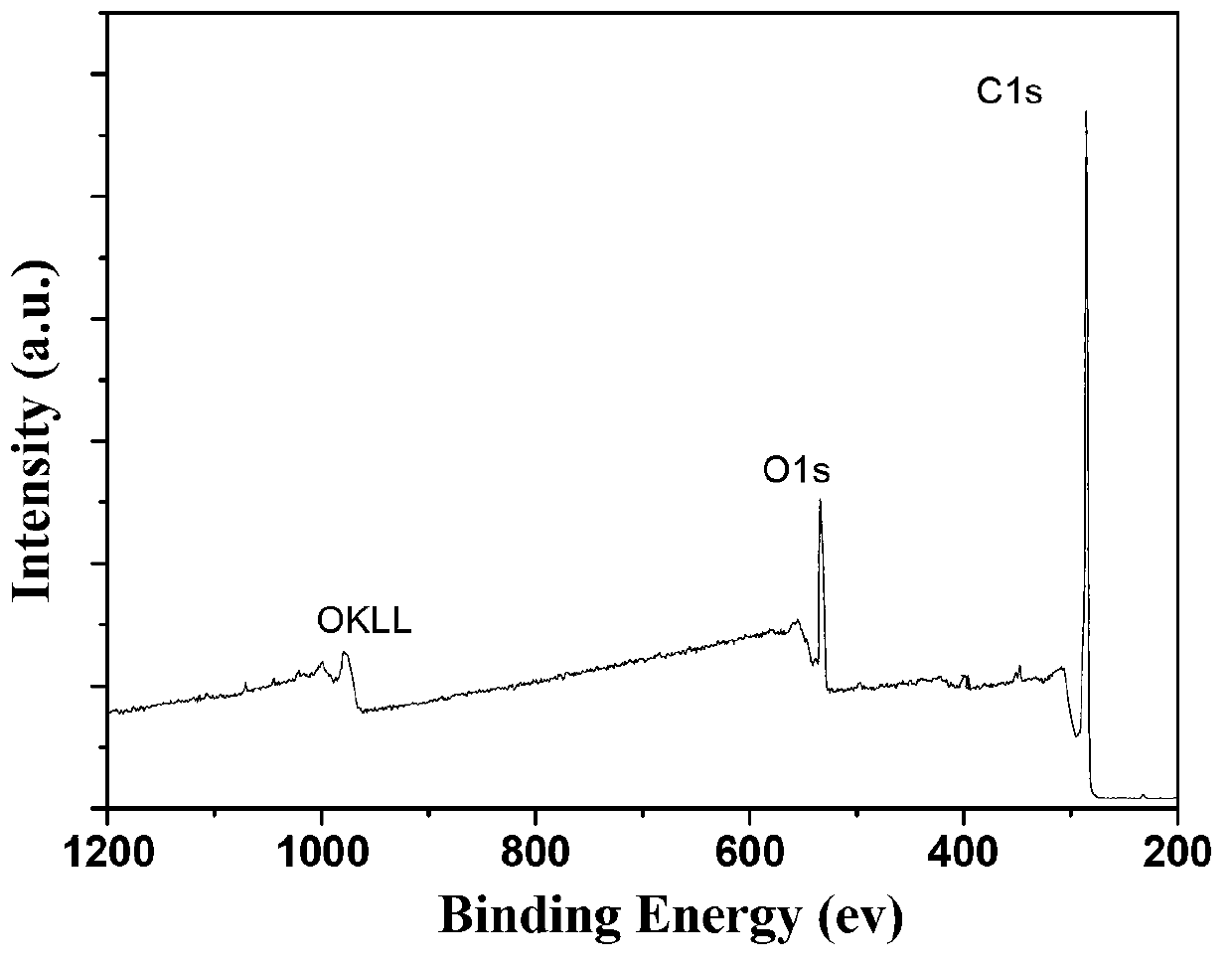

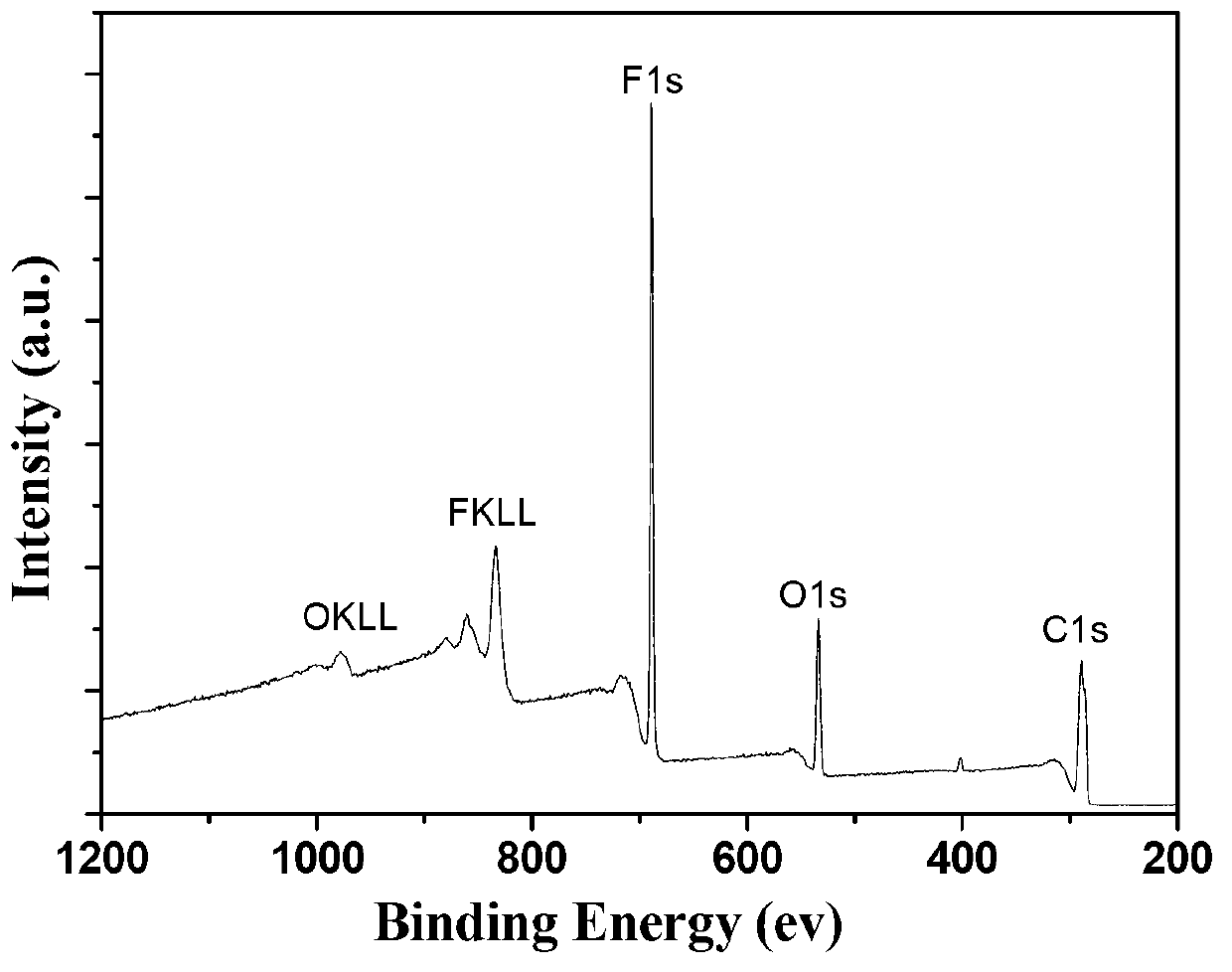

Method for improving flashover performance of vacuum edge surface of polymer insulator

The invention belongs to the technical field of high-voltage electrical insulating material, and particularly relates to an effective method for improving the flashover performance of a vacuum edge surface of a polymer insulator. The method comprises the step of enabling the polymer insulator to be contacted with fluorine-containing gas with a certain proportion at a certain temperature for generating fluoridation to form a fluoride layer with a certain thickness on the surface of the polymer. The method has the characteristics that the fluoride layer is formed on the surface of the polymer such as polyethylene, polypropylene, nylon and the like by the fluoridation of the gas, so that the flashover performance of the vacuum edge surface of the insulator can be improved, the surface breakdown voltage of the insulator is increased, and the insulating strength of the surface of the fluorizated insulator is 1.2-1.6 times higher than that of the non-fluorizated insulator.

Owner:NORTHWEST INST OF NUCLEAR TECH

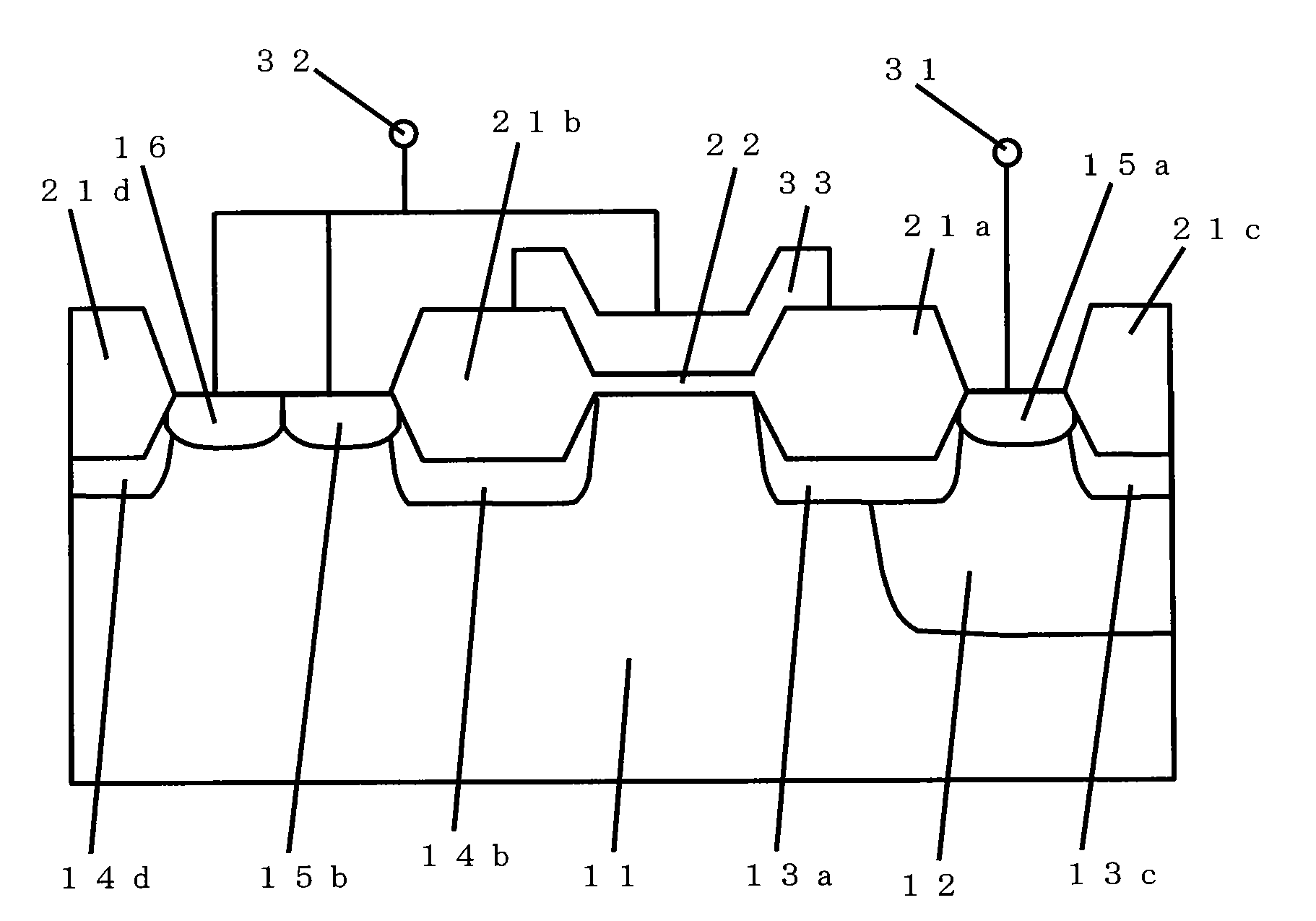

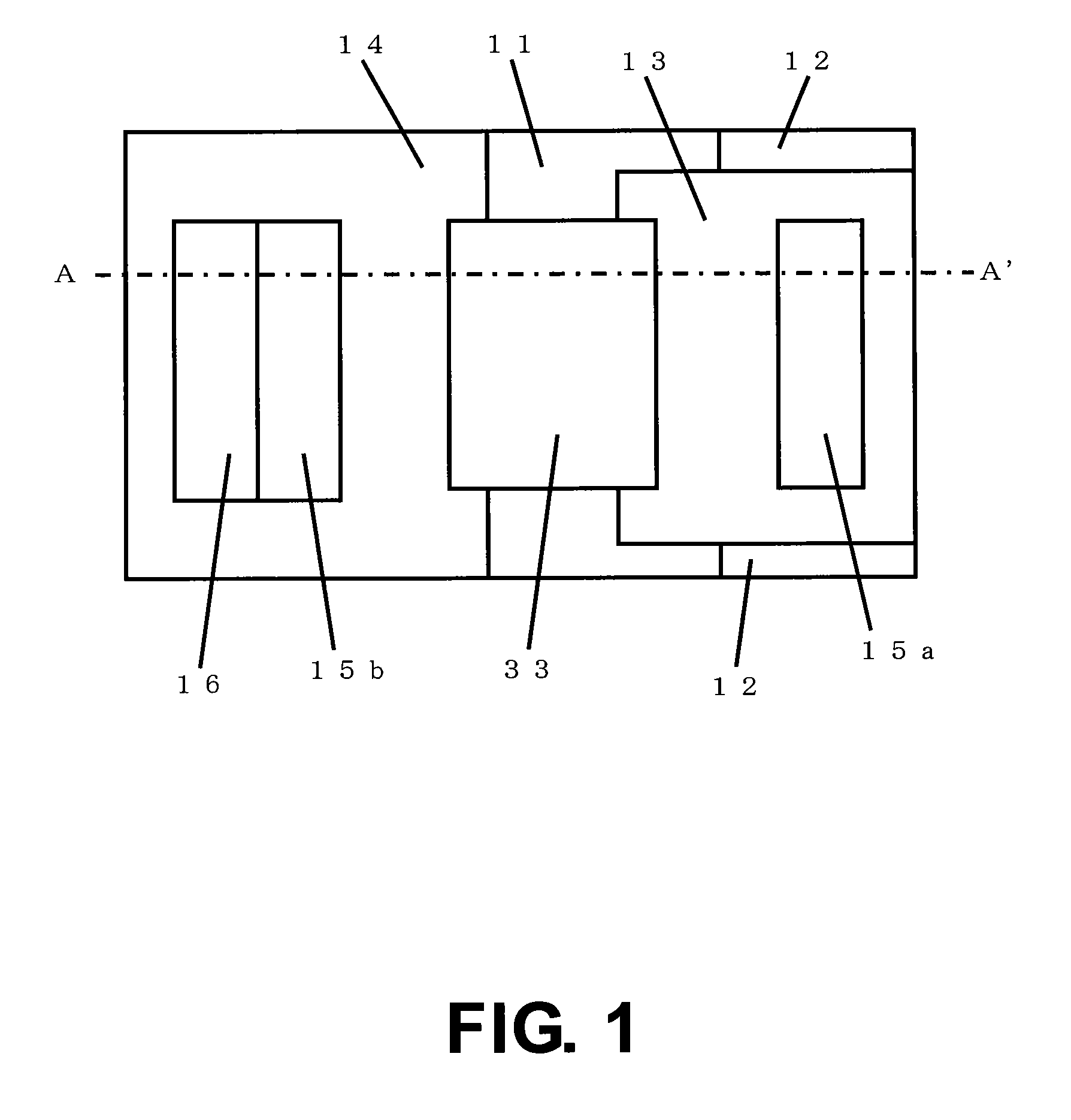

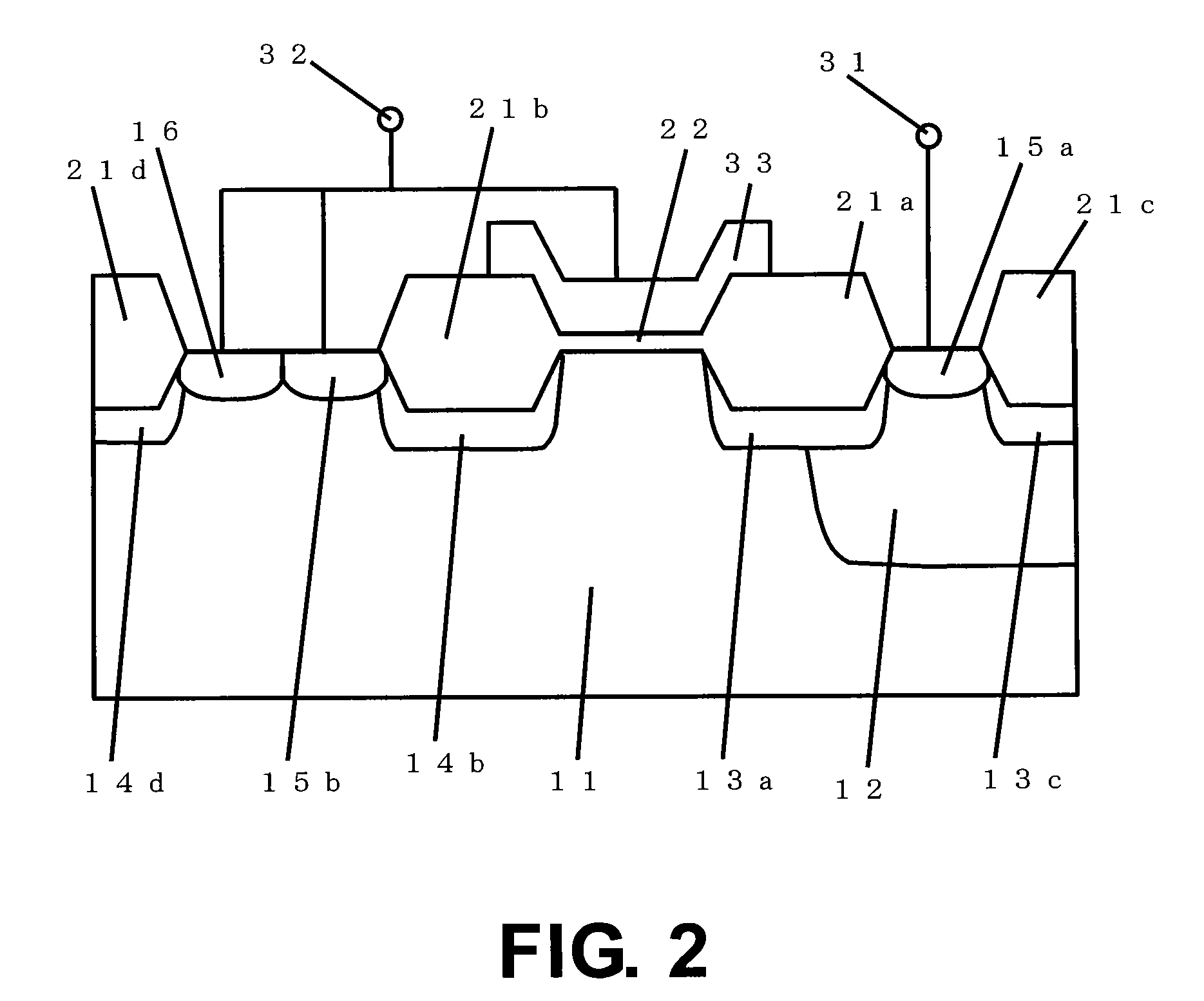

Semiconductor device and method of forming the same

A semiconductor device and a method of forming thereof have a semiconductor substrate, an active region, and an inclined trench formed around the outer periphery of the active region. The semiconductor substrate at least includes an n-type high impurity concentration layer inhibiting a depletion layer from spreading, an n-type low impurity concentration drift layer, and a p-type high impurity concentration layer forming a p-n main junction between the drift layer, which are arranged in this order. In the active region, an effective current flows in the direction of the thickness of the substrate. The inclined trench cuts the p-n main junction at a positive bevel angle from the semiconductor substrate surface on the side of the n-type high impurity concentration layer to penetrate through the substrate for separating it into chips. In the semiconductor device, along the sidewall of the inclined trench in the n-type drift layer, an n-type surface region is formed with an impurity concentration lower than that in the n-type drift layer. Thus provided semiconductor device can prevent the electric field strength therein from reaching the critical electric field strength that causes a breakdown in a surface breakdown voltage blocking structure prior to in the active region, as well as reducing the area ratio of the surface breakdown voltage blocking structure to the entire chip area.

Owner:FUJI ELECTRIC HLDG CO LTD

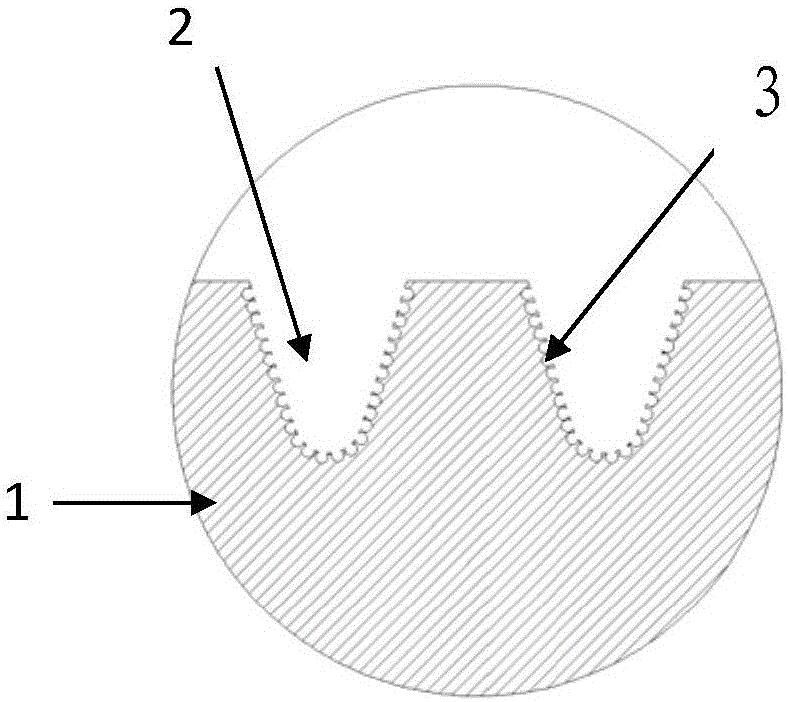

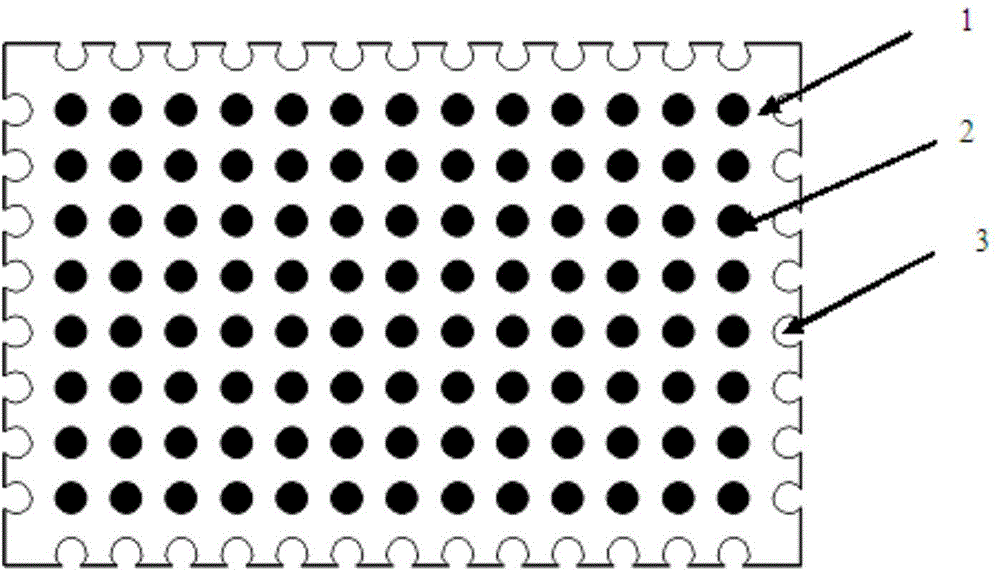

Insulator possessing hole microgroove texturing surface and manufacturing method thereof

The invention discloses an insulator which possesses a hole microgroove texturing surface and is applied to the high voltage insulating material technology field and a manufacturing method thereof. In the prior art, a surface breakdown voltage resistance ability is poor; reliability is not high and repeatability is poor, which is difficult to satisfy a vacuum insulation requirement of a high voltage apparatus; and there are other technical problems. By using the insulator and the method of the invention, the above problems are mainly solved. The insulator comprises an insulator body. The insulator body is made of a polymer material and a surface is woven with periodically parallel V-shaped microgroove arrays. Microgroove surfaces are uniformly distributed with holes with a micron order size. The microgrooves are etched by a laser. And the holes are formed through ablation by the laser. The manufacturing method comprises the following steps of using laser grooving to etch the microgroove arrays on an insulator body surface; and using laser ablation so as to form the holes on the microgroove surfaces. The insulator and the method can be applied to the vacuum high-voltage insulation device field and the high-voltage insulation fields under other environments.

Owner:NORTHWEST INST OF NUCLEAR TECH

Microfabricated triggered vacuum switch

ActiveUS7714240B1Reduce surface cracksPrevent surfaceVacuum tubesBeam/ray focussing/reflecting arrangementsNiobiumCarbon nanotube

A microfabricated vacuum switch is disclosed which includes a substrate upon which an anode, cathode and trigger electrode are located. A cover is sealed over the substrate under vacuum to complete the vacuum switch. In some embodiments of the present invention, a metal cover can be used in place of the trigger electrode on the substrate. Materials used for the vacuum switch are compatible with high vacuum, relatively high temperature processing. These materials include molybdenum, niobium, copper, tungsten, aluminum and alloys thereof for the anode and cathode. Carbon in the form of graphitic carbon, a diamond-like material, or carbon nanotubes can be used in the trigger electrode. Channels can be optionally formed in the substrate to mitigate against surface breakdown.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

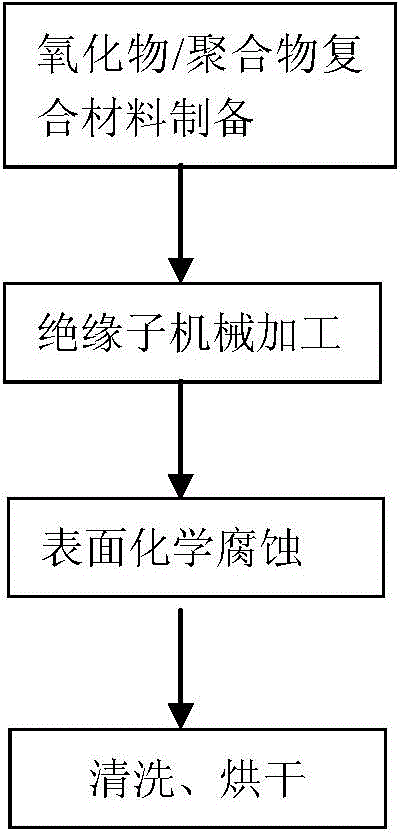

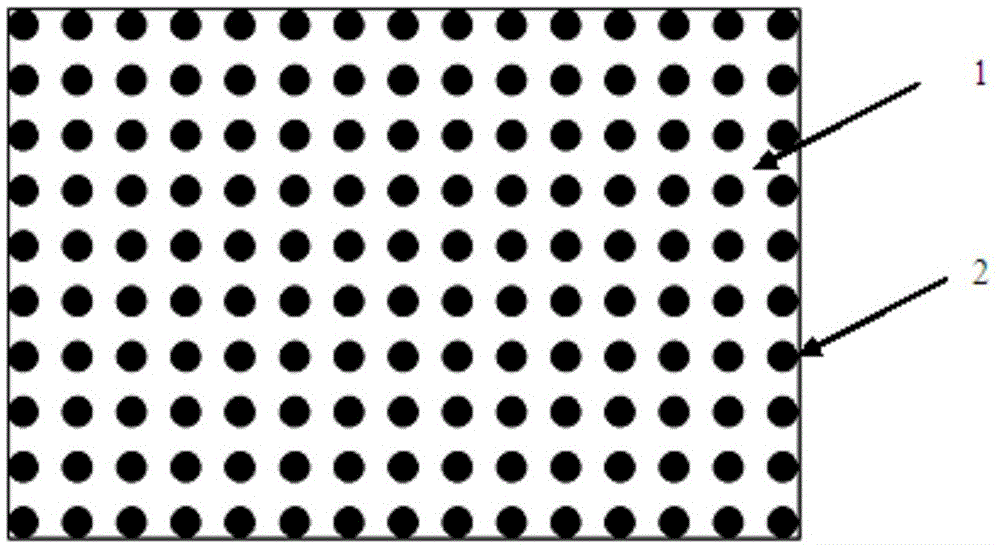

Polymer insulator with uniform hole distribution on surface and preparation method thereof

ActiveCN104900299AImprove mechanical propertiesUniform distribution of holesPlastic/resin/waxes insulatorsQuartz/glass/vitreous enamelsPolymer scienceGas phase

The invention relates to a polymer insulator with uniform hole distribution on the surface and a preparation method thereof. The method mainly includes the following steps: a composite material with uniform oxide particle distribution is obtained through a polymerization reaction by taking fumed silica as a thixotropic agent and oxide particles ranging from tens of nanometers to several microns as a surface pore-forming agent in polymer monomer solution; and after the composite material is machined into a polymer insulator, the oxide particles on the surface are etched and removed by a chemical etching method to obtain a polymer insulator with uniform hole distribution on the surface. By adjusting the size and mass ratio of the oxide particles, control on the hole size and hole density distribution on the surface of the polymer insulation material is realized, the vacuum surface flashover characteristic of the insulator is improved, and the surface breakdown voltage of the insulator is improved. The vacuum surface flashover field strength of an insulator with a special surface structure is improved by 20-50% compared with a pure polymer insulator.

Owner:NORTHWEST INST OF NUCLEAR TECH

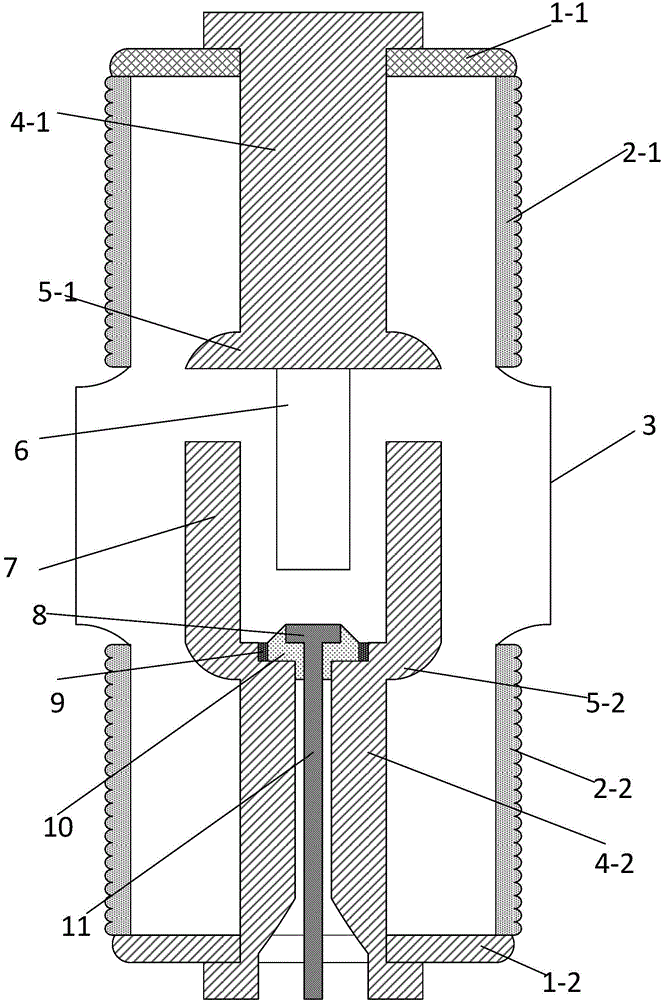

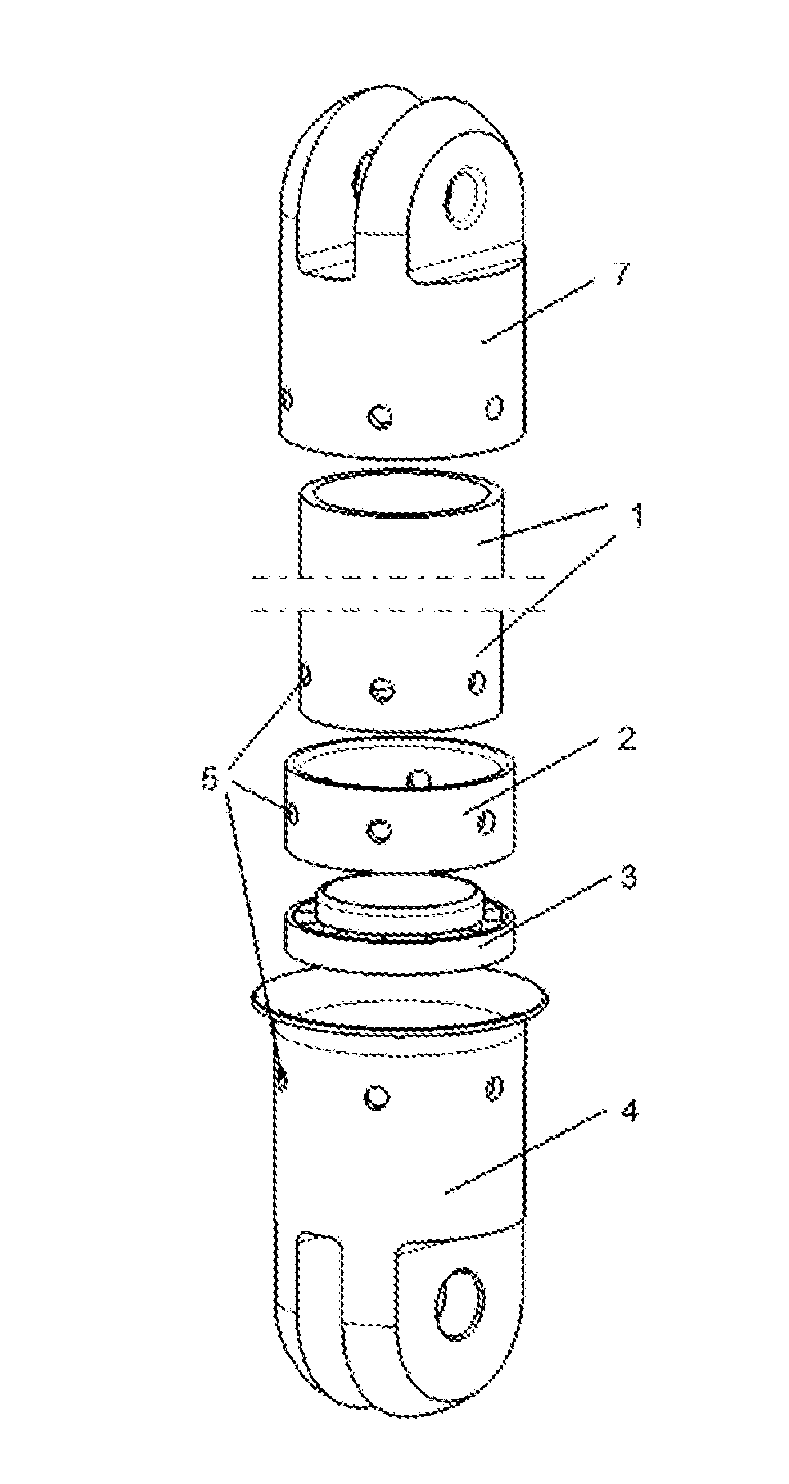

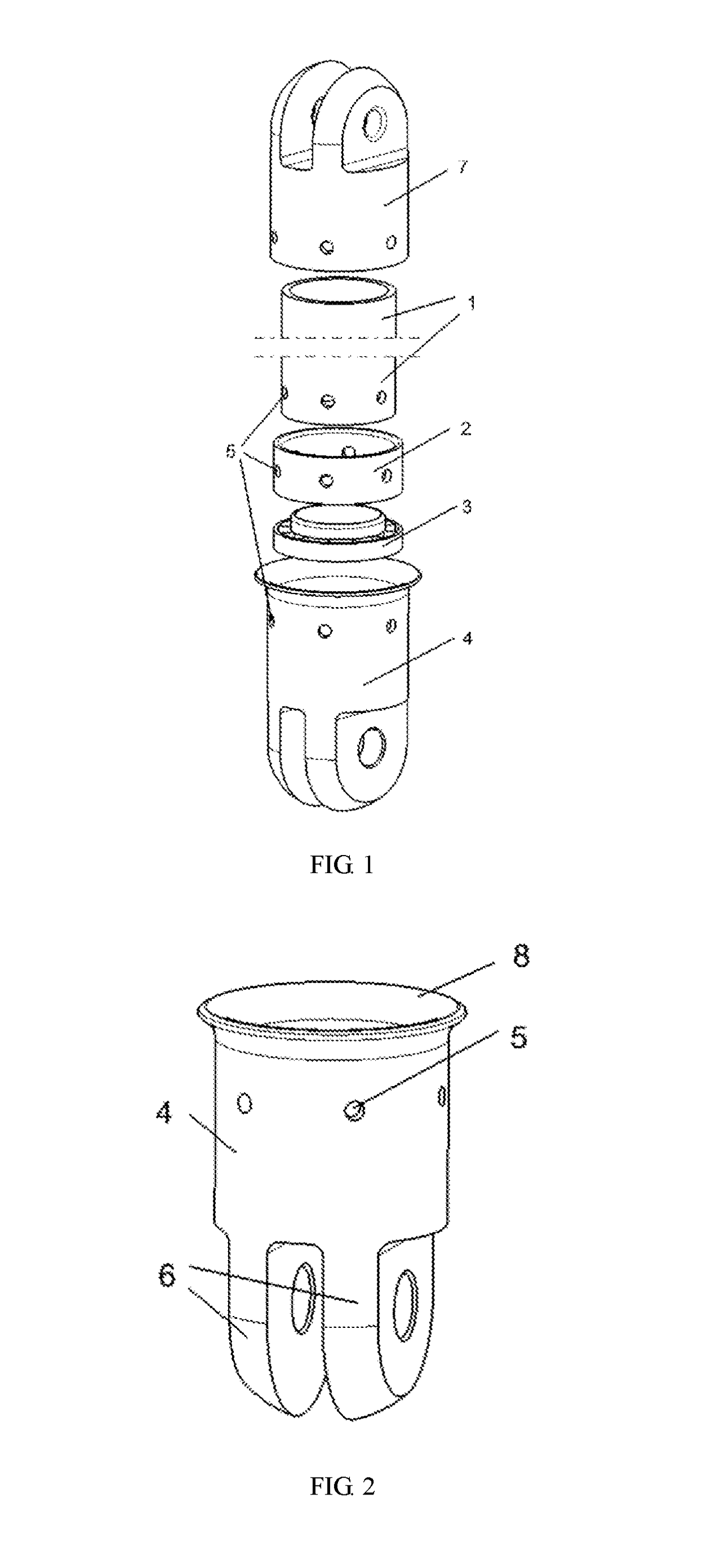

Surface-breakdown-type vacuum switch trigger electrode

ActiveCN103296579AExtend your lifeReduce splashSpark gaps with auxillary triggeringHigh-tension/heavy-dress switchesLow voltageSurface breakdown

The invention discloses a surface-breakdown-type vacuum switch trigger electrode comprising a low-voltage electrode, a molybdenum ferrule, a ceramic tube, a metal trigger electrode, a molybdenum ring, a semiconductor coating layer and a trigger electrode groove. The ceramic tube is arranged in a through hole between the low-voltage electrode and the center of the molybdenum ferrule and tightly contacts with the molybdenum ferrule to guarantee electrical insulation between the low-voltage electrode and the metal trigger electrode; the metal trigger electrode is arranged in a through hole at the centers of the ceramic tube and the molybdenum ring to guarantee equal potential of the molybdenum ring and the metal trigger electrode; the molybdenum ring is arranged on the upper portion of the ceramic tube; the semiconductor coating layer is arranged on the tube wall of the ceramic tube between the molybdenum ferrule and the molybdenum ring; the direction of the semiconductor coating layer is in accordance with the direction of a gap electric field applied by a high-voltage electrode; the trigger electrode groove is formed in the low-voltage electrode on the periphery of the molybdenum ferrule, the molybdenum ring and the semiconductor coating layer. The surface-breakdown-typed vacuum switch trigger electrode can solve problems of short service life, poor high temperature resistance and easiness in damage by ablation of the existing trigger electrodes.

Owner:武汉智瑞捷电气技术有限公司

Plasma generation device and method based on back corona creeping-surface breakdown of catalyst as well as application thereof

InactiveCN102958264ATightly boundEffective combinationDispersed particle separationPlasma techniqueElectricityLow voltage

The invention discloses a plasma generation device based on back corona creeping-surface breakdown of a catalyst. The plasma generation device comprises a plasma generator and a high-voltage power supply, wherein high-low-voltage electrode pairs consisting of corona electrodes and porous electrodes are arranged in the plasma generator; a high specific resistance catalyst layer is arranged between the high-low-voltage electrode pairs; and a high-voltage power supply is connected with the high-low-voltage electrode pairs. The invention further discloses a plasma generation method. According to the plasma generation method, basic conditions of a charge accumulated on the catalyst are provided by adopting a high specific resistance catalyst which has low possibility of releasing the charge; the charge generated by corona discharge forms back corona creeping-surface breakdown on the high specific resistance catalyst layer and generates a plasma on the creeping surface of the catalyst, so that the plasma is tightly combined with the catalyst.

Owner:ZHEJIANG UNIV

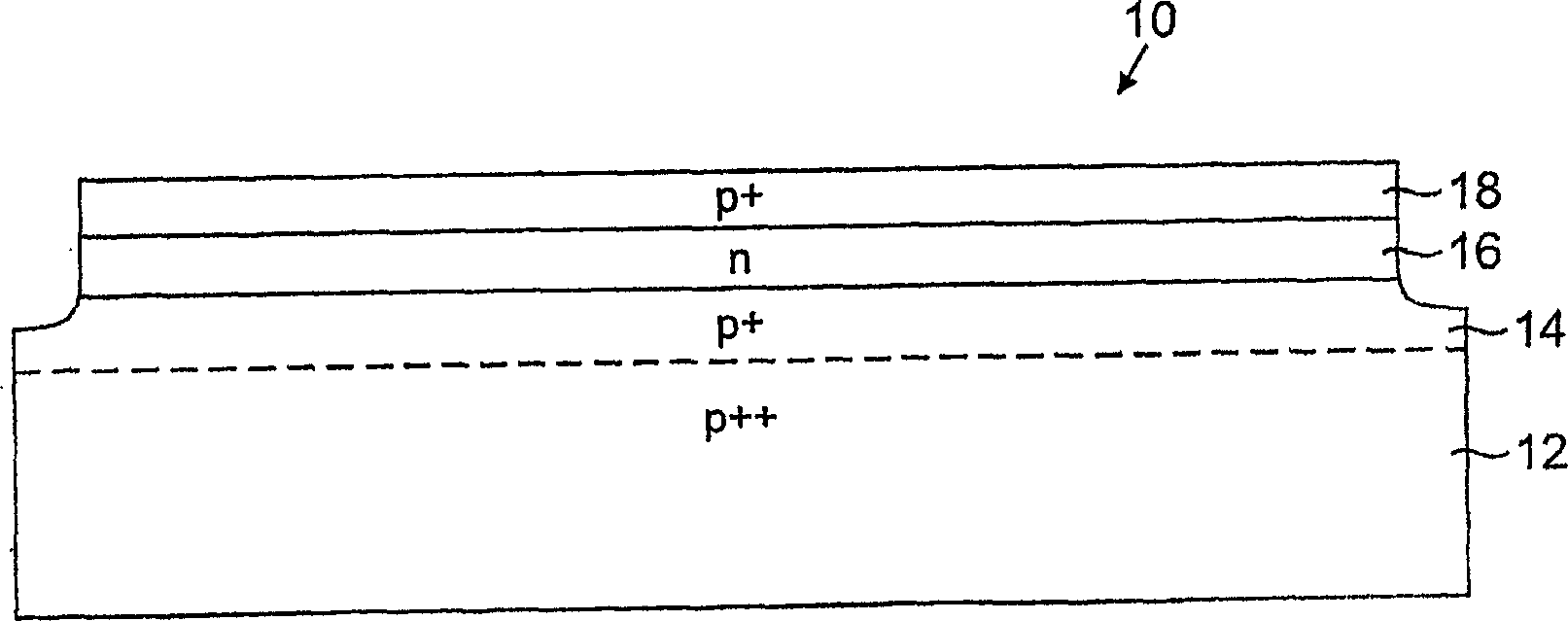

Low-voltage punch-through bi-directional transient-voltage suppression devices having surface breakdown protection and methods of making the same

InactiveCN1605127AReduce capacitanceHigh maximum doping concentrationTransistorSemiconductor/solid-state device detailsLow voltageDirectional antenna

Owner:GEN SEMICON

Superjunction device having a dielectric termination and methods for manufacturing the device

InactiveUS8159039B2Avoid voltage breakdownSolid-state devicesSemiconductor/solid-state device manufacturingDielectricSurface breakdown

A superjunction semiconductor device is provided having at least one column of a first conductivity type and at least one column of a second conductivity type extending from a first main surface of a semiconductor substrate toward a second main surface of the semiconductor substrate opposed to the first main surface. The at least one column of the second conductivity type has a first sidewall surface proximate the at least one column of the first conductivity type and a second sidewall surface opposed to the first sidewall surface. A termination structure is proximate the second sidewall surface of the at least one column of the second conductivity type. The termination structure includes a layer of dielectric of an effective thickness and consumes about 0% of the surface area of the first main surface. Methods for manufacturing superjunction semiconductor devices and for preventing surface breakdown are also provided.

Owner:ICEMOS TECH

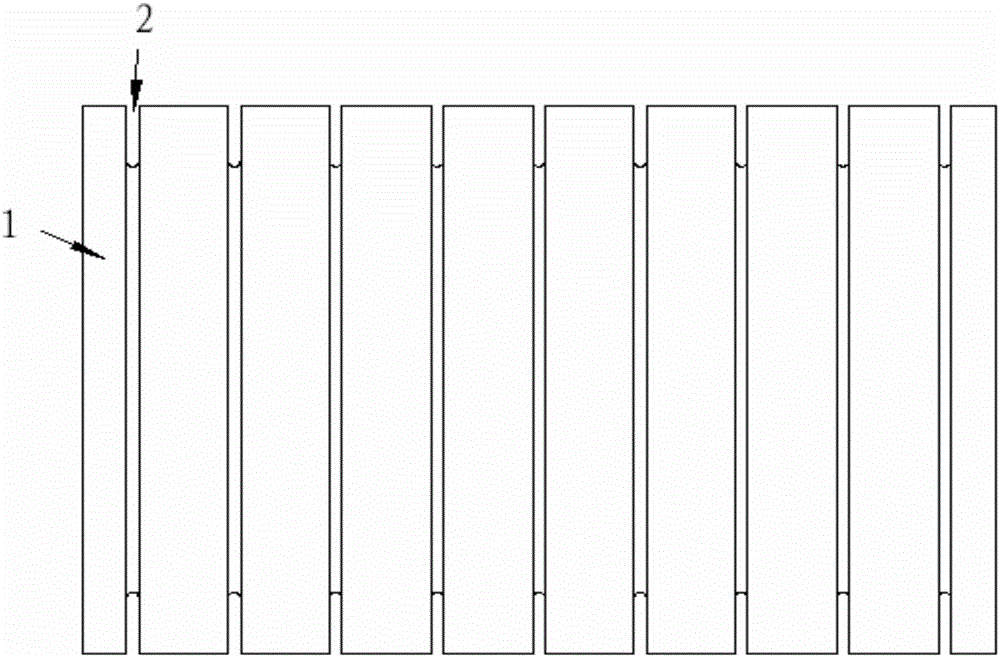

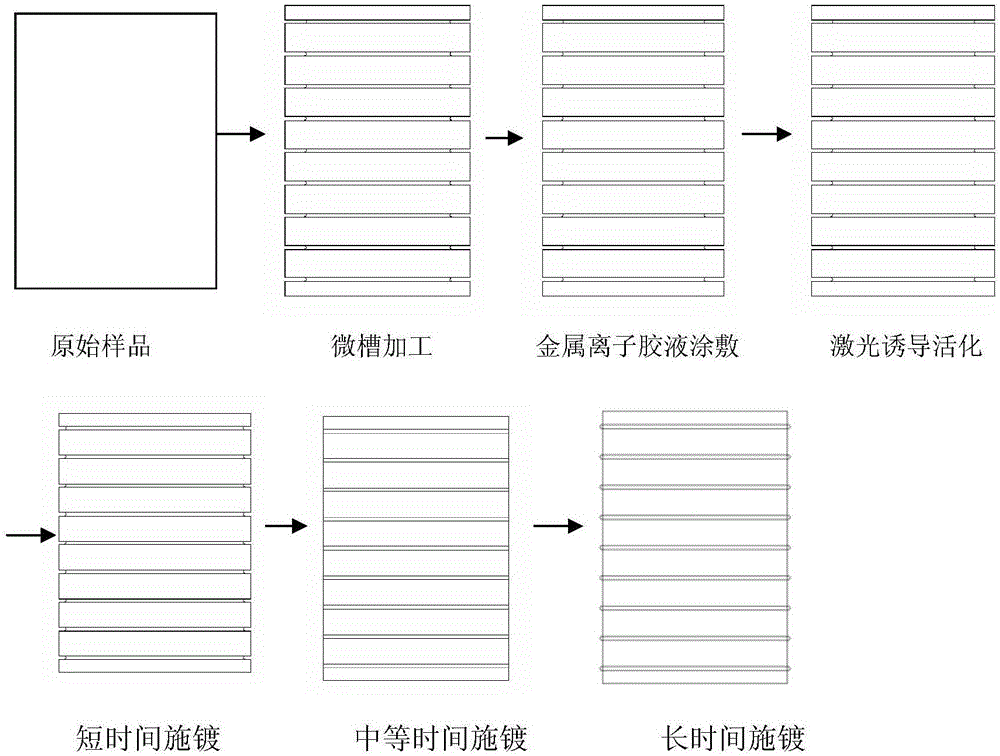

High-gradient surface micro-strip insulator and preparation method thereof

ActiveCN106782932AEasy to control growth heightLow emissivitySuspension/strain insulatorsHigh power lasersChemical plating

The invention discloses a high-gradient surface micro-strip insulator and a preparation method thereof, which are applied to the field of high-voltage insulating, and mainly solve the problems that a preparation process is complicated, the insulator reliability is poor, the surface breakdown voltage resistance is low, and the requirements on vacuum insulating of a high-voltage device is difficult to meet in the prior art. Periodic microgroove arrays are engraved in the surface of an insulator body; metal micro-strips which grow in situ are arranged in the microgrooves. The preparation method comprises the following steps: [1] machining the insulator body according to designed insulator outline dimensions; [2] engraving the periodic microgroove arrays in the surface of the insulator body; [3] preparing PdC12 / PVP / ethyl alcohol or AgNO3 / PVP / ethanol adhesive solution, and naturally drying the engraved insulator body after the engraved insulator body is soaked or coated; [4] forming metal particles on the surfaces of the microgrooves by adopting a laser induced activating method; [5] growing the metal micro-strips in the microgrooves in situ by adopting a chemical plating method. The high-gradient surface micro-strip insulator and the preparation method thereof can be applied to the field of insulating of sophisticated equipment, such as a high-power microwave technology, a high-power laser and a dielectric-wall accelerator.

Owner:NORTHWEST INST OF NUCLEAR TECH

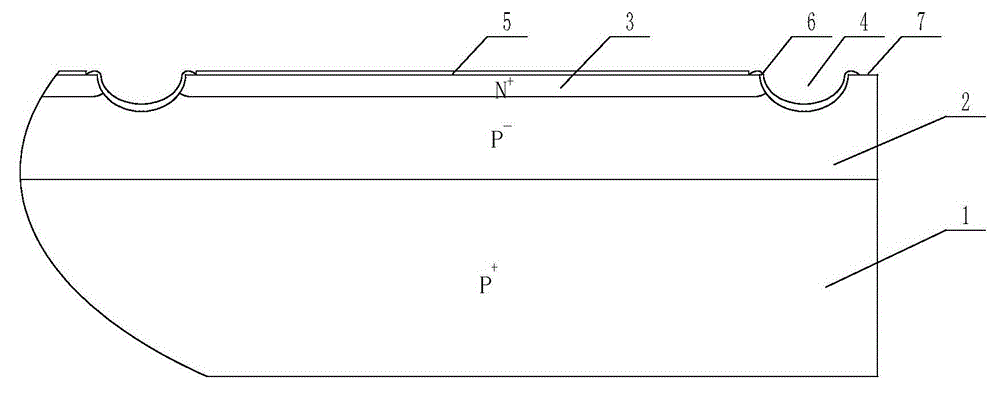

Transient voltage suppression diode array chip according to mesa trench isolation method and production technology thereof

ActiveCN104810281AWidth is easy to controlWidth limitSemiconductor/solid-state device manufacturingSemiconductor devicesCapacitanceManufacturing technology

The invention relates to a transient voltage suppression diode array chip according to a mesa trench isolation method and a manufacturing technology thereof. A method that a mesa isolation trench is manufactured on an N+ surface by adopting the mesa technology is adopted so that multiple transient suppression diodes can be thoroughly separated, surface breakdown can be changed into body breakdown and thus reliability of the diodes is increased; a method that P+ junctions are formed by coating a liquid boron source through deep junction diffusion is adopted so that an epitaxial wafer can be substituted for chip manufacturing, diffused junction depth is flat and uniform, and width of a substrate passive region is controllable without limitation of width of an epitaxial layer; a mesa protective layer is formed by adopting glass powder electrophoresis so that mechanical damage resistant capacity of the diode array can be enhanced and anti-surge capacity of the diode array can also be enhanced; and a glass burning method with chlorine is adopted so that width of a diode PN-junction depletion layer can be increased, junction capacitance can be reduced, surge voltage of the diodes is enabled to be rapidly clamped to a safe voltage range, and thus subsequent digital circuits can be protected from being damaged.

Owner:SUZHOU QILAN POWER ELECTRONICS

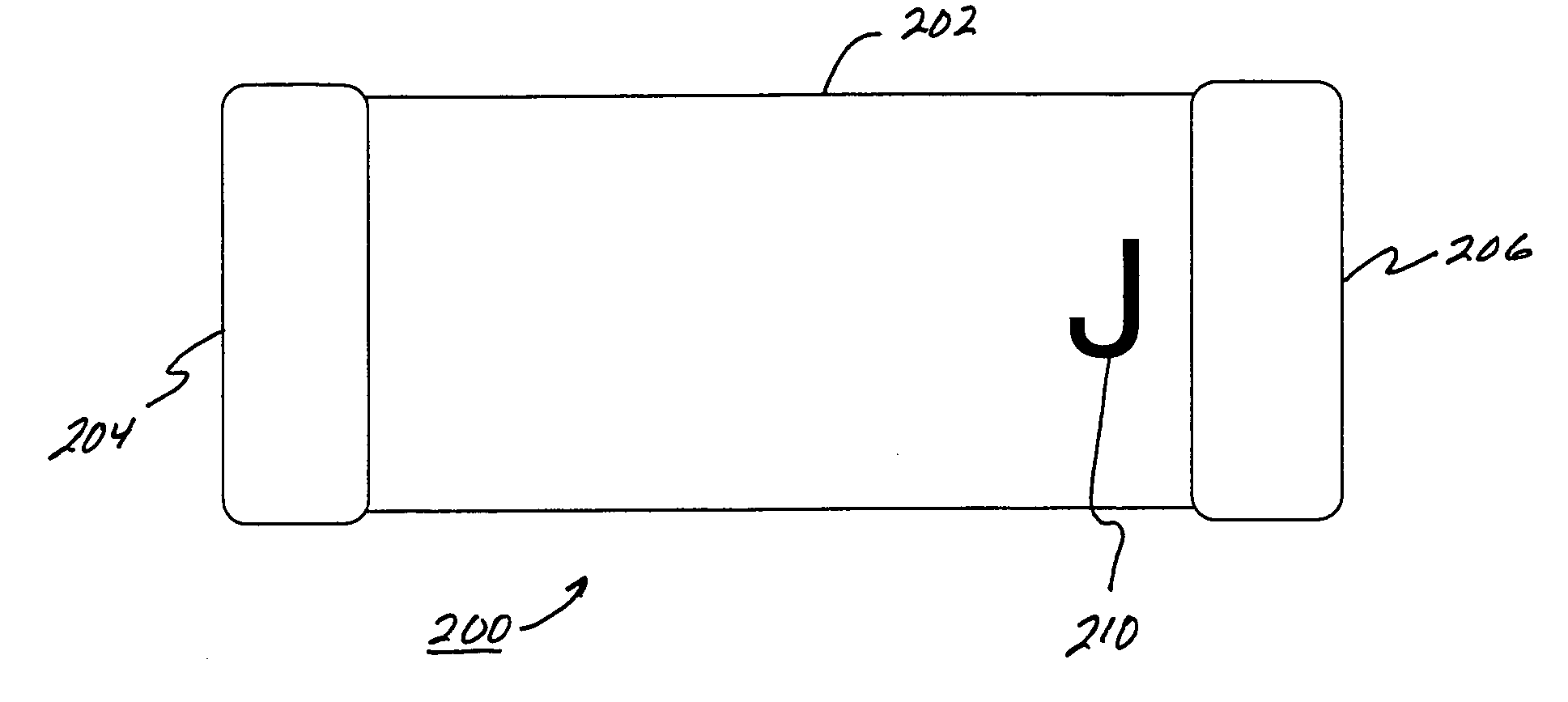

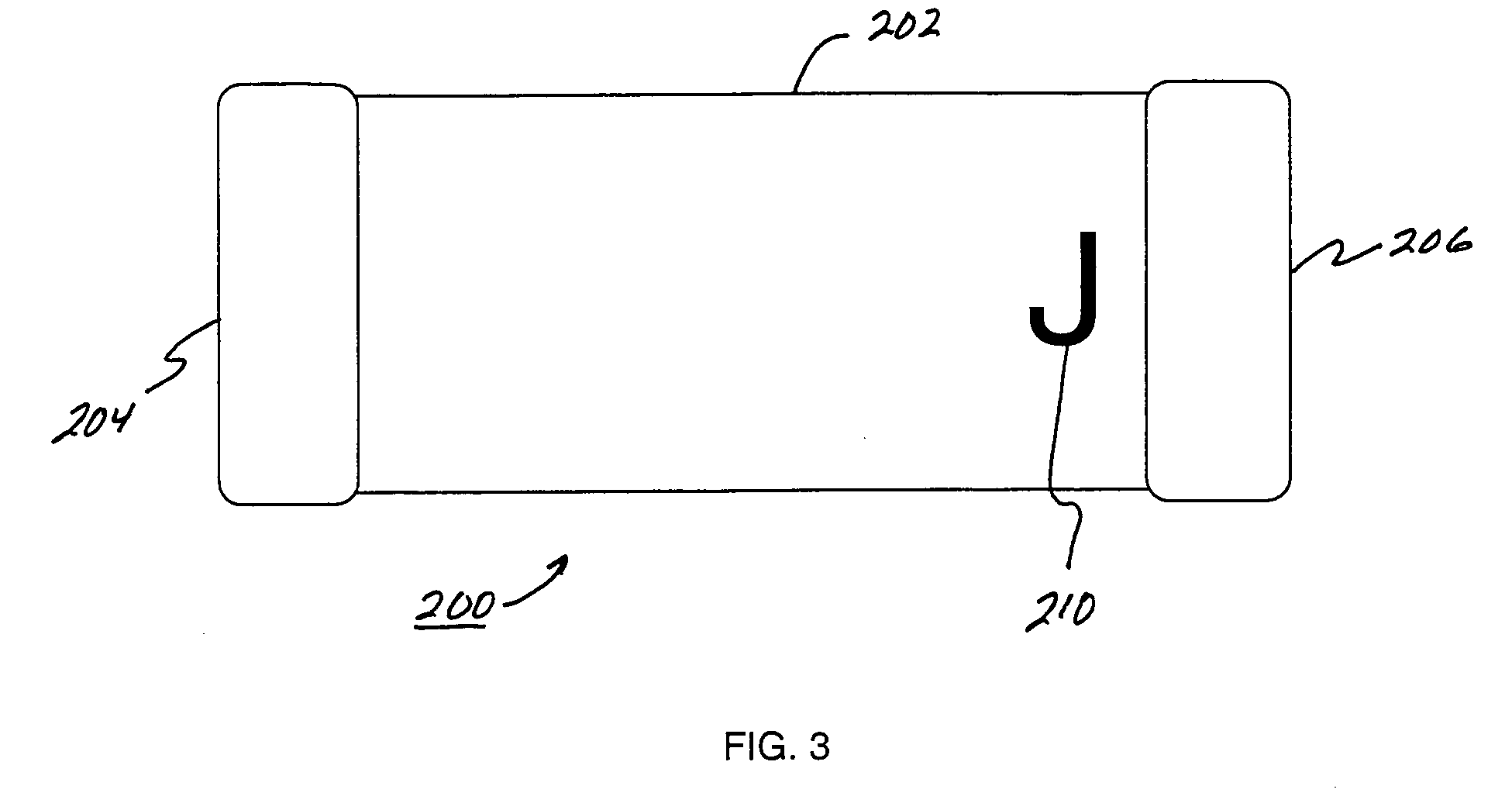

Capacitor having improved surface breakdown voltage performance and method for marking same

InactiveUS7667949B2Improved breakdown voltage performanceImprove capacitor performanceAnti-noise capacitorsFeed-through capacitorsSurface breakdownExact location

A capacitor having improved surface breakdown voltage performance and a method for applying laser marking to capacitors which does not reduce capacitor surface breakdown voltage, can be applied using existing laser marking technologies and apparatus, and which results in a mark that is legible and clear, is disclosed. In a first exemplary embodiment a capacitor includes a laser mark which is located near one of the capacitor terminals. The exact location is not critical as long as the mark does not make physical contact with the terminal. Conventional laser marking technologies and apparatus may be used to fix the mark in the new location. In a second embodiment the laser mark is oriented so that a flat portion of the mark is is oriented closest to the adjacent terminal.

Owner:MAXWELL JOHN

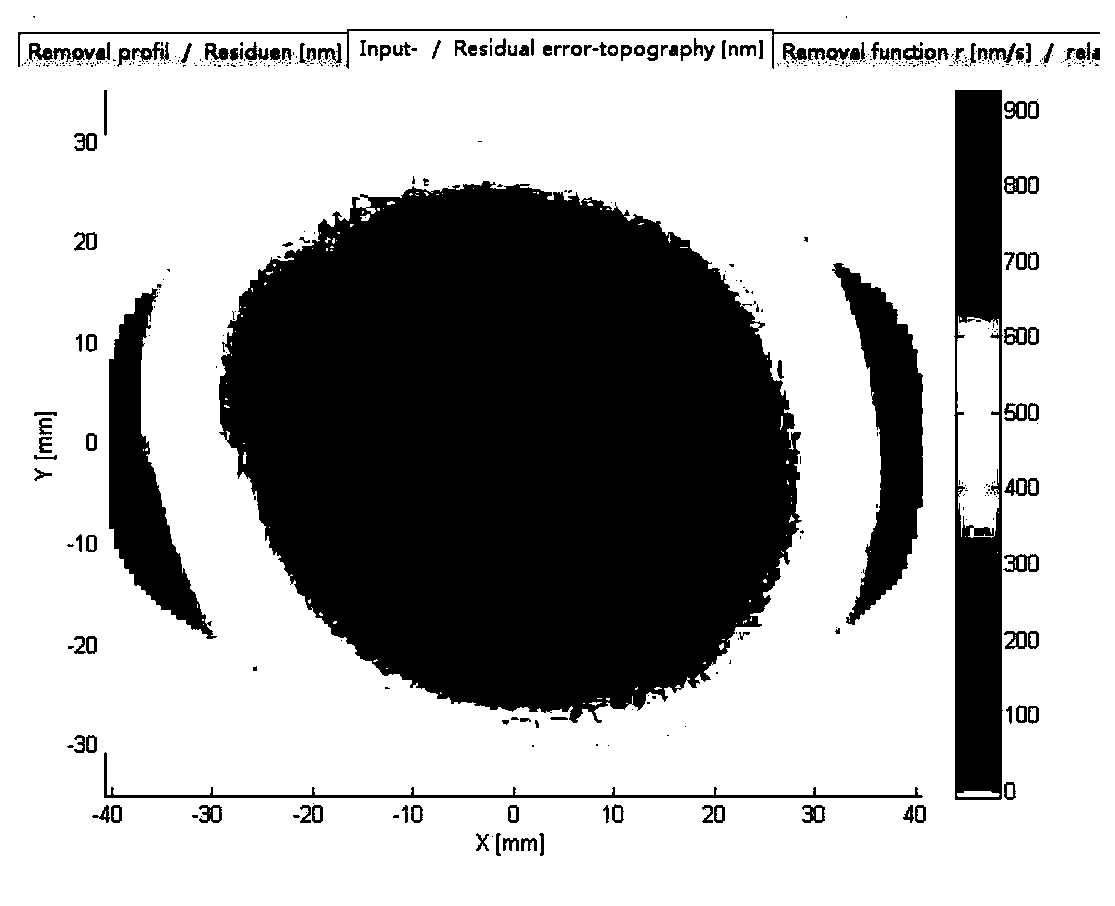

Method for polishing metal mirror by using diamond single-point vehicle auxiliary ion beam

The invention provides a method for polishing a metal mirror by using a diamond single-point vehicle auxiliary ion beam, and belongs to the technical field of optical processing. According to the method, a layer of uniform lower surface destruction layer with a certain thickness is formed on the surface of a metal mirror by using a diamond single-point vehicle, the mirror surface is polished by utilizing the ion beam, due to the fact that the material removal characteristic of the mirror surface with the specific lower surface destruction layer in the ion beam polishing process changes, the material removal rate of the ion beam polishing is improved, and meanwhile, the surface roughness of the metal mirror is not changed. The damage layer on the lower surface of the metal mirror changes the material removal characteristic of the metal material in the ion beam processing process, not only is the material easier to remove, but also the surface roughness of the metal mirror is kept unchanged.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

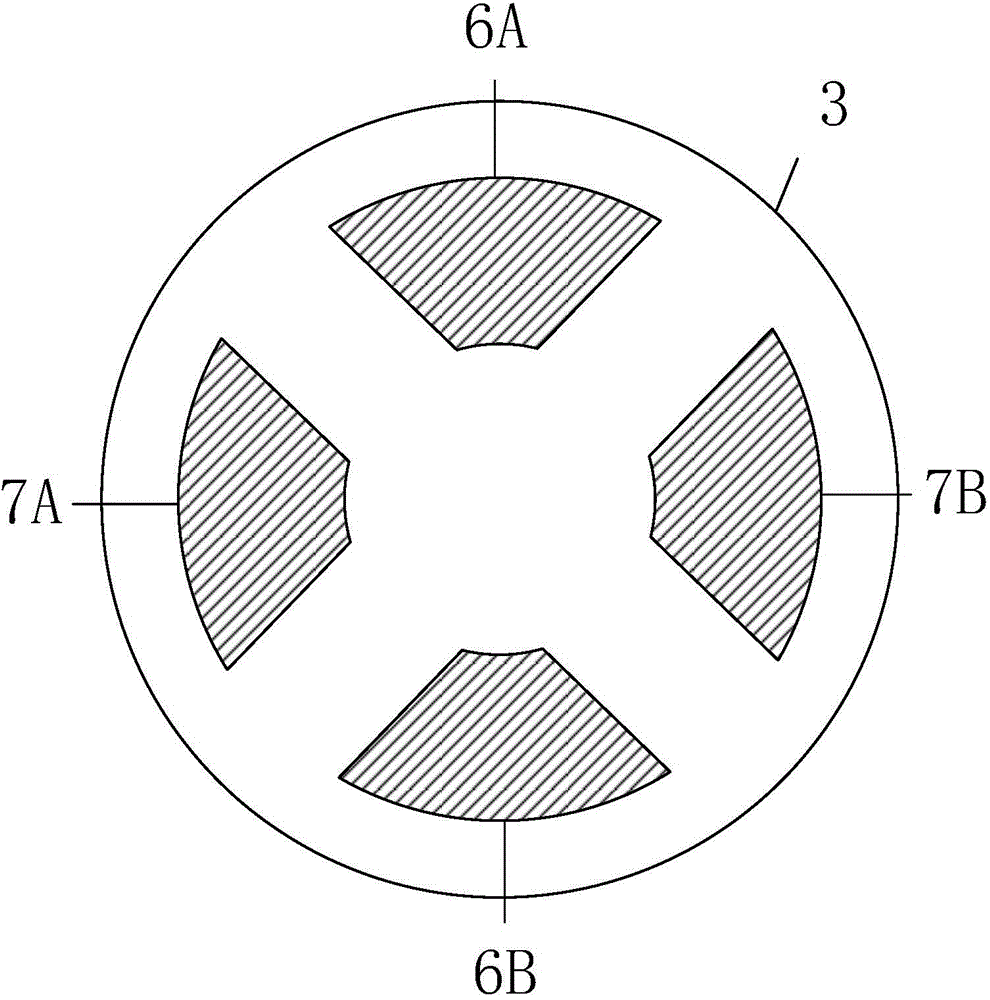

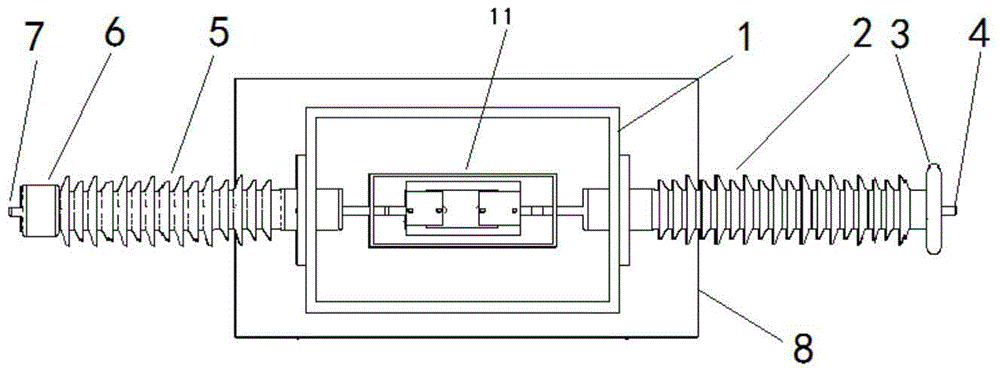

Surface breakdown type two-pair-rod electrode structural triggered vacuum switch

ActiveCN104617491AIncrease insulation distanceImprove the withstand voltage levelElectrical apparatusPower flowSurface breakdown

The invention discloses a surface breakdown type two-pair-rod electrode structural triggered vacuum switch. The triggered vacuum switch is of a three-section structure, comprising a corrugated ceramic housing at the upper section, another corrugated ceramic housing at the lower section, a metal shielding cover in the middle section, an upper electrode, a lower electrode, a triggering electrode, an upper electrode metal connecting rod, an upper electrode flange plate, a lower electrode metal connecting rod and a lower electrode flange plate; the upper electrode and the lower electrode are arranged in the metal shielding cover; the upper electrode flange plate is connected with the corrugated ceramic housing at the upper section; the lower electrode flange plate is connected with the corrugated ceramic housing at the lower section and forms a closed housing with the metal shielding layer; the upper electrode flange plate is connected to the corrugated ceramic housing at the upper section, and the lower electrode flange plate is connected to the corrugated ceramic housing at the lower section, so as to effectively increase the creepage distance between the upper electrode flange plate and the lower electrode flange plate. The triggered vacuum switch is high in working voltage, large in arcing area, high in transfer coulomb during conducting, long in service life under large current, uniform in electrode ablation degree, and high in power frequency withstand voltage after quenching of arc.

Owner:HUAZHONG UNIV OF SCI & TECH

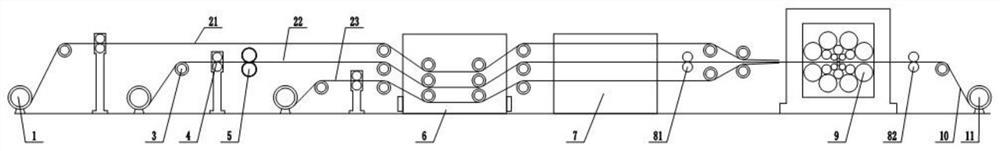

Method of adopting multi-roll mill to roll three-layer composite extremely thin belt

ActiveCN111702008AIncreasing the thicknessHigh bonding strengthLamination ancillary operationsLaminationBond interfaceInter layer

The invention discloses a method of adopting a multi-roll mill to roll a three-layer composite extremely thin belt. The method comprises the steps of applying tension, carrying out surface treatment on the extremely thin belt, carrying out roll-in treatment on a middle layer extremely thin belt, and carrying out washing, drying and rolling on the surface of the extremely thin belt. According to the method, an ultrasonic auxiliary polishing device is adopted to remove an oxide film on the surface of the extremely thin belt, so that surface breakdown holes and other damage to the extremely thinbelt caused by a conventional method is avoided; roll-in treatment is carried out on the middle layer extremely thin belt to prepare a micro-bulge to enable the micro-bulge to form strong stress at alocal position to strengthen mechanical occlusion during the rolling and recombination process, and in addition, the shape of a bonding interface is improved to be three-dimensional from the traditional two dimensions to improve the bonding strength of all metal surfaces; during the rolling process, pulse current is applied, based on the special structure of the micro-bulge, a tiny gap is createdbetween layers of the extremely thin belt, the point discharge effect is generated after electrifying, and efficient rolling bonding is realized under a smaller reduction rate. The method can realizehigh-strength bonding of the three-layer composite extremely thin belt under the smaller reduction rate and can be used for industrial volume production of composite belts.

Owner:TAIYUAN UNIV OF TECH

Semiconductor device

ActiveUS20100038706A1Well representedIncrease operating voltageTransistorSemiconductor/solid-state device detailsHigh concentrationStable state

Provided is an ESD protection element, in which: LOCOS oxide films are formed at both ends of a gate electrode, and a conductivity type of a diffusion layer formed below one of the LOCOS oxide films which is not located on a drain side is set to a p-type, to thereby limit an amount of a current flowing in a portion below a source-side n-type high concentration diffusion layer, the current being generated due to surface breakdown of a drain. With this structure, even in a case of protecting a high withstanding voltage element, it is possible to easily satisfy a function required for the ESD protection element, the function of being constantly in an off-state during a steady state, while operating, upon application of a surge or noise to a semiconductor device, so as not to reach a breakage of an internal element, discharging a generated large current, and then returning to the off-state again.

Owner:ABLIC INC

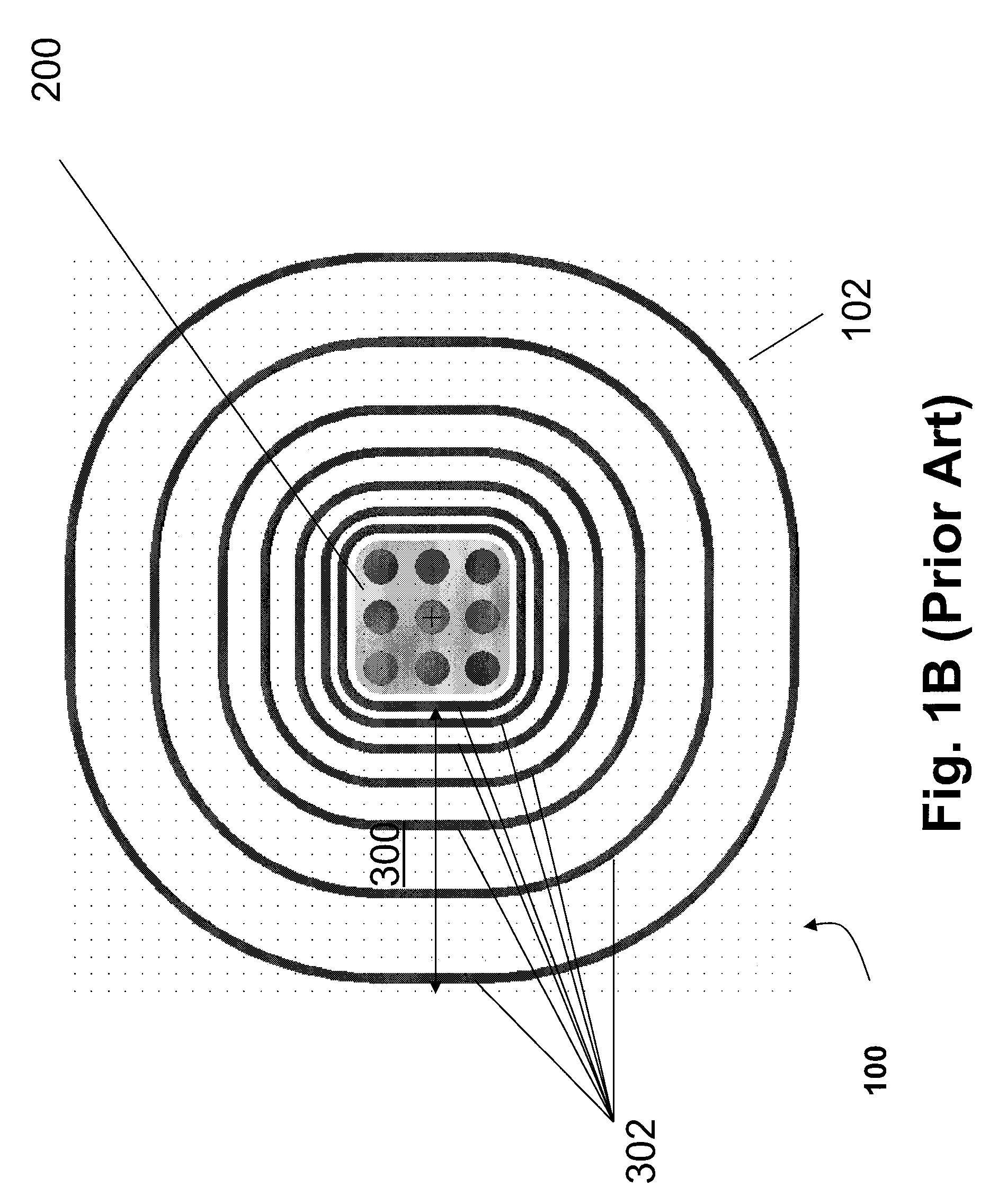

Avalanche photodiode having electric-field confinement by mesas

ActiveUS9466751B1Total current dropThin thicknessPhotovoltaic energy generationSemiconductor devicesIndiumSurface breakdown

A novel photodetecting device having field confined by mesas is provided. The device is an avalanche photodiode (APD) of indium aluminum arsenide (InAlAs). The device has epitaxial layers with a multiplication layer at bottom as a cathode. Hence, the strongest electric field is confined inside the bottom of the device to avoid surface breakdown. Double mesa is used to confine the electric field of the multiplication layer. Furthermore, a composite multiplication layer with supper thin thickness and wide bandgap is used to reduce the tunneling dark current. Hence, the thickness of equivalent multiplication layer can be reduced to enhance sensitivity.

Owner:NAT CENT UNIV

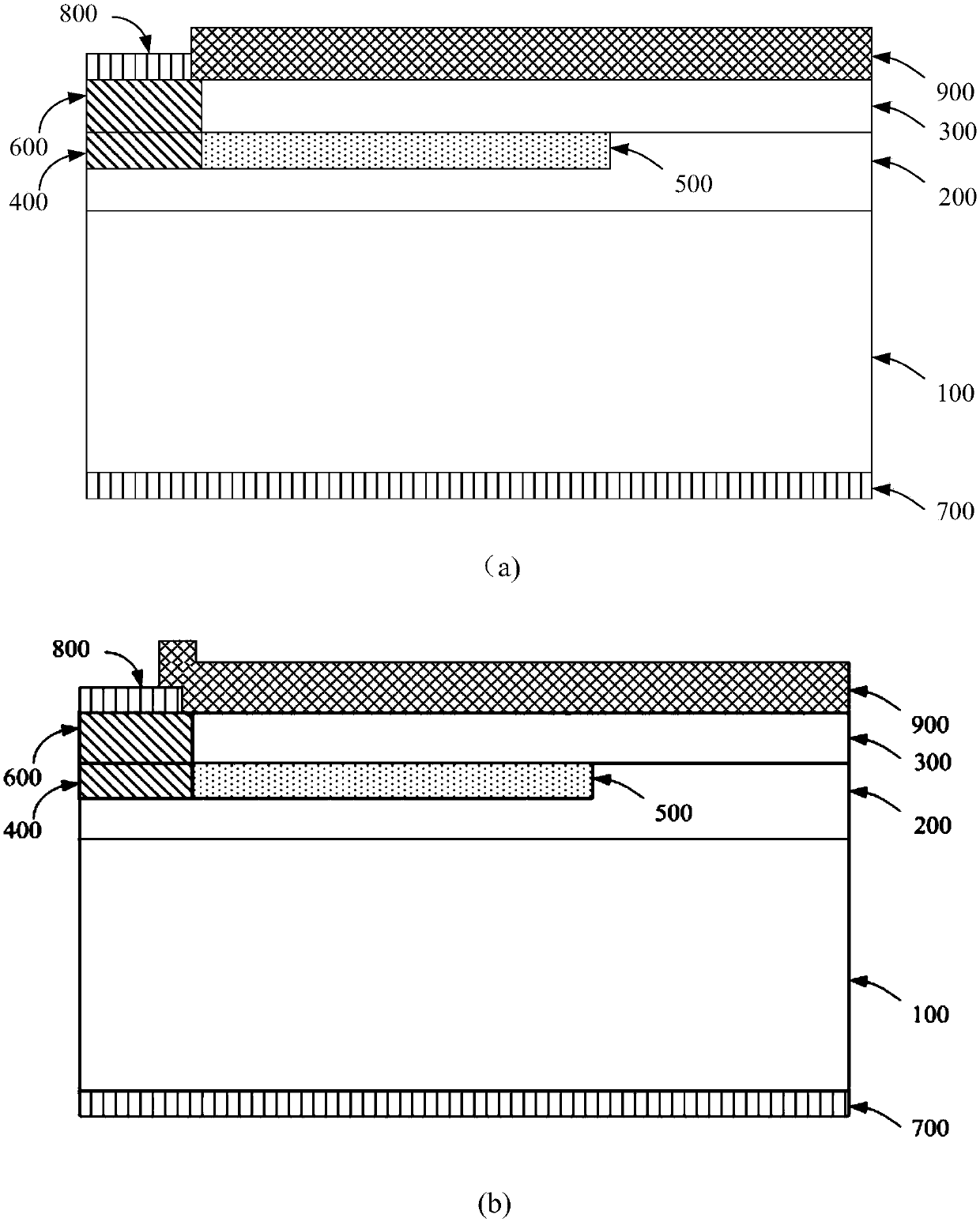

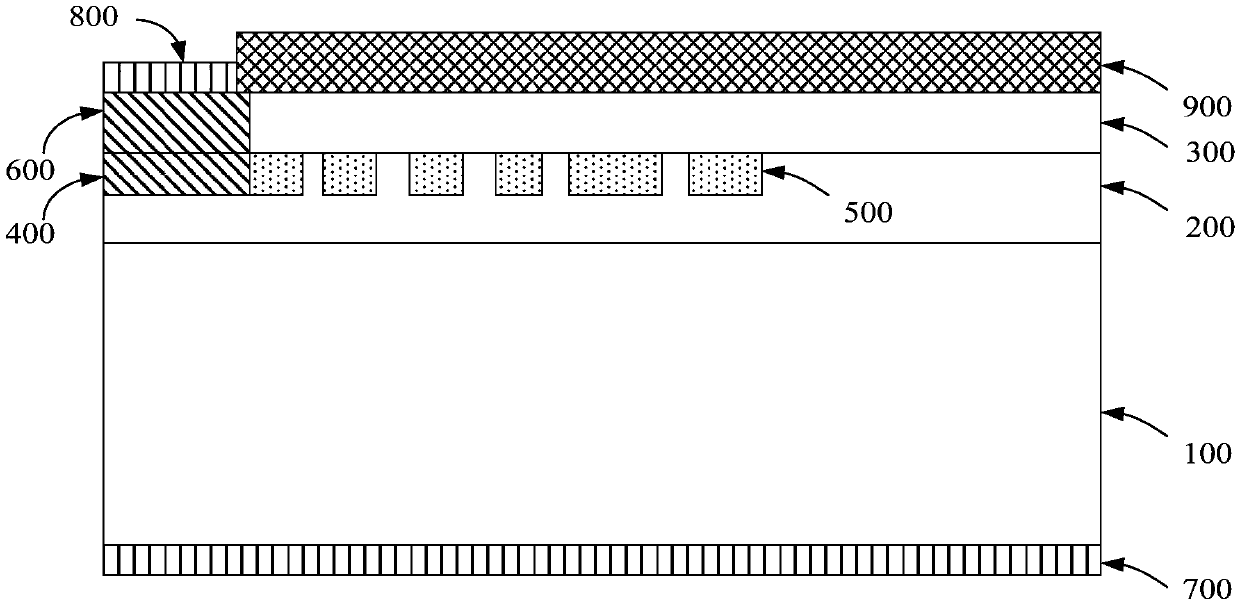

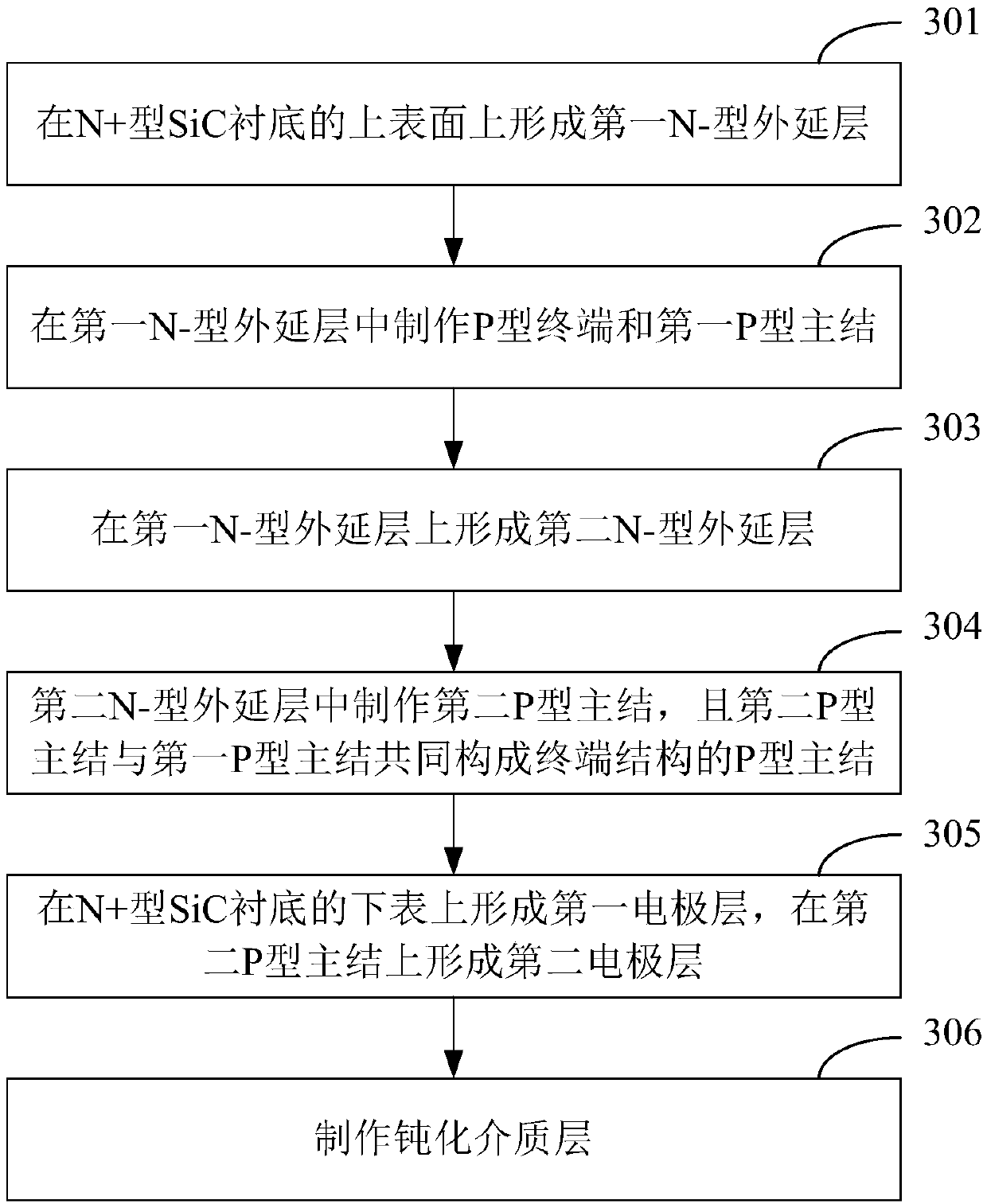

Silicon carbide device terminal structure and manufacturing method thereof

ActiveCN109545842AImprove reliabilitySolve the problem of prone to surface breakdownSemiconductor/solid-state device manufacturingSemiconductor devicesSurface breakdownPeak value

The invention relates to the technical field of semiconductors, and discloses a silicon carbide device terminal structure and a manufacturing method thereof. The silicon carbide device terminal structure comprises an N+ type SiC substrate, a first N- type epitaxial layer, a second N- type epitaxial layer, a P-type main junction, a P-type terminal, a second P-type main junction, a first first electrode layer and a second electrode layer. The P-type electrode is disposed at a position, far away from the surface, in the first N- type epitaxial layer, and enables a peak electric field to be located in a SiC material when the silicon carbide device is reversely biased, so that the problem that surface breakdown easily occurs in a terminal structure of an existing silicon carbide device can be solved. Meanwhile, the requirements for the interface quality of SiC and a passivation medium can be lowered, and the reliability of the device is improved.

Owner:北京国联万众半导体科技有限公司

Avalanche Photodetector with Single Mesa Shape

A photodetector is provided. The photodetector is an avalanche photodiode of indium aluminum arsenide (InAlAs). An epitaxial-layers structure with n-side down is used. The strongest electric field of a multiplication layer (M-layer) is coated in inner bottom layers to avoid surface breakdown. An intrinsic layer is thickened; only one absorption layer is used; and a DBR layer is added below an n-type ohmic contact layer. A graded bandgap layer is etched to form a single mesa shape. Through the single mesa shape, all layers are far below breakdown except the M-layer has a particularly high electric field for restraining the electric field. Thus, the present invention changes holes into electrons through p-type-doping the absorption layer; because electrons run fast, carriers is made run fast; and junction capacitance is reduced with surface area increased by depletion layer thickened. Consequently, fast response speed is obtained while sensitivity is effectively improved.

Owner:NAT CENT UNIV

Test method for assessing transformer oil surface breakdown voltage

The invention discloses a test method for assessing transformer oil surface breakdown voltage, and belongs to the technical field of power insulated oil insulation performance assessment. Parts of an electrode cup are cleaned, dried and assembled, a sample plate is placed on the bottom plate of the electrode cup, and vacuum drying processing needs to be carried out on the sample plate; a sampler measures the processed transformer oil, the transformer oil, is injected in the electrode cup body, the injection amount needs to be enough so as to ensure overall electrode rods and electrode heads to be fully immersed in the oil sample, and during the injection process, bubbles on the upper surface and the lower surface of the sample plate need to be removed; the electrode cup is placed in an oil tank of a test electrode box, a hemispherical electrode head is connected with a low-voltage conductive rod of the oil tank, the low-voltage conductive rod is connected with a ground line, a semi-conic electrode head is connected with a high-voltage conductive rod of the oil tank, the high-voltage conductive rod is connected with a high-voltage generator via a voltage divider and a guarantee resistor; insulated liquid is injected in the oil tank, the overall electrode cup is fully immersed for external insulation for the electrode cup, and after an oil tank cover is covered, surface breakdown test is carried out.

Owner:PETROCHINA CO LTD

Methods for manufacturing superjunction semiconductor device having a dielectric termination

InactiveUS20120184072A1Avoid voltage breakdownSolid-state devicesSemiconductor/solid-state device manufacturingDielectricSurface breakdown

A superjunction semiconductor device is provided having at least one column of a first conductivity type and at least one column of a second conductivity type extending from a first main surface of a semiconductor substrate toward a second main surface of the semiconductor substrate opposed to the first main surface. The at least one column of the second conductivity type has a first sidewall surface proximate the at least one column of the first conductivity type and a second sidewall surface opposed to the first sidewall surface. A termination structure is proximate the second sidewall surface of the at least one column of the second conductivity type. The termination structure includes a layer of dielectric of an effective thickness and consumes about 0% of the surface area of the first main surface. Methods for manufacturing superjunction semiconductor devices and for preventing surface breakdown are also provided.

Owner:ICEMOS TECH

Method for determining influence of mechanical force and thermal ageing on dielectric properties of silicone rubber

The invention discloses a method for determining influence of mechanical force and thermal ageing on dielectric properties of silicone rubber and belongs to the technical field of high voltage and insulation. The method disclosed by the invention comprises the following steps: 1, testing influences of pressure and temperature on dielectric properties of silicone rubber; 2, testing influences of pressure and temperature on surface breakdown strength of the silicone rubber; 3, testing the influence of tension on electrical tree aging of the silicone rubber; 4, testing influences of tension and temperature on breakdown strength of the silicone rubber; 5, performing thermal ageing test; 6, collecting and analyzing data, forming a form and a numerical distribution map, and determining the influences of mechanical force and thermal ageing on dielectric properties of the silicone rubber. According to the method for determining the influences of mechanical force and thermal ageing on dielectric properties of the silicone rubber disclosed by the invention, effective determination of the mechanical force and thermal ageing on the dielectric properties of the silicone rubber can be completed.

Owner:HARBIN UNIV OF SCI & TECH

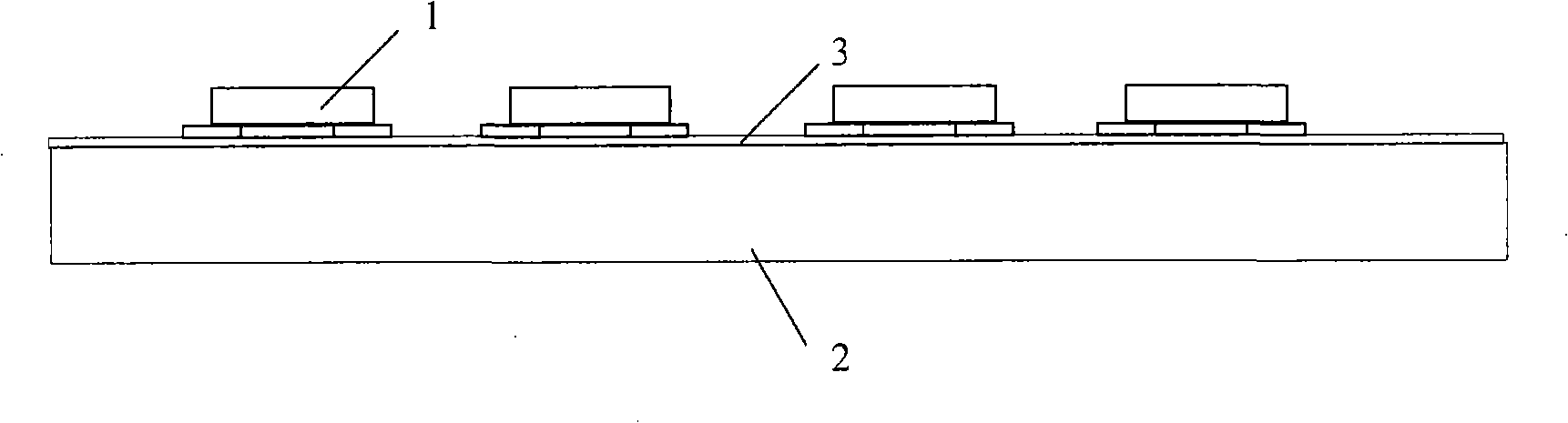

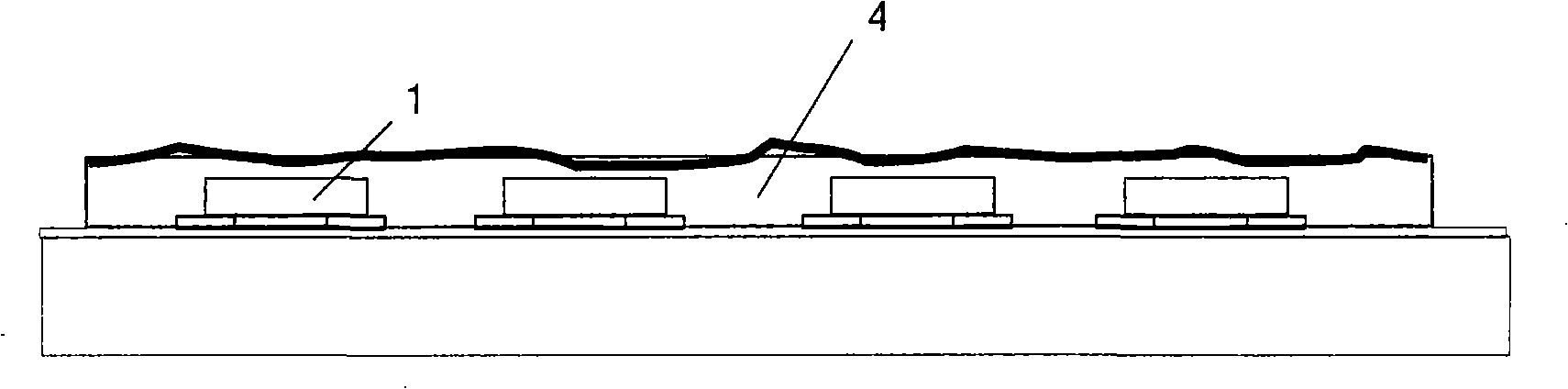

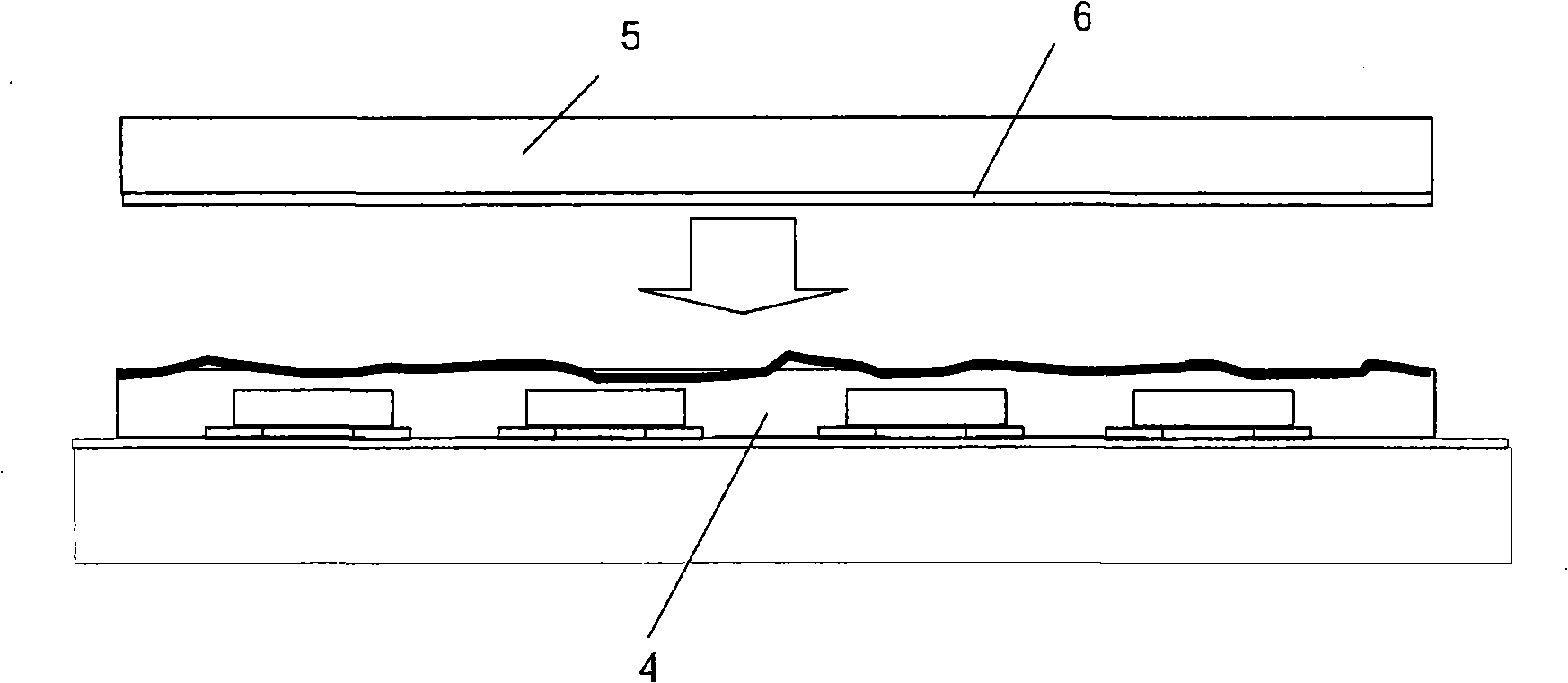

Panel/wafer molding apparatus and method of the same

InactiveCN101295655ANo warpingControl thicknessSolid-state devicesSemiconductor/solid-state device manufacturingSurface breakdownEngineering

The present invention provides an apparatus and a method for panel / wafer molding. The present invention discloses a base with a first separation layer, an upper molding base with a second separation layer, a cheap molding layer and a vacuum panel bonding machine for bonding, a curing unit, a cleaning unit and a separating unit; wherein upper molding base is rectangular or round. Therefore the present invention providing a simple, cheap universal panel / wafer molding apparatus for a round or rectangular type panel, and does no harm to the chip active surface.

Owner:ADVANCED CHIP ENG TECH INC

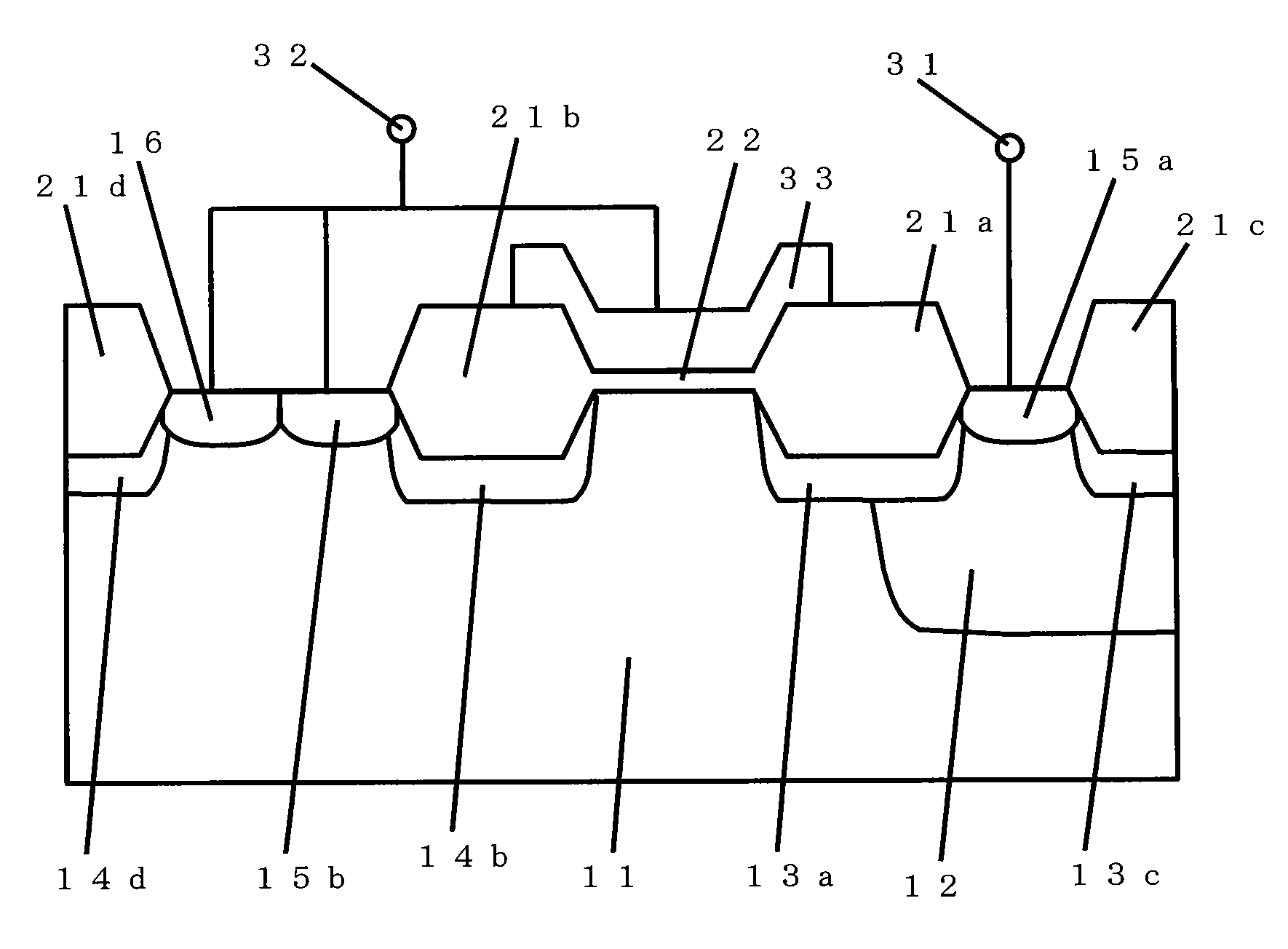

Terminal structure of super-junction semiconductor device

ActiveCN106024859ASuppression of disequilibriumSolve pressureSemiconductor devicesPower semiconductor deviceSurface breakdown

The invention belongs to the technical field of a longitudinal super-junction semiconductor device, and specifically relates to a terminal structure of a super-junction semiconductor device. According to the terminal structure provided by the invention, the width of the first conductive type semiconductor drifting strip is adjustable, and the width is gradually changed from a cellular region to the boundary, so that the terminal charge can be well balanced so as to improve the voltage withstand of the device; next, a second conductive type surface doping region constantly covers a second conductive type semiconductor column, and extends towards the boundary for a certain distance so as to ensure that the border position of the two types of semiconductor drifting regions is fully covered to lower the surface peak electric field; and the first conductive type surface doping region in the second conductive type surface doping regions provides a positive charge center downwardly to further lower the surface electric field of the device so as to lower the probability of surface breakdown of the super-junction terminal in order to improve the overall voltage withstand of the device.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

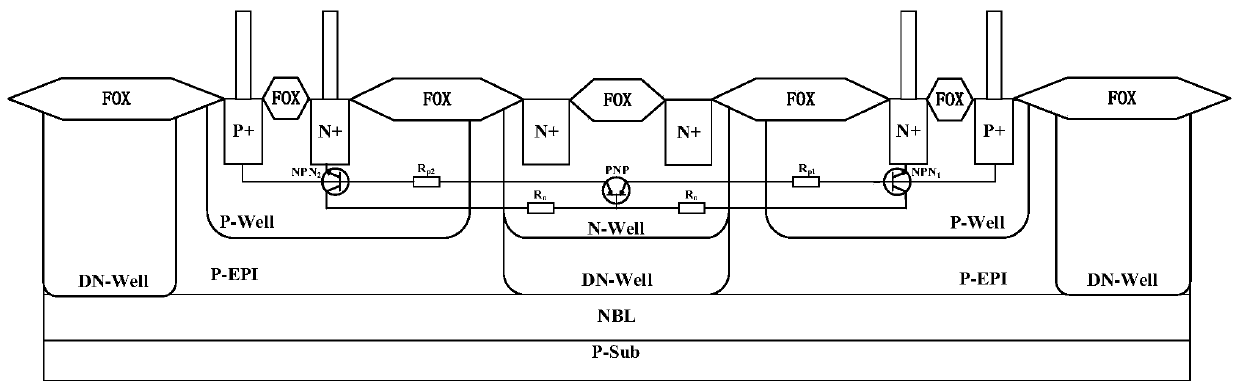

Bidirectional enhanced grid-control SCR (silicon controlled rectifier) electrostatic protection device and manufacturing method thereof

ActiveCN110289257ALower on-resistanceReduce leakage currentTransistorSolid-state devicesSilicon-controlled rectifierDIAC

The invention discloses a bidirectional enhanced grid-control SCR (silicon controlled rectifier) electrostatic protection device, and the device comprises a substrate P-Sub, an NBL region is arranged on the substrate P-Sub, and a first DN-Well region, a first P-EPI region, a second DN-Well region, a second P-EPI region and a third DN-Well region are arranged on the NBL region; a first P-Well region is arranged in the first P-EPI region, and a first polysilicon gate is arranged in the first P-Well region; and a second P-Well region is arranged in the second P-EPI region, and a second polysilicon gate is arranged in the second P-Well region. According to the invention, the first polysilicon gate and the second polysilicon gate form an enhanced gate control structure, and the enhanced gate control structure is adopted, so that the conduction resistance of the bidirectional silicon controlled rectifier device can be reduced, the positive feedback loop gain of the silicon controlled rectifier is improved, the failure current is effectively improved, and the phenomena of premature soft failure and surface breakdown are avoided.

Owner:HUNAN NORMAL UNIVERSITY

Bonding method of tramcar roof made of light composite material

The invention provides a bonding method of a tramcar roof made of a light composite material, and belongs to the field of connection methods of railway vehicle light composite material car roof structures and car body steel structural skeletons. According to the method, the bonding property is improved by conducting surface treatment on the surface of the light composite material, bonding glue suitable for the light composite material is selected, fixing and limiting methods which cause less damage to the surface of a light composite material plate and are light and accurate are adopted, the environment condition of construction is adjusted, the solidification time is shortened, and thus bonding of a car roof component made of a light carbon fiber composite material and a car body steel structure is achieved. As the replacing technology of the welding technology, the manufacturing method of the car roof component by adopting the bonding method is simple, convenient and practical, and safe and reliable, the bonding strength completely conforms to the design requirement, and the light carbon fiber composite material can be successfully applied to the field of production and manufacturing of railway vehicles, accordingly the total weight of the car body is sharply lowered, the production efficiency is greatly improved, and the power nuclear energy sources needed by operation of the vehicles are saved.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Semiconductor device

ActiveUS8227856B2Well representedHigh voltageTransistorSemiconductor/solid-state device detailsHigh concentrationStable state

Provided is an ESD protection element, in which: LOCOS oxide films are formed at both ends of a gate electrode, and a conductivity type of a diffusion layer formed below one of the LOCOS oxide films which is not located on a drain side is set to a p-type, to thereby limit an amount of a current flowing in a portion below a source-side n-type high concentration diffusion layer, the current being generated due to surface breakdown of a drain. With this structure, even in a case of protecting a high withstanding voltage element, it is possible to easily satisfy a function required for the ESD protection element, the function of being constantly in an off-state during a steady state, while operating, upon application of a surge or noise to a semiconductor device, so as not to reach a breakage of an internal element, discharging a generated large current, and then returning to the off-state again.

Owner:ABLIC INC

Shock absorber based on the cutting, inward-folding and crushing of composite tube

ActiveUS20180202505A1Simple structureImproving interaction forceSpringsSprings/dampers design characteristicsState of artEnergy absorption

The present invention relates to an shock absorber based on the cutting, inward-folding and crushing of composite tube, comprising a destructing cap, a flat-pressing cap, a cutter and a positioning tube. The cutter is positioned in the destructing cap, and has a lower end connected to an inner flange of the destructing cap and an upper end connected to the positioning tube. The positioning tube is positioned in the destructing cap and closely connected to the inner wall of the destructing cap, and has a lower surface in contact with the cutter. The destructing cap, the positioning tube and the composite tube are respectively provided with aligned pin holes, and bound together with a pin. Energy is absorbed through destruction generated due to cutting and inward-folding of the composition tube. Energy can also be absorbed through destruction generated due to the inward-folding of the composite tube, without using the cutter. Compared to existing technology, the device may be used as a structural component in a normal working state. In the colliding and crushing state, the device fully destructs the composite. The present invention has the following advantages: the energy-absorption ratio is high; and the energy absorbing device only bears an axial force in the process that the composite is being destroyed, does not bend or rupture, keeps the structure stable, and avoids spattering of scraps.

Owner:SHANGHAI JIAO TONG UNIV

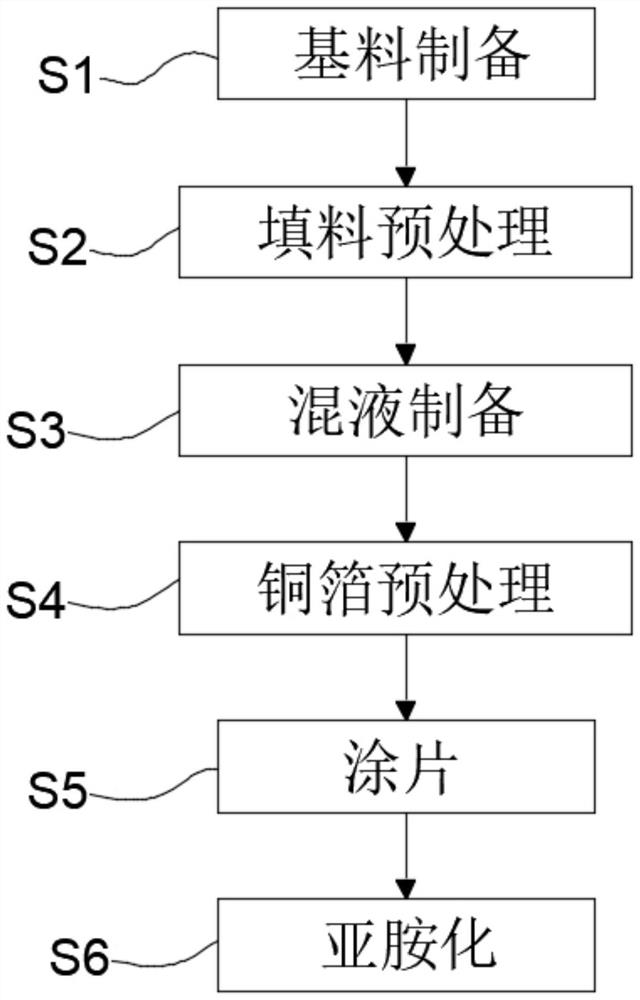

Preparation method of insulating paint with heat transfer function

ActiveCN114032024AOvercoming the disadvantages of poor thermal conductivityImprove liquidityCoatingsMaterials preparationComposite media

A preparation method of insulating paint with a heat transfer function comprises the following steps: base material preparation, filler pretreatment, mixed liquid preparation, copper foil pretreatment, smearing and imidization. According to the invention, the defect of poor heat conduction capability of heat conduction paint is overcome, the insulating paint is simple and practical, the insulating paint has high heat conduction performance and voltage breakdown resistance by adopting a compound heat conduction powder accumulation mode, and a voltage breakdown test is carried out on a cured paint film to verify that the insulating paint has excellent heat conduction performance and surface breakdown resistance; a compounded heat-conducting filler has relatively high flowability and is easy to disperse, the thickness of a paint film is controllable, a composite medium does not have macroscopic bubbles, the preparation process is simple and controllable, and the rejection rate is low; and the obtained high polymer material is low in price, easy to process and low in cost, and can be subjected to industrial production.

Owner:珠海格力新材料有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com