Test method for assessing transformer oil surface breakdown voltage

A technology of transformer oil and surface breakdown, applied in the direction of testing dielectric strength, etc., can solve the problems of damage to the front end of the electrode, inconvenient operation, and uncertain breakdown position, etc., to achieve improved withstand voltage level, good repeatability, and improved The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Obviously, many modifications and changes made by those skilled in the art based on the gist of the present invention belong to the protection scope of the present invention.

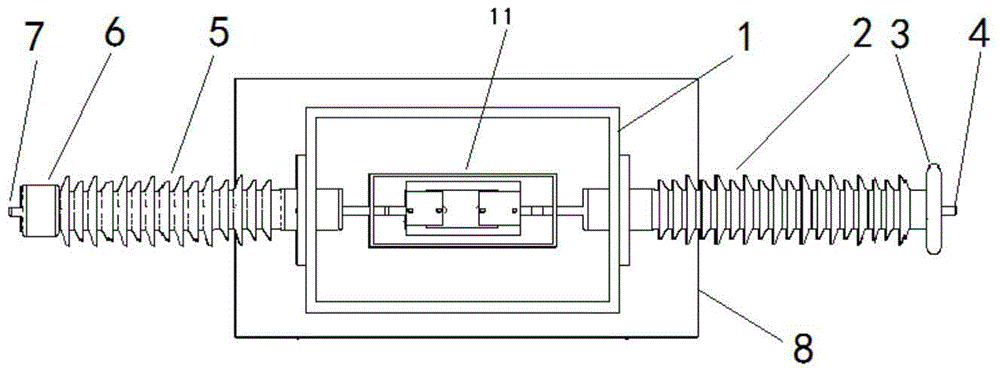

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Figure 6 As shown, a test device for evaluating the measurement of transformer oil breakdown voltage along the surface includes a console 100, an impulse power supply unit II, and a test electrode box 300.

[0032]A test device for evaluating the measurement of the surface breakdown voltage of transformer oil, including an oil tank 1, a high-voltage bushing 2, a pressure equalizing ring 3, a high-voltage conductive rod 4, a low-voltage bushing 5, a pressure equalizing cover 6, a low-voltage conductive rod 7, and a support plate 8. Support insulator 9, bottom plate 10 with direction wheels and electrode cup 11. The equalizing ring 3 is fixed on one end of the high-voltage conductive rod 4, passes through the high-vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com