Method for polishing metal mirror by using diamond single-point vehicle auxiliary ion beam

A technology of polishing metal and ion beam, which is applied in the field of optical processing, can solve the problem that the processing accuracy is difficult to meet the requirements of high-quality optical systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

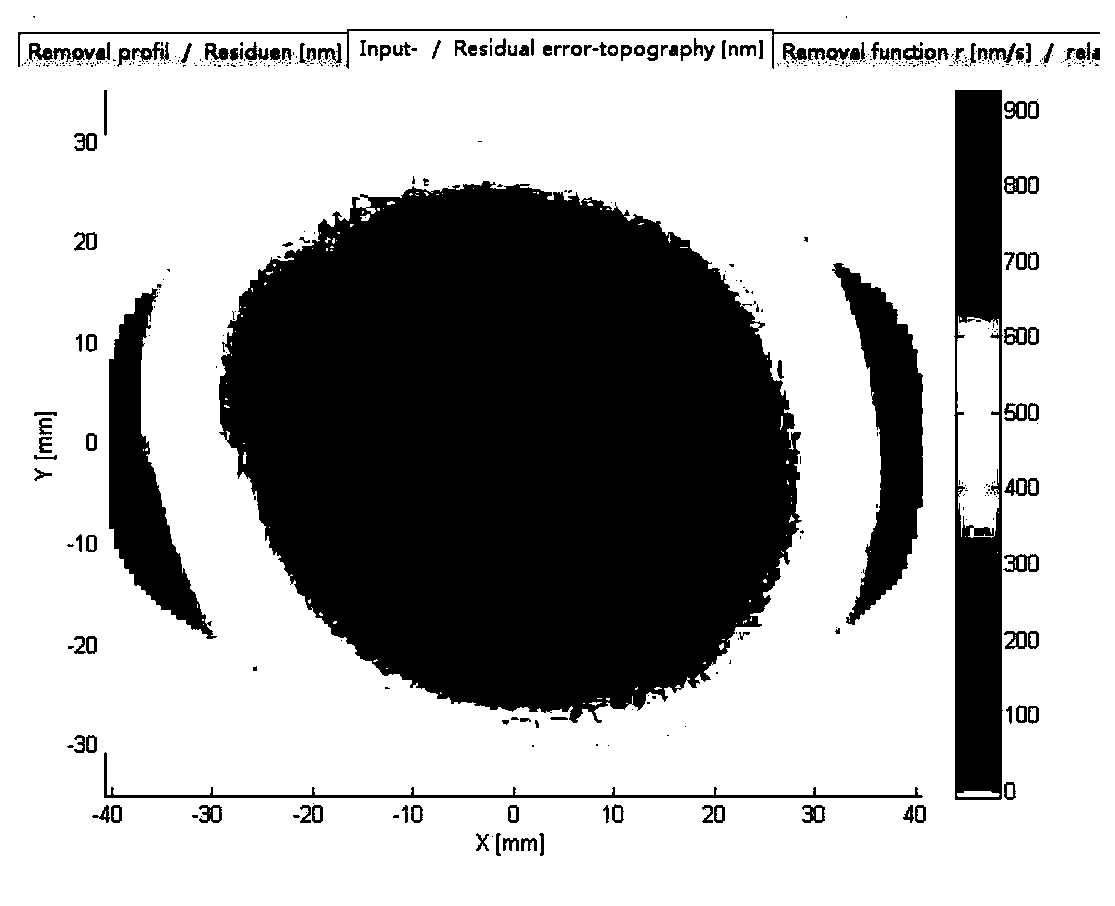

Image

Examples

Embodiment 1

[0035] Aluminum mirror processing

[0036] Aluminum alloy reflector, size 62mm*82mm

[0037] Its processing flow is as follows:

[0038] 1) Single-point lathe processing until the mirror surface error rms value is 28.2nm, PV value is 850nm, surface roughness Ra1.95nm, and the thickness h of the damaged layer on the lower surface that needs to be produced is greater than 850nm;

[0039] 2) Adjust the working parameters of diamond single-point turning, and the processing parameters of single-point turning are as follows:

[0040] Speed 1200rpm

[0041] x feed is 3mm / min

[0042] Penetration depth 3μm

[0043] 3) Single-point car removes material uniformly on the mirror surface, the material removal thickness is 5 μm, and the thickness h of the damaged layer on the lower surface is 920nm, satisfying h≥PV;

[0044] 4) Detect the mirror surface error RMS value of 29.1nm to prepare for the next step of ion beam processing;

[0045] 5) Set the working parameters of ion beam p...

Embodiment 2

[0049] Using this method to process a 132mm diameter aluminum alloy convex reflector

[0050] 1) Single-point lathe processing until the mirror surface error rms value is 29.6nm, PV value is 1040nm, surface roughness Ra2.01nm, and the thickness h of the damaged layer on the lower surface that needs to be produced is greater than 1040nm;

[0051] 2) Adjust the working parameters of diamond single-point turning, and the processing parameters of single-point turning are as follows:

[0052] Speed 1800rpm

[0053] x feed is 2mm / min

[0054] Penetration depth 2μm

[0055] 3) Single-point car removes material evenly on the mirror surface, the material removal thickness is 6 μm, and the thickness h of the damaged layer on the lower surface is 1100nm, satisfying h≥PV;

[0056] 4) Detect the mirror surface error RMS value of 30.5nm, to prepare for the next step of ion beam processing;

[0057] 5) Set the working parameters of ion beam polishing: the ion energy is 800ev, the gas i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com