Preparation method for three-dimensional porous lithium ion battery negative electrode sheet

A lithium-ion battery, three-dimensional porous technology, used in battery electrodes, secondary batteries, electrode carriers/current collectors, etc., can solve the problem of poor adhesion of active materials, poor three-dimensionality of porous foils, and foil winding Easy to loosen and other problems, to solve the difficulty of preparation, efficient and fast production, and improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

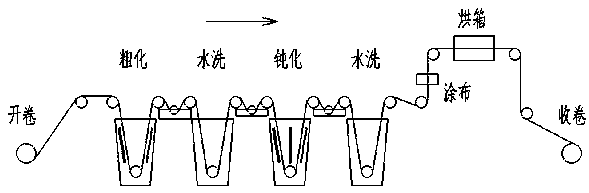

Method used

Image

Examples

example 1

[0019] 8-micron porous double-sided smooth copper foil is used, with a pore size of 100 microns, a porosity of 17%, and a copper foil speed of 4m / min.

[0020] 1) Three-dimensional roughening process parameters: keep copper ion concentration at 17g / L, sulfuric acid concentration at 100g / L, solution temperature at 18-22°C, solution flow rate at 1m 3 / h, the current density is maintained at 90A / dm 2 .

[0021] 2) Washing process parameters: 10 nozzles are used, the water supply pressure of the nozzles is 2kgf, the flow rate is 5L / H, and the water temperature is kept at 20°C-30°C.

[0022] 3) Passivation process parameters: phosphoric acid content 0.65g / L, chromium trioxide 0.8g / L, zinc sulfate content 1.3g / L, current density maintained at 20A / dm 2 , the flow rate of passivation solution is 2 m 3 / h, temperature 20-22°C. 10 nozzles are used for water washing, the water supply pressure of the nozzles is 2kgf, the flow rate is 5L / H, and the water temperature is kept at 20°C-30°...

example 2

[0025] 9 micron porous double-sided smooth copper foil is used, with a pore size of 95 microns, a porosity of 20%, and a copper foil speed of 6m / min.

[0026] 1) Three-dimensional coarsening process parameters: the copper ion concentration is kept at 19g / L, the sulfuric acid concentration is kept at 100g / L, the solution temperature is kept at 18-22°C, and the solution flow rate is kept at 2m 3 / h, the current density is maintained at 100A / dm 2 .

[0027] 2) Washing process parameters: 12 nozzles are used, the water supply pressure of the nozzles is 2.5kgf, the flow rate is 3L / H, and the water temperature is kept at 20°C-30°C.

[0028] 3) Passivation process parameters: phosphoric acid content 0.7g / L, chromium trioxide 0.9g / L, zinc sulfate content 1.6g / L, current density maintained at 25A / dm 2 , the flow rate of passivation solution is 2 m 3 / h, temperature 20-22°C. 12 nozzles are used for water washing, the water supply pressure of each nozzle is 2.5kgf, the flow rate is 3...

example 3

[0031] 12 micron porous double-sided smooth copper foil is used, with a pore size of 95 microns, a porosity of 25%, and a copper foil speed of 8m / min.

[0032] 1) Three-dimensional roughening process parameters: keep copper ion concentration at 20g / L, sulfuric acid concentration at 105g / L, solution temperature at 20-25°C, solution flow rate at 2m 3 / h, the current density is maintained at 120A / dm 2 .

[0033] 2) Washing process parameters: 14 nozzles are used, the water supply pressure of the nozzles is 3kgf, the flow rate is 2L / H, and the water temperature is kept at 20°C-30°C.

[0034] 3) Passivation process parameters: phosphoric acid content 0.7g / L, chromium trioxide 1.1g / L, zinc sulfate content 2g / L, current density maintained at 30A / dm 2 , the flow rate of passivation solution is 2 m3 / h, temperature 20-22°C. Washing process parameters: 14 nozzles are used, the water supply pressure of the nozzles is 3kgf, the flow rate is 2L / H, and the water temperature is kept at 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com