Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6561 results about "Lithium ion battery anode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

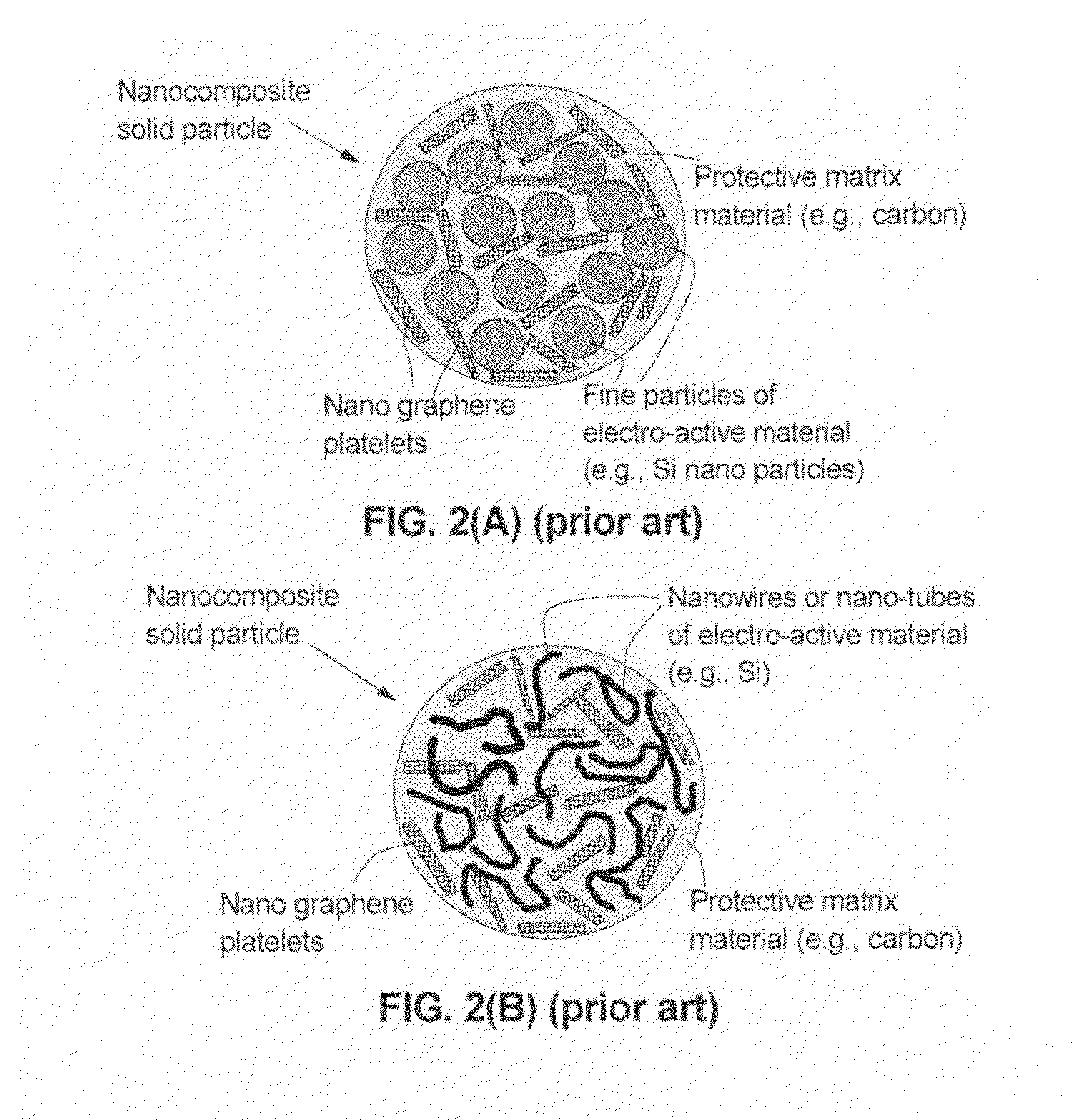

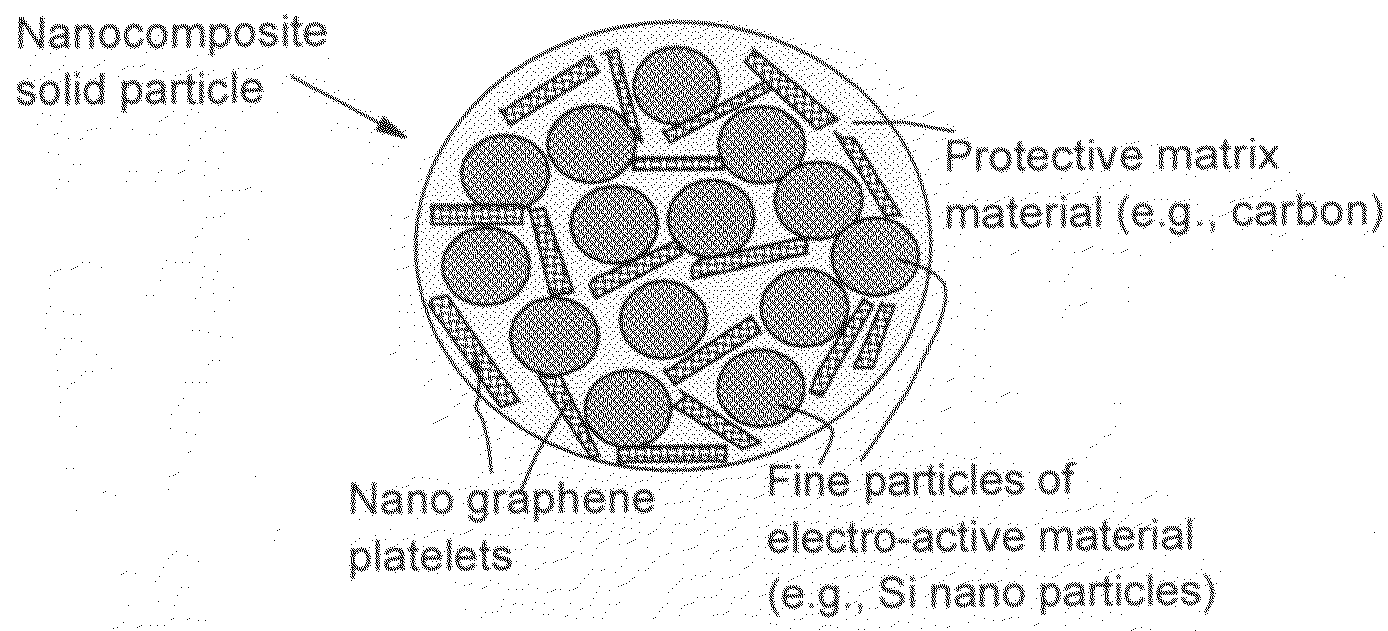

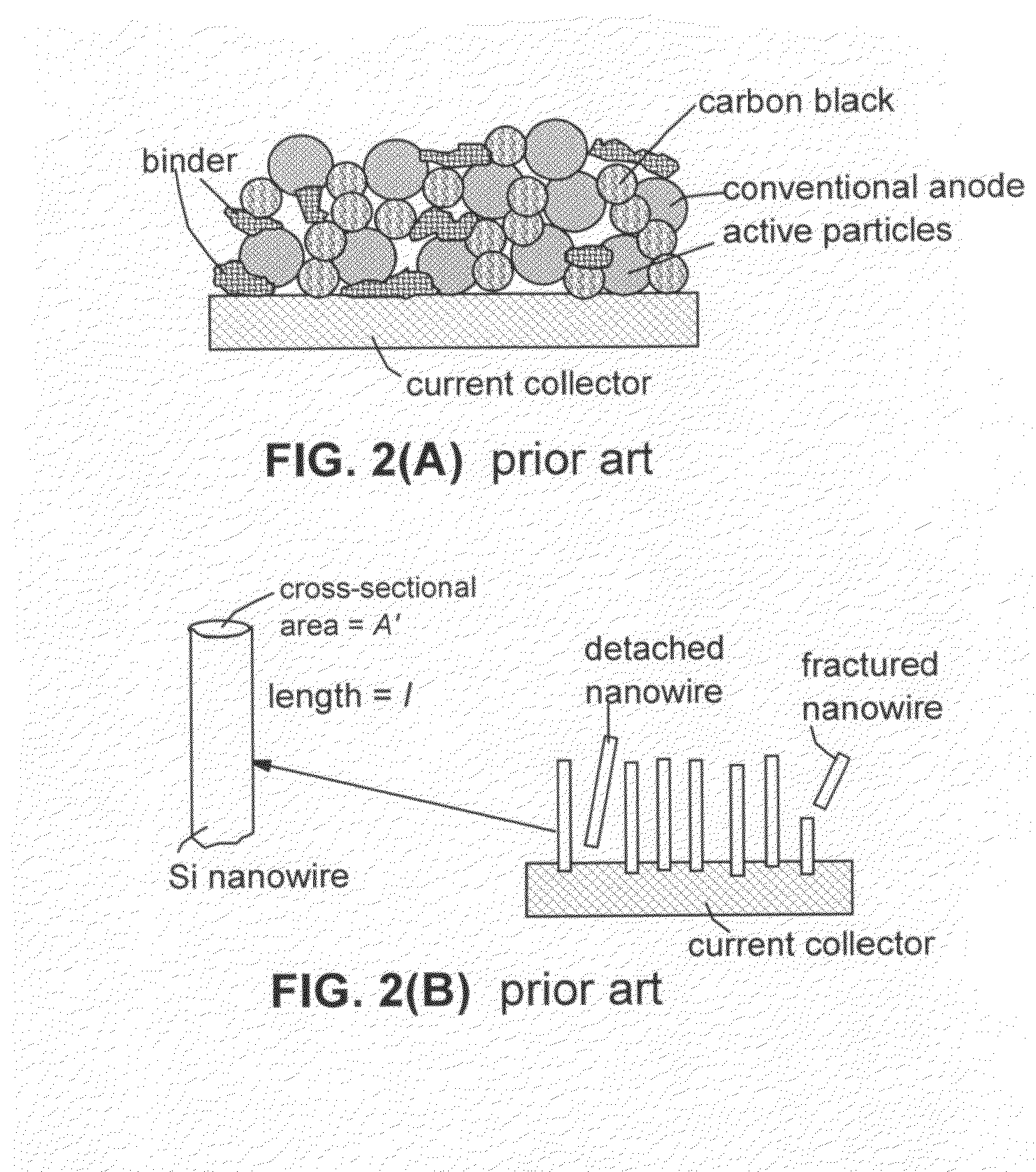

Nano graphene reinforced nanocomposite particles for lithium battery electrodes

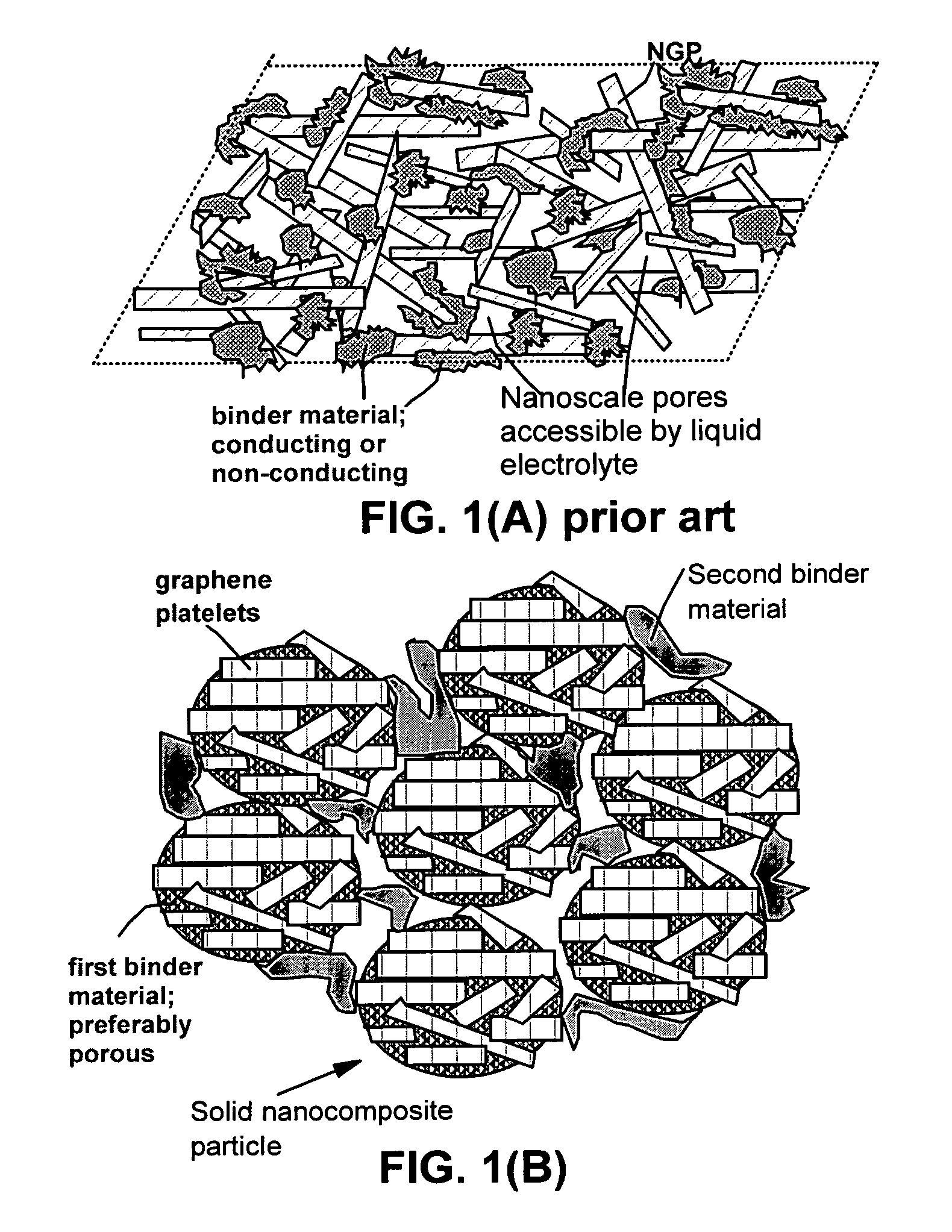

ActiveUS20100143798A1Increase stiffnessHigh strengthActive material electrodesSecondary cellsLithium metalNanocomposite

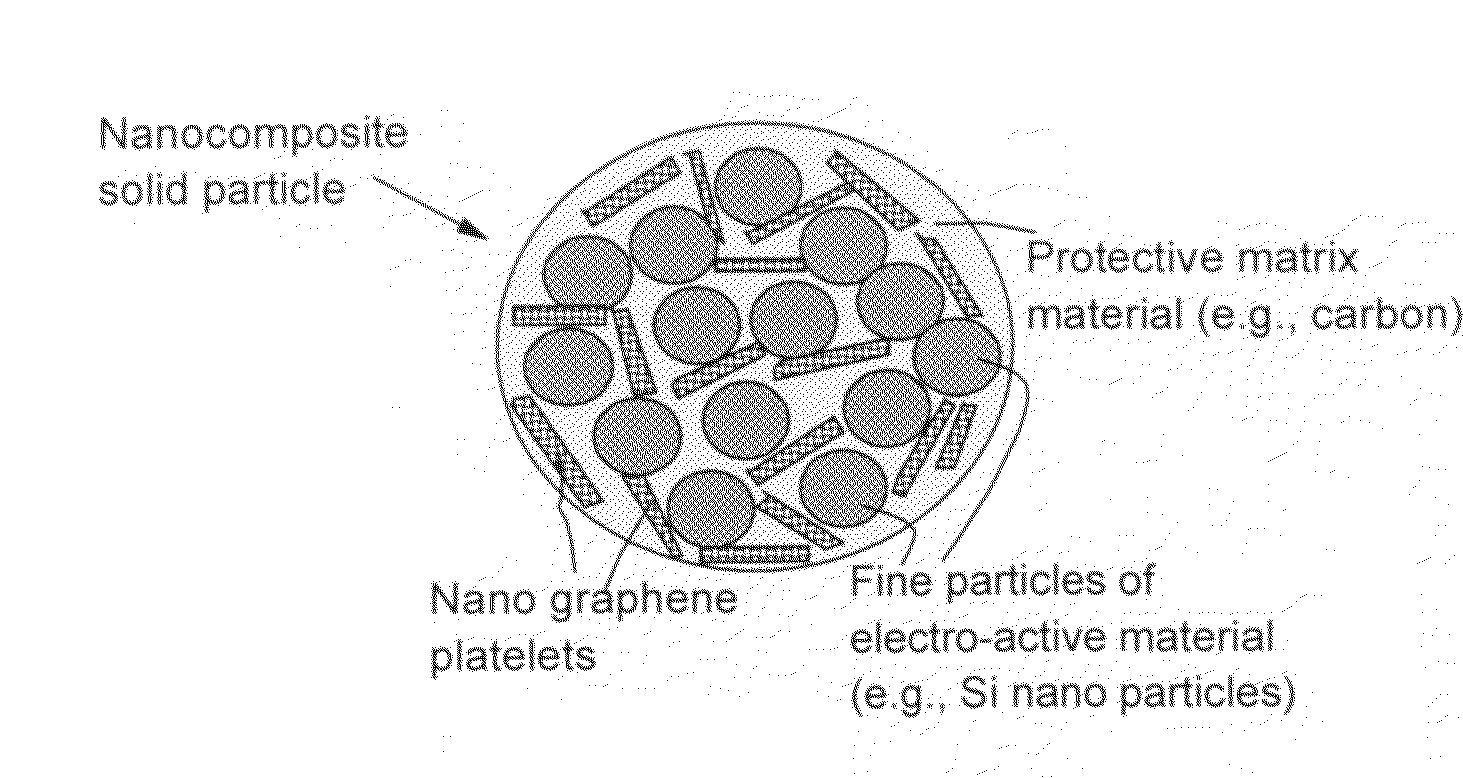

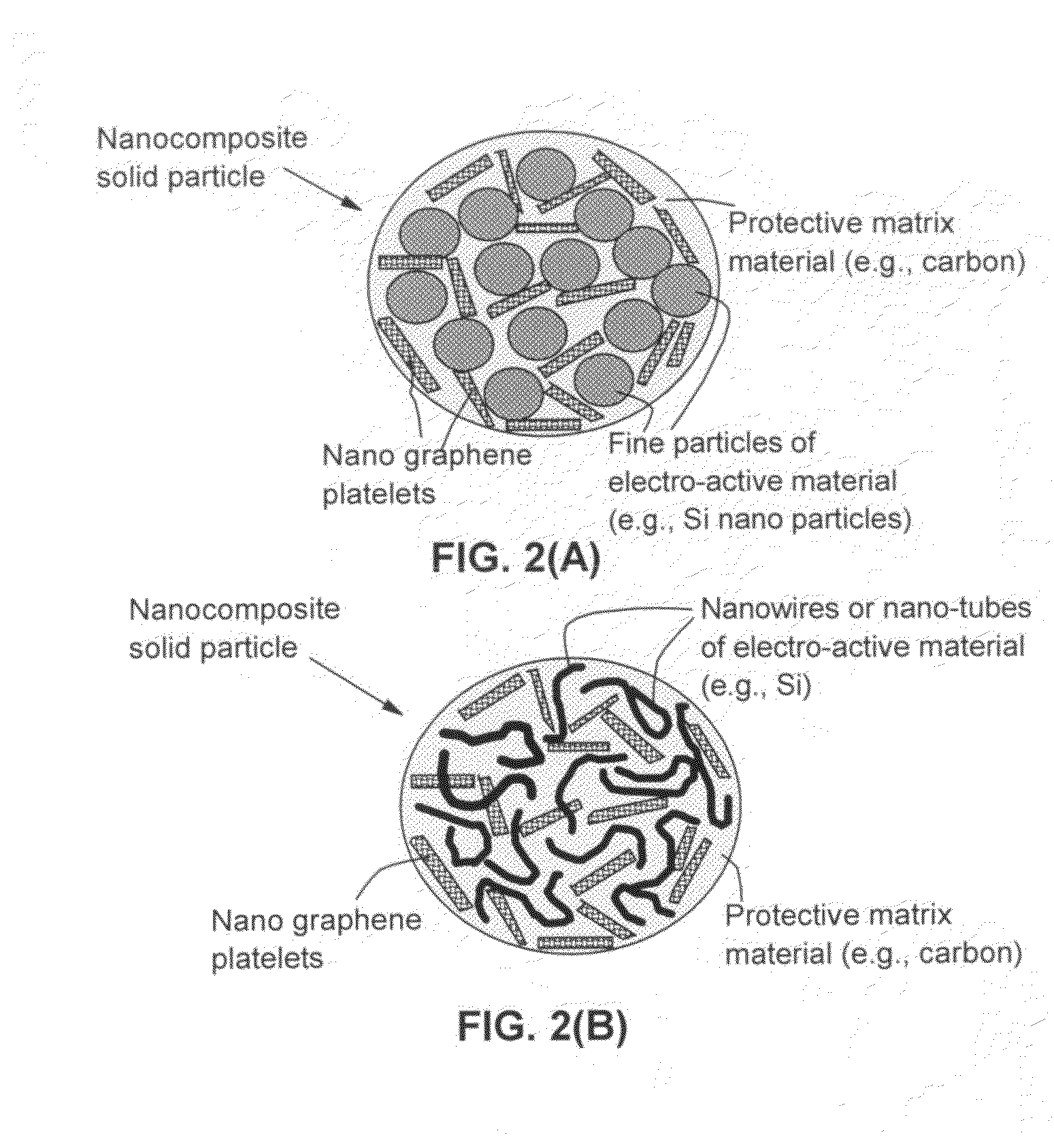

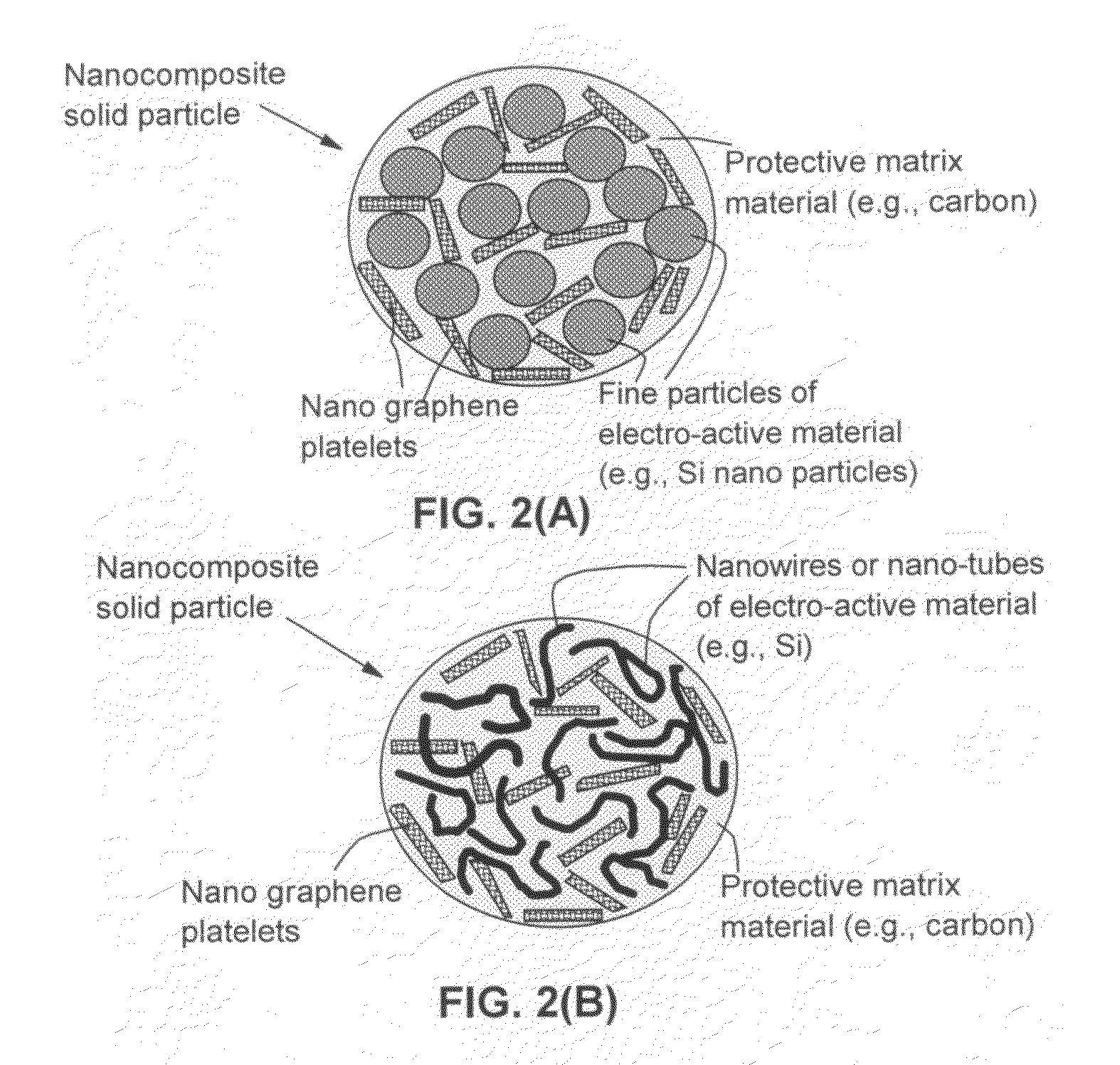

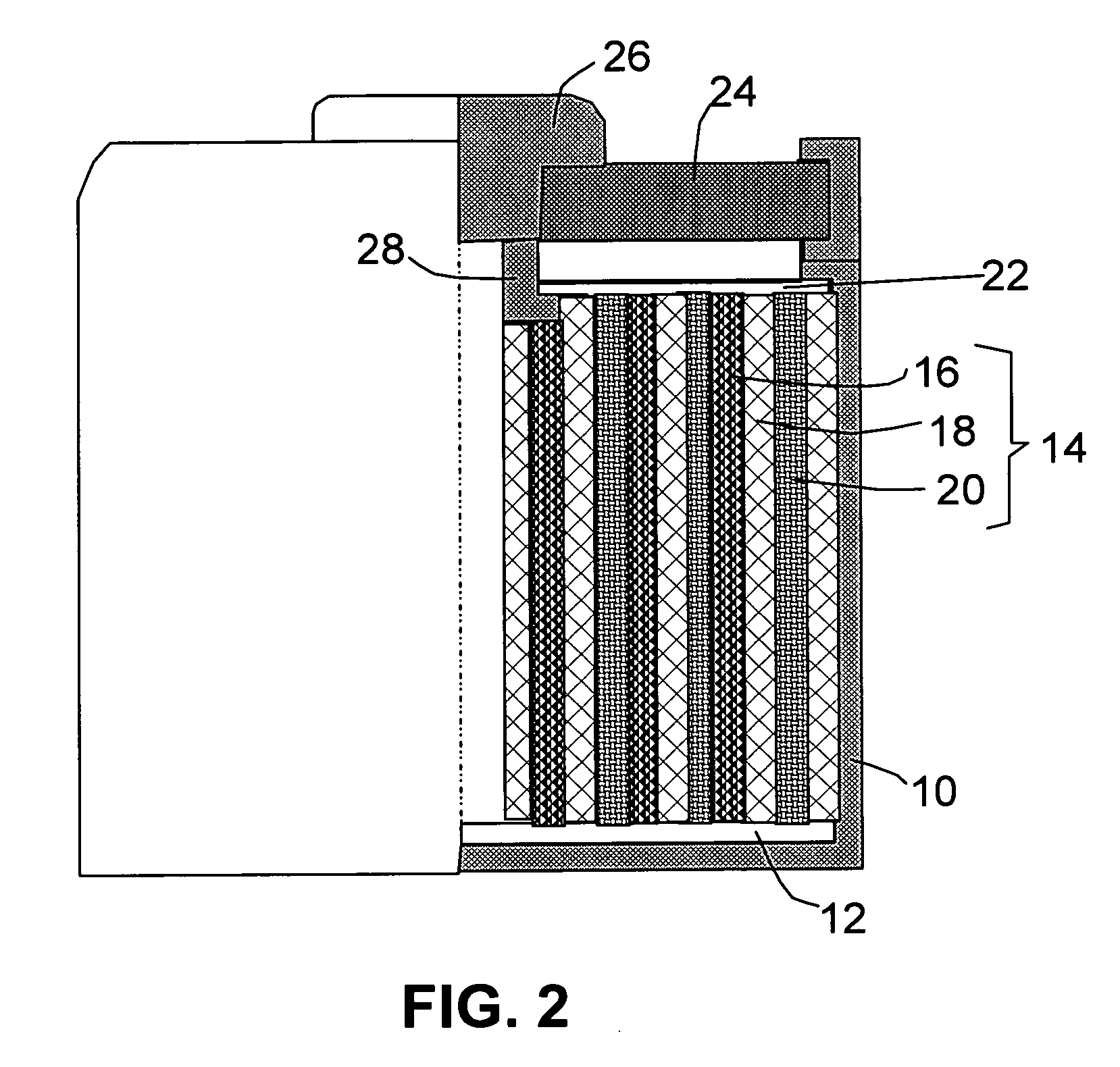

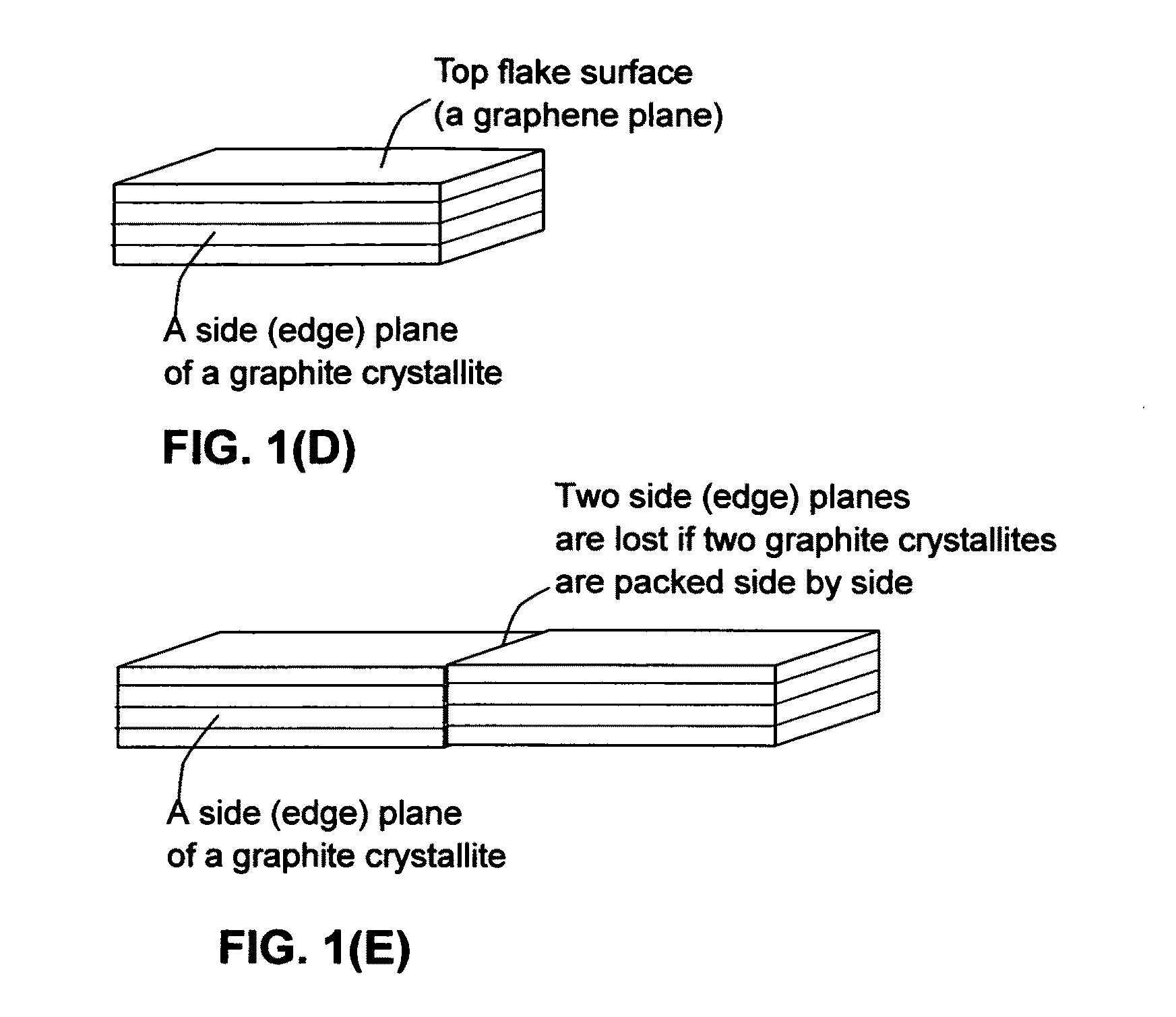

A solid nanocomposite particle composition for lithium metal or lithium ion battery electrode applications. The composition comprises: (A) an electrode active material in a form of fine particles, rods, wires, fibers, or tubes with a dimension smaller than 1 μm; (B) nano graphene platelets (NGPs); and (C) a protective matrix material reinforced by the NGPs; wherein the graphene platelets and the electrode active material are dispersed in the matrix material and the NGPs occupy a weight fraction wg of 1% to 90% of the total nanocomposite weight, the electrode active material occupies a weight fraction wa of 1% to 90% of the total nanocomposite weight, and the matrix material occupies a weight fraction wm of at least 2% of the total nanocomposite weight with wg+wa+wm=1. For a lithium ion battery anode application, the matrix material is preferably amorphous carbon, polymeric carbon, or meso-phase carbon. Such a solid nanocomposite composition provides a high anode capacity and good cycling stability. For a cathode application, the resulting lithium metal or lithium ion battery exhibits an exceptionally high cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD

Graphene-enhanced anode particulates for lithium ion batteries

ActiveUS20120064409A1Enhanced Li-ion insertionIncrease capacityNon-metal conductorsMaterial nanotechnologyParticulatesMicroparticle

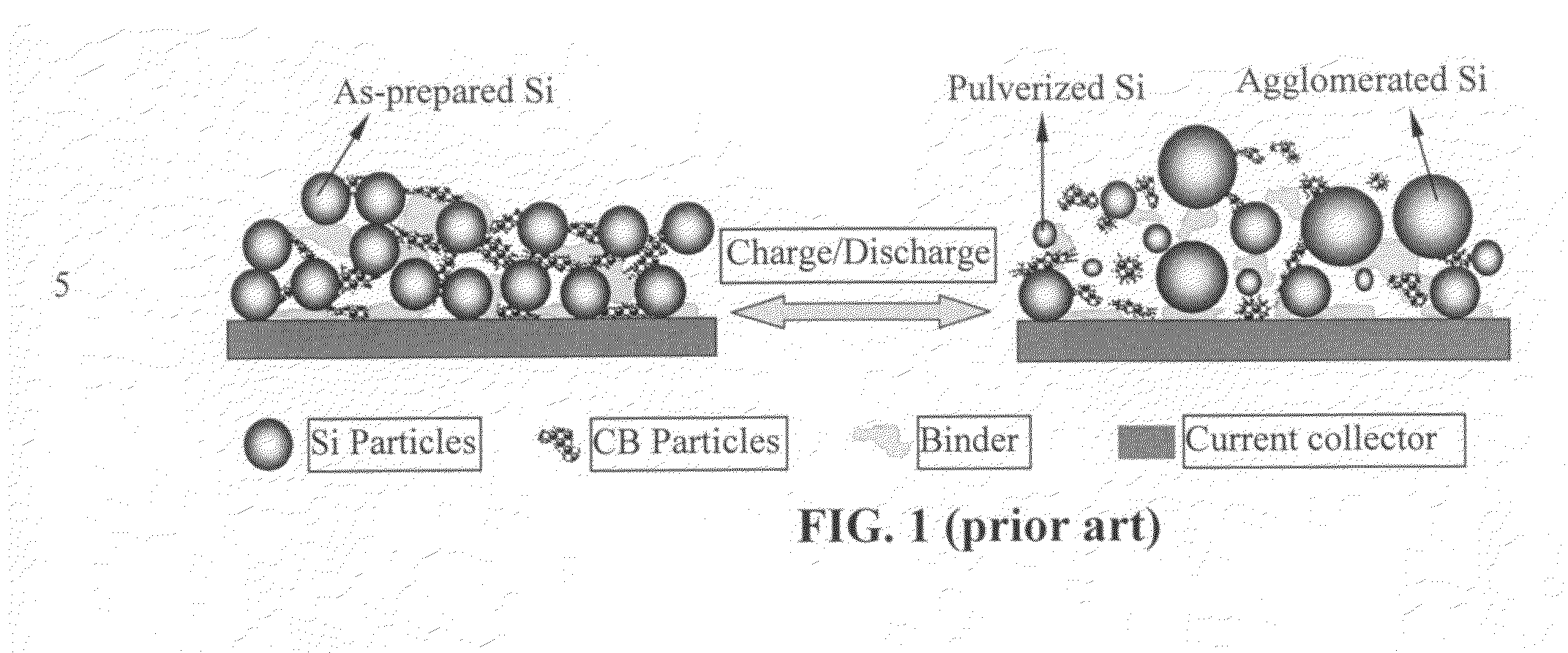

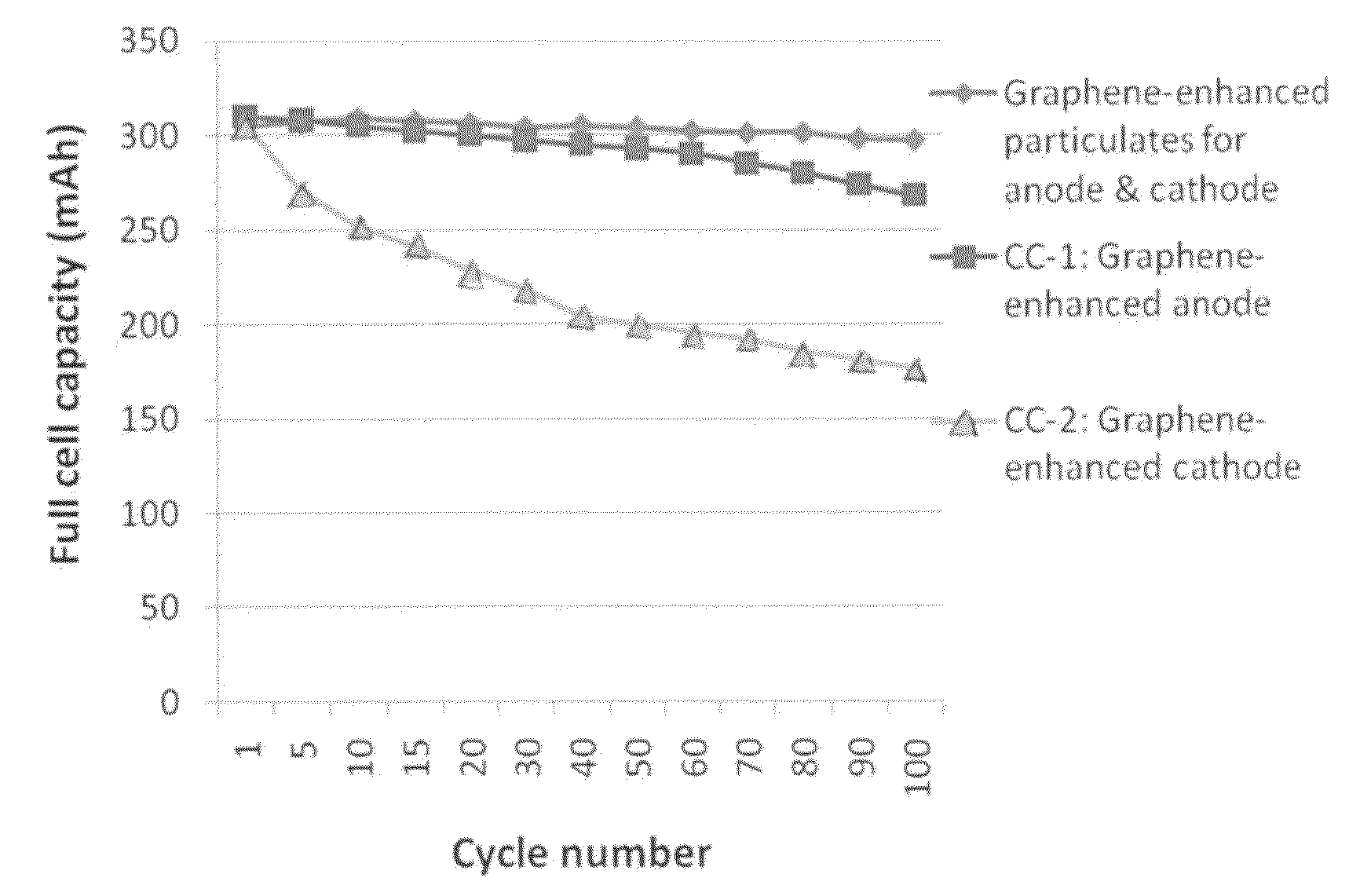

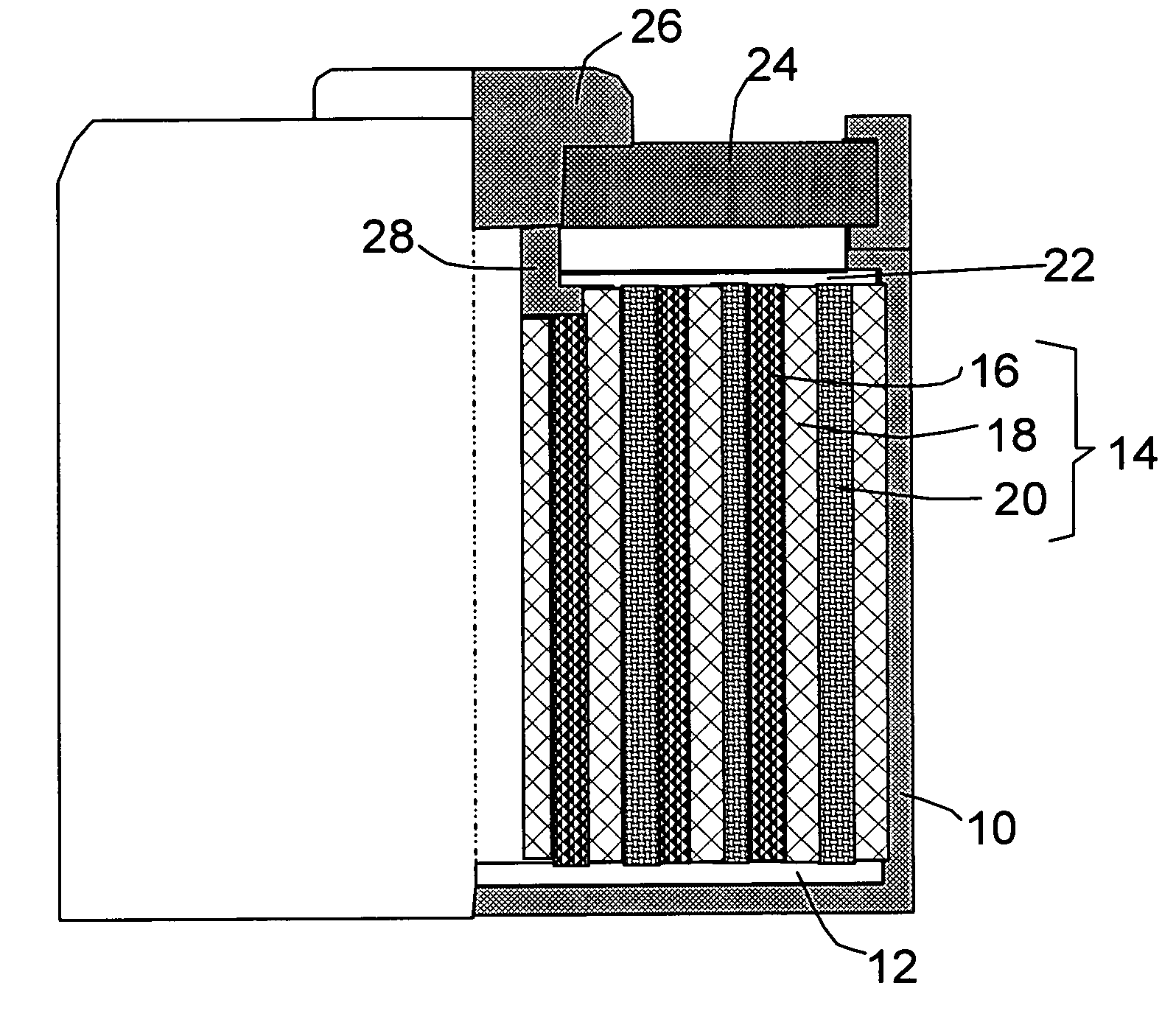

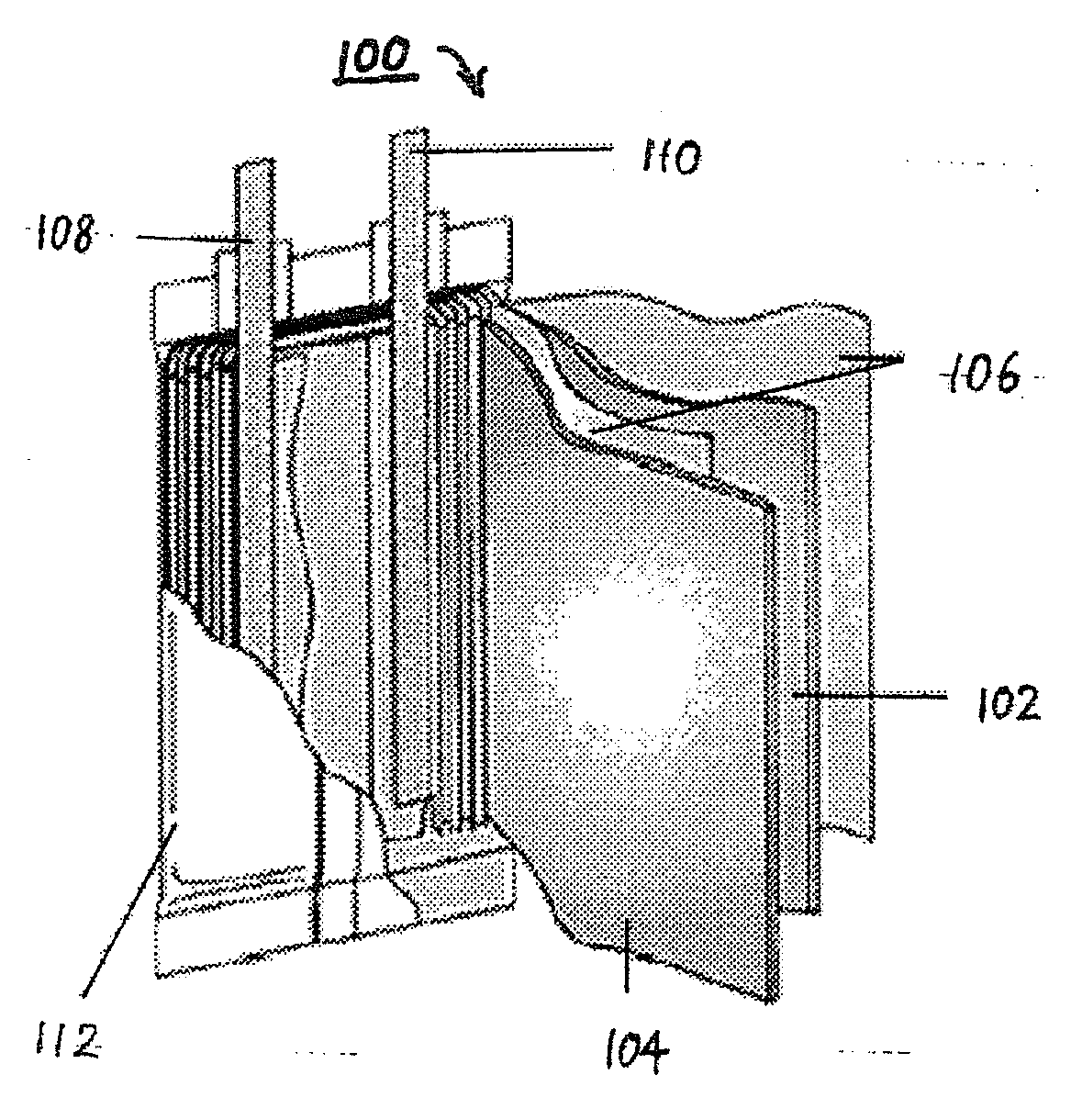

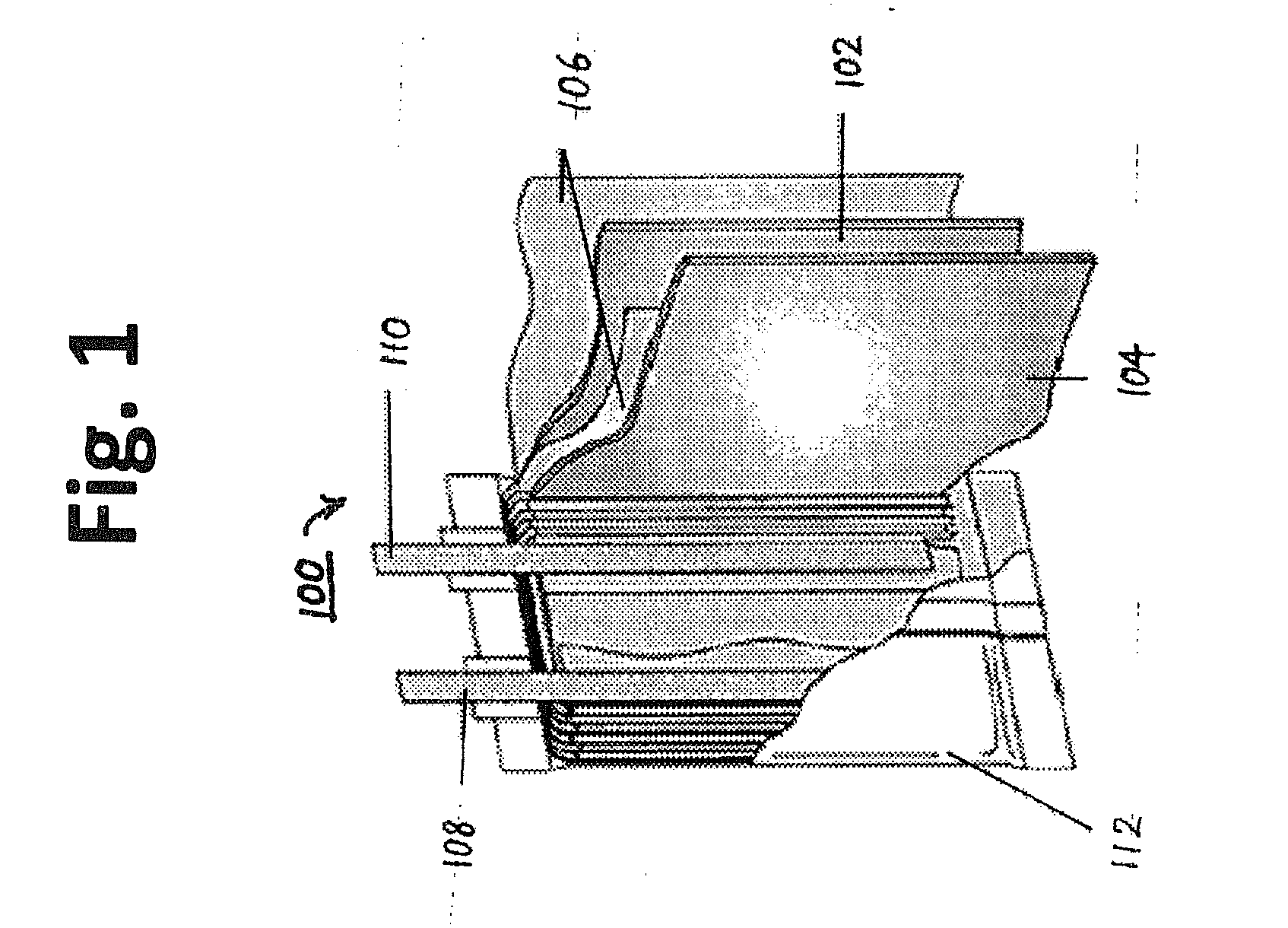

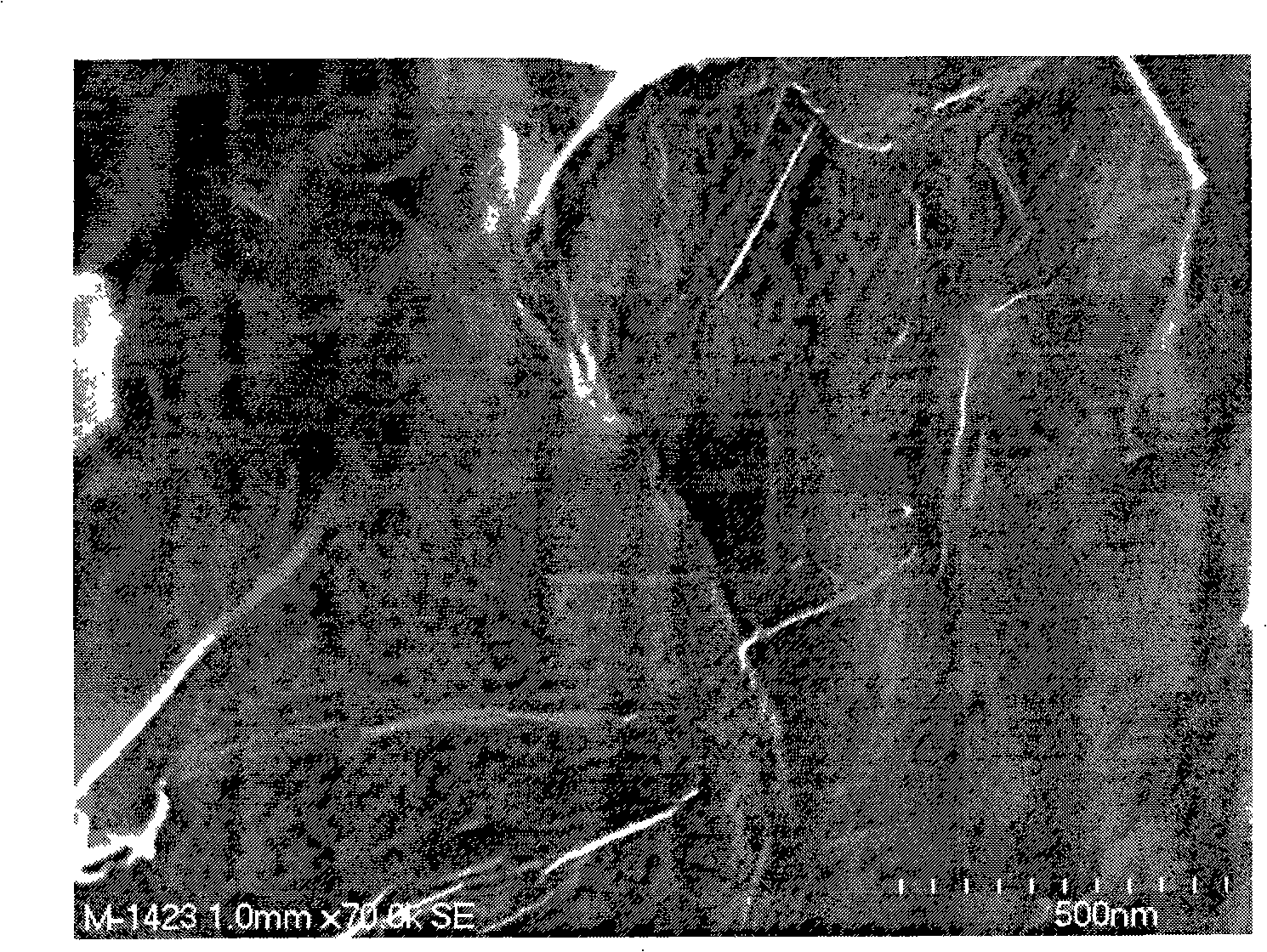

A nano graphene-enhanced particulate for use as a lithium-ion battery anode active material, wherein the particulate is formed of a single sheet of graphene or a plurality of graphene sheets and a plurality of fine anode active material particles with a size smaller than 10 μm. The graphene sheets and the particles are mutually bonded or agglomerated into the particulate with at least a graphene sheet embracing the anode active material particles. The amount of graphene is at least 0.01% by weight and the amount of the anode active material is at least 0.1% by weight, all based on the total weight of the particulate. A lithium-ion battery having an anode containing these graphene-enhanced particulates exhibits a stable charge and discharge cycling response, a high specific capacity per unit mass, a high first-cycle efficiency, a high capacity per electrode volume, and a long cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD +1

Process for producing nano graphene reinforced composite particles for lithium battery electrodes

ActiveUS20100176337A1Increase stiffnessHigh strengthCell electrodesLi-accumulatorsFiberLithium metal

Owner:SAMSUNG ELECTRONICS CO LTD

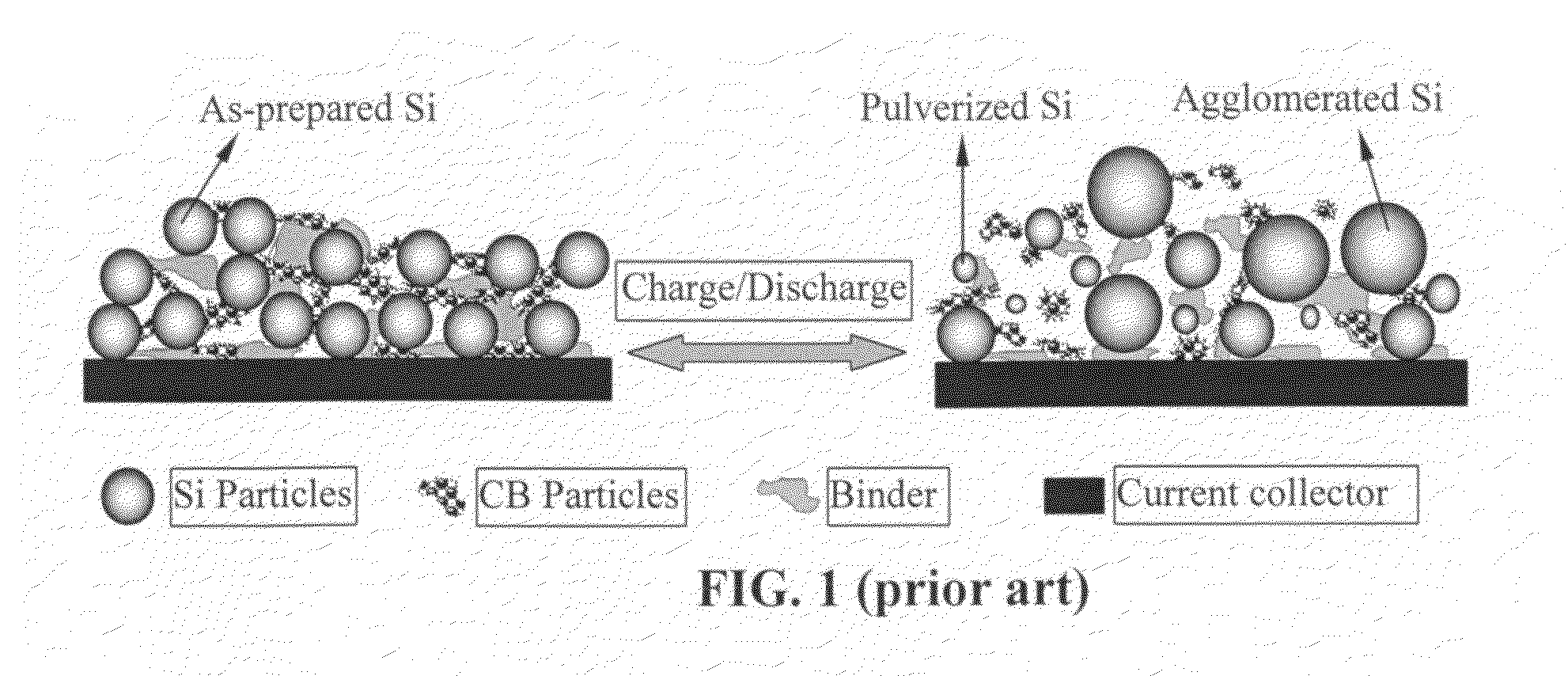

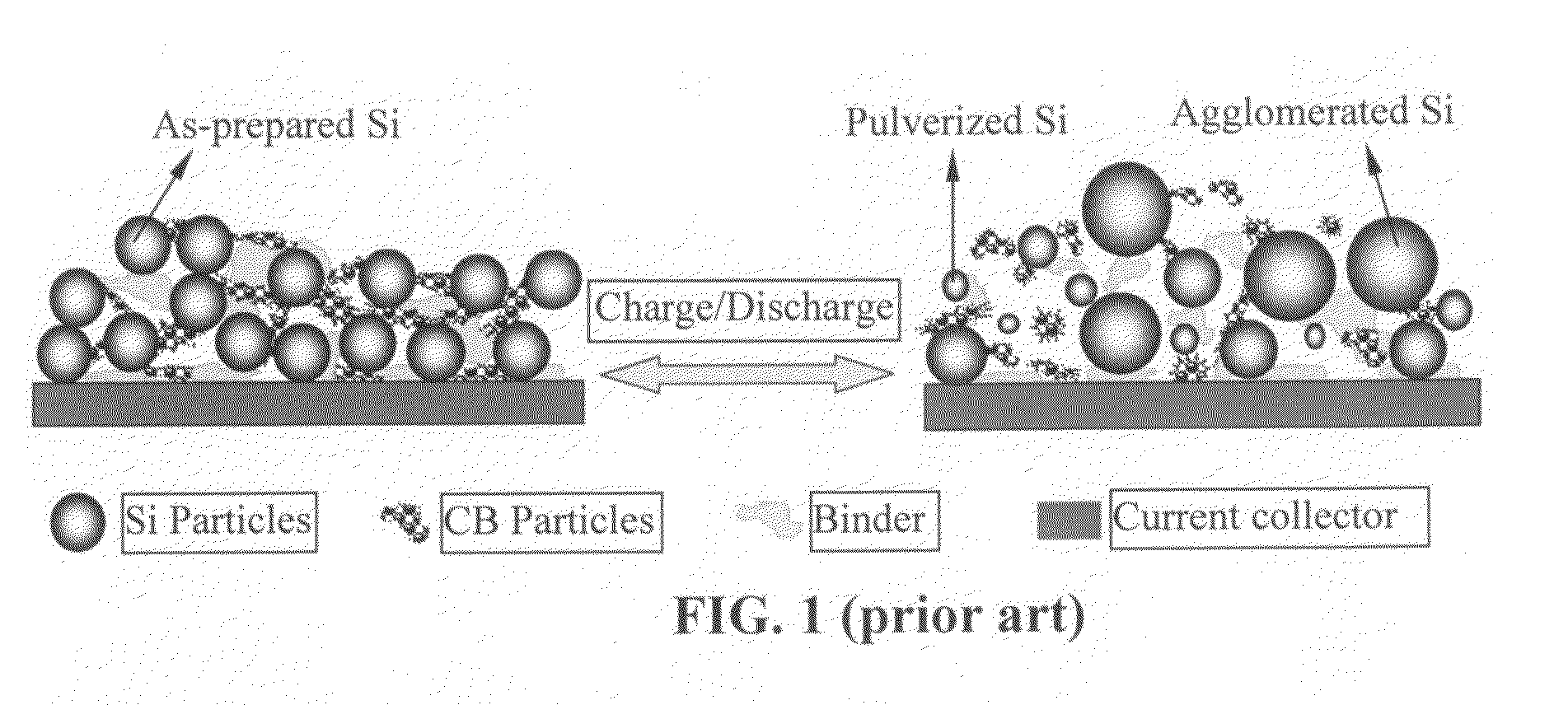

High energy lithium ion batteries with particular negative electrode compositions

ActiveUS20090305131A1Degree of crystallinity of will decreaseAlkaline accumulatorsElectrode manufacturing processesHigh energyMetal alloy

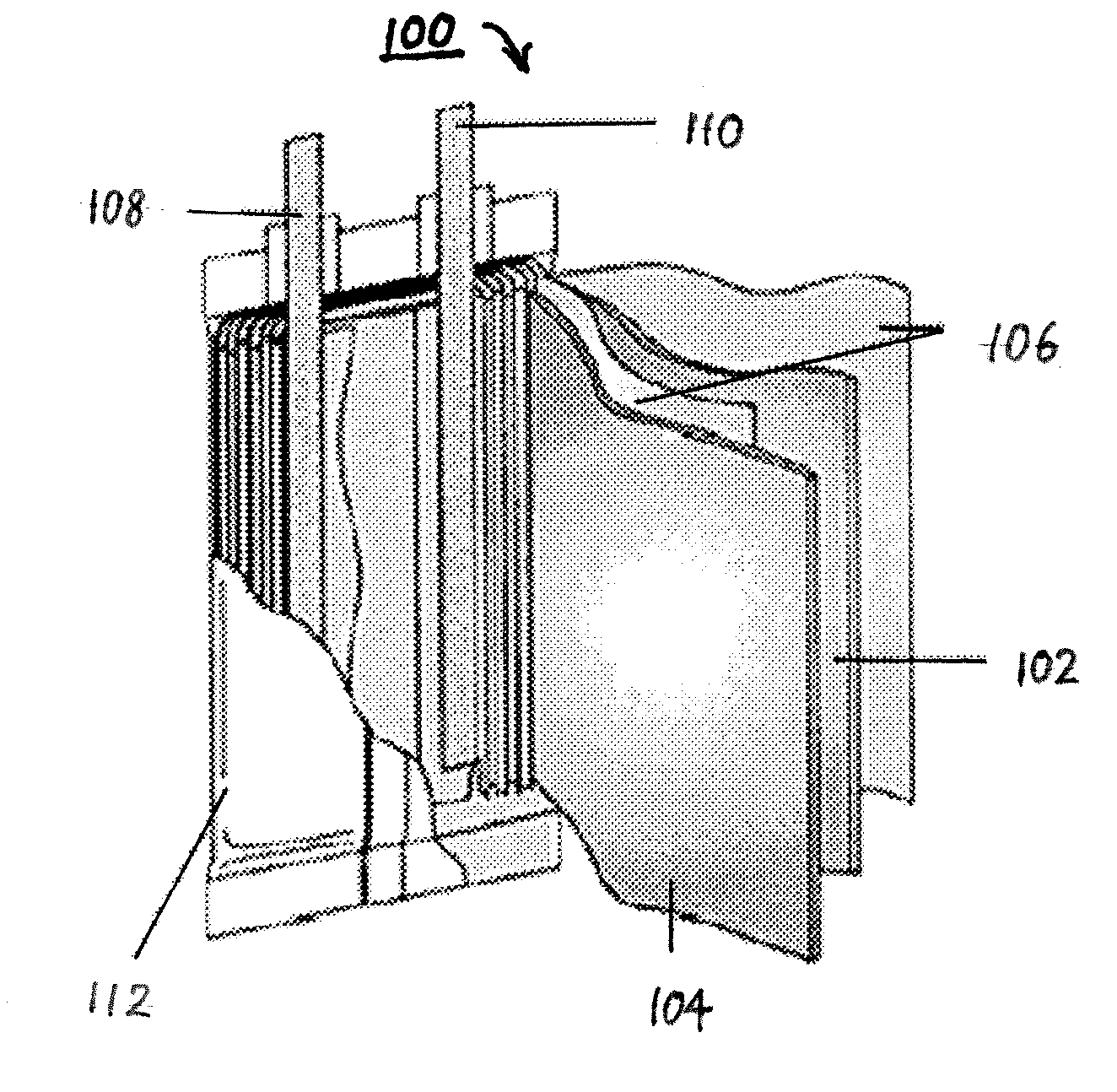

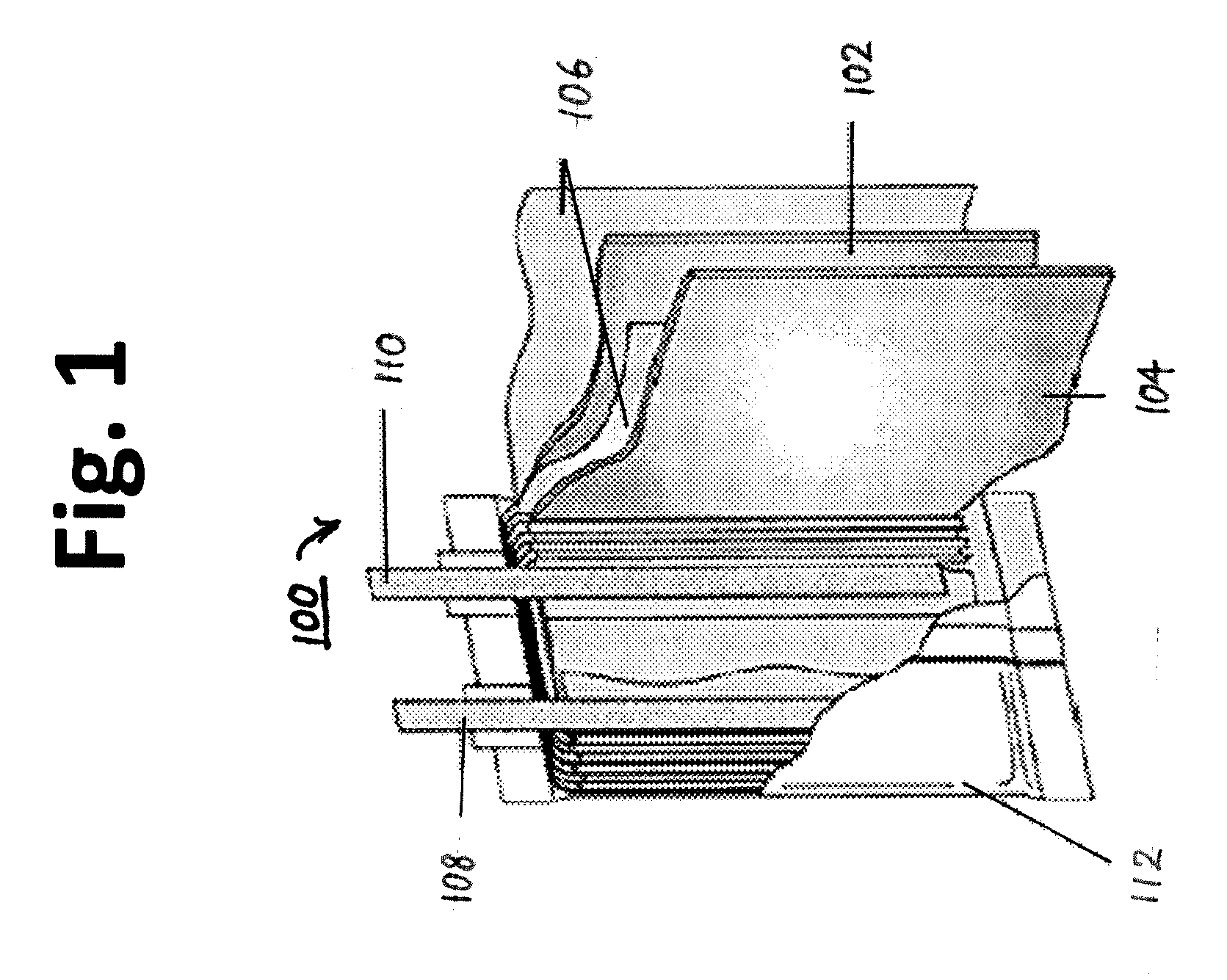

Combinations of materials are described in which high energy density active materials for negative electrodes of lithium ion batteries. In general, metal alloy / intermetallic compositions can provide the high energy density. These materials can have moderate volume changes upon cycling in a lithium ion battery. The volume changes can be accommodated with less degradation upon cycling through the combination with highly porous electrically conductive materials, such as highly porous carbon and / or foamed current collectors. Whether or not combined with a highly porous electrically conductive material, metal alloy / intermetallic compositions with an average particle size of no more than a micron can be advantageously used in the negative electrodes to improve cycling properties.

Owner:IONBLOX INC

Graphene nanocomposites for electrochemical cell electrodes

ActiveUS20100021819A1High and reversible anode capacityTedious and energy-intensiveMicroscopic fiber electrodesHybrid capacitor electrodesGraphene nanocompositesSolid particle

A composite composition for electrochemical cell electrode applications, the composition comprising multiple solid particles, wherein (a) a solid particle is composed of graphene platelets dispersed in or bonded by a first matrix or binder material, wherein the graphene platelets are not obtained from graphitization of the first binder or matrix material; (b) the graphene platelets have a length or width in the range of 10 nm to 10 μm; (c) the multiple solid particles are bonded by a second binder material; and (d) the first or second binder material is selected from a polymer, polymeric carbon, amorphous carbon, metal, glass, ceramic, oxide, organic material, or a combination thereof. For a lithium ion battery anode application, the first binder or matrix material is preferably amorphous carbon or polymeric carbon. Such a composite composition provides a high anode capacity and good cycling response. For a supercapacitor electrode application, the solid particles preferably have meso-scale pores therein to accommodate electrolyte.

Owner:NANOTEK INSTR GRP LLC

Composite compositions, negative electrodes with composite compositions and corresponding batteries

Compositions are described that can provide high energy density active materials for use in negative electrodes of lithium ion batteries. These materials generally comprise silicon and / or tin, and may further comprise carbon and / or zinc as well as other elements in appropriate embodiments. The active materials can have moderate volume changes upon cycling in a lithium ion battery.

Owner:IONBLOX INC

Graphene/metal oxide composite cathode material for lithium ion battery and preparation

InactiveCN102646817APromote circulationExcellent rate performanceCell electrodesHigh energyIn situ polymerization

The invention belongs to the fields of material synthesis and energy technology, and especially relates to a graphene / metal oxide composite cathode material for lithium ion batteries and a preparation method thereof. Grapheme is dispersed into various metal oxide precursor salt solutions; a graphene / metal oxide compound is obtained directly by a hydrothermal method, or an graphene / metal oxide compound is obtained by a liquid in-situ polymerization method or a coprecipitation process; and the graphene / metal oxide compound is obtained by heat treatment or hydrothermal treatment. In the invention, the novel three-dimensional composite cathode material of graphene-coated metal oxide or graphene-anchored metal oxide is prepared by carrying metal oxide particles with graphene as a carrier. The obtained composite material can be used as a lithium ion battery cathode, which has a high specific capacity, excellent cycle stability and rate capability, and is expected to be used as a lithium ion battery cathode material with a high energy density and a high power density.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

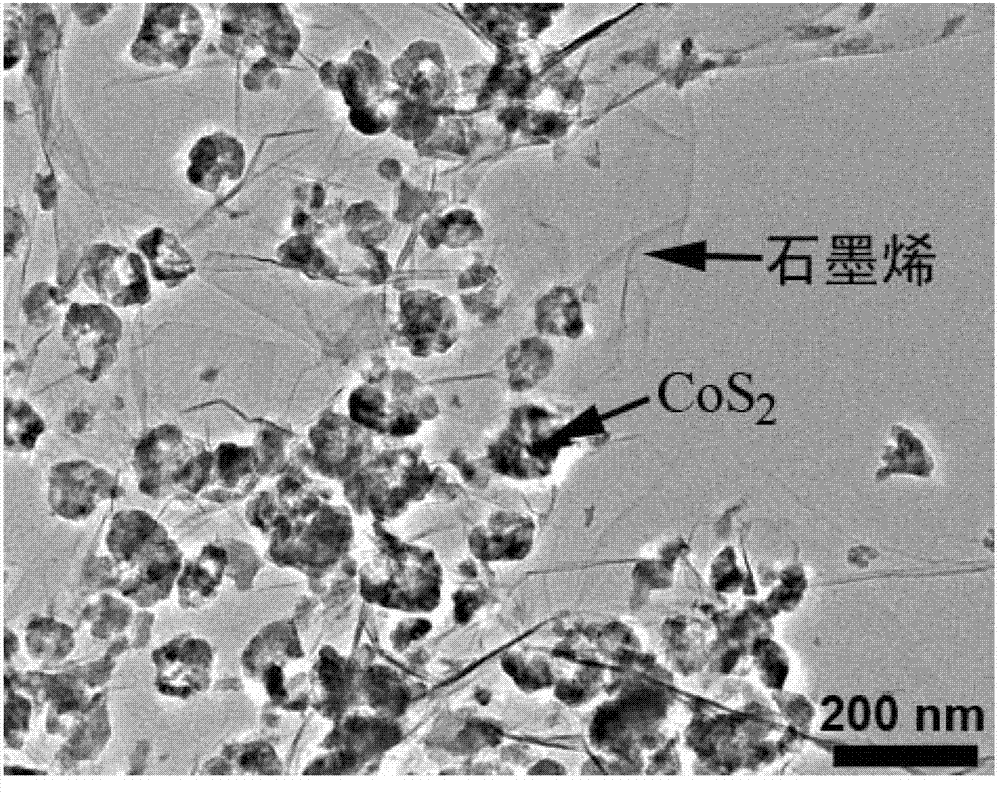

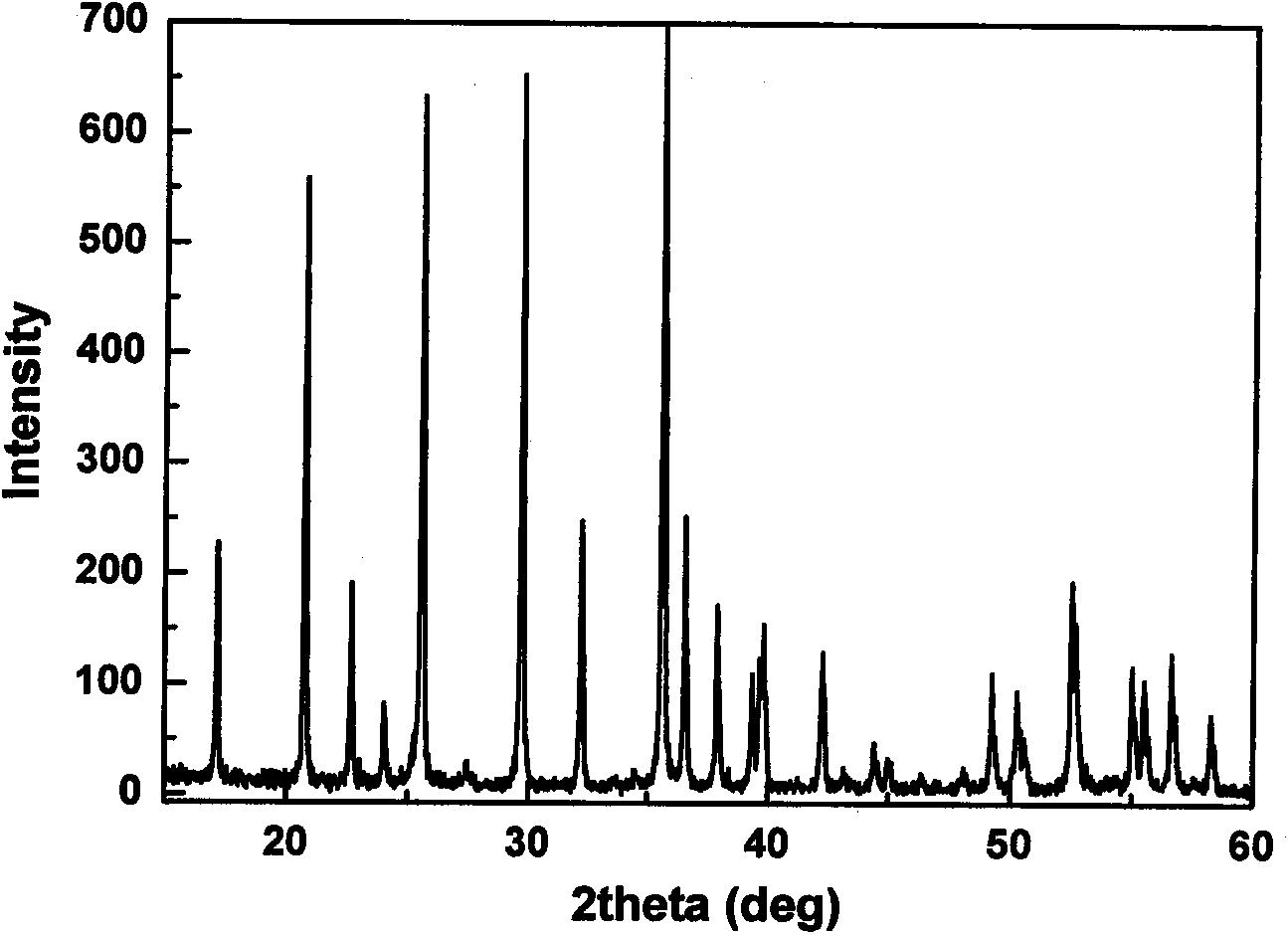

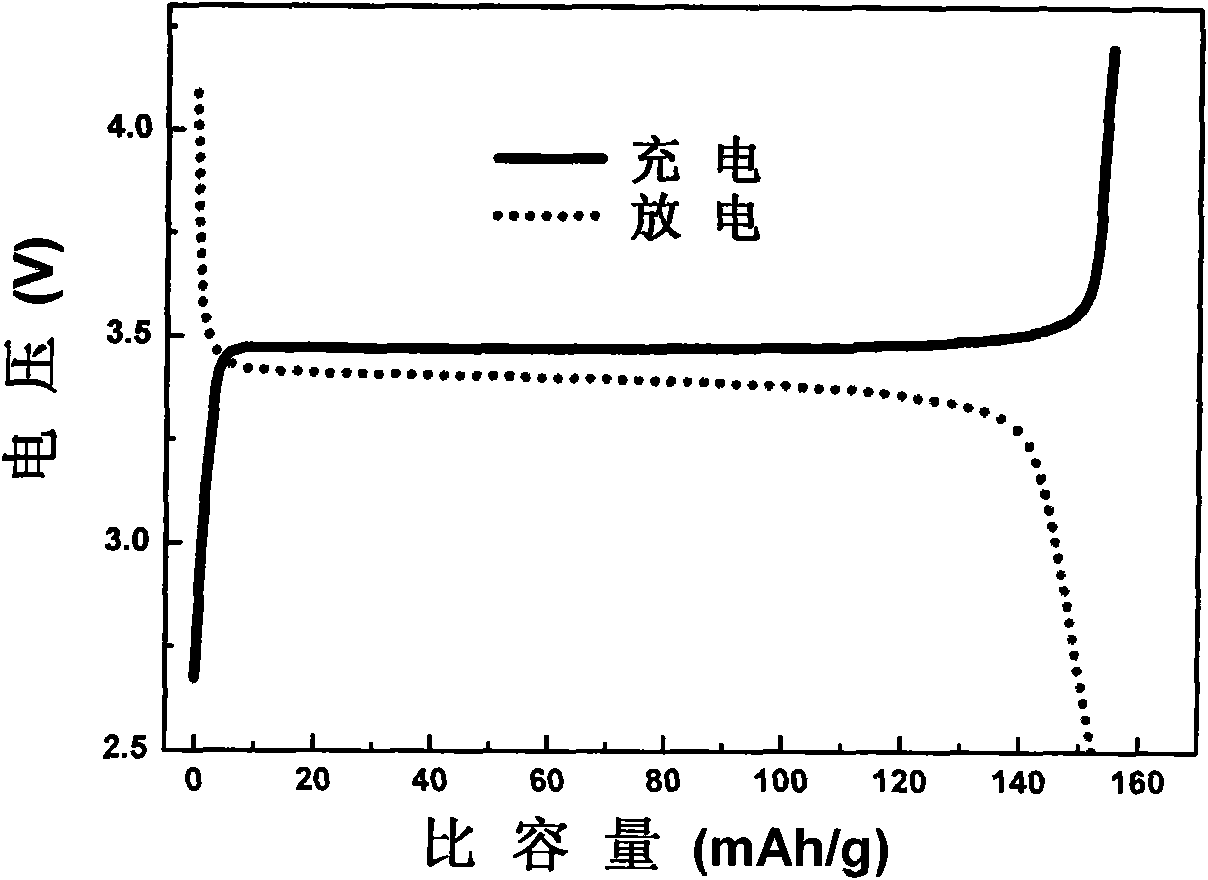

Transition metal sulfide/graphene composite material, and preparation method and application thereof

The invention discloses a transition metal sulfide / graphene composite material which is composed of a nano transition metal sulfide and graphene, wherein the transition metal sulfide is Ni2S3, NiS, FeS, FeS2, CoS, CoS2, CuS2, CuS, MnS or MnS2. Under the dispersion and loading actions of the graphene, the transition metal sulfide can be uniformly distributed and have small particle size, the stability and loop stability of the transition metal sulfide in the charging and discharging process can be effectively enhanced, and the composite material can be used as a lithium ion battery negative pole material. The invention also discloses a one-step low-temperature preparation method of the composite material, which has the advantages of simple technique, low cost, short cycle, low energy consumption and the like and is suitable for large-scale industrial production.

Owner:ZHEJIANG UNIV

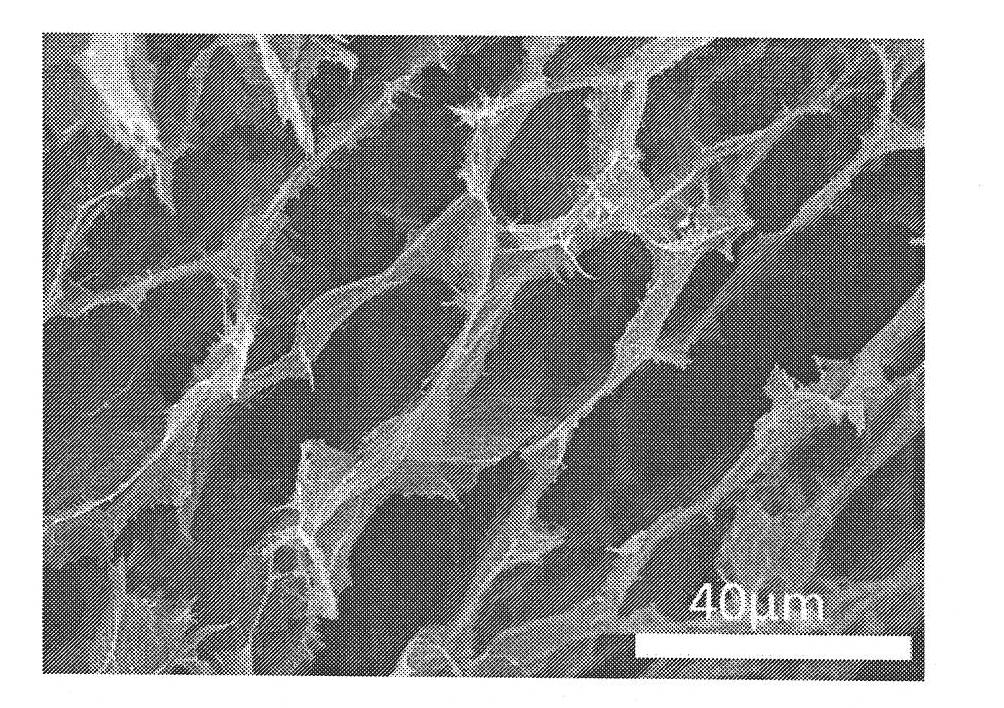

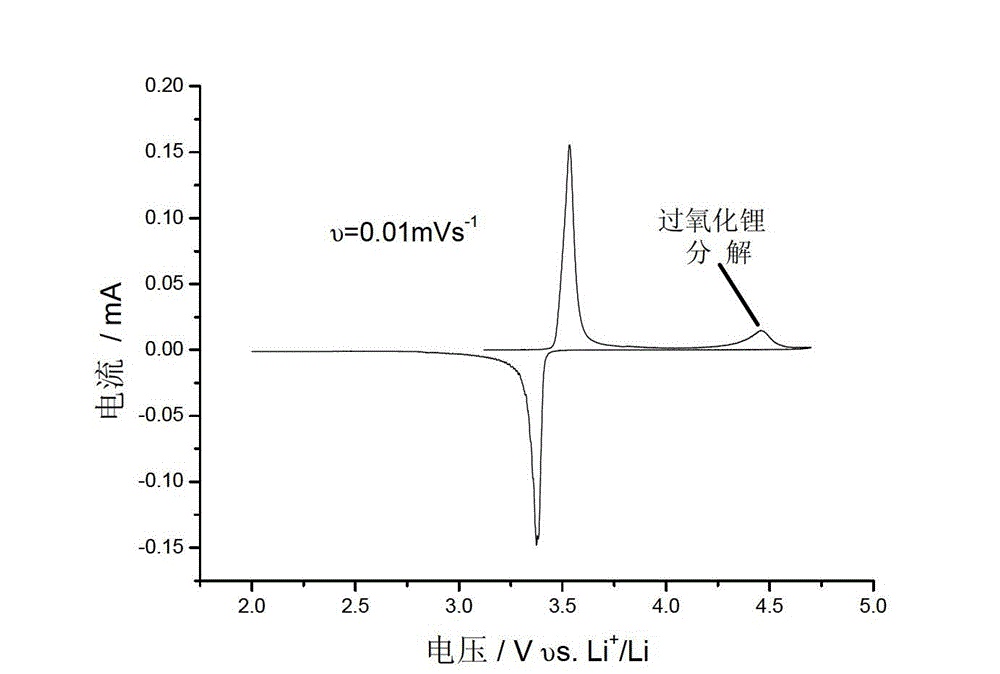

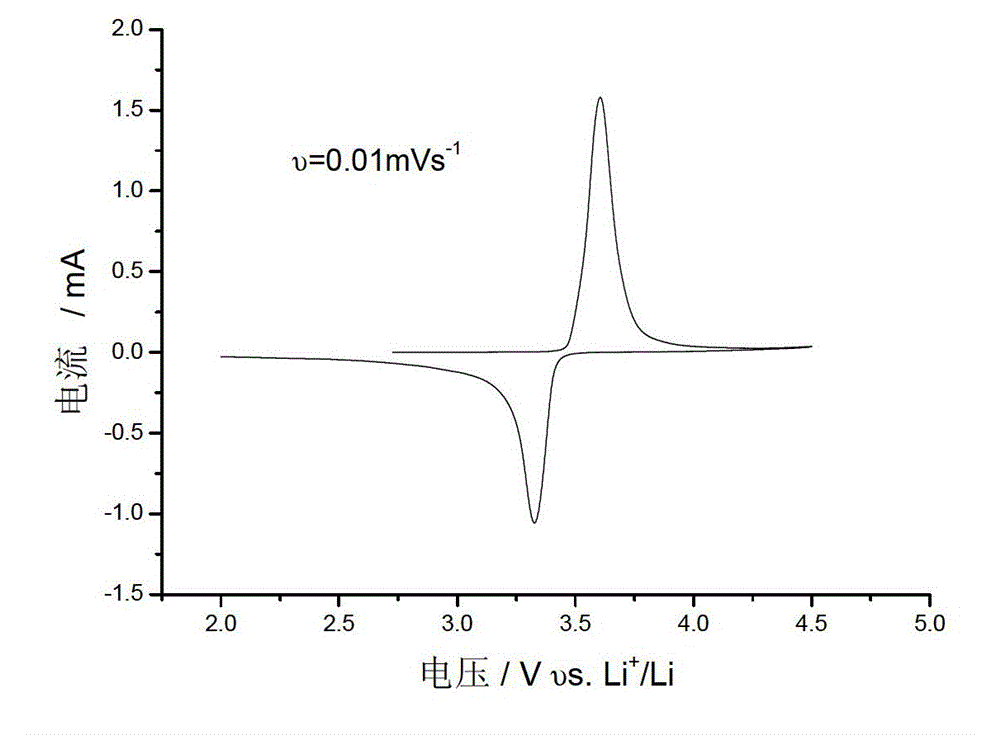

Graphite composite lithium ion battery anode material lithium iron phosphate and preparation method thereof

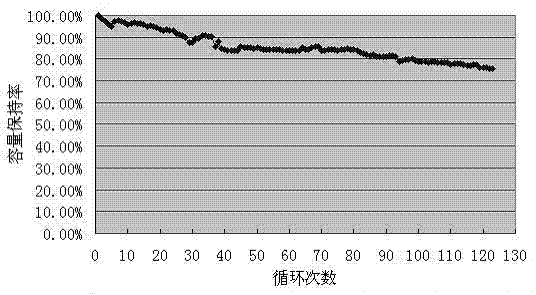

ActiveCN101562248AImprove electronic conductivityImprove tap densityElectrode manufacturing processesPower batteryChemical Linkage

The invention relates to a graphene composite lithium ion battery anode material lithium iron phosphate and a preparation method thereof. The composite material of lithium iron phosphate and graphene is connected by interface of chemical bonding. The invention also provides the method for preparing the graphene composite lithium ion battery anode material lithium iron phosphate in an in-situ symbiosis reaction mode, and the obtained anode material has high tap density and good magnifying performance, and is suitable to be used as a anode material of a lithium ion power battery.

Owner:龚思源

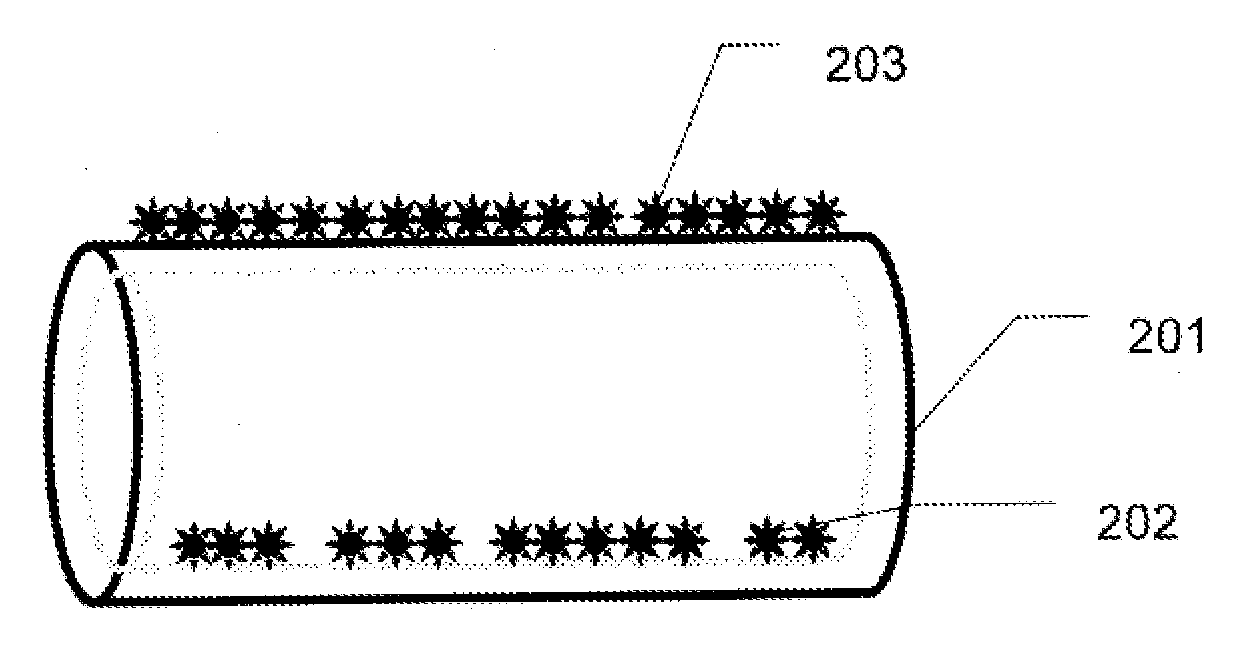

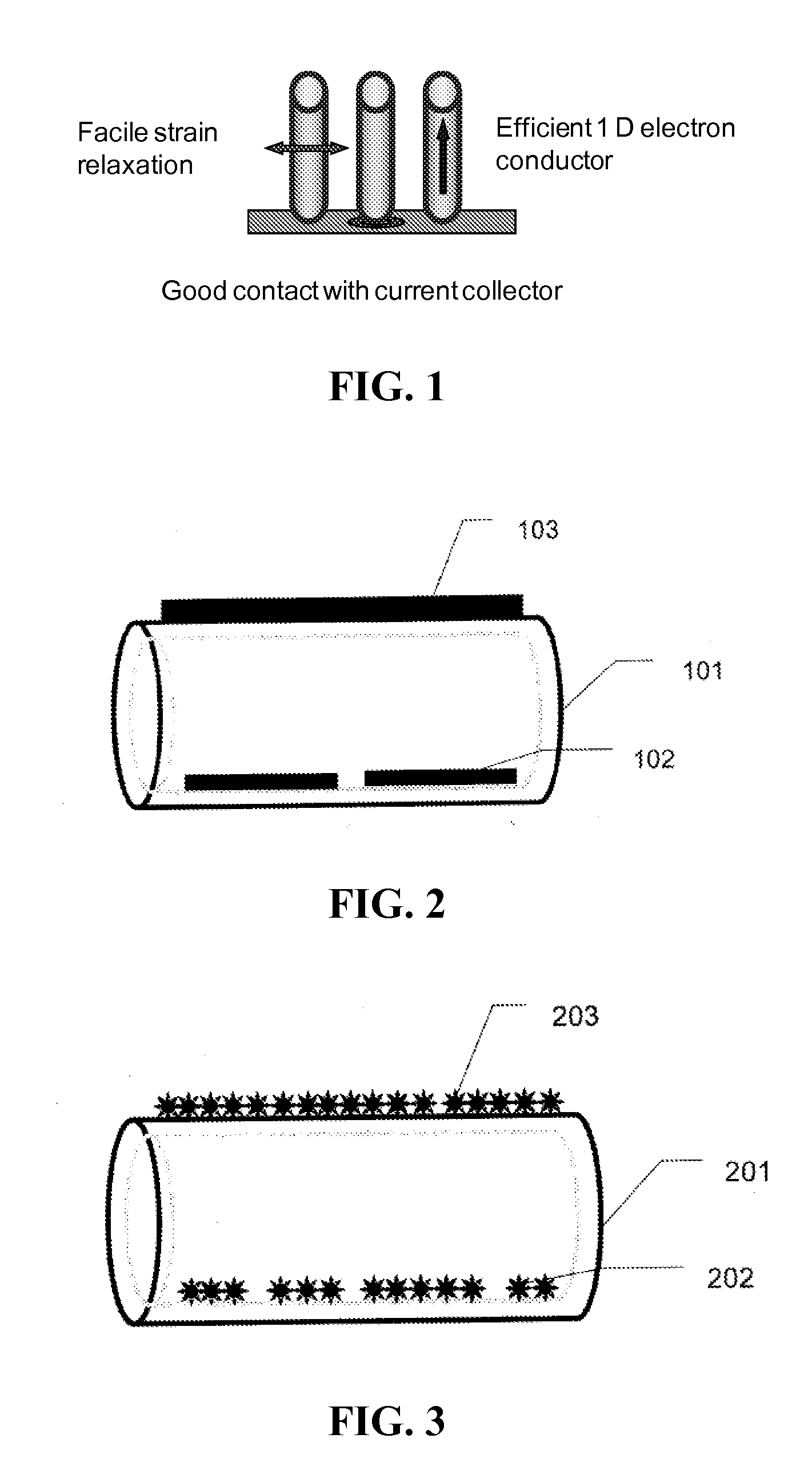

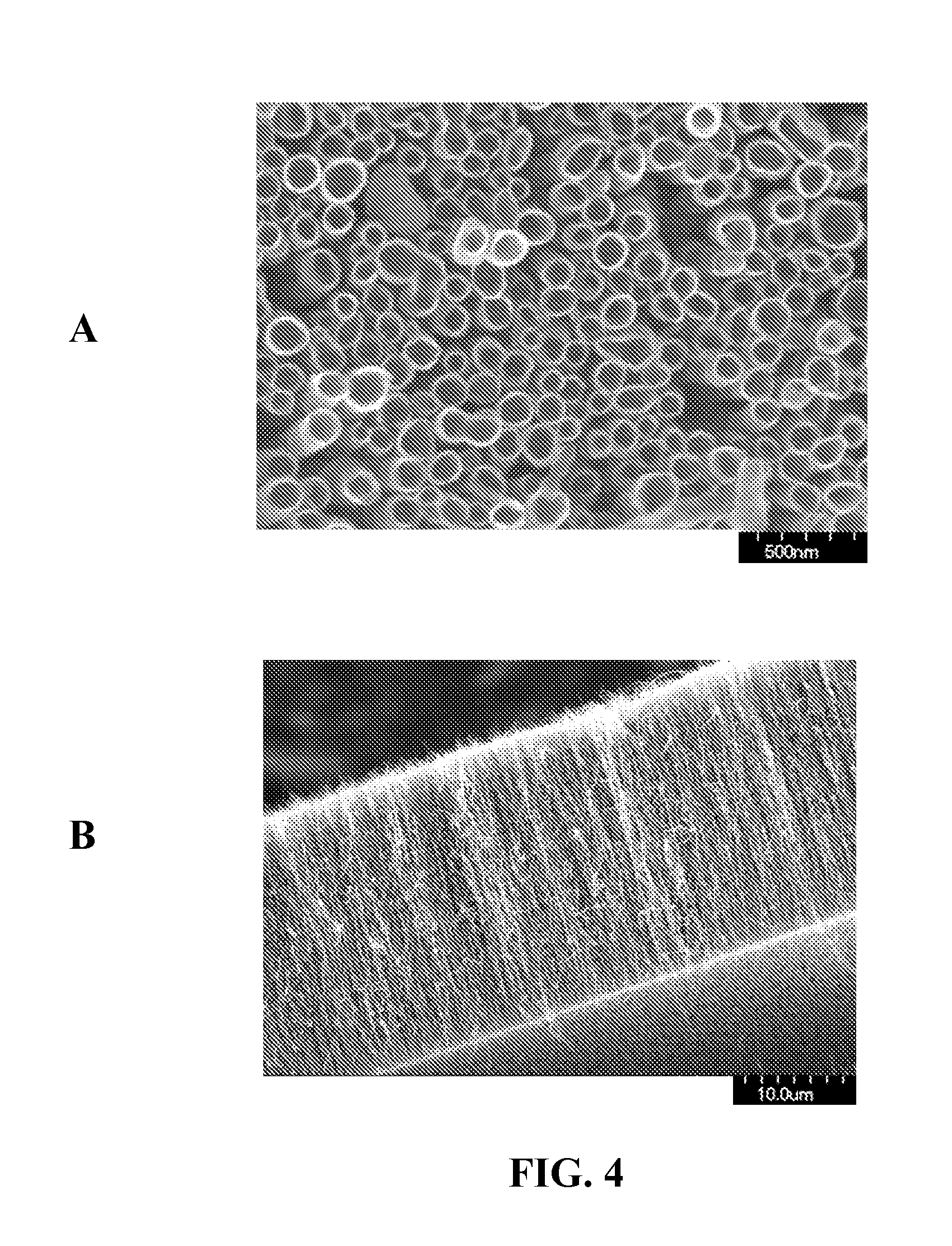

Nanotube composite anode materials suitable for lithium ion battery applications

The present invention provides a composite material suitable for use in an anode for a lithium ion battery, the composite material comprising a layer of a lithium-alloying material on the walls of an aligned nanotubular base material. Preferably, the lithium-alloying material comprises a material selected from the group consisting of Si, Sn, Pb, Al, Au, Pt, Zn, Cd, Ag, Mg, and a combination of two or more of the foregoing.

Owner:UCHICAGO ARGONNE LLC

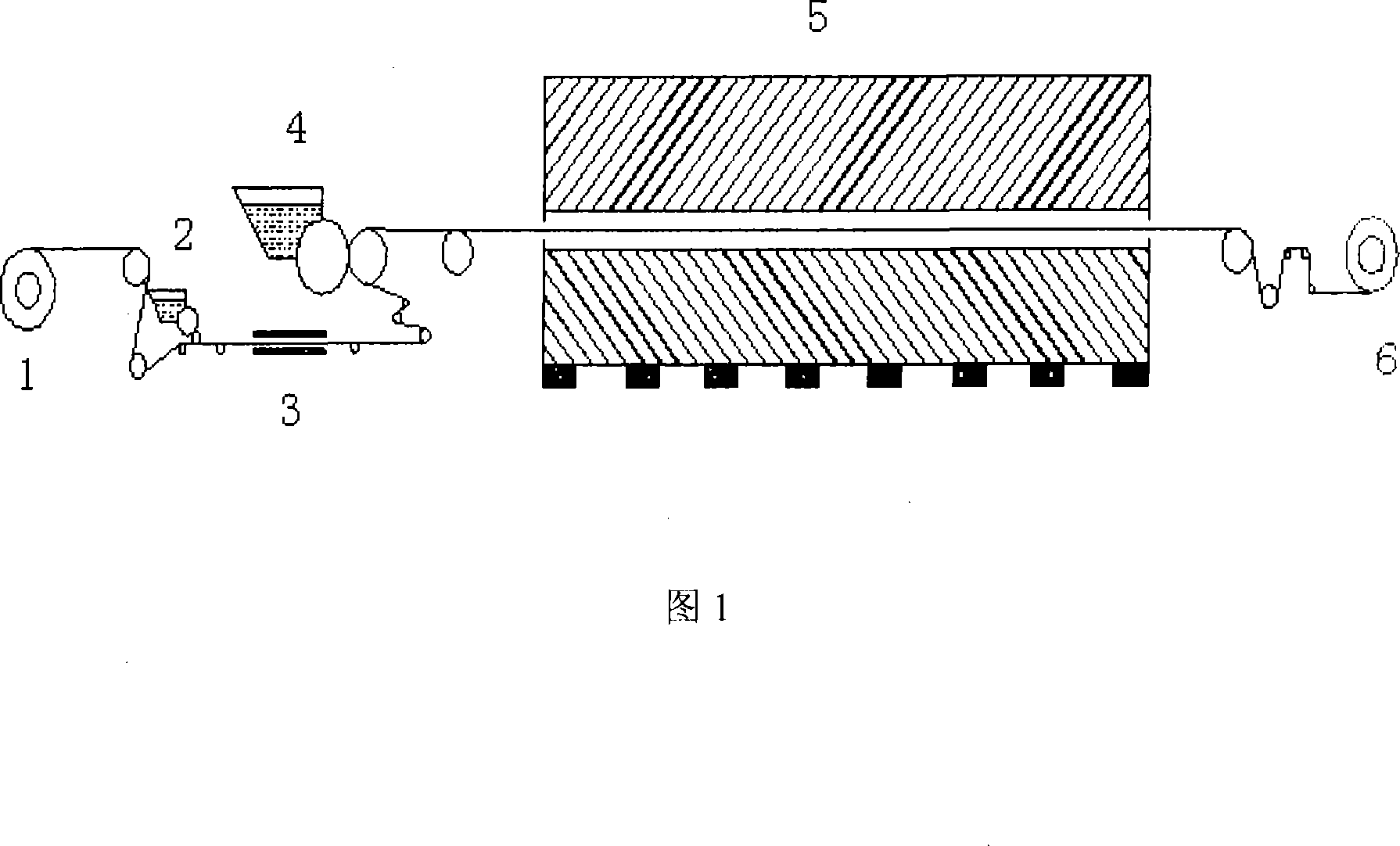

Anode or cathode pole piece of lithium ion battery and coating method thereof

InactiveCN101174685ALower surface energyLow densityElectrode manufacturing processesActive material electrodesCyclic processPole piece

The present invention relates to a lithium-ion battery anode or cathode pole piece and a spreading method of the anode pole piece or the cathode pole piece, wherein, the anode pole piece and the cathode pole piece consists of a foil, a conducting adhesive thin layer and an electrode active material layer in turn; the thickness of the conducting adhesive thin layer is five to ten microns. The electrode pole piece is made in the procedures that a layer of conducting adhesive thin layer in the thickness of five to ten microns are pre-coated on the surface of the foil before the sizing agent is spread, so that a conducting adhesive thin layer having good adhesive force, good conductivity and compact structure is formed on the surface of the foil. Then the electrode active material sizing agent is spread on the conducting adhesive thin layer, and is dried under an appropriate temperature to produce a required pole piece. The present invention can reduce the surface of the foil, and can improve the wetting quality of the sizing agent, thereby improving the adhesion performance of the anode material and the collecting body (aluminum foil) so as to reduce the powder-dropping of the battery during the cycling process, and to prolong the cycling service life of the battery; moreover, the present invention can reduce the content of the adhesive agent in the sizing agent, and improve the utilization rate of the active substance, and the method of the present invention does not produce negative influence on the performance of the battery.

Owner:CENT SOUTH UNIV

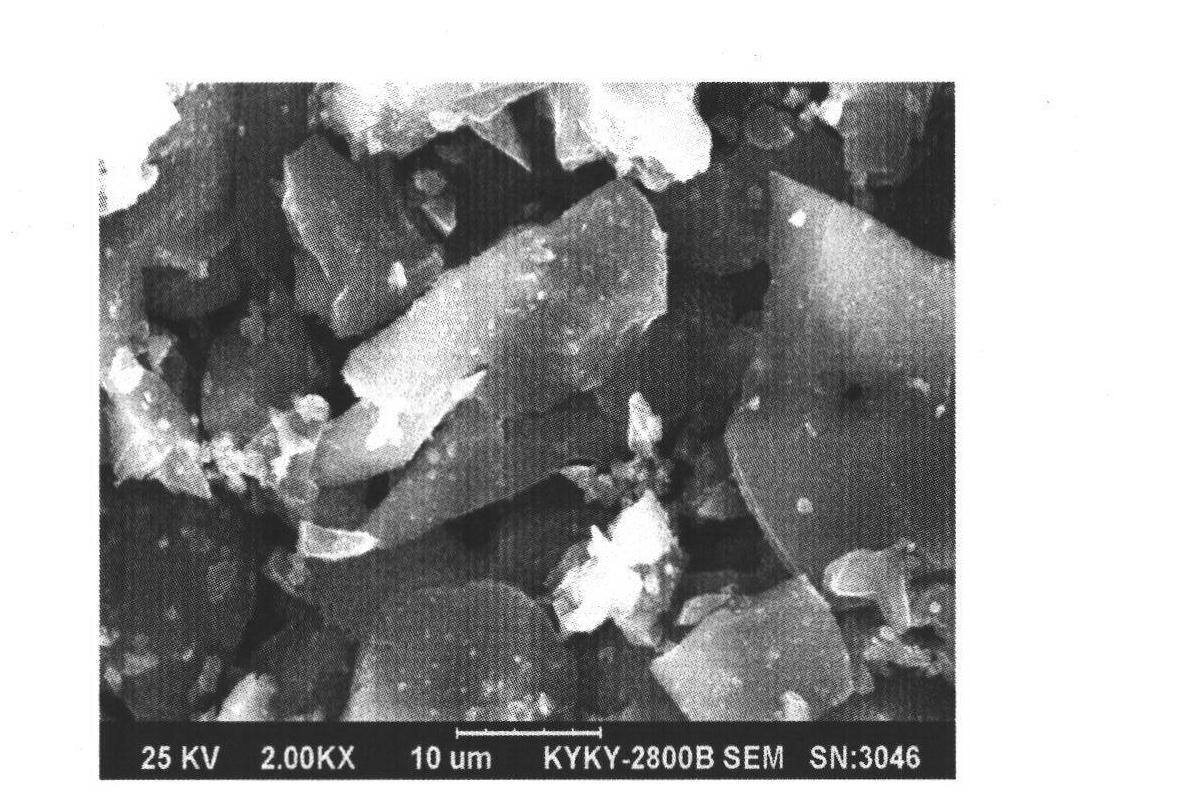

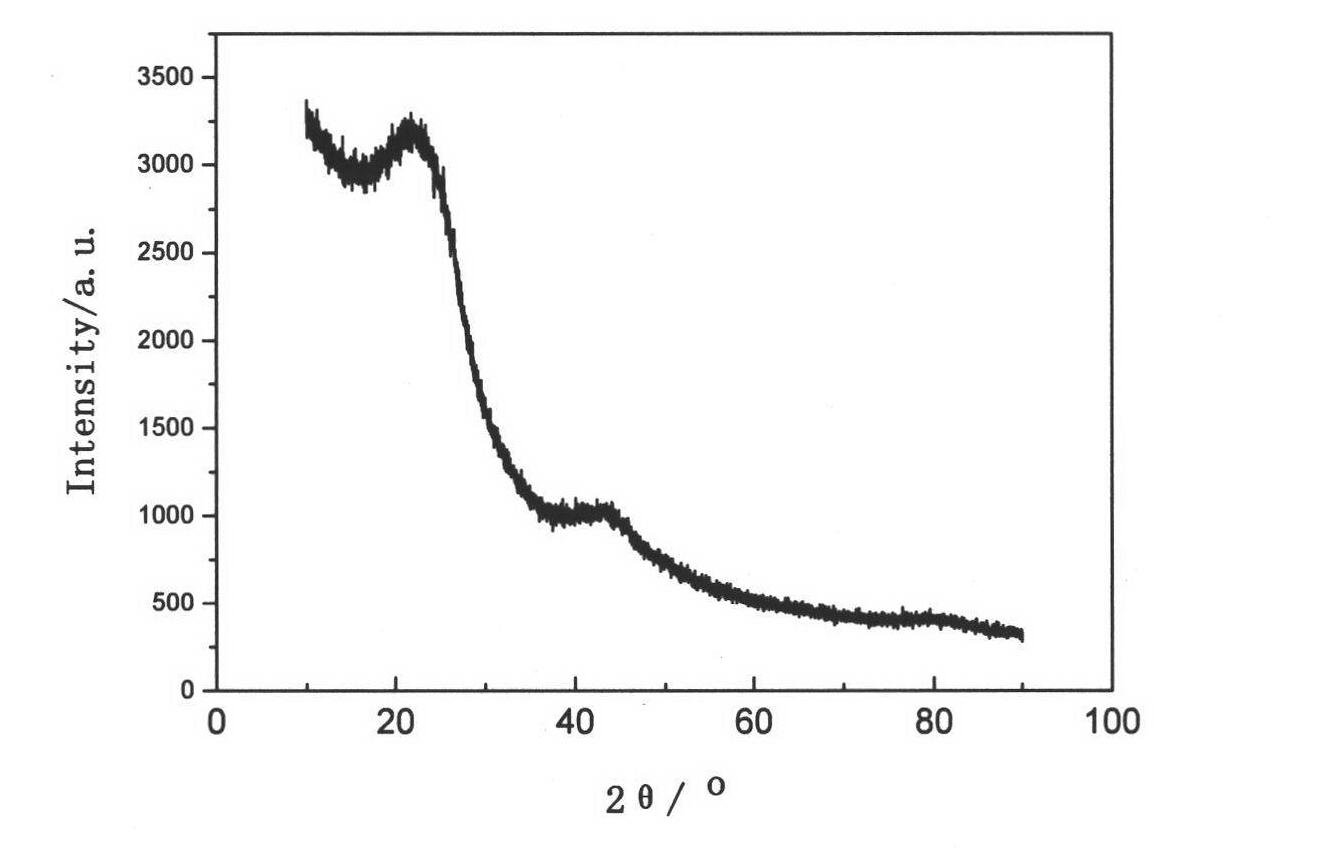

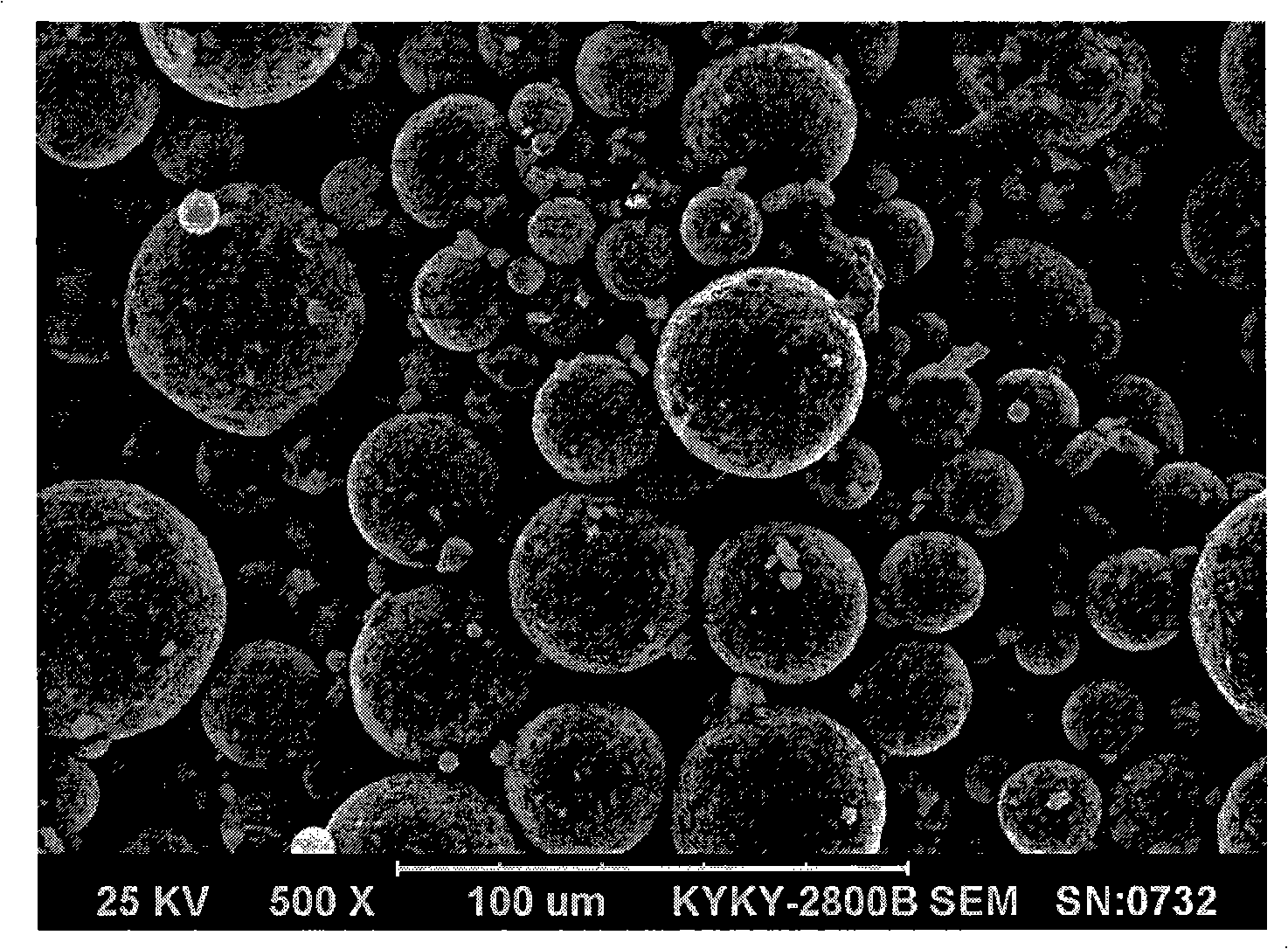

Graphite powder of lithium ionic cell cathode and preparation thereof

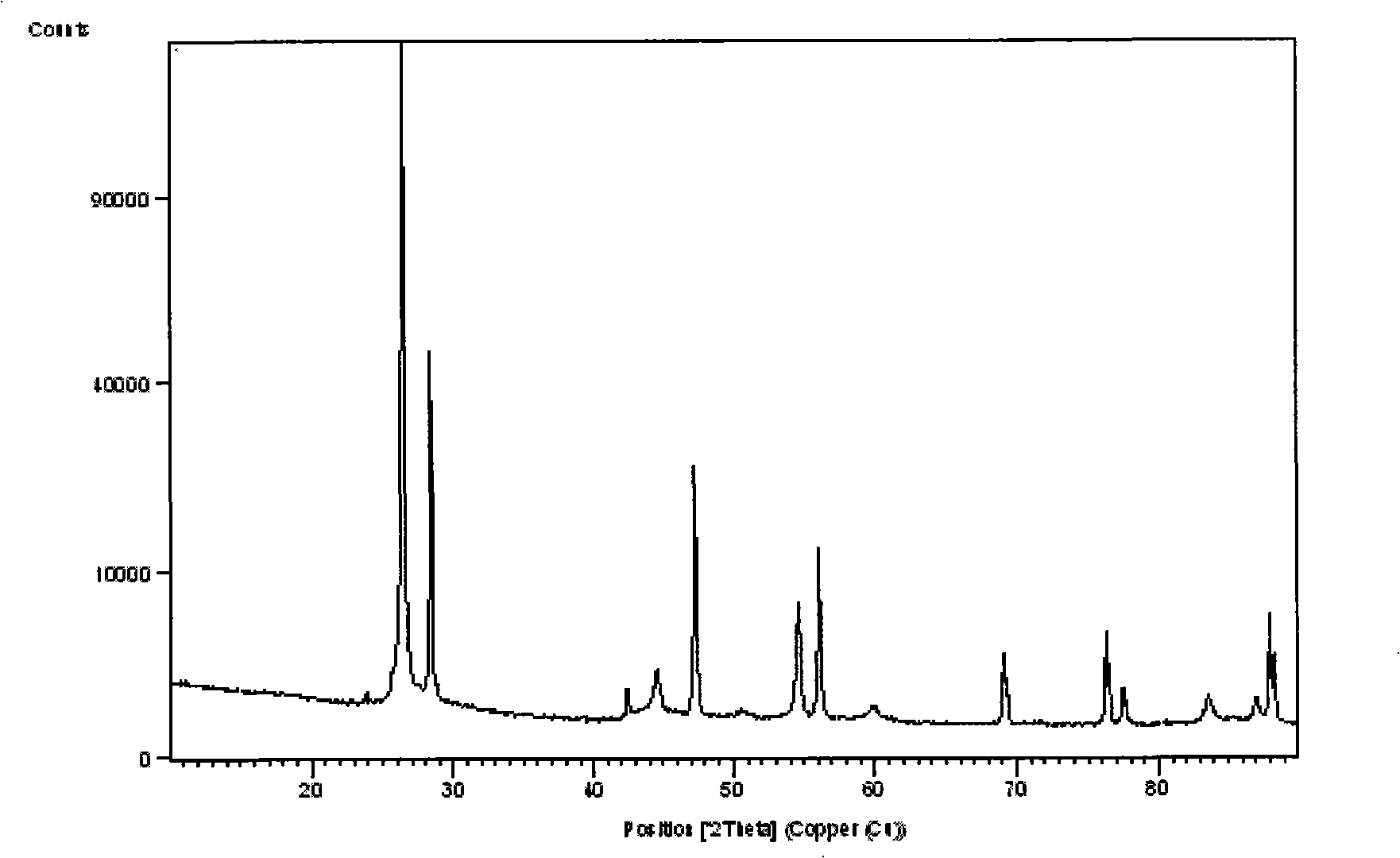

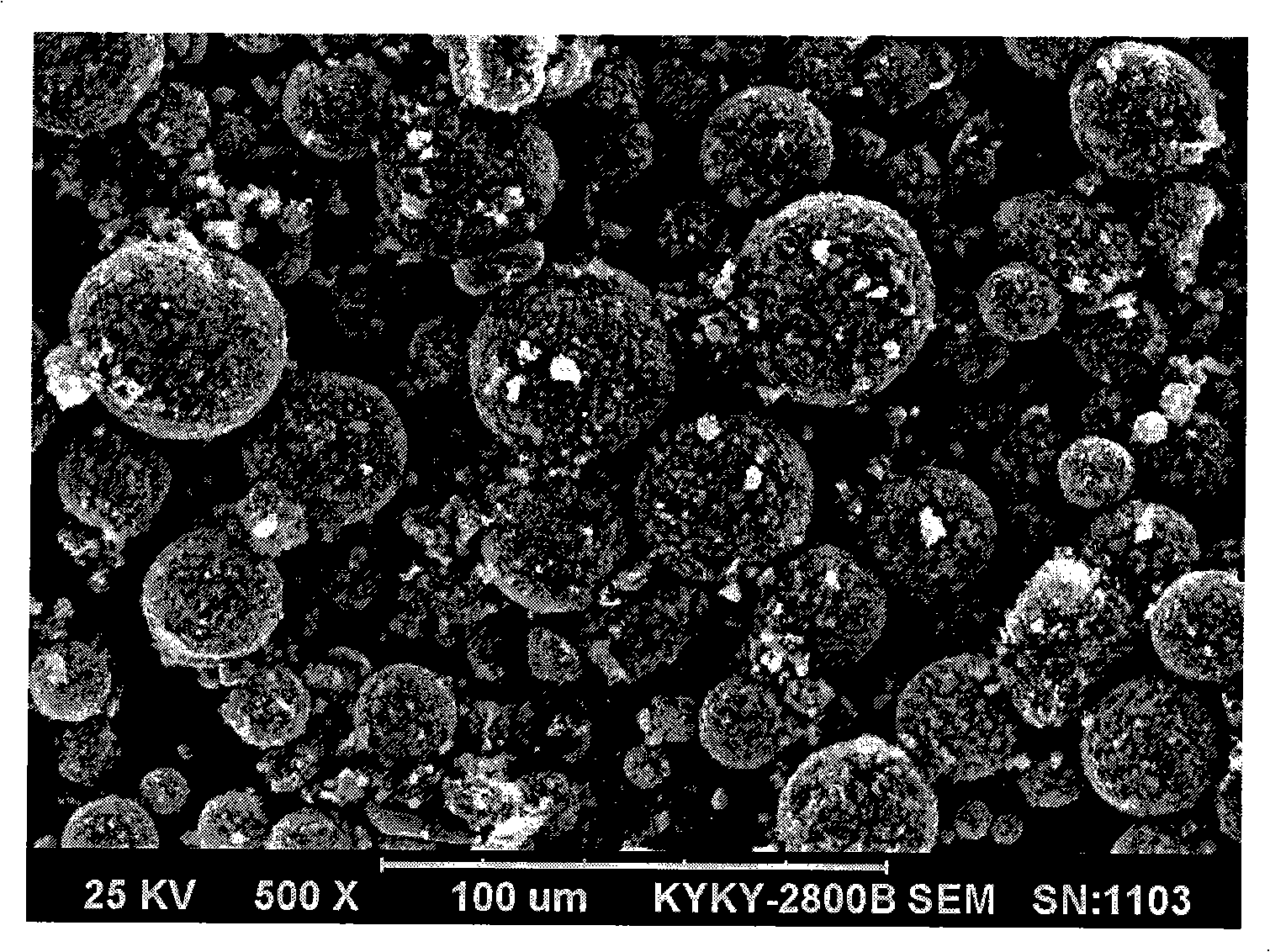

ActiveCN101323447AHigh purityImprove liquid absorption capacityCell electrodesSpherical shapedGraphite

The invention discloses a graphite powder of the cathode of a lithium ion battery, and a preparation method thereof; the technical problem to be solved is that the transmission speed of a lithium ion and an electrolyte to the inside of the electrode needs to be increased. The graphite powder of the cathode of the lithium ion battery of the invention has the microscopic feature of massive, spherical and near-spherical shapes and has the characteristics of nano-porous. The preparation method thereof comprises the following steps of: grinding, adding coating modifiers or / and catalysts, mixing, dissolving, and carrying out preheating treatment and heat treatment. Compared with the prior art, the invention carries out modifying treatment to graphite material and realizes the characteristic of nano-porous by adding pore-forming agents, thus being beneficial to the transmission of the lithium ion, improving the liquid-absorbing performance of a pole piece after compaction, reducing the content of impurity in the graphite, improving the liquid-absorbing performance and the magnification performance of the graphite material, meeting the requirements of the lithium ion dynamic battery for the compatibility and the charging and discharging performance with large magnification of the electrolyte of the graphite material and having the advantages of lower production cost, simple technique and easy industrialization.

Owner:BTR NEW MATERIAL GRP CO LTD

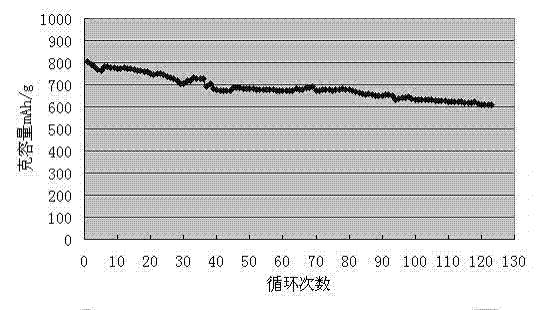

Graphene/silicon lithium ion battery cathode material and preparation method thereof

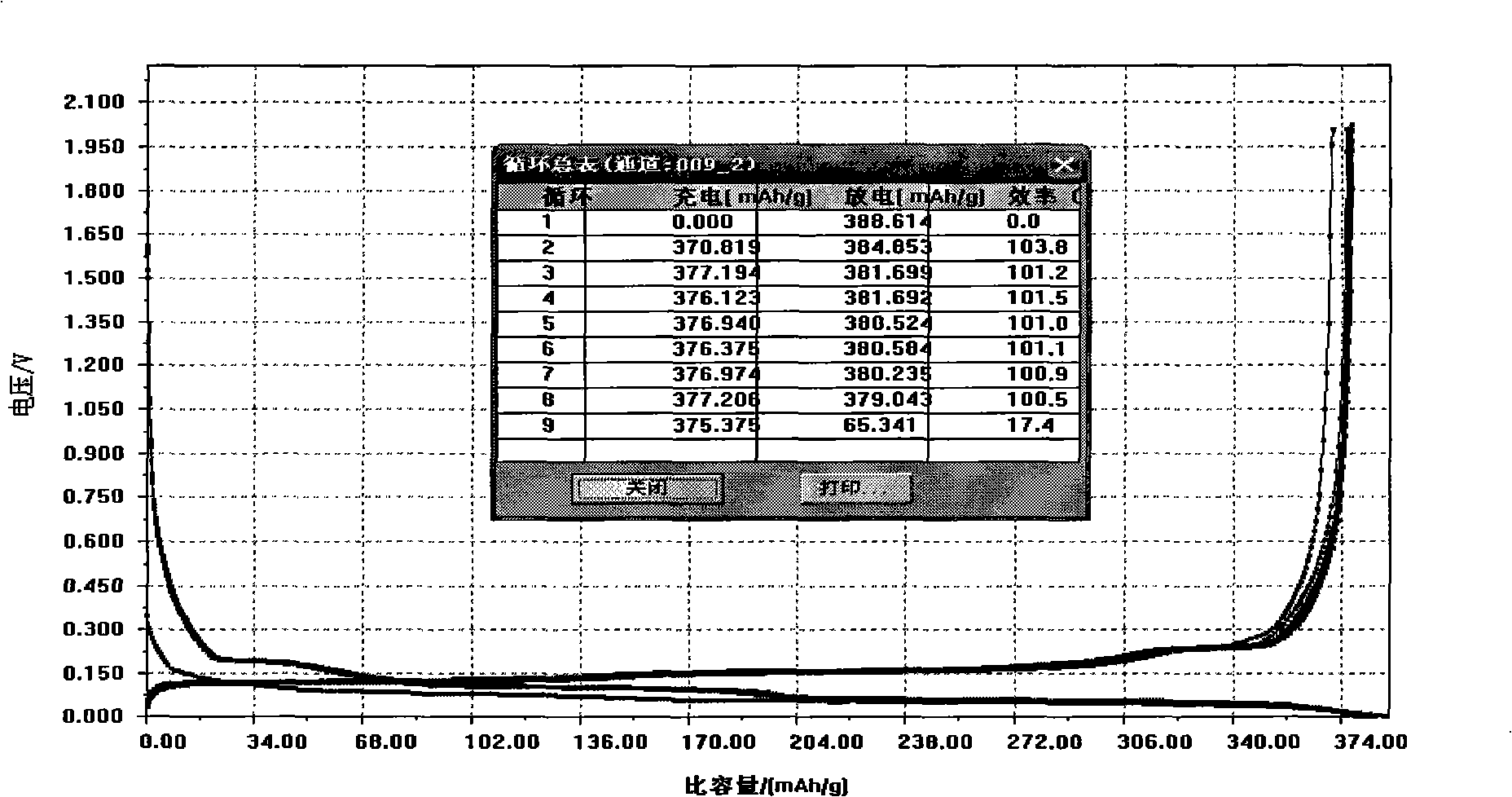

InactiveCN101924211AHigh specific capacityImprove cycle stabilityCell electrodesComposite filmNew energy

The invention discloses a grapheme / silicon composite material for a lithium ion battery cathode material and a preparation method thereof, belonging to the fields of electrochemistry and new energy materials. The method comprises the following steps of: using graphite as a raw material; oxidizing the graphite into oxidized graphite by adopting oxidants of concentrated sulfuric acid and potassium permanganate; then, ultrasonically stripping the oxidized graphite to prepare oxidized graphene; mixing oxidized graphene in different proportions with nano silicon powder; ultrasonically dispersing, filtering or directly drying into a cake / film; and roasting under a reduction atmosphere to prepare self-support graphene / silicon composite film materials in different proportions. Proved by electrochemistry tests, the graphene / silicon composite film material prepared by the method has higher specific capacity and cycle stability, simple preparation method and easy mass production and consequently is an ideal high-energy lithium ion battery cathode material.

Owner:UNIV OF SCI & TECH BEIJING +1

Method for preparing porous silicon/carbon composite material by using diatomite as raw material and application

The invention provides a method for preparing a porous silicon / carbon composite material by using diatomite as the raw material, which is characterized by comprising the following steps of: with the diatomite as the raw material, performing simple refinement and purification processing to obtain silicon with a porous structure by means of metallothermic reduction; performing mechanical ball-milling with the carbon materials and / or precursors of carbon, hydro-thermal carbonization, pyrolytic carbonization or chemical vapor deposition to prepare the porous silicon / carbon composite material. Thecomposite material can be directly used as the cathode of the lithium ion battery, or can be mixed with other cathode materials to be used as the cathode materials of the lithium ion battery. Compared with a pure silicon material as the cathode material of the lithium ion battery, the porous silicon / carbon composite material has the advantages that the first reversible capacity and the circulation stability of the material are greatly improved. In the method, the inexpensive and accessible natural minerals are used as the raw materials, thus the cost is low and the preparation method is simple.

Owner:UNIV OF SCI & TECH BEIJING

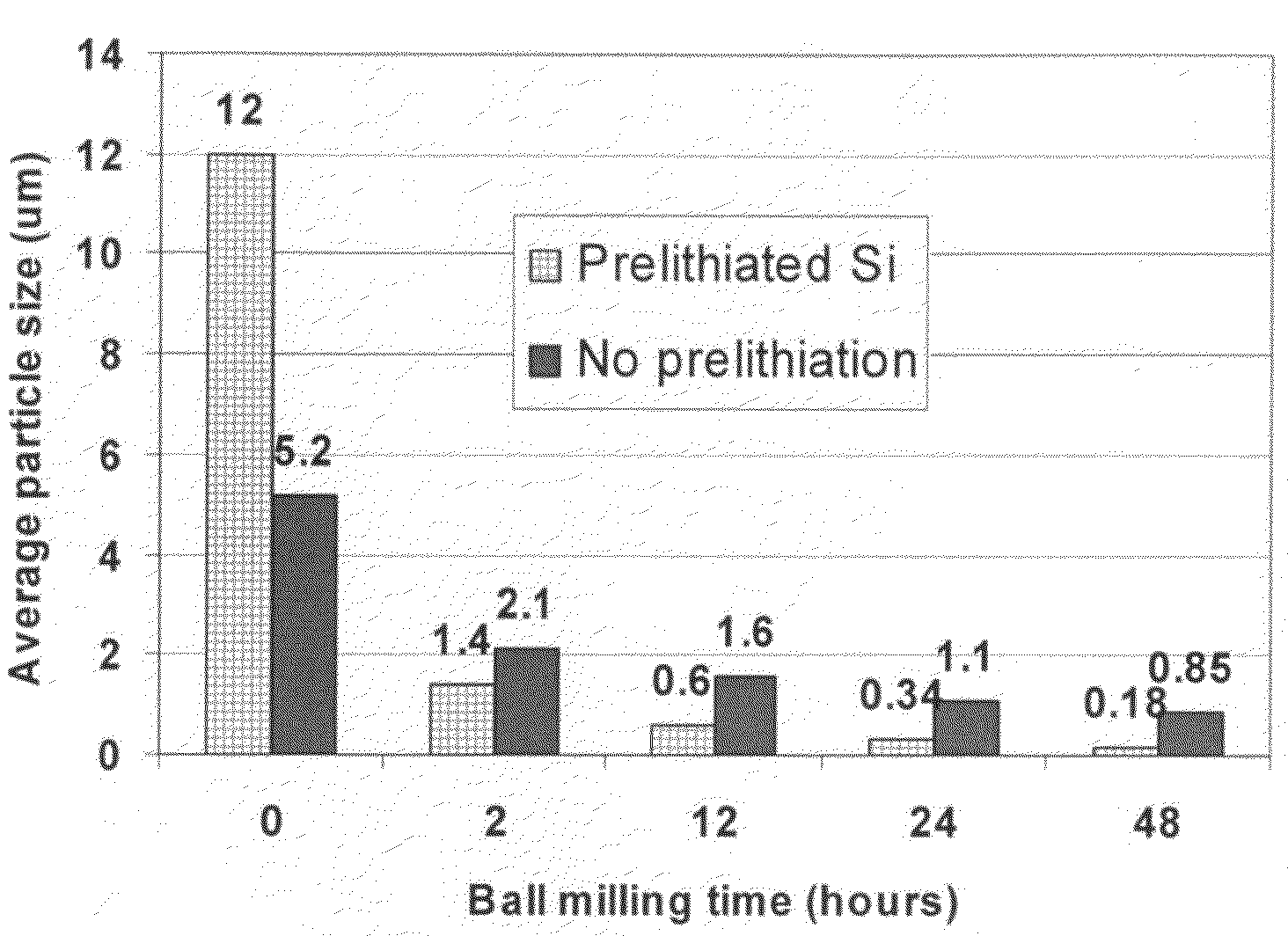

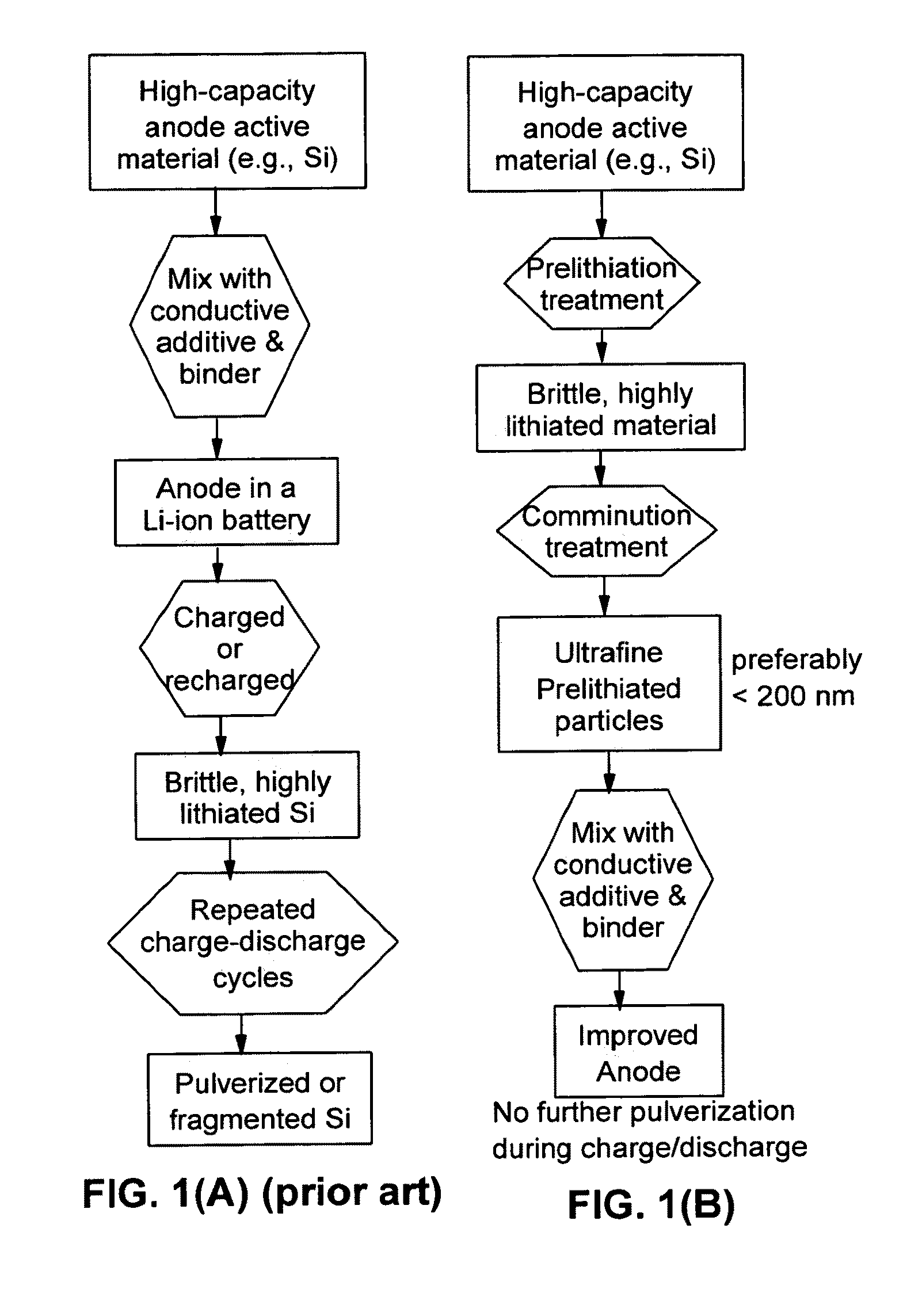

Method of producing prelithiated anodes for secondary lithium ion batteries

ActiveUS20100120179A1High specific capacityLong charge-discharge cycle lifeElectrode manufacturing processesActive material electrodesAverage sizeMaterials science

A method of producing a lithium-ion battery anode comprising: (a) providing an anode active material; (b) intercalating or absorbing a desired amount of lithium into this anode active material to produce a prelithiated anode active material; (c) comminuting the prelithiated anode active material into fine particles with an average size less than 10 μm (preferably sub-micron and more preferably <200 nm); and (d) combining multiple fine particles of prelithiated anode active material with a conductive additive and / or a binder material to form the anode. The battery featuring such an anode exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

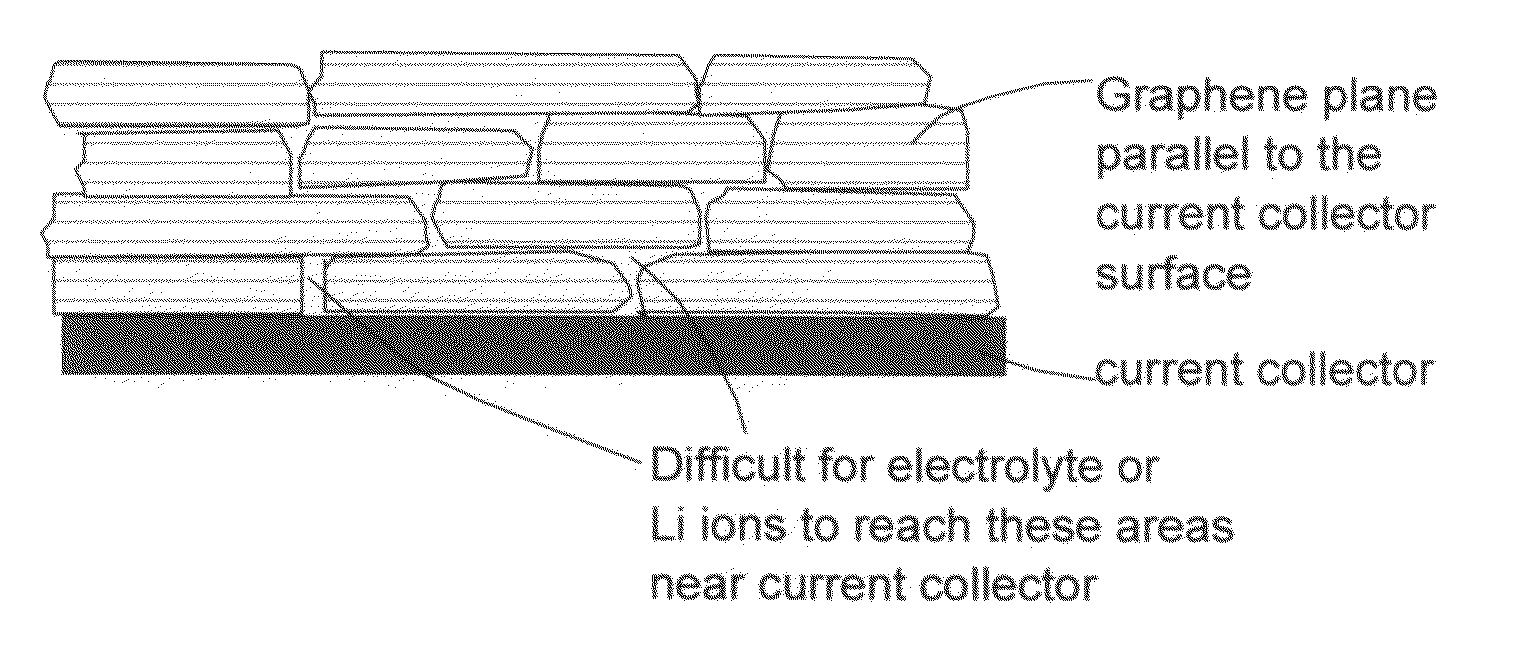

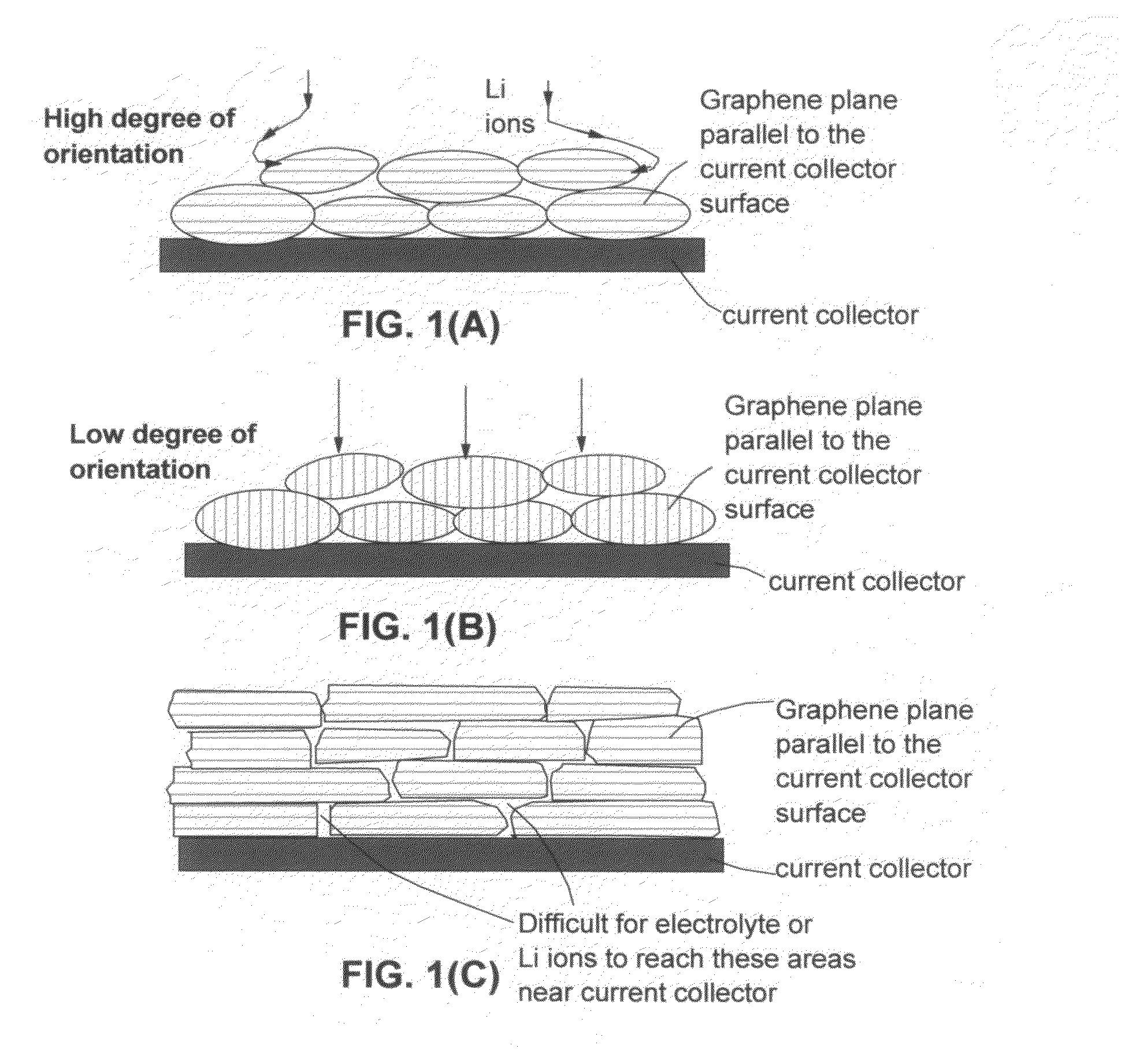

Graphite or carbon particulates for the lithium ion battery anode

This invention provides a graphite or graphite-carbon particulate for use as a lithium secondary battery anode material having a high-rate capability. The particulate is formed of a core carbon or graphite particle and a plurality of satellite carbon or graphite particles that are each separately bonded to the core particle wherein the core particle is spherical in shape, slightly elongate in shape with a major axis-to-minor axis ratio less than 2, or fibril in shape, and wherein the satellite particles are disc-, platelet-, or flake-like particles each containing a graphite crystallite with a crystallographic c-axis dimension Lc and a lateral dimension. Preferably, Lc is less than 100 nm and the flake / platelet lateral dimension is less than 1 μm. The core particle may be selected from natural graphite, artificial graphite, spherical graphite, graphitic coke, meso-carbon micro-bead, soft carbon, hard carbon, graphitic fibril, carbon nano-fiber, carbon fiber, or graphite fiber. Preferably, the flat-shaped particles are randomly oriented with respect to one another.

Owner:GLOBAL GRAPHENE GRP INC

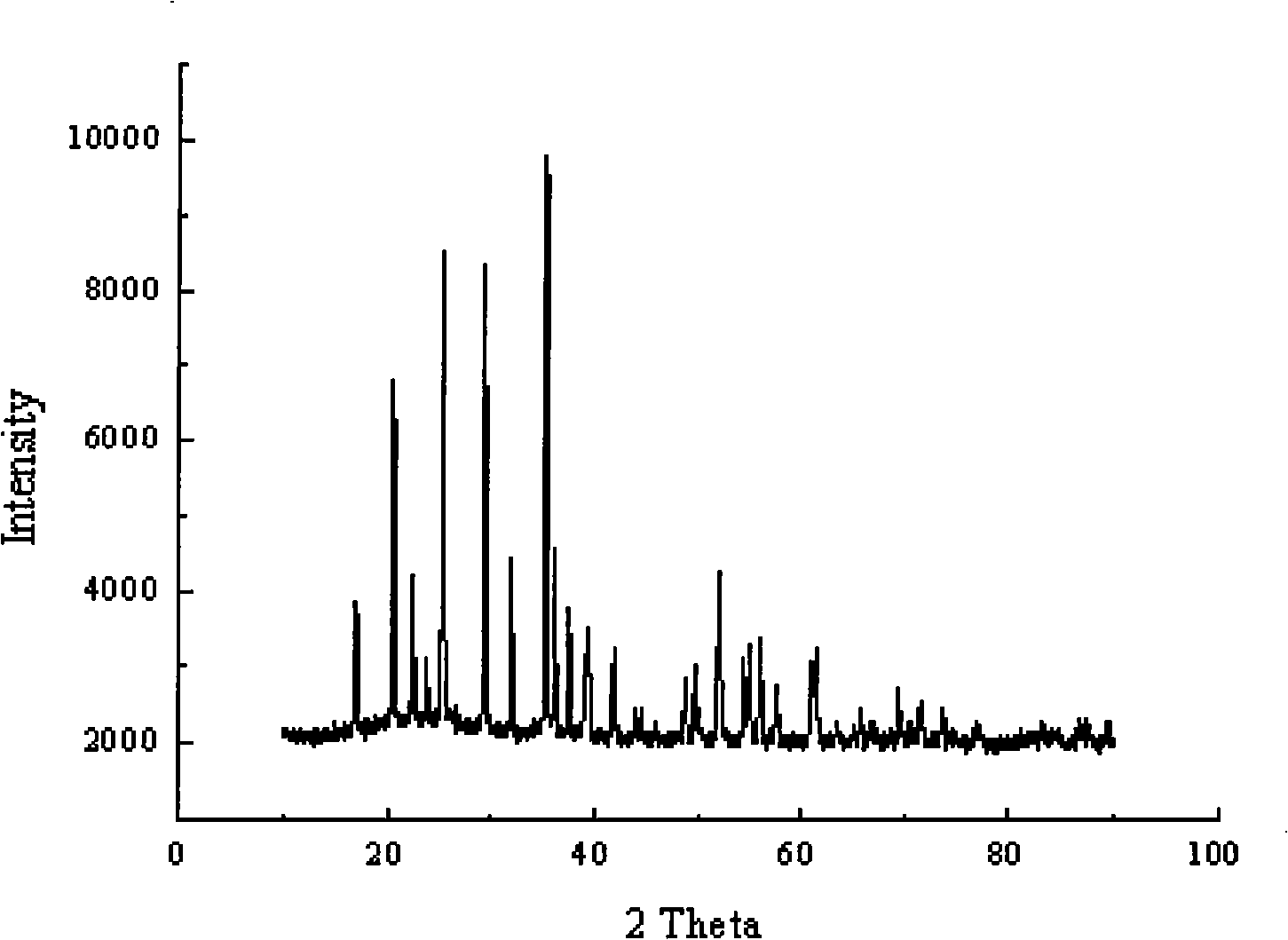

High performance lithium ion battery anode material lithium manganate and preparation method thereof

The invention provides a high performance lithium ion battery anode material lithium manganate and a preparation method of the material. The lithium manganate is a doped lithium manganate LiMn2-yXy04 which is doped with one kind or a plurality of other metal elements X, wherein X element is at least one kind selected form the group of aluminium, lithium, fluorine, silver, copper, chromium, zinc, titanium, bismuth, germanium, gallium, zirconium, stannum, silicon, cobalt, nickel, vanadium, magnesium, calcium, strontium, barium and rare earth elements lanthanum, cerium, praseodymium, neodymium, promethium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium and lutetium, and y is larger than 0 but less than or equal to 0.11. The lithium ion battery anode material lithium manganate provided in the invention has extraordinary charge and discharge cycle performance both in the environments of normal temperature and high temperature. According to the invention, the preparation method of the material is a solid phase method, the operation is simple and controllable and the cost is low so that it is easy to realize large-scale productions.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method of high power capacity lithium ion battery cathode material

ActiveCN102769139AHigh specific capacityImprove cycle stabilityCell electrodesNanotechnologyCyclic stability

A preparation method of a high power capacity lithium ion battery cathode material uses natural spherical graphite to serve as raw materials, uses concentrated sulfuric acid to serve as an inserting layer agent, uses potassium permanganate to serve as an oxidizing agent, conducts expansion treatment at high temperature to obtain micro-expanded graphite, then enables the micro-expanded graphite in different proportions to be mixed with nanometer ganister sand, conducts ultrasonic dispersion, suction filtration and dying to obtain the micro-expanded graphite with the nanometer ganister sand inserted in layers, enables the micro-expanded graphite to be mixed and coated with carbon source carbon source according to certain proportion, and finally conducts carburizing sintering under inert gas shielding to prepare completely coated silicon carbon composite cathode material with sufficient obligated obligate inside. Electrochemistry shows that the silicon carbon composite material prepared by the preparation method has high specific capacity and cycling stability and is the ideal high power capacity lithium ion battery cathode material.

Owner:内蒙古斯诺新材料科技有限公司

Method for supplementing lithium for negative electrode of lithium ion battery

ActiveCN102916165AAvoid LithiumAvoid deformationElectrode manufacturing processesElectrolyte/reactants regenerationMetallic lithiumElectrical battery

The invention belongs to the technical field of lithium ion batteries, in particular to a method for supplementing lithium for a negative electrode of a lithium ion battery. The method comprises the following steps: spraying or dripping an organic lithium solution on a surface of a negative electrode in an inert atmosphere, so that lithium ions in the organic lithium solution are reverted to metal lithium which is embedded into the negative electrode; and drying the negative electrode. Compared with the prior art, in the method, the organic lithium solution is sprayed or dipped on the surface of the negative electrode evenly so as to realize lithium supplementation in a wet process, thereby effectively avoiding metallic lithium powders floating in the air in a dry process to ensure safe production; and the whole process is simple, the cost is lower, the amount of the lithium supplementation can be controlled accurately through the amount and the time by spraying or dripping the organic lithium solution so as to supplement the lithium evenly, thereby preventing lithium precipitation and deformation of the negative electrode and improving the initial efficiency of the battery. Therefore, the the energy density of the battery is improved. Additionally, the invention further discloses another method for supplementing the lithium for the negative electrode of the lithium ion battery.

Owner:DONGGUAN AMPEREX TECH +1

Method for preparing composite material of lithium ion battery cathode, and cathode and battery

ActiveCN101442124AGood lithium intercalation performanceHigh lithium intercalation abilityElectrode manufacturing processesActive material electrodesSlurrySolvent

The invention relates to a method for preparing a composite material for a cathode of a lithium ion battery, and the cathode and the battery which comprise the cathode material. The preparation method comprises: uniformly mixing silicon powder, graphite, pyrolytic carbon precursor and a solvent to prepare slurry, wherein the silicon powder comprises micro-silicon powder and nano-silicon powder, and the weight ratio of the micro-silicon powder and the nano-silicon powder is 2-20:1; and removing the solvent in the slurry, performing primary sintering under the protection of inert gas, performing primary ball grinding, performing secondary sintering under the protection of the inert gas, and performing secondary ball grinding, wherein the temperature of the secondary sintering is higher than that of the primary sintering. The battery made from the composite material for the cathode of the lithium ion battery obtained by the method has good cycling performance and charge and discharge capacity.

Owner:BYD CO LTD

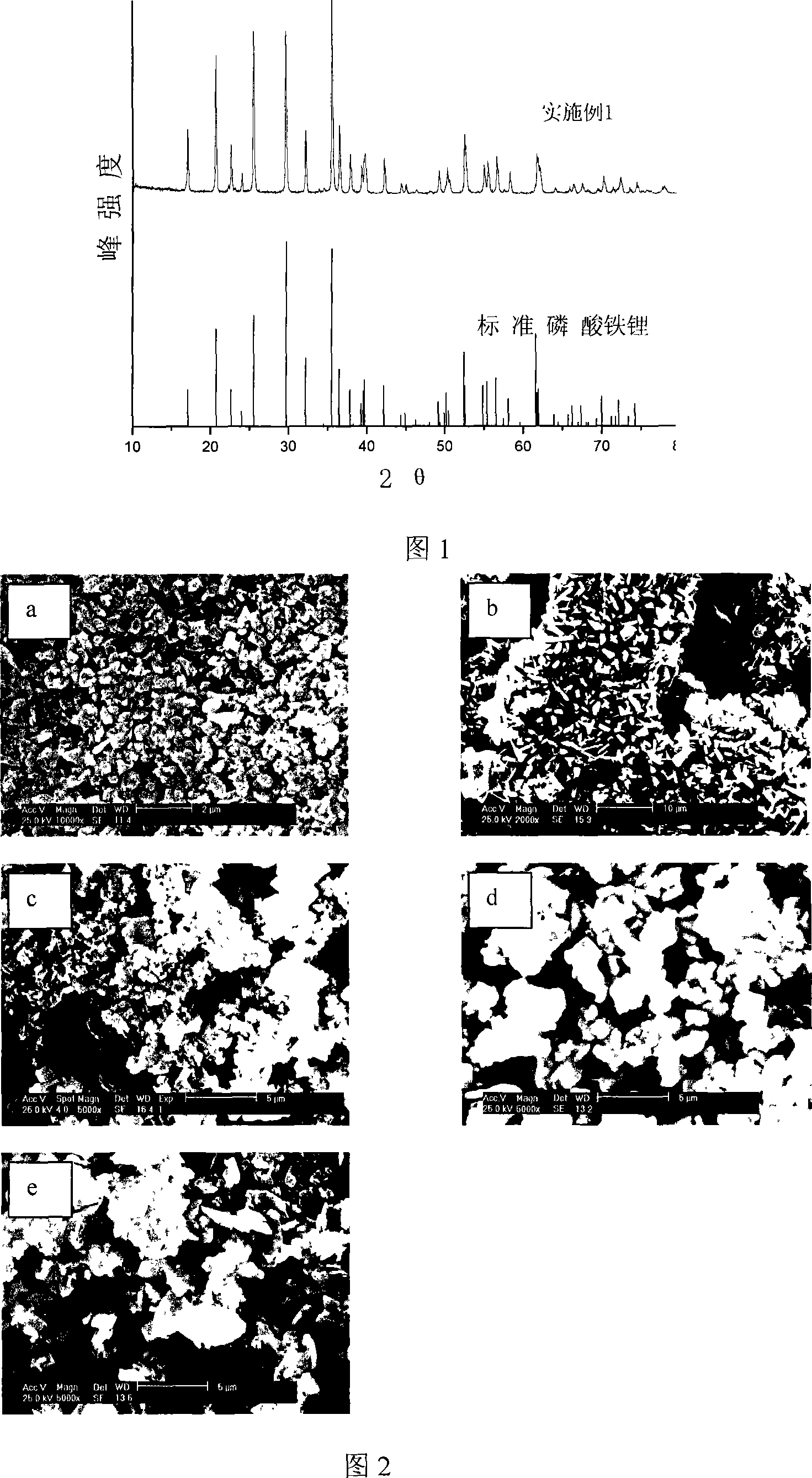

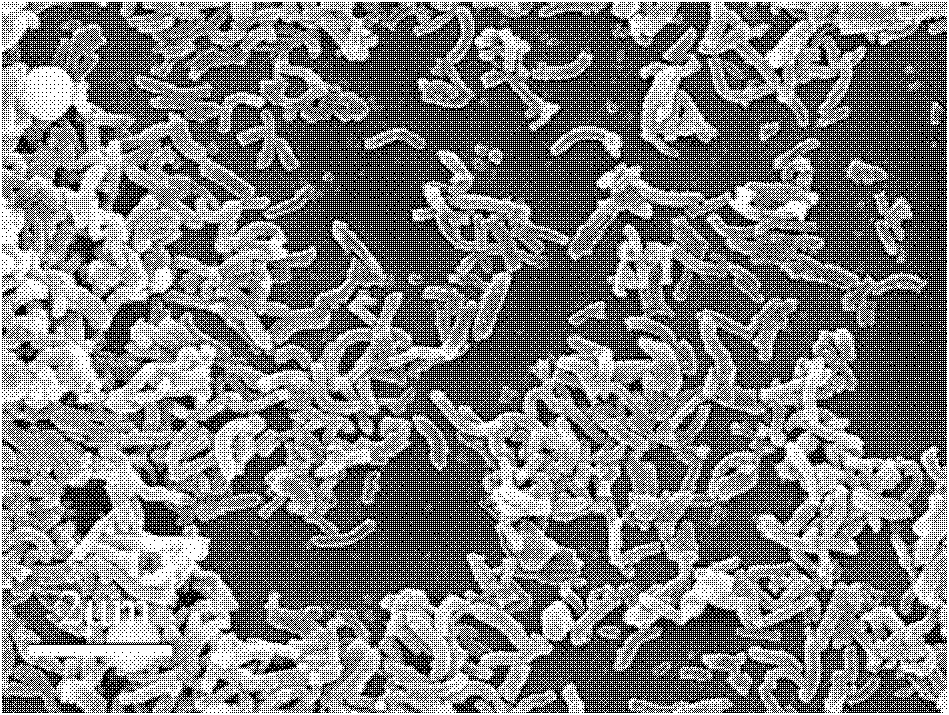

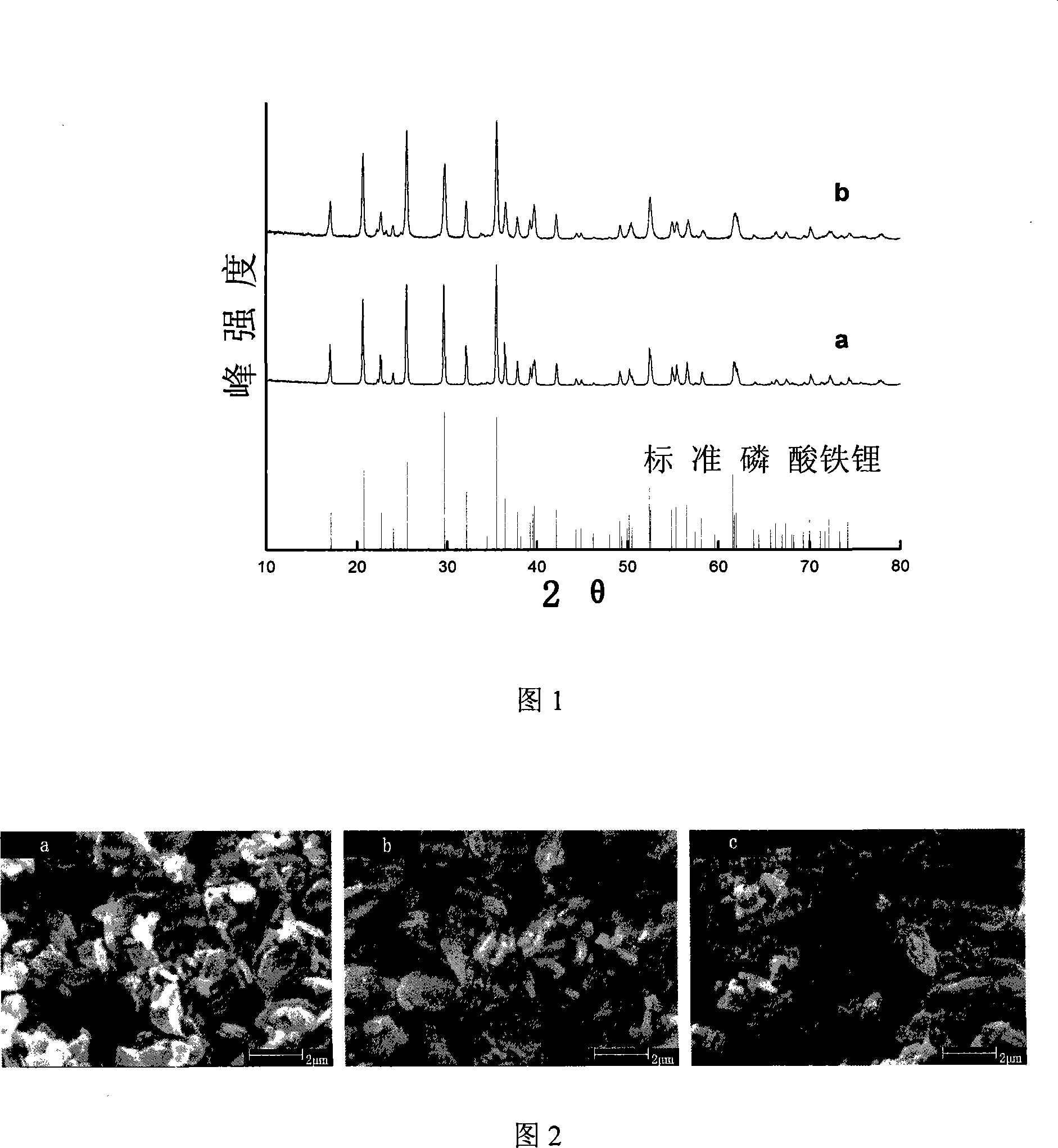

Hydrothermal synthesis method for lithium ion-cell anode material of ferric phosphate lithium

InactiveCN101117216AImprove electrochemical performanceShorten the diffusion pathCell electrodesPhosphorus compoundsExhaust valveDead volume

The invention discloses a hydrothermal synthesis method of lithium-ion battery anode material of lithium iron phosphate, relating two kinds of metal phosphate. The steps are as follows: lithium source and phosphorus source are dissolved in water or mixed with water, and added into the reaction autoclave, the quaternary cationic surfactants and the alkylphenols polyoxyethylene ethers nonionic surfactant is also added into the reaction autoclave, the air in the dead volume of the autoclave inside is purged by the inert gas, the autoclave is sealed and heated to 40-50 DEG C with stirring, a feed valve and an exhaust valve are opened, pure ferrous salting liquid is added into the autoclave, and then the autoclave is sealed for the reaction of the material at 140 to 180 DEG C for 30 to 480 minutes; the mixture ratio of the invention is set as follows: the molar ratio of Li, Fe and P is 3.0-3.15:1:1.0-1.15, and then the resultant is filtered, washed, dried and carbon-coated, thus the lithium iron phosphate is obtained. The lithium iron phosphate which is produced by the invention has the advantages that: the electrochemical performance is excellent, the particle size distribution of which the D50 is between 1.5 um to 2 um is even, the phase purity is above 99 percent and the electronic conductivity of the material is improved.

Owner:HEBEI LITAO BATTERY MATERIAL

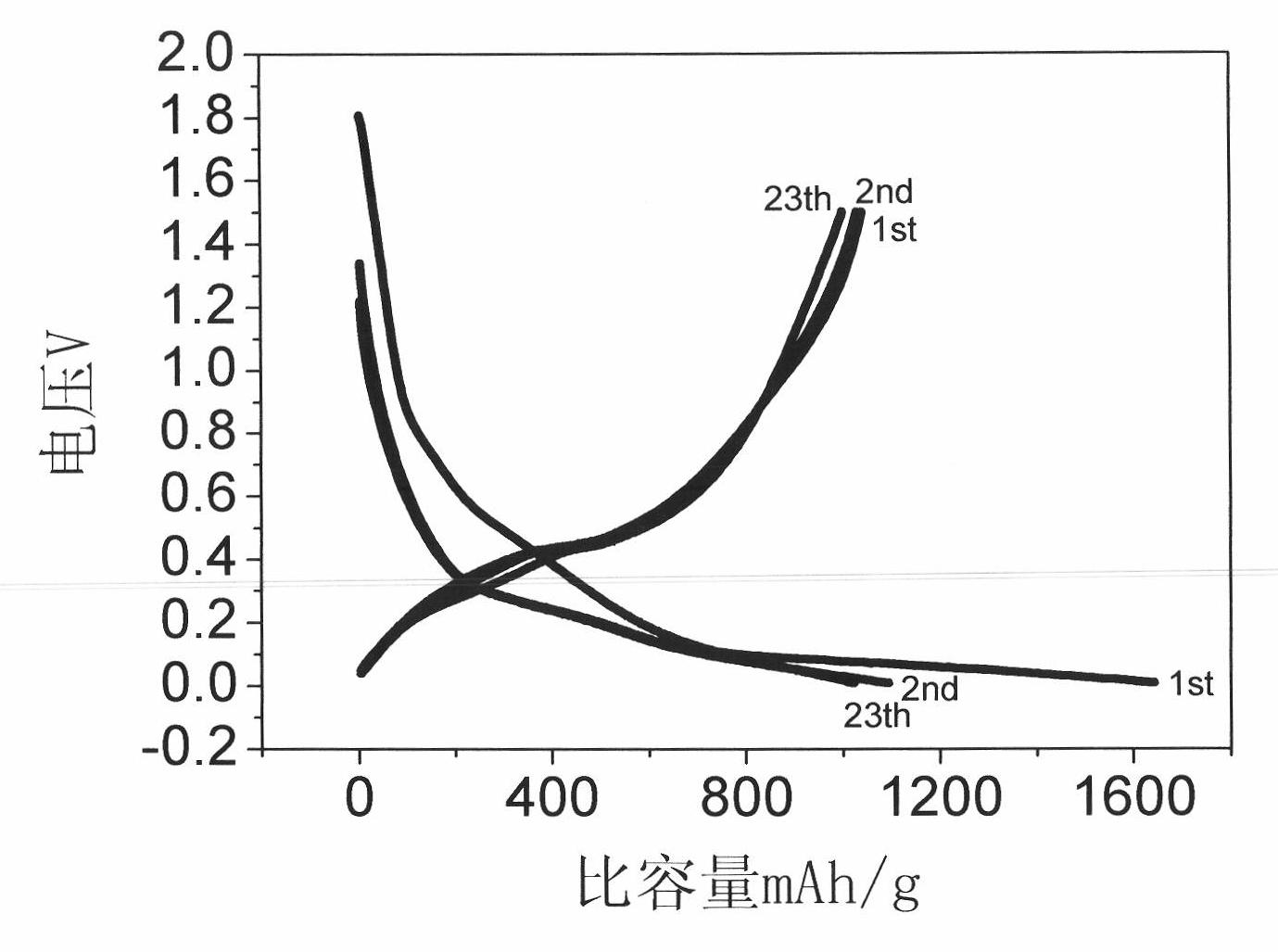

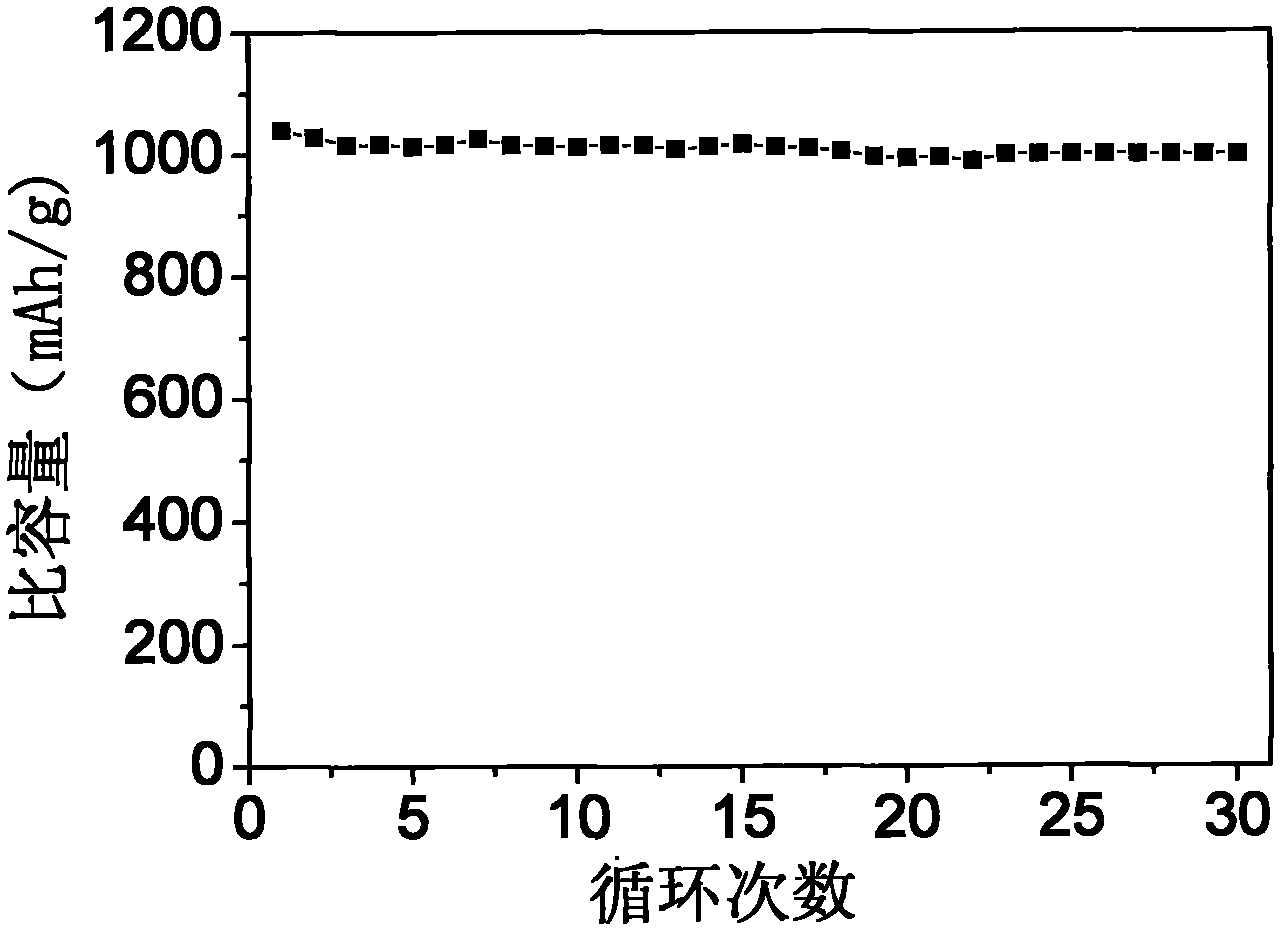

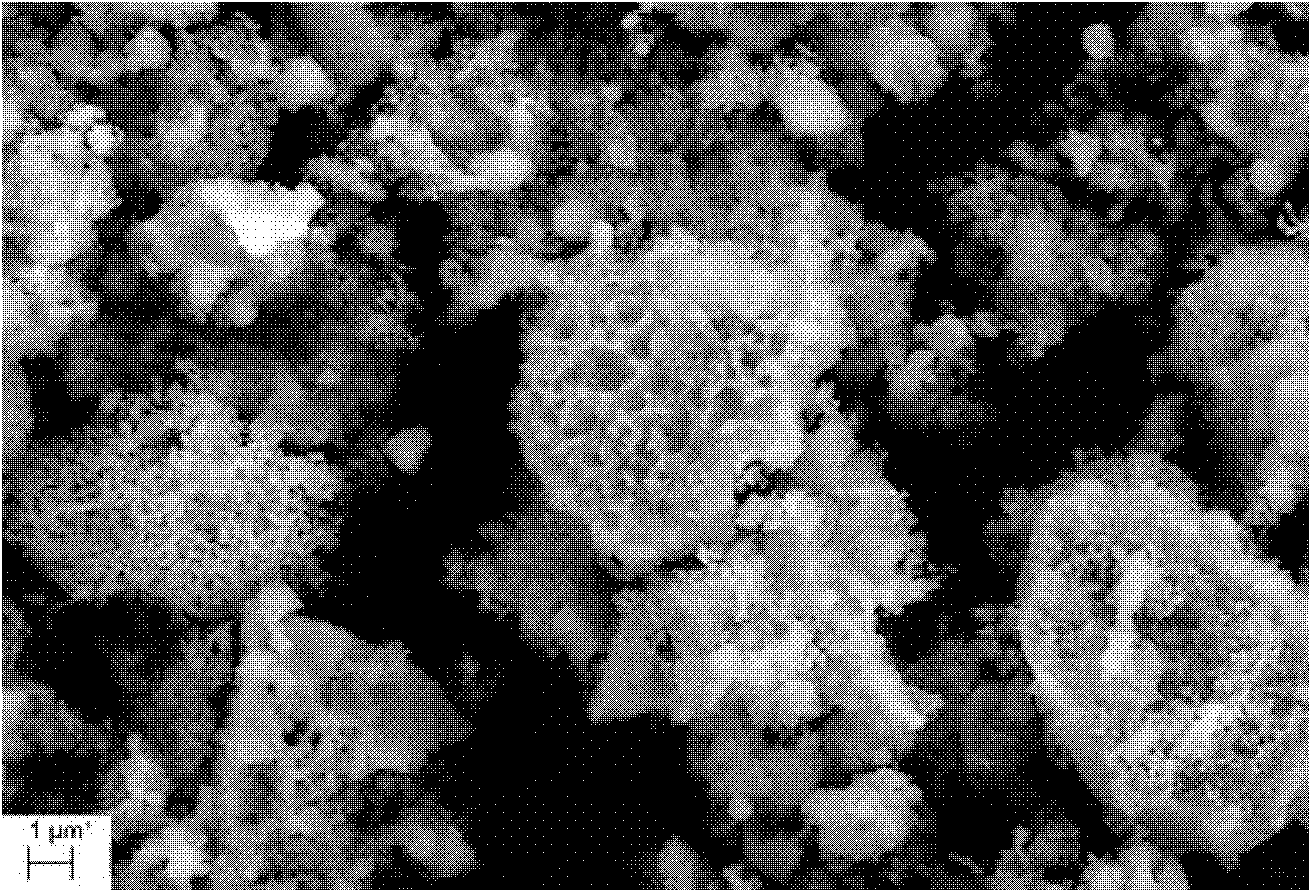

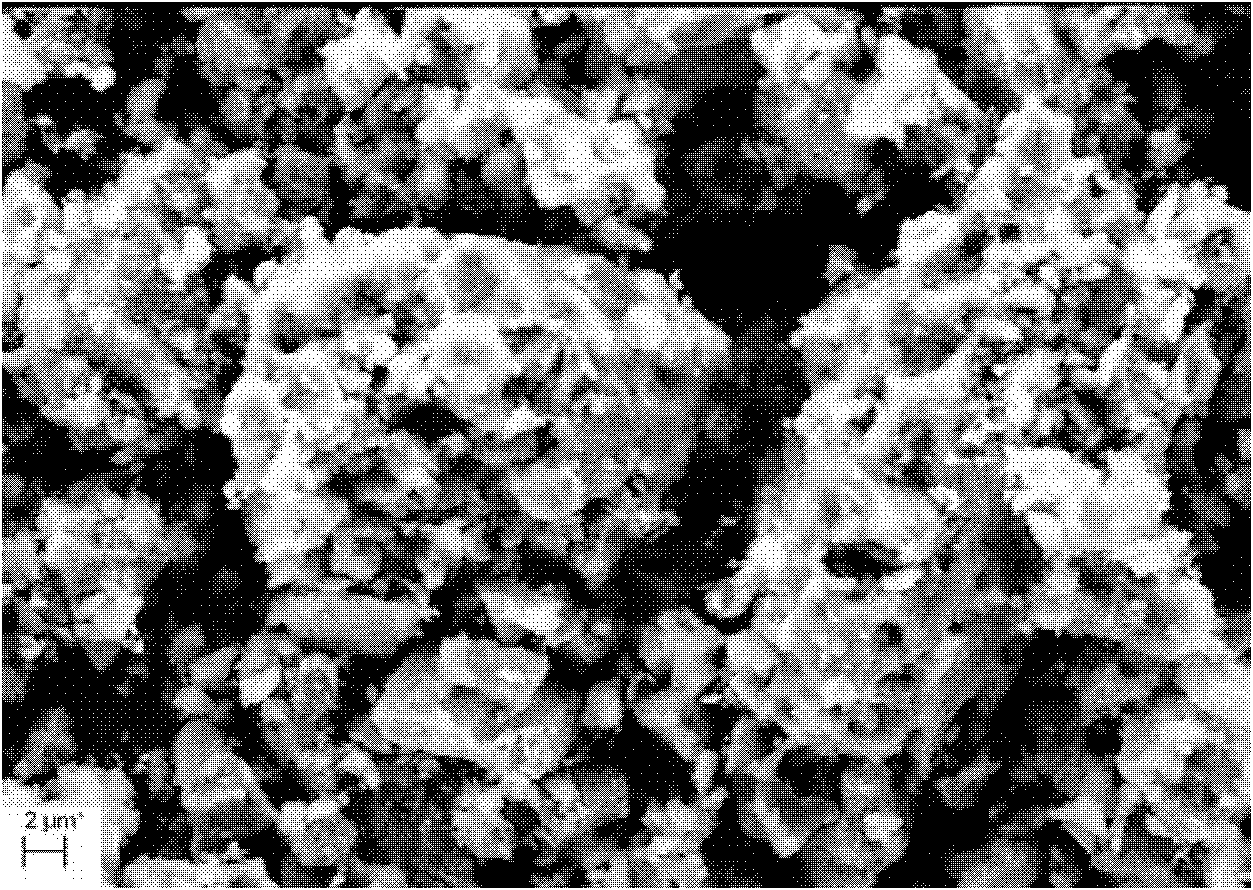

Porous silicon/carbon composite material and preparation method thereof

ActiveCN102208634AHigh specific capacityImprove cycle stabilityCell electrodesCarbon compositesNew energy

The invention discloses a porous silicon / carbon composite material and a preparation method thereof, and belongs to the fields of electrochemistry and new energy materials. The method comprises the following steps of: preparing porous silicon dioxide by using ethyl orthosilicate, silicon tetrachloride, methyl silicone oil and sodium silicide as raw materials, reducing the porous silicon dioxide into porous silicon, coating the porous silicon by adopting an organic carbon source, and performing thermal treatment under an inert atmosphere to prepare the porous silicon / carbon composite material. The material can be directly used as the lithium ion battery cathode material, the first discharge specific capacity of the material can reach 1,245mAh / g, the specific capacity can also reach 1,230mAh / g after 30 cycles, and the material has excellent charge / discharge performance.

Owner:SUZHOU QINGTAO NEW ENERGY TECH CO LTD

Silicon-carbon negative electrode material of lithium ion battery and preparation method thereof

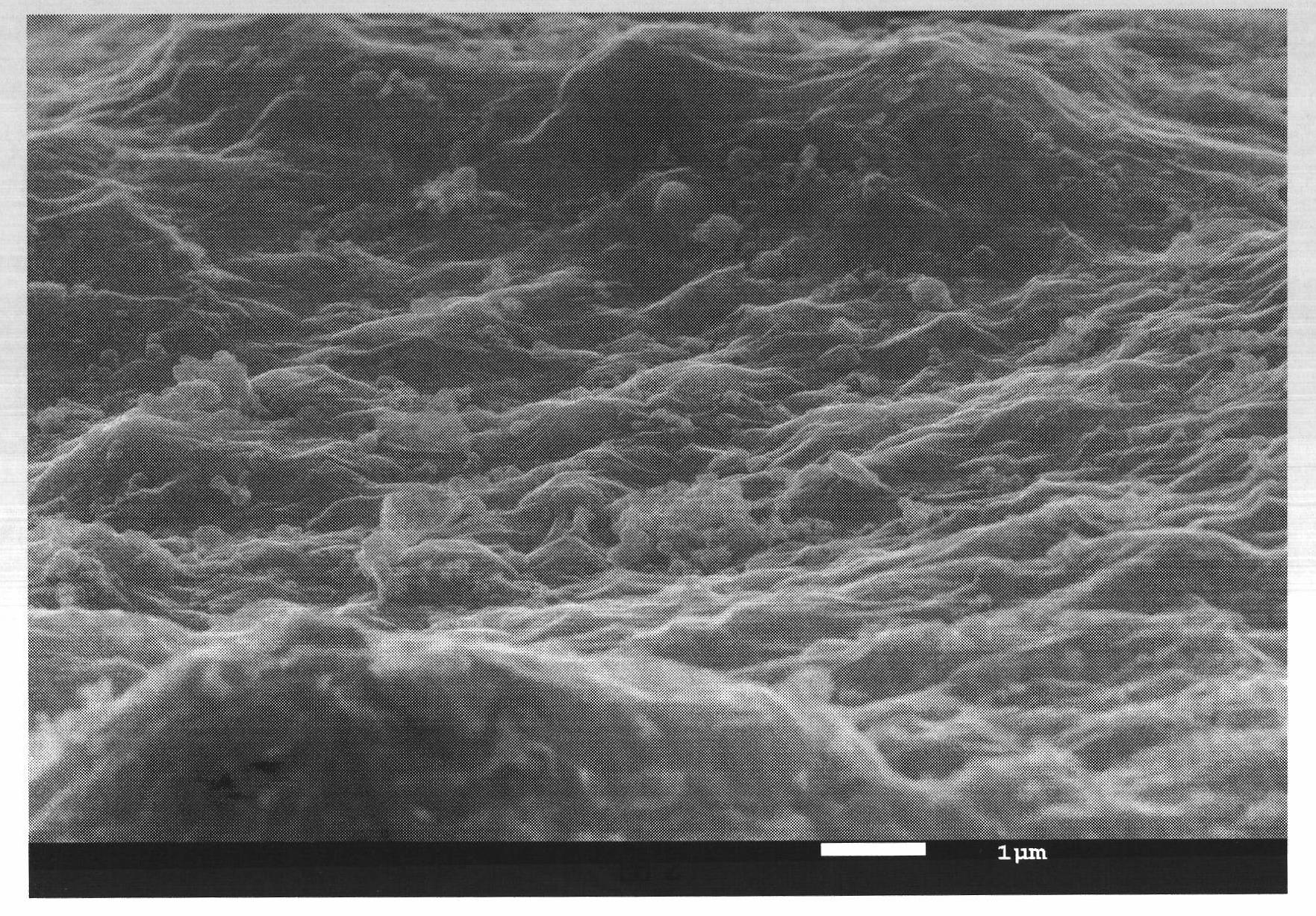

ActiveCN102394287AExcellent intercalation and delithiation abilityImprove cycle stabilityCell electrodesFiberCarbon composites

The invention discloses a silicon-carbon negative electrode material of a lithium ion battery and a preparation method thereof, and solves the technological problem of improving the charge and discharge cycling stability of the electrode material. The silicon-carbon negative electrode material is prepared by mixing a silicon-carbon composite material and a natural graphite material, wherein the weight of the silicon-carbon composite material is 7-20% and the silicon-carbon composite material is prepared by depositing carbon nanotube and / or carbon nanofiber on the surface of nanometer silica fume and / or embedding into the nanometer silica fume to form core, the surface of which is covered with 3-15wt% of a carbon layer. The preparation method provided by the invention comprises steps of: precursor silicon powder preparation; chemical vapor deposition; liquid-coating roasting; crushing; and mixing. In comparison with the prior art, the reversible specific capacity of the silicon-carbon composite negative electrode material is greater than 500mAh / g; the coulombic efficiency for a first cycle is greater than 80%; the capacity conservation rate of cycling for 50 weeks is greater than 95%. The preparation method is simple, is easy to operate, requires low cost and is suitable for a high-volume negative electrode material of lithium ion batteries used for various portable devices.

Owner:BTR NEW MATERIAL GRP CO LTD

Method for preparing lithium ion battery anode/cathode material from reduced graphene oxide

The invention discloses a method for preparing a lithium ion battery anode / cathode material from reduced graphene oxide. The method comprises the following steps: performing ultrasonic dispersion on graphite oxide in an organic solvent, thereby obtaining a graphene oxide dispersion liquid; reducing by using an appropriate reducing agent or directly using a solvent, oxidizing graphene through oil bath backflow, a hydrothermal method or other reduction methods, thereby obtaining a reduced graphene oxide material containing part of oxygen-containing groups. When the prepared reduced graphene oxide material is used in a lithium ion battery anode material, a relatively high specific discharge capacity can be achieved, that is, is up to 280mAh / g, and good circulation stability and excellent rate performance are achieved. The prepared reduced graphene oxide material can be also used in a lithium ion battery cathode material, the specific discharge capacity can be kept being 900mAh / g and more than 900mAh / g after 100 rounds of charge / discharge circulation, and the circulation stability is relatively good. The method can be a significant study point of high-performance low-cost electrode materials of lithium ion batteries.

Owner:TIANJIN NORMAL UNIVERSITY

Graphene three-dimensional material as well as preparation method and application thereof

The invention discloses a graphene three-dimensional material as well as a preparation method and an application thereof. The material consists of 10 to 99% of graphene and 1 to 90% of the oxide of manganese, nickel, iron or cobalt. The preparation method comprises the following steps: performing ultrasonic dispersion on graphite oxide to prepare a graphite oxide solution; adding a metal salt solution while stirring or under ultrasonic conditions, and adding a hydrazine hydrate solution; conducting reaction in a drying oven or a hydro-thermal reaction kettle; and then drying to obtain the graphene three-dimensional material. The graphene three-dimensional material is applied to a super capacitor with the capacity of 200 to 800 F / g, or used for making the cathode of a lithium ion battery with the capacity of 300 to 1,400 mAh / g. According to the invention, the preparation process is simple; the prepared graphene three-dimensional macroscopic material has high conductivity and strength; and when being used for the cathode of the lithium ion battery and the super capacitor, the material has high performance.

Owner:TIANJIN UNIV

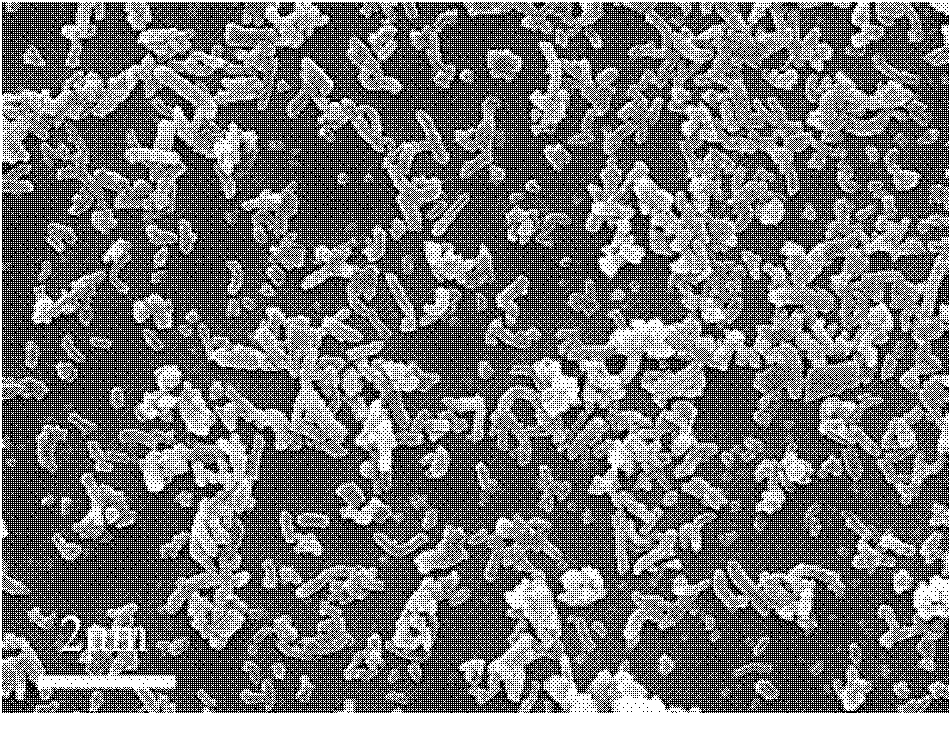

Hydro-thermal synthetic preparation method for lithium ion battery anode material lithium iron phosphate

InactiveCN101121509AImprove electrochemical performanceHigh purityCell electrodesPhosphorus compoundsPhosphateInlet valve

The present invention relates to a hydrothermal synthesis preparation method of a lithium iron phosphate of an anode material used by a lithium ion battery, concerning a phosphate containing two metals. The step is that a lithium source and a phosphor source are solubilized into the water or mixed with the water and then put into a high pressure kettle. After the air in the kettle is blown out by an inert gas, the high pressure kettle is sealed and heated to a temperature between 40 DEG C and 50 DEG C from a room temperature after being stirred. An inlet valve and a vent valve are opened and then a prepared divalent ferric salt liquor is added in. The high pressure kettle is sealed and the reaction time lasts from 200 minutes to 480minutes at the temperature between 140 DEG C and 170 DEG C. At the time, the inner pressure corresponding to the system is from 0.36 MPa to 0.85 MPa. The mixture rate of the added substance is Li: Fe: P and the mol ratio is 3.0-3.15: 1: 1.0-1.15. When the reaction starts, the reactant concentration is from mol / L 0.2 to 1.0mol / L, computed according to the concentration of the ferrous ion and then the resultant is filtrated, cleaned, dried and coated with the carbon. Finally the lithium iron phosphate product can be obtained. The present invention has the advantages of simple technology, good batch stability, good electrochemical performance and even distribution. The purity quotient can be more than 99 percent and the grain diameter D50 is between1.5Mu m and 2Mum.

Owner:HEBEI UNIV OF TECH

Lithium ion battery anode film, preparation and application thereof

InactiveCN104037418AImprove reversible charge and discharge capacityPerformance is not affectedLi-accumulatorsNon-aqueous electrolyte accumulator electrodesAdhesiveLithium electrode

Provided is a positive electrode film of a lithium battery, comprising: (i) a positive electrode material of a lithium intercalated transition metallic oxide; (ii) a lithium ion replenisher; and (iii) a conductive agent and an adhesive. The lithium ion replenisher in the positive electrode film decomposes during initial charging and then releases lithium ions, so as to make up for a loss of lithium ions forming an SEI film on a negative electrode surface, thereby improving the reversible charging and discharging capacity of the lithium ion battery. In the prepared positive electrode film, the lithium ion replenisher can be mixed in the positive electrode material or the conductive agent in advance, and can be coated on the surface of the positive electrode of the lithium ion battery as well.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

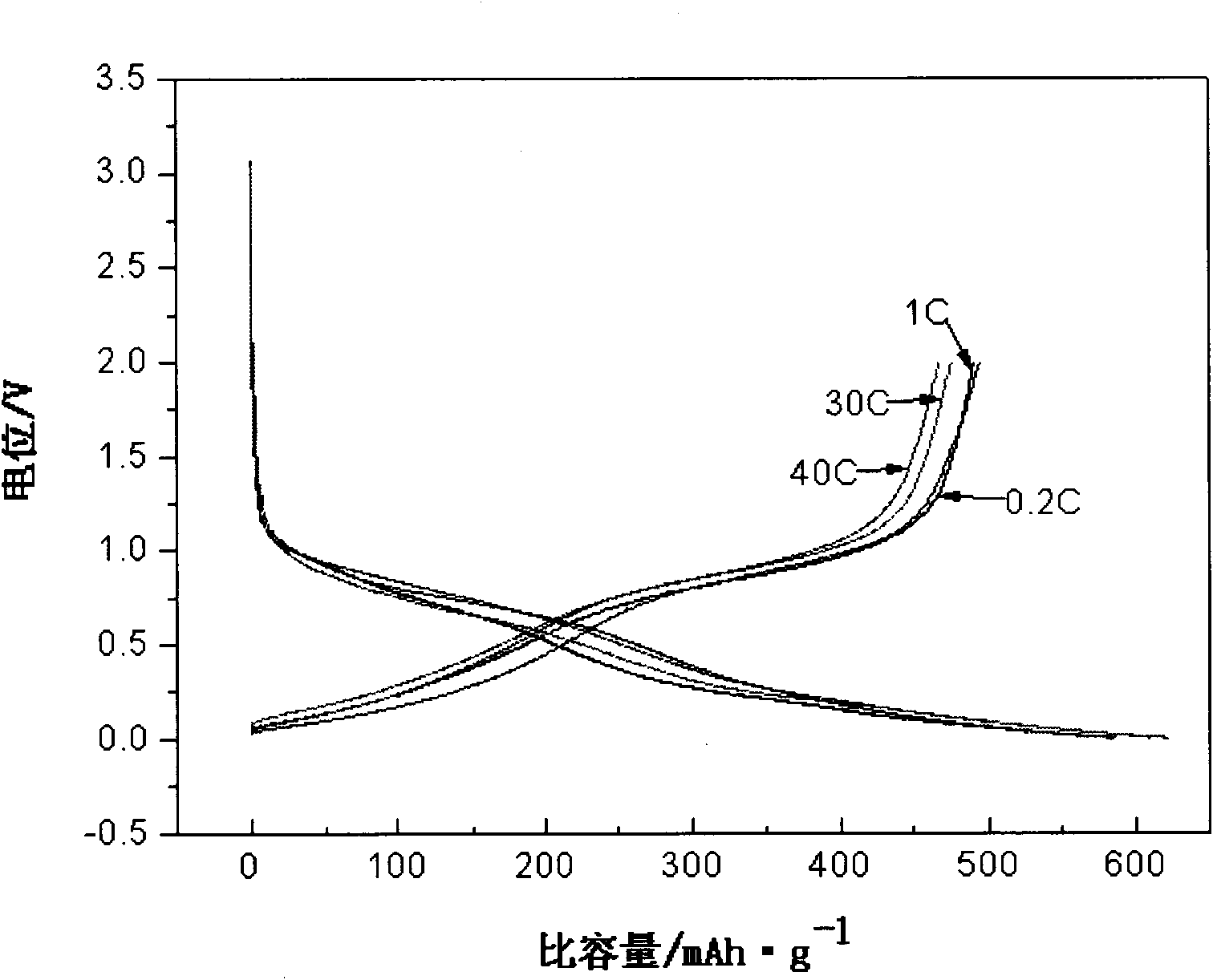

Hard carbon material for power and energy-storage battery and preparation method thereof

ActiveCN101916845AExcellent intercalation and delithiation abilityImprove cycle stabilityCell electrodesHigh rateCharge discharge

The invention discloses a hard carbon material for a power and energy-storage battery and a preparation method thereof, and aims to solve the technical problem of improving high-rate charge-discharge performance of lithium-ion batteries. The material is provided with a hard carbon matrix, and a coating is coated outside the hard carbon matrix; and the surface of the hard carbon matrix has a honeycomb opening structure. The preparation method comprises the following steps of: dipping, washing, dewatering and drying, presintering at low temperature, crushing, pyrolyzing, crushing and coating. Compared with the prior art, the hard carbon material has the reversible specific capacity of more than 450mAh / g, the first cycle columbic efficiency of over 81 percent, 0.2C 300-cycles capacity-retaining rate of over 97 percent at the temperature of 60 DEG C, and the 0.2C 300-cycles capacity-retaining rate of over 88 percent at the temperature of -30 DEG C, has the advantages of excellent lithium intercalation and deintercalation capability and cycling stability, and simple preparation process, and is applicable to the lithium ion battery cathode materials for lithium ion power batteries, various portable devices and electric tools.

Owner:深圳贝特瑞钠电新材料科技有限公司

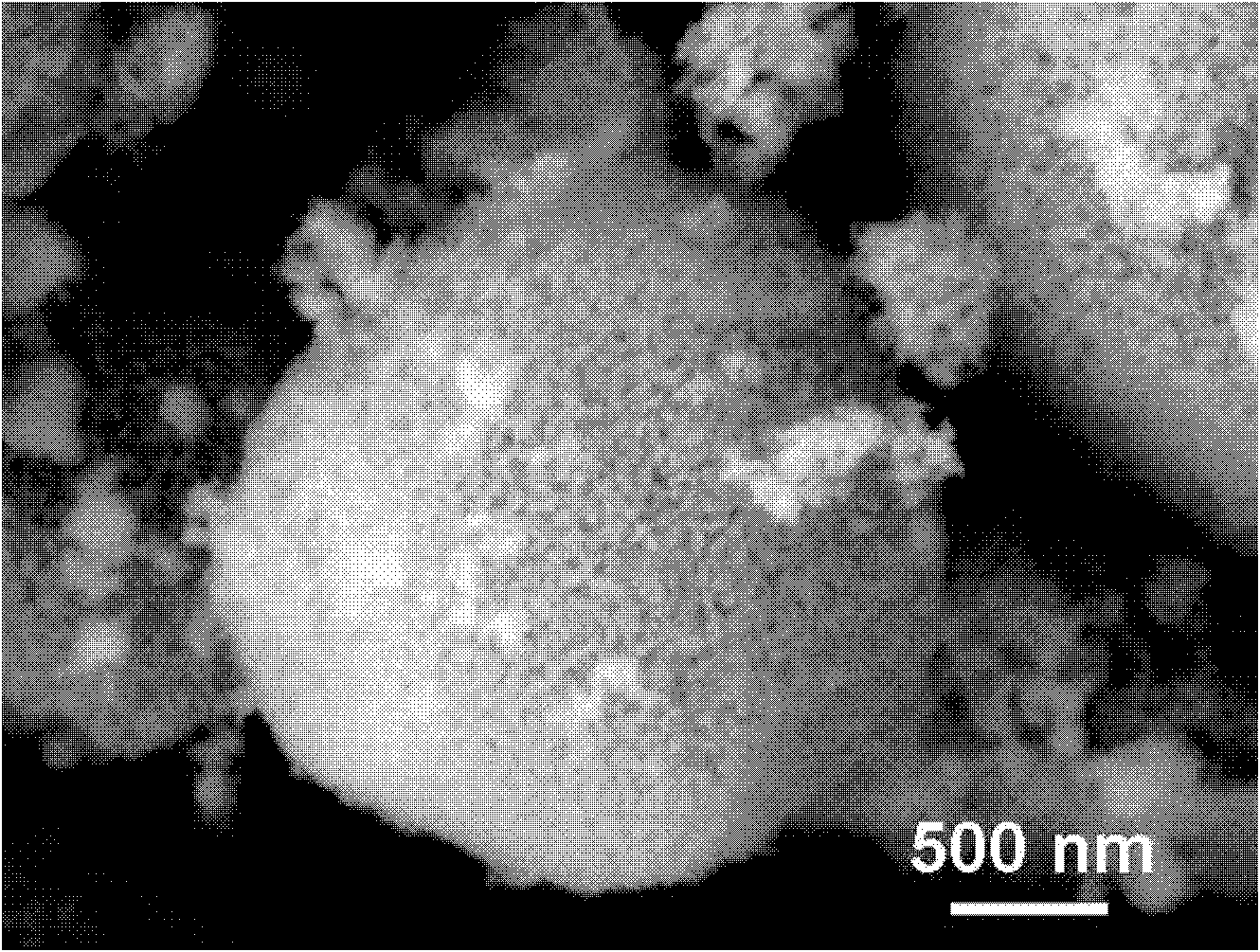

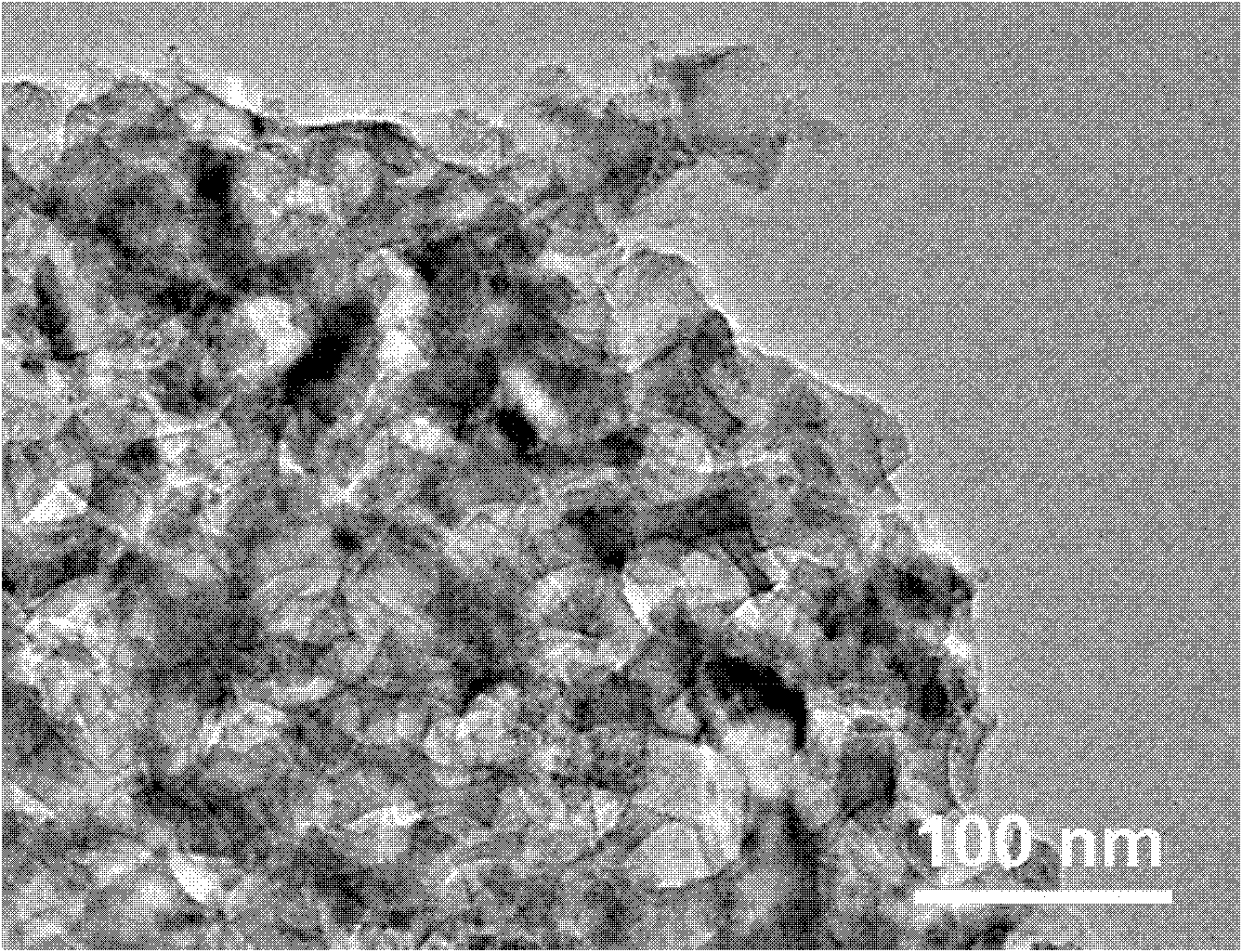

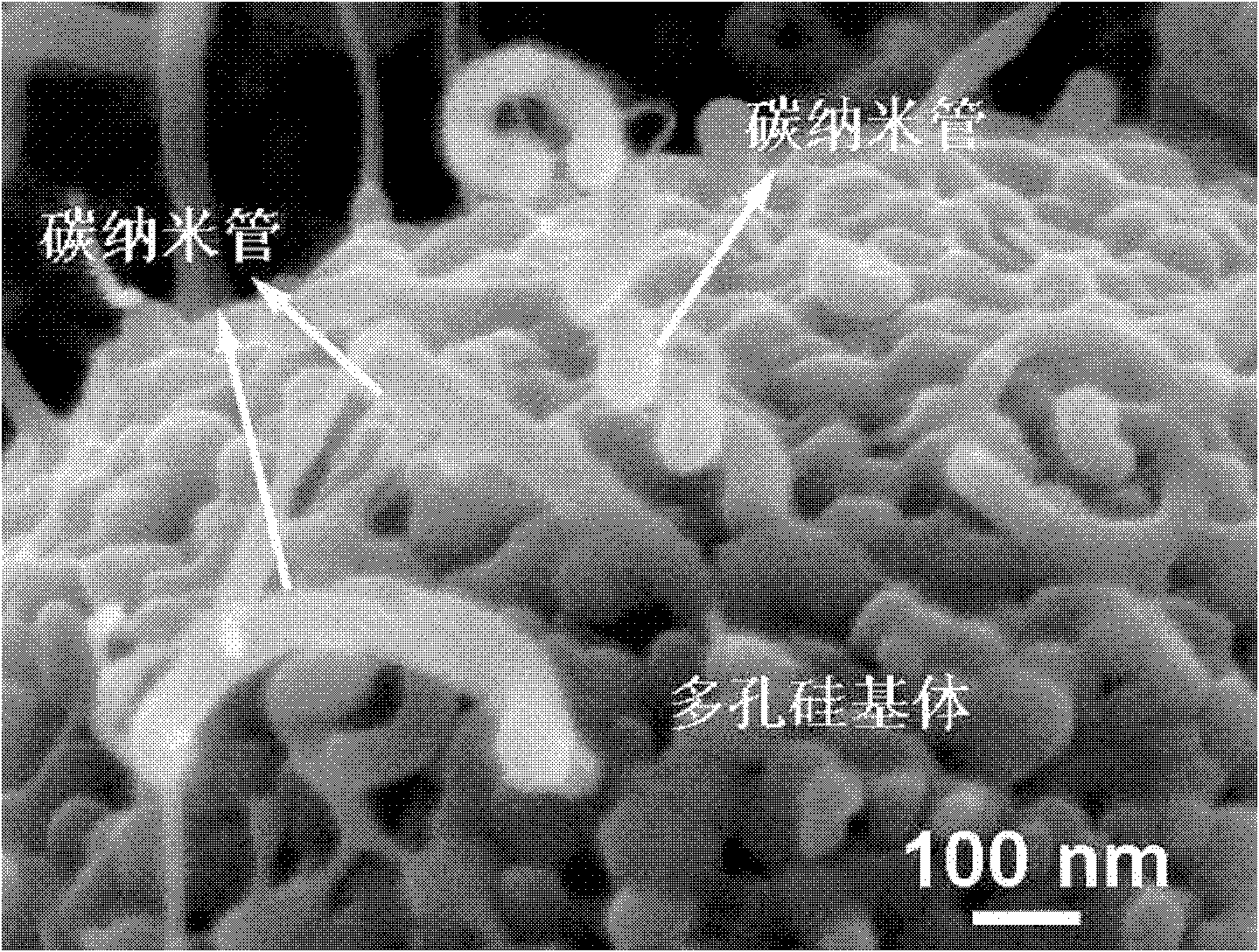

Silicon carbon composite material and preparation method thereof

ActiveCN102185128AIncrease productivityReduce manufacturing costCell electrodesFiberCarbon composites

The invention discloses a silicon carbon composite material and a preparation method thereof. The material disclosed by the invention comprises a porous silicon substrate, a one-dimensional carbon nano material and amorphous carbon, wherein the one-dimensional carbon nano material is a carbon nano tube or carbon nano fiber. The preparation method disclosed by the invention comprises the following steps: preparing the porous silicon substrate; loading a catalyst precursor; and carrying out the chemical vapor deposition. The one-dimensional carbon nano material directly grows on the porous silicon substrate, and the one-dimensional carbon nano material and the porous silicon substrate are coated with the amorphous carbon. The silicon carbon composite material provided by the invention is suitable for the cathode material of a lithium ion battery, and has the advantages of high capacity and stable circulation performance. A constant-current charge and discharge test is carried out under the 300mA / g current density, and the silicon carbon composite material disclosed by the invention has the characteristics that the first reversible capacity is 1149mAh / g; the reversible capacity is 1087mAh / g after the circulation is carried out for 100 times; and the capacity conservation rate is up to 95%.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

Lithium ion battery anode material manganese lithium phosphate and preparation method thereof

ActiveCN101320809AImprove electronic conductivityEvenly dispersedElectrode manufacturing processesPhosphorus compoundsCapacitanceLithium iron phosphate

The invention discloses a manganese / lithium phosphate of lithium iron battery positive pole material and a production method thereof, the technical issue to be solved is to improve electrochemical performances of the positive pole material. The material of the invention includes substrates of manganese / lithium phosphate which are covered by a carbon material covering layer, the lithium covering the manganese / lithium phosphate behind the carbon material covering layer is spherical and has microscopic characteristics of being near spherical, rhombic, tapered, tabular, layered or / and block-shaped as well as of having 0.5-30 mum long and short axles. The production method comprises the following steps of: production of nanometer particles, liquid phase mixed reaction, production of precursor, sintering treatment, covering organic substances. Compared with the prior art, the invention improves the electron conductivity of the manganese / lithium phosphate by covering with carbon liquid phase, the carbon sufficiently covers active materials to efficiently prevent particle aggregation, the invention has the characteristics of about 4V of discharge voltage, high discharge and charge capacitance, excellent circulation stability, high safety, simple process, low cost and little influence on the environment.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com