Graphene three-dimensional material as well as preparation method and application thereof

A graphene and structure technology, applied in the field of graphene, to achieve the effects of good electrical conductivity and strength, adjustable shape and size, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

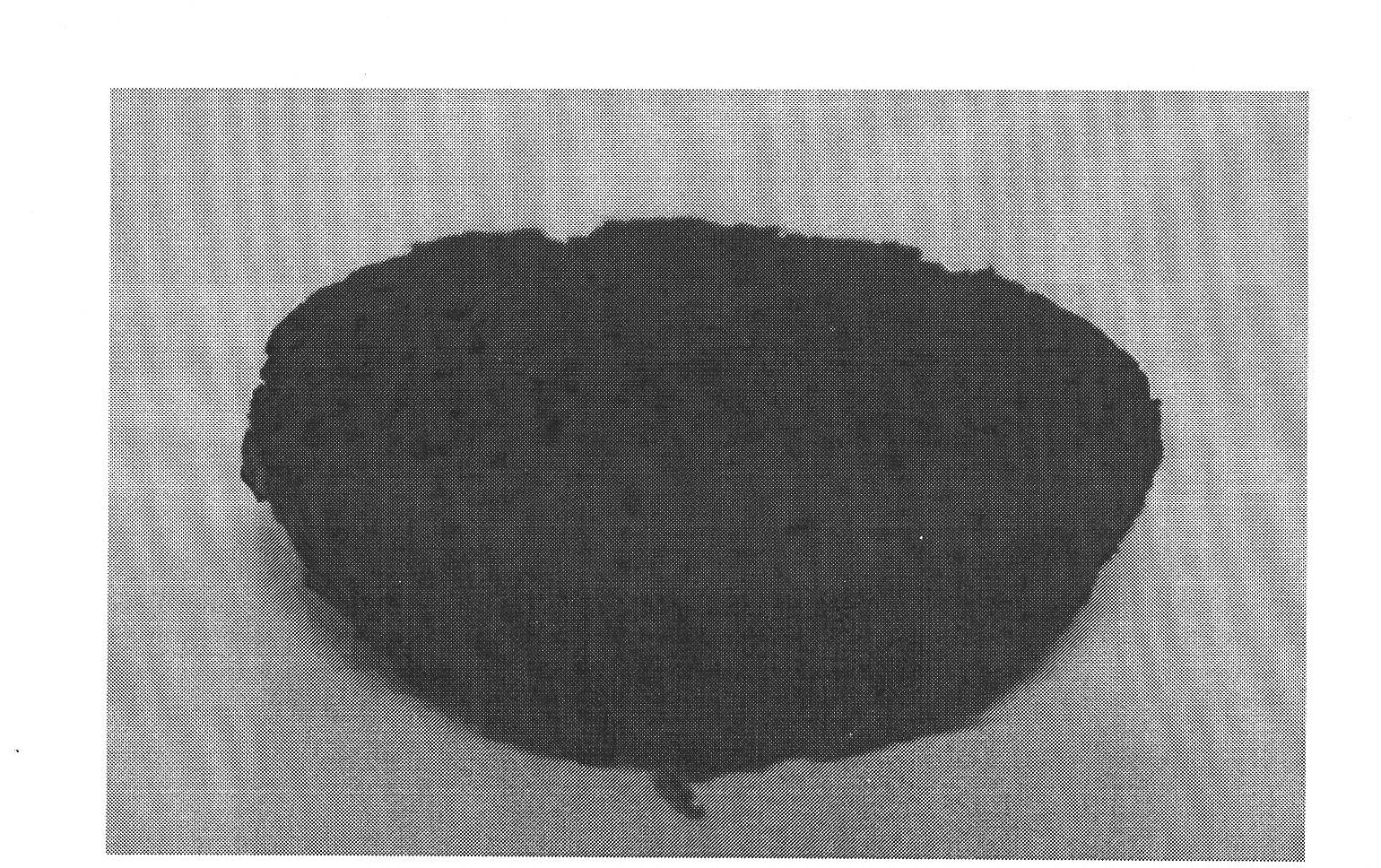

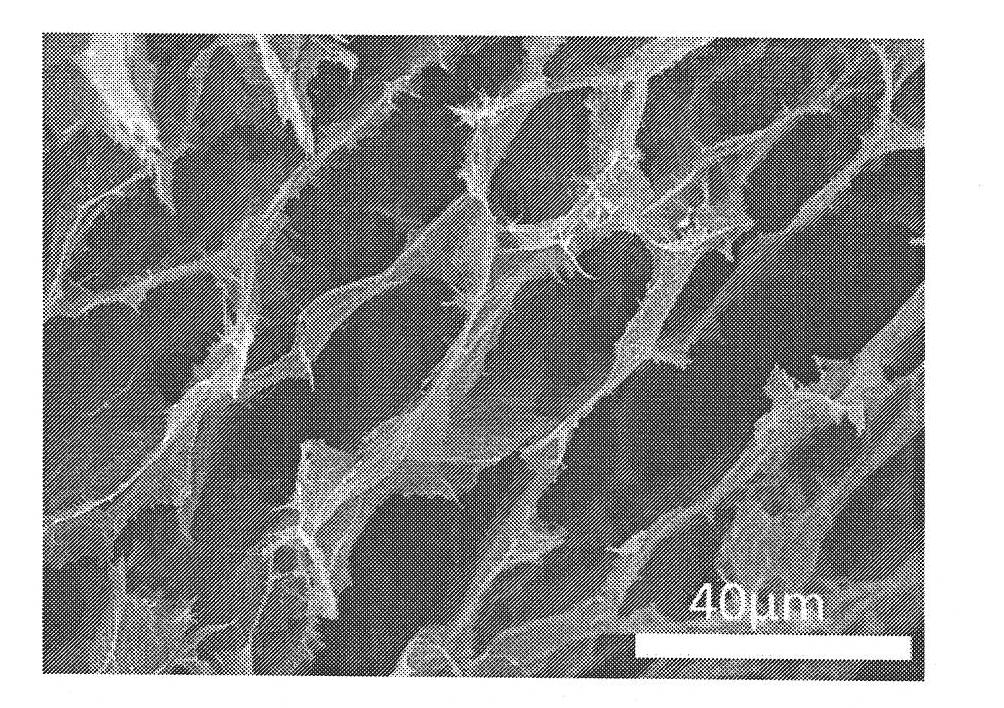

[0017] Weigh 100mg of graphite oxide powder material into a 150mL beaker, add 100mL of deionized water, ultrasonically disperse for 2 hours, and ultrasonic power is 100W, to obtain a well-dispersed graphene oxide solution. Then, 5 mL of ammonia water was added under stirring condition to adjust the pH to 10. Then add 5 mL of potassium permanganate solution with a mass concentration of 40%, and continue to sonicate for 20 min to make it evenly mixed. Under ultrasonic conditions, 60 μL of 80% hydrazine hydrate solution was added, and stirring was continued for 2 h after the addition was completed to obtain a uniformly dispersed solution. The above solution was moved into a drying oven at a temperature of 70° C. for 12 hours, and finally freeze-dried to obtain a three-dimensional macroscopic material composed of graphene self-assembly. Instructions attached figure 1 The photo of the graphene three-dimensional structure material prepared for the present embodiment, figure 2 It...

Embodiment 2

[0021] Weigh 50mg of graphite oxide powder material into a 100mL beaker, add 80mL of water, ultrasonically disperse for 2h, ultrasonic power 200W, to obtain a well-dispersed graphene oxide solution. Then, 1 mL of ammonia water was added under stirring condition to adjust the pH to 11. Then add 10 mL of nickel nitrate solution with a mass concentration of 80%, and continue to sonicate for 50 min to make it evenly mixed. Under ultrasonic conditions, 5 μL of 80% hydrazine hydrate solution was added, and stirring was continued for 2 h after the addition was completed to obtain a uniformly dispersed solution. The above solution was moved into a drying oven at 70° C. for 18 hours, and finally freeze-dried to obtain a three-dimensional macroscopic material composed of graphene self-assembly. According to the method for preparing a supercapacitor as described in Example 1, the supercapacitor of the graphene three-dimensional bulk material prepared in this embodiment is prepared, and ...

Embodiment 3

[0023] Weigh 150mg of graphite oxide powder material into a 200mL beaker, add 150mL of water, ultrasonically disperse for 2h, ultrasonic power 150W, to obtain a well-dispersed graphene oxide solution. Then, 10 mL of ammonia water was added under stirring condition to adjust pH=8. Then add 20 mL of manganese acetate solution with a mass concentration of 20%, and continue to sonicate for 50 min to make it evenly mixed. Under ultrasonic conditions, add 100 μL of 80% hydrazine hydrate solution, and continue ultrasonication for 20 h after addition to obtain a uniformly dispersed solution. The above solution was transferred into a hydrothermal reaction kettle and reacted at 120°C for 24h. Finally, a macroscopic material with a three-dimensional structure composed of graphene self-assembly is obtained by vacuum drying. According to the method for preparing supercapacitors described in Example 1, the supercapacitor of the graphene three-dimensional structure material prepared in thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com