Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60 results about "Ganister" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A ganister (or sometimes gannister ) is hard, fine-grained quartzose sandstone, or orthoquartzite, used in the manufacture of silica brick typically used to line furnaces. Ganisters are cemented with secondary silica and typically have a characteristic splintery fracture.

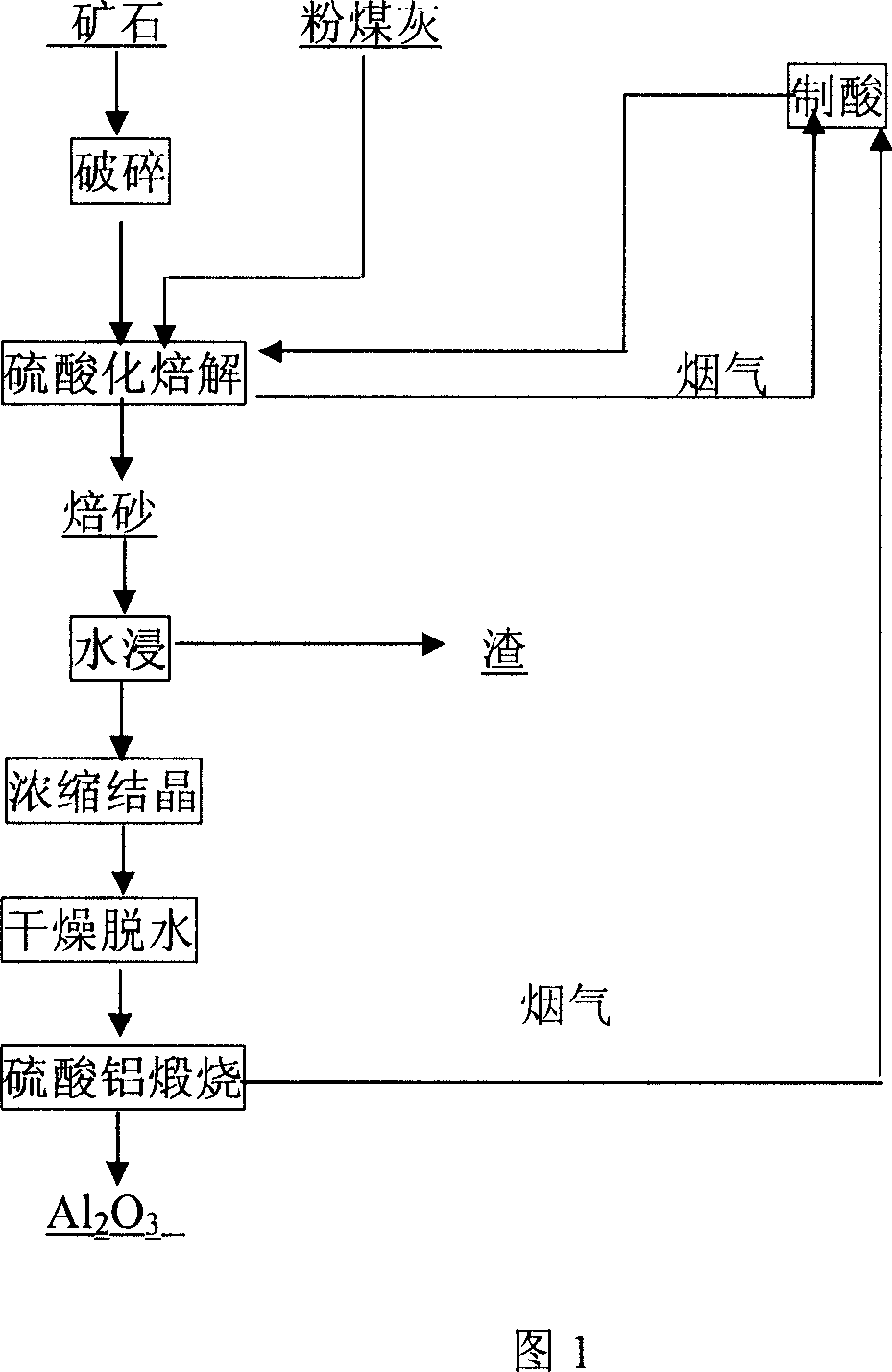

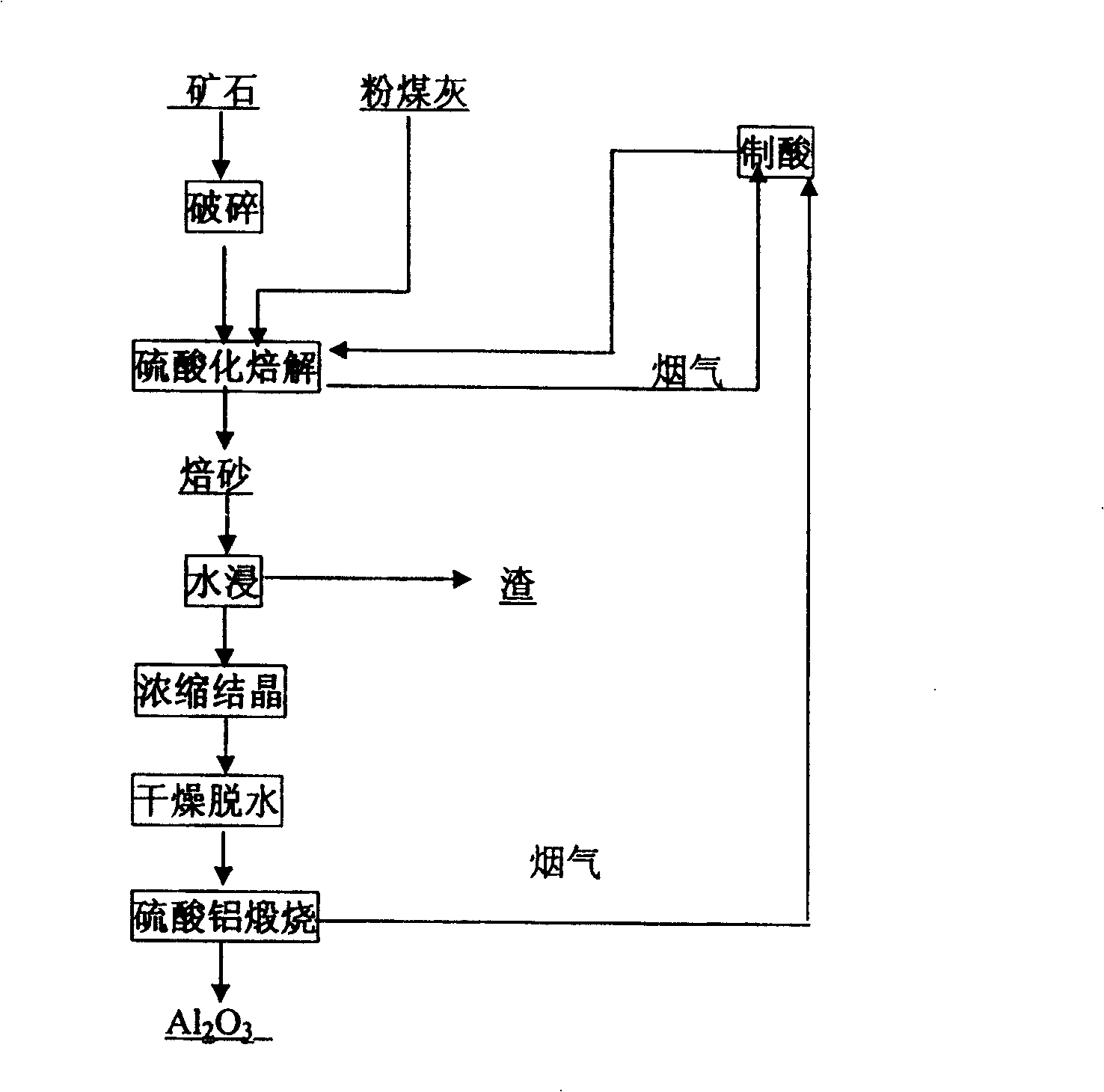

Method of acid extracting aluminium from high-silicon alumina-containing raw mineral materials

The invention relates the method of extracting aluminium from high-silicon siliceous mineral. The method comprises the following steps: mixing the aluminous ore and sulfuric acid, baking, leaching with water, filtering leachate, getting aluminium sulphate solvent, thickening filter liquor, separating out aluminium sulphate, drying, dewatering, getting anhydrous aluminium sulphate; calcining aluminium sulphate, and getting Al2O3. The invention can extracte aluminium from high-silicon siliceous mineral, coal gangue, coal ash, China clay, andalusite, feldspath, ganister, nepheline and vermiculite without baking. The method has the advantages of simple technology, little corrosion, easy operation and high recovery ratio.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

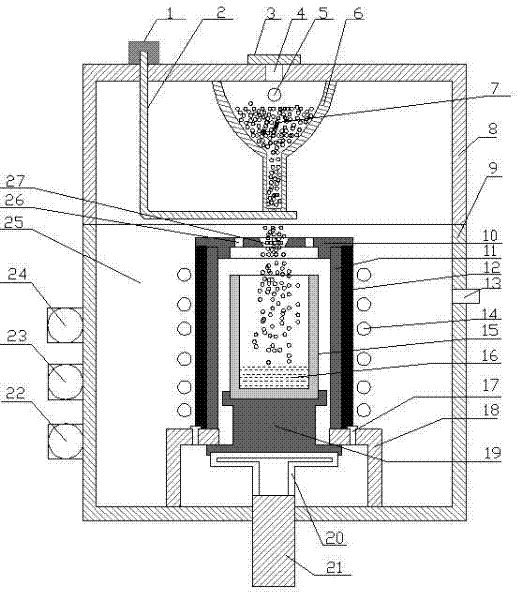

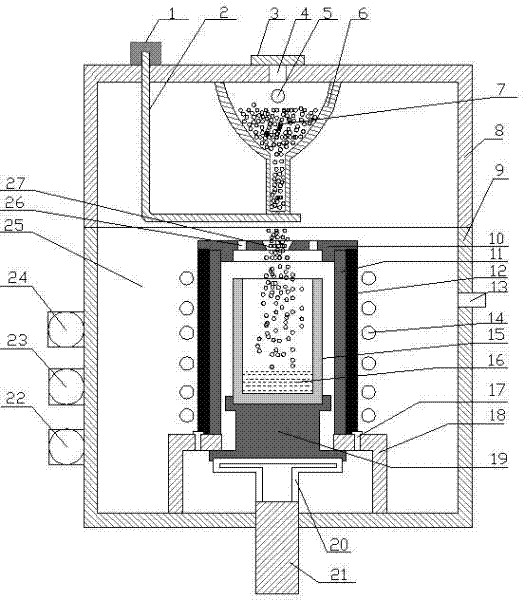

Method and equipment for removing phosphorus and metal impurities in ganister sand through vacuum induction melting

The invention belongs to the field of polycrystalline silicon purification in the metallurgical method. The method for removing phosphorus and metal impurities in ganister sand through vacuum induction melting comprises the steps of firstly removing the phosphorus impurity in the polycrystalline silicon through smelting the ganister sand in the induction heating mode under high vacuum state, then conducting ingot stretching, and then removing the metal impurities in the ganister sand through the directional solidification technology. The method disclosed by the invention is simple, the ganister sand is smelted with good impurity removal effect and high removal efficiency since the phosphorus and metal impurities in the polycrystalline silicon are removed through the vacuum induction melting and directional solidification technology, the characteristic of high temperature of the inductance coil heating is effectively used; and the method is simple and easy, integrates the double effects of phosphorus removal and metal removal, is high in yield and stable in purification effect, and is suitable for mass industrial production.

Owner:DALIAN UNIV OF TECH

Light Al2O3-SiC-C refractory brick and preparation method thereof

The invention relates to a light Al2O3-SiC-C refractory brick and a preparation method thereof. The preparation method comprises the steps of: taking 45-65wt% of porous corundum particles, 18-25% of fine corundum powder, 4-8wt% of SiC particles, 4-8wt% of fine SiC powder, 6-12wt% of crystalline flake graphite, 1.5-2.5wt% of ganister sand and 0.2-0.6wt% of aluminite powder as materials; adding 3.5-5wt% of phenolic resin to evenly stir; and mechanically pressing and molding, carrying out heat preservation on the molded billet for 12-36 hours at 200-240 DEG C, and then carrying out heat preservation for 2-6 hours at 1400-1500 DEG C under the condition of reducing atmosphere, so as to obtain the light Al2O3-SiC-C refractory brick. The light Al2O3-SiC-C refractory brick is simple in preparation process; the prepared light Al2O3-SiC-C refractory brick not only has the characteristics of high strength, excellent thermal shock resistance, strong medium erosion resistance and low thermal conductivity, but also has the characteristics of apparent porosity and pore size controllability, and is suitable for the devices such as torpedo hot metal mixer cars, metal mixers, and ladles (tanks).

Owner:WUHAN UNIV OF SCI & TECH

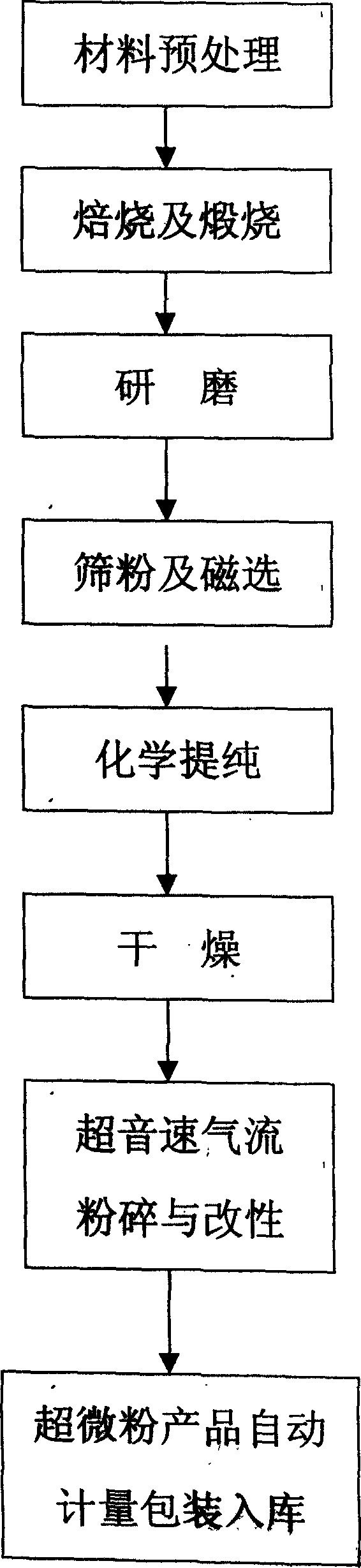

Hyperpure, superfine silicon powder and preparation method

The invention relates to a semiconductor material, in particular to a method for producing superfine and superpure ganister sand. Its main compositions are: silica is more than 99.96 percent, iron is less than 0.003 percent, diam of the ganister sand partical is less than 1 um and its outside surface is clad by silane bimorph agent. The producing steps are: a. material pretreatment; b. roasting and baking; c. grinding, cold ore is send into column grinder to be grinded to ganister sand with size 325 mesh; d. screening and magnetic separating, said ganister sand is send into screener to be screened, the one less than 325 is send into magnetic separater separater to get rid of magnetic substances in it; e. chemical refining, the ganister sand without magnetic substance is put into reaction container to react to react with weak acid solution mixed with weak hydrofluoric acid and weak hydrochloric acid; f. drying; g. supersonic airflow crushing and modifying.

Hole sealing agent for seismic exploration and method of manufacturing the same

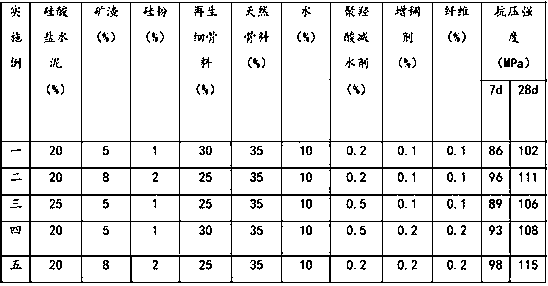

InactiveCN101318802ASlow reaction speedIncrease coagulation strengthSeismic energy generationGanisterUltimate tensile strength

The invention belongs to the seismic exploration technical field, in particular relating to a hole sealing agent and a preparation method thereof. The seismic exploration hole sealing agent is characterized in that the agent is prepared by superburning calcium oxide, cement with a strength grade more than 32.5 and an inorganic material; the raw materials by weight percentage of the hole sealing agent are: 40 to 97 percent of the superburning calcium oxide, 2 to 40 percent of the cement with the strength grade more than 32.5, and 1 to 30 percent of the inorganic material which is ganister sand or heavy calcium powder. The hole sealing agent has the advantages of simple construction, low difficulty to master, good sealing effect, safe use and low cost, etc.

Owner:武汉山友爆破科技工程有限公司

Method for preparing absorbent with phosphor concentration and phosphor reclaim function

InactiveCN1765488ALarge particlesProportionally largeSilicon compoundsWater/sewage treatment by sorptionCalcium in biologySorbent

Disclosed a method for preparing the adsorbent with the phosphor collection and recycle functions, utilizes the natural mineral as raw material to mix the calcium material in 100 weight and the silicon material in 80-200 weight uniformly, then adds the water and synthetic adjuvant as natrium hydrate or calcium hydrate solution to be laid for activation, puts it into water heat reaction kettle to for heated and pressurized synthesis while the synthesis temperature is 120-280 Deg. C and the synthesis pressure is 10-40mpa and the synthesis time is 3-24 times; then cools and dries the material after aforementioned process to be milled or processed into grains which is said high effective absorbent with the phosphor collection and recycle functions. Wherein, said calcium material can be selected from lime hydrate, burnt lime and conch; said silicon material can be selected from silica dioxide, sodium silicate, ganister, bermehl and rice husk ash, which have wide resource and lower cost. The prepared absorbent has the characters that large process handling capacity of unit weight phosphor, lower producing cost, and realization of absorbing and recycling phosphor.

Owner:SHANGHAI JIAO TONG UNIV

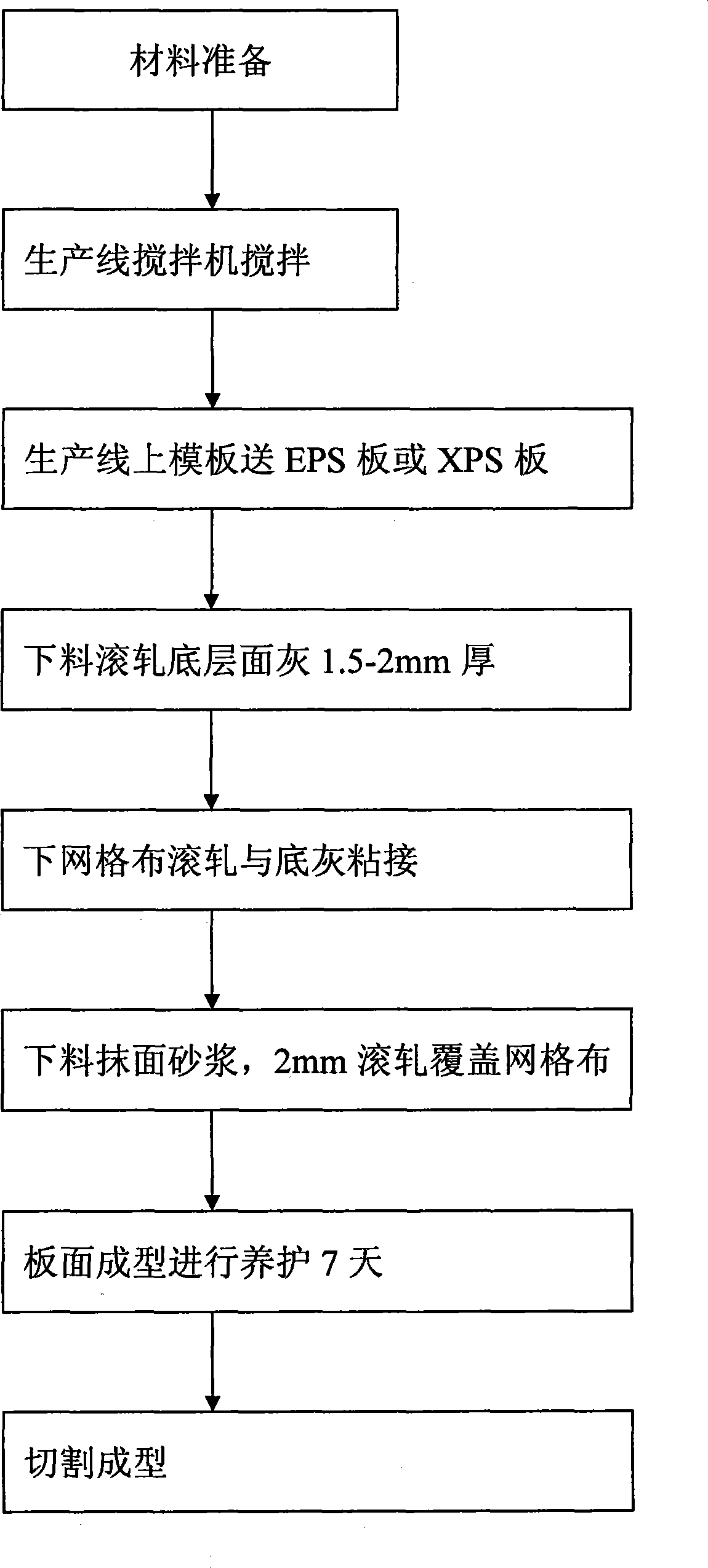

Polymer mortar face outside wall heat-insulating board and preparing technique thereof

The invention belongs to the field of external wall heat-insulating board for architectural decoration. A polymer sand pulp face external wall heat-insulating board is characterized in that the invention includes polyphenylacetylene foam board or polyphenylacetylene extruded sheet, one side of the polyphenylacetylene foam board or the polyphenylacetylene extruded sheet is bottom layer ash, the outer side of the bottom layer ash is net-case cloth and the polymer sand pulp layer is on the net-case cloth. The sand pulp of the fabric strengthening polymer sand pulp layer is composed according to the following weight proportioning: glue powder takes 5-10, lignin takes 0.1-1, tear resistant fiber takes 0.1-1, cement takes 50-100, ganister sand takes 100-200 and heavy calcium takes 5-20. The total raw materials above and water synthesize glue pulp according to the weight proportioning of 1:5. The invention proceeds aggressive construction in site, has no wet processing, has strong plasticity and very easy to be cut.

Owner:TIANJIN HAOWEI BUILDING MATERIALS TECH DEV

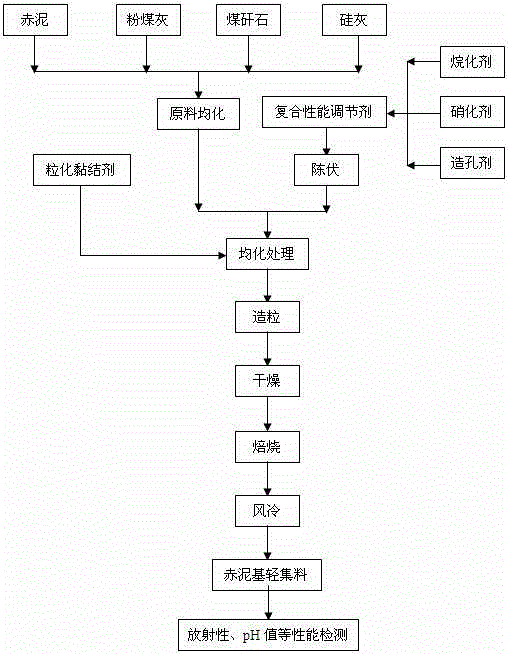

Red-mud-based sintered light aggregate and preparation method thereof

ActiveCN105294142ASuppress radioactivityPlay a solid alkali effectSolid waste managementCeramicwareRed mudAdhesive

The invention discloses red-mud-based sintered light aggregate and a preparation method thereof and belongs to the technical field of industrial solid waste comprehensive utilization and novel ecological building materials. The red-mud-based sintered light aggregate is prepared from, by weight, 40-80 parts of red mud, 10-30 parts of coal ash, 5-30 parts of coal gangue, 0-20 parts of silica fume, 10-20 parts of alkylating agent, 5-30 parts of nitration agent, 30-60 parts of carbonaceous pore forming material and 10-30 parts of pelletization adhesive. The red mud is on the basis of the weight of a dry base. The red mud, the coal ash, the coal gangue, ganister sand and other industrial solid waste are adopted in the main raw materials, and eco-environment friendliness is achieved. A compound performance modifier formed by the alkylating agent and the nitration agent can be matched with a proper baking process, the radioactivity of the red mud can be effectively restrained, and the solid caustic soda effect is achieved. The overall preparation process is simple, existing equipment can be utilized for production, cost is effectively reduced, and large-scale consumption of the red mud is achieved.

Owner:江西林宇建设工程有限公司

High-strength weather-resistant welding rod

ActiveCN1743126AGood atmospheric corrosion resistanceImprove performanceWelding/cutting media/materialsSoldering mediaIron powderFerrosilicon

A sort of strong clime-withstanding welding rod is disclosed, whose coating content as follows, marble 35-40%, fluorite 15-20%, ferrotitanium 8-11%, mid-carbon Fe-Mn 3-8%, ferrosilicon 45%, synthesized isinglass(40 mesh) 2-3%, tiny ganister sand 2-4%, iron powder 12-20%, chrome 1-2%, copper powder 0.5-1%, nickel powder 1-2%, titanium pigment 4-8%. The fused metal and welded joint obtained by the invention has the good performance of withstanding clime and comprehensive performance, especially at -40deg.C it has good low temperature impact toughness, yield strength>=450MPa, tensile strength>=550MPa, elongation rate >=22%, Akv>=100j.

Owner:BAOSHAN IRON & STEEL CO LTD +1

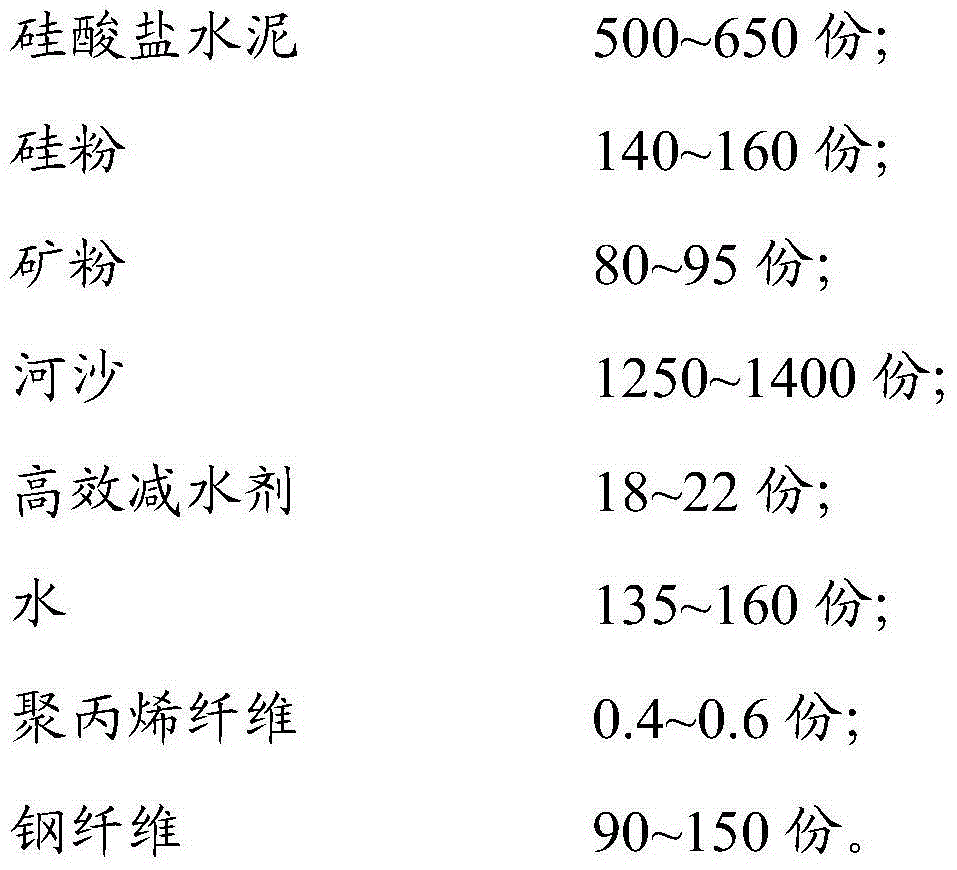

Concrete annular pole and preparation method thereof

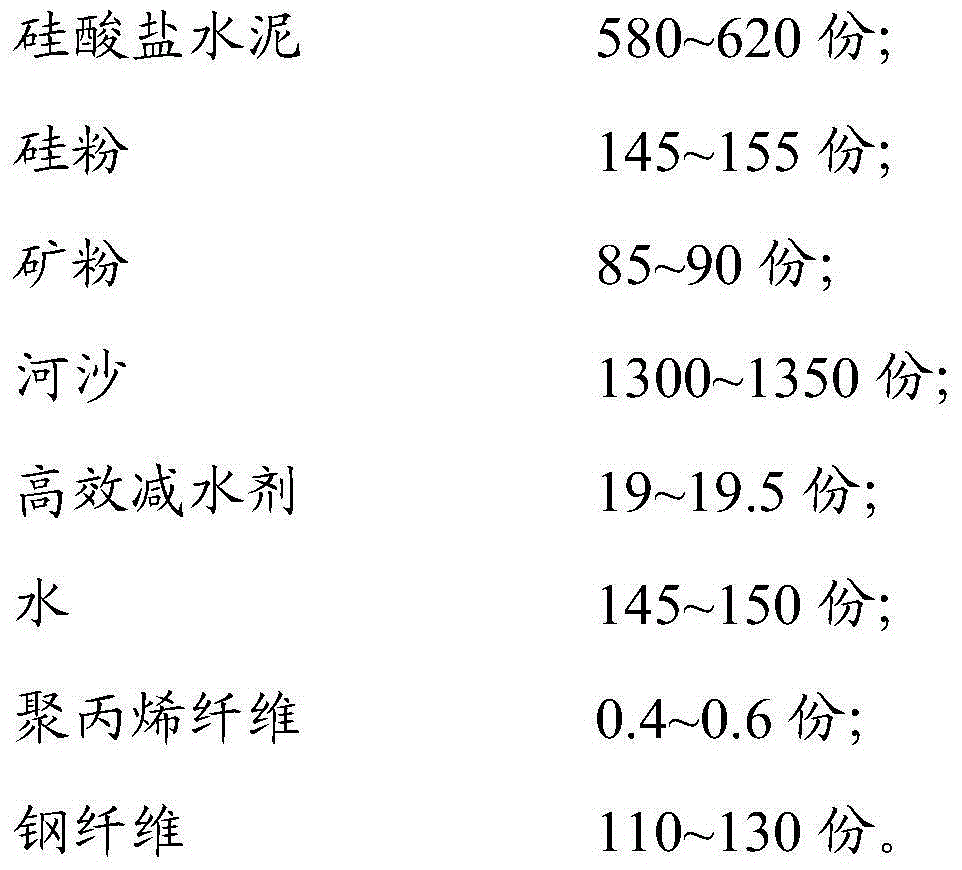

The invention belongs to the field of building materials, and provides a concrete annular pole and a preparation method thereof. The concrete annular pole is composed of powder concrete with ultra-high performance and mesh reinforcement, and the powder concrete with the ultra-high performance comprises, by weight, 500-650 parts of portland cement, 140-160 parts of ganister sand, 80-90 parts of mineral powder, 1,250-1,400 parts of river sand, 18-22 parts of efficient water reducing agents, 135-160 parts of water, 0.4-0.6 part of polypropylene fibers and 90-150 parts of steel fibers. The concrete annular pole has the advantages of being good in carbonization resistance, good in freeze thawing resistance, high in compressive strength, good in cracking resistance, low in weight, capable of being used as a common pole, part of prestress poles, prestress poles and the like, and suitable for building various power grids and the like.

Owner:黄贺明

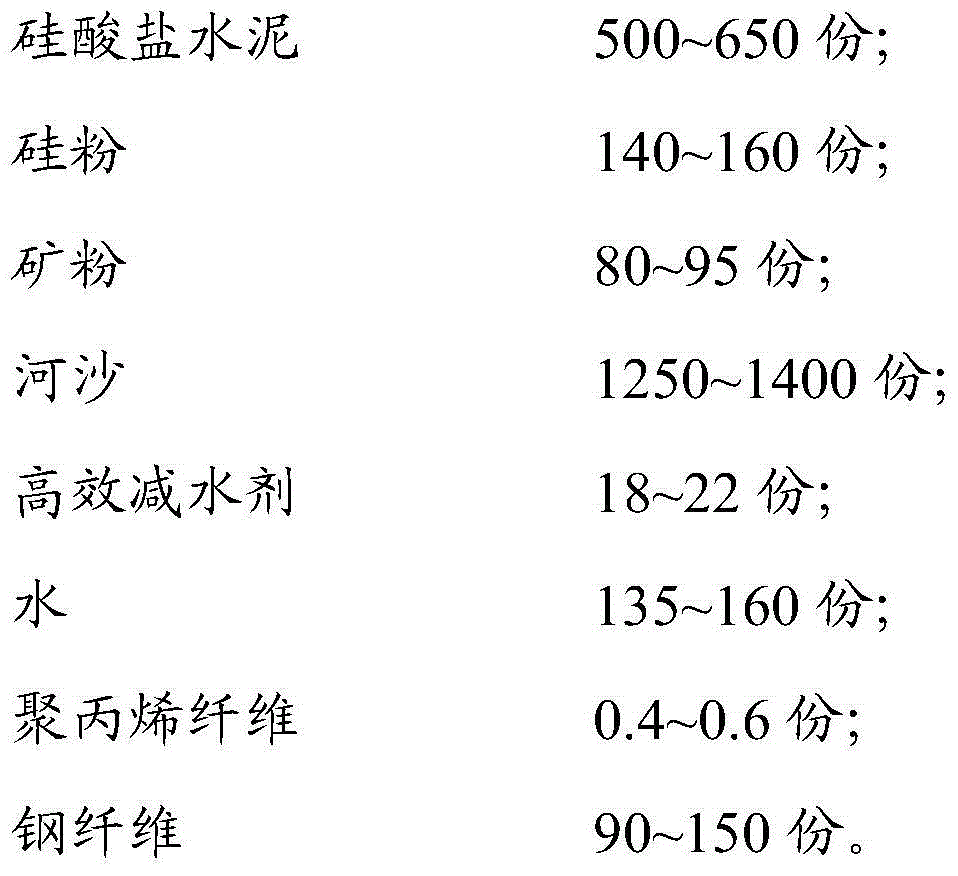

Superfluid self-compacting concrete and preparing method thereof

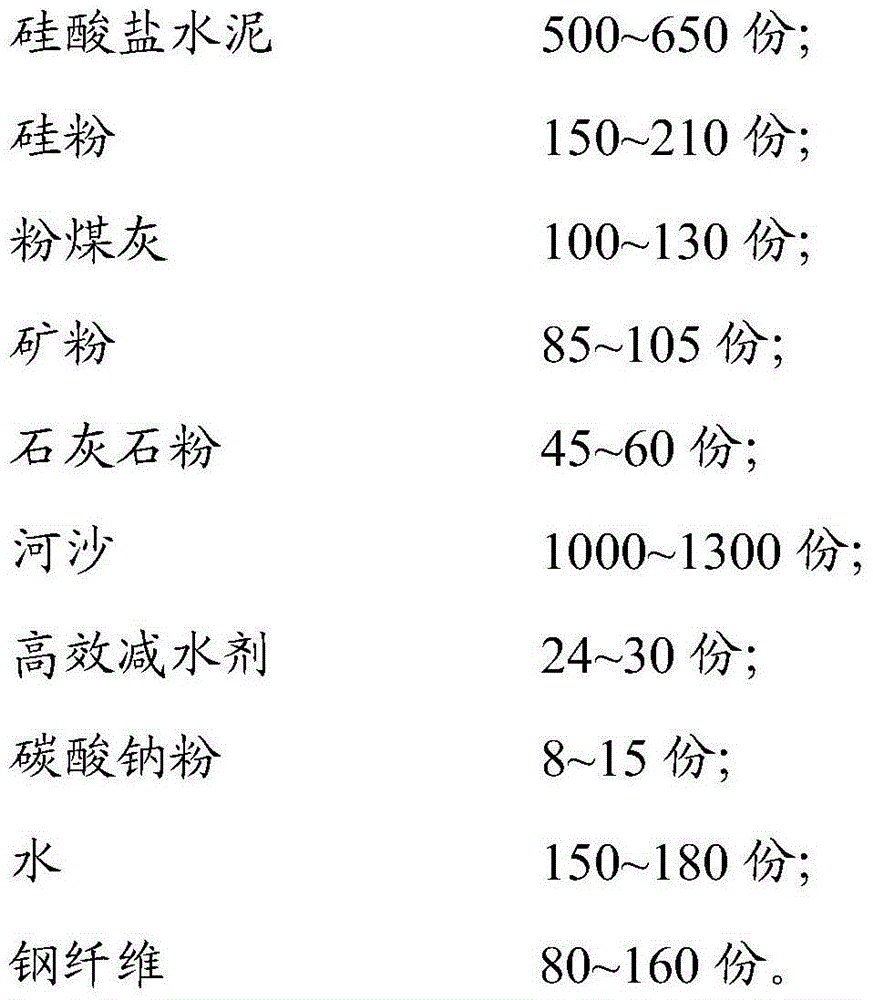

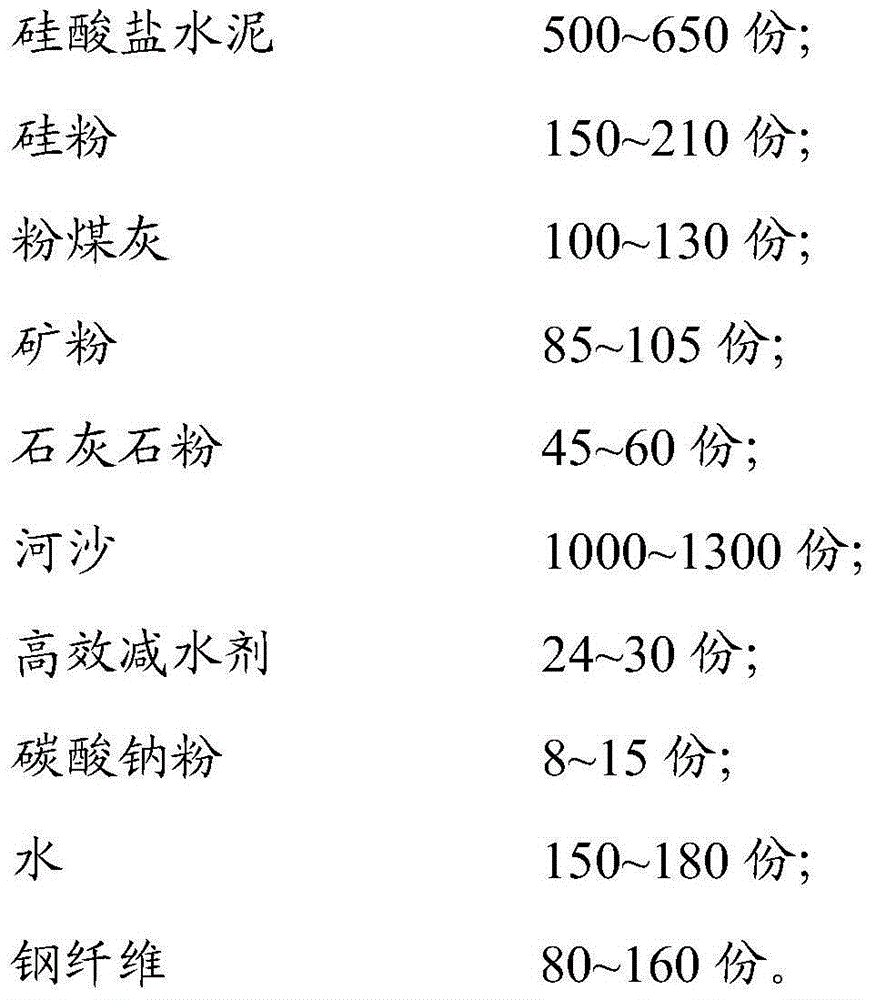

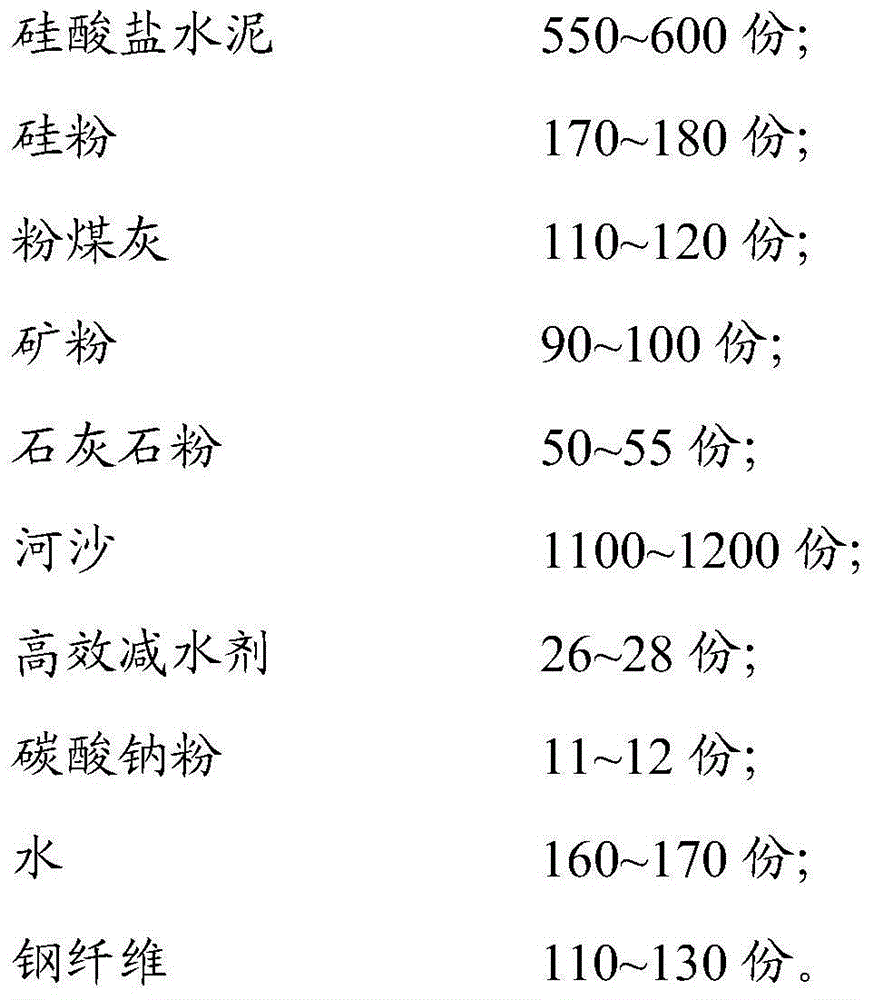

The invention belongs to the field of building materials and provides superfluid self-compacting concrete and a preparing method thereof. The superfluid self-compacting concrete comprises, by weight, 500-650 parts of Portland cement, 150-210 parts of ganister sand, 100-130 parts of coal ash, 85-105 parts of mineral powder, 45-60 parts of limestone flour, 1000-1300 parts of river sand, 24-30 parts of high-efficiency slushing agents, 8-15 parts of sodium carbonate powder, 150-180 parts of water and 80-160 parts of steel fiber. The superfluid self-compacting concrete has the advantages of being superhigh in strength, high in tenacity and durability and stable in size. Cohesiveness can be reduced, self-compacting performance and mobility can be improved, bleeding and dispersing phenomena do not exist, environment friendliness is achieved, and cost is low.

Owner:黄贺明

Recycled fine aggregate high-strength self-compact concrete

InactiveCN109160791ASimple preparation processImprove the interface transition areaFiberSuperplasticizer

The invention discloses recycled fine aggregate high-strength self-compact concrete. The concrete comprises the following raw materials: Portland cement, slags, a ganister powder, recycled fine aggregates, natural aggregates, water, a polycarboxylate superplasticizer, a thickening agent and a fiber. A production method of the concrete comprises the following steps: adding the weighed Portland cement, slags, a ganister powder and a half of the whole water into an agitator to carry out agitation for 1 min for sufficient wetting; adding the thickening agent, the fiber and the polycarboxylate superplasticizer to carry out agitation for 5-8 minutes for sufficient mixing and dispersion so as to obtain a pasty mixture A; and mixing and agitating the recycled fine aggregates and the residual waterfor 3-5 minutes, and adding the mixture A and the natural aggregates to agitate for 10 minutes so as to obtain a finished product. The whole mechanical property of the obtained concrete is remarkablyimproved; the recycled fine aggregates are produced by utilizing building waste, so that the resources are recycled; and crop straws are sufficiently utilized, so that the raw materials are saved, the living environment of the human beings is improved, the environment is protected and the energy is reduced.

Owner:四川国泰高新管廊产业投资有限公司

Waterproof, thermal insulating fire resisting coating

InactiveCN1560142ASuitable for crackingSuitable for solving variantsCoatingsAntimony trioxideThermal printing

The invention is a waterproof, heat-insulating and flame-retardant coating, including auxiliary and basal material; the main material has the components in weigh share: pentaerythritol 5-16 weight shares, antimonous oxide 0.2-6 weight shares, chloroparaffin 0.2-6 weight shares, mica 2-20 weight shares, and sepiolite 2-20 weight shares; the main material also includes melamine 1-11 weight shares, and ganister sand 0.3-7 weight shares; the main material also includes ammonium phosphate 1-18 weight shares, and perlite 5-40 weight shares. The invention has no toxicity and flavor, safety and environmental protection, stable properties, and remarkable water-proofing, heat-insulating and flame-retardant effects, and can be widely applied to walls, roofs, floors, basements, pipelines, wood plates, and metals.

Owner:王进文

Method for preparing diamond-silicon carbide electronic packaging material fast

InactiveCN102184873AReduce processing requirementsShort processing cycleSemiconductor/solid-state device detailsSolid-state devicesPorosityArgon atmosphere

The invention provides a method for preparing a diamond-silicon carbide electronic packaging material fast. The method is characterized in that according to weight percentage, 10-15 percent of adhesive, 5-20 percent of graphite, 20-40 percent of ganister sand and 30-60 percent of diamond are wet-mixed for 16-24h, then a composite material blank is obtained through forming under 100 to 200 DEG C and 10-50MPa pressure; the composite material blank is fired for 16-24h under 1,000 to 1,100 DEG C in the argon atmosphere, and a diamond / silicon / carbon polyporous matrix having a certain strength and porosity is obtained after cooling; the diamond / silicon / carbon polyporous matrix prepared is placed in a graphite crucible and then is embedded through liquidphase infiltration infiltrated material, and then the crucible is placed in a high vacuum fritting furnace for vacuum liquidphase infiltration for 0.5-1h, and the infiltration temperature is 1,450-1,550 DEG C, and the vacuum degree is -0.08 to -0.01MPa; and the compact diamond-silicon carbide electronic packaging material can be obtained after cooling.

Owner:UNIV OF SCI & TECH BEIJING

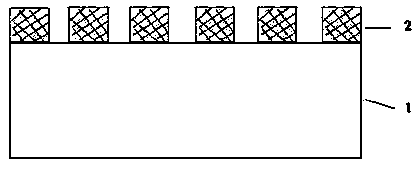

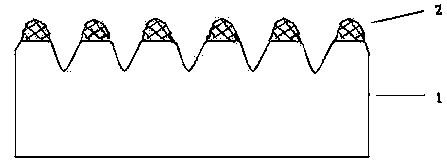

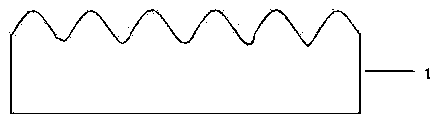

Texturing method for solar cell

ActiveCN103378212AImprove performanceSimple processAfter-treatment detailsFinal product manufactureSlurrySolar cell

The present invention provides a texturing method for a solar cell. The texturing method comprises a step A. coating a surface of a silicon wafer with a silicon slurry which is a mixture of ganister sand, a binder and water to form a ganister sand dot matrix with a height of 3-30[Mu]m; and a step B. carrying out chemical etching on the surface, where the ganister sand dot matrix is formed, of the silicon wafer, and forming a concave-convex antireflection structure on the surface of the silicon wafer after etching to obtain a textured silicon wafer. According to the texturing method for the solar cell, texturing reflectance of the silicon wafer is below 5% with regular and uniform texturing and few surface defects, and therefore the performance of the solar cell can be effectively improved. In addition, the process is simple and mass production can be achieved.

Owner:HUIZHOU BYD BATTERY

Reducing agents for smelting chemical grade metallic silicon

The invention relates the reducing agent of smelting chemical grade metallic silicon, comprising ganister, oil coke and bituminous coal. The mass ratio of ganister and fixed charcoal content is between 2.7:1.3 and 2.9:1.1. The invention has the advantages of reducing the cost of metallic silicon and good economic benefit and social benefit.

Owner:上海广济硅材料有限公司 +1

Method for increasing smelting point of coal ash

Provided is a process for increasing the fusing point of coal ash, which is characterized in that low-melting-point coal acts as raw material and is blended with addition agent to realize the process. The content of the low-melting-point coal as the raw material is 85 percent to 95 percent, the content of sulfur S is controlled no more than 1 percent, and the content of the blended addition agent is 6 percent to 13 percent. The addition agent can be ganister sand, porcelain clay or kaolin. The process of increasing the fusing point of the coal ash which is introduced by the invention not only is simple and practical, but also can enable the fusing point of coal ash to be increased to proper value through regulating the content of the blended addition agent, which meets the application of fire coal in industry or in daily life.

Owner:张宏光

Method for preparing nano silicon carbide

The invention provides a preparation method of nanometer carborundum. The preparation method of the nanometer carborundum has the steps that: firstly, sundries are removed from plant cotton; secondly, analytically pure ganister sand is put into a plumbago pot, the plant cotton which is processed in the step (1) is arranged on the ganister sand, and the plumbago pot is covered; thirdly, the plumbago pot which is filled with the plant cotton and the ganister sand in the step two is put into a high temperature vacuum furnace which is vacuumized to 10 to 3 Pa and then is heated to 600 DEG C to 1000 DEG C, charing for 30 minutes is performed under heat preservation, siliconization for 150 to 180 minutes is preformed under heat preservation after being heated to 1400 DEG C-1500 DEG C, and then the temperature of the plumbago pot is descended to a normal temperature along with the high temperature vacuum furnace, therefore, the nanometer carborundum is produced, and the diameter of the carborundum is between 3nm to 15nm. The invention is characterized in that the plant cotton, in particular to the waste cotton, is used as the material, the plant cotton performs the charing and the siliconization under vacuum condition, and therefore the nanometer carborundum is produced. The invention can be applied to other animal fiber and plant fiber, in particular to waste animal fiber and plant fiber, so as to produce the nanometer carborundum. The technology of the invention is relatively simpler.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Method of acid extracting aluminium from high-silicon alumina-containing raw mineral materials

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Glue injecting formula of chlorinated polyethylene gas inlet rubber tube

InactiveCN101519515AEasy to operateImprove material performanceFlexible pipesPolymer scienceQuinoline

The invention relates to a rubber injecting formula of a chlorinated polyethylene gas inlet rubber tube comprising the following ingredients by weight: 100 portions of chlorinated polyethylene rubber, 30 to 50 portions of semi-reinforcing carbon black (N774), 60 to 90 portions of ganister sand (B-66), 20 to 30 portions of dioctyl-o-phthalate (DOP), 5 to 10 portions of magnesium oxide, 2.5 to 3.5 portions of FYLP-2, 1 to 2 portions of paraffin, 2 to 4 portions of calcium stearate, and 1 to 3 portions of 2,2,4-trimethyl-1,2-dihydro quinoline polymer (RD). The application of the chlorinated polyethylene gas inlet rubber tube prepared according to the formula to an automobile shows that the chlorinated polyethylene gas inlet rubber tube has optimal material property when being applied to an automobile, the tensile-strength of more than 13.0MPa, and the maximum elongation of more than 300 percent and the resistance to temperature of 130 DEG C for a long time when in use. Compared with a traditional formula, the formula greatly enhances the resistance to No.1and No.3 5w-40 engine oil and ensures the stable operation of CM rubber injecting technology, thereby better meeting the requirements of the gas inlet rubber tube of the automobile resisting heat and oil.

Owner:TIANJIN PENGYI GRP CO LTD

Rubber aggregate grouting material

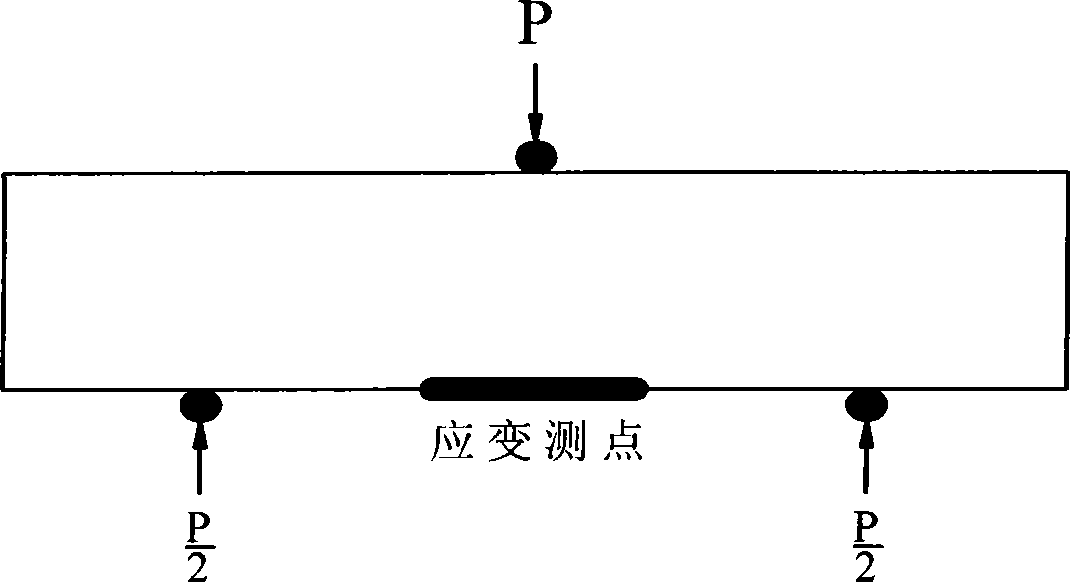

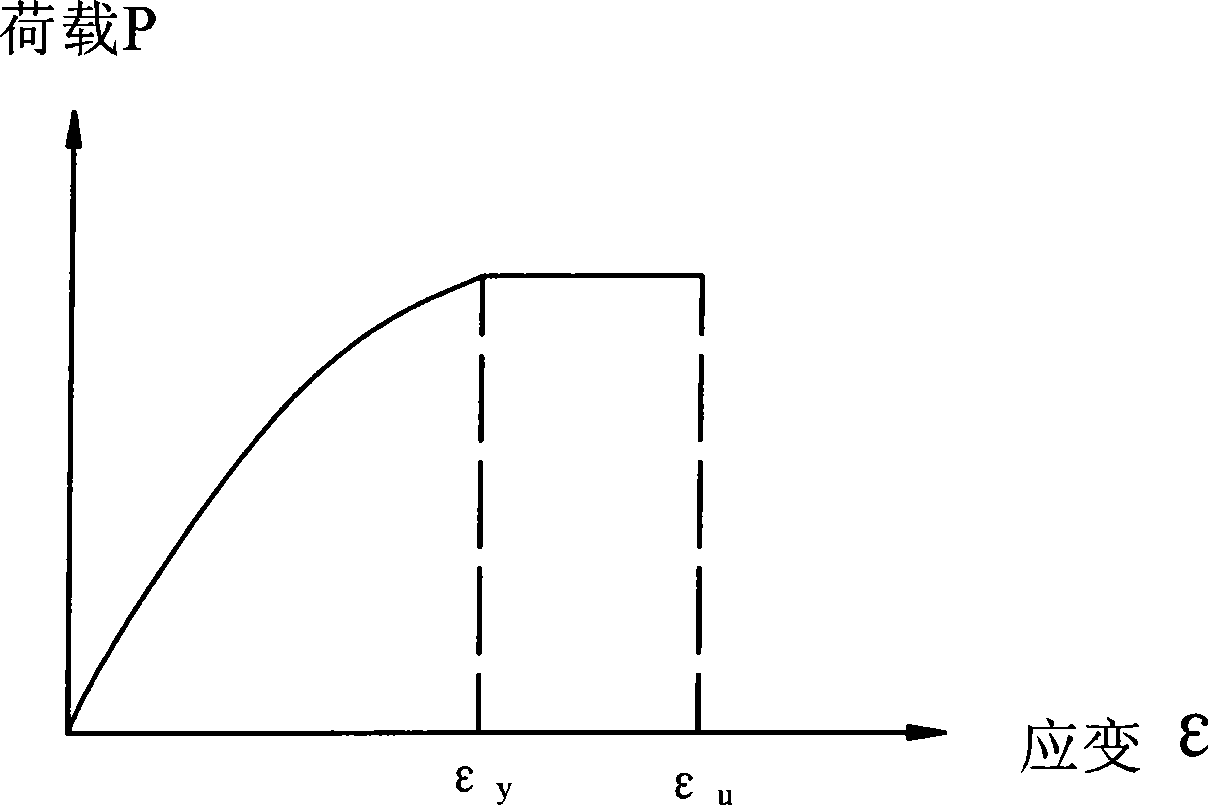

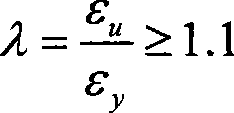

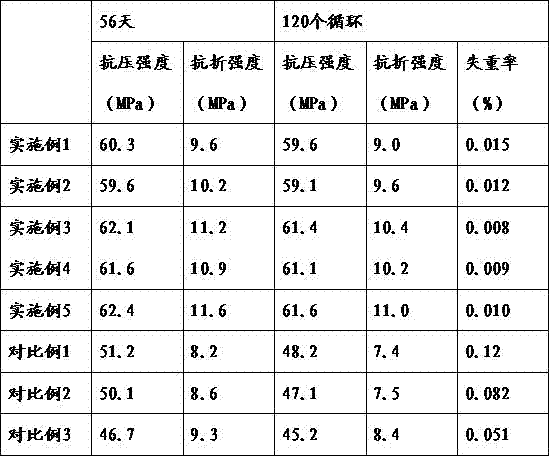

InactiveCN101397202AImprove liquidityLong operating timeSolid waste managementDuctility factorGanister

The invention discloses a rubber crumbs grouting material, which comprises the following components by weight proportion: 4-8 parts of rubber crumbs, 65-87 parts of sand, 55-85 parts of cement, 4-10 parts of admixture, 20-32 parts of water and 4-12 parts of additive; wherein, the admixture consists of 2-5 parts of fly ash, 1-2 parts of ganister sand and 1-3 parts of powered ore while the additive consists of 3-10 parts of expanding agent and 1-2 parts of super plasticizing agent. The rubber crumbs grouting material of the invention is characterized by better fluidity, longer operation time, expansion rate not less than 0.02%, trabecular ductility factor not less than 1.1 and high compressive strength; can utilize waste materials and lower the cost.

Owner:CHINA CONSTR SIXTH ENG DIV CORP +2

Guava leaf-bud cutting propagation method

The invention provides a guava leaf-bud cutting propagation method. The method comprises the following steps of 1, selecting nutrient soil, adding ardealite ganister sand into the nutrient soil per cubic meter and placing the mixture into a container for use after stirring is performed, wherein the nutrient soil is smashed red earth or the mixture of coco coir and peat soil; 2, building a cuttagegreenhouse, and placing the container with the nutrient soil into the greenhouse; selecting guava branches as a cuttage material, and soaking the branches with a rooting solution and then performing cuttage in a plastic cup, wherein the preparation method for the rooting solution comprises the step that indolebutyric acid and bone meal are added into per kilogram of water to be mixed to be uniformto obtain the rooting solution. According to the guava leaf-bud cutting propagation method, due to the rooting solution prepared from indolebutyric acid and animal bone meal, root growth and development are promoted. The principle that rooting is promoted due to the fact that green branch cuttage is performed for manufacturing a carbon source by means of the green leaf photosynthesis is utilized,and the method has the advantages that rooting seedling formation is promoted, the seedling growing period is shortened, operation is easy, nursery stock grows rapidly and the cost is low.

Owner:GUANGXI YUHUALING TECH DEV CO LTD

High-strength iron-based high-chrome ceramic composite coating for ship side plate and preparing method of high-strength iron-based high-chrome ceramic composite coating

InactiveCN105039890AHigh impact strengthEnhanced resistance to peelingMolten spray coatingCeramic compositeBoron fiber

A high-strength iron-based high-chrome ceramic composite coating for a ship side plate comprises, by weight, 1.6-1.8 parts of graphite powder, 25-27 parts of chromium powder, 4.3-4.6 parts of nickel powder, 4.1-4.4 parts of ganister sand, 0.3-0.4 part of boron powder, 40-42 parts of iron powder, 10-12 parts of TiAl powder, 20-21 parts of B4C powder, 1.2-1.5 parts of nano boron fiber, 0.7-0.9 part of magnesium fluoride, 3-4 parts of zircon powder and 0.2-0.3 part of yttrium oxide. According to the metallurgy coating, the iron-based high-chrome material is used, and superior seawater corrosion resisting performance is achieved; by means of the TiAl and the B4C and alloying treatment, ceramic phases and metal phases can be combined tightly, and the association performance with the iron-based material, the seawater corrosion resisting performance, the impact resisting performance and the abrasion resisting performance are improved; and the impact resisting strength and spalling resistance of the coating are good, the number of gaps is reduced, contact between a corrosion medium and a base body of the ship side plate is effectively prevented, and the corrosion speed is reduced.

Owner:MAANSHAN XINGLONG FOUNDRY CO LTD

Hydrophobic oleophilic self-cementing sand and its preparation method

InactiveCN1884397AAchieve sand controlTo increase oilPigment treatment with organosilicon compoundsSoluble glassGanister

The invention relates the lipophilicity backup sand and preparing method. On the surface of ganister sand there is lipophilicity film. The film is made by composite additive, which is mixture composed by 0.5-2 parts organic silicate or aliphatic acid or aliphatic acid salt and 5-15 parts soluble glass or 5-15 parts cement binding agent or 1-5 parts curing agent or 1-5 parts organic binding agent. The invention mixes the ganister sand and composite additive in pelleting machine to get backup sand.

Owner:SOUTHWEST PETROLEUM UNIV +1

Anti-corrosion high-strength coastal building cement and preparation method thereof

The invention relates to anti-corrosion high-strength coastal building cement and a preparation method thereof. The anti-corrosion high-strength coastal building cement comprises the following materials in parts by weight: 30-40 parts of sulfate aluminum cement clinker, 5-10 parts of ganister sand, 5-10 parts of gypsum, 20-30 parts of quartz sand, 0.1-0.5 part of silicon nitride, 10-20 parts of titanium bearing slag, 1-3 parts of water reducer and 1-3 parts of compound early strong preservative. The coastal building cement provided by the invention has the excellent performance of high strength, compactness, and resistance to permeability, marine corrosion and marine water flushing, and is particularly applicable to underground, port and wharf projects and the other projects corroded by corrosion mediums such as sulfate.

Owner:余思哲

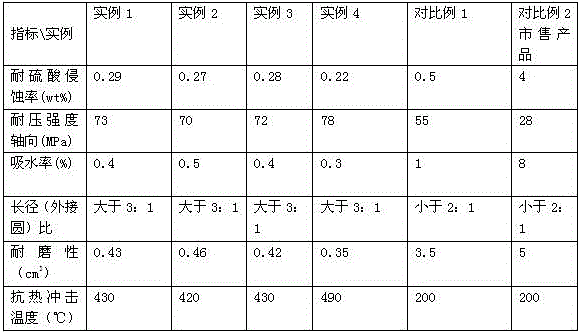

Lanthanum oxide large-specification ceramic heat accumulator and preparation process thereof

InactiveCN105967731AAvoid misalignmentHigh porosityHeat storage plantsIndirect carbon-dioxide mitigationMulliteBoron nitride

Provided is a lanthanum oxide large-specification ceramic heat accumulator. The lanthanum oxide large-specification ceramic heat accumulator is characterized in that the heat accumulator is of a column structure, a plurality of hole channels penetrating through the column are arranged in the heat accumulator, the heat accumulator is formed by sintering inorganic powder and an additive, and the inorganic powder is prepared from, by weight, 30-50 parts of aluminum titanate, 40-50 parts of Al2O3, 3-8 parts of mullite, 3-9 parts of zirconium oxide, 2-4 parts of silicon nitride, 3-5 parts of boron nitride, 3-9 parts of ganister sand and 1-3 parts of lanthanum oxide. The lanthanum oxide large-specification ceramic heat accumulator has good forming performance and shape keeping performance. The formula and a production method are adopted, the hole channels of the heat accumulator are dense, the wall thickness is small and is only 1 mm, the section size is large and is larger than 100 cm<2>, the draw ratio is large, the length reaches 1,000 mm, and all the hole channels have the advantages of being small in resistance, less in accumulated dust, not likely to be blocked, good in dust removal performance and the like.

Owner:HUBEI SHENWU THERMAL ENERGY TECH

Preparation method of slate alkali reactivity restraining addition agent

The invention discloses a preparation method and a material using standards of a slate alkali reactivity restraining addition agent (FLSR-I). The addition agent is composed of mixing materials, ganister sands, nanometer SiO2, triethanolamine, a high-efficient plasticizing agent and an air entraining agent, the preparation method comprises accurately weighting dosage of the mixing materials, the ganister sands, the nanometer SiO2, the triethanolamine, the high-efficient plasticizing agent and the air entraining agent in proportion during preparation; sufficiently blending the mixing materials,the ganister sands, the nanometer SiO2, the high-efficient plasticizing agent and the air entraining agent, and manufacturing end products of the restraining addition agent by blending with the triethanolamine; and mixing in preparation of alkali reactive aggregate concrete in carious grades in proportion. The preparation method can effectively restrain reaction of slate alkali aggregate with expansion ratio between 0.2% to 0.5% and is obvious in restraining effect, simple and convenient in using method and free of needs of special construction control, thereby being capable of greatly lowering engineering using materials and transportation cost, and expanding material selecting range of the engineering using materials simultaneously.

Owner:CHINA RAILWAY NO 5 ENG GRP

Process for purifying ganister sand from silicon carbide reclamation sand

InactiveCN106583031AReduce power generation costsAchieve recyclingMechanical material recoveryWet separationResource utilizationBromine

The invention discloses a process for purifying ganister sand from silicon carbide reclamation sand. The process includes the following steps that silicon carbide reclamation sand mortar is subjected to filter pressing, so that a silicon carbide filter cake is obtained; the silicon carbide filter cake and water are put into a ground pool at the weight ratio of 1:8, mixed and thoroughly stirred evenly; silicon carbide filter cake suspension liquid obtained after stirring is conveyed to a swirling tank through a pump to be swirled; obtained upper-layer ganister sand suspension liquid is subjected to filter pressing, and wet raw ganister sand is obtained; the wet raw ganister sand, industrial bromine and water are added into an agitator at the weight ratio of 4:1:5 and stand after being thoroughly stirred evenly; and high-purity ganister sand separated from the upper layer is subjected to filter pressing through a filter press and then collected. The process for purifying the ganister sand from the silicon carbide reclamation sand can improve the resource utilization rate, reduce environment pollution, turn waste into wealth and enable crystalline silicon and silicon carbide to be used reasonably, so that the long-term problem of waste pollution is solved.

Owner:新郑市宝德高技术有限公司

Finishing mucilage capable of forming thick coating on surface of EPS (Expandable Polystyrene) plate and preparation method of finishing mucilage

The invention provides a finishing mucilage capable of forming a thick coating on the surface of an EPS (Expandable Polystyrene) plate and a preparation method of the finishing mucilage, belongs to building materials, and overcomes the defects that the conventional finishing mucilage is low in bonding strength, is easy to crack, cannot form a thick coating, and is difficult to meet the fire-proof requirement. The finishing mucilage is prepared by mixing limestone powder, ganister sand, cement, a PP (Propene Polymer) fiber, a wood fiber, a modifying agent, a water repellent and water. The finishing mucilage capable of forming the thick coating on the surface of the EPS (Expandable Polystyrene) plate and the preparation method of the finishing mucilage have the positive effects that the bonding tensile strength of a mucilage layer and a benzene adhesive plate exceeds 0.1 Mpa. The cost of the finishing mucilage is lowered by about one third. The expansion and contraction deformation of the finishing mucilage generated under the influence of external natural conditions can be better absorbed, and the temperature difference deformation stress is dispersed around uniformly, so that the generation of cracks is effectively prevented. The thicknesses of external thermal insulation protecting layers can respectively reach 13 mm, 18 mm, 23 mm, 28 mm and 33 mm through adjusting the formula and the construction process and the like.

Owner:JILIN KELONG BUILDING ENERGY SAVING TECH

Method of producing silicon-calcium-barium steel cleaning agent by shaft furnace

InactiveCN1920060ASimple production and operationIncrease productionCalcium silicateEconomic benefits

The invention discloses the method for producing calcium silicate barium cleansing steel agent with high furnace, comprising the following steps: using ganister, lime rock, barite powder and fluorite as raw materials, adding them into high furnace, smelting, and getting the product. The method has the advantages of simple operation, high output and good economic benefit.

Owner:刘长福

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com