Recycled fine aggregate high-strength self-compact concrete

A technology of self-compacting concrete and recycled fine aggregates, which is applied in the field of concrete configuration, can solve the problems of poor comprehensive mechanical properties of self-compacting concrete, and achieve the effects of good resistance to tensile deformation, enriching straw resources, and improving the preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

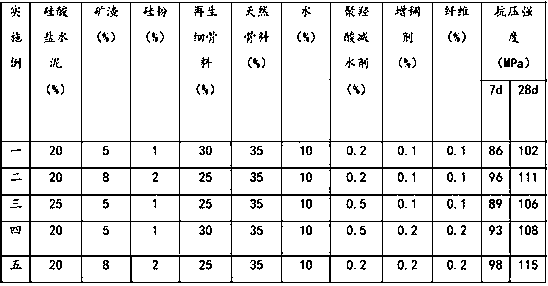

Examples

Embodiment 1

[0027] A kind of recycled fine aggregate high-strength self-compacting concrete, including the following raw materials expressed by weight percentage:

[0028] Portland cement 20%;

[0029] Slag 5%;

[0030] Silicon fume 1%;

[0031] Recycled fine aggregate 30%;

[0032] Natural aggregate 35%;

[0033] water 10%;

[0034] Polycarboxylate superplasticizer 0.2%;

[0035] Thickener 0.1%;

[0036] Fiber 0.1%.

[0037] Preferably, the ore powder is S95 grade granulated blast furnace slag powder, and the density of silicon powder is 2400kg / m 3 , the specific surface area is 15000m 2 / kg, recycled fine aggregate refers to the recycled fine aggregate particles obtained by crushing, reshaping, and screening waste concrete, and the particle size is not greater than 4.5mm. Natural aggregate is composed of fine aggregate and coarse aggregate, of which fine aggregate The fineness modulus of the aggregate is 2.5-3.0, and the particle size of the coarse aggregate is 10-20mm, continu...

Embodiment 2

[0044] A kind of recycled fine aggregate high-strength self-compacting concrete, including the following raw materials expressed by weight percentage:

[0045] Portland cement 20%;

[0046] Slag 8%;

[0047] Silicon fume 2%;

[0048] Recycled fine aggregate 25%;

[0049] Natural aggregate 35%;

[0050] water 10%;

[0051] Polycarboxylate superplasticizer 0.2%;

[0052] Thickener 0.1%;

[0053] Fiber 0.1%.

[0054] Preferably, the ore powder is S95 grade granulated blast furnace slag powder, and the density of silicon powder is 2400kg / m 3 , the specific surface area is 15000m 2 / kg, recycled fine aggregate refers to the recycled fine aggregate particles obtained by crushing, reshaping, and screening waste concrete, and the particle size is not greater than 4.5mm. Natural aggregate is composed of fine aggregate and coarse aggregate, of which fine aggregate The fineness modulus of the aggregate is 2.5-3.0, and the particle size of the coarse aggregate is 10-20mm, continu...

Embodiment 3

[0061] A kind of recycled fine aggregate high-strength self-compacting concrete, including the following raw materials expressed by weight percentage:

[0062] Portland cement 25%;

[0063] Slag 5%;

[0064] Silicon fume 1%;

[0065] Recycled fine aggregate 25%;

[0066] Natural aggregate 35%;

[0067] water 10%;

[0068] Polycarboxylate superplasticizer 0.5%;

[0069] Thickener 0.1%;

[0070] Fiber 0.1%.

[0071] Preferably, the ore powder is S95 grade granulated blast furnace slag powder, and the density of silicon powder is 2400kg / m 3 , the specific surface area is 15000m 2 / kg, recycled fine aggregate refers to the recycled fine aggregate particles obtained by crushing, reshaping, and screening waste concrete, and the particle size is not greater than 4.5mm. Natural aggregate is composed of fine aggregate and coarse aggregate, of which fine aggregate The fineness modulus of the aggregate is 2.5-3.0, and the particle size of the coarse aggregate is 10-20mm, continu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com