Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Improve the interface transition area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

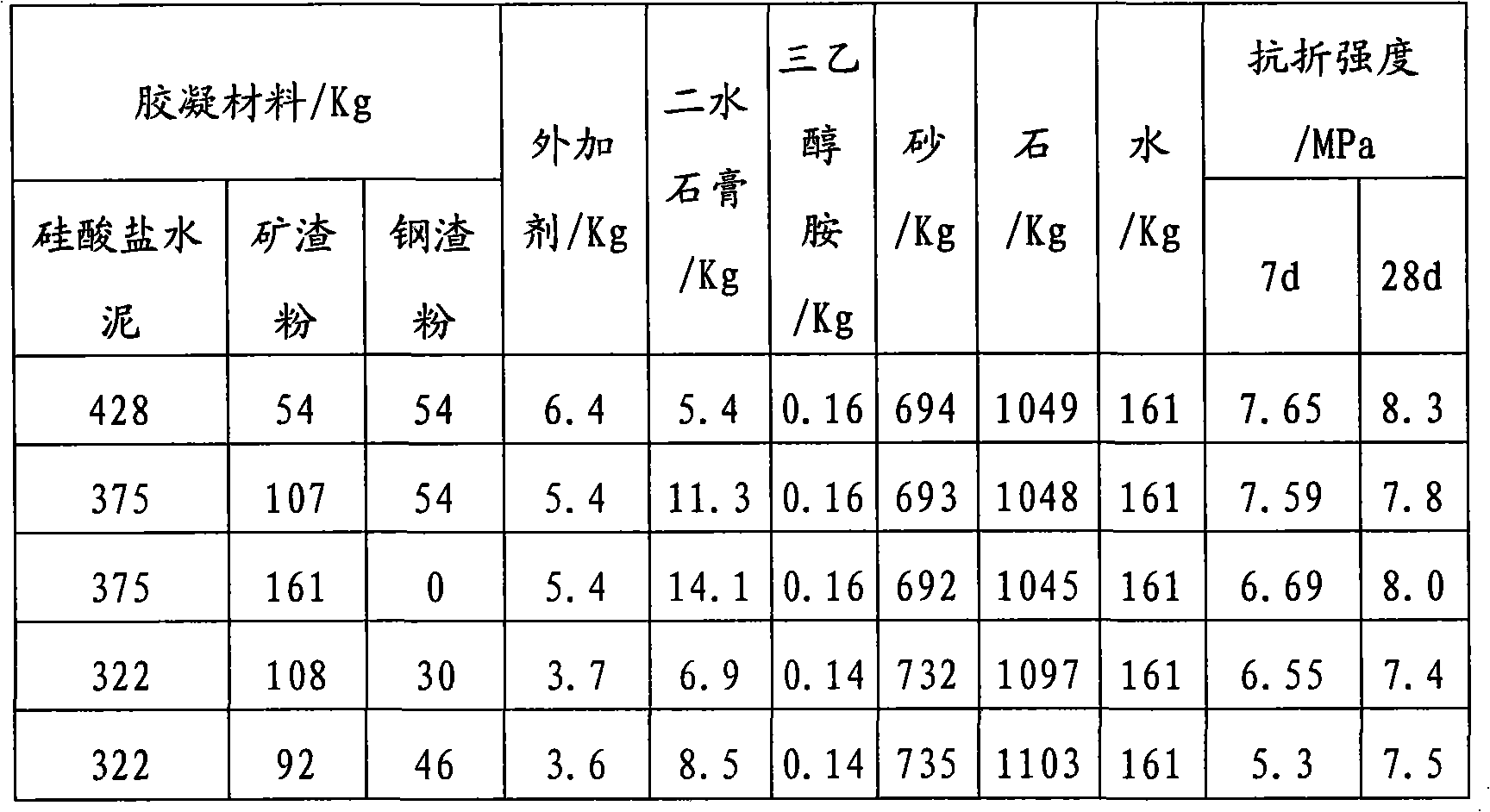

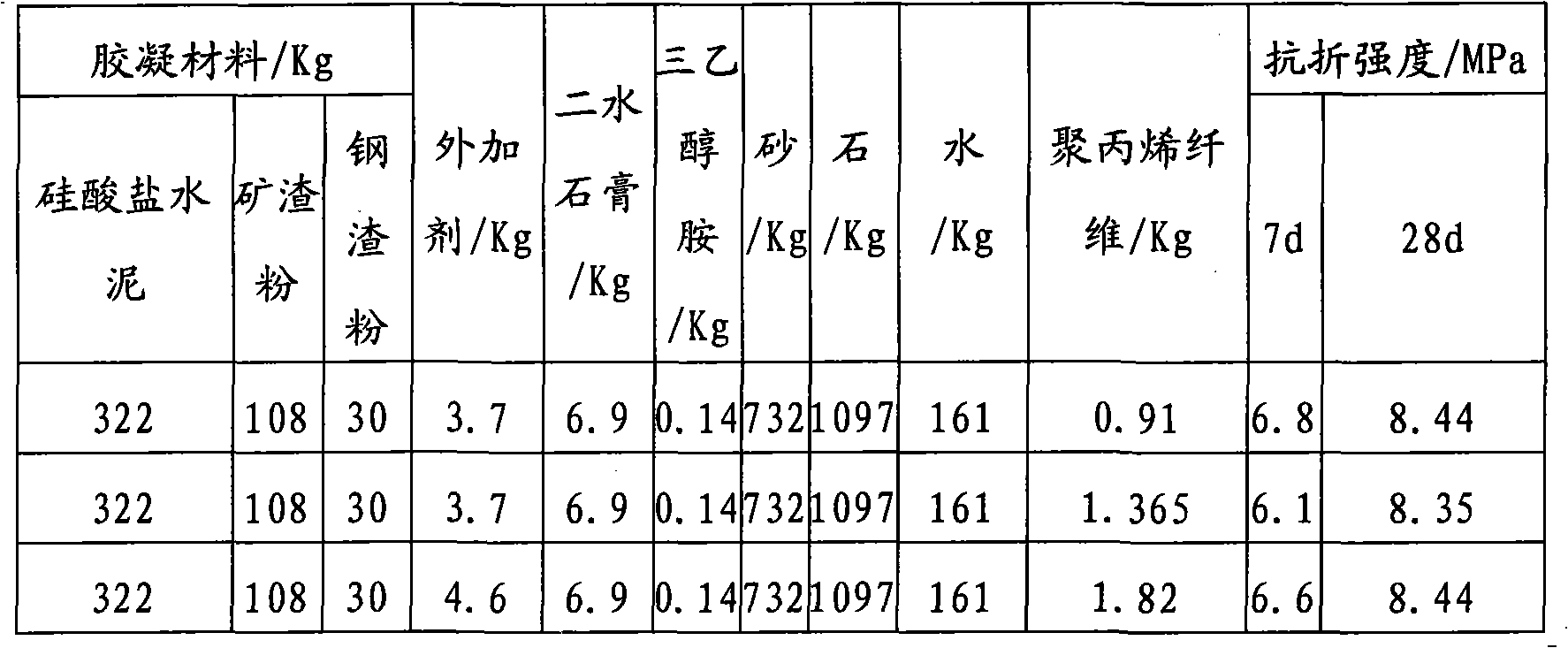

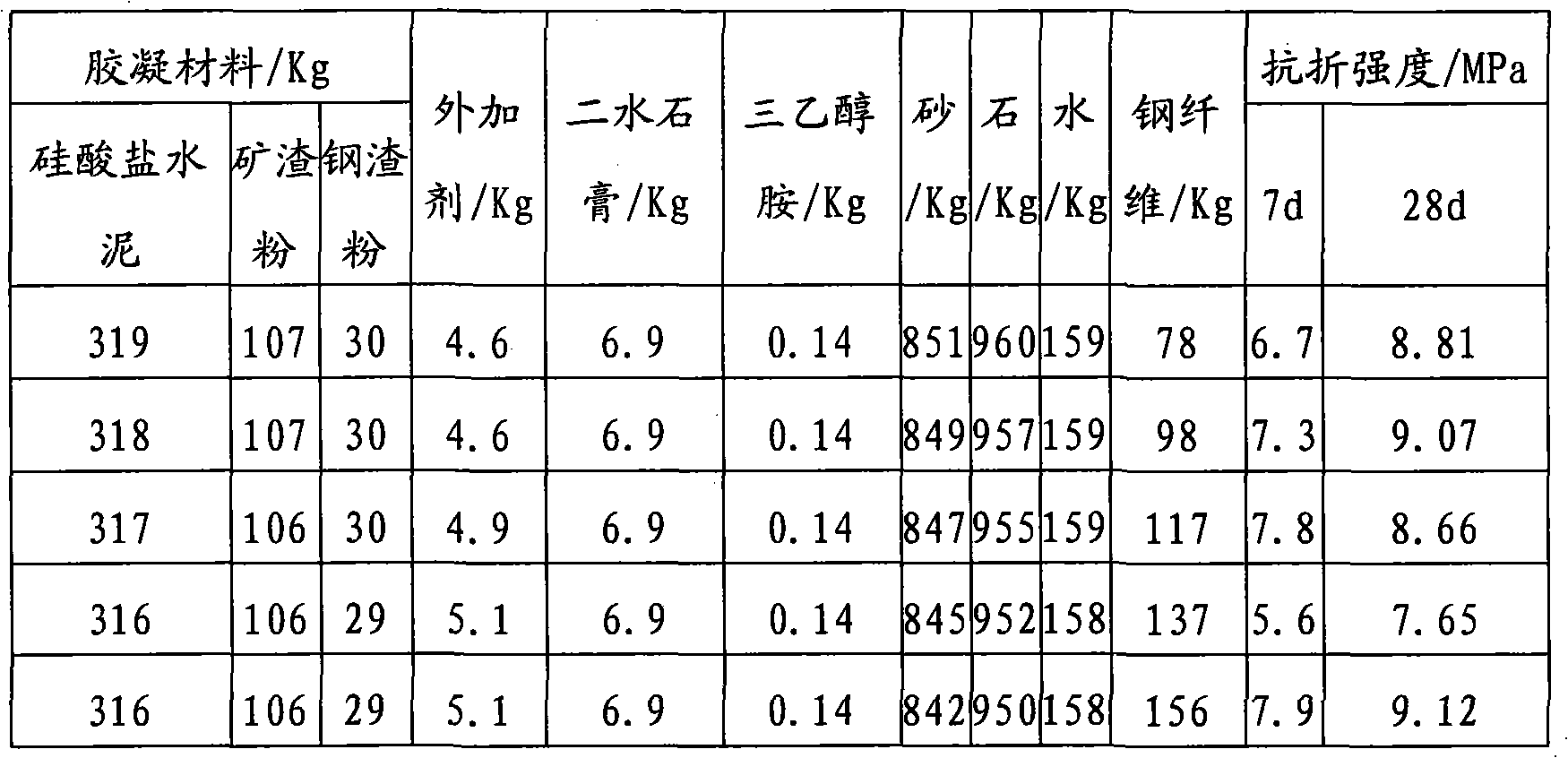

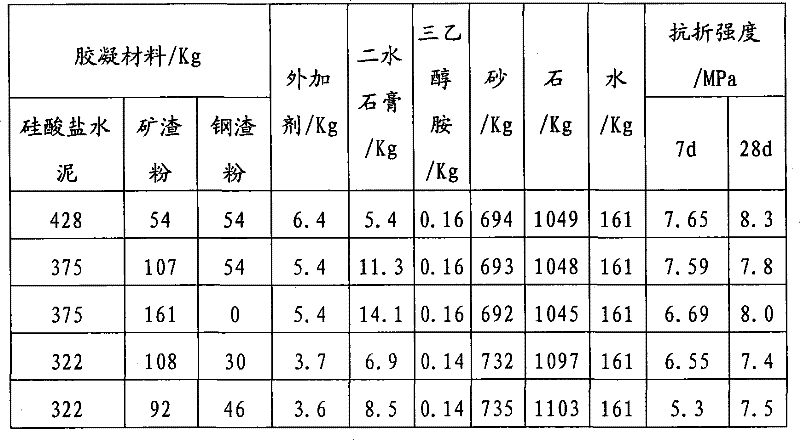

High folding resistance road concrete material and preparing method thereof

InactiveCN101265066AImprove compactnessImprove flexural strengthSolid waste managementSlagSodium fluoride

The invention discloses a road concrete material with high folding strength and a production method thereof. The road concrete material with high folding strength mainly contains binding agent, sand stone aggregate, mixing water, concrete admixture and excitant. The binding agent is composed of common silicate cement, ore slag powder and steel slag powder. The mass percentages of the components are as follows: 60-70% of common silicate cement, 20-30 % of ore slag powder and 0-10% of steel slag powder. The additional amount of the excitant is 5.0-10.0% of the total mass of the ore slag powder and the steel slag powder. The excitant is selected from gypsum, sodium sulfate, sodium fluoride, triethanolamine or a mixture thereof. By adding the excitant, the latent activity of the ore slag and the steel slag is excited, so that the compactness of concrete is improved and the folding strength of the road concrete is greatly improved.

Owner:SHENZHEN UNIV

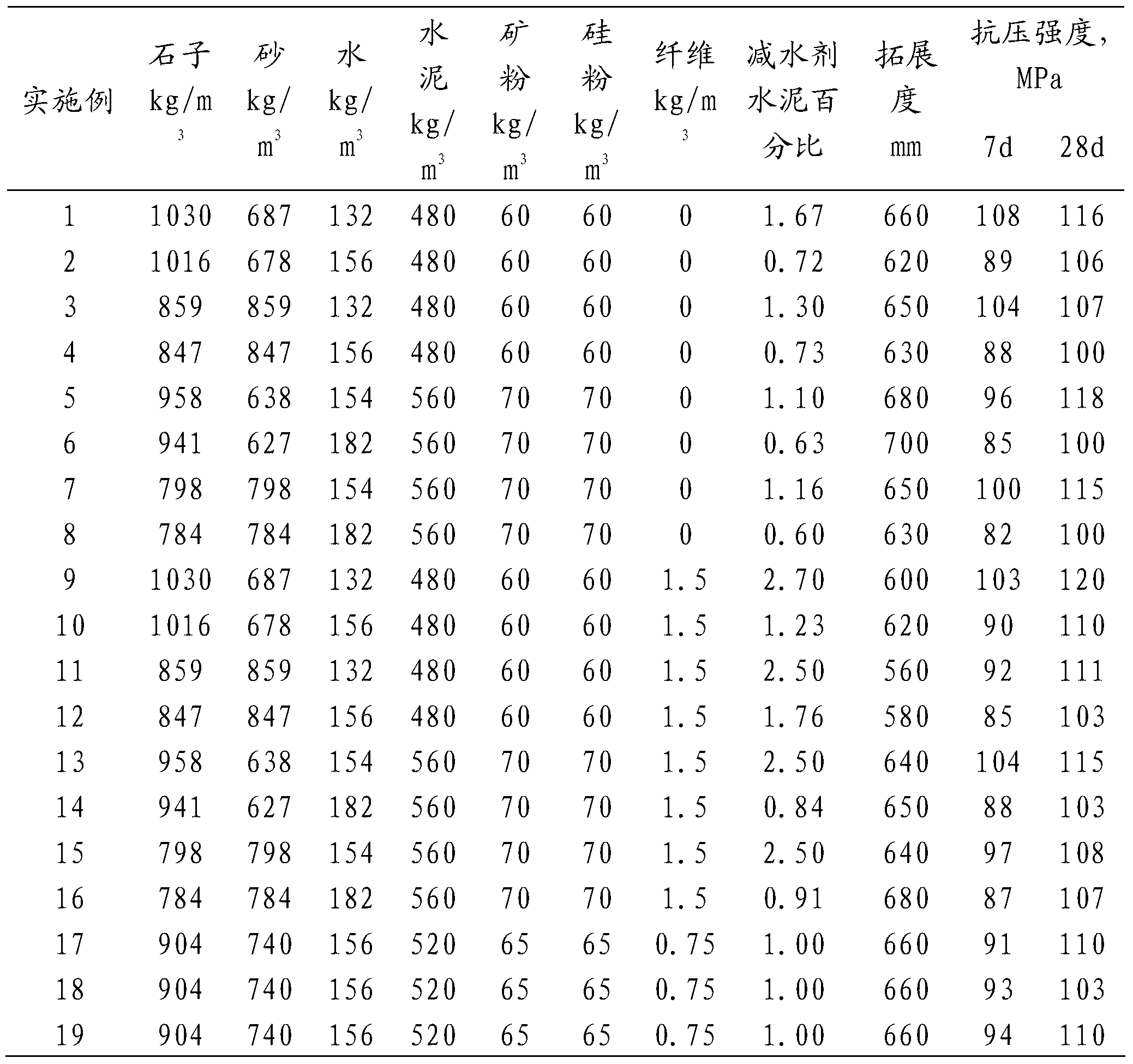

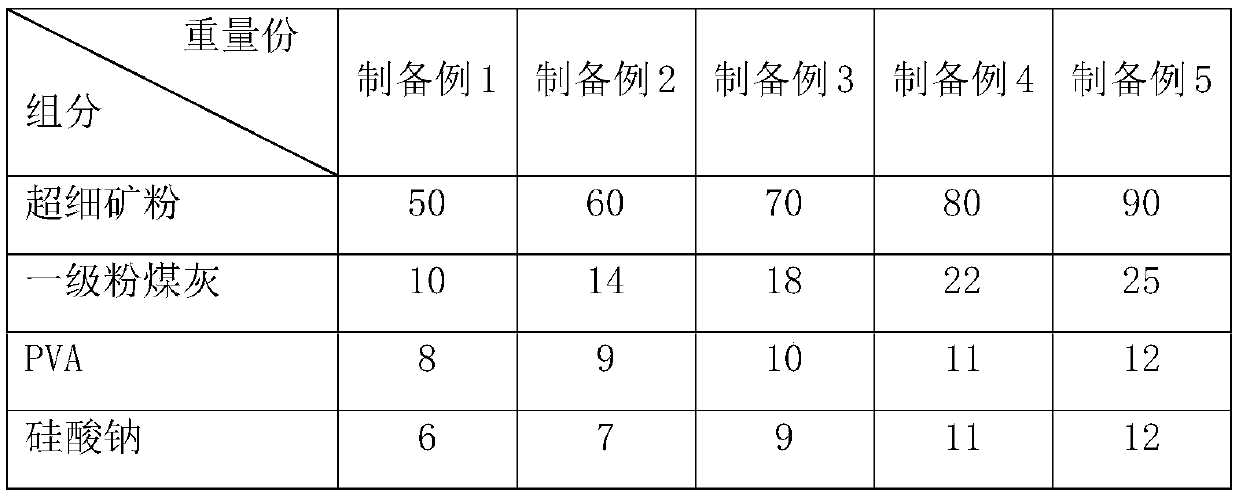

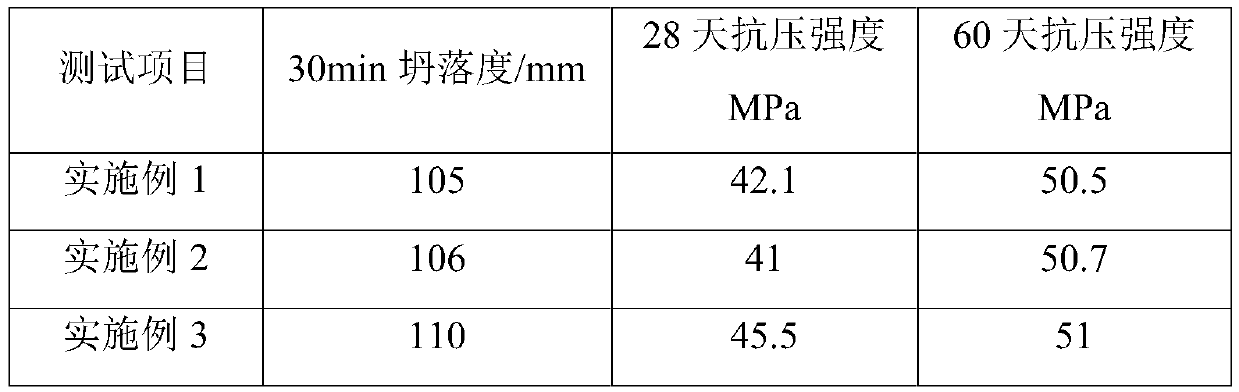

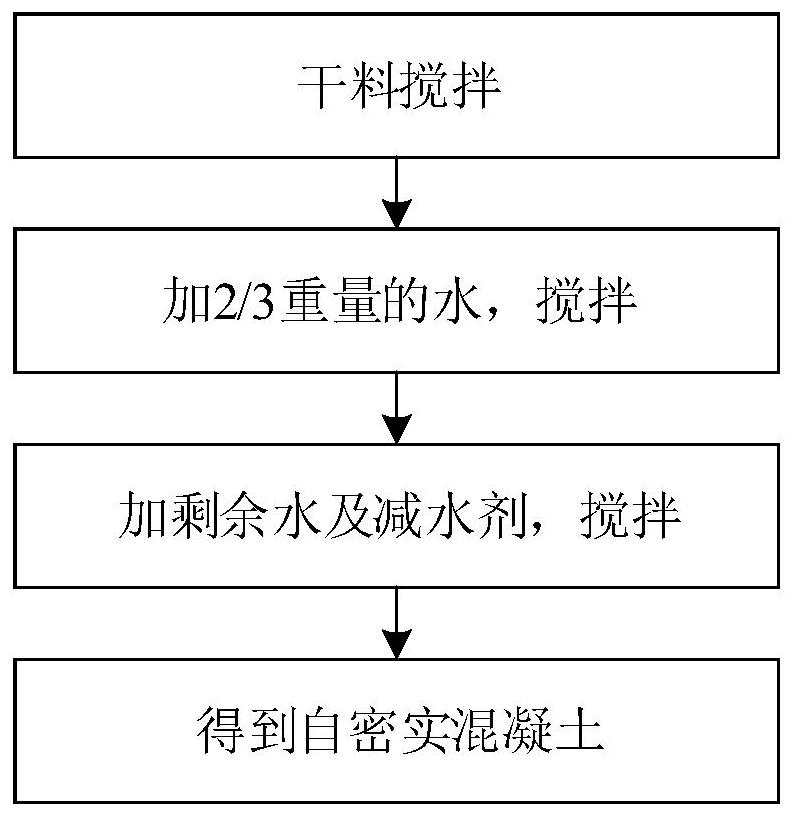

Ultrahigh-strength self-compacting concrete and preparation method thereof

InactiveCN103304206AImprove microscopic propertiesImprove the interface transition areaFiberPolyvinyl alcohol

The invention discloses an ultrahigh-strength self-compacting concrete and a preparation method thereof. The ultrahigh strength self-compacting concrete is mainly composed of a cementing material, an efficient water reducer, a fine aggregate, a coarse aggregate, water and PVA (Polyvinyl Alcohol) fibers, wherein the cementing material is composed of 70%-80% of common silicate cement, 10%-20% of mineral slag and 5%-10% of silicon powder by weight percentage; the fine aggregate is medium sand; the coarse aggregate is granite macadam. The ultrahigh-strength self-compacting concrete has the beneficial effects that the advanced techniques of the ultrahigh-strength concrete and the self-compacting concrete in the field of the concrete materials at present are studied, the advantages of the two concrete techniques are combined so that the dosage of the cement is reduced while ultrahigh performance of the concrete is realized, and furthermore, the purposes of emission reduction of CO2, materials saving and environmental protection as well as green construction are achieved.

Owner:SHENZHEN UNIV

Modified recycled concrete and preparation method thereof

The invention discloses modified recycled concrete and a preparation method thereof. The concrete is prepared from the following raw materials in parts by weight: 100 parts of cement, 235 to 260 partsof recycled aggregate, 145 to 165 parts of sand, 35 to 45 parts of water, 3 to 10 parts of silica fume, 0.5 to 2.5 parts of nano-silica, 0.5 to 2.5 parts of a water reducing agent, and 0.5 to 1.5 parts of cellulose ether. According to the modified recycled concrete and the preparation method thereof, the recycled aggregate is mechanically activated to remove particles and corners which can easilypeel off, so that the performance of the recycled aggregate is improved. Both nano-silica and silica fume have pozzolanic activity, can react with calcium hydroxide produced by cement hydration to form C-S-H gel, and can effectively improve the performance of the recycled aggregate concrete. The raw material components have a synergistic effect, and the obtained concrete has excellent mechanicalproperties and durability.

Owner:YOUNGWOO CHEMTECH

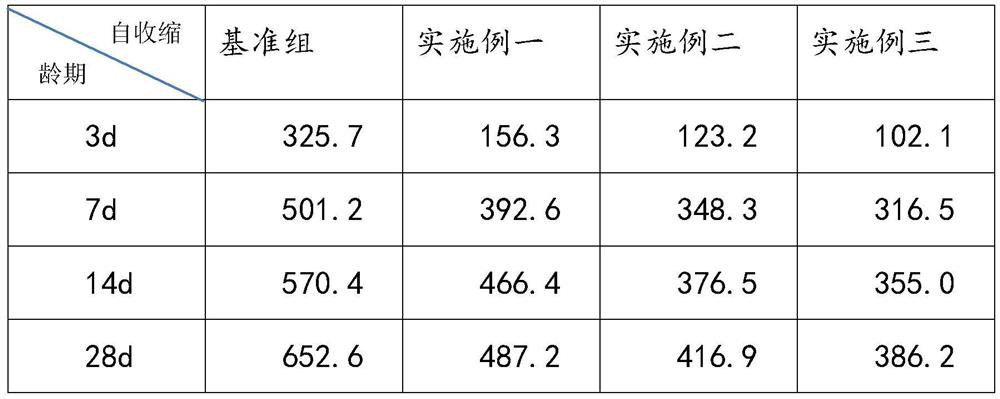

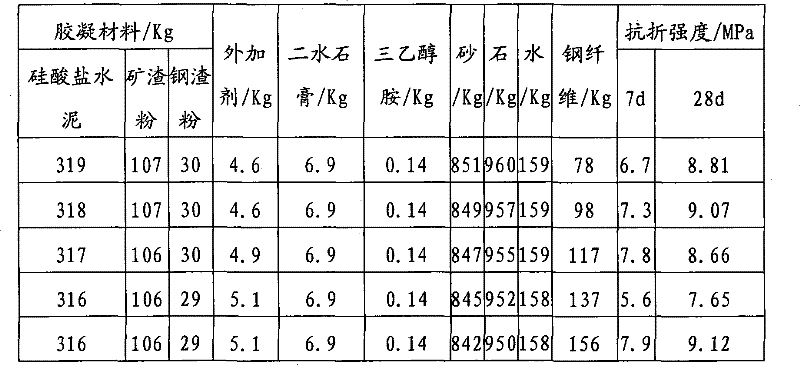

Low-shrinkage creep wet joint ultrahigh-strength concrete material and preparation method thereof

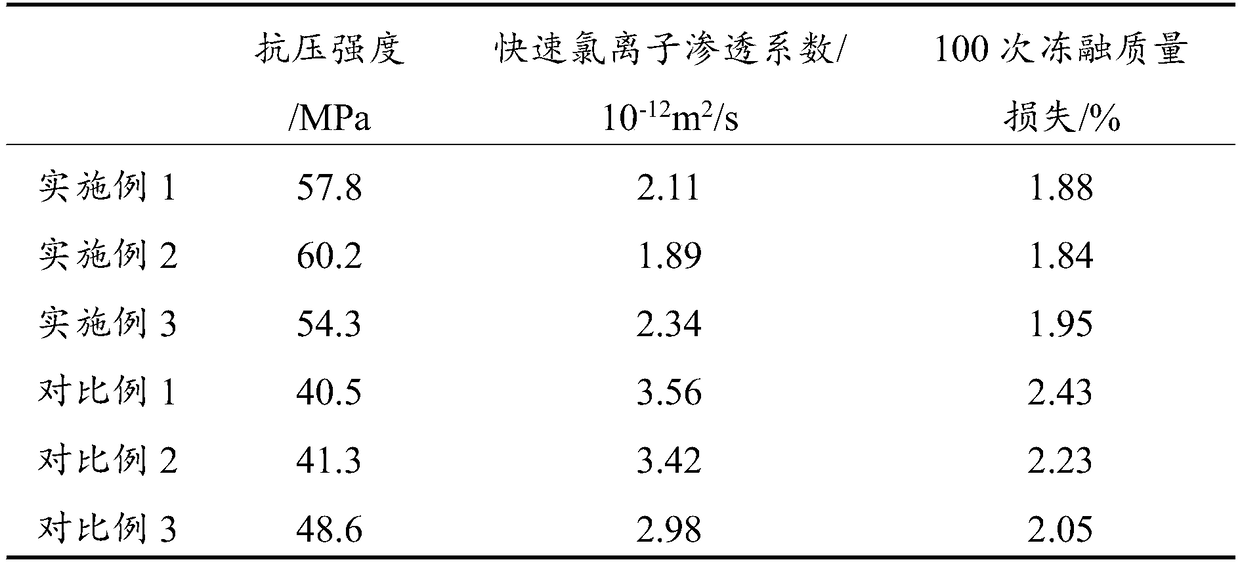

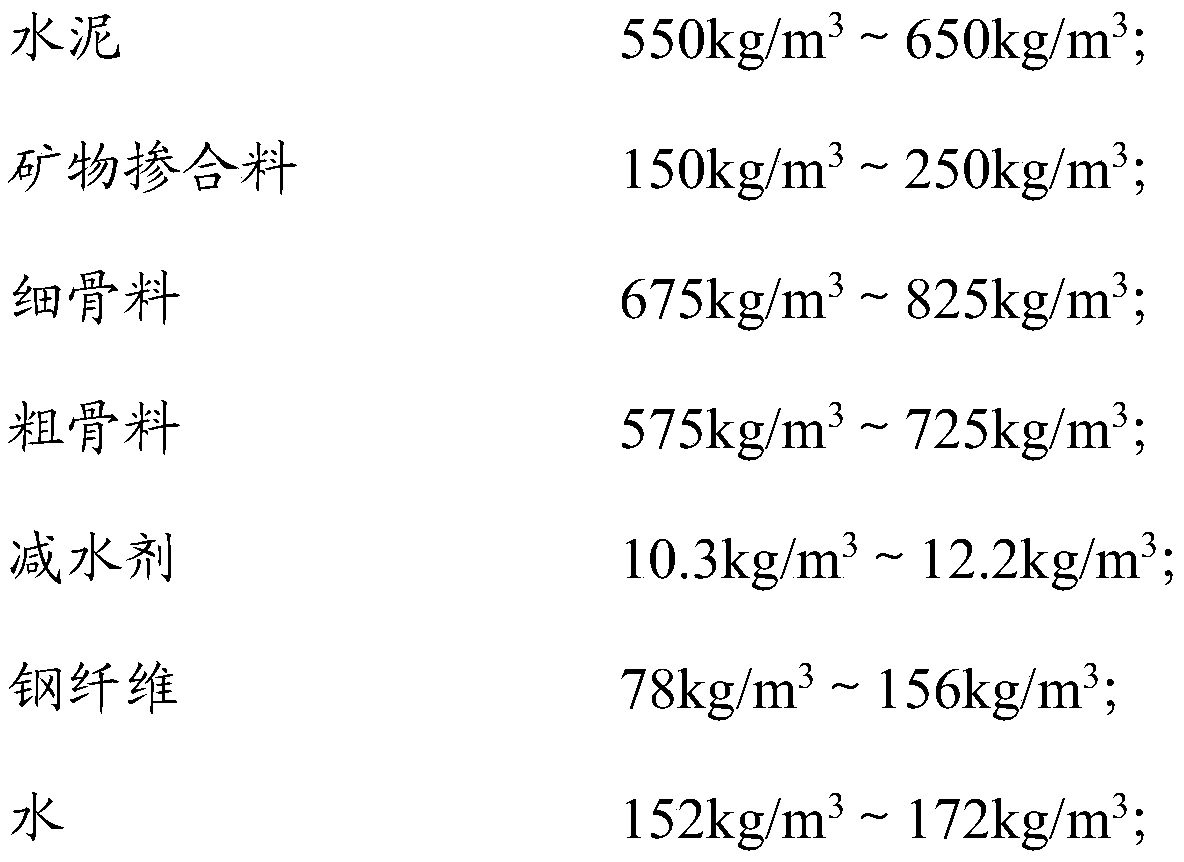

The invention relates to a low-shrinkage creep wet joint ultrahigh-strength concrete material and a preparation method thereof. The material comprises the following raw materials in proportion: 550kg / m<3> to 650kg / m<3> of cement, 150kg / m<3> to 250kg / m<3> of a mineral admixture, 675kg / m<3> to 825kg / m<3> of fine aggregate, 575kg / m<3>-725kg / m<3> of coarse aggregate, 10.3kg / m<3>-12.2kg / m<3> of a waterreducing agent, 78kg / m<3> to 156kg / m<3> of steel fibers, and 152kg / m<3> to 172kg / m<3> of water, wherein the mineral admixture is composed of an expanding agent and at least two of silica fume, superfine mineral powder, limestone powder, rice hull ash, metakaolin and fly ash microspheres, the coarse aggregate is any one or more of basalt, granite and diabase, the particle size is 5-10mm, and the needle sheet shape content is smaller than or equal to 1%. The low-shrinkage creep wet joint ultrahigh-strength concrete material prepared from the raw materials has the advantages of low shrinkage creep, good working performance, excellent mechanical properties, excellent durability and the like, is used for bridge wet joints, and can reduce the influence of shrinkage creep, guarantee the later durability and prolong the service life of bridges.

Owner:CHINA RAILWAY BRIDGE SCI RES INST LTD +1

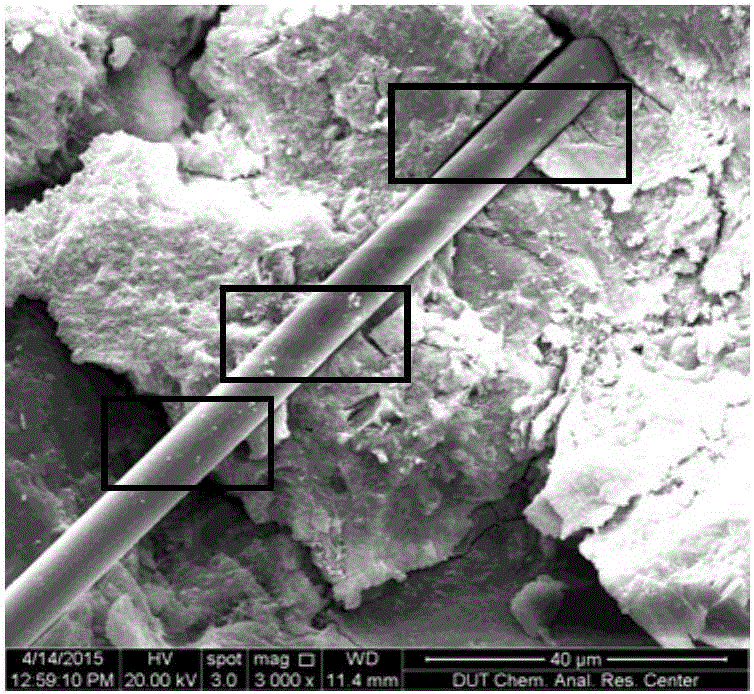

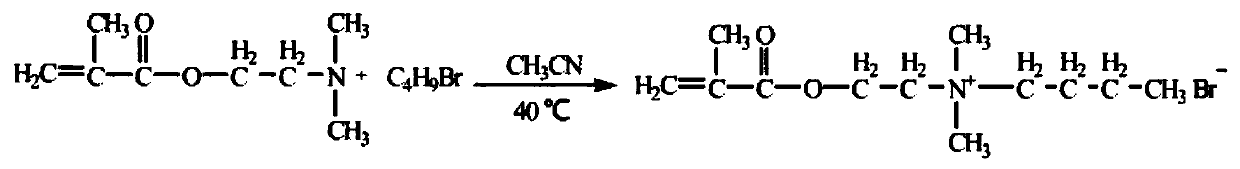

Compound mortar with compound addition of carbon fibers and nano-silica and preparation technology and application thereof

The invention discloses compound mortar with compound addition of carbon fibers and nano-silica and a preparation technology thereof. Raw materials are taken according to a certain weight ratio, water, a water reducing agent, carbon fibers and nano-silica are added into a container, stirred evenly and subjected to ultrasonic treatment at the temperature not higher than 30 DEG C to obtain a mixture, and then the mixture, cement and sand are added into a cement mortar stirring pot and evenly stirred to obtain a mix; the mix is poured into a mould, and the mould is placed on a vibrating table to be vibrated till slurry spills out of the surface; an electrode used for being connected with an external circuit is inserted into the mould according to the size of the mix in the mould; vibration is performed again; the mould is put into a curing box, and after curing is performed for 24 h under the conditions that the temperature is 20+ / -1 DEG C and the humidity is larger than 95%, demoulding is performed to obtain a test piece. By combining the advantages of nano-silica and the advantages of carbon fibers and utilizing the reinforcement mechanism and synergetic reinforcement prompting effect of nano-silica and carbon fibers, the compound mortar with compound addition of carbon fibers and nano-silica is finally prepared and is good in fracture resistance and compression resistance and small in resistivity variation coefficient.

Owner:DALIAN UNIV OF TECH

High-compressive-strength recycled concrete and preparation process thereof

The invention discloses high-compressive-strength recycled concrete and a preparation process thereof. The high-compressive-strength recycled concrete comprises the following components in parts by weight: 300-420 parts of reinforced recycled aggregate, 25-35 parts of recycled micro powder, 100-200 parts of natural coarse aggregate, 120-200 parts of natural fine sand, 120-170 parts of cement, 50-130 parts of fly ash, 50-120 parts of mineral powder, 6-12 parts of a waterproof agent, 0.8-2.2 parts of an air entraining agent, 120-160 parts of water and 20-35 parts of polypropylene mixed filler. The preparation process comprises the following steps: S1, weighing corresponding amounts of cement and natural fine sand, putting the cement and the natural fine sand into a stirrer, and stirring for40-60 seconds; S2, weighing the regenerated micro-powder, the fly ash, the mineral powder and the polypropylene mixed filler according to corresponding proportions, adding the weighed materials into the stirrer in the step S1, continuing to stir and mix for 30-40 seconds, adding half of the water according to the proportion, continuing to stir for 30-40 seconds, and mixing to obtain mortar with uniform color; and S3, adding the rest half of the water, the reinforced recycled aggregate, the natural coarse aggregate, the air entraining agent and the waterproof agent according to the proportion in the step S2, and continuously stirring for 60-80 seconds until the mixture is uniform.

Owner:西安百固源混凝土有限公司

Modified material and treatment method of low-quality aggregate

The invention belongs to the technical field of building materials, and specifically relates to a modified material and treatment method of a low-quality aggregate. The modified material of the low-quality aggregate provided by the invention comprises the following components in percentage by mass: 46-50% of cement, 10-15% of a mineral admixture, 2-5% of an active powder, 0.2-0.6% of a water reducing agent, 0.001-0.004% of a viscosity adjusting agent, 0-3.2% of an expanding agent, 0-0.12% of an air entraining agent, and 0-0.0007% of a defoaming agent. The modified material provided by the invention can realize effective filling and coating modification of the low-quality aggregate through the cooperation between the components, and the adjustment of the use amount, and especially through the cooperation of the specific use amount of the cement, active powder and viscosity adjusting agent, the surface tension and viscosity of the modified material can be effectively adjusted, and a porepenetration amount and a shell coating thickness are coordinately optimized. The combined use of the inorganic and organic components promotes the secondary hydration / chemical bonding of a slurry layer, and improves the strength of an interface between the aggregate and the slurry layer. The cylindrical compress strength of the aggregate after modification treatment is increased by 40% or more, acrushing value is reduced by 30% or more, and a water absorption rate in 24 h is reduced by 15% or more.

Owner:CHINA BUILDING MATERIALS ACAD

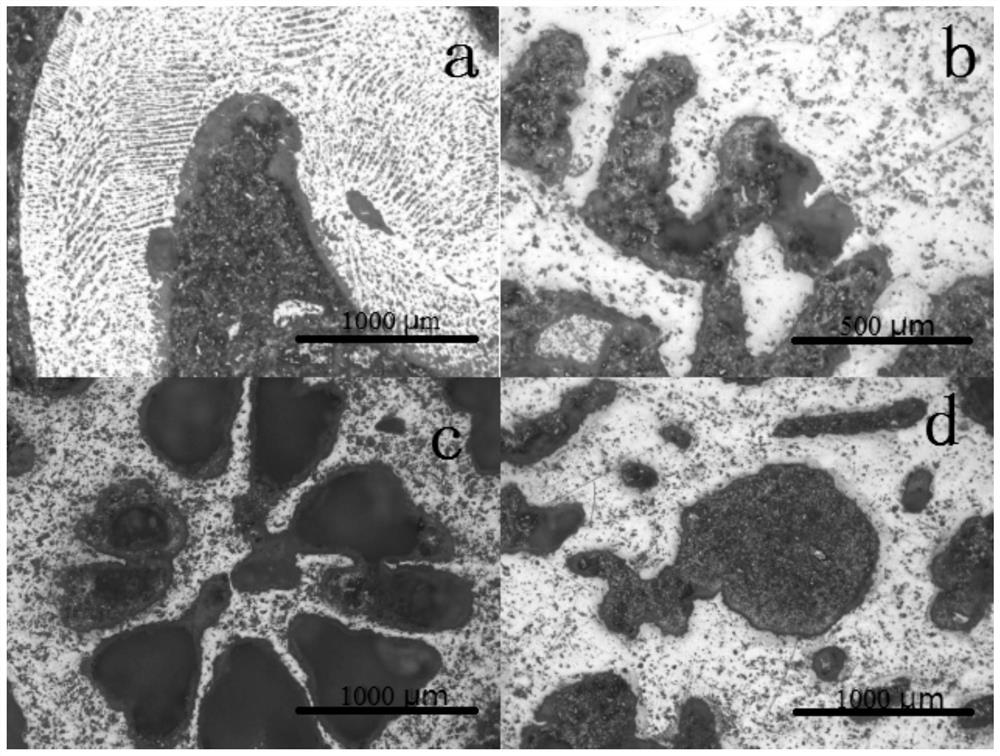

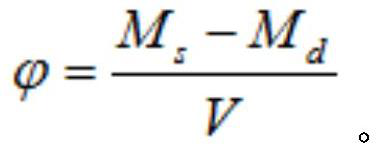

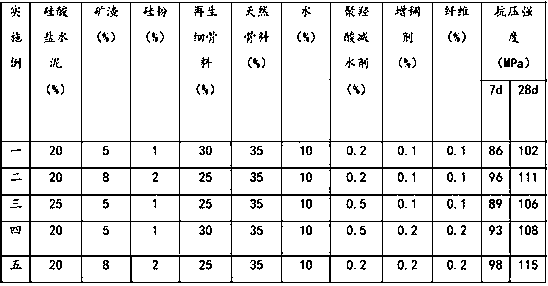

Recycled fine aggregate high-strength self-compact concrete

InactiveCN109160791ASimple preparation processImprove the interface transition areaFiberSuperplasticizer

The invention discloses recycled fine aggregate high-strength self-compact concrete. The concrete comprises the following raw materials: Portland cement, slags, a ganister powder, recycled fine aggregates, natural aggregates, water, a polycarboxylate superplasticizer, a thickening agent and a fiber. A production method of the concrete comprises the following steps: adding the weighed Portland cement, slags, a ganister powder and a half of the whole water into an agitator to carry out agitation for 1 min for sufficient wetting; adding the thickening agent, the fiber and the polycarboxylate superplasticizer to carry out agitation for 5-8 minutes for sufficient mixing and dispersion so as to obtain a pasty mixture A; and mixing and agitating the recycled fine aggregates and the residual waterfor 3-5 minutes, and adding the mixture A and the natural aggregates to agitate for 10 minutes so as to obtain a finished product. The whole mechanical property of the obtained concrete is remarkablyimproved; the recycled fine aggregates are produced by utilizing building waste, so that the resources are recycled; and crop straws are sufficiently utilized, so that the raw materials are saved, the living environment of the human beings is improved, the environment is protected and the energy is reduced.

Owner:四川国泰高新管廊产业投资有限公司

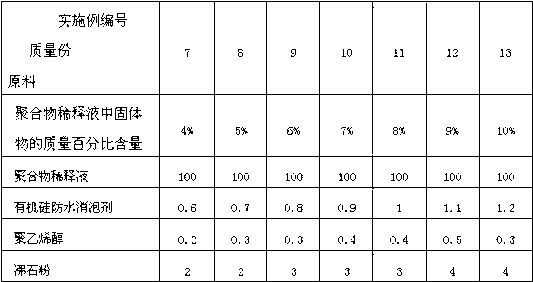

Modified high carbon ferro-chrome slag aggregate for road concrete and preparation method of modified high carbon ferro-chrome slag aggregate

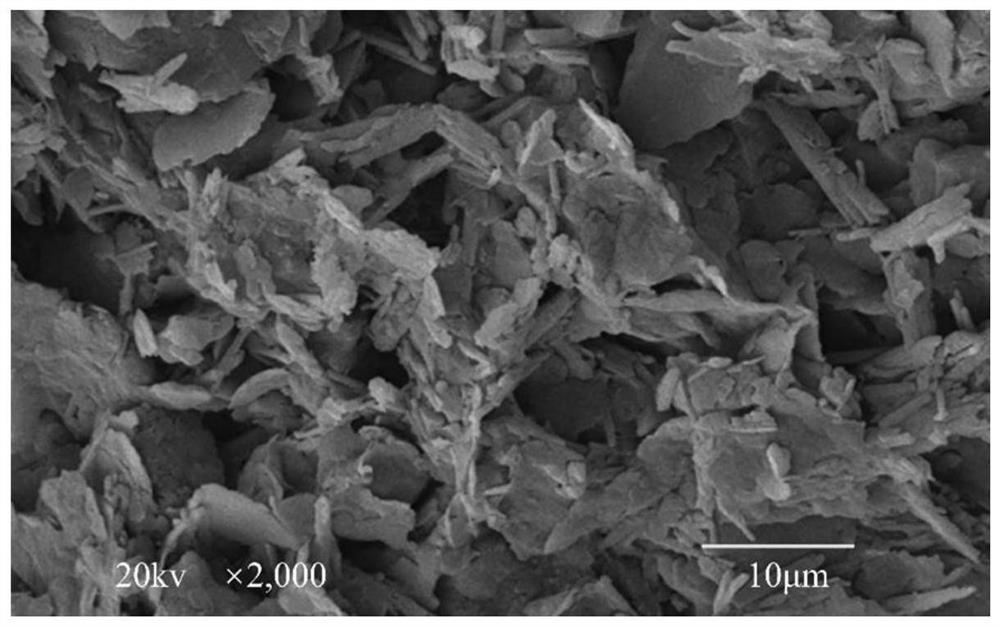

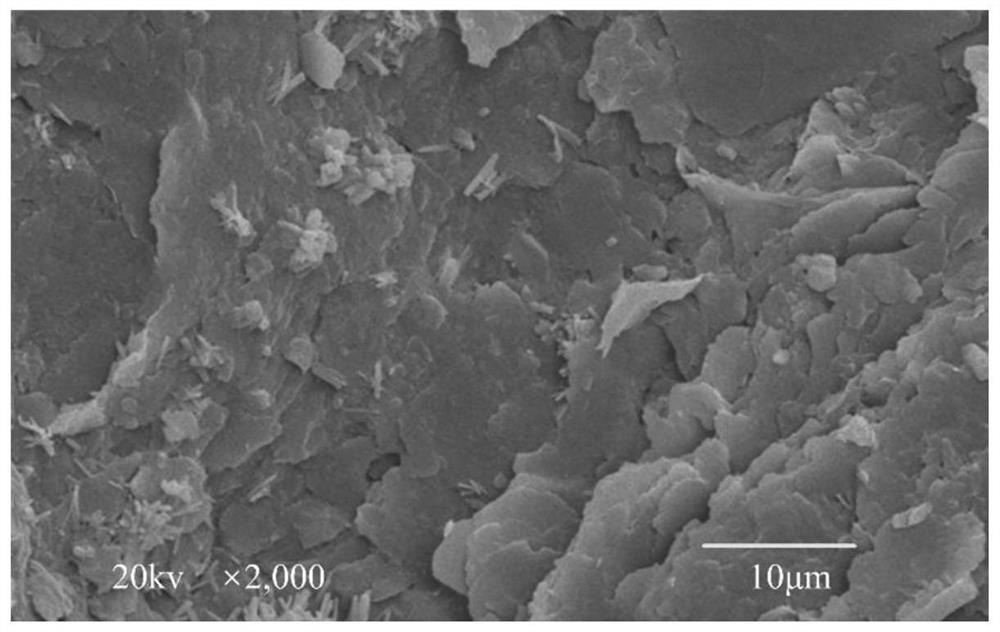

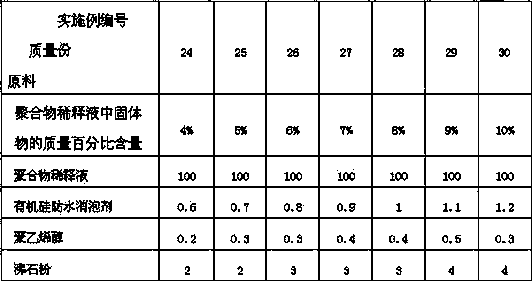

ActiveCN103073210AFix bugsSolve hidden dangersSolid waste managementPolyethylene vinyl acetatePolyvinyl alcohol

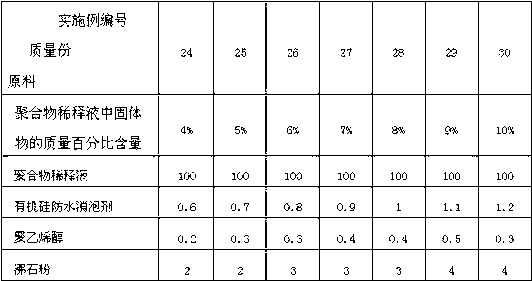

The invention discloses a modified high carbon ferro-chrome slag aggregate for road concrete and a preparation method of the modified high carbon ferro-chrome slag aggregate. The modified high carbon ferro-chrome slag aggregate is characterized by being prepared from a high carbon ferro-chrome alloy slag aggregate and a chemical modifying agent accounting for 2-6 percent of the mass of the high carbon ferro-chrome alloy slag aggregate through mixing, wherein the chemical modifying agent is prepared from 100 parts by mass of polymer diluting solution, 0.5-1.2 parts by mass of organic silicon waterproof defoaming agent, 0.2-0.5 part by mass of polyvinyl alcohol and 2-4 parts by mass of zeolite powder through uniform mixing; the polymer diluting solution is prepared by diluting a polymer emulsion stock solution through adding water; and the polymer emulsion stock solution is any one of a butylbenzene emulsion, a polyacrylate emulsion, a polyethylene-vinyl acetate emulsion and a styrene-acrylic emulsion. By adopting the invention, waste alloy waste is used as a raw material, and thus building materials of carbon chromic slag can be recycled and efficiently utilized, and the defects and the hidden dangers of the carbon chromic slag as the concrete aggregate are solved; and the preparation method is simple and easy to realize and is strong in practicability.

Owner:李素娥

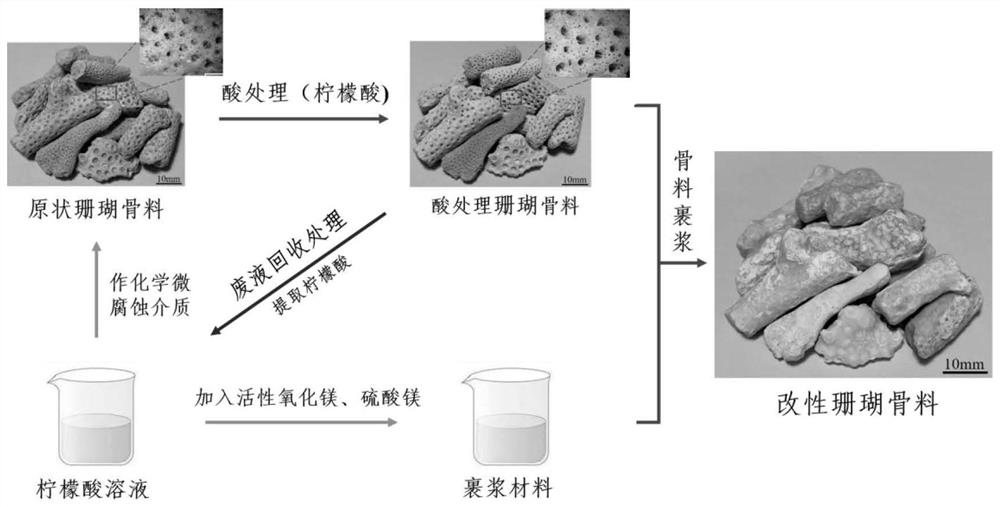

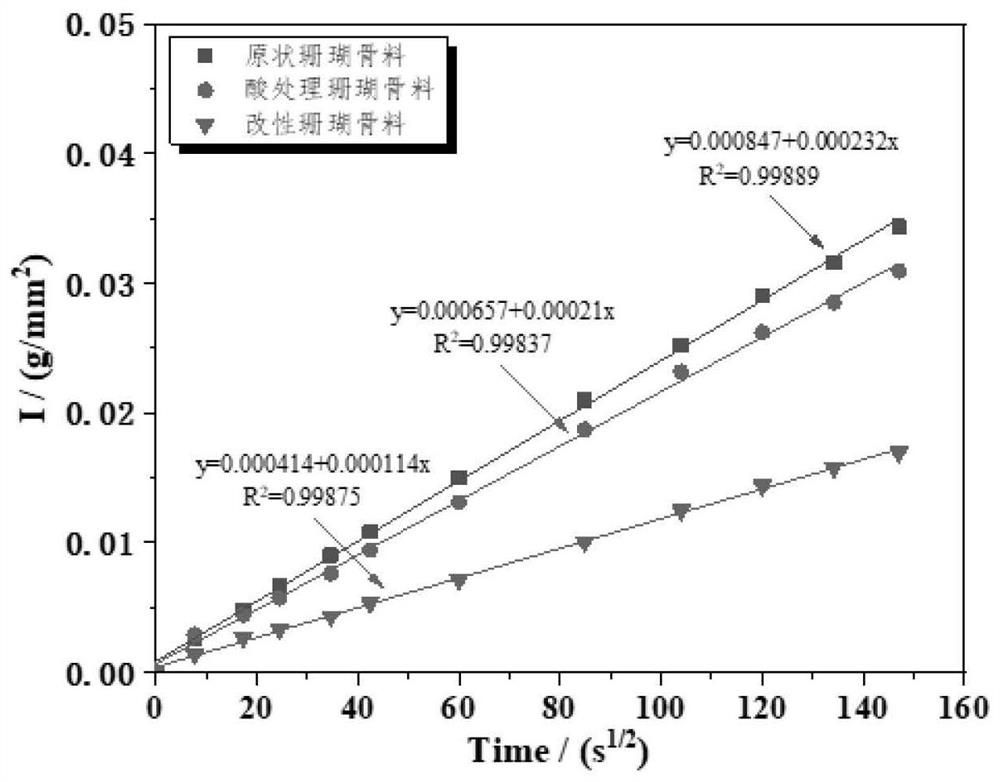

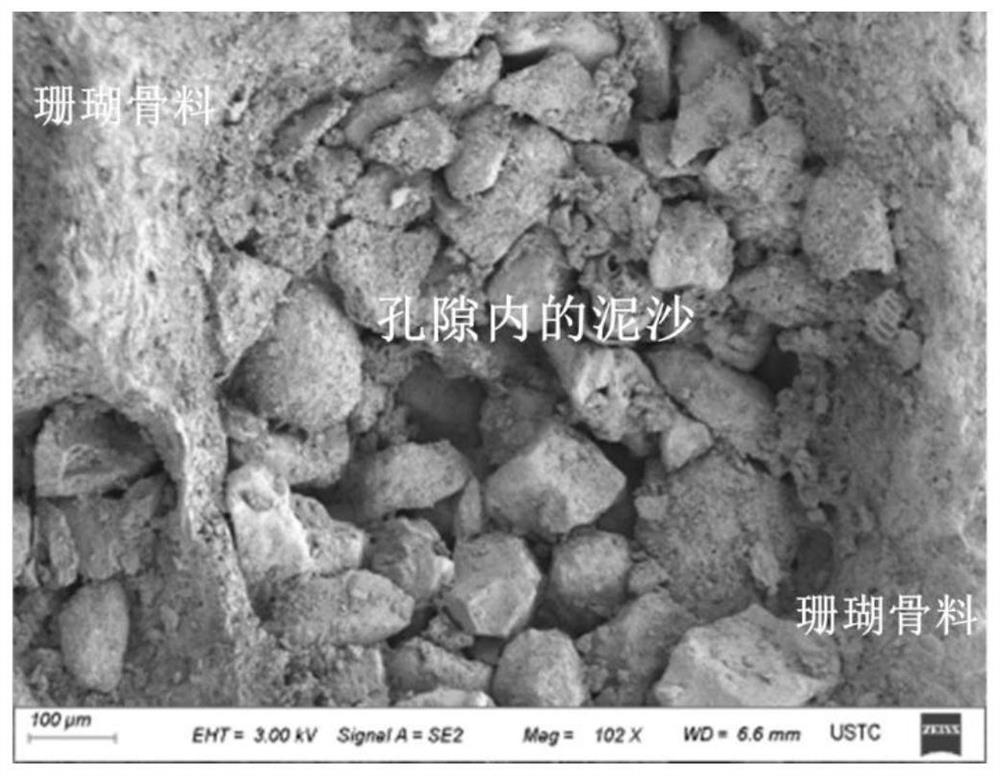

Preparation method of modified coral aggregate and basic magnesium sulfate cement gradient composite coral aggregate concrete

The invention relates to the technical field of concrete, and particularly discloses a preparation method of modified coral aggregate and basic magnesium sulfate cement gradient composite coral aggregate concrete. The preparation method comprises the following steps: firstly, soaking original coral aggregate in a weak acid aqueous solution for micro-corrosion to obtain acid-treated coral aggregate, and then soaking the acid-treated coral aggregate in a basic magnesium sulfate cement-based slurry coating material prepared from active magnesium oxide, magnesium sulfate heptahydrate, citric acid and water to obtain modified coral aggregate; and preparing the basic magnesium sulfate cement-based coral aggregate concrete from the aggregate, active magnesium oxide, magnesium sulfate heptahydrate, citric acid and water as raw materials. Based on a core admixture and a gradient composite technology, the invention provides a method for enabling basic magnesium sulfate cement whiskers to grow in communicated pores of coral aggregate, and external pores of the coral aggregate are fully filled with gradient composite basic magnesium sulfate cement. The effects of reducing the overall porosity of the coral aggregate concrete, optimizing the concrete interface transition area and improving the working performance and the mechanical property of the concrete are achieved.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

High-compactness and ultrahigh-strength cement-based composite material for financial equipment in bank

The invention discloses a high-compactness and ultrahigh-strength cement-based composite material for financial equipment in a bank. The composite material is prepared by uniformly mixing microfine cement, silicon ash, ultrahigh-strength basalt sand, high-efficiency water reducing agent, copper-plated steel fiber and water according to certain ratio, and carrying out standard curing, wherein the weight ratio of all the components in the cemented-based composite material relative to the microfine cement is as follows: the microfine cement is 1, the silicon ash is 0.15-0.25, the ultrahigh-strength basalt sand is 1.2-1.8, the high-efficiency water reducing agent is 0.005-0.010, the copper-plated steel fiber is 0.40-0.60 and water is 0.19-0.25. The compressive strength of the prepared composite material is more than 180MPa.

Owner:TRI STAR

Wood nanocellulose modified cemented filling material for deep ground structure filling and preparation method of wood nanocellulose modified cemented filling material

ActiveCN114149226AGood dispersionIncrease costSolid waste managementMining engineeringUnderground space

The invention discloses a wood nanocellulose modified cemented filling material for deep ground structure filling and a preparation method of the wood nanocellulose modified cemented filling material, and belongs to the technical field of mine filling materials. The wood nanocellulose modified cemented filling material is prepared from the following raw materials in parts by mass: 300 to 450 parts of cement, 100 to 150 parts of coal ash, 500 to 550 parts of fine aggregate, 1000 to 1200 parts of coal gangue, 0.3 to 0.6 part of modified wood nanocellulose and 400 to 500 parts of water, the modified wood nano cellulose is wood nano cellulose modified by cationic styrene-acrylic emulsion. By optimizing the formula and the preparation process of the mine filling material, the high-strength wood nanocellulose modified cemented filling material capable of being used for filling a deep ground structure is prepared, and a foundation is provided for the idea of reutilization of an underground space formed by a goaf.

Owner:CHINA UNIV OF MINING & TECH

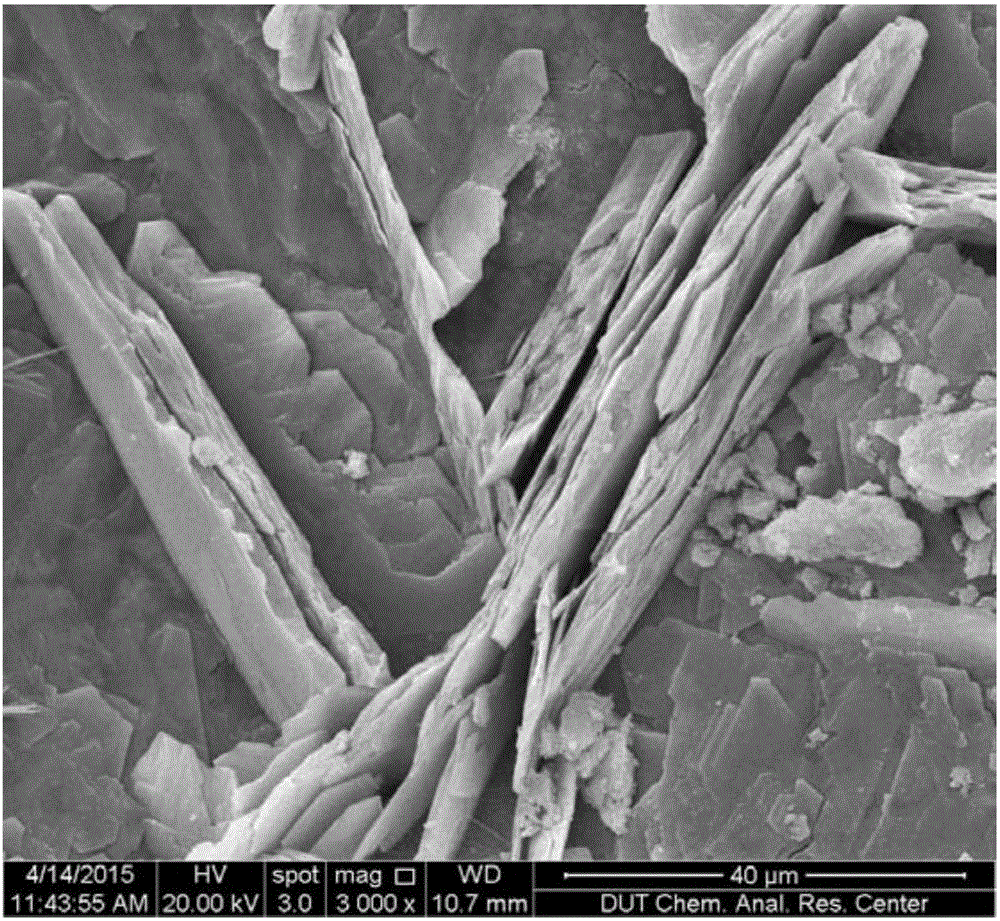

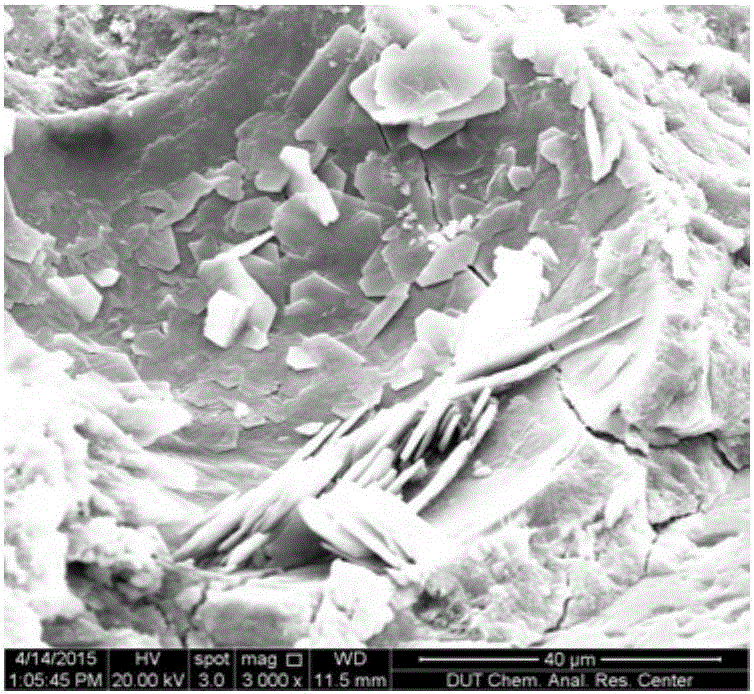

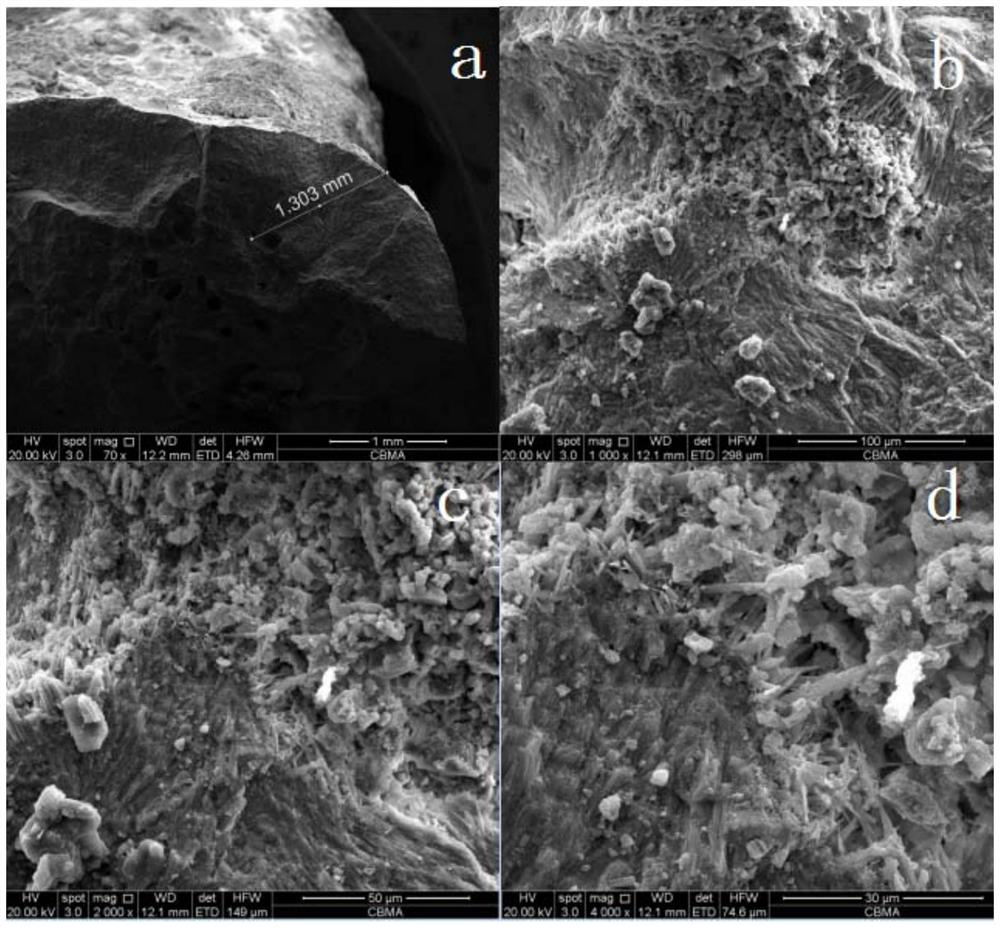

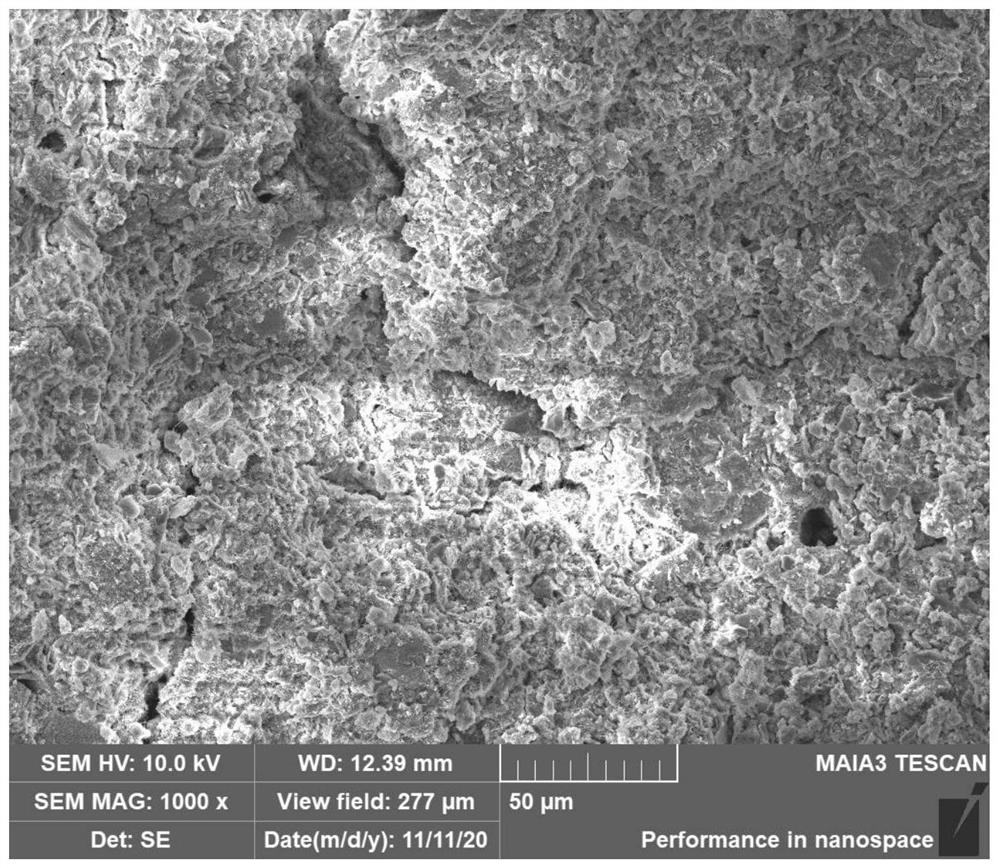

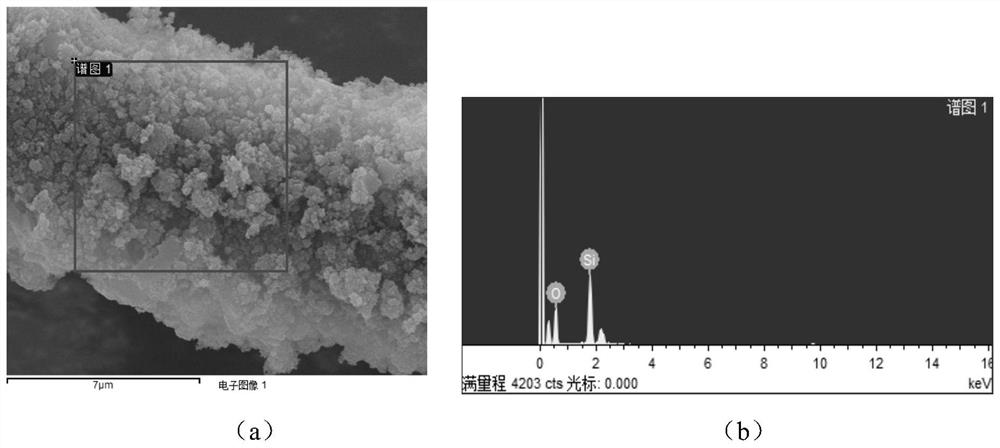

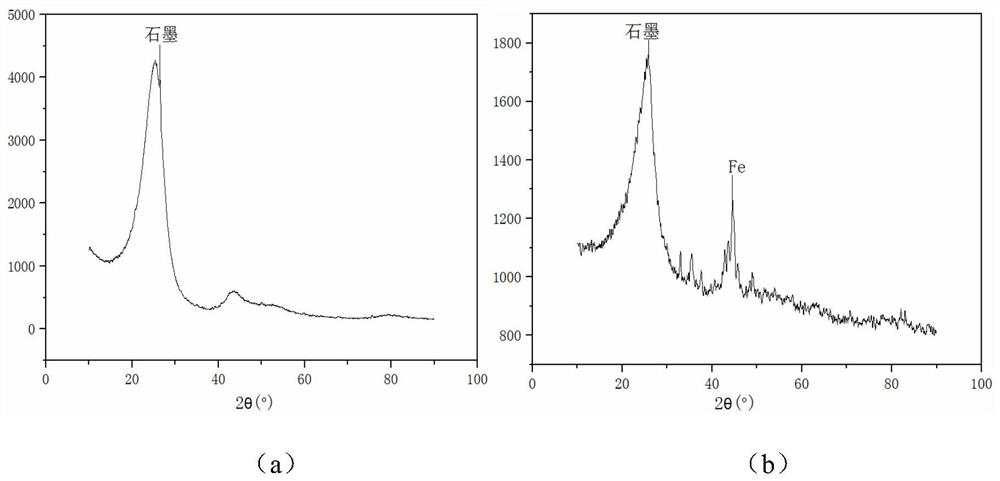

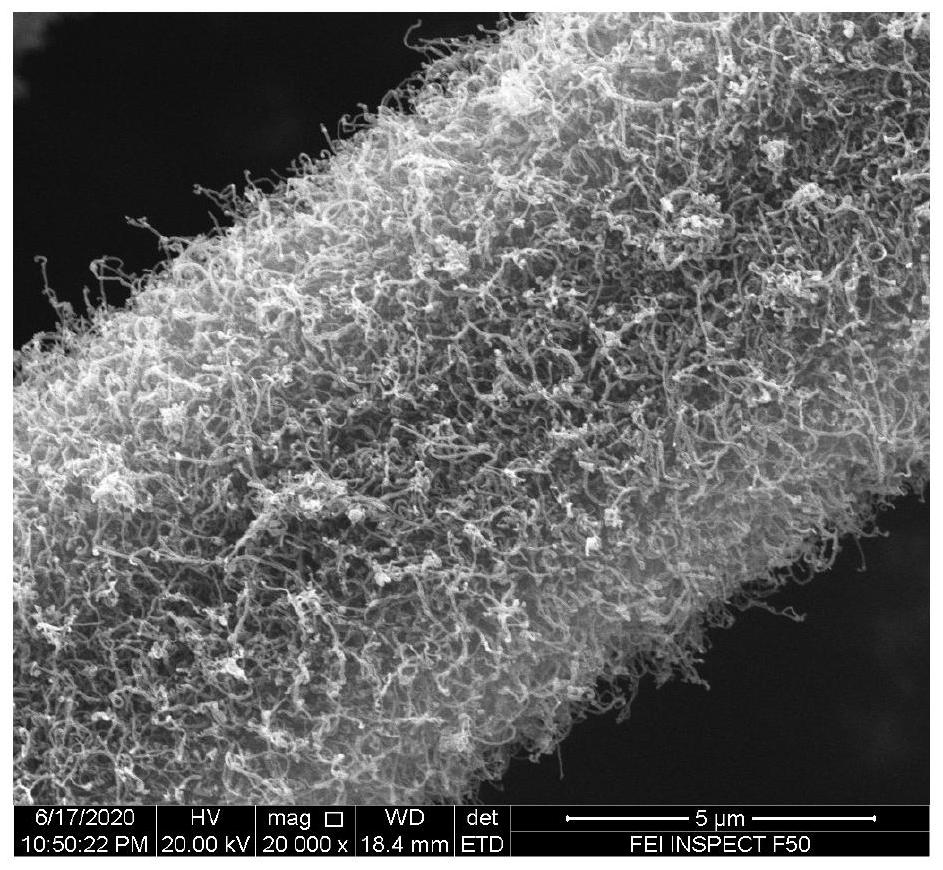

Modified carbon fiber, preparation method thereof and modified carbon fiber reinforced cement-based material

The invention discloses a modified carbon fiber, a preparation method thereof and a modified carbon fiber reinforced cement-based material. The modified carbon fibers are carbon fibers with nano silicon dioxide and carbon nanotubes grown on the surfaces in situ. The preparation method of the modified carbon fiber comprises the following steps: (1) removing an epoxy coating on the surface of the carbon fiber; (2) oxidizing the surface of the carbon fiber; (3) performing in-situ growth of nano silicon dioxide on the surface of the surface-oxidized carbon fiber; and (4) growing carbon nanotubes on the surface of the product obtained in the step (3) in situ. The nano silicon dioxide and the carbon nanotubes simultaneously grow on the surfaces of the carbon fibers in situ, the modified carbon fibers combine the pozzolanic effect of the nano silicon dioxide and the bridging nucleation effect of the carbon nanotubes, and the modified carbon fibers are doped into the cement-based material, so that the interfacial strength of the carbon fibers and the cement-based material can be remarkably improved. Pores of the cement-based material are filled with the modified carbon fibers, so that the structure of the cement-based material is more compact, and the early-stage shrinkage performance of the cement-based material is effectively improved.

Owner:SOUTHEAST UNIV +1

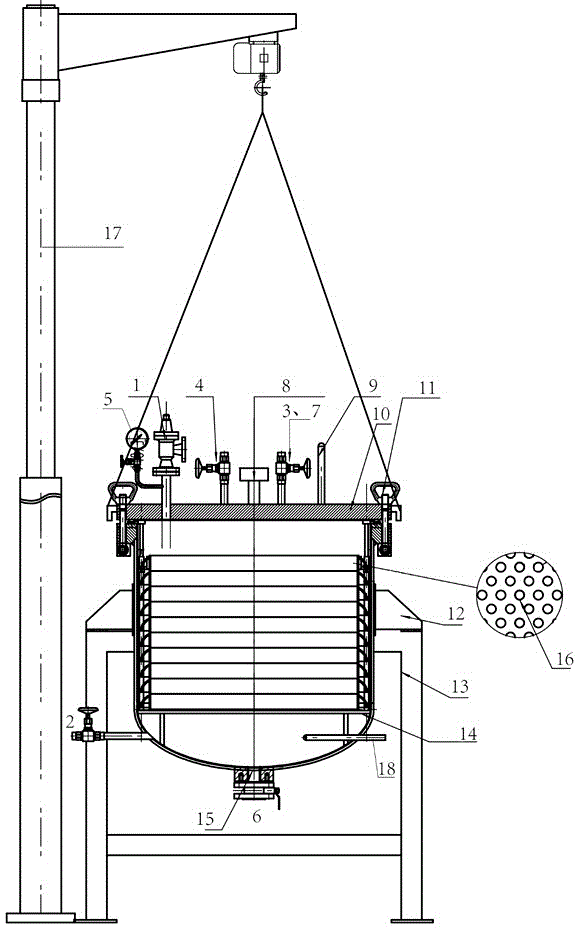

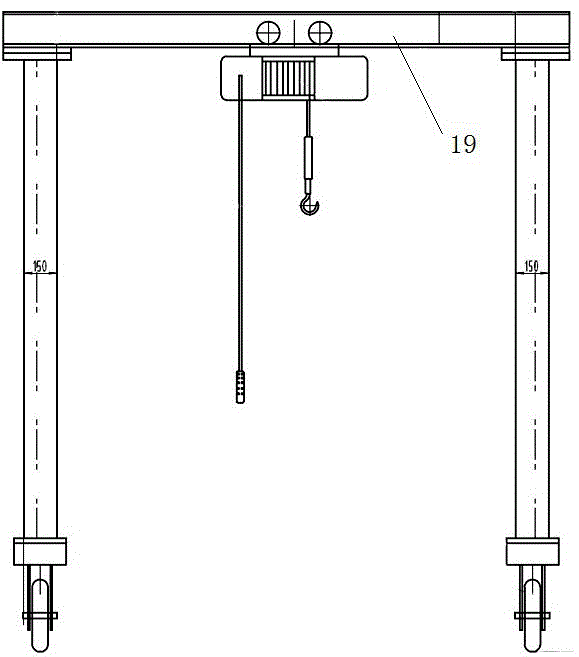

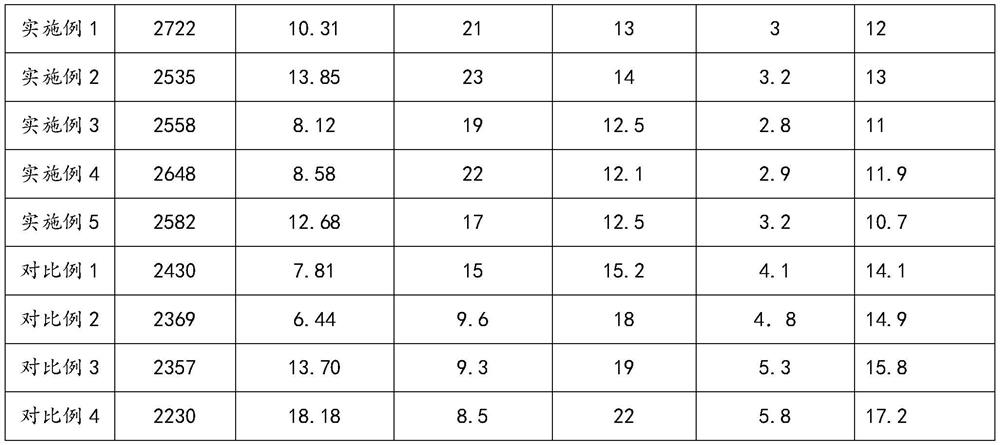

Device and method for strengthening recycled aggregate by means of CO2

ActiveCN106277885AEnhance basic propertiesLow water absorptionSolid waste managementPorosityCarbon dioxide cylinder

The invention relates to a device and method for strengthening recycled aggregate by means of CO2. The device comprises a reaction kettle with a kettle cover, a plurality of layers of stacked material frames are arranged in the reaction kettle, a gas inlet connected with a carbon dioxide steel cylinder is formed in the side of the reaction kettle, a pressurizing opening is formed in the kettle cover and connected with the carbon dioxide steel cylinder through a booster pump, and the kettle cover is further provided with an exhaust port and a vacuum opening connected with a vacuum pump. The device is simple in structure, convenient to install and maintain, convenient to clean and high in universality. By means of reaction of CO2 and recycled aggregate, the recycled aggregate is strengthened, basic properties of the recycled aggregate are improved, the water absorption rate and porosity of the recycled aggregate are reduced, the aperture is reduced, carbonization time is shortened, carbonization depth is increased, the treatment effect is improved, the yield is increased, and the equipment utilization rate is increased.

Owner:FUZHOU UNIV

Aggregate with irradiation-resistant function and preparation method and application thereof

The invention provides an aggregate with an irradiation-resistant function and a preparation method and application thereof. The aggregate comprises boron industrial waste residue recycled aggregate and a cement-based shell coating the surface of the boron industrial waste residue recycled aggregate; the boron industrial waste residue recycled aggregate is prepared from the following raw materialsin percentage by weight: 42 to 50 percent of boron mud, 27 to 35 percent of shale, 22 to 30 percent of metakaolin and 1 to 5 percent of a fluxing agent; the cement-based shell layer is prepared fromthe following raw materials in percentage by weight: 46 to 50 percent of cement, 10 to 13 percent of coal ash, 4.2 to 5.1 percent of silica fume, 25.6 to 30.7 percent of water, 1.0 to 1.6 percent of awater reducing agent and 3.9 to 5.2 percent of an expanding agent. The boron industrial waste residue recycled aggregate is subjected to surface modification by adopting a cement-based material, so that the surface structure and performance of the aggregate can be optimized, the porosity and water absorption rate are reduced, the compactness is improved, and the mechanical property, durability and radiation resistance of the aggregate are further enhanced.

Owner:CHINA BUILDING MATERIALS ACAD

Foamed light soil and preparation method thereof

A low environmental load type foamed light soil disclosed in the invention is prepared from cement, industrial waste residue powder, an expansion agent, a high mud resistance composite admixture, a waterproof agent, air bubbles, a filler and water. The industrial waste residue powder is adopted to replace a part of cement, and the filler can select mine tailings sand or machine-made sands, so environmental damage and land resource wastes, caused by stacking of the industrial waste residues, are reduced, and the environmental load is low; a part of the expansion agent is added to reduce the shrinkage of the foamed light soil and improve the volume stability and the early cracking resistance of the foamed light soil; and the high mud resistance admixture can fully disperse the cement and other cementing particles in the case of the filler containing fine powder particles with a high adsorption capacity, so the cementing ability and the construction performance of the foamed light soil are improved. The low environmental load type foamed light soil prepared in the invention effectively utilizes solid wastes, has great environmental protection significance, and also has the characteristics of light weight, high compressive strength, good integrity, solidifying independence and thermal insulation.

Owner:HEBEI COMM INVESTMENT TECH DEV CO LTD

Process for preparing water-permeable material for landscaping pavement

The invention discloses a process for preparing a water-permeable material for a landscaping pavement. The water-permeable material comprises a rubber layer, a water-permeable layer, a mortar layer and a matrix layer, wherein the matrix layer is formed by compression molding after uniformly stirring and mixing cement, solid waste coarse aggregate and solid waste fine aggregate; the water-permeablelayer is formed by compression molding after uniformly mixing cement, solid waste coarse aggregate and reinforcing fibers; the rubber layer is formed by mixing natural rubber, styrene butadiene rubber, white carbon black, silicon carbide, absorbent resin, a vulcanizing agent, an active agent and an ecological additive, casting the mixture on the water-permeable layer and carrying out vulcanizing;the coarse aggregate is formed by carrying out water quenching on high-temperature slag to form porous slag with a large internal pore diameter and then crushing the porous slag; the fine aggregate is formed by naturally cooling the high-temperature slag to form dense slag with a small internal pore diameter, and then grinding the dense slag into fine powder to be sintered into dense particles; and both coarse and fine aggregates are put into modification liquid for surface hydrophobic modification. The process provided by the invention uses solid wastes to prepare the water-permeable material which can be widely applied to water-permeable layers of pavements of sidewalks, parks and the like, and is beneficial to groundwater circulation.

Owner:HENAN UNIV OF SCI & TECH

Anti-ponding ecological rod surface for landscaping and preparation method

InactiveCN108316090AImprove permeabilitySmall water absorptionIn situ pavingsPaving gutters/kerbsCoal ganguePore diameter

The invention discloses an anti-ponding ecological rod surface for landscaping and a preparation method. The ecological rod surface is formed by pressing after mixing binder, reinforced fibers, coarseaggregate materials with larger internal bore diameter and fine aggregate materials with small internal bore diameter, and the coarse aggregate materials with the larger internal bore diameter and the fine aggregate materials with the small internal bore diameter are made of solid waste such as steel slag, ferrochrome slag and coal gangue after surface hydrophobic treatment. The ecological rod surface specifically comprises a base body layer, a permeable layer and a mortar layer, the base body layer comprises, by weight, 45-55 parts of composite binders, 120-180 parts of solid waste coarse aggregate, 100-120 parts of solid waste fine aggregate, 10-20 parts of addition agents, and 15-25 parts of water; the permeable layer comprises, by weight, 40-45 parts of the binder, 120-180 parts of the solid waste coarse aggregate, 80-120 parts of the reinforced fibers, 5-8 parts of the addition agents and 8-10 parts of the water; the coarse aggregate is formed by crushing multi-hole slag with thick internal bore diameter which is formed by water quenching high-temperature slag, and the fine aggregate is formed by burning fine powders formed by grinding dense slag with small internal bore diameter and the dense slag is formed by natural cooling the high-temperature slag. According to the anti-ponding ecological rod surface for the landscaping and the preparation method, solid waste is usedfor manufacturing seepage materials, and the anti-ponding ecological rod surface for the landscaping can be widely used in permeable layers of road surfaces.

Owner:HENAN UNIV OF SCI & TECH

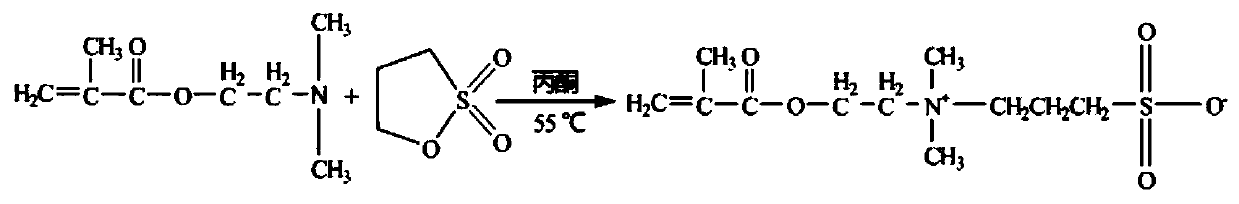

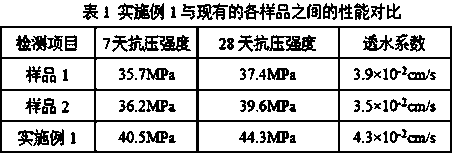

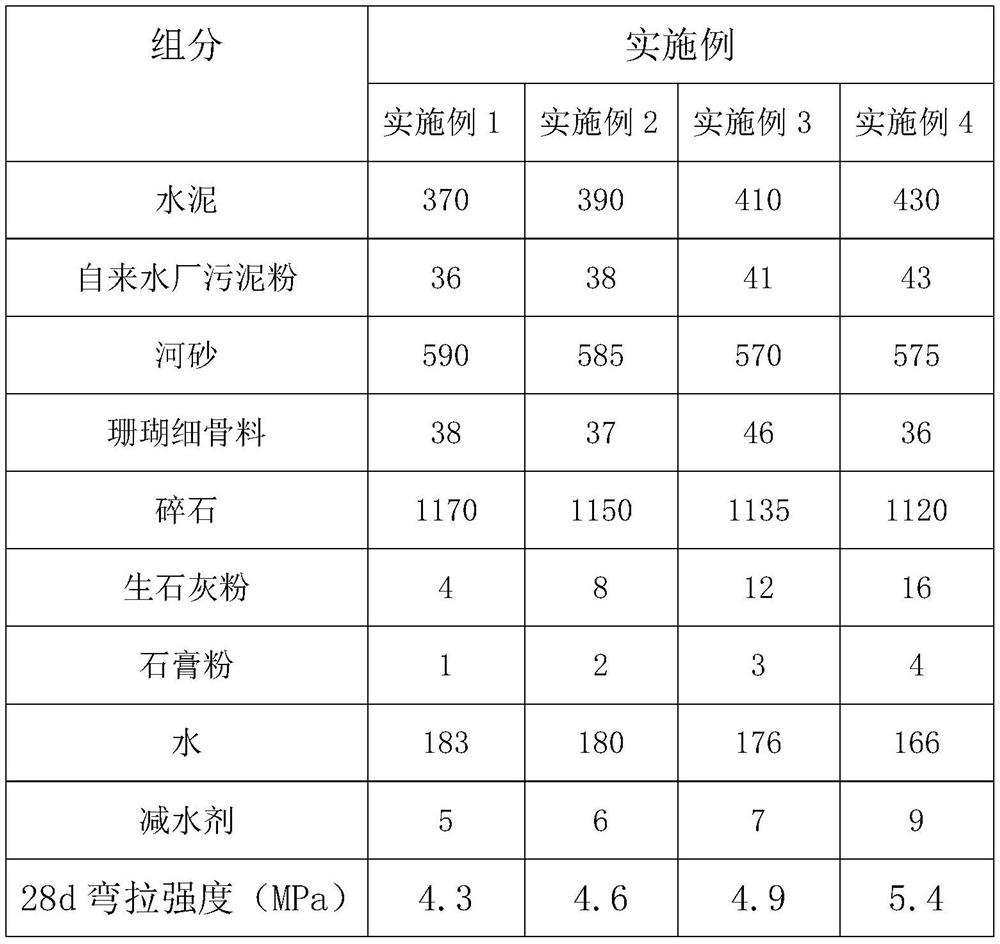

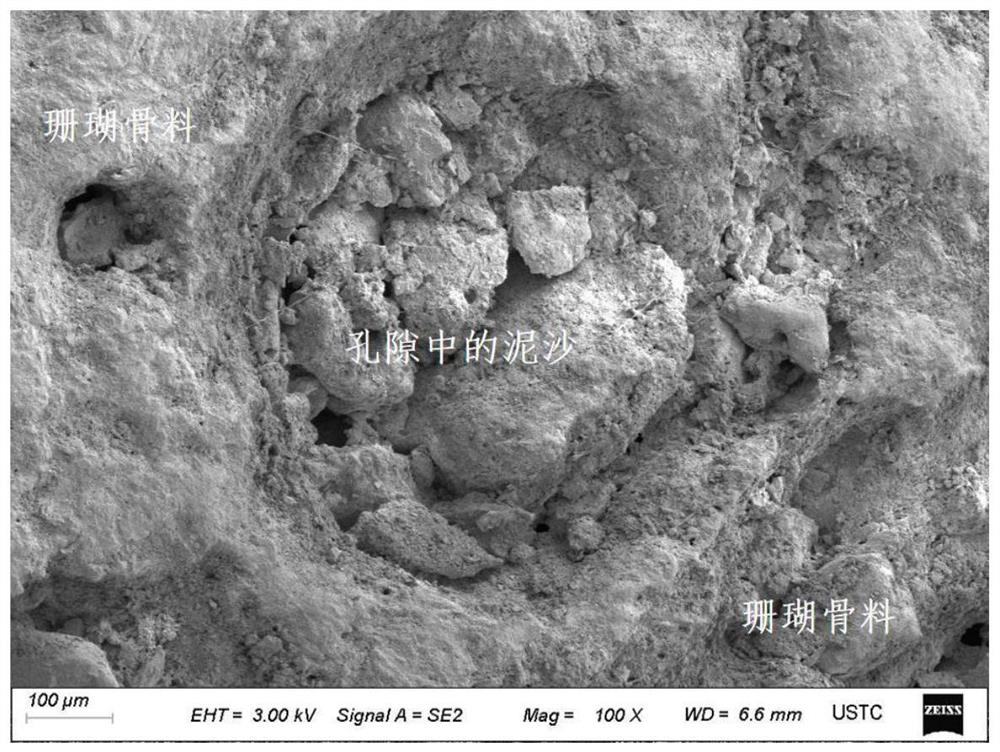

Road concrete prepared from waterworks sludge powder and coral fine aggregate

The invention discloses road concrete prepared from waterworks sludge powder and coral fine aggregate. The road concrete comprises the following components in parts by weight: 370-430 parts of cement,36-43 parts of waterworks sludge powder, 570-590 parts of river sand, 36-46 parts of coral fine aggregate, 1120-1170 parts of broken stone, 4-16 parts of quicklime powder, 1-4 parts of gypsum powder,166-183 parts of water and 5-9 parts of water reducing agent, wherein the water-binder ratio is 0.35-0.45. According to the invention, waterworks sludge powder is used as a mineral admixture to replace part of cement, and quicklime powder and gypsum powder are doped to further stimulate and improve the activity of the waterworks sludge powder; and coral fine aggregate is used for replacing part of river sand, aggregate grain composition and the 'micro-pump' effect of the coral aggregate are further improved, the local water-binder ratio of the aggregate surface can be adjusted, and the performance of concrete for roads is improved. The concrete for the road is prepared from the perspective of optimal design of cementing materials and aggregates, so that the performance of the concrete isimproved, the high-added-value green application of sludge powder and coral fine aggregates of waterworks is facilitated, and the comprehensive benefit is high.

Owner:SHAOXING MUNICIPAL DESIGN INST +1

Preparation methods of chemical micro-corroded coral aggregate and geopolymer-based ultrahigh-strength coral concrete

ActiveCN113200697AProlong clotting timeSlow down the hardening processCement productionPhosphoric acidChemistry

The invention discloses preparation methods of chemical micro-corroded coral aggregate and geopolymer-based ultrahigh-strength coral concrete, and relates to the technical field of concrete. The preparation method of the aggregate specifically comprises the steps that coral coarse aggregate is placed and soaked in a phosphoric acid solution, taken out and directly dried to obtain chemical micro-corroded coral coarse aggregate; and after ball milling and sieving, compounding is performed by adopting a directional grading compounding method to obtain chemical micro-corroded coral sand. The coral coarse aggregate is subjected to micro-corrosion by using phosphoric acid, so that phosphate grows on the surface of the coral aggregate and in communicated pores in situ, and the porosity of the coral coarse aggregate is reduced. The chemical micro-corroded coral coarse aggregate is subjected to ball milling and screening to obtain chemical micro-corroded coral fine aggregate, and then the coral aggregate is compounded in a directional grading compounding mode to obtain coral sand with low void ratio and high close packing density. The concrete is prepared by taking the substance as aggregate and an alkali-activated active powder material as a cementing material, so that the effects of delaying the setting time of the geopolymer-based coral aggregate concrete, optimizing a concrete interface transition region and improving the mechanical property of the concrete can be achieved.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

Preparation of recycled concrete through compound enhancement of low-elasticity-modulus modified coarse fibre and active mineral material

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

C30 high-impermeability concrete with low cementing material consumption and preparation method thereof

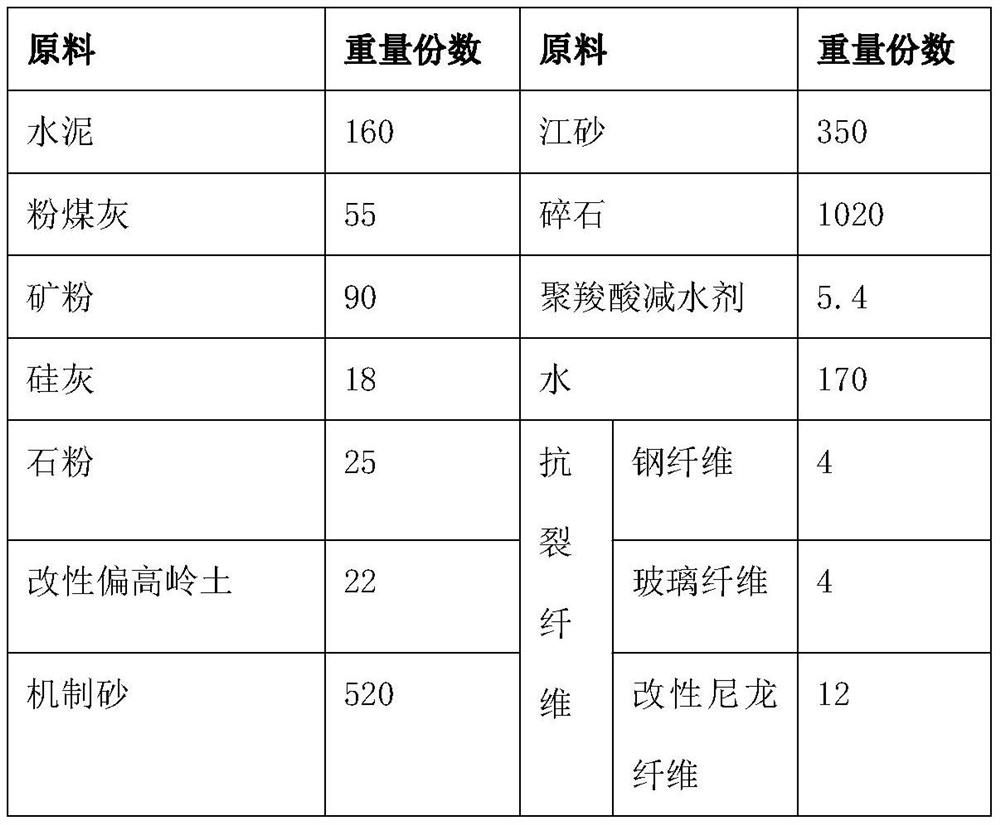

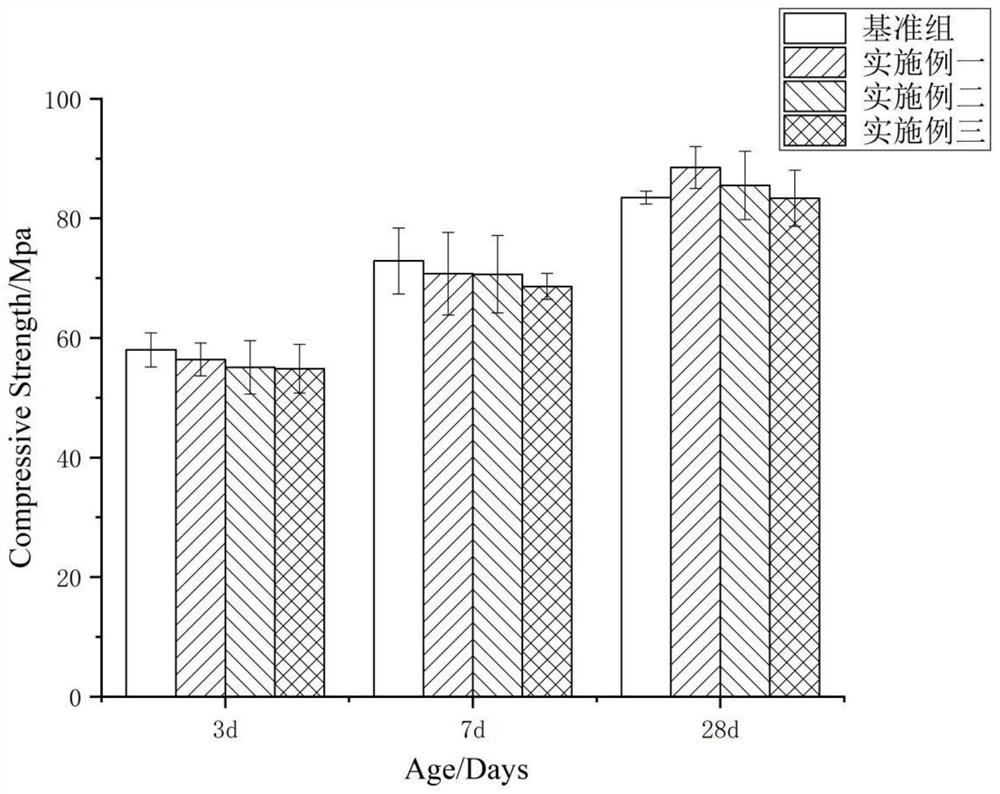

InactiveCN111704409AImprove the interface transition areaImprove impermeabilityArtifical filament manufactureMonocomponent polyamides artificial filamentEpoxyFiber

The invention relates to the technical field of building materials, and specifically relates to a C30 high-impermeability concrete with low cementing material consumption and a preparation method thereof. Each cubic meter of the concrete comprises the following components in parts by weight: 140-170 parts of cement, 40-60 parts of fly ash, 70-90 parts of mineral powder, 15-25 parts of silica fume,20-30 parts of stone powder, 18-22 parts of modified meta-kaolin, 490-520 parts of machine-made sand, 335-350 parts of river sand, 990-1020 parts of gravels, 5.1-6.1 parts of a polycarboxylate waterreducer, 165-175 parts of water and 15-25 parts of anti-cracking fibers, wherein the modified meta-kaolin is prepared by exciting and modifying gypsum, epoxy silane and modified polystyrene. The provided C30 high-impermeability concrete has good impermeability.

Owner:湖北合力久盛混凝土有限公司

High-strength shrinkage-reducing cement mortar doped with steel fibers and floating beads and preparation method of high-strength shrinkage-reducing cement mortar

InactiveCN114315270APromote hydrationControl cracking behaviorSolid waste managementSuperplasticizerKaolin clay

The invention discloses high-strength shrinkage-reducing cement mortar doped with steel fibers and floating beads and a preparation method of the cement mortar. The cement mortar is prepared from water, cement, silicon powder, metakaolin, quartz sand, saturated floating beads, the steel fibers and a polycarboxylate superplasticizer. The mass ratio of the water to the cement to the silicon powder to the metakaolin to the quartz sand to the saturated floating beads is 1042: 4168: 521: 521: (2800-4000): (286-859). The volume mixing amount of the steel fiber is 3%, and the mixing amount of the polycarboxylic acid type water reducing agent is 3% of that of the cementing material. The excellent water saturation and water release performance of the floating beads are combined, quartz sand is replaced with the floating beads, the problem of self-constriction of low-water-binder-ratio cement mortar is solved, meanwhile, it is guaranteed that the strength of the cement mortar is not greatly reduced, and good practical application value is achieved.

Owner:ANHUI UNIV OF SCI & TECH

High folding resistance road concrete material and preparing method thereof

InactiveCN101265066BImprove microscopic propertiesImprove the interface transition areaSolid waste managementSlagSodium fluoride

The invention discloses a road concrete material with high folding strength and a production method thereof. The road concrete material with high folding strength mainly contains binding agent, sand stone aggregate, mixing water, concrete admixture and excitant. The binding agent is composed of common silicate cement, ore slag powder and steel slag powder. The mass percentages of the components are as follows: 60-70% of common silicate cement, 20-30 % of ore slag powder and 0-10% of steel slag powder. The additional amount of the excitant is 5.0-10.0% of the total mass of the ore slag powder and the steel slag powder. The excitant is selected from gypsum, sodium sulfate, sodium fluoride, triethanolamine or a mixture thereof. By adding the excitant, the latent activity of the ore slag and the steel slag is excited, so that the compactness of concrete is improved and the folding strength of the road concrete is greatly improved.

Owner:SHENZHEN UNIV

Cement-based composite material with high drilling resistance used in bank financial equipment and preparation method thereof

InactiveCN102381859AImprove close packing performanceImprove anti-drilling performanceAggregate (composite)Water reducer

The invention belongs to the technical field of bank financial equipment manufacturing, and relates to a cement-based composite material with high drilling resistance used in bank financial equipment. The composite material is characterized by comprising the following components such as cement, siliceous dust, carborundum, an efficient water reducer, steel fiber and water at the weight ratio of 1:(0.10-0.20):(1.4-2.6):(0.005-0.010):(0.30-0.45):(0.23-0.29). The cement-based composite material is applied to the technical field of bank financial equipment, and has the following advantages that the carborundum with Mohs hardness up to 9.0 is taken as an aggregate so as to greatly improve the drilling resistance of the cement-based composite material; and the composite material is naturally cured without high-temperature steam or dry-heat curing procedure, thus simplifying the operating procedures, saving the energy cost and being applicable to large-scale production.

Owner:TRI STAR

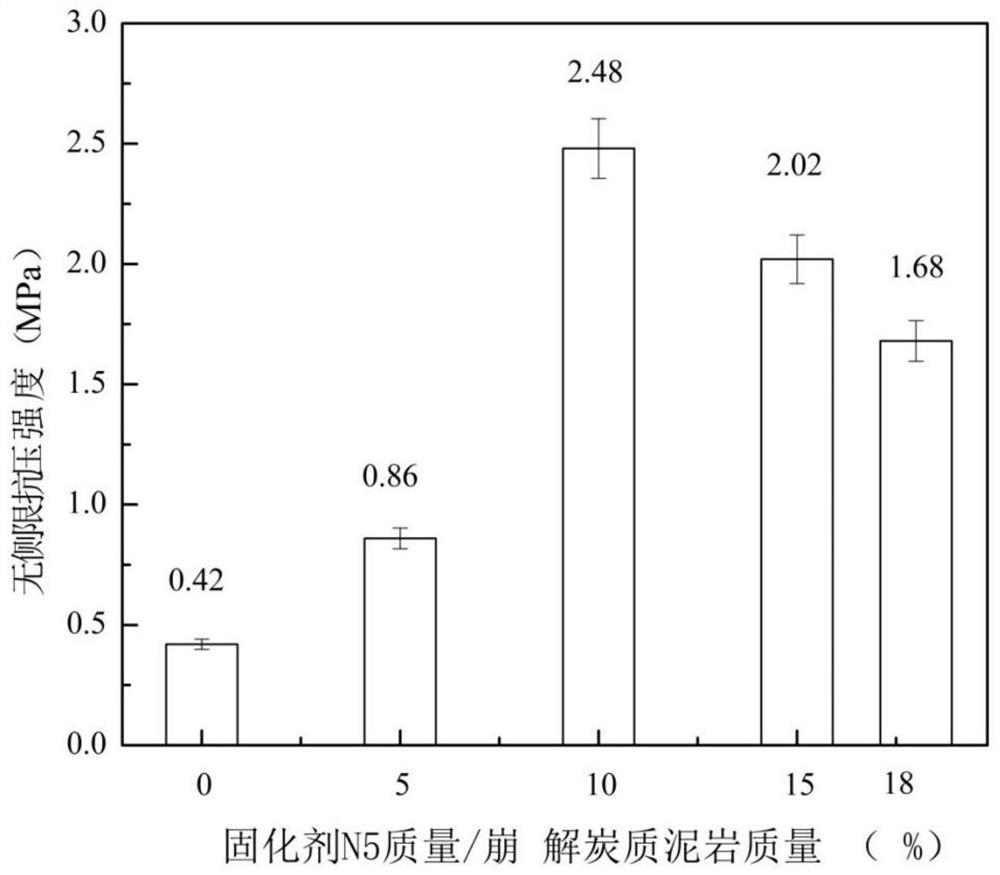

Nano-fiber curing agent for disintegrating carbonaceous mudstone and its preparation and use methods

The invention discloses a nano-fiber curing agent for disintegrating carbonaceous mudstone and its preparation and use methods. The nano-fiber curing agent for disintegrating carbonaceous mudstone consists of the following parts by weight: 30-40 parts of cement , 2-5 parts of nanomaterials, 5-10 parts of organic gel, 0.5-1 parts of disodium edetate, 25-35 parts of slag, 2-6 parts of fiber materials, and 16-25 parts of water. The nano-fiber curing agent for disintegrating carbonaceous mudstone provided by the present invention is an inorganic-organic composite curing agent, and the cured disintegrating carbonaceous mudstone has unconfined compressive strength under the synergy of various components The advantages of high quality and good structural integrity realize the reuse of slag while reducing the amount of cement, low cost, energy saving and pollution reduction.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Waterlogging-proof ecological pavement for landscaping and preparation method thereof

InactiveCN108316090BImprove permeabilitySmall water absorptionIn situ pavingsPaving gutters/kerbsFiberAggregate (composite)

The invention discloses an anti-ponding ecological rod surface for landscaping and a preparation method. The ecological rod surface is formed by pressing after mixing binder, reinforced fibers, coarseaggregate materials with larger internal bore diameter and fine aggregate materials with small internal bore diameter, and the coarse aggregate materials with the larger internal bore diameter and the fine aggregate materials with the small internal bore diameter are made of solid waste such as steel slag, ferrochrome slag and coal gangue after surface hydrophobic treatment. The ecological rod surface specifically comprises a base body layer, a permeable layer and a mortar layer, the base body layer comprises, by weight, 45-55 parts of composite binders, 120-180 parts of solid waste coarse aggregate, 100-120 parts of solid waste fine aggregate, 10-20 parts of addition agents, and 15-25 parts of water; the permeable layer comprises, by weight, 40-45 parts of the binder, 120-180 parts of the solid waste coarse aggregate, 80-120 parts of the reinforced fibers, 5-8 parts of the addition agents and 8-10 parts of the water; the coarse aggregate is formed by crushing multi-hole slag with thick internal bore diameter which is formed by water quenching high-temperature slag, and the fine aggregate is formed by burning fine powders formed by grinding dense slag with small internal bore diameter and the dense slag is formed by natural cooling the high-temperature slag. According to the anti-ponding ecological rod surface for the landscaping and the preparation method, solid waste is usedfor manufacturing seepage materials, and the anti-ponding ecological rod surface for the landscaping can be widely used in permeable layers of road surfaces.

Owner:HENAN UNIV OF SCI & TECH

Modified high carbon ferro-chrome slag aggregate for road concrete and preparation method of modified high carbon ferro-chrome slag aggregate

ActiveCN103073210BFix bugsSolve hidden dangersSolid waste managementPolyethylene vinyl acetateHigh carbon

The invention discloses a modified high carbon ferro-chrome slag aggregate for road concrete and a preparation method of the modified high carbon ferro-chrome slag aggregate. The modified high carbon ferro-chrome slag aggregate is characterized by being prepared from a high carbon ferro-chrome alloy slag aggregate and a chemical modifying agent accounting for 2-6 percent of the mass of the high carbon ferro-chrome alloy slag aggregate through mixing, wherein the chemical modifying agent is prepared from 100 parts by mass of polymer diluting solution, 0.5-1.2 parts by mass of organic silicon waterproof defoaming agent, 0.2-0.5 part by mass of polyvinyl alcohol and 2-4 parts by mass of zeolite powder through uniform mixing; the polymer diluting solution is prepared by diluting a polymer emulsion stock solution through adding water; and the polymer emulsion stock solution is any one of a butylbenzene emulsion, a polyacrylate emulsion, a polyethylene-vinyl acetate emulsion and a styrene-acrylic emulsion. By adopting the invention, waste alloy waste is used as a raw material, and thus building materials of carbon chromic slag can be recycled and efficiently utilized, and the defects and the hidden dangers of the carbon chromic slag as the concrete aggregate are solved; and the preparation method is simple and easy to realize and is strong in practicability.

Owner:李素娥

Self-compacting concrete for floor heating protection layer and preparation method thereof

ActiveCN113372070APrevent shrinkage crackingLow apparent densitySolid waste managementShrinkage crackingSlag

The invention discloses a self-compacting concrete for a floor heating protection layer and a preparation method thereof, the self-compacting concrete comprises the following raw materials in percentage by mass: 30%-35% of fluidized bed combustion ash, 35%-40% of slag, 12%-18% of cement, 1.0%-2.0% of a water reducing agent and 15%-18% of water, and the sum of the mass percentages of the raw materials is 100%. According to the invention, the furnace slag is used as aggregate, the fluidized bed combustion ash and the cement are used as gel materials, and the volcanic ash activity, self-hardening performance and expansion performance of the fluidized bed combustion ash are fully utilized; shrinkage cracking of the floor heating protection layer is avoided; as the apparent density of the furnace slag is small, the dry apparent density of the self-compacting concrete prepared from the fluidized bed combustion ash and the furnace slag is small, and the increased load on the floor is small.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Fiber-reinforced recycled aggregate pervious concrete

PendingCN114804763ABalanced road mechanical propertiesBalanced with long-term performanceSlurryRoad surface

The invention discloses fiber-reinforced recycled aggregate pervious concrete, which is prepared by adopting the following formula: 270-350 kg / m < 3 > of cement, 355-450 kg / m < 3 > of water, 1360-1950 kg / m < 3 > of coarse aggregate, 35-100% of recycled aggregate, 0-30 kg / m < 3 > of polymer emulsion, 0-9.6 kg / m < 3 > of water reducing agent, 0-5 kg / m < 3 > of high-performance admixture, a water-binder ratio of 0.24-0.42, a slurry-bone ratio of 1: 3.8-1: 4.7, the maximum nominal particle size of the coarse aggregate is 5-20 mm, the maximum nominal particle size of the recycled aggregate is 5-20 mm, and the maximum nominal particle size of the recycled aggregate is 5-20 mm. The pervious concrete is prepared from the recycled aggregate, carbon emission in the whole life cycle of ground and pavement paving materials is further reduced, meanwhile, construction waste and solid waste are effectively utilized, the breaking strength and toughness of a pervious paving layer are greatly improved through the fiber reinforcement technology, a premixing mode is adopted for production in a breakthrough mode, the production efficiency is greatly improved, and the production cost is reduced. And the quality stability of a pervious concrete product is ensured to a greater extent.

Owner:CHENGBANG ECO ENVIRONMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com