Ultrahigh-strength self-compacting concrete and preparation method thereof

A dense concrete, ultra-high technology, applied in the field of inorganic non-metallic materials, can solve the problem of difficult to achieve ultra-high strength and high fluidity of concrete at the same time, and achieve the effects of excellent flow performance, reduced slurry dosage, and reduced porosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

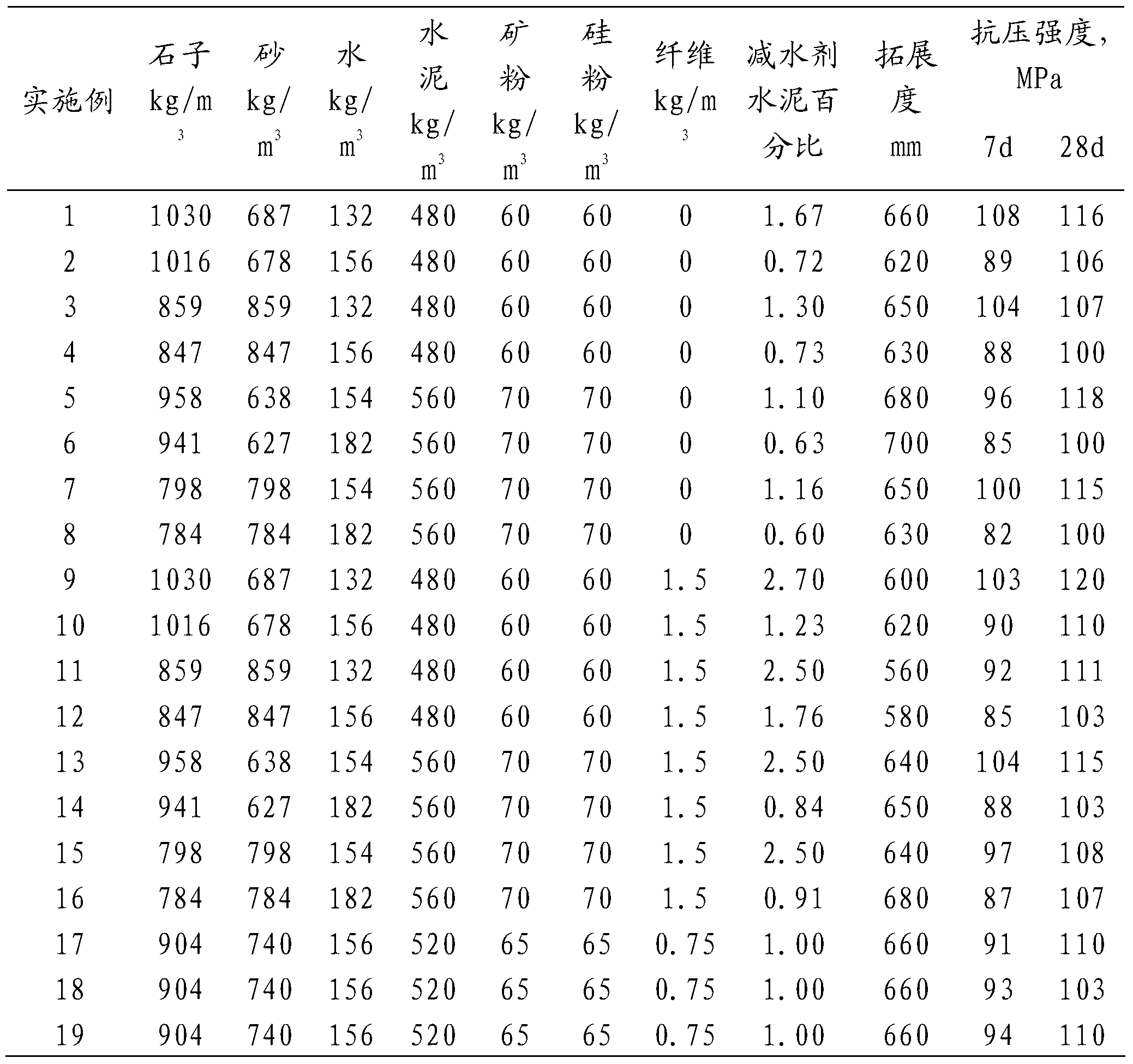

[0026] In order to better understand the present invention, the content of the present invention will be further clarified below in combination with tables and specific implementation examples, but the content of the present invention is not limited to the following examples.

[0027] Concrete of the present invention is mainly composed of cementitious material, water reducing agent, fine aggregate, coarse aggregate and fiber; said cementitious material is composed of ordinary Portland cement, slag, silica fume, and in every 1m of concrete, water 150kg, 700kg of fine aggregate, 900kg of coarse aggregate, 650kg of cementitious material, 1kg of fiber, and the amount of water reducer is 1.5% of the cement amount.

[0028] At the same time, the ordinary Portland cement is 52.5R cement; the silica fume adopts a density of 2400kg / m 3 , the specific surface area is 15000m 2 / kg of silicon powder; the superplasticizer is polycarboxylate high-efficiency superplasticizer; the fine aggr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com