Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

91results about How to "Improve macro performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength high-conductivity copper alloy contact wire for rapid transit railway

ActiveCN1811998AExcellent thermal stability and corrosion and wear resistanceFine grain structureSingle bars/rods/wires/strips conductorsCable/conductor manufactureCrystalliteChromium

Owner:郑茂盛 +1

Method for preparing light concrete by municipal solid waste incineration fly ash

InactiveCN101531492ATo achieve the purpose of harmless treatmentSimple processSolid waste managementApparent densityPortland cement

The invention discloses a method for preparing light concrete by municipal solid waste incineration fly ash. The light concrete comprises the following compositions according to material ratio: 330 to 370kg / m<3> of the municipal solid waste incineration fly ash, 450 to 475kg / m<3> of 525# common Portland cement, 325 to 340kg / m<3> of water-granulated slag, 350 to 370kg / m<3> of ordinary clay porcelain granules, 230 to 240kg / m<3> of diabase slag, and 2.7 to 2.9kg / m<3> of admixture. The method uses the municipal solid waste incineration fly ash to prepare the light concrete, can solidify heavy metal in fly ash, thereby achieving the aim of innocent treatment of the municipal solid waste incineration fly ash. The method has a simple process, and the obtained finished product has strength grade of CL40 and apparent density of 1800, and has good macroscopic performance.

Owner:SHANGHAI INST OF TECH

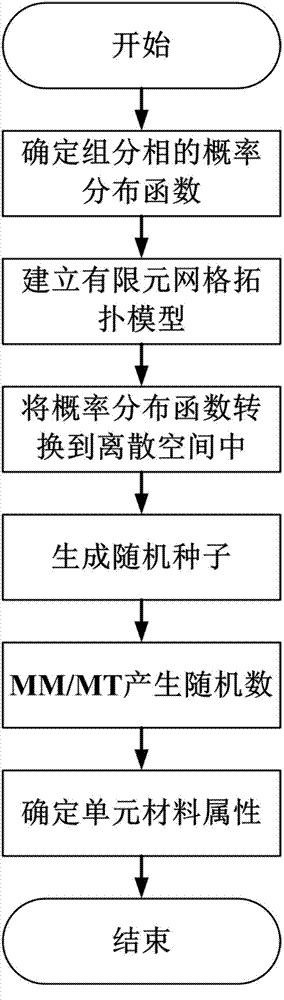

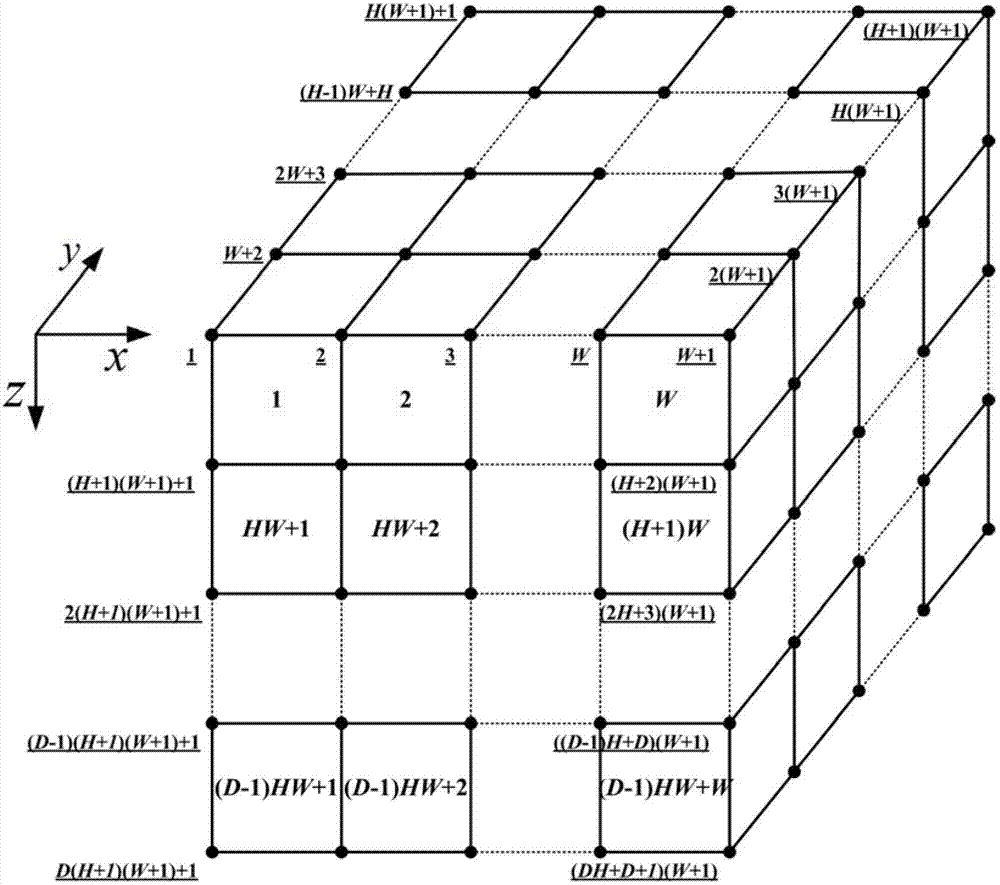

Finite element modeling method of random microstructure of heterogeneous material

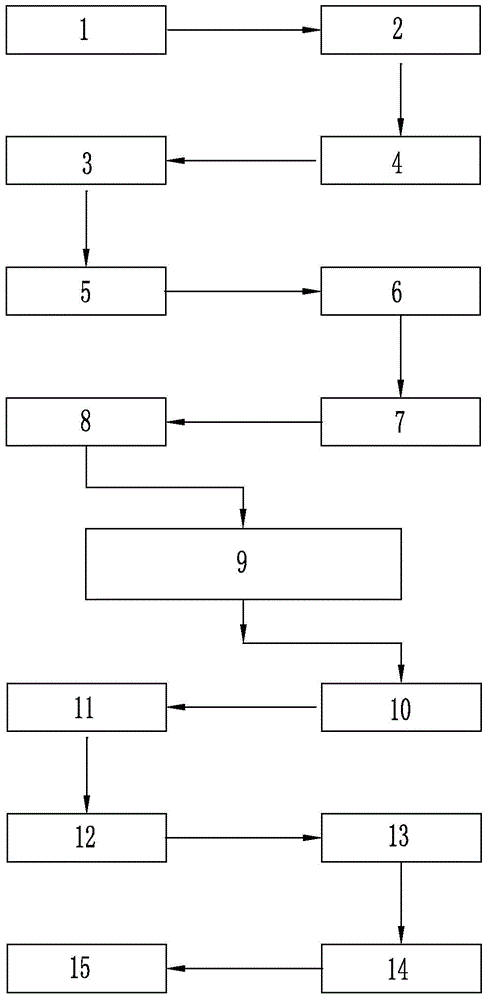

InactiveCN102819647AGood macro performanceImprove macro performanceSpecial data processing applicationsElement modelStochastic algorithms

The invention provides a finite element modeling method of a random microstructure of a heterogeneous material, and particularly relates to a method of establishing a finite element network model of the random microstructure of the heterogeneous material based on microstructure probability distribution information and a random algorithm. The method comprises the following steps of: determining a microstructure probability distribution function by using a real or dummy heterogeneous material component phase physical distribution form; converting a probability distribution function into a discrete space of the model on the basis of establishing the finite element network topological model of the material; and determining material attributes of each unit in the definite element model by using random real numbers generated by a pseudo random number generator and consistently distributed in an interval [0, 1], thereby establishing the random microstructure model of the heterogeneous material. The method is suitable for the heterogeneous materials in different modes; the established definite network model can be directly used for analyzing relation among microscopic property, microscopic structure, macroscopic performance of the heterogeneous material; and basis is provided for development and preparation of a new material.

Owner:XI AN JIAOTONG UNIV

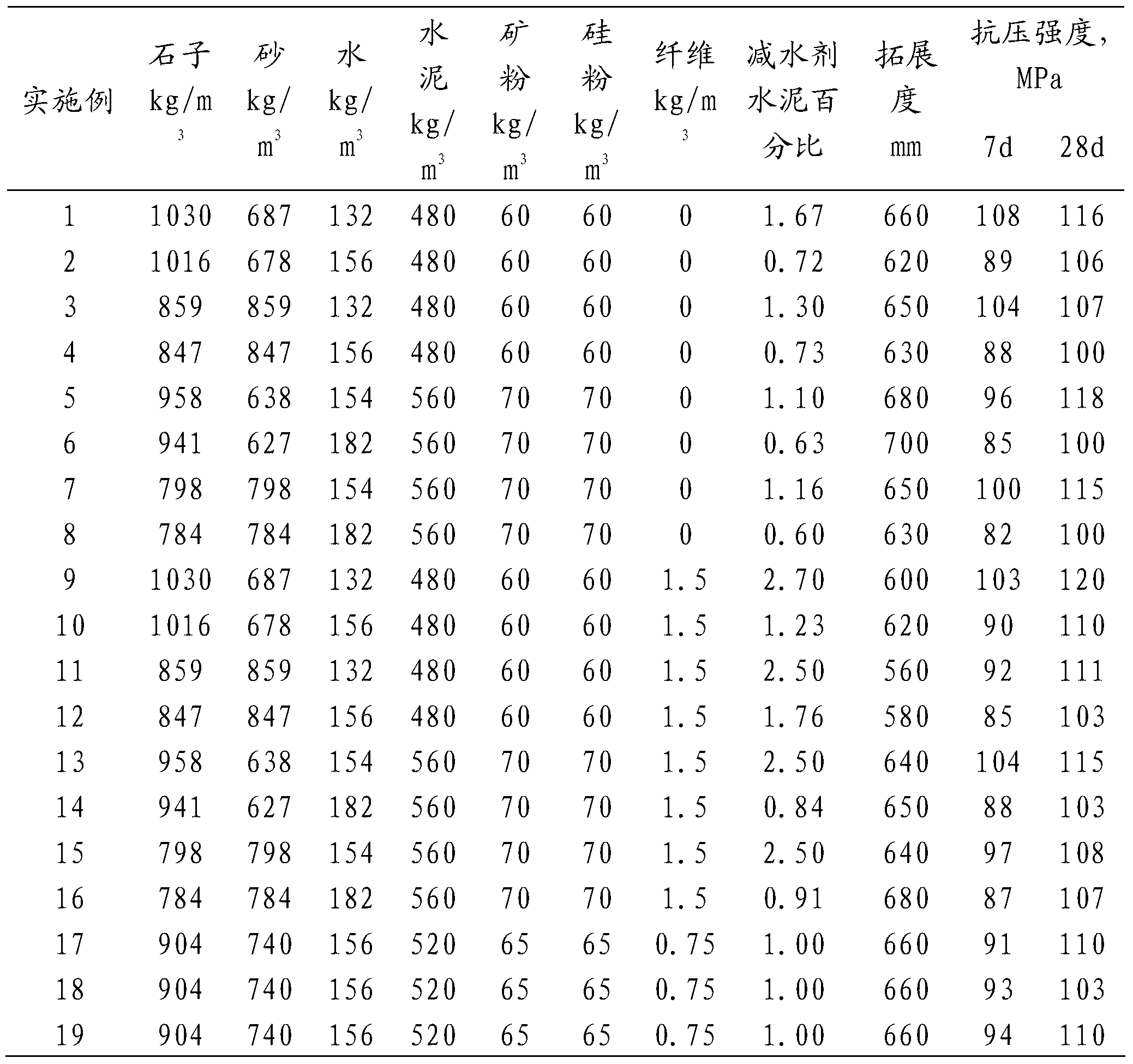

Ultrahigh-strength self-compacting concrete and preparation method thereof

InactiveCN103304206AImprove microscopic propertiesImprove the interface transition areaFiberPolyvinyl alcohol

The invention discloses an ultrahigh-strength self-compacting concrete and a preparation method thereof. The ultrahigh strength self-compacting concrete is mainly composed of a cementing material, an efficient water reducer, a fine aggregate, a coarse aggregate, water and PVA (Polyvinyl Alcohol) fibers, wherein the cementing material is composed of 70%-80% of common silicate cement, 10%-20% of mineral slag and 5%-10% of silicon powder by weight percentage; the fine aggregate is medium sand; the coarse aggregate is granite macadam. The ultrahigh-strength self-compacting concrete has the beneficial effects that the advanced techniques of the ultrahigh-strength concrete and the self-compacting concrete in the field of the concrete materials at present are studied, the advantages of the two concrete techniques are combined so that the dosage of the cement is reduced while ultrahigh performance of the concrete is realized, and furthermore, the purposes of emission reduction of CO2, materials saving and environmental protection as well as green construction are achieved.

Owner:SHENZHEN UNIV

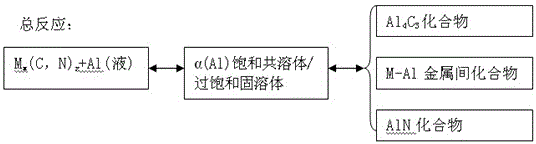

High-strength aluminum alloy subjected to carbonitride complex treatment and preparation method thereof

The invention discloses a high-strength aluminum alloy subjected to carbonitride complex treatment and a preparation method thereof. The alloy comprises the following components in percentage by weight: 2.0-3.2 percent of Cu, less than or equal to 0.2 percent of Mn, 0.2-0.5 percent of Mg, less than or equal to 0.01 percent of Cr, less than or equal to 0.01 percent of Ni, less than or equal to 0.1 percent of Zn, less than or equal to 0.15 percent of Ti, less than or equal to 0.5 percent of Si, less than or equal to 0.5 percent of Fe, and the balance of Al and inevitable trace impurities, wherein the carbonitride MX(C,N)Y is 0.05-2.5 percent of total mass of the furnace burden. The aluminum alloy has the characteristics of high strength and good casting performance.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

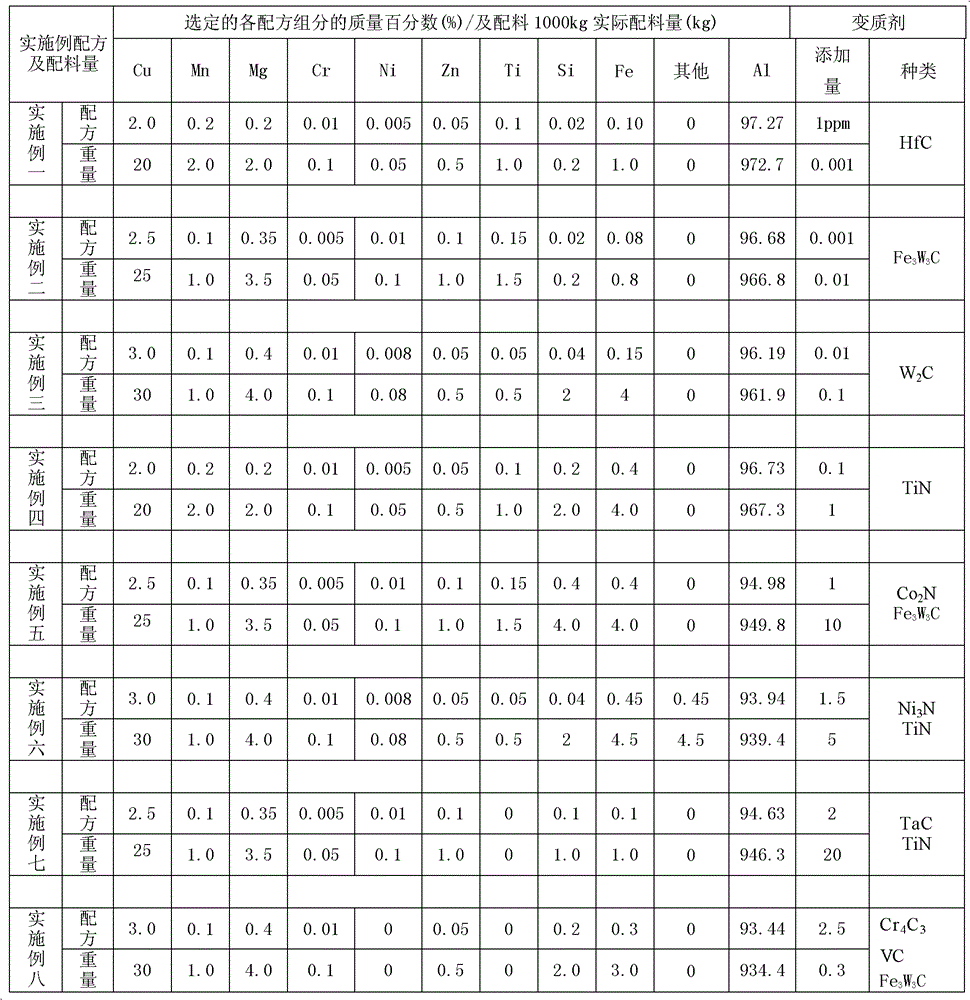

Interference coordinating method, base station and user equipment

ActiveUS20140010197A1Performance is not affectedEliminate distractionsPower managementRadio transmissionEngineeringControl channel

A method of interference coordination, base station and user equipment. The method comprises: precoding by a macro cell eNB the signals of the downlink control channel of scheduled macro cell UE by using pre-obtained precoded matrixes, such that the signal null space formed by precoding is pointed to pico cells and / or the characteristic value space of the signals is pointed to the macro cell UE. With such a method, almost all the interference caused by the PDCCH of the macro cell to the pico cell is eliminated, and the performances of the macro cell are not affected, solving the problem existed in the prior art; or improving the receiving performance of the macro cell UE, and further alleviating the interference of the macro cell on the pico cells.

Owner:FUJITSU LTD

Skull repairing anti-adhesion charged composite membrane and preparation method thereof

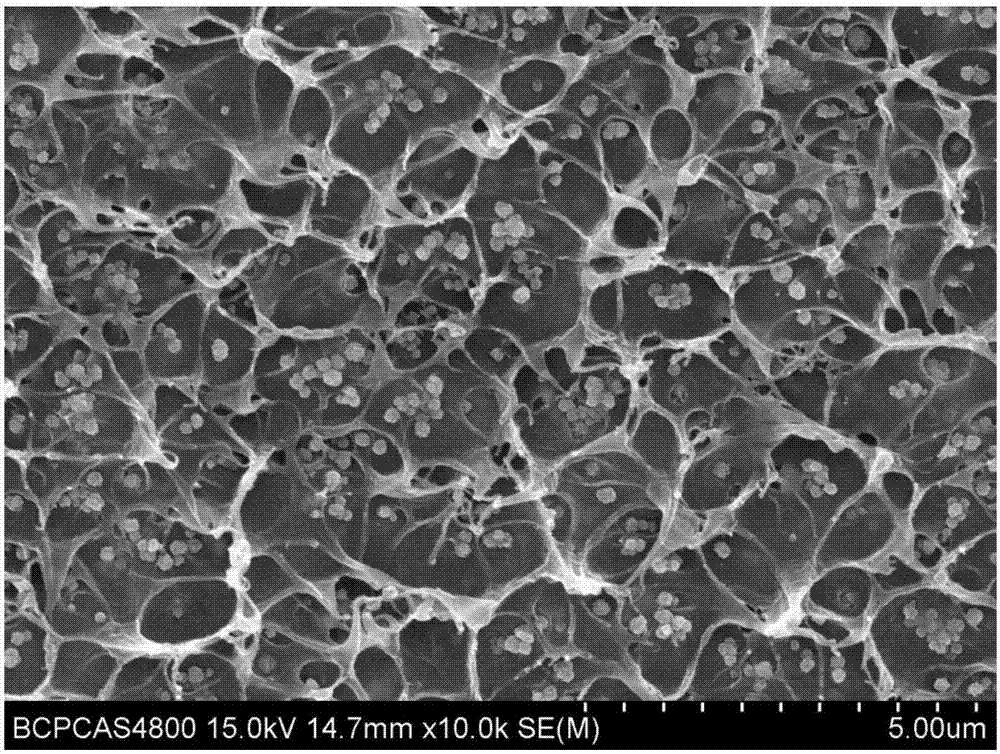

InactiveCN107233625AUniform structureImprove performanceTissue regenerationProsthesisRepair materialPolyvinylidene difluoride

The invention relates to a skull repairing anti-adhesion charged composite membrane and a preparation method thereof. The skull repairing anti-adhesion charged composite membrane and the preparation method thereof solves the technical problem that existing materials require further improvement in aspects of mechanical performance and electrical performance. The skull repairing anti-adhesion charged composite membrane is composed of high-molecular polymer and piezoelectric ceramic particles, wherein the high-molecular polymer is one or a compound of ferroelectric high-molecular polyvinylidene fluoride or polyvinylidene fluoride-trifluoroethylene. The invention also provides the preparation method of the skull repairing anti-adhesion charged composite membrane. The skull repairing anti-adhesion charged composite membrane and the preparation method thereof can be widely applied to the field of neurosurgical repair materials.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

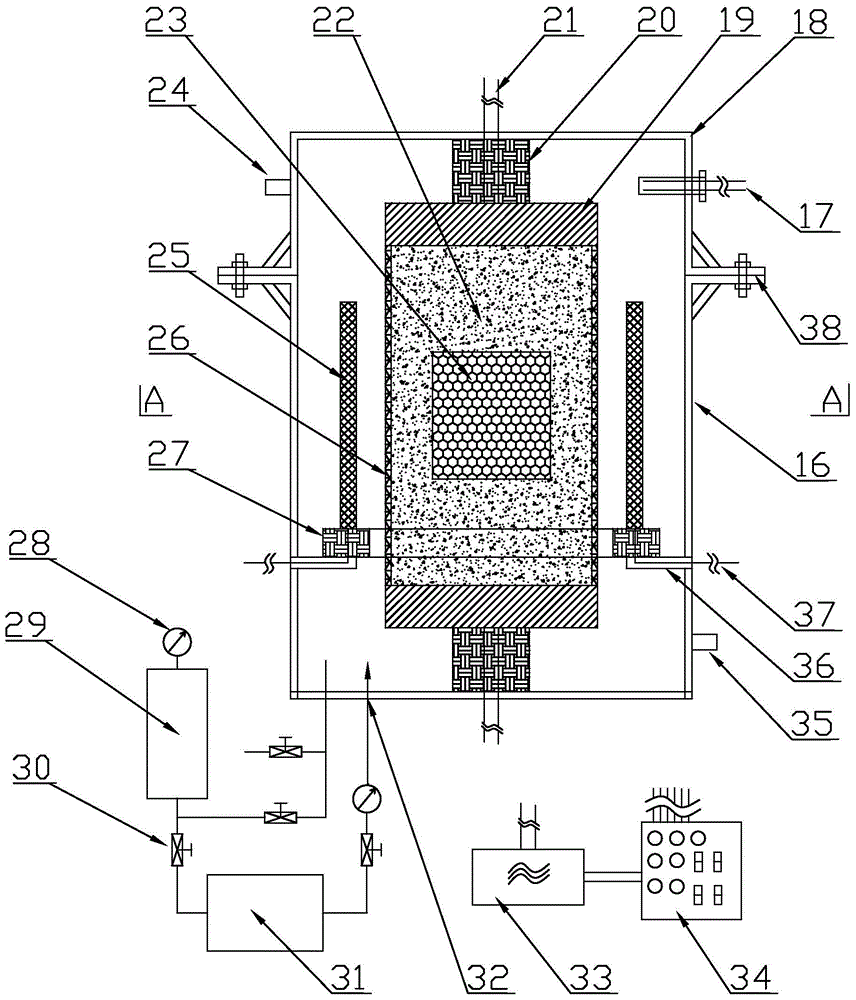

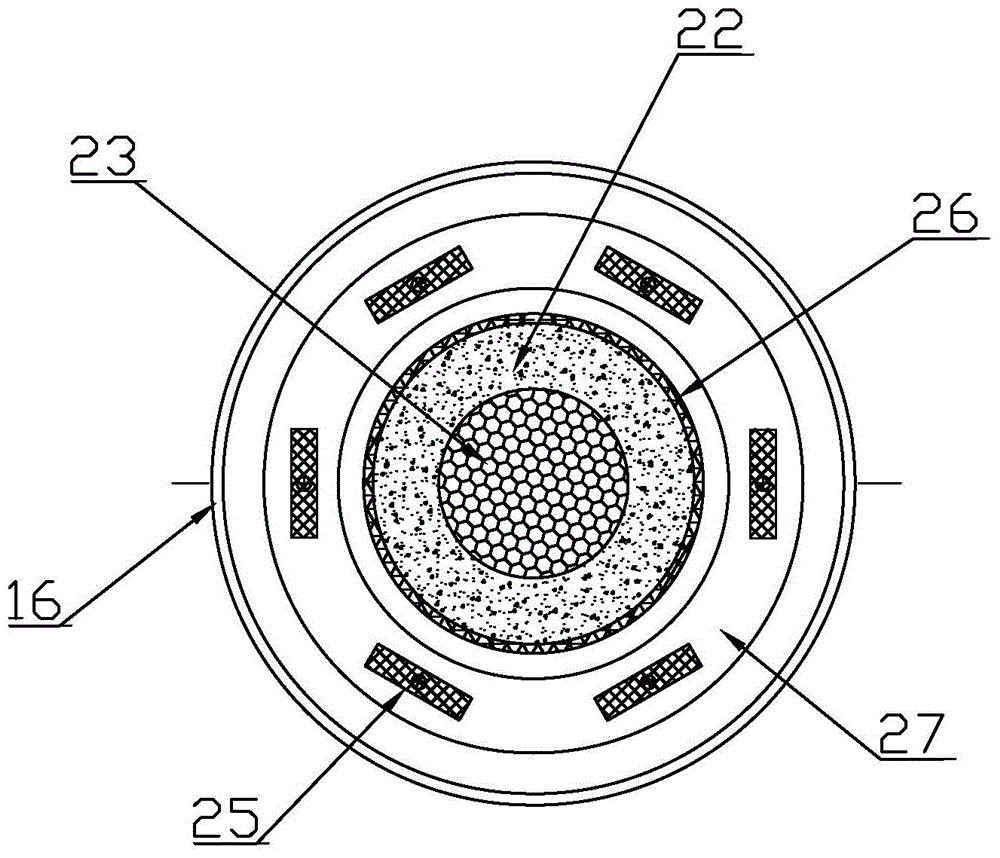

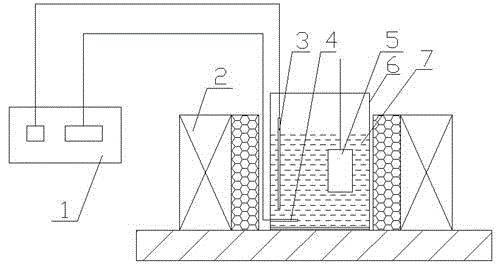

Ceramic material sintering furnace and isostatic pressing field-controlled spark pulse sintering method

ActiveCN103819202AHomogeneous microstructureImprove efficiencyFurnace coolingControl devices for furnacesGrain boundaryGraphite

The invention discloses a ceramic material sintering furnace and an isostatic pressing field-controlled spark pulse sintering method, namely isostatic pressing and spark pulse field controlled sintering for short. The isostatic pressing and spark pulse field controlled sintering is characterized by comprising preparation of a ceramic blank, an isostatic pressing and spark pulse field controlled sintering furnace, processing of a ceramic sintering body, and an isostatic pressing and spark pulse field controlled sintering method, wherein the isostatic pressing and spark pulse field controlled sintering furnace comprises a lower furnace body, a thermocouple, an upper furnace body, an electrode plate, an bench insulator, an electrode lead, a graphite packing, a control electric field, a rubber seal cartridge, an insulating ring adaptor, a pressure gauge, a gas cylinder, a gas valve, a compressor, a gas inlet, a gas outlet, an impulse current generator, a sintering controller and fixing support feet, the isostatic pressing and spark pulse field controlled sintering method enables the transfer and direction of the heat energy, pressure and electromagnetic field of macroscopic and microcosmic ceramic materials to tend to be uniform due to the application of the discharge plasma pulse currents and alternating electromagnetic fields on the blank and the comprehensive action of gas isostatic pressing, the ceramic material is uniformly and isotropously sintered in the microcosmic crystal lattice, the grain boundary and the dot matrix, so that the various performances of the sintered structural ceramic material are improved.

Owner:SUZHOU EVERBEST ENG CERAMICS

Method for producing lithium ion cells positive electrode material and equipment thereof

InactiveCN1610149AOvercomes the inherent disadvantages when used aloneUniform temperatureElectrode manufacturing processesLithium compoundsLithiumElectric arc furnace

The preparation process of positive pole material for lithium ion cell includes the following steps: setting the mixture of hydroxide, oxide or salt of lithium and hydroxide, oxide or salt of transition metal in certain ratio in crucible; setting the crucible in microwave oven to calcine the mixture; setting the crucible in electric furnace to sinter the calcined matter; cooling the crucible with sintered matter in cooling cavity; crushing and sieving the sintered matter to obtain the positive pole material product for lithium ion cell. The apparatus for preparing positive pole material for lithium ion cell, combined microwave-electric heating furnace, is also disclosed. The present invention is suitable for continuous large-scale production of positive pole material for lithium ion cell.

Owner:广州鸿森材料有限公司

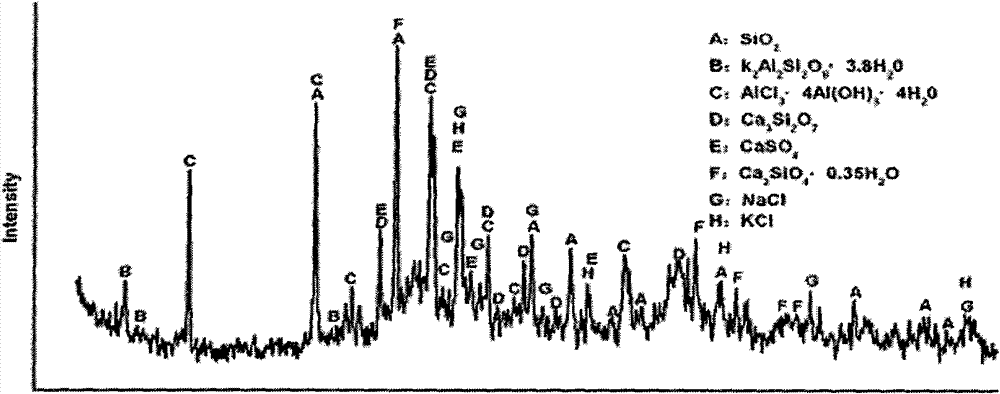

Method for preparing high-strengthalpha-semihydratetitanium gypsum with industrial wastedihydratetitanium gypsum

InactiveCN103964716APromote high-value and high-volume comprehensive utilizationSmall footprintGypsumMineralogy

The invention provides a method for preparing high-strengthalpha-semihydratetitanium gypsum with industrial wastedihydratetitanium gypsum. The method comprises the steps as follows: placing the industrial wastedihydratetitanium gypsum of titanium dioxideproduced with a sulfuric acid method in a drying oven to dry thedihydratetitanium gypsum to the constant weight, grinding the dihydratetitanium gypsum to be fine, and adding water to prepare the dihydratetitanium gypsum into slurry; adding a compound crystalloblastic agent to obtain a suspension liquid, adjusting the pH of the suspension liquid with an acid or an alkali, adding the suspension liquid into a reaction kettle, feeding an inert gas of certain pressure into thesuspension liquidwhile stirring, heating the reaction kettle to the temperature of 120-160 DEG C, and performing constant-temperature, constant-pressure and low-speed stirring to realize dehydration crystallization; turning on a vent valve to relieve the pressure to be within 0.1 MPa, continuing heating, keeping the temperature in the kettle to be in a range of 100-150 DEG C, after complete drying, taking out and grinding the material to be fine, mixing the material according to certain grading so as to obtain thehigh-strengthalpha-semihydratetitanium gypsum with the drycompressive strength higher than 60 MPa. According to the method, the industrial byproductdihydratetitanium gypsum is recycled, the method is simple in technology, low in cost and high in efficiency, and the alpha-semihydratetitanium gypsum is excellent in crystal appearance, short-hexagonal-prism-shaped, uniform in size, high in drycompressive strength and excellent in product quality.

Owner:HUBEI UNIV

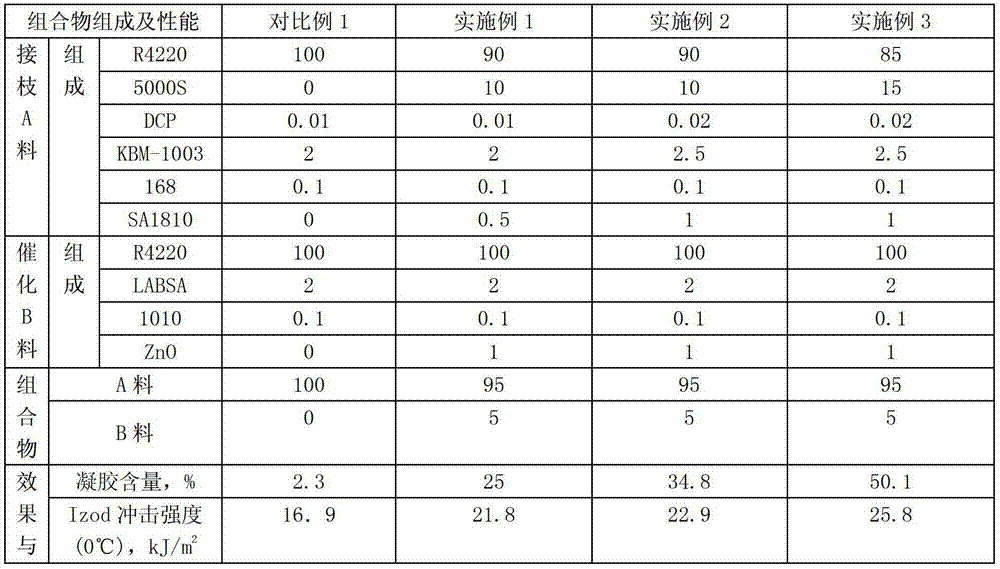

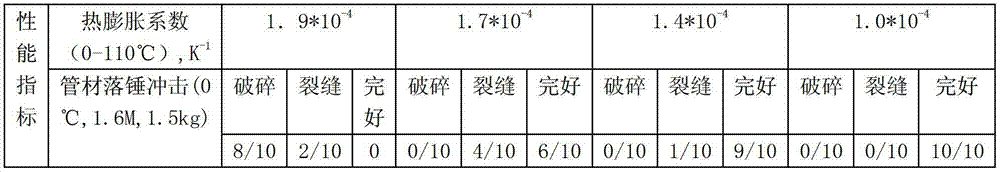

Special material for silicane grafted PPR (polypropylene random) pipe and preparation method thereof

The invention discloses a special material for a silicane grafted PPR (polypropylene random) pipe. The special material for the silicane grafted PPR pipe is formed by a material A and a material B in ratio in parts by weight of 90:10-95:5, wherein the material A comprises 80-95 parts of PPR, 5-20 parts of high-density polyethylene, 1-3 parts of unsaturated silicane, 0.01-0.03 part of initiator, 0.1-0.5 part of antioxidant and 0.1-2 parts of auxiliary crosslinking agent; and the material B comprises 100 parts of PPR, 1-3 parts of catalyst, 0.1-0.5 part of antioxidant and 1-5 parts of auxiliary catalyst. The preparation method comprises that the material A and the material B are respectively independently extruded and pelletized, then the material A and the material B are mixed to be uniform in proportion, and a pipe can be directly extruded. The special material disclosed by the invention is good in impact strength and creep resistance and can be widely applied to various pipeline products such as a hot and cold water pipe; and the preparation method is simple, and a long-time high temperature poaching process is not required, so that the preparation method disclosed by the invention is convenient for industrial production.

Owner:杭州恒标管业有限公司

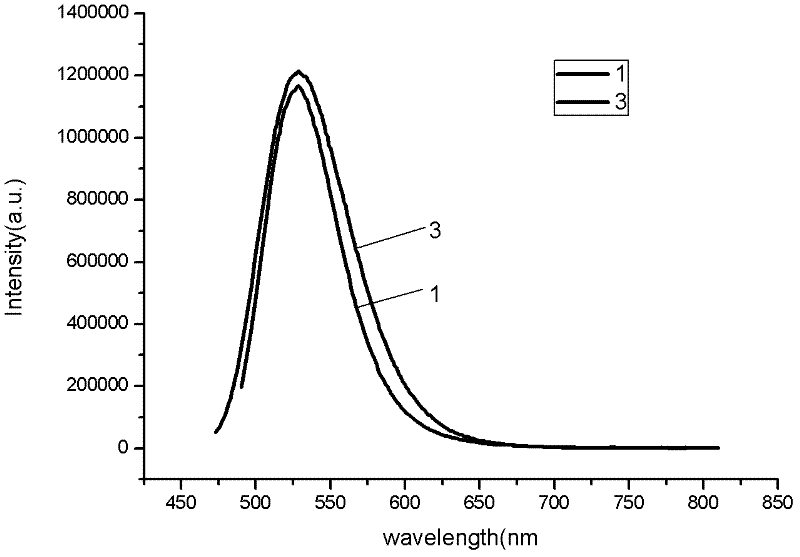

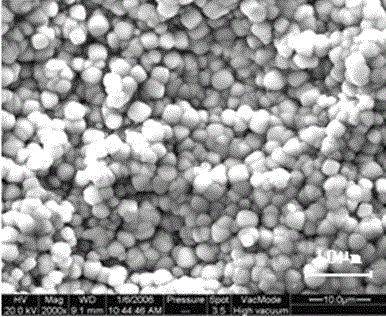

Method for preparing nanometer silicate fluorescent powder

InactiveCN102643642ALarge grainSimple structureLuminescent compositionsHYDROSOLParticle-size distribution

The invention discloses a method for preparing nanometer silicate fluorescent powder. A chemical general formula of the silicate fluorescent powder is BaxAySiO4: (2-x-y) Eu. Common inexpensive compounds are adopted as raw materials, the mixing of a precursor is carried out in solution when gel is prepared through a sol-gel method so as to be uniform in a short time, and nanoscale and even molecular-scale can be reached, so that the silicate fluorescent powder has better reactivity; two stages of sintering during sintering are carried out, so that oversize crystal particles produced in a high-temperature process are avoided; the microscopic structure and the macroscopic performance of the material can be improved; luminescent materials with uniform size distribution can be obtained; the sintering temperature is reduced by 300-500 DEG C compared with a high temperature solid state method; the product is fluffy and easy to smash; and a better luminescent effect can be obtained.

Owner:IRICO

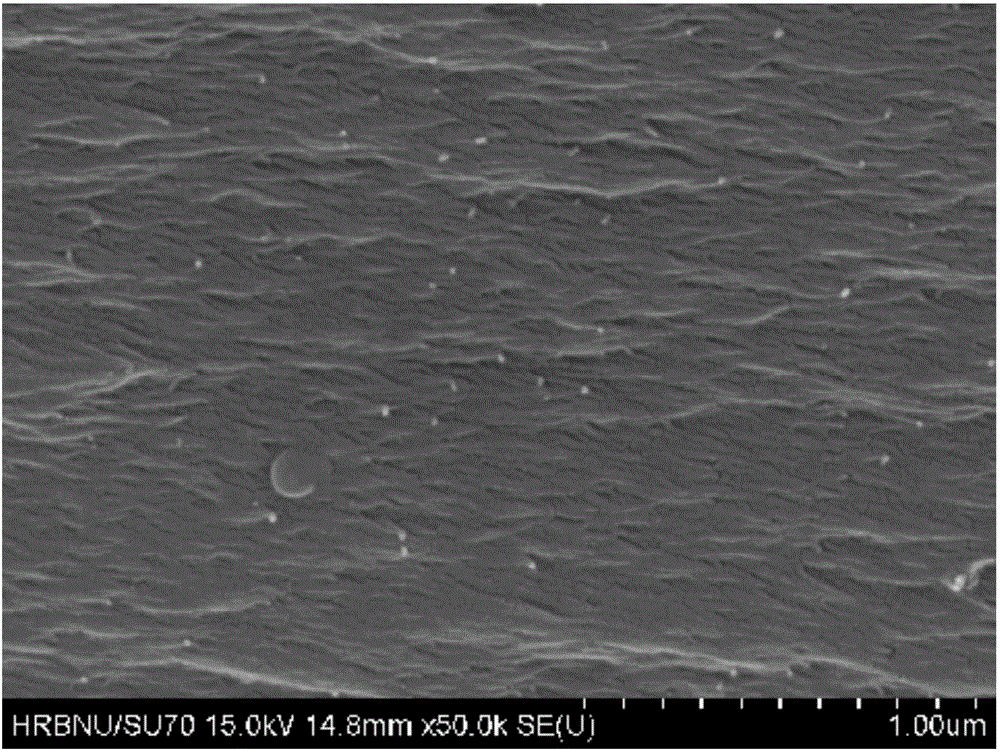

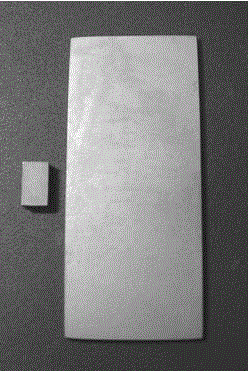

Preparation method of boron nitride and aluminum nitride co-doped high-heat-conduction and high-insulation polyimide composite thin film

ActiveCN106380844AImprove electrical insulation and mechanical propertiesHigh thermal conductivityHeat-exchange elementsInsulation resistanceBoron nitride

The invention provides a preparation method of a boron nitride and aluminum nitride co-doped high-heat-conduction and high-insulation polyimide composite thin film and relates to a preparation method of a composite thin film, aiming at solving the problems of an existing polyimide composite thin film that the heat conductivity, insulation property and mechanical properties are poor so that the application of the existing polyimide composite thin film in the field of electric insulation is limited. The preparation method comprises: 1, preparing ultrathin boron nitride powder; 2, preparing a viscous polyamic acid solution containing ultrathin-layer boron nitride and aluminum nitride; 3, preparing a composite thin film to obtain the boron nitride and aluminum nitride co-doped high-heat-conduction and high-insulation polyimide composite thin film. According to the boron nitride and aluminum nitride co-doped high-heat-conduction and high-insulation polyimide composite thin film prepared by the preparation method provided by the invention, the coefficient of heat conductivity is improved by 68 percent to 330 percent, the insulating resistance is improved by 0.8 to 4.1 times and the tensile strength is improved by 1 percent to 31 percent. The preparation method provided by the invention is suitable for preparing the boron nitride and aluminum nitride co-doped high-heat-conduction and high-insulation polyimide composite thin film.

Owner:大同共聚西安科技有限公司

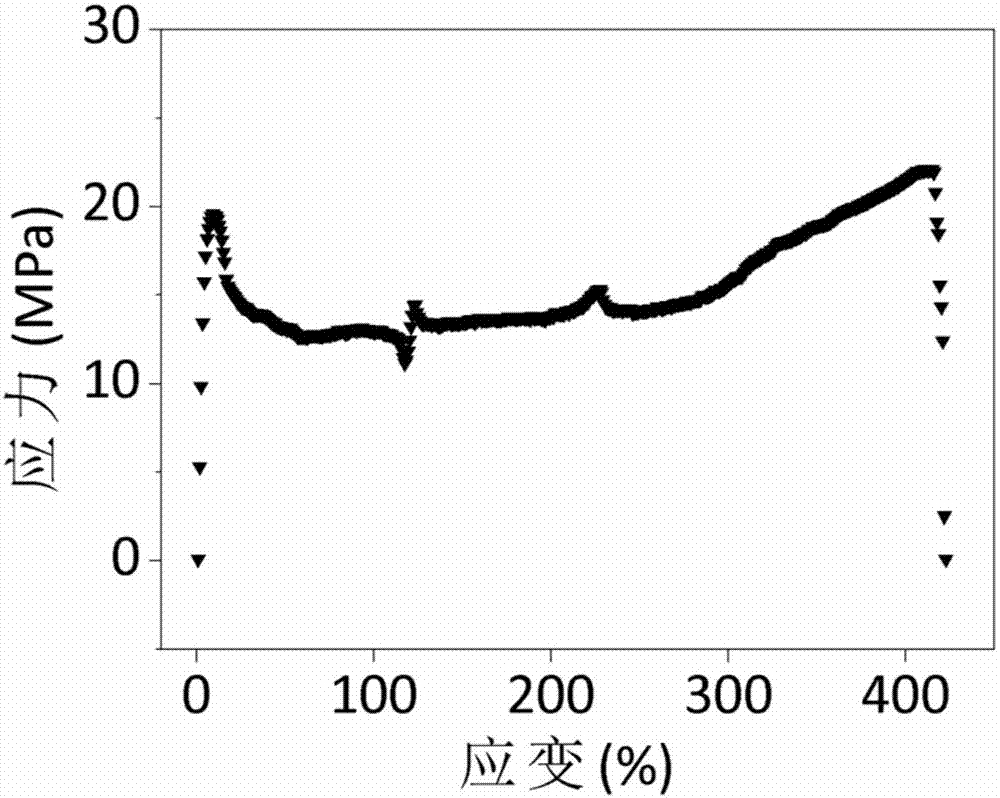

Waterborne/solvent-free mirror surface polyurethane synthesis leather preparation process

InactiveCN107160750AImprove macro performanceHigh surface hardnessSynthetic resin layered productsLaminationSurface layerThermoplastic polyurethane

The invention relates to a process for preparing water-based / solvent-free mirror-surface polyurethane synthetic leather. The steps are as follows: 1) immersing a non-woven fabric base cloth in an aqueous polyurethane solution, and the impregnation amount of the dipping solution is 70-75% of the non-woven fabric base cloth ; 2) Pull out the impregnated material to drain excess liquid, and then dry; 3) Evenly coat one layer of WPU surface layer on one side of the dried material; 4) Pass the WPU surface on the dried material Layer bonding TPU film, and heat lamination can be sterilized at high temperature. After sterilization, it is cooled with cold water in time and then vacuum-packed to make vacuum foie gras. The present invention not only solves the problems of easy fogging, poor flexibility, and intolerance to yellowing, but also improves the air permeability, mechanical properties and environmental protection performance of the product of the present invention.

Owner:安徽宝博新材料科技有限公司

Aluminum alloy capable of digesting high-hardness compounds and smelting method of aluminum alloy

The invention discloses an aluminum alloy capable of digesting high-hardness compounds and a smelting method of the aluminum alloy. The method comprises the following steps of: heating aluminum ingots or molten aluminum till complete melting; adding Si, Fe, Cu, Mn, Mg, Cr, Zn and Ti, and completely dissolving and melting the elements; preserving the heat at the temperature of between 700 and 1,000 DEG C after refining, and obtaining an alloy melt; performing degassing purification operation on the alloy melt by using nitrogen or inert gas or mixed gas of the nitrogen and the inert gas in a random ratio, and continuously introducing the gas till the reaction is finished; adding LaH3 powder into the alloy melt in a fluidized form together with the gas; stirring to make the LaH3 distributed uniformly in the alloy melt and fully reacted with the alloy melt; and standing, regulating the temperature to 680-730 DEG C, and discharging the molten alloy for casting. By the method, the defects of the properties of the conventional aluminum alloy can be overcome, the toughness, the forming property and the hardening capacity of the aluminum alloy are improved, and a high-end base material is provided for efficient deep processing.

Owner:GUIZHOU ALUMINUM MATERIALS ENG TECHRES CENT

A processing auxiliary agent having compatibility-enabling and coupling functions and a preparing method thereof

A processing auxiliary agent having compatibility-enabling and coupling functions and a preparing method thereof are provided. The processing auxiliary agent includes, by weight, 65-85 parts of polypropylene wax, 10-30 parts of a modified oligomer, 0-15 parts of an unsaturated functional monomer, 0-5 parts of vinyl silane and 0.5-2.5 parts of a free radical initiator. The processing auxiliary agent integrates compatibility-enabling and coupling functions, has obvious functions in the fields of plastic alloys, plastic filing, inorganic filler surface treatment, and the like, and can improve interfacial force between resin and resin as well as interfacial force between resin and a filler, thus improving appearance quality of a final product and improving macroscopic performance and processing performance of products.

Owner:ZHEJIANG KINLEAD PACKAGING MATERIAL

Surface treatment method for magnesium alloy

InactiveCN104561980AAddress different levels of hazardsNo pollution in the processMetallic material coating processesElectrical resistance and conductanceProduction line

The invention relates to a surface treatment method for magnesium alloy. The surface treatment method disclosed by the invention comprises the following steps: (1), polishing and feeding a magnesium alloy component; (2), carrying out pre-treatment, such as acid pickling, ultrasonic treatment, degreasing and activating; and (3), carrying out chemical film-forming treatment, ultrasonic oscillation cleaning and the like under the action of a magnetic field. According to the invention, a film is chemically formed by using a treatment solution mainly containing stannate under the action of the magnetic field, so that the surface treatment method is free from pollution and environment-friendly; the treatment solution can be repetitively used; therefore, the resource is saved; the production cost is reduced; the process is simple; an automatic production line is easily formed; the adhesive force and the anti-corrosion property of a chemical conversion film and the macro-properties of parts formed under the action of the magnetic field are good; the properties are better; a stannate film layer is thinner; the average resistance is less than 0.5 omega; and the surface treatment method for magnesium alloy disclosed by the invention has good electrical conductivity and electromagnetic shielding effect, and is particularly applied to surface protection of magnesium alloy electronic products.

Owner:NANCHANG UNIV

Bull-horn-imitation car door anti-collision beam based on negative poisson ratio structure and optimization method thereof

PendingCN107415654AGuaranteed stiffnessGuaranteed toughnessGeometric CADDesign optimisation/simulationEngineeringCollision resistance

The invention discloses a bull-horn-imitation car door anti-collision beam based on a negative poisson ratio structure and an optimization method thereof. The bull-horn-imitation car door anti-collision beam takes a bull horn as a bionic object and comprises a bull-horn-imitation shell, a bone core, a front mounting bracket and a rear mounting bracket. The bull-horn-imitation shell is a hollow round tube; the bone core is formed by two-dimensional four-angle star-shaped negative poisson ratio single cell arrays; the bone core and the inner wall of the bull-horn-imitation shell are flexibly connected; and the two ends of the bull-horn-imitation shell are rigidly connected with an arced pipeline of the front mounting bracket and an arced pipeline of the rear mounting bracket correspondingly. In optimizing, an experimental optimization method (DOE), simulation calculation, establishment of an agent model and multi-objective optimization are sequentially conducted, all characteristic parameter values of the bull-horn-imitation car door anti-collision beam structure are determined, the collision prevention performance and collision resistance are improved, and the lightweight effect is achieved while injury to persons in a car is reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

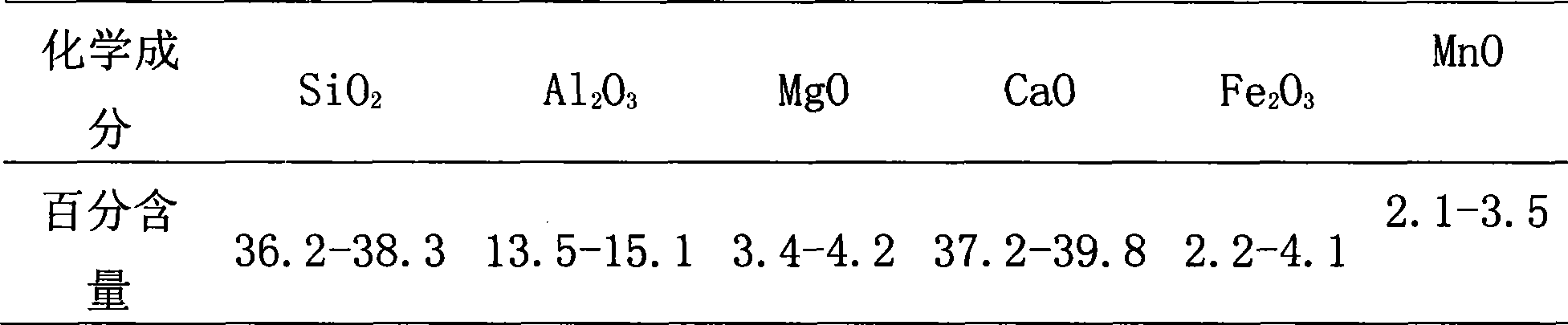

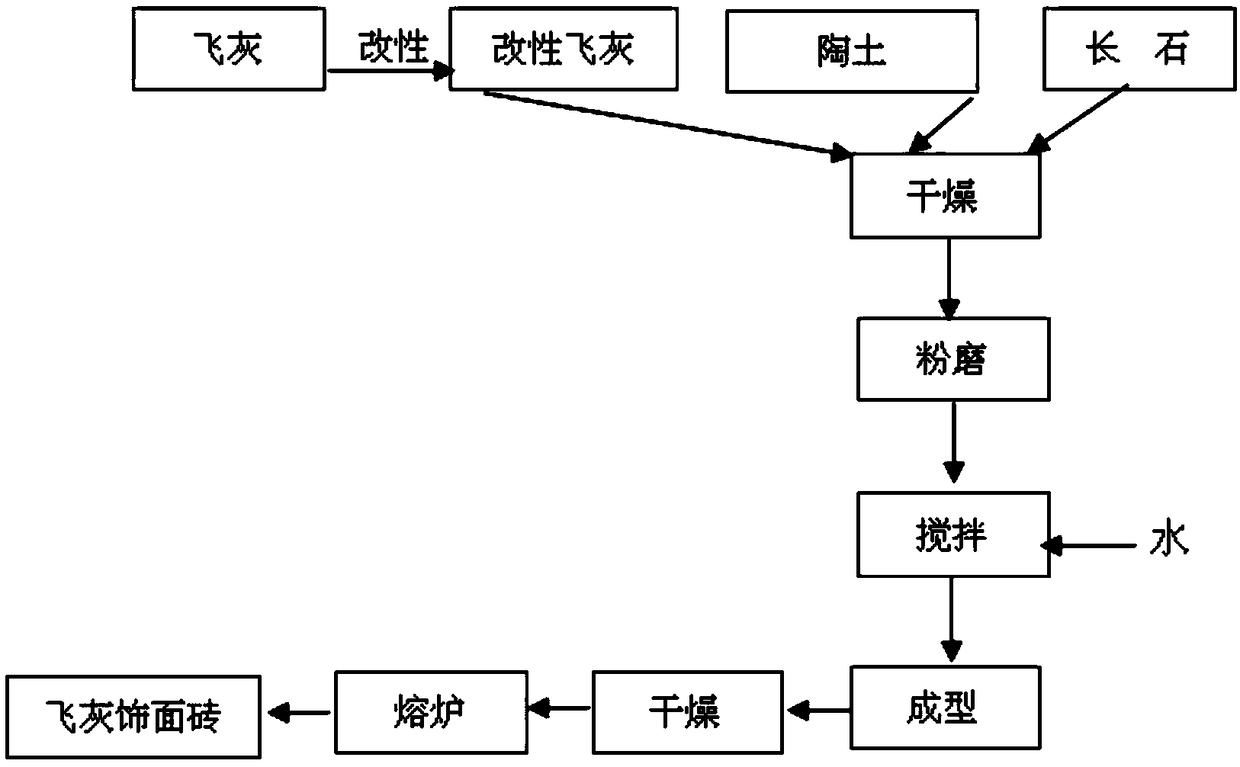

Preparation method for preparing facing bricks by modifying household waste incinerated fly ash

InactiveCN109437849ACost savingsSave land resourcesAuxillary shaping apparatusCeramic materials productionBrickLand resources

The invention relates to a preparation method for preparing facing bricks by modifying household waste incinerated fly ash. The preparation method comprises the following steps: taking a NaOH solutionas a modifier, mixing and stirring with fly ash, and washing with water, performing suction filtration and drying to obtain modified fly ash; mixing the modified fly ash, china clay and feldspar, performing aeration-drying in a drying chamber for 36-48 hours, grinding, adding the material obtained by grinding into a stirrer, adding water to stir, standing at a room temperature for 12-24 hours soas to age, and screening the aged material by a screen of 50-100 meshes; and performing compression molding on the aged and screened material on a brick making machine, drying the molded green body ina dry kiln for 12+ / -2 hours, and calcining the dried green body in a smelting furnace, thereby obtaining the product. According to the method disclosed by the invention, potential secondary pollutionof the fly ash in the landfill process can be avoided, potential hazards to the society are reduced, and lots of fly ash safety landfill disposal cost and land resources can be saved.

Owner:SHANGHAI INST OF TECH

High-strength aluminum alloy added with AlCrN and RbH and preparation method of aluminum alloy

The invention discloses a high-strength aluminum alloy added with AlCrN and RbH and a preparation method of the aluminum alloy. The method comprises the following steps of: heating aluminum ingots or molten aluminum till complete melting; adding Si, Fe, Cu, Mn, Mg, Zn and Ti, and completely dissolving and melting the elements; preserving the heat at the temperature of between 700 and 1,000 DEG C after refining, and obtaining an alloy melt; performing degassing purification operation on the alloy melt by using nitrogen or inert gas or mixed gas of the nitrogen and the inert gas in a random ratio, and continuously introducing the gas till the reaction is finished; adding AlCrN and RbH powder into the alloy melt in a fluidized form together with the gas; stirring to make the AlCrN and the RbH distributed uniformly in the alloy melt and fully reacted with the alloy melt; and standing, regulating the temperature to 680-730 DEG C, and discharging the molten alloy for casting. By the method,the defects of the properties of the conventional aluminum alloy can be overcome, the toughness, the forming property and the hardening capacity of the aluminum alloy are improved, and a high-end base material is provided for efficient deep processing.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Lubricant for carbon fiber sizing agent and preparation method

InactiveCN105803781AImprove mechanical propertiesImprove interface performanceCarbon fibresAdditivesFiberCentrifugation

The invention relates to a lubricant for a carbon fiber sizing agent and a preparation method. The lubricant is prepared from polyacrylic acid modified nano lamella tungsten disulfide dispersion, a dispersing agent, silicon oil and higher aliphatic acid; the polyacrylic acid modified nano lamella tungsten disulfide dispersion is a dispersion obtained by modifying a nano lamella tungsten disulfide dispersion through polyacrylic acid. The preparation method comprises: firstly, preparing an aqueous solution of isopropyl alcohol, and then adding tungsten disulfide of which a microcrystalline size is smaller than 100 micrometers so as to form the dispersion; 2, after carrying out ultrasonic processing and standing, carrying out centrifugation to obtain a supernatant dispersion; 3, carrying out polyacrylic acid modification processing to obtain the polyacrylic acid modified nano lamella tungsten disulfide dispersion, and then mixing the polyacrylic acid modified nano lamella tungsten disulfide dispersion with the dispersing agent, the silicon oil and the higher aliphatic acid according to a matching principle. By the nano lamella tungsten disulfide dispersion prepared by using the polyacrylic acid to carry out modification, the lubricant can be used for preparing the sizing agent with special purposes and partially optimizes interface performance and macroscopic properties of fibers and a composite material of the fibers.

Owner:FUDAN UNIV

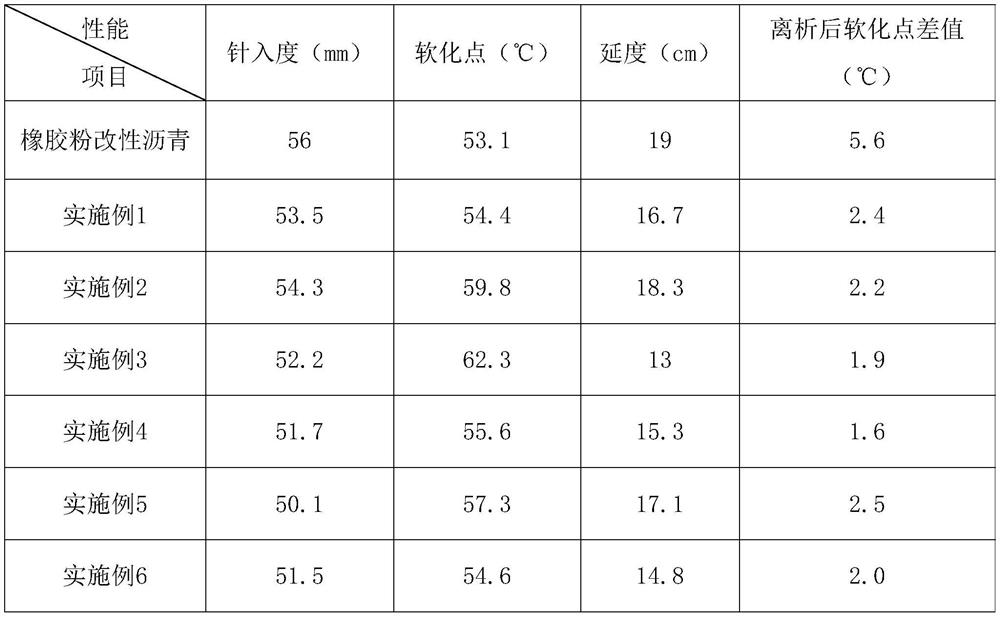

Novel rubber powder composite modified asphalt and preparation method thereof

InactiveCN111793368AChange structural propertiesImprove macro performanceBuilding insulationsAsphaltWaste tires

The invention provides novel rubber powder composite modified asphalt and a preparation method thereof. The novel rubber powder composite modified asphalt is prepared from the following components bymass percentage: 12%-18% of waste tire rubber powder, 2%-5% of nano-material modifier and 80%-86% of matrix asphalt; by compounding the nano material with the rubber powder modified asphalt, the structural characteristics of the raw materials can be changed on the nanoscale, so that the macroscopic properties of the material are greatly optimized, the high-temperature rutting resistance of the rubber powder modified asphalt can be improved, and the storage stability of the rubber powder modified asphalt is improved.

Owner:CHANGAN UNIV

Fly ash baked brick prepared by washed incineration fly ash of house refuse and preparation method thereof

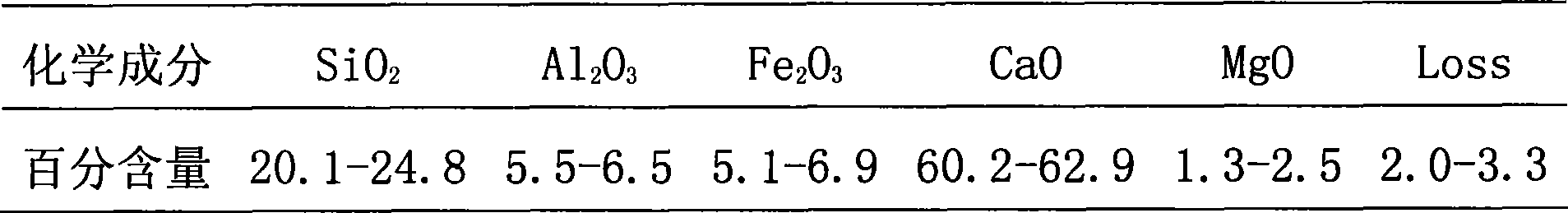

InactiveCN101905967BImprove macro performanceTo achieve the purpose of harmless treatmentSolid waste disposalCeramic materials productionBrickFly ash

The invention discloses a fly ash baked brick prepared by washed incineration fly ash of house refuse and a preparation method thereof. The fly ash baked brick consists of 25-35% of washed incineration fly ash of house refuse, 45-70% of clay and 5-20% of feldspar in percentage by weigh. The preparation method comprises seven steps of washing treatment of incineration fly ash of house refuse, pretreatment before crushing materials, material crushing, aging of raw materials, forming of raw materials, green body drying and sintering to form brick. Finally, the fly ash baked brick prepared by washed incineration fly ash of house refuse is obtained. In the invention, the washed incineration fly ash of house refuse is used to prepare the baked brick; by calcining, dioxin in the incineration flyash can be destroyed thoroughly and heavy metals in the fly ash can be cured, thereby achieving the purpose of innocent treatment of incineration fly ash of house refuse and turning the waste into valuable. The manufacturing process of the fly ash baked brick is simple and the fly ash baked brick has good macroscopic properties and can be used for paving roads.

Owner:SHANGHAI INST OF TECH

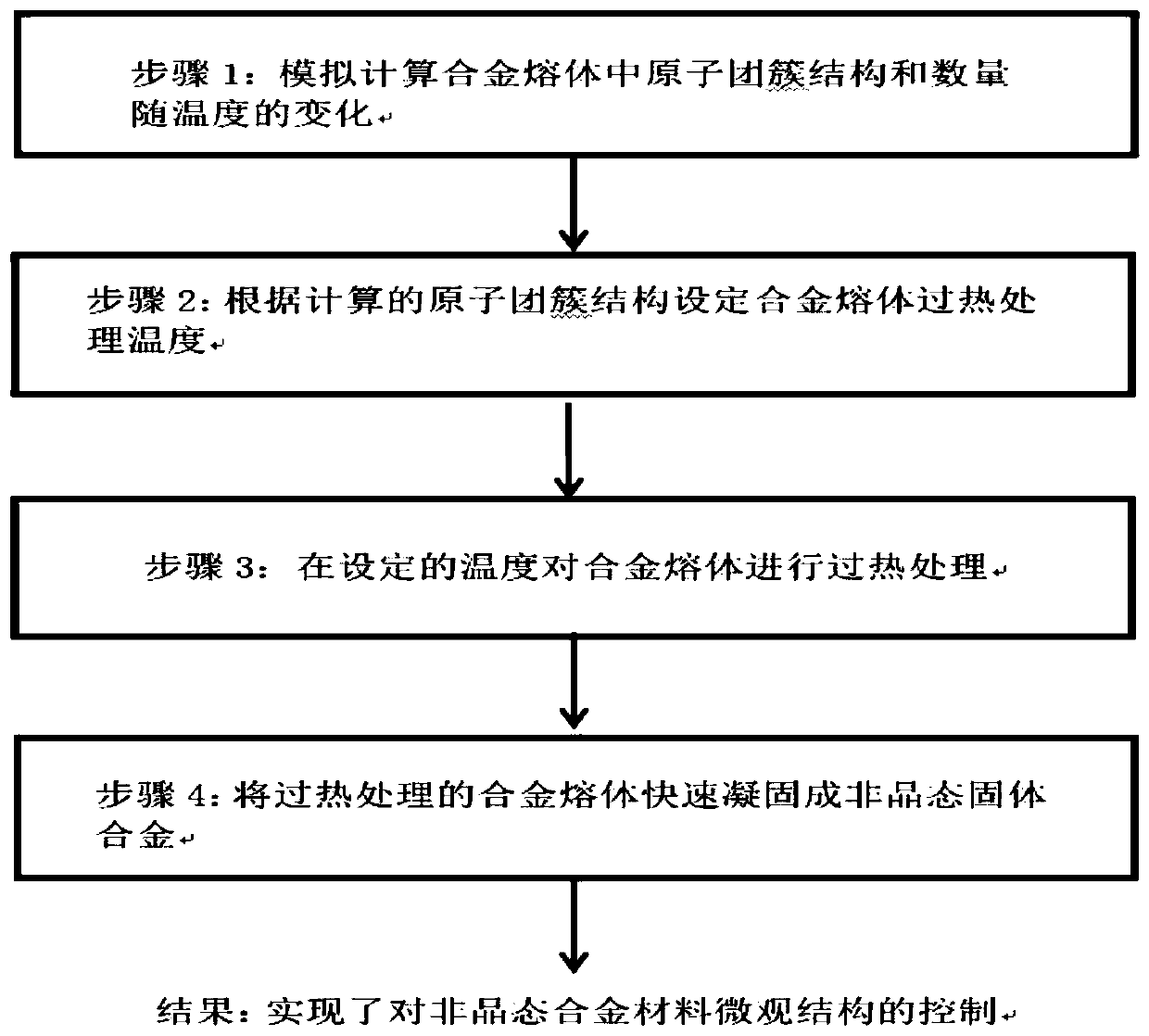

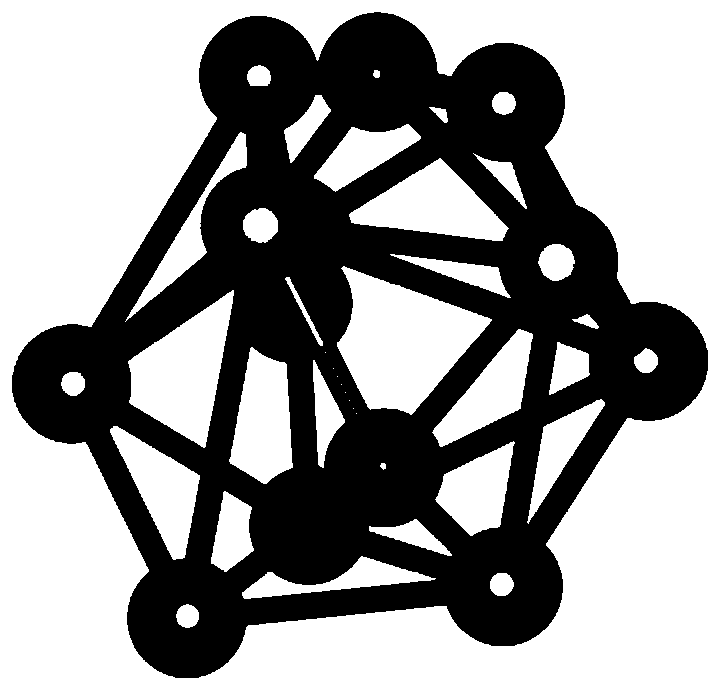

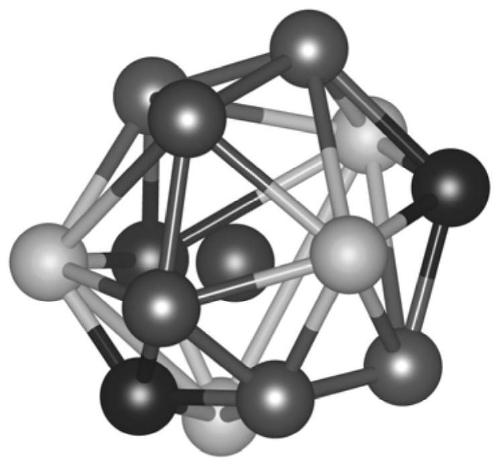

Method for adjusting microstructure of amorphous solid alloy by utilizing configuration and number of melt atomic clusters

InactiveCN109778084AImprove macro performanceStrong designabilityMolecular entity identificationComputational theoretical chemistryAtomic clusterAlloy

The invention discloses a method for adjusting the microstructure of amorphous solid alloy by utilizing the configuration and number of melt atomic clusters. The method comprises the following steps:carrying out analog calculation on the configuration and number of the atomic clusters in alloy melt, to be specific, according to the components of to-be-prepared alloy, calculating the configurationand number of atomic clusters in the alloy melt at different temperatures, and obtaining a calculating result that the configuration and number of the atomic clusters vary with the temperatures; carrying out superheat treatment on the alloy melt, to be specific, choosing required configuration and number of the atom clusters according to the calculating result, determining that the temperature corresponding to the chosen configuration and number of the atomic clusters is the superheat treatment temperature of the alloy melt, and carrying out heat preservation on the alloy melt at the superheat treatment temperature so as to obtain the superheat-treated alloy melt; and carrying out rapid solidification, to be specific, carrying out rapid solidification on the superheat-treated alloy melt to obtain the amorphous solid alloy. The invention creates a novel scheme for the controllable preparation of the microstructure of the amorphous solid alloy.

Owner:JIANGSU JICUI ANTAI CHUANGMING ADVANCED ENERGY MATERIALS RES INST CO LTD

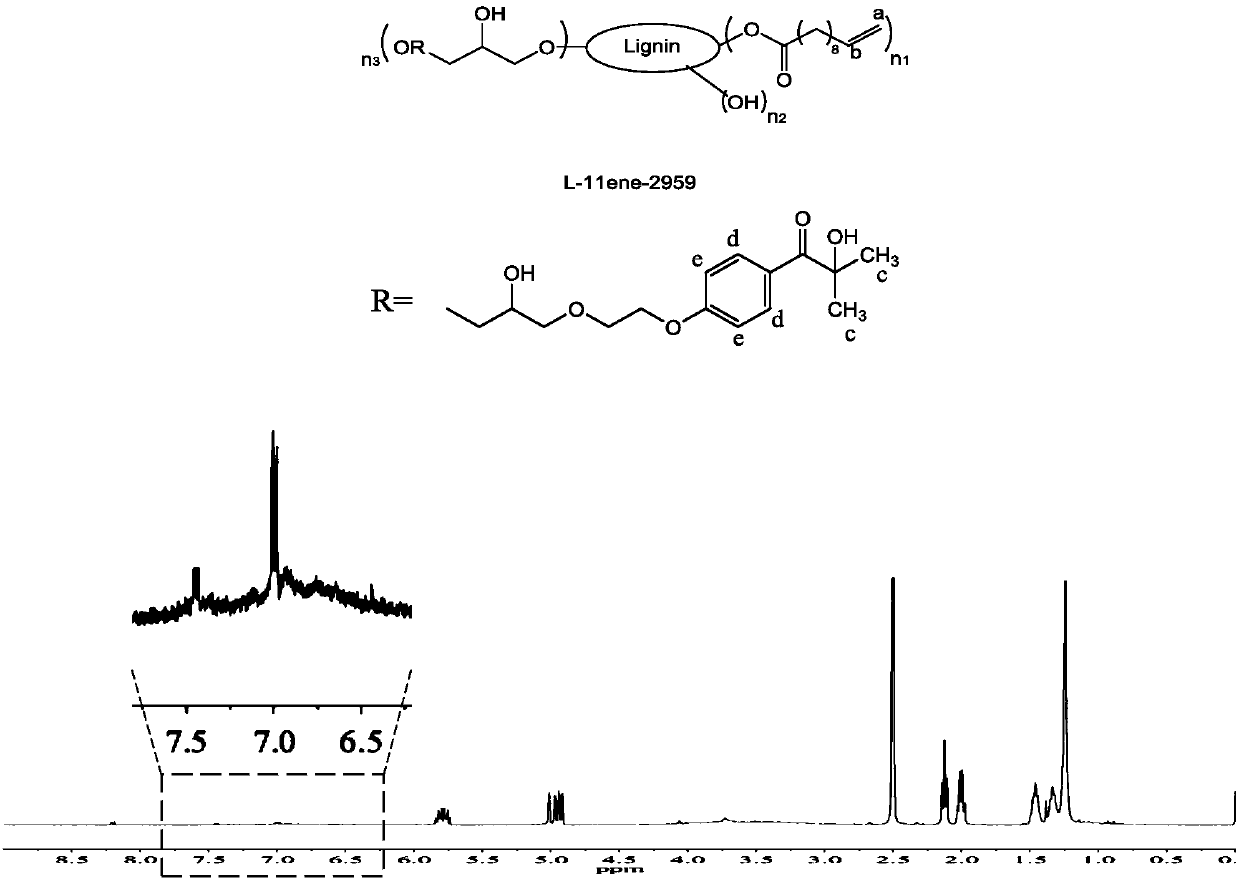

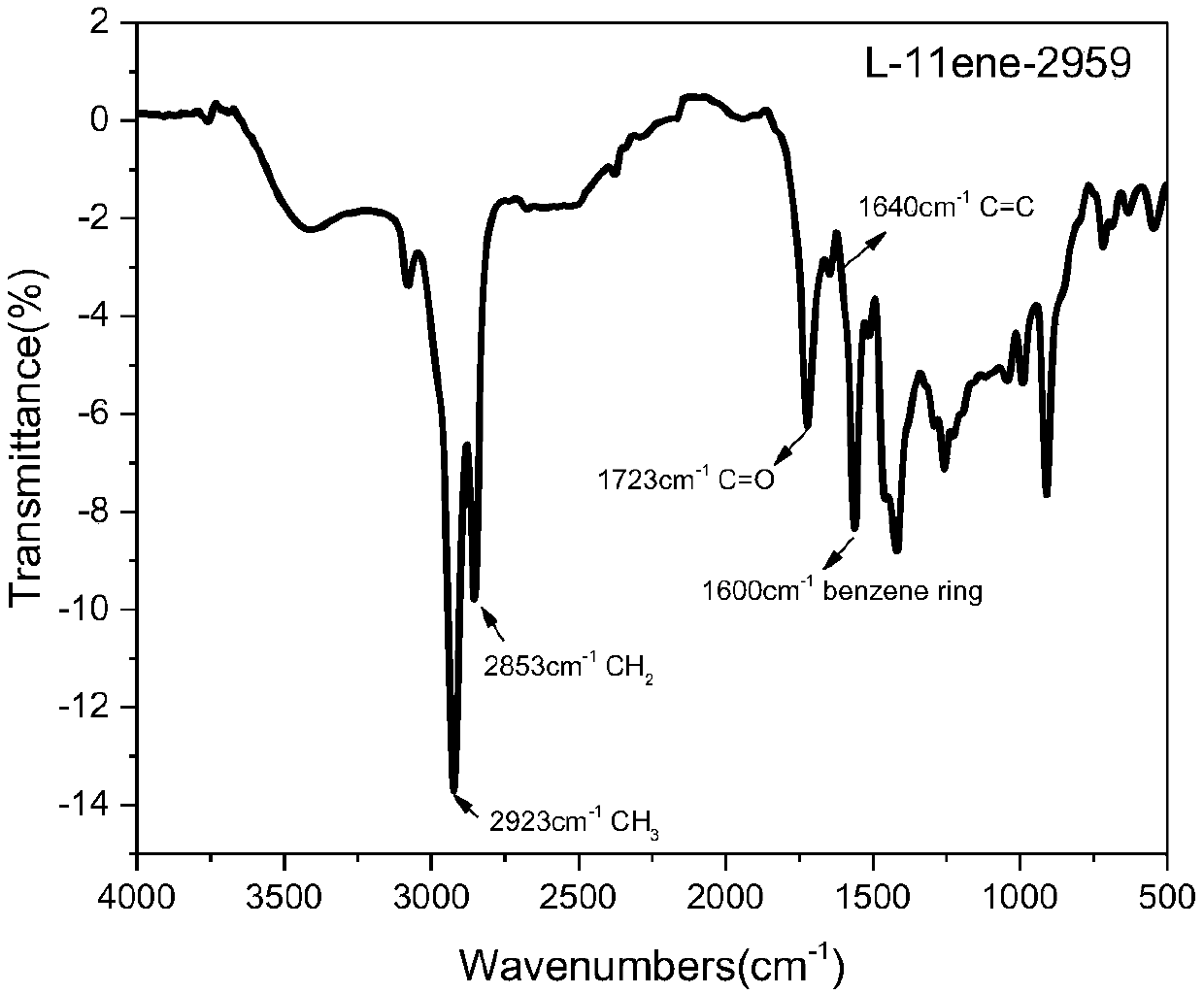

Polymerizable lignin-based macromolecular photoinitiator, preparation method and applications thereof

ActiveCN110857336AImprove performanceHigh photoinitiative activityAdditive manufacturing apparatusPolyurea/polyurethane coatingsEpoxyAlkane

The invention discloses a polymerizable lignin-based macromolecular photoinitiator, a preparation method and applications thereof, wherein the structure formula of the polymerizable lignin-based macromolecular photoinitiator is represented by the following formula I, wherein the group defined in the specification is a terminal-hydroxyl-free molecular skeleton of lignin, M1 is a terminal-hydroxyl-free and halogen-atom-free molecular skeleton after epoxy haloalkane is subjected to an epoxy ring-opening reaction, M2 is an acyl-chloride-free and double-bond-free molecular skeleton of a solubilizing compound, M3 is a hydroxyl-free molecular skeleton of a cracking type photoinitiator, n1 and n3 are natural numbers of greater than or equal to 1, n2 is an integer of greater than or equal to 0, andthe sum of n1, n2 and n3 is the number of the terminal hydroxyl groups of lignin. The invention also discloses a preparation method and applications of the photoinitiator. The photoinitiator disclosed by the invention has characteristics of good ester solubility, good polymerizability, high photo-initiation activity, good thermal stability, good storage performance, low viscosity, low mobility, low toxicity and no volatilization.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

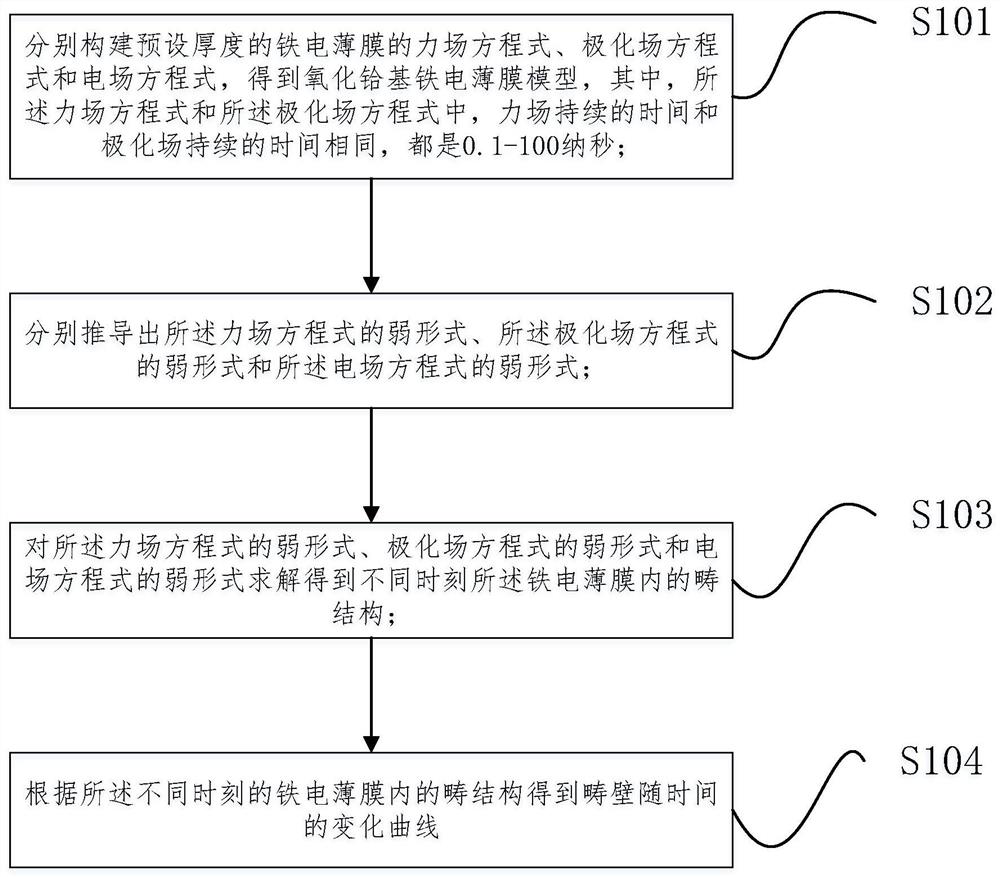

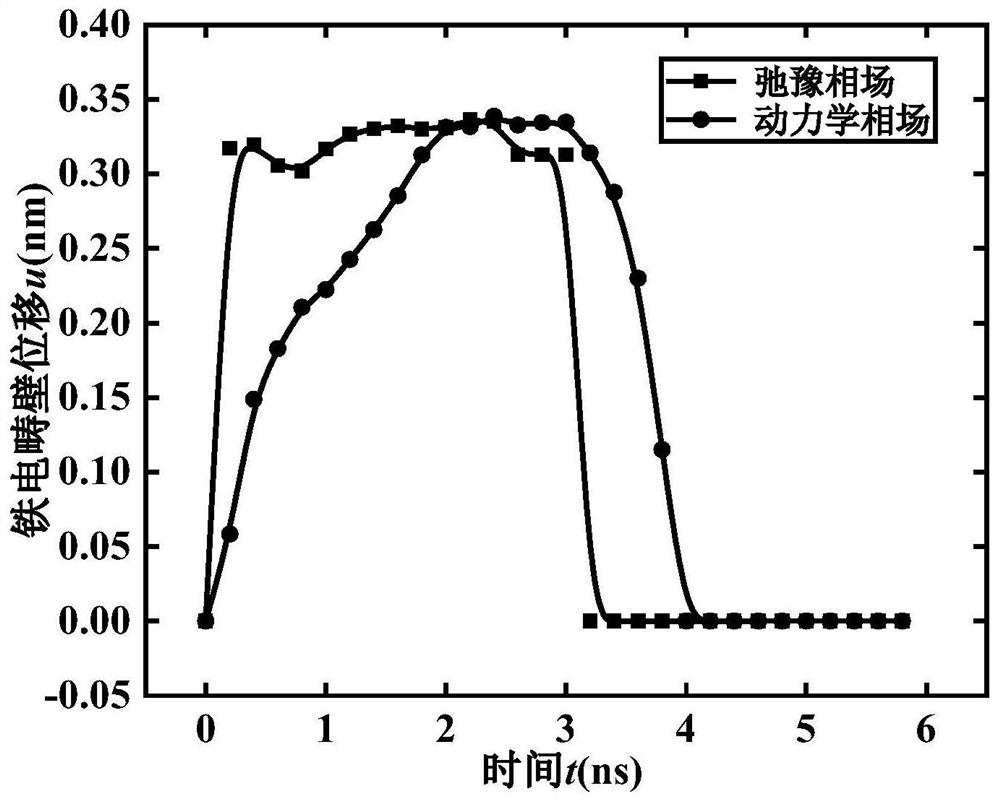

Method for analyzing domain and domain wall movement of hafnium oxide-based ferroelectric film under ultrafast electric pulse

ActiveCN112307661AImprove macro performanceDesign optimisation/simulationSpecial data processing applicationsThin membraneElectric field

The invention relates to a method for analyzing domain and domain wall movement of a hafnium oxide-based ferroelectric film under ultrafast electric pulse, which comprises the following steps of: respectively constructing a force field equation, a polarization field equation and an electric field equation of the hafnium oxide-based ferroelectric film with preset thickness to obtain a hafnium oxide-based ferroelectric film model, wherein in the force field equation and the polarization field equation, the duration time of the force field and the duration time of the polarization field are the same and are both 0.1-100 nanoseconds; respectively deducing a weak form of the output field equation, a weak form of the polarization field equation and a weak form of the electric field equation; solving the weak form of the force field equation, the weak form of the polarization field equation and the weak form of the electric field equation to obtain domain structures in the ferroelectric filmat different moments; and according to the domain structures in the ferroelectric film at different moments, obtaining a change curve of the domain wall along with time. The correlation between the ultrafast electric pulse amplitude and duration and the hafnium oxide-based ferroelectric film retention performance and wake up effect is obtained through analysis, and guidance is provided for optimization of the macroscopic performance of the hafnium oxide-based ferroelectric film.

Owner:XIANGTAN UNIV

Calcium-magnesium-based composite material for dewatering and curing dredged sludge, and preparation method and application of composite material

InactiveCN110218073ASpeed up water evaporationPromote water conversionSoil preservationMetakaolinSuperabsorbent polymer

The invention provides a calcium-magnesium-based composite material for dewatering and curing dredged sludge, and a preparation method and application of the composite material, and can effectively solve the problems that dredged sludge is high in water content, low in bearing capacity, low in compression resistance and shear strength, and the like, and the sludge has good physical and mechanicalproperties after treatment. The calcium-magnesium-based composite material for dewatering and curing dredged sludge comprises the following components based on dry powder: 0.25-1 wt% of a resin superabsorbent polymer (SAP), 6-12 wt% of cement, 6-15 wt% of dead burned MgO, 8-22 wt% of magnesium phosphate, 6-18 wt% of metakaolin, 6-15 wt% of active MgO, 10-25 wt% of magnesium chloride, 2-4 wt% of quicklime, 3-8 wt% of sodium silicate, 3-6 wt% of sodium hydroxide, 15-40 wt% of slag powder and 10-30 wt% of fly ash.

Owner:WUHAN UNIV

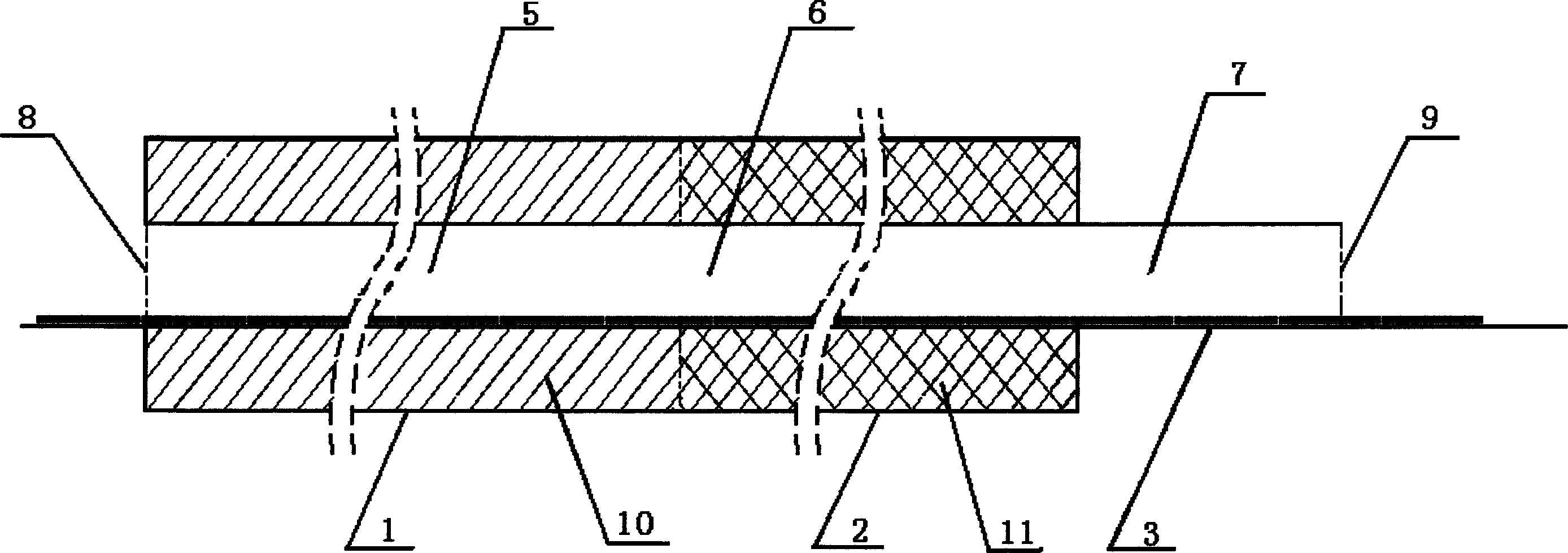

Textured cobalt ferrite film material and preparation method thereof

InactiveCN103183505BEasy accessImprove macro performanceInorganic material magnetismSlurryFilm material

The invention relates to a method for preparing a textured cobalt ferrite CoxFe3-xO4 film material. The method comprises the following steps: taking rod-shaped alfa-FeOOH particles as the templated grains, adding a casting precursor slurry prepared by taking CoO and Fe2O3 as the raw materials, carrying out stirring and debubbling to obtain a CoxFe3-xO4 mixed casting slurry, preparing a CoxFe3-xO4 blank body by a tape casting, and then carrying out drying, lamination, tabletting, binder removal and sintering to obtain the textured cobalt ferrite CoxFe3-xO4 film after shaping. X is larger than or equal to 0.5 and is less than or equal to 1, and the thickness ranges from 50 mum to 5 mm. The macroscopic properties of the ceramic material are greatly enhanced, the process is simple, and the raw materials are easily obtained.

Owner:JIANGSU UNIV OF SCI & TECH

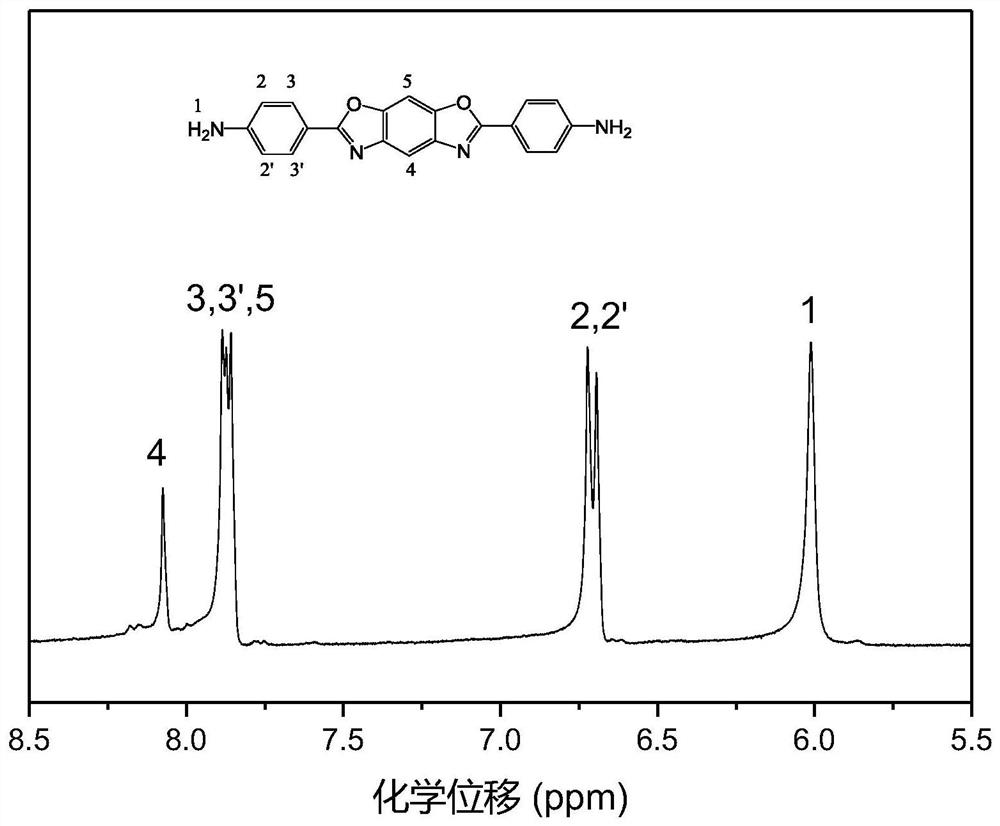

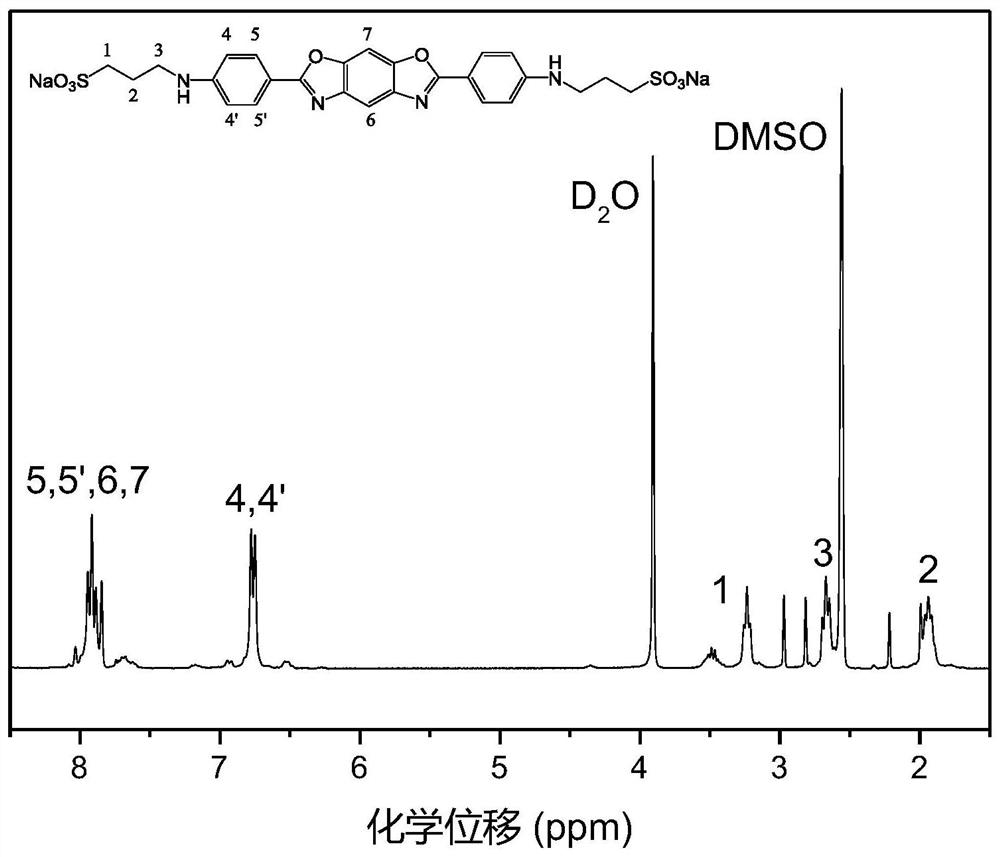

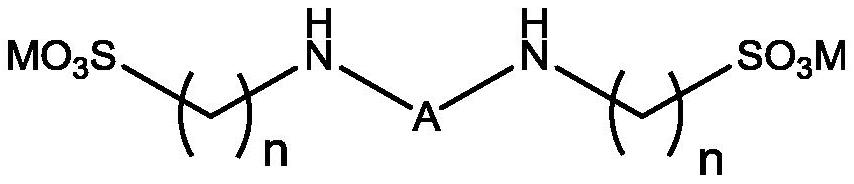

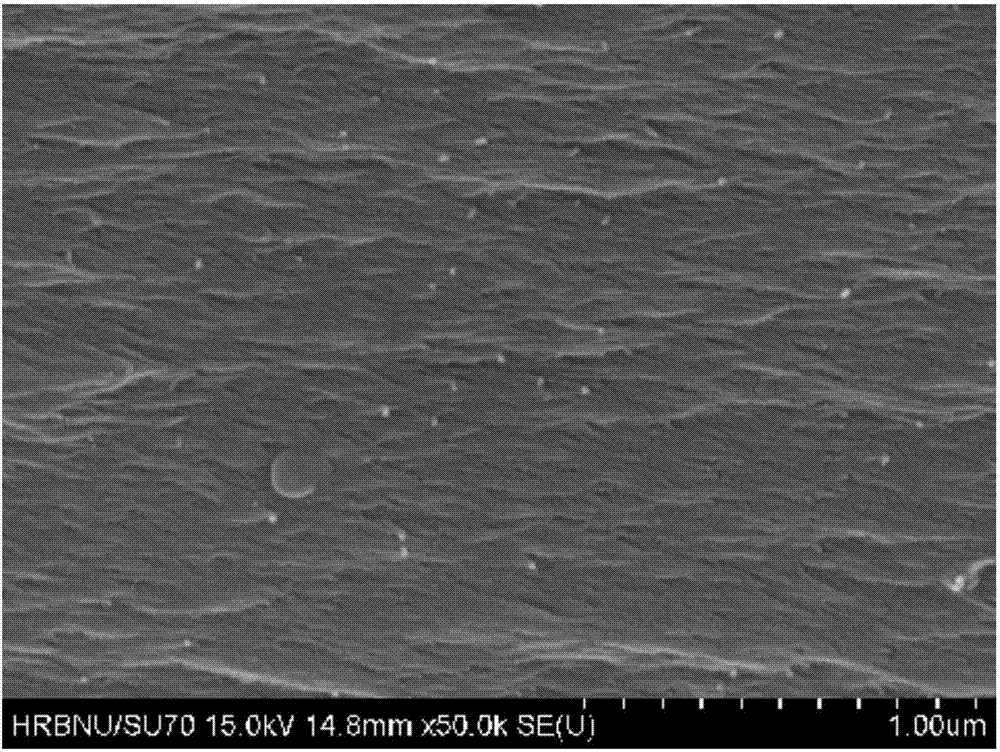

Benzoxazole ionic compound, PBO fiber emulsion sizing agent containing benzoxazole ionic compound and preparation method of PBO fiber emulsion sizing agent

ActiveCN111825696ANovel structureGood compatibilityOrganic chemistryFibre typesBenzoxazoleOrganic solvent

The invention discloses a benzoxazole ionic compound shown as a formula X, a sizing agent containing the compound, and a preparation method and application of the sizing agent. The benzoxazole ionic compound shown in the formula X is similar to the PBO fiber in chemical structure, the compatibility of the sizing agent and the PBO fiber can be improved, and the preparation process is simple and easy to operate. According to the sizing agent, the problems that an existing sizing agent is poor in compatibility with the PBO fiber, a large number of flammable and combustible organic solvents need to be used in the sizing agent, and nano reinforcements in the sizing agent are difficult to effectively cover the surfaces of the fibers are solved. The sizing agent takes water as a solvent, is greenand efficient, is simple and environment-friendly to prepare, and not only can keep the original tensile strength of PBO fibers, but also can remarkably improve the IFSS of the composite material.

Owner:INST OF CHEM CHINESE ACAD OF SCI

A preparation method of boron nitride and aluminum nitride co-doped polyimide composite film with high thermal conductivity and high insulation

ActiveCN106380844BImprove insulation performanceImprove mechanical propertiesHeat-exchange elementsComposite filmBoron nitride

The invention provides a preparation method of a boron nitride and aluminum nitride co-doped high-heat-conduction and high-insulation polyimide composite thin film and relates to a preparation method of a composite thin film, aiming at solving the problems of an existing polyimide composite thin film that the heat conductivity, insulation property and mechanical properties are poor so that the application of the existing polyimide composite thin film in the field of electric insulation is limited. The preparation method comprises: 1, preparing ultrathin boron nitride powder; 2, preparing a viscous polyamic acid solution containing ultrathin-layer boron nitride and aluminum nitride; 3, preparing a composite thin film to obtain the boron nitride and aluminum nitride co-doped high-heat-conduction and high-insulation polyimide composite thin film. According to the boron nitride and aluminum nitride co-doped high-heat-conduction and high-insulation polyimide composite thin film prepared by the preparation method provided by the invention, the coefficient of heat conductivity is improved by 68 percent to 330 percent, the insulating resistance is improved by 0.8 to 4.1 times and the tensile strength is improved by 1 percent to 31 percent. The preparation method provided by the invention is suitable for preparing the boron nitride and aluminum nitride co-doped high-heat-conduction and high-insulation polyimide composite thin film.

Owner:大同共聚西安科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com