Surface treatment method for magnesium alloy

A surface treatment, magnesium alloy technology, applied in the direction of metal material coating process, etc., can solve the problems of poor electromagnetic shielding effect, corrosion resistance, low adhesion, not suitable for surface protection of magnesium alloy electronic products, etc., and the production time is short , good electrical conductivity, meet the effect of environmental protection and sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

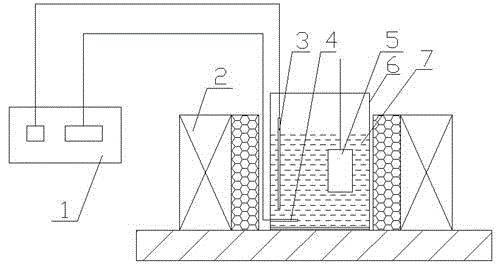

Method used

Image

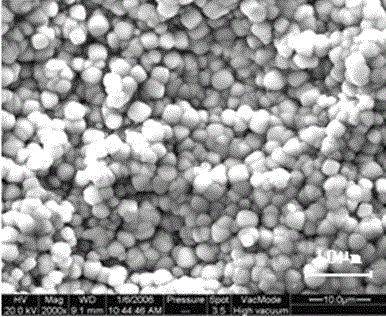

Examples

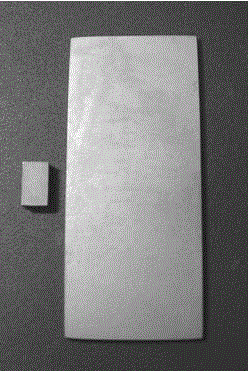

Embodiment 1

[0030] (1) Grind and load the AZ91D magnesium alloy chain tensioning mechanism.

[0031] (2) Pretreatment process: immerse the polished AZ91D magnesium alloy chain tensioning mechanism in a pickling tank filled with a phosphoric acid solution with a concentration of 85%, ultrasonically treat it for 2.5 minutes at room temperature, and then enter the first distilled water washing tank , ultrasonic treatment at room temperature for 30 seconds, take it out and dry it with hot air; then immerse it in a degreasing tank filled with sodium hydroxide 5g / L, trisodium phosphate 40g / L, sodium carbonate 25g / L, heat to 58°C, and ultrasonically treat for 8 Minutes later, enter the second distilled water washing tank, ultrasonic treatment at room temperature for 20 seconds, take it out and dry it with hot air; after that, immerse it in an activation tank with a concentration of 5% hydrofluoric acid, and conduct ultrasonic treatment at room temperature for 60 seconds. Then immerse in the thir...

Embodiment 2

[0034] (1) Grind and load the magnesium alloy fuel tank.

[0035] (2) Pretreatment process: immerse the polished magnesium alloy fuel tank in a pickling tank filled with a phosphoric acid solution with a concentration of 85%, ultrasonically treat it at room temperature for 0.5 minutes, then enter the first distilled water washing tank, and ultrasonically treat it at room temperature Treat for 50 seconds, take it out and dry it with hot air; then immerse it in a degreasing tank filled with sodium hydroxide 30g / L, trisodium phosphate 10g / L, sodium carbonate 12g / L, heat to 68°C, ultrasonic treatment for 15 minutes, enter In the second distilled water washing tank, ultrasonic treatment at room temperature for 50 seconds, take it out and dry it with hot air; after that, immerse it in the activation tank with 5% hydrofluoric acid, ultrasonic treatment at room temperature for 20 seconds, and then immerse in the third Distilled water washing tank, ultrasonic cleaning at room temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com