Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1364 results about "Chemical conversion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

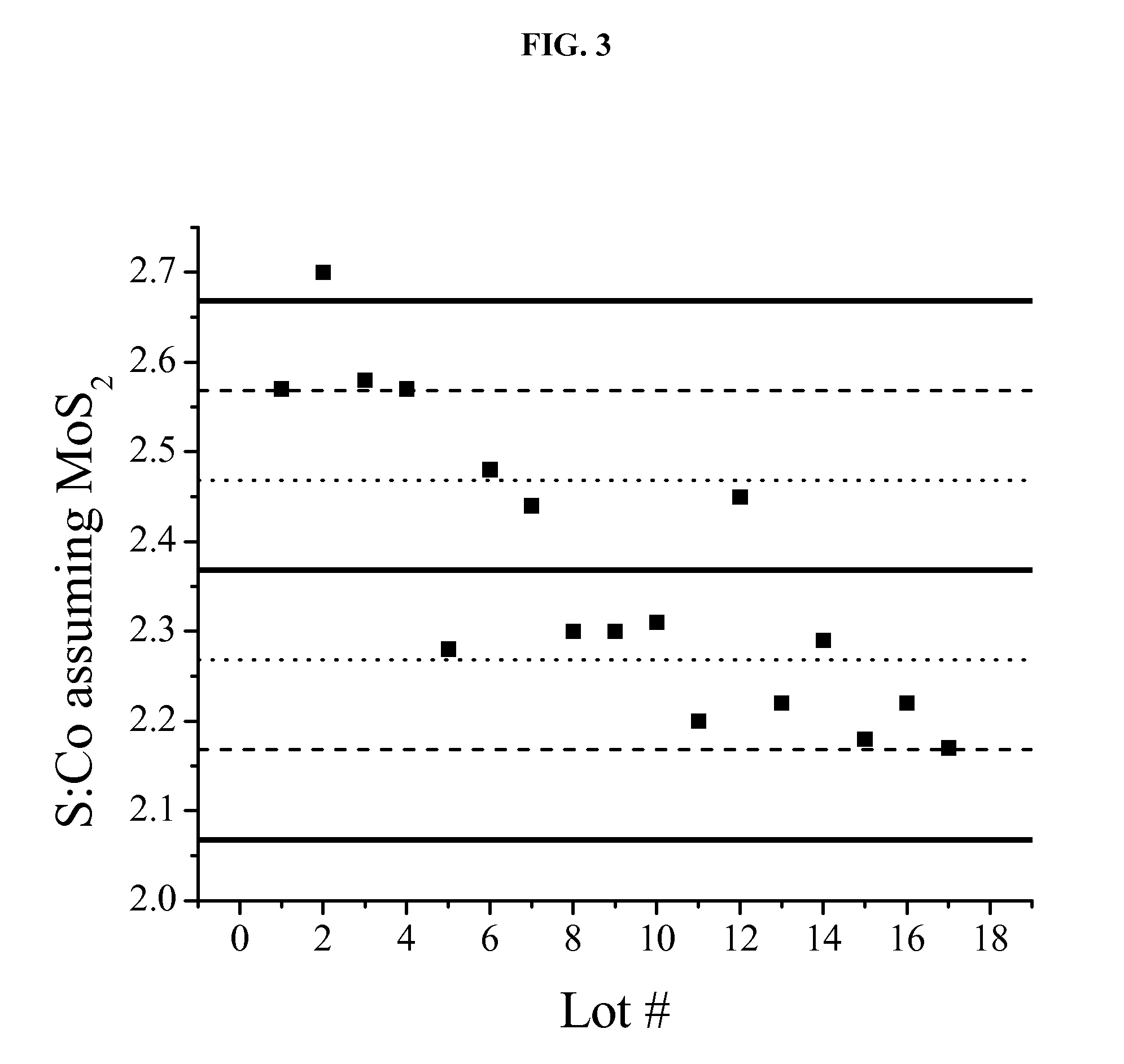

Cobalt-molybdenum sulfide catalyst materials and methods for ethanol production from syngas

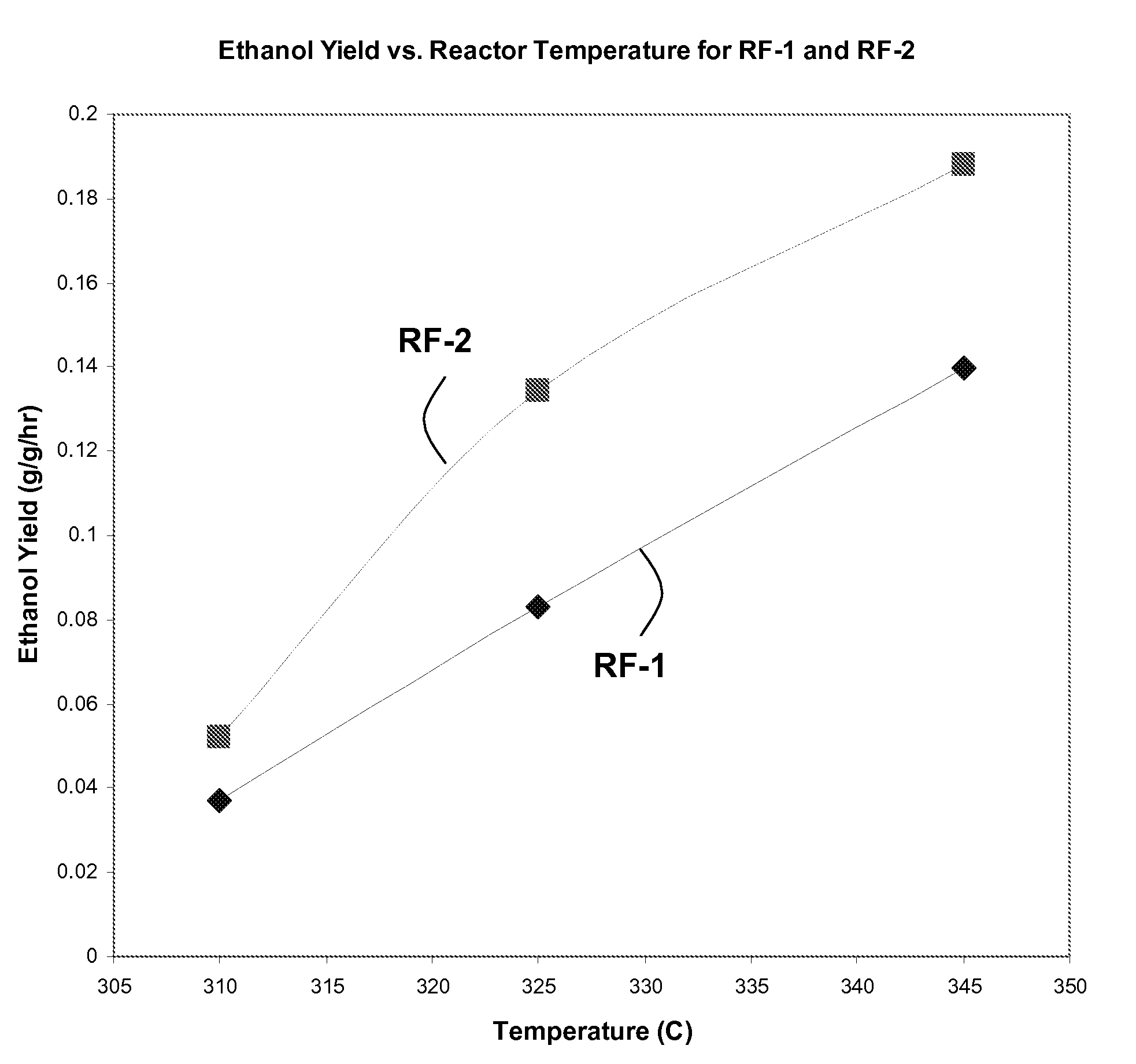

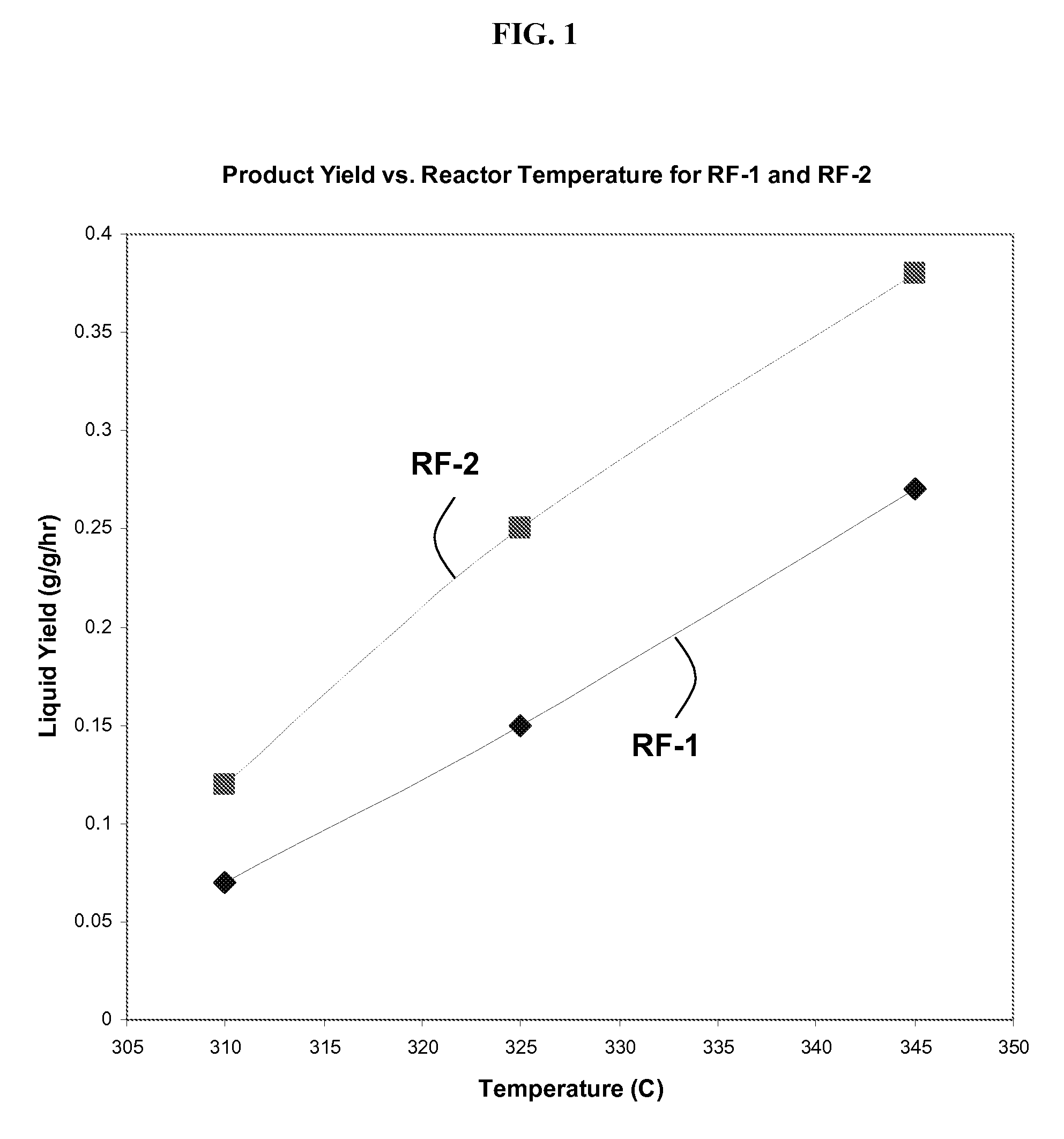

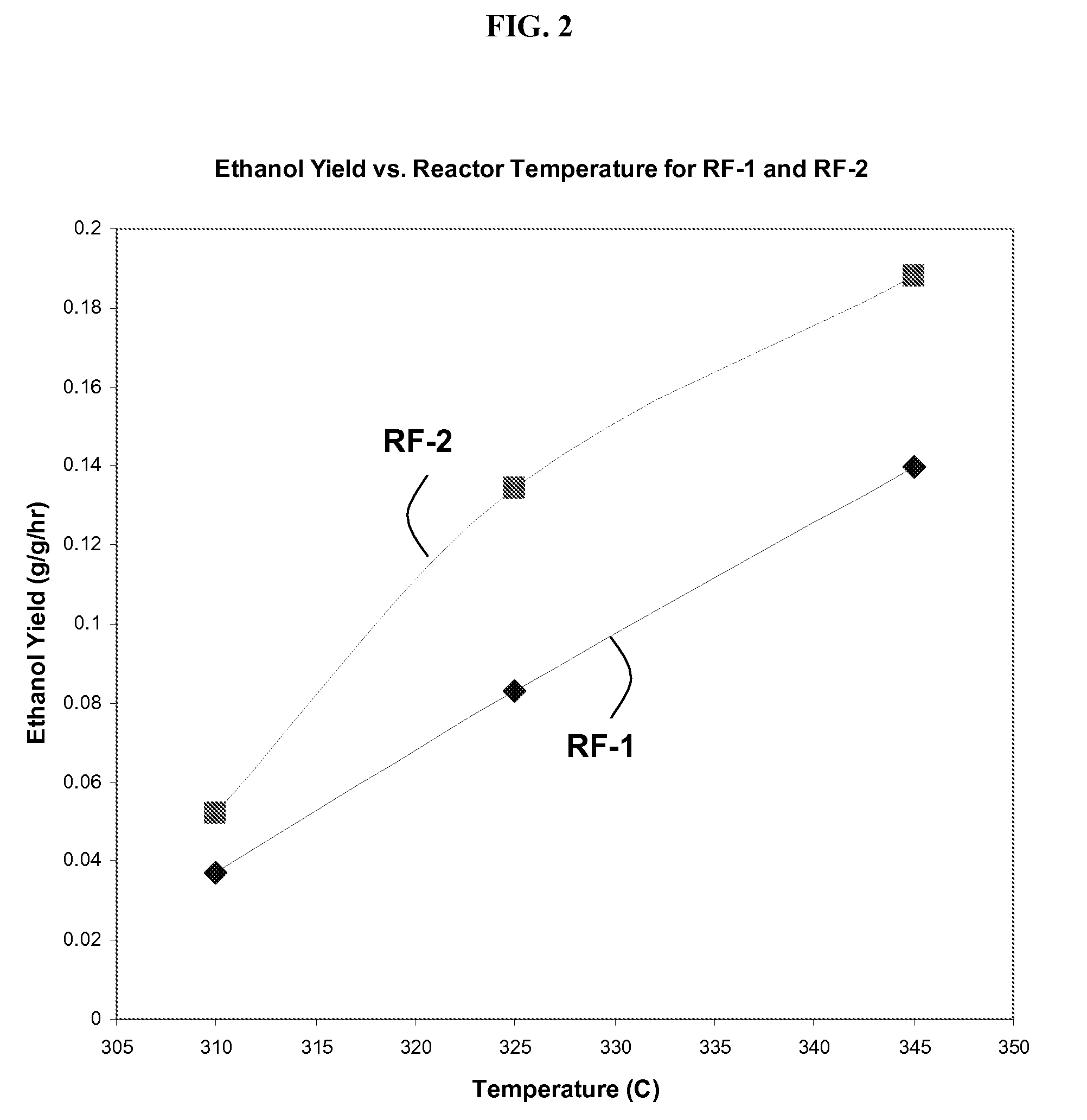

The present invention provides methods and compositions for the chemical conversion of syngas to alcohols. The invention includes catalyst compositions, methods of making the catalyst compositions, and methods of using the catalyst compositions. Certain embodiments teach compositions for catalyzing the conversion of syngas into products comprising at least one C1-C4 alcohol, such as ethanol. These compositions generally include cobalt, molybdenum, and sulfur. Preferred catalyst compositions for converting syngas into alcohols include cobalt associated with sulfide in certain preferred stoichiometries as described and taught herein.

Owner:ALBEMARLE CORP

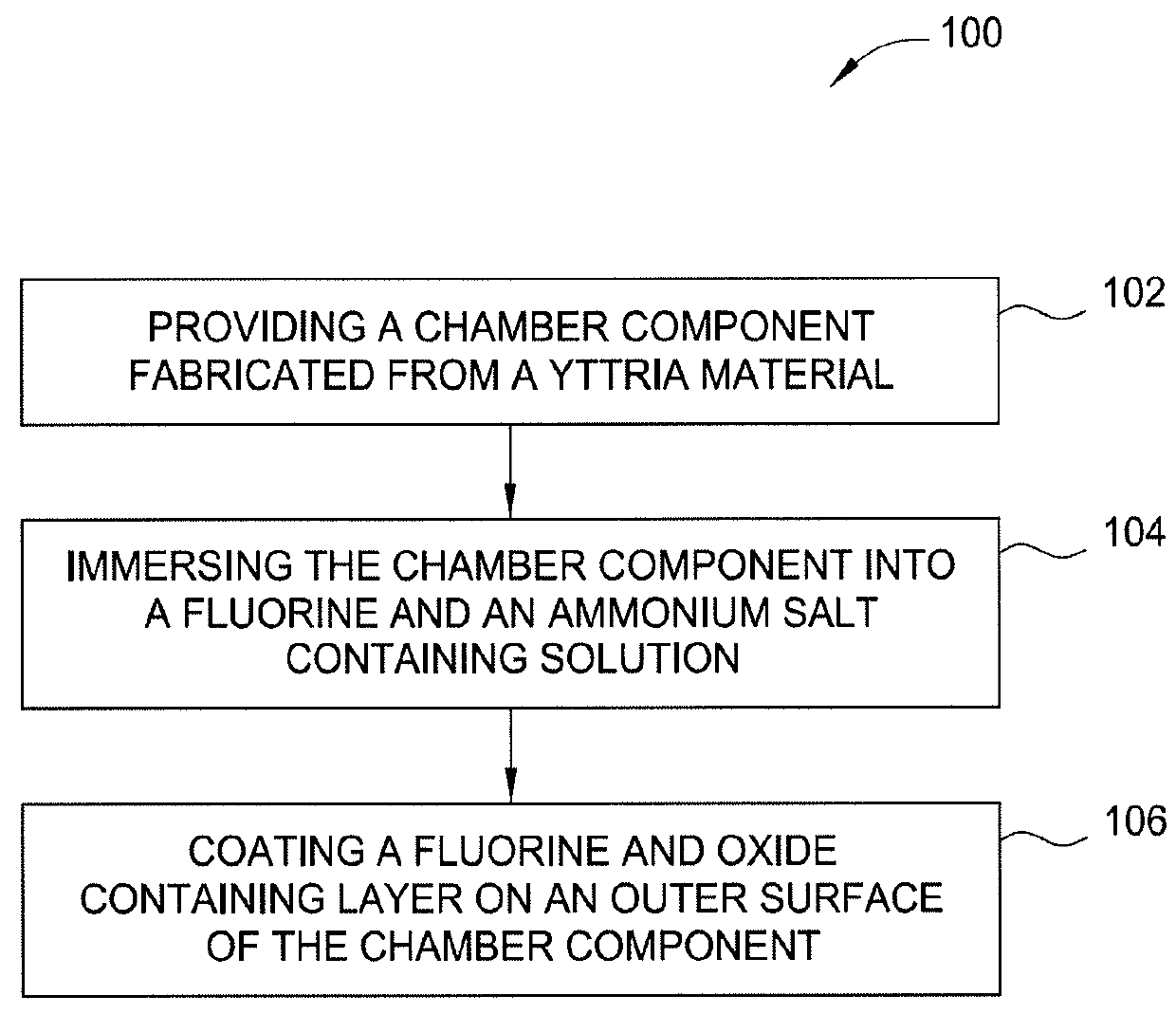

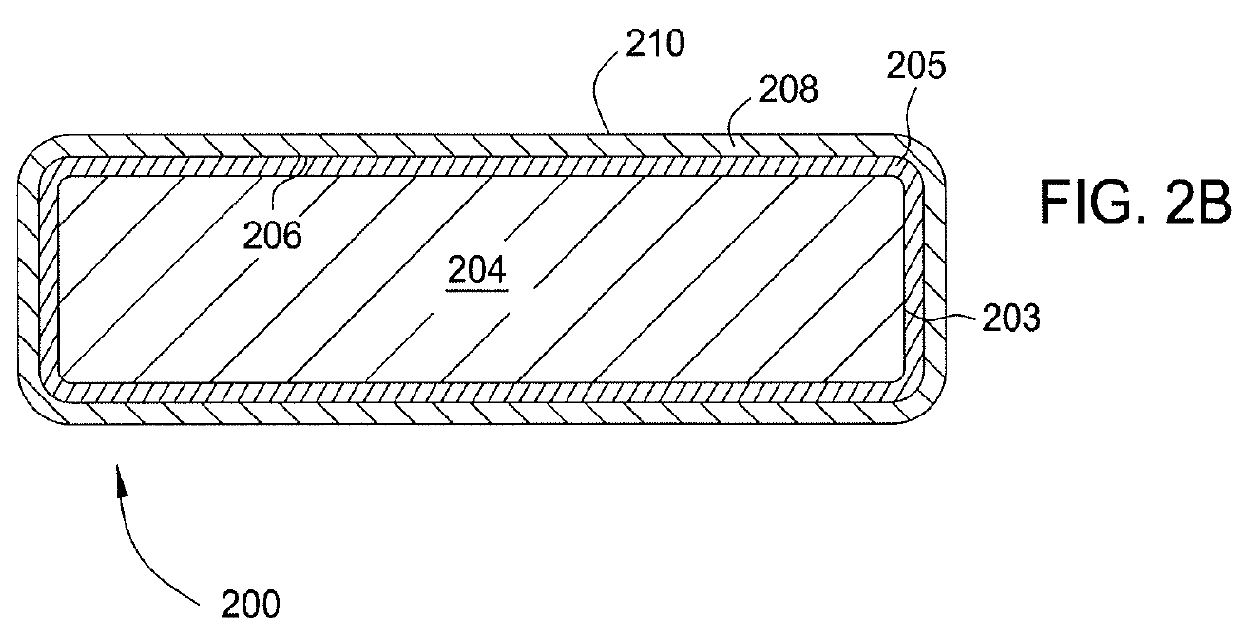

Chemical conversion of yttria into yttrium fluoride and yttrium oxyfluoride to develop pre-seasoned corossion resistive coating for plasma components

Embodiments of the disclosure provide a chamber component for use in a plasma processing chamber apparatus. The chamber component may include a coating layer that provides a fluorine-rich surface. In one embodiment, a chamber component, for use in a plasma processing apparatus, includes a body having an outer layer comprising yttria having a coating layer formed thereon, wherein the coating layer comprises a yttrium fluoride containing material.

Owner:APPLIED MATERIALS INC

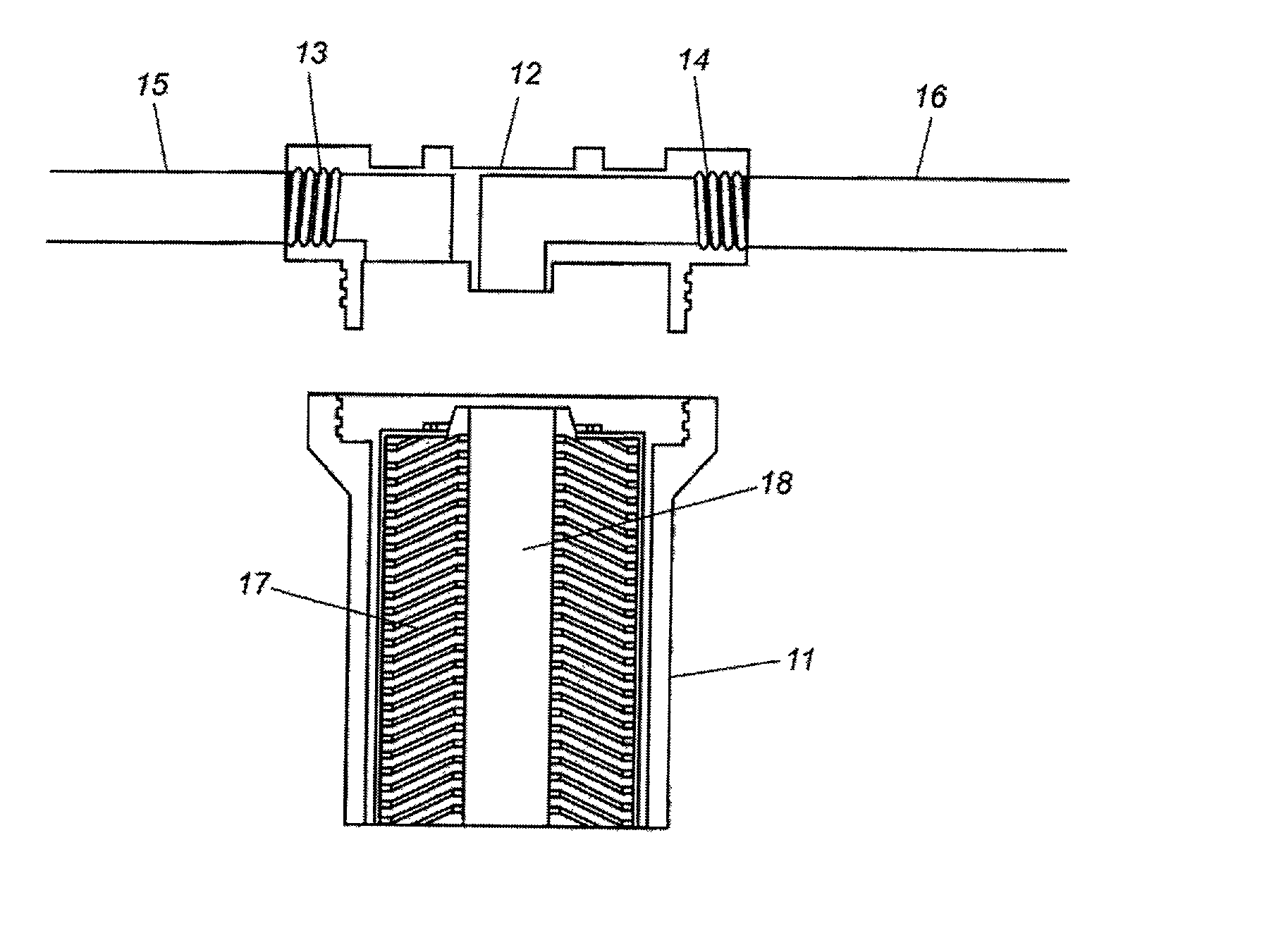

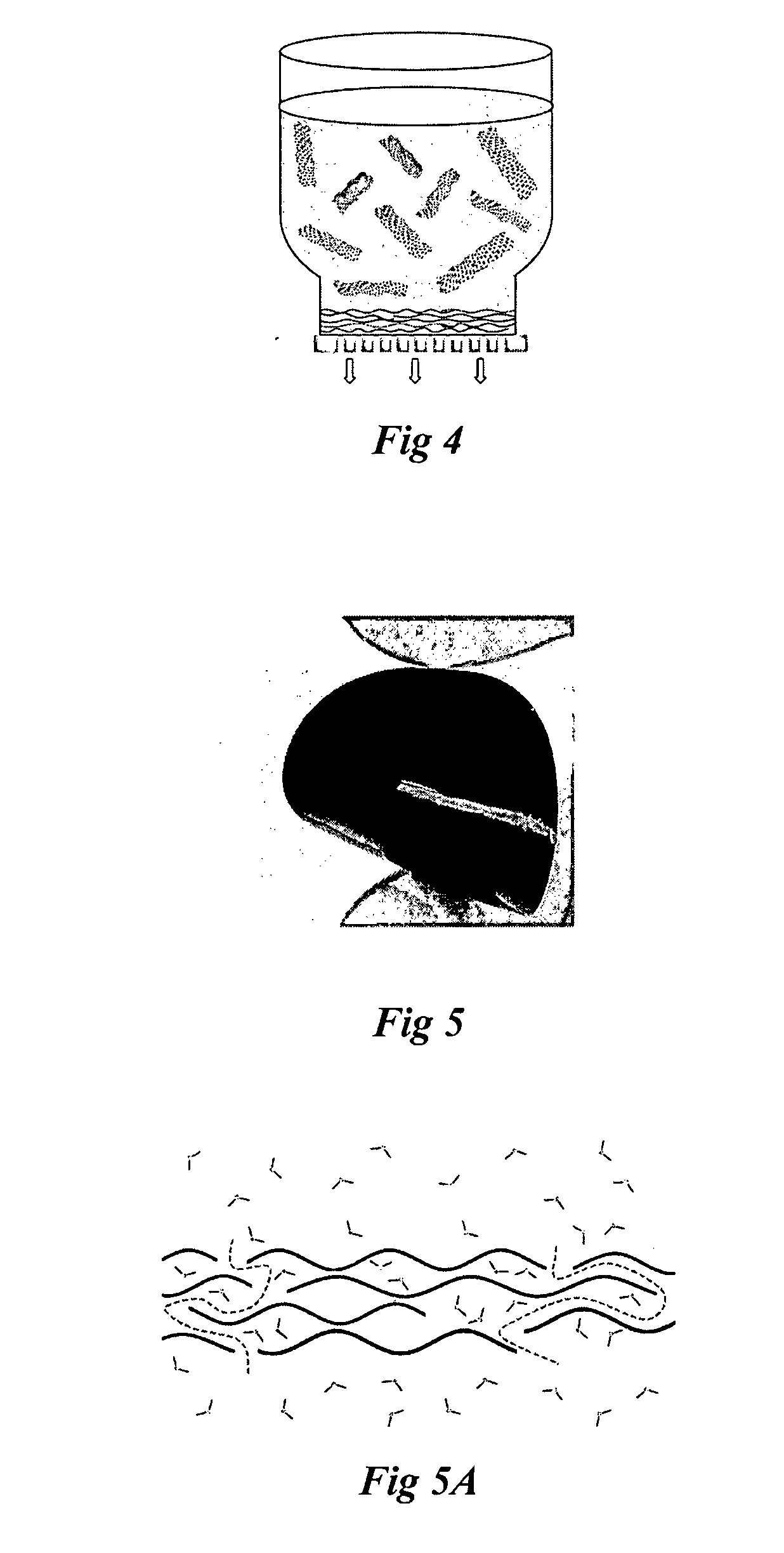

Reactive compositions for fluid treatment

InactiveUS6861002B2Easy to disassembleImprove efficiencyPerfluorocarbons/hydrofluorocarbons captureLoose filtering material filtersCystFiltration

A method and device for the chemical conversion, filtration and / or purification of fluids water or other solutions containing microbiological and chemical contaminants, such as fluids containing arsenic, chlorine, bacteria, viruses, and cysts, where the fluid is passed through a purification material composed of fluid treatment carbon, metal phosphates, metal oxides, reduced metals, metal silicates, metal sulfates, metal carbonates, metal hydroxides, or combinations thereof. The material may be included in a fixed binder matrix.

Owner:WATERVISIONS INT

Reactive compositions for fluid treatment

InactiveUS20030196966A1Perfluorocarbons/hydrofluorocarbons captureLoose filtering material filtersFiltrationPhosphate

A method and device for the chemical conversion, filtration and / or purification of fluids water or other solutions containing microbiological and chemical contaminants, such as fluids containing arsenic, chlorine, bacteria, viruses, and cysts, where the fluid is passed through a purification material composed of fluid treatment carbon, metal phosphates, metal oxides, reduced metals, metal silicates, metal sulfates, metal carbonates, metal hydroxides, or combinations thereof. The material may be included in a fixed binder matrix.

Owner:WATERVISIONS INT

Electrostatic method and means for removing contaminants from gases

InactiveUS6224653B1Easy to operateHigh voltageGas treatmentDispersed particle separationHigh concentrationCorona discharge

An electrical apparatus includes a reaction chamber. A stream of contaminated gasses flows through the chamber. An elongated coronating electrode is positioned in the reaction chamber for producing a corona discharge within the chamber. A multi-stage Fitch generator connected to the electrode produces a high level, rapidly pulsating voltage in the electrode. Controlled amounts of an inert gas or inert gas-air mixture are combined with the contaminated gases to provide a high concentration of inert gas in the reaction chamber. In the inert gas-enriched atmosphere, the pulsating corona discharge produces a high concentration of metastable intermediates that greatly increase the rate of chemical conversion of the contaminants. Switching circuitry allows the pulsating voltage output of the Fitch generator to be superimposed on a constant direct current voltage in the electrode, setting up an electrostatic field in the reaction chamber for removing conversion byproducts from the gas stream.

Owner:PULSATRON TECH CORP

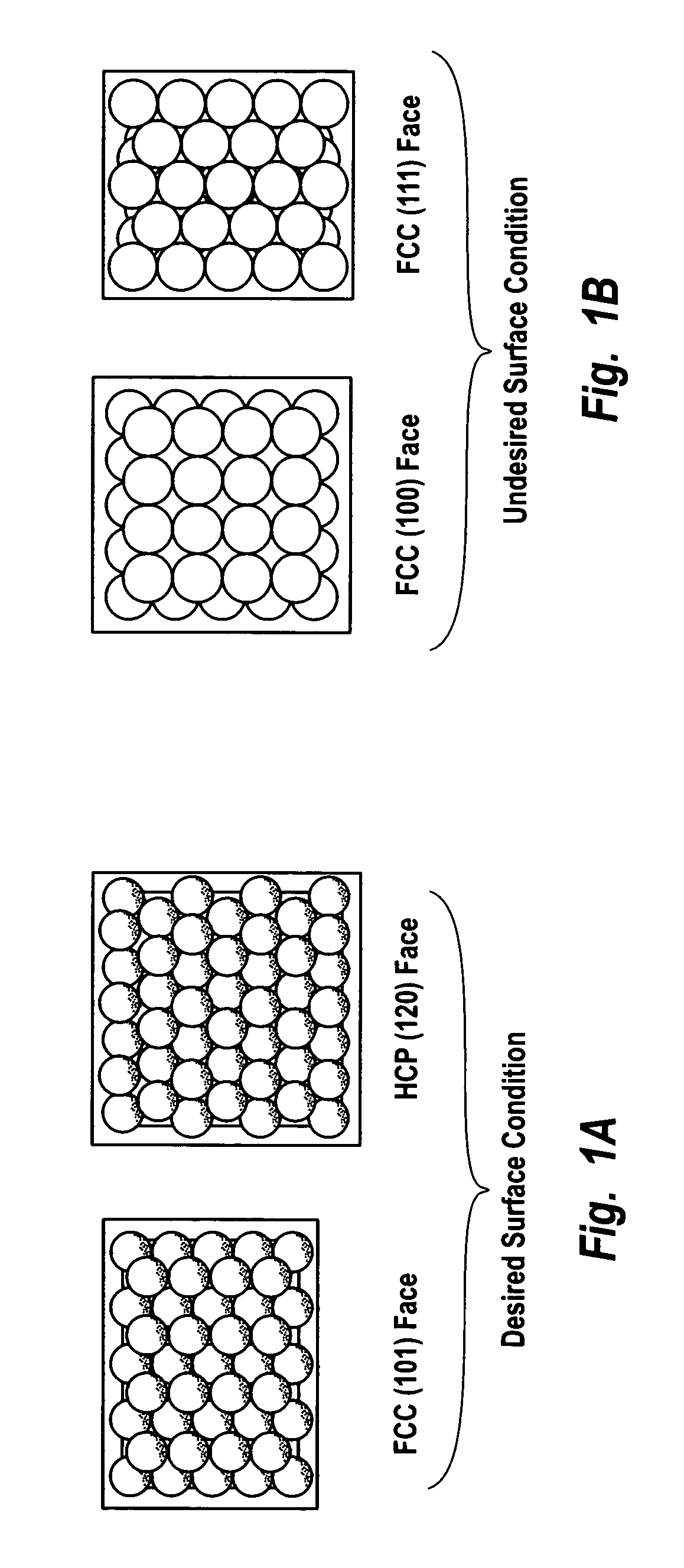

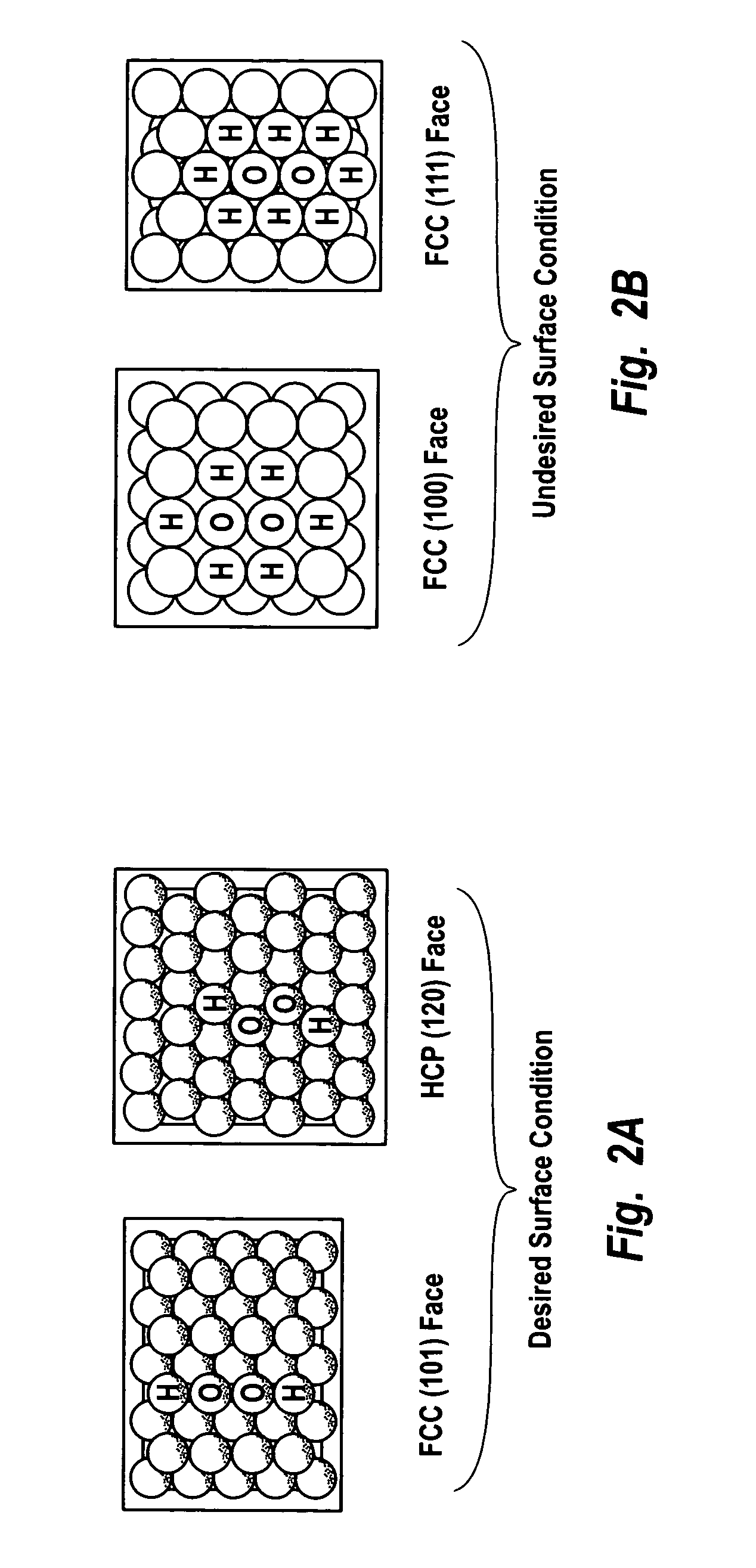

Supported catalysts having a controlled coordination structure and methods for preparing such catalysts

ActiveUS7011807B2Reduce molecular weightReduce the possibilityHydrogen peroxideHydrogenHydrogenOrganic fluid

Supported reactive catalysts having a controlled coordination structure and methods for their production are disclosed. The supported catalysts of the present invention are useful for the preparation of hydrogen peroxide with high selectivity in addition to other chemical conversion reactions. The supported catalyst comprises catalyst particles having top or outer layer of atoms in which at least a portion of the atoms exhibit a controlled coordination number of 2. The catalyst and methods may be used for the concurrent in situ and ex situ conversion of organic compounds. In addition, a process is provided for catalytically producing hydrogen peroxide from hydrogen and oxygen feeds by contacting them with the catalysts of the invention and a suitable organic liquid solvent having a Solvent Selection Parameter (SSP) between 0.14×10−4 and 5.0×10−4.

Owner:BORAL IP HLDG

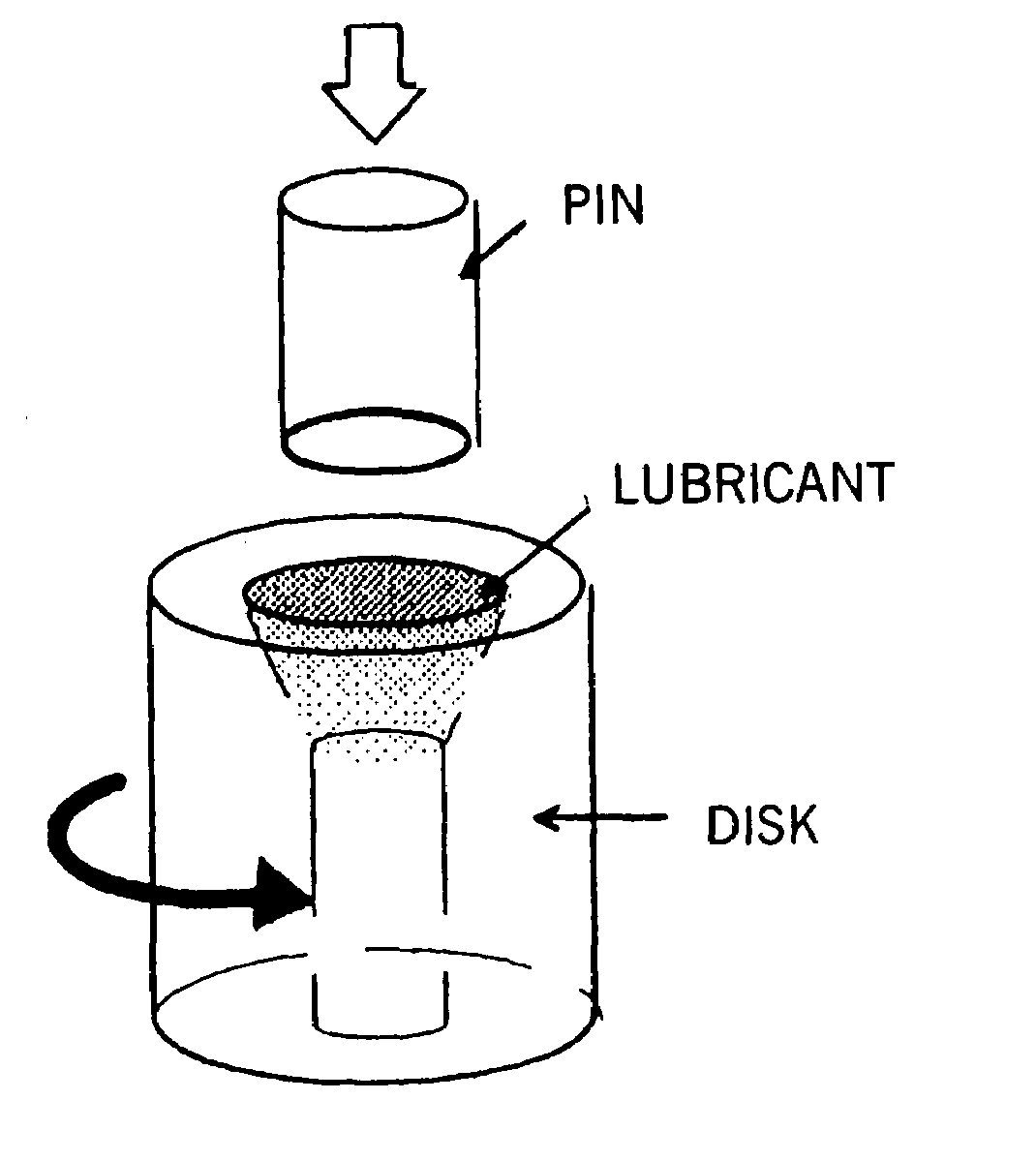

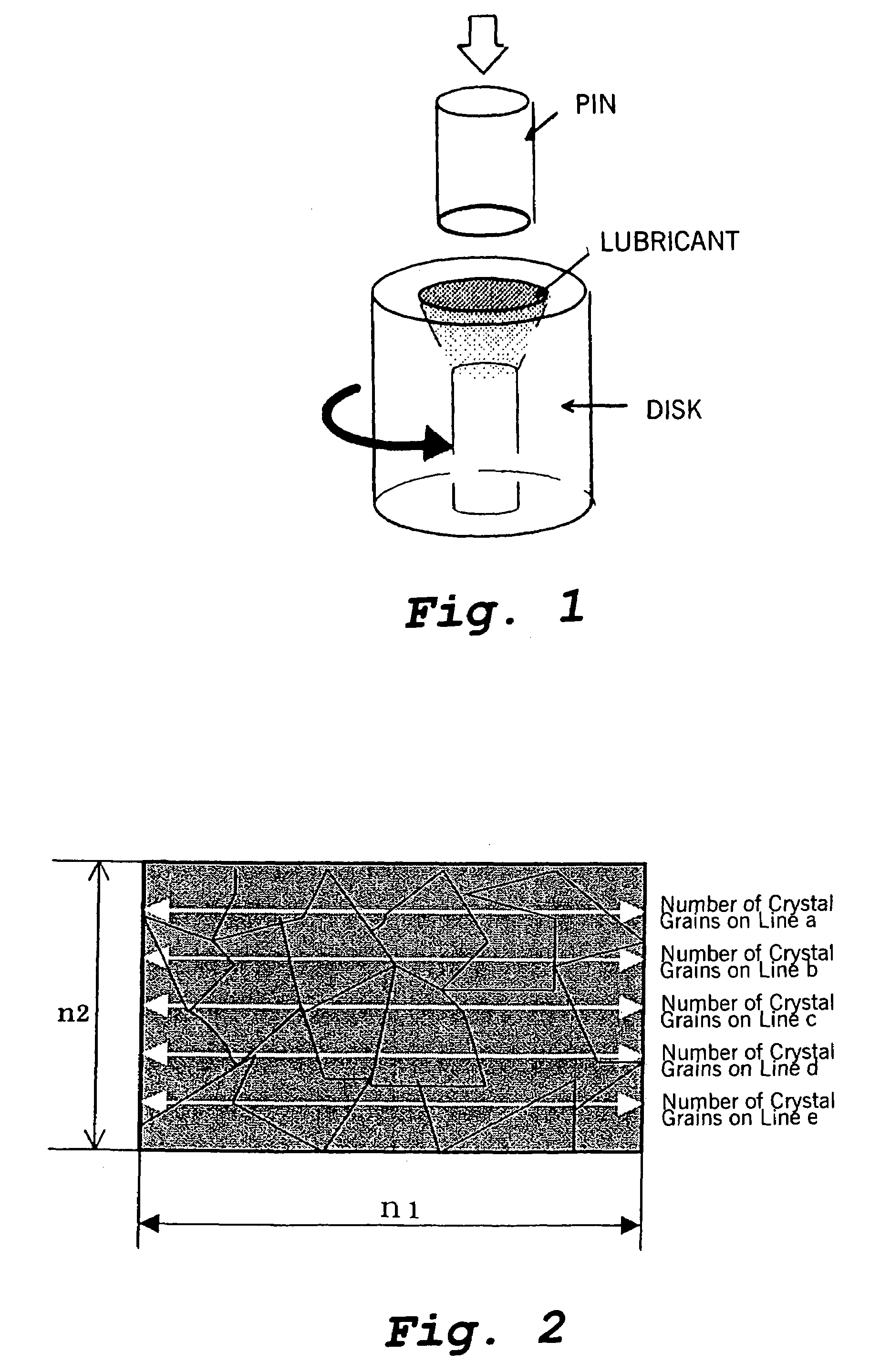

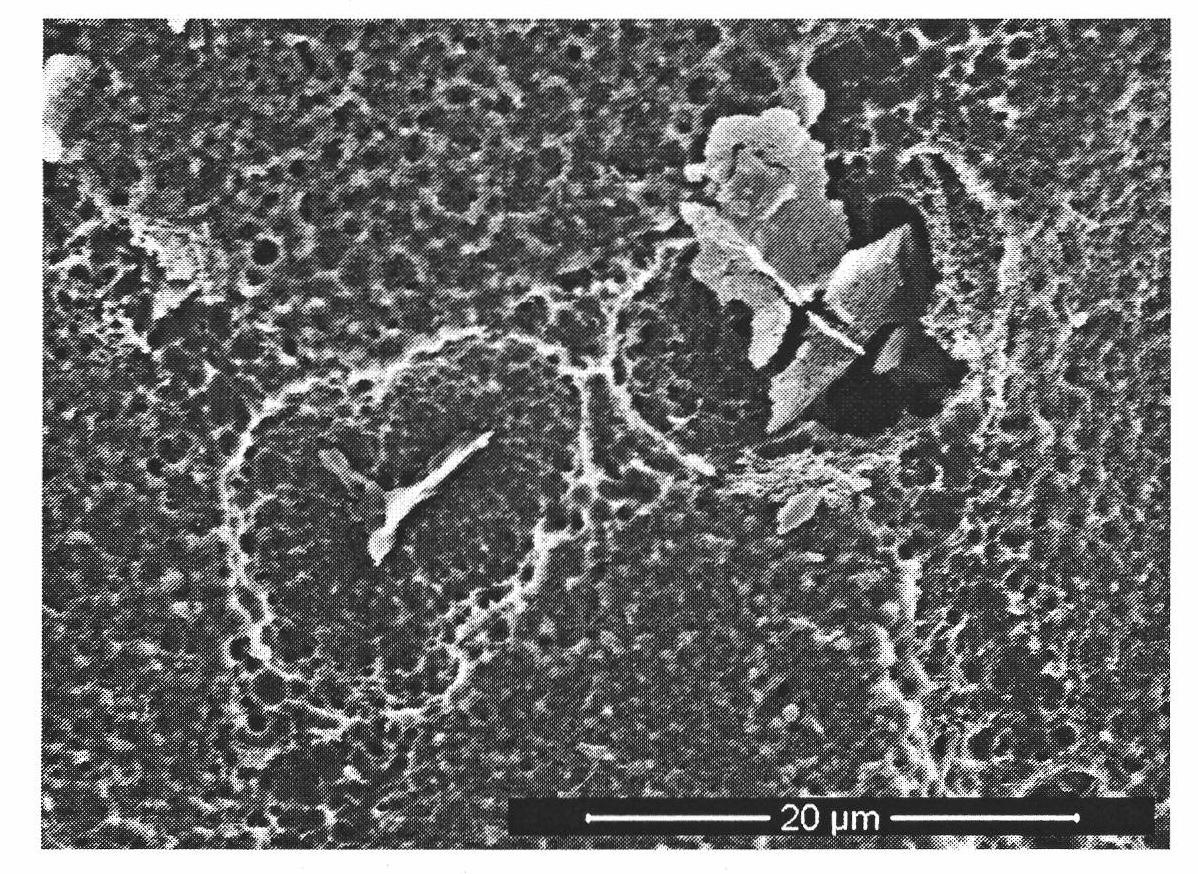

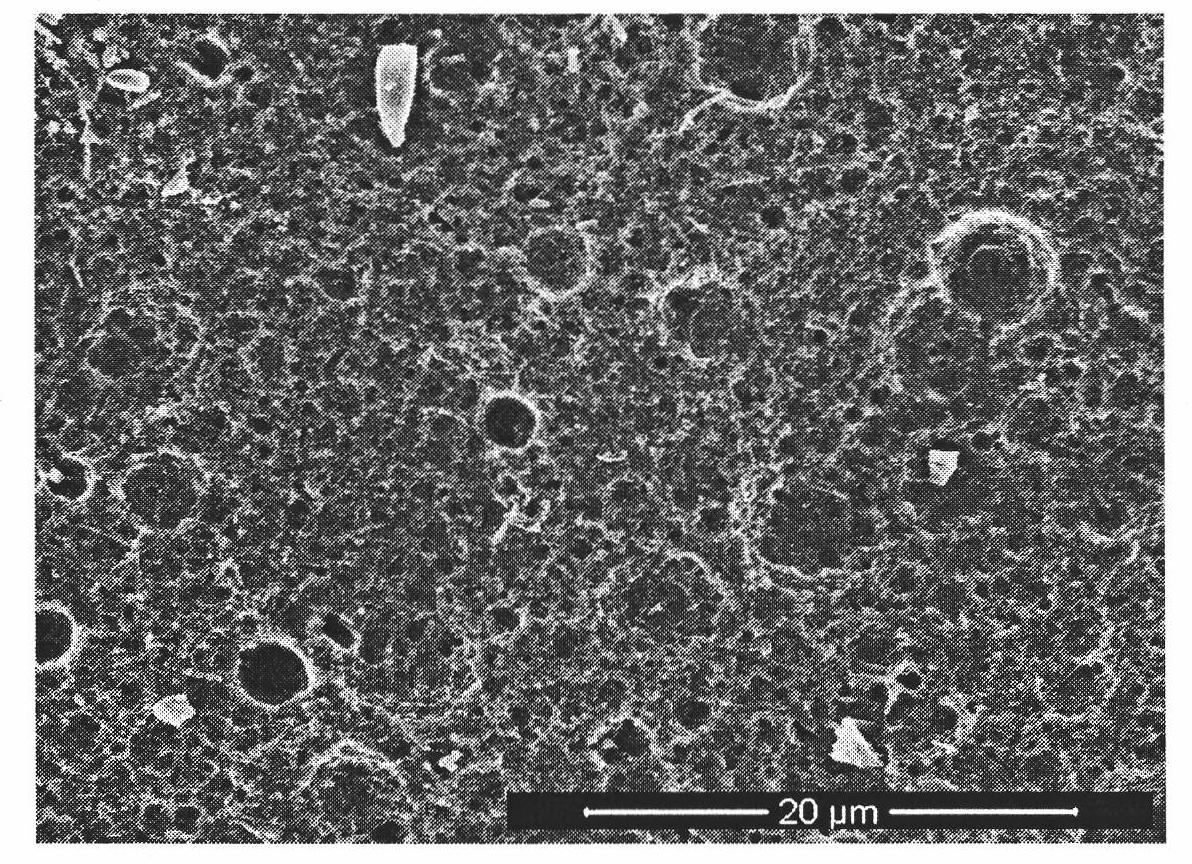

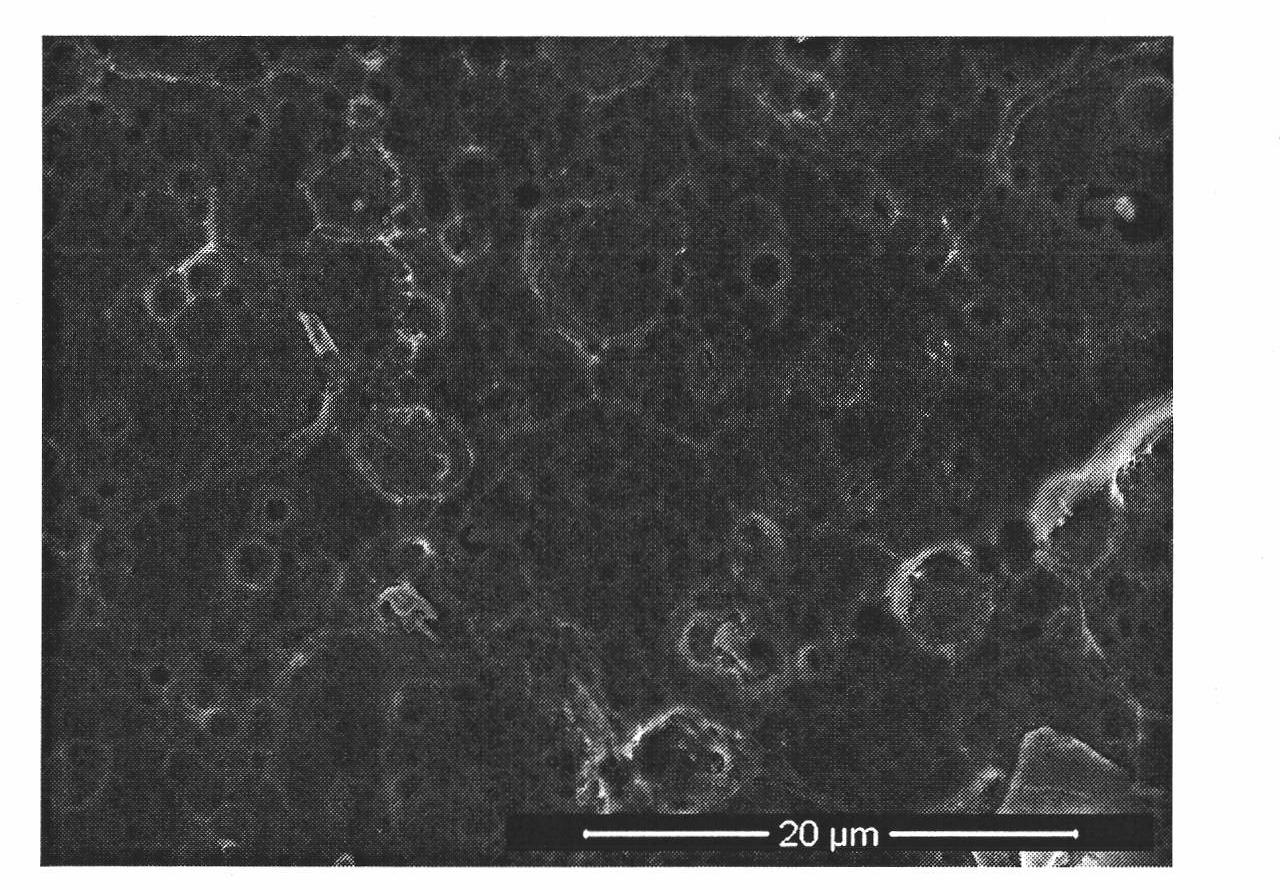

Surface conditioning prior to chemical conversion treatment of a steel member

ActiveUS7666266B2Optimized diameterShort timeOther chemical processesCorrosion preventionPotassiumMaterials science

By subjecting a threaded joint for OCTG (oil country tubular goods) to surface conditioning with an aqueous solution of potassium tetraborate or sodium tetraborate prior to manganese phosphate chemical conversion treatment, a manganese phosphate chemical conversion coating having coarse crystal grains with an average crystal grain diameter of 10-110 micrometers is formed on the surface of the steel member which may be any steel including a high Cr steel. This manganese phosphate chemical conversion coating can hold a large amount of a liquid lubricant, and it is effective at preventing the occurrence of galling at the time of makeup of a threaded joint for OCTG.

Owner:NIPPON STEEL CORP

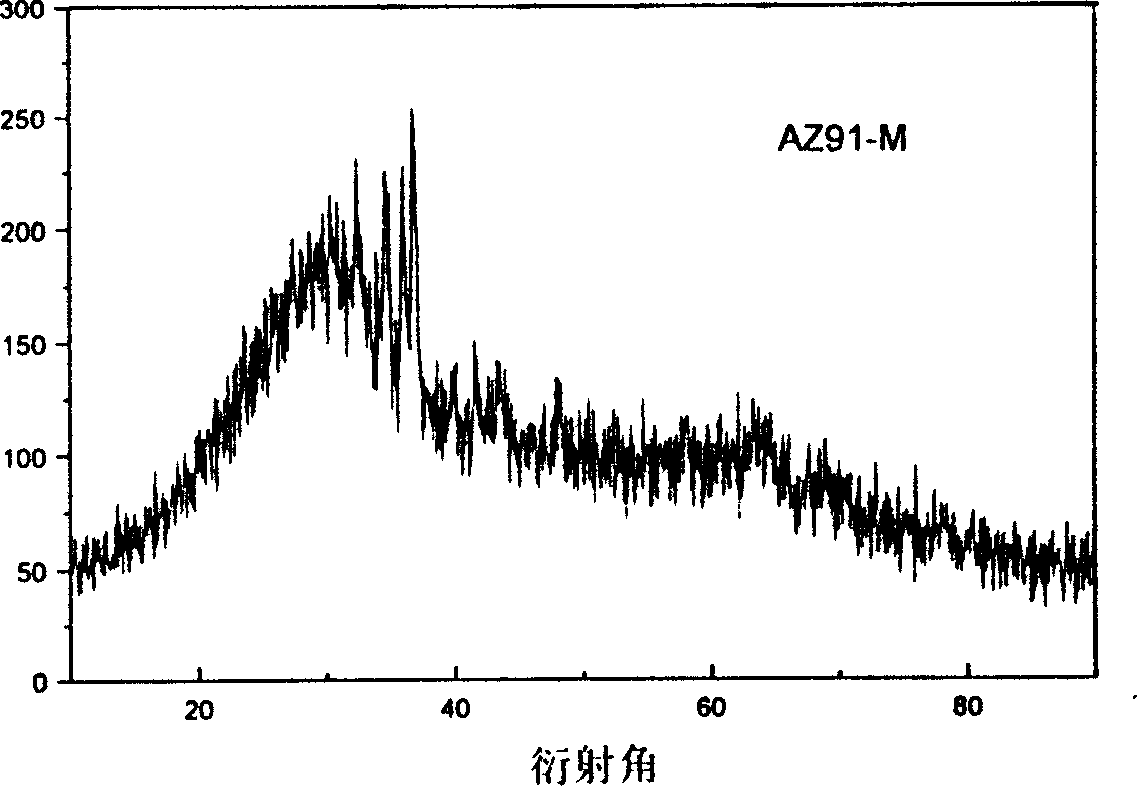

Acidic solution for treating surface of magnesium alloy and processing method

InactiveCN101285193AFully activatedHigh activityMetallic material coating processesGlutaric acidBinding force

The invention relates to acid solution used for processing the magnesium alloy surface. The acid solution is water solution which contains acids, inhibitor and wetting agent, wherein, the acids are first acids or mixture of first acids and second acids; the first acids are selected from one type or a plurality of types among citric acids, oxalic acids, tartaric acids, methanoic acids, acetic acids, metacetonic acids, butyric acids, glutaric acids, phenylformic acids, benzene dicarboxylic acids, lactic acids, glycolic acids, glyoxylic acids and amino acids; and the second acids are hydrochloric acids and / or nitric acids. By adoption of the acid solution, the magnesium alloy surface can be fully activated; the membranous layer of a converting film which is formed on the magnesium alloy surface after chemical conversion process is compact, has erosion resistance and good binding force with a paint film. Moreover, the method is a environment-friendly method for processing the magnesium alloy surface.

Owner:BYD CO LTD

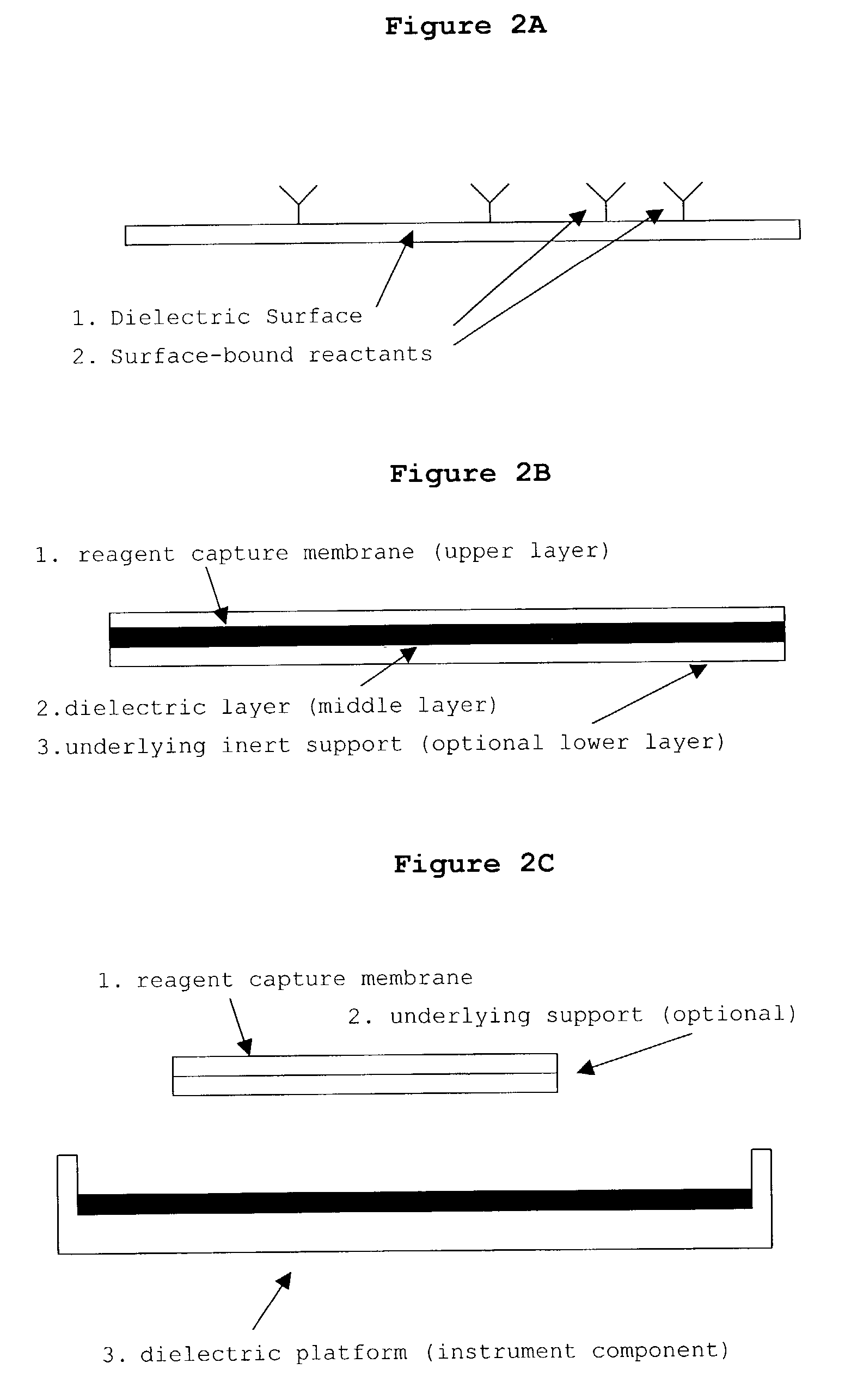

Directed microwave chemistry

InactiveUS7348182B2Improve adsorption capacityFast bindingImmobilised enzymesBioreactor/fermenter combinationsChemical reactionChemical physics

The present invention concerns a novel means by which chemical preparations can be made. Reactions can be accelerated on special chips using microwave energy. The chips contain materials that efficiently absorb microwave energy causing chemical reaction rate increases. The invention is important in many small scale chemical transformations including those used in protein chemistry and in combinatorial chemistry.

Owner:MIRARI BIOSCI

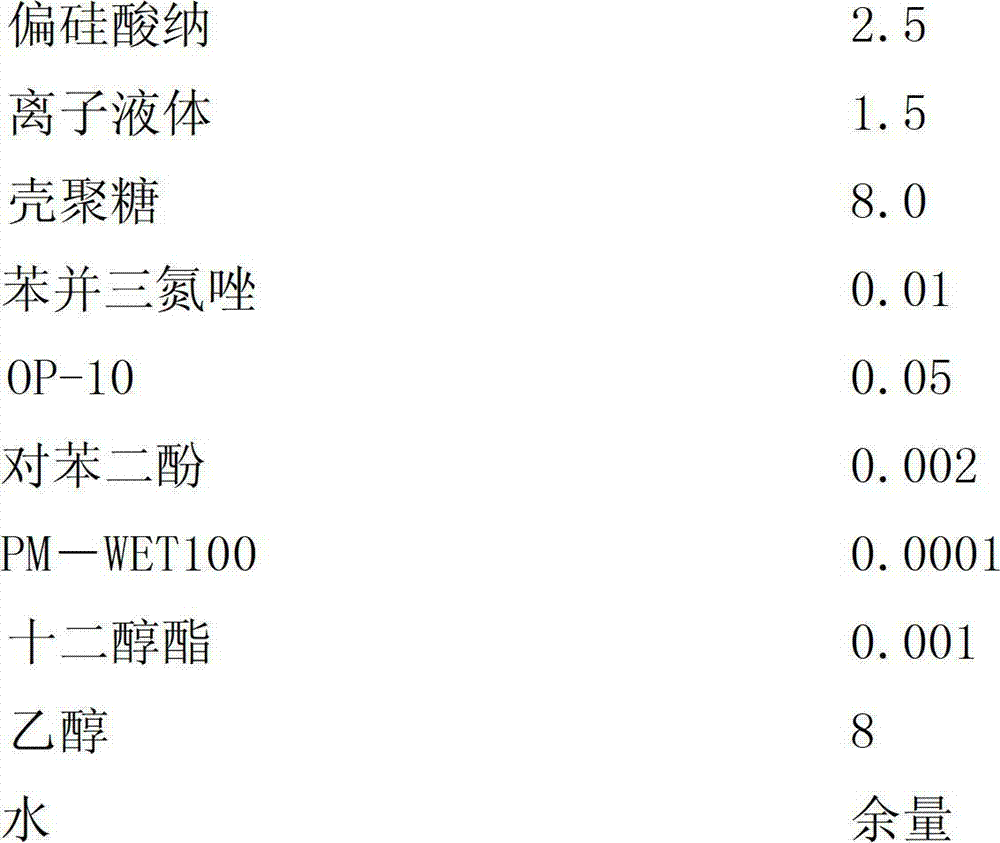

Metal surface treating agent

InactiveCN102051611AReduce corrosion rateReduce surface tensionMetallic material coating processesMetasilicateChemical conversion

The invention relates to a metal surface treating agent which comprises the following components: silicate or metasilicate, chitosan, corrosion inhibitor, surfactant, antioxidant, wetting agent, film-forming additive, ethanol and water, wherein one or more of nanosized titanium dioxide, zirconium oxide or zirconium fluoride are evenly mixed with silicate or metasilicate and account for 3wt%-25wt% of silicate or metasilicate; the particle size of nanosized titanium dioxide, zirconium oxide or zirconium fluoride is less than 100nm; the degree of deacetylation of chitosan is 55%-100%; and the pH value of the composite is adjusted to 5.0-9.0. The invention provides the metal surface treating agent which uses environmentally friendly aqueous solution to form a metal chemical conversion film so as to inhibit the surface corrosion of metal; when the metal surface treating agent is used to treat the surface of the cold-rolled steel plate product, the rust-proof effect is especially good; and the metal surface treating agent can not cause environmental pollution and be green and environmentally friendly.

Owner:DALIAN POLYTECHNIC UNIVERSITY

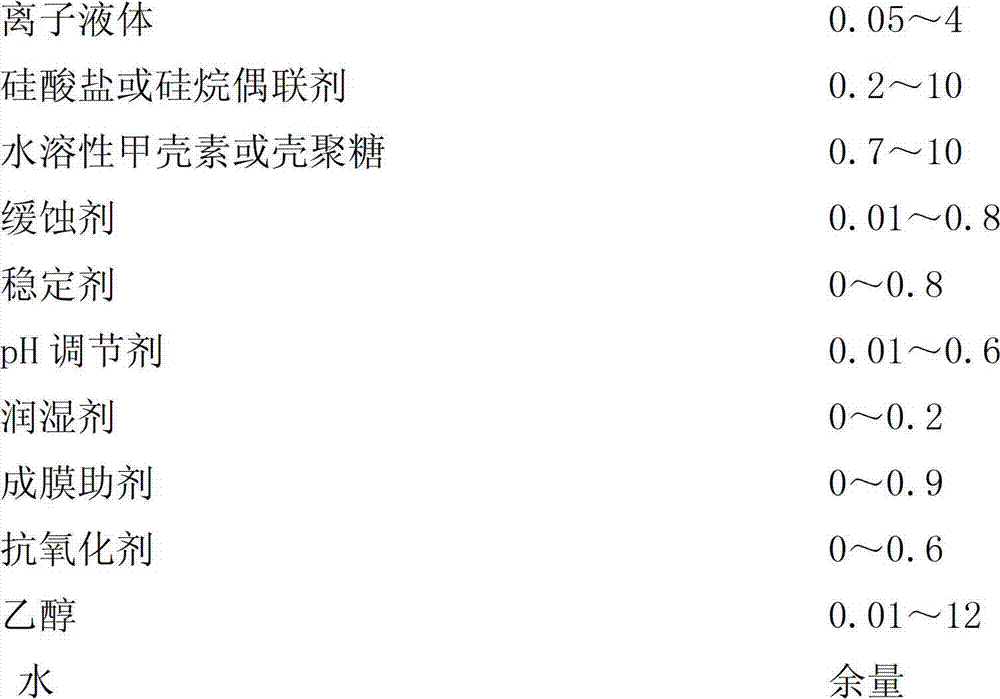

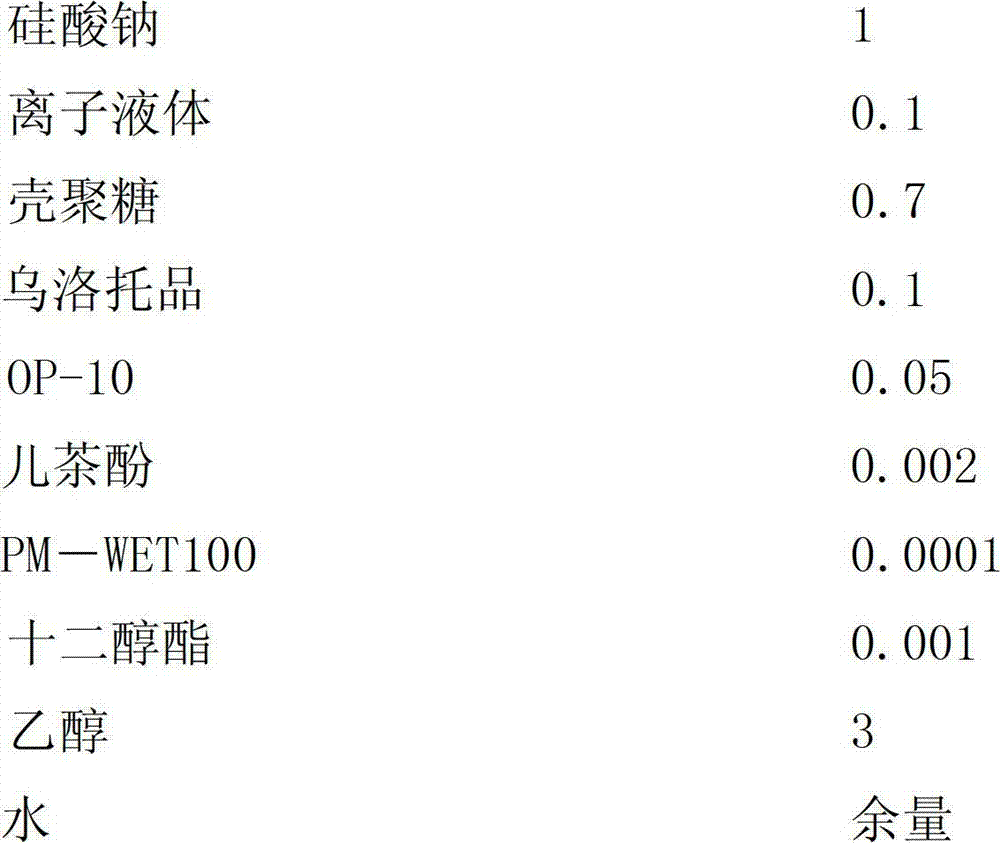

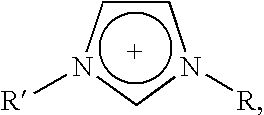

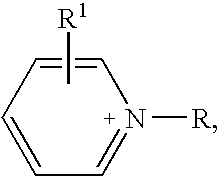

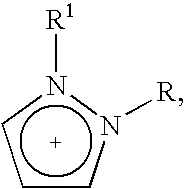

Metal surface treatment agent

InactiveCN102787310AReduce corrosion rateReduce surface tensionMetallic material coating processesNitrogenous heterocyclic compoundIonic liquid

The invention provides a metal surface treatment agent composed of aqueous solution or aqueous emulsion containing ionic liquid. The metal surface treatment agent comprises the ionic liquid, silicate or silane coupling agent, water-soluble chitin or chitosan, corrosion inhibitor, stabilizer, pH modifier, wetter, coalescing agent, antioxidant, ethanol and water, the ionic liquid is room-temperature ionic liquid consisting of nitrogenous heterocyclic compound cations and inorganic or organic anions, one or more of nanoscale titanium dioxide, zirconium oxide or zirconium fluoride is uniformly mixed into the silicate or silane coupling agent by the weight equivalently accounting for 3%-25% of that of the silicate or silane coupling agent. A chemical conversion coating is formed on a metal surface by the metal surface treatment agent, can inhibit corrosion of the metal surface, and has a fine coating performance. The metal surface treatment agent is used for treating cold-rolled plates, galvanized plates and aluminum plates, and the metal surface treated by the metal surface treatment agent has the coating adhesion force equivalent to that of a metal surface treated by a phosphorus-containing metal surface treatment agent.

Owner:DALIAN POLYTECHNIC UNIVERSITY

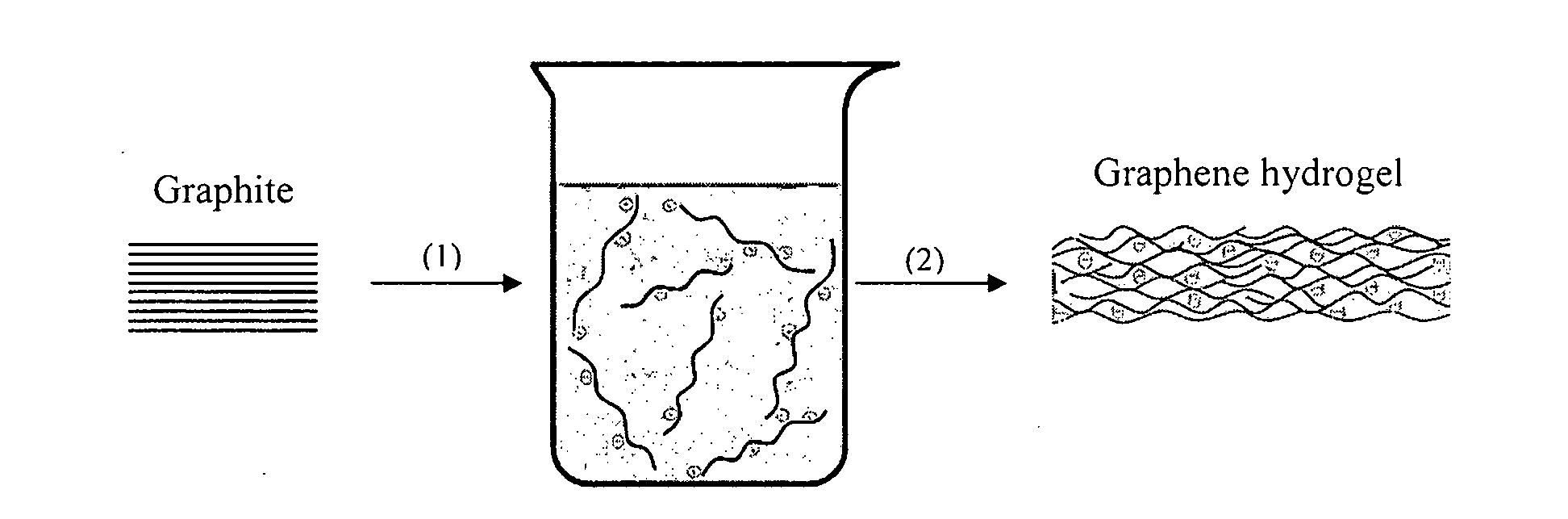

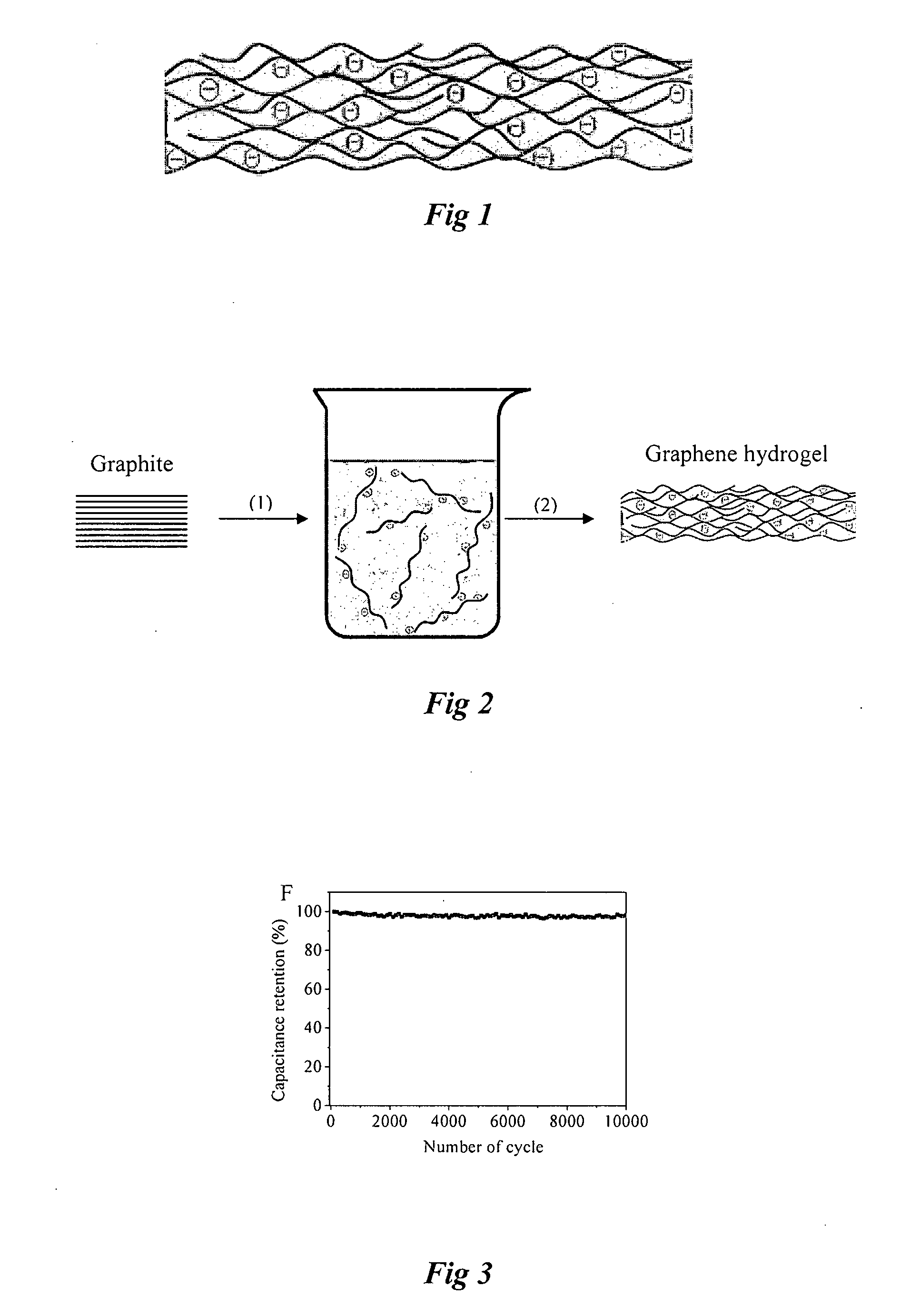

Material and applications therefor

ActiveUS20130180912A1Increase temperatureLarge inter-sheet spacingMaterial nanotechnologyCarbon compoundsPolymer scienceDispersed media

A gel film or an isolated gel film comprising sheets of graphene or chemically converted graphene at least partially separated by a dispersion medium, such as water, and arranged in a substantially planar manner to form an electrically conductive matrix.

Owner:MONASH UNIV

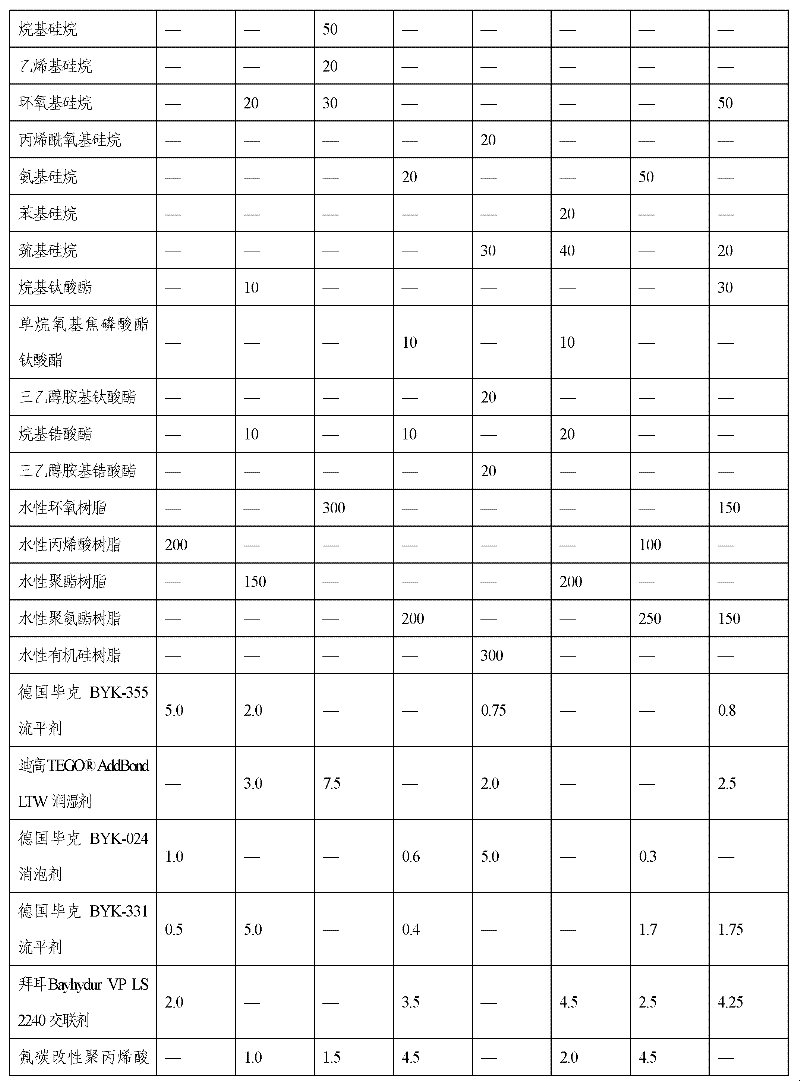

Corrosion-contamination resistant chemical conversion agent and method for preparing chromium-free chemical conversion film

InactiveCN102409332AAccelerated corrosionImprove stain resistanceMetallic material coating processesChromium freePhosphate

The invention relates to the field of aluminum alloy decoration and protection coating for ships, in particular relates to an environmentally-friendly corrosion-contamination resistant chemical conversion agent and application thereof in a chromium-free chemical conversion film, and solves the problems of poor corrosion resistance, high cost, difficulty in large-area construction and the like in the prior art. The chemical conversion agent comprises a component A and a component B. The method for preparing a chemical conversion film comprises the following steps of: forming a first inorganic chemical conversion film layer by the component A and forming an organic contamination resistant closed film by the component B. The component A is a water solution prepared from a main salt, a film-forming accelerator, a buffering agent, a surfactant and the like, and the component B is prepared from silicate, silane, a silica sol, titanate, zirconate, waterborne resins and the like. The chemicalconversion agent does not contain chromium ions and phosphates, and the chromium-free chemical conversion film prepared from the chemical conversion agent has excellent corrosion resistance and contamination resistance, can be used for construction of large-area aluminum alloy sections, and can be used as surface decoration and protection coatings for 5xxx and 6xxx series aluminum alloys.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

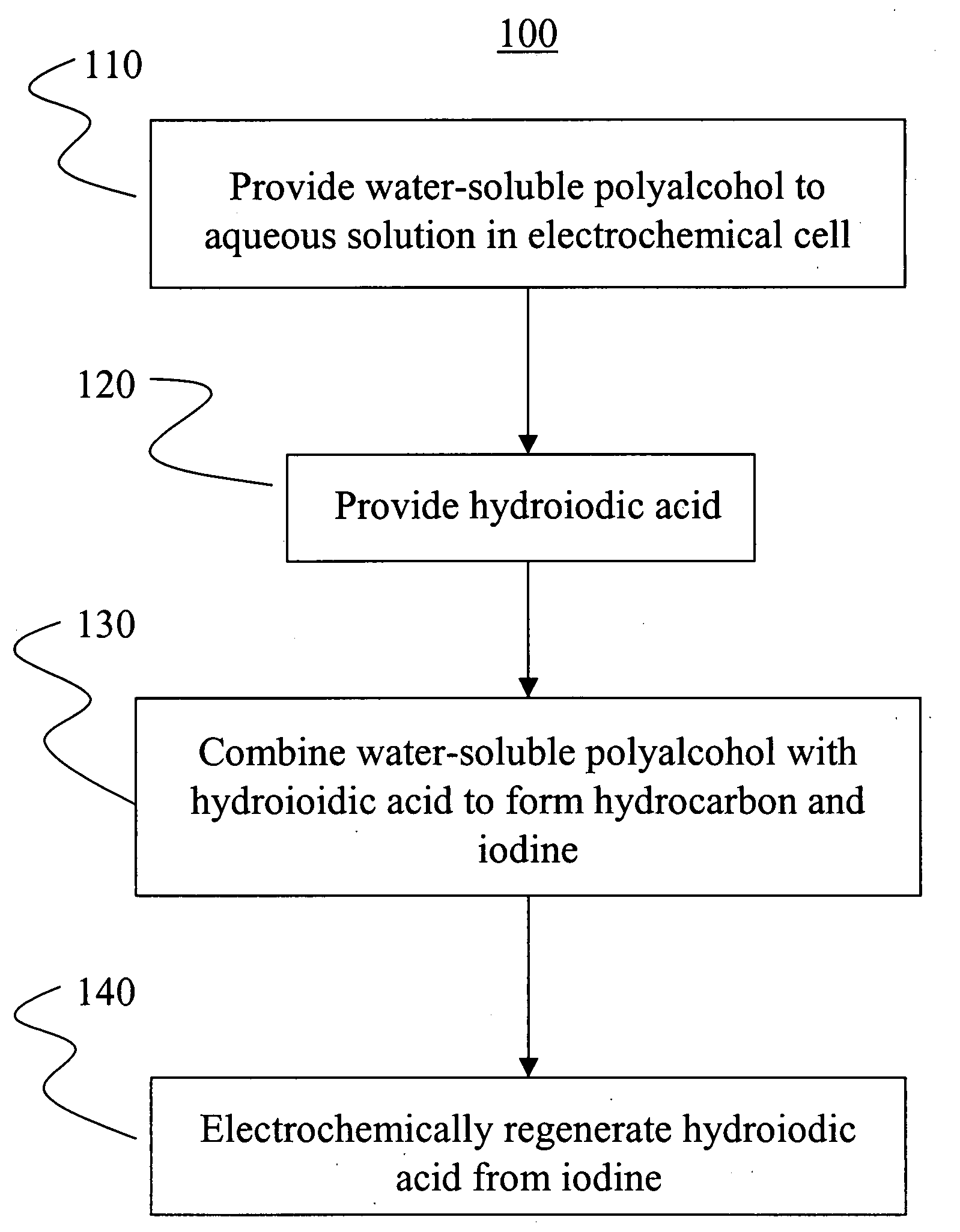

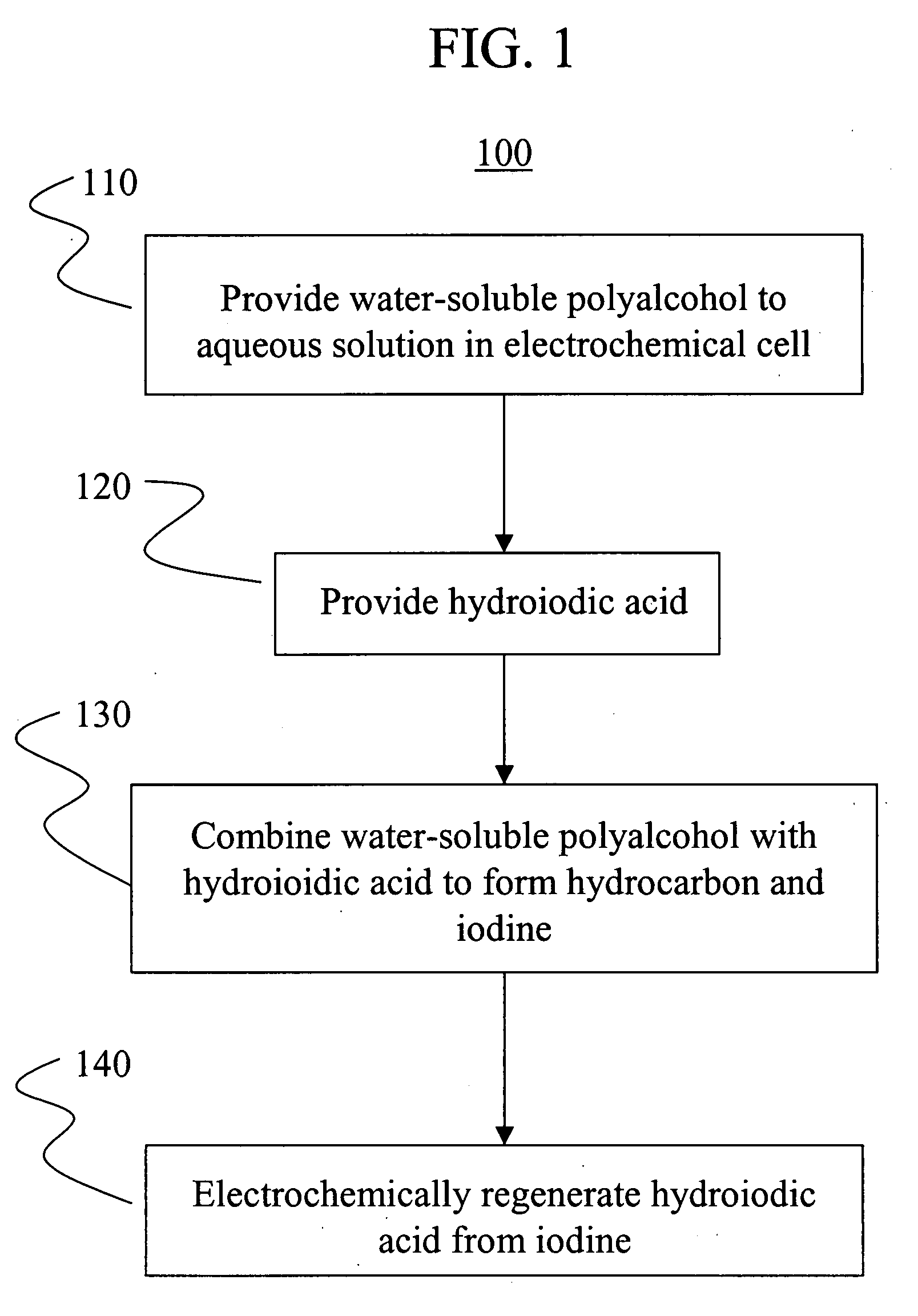

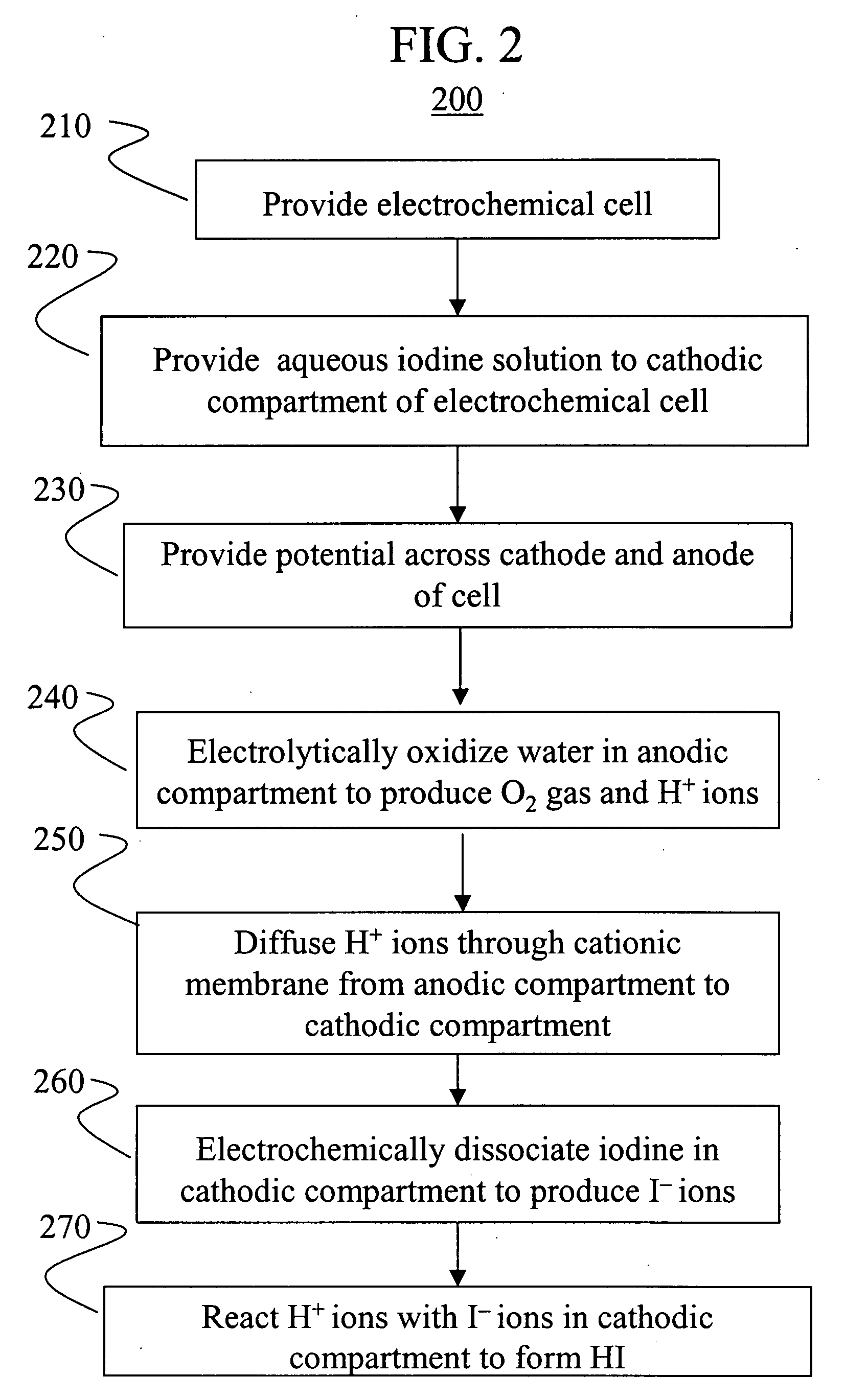

Electrochemical conversion of polyalcohols to hydrocarbons

A method of making hydrocarbons from polyalcohols, such as carbohydrates. The polyalcohols and carbohydrates may be provided from biomass, including paper, cardboard or urban generated paper product waste; wood and wood products, including forest slash and deadfall; agricultural waste; and the like. The polyalcohols and carbohydrates are combined with hydroiodic acid in aqueous solution to form the hydrocarbon and elemental iodine. Hydroiodic acid is then electrochemically regenerated by reducing the elemental iodine in a parallel reaction. A method of electrochemically generating hydroiodic acid from elemental iodine in aqueous solution is also described.

Owner:RGT UNIV OF CALIFORNIA

Preparation method of magnesium alloy chromeless chemical conversion film and its used film forming solution

InactiveCN1475602AReduce pollutionUniform thicknessMetallic material coating processesPhosphatePre treatment

A chemically transferred non-chromium Mg-alloy film is prepared through grinding said Mg-alloy, removing impurities, washing with alkali solution for defatting, washing with acidic solution for removing surfacial oxide, removing very thin oxidized film and pickling ash from its surface by fluoric acidic solution, immersing the Mg-alloy in filming solution to obtain phosphate film, and immersing in alkaline aqueous solution at 15-100 deg.C for 3-60 min for closing the pores in the film. Said filming solution is prepared from Mn salt, phosphate, fluoride and water.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Halogen-free ionic liquids

InactiveUS20050070717A1Improve hydrolytic stabilityOrganic compounds purification/separation/stabilisationGroup 5/15 element organic compoundsHeat carrierHalogen

An ionic liquid according to the invention is substantially halogen-free, has a low viscosity and is stable to hydrolytic degradation under test conditions. The ionic liquid is a compound of the formula (cation) (R′—O—SO3), (cation) (R′—SO3), or a mixture of the two compounds. It can be used in processes for the chemical conversion and separation of materials by employing the ionic liquid as a solvent, solvent additive, extraction agent or phase-transfer catalyst. It can also be used in a heat exchange device wherein the ionic liquid serves as a heat carrier or heat carrier additive.

Owner:MERCK PATENT GMBH

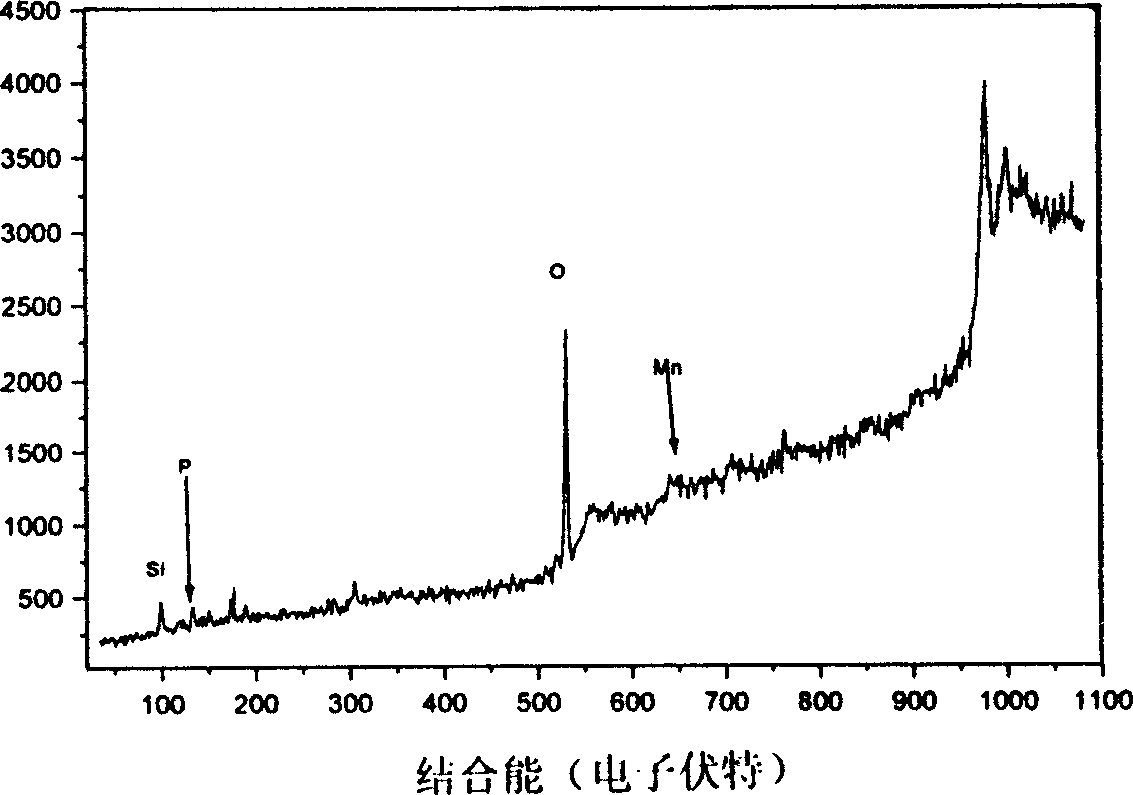

Transformation liquid for preparation of corrosion-resistant oxidation film on aluminium alloy surface and method of use thereof

InactiveCN101139708AImprove corrosion resistanceGood adhesionMetallic material coating processesHigh resistancePersulfate

The invention discloses a transforming solution for preparing anti-corrosion compound oxidation film on an aluminum alloy surface and a using method for the oxidation film. The invention is characterized in that, the transforming solution is a film-forming promoter containing rare-earth salt (nitrate or sulfate and compound salt of cerium, praseodymium, and neodymium), such compound oxidant as radical of permanganate, nitrate and perchlorate, etc., film-forming promoter of vanadium salt and strontium salt, etc.; the transforming solution contains no sexavalent chromium, is environmental friendly; the reaction speed is improved by the compound oxidant and the film-forming promoter, no heating is needed for the chemical transforming, the treating time is 1-5 min. The invention can rapidly prepare under room temperature compound oxidation film comprising compound rare-earth oxide, alumina and manganese oxide with good resistance to corrosion on aluminum alloy surface. The treating solution from the invention is of rapid film-forming speed, simple process, even film layer, high resistance to corrosion, and low environmental pollution, etc.

Owner:陈东初 +2

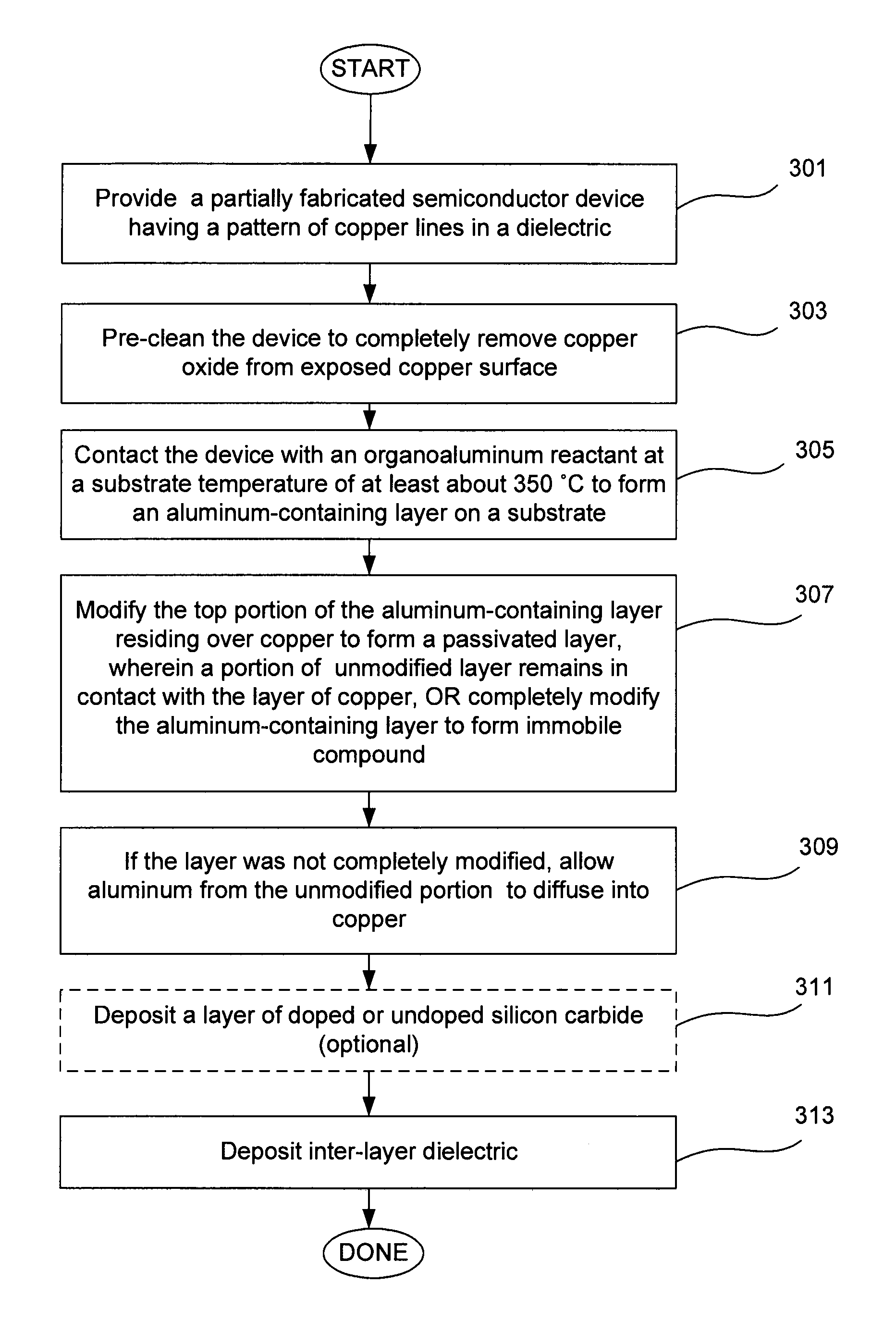

Interfacial layers for electromigration resistance improvement in damascene interconnects

ActiveUS7858510B1Improved electromigration propertiesImprove adhesionSemiconductor/solid-state device detailsSolid-state devicesDielectricNitrogen

Protective caps residing at an interface between metal lines and dielectric diffusion barrier (or etch stop) layers are used to improve electromigration performance of interconnects. Protective caps are formed by depositing a first layer of aluminum-containing material over an exposed copper line by treating an oxide-free copper surface with an organoaluminum compound in an absence of plasma at a substrate temperature of at least about 350° C. The formed aluminum-containing layer is passivated either partially or completely in a chemical conversion which forms Al—N, Al—O or both Al—O and Al—N bonds in the layer. Passivation is performed in some embodiments by contacting the substrate having an exposed first layer with an oxygen-containing reactant and / or nitrogen-containing reactant in the absence of plasma. Protective caps can be formed on substrates comprising exposed ULK dielectric. The aluminum-containing layer residing on the dielectric portion will typically spontaneously form non-conductive layer comprising Al—O bonds.

Owner:NOVELLUS SYSTEMS

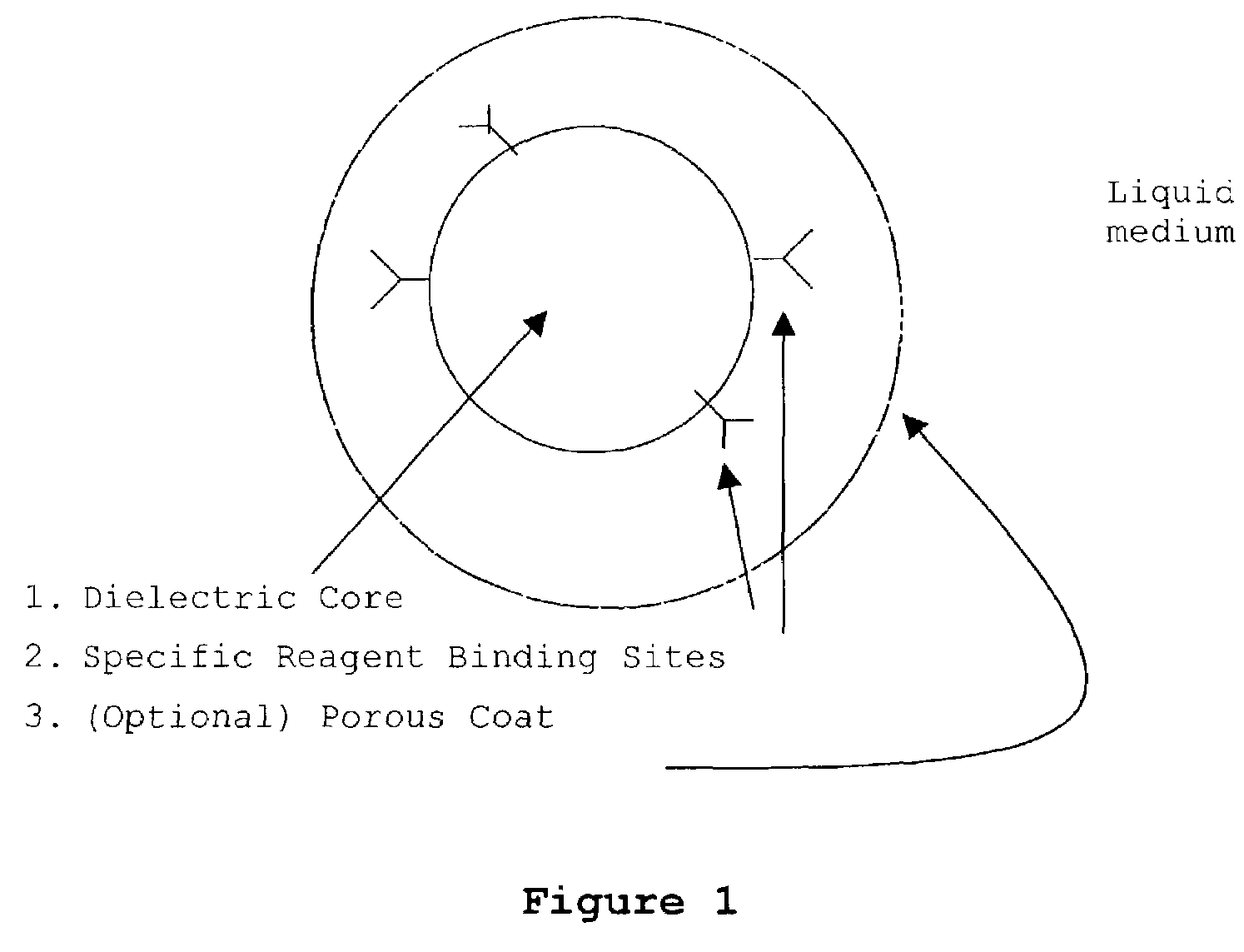

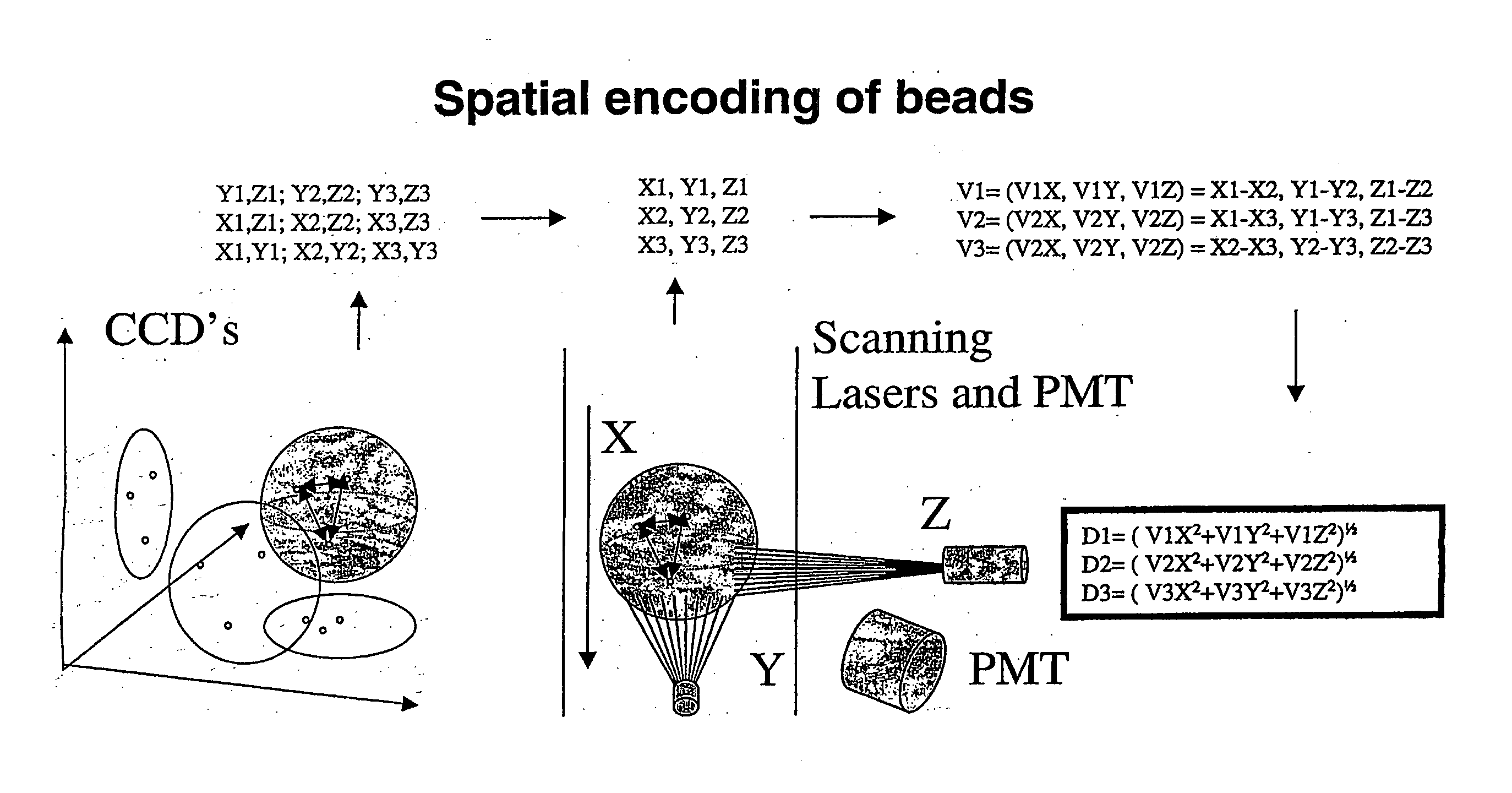

Spatially encoded polymer matrix

ActiveUS20060127369A1Increase diversityIncrease in sizeBiocideSequential/parallel process reactionsSolid phasesChemistry

The invention relates to a spatially encoded polymer matrix in the form of a bead or a granule for combinatorial solid phase synthesis, assaying, functional proteomics and diagnostic use. Compositions of such beads or granules are also provided. Each beaded polymer matrix of the composition comprises a plurality of spatially immobilised particles. The spatial immobilisation of the particles confers on each beaded polymer matrix a “fingerprint” which enables identification of unique beads in a population of beads. The unique identification of individual beads makes it possible to perform combinatorial chemistry strategies while logging individual chemical transformation. Also provided are methods for detection of relative positions in space of particles, methods for generating matrices, methods for distance matrix determination, methods for identifying individual matrices and devices for recording and storing images of matrices.

Owner:MPM HLDG APS

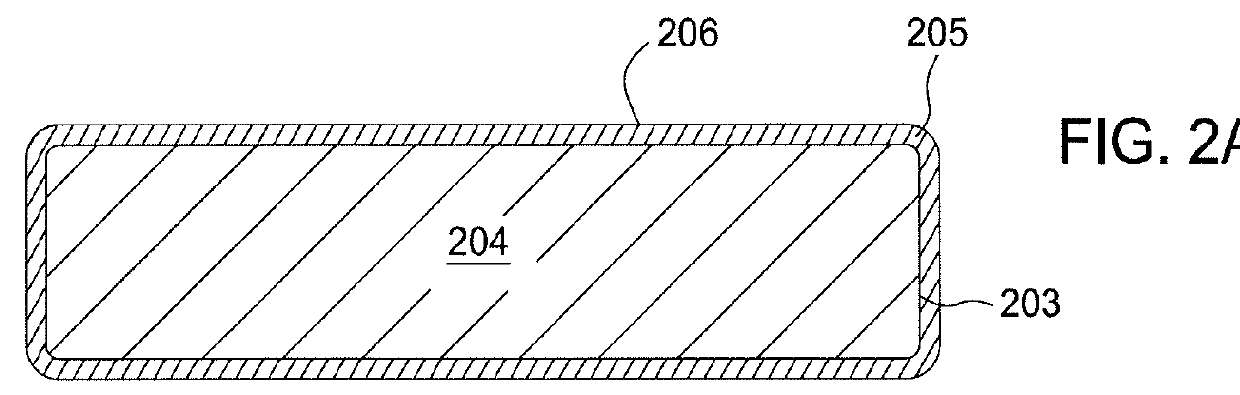

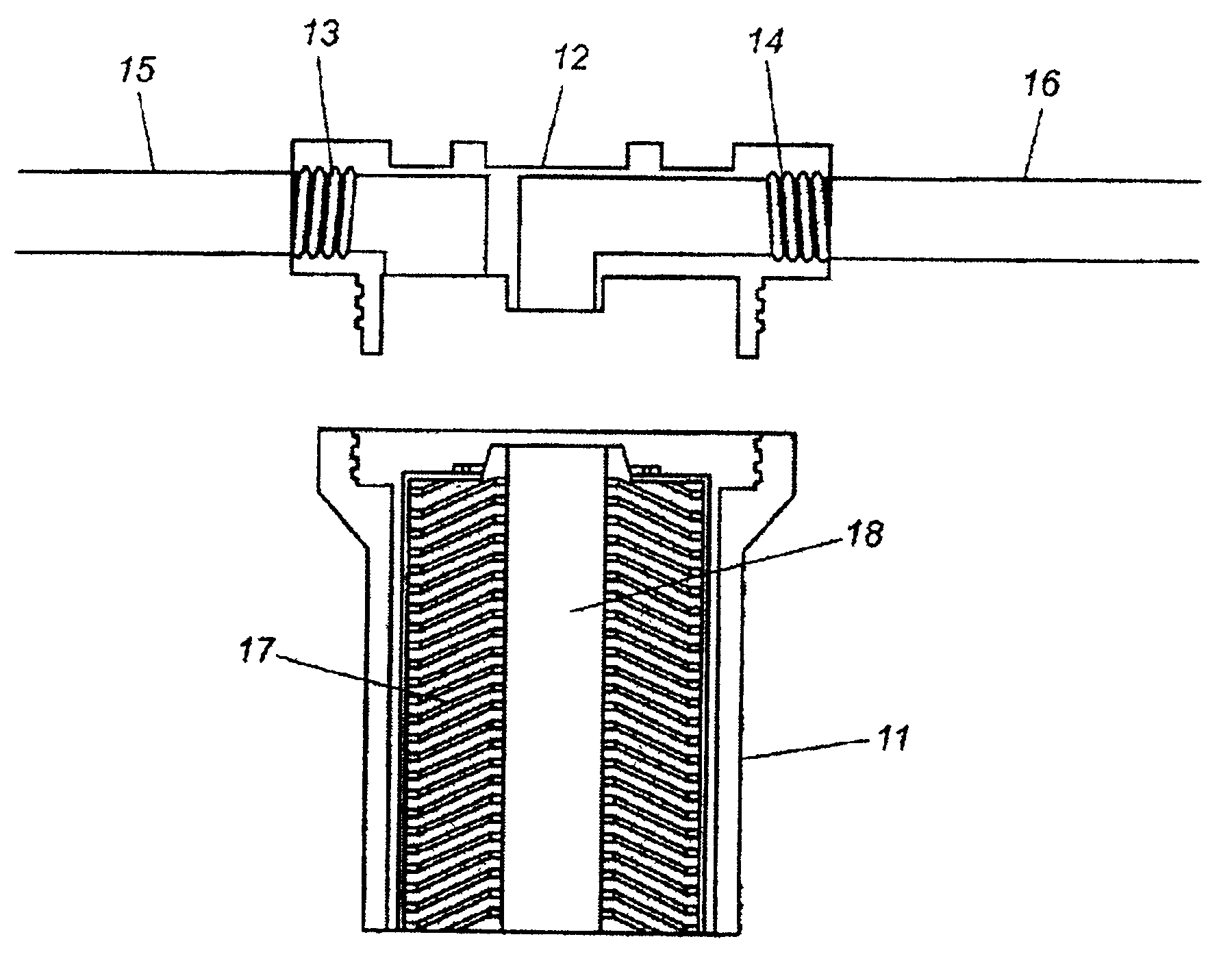

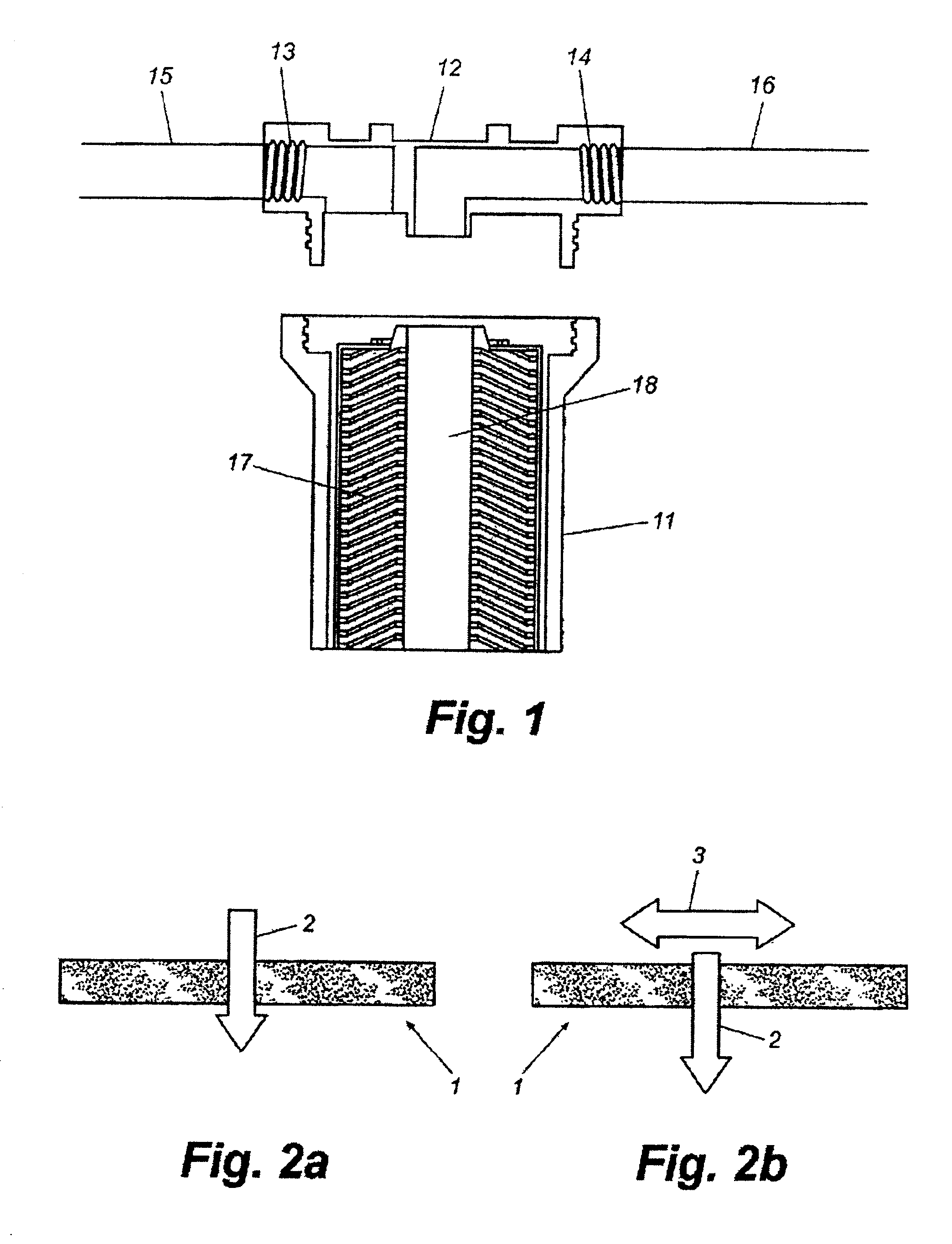

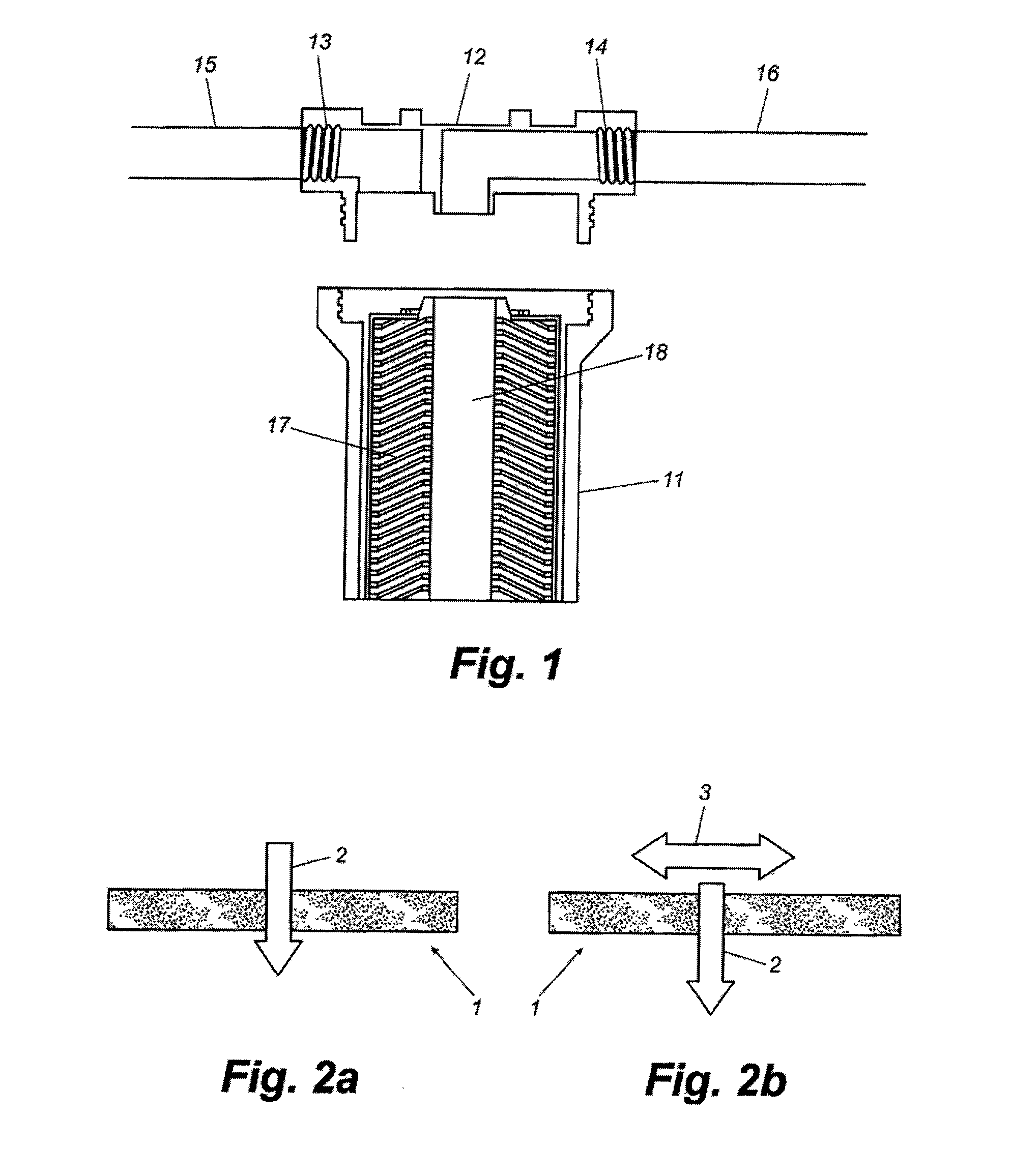

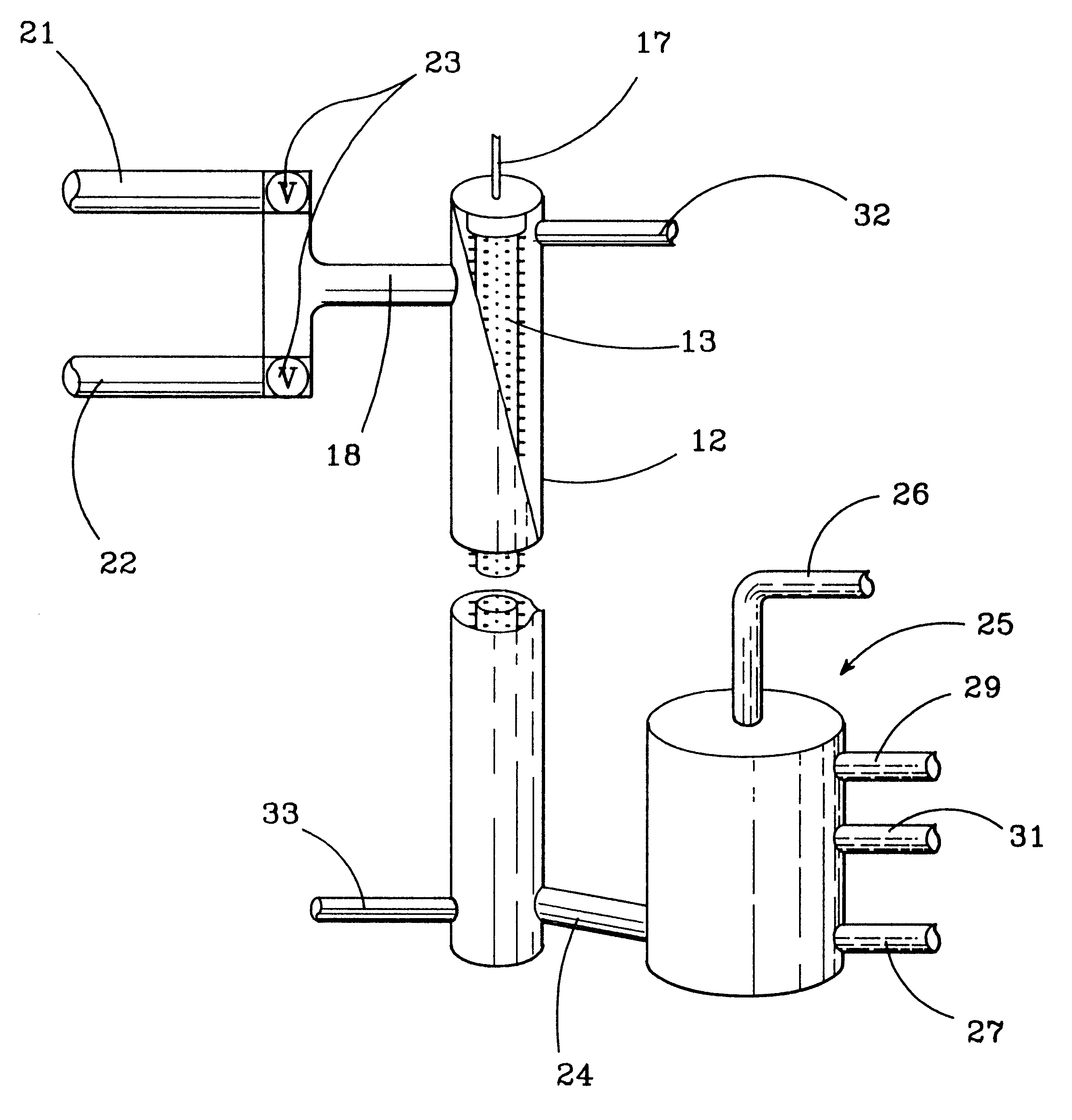

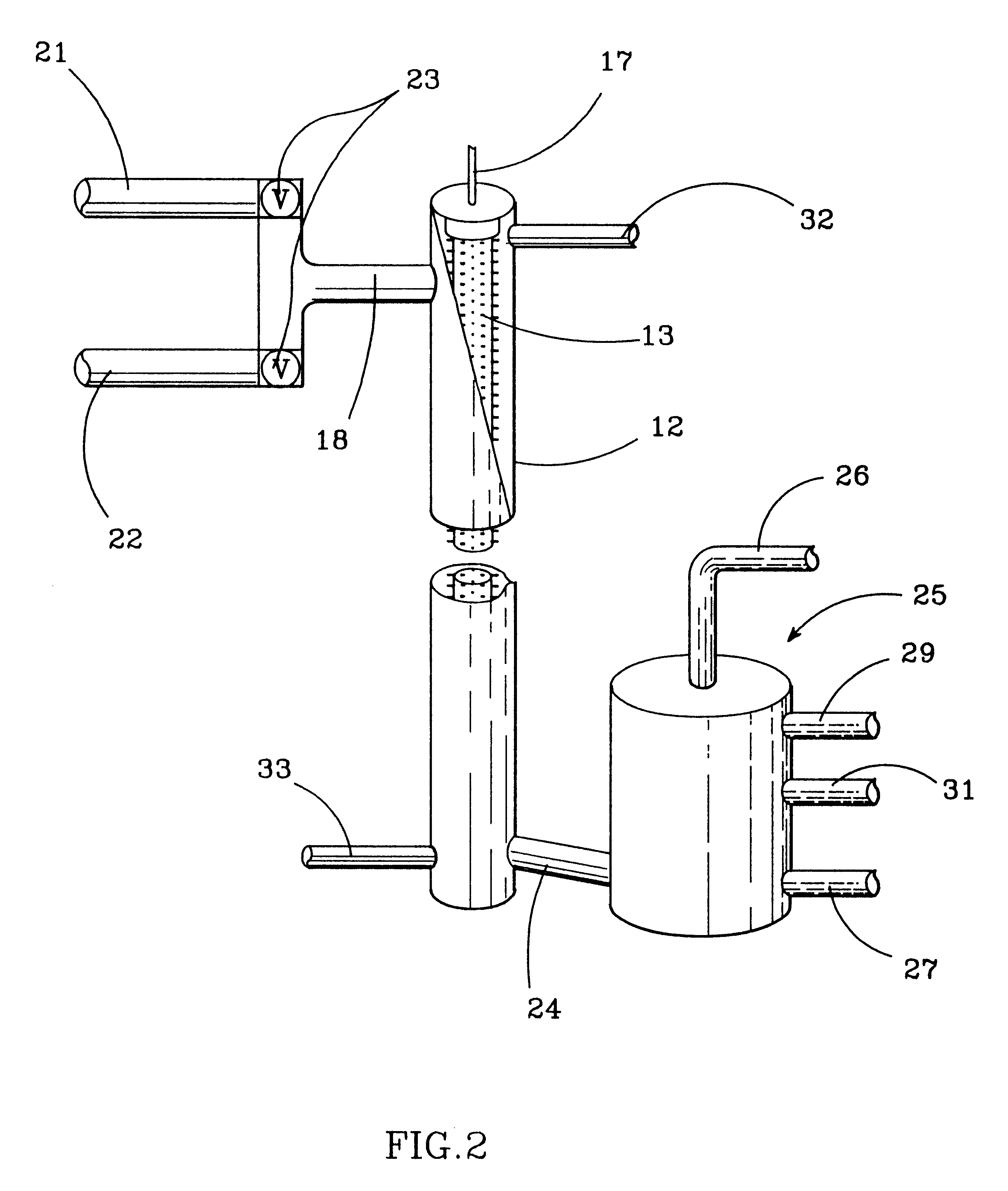

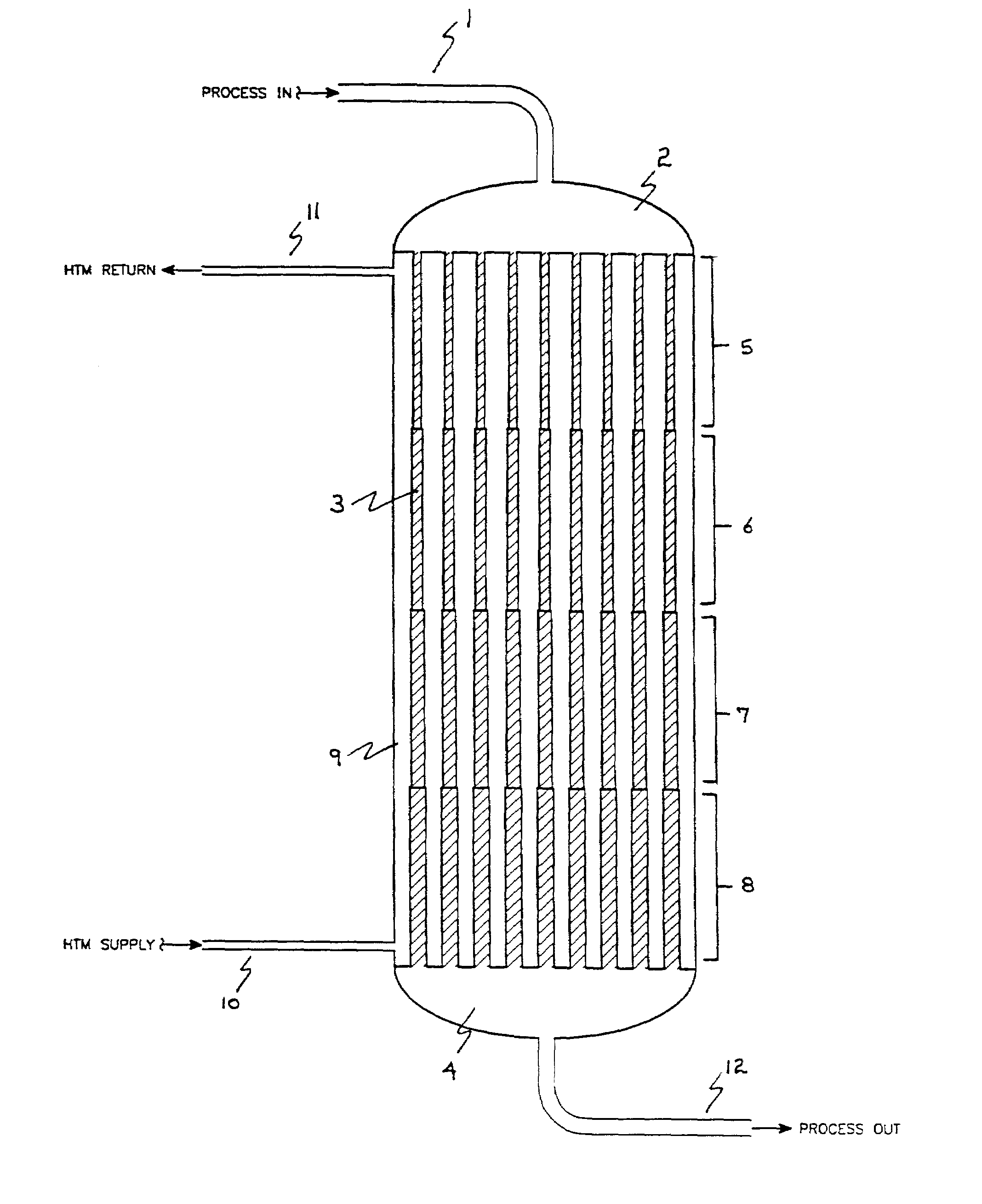

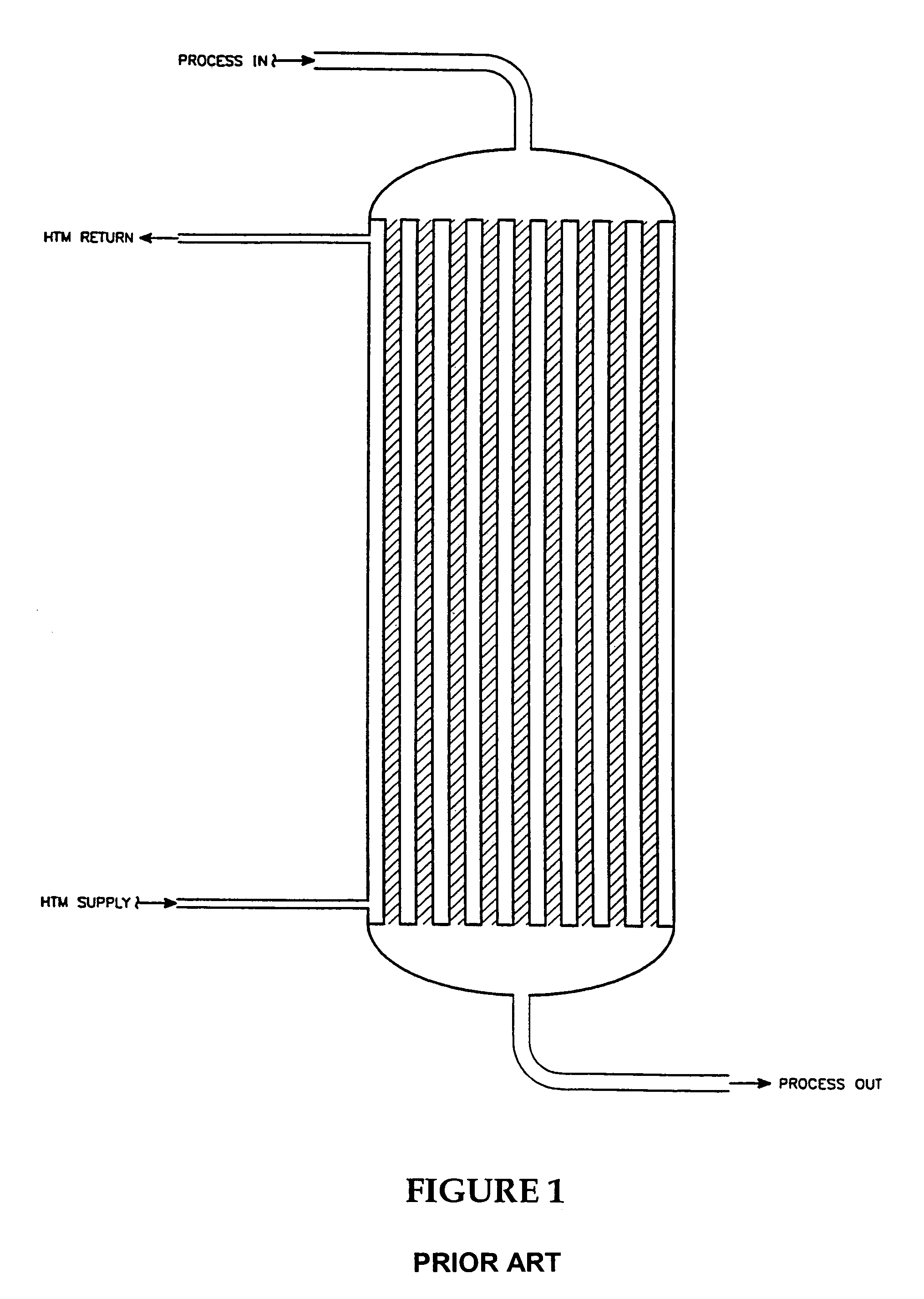

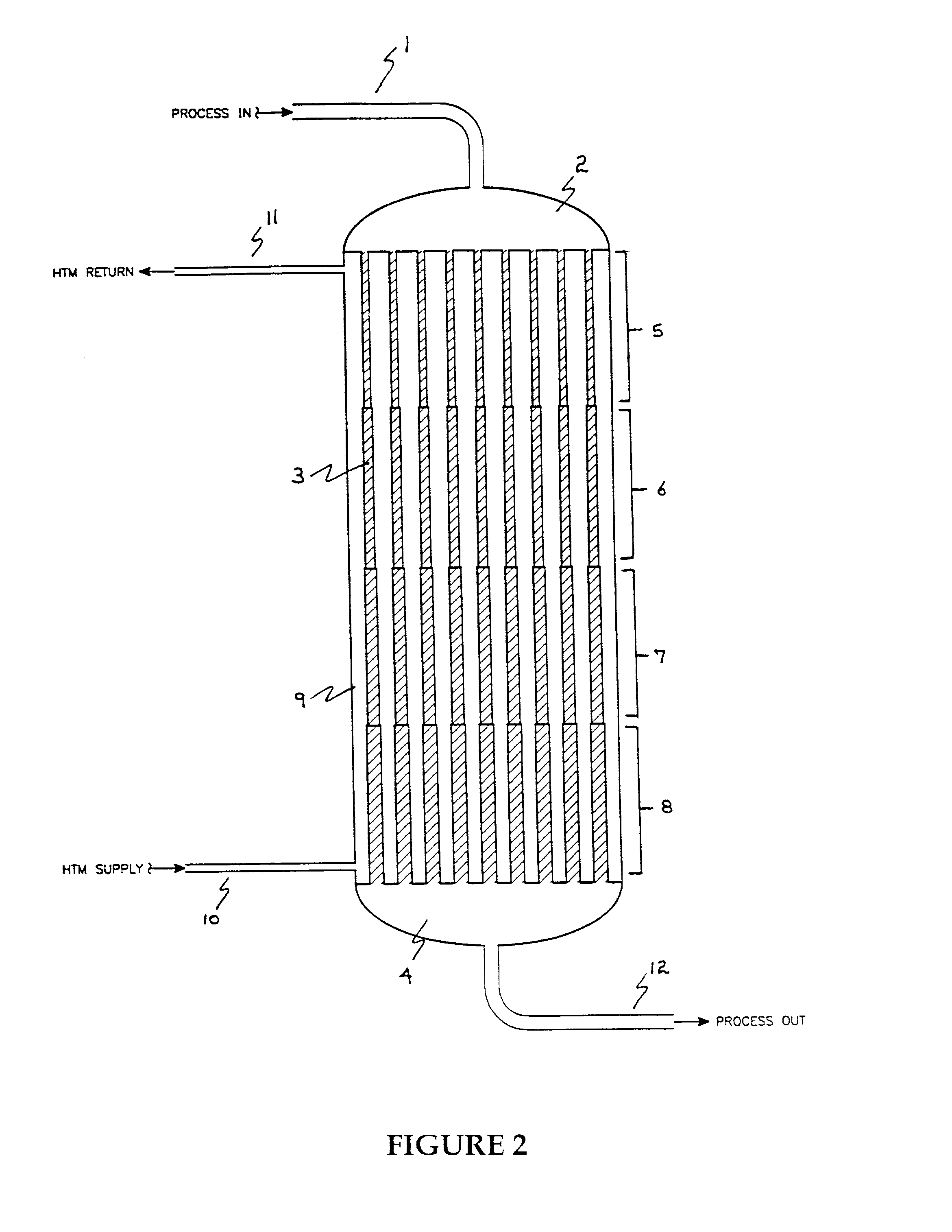

Flow reactors for chemical conversions with heterogeneous catalysts

InactiveUS7316804B2High trafficPhysical/chemical process catalystsOrganic compound preparationProcess systemsProcess engineering

Improved apparatus for use in process systems which include exothermic chemical conversions of organic compounds to value added products is disclosed, more particularly, flow reactors for exothermic chemical conversions using a fixed heterogeneous catalyst with means for control of the exotherm. Flow reactors of the invention comprise a plurality of walled conduits each having an outer surface disposed for contact with a heat-transfer medium, an inlet distribution manifold adapted for flow communication with a downstream manifold through channels formed by heterogeneous catalytic material disposed within each conduit during operation in a sequence of zones for catalyst having the same or different length along the longitudinal coordinate of the conduit and within each zone essentially uniform cross-section of the conduit measured in a plane perpendicular to the longitudinal coordinate thereby defining volume of the zone, and the sequence of zones comprising of at least two zones such that each downstream zone has a larger or smaller cross-section than the contiguous upstream zone. Another aspect of the invention includes processes which use such flow reactors, for example the continuous manufacture of maleic anhydride.

Owner:BP CORP NORTH AMERICA INC

Treatment liquid and method or preparing Ti/Zr-containing yellow passive film on surface of aluminum alloy

InactiveCN101967633AHigh bonding strengthImprove the protective effectMetallic material coating processesOrganic acidRoom temperature

The invention discloses treatment liquid and a method for preparing a Ti / Zr-containing yellow passive film on the surface of an aluminum alloy. Each liter of treatment liquid comprises the following components by weight: 0.5 to 2.0g of fluorotitanic acid, 0.4 to 2.0g of fluorozirconic acid, 2.0 to 5.0g of manganate and 0.5 to 2.0g of organic acid; and the pH value of the treatment liquid is between 2.0 and 3.0. The treatment liquid of the invention does not contain chromium or other toxic substances, conversion treatment is realized without heating, the treatment time is between 5 and 30 minutes, and a yellow Ti / Zr-containing chemical conversion film can be prepared on the surface of the aluminum alloy. The chemical conversion film prepared by the method has high decay resistance and high bonding strength with a substrate, and is treated at room temperature by a simple process; and the coating does not contain hexavalent or trivalent chromium which is harmful to environment and human bodies.

Owner:SOUTH CHINA UNIV OF TECH

Bioactivity surface modification method of biological medical degradable magnesium alloy

ActiveCN101461964ADegradation rate can be controlledSolve the speed problemCoatingsProsthesisDrug biological activityBond strength

The invention relates to the technical field of biomaterial, is particularly applicable to the field of surface modification of a biological medical material, in particular to a biological activity surface modification method for a biological medical degradable magnesium alloy. The method is to prepare a surface coating on magnesium or a magnesium alloy, and comprises the following steps that: anintermediate chemical conversion film is prepared on the surface of the magnesium or the magnesium alloy; and then a ceramic layer with biological activity is prepared on the outer layer. The surfacecoating not only can control the degradation speed of a matrix of the magnesium or the magnesium alloy, but also has surface activity. The surface coating comprises the intermediate chemical conversion film and the outer biological activity ceramic layer, wherein the intermediate chemical conversion film not only can control the degradation speed of the matrix of the magnesium matrix, but also can improve the preparation performance and bonding force with the matrix of the outer biological activity ceramic layer; and the outer biological activity ceramic layer improves the biological activityof an implanting body, and enhances bonding strength of the implanting body and an organism so as to improve the success ratio of implantation. The invention aims to solve the problems of fast degradation and low surface biological activity of a degradable biological medical magnesium alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

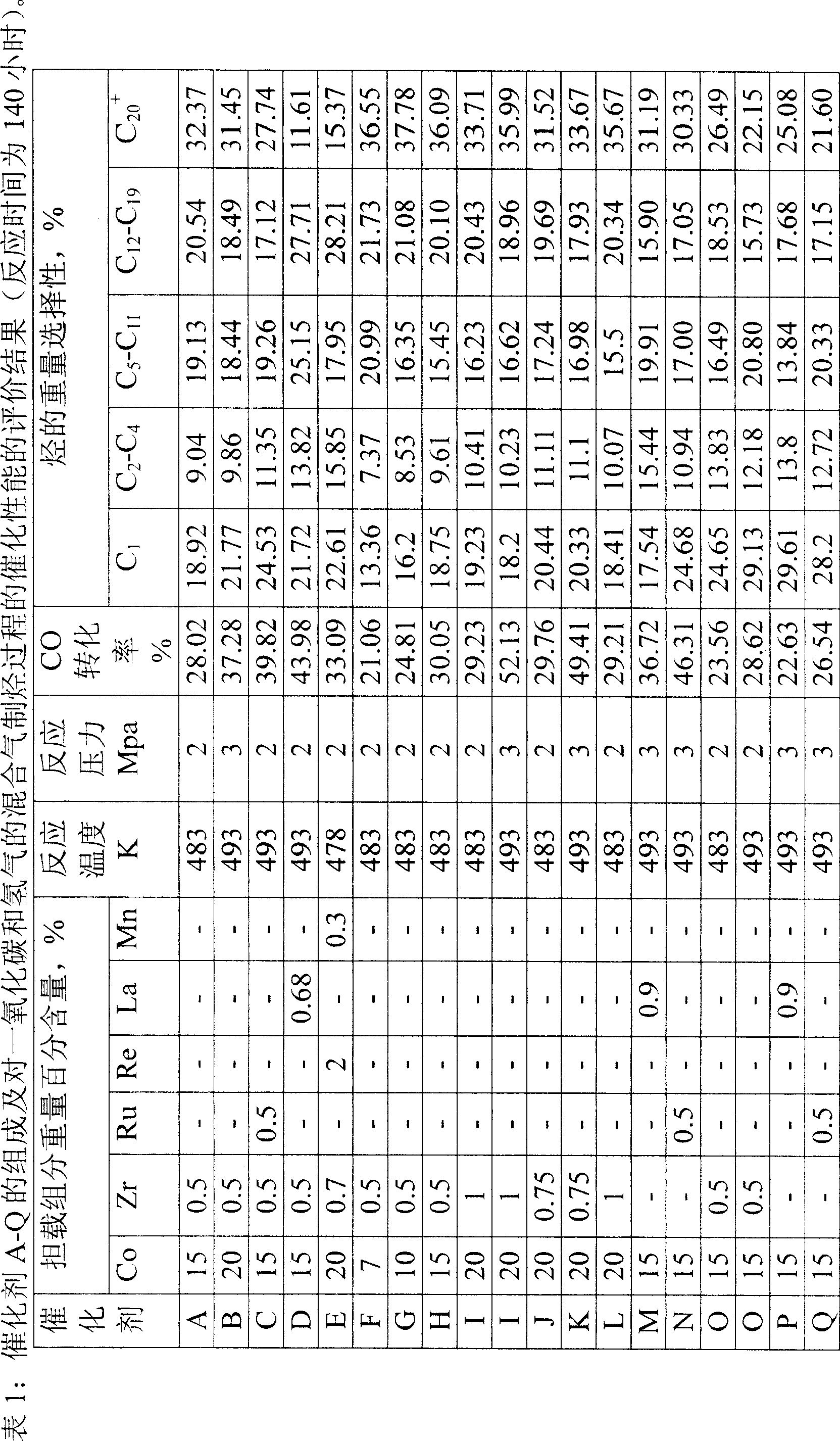

Method for preparing catalyst and application thereof

ActiveCN101143325AEasy to manufactureEasy to operateCatalyst carriersHydrocarbon from carbon oxidesHydrogenActive component

The invention provides a catalyst preparation method. The procedure is that:1} a solution containing soluble compounds with loaded components is prepared; 2} the solution produced in procedure 1 is sprayed on a rolling carrier or a carrier preloading one or a plurality of components and the carrier is heated in the process of spraying; 3) the product produced in procedure 2 is dried or roasted; 4) the procedures 2 and 3 are repeated. The active components of the catalyst prepared in the method of the invention contain group eight elements. When the catalyst preparation method of the invention is applied in the hydrocarbon preparation procedure from mixed gas of carbon monoxide and hydrogen, the active components of the catalyst prepared contain group eight elements. The invention provides a better shell catalyst preparation technique, which solve the problem of internal diffusion in certain chemical conversion procedures. The catalyst can be applied in hydrocarbon preparation reaction of gas mixture of carbon monoxide and hydrogen.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

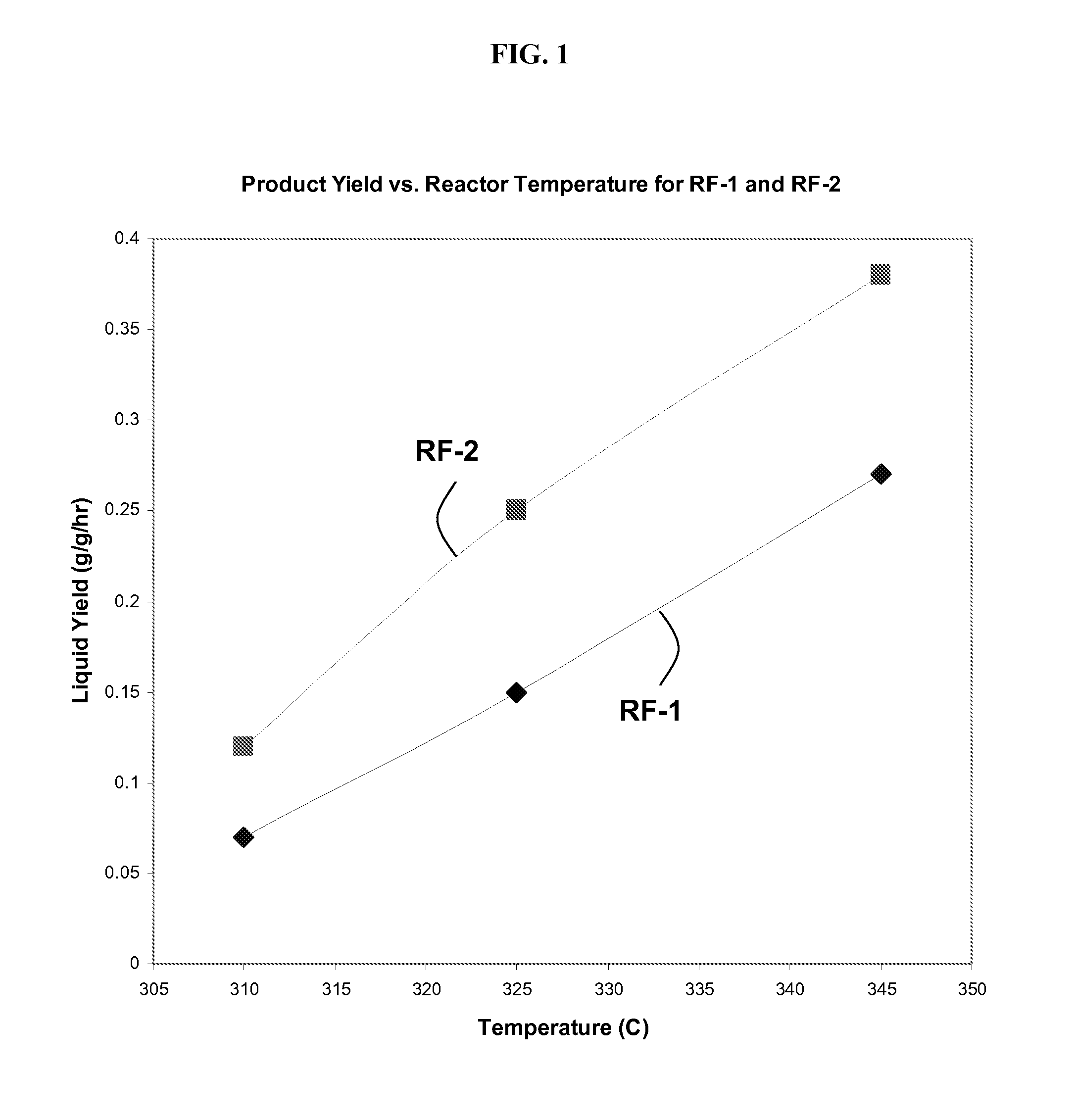

Cobalt-molybdenum sulfide catalyst materials and methods for stable alcohol production from syngas

The present invention provides methods and compositions for the chemical conversion of syngas to alcohols. The invention includes catalyst compositions, methods of making the catalysts, and methods of using the catalysts including techniques to maintain catalyst stability. Certain embodiments teach compositions for catalyzing the conversion of syngas into products comprising at least one C1-C4 alcohol, such as ethanol. These compositions generally include cobalt, molybdenum, and sulfur, and avoid metal carbides both initially and during reactor operation.

Owner:ALBEMARLE CORP

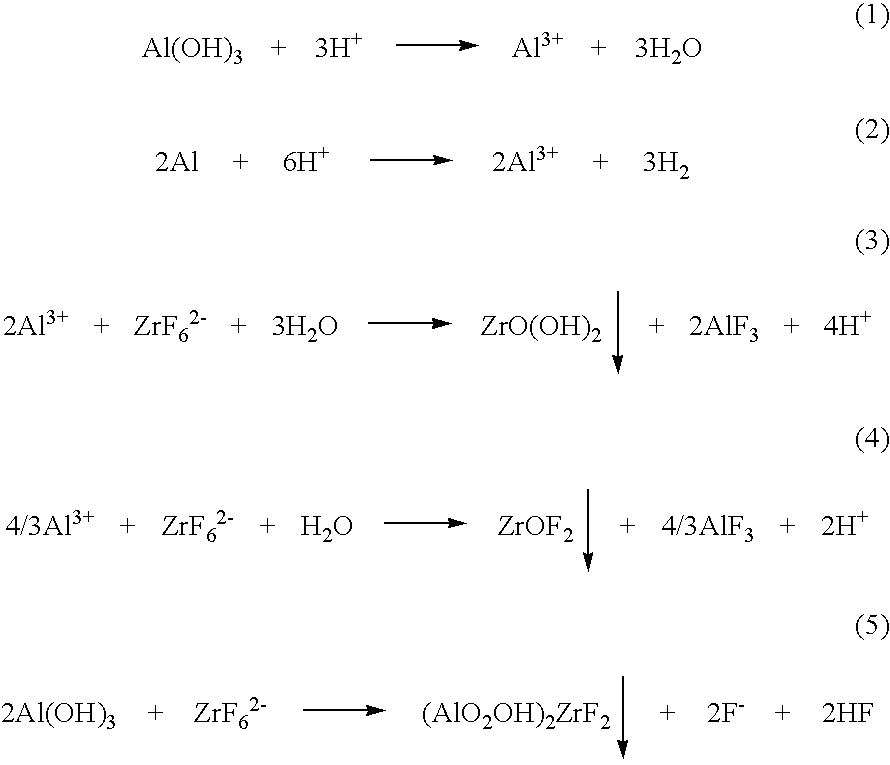

Method of surface treating metal and metal surface treated thereby

InactiveUS20040244875A1Improve corrosion resistanceImprove uniformityElectrolytic inorganic material coatingSurface reaction electrolytic coatingElectrolysisMetallic substrate

It is an object of the present invention to provide a method of metal surface treatment and a surface treated metal thereby, which has excellent corrosion resistance and can form a coat having high corrosion resistance on metal substrates such as iron, zinc, aluminum and magnesium. A method of metal surface treatment comprising the step of forming a chemical conversion coat on the surface of a metal article to be treated by a chemical conversion treatment reaction by a chemical conversion treatment agent containing a zirconium-containing compound and a fluorine-containing compound, wherein said chemical conversion treatment reaction is conducted through cathodic electrolysis treatment.

Owner:NIPPON PAINT CO LTD

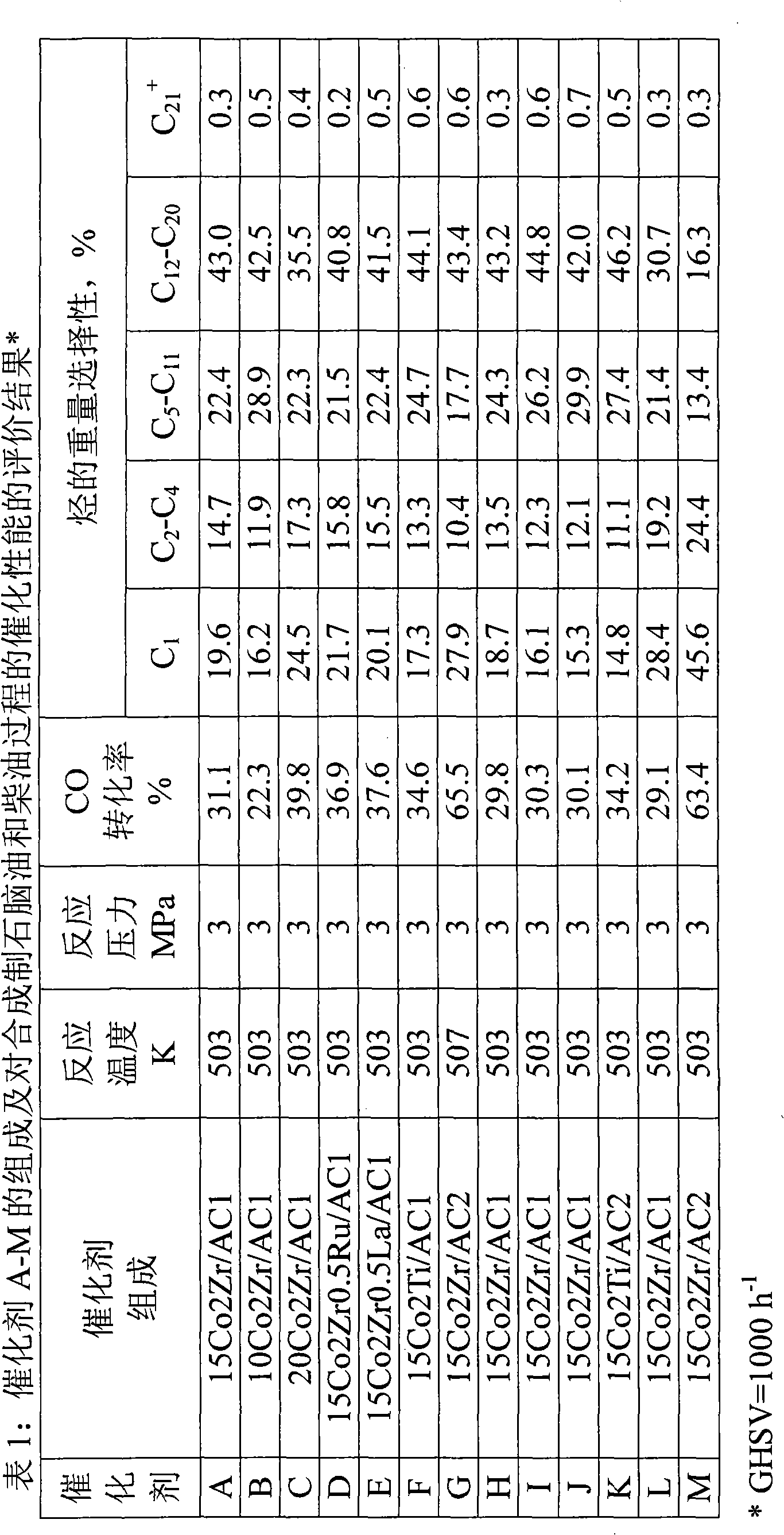

Lamella catalyst for preparing petroleum naphtha and diesel oil, preparation method and application thereof

ActiveCN101318133AEasy to manufactureEasy to operateLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsActivated carbonNaphtha

The invention relates to a shell catalyst used for preparing naphtha and diesel oil, which takes active carbon loaded with 5-35 percent of active component and 0.01-5 percent of auxiliary components by weight as a carrier; wherein, the active component is cobalt and the auxiliary components can be one or a plurality of La, Ce, Zr, Cr, Ti, V, B, Mn, Re, K, Pt, Ru, Mg, Ba and Ca. The preparation method of the catalyst comprises: a) preparing the solution containing soluble compounds of the loaded component; b) spraying the solution prepared in the step a) on the rolling carrier; c) drying or roasting the catalyst prepared in the step b) in inert gases. The invention can easily prepare eggshell type catalyst, which has the advantages of simple operation, uniform shell, easily controlled preparation process and good repeatability, thus being easy for large-scale production. Furthermore, the obtained catalyst has great service effect in overcoming the diffusion control problem in the chemical conversion process.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

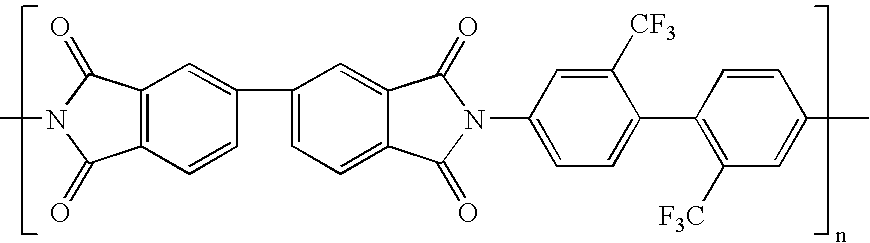

Low color polyimide compositions useful in optical type applications and methods and compositions relating thereto

ActiveUS20080138537A1Low color requirementLiquid crystal compositionsFilm/foil adhesivesIn planeDisplay device

Perfluorinated polyimides (and co-polyimide) compositions, particularly films are disclosed, comprising at least 50 mole percent of a polymeric repeat unit derived from contacting 3,3′,4,4′-biphenyltetracarboxylic dianhydride (BDPA) and 2,2′-bis(trifluoromethyl) benzidine (TFMB) monomers. The perfluorinated polyimide (and co-polyimide) films of the invention have an in-plane coefficient of thermal expansion (CTE) between −5 and +20 ppm / ° C. and a average light transmittance percent of from about 65.0 to about 99.0 (on a 75-micron thick film basis). The films of the present invention were converted to a polyimide using a chemical conversion method instead of typically employed thermal conversion step thus yielding these desirable properties. The films of the present invention can be an excellent substrate in an optical display device and can be used to replace rigid glass substrates. Finally, the polyimide films of the invention can also be used to manufacture flexible display devices (e.g., cellular phones, personal digital assistants, portable video games, laptops, and the like).

Owner:DUPONT ELECTRONICS INC

Environmentally-friendly magnesium alloy chemical conversion film, microarc oxide film hole sealing solution and hole sealing method

InactiveCN101709497ANo pollution in the processSimple ingredientsAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention relates to an environmentally-friendly magnesium alloy chemical conversion film, microarc oxide film hole sealing solution and a hole sealing method. The hole sealing solution comprises phytate or phytic acid and one or more following substances of alkali metal hydroxide, silicate, phosphoric acid or phosphate. The hole sealing method is operated according to the following steps: preliminary treatment; chemical conversion or micro-arc oxidation; post treatment: in phytate, one of or several kinds of silicate, phosphoric acid or phosphate are added, the pH value of solution is adjusted by the alkali metal hydroxide or ammonia water, solution temperature is controlled at 30-100 DEG C, and hole sealing treatment is carried out. The hole sealing solution used by the invention does not contain Cr6 and F-, thus causing no pollution to environment. After sealing holes, the size of the crack or the micropore of the chemical conversion film or oxide film is obviously decreased, and corrosion resisting property is improved; meanwhile, the film layer and the organic coating obtained by next-step painting have favourable adhesive force.

Owner:JIANGXI SCI & TECH NORMAL UNIV

Chemical conversion coating agent and surface-treated metal

ActiveUS7510612B2Reduce environmental impactConvenient treatmentOther chemical processesSolid state diffusion coatingHafniumWater soluble

The present invention disclosure provides a chemical conversion coating agent which places a less burden on the environment and can apply good chemical conversion treatment to all metals such as iron, zinc and aluminum, and a surface-treated metal obtained using the same. The chemical conversion coating agent comprising: at least one kind selected from the group consisting of zirconium, titanium and hafnium; fluorine; and a water-soluble resin, wherein said water-soluble resin has, in at least a part thereof, a constituent unit expressed by the chemical formula (1):and / or the chemical formula (2):

Owner:NIPPON PAINT CO LTD

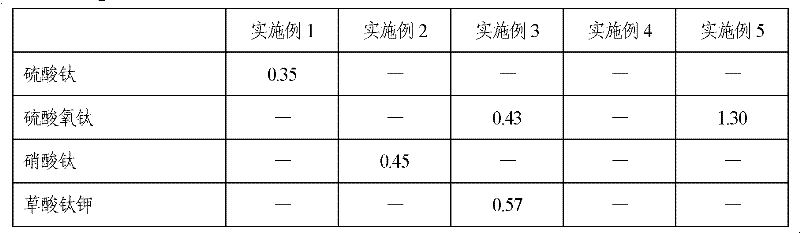

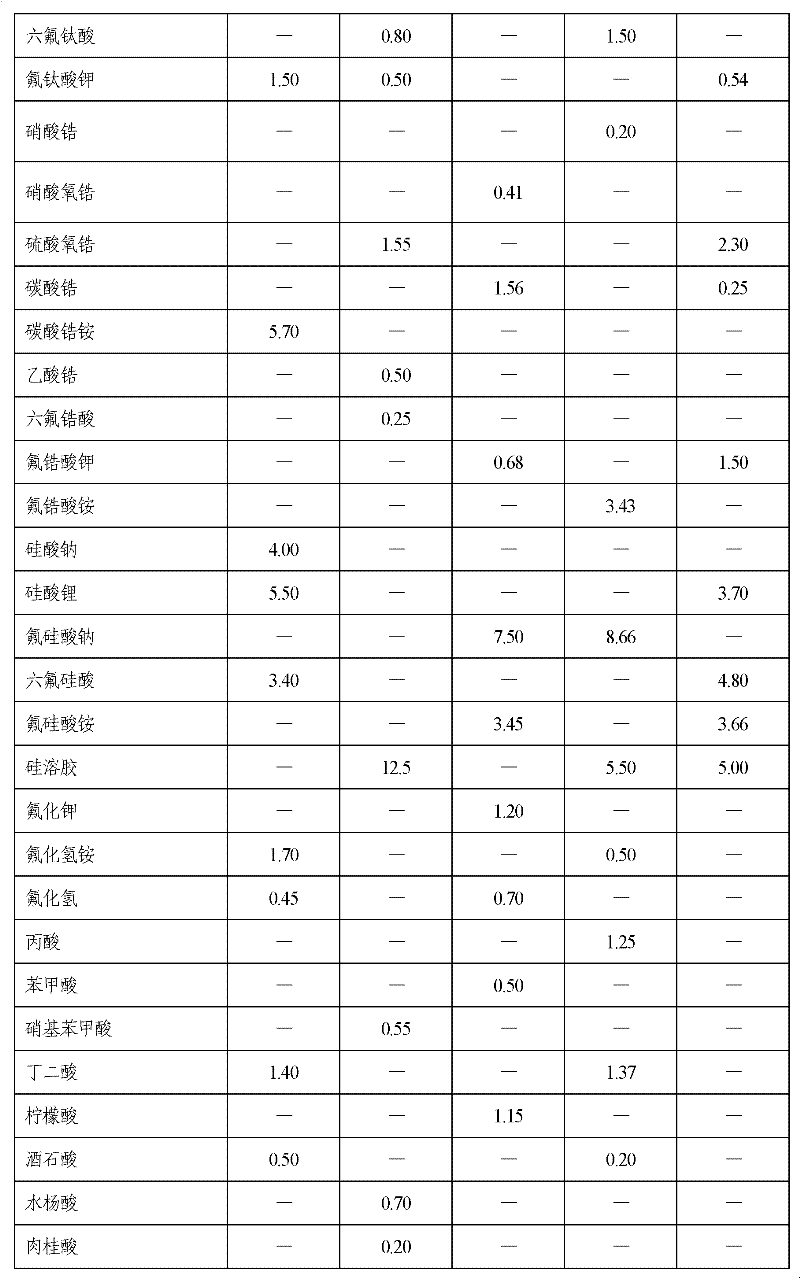

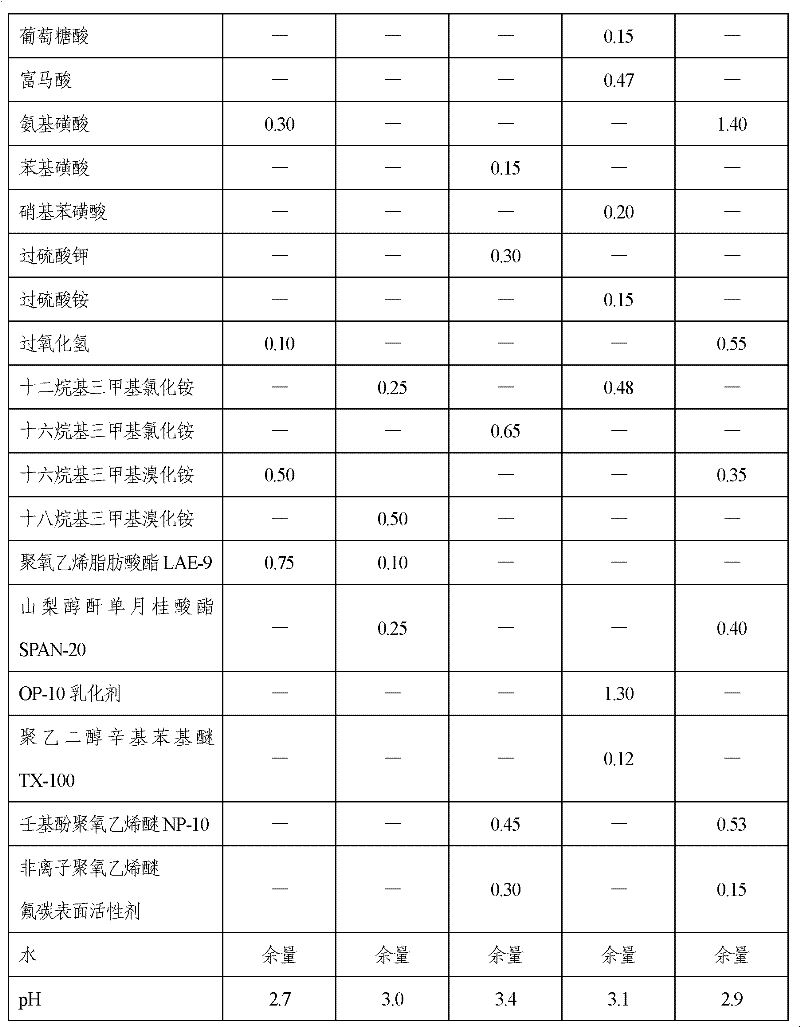

Aluminum alloy scratch resistant and fingerprint resistant chromium-free chemical conversion solution for ship and preparation method of conversion film

InactiveCN102443794AImprove corrosion resistanceImprove scratch resistanceMetallic material coating processesChromium freeTitanium

The invention relates to the field of aluminum alloy decoration and protection coatings for ships, in particular to an aluminum alloy scratch resistant and fingerprint resistant chromium-free chemical conversion solution for a ship and application of the aluminum alloy scratch resistant and fingerprint resistant chromium-free chemical conversion solution to a chemical conversion film. The chemical conversion solution contains titanium salts, zirconium salts, a silicon compound, an accelerator, a surfactant and the balance water, wherein the concentration of the titanium salts in the chromium-free chemical conversion solution ranges from 0.02 to 10g / L; the concentration of the zirconium salts in the chromium-free chemical conversion solution ranges from 0.1-10 g / L; the concentration of thesilicon compound in the chromium-free chemical conversion solution ranges from 2 to 25g / L; the concentration of the accelerator in the chromium-free chemical conversion solution ranges from 0.5-12 g / L; and the concentration of the surfactant in the chemical conversion solution ranges 0.1 to 10g / L. Chemical conversion films are formed on the surfaces of 5xxx or 6xxx series aluminum alloys by adopting an impregnating, brush coating, roller coating or spraying mode; and the chemical conversion films have favorable corrosion resistance, scratch resistance and fingerprint resistance and can be used as the surface decoration and protection coating of the aluminum alloy for the ship.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com