Corrosion-contamination resistant chemical conversion agent and method for preparing chromium-free chemical conversion film

A transforming agent and corrosion-resistant technology, applied in the direction of metal material coating process, etc., can solve the problems of high cost, difficult construction in large areas, unsatisfactory corrosion resistance, etc., and achieve low cost, excellent stain resistance, and convenient construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation method of the present invention is described in detail below, but not limited:

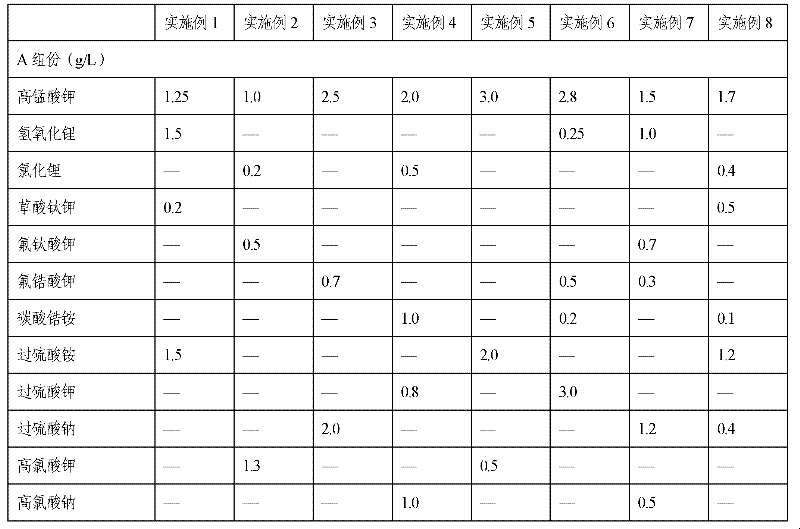

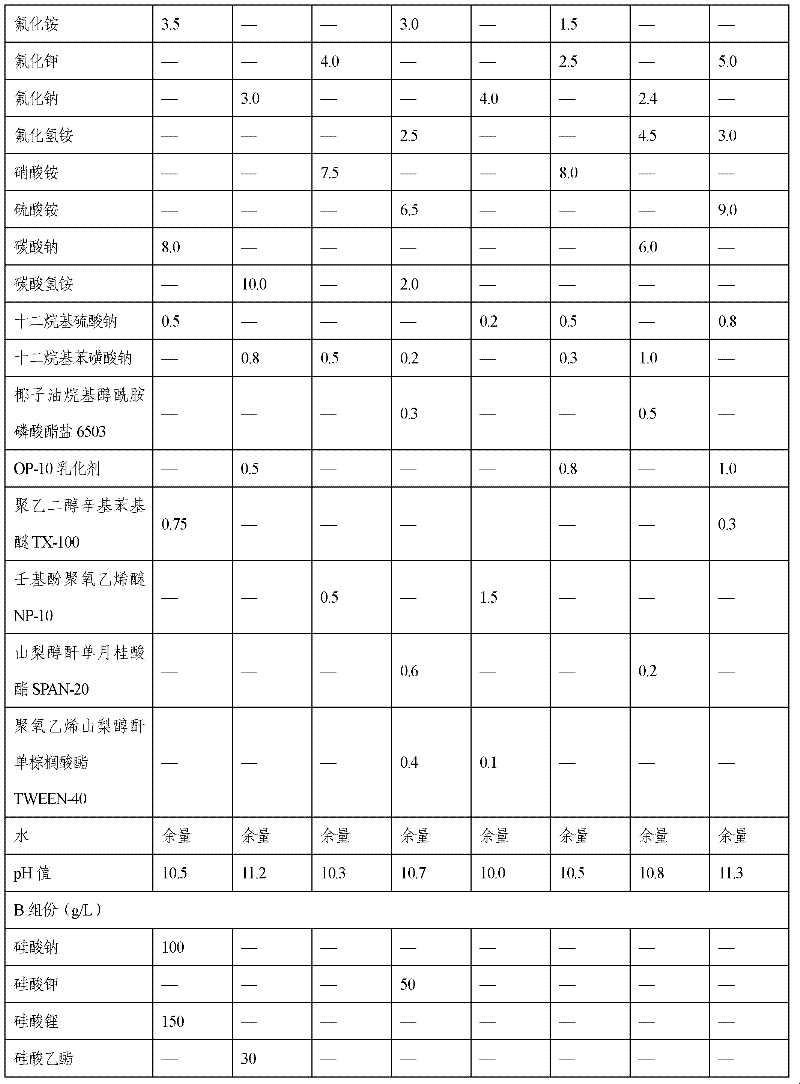

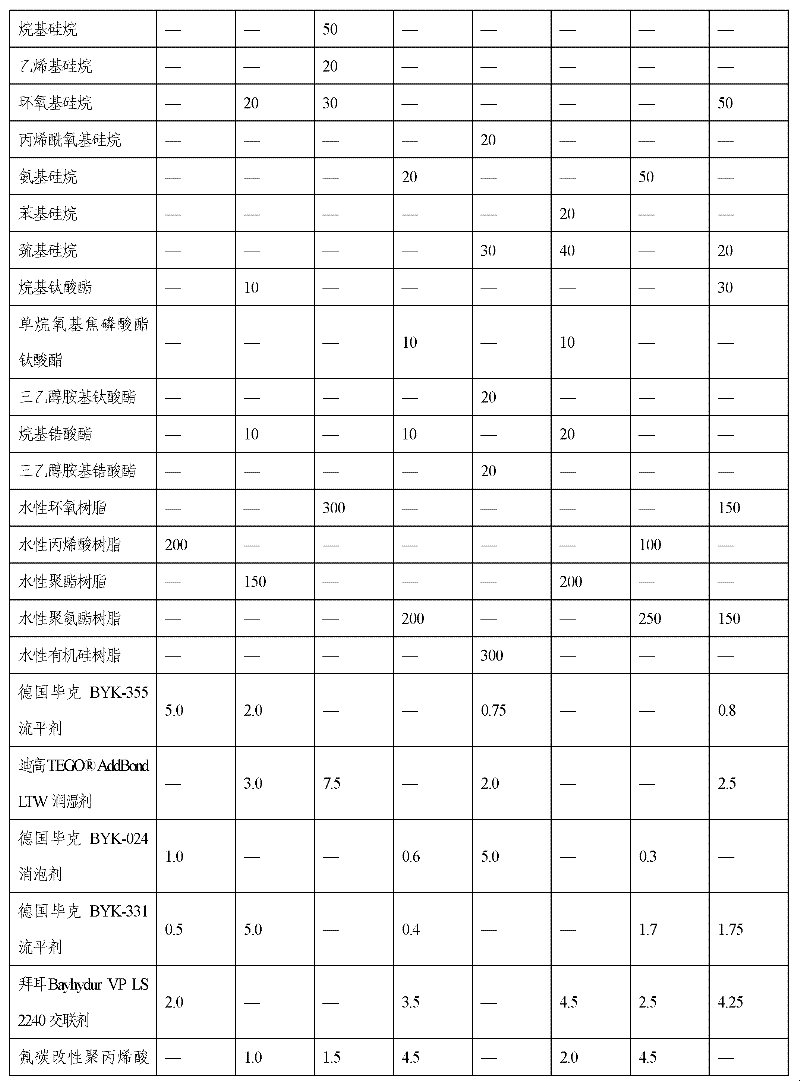

[0027] The anti-corrosion and anti-pollution chemical conversion agent of the present invention consists of two components, A and B, both of which are aqueous solutions. Component A includes main salt, film-forming accelerator, buffer and surfactant, etc. Component B includes silicate, silane, silica sol, titanate, zirconate, water-based resin and additives, and water.

[0028] The corrosion-resistant and anti-pollution chemical conversion agent is used to prepare a composite conversion film. The conversion film is a composite conversion film formed by two components A and B in the chemical conversion agent. Component A first forms the bottom inorganic chemical conversion film, The thickness of the chemical film is 0.5-1 μm, and then the top organic sealing film is formed from the component B, and the thickness of the sealing film is 2-3 μm. The implementation m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com