Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3216 results about "Alloy surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

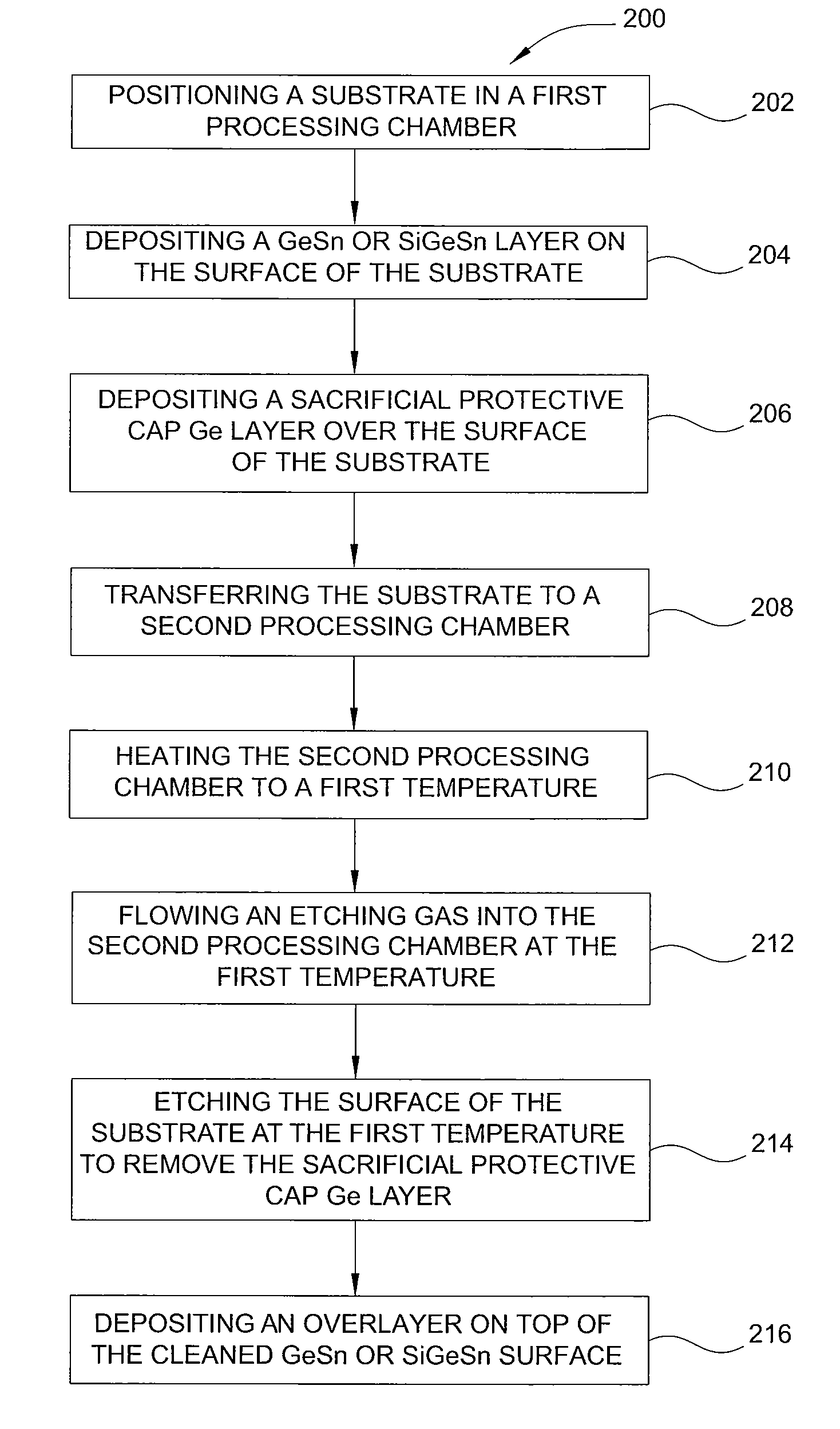

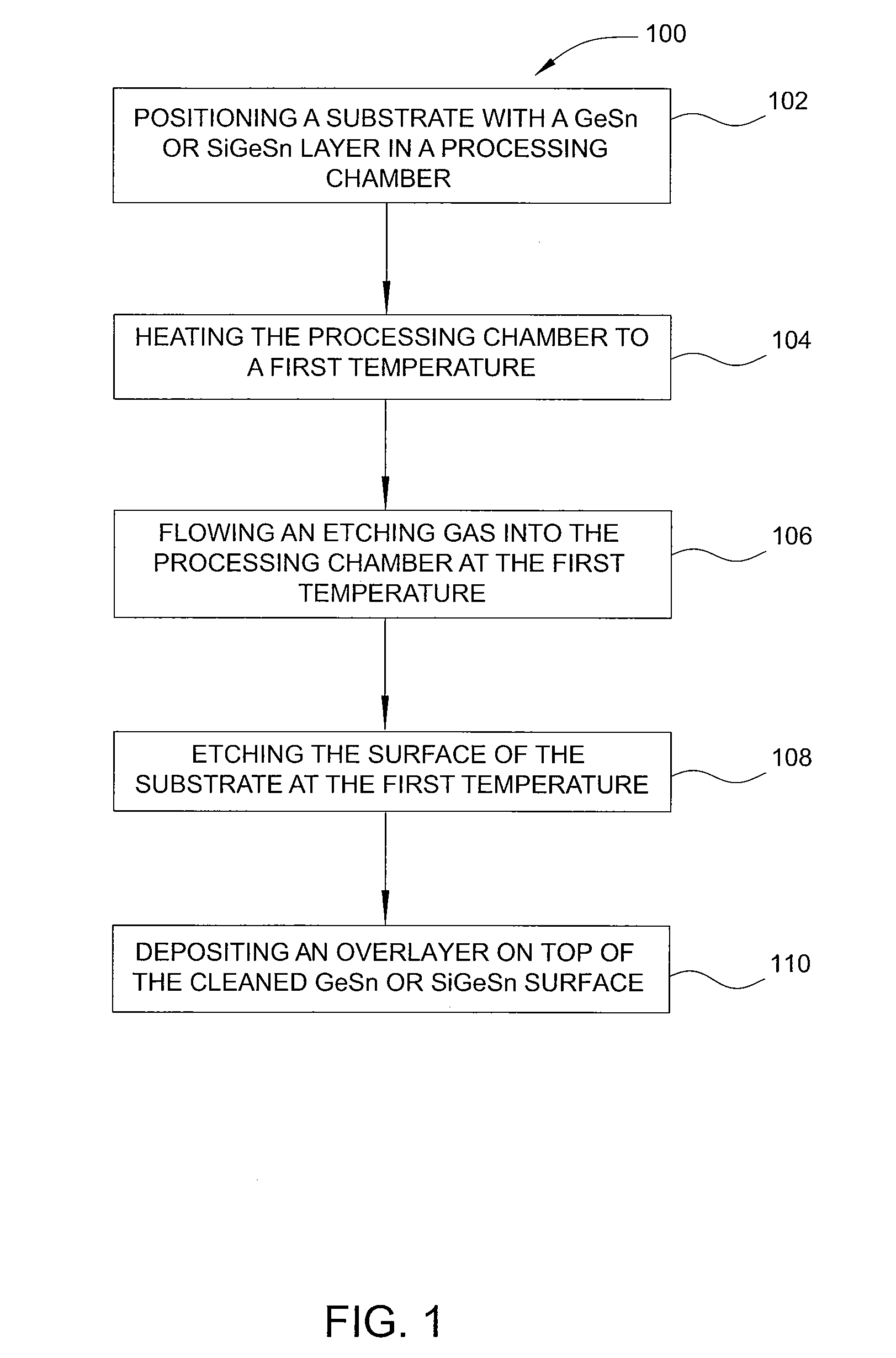

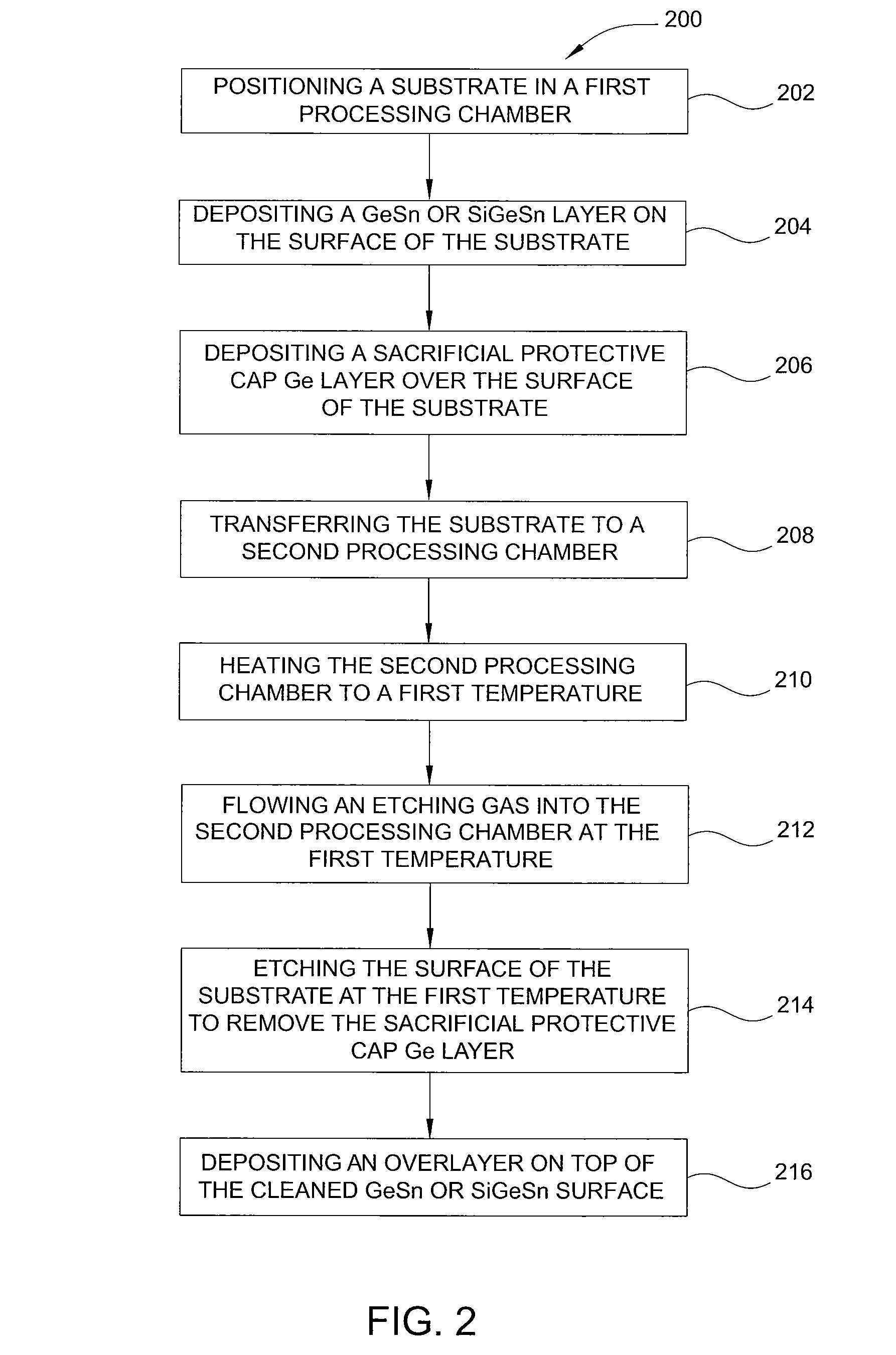

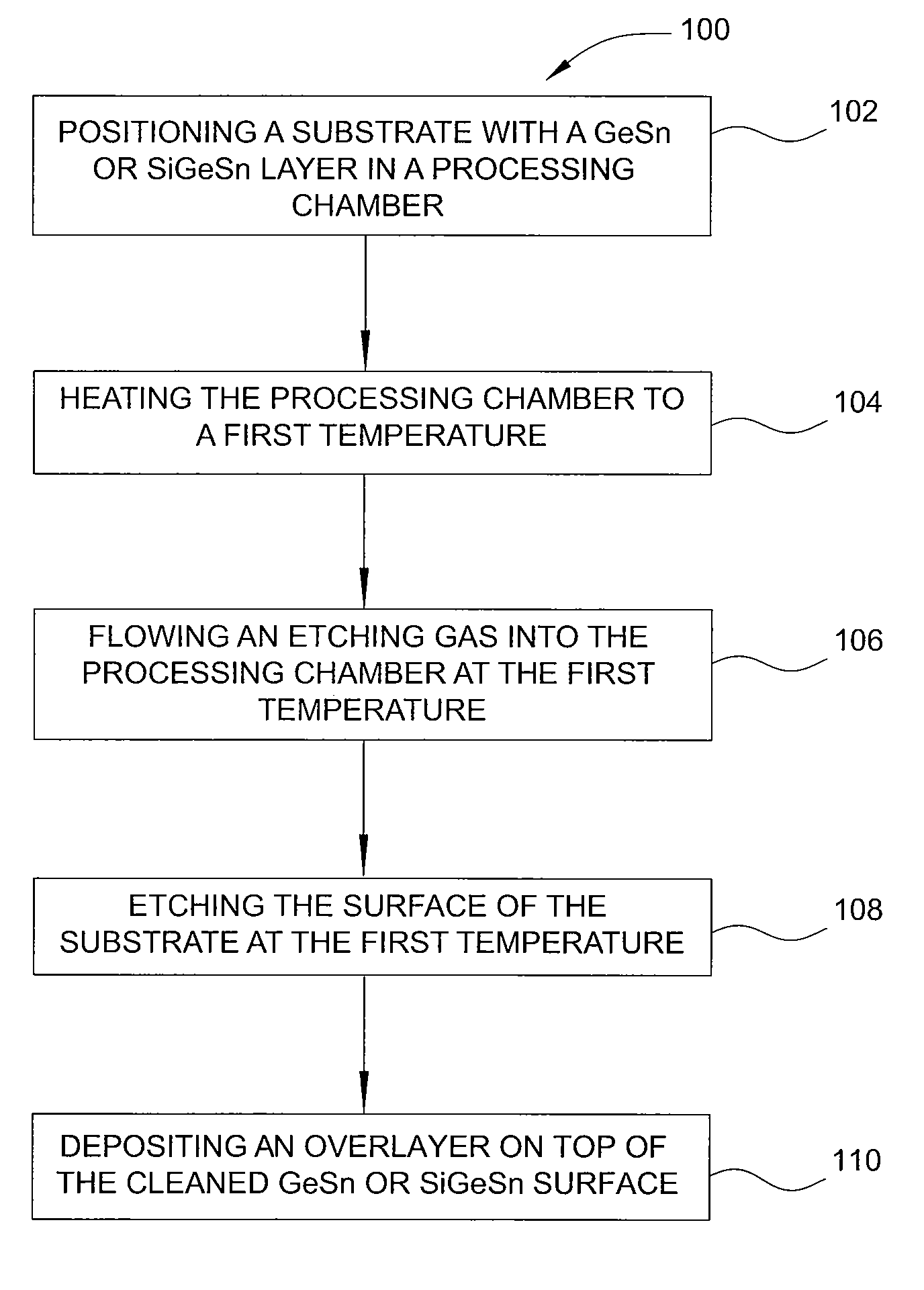

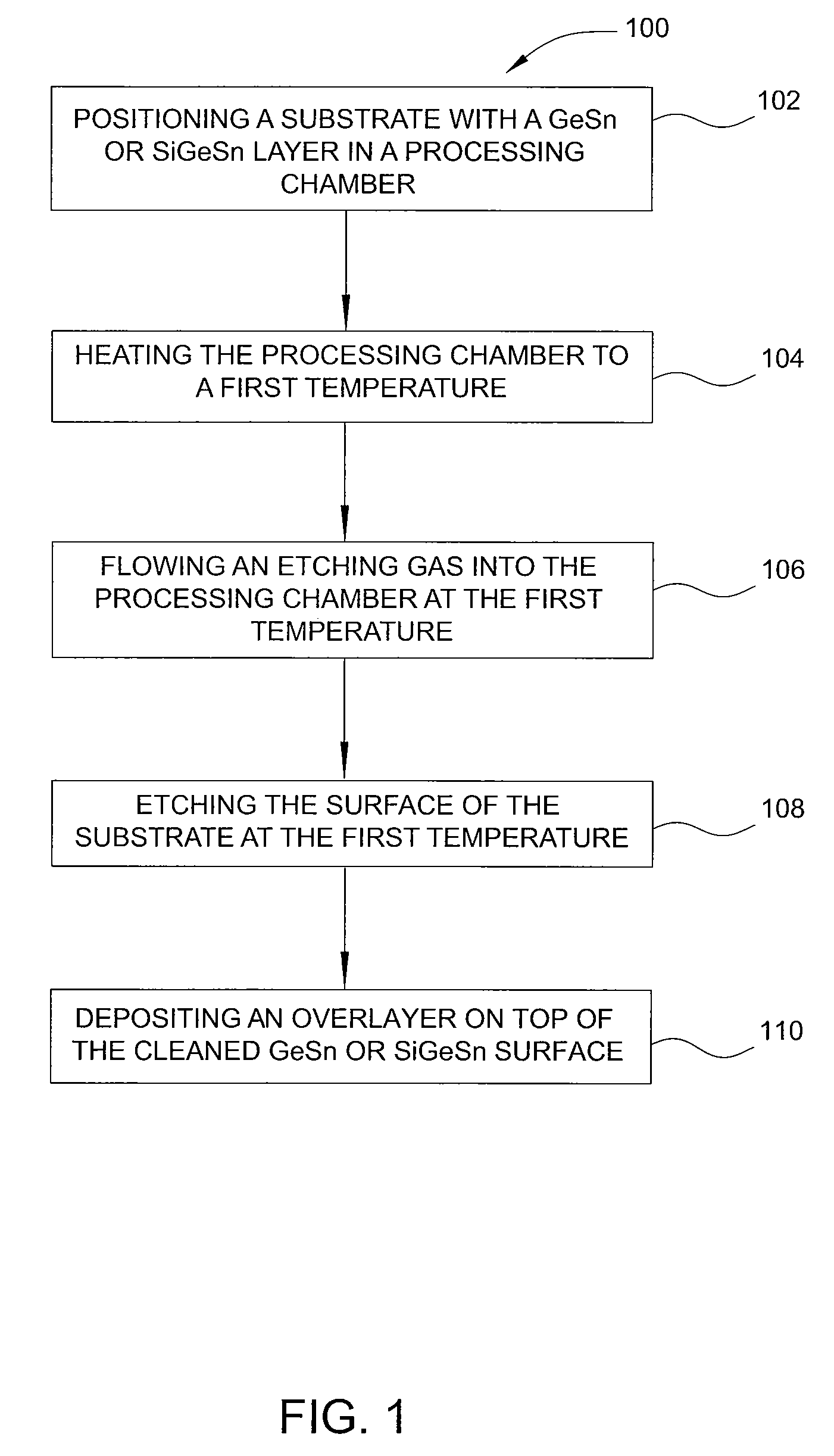

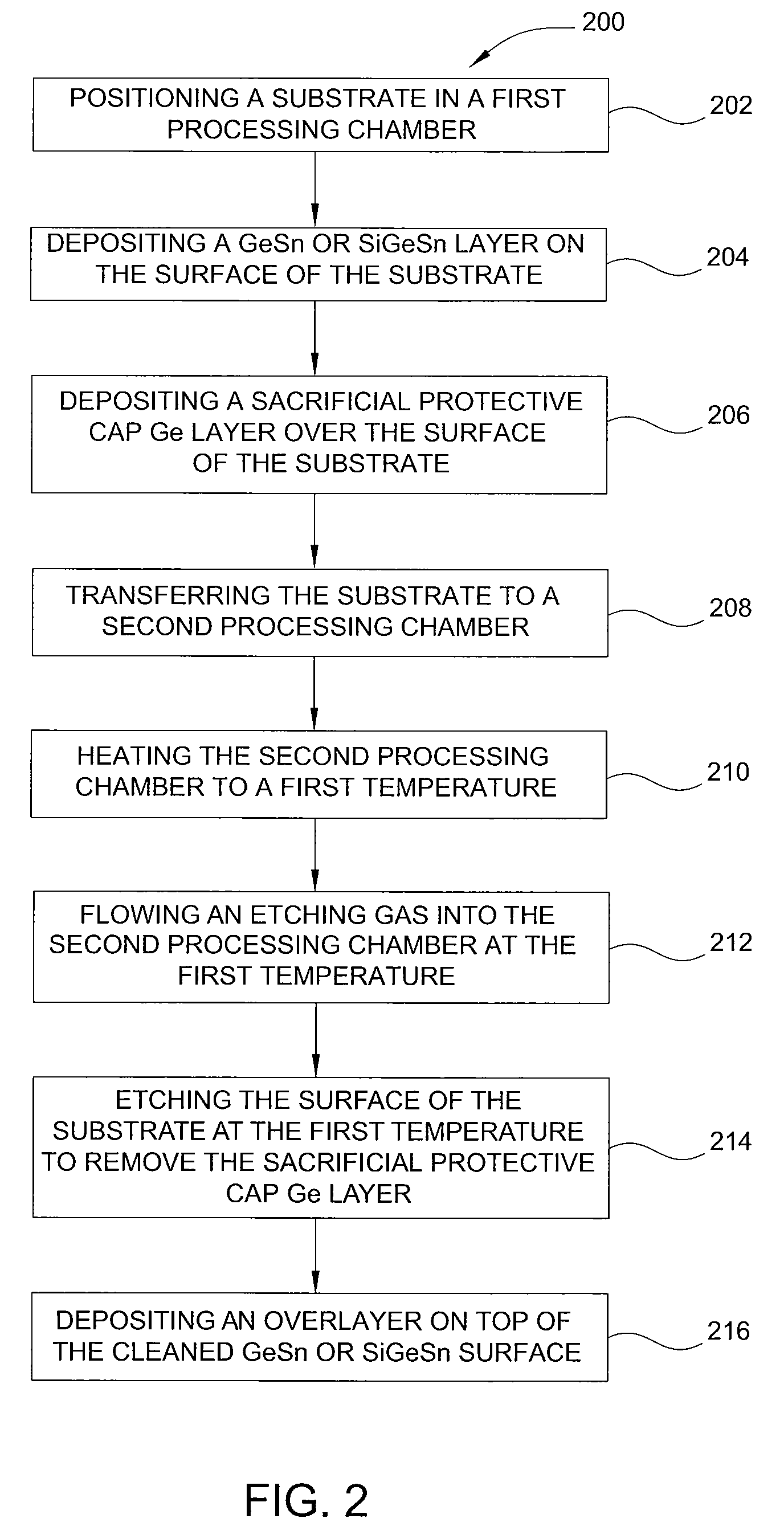

Method of epitaxial germanium tin alloy surface preparation

ActiveUS20130288480A1Increase temperatureStop the flowSemiconductor/solid-state device manufacturingPhotovoltaic energy generationEtchingRapid thermal annealing

Methods of preparing a clean surface of germanium tin or silicon germanium tin layers for subsequent deposition are provided. An overlayer of Ge, doped Ge, another GeSn or SiGeSn layer, a doped GeSn or SiGeSn layer, an insulator, or a metal can be deposited on a prepared GeSn or SiGeSn layer by positioning a substrate with an exposed germanium tin or silicon germanium tin layer in a processing chamber, heating the processing chamber and flowing a halide gas into the processing chamber to etch the surface of the substrate using either thermal or plasma assisted etching followed by depositing an overlayer on the substantially oxide free and contaminant free surface. Methods can also include the placement and etching of a sacrificial layer, a thermal clean using rapid thermal annealing, or a process in a plasma of nitrogen trifluoride and ammonia gas.

Owner:APPLIED MATERIALS INC

Method of epitaxial germanium tin alloy surface preparation

Methods of preparing a clean surface of germanium tin or silicon germanium tin layers for subsequent deposition are provided. An overlayer of Ge, doped Ge, another GeSn or SiGeSn layer, a doped GeSn or SiGeSn layer, an insulator, or a metal can be deposited on a prepared GeSn or SiGeSn layer by positioning a substrate with an exposed germanium tin or silicon germanium tin layer in a processing chamber, heating the processing chamber and flowing a halide gas into the processing chamber to etch the surface of the substrate using either thermal or plasma assisted etching followed by depositing an overlayer on the substantially oxide free and contaminant free surface. Methods can also include the placement and etching of a sacrificial layer, a thermal clean using rapid thermal annealing, or a process in a plasma of nitrogen trifluoride and ammonia gas.

Owner:APPLIED MATERIALS INC

Surface anti-corrosion sol for aeronautic aluminum alloy material and treatment method thereof

The invention discloses surface anti-corrosion sol for an aeronautic aluminum alloy material and a treatment method thereof in the technical field of aluminum alloy surface treatment. The sol comprises the following components in percentage by weight: 1-15 percent of organosiloxane, 45-93 percent of organic solvent, 0.1-10 percent of additive, 0.5-10 percent of rare earth salt, 5-50 percent of deionized water and 0.1-5 percent of catalyst. In the invention, a coating with a compact netlike crosslinking structure is formed on the surface of an aluminum alloy matrix and has high chemical stability and thermal stability, so that influence of an external acidic and alkaline environment and temperature variation on the coating can be resisted; and the coating has higher mechanical strength, rain washing resistance, friction resistance and scratch resistance. The technical method is simple, is easy and convenient to operate, does not have high requirement on equipment and is environmentally-friendly and pollution-free.

Owner:SHANGHAI JIAO TONG UNIV +1

Fluxless heat-and wear-resistant cast iron alloy surfacing welding electrodes and manufacture thereof

InactiveCN1530201AReduce labor intensityImprove welding productivityArc welding apparatusWelding/cutting media/materialsWear resistantRefractory

An uncoated refractory antiwear welding cast iron alloy electrode for build-up welding contains C (2.5-6.5 wt.%), Si (0.8-2.5), Mn (0.4-1.5), Cr (16-35), Nb (0-1.5), Mo (0-3.5), Ni (0-2.0), W (0-2.5), V (0.1-2.0), Ti (0-0.8), Cu (0-1.0), S (0-0.08), P (0-0.1), O (0-0.08), N (0-0.08), Al (0-0.1) and Fe (rest), and is made up by casing method. Its advantages are high hardness of welded layer (more than 42 HRC), and low cost.

Owner:攀钢集团钢城企业总公司溶解乙炔厂

Copper-based alloy and its manufacturing method

As a rawmaterial of a copper base alloy containing at least one of 0.2 to 12 wt% of tin and 8 to 45 wt% of zinc, at least one of a copper base alloy having a large surface area and containing carbon on the surface thereof, a copper base alloy having a liquidus line temperature of 1050 DEG C or less, a copper base alloy surface-treated with tin, and a copper base alloy containing 20 to 1000 ppm of carbon, is used for obtaining a copper base alloy having an excellent hot workability. If necessary, when the raw material of the copper base alloy is melted, the material of the copper base alloy may be coated with a solid material containing 70 wt% or more of carbon, or 0.005 to 0.5 wt% of a solid deoxidizer having a stronger affinity with O than C with respect to the weight of the molten metal may be added to the molten metal.

Owner:DOWA HLDG CO LTD

Aluminum alloy surface strengthening method using laser melting and coating

InactiveCN101012561APrevent excessive meltingPrevent collapseMetallic material coating processesLaser beam welding apparatusSoluble glassWavelength

The invention discloses a reinforcing method of aluminium alloy surface fused and covered by laser, which comprises the following steps: 1. predisposing aluminium alloy base; 2. allocating laser fusing and covering material with the bulk rate of Al-Si alloy powder and SiC ceramic powder at 1:(4-2); setting the Si content in the Al-Si alloy at 10-15(wt%) with grain size at - 140-+325; setting the grain size of SiC at -200; 2. modulating evenly blended fusing and covering material into paste through soluble glass; coating on the surface of aluminium alloy with thickness at 0.8-1.2mm; drying at 100-150 deg.c for 0.5-2h; 4. adopting crossflow CO2 laser to irradiate the coated layer on the surface of aluminium alloy base; setting the output power of laser at 3-4kW and optical beam scanning velocity at 2-5mm / s and optical spot dimension at 1-4mm; protecting fusing pond through high-purity argon in the laser fusing and covering course with argon flow at 20-30L / min.

Owner:TIANJIN POLYTECHNIC UNIV

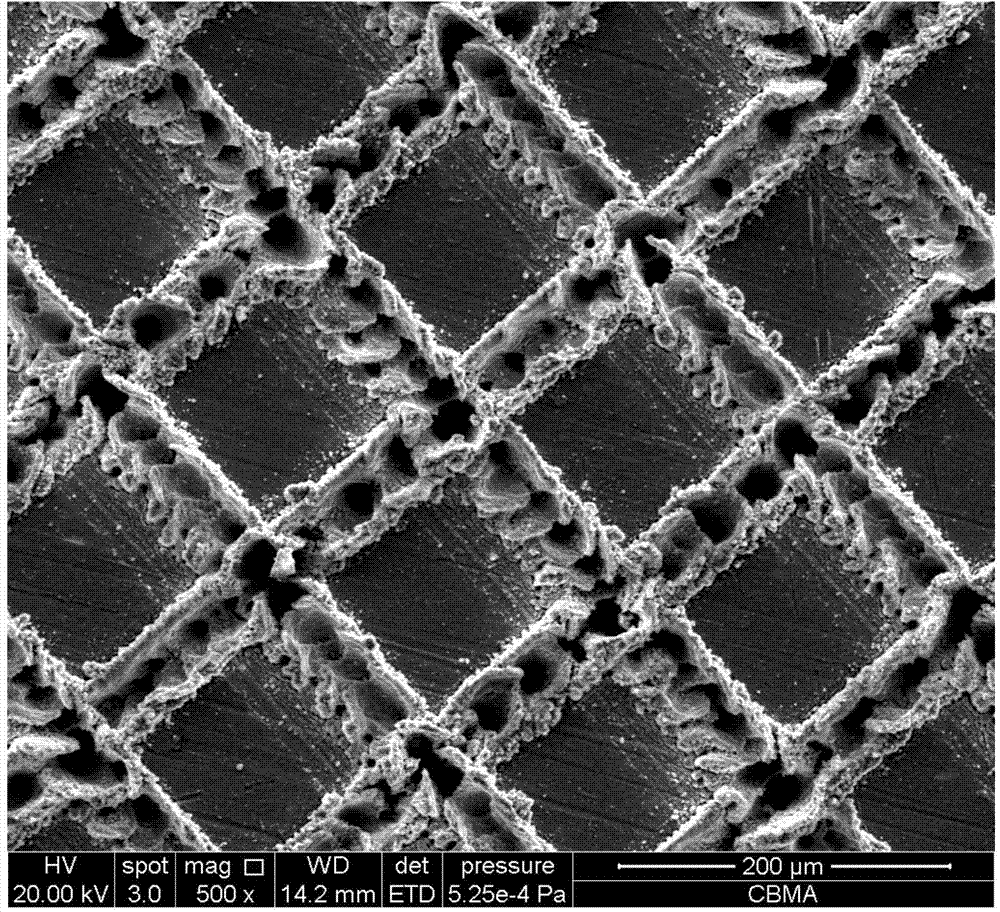

Production method of aluminum alloy bionic superhydrophobic surface

ActiveCN103204457AImprove hydrophobicityImprove adhesionDecorative surface effectsChemical vapor deposition coatingMicro nanoAlcohol

The invention relates to the technology of metal material surface modification, in particular to a production method of bionic superhydrophobic surface of an aluminum alloy base, and aims to improve hydrophobicity of the aluminum alloy surface. The production method includes: pre-processing, namely washing aluminum alloy with absolute ethyl alcohol; subjecting the surface of the aluminum alloy to laser processing to obtain a plurality of micro-scale crater structures on the surface of a sample; immersing the sample in chemical etching solution to change morphology features of the surface of the sample, keep the surface to contain chemical elements different from the base, and form micro-nano double-layer hierarchical structure on the surface of the aluminum alloy; and after reaction, placing the chemically etched aluminum alloy sample in DTS-bearing (dodecyltrichlorosilane-bearing) toluene solution for modification so that a low surface energy film gradually forms on the surface. Therefore, the surface of the aluminum alloy in the micro-nano double-layer hierarchical structure has typical biological super-hydrophobicity and has typical petal-effect adhesion.

Owner:JILIN UNIV

Processing method of aluminum and aluminum alloy super hydrophobic surface

InactiveCN101007304ASuperhydrophobicEasy to rollAntifouling/underwater paintsPretreated surfacesNickel saltCopper

The invention involves an aluminum or aluminum alloy super-hydrophobic surface preparation method. The method is: polishing the surface of aluminum or aluminum alloy using metallographic sandpaper or polishing paste, pure water washing, acetone ultrasonic cleaning, pure water washing and other clean treatment, handing it with chemical etching solution containing nitric acid and metal salts (copper or nickel salt) 30s-20min under 90 ~ 100 degree C, then coating low surface energy material on its surface to get super-hydrophobic property. The aluminum or aluminum alloy surface treated by the invention has excellent hydrophobicity, the contact angle of water and surface can be as high as 150-165 degree, droplets are easy to roll on the surface. The method of the invention need not complex equipment, cost is low, technology is simple and repeatability is good.

Owner:SOUTH CHINA UNIV OF TECH

Method for processing anode of aluminum or aluminum alloy surface

The invention relates to method for processing the anode of an aluminum or aluminum alloy surface, comprising the following steps: providing an aluminum or aluminum alloy base body which comprises aninner surface and an outer surface opposite to the inner surface; carrying out first machining processing on the outer surface of the aluminum or aluminum alloy base body so that the outer surface hasfirst machining surface effect; carrying out first-time anode processing on the aluminum or aluminum alloy base body so that the surface of the aluminum or aluminum alloy base body forms an oxidationfilm with a first color; removing a part or all of the oxidation film formed on the inner surface of the aluminum or aluminum alloy base body so that the aluminum or aluminum alloy base body is conductive; carrying out second machining processing on the outer surface of the aluminum or aluminum alloy base body; removing a part of the oxidation film positioned on the outer surface and enabling anarea the oxidation film of which is removed to have second machining surface effect; and carrying out second-time anode processing for the aluminum or aluminum alloy base body so that the area which has the second machining surface effect forms an oxidation film with a second color. The method can obtain different surface effects on a same base body.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

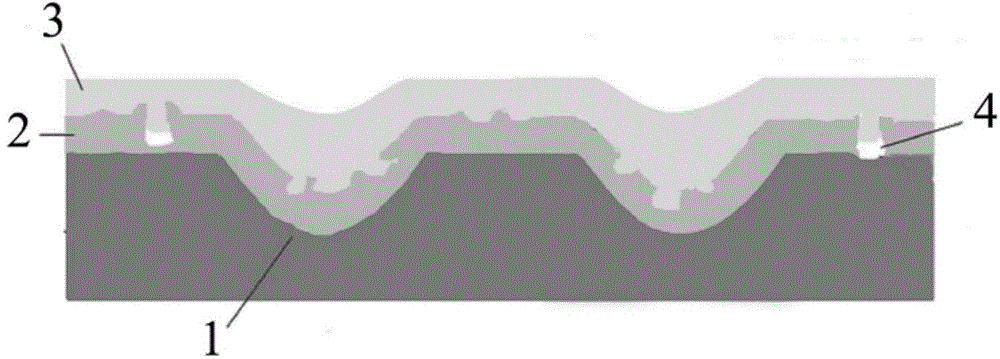

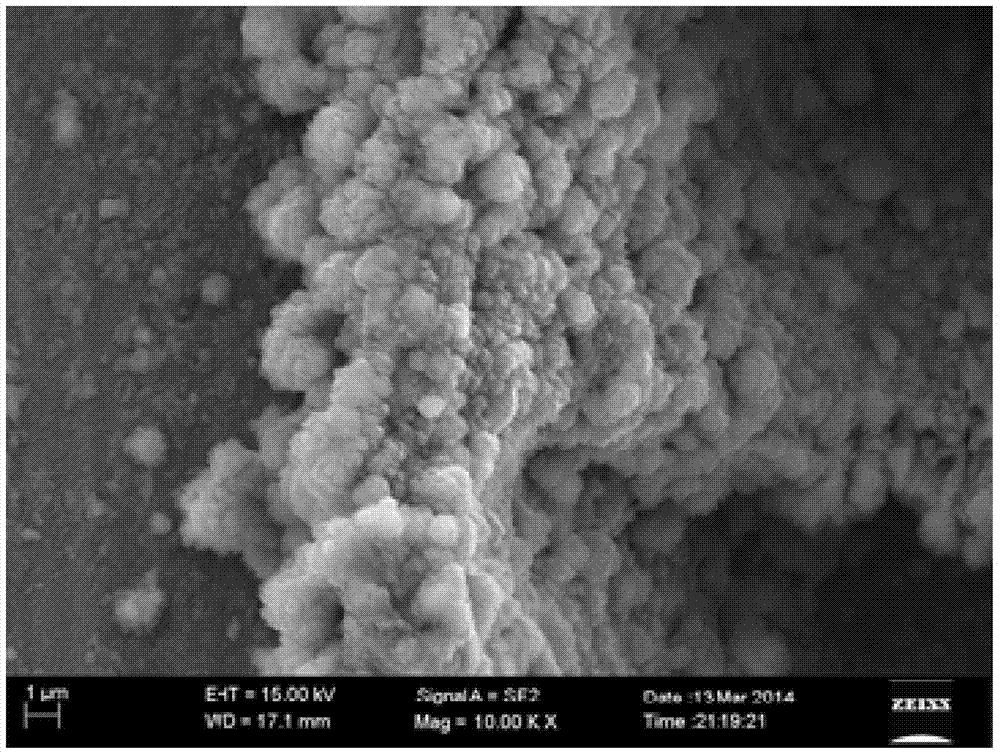

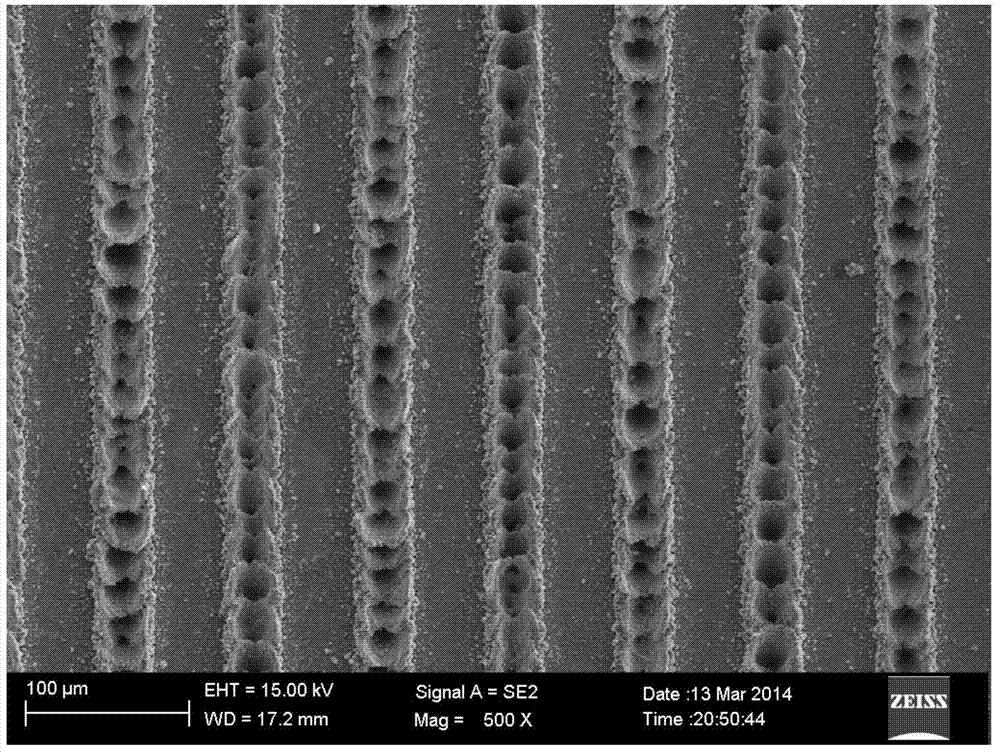

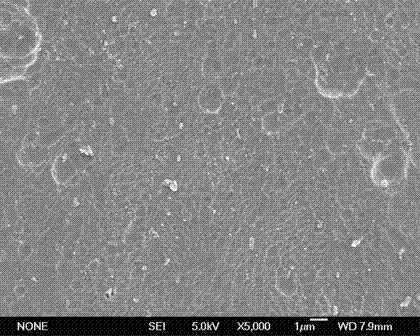

Composite wear-resistant antifriction coating on titanium alloy surface and preparation method thereof

InactiveCN104480511AImprove wear resistanceHigh bonding strengthSurface reaction electrolytic coatingOxide ceramicPlasma electrolytic oxidation

The invention discloses a composite wear-resistant antifriction coating on a titanium alloy surface and a preparation method thereof. The coating comprises a laser texturing surface, an oxide ceramic layer and a self-lubricating coating which are connected in sequence, wherein micropore arrays are uniformly distributed on the laser texturing surface; the oxide ceramic layer is a hard oxide ceramic coating; and the self-lubricating coating is a MoS2 coating, PTFE (polytetrafluoroethylene) coating or graphite coating. In the invention, the laser surface texturing technology is combined with the plasma electrolytic oxidation technology, and a texturing / ceramization composite coating is prepared on the titanium alloy surface which is then coated with a solid lubricant to improve the friction performance of the surface.

Owner:NANJING UNIV OF SCI & TECH +1

Transformation liquid for preparation of corrosion-resistant oxidation film on aluminium alloy surface and method of use thereof

InactiveCN101139708AImprove corrosion resistanceGood adhesionMetallic material coating processesHigh resistancePersulfate

The invention discloses a transforming solution for preparing anti-corrosion compound oxidation film on an aluminum alloy surface and a using method for the oxidation film. The invention is characterized in that, the transforming solution is a film-forming promoter containing rare-earth salt (nitrate or sulfate and compound salt of cerium, praseodymium, and neodymium), such compound oxidant as radical of permanganate, nitrate and perchlorate, etc., film-forming promoter of vanadium salt and strontium salt, etc.; the transforming solution contains no sexavalent chromium, is environmental friendly; the reaction speed is improved by the compound oxidant and the film-forming promoter, no heating is needed for the chemical transforming, the treating time is 1-5 min. The invention can rapidly prepare under room temperature compound oxidation film comprising compound rare-earth oxide, alumina and manganese oxide with good resistance to corrosion on aluminum alloy surface. The treating solution from the invention is of rapid film-forming speed, simple process, even film layer, high resistance to corrosion, and low environmental pollution, etc.

Owner:陈东初 +2

Method for preparing environment-friendly micro-arc oxidation black ceramic film on aluminum alloy surface

ActiveCN102154673AUniform colorImprove corrosion resistanceAnodisationPlasma electrolytic oxidationMicro arc oxidation

The invention discloses a method for preparing an environment-friendly micro-arc oxidation black ceramic film on an aluminum alloy surface, and the method comprises the following steps: firstly, pouring deionized water into an oxidation tank, weighing 1-10g / L of sodium hexametaphosphate, 1-3g / L of sodium silicate, 0.5-2g / L of potassium hydroxide, 0.2-2g / L of sodium fluoride and 0.5-20g / L of ferric ammonium oxalate in terms of the volume of the added deionized water, and uniformly stirring and mixing the sodium hexametaphosphate, the sodium silicate, the potassium hydroxide and the sodium fluoride to obtain a micro-arc oxidation base electrolyte; adding the weighed ferric ammonium oxalate into the base electrolyte, and stirring and mixing uniformly to obtain an aluminum alloy micro-arc oxidant solution; and then, sequentially carrying out surface deoiling and cleaning, water washing, aluminum alloy micro-arc oxidation, sealing and drying on the aluminum alloy to prepare the environment-friendly micro-arc oxidation black ceramic film on the aluminum alloy surface. By means of the preparation method disclosed by the invention, the problems of single color, limited application range, and environment pollution caused by a vanadate electrolyte, of the existing aluminum alloy ceramic film layer, are solved.

Owner:CSIC NO 12 RES INST

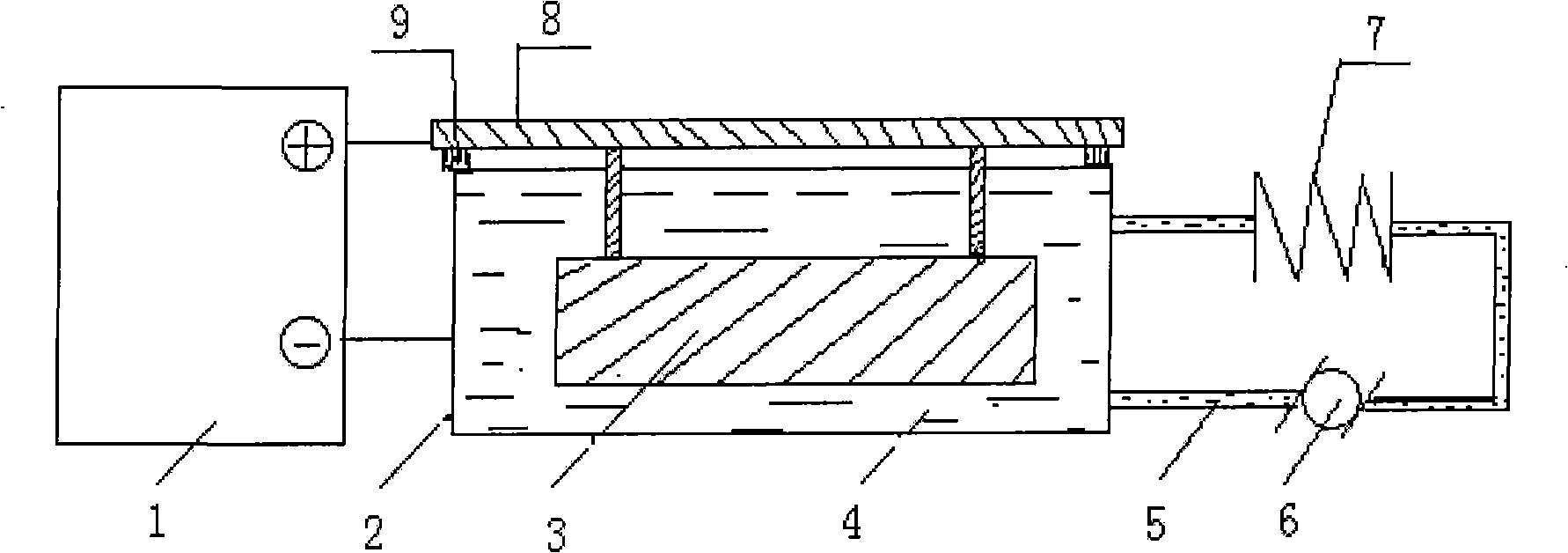

Method for preparing corrosion protection abrasion resistant ceramic coating with alloy surface differential arc oxidization

InactiveCN101270495ALow power density per unitFast film formationAnodisationPlasma electrolytic oxidationMicro arc oxidation

The invention discloses a method for preparing an antisepsis and antiwear ceramics coating layer on the surface of alloy through microarc oxidation. The method includes three steps of collocating electrolyte, arranging power electric parameters and microarc oxidation treatment; wherein, the component concentrations of the electrolyte are sodium silicate of 20 to 100g / L, sodium hydroxide of 5 to 10g / L and organic amine additive of 5 to 15ml / L; the current density of unit area is 50 to 100A / centiare; the pulse frequency is 100 to 700Hz; the pulse dutyfactor is 20 to 90 percent; the temperature of the electrolyte in the microarc oxidation treatment is not higher than 45 DEG C. The method needs lower unit power density and has fast film forming speed to prepare the ceramics coating layer on the surface of aluminum and magnesium alloys; the method adopts 100KVA power which can treat at least 2 centiares of the surface area of the aluminum alloy for one time; the growing speed of the ceramics coating layer can reach 1 to 1.5 micron / min. The formed ceramics coating layer is uniform and compact; the rigidity of the aluminum alloy can reach 1200 to 1300Hv.

Owner:SOUTH CHINA UNIV OF TECH

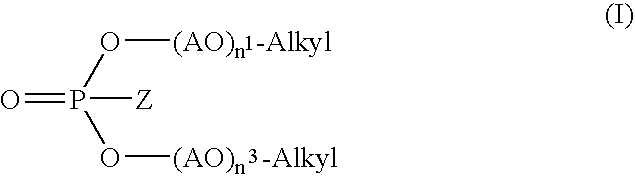

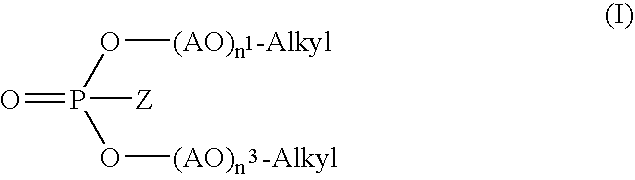

Cleaning and Corrosion Inhibition System and Composition for Surfaces of Aluminum or Colored Metals and Alloys Thereof Under Alkaline Conditions

InactiveUS20080108539A1Inhibit and reduce of surfaceReliably inhibit reduce corrosionInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsAlkaline earth metalPharmaceutical industry

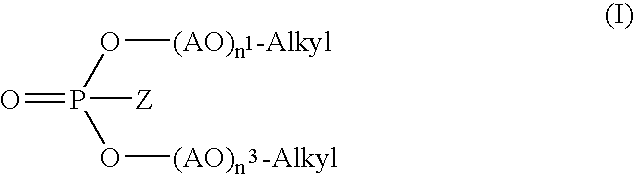

The present invention relates to corrosion inhibitor systems, in particular to cleaning and corrosion inhibiting compositions for surfaces of aluminum or colored metals and alloys thereof under alkaline conditions, especially in the food and pharmaceutical industries. The cleaning and corrosion inhibiting compositions comprise as a corrosion inhibitor at least one alkyleneoxy alkylphosphate di- or triester having the general formula (I) where Z is either —O—M or —O—(AO)n2— Alkyl wherein M is an ammonium, alkali metal or alkaline earth metal cation, Alkyl is a C5-C22 alkyl or alkylaryl group, AO is a C2-4-alkylene oxide unit and n1, n2 and n3 each are integers from 2 to 10.

Owner:JOHNSONDIVERSEY INC

Method for preparing wear-resistant coating on surface of driving sheave race of elevator by laser cladding

ActiveCN102453904AExcellent wear resistance and corrosion resistanceImprove wear resistanceMetallic material coating processesLaser beam welding apparatusHigh power lasersWear resistant

The invention relates to a method for preparing a wear-resistant coating on the surface of a driving sheave race of an elevator by laser cladding. A rendering transition layer with good toughness, which is clad on the surface of the race and forms metallurgical bonding with a base body, is rapidly scanned by laser through high-power laser; and a wear-resistant cobalt-base alloy which has good corrosive resistance and a frication coefficient in fit with that of a steel wire rope is prepared on a rendering alloy surface through laser cladding. The method is characterized by comprising the following special steps of: firstly, pre-treating the surface of the race; secondly, selecting alloy powder and an automatic powder sending device; thirdly, carrying out the laser cladding on the rendering alloy and the cobalt-base alloy powder with the frication coefficient in fit with that of the steel wire rope so that a wear-resistant coating with the thickness of 0.5-1.2 mm is formed on the surface of the race; and finally, carrying out flaw detection after cladding. The method provided by the invention has the characteristics of high productivity, lower energy consumption, small machining allowance of a cladding layer, high field, low combined cost and the like.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

Preparation method of super-hydrophobic micro-nano structure on titanium alloy surface

The invention provides a preparation method of a super-hydrophobic micro-nano structure on a titanium alloy surface. The preparation method comprises the following steps: performing ultrasonic cleaning on a titanium alloy sample respectively with acetone and anhydrous alcohol, to obtain a titanium alloy sample with a clean surface; performing femtosecond laser photoetching processing on the surface of the titanium alloy sample with the clean surface, to obtain the titanium alloy sample with the surface having the super-hydrophobic micro-nano structure in one step, wherein a femtosecond laser beam is fixed and perpendicular to the surface of a processed material, the single pulse energy of the femtosecond laser beam is 100mu J-800mu J, the pulse width is 100fs-500fs, the central wavelength is 500nm-1000nm, the repetition frequency is 500Hz-2kHz, and the size of the etched facula of the femtosecond laser beam is 0.5mum-300mum; the surface of the titanium alloy sample moves relative to the etched facula of the femtosecond laser beam along the three-dimensional directions x, y and z, the motion positioning precision in x and y directions is 50nm-100nm, and the motion positioning precision in z direction is 5nm-10nm.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Aluminum alloy surface treatment method

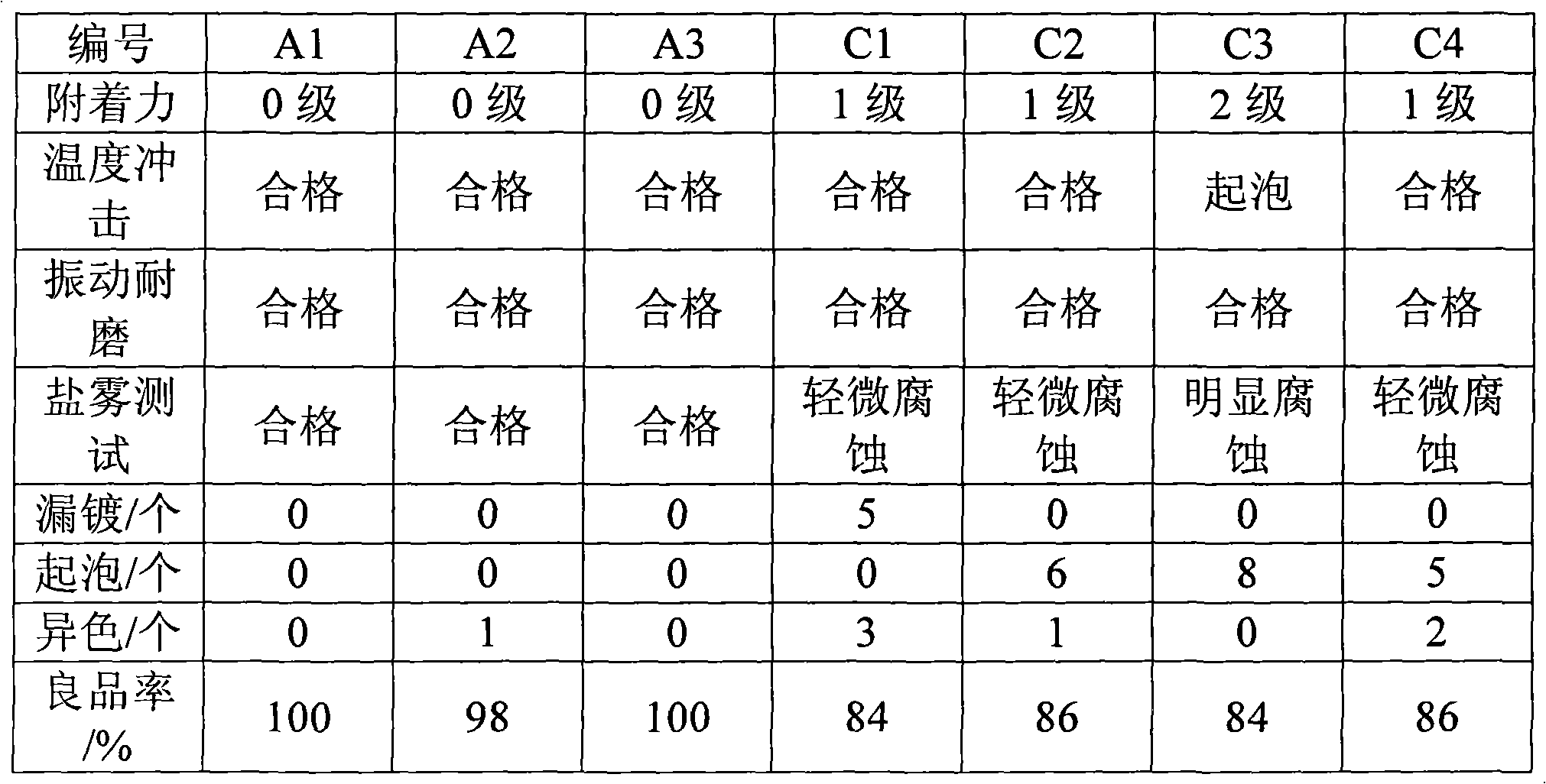

InactiveCN101922010ALess prone to missing platingNot prone to foamingHot-dipping/immersion processesAnodisationAcid etchingLaser etching

The invention provides an aluminum alloy surface treatment method which comprises the steps of sequentially carrying out pretreatment, chemical plating and electroplating on an aluminum alloy matrix, wherein the pretreatment comprises the steps of sequentially carrying out anode oxidation, laser etching, erosion and acid etching on the aluminum alloy matrix. By using the method for forming electroplating texture on the surface of an aluminum alloy, the obtained product has natural texture, is not subject to skip plating, bubbling and discoloration phenomena and has a good decorative effect. Besides, the method has the advantage of simple operation, realizes the unshaded treatment and the convenient maintenance by using the technology of anode oxidation plus electroplating, and facilitates the mass production.

Owner:BYD CO LTD

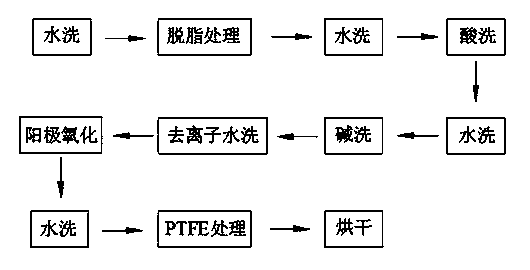

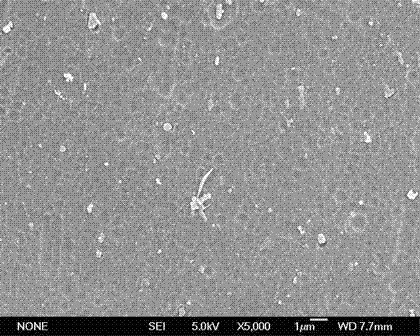

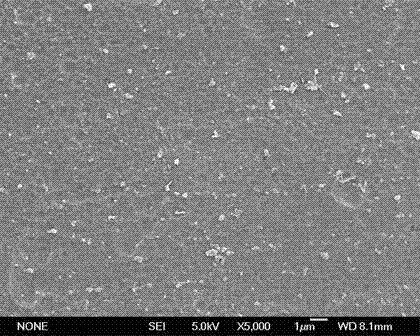

Aluminum and aluminum alloy surface treatment method

The invention discloses an aluminum and aluminum alloy surface treatment method which is characterized by comprising steps as follows: water washing, degreasing treatment, water washing, pickling, water washing, alkali washing, deionized water washing, anodic oxidation, water washing, PTFE (polytetrafluoroethylene) treatment, and drying. According to the aluminum and aluminum alloy surface treatment method, an aluminum and aluminum alloy oxide film with good uniformity can be obtained, and the film is high in hardness, abrasion-resistant, corrosion-resistant and the like.

Owner:GUANGXI POLYTECHNIC VOCATIONAL & TECHN COLLEGE

Surface treatment method of aluminum alloy and treatment liquid

InactiveCN101709459AImprove anti-corrosion performanceUniform thicknessLiquid/solution decomposition chemical coatingSalt resistanceChemical plating

The invention relates to a surface treatment method of aluminum alloy, which comprises the following steps of: pre-treating: removing oil stains on the aluminum alloy surface by adopting an alkali degreasing solution; alkali washing: purifying the aluminum alloy surface at 50-60 DEG C by adopting alkali wash to remove a natural oxide film on the aluminum alloy surface; acid pickling: treating the aluminum alloy surface at room temperature for 1-5 minutes by adopting a pickling solution to further remove residual spots left on the aluminum alloy surface after alkali washing; and chemically plating Ni-P: forming a Ni-P plating layer on the aluminum alloy surface by adopting a pre-prepared chemical plating Ni solution with pH value of 5-6.5 at 85-90 DEG C for 90-240 minutes. By adopting a chemical plating Ni-P layer process to form a uniform favorable plating layer with good acid resistance, alkali resistance and salt resistance outside an aluminum alloy shell, the invention avoids the phenomena of uneven thickness of a protective layer and spraying missing on a complex structure part, and remarkably improves the anticorrosion performance of the aluminum alloy.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Preparation method of anti-creeping and anti-corrosive titanium or titanium alloy material

ActiveCN102051615AMaintain superamphiphobic propertiesImprove corrosion resistanceSurface reaction electrolytic coatingChemical vapor deposition coatingTemperature resistanceTitanium alloy

The invention discloses a preparation method of an anti-creeping and anti-corrosive titanium or titanium alloy material with a super-hydrophobic and super-oleophobic surface. The preparation method comprises the following steps: microprocessing the surface of metal titanium or titanium alloy through laser etching to obtain a roughened surface with a micron structure; then, forming a layer of titanium dioxide nanotube array film on the surface of the micron structure through anodic oxidation treatment; and finally, modifying by perfluorosilane or perfluorosiloxane to obtain the super-hydrophobic and super-oleophobic surface. The microstructure on the surface of the prepared metal titanium and titanium alloy is very stable and has good high temperature resistance; and after the chemical modification, the surface has super-hydrophobic (acid, base and salt solution) and super-oleophobic property, namely the contact angles to most of organic liquids and aqueous solutions are more than 150 degrees.

Owner:甘肃中安瑞科科技有限公司

Treating fluid and method for preparing vanadium-zirconium composite conversion coatings with self-repairing performance on aluminum alloy surfaces through same

ActiveCN102766862AImprove corrosion resistanceGuaranteed stabilityMetallic material coating processesMetallic bondingSodium fluoride

The invention belongs to the technical field of chemical materials, and relates to a treating fluid and a method for preparing vanadium-zirconium composite conversion coatings with self-repairing performance on aluminum alloy surfaces through the same. The method includes the steps of firstly preparing the treating fluid containing fluorozirconate, metavanadate, sodium fluoride, nitrate, an accelerate and an additive; then putting an aluminum alloy after surface pretreatment into a working fluid made of the diluted treating fluid for 2min-10min; and finally subjecting the aluminum alloy to washing, drying and cooling to obtain the vanadium-zirconium composite conversion coatings. The preparation process is simple, heavy metals such as hexavalent chromium and nickel are not contained, the environment is friendly, the conversion coatings of the aluminum alloy after a conversion coating treatment are dense and high in binding force, metal ions in the conversion coatings can bond with base metal under a corrosion environment and provided with a certain self-repairing performance, and the treating technology of vanadium-zirconium conversion coatings can effectively replace chromate treatment on aluminum alloy surfaces.

Owner:湖南松井先进表面处理与功能涂层研究院有限公司

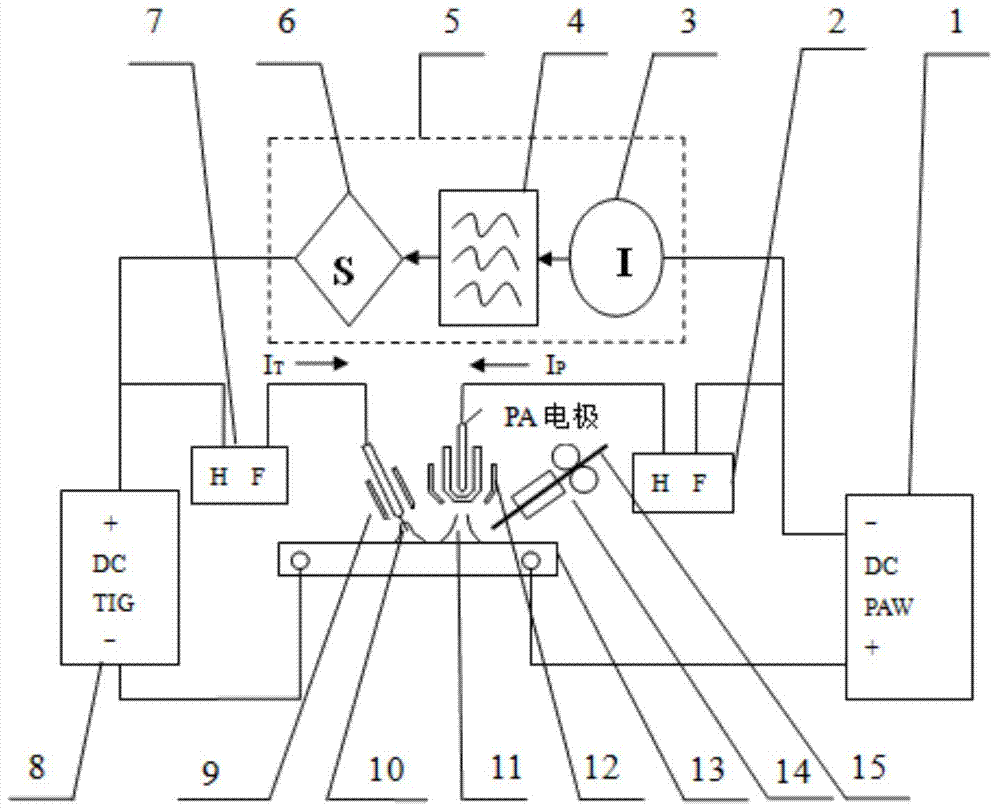

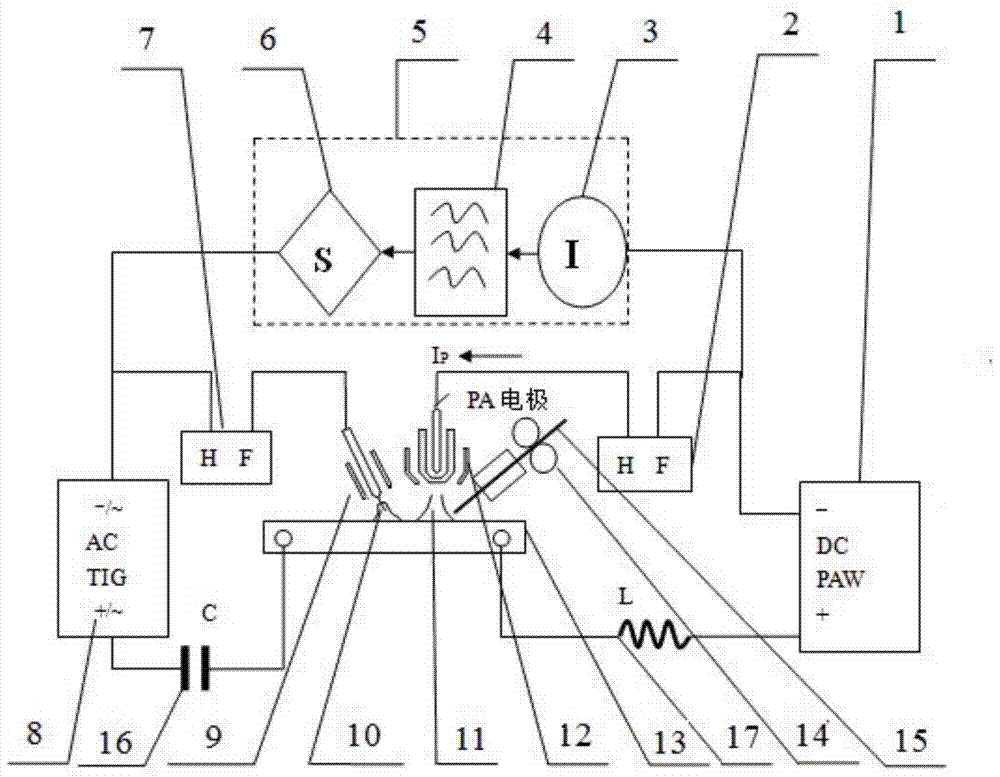

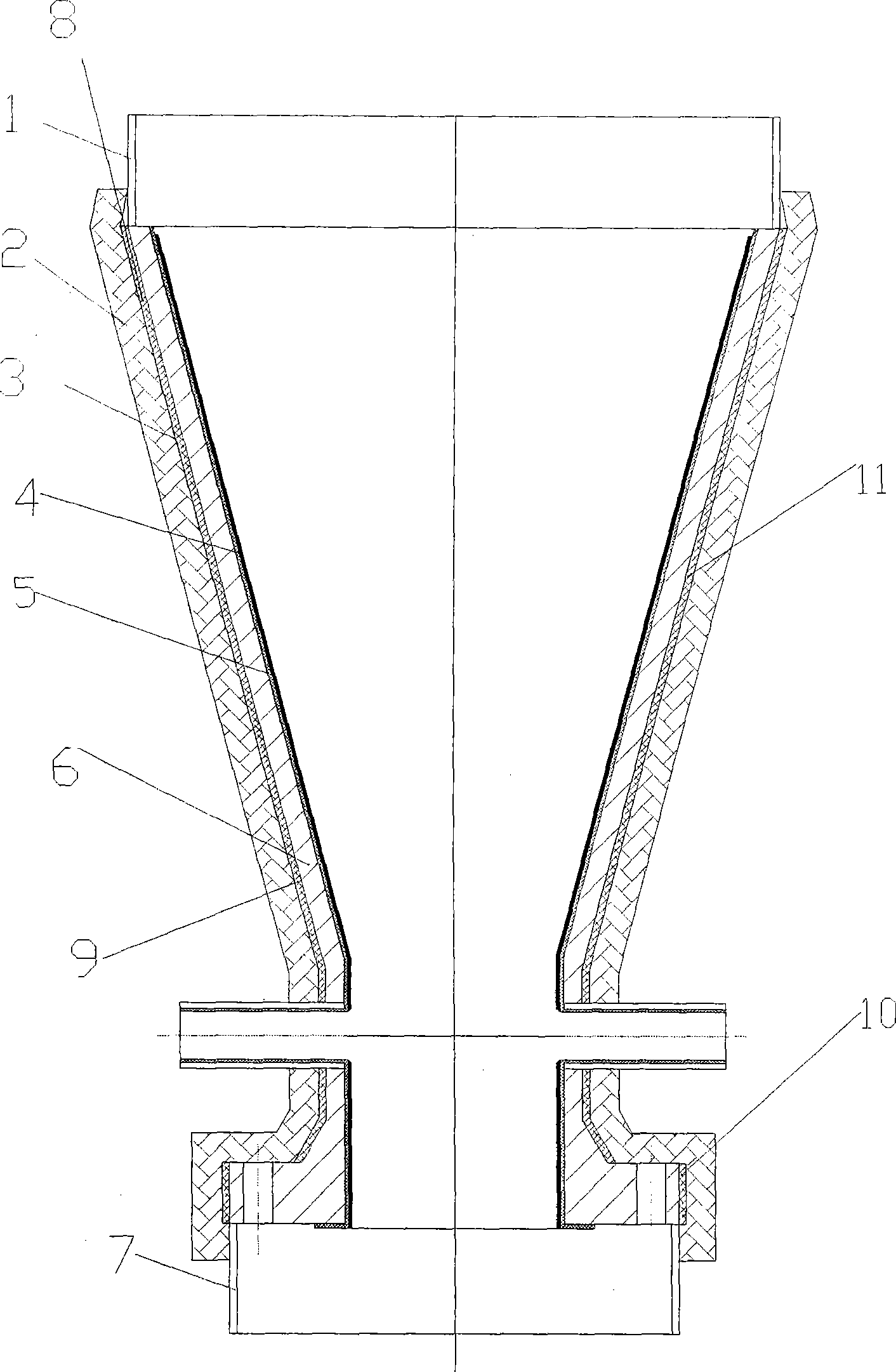

Aluminum alloy direct current plasma-tungsten electrode argon arc hybrid welding method based on pulse coordination control

ActiveCN103567652AAchieve cleanupRealize DC piercing plasma arc weldingArc welding apparatusPlasma welding apparatusHalf wavePlasma arc welding

The invention aims to provide an aluminum alloy direct current plasma-tungsten electrode argon arc hybrid welding method based on pulse coordination control. A tungsten electrode argon arc welding gun is exerted on one side of a plasma arc welding gun, in the welding process, the tungsten electrode argon arc welding gun is utilized to remove oxidation films on the surface of aluminum alloy in front of the direct current plasma welding gun, and the direct current plasma welding gun is utilized to conduct welding behind the tungsten electrode argon arc welding gun. In order to avoid electromagnetic interference between plasma arcs and tungsten electrode argon arcs in the welding process, when a plasma arc current is in a pulse basic value pilot arc stage, a pulse signal controller is triggered, and a tungsten electrode argon arc current is adjusted to be in a negative half wave crest value for removing the oxidation films on the surface of the aluminum alloy; when the plasma arc current is in a pulse crest value welding stage, the pulse signal controller is utilized to adjust the tungsten electrode argon arc current to be in pulse basic value output, and the steps are repeatedly executed in this way. According to the method, the current pulse wave form of the tungsten electrode argon arcs and the current pulse wave form of a plasma arc power supply are reasonably adjusted, the effect of cleaning the oxidation films on the surface of the aluminum alloy and weld penetration are controlled, and therefore weld formation is guaranteed, tungsten electrode burning losses are reduced, and welding efficiency is improved.

Owner:哈尔滨哈船特装科技发展有限公司

Normal temperature fast filming fluid for aluminium alloy surface and its usage

InactiveCN101021006AReduce pollutionLow costMetallic material coating processesTemperature controlFluoride

The present invention discloses one kind of normal temperature fast filming fluid for aluminum alloy surface and its usage. The filming fluid contains silicate, titanate, peroxide, fluoride and trivalent metal salt. When it is used, the filming fluid is controlled to be in the temperature of 1-40 deg.c and pH value of 2-8, and to be contacted with aluminum alloy for 1-10 min. The filming fluid can form film with high anticorrosive performance and excellent adhering performance, and has less environmental pollution, fast filming speed, low production cost and capacity of being used in industrial production.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Overlaying welding method of large area carbide alloy of workpiece wear layer

ActiveCN101433990ASurface red hardness is goodImprove corrosion resistanceArc welding apparatusHeat resistanceHardness

The invention relates to a resurfacing welding method for a large-area hard alloy of an abrasion resistant layer of a workpiece, which comprises the following steps: 1) processing a steel substrate of a resurfacing welding workpiece; 2) resurfacing welding of a transition layer; 3) heat treatment for relieving stress; 4) cleaning and checking a surface to be welded; 5) welding a technical ring; 6) cladding by a heater, namely, adopting a track heater to clad the integral workpiece; 7) preheating and insulating, namely, heating the workpiece to be within a range of 300 +- 20 DEG C, and then performing resurfacing welding on the work piece after the work piece is insulated for 30 to 40 minutes; 8) resurfacing welding of a hard alloy layer; and 9) heat treatment after the welding. The method effectively controls generation of resurfacing welding cold cracks, thoroughly solves the problem of cold cracks during welding, provides favorable conditions for preventing the generation of the welding cold cracks, provides effective guarantee for quality of the hard alloy surface, and thoroughly solves the problem of difficult maintenance for surface defects of the hard alloy. The resurfacing welding layer has the advantages of good surface red hardness, corrosion resistance and heat resistance.

Owner:NANJING BAOSE

Method For Preparing BioMedical Surfaces

ActiveUS20070187253A1Faster and strong and robust interfacial adhesionImprove adhesionElectrolysis componentsDecorative surface effectsBeta phaseDissolution

A method for selectively dissolving the beta (β) phase of a titanium alloy out of the surface of the alloy, thereby leaving behind a nano-scale porous surface having enhanced bonding properties with either a biological tissue, such as bone, or an adhesive material, such as a polymer or ceramic by immersing the alloy in an ionic aqueous solution containing high levels of hydrogen peroxide and then exposing the alloy to an electrochemical voltage process resulting in the selective dissolution of the beta phase to form a nano-topographic metallic surface.

Owner:SYRACUSE UNIVERSITY

Aluminium alloy chromium-free chemical converting liquid and its using method

The present invention relates to surface treatment of aluminum alloy, and especially a kind of chromium-free chemical aluminum alloy converting solution capable of endowing aluminum alloy surface with excellent corrosion resistance and its usage. The chromium-free chemical aluminum alloy converting solution consists of silicate, titanium salt, peroxide, fluoride, and water solution of sulfuric acid. The solution is used in 50-99 deg.c and pH 4-9 and has aluminum alloy contacting time of 2-20 min. The solution contains no hexavalent chromium and potassium ferricyanate, and has less environmental pollution, low cost, easy filming and high corrosion resistance.

Owner:郭瑞光

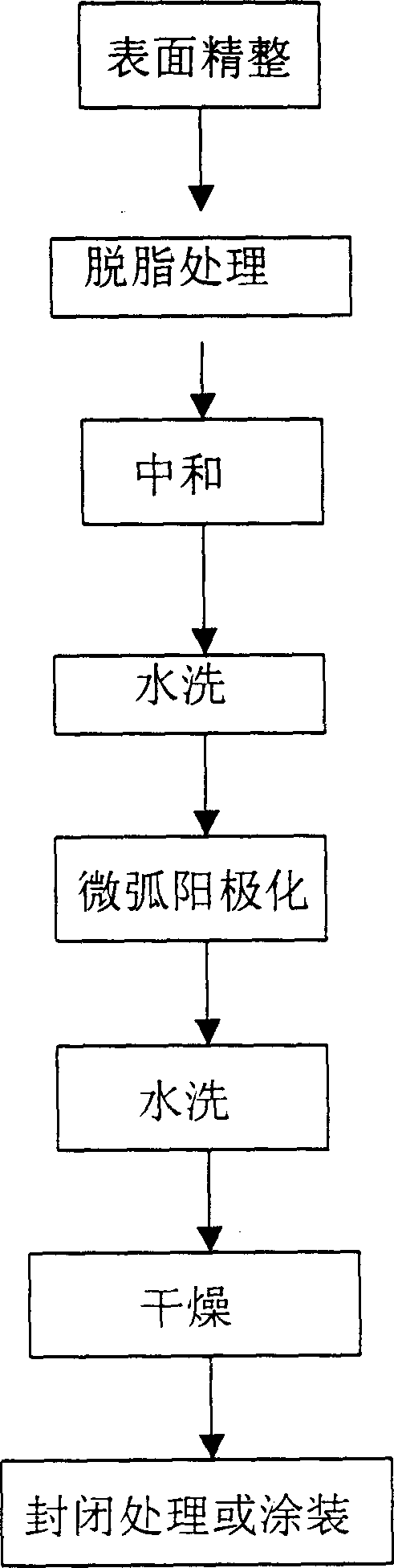

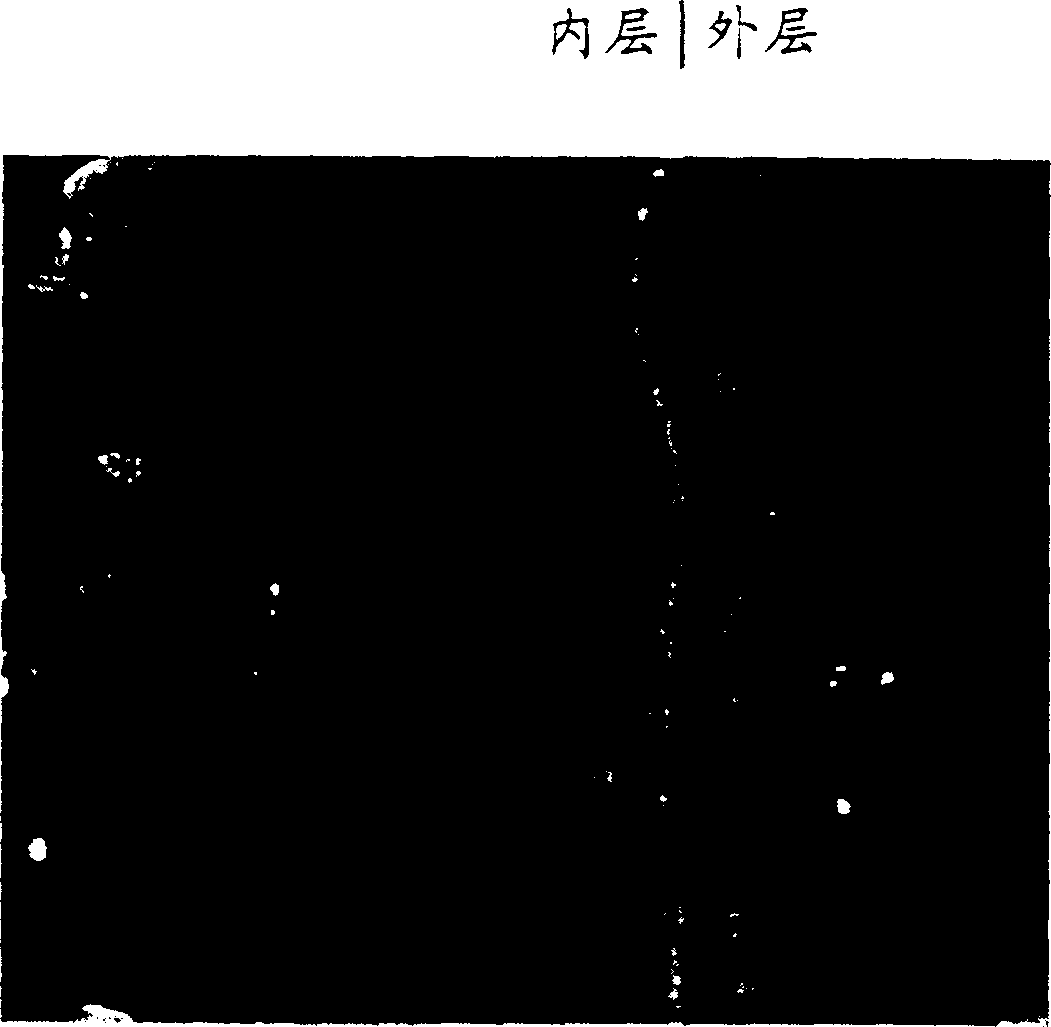

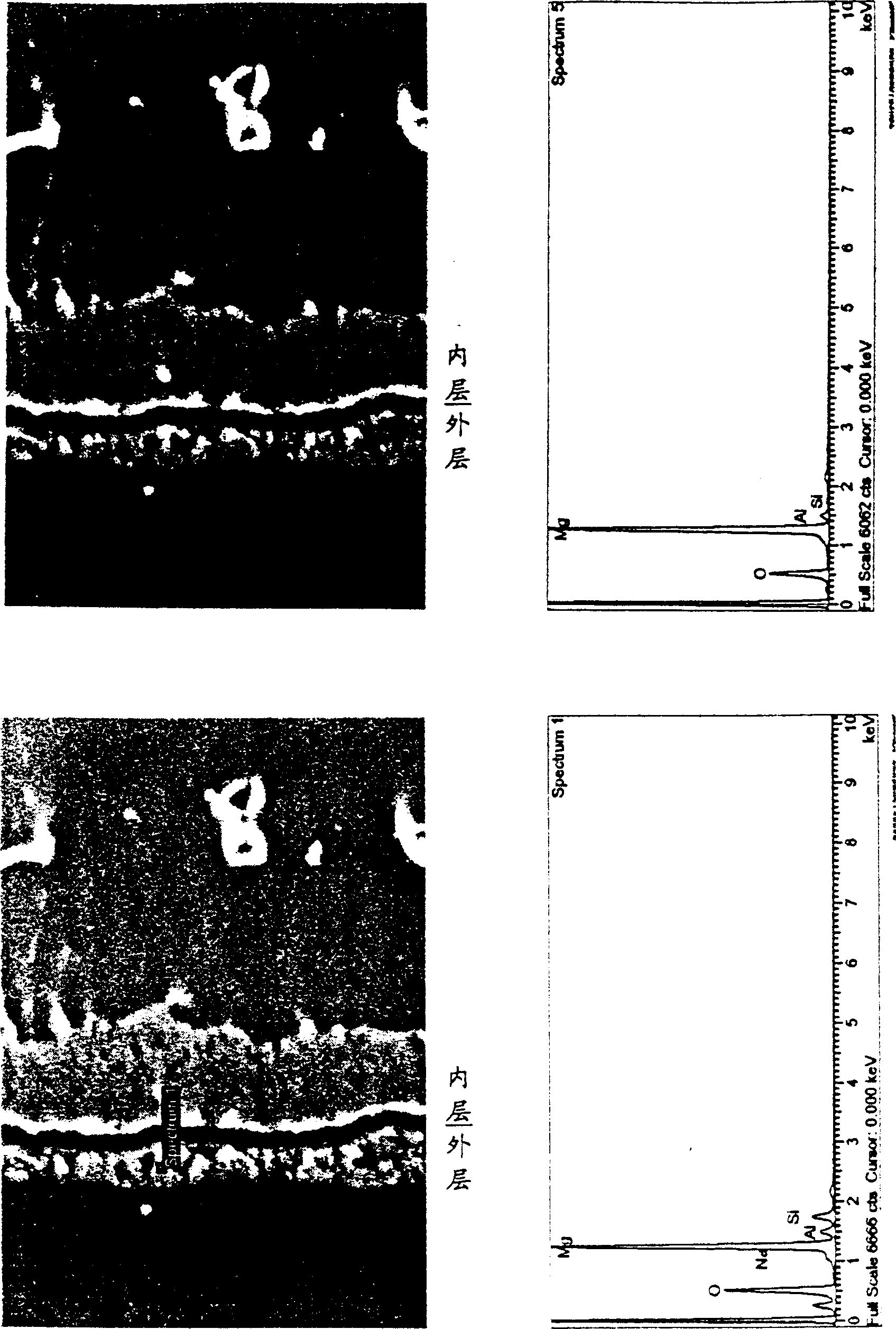

Composite ceramic film on surface of magnesium alloy and its forming process

InactiveCN1388272AOvercoming brittlenessOvercoming the formation of voids in the film layerAnodisationMicro arc oxidationPlasma electrolytic oxidation

The present invention features that the composite ceramic film consists of two layers, the inner layer film of silicon-containing composite Mg-Al oxide and the outer layer film of Mg-Al silico-oxide of 5-70 micron thickness each. The composite ceramic film is formed through surface treatment, degreasing, neutralizing, water washing, micro-arc anodizing, water washing, drying, closing treatment or painting. The composite ceramic film has no holes and cracks, high corrosion resistance, high wear resistance and smooth surface.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

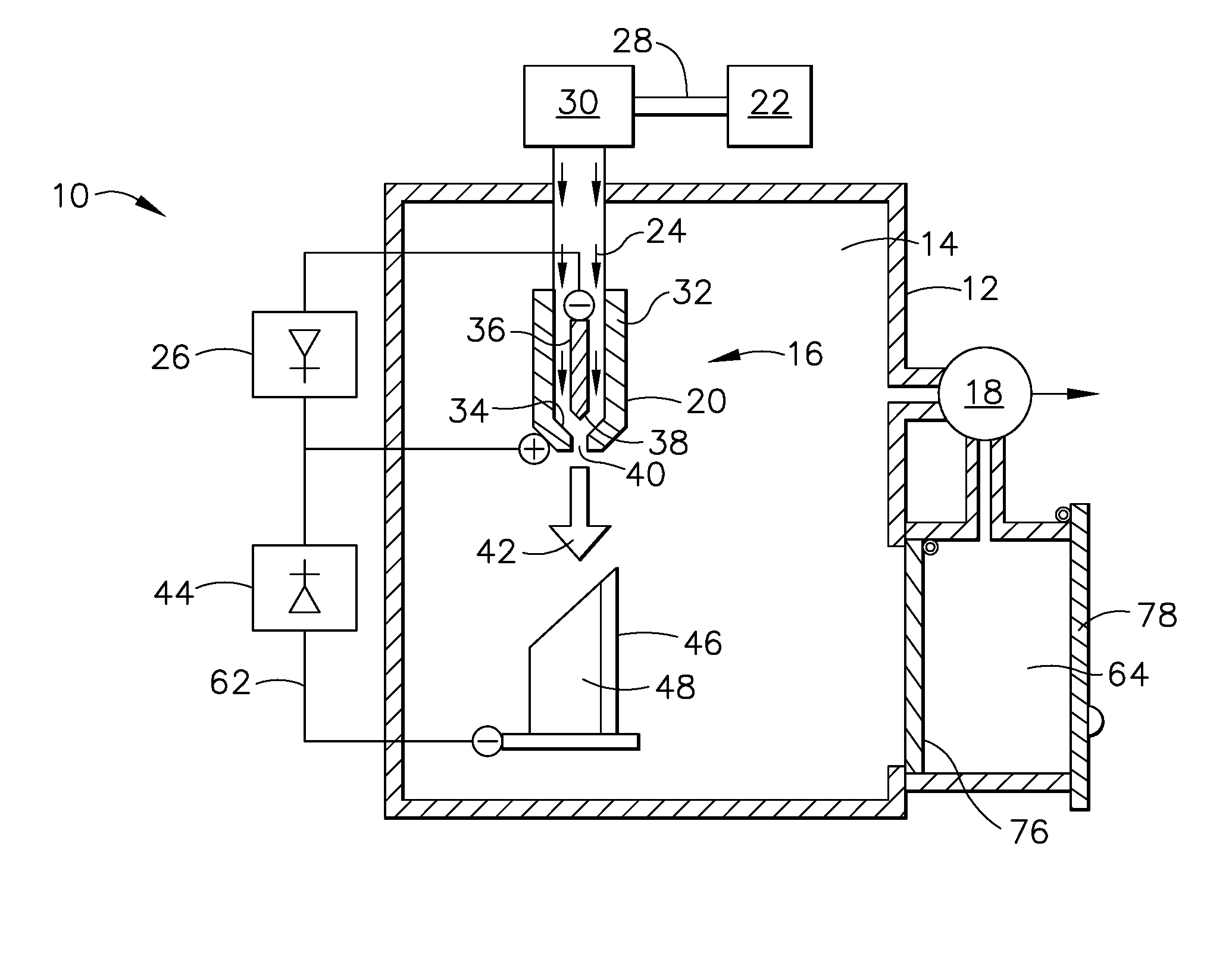

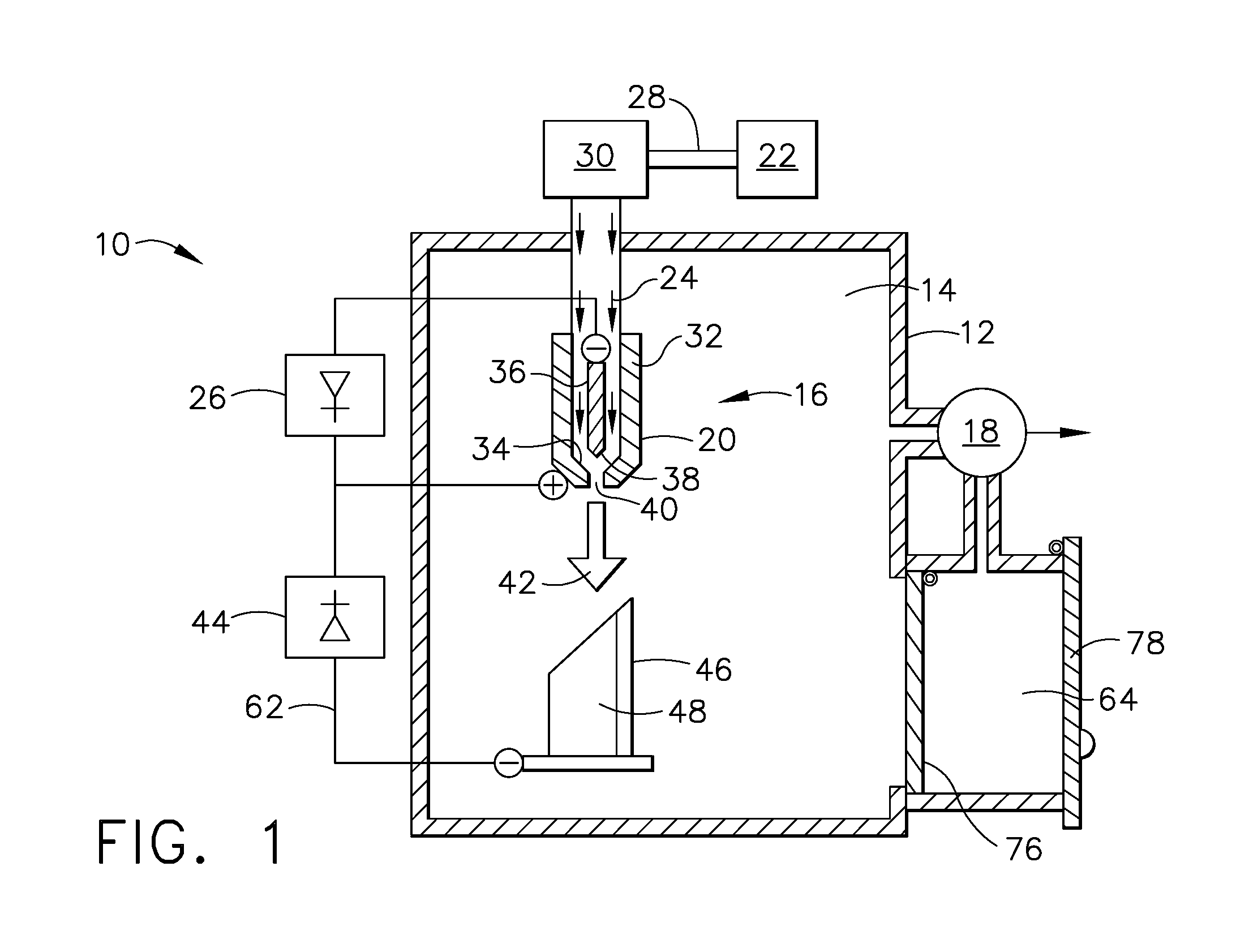

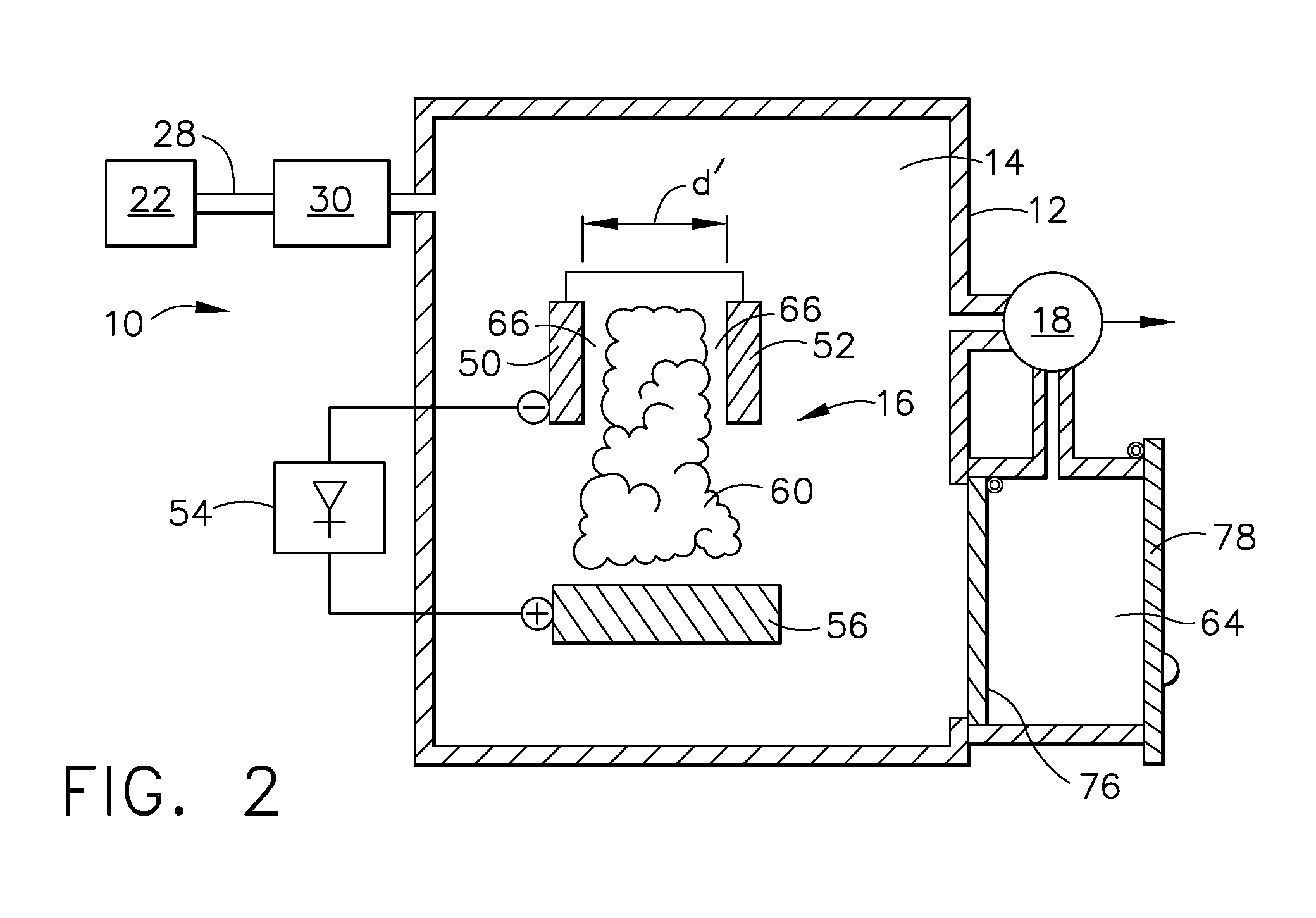

Apparatus and method for reducing metal oxides on superalloy articles

InactiveUS20050035085A1Good effectEfficient removalEngine manufactureDecorative surface effectsSuperalloyPlasma flow

A method of removing a metal oxide from an alloy surface of an article, such as a superalloy turbine blade for a gas turbine engine, by contacting the alloy surface within the vacuum environment of a vacuum chamber with a reductive plasma for a time sufficient to reduce the metal oxide. Typically, the reductive plasma stream is provided by a plasma torch that electrically charges a stream of hydrogen gas, most typically mixed with a much greater portion of an inert gas such as 95% argon, to generate an active plasma stream of H3+ ions. Typically, a biasing circuit is made between the plasma torch and the alloy article to direct the plasma stream to the alloy surface.

Owner:GENERAL ELECTRIC CO

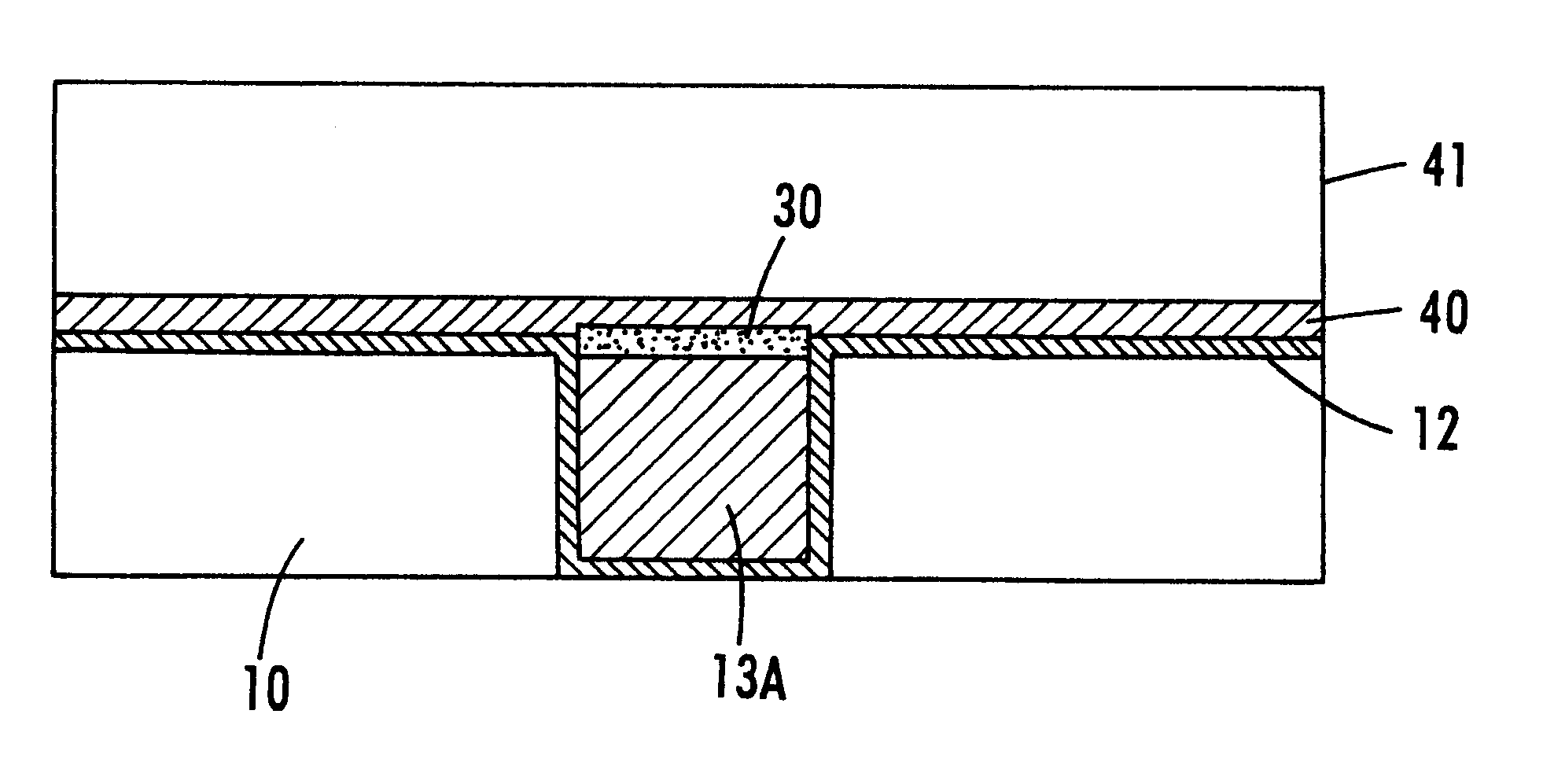

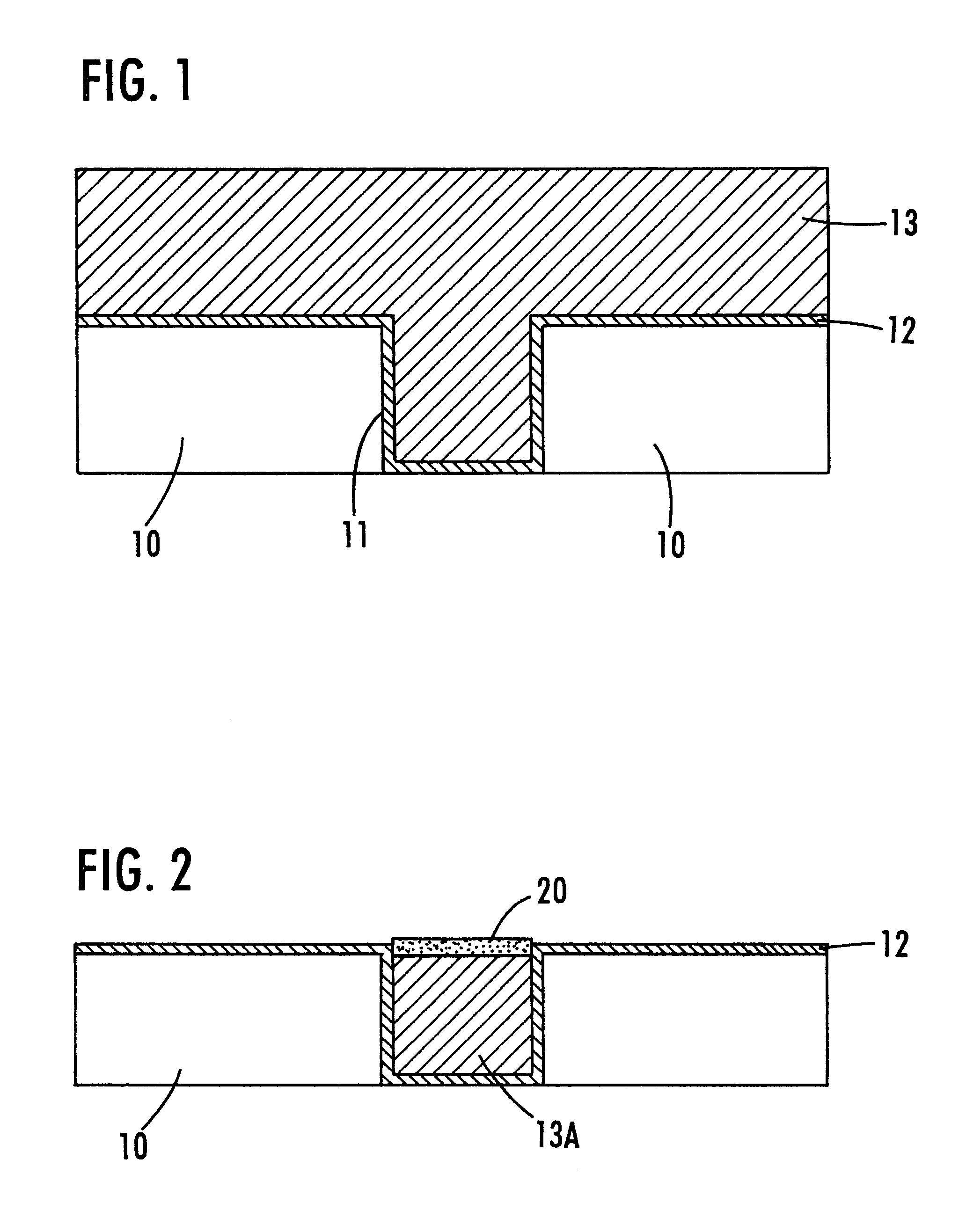

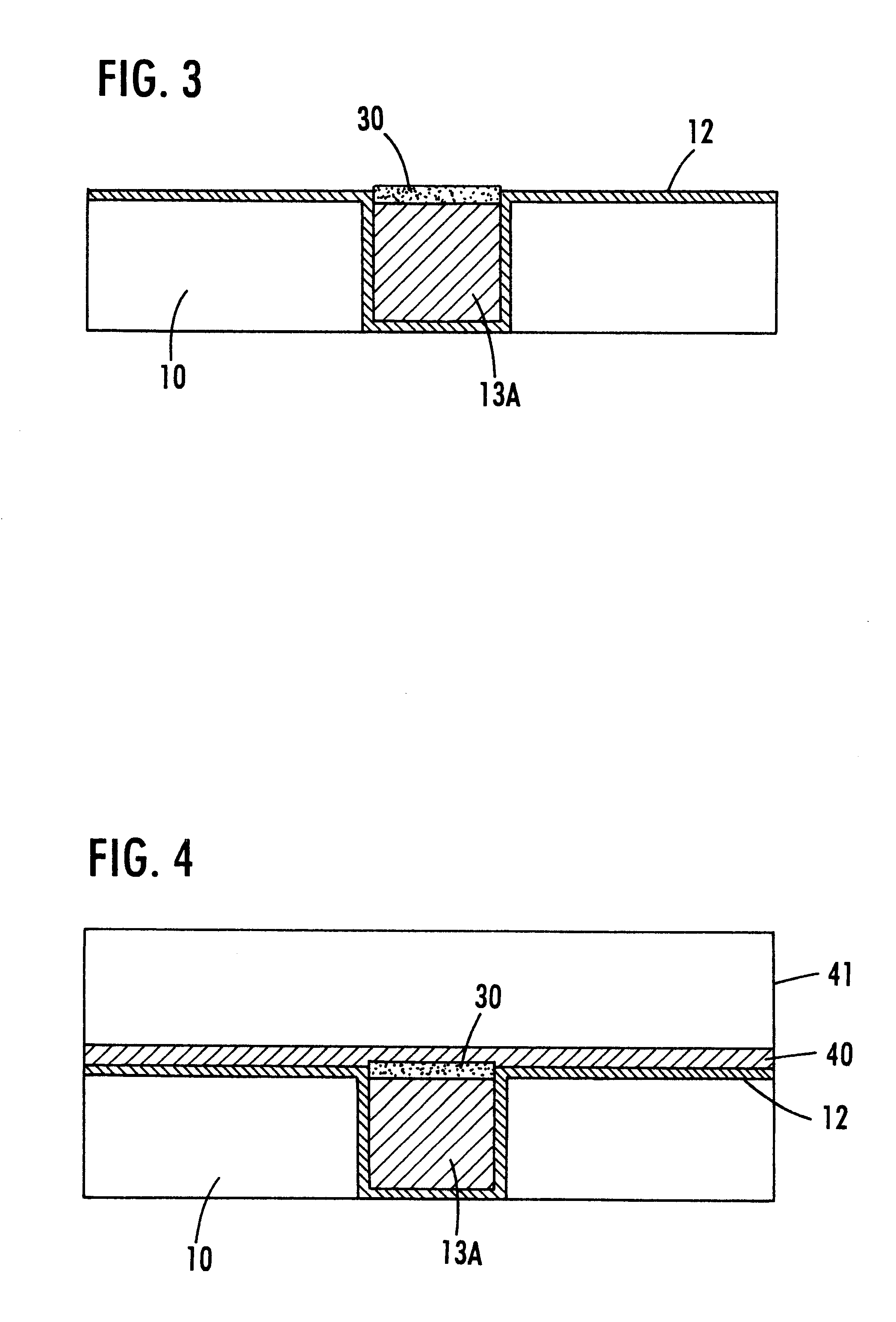

Method of improving adhesion of capping layers to copper interconnects

InactiveUS6383925B1Efficient and cost-effectiveSemiconductor/solid-state device detailsSolid-state devicesCopper interconnectHigh density

The adhesion of a barrier or capping layer to a Cu or Cu alloy interconnect member is significantly enhanced by treating the exposed surface of the Cu or Cu alloy interconnect member, after CMP, in a reaction chamber with a plasma containing ammonia and nitrogen for a brief period of time to reduce the surface oxide and then introducing silane into the reaction chamber to deposit the barrier layer, e.g., silicon nitride, under high density plasma conditions in the presence of nitrogen. The presence of nitrogen during plasma oxide layer reduction and plasma barrier layer deposition significantly improves adhesion of the barrier layer to the Cu or Cu alloy surface.

Owner:ADVANCED MICRO DEVICES INC

Method for preparing titanium-alloy surface micro-arc oxidation antifriction compound film layer

InactiveCN102021629AGood anti-frictionReduce pollutionSurface reaction electrolytic coatingElectrolytic agentMicro arc oxidation

The invention relates to a method for preparing a titanium-alloy surface micro-arc oxidation antifriction compound film layer, which is characterized by comprising the following steps of: (1) micro-arc oxidation of an electrolyte; and (2) preparation of a compound film. The invention has the technical effects that: 1. the method provided by the invention is used for preparing the micro-arc oxidation compound film layer with an antifriction effect by introducing a solid lubricant and experimenting on a one-step method in the titanium-alloy micro-arc oxidation process on the premise of not destroying a micro-arc oxidation film layer, and the antifriction effect is remarkable; and 2. the composition raw materials of a sodium-silicate system electrolyte adopted by the invention are simply and easily obtained, a solution is neutral or weakly alkaline, the solution does not contain heavy metal ions, such as chromium ions and the like or environment-friendly constraint elements and does not contain substances harmful to human bodies and environments, the environmental pollution is small, and the requirements of high-quality clean production are satisfied.

Owner:NANCHANG HANGKONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com