Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Excellent wear resistance and corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser fusing and coating process for wear resistant and etch-resistant coating of hydraulic support column cylinder and piston rod

ActiveCN101338427AExcellent wear resistance and corrosion resistanceImprove wear resistanceMetallic material coating processesWear resistantRoom temperature

A laser cladding process of the wear-resisting anticorrosive coating of a hydraulic pressure support pillar cylinder barrel or a piston rod cylinder barrel comprises procedures as follows: the surfaces of the standing pillar cylinder barrel and the piston rod cylinder barrel are pretreated; the surfaces of the standing pillar cylinder barrel and the piston rod cylinder barrel are decreased, de-rusted and cleaned up by alcohol under room temperature; alloying powder is chosen and an automatic powder feeder is adjusted; the iron base alloying powder with good wear-resisting anticorrosive property and sound metallurgy compatibility with a matrix is selected and the iron base alloying powder contains major constituents, including Fe, C, Cr, Ni, Mo, Si, N, Nb, Ta and B; and at last, the automatic powder feeder is adjusted. Adjusting the automatic powder feeder can lead the alloying powder from an automatic feeding end to a laser melting pool and feeding amount is adjusted so that the thickness of the alloying coating reaches 0.6mm to1.2mm. The alloying coating of the invention is even and dense and has good wear-resisting anticorrosive property. Compared with galvanization, the wear-resisting anticorrosive property and the service life of the standing pillar cylinder barrel and the piston rod manufactured by the invention are greatly improved.

Owner:CHONGQING JIANGLU LASER TECH

Method for preparing wear-resistant coating on surface of driving sheave race of elevator by laser cladding

ActiveCN102453904AExcellent wear resistance and corrosion resistanceImprove wear resistanceMetallic material coating processesLaser beam welding apparatusHigh power lasersWear resistant

The invention relates to a method for preparing a wear-resistant coating on the surface of a driving sheave race of an elevator by laser cladding. A rendering transition layer with good toughness, which is clad on the surface of the race and forms metallurgical bonding with a base body, is rapidly scanned by laser through high-power laser; and a wear-resistant cobalt-base alloy which has good corrosive resistance and a frication coefficient in fit with that of a steel wire rope is prepared on a rendering alloy surface through laser cladding. The method is characterized by comprising the following special steps of: firstly, pre-treating the surface of the race; secondly, selecting alloy powder and an automatic powder sending device; thirdly, carrying out the laser cladding on the rendering alloy and the cobalt-base alloy powder with the frication coefficient in fit with that of the steel wire rope so that a wear-resistant coating with the thickness of 0.5-1.2 mm is formed on the surface of the race; and finally, carrying out flaw detection after cladding. The method provided by the invention has the characteristics of high productivity, lower energy consumption, small machining allowance of a cladding layer, high field, low combined cost and the like.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

Laser cladding process for abrasion-resistant anticorrosion coating of water turbine unit runner

InactiveCN101994112AExcellent wear resistance and corrosion resistanceImprove wear resistanceMetallic material coating processesMelting tankCoronal plane

The invention discloses a laser cladding method for an abrasion-resistant anticorrosion coating of a water turbine unit runner. The method is characterized by comprising the following steps of: performing surface cleaning on greasy dirt and rust layers on the surface of the water turbine unit runner; then selecting iron-based alloy powder, making the alloy powder discharged from an automatic powder feeding head fall into a laser molten pool by adopting laser equipment and an adjustable automatic powder feeding device, adjusting the powder feeding amount, and forming uniform and dense laser claddings on the processing surfaces of the upper and lower coronal planes, wherein the thicknesses of the laser claddings reach 0.2 to 1.8 millimeters; and finally, checking the processing parts of the upper and lower coronal planes of the runner by using a dye penetrant inspection method, wherein the processing parts are required without defects of cracks, air holes and the like. The laser cladding coating is uniform and dense, forms firm metallurgical bonding together with a matrix, has good abrasion resistance and anticorrosion performance, and can remarkably improve the abrasion-resistant and anticorrosion performance of the water turbine unit runner and prolong the service life of the water turbine unit runner.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

Method for preparing air inlet edge surface wear-resistant anti-corrosion alloy coating of tail stage blade of steam turbine

InactiveCN102453896AMelting fastFreeze fastMetallic material coating processesNumerical controlEdge surface

The invention relates to a method for preparing an air inlet edge surface wear-resistant anti-corrosion alloy coating of a tail stage blade of a steam turbine. The method is characterized by comprising the following steps that: 1) the air inlet edge surface of the tail stage blade of the steam turbine is pre-treated; 2) alloy powder is selected, and an automatic powder conveyor is regulated; 3) light beams are regulated; 4) the wear-resistant anti-corrosion coating laser cladding is carried out, a DL-HL-T5000 type CO2 laser is adopted, a work table is a SIMENS numerical control laser processing machine, a synchronous powder conveyor is adopted for conveying the alloy powder into a laser molten pool, high-power focus laser beams and an automatic powder conveying head are fed in the specified direction of the air inlet edge surface of the blade, and uniform and compact laser cladding layers are formed on the blade surface through processing; and 5) flaw detection is carried out after the cladding. According to the method, the laser cladding is adopted for uniformly cladding the alloy powder with the wear-resistant anti-corrosion performance onto the blade of the steam turbine, the uniform and compact metallurgical combining coatings are formed, the anti-corrosion performance reaches the stainless steel level, the cladding layer and a substrate form firm metallurgical combination, and the peeling is not easy to occur.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

Method for preparing WC hard alloy wear resistance area on petroleum drill rod surface

ActiveCN102453901AExtended service lifeImprove toughnessMetallic material coating processesLaser beam welding apparatusHigh power lasersAlloy coating

The invention relates to a method for preparing a WC hard alloy wear resistance area on a petroleum drill rod surface. The method is characterized in that: the method comprises the following steps: (1) carrying out a pretreatment for the petroleum drill rod surface; (2) selecting alloy powder and adjusting an automatic powder feeding device; (3) cladding a bottoming alloy coating by a high power laser; (4) cladding spherical WC and Ni-Cr-B-Si mixed alloy powder by the high-power laser; (5) carrying out defectoscopy inspection after cladding. According to the present invention, the gradient coating method is adopted to prepare the WC hard alloy wear resistance area on the petroleum drill rod surface, the nickel-base alloy powder is adopted as the bottoming layer, the high wear resistance WC hard alloy powder is adopted as the working layer, such that the good binding strength of the working layer and the substrate is ensured in the case of meeting of the working layer characteristics, and the cracks can be prevented from expanding to the substrate during the using process, wherein the nickel-base alloy powder has good toughness and high strength, and has good metallurgy compatibility with the substrate.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

Anticorrosive and antiwear cast cobalt-base alloy

The present invention relates to Co-base alloy, especially, an anticorrosive and antiwear cast Co-base alloy. The alloy consists of C 1.0-2.5 wt%, Cr 20-35 wt%, W 5-20 wt%, Mo 1-6 wt%, Nb 1-8 wt%, Cu0.5-2.0 wt%, Si 0.5-3.0 wt%, Ni 2-15 wt% and Co 35-65 wt%. It has excellent anticorrosive performance and average hardness of about 48 HRC, and may be used in making cutter of water flow type chemical fiber cutting machine. Substituting partial Co with Ni can reduce the cost of the alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for preparing WC (Wolfram Carbide) cemented carbide wearing layer on surface of petroleum drilling tool stabilizer through laser cladding

InactiveCN103484852AUniform coatingExcellent wear resistance and corrosion resistanceMetallic material coating processesCemented carbideAutomatic control

The invention discloses a method for preparing a WC (Wolfram Carbide) cemented carbide wearing layer on a surface of a petroleum drilling tool stabilizer through laser cladding. A tough bottoming transition layer which is in good metallurgical bonding with a matrix is formed on the surface of a shell in a fusion covering manner through rapid laser scanning by using a high-power laser, and mixture alloy powder of spherical WC and Ni-Cr-B-Si, which is wearing-resisting and excellent in corrosion resistance, is prepared on the surface of the bottoming alloy through laser cladding. The power, position, shape and the like of a laser beam of the method can be accurately controlled, selective area or even micro-area fusion covering is easy to realize, the dilution rate of coating components is low, the coating thickness can be accurately controlled, non-contact type treatment is adopted, and automatic control is easy to realize in the whole process; in addition, a laser cladding process is non-pollution on the environment, free of radiation and low in noise, has the characteristics that the productivity is high, the energy consumption is low, the cladding layer machining margin is small, the finished product rate is high, the comprehensive cost is low, and the like, and can be widely applied.

Owner:武汉团结点金激光科技有限公司

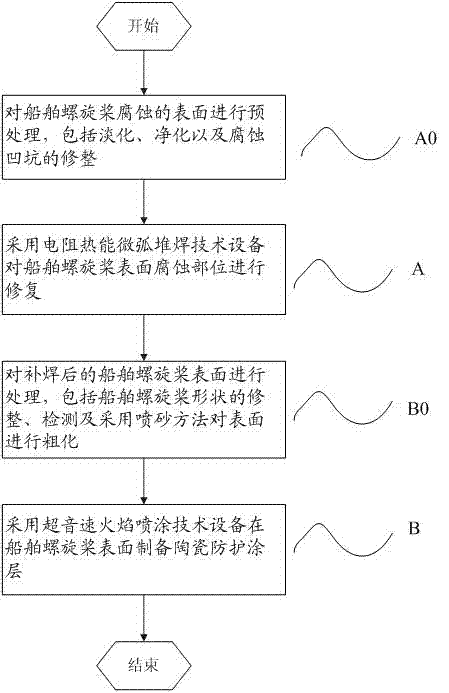

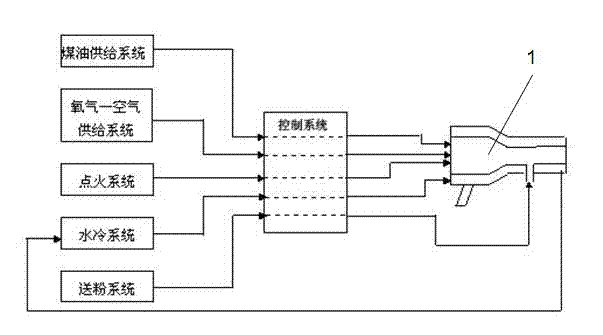

Method for corrosion repair and long-term protection of ship propeller

ActiveCN103801893AExcellent wear resistance and corrosion resistancePlay a long-term protective effectMolten spray coatingHeat-affected zoneCeramic coating

The invention provides a method for corrosion repair and long-term protection of a ship propeller. The method includes the following steps that firstly, a resistance heat energy micro arc build up welding device is utilized to repair corroded parts on the surface of the ship propeller; secondly, a high velocity oxy-fuel device is utilized to prepare a ceramic protective coating on the surface of the ship propeller. According to the method for corrosion repair and long-term protection of the ship propeller, firstly the resistance heat micro arc build up welding device is utilized to weld up corrosion defects on the surface of the ship propeller, in the welding-up process, welding materials and a base body can be well metallurgically bonded, the heat affected zone is small, accuracy can be controlled, and maintenance risks are low; then the high velocity oxy-fuel device is utilized to prepare the ceramic coating on the surface of the ship propeller, the ceramic coating is ultra-strong in hardness, high in bonding strength with the base body and excellent in wear resistance and corrosion resistance, the surface of the propeller can be protected for a long term, and therefore the service life of the propeller can be greatly prolonged.

Owner:QINGDAO QIANJIN SHIPYARD

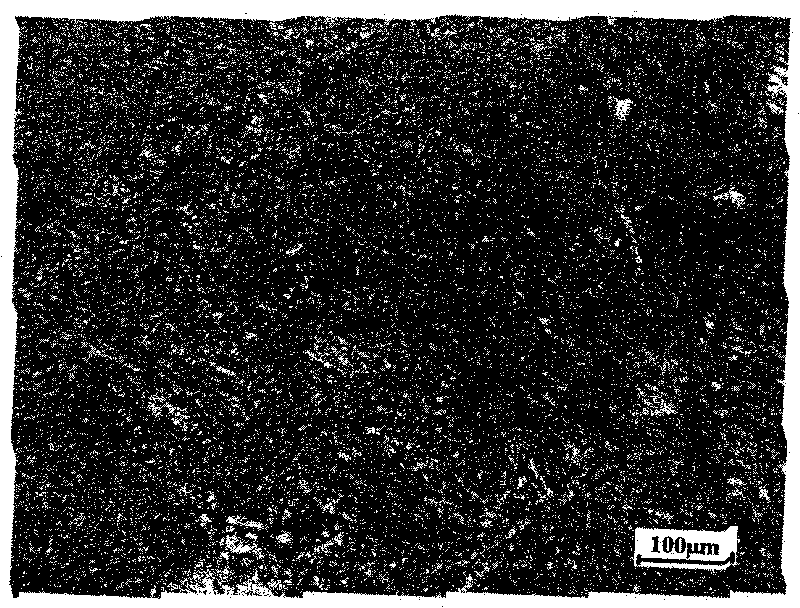

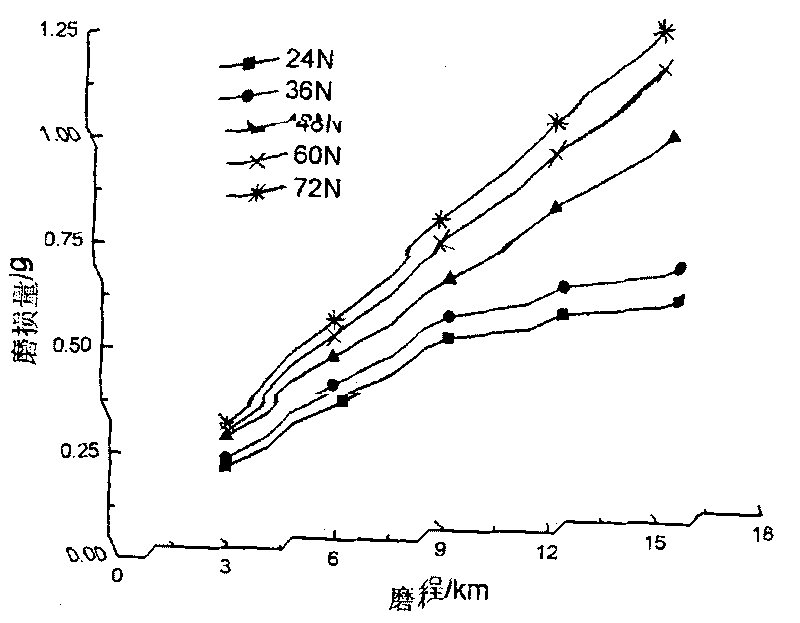

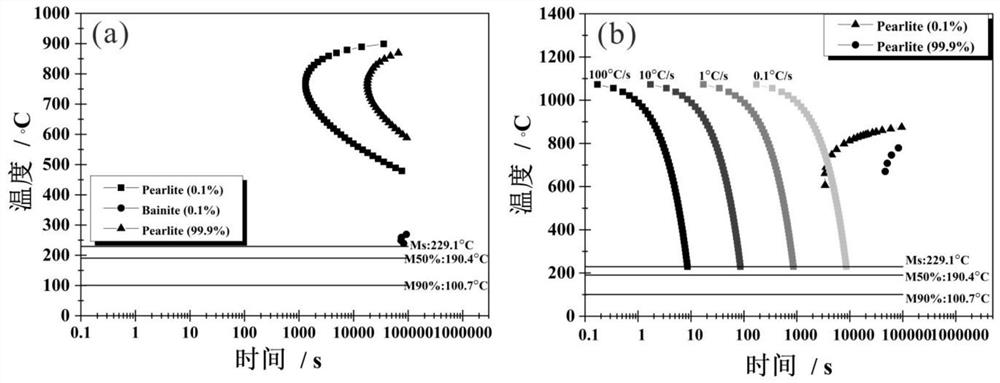

Low-alloy abrasion-proof and corrosion resistant steel and method for producing the same

InactiveCN101423916AStrong resistance to seawater corrosionImprove corrosion resistanceElectric furnaceProcess efficiency improvementWear corrosionWear resistant

The invention relates to low alloy wearing resistance corrosion resistance steel which is suitably used in the ocean mud-sand wearing and corrosive environment, which is produced by the following steps: Mn-Si-Cr-Mo system non-carbide bainite alloy steel is taken as research basis, the carbon content and other alloy element contents are properly adjusted, elements of Al, Nb and rare earth contributing to improving the corrosion resistance of the alloy steel are added for modification, and the Mn-Si-Cr-Mo-Al system non-carbide bainite steel is formed by the progression quenching heat treatment process, so that the low alloy wearing resistance corrosion resistance steel is obtained. The steel has good obdurability, wearing resistant and corrosion resistant comprehensive performance and welding repair performances, and can be used to solve the problem of repairing worn blades of a centrifugal pump of a ship, and can also be applied to other ocean wearing resistance welding parts.

Owner:HOHAI UNIV +1

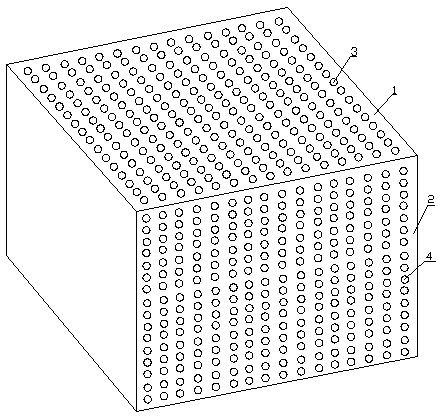

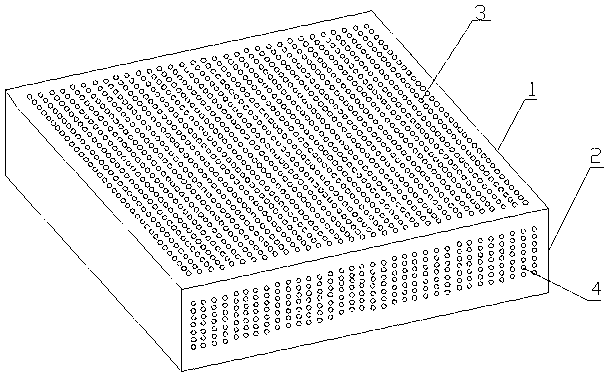

Heat exchanging component made of ceramic materials and preparation method thereof

The invention discloses a heat exchanging component made of ceramic materials and a preparation method thereof, and more specifically relates to a ceramic material, a ceramic heat exchanging component, and preparation methods thereof, wherein the ceramic material has the properties of thermal shock property, corrosion resistance, wear resistance, low cost, high strength, high heat exchange efficiency, and the like. According to the invention, the ceramic material and the ceramic heat exchanging component are prepared through selecting 70-85% of silicon carbide, 0-5% of silicon nitride, 0-5% of theron, 0-5% of aluminum nitride, 0.9-3.2% of a fluxing agent, 10-20% of a binder and 0-2.5% of a forming additive; the heat exchanging component has good thermal conductivity and thermal shock properties, especially when the heat exchanging component is used for waste heat recovery, the temperature of tail gas discharged by oil and gas combustion can be reduced to a temperature below the water dew point, so that the sensible heat in the tail gas is fully recovered, and the latent heat of liquefaction of dry steam is recovered, therefore, the heat exchanging component made of ceramic materials and preparation method thereof disclosed by the invention provide a new technical route for a process for the effective governance of tail gas discharged by oil and gas combustion, and can be applied to a technical scheme of effectively preventing the formation of a haze weather caused by oil and gas combustion emissions.

Owner:广西蓝熵科技开发有限公司

Method for laser cladding manufacturing or remanufacturing of wear and corrosion resistant wind power generator shaft

ActiveCN103194747AExcellent wear resistance and corrosion resistanceImprove wear resistanceMetallic material coating processesHigh power lasersWear resistant

The invention relates to a method for the laser cladding manufacturing or remanufacturing of a wear and corrosion resistant wind power generator shaft. The method is characterized in that the method comprises the following steps: 1, preprocessing the surface of a motor shaft; 2, selecting alloy powder having a wear abrasion matched with the performances of the motor shaft as a work layer, adjusting a gravity powder sending device, and pre-setting the powder; 3, cladding the wear resistant alloy powder through a high power laser; and 4, examining the obtained wind power generator shaft through ultrasonic flaw detection after cladding. A wear and corrosion resistant coat which can form metallurgic combination with a matrix on the wind power generator shaft through using a high power CO2 laser, so the corrosion, wear and oxidation resistance characteristics of the wind power generator shaft are substantially improved, use requirements of the wind power generator are reached, and the characteristics comprising high productivity, low energy consumption, small cladding layer working allowance, high yield, low comprehensive cost and the like are possessed.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

Manufacturing technique for bearing

The invention discloses a manufacturing technique for a bearing. Through control over the normalizing and heat preservation time and temperature in heat treatment, deformation of a metal part can be reduced, energy consumption is saved, and the production cost is reduced; through control over the speed and the power of a grinding machine, the accuracy and the abrasion resistance of the bearing are further improved; through acid dipping after degreasing, on one hand, oxide on the surface of a steel pipe can be removed, as aftertreatment is carried out after surface grinding, the antiseptic property of the bearing can be improved, and the service life of the bearing is accordingly prolonged. The bearing produced with the method has the advantages of being high in fatigue resistance and long in service life; and the market potential is huge, and the prospect is wide.

Owner:南阳防爆(苏州)特种装备有限公司

Method for preparing WC hard alloy wear resistance area on petroleum drill rod surface

ActiveCN102453901BExcellent wear resistance and corrosion resistanceImprove surface wear resistanceMetallic material coating processesHigh power lasersAlloy

The invention relates to a method for preparing a WC hard alloy wear resistance area on a petroleum drill rod surface. The method is characterized in that: the method comprises the following steps: (1) carrying out a pretreatment for the petroleum drill rod surface; (2) selecting alloy powder and adjusting an automatic powder feeding device; (3) cladding a bottoming alloy coating by a high power laser; (4) cladding spherical WC and Ni-Cr-B-Si mixed alloy powder by the high-power laser; (5) carrying out defectoscopy inspection after cladding. According to the present invention, the gradient coating method is adopted to prepare the WC hard alloy wear resistance area on the petroleum drill rod surface, the nickel-base alloy powder is adopted as the bottoming layer, the high wear resistance WC hard alloy powder is adopted as the working layer, such that the good binding strength of the working layer and the substrate is ensured in the case of meeting of the working layer characteristics, and the cracks can be prevented from expanding to the substrate during the using process, wherein the nickel-base alloy powder has good toughness and high strength, and has good metallurgy compatibility with the substrate.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

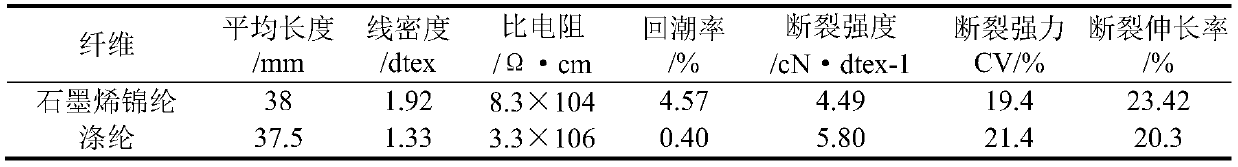

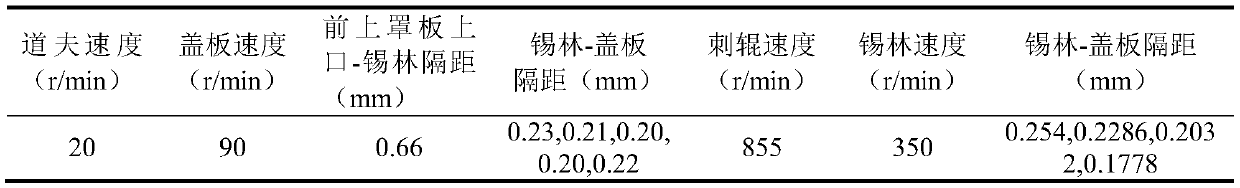

Production method of antibacterial blended yarn

The invention provides a production method of antibacterial blended yarn. Graphene nylon and small-scale polyester are directly mixed in the opening picking procedure, so that slipping of fiber due toaccidental stretching of the graphene nylon is reduced, the friction force and cohesive force between two kinds of fiber are enhanced, and the problem of difficulty in individual rolling due to smallcohesive force between graphene nylon fiber is effectively solved, meanwhile, a mixed roll obtained after mixing is carded by a carding machine with two-time carding functions, for the first carding,carding needle cloth and a carding technology are set on the basis of the property of the graphene nylon fiber, and for the second carding, the carding needle cloth and the carding technology are seton the basis of the property of the polyester fiber, so that two kinds of fiber are carded respectively, mixed sliver is prepared, then, the mixed sliver and polyester sliver are subjected to drawingand second mixing, accurate blending ratio control of two kinds of fiber is realized, and finally, uniform mixing of the two kinds of fiber and production of yarn with excellent anti-static, anti-ultraviolet, antibacterial, bacteriostatic, low-temperature infrared, wear-resistant, corrosion-resistant characteristics are realized.

Owner:合肥经新科技有限公司

Method for preparing intermetallic compound powder cored filament material for electric arc spraying

The preparation process of intermetallic compound filament with powder core for arc spraying includes the following steps: mixing aluminum powder of granularity 38-44 micron and purity not lower than 99.5 % and iron (nickel ) powder of granularity 53-61 micron and purity not lower than 99.5 % in the atom ratio of 1 to 1; pressing the mixture in a hydraulic press into blank and painting the surface with one thin graphite layer; self-spreading reaction in a vacuum combustor to obtain loose intermetallic compound block; crushing, grinding, sieving to obtain 200-325 mesh granularity powder material and drying; and making Fe (Ni)-Al compound filament with powder core. The present invention has good spraying performance, good coating layer performance, high performance / cost ratio, wide use temperature range, simple technological process and low power consumption.

Owner:SHANDONG UNIV OF SCI & TECH

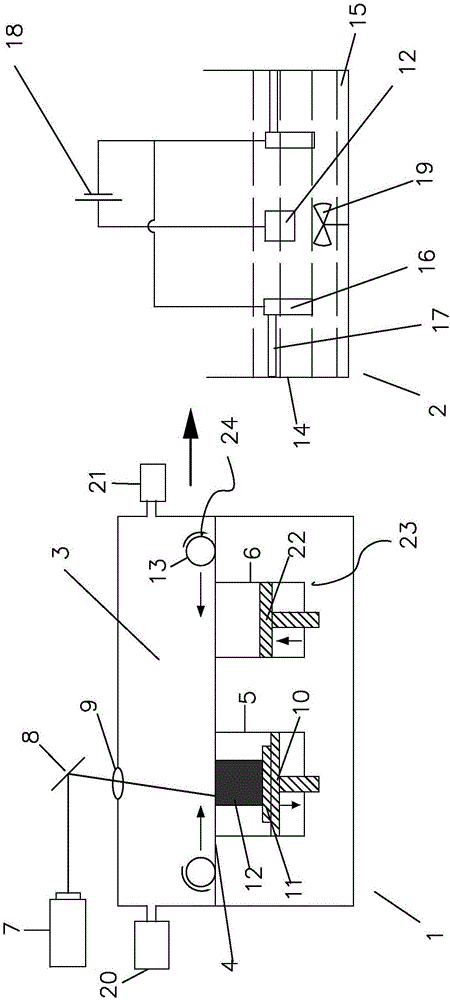

3D printing and electrolytic polishing combined machining system for CoCrMo dental crown

InactiveCN106424733AImprove preparation efficiencyThe surface roughness satisfiesAdditive manufacturing apparatusElectrolysis componentsAlloyMechanical property

The invention discloses a 3D printing and electrolytic polishing combined machining system for a CoCrMo dental crown. The combined machining system comprises laser selective melting printing equipment and electrolytic polishing equipment, wherein the laser selective melting printing equipment comprises an optical transmission system and a vacuum chamber which can be incident by laser of the optical transmission system, a moulding platform which can be lifted is arranged in the vacuum chamber, a powder feeding device used for conveying printing powder is also arranged in the vacuum chamber, the powder feeding device is connected with a power laying device which can lay the printing powder on the powder feeding device onto the moulding platform; the electrolytic polishing equipment comprises an electrolytic tank which is used for placing a product and filled with electrolyte, a para-position electrode is fixed in the electrolytic tank, the para-position electrode is connected with the cathode of a power supply, and when electrolytic polishing is carried out on the product, the product is connected with the anode of the power supply. The combined machining system disclosed by the invention has the advantages that the laser selective melting printing equipment and the electrolytic polishing equipment are combined, surface roughness of the treated product meets post processing requirement, tissues are compact and controllable, mechanical properties can be configured, and anticorrosion and wear-resistant properties are excellent.

Owner:广东汉唐快速制造应用技术研究院有限公司 +1

Low-alloy abrasion-proof and corrosion resistant steel and method for producing the same

InactiveCN101423916BImprove corrosion resistanceFix fixesElectric furnaceProcess efficiency improvementWear corrosionWear resistant

The invention relates to low alloy wearing resistance corrosion resistance steel which is suitably used in the ocean mud-sand wearing and corrosive environment, which is produced by the following steps: Mn-Si-Cr-Mo system non-carbide bainite alloy steel is taken as research basis, the carbon content and other alloy element contents are properly adjusted, elements of Al, Nb and rare earth contributing to improving the corrosion resistance of the alloy steel are added for modification, and the Mn-Si-Cr-Mo-Al system non-carbide bainite steel is formed by the progression quenching heat treatment process, so that the low alloy wearing resistance corrosion resistance steel is obtained. The steel has good obdurability, wearing resistant and corrosion resistant comprehensive performance and welding repair performances, and can be used to solve the problem of repairing worn blades of a centrifugal pump of a ship, and can also be applied to other ocean wearing resistance welding parts.

Owner:HOHAI UNIV +1

Preparation method of corrosion-resistant and wear-resistant molybdenum-based amorphous coating for boiler tube bundle

InactiveCN104313532AExtended service lifeImprove corrosion resistanceMolten spray coatingWear resistantAlloy

The invention discloses a preparation method of a corrosion-resistant and wear-resistant molybdenum-based amorphous coating for a boiler tube bundle. The method comprises the following steps: firstly, preparing molybdenum-based amorphous alloy powder by adopting an aerosol method, wherein the molybdenum-based amorphous alloy powder is formed by mixing the following raw materials in percentage by mass: 7.0-11.0% of Fe, 11.0-20.0% of Cr, 1.0-10.0% of Ni, 6.0-9.0% of Si, 0.5-2.0% of Al, 2.6-8.0% of C, 0.5-5.5% of W, 0-2% of Y and the balance of Mo and unavoidable impurities; secondly, preparing and obtaining the corrosion-resistant and wear-resistant molybdenum-based amorphous coating on the surface of the boiler tube bundle by adopting a plasma spraying technology. The molybdenum-based amorphous coating prepared by the invention has excellent corrosion resistance, wear resistance and high-temperature stability, and can protect the heat erosion surface of the boiler tube bundle better in an environment with the combined effect of heat corrosion and erosion, so that the service life of the boiler tube bundle is effectively prolonged.

Owner:CHANGAN UNIV

Method for preparing intermetallic compound powder cored filament material for electric arc spraying

The preparation process of intermetallic compound filament with powder core for arc spraying includes the following steps: mixing aluminum powder of granularity 38-44 micron and purity not lower than 99.5 % and iron (nickel ) powder of granularity 53-61 micron and purity not lower than 99.5 % in the atom ratio of 1 to 1; pressing the mixture in a hydraulic press into blank and painting the surface with one thin graphite layer; self-spreading reaction in a vacuum combustor to obtain loose intermetallic compound block; crushing, grinding, sieving to obtain 200-325 mesh granularity powder material and drying; and making Fe (Ni)-Al compound filament with powder core. The present invention has good spraying performance, good coating layer performance, high performance / cost ratio, wide use temperature range, simple technological process and low power consumption.

Owner:SHANDONG UNIV OF SCI & TECH

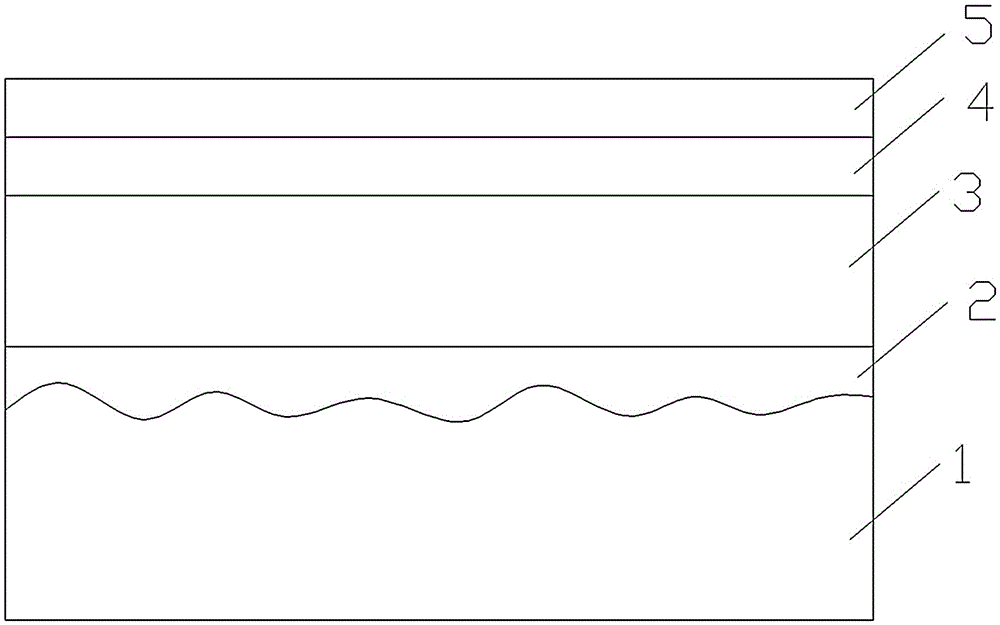

Selective solar energy absorbing film system and preparation method thereof

ActiveCN105546857AImprove adhesionPromote absorptionSolar heat devicesVacuum evaporation coatingSolar lightRefractive index

The invention discloses a selective solar energy absorbing film system and a preparation method thereof. The selective solar energy absorbing film system comprises a metal substrate; a top surface of the metal substrate is of an uneven microstructure; a TiAlN absorption blocking layer is deposited on the top surface of the metal substrate, a TiNxOy absorption layer is deposited on the TiAlN absorption blocking layer, a SiO2 anti-reflection layer is deposited on the TiNxOy absorption layer and an AlN anti-reflection protective layer is deposited on the SiO2 anti-reflection layer; the top surface of the metal substrate is etched by using a reactive ion beam technique to form the microstructure, thereby improving adhesion between the metal substrate and the film layer, leading to that the film layer does not fall easily and the service life of the film system is prolonged; each film layer is deposited by means of magnetron sputtering; the TiAlN absorption blocking layer is capable of preventing diffusion between the metal substrate and the TiNxOy absorption layer and thus increasing the absorption of the whole film system to solar light; the anti-reflection effect may be enhanced by means of a double-layer anti-reflection film layer composed of AlN and SiO2 having different refractive indices; the AlN anti-reflection protective layer has excellent corrosion resistance and abrasion resistance; the service life of each film layer is long in high-temperature atmospheric environments, and the service life of the selective solar energy absorbing film system thus is prolonged.

Owner:TRIUMPH PHOTOVOLTAIC MATERIAL CO LTD +1

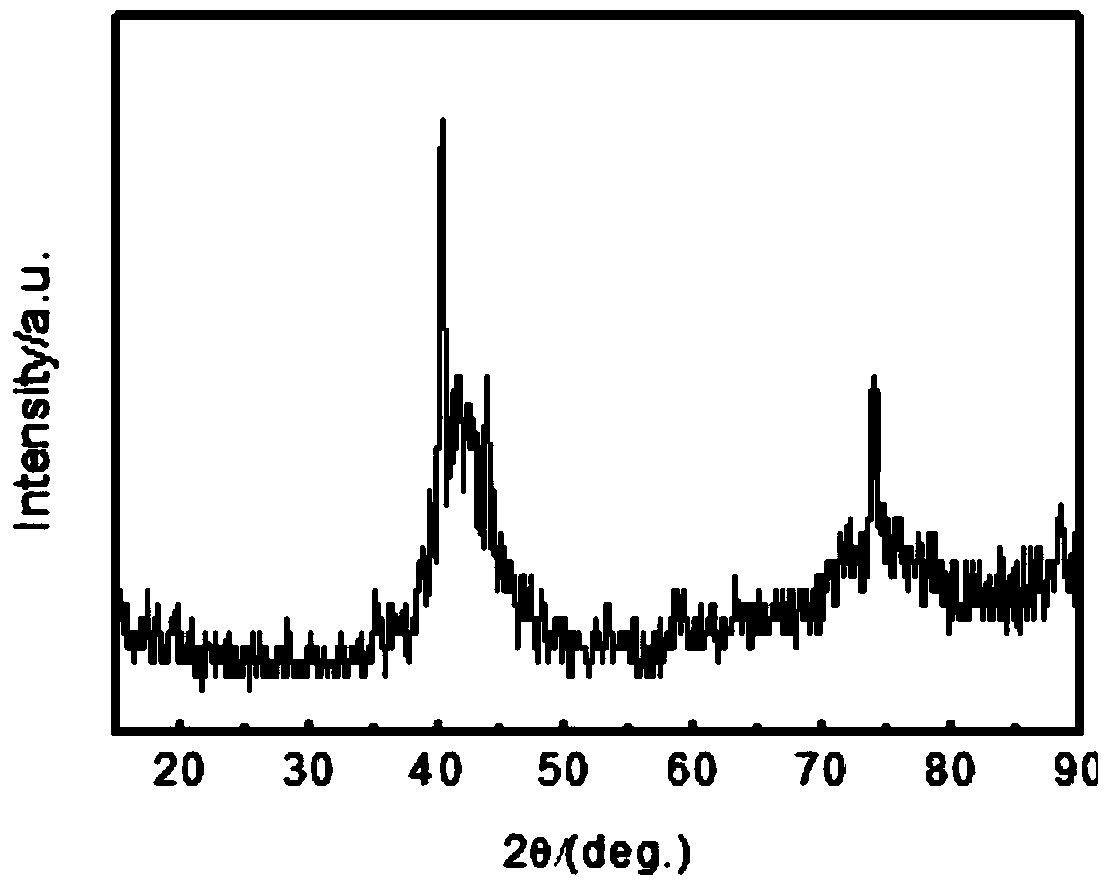

Ti-containing high-silicon aluminum alloy capable of achieving aging strengthening and preparation method for deformation material of Ti-containing high-silicon aluminum alloy

InactiveCN105695811AThe ingredients are designed to be simpleLow costSingle elementThermal deformation

The invention belongs to the technical field of aluminum alloy, and relates to a Ti-containing high-silicon aluminum alloy capable of achieving aging strengthening. The Ti-containing high-silicon aluminum alloy is characterized by being prepared from, by weight, 11% to 13% of Si, 0.5% to 1.0% of Mg, 0.1% to 0.8% of Ti, not larger than 0.5% of Fe, not larger than 0.15% of a single element in other alloy elements and the balance Al, wherein the total weight content of the other alloy elements is not larger than 0.5% by weight. A preparation method for the aluminum alloy and a deformation material of the aluminum alloy comprises the following steps of 1 alloy smelting, 2 casting forming, 3 pretreatment, 4 homogenization treatment, 5 thermal deformation, 6 solid solution water quenching treatment and 7 aging. The Ti-containing high-silicon aluminum alloy has the beneficial effects that the alloy is low in cost, no modification is needed, a DC casting process is adopted, double-stage homogenization is combined with deformation thermal treatment, and therefore the thermal forming performance of the alloy is improved, and a thermal deformation material production process is easy and convenient to control. The deformation material of the alloy has high strength and plasticity, meanwhile has excellent abrasion resisting performance and can partially replace an existing 6xxx series aluminum alloy and steel to be widely applied to the fields of building decoration, guide rails, track traffic, containers and the like.

Owner:NORTHEASTERN UNIV LIAONING

Method for manufacturing large profile universal rolling mill horizontal roller through laser

InactiveCN106480449AExcellent wear resistance and corrosion resistanceExtended service lifeMetallic material coating processesRoom temperatureAlloy

The invention discloses a method for manufacturing a large profile universal rolling mill horizontal roller through laser. The method comprises the following steps: turning a graphite steel or spheroidal graphite cast iron material with high strength and toughness into a large profile universal rolling mill horizontal roller through laser substrate with a reserved certain laser cladding size and deoiling and derusting the large profile universal rolling mill horizontal roller under the room temperature; selecting nickel-based alloy powder with high wear resistance, high corrosion resistance and high metallurgical compatibility the substrate, adjusting an automatic powder feeding device and enabling alloy powder out of an automatic powder feeding head to just fall into a laser cladding tank; automatically feeding the alloy powder into the laser cladding tank by using a synchronous powder feeding device, feeding high-power focused laser beams and the automatic powder feeding head along an axial direction, rotating the large profile universal rolling mill horizontal roller according to a set rotation rate and forming a uniform and dense laser cladding layer on the external surface of the horizontal roller; and carrying out subsequent heat treatment by slowly cooling the horizontal roller after broadband laser cladding of the nickel-based alloy, fully wrapping the horizontal roller body by using heat preservation cotton, and distressing and annealing the horizontal roller under the room temperature.

Owner:沈阳大陆激光工程技术有限公司

Mn containing high-silicon aluminum alloy capable of achieving ageing strengthening and preparation method of deformation material thereof

ActiveCN105695810AThe ingredients are designed to be simpleLow costSingle elementThermal deformation

The invention discloses an Mn containing high-silicon aluminum alloy capable of achieving ageing strengthening, and belongs to the technical field of aluminum alloy. The Mn containing high-silicon aluminum alloy is characterized in that the alloy is prepared from, by weight, 11% to 13% of Si, 0.5% to 1.0% of Mg, 0.1% to 3.0% of Mn, not larger than 0.5% of Fe, not larger than 0.2% of a single element in other alloy elements and the balance Al, wherein the total weight content of the other alloy elements is not larger than 0.5%. The preparation method of the aluminum alloy comprises the following steps of 1 alloy smelting, 2 casting forming, 3 pretreatment, 4 homogenization treatment, 5 thermal deformation, 6 solid solution water quenching treatment and 7 ageing. The Mn containing high-silicon aluminum alloy has the beneficial effects that the alloy is low in cost, a DC casting melt casting process is adopted, and modification is not needed; and double-stage homogenization is combined with deformation thermal treatment, the thermal forming performance of the alloy is improved, and a thermal deformation material production process is easy and convenient to control. The deformation material of the alloy has high strength and plasticity, meanwhile has excellent abrasion resisting performance, and can partially replace an existing 6xxx series aluminum alloy and steel to be widely applied to the fields of building decoration, guide rails, track traffic, containers and the like.

Owner:NORTHEASTERN UNIV LIAONING

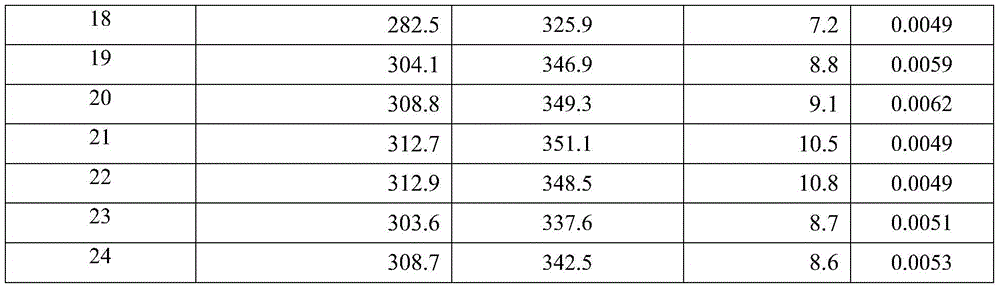

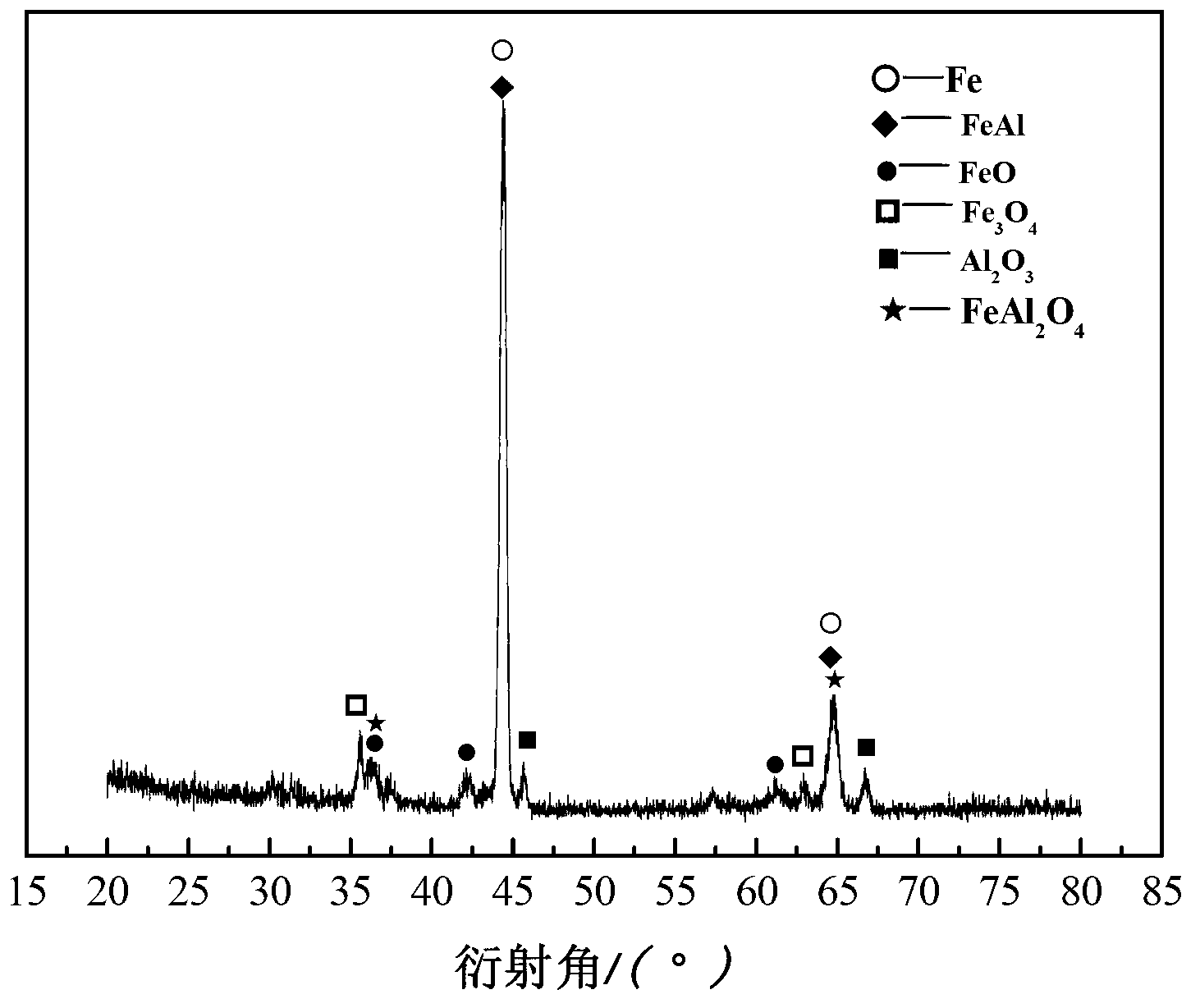

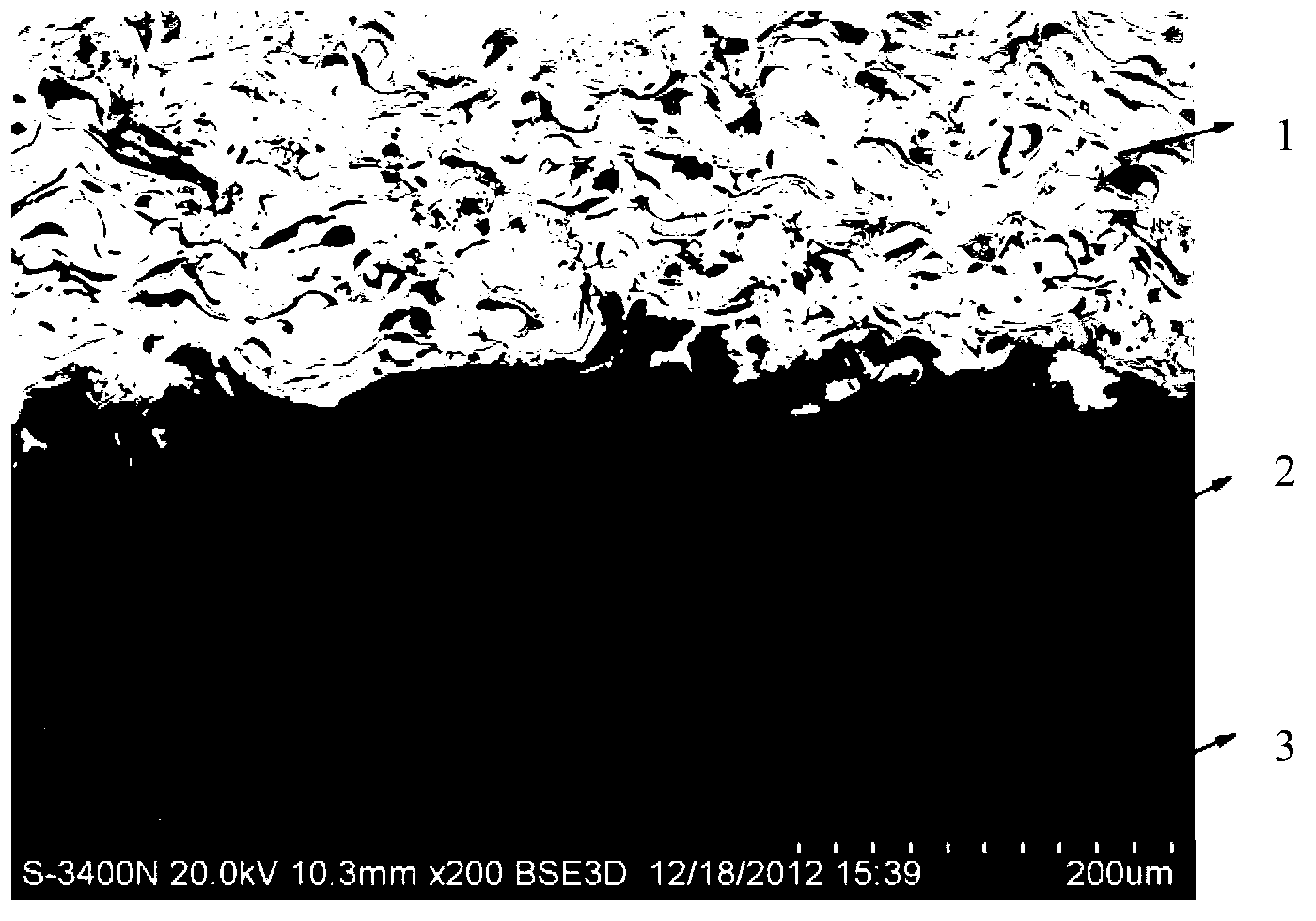

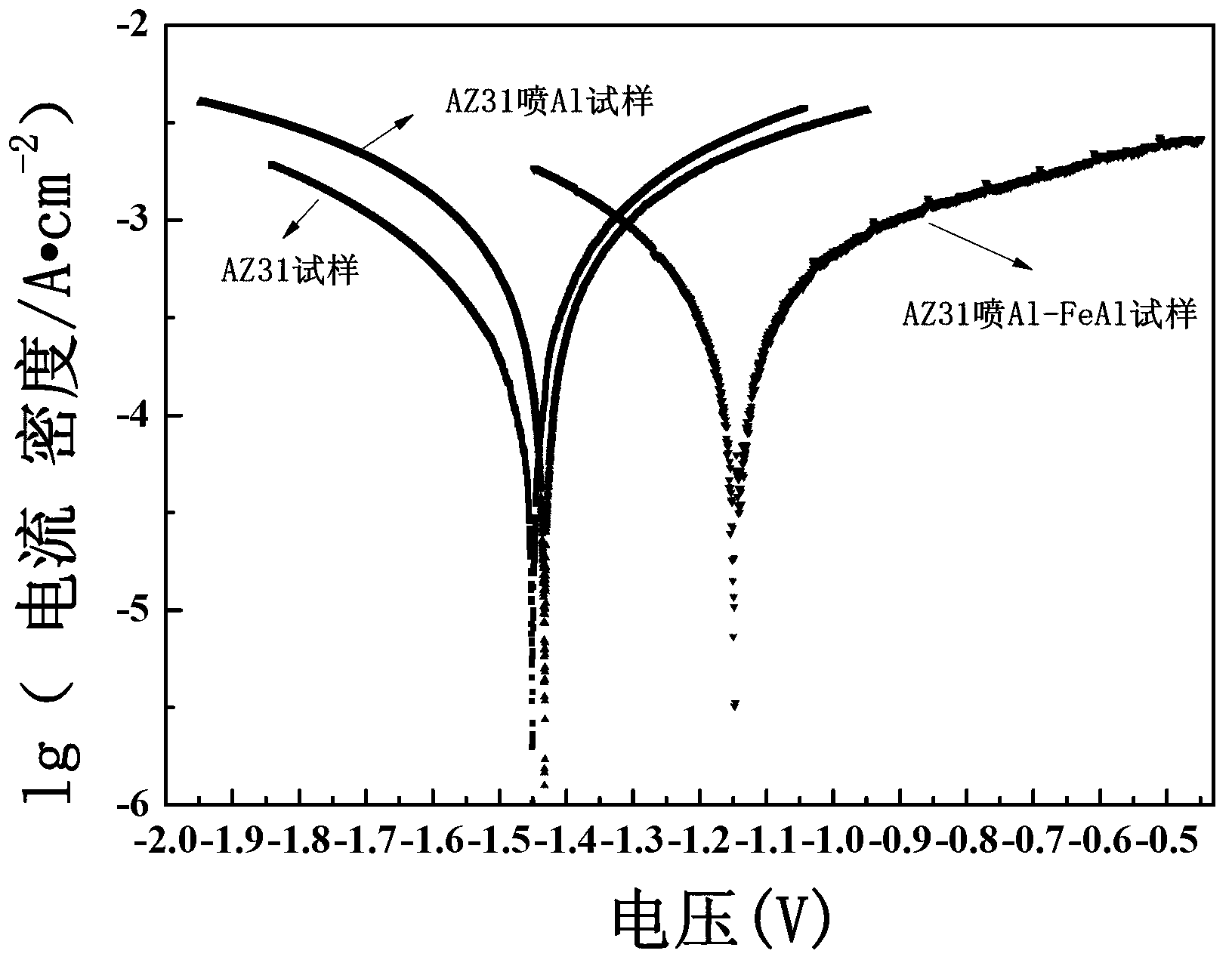

Corrosion and wear resistant coating for magnesium alloy surface and preparation method of corrosion and wear resistant coating

ActiveCN103255365AExcellent wear resistance and corrosion resistanceIncrease practical rangeMolten spray coatingHigh resistanceThermal spraying

The invention provides a corrosion and wear resistant coating for a magnesium alloy surface and a preparation method of the corrosion and wear resistant coating, and belongs to the field of thermal spraying of material processing engineering. The corrosion and wear resistant coating is an Al-FeAl composite coating formed in a way that a FeAl coating is compounded on an Al bottoming layer. The preparation method comprises the following steps of: cleaning and roughening the magnesium alloy surface; and then depositing the Al-FeAl composite layer on the surface in an electric arc spraying way. The composite coating prepared by the preparation method is able to provide a coating with high resistance to corrosion and wear to the magnesium alloy surface; the composite coating has low cost, is hardly affected by the environment, and can reach the purposes of resource conservation, practicability, feasibility, and small effects of the environment, as well as the purpose of expanding the applicable scope of magnesium alloy.

Owner:BEIJING UNIV OF TECH

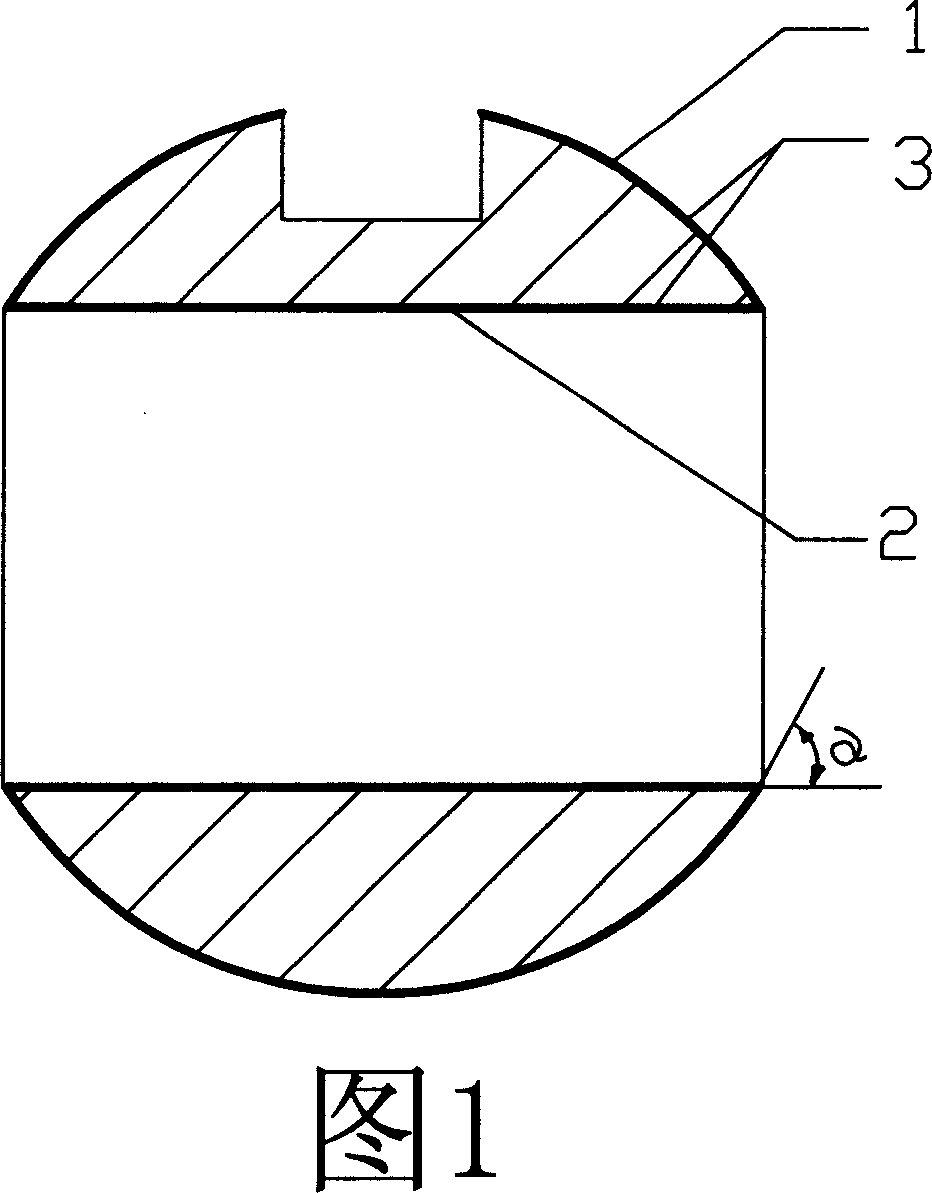

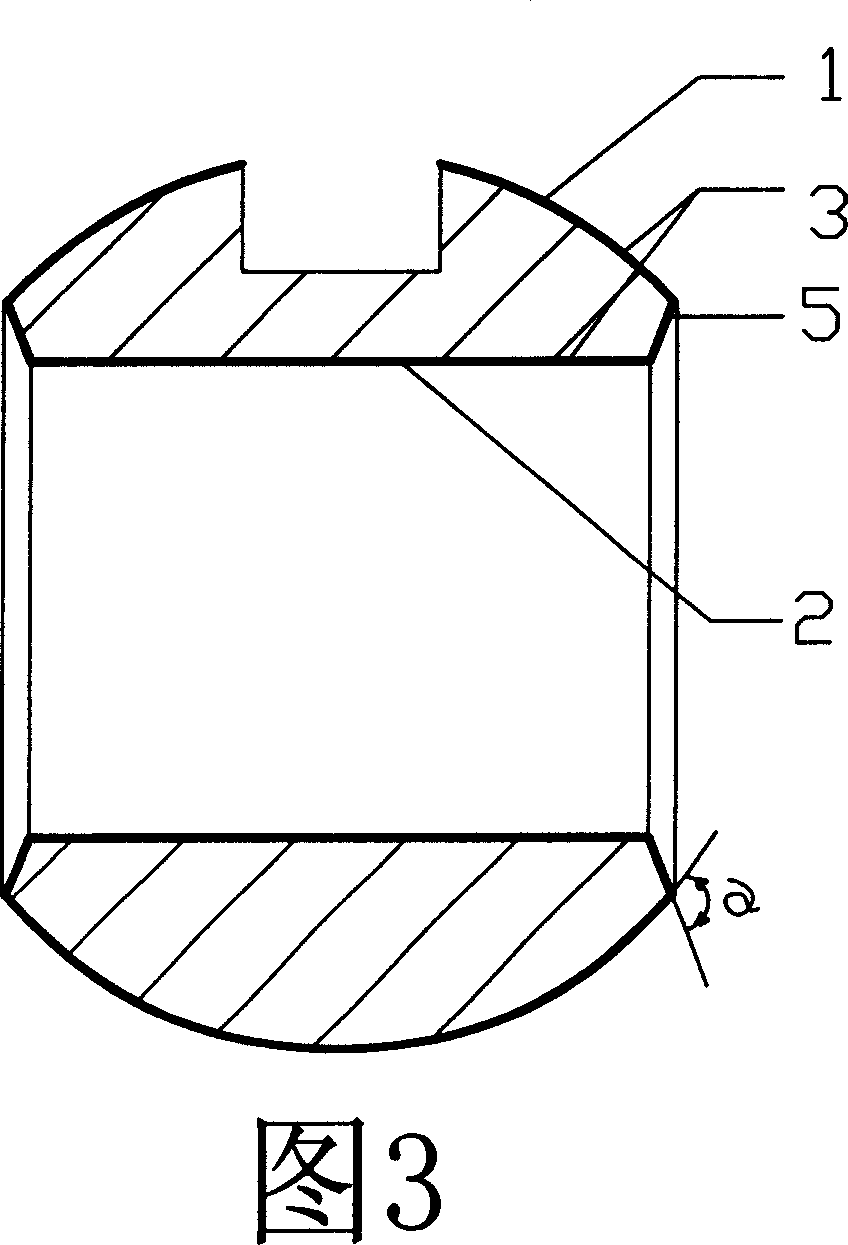

Valve core of ball valve

The invention offers a kind of ball valve spool which includes external sphere (1) and interlock pore internal straight face (2) and the chrome oxide coat (3) covers on the external sphere (1) with non-rust steel spool and the interlock pore internal straight face (2). There sets up a transitional face at the conjoining location of the external sphere (1) with non-rust steel spool and the interlock pore internal straight face (2) and the included angle of the transitional face and the external sphere (1) at the conjoining location and the transition also covers the chrome oxide coat (3). It is a kind of ball valve spool with low cost, long life, credibility use and wearing and corrosion resistance.

Owner:林振龄

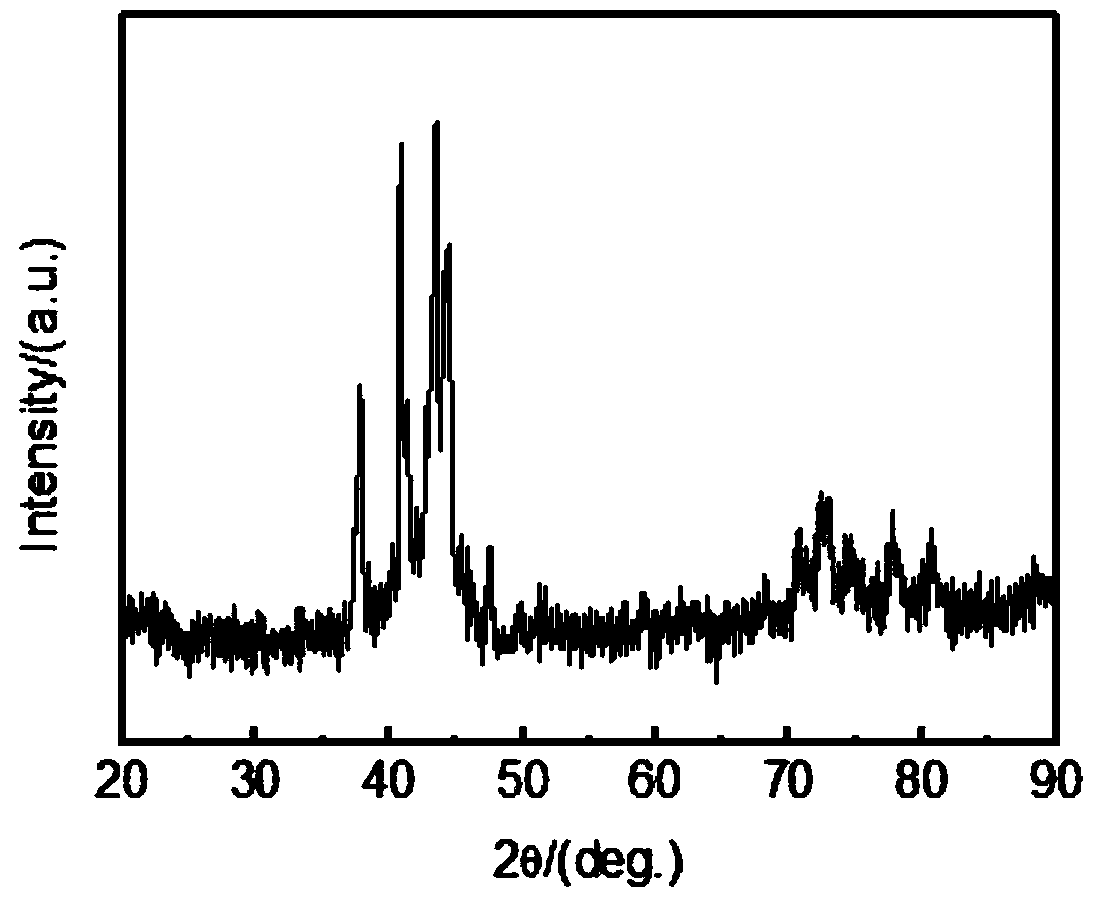

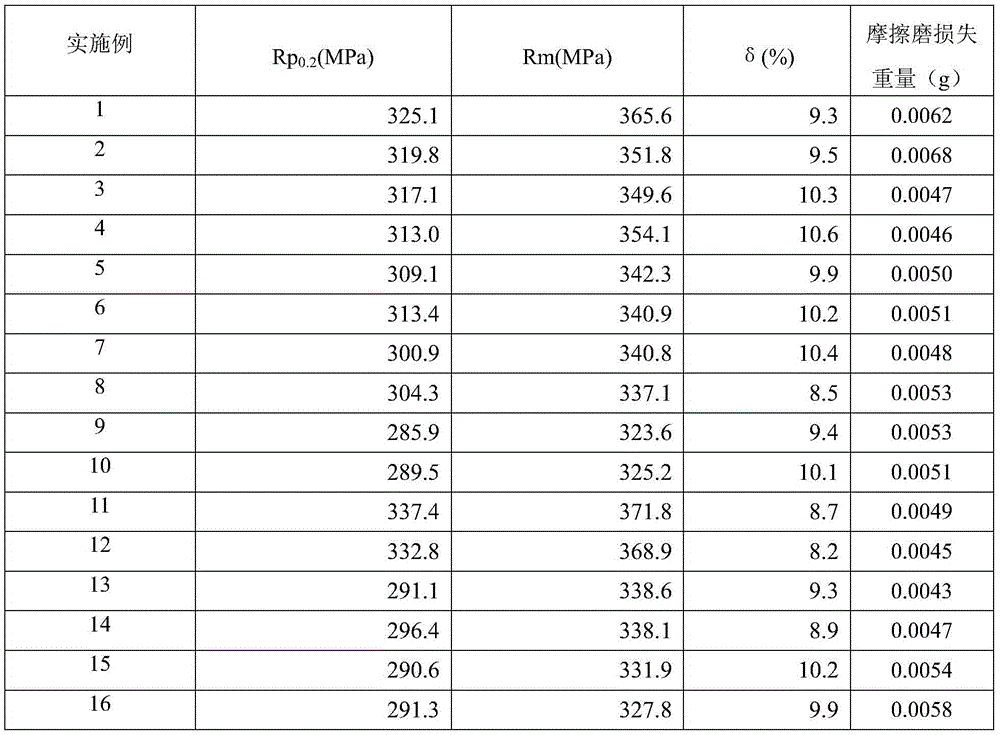

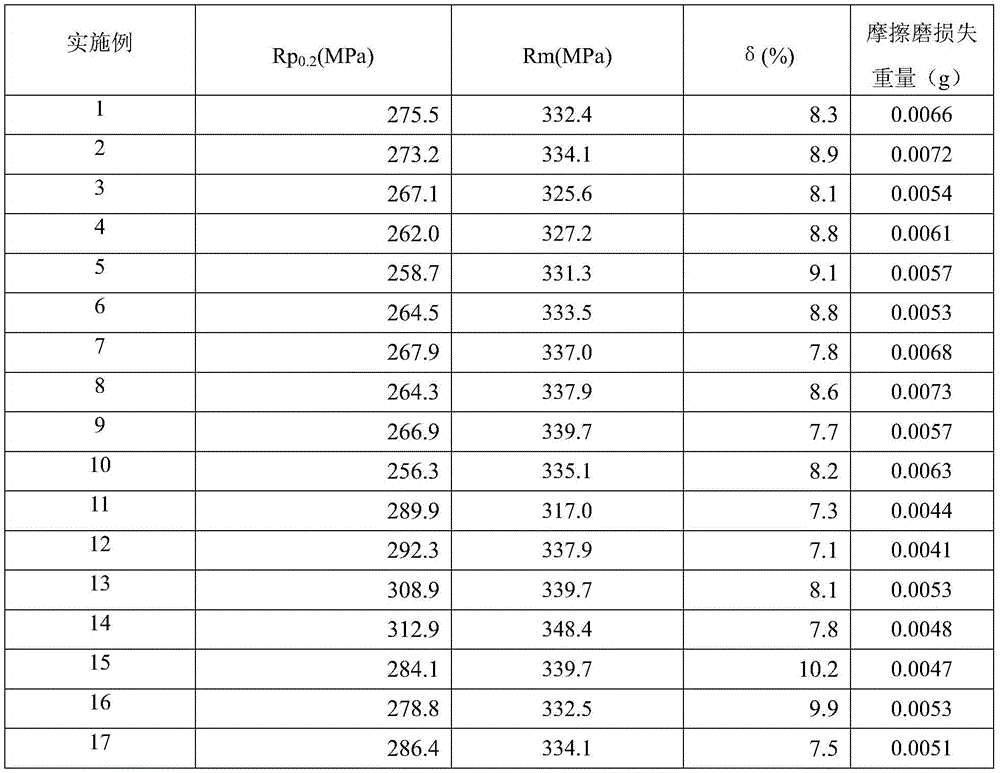

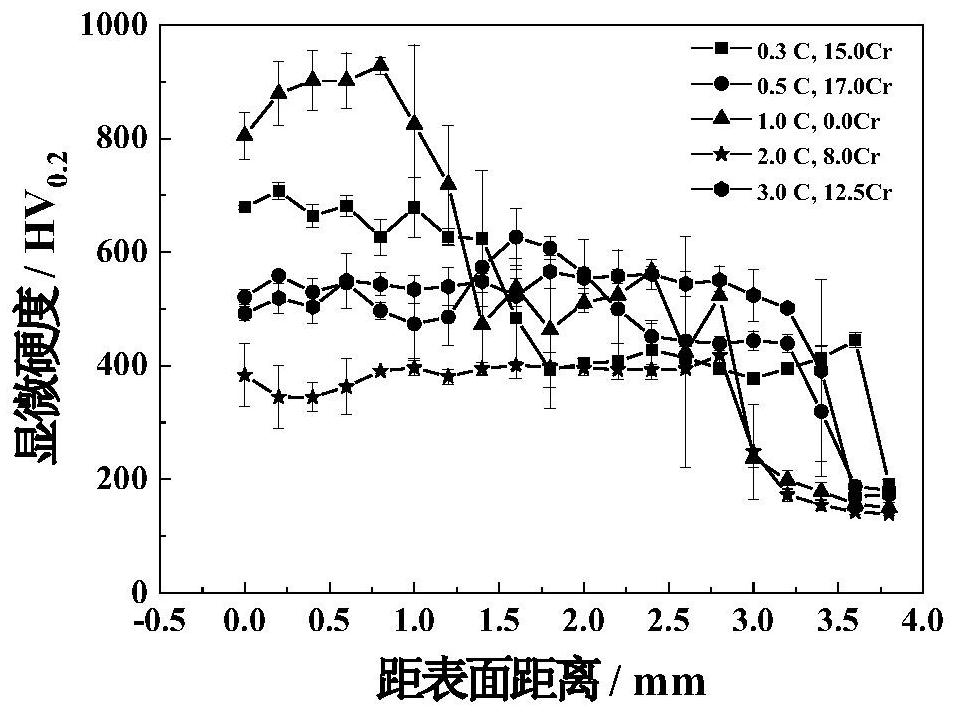

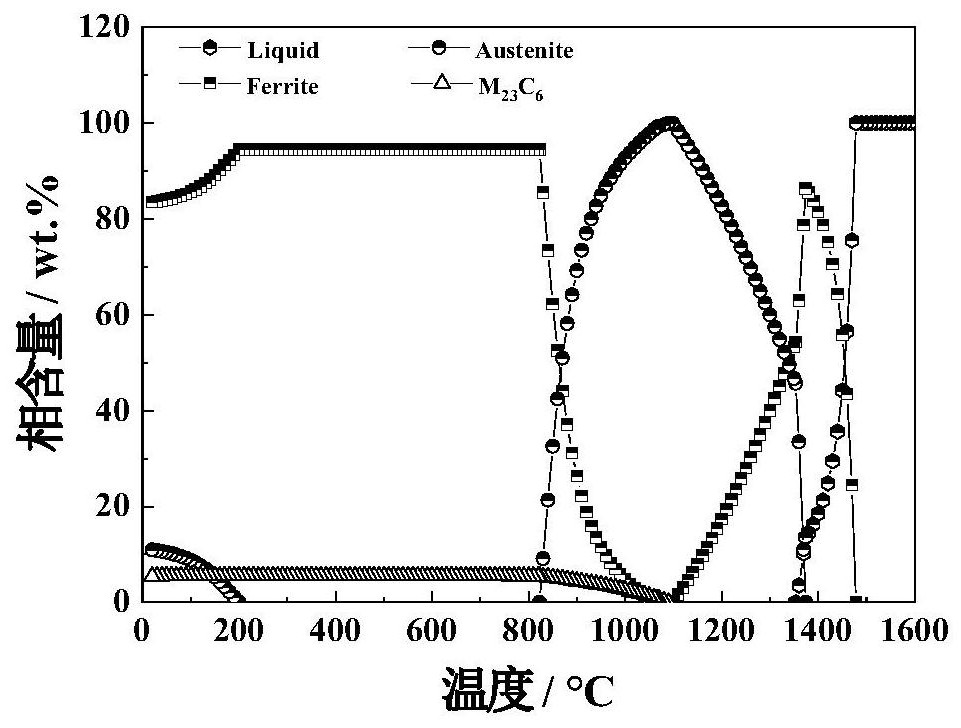

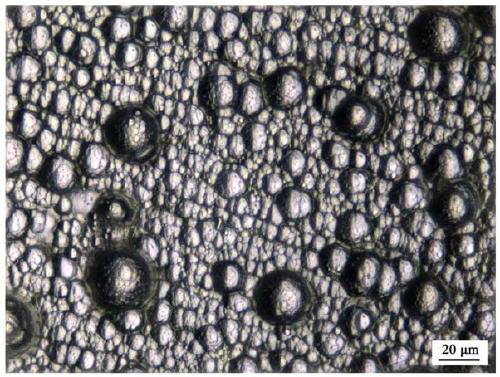

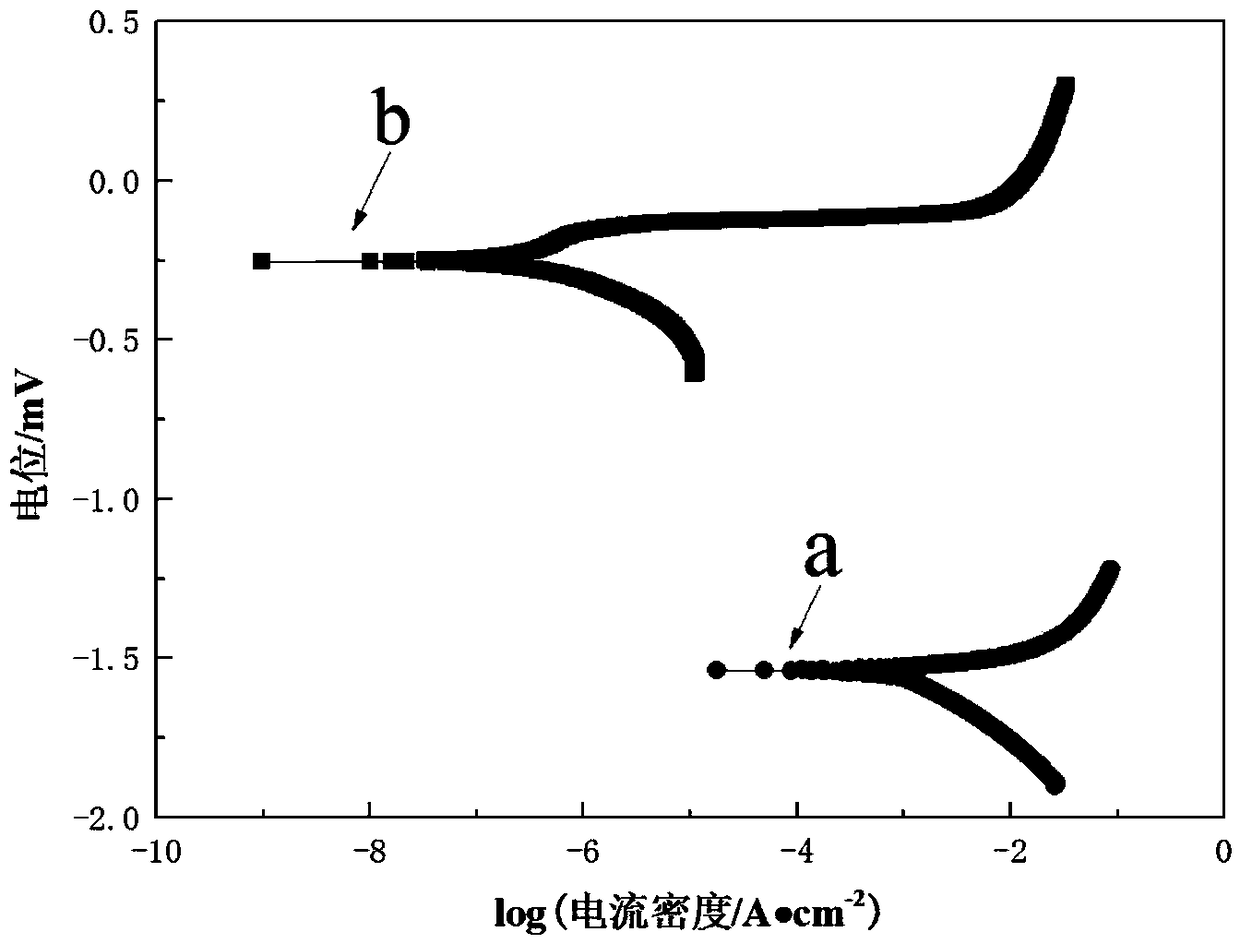

30Cr15MoY alloy steel powder for laser additive manufacturing or remanufacturing and using method of 30Cr15MoY alloy steel powder

ActiveCN112548094AMeet the performance requirements of strength and toughness matchingMeet the performance requirements of high hardness, high wear resistance and corrosion resistanceAdditive manufacturing apparatusTransportation and packagingWear corrosionHardness

The invention discloses novel 30Cr15MoY alloy steel powder for laser additive manufacturing or remanufacturing and a preparation method of the novel 30Cr15MoY alloy steel powder. The 30Cr15MoY alloy steel powder is prepared from 0.25-0.35% of C and 14.5-15.5% of Cr, has the characteristics of medium C content and high Cr content, and has the oxygen content of 0.05% or below, the sphericity degreeof 99% or above, the hollow sphere rate of 1% or below, the apparent density of 4.5-4.95g / cm<3> and the fluidity of 15-15.5s / 50g. The average microhardness of a 30Cr15MoY alloy steel formed part sample prepared through laser additive manufacturing is 370-430 HV, the tensile strength is 1090-1300MPa, the yield strength is 800-980MPa, the elongation percentage is 7-14%, and high strength and toughness matching performance is achieved. The average microhardness of a 30Cr15MoY alloy steel coating sample prepared by laser remanufacturing is 650-750HV, the tensile strength is 1007-1438MPa, the wearrate is 6*10<-6>-8*10<-6>mm<3> / (N.m), the corrosion current density is 1.93*10<-7>-5.6*10<-7>A.cm<-2>, the corrosion voltage is -221 to -576mV, and the characteristics of wear-resistant and corrosion-resistant alloy samples are realized. The alloy steel powder disclosed by the invention has wide application prospects in the fields of laser additive manufacturing for preparing formed parts and laser remanufacturing for repairing worn, corroded and failed parts.

Owner:NORTHEASTERN UNIV

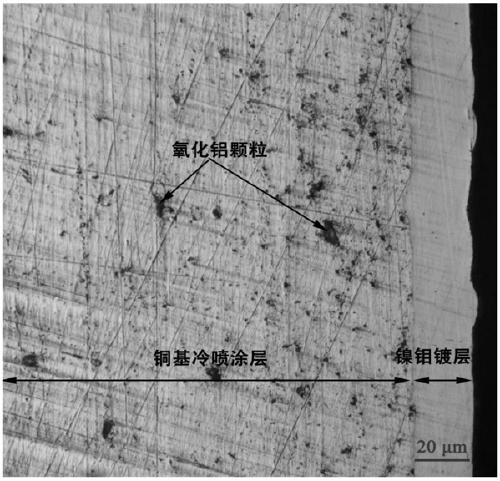

Method for rapid electrolytic-deposition of coating on surface of magnesium alloy

ActiveCN109487261AImprove the protective effectSimple and efficient processSuperimposed coating processHeat inorganic powder coatingSpray coatingPollution

The invention belongs to the technical field of metal surface treatment, and discloses a method for rapid electrolytic-deposition of a coating on a surface of a magnesium alloy. According to the method, sand blasting equipment is adopted for carrying out sand blasting treatment on the surface of the magnesium alloy, then ultrasonic cleaning is carried out on the surface of the magnesium alloy, anda coating material is sprayed on the surface of the magnesium alloy which is subjected to the sand blasting treatment by adopting a cold spraying method; the working gas of the cold spraying is compressed air, wherein the pressure is 0.6 MPa to 0.8 MPa, the preheating temperature of the cold spraying gas is 400-600 DEG C, the powder feeding distance is 10 mm, the relative moving speed of a nozzleis 600-2000 mm / min, and a cold-sprayed copper-based coating is prepared; and the cold-sprayed copper-based coating is placed in an electroplating solution, electroplating parameters are set, and a composite coating of a copper base and an electroplating layer is prepared through electroplating. The composite coating is good in microstructure and stable in physical property, the bonding strength of the cold-sprayed coating and the base material is high, the thickness of the cold spraying layer and the base material is controllable, and the composite coating has excellent corrosion resistance and wear resistance. According to the method, the electroplating process of the magnesium alloy is simplified, and the pollution to the environment is reduced.

Owner:东莞市先力得热处理有限公司

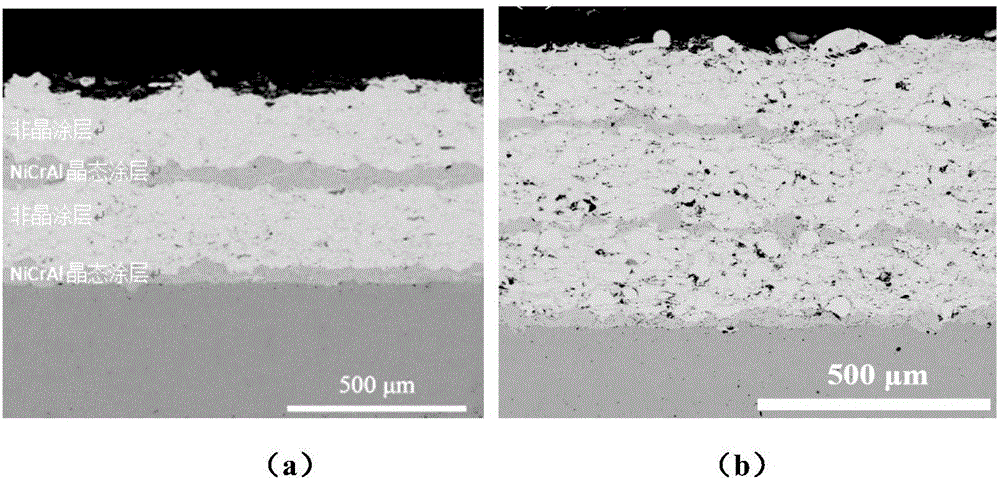

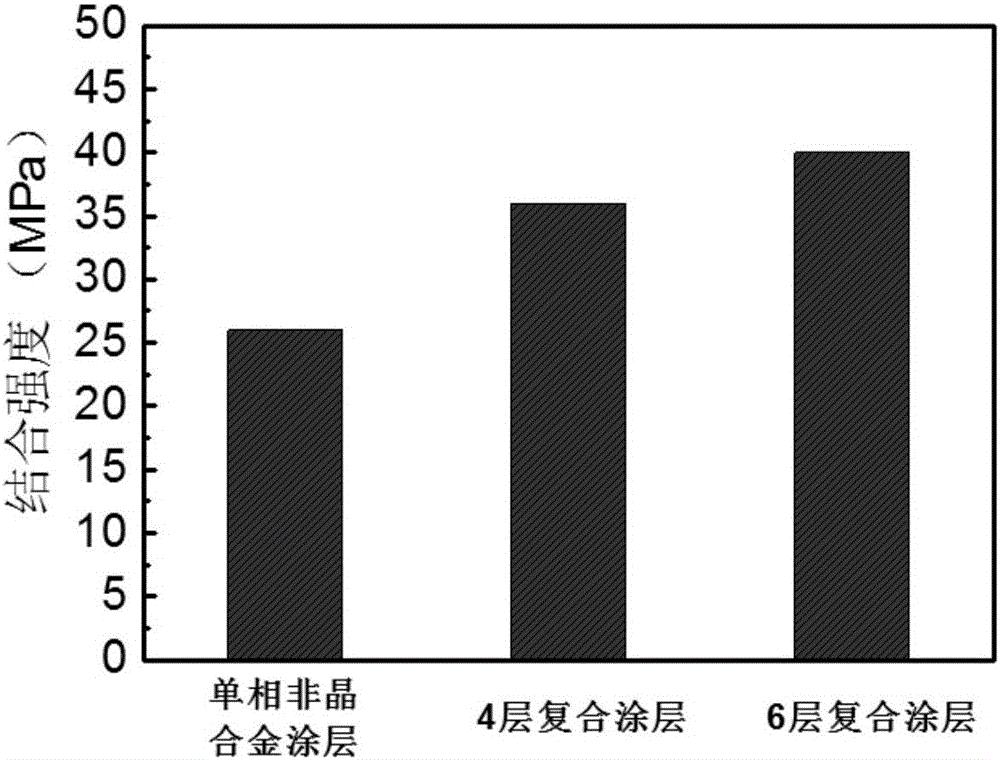

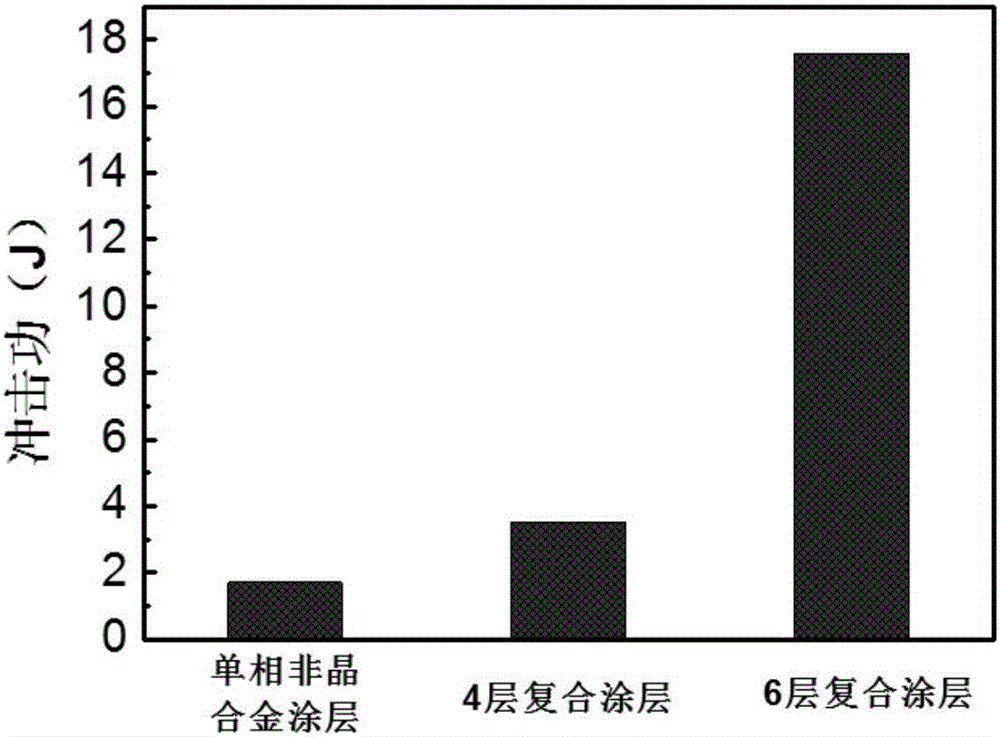

A Novel High Impact Toughness Amorphous Matrix Composite Coating and Its Preparation Method

InactiveCN103538314BOptimal Control StructureRealize industrial productionMolten spray coatingMetal layered productsMetal coatingPetrochemical

The invention provides a novel amorphous matrix composite coating with high impact toughness and a preparation method thereof. The composite coating is composed by interactively overlapping an iron-based amorphous alloy coating and a crystalline metal coating; the crystalline metal coating is in direct contact with a matrix; the iron-based amorphous alloy coating is on the outmost layer of the composite coating; the interfaces of the amorphous coating and the crystalline coating in the composite coating are tightly combined without continuous gaps; the composite coating is acquired through a hypersonic flame spraying technology; the composite coating can be tightly bonded with a metal matrix; the impact toughness of the composite coating is much higher than that of a single-phase iron-based amorphous alloy coating. The composite coating acquired by the invention can be extensively coated on the surfaces of all kinds of metal matrixes and has wide application prospects in the surface antiseptic and anti-wear treatment of devices and components in many fields of boat decks, oil-gas field development, petrochemical industry and water conservancy and hydropower.

Owner:HUAZHONG UNIV OF SCI & TECH

Wear-resistant and corrosion-resistant aluminum bronze brazing alloy

InactiveCN102312122AHigh strengthExcellent wear resistance and corrosion resistanceCorrosion resistantWear resistant

The invention discloses a wear-resistant and corrosion-resistant aluminum bronze brazing alloy. The brazing alloy provided by the invention is composed of the following components in percentage by mass: 10-11.5% of Al, 2.0-5.0% of Fe, 0.4-0.7% of Mn, 0.004-0.015% of Se, 0.02-0.5% of Ti and the balance of Cu. The aluminum bronze brazing alloy provided by the invention is high in strength and hardness and good in wear resistance and corrosion resistance.

Owner:TIANJIN JINLONG WELDING MATERIAL

Method for preparing wear-resistant coating of resistance-reduction and torsion-reduction tool of large-displacement well through laser

InactiveCN106480448AExcellent wear resistance and corrosion resistanceImprove toughnessMetallic material coating processesMelting tankWear resistant

The invention discloses a method for preparing a wear-resistant coating of a resistance-reduction and torsion-reduction tool of a large-displacement well through laser. The method comprises the following steps: pretreating the surface of the resistance-reduction and torsion-reduction tool of the large-displacement well by deoiling and derusting the surface of the surface of the resistance-reduction and torsion-reduction tool of the large-displacement well under the room temperature; selecting specially-prepared nickel-based alloy powder, adjusting an automatic powder feeding device, enabling alloy powder out of an automatic powder feeding head to just fall into a laser cladding tank, adjusting powder feeding amount and enabling the thickness of an alloy powder coating to reach 0.8-1.2mm; carrying out laser cladding of a wear-resistant and corrosion-resistant coating by automatically feeding the alloy powder into the laser cladding tank by using a synchronous powder feeding device, feeding high-power focused laser beams and the automatic powder feeding head along an axial direction, rotating the resistance-reduction and torsion-reduction tool of the large-displacement well according to a set rotation rate, and forming a uniform and dense laser cladding layer on the external surface of a horizontal roller; and carrying out subsequent heat treatment by slowly cooling the resistance-reduction and torsion-reduction tool after broadband laser cladding of the nickel-based alloy, fully wrapping the resistance-reduction and torsion-reduction tool by using heat preservation cotton, and distressing and annealing the resistance-reduction and torsion-reduction tool under the room temperature.

Owner:沈阳大陆激光工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com