A Novel High Impact Toughness Amorphous Matrix Composite Coating and Its Preparation Method

A composite coating, high-impact technology, applied in coatings, chemical instruments and methods, metal material coating technology, etc., can solve the problem of accurately controlling the uniform distribution of second-phase particles and reducing the corrosion resistance of amorphous-based composite coatings problems such as chemical potential difference between the second phase and the amorphous phase, etc., to achieve the effects of improving service performance and service life, good high temperature wettability, and adjustable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 (with NiCrAl coating as the crystalline metal coating, the composite coating contains 2 layers of amorphous alloy coating and 2 layers of crystalline metal coating)

[0036] The composite coating of the present embodiment adopts the following steps:

[0037] (1) Firstly, the alloy ingot is prepared by vacuum induction melting according to the above-mentioned required components, and then the alloy ingot is remelted in an atomization furnace, and amorphous alloy powder and crystalline metal are prepared by inert gas atomization technology powder.

[0038] (2) The supersonic flame spraying technology (HVOF) is used to prepare the amorphous matrix composite coating. The specific process parameters are kerosene and oxygen flow rates of 24L / h and 32m respectively. 3 / h, the powder feeding speed is 30g / min, and the spraying distance is 350mm. First, a layer of NiCrAl coating with a thickness of about 50μm is prepared on the surface of No. 45 steel substrate.

[00...

Embodiment 2

[0045] Example 2 (Using NiCrAl coating as the crystalline metal coating, the composite coating contains 3 layers of amorphous alloy coating and 3 layers of crystalline metal coating)

[0046] The difference from Example 1 is:

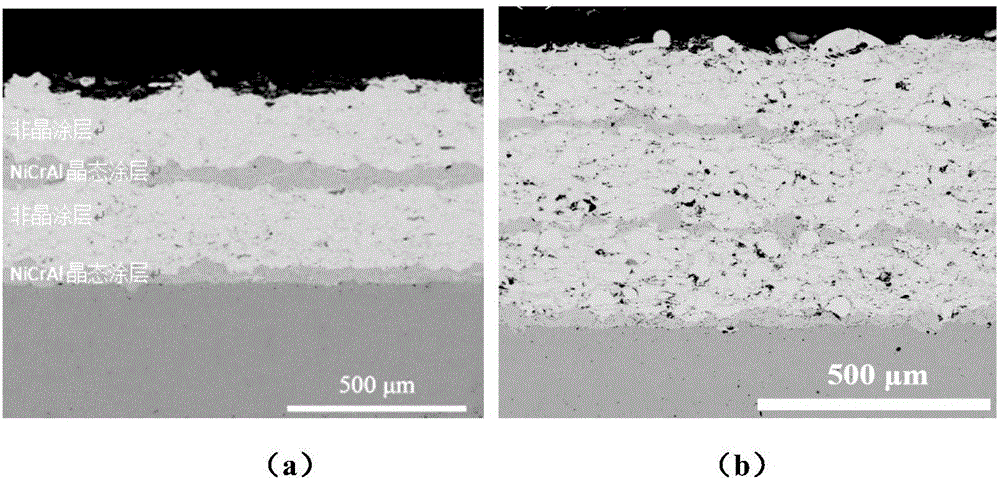

[0047] 1) The composite coating prepared in this example contains 3 layers of amorphous alloy coating and 3 layers of crystalline metal coating, such as figure 1 shown;

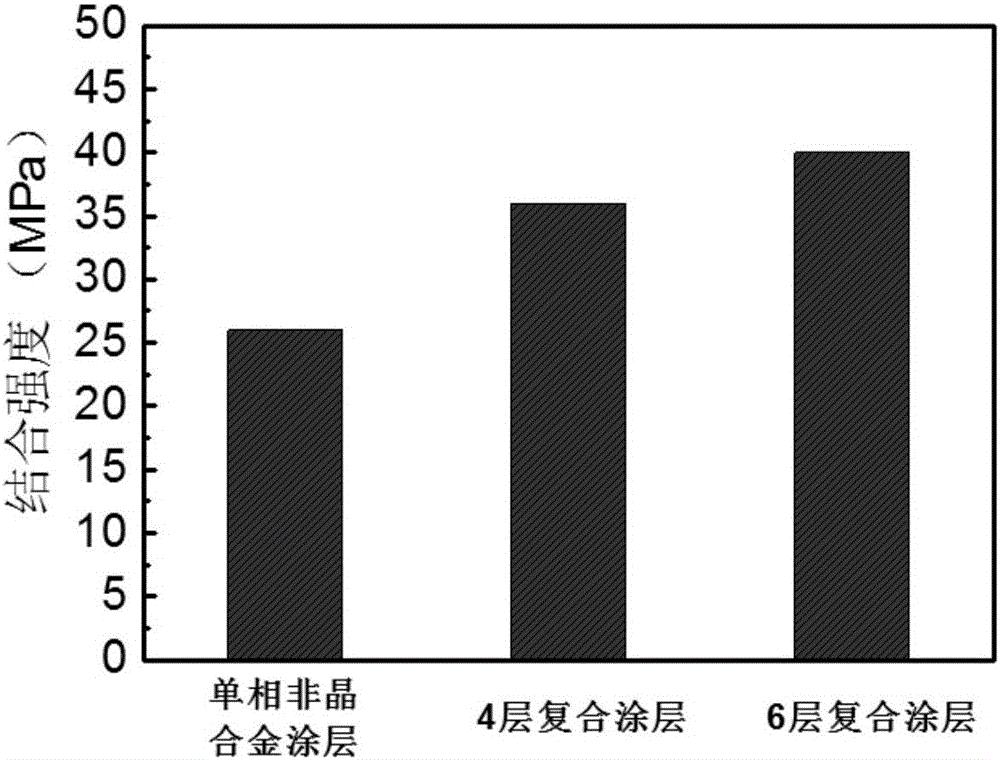

[0048] 2) The composite coating prepared in this example has a higher bonding strength, reaching 40MPa, such as figure 2 shown;

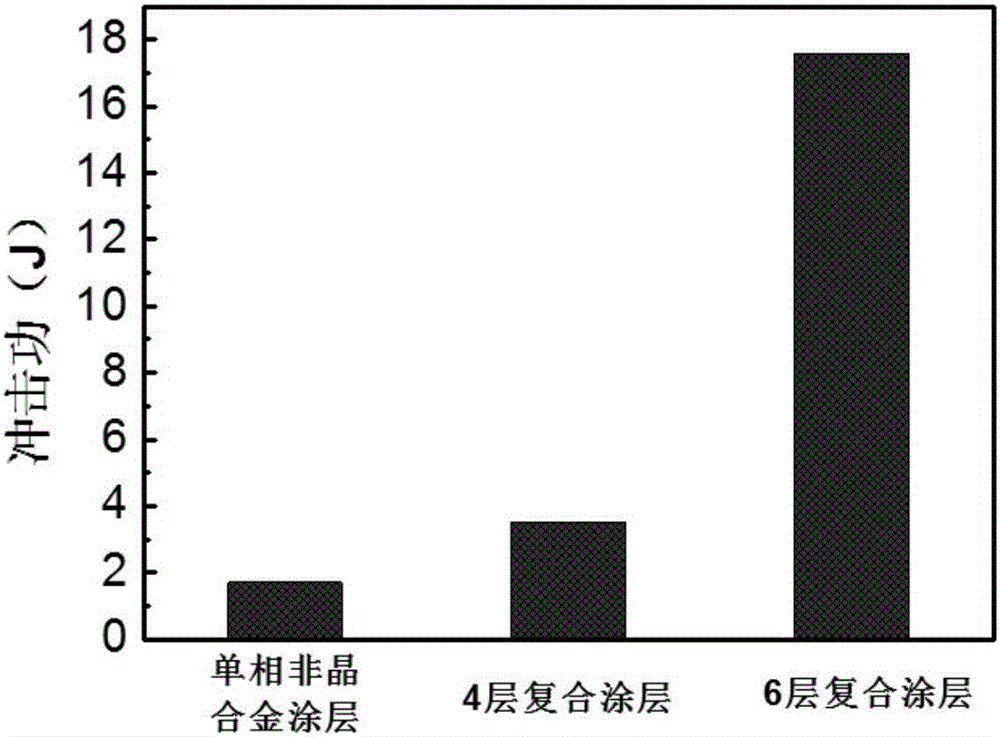

[0049] 3) The composite coating prepared in this example has higher impact toughness, reaching 17.6J, such as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com