Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

717results about How to "Improve plastic deformation ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plugging bearing material for petroleum drilling, and preparation method and application thereof

ActiveCN102061151ASuitable for lipophilic and hydrophilic propertiesGuaranteed preparationDrilling compositionSealing/packingHigh fracturePetroleum

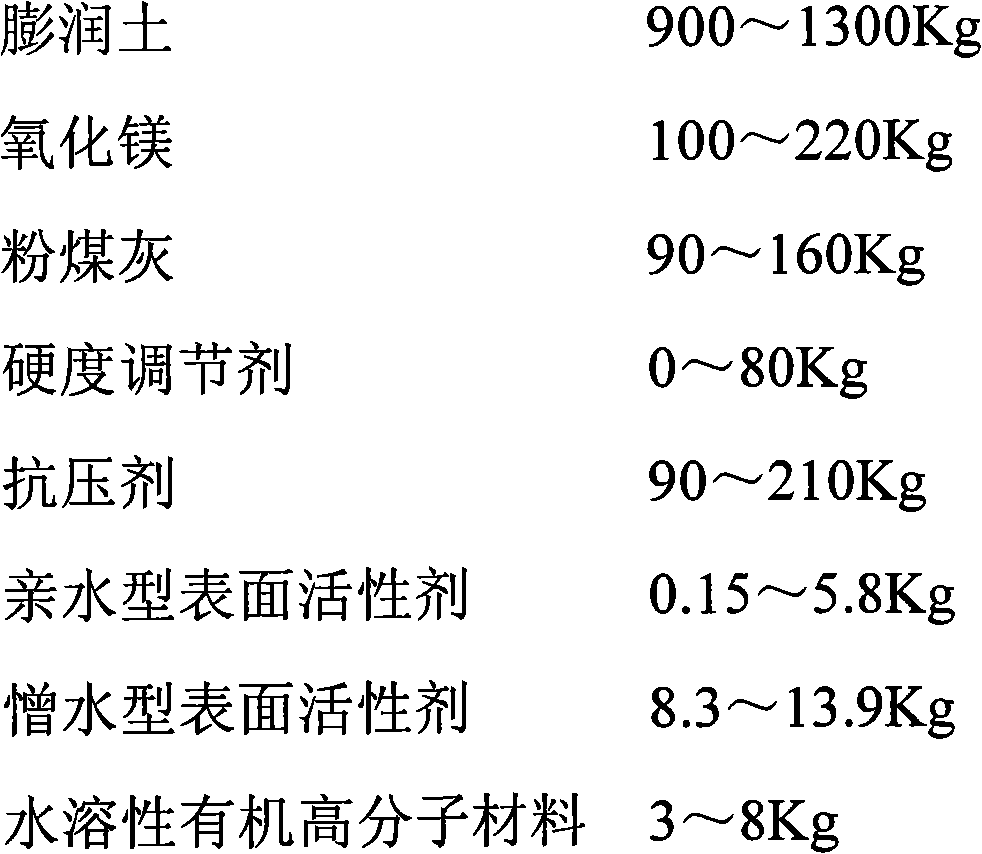

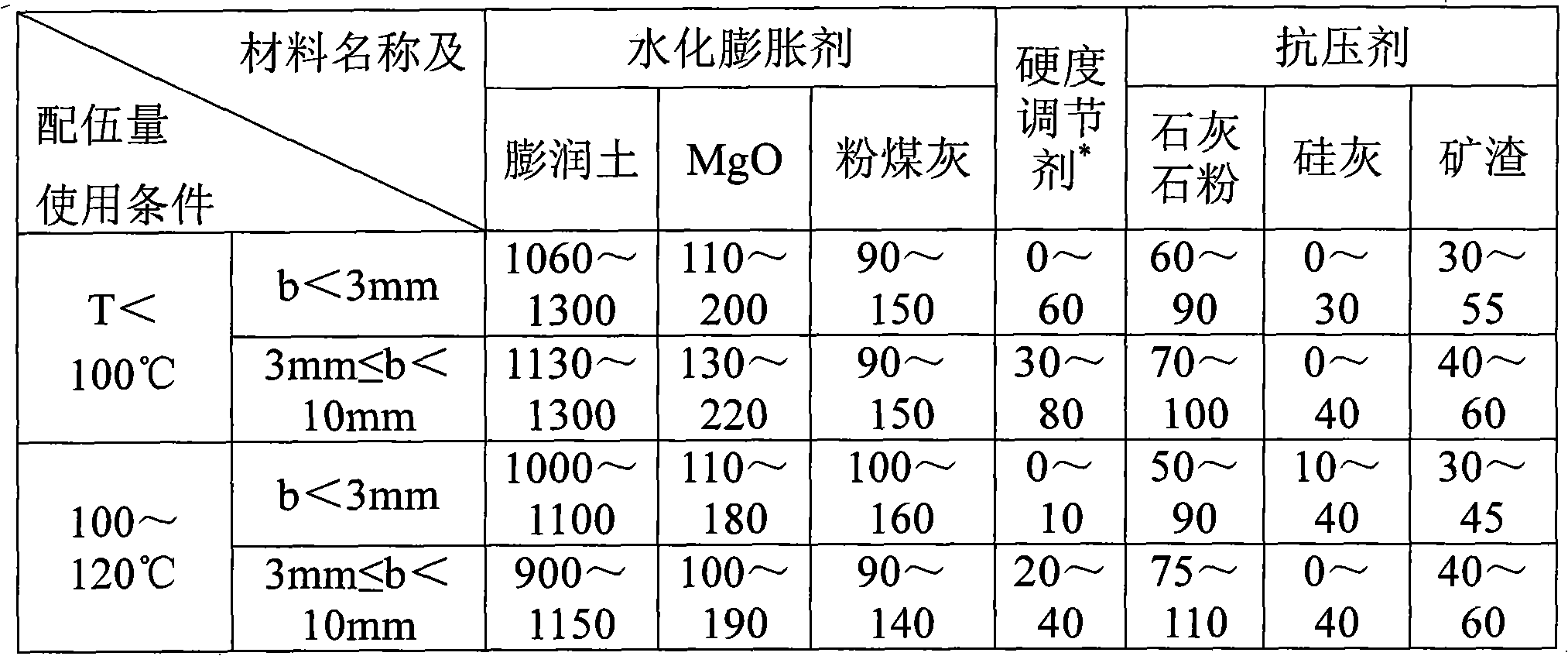

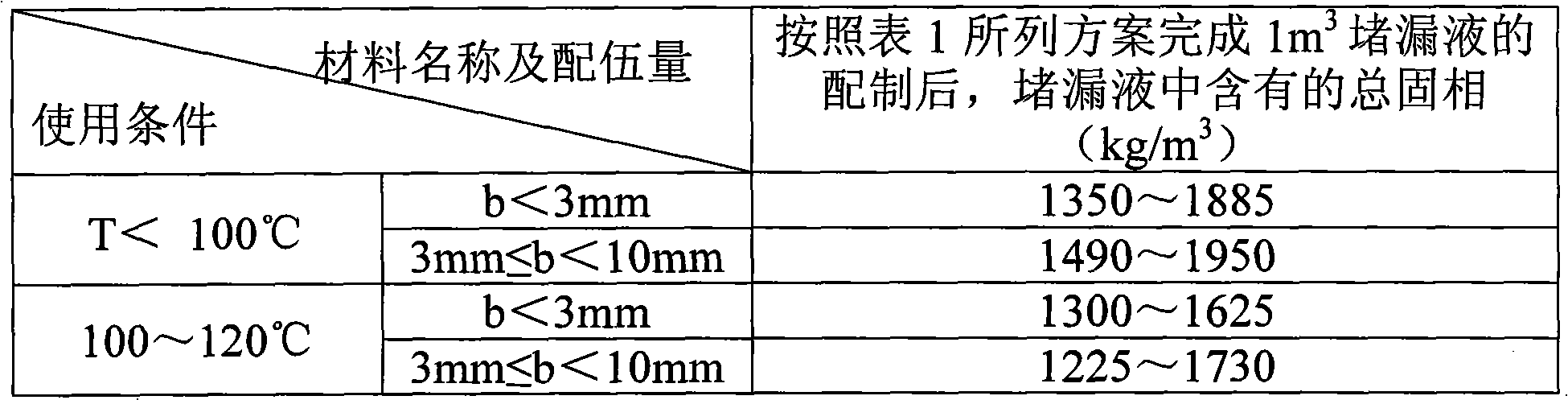

The invention provides a plugging bearing material for petroleum drilling, and a preparation method and application thereof. The plugging bearing material comprises the following components: 900 to 1,200 kilograms of bentonite, 100 to 220 kilograms of magnesium oxide, 90 to 160 kilograms of fly ash, 0 to 80 kilograms of hardness regulator, 90 to 210 kilograms of compression resisting agent, 0.15 to 5.8 kilograms of hydrophilic surfactant, 8.3 to 13.0 kilograms of hydrophobic surfactant and 3 to 8 kilograms of water-soluble organic high polymer material. A plugging material formed by the plugging bearing material has high fracture plugging capability, and a plugging belt formed by the plugging bearing material plays a certain stable role in fracturing rocks. The plugging bearing material, and the preparation method and the application thereof are suitable for processing formation leakage of various forms.

Owner:CHINA PETROLEUM & CHEM CORP +1

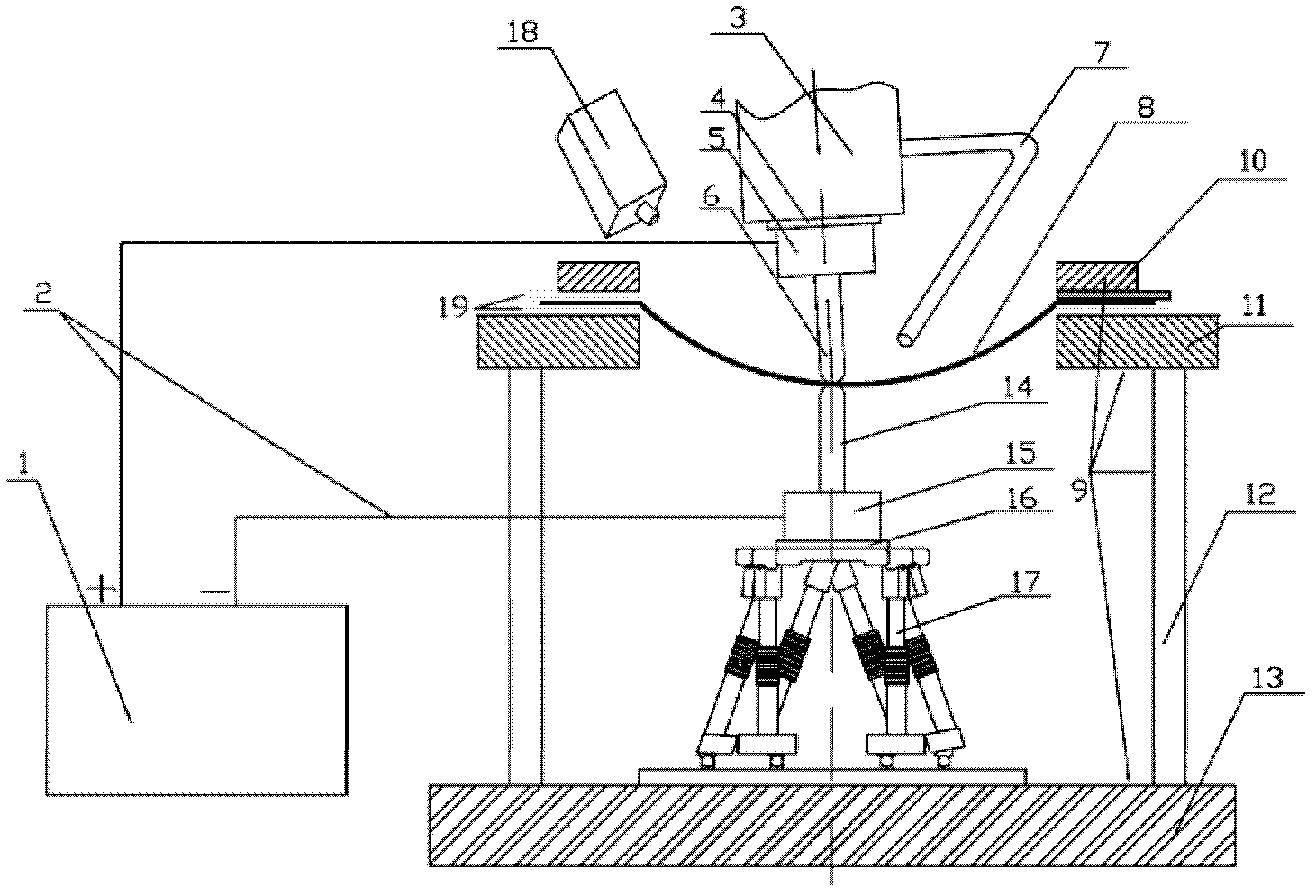

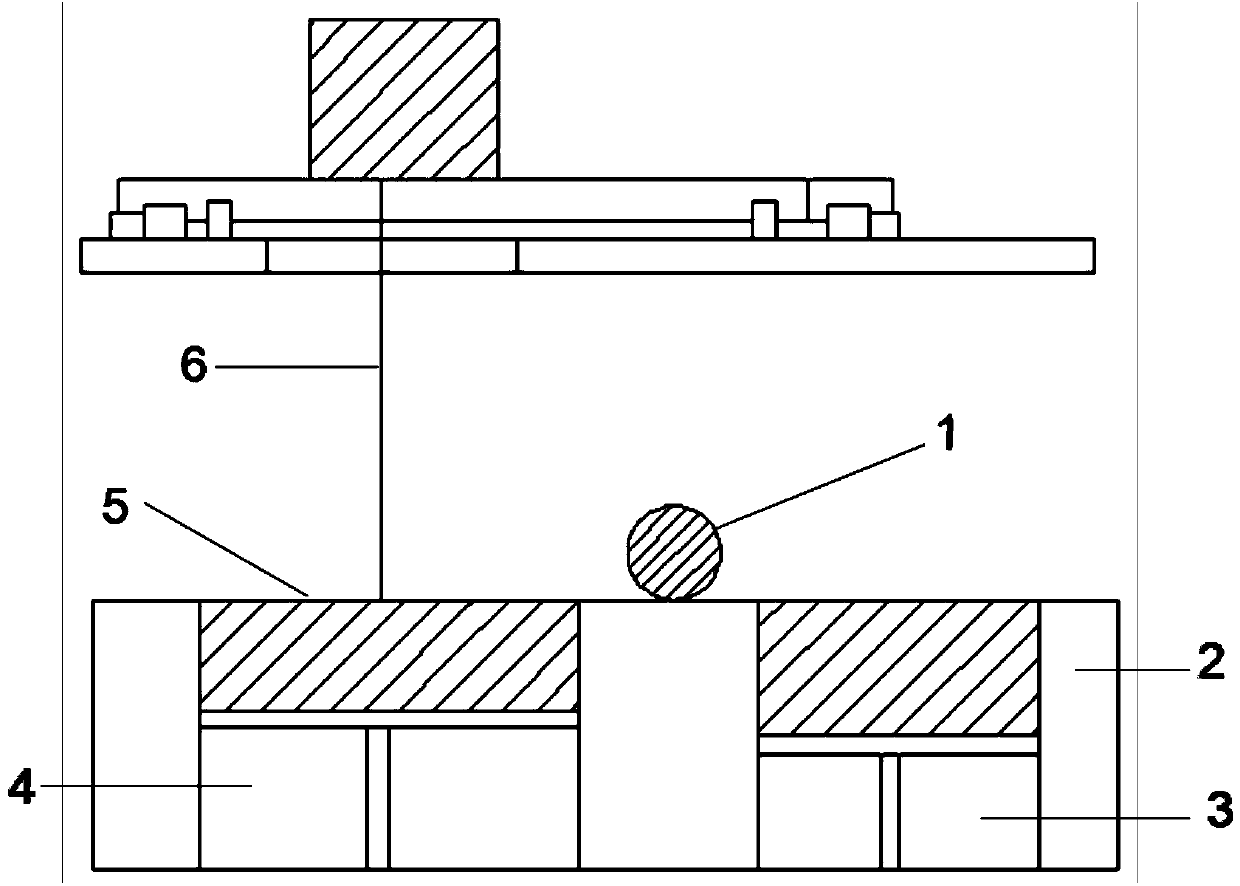

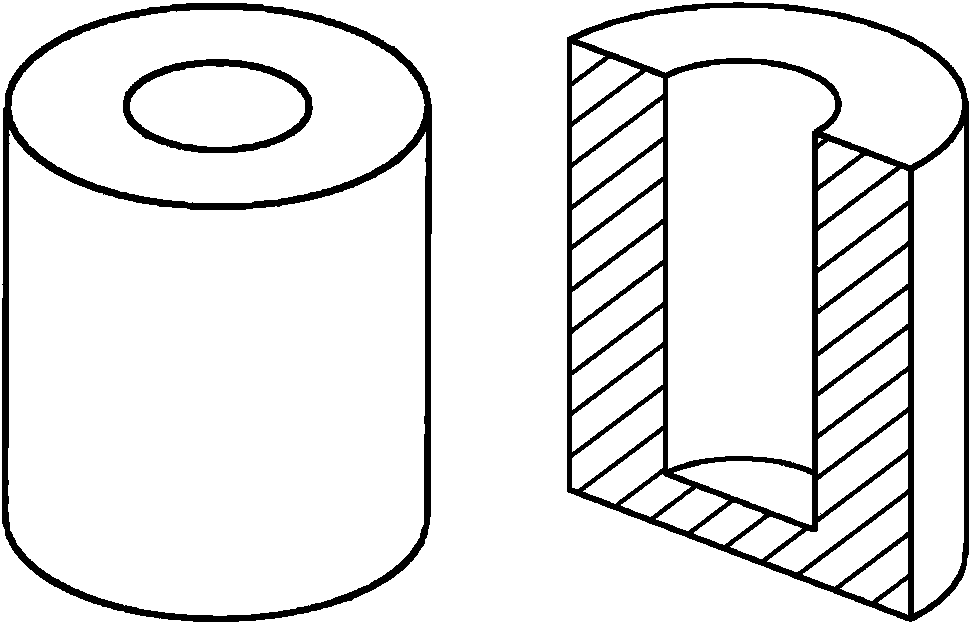

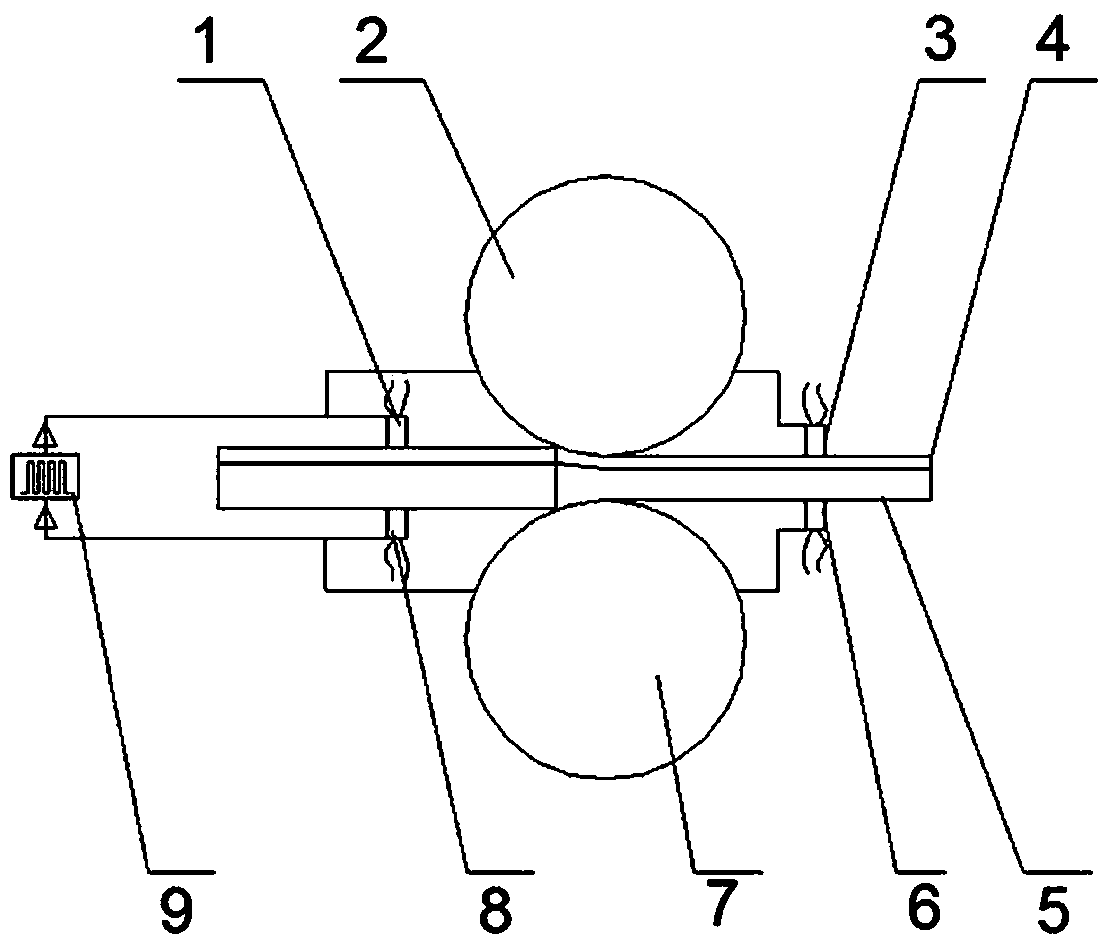

Electroplastic incremental forming device and method for plates

ActiveCN102527830ALower yield stressHigh geometric accuracyMetal-working feeding devicesPositioning devicesNumerical controlHigh energy

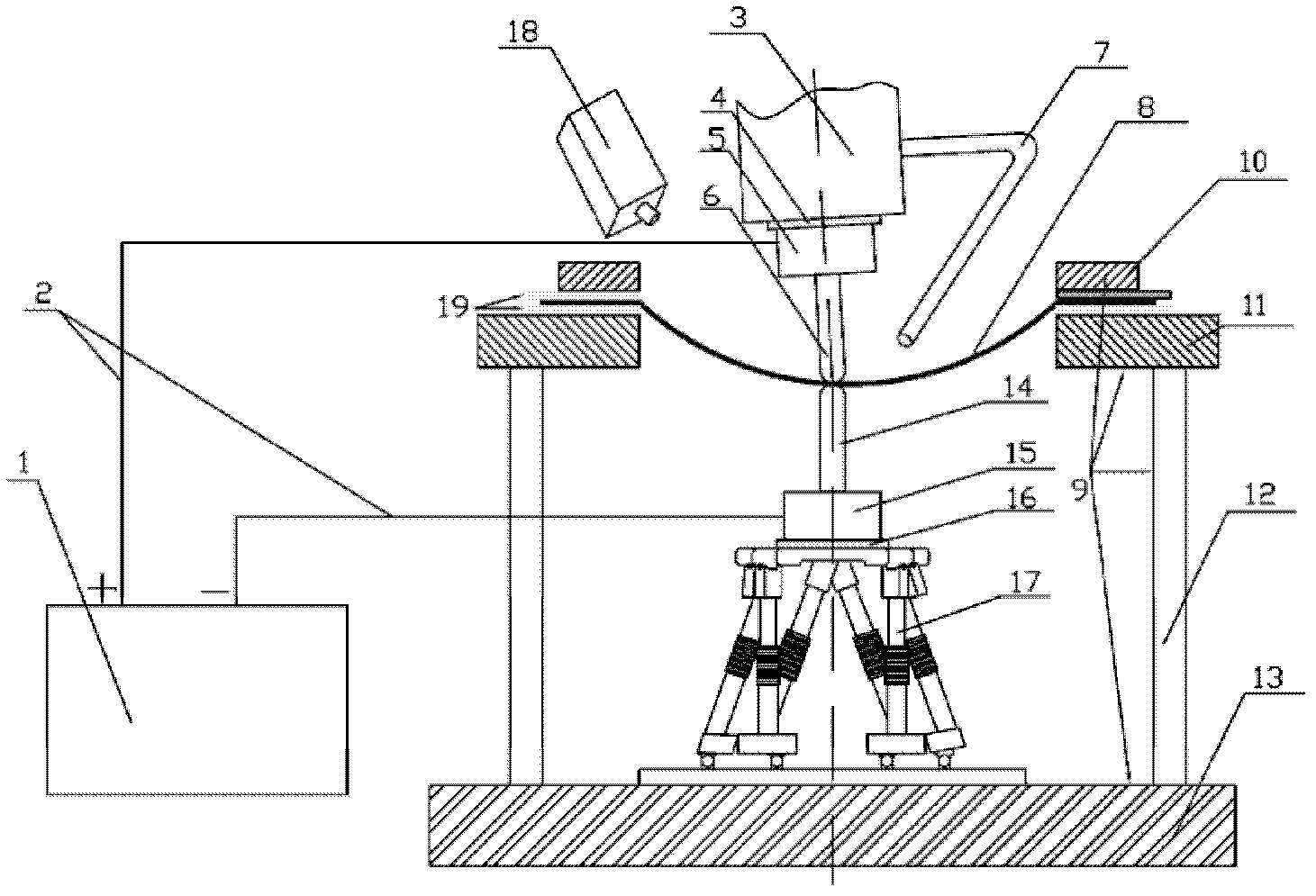

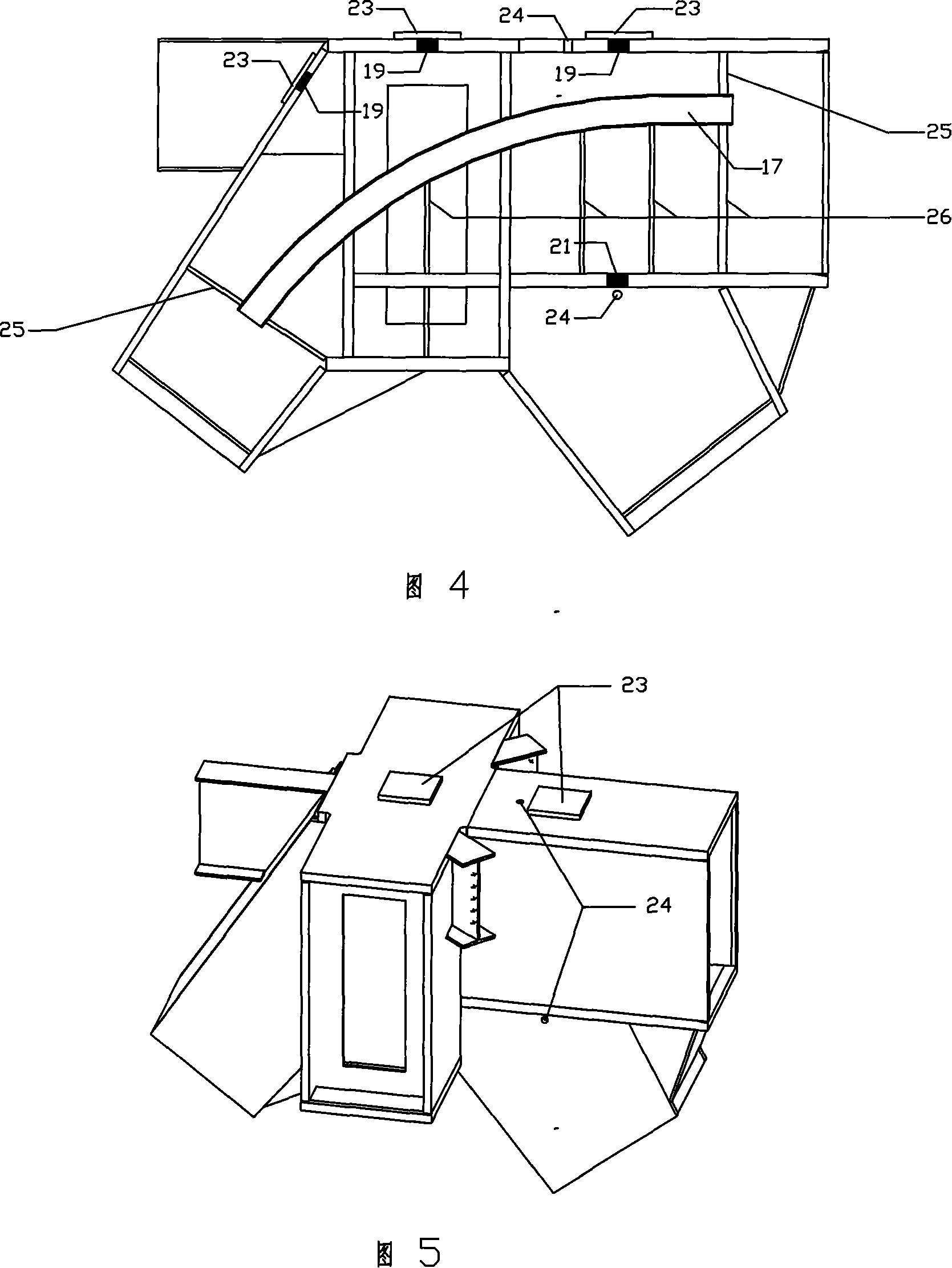

The invention relates to an electroplastic incremental forming device and an electroplastic incremental forming method for plates. The device comprises a five-axis numerical control forming machine tool, a six-axis parallel robot machining system, a plate forming clamp, a high energy pulse power supply, an infrared thermometer, and a compressed air cooling system embedded in the machine tool, wherein an upper forming pressing head is arranged at the tail end of a spindle of the five-axis numerical control forming machine tool; the six-axis parallel robot machining system is arranged on a working table of the machine tool; the top of the six-axis parallel robot machining system is provided with a lower forming pressing head; the plate forming clamp is fixed on the working table of the machine tool; positive and negative poles of the high energy pulse power supply are connected with the upper forming pressing head and the lower forming pressing head through high current-carrying conductors respectively so as to form a current loop among the high energy pulse power supply, the upper forming pressing head, the lower forming pressing head and the plates; a camera of the infrared thermometer is aligned with a central area of each plate; and the compressed air cooling system is aligned with a forming area of each plate. Compared with the prior art, the invention has the advantages of high efficiency, energy conservation, high machining precision, high surface quality and the like.

Owner:SHANGHAI JIAO TONG UNIV

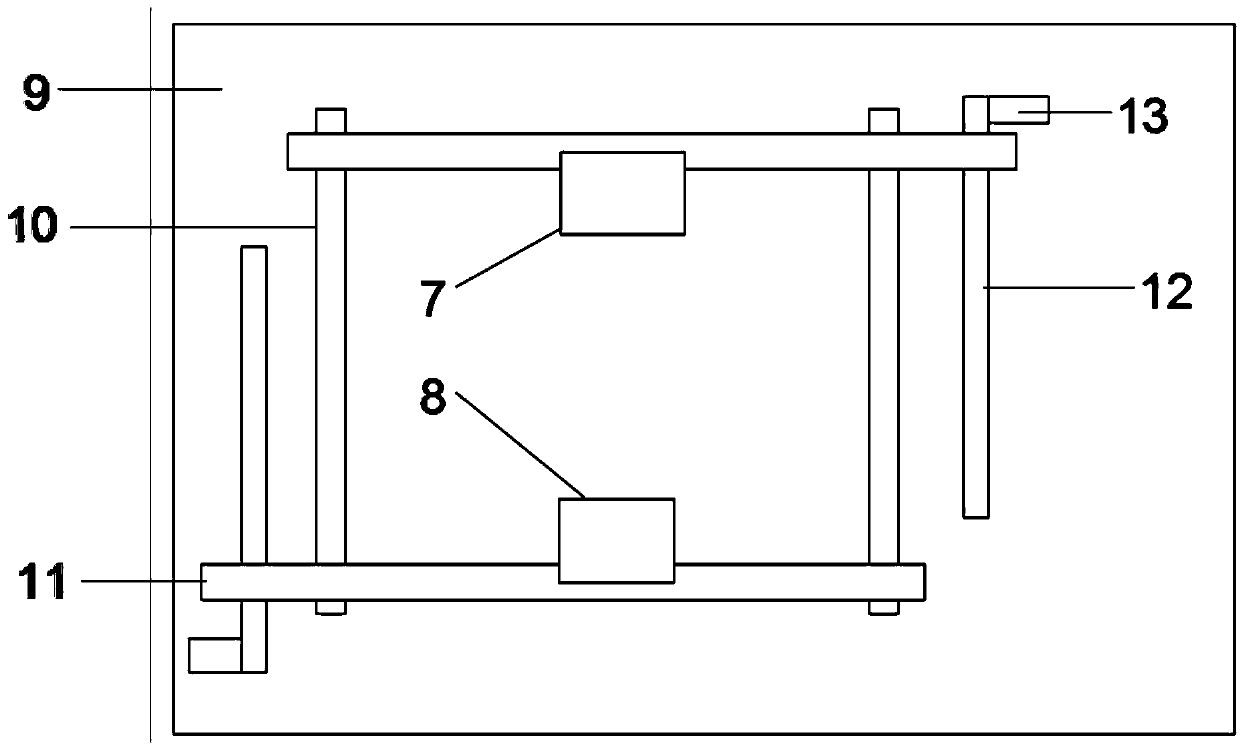

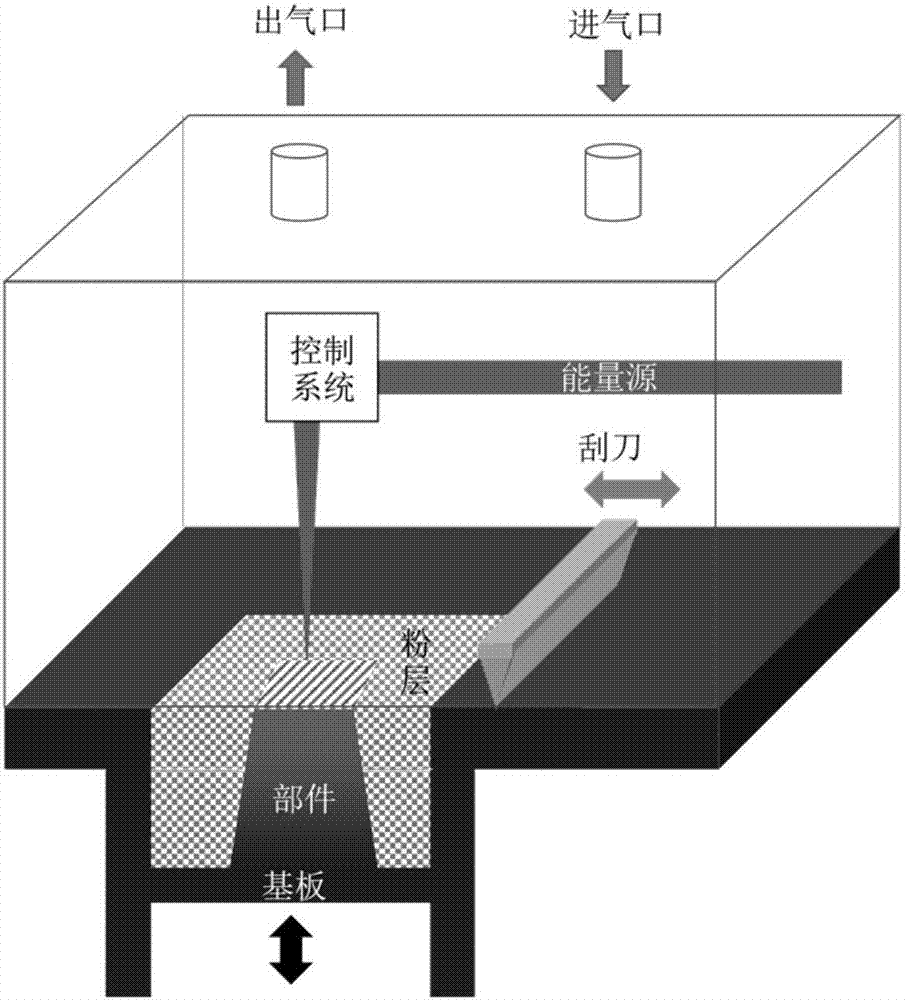

Method and device for manufacturing efficient and high-precision composite additive

ActiveCN104190931AShorten forming timeImprove forming efficiencyIncreasing energy efficiencyLight beamMetal powder

The invention discloses a method and device for manufacturing efficient and high-precision composite additive, and the method and device are achieved through composition of a laser beam and an electron beam. In the process of the action of a high energy beam and metal powder, metal powder of a surface outline is scanned and molten through the laser beam, and the surface of a part has a good surface quality. The electron beam melts the internal powder at a high speed to form a part inner cavity so as to reach the highest forming efficiency. The lower portion of the device comprises a powder laying roller, a workbench, a powder conveying cylinder and a working cylinder. The upper portion of the device comprises an electron beam generating device, a laser beam generating device, a bottom plate, two guide rails, two beams, a synchronous belt wheel and a servo motor. The electron beam generating device and the laser beam generating device are respectively integral and move to the forming area alternately to carry out scanning. By means of the method and device, the defects in the single forming technology can be overcome, and the purposes of reasonably controlling the formed microstructural organization and optimizing the comprehensive performance are achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for preparing copper and nickel alloy seamless copper tube

InactiveCN101058142AOptimize structure sizeImprove plastic deformation abilityRoll mill control devicesFurnace typesElectrolysisCupronickel

The invention relates to a copper nickel seamless copper tube with 92. 9-93. 6% copper and 6. 4-7. 1% nickel. It takes electrolytic copper and nickel to a low frequency electric oven to heat to 1320-1340deg.C, casting into solid ingot which is heated to 650-750deg.C for heat piercing to get the surface smooth ingot to heat to 650-750deg.C for squeezing to gross blank tube which is extended and peeled for cold reeling, to get the size of the product after annealing. Through calibration and rectification, cleaning and annealing, the product is inspected and put to stock. The content for nickel is 6. 4-7. 1%. It is better in processing feature due to the low nickel and better in corrosion resistant features than copper due to the content of nickel. It is also low in cost.

Owner:江阴和宏精工科技有限公司

Authigenic quasicrystal reinforced high plastic deformation magnesium alloy

The high molding distortion magnesium alloy with the autogeny allowing the crystal wnganced belongs to the metal technical domain. The invention team and the weight percent: 2-10% Zn, 0.5-6%Gd, 0-1.0%Zr, the impurity element Fe is below 0.005%, the rest is Mg. the invention alloy contains the allowing crystal phase, it is formed into the casting group as the formation of the branch crystal, the allowing crystal phase crushed to distribute along the distorting direction through the extrusion or the rolling hot distorting technology, at the same time, the dispersion distributing twice allowing crystal phase is separated out on the inner group body and the edge of the crystal during the extrusion and the rolling to improve the capability of the alloy. The allowing crystal and the group body has the good interface connecting function, it can harmonize distortion and delay the stress concentrate. So the mold distortional capability of the magnesium alloy can be improved highly. It can be used to produce the magnesium alloy distortional material with the higher distortional capability to resisting the extrusion, the rolling and the pressing. The alloy has the upper model ability and matched with the middling intensity; the resisting intension under the room temperature: 260MPa-320MPa; the extending percent: 20%-26%.

Owner:SHANGHAI INNOVATON MEDICAL TECH CO LTD

High-pressure fuel pipe for diesel engines

InactiveUS20050127665A1Improve fatigue resistanceFine surfaceFluid pressure sealed jointsJoints with sealing surfacesCavitationAlloy

There is provided a high-pressure fuel pipe for diesel engines, which is excellent in inner-pressure fatigue resistant property, vibrational fatigue resistant property, cavitation-resistant property, seat surface crack resistant property, and bending shape stability, and capable of thinning and lightening. A high-pressure fuel pipe for diesel engines, composed of a low alloy transformation inducing plastic type strength steel containing residual austenite of 5 to 40 wt %, and wherein an inner surface of a flow passage has a crack depth of 20 μm or less, and plastic working is applied to an inner surface of a flow passage.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

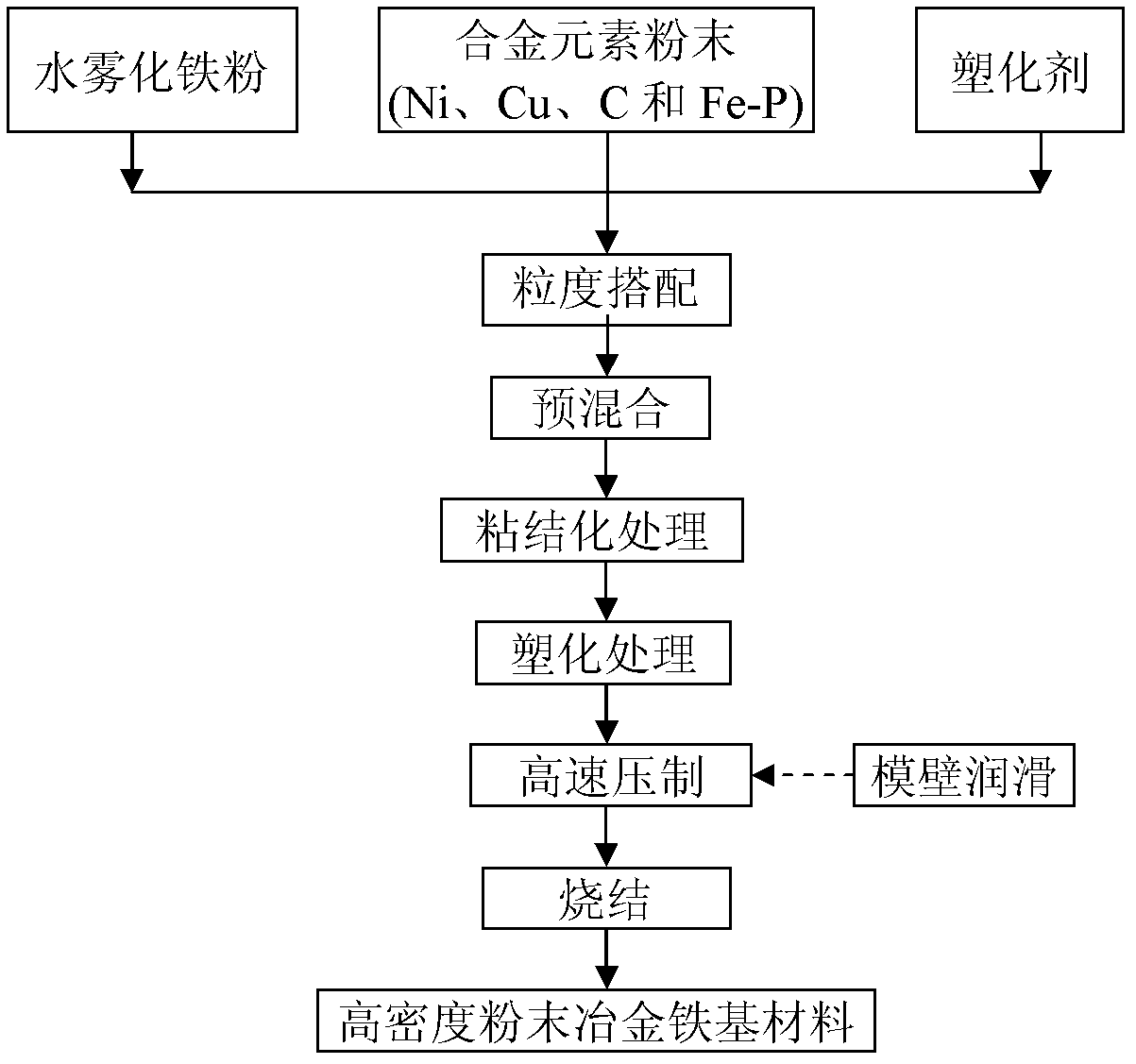

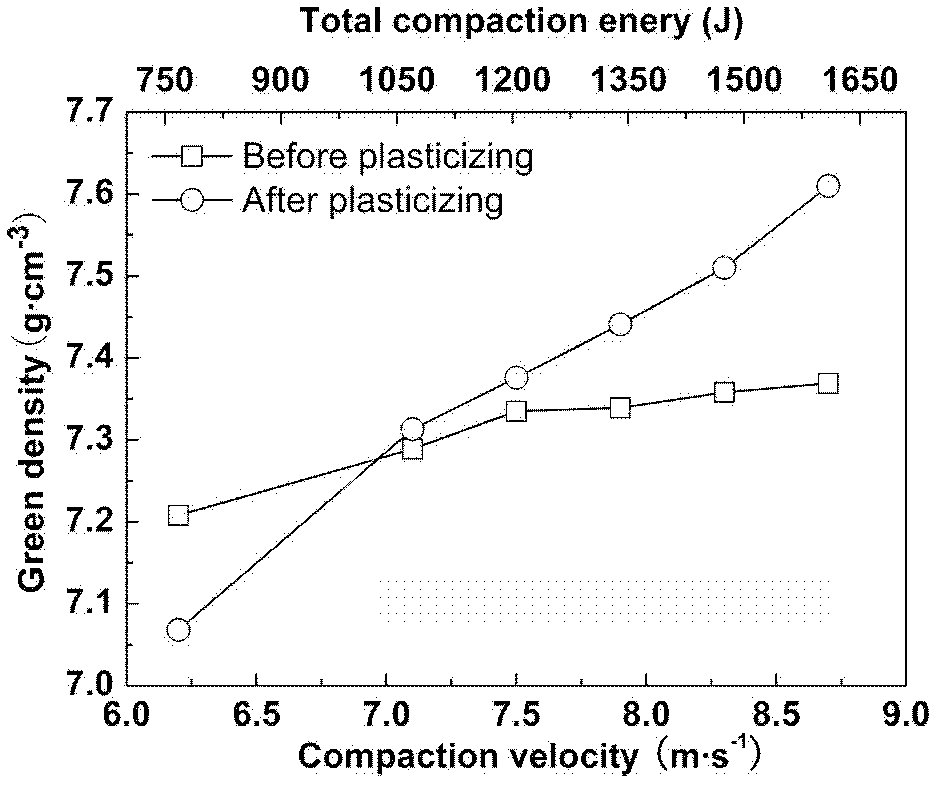

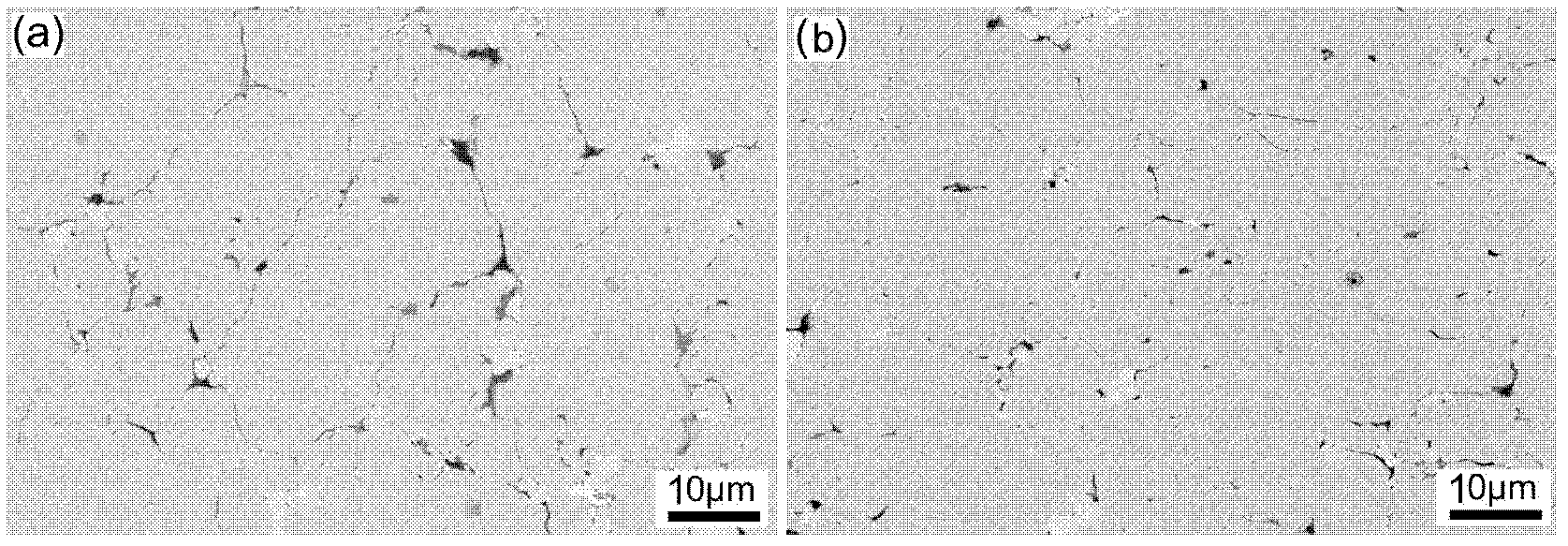

Method for forming bonded iron-based powder by high velocity compaction technology

Owner:YANGZHOUSSHINE POWDER METALLURGY

Roll forming and heat treatment method of Ti2AlNb-based alloy cartridge receiver ring element

ActiveCN104139139AReduce deformation resistanceEasy to shapeMetal rolling arrangementsHeating timePunching

The invention discloses a roll forming and heat treatment method of a Ti2AlNb-based alloy cartridge receiver ring element. The roll forming and heat treatment method comprises the following steps that a Ti2AlNb alloy bar subjected to cogging is loaded into a high-temperature heating furnace to be heated to 1000 DEG C to 1050 DEG C, after the heat preservation is carried out for 80 minutes, the upsetting and the drawing out are carried out at a strain rate being 0.01S<-1>, then, the upsetting and the punching are carried out, and a Ti2AlNb-based alloy cartridge receiver ring blank is obtained; the Ti2AlNb-based alloy cartridge receiver ring blank is rolled at a strain rate being 0.01S<-1>, the rolling process is completed in the heating times being 3 to 5, the lowest temperature in each heating time is 900 DEG C, and the total deformation quantity in the rolling process is 25 percent to 45 percent; after the forging, the Ti2AlNb-based cartridge receiver ring element is subjected to solid solution and aging heat treatment. The roll forming and heat treatment method has the advantages that the Ti2AlNb-based alloy cartridge receiver ring element can be formed at lower deformation temperature, and in addition, fine crystal and basket-weave microstructures with excellent performance are obtained.

Owner:GUIZHOU ANDA AVIATION FORGING +1

Steel pipe integral girders for constructing prestressing force and construction method thereof

InactiveCN101122159AImprove stress resistanceImprove bearing capacityGirdersJoistsPre stressPre stressing

The invention relates to a pre-stressing whole steel pipe truss; components of the truss include bars and nodes; the bars include chords and webs of upper and lower chords; the invention is characterized in that the pulled bars of the truss and the connected nodes are at least provided with a beam of pre-stress strand; both ends of the pre-stress strand are respectively fixed on both ends of pulled sections formed from the pulled bars of the truss and the connected nodes; concrete is casted in the pulled bars of the truss and the connected nodes. The whole truss is a truss system combined with a plurality of materials, such as steel, concrete, pre-stress strand, which improves the bearing capacity and rigidity of the truss, and provides the secondary defensive line for the truss system only by little economic investment. The invention also discloses the construction method of the pre-stressing whole steel pipe truss.

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

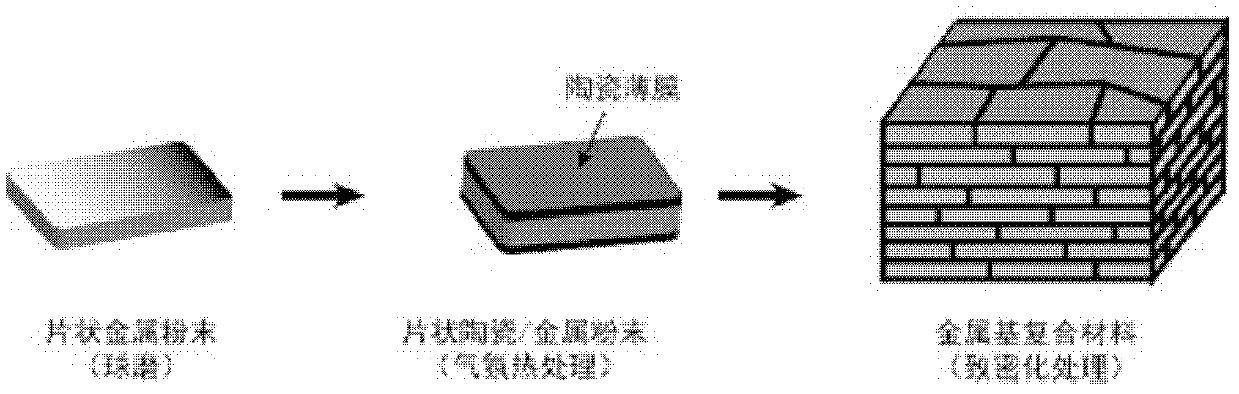

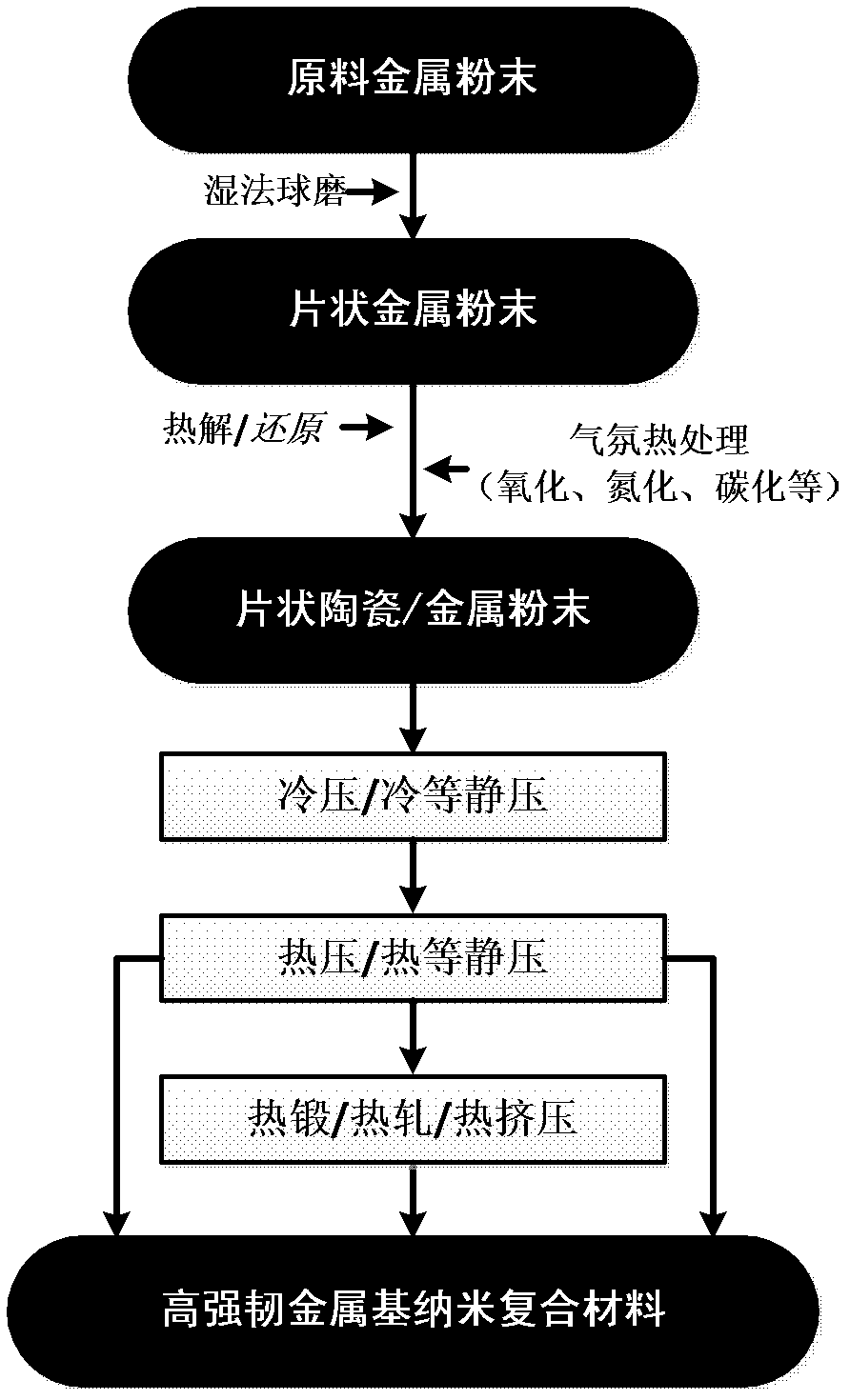

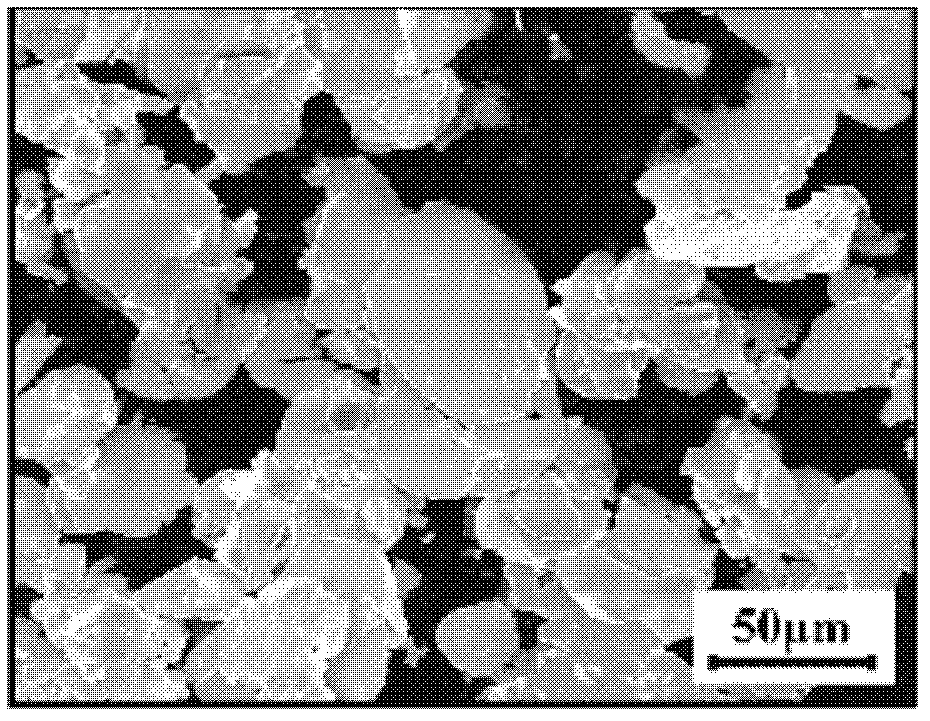

Preparation method of high-toughness metal-based nanometer composite material

The invention provides a preparation method of a high-toughness metal-based nanometer composite material and belongs to the technical field of composite materials. The preparation method provided by the invention comprises the following steps of: firstly, using an atmosphere heat treatment process, generating a layer of a nanometer ceramic thin film on the sheet-shaped metal powder through reaction in-situ; and then carrying out densifying treatment by using a powder metallurgical process, so as to obtain the large compact metal-based composite material. The metal-based composite material prepared by the invention has a metal / ceramic alternative laminated structure, wherein a ceramic layer can be used for effectively restraining the reply of a metal layer and the crystal grain growth, improving the high-position wrong storage capability, keeping a nanometer crystal matrix structure, and causing the rotation and inactivation of fissures, so as to realize mechanical properties matched with the high toughness. The preparation method provided by the invention is simple, convenient and practicable, can be used for realizing the macro-quantized preparation of the large-size composite material, and is good for prompting engineering applications of the metal-based nanometer composite material.

Owner:SHANGHAI JIAO TONG UNIV

Copious cooling asymmetrical rolling method for preparing entropy alloy foil in high-performance CrCoNi

A copious cooling asymmetrical rolling method for preparing an entropy alloy foil in high-performance CrCoNi comprises the following steps: cutting a CrCoNi alloy bar or plate into sheets; carrying out copious cooling treatment in a copious cooling box at the temperature of minus 190 DEG C to minus 150 DEG C; cooling rolls by using a liquid nitrogen spray gun; carrying out copious cooling asymmetrical rolling on samples after copious cooling; maintaining liquid nitrogen in an asymmetrical rolling process to cool the rolls; cooling the rolled materials in the copious cooling box; and repeatingthe fourth step and the fifth step until the reduction rate of rolled pieces exceeds 85%-95% and the thickness of the foil is 200 mu m-6 mu m. CrCoNi alloy has good plastic deformation capacity underthe condition of ultra-low temperature, dynamic recrystallization behavior of the grain size of a material in a large plastic deformation process is inhibited by ultra-low temperature to reduce the grain size, the thickness of the material is reduced by twisting rolling deformation in a rolled piece deformation region in the asymmetrical rolling process, thus, entropy CrCoNi alloy foil is produced, the strength and plasticity of the material are improved effectively, and thus, the prepared medium-entropy CrCoNi foil has high toughness.

Owner:CENT SOUTH UNIV +1

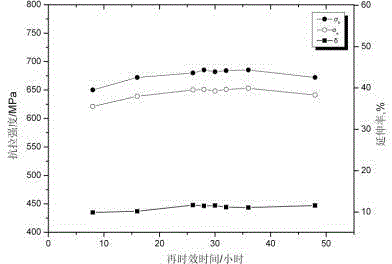

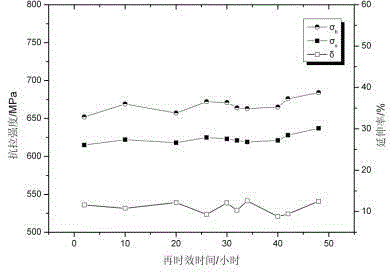

Ageing heat treatment method for low-purity Al-Zn-Mg-Cu alloy

ActiveCN104694860AIncrease nucleation rateImprove plastic deformation abilitySolution treatmentPlastic property

The invention discloses an ageing heat treatment method for a low-purity Al-Zn-Mg-Cu alloy. The method includes the steps that the low-purity aluminum alloy is treated in a solution mode at the temperature of 465 DEG C-480 EDG C for 1-2 h, then first-level ageing is carried out at the temperature of 90 DEG C-120 DEG C for 15-26 h, and air cooling is carried out; the alloy is treated in a regression mode at the temperature of 150 DEG C-210 DEG C for 2-120 min, and intragranular precipitates are redissoluted into a matrix through water cooling; natural ageing (RT) is carried out for 2-120 h, ageing is carried out at the temperature of 50 DEG C-120 DEG C for 2-90 h, and air cooling is carried out. The low-purity Al-Zn-Mg-Cu alloy comprises, by mass ratio, 5.8-7.5% of Zn, 0.2-0.6% of Mn, 1.7-2.5% of Mg, 1.2-2.0% of Cu, 0.08-0.25% of Cr or 0.05-0.15% of Zr, 0.1-0.6% of Fe, 0.1-0.6% of Si, and balance Al. By means of the four-level ageing technology, the low-purity Al-Zn-Mg-Cu alloy obtains highly-dispersed G.P. region granules and a few eta phase intragranular tissues and therefore has ultra-high strength, good plasticity and fatigue damage resistance.

Owner:CENT SOUTH UNIV

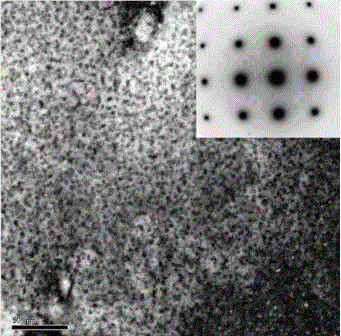

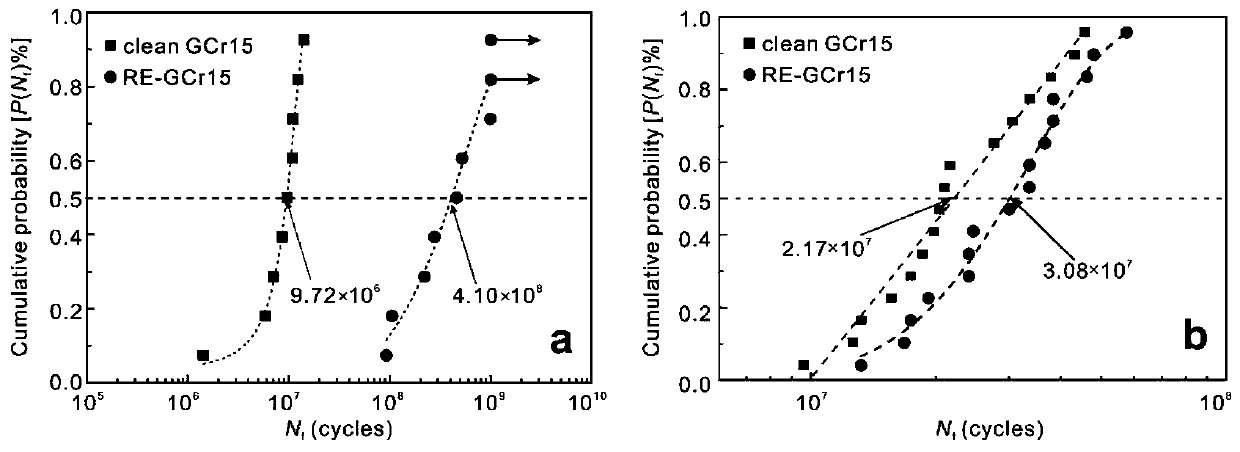

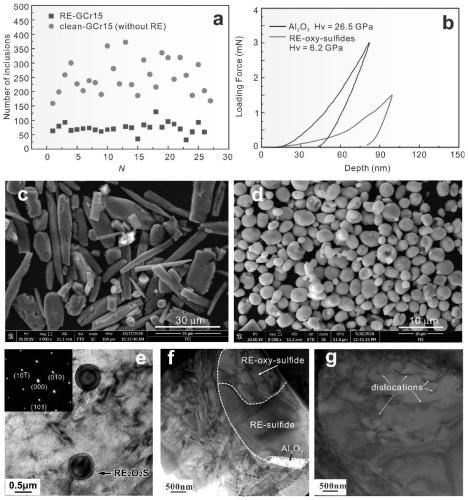

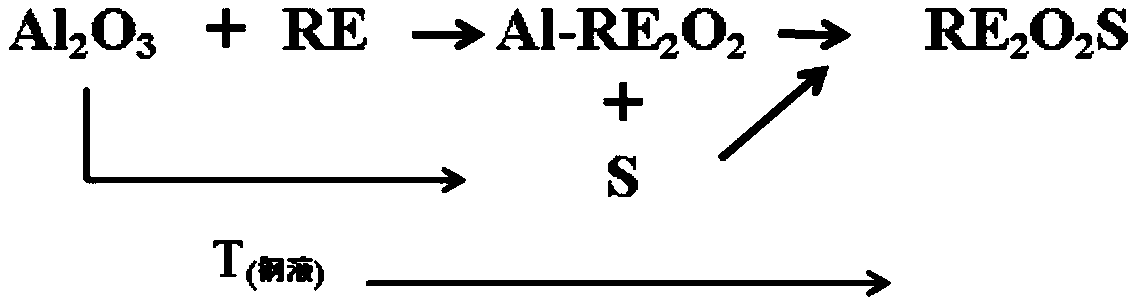

Ultra-clean rare earth steel and occluded foreign substance modification control method

ActiveCN110484811AReduce hardnessImprove fatigue lifeProcess efficiency improvementRare-earth elementMicrometer

The invention provides ultra-clean earth steel and an occluded foreign substance modification control method. 10-200 ppm of rare earth elements are included in the steel, and 50% or more occluded foreign substances in the steel are dispersed RE-oxygen-sulfide with the average equivalent diameter Dmean ranging from 1 micrometer to 5 micrometers in a spherical shape or a spheroidal shape or a granular shape. According to the method, at least 80%, preferably at least 90%, of Al2O3 occluded foreign substances in the steel are modified into RE-oxygen-sulfide, compared with steel with the same components without rare earth, the total amount of the occluded foreign substances in the steel is reduced by 18% or higher, the cracking probability caused by occluded foreign substances such as Al2O3 intraditional pure steel is reduced, the mechanical and chemical performance such as the fatigue life of the steel is remarkably improved, precise control over the modification type, distribution and dimension of the occluded foreign substances in the steel is achieved, and the method is suitable for researching and producing of high-performance steel in more varieties.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Tungsten alloy and preparation method thereof

ActiveCN107541633AImprove plasticity and toughnessImprove grain deformation resistanceShieldingAlloy elementDuctility

The invention relates to a tungsten alloy and a preparation method thereof. The alloy is composed of a tungsten matrix and alloy elements. The solid solution of alloying elements into the tungsten matrix, based on the XRD test, can give full play to the solid solution strengthening effect, improve the strength and hardness of the alloy, and improve the plasticity and toughness of the alloy at the same time. The invention also provides a 3D pure shape preparation method of this novel tungsten alloy part.

Owner:TSINGHUA UNIV

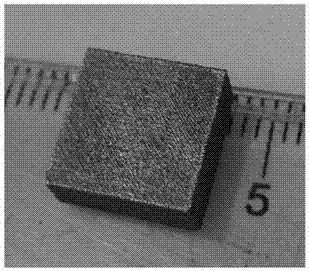

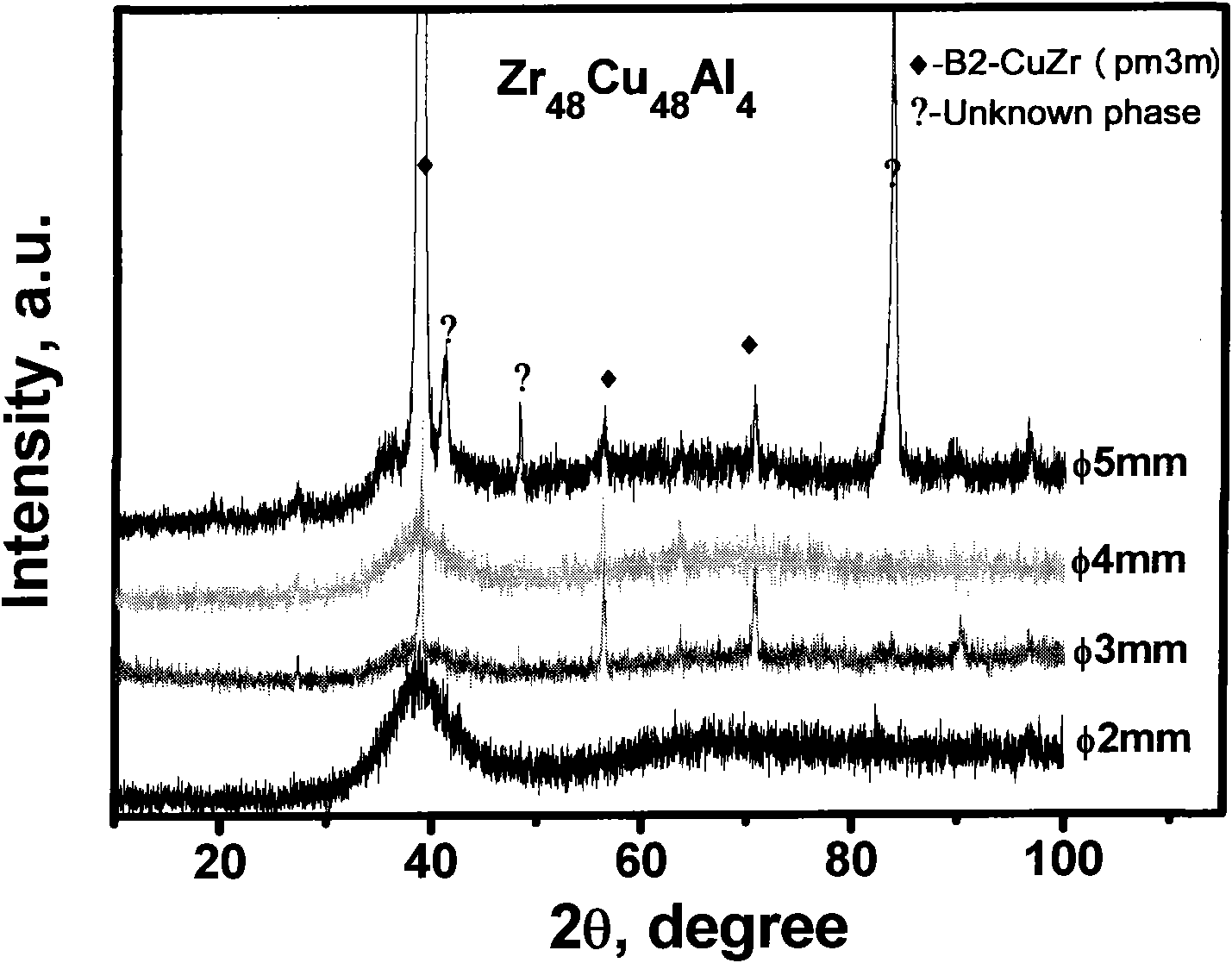

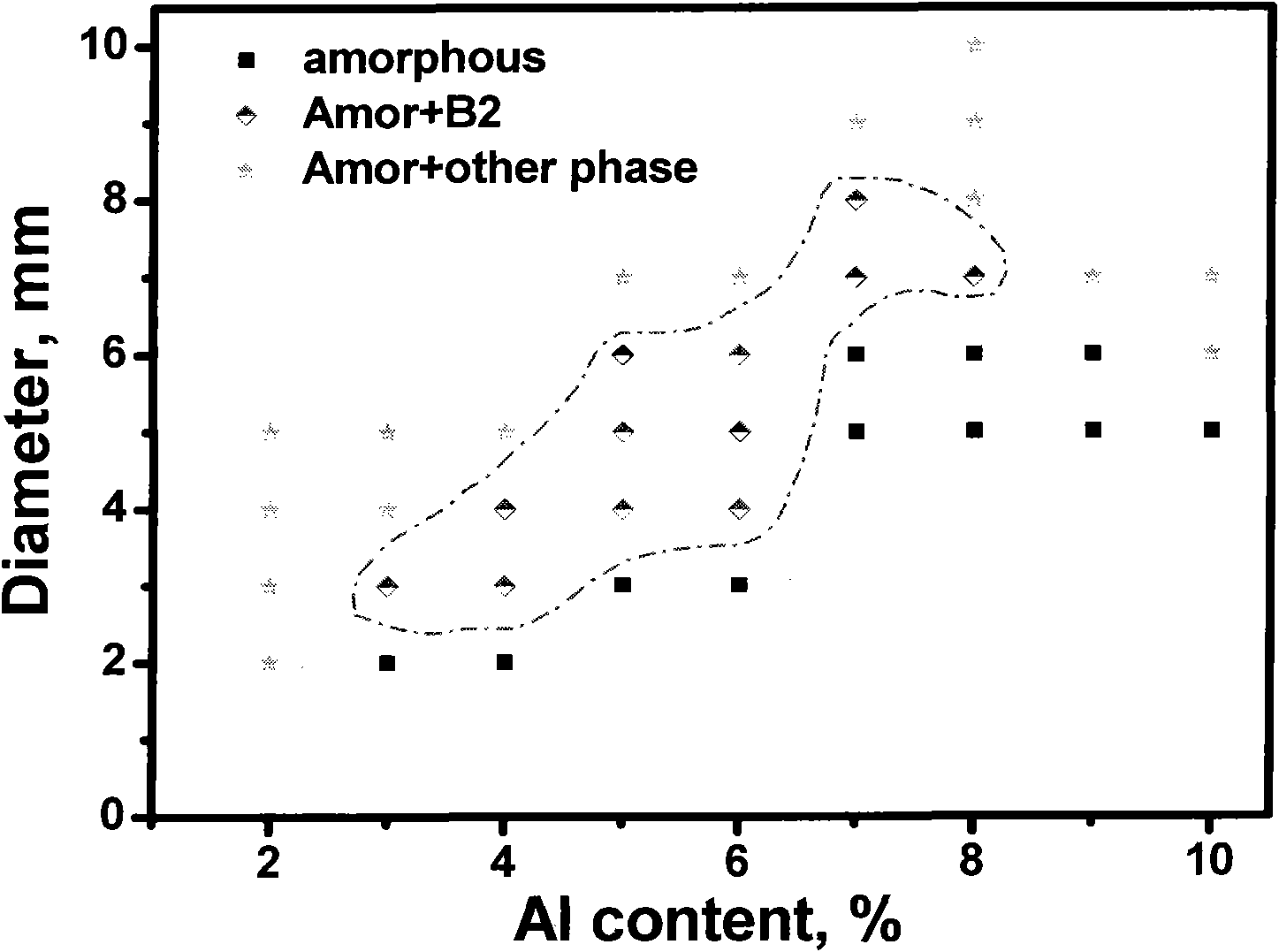

Bulk metal glass composite material with stretching plasticity and work hardening capacity

The invention relates to a bulk metal glass composite material with stretching plasticity and work hardening capacity. A crystal phase capable of producing phase change is generated in the metal glass during deforming by alloy component control and cooling speed adjustment, and the crystal phase is deformed to produce the phase change so as to prepare the composite material. The bulk metal glass composite material with the stretching plasticity and work hardening capacity is prepared by taking common pure metal elements as main components, mixing the materials according to an atomic percentage expressed by an alloy component expression, and smelting and suction casting. The bulk metal glass composite material contains 10 to 60 volume percent of crystals. The bulk metal glass composite material of the invention can undergo the phase change during deforming, has higher strength and compression plasticity, particularly has higher stretching plasticity and work hardening capacity, and can meet the requirement of practical engineering application; therefore, the composite material has quite broad engineering application prospect.

Owner:UNIV OF SCI & TECH BEIJING

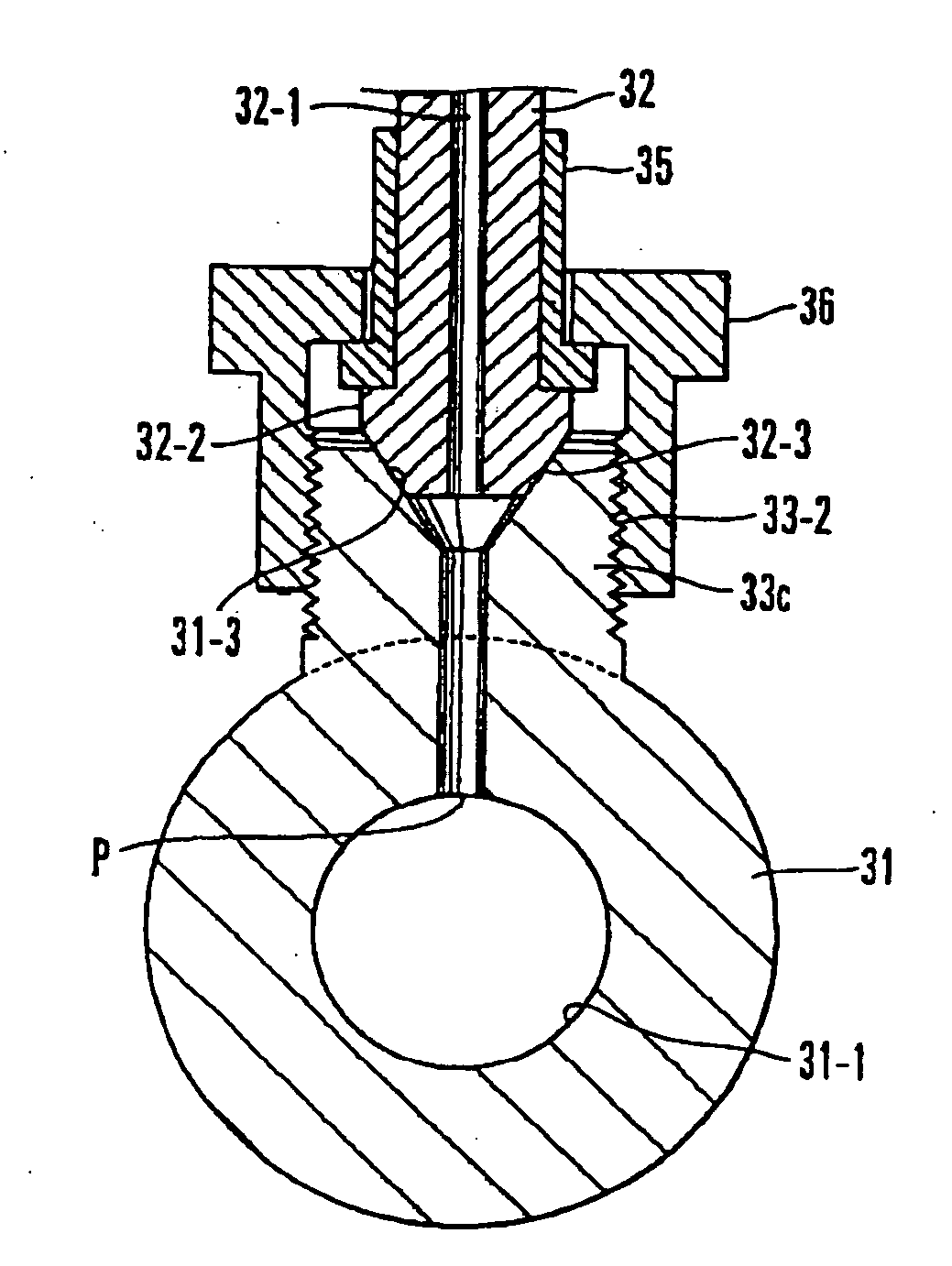

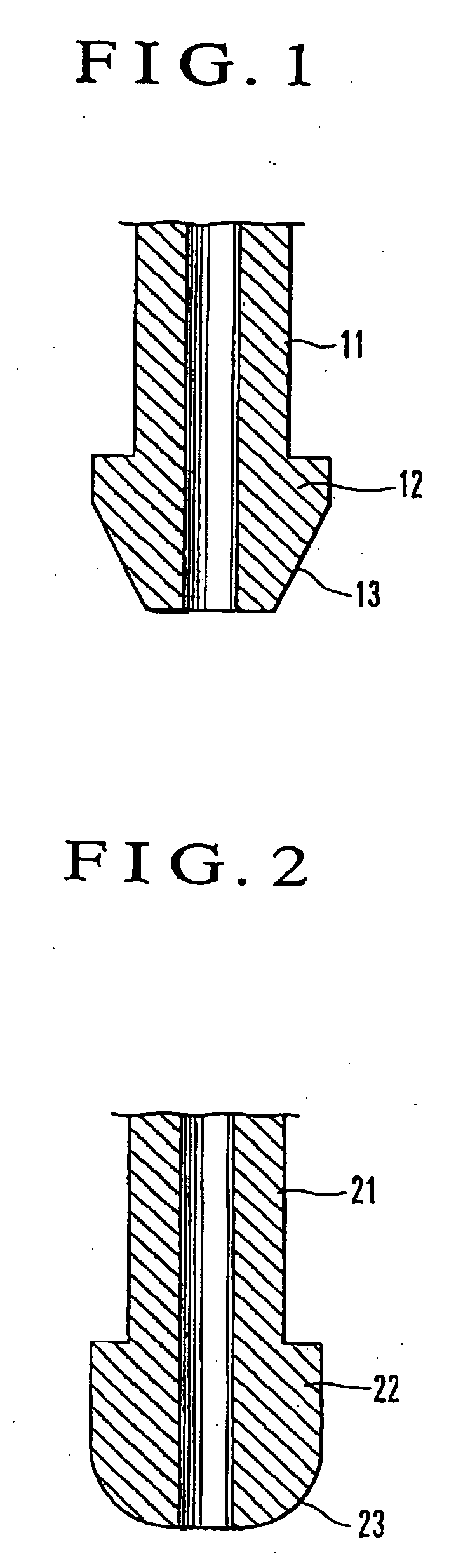

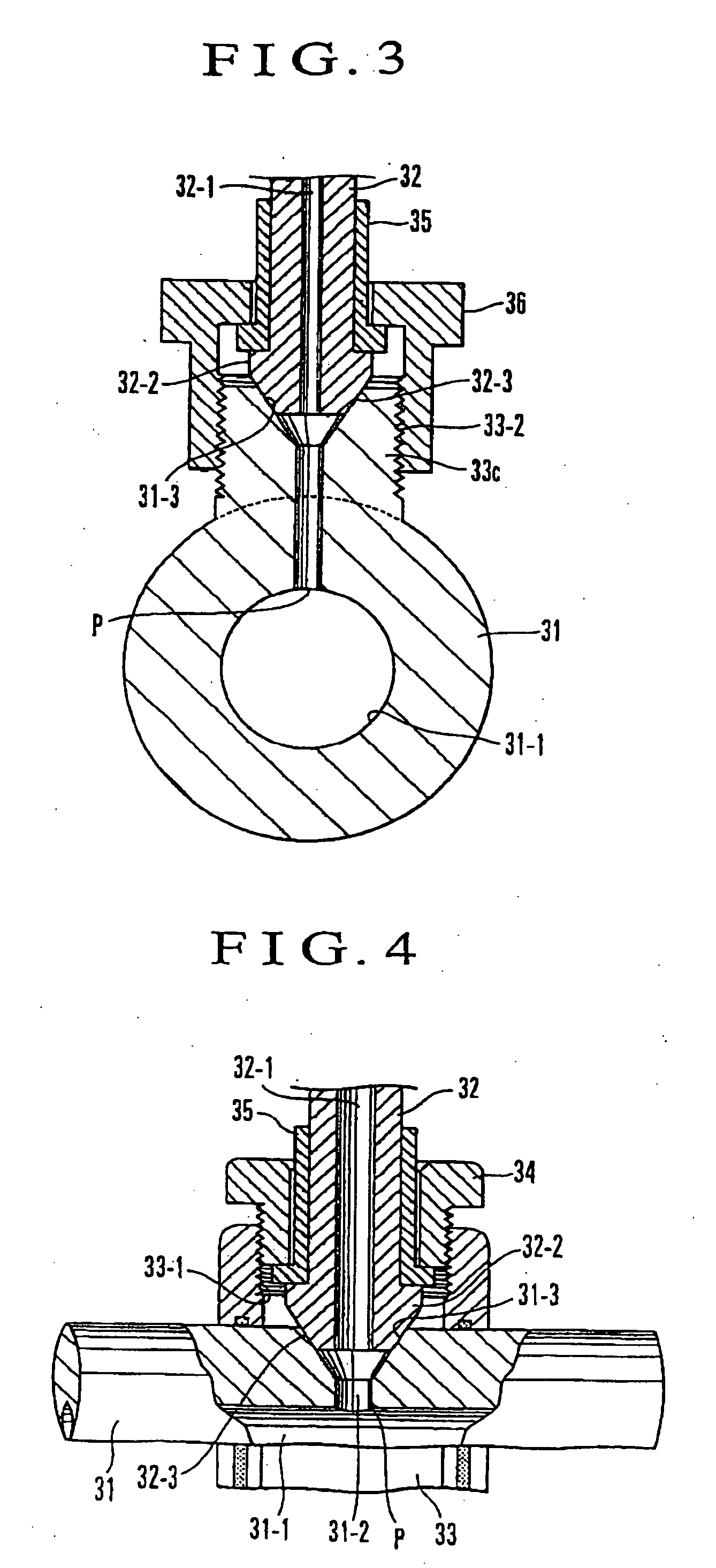

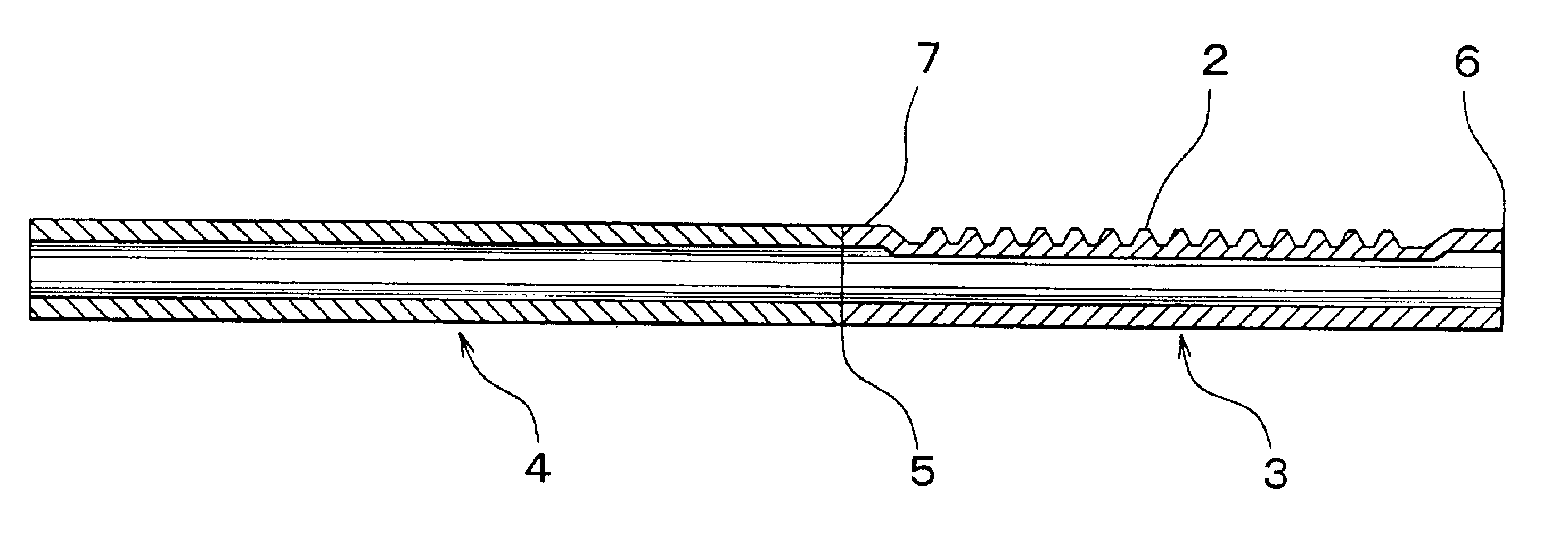

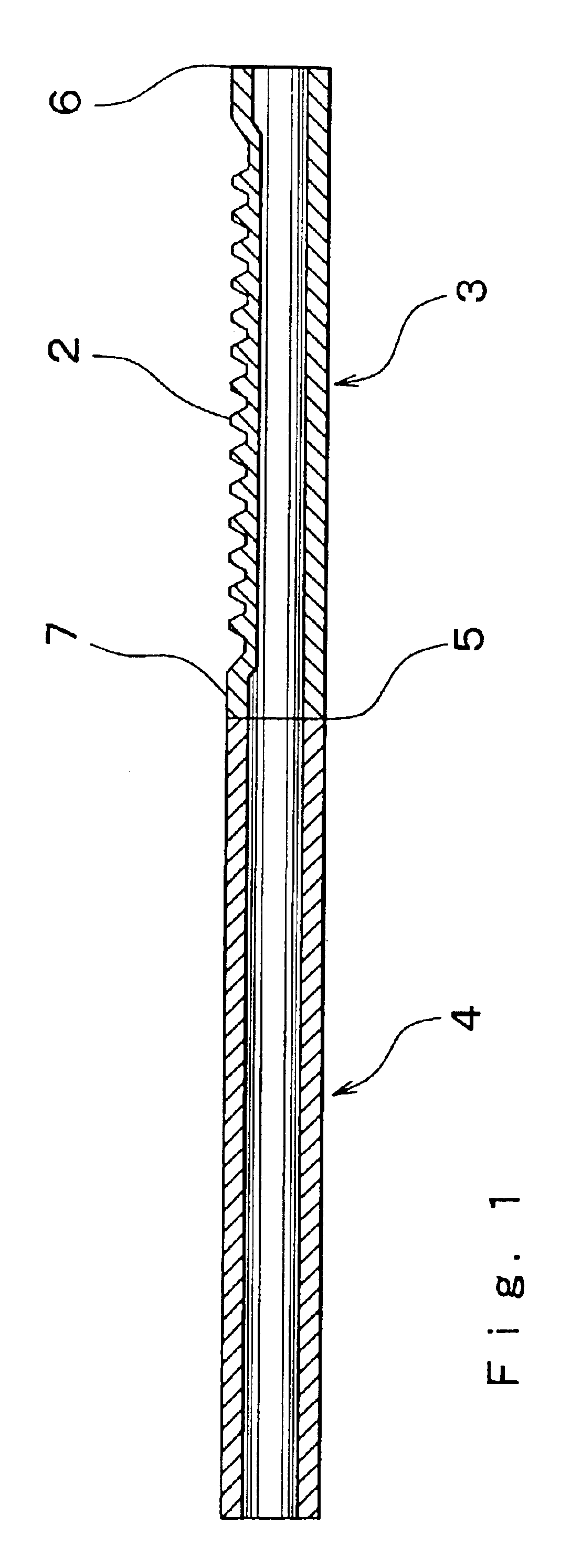

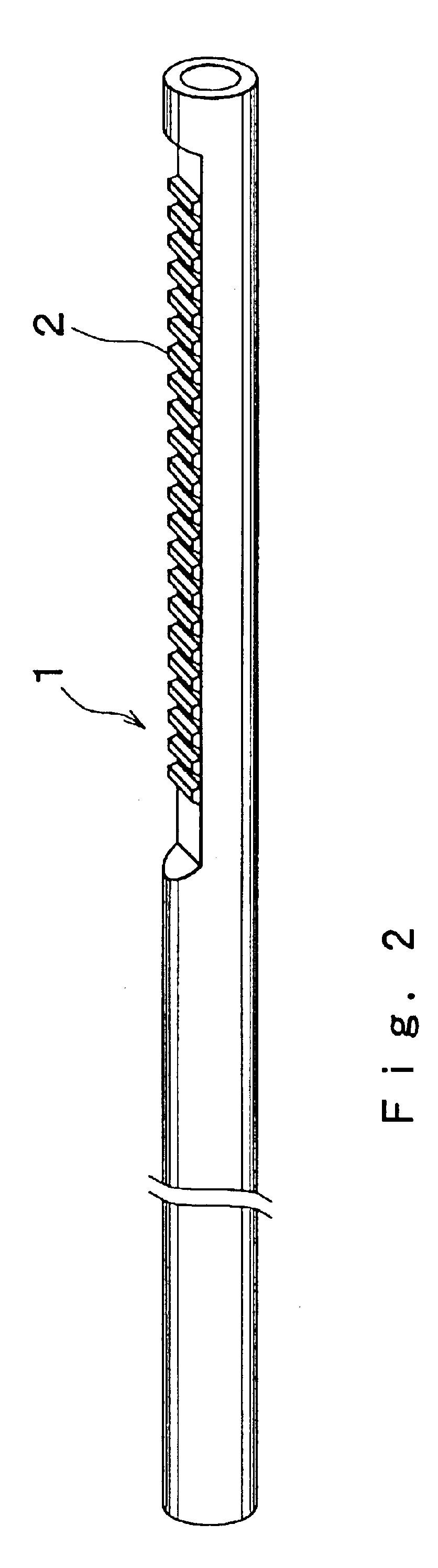

Hollow steering rack bar and its manufacturing method

ActiveUS6925899B2High costHigh material strengthPortable liftingToothed gearingsSteel tubeEngineering

Described is a steering rack bar which is low in costs, which is hollowed in overall length, and for use in steering equipment for automobiles. A rack is formed on a first steel tube by plastic working, wherein the first steel tube has good plastic workability by low carbon content, and has high strength after hardening. The above first steel tube and a second steel tube are joined to complete a hollow steering rack bar, wherein the second steel tube has a higher carbon content and is lower in cost than the first steel tube. Moreover, the second steel tube which has a margin of the strength can be thinner than the first steel tube for reduction of weight.

Owner:NETUREN CO LTD

Preparation method of enhanced magnesium alloy-based neutron absorption plate

The invention relates to a preparation method of an enhanced magnesium alloy-based neutron absorption plate. The method comprises the following steps: aiming at the actual condition of nuclear radiation protection, with boron carbide powder, boron powder, magnesium powder and aluminum alloy powder as raw materials, adopting a vacuum hot-pressing technique under the assisted action of an electric field, and preparing a magnesium alloy-based neutron absorption plate blank under electric field heating, resistance heating, pressurizing and vacuum conditions, so that B4C particles and B particles are evenly distributed in a matrix; oxidation of the material is effectively prevented by the vacuum environment; the interface bonding intensity is improved by the electric field action; the blank is molded in a hot extrusion manner; the particle distribution uniformity is improved; the plastic deformation property of the material is improved; the extruded blank is subjected to hot rolling to obtain the plate; the internal metallographic structure of the material is relatively dense; the preparation method is advanced in process, and accurate, detailed and accurate in data; the neutron absorption property of the magnesium alloy-based neutron absorption plate reaches 98%; the material density reaches 99%; the material hardness reaches HV0.1=186.7; the particle distribution is uniform; and the enhanced magnesium alloy-based neutron absorption plate is a lightweight and high-strength composite plate with good neutron absorption property.

Owner:TAIYUAN UNIV OF TECH +1

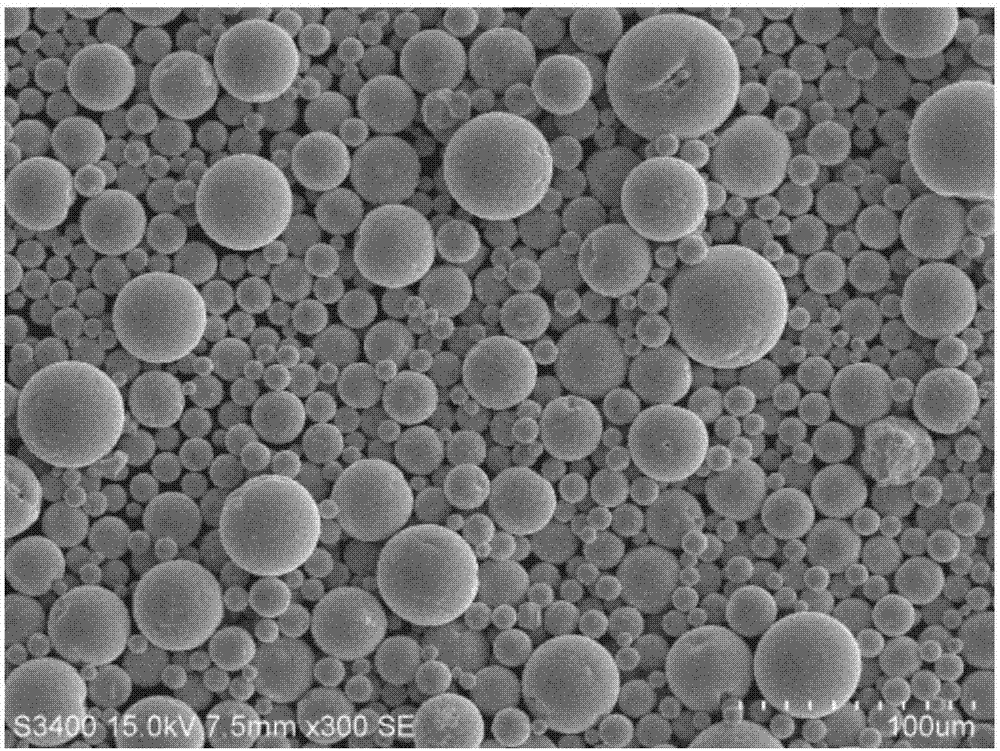

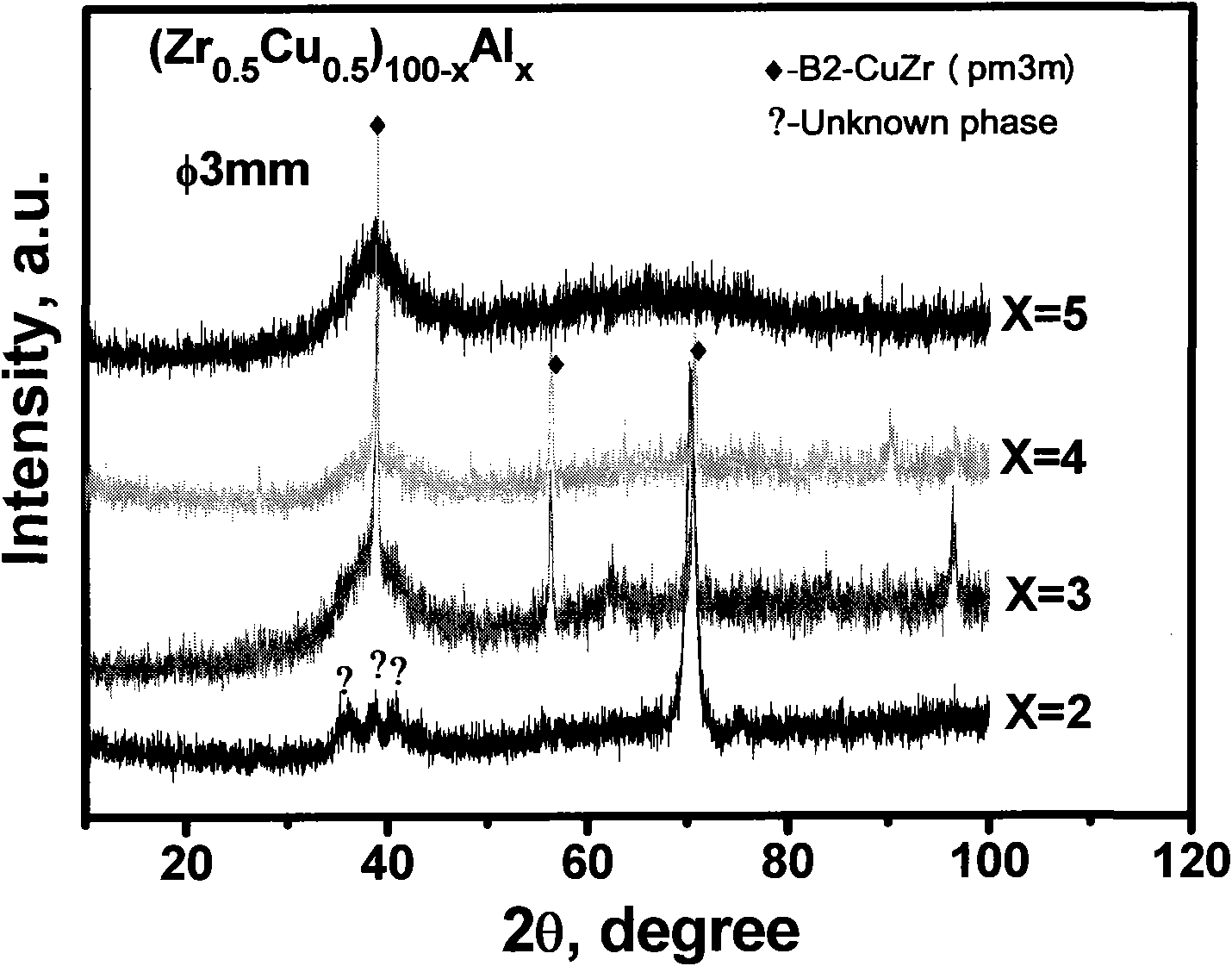

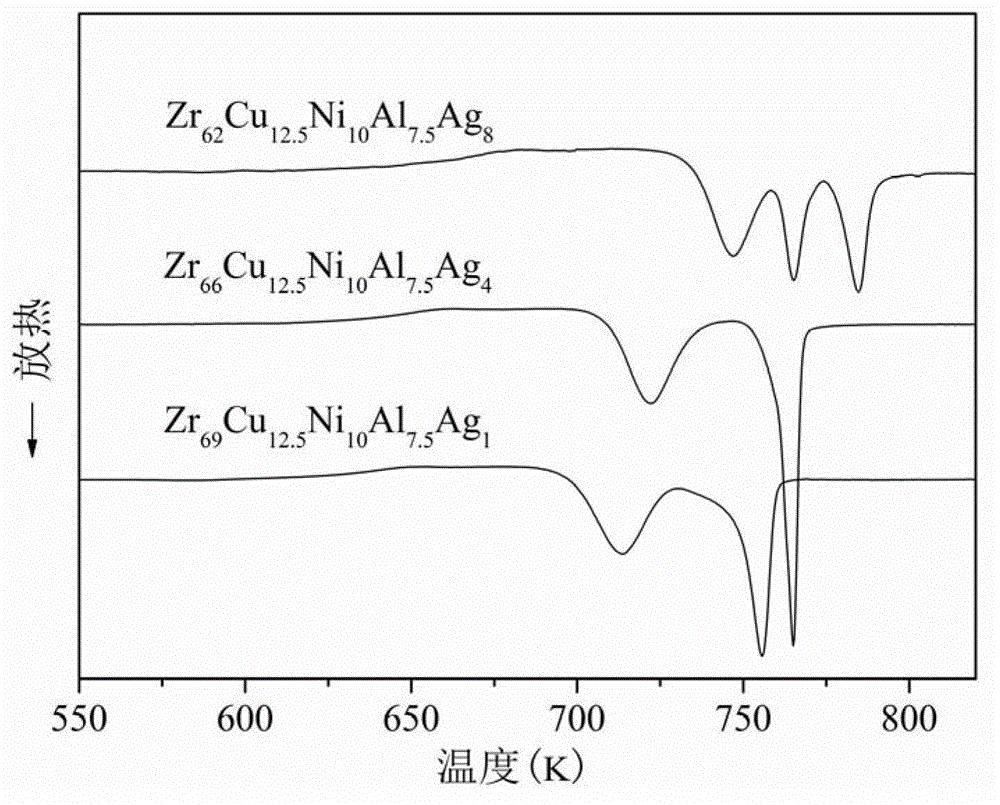

Zirconium-based amorphous alloy and preparation method thereof

InactiveCN102912261AHigh compressive strengthImprove plastic deformation abilityCopperGlass transition

The invention relates to a zirconium-based amorphous alloy. The zirconium-based amorphous alloy comprises zirconium, copper, nickel, aluminum and sliver; and the zirconium-based amorphous alloy is shown by the following formula: Zr70-xCu12.5Ni10Al7.5Agx, wherein x is more than or equal to 1 and less than or equal to 10. The preparation method comprises the steps of replacing zirconium element by a silver part, and melting by arc under vacuum, and then carrying out suction casting, so as to obtain the zirconium-based amorphous alloy. The zirconium-based amorphous alloy is excellent in plastic deformation capacity and high in strength; the amorphous alloy is high in glass transition temperature and initial crystallizing temperature, and wide in sub-cooled liquid phase area, and has a potential application prospect.

Owner:SHANGHAI JIAO TONG UNIV

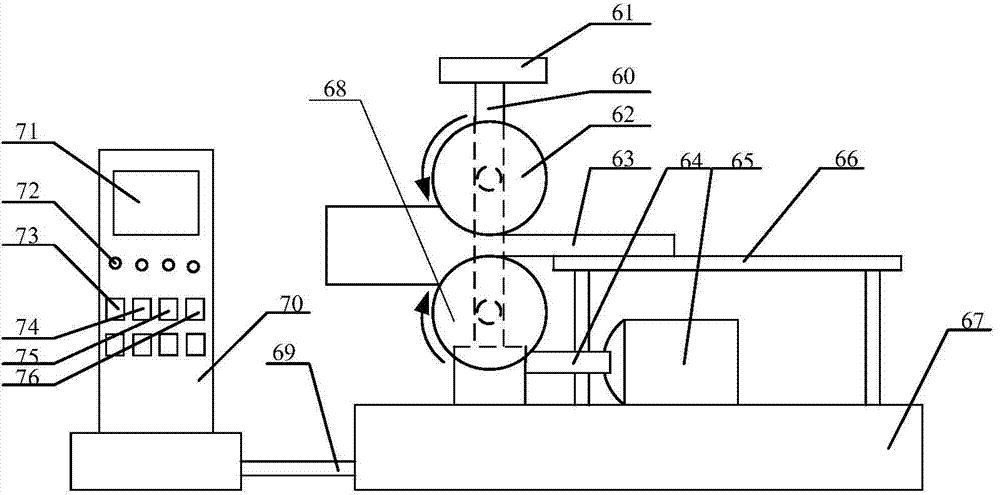

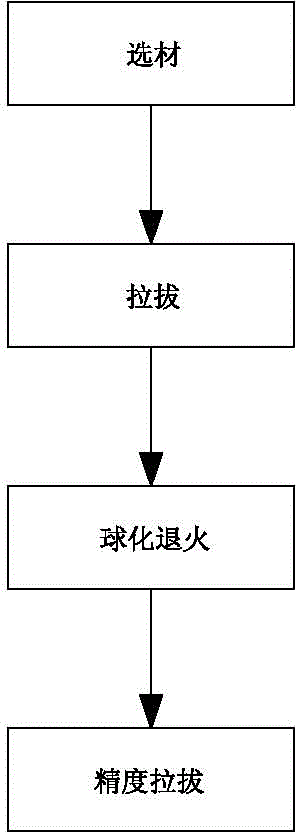

Process for producing high-nodularity fastener wire rod

The invention discloses a process for producing a high-nodularity fastener wire rod. The process comprises the following steps: (1) selecting materials, namely selecting a steel wire with the model of SWRCH22A; (2) drawing, namely drawing the steel wire by adopting a drawing machine, wherein the compression rate is more than or equal to 50 percent; (3) performing spheroidizing annealing, namely lifting the steel wire into an atmosphere protection furnace, adding a protective atmosphere into the atmosphere protection furnace, heating the steel wire to a temperature which is 20-30 DEG C higher than the austenite transformation temperature, preserving the heat for 4-6 hours, slowly cooling to a temperature which is 20-30 DEG C lower than the austenite transformation temperature at a rate of 10 DEG C per hour, preserving the heat for 3-4 hours, and performing furnace cooling until the product is discharged out of the furnace; and (4) performing precision drawing, namely drawing the steel wire again by adopting the drawing machine, wherein the compression rate is less than or equal to 10 percent. The treated steel wire has the grain size of more than or equal to 10 grades, the grains are uniform, the nodulizing grade is more than or equal to 5, the nodulizing rate is high, the pearlite is uniform in distribution, and the wire rod does not have abnormal tissues, has high plastic deformation capacity and is suitable for subsequent plastic forming, and the wire rod with excellent size and surface is obtained.

Owner:DONGGUAN KELEE STEEL WIRE

Rolling method for applying pulse current to metal composite plate

InactiveCN108356075AReduce deformation resistanceReduce the critical reduction rateAuxillary arrangementsMetal rolling arrangementsPower flowClosed loop

The invention belongs to the technical field of double-metal composite material rolling, and in particular, relates to a method for improving forming performances of a double-metal composite plate through adding pulse current in a rolling process. The method comprises main steps of treatment of coating layer metal and base layer metal before rolling, communication of the pulse current on a metal plate and rolling through startup of a rolling mill. The rolling method of the double-metal composite material is to apply the pulse current to double metal in the rolling process; and positive and negative output ends of a pulse power supply are connected with an electric brush to form a closed loop. The method has the following beneficial effects: the plasticity of the double-metal plate is improved; the rolling force is reduced; the edge cracking of the composite plate is inhibited; the element dispersion of the coating layer and base layer metal is promoted; the energy barrier is overcome;the metal atom dispersion efficiency is improved; the bonding strength is improved; and the rolling productivity is improved.

Owner:TAIYUAN UNIV OF TECH

Brazing filler metal for brazing W-Cu composite and Fe-based alloy, method and brazing technique

ActiveCN105081597AModerate melting temperatureFacilitated Diffusion and Interfacial ReactionsWelding/cutting media/materialsWelding/soldering/cutting articlesAlloy elementMicrometer

The invention discloses brazing filler metal for brazing a W-Cu composite and Fe-based alloy, a method and a brazing technique. The brazing filler metal is in a foil piece strip shape. The thickness of the brazing filler metal ranges from 50 micrometers to 100 micrometers. The brazing filler metal comprises, by weight, 6.0%-9.0% of Mn, 3.5%-5% of Co, 0.3%-1.7% of Ni, 2.0%-5.0% of Zr, 1.2%-2.8% of Ti, and the balance Cu. The brazing temperature of the brazing filler metal ranges from 1000 DEG C to 1050 DEG C, the melting temperature of the brazing filler metal is moderate, and the brazing filler metal is uniformly melted; diffusion and the interface reaction of alloy elements in the brazed connection process can be promoted through a brazing filler metal foil piece, and the wetting and spreading capacity of the brazing filler metal on the surfaces of the W-Cu composite and the Fe-based sintered alloy is improved; crystal particles are refined, residual stress is reduced, and the mechanical performance of joints is improved; the brazing technique for connecting the W-Cu composite and the Fe-based sintered alloy through the brazing filler metal is stable and reliable, vacuum brazed connection is used, a component is in a vacuum state in the heating process, the whole component does not deform, the defects such as microscopic cracks, air holes and inclusions are avoided, and the wetting and spreading capacity of the surface of the brazing filler metal is good.

Owner:JIANGSU UNIV OF SCI & TECH

Titanium aluminum alloy surface high temperature oxidation and hot corrosion resistant Al-Cr coating and preparation method thereof

InactiveCN104760349AImprove high temperature oxidation resistanceAccelerated corrosionVacuum evaporation coatingSputtering coatingOxidation resistantThermal shock

The present invention discloses a titanium aluminum alloy surface high temperature oxidation and hot corrosion resistant Al-Cr coating; an Al-rich deposition layer, an Al-Cr alloy layer and a Cr diffusion layer are successively arranged from surface to a titanium aluminum alloy substrate. The content of Al in the Al-rich deposition layer remains the same. The content of Al in the Al-Cr alloy layer gradually reduces outside-to-inside to 70%-100% of the content of Al in the titanium aluminum alloy substrate, and the rest in the Al-Cr alloy layer is Cr. The contents of Cr and Al in the Cr diffusion layer respectively gradually reduces outside-to-inside to same as the contents of Cr and Al in the titanium aluminum alloy substrate, and the rest in the Cr diffusion layer is other elements in the titanium aluminum alloy substrate, and the contents of other elements in the Cr diffusion layer respectively gradually rise to same as the contents of the other elements in the titanium aluminum alloy substrate from zero. The invention also discloses a preparation method of the titanium aluminum alloy surface high temperature oxidation and hot corrosion resistant Al-Cr coating; the titanium aluminum alloy surface high temperature oxidation and hot corrosion resistant Al-Cr coating can give titanium aluminum alloy excellent oxidation resistance and heat resistance corrosion performance under high temperature and long term service conditions, and due to the presence of the diffusion layer of the gradient components, the reliable binding strength and excellent thermal shock resistance can be realized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Cold spraying device and method for preparing 316L stainless steel coating

InactiveCN103422088AImprove plastic deformation abilityTo accelerate the expansionPressure inorganic powder coatingMetallurgyGas heater

The invention discloses a cold spraying device and a method for preparing a 316L stainless steel coating, and belongs to the cold spraying technical field. The device mainly comprises a control system, a powder feeder, a gas heater, a laval nozzle and a powder heater. One end of the gas heater is connected with the laval nozzle, and the other end of the gas heater is connected with the powder feeder. One end of the powder feeder is connected with the control system, and the other end of the powder feeder is connected with one end of the powder heater. The other end of the powder heater is connected with the laval nozzle. In preparation of 316L stainless steel coating by utilization of the device, the technological parameters are as follows: the carrier gas preheating temperature is 200-600 DEG C, the spraying distance is 10-30 mm, the spraying pressure is 1.5-2.5 MPa, and the powder-feeding heating temperature is 200-500 DEG C. The modified cold spraying device heats the stainless steel powder from the powder feeder, and a compact stainless steel coating tightly combining with a matrix is obtained.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

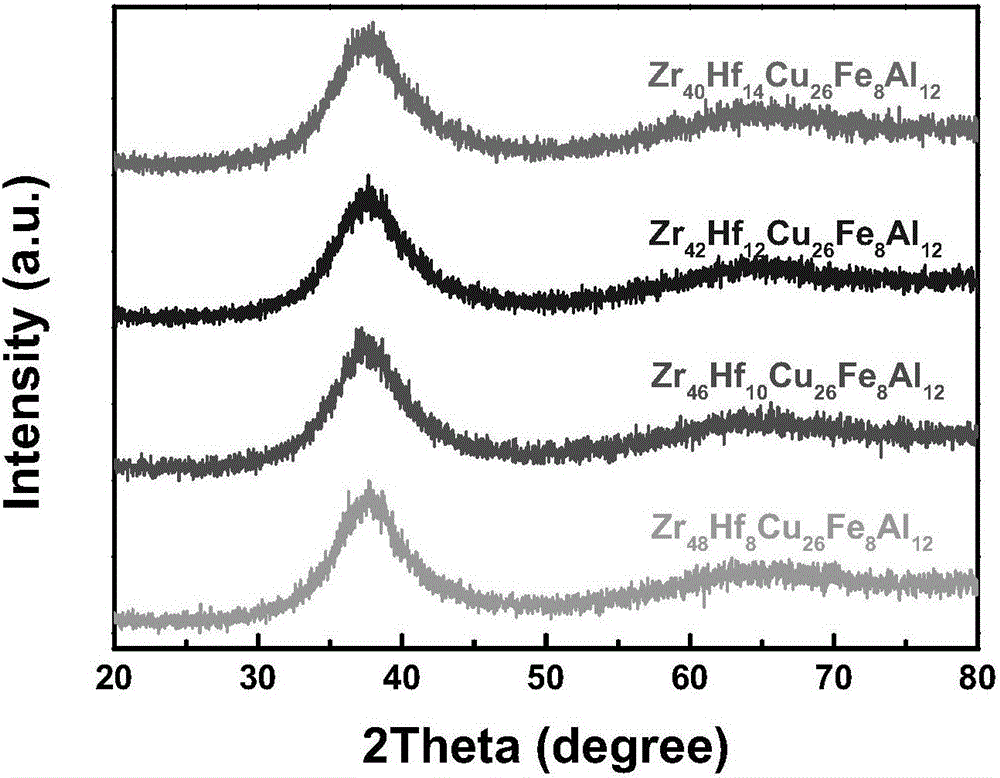

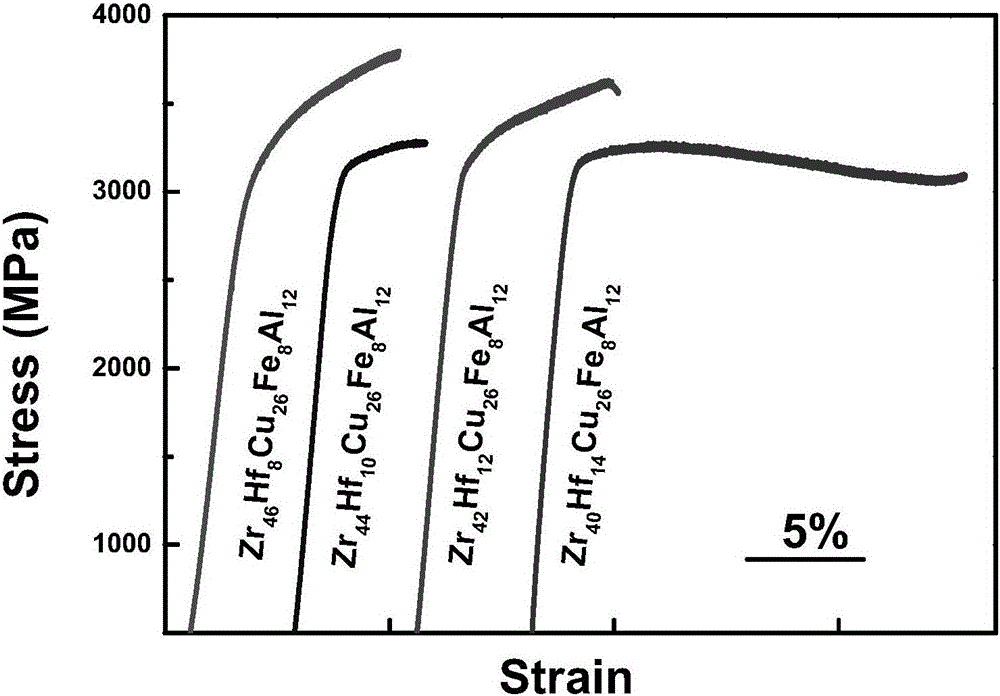

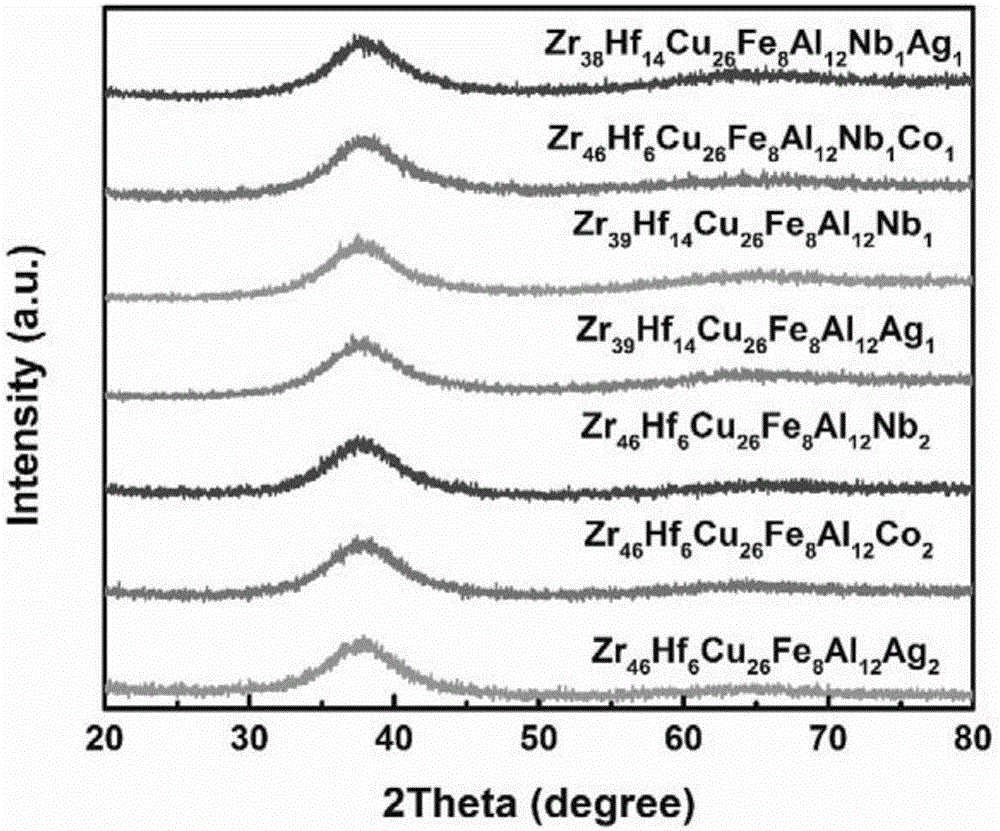

Beryllium-free nickel-free high-ductility zirconium-base block body amorphous alloy and preparation method thereof

ActiveCN106756647AGood biocompatibilityWide temperature range of subcooled liquid phase regionBiocompatibility TestingNickel free

The invention provides a beryllium-free nickel-free high-ductility zirconium-base block body amorphous alloy and a preparation method thereof. The alloy comprises, by atom, 38-50% of Zr, 2-15% of Hf, 20-30% of Cu, 5-10% of Fe, 10-15% of Al, 0-5% of Co, 0-5% of Ag and 0-5% of Nb. The electric arc melting copper mould casting method is adopted for preparation. The amorphous alloy is free of metal elements such as Be and Ni, and biocompatibility of the zirconium-base alloy is improved. The high amorphous forming capacity is achieved, and the zirconium-base block body amorphous alloy with the critical size being no less than 5 mm can be prepared through the copper mould casting method. According to the beryllium-free nickel-free high-ductility zirconium-base block body amorphous alloy, high hardness is achieved, and vickers hardness is larger than 540 Hv; the plastic deformation capacity being larger than 3% is achieved; and the super-cooled liquid phase region range is wide and reaches 92 K at most. The beryllium-free nickel-free high-ductility zirconium-base block body amorphous alloy and the preparation method thereof has very wide application prospects in the fields of biomedical materials such as a precise complex medical component, a joint prosthesis and a human skeleton.

Owner:UNIV OF SCI & TECH BEIJING

Steel adapting to high deformation and punching and used for high-surface-quality aluminum-coated substrates and production method thereof

ActiveCN108796363AImprove mechanical propertiesEnhanced interface bindingChemical compositionPunching

The invention discloses steel adapting to high deformation and punching and used for high-surface-quality aluminum-coated substrates and a production method thereof. The steel comprises the followingchemical components of, by weight, percentage, no more than 0.01% of C, 0.006-0.015% of Si, 0.05-0.3% of Mn, no more than 0.015% of P, no more than 0.01% of S, no more than 0.005% of Al, no more than0.005% of N, 0-0.05% of Ti, 0.01-0.08% of O, and the balance of Fe and inevitable impurities; and meanwhile, C+N is not more than 0.012, Mn / S is not less than 8, and Ti / (3.42N+4C) is not less than 1.The tensile strength of the steel for the aluminum-coated substrates is 280-380 MPa; and the ductility is above 40%; the steel components adopt low C-Si-Mn design similar to pure iron; a proper amountof Ti is added; the steel is produced by adopting a rolling control mode; the production process is simple; and the cost is lower. Besides of excellent plasticity and steel aluminum coating performance, the steel can meet single-pass high deformation (80-90%) requirement; and the steel is mainly used for producing aluminum-coated plate strips.

Owner:BAOSHAN IRON & STEEL CO LTD

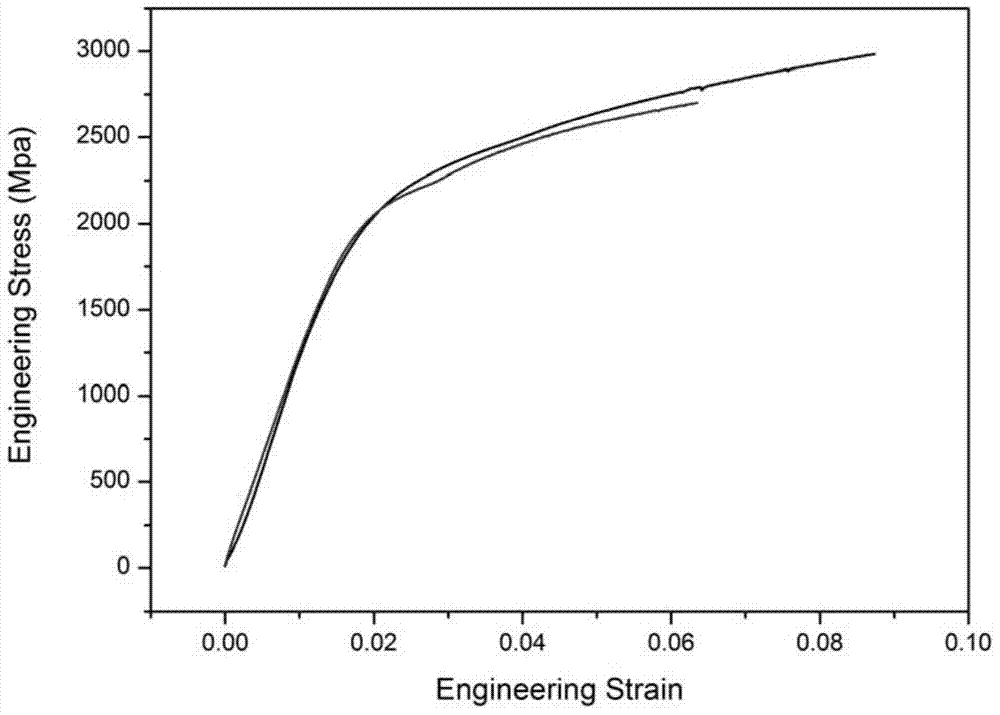

Spiral molded large-deformation-resistant submerged-arc welding pipe and manufacture method thereof

ActiveCN103192234ASmall sizeImprove construction efficiencyArc welding apparatusStress–strain curveLandslide

The invention discloses a spiral molded large-deformation-resistant submerged-arc welding pipe and a manufacture method thereof. A large-deformation-resistant hot rolled coil plate is unrolled and straightened, a welding groove is respectively machined on two sides of the plate, then the plate is placed into a spiral steel pipe molding unit to be molded and bent into a pipe shape gradually, the submerged-arc welding process is adopted to conduct welding pipe welding, and the welding pipe is subjected to following treatment such as hole enlargement, detection, hydraulic test and ultrasonic detection to form a product. The submerged-arc welding pipe has low yield ratio, larger even elongation, high deformation hardening exponent and Round-House type stress-strain curve under the premise that the welding pipe meets the requirement for high strength and high flexibility. The welding pipe is mainly applied to regions such as frozen earth zones, landslide zones, earthquake zones and the like where geological movement happens easily, serves as a steel pipe in oil and gas delivery pipes which can bear large deformation and stress, and ensures safe service of the pipes.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Magnesium alloy with high strength, super toughness and low density and preparation method thereof

InactiveCN101768689ASolve the problem of very limited effect of deformation hardening strengtheningImprove plastic deformation abilityRoom temperatureIngot

The invention discloses a super-light magnetism alloy with high strength, super toughness and low density, which comprises the following components in percentage by weight: 5-12% of Li, 1-5% of Zn, 1-6% of Y, 0-2% of Re and the balance Mg. The invention adopts an argon protection method to cast alloy after evacuation, then heat treatment is carried out on obtained as-cast magnetism alloy ingot under the condition of gas protection, and then the alloy is extruded or processed by rolling warm deformation so as to obtain the magnetism alloy after deformation processing. The invention provides a magnetism alloy the density of which is less than 1.7g / cm<3>, which has high strength and high plasticity and toughness, and can satisfy the index requirements on strength and plasticity of deformation processing sheet materials at room temperature.

Owner:XIAN UNIV OF TECH

Heavy size TRIP amorphous composite material and preparation method thereof

The invention relates to a heavy size TRIP amorphous composite material and preparation method thereof, the composite material comprises the following alloy components: CuaZrbMcNdXe(atom mol ratio), wherein M is at least one of Al, Be, Ag, Au, Pd, Pt or rare earth element, N is at least one of Ti, Fe, Co, Ni, Cr, V, Zn, Nb, Ta, Mo, Hf, W, WC, SiC, and TiC, X is at least one of Si, C, B, Sn, Ga, Ge and In, wherein a is greater than or equal to 0 and less than or equal to 70, b is greater than or equal to 0 and less than or equal to 70, c is greater than or equal to 2 and less than or equal to 15, c is greater than or equal to 0 and less than or equal to 5, e is greater than or equal to 0.05 and less than or equal to 2, and sum of a, b, c, d and e is 100. According to the invention, amorphous formation capability of a matrix can be increased by alloying and technical adjusting, and a dispersed crystalline state second phase having phase transition induction plasticity effect can be generated in-situ, deformation induction generated during a deformation process of the second phase is used for obtaining large stretching plasticity and strong processing hardening capability. The prepared composite material can realize good combination of intensity and plasticity, and has wide engineering application prospect.

Owner:UNIV OF SCI & TECH BEIJING

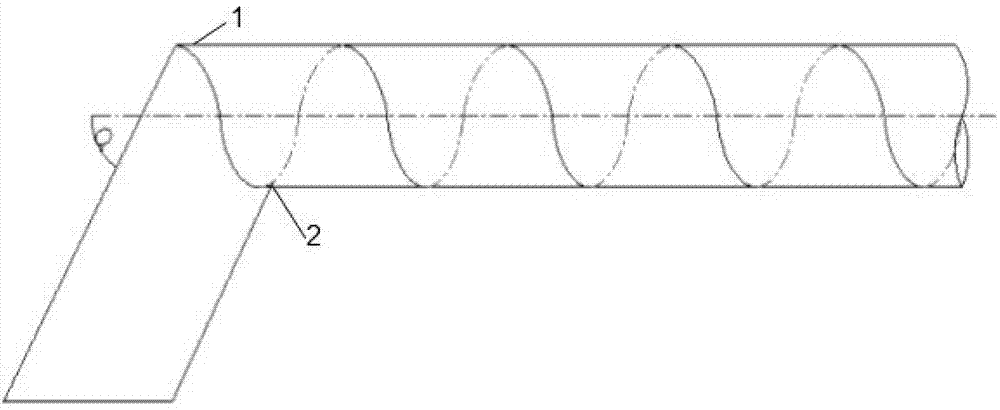

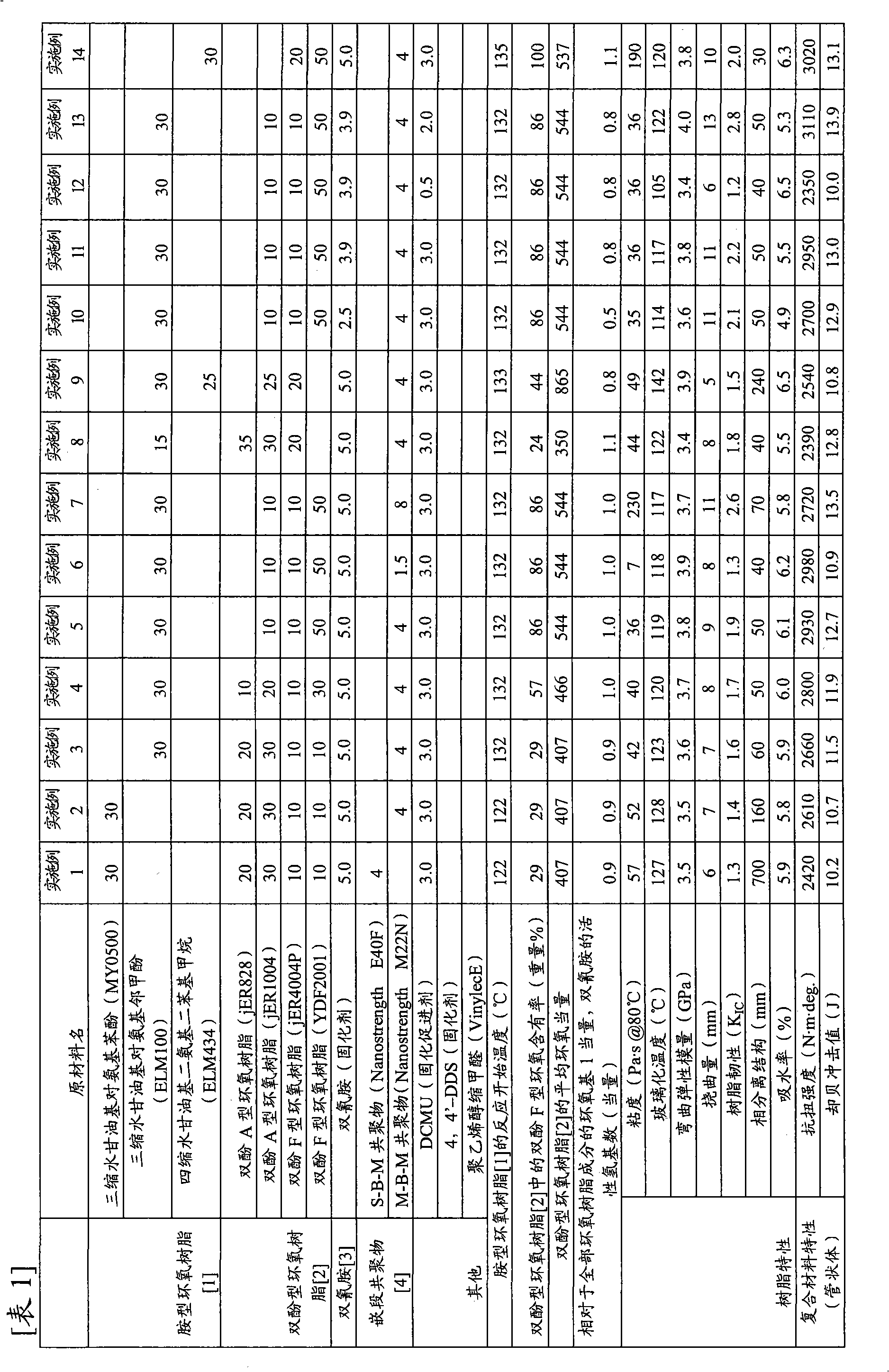

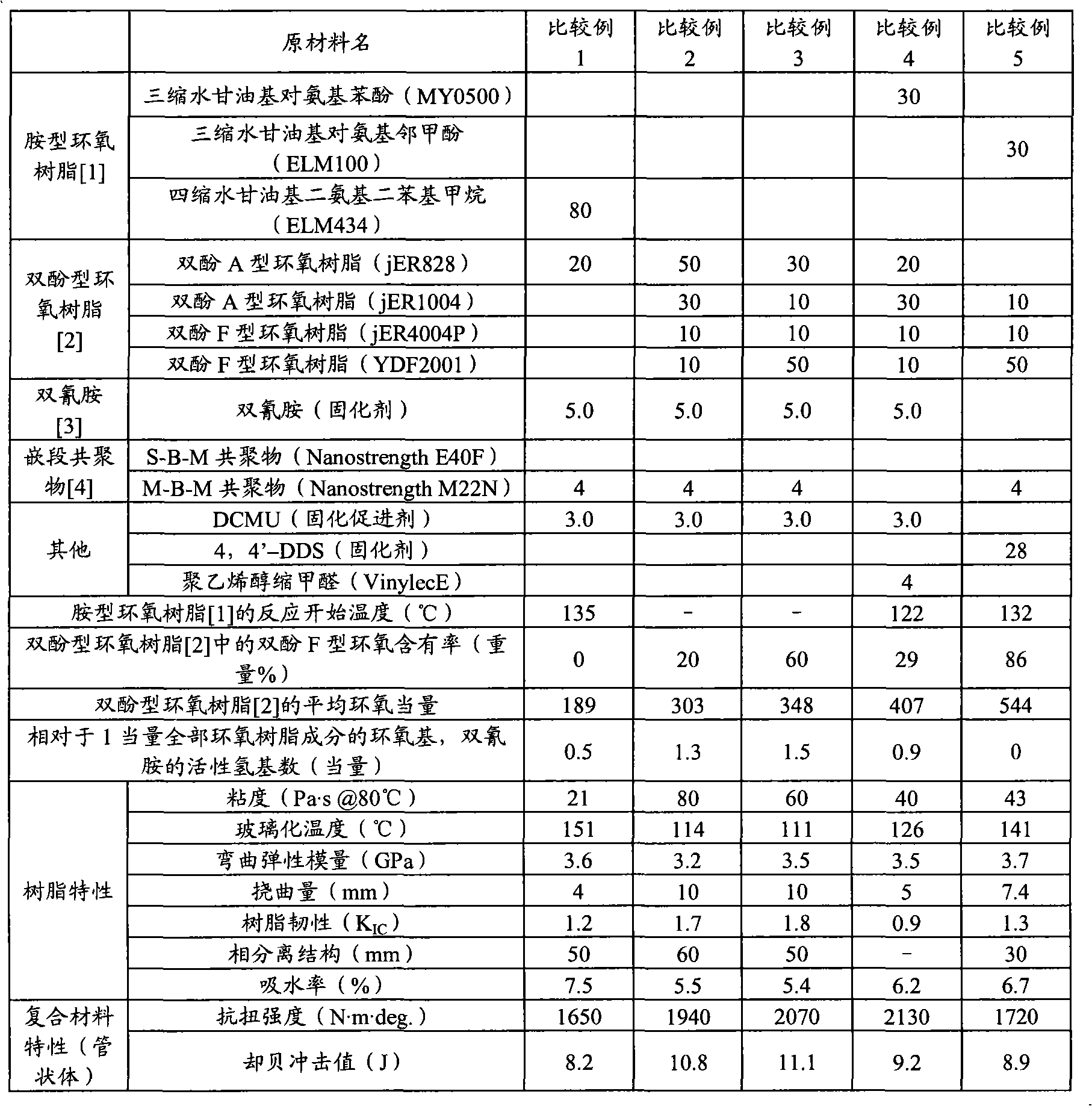

Epoxy resin composition, prepreg, and fiber-reinforced composite material

ActiveCN101679609AHigh elastic modulusImprove heat resistanceSynthetic resin layered productsRodsHigh stiffnessHeat resistance

Disclosed are: a fiber-reinforced composite material having both of excellent static strength properties and excellent impact resistance; and an epoxy resin composition for producing the fiber-reinforced composite material, specifically an epoxy resin composition which enables to produce a cured product having a high elastic modulus, high heat resistance, a high plastic deformation ability and high stiffness. Specifically disclosed are: an epoxy resin composition comprising the following components ¢A! to ¢D!; a prepreg produced by impregnating a fiber base material with the epoxy resin composition; a fiber-reinforced composite material produced by curing the prepreg; and a tubular article produced from the fiber-reinforced composite material. ¢A!: an amine-type epoxy resin: 10 to 60 partsby weight; ¢B!: a bisphenol-type epoxy resin: 40 to 90 parts by weight; ¢C!: dicyandiamide or a derivative thereof: 1 to 10 parts by weight; and ¢D!: at least one block copolymer selected from the group consisting of S-B-M, B-M and M-B-M: 1 to 10 parts by weight.

Owner:TORAY IND INC

Method for preparing hard particle coating on hard substrate through laser-assisted cold spraying

ActiveCN103469197ALower the preheat temperatureReduce hardnessHeat inorganic powder coatingSand blastingLaser power density

The invention discloses a method for preparing a hard particle coating on a hard substrate through laser-assisted cold spraying. The method comprises the following steps: subjecting the hard substrate to sand blasting, wherein the hardness of the hard substrate is 300 HV; preheating a spherical hard particle with a diameter in a range of 30 to 50 mu m, wherein preheating temperature is 300 to 600 DEG C, and the hard particle is one or more selected from the group consisting of 2Cr13, 17-4PH, Ni45, Ni60 and Inconel718; carrying out spraying on the surface of the hard substrate by using compressed air having a pressure of 1.5 to 3.0 MPa and carrying the preheated hard particle; and starting laser to synchronously heat a spraying area so as to form the hard particle coating on the surface of the hard substrate, wherein laser power density is 3*10<5> to 5*10<5> W / cm<2>, and wavelength is 850 to 1060 nm. The method provided by the invention can substantially improve plastic deformation generated during collision between the hard particle and the substrate, so the binding force of the coating is improved; thus, the coating with higher stability is obtained.

Owner:ZHEJIANG UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com