Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

298results about How to "Prevent surface oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

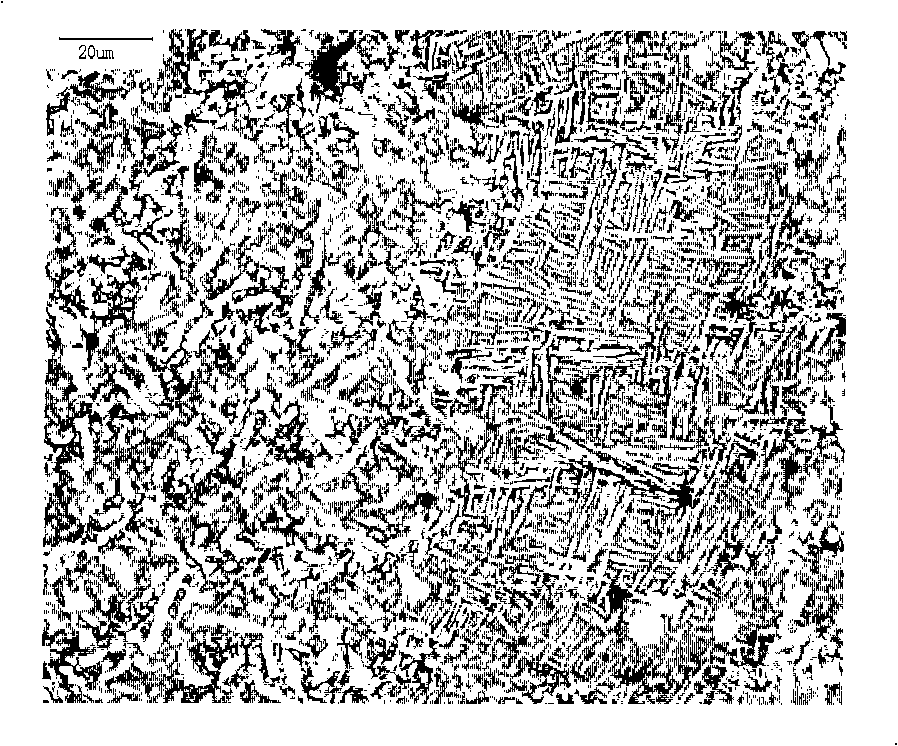

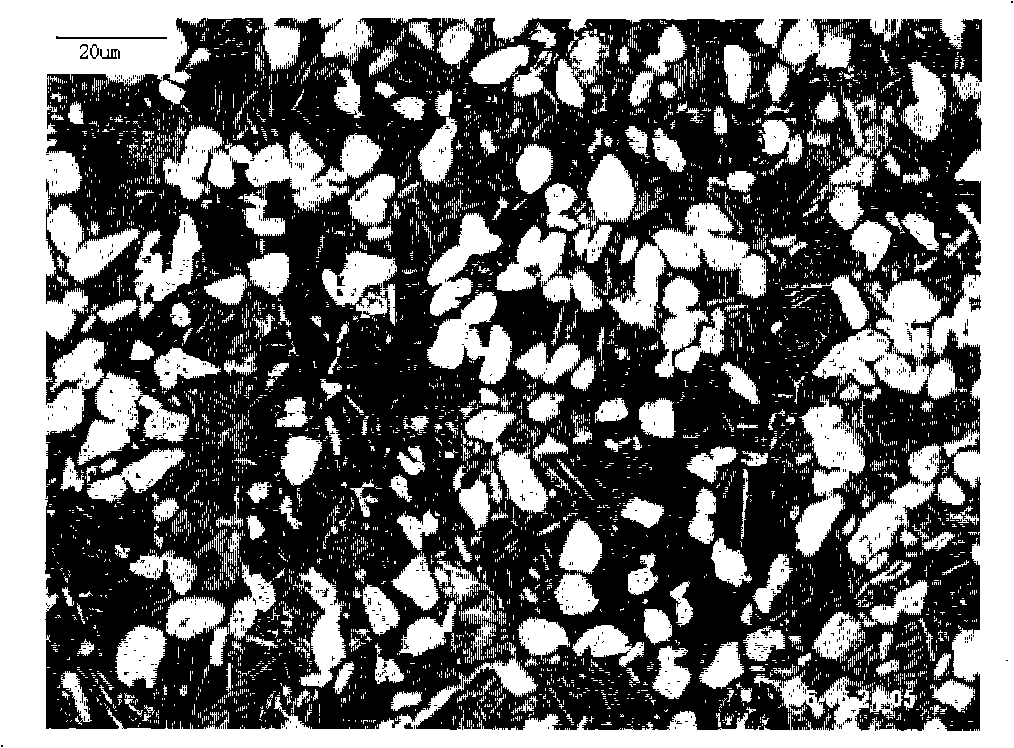

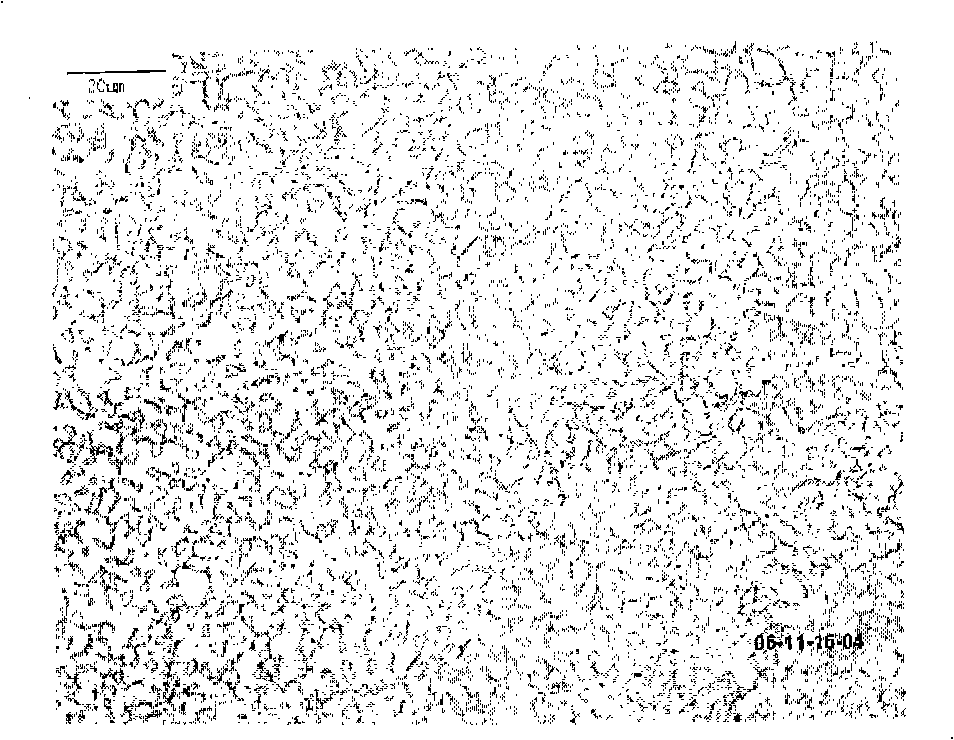

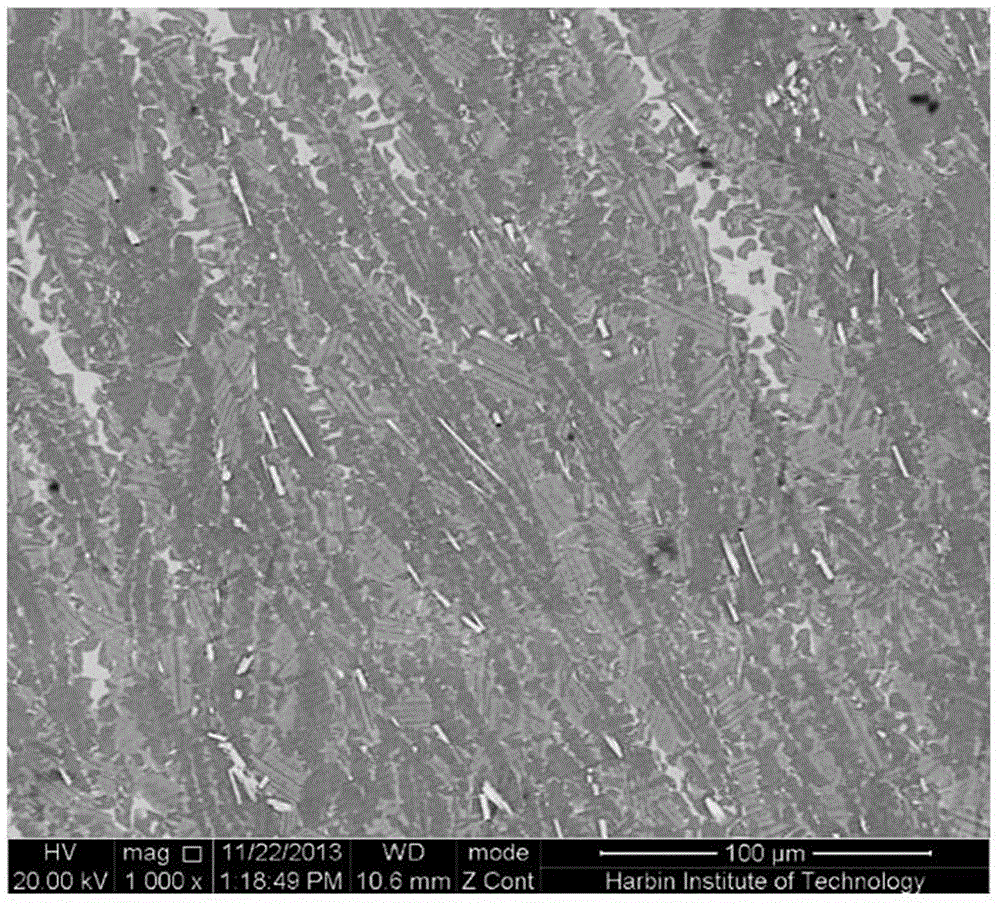

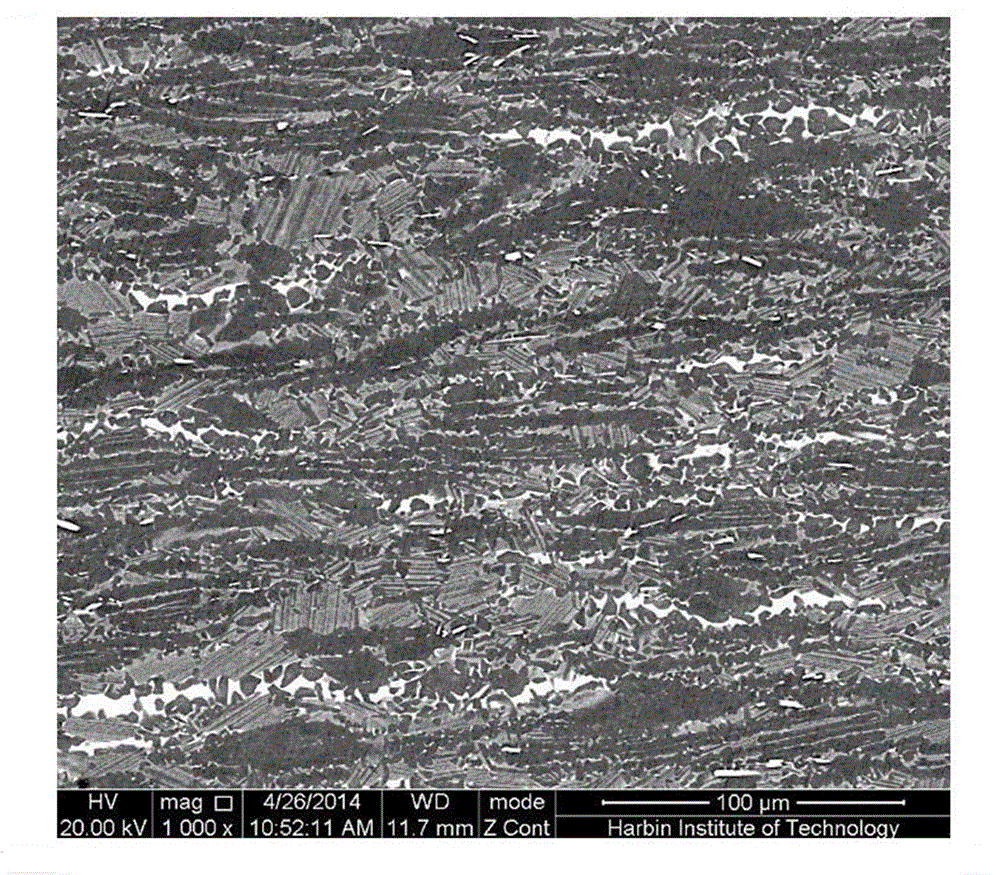

Process for manufacturing type alpha+beta titanium alloy rod bar for rotor impeller vane

InactiveCN101294264AEliminate surface oxidationPrevent surface oxidationTemperature control deviceBlade accessoriesImpellerIngot

The invention relates to an Alpha+Beta type titanium alloy steel bar fabrication technology used on a rotor vane, which comprises the following steps: (1) a cast ingot is heated, and the temperature is risen to 40 to 60 DEG C above a Beta transformation point after entering in a furnace, and the temperature is kept for 10 to 20 hours; (2) the cast ingot is processed through cogging and smithing, each pier drawing deformation amount is controlled between 30 percent to 40 percent; the smithing is performed in a two phase region after the pier drawing, and the total deformation amount is more than or equals to 90 percent; (3) the cast ingot is heated until the temperature reaches 20 to 40 DEG C above the transformation point after returning to the furnace, the temperature is preserved, and then the water quench is performed; (4) after the water quench, stocks are returned to the furnace and heated, and then are heat-preserved in the two phase region; the two phase region smithing is performed in a radial forging machine after the stocks reach a certain temperature, and the lengthening coefficient is controlled between 1.2 to 1.3; (5) after the radial smithing, the stocks is returned to the furnace and heat continuously and then is heat-preserved in the two phase region, then the stocks is rolled on a rolling mill, and the rolling temperature ranges from 910 to 940 DEG C. The Alpha+Beta type titanium alloy steel bar fabrication technology eliminates the figures on a macrostructure and the Beta spots on a microstructure of the heat strong two-phase titanium alloy caused by the hot work, and obtains a small-size two-phase titanium alloy steel bar with a fine and uniform equiaxed two-state structure.

Owner:BAOSHAN IRON & STEEL CO LTD

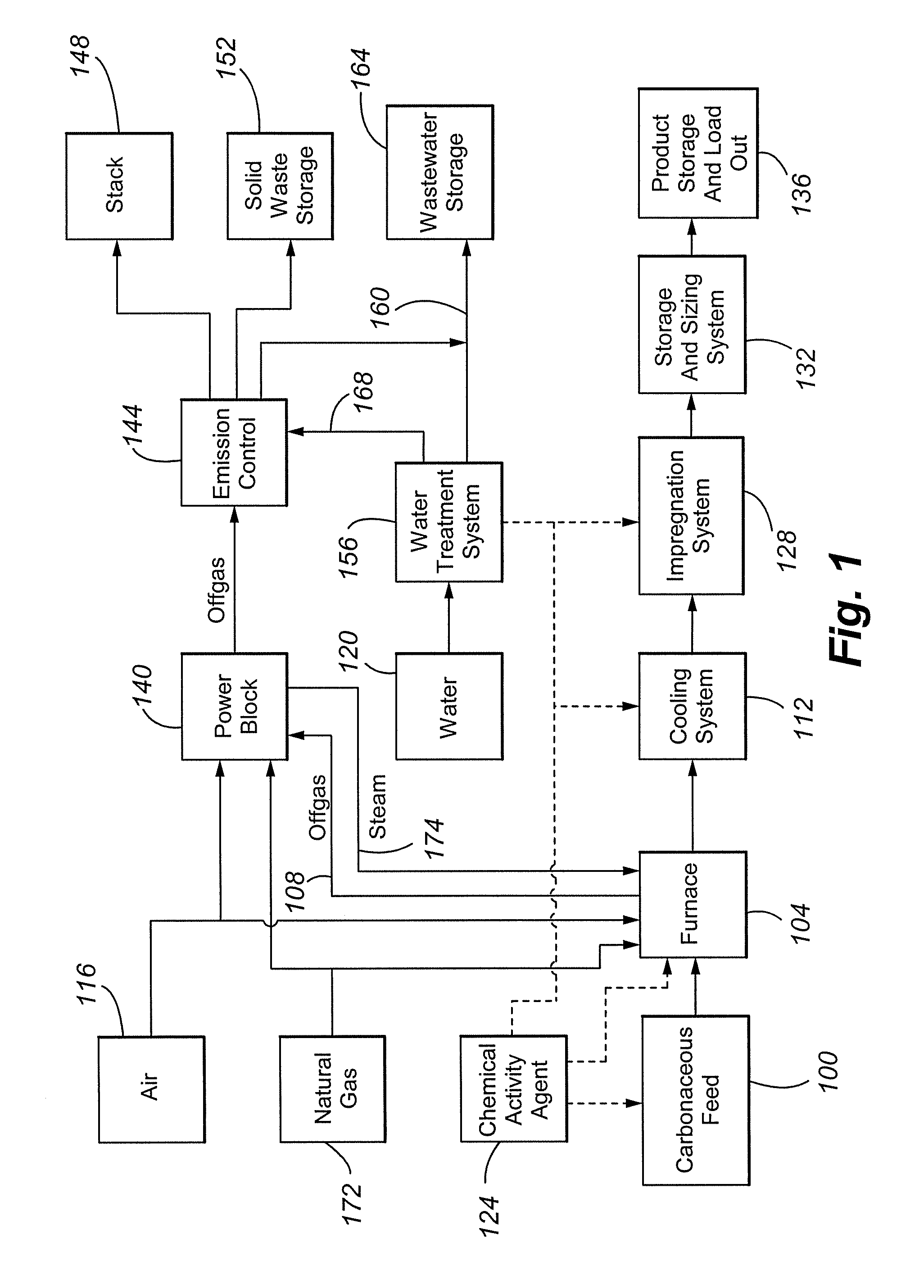

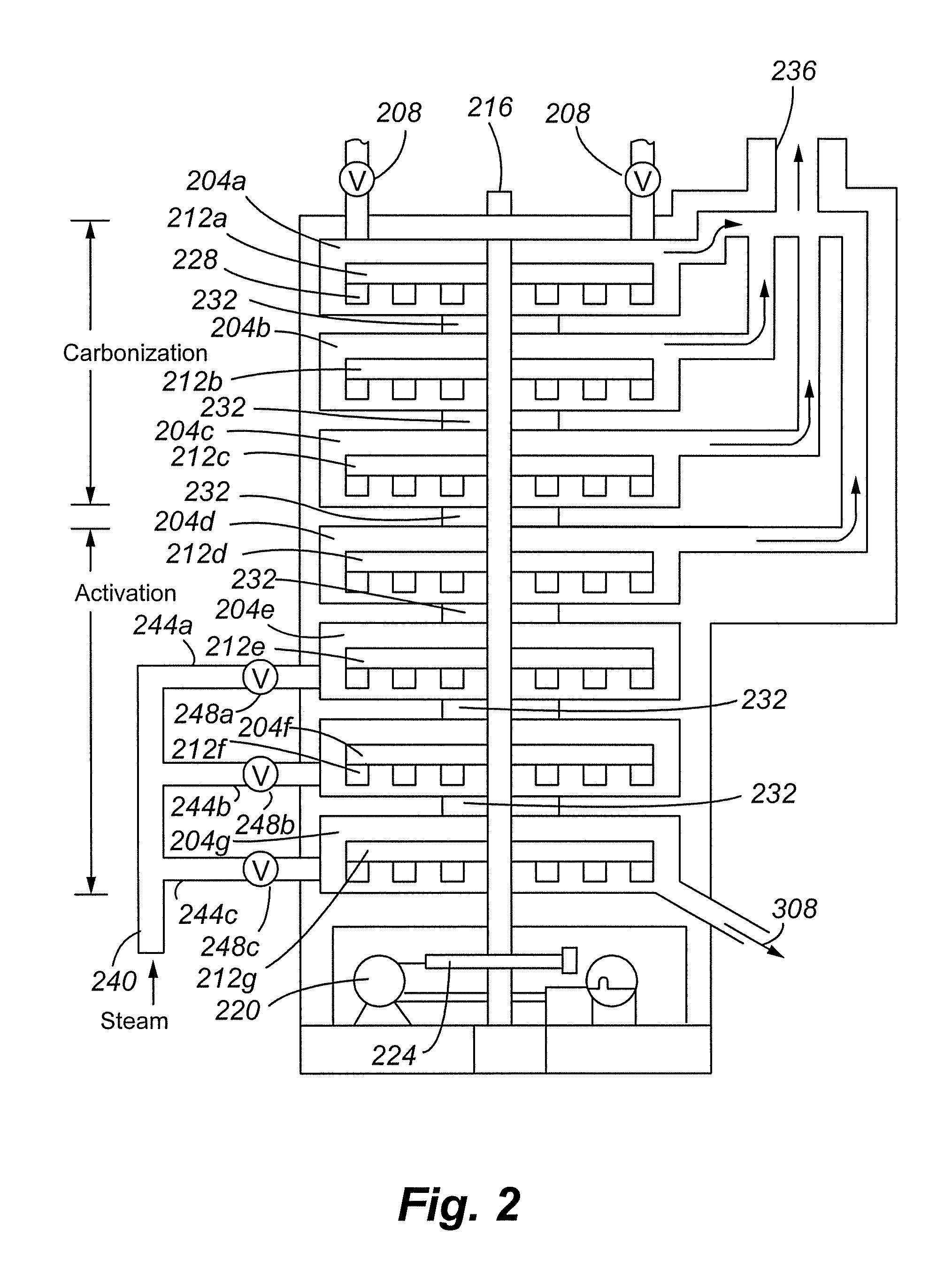

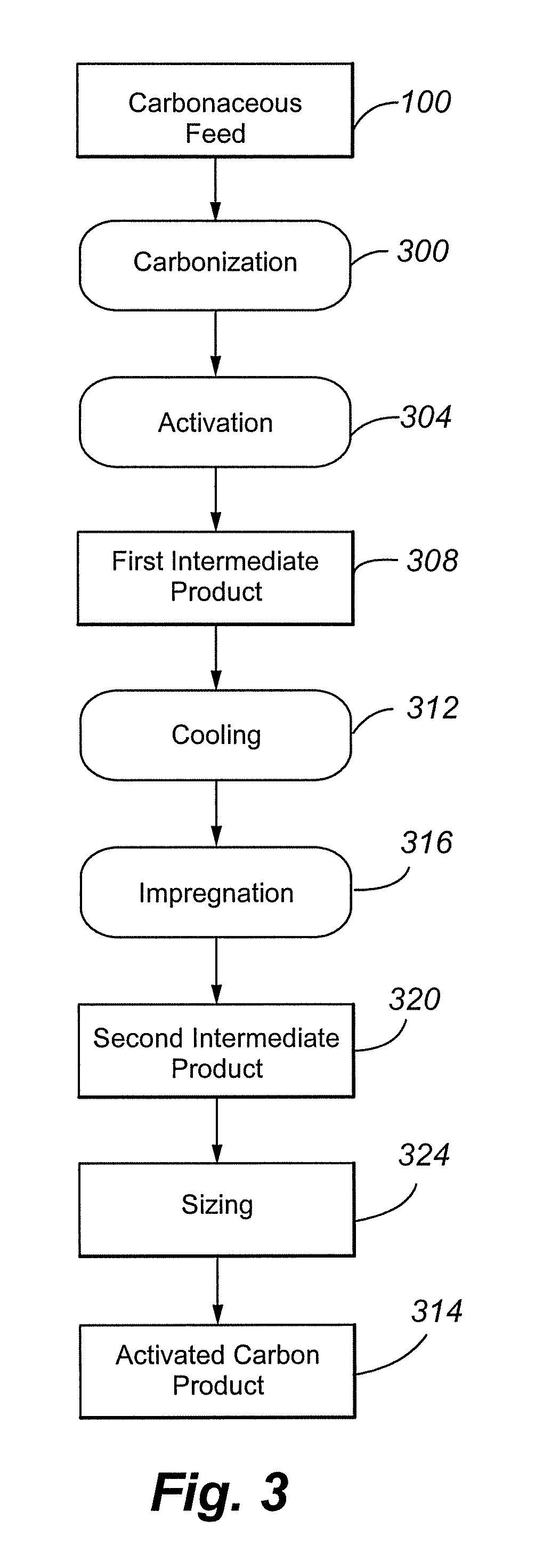

Process for the manufacture of carbonaceous mercury sorbent from coal

InactiveUS20070254807A1Large specific surface areaYield maximizationGas treatmentCarbon compoundsActivated carbonSorbent

The present invention is directed to a process for manufacturing a carbonaceous sorbent, particularly activated carbon, that uses lower average residence times and / or higher operating temperatures to produce activated carbon having favorable properties for mercury collection.

Owner:ADA CARBON SOLUTIONS

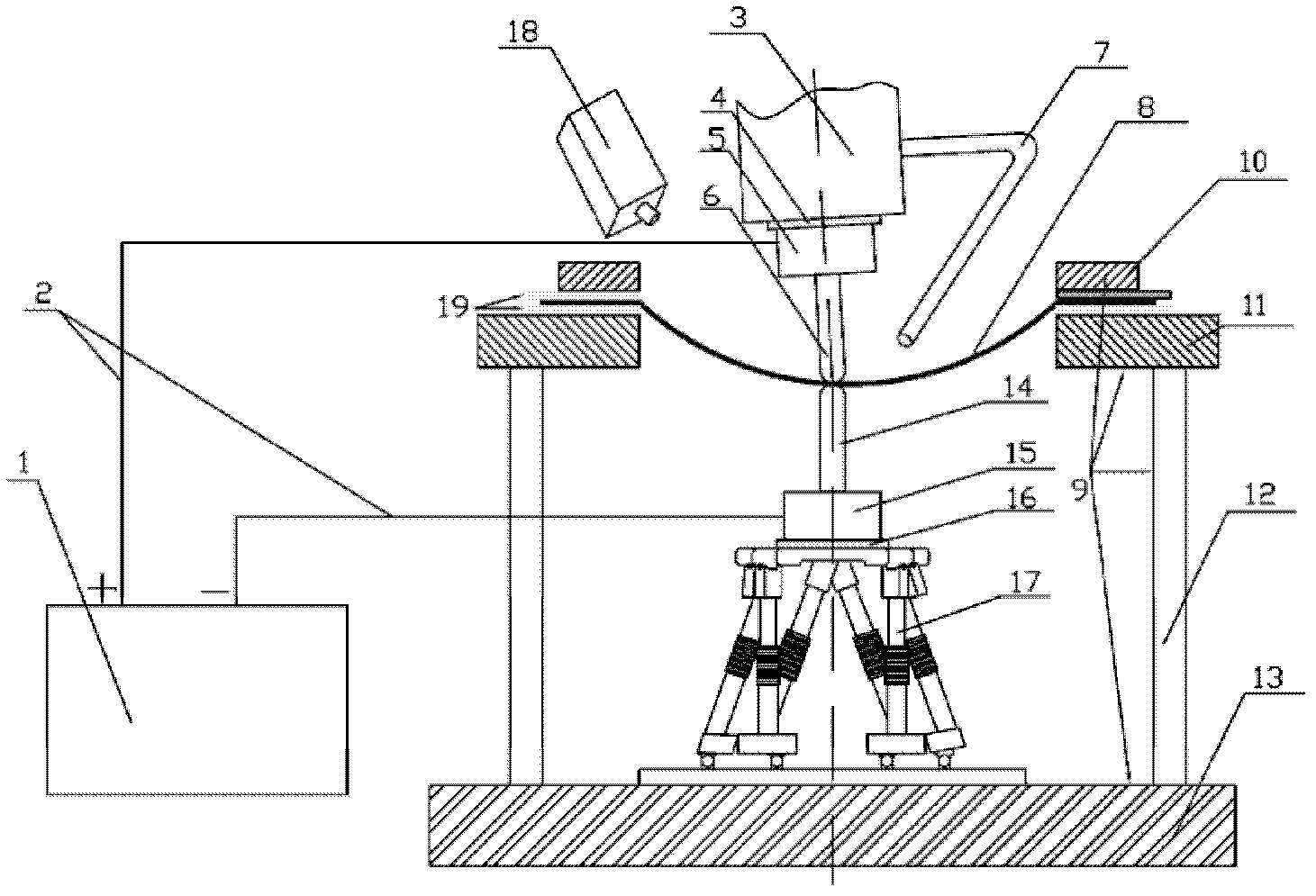

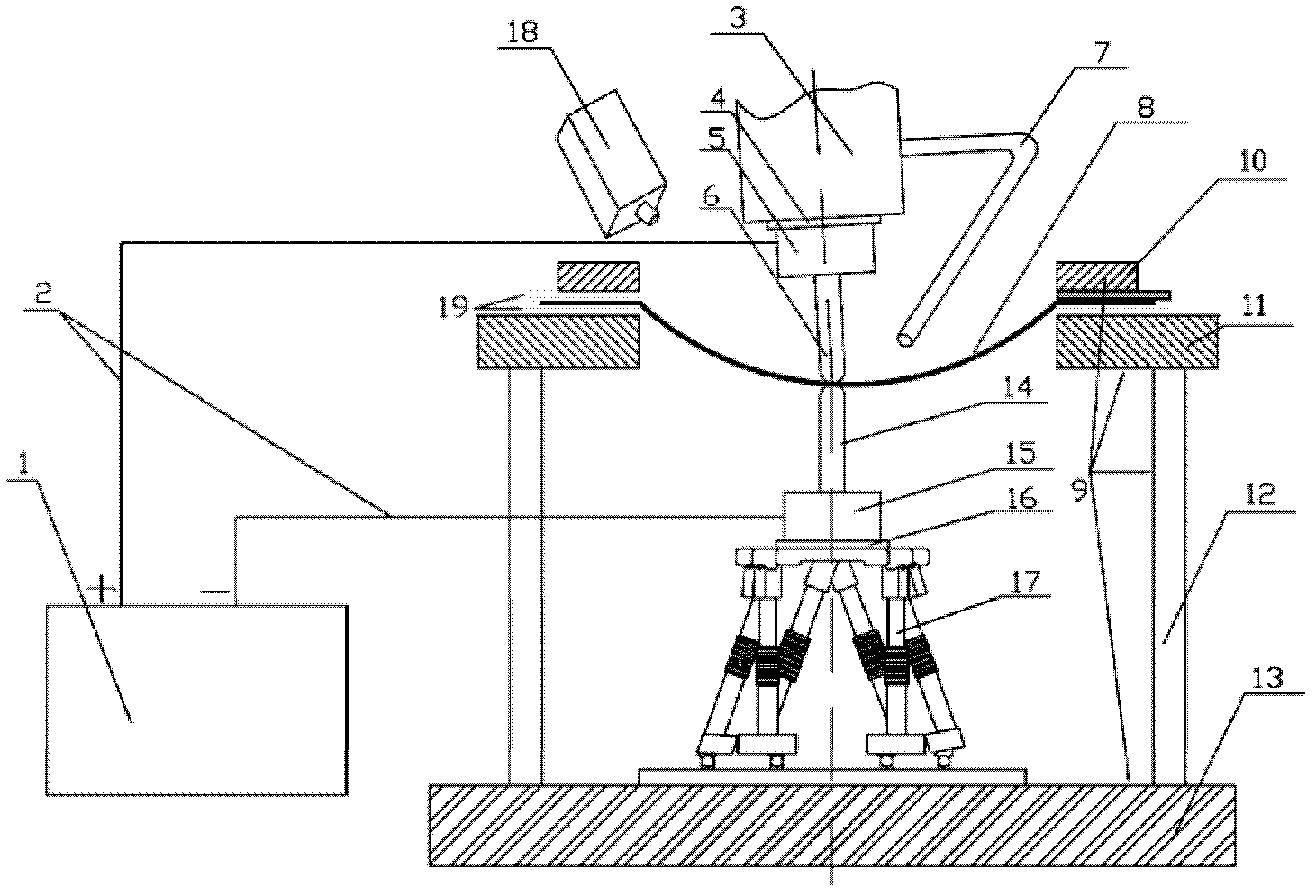

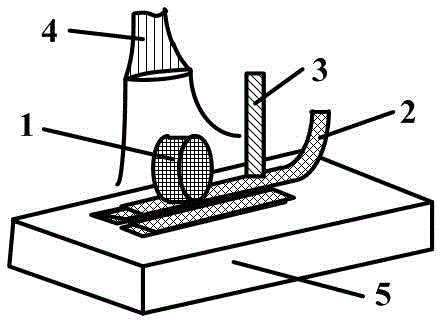

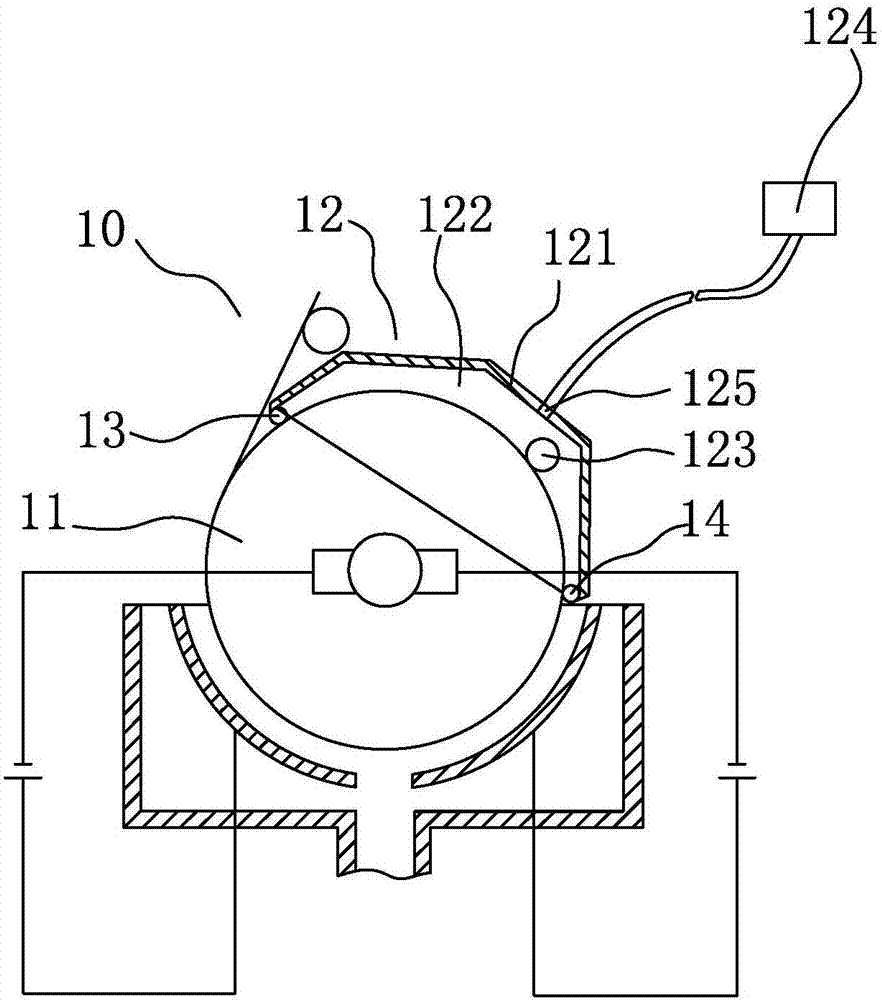

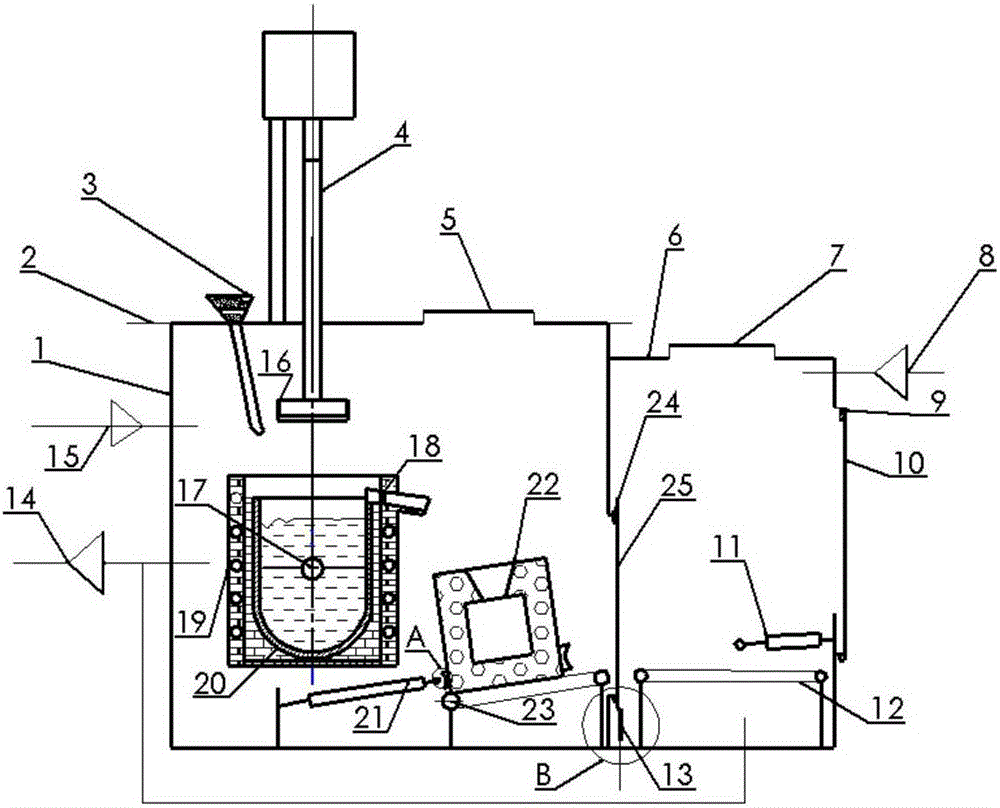

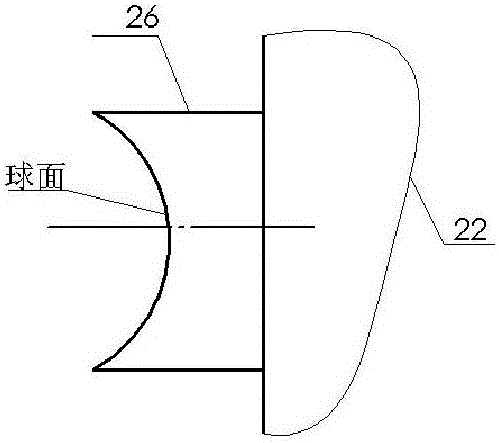

Electroplastic incremental forming device and method for plates

ActiveCN102527830ALower yield stressHigh geometric accuracyMetal-working feeding devicesPositioning devicesNumerical controlHigh energy

The invention relates to an electroplastic incremental forming device and an electroplastic incremental forming method for plates. The device comprises a five-axis numerical control forming machine tool, a six-axis parallel robot machining system, a plate forming clamp, a high energy pulse power supply, an infrared thermometer, and a compressed air cooling system embedded in the machine tool, wherein an upper forming pressing head is arranged at the tail end of a spindle of the five-axis numerical control forming machine tool; the six-axis parallel robot machining system is arranged on a working table of the machine tool; the top of the six-axis parallel robot machining system is provided with a lower forming pressing head; the plate forming clamp is fixed on the working table of the machine tool; positive and negative poles of the high energy pulse power supply are connected with the upper forming pressing head and the lower forming pressing head through high current-carrying conductors respectively so as to form a current loop among the high energy pulse power supply, the upper forming pressing head, the lower forming pressing head and the plates; a camera of the infrared thermometer is aligned with a central area of each plate; and the compressed air cooling system is aligned with a forming area of each plate. Compared with the prior art, the invention has the advantages of high efficiency, energy conservation, high machining precision, high surface quality and the like.

Owner:SHANGHAI JIAO TONG UNIV

Method for controlling pitting on surface of medium steel plate

InactiveCN101704026AGuaranteed performanceReduce incidenceTemperature control deviceWork treatment devicesChemical compositionMetallurgy

The invention discloses a method for controlling pitting on the surface of a medium steel plate, which prevents the surface of the medium steel plate from generating the pitting by controlling the components of a billet and adopting different heating and descaling processes according to different components, wherein the billet comprises the following chemical components in percentage by mass: 0.08 to 0.20 percent of C, 0.13 to 0.20 percent of Si, 0.90 to 1.60 percent of Mn, less than or equal to 0.02 percent of P, less than or equal to 0.02 percent of S, 0 to 0.04 percent of Nb, 0 to 0.018 percent of Ti, 0.02 to 0.05 percent of Alt and the balance of Fe and impurities; for a steel type containing a microalloy, a method for reducing Si content, heating the steel at a high temperature, descaling at the high temperature and fast cooling the steel after rolling the steel is adopted; and for a steel type containing no microalloy, a method for reducing Si content, heating the steel at a low temperature, descaling at the low temperature and fast cooling the steel after rolling the steel is adopted. The method of the invention can substantially clear off primary scales on the surface of the medium steel plate, thereby greatly reducing the occurrence of the pitting on the surface of the medium steel plate, and reducing the energy consumption and production cost and improving the production efficiency and the economic benefit of enterprises while guaranteeing the properties of the steel plate. The method is suitable to be popularized on a national scale.

Owner:NANJING IRON & STEEL CO LTD

Metallic Pigment and Coating Material Containing the Same

InactiveUS20080081864A1Improve corrosion resistanceImprove adhesionPigmenting treatmentChemical recyclingNitrogenDouble bond

Disclosed is a metallic pigment which enables to provide a coating film with very brilliant appearance and excellent corrosion resistance at the same time. Also disclosed is a coating material containing such a metallic pigment. Specifically disclosed is a metallic pigment which is composed of aluminum particles as the base particles whose surfaces are covered with a coating-layer composed of one or more layers. The outermost layer of the coating-layer contains a polymer which is obtained by polymerizing a monomer having a basic group and at least one polymerizable double bond. The monomer may preferably contain nitrogen. The metallic pigment may preferably be provided with a surface modification layer. Also specifically disclosed is a coating material containing such a metallic pigment.

Owner:TOYO ALUMINIUM KK

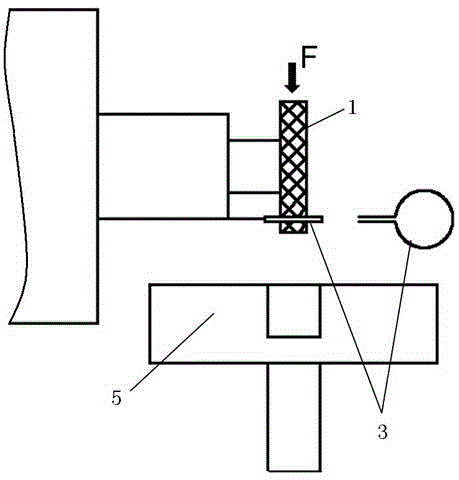

Method and device for auxiliary heating type ultrasound rapid forming

ActiveCN103600166AAvoid formingGuaranteed solid phase junction propertiesNon-electric welding apparatusNumerical controlMetal foil

The invention belongs to the technical field of rapid forming, and particularly relates to a method for achieving multilayer bead welding of metal foil strips through combination of extra auxiliary heating and ultrasonic welding. According to the method, preheating is conducted on metal foil or a base body material in rapid forming, the metal foil or the base body material is softened through preheating conducted by an external heating field, good gas protection is provided, and the welding thickness and width of a metal foil sheet are increased under the condition that the ultrasonic welding power is limited, so that multilayer one-time ultrasonic bead welding or multilayer multi-time ultrasonic bead welding of the metal foil is achieved and a three-dimensional solid block is formed in the solid-phase connection mode. Finally, a machining platform controlled by a numerical control program is applied, so that geometrical characteristic machining of a needed part is achieved. A metal piece obtained according to the method has the advantages of being low in cost, high in efficiency, compact in organization, free of casting-state structure, capable of achieving rapid forming of a functionally gradient material and the like.

Owner:WEIHAI WANFENG MAGNESIUM IND DEV

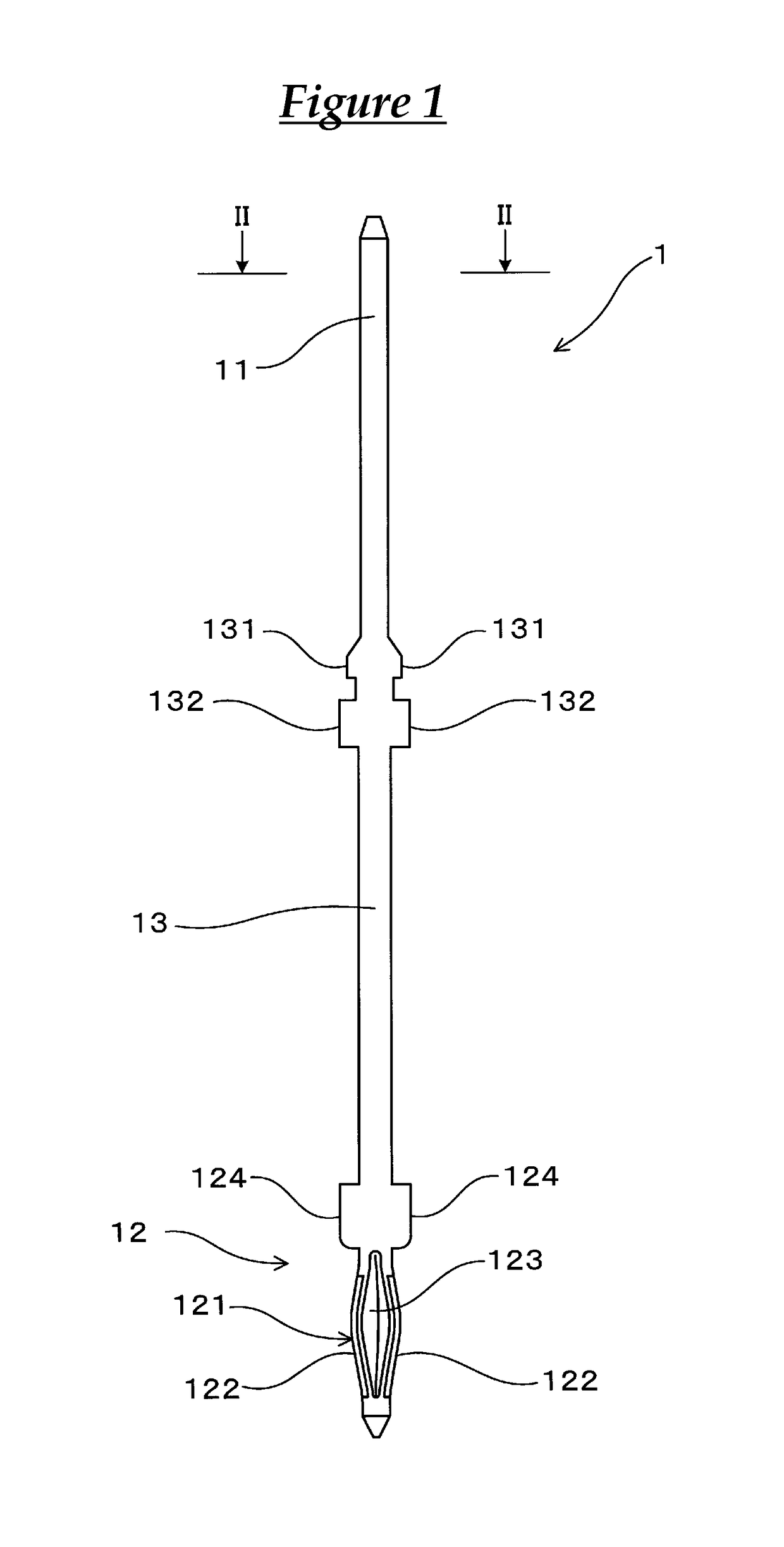

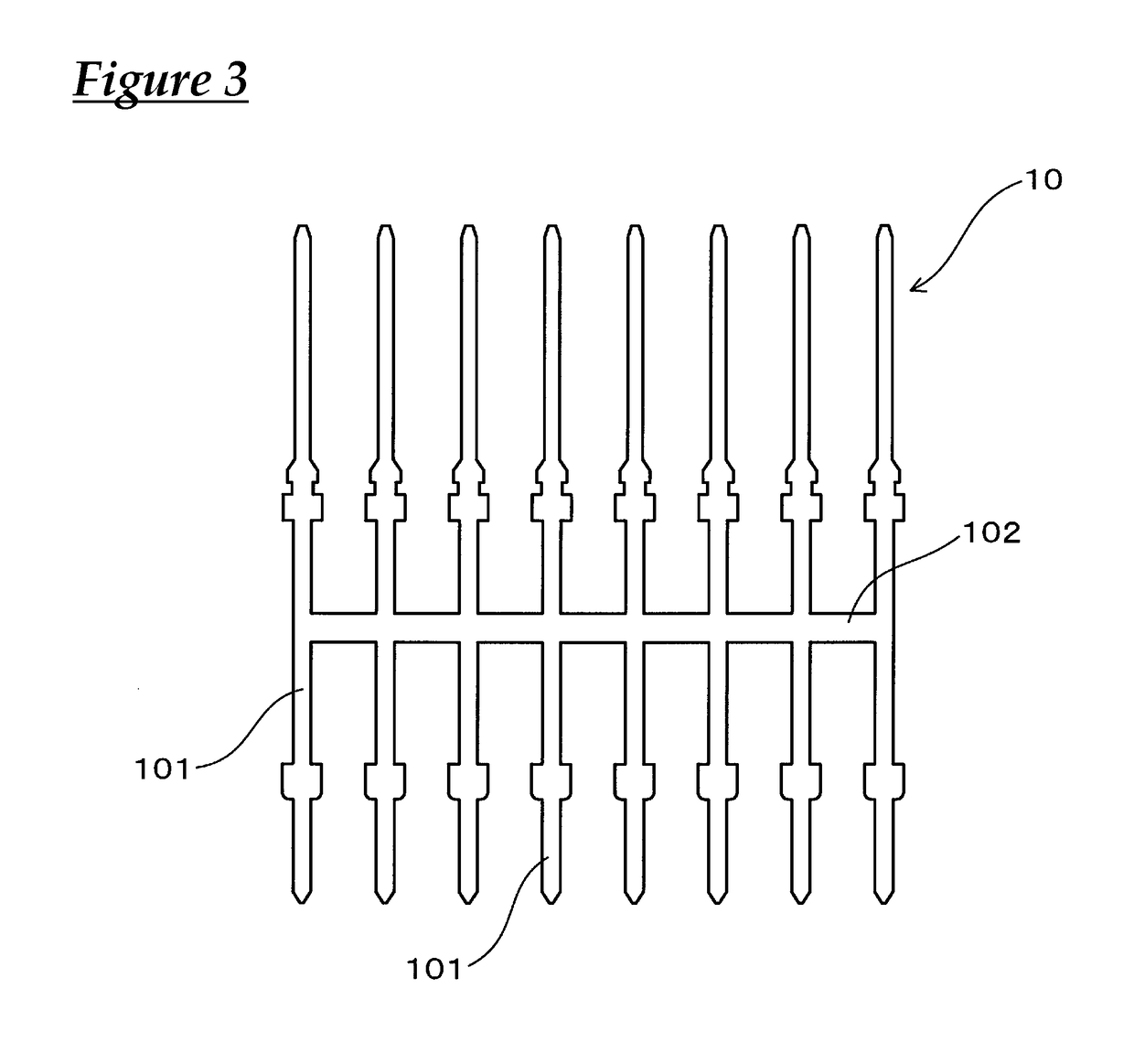

Terminal fitting and connector

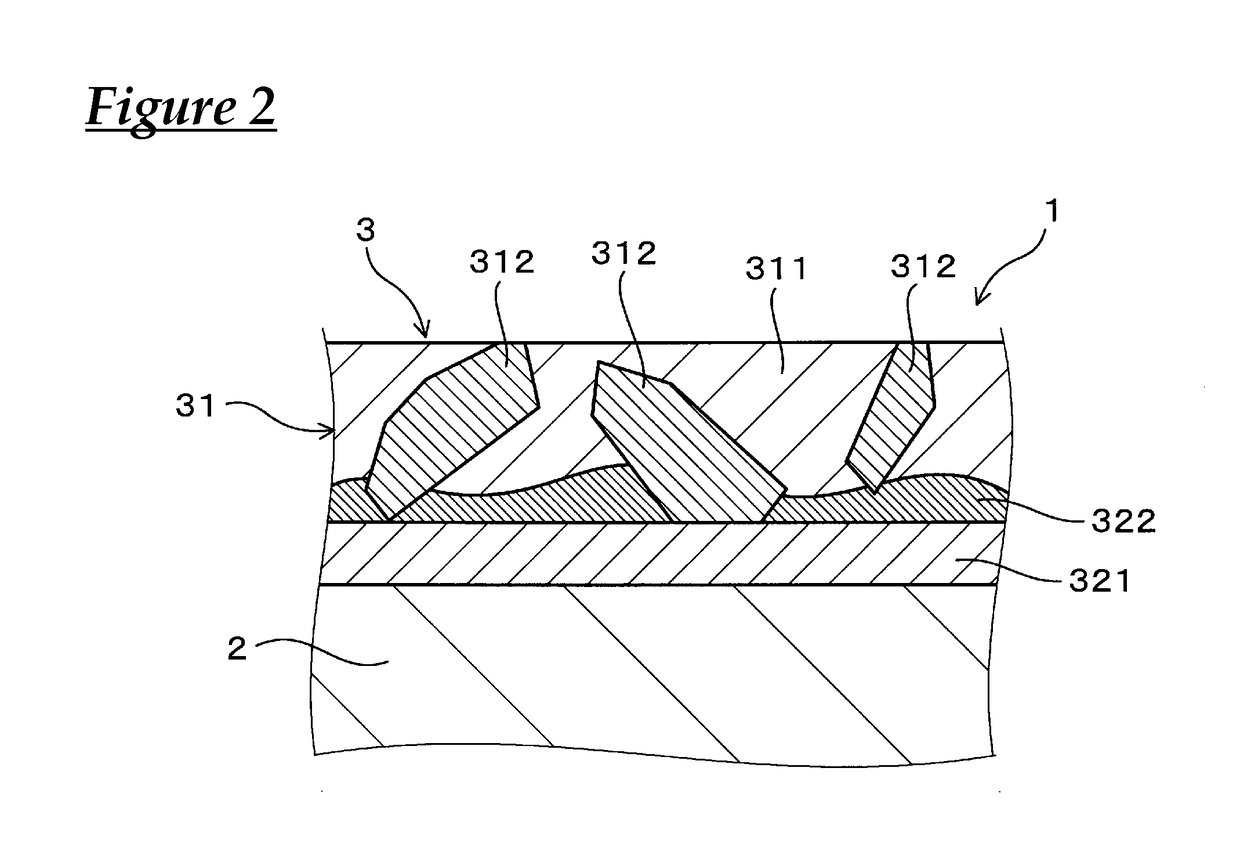

ActiveUS10218102B2Less insertion forcePrevent surface oxidationContact member manufacturingCoupling contact membersSurface oxidationEngineering

A terminal fitting that can reduce the terminal insertion force and can suppress surface oxidation of a plating film, even if the terminal fitting is exposed to a hot and humid environment, and a connector that uses the terminal fitting. The terminal fitting includes a metal base material, and the plating film. The plating film includes a Ni foundation layer, an outermost layer exposed at the outermost surface, and a Ni3Sn4 layer formed between the Ni foundation layer and the outermost layer. The outermost layer includes a Sn parent phase, and intermetallic compound that is dispersed in the Sn parent phase, and is made of (Ni0.4Pd0.6)Sn4. The intermetallic compound protrudes from the lower side of the outermost layer to the Ni3Sn4 layer side, and is partially buried in the Ni3Sn4 layer. A connector includes the terminal fitting, and a housing that holds the terminal fitting.

Owner:AUTONETWORKS TECH LTD +2

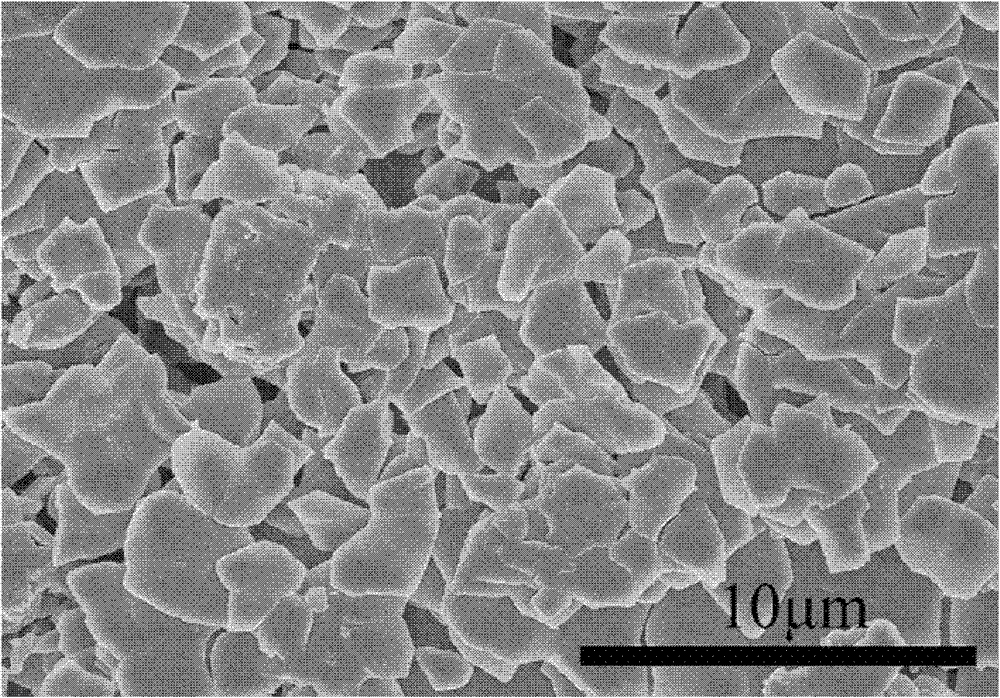

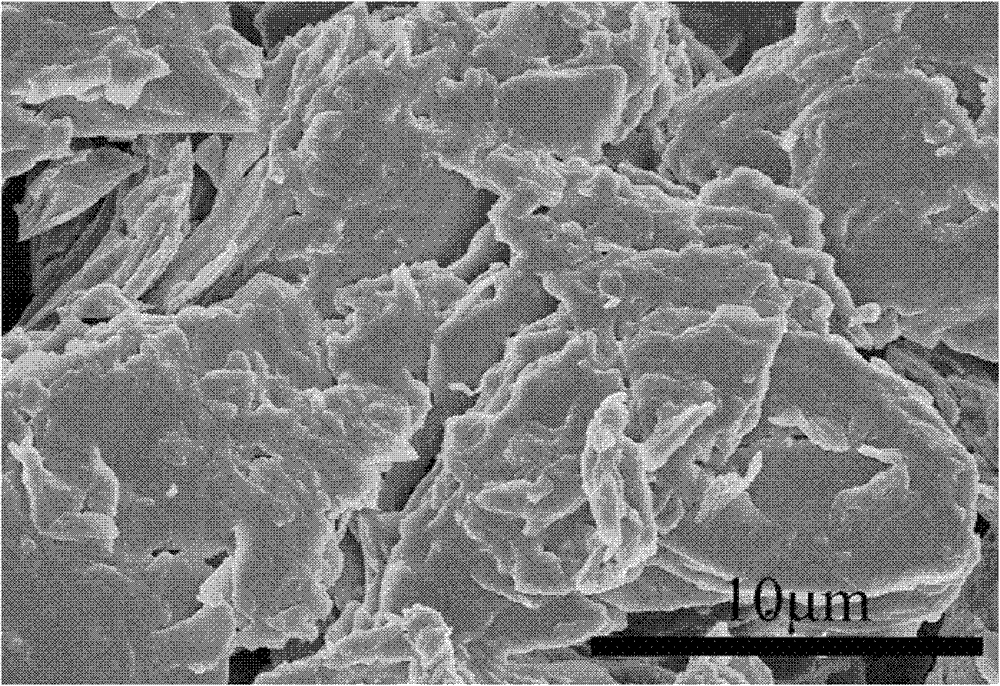

Tin electrodeposits having properties or characteristics that minimize tin whisker growth

InactiveUS20070007144A1Minimizing and preventing tin whisker formationMinimizing and preventing and growthSemiconductor/solid-state device detailsPrinted circuit aspectsCorrosion reactionMaterials science

A method of reducing tin whisker formation by creating a tin deposit which is inherently less prone to tin whisker formation or growth facilitated by oxide presence or corrosion reactions on the tin deposit surface. This is obtained by one or more of: (i) the deposition of a fine-grained tin deposit having an average grain diameter in the range of 0.05 to 5 microns; (ii) a phosphorous compound in the solution that is used to electroplate the tin deposit so that that the deposit incorporates trace amounts of phosphorous which in turn reduces tin whisker formation by preventing surface oxides even when exposed to heat or humidity; or (iii) a phosphorous compound, mercaptan, or organic or organo-metallic compound in a solution that applies a protective coating to the surface of a previously electroplated tin deposit, wherein the protective coating acts to minimize or prevent oxide formation or corrosion of the tin deposit during exposure to heat or humidity. Such tin deposits containing 80% to 100% by weight of tin exhibit minimal to no tin whisker growth.

Owner:TECHNIC INC

Preparation method of silicon carbon lithium ion battery cathode material

ActiveCN102790204AImprove cycle performanceIncrease capacityCell electrodesSurface oxidationFreeze-drying

The invention provides a preparation method of a silicon carbon lithium ion battery cathode material, which comprises the following steps: a) mixing a polymer solution, silicon powder and graphite to obtain a mixed solution; b) performing freeze drying of the mixed solution to obtain a solid mixture; c) sintering the solid mixture to obtain the silicon carbon lithium ion battery cathode material. The invention adopts freeze drying instead of a common drying method; the freeze drying means freezing the material, allowing the solvent component to rapidly become a solid state and to directly sublime under a vacuum condition so as to reach the drying purpose. With the process, the composite material and a carbon source can rapid coagulate within a short period, which avoids the problems of surface oxidation of the silicon material caused by normal temperature drying or high temperature drying, and non-uniform coating caused by settlement of the composite material powder. The obtained carbon-coated material has improved recycle performance and capacity when compared with materials obtained by common drying.

Owner:宁波富理电池材料科技有限公司

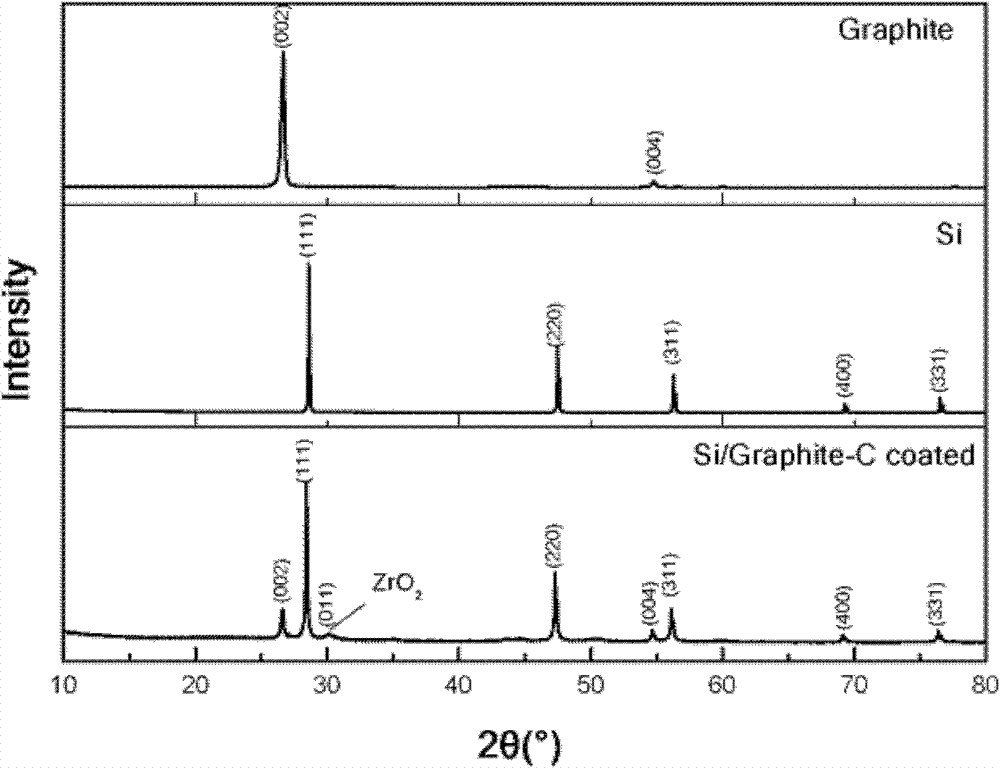

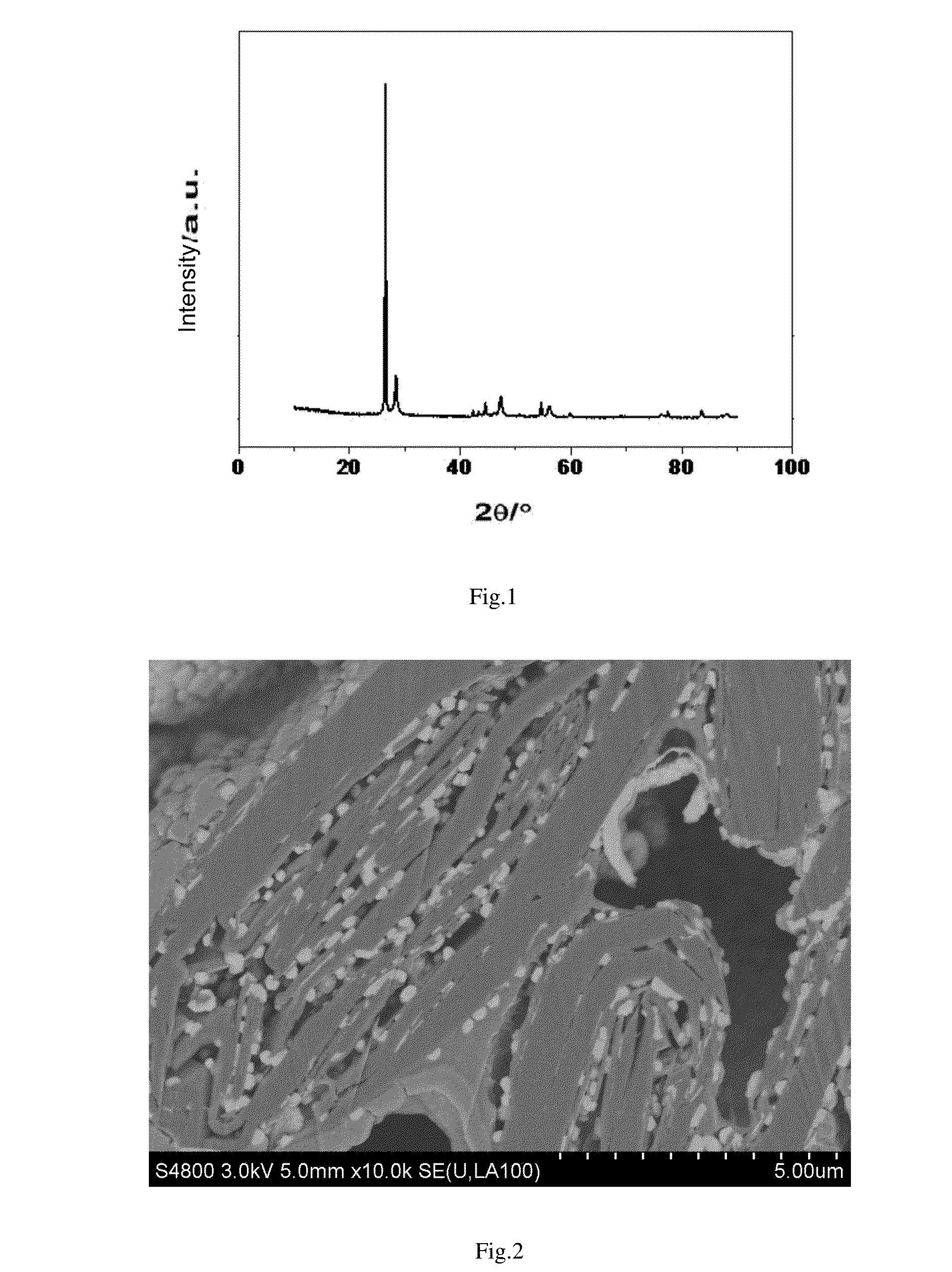

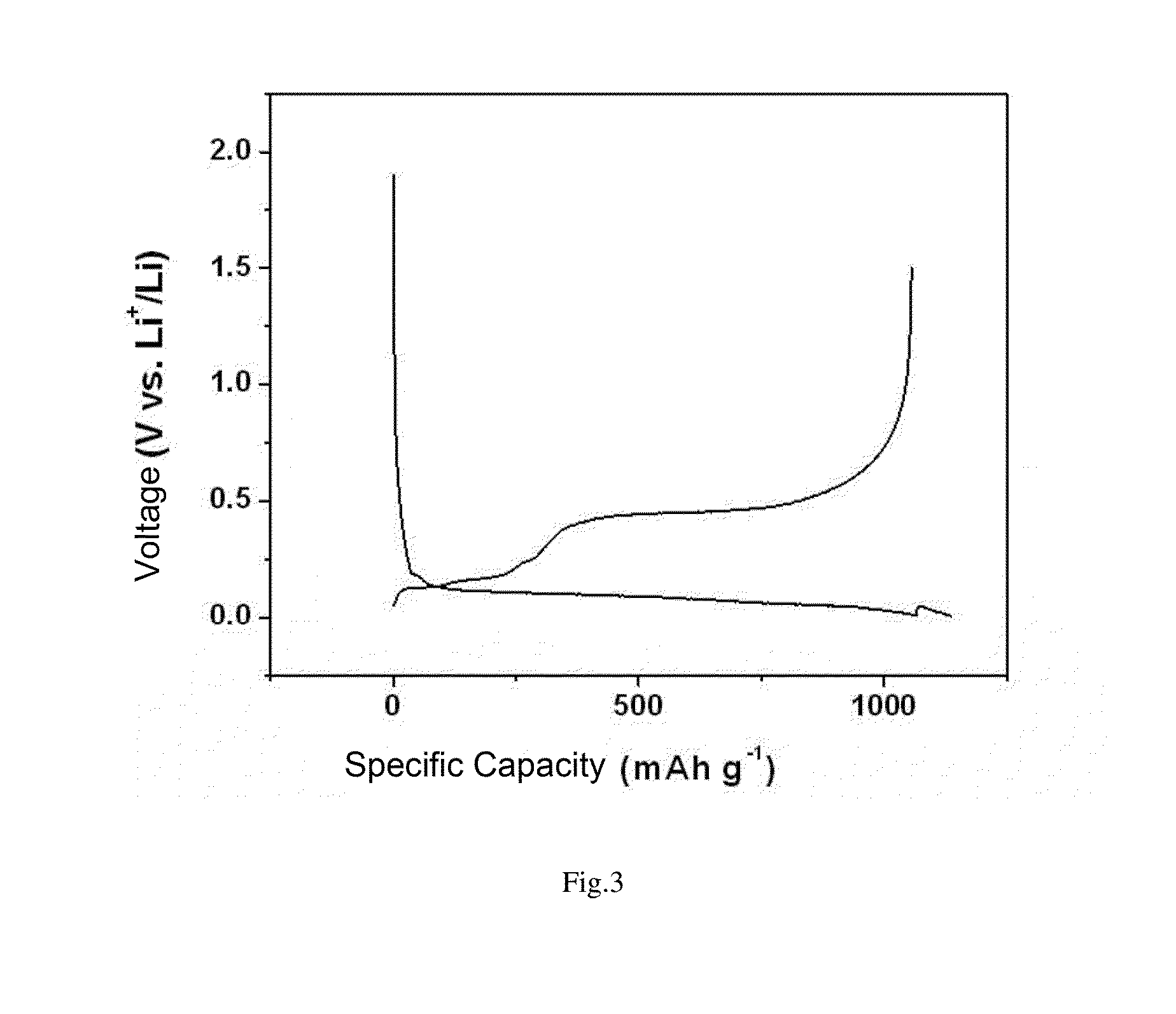

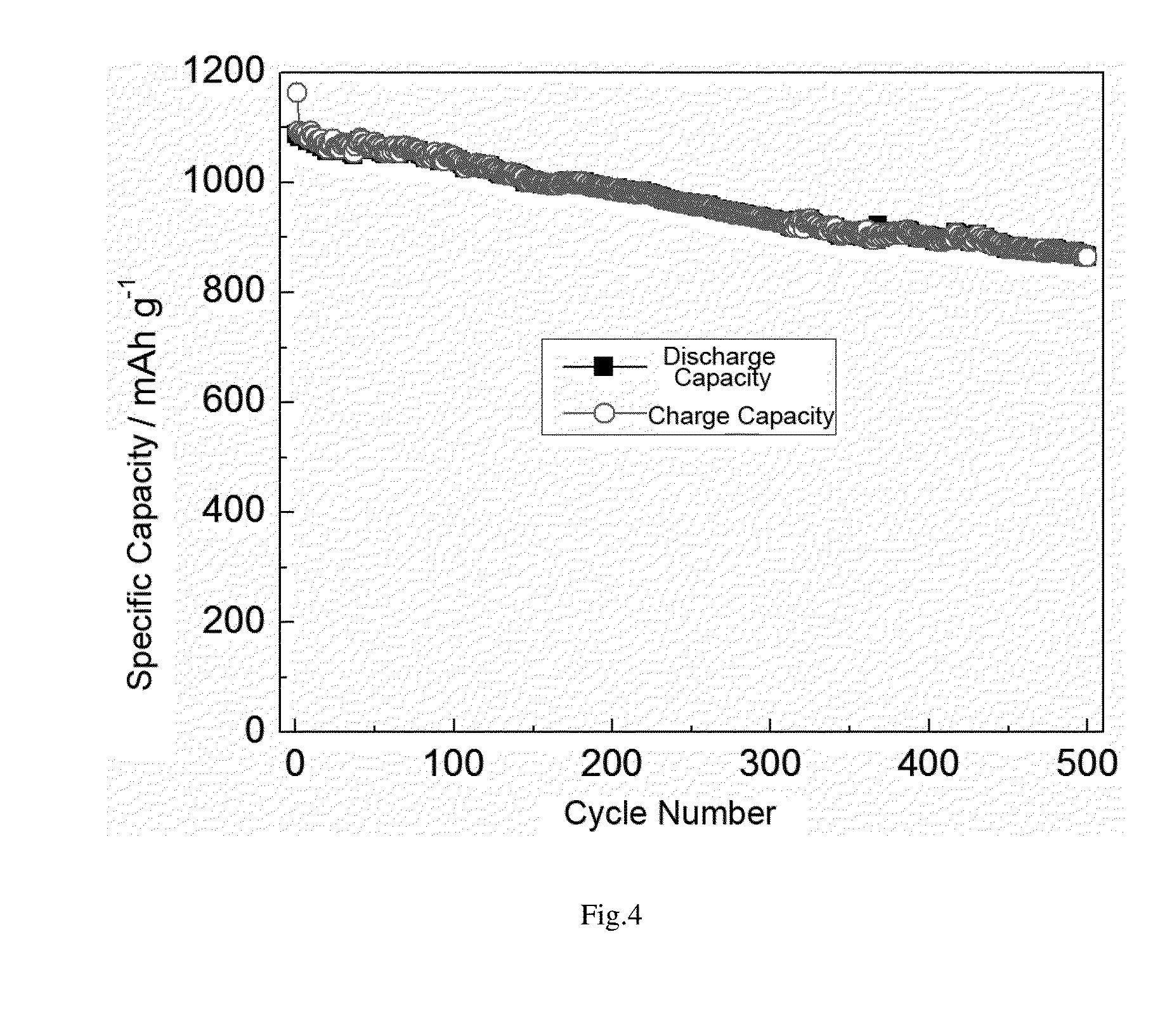

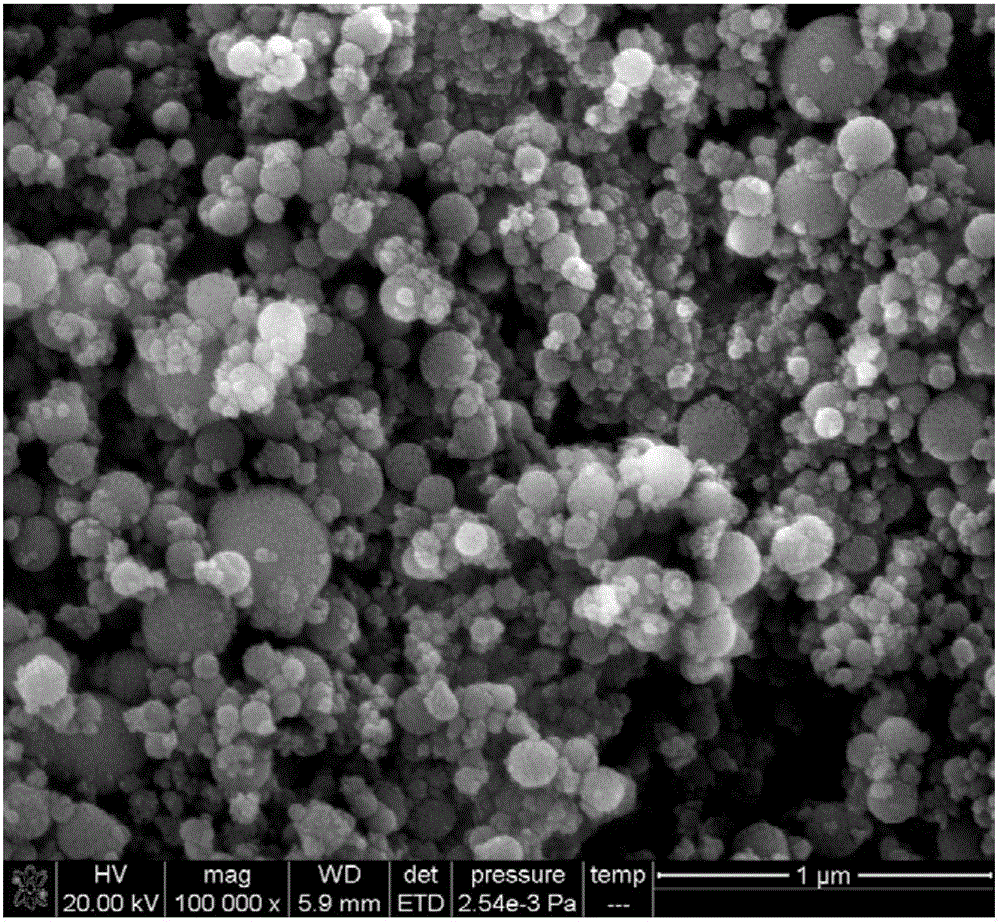

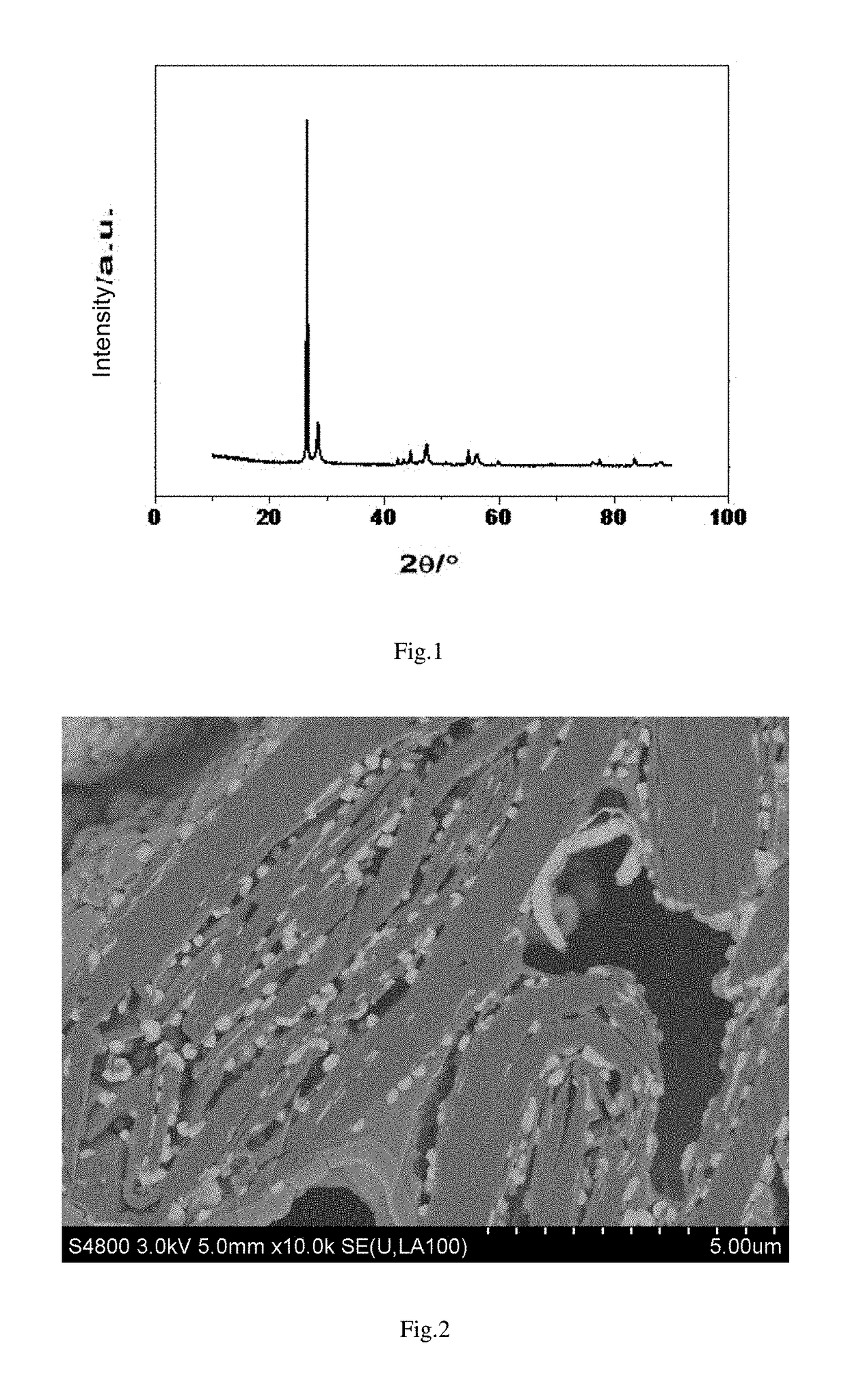

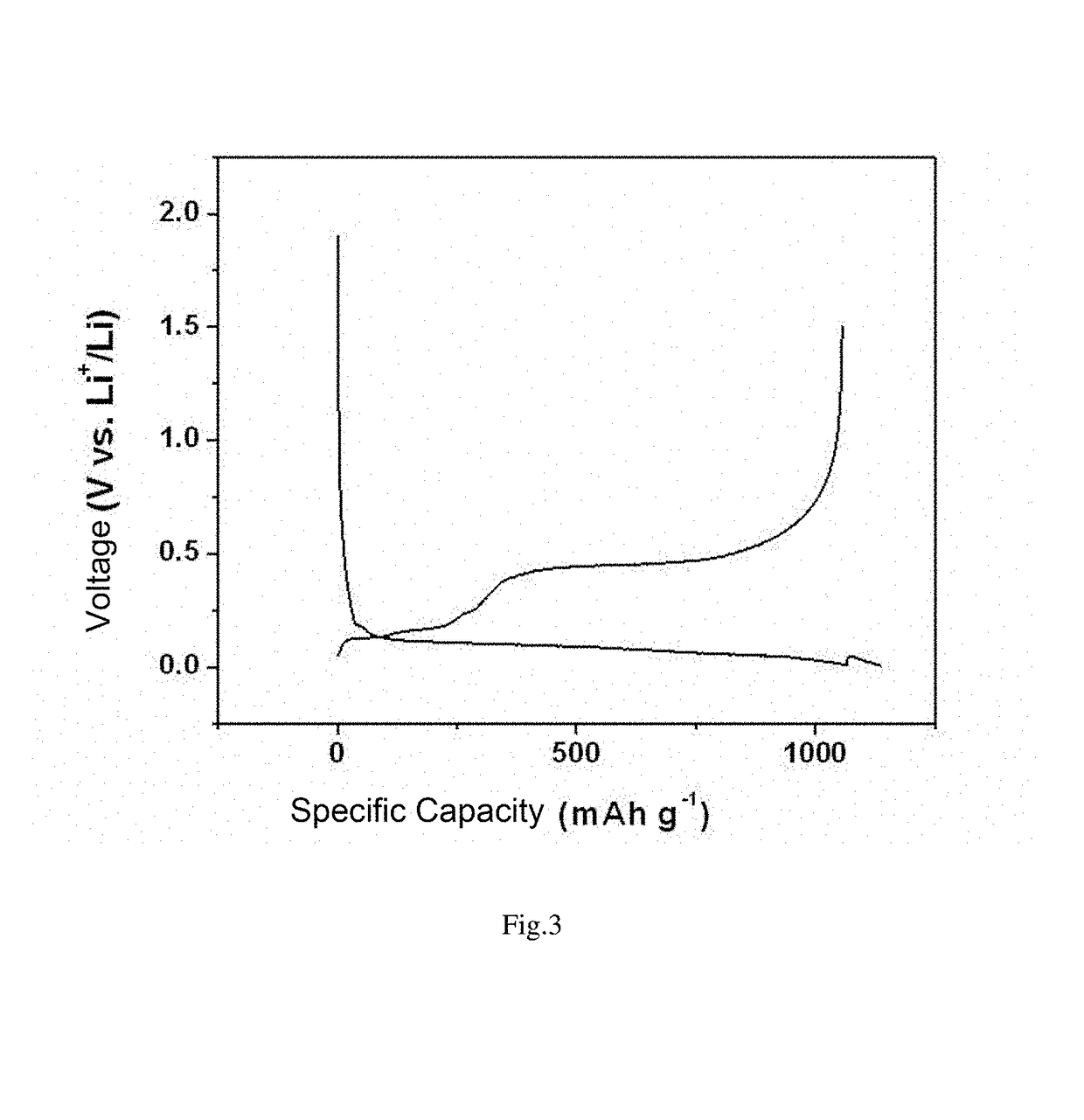

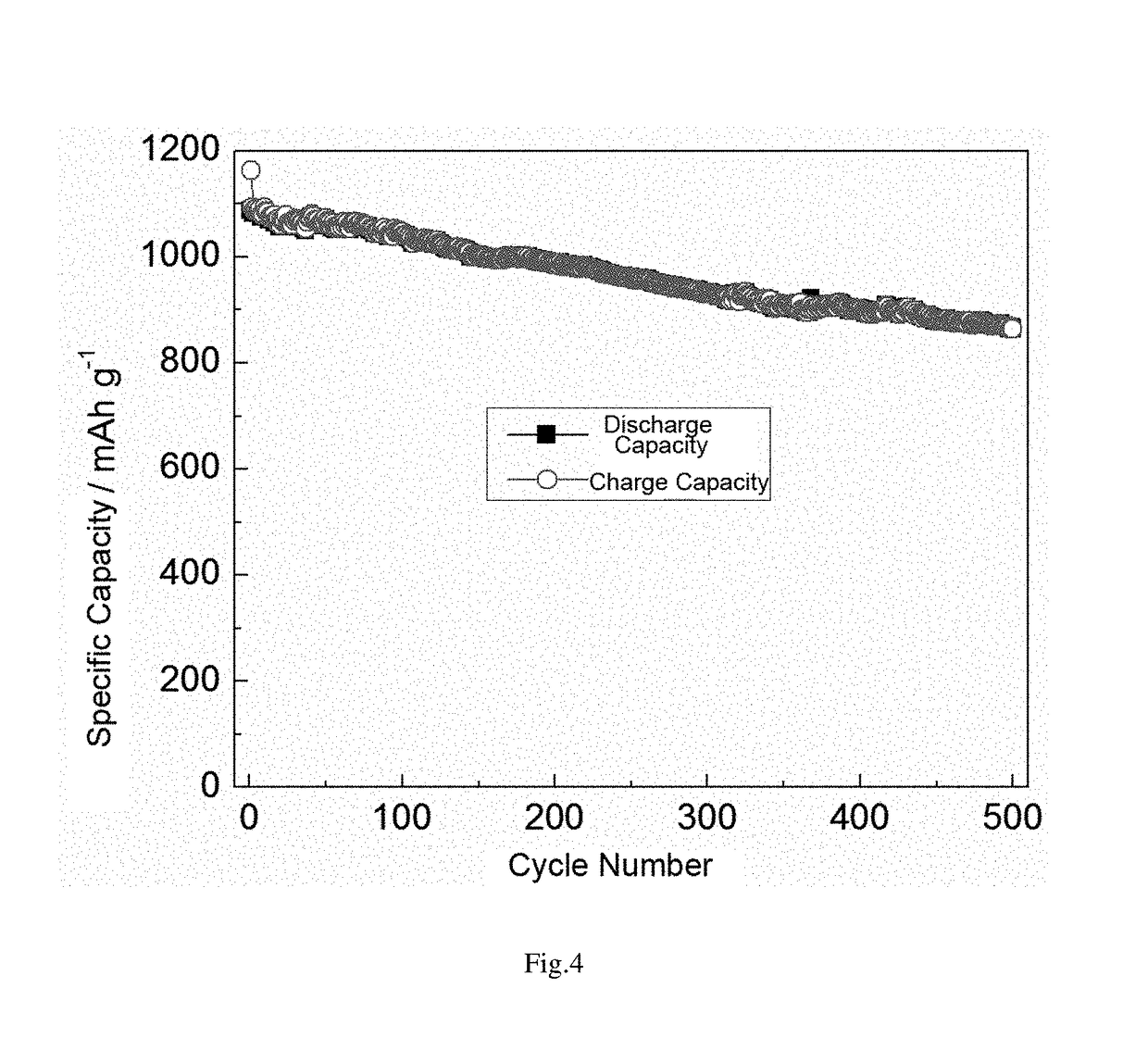

Nano-silicon composite negative electrode material used for lithium ion battery, process for preparing the same and lithium ion battery

ActiveUS20160211511A1Large capacityImprove efficiencyMaterial nanotechnologyElectrode thermal treatmentNano siliconGas phase

The present invention relates to a nano-silicon composite negative electrode material, including graphite matrix and nano-silicon material homogeneously deposited inside the graphite matrix, wherein the nano-silicon composite negative electrode material is prepared by using silicon source to chemical-vapor deposit nano-silicon particles inside hollowed graphite. The nano-silicon composite negative electrode material of the present invention has features of high specific capacity (higher than 1000 mAh / g), high initial charge-discharge efficiency (higher than 93%) and high conductivity. The preparation process of the present invention is easy to operate and control, and has low production cost and is suitable for industrial production.

Owner:BTR NEW MATERIAL GRP CO LTD

Spectral standard sample of Al-Li alloy and its prepn

InactiveCN1403613AAvoid burnsPrevent surface oxidationPreparing sample for investigationAnalysis by material excitationIngotLi element

The present invention is a spectral standard sample of Al-Li alloy and its preparation process. The present invention features the alloy contains the following chemical elements dispersed homogeneously in aluminum: Si 0.025-0.223 wt%, FE 0.044-0.264 wt%, Cu 0.0019-1.61 wt%, Mg 0.193-6.000 wt%, Li 0.930-2.530 wt%, Zr 0.042-0.168 wt%, Zn 0.023-0.205 wt%, Ti 0.0026-0.134 wt% and Mn 0.015-0.139 wt%. The present invention can avoid the burn loss and surface oxidation of Li element to ensure the correct ratio of Li element in the standard sample. The intermittent semi-continuous casting process prevents the cracking of the alloy ingot.

Owner:SOUTHWEST ALUMINUM GRP

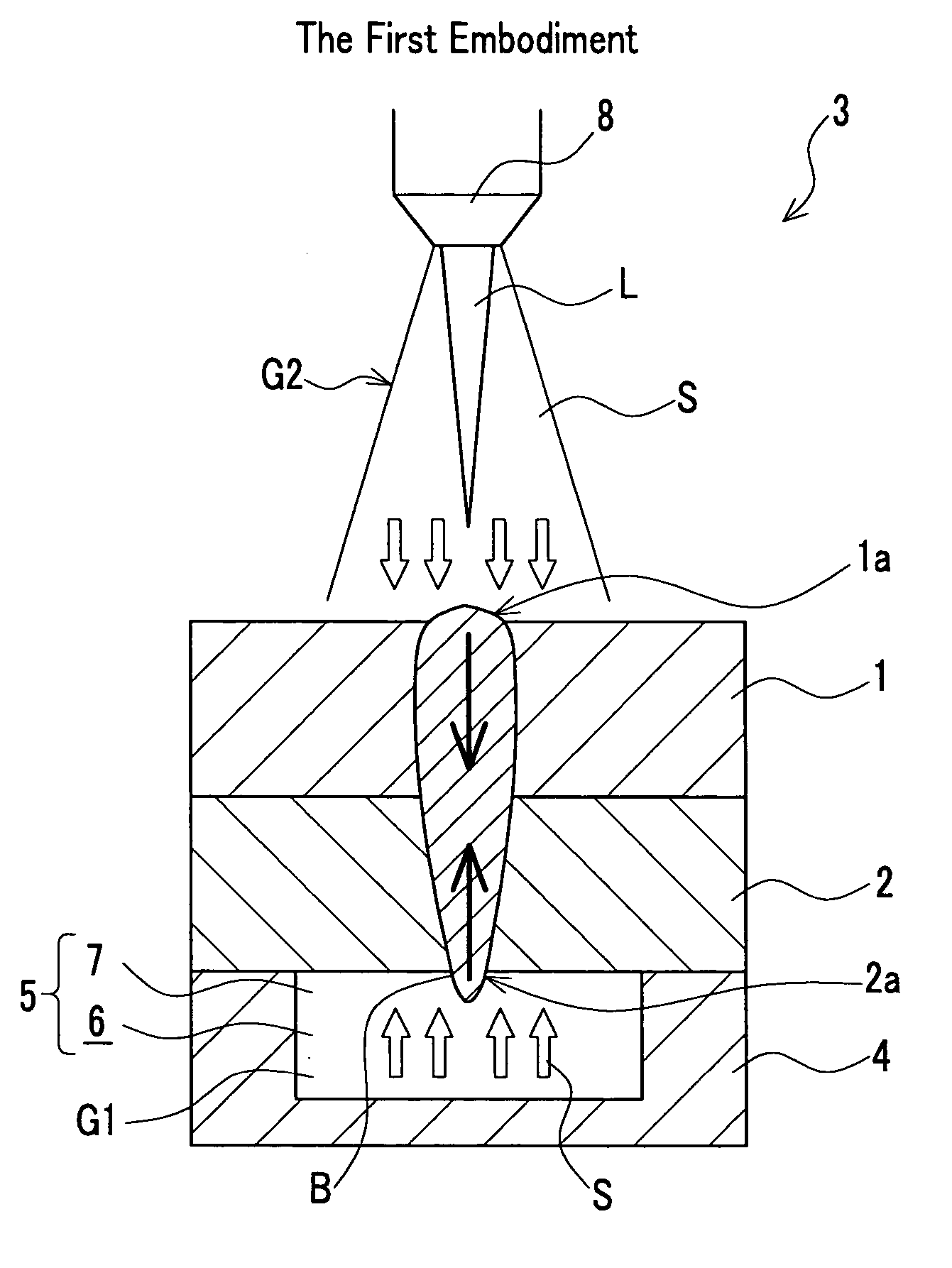

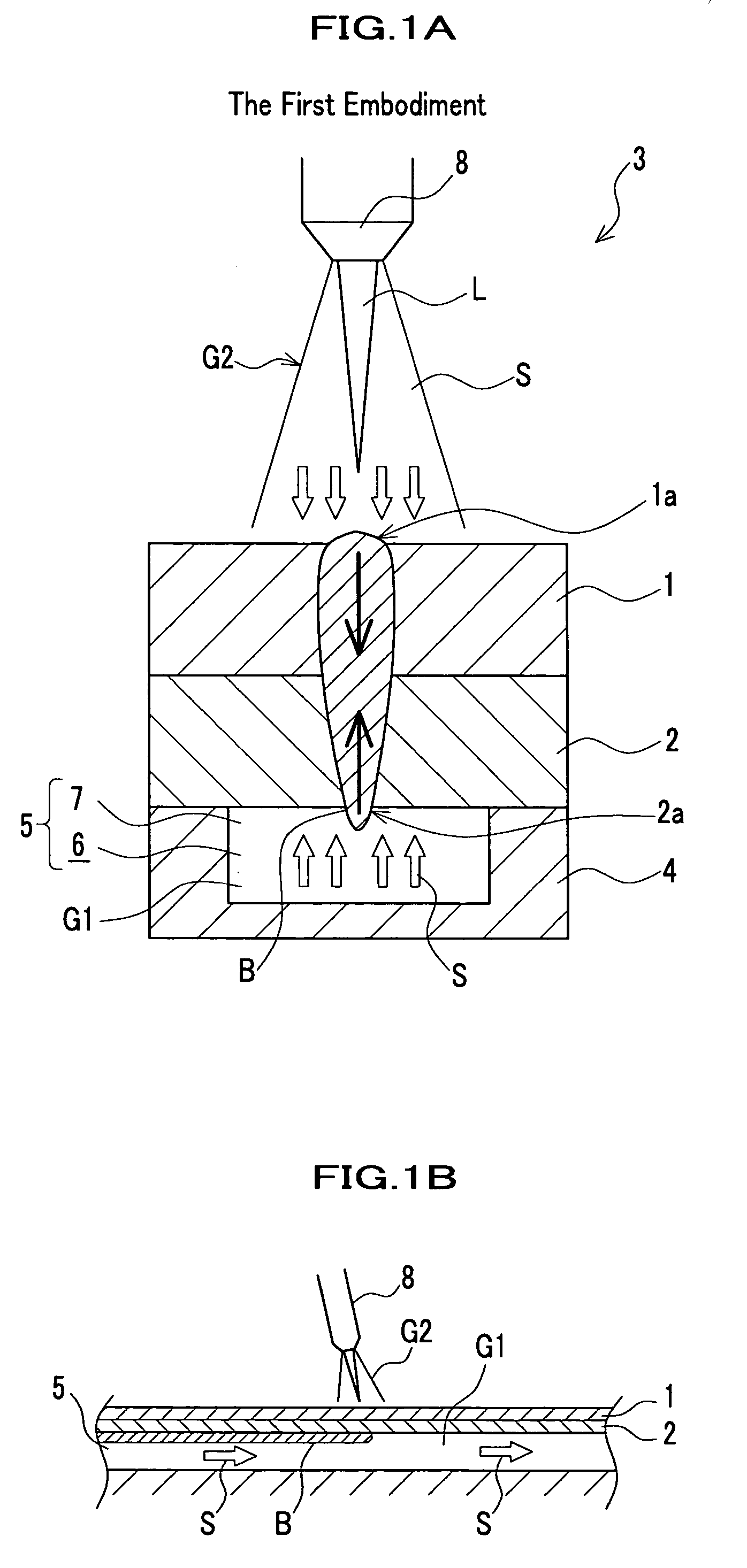

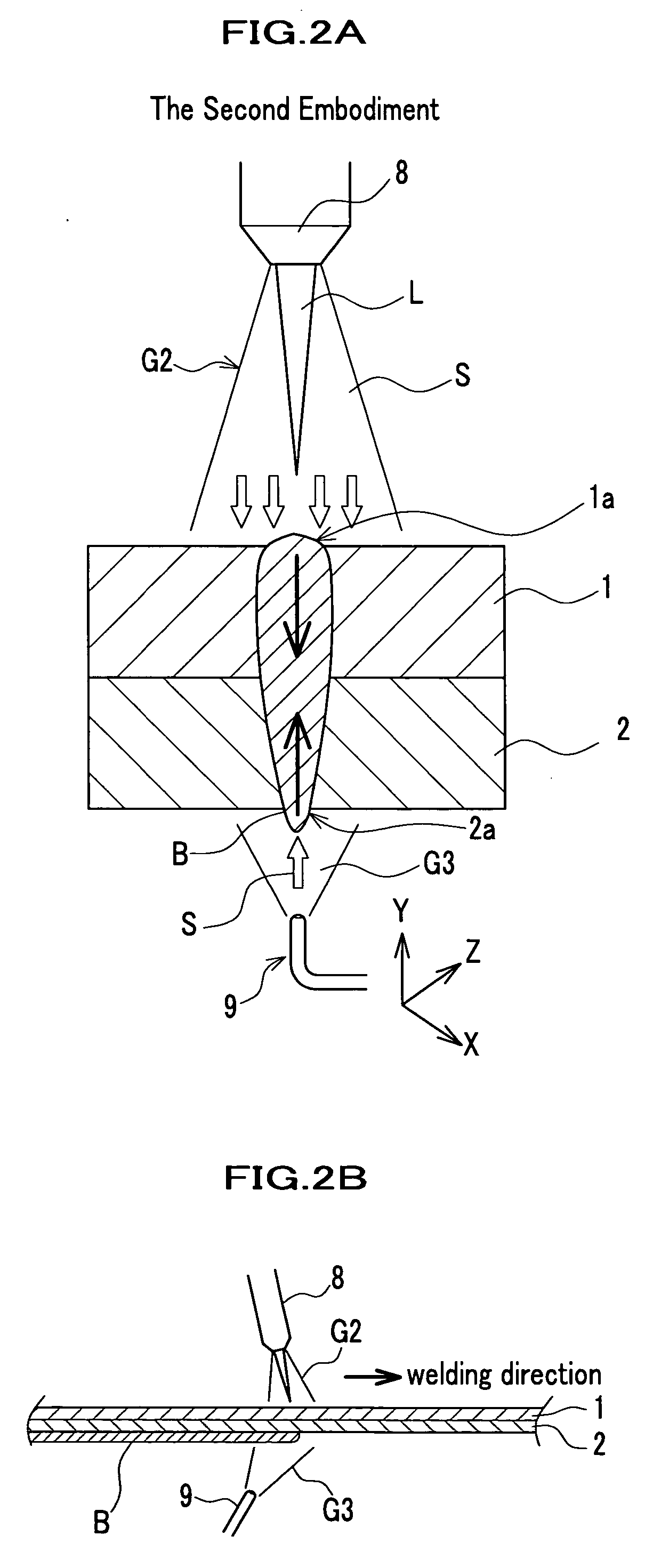

Through weld for aluminum or aluminum alloy base metals by using high-density energy beams

InactiveUS20040084425A1Avoid formingHigh bonding strengthElectron beam welding apparatusWelding/soldering/cutting articlesHigh energyShielding gas

This invention provides a new through weld method to carry out welding of a base metal made of aluminum or that of aluminum alloy using high energy beams wherein a shield gas ambience (an inert gas ambience) to cover a welding site in a submerged-scar is formed, even a shield gas ambience (an inert gas ambience) to cover a welding site irradiated by the high energy beams. Since the former shield gas ambience to cover the submerged-scar pushes the keyhole against the gravity and / or the gas pressure force of the latter shield gas supplied to the laser irradiation side, then the forming of hang down of beads and the resultant projection of the welding base metal are prevented.

Owner:HONDA MOTOR CO LTD

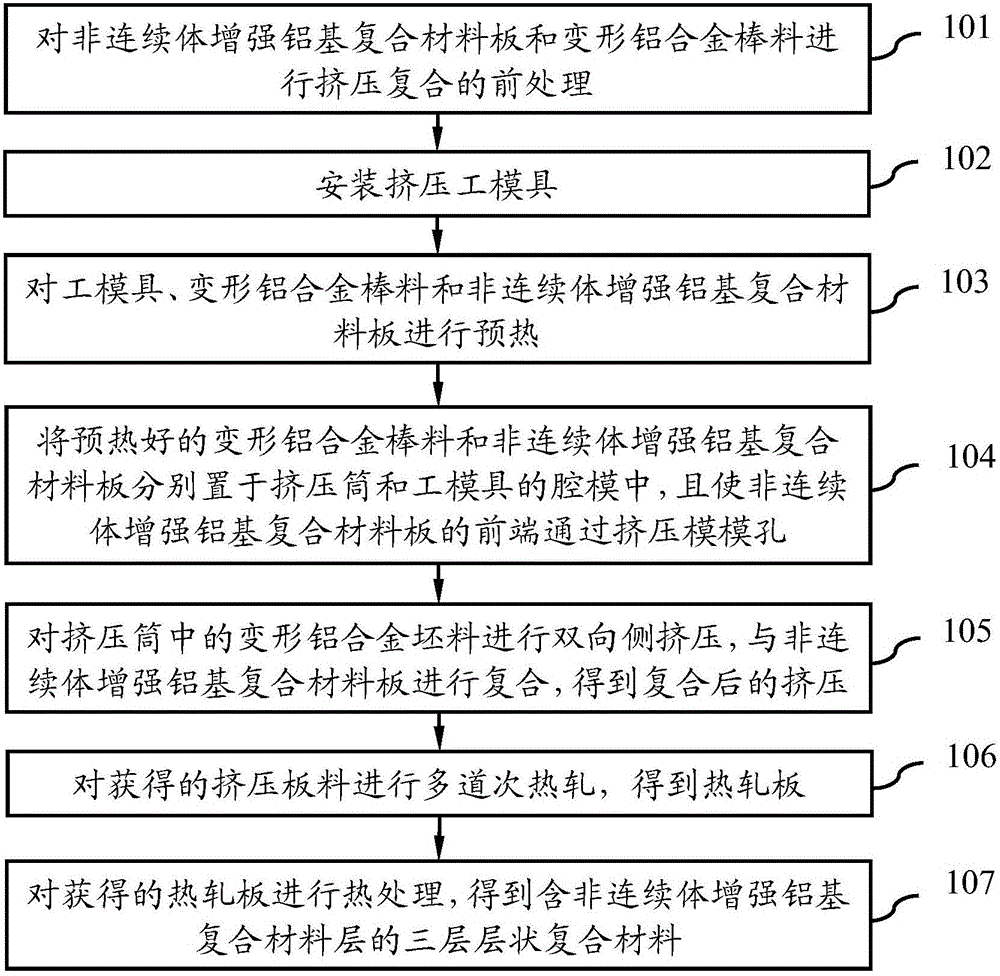

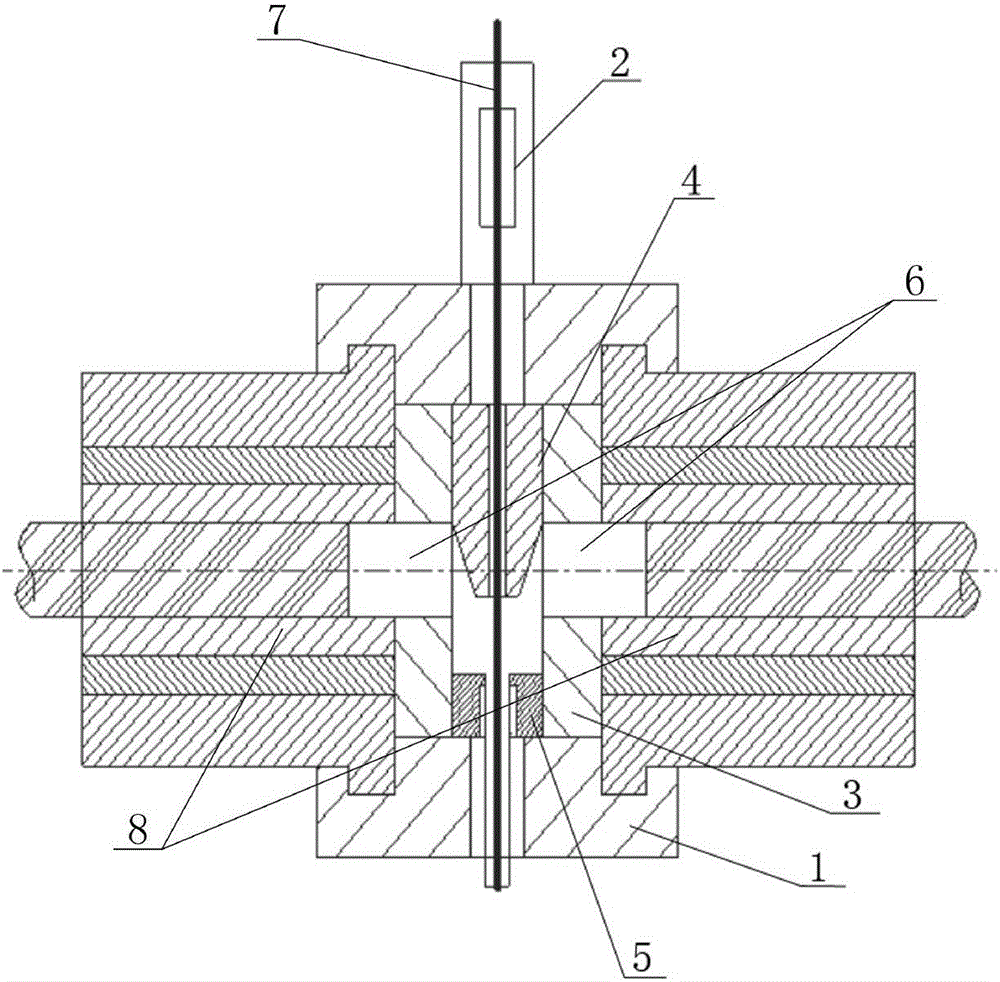

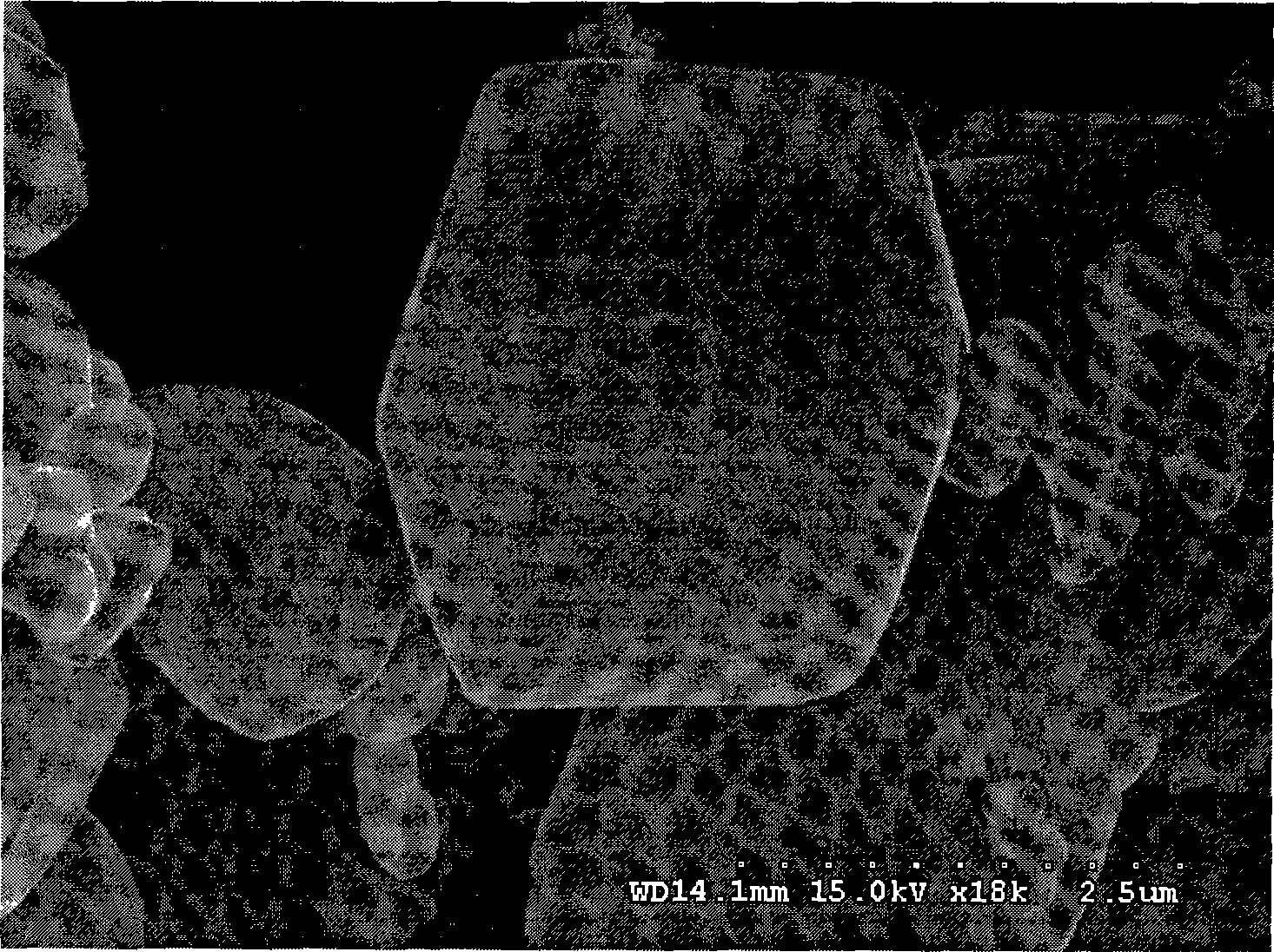

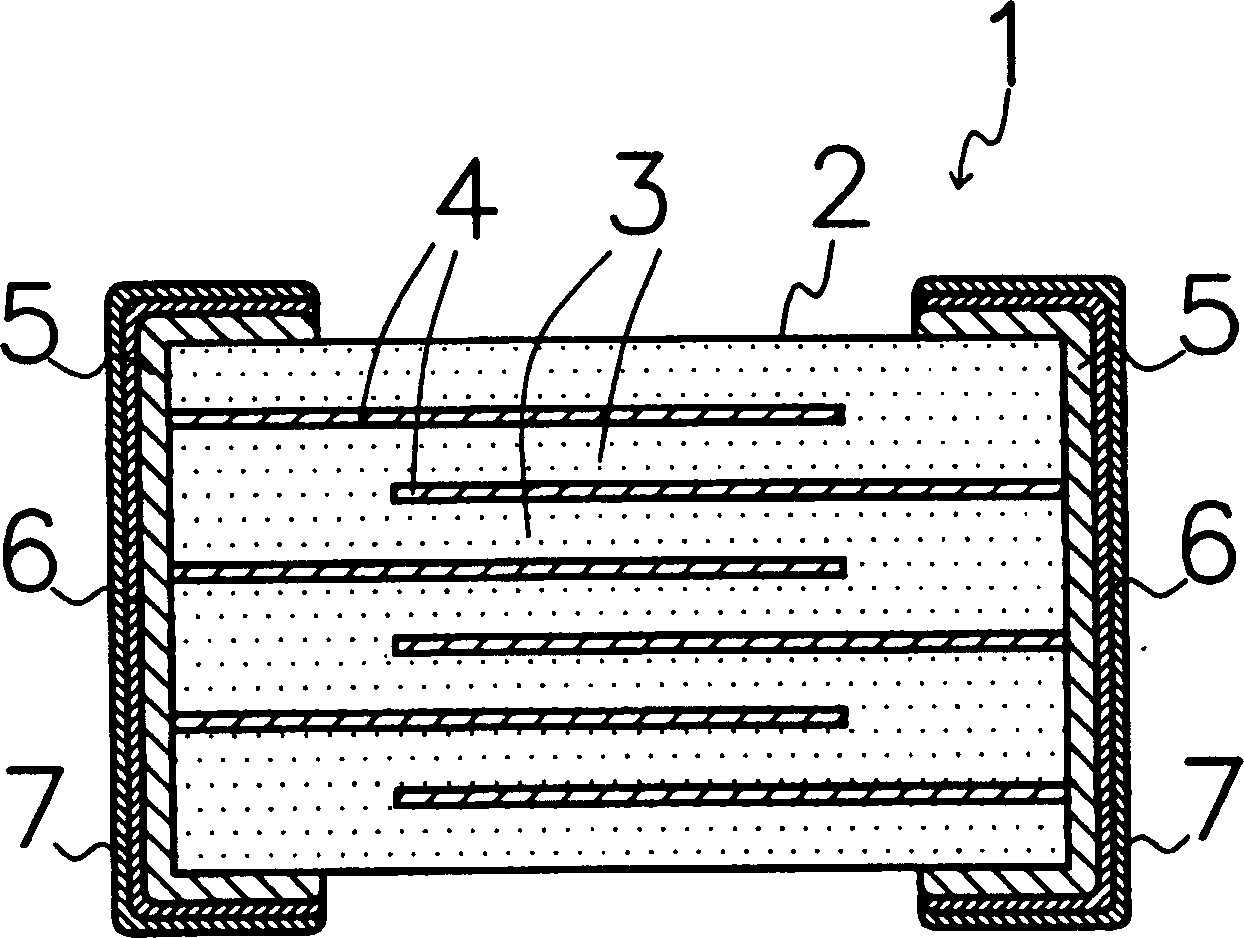

Laminar composite and preparation method thereof

InactiveCN106079739AAvoid bendingAvoid crackingLaminationLamination apparatusCorrosionAluminum matrix composites

The invention discloses a laminar composite, comprising a first wrought aluminum alloy, a non-continuum-reinforced aluminum-based composite layer and a second wrought aluminum alloy which contact with each other in sequence, wherein the non-continuum-reinforced aluminum-based composite layer is a coated middle layer. According to the preparation method, the three-layer laminar composite containing the non-continuum-reinforced aluminum-based composite layer is prepared through a combination of extrusion cladding and rolling, wherein the extrusion cladding refers to bidirectional side extrusion of the non-continuum-reinforced aluminum-based composite layer located at the middle by wrought aluminum alloy rods located at two sides. The laminar composite provided by the invention inherits the advantages of high specific strength, high specific rigidity and high modulus of a non-continuum-reinforced aluminum-based composite and the advantages of good fatigue resistance, fracture toughness and corrosion resistance of wrought aluminum alloy.

Owner:INNER MONGOLIA UNIV OF TECH

Method of manufacturing ultrafine molybdenum powder or ultrafine tungsten powder surface clad metal copper

The invention relates to a preparation method for a metal copper covered on the surface of ultrafine molybdenum powder or ultrafine tungsten powder, which belongs to the field of new materials. The preparation method is characterized in that the method mainly adopts the ultrafine molybdenum powder or the ultrafine tungsten powder with the average particle diameter D50 not more than 1.3 Mum, which is mixed with Cu<2+> soluble salt solution under the continual stirring, polymeric surfactant of coordination group with N atom and O atom is added, one of hydrazine hydrate, sodium hydrosulfite or sodium hypophosphite is added as reducing agent, and an appropriate amount of alkali is dropwise added to adjust pH value in the period so that pH value of the reaction system is from 5.5 to 12.0; in addition, in the range of 20 to 95 DEG C, the reaction continues for 0.5 to 3 hours; the ultrafine molybdenum powder or the ultrafine tungsten powder is filtered through flushing by diluted NH4Cl or NH4NO3 solution, the powder is pulped by alcoholic solution with 0.2-3.0 percent of fatty acid, and the ultrafine molybdenum powder or the ultrafine tungsten powder is filtered again, the powder is heated and dried by H2, to prepare the ultrafine molybdenum powder or the ultrafine tungsten powder of the metal copper covered with the even surface. Through adjusting the proportion of soluble salt of the ultrafine molybdenum powder or the ultrafine tungsten powder and the copper, the ultrafine molybdenum powder or the ultrafine tungsten powder covered by metal copper with different composition proportions can be prepared to meet different demands.

Owner:GRIMAT ENG INST CO LTD

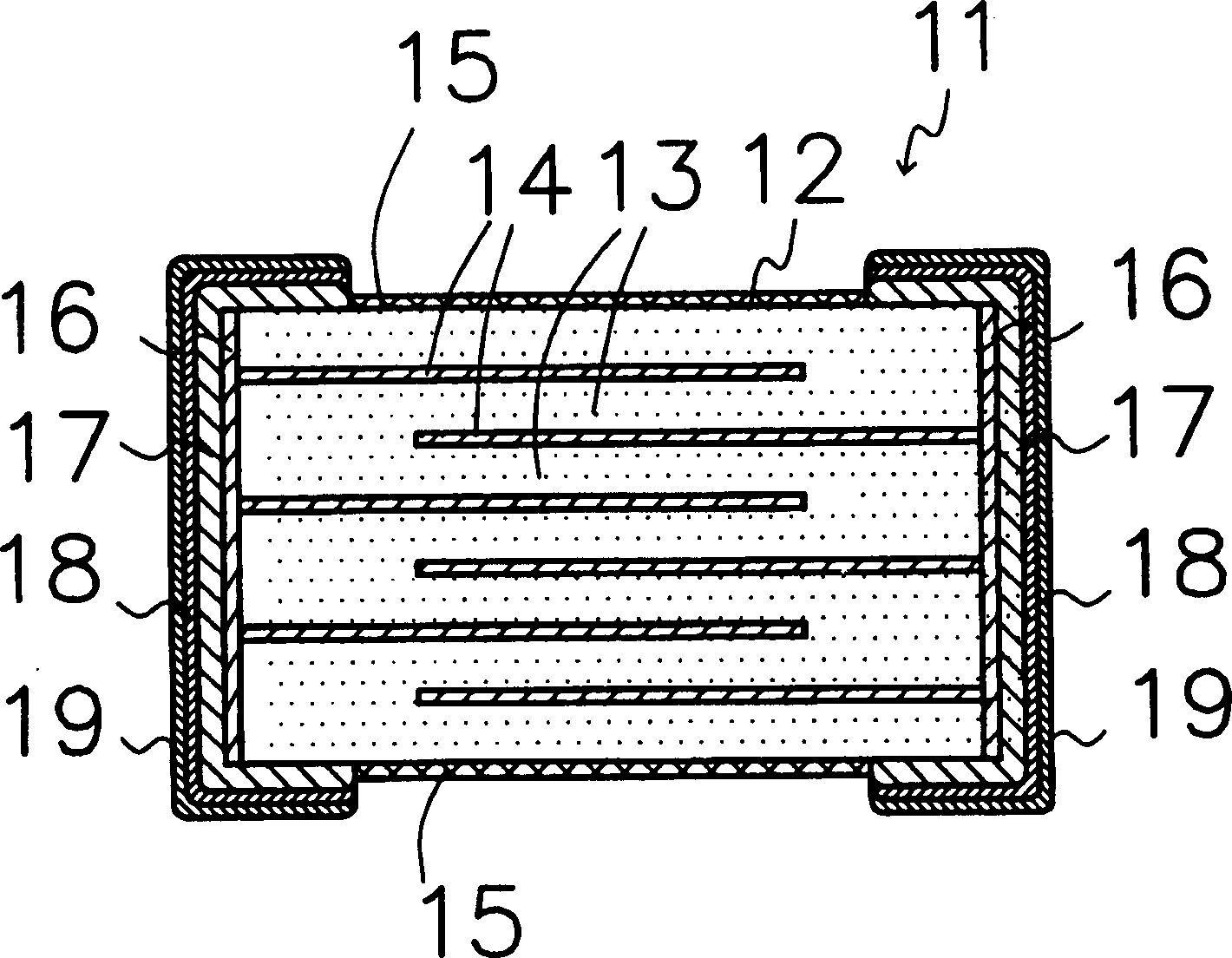

Conductive paste, lamina ceramic electronic element producing method and lamina ceramic electronic element

InactiveCN1405791APrevent surface oxidationFixed capacitor dielectricStacked capacitorsConductive pasteAlloy

Provided is a Ag-based conductive paste for a terminal electrode which suppresses oxidation of the Ni surface of an internal conductor and therefore brings about excellent joining with Ni even when baking is performed in the atmosphere in the case where Ni is used as the internal conductor of a laminated ceramic electronic component. The conductive paste includes at least one of an Ag powder and an Ag alloy powder, a nickel boride powder, an inorganic binder and an organic vehicle, wherein the quantity of the nickel boride powder is within the range of about 5% by weight or more, but less than about 60% by weight of the total paste.

Owner:MURATA MFG CO LTD

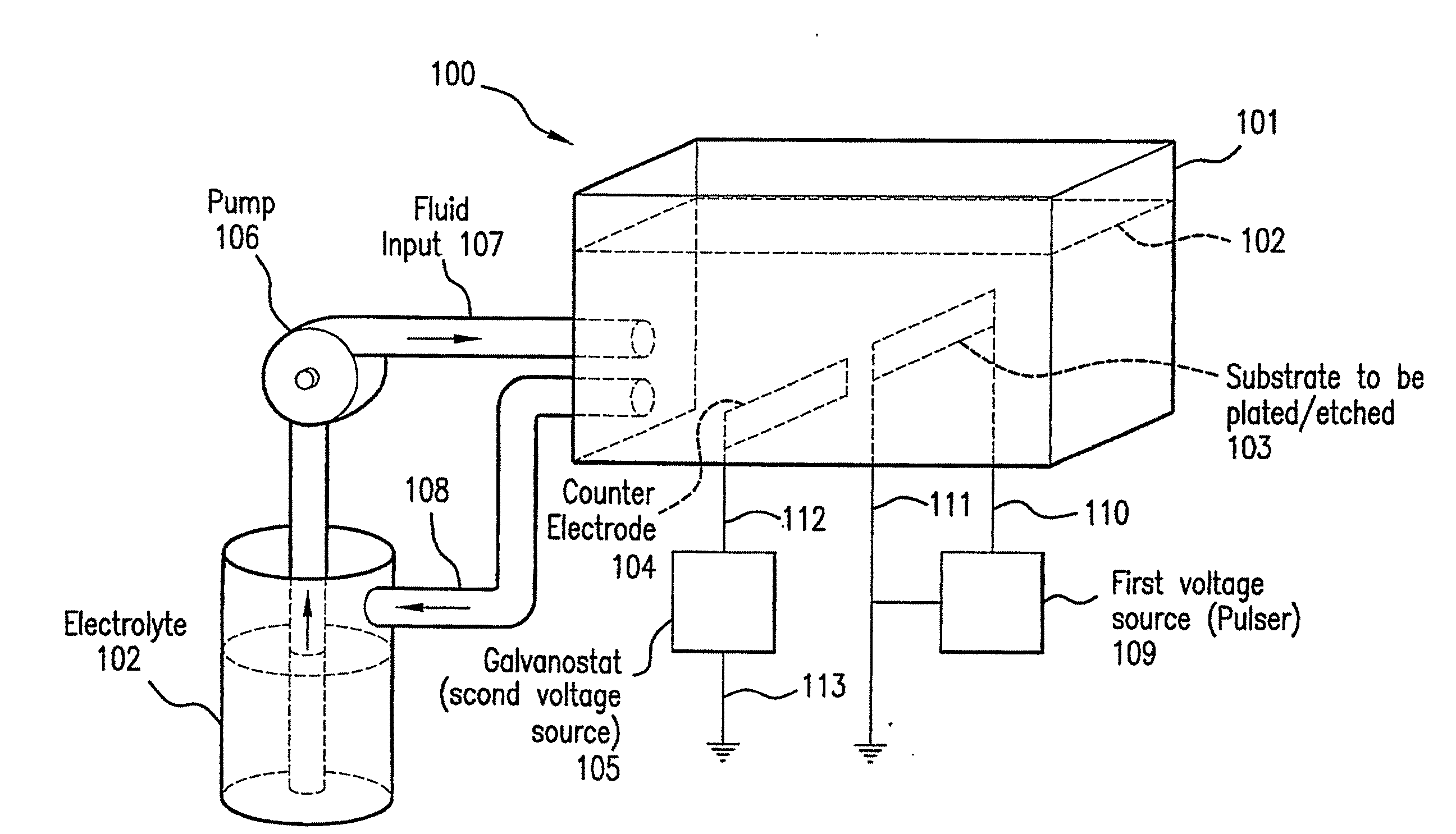

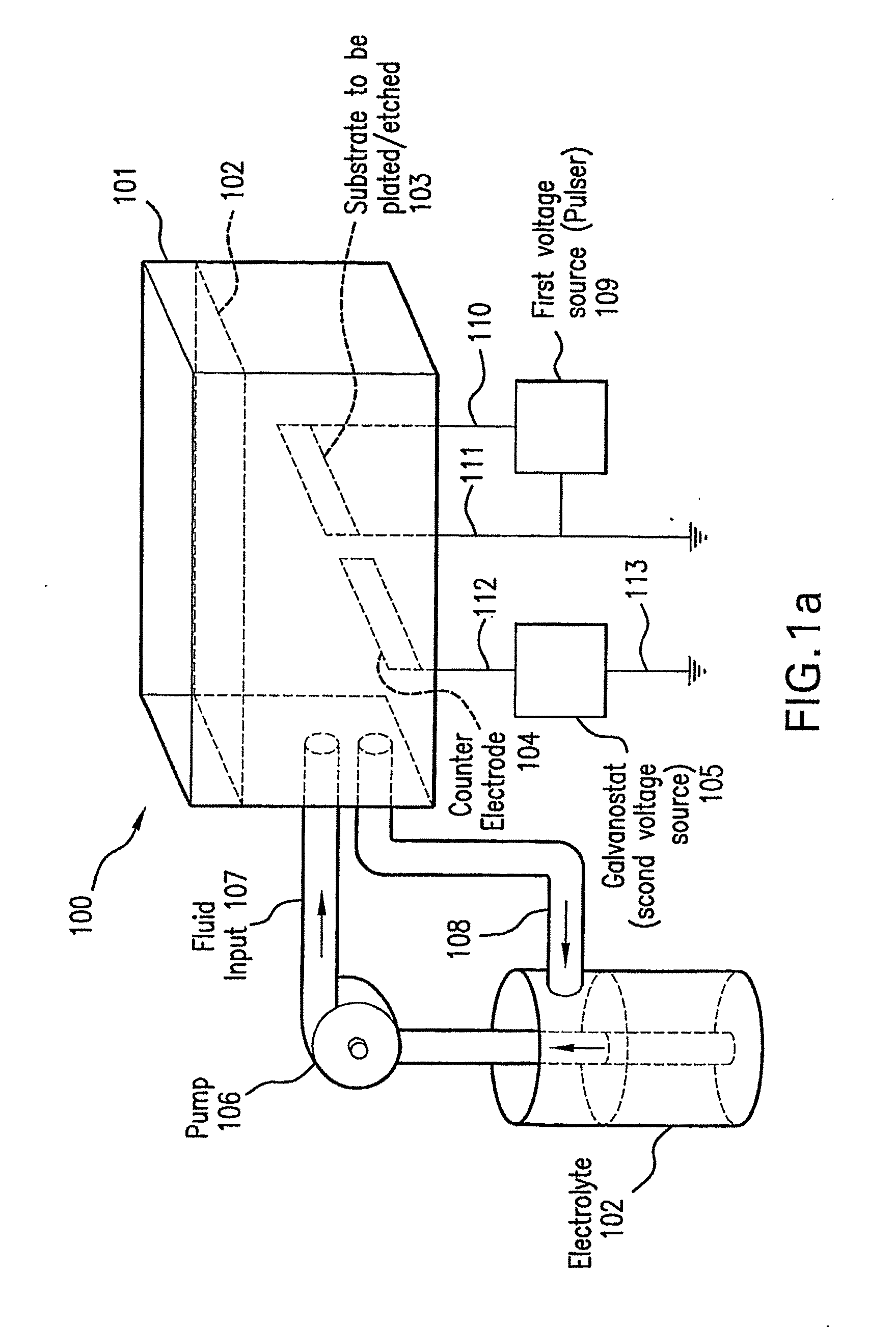

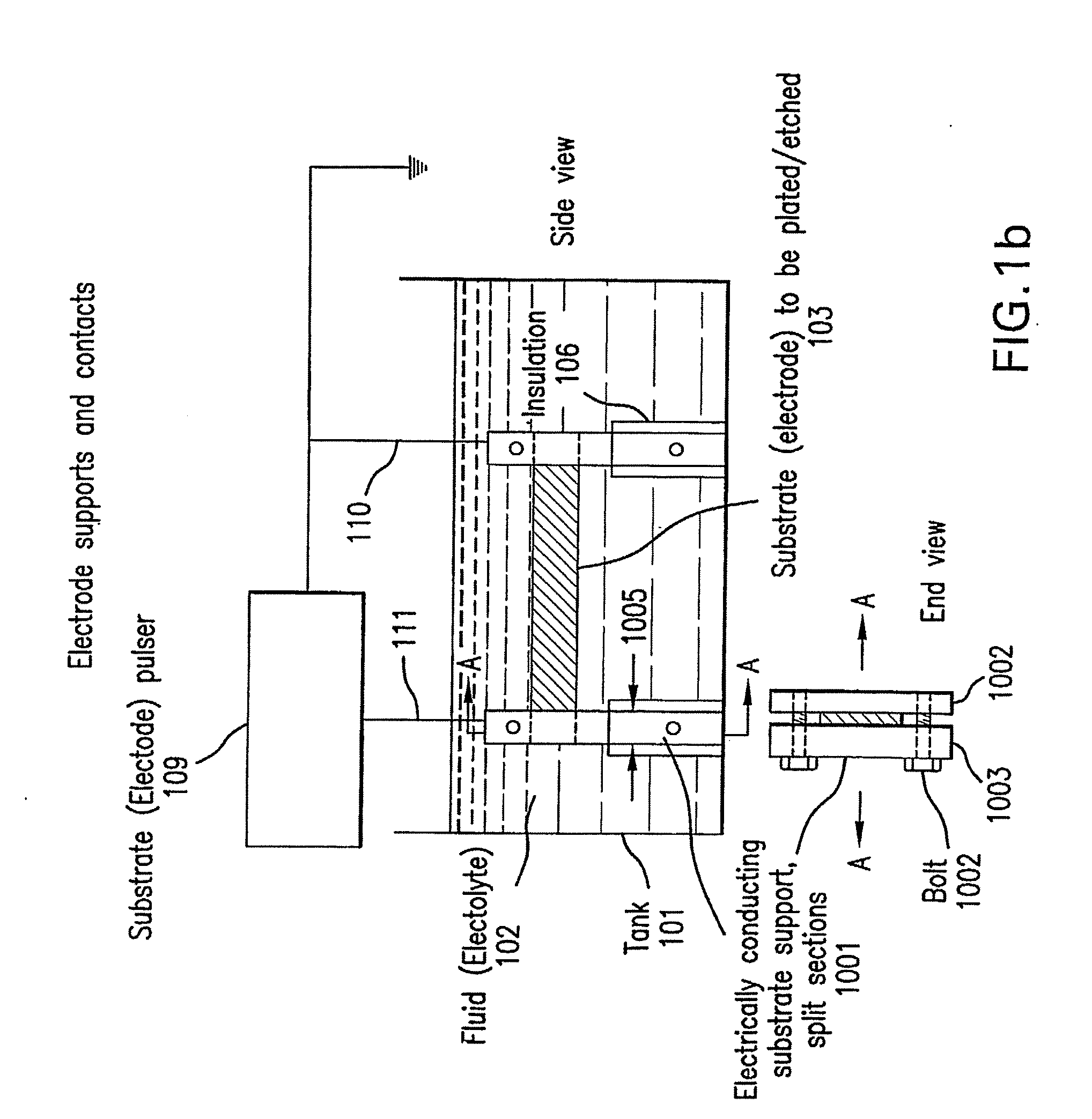

In situ plating and etching of materials covered with a surface film

Systems and methods for plating and / or etching of hard-to-plate metals are provided. The systems and methods are designed to overcome the deleterious effect of superficial coating or oxide layers that interfere with the plating or etching of certain metal substrates. The systems and methods involve in situ removal of coating materials from the surfaces of the metal substrates while the substrates are either submerged in plating or etching solutions, or are positioned in a proximate enclosure just prior to submersion in the plating or etching solutions. Further, the substrates can be in contact with a suitable patterning mask to obtain patterned oxide-free regions for plating or etching. This in situ removal of coating layers may be achieved by pulse heating or photoablation of the substrate and the inhibiting coating layers. Electrical energy or laser light energy may be used for this purpose. Additionally or alternatively, the coating materials may be removed by mechanical means.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

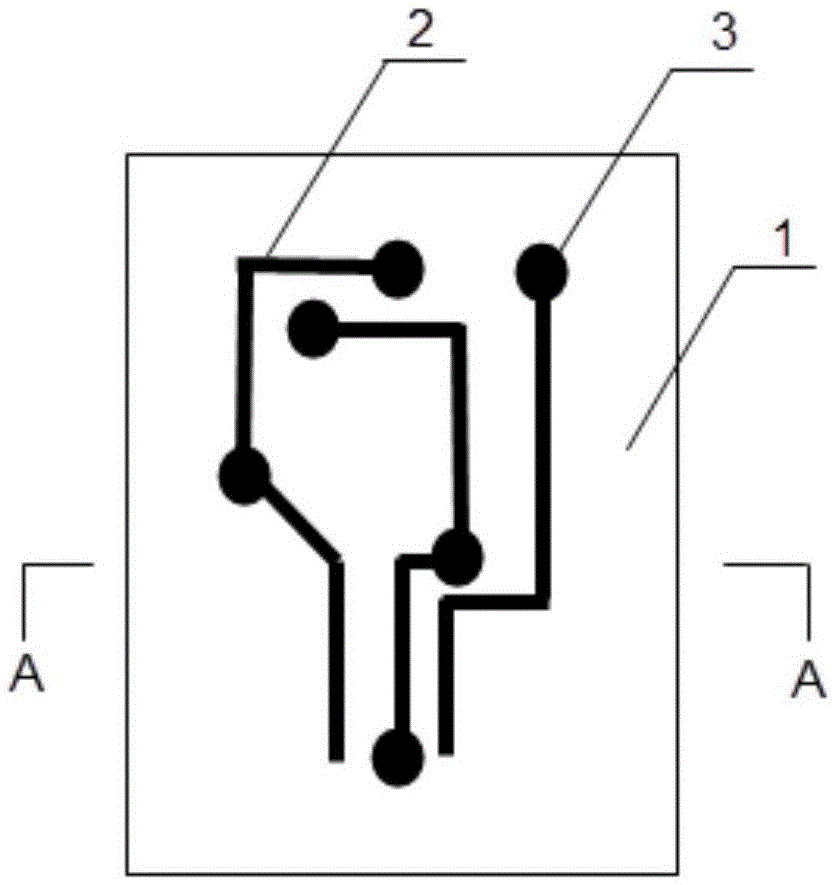

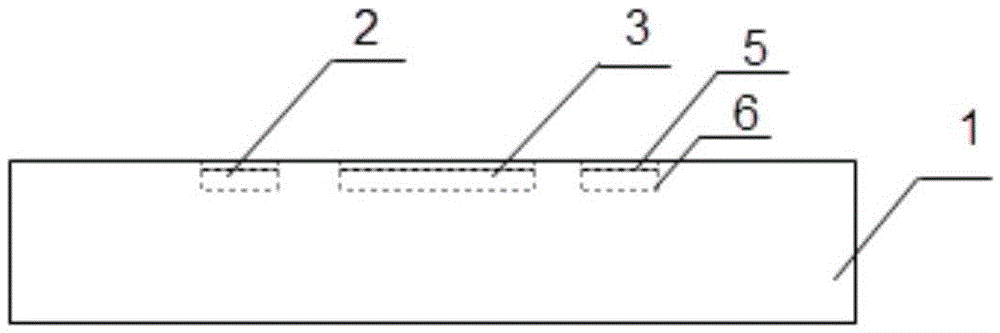

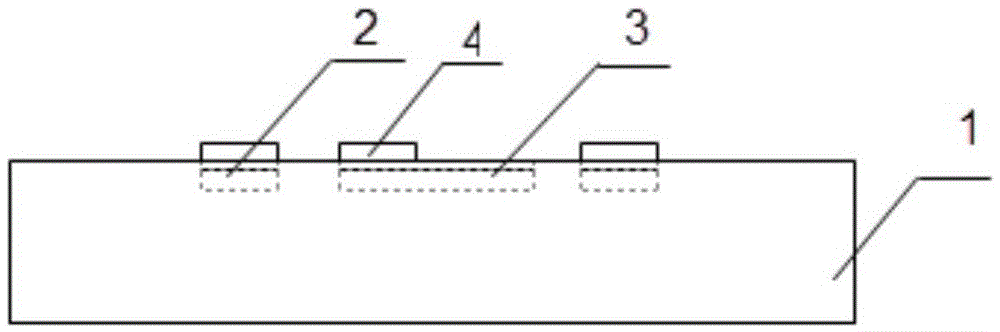

High-conductivity transparent glass-based circuit board

ActiveCN105555023ACloselyCapable of superconductingDiffusion patterningTransparent dielectricsConductive pasteOptoelectronics

The invention provides a high-conductivity transparent glass-based circuit board. The high-conductivity transparent glass-based circuit board comprises a glass substrate, wherein the glass substrate is a tempered glass substrate, a conductive paste printed on an air surface of the tempered glass substrate is arranged on the surface of the tempered glass substrate and melted with a conductive circuit on the surface of the tempered glass substrate after roasting, heating and cooling, the surface of the tempered glass substrate is flush with the upper surface of the conductive circuit, and a part, except a bonding pad of a component to be welded, on the surface of the conductive circuit is coated with printed circuit board (PCB) organic soldering resistance paint. In the high-conductivity transparent glass-based circuit board, a melting relation is generated between the glass substrate and the conductive circuit, the glass substrate and the conductive circuit are in close link, the surface of the glass substrate is flush with the upper surface of the conductive circuit, the whole high-conductivity transparent glass-based circuit board is smooth in surface, the conductive circuit is difficult to damage, and the conduction capability is high.

Owner:WUHAN HSURICH TECH CO LTD

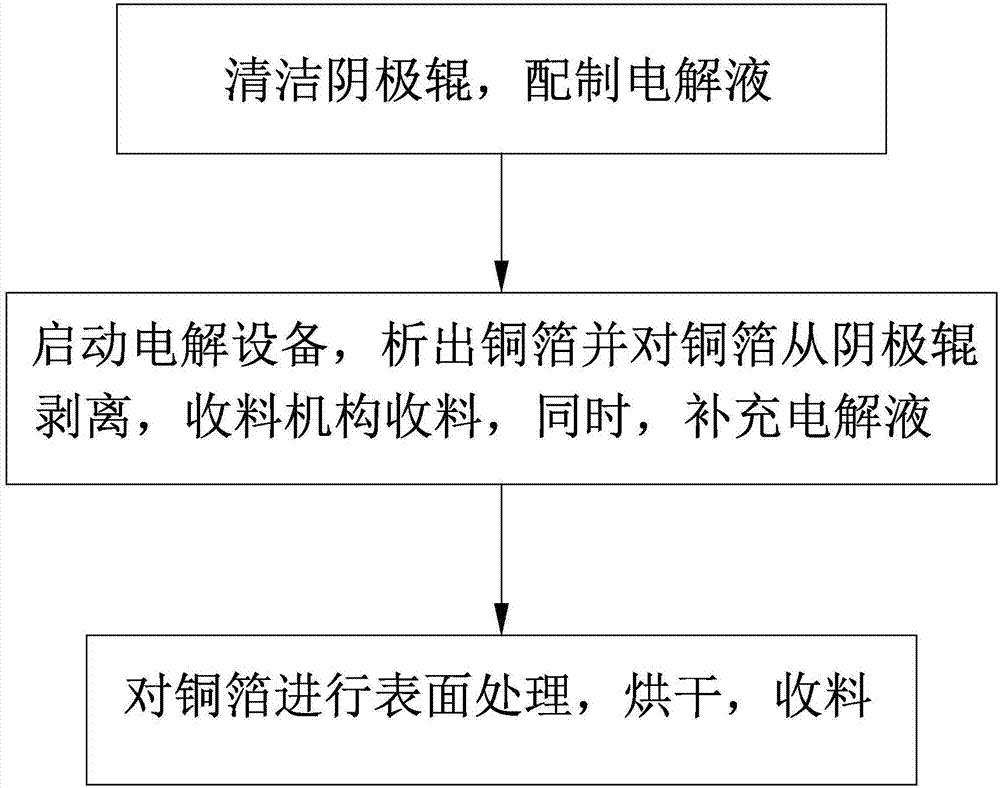

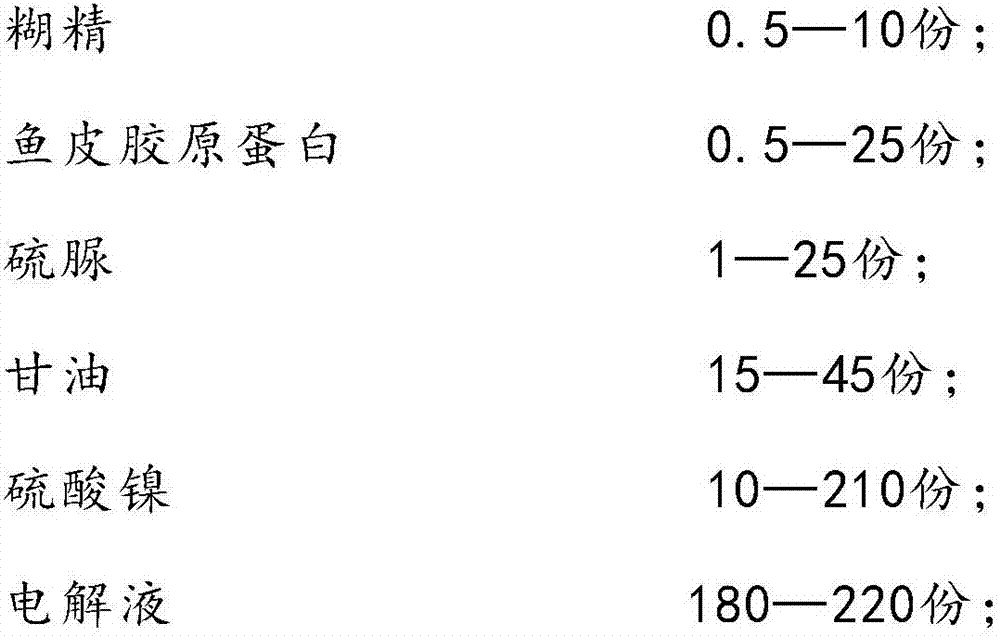

Copper foil electrolyte, copper foil production method and copper foil electrolysis equipment

ActiveCN106968000AClose and uniform contactImprove stabilityElectroforming processesLithiumElectrolysis

The invention discloses copper foil electrolyte, a copper foil production method and copper foil electrolysis equipment. The copper foil electrolyte comprises the following substances in parts by weight: 0.5-15 parts of dextrin, 1-30 parts of fish skin collagen, 1-25 parts of thiourea, 10-50 parts of glycerin, 10-250 parts of nickel sulfate, and 150-300 parts of electrolyte, wherein the electrolyte sulfuric acid concentration is 60-110 g / L; and the copper ion concentration is 60-90 g / L. When a produced electrolytic copper foil serves as a solid-state metal lithium positive pole current collector, the chemical corrosion resisting capacity is prominently improved; and two-surface active substances are tightly and uniformly contacted with the current collector, so that the battery charge / discharge stability is improved, and the capacity of resisting rupture and increasing the coating quantity of positive pole active pulp in the charge / discharge process is improved.

Owner:佛冈建滔实业有限公司

High-strength galvanized steel sheet and method for manufacturing the same

ActiveUS20120018060A1Improve coating appearanceImprove the immunityHot-dipping/immersion processesFurnace typesFurnace temperatureMachining

Provided is a method for manufacturing a high-strength galvanized steel sheet, made from a steel sheet containing Si and / or Mn, having excellent exfoliation resistance during heavy machining. When a steel sheet containing 0.01% to 0.18% C, 0.02% to 2.0% Si, 1.0% to 3.0% Mn, 0.001% to 1.0% Al, 0.005% to 0.060% P, and 0.01% or less S on a mass basis, the remainder being Fe and unavoidable impurities, is annealed and galvanized in a continuous galvanizing line, a temperature region with a furnace temperature of A° C. to B° C. (600≦A≦780 and 800≦B≦900) is performed at an atmosphere dew-point temperature of −5° C. or higher in a heating process.

Owner:JFE STEEL CORP

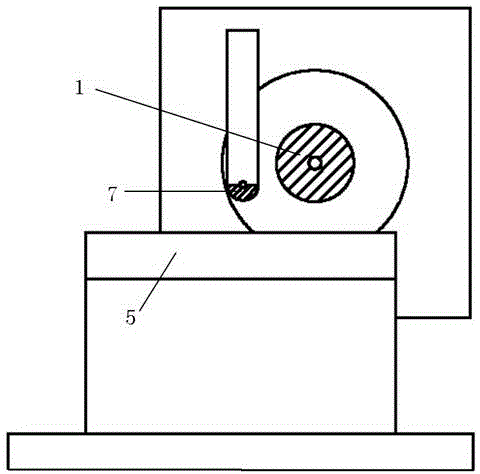

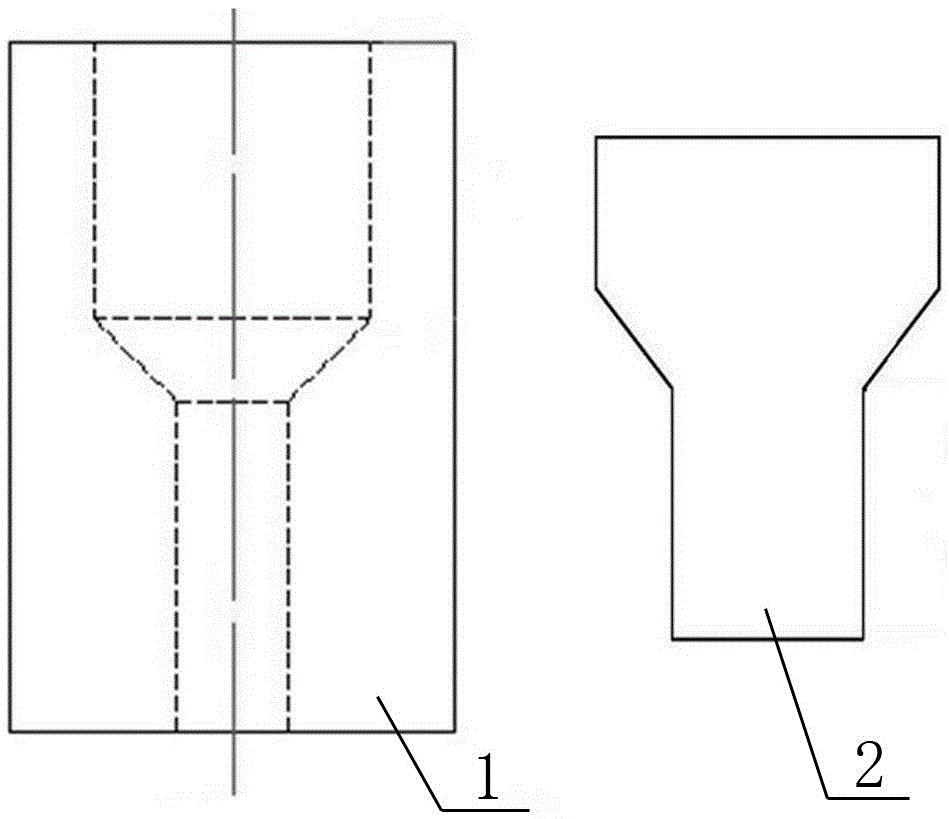

Preparation method for TiAl alloy bar

ActiveCN106636741ASolve the problem of severe segregationPrevent surface oxidationExtrusion diesIngotSkull

The invention discloses a preparation method for a TiAl alloy bar and relates to a preparation method for a bar. The preparation method for the TiAl alloy bar aims at solving the problems that according to a TiAl alloy bar prepared through an existing method, the preparation process is complex, the surface of the bar cracks, the diameter is nonuniform, the bar structure grain size is nonuniform, and TiAl alloy reacts with package materials and is molten when the extrusion temperature is too high. The preparation method for the TiAl alloy bar comprises the specific steps that 1, all raw material components are weighed; 2, a cast ingot is prepared through water cooling copper crucible induction skull melting; 3, pretreatment is conducted on an extrusion blank; and 4, bar extrusion is conducted, and thus the TiAl alloy bar can be obtained. The surface of the TiAl alloy bar obtained through the preparation method is free of cracking, the diameter is uniform, the bar structure grain size is uniform, and the process is simple.

Owner:山西中工重型锻压有限公司

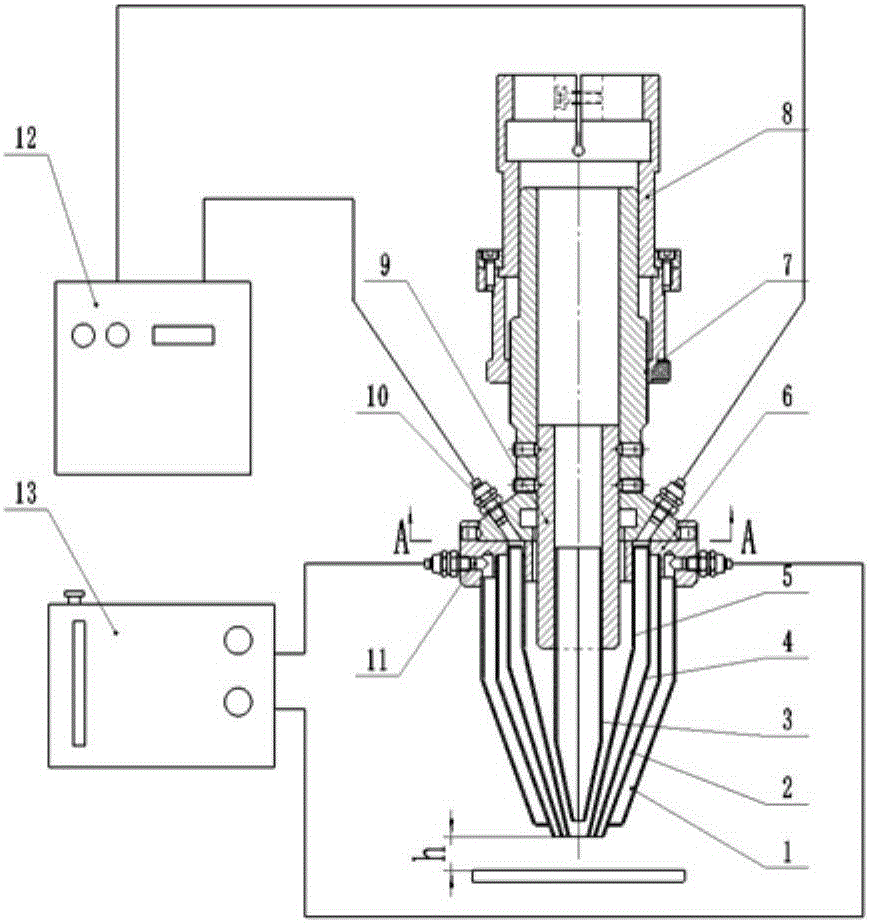

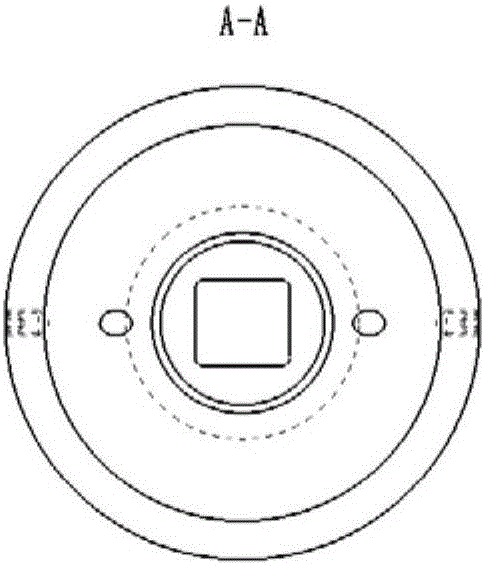

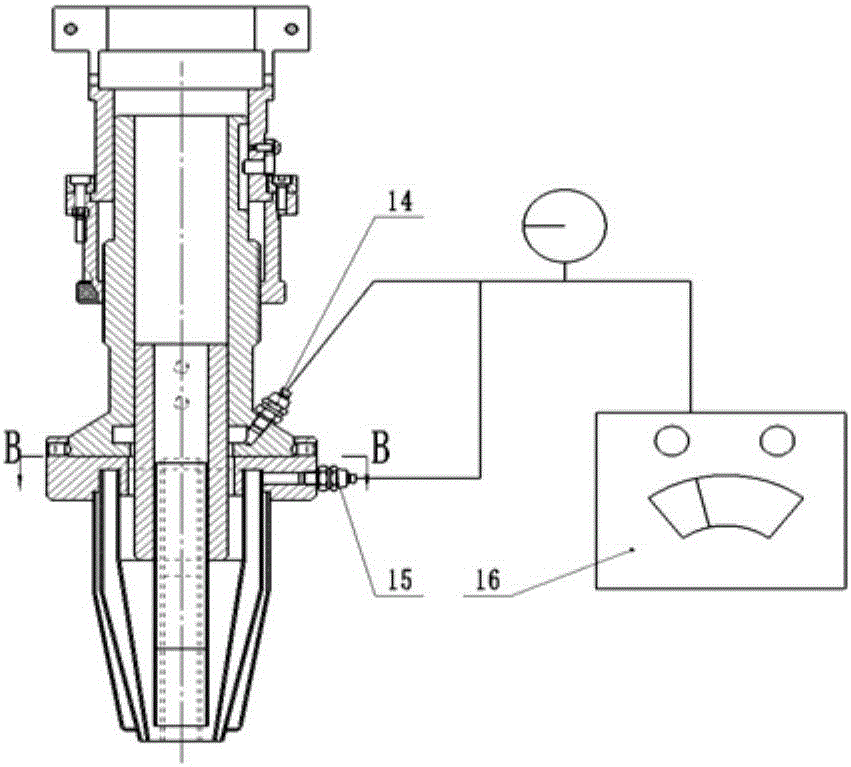

Coaxial powder feeding device for broadband laser cladding and powder feeding method thereof

ActiveCN106521485AAchieve mutual isolationPrevent surface oxidationMetallic material coating processesLight beamEngineering

The invention relates to a coaxial powder feeding device for broadband laser cladding and a powder feeding method thereof. The device comprises a sleeve module; a light beam isolation cover, and an inner-layer air cover, an outer-layer air cover and a cooling water cover for coating the light beam isolation cover in sequence from inside to outside are arranged at the bottom end of the sleeve module; two powder feeding pipes symmetrically arranged about the light beam isolation cover are arranged between the inner-layer air cover and the outer-layer air cover at the bottom end of the sleeve module; outlets of the powder feeding pipes are rectangular pipes; outlets of the light beam isolation cover, the inner-layer air cover, the outer-layer air cover and the cooling water cover at the bottoms are rectangular; and the sleeve module is provided with a water injecting port, a water outlet, an outer-layer protective gas inlet, an inner-layer protective gas inlet and a powder feeding inlet. The method comprises three steps of connection of external source equipment, powder feeding device parameter adjustment and coaxial broadband powder feeding laser cladding. The device can prevent fused metal liquid from splashing to block the outlet of the powder feeding device, can enable the powder spot pavement to become more uniform in powder spot shaping, and is simple in structure and easy to machine.

Owner:WUHAN UNIV OF TECH

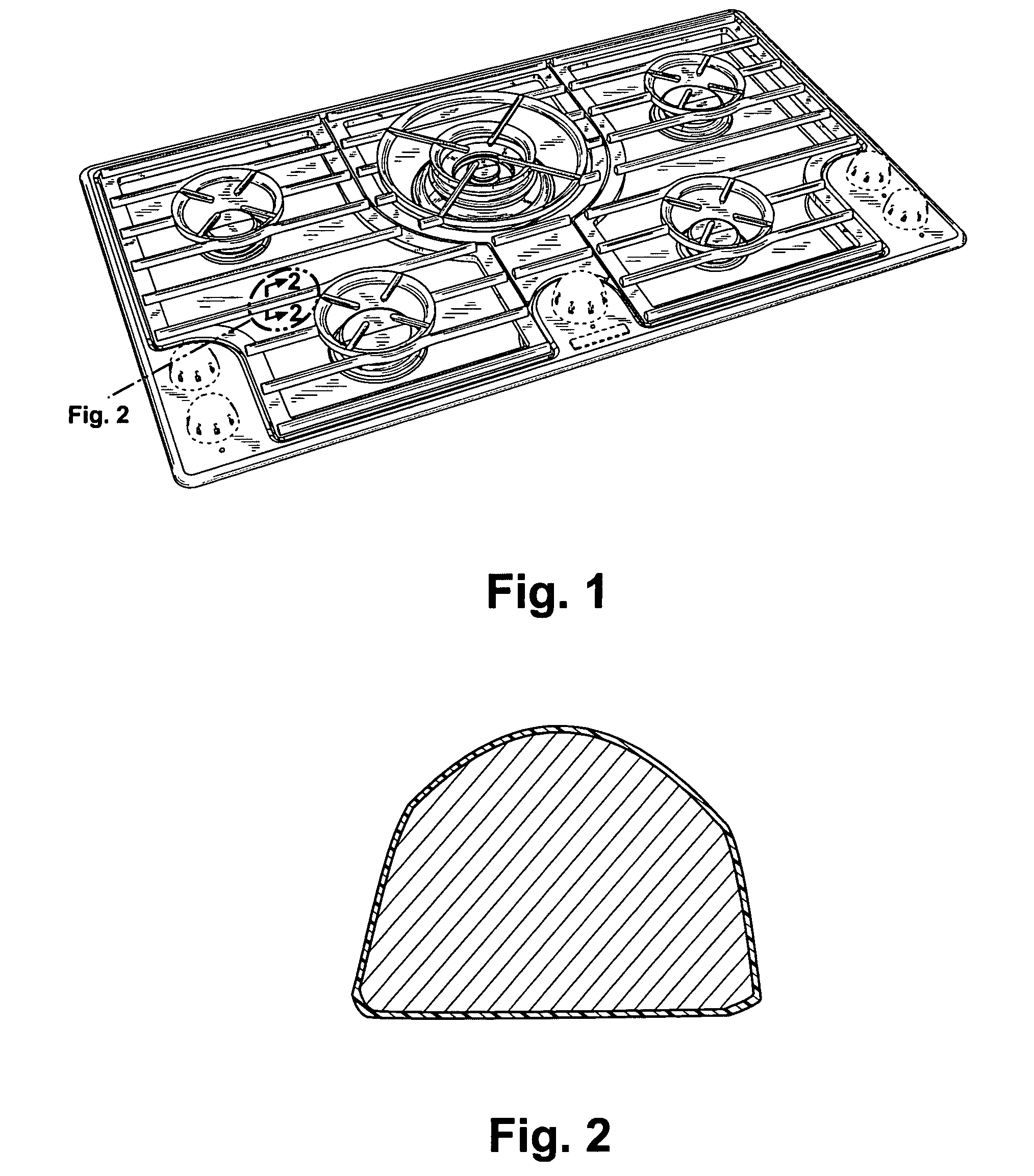

Transparent high temperature resistant and protective coating for domestic appliances and method for its deposition

ActiveUS7683293B2Good removal effectIncrease depositionLiquid surface applicatorsDomestic stoves or rangesSilicon oxideMetal

A domestic appliance, particularly a cooking appliance, having a metallic surface, is provided with a coating based on silicon oxide. Such coating is deposited on the metallic surface by plasma enhanced chemical vapor deposition (PECVD). The coating protects the metallic surface from scratching, staining and thermal yellowing.

Owner:WHIRLPOOL CORP

Integrated preparing and forming device for magnesium alloy thin-walled pieces

The invention relates to an integrated preparing and forming device for magnesium alloy thin-walled pieces. The forming device comprises a smelting-pouring tank and a protective atmosphere solidification tank, wherein the smelting-pouring tank and the protective atmosphere solidification tank are used for preparing a magnesium alloy. The smelting-pouring tank and the protective atmosphere solidification tank are both connected with a vacuumizing device and a protective gas injection device. By means of the integrated preparing and forming device, the magnesium alloy can be smelted under the vacuum condition, preparation is completed and pouring is conducted under the condition that the protective gas is injected, and pressurized solidification is conducted under the condition that the protective gas is injected in the protective atmosphere solidification tank. The integrated preparing and forming device is suitable for producing complex and thin-walled magnesium alloy castings, the production safety is high, the surfaces of the castings are free of oxidation defects, internal defects such as slag inclusion, shrinkage porosity and cold shut are basically solved, the structure is compact, performance is good, production requirements are met, the integrated preparing and forming device is easy to popularize, and the yield of the castings is high.

Owner:HENAN POLYTECHNIC UNIV

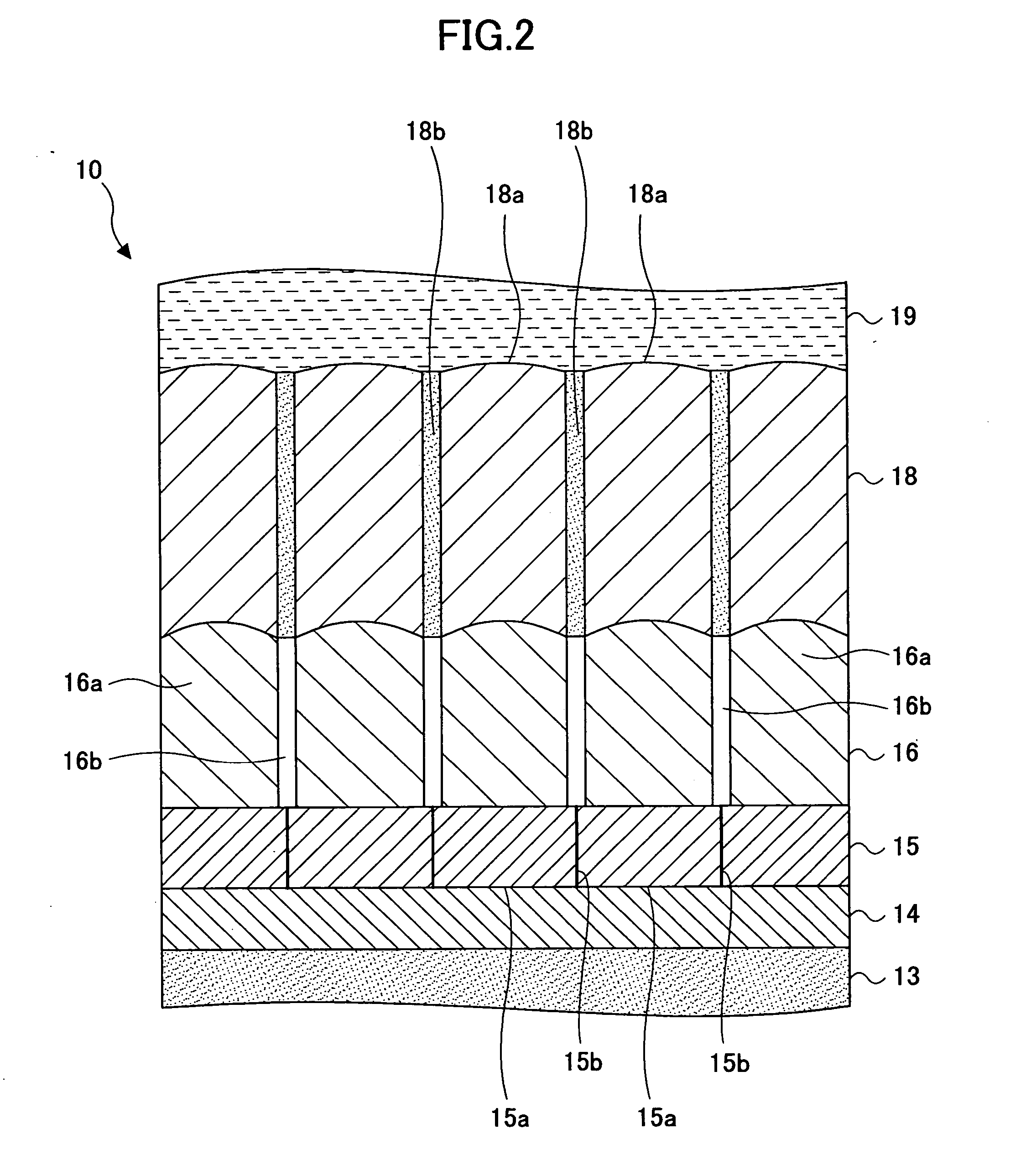

Perpendicular magnetic recording medium, method of manufacturing the same, and magnetic storage unit

InactiveUS20070231608A1Good crystallinity and crystal orientationHigh recording densityVacuum evaporation coatingSputtering coatingCrystalliteMagnetic storage

A perpendicular magnetic recording medium is disclosed that includes a substrate; a soft magnetic underlayer formed on the substrate; a seed layer of an amorphous material formed on the soft magnetic underlayer; an oxidation prevention layer formed on the seed layer; an underlayer formed on the oxidation prevention layer, the underlayer including multiple crystal grains formed of Ru or a Ru alloy having an hcp crystal structure, and a first air gap part configured to separate the crystal grains from each other; and a recording layer formed on the underlayer, the recording layer including multiple magnetic particles having a magnetocrystalline easy axis in a direction substantially perpendicular to the surface of the substrate, and one of a second air gap part and a non-magnetic non-solid-solution phase, the one being configured to separate the magnetic particles from each other. The oxidation prevention layer includes a noble metal element other than R.

Owner:SHOWA DENKO KK

Method for preparing nanometer silicon powder

ActiveCN106185947AHigh purityLarge specific surface areaNanotechnologySilicon compoundsInduction plasma technologyPlasma generator

The invention discloses a method for preparing nanometer silicon powder. The nanometer silicon powder is made of coarse silicon powder. Inert gas is used as carrier gas. The method includes carrying the coarse silicon powder by the carrier gas, allowing the coarse silicon powder to penetrate plasmas generated by a high-frequency plasma generator and feeding the coarse silicon powder into a reaction chamber; quickly gasifying the coarse silicon powder in high-temperature plasma regions in the reaction chamber to generate silicon atom steam cloud; forming tiny silicon particles by the generated silicon atom steam cloud under the effects of cooling gas flow when the silicon atom steam cloud flows through cooling regions; driving the silicon particles by gas flow to flow into a cyclone classification chamber; detaining the classified coarse silicon particles in the cyclone classification chamber; carrying the fine silicon particles into a gas-solid separation chamber by the aid of the gas flow; ultimately depositing the fine silicon particles on a filter of the gas-solid separation chamber; collecting the silicon particles on the filter to obtain the nanometer silicon powder. The method has the advantages that the induction plasmas are used as heat sources, accordingly, electrode pollution can be prevented in preparation procedures, the nanometer silicon powder prepared by the aid of the method is high in purity, and the particles are in spherical or approximately spherical morphology, have large specific surface areas and are high in surface activity and good in flowability and dispersibility.

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD

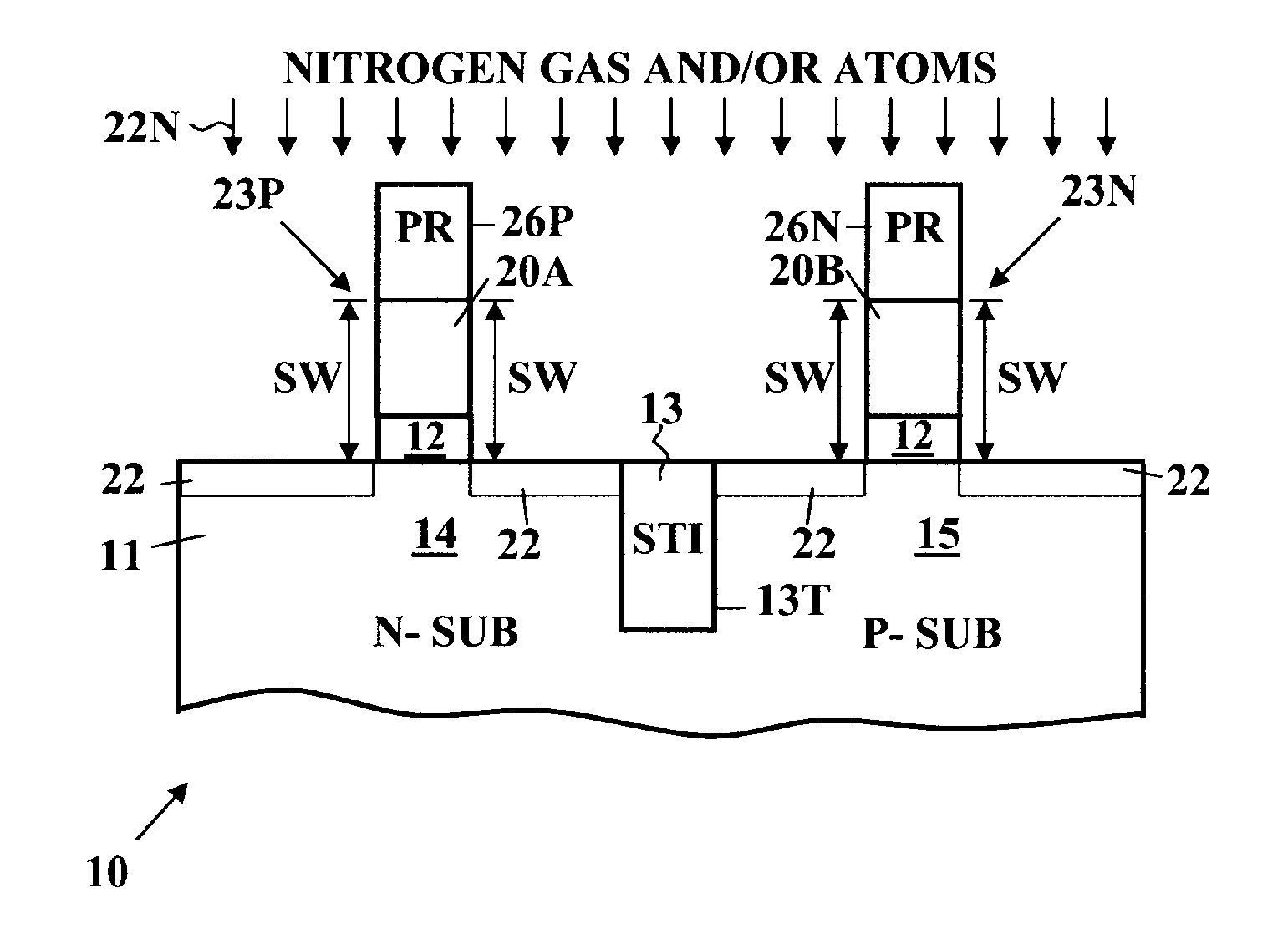

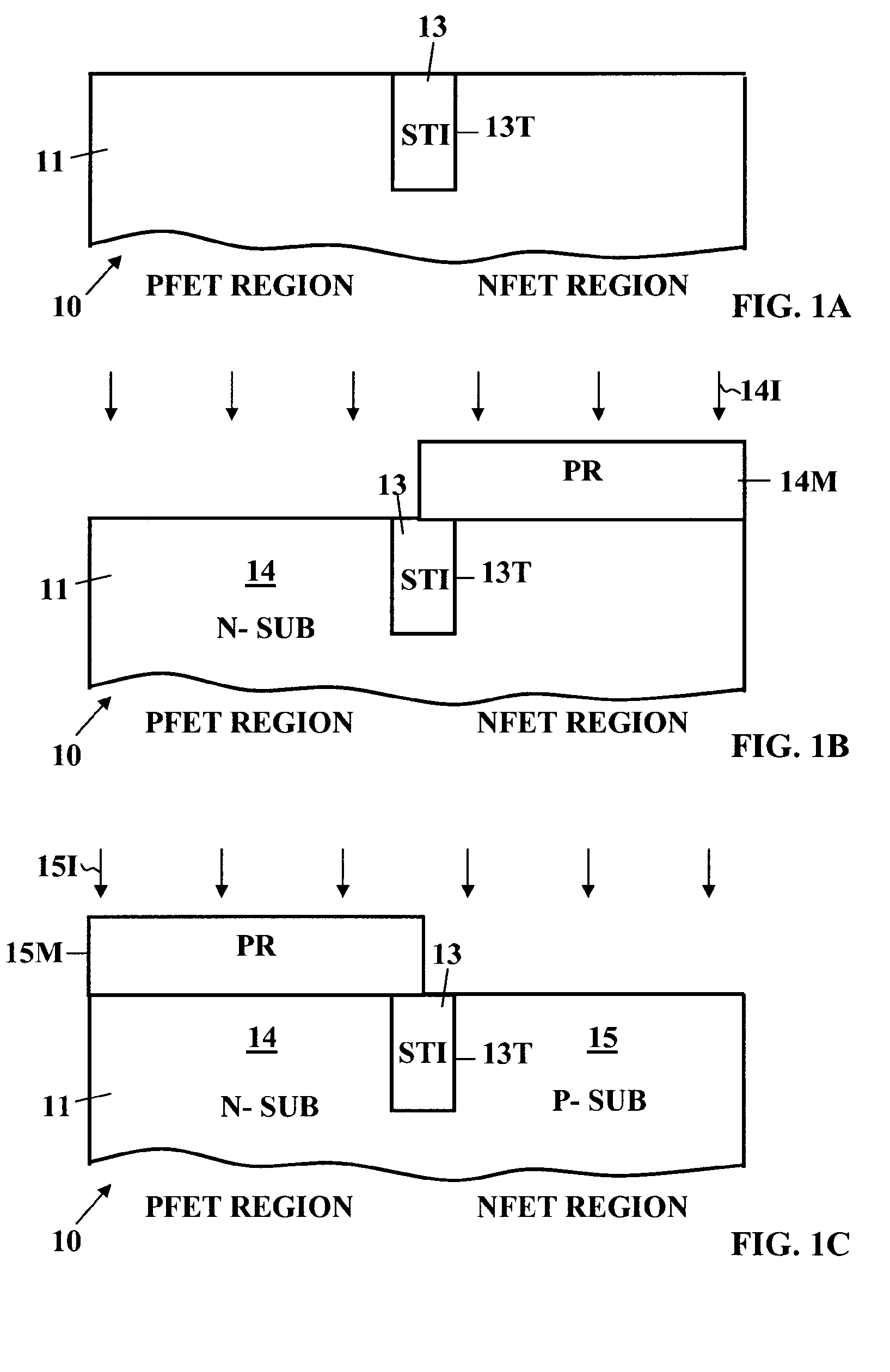

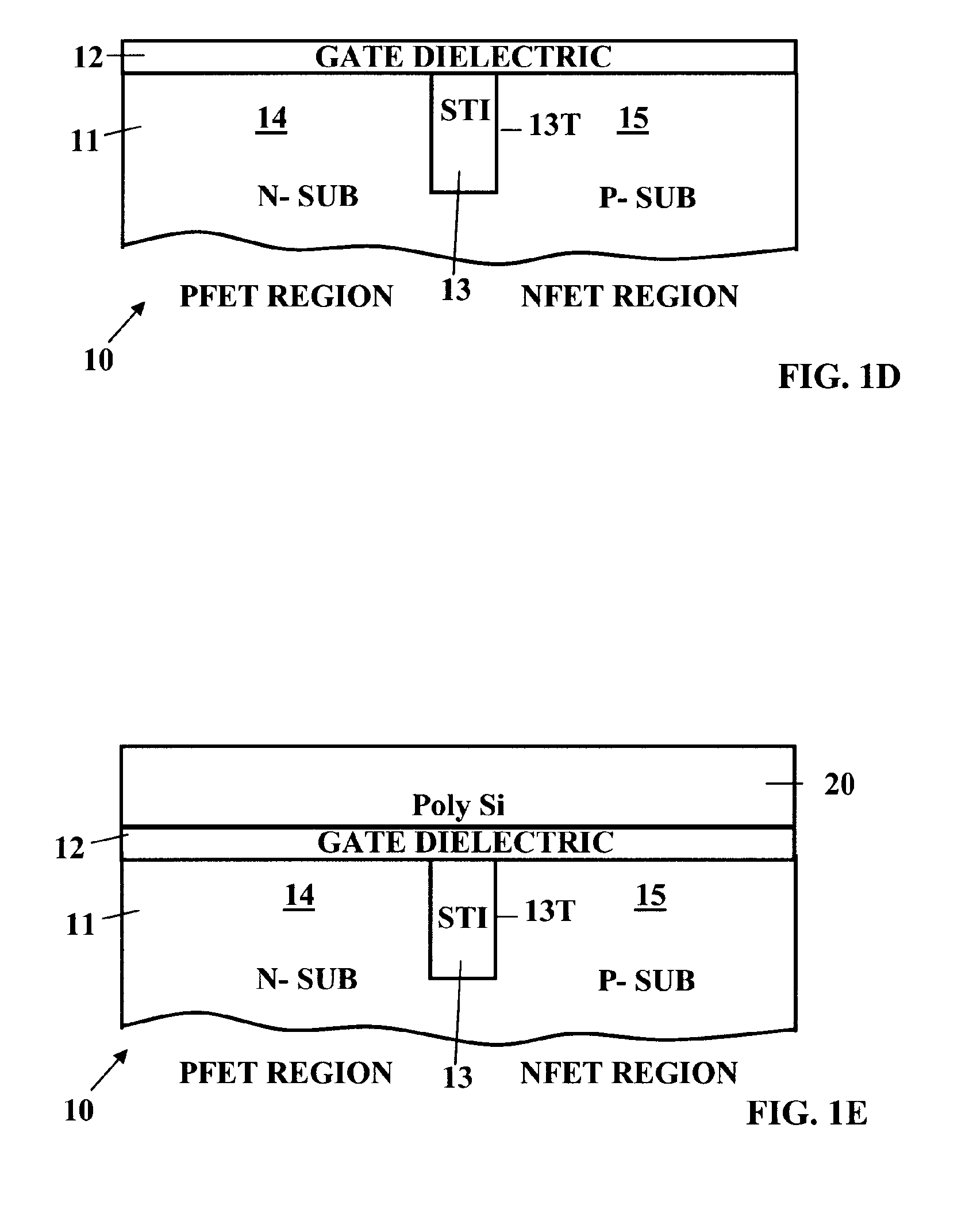

Ion implantation of nitrogen into semiconductor substrate prior to oxidation for offset spacer formation

InactiveUS20070114605A1Prevent surface oxidationWeaken energySemiconductor/solid-state device detailsSolid-state devicesGate dielectricNitrogen

A method of formation of integrated circuit devices includes forming a gate electrode stack over a portion of a semiconductor. The stack includes a gate dielectric layer with a gate electrode thereabove. Implant diatomic nitrogen and / or nitrogen atoms into the substrate aside from the stack at a maximum energy less than or equal to 10 keV for diatomic nitrogen and at a maximum energy less than or equal to 5 keV for atomic nitrogen at a temperature less than or equal to 1000° C. for a time of less than or equal to 30 minutes. Then form silicon oxide offset spacers on sidewalls of the stack. Form source / drain extension regions in the substrate aside from the offset spacers. Form nitride sidewall spacers on outer surfaces of the offset spacers over another portion of the nitrogen implanted layer. Then form source / drain regions in the substrate aside from the sidewall spacers.

Owner:IBM CORP

Nano-silicon composite negative electrode material used for lithium ion battery, process for preparing the same and lithium ion battery

ActiveUS10170753B2Large capacityImprove efficiencyMaterial nanotechnologyElectrode thermal treatmentNano siliconGas phase

The present invention relates to a nano-silicon composite negative electrode material, including graphite matrix and nano-silicon material homogeneously deposited inside the graphite matrix, wherein the nano-silicon composite negative electrode material is prepared by using silicon source to chemical-vapor deposit nano-silicon particles inside hollowed graphite. The nano-silicon composite negative electrode material of the present invention has features of high specific capacity (higher than 1000 mAh / g), high initial charge-discharge efficiency (higher than 93%) and high conductivity. The preparation process of the present invention is easy to operate and control, and has low production cost and is suitable for industrial production.

Owner:BTR NEW MATERIAL GRP CO LTD

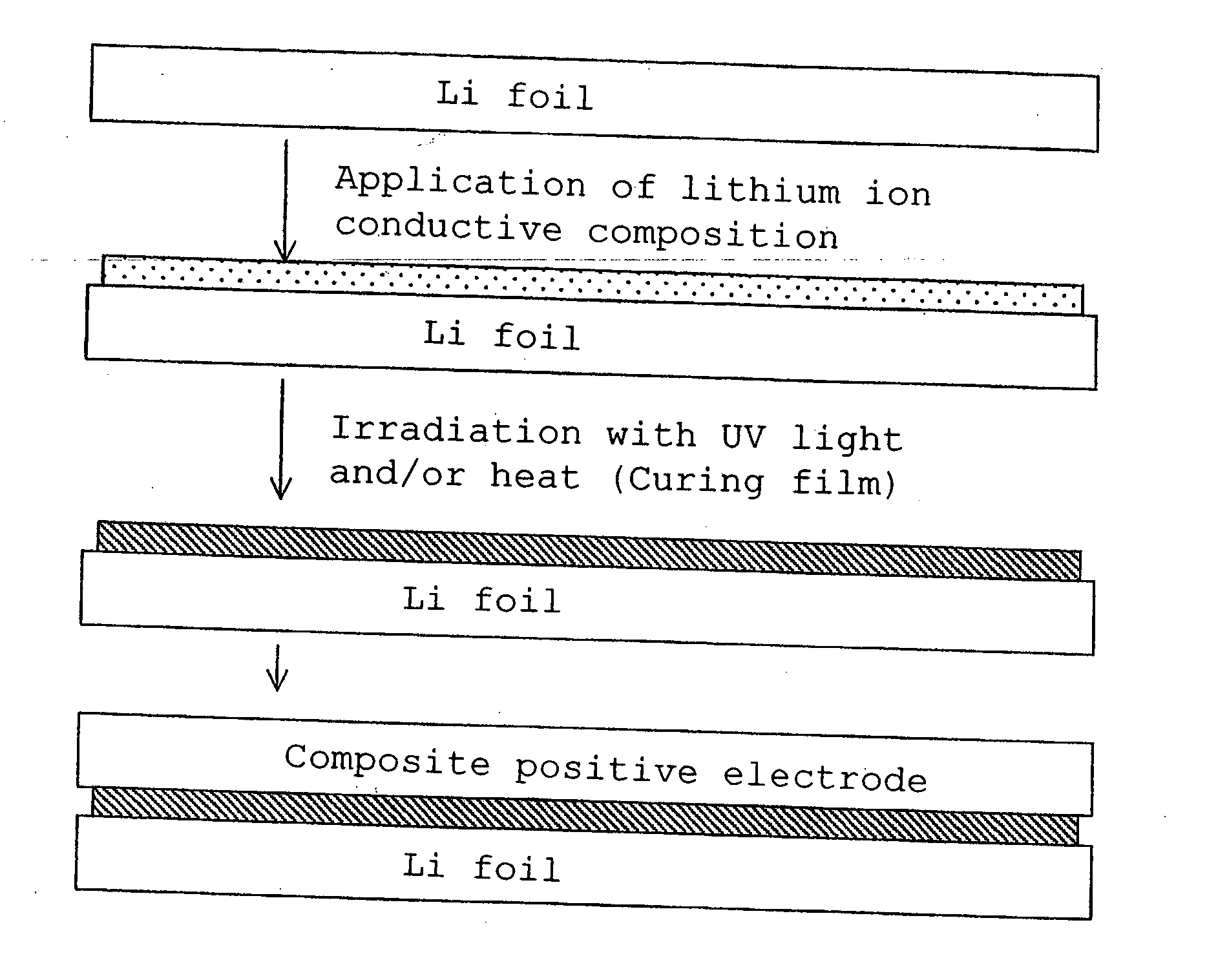

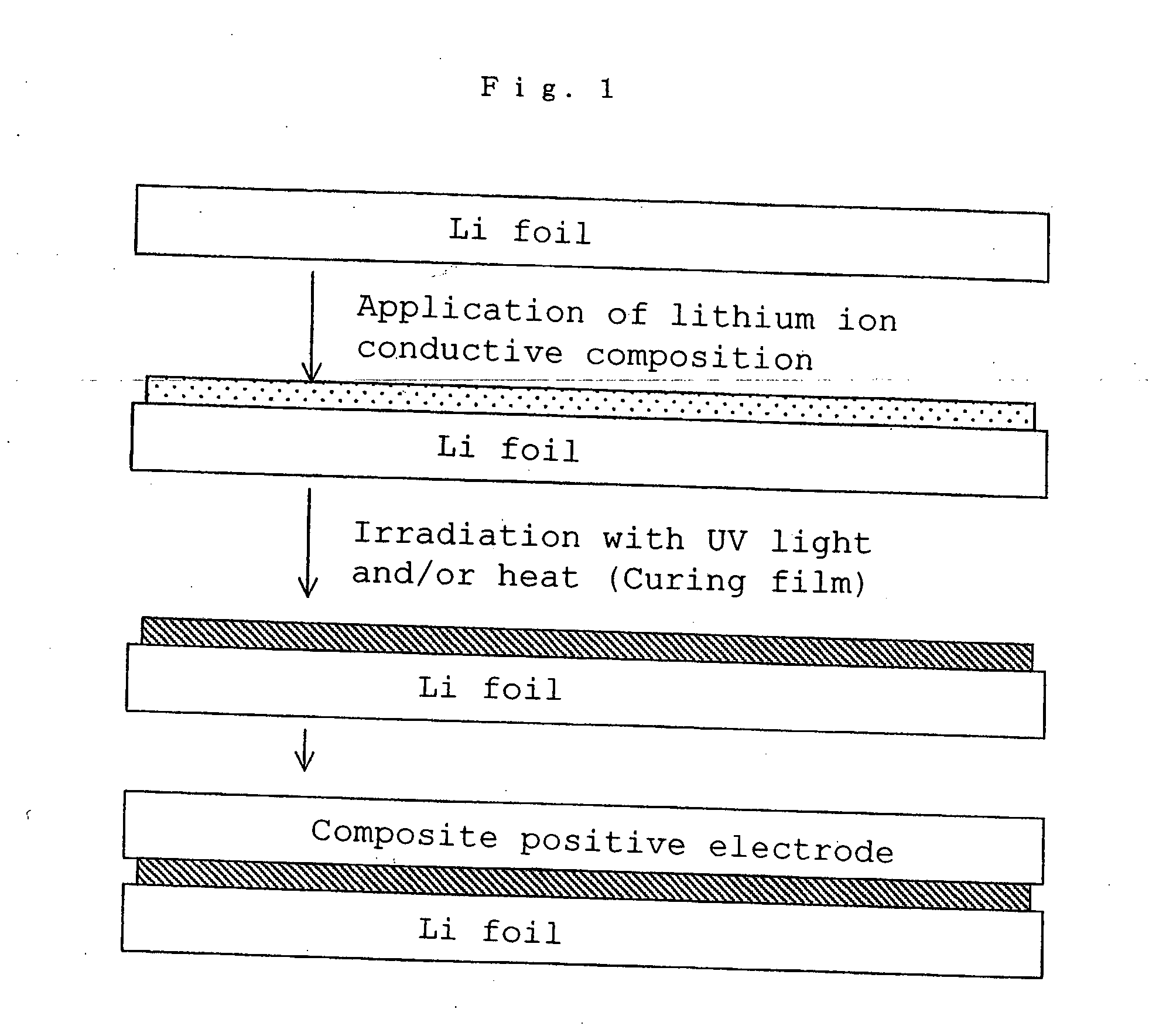

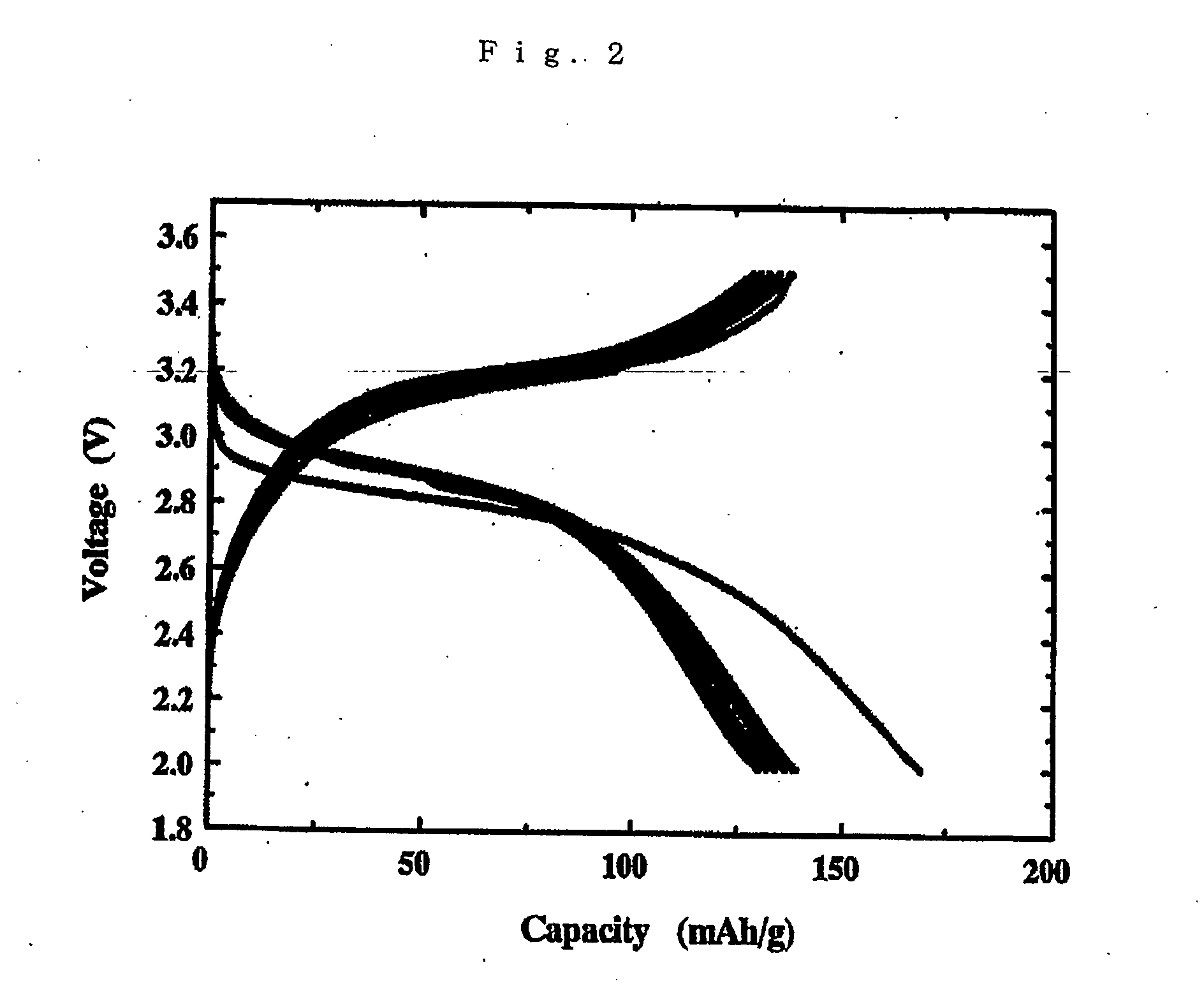

Lithium polymer cell and manufacturing method thereof

InactiveUS20050003276A1Satisfaction intensityImprove battery performanceSolid electrolytesFinal product manufactureLithiumElectrolysis

The present invention provides a lithium polymer cell having high ion conductivity and solid strength high enough to be used as a solid electrolyte for electro-chemical element. The present invention relates to a lithium polymer cell sandwiching between a positive electrode and a negative electrode a solid electrolyte formed from a cured film formed of a lithium ion conductive composition comprising one or more curable oligomers, one or more ethylenically unsaturated monomers and electrolytic salts, and a manufacturing method thereof.

Owner:THE NIPPON SYNTHETIC CHEM IND CO LTD +1

Method for preparing TiAl alloy plate without canning

The invention discloses a method for preparing a TiAl alloy plate without canning in order to solve the problems that an existing ingot metallurgy canning and rolling the TiAl alloy plate is complicated in process, high in machining cost and low in raw material utilization rate, and a TiAl alloy bar prepared through a powder metallurgy method is easy to introduce impurities and is high in cost. The method comprises the specific steps of 1, weighing all raw material ingredients; 2, preparing a casting ingot through induction skull melting of a water-cooling copper crucible and melted model precision casting; 3, carrying out blank pre-treatment; 4, carrying out a first plate extrusion stage; 5, carrying out a second plate extrusion stage, thus obtaining the TiAl alloy plate. According to the method for preparing the TiAl alloy plate without canning, disclosed by the invention, the surface of the obtained plate is smooth and has no cracks, and the TiAl alloy plate is uniformly organized, is small in crystal grain and has excellent mechanical performance.

Owner:TAIYUAN UNIV OF TECH

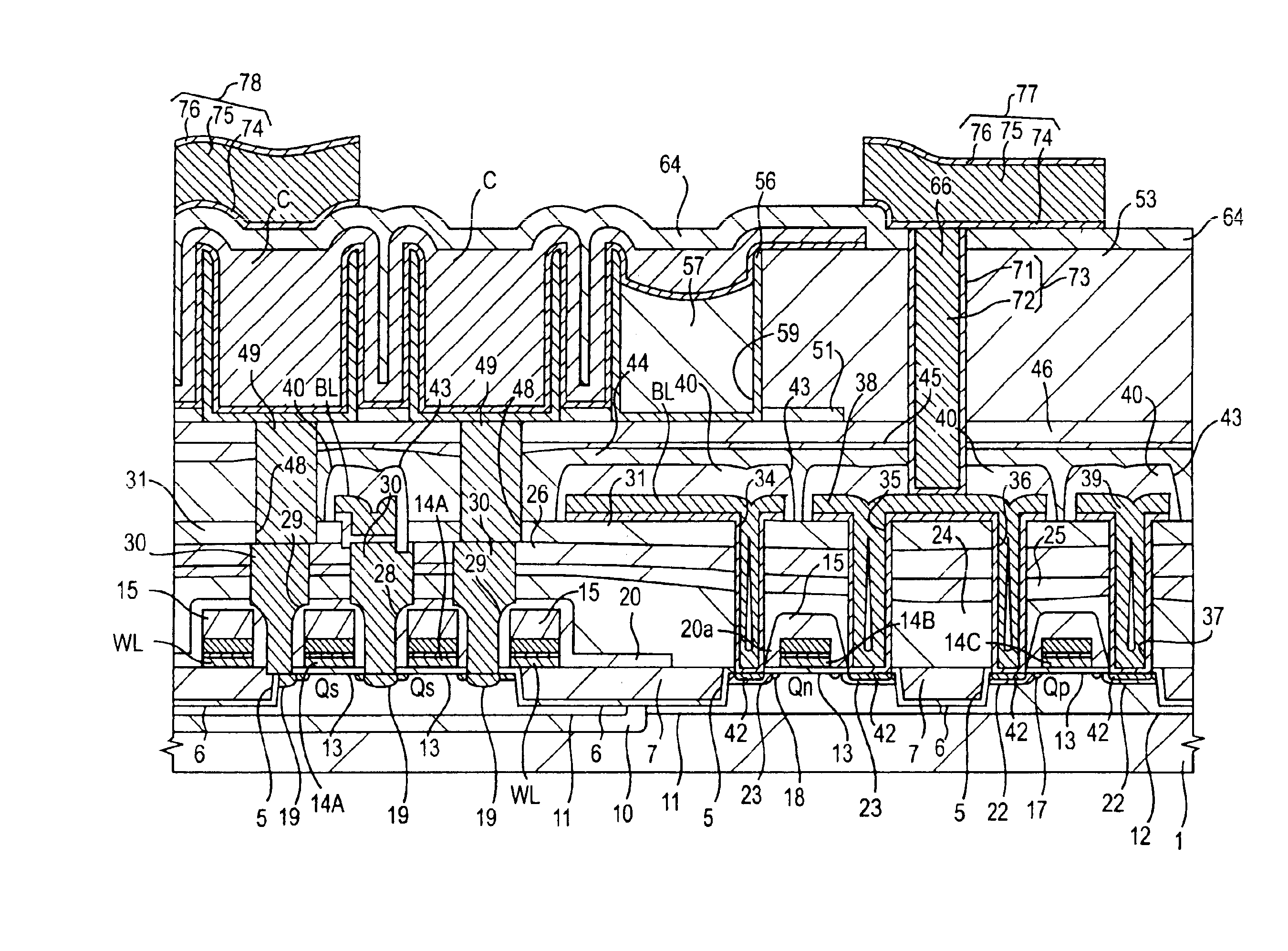

Method for fabricating semiconductor integrated circuit

InactiveUS6853081B2Easy to corrodeReduce corrosionSemiconductor/solid-state device detailsSolid-state devicesDevice materialSilicon oxide

The semiconductor device is formed according to the following steps. A TiN film 71 and a W film 72 are deposited on a silicon oxide film 64 including the inside of a via-hole 66 by the CVD method and thereafter, the W film 72 and TiN film 71 on the silicon oxide film 64 are etched back to leave only the inside of the via-hole 66 and form a plug 73. Then, a TiN film 74, Al-alloy film 75, and Ti film 76 are deposited on the silicon oxide film 64 including the surface of the plug 73 by the sputtering method and thereafter, the Ti film 76, Al-alloy film 75, and TiN film 74 are patterned to form second-layer wirings 77 and 78.

Owner:LONGITUDE SEMICON S A R L

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com