Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

249 results about "Radial forging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

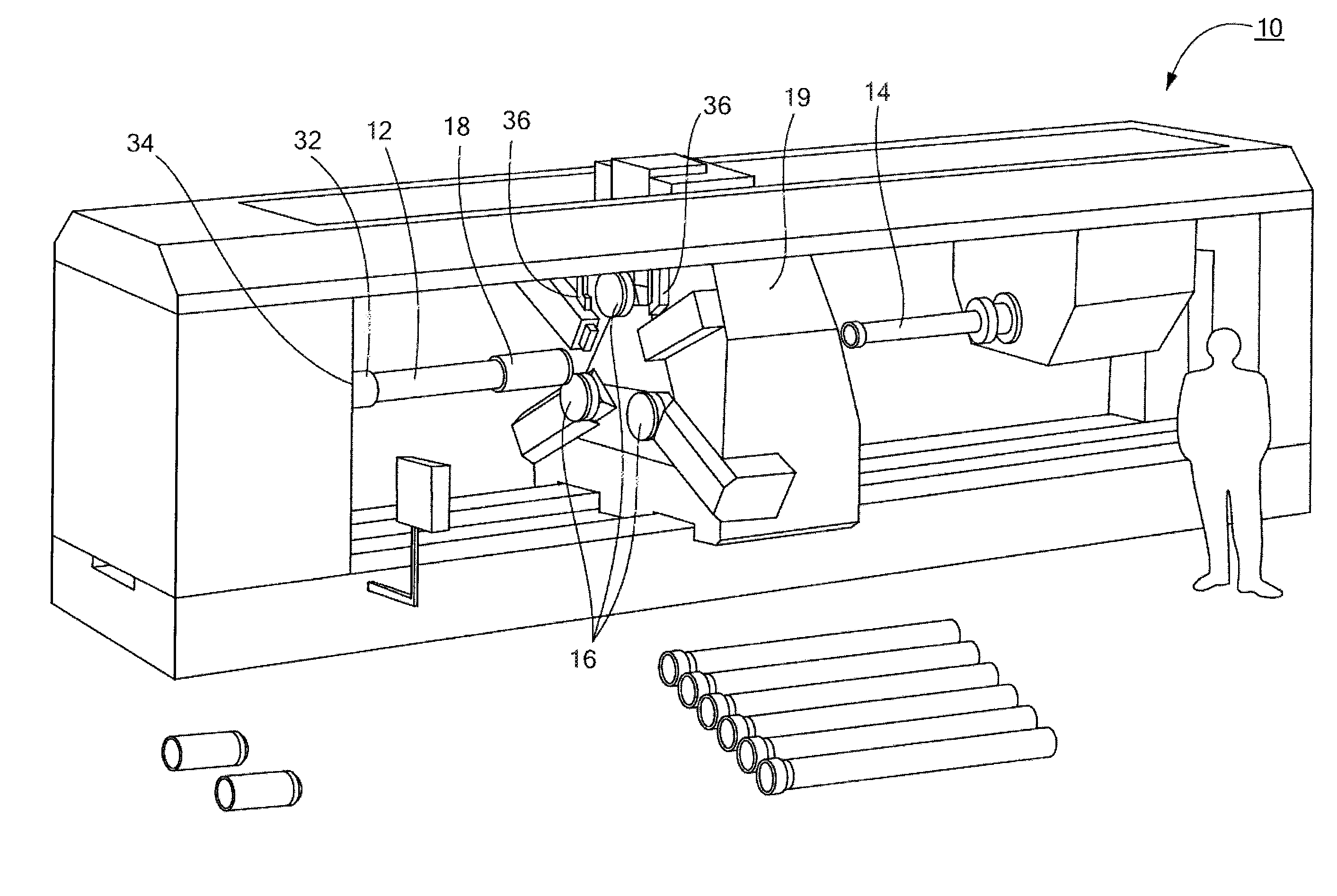

Radial Forging Process Radial forging is an open-die process for converting ingots to billets, reducing cross sections of billets, and forging shafts and axles. The radial forging machine at Teledyne is a Model SXP-55 GFM (Gesellschaft fur Fertigung und Maschinenbau).

Forging method of high-temperature alloy fine-grained bars

The invention belongs to the technical field of forging, and relates to a forging method of high-temperature alloy fine-grained bars. According to the invention, a combined breakdown production method of upsetting and stretching, and radial forging is adopted. A deflection is large, deflection directions are changed alternately, carbide is sufficiently crushed, and carbide is distributed in a dispersed state, such that the fatigue property of the alloy is improved. The bar is finally subject to one-heating molding through radial forging, such that grain growing caused by the direct fired bar which is delivered back to a furance is avoided. Also, the method is beneficial for excircle deflection of the bar. Therefore, fine-grained bars with a grain grade difference smaller than 2 grades areobtained. The method is a novel method with a good prospect. The method is suitable for high-temperature alloy fine-grained bar productions. If the method is popularized, good social and economical benefits can be brought in.

Owner:CENT IRON & STEEL RES INST

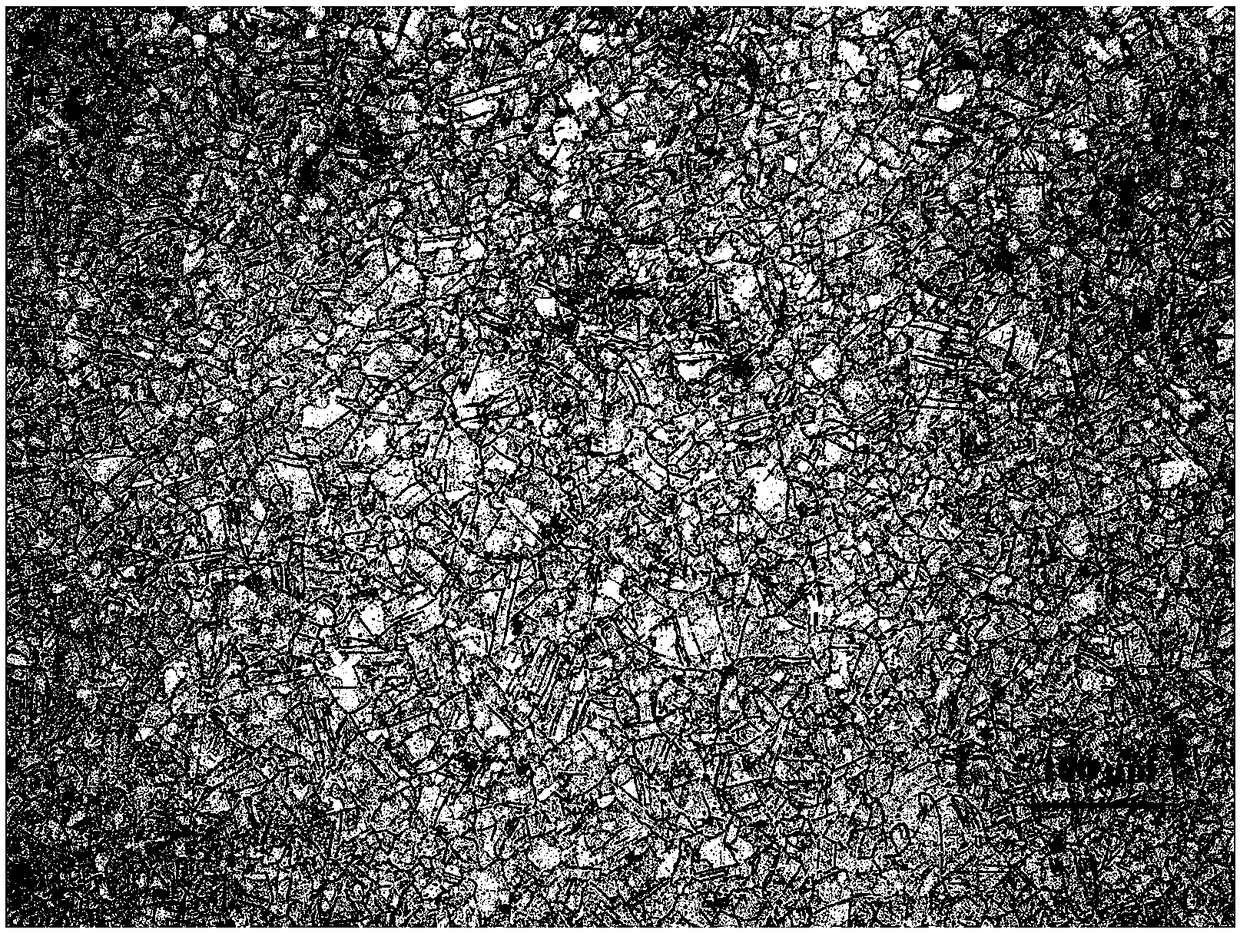

Process for manufacturing type alpha+beta titanium alloy rod bar for rotor impeller vane

InactiveCN101294264AEliminate surface oxidationPrevent surface oxidationTemperature control deviceBlade accessoriesImpellerIngot

The invention relates to an Alpha+Beta type titanium alloy steel bar fabrication technology used on a rotor vane, which comprises the following steps: (1) a cast ingot is heated, and the temperature is risen to 40 to 60 DEG C above a Beta transformation point after entering in a furnace, and the temperature is kept for 10 to 20 hours; (2) the cast ingot is processed through cogging and smithing, each pier drawing deformation amount is controlled between 30 percent to 40 percent; the smithing is performed in a two phase region after the pier drawing, and the total deformation amount is more than or equals to 90 percent; (3) the cast ingot is heated until the temperature reaches 20 to 40 DEG C above the transformation point after returning to the furnace, the temperature is preserved, and then the water quench is performed; (4) after the water quench, stocks are returned to the furnace and heated, and then are heat-preserved in the two phase region; the two phase region smithing is performed in a radial forging machine after the stocks reach a certain temperature, and the lengthening coefficient is controlled between 1.2 to 1.3; (5) after the radial smithing, the stocks is returned to the furnace and heat continuously and then is heat-preserved in the two phase region, then the stocks is rolled on a rolling mill, and the rolling temperature ranges from 910 to 940 DEG C. The Alpha+Beta type titanium alloy steel bar fabrication technology eliminates the figures on a macrostructure and the Beta spots on a microstructure of the heat strong two-phase titanium alloy caused by the hot work, and obtains a small-size two-phase titanium alloy steel bar with a fine and uniform equiaxed two-state structure.

Owner:BAOSHAN IRON & STEEL CO LTD

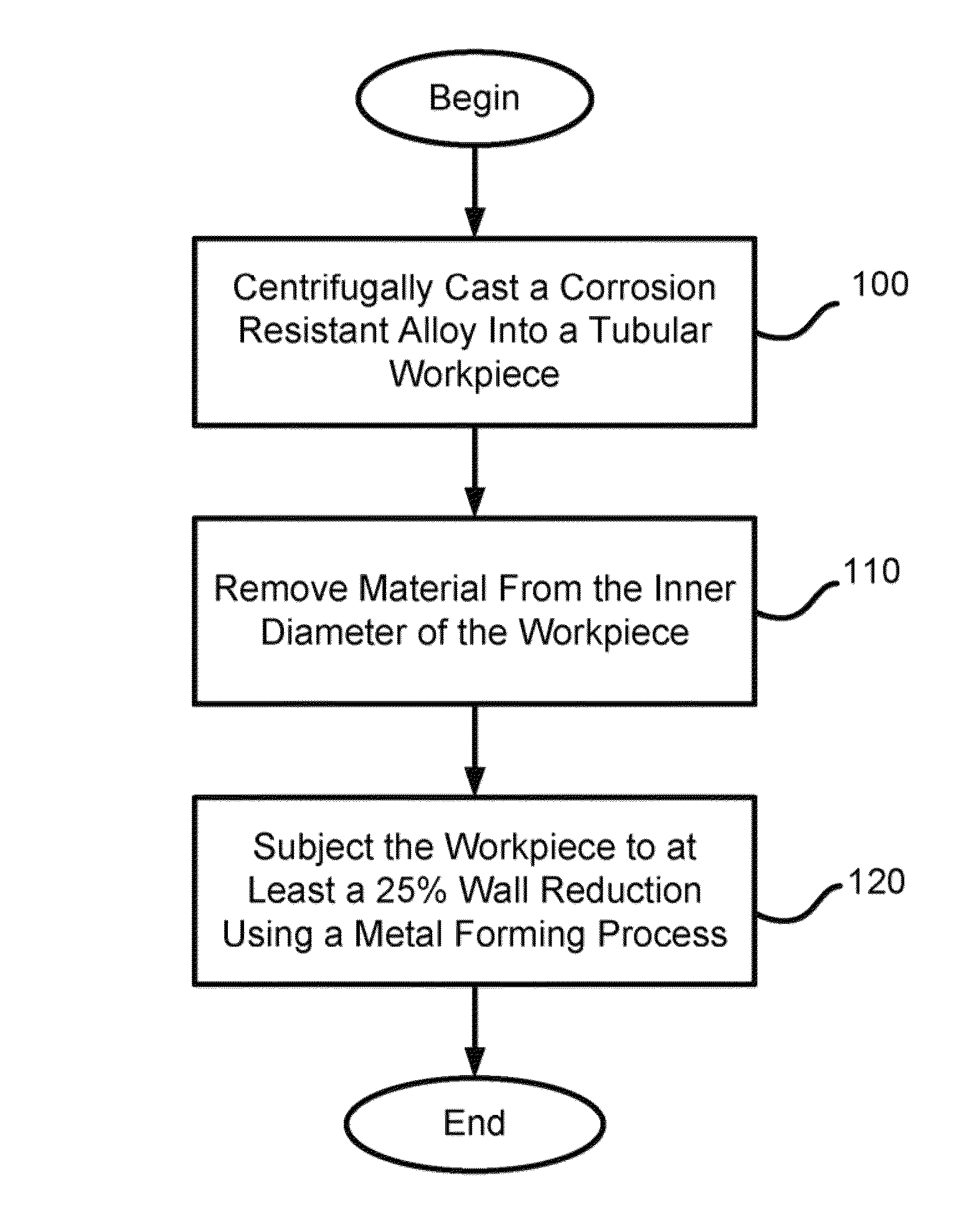

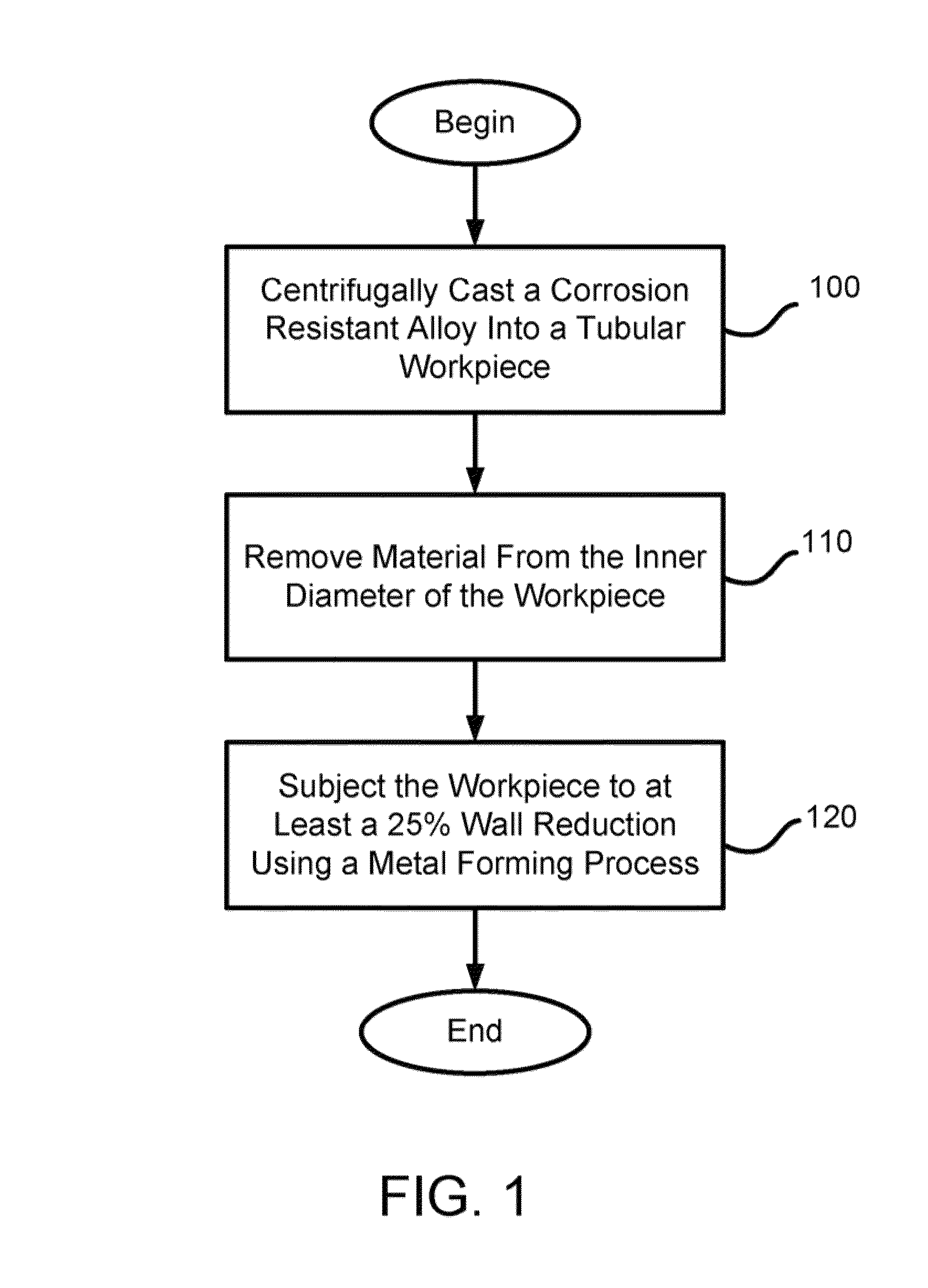

Method of producing cold-worked centrifugal cast tubular products

A method of producing a seamless, tubular product includes centrifugally casting a corrosion resistant alloy into a tubular workpiece having an inner diameter and an outer diameter. The method then removes material from the inner diameter of the workpiece and subjects the workpiece to at least about a 25% wall reduction at a temperature below a recrystallization temperature of the workpiece using a metal forming process. The metal forming process includes radial forging, rolling, pilgering, and / or flowforming.

Owner:ATI FLOWFORM PROD

GH3600 alloy fine thin-walled seamless pipe manufacturing method

The invention relates to a GH3600 alloy fine thin-walled seamless pipe manufacturing method, which comprises: adopting methods of vacuum induction smelting and electroslag remelting smelting to smelt a casting ingot meeting requirements; adopting a 2000 or 4000 ton rapid forging and 1300 ton radial forging thermal combined forging process to carry out cogging on the casting ingot so as to ensure complete crushing of the thick and large structure of the casting ingot, produce the round pipe billet with the uniform structure, increase the plasticity of material, and saves energy consumption; adopting a hot extrusion process to produce a lateral so as to ensure the uniformity of the internal structure of the lateral and the high quality of the external surface of the lateral, and make the performance of the produced finished product pipe excellent; and adopting a multi-pass cold rolling and cold drawing process and the matched heat treatment process, and assistedly adopting the special lubrication process and the cleaning process to control the structure and the high performance of the pipe so as to finally obtain the GH3600 alloy fine thin-walled pipe with characteristics uniform and fine pipe structure and high comprehensive performance.

Owner:宝武特种冶金有限公司

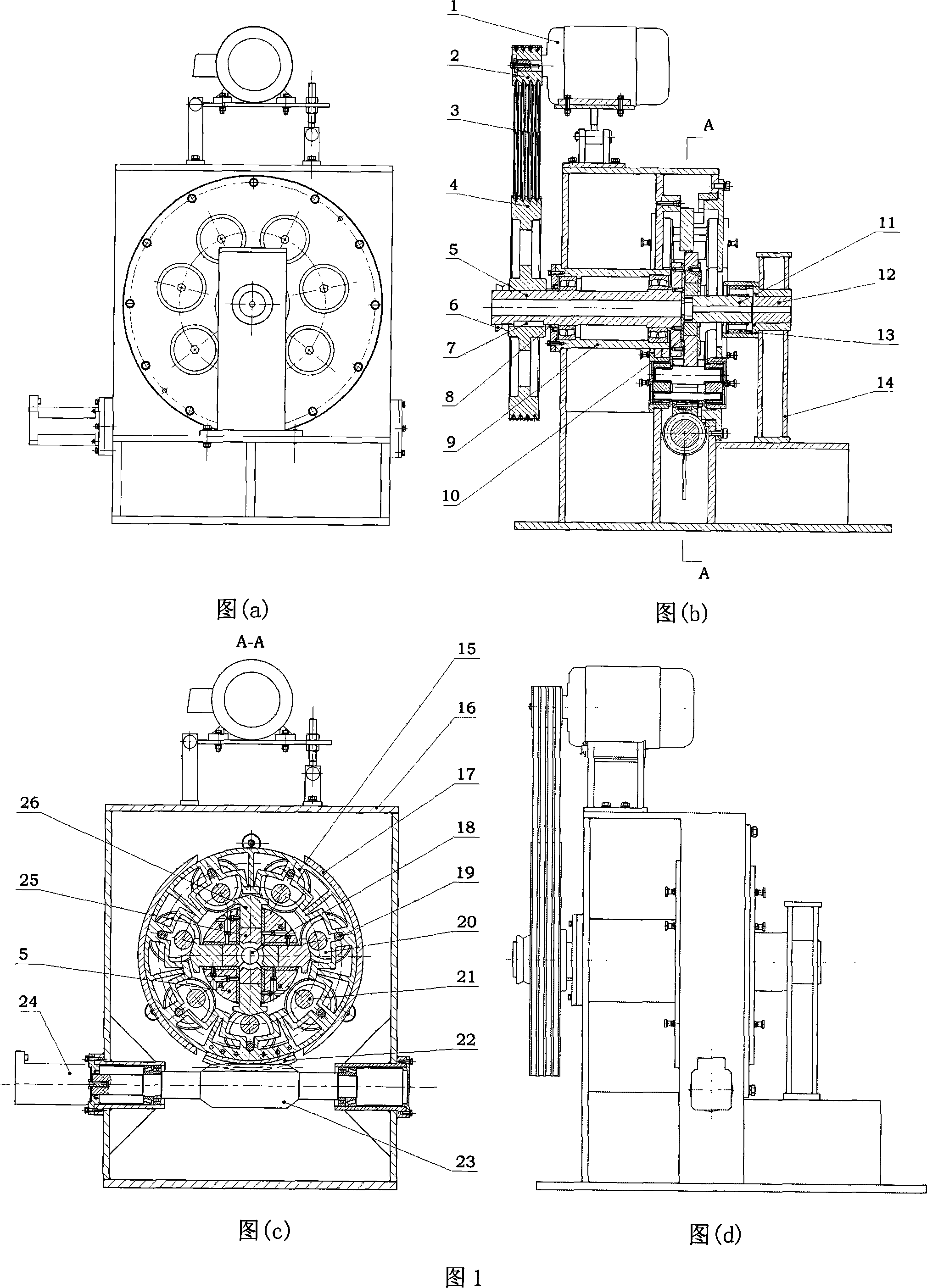

Unsymmetrical radial welding punched high performance precision blanking machine

InactiveCN101058110AEnsure stabilityGuaranteed mechanical propertiesHammer drivesForging/hammering/pressing machinesKinematicsEngineering

The invention relates to an asymmetrical radial forging highly efficient precision feeder which comprises at least the drive mechanism, radial forging feeding and stroke micro tuning structure and bar material fixture device, with the radial feeding device using hammer cycloid design, cam using cylinder roller device, without impact and stable movement. The turbine worm stroke adjusting device uses separate turbine gear structure, and be able to improve stroke adjustment structure' kinematic behavior. Through servo generator variable-frequency control function, it can make precise blank with various material and different size.

Owner:XI AN JIAOTONG UNIV

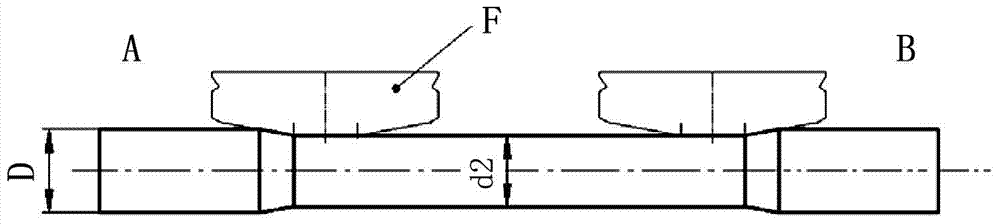

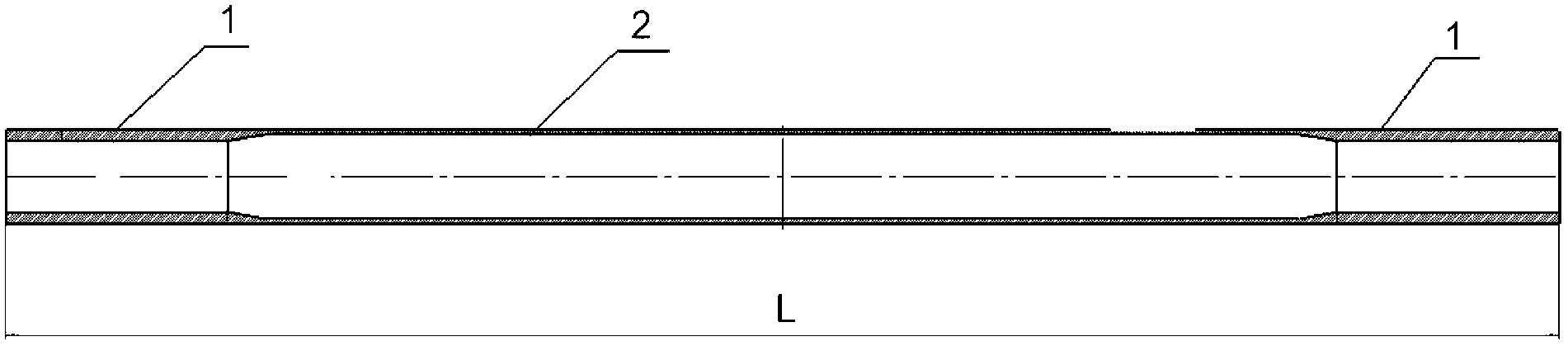

Radial forging method for high temperature alloy step shaft

The invention provides a radial forging method for a high temperature alloy step shaft. The method includes: upsetting and drawing out a steel ingot, and providing a blank to a forging machine; forging the blank in multiple passes, and pre-forging to form a first step shaft; forging the middle of the first step shaft in multiple passages so as to form a middle step shaft, and forming a transition section between the first step shaft and the middle step shaft, wherein pulling speed for forming the first step shaft is controlled to be 3-5.5m / min, deformation of each pass for forming the middle step shaft is controlled to be 10-25%, and pulling speed for forming the middle step shaft is controlled to be 3-5.5m / min. By control on forging frequency, reduction in pass and pull speed of the radial forging method and by control on final forging temperature, the property structure of a step shaft product is controlled, quality stability and structure property uniformity of the product are improved greatly while comprehensive yield and qualified rate of the product are increased greatly.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

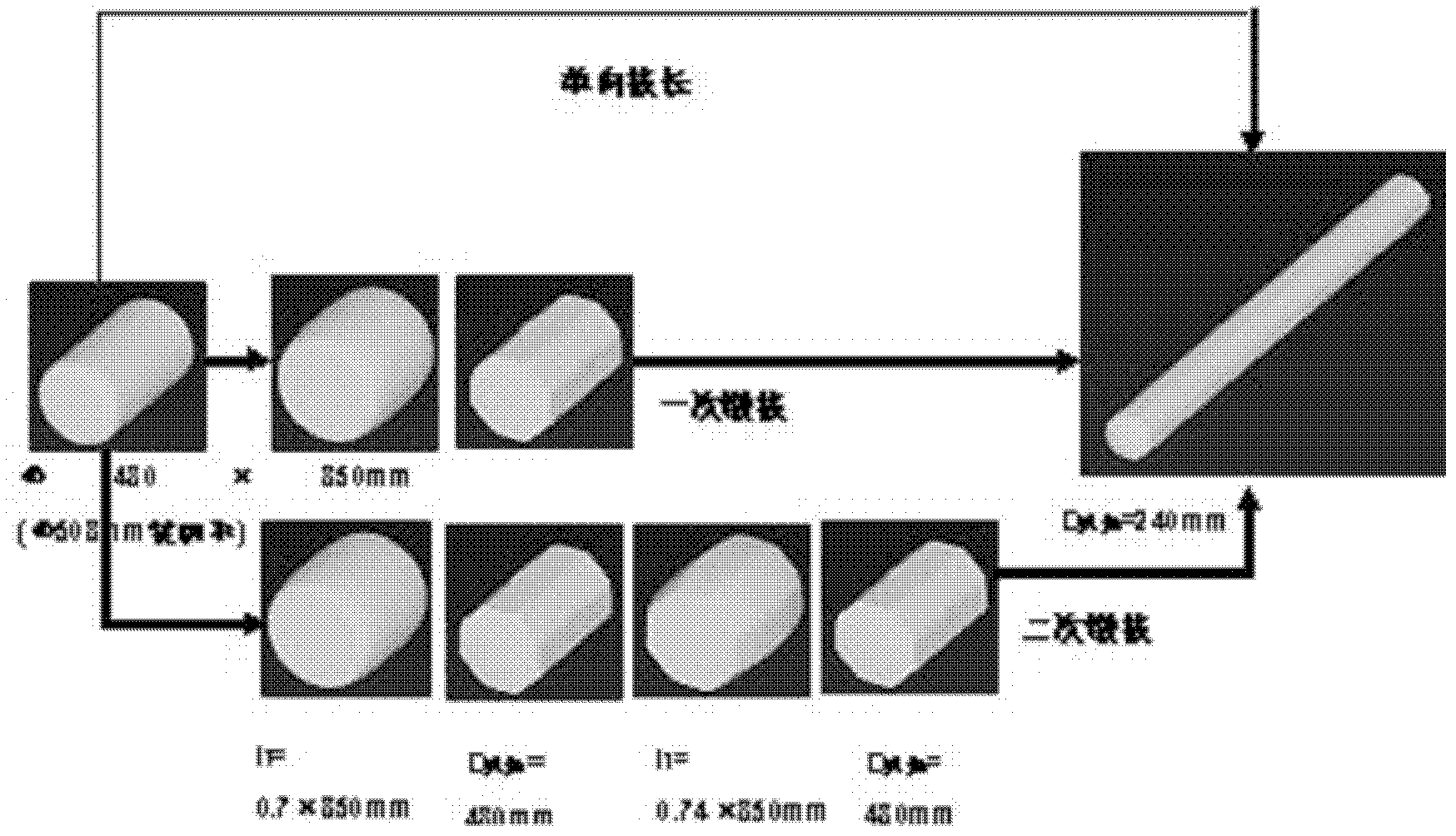

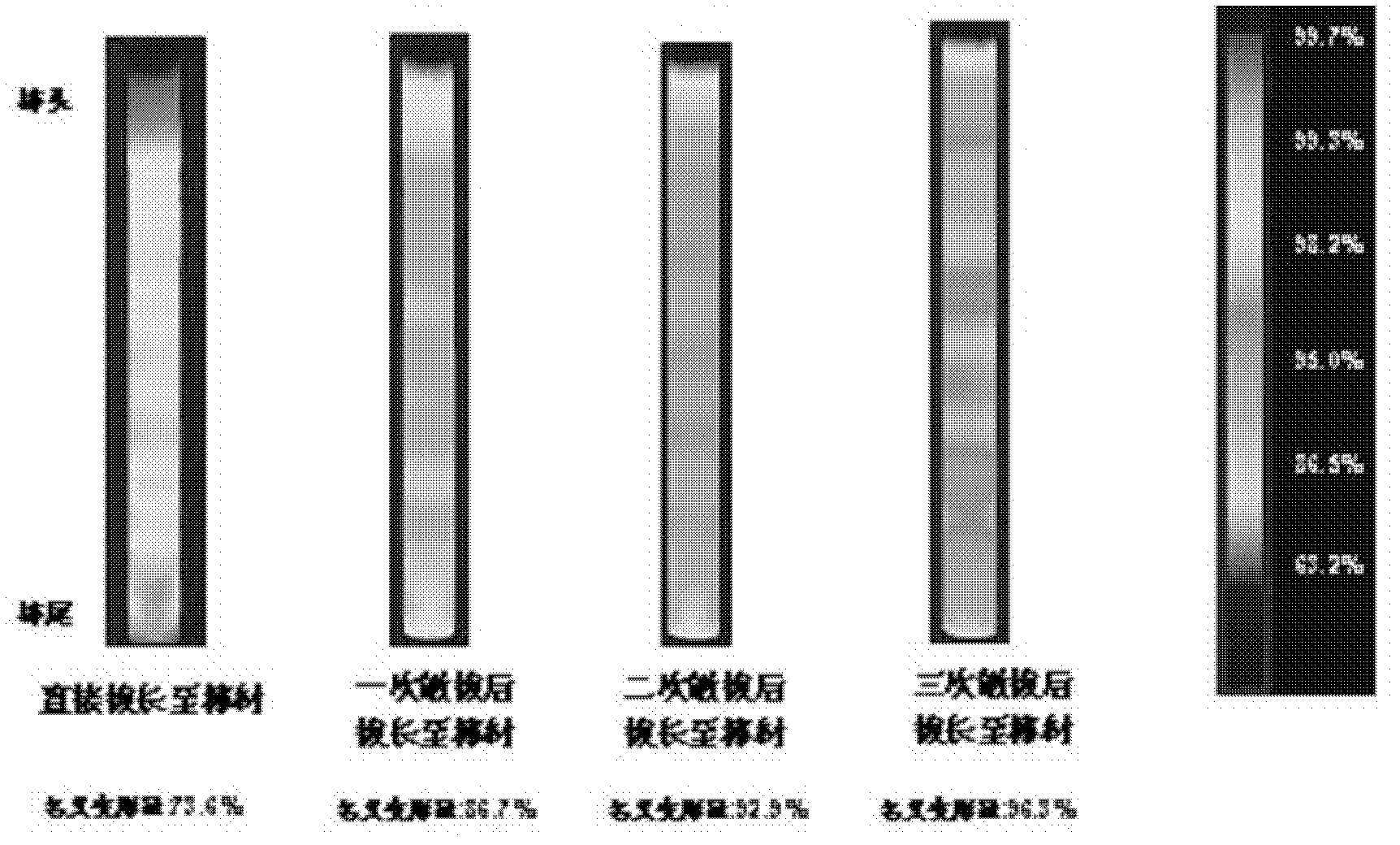

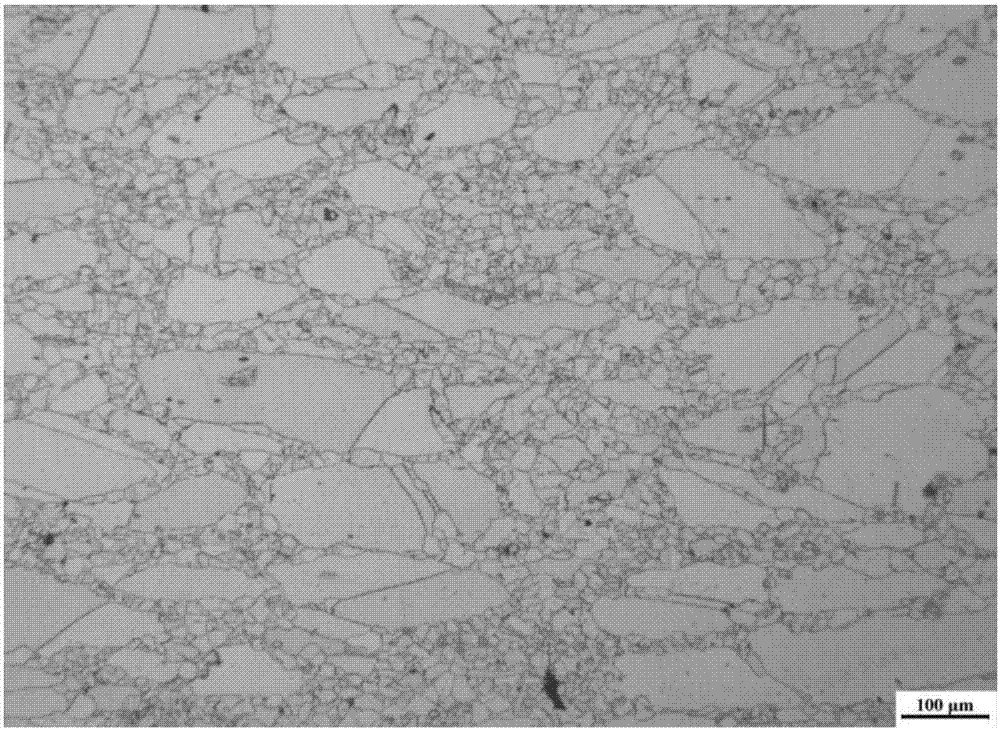

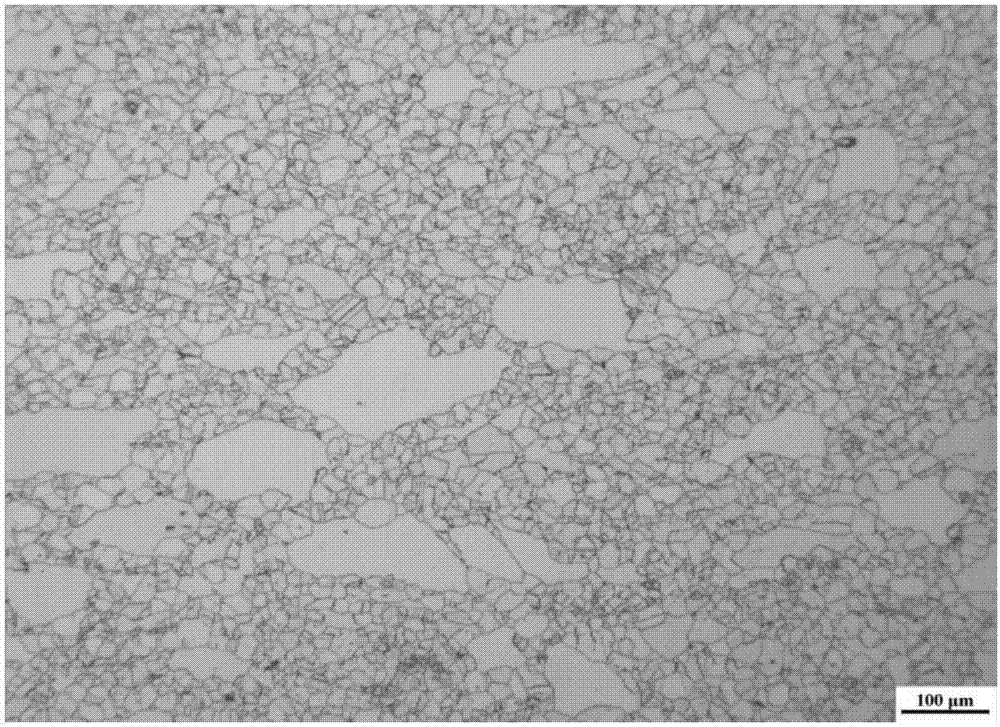

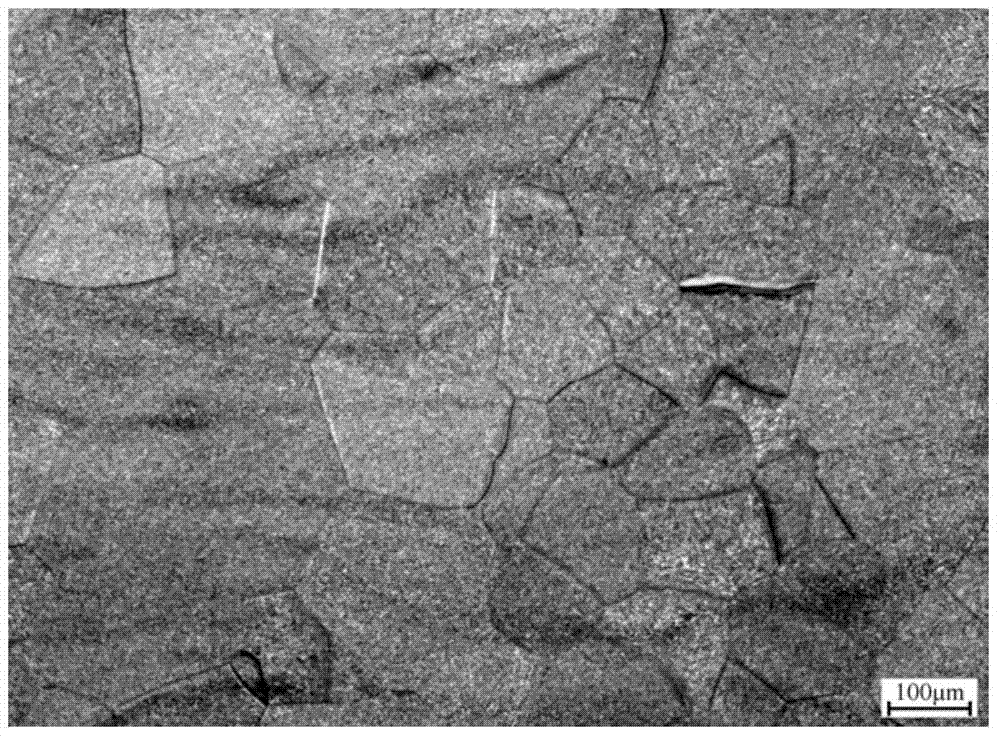

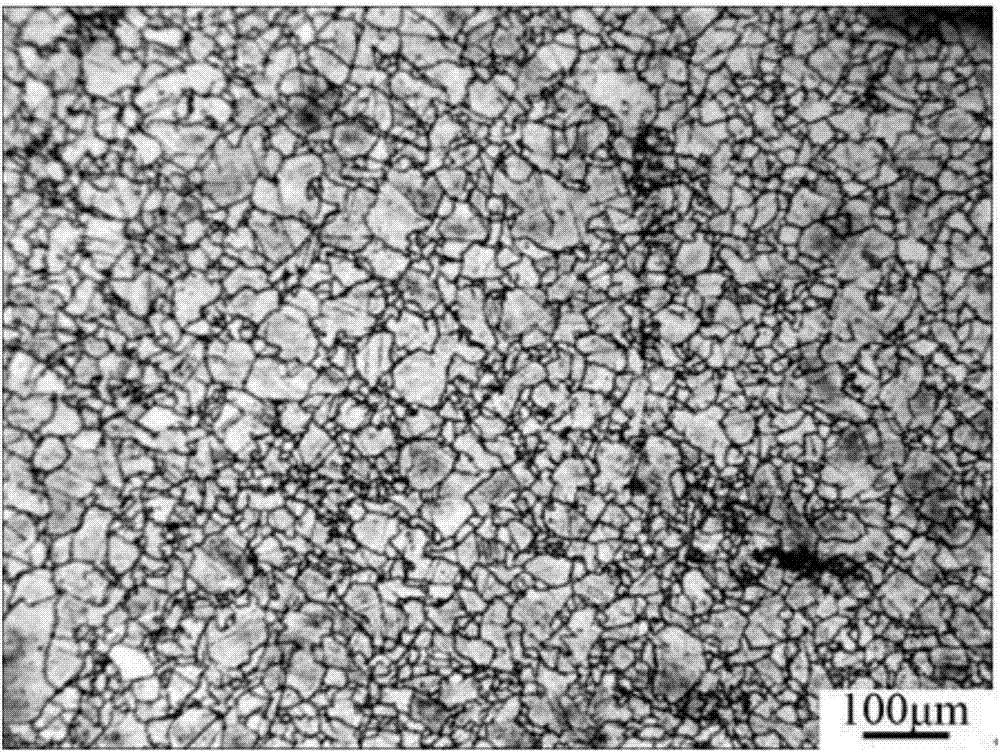

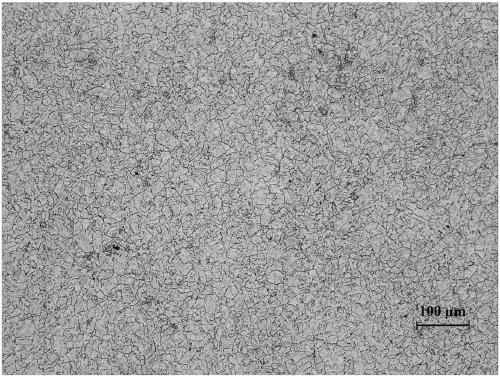

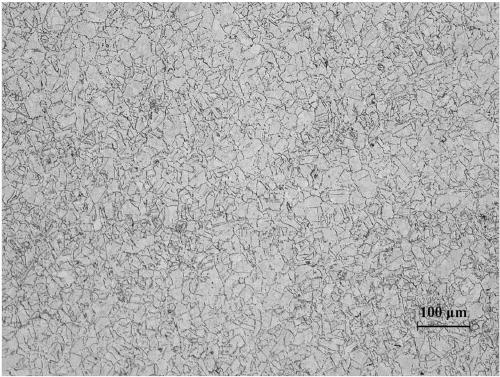

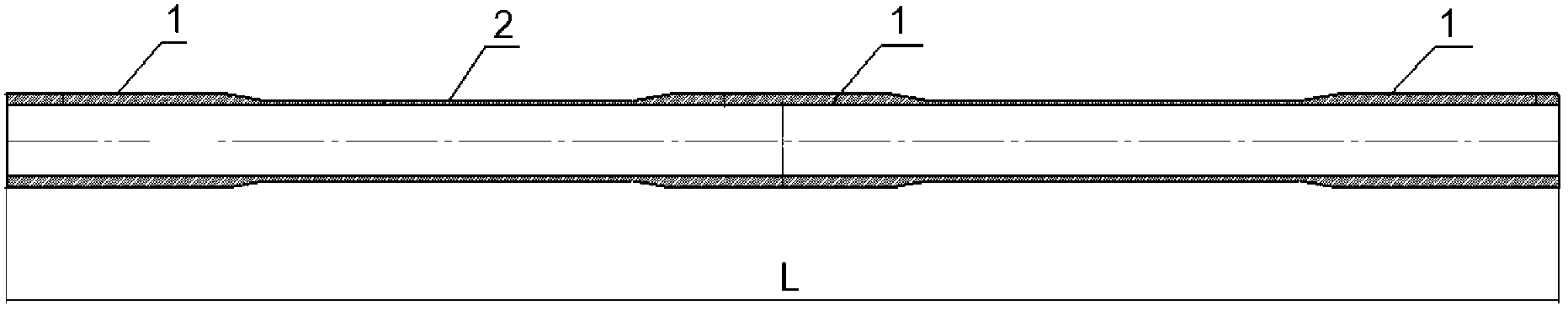

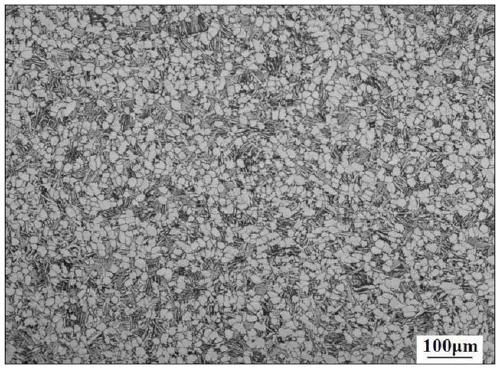

Manufacturing method for producing high-temperature alloy GH4169 fine-grained bar through combined high-speed and radial forging

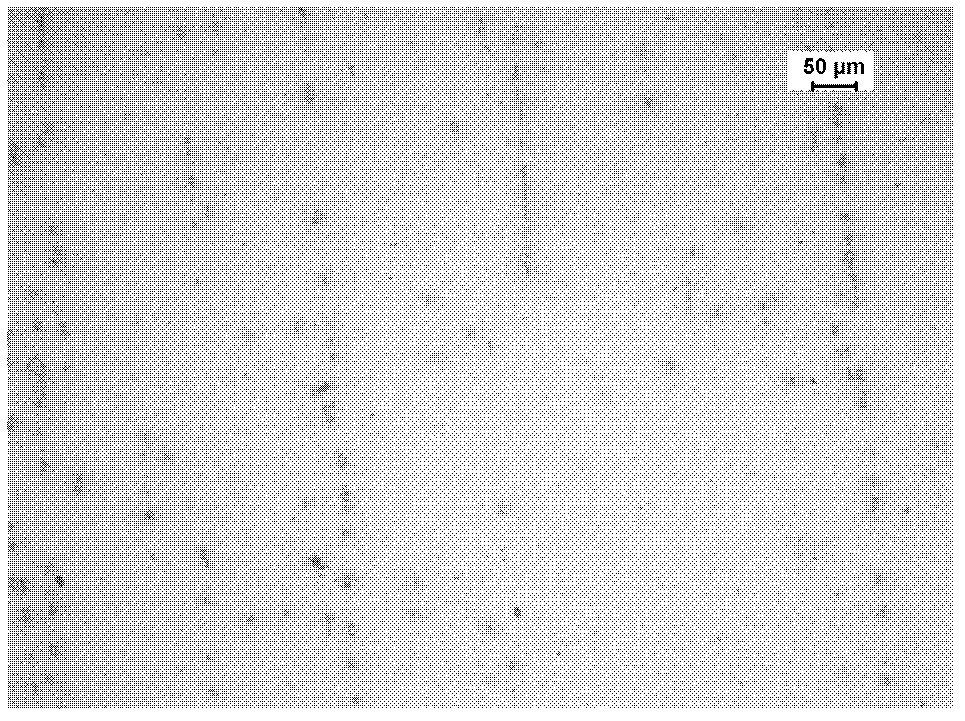

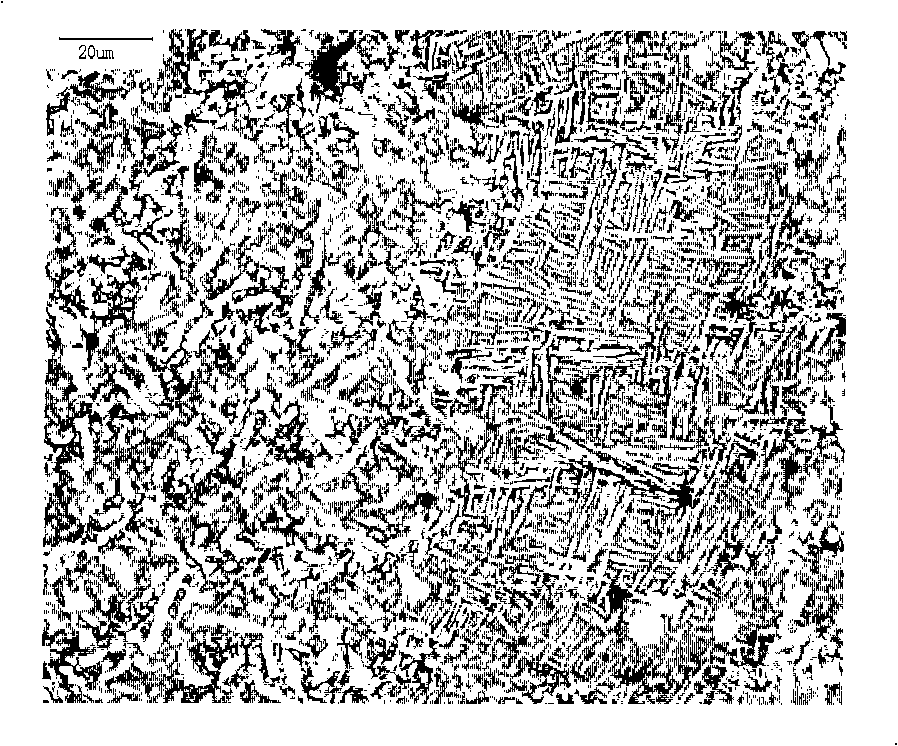

The present invention discloses a manufacturing method for producing a high-temperature alloy GH4169 fine-grained bar through combined high-speed and radial forging with the purpose of providing the alloy bar with grains at an equally high grain size number. The present invention employs the following technical scheme: repeated upsetting and stretching are carried out to an alloy ingot using a high-speed forging machine, with 25% to 35% upsetting deformation in each firing; cooling and cogging are carried out firing by firing, with a cooling gradient d from 1110+ / -10 DEG C to 1100+ / -10 DEG C to 1080+ / -20 DEG C to 1040+ / -20 DEG C; before radial forging, a blank is heated at a temperature ranging from 990 to 1020 DEG C with heat preserved for 40 to 120 min, and then forged in one firing on a radial forging machine to a finished bar size, with a final forging temperature not lower than 950 DEG C, and carrying out water cooling to a room temperature after the radial forging. The manufacturing method for producing a high-temperature alloy GH4169 fine-grained bar through combined high-speed and radial forging has the following technical effects: (1) the microstructure uniformity of a bar is significantly improved with a completely recrystallized equiaxial grain structure from the periphery to the center of the bar, and the grain size may reach grade six or higher; and (2) the head and tail of a bar are uniform and homogeneous in structure; and (3) stable batch production of bars is achieved.

Owner:FUSHUN SPECIAL STEEL SHARES

High-strength metastable beta-type titanium alloy bar and production method thereof

The invention discloses a high-strength metastable beta-type titanium alloy bar. The high-strength metastable beta-type titanium alloy bar comprises, by atomic percent, 13% of Al, 5% of V, 5% of Mo, 4%-6% of Cr and the balance Ti and inevitable impurities. Additionally, the invention further discloses a production method of the high-strength metastable beta-type titanium alloy bar. The production method includes firstly, preparing titanium alloy casting ingots; secondly, producing forging billets by billet forging; thirdly, producing a semi-finished titanium alloy bar by upsetting and stretching forging and radial forging; fourthly, subjecting the semi-finished titanium alloy bar to solid solution treatment and aging treatment so as to obtain the metastable beta-type titanium alloy bar. The high-strength metastable beta-type titanium alloy bar produced by the specific heat forging technique and a solid solution and aging treatment system has excellent comprehensive mechanical property; at the room temperature, tensile strength of the high-strength metastable beta-type titanium alloy bar is not less than 1290MPa, yield strength thereof is not less than 1190MPa, elongation percentage thereof is not less than 11%, and section shrinkage rate thereof is not less than 45%.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

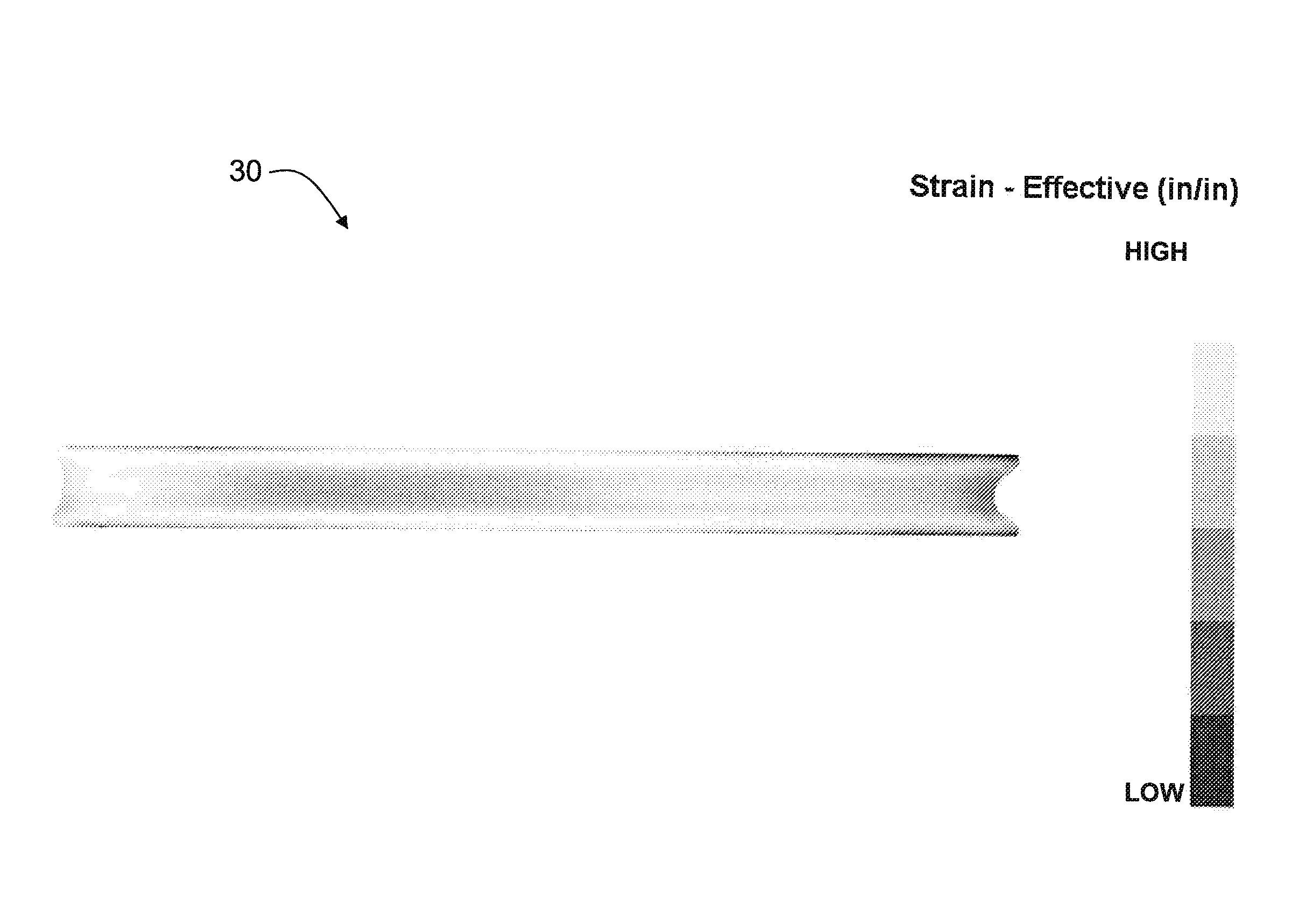

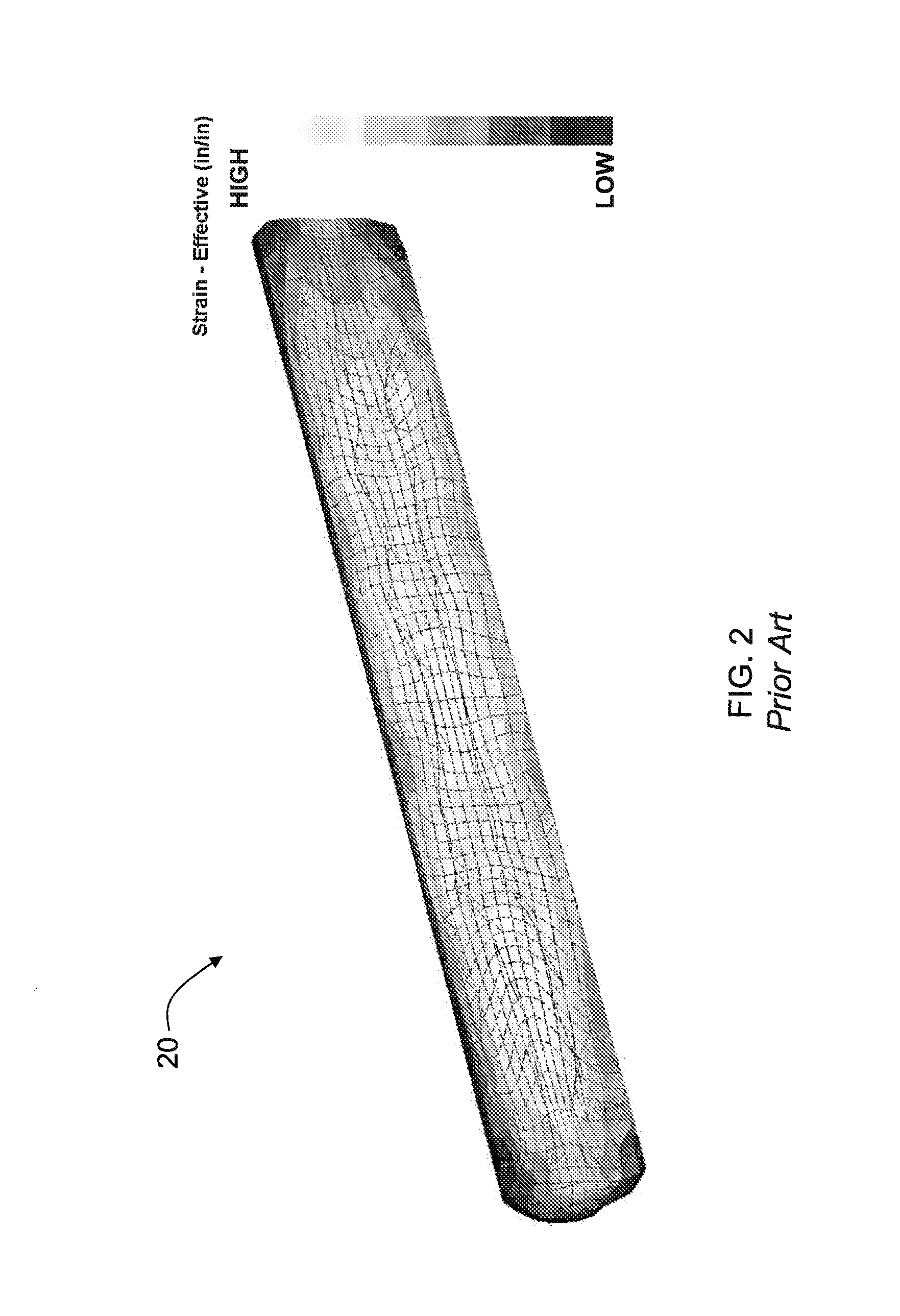

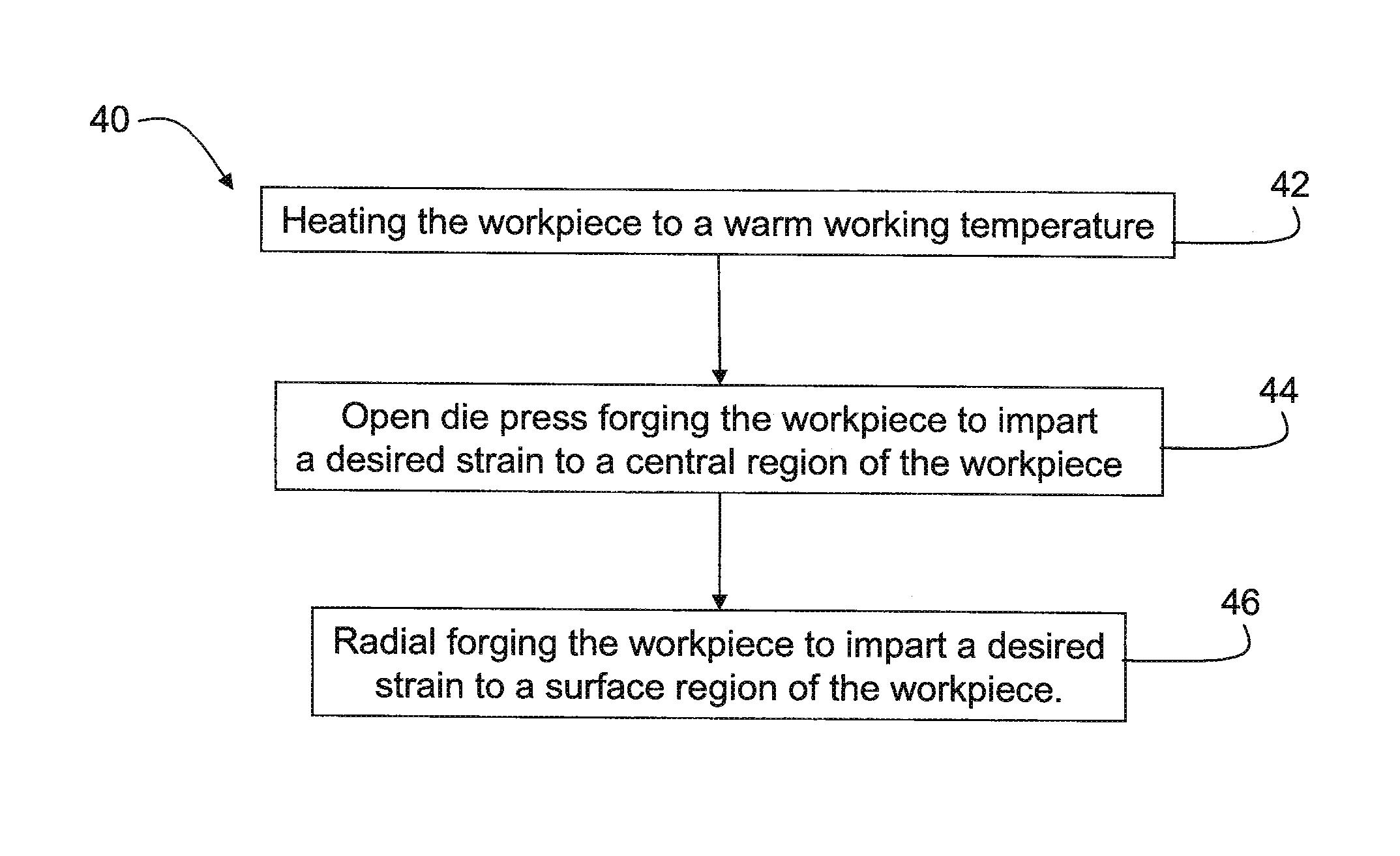

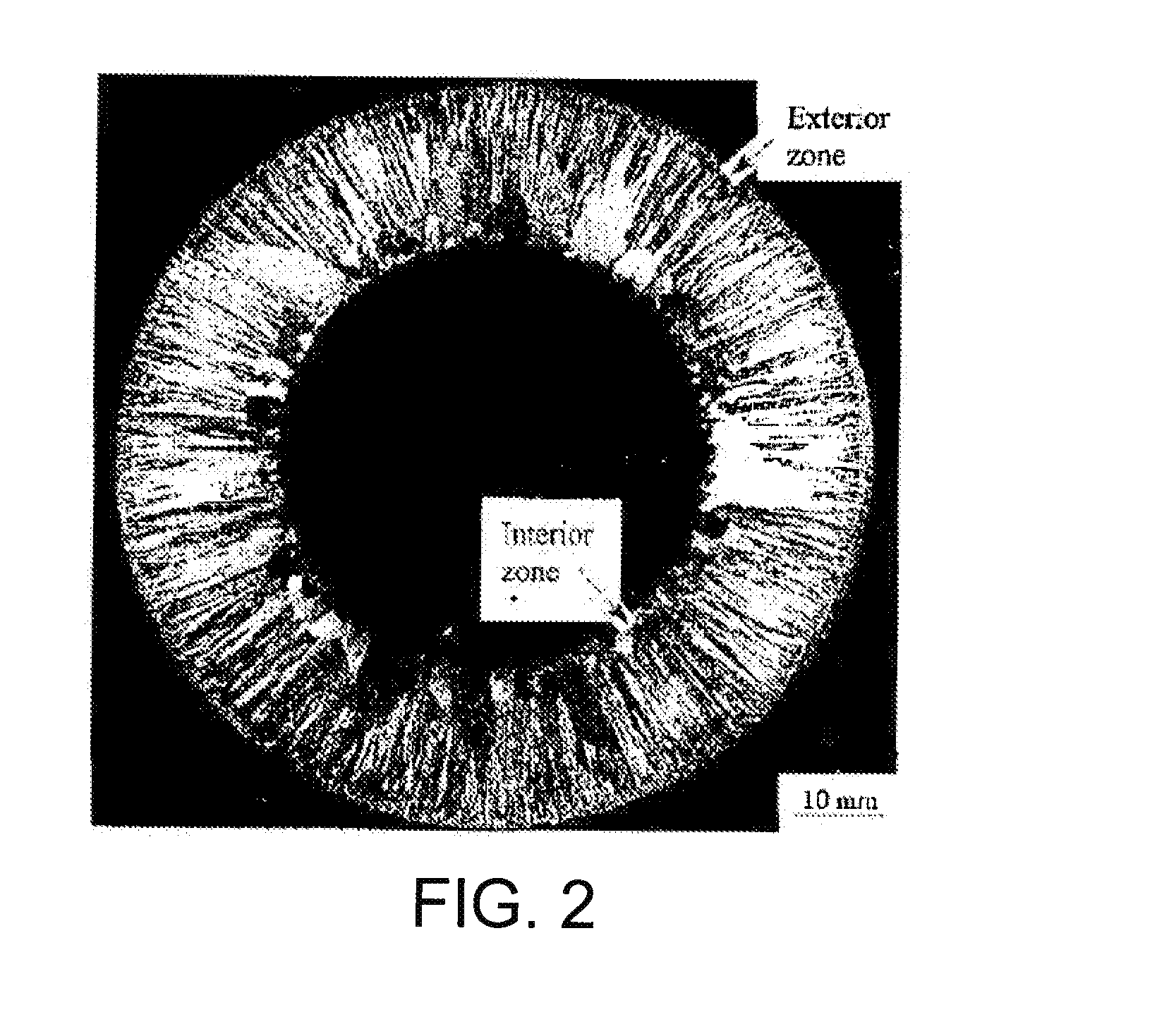

Thermomechanical processing of high strength non-magnetic corrosion resistant material

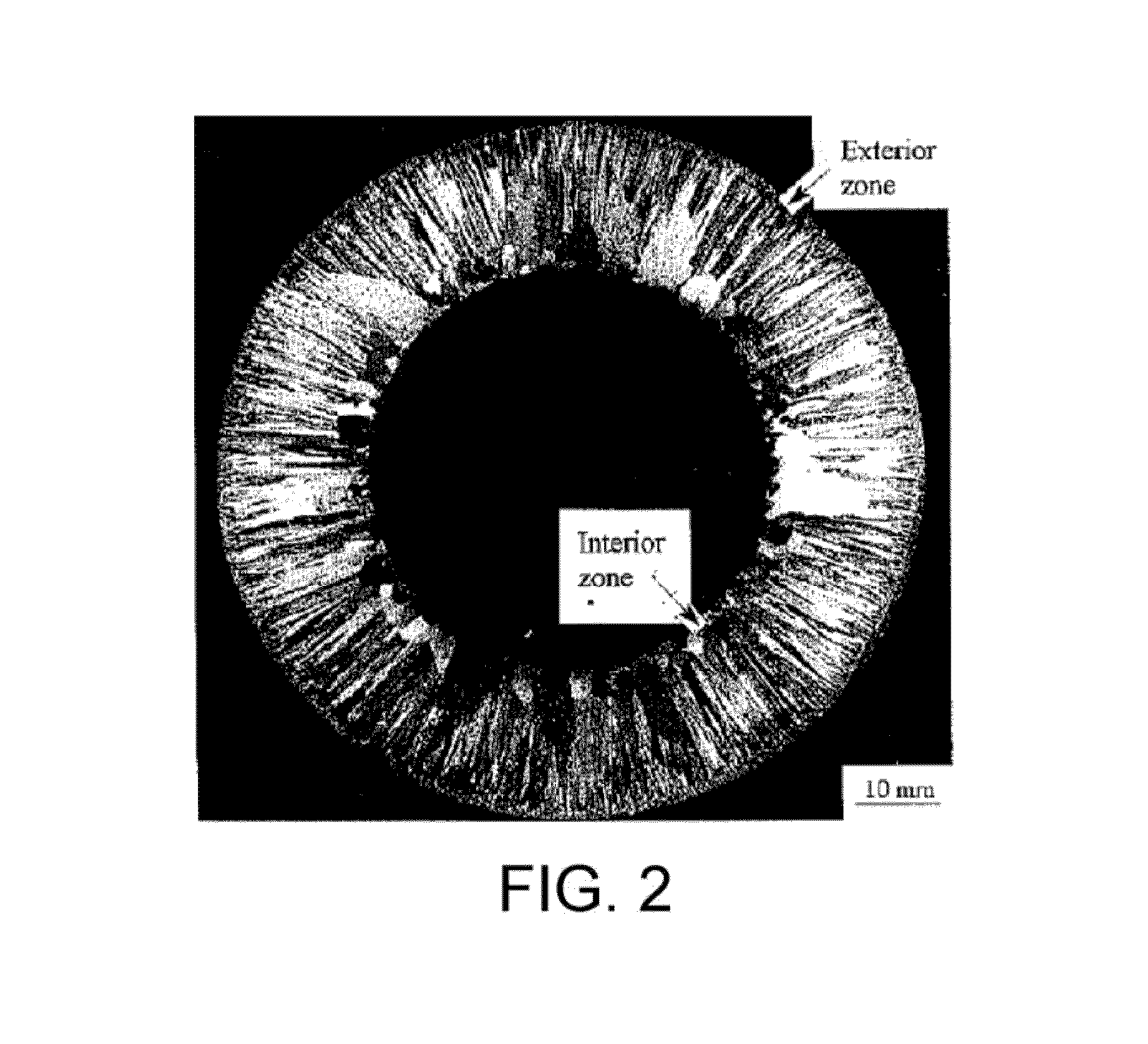

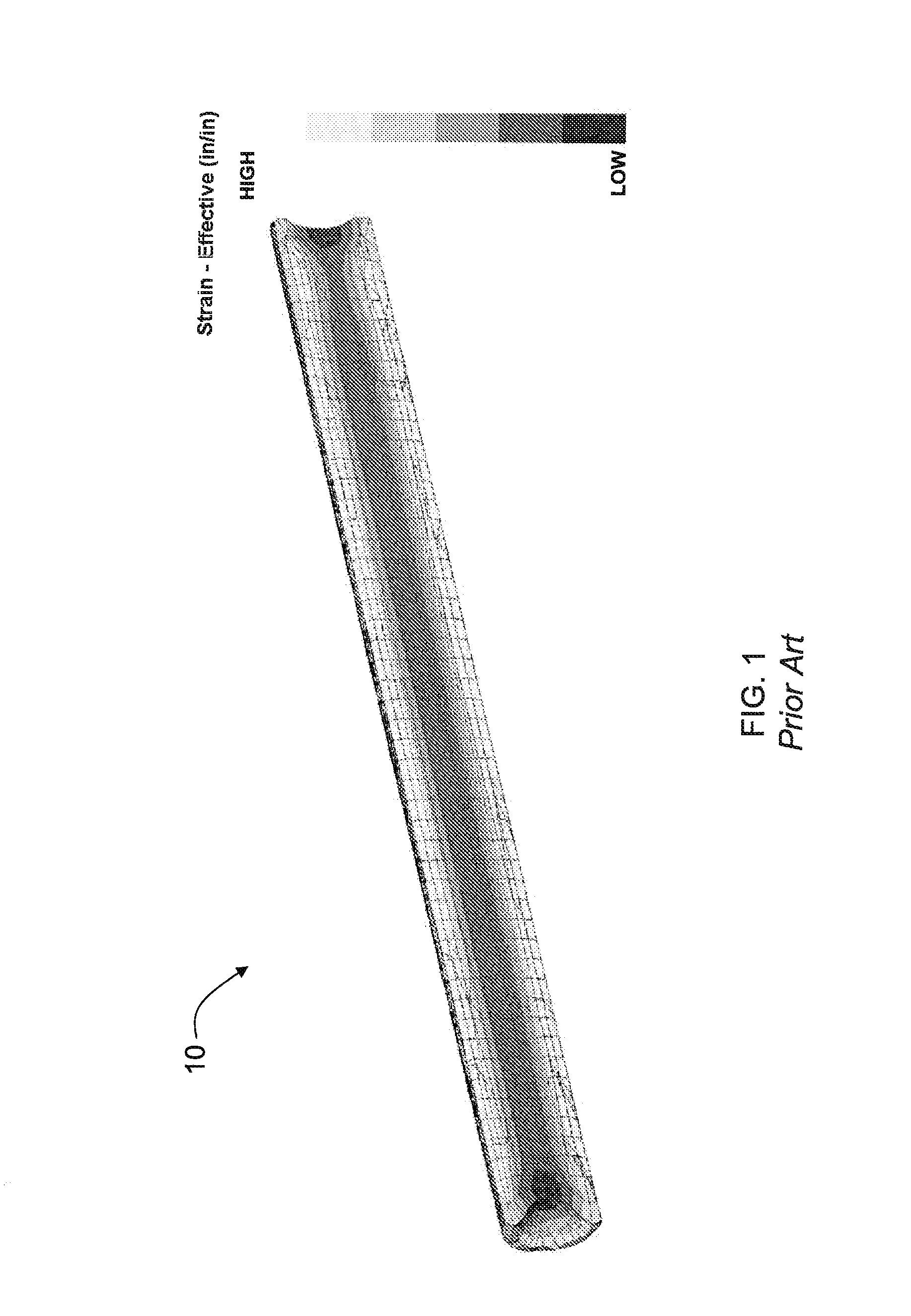

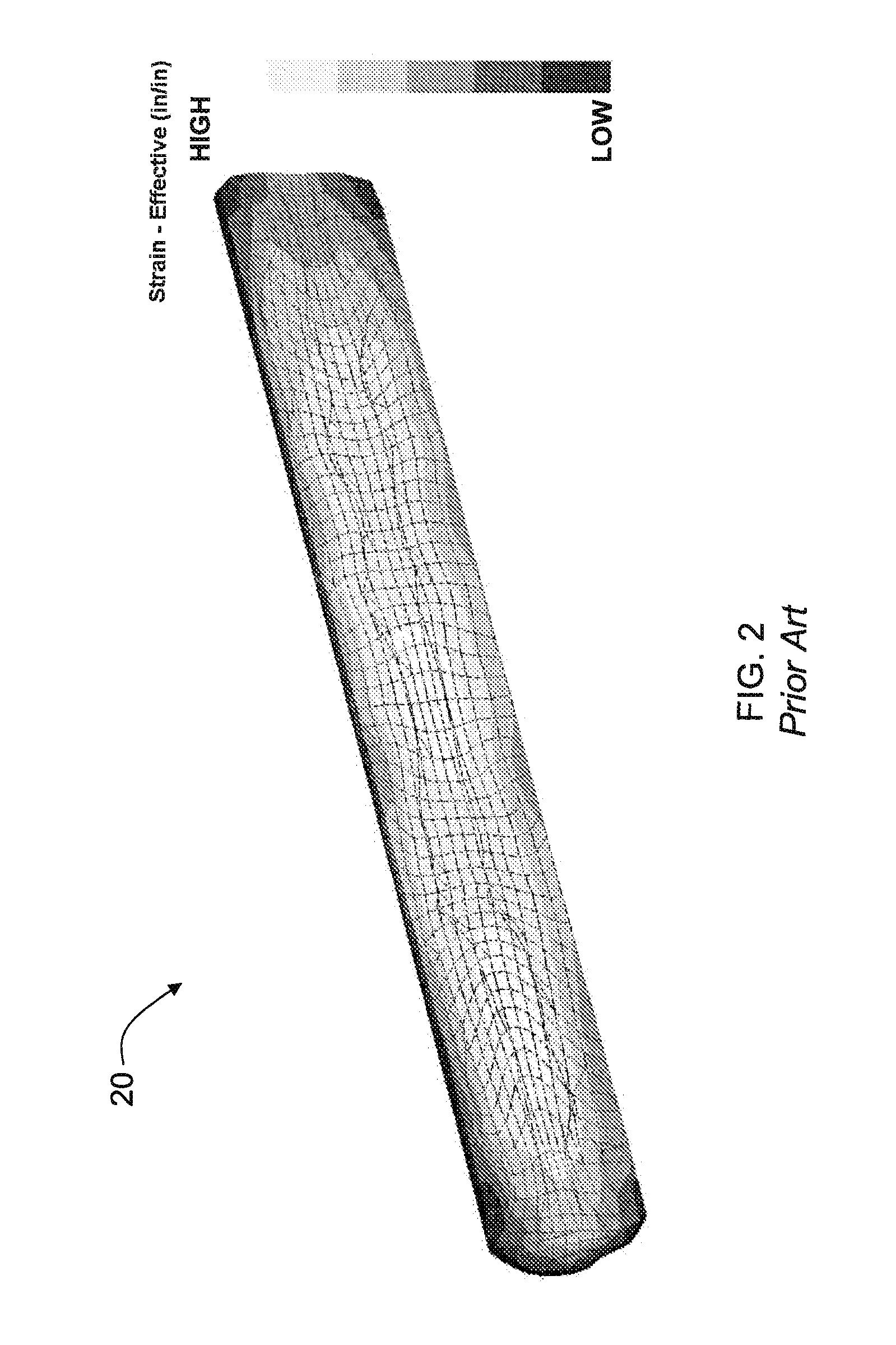

A method of processing a non-magnetic alloy workpiece comprises heating the workpiece to a warm working temperature, open die press forging the workpiece to impart a desired strain in a central region of the workpiece, and radial forging the workpiece to impart a desired strain in a surface region of the workpiece. In a non-limiting embodiment, after the steps of open die press forging and radial forging, the strain imparted in the surface region is substantially equivalent to the strain imparted in the central region. In another non-limiting embodiment, the strain imparted in the central and surface regions are in a range from 0.3 inch / inch to 1 inch / inch, and there exists no more than a 0.5 inch / inch difference in strain of the central region compared with the strain of the surface region of the workpiece. An alloy forging processed according to methods described herein also is disclosed.

Owner:ATI PROPERTIES LLC

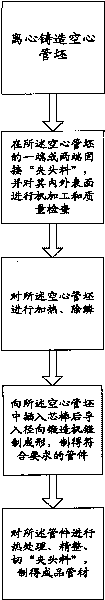

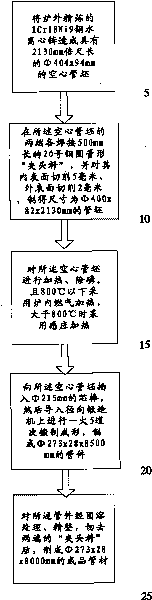

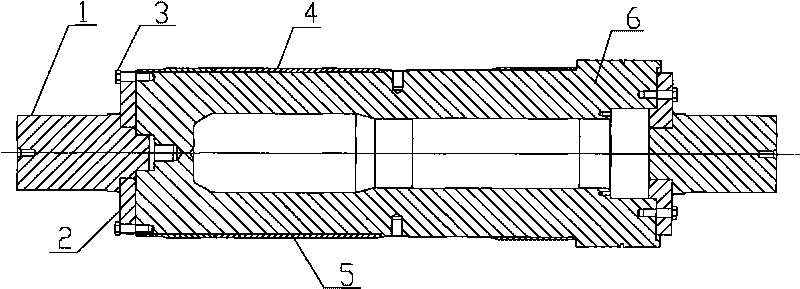

New method for producing medium and large caliber alloy steel seamless pipe by utilizing radial forging technology

The invention relates to a new method for producing medium and large caliber alloy steel seamless pipes by utilizing a radial forging technology, which comprises the following steps of: A. centrifugally casting a medium and large caliber hollow pipe blank through external refining molten steel; B. machining the internal and external surfaces of the medium and large caliber hollow pipe blank, fixedly connecting a carbon steel 'chuck material' at one end or both ends thereof and then carrying out quality inspection; C. heating and descaling the medium and large caliber hollow pipe blank; D. inserting a mandrel into the medium and large caliber hollow pipe blank and then leading into a radial forging machine for forging molding to manufacture a pipe of which the wall thickness, the diameter and the length meet requirements; and E. carrying out heat treatment, finishing and 'chuck materia' cutting for the pipe to manufacture a qualified finished product pipe. A technologic relation is established between high-quality centrifugal casting and radial forging with more ideal deforming state and tiny temperature drop by the method for the first time, thereby forming a new short-flow production process which has the advantages of energy saving, consumption reduction, high quality and economical efficiency and is used for producing alloy steel seamless pipes with large caliber, medium wall thickness and difficult deformation, and improving the product quality and the qualified rate; moreover, one end or both ends of the pipe blank is / are fixedly connected with the 'chuck material', thereby not only rapidly realizing stable deformation, but also reducing the remarkable difference of longitudinal temperature and dimensional precision of workpieces, lowering the consumption of an expensive alloy steel material and improving the yield of a finished product.

Owner:北京蓝海科融新技术有限公司

Repairing method of master cylinder plunger piston of radial forging machine

The invention discloses a repairing method of a master cylinder plunger piston of a radial forging machine; in the invention, two false shafts are manufactured and are connected to two ends of the master cylinder plunger piston as the standard for processing the master cylinder plunger piston and a thin-wall steel sleeve; the thin-wall steel sleeve adopts a 38CrMoAl forging piece, and heat treatment tempering and multichannel heat treatment stress elimination are carried out to the thin-wall steel sleeve, and nitriding treatment is carried out to the surface of the thin-wall steel sleeve to improve the hardness, after cylinder type fixing glue is coated on the surface of the master cylinder plunger piston, the thin-wall steel sleeve is embedded and sheathed on the master cylinder plunger piston after heat treatment is carried out, and the thin-wall steel sleeve is grounded into design size; by adopting the method, the damaged master cylinder plunger piston can be repaired, and repairing can be carried out repeatedly, the effectiveness of the master cylinder plunger piston is restored, the maintaining cost and repairing period can be greatly reduced and the normal operation of the production equipment can be ensured.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

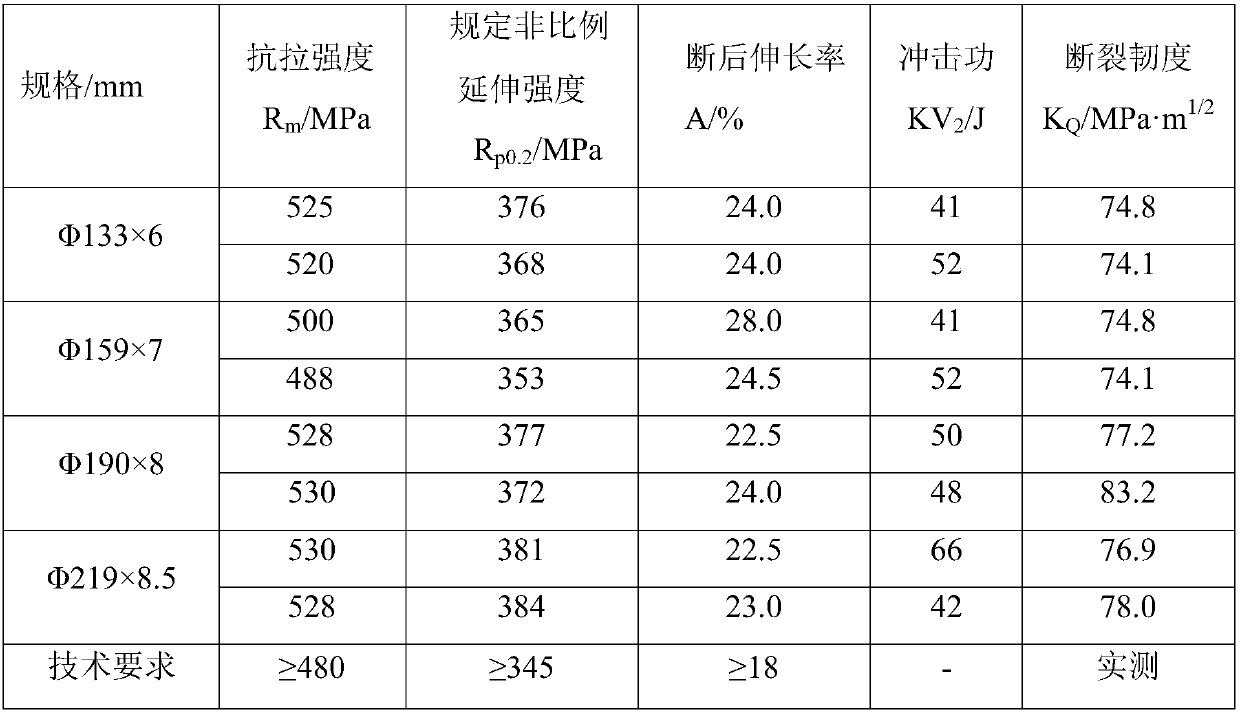

Machining method of titanium alloy large-diameter seamless thin-wall pipe

ActiveCN107649531AGood mechanical properties at room temperatureMeet technical requirementsFurnace typesHeat treatment furnacesRoom temperatureIngot

The invention discloses a machining method of a titanium alloy large-diameter seamless thin-wall pipe. The machining method comprises the steps that a titanium alloy casting ingot is heated and subject to heat preservation, blooming forging to form a bar billet is achieved, the bar billet is machined to obtain a hollow tubular billet, the hollow tubular billet is heated and subject to radial forging, a tube billet is obtained, and after annealing, turning is carried out to obtain a titanium alloy pipe with the outer diameter being phi 133 mm to phi 219 mm, the wall thickness ranging from 6 mmto 8.5 mm and the length larger than 3000 mm. According to the method, the titanium alloy casting ingot is machined into the pipe with the diameter larger than 120 mm and the wall thickness ranging from 6 mm to 8.5 mm, the pipe room temperature mechanical property is good, and compared with a traditional extrusion rolling machining method, the method is simple and short in flow, the obtained pipeis good in surface quality, high in size precision, and uniform in wall thickness. The method is low in production cost, the obtained titanium alloy pipe can be used for fields of ships, petroleum, chemical engineering, ocean engineering and the like, and the machining blank of the domestic titanium alloy large-diameter seamless thin-wall pipe is filled up.

Owner:BAOJI TITANIUM IND +1

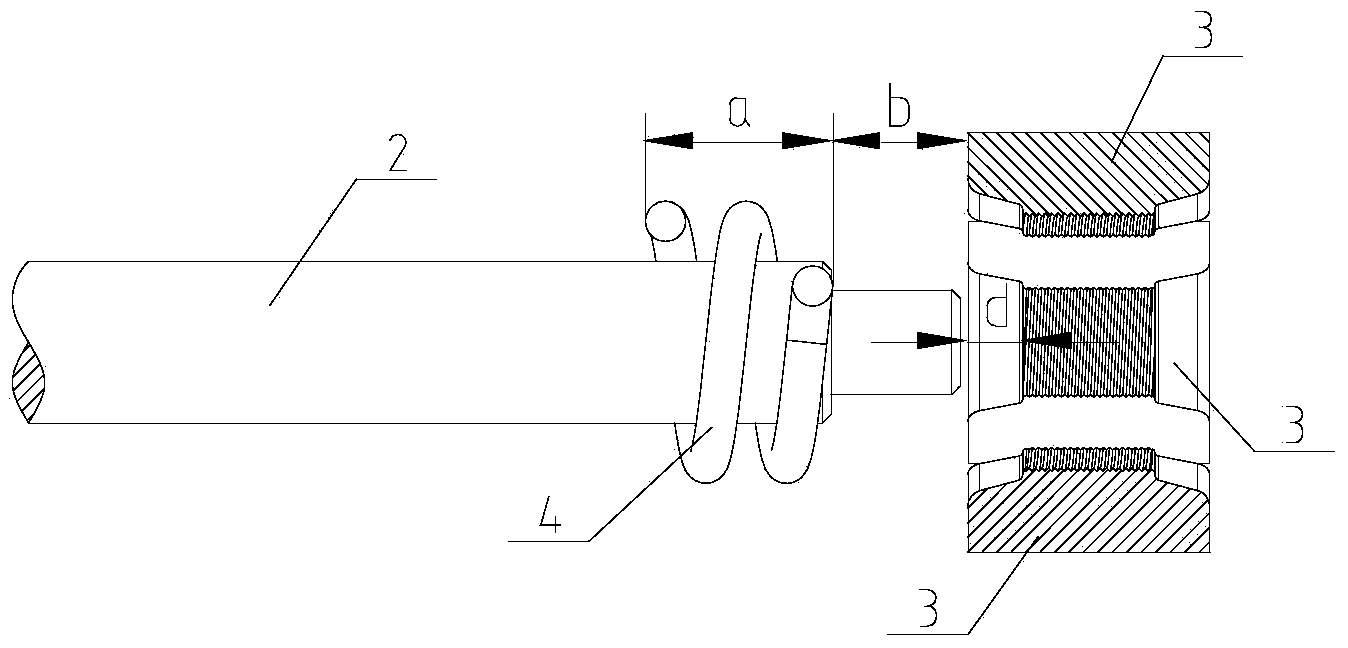

Method utilizing middle and high-frequency induction to heat radial forging to form screws

ActiveCN103752742AImprove mechanical propertiesReduce deformation resistanceMetal-working apparatusHardnessManipulator

The invention discloses a method utilizing middle and high-frequency induction to heat radial forging to form screws. The method includes clamping workpieces, heating partial surface of forming screw section end portion area of the workpieces, conveying workpieces heat section in a radial forging hammer direction, performing middle and high-frequency induction heating continuously, finishing thread shape forming of 1 / 2-2 / 3 portion of the forming screw section of workpieces via the hammer, clamping the other end of the workpieces via a second mechanical arm, loosening and retreating the first mechanical arm, performing middle and high-frequency induction heating continuously, finishing thread shape forming of unformed portion of the forming screw section of workpieces via the hammer, rapidly conveying the workpieces via the second mechanical arm in a clamping shaft direction, and discharging materials. The forming screw parts are formed via the middle and high-frequency induction heating and radial forging method, material using rate is increased, production circle is shortened, forming load is small, material flowing performance is good, forming accuracy is high, surface quality is good, screws with large material deformation resistance, high in hardness and large in diameter.

Owner:XI AN JIAOTONG UNIV

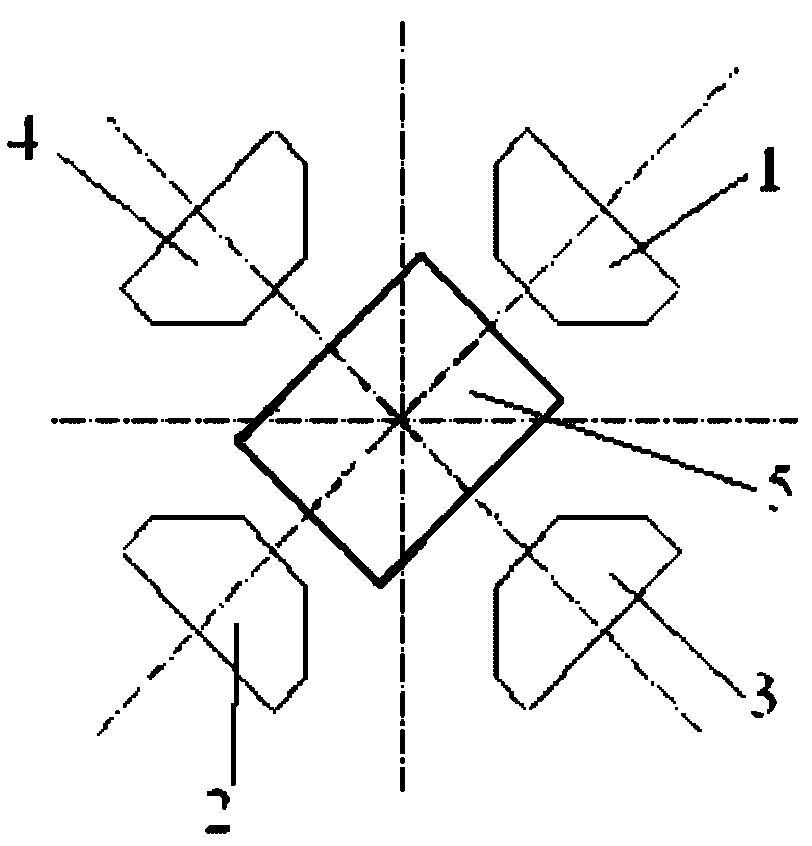

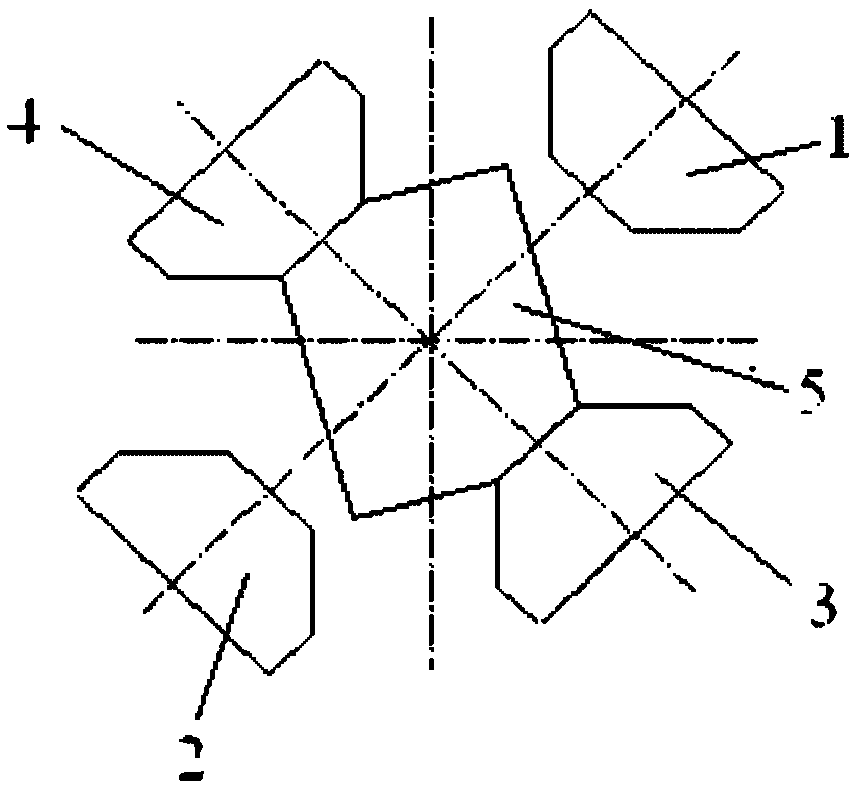

Forging and striking production process for blank with rectangular section

ActiveCN102513483AGuarantee the quality after forgingGuaranteed RegularityForging hammersRadial forgingSquare Shape

The invention discloses a forging and striking production process for a blank with a rectangular section. Equipment adopted in the striking and forging production process comprises two pairs of forging hammers which are mutually vertically distributed, wherein one pair of forging hammers include a first hammer and a second hammer, and the other pair of forging hammers include a third hammer and a fourth hammer; and the section of the blank is forged and struck for seven passes to become rectangular, approximately square, octagonal until circular. Due to the adoption of the technical scheme, a process for forging and striking the blank with the rectangular section to form a circular blank is precisely obtained through simple and effective derivation of equations by utilizing the forging characteristics of a radial forging machine; the forging and striking production process accords with a common forging and striking deformation process, the regularity of the shape of a forged product is ensured through a reasonable deformation step; and each pass reduction is determined through careful calculation, therefore, the quality of the forged blank is ensured, and defects such as folding, cracks and the like are prevented from being caused.

Owner:WUHU XINXING DUCTILE IRON PIPES

Thermomechanical processing of high strength non-magnetic corrosion resistant material

A method of processing a non-magnetic alloy workpiece comprises heating the workpiece to a warm working temperature, open die press forging the workpiece to impart a desired strain in a central region of the workpiece, and radial forging the workpiece to impart a desired strain in a surface region of the workpiece. In a non-limiting embodiment, after the steps of open die press forging and radial forging, the strain imparted in the surface region is substantially equivalent to the strain imparted in the central region. In another non-limiting embodiment, the strain imparted in the central and surface regions are in a range from 0.3 inch / inch to 1 inch / inch, and there exists no more than a 0.5 inch / inch difference in strain of the central region compared with the strain of the surface region of the workpiece. An alloy forging processed according to methods described herein also is disclosed.

Owner:ATI PROPERTIES LLC

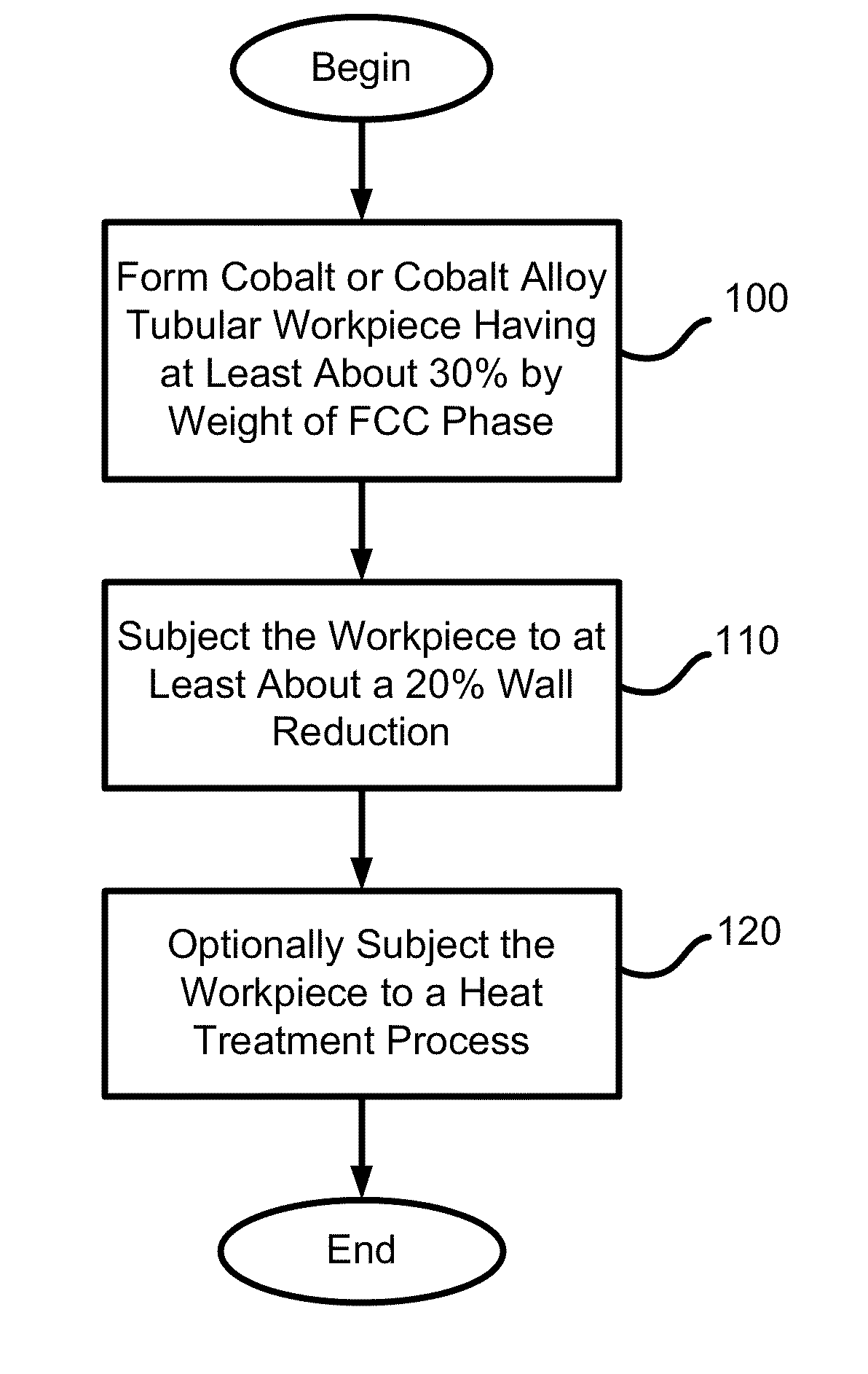

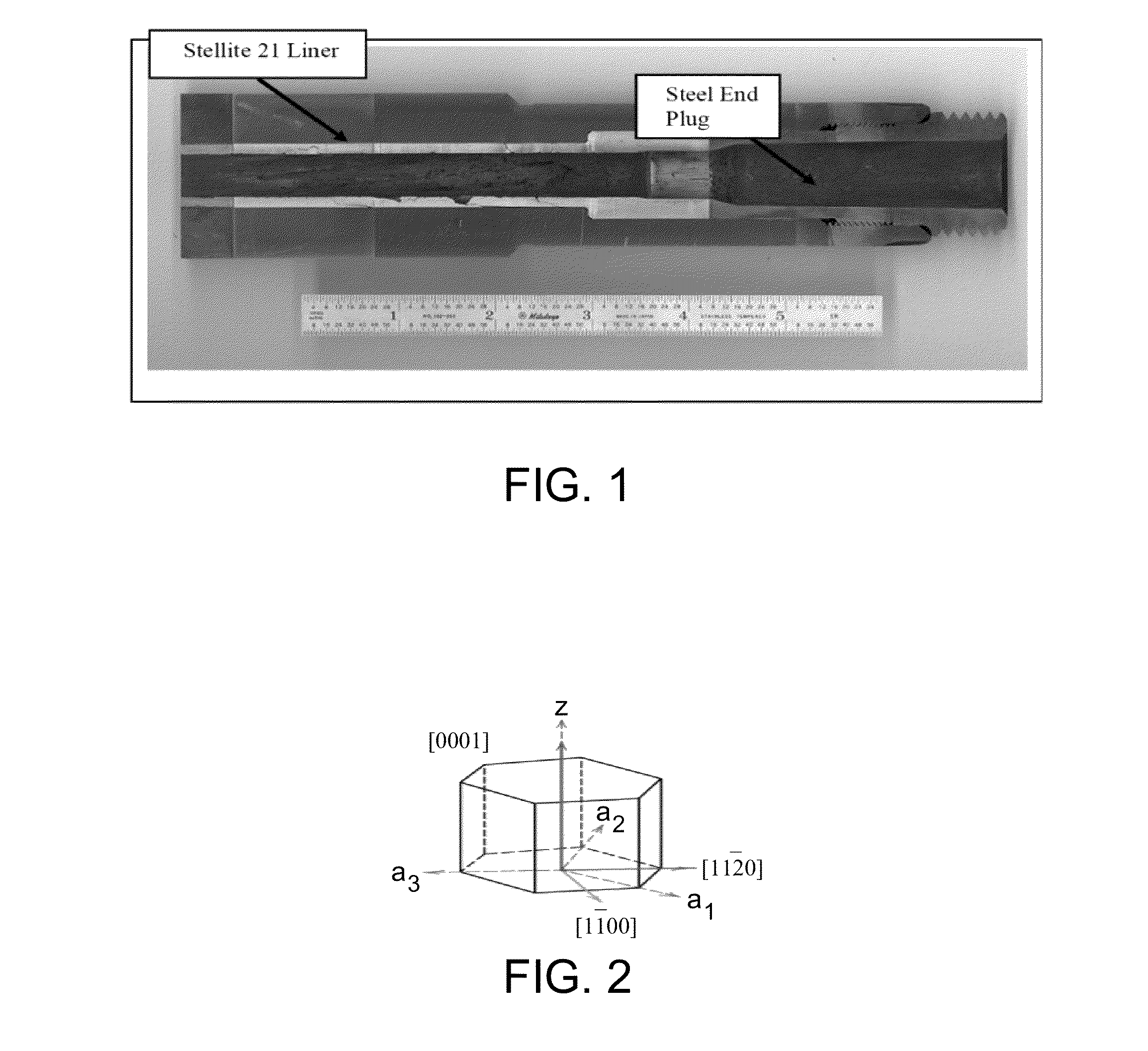

Stress Induced Crystallographic Phase Transformation and Texturing in Tubular Products Made of Cobalt and Cobalt Alloys

A method of producing a cobalt-based tubular product includes forming a cobalt or cobalt alloy tubular workpiece having at least about 30% by weight of fcc phase and subjecting the workpiece to at least about a 20% wall reduction at a temperature below a recrystallization temperature of the workpiece using a metal forming process. The metal forming process may include radial forging, rotary swaging, pilgering and / or flowforming. A gun barrel includes a tubular component made of a cobalt-based superalloy material. The component has at least about 25% by weight of hcp phase with basal planes radially oriented perpendicular to an inner diameter of the component.

Owner:ATI FLOWFORM PROD

Special forging method suitable for super duplex stainless steel bars

ActiveCN105689613AImprove material yieldIncrease productivityHeating/cooling devicesSolution treatmentManufacturing technology

The invention belongs to the technical field of pressure machining and manufacturing and relates to a special forging method suitable for super duplex stainless steel bars. The novel special forging method suitable for the super duplex stainless steel bars is innovatively created with the advantages and disadvantages of radial forging machines and rapid forging presses fully considered and the characteristics of super duplex stainless steel considered. With steel ingots as raw materials, the method sequentially comprises the processes of radial forging and rapid forging combined blooming, radial forging finishing, air cooling and solution treatment. The yield of finished products of the super duplex stainless steel bars forged through the technology is high and is increased by more than 5% than the yield of original methods, the production efficiency is high, and the energy consumption is low. According to the method, the square or polygonal steel ingots with the section being 200-700*200-700 can be forged into the bars with Phi ranging from 60 mm to 400 mm.

Owner:DAYE SPECIAL STEEL CO LTD

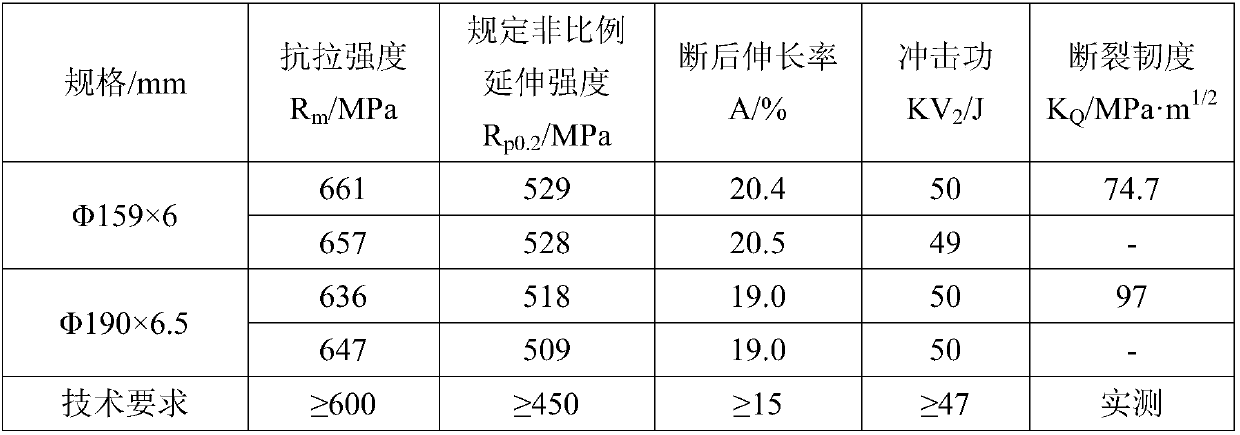

High-performance and high-nitrogen austenitic stainless steel for non-magnetic drill collar and manufacturing method thereof

ActiveCN104264071AAvoid sensitive temperature rangesReduce manufacturing costDrilling rodsDrilling casingsRoom temperatureNon magnetic

The invention provides high-performance and high-nitrogen austenitic stainless steel for a non-magnetic drill collar and a manufacturing method thereof, and belongs to the technical field of stainless steel. The stainless steel comprises components in percentage by weight as follows: larger than or equal to 21.5% and smaller than or equal to 22.5% of Cr, larger than or equal to 0.5% and smaller than or equal to 1.5% of Mo, smaller than or equal to 0.040% of C, larger than or equal to 0.65% and smaller than or equal to 0.75% of N, larger than or equal to 0.40% and smaller than or equal to 0.50% of Nb, larger than or equal to 1.95% and smaller than or equal to 2.05% of Ni, larger than or equal to 16.0% and smaller than or equal to 17.0% of Mn, smaller than or equal to 0.20% of Si, smaller than or equal to 0.020% of P, smaller than or equal to 0.010% of S and the balance of Fe, wherein the sum of weight percentage of Cr, a product obtained by multiplying the weight percentage of Mo by 3.3 and a product obtained by multiplying the weight percentage of N by 16.0 is larger than or equal to 33.0%. The manufacturing method of the high-performance and high-nitrogen austenitic stainless steel comprises the steps as follows: smelting by an electric furnace, argon oxygen decarburization for secondary refining, electroslag remelting, cogging by a fast forging machine, forming by a radial forging machine and water cooling treatment. The high-performance and high-nitrogen austenitic stainless steel for the non-magnetic drill collar has the advantages of good room-temperature strength as well as excellent spot corrosion resistance and intercrystalline corrosion resistance.

Owner:CENT IRON & STEEL RES INST

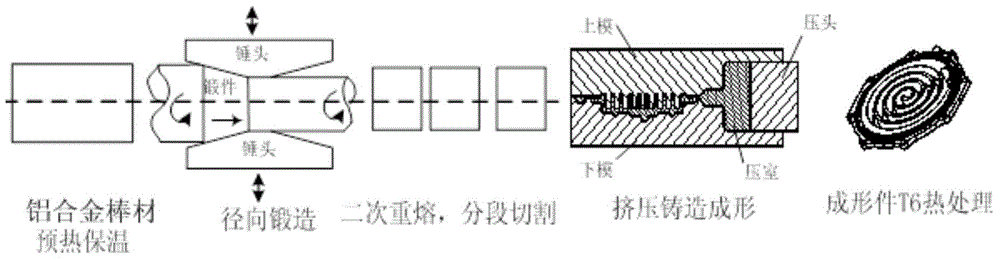

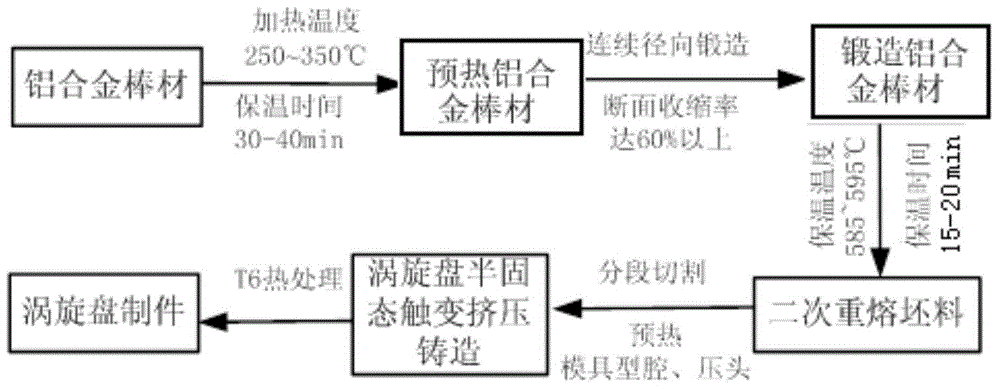

Process for preparing semi-solid state aluminum alloy scroll plate by radial forging strain induction method

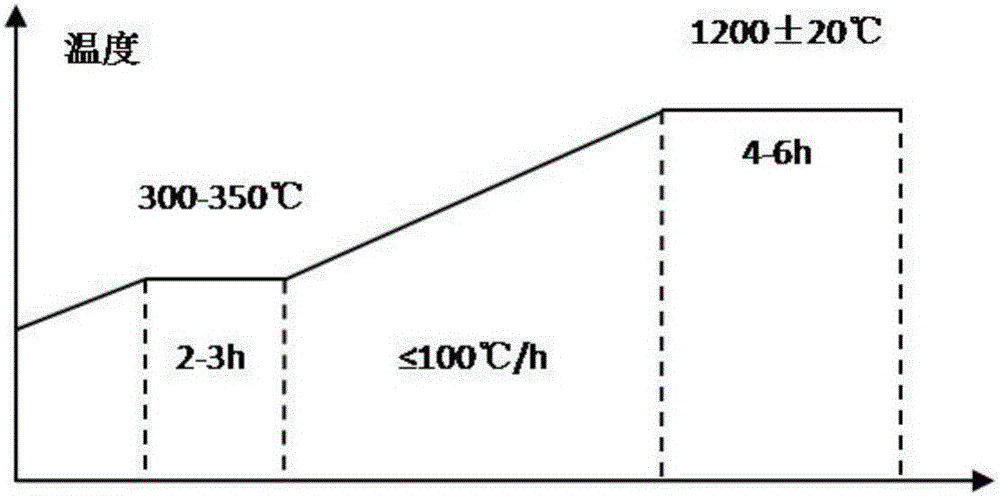

InactiveCN104561852AAvoid uneven defectsReduce plastic forming forceIncreasing energy efficiencySemi solidInduction method

The invention discloses a process for preparing a semi-solid state aluminum alloy scroll plate by a radial forging strain induction method. The method comprises the following steps: pre-heating an aluminum alloy rods at first; performing radial forging on the aluminum alloy rods; performing secondary remelting on blanks subjected to radial forging; performing extrusion casting on the aluminum alloy scroll plate; performing T6 heat treatment on the aluminum alloy scroll plate acquired by extrusion casting in a semi-solid state to increase the mechanical property. According to the process, the aluminum alloy semi-solid state blanks which are uniform and free of microdefect are prepared and are subjected to extrusion casting to form a scroll plate workpiece with less microdefects and high mechanical performance, and the process is simple and easy to operate.

Owner:XI AN JIAOTONG UNIV

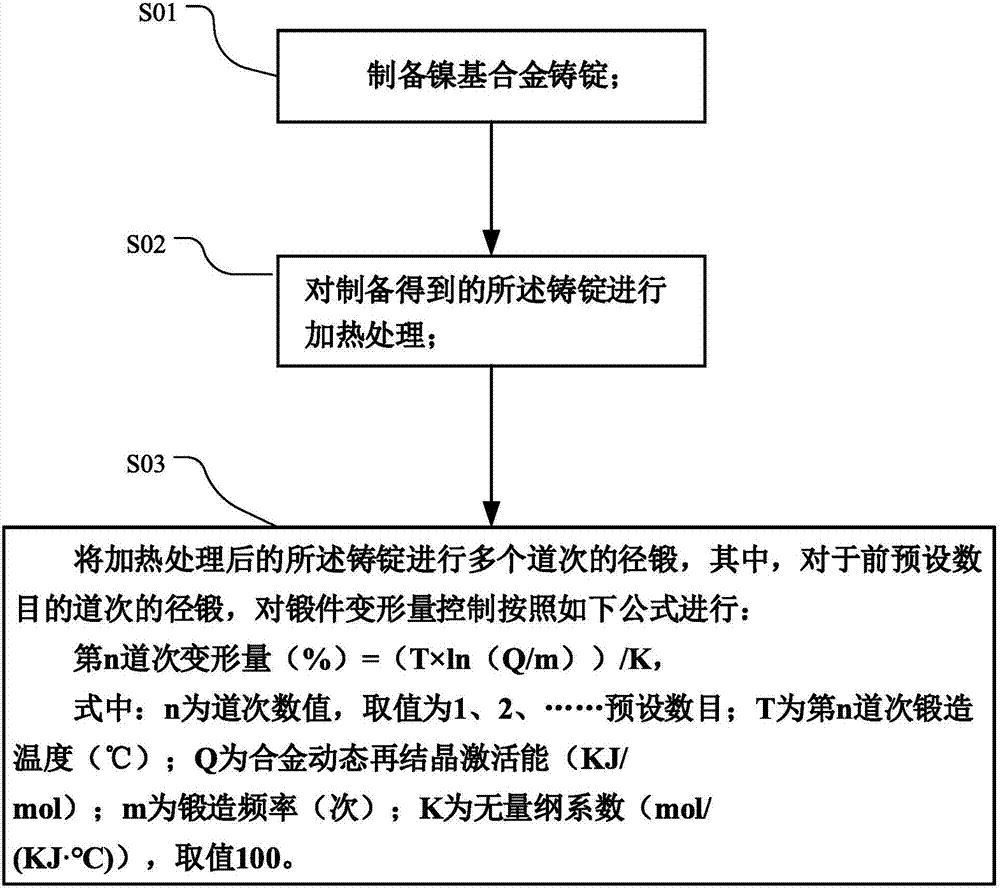

Nickel-based alloy radial-forging structure control method

The invention discloses a nickel-based alloy radial-forging structure control method. The nickel-based alloy radial-forging structure control method comprises the following steps that a), a nickel-based alloy casting ingot is manufactured; b), the manufactured casting ingot is heated; c), the heated casting ingot is subjected to multiple passes of radial forging, wherein for radial forging of passes of a preset number, control on deformation of a forged workpiece is performed according to the following format: deformation of the nth pass (%) is equal to (T multiplied by ln)(Q / m)) / K; in the format, n is the value of the pass and can be 1, 2 and other preset numbers; T is forging temperature (DEG C) of the nth pass; Q is alloy dynamic recrystallization activating energy (KJ / mol); m is forging frequency (times); and K is a nondimensional coefficient (mol / (KJ.DEG C)), and is 100. According to the nickel-based alloy radial-forging structure control method, effective control for a nickel-based alloy radial forging in a forging process can be realized, and therefore, by utilizing the nickel-based alloy radial-forging structure control method, a deformation technological system can be rapidly formulated according to features of different steel types, so that problems of insufficient forging, crystal doping in the radial forging and the like are solved.

Owner:太原钢铁(集团)有限公司

Forging process of GH4169 alloy bar

The invention relates to a forging process of a GH4169 alloy bar, in particular to the forging process of the GH4169 alloy bar in the technical field of high temperature alloy forging. In order to solve the technical problem, the invention adopts the forging process of the GH4169 alloy bar. The forging process comprises the following steps: A, homogenizing heat treatment; B, five heating numbers-three upsetting-three drawing blooming forging; C, air cooling on an intermediate slab forged in the step B, turning and rounding, then feeding into a heating furnace of the temperature of 1040 to 1060DEG C, and solid solution treatment for 2 hours; and D, radial forging and blooming forging after the step C is completed. The forging process can sufficiently improve the interior quality and the grain size uniformity of a blank, and reduce the grain size grade difference.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Manufacturing method of N08028 seamless alloy steel pipe

The invention discloses a manufacturing method of a N08028 seamless alloy steel pipe, and relates to the technical field of seamless steel pipe manufacturing. The method includes the steps of (1) centrifugal casting: adopting a centrifugal casting technology to produce a N08028 hollow alloy pipe billet; (2) radial forging: utilizing a radial forging machine to perform radial forging on the hollow pipe billet to form a radial-forged billet; (3) hot broaching: utilizing a broaching machine to perform hot broaching on the radial-forged billet to form a billet; (4) hot extrusion: utilizing an extruder to perform hot extrusion forming on the billet to form a hot-extruded pierced billet; (5) cold deformation: utilizing a cold rolling machine unit or the radial forging machine to perform cold deformation on the hot-extruded pierced billet to form the seamless steel pipe. The method is high in material utilization rate and low in manufacturing cost and rejection rate, and the N08028 seamless alloy steel pipe is good quality, can meet requirements on corrosion resistance as well as meet working requirements of severe oil-gas field environments, and has high strength and hardness.

Owner:XINXING DUCTILE IRON PIPES CO LTD

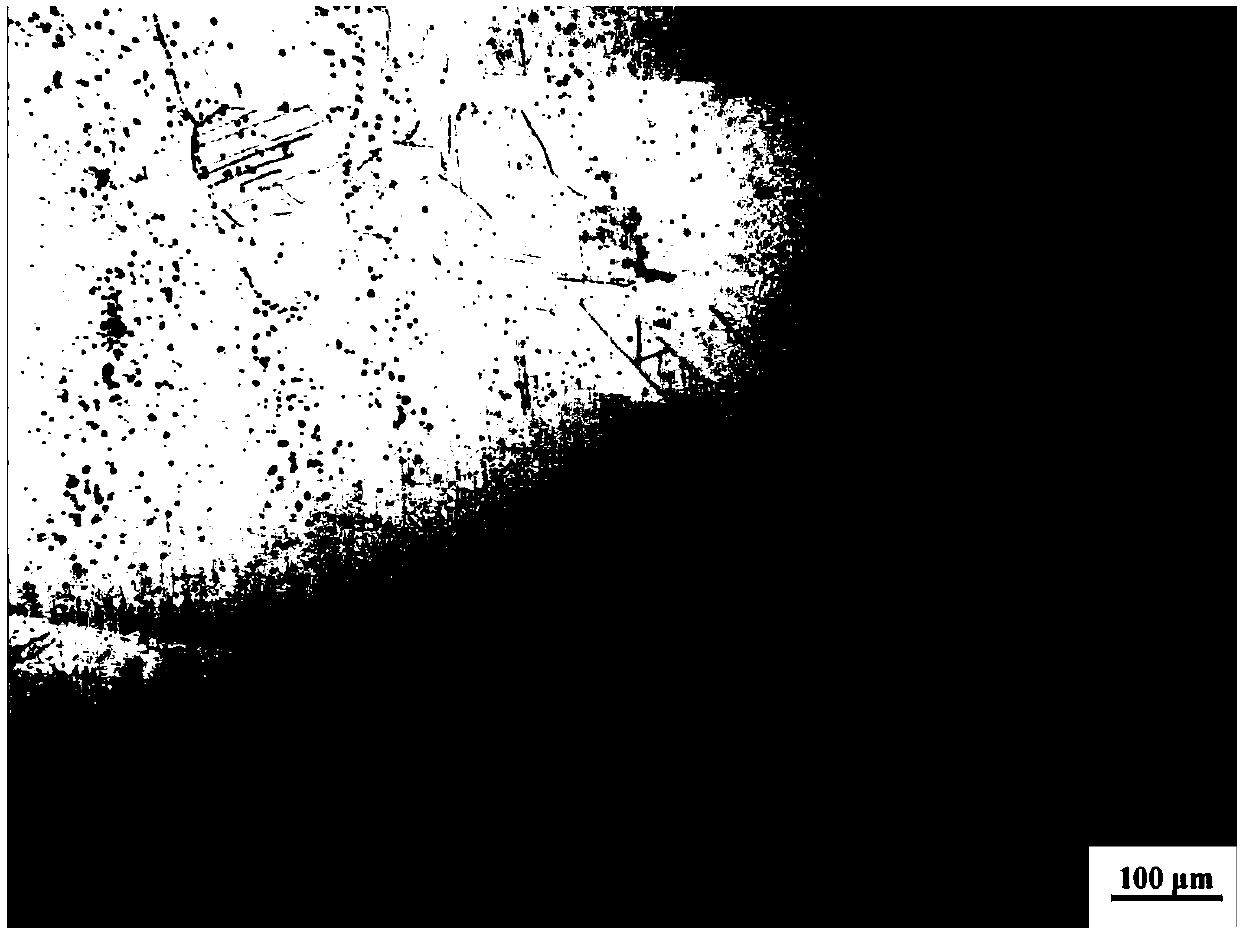

High-performance cold extrusion die steel and metallurgical manufacturing method thereof

ActiveCN101649419AReduced brittle tendencyImprove metallurgical qualitySteelmakingChemical composition

The invention provides high-performance cold extrusion die steel and metallurgical manufacturing method thereof. The high-performance cold extrusion die steel comprises the following chemical components in percentage by mass: 0.95 to 1.02 percent of C, 0.20 to 0.40 percent of Mn, 8.60 to 9.00 percent of Cr, 0.87 to 1.10 percent of Si, 1.80 to 2.00 percent of Mo, 0.40 to 0.60 percent of V, less than or equal to 0.30 percent of Cu, less than or equal to 0.25 percent of Ni, less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S, and the balance of Fe and inevitable impurities. According to the component proportion, the toughness performance of the high-performance cold extrusion die steel can be greatly improved. The metallurgical manufacturing method comprises theprocesses of electric furnace steel making, electroslag remelting and steel forging by a radial forging press. In the process of electroslag remelting, the voltage is between 57 and 59V, and the current is between11,000 and 12,000A; and in the process of steel forging by the radial forging press, steel ingots are heated to between 1,150 DEG C and 1,170 DEG C, and the temperature keeps for 2 to 4hours. The method is simple and convenient, and can remarkably improve the performance index of the steel.

Owner:宝武特种冶金有限公司

Radial forging process of cast-state magnesium alloy tube

InactiveCN102632175AReduce manufacturing costImprove mechanical propertiesMetal-working apparatusMetalworkingSurface roughness

The invention relates to a radial forging process of a cast-state magnesium alloy tube, belonging to non-ferrous metal processing. The process comprises the following steps of firstly carrying out homogenizing annealing, forging, finishing and finally carrying out surface machining. By using the process, two problems for limiting the development of seamless magnesium alloy tubes, namely difficult hot piercing and low yield, are fundamentally solved, so that the yield of the magnesium alloy tube is raised from 45-55% currently at home and abroad to above 90%, the production cost of tubes is reduced by above 40% and leapfrog development is realized in the production of the magnesium alloy seamless tubes. The processed product has the advantages of excellent mechanical property, high production efficiency, high material utilization ratio, high precision of forging member and low surface roughness.

Owner:江苏诚德钢管股份有限公司

Method of Producing Cold-Worked Centrifugal Cast Tubular Products

ActiveUS20150183015A1Rigid pipesMetal rolling arrangementsCorrosion resistant alloyMetal forming process

A method of making a seamless, tubular article comprises subjecting a cast tubular workpiece of a corrosion resistant alloy to at least about a 25% wall reduction at a temperature below a recrystallization temperature of the workpiece using a metal forming process comprising at least one of radial forging, rolling, pilgering, and flowforming. The cast tubular workpiece is a centrifugally cast tubular workpiece comprising an inner diameter and an outer diameter.

Owner:ATI FLOWFORM PROD

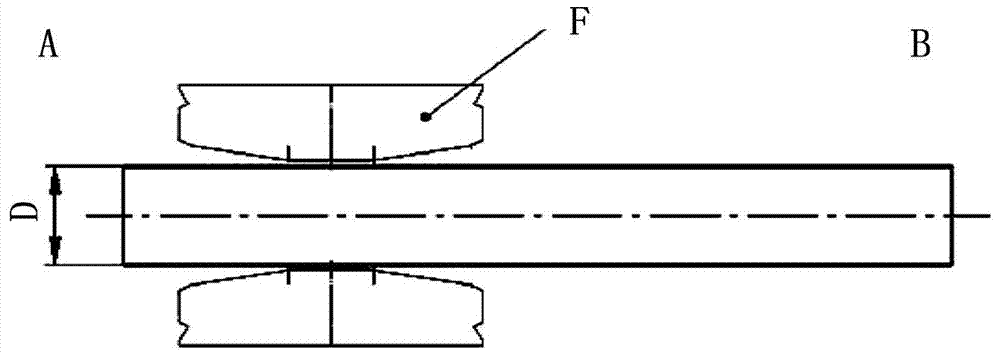

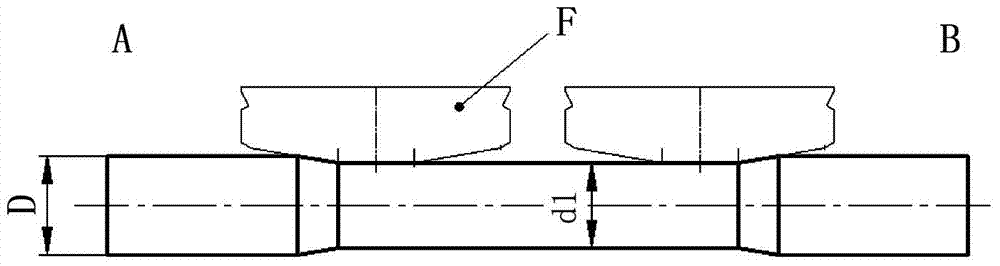

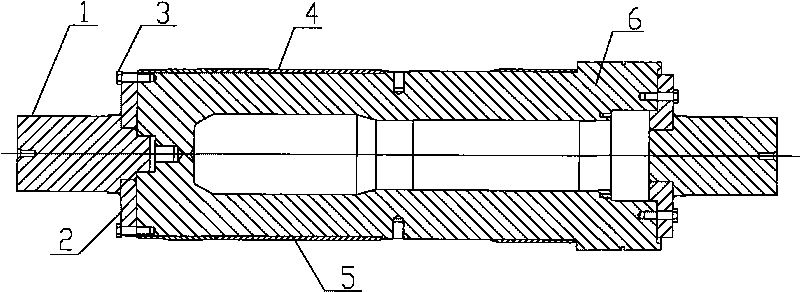

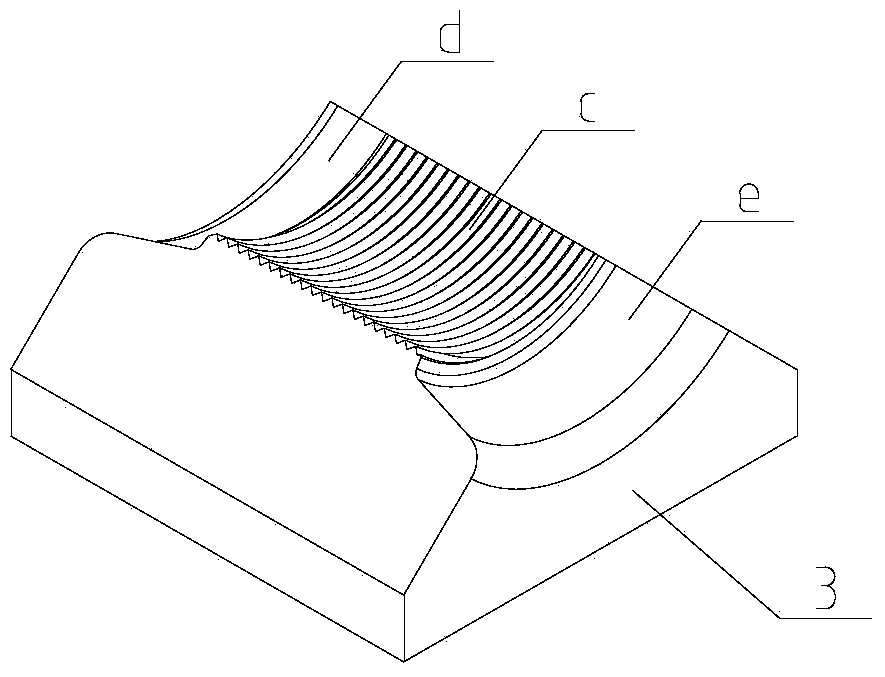

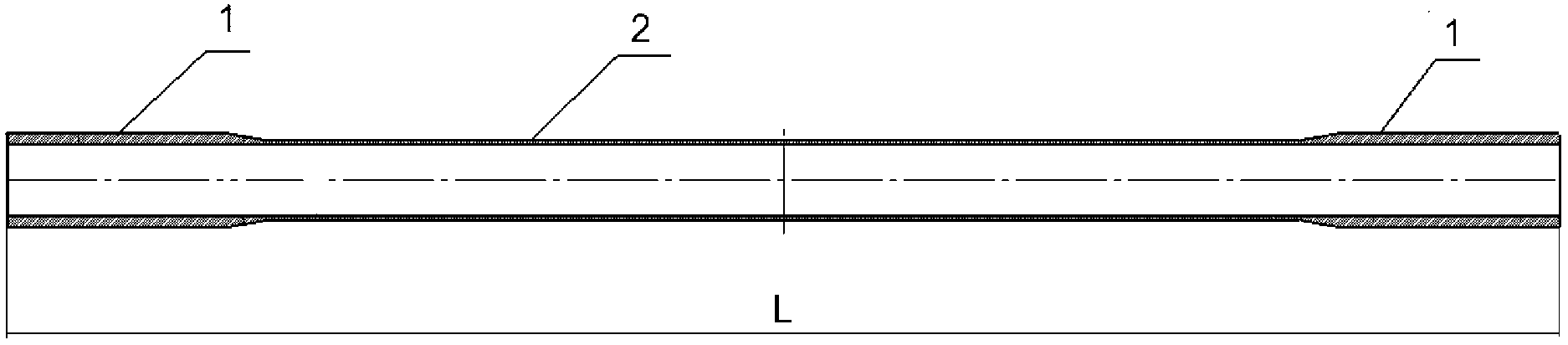

Titanium alloy seamless pipe with variable wall thickness as well as radial forging and forming mechanism and method of titanium alloy seamless pipe

InactiveCN102700668AHigh dimensional accuracyImprove surface qualityElongated constructional elementsForging hammersVehicle frameMetallurgy

The invention provides a titanium alloy seamless pipe with variable wall thickness as well as a radial forging and forming mechanism and a radial forging and forming method of the titanium alloy seamless pipe. The invention has the benefits as follows: a simple radial forging process is adopted; various seamless titanium alloy thin-wall pipes with variable wall thicknesses can be manufactured through core rods and the radial forging and forming mechanism; the manufactured pipes have the advantages of high size precision and good surface quality, and can meet the use requirements of bicycle frames and parts; and the weight of the frames can be reduced on the basis of not reducing the structural strength of the frames, so as to achieve the purpose of increasing the speed of bicycles.

Owner:天津轻钛运动器材有限公司

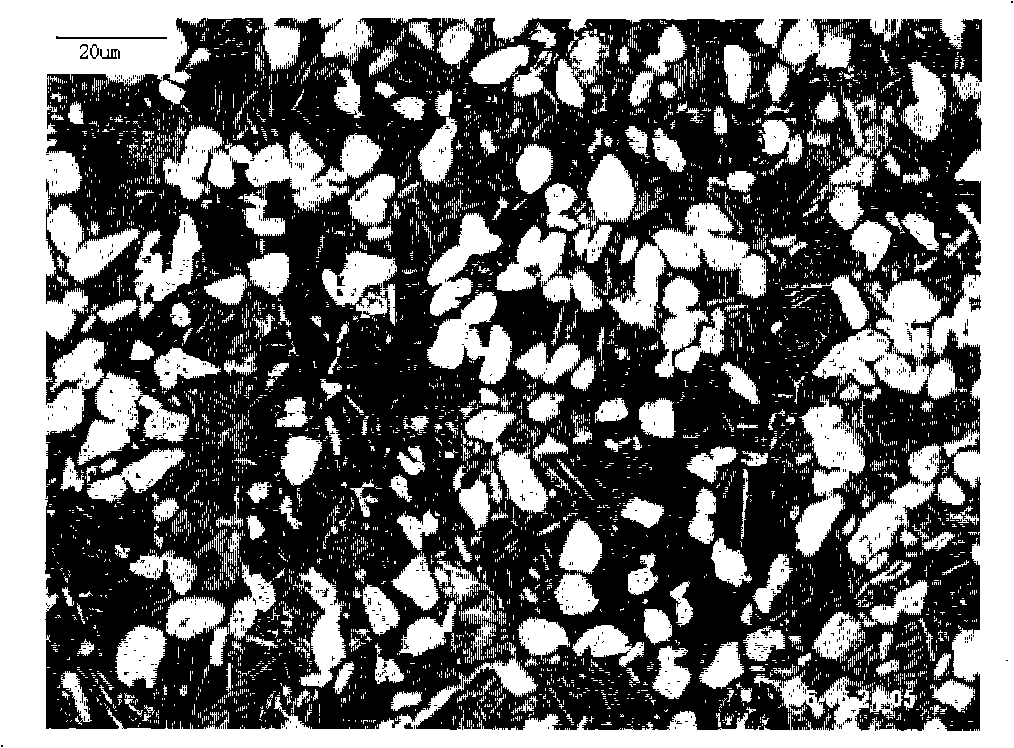

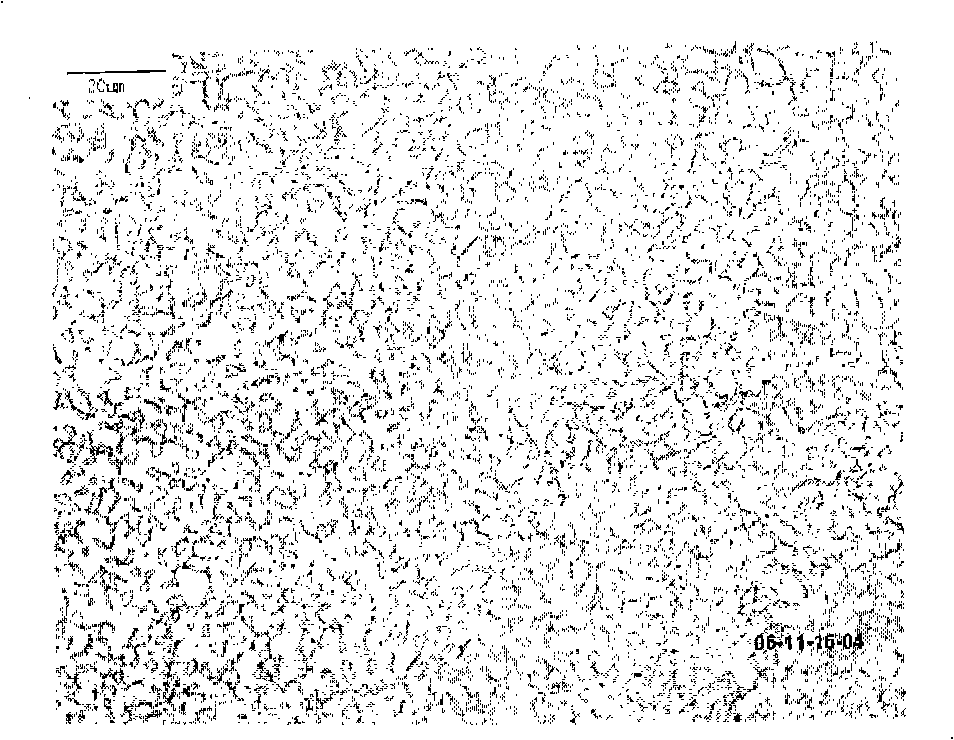

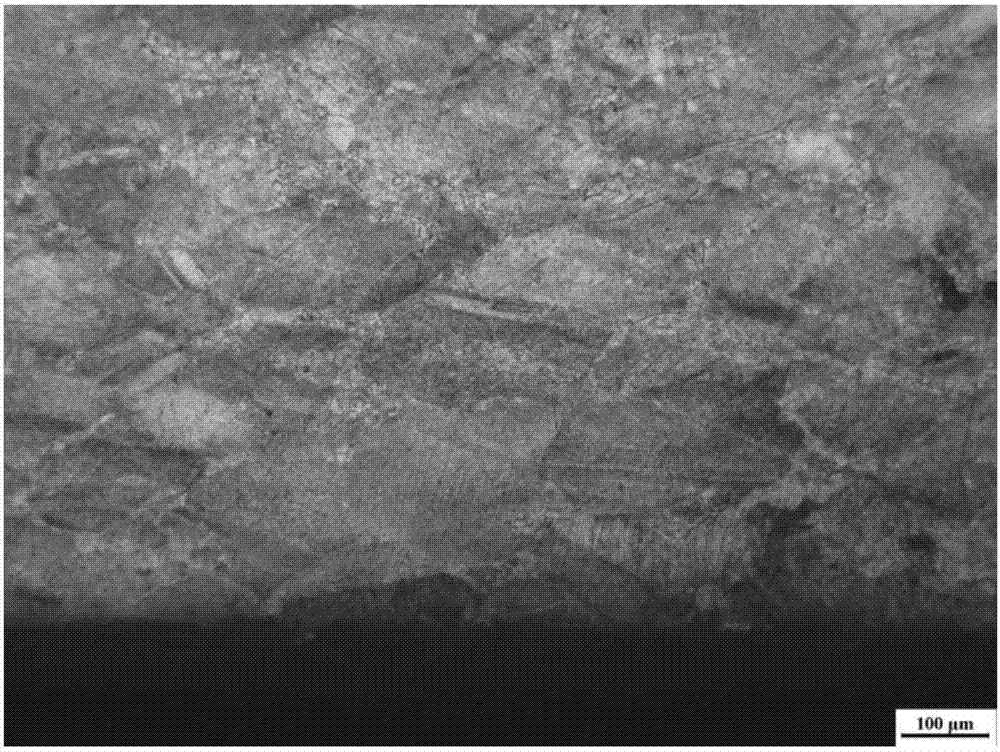

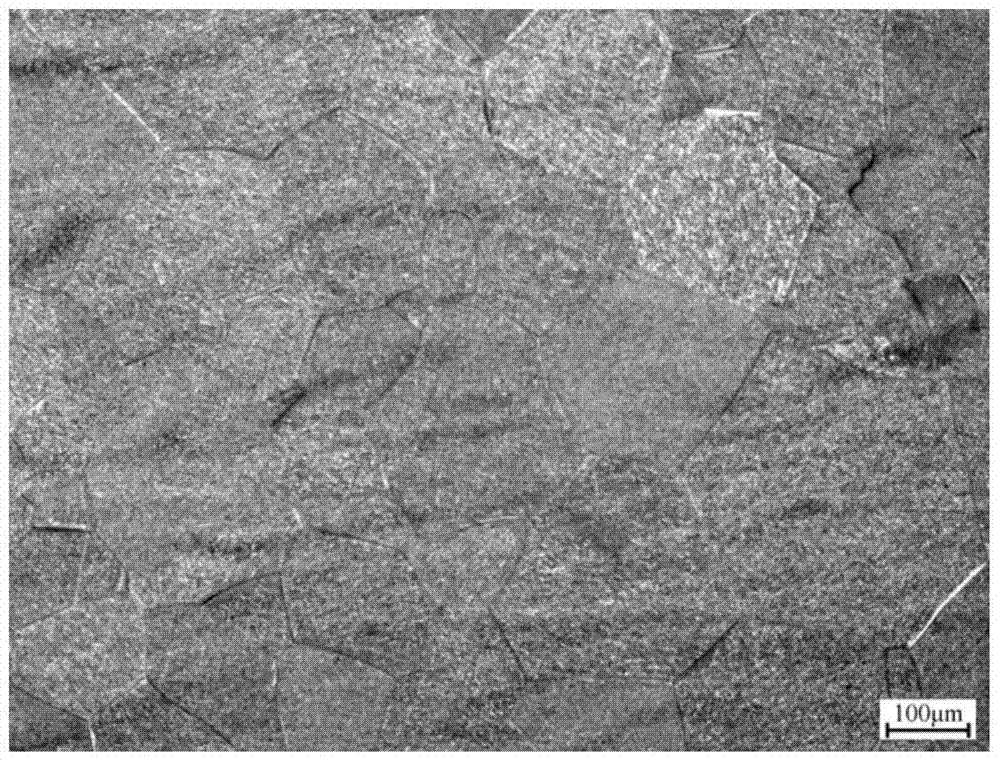

Manufacturing technology for optimized cobalt-base deformed high-temperature alloy forged bar

The invention discloses a manufacturing technology for an optimized cobalt-base deformed high-temperature alloy forged bar and aims to achieve the technical effect that a high-temperature alloy GH 5188 finished product bar reaches a state that carbide is distributed in a dispersing manner. According to the technical scheme, the manufacturing technology for the optimized cobalt-base deformed high-temperature alloy forged bar comprises the steps that repeated upsetting, drawing out and reburning heating technologies are adopted, and a combined forging manner of fast forging and radial forging isadopted; the deformation amount is controlled between 35% and 45%, the fast forging end fire one-way drawing out deformation amount is controlled between 45% and 55%, and the radial forging deformation amount is larger than 30% so that bar billet structures can be fully crushed; and the middle heating number heating time is two hours to three hours so that static recrystallization can be fully completed by non-recrystallizing structures in fast forging and accumulated carbide can be precipitated again in a dispersing manner after being fully redissolved, and the forged bar with carbide distributed in a dispersing manner is finally acquired. The manufacturing technology for optimized cobalt-base deformed high-temperature alloy forged bar has the advantages that firstly, through control over the number of upsetting times and the deformation amount of each heating number, uniformity of microstructures of the bar is improved; and secondly, through adjustment of the reburning heating time,structures which do not fully recrystallize in a previous heating number is prompted to fully complete static recrystallization, and the accumulated carbide is precipitated in a dispersing manner ina reforging process after being fully redissolved.

Owner:FUSHUN SPECIAL STEEL SHARES

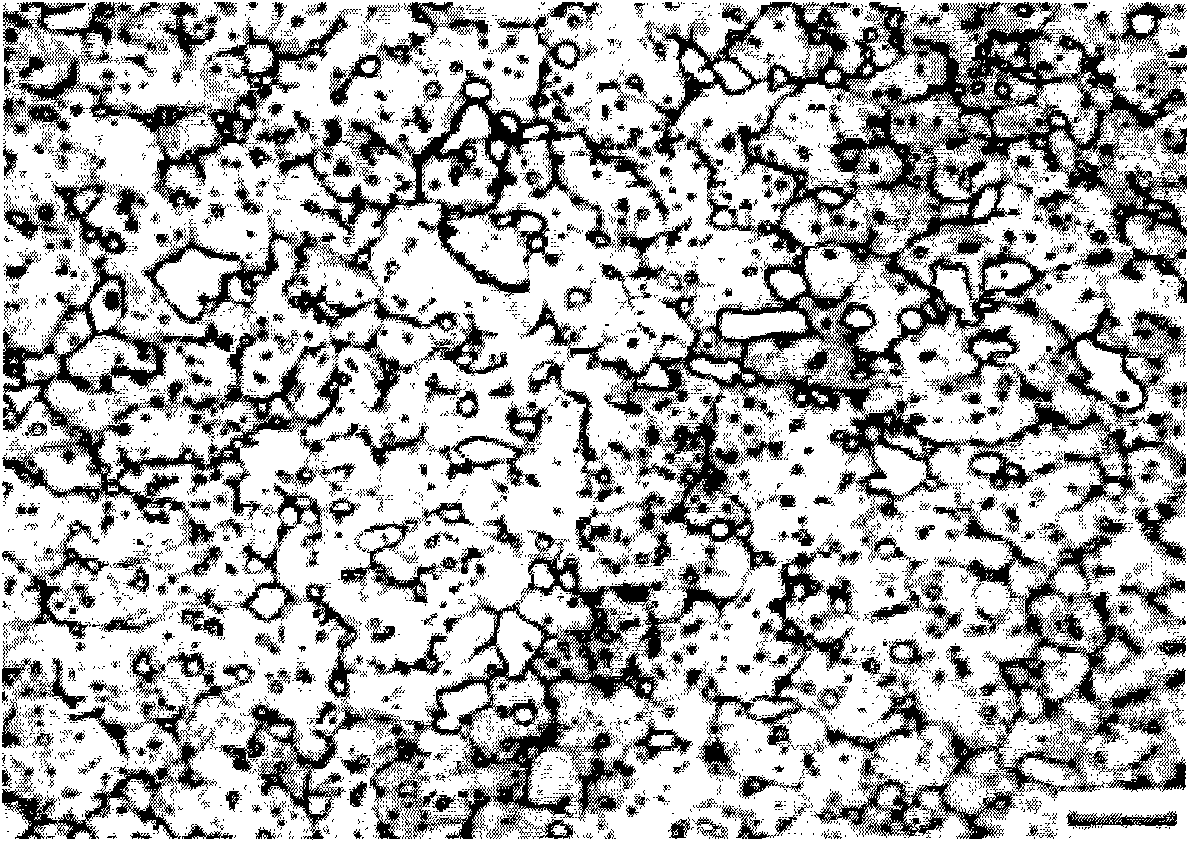

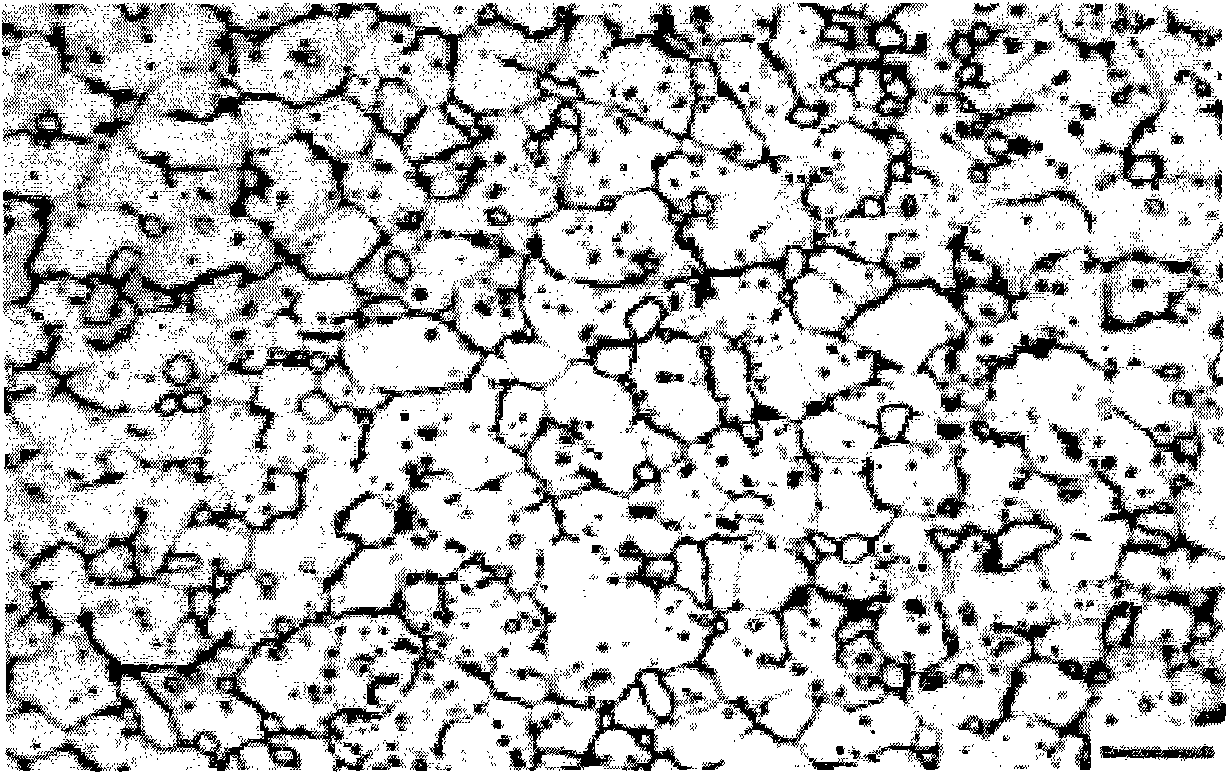

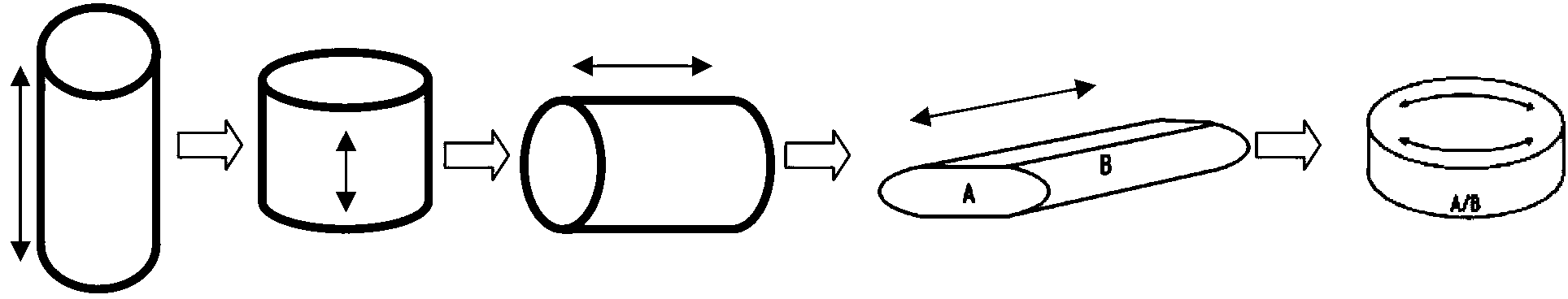

TC4 titanium alloy fine-equiaxed-structure large-size bar short-process preparation method

The invention discloses a TC4 titanium alloy fine-equiaxed-structure large-size bar short-process preparation method which comprises the following steps: 1, a TC4 titanium alloy ingot is subjected tocogging forging by the adoption of a large-tonnage pressing machine, and a primary forged billet is obtained after air cooling; 2, the primary forged billet is subjected to upsetting-stretching forging by the adoption of the large-tonnage pressing machine, and an intermediate forged billet is obtained after quick cooling to the room temperature; 3, the intermediate forged billet is subjected to one-heating-number radial forging by the adoption of a large-tonnage precision forging machine, and a finished radial forged bar is obtained; and 4, the finished radial forged bar is subjected to annealing heat treatment, and a large-size TC4 titanium alloy bar of the fine grain structure is obtained. According to the TC4 titanium alloy fine-equiaxed-structure large-size bar short-process preparation method, the process of billet hot-forging through the large-tonnage pressing machine and radial forming through the large-tonnage precision forging machine is adopted, so that crystal grains can besufficiently crushed and refined, the crystal grain refining efficiency can be improved, the heating number during the forging process can be remarkably reduced, the preparation process can be shortened, the production cost can be reduced, and the TC4 titanium alloy bar yield can be improved.

Owner:WESTERN TITANIUM TECH

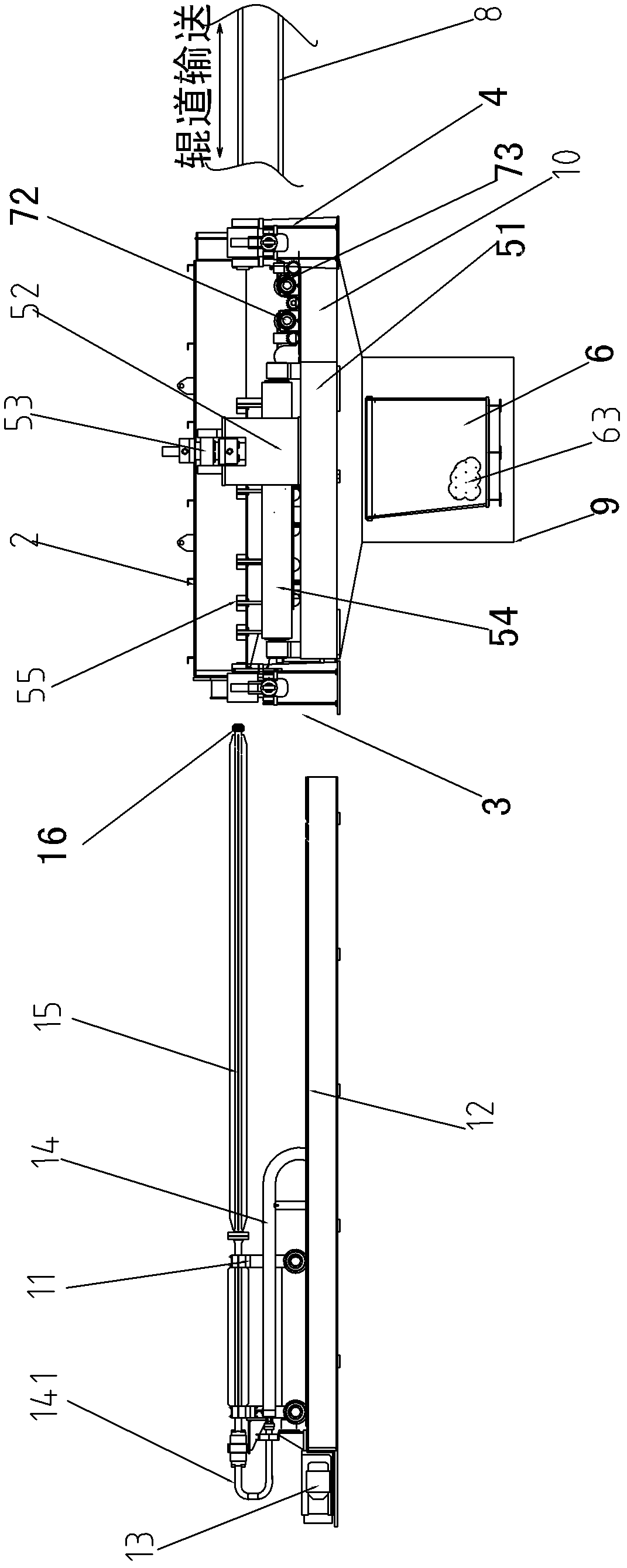

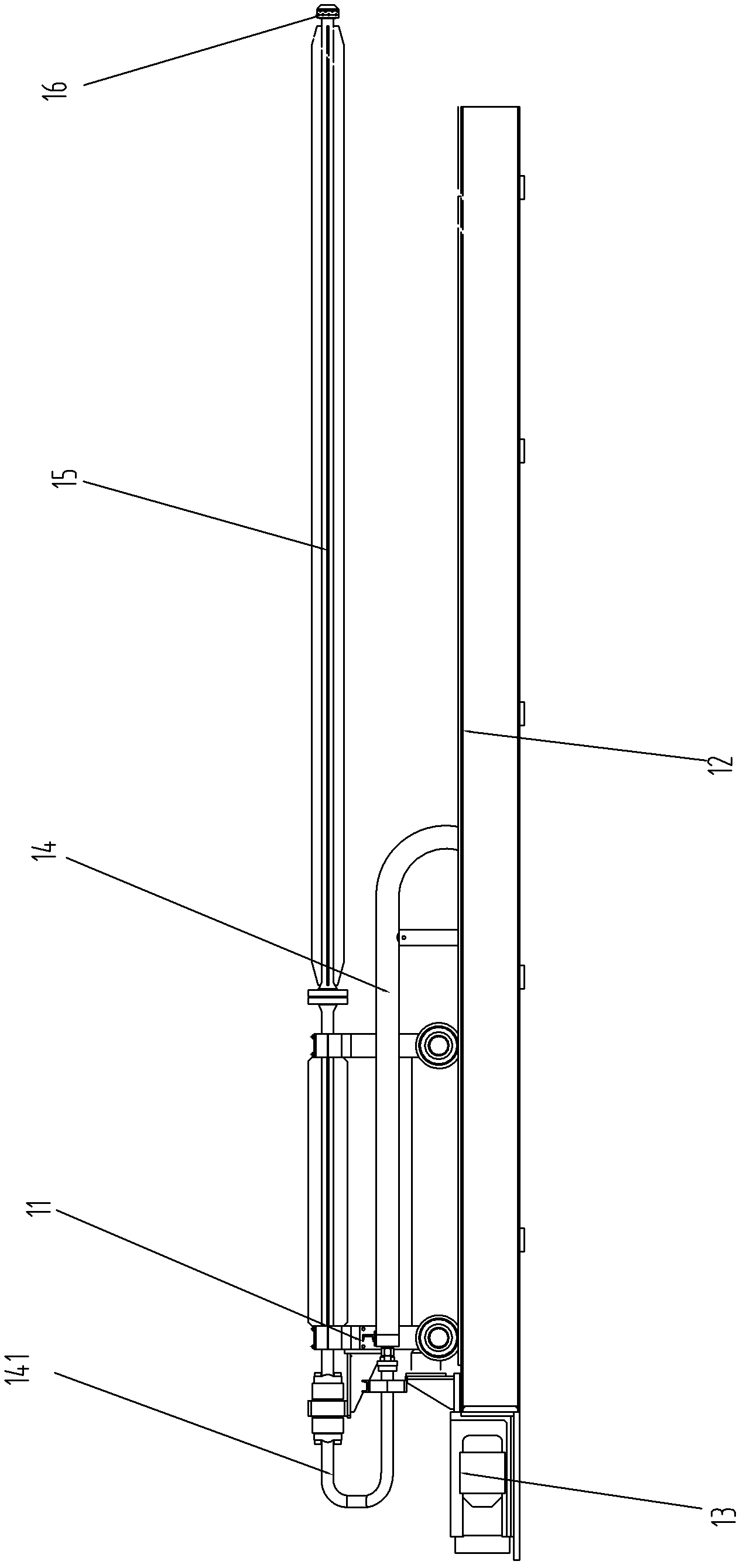

High pressure water descaling equipment

InactiveCN102284524AImprove work efficiencyEfficient removalWork treatment devicesMetal rolling arrangementsCharge dischargeEngineering

The invention discloses a device for descaling by high-pressure water, comprising a high-pressure water convey device, a shield, a left baffle closing device, a right baffle closing device, a charge-discharge roller way, a centring device, and an oxide scale collecting device, wherein the high-pressure water convey device is located at the left side of the shield; a trolley is located on a rail; a nozzle is installed at the outlet end of a high-pressure water tube; the shield is a cover body with respectively open left end, right end and bottom; the left and right baffle closing devices are located at the left and right ends of the shield respectively, for closing the openings at the left and right ends of the shield; the centring device is located in front of the shield; and the oxide scale collecting device is placed below the shield. The device for descaling by high-pressure water disclosed by the invention can efficiently remove the oxide scale on the inner surface of a tube blank, and increase the quality of the forged inner surface of the tube; the high labour intensity of manual descaling is avoided; the descaling working efficiency of the tube blank and the forging production efficiency of the tube are increased; the oxide scale removal effect is good; and the actual problems in a radial forging production are solved.

Owner:WUHU XINXING DUCTILE IRON PIPES

Method for improving optional performances of large H13 steel hot-extrusion mould

The invention relates to the field of aluminum alloy hot-extrusion moulds and in particular relates to a method for improving optional performances of a large H13 steel hot-extrusion mould. The method is characterized by comprising transverse fiber flow-direction forging, normalizing and spheroidizing annealing after the forging in the forging process, wherein the method specifically comprises the following steps of: (1) filling the blanks to a furnace and heating up the blanks to 1180 DEG C to 1200 DEG C; (2) axially forging the blanks and continuously forging the blanks in a radial direction, wherein the peripheral direction of the mould blanks is the fiber flow direction, and the forging ratio is not smaller than 4; and (3) carrying out the normalizing and the spheroidizing annealing after the forging. Compared with the prior art, the method has the beneficial effects that the fiber flow direction on the center part of the mould is distributed in the peripheral direction by virtue of the transverse fiber flow-direction forging process, so that the tissue of the mould is uniform and compact; moreover, the thermal treatment process of the normalizing and spheroidizing annealing after the forging is adopted, so that the netlike carbide can be removed and the crystal-phase tissue structure is improved, and therefore, the service life of the mould is prolonged twice or more.

Owner:JINGANG FORGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com