Method utilizing middle and high-frequency induction to heat radial forging to form screws

A technology of high-frequency induction heating and radial forging, applied in metal processing equipment, etc., can solve the problems of large-diameter screw rods formed by radial forging without warm forming technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

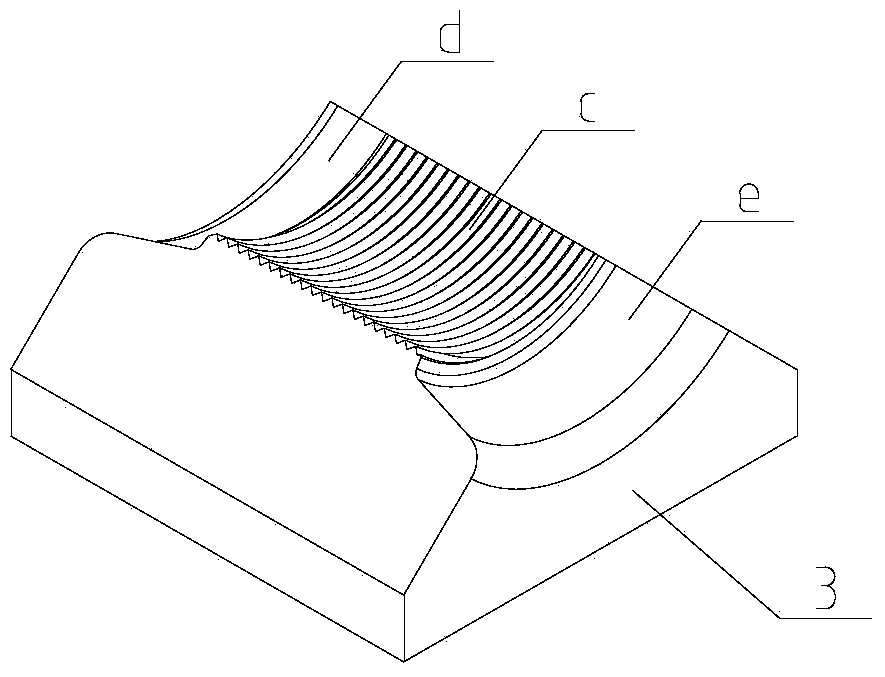

[0047] This example uses four hammer heads, which are arrayed at equal intervals along the axis of the workpiece in space, and the screw material is 42CrMo high-strength steel.

[0048] A method for a medium and high frequency induction heating radial forging lead screw, comprising the following steps:

[0049] Step 1: Clamp the workpiece 2, and one end of the workpiece 2 is clamped by the first manipulator 1;

[0050]Step 2, the surface of the end area of the forming lead screw segment on the workpiece 2 is locally heated, specifically:

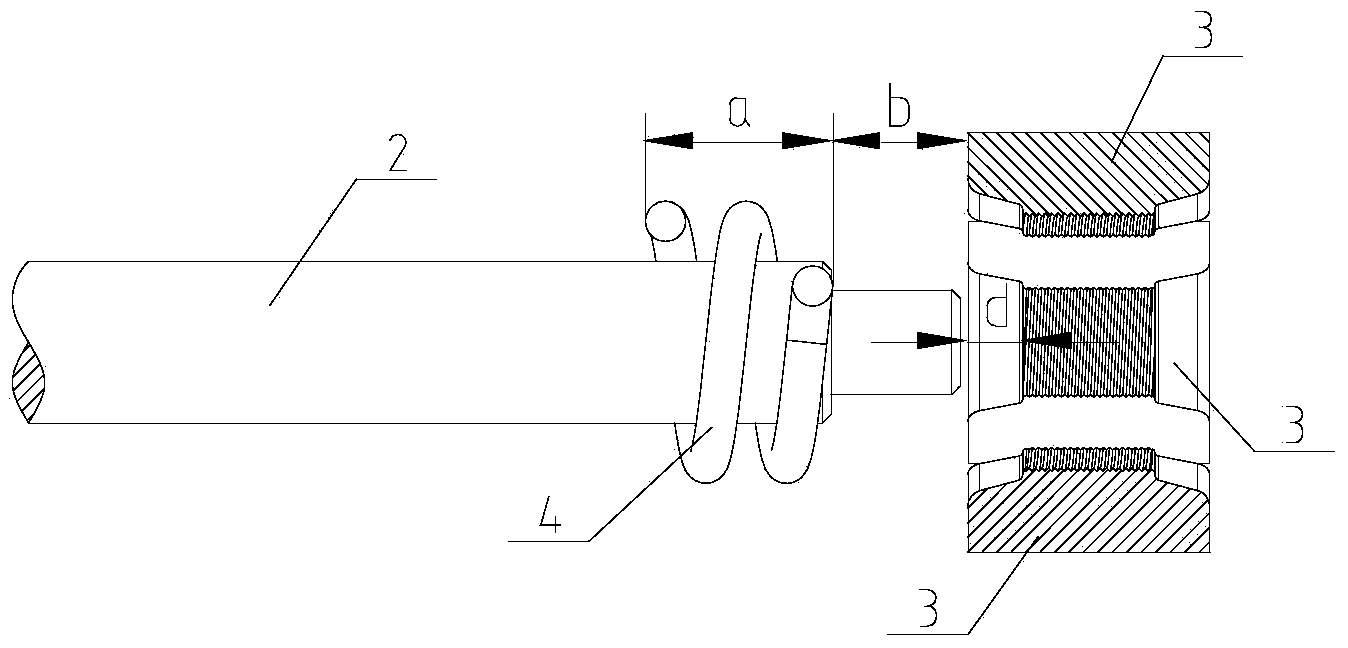

[0051] 2.1. Reference figure 1 , the workpiece 2 is fed in the direction of the radial forging hammer head 3, the formed lead screw segment on the workpiece 2 enters the medium and high frequency induction heater 4, and the medium and high frequency induction heater 4 is arranged between the hammer head 3 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com