Machining method of titanium alloy large-diameter seamless thin-wall pipe

A technology of thin-walled pipes and processing methods, which is applied in the field of material processing, can solve problems such as the unformed production process system, low material utilization rate, and long processing cycle, and achieve flexible production methods, high material utilization rate, and good surface quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

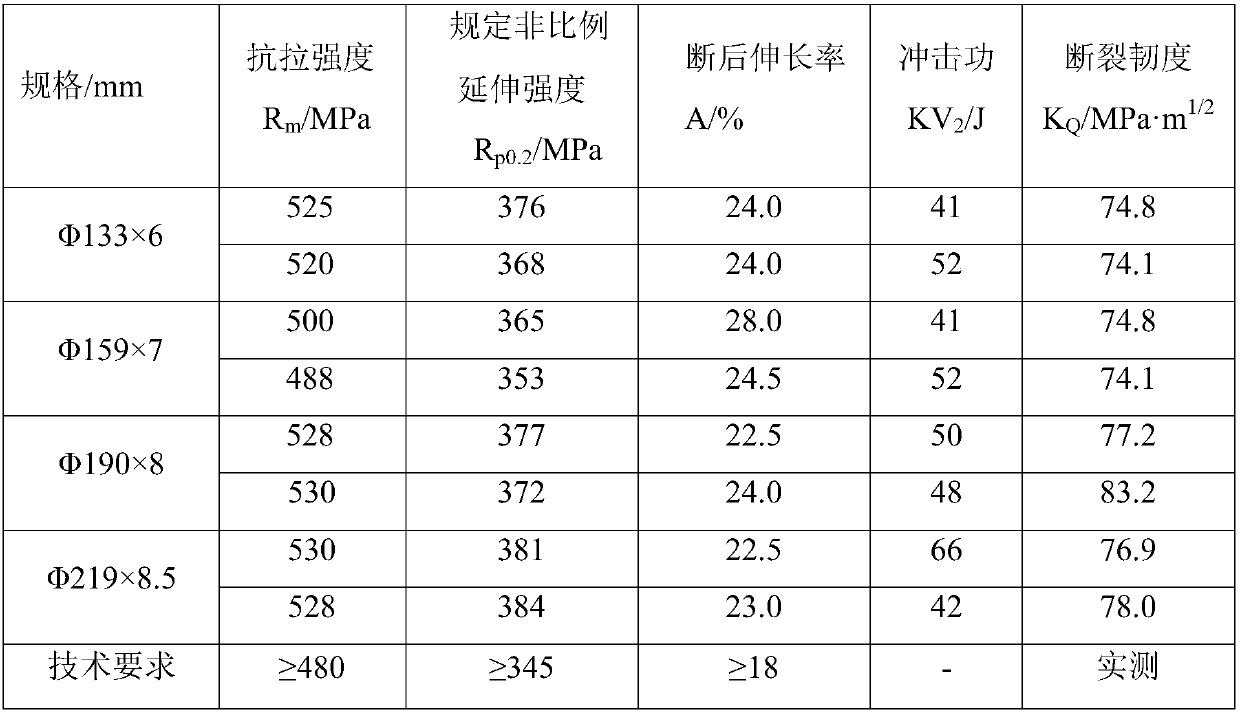

Embodiment 1

[0037]Preparation of TA10 titanium alloy Φ133×6mm (diameter×wall thickness) pipe:

[0038] Step 1: TA10 titanium alloy Φ720mm ingot was prepared by smelting twice in a vacuum consumable electric arc furnace, and the phase transition point of the ingot was measured as 885-895°C by quenching metallographic method;

[0039] Step 2: After planing and milling the ingot, the surface is coated with an anti-oxidation protective coating, heated and kept in a natural gas furnace (temperature control accuracy ±15°C) and then released from the furnace, and then forged on a 10,000-ton fast forging machine to Φ220× 1200mm billet, specifically forging 2 to 3 times in the single-phase zone and 2 to 3 times in the (α+β) two-phase zone, where the heating temperature in the single-phase zone is 950-1000°C, 820~880℃;

[0040] Step 3, using a cutter to take out a Φ90mm solid bar from the center of the Φ220mm bar blank to obtain a Ф220 / Ф140×1200mm hollow capillary;

[0041] Step 4, heat the hollo...

Embodiment 2

[0046] Preparation of TA10 titanium alloy Φ159×7mm (diameter×wall thickness) pipe:

[0047] Step 1: TA10 titanium alloy Φ720mm ingot was prepared by smelting twice in a vacuum consumable electric arc furnace, and the phase transition point of the ingot was measured as 885-895°C by quenching metallographic method;

[0048] Step 2: After planing and milling the ingot, the surface is coated with an anti-oxidation protective coating, heated and kept warm in a natural gas furnace, and then released from the furnace, and then forged on a 10,000-ton fast forging machine to form a billet of Φ250×1200mm. 2-3 times of forging in the single-phase area, 2-3 times of forging in the (α+β) two-phase area, wherein the heating temperature of the single-phase area is 950-1000 °C, and the heating temperature of the two-phase area is 820-880 °C;

[0049] Step 3, taking out the solid bar of Φ115mm from the center of the bar blank through mechanical processing to obtain a hollow capillary of Ф250 / Ф...

Embodiment 3

[0055] Preparation of TA10 titanium alloy Φ190×8mm (diameter×wall thickness) pipe:

[0056] Step 1: TA10 titanium alloy Φ720mm ingot was prepared by smelting twice in a vacuum consumable electric arc furnace, and the phase transition point of the ingot was measured as 885-895°C by quenching metallographic method;

[0057] Step 2: After planing and milling the ingot, the surface is coated with an anti-oxidation protective coating, heated and kept warm in a natural gas furnace, and then released from the furnace, and then forged on a 10,000-ton fast forging machine to form a billet of Φ268×1200mm. 2-3 times of forging in the single-phase area, 2-3 times of forging in the (α+β) two-phase area, wherein the heating temperature of the single-phase area is 950-1000 °C, and the heating temperature of the two-phase area is 820-880 °C;

[0058] Step 3, take out the solid bar material of Φ130mm from the center of the bar blank through mechanical processing to obtain the hollow capillary ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition point | aaaaa | aaaaa |

| Phase transition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com