Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

891results about How to "Meet technical requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

X80 steel bend pipe and bending technique thereof

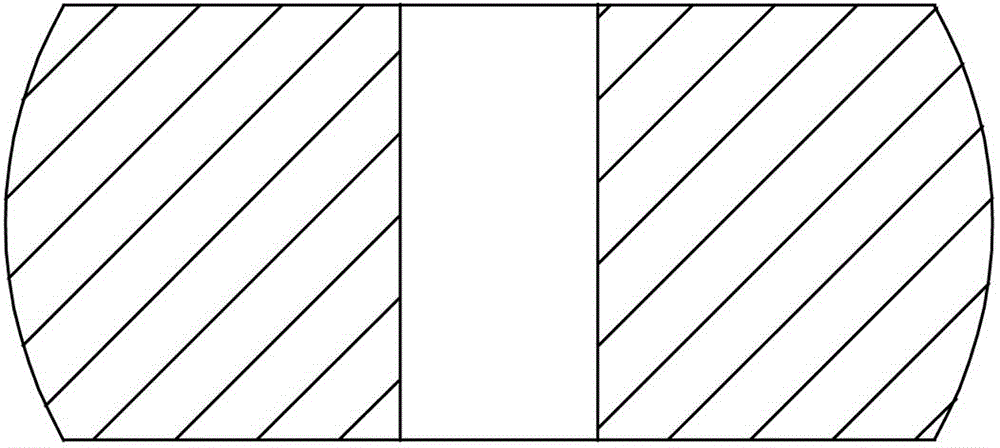

The invention relates to an X80 steel bent pipe and a process for bending the same, wherein the bent pipe is made of X80 steel. The weight percentage compositions of the steel are: 0.06 to 0.15 percent of C, 0.1 to 0.3 percent of Si, 1.4 to 2.0 percent of Mn, less than or equal to 0.015 percent of P, 0.01 percent of S, 0 to 0.45 percent of Cr, 0 to 0.3 percent of Mo, 0 to 0.3 percent of Cu, 0 to 0.5 percent of Ni, 0.05 to 0.15 percent of Nb, 0 to 0.06 percent of Ti, 0 to 0.06 percent of V, Ceq controlled between 0.36 and 0.44 percent, Pcm controlled between 0.17 and 0.23 percent. The steel controlled rolled steel plate is made into steel pipe and is formed into bent pipe by induction heating bending process. The properties of the bent pipe can completely meet the technical requirement on X80 steel pipes by controlling parameters of heating temperature of the induction heating, bending velocity, cooling velocity, etc. during the bending process, thereby being suitable to be used as bent pipes for oil and gas pipelines.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

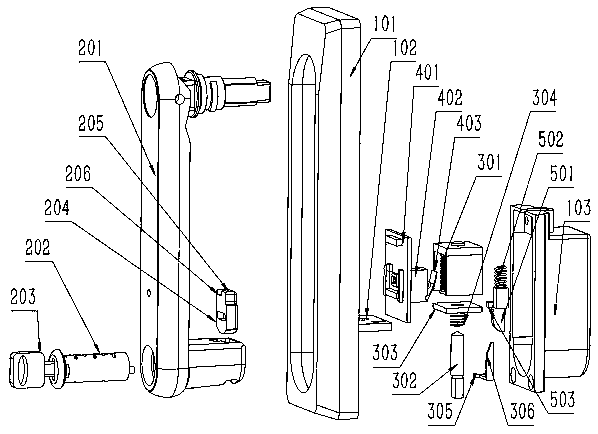

Device for directly combining nano fiber diaphragm on lithium ionic cell electrode surface and the method

InactiveCN101192681AInnovation of traditional assembly processMeet technical requirementsActive material electrodesSecondary cellsFiberCompound a

The invention relates to a device for directly preparing and compounding a nano fiber diaphragm on the surface of an electrode slice in a lithium ion battery and a method based on the device. The invention enables two processes of preparation of the diaphragm on the lithium ion battery and the assembly of the diaphragm and the electrode slice to be completed in one time. The invention is realized by an electrostatic spinning machine for the diaphragm on the lithium ion battery which can be produced continuously, and the key component is a spinneret of high-efficiency electrostatic spinning. By applying an electrostatic spinning method to directly spray a polymer nano fiber diaphragm on the surface of the electrode slice in the lithium ion battery (which takes platinum analogs as a substrate) under a specific technological condition, the two technological processes of preparation of the diaphragm on the lithium ion battery and the assembly of the diaphragm / electrode slice are completed in one time. The invention can not only produce the diaphragm on the lithium ion battery with high performance, but also renovate the traditional assembly technique of the lithium ion battery. The produced composite material of the diaphragm / electrode slice meets the technical requirements of a common lithium ion battery and a power lithium iron battery.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

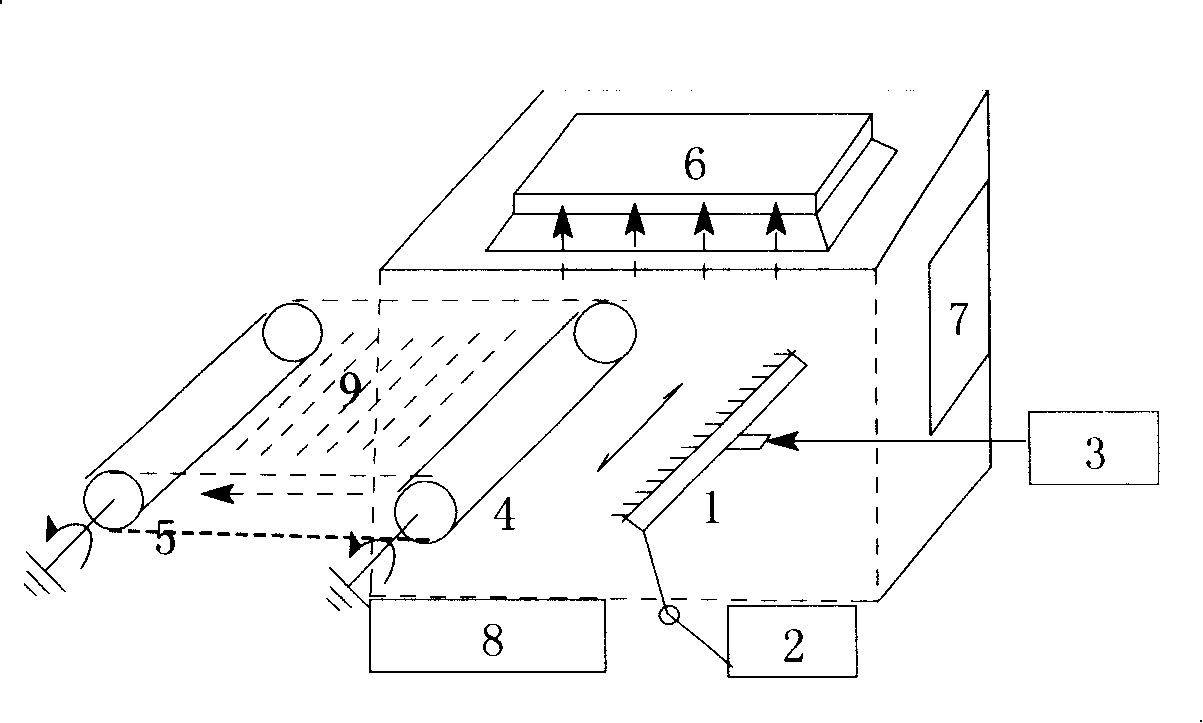

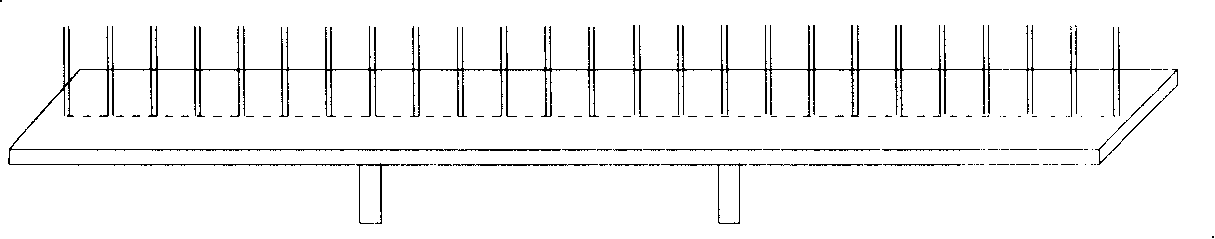

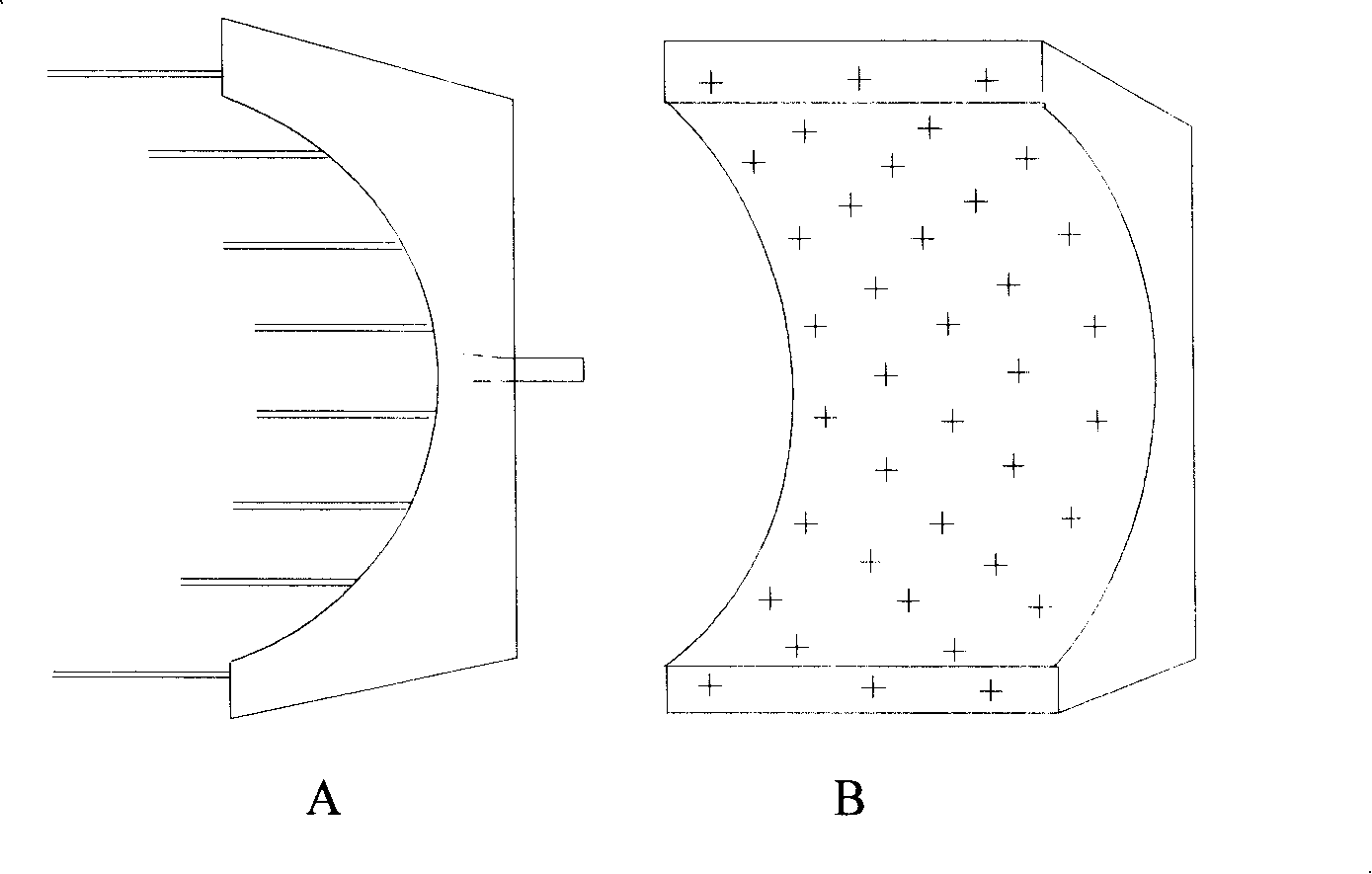

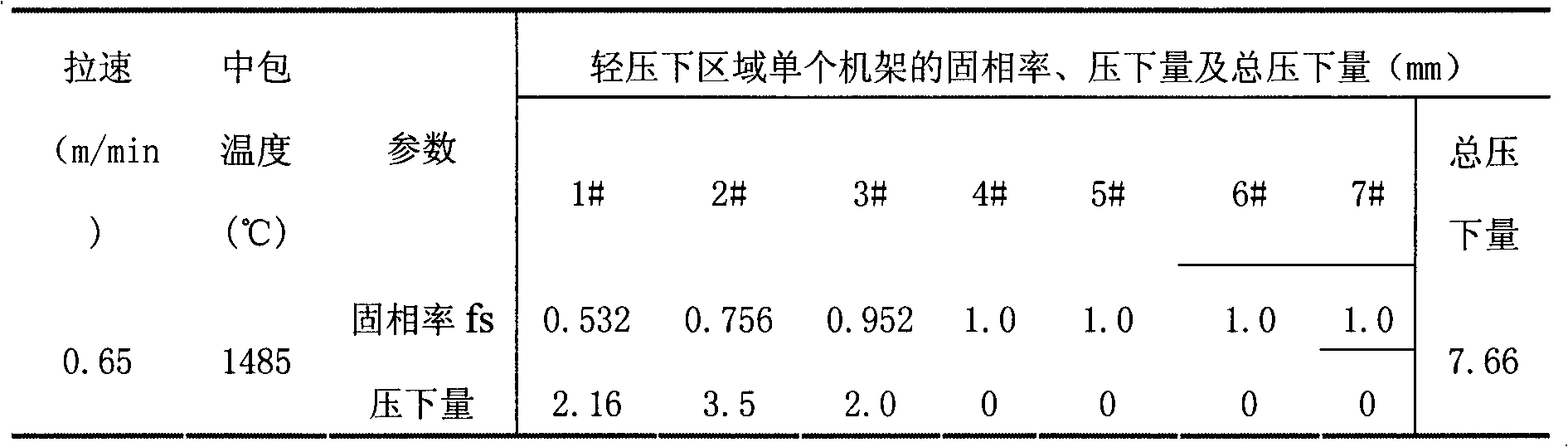

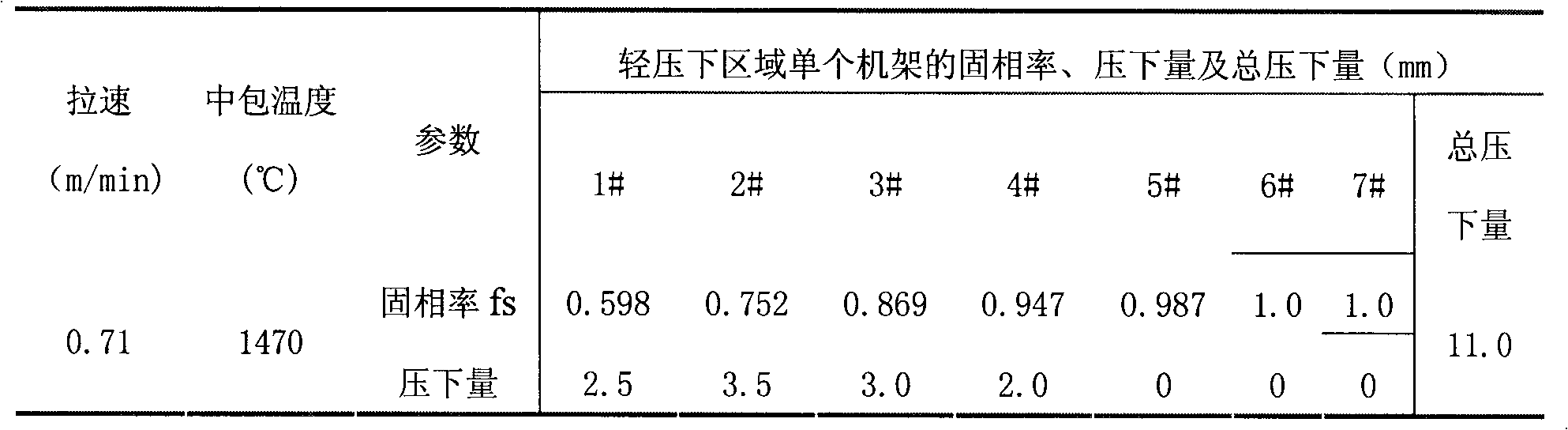

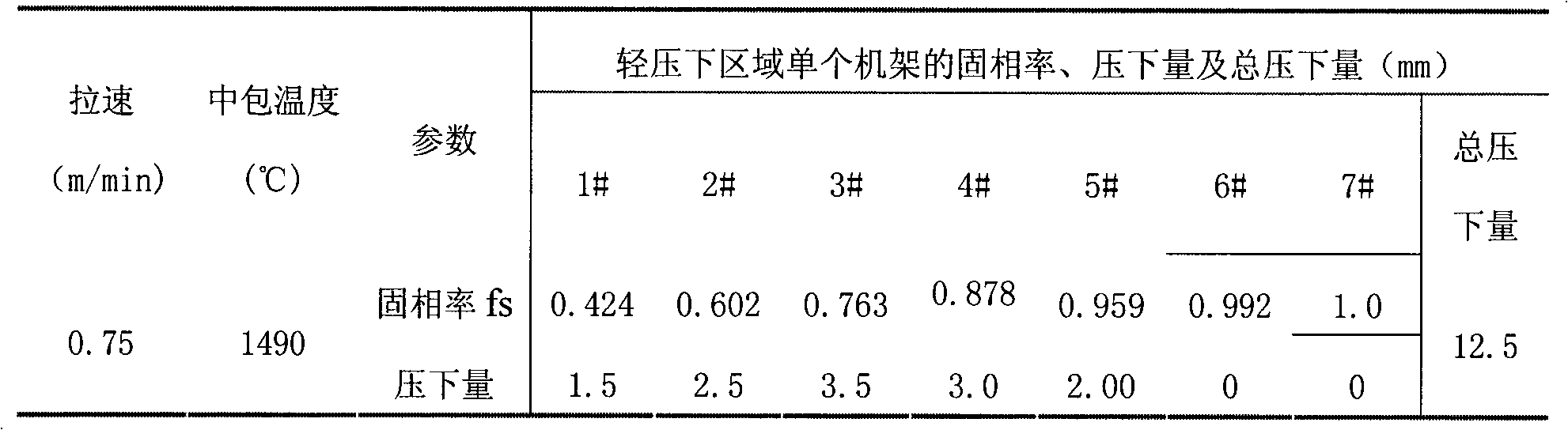

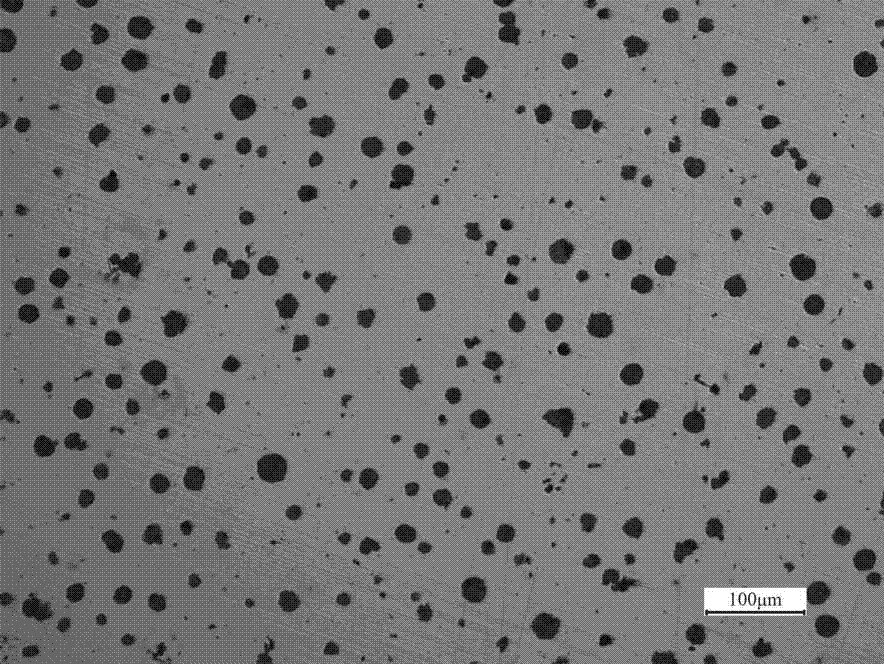

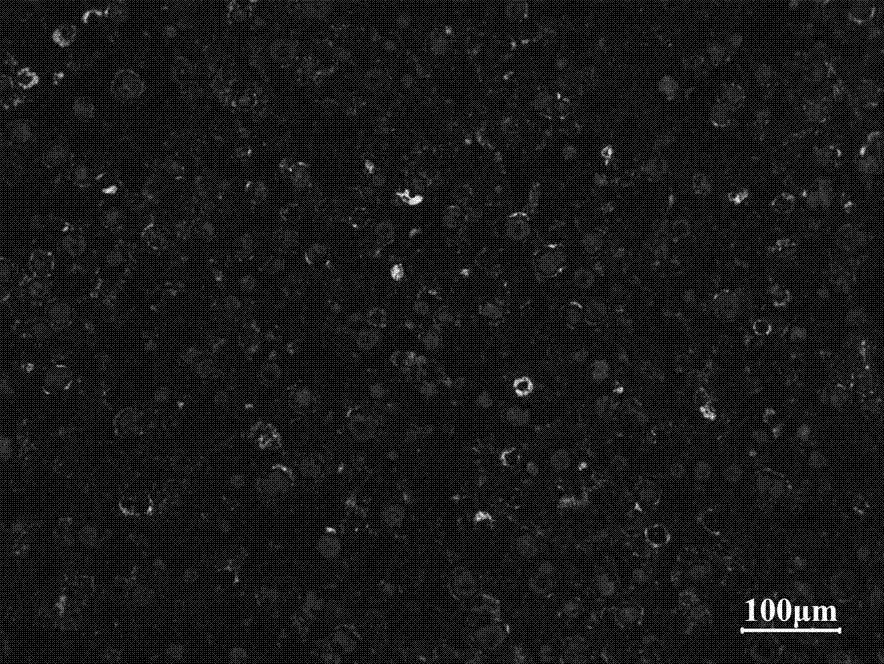

GCr15 bearing steel bloom continuous casting dynamic soft reduction process

InactiveCN101642774AEasy to loosenMeet technical requirementsMetal rolling arrangementsMetallurgySteel casting

The invention relates to a GCr15 bearing steel bloom continuous casting dynamic soft reduction process, which belongs to the technical field of metallurgical continuous casting and is used for solvingthe problems that the GCr15 bearing steel bloom continuous casting is easy to cause central segregation, central looseness, central parosity and other casting slab internal quality defects. The technical scheme is as follows: the reduction of a continuous casting soft reduction region is controlled through the change of central solid phase rate fs of a casting slab, and the relationship between the reduction of a soft reduction rack and the central solid phase rate of the casting slab is given out. The adoption of the soft reduction process of dynamic control can significantly reduce the central segregation of the GCr15 bearing steel casting slab, the central carbon segregation index of the casting slab is 0.95-1.08, and the average central segregation is 1.03; the process can also obviously improve the central looseness and the central parosity of the GCr15 bearing steel casting slab, the proportion of the central looseness of the casting slab which is not more than 1.0 grade is morethan 90%, and the central parosity is not more than 0.5 grade.

Owner:XINGTAI IRON & STEEL +1

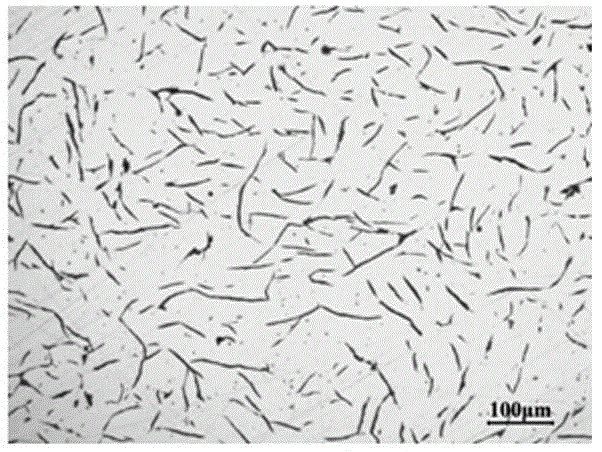

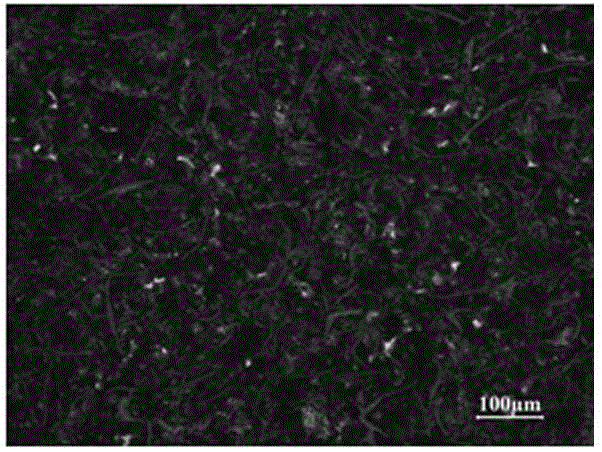

High-strength low stress cast nodular cast iron with high elasticity modulus and manufacturing method thereof

The invention discloses a high-strength low stress cast nodular cast iron with high elasticity modulus. The nodular cast iron comprises the following components by mass percent: 3.7-3.9% of C, 2.0-2.2% of Si, 4.50-4.65% of CE, 0.5-0.6% of Mn, less than or equal to 0.03% of P, less than or equal to 0.02% of S, 0.03-0.06% of Mg, 0.01-0.02% of RE, 0.5-0.7% of Cu, and 0.05-0.06% of Sn. A manufacture method of the nodular cast iron is characterized by high temperature pure iron liquid of base iron, compound alloying and accurate addition; according to the microscopic structure of the manufactured nodular cast iron, the content of pearlite is more than or equal to 95%, the nodularity is more than or equal to 90%, spherulitic graphite number in unit area is 200-380 / mm<2>, the yield strength is over 400MPa, the strength of extension is over 700MPa, the elastic modulus is more than 170GPa, the hardness HB is 190-250, the elongation is more than 3%, the casting inner stress is less than or equal to 50MPa, namely, with high carbon equivalent and high silicon-carbon ratio, the nodular cast iron has excellent performances such as high strength, high elasticity modulus and low stress, thus meeting the technical requirement of casting of machine tools.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

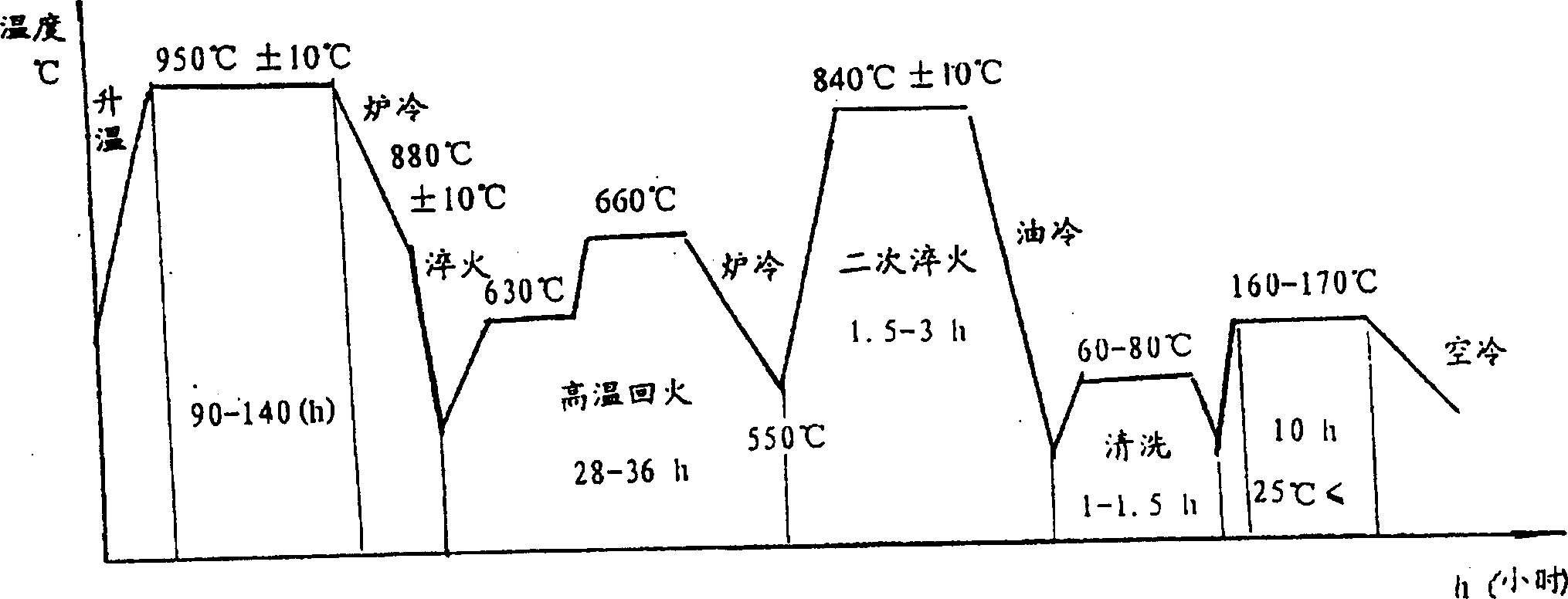

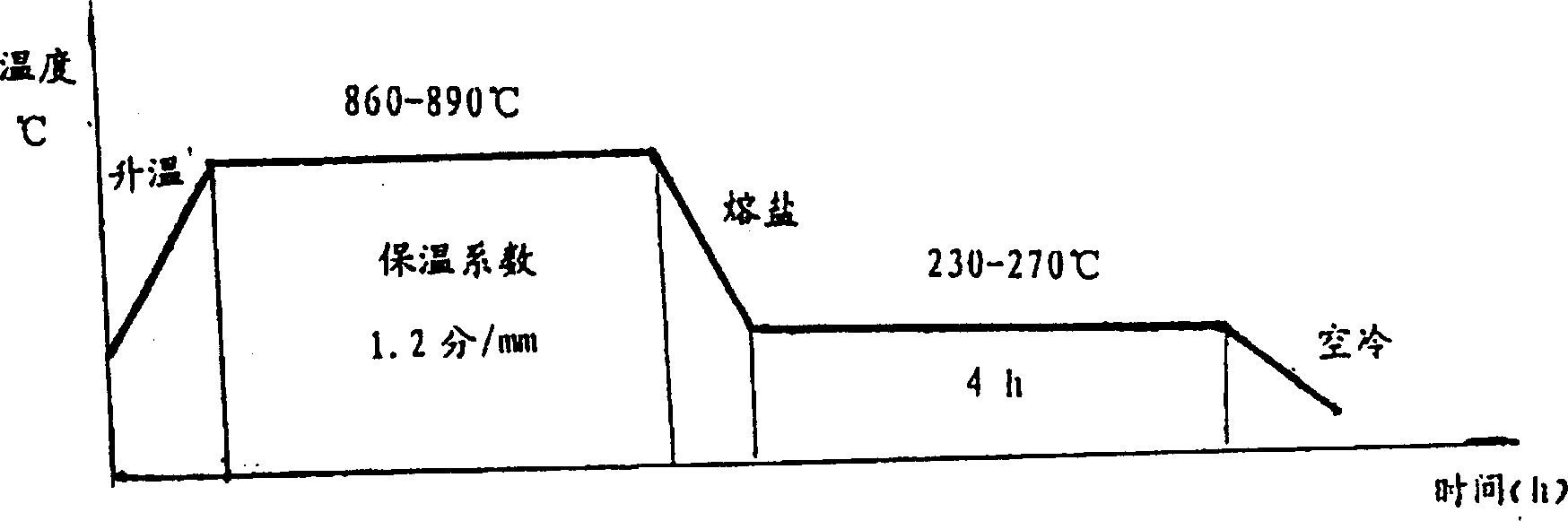

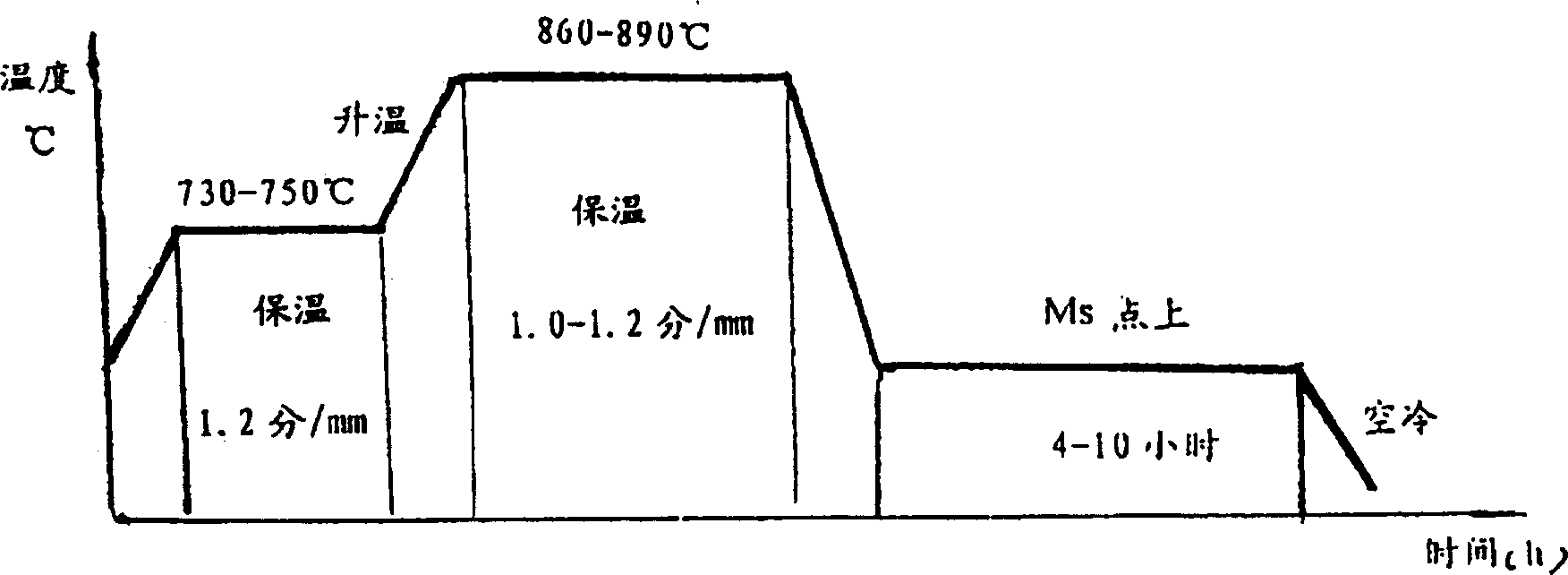

High-strength high-impact toughness bearing steel and its heat treatment process

The chemical composition of said invented high-strength high impact toughness bearing steel contains: C 0.6-1.0, Si 0.7-1.8, Mn 0.3-0.85, Cr 0.1-1.9, MO 0.15-0.8, V 0.15-0.6,l W, 0.1-0.6, rare earth 0.01-0.20, S is less than or equal to 0.25, P is less than or equal to 0.025 and the rest is Fe and inevitable impurity. Said invention adopts a simple high-frequency surface quenching process, and can attain the performance requirements of bearings used in the roll mill, railway machines, petroleum machines and mine machines under the condition of large load and heavy impact.

Owner:董元宇

Casting method for large thin-wall valve body steel casting

ActiveCN103506580AImprove production efficiencyReduce manufacturing costFoundry mouldsFoundry coresPhysical modelCasting defect

A casting method for a large thin-wall valve body steel casting comprises the following steps: 1, manufacturing a composite physical model: manufacturing an upper half valve body external mold, a lower half valve body external mold, the overall frame of a second core box, and an irregular-shaped section template; filling a mixed filler between the frame and the section template; tamping, smoothly trimming the filler; performing natural curing after the dimensional requirement is met; 2, sand mulling; 3, modeling and core manufacturing; 4, painting, mounting the core, and combining boxes; 5, smelting and casting; 6, performing post-treatment. The large thin-wall valve body steel casting is prepared through the steps. The casting method adopting the composite model can improve the model manufacturing efficiency, saves wood, and reduces the model manufacturing cost; through the adoption of stepped flat ingate system, as well as the manner that a chiller, a riser and compensation are combined, the thin-wall valve body steel casting is protected from fracture, insufficient casting, cold shut, wrinkling, and other casting defects, so as to realize the sequential solidification of the valve body steel casting, and meet the technical requirement of the valve body steel casting.

Owner:YICHANG MARINE DIESEL ENGINE

Special process for freely forging EH36 optimized material steel ingot into plate-shaped bearing seat forged piece

The invention relates to a special process for freely forging a plate material, namely, EH36 optimized material steel ingot, into a plate-shaped bearing seat forged piece with the thickness of 250mm, and the mechanical property of a rolled steep plate which is much thinner than that of the rolled steel plate can be achieved although the thickness of the rolled steel plate cannot be achieved. The material comprises the following components in percentage by mass: less than or equal to 0.18% of C, 0.15-0.40% of Si, 1.20-1.60% of Mn, less than or equal to 0.015% of S, less than or equal to 0.020% of P, less than or equal to 0.35% of Cu, less than or equal to 0.20% of Cr, less than or equal to 0.40% of Ni, 0.05-0.10% of Nb, 0.05-0.10% of V, less than or equal to 0.02% of Ti, less than or equal to 0.08% of Mo, 0.02-0.03% of Al and the balance of Fe.

Owner:宝鼎重工有限公司

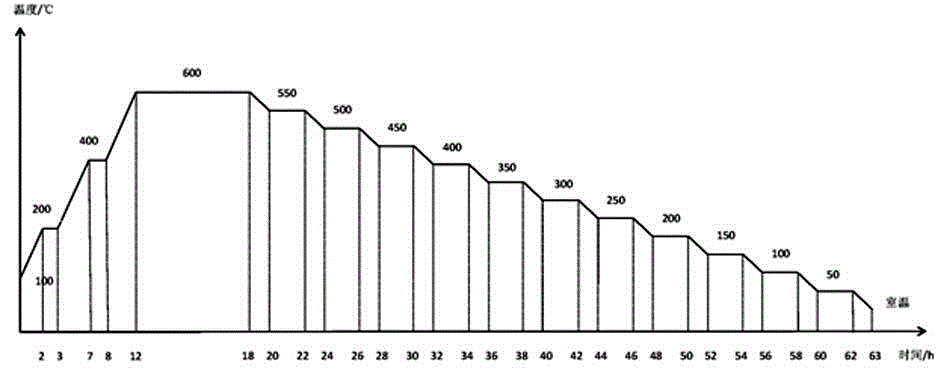

X80 steel made pipe fittings and manufacture technique thereof

ActiveCN101205594AMeet technical requirementsFurnace typesRigid pipesChemical compositionPipe fitting

The invention relates to a pipeline made of X80 steel and a method for manufacturing the same. The chemical compositions are that: 0.06 to 0.1 percent of C, 0.1 to 0.3 percent of Si, 1.4 to 2.0 percent of Mn, less than or equal to 0.015 percent of P, 0.01 percent of S, 0 to 0.45 percent of Cr, 0 to 0.3 percent of Mo, 0 to 0.3 percent of Cu, 0 to 0.5 percent of Ni, 0.05 to 0.15 percent of Nb, 0 to 0.06 percent of Ti, 0 to 0.06 percent of V, Ceq controlled between 0.36 and 0.44 percent, Pcm controlled between 0.17 and 0.23 percent. The pipeline manufactured with the controlled rolled steel plate of the compositions by means of controlling the forming temperature, hardening heat, drawing temperature, cooling velocity, etc. has low-temperature impact toughness more than 90 J, completely meets the technical requirement on the X80 pipelines and is suitable to be used as X80 steel pipelines for oil and gas pipelines.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

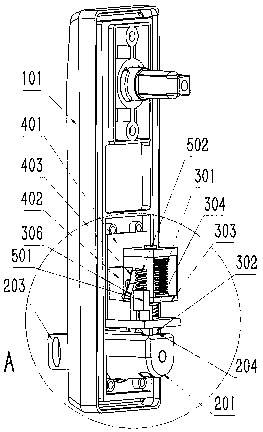

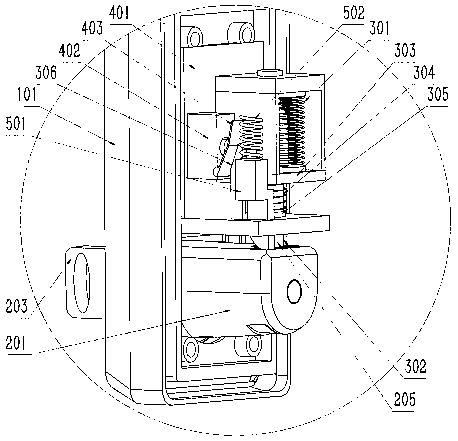

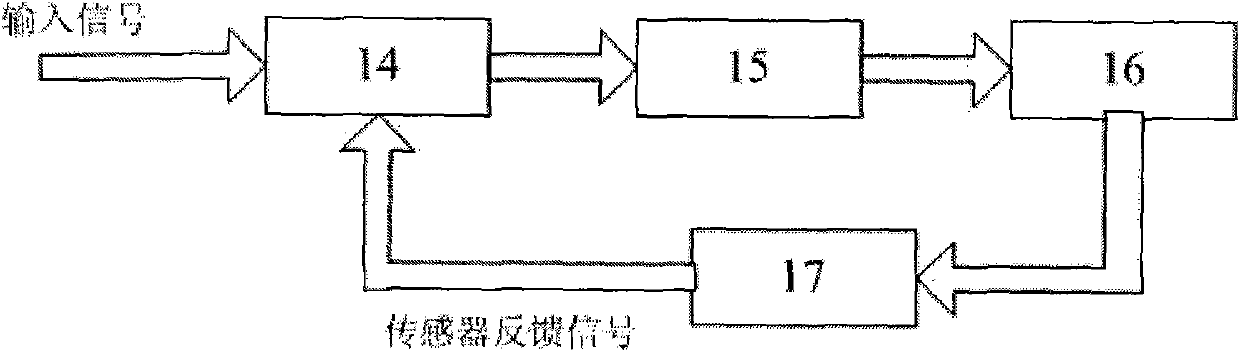

Electronic cabinet lock and control method thereof

ActiveCN105507685AThe overall structure is simple and reliableMeet technical requirementsWing handlesKeyhole guardsMechanical engineeringReliability engineering

Owner:WUHAN PULINGUANGTONG TECH

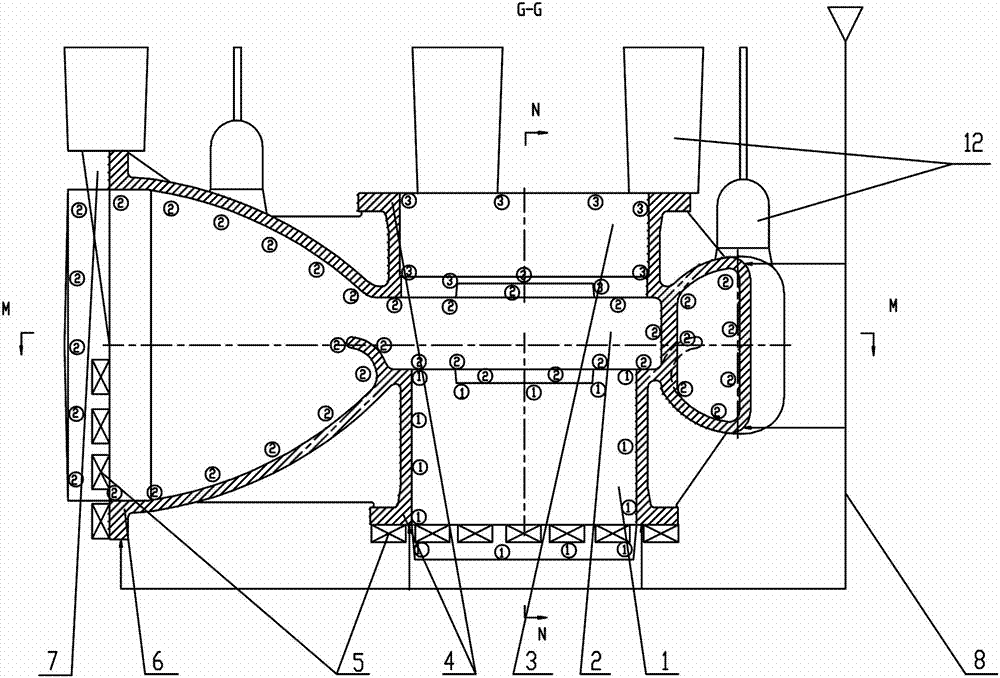

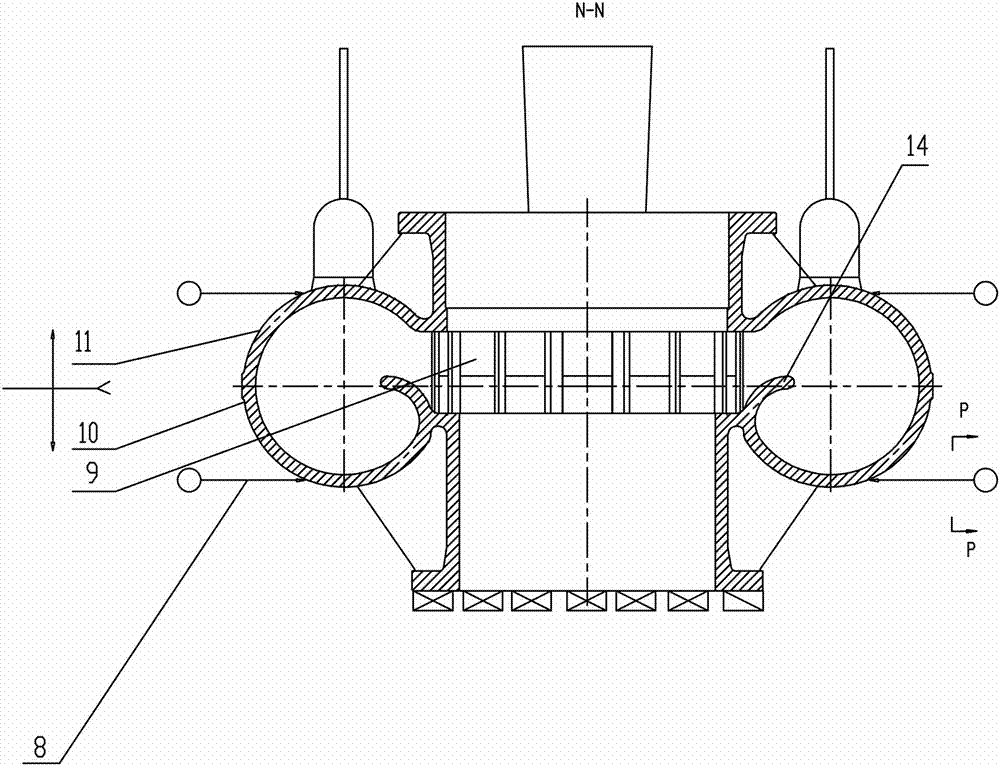

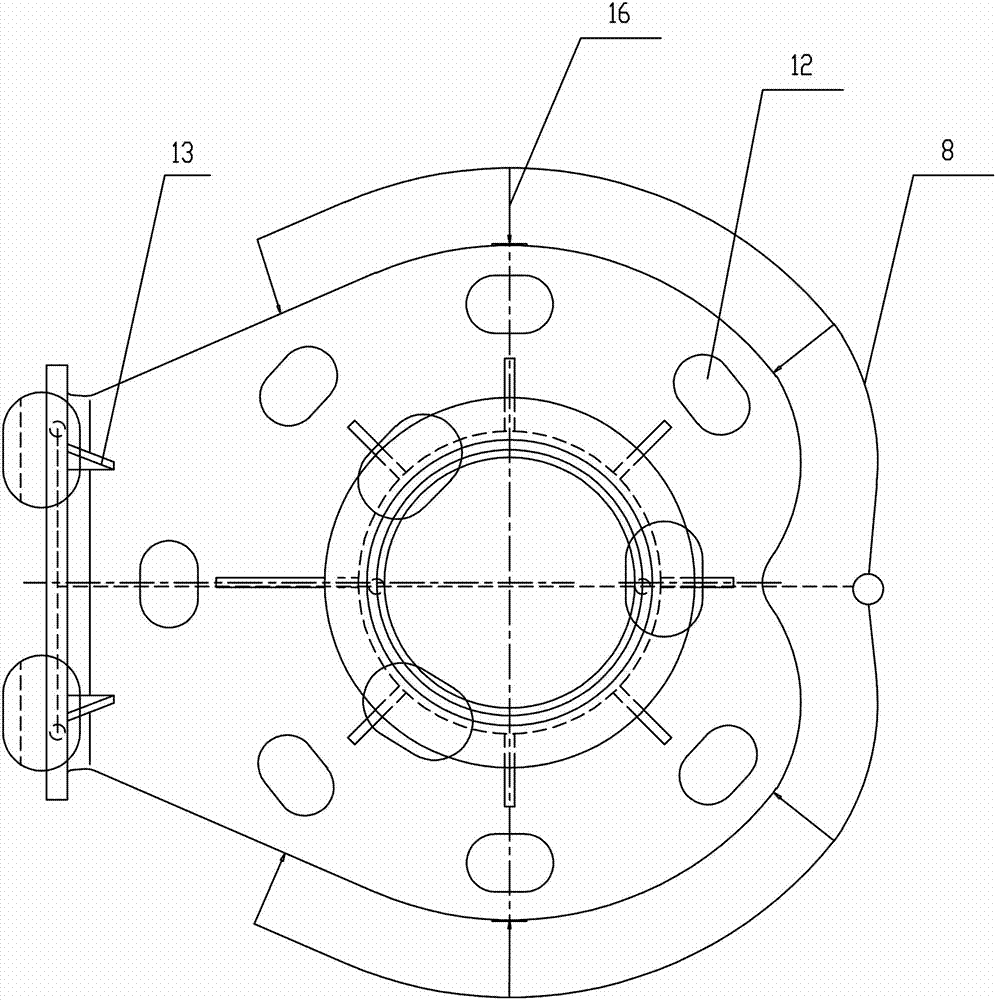

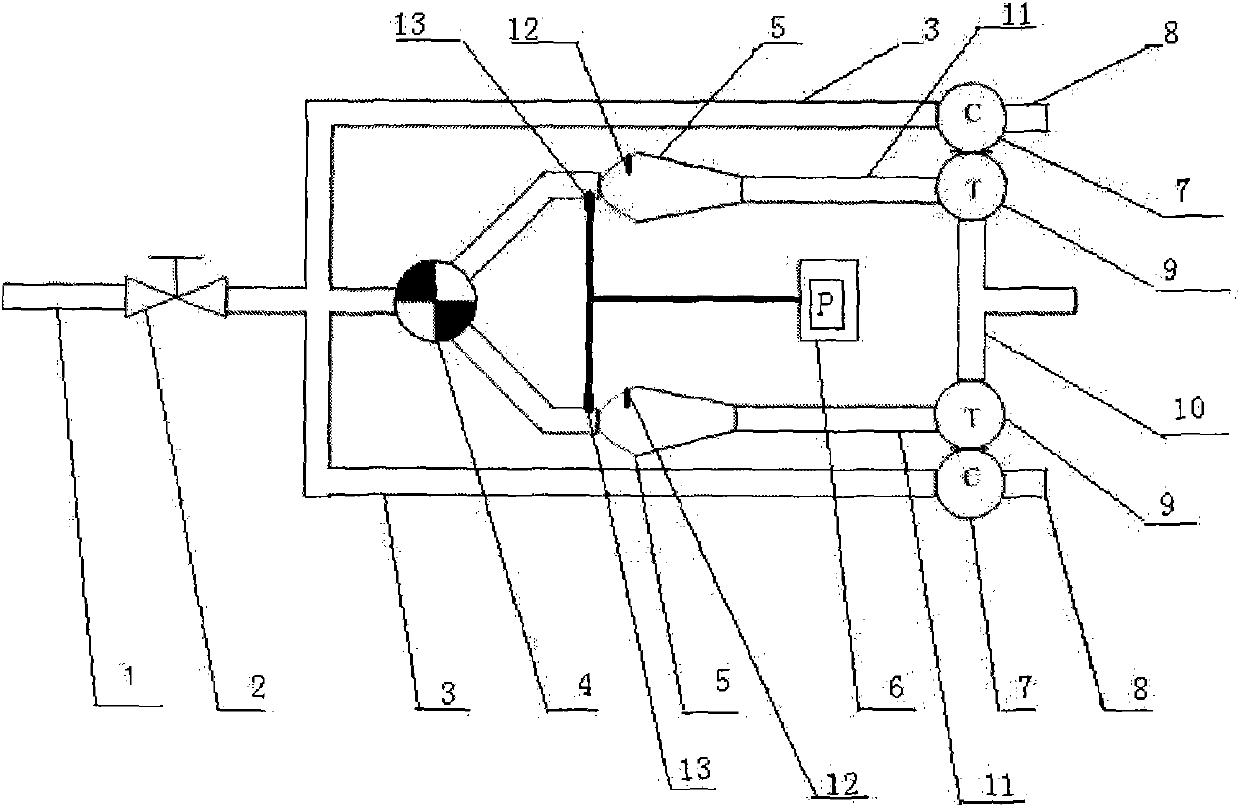

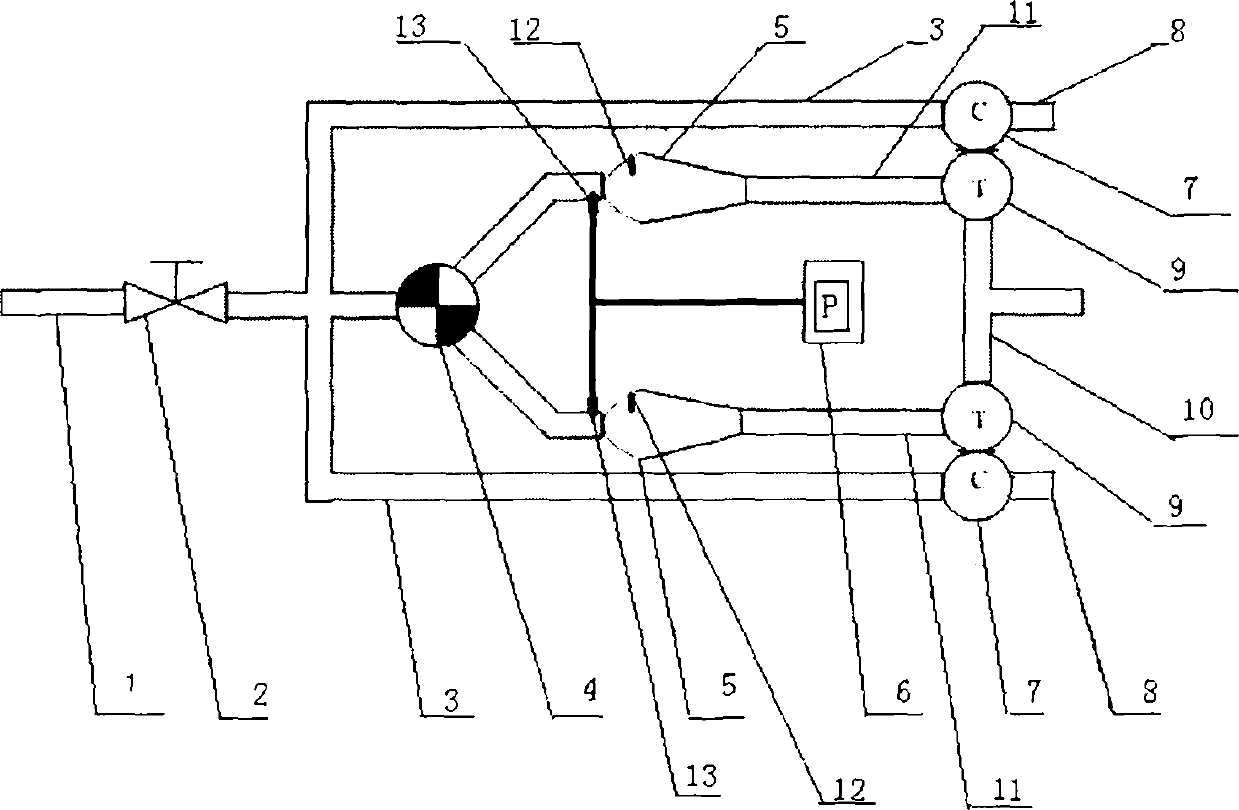

Test bench with double combustion chambers, double superchargers and low cycle fatigue based on self-circulation mode

InactiveCN101793619AReduce dependenceReduce consumptionInternal-combustion engine testingCombustion chamberPrice ratio

The invention relates to a test bench with double combustion chambers, double superchargers and low cycle fatigue based on a self-circulation mode, belonging to the technical field of power machinery. When the test bench with superchargers and low cycle fatigue which adopts a self-circulation principle is started and works, an external gas source firstly supplies gas to the combustion chambers and is closed after the superchargers stably runs, and a turbine and a compressor form self circulation, thereby reducing the dependency to power and the consumption of power, only needing fuel oil with a certain quantity and lowering the requirement of a low cycle fatigue test to compressed air and further reducing the requirement to an air compressor. In the test bench, air flows are respectively supplied to turbines of the two superchargers by adopting the two combustion chambers, and a measure that a flow distribution valve is installed before each combustion chamber enables the test bench with the double combustion chambers, the double superchargers and the low cycle fatigue to realize different gas inlet temperatures of each supercharger, thereby the mechanical load and the heat load needed by the low cycle fatigue test is changed, and the high temperature resistance requirements of materials of the flow distribution valve is reduced with high performance price ratio.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

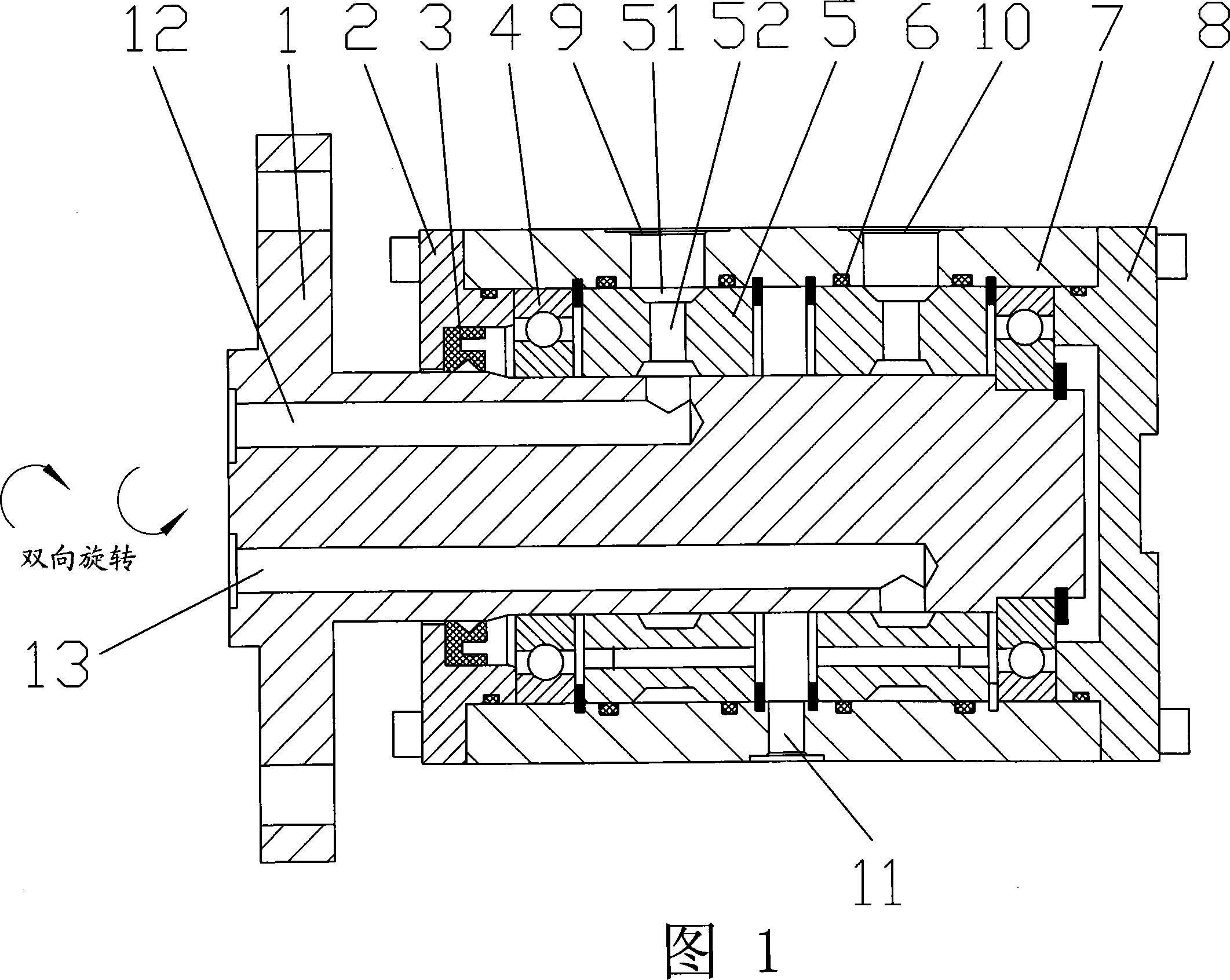

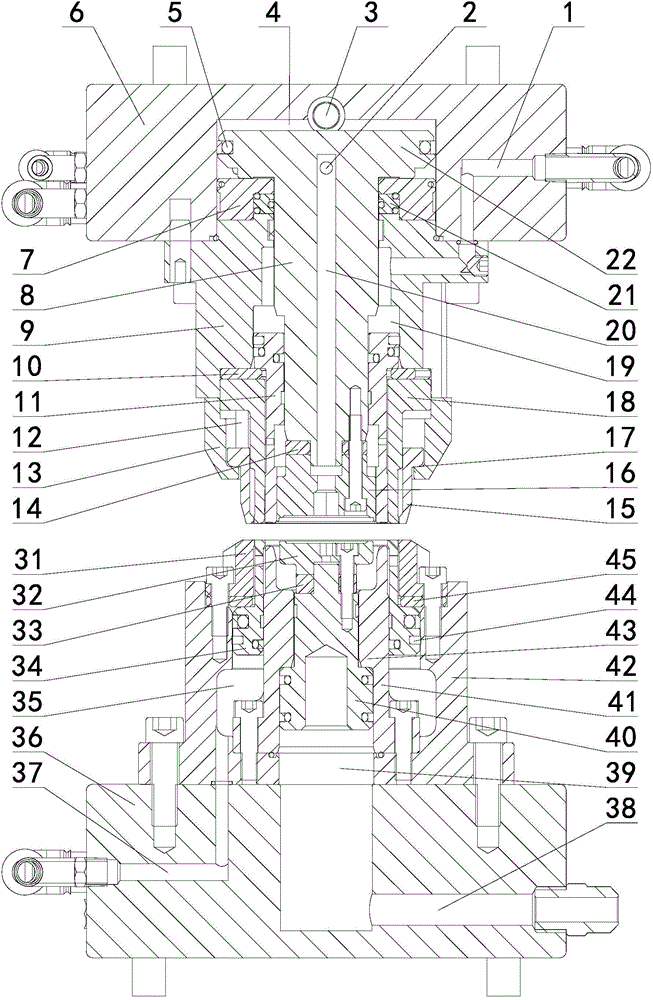

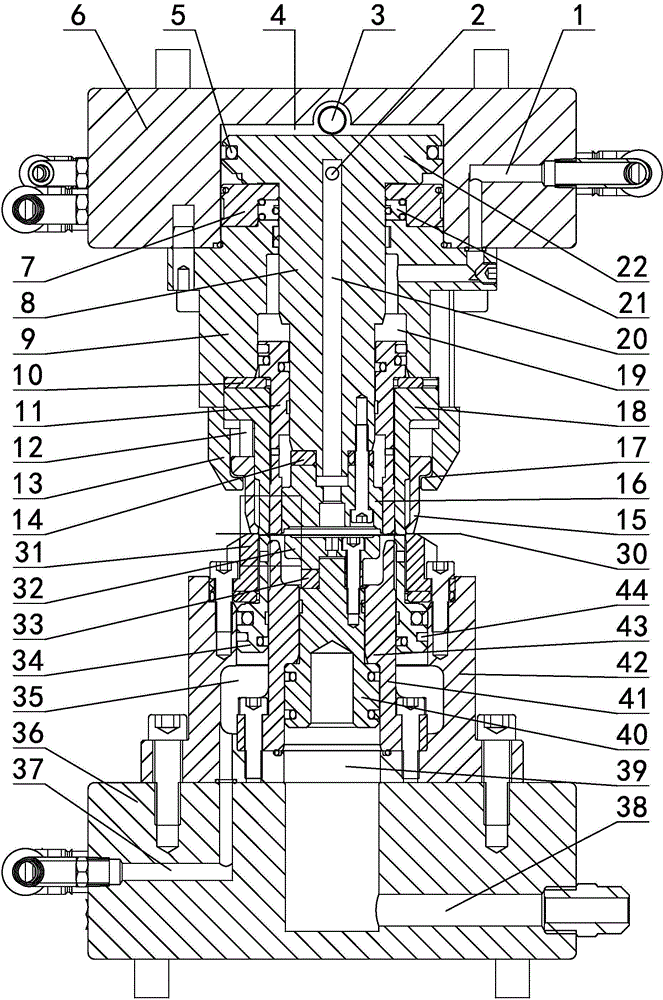

High pressure high speed rotation joint

InactiveCN101169205AReasonable structureMeet technical requirementsAdjustable jointsHydraulic cylinderHigh pressure

The invention relates to a high-pressure high-speed rotating joint, which comprises a core shaft and a casing, wherein, the core shaft does the high-speed rotation while the casing stays still; the core shaft and a hydraulic cylinder are fixed together and rotate with a main machine; a servo ring is arranged between the casing and the core shaft; the servo ring is under the control of an O-shaped ring and the working pressure to realize constant clearance control and servo self-defined aligning control. Working medium enters a working oil opening A or a working oil opening B on the casing through a pipeline, then the working medium is input into the core shaft which does rotary movements with the main machine via the static casing and the static servo ring. In this way, continual transmission of the working medium in the rotary members is realized. The invention adopts clearance sealing technology to achieve the technological requirements of low friction and high durability, and adopts static pressure controlled clearance sealing technology to keep constant the sealed clearance and permanently prevent lock of internal structures of the rotating joint under constant pressures. The invention has the advantages of rational structure, excellent running performance and easy maintenance.

Owner:韶关液压件厂有限公司

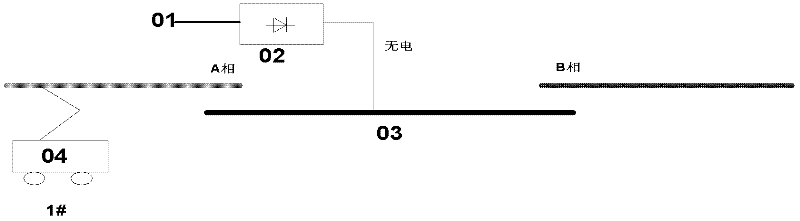

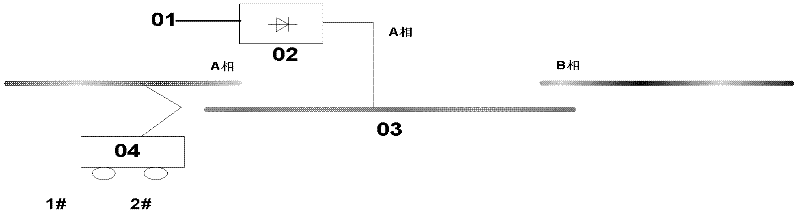

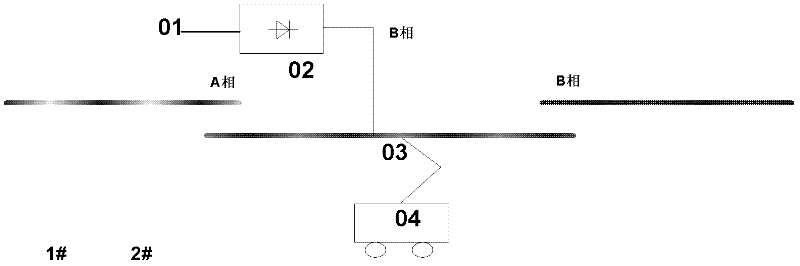

Method for realizing electric auto-passing neutral section of train by utilizing power electronic switching device

InactiveCN102343835AAchieve continuous and uninterruptedAchieve smooth transitionPower supply linesElectric locomotivesCurrent transducerManufacturing technology

The invention relates to a method for realizing an electric auto-passing neutral section of a train by utilizing a power electronic switching device and belongs to the technical field of the manufacturing of the power electronic switching device. An existing modern power electronic technology, namely a high-power voltage current transducer control technology, is adopted to realize the complete equipment of power electronic switching device which is used as a 'phase-change switch for a ground auto-passing neutral section device', thereby optimizing an existing 'uninterrupted automatic electricphase-separating system for electrically dragged train', exactly realizing an uninterrupted automatic electric phase-separating function of an electrically dragged railway train and overcoming inherent defects of technical performance of an original system.

Owner:BEIJING LANDER QUICK TECH

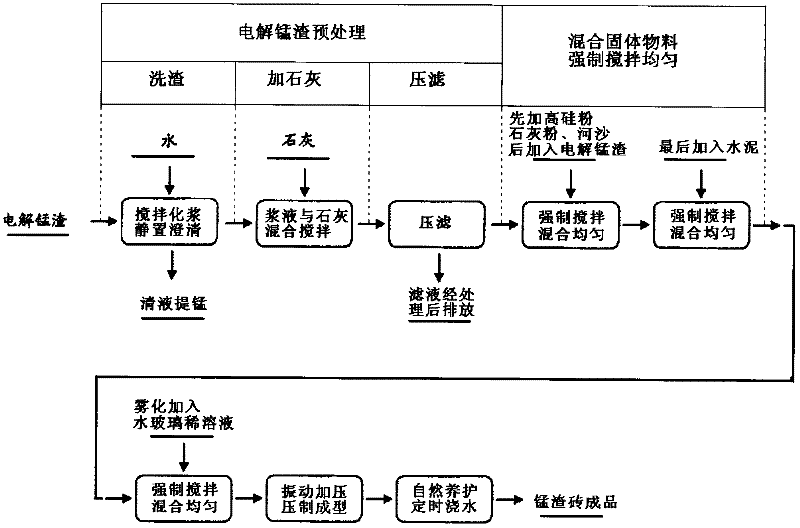

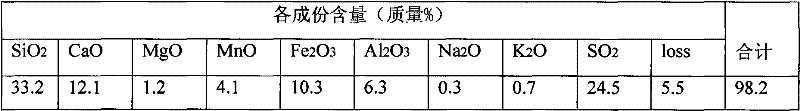

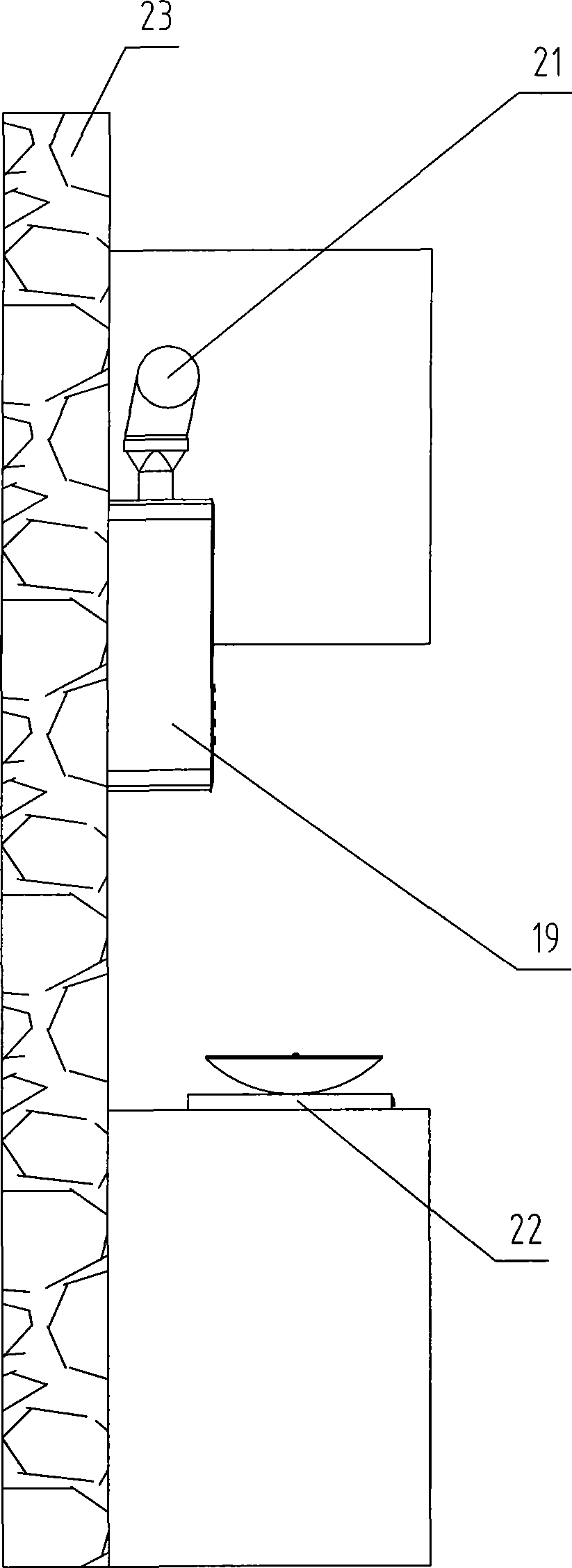

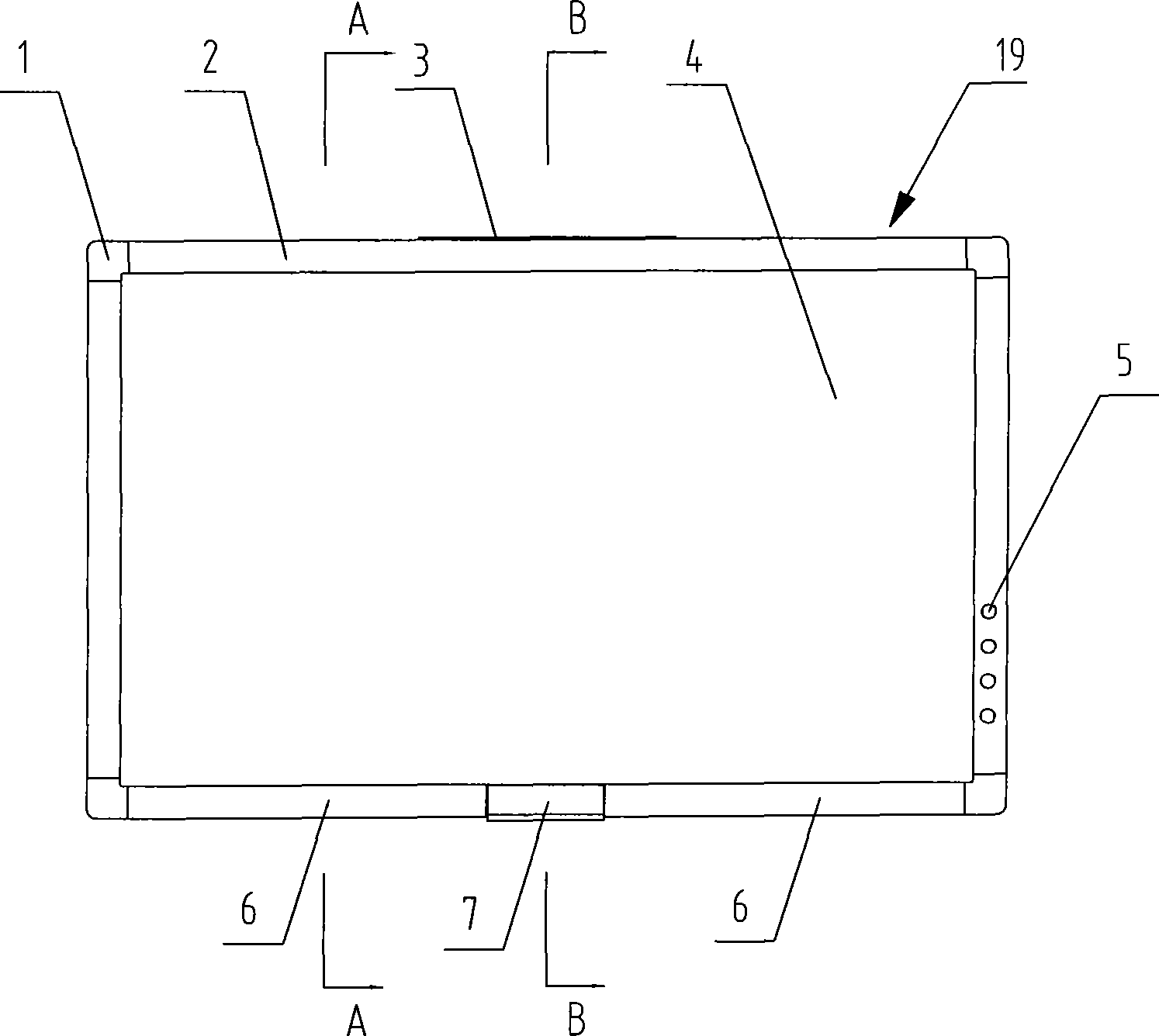

New formula and process method for preparing electrolytic manganese slag brick

The invention provides a new formula and a process method for preparing an electrolytic manganese slag brick, and belongs to the fields of the comprehensive utilization of industrial solid wastes and building materials. At present, the patent technology of preparing the building materials by using manganese slag has the common defect that before alkaline materials such as cement and the like are added, a large quantity of ammonium salts such as ammonium sulfate in the electrolytic manganese slag are not extracted, and the ammonium salts react with the alkaline materials to release a large amount of ammonia during operation, so environmental pollution and the loss of ammonia nitrogen are caused; and before being used, the electrolytic manganese slag is not modified, so the gelatinization activity of the electrolytic manganese slag cannot be well exerted. In order to solve the problem, programs for washing the slag and processing lime slurry and the operations of atomizing and adding a water glass dilute solution are added specially in the process, wherein by the program for washing the slag, the problem of the pollution of the electrolytic manganese slag is solved; and water glass is used as an active initiator for the electrolytic manganese slag serving as gelled materials and a reinforcer for reinforcing the strength of silicate concrete, so that the strength of the electrolytic manganese slag brick serving as a finished product can be reinforced greatly.

Owner:卿富安

Wall-hung thin type lampblack depurating machine

ActiveCN101545651AImprove purification efficiencyCompact structureDomestic stoves or rangesLighting and heating apparatusEngineeringOperating life

The invention discloses a wall-hung thin type lampblack depurating machine, which is provided with flat cuboid-shaped shell, wherein a double-volute is arranged in the shell, and two isolated chambers of the double-volute share an air outlet passage on the top of the shell; a turbo-fan with a horizontal output shaft is arranged in the two isolated chambers of the double-volute respectively, and the front end of the output shaft of the turbo-fan extends out of the double-volute and is connected with at least one vertical rotary centrifugal filter screen plate; and the outside of the rotary centrifugal filter screen plate is provided with an annular oil guide ring, the bottom of the annular oil guide ring is provided with an oil leak opening, a fume flow distribution plate is arranged below the annular oil guide ring, an oil guide tank is arranged on the fume flow distribution plate, and the bottom of the shell is provided with an air inlet passage and an oil collection box. The wall-hung thin type lampblack depurating machine has ultra-high efficiency for holding up and collecting lampblack, can basically put an end to the pollution caused by the lampblack to the air, the shell and the external wall of a building, and has the characteristics of overall closure, simple structure, convenient cleaning, energy saving and noise reduction, large cooking space, safe running and long service life.

Owner:武汉创新环保工程有限公司

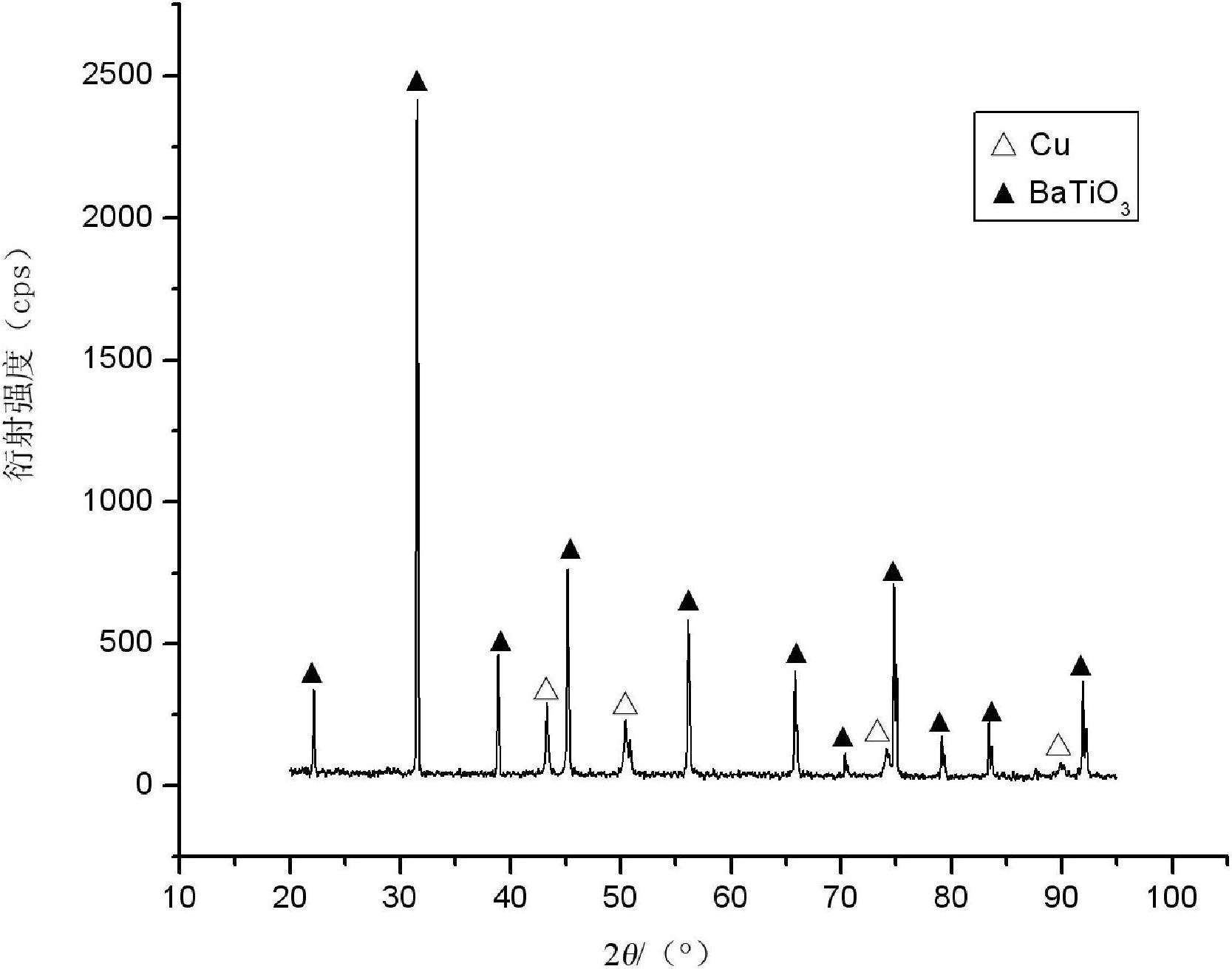

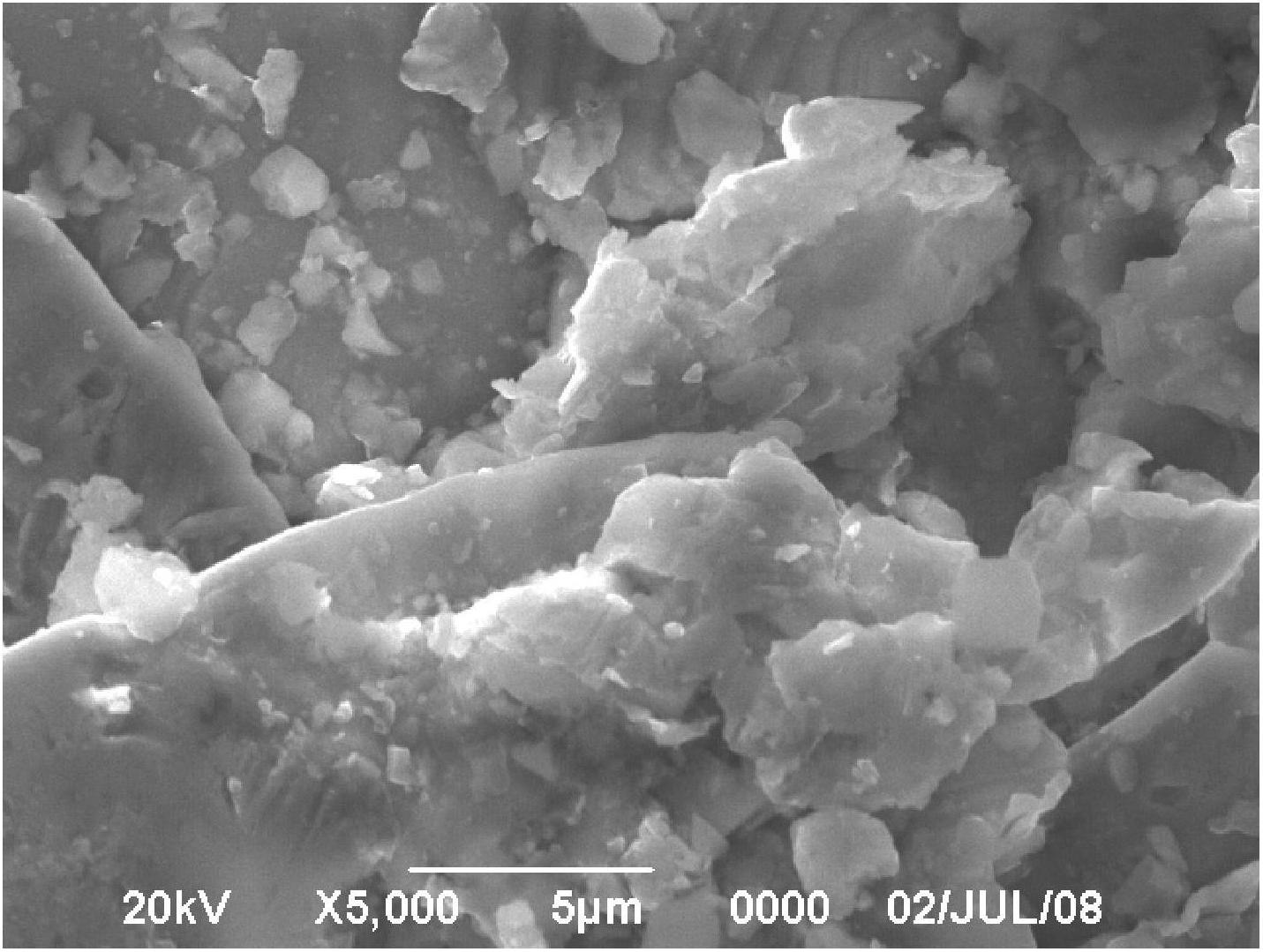

Conductive copper paste for surface electrodes of chip ceramic capacitor and preparation method thereof

InactiveCN102664057AMeet technical requirementsImprove liquidityFixed capacitor electrodesNon-conductive material with dispersed conductive materialScreen printingSilver paste

The invention discloses conductive copper paste for surface electrodes of a chip ceramic capacitor. The conductive copper paste comprises the following raw materials in percentage by mass: 65 to 72 percent of metal powder, 4 to 7 percent of glass powder and 24 to 30 percent of organic binder, wherein the metal powder consists of Cu and W or Cu and Mo; the glass powder consists of CaO, ZnO, Bi2O3, BaO, SiO2, B2O3 and Al2O3; and the organic binder consists of solvent, ethyl cellulose, silane coupling agent and surfactant. The conductive copper paste is printed through silk screens and sintered under the protection of N2 gas, the performance of the obtained finished product of the chip ceramic capacitor can completely meet the technical requirements of the ceramic capacitor, and the conductive copper paste can be used for replacing conductive silver paste on the surface of the corresponding chip ceramic capacitor.

Owner:HEFEI UNIV OF TECH

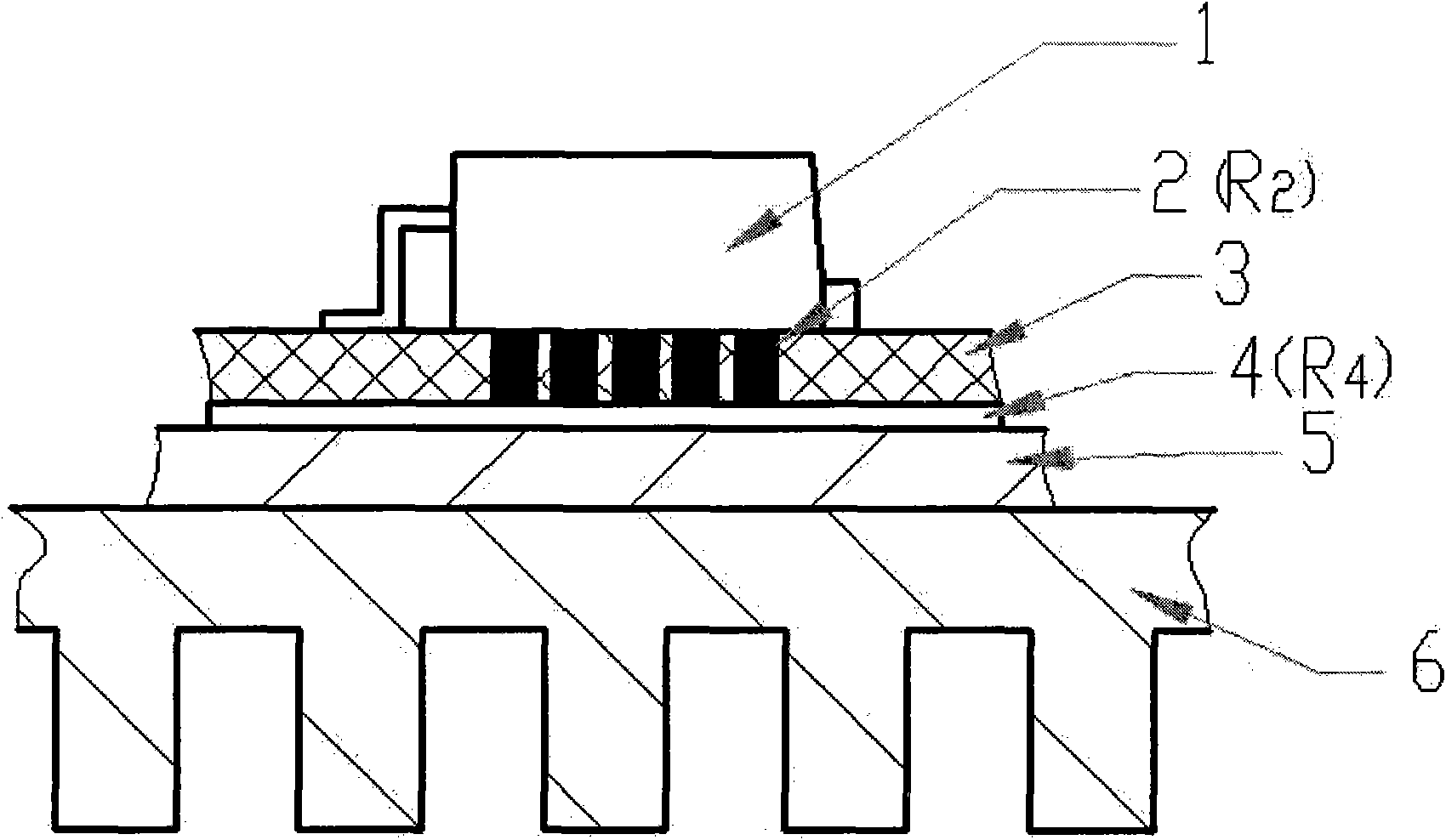

Heat radiation structure of surface mounting high-power element

InactiveCN101556941AFast conductionReduce heat dissipationSemiconductor/solid-state device detailsSolid-state devicesHeat conductingSurface mounting

The invention provides a heat radiation structure of a surface mounting high-power element for conducting heat energy radiated by the high-power element, comprising a heat-conducting copper block, an aluminum base heat radiation panel, a heat radiation shell. The heat-conducting copper block is embedded in a circuit board and has thickness the same as that of the circuit board; the aluminum base heat radiation panel is plated with a copper welding pan at one surface, while the other surface thereof is connected with the heat radiation shell; and the heat radiation shell radiates heat energy to air in a way of natural convection. The high-power element is enveloped in a way of surface mounting. The installation of the high-power element is characterized in that the high-power element is connected with the front surface of the heat-conducting copper block embedded on the circuit board by welding. The installation of the aluminum base heat radiation panel is characterized in that the aluminum base heat radiation panel is connected with the reverse surface of the heat-conducting copper block embedded on the circuit board by welding. The invention adopts a following heat radiation access: the high-power element-the heat-conducting copper block-the aluminum base heat radiation panel-the air, effectively reduces the work temperature of the high-power element, remains the work temperature of the high-power element at a rated range, and meets the technical requirement of on-vehicle electronic equipment. The heat radiation structure has the advantages of good heat radiation effect, simple structure, low cost, and the like.

Owner:重庆三祥汽车电控系统有限公司

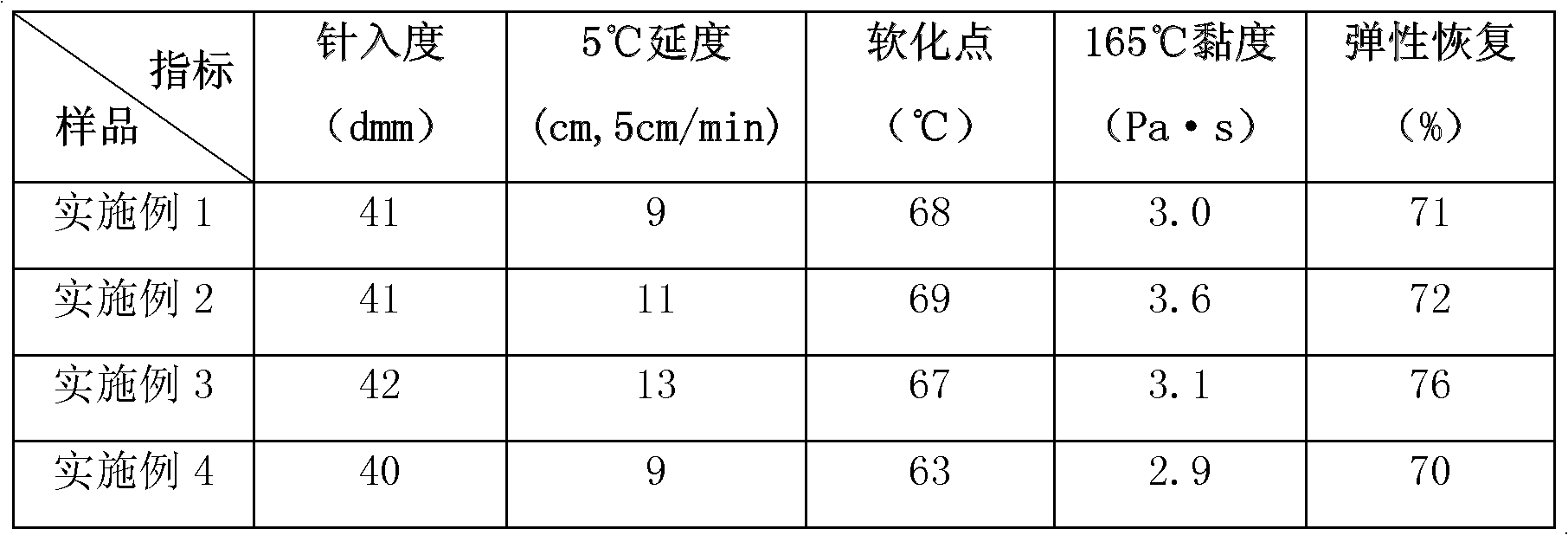

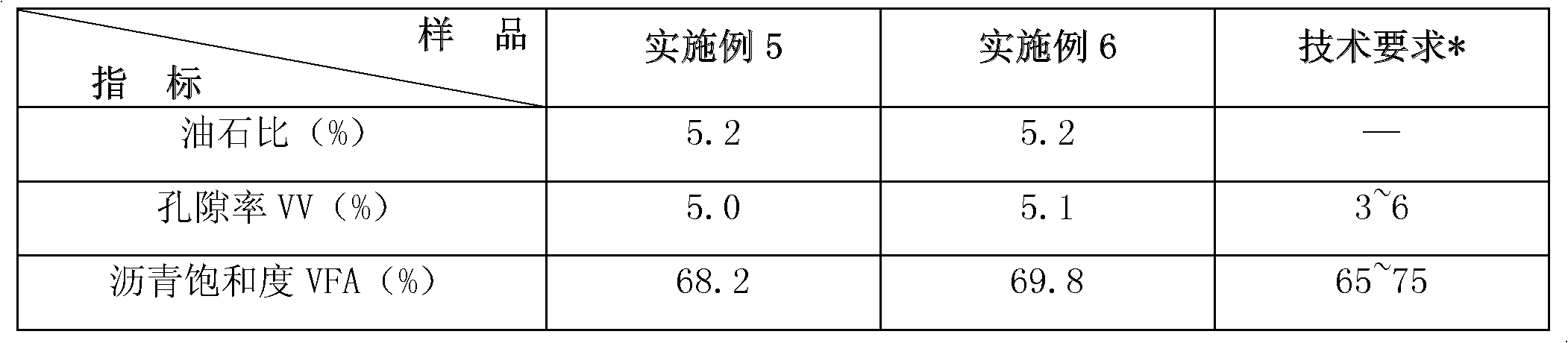

Preparation method of modified rubber powder, rubber powder modified asphalt and mixture and preparation method thereof

The invention relates to a preparation method of modified rubber powder, which comprises the following steps: blending polymer and asphalt to prepare modified asphalt having uniform and stable performance, uniformly coating the modified asphalt on the surface of rubber powder, enabling the rubber powder to be thoroughly pre-swollen, and separating rubber powder particles with separant to keep therubber powder in a powder form and consequently achieve the purpose of enhancing dispersion, thus obtaining the novel modified rubber powder, wherein the separant can lower the processing difficulty during the mixture of the rubber powder and the asphalt while enhancing dispersion and keeping the rubber powder in the powder form. The invention also includes rubber powder modified asphalt using the modified rubber powder and a preparation method thereof, and a modified asphalt mixture and a preparation method thereof. When being used in the field of modified asphalt, the modified rubber powdercan be simultaneously used for improving the processing technique based on the wet method and the product performance based on the dry method.

Owner:CHINA RUBBER RESOURCE REGENERATION QINGDAO

High-strength, high-elasticity modulus and low-stress gray cast iron and manufacturing method thereof

ActiveCN104894466AReduce harmful trace elementsImprove nucleation abilityProcess efficiency improvementPearliteIron phosphide

The invention discloses high-strength, high-elasticity modulus and low-stress gray cast iron and a manufacturing method thereof; and under the conditions of improving the carbon equivalent and the silicon-carbon ratio, the gray cast iron with excellent comprehensive performances is obtained through optimizing the raw material ratio by combining with the alloying, the smelting improvement, the inoculation and the aging treatment process. The gray cast iron comprises the components of 3.15-3.25% of C, 1.80-2.00% of Si, 3.75-3.90% of CE, 0.70-1.00% of Mn, P not more than 0.07%, 0.06-0.10% of S, 0.50-0.70% of Cu, and 0.20-0.30% of Cr; and the gray cast iron has the structure and the performance as follows: the pearlite content is not lower than 95%; the length of A type graphite is 4-5 grade; the content of cementite and iron phosphide eutectic is lower than 0.5%; the tensile strength is not higher than 300 MPa; the elasticity modulus is not higher than 120 GPa; the hardness HB is 190-220; and the internal stress is not lower than 20 MPa. The gray cast iron solves the technical difficulty that a gray iron casting for a machine tool is difficult to synchronously achieve high strength, high elasticity modulus and low stress, and effectively reduces the deformation and the rupture of the casting caused by the release of residual stress along with the time.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

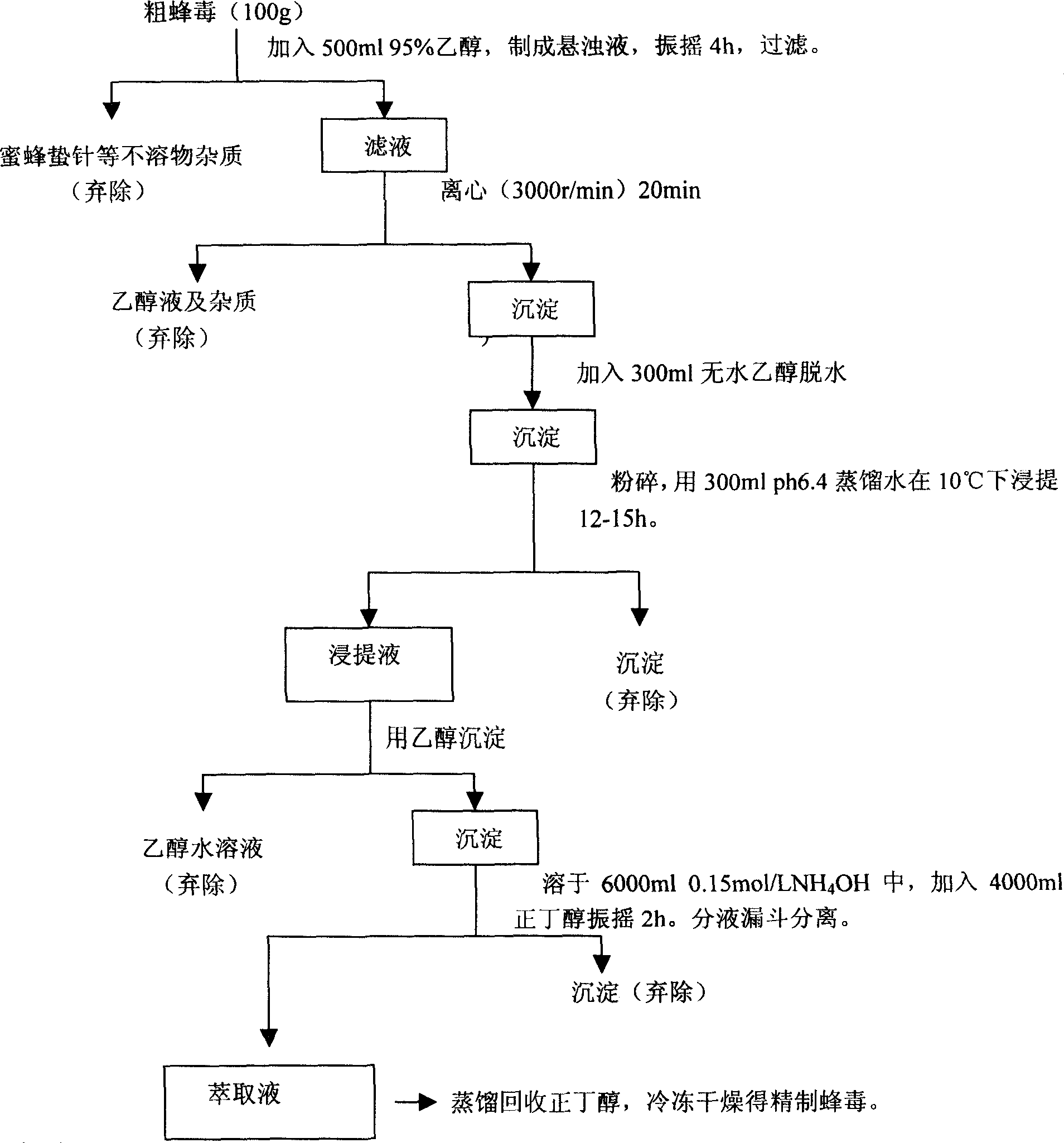

Bee venom refining process

InactiveCN101088514AScientific and reasonable processMeet technical requirementsAnthropod material medical ingredientsMelittinChemistry

The bee venom refining process includes the following steps: dissolving coarse bee venom in alcohol to form suspension, filtering to eliminate propolis, honey and other impurity, centrifuging the filtrate and eliminating liquid phase, dewatering the precipitate with anhydrous alcohol, leaching the precipitate in water at 10+ / -2 deg.c for 12-15 hr, precipitating the leached liquid with alcohol, eliminating water solution of alcohol, extracting the precipitate in ammonium hydroxide and n-butanol solution, distilling the extracted liquid, concentrating and freeze drying to obtain refined bee venom. The refined bee venom may be used in different clinical research and application fields, including preparing electrophoresis level melittin.

Owner:张文礼

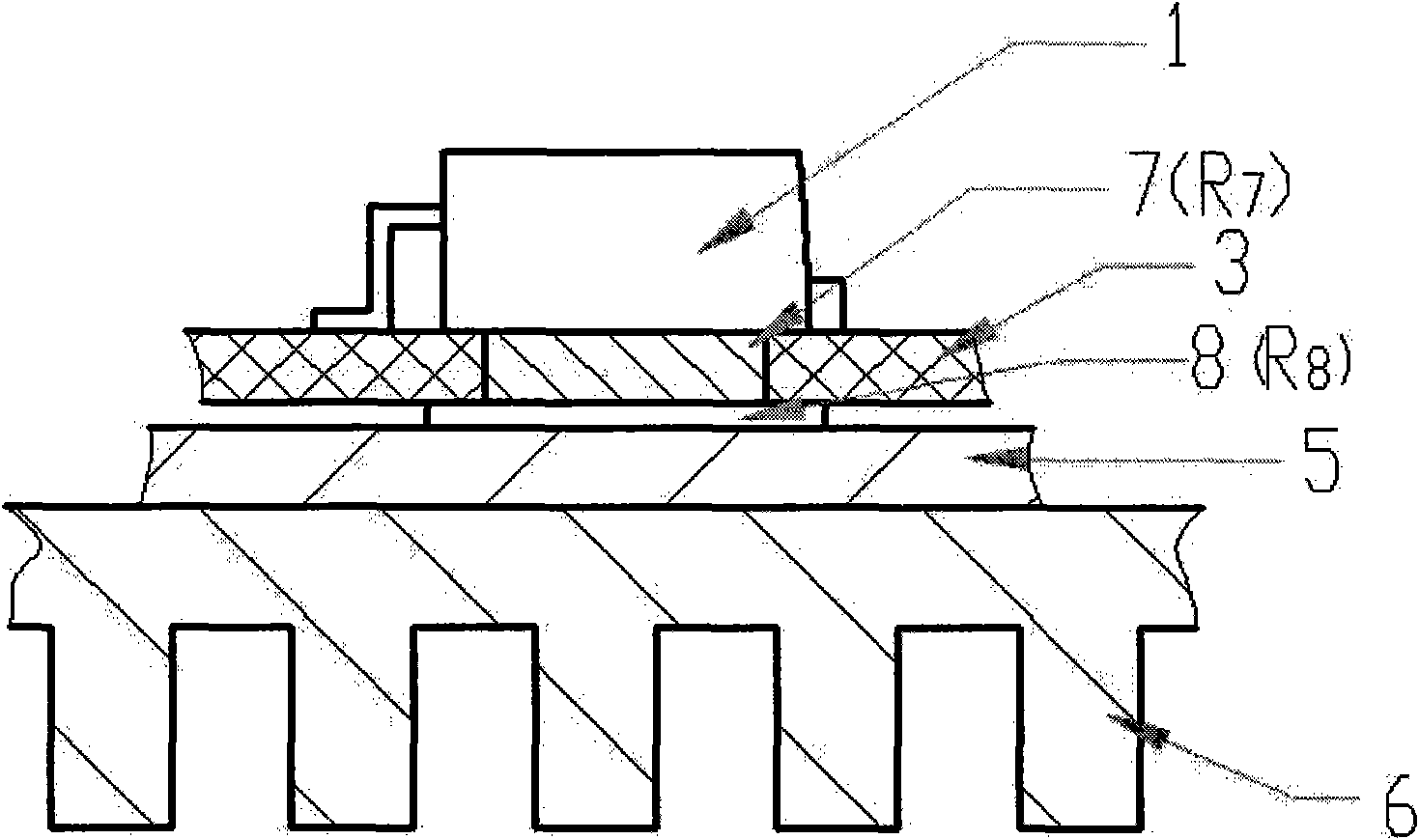

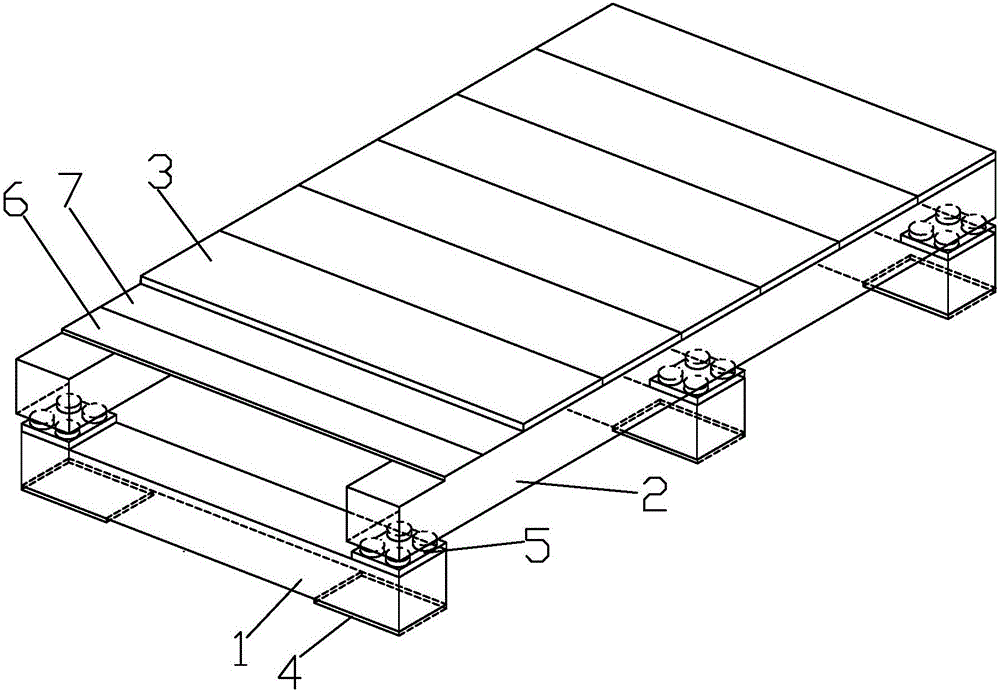

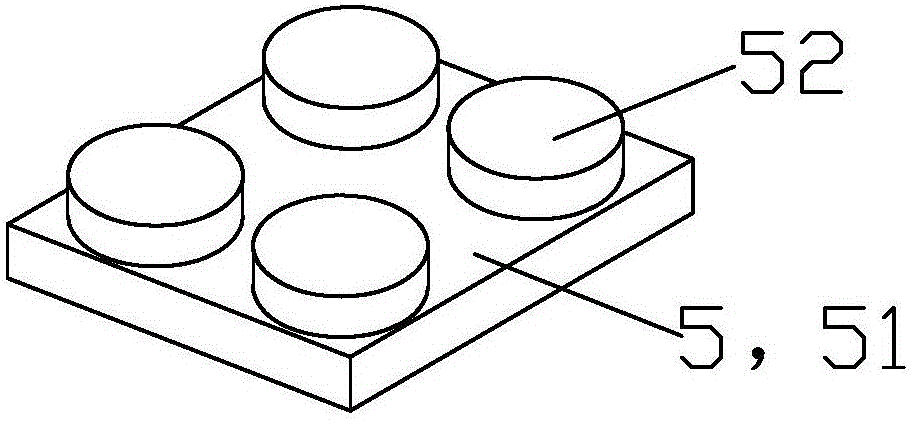

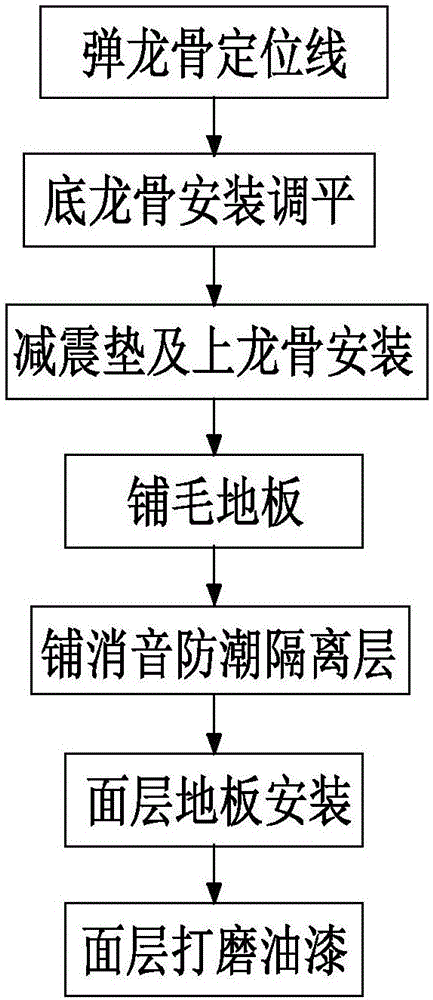

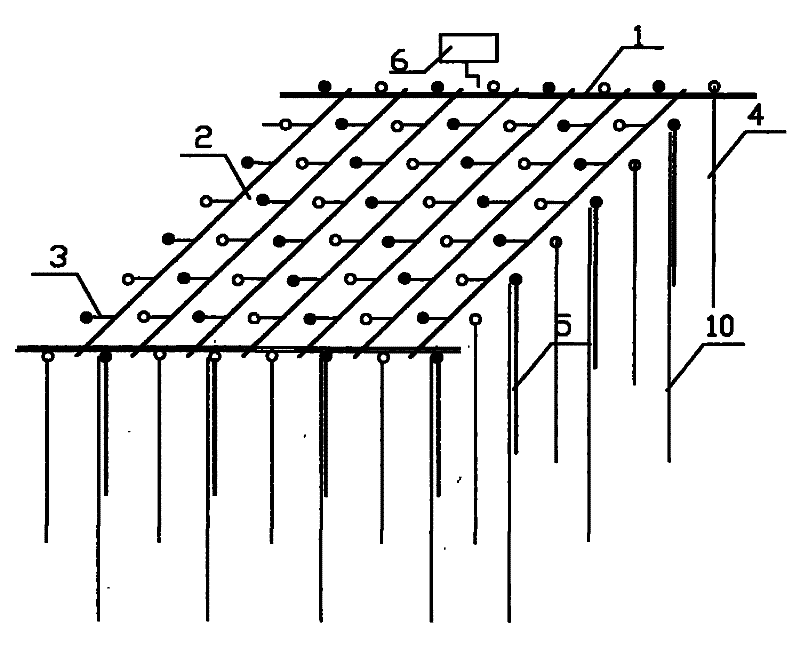

Suspension type sports wood floor system and construction method thereof

InactiveCN106499154AGood shock absorptionGood sports performanceFlooring insulationsResiliently-mounted floorsWork periodEngineering

The invention provides a suspension type sports wood floor system and a construction method thereof. The system comprises a levelling floor mat, a bottom keel, a shock pad, an upper keel, a subfloor, a sound-muffling and moisture-proof isolation layer and a surface floor. The levelling floor mat is arranged under the bottom keel, and is paved on the ground. The upper keel is vertically placed on the upper end of the bottom keel, the shock pad is arranged at the junction portion of the upper keel and the bottom keel and the three parts are fixedly connected, and the subfloor is fixedly arranged on the upper keel. The sound-muffling and moisture-proof isolation layer is paved on the subfloor. The surface floor is positioned on the sound-muffling and moisture-proof isolation layer and fixed on the subfloor. The construction method comprises the steps of paving and levelling the bottom keel, amounting the shock pad, the upper keel, the subfloor, the sound-muffling and moisture-proof isolation layer, the surface floor and the like. According to suspension type sports wood floor system and a construction method thereof, the floor system is good in the performances of sports, stability, moisture-proof and the like, small in deformation, long in service life and free of abnormal sound during use; the construction method is simple, and saves work-period.

Owner:CHANGZHOU NO 1 CONSTR GRP

Hot-rolled high-strength strip steel and manufacturing method thereof

InactiveCN102424933AMeet technical requirementsReasonable match of strengthProcess efficiency improvementStrip steelMolten steel

The invention relates to hot-rolled high-strength strip steel and a manufacturing method thereof. The strip steel comprises the following components: 0.05-0.10% of C, 0-0.30% of Si, 1.0-1.80% of Mn, not more than 0.015% of P, not more than 0.008% of S, 0.01-0.07% of Nb, 0.01-0.12% of Ti, 0.01-0.05% of Al, not more than 0.0012% of O, not more than 0.0035% of N; the ReH is 580-670 MPa; the Rm is 690-750 MPa; A is 19-30%; -40 DEG C AKv is 50-180 J; and 180-degree d = 2a. The manufacturing method comprises the following steps of: I. converter smelting, wherein the molten steel is processed to contain not more than 0.010% of P and not more than 0.020% of S; II. LF refining, wherein the components are adjusted finely; steel tapping when the components of the molten steel meet the requirements; III. continuous casting, wherein whole-course argon blowing is performed to protect the casting; soft reduction technology is employed; the casting temperature is controlled at 1530-1560 DEG C; VI. hot continuous rolling, wherein the finishing temperature is 820-880 DEG C; a laminar flow cooling mode is employed; and a coiling temperature CT is 530-620 DEG C. The hot-rolled high-strength strip steel manufactured by the invention meets the requirements of steel for engineering machinery.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

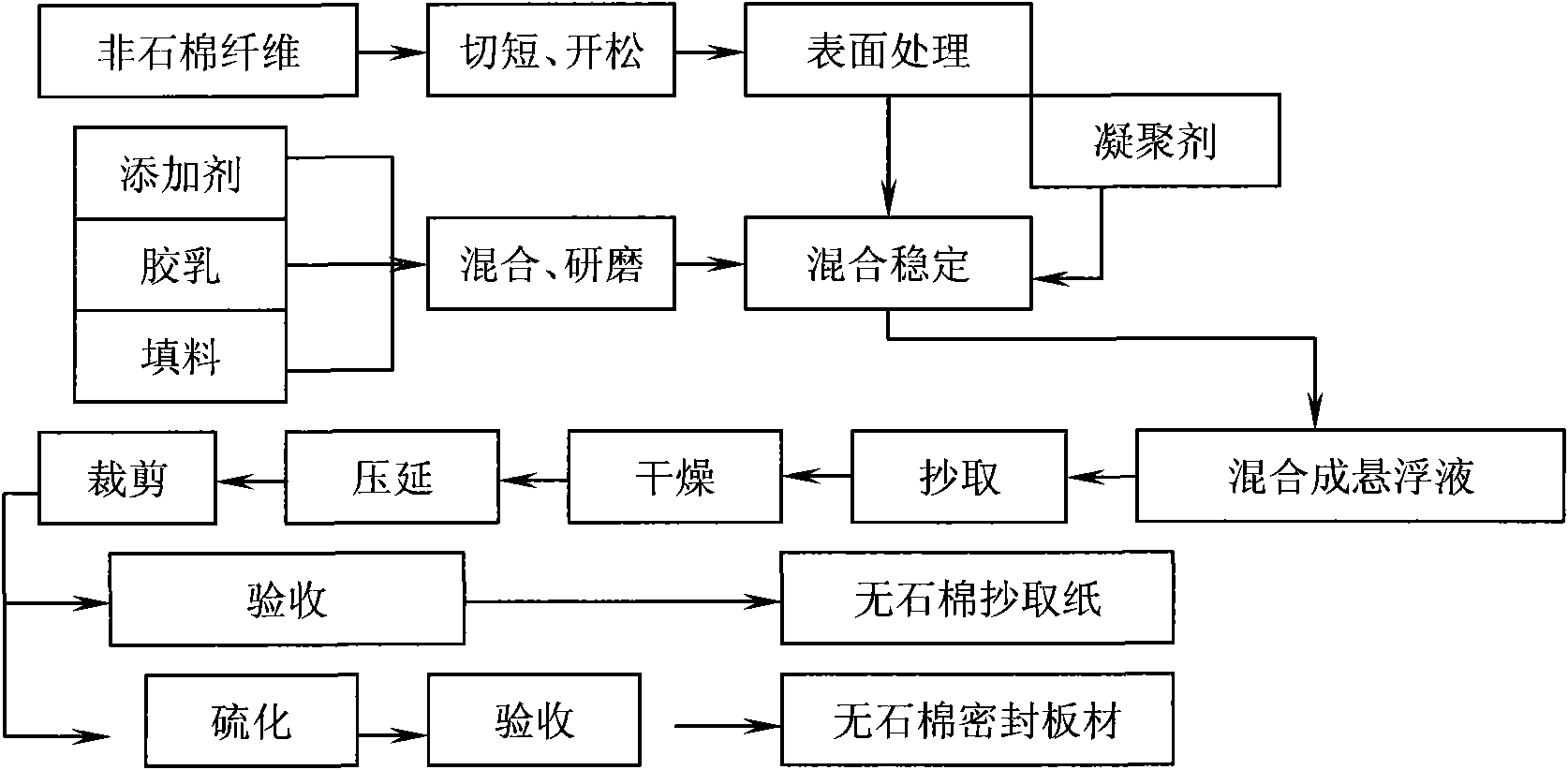

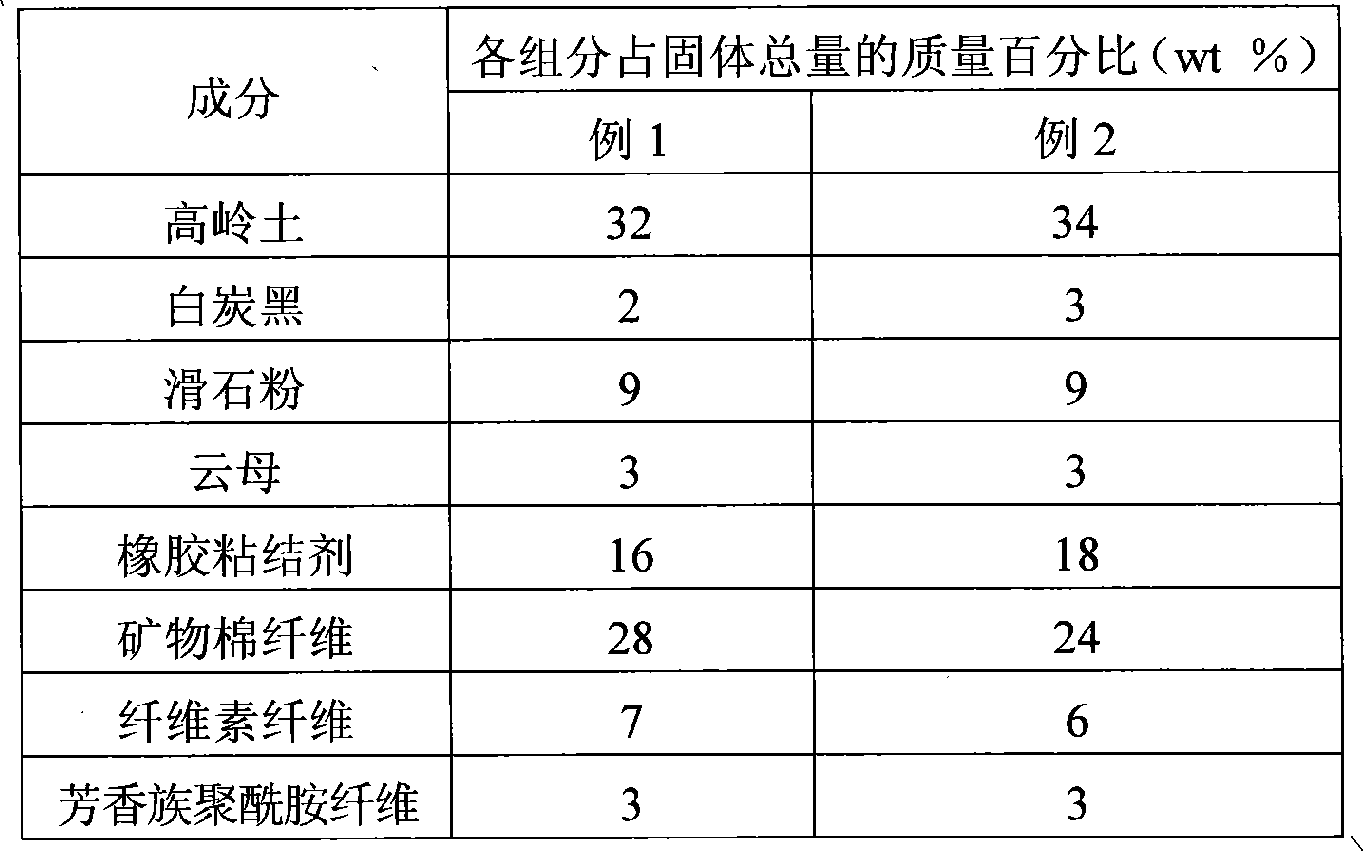

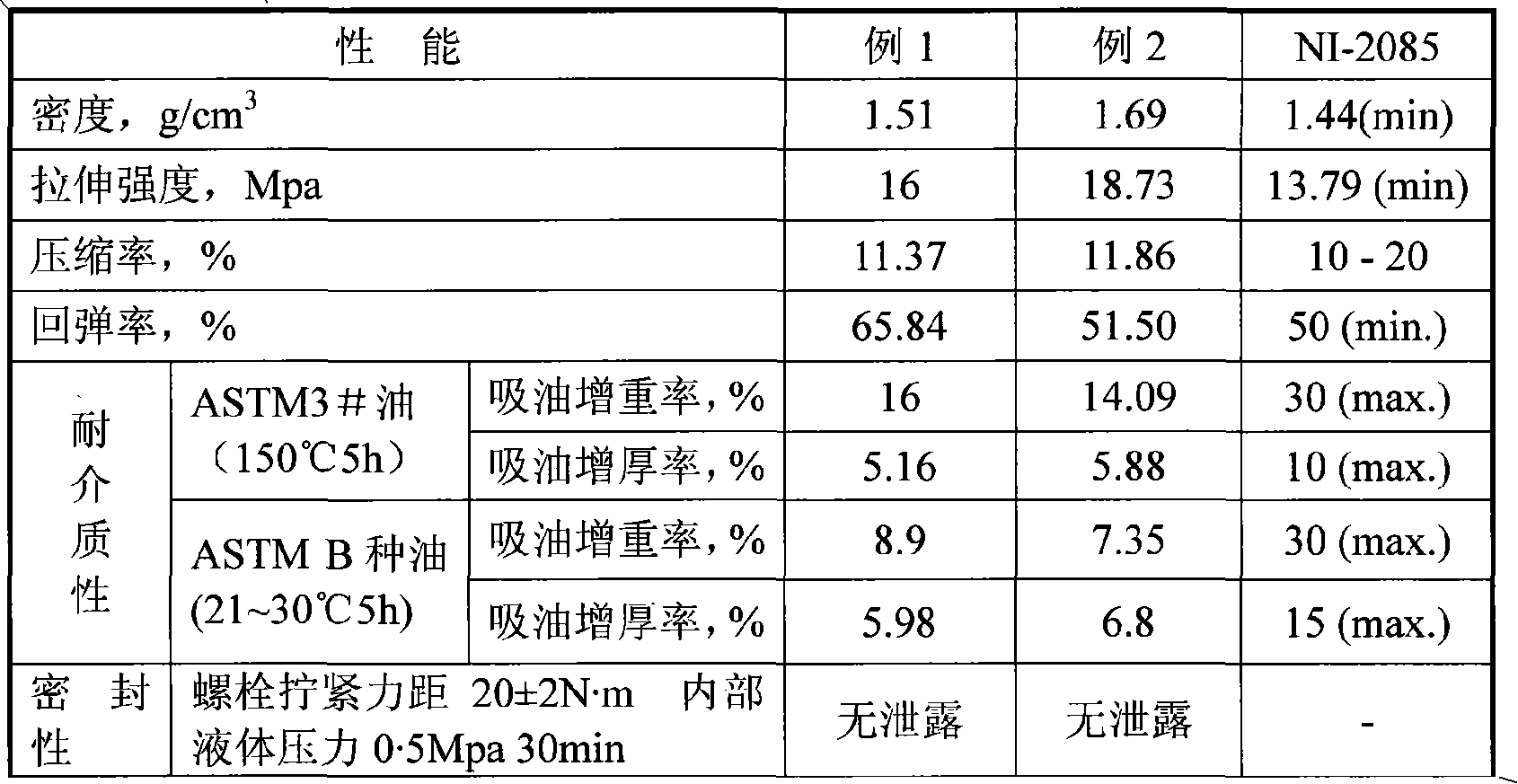

Method for preparing copy sheet used for sealing gasket

InactiveCN101575829AReasonable choiceNo pollution in the processFibreboardInorganic fibres/flakesAsbestos sheetVulcanization

The invention relates to a method for manufacturing a sealing gasket, in particular to a method for preparing a copy sheet used for a sealing gasket which does not contain asbestos fiber, belonging to the field of sealing materials. The copy sheet contains the main components of mineral cotton fiber, cellulose fiber, aromatic polyamide fiber, rubber cement and kaoline; the components are mixed to a dispersed system containing water, then a paper-making technique is adopted to dehydrate gradually and form a layer, and a finished product of the copy sheet is manufactured by compression, drying and vulcanization. The sealing gasket manufactured by the sheet has tensile strength, compression resilience performance, medium resistance and sealing performance and the like equivalent to that of the copying asbestos sealing gasket and can completely replace asbestos sheets for manufacturing the sealing materials of the gasket and the like.

Owner:KUNMING UNIV OF SCI & TECH +1

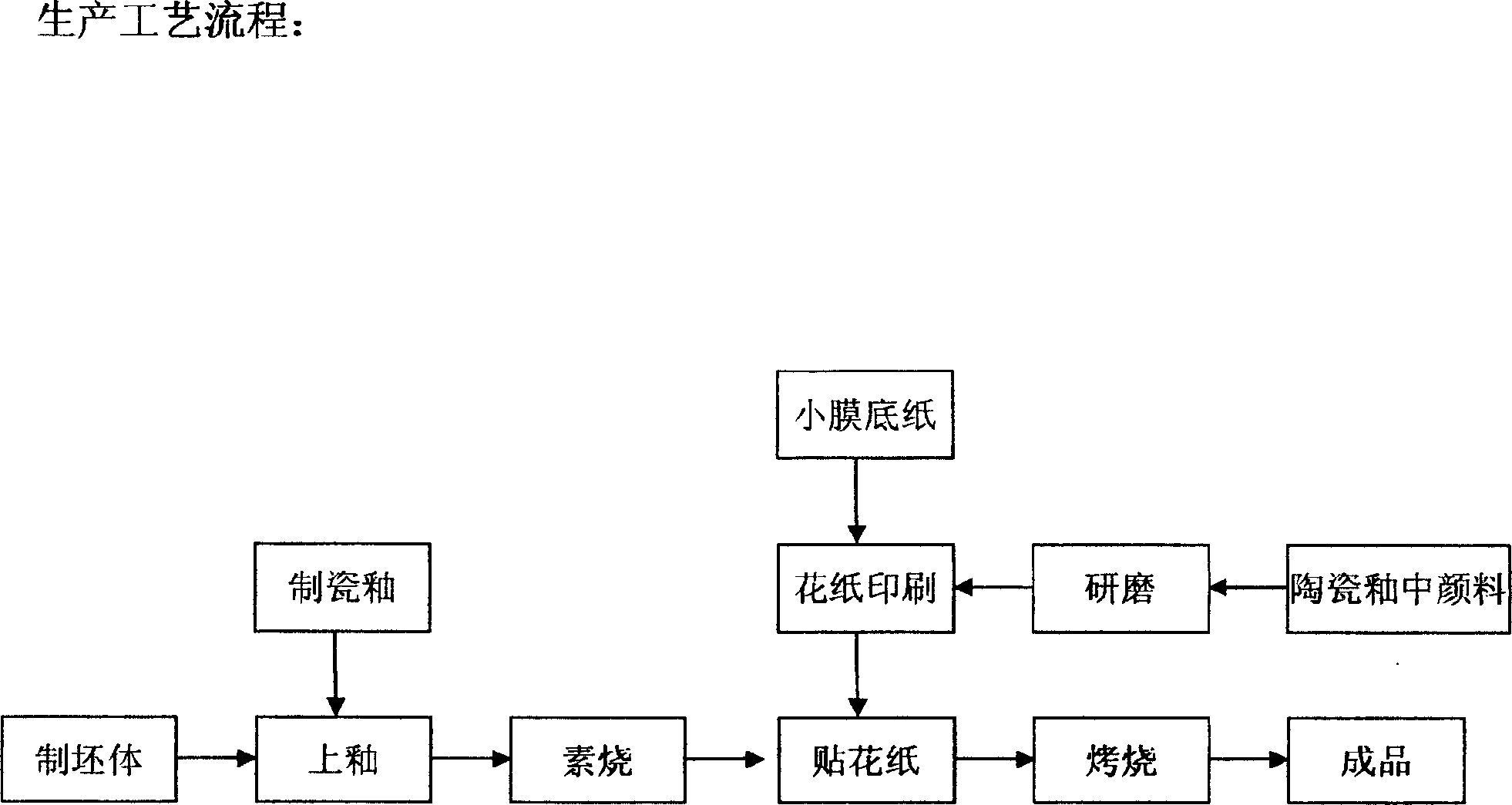

Glaze coloured decoration daily use poocelain and its production method

InactiveCN1911855AMeet technical requirementsMeet the process requirementsHigh volume manufacturingThermal stability

The present invention relates to ceramic product, and is especially one kind of in-glaze color decorated daily use porcelain product and its production process. The materials for the in-glaze color decorated daily use porcelain include Longyan clay, weathered potash feldspar, Jiepai clay, potash feldspar, calcined alumina, Guizhou clay and quarztz. The production process of the in-glaze color decorated daily use porcelain product includes the steps of making biscuit, preparing glaze and in-glaze color paper, glazing the biscuit, firing biscuit, adhering the in-glaze color paper, and baking to obtain the product. The in-glaze color decorated daily use porcelain has rich bright colors, smooth and fine glaze surface, low Pb and Cd leaching out amount, high strength, and other advantages.

Owner:林伟河

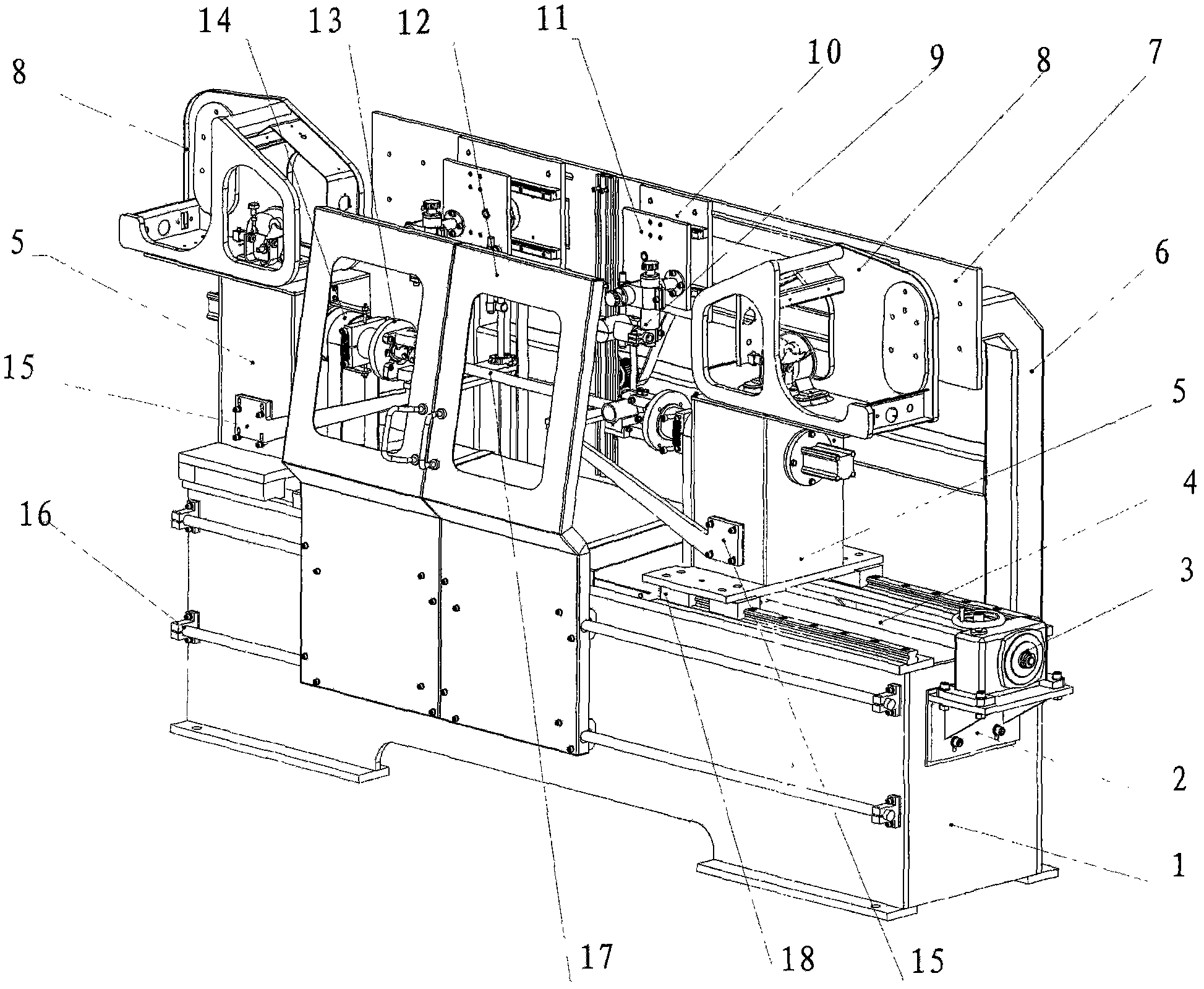

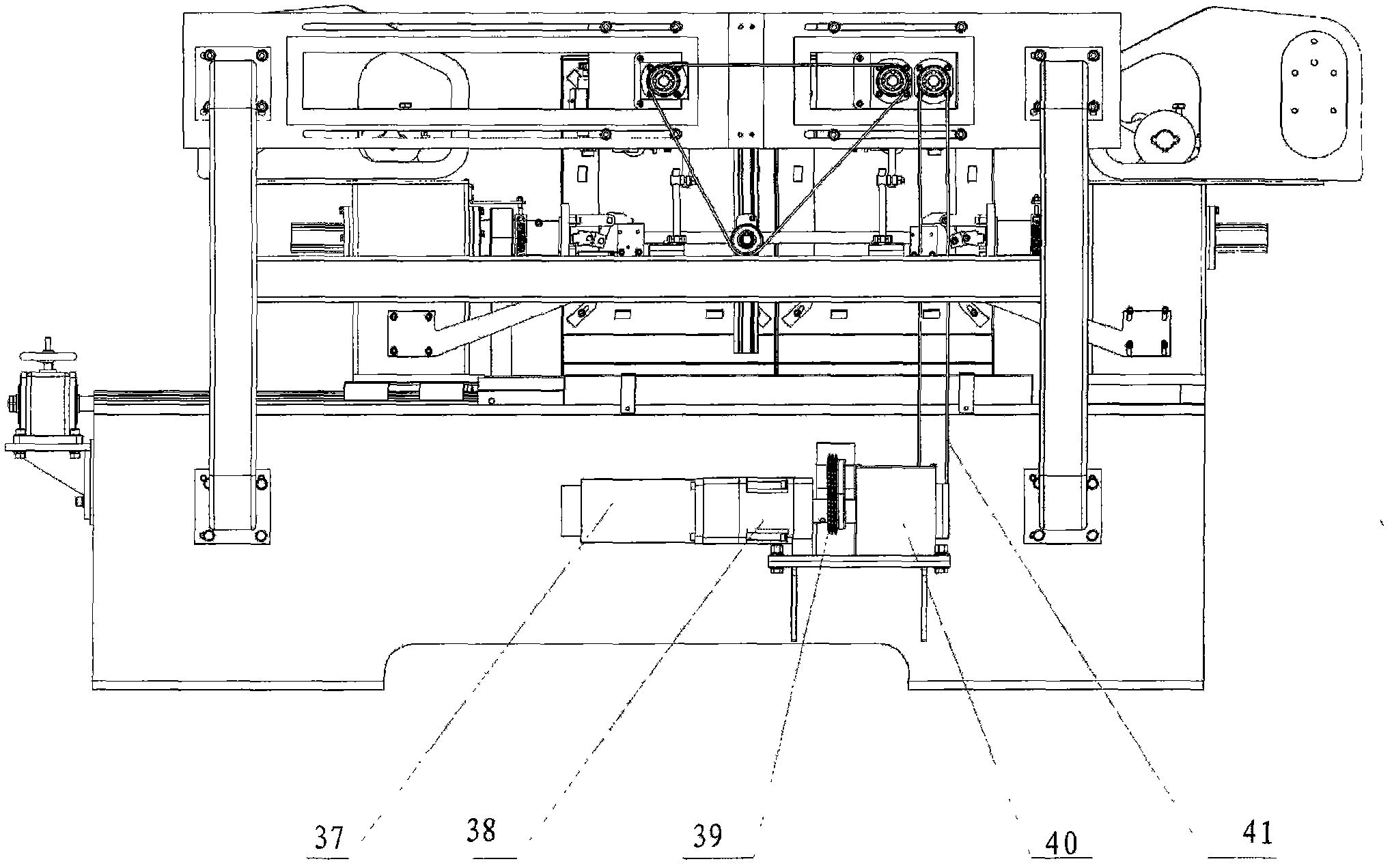

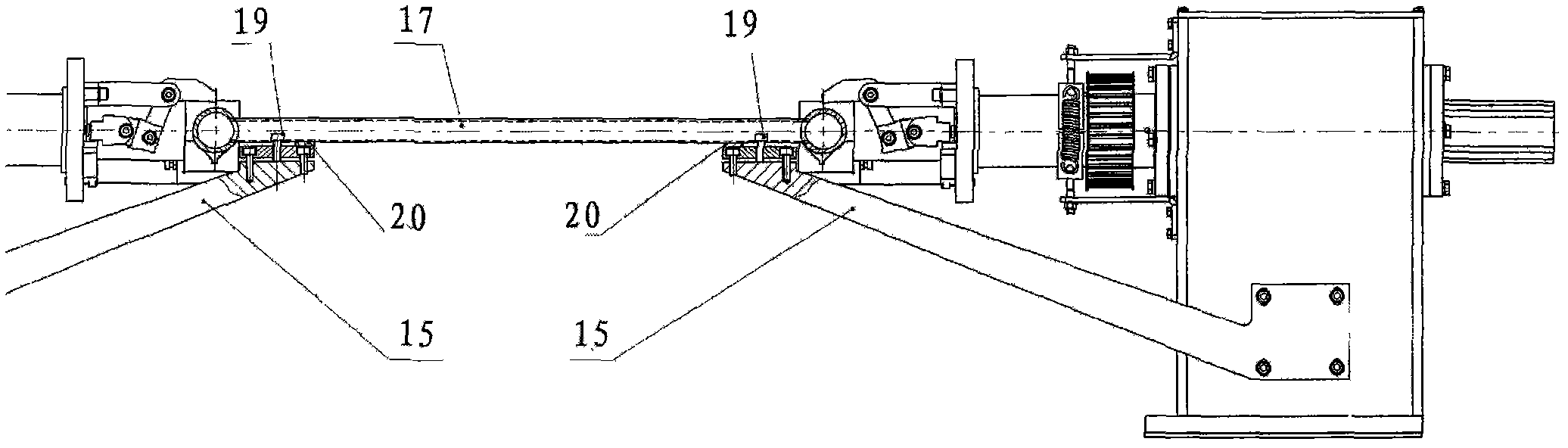

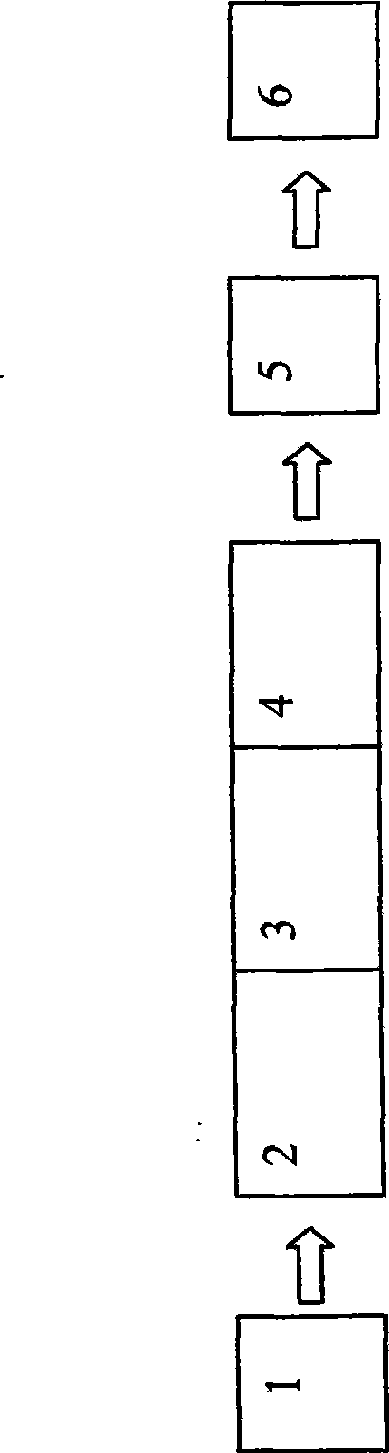

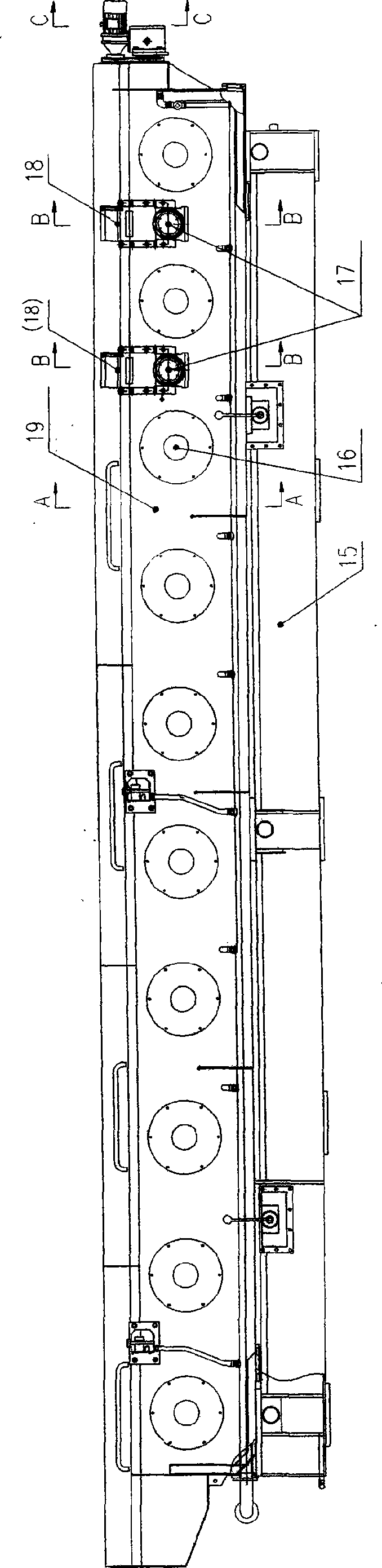

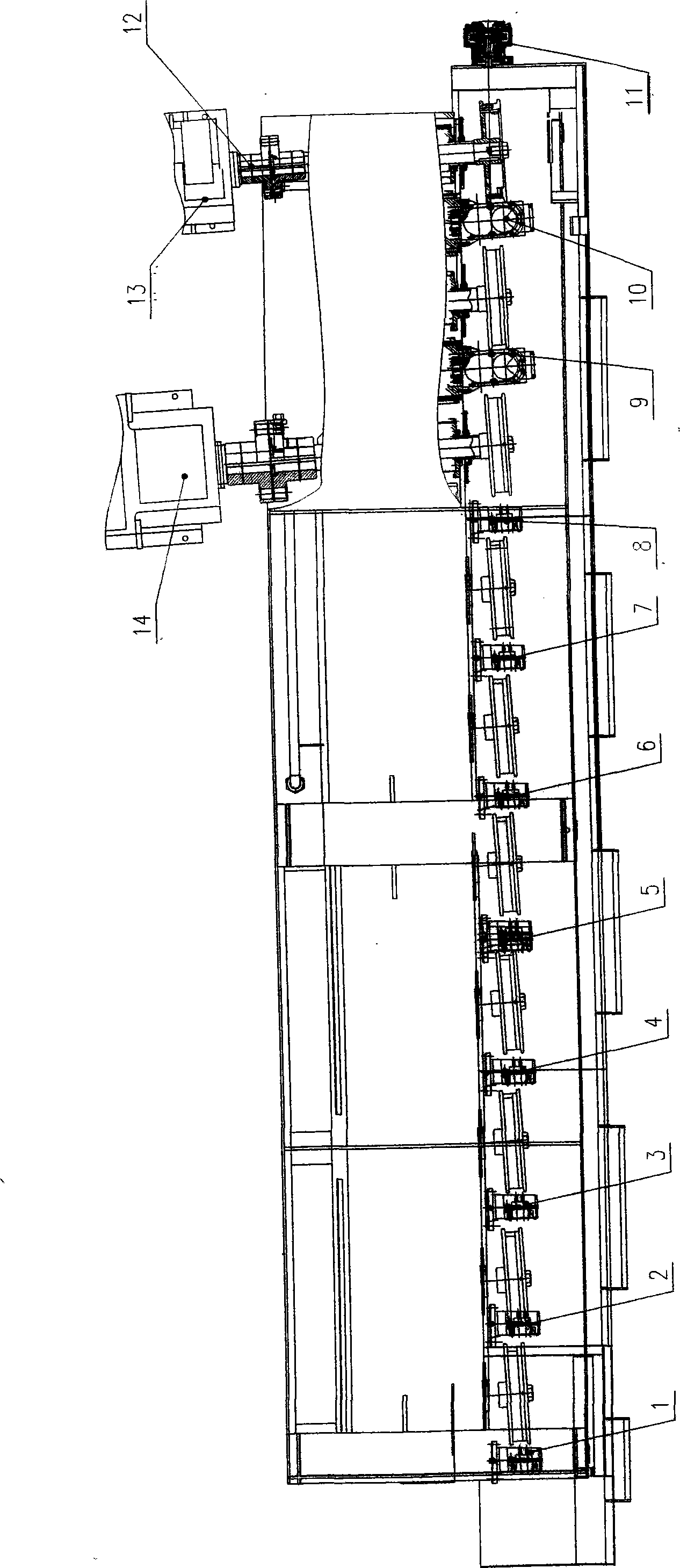

Intersecting line girth welding device

InactiveCN102059434AEliminate pointing processSimple welding processWelding accessoriesEngineeringWeld seam

The invention relates to an intersecting line girth welding device which is a circular tube girth welding device, and in particular relates to an automatic intersecting line girth welding machine between circular tubes, which has very high requirements for the welding line tracking technology, belonging to the technical field of a welding device. The intersecting line girth welding device mainly comprises a base, a tail seat adjusting device, a power driving device, a workpiece clamping device, a workpiece locating device, a cam mechanism, a welding gun adjusting device, an arc light protecting screen and the like. Compared with the prior art, the invention has the prominent substantial characteristics and remarkable progresses that the working procedure of defining a point is omitted, location and automatic welding are directly combined into the same station to be completed, the welding technique is simplified, the efficiency is improved, a spot welding fixture is omitted, and the accuracy of a welding part and the welding line tracking accuracy are guaranteed.

Owner:上海气焊机厂有限公司

Hollow forging method of nuclear power main pipeline

ActiveCN103143659AMeet technical requirementsIncrease profitMetal-working apparatusPunchingNuclear power

The invention relates to a hollow forging method of a nuclear power main pipeline, and belongs to the technical field of forging. According to the forging method, hollow forging is carried out in a free forging manner, a boss part is formed in an annular belt manner, and the deformation is reserved before a core rod is drawn out to be in a final shape. The forging method comprises the following processing steps of: (1) upsetting; (2) drawing out; (3) upsetting and punching; (4) chambering and drawing out the core rod; (5) carrying out shoulder feeding; (6) carrying out shoulder splitting; (6) drawing out the core rod: heating a hollow forged piece obtained in the step (5) till 1000-1050 DEG C, and drawing out till a final shape is formed; heating multiple times till 1000-1050 DEG C if the shape cannot be formed after one heating number, and drawing out till the final shape is formed. The nuclear power main pipeline with the boss is forged in the manners of punching, chambering and drawing out the core rod, the boss part is forged into an annular manner, and the shape of the nozzle of the boss is ensured. The forged piece is directly forged into a hollow pipeline, so that the subsequent machining is reduced, and the manufacturing period is shortened. The technical requirement of the third generation forging main pipeline can be met, and the utilization ratio of raw material is high.

Owner:TONGYU HEAVY IND

Technology and apparatus for manufacturing shaped conductor

InactiveCN101510455AMeet the requirements of flow productionOut of line fastDrawing diesSingle bars/rods/wires/strips conductorsFiberEngineering

The invention relates to a shaped conductor manufacturing technique and a device thereof, wherein, the manufacturing technique comprises payingoff step, lead-forming step and lead-drawing step and is characterized in that the lead-forming step adopts the technique of combing drawing and rolling; the section of a lead is shaped by rolling; the sectional area of the lead meets requirement by drawing; the device comprises a payingoff device, a shaped conductor forming device and a lead-drawing device which are sequentially arranged, wherein, the shaped conductor forming device is provided with a shaped groove roller device. The technique ensure the quality of products, greatly improves producing efficiency and meets the production requirement of compound carbon fiber aluminum stranded conductors required by ultra-high and super-high power transmission.

Owner:德阳东佳港智能装备制造股份有限公司

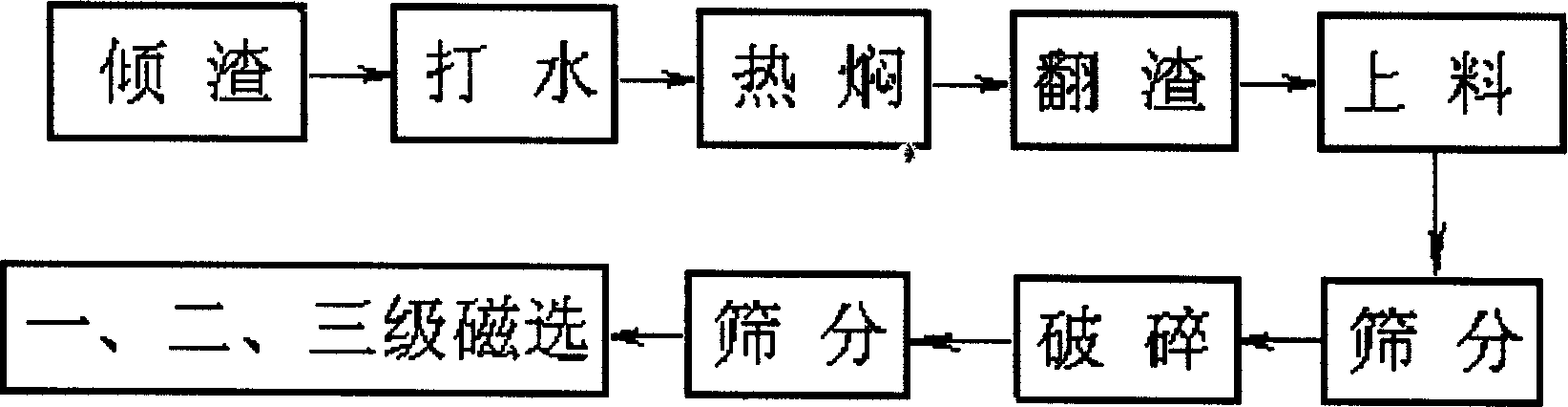

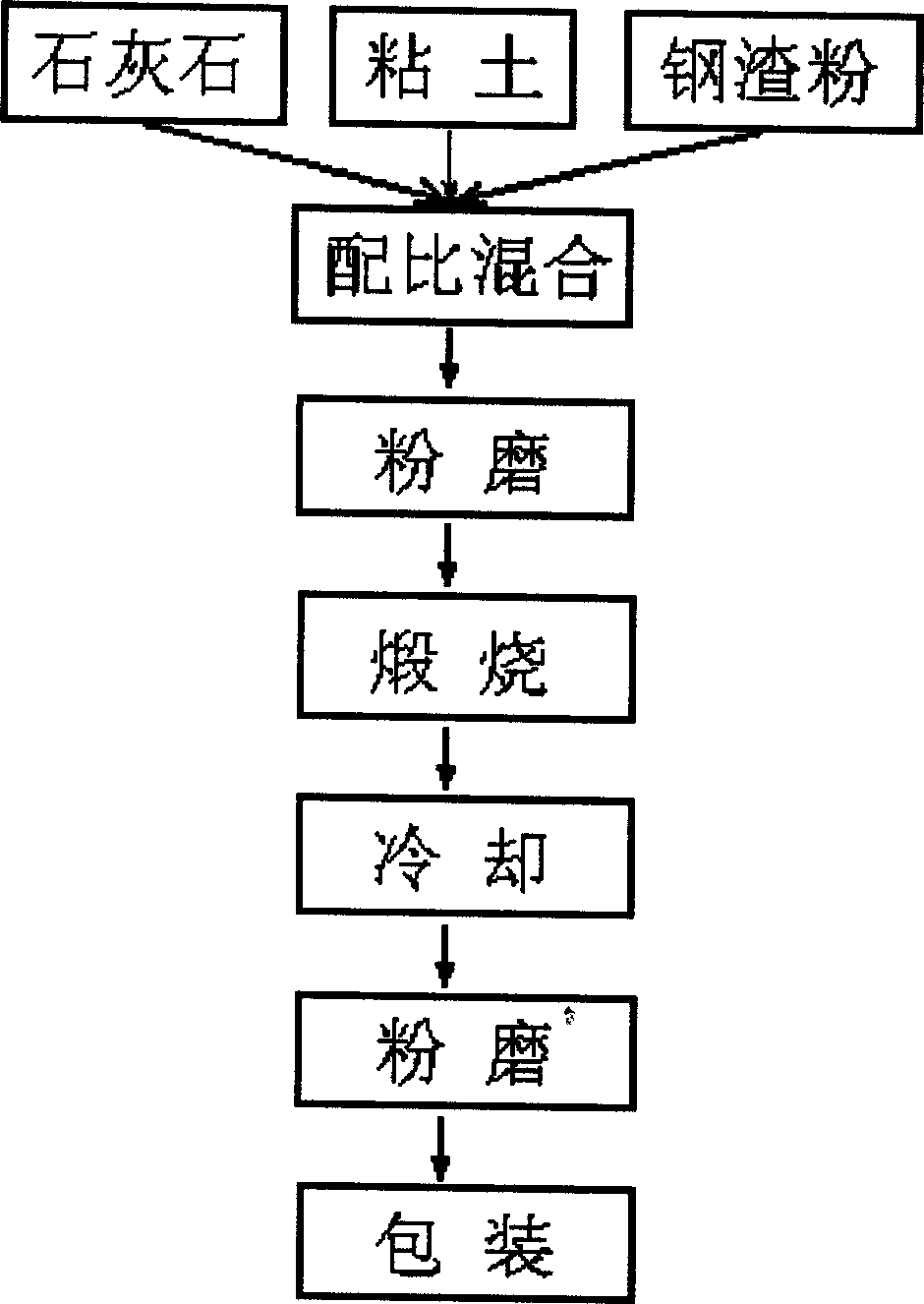

Method of using vanadium titanium rotary furnace steel slag as cement iron correction material

The present invention relates to a method capable of using vanadium-titanium converter steel slag as cement iron correction raw material. Said method includes the following steps: cooling molten steel slag, breaking, magnetic separation to obtain steel slag powder, mixing steel slag powder, limestone and clay, grinding them, calcining, cooling and secondary grinding so as to obtain the invented cement clinker.

Owner:WASTE & OLD MATERIAL BRANCH OF PANGANG GROUP GANGCHENG ENTERPRISE CORP

Method for manufacturing steel pipe for bearing ring

InactiveCN102626723AAvoid wastingMeet technical requirementsFurnace typesHeat treatment furnacesHeat conservationContinuous annealing

The invention discloses a method for manufacturing a steel pipe for a bearing ring, belonging to the technical field of manufacturing of steel pipes. The method comprises the following steps of: perforating a bearing steel bar material in a heated state, and quickly cooling after perforation to obtain a pierced billet; introducing the pierced billet into an annealing furnace for annealing to obtain an annealed pierced billet; introducing the annealed pierced billet into a cold rolling mill for performing cold rolling to obtain a cold-rolled pipe blank; introducing the cold-rolled pipe blank into the annealing furnace for performing relief annealing to obtain a stress-relieved pipe blank; washing the stress-relieved pipe blank with acid, and phosphorizing treatment to obtain a pipe blank to be subjected to cold drawing; performing cold drawing on the pipe blank to be subjected to cold drawing, and controlling the cold drawing extension multiple to obtain a cold-drawn pipe; and introducing the cold-drawn pipe into a continuous annealing furnace for performing finished product thermal treatment, controlling the thermal treatment temperature and heat preserving time of a finished product, cooling along with the furnace after heat preservation is completed, and discharging to obtain the steel pipe for the bearing ring. The method has the advantages that: the technical requirements of the bearing ring manufactured with a cold rolling process can be met; and the method has simple process steps, and can meet the requirement of industrial mass production.

Owner:常熟市旋力轴承钢管有限公司

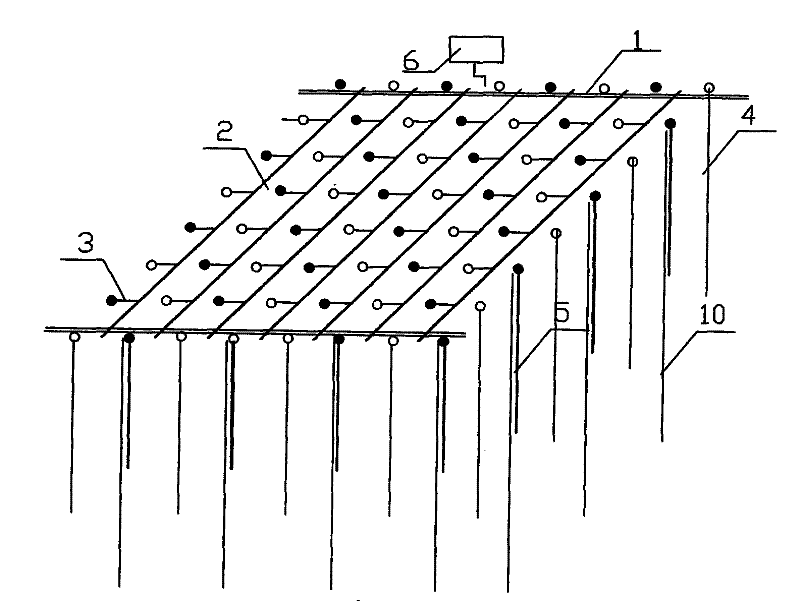

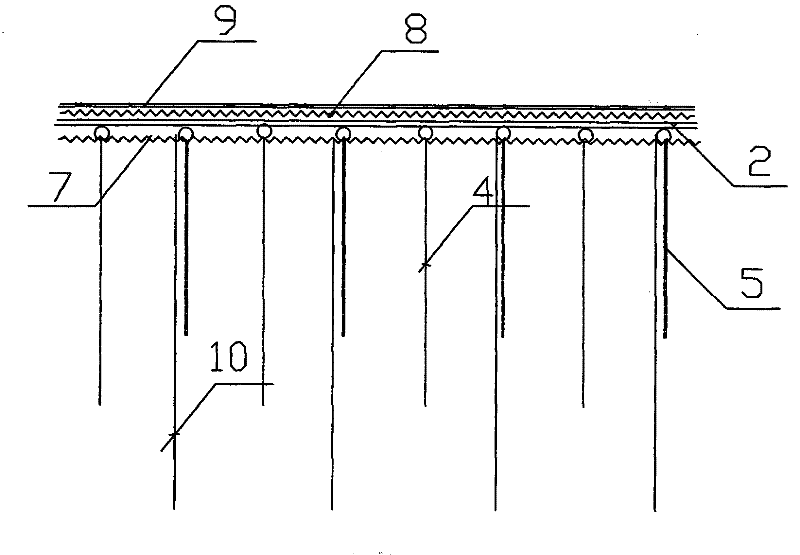

Large-area soft soil foundation duplex negative pressure consolidation processing method

InactiveCN101748721AEnhanced transfer processAccelerated dissipationSoil preservationDynamic compactionProcess region

The invention relates to a large-area soft soil foundation duplex negative consolidation processing method, comprising the following processes of: step 1, negative pressure consolidation: (a) paving plastic woven cloths in an area to be processed, driving a vertical plastic drainage board and a vertical plastic soak-away trench; (b) paving a main pipe and a branch pipe, wherein the vertical plastic drainage board and a transverse plastic drainage board are connected with the branch pipe; (c) paving a geo-membrane, and paving two to three sealing membranes on the geo-membrane; (d) excavating a side ditch pressing membrane; (e) installing a vacuum pump to vacuumize for negative pressure precipitation, wherein the main pipe is connected with the vacuum pump; step 2, well point dynamic arrangement: (a) inserting a well point pipe in a hole inserted by a vertical plastic soak-away trench or nearby the hole; (b) paving the branch pipe, the main pipe and the vacuum pump, carrying out the well point dynamic arrangement; and step 3, dynamic consolidation: a) precipitating and dynamically compacting in the first and second times, carrying out precipitation and dynamic compaction processes on the area to be processed for several times, carrying out multiple rounds of point compactions and finally carrying out a full compaction. According to the large-area soft soil foundation duplex negative consolidation processing method, the bearing capacity of the processed field is higher, the hard crust is thicker and the post-construction settlement is less.

Owner:曾国海 +3

Can cap multi-level composite air pressure reverse mold and forming method

ActiveCN104607540AMeet job requirementsMeet technical requirementsShaping toolsHollow articlesAtmospheric pressureStamping process

The invention discloses a can cap multi-level composite air pressure reverse mold and a forming method. The can cap multi-level composite air pressure reverse mold comprises an upper mold and a lower mold, the upper mold and the lower mold are both of a combined structure formed by stacking a plurality of annular single mold bodies in an inner and outer concentric sleeving mode, the upper mold comprises an upper mold core, a cap striking ring, a male and female mold and a discharging ring from inside to outside in sequence, and the lower mold comprises a lower mold inner core, a lower mold core, an edge pressing ring and a female mold from inside to outside in sequence. Blanking and forward and reverse stretching of can cap materials are achieved to complete formation of can caps by controlling the single mold bodies of different functions to move through air pressure, and thus the thinning amount of the can cap materials is effectively reduced. According to the can cap mold and the can cap forming method, the material deformation is small in the stamping process, the material cost is low, formation of the can cap can be achieved by completing multiple processes at a time, and very high practical value is achieved.

Owner:YIWU EASY OPEN END INDAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com