Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

975results about How to "Easy to loosen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

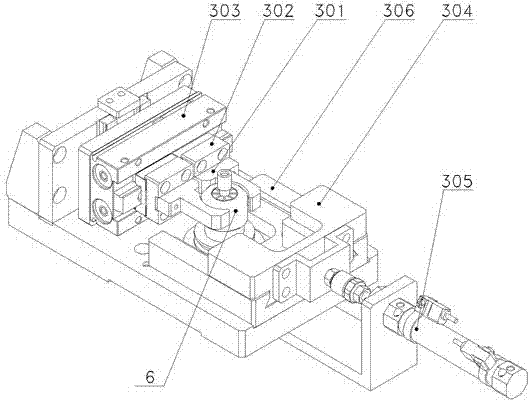

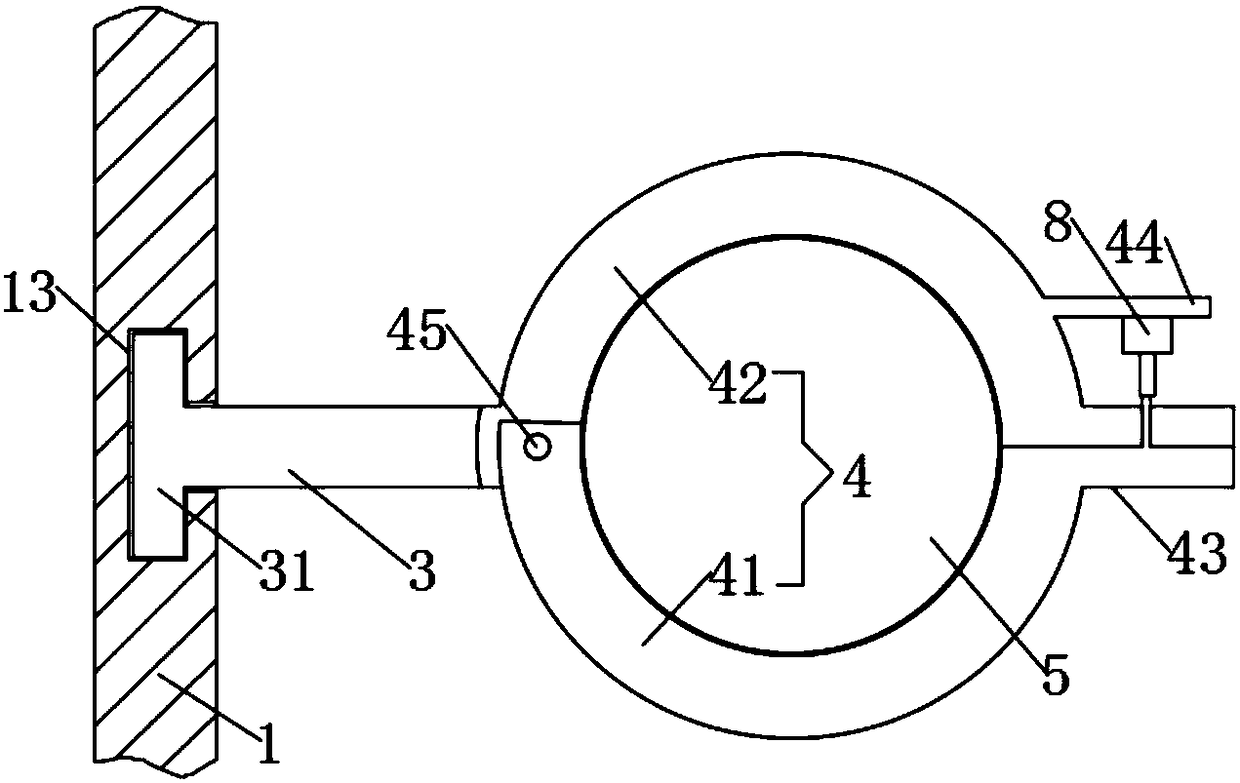

Thin-wall sliding sleeve disassembling fixture

PendingCN108555826AEasy loadingGuaranteed fitMetal-working hand toolsEngineeringMechanical engineering

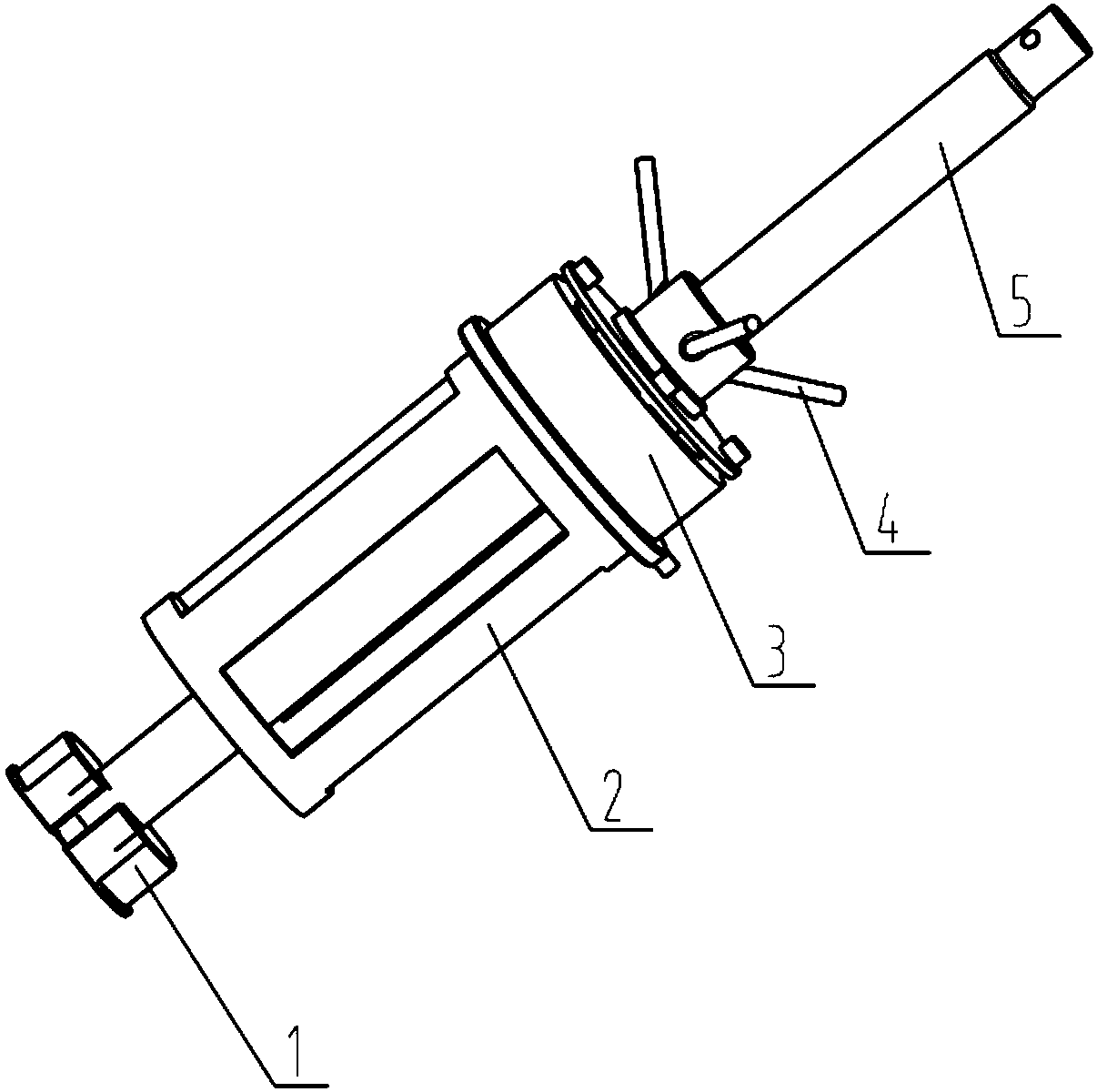

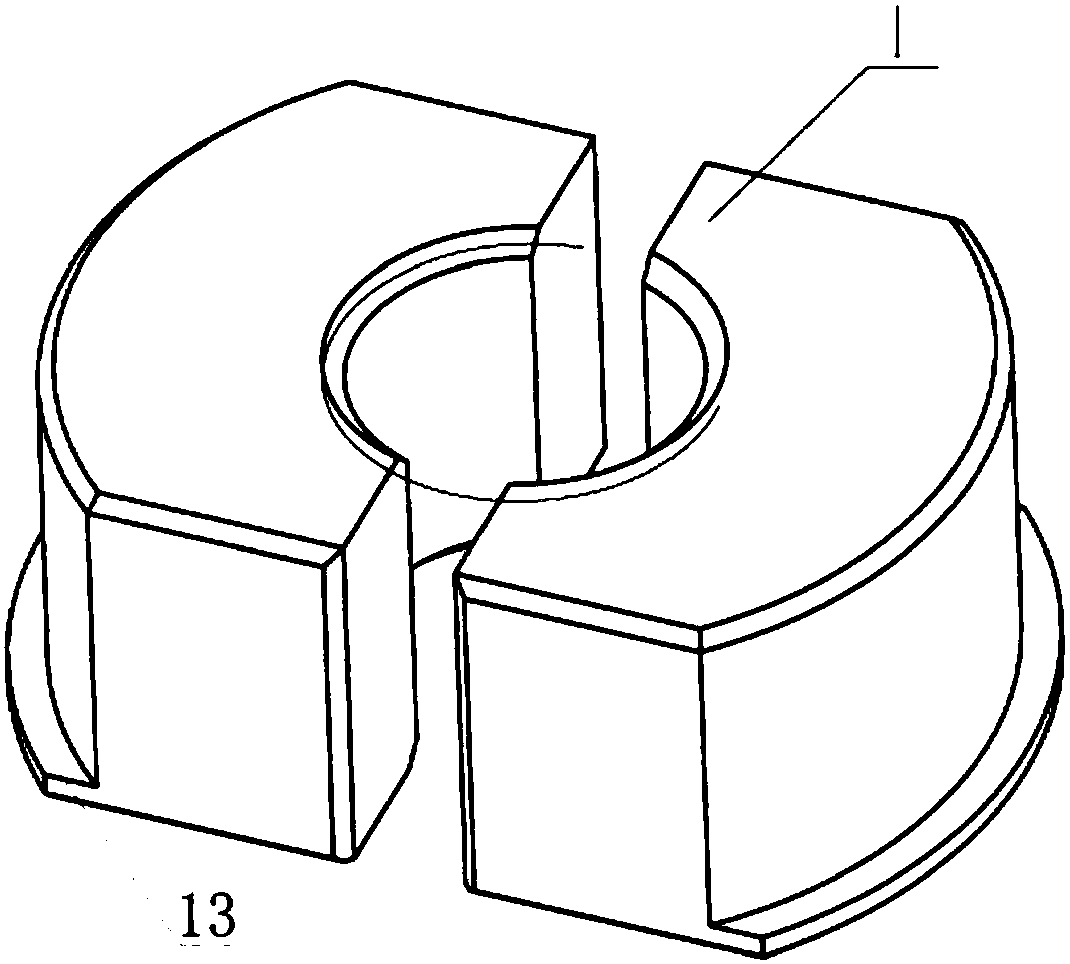

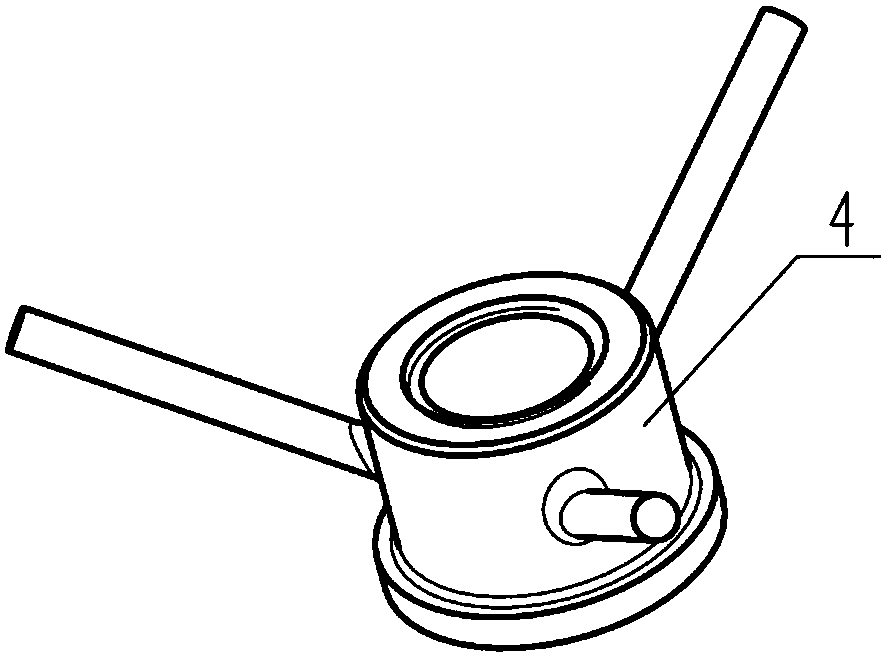

The invention provides a thin-wall sliding sleeve disassembling fixture. The thin-wall sliding sleeve disassembling fixture comprises a puller nut and a puller screw. The puller screw is in threaded connection with the puller nut. One end of the puller screw is provided with a clamping jaw. The puller screw is in threaded connection with the clamping jaw. A bracket and a hydraulic system are installed between the puller nut and the clamping jaw. The bracket and the hydraulic system are sheathed on the puller screw. The bracket is adjacent to the clamping jaw. The hydraulic system is adjacent to the puller nut. Through controlling the hydraulic system to boost pressure and reduce pressure, the disassembly of a thin-wall sliding sleeve can be realized. The thin-wall sliding sleeve disassembling fixture is small in volume, light in weight, smooth and steady in movement, and safe and convenient in operation, and capable of preventing the deformation of the thin-wall sliding sleeve and thescratching of a hole wall in an disassembling process.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

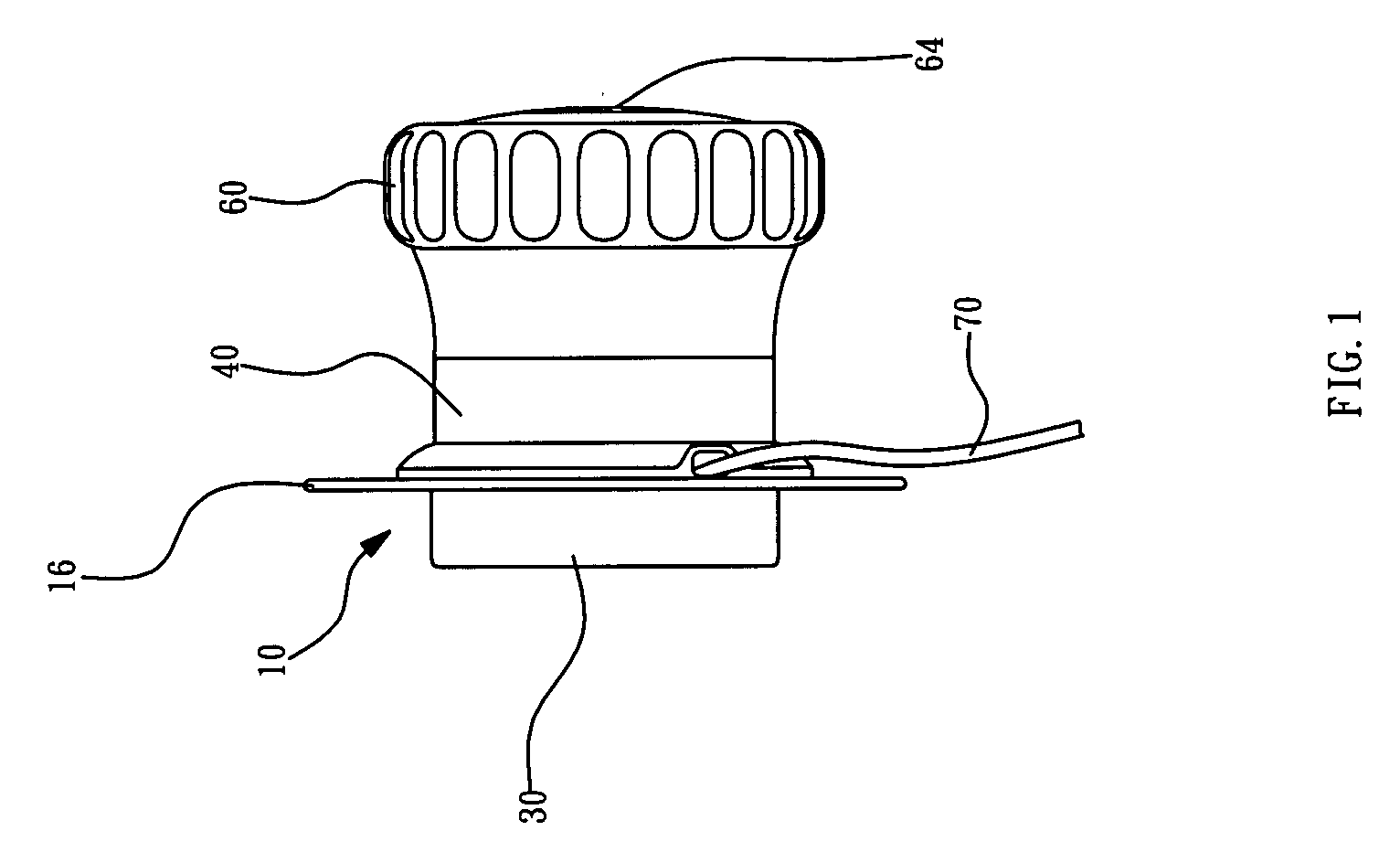

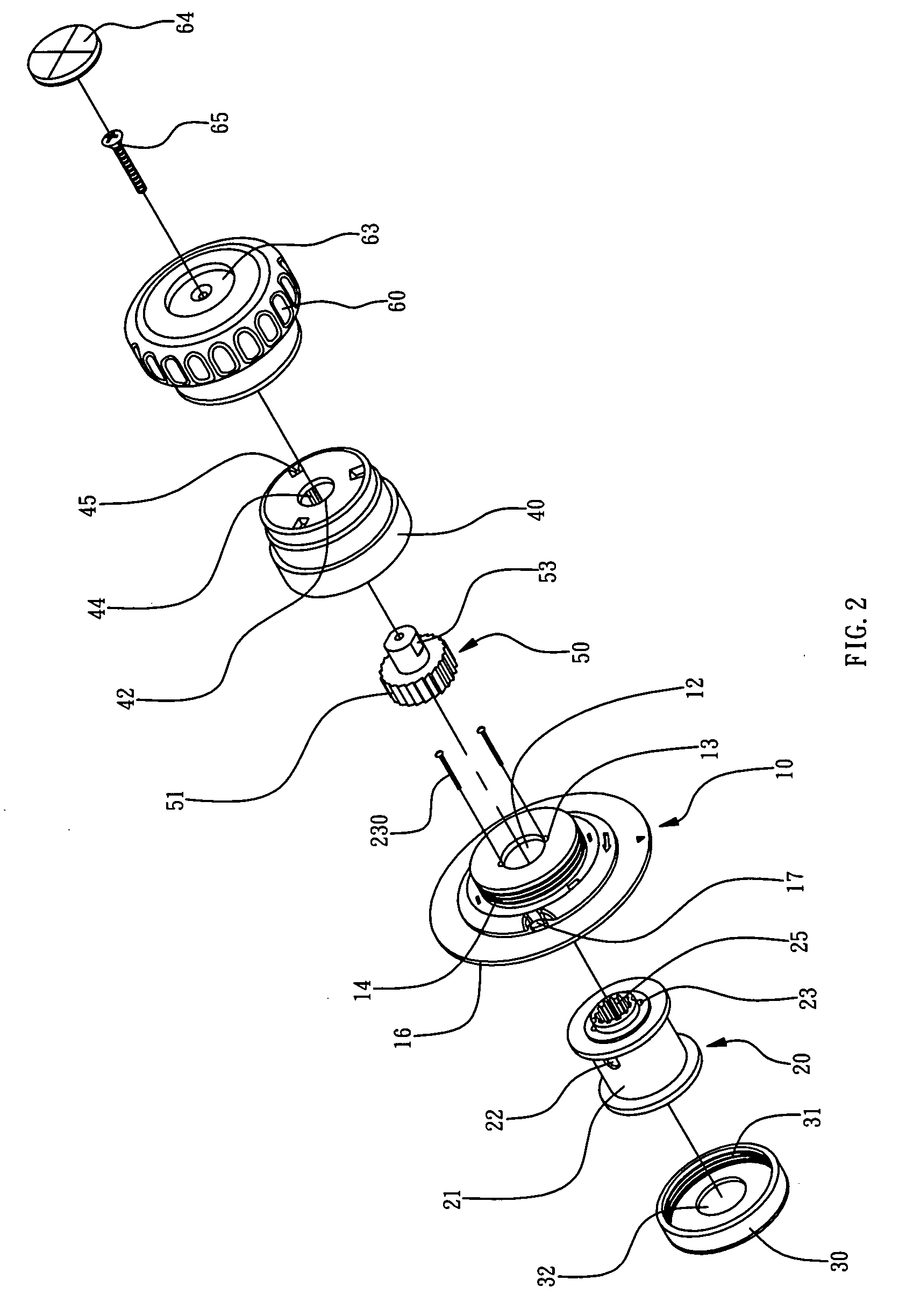

Shoelace reel operated easily and conveniently

InactiveUS20080196224A1Easy to operateThe process is convenient and fastSnap fastenersShoe lace fasteningsEngineeringMechanical engineering

Owner:MENG HANN PLASTIC

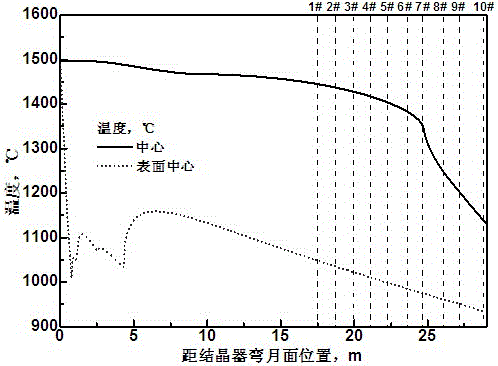

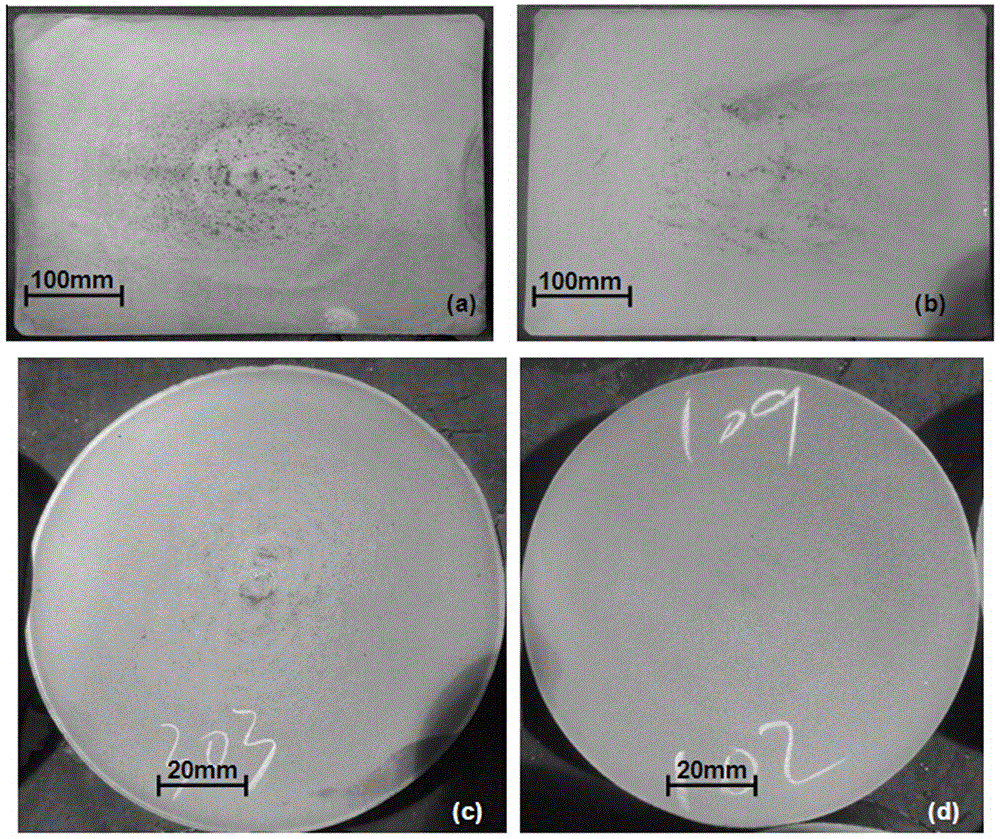

Method for continuous casting billet two-stage continuous and dynamic heavy downward pressing

The invention belongs to the field of continuous casting production, and particularly relates to a method for continuous casting billet two-stage continuous and dynamic heavy downward pressing. The method for the c two-stage continuous and dynamic heavy downward pressing is provided for the characteristics of a bloom caster and a wide and thick plate continuous casting machine. A specific process parameter design method of heavy downward pressing process implementation is given and includes downward pressing interval section and division and downward pressing amount design. The casting billet segregation defect is overcome in the first stage of downward pressing, the looseness defect of casting billets is overcome in the second stage of continuous downward pressing, and therefore the synchronous improvement of casting billet segregation and looseness is achieved.

Owner:NORTHEASTERN UNIV

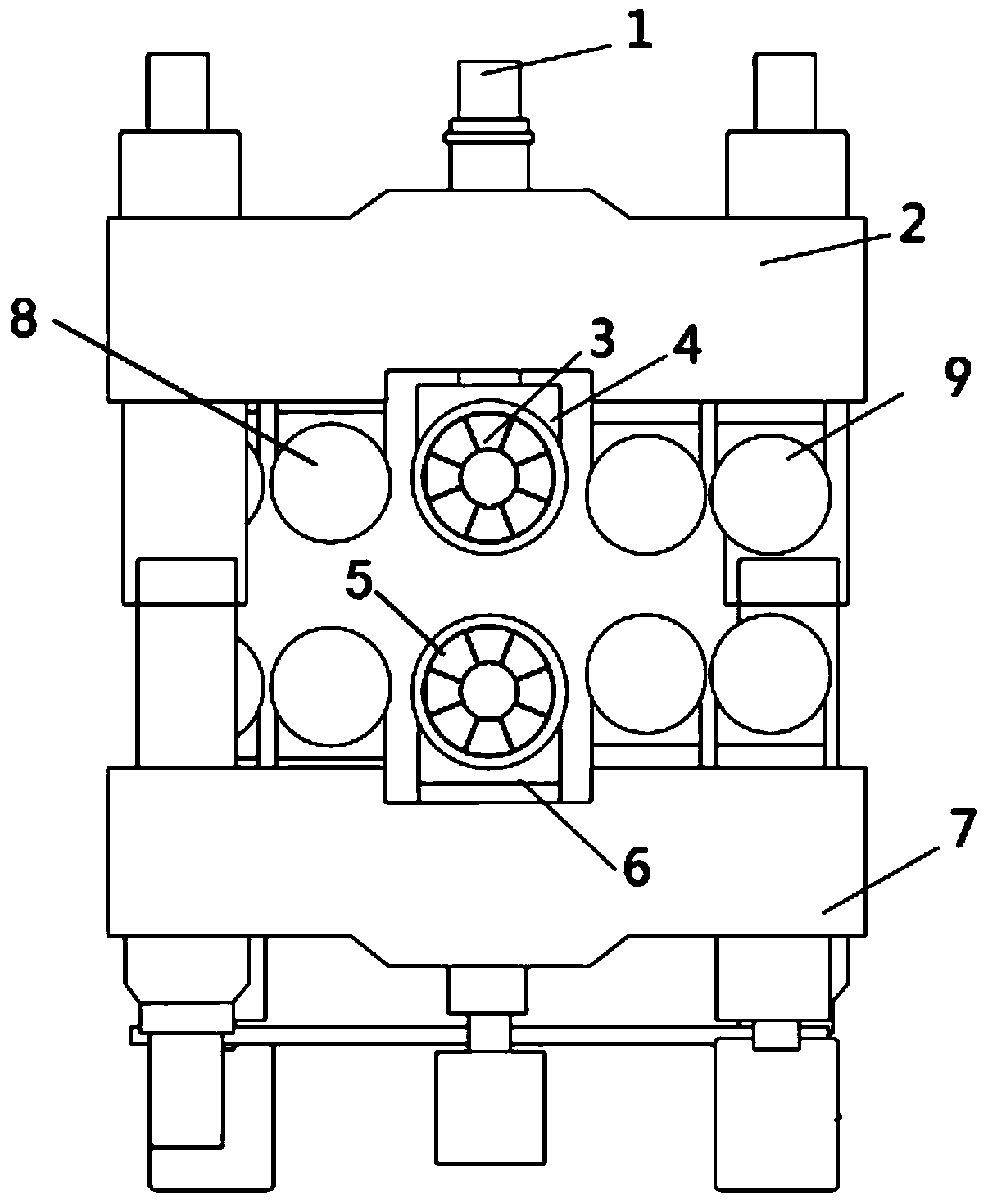

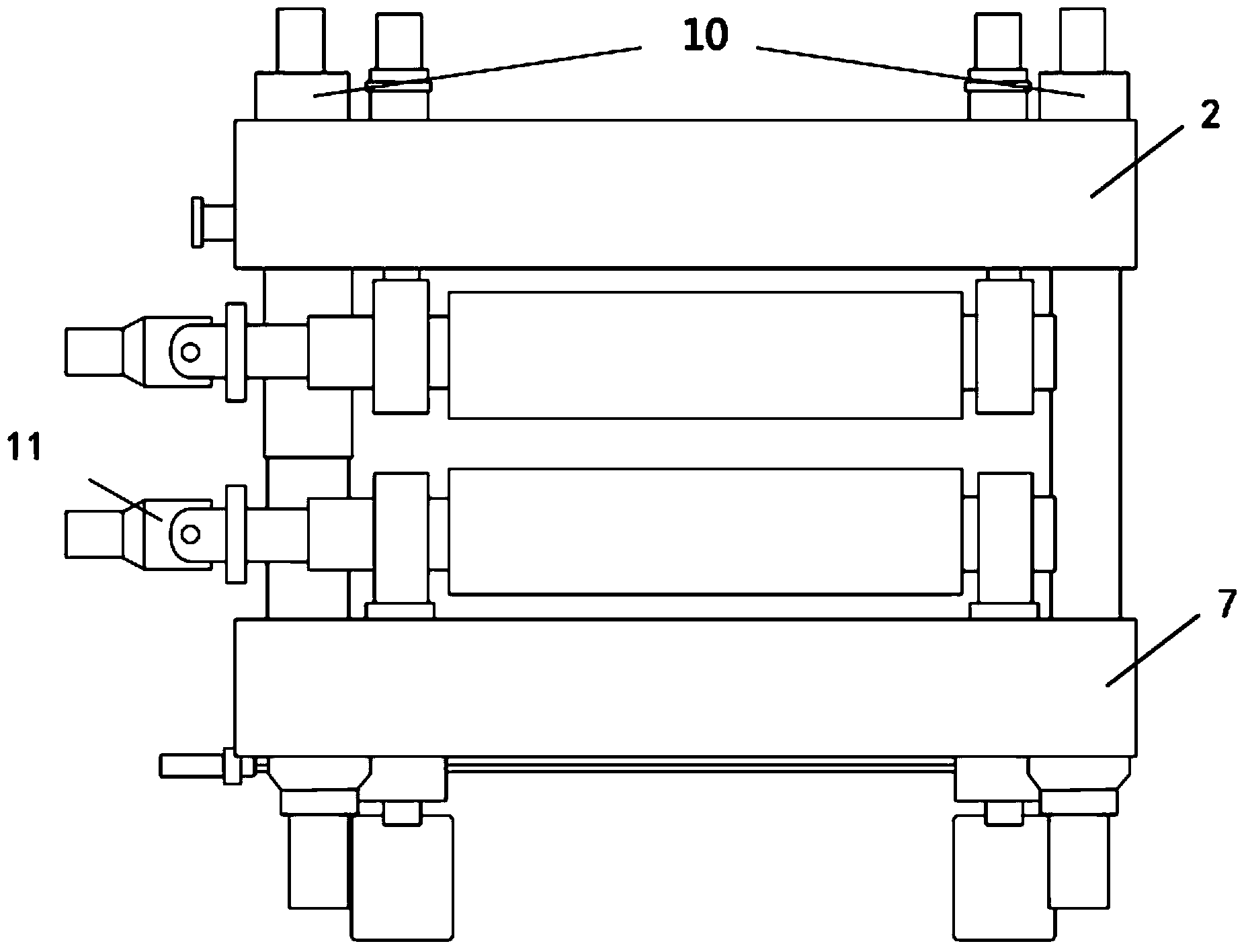

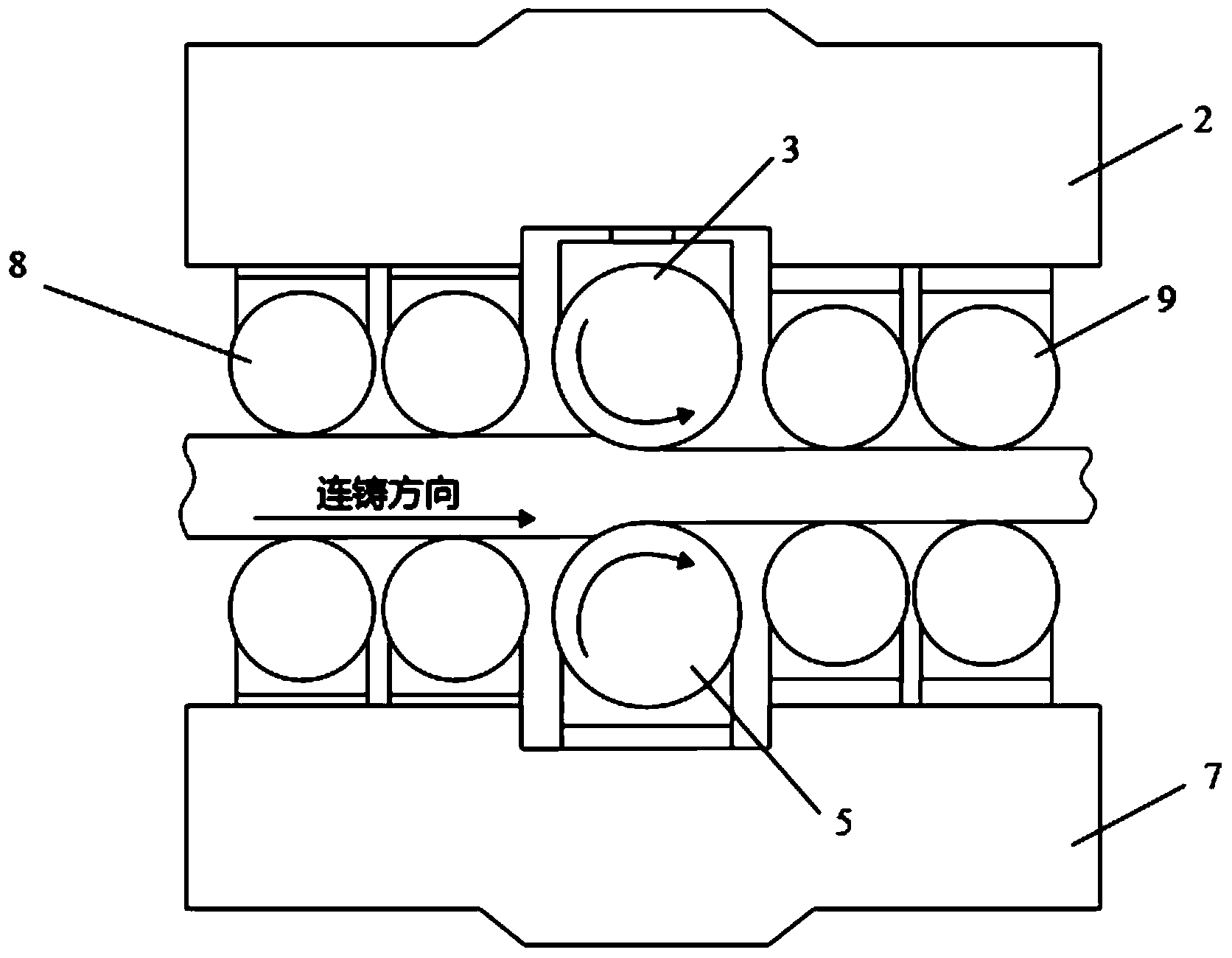

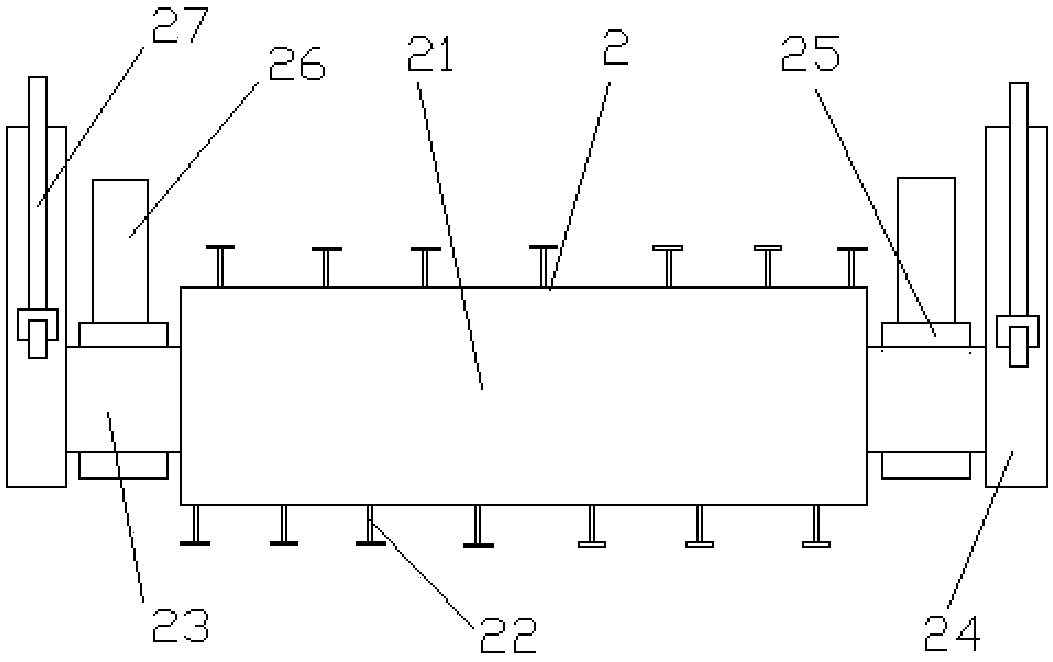

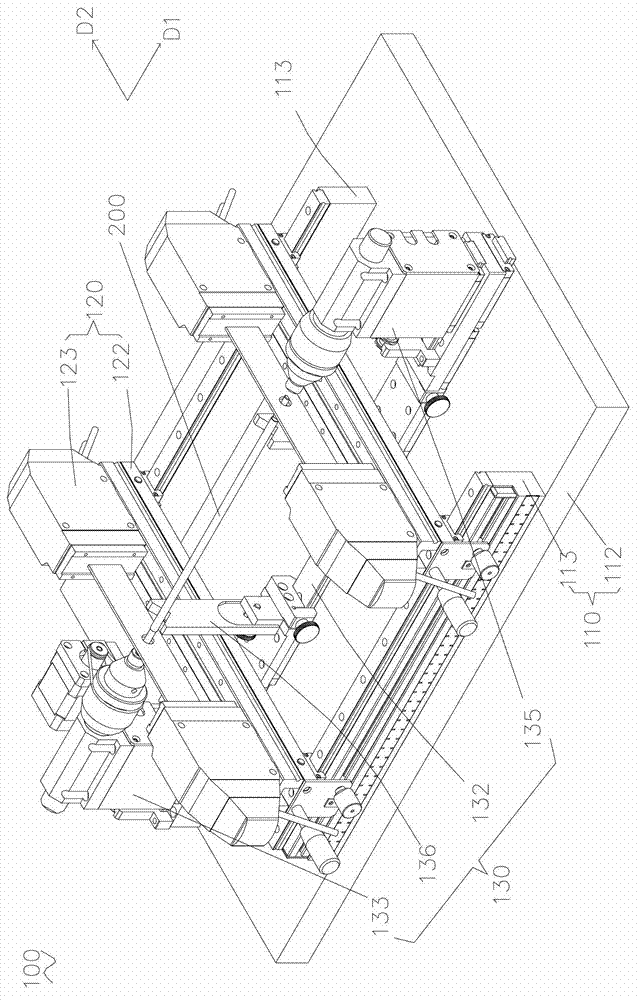

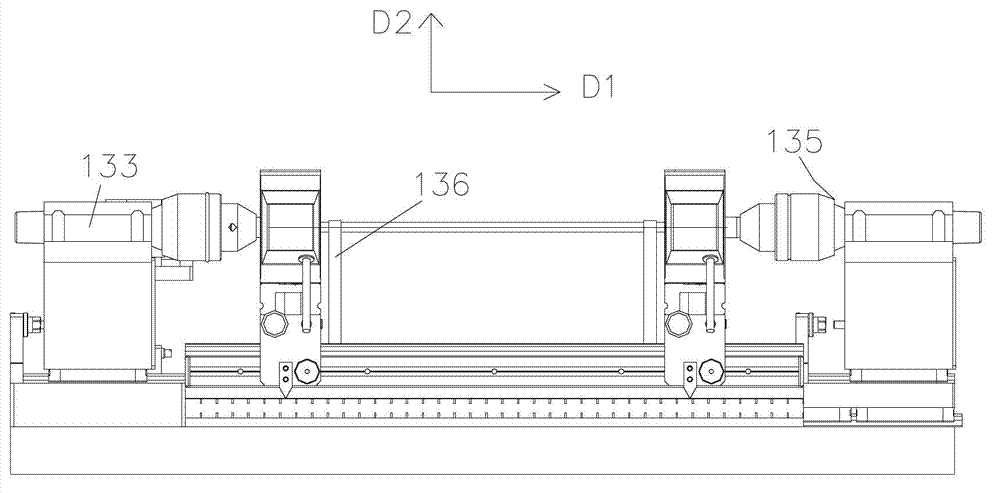

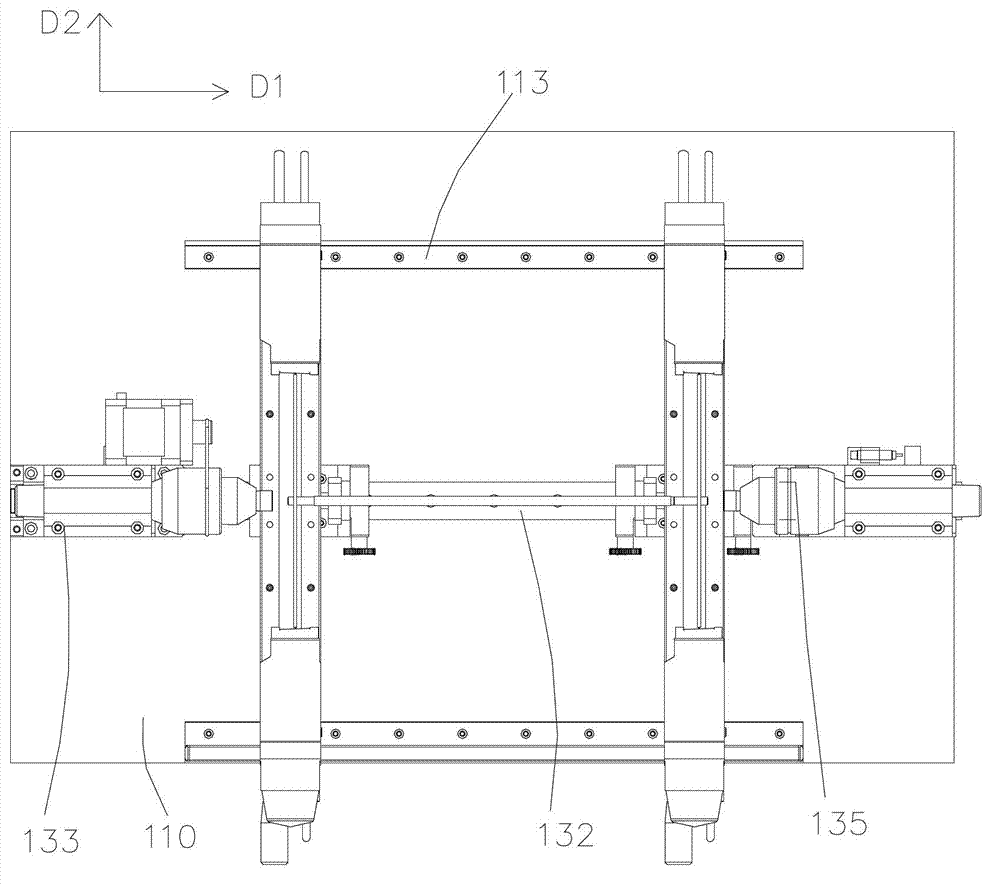

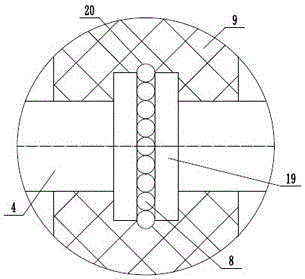

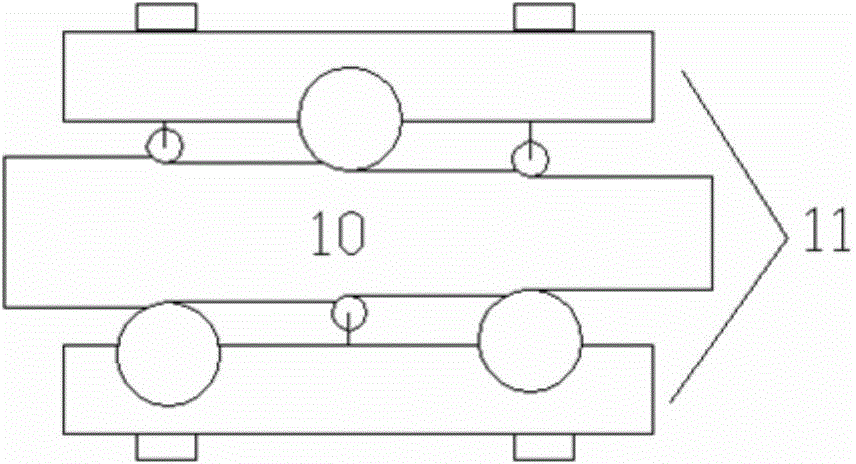

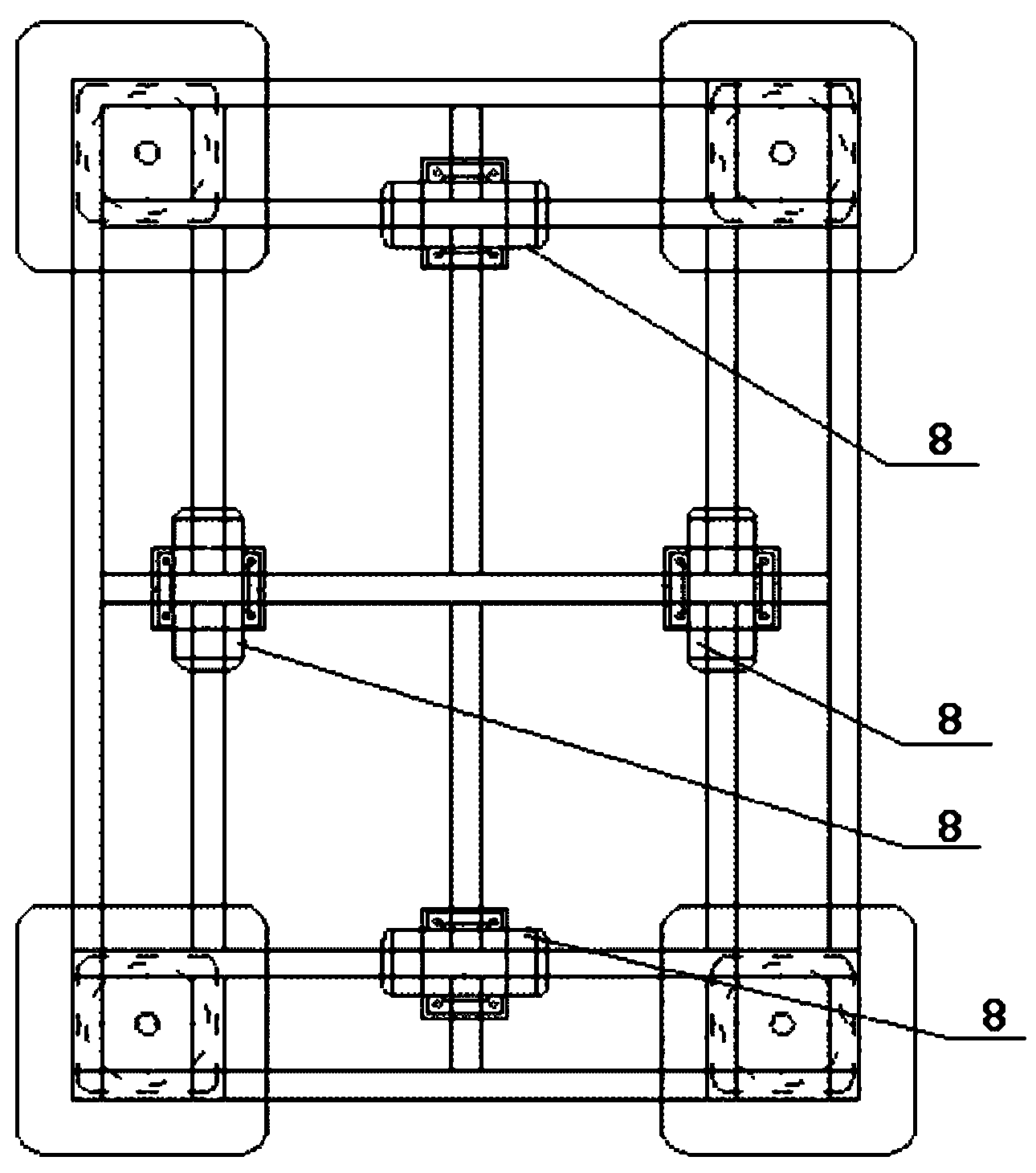

Continuous casting machine sector section for deep pressing of continuous casting blank solidification tail end and deep pressing method of continuous casting machine sector section

ActiveCN104057049AReduced plastic deformation contact areaTotal Deformation Force ReductionMaterials scienceContinuous casting

The invention provides a continuous casting machine sector section for deep pressing of the continuous casting blank solidification tail end and a deep pressing method of the continuous casting machine sector section. The continuous casting machine sector section comprises an upper frame, a lower frame, an upper driving roll, a lower driving roll, a left driven roll set, a right driven roll set, a pressing device and a clamping cylinder, wherein the upper frame, the lower frame, the upper driving roll, the lower driving roll, the left driven roll set, the right driven roll set, the pressing device and the clamping cylinder are arranged on the sector section; the clamping cylinder is used for clamping the upper frame and the lower frame to be kept in a certain set gap; the upper driving roll is connected with the pressing device and connected to the upper frame through a bearing base, the lower driving roll is connected to the lower frame through a bearing base, the left driven roll set and the right driven roll set are located on the two sides of the driving rolls respectively, the left driven roll set is used for clamping a casting blank before pressing, the right driven roll set is used for clamping the casting blank after pressing, and the radio of the diameter of each driving roll to the diameter of each driven roll is 1.1:1 to 2:1. According to the continuous casting machine sector section for deep pressing of the continuous casting solidification tail end and the deep pressing method of the continuous casting machine sector section, the deformation permeability is improved, deformation achieved through the continuous casting machine sector section is equivalent to that achieved by one rolling pass of a twin rolling mill with the large rolling diameter, and the improvement in loosening and segregating of a central zone of the casting blank is facilitated.

Owner:UNIV OF SCI & TECH BEIJING

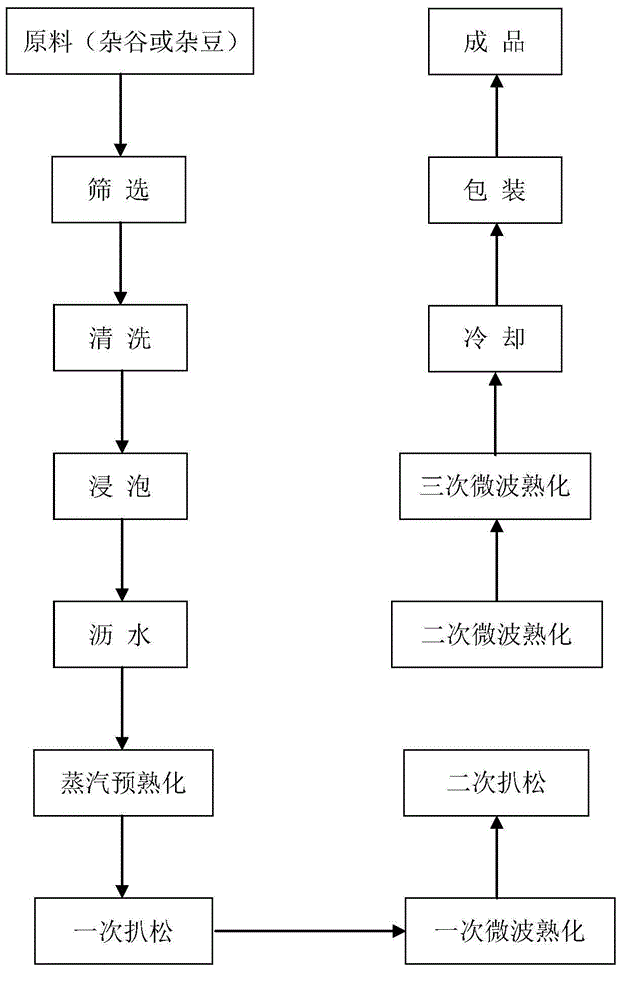

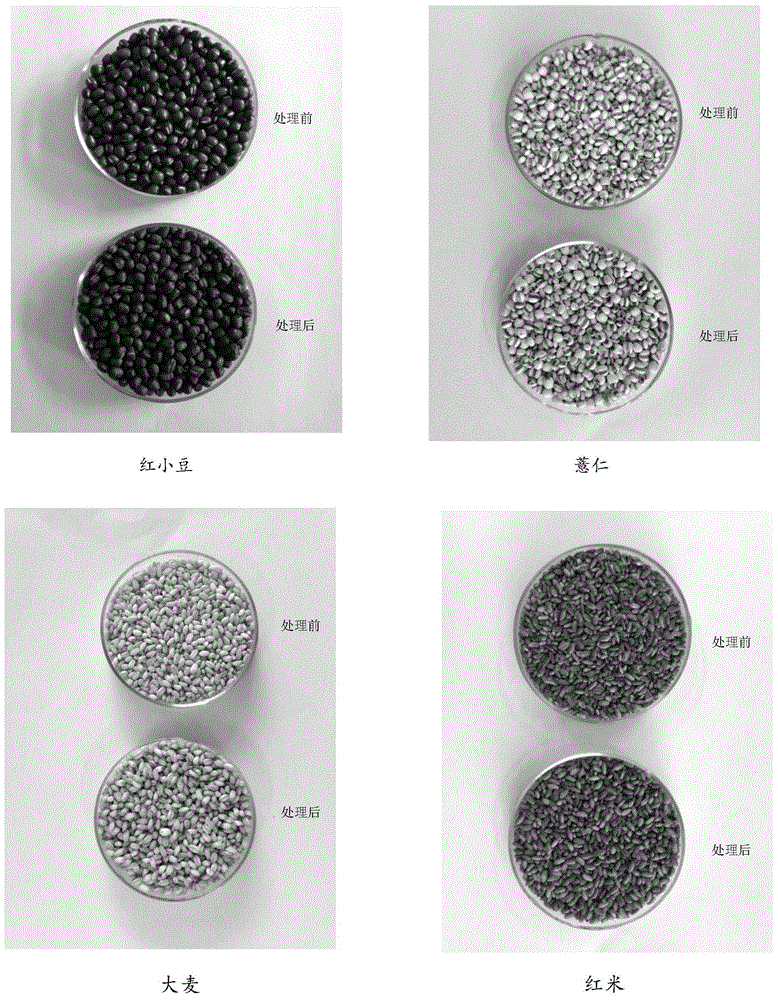

Processing method of precooked coarse grains simultaneously boiled and cooked with rice

The invention discloses a processing method of precooked coarse grains simultaneously boiled and cooked with rice, and belongs to the technical field of deep processing of agricultural products. The method comprises the following steps: screening mixed beans or coarse grains as a raw material, cleaning, immersing, carrying out fumigating precuring treatment on the raw material by using steam to obtain a precooked raw material, carrying out loosening and microwave slaking alternative treatment on the precooked raw material, cooling, and packaging to obtain precooked coarse grains. The method has the advantages of low production cost of the processing process, short processing period, and products processed through the method have the characteristics of maintenance of the original appearance form, less nutrition component loss, maintenance of the original smell of coarse grains, storage and transportation benefiting, and adaptation to the industrialized popularization.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

Dynamic soft reduction technologies for bloom continuous casting of heavy rail

The invention discloses a process of continuous casting dynamic with less reduction heavy rail steel cogged ingot, the process is applied in the continuous casting of high carbon steel cogged ingot, which can not only evidently alleviate center segregation, center porosity, center line shrinkage, center crack and so on defects and prevent the casting ingot center crack, middle crack and so on underbead crack, but also can improve component homogenization of rail rolled by the casting ingot, stabilize and improve mechanical property and functional performance of the rail and reach technical requirements of the high speed rail. The technical measure as follows: controlling continuous casting pulling rate and molten steel temperature of the heavy rail steel, the continuous casting pulling rate is 0.60-0.80m / min, the molten steel superheating temperature is 15-40 DEG C; adopting even and assuasive control mode in the secondary cooling zone, the continuous casting ratio water amount is 0.25-0.30L / kg, the casting ingot surface temperature on the area with less reduction is 900-1020 DEG C; the reduction is controlled on the area with less reduction, the casting ingot solidification rate on the area with less reduction fs=30%-100%, total reduction is 1.6-7.0 mm.

Owner:PANZHIHUA IRON AND STEEL

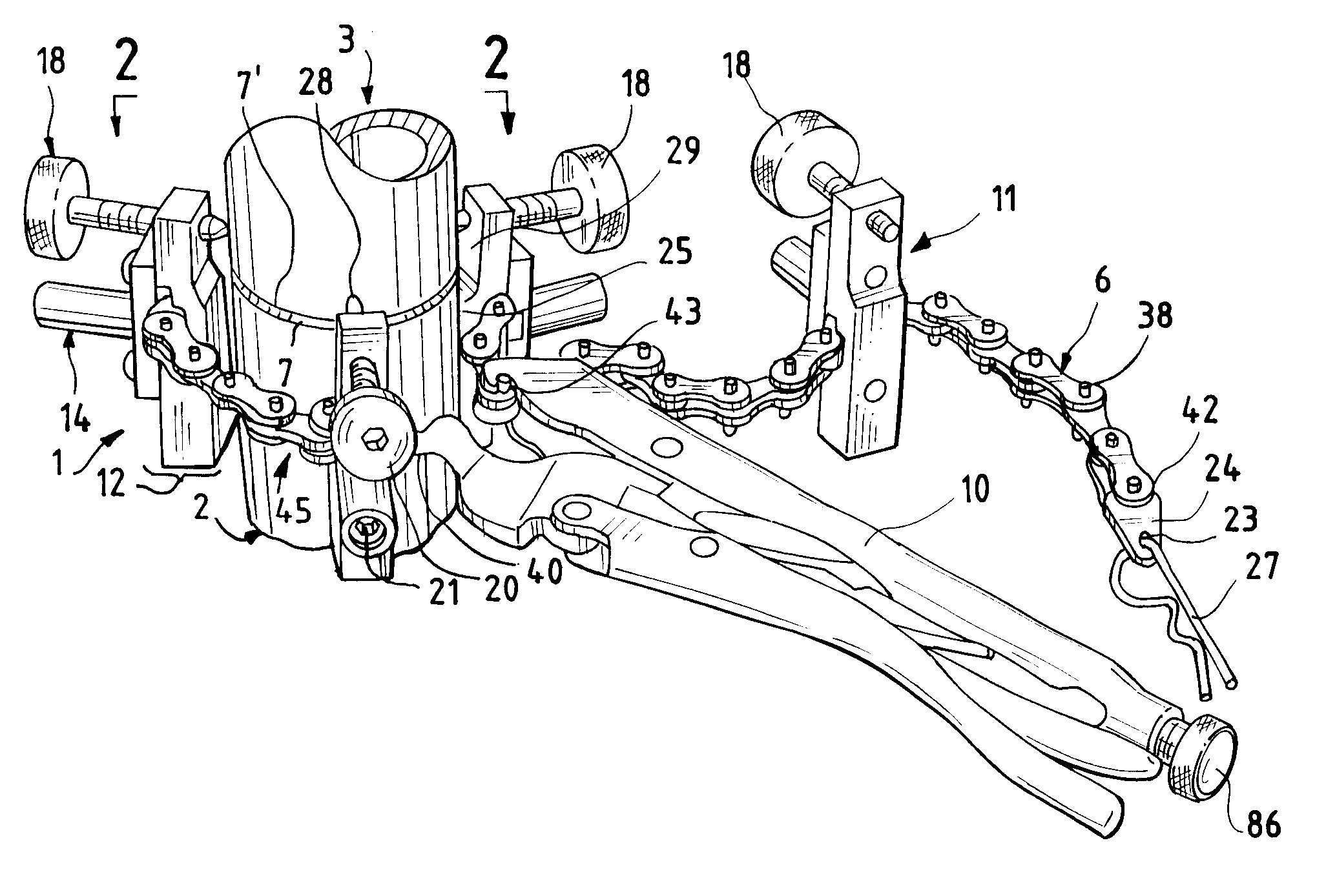

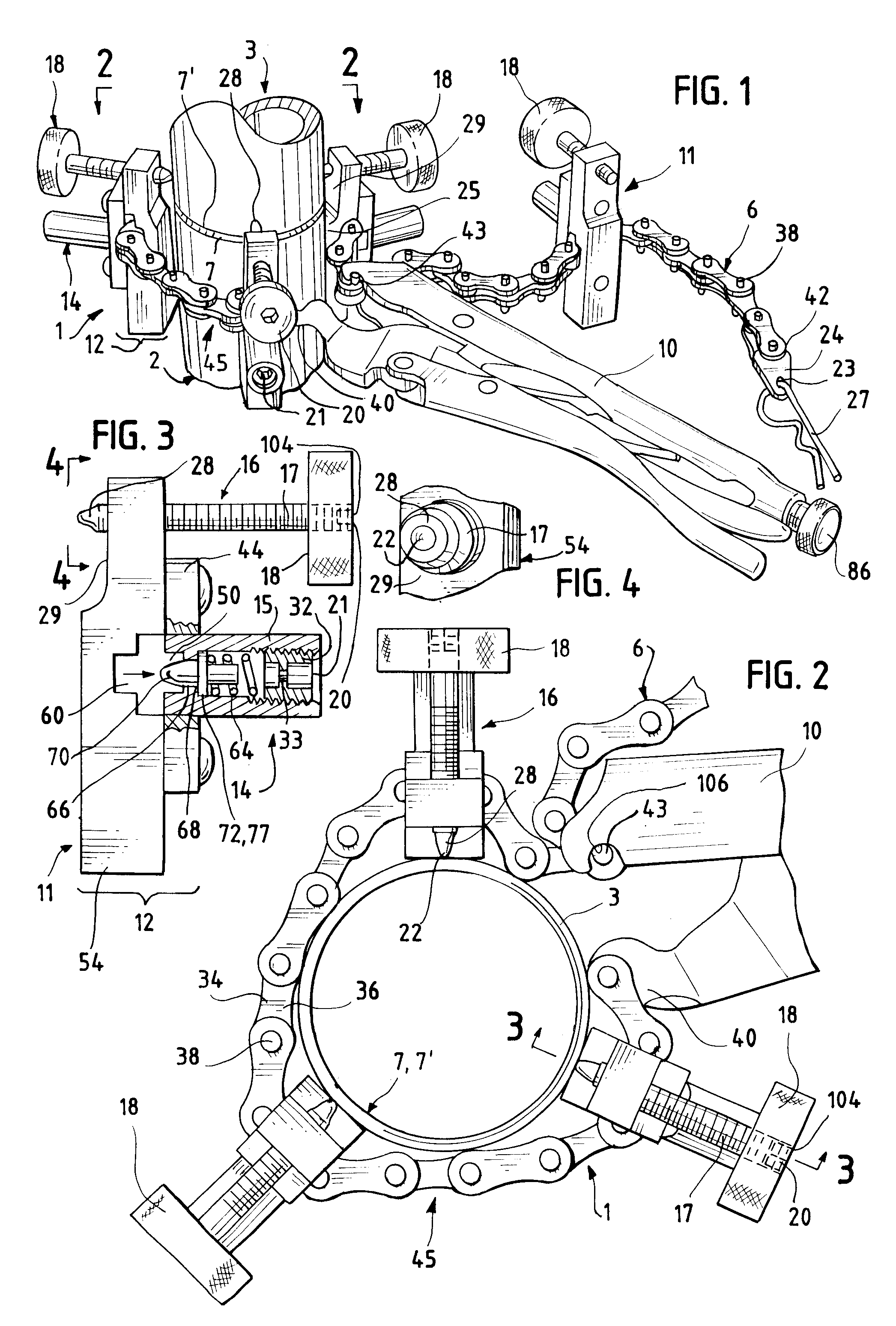

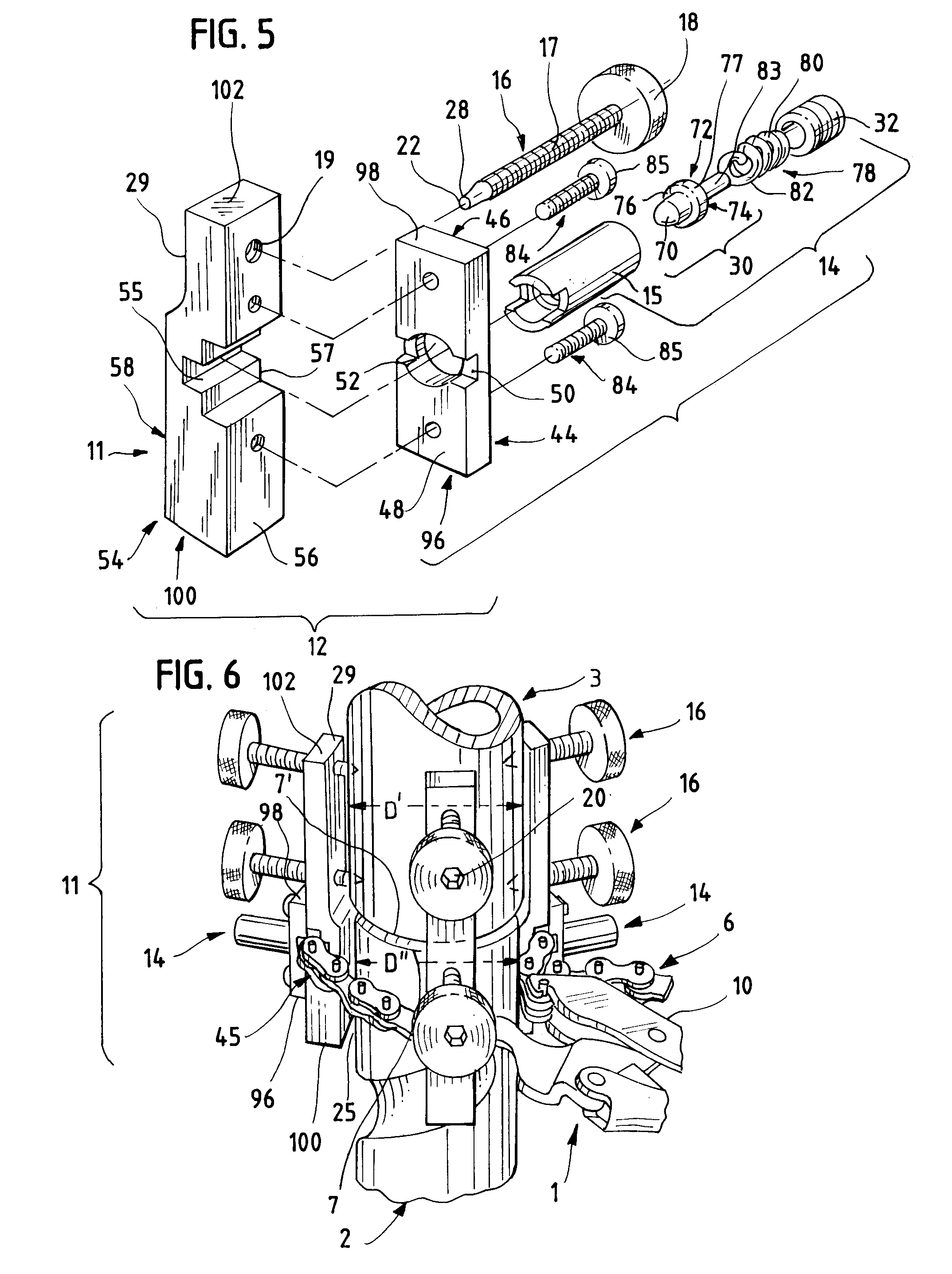

Alignment clamp

InactiveUS6651967B1Effective alignmentReduce usageWelding/cutting auxillary devicesSpannersCruciformDetent

A clamp for aligning the confronting ends of two or more workpieces, preparatory to their permanent joining. This clamp utilizes a chain of cruciform cross-section, and one or more alignment apparatuses, to encompass and secure the first workpiece, and align the remaining connecting workpiece(s). The chain may be fitted to the first workpiece, using color coding to select added chain-link sections for larger workpieces. Each alignment apparatus is slid on the chain, and secured by a spring-biased detent. The chain is then secured about the first workpiece. The alignment apparatus overlies the connecting workpieces, which are then aligned for joining, using one or more adjustable fasteners mounted on the alignment apparatus.

Owner:BARBER FRLIN R

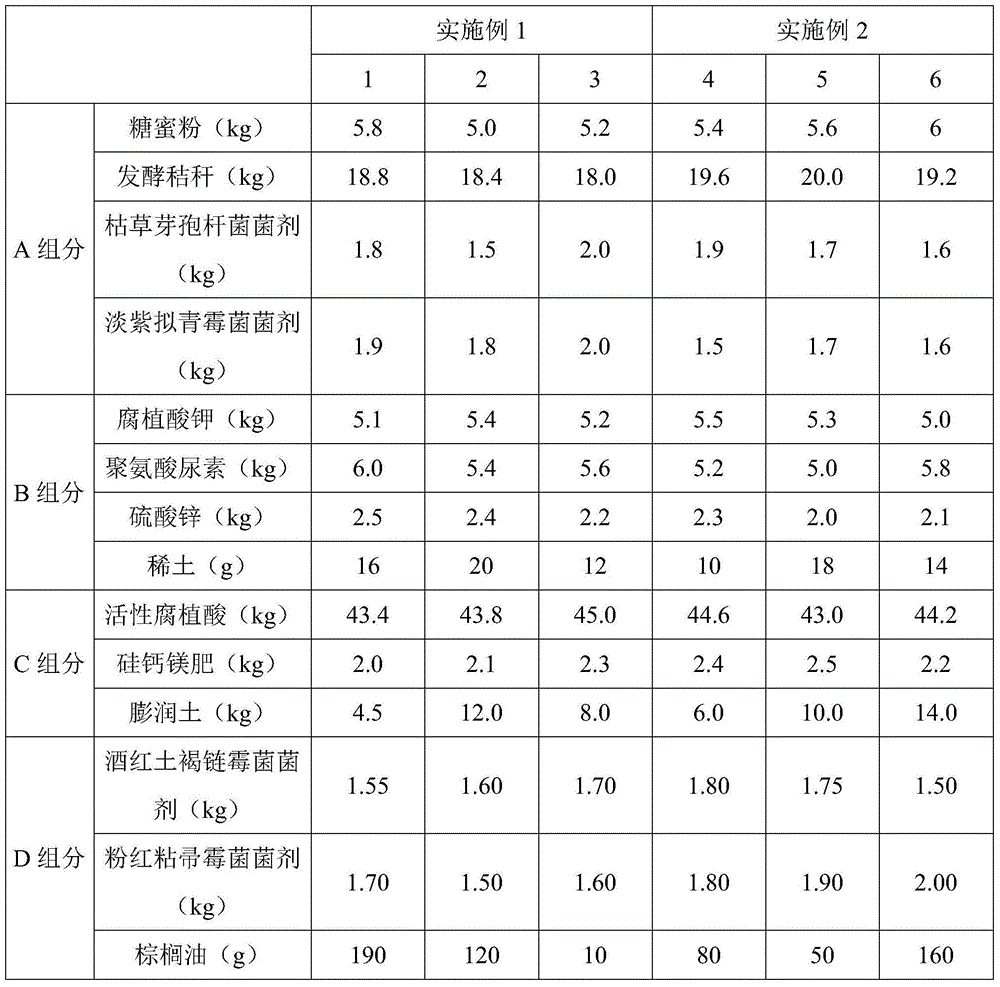

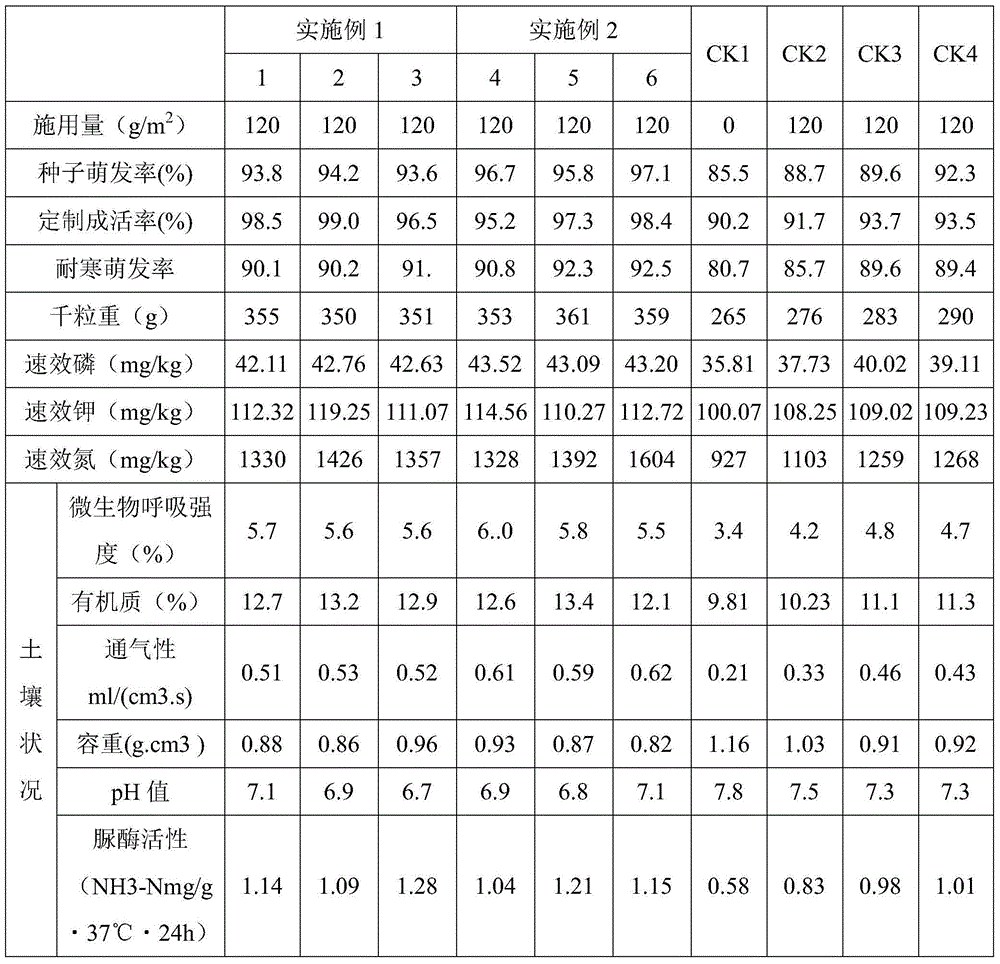

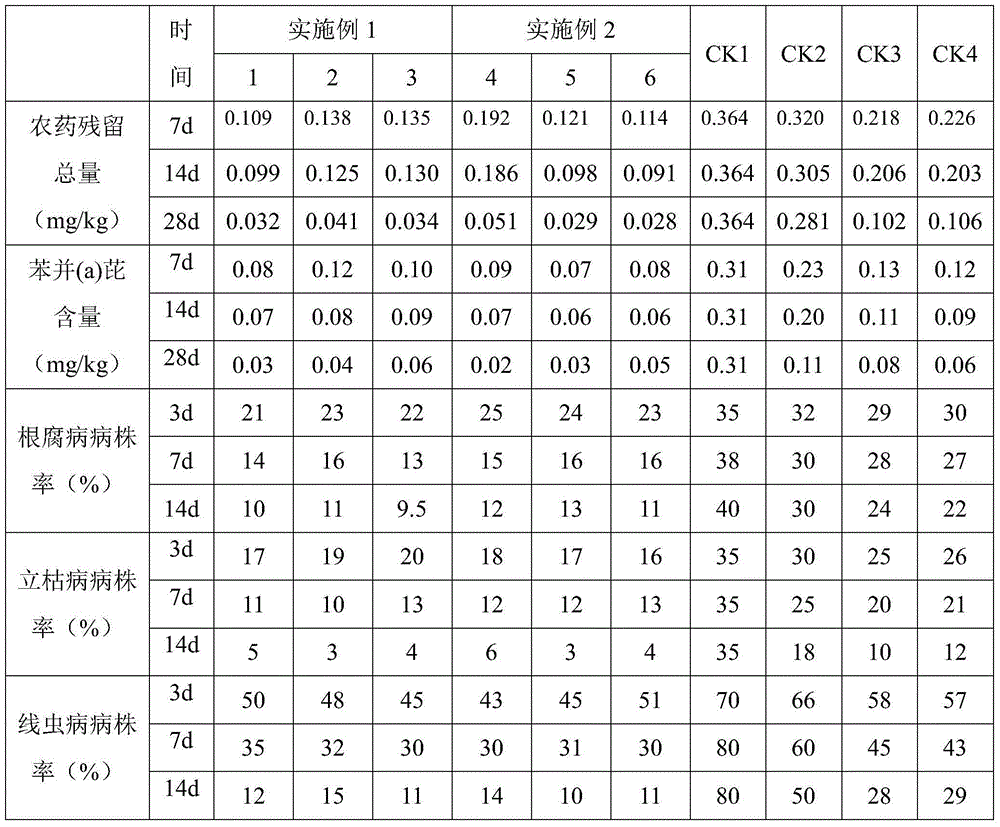

Multifunctional active organic fertilizer and preparation method thereof

InactiveCN104672009AImprove aggregate structureImprove water and fertilizer retention performanceCalcareous fertilisersBioloigcal waste fertilisersPaecilomyces lilacinusStreptomyces thermodiastaticus

The invention provides a multifunctional active organic fertilizer and a preparation method thereof, relating to an organic fertilizer containing bacteria, fungi and spores, particularly an active organic fertilizer with functions of soil restoration and disease / pest resistance. The invention aims to provide a multifunctional active organic fertilizer capable of restoring soil pollution and improving product quality and a preparation method thereof. The multifunctional active organic fertilizer is composed of three layers from inside to outside, wherein the innermost layer is composed of a component A of which the main effective components are Bacillus subtilis and Paecilomyces lilacinus; the middle layer is composed of a component B and a component C containing multiple rich nutritive elements; and the outermost layer is composed of a component D of which the main effective components are Streptomyces vinaceus-drappus and Gliocladium roseum. The multifunctional active organic fertilizer can passivate heavy metals in soil, activate the soil, improve the microecological environment of the rhizosphere, degrade the chemical pesticides and improve the crop quality. The multifunctional active organic fertilizer is used in the field of agricultural planting.

Owner:廊坊华昌物联网科技有限公司

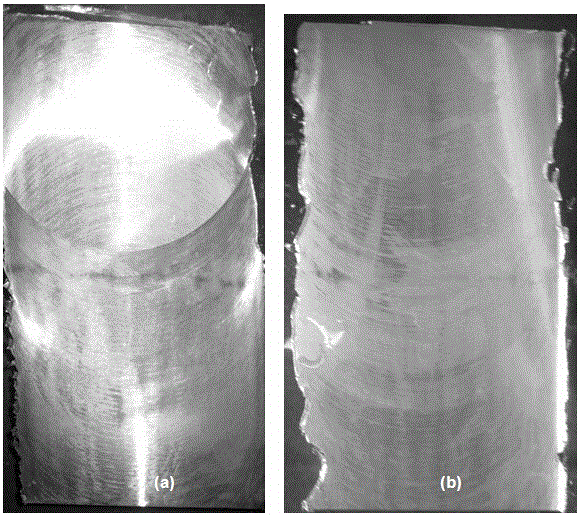

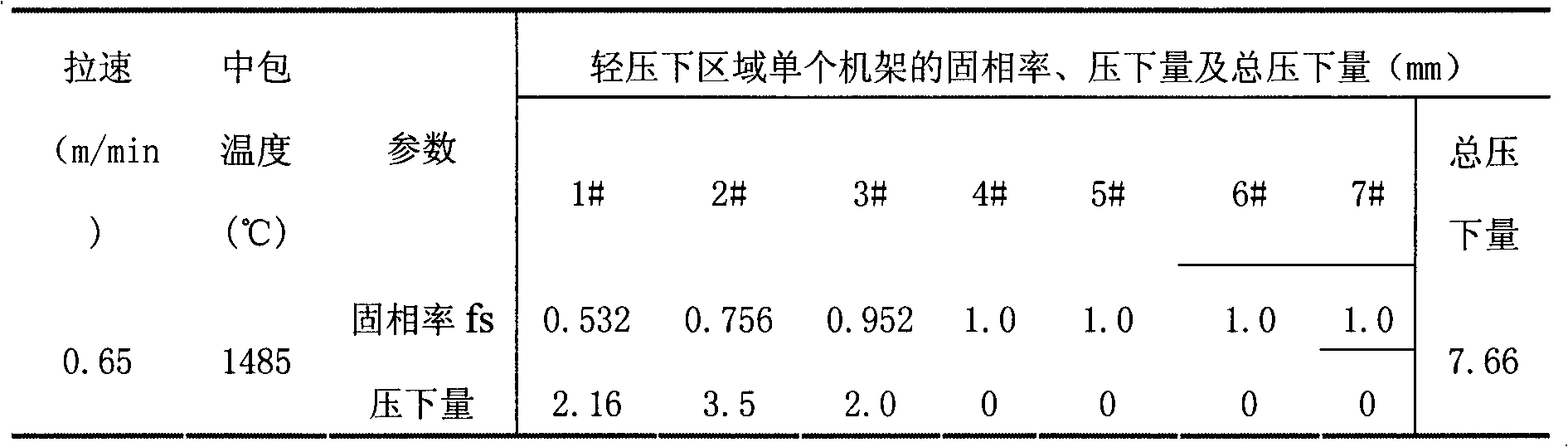

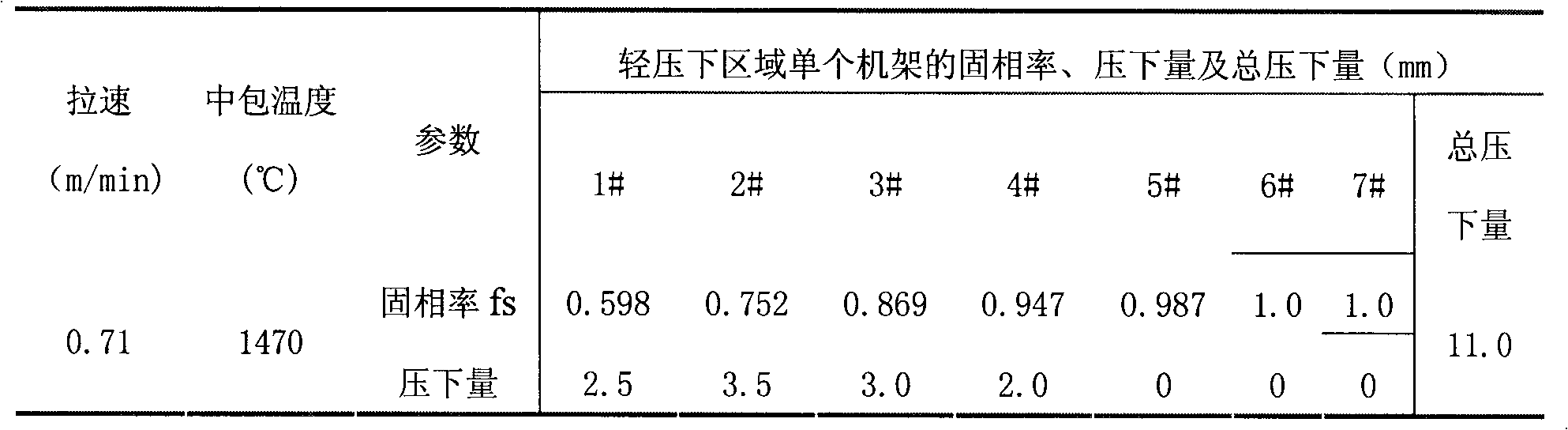

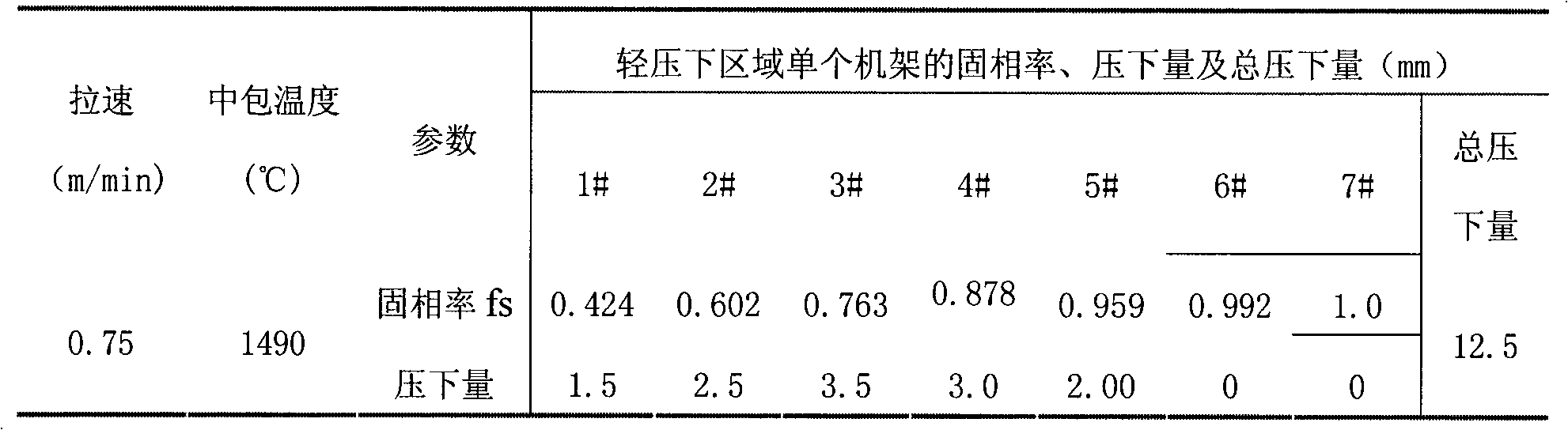

GCr15 bearing steel bloom continuous casting dynamic soft reduction process

InactiveCN101642774AEasy to loosenMeet technical requirementsMetal rolling arrangementsMetallurgySteel casting

The invention relates to a GCr15 bearing steel bloom continuous casting dynamic soft reduction process, which belongs to the technical field of metallurgical continuous casting and is used for solvingthe problems that the GCr15 bearing steel bloom continuous casting is easy to cause central segregation, central looseness, central parosity and other casting slab internal quality defects. The technical scheme is as follows: the reduction of a continuous casting soft reduction region is controlled through the change of central solid phase rate fs of a casting slab, and the relationship between the reduction of a soft reduction rack and the central solid phase rate of the casting slab is given out. The adoption of the soft reduction process of dynamic control can significantly reduce the central segregation of the GCr15 bearing steel casting slab, the central carbon segregation index of the casting slab is 0.95-1.08, and the average central segregation is 1.03; the process can also obviously improve the central looseness and the central parosity of the GCr15 bearing steel casting slab, the proportion of the central looseness of the casting slab which is not more than 1.0 grade is morethan 90%, and the central parosity is not more than 0.5 grade.

Owner:XINGTAI IRON & STEEL +1

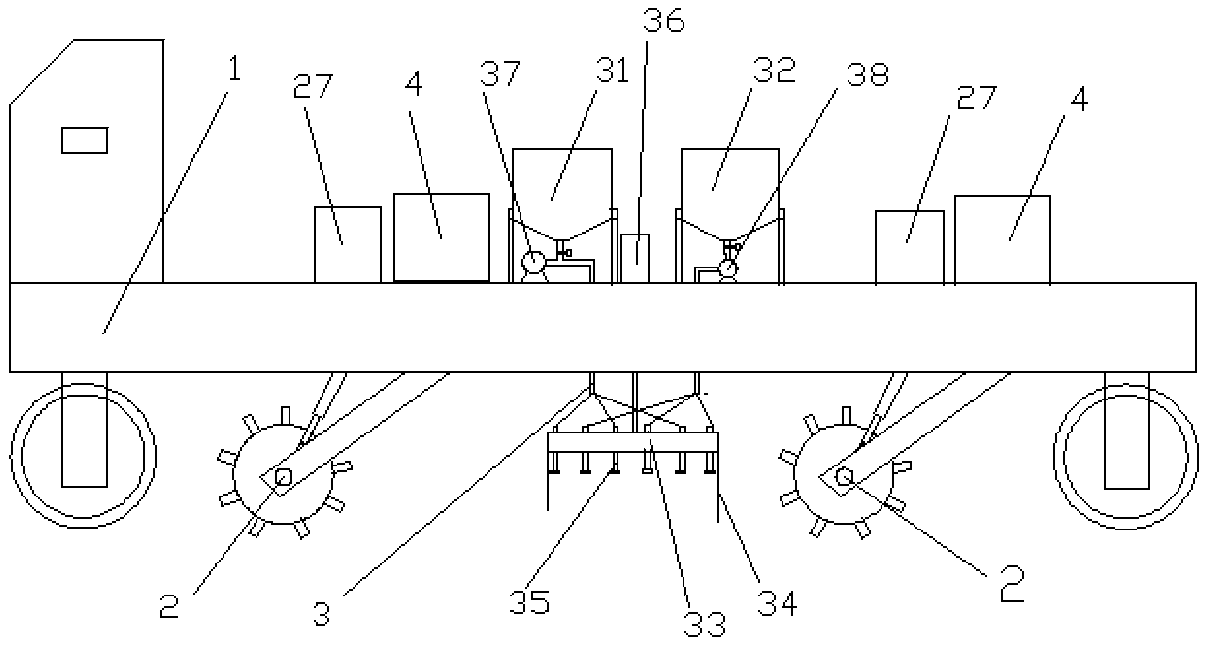

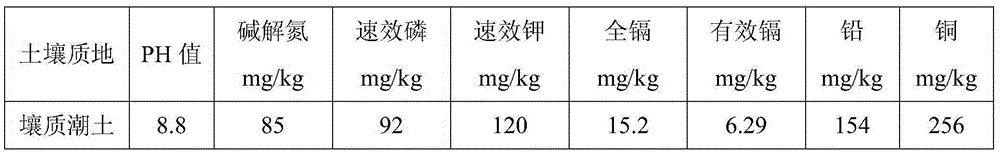

Scarifying improvement device for scarifying polluted soil

The invention provides a scarifying improvement device for scarifying polluted soil. The scarifying improvement device comprises a vehicle body, a soil conditioner spraying mechanism and two soil scarifying mechanisms, wherein each of the soil scarifying mechanisms comprises a roller assembly for scarifying soil and a driving device for driving the roller assembly to rotate; the roller assembly ismovably connected with the bottom of the vehicle body; the driving device is arranged at the top of the vehicle body; the soil conditioner spraying mechanism comprises a soil conditioner storage tankarranged at the top of the vehicle body and a sprayer assembly connected with the soil conditioner storage tank; and the sprayer assembly is fixed at the bottom of the vehicle body and is positionedbetween the two soil scarifying mechanisms. According to the scheme, the scarifying improvement device uniformly mixes and stirs a soil conditioner in the soil while scarifying the soil to improve andrepair the soil, is simple in structure and suitable for improvement operation on polluted large-area soil and carries out scarifying and mashing preparation operation on aftertreatment of the polluted soil.

Owner:ZHENGZHOU QISHUO ELECTRONICS TECH CO LTD

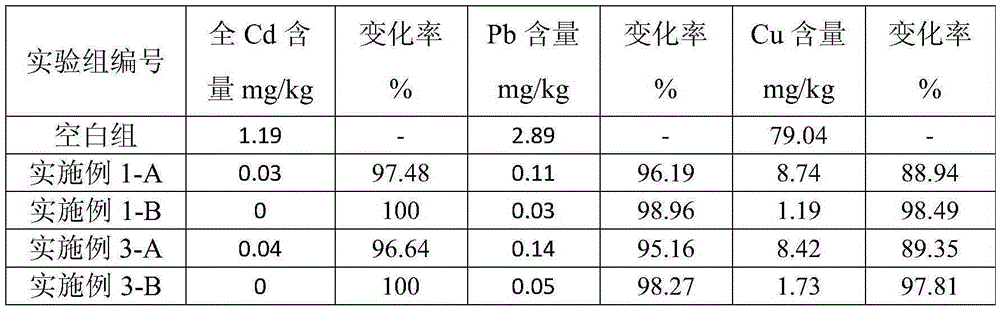

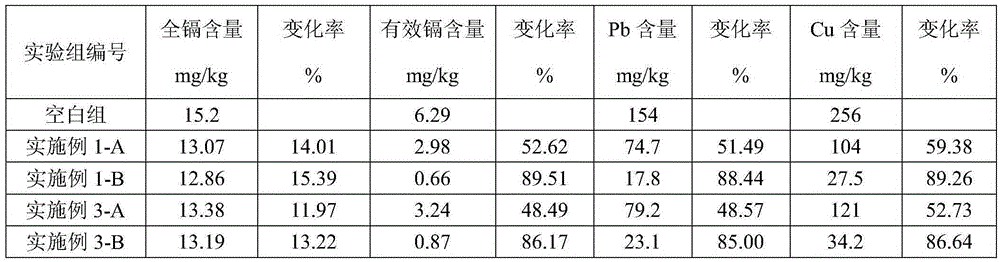

Biological organic repairing agent for soil pollution and application and preparation method thereof

InactiveCN105347884AReduce absorptionReduced enrichmentBio-organic fraction processingExcrement fertilisersBiotechnologyPollution

The invention relates to the field of soil fertilizer and provides a biological organic repairing agent for soil pollution and its application and preparation method. The biological organic repairing agent of the invention is composed of, by weight, 1.5-3 parts of eymogenic bacterium, 1-1.5 parts of wheat bran, 1.5-2 parts of molasses meal, 45-50 parts of ammonium humate, 45-50 parts of hydrolase dregs, 150-200 parts of soybean meal, 100-150 parts of humic acid powder, 80-100 parts of zeolite powder, 25-40 parts of a calcium magnesium phosphate fertilizer, 150-200 parts of cattle and sheep manure, 150-204 parts of plant straw, 25-40 parts of potassium humate, 1.5-3 parts of bacillus mucilaginosus, 1-1.5 parts of Gliocladium roseum, 1.5-2 parts of Streptomycesvinaceus-drappus, 1-1.5 parts of trichoderma spp, 1-1.5 parts of Paecilomyces lilacinus, 1-1.5 parts of bacillus subtilis and 1-1.5 parts of micrococcus. According to the invention, soil pollution control, improvement and nutrition are integrated.

Owner:HEBEI CIXIN ENVIRONMENTAL PROTECTION TECH CO LTD

Continuous casting method of continuous-cast round billets

ActiveCN104259415AReduce temperature gradientIncrease the ratio of axial crystalsSteelmakingPorosity

The invention discloses a continuous casting method of continuous-cast round billets. The method comprises the steps of 1) obtaining high-purity molten steel through steel-making; 2) pouring the obtained molten steel into a tundish under large-tundish long-nozzle argon blowing protection, controlling the degree of superheat of the molten steel inside the tundish to be 15-30 DEG C; 3) pouring the molten steel into a crystallizer through a tundish integrated type submerged nozzle, controlling the depth of the a crystallizer submerged nozzle inserted into the surface of the molten steel to be 100-120 mm; (4) perform constant-speed continuous casting, control the casting speed to be 0.16-0.22 m / min for different kinds of steel; 5) utilizing an air-water atomizing cooling mode in a secondary cooling area at a specific water flow rate of 0.12-0.22 L / kg; 6) performing dynamic soft reduction through a withdrawal and straightening machine to obtain the continuous-cast round billets. The continuous casting method of the continuous-cast round billets effectively reduces the temperature gradient of molten steel from a billet shell to a casting core and the degree of superheat of the molten steel in the center, improves the proportion of isometric crystal of the cast billets, enhances the structural density of the cast billets and significantly improves the effects of center porosity, center segregation and contraction of large continuous-cast round billets.

Owner:SHANDONG IRON & STEEL CO LTD

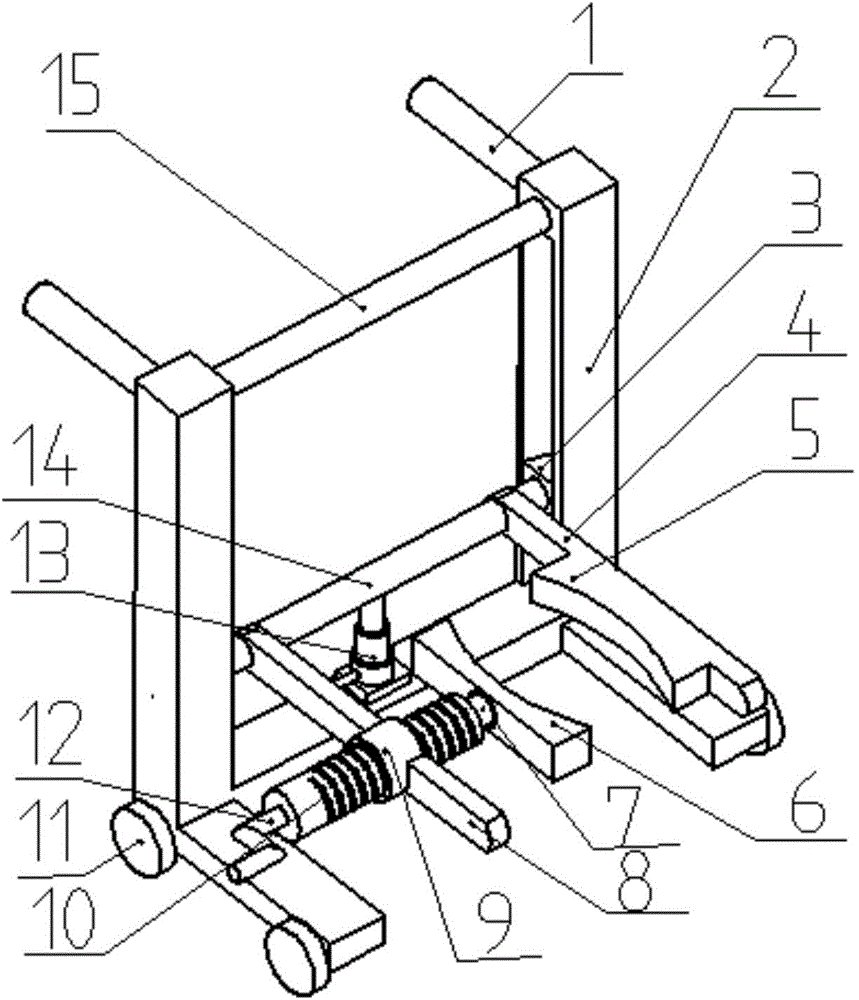

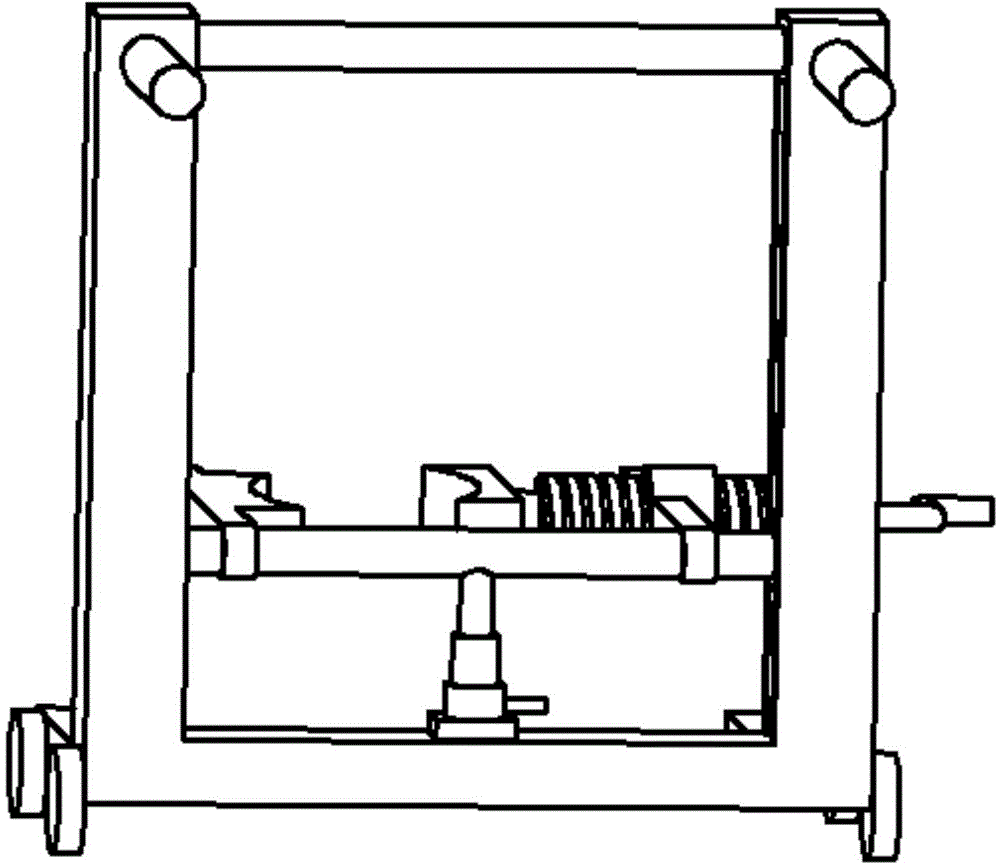

Indoor large flower pot carrying device

The invention discloses an indoor large flower pot carrying device, and belongs to the field of living furniture. The indoor large flower pot carrying device consists of a handle, a frame, a slide block, a back clamping plate, a back clamping handle, a front clamping handle, a linear bearing, a front clamping plate, a threaded sleeve, a threaded rod, wheels, a hand-operated handle, a hydraulic jack, an elevating rod and a grab bar, wherein the handle is connected to the frame; the elevating rod is fixedly connected with the slide block; the slide block is arranged in a frame sliding chute; the elevating rod is fixedly arranged above the hydraulic jack; the hydraulic jack is arranged above a frame bottom plate; the back clamping plate is fixed on the right side of the elevating rod; the front clamping plate is fixed on the right side of the elevating rod; the threaded sleeve is arranged on the front clamping plate; the threaded rod is arranged on the threaded sleeve; the front clamping handle is fixedly arranged at the front end of the threaded rod through the linear bearing; a vehicle body is arranged above the wheels. The indoor large flower pot carrying device has the beneficial effects that a flower pot is clamped through threaded connection, and self-locking property is realized, so that the flower pot can be clamped more tightly, the working efficiency is increased, and the labor force is reduced.

Owner:嘉兴晟源工业设计有限公司

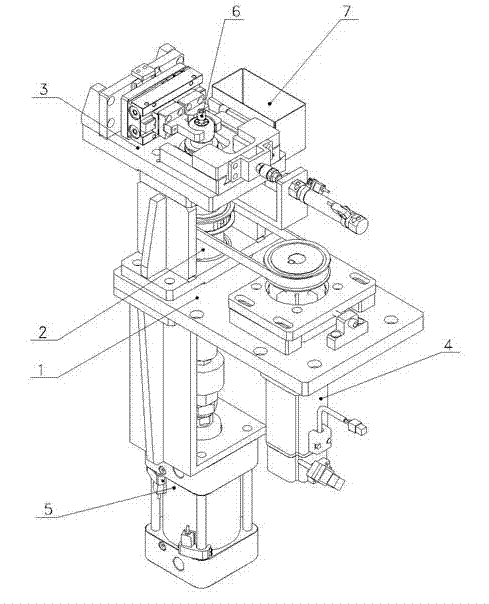

Detection device and method for detecting outer diameter, runout value and roundness of circular shaft

InactiveCN102901456AAccurate automatic detectionFast and accurate titrationUsing optical meansProgrammable logic controllerPersonal computer

The invention relates to a detection device and a method for detecting an outer diameter, a runout value and roundness of a circular shaft. The detection device comprises a base portion, an optical measurement portion, a center portion and a personal computer (PC)-programmable logic controller (PLC) control center, wherein the base portion comprises a base board and two base board guide rails, the optical measurement portion and the center portion are installed on the base portion in a sliding mode, the optical measurement portion comprises an optical measurement instrument guide rail and an optical measurement instrument, the optical measurement instrument guide rail is arranged on the base board guide rails in a sliding mode, the optical measurement instrument is arranged on the optical measurement instrument guide rail in a sliding mode, the center portion comprises a center guide rail, a first center structure and a second center structure, the first center structure and the second center structure are arranged on the center guide rail in a sliding mode, and the PC-PLC control center controls the optical measurement portion and the center portion to move relative to the base portion. The optical measurement instrument is used for measuring a round shaft to be detected, measured data are fed back to the PC-PLC control center, and the PC-PLC control center calculates the outer diameter, the runout value and the roundness of the circular shaft to be detected according to the measured data.

Owner:SHENZHEN SHENLAN PRECISION MACHINERY

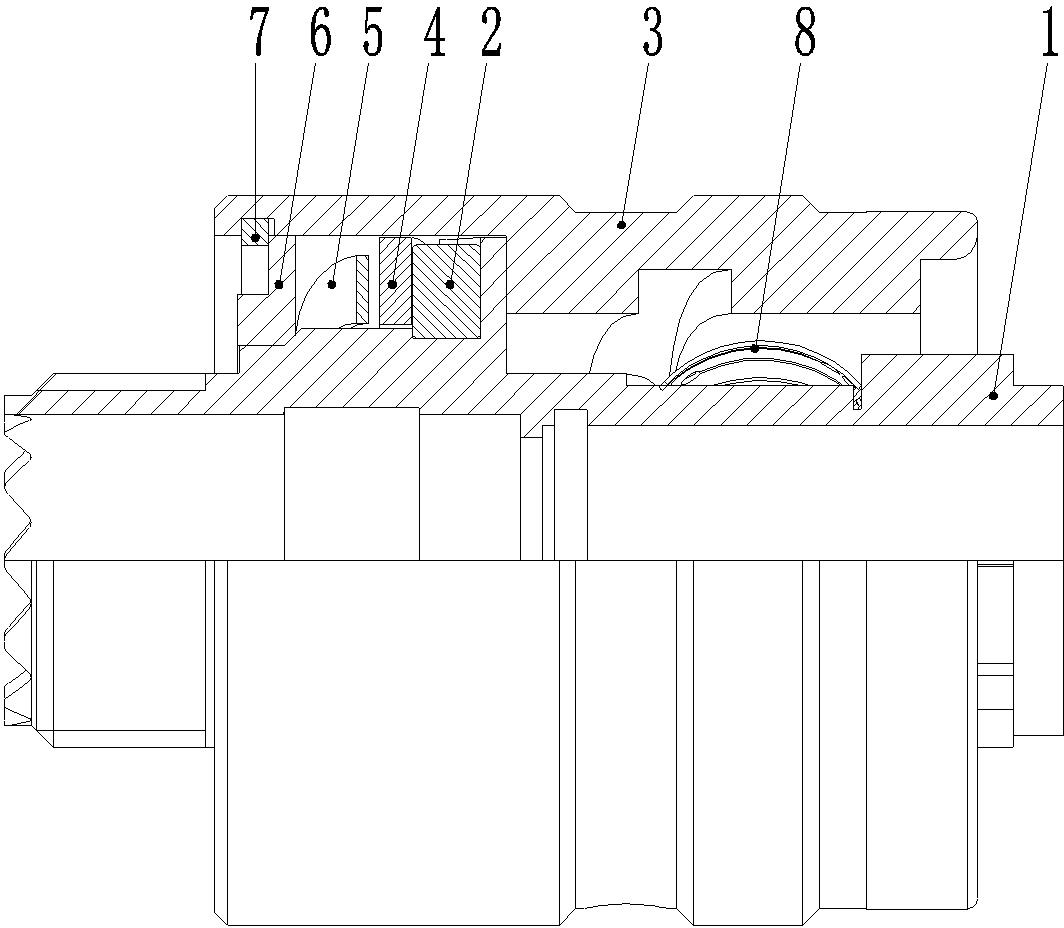

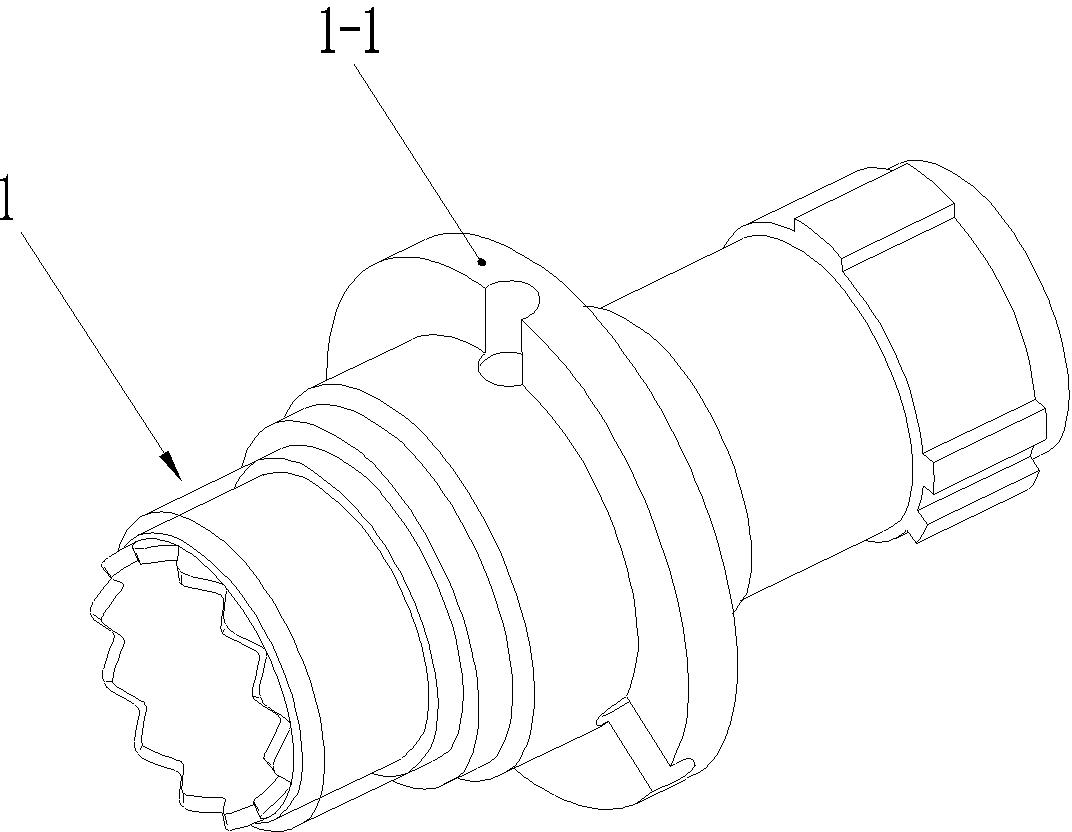

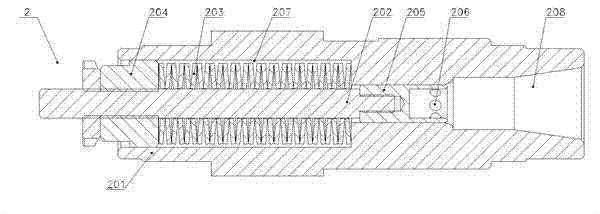

Plug shell assembly and plug with same

InactiveCN102544893APrevent looseningEasy to loosenCoupling device detailsCoupling light guidesEngineeringScrew thread

The invention relates to a plug shell assembly and a plug with the same. The plug shell assembly comprises a plug shell and a coupling nut sleeved on the plug shell in a coaxially rotating way, wherein the coupling nut is provided with internal threads on the front end and is matched with the plug shell in an axial direction in an anti-dropping manner; a bumping post is arranged on the periphery of the plug shell; one end of the bumping post is assembled to the plug shell, and the other end of the bumping post is diverged and extended along a radial direction of the plug shell; the coupling nut is internally provided with a lock washer movably along an axial direction on the rear part of the bumping post; the lock washer is matched with the coupling nut in a rotating stoppage way and is provided with a V-shaped clamped slot or a clamped slot with a cutter head being in a V shape on the front side face; in two vertical walls of the clamped slot, the slope of an inner wall face of one vertical wall on the front part in a screwing direction of the coupling nut is larger than the slope of an inner wall face of the other vertical wall; and a corrugated spring is arranged between the rear side of the lock washer and the coupling nut in an ejecting way. The problem that the coupling nut is easy to loosen when the existing connector plug is used in vibration environment is solved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

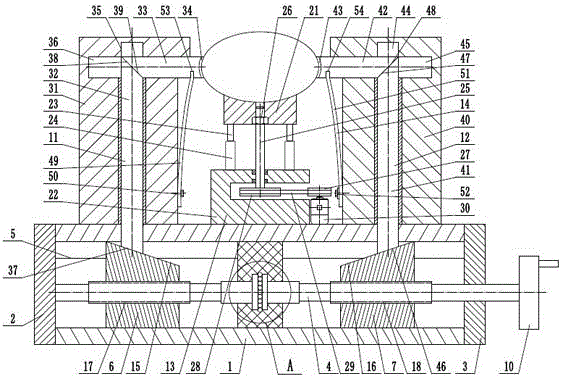

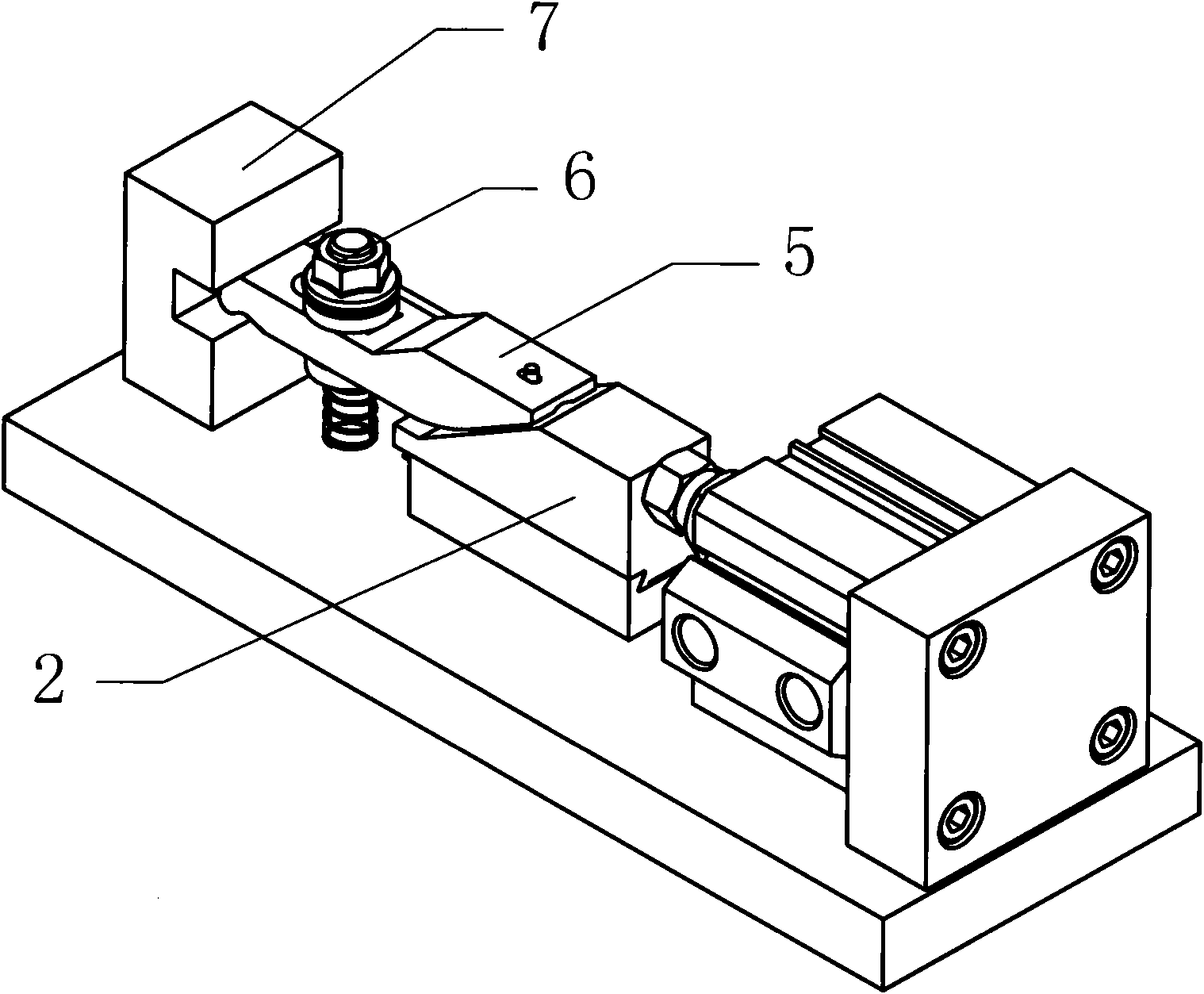

Centering clamping apparatus of ellipsoidal workpiece

PendingCN106826294APrevent axial slippageAchieve peace of mindPositioning apparatusMetal-working holdersLever pressingScrew thread

The invention provides a centering clamping apparatus of an ellipsoidal workpiece, which belongs to the technical field of a clamping device. The centering clamping apparatus comprises a screw, a left slide block, a right slide block, a left centering clamping assembly, a right centering clamping assembly, a height adjusting assembly and a return assembly, wherein both the left slide block and the right slide block can be arranged on a guiding seat in a sliding manner, a left threaded section of the screw is connected with the left slide block in a threading manner, a right threaded section of the screw is connected with the right slide block in a threading manner, a carrier frame of the height adjusting assembly is arranged on a fixed seat in an up-down sliding manner by virtue of a guide rod and a guide column, a left centering clamping assembly and a right centering clamping assembly are symmetrically arranged at the left side and the right side of the height adjusting assembly, the lower end of a left leaf spring of the return assembly is installed on a left supporting frame by virtue of a left nail, and the upper end of a right leaf spring is inserted into a right clamping groove of a right centering pressure rod. The centering clamping apparatus not only rapidly centers and clamps the ellipsoidal workpiece and is reasonable in structure, but also can be suitable for various models of ellipsoidal workpieces, and is high in universality.

Owner:全彬强

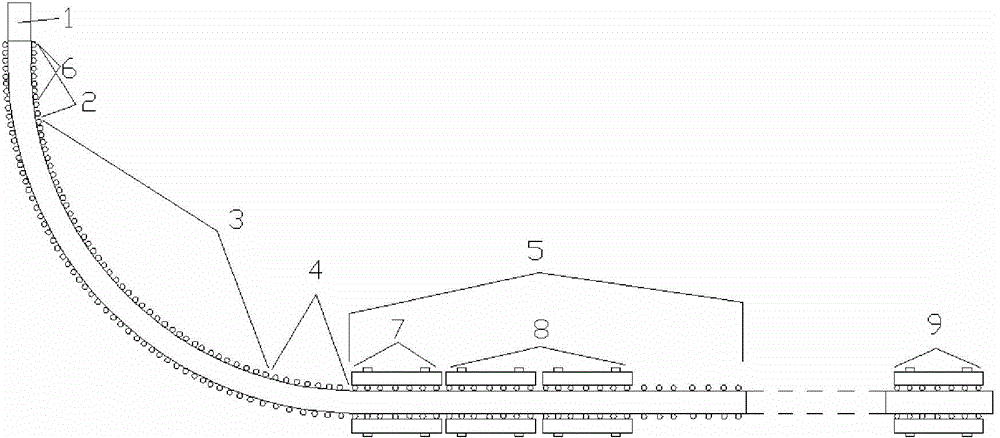

Method for producing ultra-thick plate continuous casting blank

The invention relates to the field of metal continuous casting manufacturing, in particular to a method for producing an ultra-thick plate continuous casting blank by adopting fast cooling and unsymmetrical great pressing-down. According to the method, a continuous casting blank sequentially passes through a vertical section (2), an arc-shaped section (3), a straightening section (4) and a horizontal section (5) under a crystallizer (1), through the implementation of fast cooling and unsymmetrical great pressing-down in a secondary cooling region of a casting machine, the ferritiszation process of the casting blank surface layer is realized before the bending or straightening through the fast cooling process, in addition, the balanced separation of second-phase particles in crystals and at crystal boundaries is ensured, the surface layer tissues of the casting blank are improved, meanwhile, the deformation of a blank core part can be increased through the unsymmetrical great pressing-down process, the occurrence of surface cracks of medium and ultra-thick casting blanks in the bending and straightening process is prevented, and meanwhile, the center segregation and the center looseness of the ultra-thick casting blank is avoided. The method provided by the invention has the advantages that the surface quality and the center quality of the ultra-thick plate continuous casting plate can be better improved, so that the ultra-thick plate continuous casting blank can realize the rolling production of ultra-thick steel plates with the thickness being greater than 120mm at a low compression ratio.

Owner:ZHONG NAT ENG & RES CENT

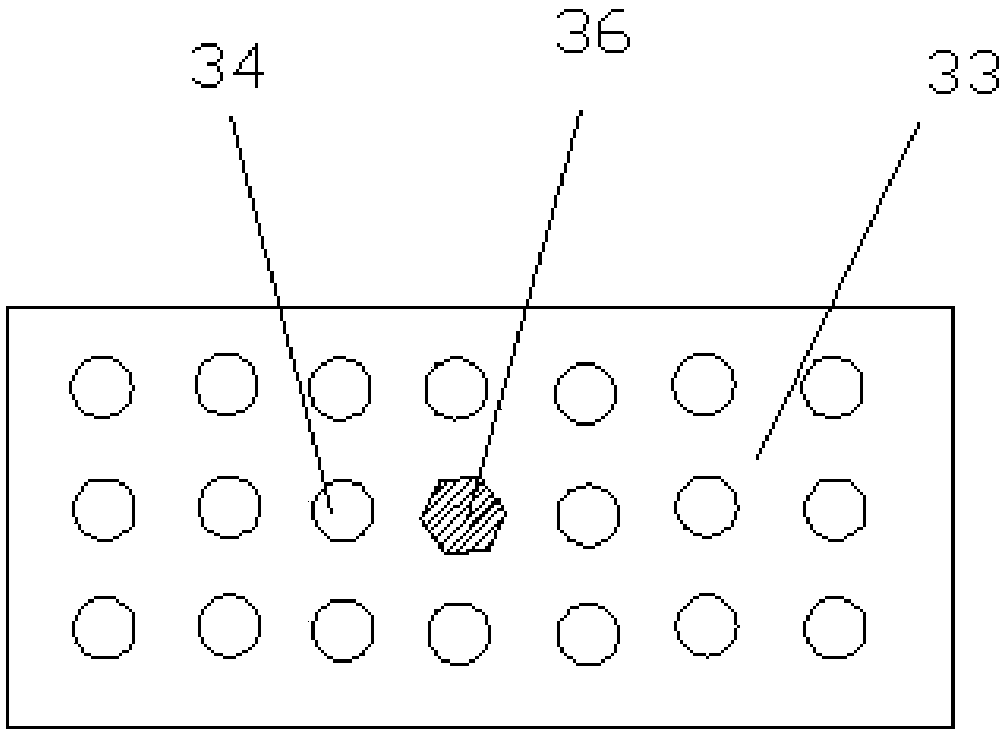

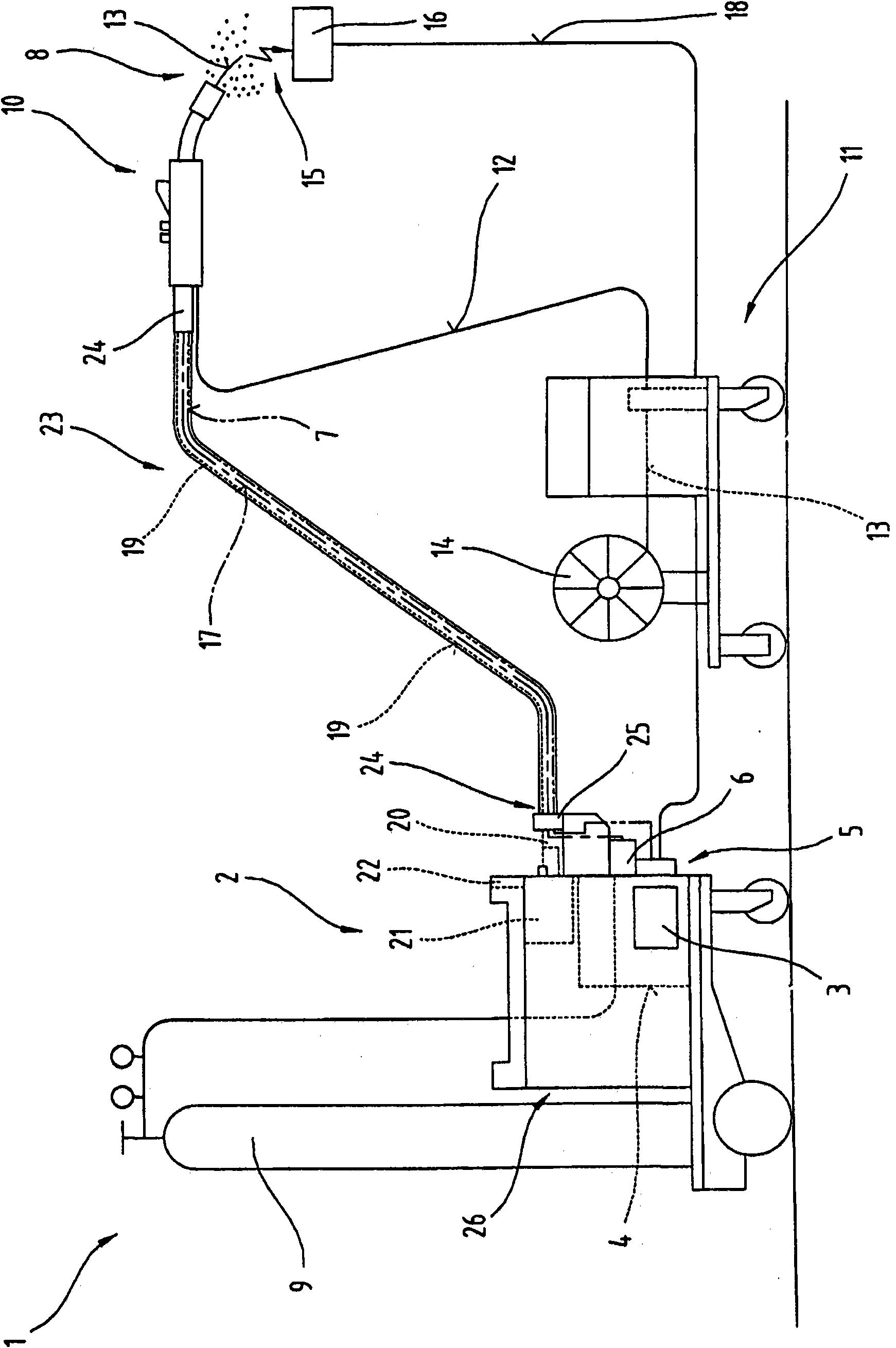

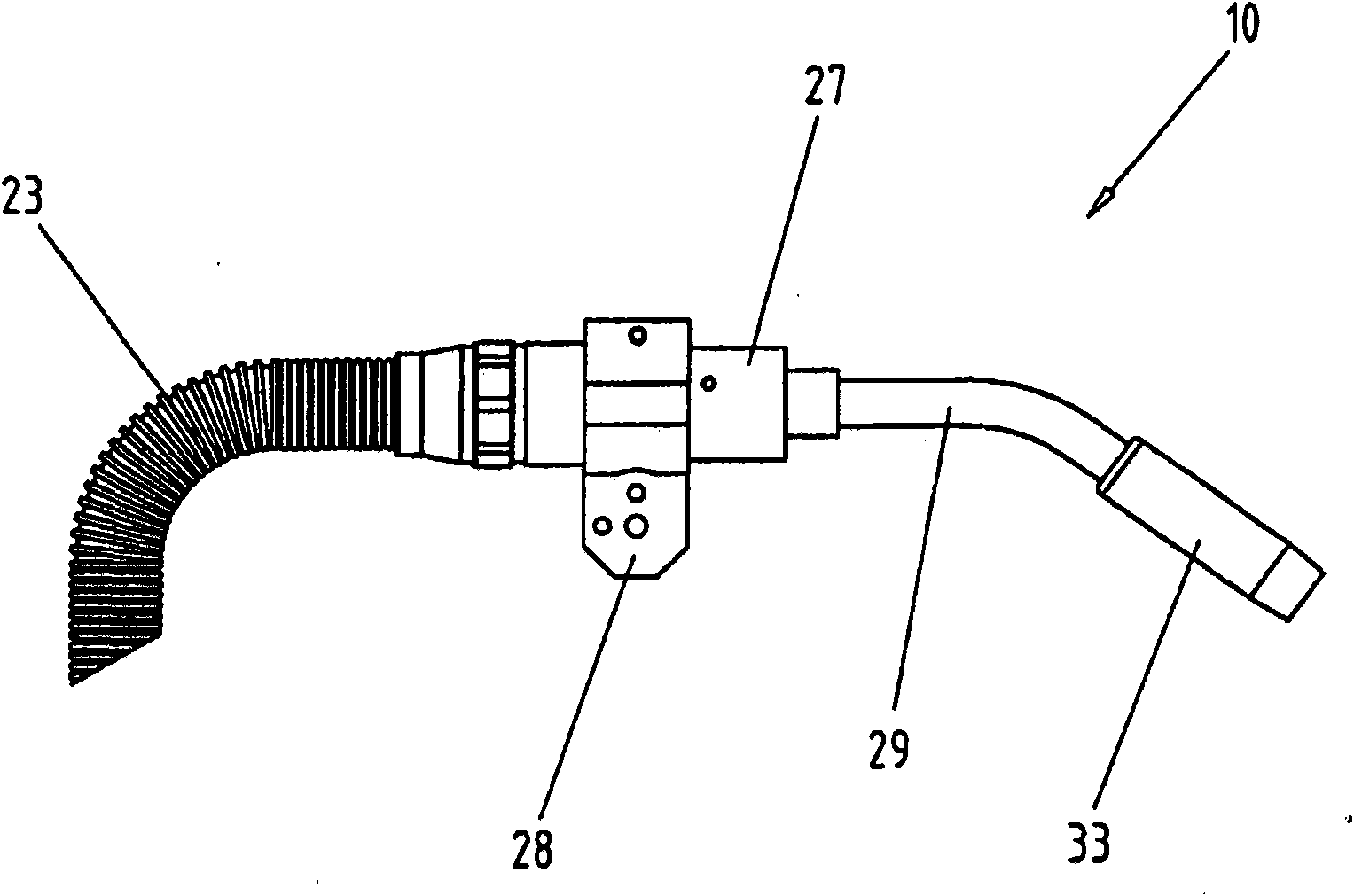

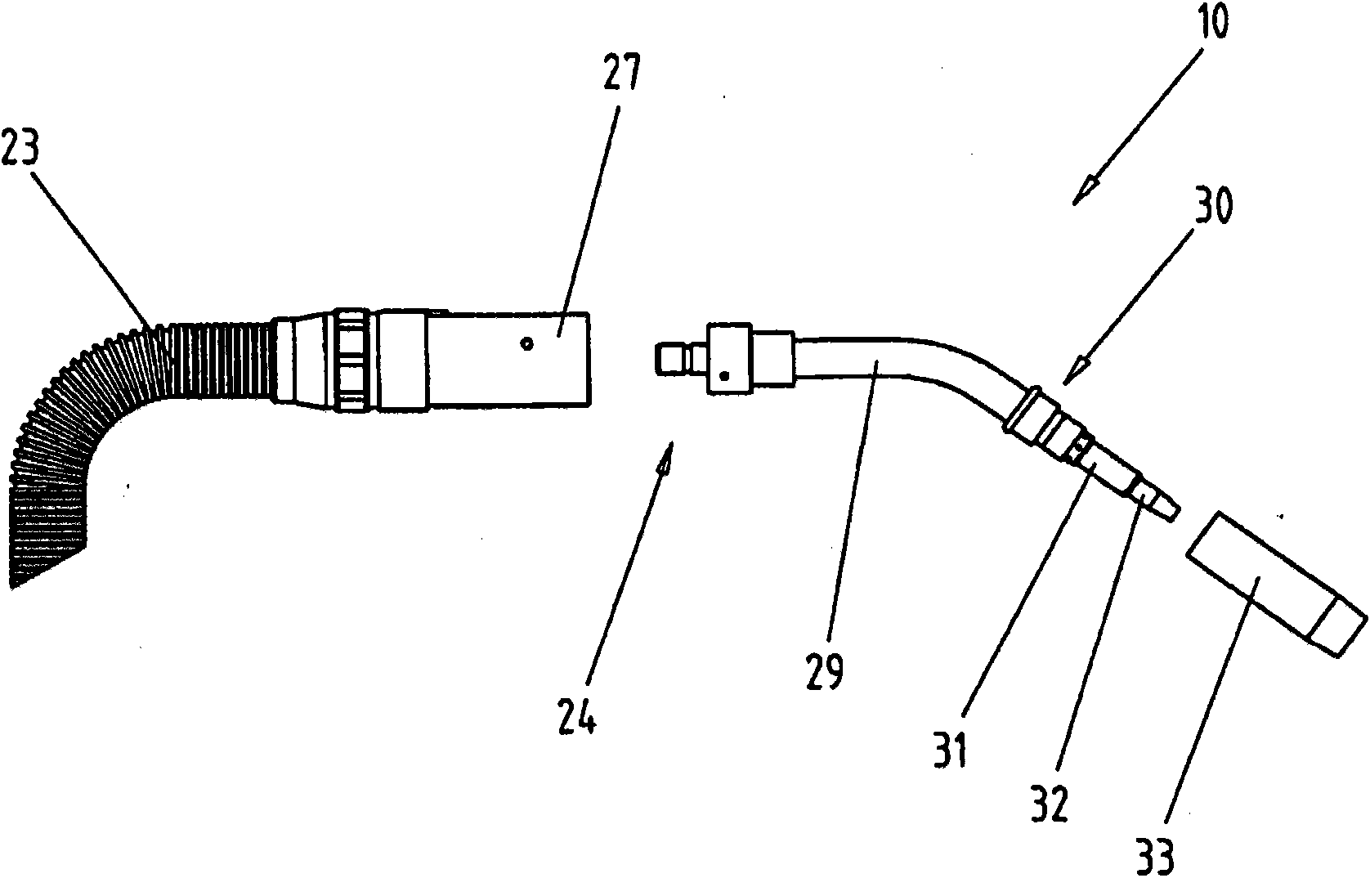

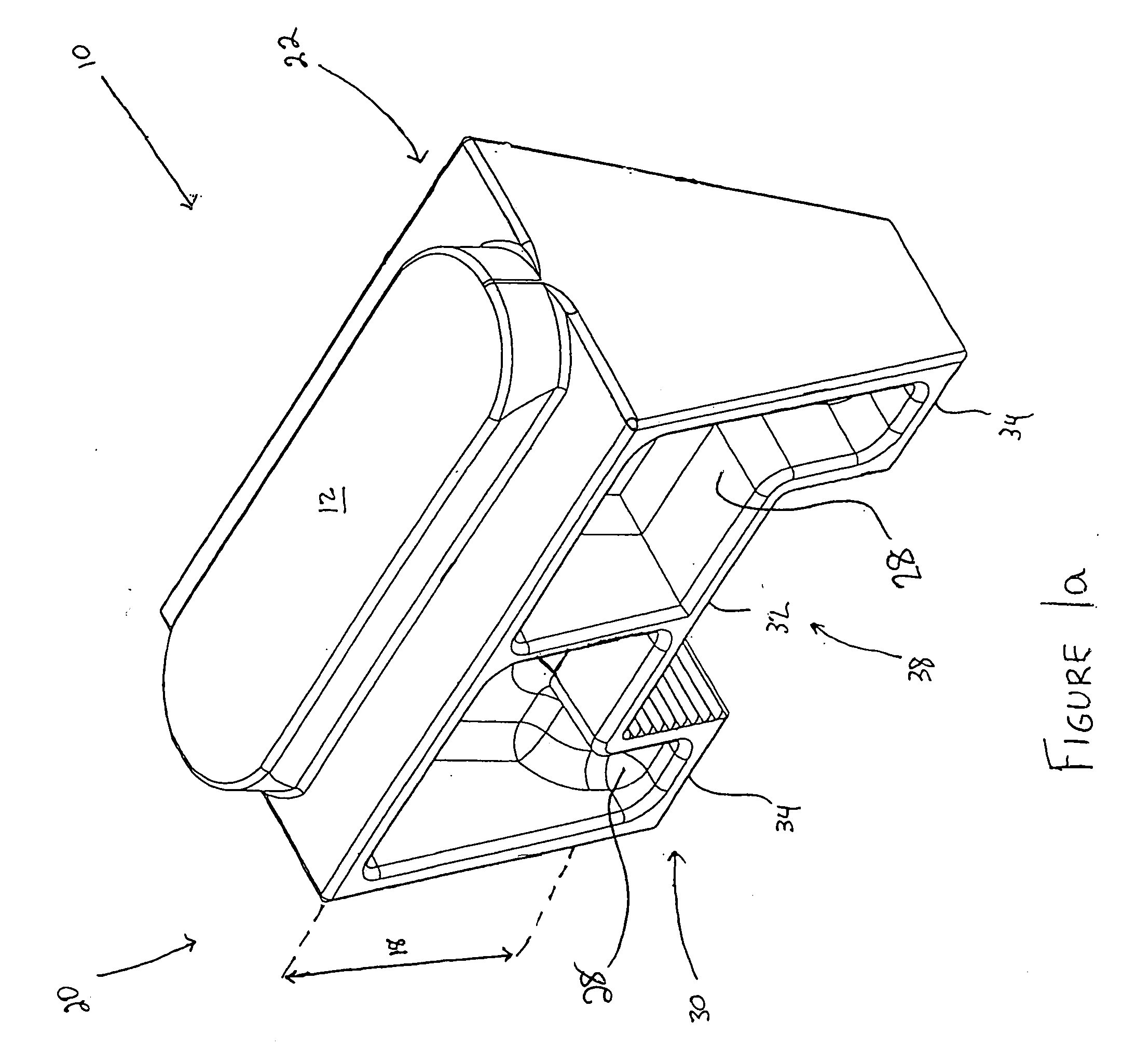

Gas nozzle attachment

ActiveCN101925433AEasy to installEasy to replaceSupport devices with shieldingEngineeringWelding torch

The invention relates to a system for attaching a gas nozzle (33) to a gas nozzle holder (30) disposed on a welding torch (10), said holder being configured for the removable attachment of the gas nozzle (33). One part of the gas nozzle holder (30) is configured eccentrically. In order to create such an attachment, the eccentric part of the gas nozzle holder (30) is configured for receiving a ring fixing element (35) and that another part of the gas nozzle holder (30) together with at least one part of the nozzle fitting (31) of the welding torch (10) forms a guide for the gas nozzle (33) and the gas nozzle (33) can be attached by way of rotary movement. The fixing element (35) is formed by an open ring. Each end of the ring rises in a radial direction relative to the outline of the circular ring part.

Owner:FRONIUS INTERNATIONAL GMBH

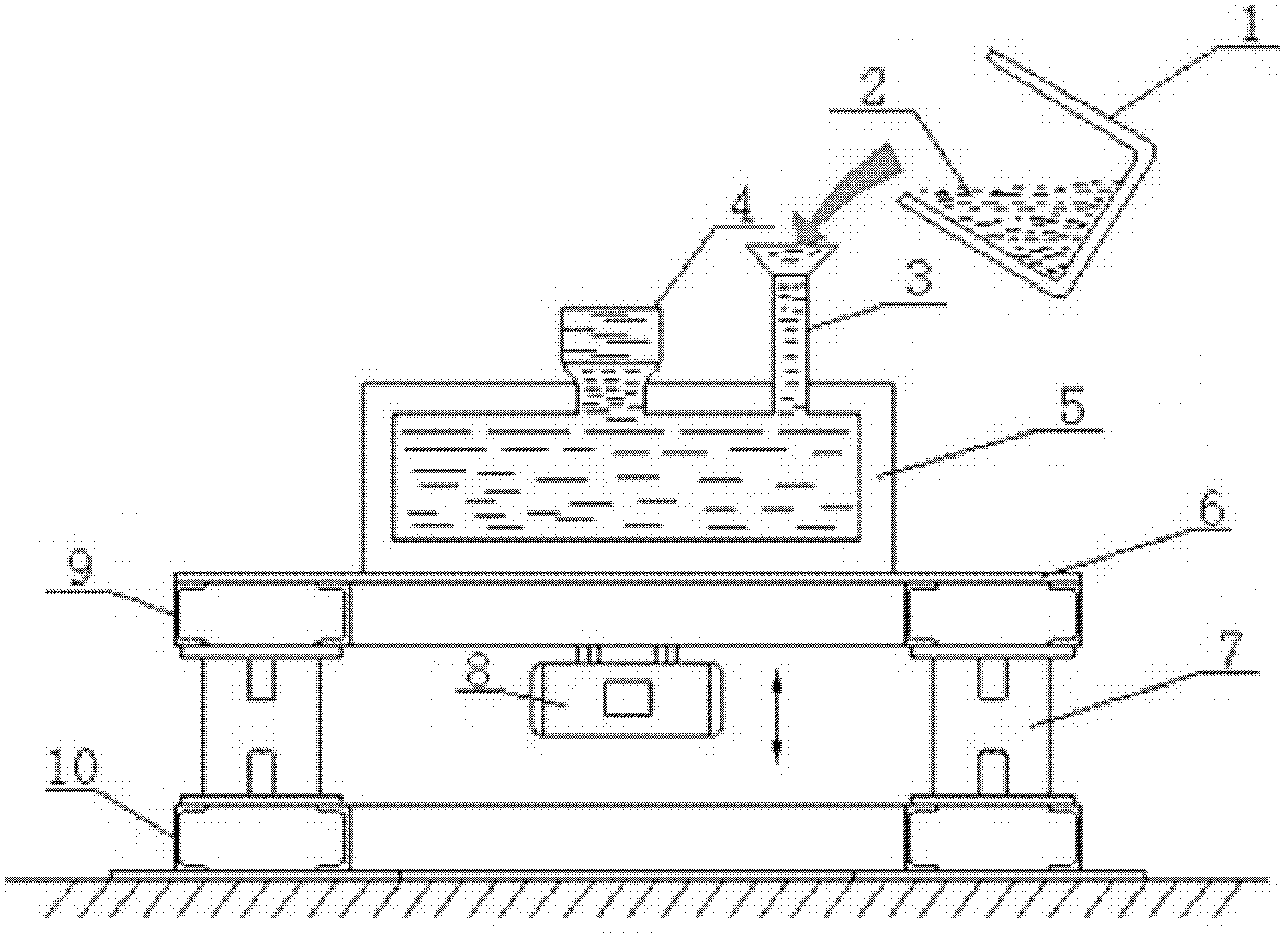

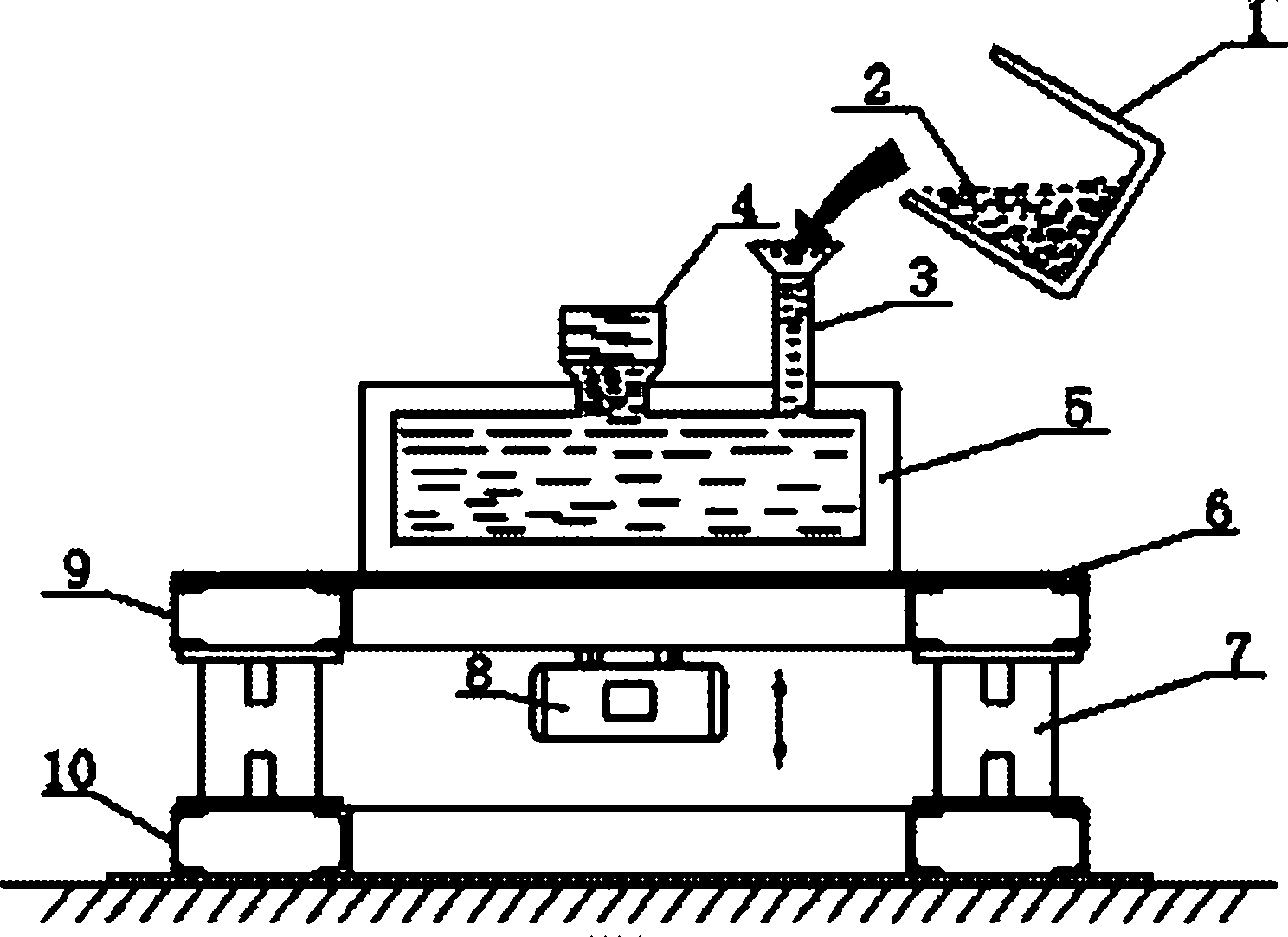

Sand mold casting technology and equipment

The invention relates to a sand mold casting technology comprising steps that: modeling sand is manufactured, wherein casting sand with a size of 40-70 meshes are added to 1-3% of water glass; the mixture is uniformly mixed in a fracturing blender; molding and core-making are carried out; a manufactured mould cavity is vibrated on a vibration platform; casting is carried out during vibration; when a metal solution starts to solidify, the vibration step is stopped. The equipment suitable for the sand mold casting technology comprises a lower platform rack which is used for supporting an upper platform rack used for bearing the mould cavity, wherein the supporting is realized by using a rubber spring. A high-frequency motor used for generating vibration is arranged on the upper platform rack. The equipment and the technology are advantaged in that: the technology and the equipment are environment-friendly; reproducibility for used sand recycling is good; and collapsibility of used sand is good.

Owner:ZHEJIANG MAYANG INDS

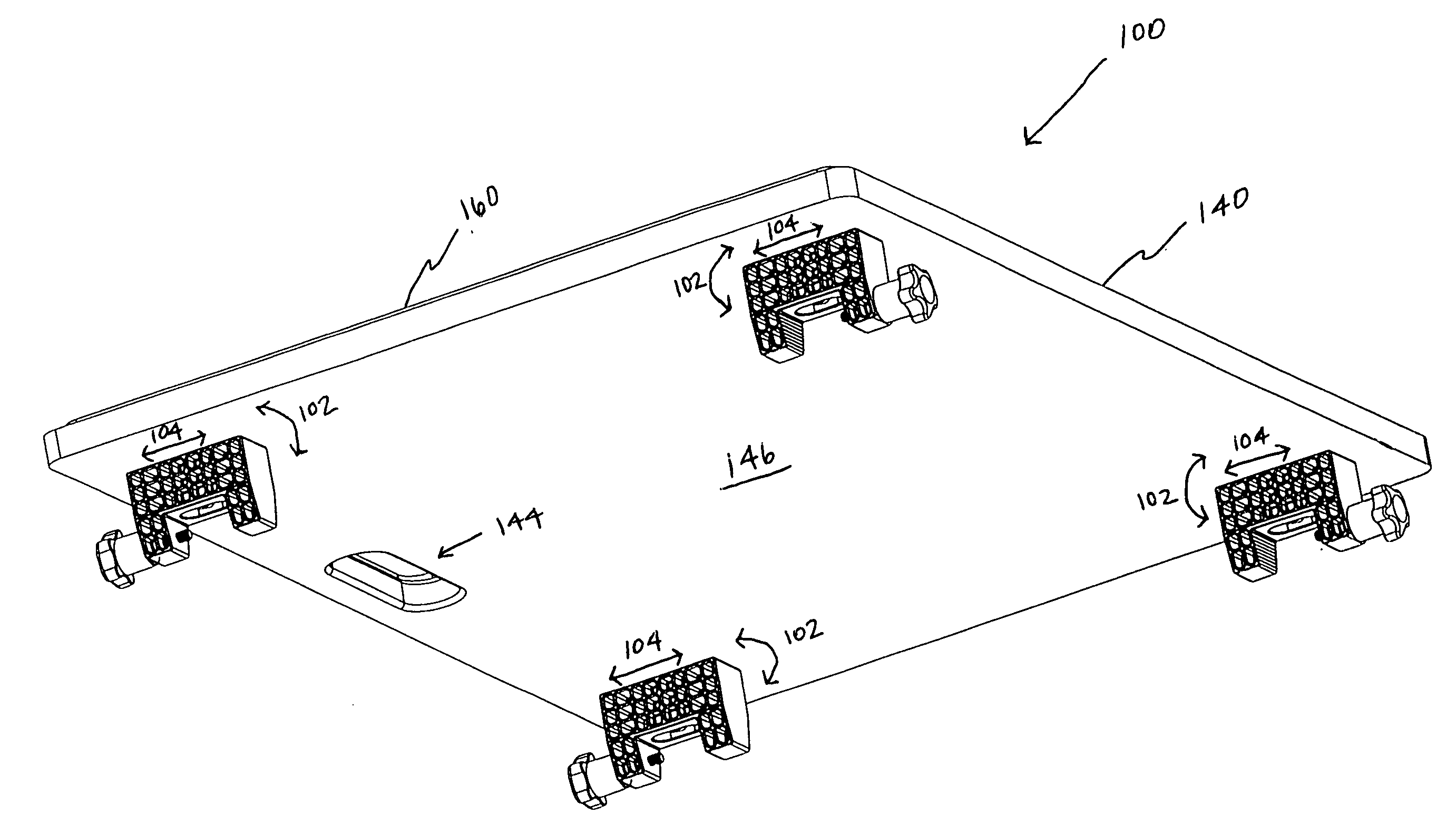

Storage assembly structured to be supported on base

A storage assembly structured to be supported on a base is presented, wherein the base includes a plurality of spaced apart beams. At least one embodiment of the storage assembly includes a platform and at least one mounting device attached or otherwise connected to the platform. The mounting device(s) comprises an attachment mechanism which is structured to be removably engaged with the base and / or one or more beams thereof. Further, in at least one embodiment, the mounting device(s) is disposed and structured to removably support the platform in a predetermined spaced relation to said base.

Owner:WAINLAND ROBERT ANDREW

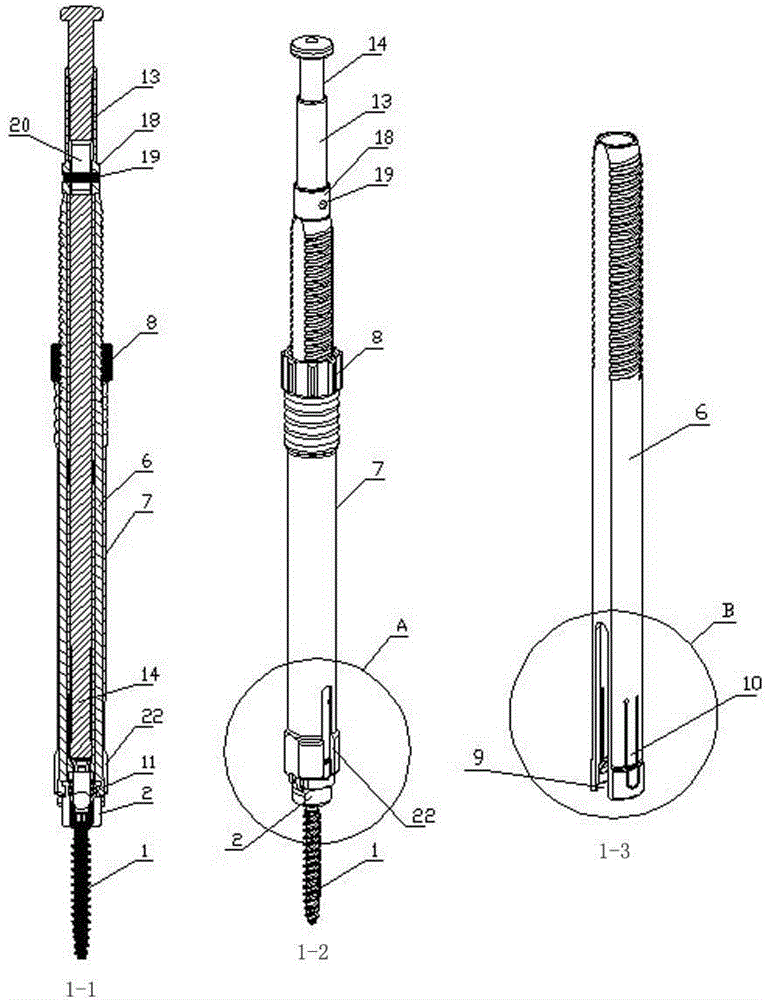

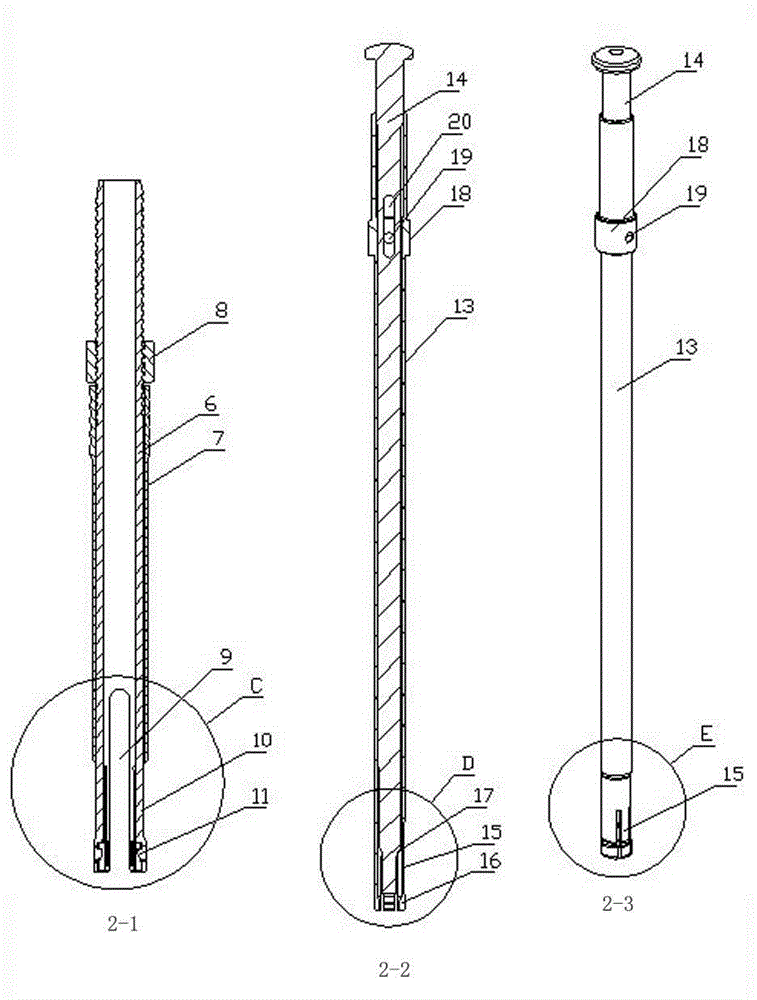

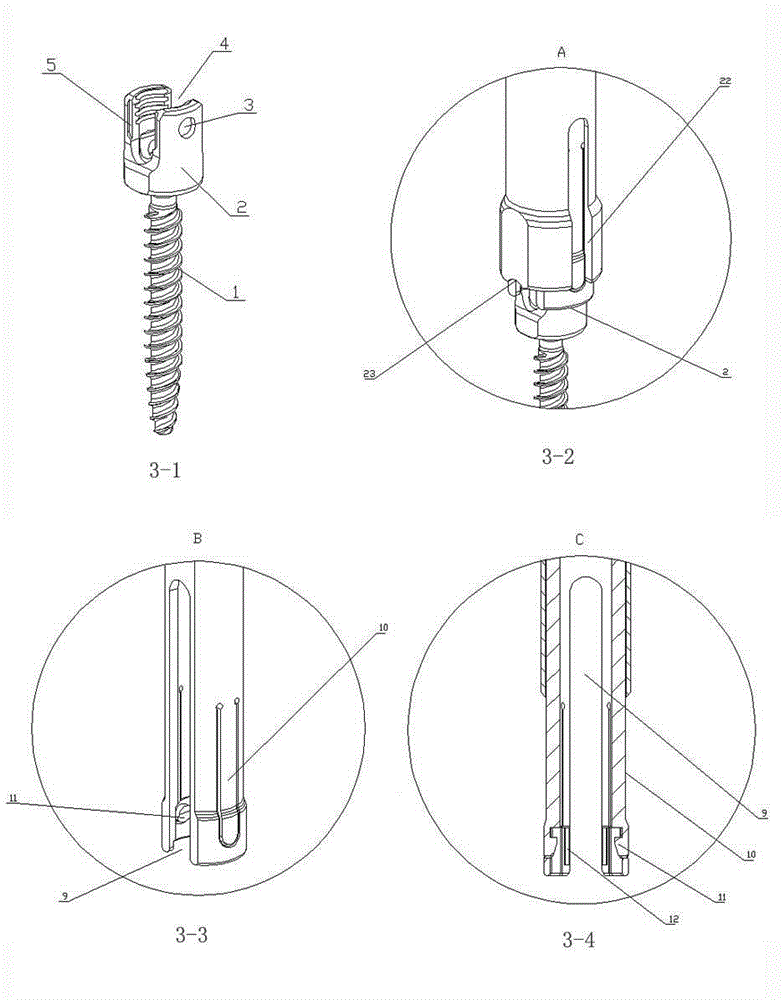

Pedicle screw and bar pressing device

ActiveCN104783879APrecise position controlEasy to disassembleInternal osteosythesisFastenersEngineeringBlock match

The invention provides a pedicle screw and a bar pressing device. The pedicle screw comprises a screw body and a screw base. A U-shaped bar containing groove divides the screw base into a left board body and a right board body. Positioning grooves are formed in the left side of the left board body and the right side of the right board body respectively. The pedicle screw is characterized in that positioning chutes with the upper open ends are longitudinally formed in the front sides and the rear sides of the upper ends of the left board body and the right board body respectively. The bar pressing device comprises an extension sleeve, a bar pressing sleeve and a bar pressing nut. A bar pressing groove is formed in the lower portion of the extension sleeve. Two opposite strip openings are formed in the side wall of the extension sleeve. Positioning elastic pieces are arranged in the strip openings. Positioning protrusions are arranged on the inner sides of the lower ends of the two positioning elastic pieces. Positioning sliding blocks matched with the positioning chutes and protruding inwards are arranged on the inner wall of the extension sleeve, the extension sleeve is sleeved with the bar pressing sleeve, and the bar pressing nut is arranged at the upper portion, above the bar pressing sleeve, of the extension sleeve. The pedicle screw and the bar pressing device have the advantages that connection is easy, convenient and quick, connection reliability is high, disengagement is not likely to happen, detachment is easy, the bar pressing operation speed is high, and efficiency is high.

Owner:SHANDONG WEIGAO ORTHOPEDIC DEVICE COMPANY

Telescopic plate pressing device

The invention relates to a telescopic plate pressing device, which comprises a plate pressing device main body, and is characterized in that: one end of the plate pressing device main body is provided with a cylinder, and the tail end of a piston is arranged in the cylinder, and separates the cylinder into two working cavity bodies. Simultaneously, the head part of the piston is connected with a push pin through an elastic part, and the head part of the piston and the jacket of the push pin are respectively provided with a slide block. In addition, the slide blocks are connected with one end of a pressing plate through a fixed pin, and the other end of the pressing plate is a working end. Moreover, the working end is a hollow-out groove, a screw stem penetrates through the hollow-out groove, and the bottom of the screw stem is fixed on the plate pressing device main body. Consequently, a workpiece with a groove can be conveniently pressed and loosened, so the quick clamping is realized, the technical point pressing step is not required to be added, and accordingly, the processing time is saved.

Owner:SUZHOU CHUNXING PRECISION MECHANICAL

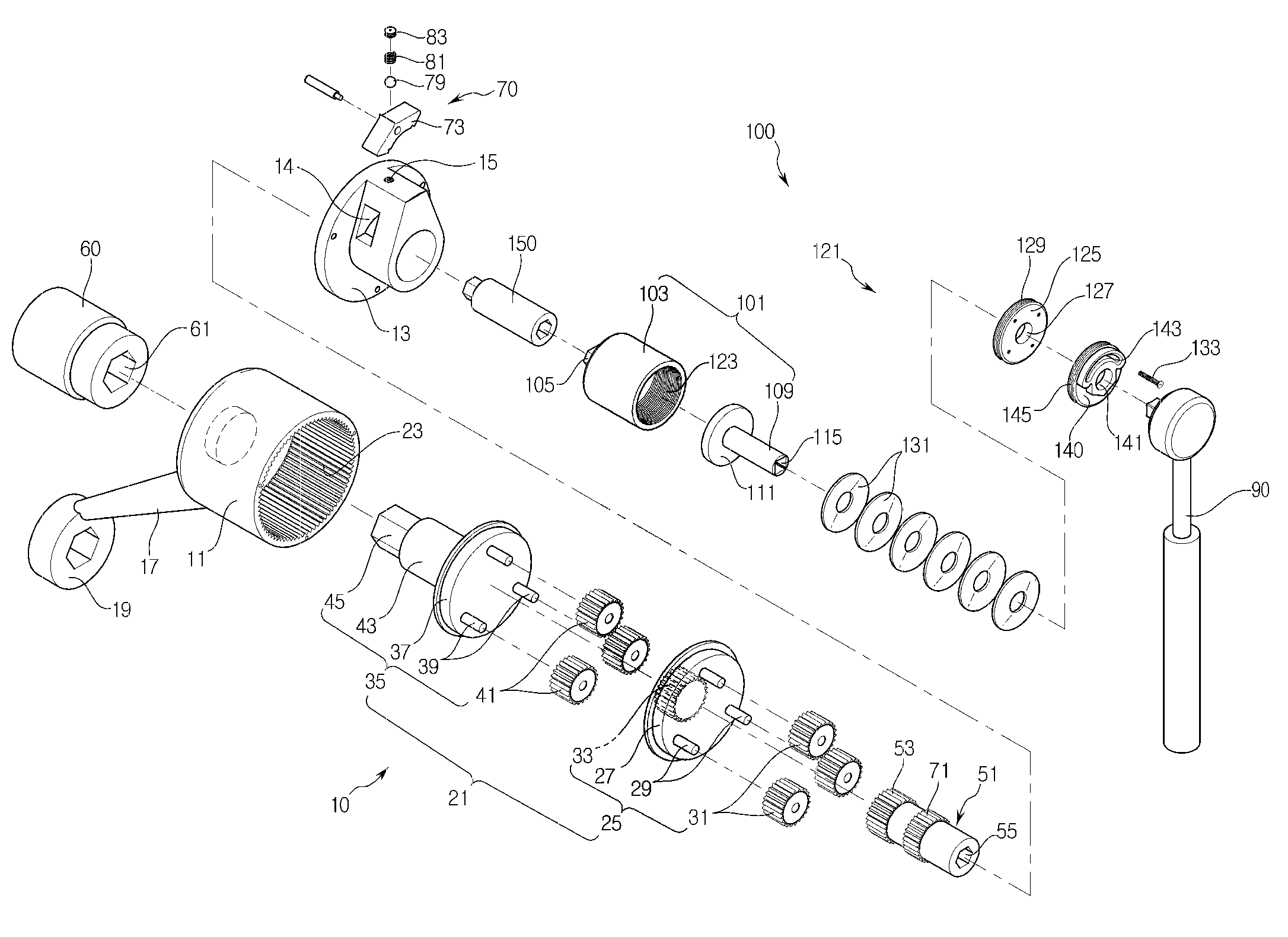

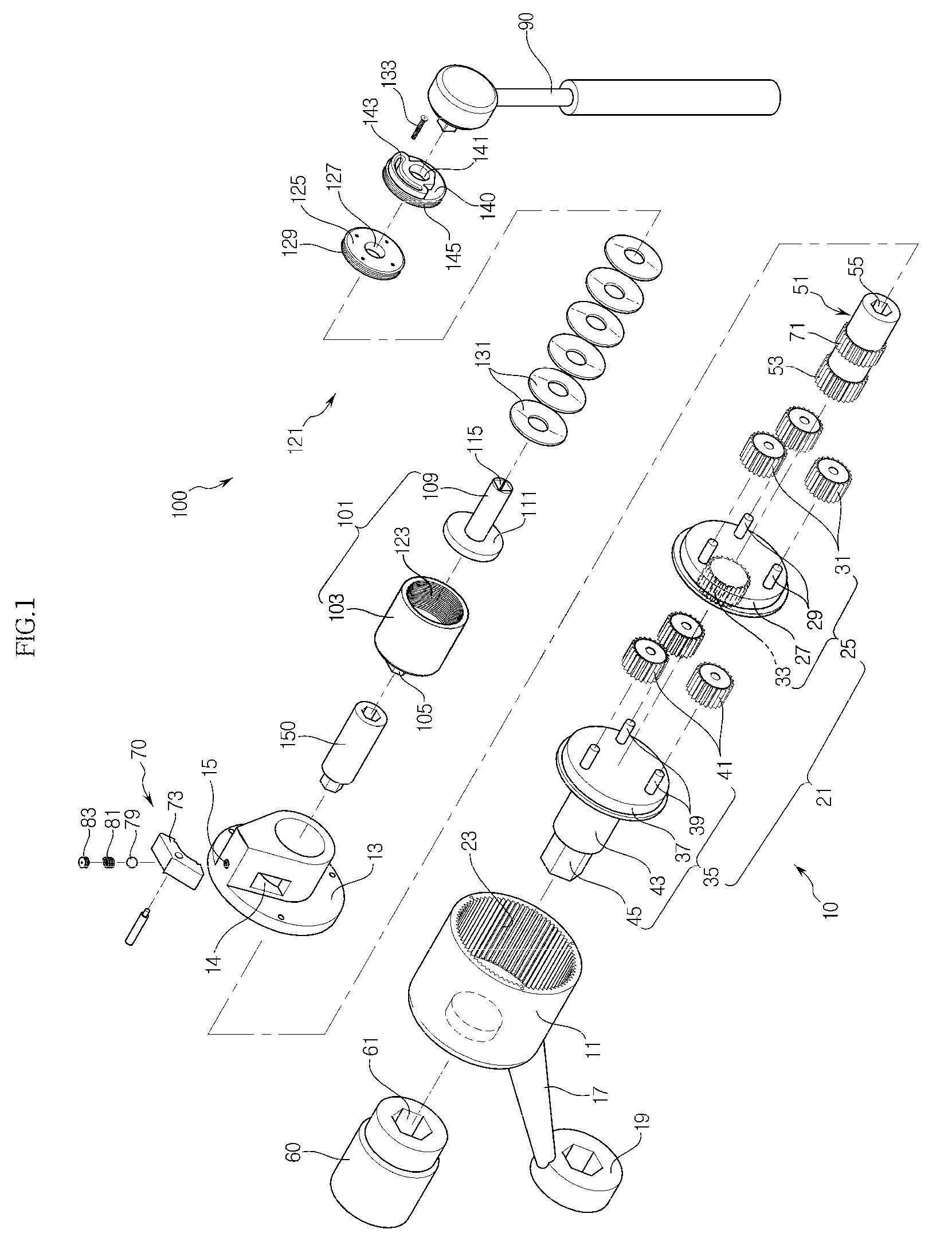

Torque control wrench for both left-hand thread and right-hand thread

InactiveUS8443699B2Accurate torqueEasy to tightenWheel mounting apparatusSpannersEngineeringControl theory

A torque control wrench for both a left-hand thread and a right-hand thread is disclosed. The torque control wrench includes a wrench unit having a transmission unit, a movable shaft engaged with the transmission unit, for rotating the transmission unit with external force, and a socket for receiving rotational force at a rotation speed changed by the transmission unit and tightening or loosening a bolt with the received rotational force, a handle for generating the rotational force with which the socket tightens or loosens the bolt, and a torque controller between the wrench unit and the handle, for controlling a torque applied from the handle to the socket, including a clutch for rotating along with rotation of the handle and thus rotating the movable shaft and, if a torque equal to or greater than a preset torque value is applied, rotating idly, and a clutch torque controller for controlling the torque applied from the handle to the clutch.

Owner:SEWON PM TECH

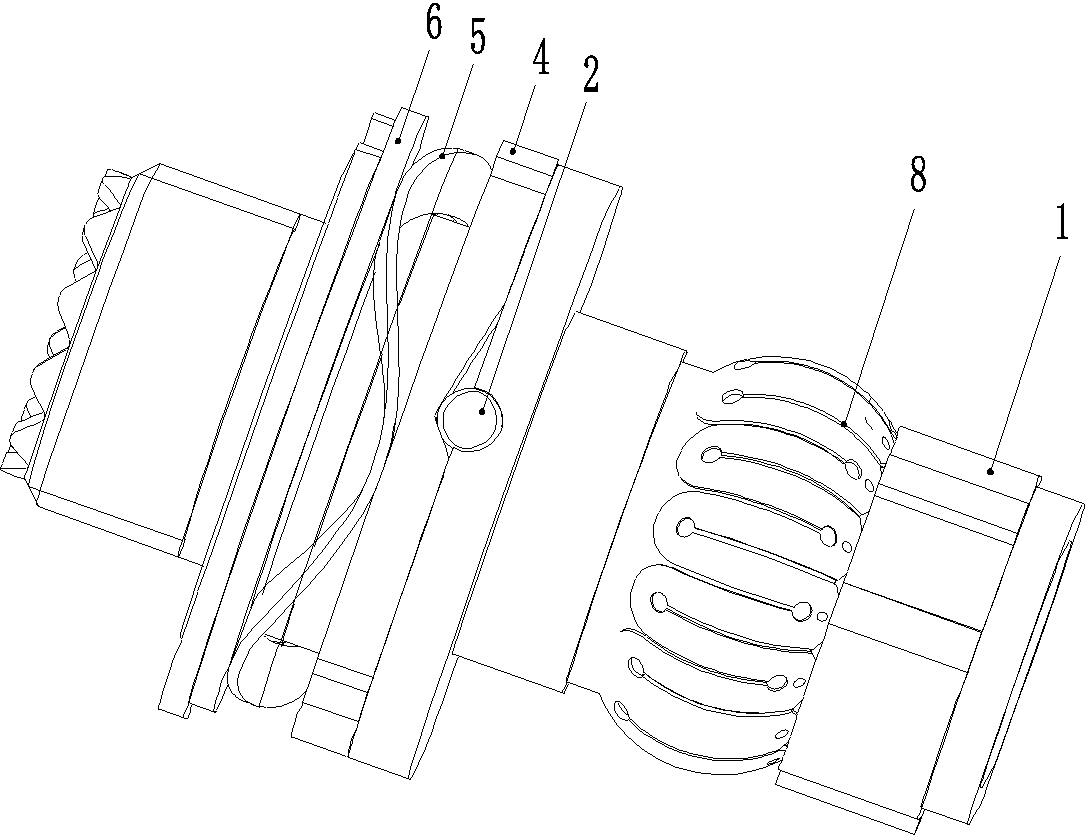

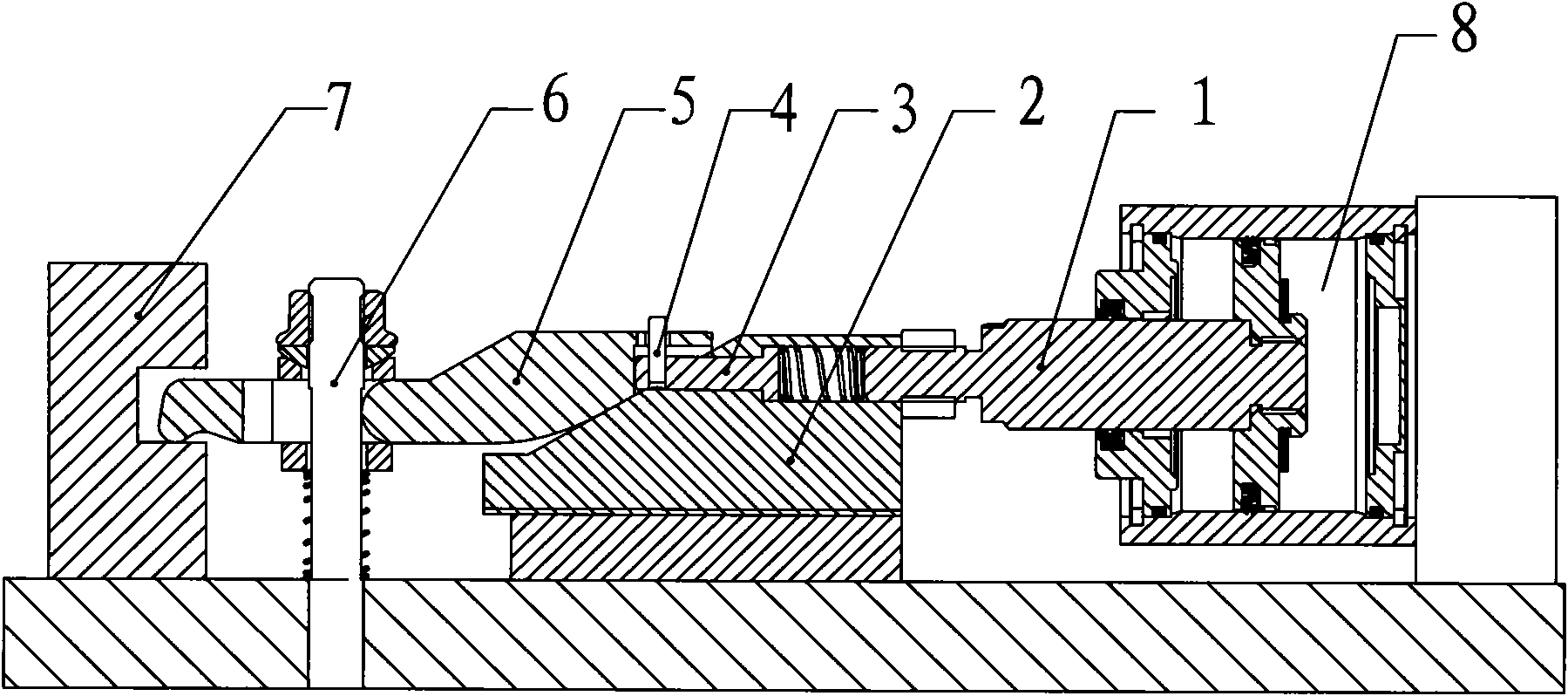

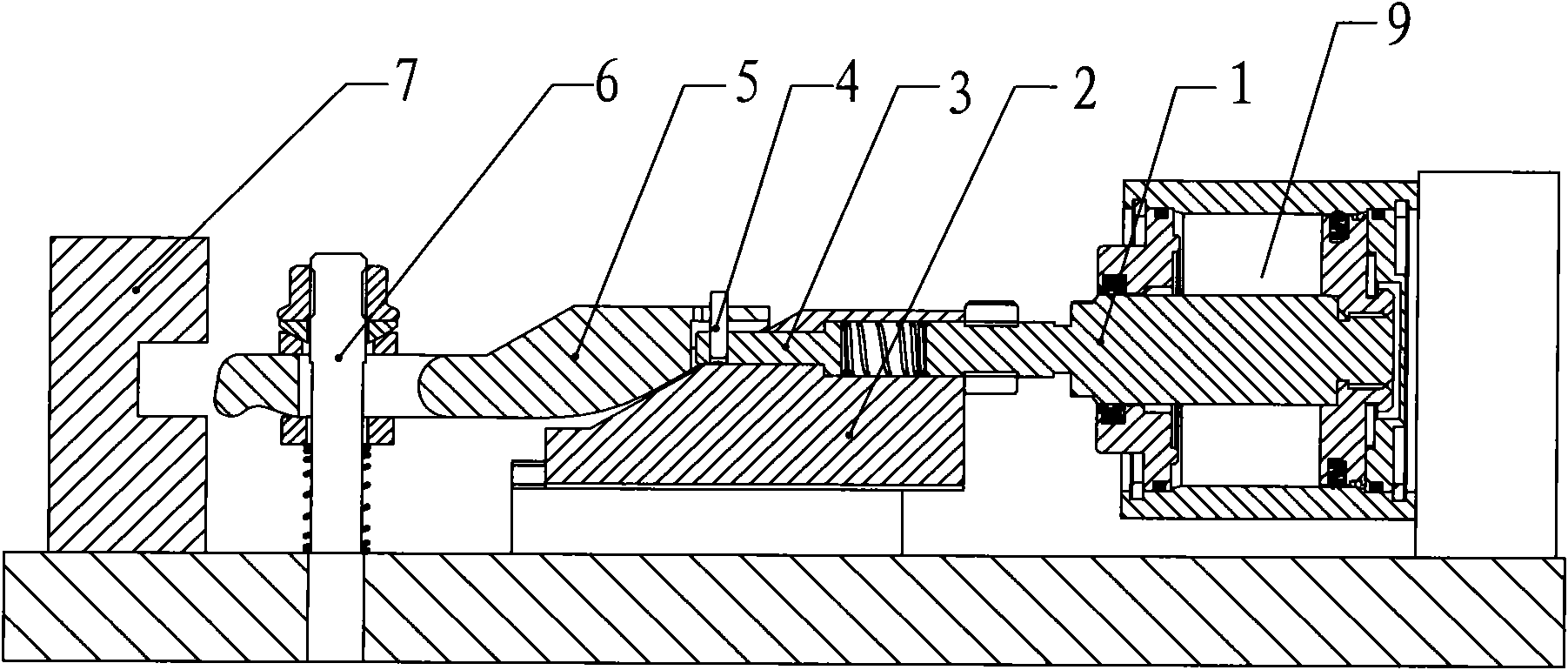

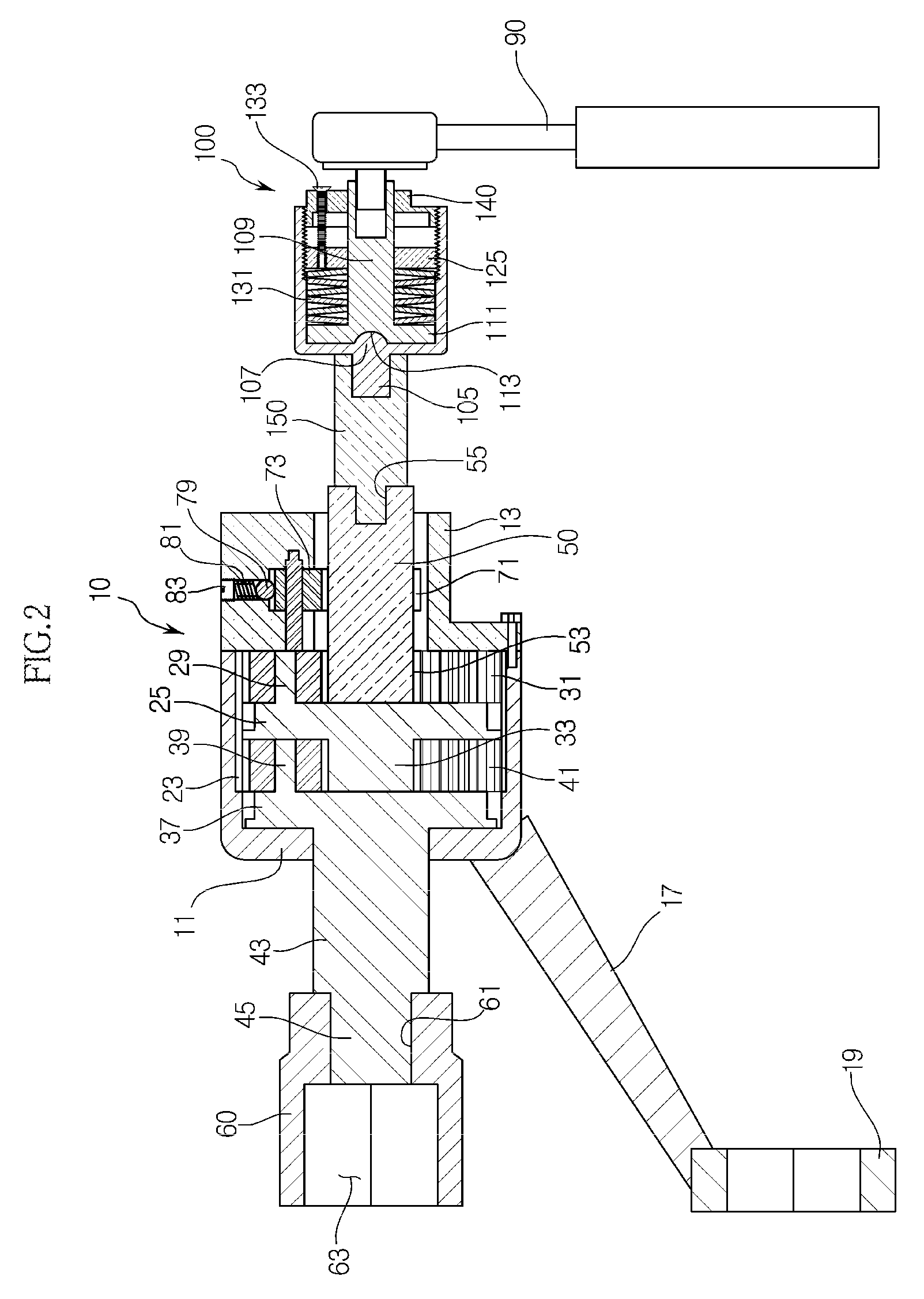

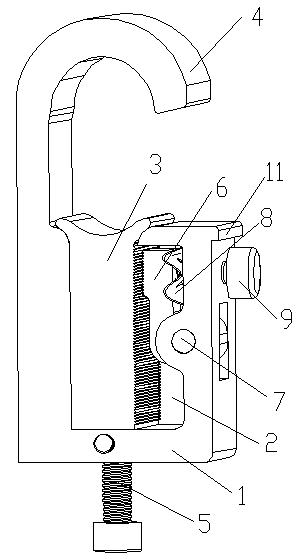

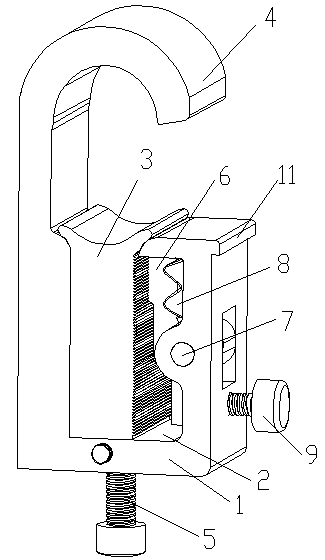

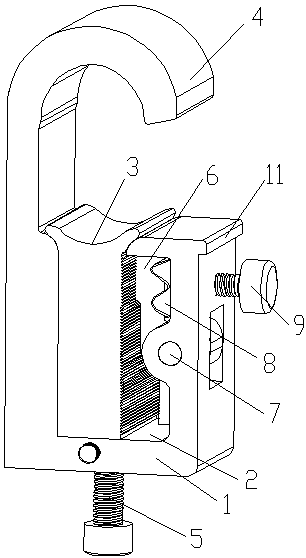

Automatic cutter disassembling device

ActiveCN104842201AEasy to loosenRealize the function of removing the knifePositioning apparatusMetal-working holdersSteel ballMechanical engineering

The invention discloses an automatic cutter disassembling device, which comprises a fixed bottom plate, a main shaft mechanism, a cutter handle clamping mechanism, a transmission mechanism and a jacking cylinder mechanism, wherein the main shaft mechanism is vertical with the fixed bottom plate, one end of the main shaft mechanism is connected to the fixed bottom plate through a bearing, the cutter handle clamping mechanism is located above the main shaft mechanism, the transmission mechanism controls the main shaft mechanism to rotate, and the jacking cylinder mechanism is located below the main shaft mechanism; the main shaft mechanism comprises a main shaft, a pull rod located at an axis of the main shaft, a disc spring surrounding the pull rod, a disc spring compression nut which is in threaded connection with the lower part of the pull rod, a pulling claw which is in threaded connected with the top part of the pull rod, and a steel ball located at the end, which is away from the pull rod, of the pulling claw; the cutter handle clamping mechanism comprises a clamping claw and a first cylinder controlling the clamping claw to open or close; and the jacking cylinder mechanism is used for controlling rising of the pull rod. The automatic cutter disassembling device can loosen a cutter assembly very conveniently, realizes an automatic cutter disassembling function, and is low in labor intensity and high in efficiency. In addition, the automatic cutter disassembling device can also realize a cutter changing function. A new cutter is placed in a cutter handle, and the cutter can be clamped automatically through reversed rotation of a motor.

Owner:KEYIZHAN INTELLIGENT EQUIP CO LTD

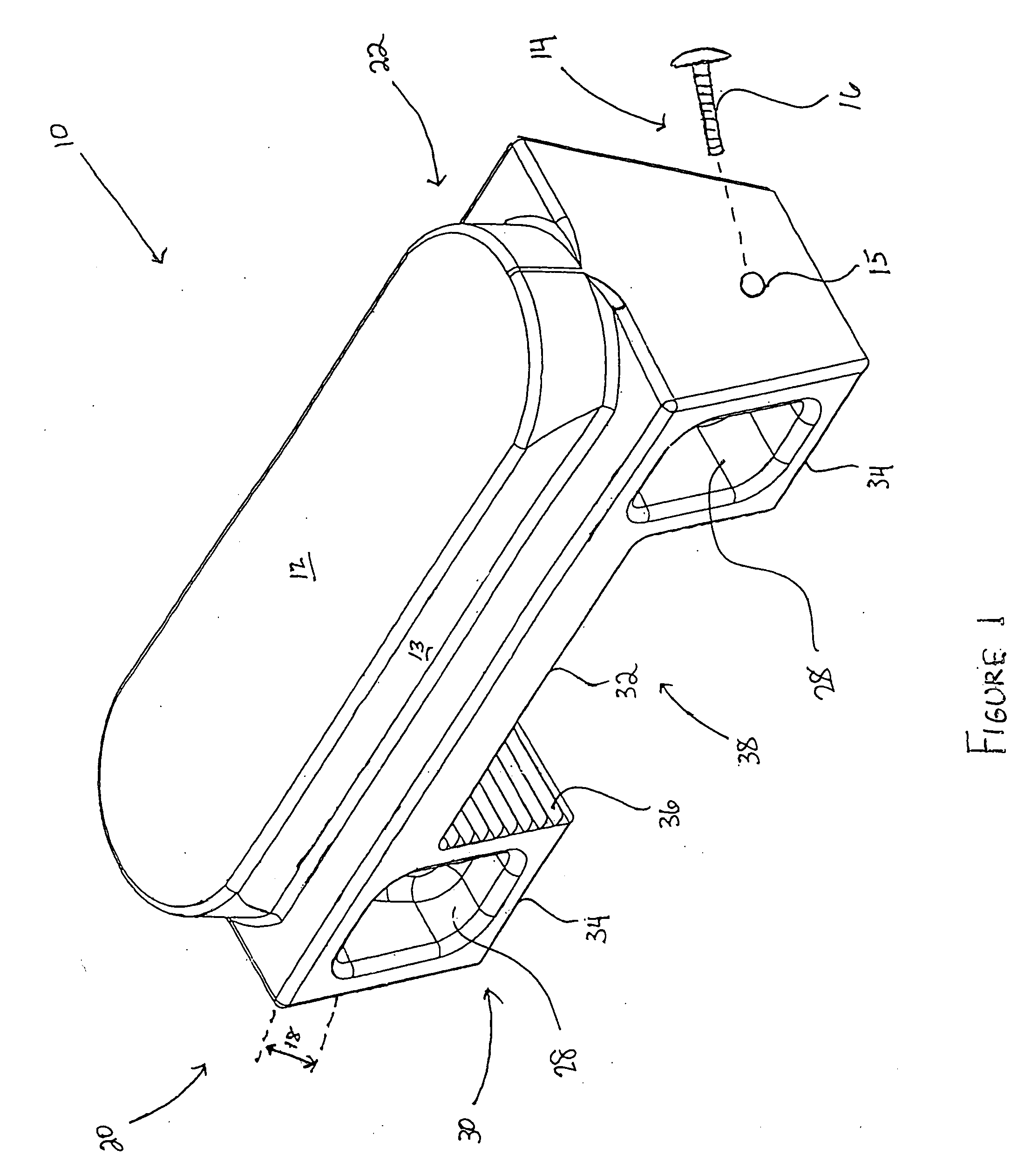

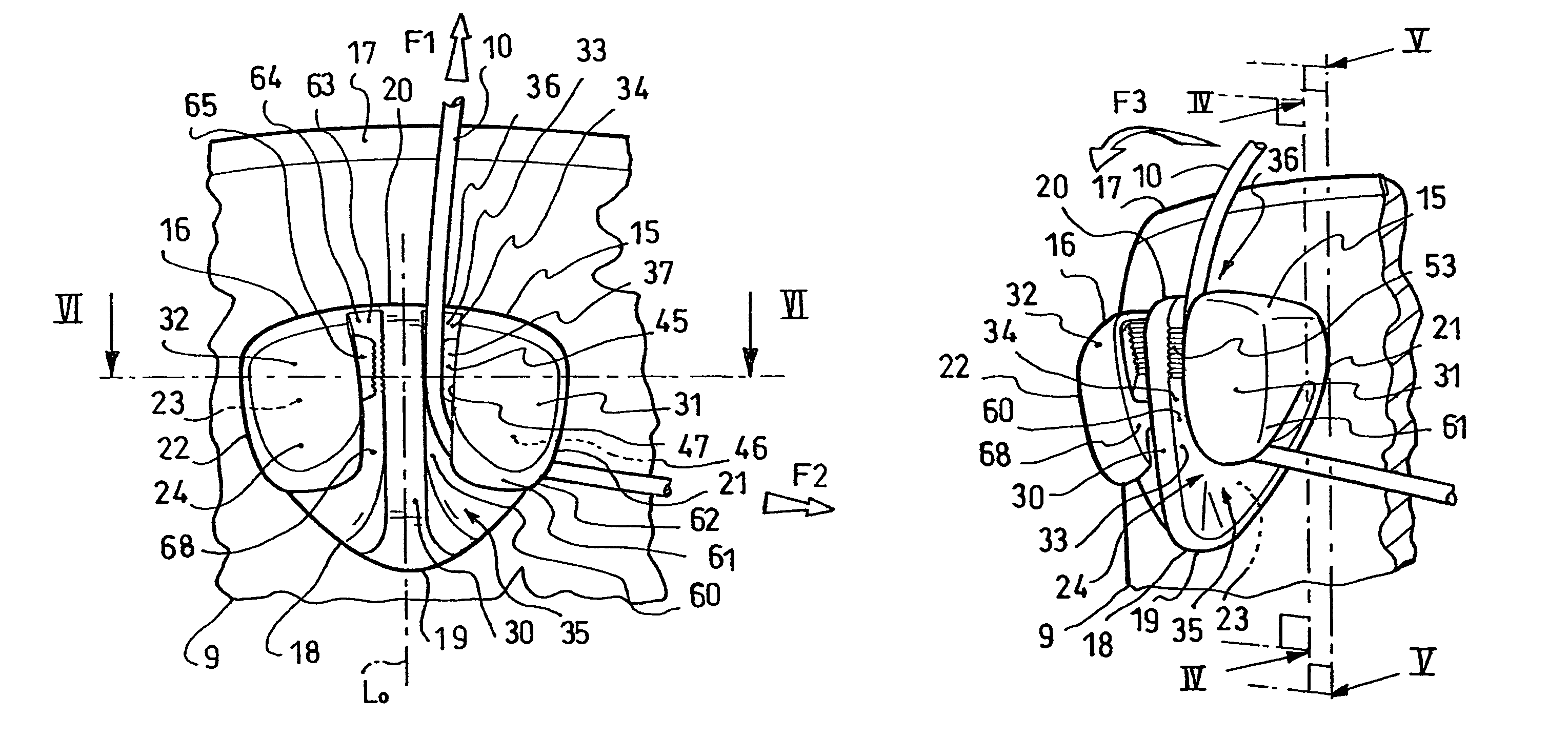

Device for blocking flexible strands

InactiveUS7946007B2Easy to loosenEasy to tightenSnap fastenersDoor/window protective devicesFirst pathwayEngineering

A blocking device adapted to act on at least one lace or strand, the blocking device including a body, a first cavity defining a first pathway for the strand, the device including a first blocking member, a first guide for guiding the first blocking member relative to the body, and first elastic member to bias the first blocking member in a direction to press the strand against a surface of the pathway, the device functioning by cooperation of a first blocking member with the first pathway for blocking the strand by a wedging effect. The first cavity is open, so as to enable the strand to be inserted and disengaged in a direction other than that of the pathway.

Owner:SALOMON SA

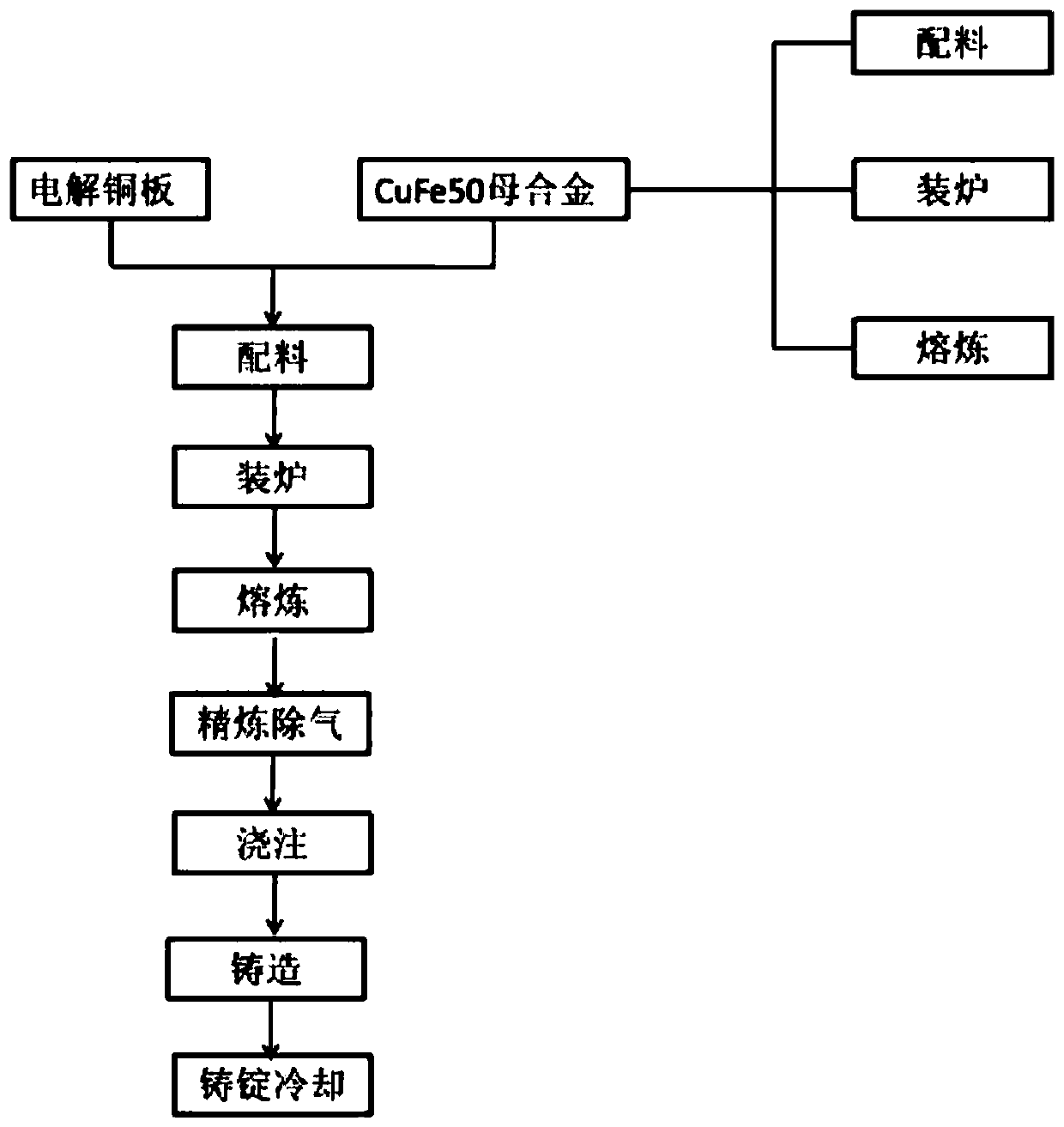

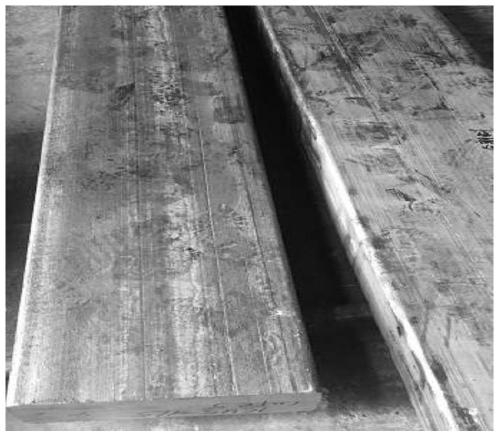

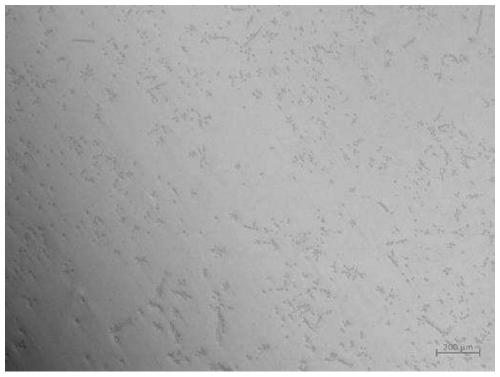

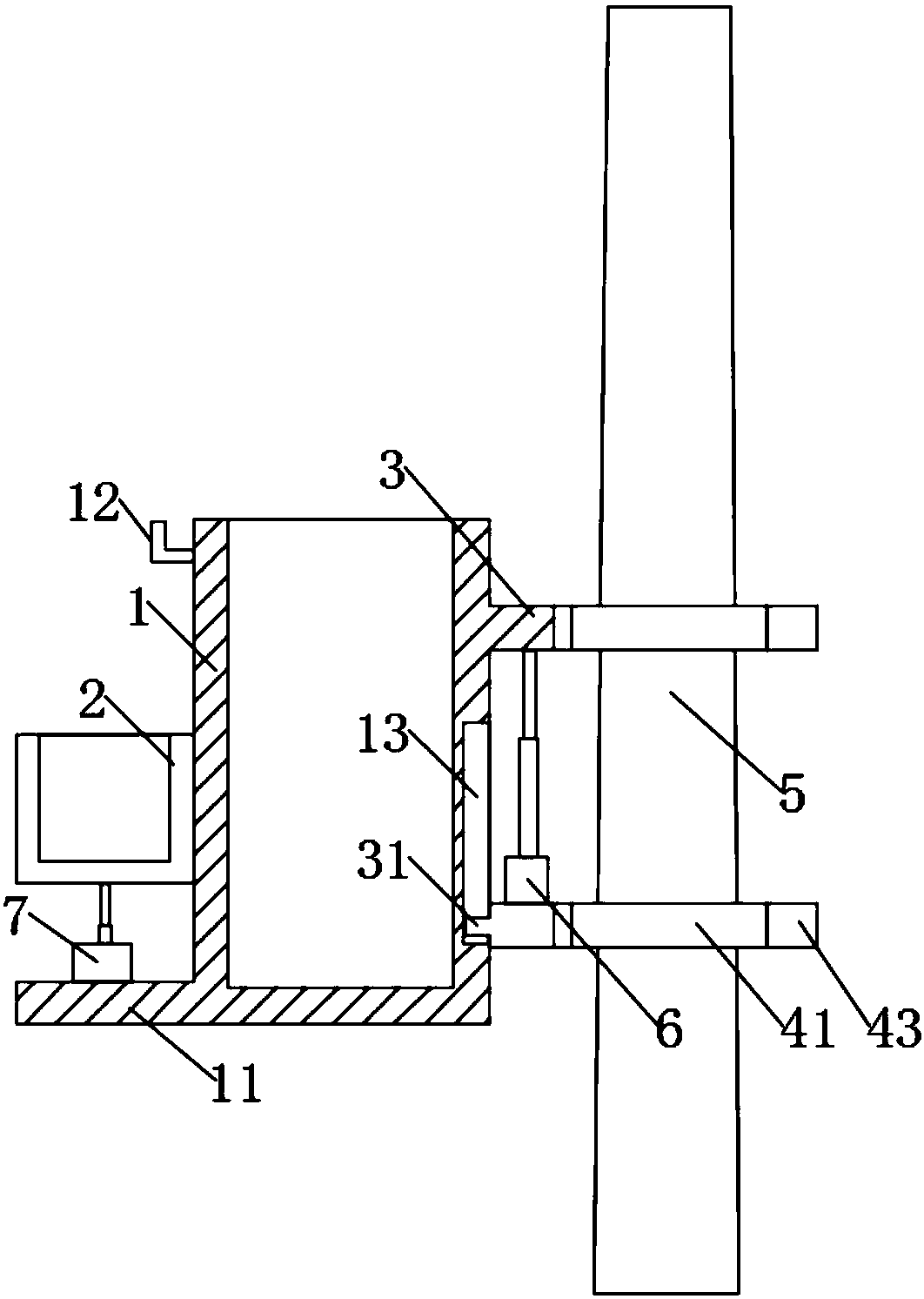

Production process of non-vacuum downwards-drawing continuous casting copper-iron alloy slab ingot

The invention discloses a production process of a non-vacuum downwards-drawing continuous casting copper-iron alloy slab ingot. The production process mainly comprises the following steps of burdening, charging, smelting, refining degassing, pouring, casting and ingot casting, wherein the copper-iron alloy slab ingot is successfully prepared by using an electrolytic copper plate and a CuFe50 master alloy as smelting raw materials through a non-vacuum downwards-drawing continuous casting process, and compared with a traditional vacuum casting process, the equipment requirement is low; inert gasprotection is adopted in the casting process, appropriate measures such as iron content are adjusted, and the alloy composition and the oxygen content are effectively controlled; the process has theadvantages of being stable in process, simple and convenient to operate, low in casting production cost and capable of realizing industrial production of the copper-iron alloy slab ingot.

Owner:SIRUI ADVANCED COPPER ALLOY CO LTD

Greenhouse seedling cultivating method for kalopanax septemlobus seeds

InactiveCN105746224AImprove survival rateEasy to masterGrowth substratesCulture mediaKalopanaxSeedling

The invention discloses a greenhouse seedling cultivating method for kalopanax septemlobus seeds.The method comprises steps of seed collecting, seed processing, seed sprouting, sowing, seedling stage management, outplanting and kalopanax septemlobus seedling cultivating.The greenhouse seedling cultivating method is characterized in that for the seed sprouting process, the bottom of a sprouting disc provided with holes at the bottom is loaded with vermiculite which is 5-6 cm deep, the vermiculite is watered with sufficient water, the disinfected seeds are broadcast on the surface of the vermiculite and covered with a layer of vermiculite of 1-1.5 cm, the sprouting disc is covered with a layer of gauze and watered with sufficient water, the sprouting disc is put in a sunlight greenhouse, the greenhouse temperature is controlled to range from 0 DEG C to 25 DEG C under natural lighting, and the sprouting disc containing the seeds is kept wet.According to the greenhouse seedling cultivating method for the kalopanax septemlobus seeds, highly integrated control over the whole seedling cultivation process is achieved, the method is easy to master, the obtained cultivated kalopanax septemlobus seedlings are high in survival rate, and the technology is convenient to popularize and specially suitable for large-scale industrial seedling cultivation.

Owner:SHANDONG FOREST GERMPLASM RESOURCES CENT

Power maintenance climbing box

ActiveCN108462112ASolve slippageFix security issuesApparatus for overhead lines/cablesEngineeringElectric power

The invention discloses a power maintenance climbing box. The power maintenance climbing box comprises a climbing box body, a tool kit, fixing rods and fixing rings; a fixing plate is arranged at thelower end of the climbing box body; an air cylinder II for driving the tool kit to ascend and descend is arranged on the fixing plate; the upper end of the air cylinder II is connected to the tool kit; the fixing rings at least comprise an upper fixing ring and a lower fixing ring which sleeve a telegraph pole and are connected to the climbing box body through the fixing rods; the at least two fixing rods comprise an upper fixing rod and an lower fixing rod, wherein the upper fixing rod is fixedly arranged at the upper end of the side surface of the climbing box body, and the lower fixing rodis arranged at the lower end of the climbing box body in a sliding mode along the side surface of the climbing box body; and an air cylinder I connected to the upper fixing rod is arranged on the lower fixing rod. The power maintenance climbing box has the advantages that the potential safety hazard that people slide off and are insecure when climbing the telegraph pole through a foot-operated auxiliary device can be eliminated, the problems that the cost is high, and the space is limited due to the fact that maintenance personnel are lifted to a high place to maintain equipment by using a crane can be solved, and the safety performance is higher.

Owner:NINGBO LONGER LIGHTING

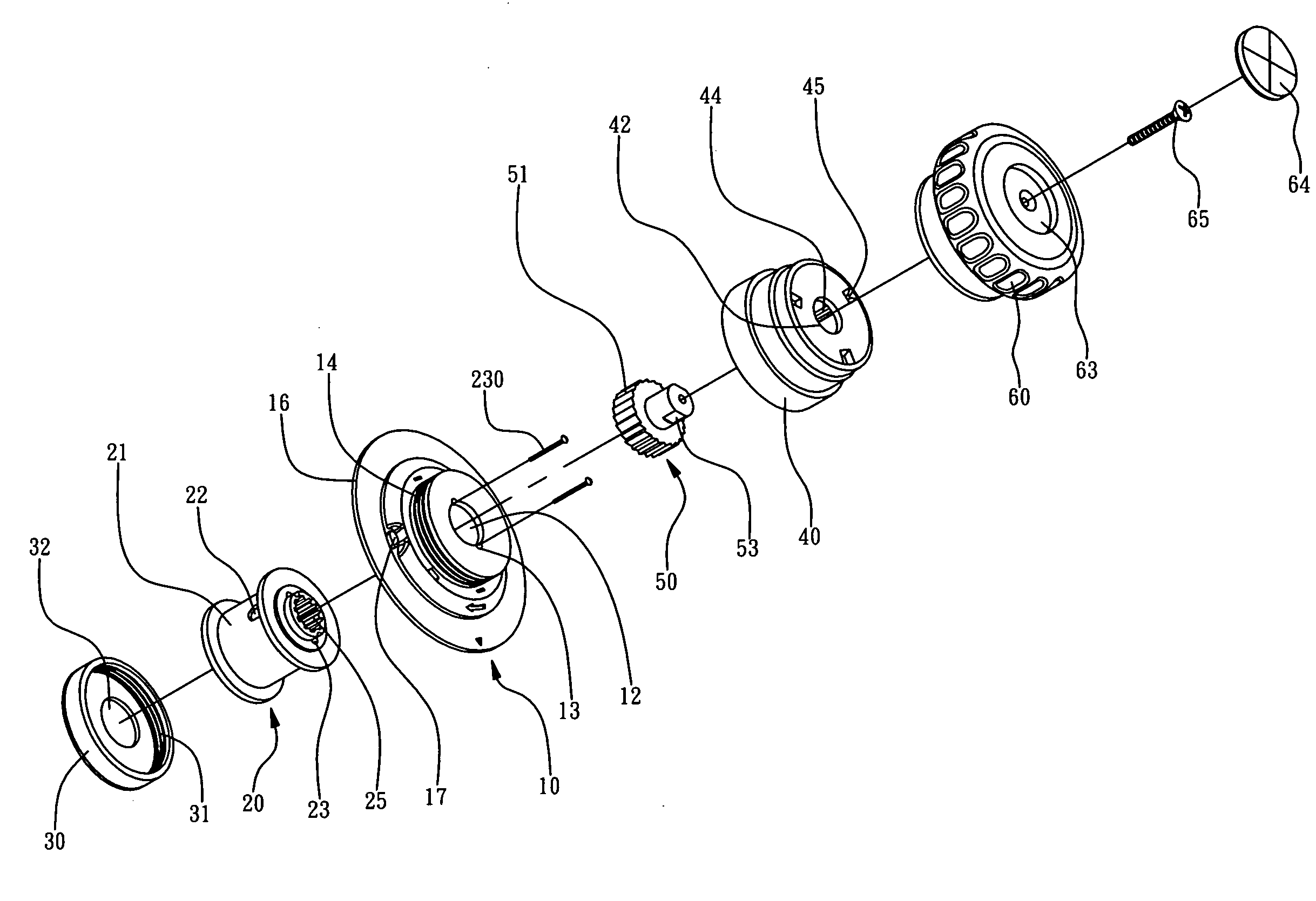

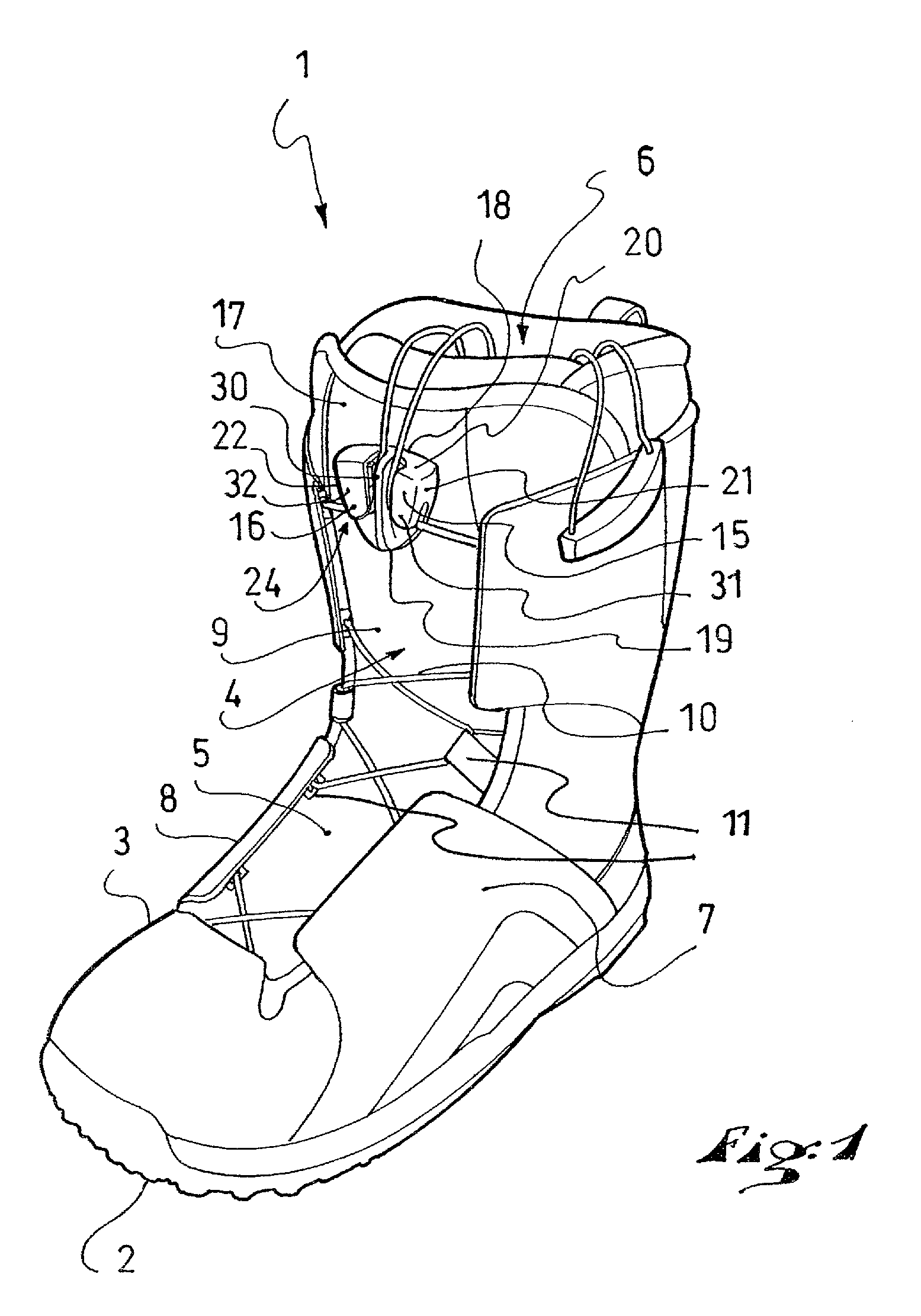

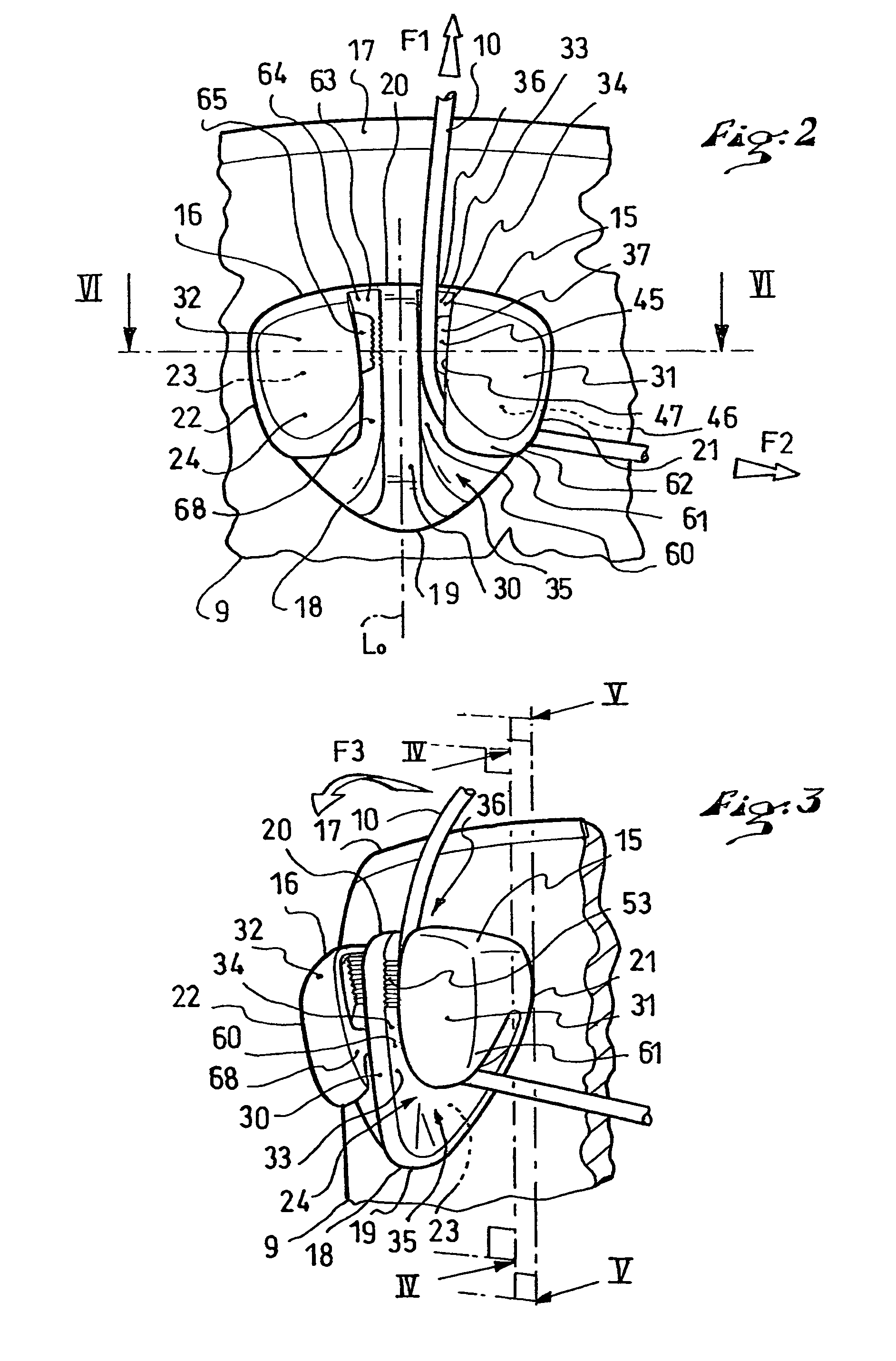

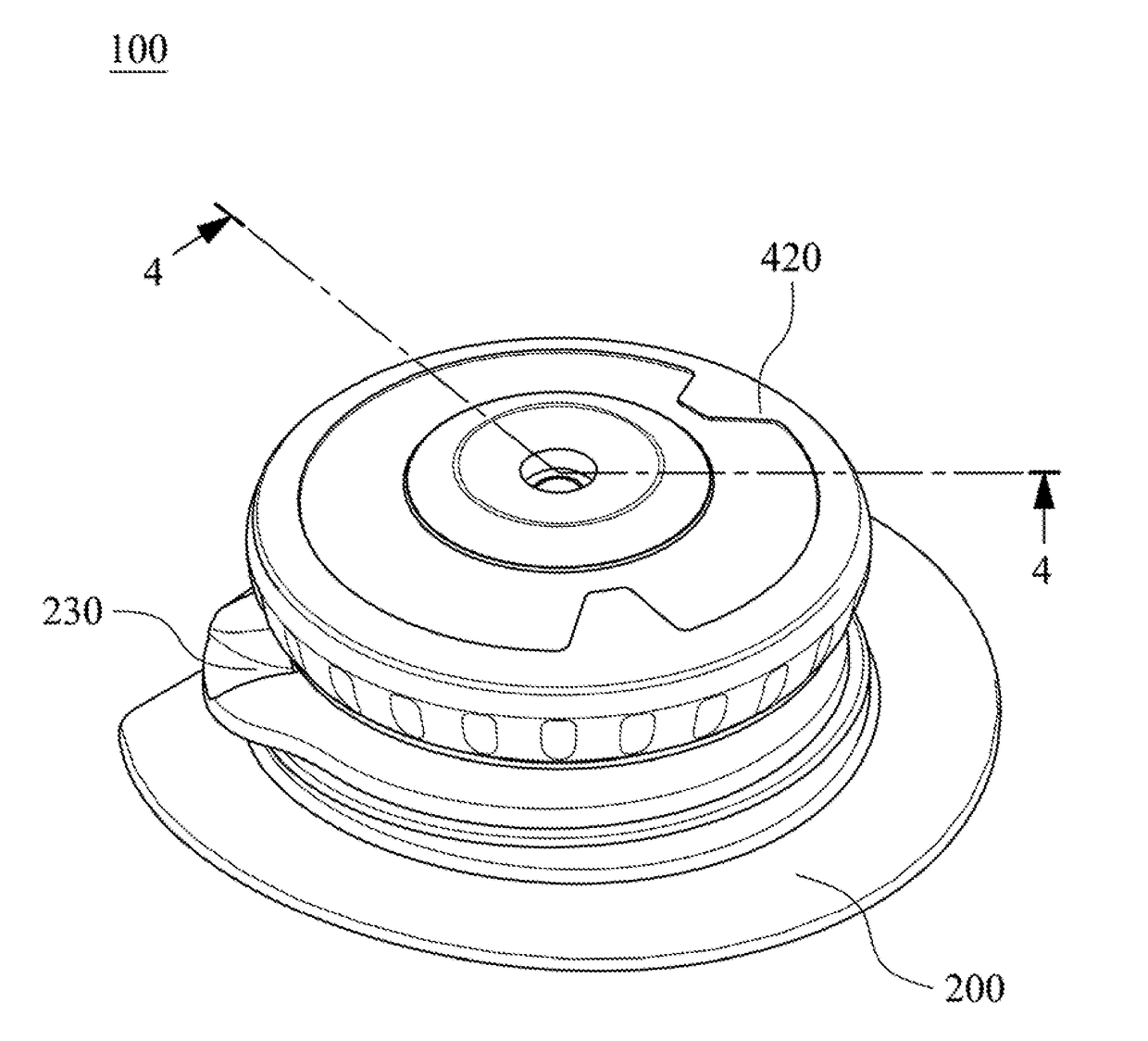

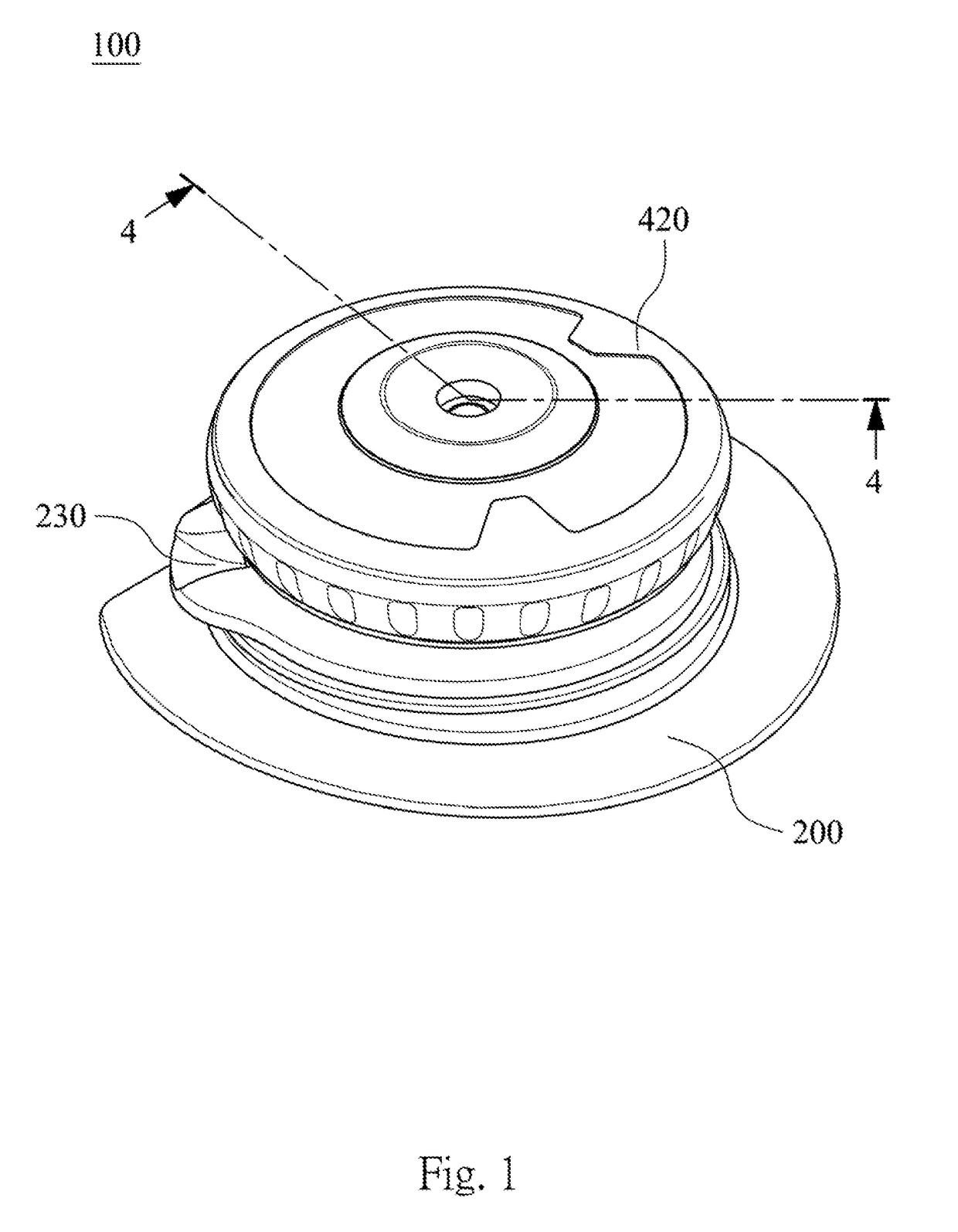

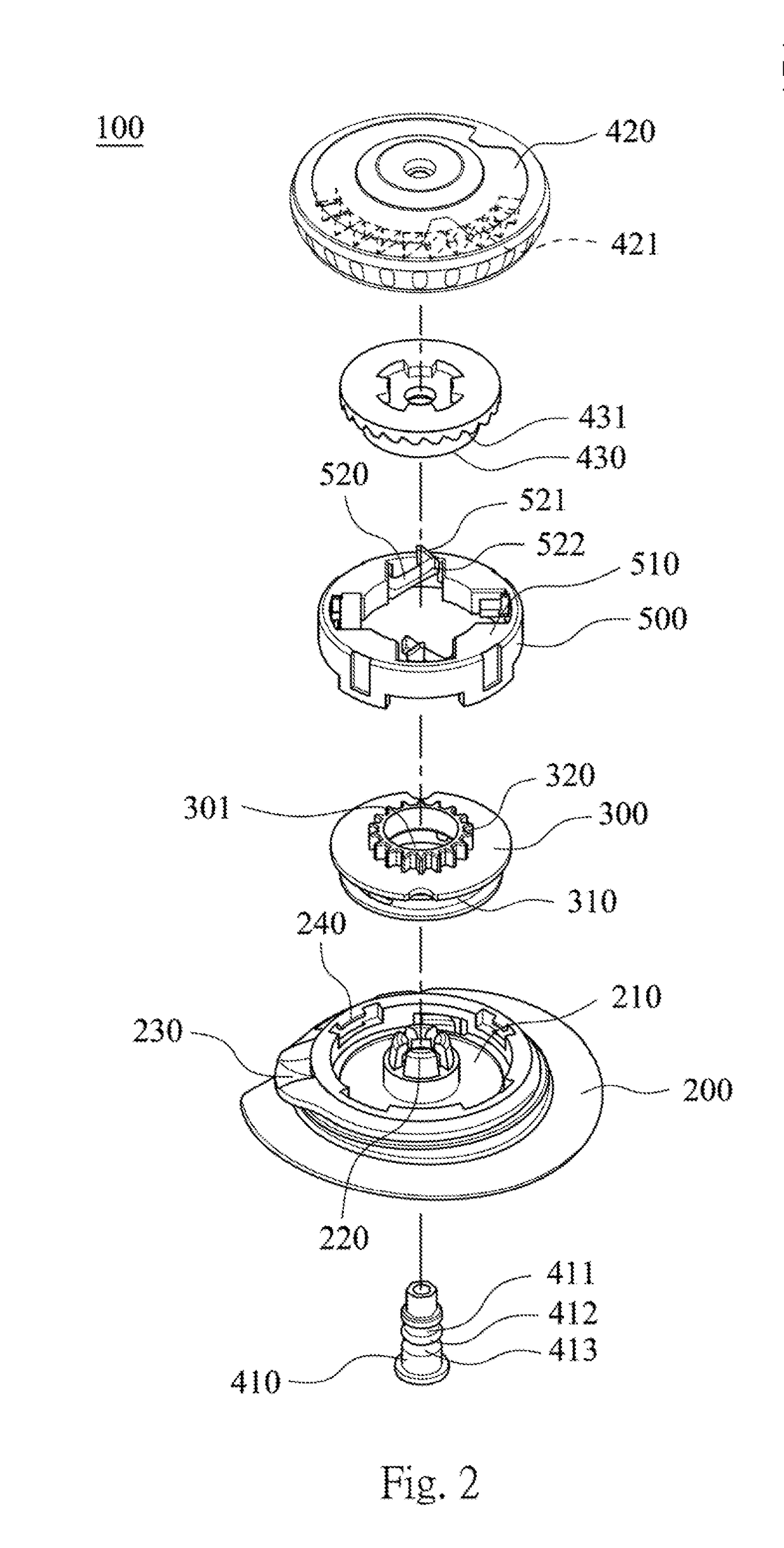

Apparatus and method for tightening and loosening lace

ActiveUS20170295888A1Easy to assembleReduce complexityShoe lace fasteningsEngineeringMechanical engineering

An apparatus for tightening and loosening a lace includes a base, a lace tightening and loosening member, a releasing unit and an interlocking member. A temporary sliding portion is disposed between a first positioning portion and a second positioning portion. A stopping member is passed through the temporary sliding portion by a preliminary force. When the stopping member is positioned by the first positioning portion, a second combining portion is correspondingly connected to a first combining portion. When the stopping member is positioned by the second positioning portion, the second combining portion is separated from the first combining portion. When the releasing unit is located at a first position, the elastic abutting arm substantially stops the releasing unit to rotate in a loosening direction and does not substantially stop the releasing unit to rotate in a tightening direction.

Owner:CHEN CHIN CHU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com