Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1337 results about "Bar pressing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

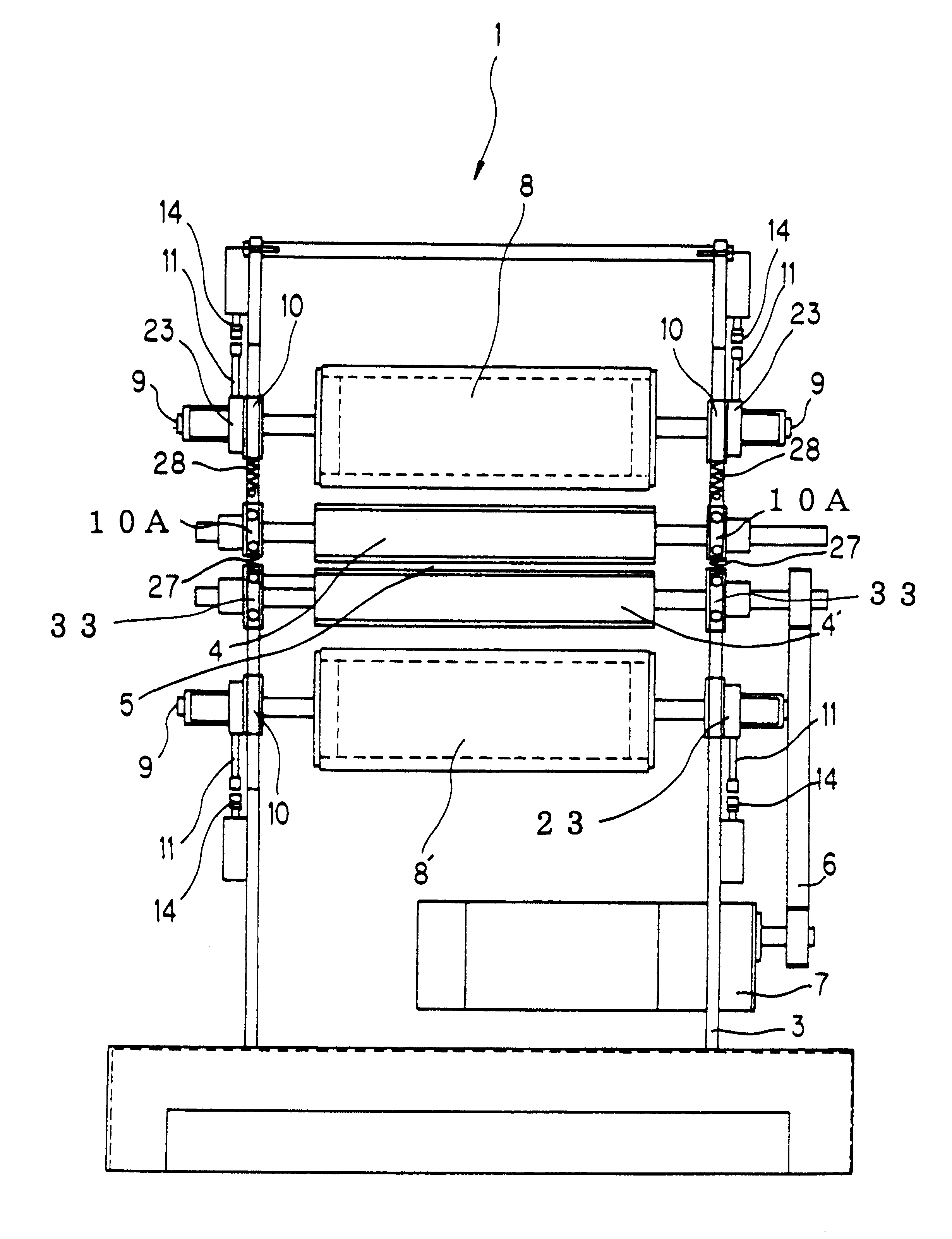

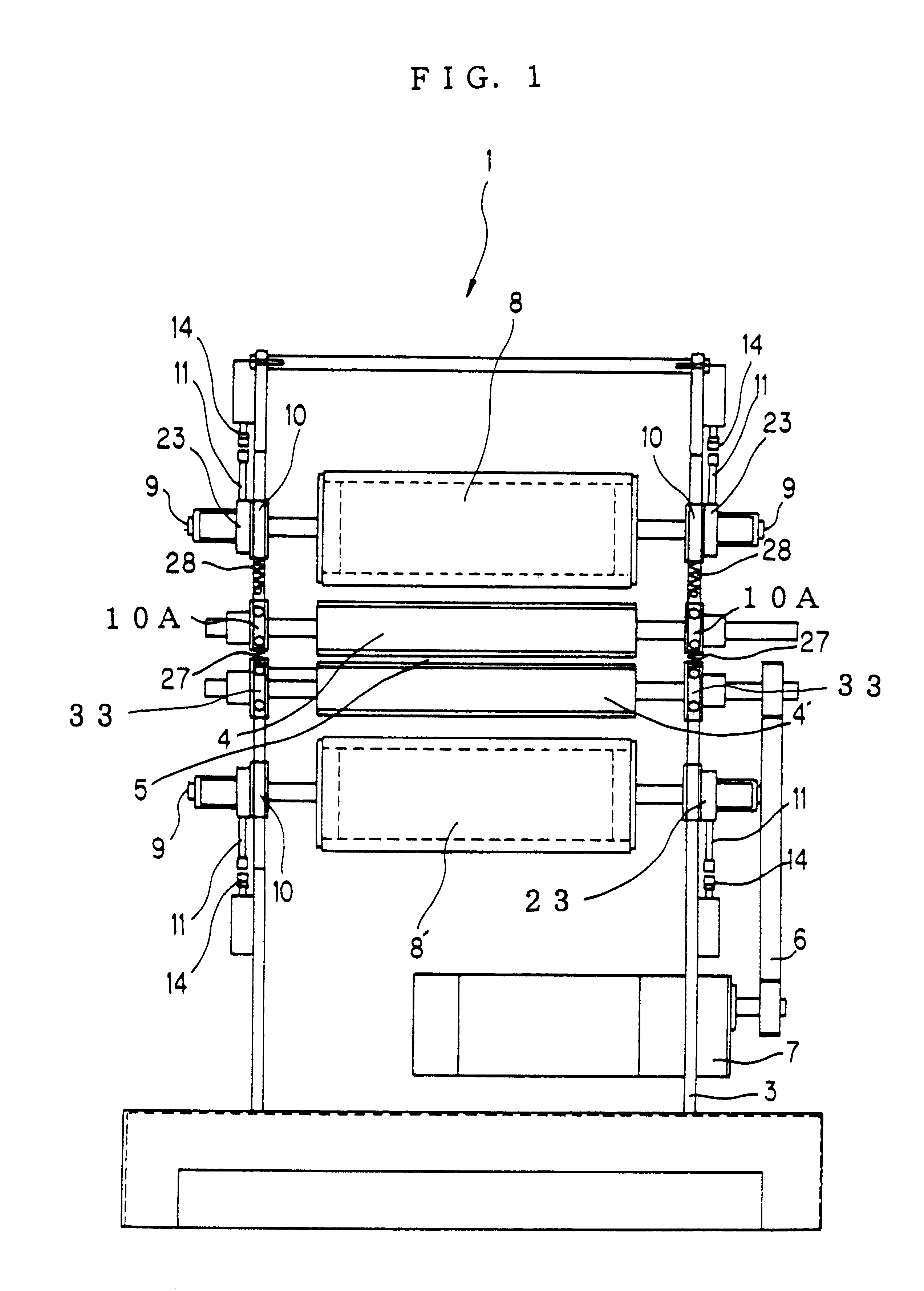

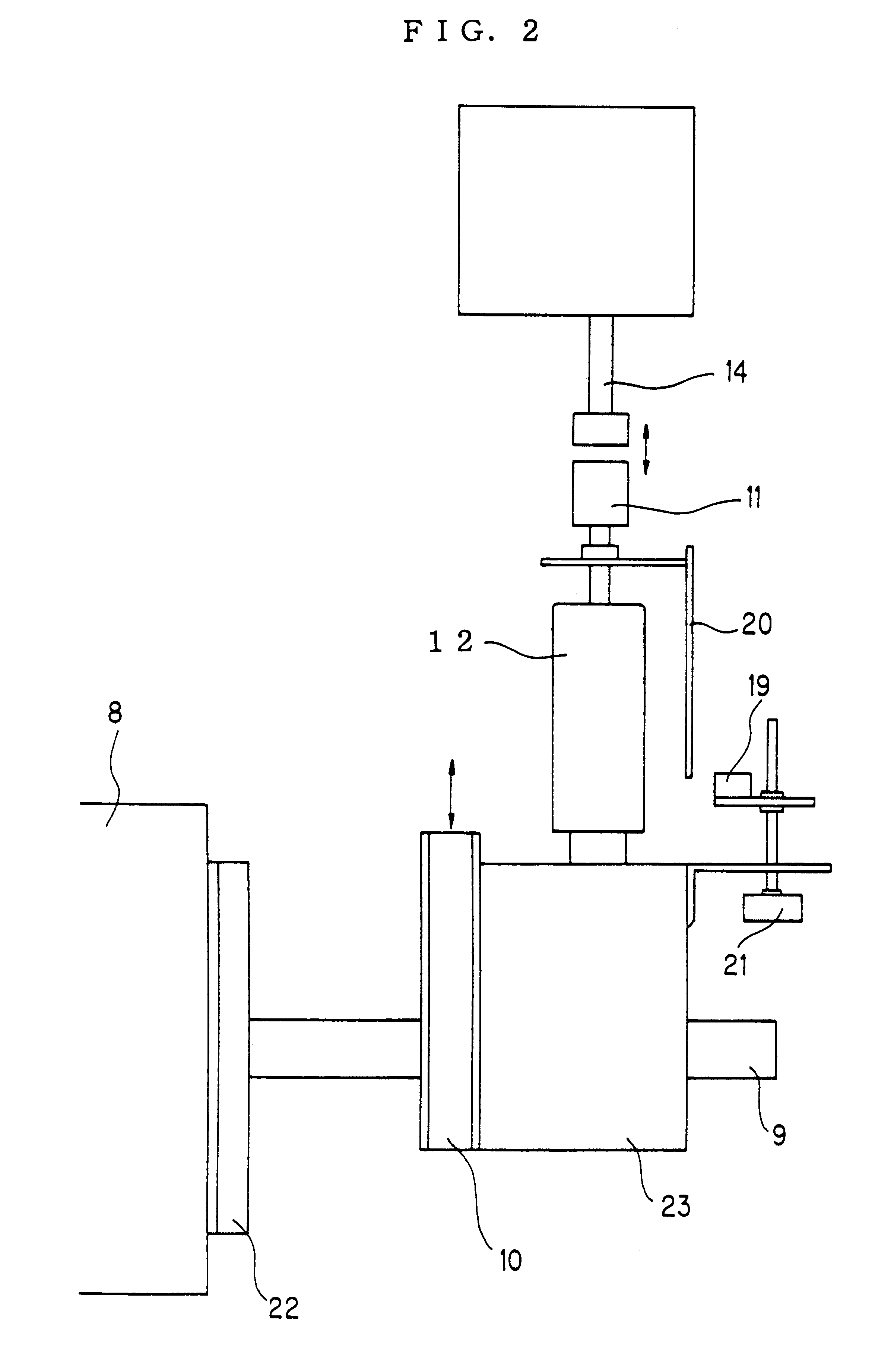

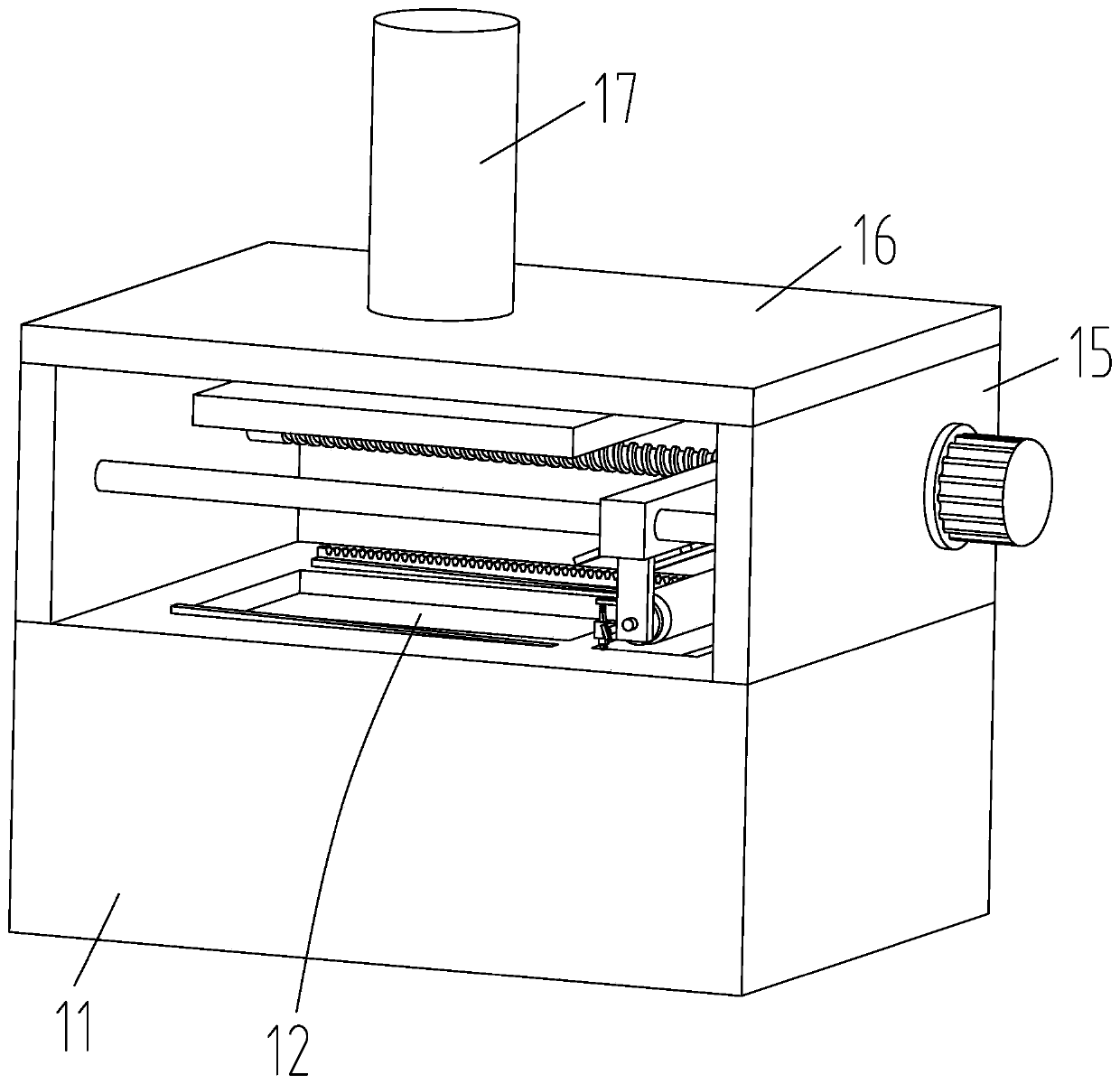

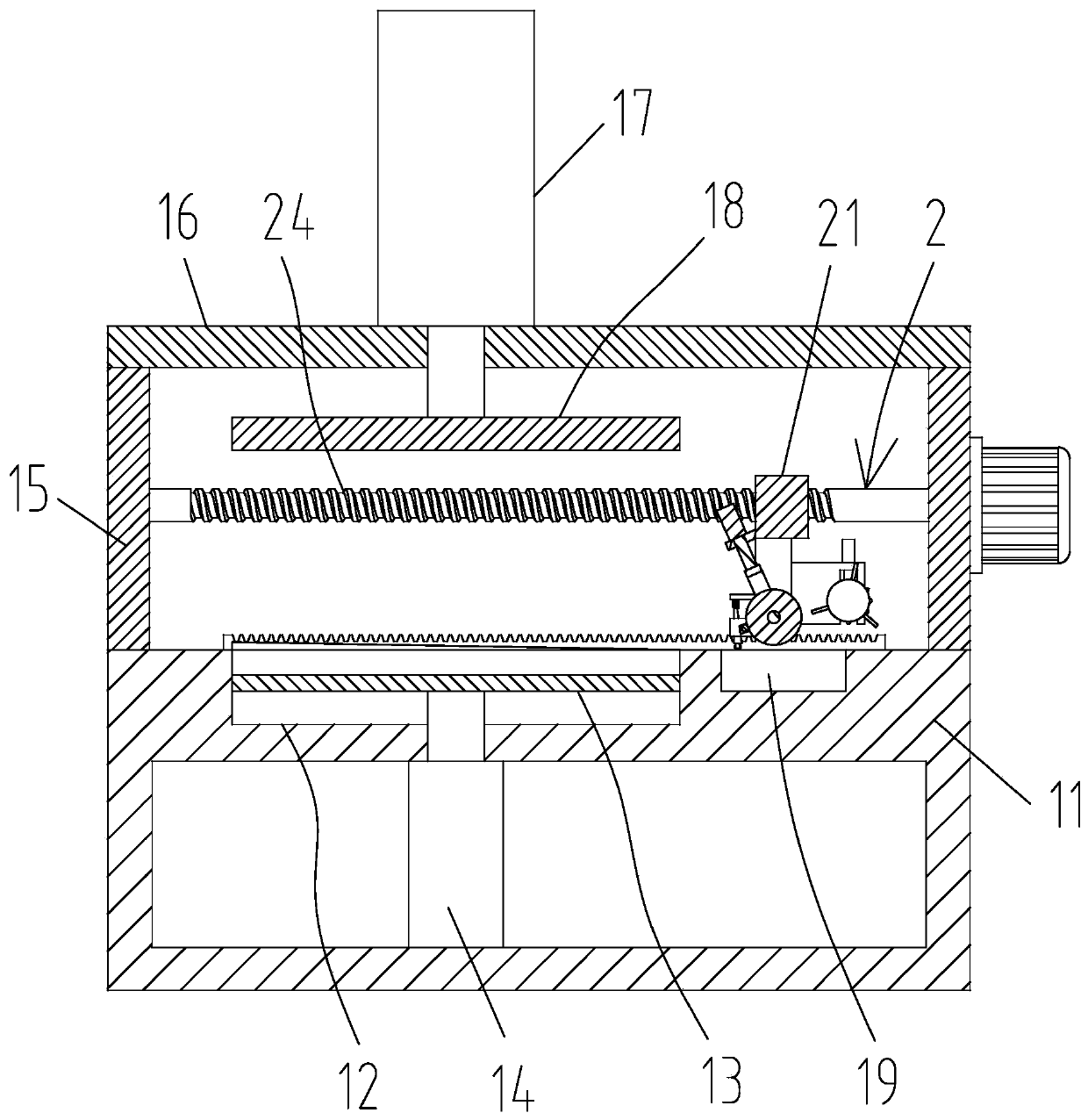

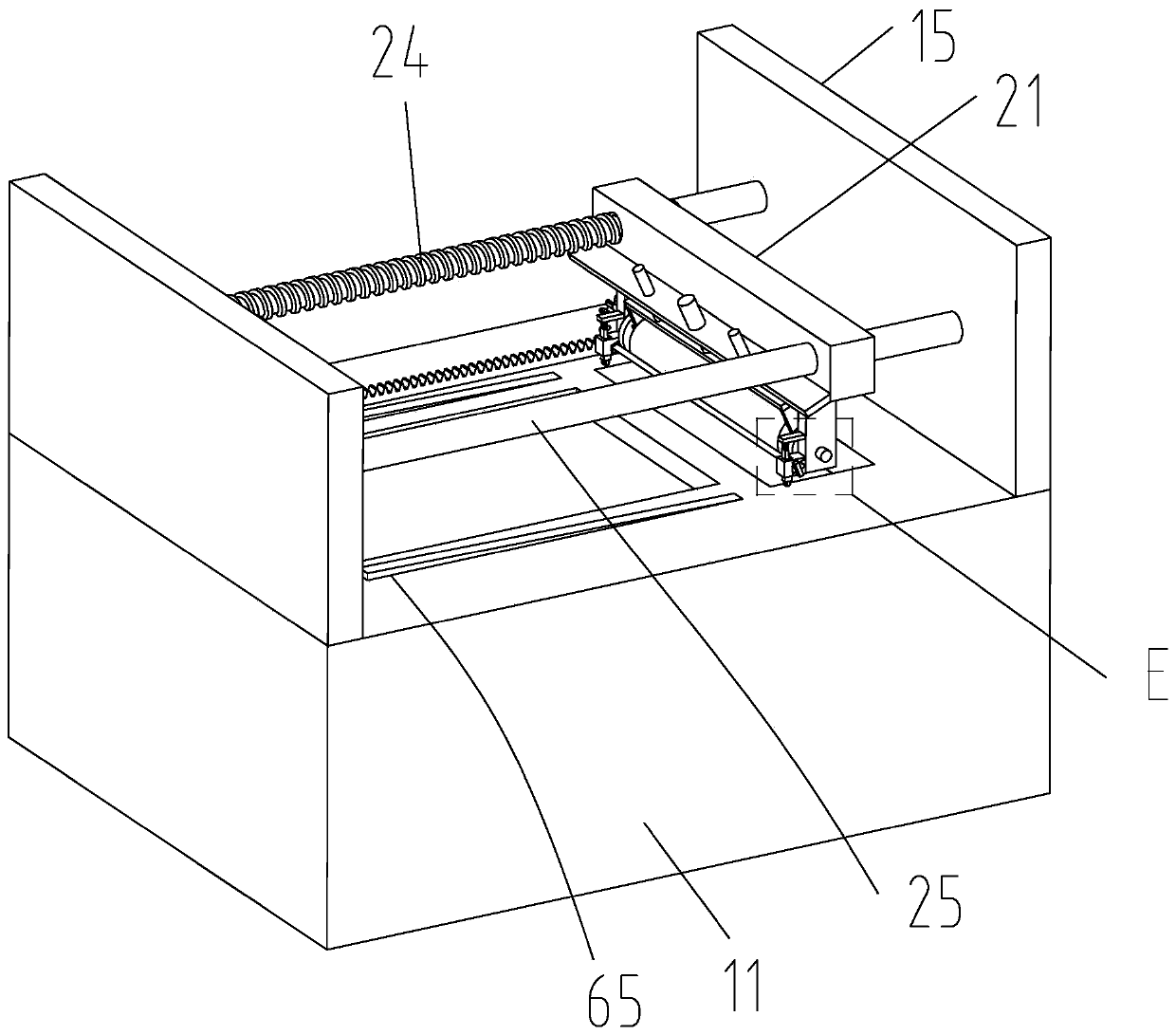

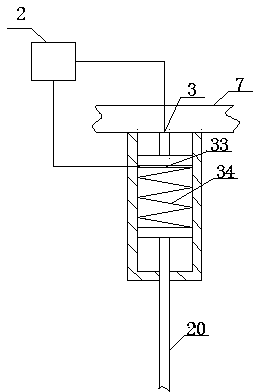

Substrate or sheet surface cleaning apparatus

InactiveUS6237176B1Efficient captureEfficient removalLiquid processingCarpet cleanersFixed bearingSurface cleaning

A substrate or sheet surface cleaning apparatus is provided with at least one tacky rubber roller and at least one adhesive tape roll which is brought into close contact with the tacky rubber roller. The roller and roll are rotatably supported at opposite ends of their shafts by bearings which are slidable in a vertical direction. Pressed rods are arranged integrally on the slidable bearings for the roll. By urging the pressed rods with pressing rods driven by d.c. motors via gear trains while controlling the d.c. motors by a position sensor, the pressure between the roll and the roller and the pressure between the roller and the substrate or sheet are optimized so that dirt or particles can be efficiently removed from an opposing surface of the substrate or sheet. Another substrate or sheet surface cleaning apparatus is provided two tacky rubber rollers arranged in an up-and-down parallel relationship and two adhesive tape rolls arranged above the upper roller and below the lower roller, respectively. Position adjusters with one or more springs disposed therein are arranged between slidable bearings supporting the upper roller and fixed bearings supporting the lower roller to correct tilting, if any, of the upper roller.

Owner:RAYON IND

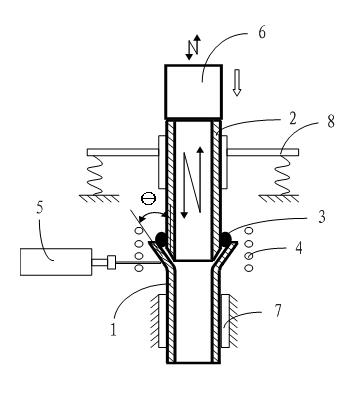

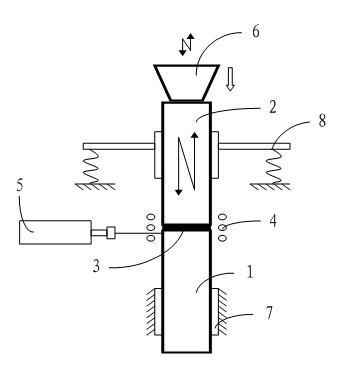

Dissimilar metal material brazing method

ActiveCN102151930AImprove the mixing effectReduce spreadWelding/cutting media/materialsSoldering mediaMetallic materialsUltrasonic vibration

The invention discloses a dissimilar metal material brazing method. The dissimilar metal material includes a first base metal and a second base metal different from each other. The method comprises the following steps: clamping the first base metal on a telescopic fixture and clamping the second base metal on a fixed fixture in such a manner that the welding surfaces of the first base metal and the second base metal face to each other, and placing a solder between the welding surfaces; applying a pre-pressure on the first base metal relative to the welding surface; locally rapidly heating thewelding parts of the first base metal and the second base metal to a preset temperature and keeping the temperature; increasing the pre-pressure to a welding pressure; applying ultrasonic vibration to the first base metal relative to the welding surfaces by an ultrasonic compression bar; and continuously keeping the temperature and the pressure after the ultrasonic vibration completes, stopping heating, and further keeping the pressure until the welding parts are cooled. The method can improve the strength of a brazed joint of dissimilar metal materials by reducing the formation of laminar brittle intermetallic compounds and the like.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

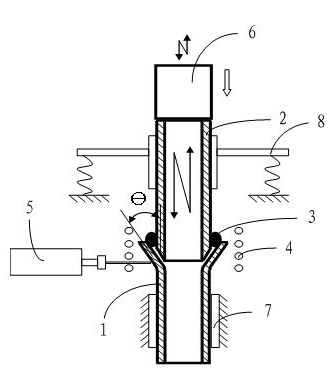

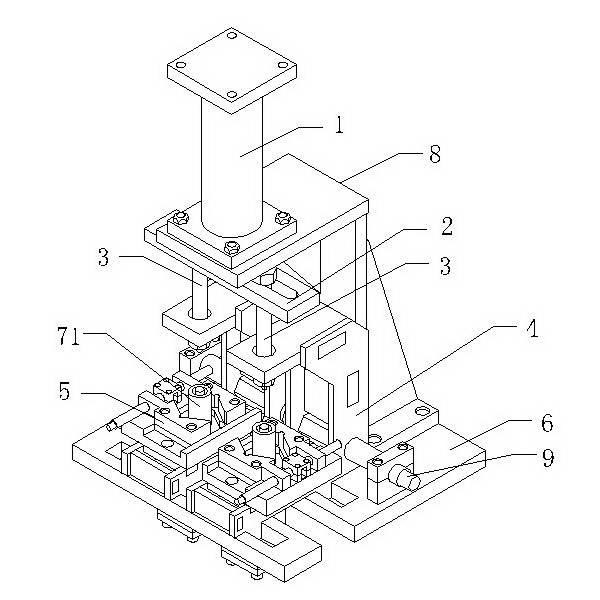

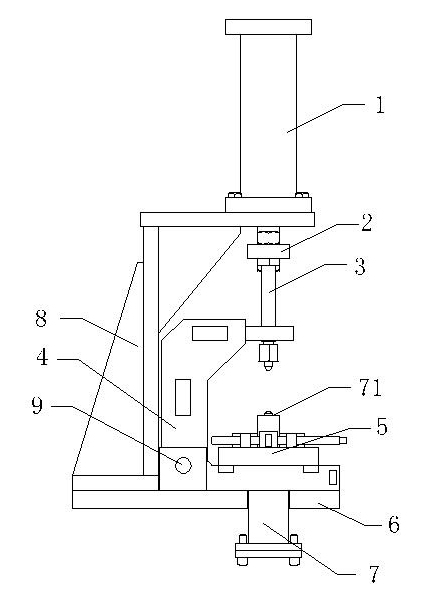

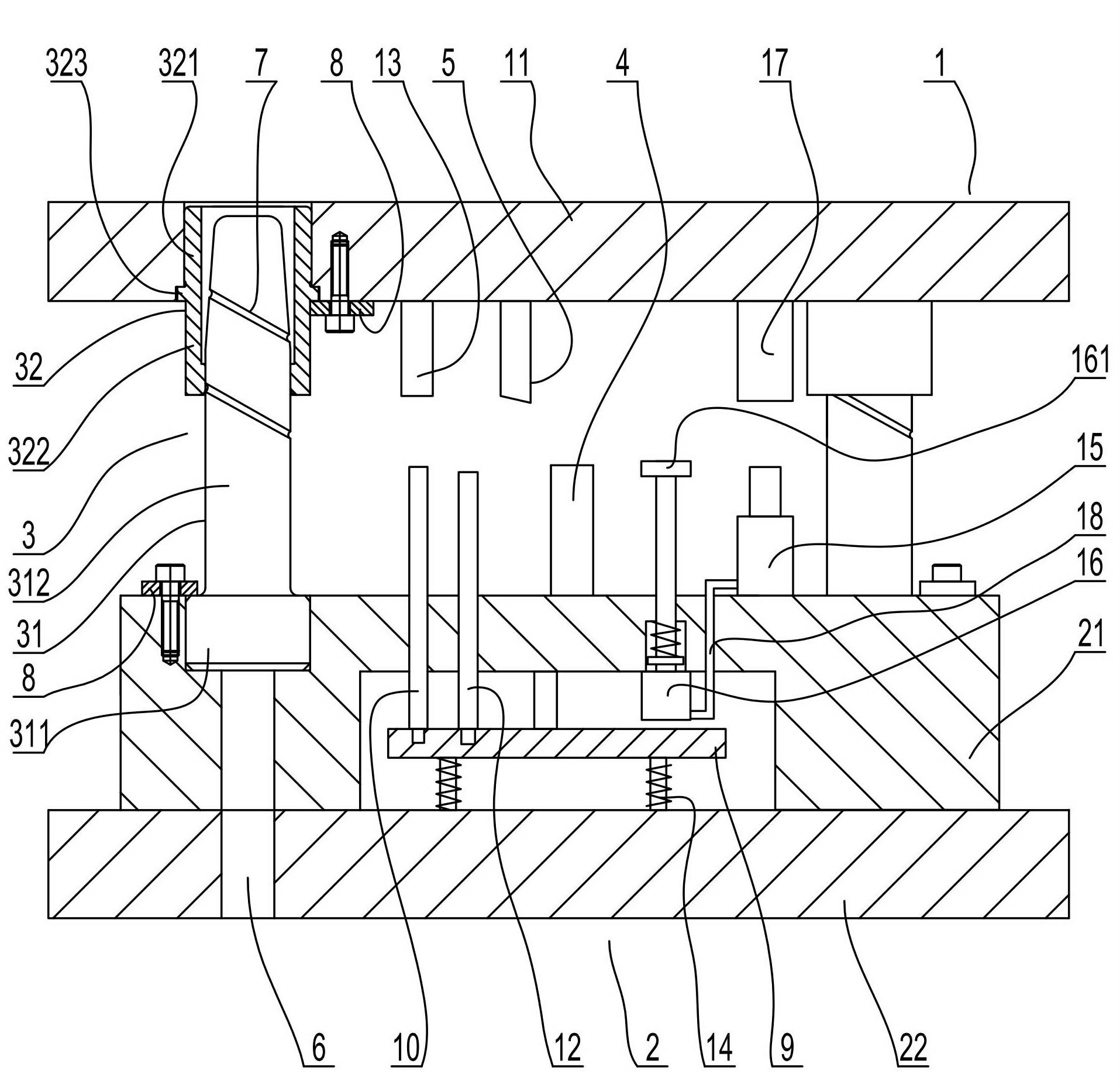

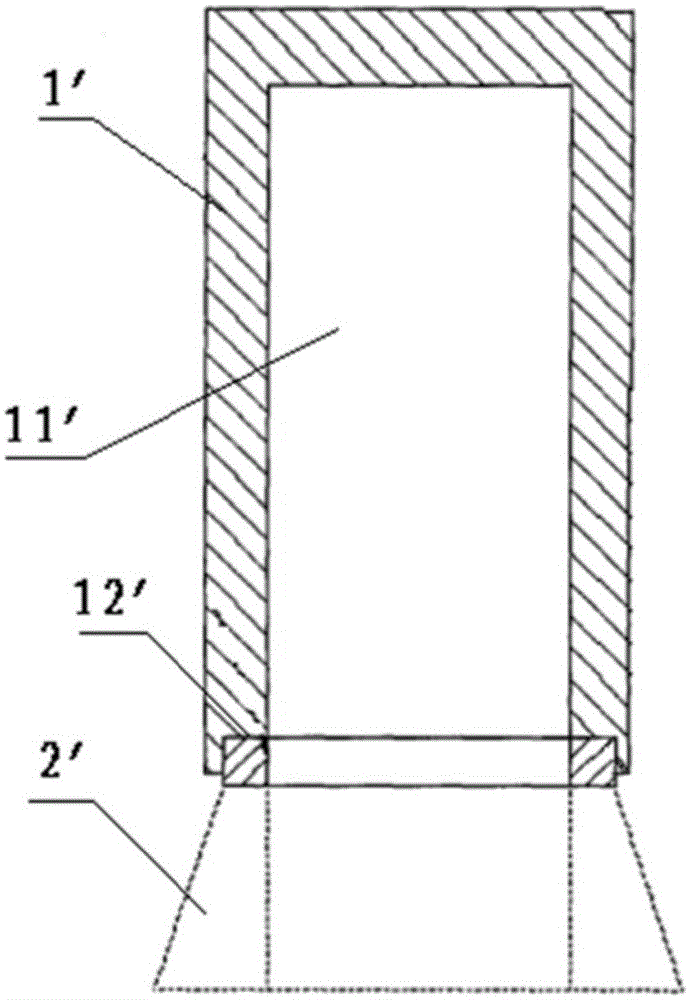

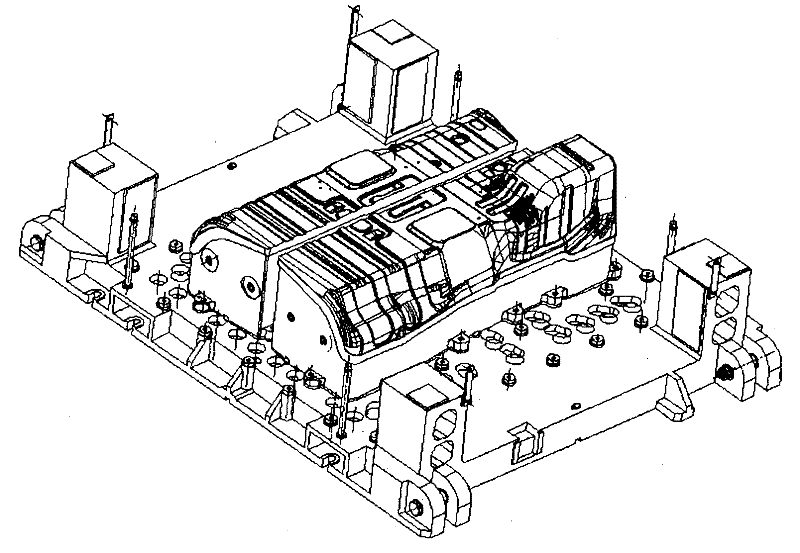

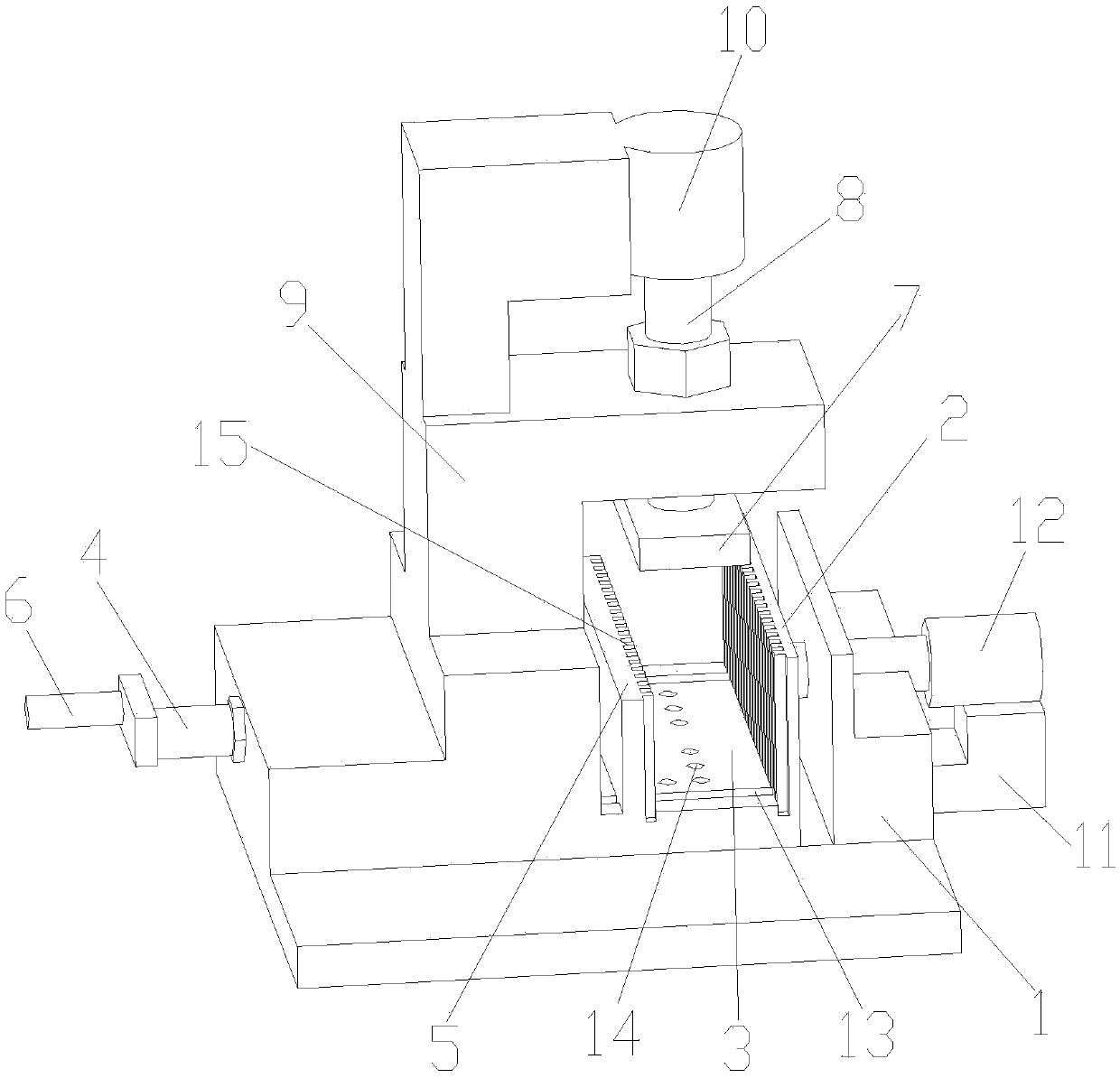

Bush fixture

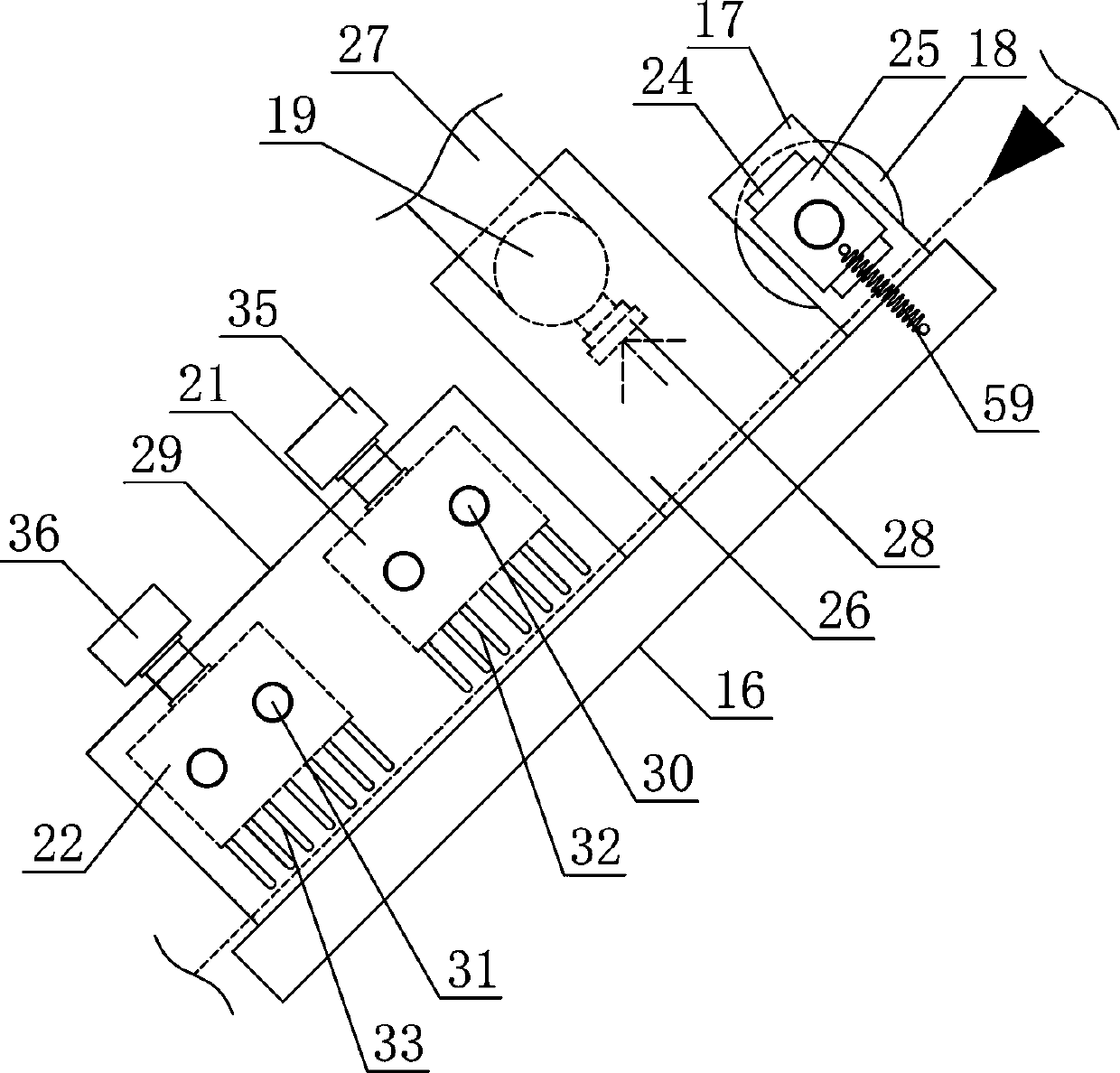

ActiveCN102069376AGuaranteed pressing accuracyGuaranteed to control the pressing forceMetal working apparatusEngineeringBar pressing

The invention relates to a bush fixture. The bush fixture comprises a body and a table, wherein a pressure rod device, the pressure rod fixing plate of the pressure rod device and a drive element matched with the pressure rod device are arranged on the body; the pressure rod device comprises at least a pair of pressure rods; support carriages corresponding to the pressure rods respectively are movably connected to the table; one end of every pressure rod is movably connected to the pressure rod fixing plate; the other end of every pressure rod is sleeved on the corresponding support carriage; every support carriage is provided with a product positioning device and a returning device; the product positioning device is connected with the returning device; and the returning device is provided with a bush installation rod which is matched with the product positioning device. The bush fixture can be used for pressing bushes on multiple types of automobile frames, can ensure pressing precision and control pressing force, can adjust a positioning fixture to accomplish pressing action according to the sizes of the automobile frames and the distances among the bushes on the automobile frames, and improves assembling efficiency and accuracy.

Owner:泛美汽车零部件(宁波)有限公司

Mold-pressing device

A mold-pressing device including a seat body formed with a horizontal fissure at one end and a vertical chamber communicated with the fissure. A mold block is disposed in the chamber. One face of the mold block is disposed with a solid die, while the other face of the mold block is disposed with a channel passing through the mold block. A pressing lever is pivotally disposed in the channel of the mold block. A housing covers the seat body and is formed with a window for a pressing section of the pressing lever to extend therethrough. In use, a paper or a sheet is pushed into the fissure of the seat body and then the pressing section of the pressing lever is depressed, whereby a protuberance of the pressing lever is moved downward to force the mold block downward with the die punching the paper or the sheet placed in the fissure. Therefore, a product with a shape as that of the die is formed.

Owner:WALTJUN INDAL

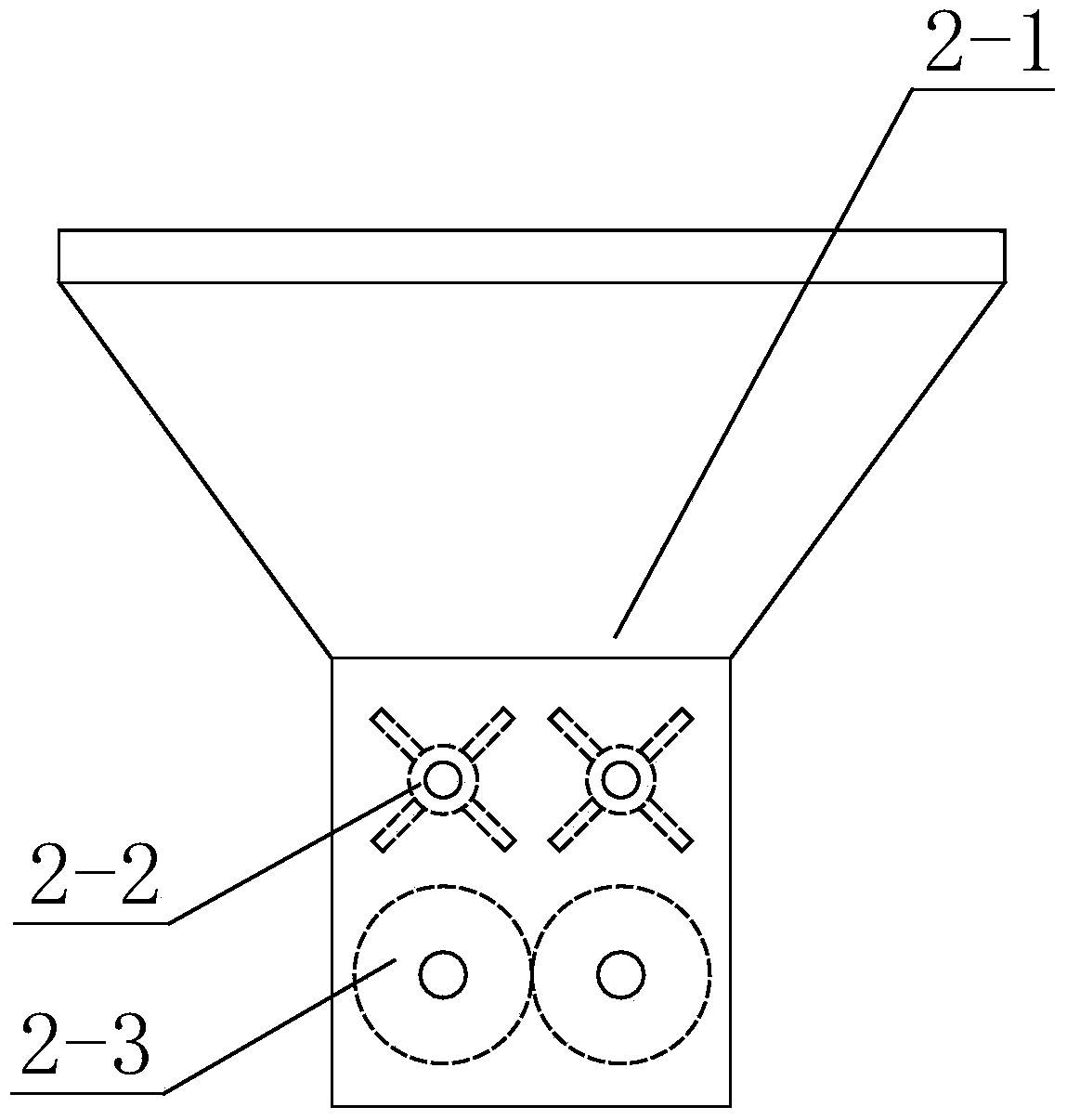

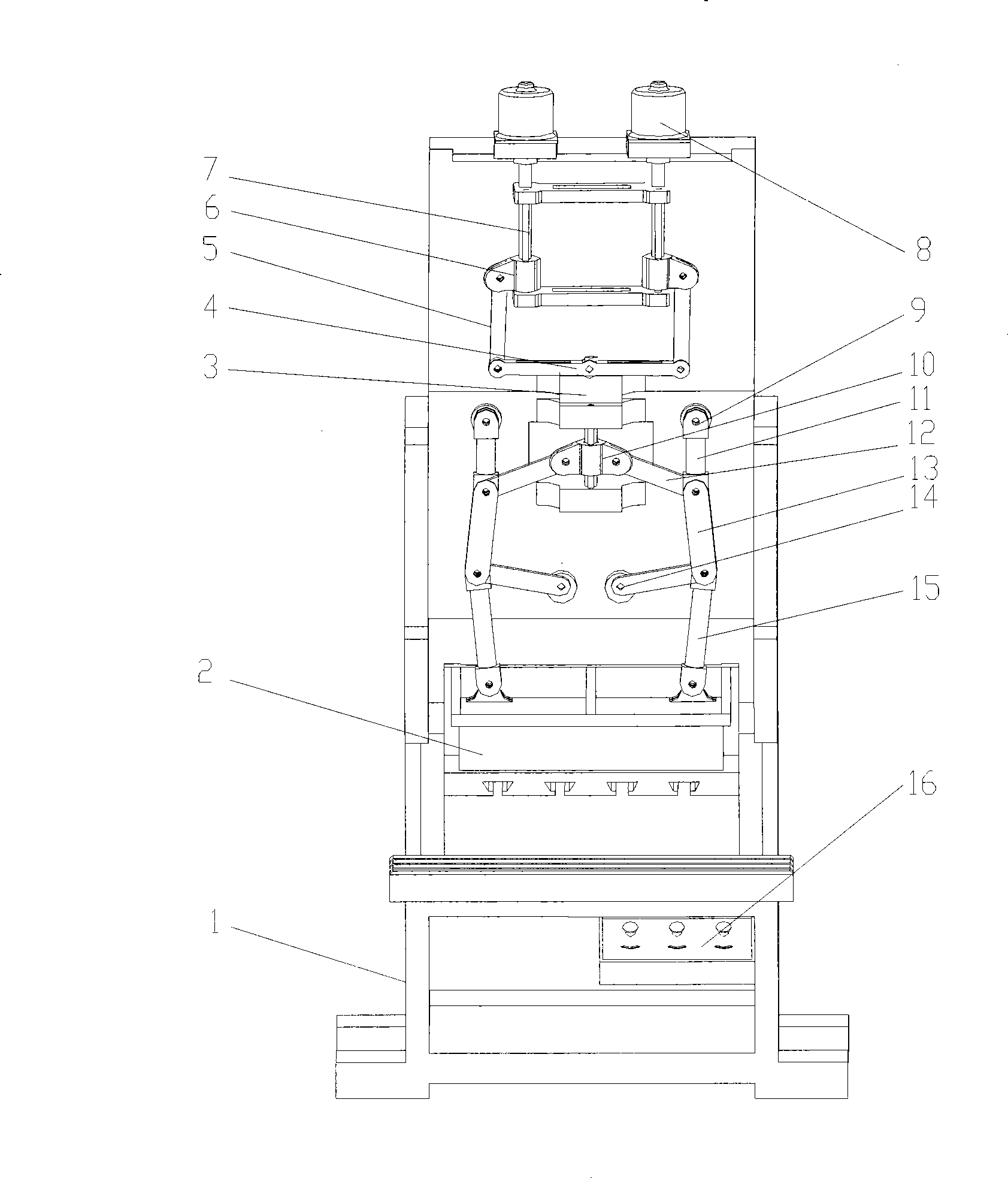

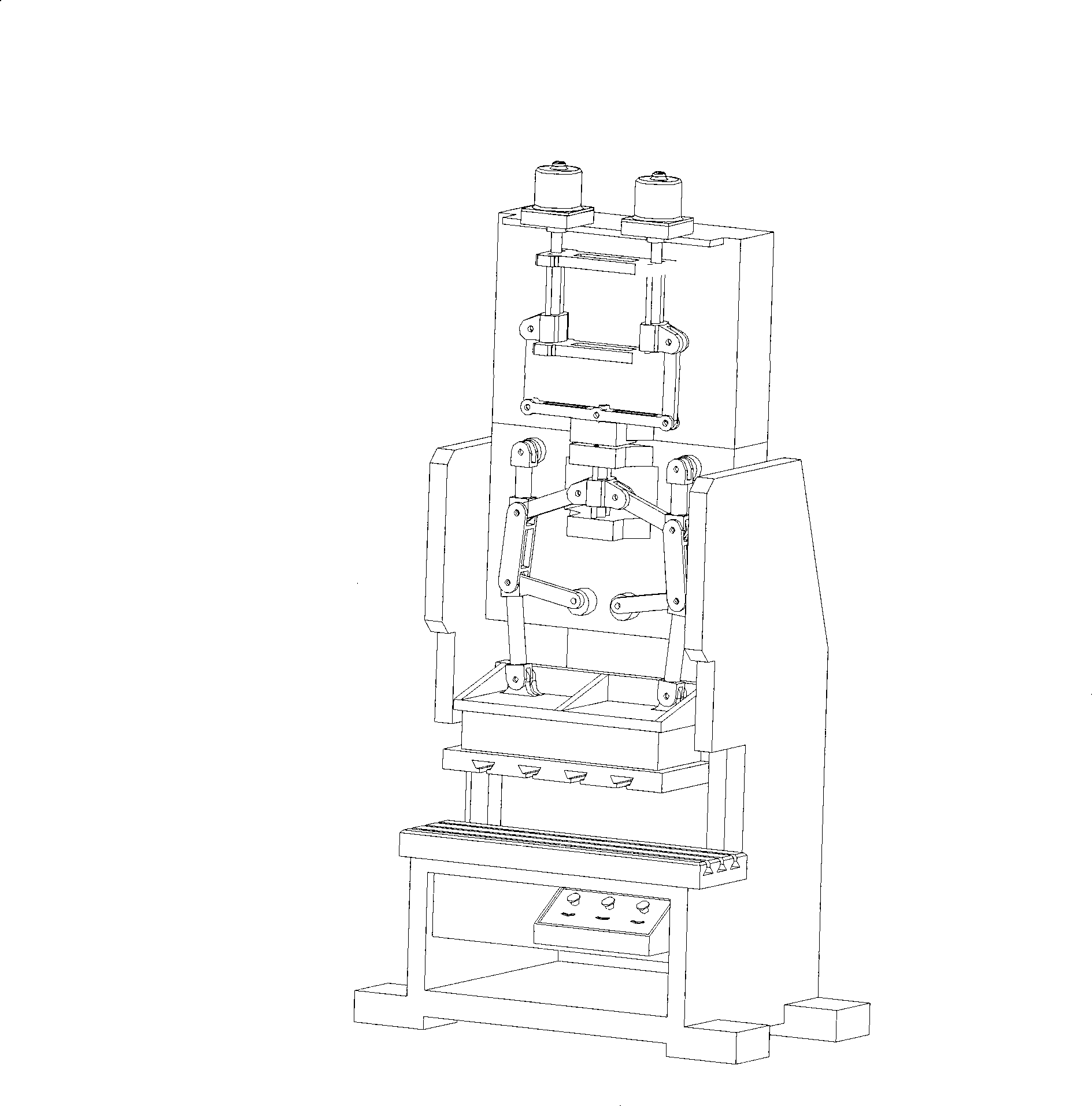

Sludge treatment device

ActiveCN103708690AStrong continuous processing abilityShort cycle and high efficiencySludge treatment by de-watering/drying/thickeningSocial benefitsSludge

The invention relates to a sludge treatment device. The sludge treatment device comprises a sludge conveyor, a sludge crushing forming machine and a sludge drying machine, wherein a pair of sludge crushing rollers and a pair of sludge bar pressing forming rollers, which are driven by a variable-frequency motor, are arranged inside a sludge hopper of the sludge crushing forming machine from top to bottom; a drying bin inner cavity of the sludge drying machine is divided into a drying chamber and a circulating air heating chamber, a plurality of layers of stainless steel mesh-belt conveying tables are arranged in the drying chamber, and a discharging port of the sludge hopper of the sludge crushing forming machine is arranged right above a conveying starting end of the stainless steel mesh-belt conveying table on the topmost layer in the drying chamber of the sludge drying machine. When the sludge treatment device is used for treating the urban domestic sludge, the sludge treatment device has remarkable advantages of strong continuous treatment capacity, short period, high efficiency, good treatment effect, no secondary pollution, environmental protection, stability and safety in operation, low energy consumption, high automation degree and the like. The input-output ratio is high, the social benefit is high, and the application prospect is wide.

Owner:CHANGZHOU XINGANG THERMOELECTRICITY

Double-motor mechanical coordination in-phase slider driven eight-bar servo pressure device

InactiveCN101396876AGuaranteed normal movementGuaranteed powerPress ramElectric machineryEngineering

The invention relates to a key synchronizer driving eight-rod servo press coordinated with dual electric machinery. Two servomotors arranged symmetrically left and right are connected with a driving slide block by a key synchronizer driving mechanism coordinated with a set of dual electric machinery, and the driving sliding block is connected with a pressing slide block by two sets of eight-connecting bar pressing mechanism arranged symmetrically left and right. The key synchronizer driving mechanism coordinated with the dual electric machinery comprises a screw rod, a small connecting bar, a horizontal connecting bar and a sliding stand; each set of eight-connecting bar pressing mechanism comprises a short connecting bar, an upper elbow connecting bar, a lower elbow connecting bar and a punch connecting bar. The two servomotors can drive synchronously according to the set law of motion; the key synchronizer driving mechanism coordinated with the dual electric machinery can drive the driving slide block to move, and the driving slide block can push the pressing slide block to move by the two sets of eight-connecting bar pressing mechanism, therefore, the synthesis of the movement and the power of the two servomotors can be realized, and the large-tonnage ram pressure and movement are obtained, thus realizing the large-tonnage servo pressing with lower cost.

Owner:SHANGHAI JIAO TONG UNIV

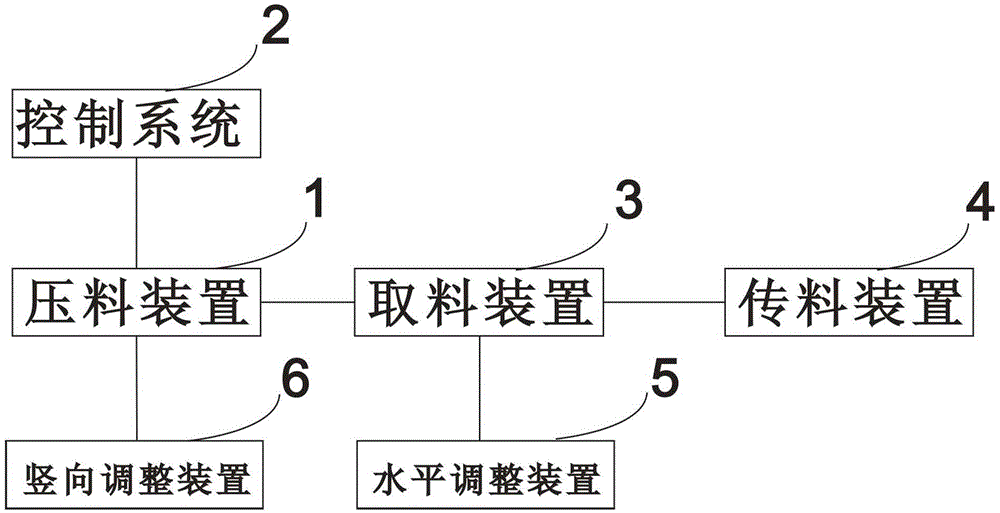

Bar conveyor

InactiveCN103144944ASolve the problem that the size cannot be adjusted arbitrarilyReduce labor intensityConveyor partsAutomatic controlControl system

Owner:XIAMEN LANGUAN AUTOMATION TECH

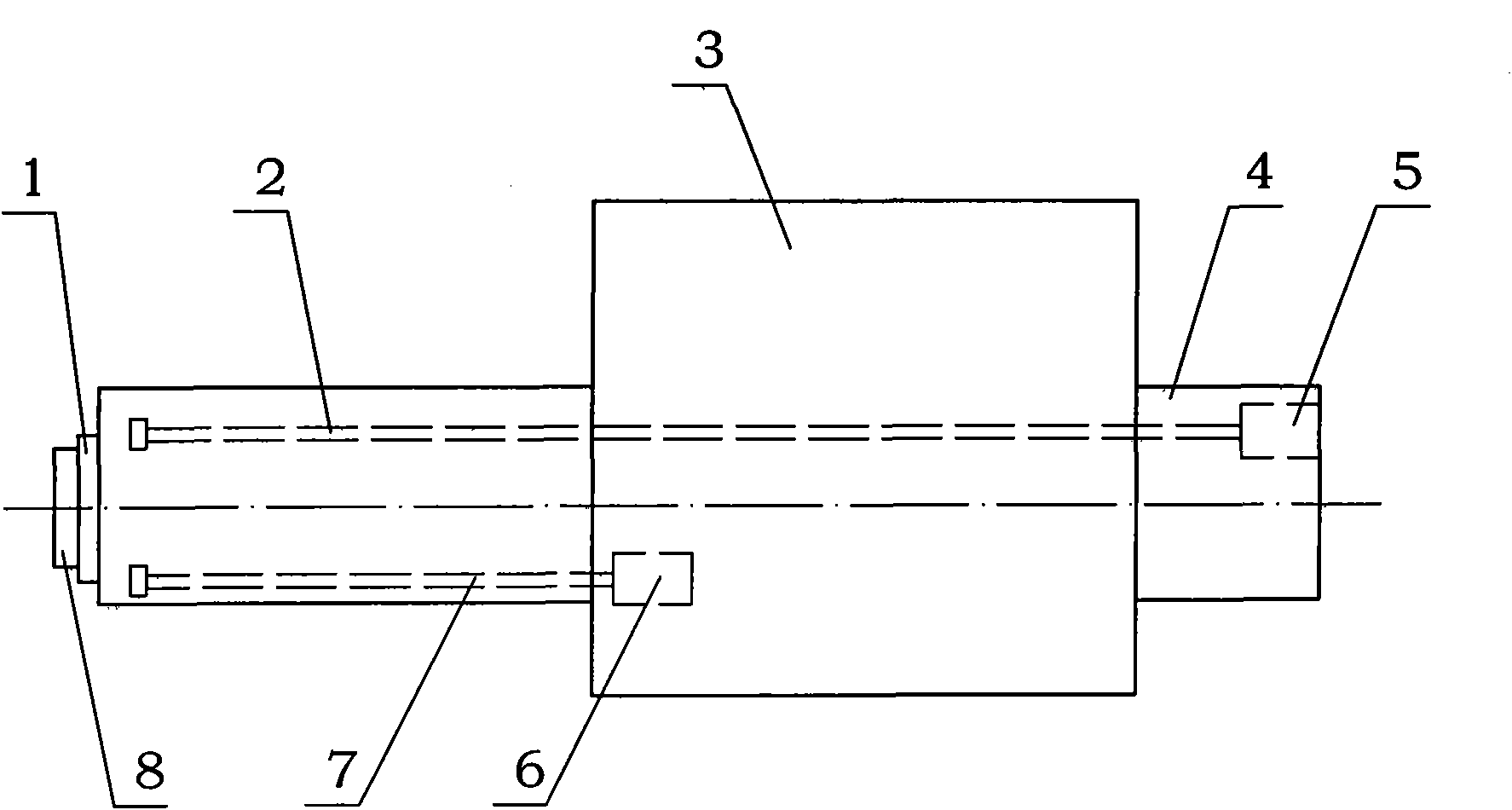

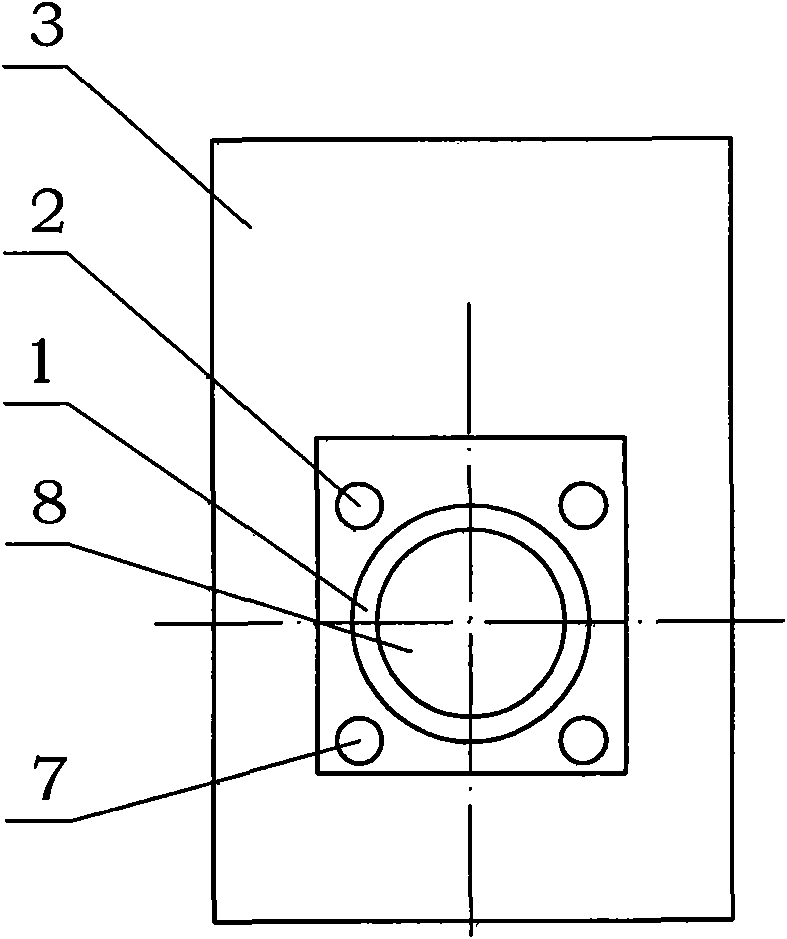

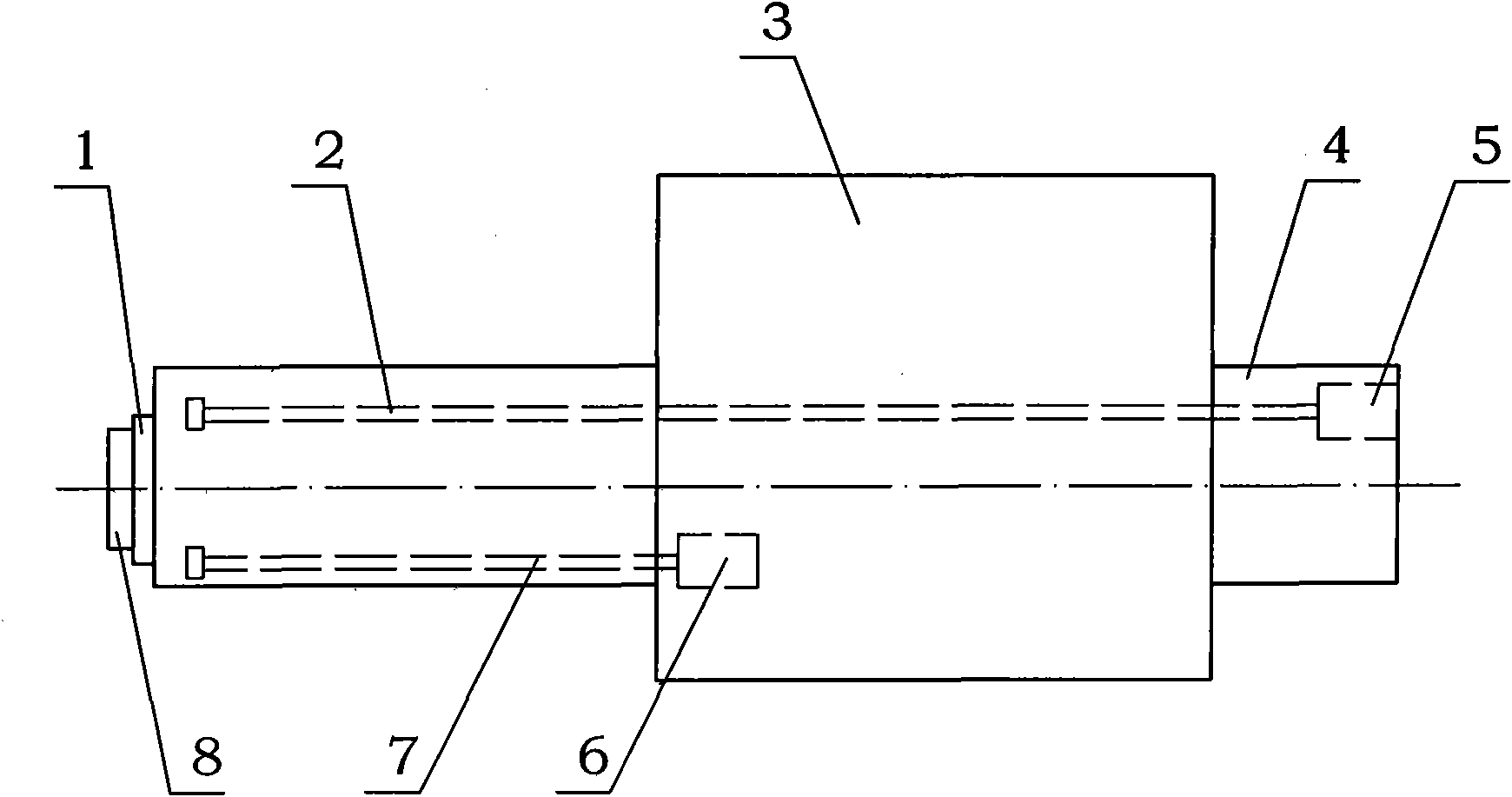

Ram bending deformation two-way compensating device

InactiveCN101913106ASmall rated pressureOther manufacturing equipments/toolsLarge fixed membersEngineeringBar pressing

The invention relates to a ram bending deformation two-way compensating device, mainly solving the problem that the traditional draw bar compensating device causes the axial deformation of a ram because draw bars are eccentric. The invention is characterized in that the lower part of the ram (4) is provided with two compression bars (7) and a push action cylinder (6) connected with the compression bars (7); the compression bars (7) and the draw bars (2) are symmetrical up and down along the centre line of a milling spindle (1); the two compression bars (7) are symmetrical left and right along the centre line of the milling spindle (1); and the push action cylinder (6) is arranged in a main spindle box (3). The two-way compensating device does not generate the additional axial deformation while compensating the bending deformation of the ram. Compared with the traditional pure draw bar compensating method, the pressure required to be provided for the cylinder is small under the condition of compensating the same deflection, and therefore, the required rated pressure of the cylinder is smaller.

Owner:通用技术齐齐哈尔二机床有限责任公司

Intelligent detection equipment for printing and dyeing wastewater

InactiveCN107449653AEasy to disassembleEasy to replace and maintainPreparing sample for investigationStationary filtering element filtersClamp connectionEngineering

The invention provides intelligent detection equipment for printing and dyeing wastewater and relates to the field of detection equipment. The intelligent detection equipment for the printing and dyeing wastewater comprises a box body, wherein a first motor seat is fixedly mounted at the top of the box body; a first motor is arranged at the top of the first motor seat; a feeding pipe is arranged at the top of the box body and is located at the left side of the first motor seat; the bottom of the feeding pipe penetrates through the box body and is communicated with the top of the box body. According to the intelligent detection equipment for the printing and dyeing wastewater, a connection box is arranged and a cavity and a square hole are formed in the connection box, a clamping device and a second pressing rod which is fixedly connected with a second pressing block are arranged, and a rotary shaft which is in clamping connection with the square hole and holes which are symmetrically formed in left and right sides of the rotary shaft and are in clamping connection with the second pressing rod are arranged; the second pressing rod is separated from the holes through downward pulling the rotary shaft, so that the rotary shaft is convenient to detach; finally, the rotary shaft is convenient to replace and maintain and time and labor are saved.

Owner:湖州同晟管理咨询有限公司

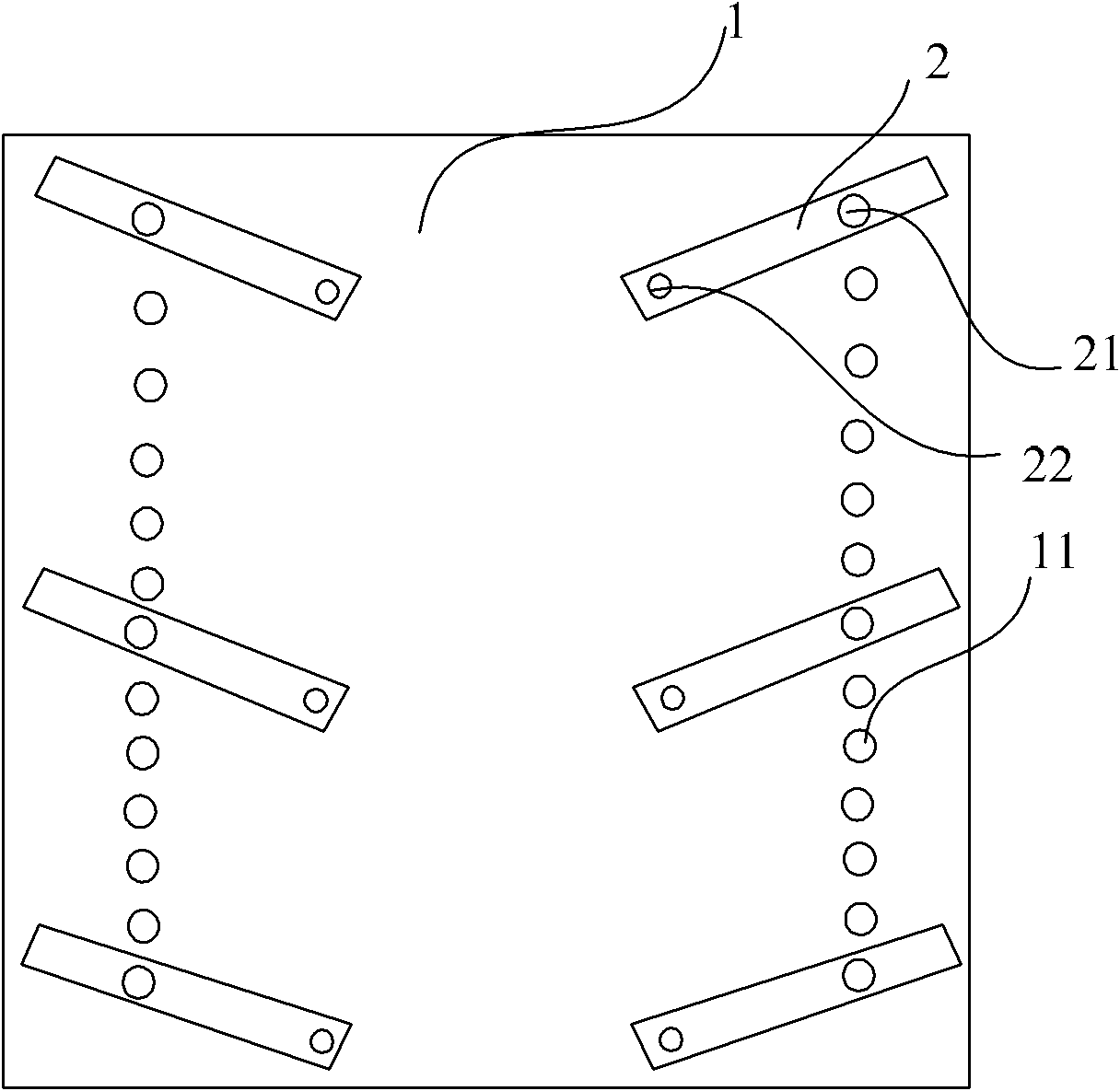

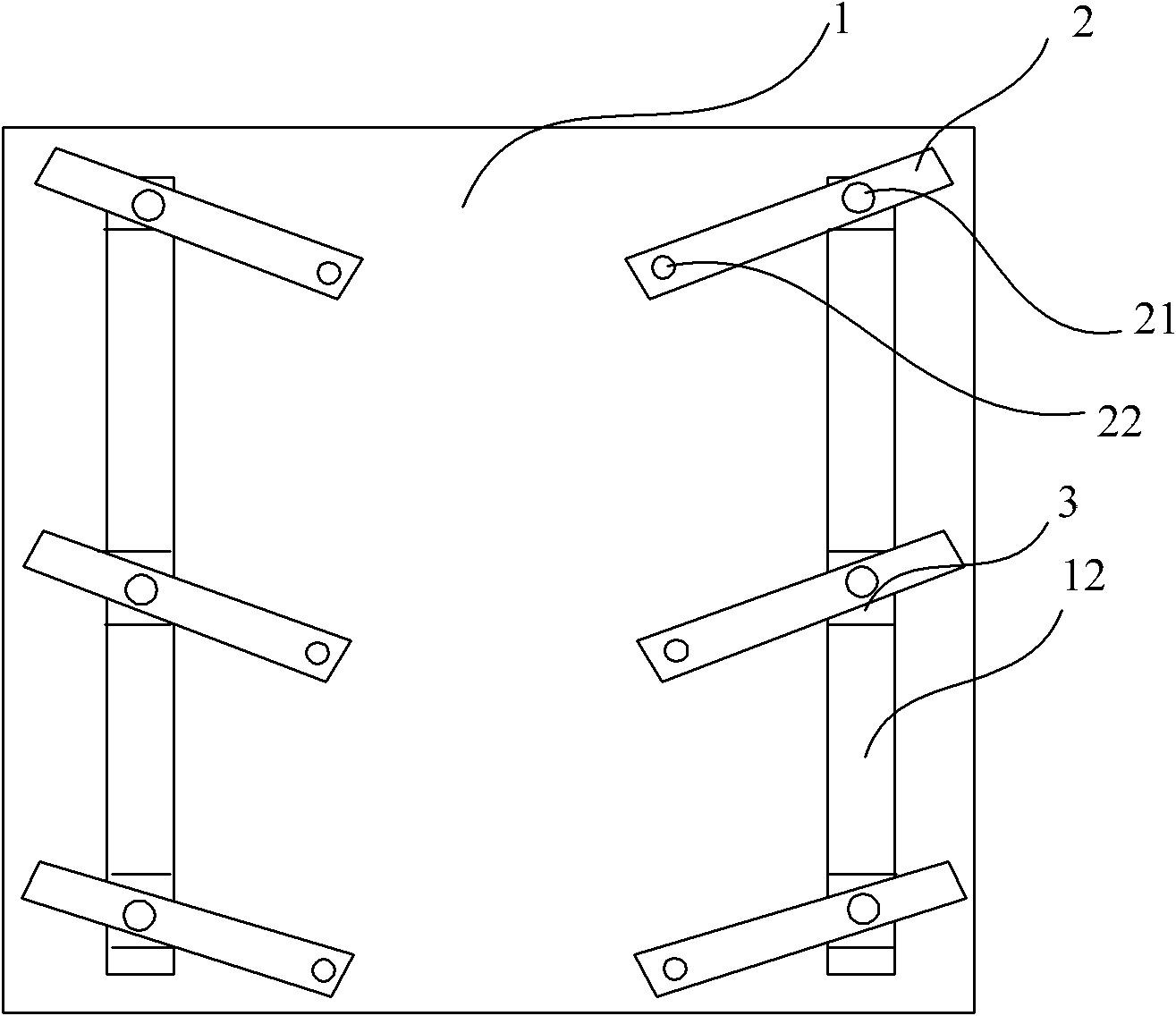

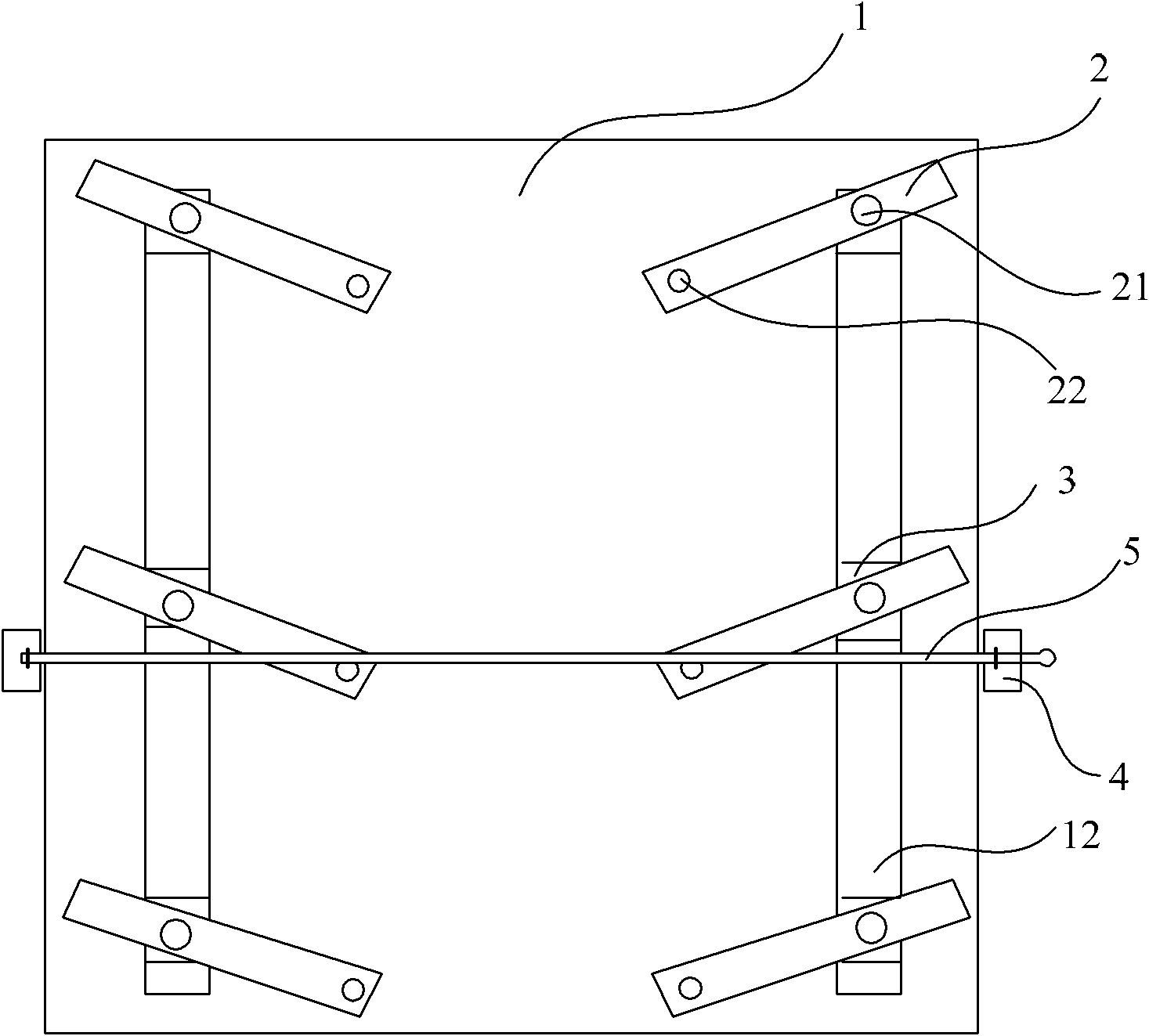

Main board locating device of mobile phone

InactiveCN103170783ALow costMake full use of resourcesWelding/cutting auxillary devicesWork holdersBar pressingMobile phone

The invention discloses a main board locating device of a mobile phone. The locating device comprises a base board and a plurality of locating press bars, wherein the locating press bars are connected on the base board in a rotary mode and respectively arranged into two lines which are parallel and opposite to each other, and locating thimbles used for locating the locating press bars are arranged on opposite end portions among the locating press bars. The main board locating device of the mobile phone conducts location to a main board of the mobile phone through the locating press bars and the locating thimbles, is suitable for preprocessing of various kinds of main boards of mobile phones, and can be used universally by various products, multiple work positions and used in a recycling mode. In addition, a press strip or an inclined foot can be arranged according to needs, and therefore a tool is enabled to be never scrapped, resources are fully used, and the production cost of the locating device is greatly saved.

Owner:SHENYANG CHENXUN SIMCOM TECH

Device and method for detecting bending degree of steel structure cross beam

ActiveCN109991101AReduce labor costsEasy to operateMaterial strength using steady bending forcesStress pointArchitectural engineering

The invention discloses a device and a method for detecting bending degree of a steel structure cross beam, and relates to the technical field of steel structures. The device comprises a mounting base, wherein two symmetric supporting plates are fixedly arranged on the upper surface of the mounting base; a fixing plate is arranged on the upper parts of the supporting plates; the upper surface of each supporting plate is fixedly connected to the bottom surface of the fixing plate; a pressing detection mechanism is fixedly arranged on the bottom surface of the fixing plate; a supporting mechanism is fixedly arranged on the upper surface of the mounting base; and the pressing detection mechanism comprises a movable plate, pressing plates, rollers, a pressing rod and an arc-shaped block. According to the device and the method for detecting the bending degree of the steel structure cross beam, the detection device can simultaneously detect multiple stress points of the steel structure crossbeam through the arrangement of the pressing detection mechanism and the supporting mechanism, a problem that the next stress point of the steel structure cross beam is detected after a worker movesthe steel structure cross beam in order to reduce the labor cost of the worker can be effectively avoided, and the operation is convenient.

Owner:曾庆雪

Non-linear press-rod spring device

InactiveCN1936357AImprove carrying capacityReduced carrying capacityNon-rotating vibration suppressionShock absorbersEngineeringBar pressing

Owner:HARBIN INST OF TECH

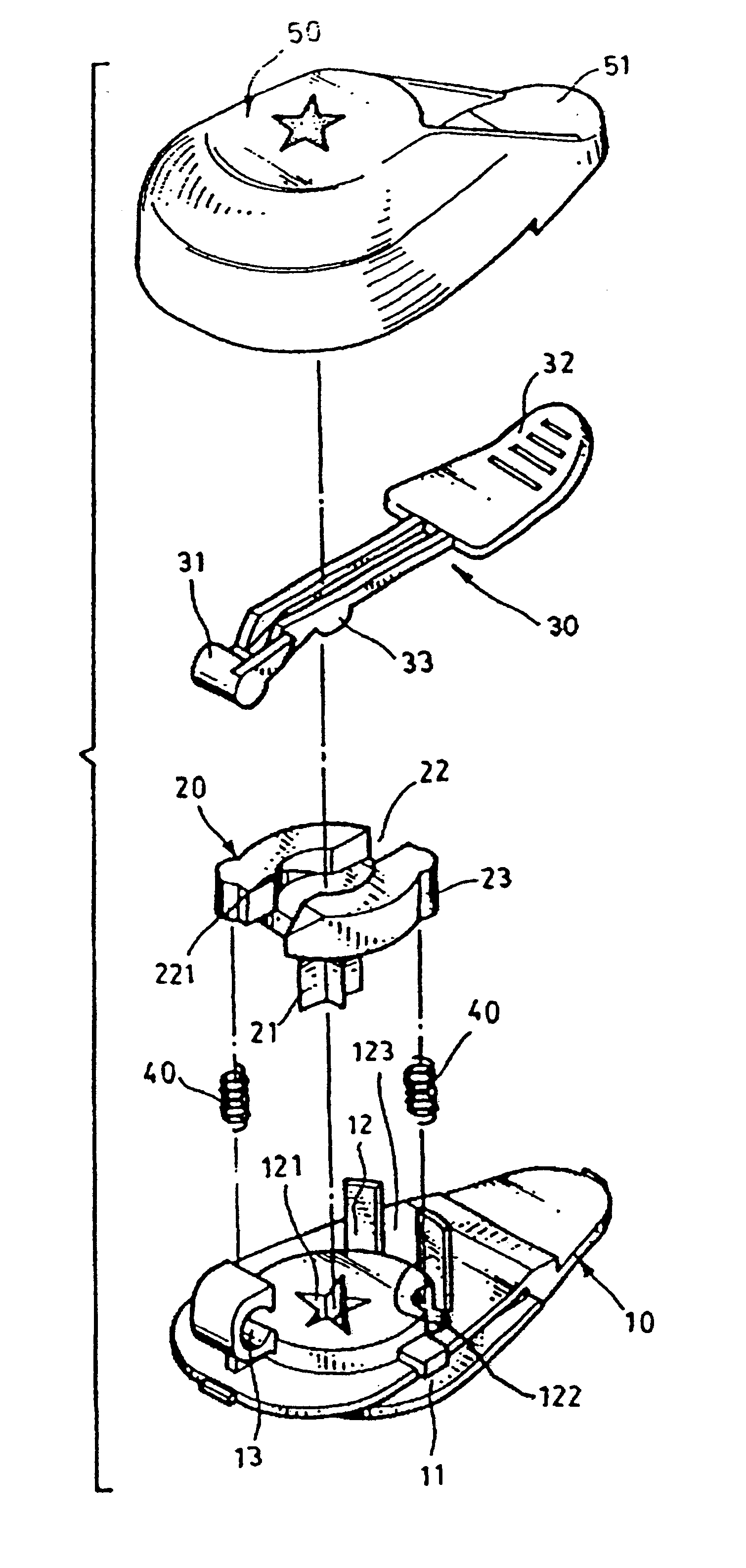

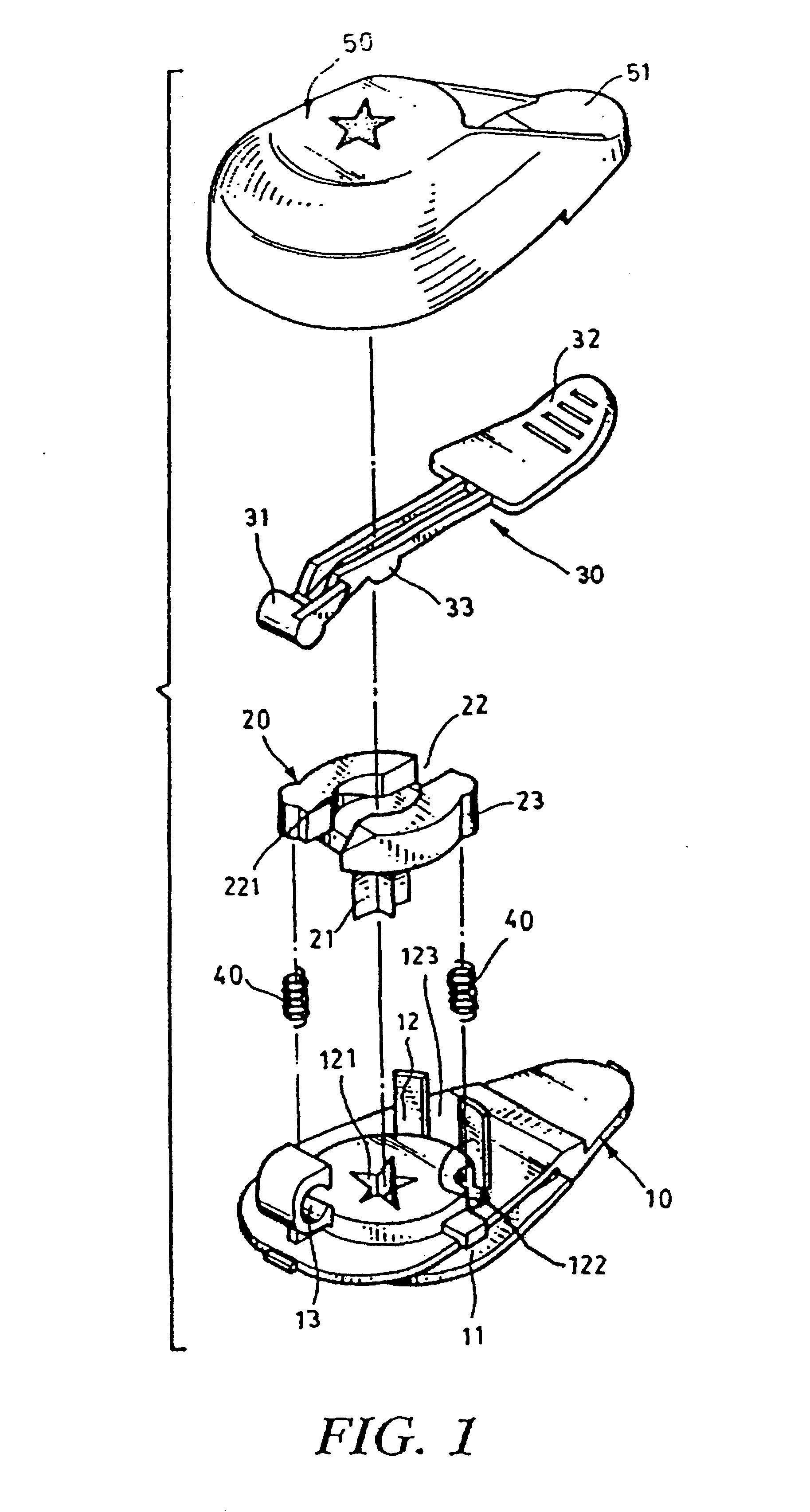

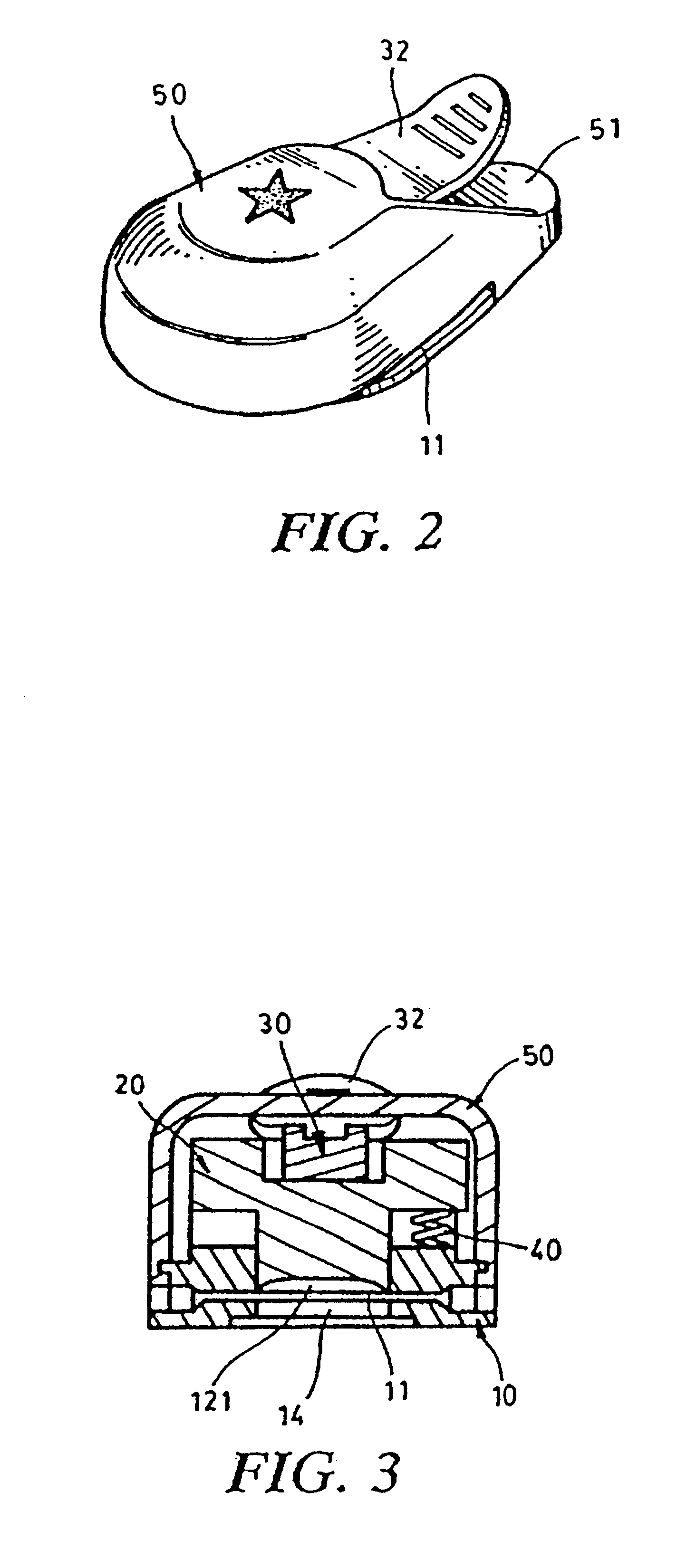

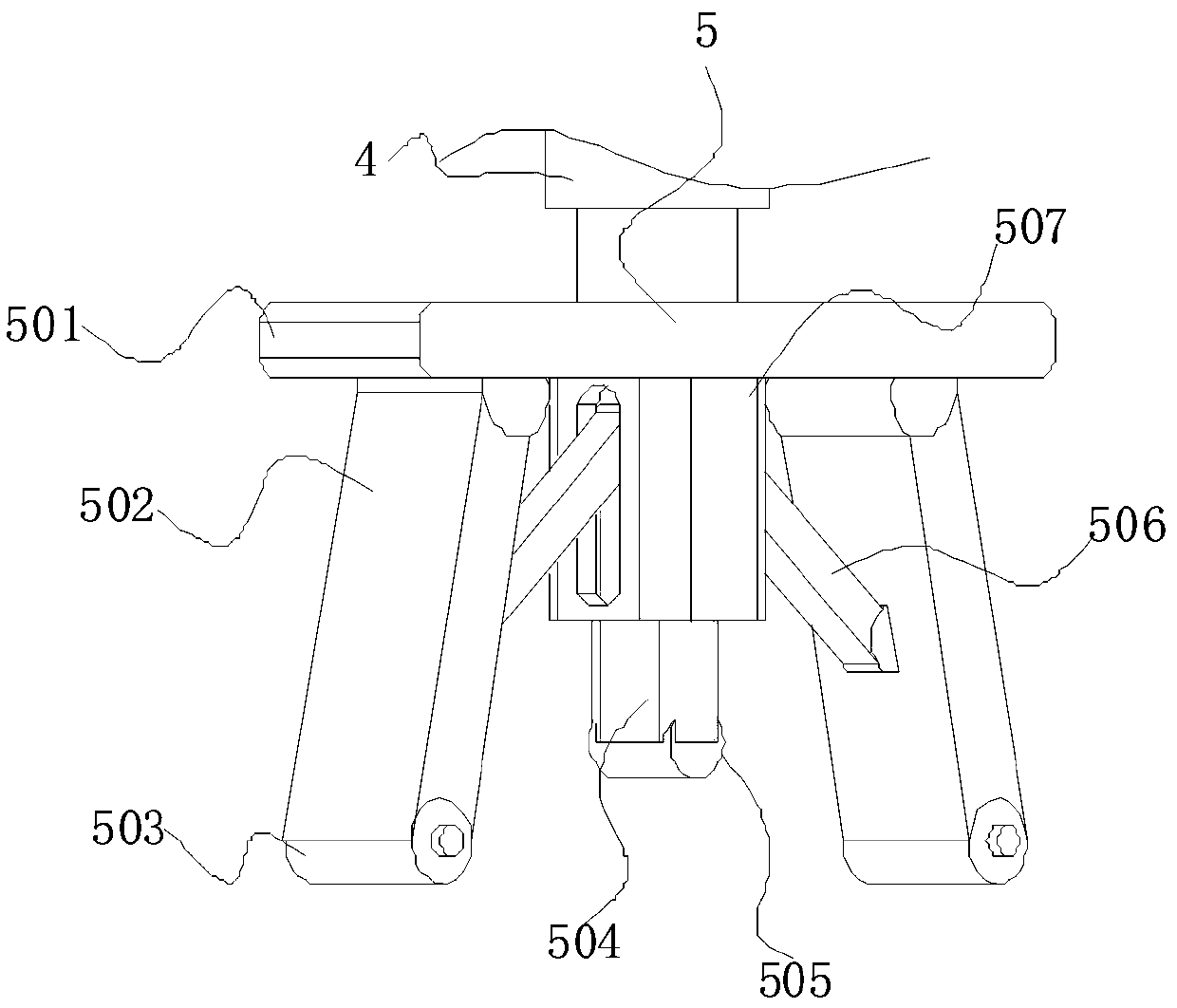

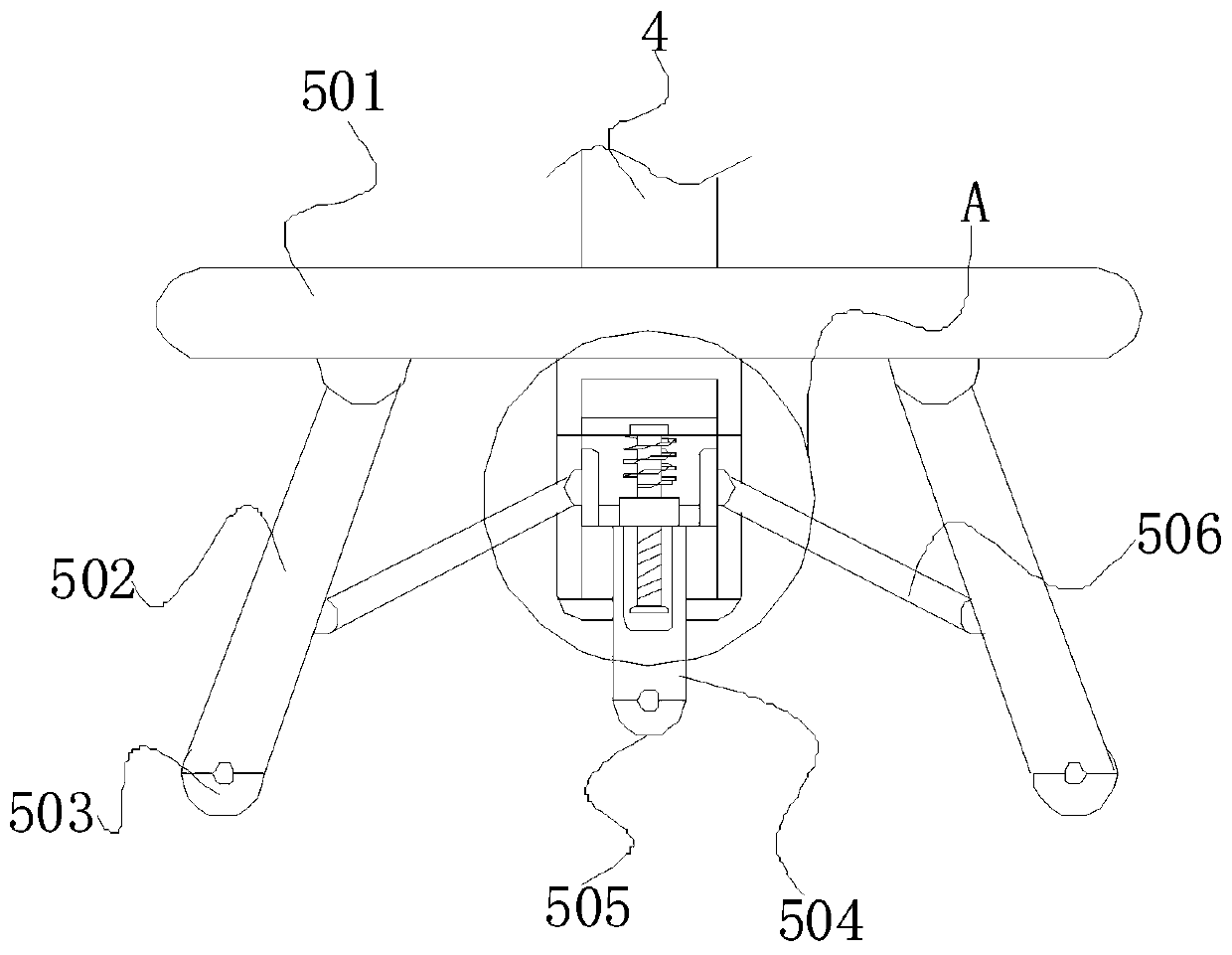

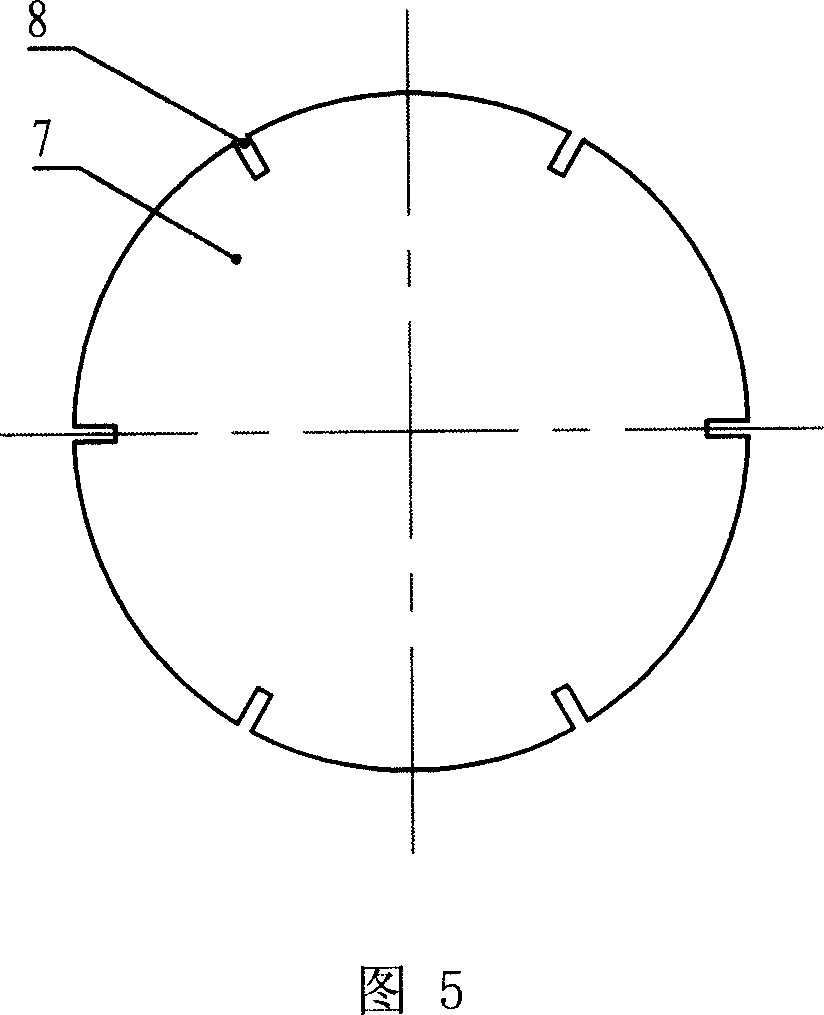

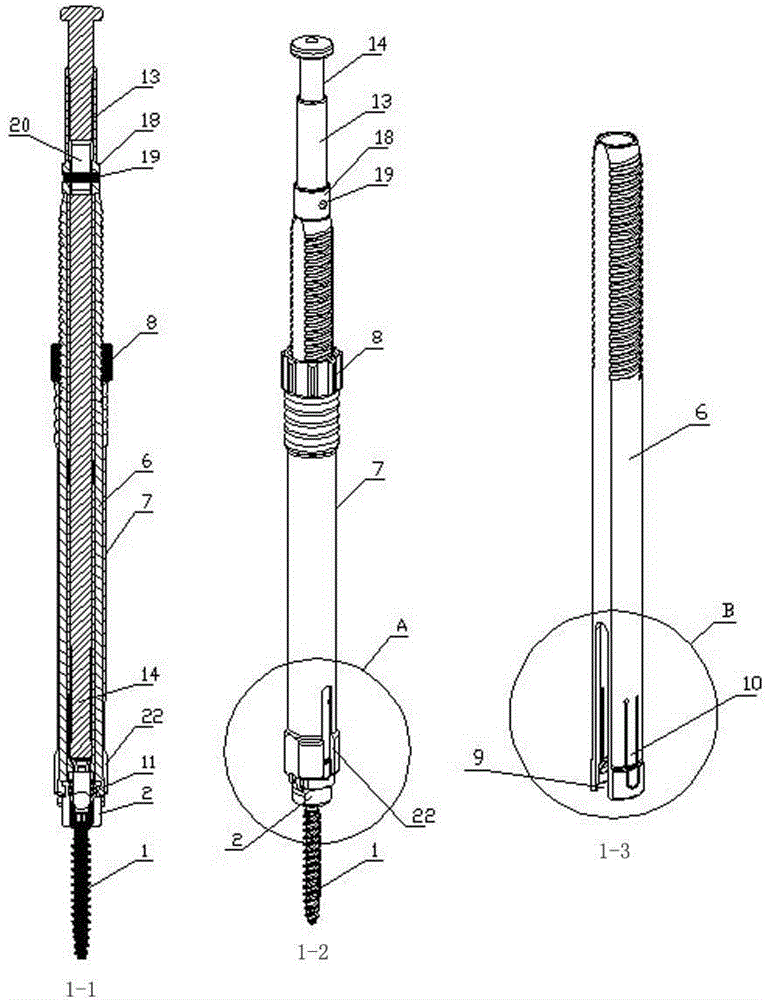

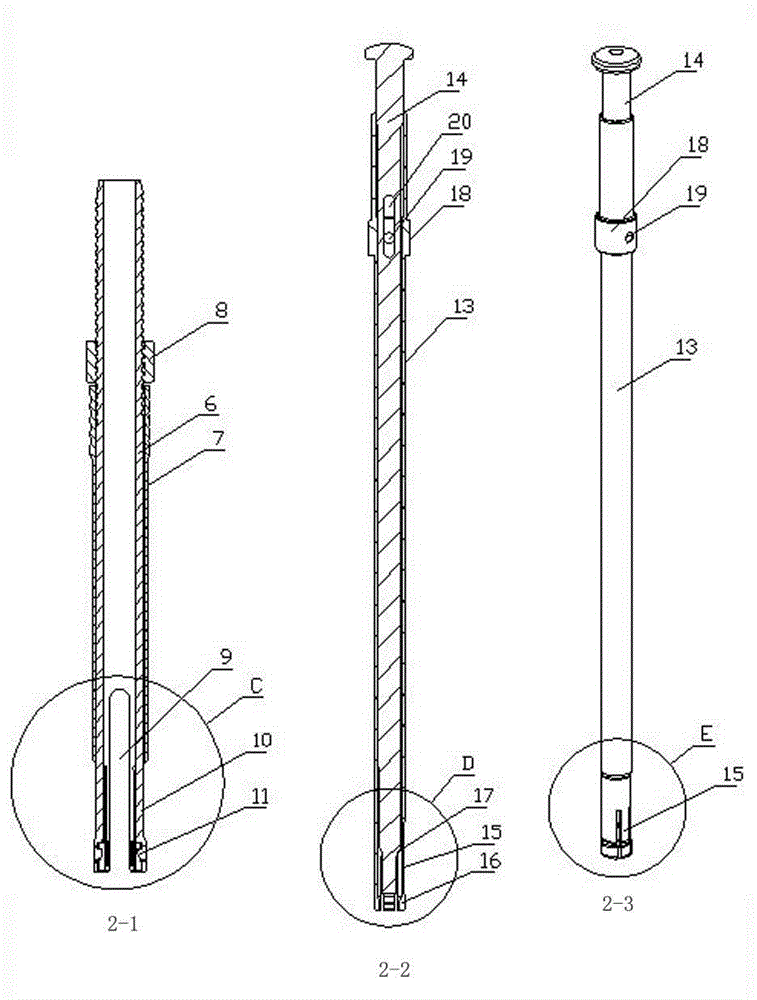

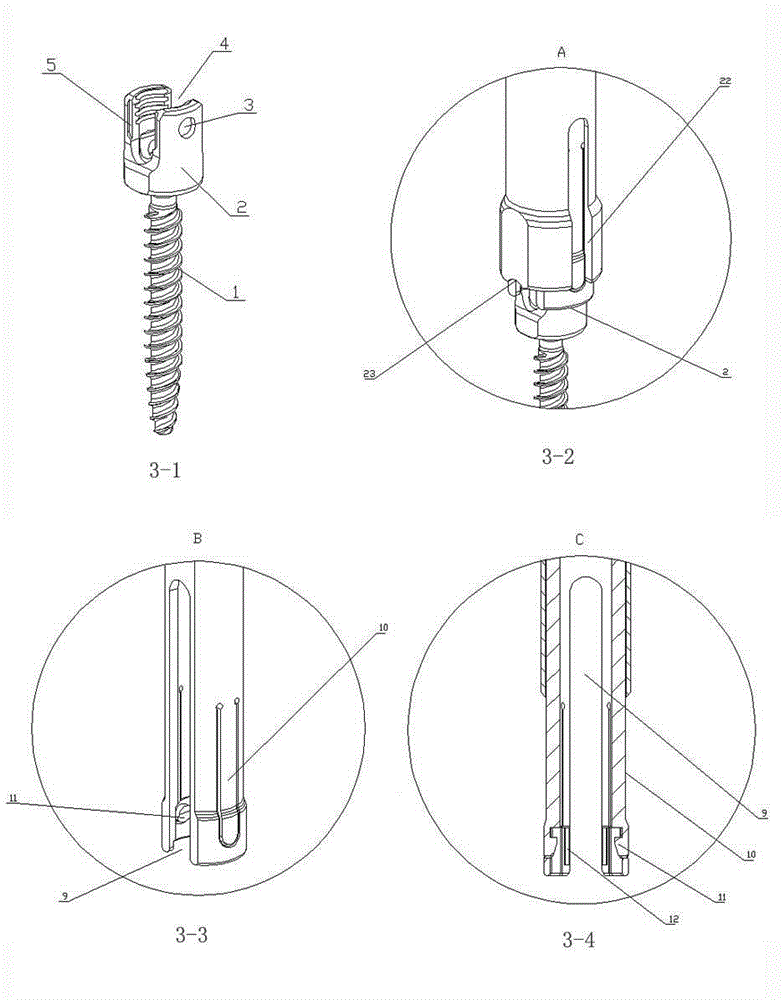

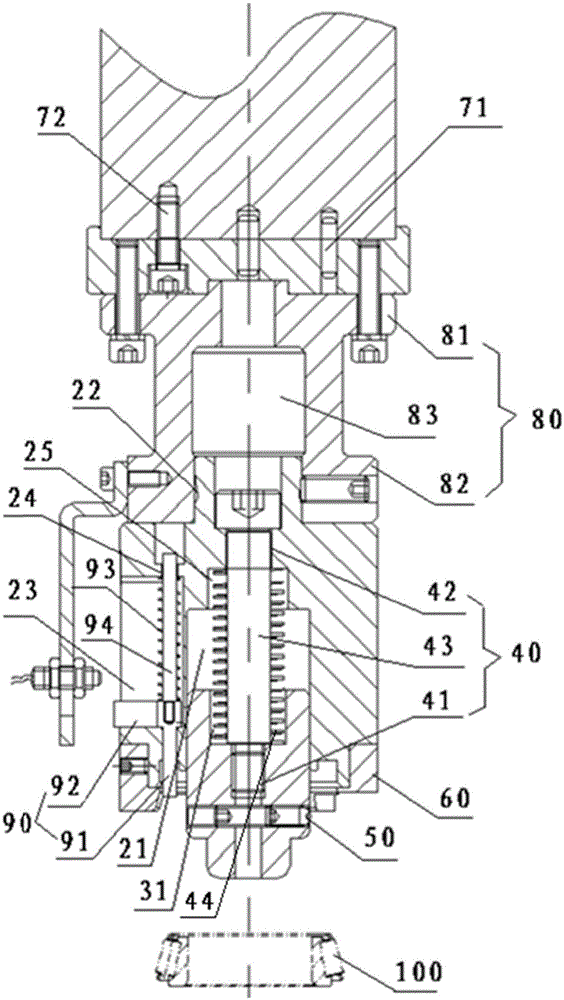

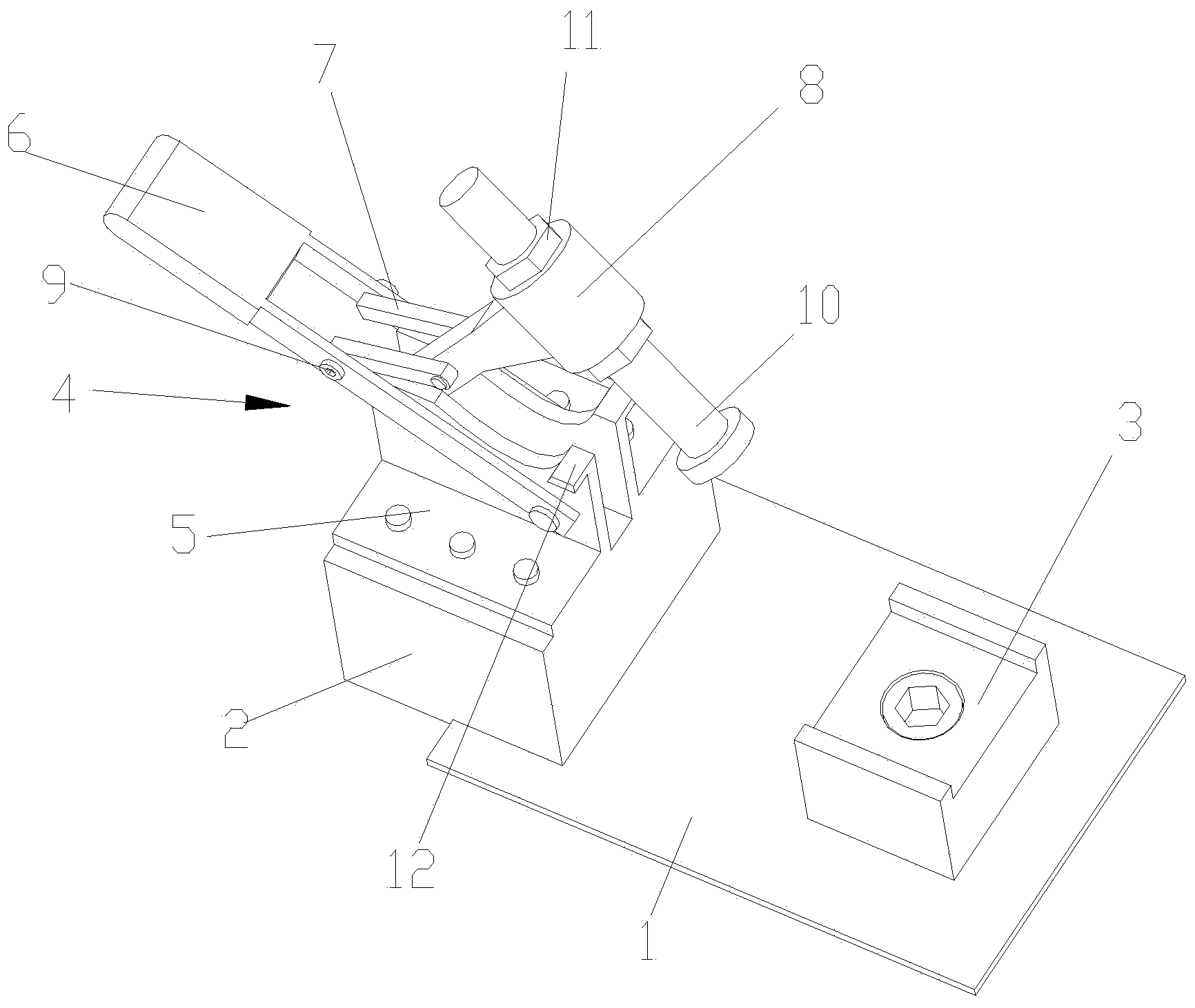

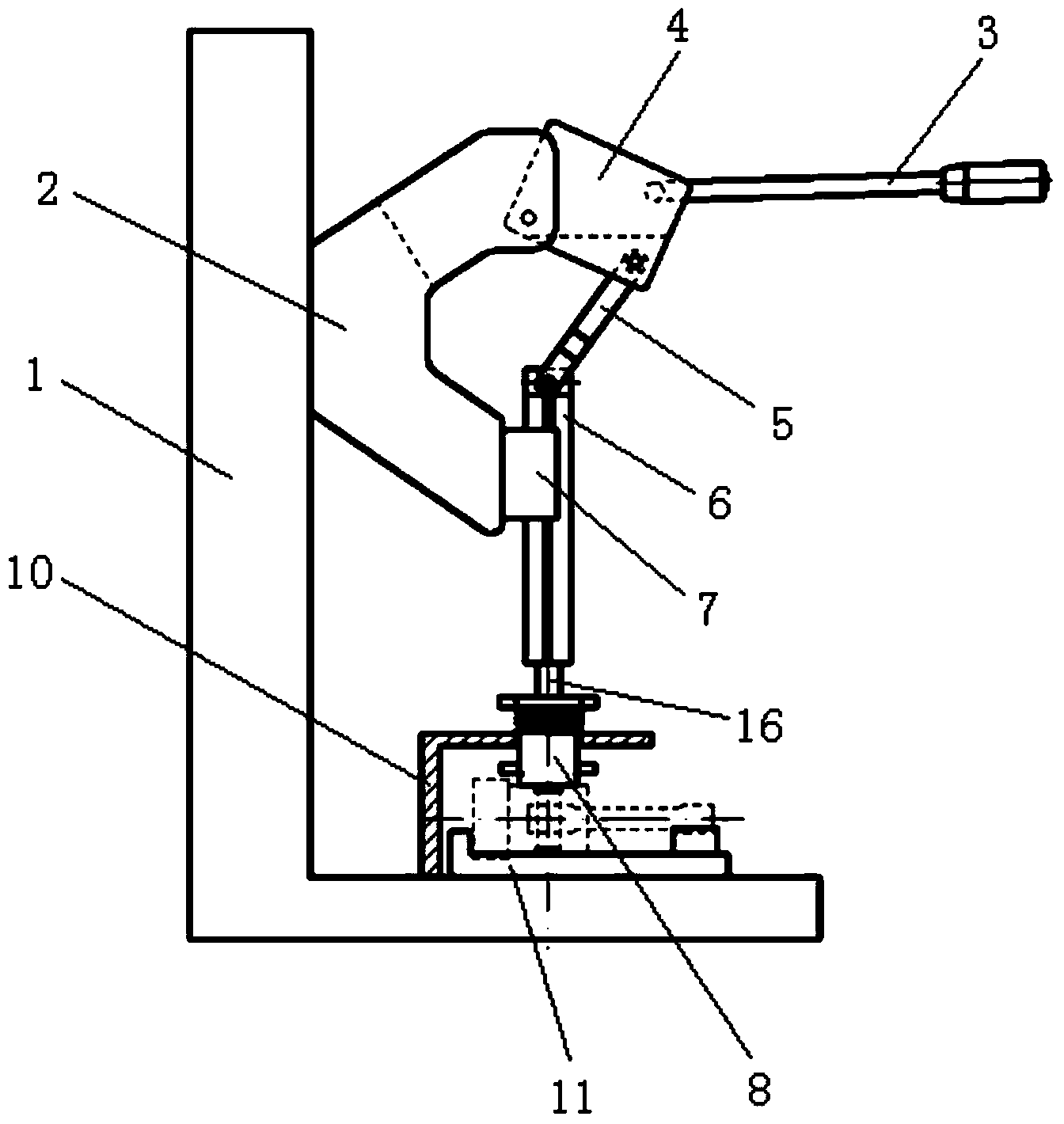

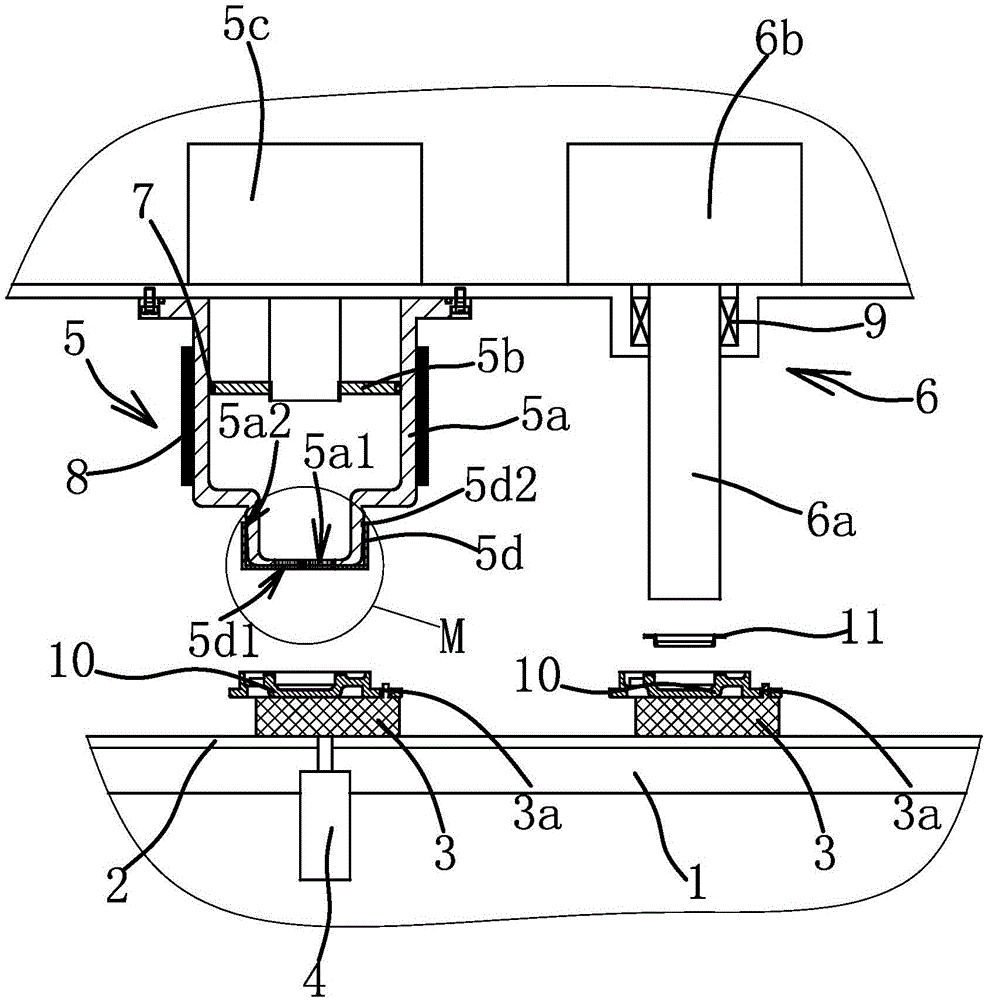

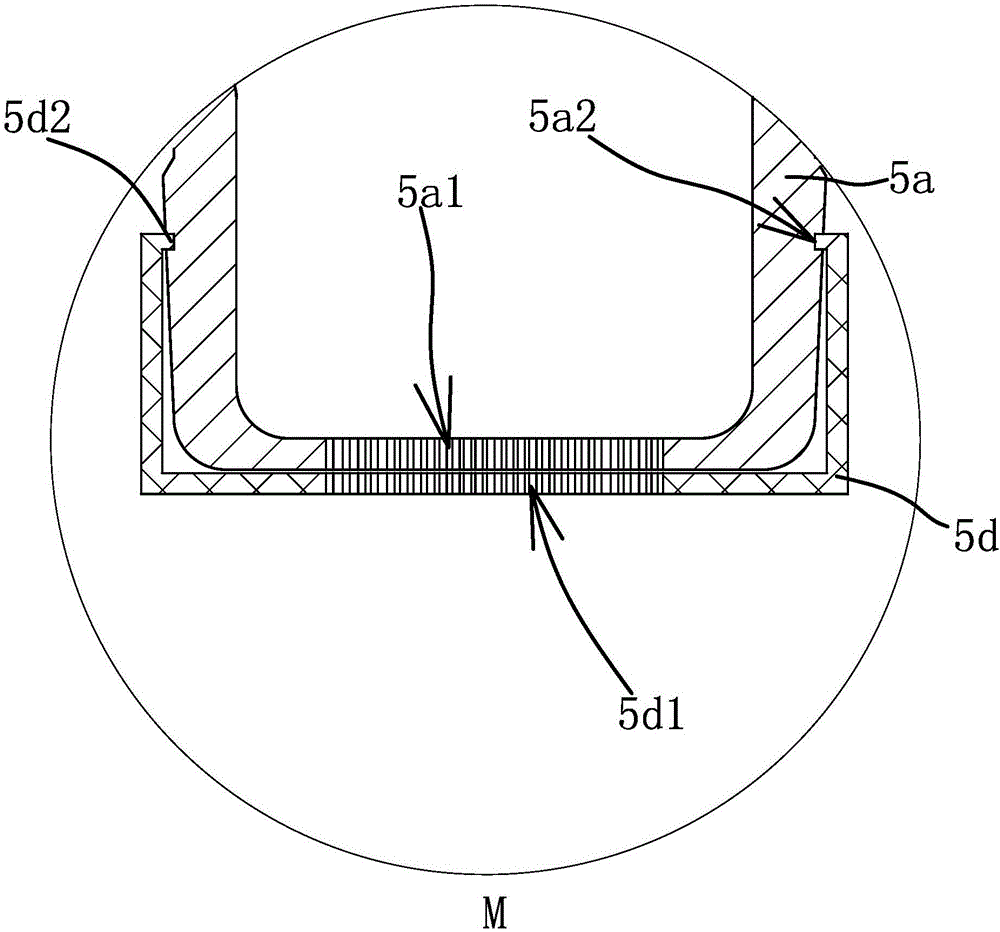

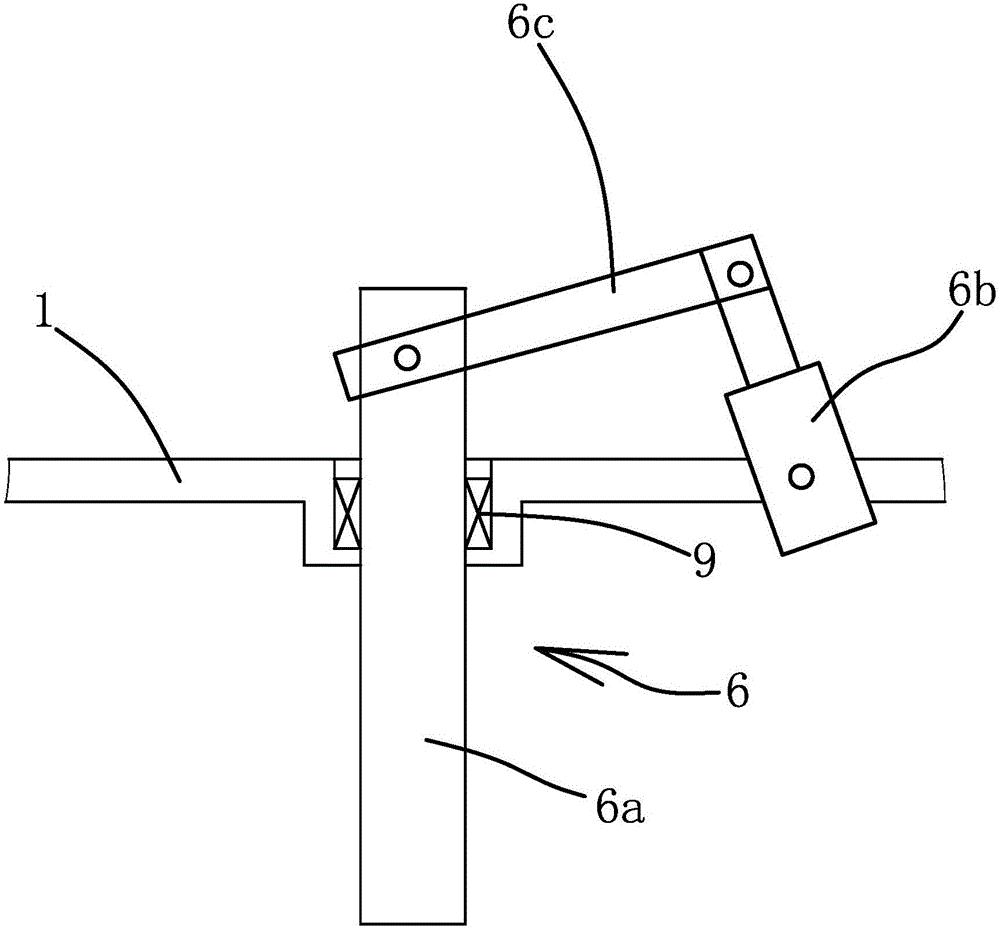

Pedicle screw and bar pressing device

ActiveCN104783879APrecise position controlEasy to disassembleInternal osteosythesisFastenersEngineeringBlock match

The invention provides a pedicle screw and a bar pressing device. The pedicle screw comprises a screw body and a screw base. A U-shaped bar containing groove divides the screw base into a left board body and a right board body. Positioning grooves are formed in the left side of the left board body and the right side of the right board body respectively. The pedicle screw is characterized in that positioning chutes with the upper open ends are longitudinally formed in the front sides and the rear sides of the upper ends of the left board body and the right board body respectively. The bar pressing device comprises an extension sleeve, a bar pressing sleeve and a bar pressing nut. A bar pressing groove is formed in the lower portion of the extension sleeve. Two opposite strip openings are formed in the side wall of the extension sleeve. Positioning elastic pieces are arranged in the strip openings. Positioning protrusions are arranged on the inner sides of the lower ends of the two positioning elastic pieces. Positioning sliding blocks matched with the positioning chutes and protruding inwards are arranged on the inner wall of the extension sleeve, the extension sleeve is sleeved with the bar pressing sleeve, and the bar pressing nut is arranged at the upper portion, above the bar pressing sleeve, of the extension sleeve. The pedicle screw and the bar pressing device have the advantages that connection is easy, convenient and quick, connection reliability is high, disengagement is not likely to happen, detachment is easy, the bar pressing operation speed is high, and efficiency is high.

Owner:SHANDONG WEIGAO ORTHOPEDIC DEVICE COMPANY

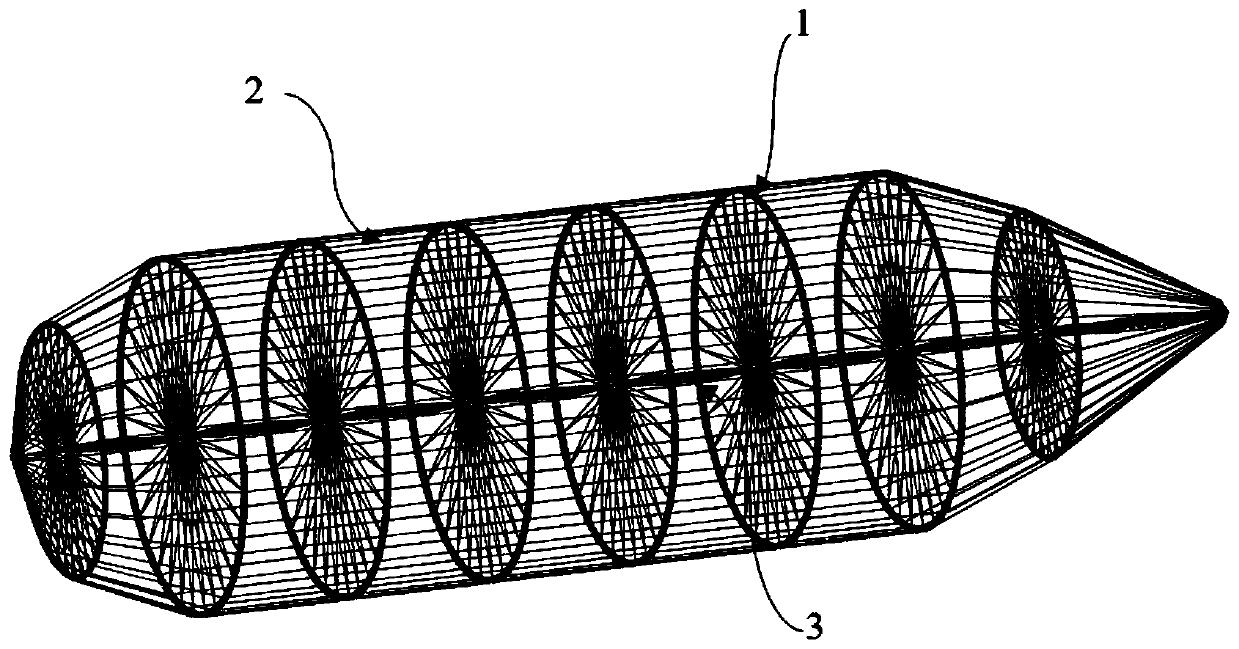

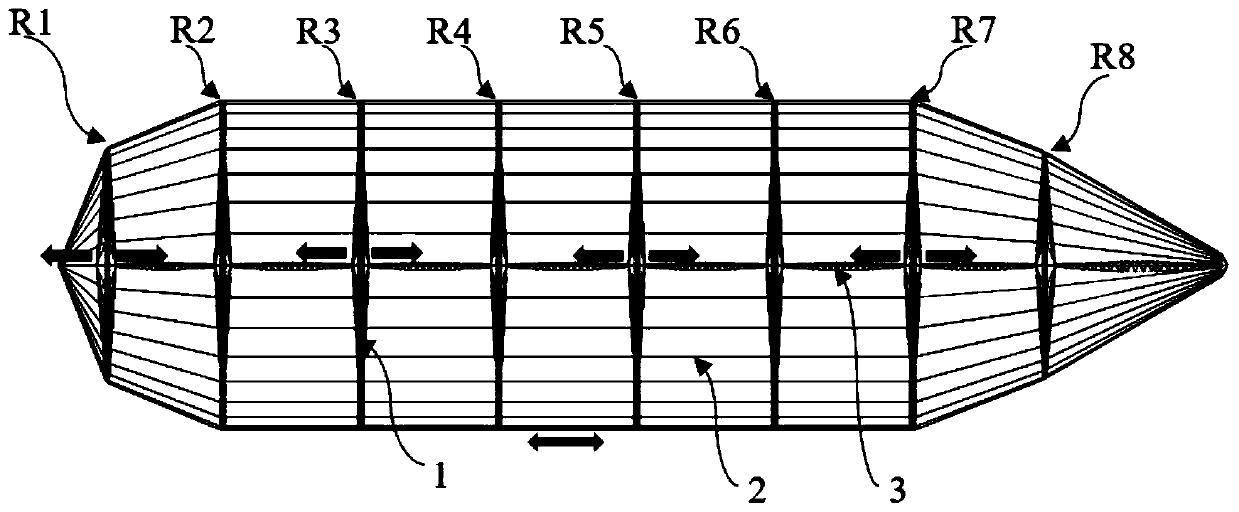

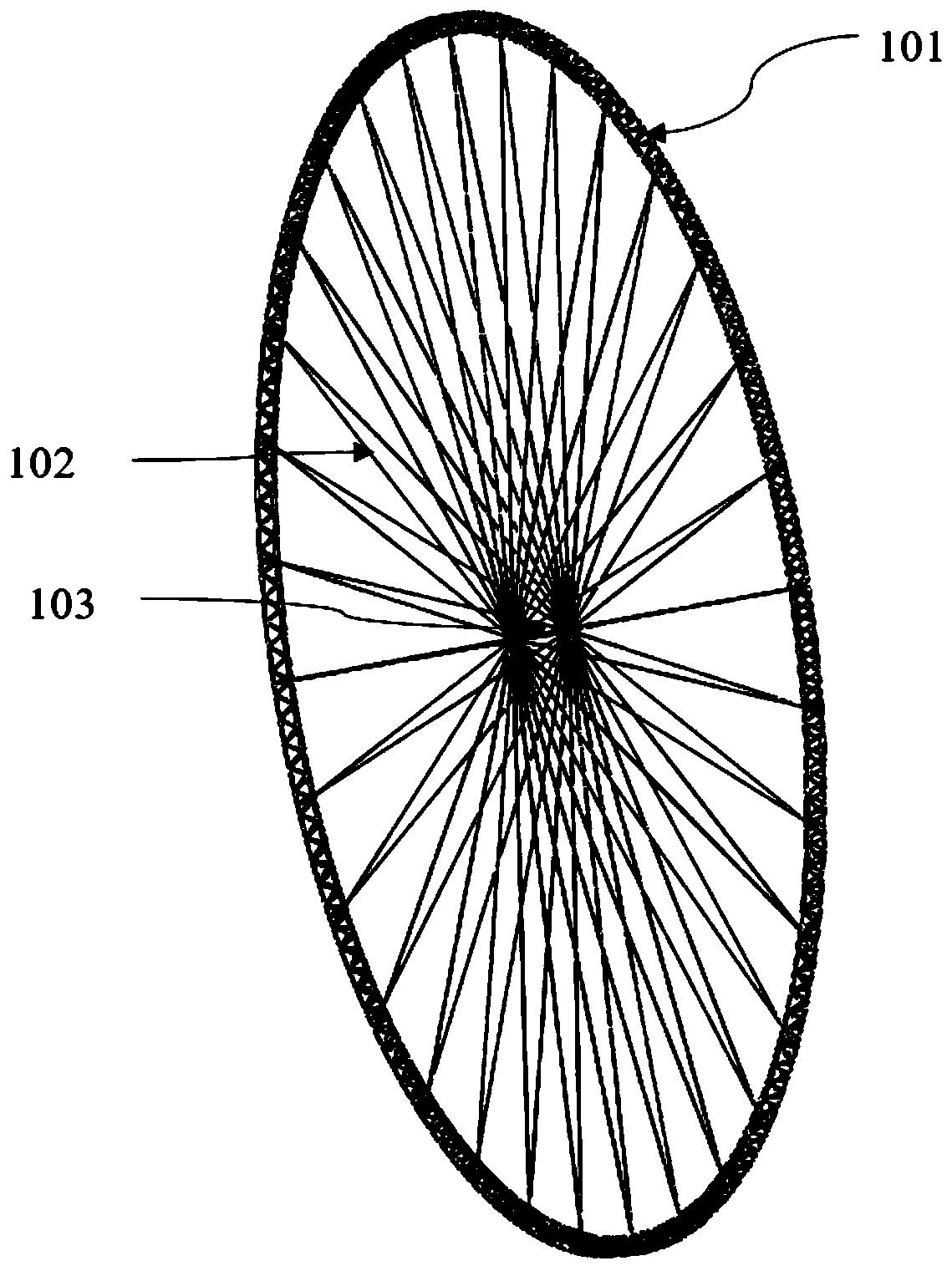

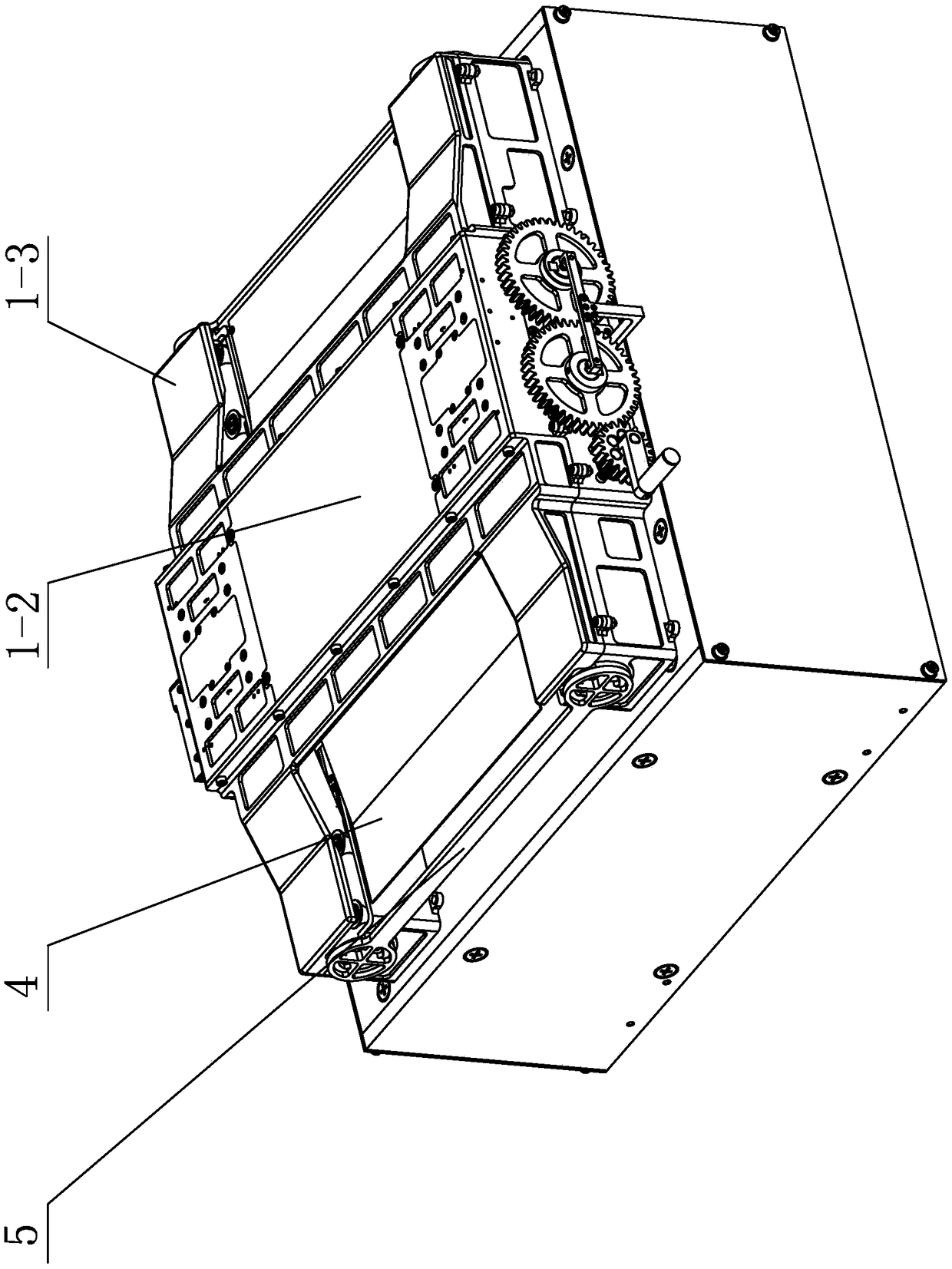

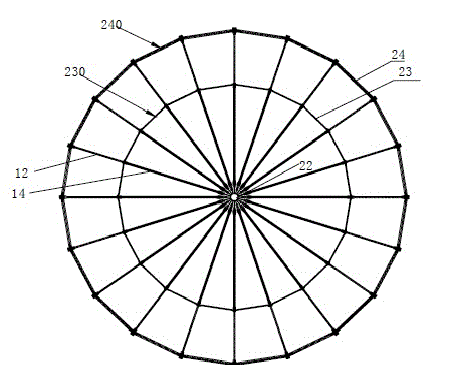

Compression bar contact type tensegrity structure and integration and tension exertion method

ActiveCN109969373AReduce weightIncrease stiffnessGeometric CADGirdersHigh stiffnessGeometric stability

The invention discloses a compression bar contact type tensegrity structure and an integration and tension exertion method, and relates to the technical field of engineering structure. The compressionbar contact type tensegrity structure comprises stiffening ring triangular trusses, core shaft triangular trusses and longitudinal pulling rods. The stiffening ring triangular trusses are pressed inan isolation mode; the core shaft triangular trusses bear pressure in a contact mode; and the longitudinal pulling rods are constantly pulled, and a plurality of paralleled outer rings of the stiffening ring triangular trusses in the heat-to-tail sequence and are closed to tails. The compression bar contact type tensegrity structure is a self-balance and self-bearing structure, segmented assemblage is adopted, the compression bar contact type tensegrity structure symmetrically extends, modules are integrated in an assembly mode, the longitudinal pulling rods are enabled to exert uniform tension through the graded and symmetric synchronized push of ends of the core shaft triangular trusses. The compression bar contact type tensegrity structure and the integration and tension exertion methodhave the characteristics of light weight, high stiffness, high geometric stability, and high practicability; the installation integration method is simple, convenient and safe, and has a high expandability; and the tension exertion method is effective, the tension exertion equipment is less, control is easy, the tension is uniform and precise, and the structural joint is simple and neat.

Owner:SHANGHAI JIAO TONG UNIV +1

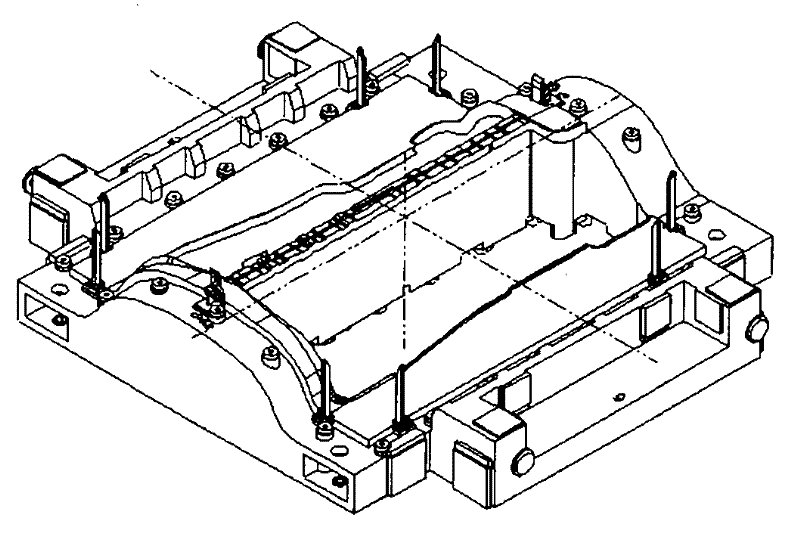

Aluminum alloy die casting piece trimming die with smooth cut

InactiveCN102527820AAvoid breakingEasy to assemble and disassembleShaping toolsBar pressingAluminium alloy

The invention discloses an aluminum alloy die casting piece trimming die with a smooth cut. The aluminum alloy die casting piece trimming die comprises an upper die, a lower die, a guide structure arranged between the upper die and the lower die, a product positioning structure arranged on the lower die, and a trimming cut arranged on the upper die. A hollow cavity is formed below a lower die fixing plate and internally provided with a support plate capable of moving up and down, the support plate is provided with a return rod and a plurality of support rods for supporting a feeding handle, the upper ends of the return rod and the support rods extend out of the upper surface of the lower die and is connected with the lower die in a sliding manner, a compression rod is arranged at a position of the upper die, which corresponds to the return rod, and an elastic reset element is arranged between the support plate and a lower compression plate of the lower die. According to the aluminum alloy die casting piece trimming die disclosed by the invention, when the punching is conducted, the feeding handle is kept at the horizontal state all the time, so that the cut of a product after being punched is smooth and orderly; and when the punching is conducted, the product is ejected synchronously so as to be easy to take out, and the surface of the product is avoided from damaging; and a guide pillar and a guide sleeve can be disassembled conveniently, and the guide pillar is not easy to break.

Owner:宁波久腾车灯电器有限公司

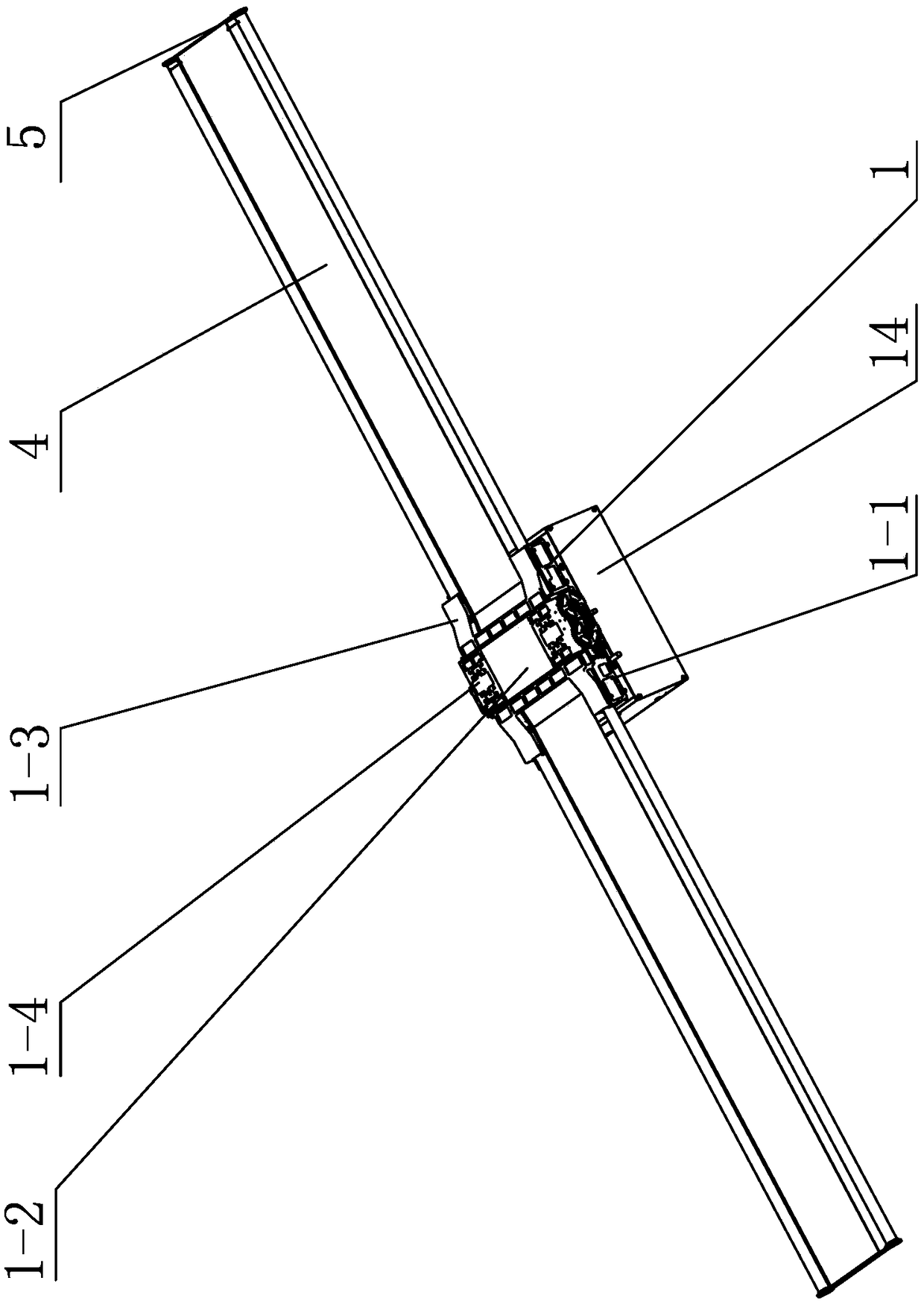

A flexible solar wing elastic stretching rod repetitive unfolding and retracting mechanism

ActiveCN109094821AReduce weightHigh specific powerCosmonautic vehiclesCosmonautic power supply systemsSpace powerBar pressing

The invention relates to a flexible solar wing elastic stretching rod repetitive unfolding and retracting mechanism, which relates to the field of aerospace space mechanism. The invention solves the problems of large folding envelope, heavy weight and low specific power of the prior rigid and semi-rigid solar wing which adopts the unilateral deployment mode. The two force transmission devices of the invention are fixed on the mounting base side by side, A deployment bar is arranged on both sides of the flexible solar blanket, A flexible solar blanket is connected to the deployment lever by a rope, At that end of the flexible solar blanket is wound up on a solar blanket take-up roll, At that end of the unwrap bar is wound up on the unwrapping bar take-up drum, A distal end of that deployment bar is press against the deployment bar retracting roll by a deployment bar pressing device, Four unfolding bar guides correspond to four unfolding bars one by one. An initial driving device is arranged inside the inner guide cylinder of the unfolding bar guide. An initial pressing and releasing device is installed at one end of the force transmission device of the unfolding roller, and an electric recovery driving device is installed at the other end of the force transmission device of the unfolding roller. A space power supply for a spacecraft is provided.

Owner:HARBIN INST OF TECH

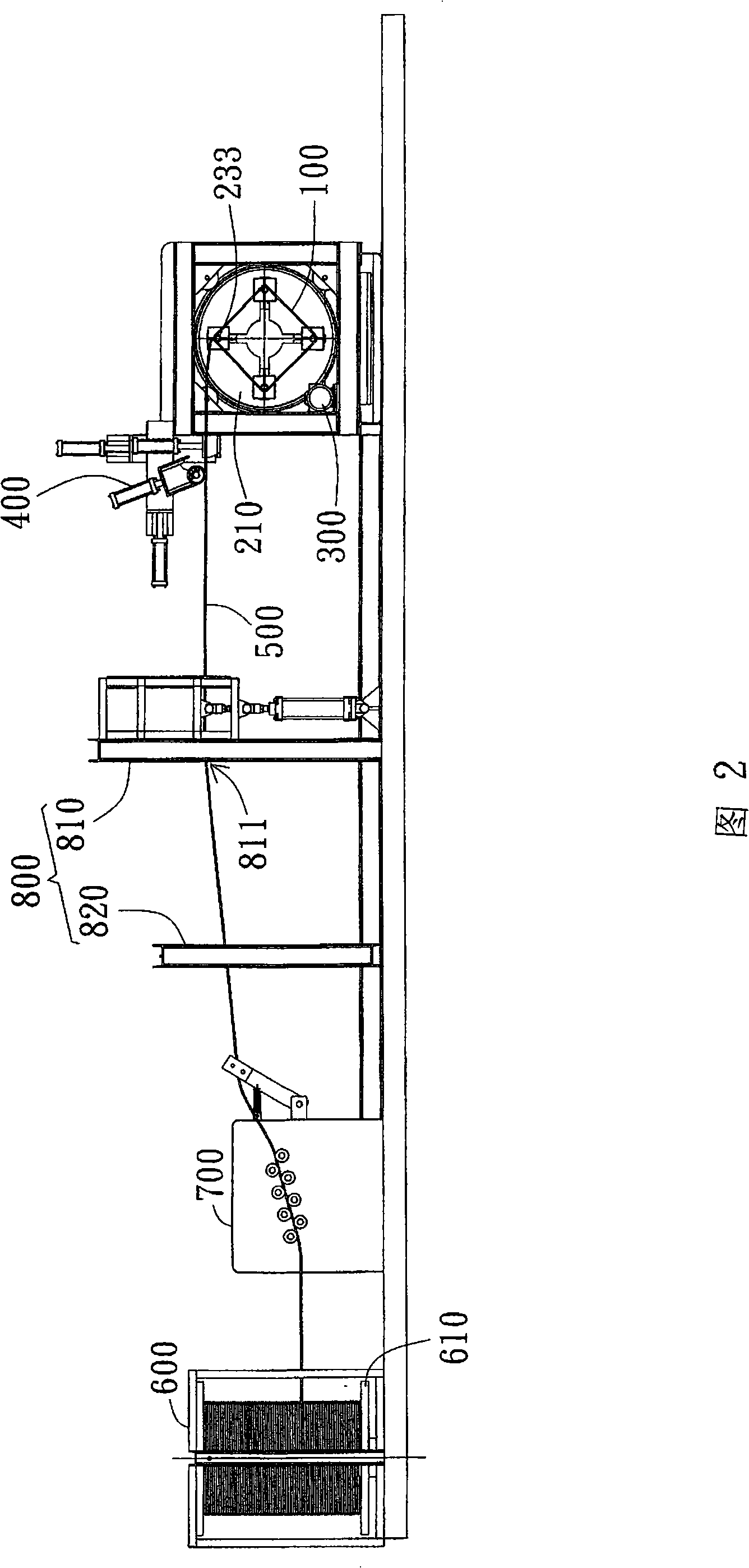

Fabric compounding apparatus

ActiveCN110802909AUnwinding is smooth and orderlyEfficient and smooth coatingSpraying apparatusLaminationElectric machineryMechanical equipment

The invention discloses a fabric compounding apparatus, and belongs to the field of textile processing machinery and equipment. In the apparatus, the middle of an unwinding turntable is horizontally and fixedly provided with an unwinding bearing rod, the terminal end of a pressure disc rotation rod at the upper side of the unwinding turntable is vertically and rotationally connected with a dampingrotation wheel, a pressure rod slide block is arranged on a rotation guide rod in a sliding manner, a cloth guide bearing plate is tilted downwards and fixedly arranged on a composite support frame at the lower side of the unwinding bearing rod, a feeding roller is horizontally arranged at the upper side of the cloth guide bearing plate, a plurality of gluing nozzles are arranged at the lower side of a glue spraying guide pipe, an upper material guide roller and a lower material guide roller are arranged in a compression fit manner, an upper pressing support frame and a lower pressing supportframe are arranged on the composite support frame in order from top to bottom, and a cloth pulling motor and a cloth pulling roller are connected by a cloth pulling chain in a transmission manner. The structure design of the apparatus is reasonable, the continuous and smooth compounding of the fabric can be performed rapidly and efficiently during the material transfer process, the efficiency andquality of fabric compounding are improved, the automation degree is high, and the needs of processing and use are met.

Owner:TONGXIANG YUESHUN WRAP KNITTING

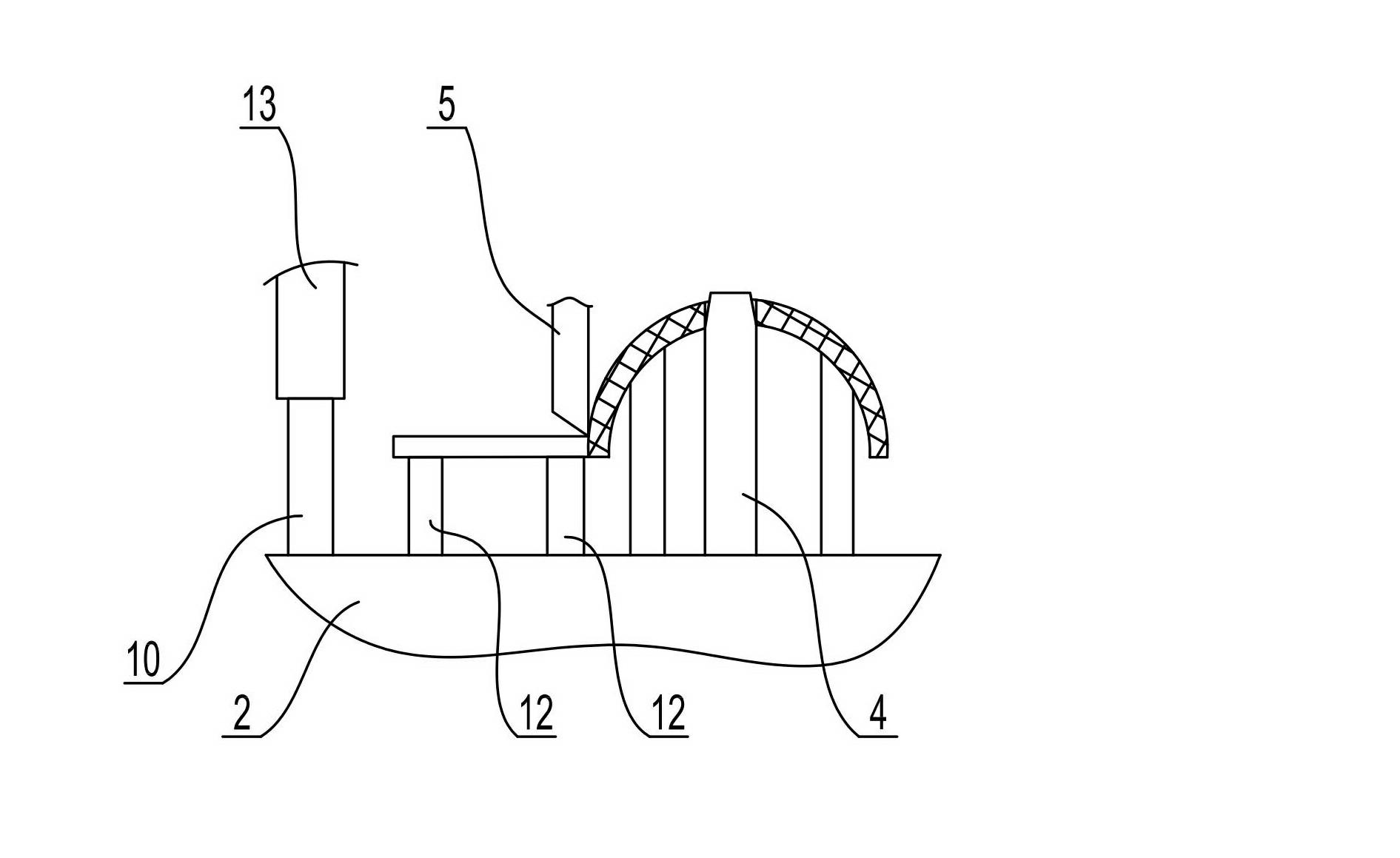

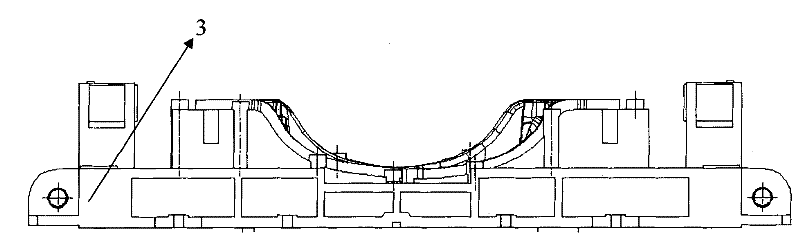

Grooved roller type separating and broken seedling removing mechanism of potato tubers

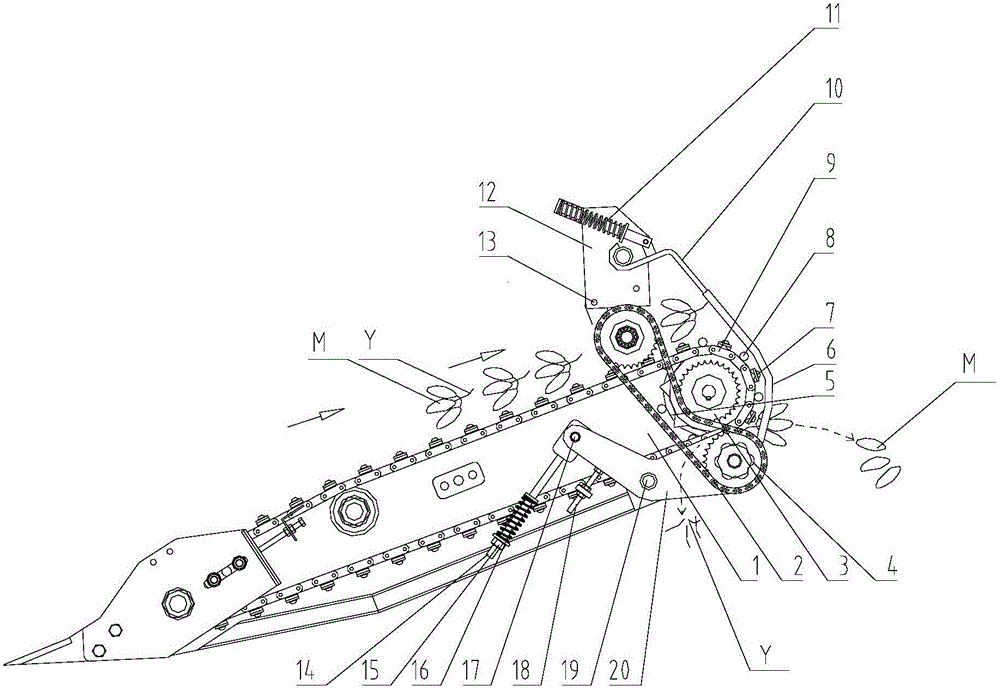

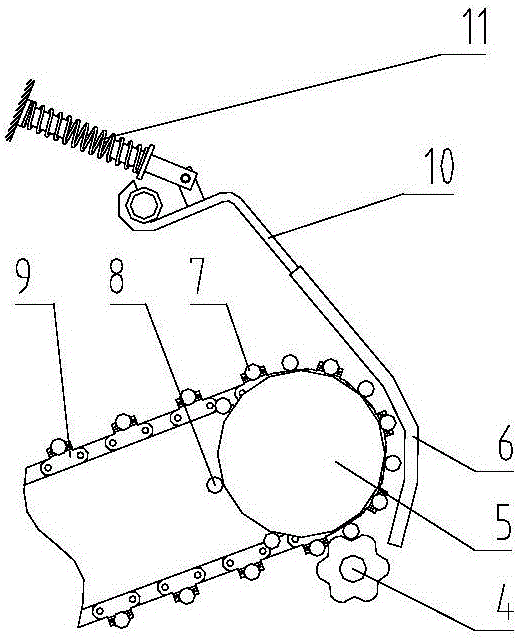

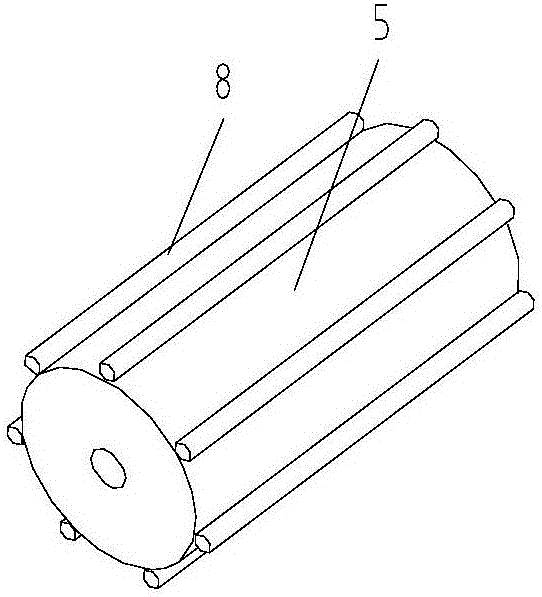

ActiveCN105052340ALess chance of breaking freeHigh removal rateTopping machinesEngineeringBar pressing

The invention relates to a grooved roller type separating and broken seedling removing mechanism of potato tubers and belongs to the mechanical field of agricultural harvesting machines. The mechanism comprises a conveying bar elevator chain (9) of a surrounding excavation conveying device (1). A bar pressing roller (5) driven by a power device is arranged on a high end of the conveying bar elevator chain (9). An elastic bar mechanism (12) is arranged on the bar pressing roller and extends out of an elastic bent bar (10) which is pressed on the output end of the conveying bar elevator chain. A groove type seedling removing roller (4) engaged to the bar pressing roller is installed under the bar pressing roller via axially-extending grooves uniformly distributed in the outer periphery. The mechanism is capable of allowing seedlings entering thereof to be in concave and convex compression sate, so frictional drawing force is remarkably increased and it is improbable for the seedlings to struggle against the mechanism but being drawn off from potatoes, so seedling removing rate is remarkably increased.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

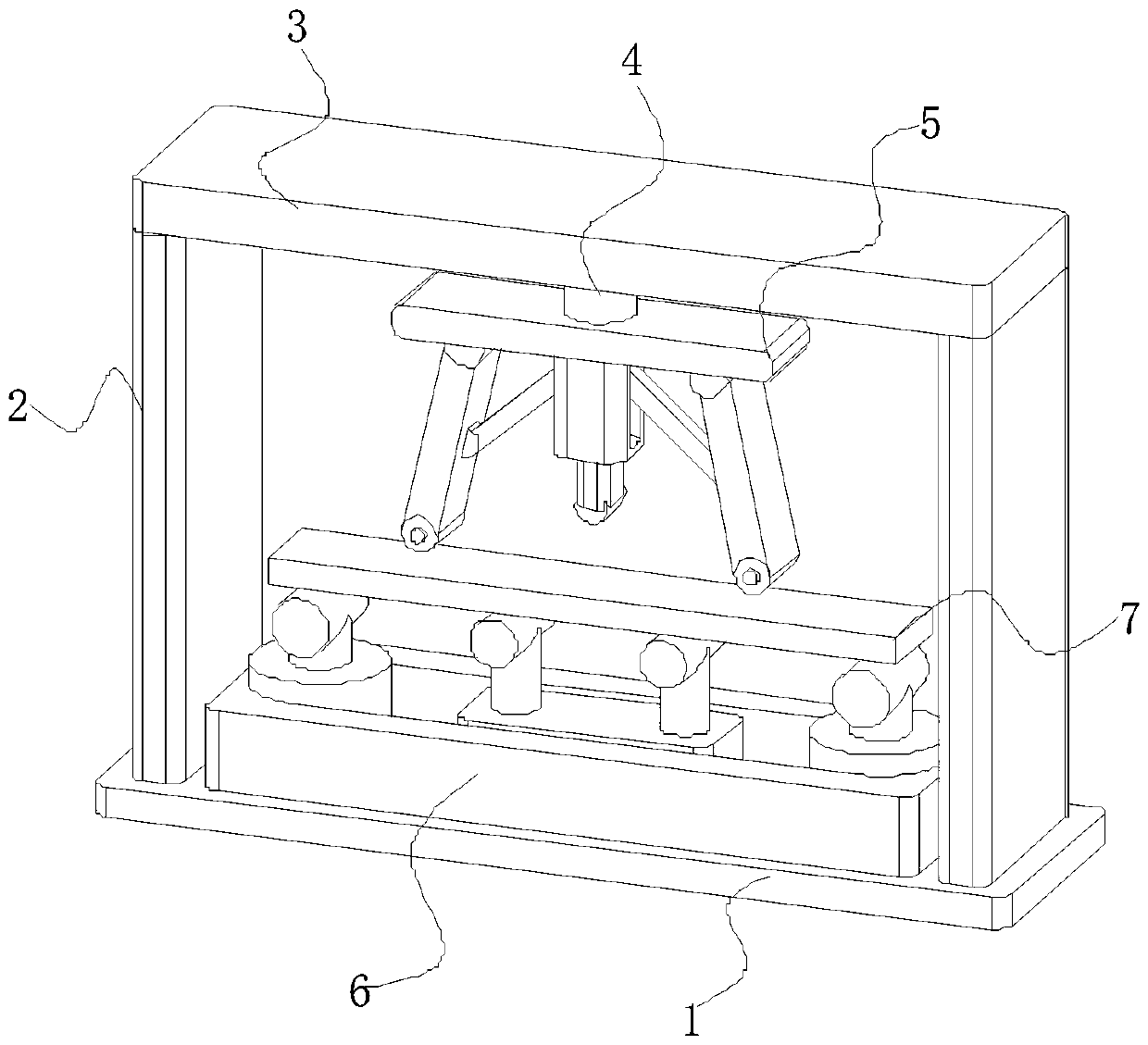

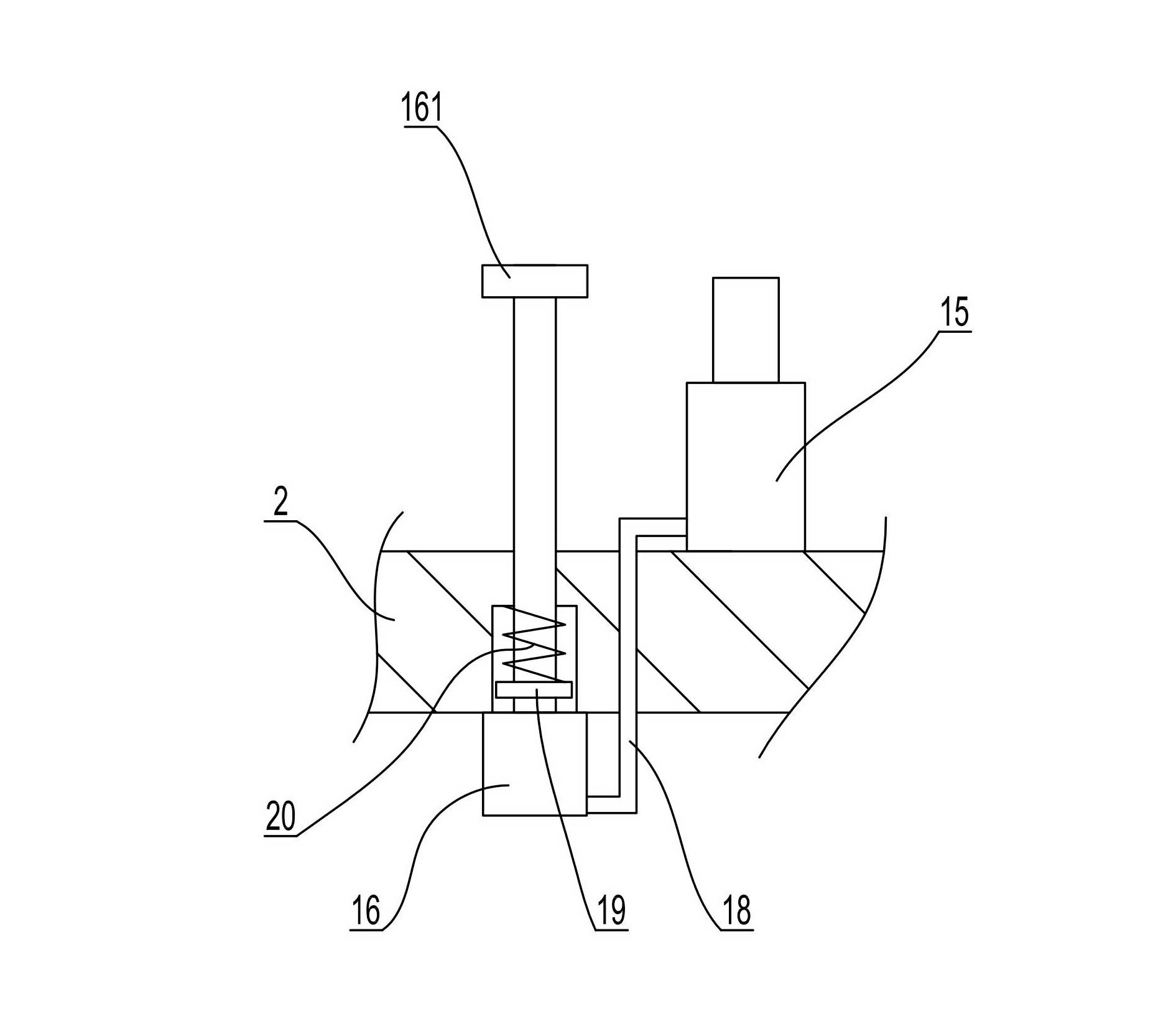

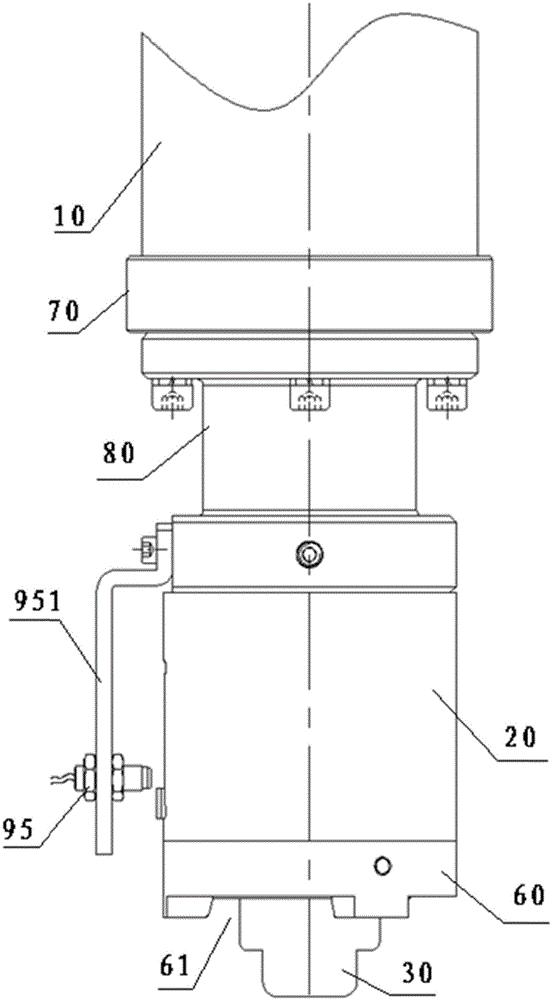

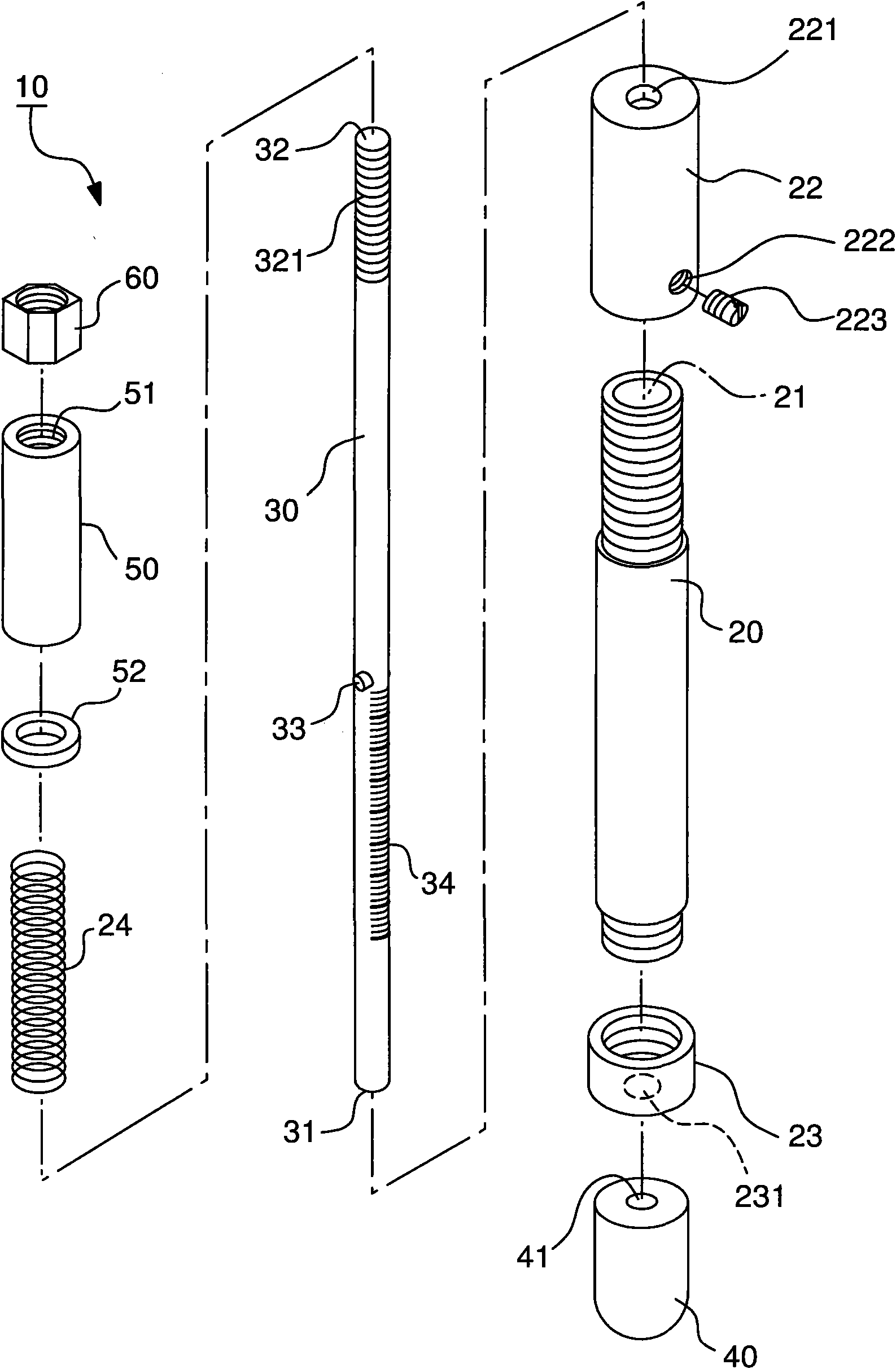

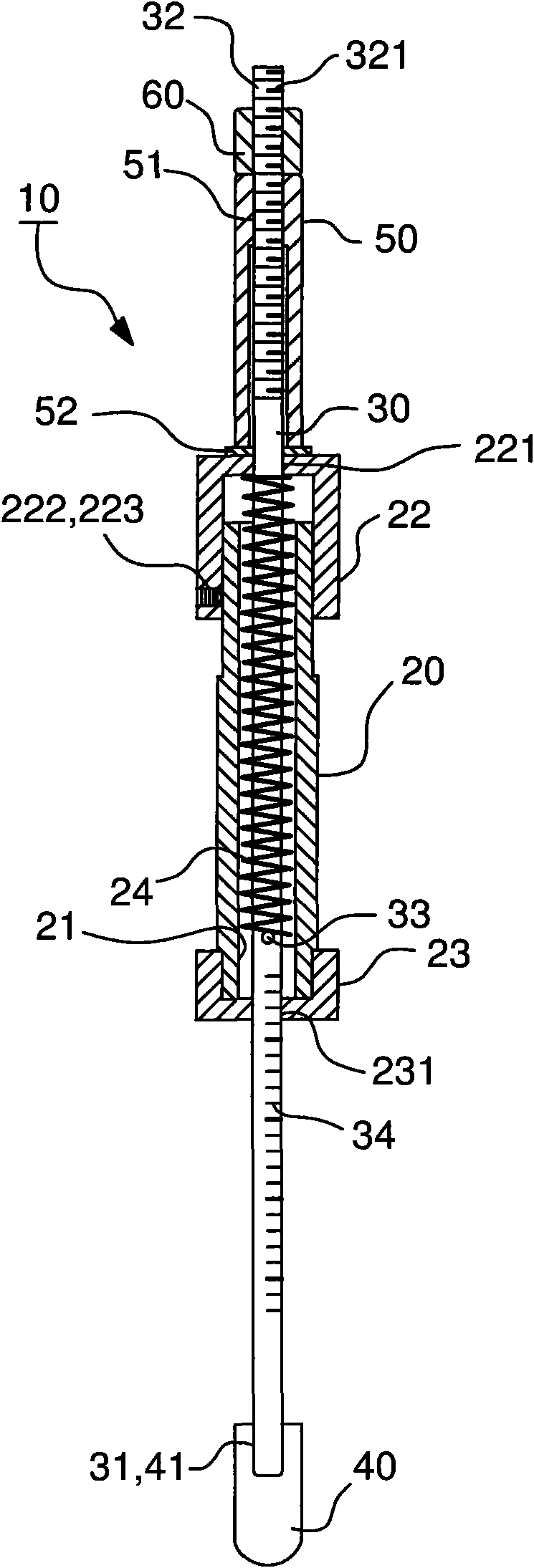

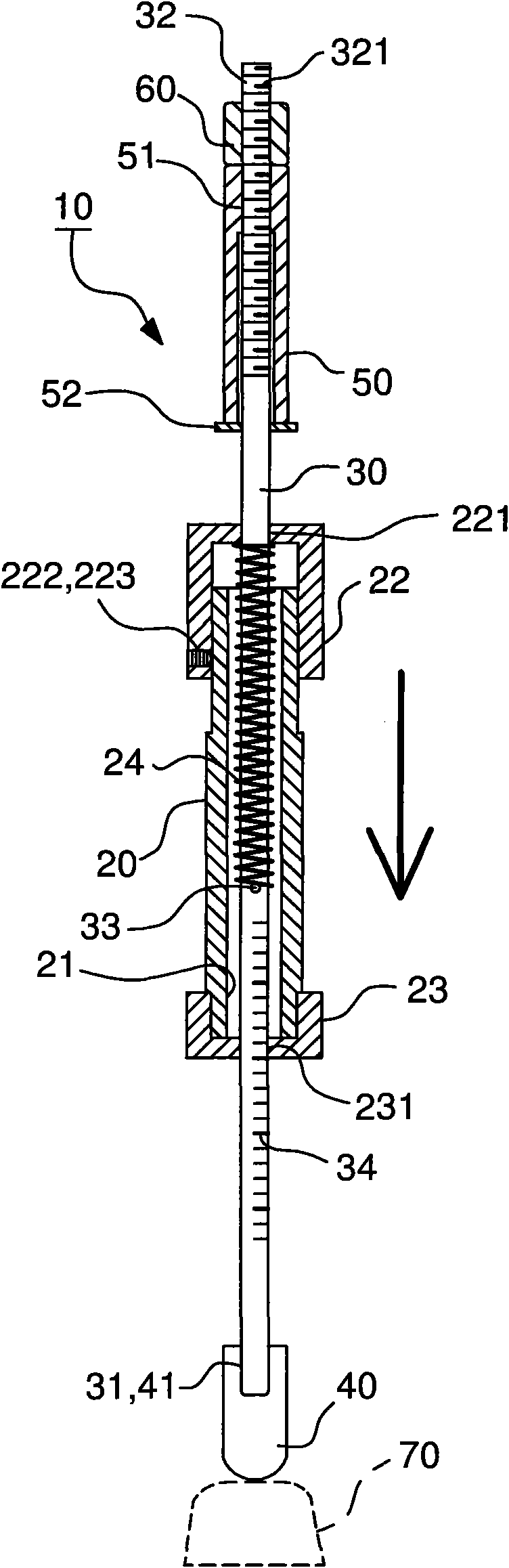

Tapered roller bearing pressing and assembling device

ActiveCN105134804AImprove press fit accuracyReduce work intensityBearing componentsSpring forceBar pressing

The invention discloses a tapered roller bearing pressing and assembling device. The tapered roller bearing pressing and assembling device comprises a pressure machine, and a pressing rod, a pressing head and a guiding head which are sequentially connected along a pressure effect line of the pressure machine, wherein the pressing rod is fixedly connected to the pressure machine, a cavity is formed in the pressing head, the guiding head is fixedly connected to the inner part of the cavity through a connecting rod, and under the effect of spring force, the guiding head moves back and forth along the pressure effect line in the cavity; under the feed condition, a tapered roller bearing is assembled outside the guiding head in a sleeving manner and fixed on the guiding head through a ball head plunger, and the end surface of the tapered roller bearing is abutted to the guiding head; under the pressing and assembling condition, the guiding head is embedded into a positioning hole in a shaft to be pressed and assembled, and the pressing head is connected with the tapered roller bearing in a pressing manner on the shaft to be pressed and assembled. Through the adoption of the technical scheme, the working strength of manual pressing and manual assembling of an operator is reduced, and besides the pressing accuracy and the assembling accuracy of the tapered roller bearing are improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Drawing die

InactiveCN102294397AShorten the development cycleReduce development costsShaping toolsEngineeringBar pressing

The invention relates to a new type of drawing die, including a concave die, a punch and a blank holder; wherein the punch is two independent punches, and the blank holder is in the shape of "日"; the "日" character The blank holder includes a frame and a pressure bar connected to the corresponding frame; the drawing die is different from the parting structure of the traditional mold, but divides a punch into two independent punches, and the blank holder It is designed in a "day" shape, so that two parting lines are formed at the predetermined gap between the middle pressure rod of the "day" shape blank holder ring and the punch, which can ensure that the complex plate parts can be cut at one time without division. Successful drawing can avoid wrinkling, which can reduce the difficulty of drawing forming debugging, shorten the mold development cycle, and reduce the mold development cost.

Owner:BEIQI FOTON MOTOR CO LTD

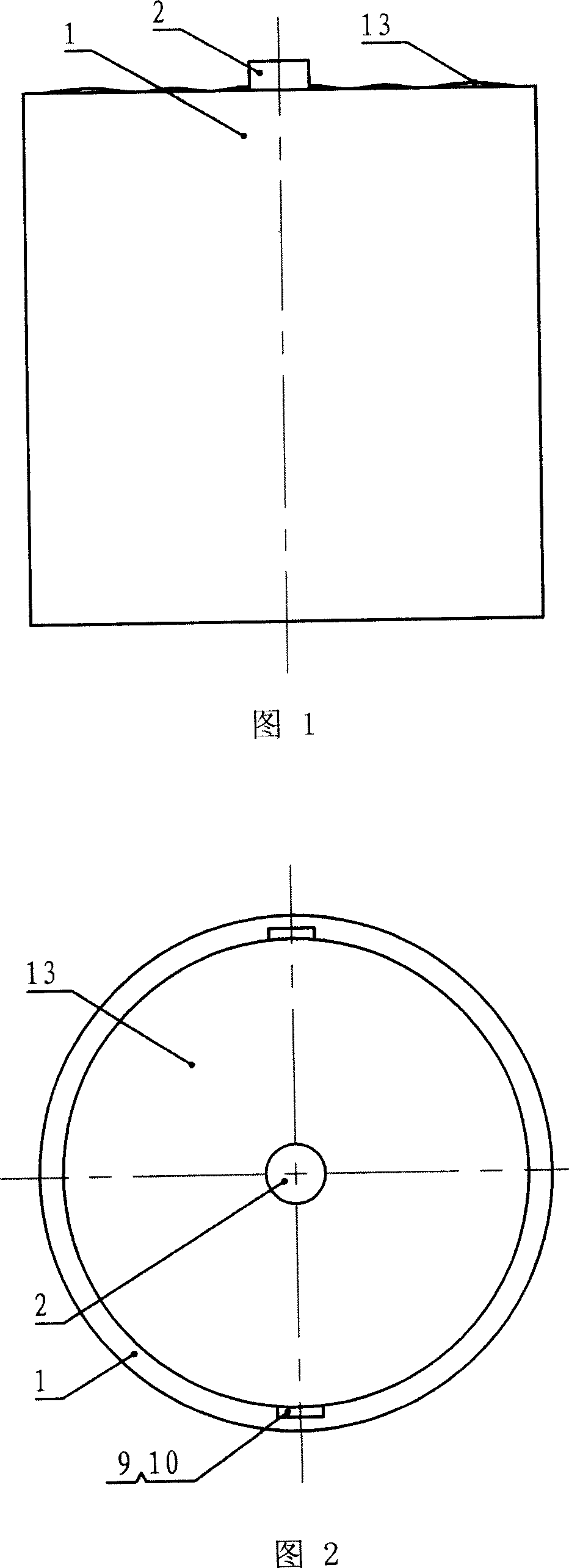

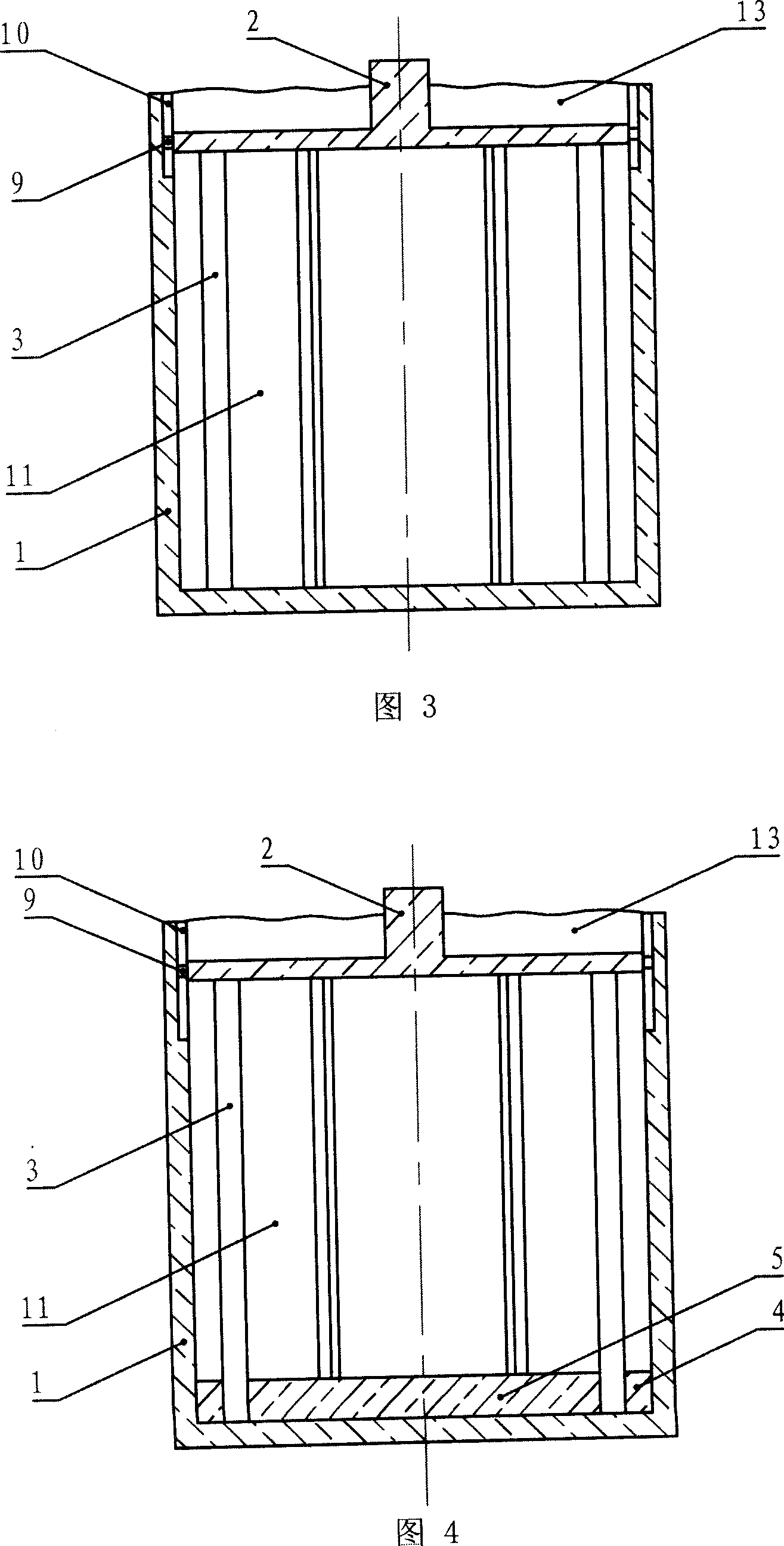

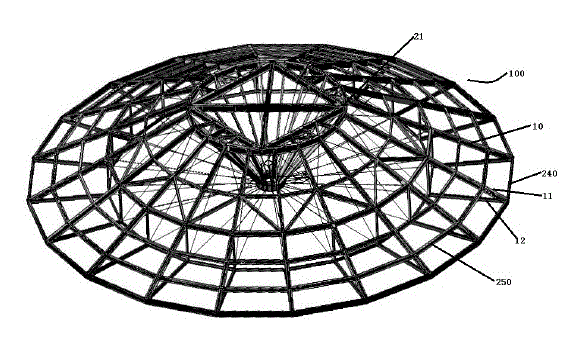

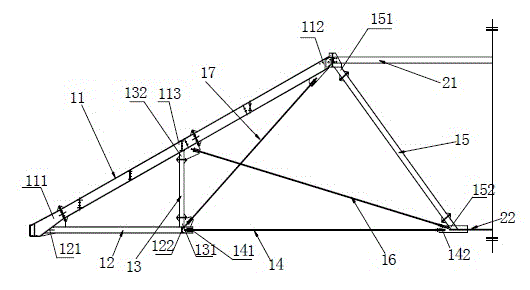

Space truss platform for round building construction and construction method using same

ActiveCN102912973ASimple structureStable structureBulk storage containerBuilding support scaffoldsPull forcePre stress

The invention relates to a space truss platform for round building construction. A plurality of steel frame units are spliced along the circumferential direction into a stable conical platform space structure by connectors, wherein the steel frame units are arranged along the radial direction of the stable conical platform. Each steel frame unit comprises an upper cord pull rod on the side of the stable conical platform, a lower cord pull rod at the bottom of the stable conical platform, a first profile steel web member and a second profile steel web member which are in the inner cavity of the stable conical platform, and first, second and third reinforcing steel bar prestressed pull rods to which prestress can be applied. Each connector comprises an upper pressure ring, a lower pressure ring, an enclosure, an upper circumferential-direction connecting rod and a lower circumferential-direction connecting rod. Pressed rods are rigid rods (profile steel), pull rods are flexible rods (round bar steel) and prestress can be applied to the pull rods. The invention also relates to a method for constructing a round building by using the space truss platform, wherein the platform has two functions; in slide form on a cylinder wall, the platform functions as a slip form platform; in top cover construction, the platform functions as a form supporting platform. The space truss platform is assembled in field, is simple in structure, high in bearing capacity and convenient to assemble and disassemble and can be reused.

Owner:GUANGZHOU HENGSHENG CONSTR ENG

Adjustable pressing test bar

InactiveCN101832878ACalibration errorEasy to adjust pressing forceStructural/machines measurementForce measurement by elastic gauge deformationEngineeringBar pressing

Owner:KUSN ZHONGRUIDA ELECTRONICS

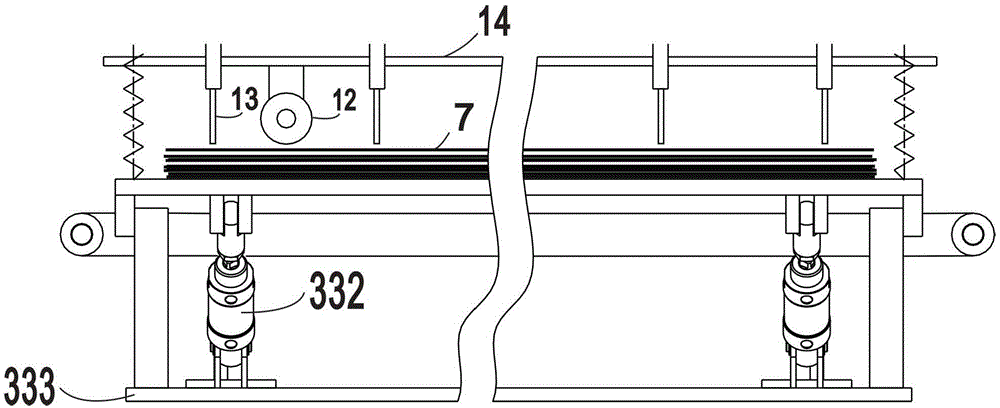

Press fit equipment for plywood

InactiveCN111113587AAvoid unevennessGuarantee product qualityPlywood pressesVeneer pressesEngineeringStructural engineering

The invention discloses press fit equipment for a plywood. The equipment comprises a box. The upper side of the box is provided with a gluing device, the gluing device comprises a mobile block, and the mobile block is slidingly arranged between two vertical plates. Two vertical plates are symmetrically and fixedly connected to the bottom of the mobile block, a sponge roller is rotatably connectedbetween the two vertical plates, a mounting block is fixedly connected to one side of each vertical plate, and a press rod is connected between the two mounting blocks and extrudes the sponge roller through an extrusion device. According to the press fit equipment for the plywood, when the mobile block moves in the direction away from a glue tank, second inclined plates make wedge blocks moving onthe second inclined plates gradually move upwards, through the interaction of wedge surfaces, the wedge blocks push second slide blocks to press the sponge roller, the press rod extrudes the glue adsorbed by the sponge roller, the glue directly falls on the surface of the plywood, and the problem is solved that when the sponge roller is applied to painting, the amount of the glue is gradually reduced, and the glue on the plywood is uneven. It is guaranteed that the glue is applied evenly, and the quality of the product is guaranteed.

Owner:ANHUI FUYANG QINGLIN WOOD PROD CO LTD

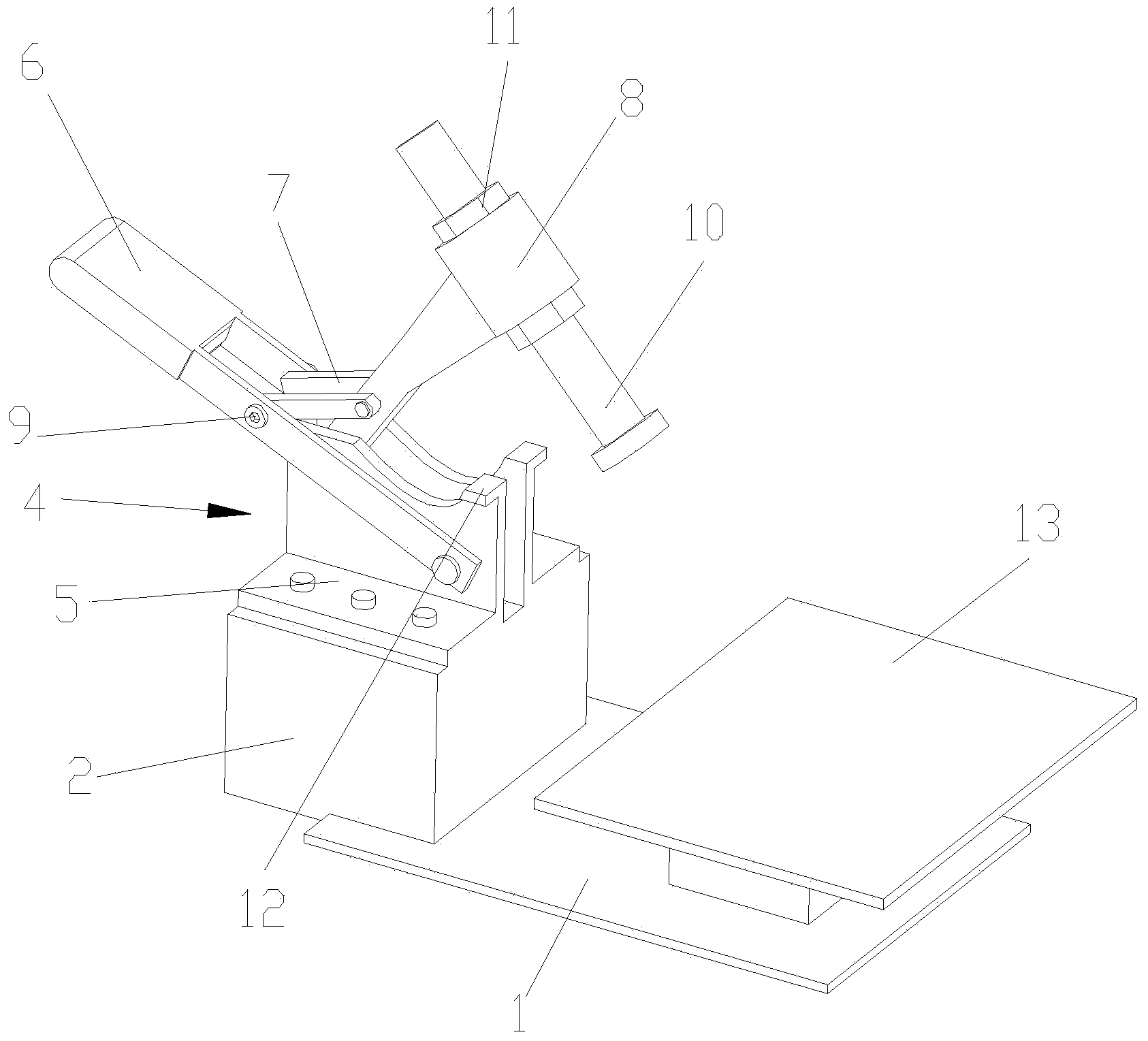

Pressing plate clamp

InactiveCN104353953AQuick compressionQuick releaseMetal-working feeding devicesWelding/cutting auxillary devicesInterference fitEngineering

The invention discloses a pressing plate clamp. The pressing plate clamp comprises a base plate and a base, wherein the base is arranged on one side of the base plate; a pressing table is further arranged at the front end of the base on the base plate; a compressing device is arranged on the base; the compressing device comprises a support, a handle, a connecting rod and a pressing pipe; the support is arranged on the base; the handle is connected onto the support through bolts; one end of the connecting rod is connected onto the handle, and the other end of the connecting rod is connected onto the pressing pipe; one end of the pressing pipe is connected onto the support, and an adjusting pressing rod is arranged at the other end of the pressing pipe; the pressing pipe and the base are in interference fit at a matched clamping position; an adjusting nut is further arranged between the adjusting pressing rod and one end of the pressing pipe. According to the pressing plate clamp, the connecting rod is driven through the movement of the handle, and thus the pressing pipe is driven to move, the adjusting pressing rod moves downwards, a product placed under the adjusting pressing rod is compressed, and the adjusting pressing rod can carry out adjustment according to the thickness of the product to realize quick compressing and loosening, so that the operation is convenient through the design, and quick clamping is realized.

Owner:SUZHOU JINDEYU PRECISION MACHINERY

Pneumatic fixing clamp

InactiveCN105364579AAchieve fixationImprove stabilityWork clamping meansPositioning apparatusBiochemical engineeringBar pressing

The invention discloses a pneumatic fixing clamp. The pneumatic fixing clamp comprises a base and a fixed baffle plate, wherein a mounting groove is formed between the base and the fixed baffle plate; a clamping block which is connected and driven through one end of a screw is arranged in the mounting groove; the other end of the screw extends out of the base and is connected to a screw handle; a compressing block, which is arranged on the mounting groove, is positioned at one end of a pressing rod and fixed to the fixing rack; a downward pressing cylinder is connected to the other end of the pressing rod; a compressing cylinder is arranged at one side of the base through a supporting seat, and a piston rod of the compressing cylinder passes through the base to be connected to the fixed baffle plate. According to the scheme, a processed part is clamped in three directions, so that the processed part can well fixed, the stability of the processed part can be improved, the product accuracy can be improved, and the product qualification ratio can be improved.

Owner:吴中区光福华宇钣金厂

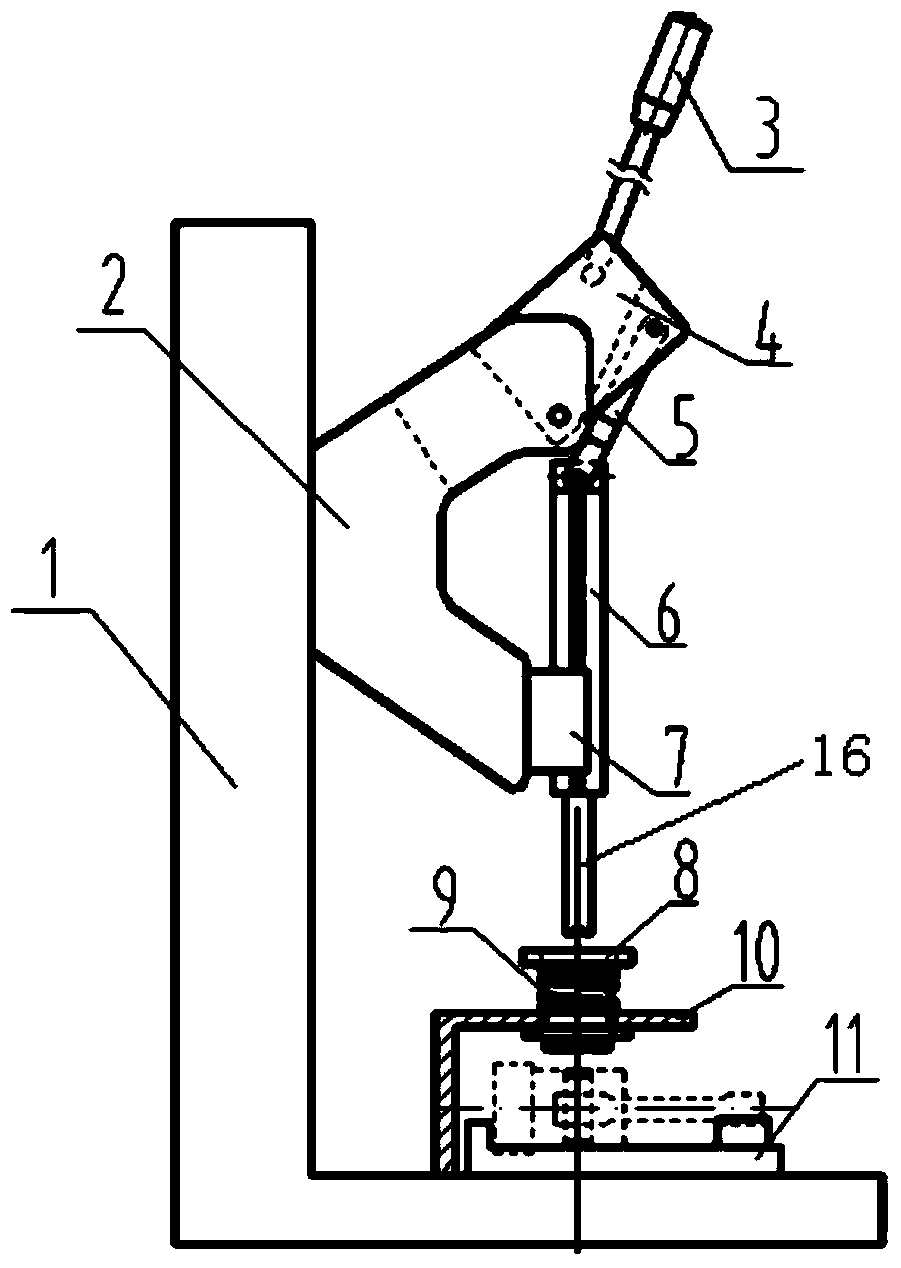

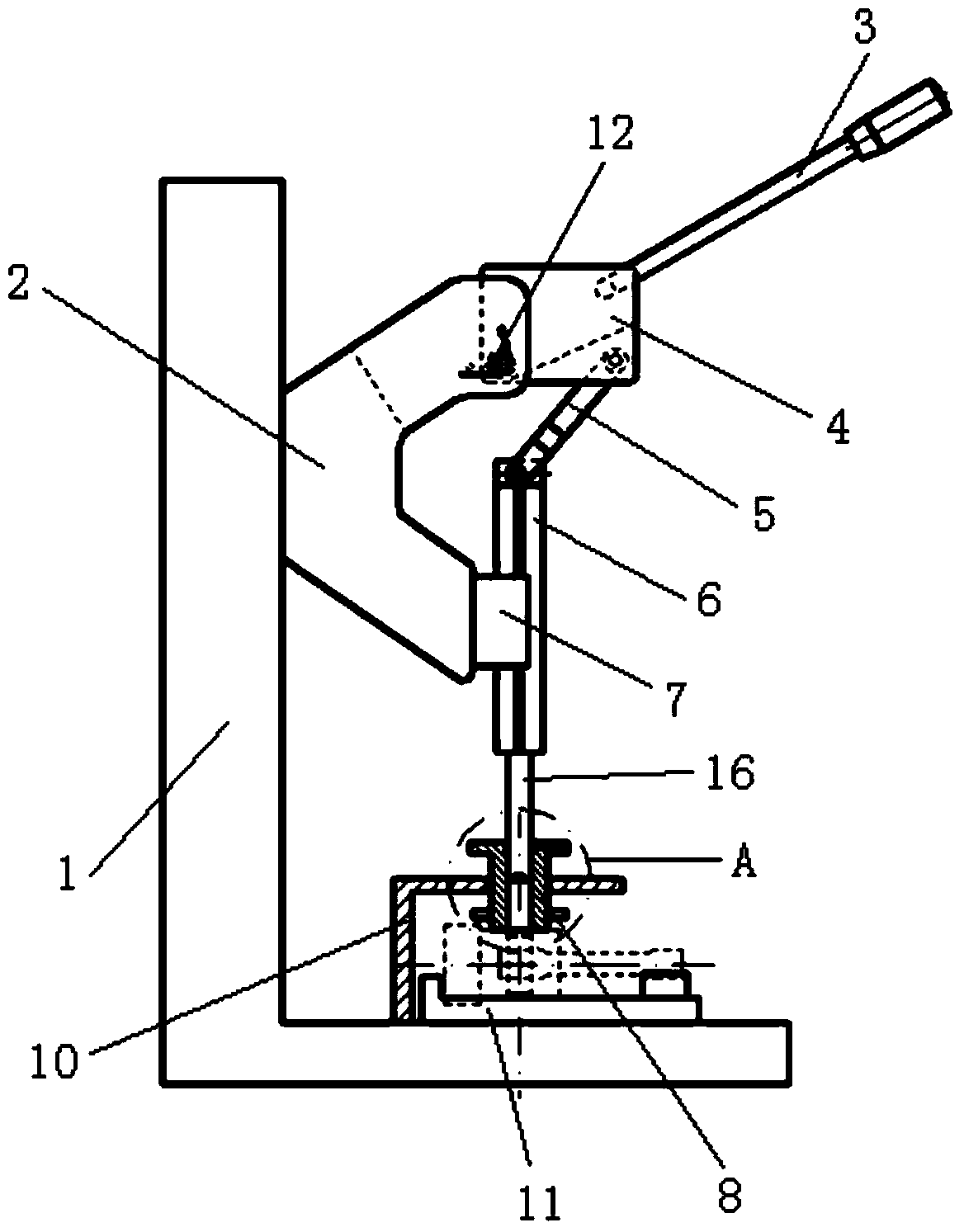

Piston pin clamp spring press-fitting device

InactiveCN104209920AReduce labor intensityImprove work efficiencyMetal-working hand toolsNatural stateEngineering

The invention discloses a piston pin clamp spring press-fitting device, which comprises an L-shaped base, wherein a rotating element is hinged to a longitudinal part of the L-shaped base, one end of the rotating element is provided with a handle, the other end of the rotating element is hinged to a press rod, a guide frame and a piston connecting rod assembly frame are arranged on the transverse part, vertical to the longitudinal part, of the L-shaped base, a guide block is arranged on the guide frame, a guide hole is formed in the axial direction of the guide block, the hole diameter of the guide hole is smaller than the outer diameter of a clamp spring in the natural state, and is greater than the outer diameter of the clamp spring in the compression limit state, the outer diameter of the press rod is smaller than the hole diameter of the guide hole, and the axial direction of the press rod is over against the guide hole and approaches to or leaves away from the guide hole in the axial direction. Therefore the auxiliary press-fitting effect can be provided during the manual installation of the clamp spring through the piston pin clamp spring press-fitting device, so the press-fitting efficiency is improved, and the labor intensity of workers is reduced. Meanwhile, the clamp spring is prevented from slipping and disengaging in the installing process, and the safety during the installation is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

High flexibility pre-pressing method pre-stress steel bar and implementation method thereof

InactiveCN101614053ANo instability limitIncrease the lengthBuilding reinforcementsBuilding material handlingRebarPure bending

A high flexibility pre-pressing method pre-stress steel bar and an implementation method thereof are disclosed in the invention. The penetrated steel bar is stretched, the balance of the straight line with a pressed center is replaced by the slight bend shape of slight eccentric accumbent stretched steel bar under the action of an axial pressure exceeding critical force, so that the pressure of the high flexibility pressure lever is larger than the critical force without occurring obvious bending and being the problem of combined deformation. The deformation form of the member is a combination of axial compression (or stretching) and pure bending, the stretching phase of the member is in a phase of slight deformation elasticity, and the installation phase is in an elasticity phase. At the same time, a twisted curve and a stress equation of the combined deformation of the member is established, and other conditions can be solved from the known conditions, thus section design and bearing capacity check can be carried out on the member. The invention needs no additional restriction, therefore the construction needs no special measures, and stretching, anchoring and installing adopt common methods. The invention has no instability restriction, large length, small section, free transverse press bending and slight deformation during pre-pressing and can be connected section by section for prolonging.

Owner:SHANGHAI MUNICIPAL TRANSPORTATION DESIGN INST

Press fitting mechanism for workpiece

ActiveCN106089886AAchieve adhesionImprove the pressing effectLiquid surface applicatorsMaterial gluingEngineeringBar pressing

Owner:LEO GRP ZHEJIANG PUMP CO LTD

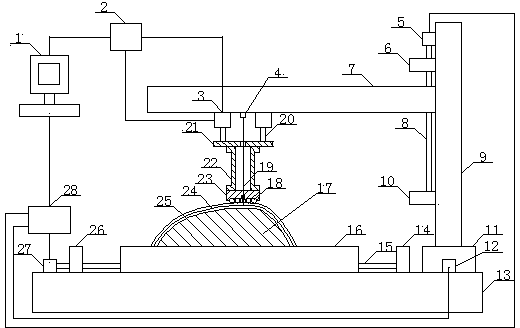

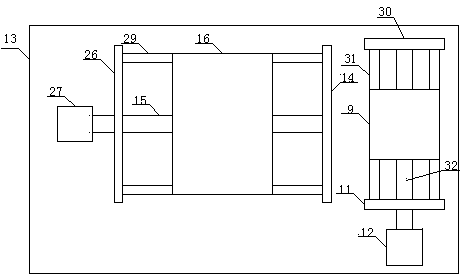

Ball type laser transmission welding clamping device

InactiveCN104191606ASimple 2D WeldingPrecise control of welding positionThermoplasticElectric machinery

A ball type laser transmission welding clamping device comprises a PC (personal computer), a stepping motor control system, X-axis, Y-axis and Z-axis feed mechanisms, pressure application mechanisms, a connecting mechanism and a pressing mechanism, wherein a hydraulic control system adjusts a small hydraulic ejector pin, so that the sum of downward pressing force of four press rods is equal to a pre-pressing force; the connecting mechanism transfers the pressing force to a clamping mechanism, so that the downward pressing force of a pressing block is equal to the pre-pressing force; a bottom die in the pressing mechanism is matched with an upper pressing device to clamp an upper workpiece and a lower workpiece, so that the curved surface workpiece is clamped; and the stepping motor control system controls laser to move along a preset line, and the curved surface workpiece is welded. The laser transmission welding clamping device for thermoplastic plastics can weld the curved surface workpiece, meanwhile, the welding path and pressing force can be accurately controlled, the overall strength and stiffness of a weld assembly are improved, a plurality of balls are used for pressing, single-point contact is avoided, and the quality of a processing workpiece is improved.

Owner:JIANGSU UNIV

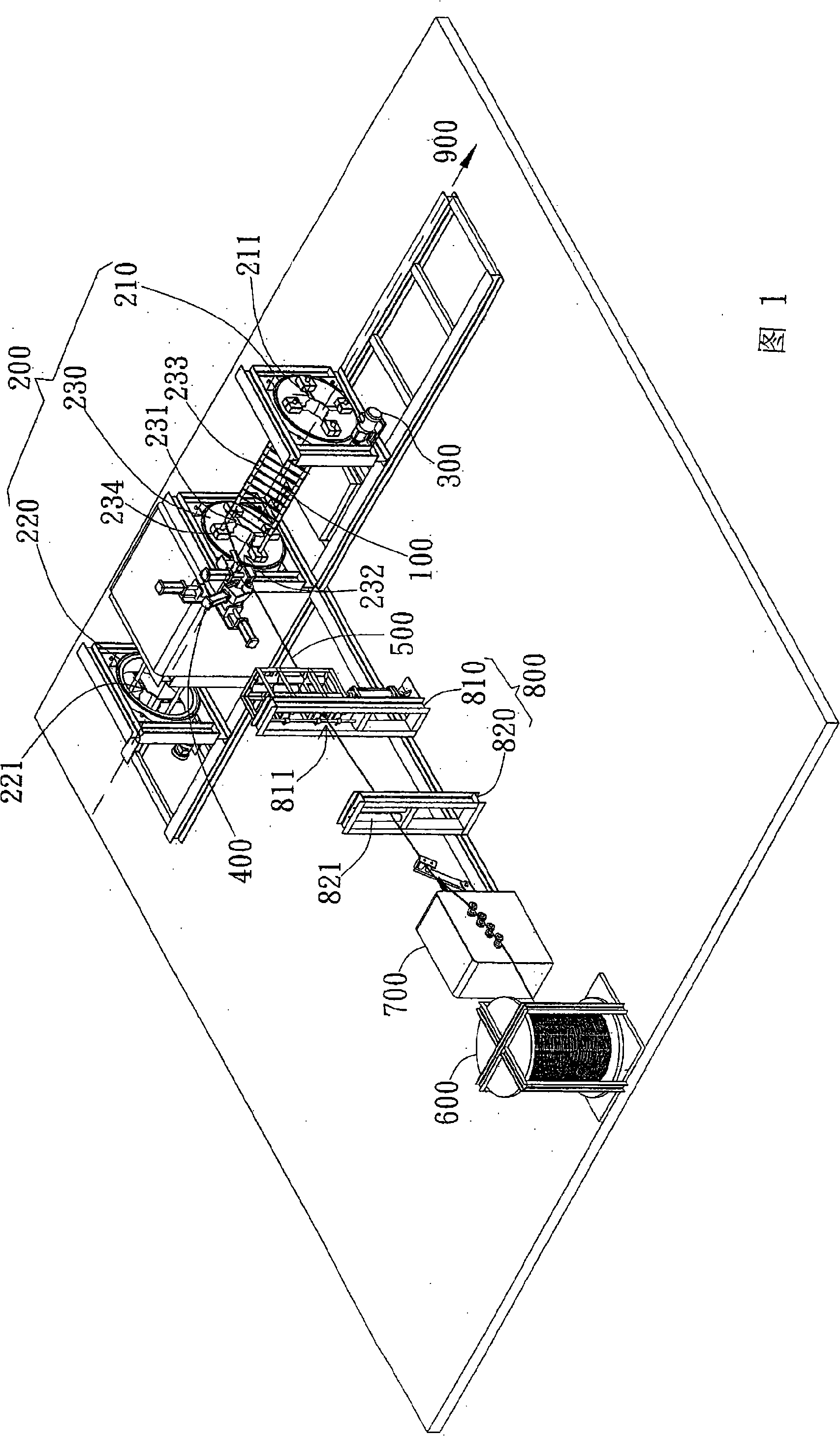

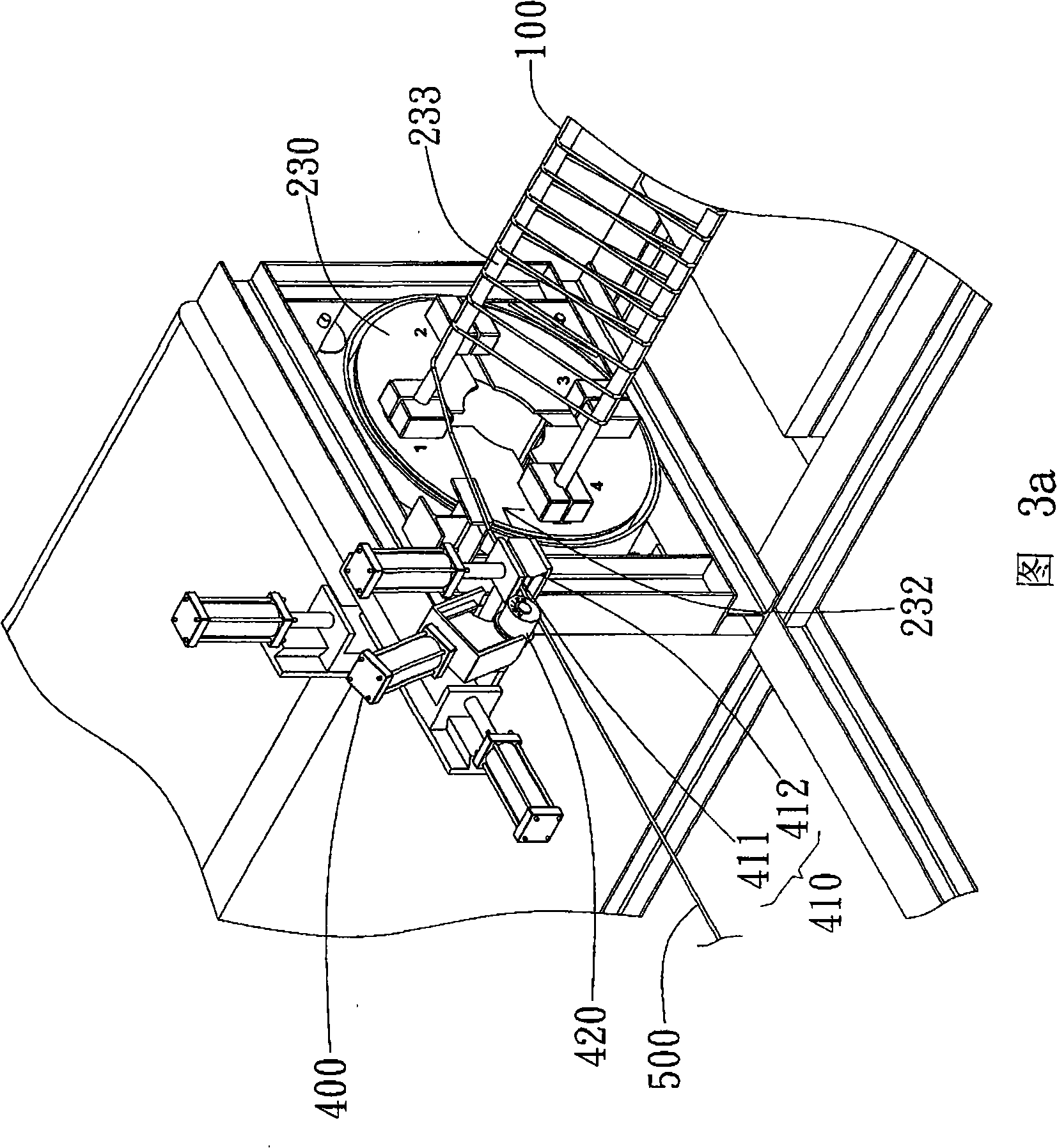

Spiral square hoop forming apparatus and its forming method

The invention provides a screw square hoop forming device and a forming method thereof, comprising a central rotation part, a first rotation part, a plurality of axial enwinding parts and a bar bending device. The central rotation part and the first rotation part are arranged in parallel; the bar inlet side and a plurality of axial enwinding parts are arranged at the periphery of the central rotation part; wherein, each axial enwinding part is connected with the first rotation part in a detachable way; furthermore, the first rotation part can move along the axial direction correspondingly to the central rotation part; the bar bending device is arranged at the bar inlet side and comprises a positioning part and a bar pressing part; when bars extend into the central rotation part from the bar inlet side, the positioning part clamps the bars and the bar pressing part moves correspondingly to the positioning part and presses the bars to form a bending part; the bending part is buckled with the axial enwinding parts under the driving of the rotation of the central rotation part.

Owner:RUNHORN PRETECH ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com