Non-linear press-rod spring device

A spring device and nonlinear technology, applied in the field of spring devices, can solve the problems of stability of vibration isolation system, reduce system vibration isolation bandwidth, unfavorable popularization and application, etc., achieve low dynamic stiffness, improve internal resonance frequency, and work reliably. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

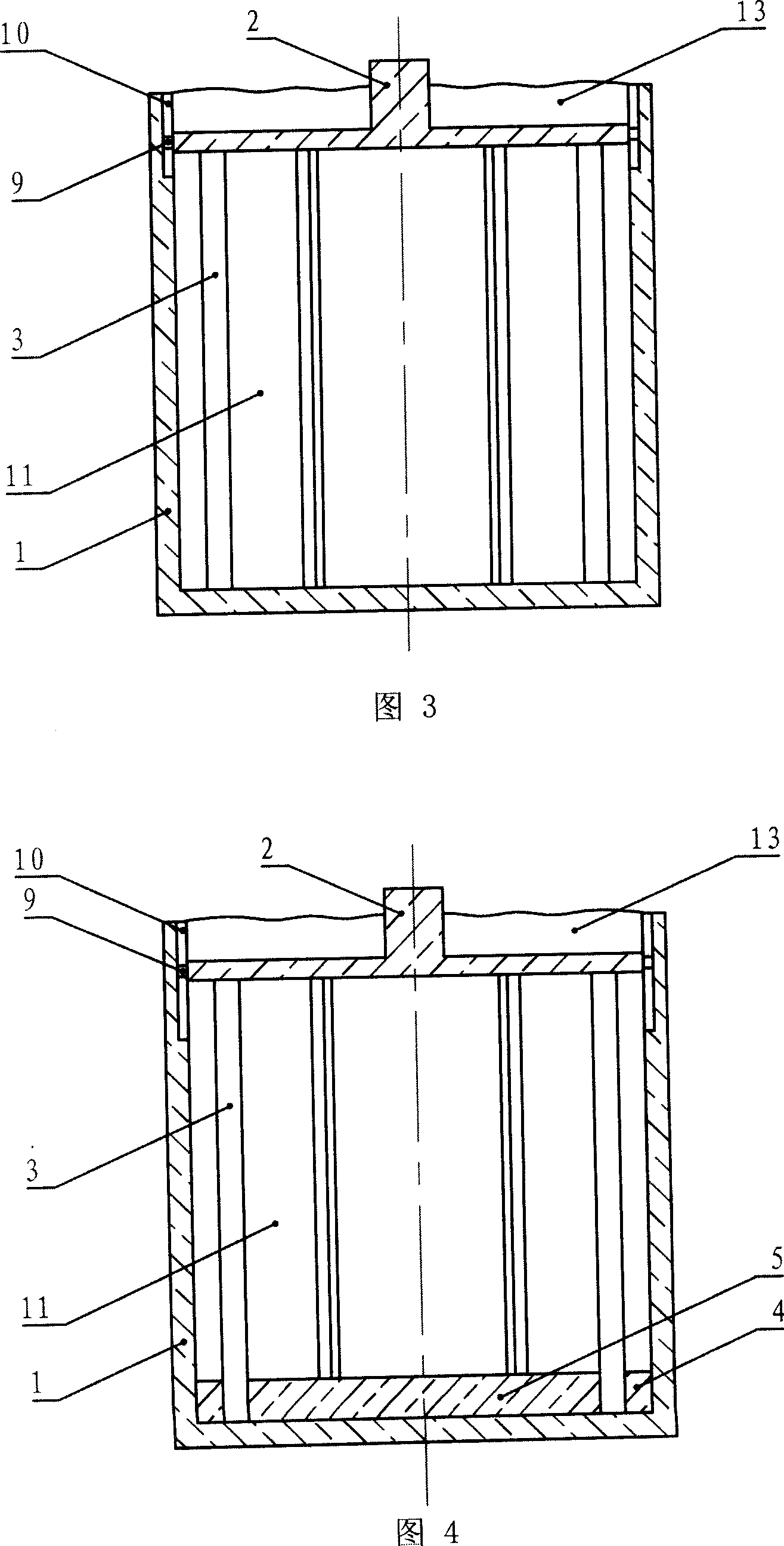

[0011] Specific embodiment 1: Referring to Fig. 3, the non-linear pressure bar spring device of the present embodiment is composed of a spring outer cover 1, an upper end cover 2, a pressure bar 3, a guide slider 9 and a guide groove 10, and the spring outer cover 1 is bottomed. The shell of the cylindrical non-linear pressure bar spring device; the upper end cover 2 is parallel to the bottom surface of the spring outer shell 1, and is embedded in the spring outer shell 1 with clearance fit, with a protruding disc in the center of the upper part; there are at least three pressure bars 3, The pressure rod 3 is evenly distributed along the circumference of the upper end cover 2, perpendicular to the bottom surface of the spring outer cover 1, and the two ends are fixedly installed on the bottom of the spring outer cover 1 and the lower surface of the upper end cover 2 respectively; there are at least two guide grooves 10, which are in the spring The upper part of the inner wall o...

specific Embodiment approach 2

[0013] Specific embodiment two: Referring to Fig. 4, the difference between the non-linear pressure bar spring device of this embodiment and specific embodiment one is that it also includes a lower fixed collar 4 and a lower fixed disc 5, and the lower fixed collar 4 is The diameter is equal to the upper end cover 2, and it is fixedly installed on the bottom surface of the inner side of the spring jacket 1, and has a certain thickness; The ring 4 has the same thickness and is evenly opened with a number of thin grooves 8 along its circumference; one end of the pressure rod 3 is inserted into the thin groove 8 of the lower fixed disk 5, and the other end of the pressure rod 3 is fixedly installed on the upper end cover 2 .

[0014] The compression rod 3 in the non-linear compression rod spring device of this embodiment adopts an installation method of fixed connection at one end and insertion at the other end, which makes the assembly of the present invention easier.

specific Embodiment approach 3

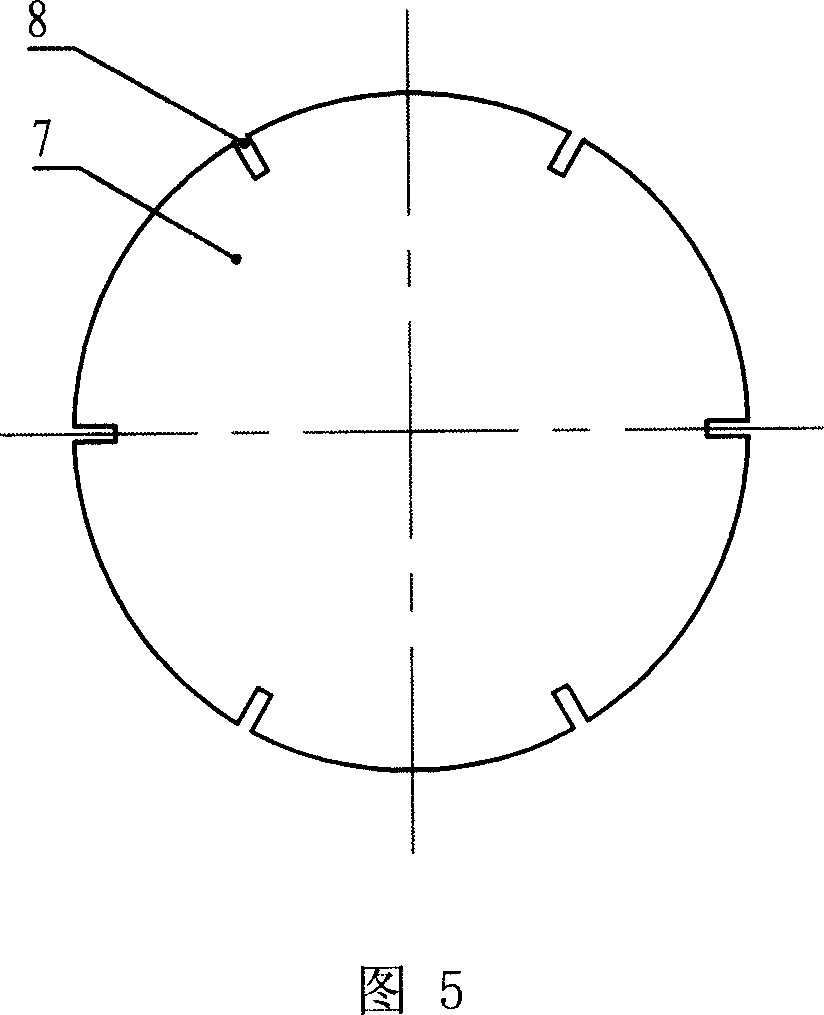

[0015] Specific embodiment three: Referring to Fig. 6, the difference between the non-linear pressure bar spring device of this embodiment and the specific embodiment two is that it also includes an upper fixed collar 6, an upper fixed disc 7, and an upper fixed collar 6 and an upper fixed collar 6. The lower fixing collar 4 has the same shape, and the upper fixing collar 6 and the upper end cover 2 are concentrically fixedly connected on the lower surface of the upper end cover 2; the upper fixing disc 7 has the same shape as the lower fixing disc 5, and the upper fixing disc 7 is embedded in the upper The interior of the fixed collar 6 is fixedly installed on the lower surface of the upper end cover 2; the two ends of the pressure rod 3 are respectively inserted into the thin grooves 8 of the upper fixed disc 7 and the lower fixed disc 5.

[0016] The compression rod 3 in the non-linear compression rod spring device of this embodiment adopts a connection mode of plugging at b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com