Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

526results about How to "Make full use of resources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

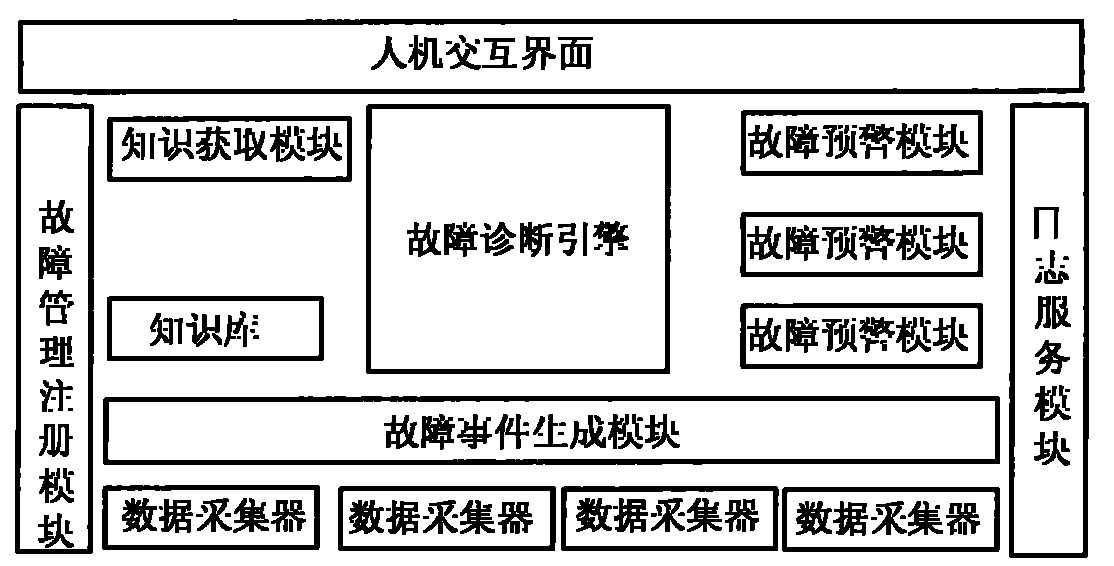

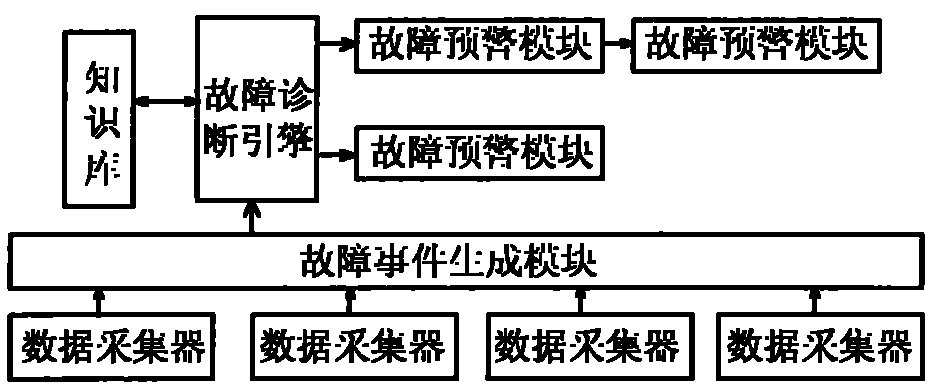

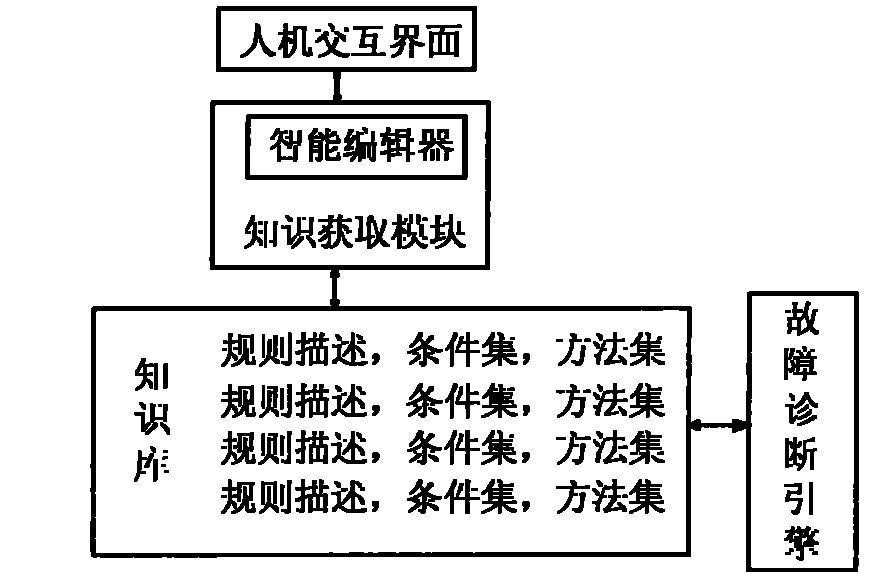

Computer fault management system based on expert system method

ActiveCN101833497AWell structured designMake full use of resourcesHardware monitoringSystems managementData acquisition

The invention provides a computer fault management system based on an expert system method, which comprises a data acquisition unit (1), a fault event generation module (2), a fault diagnosis engine (3), a knowledge base (4), a knowledge acquisition module (5), a fault isolation module (6), a fault recovery module (7), a fault early-warning module (8), a log service module (9), a fault management registration module (10) and a human-computer interaction interface (11); and a system administrator monitors and manages the data acquisition unit (1), the fault event generation module (2), the fault diagnosis engine (3), the knowledge base (4), the fault isolation module (5), the fault recovery module (6), the fault early-warning module (7) and the log service module (8) through the human-computer interaction interface (11), and accesses an intelligent editor provided by the knowledge acquisition module (5) through the human-computer interaction interface (11).

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

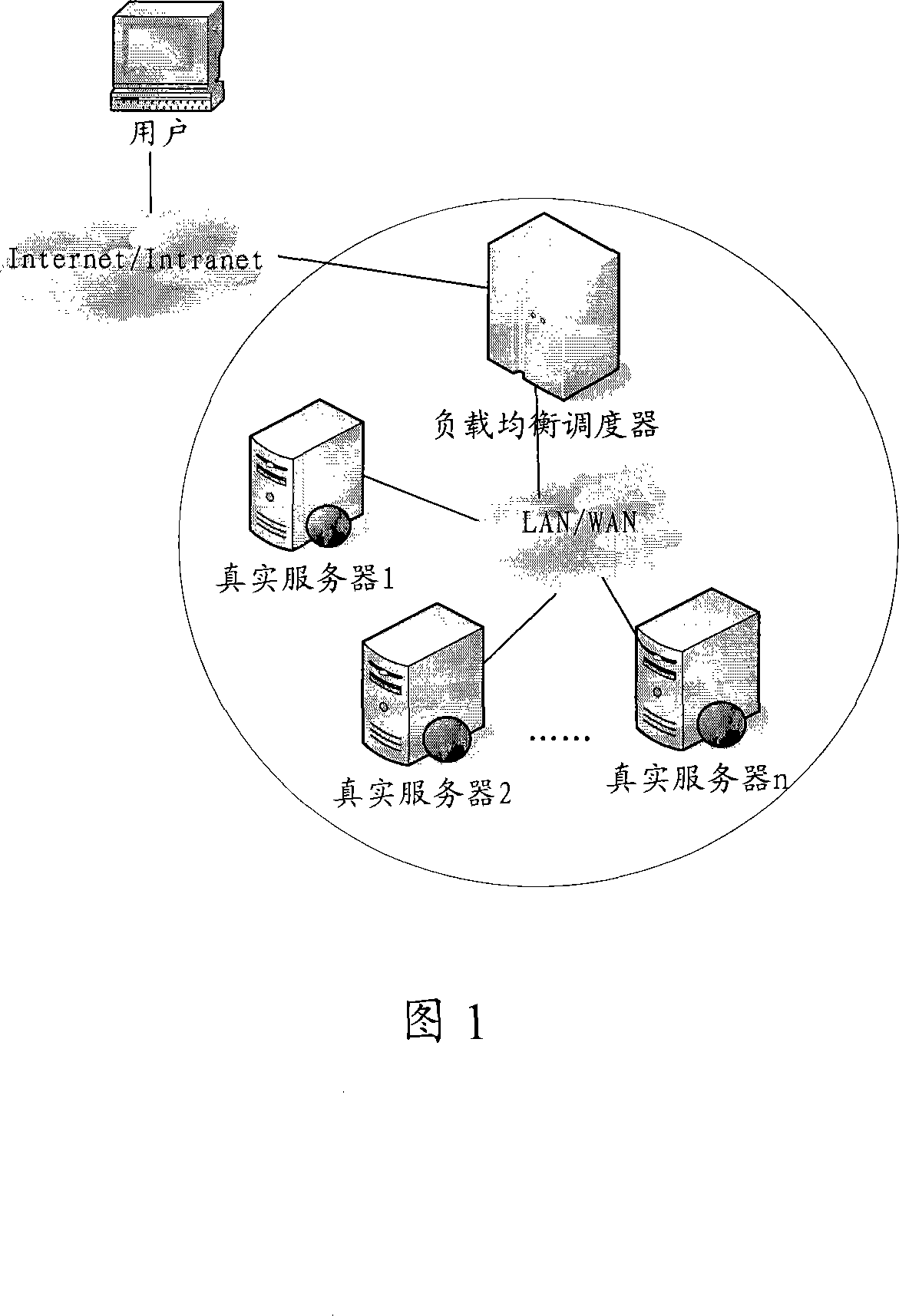

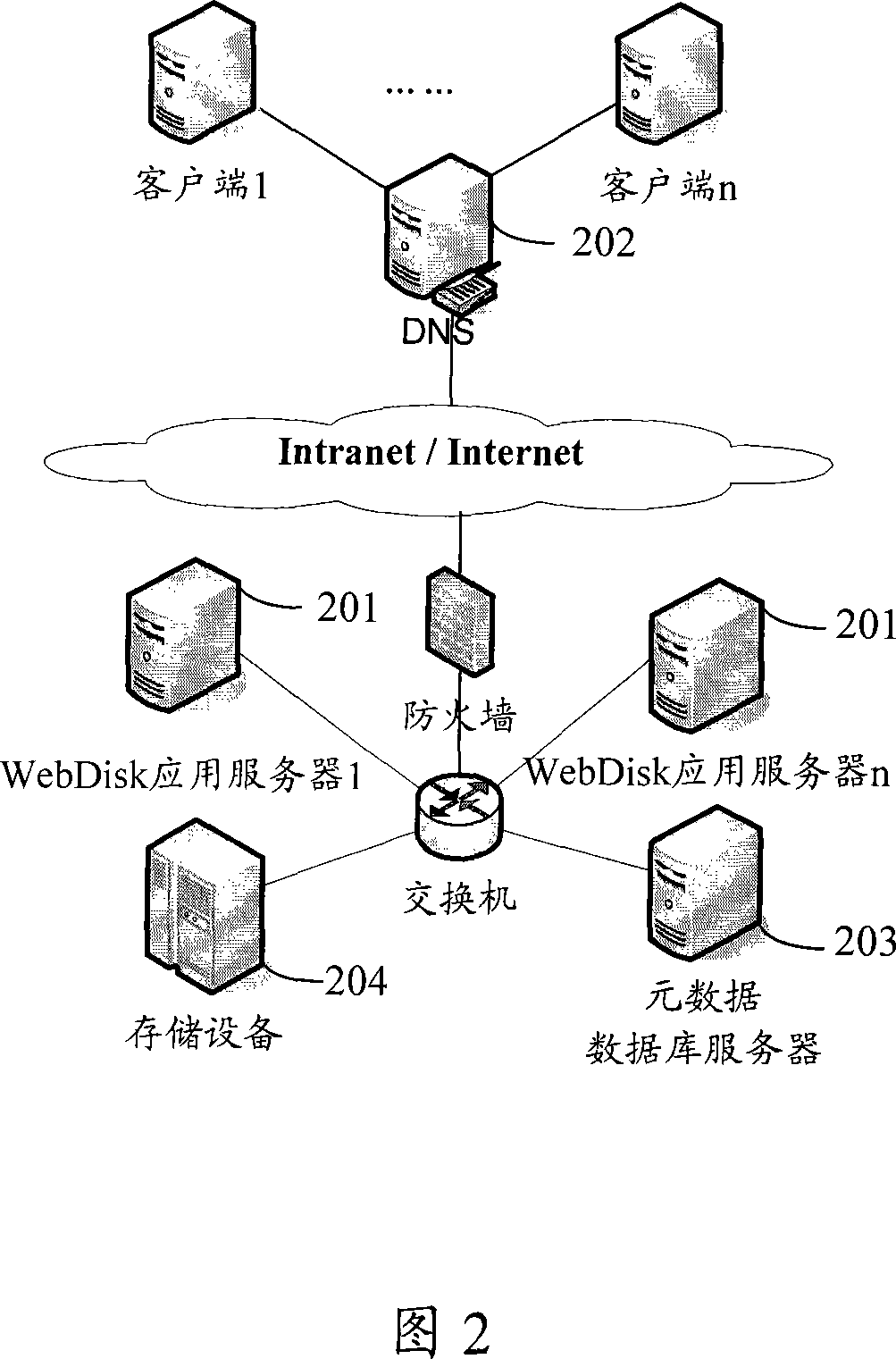

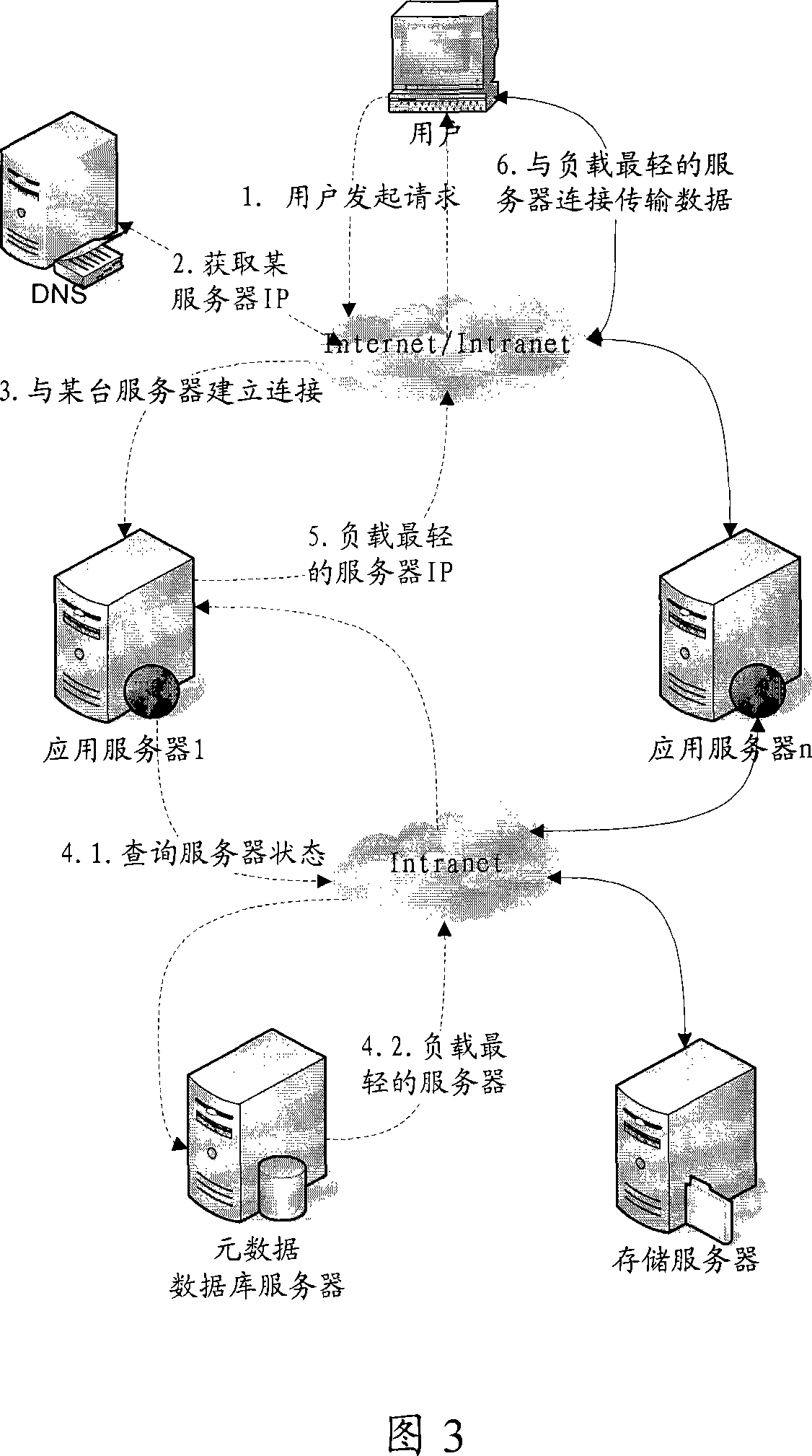

Method and system for implementing application server load balancing

ActiveCN101115016AEliminate bottlenecksEvenly distribute workData switching networksDomain nameApplication server

The invention discloses a method to realize application server, comprising the following steps: a domain name analyzing server receives a request with application server cluster domain name sent by a user, and assigns an application server with an IP address mark to the user from the pre-stored application server IP address list corresponding to the domain name; the application server assigned to the user locates an application server for the user according to the current load information of each application server in the application server cluster stored in a meta-data base server, and feedbacks the application server information to the user. The located server stores the file data uploaded by the user in the storage device at the network side during the communication with the user. The invention can realize direct P2P data transmission, balance distribution operations, and make full use of every application server resource in the application server cluster.

Owner:UNITED INFORMATION TECH H K COMPANY

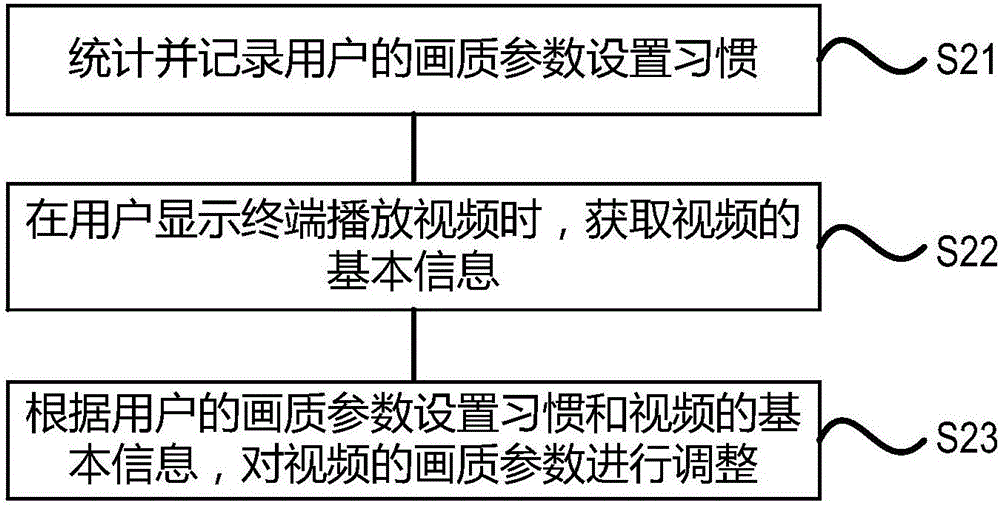

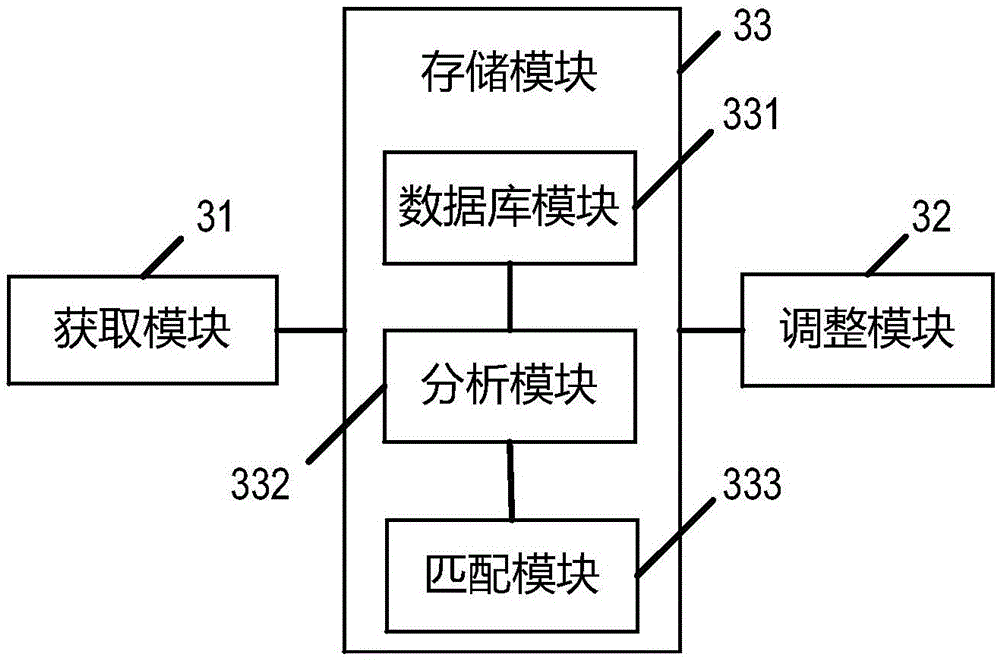

Video image quality adjusting method and apparatus

InactiveCN106534942AImprove viewing experienceAvoid perception differencesSelective content distributionComputer graphics (images)Imaging quality

The invention provides a video image quality adjusting method and apparatus. The video image quality adjusting method comprises the following steps: counting and recording an image quality parameter setting habit of a user; and obtaining basic information of a video when a user display terminal plays the video; and according to the image quality parameter setting habit and the basic information of the video, adjusting image quality parameters of the video. According to the video image quality adjusting method and apparatus provided by the invention, through a method of statistics, learning and model establishment, image quality setting parameters of the video are intelligently adjusted, watching feeling differences brought by differences between different video types are effectively avoided, operation of frequent modification of image quality parameter configuration by the user can also be reduced, and watching experience of the user is improved to a great extent.

Owner:WHALEY TECH CO LTD

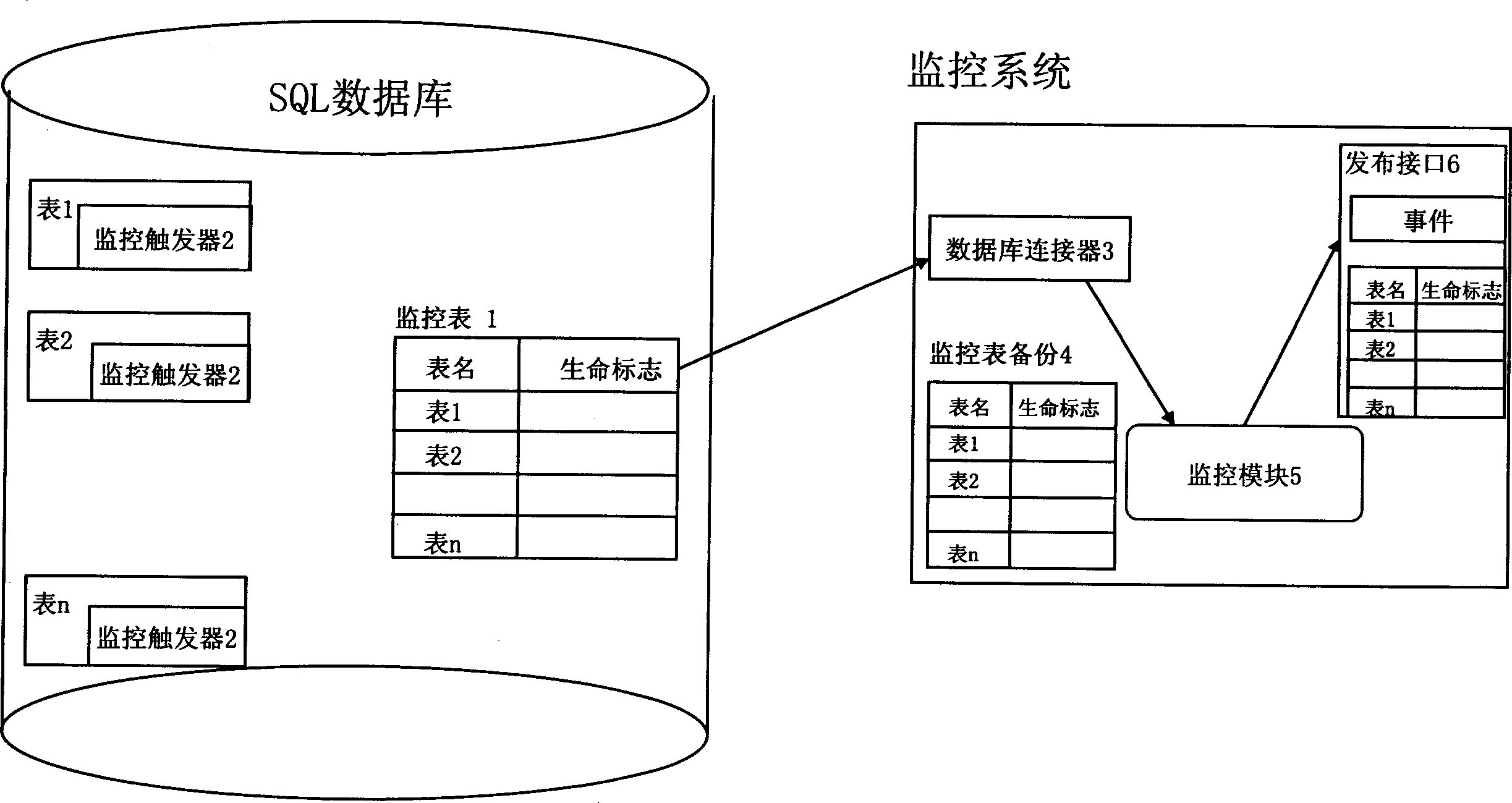

Dynamic monitoring system and method for data base list update

ActiveCN1673972AMake full use of system resourcesMaximize environmental supportHardware monitoringSpecial data processing applicationsDynamic monitoringData science

The dynamic monitoring system for updated data base list includes monitoring list for storing the names and life signs of all the user lists; monitoring trigger corresponding to the user lists one by one for intercepting the insertion, updating and deletion operations of user lists; monitoring list backup in the application part of the system; monitoring module accessing the monitoring list via data base connector to obtain the life signs of the user lists and compare the obtained life signs with those in the backup for finding altering; and issuing interface to output real-time data base list updating information. The present invention solves the technological problem of providing dynamic monitoring system and method for updated data base list.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

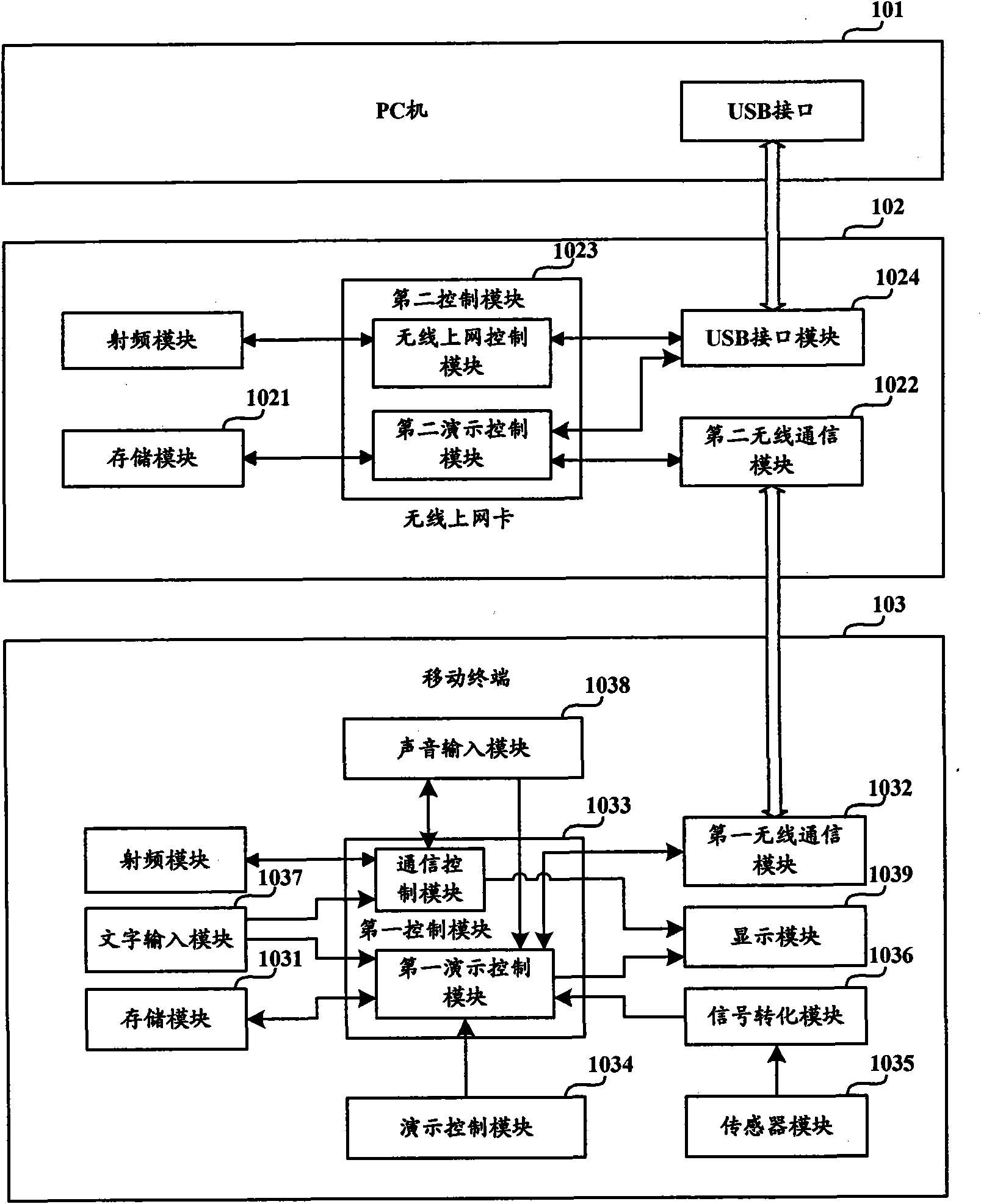

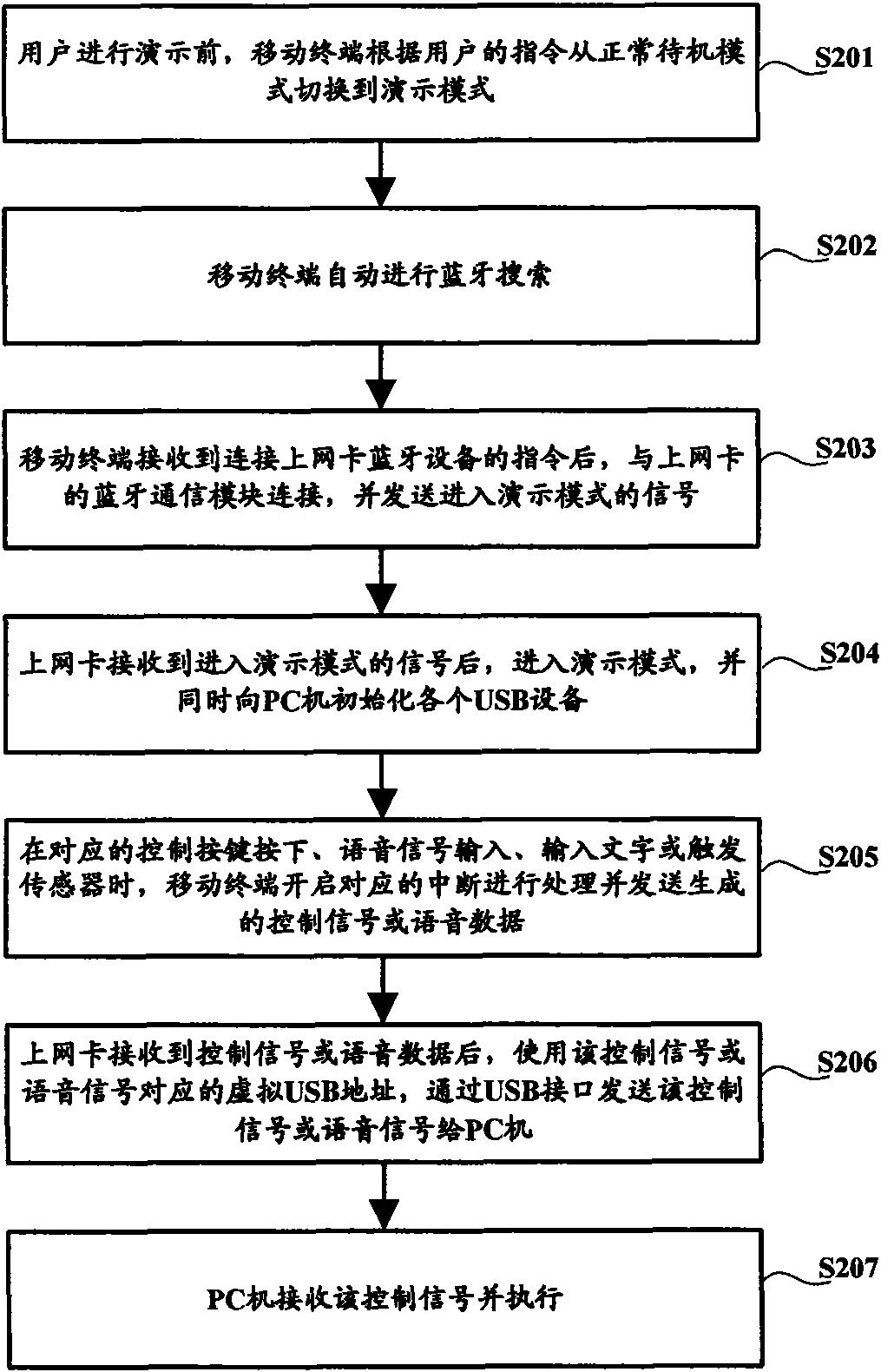

Demonstration system, mobile terminal and wireless internet access card

ActiveCN101599224AEasy to operateMake full use of resourcesNear-field transmissionSubstation equipmentWireless internet accessTelecommunications

The invention discloses a demonstration system, a mobile terminal and a wireless internet access card and relates to the wireless communication technology. In the embodiment of the invention, various instructions are converted into control signals corresponding to peripherals such as a keyboard, a mouse and the like on the mobile terminal to be sent by an added first wireless communication module, and a second wireless communication module is correspondingly added in the wireless internet access card of a PC machine connected with a USB to receive the control signals sent by the mobile terminal and transmit the control signals to the PC machine through the USB, so that a speaker can use the mobile terminal to remotely control the PC machine by bluetooth communication during a speech to control to play a demonstration file and to operate the demonstration file during the speech conveniently.

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

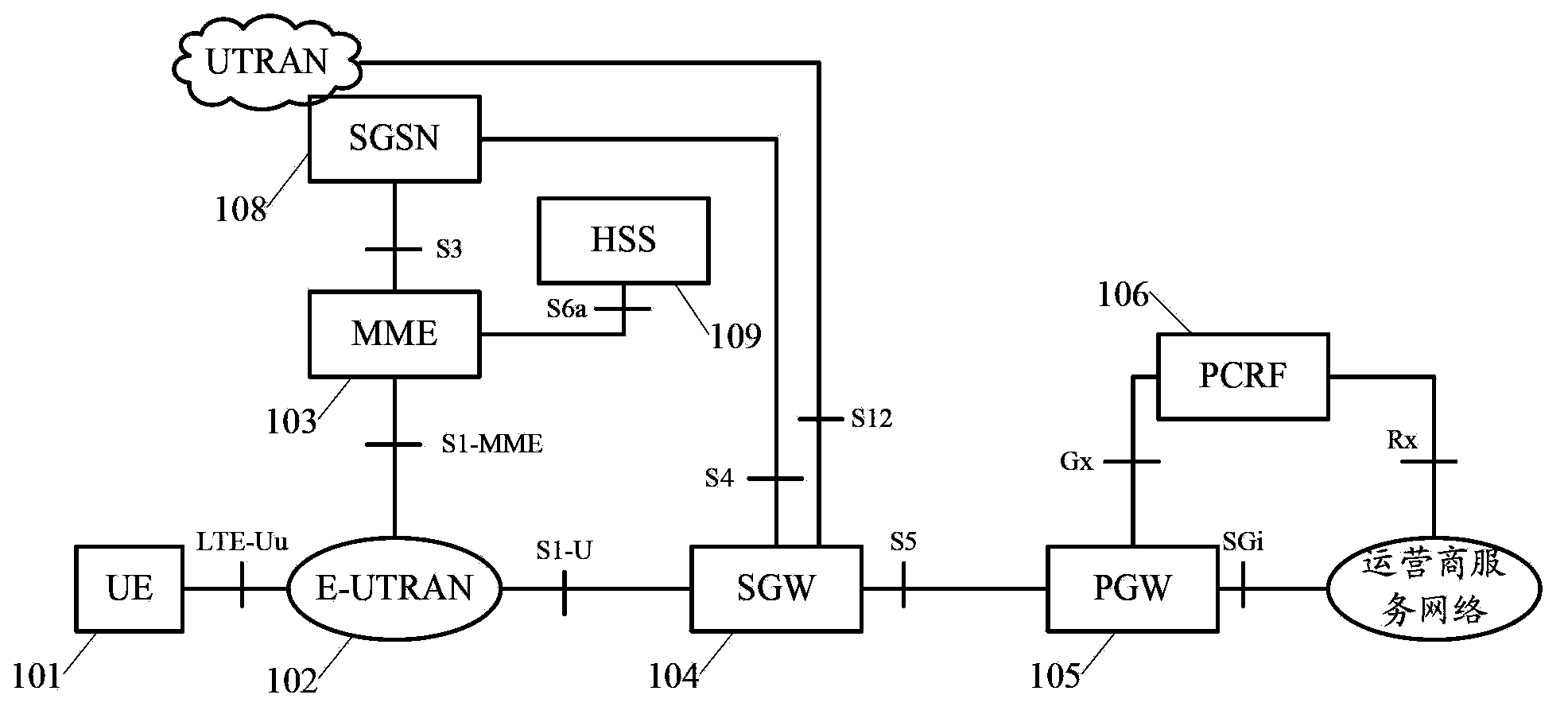

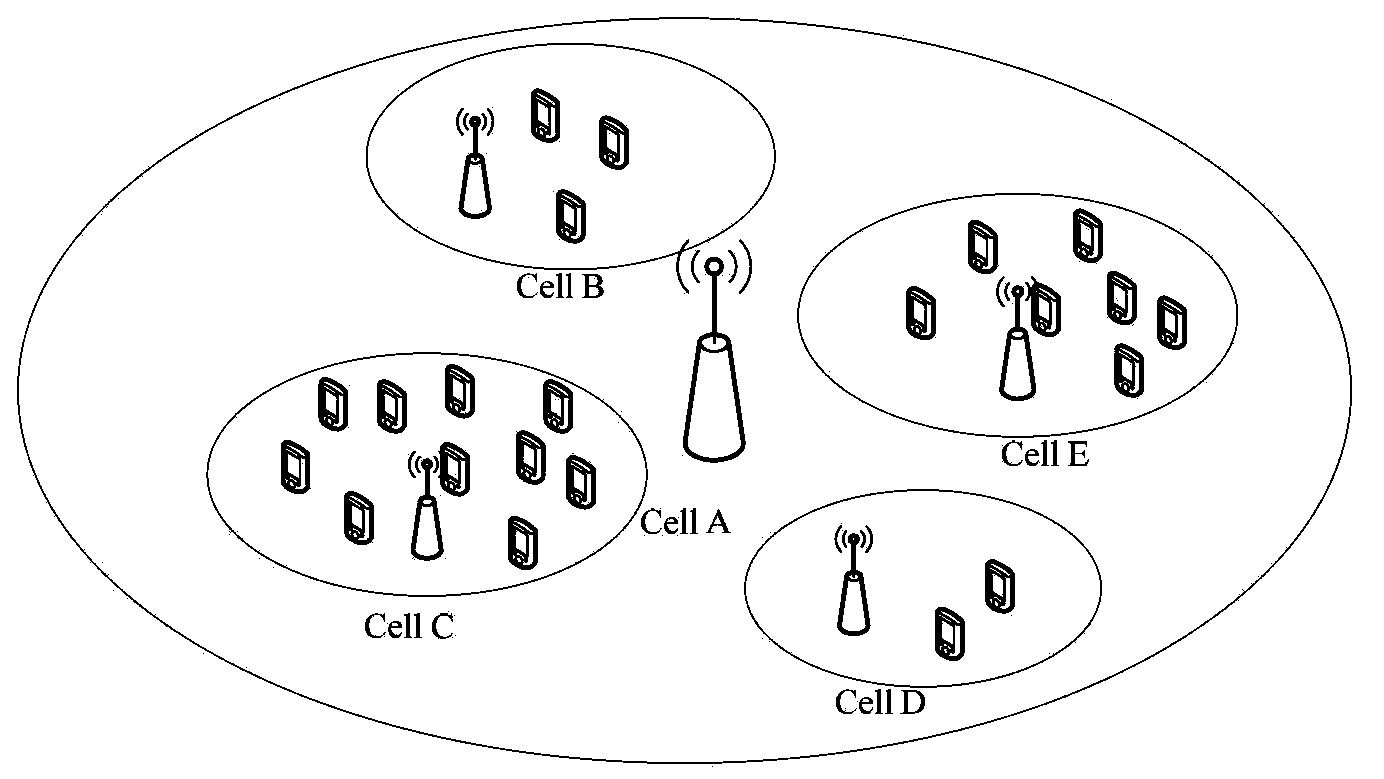

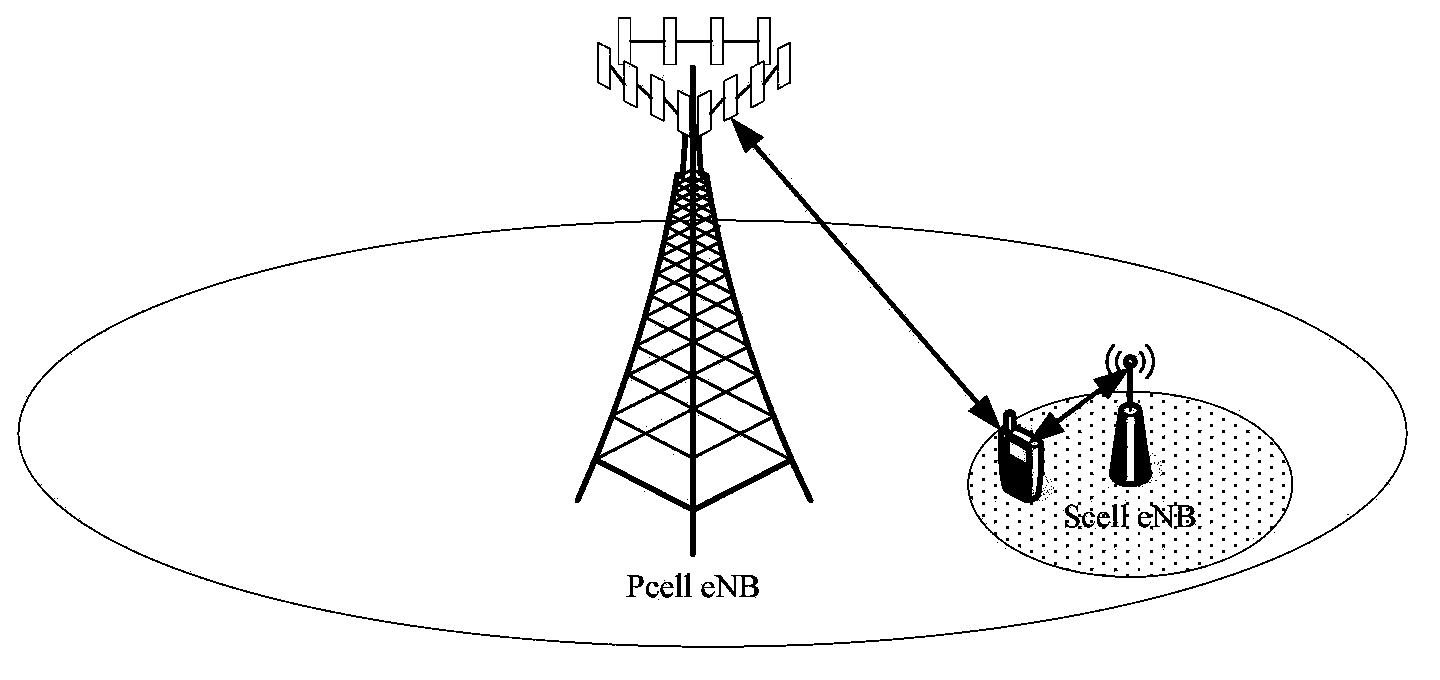

Data transmission method and system in heterogeneous network

ActiveCN103796287AAchieve synergyMake full use of resourcesPower managementConnection managementControl signalPhysical layer

The invention discloses a data transmission method in a heterogeneous network. The method comprises: a PCell of UE realizing a PDCP layer, an RLC layer, a MAC layer and a physical layer, and an SCell of the UE realizing an RLC layer, a MAC layer and a physical layer, wherein an MME sends an S1 control signaling to the PCell, and the PCell sends an RRC signaling to the UE; and an SGW sending the data of the UE to the PCell, the PCell dividing the data of the UE in the PDCP layer, then sending each path of the data to the UE via the PCell and / or the SCell of the UE, and the UE recombining the data in the PDCP layer and then sending to an application layer. The invention also discloses a data transmission system in a heterogeneous network. By adopting the technical scheme disclosed by the invention, the cooperation among heterogeneous networks can be realized, the resources of the heterogeneous networks can be fully utilized, and the overall heterogeneous networks are more energy-saving.

Owner:BEIJING SAMSUNG TELECOM R&D CENT +1

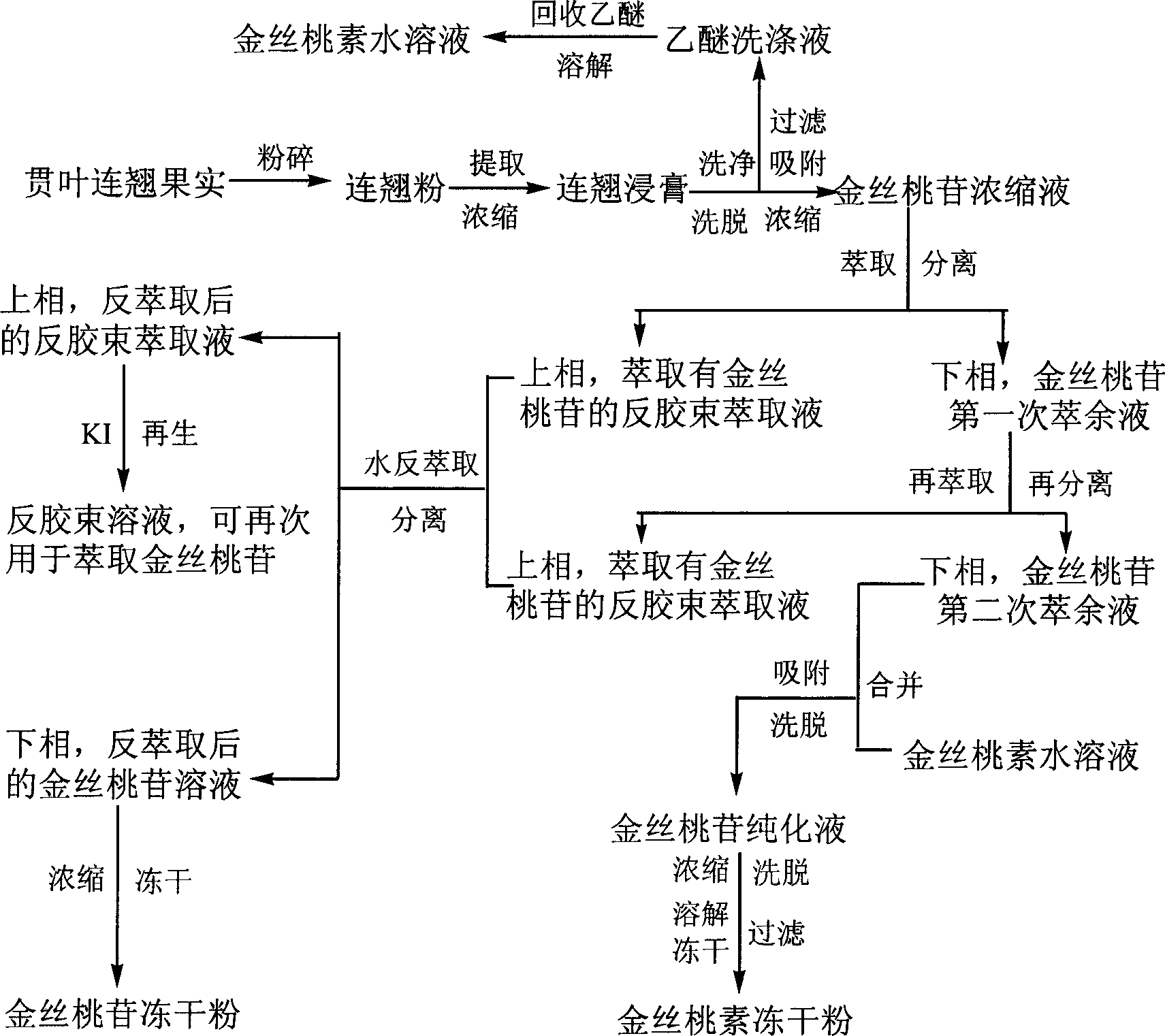

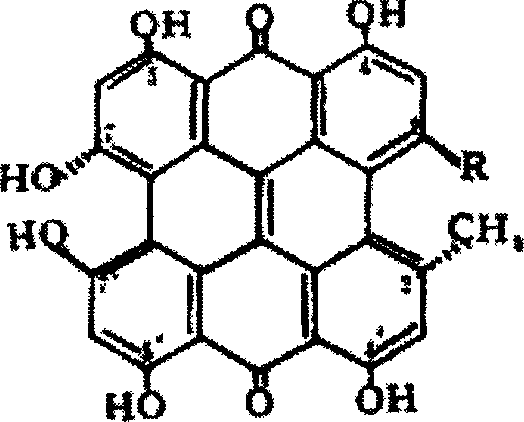

Preparation method of hyperin and hypericin of Hypericum perforatum

InactiveCN1880328AHigh yieldReduce manufacturing costOrganic active ingredientsSenses disorderHypericum perforatumHyperoside

This invention relates to a method for producing Hypericum perforatum hyperoside and hypericin. This invention comprehensively utilizes Hypericum perforatum fruits which are rich in our country to produce both hyperoside and hypericin pharmaceutical active components with high recovery rate, high product purity, and low cost. During the producing process, it achieves the recovery and cycling use of many solvents like ethanol and ethyl ether, and also achieves the regeneration and cycling use of micelle reextracting agent and absorption resin. The plant biological active compounds produced by this invention can be broadly used in heat-clearing and detoxifying, astringing to arrest bleeding and promote diuresis, and antidepressant drug.

Owner:CHONGQING UNIV

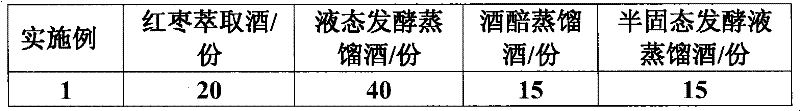

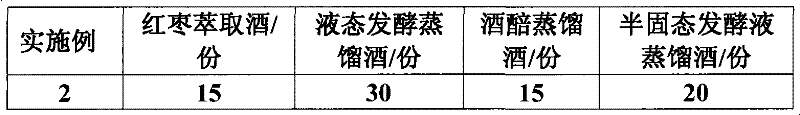

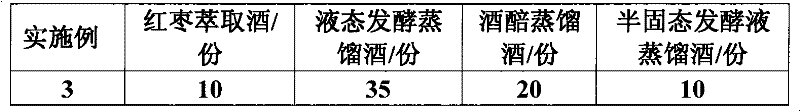

Red jujube health-care liquor and production process thereof

InactiveCN102051321AUnique flavorPromote circulationAnthropod material medical ingredientsAlcoholic beverage preparationAdditive ingredientChinese Jujube

The invention discloses red jujube health-care liquor and a production process thereof. Liquor, red jujubes, grape pips, roses and the like are selected as raw materials, and the red jujube health-care liquor is obtained by heat soaking, low-temperature soaking and repeated treatment of the raw materials. The red jujube health-care liquor is integrated with a plurality of functional raw materials, contains a plurality of effective ingredients such as general flavone, rhodioloside, crude polysaccharides and total saponins, and has multiple health-care efficacies of alleviating fatigue, enhancing immunity, promoting metabolism, promoting blood circulation, removing blood stasis, helping people maintain beauty and keep young, and removing chloasma. The red jujube health-care liquor is crystal and transparent, has unique flavor and health-care efficacy, and is suitable for long-term drinking. The product is clear, glossy, fragrant and pure and mild in taste, sweet and chill, refreshing and soft, and representative, and has a balanced body, long-lasting flavor and unique style. The production method is simple, raw materials used in preparing the red jujube health-care liquor are easy to obtain, and the red jujube health-care liquor is easy for popularization.

Owner:山西悦卜林创业投资有限公司

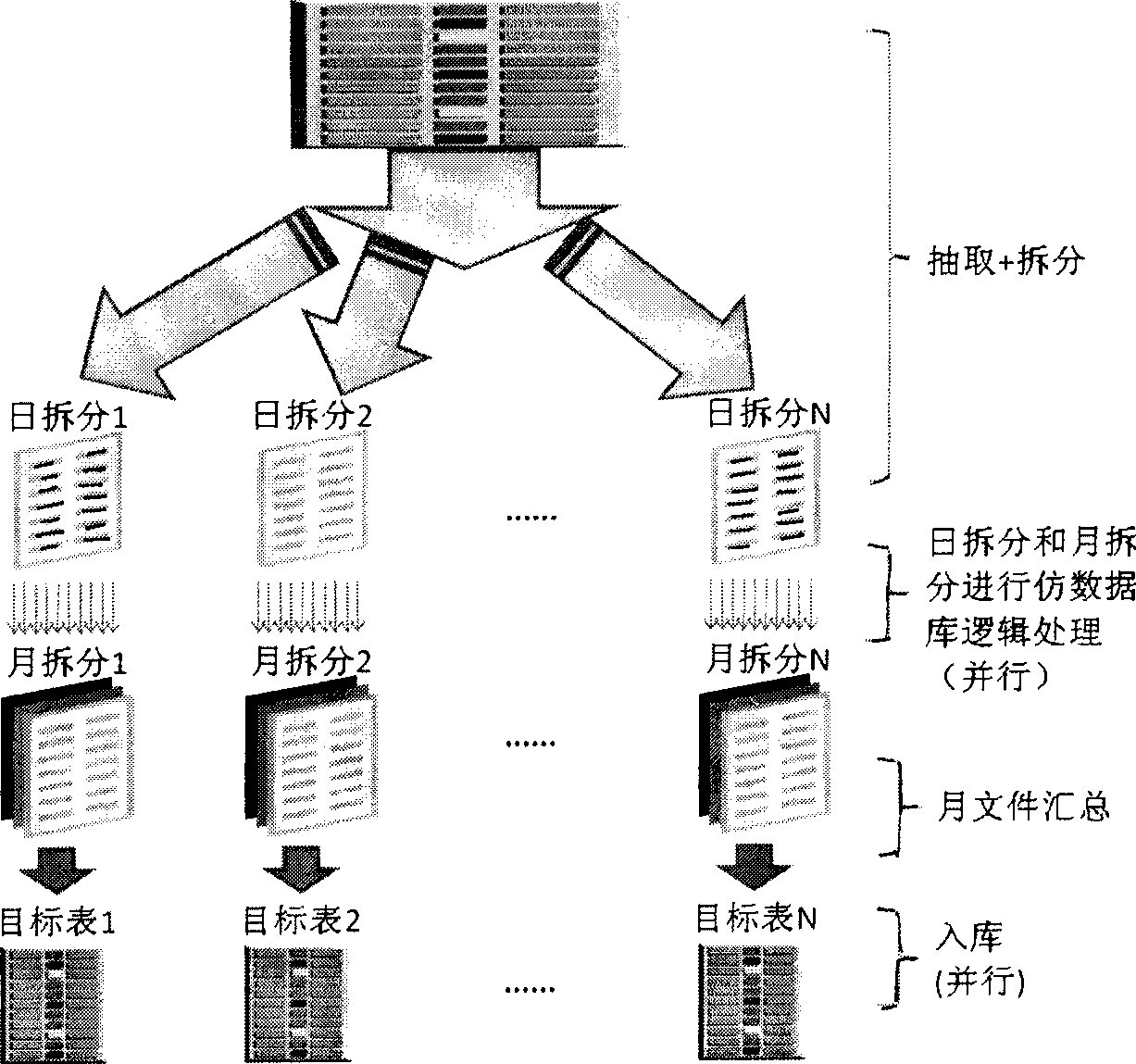

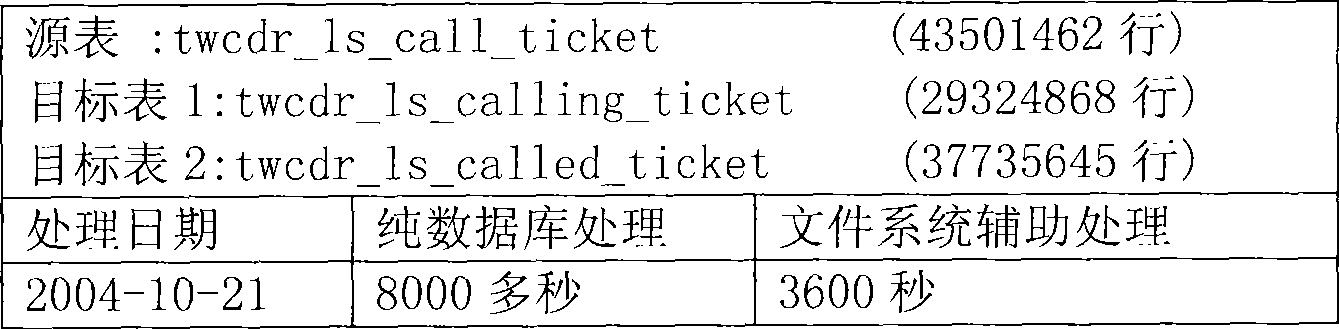

Big data quantity high performance processing implementing method based on parallel process of split mechanism

InactiveCN101510203AReduce database pressureLittle performance dependencySpecial data processing applicationsSelection arrangementsCollections dataSQL

The invention discloses a method for realizing large data amount high-performance process, which is based on splitting mechanism parallel processing. A splitting rule is set for the mass data of telegraph tickets to equally split the mass data to be processed into a plurality of files; and the multi-thread and multi-CPU parallel process of a file processing system is adopted. The quick processing of the mass data is as follows: the parallel process of the file processing system is to simulate the database sql algorithm to carry out calculation; an SQL sentence for extracting a mass data source table is established through firstly spreading out the dimensionality and index field required by each collection table and secondly obtaining the unions and then the information required by all the following mass data collection tables is read over; the assembly storing is as follows: after the work for collecting the small files formed while equally splitting a plurality of files is finished, all the result files are combined into large files according to the target table types and then are loaded into the collection tables; and the work can be completed by the peculiar quick accessing instruction of the database.

Owner:LINKAGE SYST INTEGRATION

Method for recycling epoxy resins and glass fibre from non-metal powder of waste printed circuit board

InactiveCN101407596AHigh recovery rateMake full use of resourcesSolid waste disposalPlastic recyclingPollutantChemistry

The invention discloses a method for recycling epoxide resin and glass fiber from non-metal powder in waste printed circuit boards, comprising the following steps of: (1) pretreatment, and dust removal by washing; (2) removing residue metal: inorganic acid is used for removing the residue metal in the non-metal powder, and the obtained powder can be used directly after being filtrated; (3) preliminary decomposition: the processed non-metal powder is added into inorganic acid, the obtained mixture is heated for reaction and then filtrated; the filtrated solid is added into organic solvent, stirred and filtrated and the obtained solid is the glass fiber; and the organic solvent in the filtrate is evaporated so as to obtain the solid epoxide resin; and (4) secondary decomposition: the obtained solid epoxide resin is added into inorganic acid, and heated for reaction; and then the organic solvent is used for extraction and then is evaporated so as to obtain low molecular weight epoxide resin. The invention realizes green recycling of the non-metal powder of the waste printed circuit boards under the moderate condition and has high recovery rate, thus not only being capable of reducing the emission of pollutants but also leading the resource to be fully utilized.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

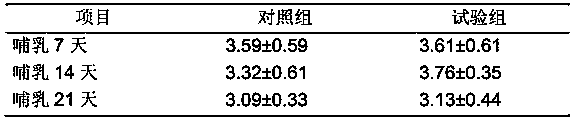

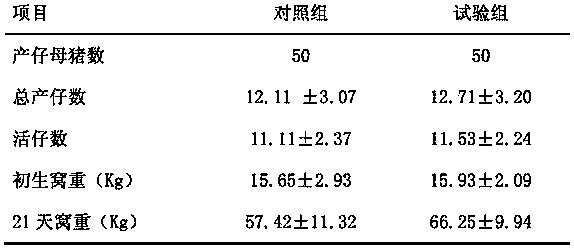

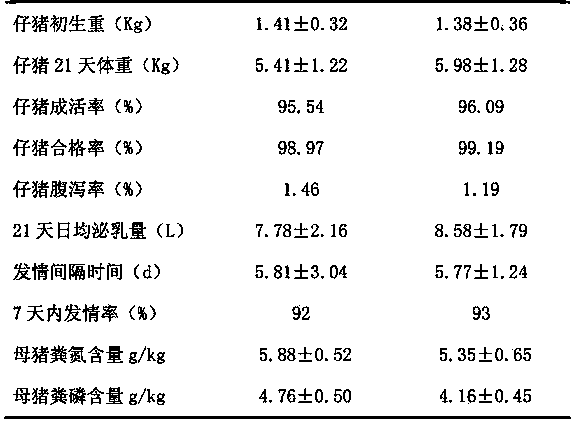

Efficient and environment-friendly compound feed for lactating sow and preparation method thereof

InactiveCN103976194AExtended shelf lifeIncrease in sizeAnimal feeding stuffAccessory food factorsAnimal scienceRoom temperature

The invention discloses an efficient and environment-friendly compound feed for lactating sow and a preparation method thereof. The compound feed is characterized by comprising the following raw materials in parts by weight: 40 to 50 parts of maize, 20 to 30 parts of wheat, 3 to 5 parts of wheat bran, 10 to 15 parts of peeled soybean meal, 1 to 2 parts of fish meal, 3 to 5 parts of biological soybean meal, 1 to 1.2 parts of rock powder, 1.2 to 1.4 parts of calcium hydrophosphate, 0.3 to 0.5 part of table salt, 1.5 to 2.5 parts of soybean oil, 0.4 to 0.45 part of lysine, 0.04 to 0.06 part of methionine, 0.1 to 0.12 part of threonine, 0.01 to 0.02 part of a complex enzyme preparation, 0.06 to 0.1 part of microecologics, 0.03 to 0.06 part of an emulsifier, and 1 to 1.5 parts of a compound premix. The preparation method comprises the following steps: weighing the various raw materials in a predetermined ratio; fine crushing maize, wheat, wheat bran, peeled soybean meal and biological soybean meal; directly adding to a horizontal twin-shaft paddle mixer in a ratio to mix; feeding the mixture to a granulating machine for granulating; processing at a temperature of 85 DEG C until the gelatinization degree is more than 90%; cooling till the temperature is not higher than room temperature by 5 DEG C after granulating; and then weighing, bagging and sealing through an automatic packing machine. The preparation method is mainly used for preparing the compound feed for lactating sow.

Owner:TANGRENSHEN GRP CO LTD

Method for preparing natural-detergent feed solution by using tea saponin fluid

InactiveCN102010807AAvoid damageReduce non-detergent ingredientsFungiBacteriaMicroorganismProteinase activity

The invention relates to a method for preparing a natural-detergent feed solution by using a tea saponin fluid, which overcomes the defect that the dirt-removing power of the existing tea saponin fluid is not strong. The method is implemented through the step of carrying out fermentation on the tea saponin fluid by microbes so as to obtain a feed solution for preparing detergents, wherein the microbes are germs, saccharomycetes and mycetes which can grow in a tea saponin solution and can produce lipases, proteases and amylase in the process of fermentation. The method provided by the invention has the advantages that because the tea saponin fluid is fermented by the microbes which can grow in a tea saponin environment so as to produce a series of enzymatic systems having dirt-removing effect, therefore, the dirt-removing effect and dirt-removing range of the tea saponin fluid are remarkably improved, meanwhile, the components without dirt-removing power can be consumed in the process of fermentation, and the dirt-removing effect of the tea saponin is also correspondingly improved.

Owner:HUNAN AGRICULTURAL UNIV +1

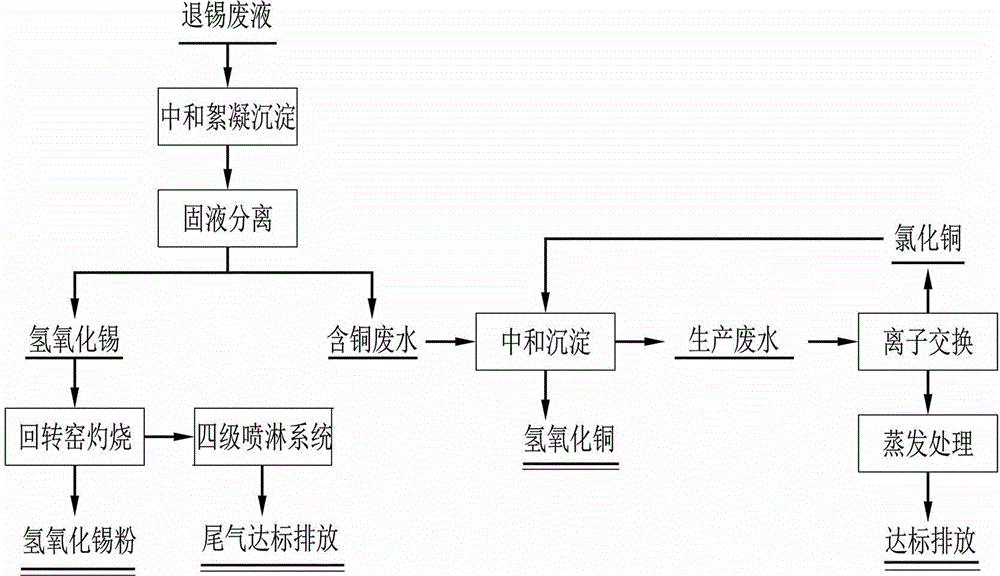

Tin stripping waste liquid treating method

InactiveCN104986892AMake full use of resourcesMaintain stabilityMultistage water/sewage treatmentProcess efficiency improvementLiquid wastePolyacrylamide

A tin stripping waste liquid treating method comprises the following steps: adding sulfate into a tin stripping waste liquid, adjusting the pH value to be 1.0-1.5, then adding a polyacrylamide flocculating agent to recycle tin, adding ammonia water with the concentration of 18-25% into copper-containing wastewater, conducting neutralization to recycle copper, and conducting further treatment on the wastewater. According to the method, sulfate is added into the tin stripping waste liquid, so that the effect of tin hydroxide colloid coagulation is achieved, and the usage amount is ammonia water can also be reduced; in the neutralization process, a certain amount of the PAM (polyacrylamide) flocculating agent is added, so that metallic tin is precipitated in the form of tin hydroxide; under the acidic condition, most metallic copper dissociates in a supernatant in the form of copper ions, the tin hydroxide is obtained through solid-liquid separation, and the filtrate is subjected to neutralization, so that copper in the filtrate is precipitated in the form of copper hydroxide, and the copper hydroxide is subjected to solid-liquid separation through a filter press, that is, in different acidity and alkalinity systems, the forms of metal ions are different, so that the metal ions are separated, tin and copper in the tin stripping waste liquid can be recycled in steps, and the resources in the tin stripping waste liquid can be fully utilized.

Owner:QINGYUAN XINLV ENVIRONMENTAL TECHNOLOGY CO LTD

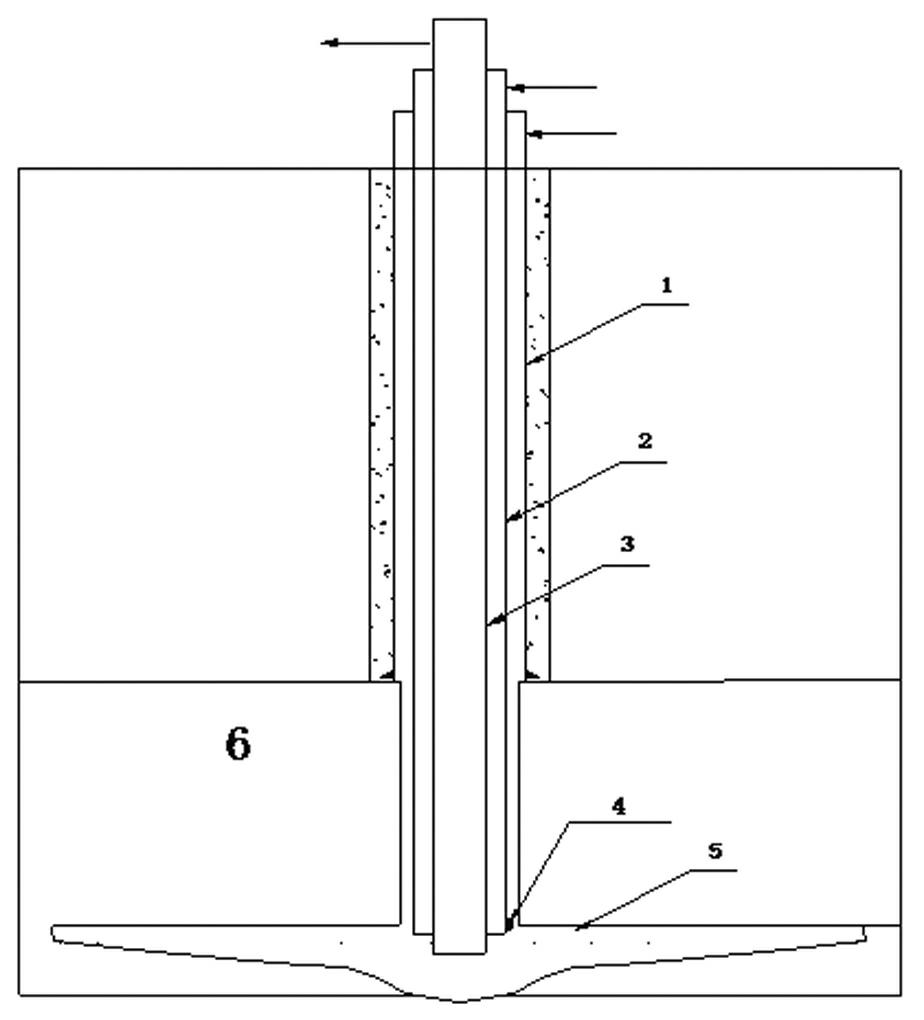

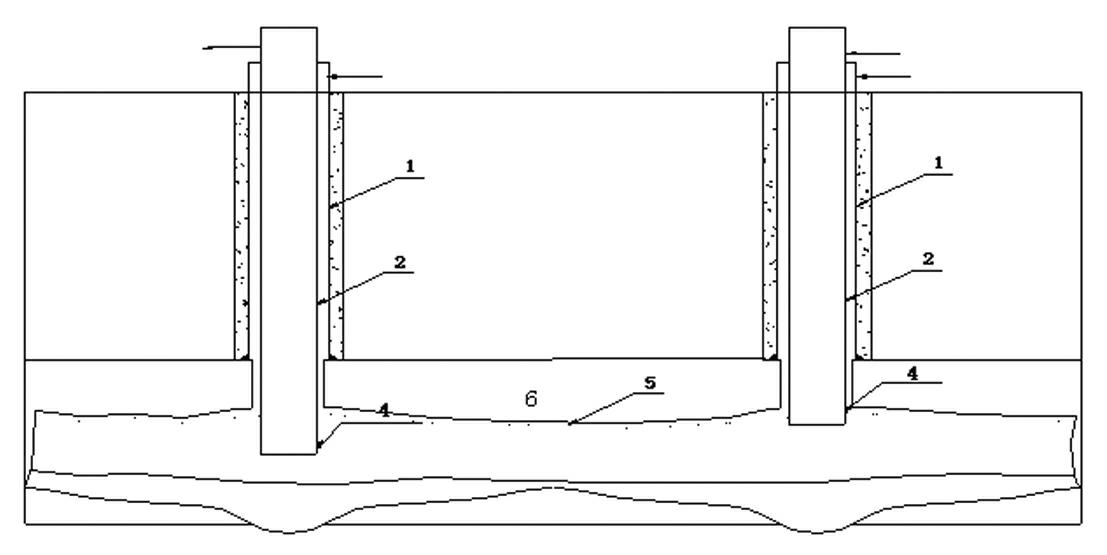

Method for mining sylvite in underground carnallite ore

The invention discloses a method for mining sylvite in underground carnallite ore, which comprises the following steps of: (1) building wells, namely, taking three-pipe structures as well bodies, wherein the three pipes include a technical sleeve pipe, a production sleeve pipe and a central pipe; (2) building a groove on a single well, namely, filling normal-temperature water in annular space of the central pipe and the production sleeve pipe, and discharging dissolved brine from the central pipe; (3) mining by non selective dissolution at normal temperature; (4) selectively mining by hot melting at high temperature, namely, communicating two wells or well groups, pulling out the central pipe, filling a sodium chloride and magnesium chloride containing filler of 75 to 90 degrees centigrade into a well, and discharging the brine for processing from the other well in the well group; and (5) refilling a mother solution into the wells. The method for mining the sylvite in the underground carnallite ore provided by the invention realizes selective mining of potassium chloride; and, the method saves energy resources and reduces production cost; moreover, the refilling process of the mother solution realizes zero discharge of the mother solution and facilitates environment protection.

Owner:中水电海外投资有限责任公司 +1

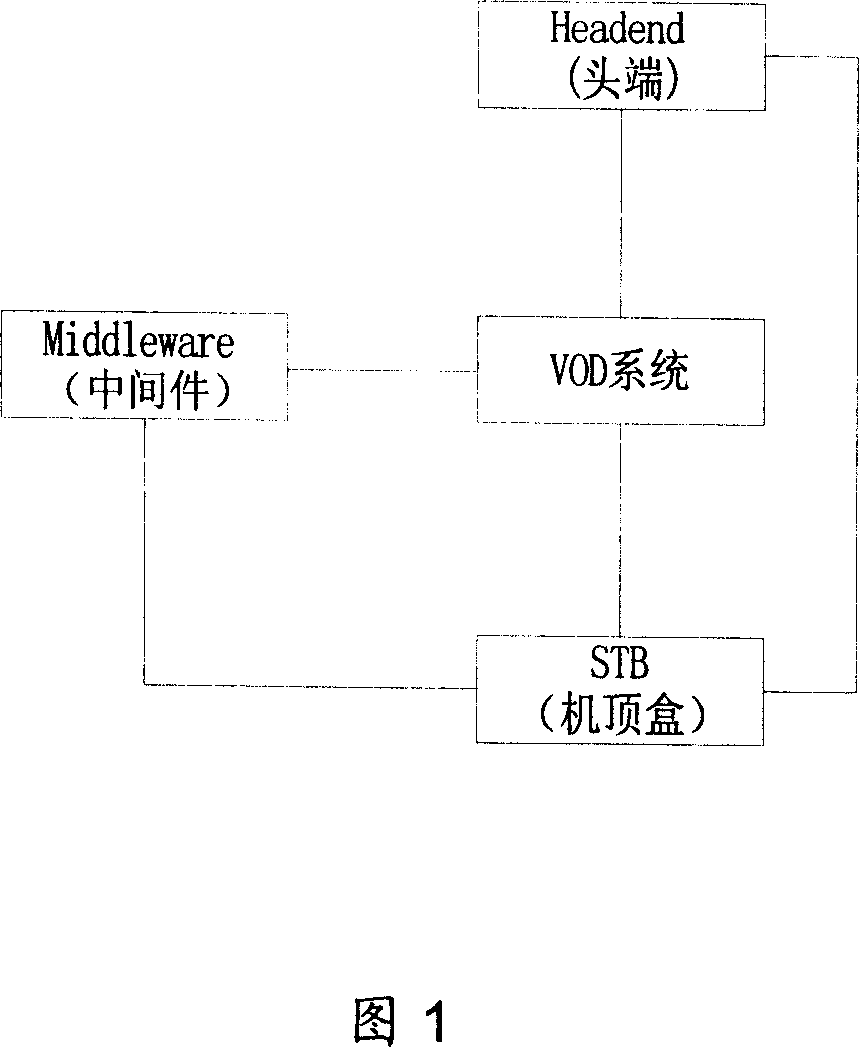

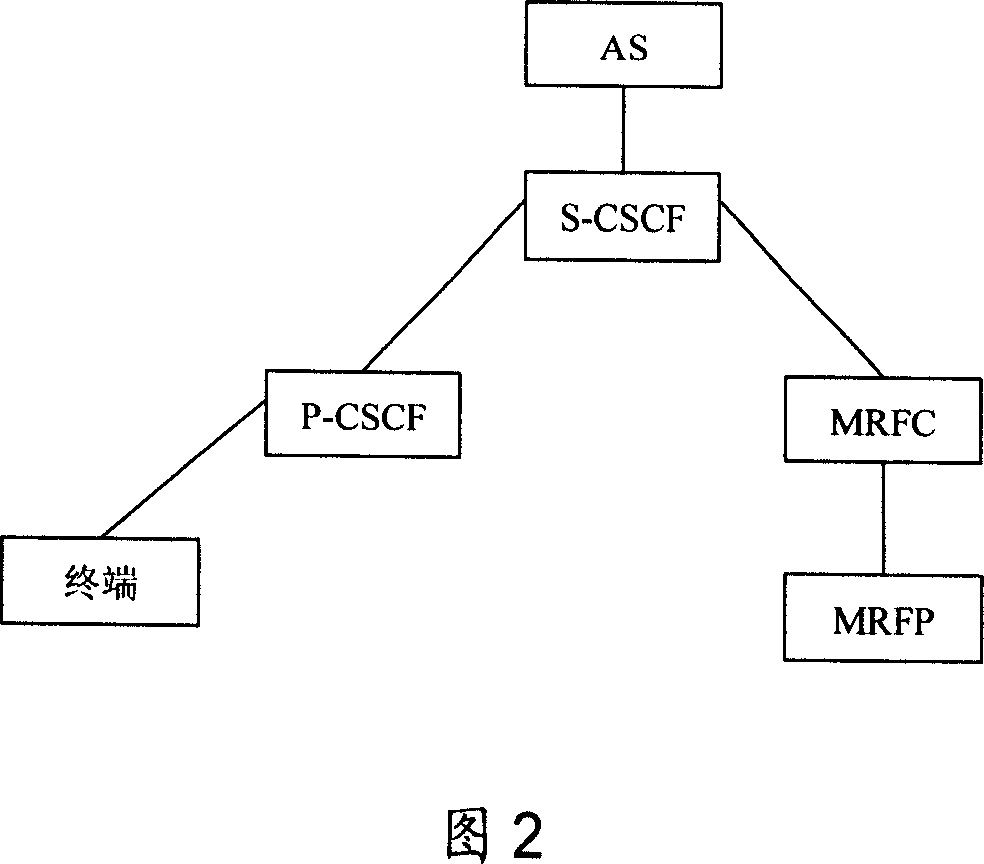

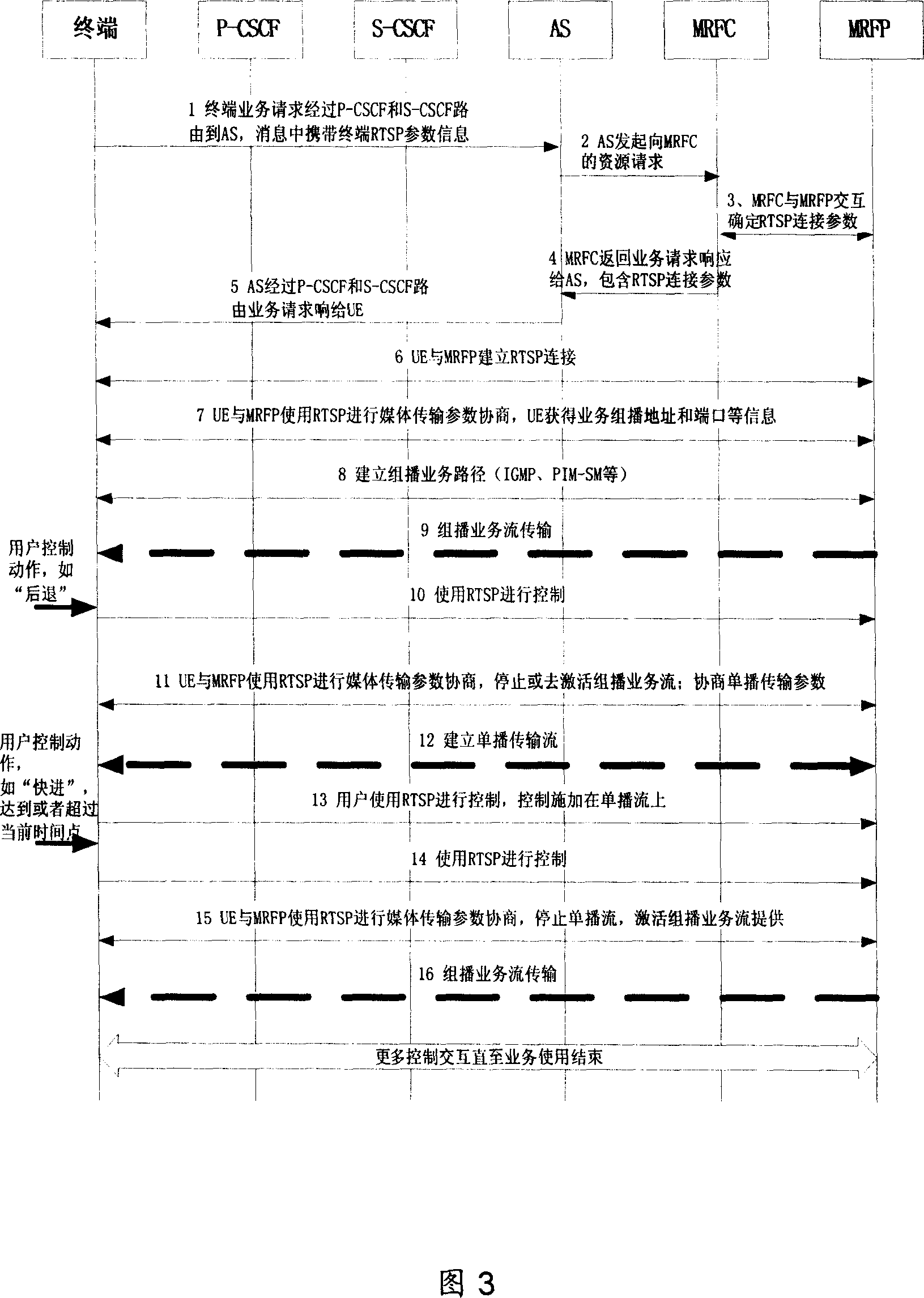

Method and system for realizing time-transferring TV-set service based on NGN network

InactiveCN101030961AMake full use of resourcesSpecial service provision for substationPulse modulation television signal transmissionApplication serverTime transfer

The method comprises: a) after application server (AS) and media resource function controller (MRFC) make negotiation, user end (UE) establishes the multicast service stream with media resource function processor (MRFP); b) when UE requests to make unicast service stream control, according to UE request and after negotiating with MRFC, AS provides the unicast service stream established between UE and MRFP to UE. The invention uses the MRFC and MRFP originally existed in NGC to complete the switching control from multicast to unicast and to provide unicast stream.

Owner:HUAWEI TECH CO LTD

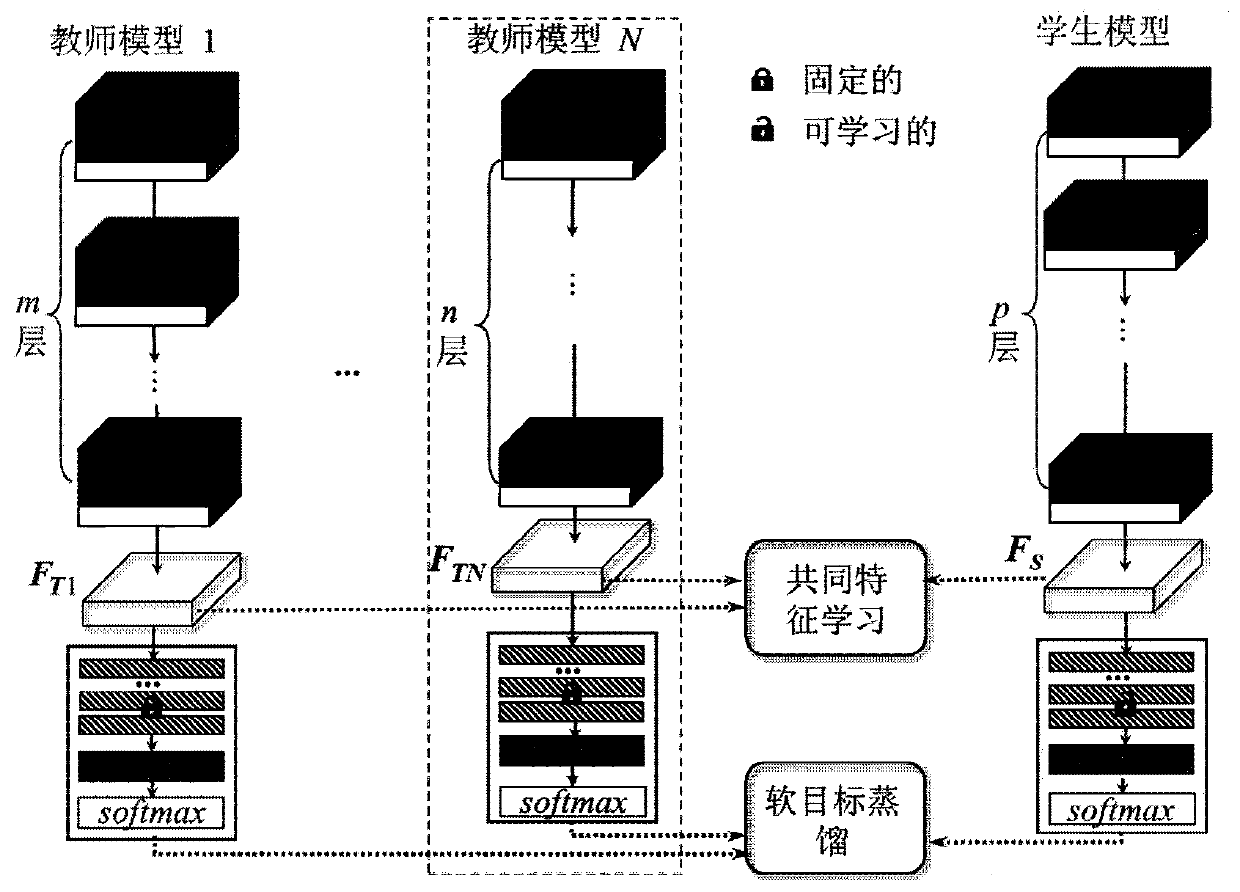

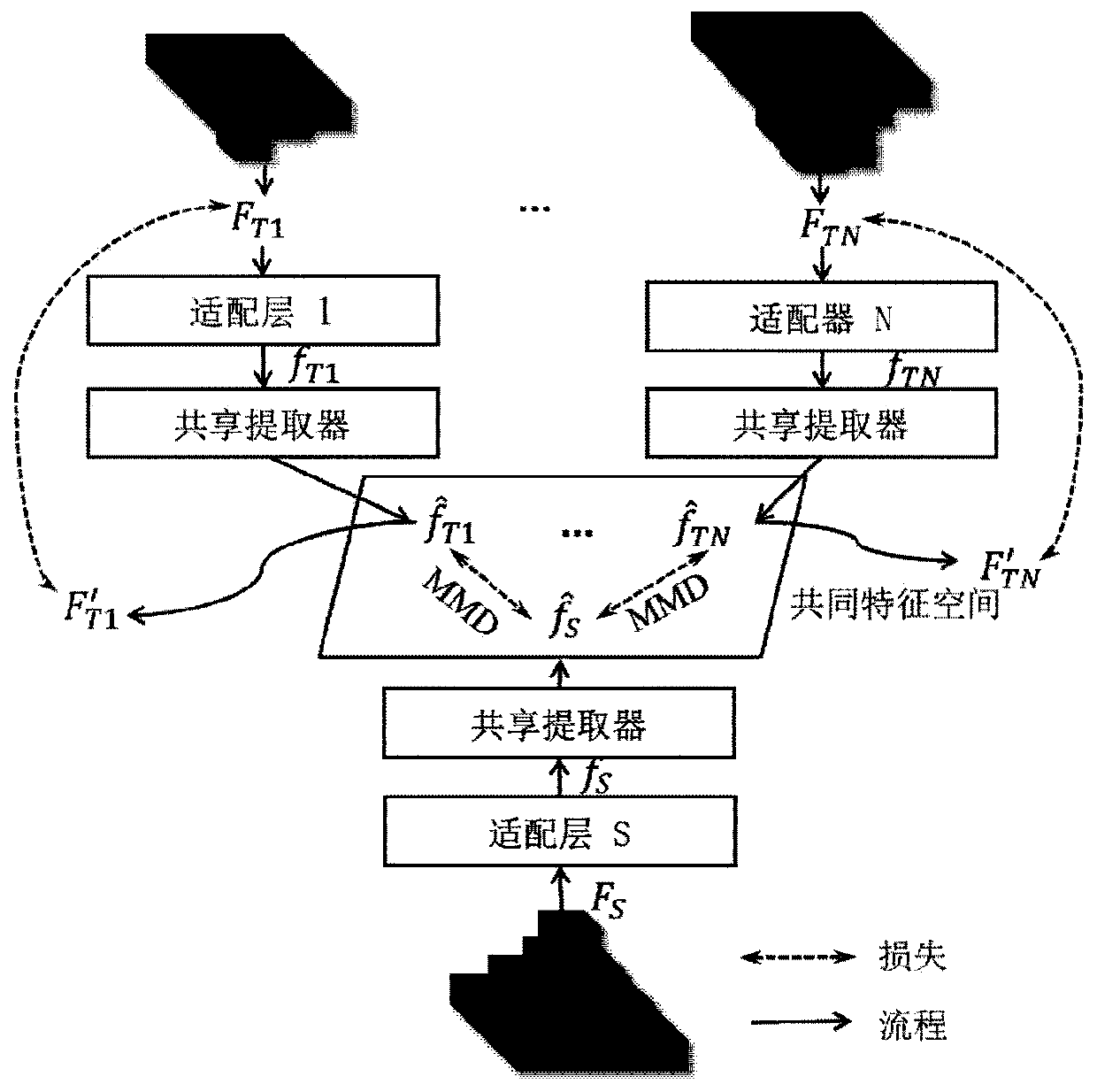

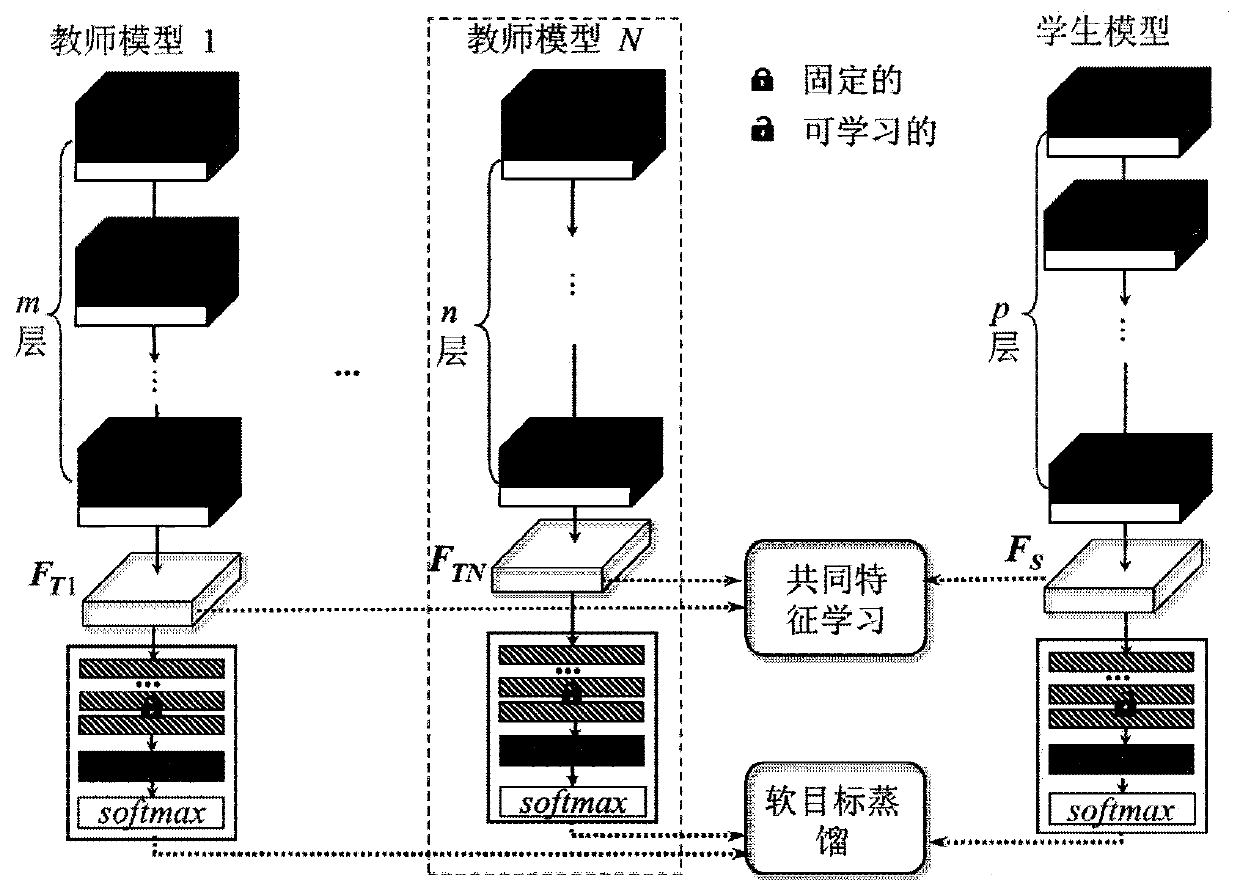

Heterogeneous neural network knowledge recombination method based on common feature learning

InactiveCN111160409ALearning robustnessReduce lossCharacter and pattern recognitionNeural architecturesFeature learningNetwork model

The heterogeneous neural network knowledge recombination method based on common feature learning comprises the steps of obtaining a plurality of pre-trained neural network models, and naming the neural network models as teacher models; guiding the training of the student model through a common feature learning and soft target distillation method by utilizing the features output by the teacher model and the output prediction result; in the common feature learning process, projecting features of a plurality of heterogeneous networks to a common feature interval, so that a student model integrates knowledge of a plurality of teacher models; the soft target distillation method enables the prediction result of the student model to be consistent with the prediction result of the teacher model, thereby obtaining a stronger student model with the task processing capability of all teacher models. Since only the prediction result of the teacher model needs to be simulated, the student model canbe obtained by training without any manual annotation. The method is suitable for knowledge reorganization of a neural network model, especially knowledge reorganization of a heterogeneous image classification task model.

Owner:ZHEJIANG UNIV

Trust model-based cooperative communication method in mobile self-organized network

ActiveCN101969647AScale upMake full use of resourcesNetwork topologiesNetwork planningTrust levelWireless ad hoc network

The invention discloses a trust model-based cooperative communication method in a mobile self-organized network. In the method, cooperation of nodes is excited under wireless Ad Hoc network environment by establishing a global trust level and safe recommendation trust level-based trust model and utilizing a trust-fading punishment mechanism and a node salvation mechanism. In the mobile self-organized network, the node determines whether the monitored node participates in the cooperation by utilizing direct monitoring and comprehensive evaluation of monitoring information of other nodes, and a reconstruction mechanism is set for a malicious node, so that the node is newly added into the network and establishes connection with the other nodes; and based on the false recommendation, iterative convergence and punishment and salvation problem of a majority of trust models, the global trust level and safe recommendation trust level-based trust model is established, and a topological transformation-based recommendation trust computation method is brought forward; and in the trust varying process described by the trust model, the cooperation of the nodes is excited under the mobile self-organized network environment by using the punishment mechanism of an updating stage and the salvation mechanism of a reestablishment stage.

Owner:王堃

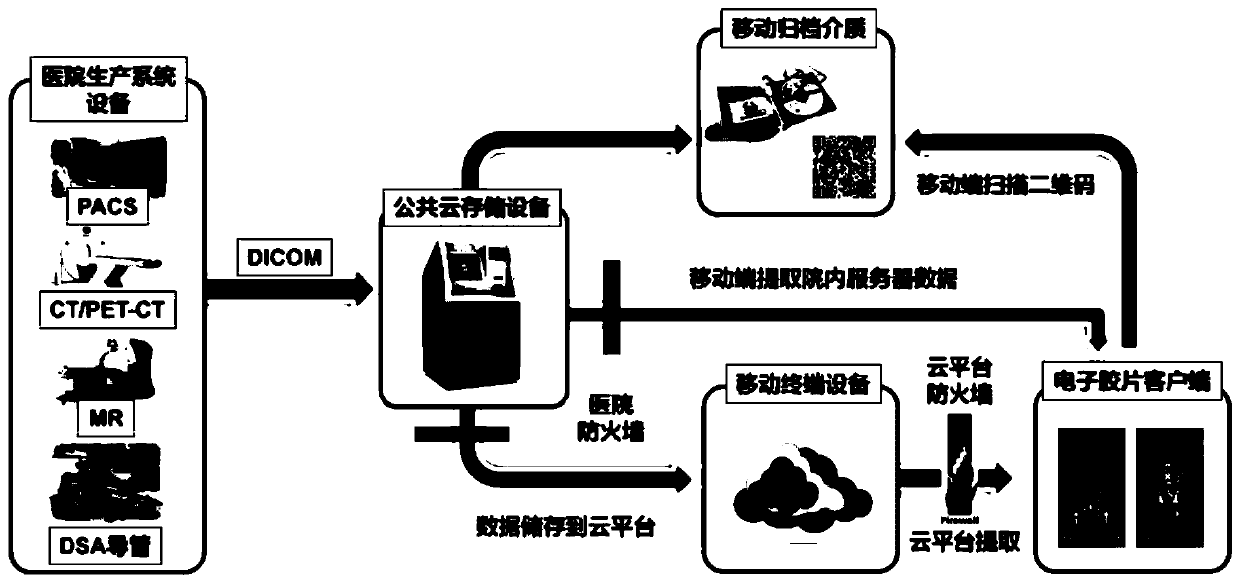

Medical image data utilizing and sharing platform

PendingCN109698022AReduce mistakesReduce referral timeMedical communicationMedical automated diagnosisCloud storageData exchange

The invention provides a medical image data utilizing and sharing platform which comprises the components of common cloud storage equipment that is used for analyzing the image information and storingan image information file, checking a patient through image equipment and obtaining image information through exchange through a DICOM communication protocol , wherein the image equipment is used forcreating a DICOM file; mobile terminal equipment which is used for reading and diagnosing a result from the image, and checking an image sequence through accessing an image list and online browsing the DICOM image of the image information by a browser, wherein the image information comprises a DICOM image, patient PHI information and surgery information, and the mobile terminal equipment extractsdata in a server in a hospital and a result obtained from the image is read and diagnosed by an application; and hospital production system equipment. The medical image data utilizing and sharing platform receives the image information in the internal network of the hospital through the internal network and an external network, and furthermore realizes data exchange through the external network,thereby realizing remote diagnosis.

Owner:天津百士德力科技有限公司

Method for extracting abalone polysaccharide

ActiveCN1749280AReasonable workmanshipEffective extraction methodAntineoplastic agentsAlcoholUltrasonic vibration

The extraction process of abalone polysaccharide includes the following steps: taking abalone meat, breaking wall in tissue stamping machine, mixing with water homogeneously, lixiviating at 20-80 deg.c for 2-6 hr, centrifugally separating, re-extracting the insoluble matter and merging supernatant; concentrating the extracted liquid to polysaccharide content of 1.5-3.0 5, alcohol precipitating at 0-4 deg.c for 12-16 hr, and vacuum drying or spray drying to obtain the product. During the extraction, alkali, ultrasonic vibration and / or enzyme, single or compound, may be added. The present invention creates the technological path of extracting abalone polysaccharide and provides technological foundation for the research of medicinal use of abalone polysaccharide.

Owner:DALIAN POLYTECHNIC UNIVERSITY +1

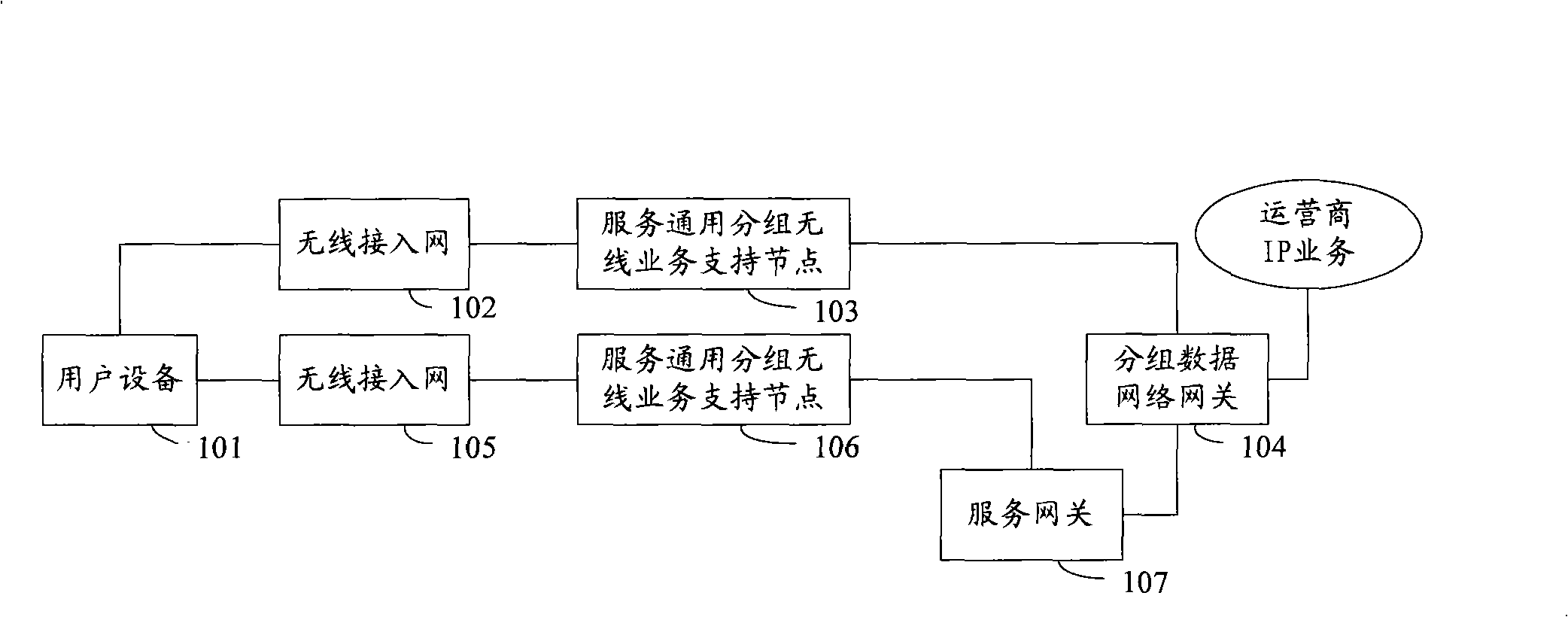

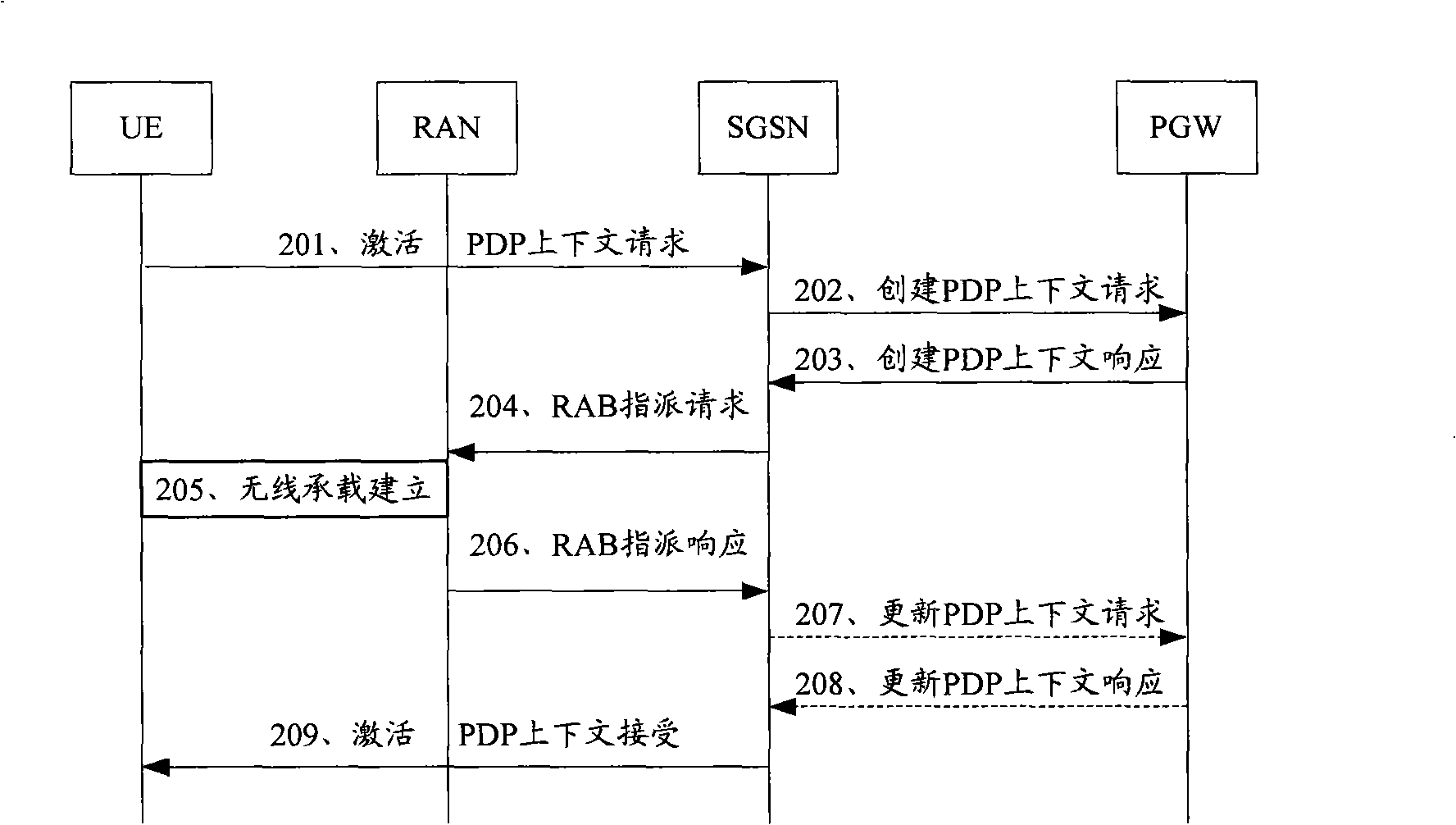

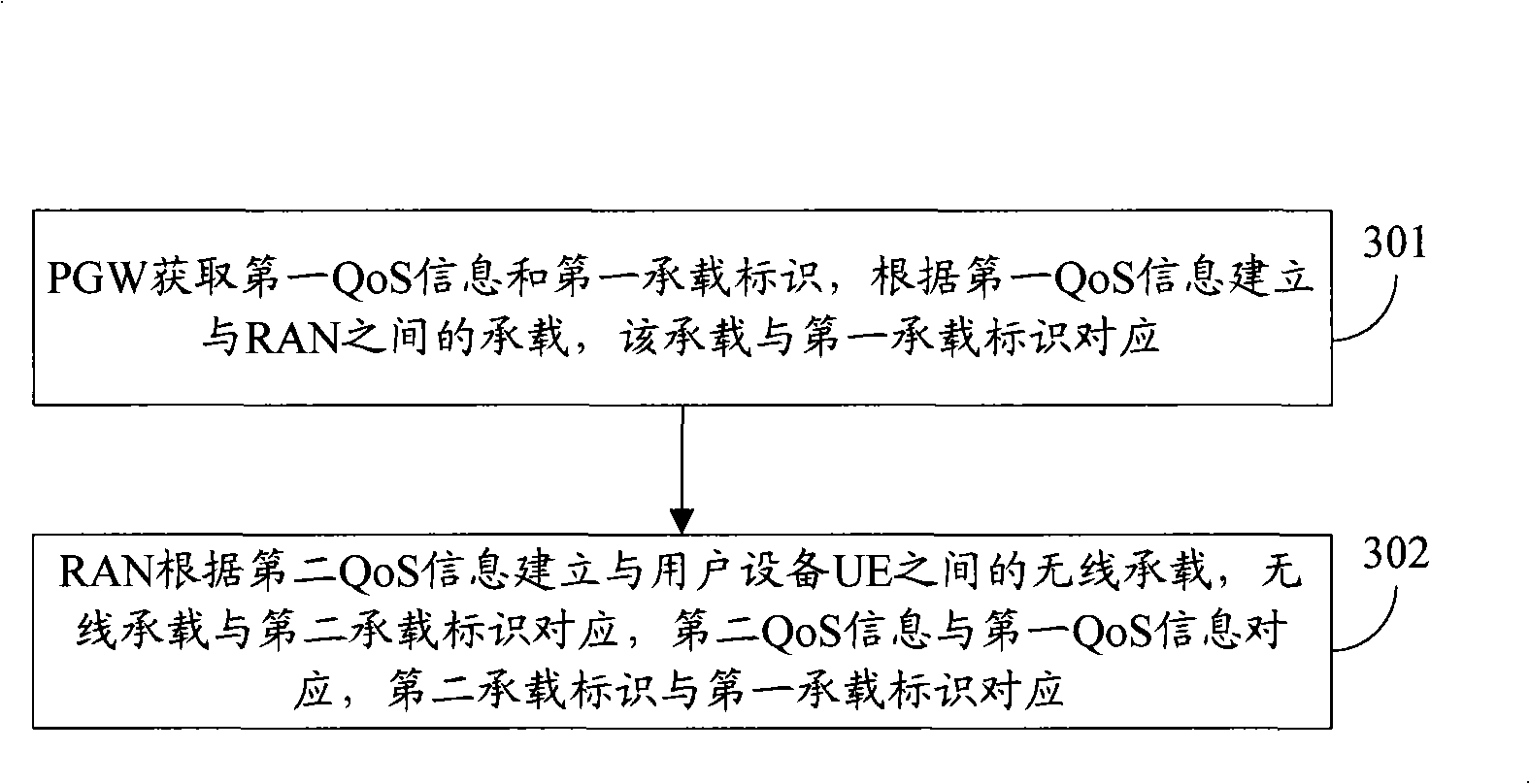

Method for establishing load bearing and relevant apparatus

ActiveCN101409951AMake full use of resourcesTake advantage ofNetwork traffic/resource managementConnection managementTelecommunicationsLoad bearing

The invention relates to the technical field of communication, and discloses a bearer establishment method and a related device, wherein, the bearer establishment method comprises the following steps: a PGW obtains a first QoS message and a first bearer identification, and establishes a bearer with an RAN according to the first QoS message, and the bearer is corresponding to the first bearer identification; and the RAN establishes a wireless bearer with a UE according to a second QoS message corresponding to the first QoS message, and the wireless bearer is corresponding to a second bearer identification which is corresponding to the first bearer identification. By using the technical scheme provided by the invention, the bearer between the UE and the PGW can be established by an SGSN and an SGW when the UE is accessed to the SGW via the SGSN, which causes full utilization of resources of various network entities in a network.

Owner:HUAWEI TECH CO LTD

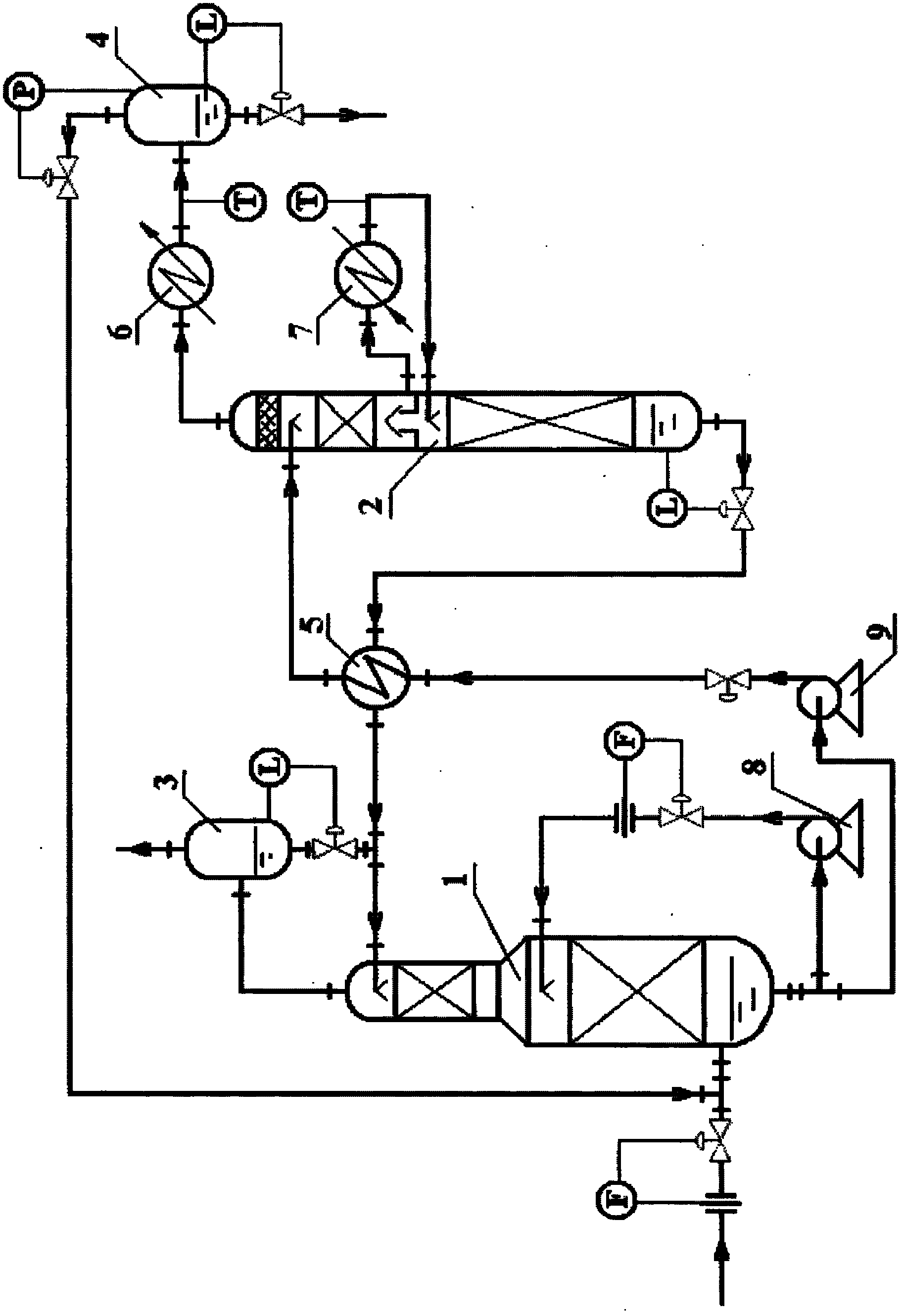

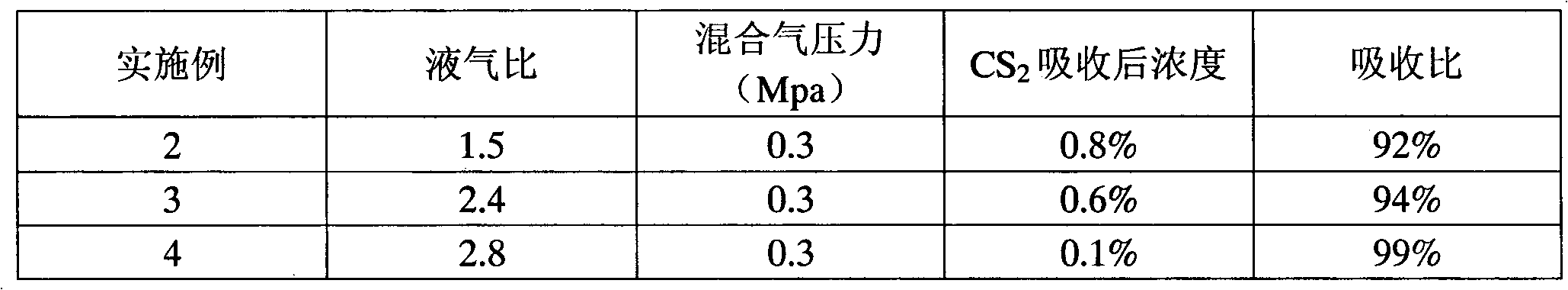

Device and method for absorbing carbon disulfide in hydrogen sulfide gas by using solvent

ActiveCN101912718AReduce the impactGood absorption and separation effectHydrogen sulfidesDispersed particle separationVapor–liquid separatorProduct gas

The invention discloses a device and a method for absorbing carbon disulfide in hydrogen sulfide gas by using solvent, which belong to the technical field of hydrogen sulfide gas and carbon disulfide preparation. The device of the invention mainly comprises an absorption tower, an analytical tower, a gas-liquid separator, a heat exchanger, a cooler, a heater, a pump, a valve and the like; and the method is to produce H2S and CS2 products by using the device and absorption and separation in a transfer mass dynamic control process and solvent. The device of the invention has a simple structure and low cost; and the method of the invention has the advantages of good absorption / separation effect, full utilization of resources, reduced energy consumption, low production cost and convenient popularization and application, wherein the absorption rate of CS2 is up to 99 percent. The device and the method of the invention can be widely applied to separation of H2S gases and CS2 in industrial production, particularly the separation of CS2 from H2S gases in the process of preparing CS2 by using natural gases.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

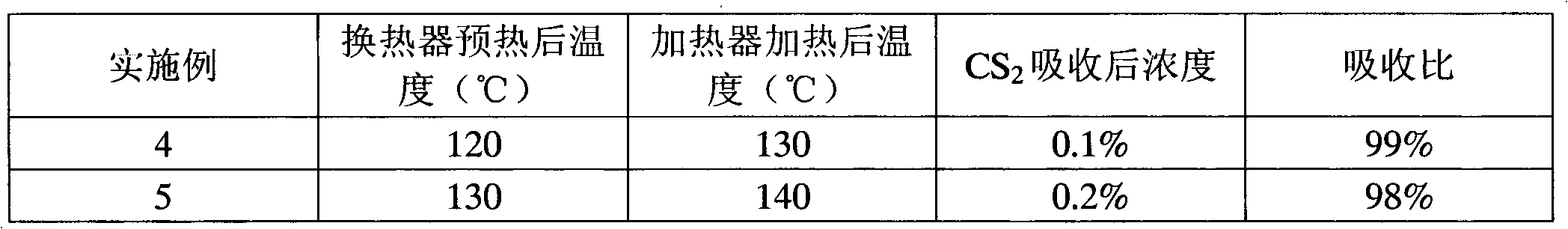

Route processing method, routing processor and router

InactiveCN101309201AImprove scalabilityMake full use of resourcesNetworks interconnectionExtensibilityLink-state routing protocol

The invention embodiment discloses a route processing method which includes that the connections among the nodes in the network are established; the nodes are processed with task scheduling; the nodes operate the link-state routing protocol, process route computation and obtain the route results according to the scheduled tasks; the route computation results of the nodes are acquired and the route summarization is processed. The invention embodiment also provides a route processor which includes a task scheduling module used for the task scheduling, a protocol operation module used for operating the link-state routing protocol according to the scheduled tasks, computing the routes and obtaining the route computation results and a route summarization module used for summarizing the route computation results. The invention embodiment also provides a router which has multi-route processor frame. The technical proposal provided by the route processing method can realize the extensibility of the link-state routing protocol.

Owner:HUAWEI TECH CO LTD +1

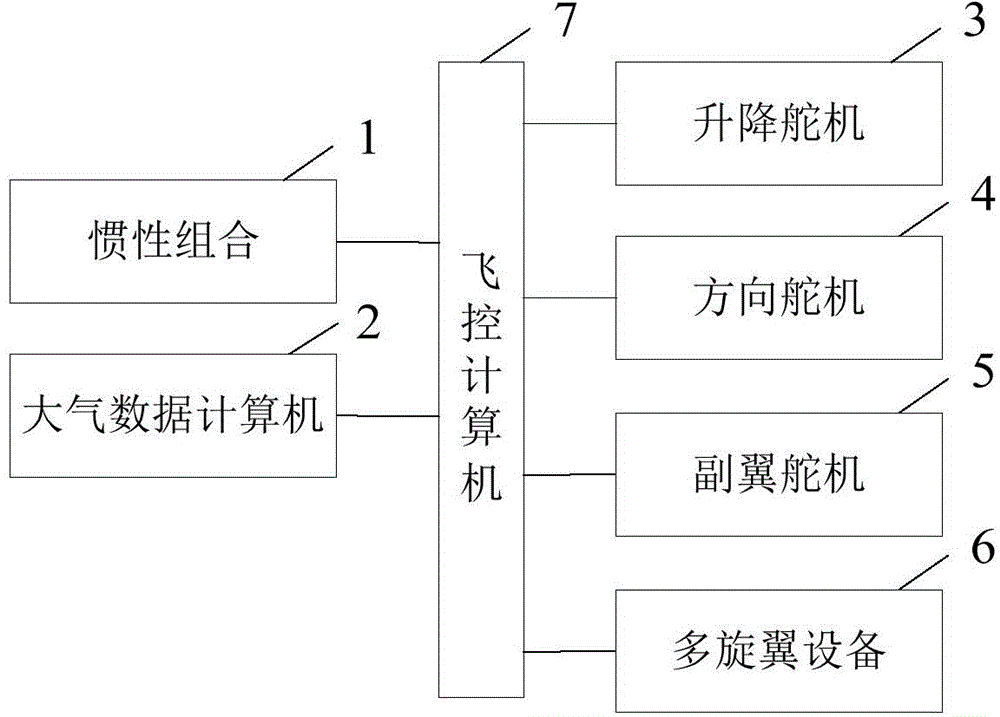

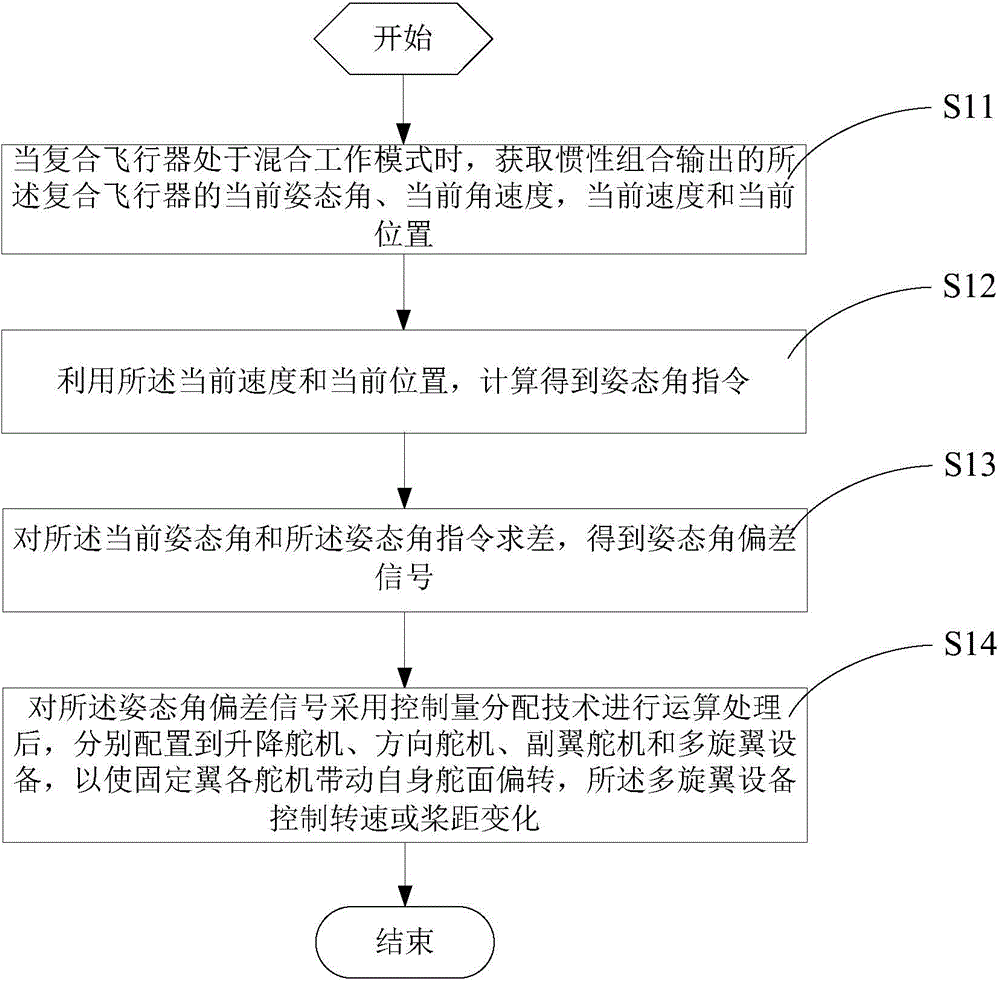

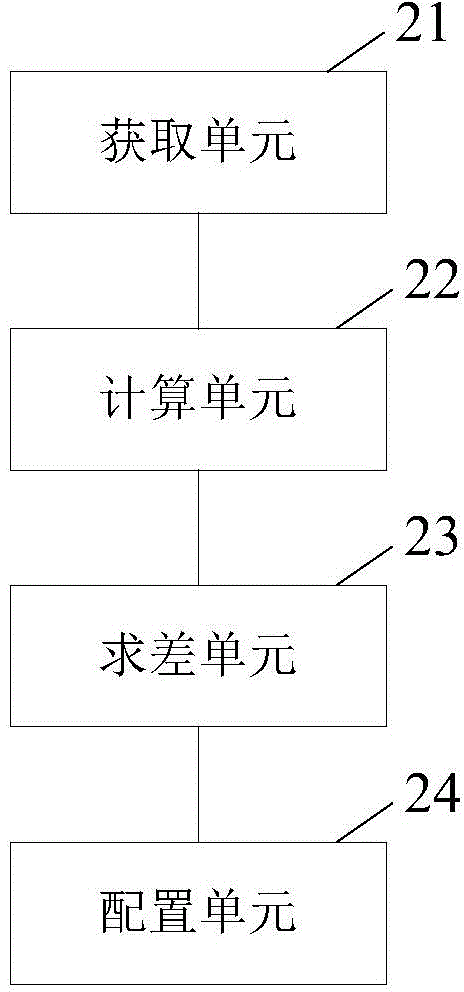

Flight control method and device of multi-rotor and fixed wing composite aircraft

ActiveCN104590557AWith flight control functionImprove control efficiencyAircraft controlRotocraftAttitude controlControl function

The invention discloses a flight control method and a flight control device of a multi-rotor and fixed wing composite aircraft. When the composite aircraft is at a mixed working mode, the current attitude angle is subtracted from the attitude angle instruction of the composite aircraft to obtain an attitude angle deviation signal, the attitude angle deviation signal is operated by a controlled quantity allocation technology and is respectively configured to a lifting steering engine, a direction steering engine, an aileron steering engine and multi-rotor equipment, so as to enable the steering engines of the fixed wing to drive the control surface thereof to deflect, the multi-rotor equipment controls a rotating speed or a propeller pitch to change, and the fixed wing and the multi-rotor respectively generate corresponding control forces to drive the machine body to move towards the direction reducing the attitude angle deviation, so as to eliminate the attitude angle deviation. Therefore, the controlled quantity allocation technology is adopted by the flight control method and the flight control device disclosed by the invention to simultaneously control the control surface of the fixed wing and the rotating speed or the propeller pitch of the multi-rotor and control the posture of the composite aircraft, and the flight control function of the composite aircraft formed by the fixed wing and the multi-rotor at the mixed working mode is achieved.

Owner:CETC SPECIAL MISSION AIRCRAFT SYST ENG

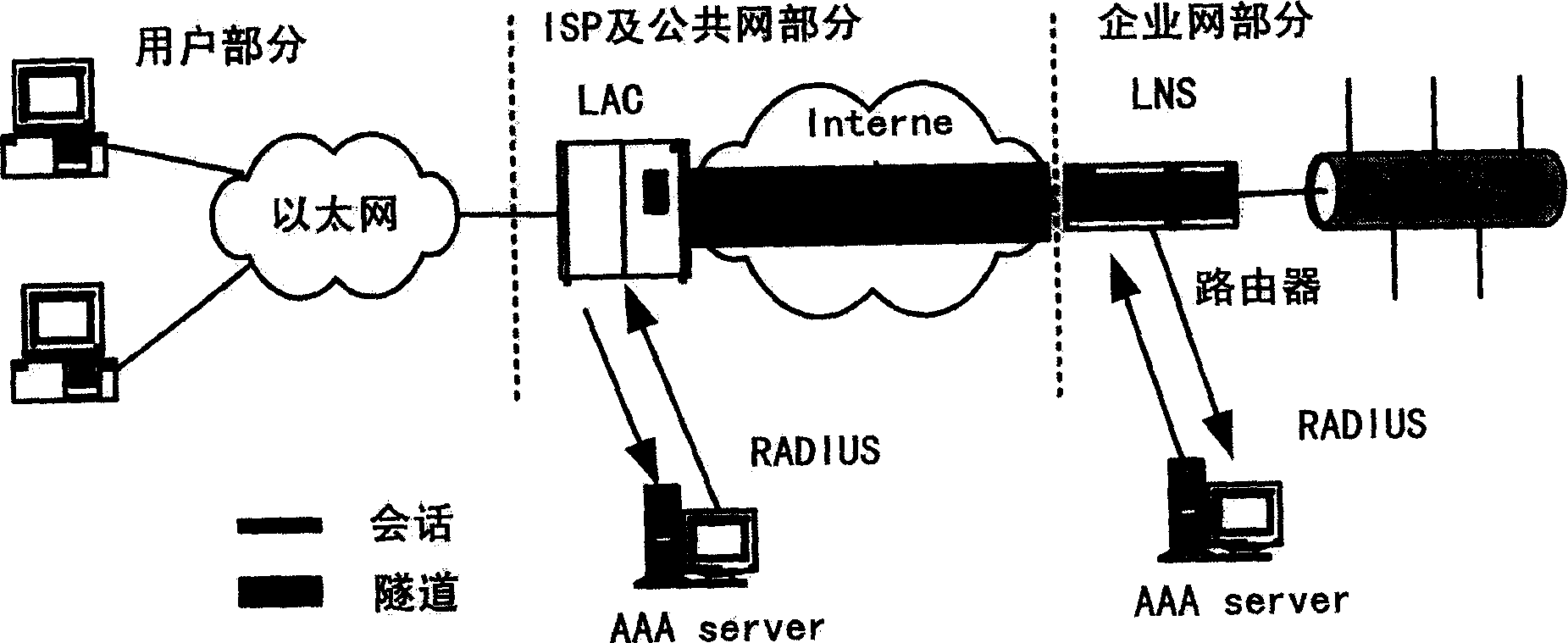

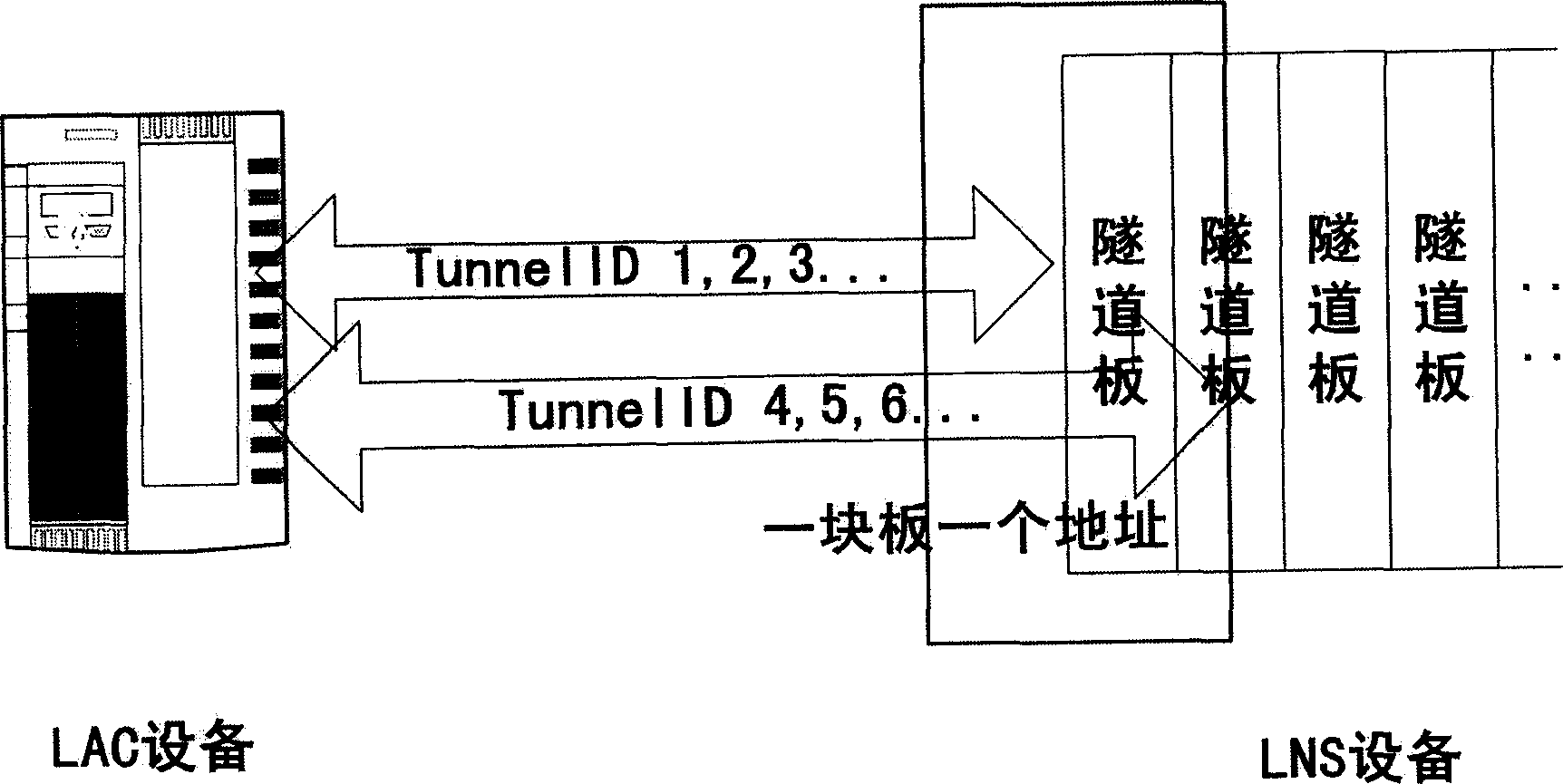

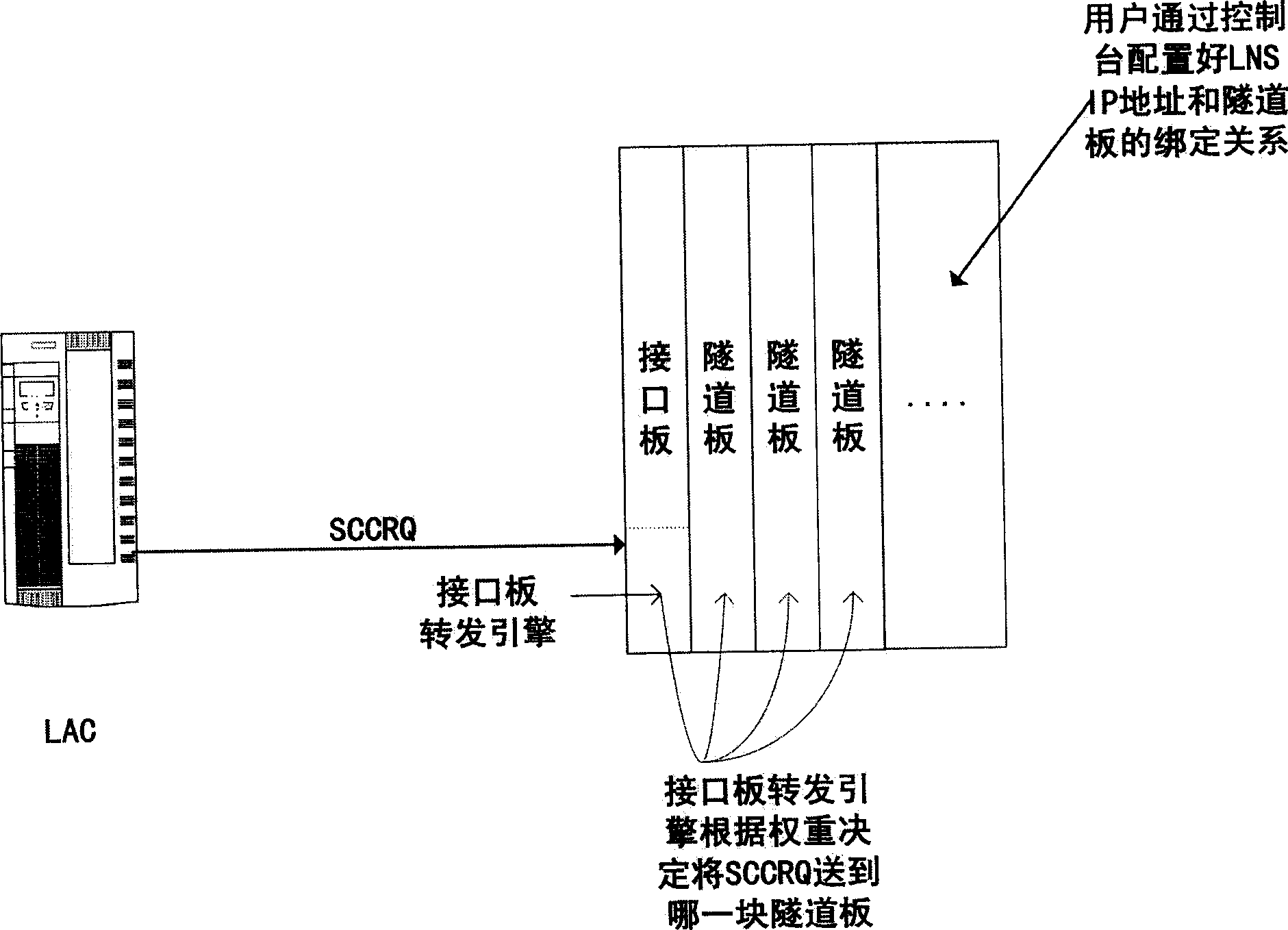

Two layer tunnel protocol network server and method for establishing tunnel thereof

The invention provides a network server, comprising plural tunnel plates and interface plate, where the interface plate comprises a tunnel distributing module, dividing these tunnel plates into plural groups, and distributing a corresponding IP address to each tunnel plate group, and simultaneously, being able to mark weight value of each tunnel plate according to the current tunnel or conversation load to establish tunnel or conversation according to the weight value. According to the weight, it uniformly distributes tunnels / messages to plural tunnel plates, which are united to the outside and implement internal user load balance of network server, thus saving addresses, simplifying networking and fully using system resources.

Owner:HUAWEI TECH CO LTD

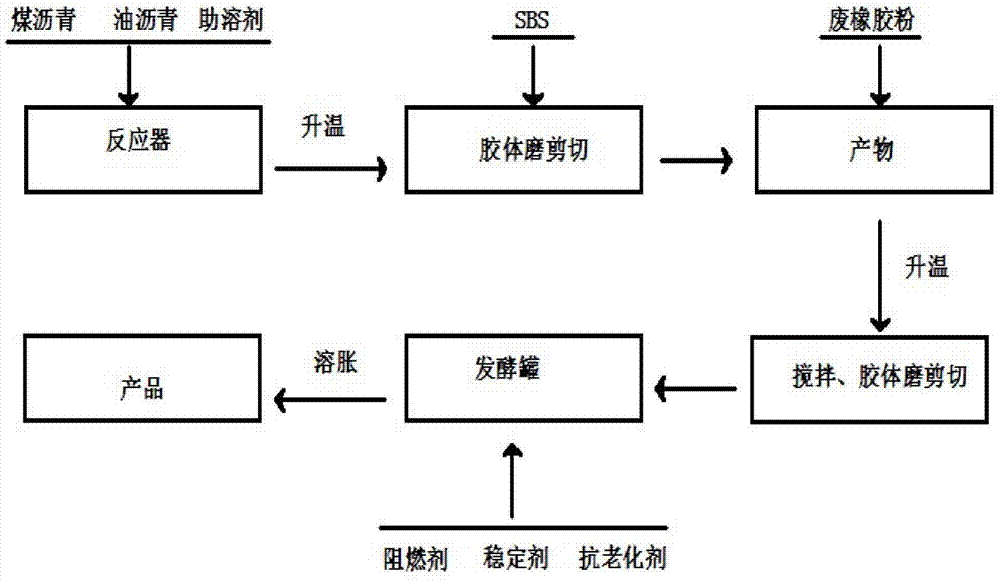

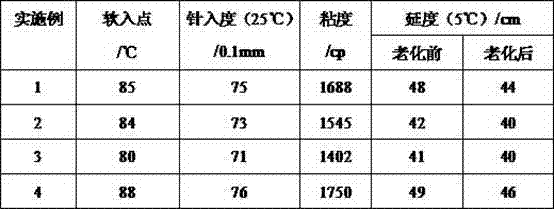

Modified coal asphalt product and preparation method thereof

ActiveCN103694716AProlong dissolution timeShorten the timeBuilding insulationsWaste rubberProcess engineering

The invention discloses a modified coal asphalt product. The modified coal asphalt product comprises the following materials in parts by weight: 50-80 parts of coal asphalt, 10-20 parts of petroleum asphalt, 1-4 parts of SBS (Styrene Butadiene Styrene), 5-35 parts of waste rubber powder, 20-30 parts of a cosolvent, 0.2-0.3 part of a stabilizer, 0.5-1 part of a flame retardant and 0.01-2 parts of an anti-ageing agent. The preparation method of the modified coal asphalt product overcomes defects in the prior art, is used for modifying the coal asphalt by adding the petroleum asphalt, the SBS, the waste rubber powder, the cosolvent, the stabilizer, the flame retardant and the anti-ageing agent into a reactor, and swelling and developing in a developing tank to obtain the modified coal asphalt product. The preparation method disclosed by the invention is simple, and the prepared product is long in service life, wide in material resource, low in cost, less in equipment investment, small in floor space and easy for large-scale production.

Owner:ANHUI AODE MINING MACHINERY & EQUIP LTD

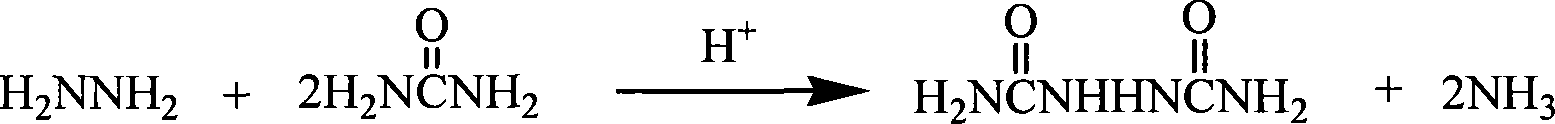

Method for recovery utilization of mother solution hydrochloric acid for ADC foaming agent production

ActiveCN101219974AAvoid degradationHigh yieldChlorine/hydrogen-chloride purificationOrganic chemistryBiureaHydrazine compound

The invention relates to a recycling and reusing method for producing an ADC foaming agent mother liquor hydrochloride, which includes the following steps: A) a hydrazine hydrate and a urea liquor carry out a concentration reaction by pumping a hydrogen chloride gas in or adding a sulfate; the hydrogen chloride gas is pumped in to control and maintain the pH value as 4 to 6 to generate a biurea and an ammonium salt; and a biurea solid and a corresponding ammonium salt mother liquor can be acquired after separation; B) the biurea is made into a suspension liquid of 10 to 40 percent and a sodium bromide which accounts for 0.2 to 1.0 percent of the amount of the biurea is added as a catalyzer to oxidize and generate the ADC foaming agent by pumping in an chlorine-oxygen, and then the ADC foaming agent and hydrochloride mother liquor can be gotten after separation; C) the separated hydrochloride mother liquor is added with an anhydrous magnesium chloride or a dihydrate magnesium chloride accounting for 20 to 40 percent of the amount of hydrochloride mother liquor feed rate, and then heated to distill a hydrogen chloride gas under the state of stirring; D) the distilled hydrogen chloride gas is returned to the biurea concentration technique to be used as the raw materials for neutralization . The beneficial effects of the invention are that the invention can save 60 percent of the amount of the acid used in the concentration process, make full use of the resources, reduce the production cost, decrease the discharging of the pollutions and has significant economic benefits.

Owner:HANGZHOU HI TECH FINE CHEM

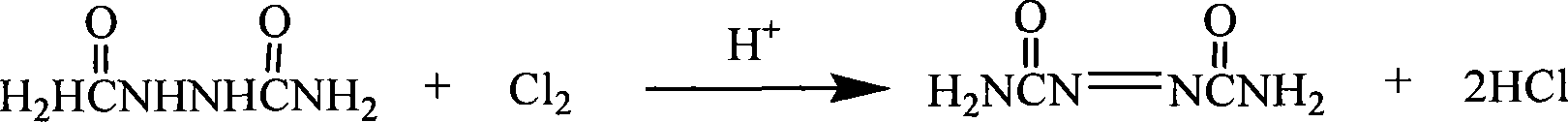

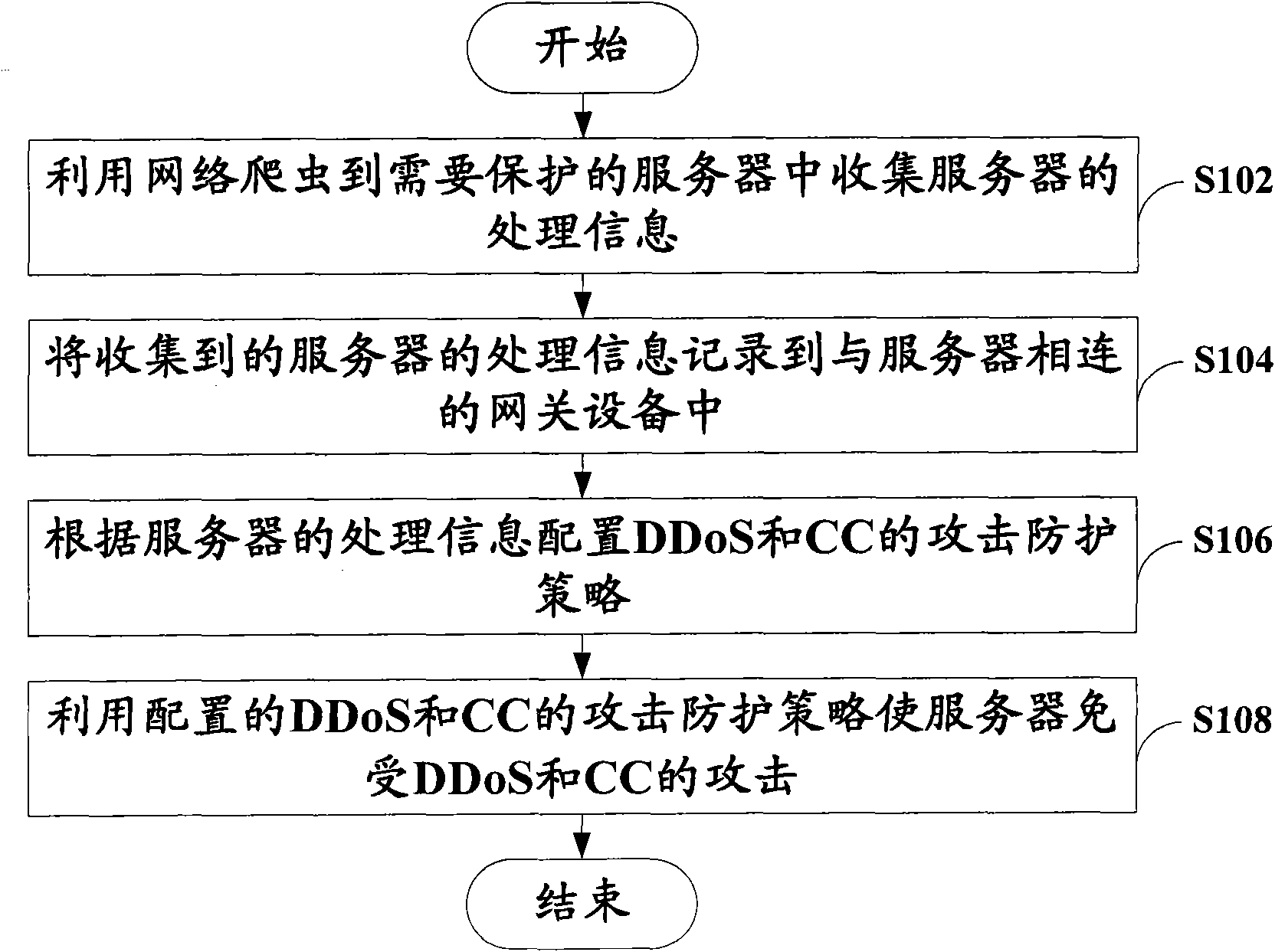

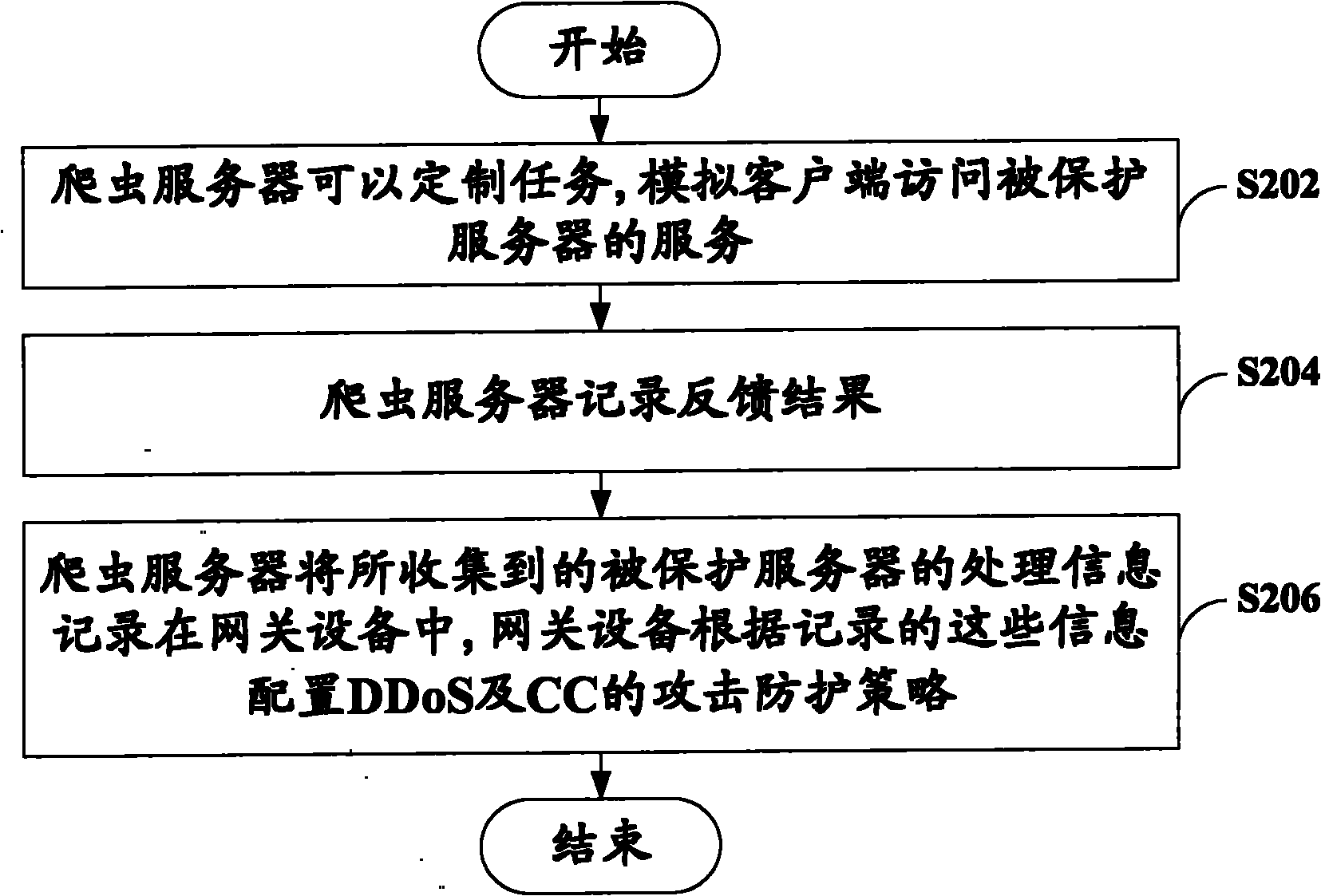

Method and device for defensing DDoS (Distributed Denial of Service) and CC (Connections Flood) attacks

The invention discloses a method and a device for defensing DDoS (Distributed Denial of Service) and CC (Connections Flood) attacks. The method comprises the following steps of: collecting the processing information of a server from the server needing to be protected by utilizing a web crawler; recording the collected processing information of the server in gateway equipment connected with the server; configuring an attack protecting strategy of DDoS and CC according to the processing information of the server; and preventing the server from attacking by DDoS and CC by utilizing the configured attack protecting strategy of DDoS and CC. The invention can carry out detailed resource analysis on the protected server by using the web crawler and defense the attacks of DDoS and CC according to an analysis result and a safety strategy and is more accurate and intelligent than the traditional protecting way. In addition, the invention can also customize the safety protecting strategy for the protected server, not only can more favorably carry out DDoS and CC attack protection, but also can fully utilize resources of the server.

Owner:CHINA TELECOM CORP LTD

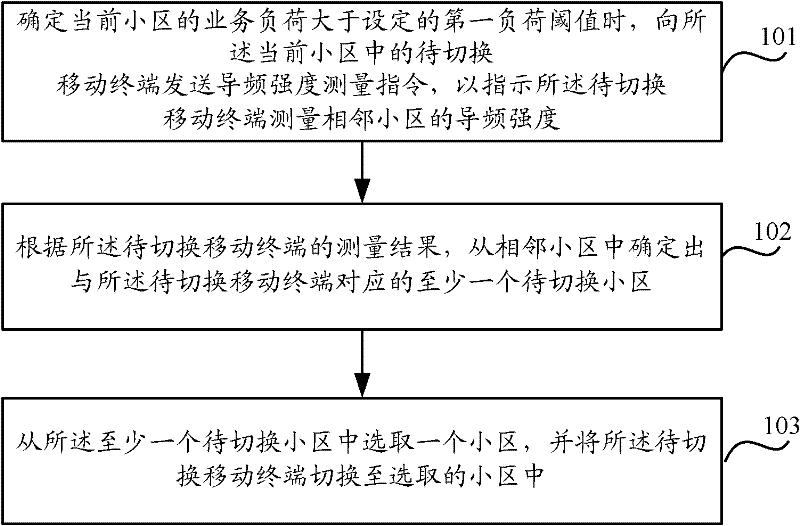

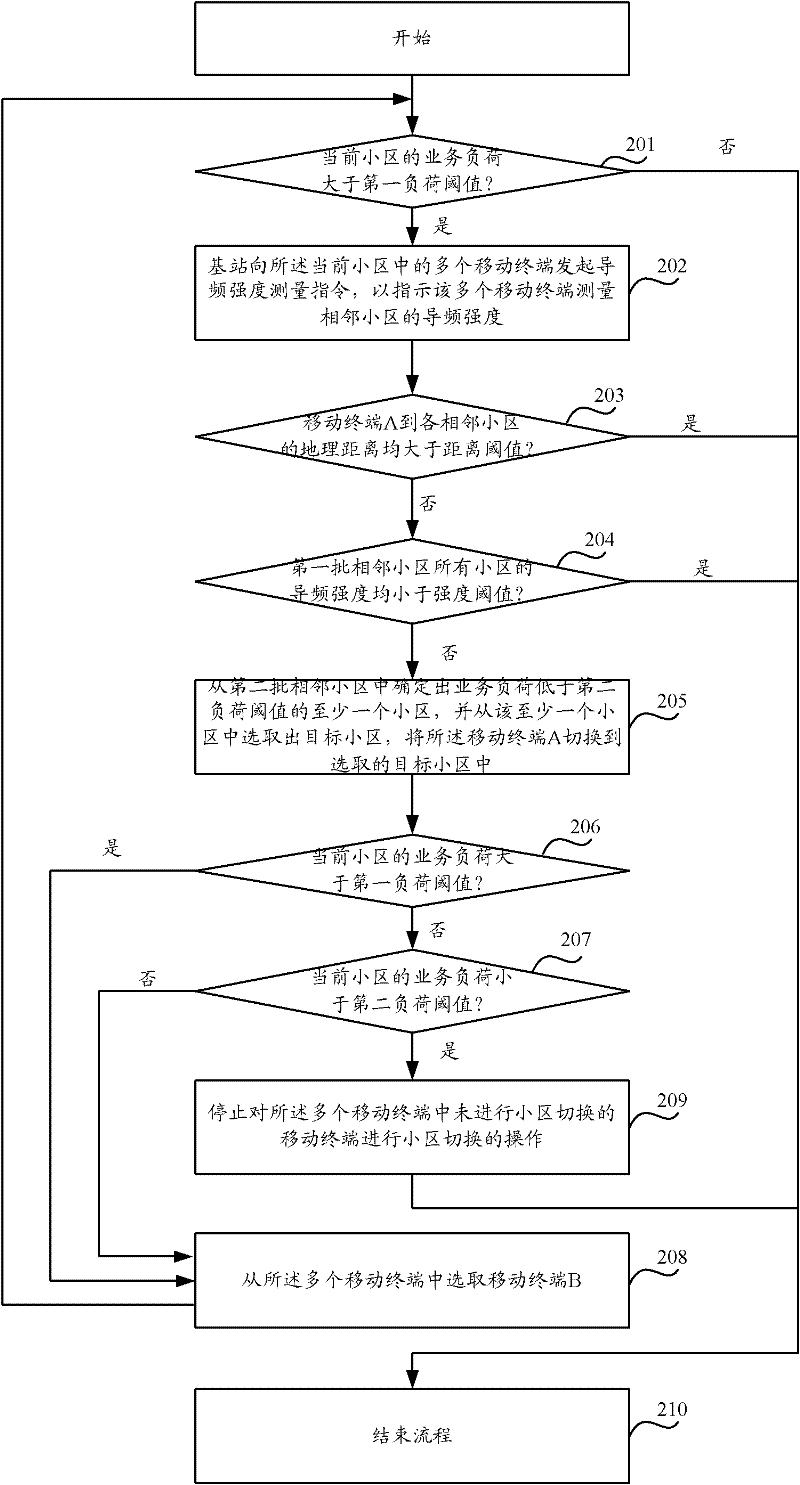

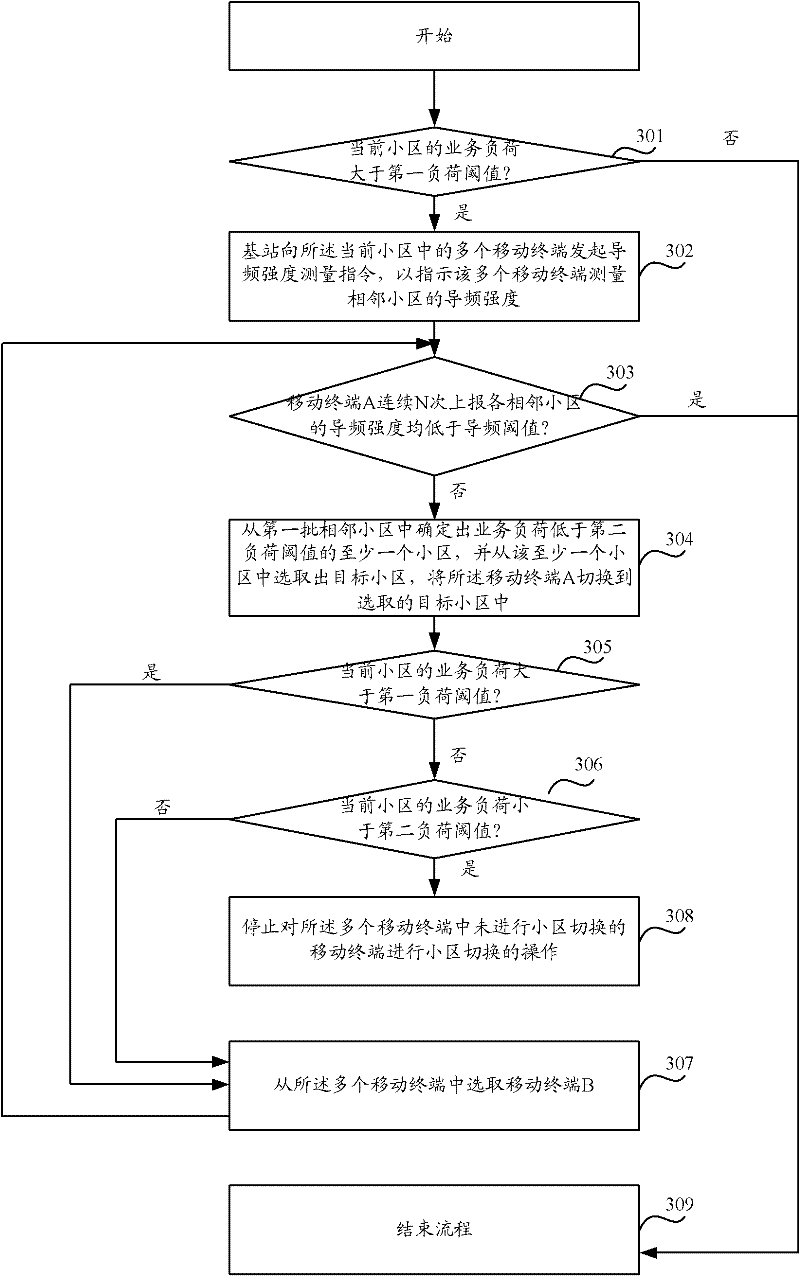

District service processing method and device and facility

InactiveCN102333342AImprove business processing efficiencyImprove resource utilizationNetwork traffic/resource managementTelecommunicationsLoad following power plant

The invention discloses a district service processing method and device and a facility. A part of edge users in the current district are switched to adjacent districts when the load of the current district exceeds a load threshold so as to reduce the service load of the current district, which not only improves the service processing efficiency of the current district but also fully utilizes the resources of the adjacent districts with lower service load. The district service processing method comprises the following steps: sending a pilot frequency strength measurement instruction to a mobile terminal to be switched in the current district when determining that the service load of the current district is larger than the set first load threshold so as to indicate the mobile terminal to be switched to measure the pilot frequency strength of the adjacent districts; determining at least one district to be switched corresponding to the mobile terminal to be switched from the adjacent districts according to the measurement result of the mobile terminal to be switched; and selecting a target district from the at least one district to be switched, and switching the mobile terminal to be switched into the target district.

Owner:DATANG MOBILE COMM EQUIP CO LTD

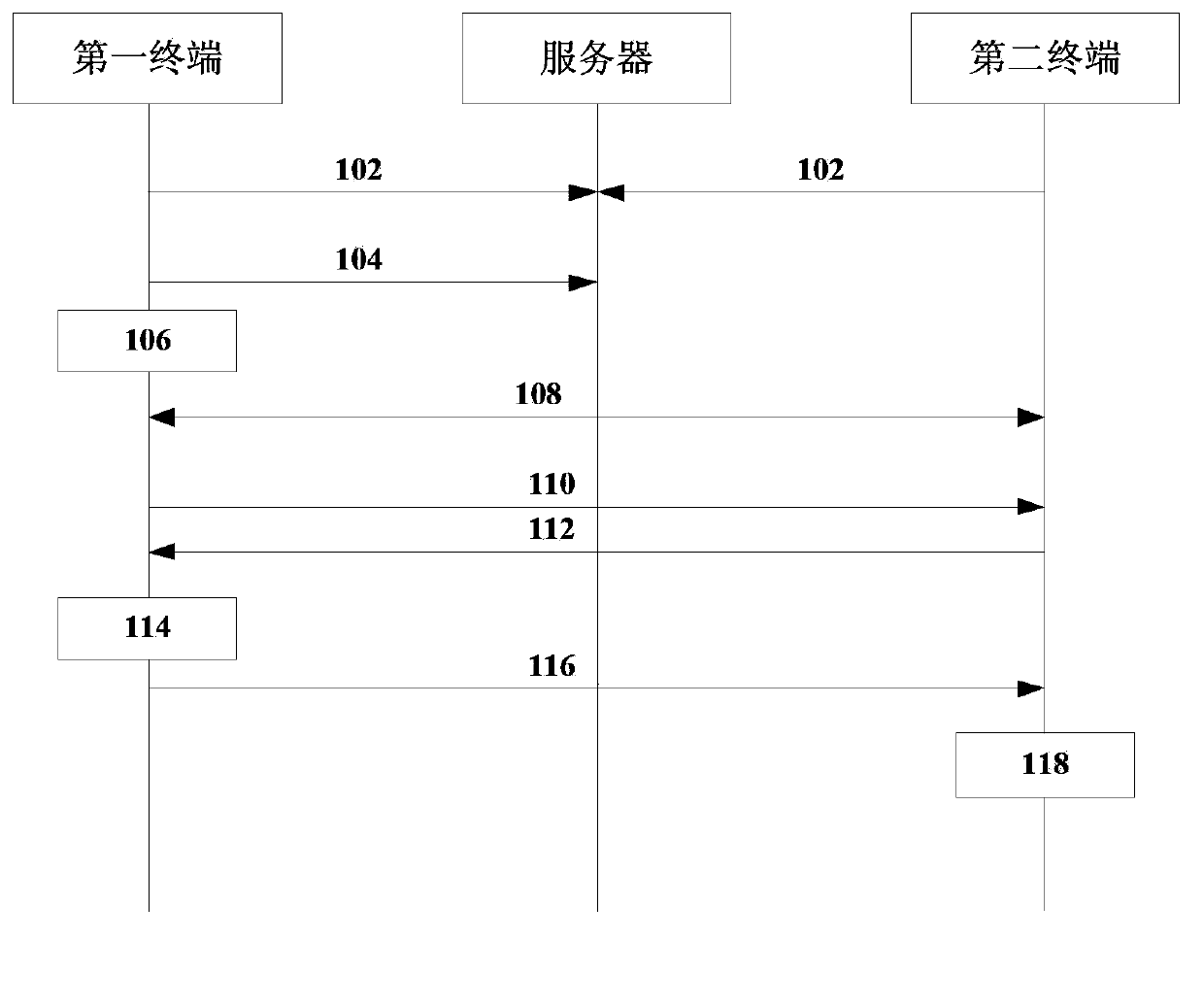

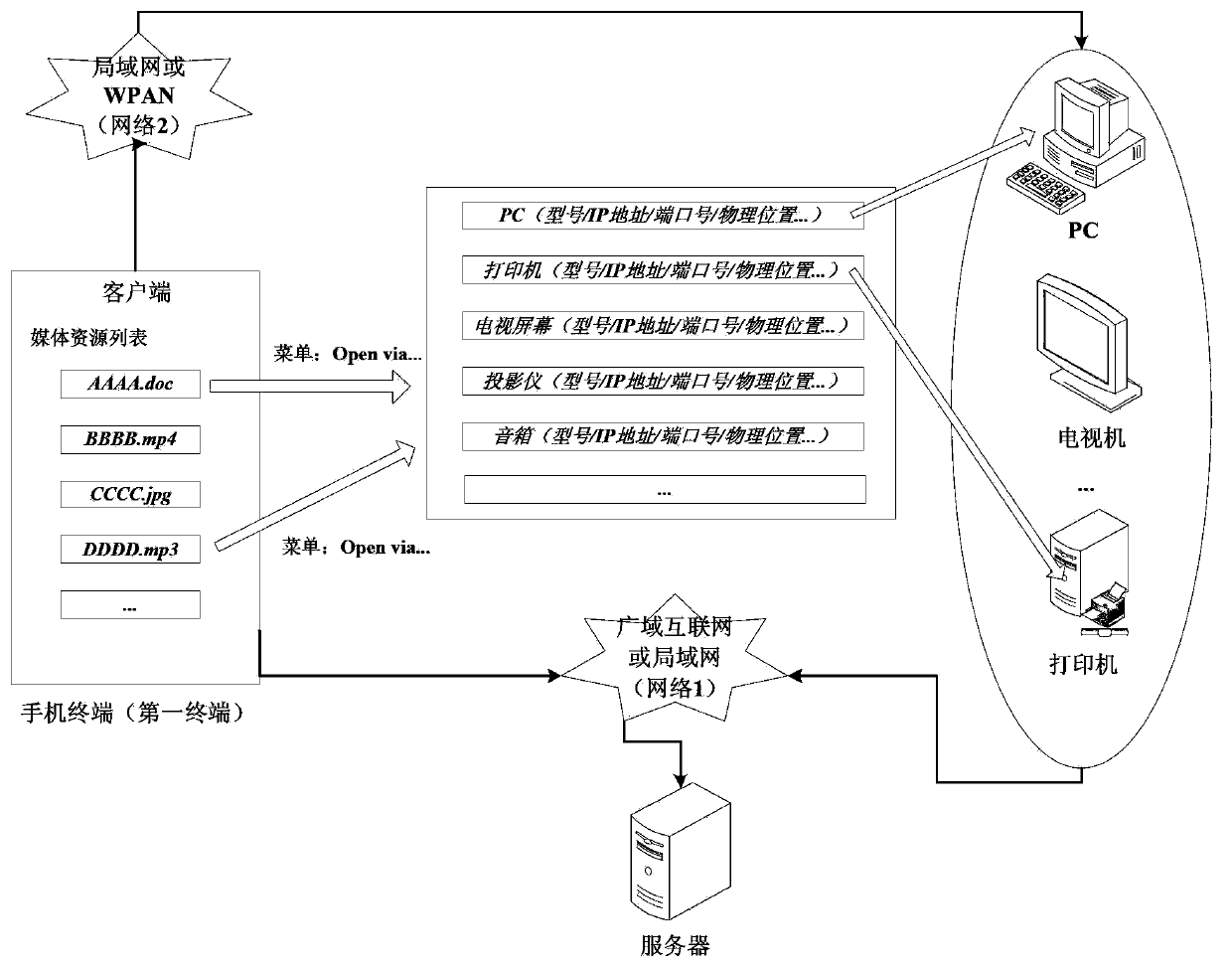

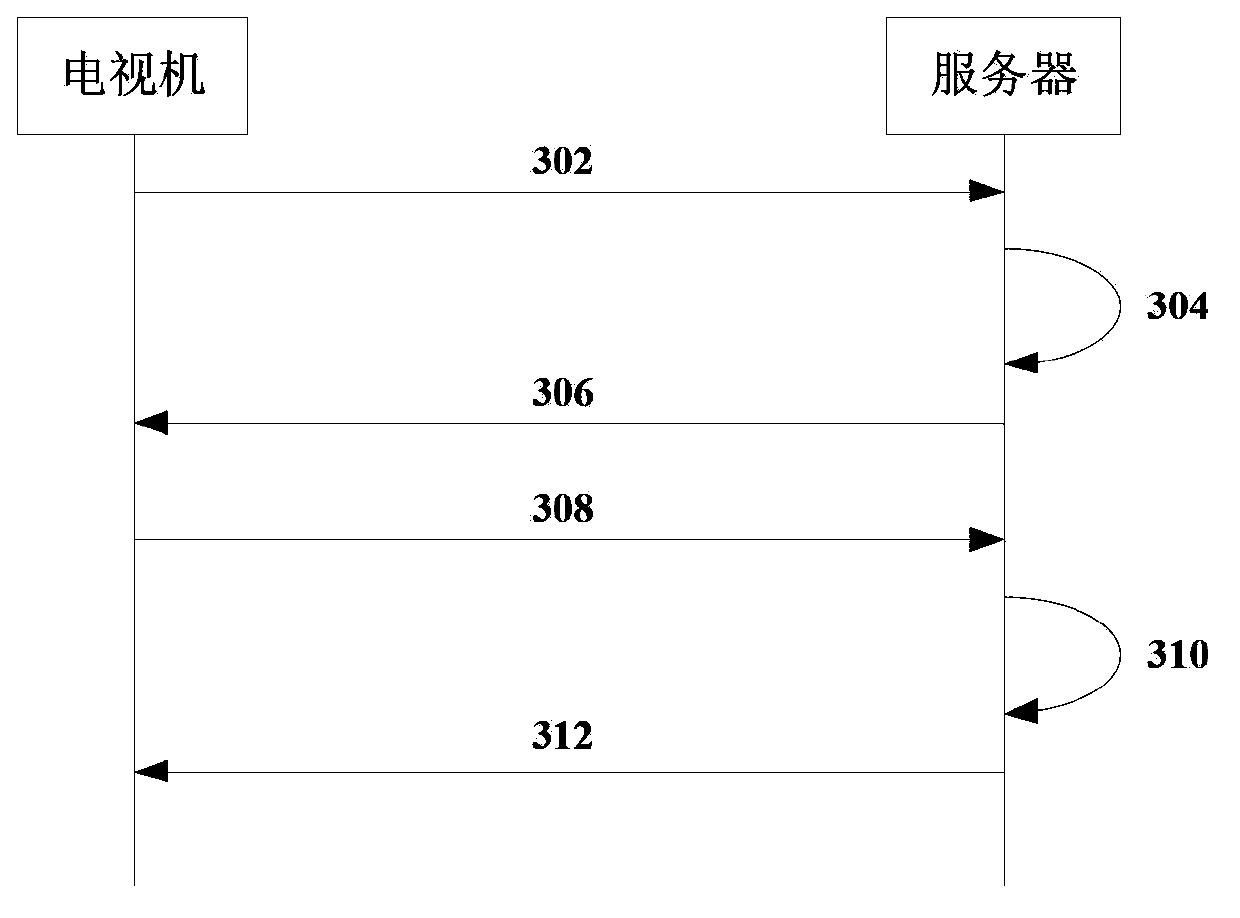

Method, device and system for processing multi-terminal cooperation information

InactiveCN103634172AImprove information processing efficiencyImprove processing efficiencyData switching by path configurationInformation resourceService provision

The invention discloses a method, a device and a system for processing multi-terminal cooperation information. The method comprises that: a first terminal acquires service capability information of other terminals, and a second terminal for providing a service is selected according to the service capability information; network connection is established between the first terminal and the second terminal, and information to be processed is sent to the second terminal; and the second terminal processes the information to be processed. With acquisition of the service capability information of other terminals, one terminal for providing the service is selected to process data to be processed, and information processing modes particularly held by the in-network other terminals can be utilized to process the information so that information resources shared by other terminals and processing capacity can be used by a user on any terminal. Connection between terminals is realized without cables, and driving programs do not need to be installed so that the terminal for providing the service can be automatically searched. Therefore, the resources of all the terminals in the network are fully utilized and information processing efficiency of the user is enhanced.

Owner:CHINA MOBILE COMM GRP CO LTD

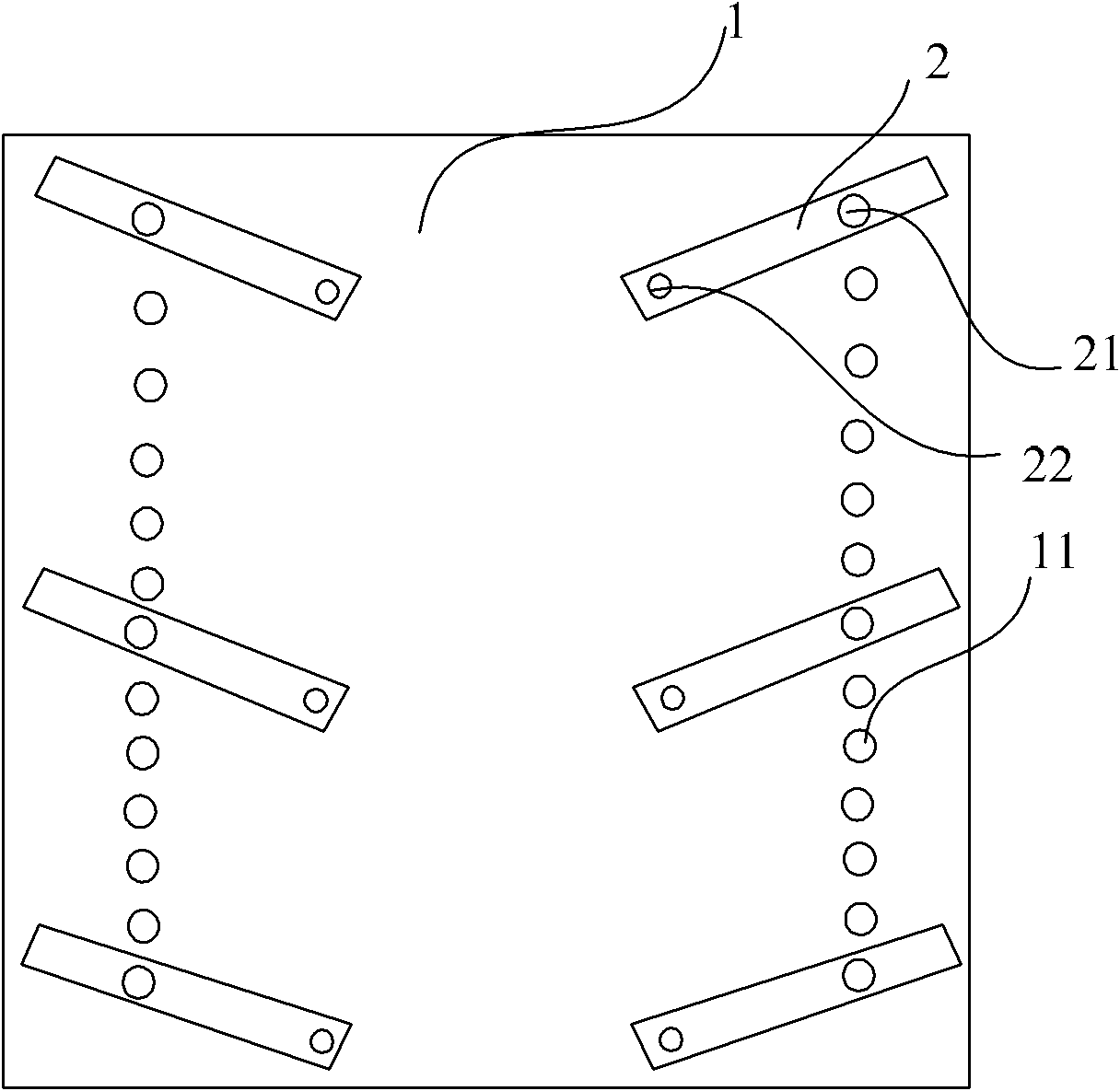

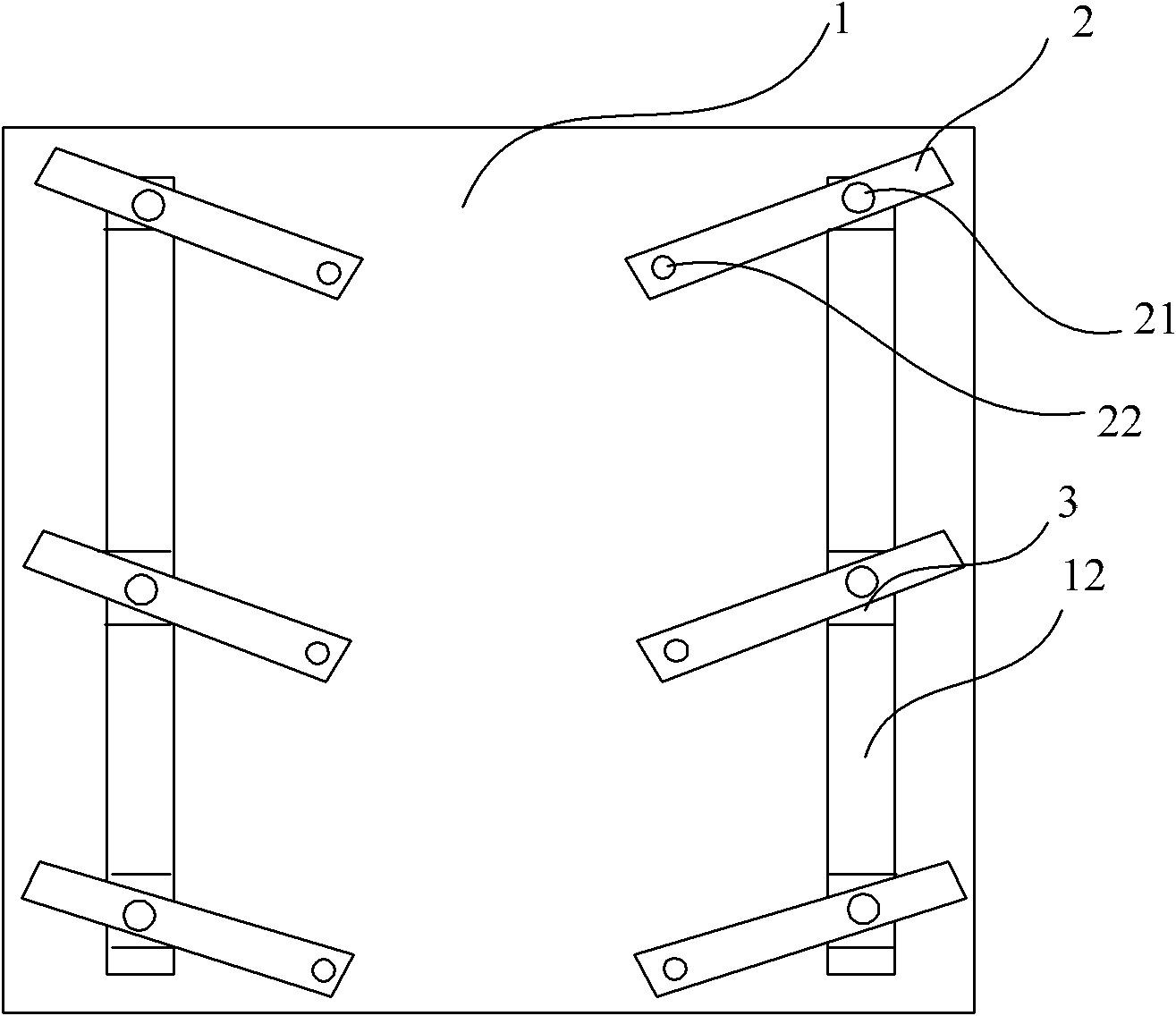

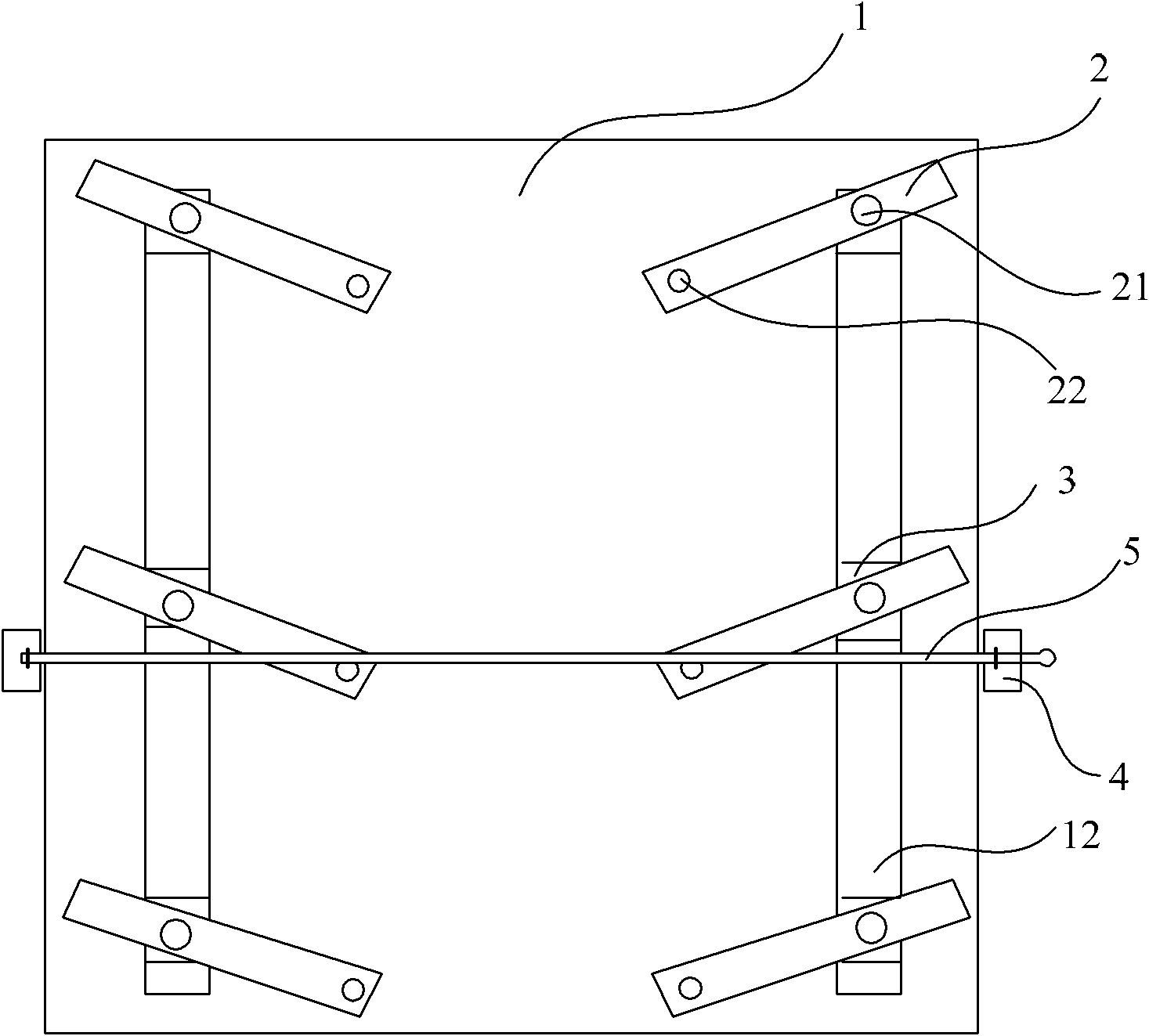

Main board locating device of mobile phone

InactiveCN103170783ALow costMake full use of resourcesWelding/cutting auxillary devicesWork holdersBar pressingMobile phone

The invention discloses a main board locating device of a mobile phone. The locating device comprises a base board and a plurality of locating press bars, wherein the locating press bars are connected on the base board in a rotary mode and respectively arranged into two lines which are parallel and opposite to each other, and locating thimbles used for locating the locating press bars are arranged on opposite end portions among the locating press bars. The main board locating device of the mobile phone conducts location to a main board of the mobile phone through the locating press bars and the locating thimbles, is suitable for preprocessing of various kinds of main boards of mobile phones, and can be used universally by various products, multiple work positions and used in a recycling mode. In addition, a press strip or an inclined foot can be arranged according to needs, and therefore a tool is enabled to be never scrapped, resources are fully used, and the production cost of the locating device is greatly saved.

Owner:SHENYANG CHENXUN SIMCOM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com