Efficient and environment-friendly compound feed for lactating sow and preparation method thereof

A technology for lactating sows and compound feed, which is applied in the field of high-efficiency and environment-friendly compound feed for lactating sows and its preparation, can solve the problems of product quality and safety, hidden dangers of product safety and hygiene, etc., and achieves improved feed digestibility, good appearance, The effect of reducing feed waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0029] Prepare the product according to the following weight ratio: 40-50 parts of corn, 20-30 parts of wheat, 3-5 parts of wheat bran, 10-15 parts of dehulled soybean meal, 1-2 parts of fish meal, 3-5 parts of biological soybean meal , 1-1.2 parts of stone powder, 1.2-1.4 parts of calcium hydrogen phosphate, 0.3-0.5 parts of table salt, 1.5-2.5 parts of soybean oil, 0.4-0.45 parts of lysine, 0.04-0.06 parts of methionine, 0.1-0.12 parts of threonine, compound Enzyme preparation 0.01-0.02 parts, probiotics 0.06-0.1 parts, emulsifier 0.03-0.06 parts, compound premix 1-1.5 parts.

[0030] Product application location: Yaojiaba Meishen Breeding Co., Ltd., Zhuzhou County, Hunan Province

[0031] Time: September 2011 - October 2011

[0032] Test method: The test adopts the method of pairing experiment, and selects 80-day-old sows with the same genetic background, similar mating age and body weight (the number of sows of the same parity in each treatment is the same), good health, ...

example 2

[0038] Product weight ratio is prepared with example 1.

[0039] Product application location: Hunan Yueyang Meishen Breeding Co., Ltd.

[0040] Time: September 2012 - October 2012

[0041] Test method: The test adopts the method of pairing experiment, and selects 80 sows with the same genetic background, similar mating age and body weight at 83 days of gestation (the same number of sows at the same parity in each treatment), good health, and more than 6 pairs of effective teats. Landrace or Large White sows with the same parity were randomly divided into 2 treatment groups (control group and experimental pigs), 40 in each group, and fed with 2 kinds of diets respectively. A certain best-selling suckling sow feed in the market is fed to the control group, and the test group is the product of the present invention. During the experimental period, the piglets were weaned on day 21.

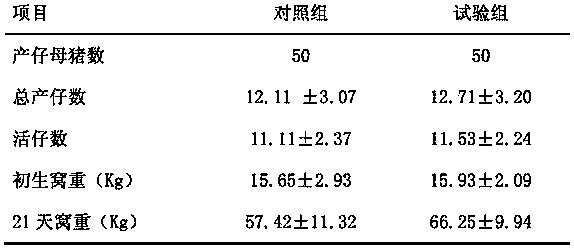

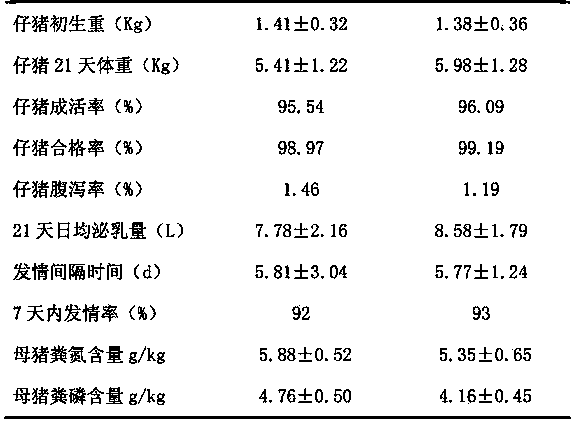

[0042] The test data are as follows:

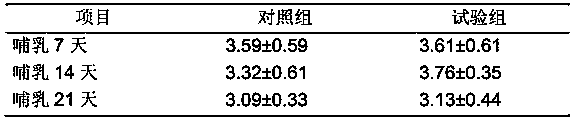

[0043] Table 2 Body condition score of lactating sows...

example 3

[0052] Product weight ratio is prepared with embodiment 1.

[0053] Product application location: Hunan Yongzhou Meishen Breeding Co., Ltd.

[0054] Time: May 2013 - August 2013

[0055] Test method: The test adopts the method of pairing experiment, and selects 80 Landrace sows with the same genetic background, similar mating age and body weight (the number of sows of the same parity in each treatment is the same), good health, and more than 6 pairs of effective teats. Or large white sows with the same parity were randomly divided into 2 treatment groups (control group and test pigs), 40 pigs in each group, and fed with 2 kinds of diets respectively. A certain best-selling suckling sow feed in the market is fed to the control group, and the test group is the product of the present invention. During the experimental period, the piglets were weaned on day 21.

[0056] The test data are as follows:

[0057] Table 4 Body condition score of sows

[0058]

[0059] As can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com