Method for recovery utilization of mother solution hydrochloric acid for ADC foaming agent production

A technology of ADC foaming agent and mother liquor, which is applied in the field of recycling hydrochloric acid of mother liquor of ADC foaming agent, can solve the problem of dilute hydrochloric acid distilled out, high energy consumption and other problems, so as to reduce pollutant discharge and low corrosion , significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

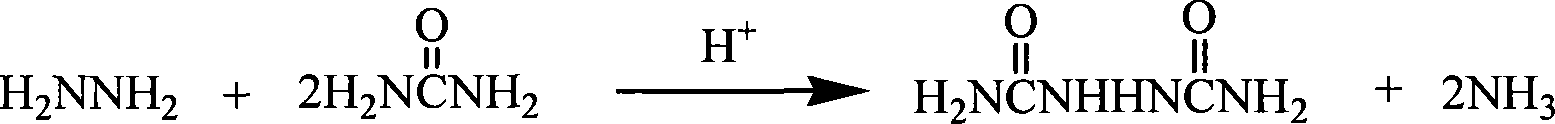

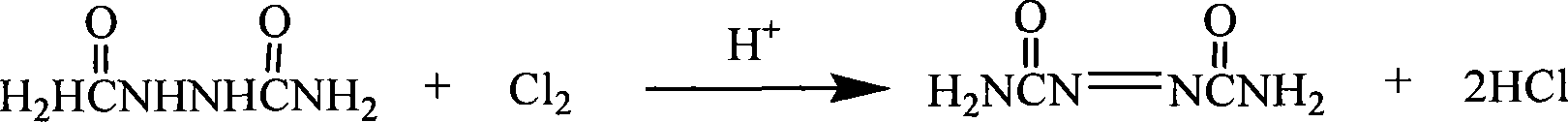

Method used

Image

Examples

Embodiment 1

[0032] Weigh 1.2 tons of biurea, add 8 kg of sodium bromide catalyst, 100 kg of ADC foaming agent mother liquor with a concentration of 16.8%, put 3 tons of water in the reactor, heat up to 40°C, and then feed chlorine for biurea The oxidation reaction of urea is cooled with cooling water in the coil during the reaction, and the reaction temperature is controlled to be 38-42°C. After the reaction reaches the end point, the ADC foaming agent and the mother liquor of hydrochloric acid are separated to obtain 1135 kg of ADC foaming agent. The measured concentration of hydrochloric acid mother liquor is 17.2%.

[0033] Put 2.8 tons of anhydrous magnesium chloride in advance in the 10 cubic distillation tower kettle, first put 4 tons of the mother liquor hydrochloric acid produced in the synthesis process of the ADC blowing agent above, start stirring, heat up distillation, and start to generate hydrogen chloride gas at 50 ° C, control Heating rate, so that hydrogen chloride gas is...

Embodiment 2

[0035] Put 2.8 tons of magnesium chloride dihydrate in advance in the 10 cubic distillation tower kettle, first put 4 tons of mother liquor hydrochloric acid produced during the synthesis of the ADC blowing agent in Example 1, start stirring, heat up distillation, and start to generate hydrogen chloride at 50 °C Gas, control the heating rate, so that hydrogen chloride gas is generated smoothly. When the temperature rises to about 105°C, start to add the remaining mother liquor hydrochloric acid continuously, control the heating rate and the flow rate of the mother liquor hydrochloric acid to ensure the stable generation of hydrogen chloride gas, and carry out distillation in accordance with the speed of the biurea condensation process. After adding 8 tons of mother liquor, stop feeding and continue to heat up to 115° C., so that the hydrogen chloride in the hydrochloric acid in the tower kettle is basically evaporated. After the distillation was finished, the concentration of ...

Embodiment 3

[0037] Put 3.0 tons of anhydrous magnesium chloride in advance in the 10 cubic distillation tower kettle, first put 4 tons of mother liquor hydrochloric acid produced during the synthesis of the ADC foaming agent in Example 1, start stirring, heat up distillation, and start to generate hydrogen chloride at 50 °C Gas, control the heating rate, so that hydrogen chloride gas is generated smoothly. When the temperature rises to about 105°C, start to add the remaining mother liquor hydrochloric acid continuously, control the heating rate and the flow rate of the mother liquor hydrochloric acid to ensure the stable generation of hydrogen chloride gas, and carry out distillation in accordance with the speed of the biurea condensation process. After adding 8 tons of mother liquor, stop feeding and keep the distillation temperature. When the amount of hydrogen chloride gas is significantly reduced, turn on the vacuum fan to keep the vacuum of -0.07--0.08MPa in the tower kettle, and cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com