Device and method for absorbing carbon disulfide in hydrogen sulfide gas by using solvent

A carbon disulfide and solvent absorption technology, applied in hydrogen sulfide, chemical instruments and methods, separation methods, etc., can solve the problems of long production cycle, unsuitable for industrial production, high energy consumption, etc., and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

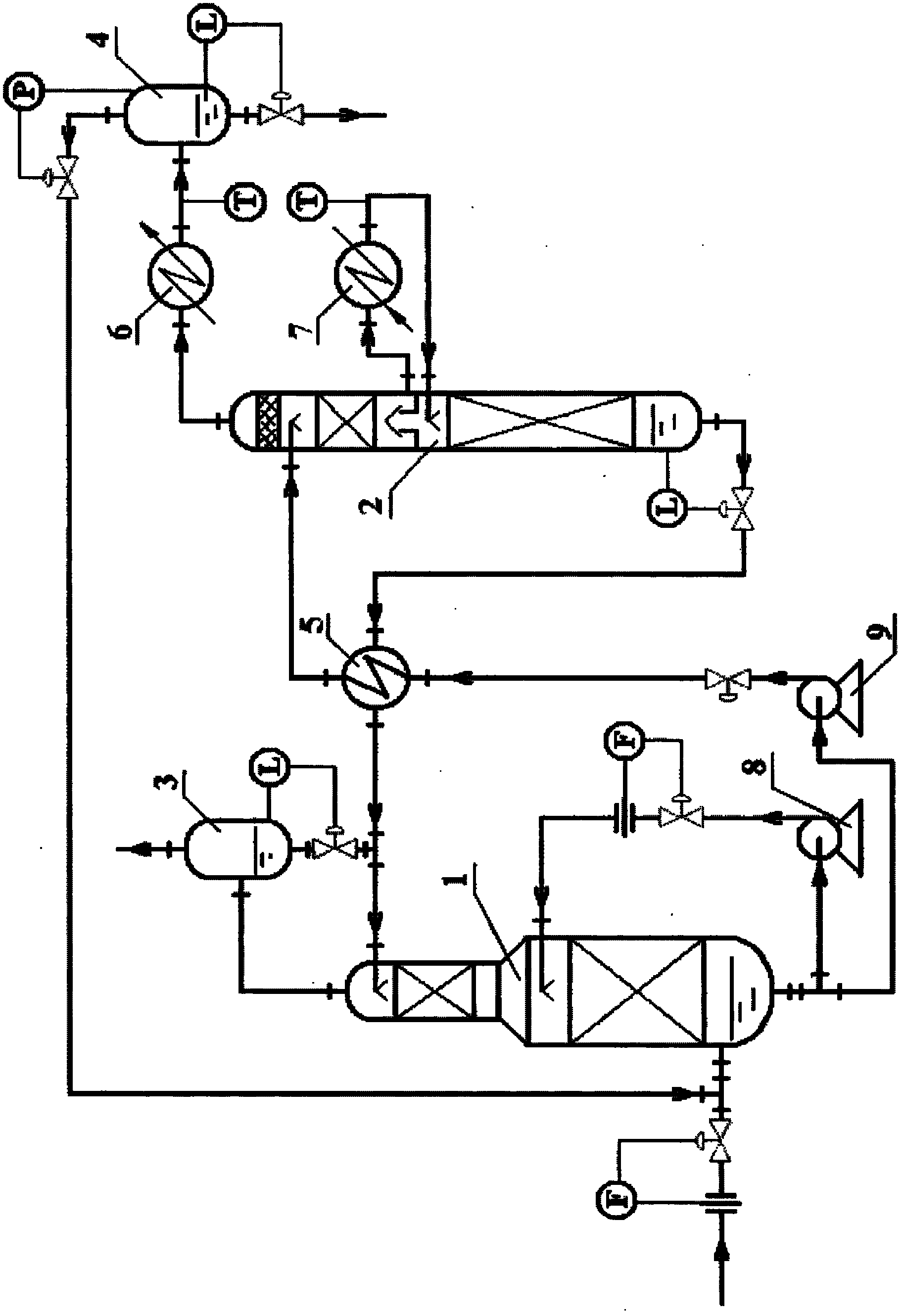

[0031] Such as figure 1 As shown, a device for absorbing carbon disulfide in hydrogen sulfide gas with a solvent mainly includes an absorption tower 1, a desorption tower 2, a gas-liquid separator 3, 4, a heat exchanger 5, a cooler 6, a heater 7, a pump 8, 9 and valves, etc.

[0032] The absorption tower 1 is composed of upper and lower sections, which are thick at the bottom and thin at the top, so as to improve absorption efficiency and save energy. A through hole is arranged on the lower side of the lower section of the absorption tower 1, and the through hole communicates the inner cavity of the lower section of the absorption tower 1 with the mixed gas generating device through the first flow control valve with a flow meter, the first three-way pipe and the connecting pipe . The mixed gas enters the lower part of the absorption tower 1 through the connecting pipe through the first flow control valve with a flow meter and the straight pipe of the first three-way pipe, an...

Embodiment 2

[0038] A kind of concrete steps of the method for absorbing carbon disulfide in hydrogen sulfide with solvent are as follows:

[0039] (1) absorption

[0040] CS 2 The initial concentration is 10%, and the mixed gas whose pressure is 0.3MPa is input from the bottom side of the lower section of the absorption tower 1, and flows from bottom to top in the absorption tower 1. The paraffin oil solvent placed in the analysis tower 2 is pressurized to 0.35Mpa through the circulation pump 8, and is input from the through hole on the upper side of the lower section of the absorption tower 1. After passing through the liquid distributor, it is sprayed from top to bottom in the lower section of the absorption tower 1. shower. The circulating rich liquid from the lower part of the analysis tower 2 is input from the through hole on the upper side of the upper part of the absorption tower 1, and is sprayed from top to bottom in the absorption tower 1 after passing through the liquid distr...

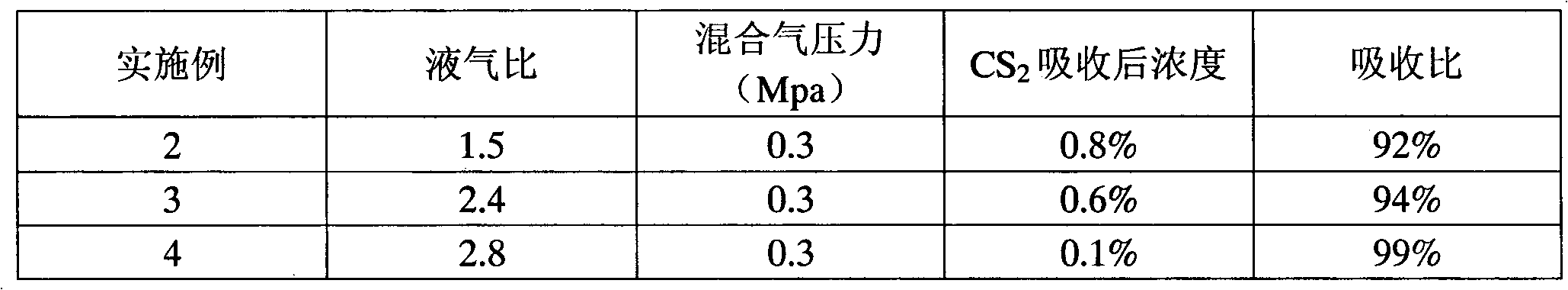

Embodiment 3

[0047] A kind of concrete steps of the method for absorbing carbon disulfide in hydrogen sulfide with solvent, with embodiment 2, wherein:

[0048] In the (1) step, the paraffin oil solvent: the mass ratio of the mixed gas is 1: 2.4.

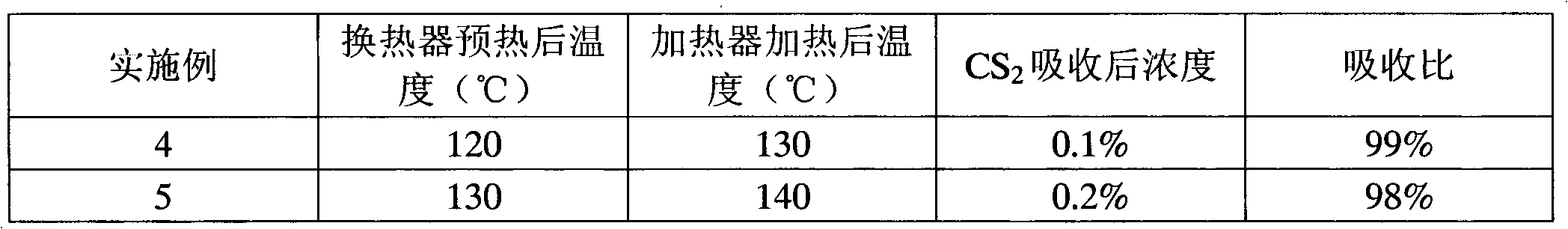

[0049] In step (2), the lean liquid is cooled to 33° C. through heat exchanger 5 .

[0050] In step (3), the gas after analysis is cooled to 8° C. through cooler 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com