Enhanced electroluminescent sign

a technology of electroluminescent signs and enhanced light, applied in the direction of illuminated signs, display means, instruments, etc., can solve the problem of increased visible speckle contrast on the sign, and achieve the effect of improving the visible speckle contrast, efficient direction, and low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0108] An enhanced electroluminescent sign in accordance with the present invention, i.e., as illustrated in FIG. 11, has increased spatial luminance uniformity, increased optical efficiency and is of low production cost. A 16″×20″ direct-lit light box sign (Ultra Thin Light Up Display from Bowman Displays) is used as a benchmark for comparison with the enhanced electroluminescent sign of this invention. The spatial luminance uniformity is measured at 0.5 cm intervals on either side of a region directly above the T8 fluorescent lamp in the white light box with the included standard symmetric diffuser film (Sample STANDARD) with a Minolta CS-100 spectrophotometer. The angular luminance profile is measured at a location directly above a fluorescent bulb with the standard symmetric diffuser film with a Minolta CS-100 luminance and tristimulous spot meter at varying 5 degree angular positions.

[0109] A light scattering film with anisotropic scattering profile was prepared by blending an...

example 2

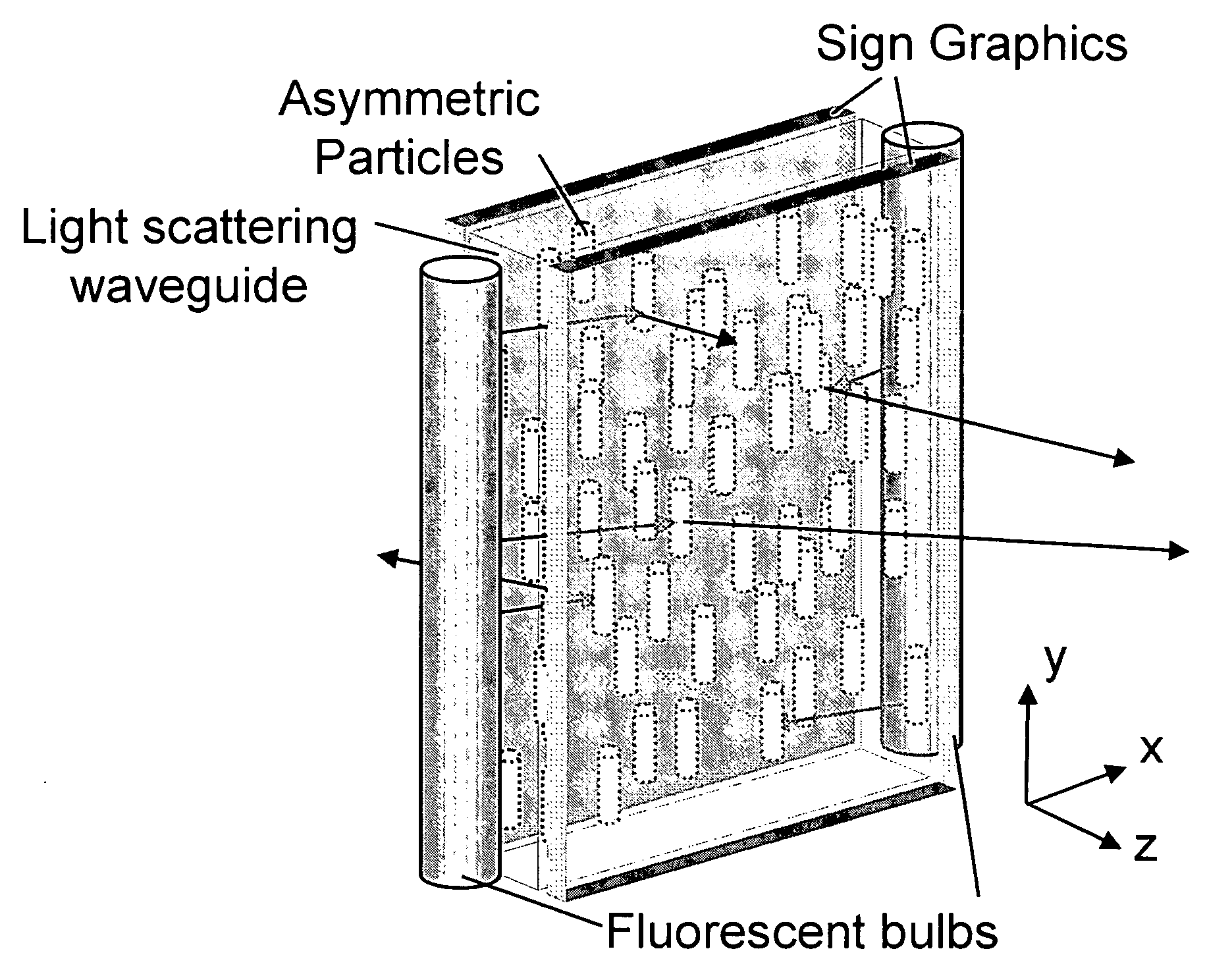

[0111] An enhanced electroluminescent sign in accordance with the present invention can be produced as described in FIG. 8, that has increased spatial luminance uniformity, increased optical efficiency, reduced speckle and lower costs of production. This is due in part to the use of the volumetric anisotropic scattering region within the waveguide to more efficiently control the light scattering. A light diffusing waveguide containing light scattering particles in a host matrix material is created by extruding, casting or coating, the mixture containing particles. The particle chosen may be a polystyrene bead of diameter 5 μm in the minor axis and 20 μm in the major axis dispersed at 10% concentration in a host matrix of acrylic. Other choices of particles and host matrix may provide equivalent performance. Asymmetry and alignment of the asymmetry can be created by stretching or extrusion processes. The resulting material suitable for waveguiding light contains asymmetric particles ...

example 3

[0112] An enhanced electroluminescent sign, in accordance with the present invention, can be produced as described in FIG. 11, that is designed to have increased spatial luminance uniformity, increased optical efficiency, reduced speckle and lower costs of production. This is due in part to the use of the volumetric anisotropic scattering element more efficiently controls the light scattering. A light diffusing film containing light scattering particles in a host matrix material is created by extruding, casting or coating, the mixture containing particles. The particle chosen may be a polystyrene bead of diameter 5 μm in the minor axis and 20 μm in the major axis dispersed at 10% concentration in a host matrix of acrylic. Other choices of particles and host matrix can provide equivalent performance. Asymmetry and alignment of the asymmetry can be created by stretching or extrusion processes. The resulting film suitable for diffusing light contains asymmetric particles and is placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com