Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Efficiently and uniformly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

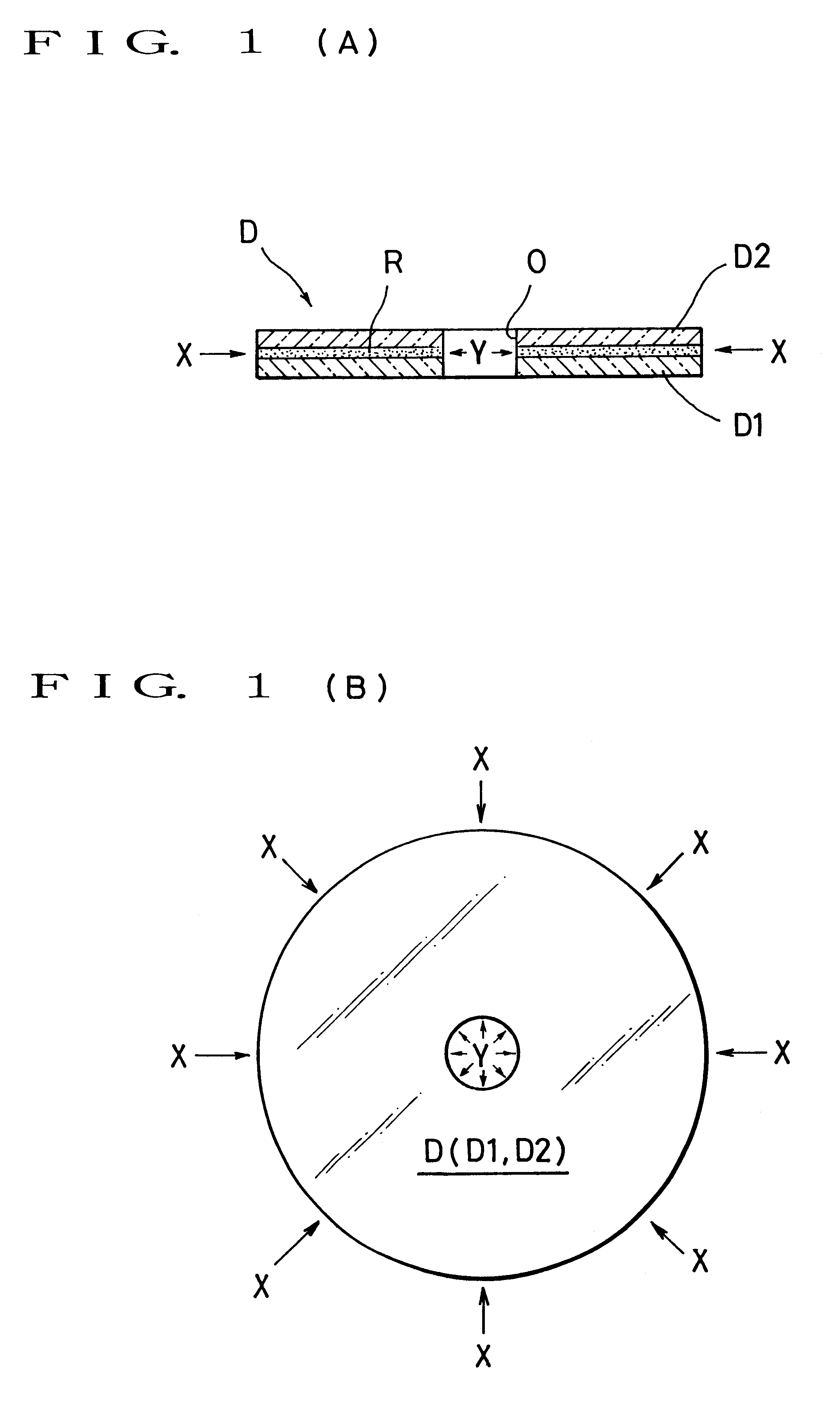

Water-absorbent resin and production process therefor

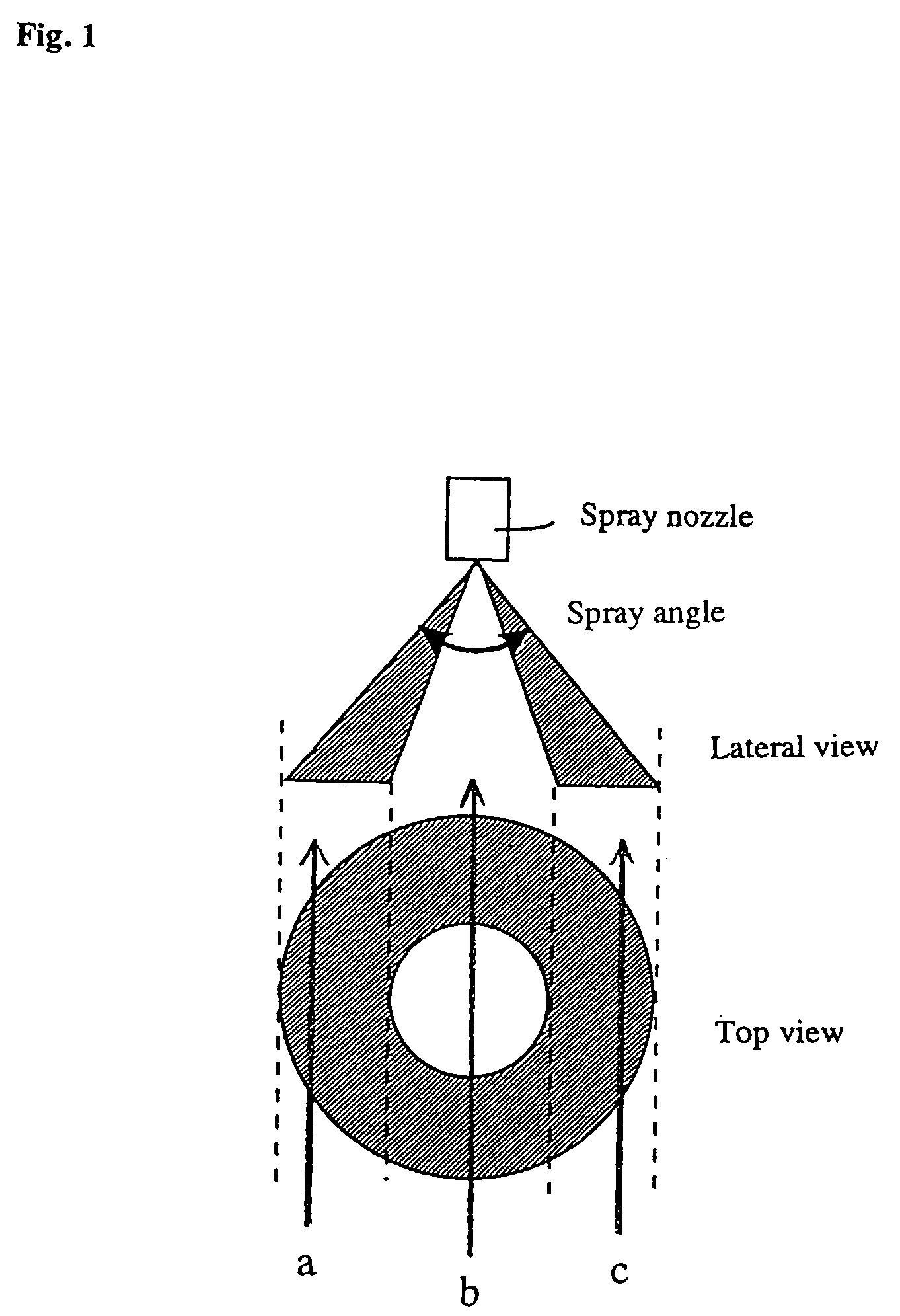

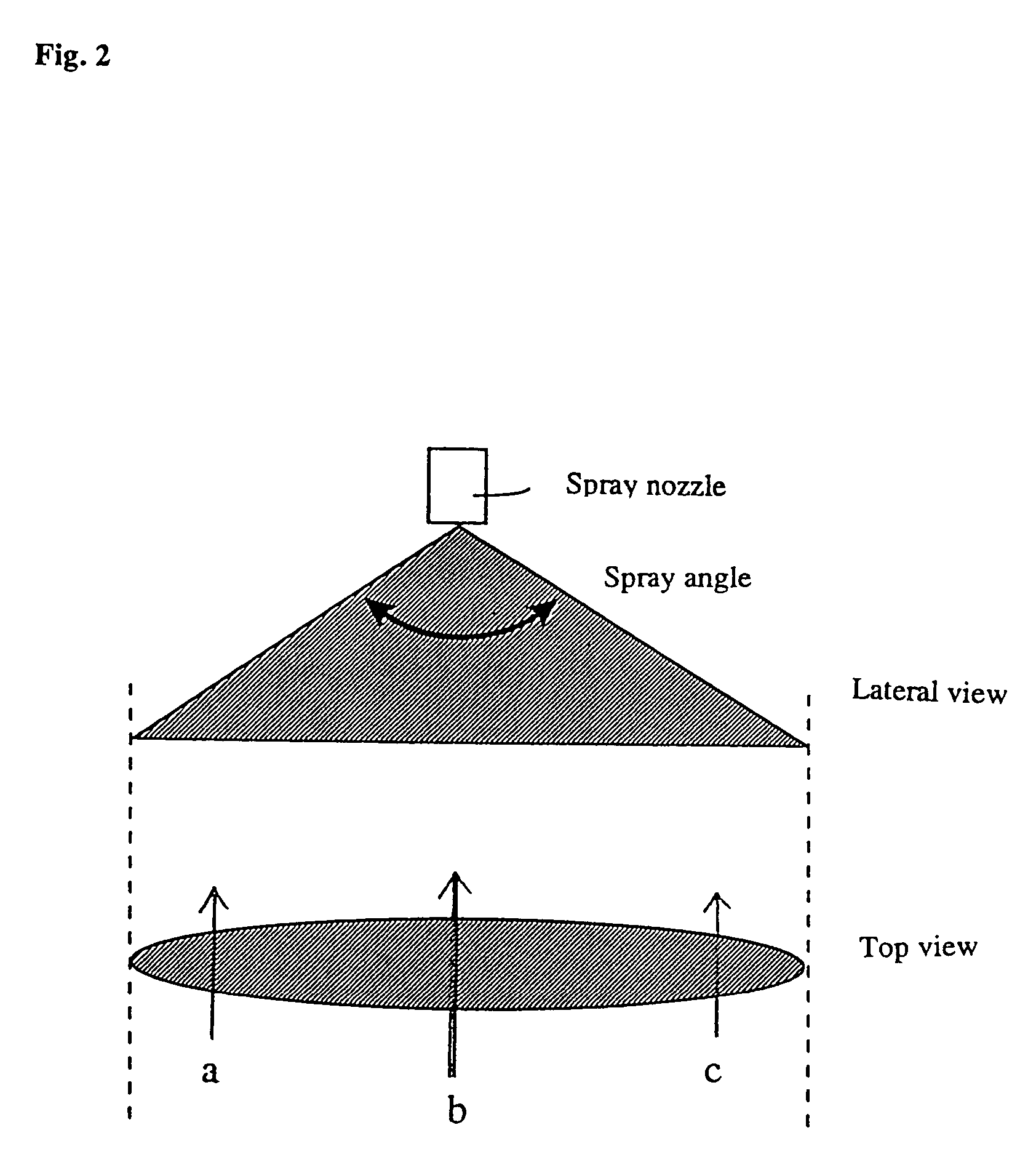

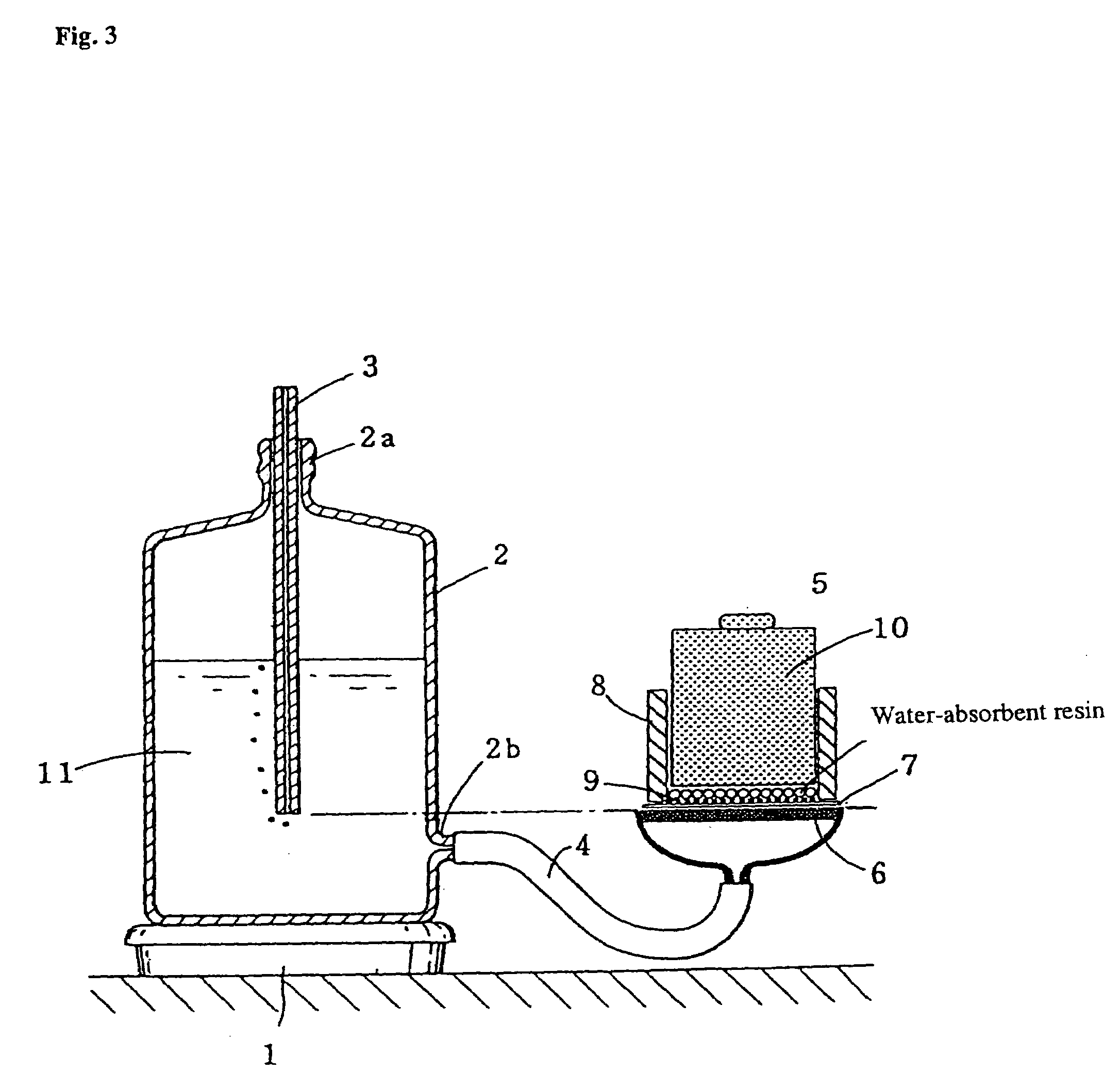

InactiveUS7183456B2Efficiently and uniformlyMaintain good propertiesSynthetic resin layered productsCellulosic plastic layered productsAbsorption capacitySpray nozzle

In a production process for a water-absorbent resin, comprising the steps of: blending a liquid material and a water-absorbent resin; and heating the resultant mixture in order to produce a modified water-absorbent resin, the present invention is to provide: a method for uniformly and efficiently treating a water-absorbent resin favorably in view of industry, and as a result, a good-balanced water-absorbent resin having various excellent properties, such absorption capacity without a load, absorption capacity under a load, and single-layer absorption capacity under a load in contact with an aqueous liquid. The production process comprises the step of spray-blending a water-absorbent resin (A) and a liquid material (B) with a blending apparatus equipped with a spray nozzle (C), wherein the liquid material (B) is sprayed from the spray nozzle (C) and its spray pattern is a circular and hollow cone shape or a double-convex-lens and elliptic cone shape. In addition, the production process comprises the step of heat-treating a water-absorbent resin under an atmosphere having a dew point of not higher than 60° C. and a temperature of not lower than 90° C., wherein the water-absorbent resin is obtained after a drying step following a pulverization step.

Owner:NIPPON SHOKUBAI CO LTD

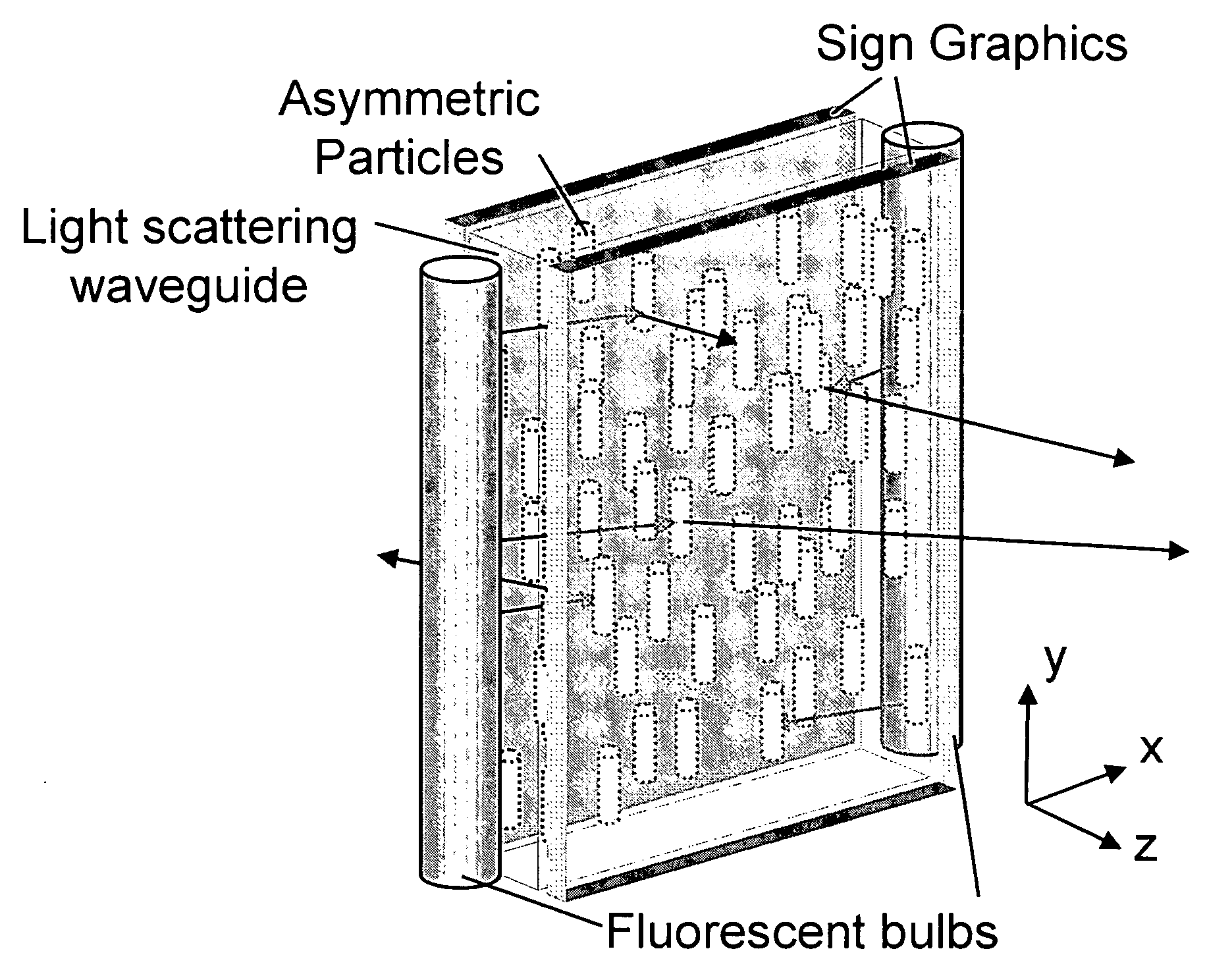

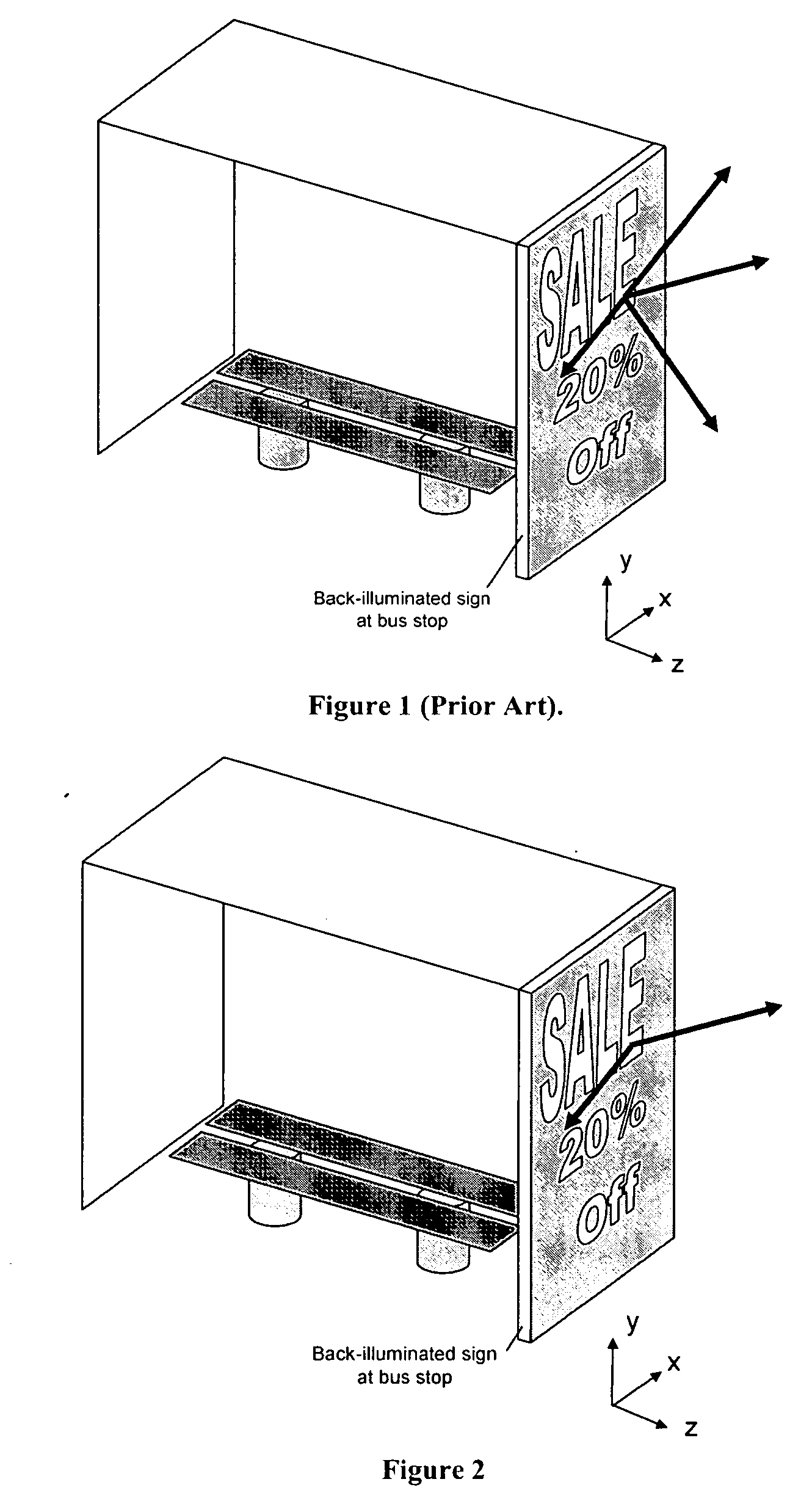

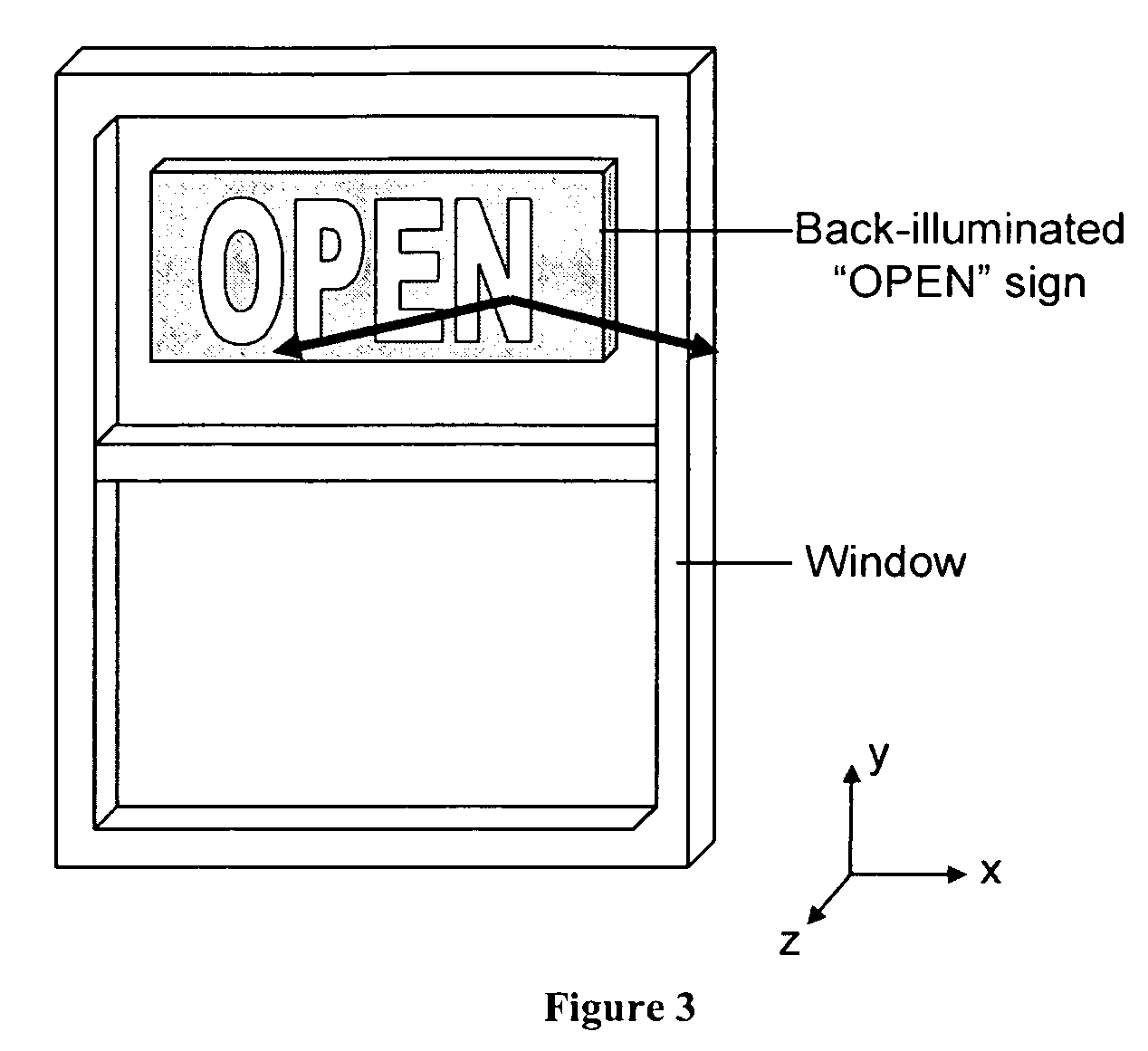

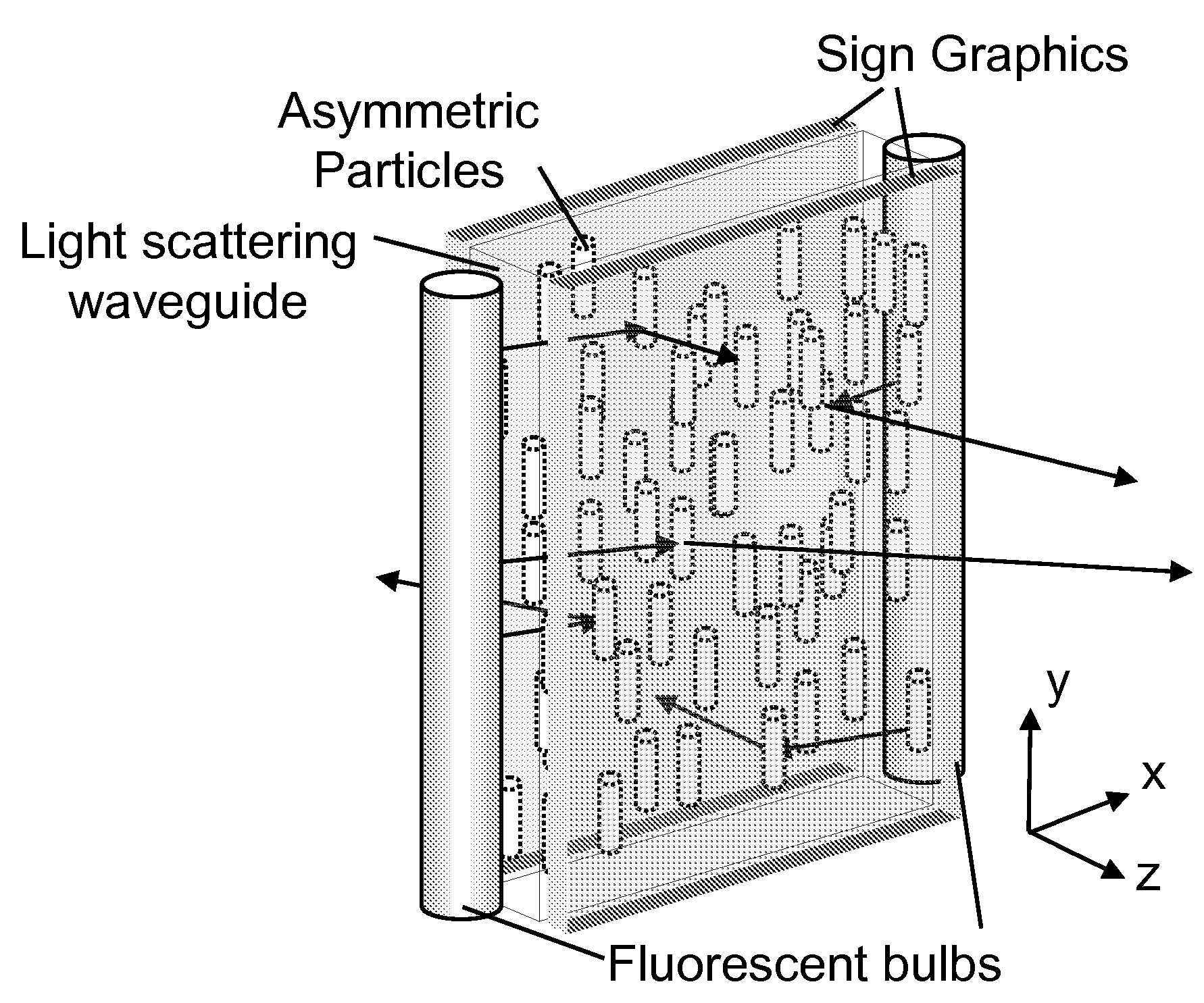

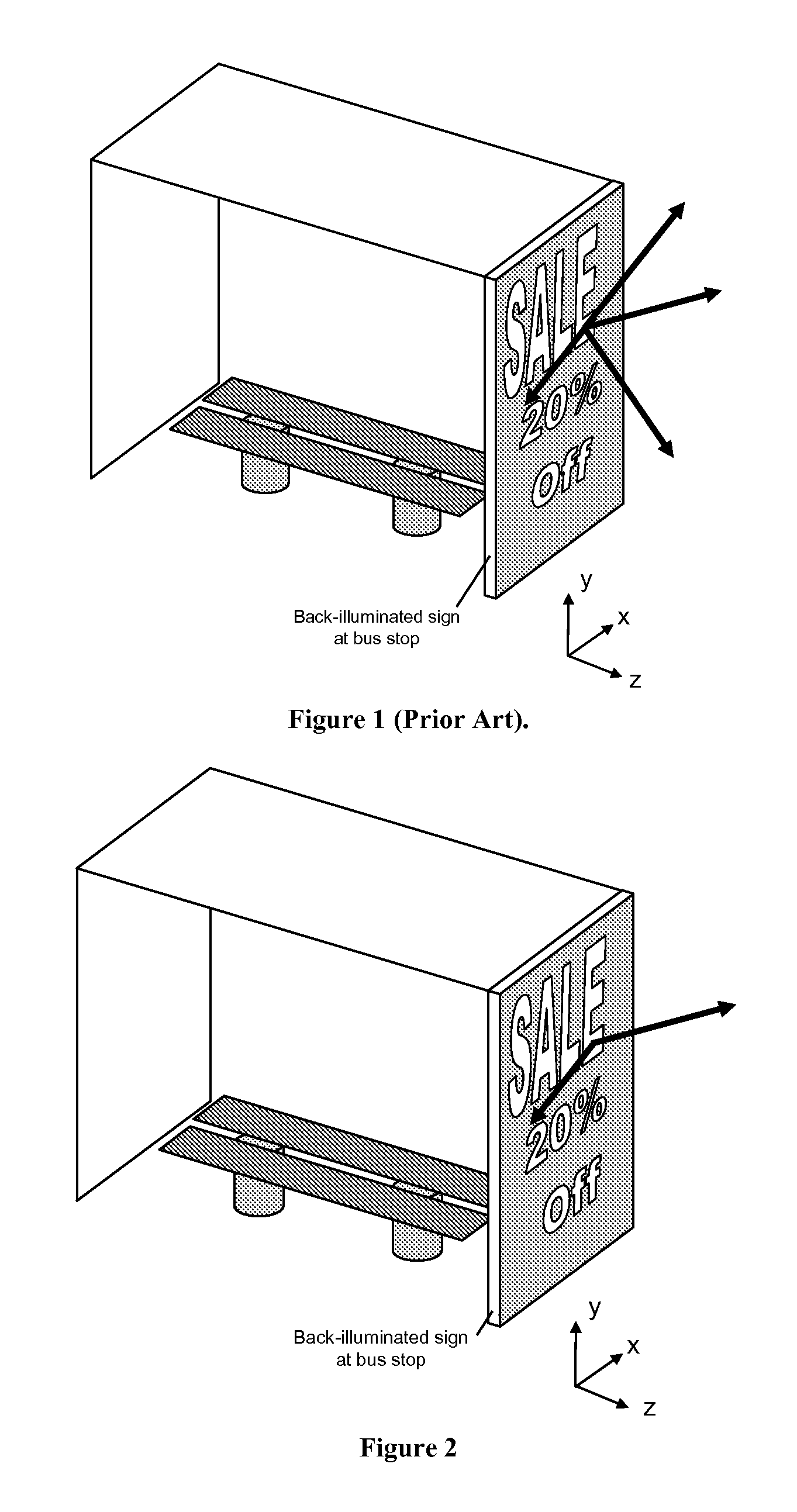

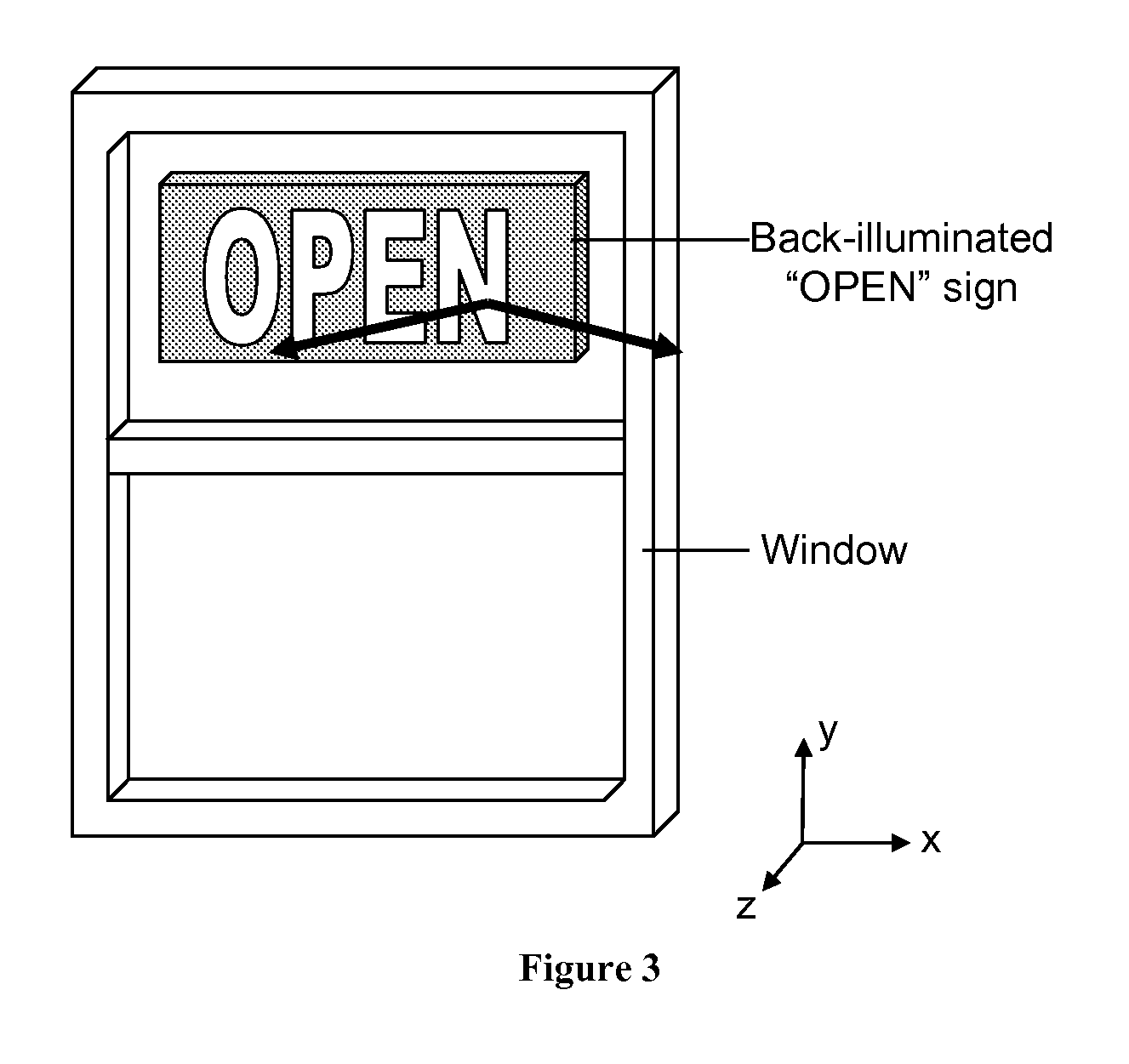

Enhanced electroluminescent sign

InactiveUS20060215958A1Signs improvedEfficiently directsCoupling light guidesIlluminated signsElectricityLightness

An enhanced electroluminescent sign containing a volumetric, anisotropic scattering element to control the angular spread of light from the sign and the spatial luminance uniformity of the sign. The anisotropic scattering element contains one or more regions of asymmetrically-shaped light scattering particles. The angular spread of light leaving a sign from a light emitting source can be efficiently controlled by using a thin, low cost, volumetric, anisotropic scattering elements to angularly and spatially distribute light, permitting the reduction in number of light sources, a reduction in power requirements, or a more tailored viewing angle.

Owner:FUSION OPTIX

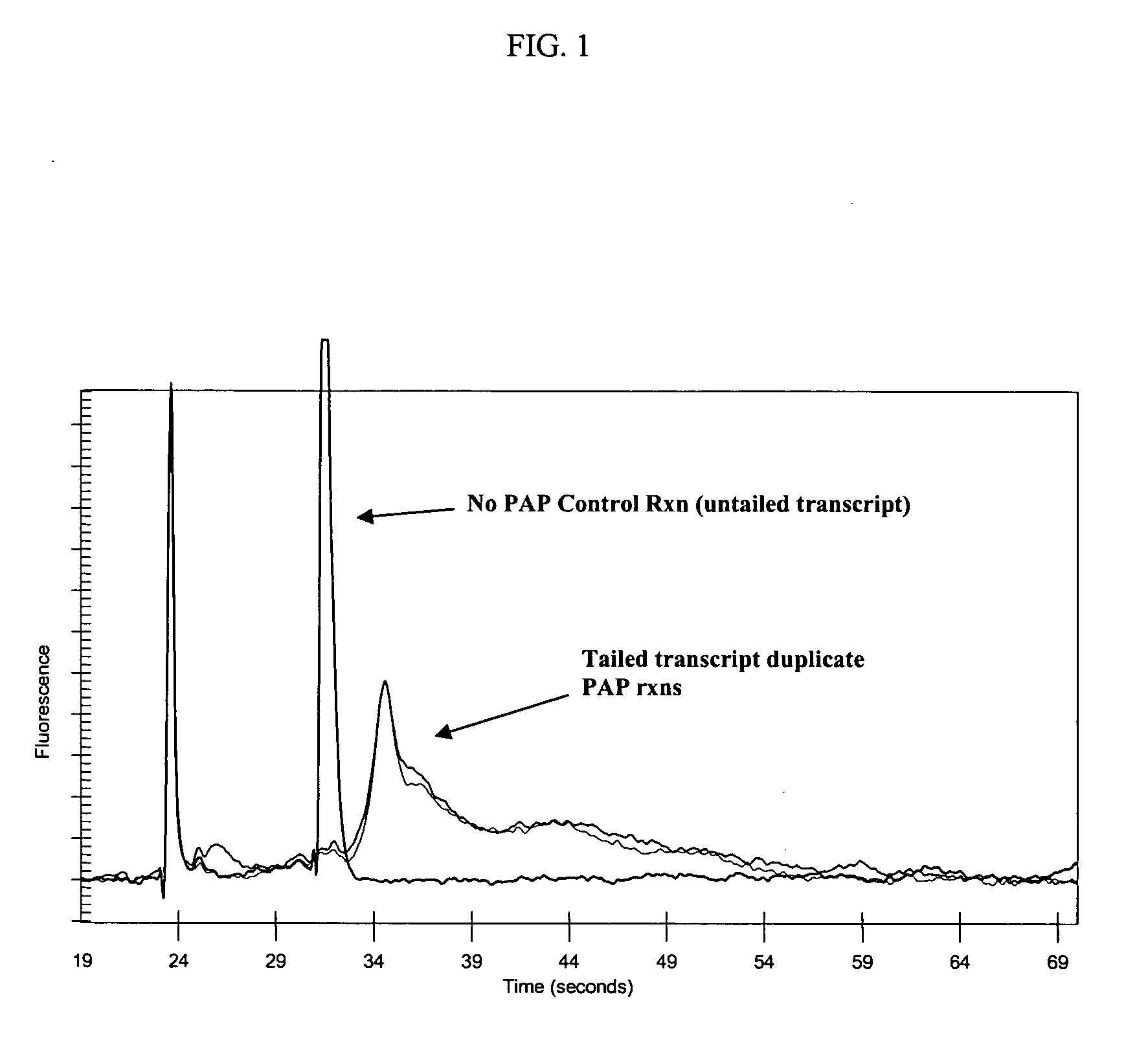

Methods and compositions for tailing and amplifying RNA

ActiveUS20060051771A1Efficiently and uniformlyEfficiently and uniformly tailMicrobiological testing/measurementFermentationGenome wide expressionGenome

The present invention provides methods and compositions that enable tagging and amplification of targeted RNA molecules. A targeted RNA molecule is any non-polyadenylated RNA molecule including, for example, miRNA, siRNA, rRNA, tRNA, synthetic RNA, or non-polyadenylated mRNA such as mRNA from bacteria. In certain aspects, the invention provides methods and compositions for the genome-wide expression analysis of bacterial genes. Significantly, the methods enable genome-wide expression analysis in circumstances where bacterial numbers were previously too low to purify adequate amounts of RNA for DNA microarray analysis or other applications. Such methods are particularly useful for the study of bacterial gene expression during host-cell infection. The invention also provides kits for tagging and amplifying targeted RNA molecules.

Owner:APPL BIOSYSTEMS INC

Dual illumination anisotropic light emitting device

ActiveUS20080094854A1Low costLower the volumeMechanical apparatusCoupling light guidesElectricityLight emitting device

An enhanced electroluminescent sign containing a volumetric, anisotropic scattering element to control the angular spread of light from the sign and the spatial luminance uniformity of the sign. The anisotropic scattering element contains one or more regions of asymmetrically-shaped light scattering particles. The angular spread of light leaving a sign from a light emitting source can be efficiently controlled by using a thin, low cost, volumetric, anisotropic scattering elements to angularly and spatially distribute light, permitting the reduction in number of light sources, a reduction in power requirements, or a more tailored viewing angle.

Owner:MASSACHUSETTS DEV FINANCE AGENCY

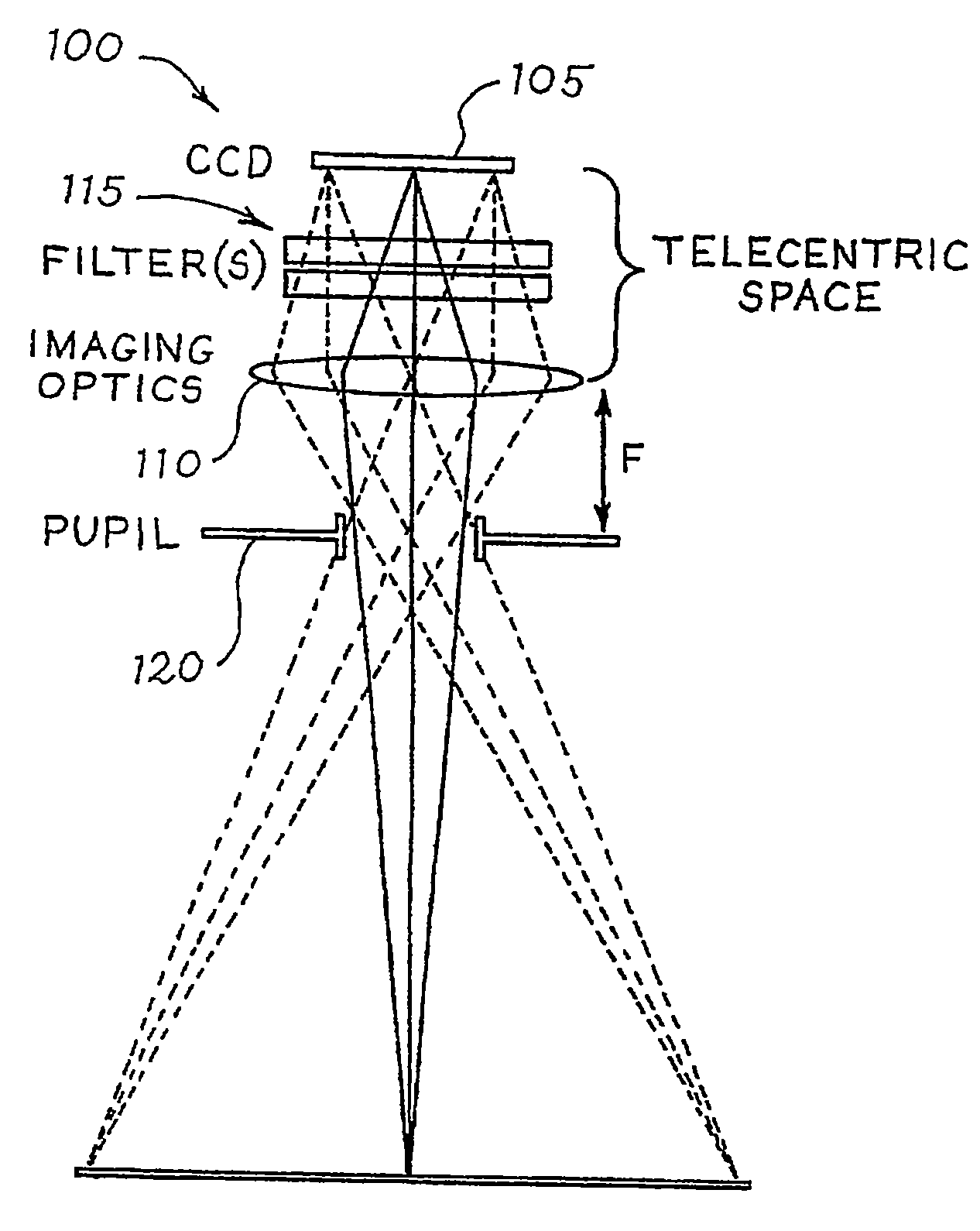

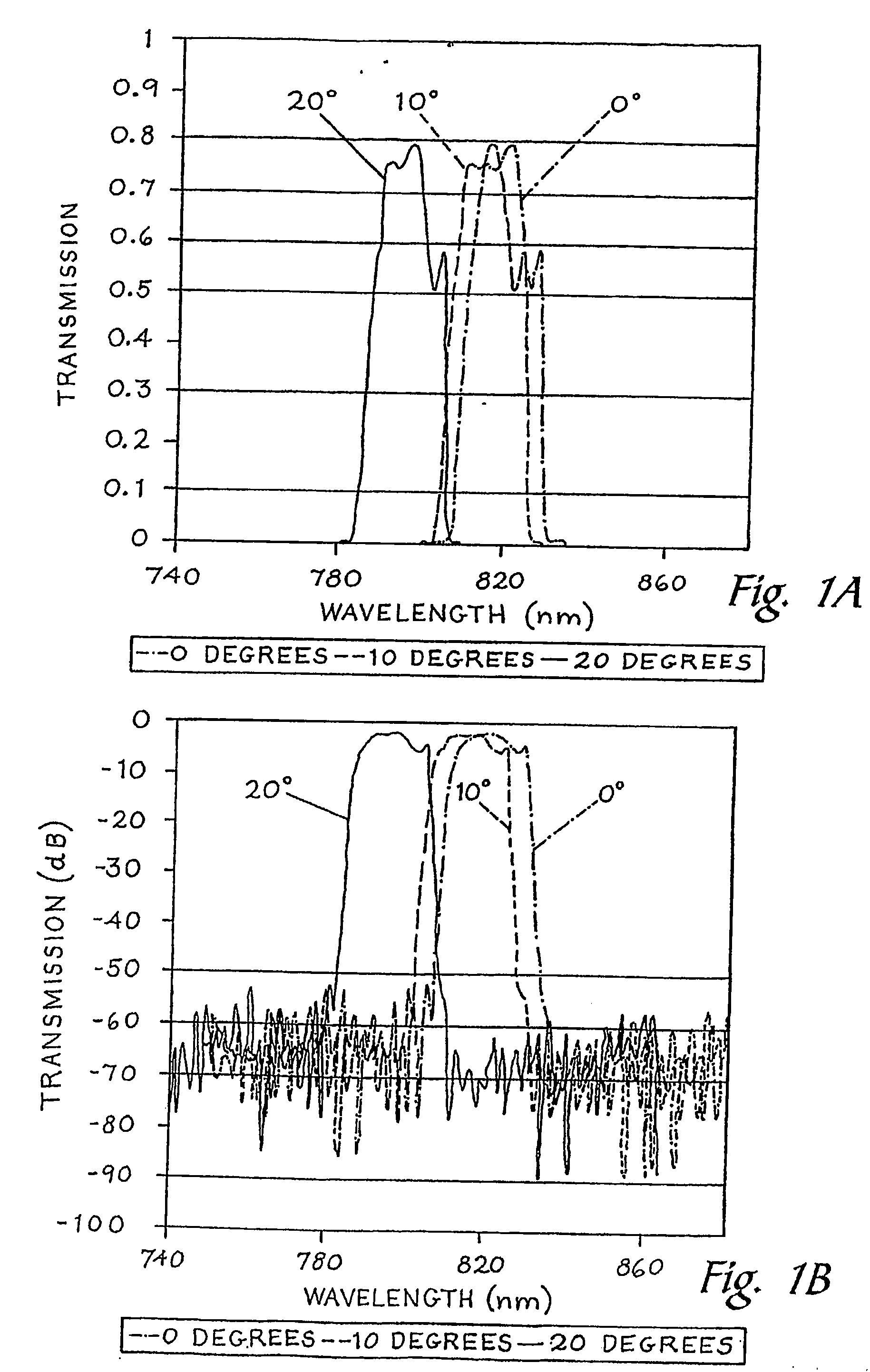

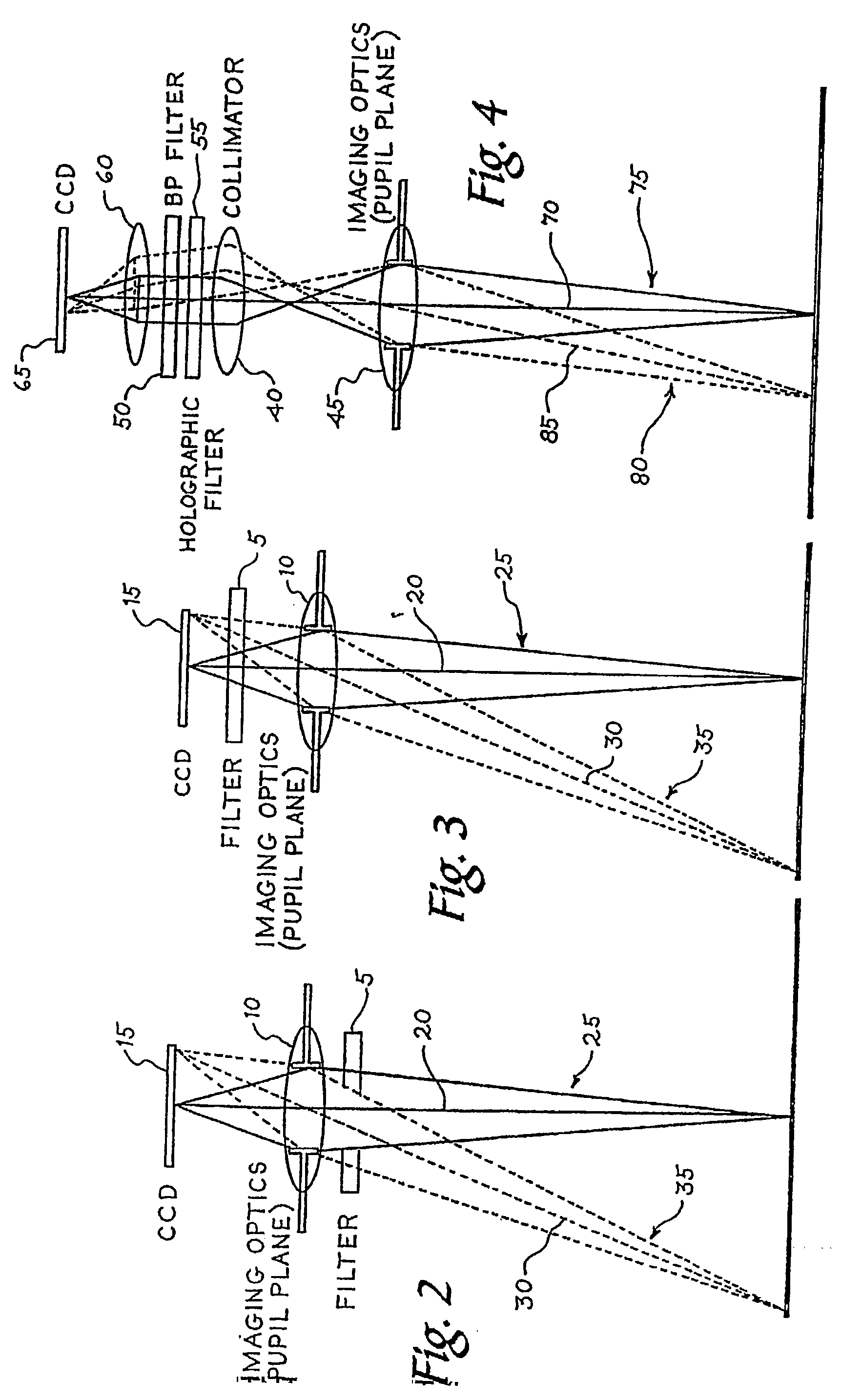

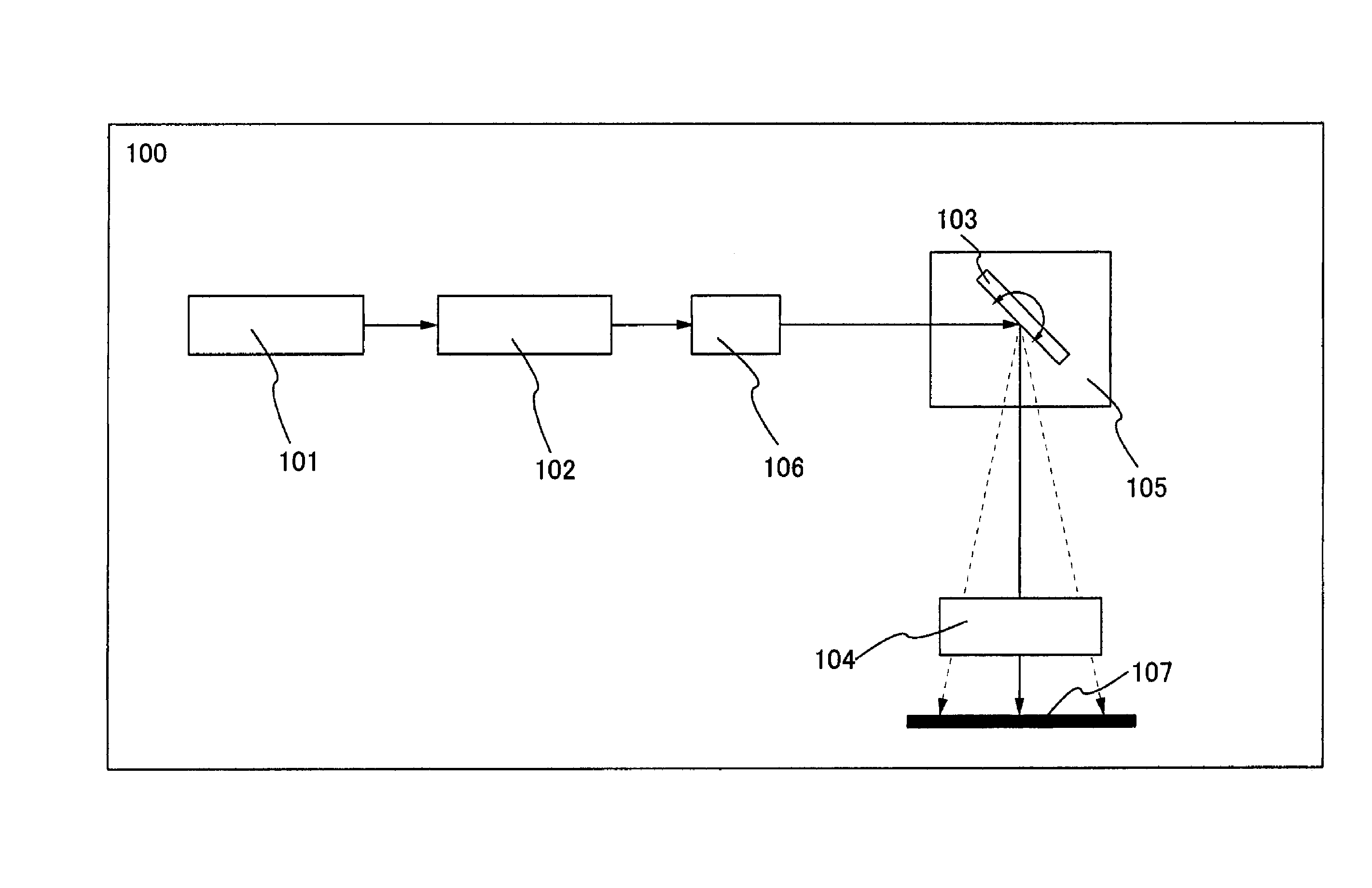

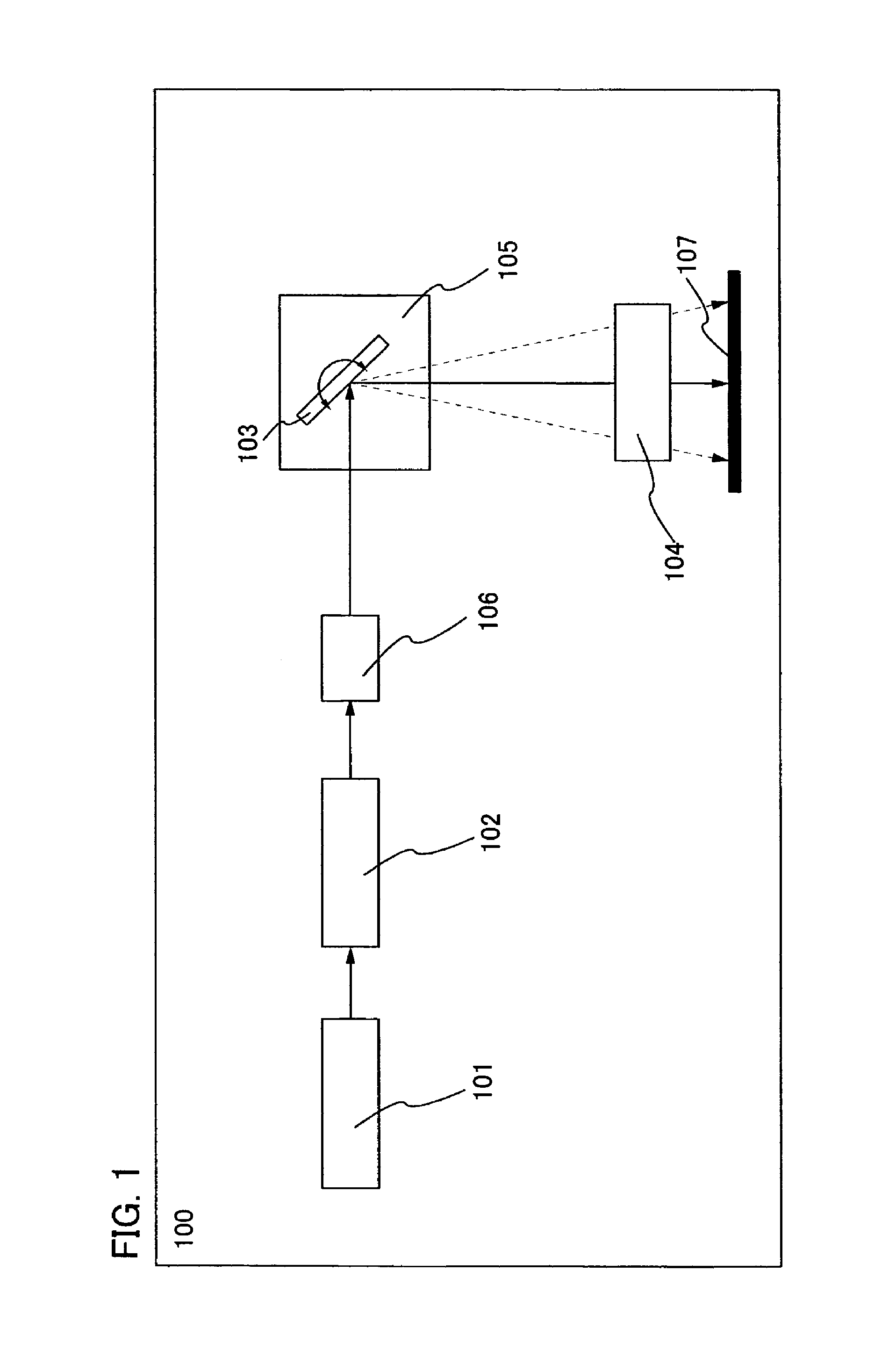

Fluorescence filtering system and method for molecular imaging

InactiveUS20090080194A1Efficiently and uniformlyHighly efficient and uniform methods of illuminationRaman/scattering spectroscopyElectric circuit arrangementsMolecular imagingFluorescent materials

An optical system is disclosed that can be used for fluorescence filtering for molecular imaging. In one preferred embodiment, a source subsystem is disclosed comprising a light source and a first set of filters designed to pass wavelengths of light in an absorption band of a fluorescent material. A detector subsystem is also disclosed comprising a light detector, imaging optics, a second set of filters designed to pass wavelengths of light in an emission band of the fluorescent material, and an aperture located at a front focal plane of the imaging optics. A telecentric space is created between the light detector and the imaging optics, such that axial rays from a plurality of field points emerge from the imaging optics parallel to each other and perpendicular to the second set of filters.

Owner:LI COR

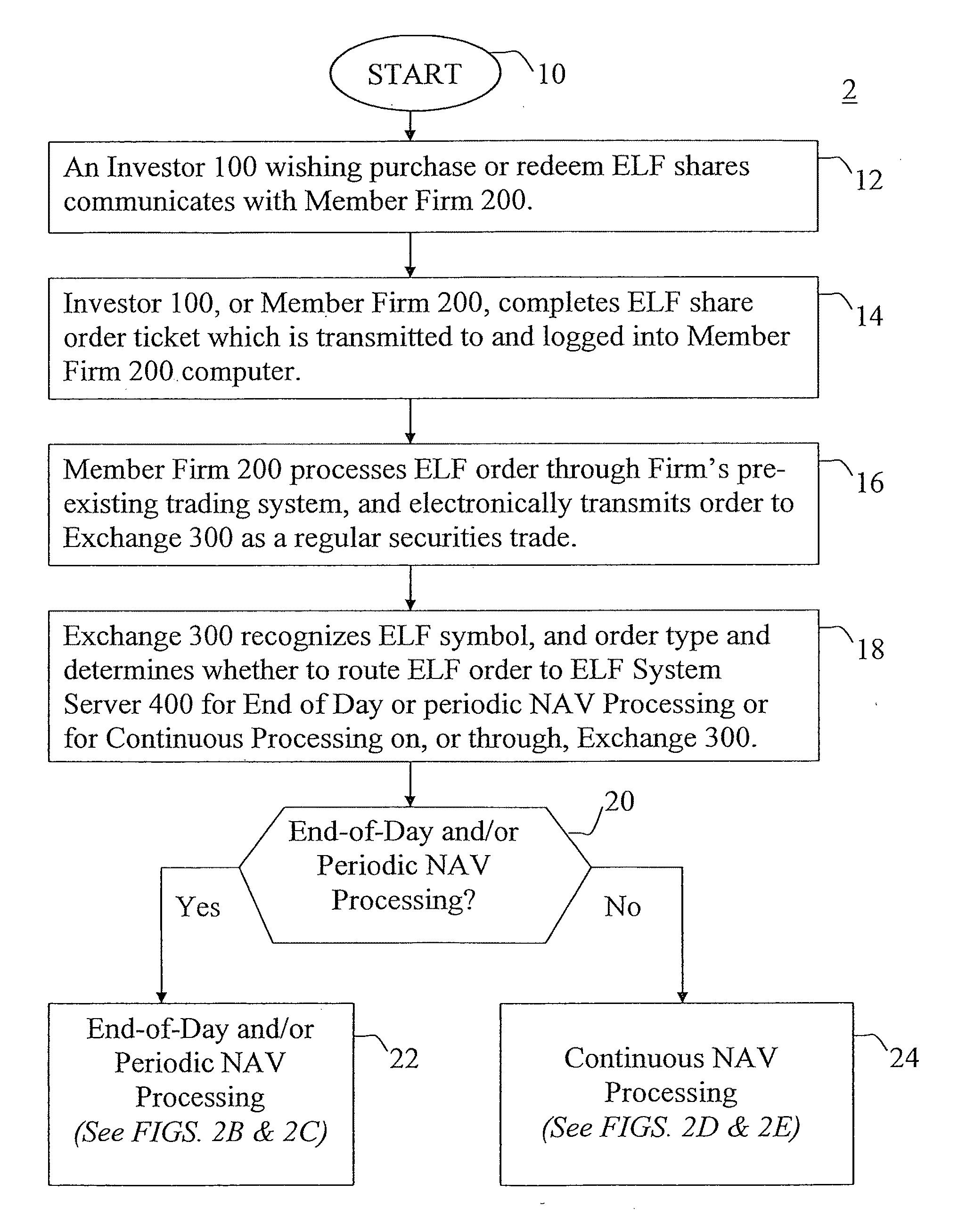

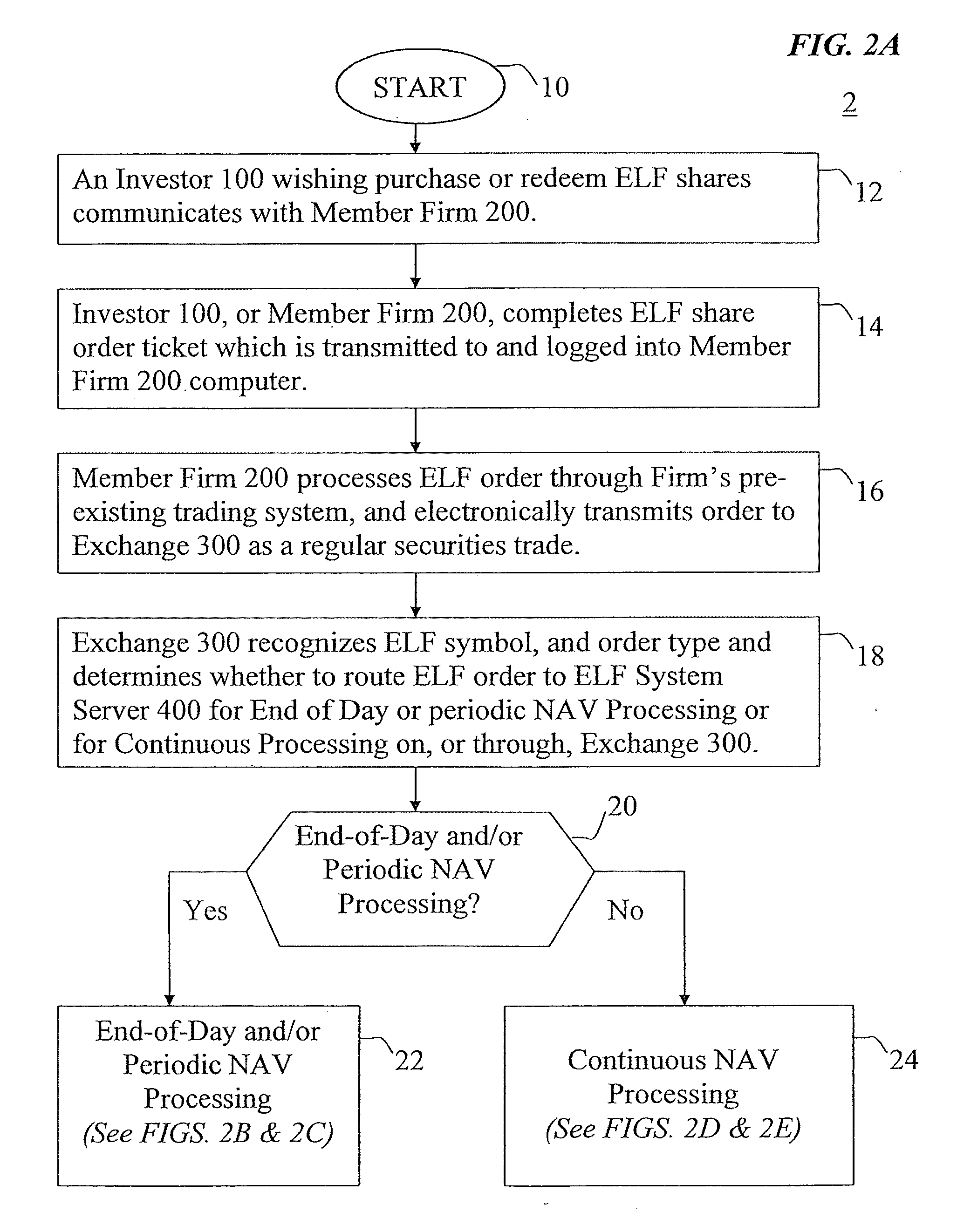

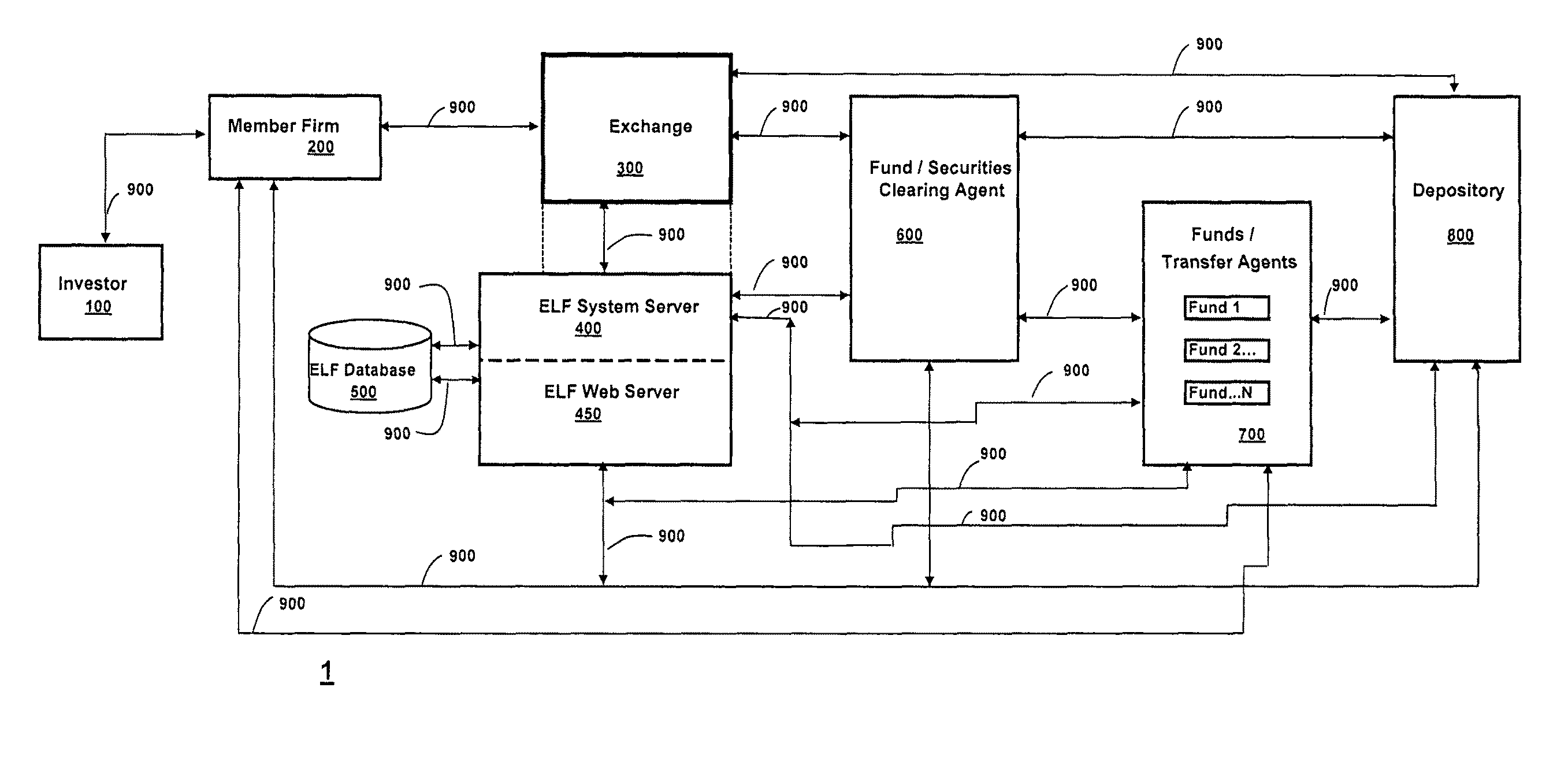

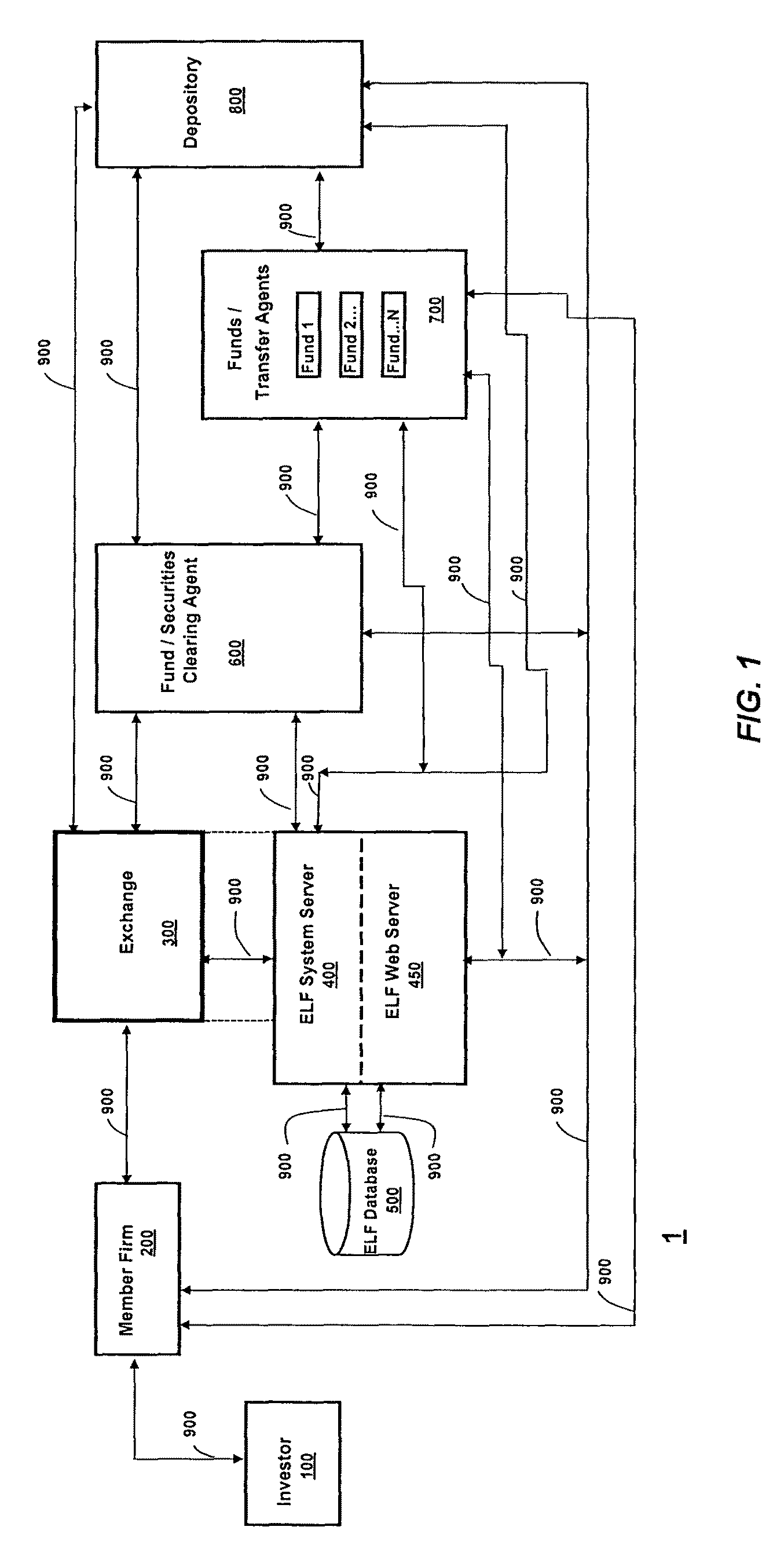

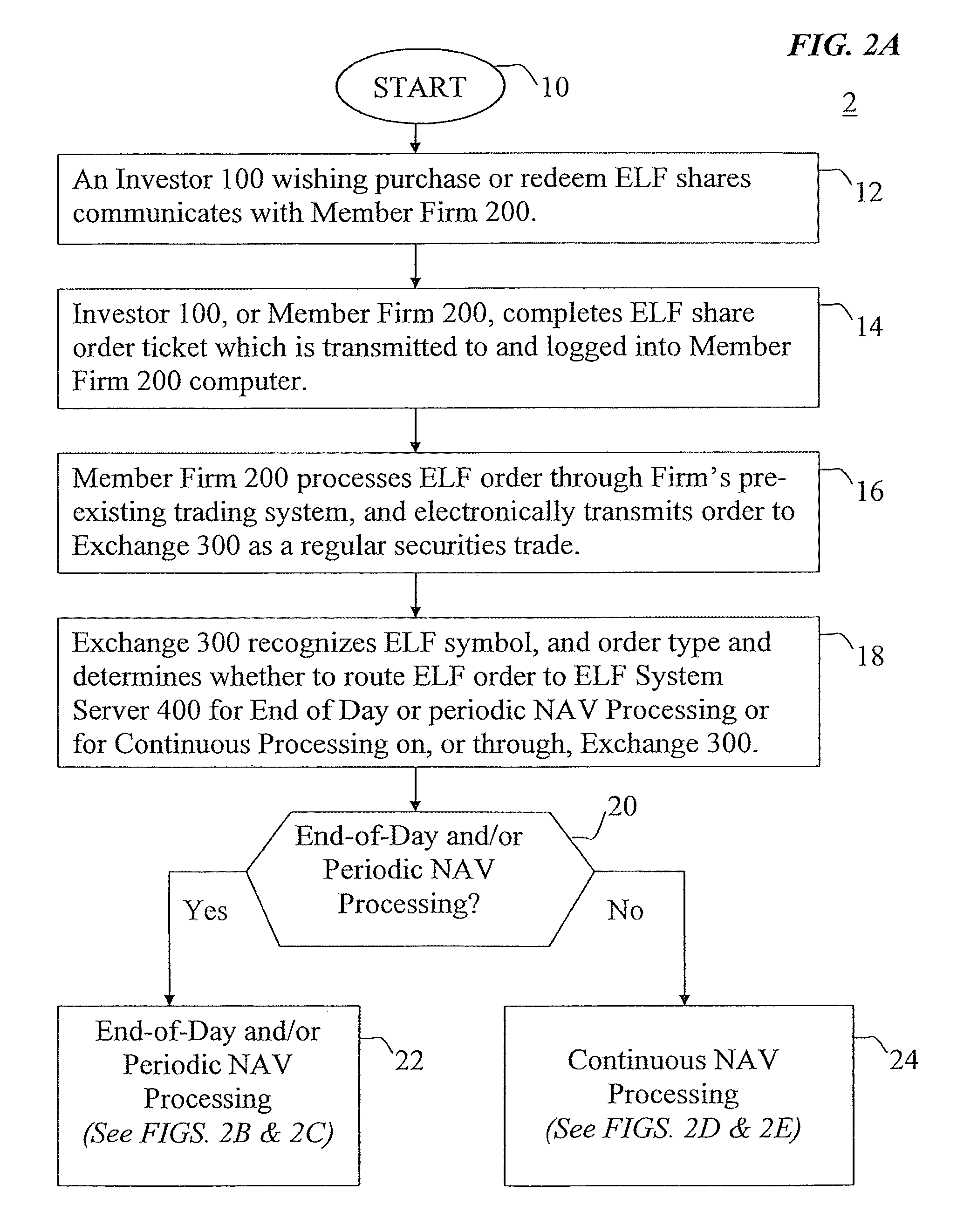

System and methods for processing open-end mutual fund purchase and redemption orders at centralized securities exchanges and other securities trading and processing platforms

InactiveUS20100057608A1Efficiently and uniformlyReduce chargeFinanceMultiple digital computer combinationsPaymentClearing Agent

A system for processing traditional open-end mutual fund purchase and redemption orders at a server at designated Exchange(s) for receiving order messages from at least one of a plurality of Brokers and Member Firms, the server having at least one processor and memory for storing routines operable to process individual or aggregated order messages, preferably based on a prioritized set of business rules, and / or match the purchase and redemption orders, reformat the orders, and transmit the reformatted orders to at least one of a plurality of Fund / Securities Clearing Agents, Funds / Transfer Agents and Depositaries for confirmation, and clearing and settlement of issuance and redemption orders for mutual fund shares, as well as payment of mutual fund dividends.

Owner:MACPHERSON JAMES

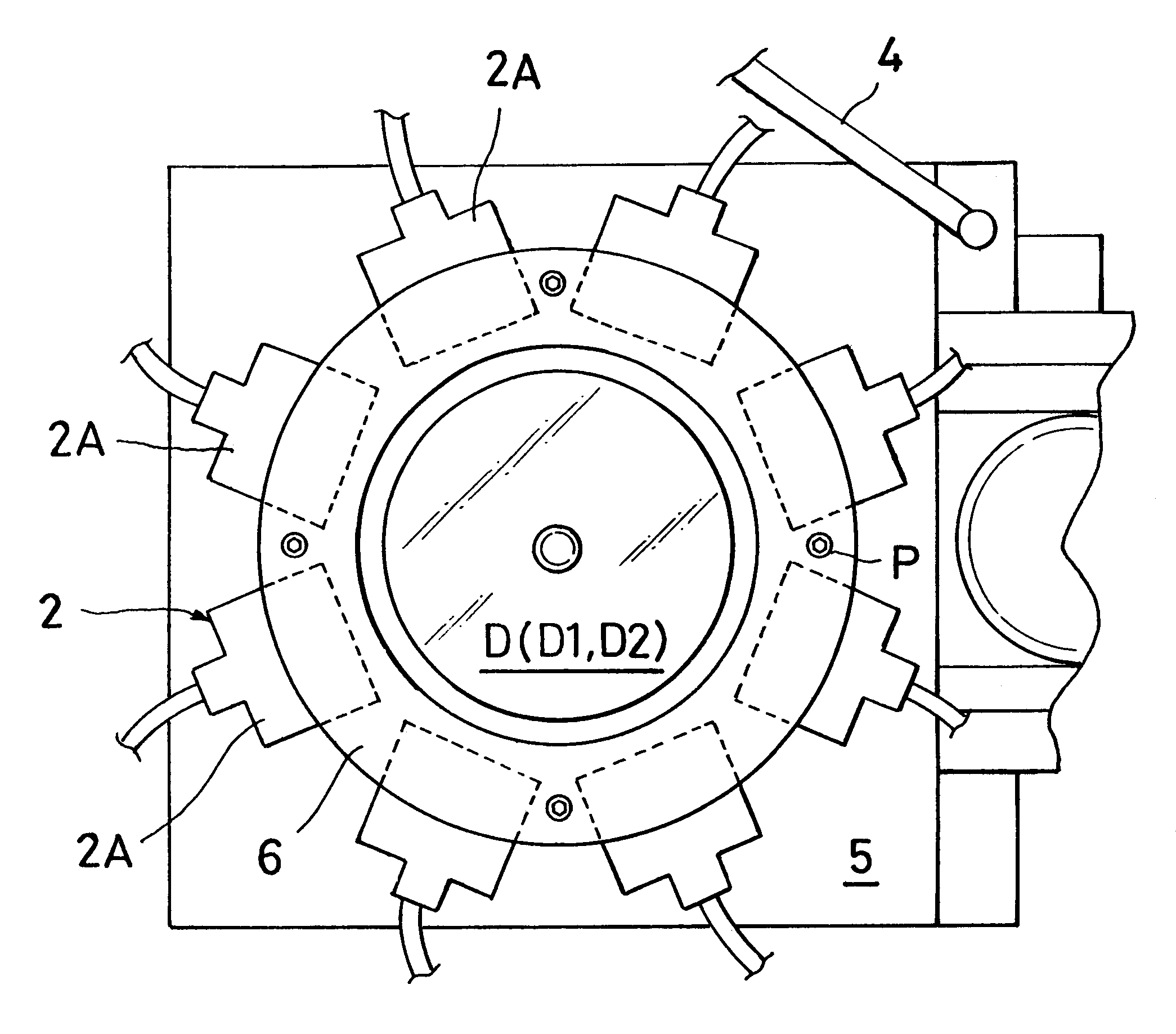

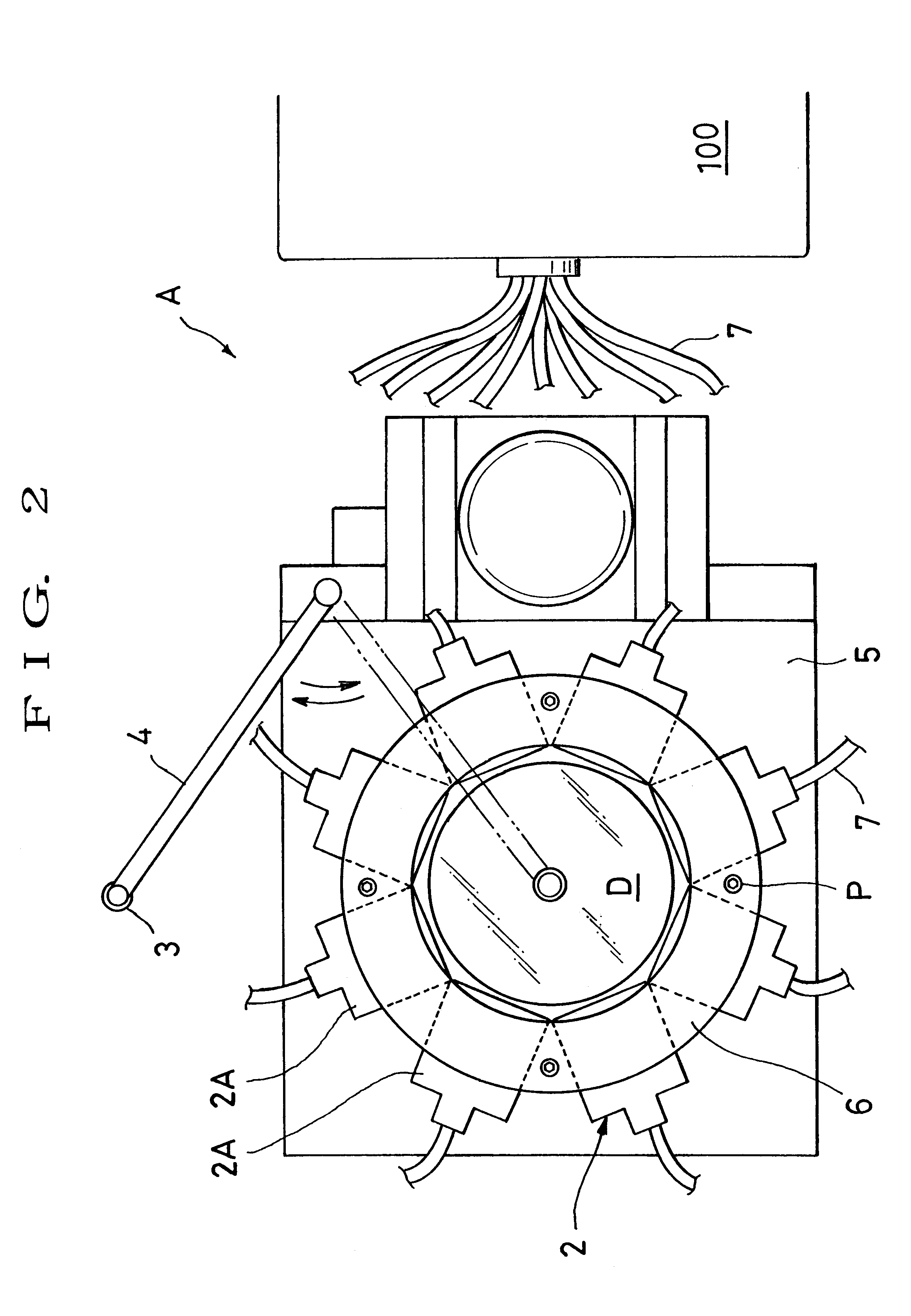

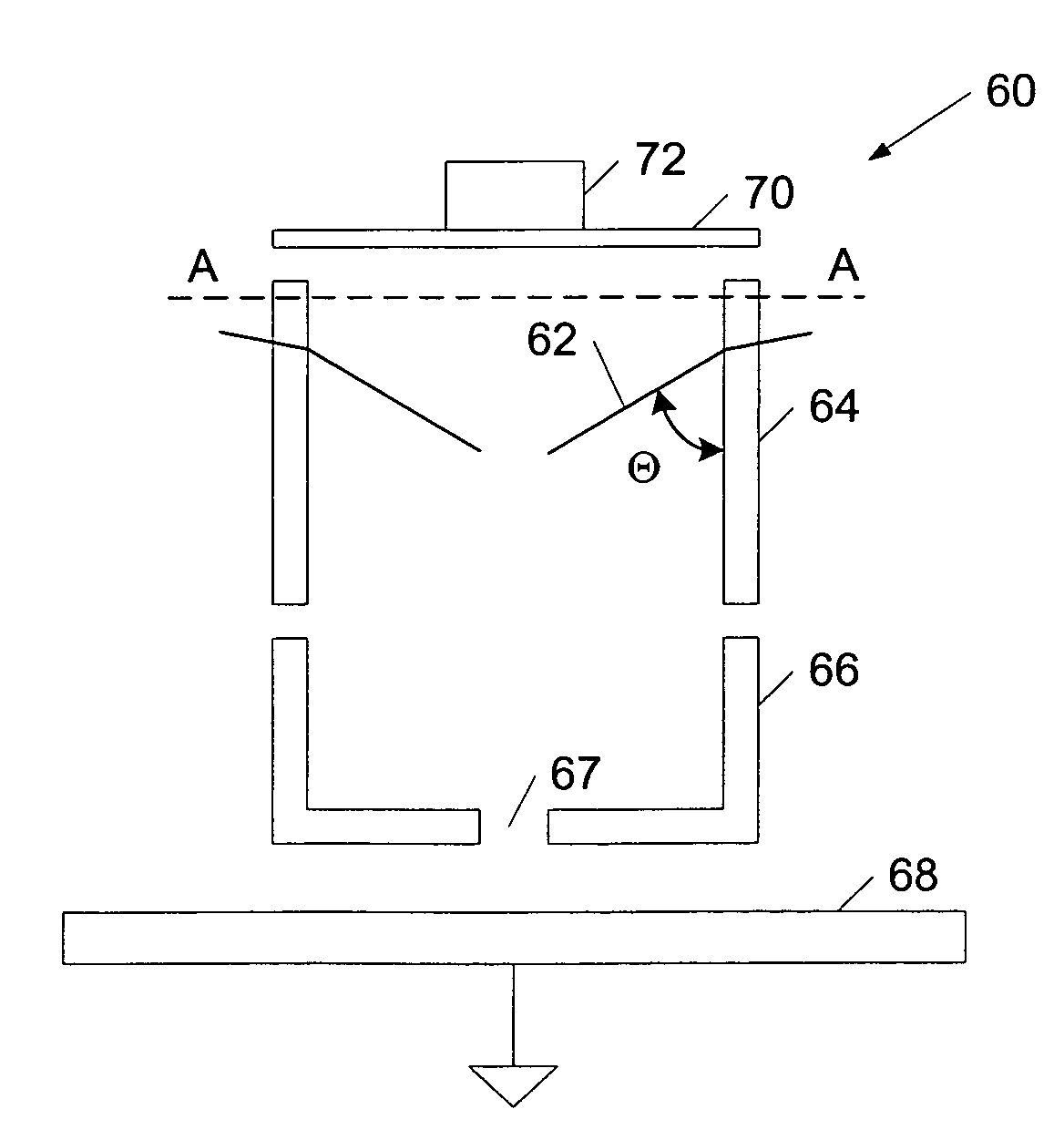

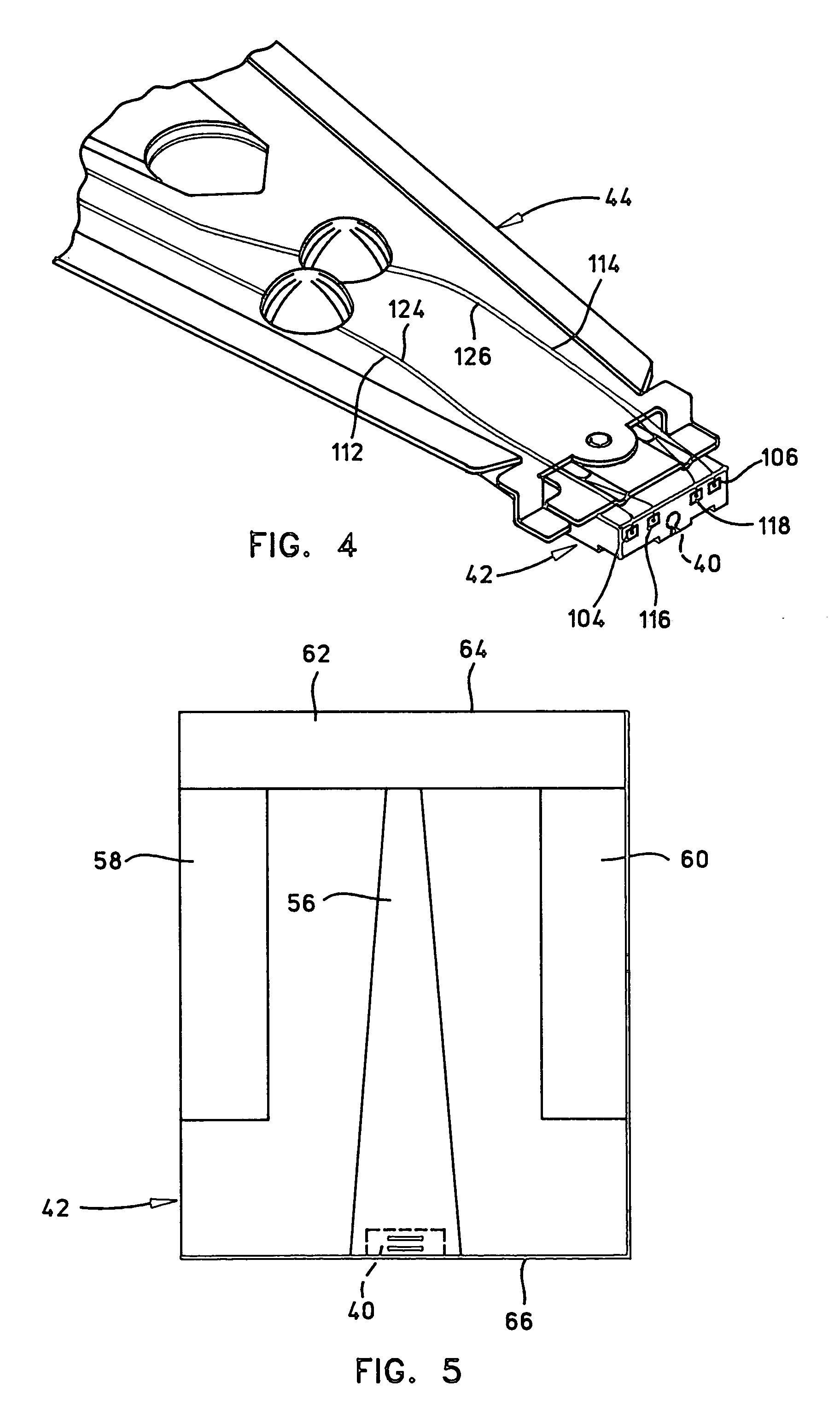

Method of and apparatus for curing an optical disc

InactiveUS6503423B1Efficient curingEfficiently and uniformlyRecord carriersMechanical working/deformationUV curingAdhesive

A method of and apparatus for curing an optical disc capable of efficiently curing ultraviolet curing resin serving as an adhesive between a pair of disc substrates. The apparatus includes a peripherally located ultraviolet irradiation unit disposed around a rotary holding table for irradiating ultraviolet from the peripheral surface of the optical disc toward the inner portion thereof so as to cure the ultraviolet curing resin, and / or a central irradiation unit disposed to irradiate ultraviolet from the central hole of the optical disc toward the outer portion thereof.

Owner:KITANO SEISAKU

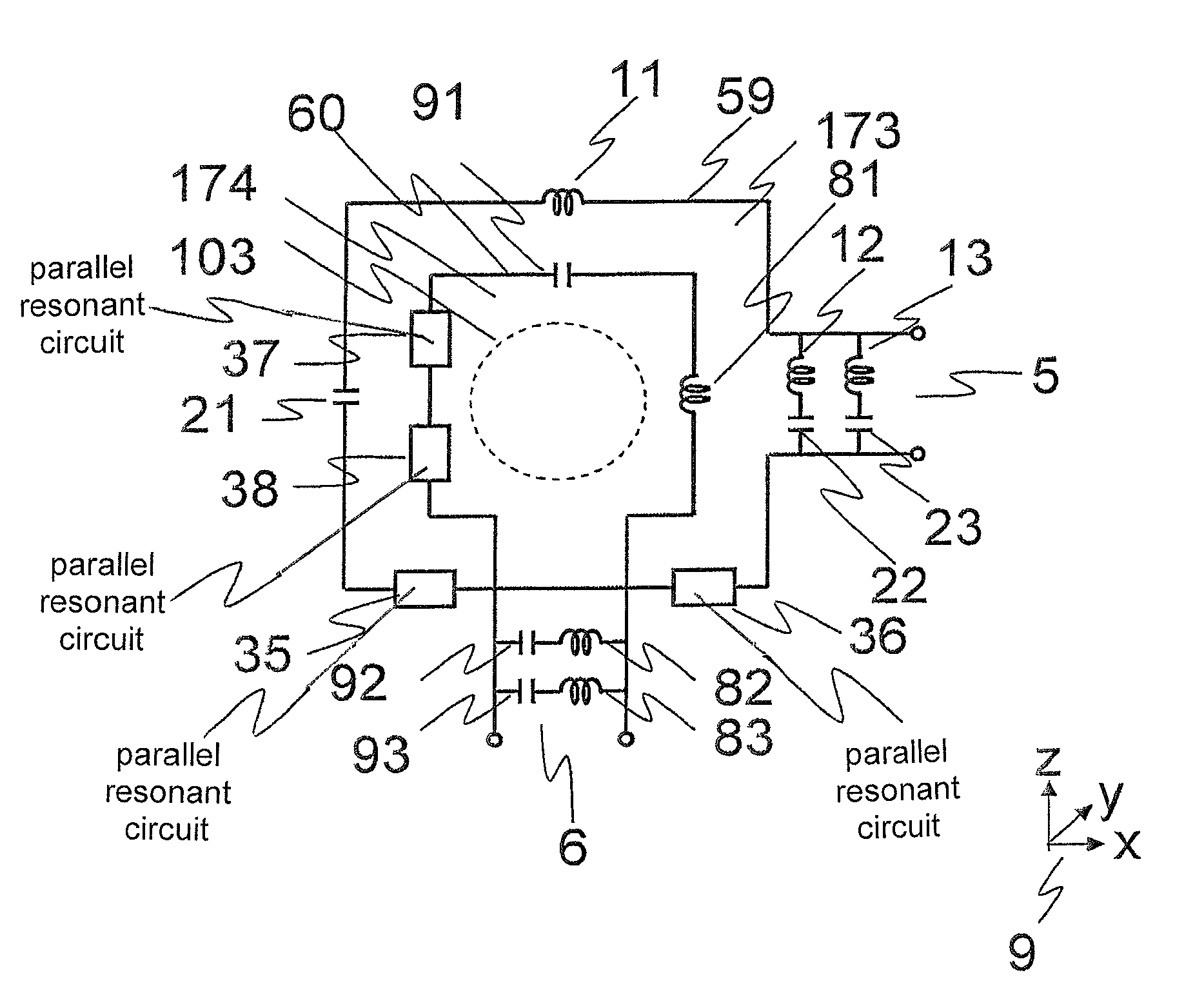

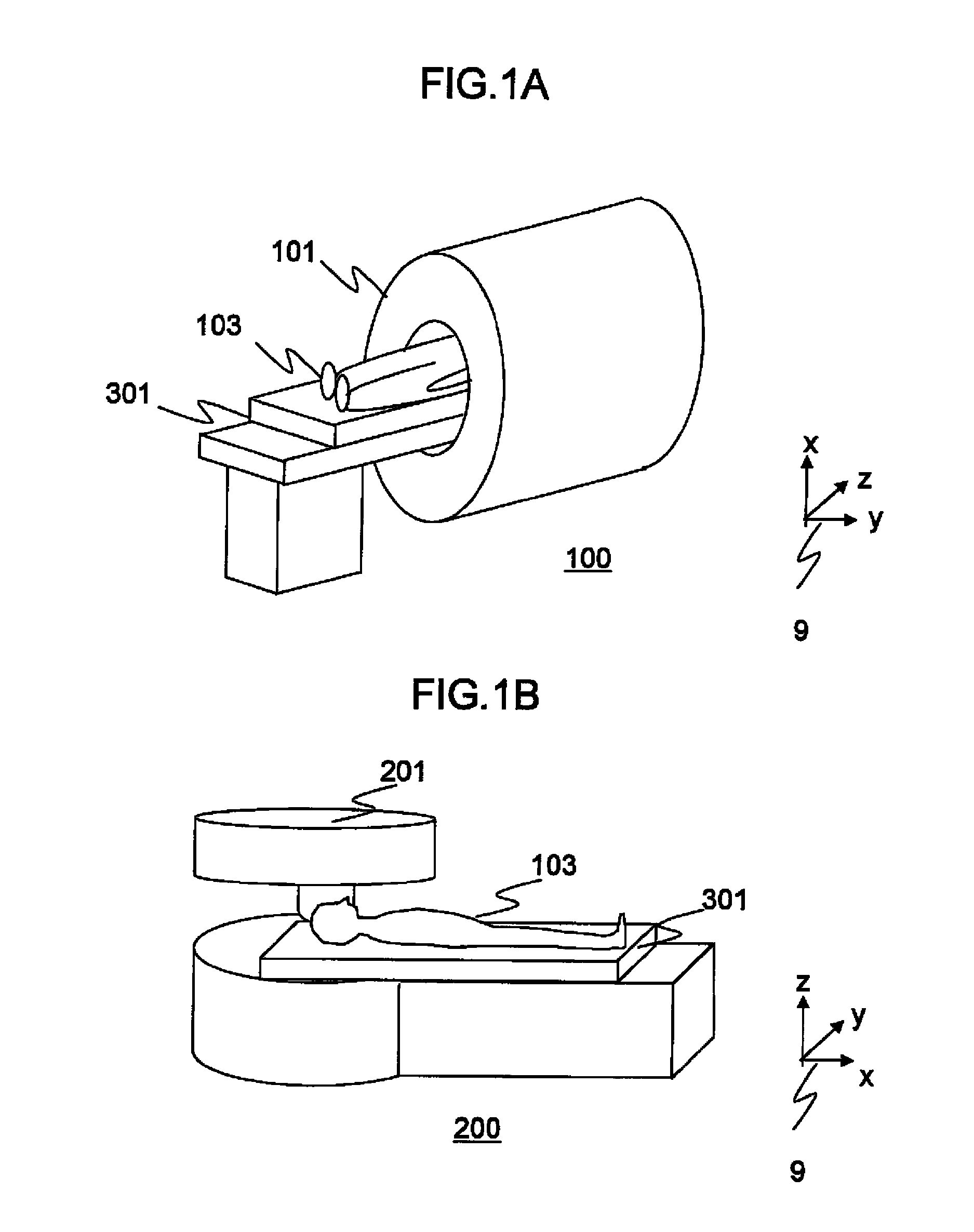

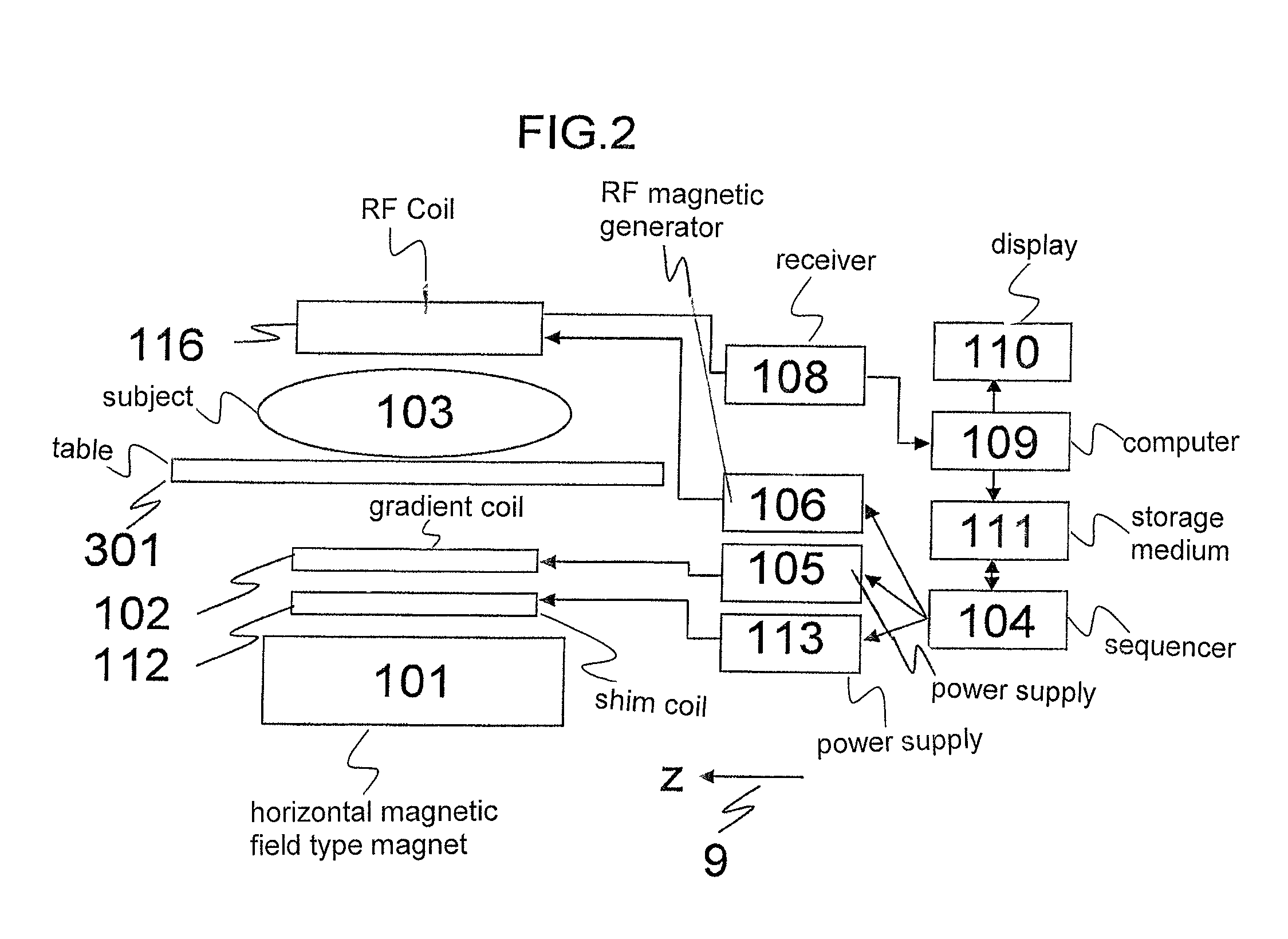

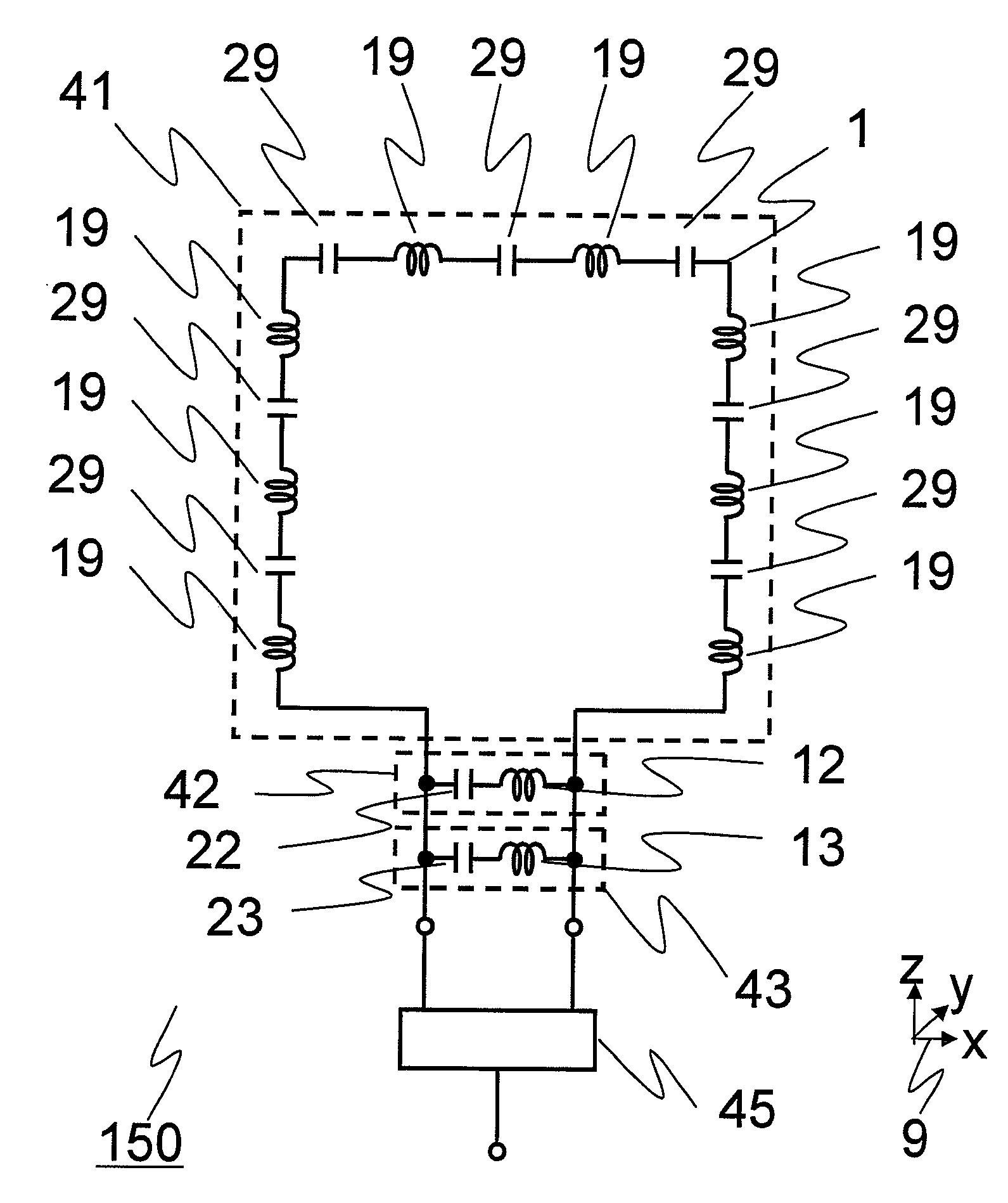

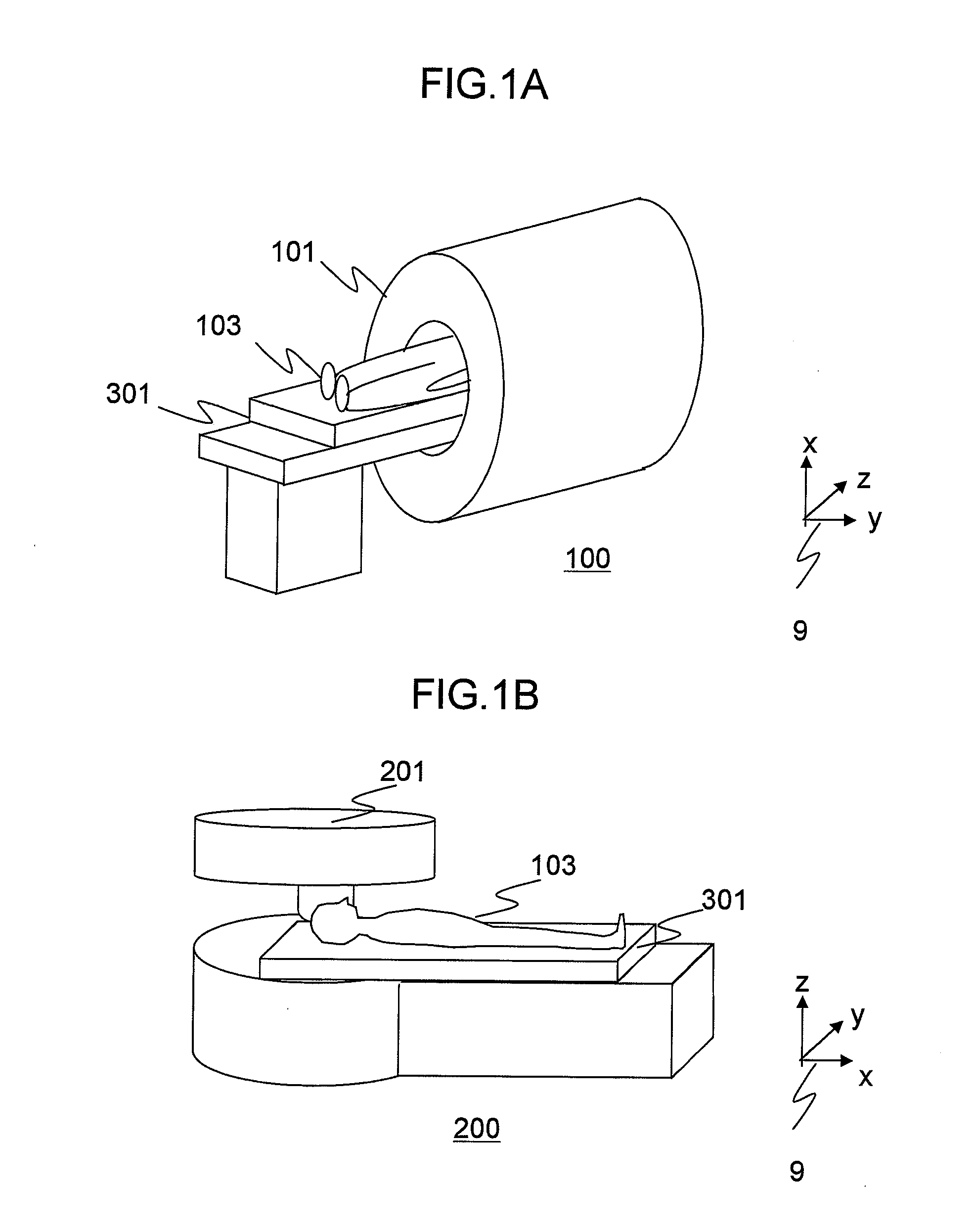

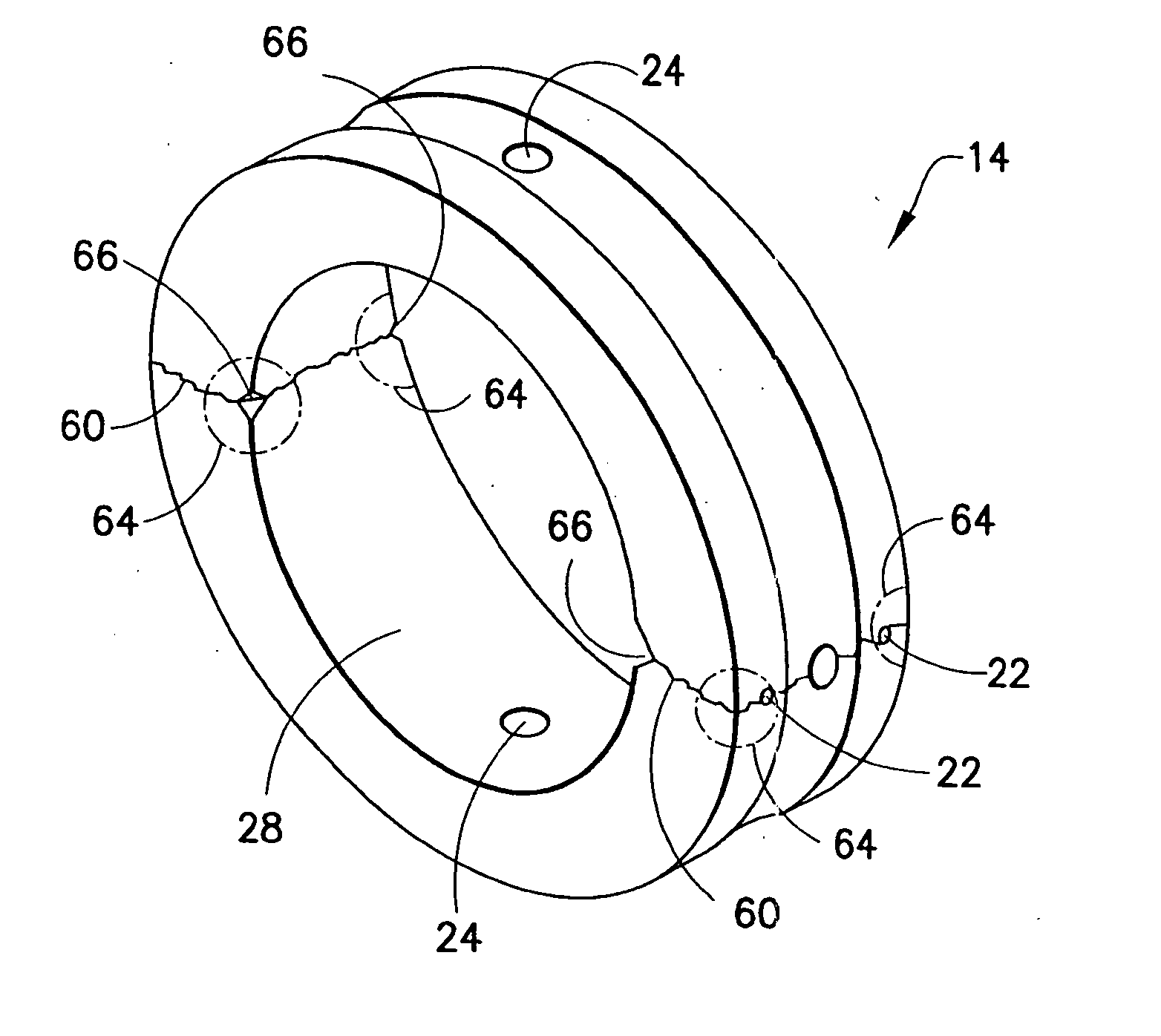

Magnetic field coil and magnetic resonance imaging apparatus

InactiveUS7733092B2Efficiently and uniformlyHigh sensitivityMagnetic measurementsElectric/magnetic detectionField coilMagnetic field

Provided is an RF coil which can highly efficiently and uniformly irradiate a RF magnetic field having two or more magnetic resonance frequencies close to each other, and receive magnetic resonance signals of two or more magnetic resonance frequencies close to each other with high sensitivity and uniform sensitivity profile in an MRI apparatus. Two or more frequencies to which the coil is tuned are adjusted so as to be between resonance frequencies of series resonant circuits constituting the RF coil.

Owner:HITACHI LTD

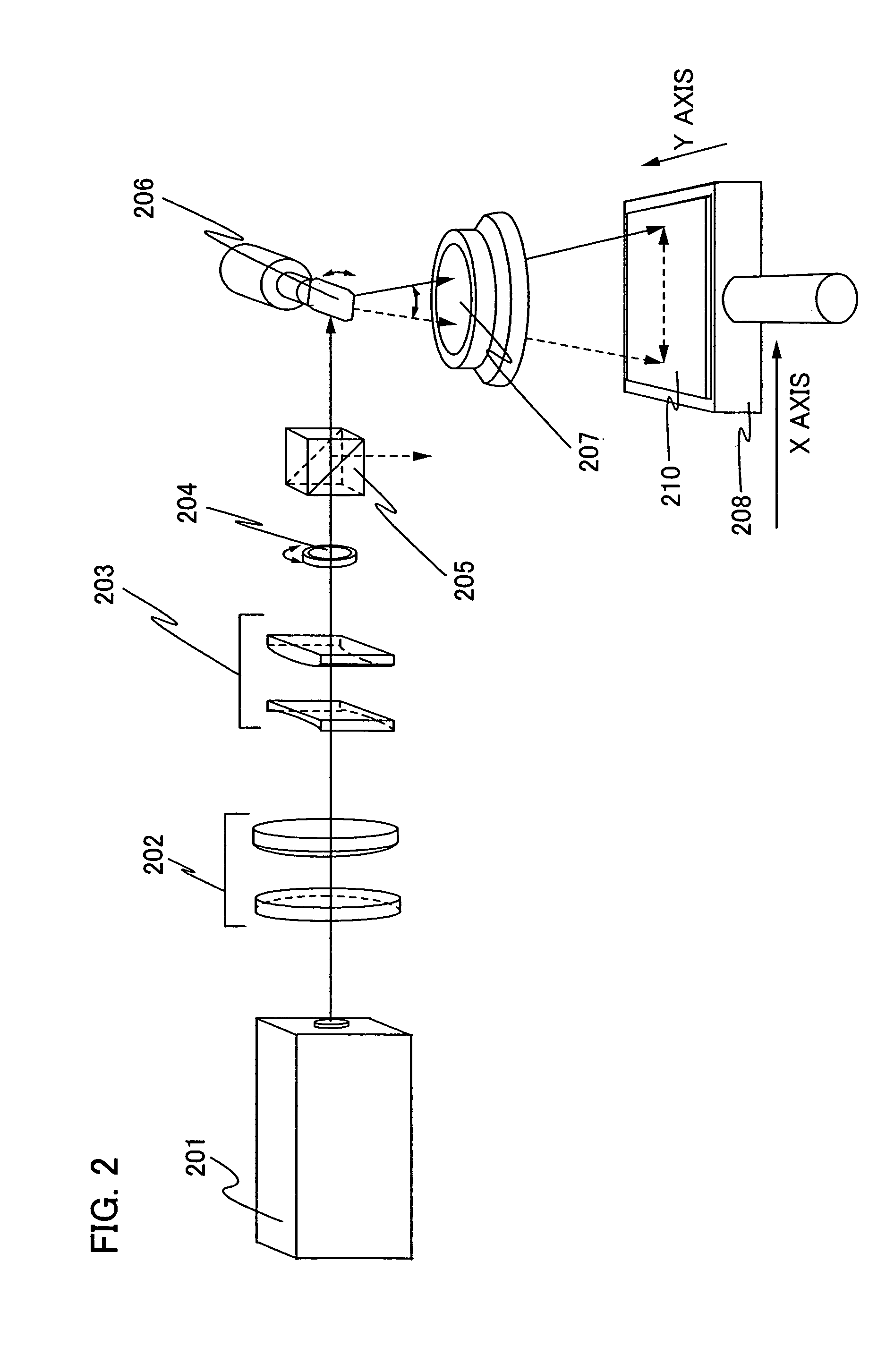

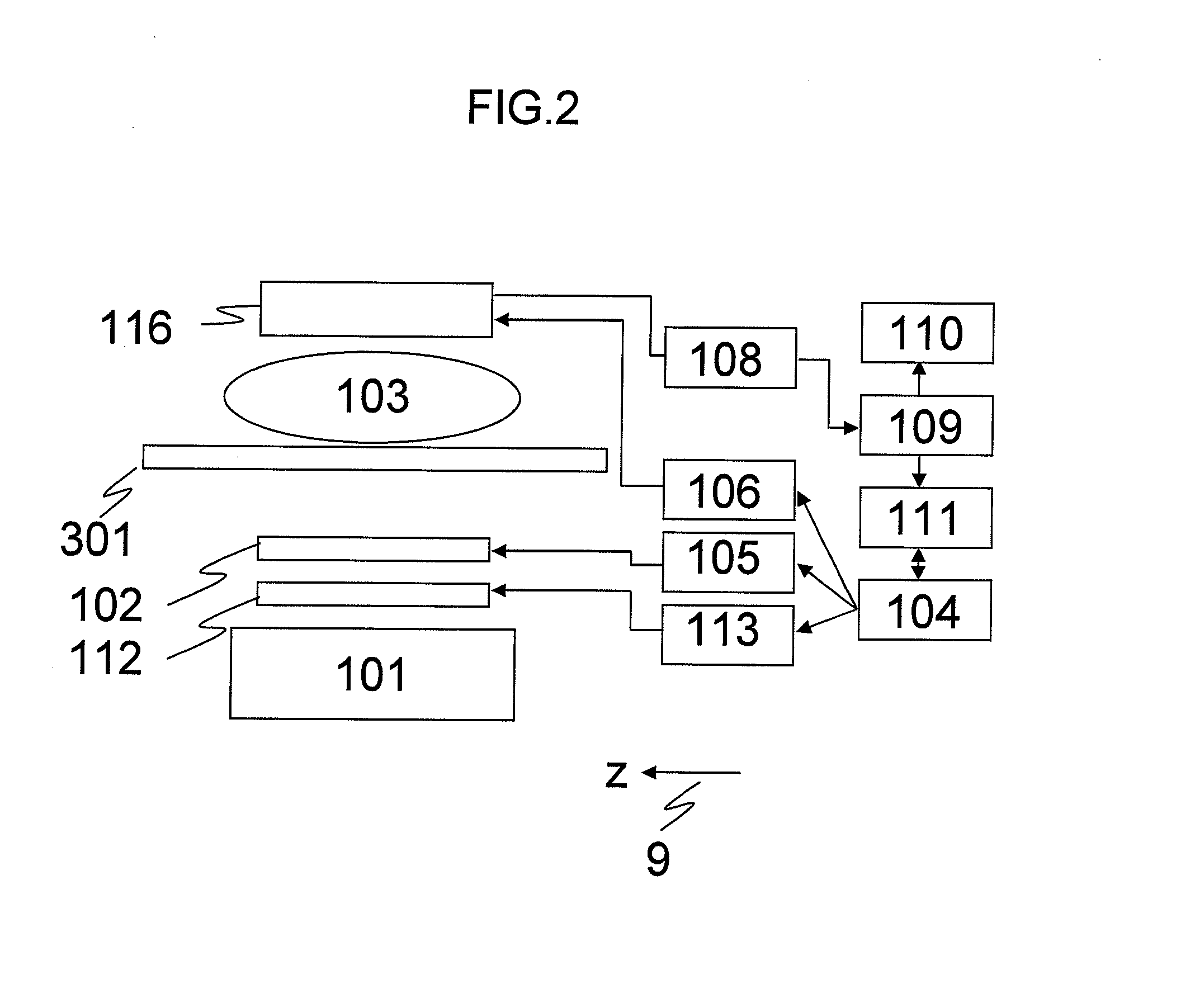

Laser irradiation apparatus and method of manufacturing semiconductor device

InactiveUS7405114B2Efficiently and uniformlySuppress fluctuationsTransistorSolid-state devicesEnergy variationGalvanometer

The present invention provides the laser irradiation apparatus that has a galvanometer mirror and an f-θ lens optical system, can offset the change of the energy due to the transmittance change of the f-θ lens, and can scan a laser beam while the change of the energy on a substrate is suppressed. Further, the laser beam energy that is incident on the lens is controlled in advance by combining the optical system changing the branching ratio of polarization of the laser beam and the optical system having dependence on direction of polarization of the laser beam and changed continuously according to the transmittance of the lens on which the laser beam is incident. The laser energy is controlled to offset the transmittance of the lens, and thereby energy fluctuation of the laser beam irradiation of a substrate can be prevented.

Owner:SEMICON ENERGY LAB CO LTD

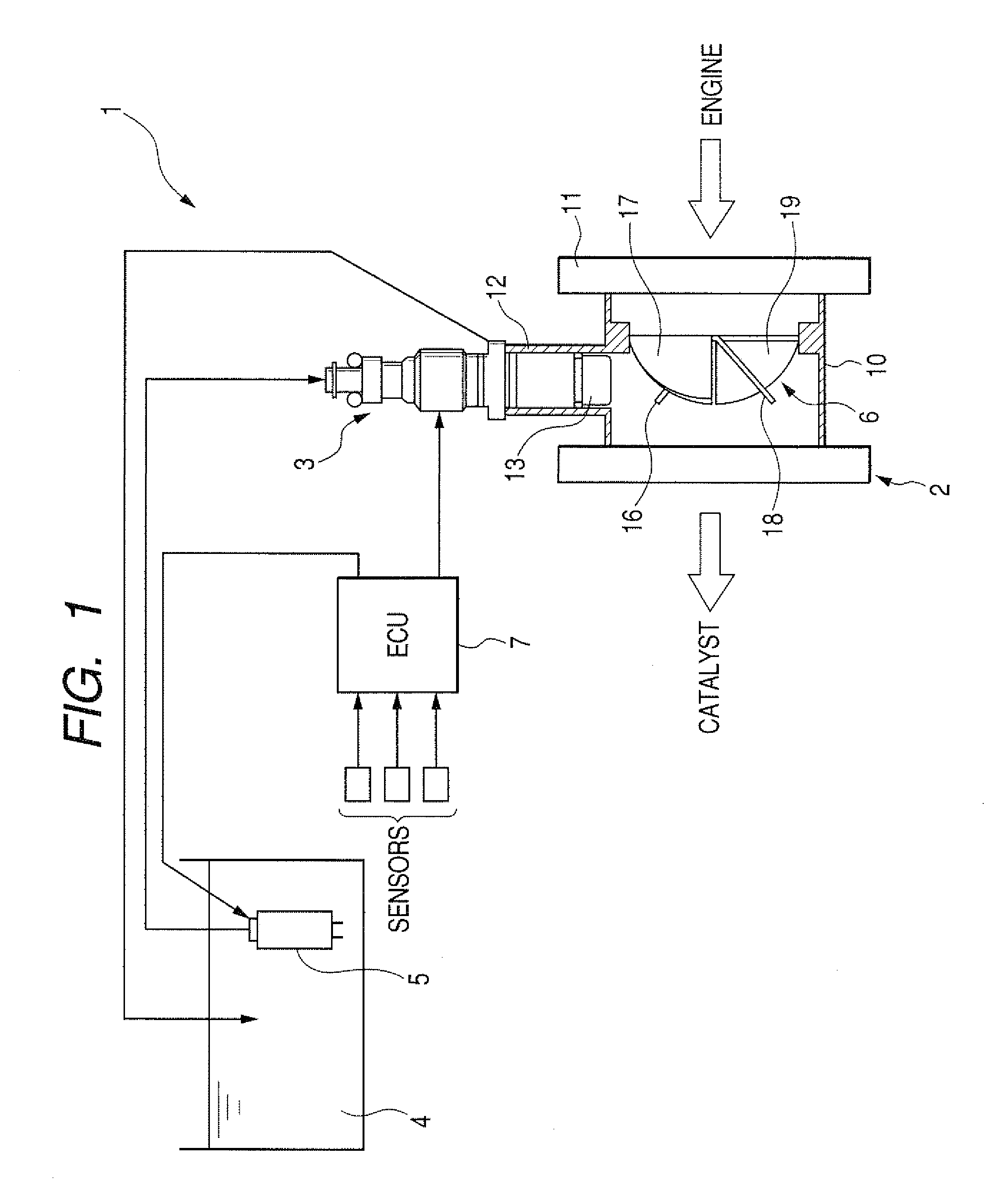

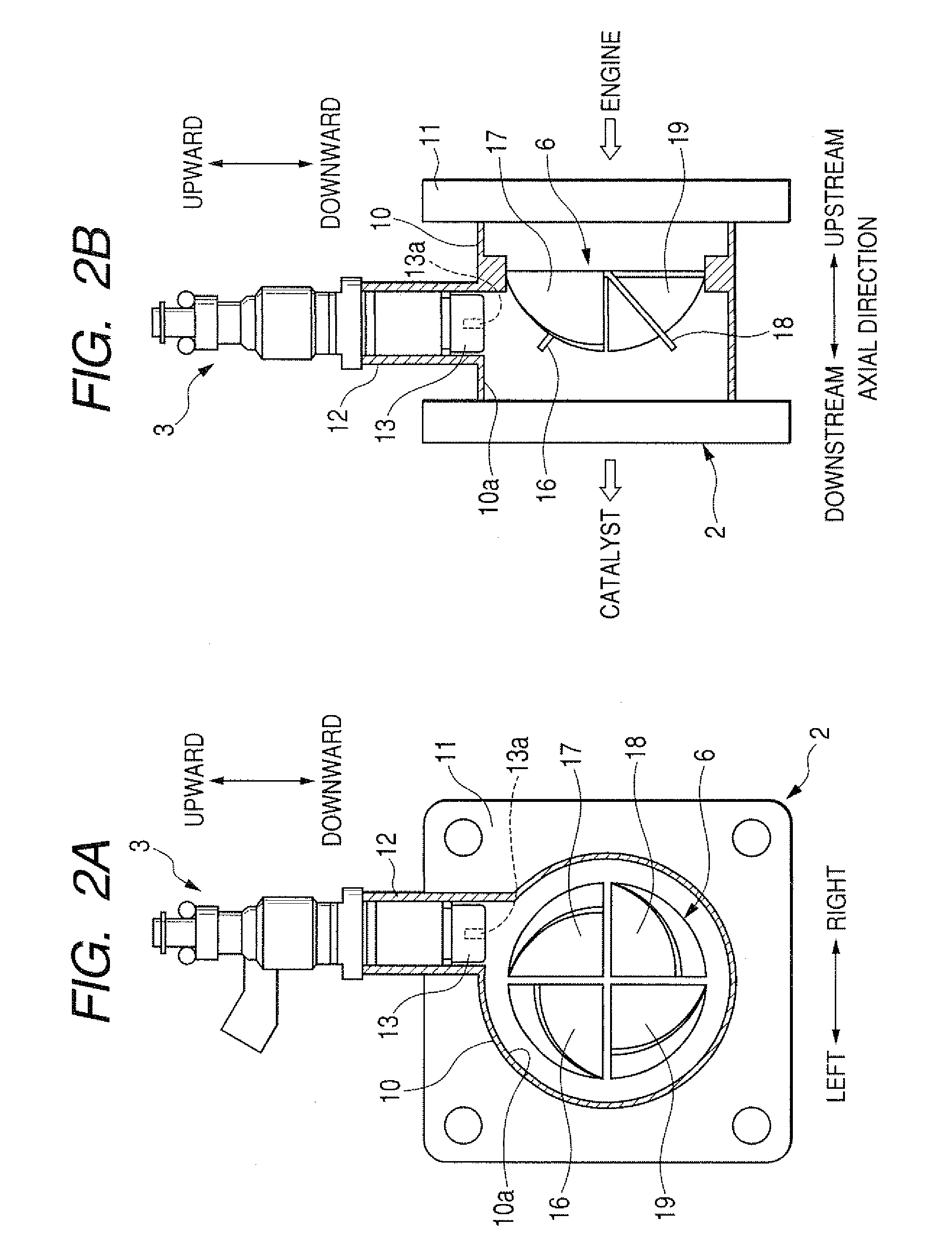

Exhaust emission control device

InactiveUS20080256931A1Improve efficiencyUniform and efficient scatteringInternal combustion piston enginesExhaust apparatusInterior spaceExhaust fumes

An exhaust emission control device includes a reducing agent adding valve for injecting a reducing agent into an exhaust pipe. The adding valve has a tip end portion having a nozzle and facing an internal space of the exhaust pipe. The tip end portion is disposed outwardly of an inner circumferential surface of the exhaust pipe. The adding valve is kept out of direct striking contact with the exhaust gas and hence is substantially free from thermal degradation and adhesion of deposits.

Owner:DENSO CORP +1

Magnetic field coil and magnetic resonance imaging apparatus

InactiveUS20080297154A1Highly efficiently and uniformly irradiateHigh sensitivityElectric/magnetic detectionMeasurements using magnetic resonanceField coilMagnetic field

Provided is an RF coil which can highly efficiently and uniformly irradiate a RF magnetic field having two or more magnetic resonance frequencies close to each other, and receive magnetic resonance signals of two or more magnetic resonance frequencies close to each other with high sensitivity and uniform sensitivity profile in an MRI apparatus. Two or more frequencies to which the coil is tuned are adjusted so as to be between resonance frequencies of series resonant circuits constituting the RF coil.

Owner:HITACHI LTD

Bearing arrangement for an axle mount of an articulated vehicle

InactiveUS20070269150A1Uniform and efficient distributionLess stressRolling contact bearingsSliding contact bearingsConvex sideEngineering

A bearing arrangement includes a hinge pin and a ring rotatably mounted on an outer surface of the hinge pin. The hinge pin has a spherical convex surface on which a spherical concave surface of the ring can ride. In a bearing having a pin and a ring that is rotatable about an outer surface of the pin, the pin has a spherical convex surface that extends around an outer surface of the pin, and the ring has a corresponding spherical concave surface that extends around an inner surface of the ring. In a method for articulably mounting an axle to a vehicle, a ring having a spherical concave surface is assembled around a hinge pin having a spherical convex surface such that the spherical concave surface and the spherical convex surface engage. A split housing is assembled around the outer surfaces of the ring.

Owner:ROLLER BEARING OF AMERICA

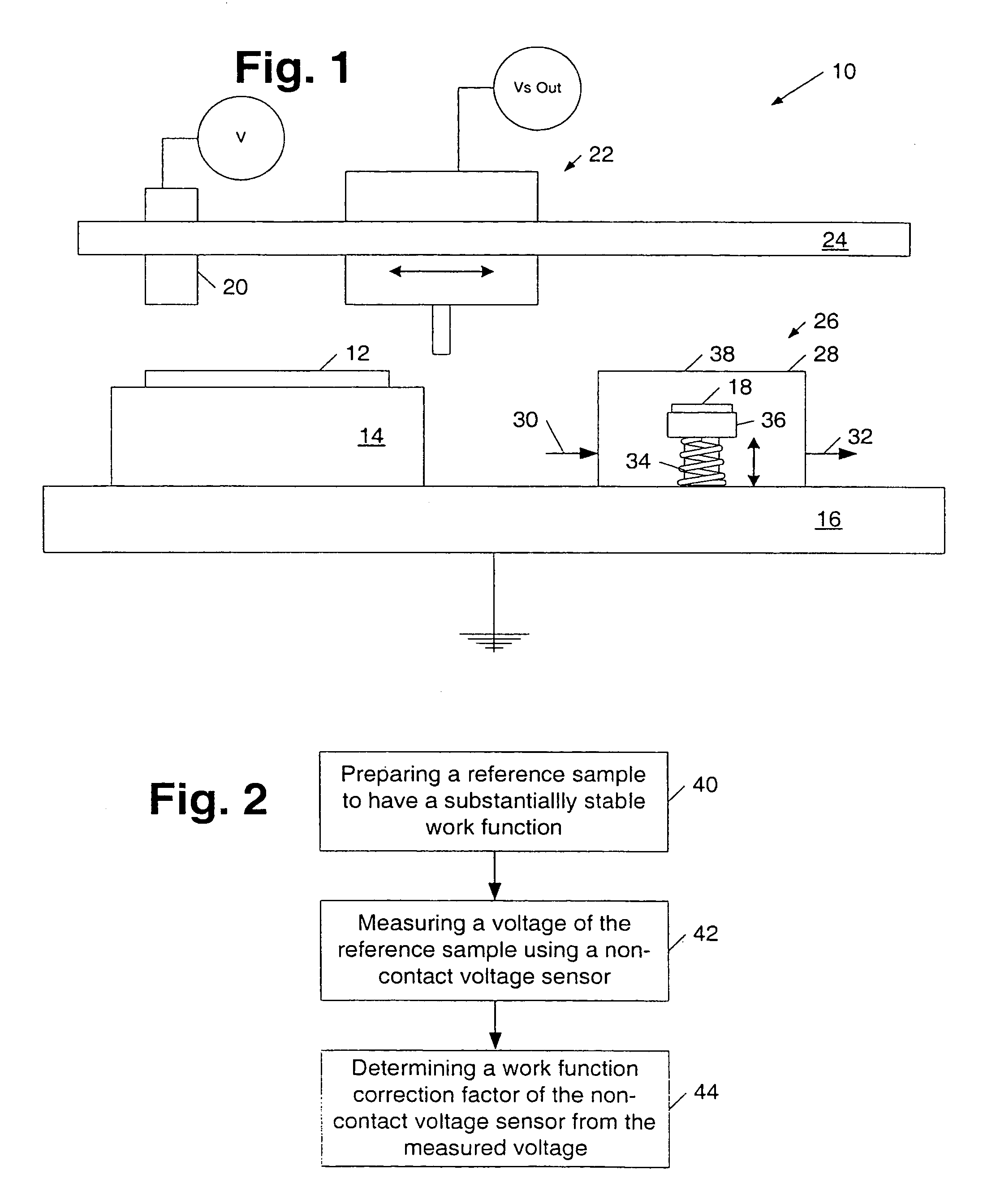

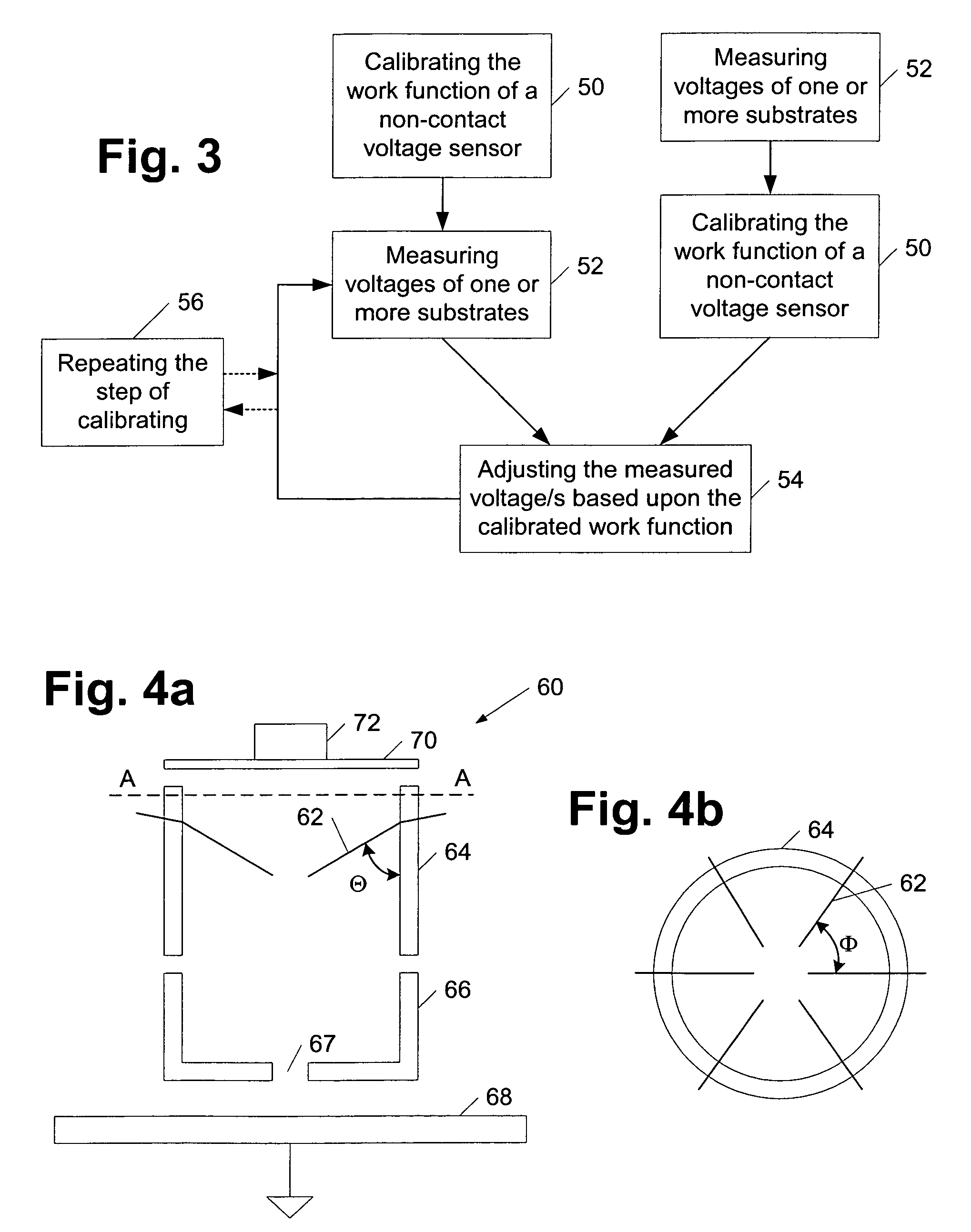

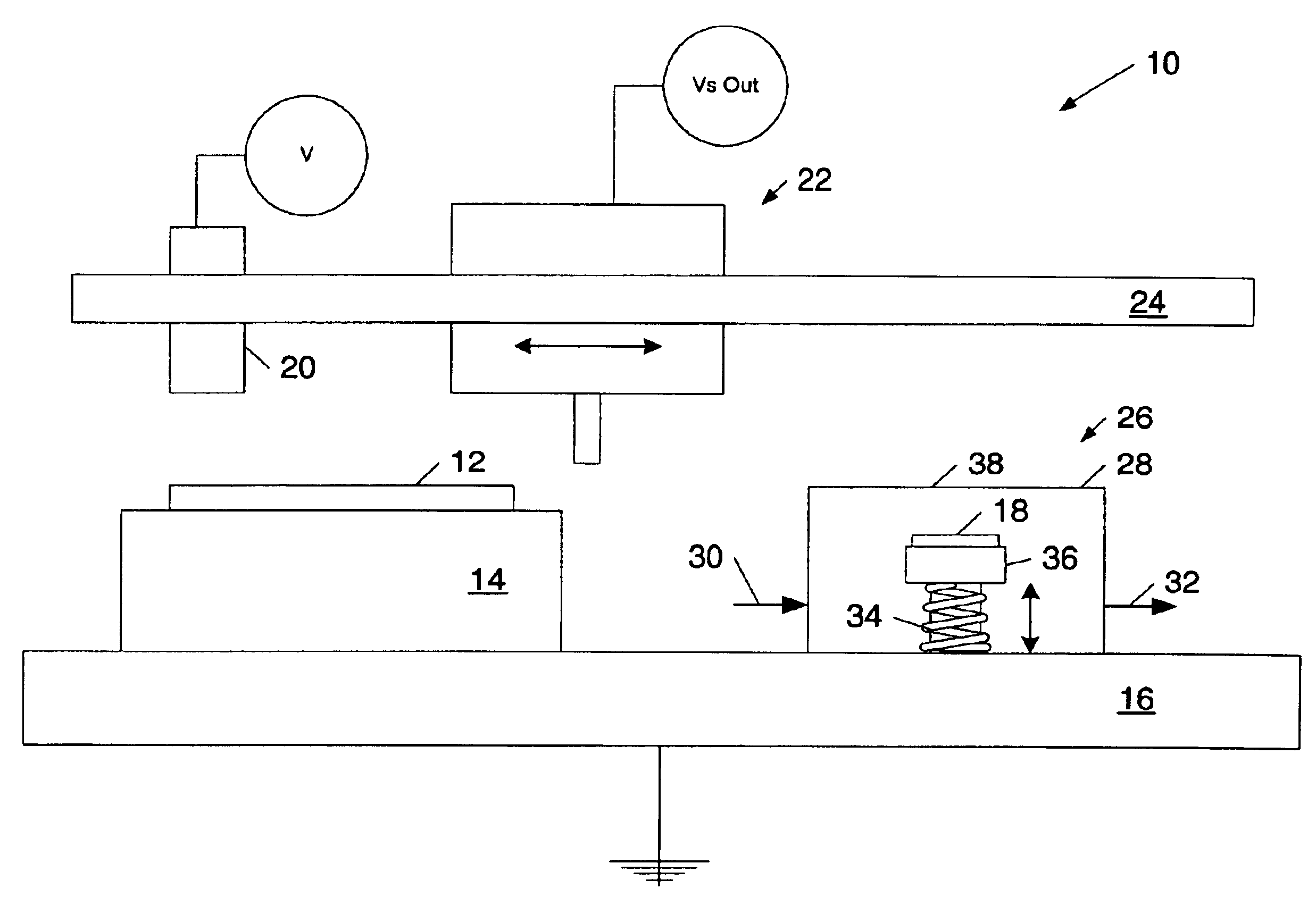

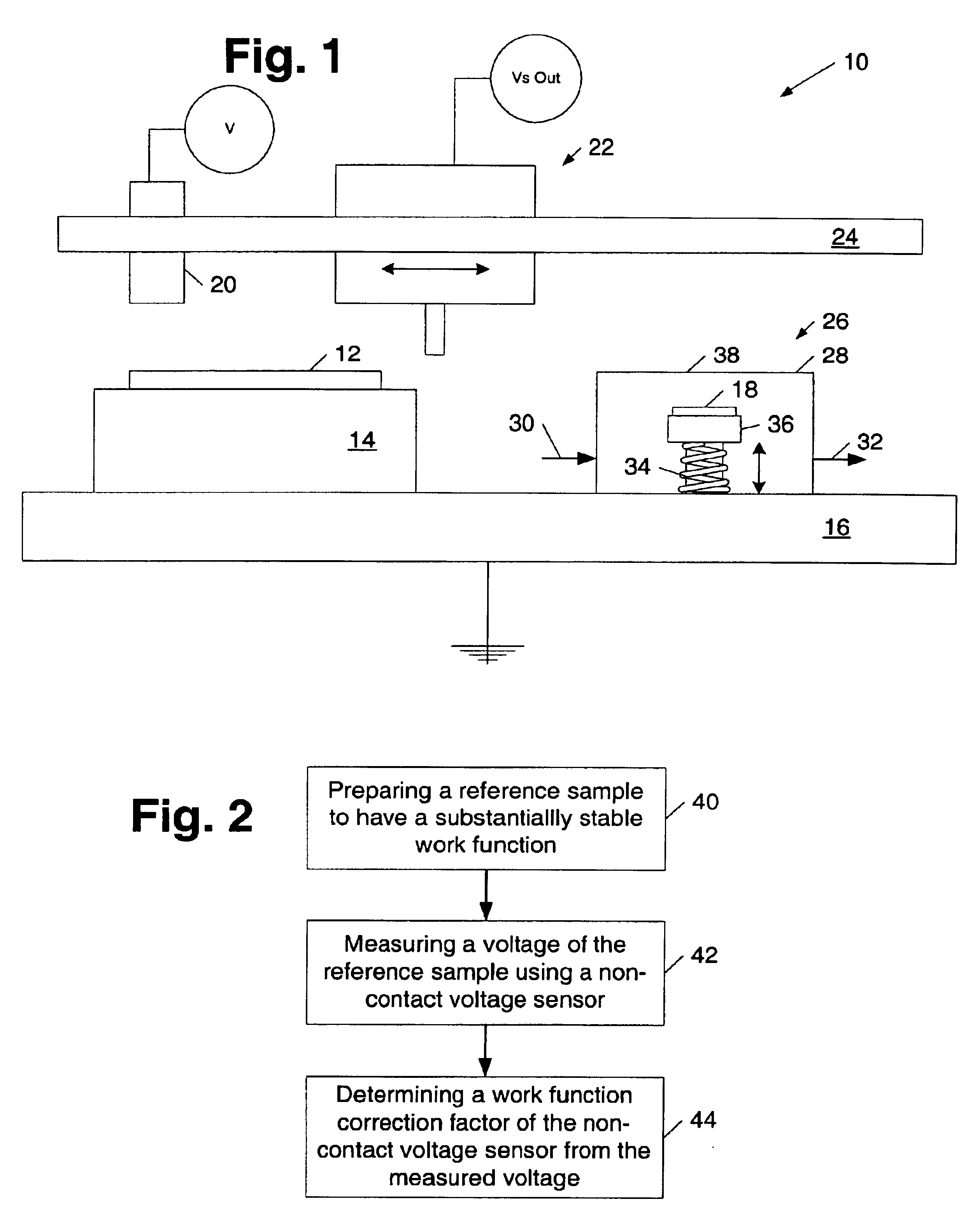

Systems and methods for using non-contact voltage sensors and corona discharge guns

InactiveUS7110238B1Accurate measurementAccurate valueMaterial work function voltageRelaysReference sampleWork function

A method and a system for calibrating the work function of a non-contact voltage sensor are provided. The method includes preparing a reference sample to have a stable work function, measuring a voltage of the sample using a non-contact voltage sensor, and determining a work function correction factor of the sensor from the measured voltage. In turn, the calibrated work function may be used to adjust voltages of substrates measured by the sensor. A corona gun which includes a first electrode and one or more conductive rods is provided. In some embodiments, the conductive rods may be angled between 0 and 90 degrees with respect to a first electrode sidewall and / or be concentrically arranged less than 90 degrees from each other. In addition or alternatively, the corona gun may be adapted to alter its length and / or include a second electrode partially inset within a space surrounded by the first electrode.

Owner:KLA TENCOR TECH CORP

Systems and methods for using non-contact voltage sensors and corona discharge guns

InactiveUS6909291B1Accurate measurementAccurate valueElectrical testingMaterial work function voltageReference sampleWork function

A method and a system for calibrating the work function of a non-contact voltage sensor are provided. The method includes preparing a reference sample to have a stable work function, measuring a voltage of the sample using a non-contact voltage sensor, and determining a work function correction factor of the sensor from the measured voltage. In turn, the calibrated work function may be used to adjust voltages of substrates measured by the sensor. A corona gun which includes a first electrode and one or more conductive rods is provided. In some embodiments, the conductive rods may be angled between 0 and 90 degrees with respect to a first electrode sidewall and / or be concentrically arranged less than 90 degrees from each other. In addition or alternatively, the corona gun may be adapted to alter its length and / or include a second electrode partially inset within a space surrounded by the first electrode.

Owner:KLA TENCOR TECH CORP

Device For Delivery Of Agents To And Through The Human Scalp

InactiveUS20090036845A1Efficiently and uniformlyPharmaceutical delivery mechanismCurling devicesScalpMinoxidil

Owner:SMITH DAVID A

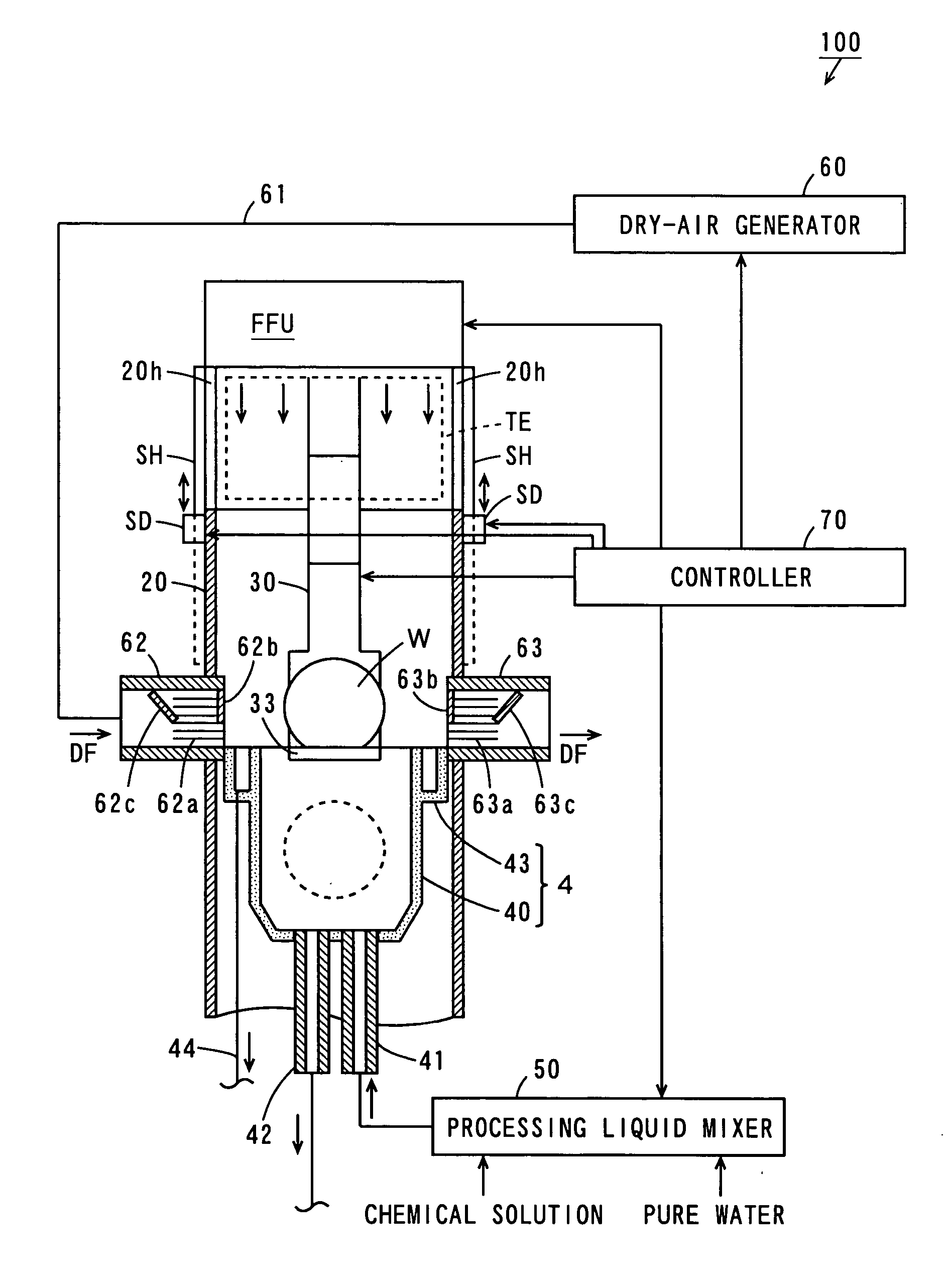

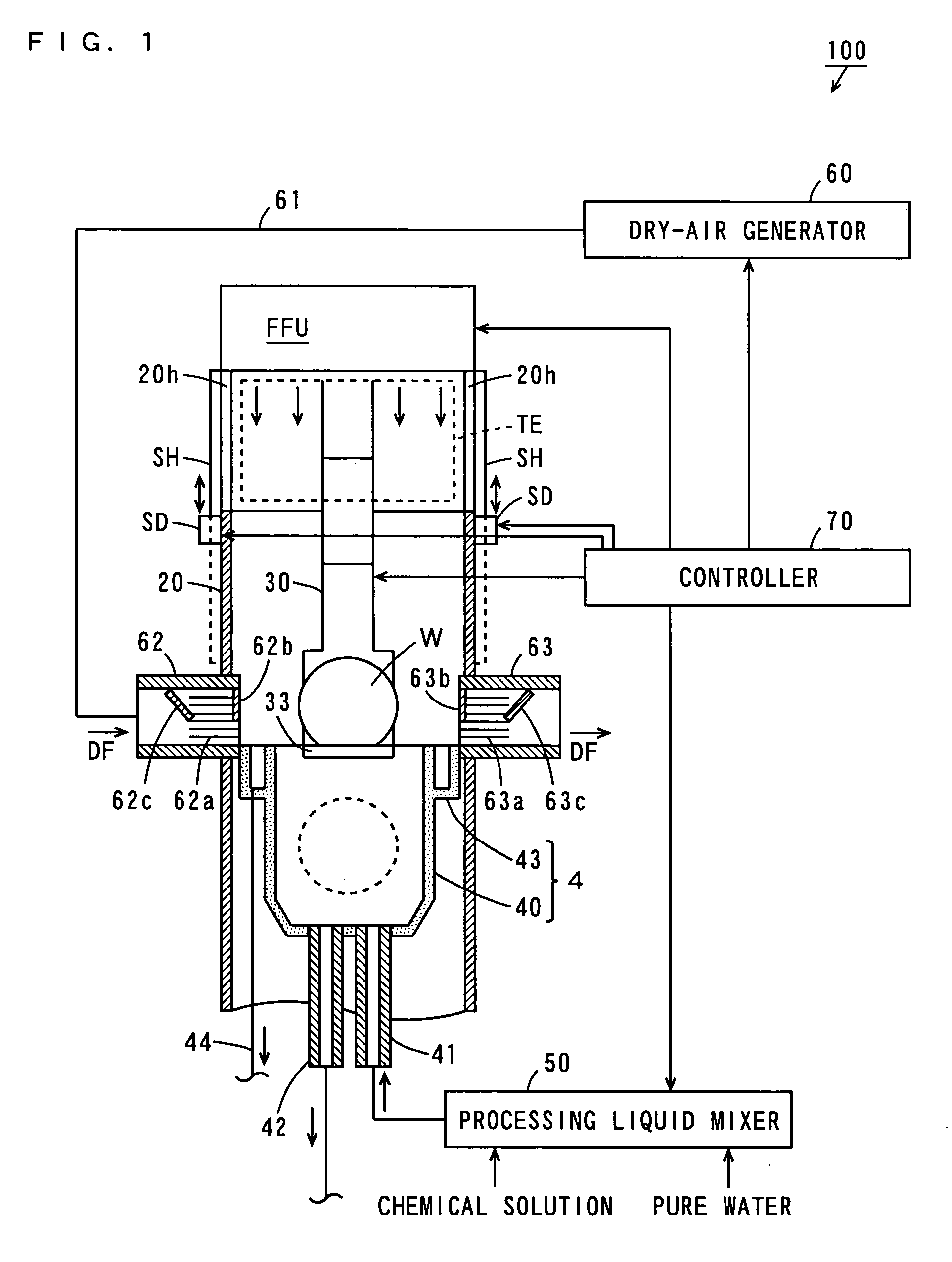

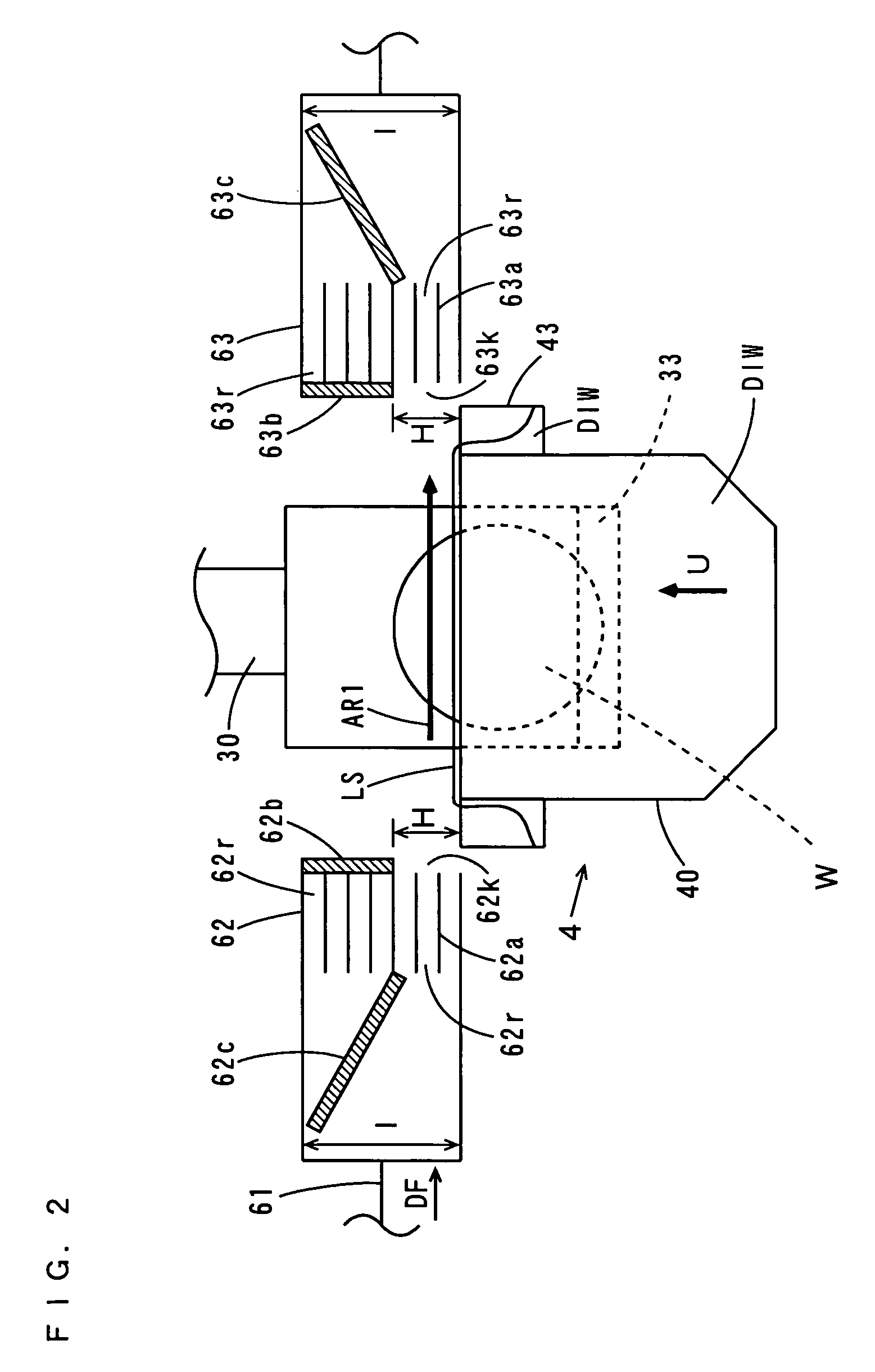

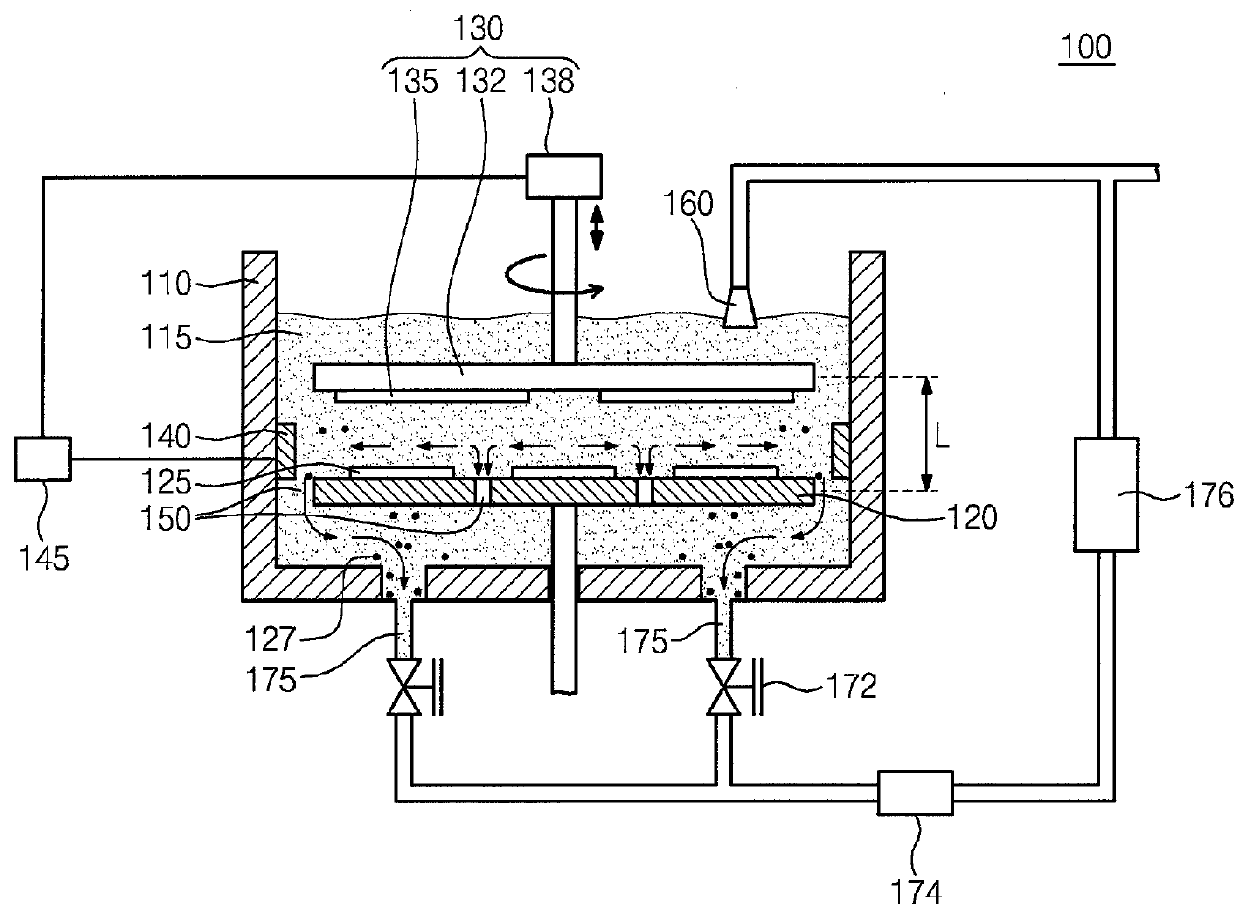

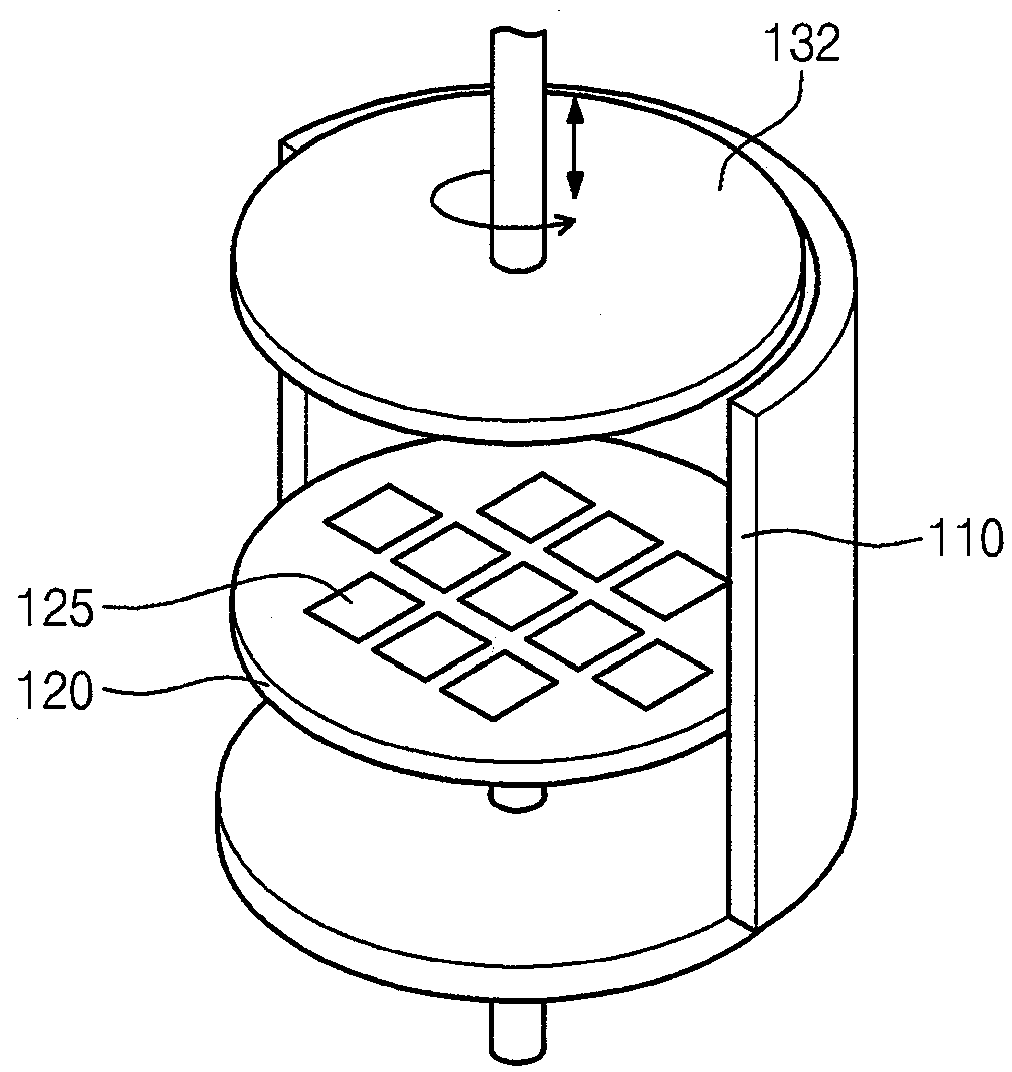

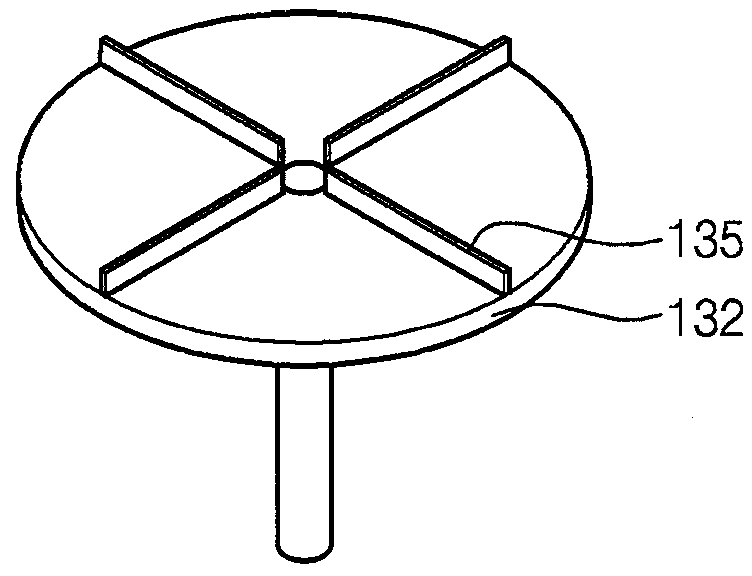

Substrate processing apparatus

InactiveUS20060219274A1Efficiently and uniformlyUniform and efficient dryingSemiconductor/solid-state device manufacturingCleaning using liquidsEngineeringMechanical engineering

A dry-air supplying duct and a dry-air exhaust duct are opposite each other across a processing tank. Inside the dry-air supplying duct, a plurality of ventilation guides are provided that extend horizontally by a predetermined length from an end of the dry-air supplying duct, and a plurality of ventilation paths are formed by the plurality of ventilation guides. To an end of the dry-air supplying duct, a partition plate is attached such that it blocks a part of the plurality of ventilation paths. Also inside the dry-air supplying duct, a partition plate is attached such that it blocks a part of the plurality of ventilation paths. These partition plates are disposed in upper part of the dry-air supplying duct. As a result, an opening for injection of dry air is formed in a lower part of the dry-air supplying duct.

Owner:DAINIPPON SCREEN MTG CO LTD

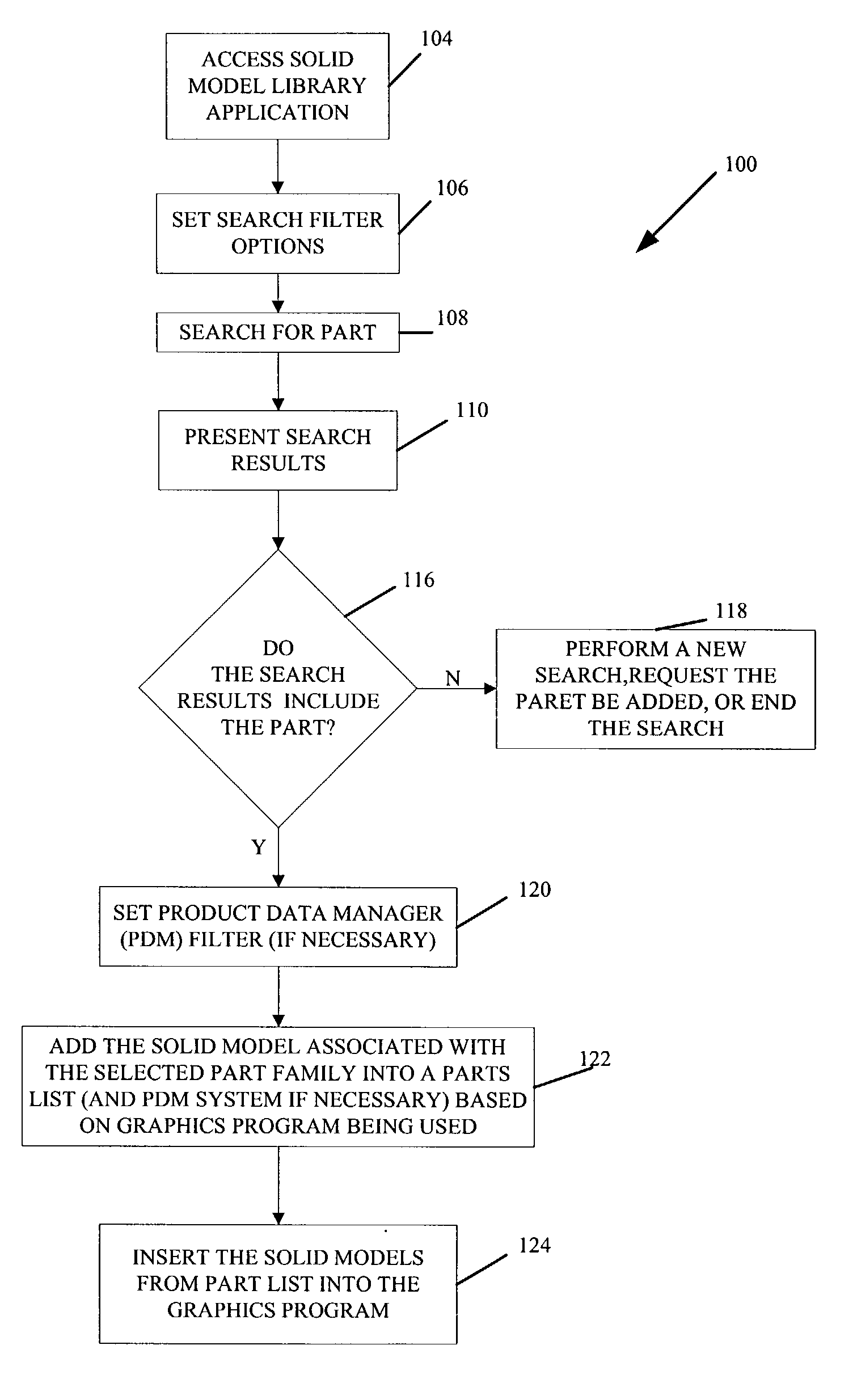

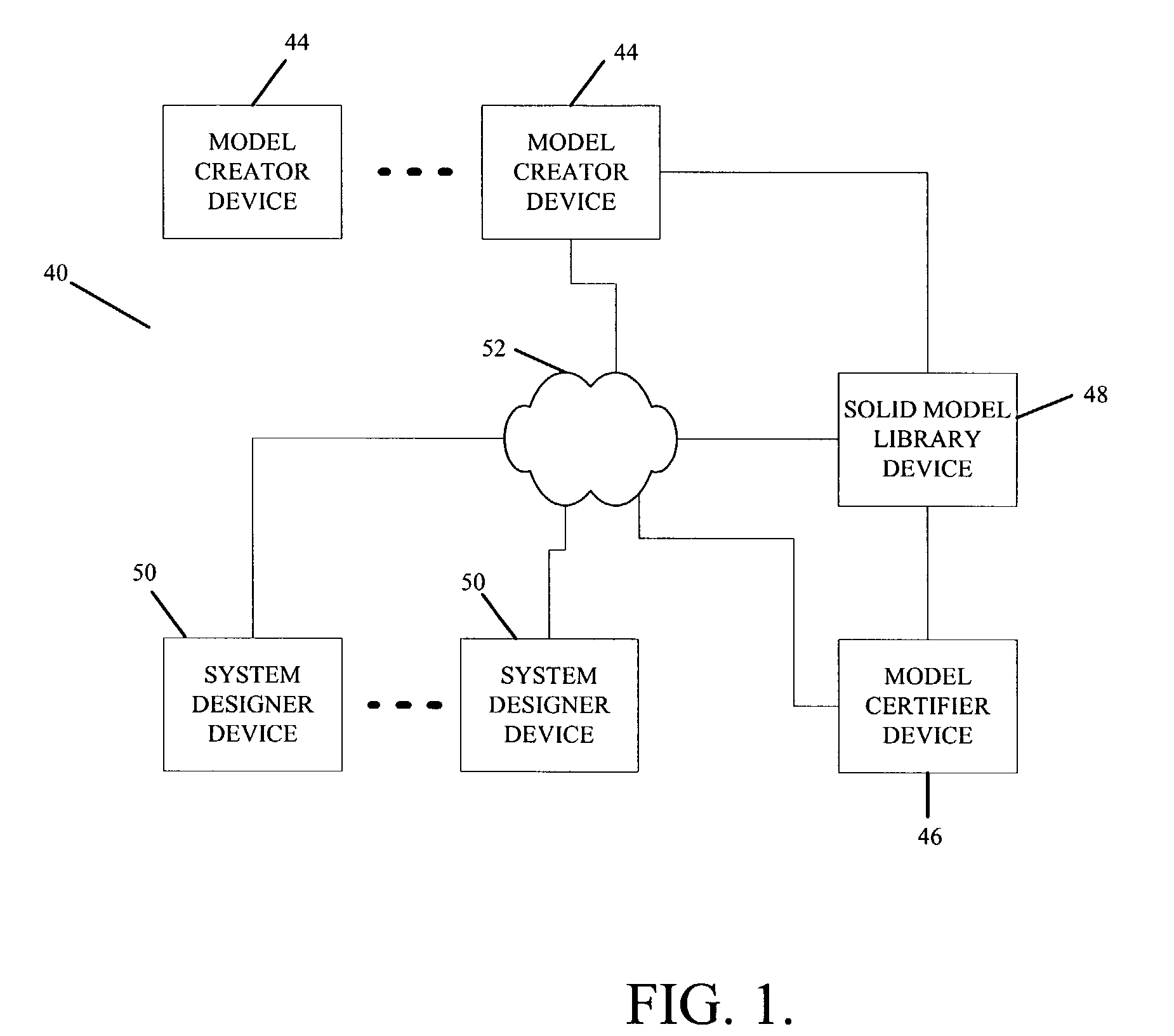

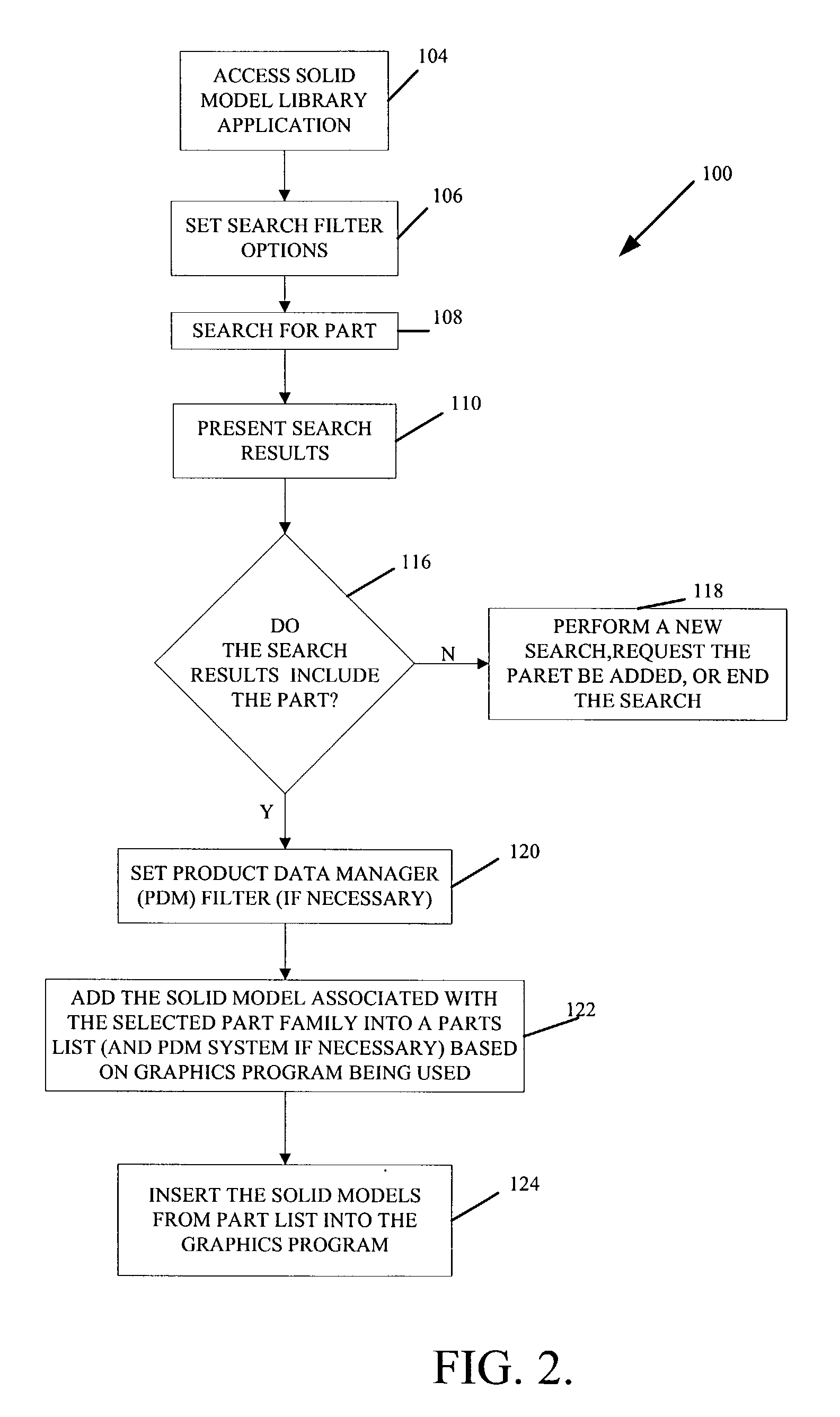

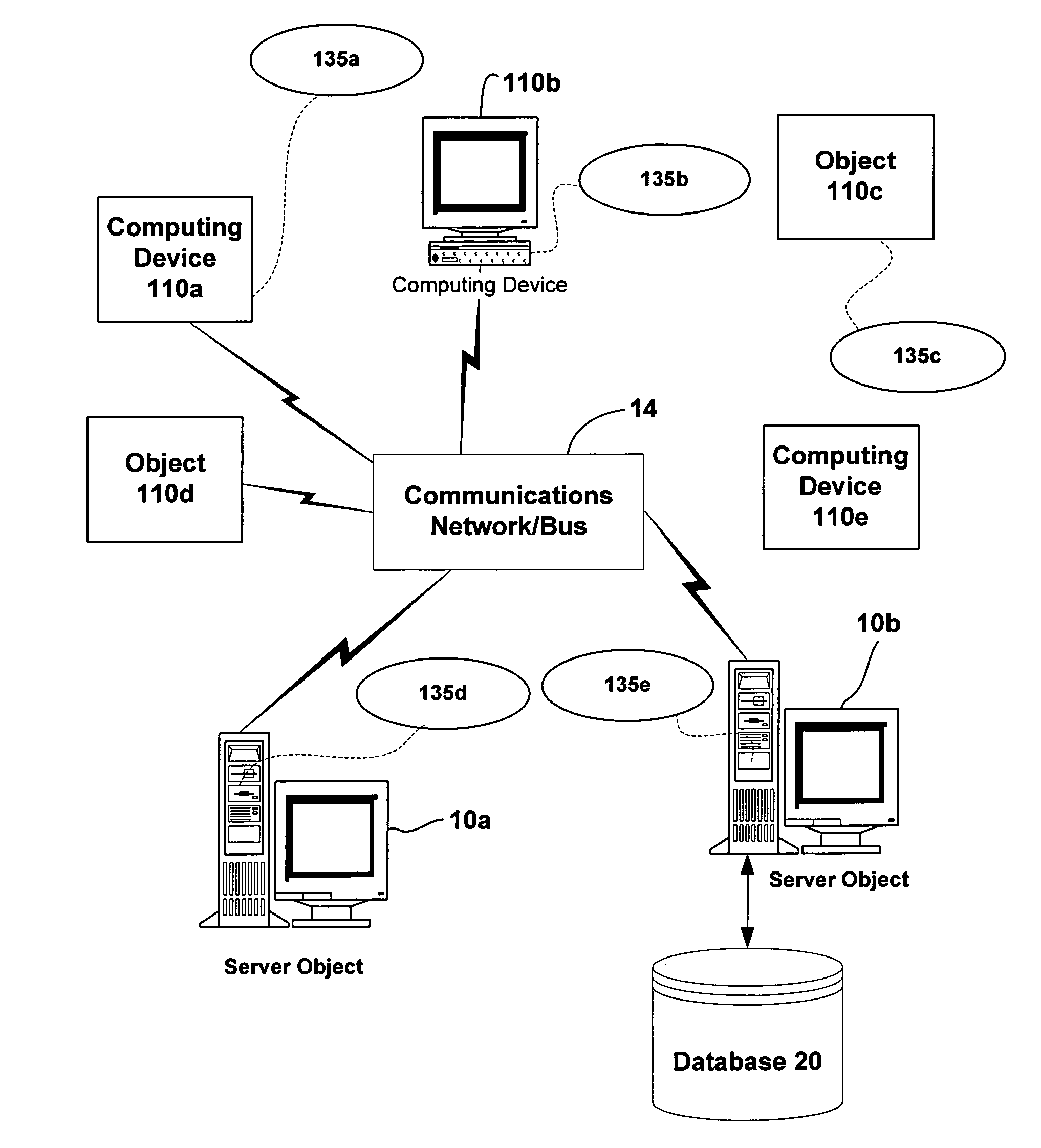

Central based computer network of solid models and associated data with search capability

InactiveUS7469242B2Efficiently and uniformlyDigital data processing detailsElectric controllersComputer Aided DesignData file

The present invention is a network-based system and method for providing a centrally controlled single source location for storing electronic data (including but not limited to part information such as Computer Aided Designed [CAD] solid models, associated textual data, images, mathematical algorithms, and links to associative websites) to be accessed by users creating various products / designs using various application programs. The system includes a central computer system and a plurality of user computer systems coupled to a network. The central computer system stores a plurality of computer solid models. From a user computer system, a user accesses an application program run by the central computer system in order to search and retrieve the stored data files (solid models).

Owner:THE BOEING CO

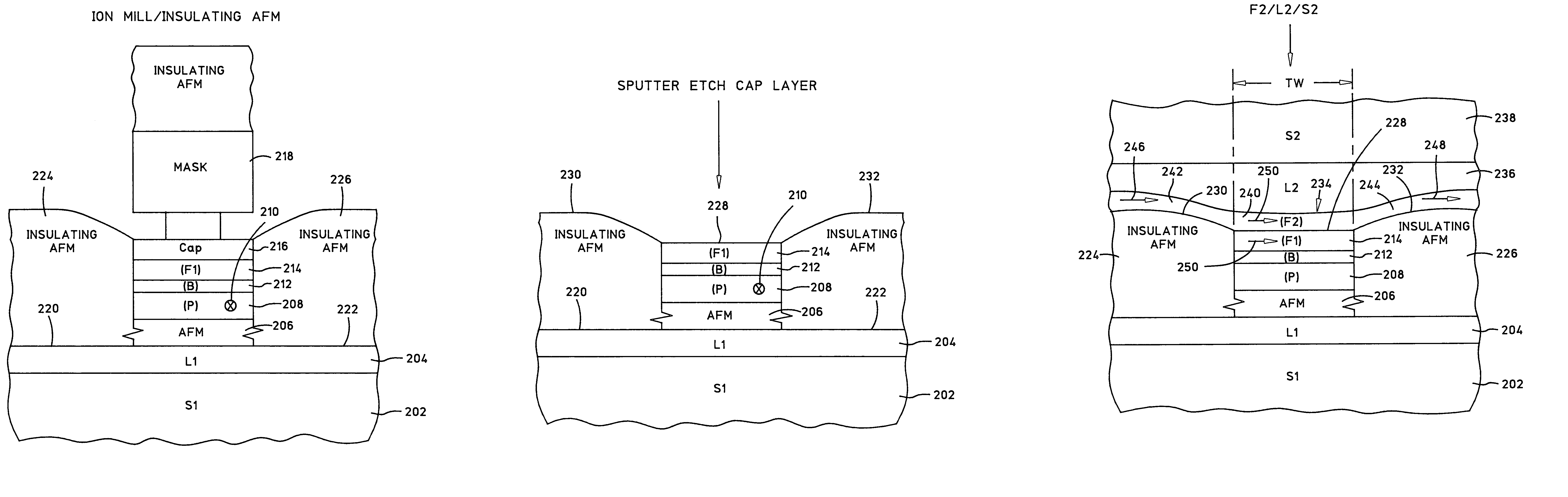

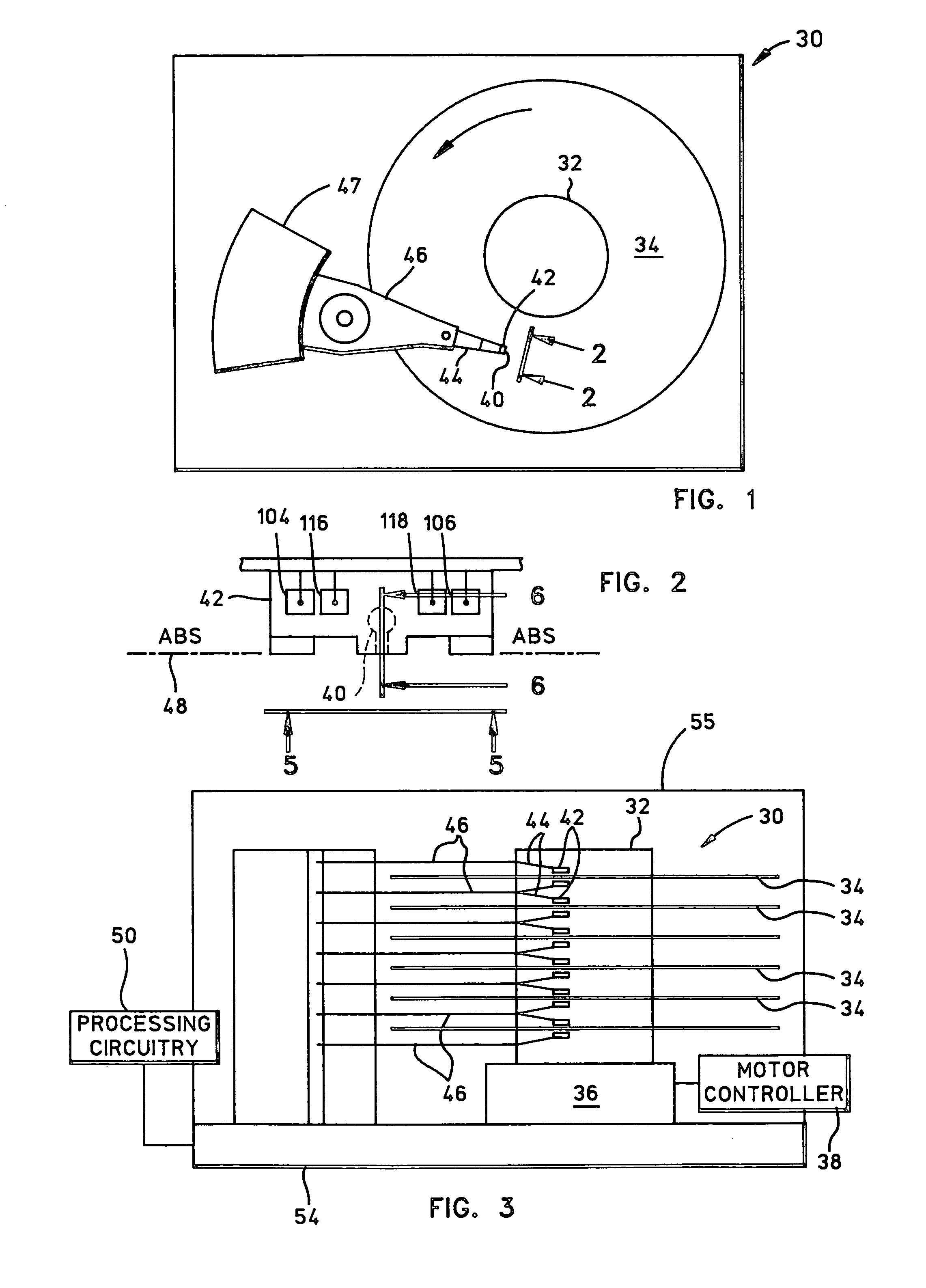

Method of making a read head having a tunnel junction sensor with a free layer biased by exchange coupling with insulating antiferromagnetic (AFM) layers

InactiveUS7054117B2Efficiently and uniformlyNanomagnetismElectrical transducersTunnel junctionMagnetic moment

Longitudinal biasing of a free layer in a current perpendicular to the planes of the layers (CPP) type of sensor in a read head is implemented by pinning magnetic moments of first and second side portions of the free layer beyond the track width of the read head with first and second insulating antiferromagnetic (AFM) layers which are exchange coupled thereto. The pinning of the magnetic moments of the first and second side portions of the free layer pin and longitudinally bias the central active portion of the free layer within the track width so that the central portion of the free layer is magnetically stable.

Owner:IBM CORP

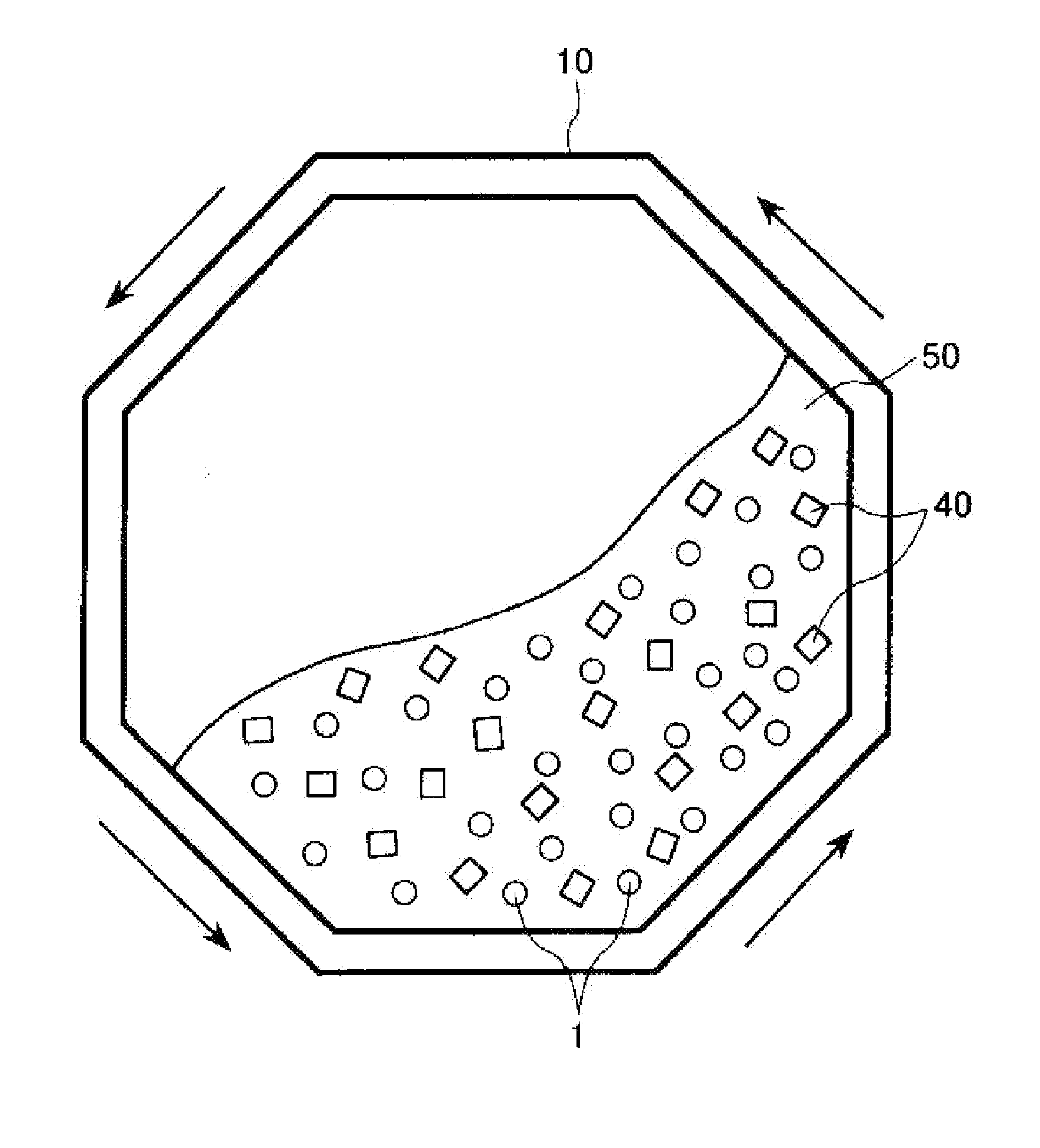

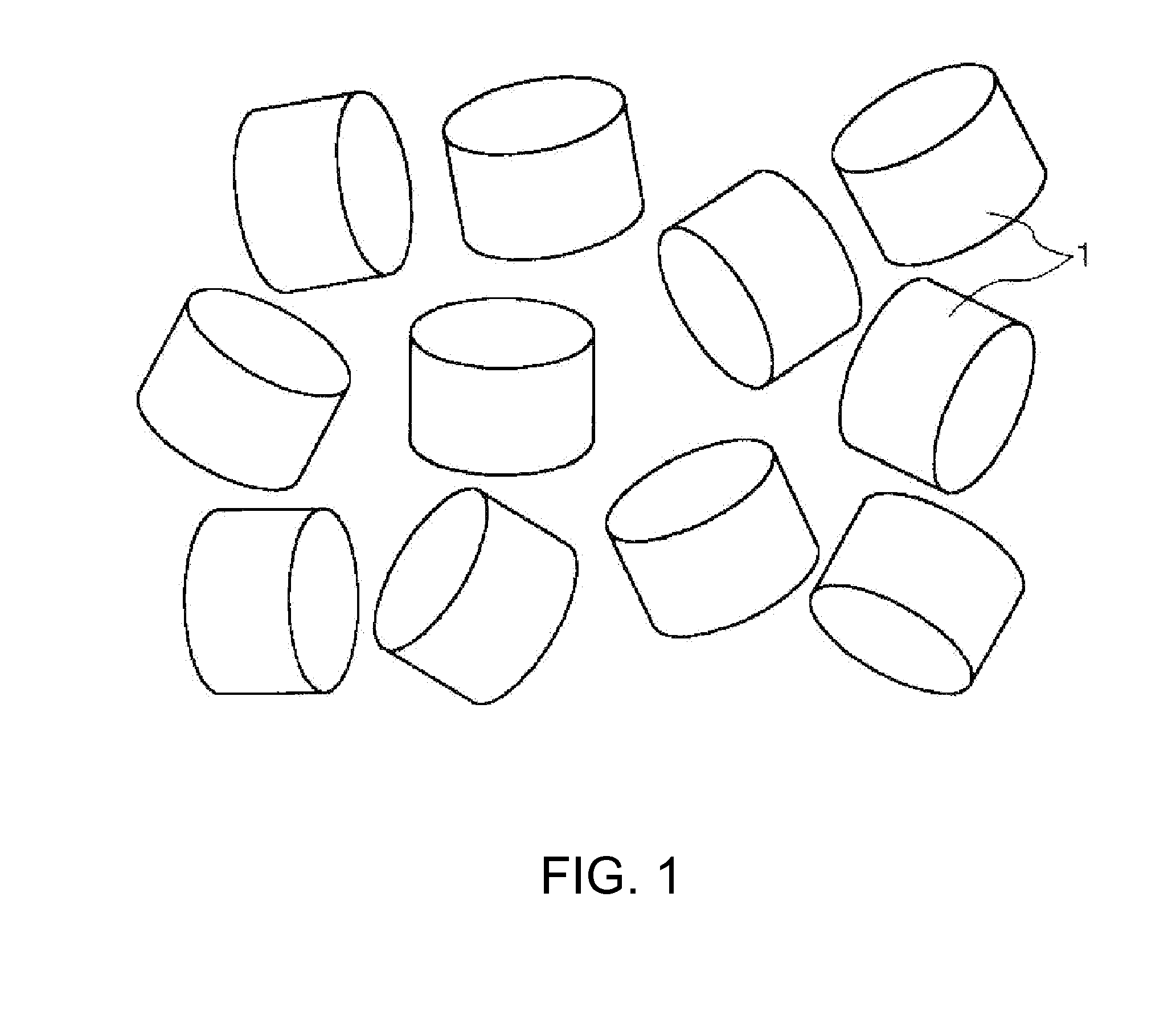

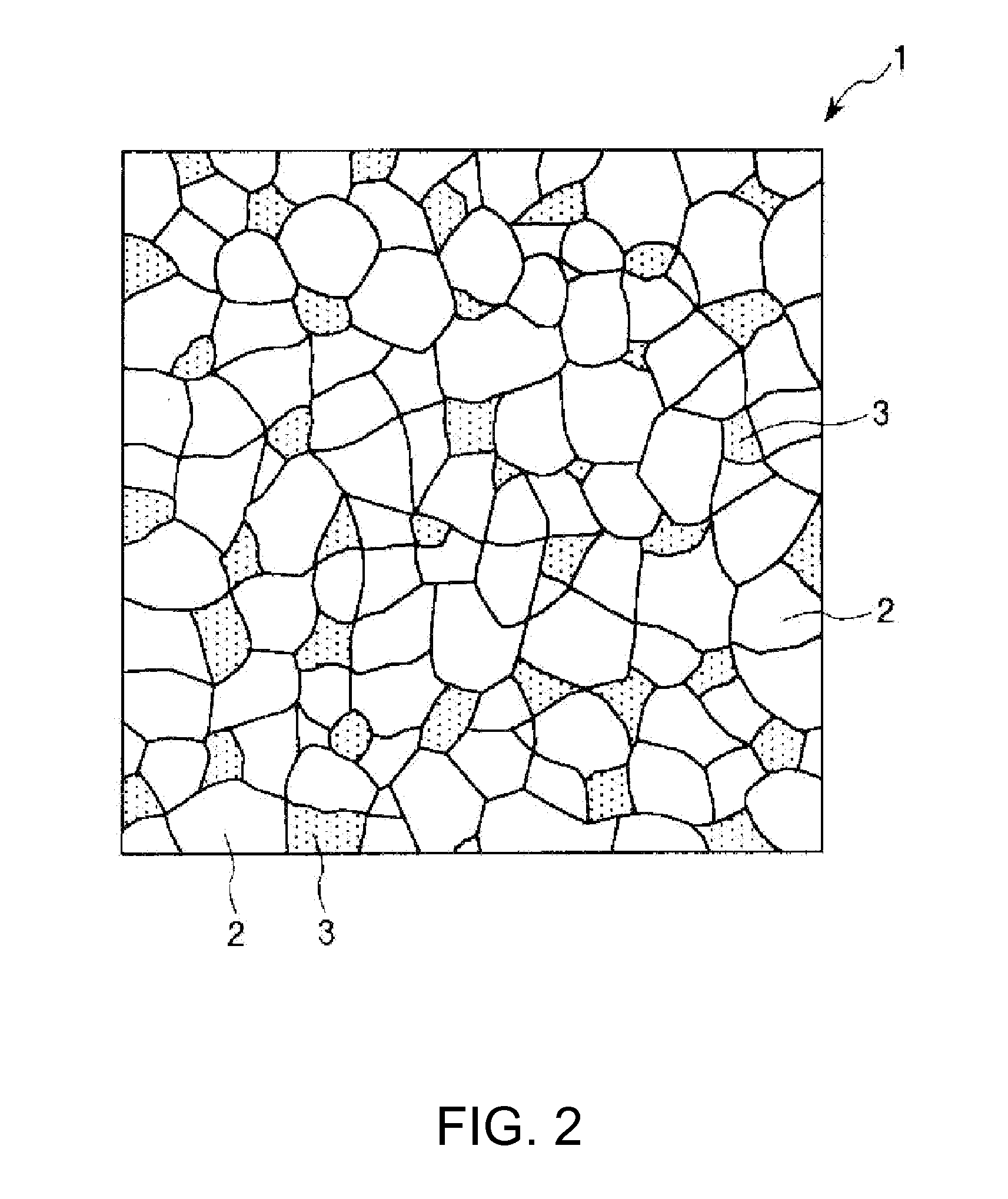

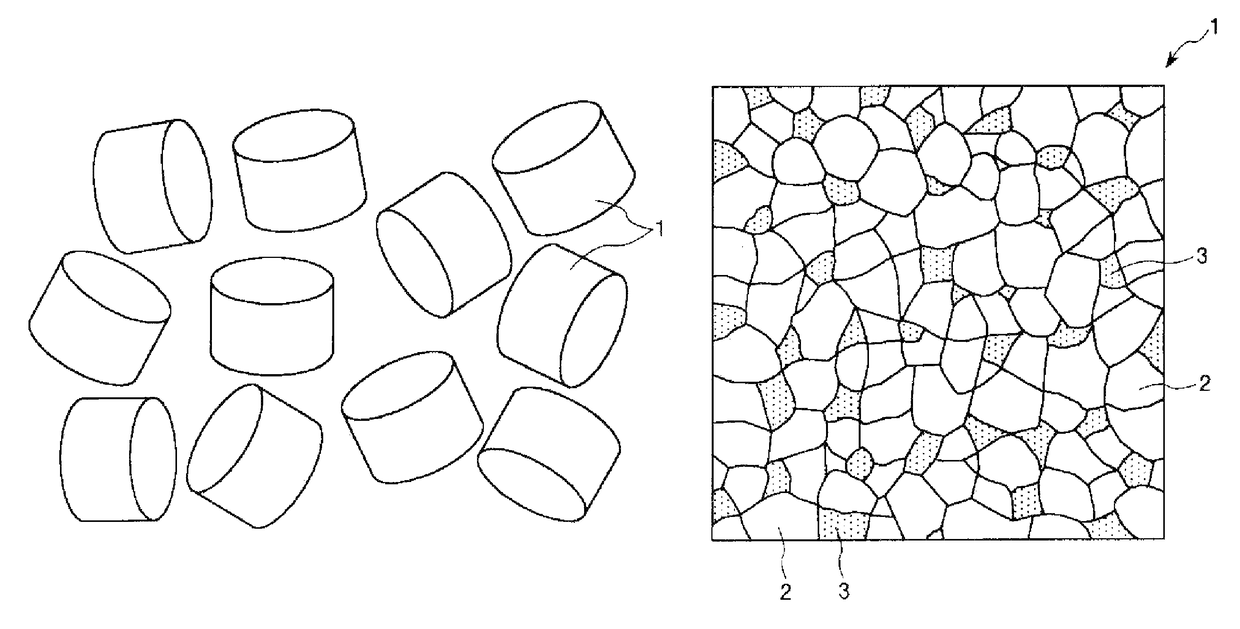

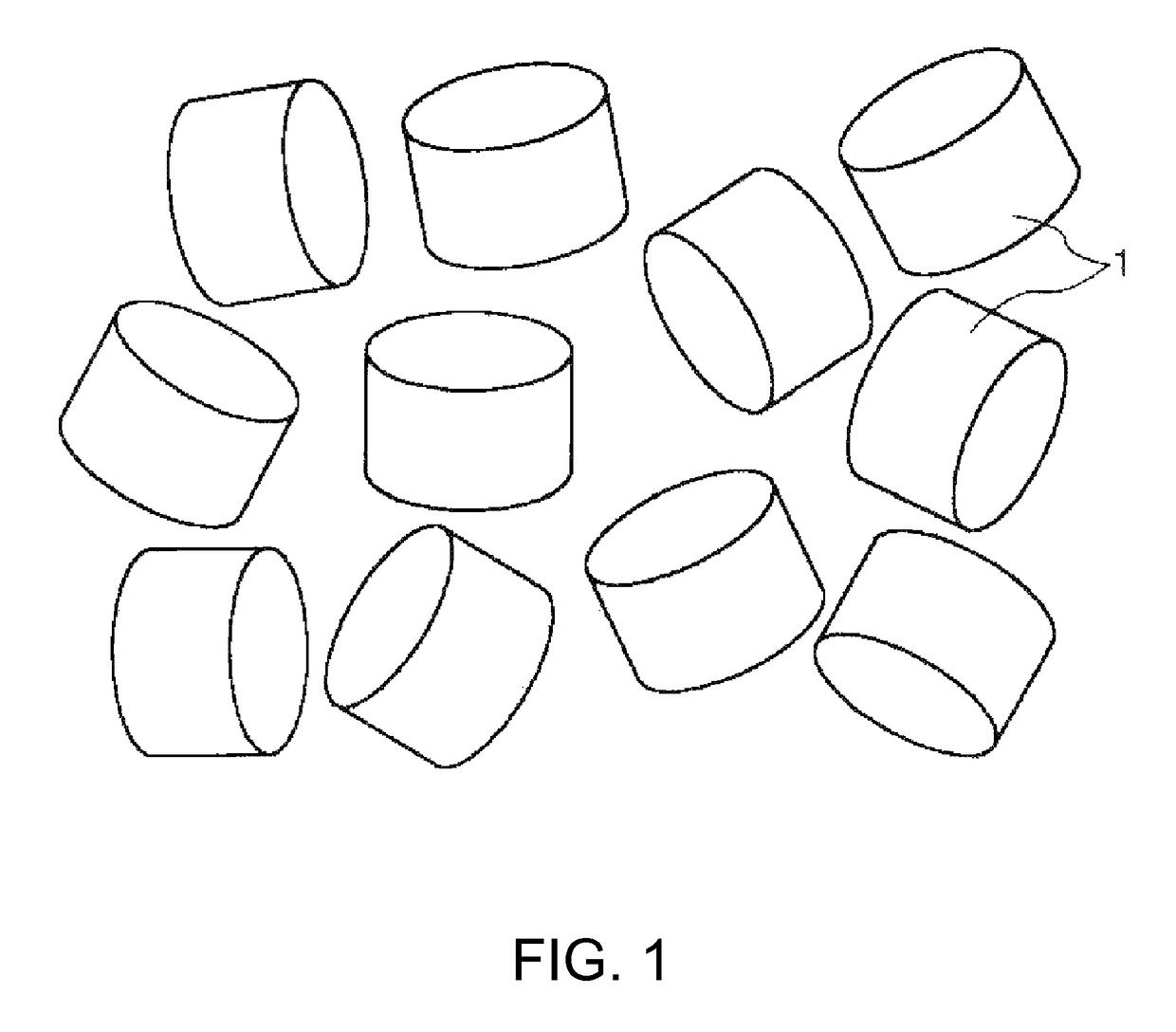

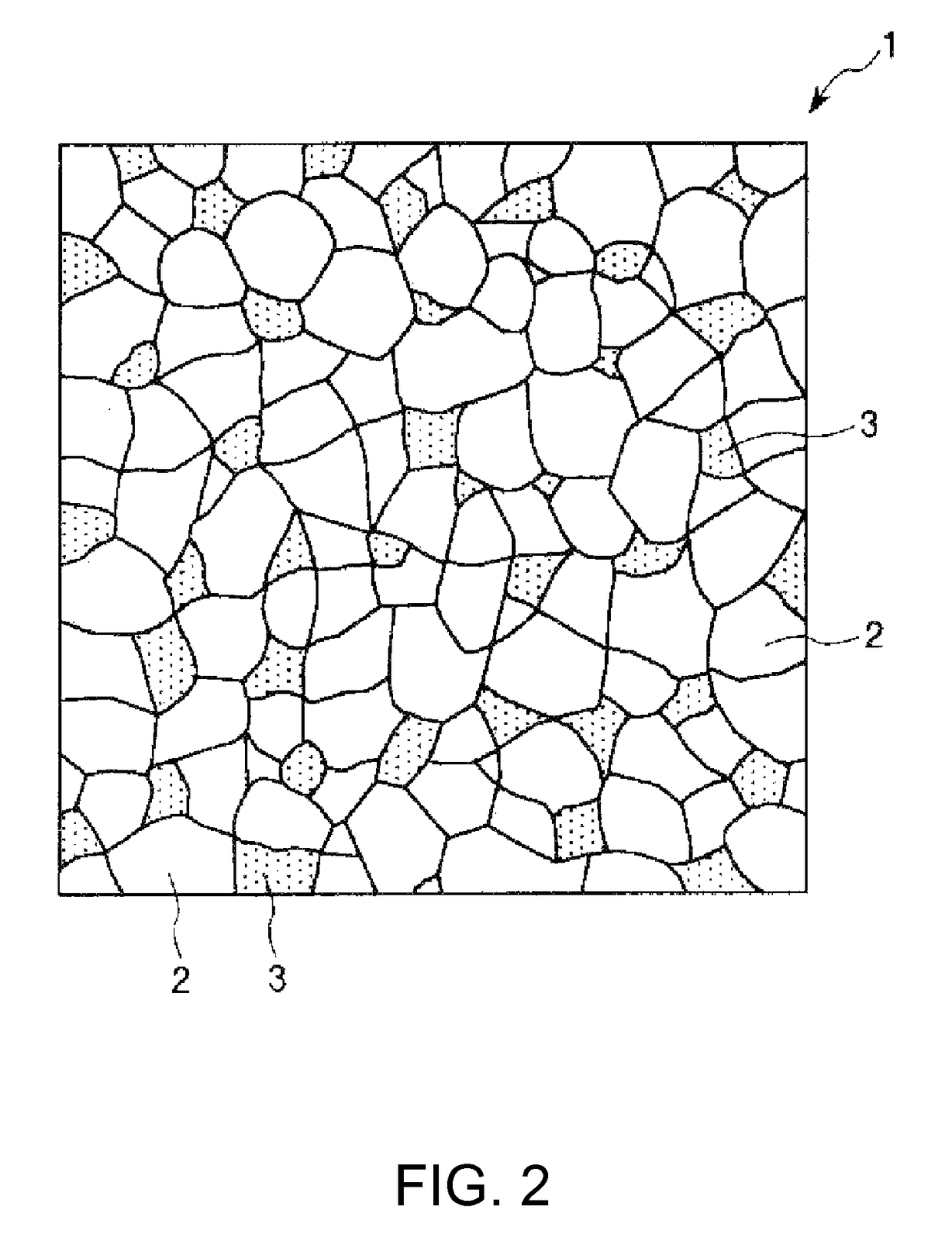

Polishing media, method for producing polishing media, and polishing method

ActiveUS20120252322A1High strengthEfficient productionPigmenting treatmentPolishing machinesShell moldingMetal powder

A polishing media is formed of a sintered body in which a metal structure and a ceramic structure are intermingled with each other. The polishing media is preferably produced by molding a mixed powder of a metal powder and a ceramic powder by an injection molding method and sintering the resulting molded article. Further, the ceramic structure is preferably formed of aluminum oxide, and the metal structure is preferably formed of tungsten.

Owner:SEIKO EPSON CORP

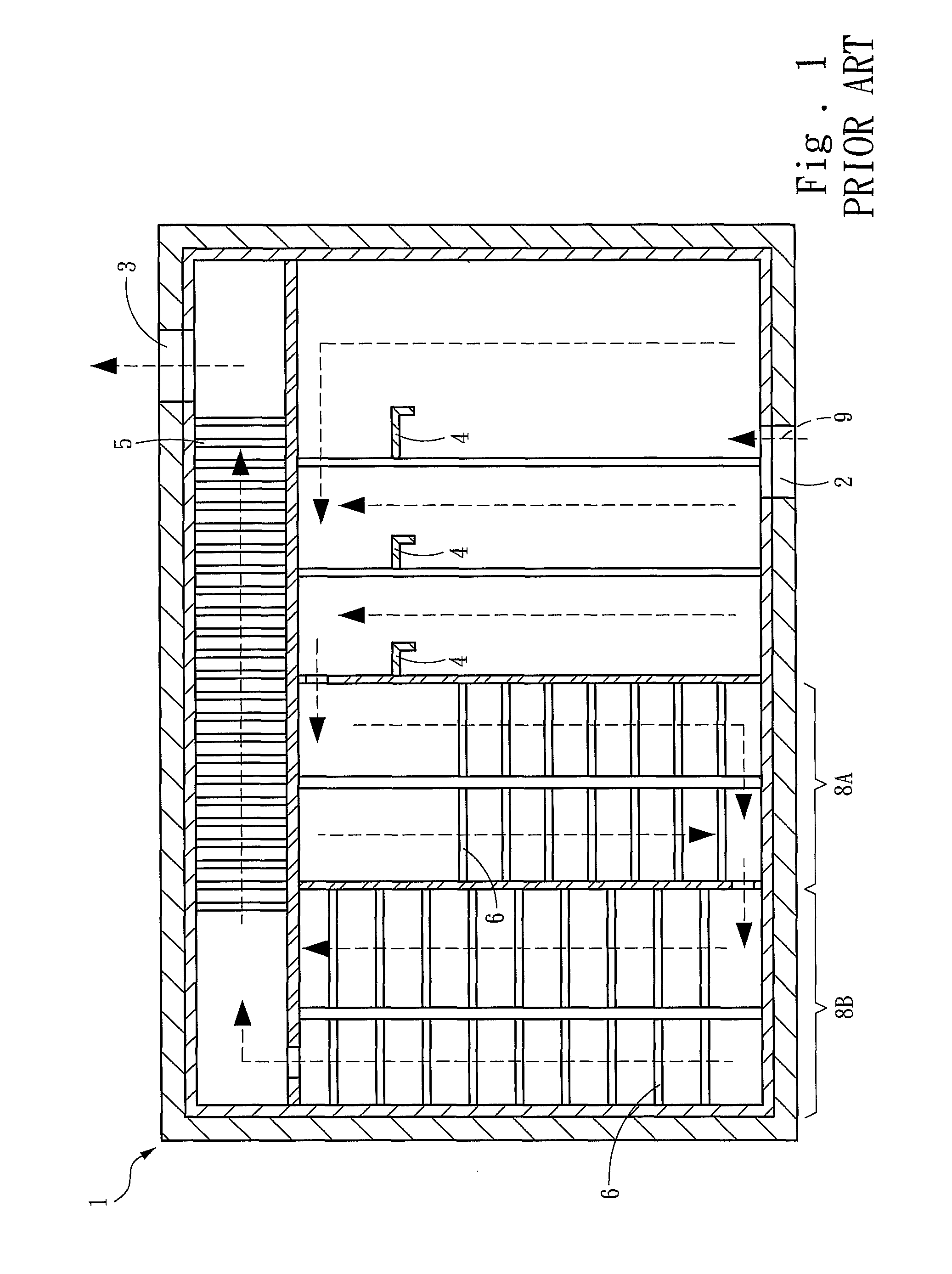

Method of effecting heating and cooling in reduced pressure atmosphere

InactiveUS20050029243A1Shorten cooling timeShorten heating timeDrying solid materials with heatMuffle furnacesIn planeEmissivity

The present invention provides a method of effecting high temperature vacuum heating and cooling suitable for conducting heat treatment to be performed on components used in a display apparatus. The present invention's heating / cooling method comprises the steps of: heating a plate-like member placed in a reduced pressure atmosphere in a chamber by heating means opposed to the plate-like member; and cooling the plate-like member by a cooling plate which is opposed to the plate-like member, with the heating means therebetween, the cooling plate having a heat reflecting function. In one aspect of the present invention, the cooling plate is designed to have a emissivity of not less than 0.50 but not more than 0.80 so as to minimizes a sum of a requisite time for the heating step and a requisite time for the cooling step. In another aspect of the present invention, the plate-like member to be heated has two main surfaces differing from each in an in-plane distribution of emissivity and the heating means is opposed to one of the two main surfaces, which has a smaller distribution ratio, thereby realizing uniform and efficient heating / cooling.

Owner:CANON KK

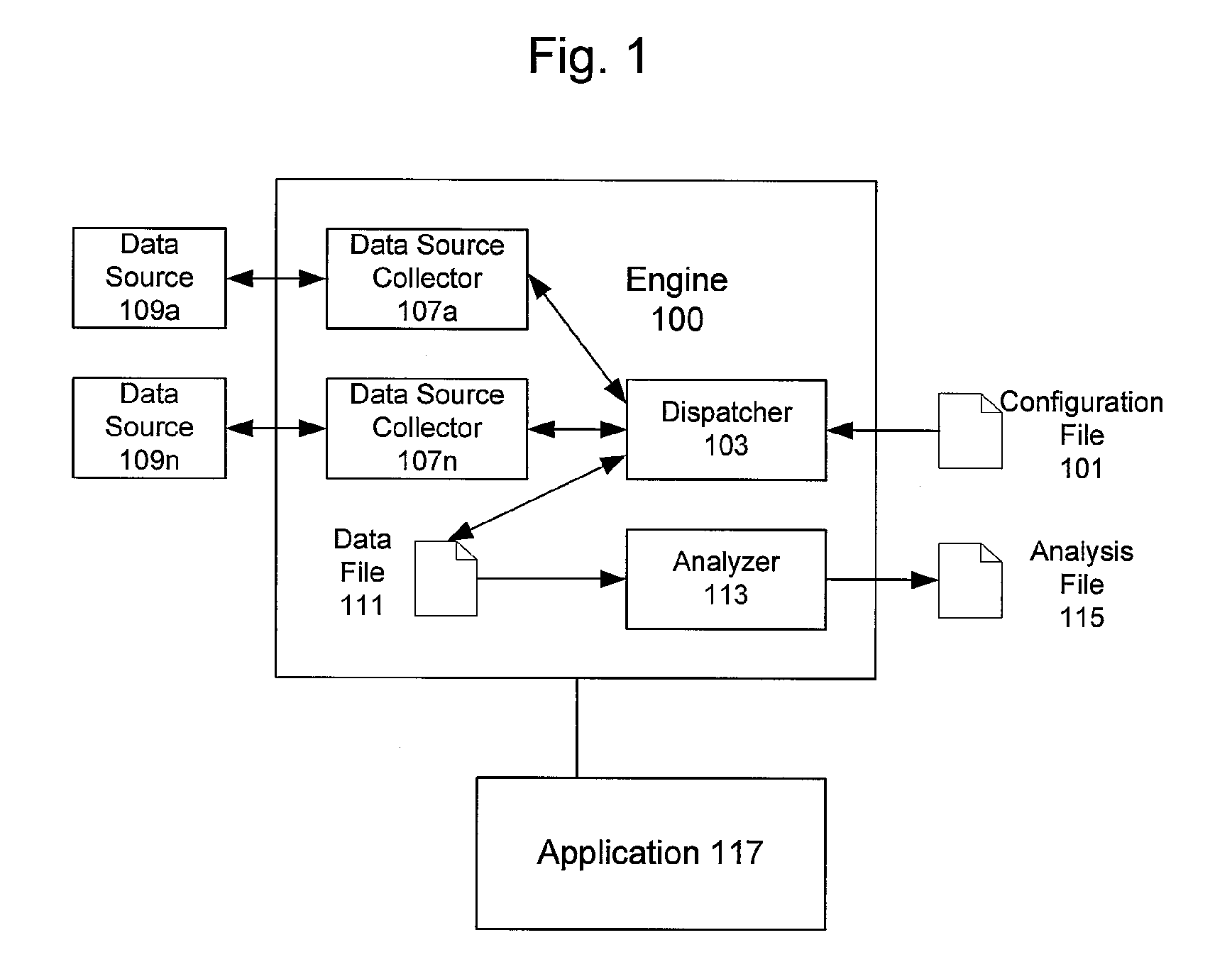

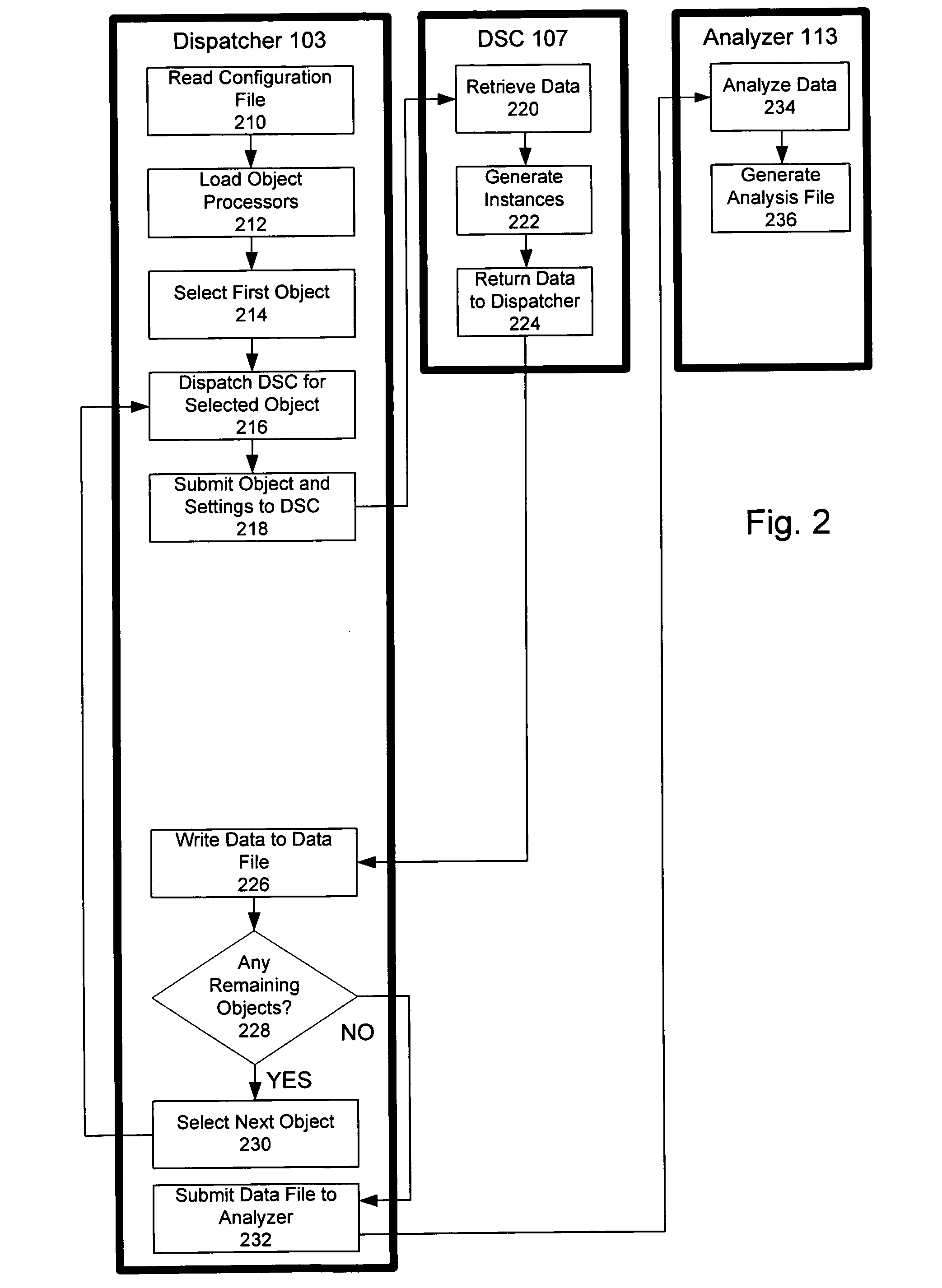

System and method for retrieving and analyzing data from a variety of different sources

InactiveUS7457809B2Efficiently and uniformlyEfficient methodData processing applicationsDatabase queryingAnalysis dataData source

A flexible, extensible, uniform, and efficient framework for retrieving and analyzing data from a number of different data sources is disclosed. Instructions for retrieving and analyzing data are provided in a configuration file that is defined in a common format irrespective of the different data sources. The configuration file is submitted to a dispatcher, which uses the information therein to dispatch a number of data source collectors. Each such data source collector is unique to a corresponding data source and is able to formulate an efficient method for retrieving the necessary data from its corresponding data source. An analyzer then analyzes the retrieved data according to the instructions in the configuration file.

Owner:MICROSOFT TECH LICENSING LLC

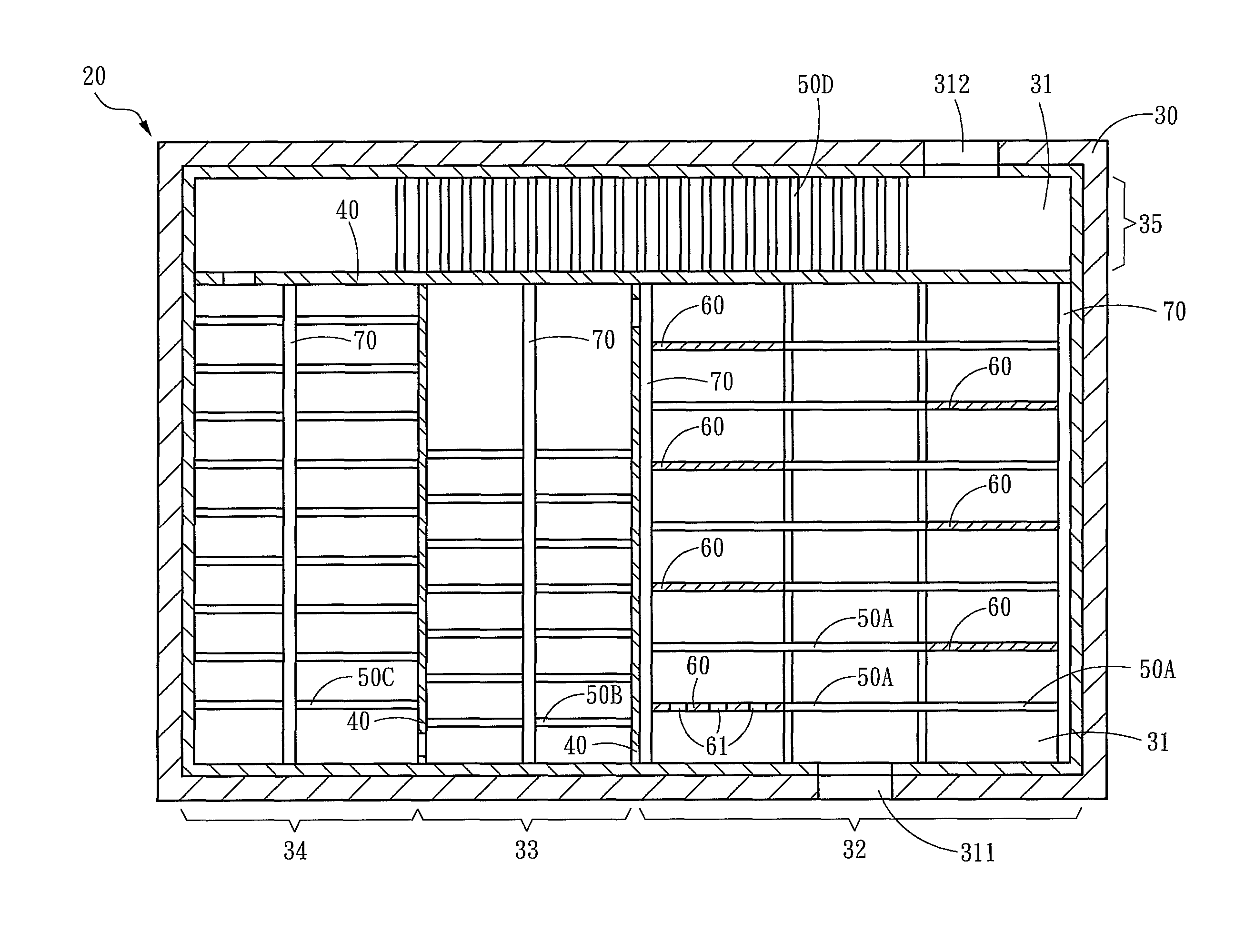

Apparatus of etching glass substrate

ActiveUS20120103520A1Efficiently and uniformlySemiconductor/solid-state device manufacturingLapping machinesMarine engineering

An apparatus for etching a glass substrate includes a vessel configured to contain an etchant; a first plate in the vessel and configured to receive a horizontally placed glass substrate thereon; and a circulating unit in the vessel facing the first plate and configured to create a flow of the etchant on a side of the first plate.

Owner:SAMSUNG DISPLAY CO LTD

Dust collector

ActiveUS8679213B2Extended service lifeAir flow easily pour into air flow channelDispersed particle separationSuperimpositionEngineering

A dust collector for catching dust generated by temperature drop comprises a box, a plurality of separating boards, a plurality of catch boards, and a plurality of baffle boards. The separating boards partition the box to form an air flow channel. The catch boards and the baffle boards are staggered in the air flow channel; a portion of the catch boards are arranged in a central column to form a superimposition region along the vertical direction. The pores of the catch boards in the superimposition region are overlapped to make the air flow pour into the air flow channel easily. The baffle boards are staggered at the left or right of the catch boards, whereby the air flow takes more time to have a longer travel in the air flow channel, and dust is not accumulated in a single area but uniformly caught by the catch boards.

Owner:MICRON TECH INC

Polishing media, method for producing polishing media, and polishing method

ActiveUS9597767B2High strengthEfficient productionEdge grinding machinesPigmenting treatmentShell moldingMetal powder

A polishing media is formed of a sintered body in which a metal structure and a ceramic structure are intermingled with each other. The polishing media is preferably produced by molding a mixed powder of a metal powder and a ceramic powder by an injection molding method and sintering the resulting molded article. Further, the ceramic structure is preferably formed of aluminum oxide, and the metal structure is preferably formed of tungsten.

Owner:SEIKO EPSON CORP

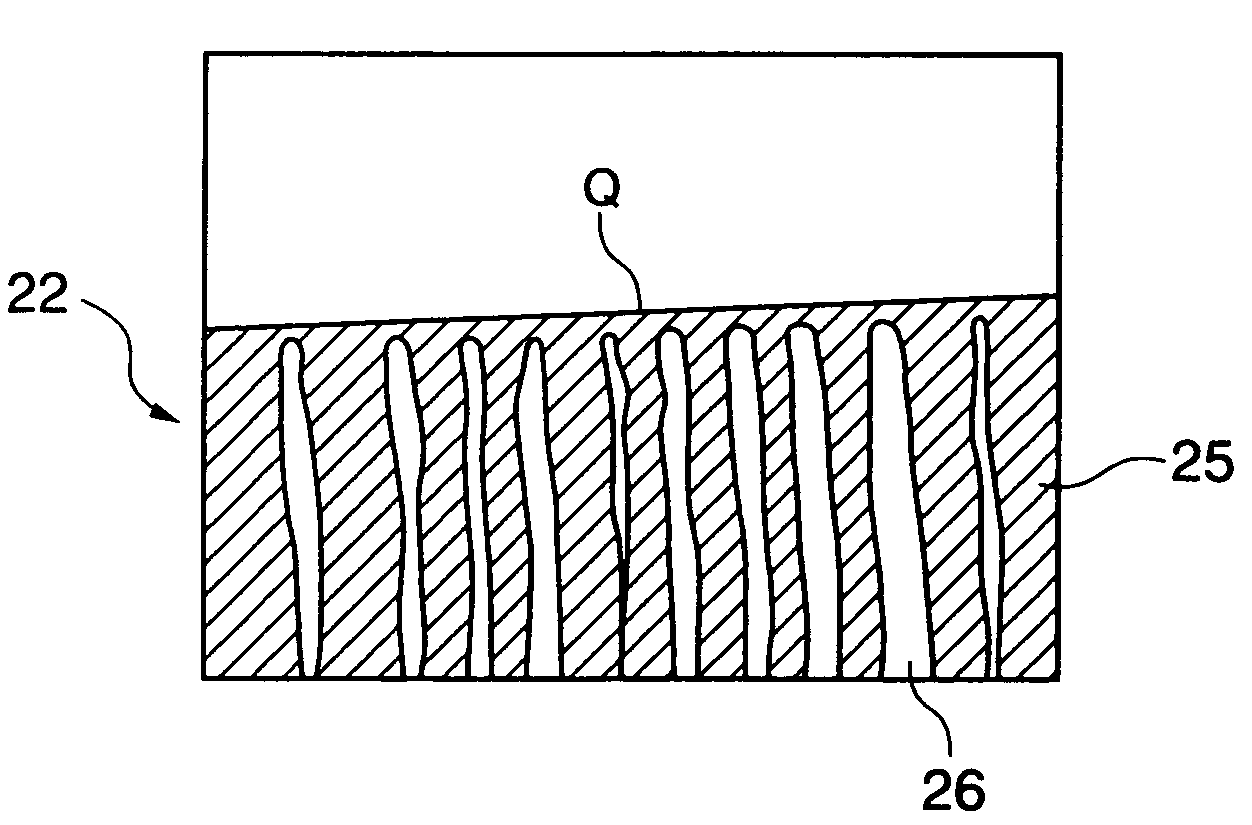

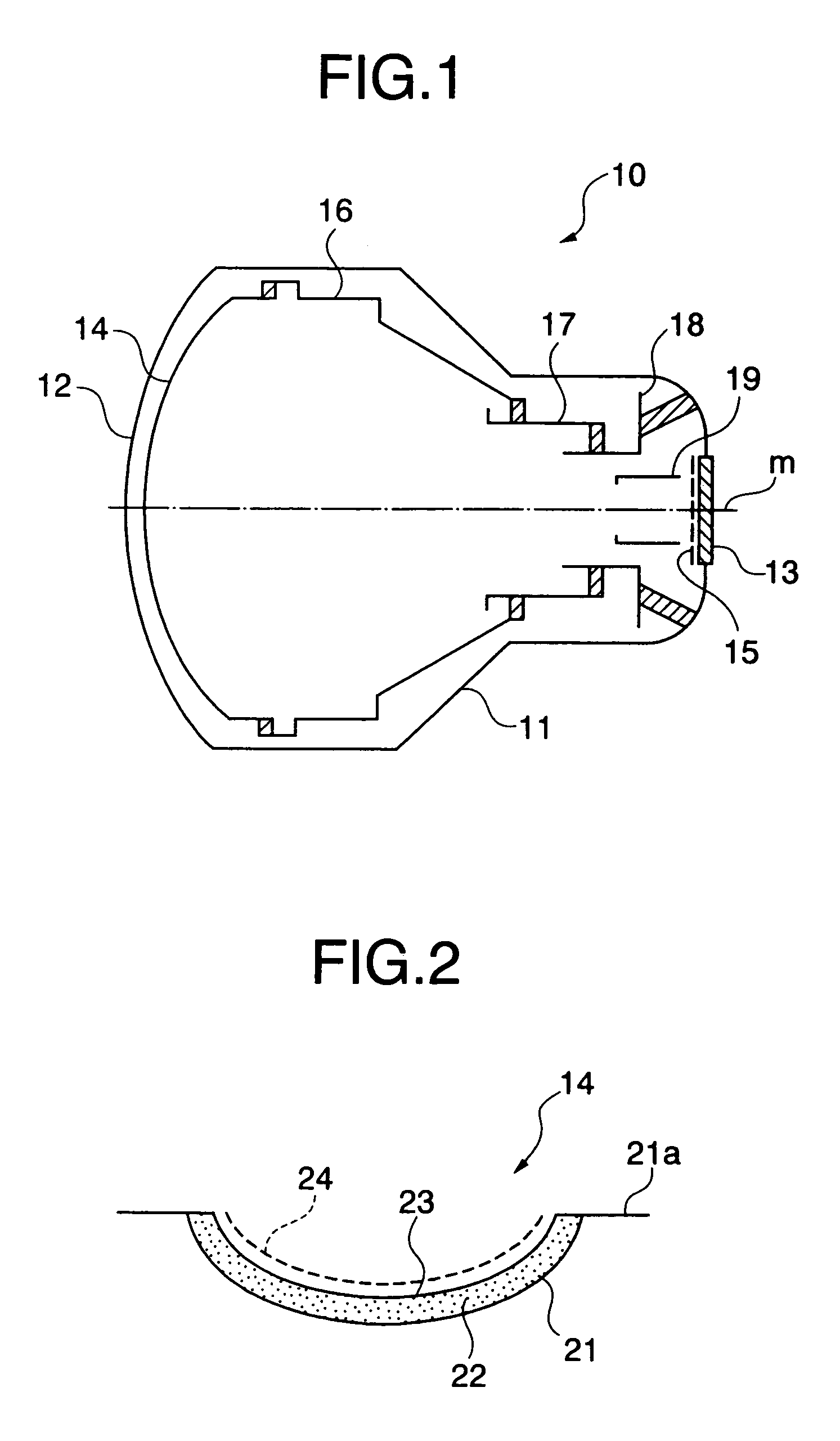

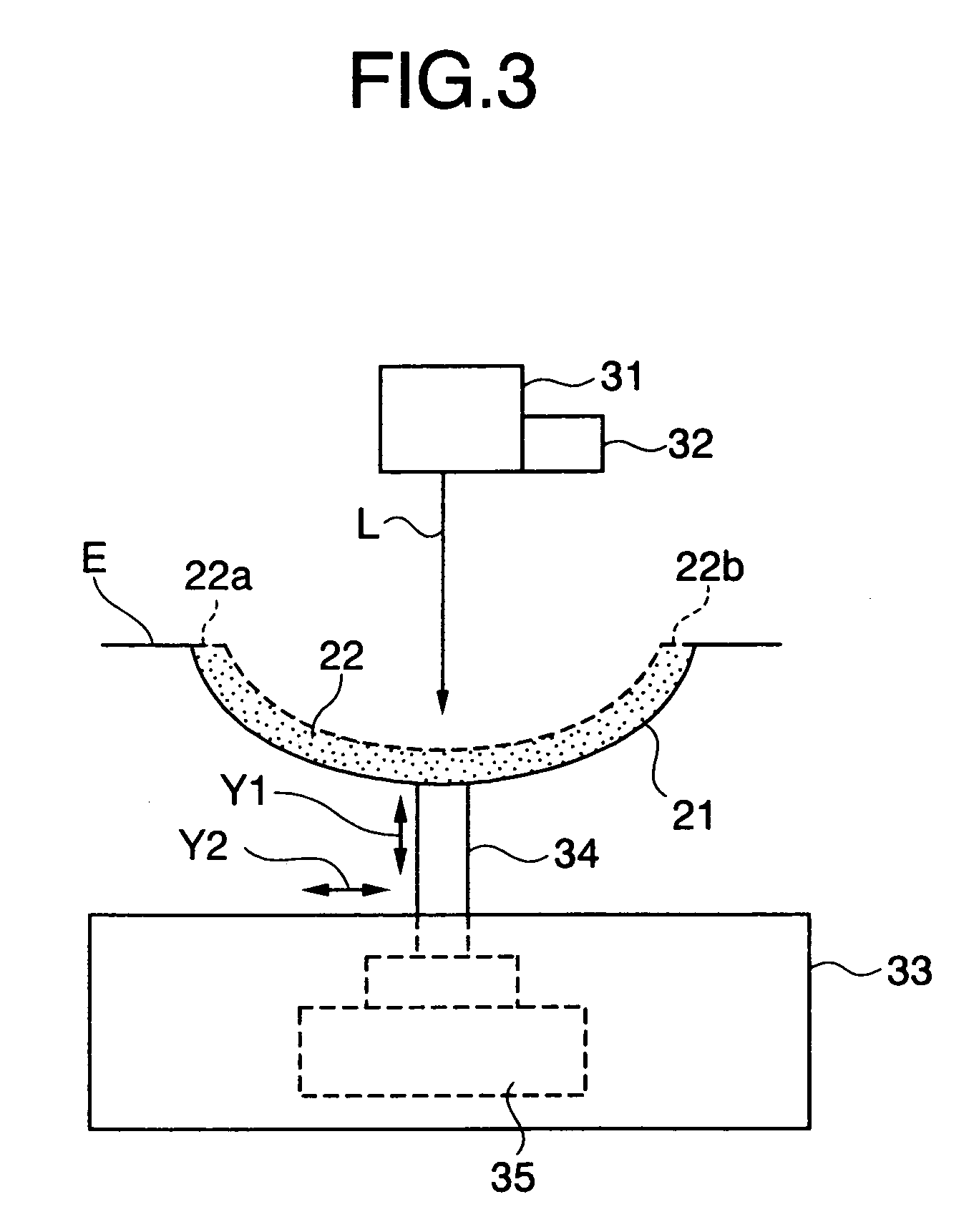

Method and device for producing X-ray image detector, and X-ray image detector

InactiveUS7067789B2Efficiently and uniformlyEfficiently and make surface portionMagnetic deflection device manufactureRadiation applicationsSoft x rayHigh energy

An X-ray light emitting phosphor film (22) such as a CsI film that converts an X-ray to light is formed on an input substrate (21) constituting an input part of an X-ray image detector. A surface portion of the X-ray light emitting phosphor film (22) is irradiated with high-energy light having a wavelength of 500 nm or less. The surface portion of the X-ray light emitting phosphor film (22) is locally sublimated and / or fused to be flattened by the irradiation with the high-energy light. The use of the high-energy light such as a laser beam makes it possible to efficiently and uniformly flatten the surface portion of the X-ray light emitting phosphor film.

Owner:KK TOSHIBA

System and methods for processing open-end mutual fund purchase and redemption orders at centralized securities exchanges and other securities trading and processing platforms

A system for processing traditional open-end mutual fund purchase and redemption orders at a server at designated Exchange(s) for receiving order messages from at least one of a plurality of Brokers and Member Firms, the server having at least one processor and memory for storing routines operable to process individual or aggregated order messages, preferably based on a prioritized set of business rules, and / or match the purchase and redemption orders, reformat the orders, and transmit the reformatted orders to at least one of a plurality of Fund / Securities Clearing Agents, Funds / Transfer Agents and Depositaries for confirmation, and clearing and settlement of issuance and redemption orders for mutual fund shares, as well as payment of mutual fund dividends.

Owner:MACPHERSON JAMES

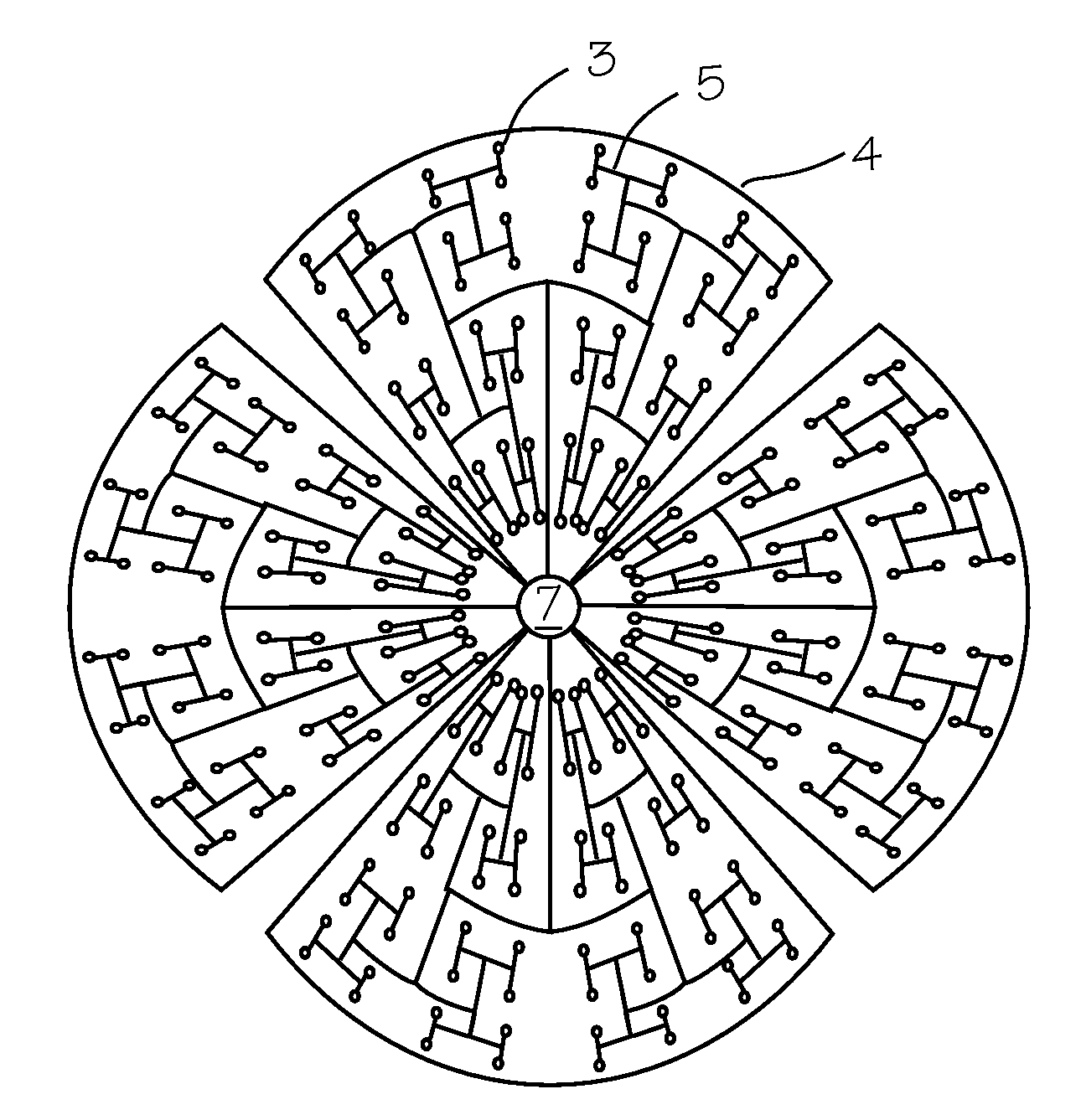

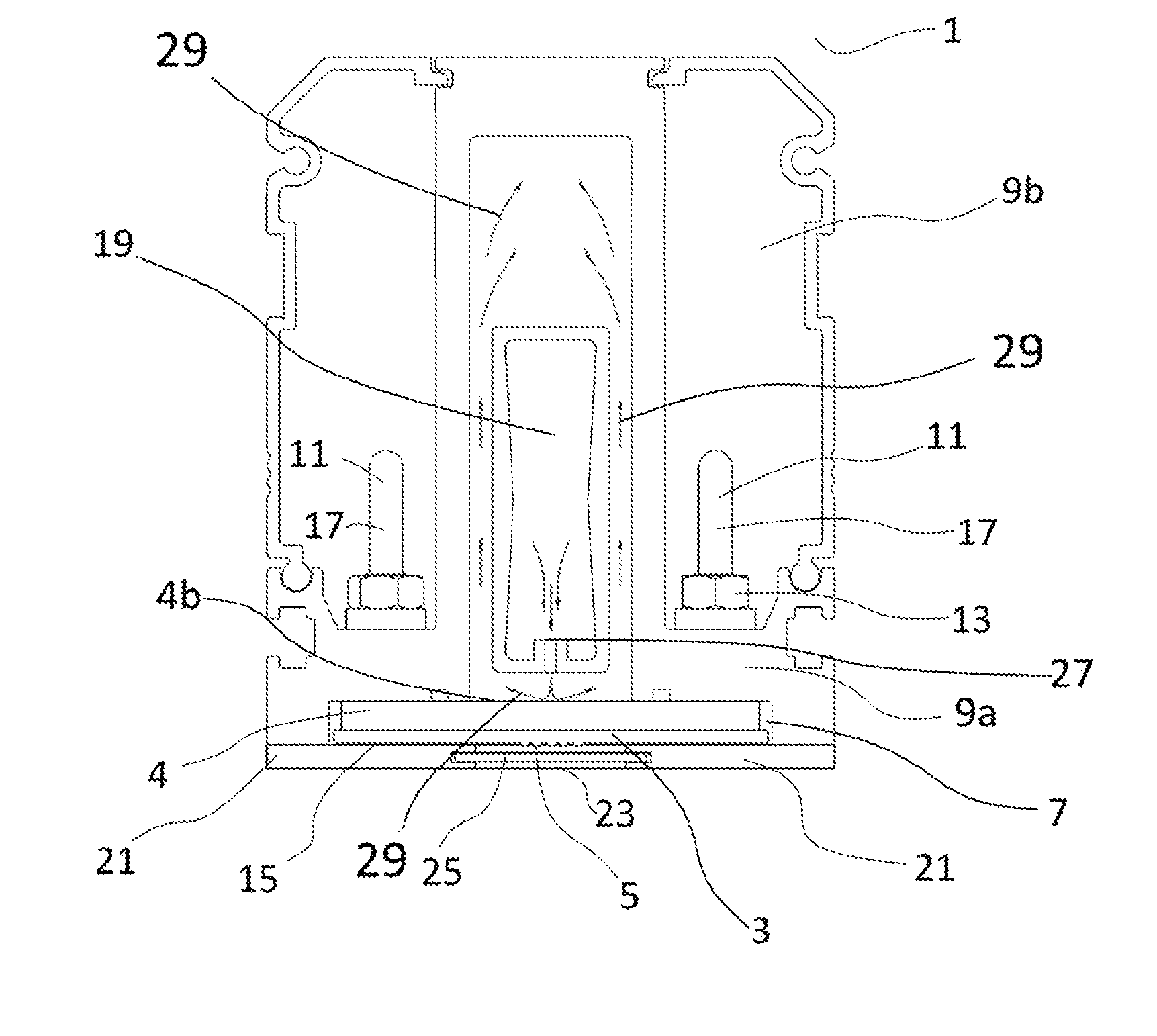

LED ink curing apparatus

InactiveUS20160211047A1Improve cooling effectEfficient heat transferDrying solid materials with heatPoint-like light sourceEngineeringHeat spreader

A print curing apparatus (1) comprising one or more LED modules (3) wherein each LED module (3) comprises at least one LED (5) and wherein the or each LED module (3) is mounted on a heat sink (4); and a cooling system (19) comprising one or more fluid jets (29) wherein the or each fluid jet (29) is directed towards the or each heat sink (4).

Owner:GEWEC

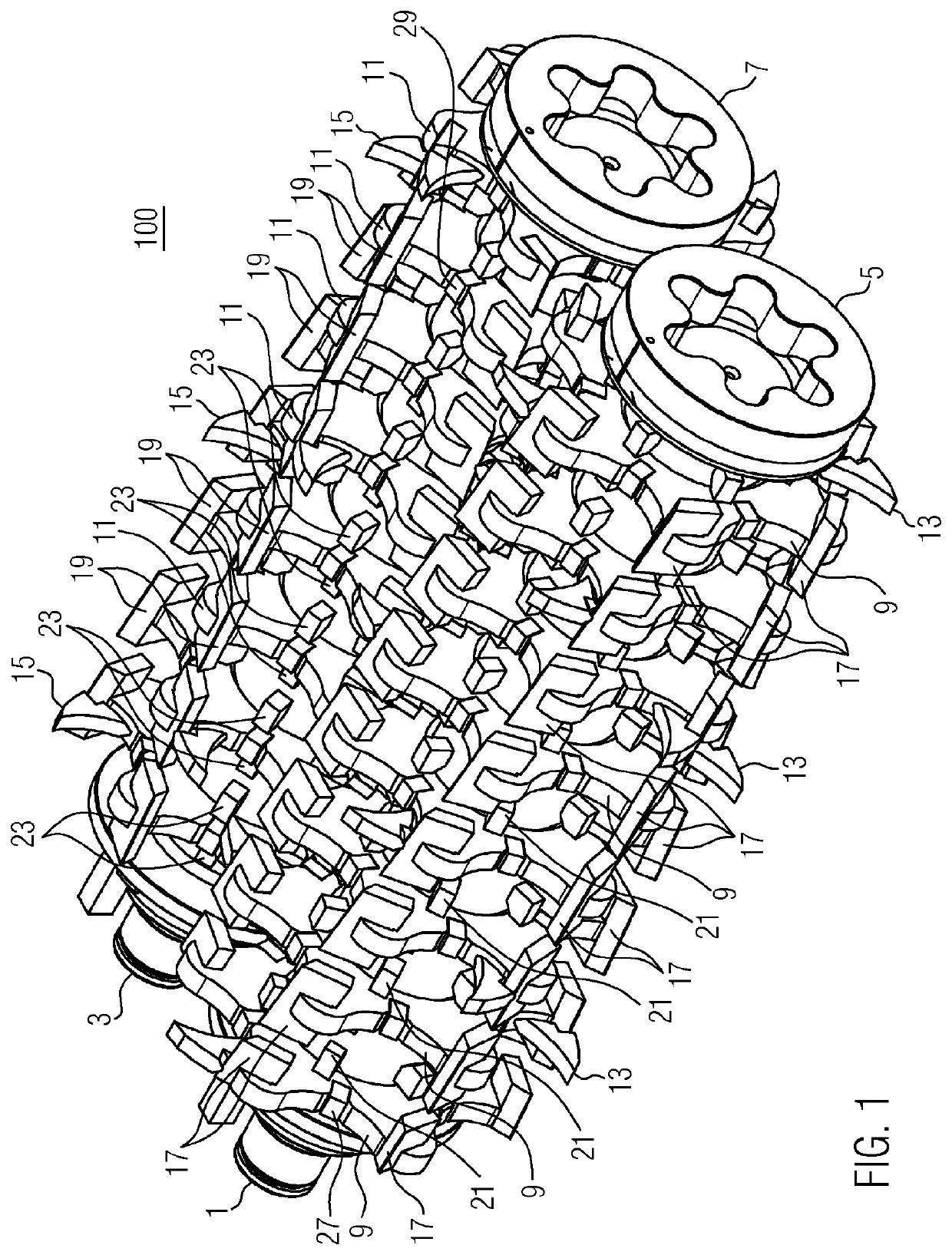

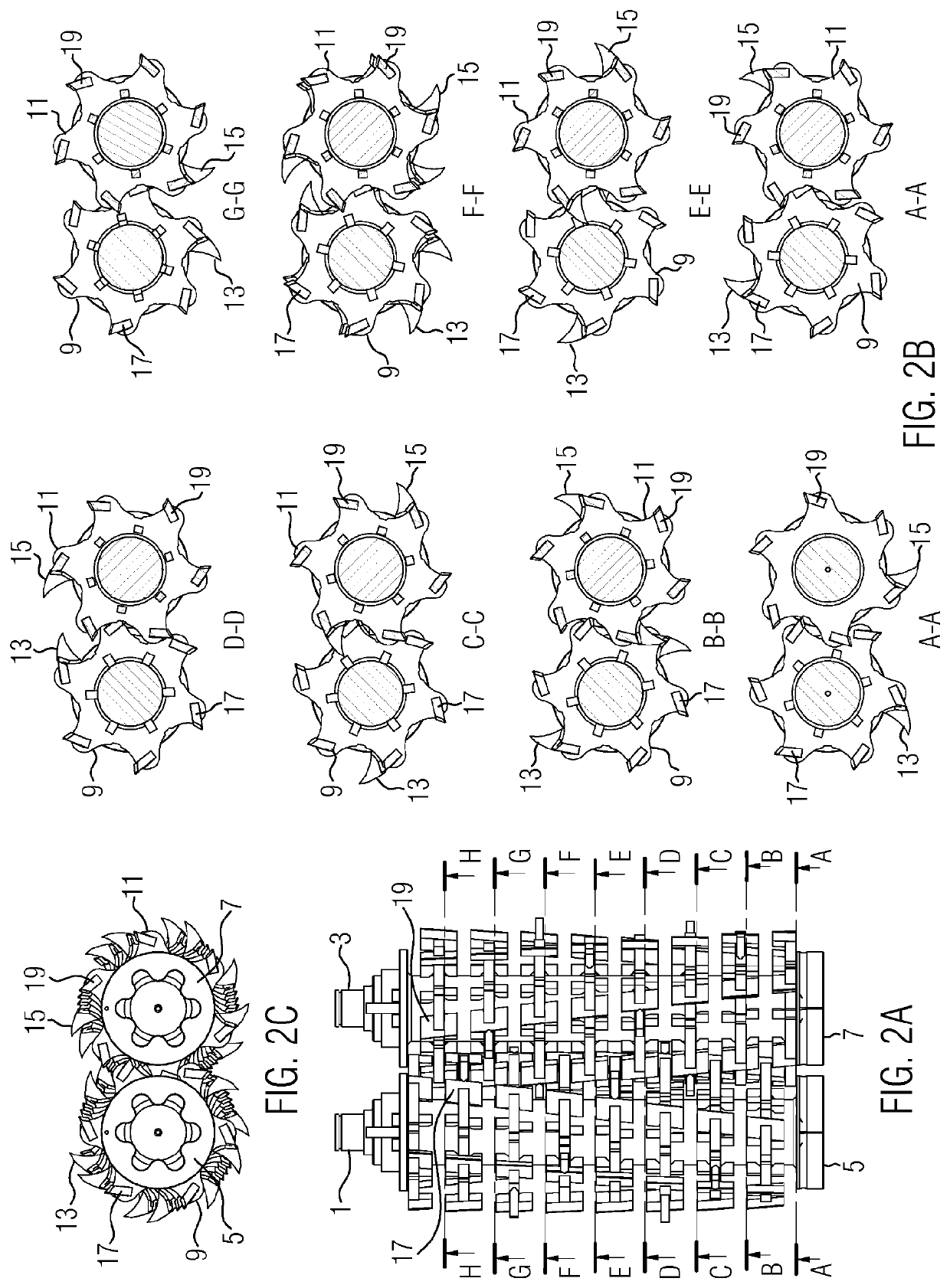

Multi-region twin-shaft cutting system

ActiveUS10799878B2Reduce areaEasy to operateGrain treatmentsClassical mechanicsStructural engineering

A multi-region twin-shaft cutting system for chopping material. The cutting system includes two shafts which are arranged in parallel and are driven in an opposed manner, each shaft is surrounded by a roll body. The system additionally includes a multiplicity of supporting elements, each supporting element is fitted radially around the roll body. The system further includes a multiplicity of severing elements which are of disc- and / or plate-like design and are each fitted symmetrically or asymmetrically tangentially to the circumferential region of the supporting elements.

Owner:LINDNER RECYCLINGTECH

Deburring device

ActiveUS20200254579A1Efficiently and uniformlyEdge grinding machinesHollow article cleaningMechanical engineeringPhysics

Owner:BUNN SR KEITH R

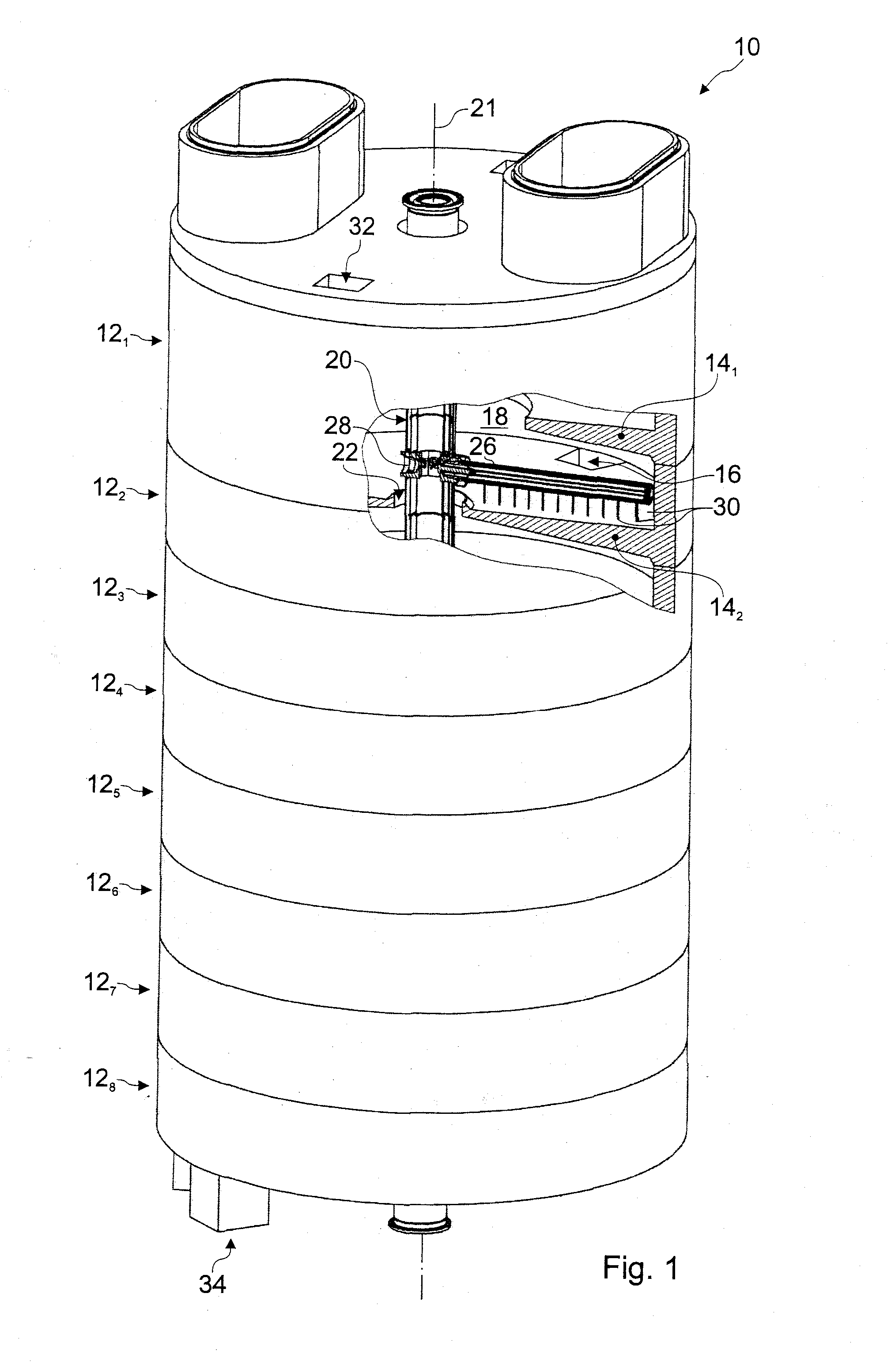

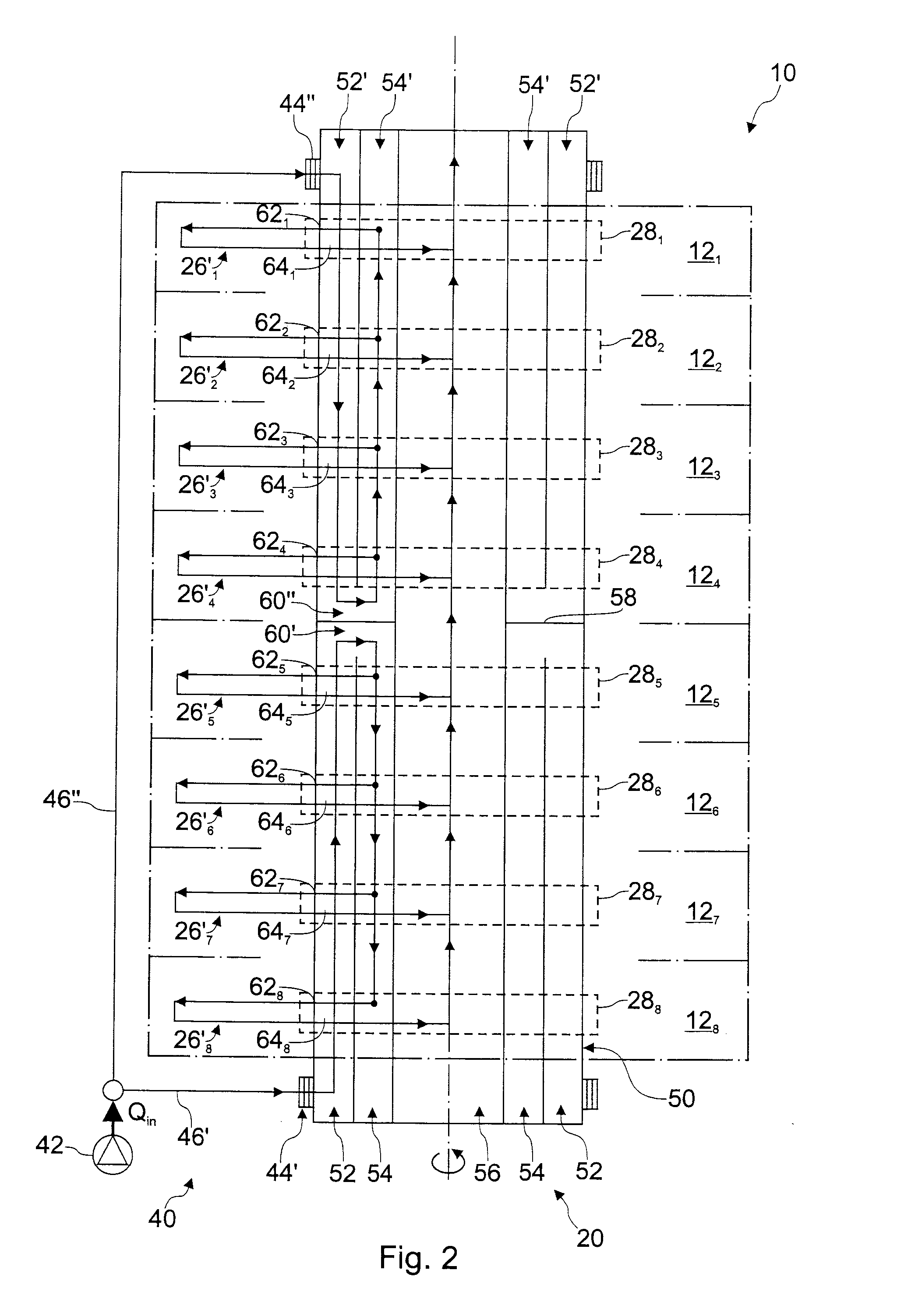

Multiple hearth furnace

InactiveUS20100119986A1Compact and strong and reliable connectionImprove the immunityCharge manipulationFurnace coolingEngineeringHearth

A multiple hearth furnace includes a gas cooling system for its central shaft and its rabble arms. This gas cooling system includes within the shaft an annular main distribution channel for supplying a cooling gas to the rabble arms and a central exhaust channel for evacuating the cooling gas leaving the rabble arms. The gas cooling system further includes an annular main supply channel surrounding the annular main distribution channel and being outwardly delimited by an outer shell of the shaft. A cooling gas inlet is connected to the annular main supply channel. A cooling gas passage between the annular main supply channel and the annular main distribution channel is spaced from the cooling gas inlet, so that cooling gas supplied to the cooling gas inlet has to flow through the annular main supply channel through several hearth chambers before it flows through the cooling gas passage into the annular main distribution channel.

Owner:PAUL WURTH SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com