Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about "Magnetic deflection device manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

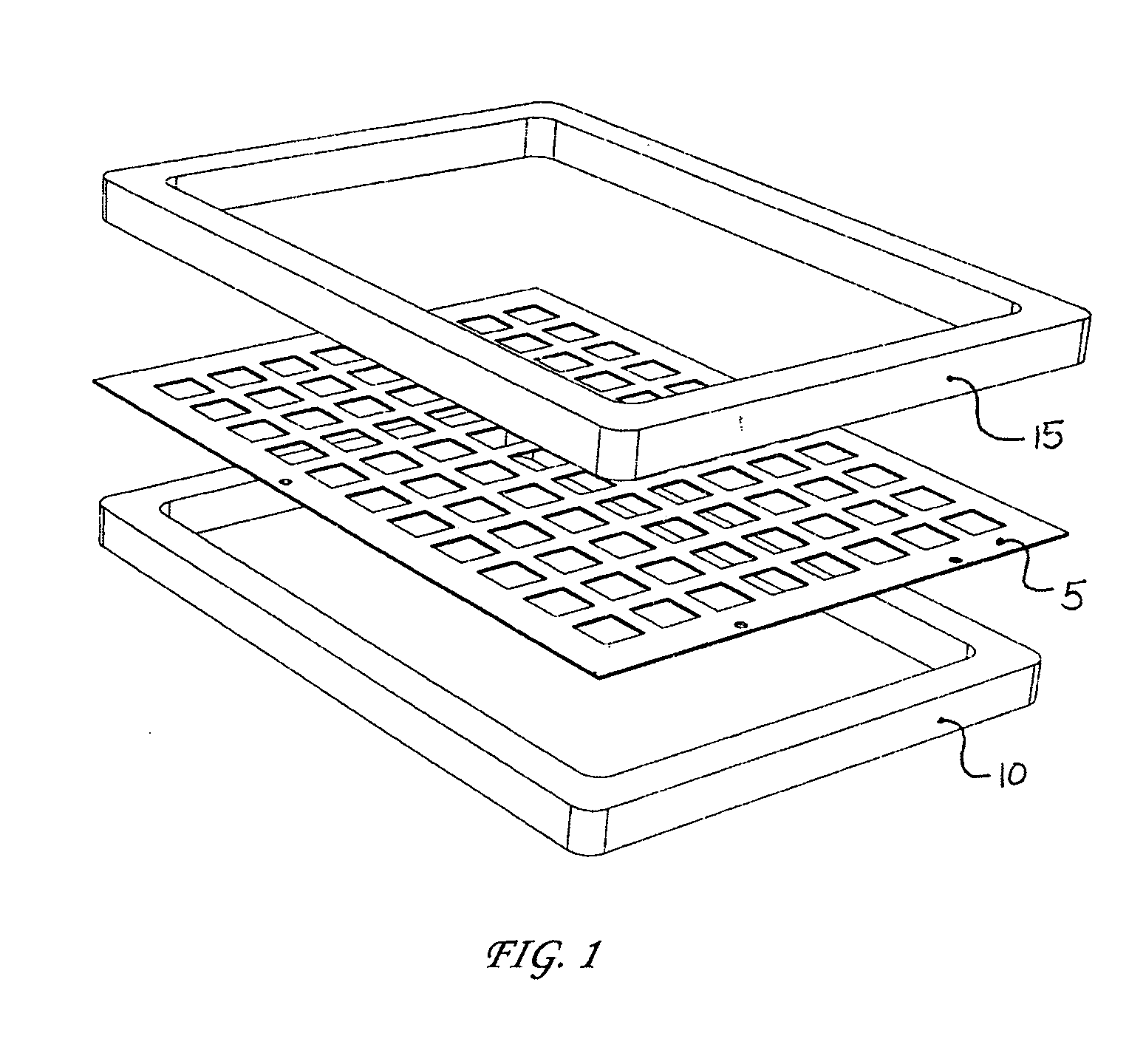

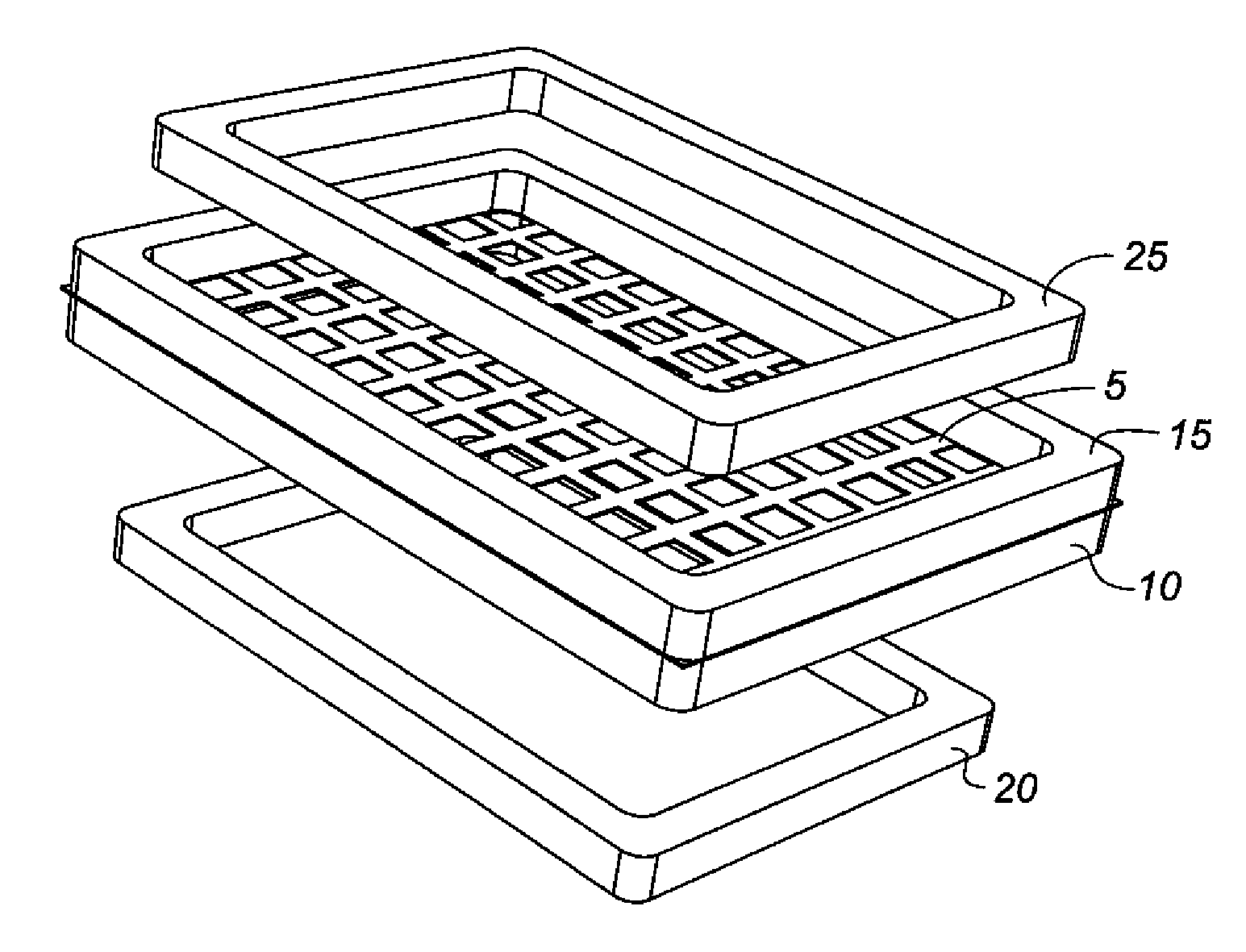

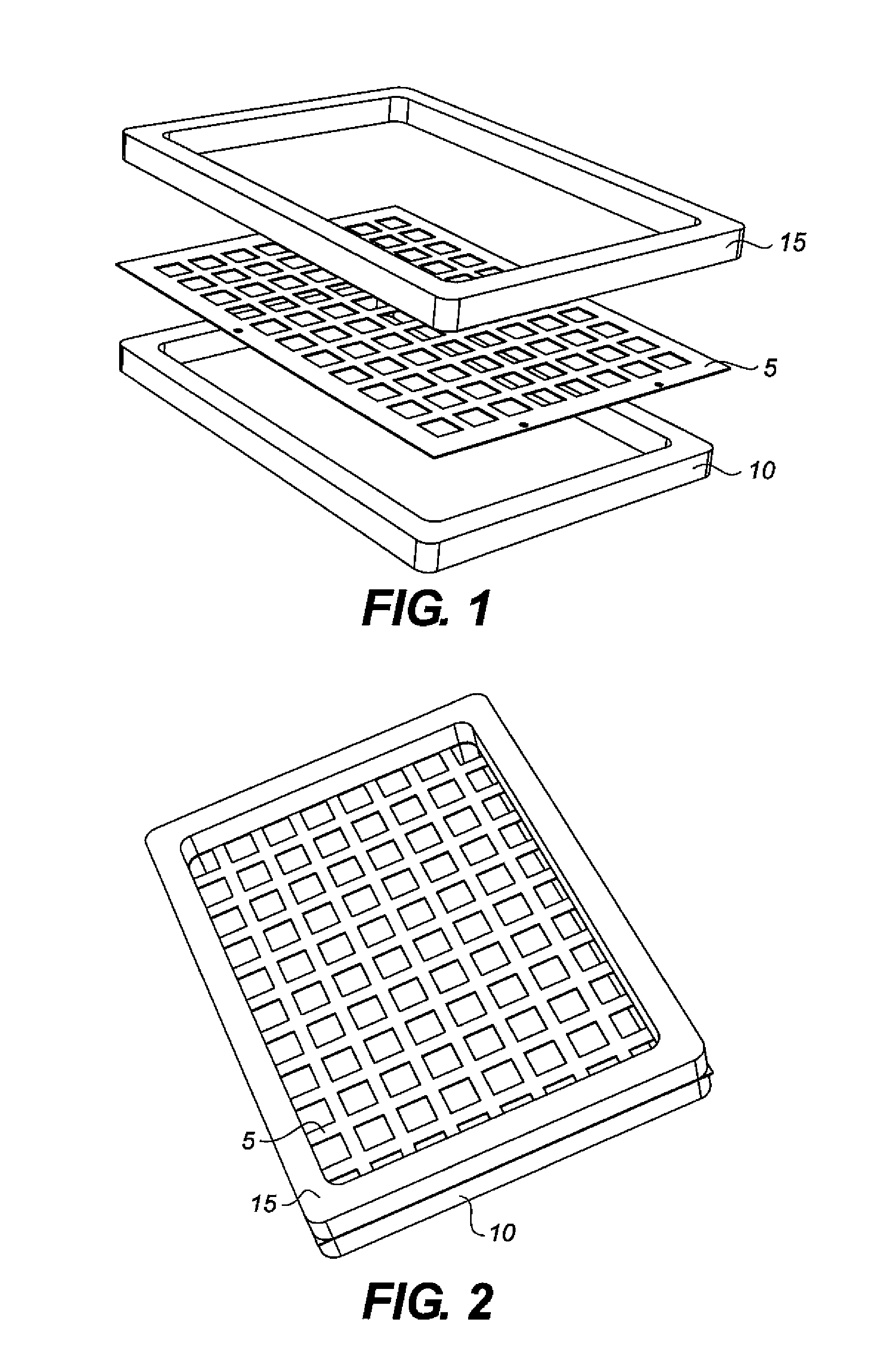

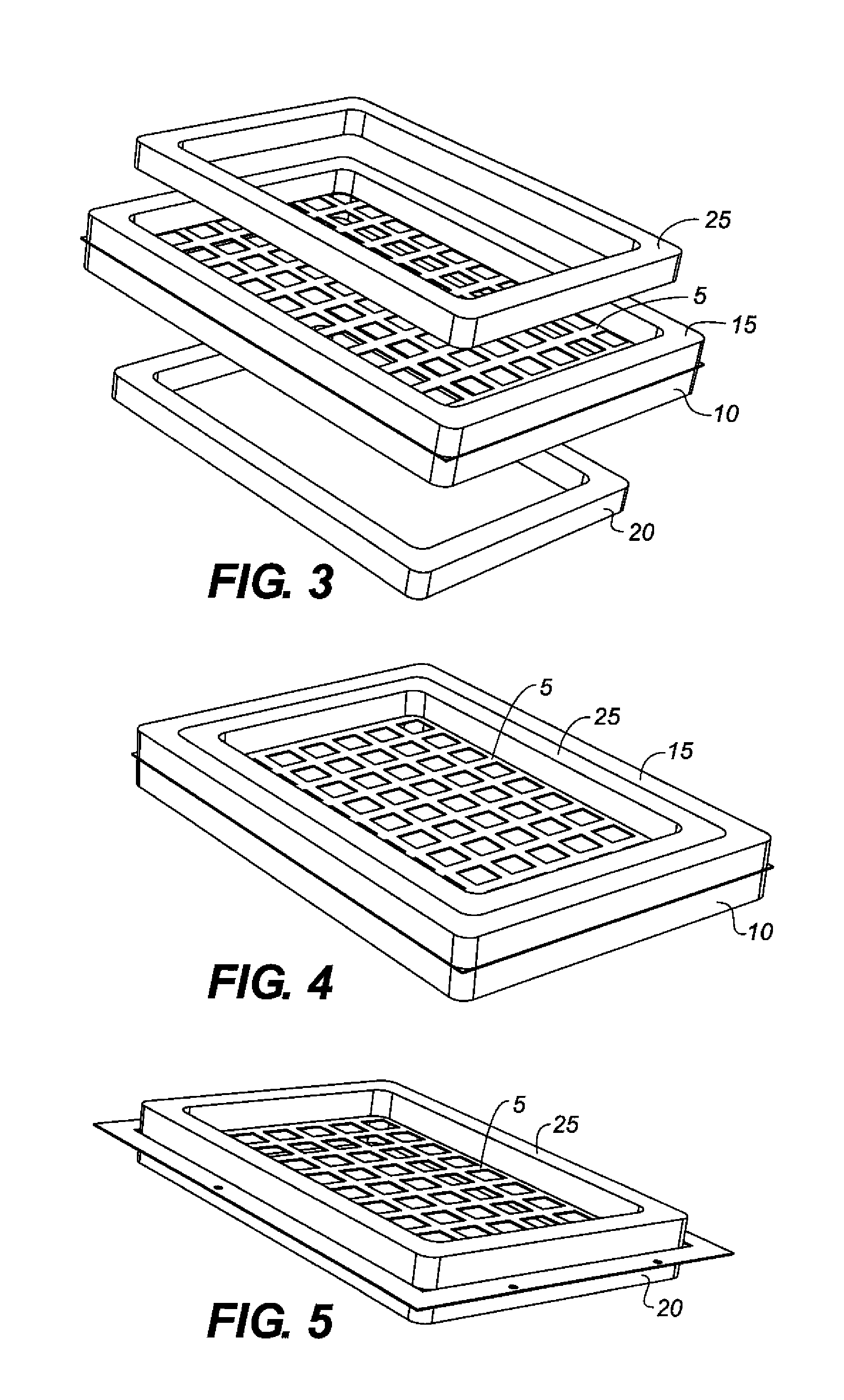

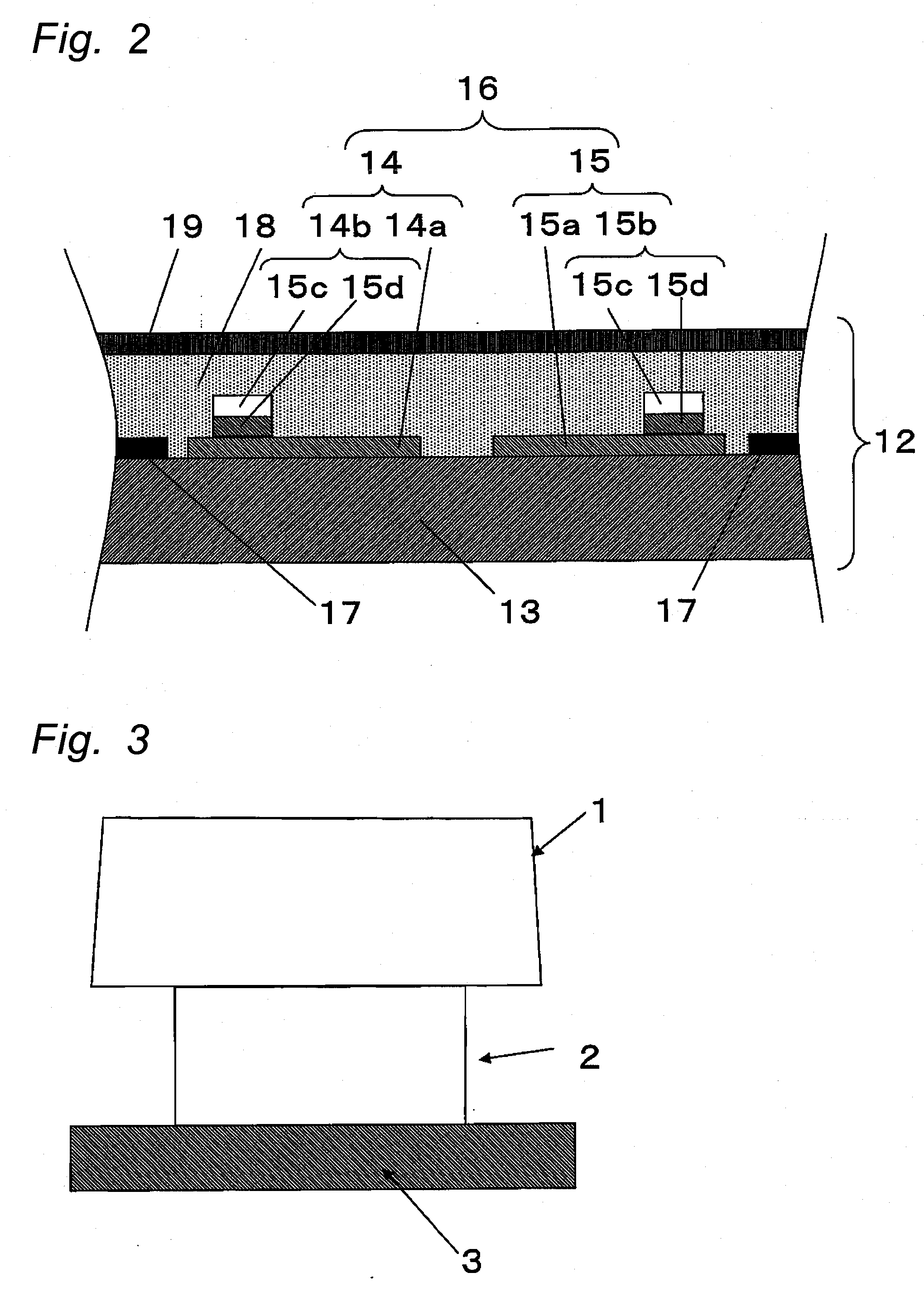

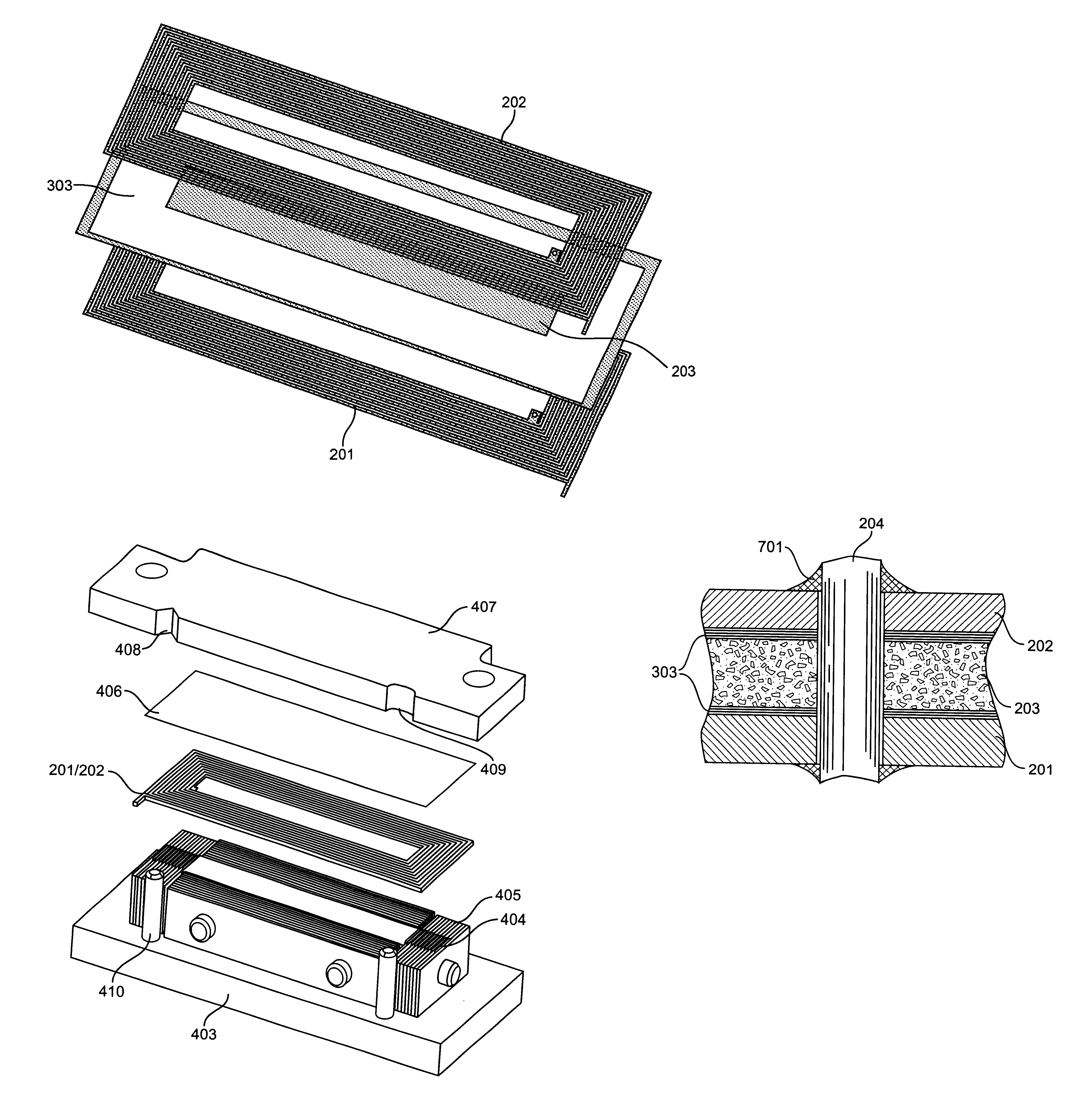

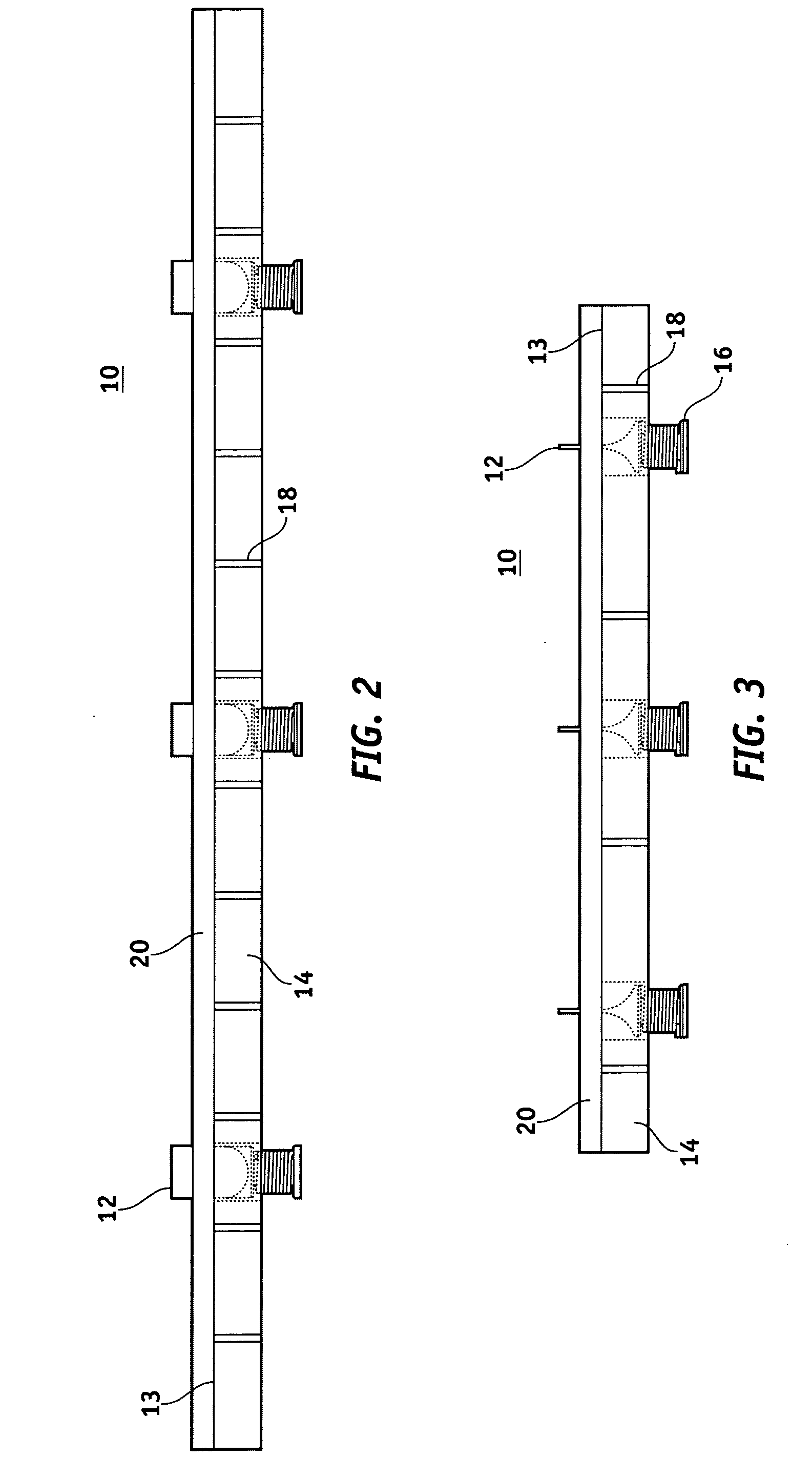

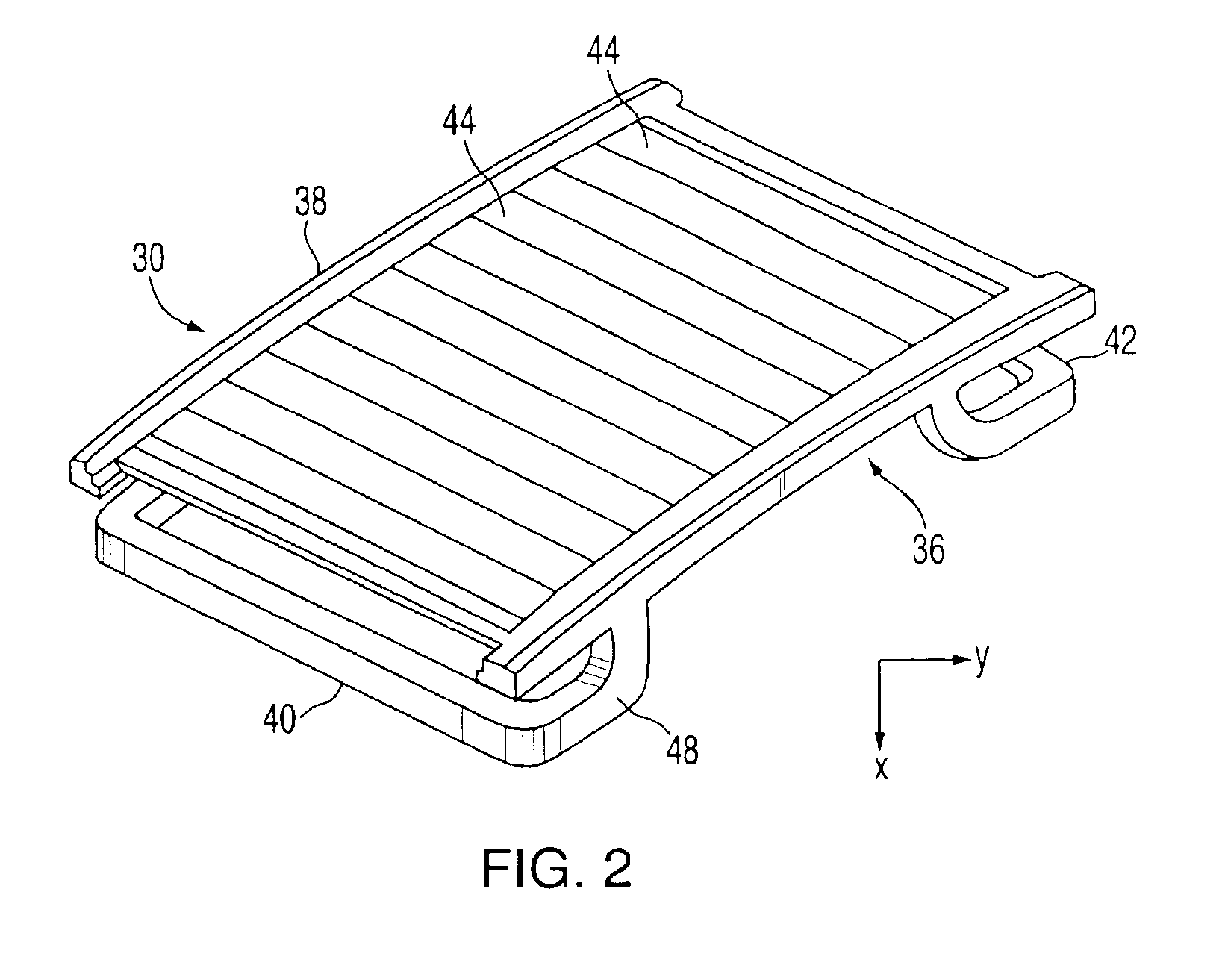

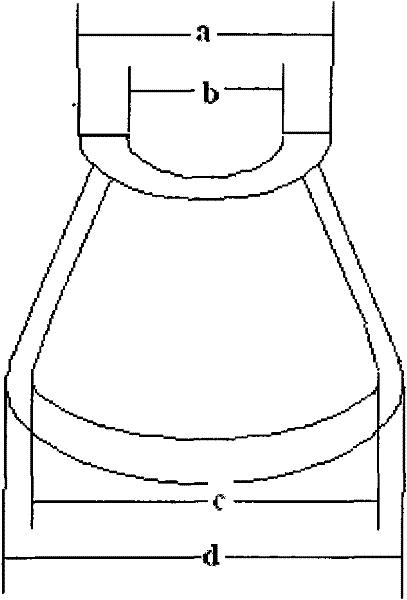

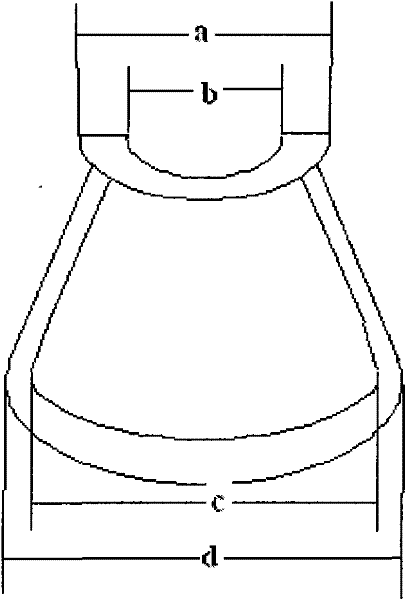

Shadow mask tensioning method

ActiveUS20070190888A1Uniform tensionLow costMagnetic deflection device manufactureSolid-state devicesEngineeringShadow mask

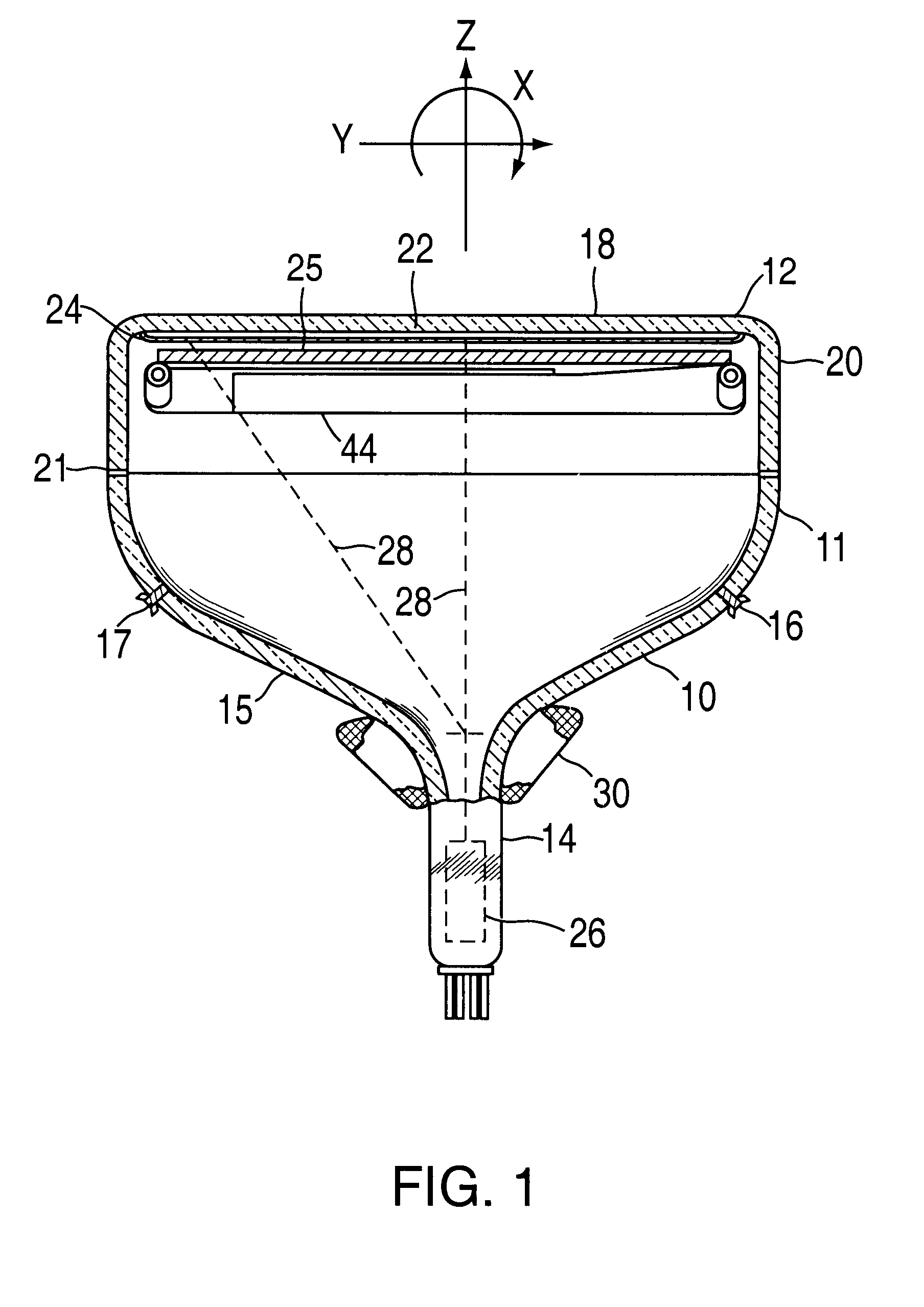

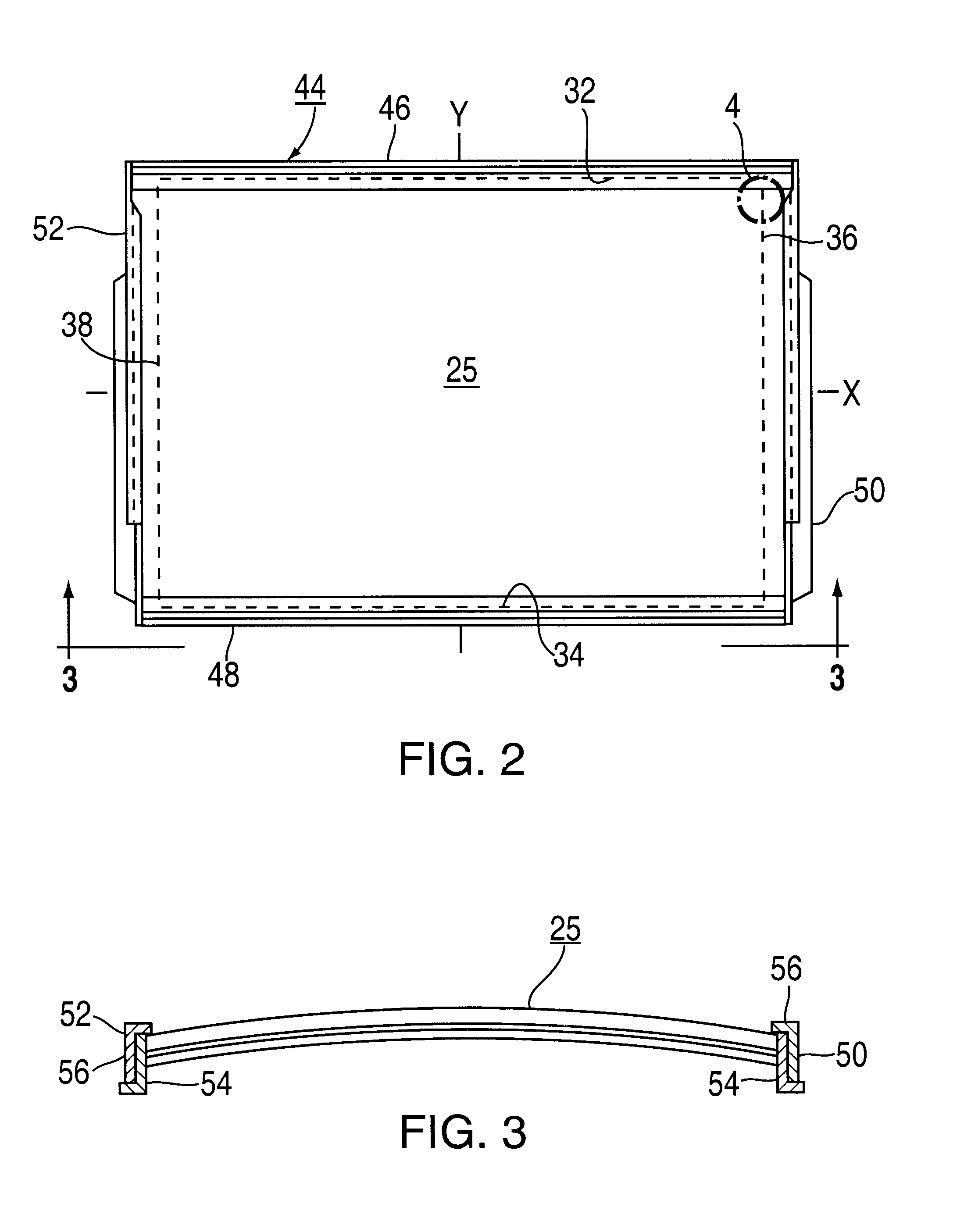

A method for tensioning a shadow mask includes positioning a first side of a shadow mask into contact with the lower half of a tensioning frame, positioning an upper half of the tensioning frame into contact with a second side of the shadow mask, and clamping the upper half of the tensioning frame to the lower half of the tensioning frame to form a tensioning frame, and rigidly clamping the shadow mask between the two tensioning frame halves. The method also includes elevating the temperature of the tensioning frame to tension the shadow mask.

Owner:GLOBAL OLED TECH

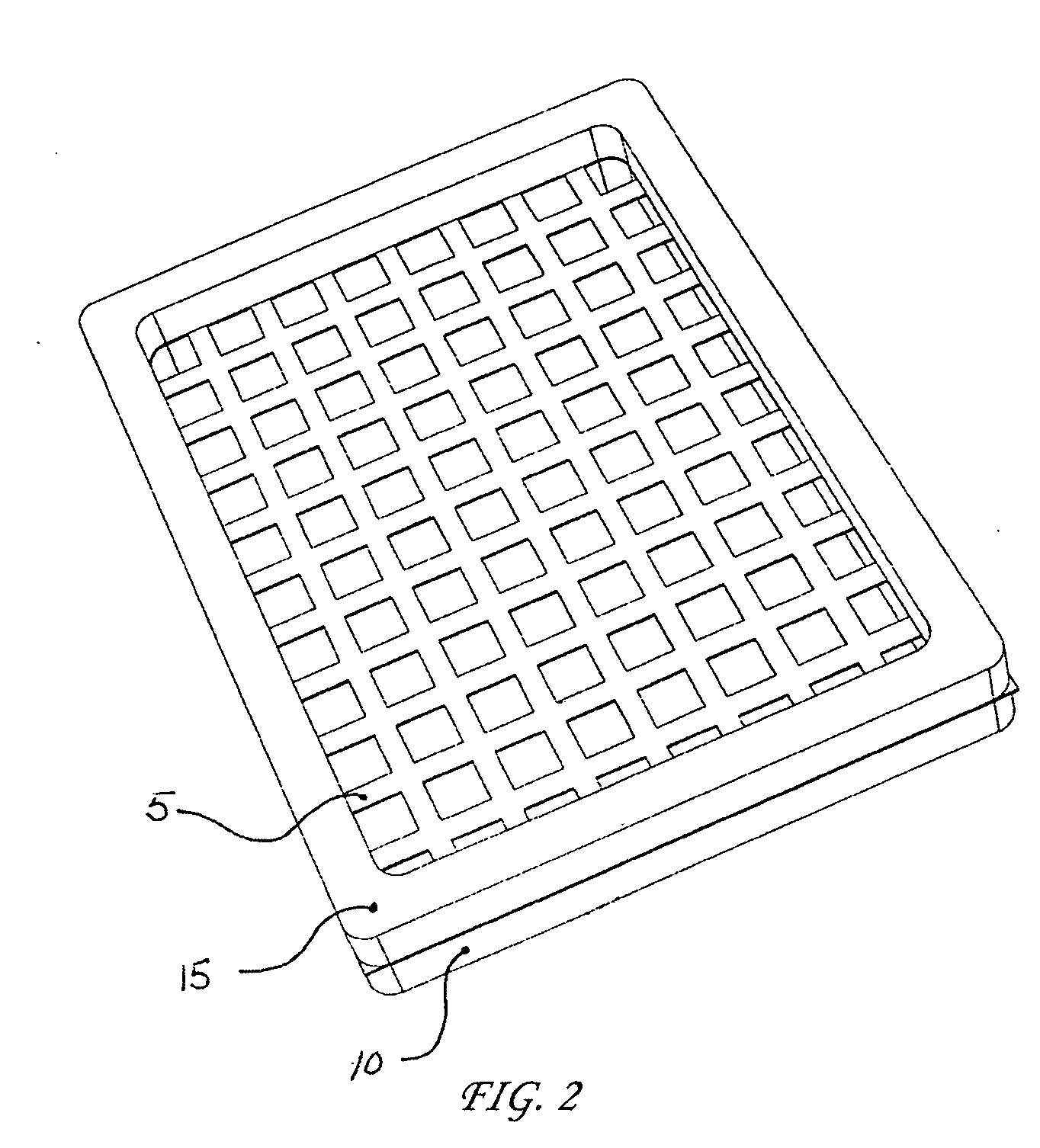

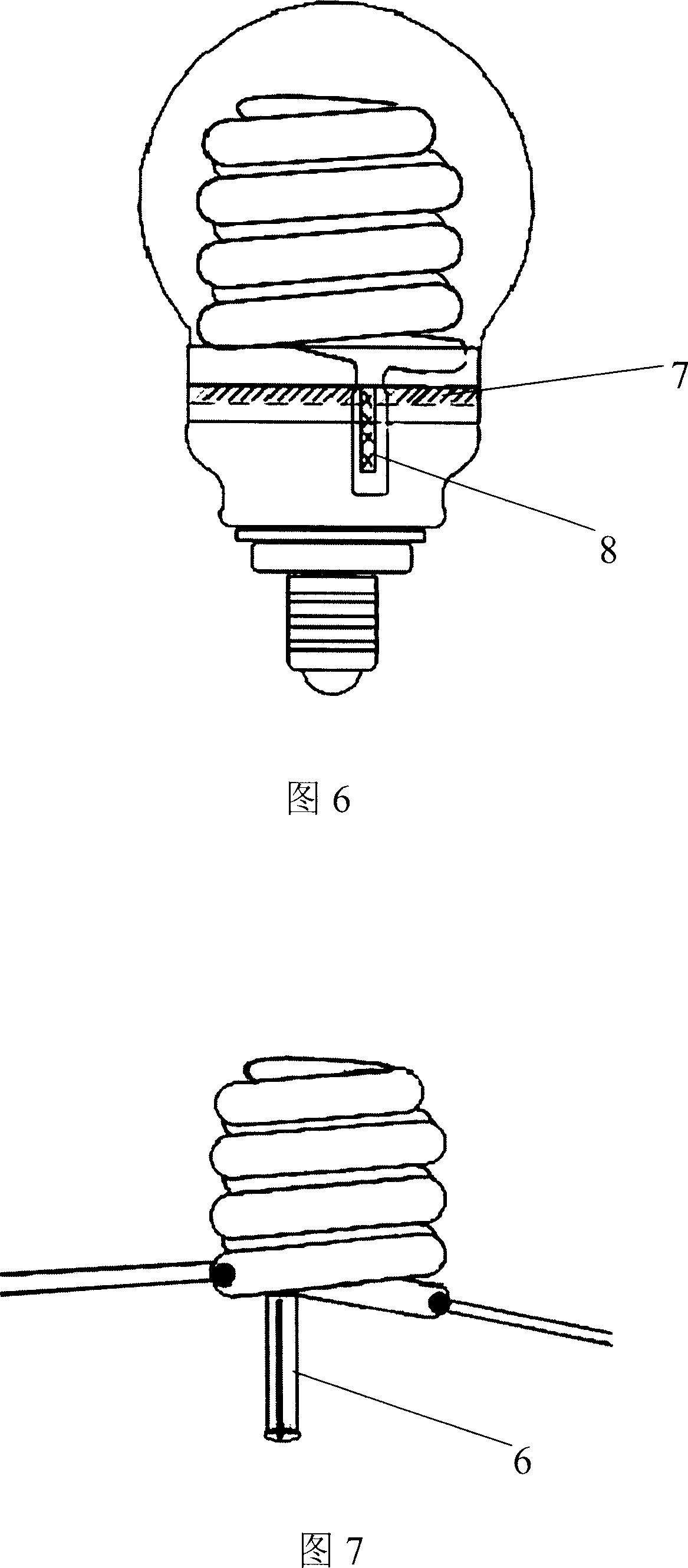

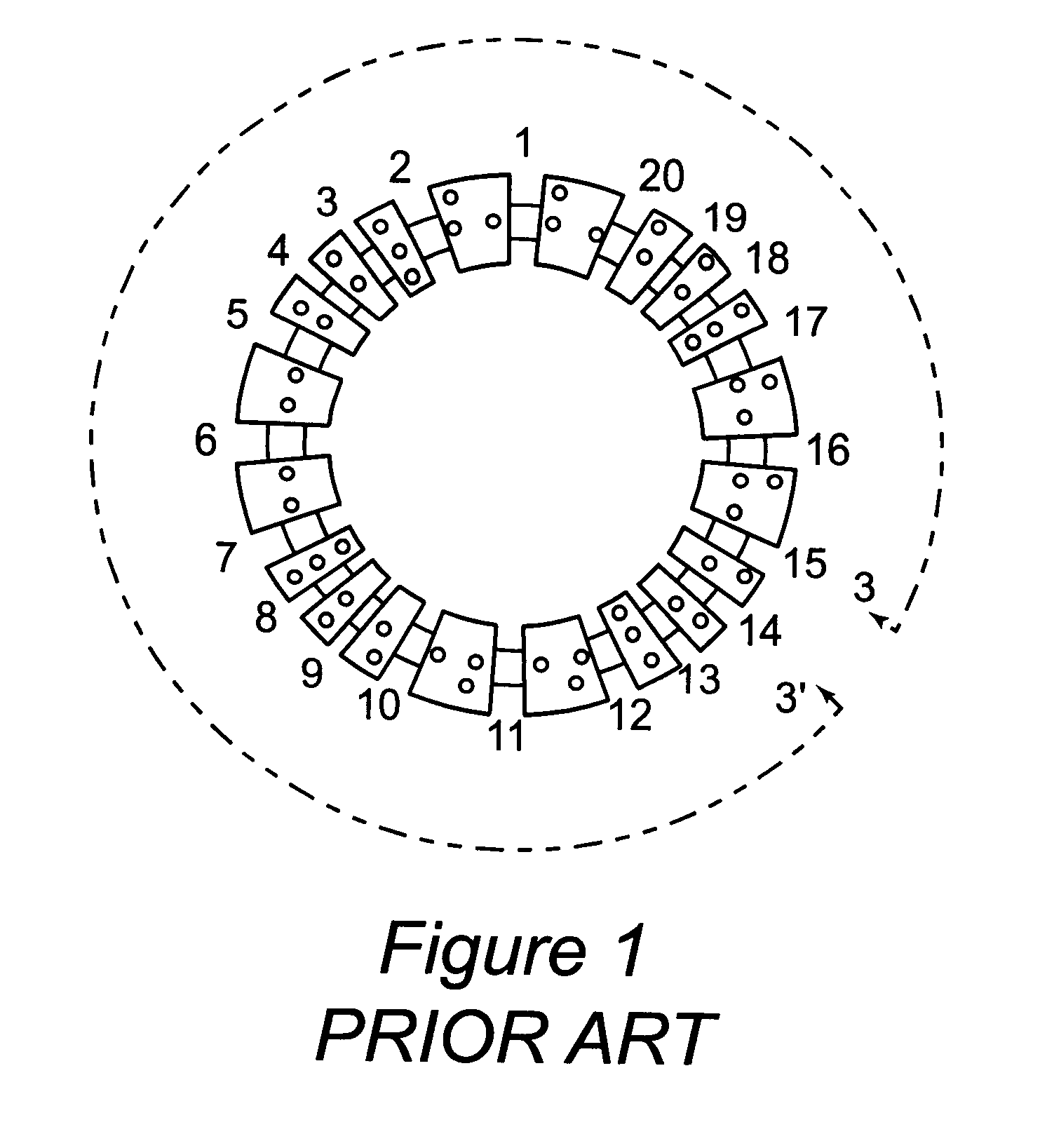

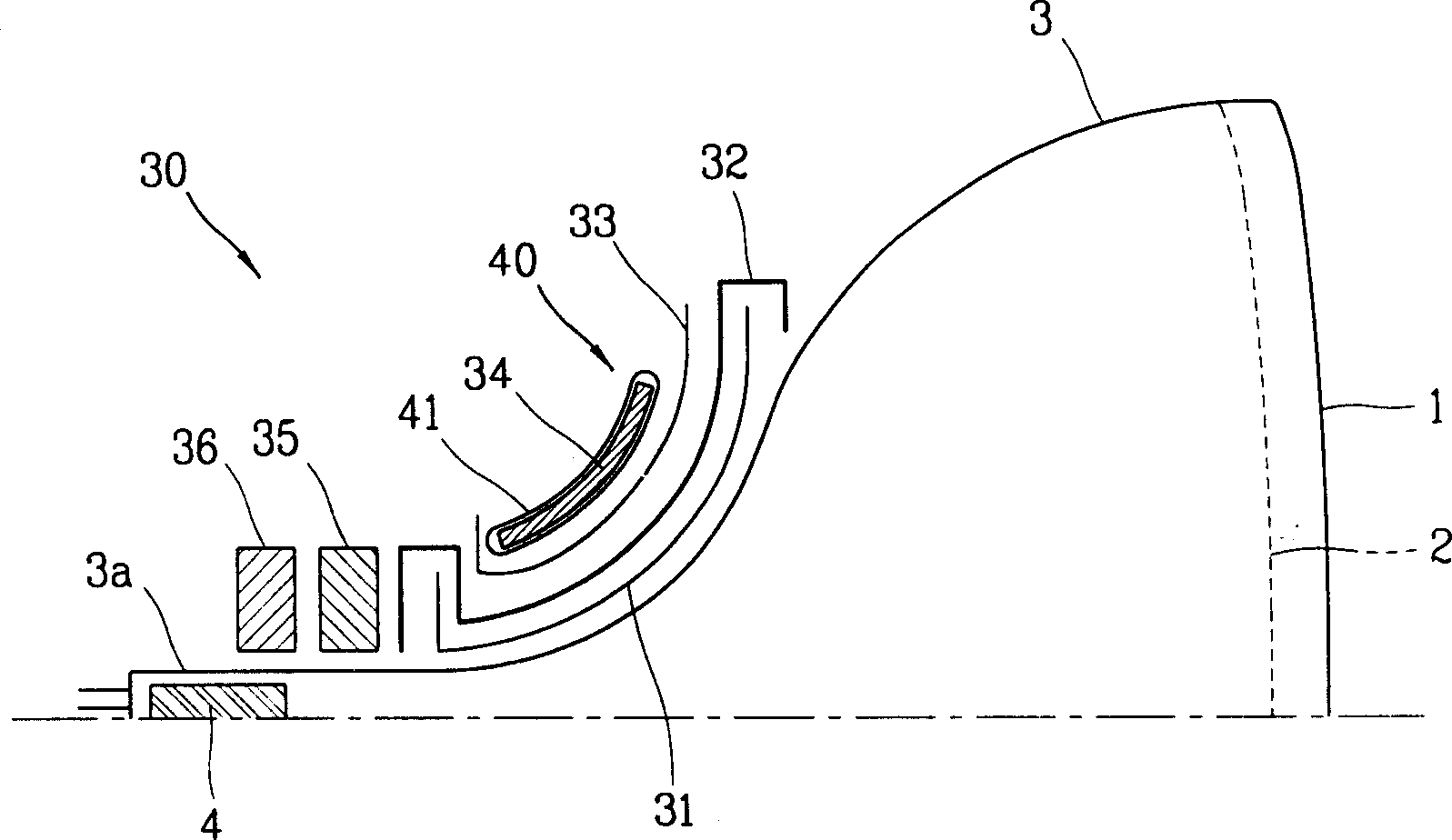

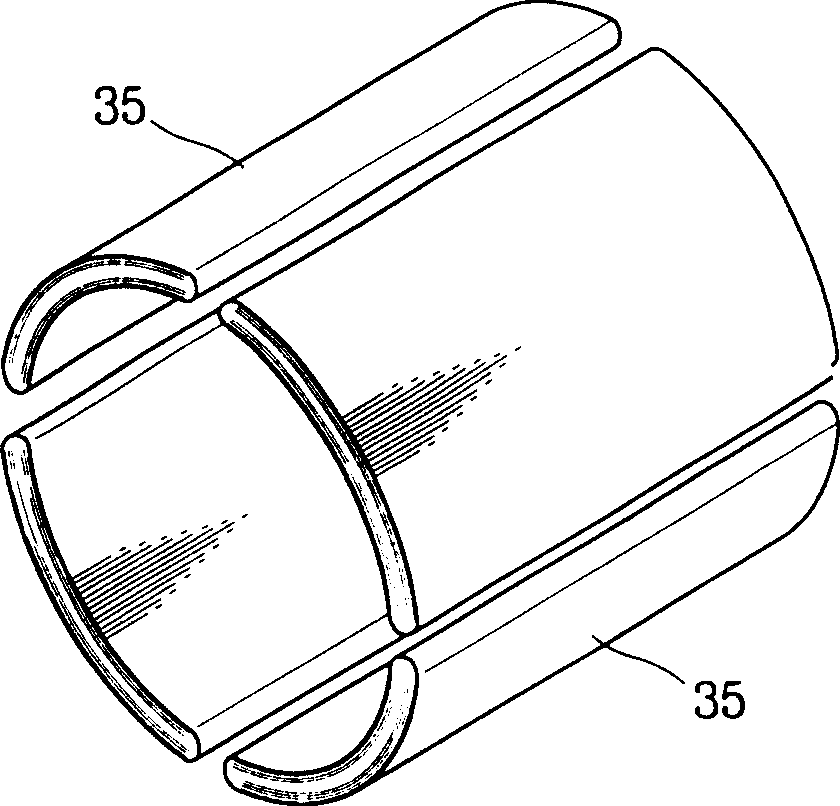

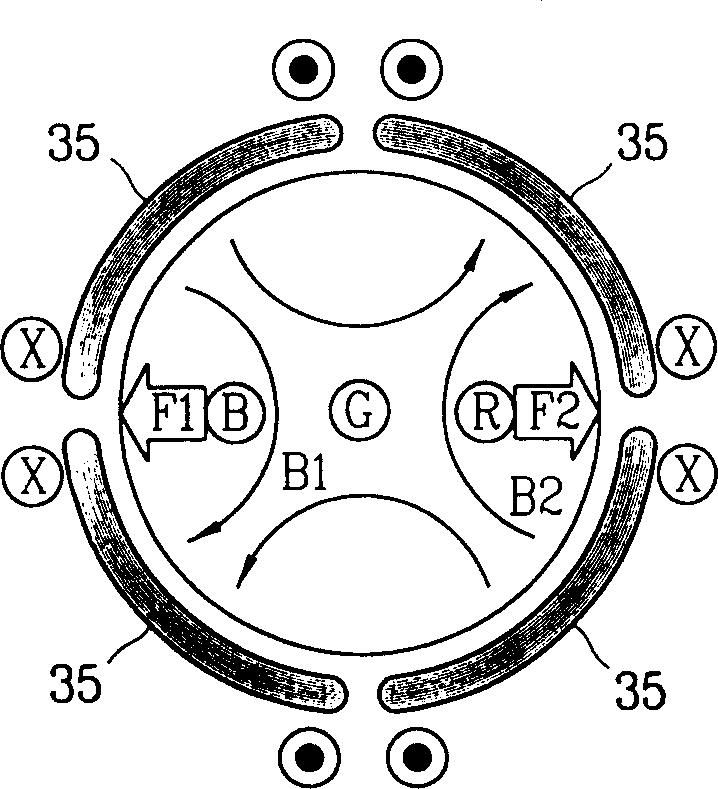

Rotation-magnetron-in-magnetron (RMIM) electrode, method of manufacturing the RMIM electrode, and sputtering apparatus including the RMIM electrode

InactiveUS7119489B2Optimizing the configuration of the basic RMIM electrodeEqually distributedCellsMagnetronsMagnetizationEngineering

An RMIM electrode, a method for manufacturing the RMIM electrode, and a sputtering apparatus using the RMIM electrode, wherein the RMIM electrode includes a magnet unit including a cylinder-shaped magnet located at a center of the magnet unit and a plurality of ring-shaped magnets having increasingly larger diameters surrounding the cylinder-shaped magnet; and a driver unit for supporting and for off-axis-rotating the magnet unit, wherein in the magnet unit, adjacent magnets have opposite magnetization directions.

Owner:SAMSUNG ELECTRONICS CO LTD

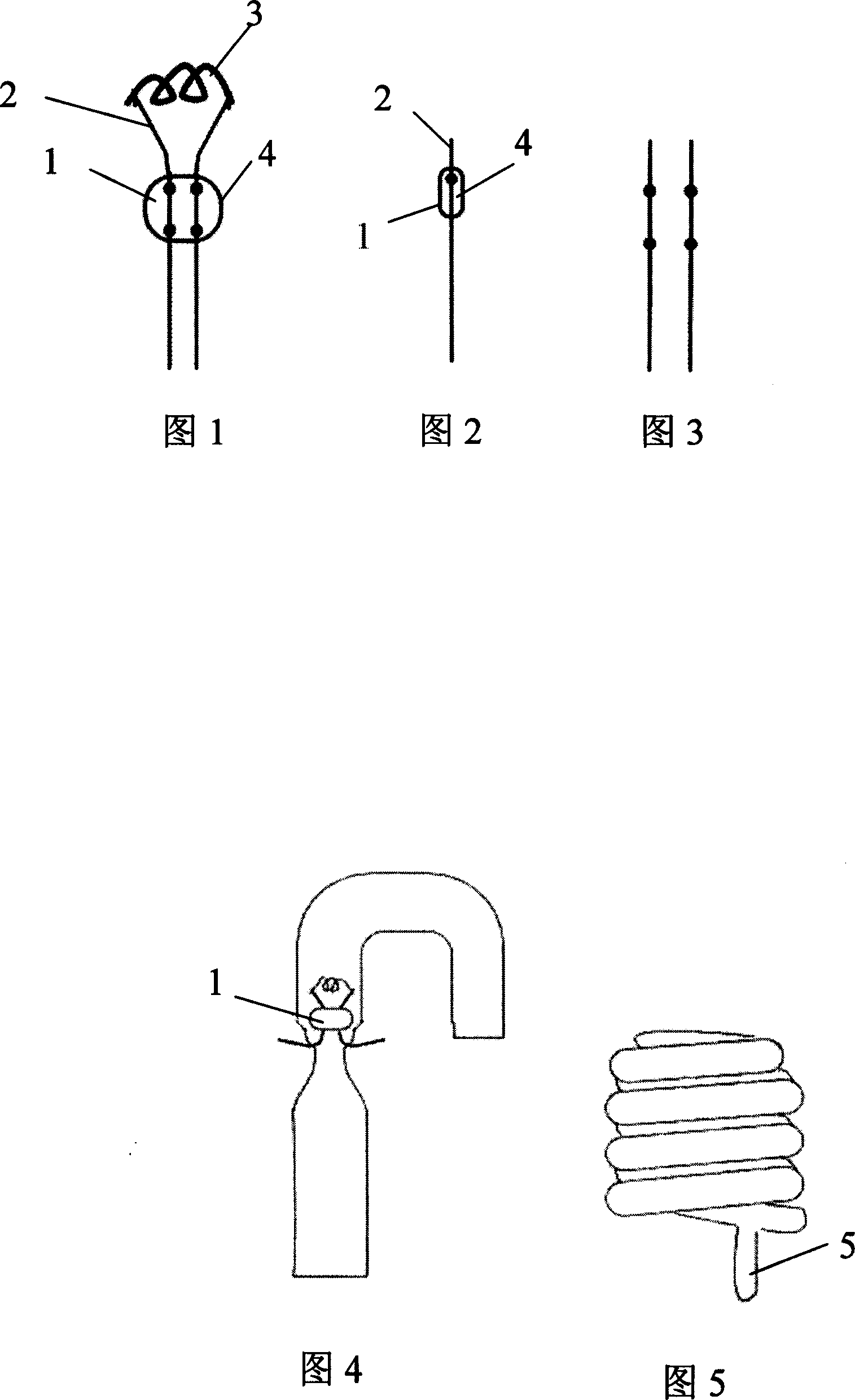

T2-T1 standard hot electrode fluorescence lamp production method

InactiveCN101145484AMagnetic deflection device manufactureCold cathode manufactureFluorescenceRare earth

A fabrication method of T2 and T1 hot-cathode fluorescent lamps is provided, which comprises processing potassium / barium glass, lead glass or borosilicate glass to a lamp tube, with the outside diameter of the lamp tube being controlled within a range of 1-9 mm; connecting two wires by glass bead fusion sealing to form a core column; winding a tungsten filament to form a spiral filament and then connecting with the wires; coating electronic powder; sealing the lamp tube and exhausting; placing mercury pills or amalgam in the entrance path at one end of the lamp tube, introducing high-purity argon gas (400-1600Pa pressure) into the lamp after exhaust operation, heating the wires by means of induction with a high frequency furnace to heat the mercury pills or amalgam to produce mercury vapors. The invention solves the technical problem of the prior fabrication process of hot-cathode fluorescent lamps rated up to T3 specification, such as large processing difficulty, difficulty in sealing lamp, failure to hermetically connect the core column with the lamp tube, difficulty in controlling processing flame, and complicated exhaust process. The invention provides an ideal technical proposal for the fabrication of hot-cathode tricolor rare earth fluorescent lamps with a tube diameter less than or equal to 7mm.

Owner:陈宗烈

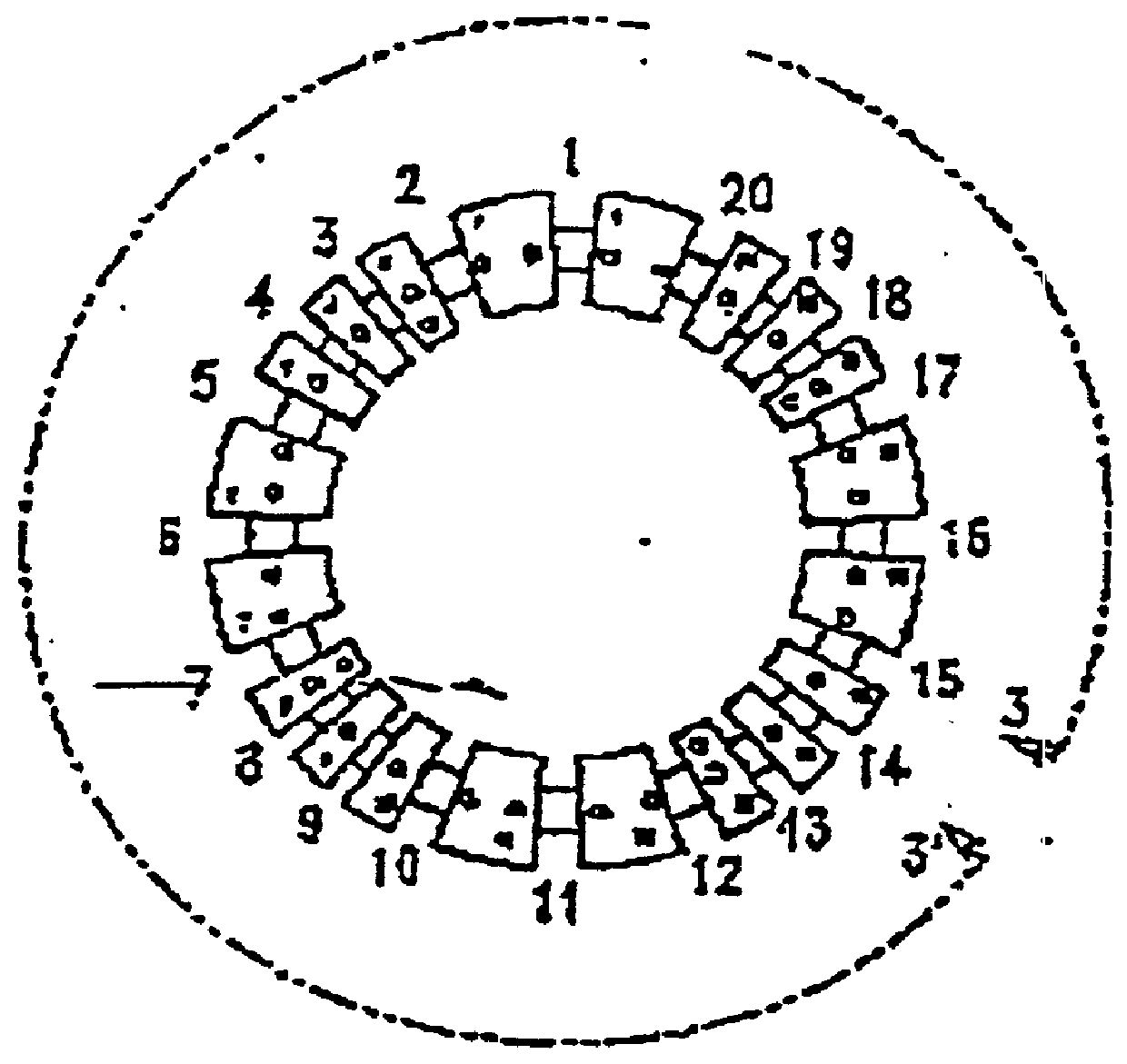

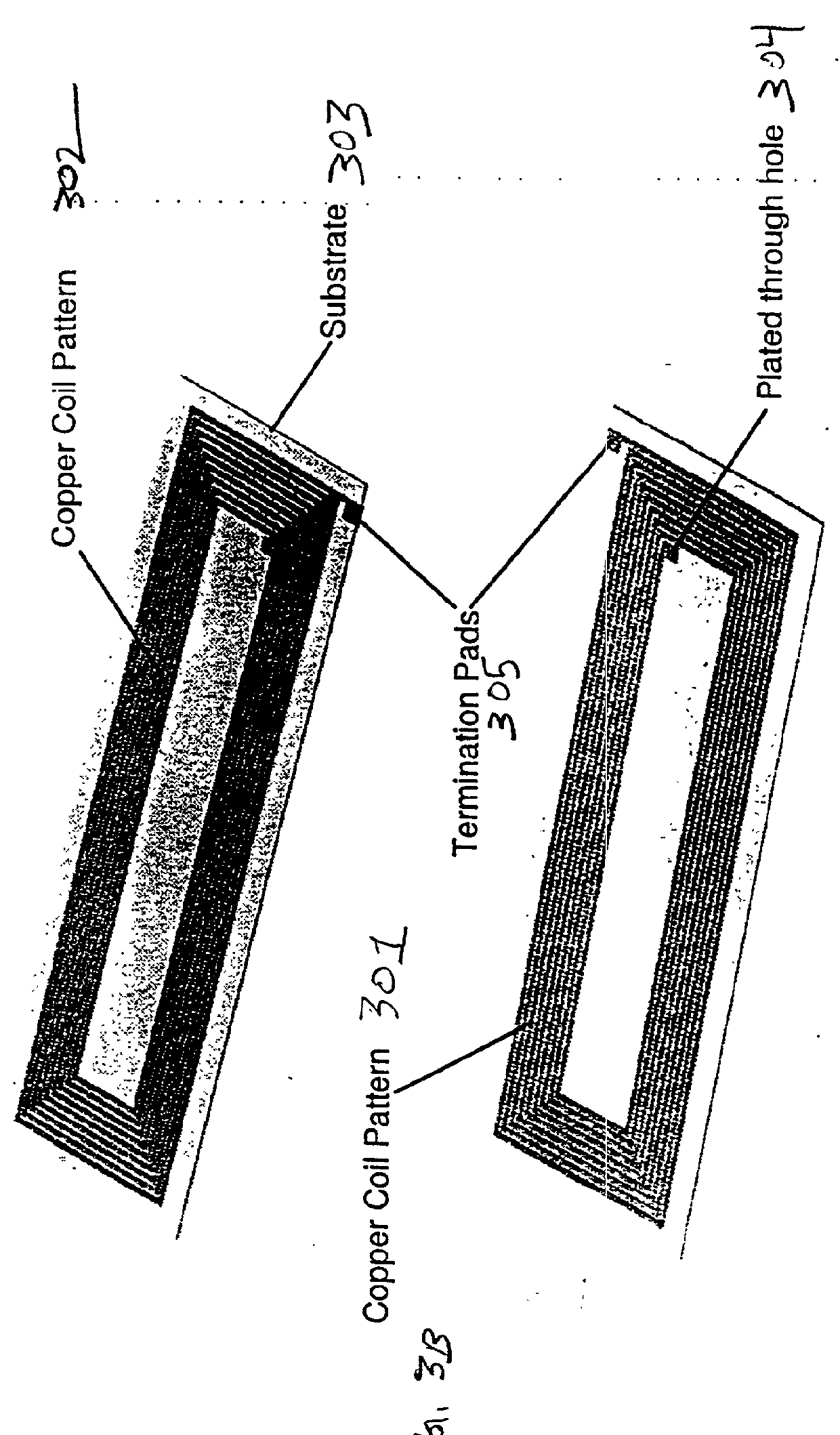

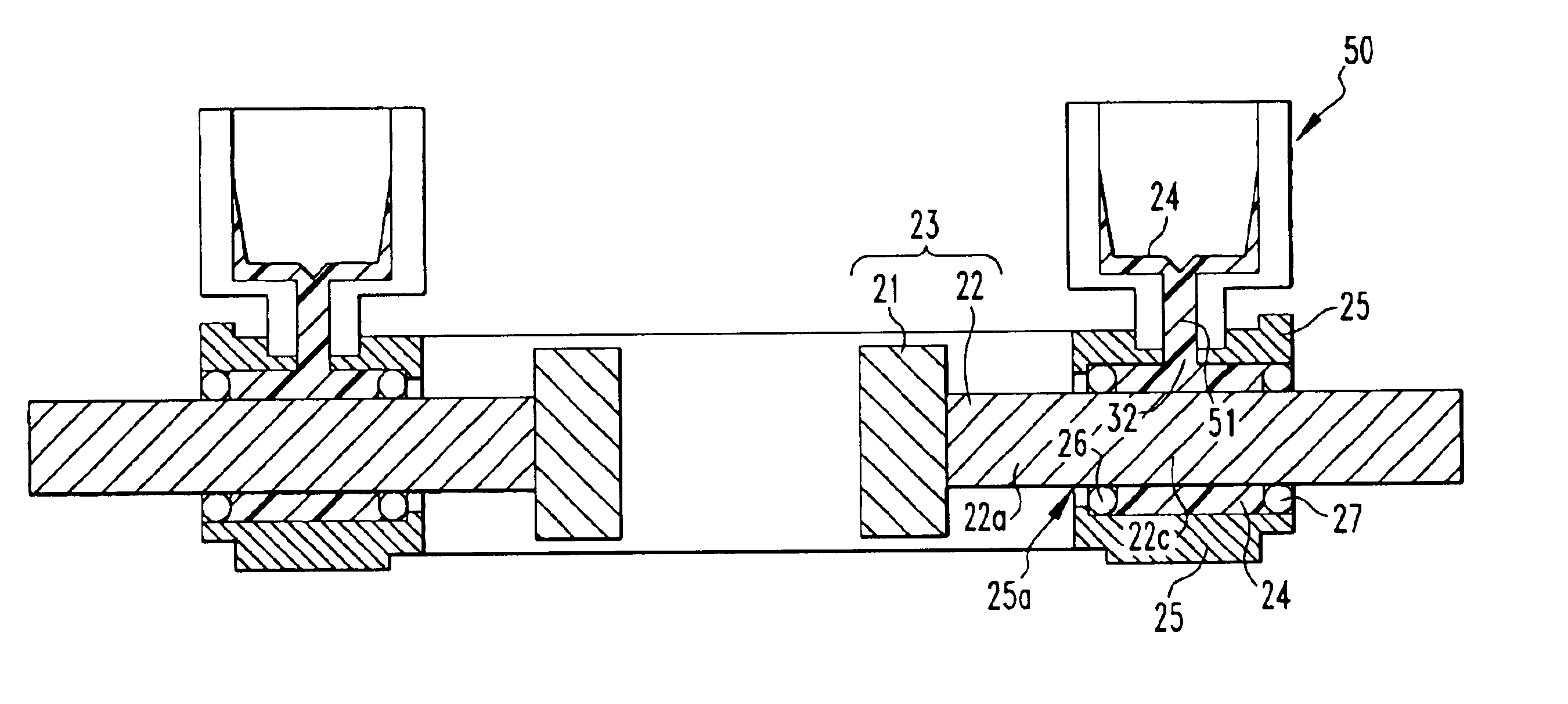

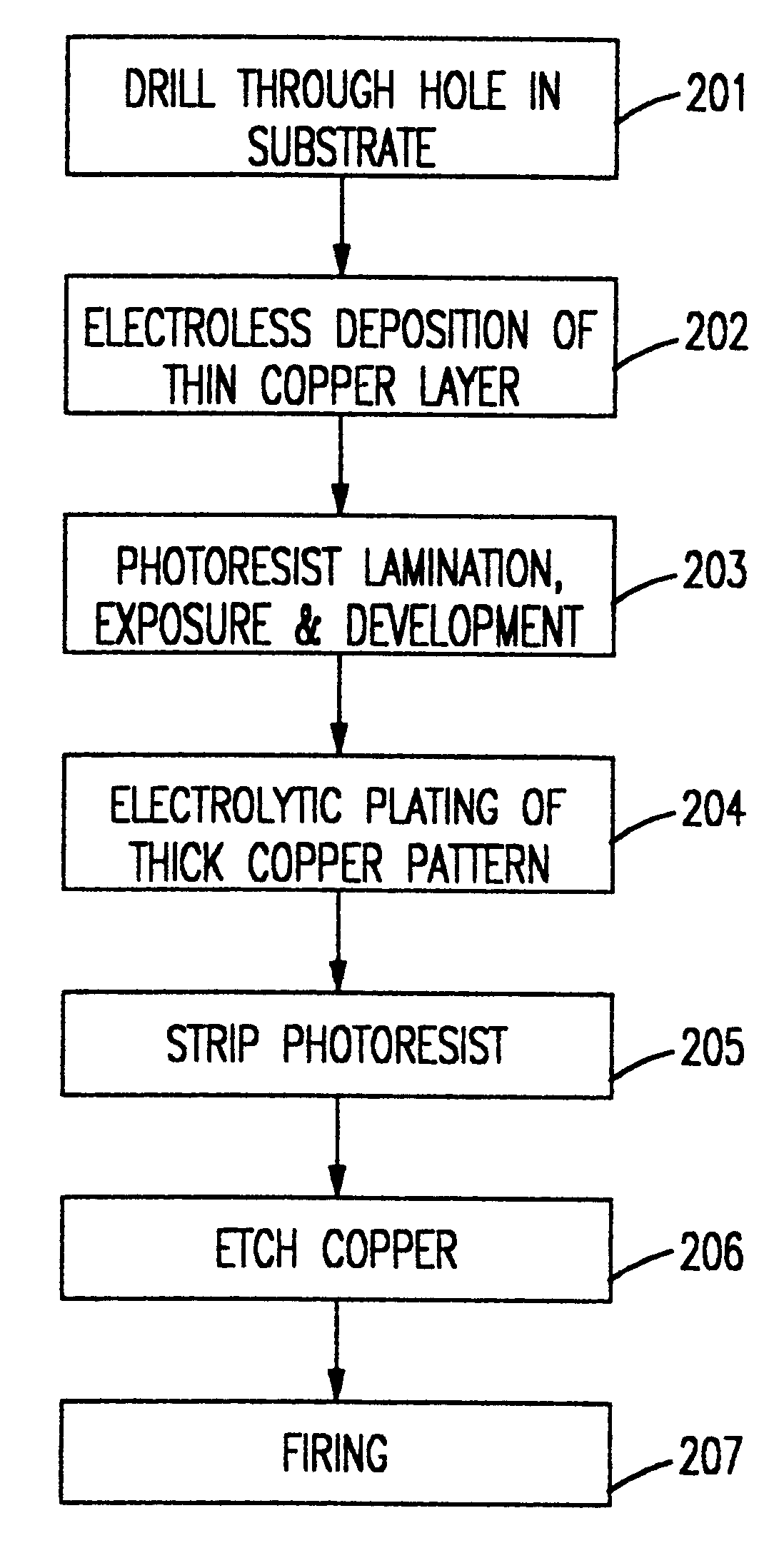

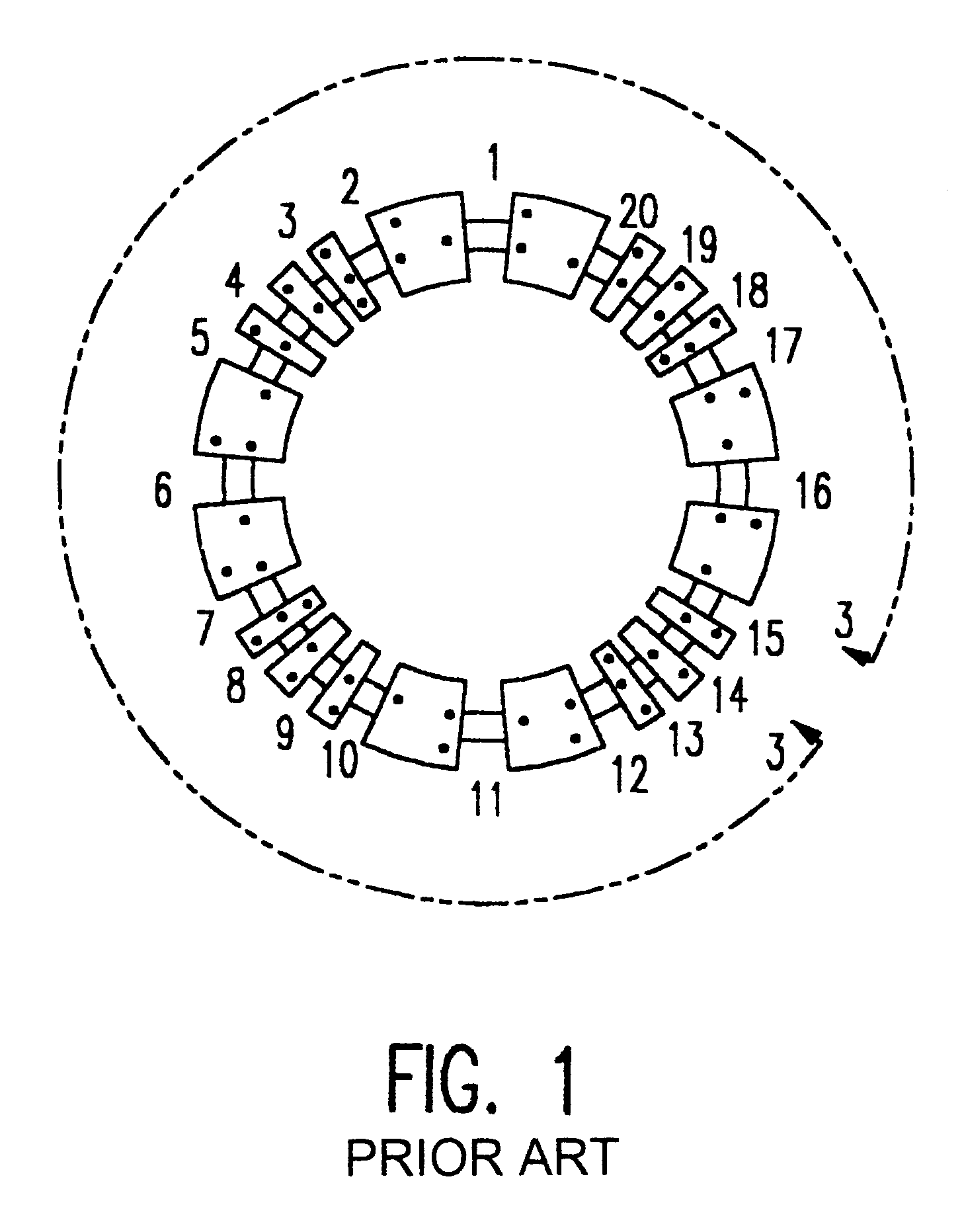

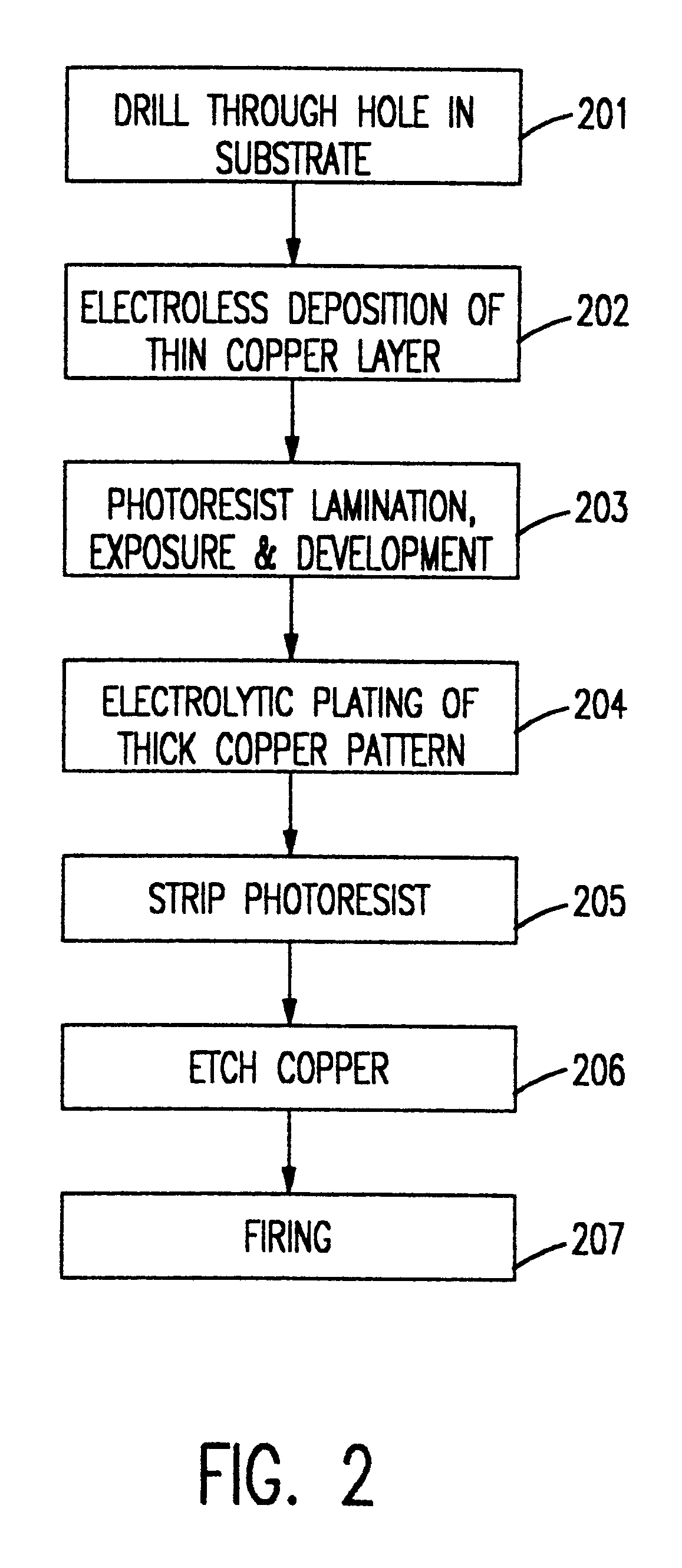

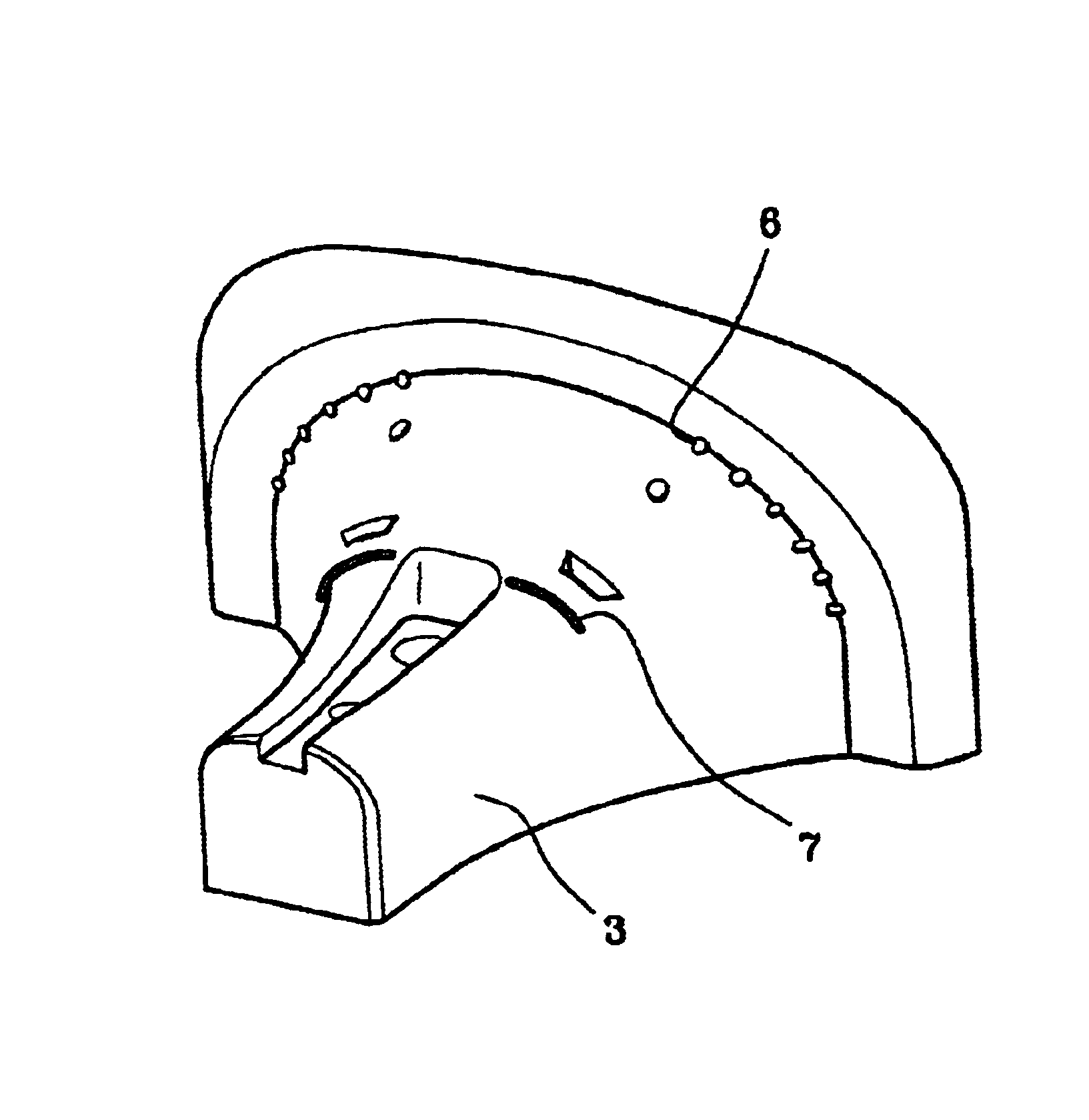

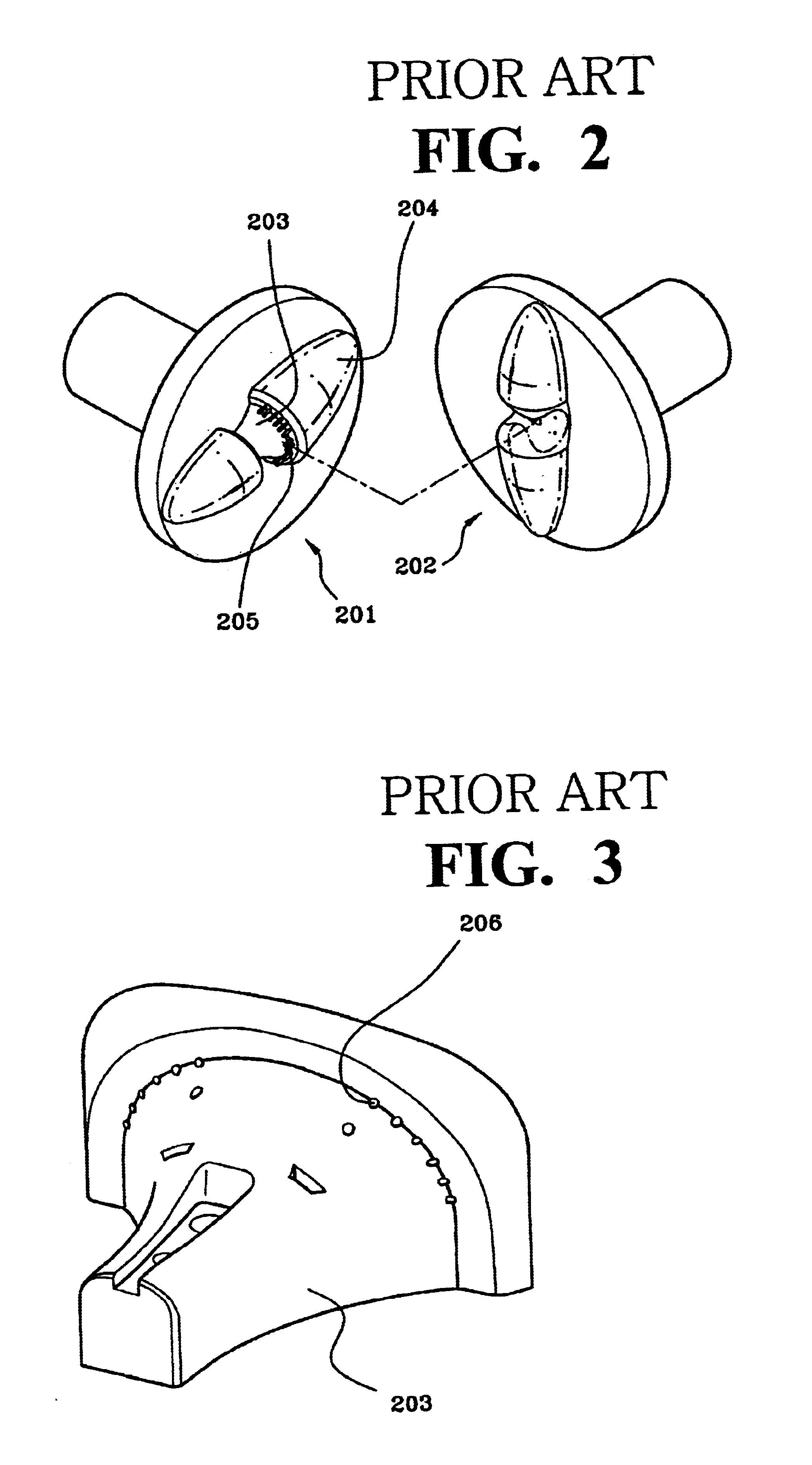

Simplified fabrication method of toroidal charged particle deflector vanes

InactiveUS20010052467A1Improve accuracyMagnetic deflection device manufactureSemiconductor/solid-state device manufacturingCopper coilCeramic

The present invention relates to a method and apparatus of fabricating electromagnetic coil vanes. The method involves photolithographically exposing high resolution, dense wire patterns in a flash coat of copper, on both sides of a ceramic vane substrate. The substrate can be pre-drilled with a through hole to connect the two copper coil patterns. Additional copper is then deposited on both high resolution patterns and in the through hole by plating until the desired thickness is obtained. A firing operation is then performed that eutectically bonds the copper to the ceramic.

Owner:NIKON CORP

Process for preparing square deflecting magnetic core and material thereof

ActiveCN1547234AReduce manufacturing costGuaranteed performance indicatorsMagnetic deflection device manufactureInorganic material magnetismTelevision receiversElectron

The invention discloses a manufacturing method for a kind of square deflection magnetism core and the materials. 1) the Fe2O3, ZnO, Mn3O4, ...MgO, and additives CuO, Bi2O3 elements are blended, prebaked, and reacted with solid phase, the compound generates the ferrite phase after being prebaked; 2) the prebaked material are grinded into pulp with particle size less than phi1.8ª–m, then the additives are added in and carries on the atomization pelleting; 3) the particles are blended and pressed, formed in the automatic presser and special model; 4) uses the flat board or bake bearing base process to carry on oriented baking. The merits of the invention are: 1) it uses cheap materials ferric oxide, with current manufacturing device and special process, it decreases the cost greatly, the key technology parameter is upgraded; 2) PF design makes the magnetic flow area and the density distributed more reasonable, it upgrades the articulation and resolution of the screen; 3)( upgrades the deflection efficiency of negative transmitting pipe of the television receiver, reduces the idle work consumption of the electron beam deflection.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Shadow mask tensioning method

ActiveUS7674148B2Uniform tensionLow costMagnetic deflection device manufactureSolid-state devicesEngineeringShadow mask

A method for tensioning a shadow mask includes positioning a first side of a shadow mask into contact with the lower half of a tensioning frame, positioning an upper half of the tensioning frame into contact with a second side of the shadow mask, and clamping the upper half of the tensioning frame to the lower half of the tensioning frame to form a tensioning frame, and rigidly clamping the shadow mask between the two tensioning frame halves. The method also includes elevating the temperature of the tensioning frame to tension the shadow mask.

Owner:GLOBAL OLED TECH

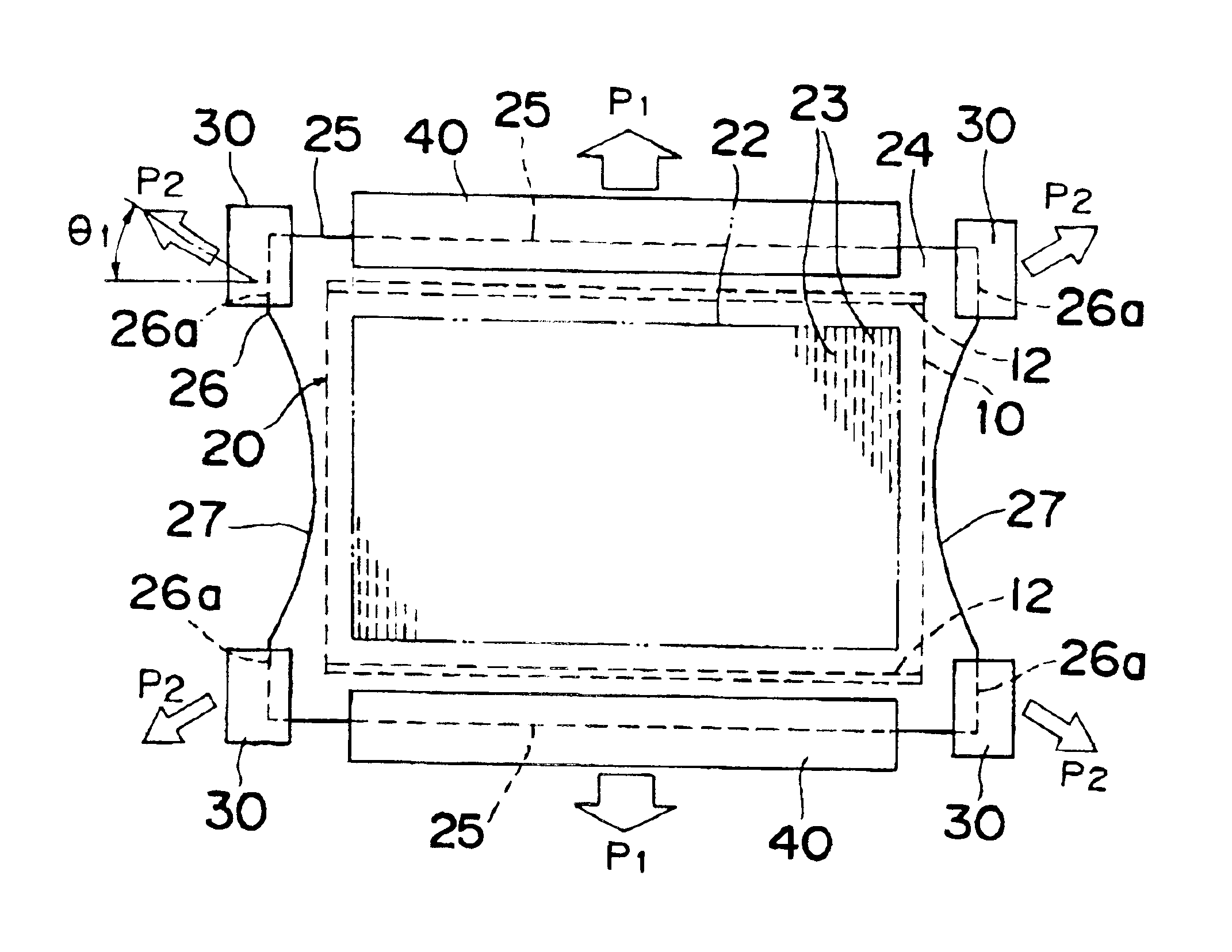

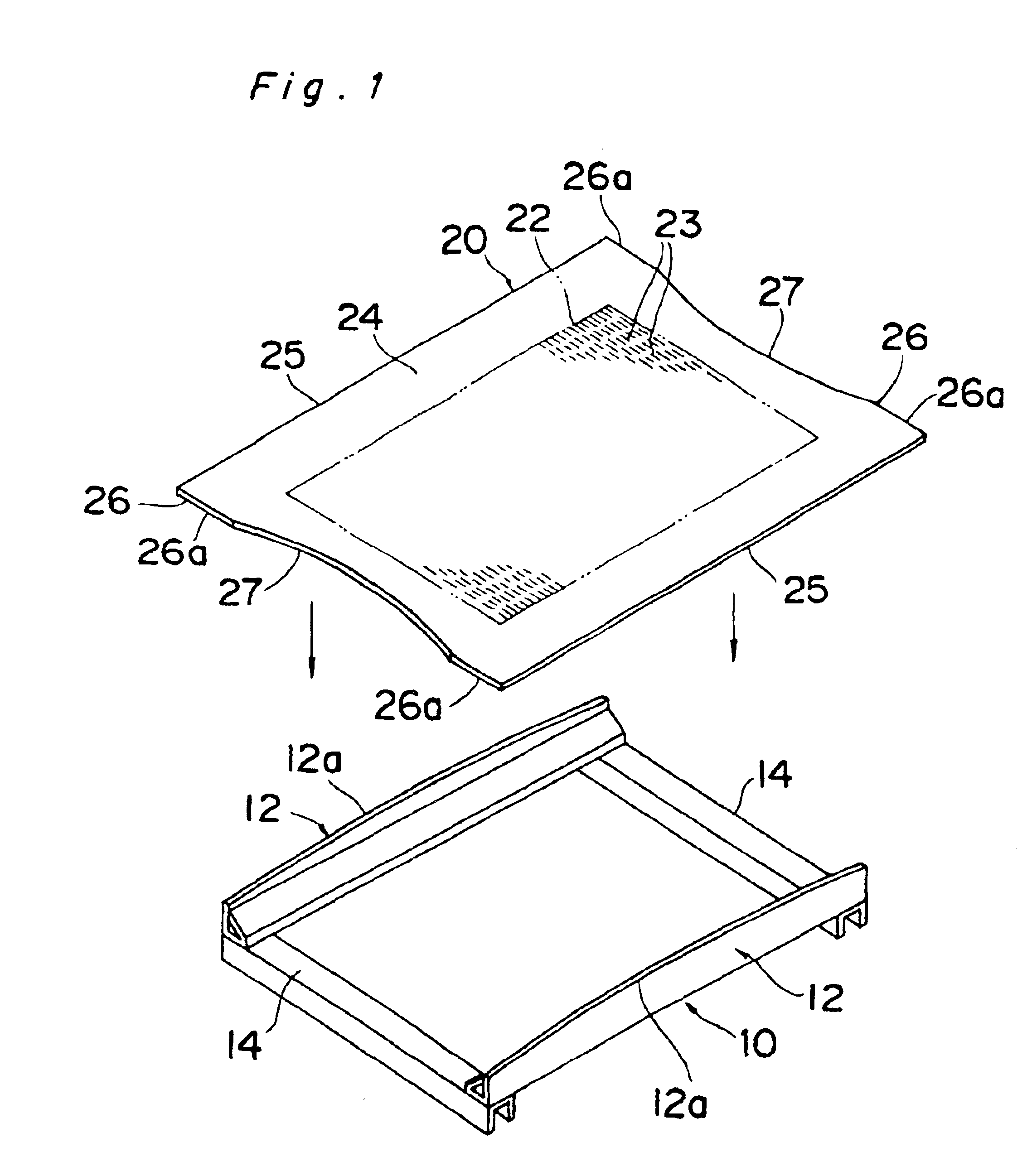

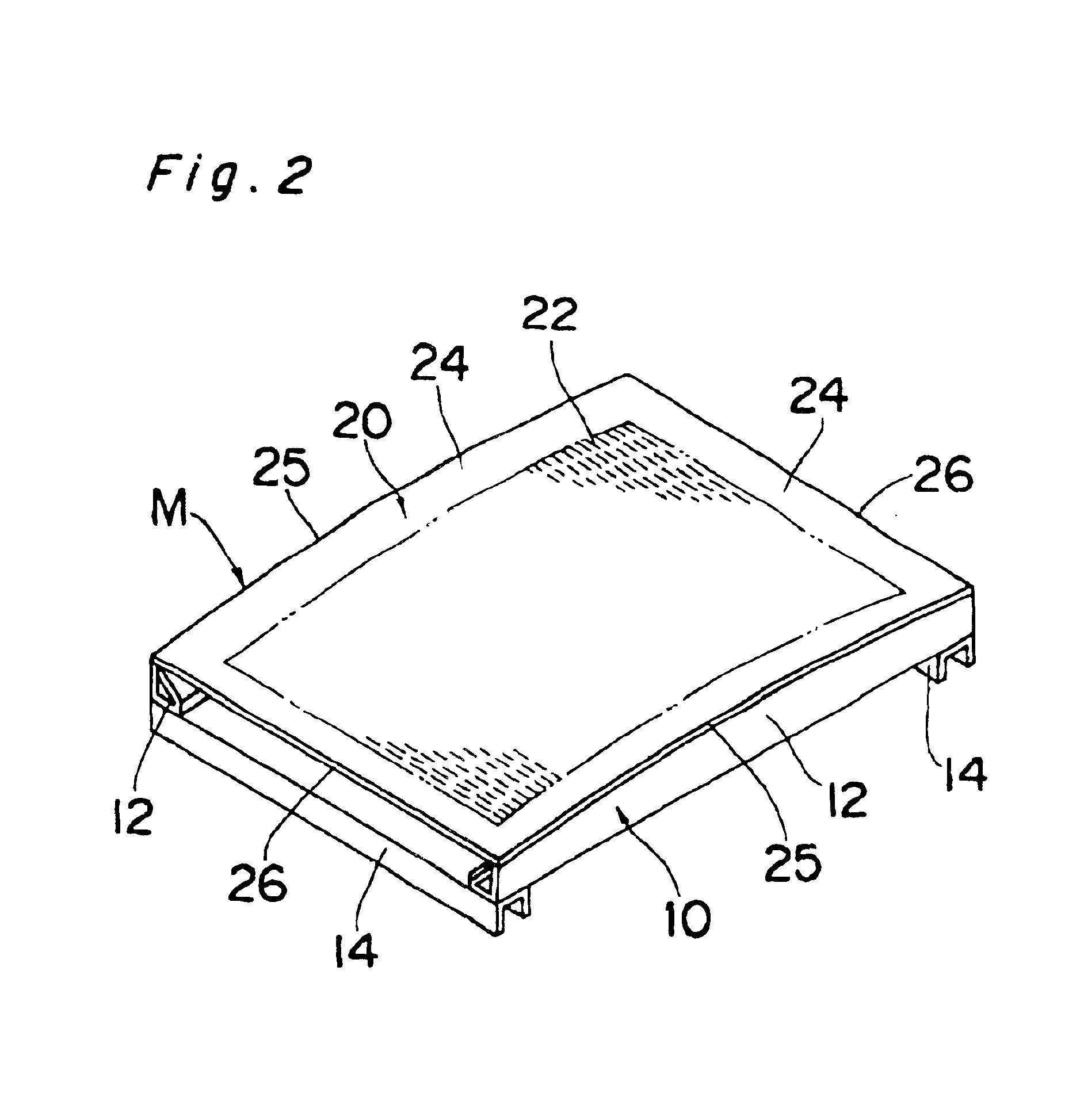

Shadow mask assembly manufacturing method and cathode ray tube manufacturing method

InactiveUS6890237B2Magnetic deflection device manufactureElectrode and associated part arrangementsEngineeringCathode Ray Tube Display

A method of manufacturing a shadow mask assembly, in which a shadow mask is fastened to a support frame in a tensioned state, includes applying a preliminary tension force with a magnitude of 9.8 to 490 N to the four corners of the shadow mask outwardly aslant with respect to sides of the shadow mask. A main tension force is then applied to each of at least a pair of mutually opposite sides of the shadow mask outwardly perpendicularly to the sides. Thereafter, the shadow mask to which the main tension forces have been applied is fastened to the frame side of the support frame.

Owner:PANASONIC CORP

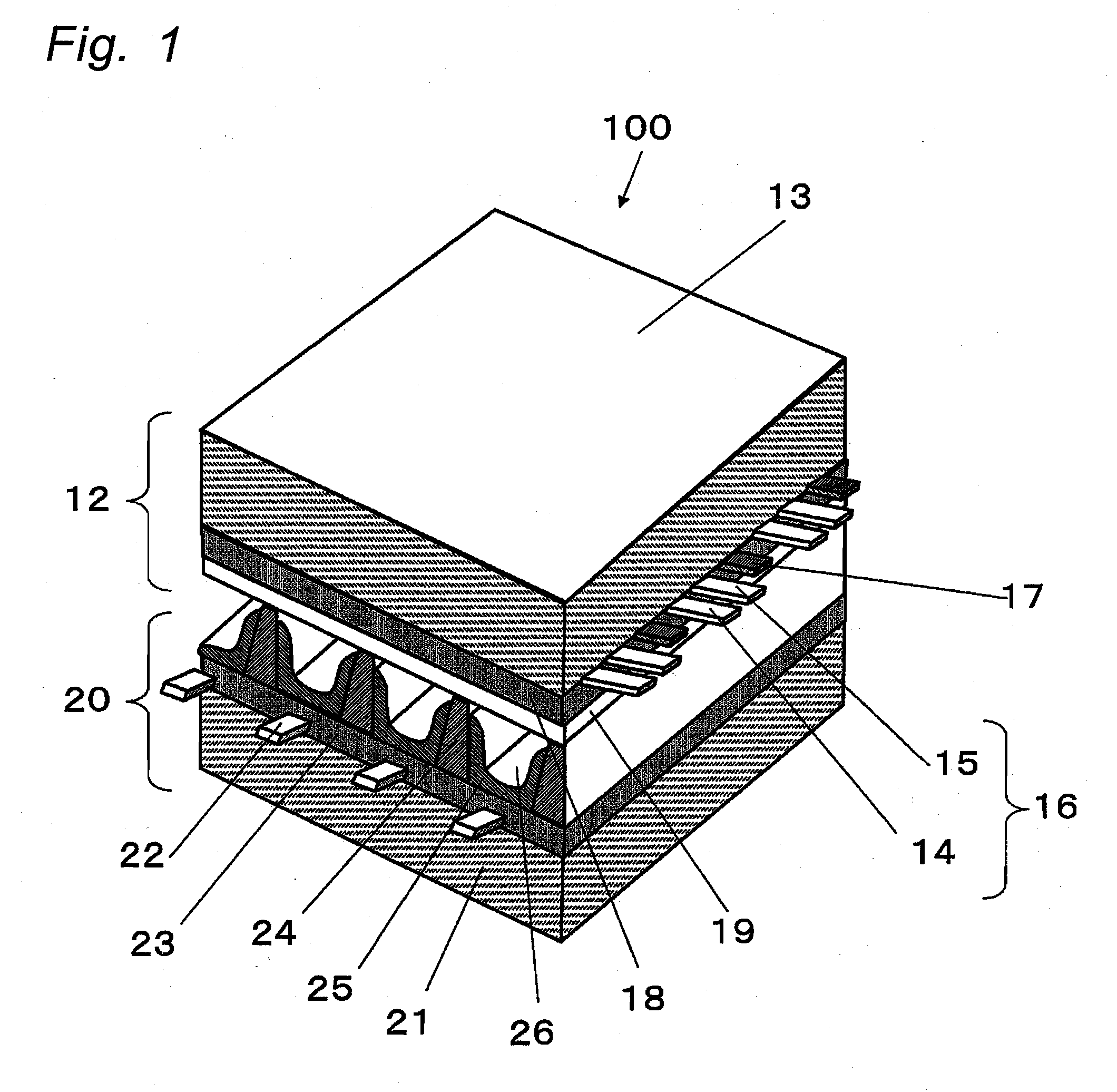

Plasma display panel and method for producing the same

InactiveUS20080272684A1Stable productionLayer is smallAddress electrodesMagnetic deflection device manufacturePhotolithographyPlasma display

A method for producing a plasma display panel wherein the projection of the end portions of electrode in the widthwise direction are suppressed so that failure in insulation and pressure proof is not caused upon forming an electrode pattern by collectively exposing and developing a bus electrode having a two-layered structure. When the electrode pattern having two-layered structure by a photolithography method using a mask, exposure is made by applying light, while a part of a surface of portion of a paste film of an electrode material which portion to be formed into the electrode pattern is shield from the light, so that a dent is formed in the electrode surface after developing and the thermal shrinkage of the center portion and the thermal shrinkage of the end portions of the electrode in the widthwise direction are controlled separately by the dent.

Owner:PANASONIC CORP

Magnetic shield material, production method thereof and color image tube assembling the material

InactiveUS6025673AMagnetic deflection device manufactureElectrode and associated part arrangementsColor imageMagnetic shield

PCT No. PCT / JP96 / 02673 Sec. 371 Date Mar. 10, 1998 Sec. 102(e) Date Mar. 10, 1998 PCT Filed Sep. 18, 1996 PCT Pub. No. WO97 / 11204 PCT Pub. Date Mar. 27, 1997Magnetic shield materials used in color picture tubes which have excellent inner magnetic shield characteristics and an excellent handling strength, method for producing the materials and color picture tubes produced by incorporating the materials are provided. The magnetic shield materials produced by subjecting hot rolled low carbon steel strips essentially consisting of equal to or less than 0.006 weight % of C, equal to or less than 0.002 weight % of N, equal to or less than 0.5 weight % of Mn, 0.5-2.5 weight % of Si, Fe as a balance and unavoidable impurities to a cold rolling and subsequently annealing the cold rolled steel strip at a temperature of 500-700 DEG C. and applying a nickel plating thereto after annealing.

Owner:TOYO KOHAN CO LTD

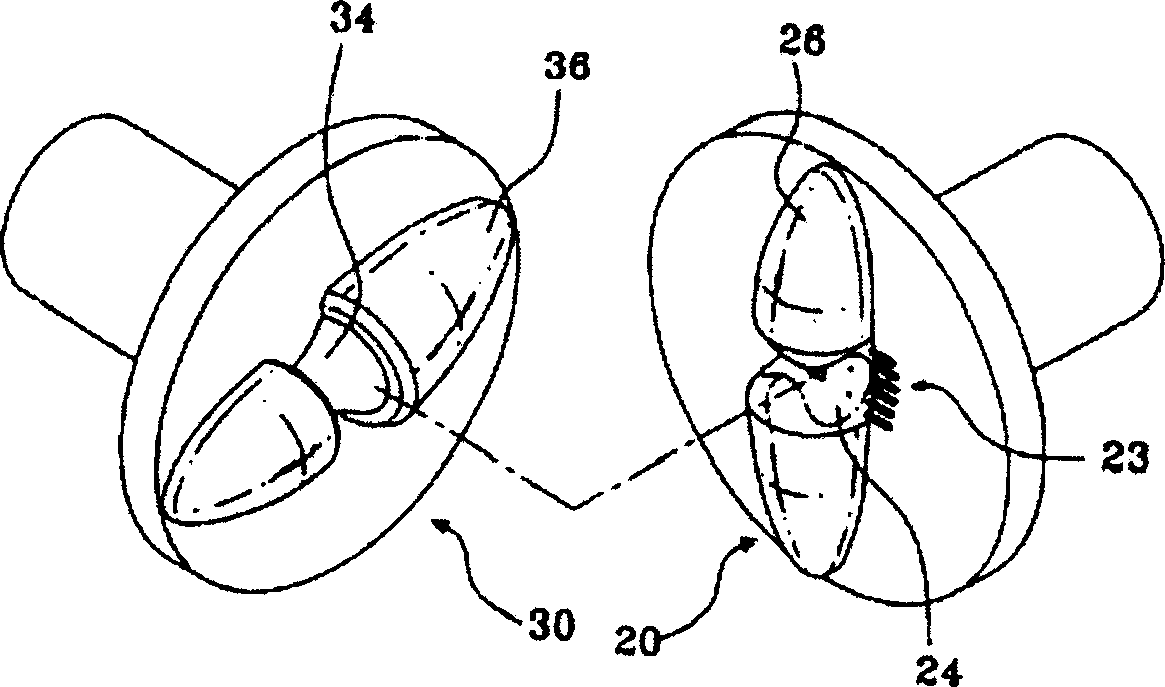

Method of fabricating multipole lens, multipole lens, and charged-particle beam instrument equipped therewith

ActiveUS6946663B2Simple and efficientSimple methodStability-of-path spectrometersMagnetic deflection device manufactureEngineeringMechanical engineering

Owner:JOEL LTD

Simplified fabrication method of toroidal charged particle deflector vanes

InactiveUS6461680B2Improve accuracyMagnetic deflection device manufactureSemiconductor/solid-state device manufacturingCopper coilCeramic

Owner:NIKON CORP

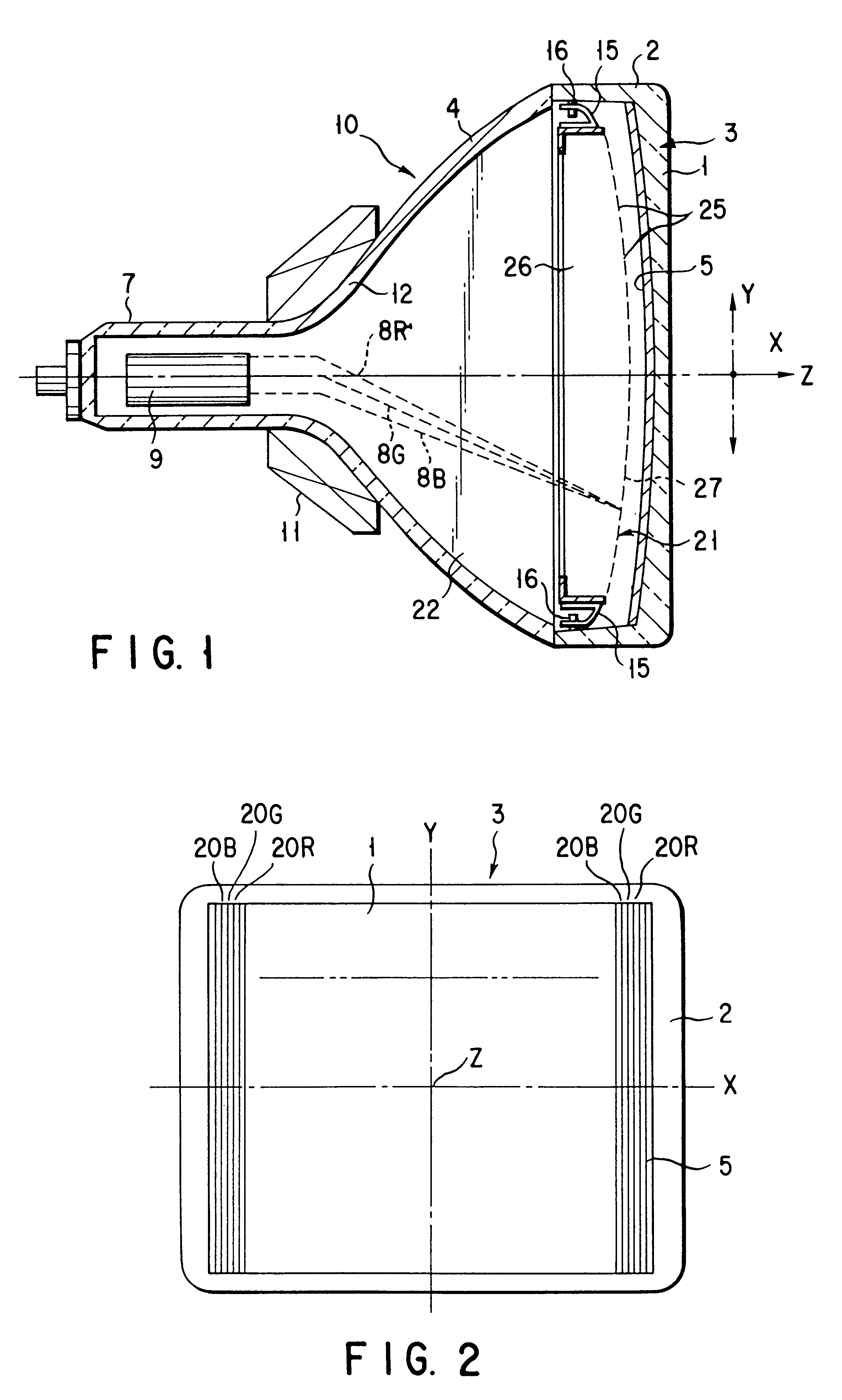

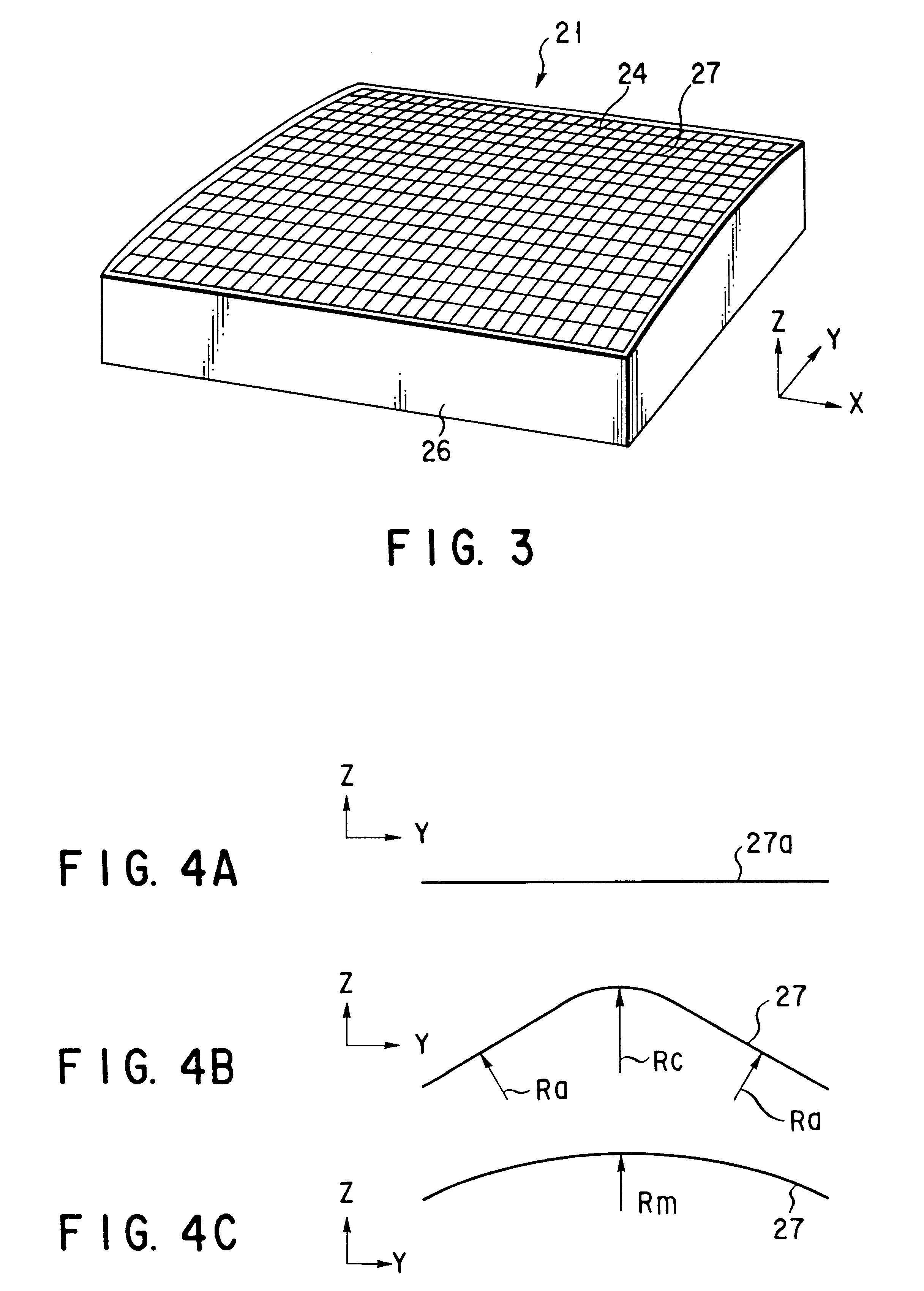

Shadow mask for color cathode-ray tube and method of manufacturing the same

InactiveUS6225735B1Inhibition transitionImprove gripMagnetic deflection device manufactureElectrode and associated part arrangementsCold cathodeEngineering

A shadow mask is arranged to face an inner surface of a substantially rectangular face panel. The shadow mask has a substantially rectangular mask body which has a number of apertures for passing an electron beam, and a rectangular mask frame which supports a peripheral edge portion of the mask body. The mask body is curved in a short axis direction, and is fixed to the mask frame in a state that an internal stress of a direction making small a radius of curvature of the short axis direction is applied. The shadow mask is manufactured in a manner that a rectangular flat mask is-plastically deformed so as to prepare the mask body having a curved surface such that a relation between a radius of curvature Rc of the short axis direction in the vicinity of the long axis and a radius of curvature Ra of the short axis direction in the vicinity of a long side becomes Rc<Ra, and thereafter, the mask body is fixed to the mask frame in a state of being elastically deformed in a direction in which a radius of curvature of the short axis direction becomes large.

Owner:KK TOSHIBA

Fabrication method of high precision, thermally stable electromagnetic coil vanes

InactiveUS6588090B1Line/current collector detailsMagnetic deflection device manufactureEngineeringElectromagnetic coil

The present invention relates to a method and apparatus of fabricating electromagnetic coil vanes. The method involves placing a bonding composition on opposing surfaces of a substrate. First and second complementary coil patterns are formed, and are aligned and bonded to respective clamp plate fixtures. The first complementary coil pattern is bonded to one surface of the opposing surfaces of the substrate via the bonding composition, and the second complementary coil pattern is bonded to the other surface of the opposing surfaces of the substrate via the bonding composition. The bonding composition is cured, and the clamp plates are removed from the first and second complementary coil patterns.

Owner:NIKON CORP

Slightly conducting insulators for cathode-ray tube (CRT) applications

InactiveUS6628057B2Magnetic deflection device manufactureElectrode and associated part arrangementsPhosphorCRTS

A color cathode-ray tube (CRT) has an evacuated envelope with an electron gun therein for generating an electron beam. The envelope further includes a faceplate panel having a luminescent screen with phosphor elements on an interior surface thereof. A focus mask, having a plurality of spaced-apart first conductive strands, is located adjacent to an effective picture area of the screen. The spacing between the first conductive strands defines a plurality of apertures substantially parallel to the phosphor elements on the screen. Each of the first conductive strands has a substantially continuous slightly conductive insulating material layer formed on a screen facing side thereof. A plurality of second conductive wires are oriented substantially perpendicular to the plurality of first conductive strands and are bonded thereto by the slightly conductive insulating material layer. The slightly conductive insulating material layer is a composite material comprising one or more transition metal oxides and a lead-zinc-borosilicate glass.

Owner:THOMSON LICENSING SA

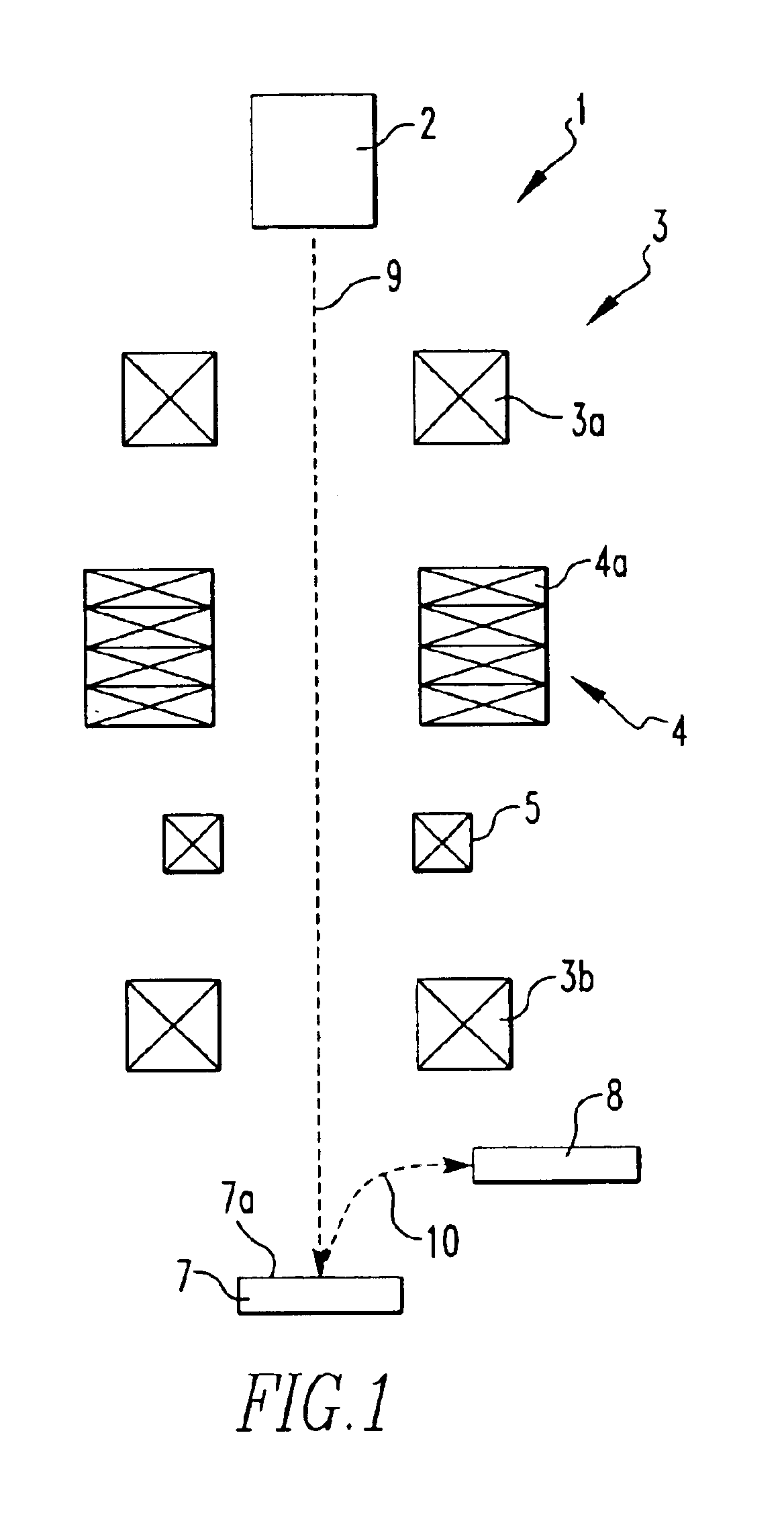

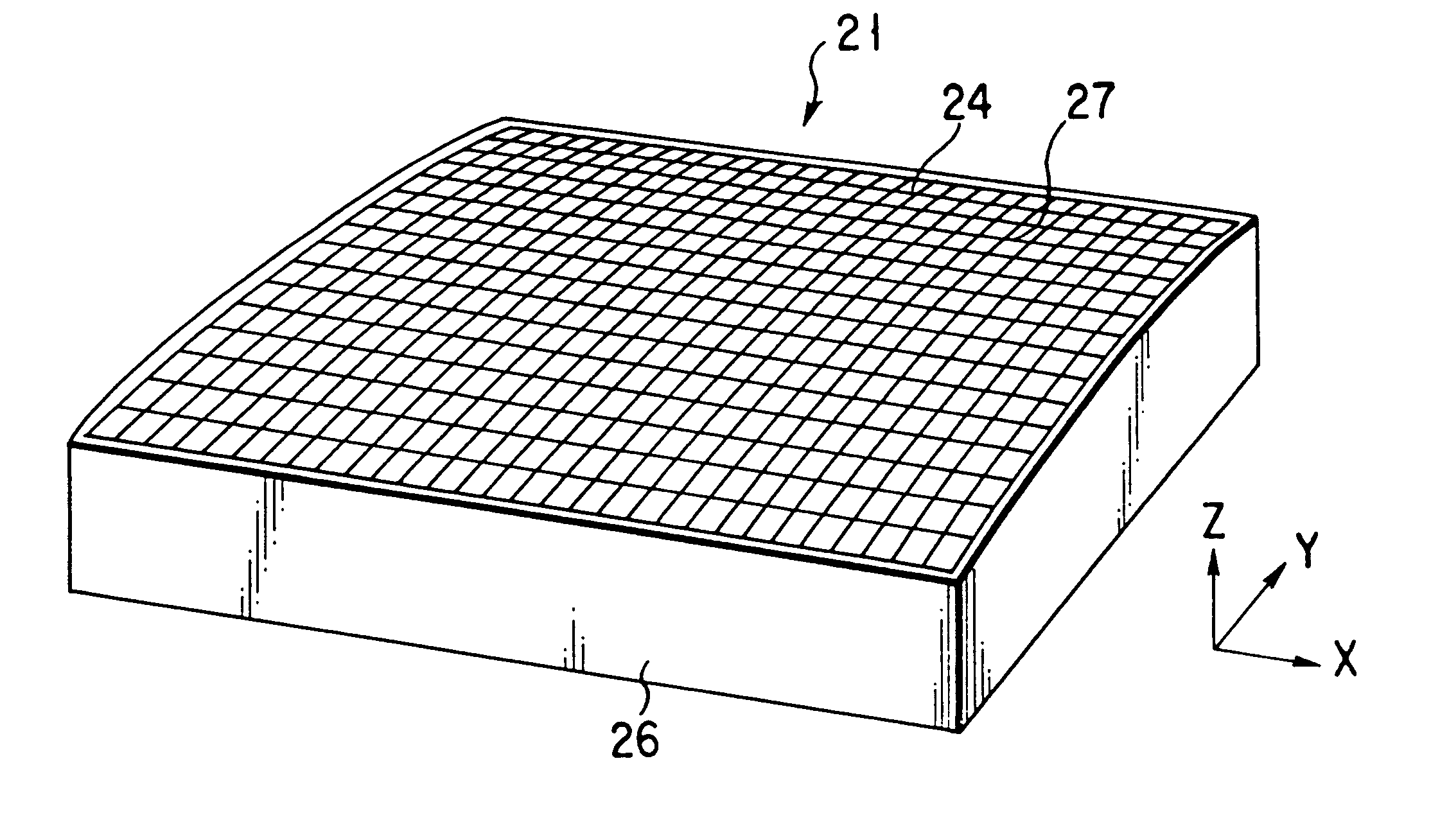

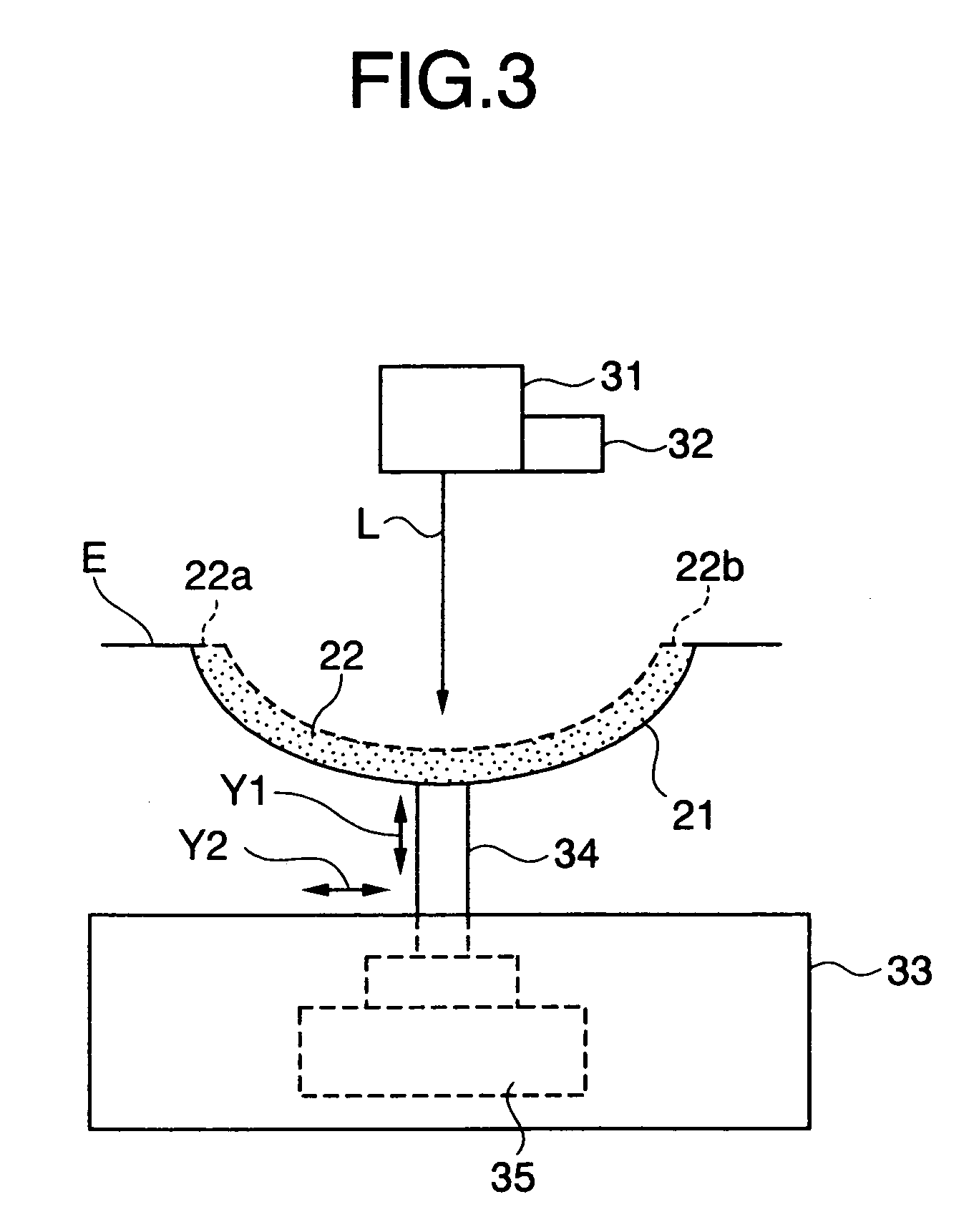

Method and device for producing X-ray image detector, and X-ray image detector

InactiveUS7067789B2Efficiently and uniformlyEfficiently and make surface portionMagnetic deflection device manufactureRadiation applicationsSoft x rayHigh energy

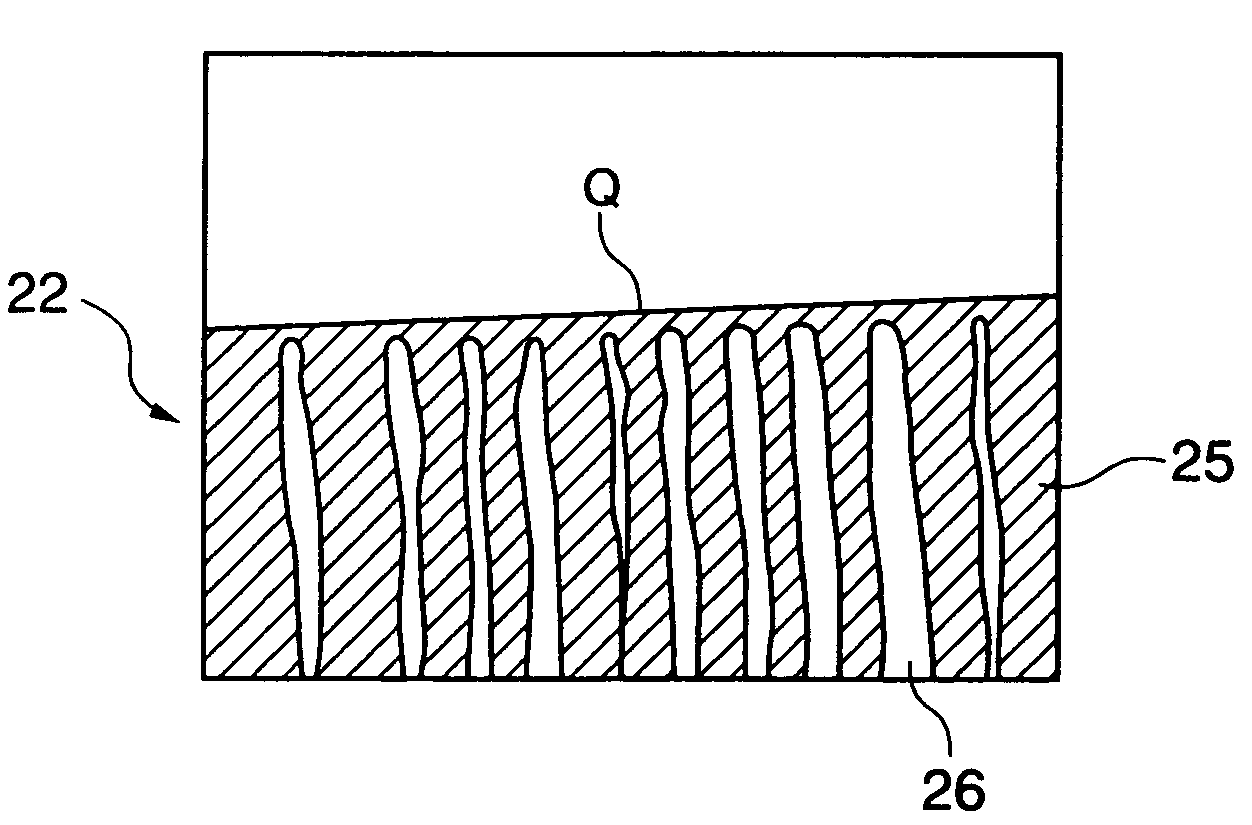

An X-ray light emitting phosphor film (22) such as a CsI film that converts an X-ray to light is formed on an input substrate (21) constituting an input part of an X-ray image detector. A surface portion of the X-ray light emitting phosphor film (22) is irradiated with high-energy light having a wavelength of 500 nm or less. The surface portion of the X-ray light emitting phosphor film (22) is locally sublimated and / or fused to be flattened by the irradiation with the high-energy light. The use of the high-energy light such as a laser beam makes it possible to efficiently and uniformly flatten the surface portion of the X-ray light emitting phosphor film.

Owner:KK TOSHIBA

Self-melting adhered insulating wire and self-melting adhered twisted wire using same

InactiveCN1177331CLess solventReduce odorMagnetic deflection device manufactureElectrode and associated part arrangementsLitz wireHeat resistance

A self-bonding insulated wire having a bonding layer on an insulated wire, the bonding layer comprising a crystalline copolyamide having a melting point within the range of 105 to 150 DEG C and a relative viscosity of 1.4 to 1.6 measured at 25 DEG C with respect to a 0.5% by weight m-cresol solution thereof, and optionally at least one member selected from the group consisting of a high-melting nylon having a melting point within the range of 200 to 300 DEG C and an antioxidant. The bonding layer can be formed from a coating having an increased resin concentration and the residual solvent content of the bonding layer is small. The self-bonding insulated wire and self-bonding litz wire comprised thereof provide deflecting coils having a decreased strain, good adhesive property and good heat resistance.

Owner:KANEKA CORP

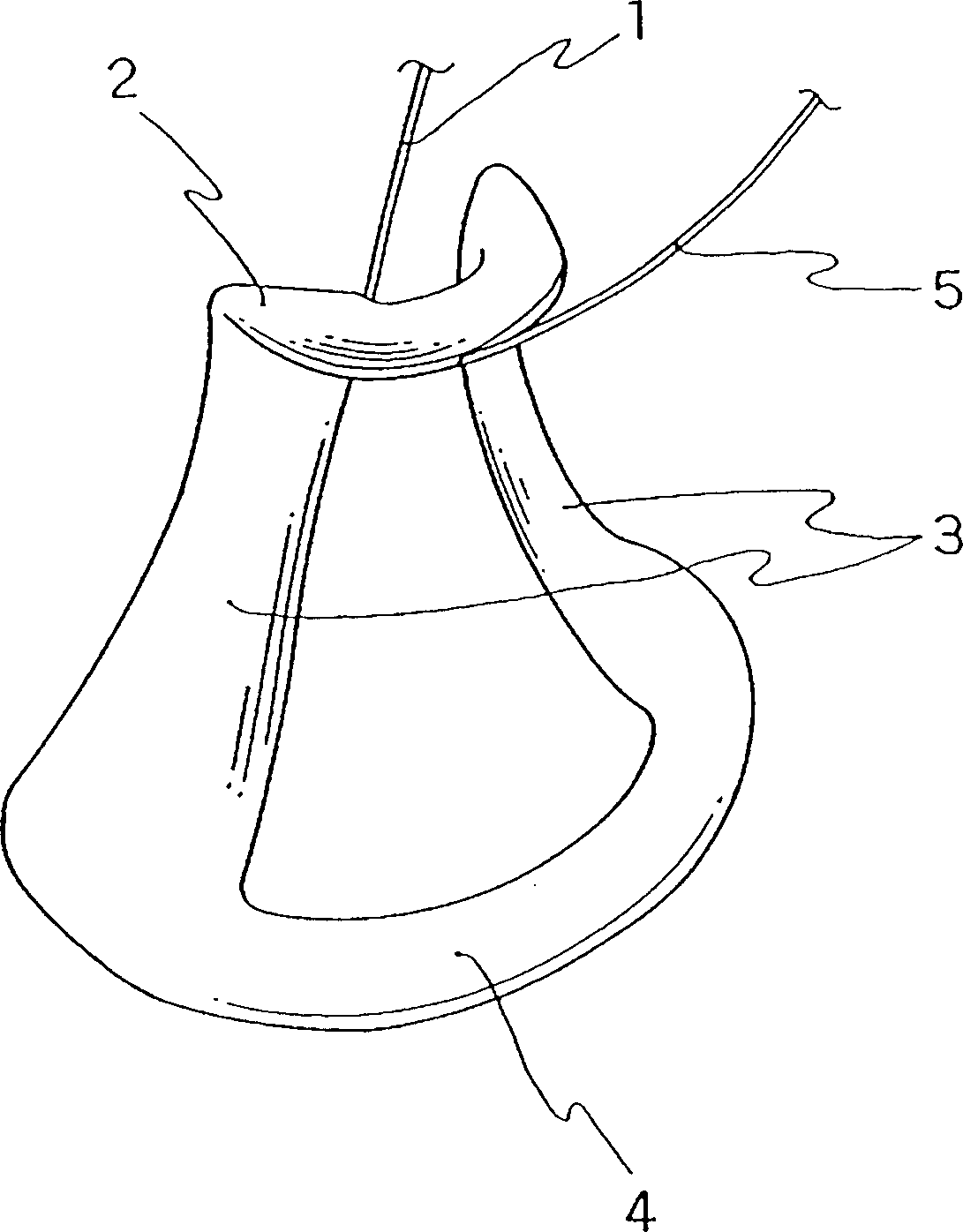

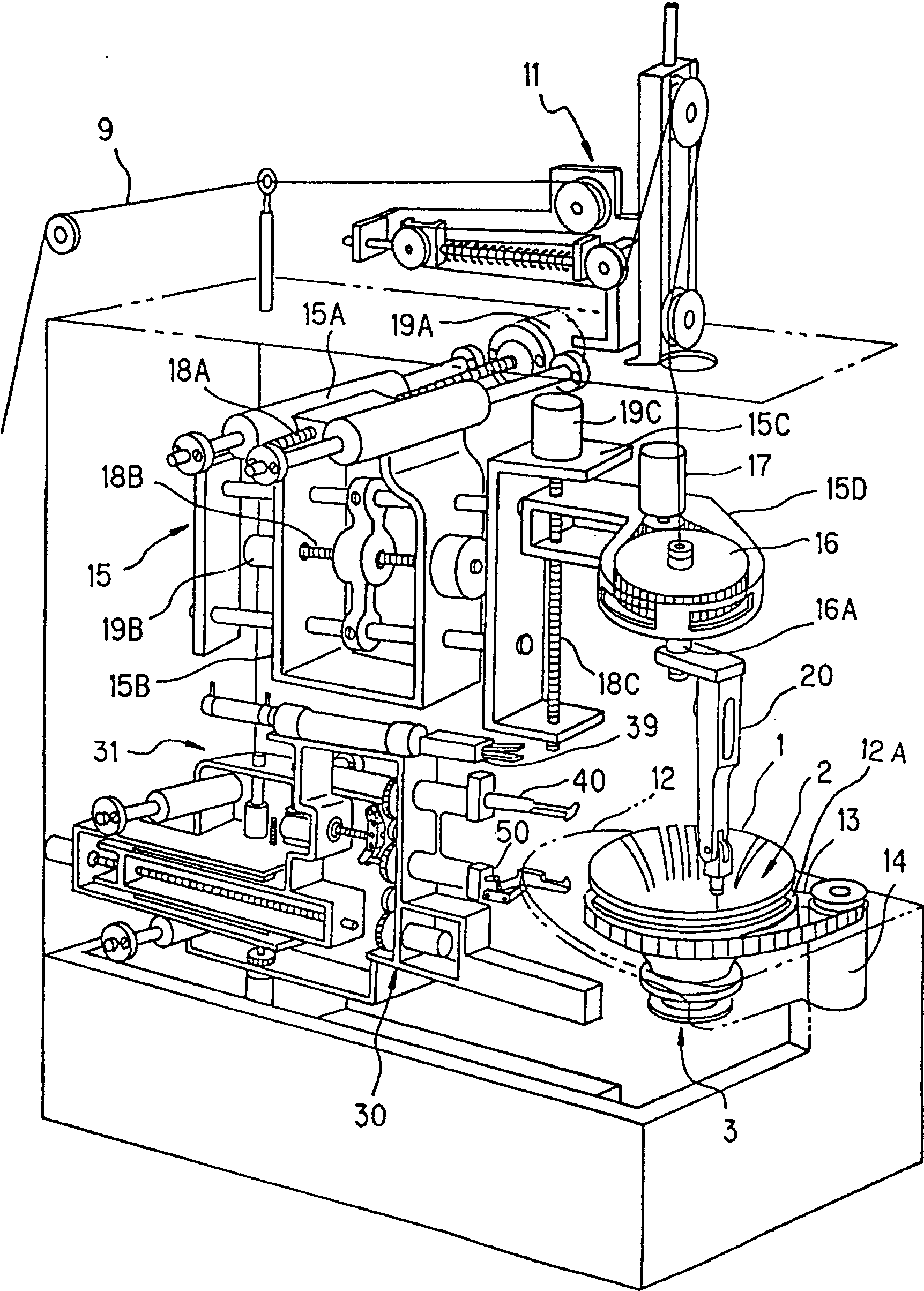

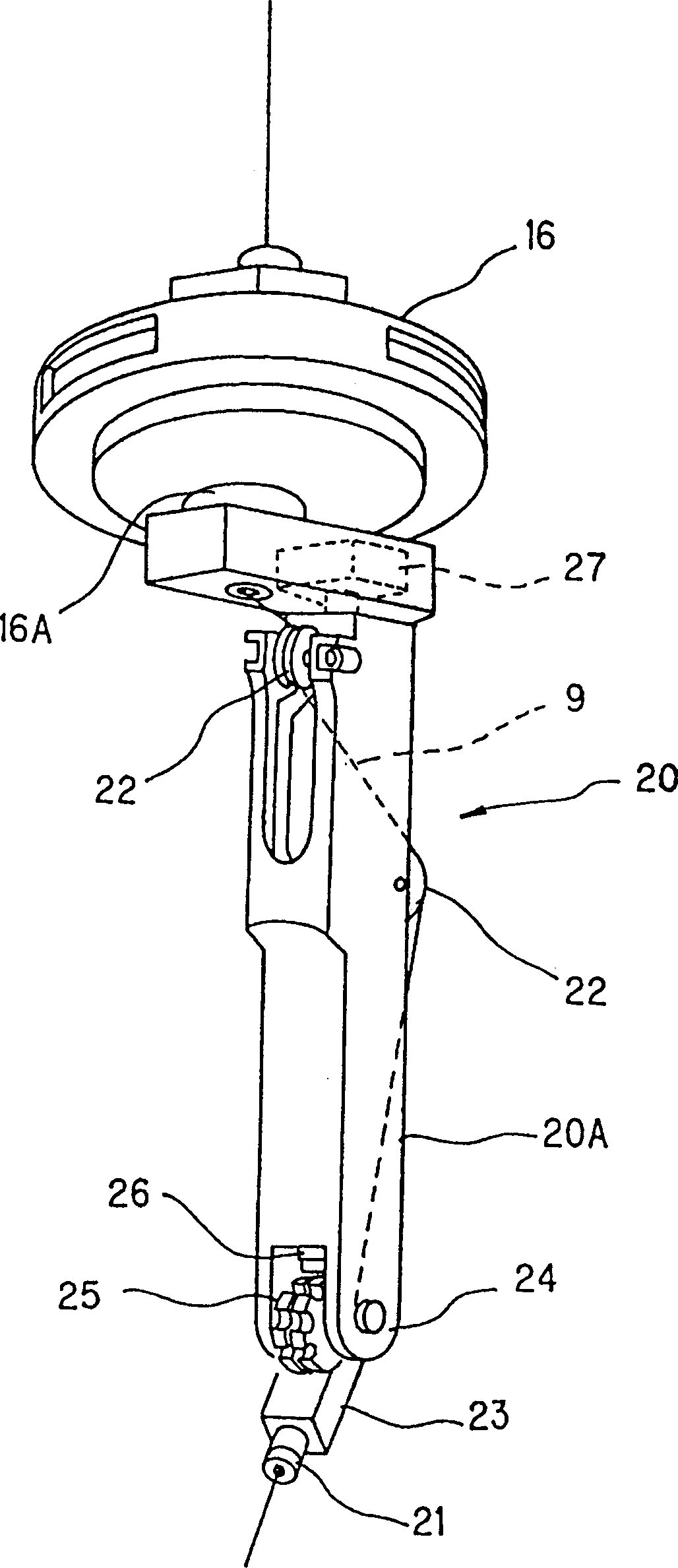

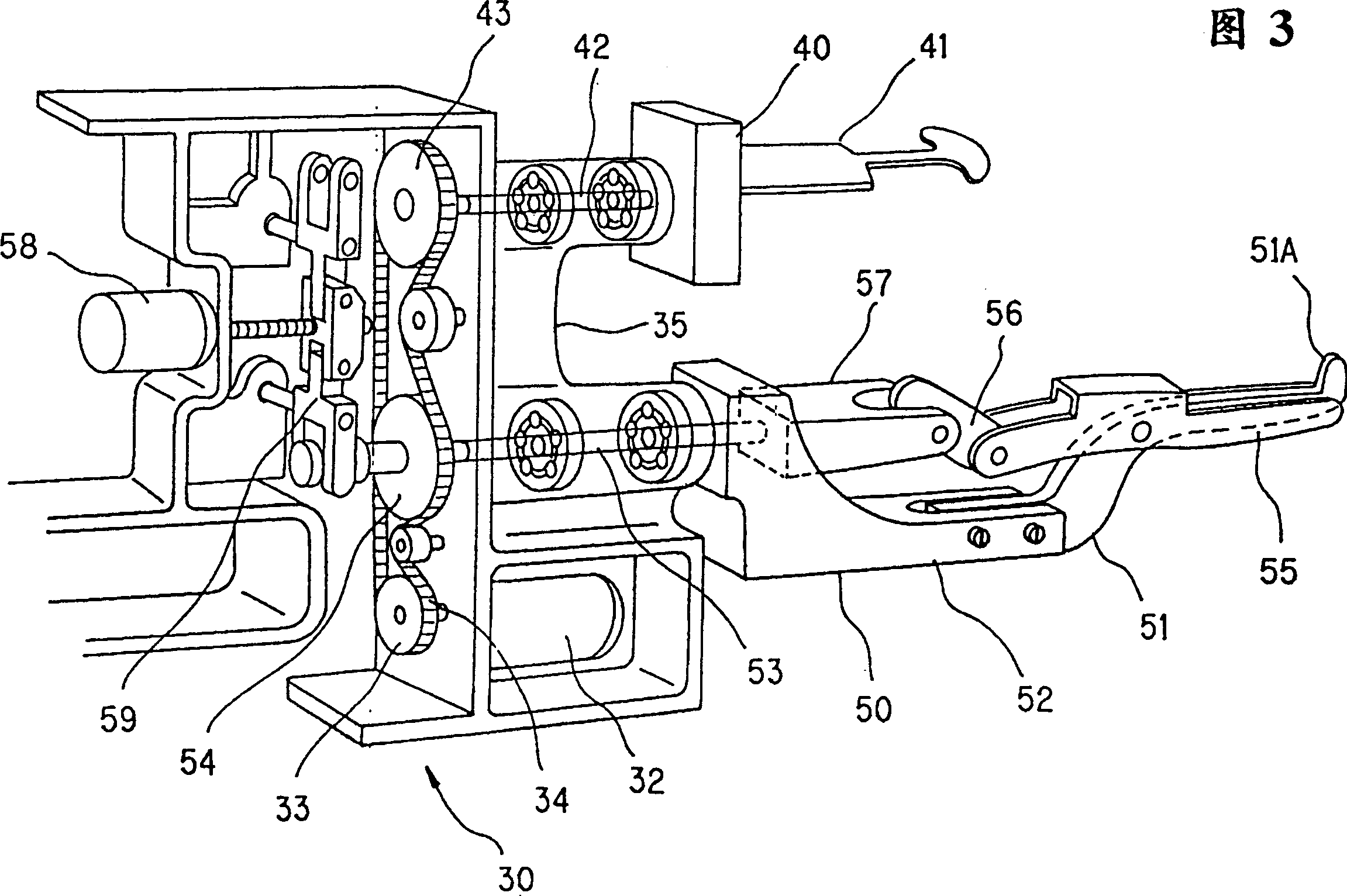

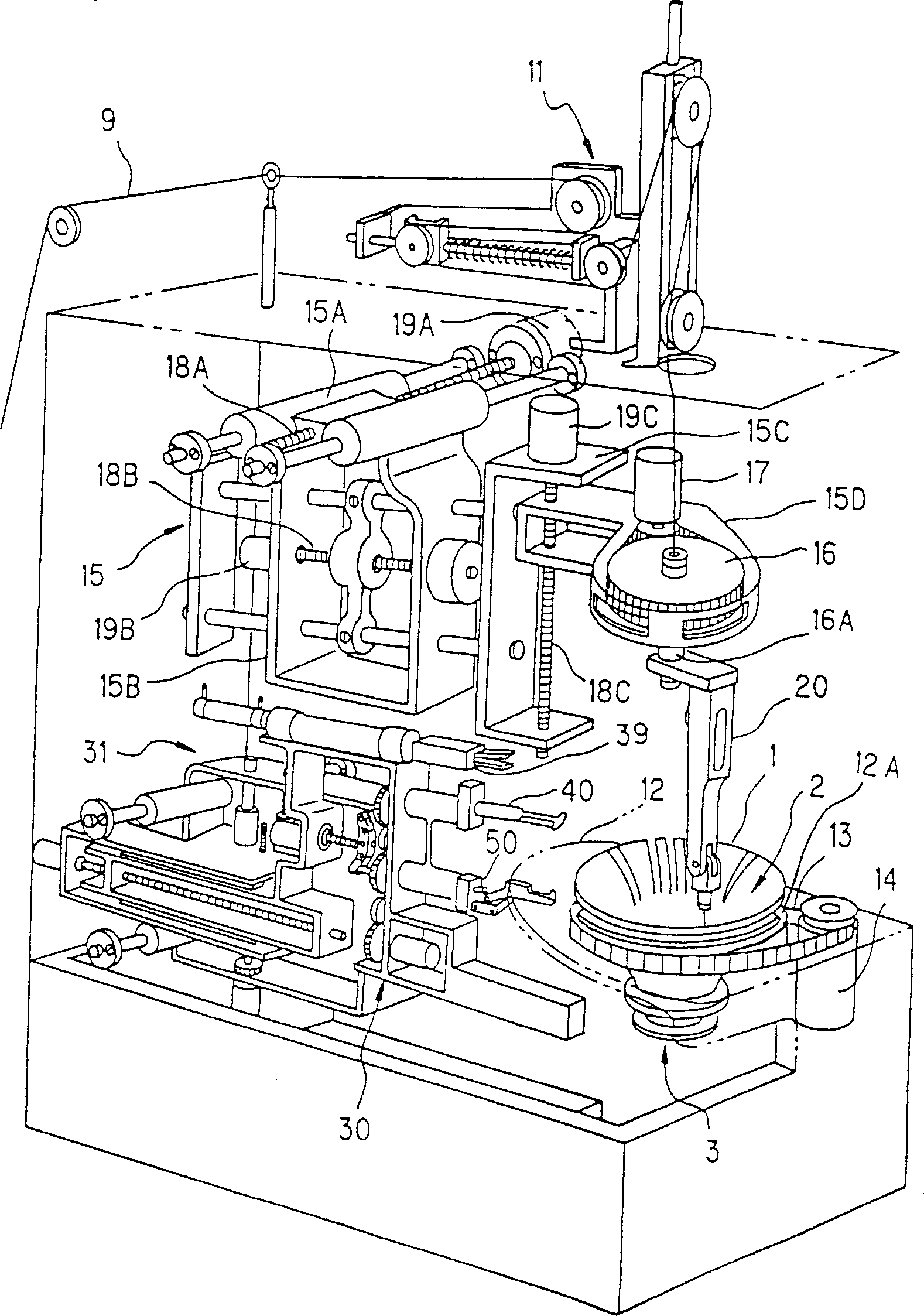

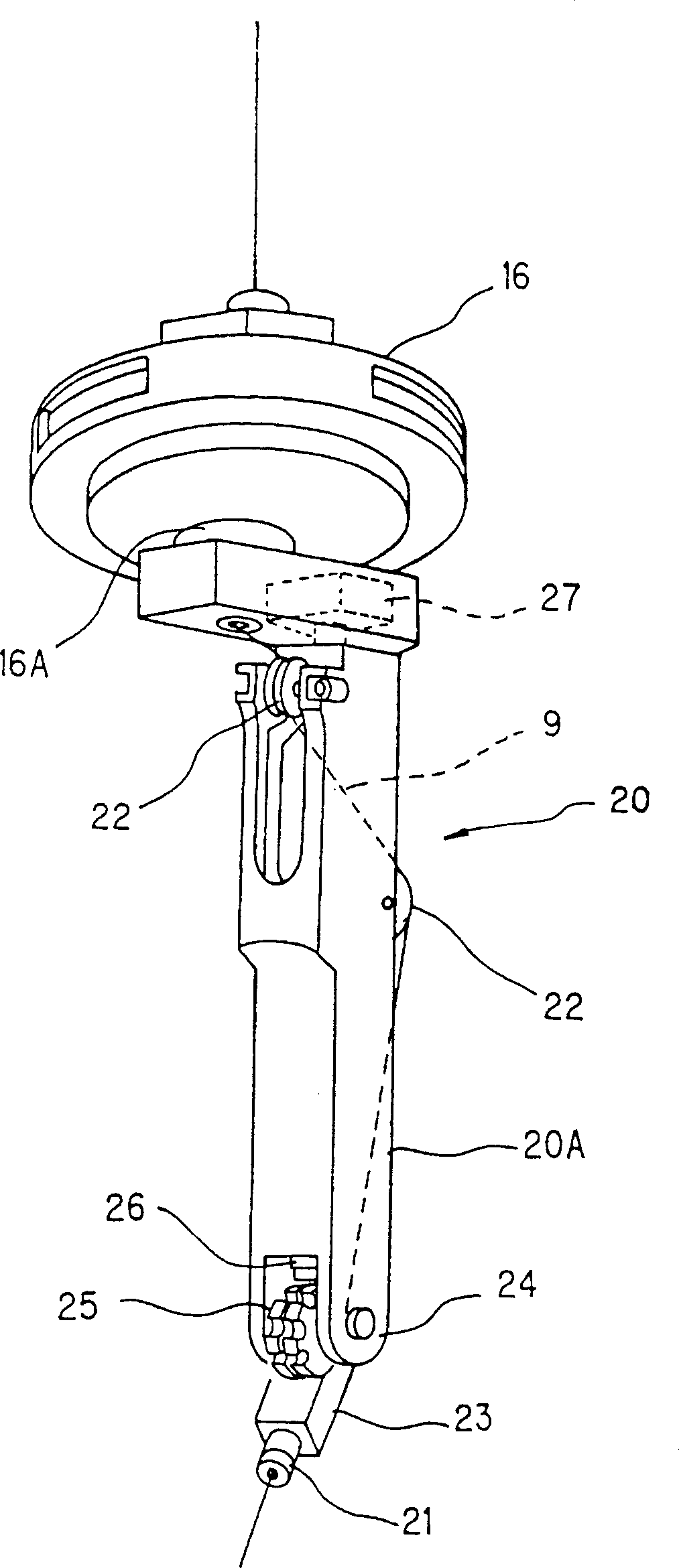

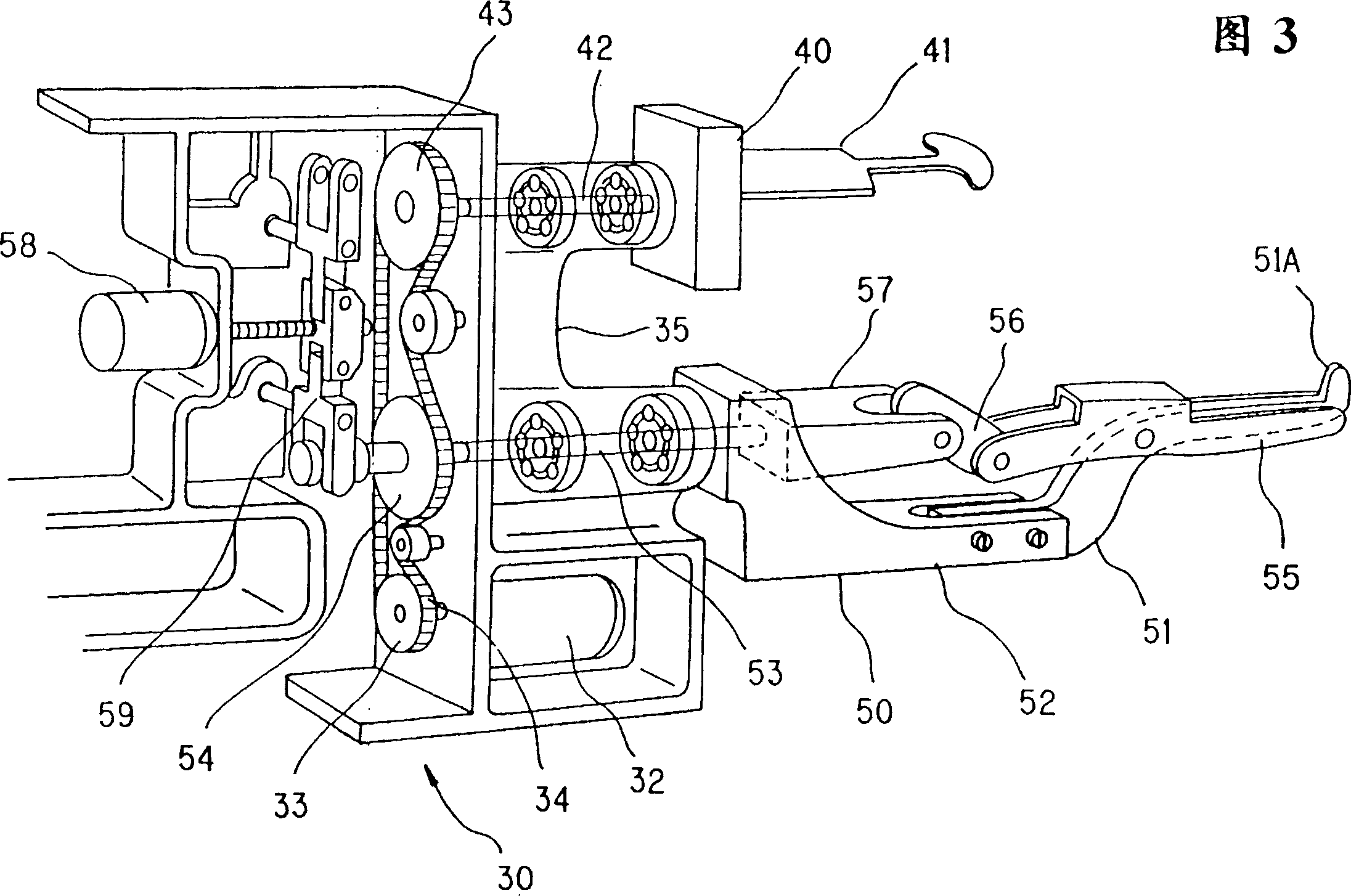

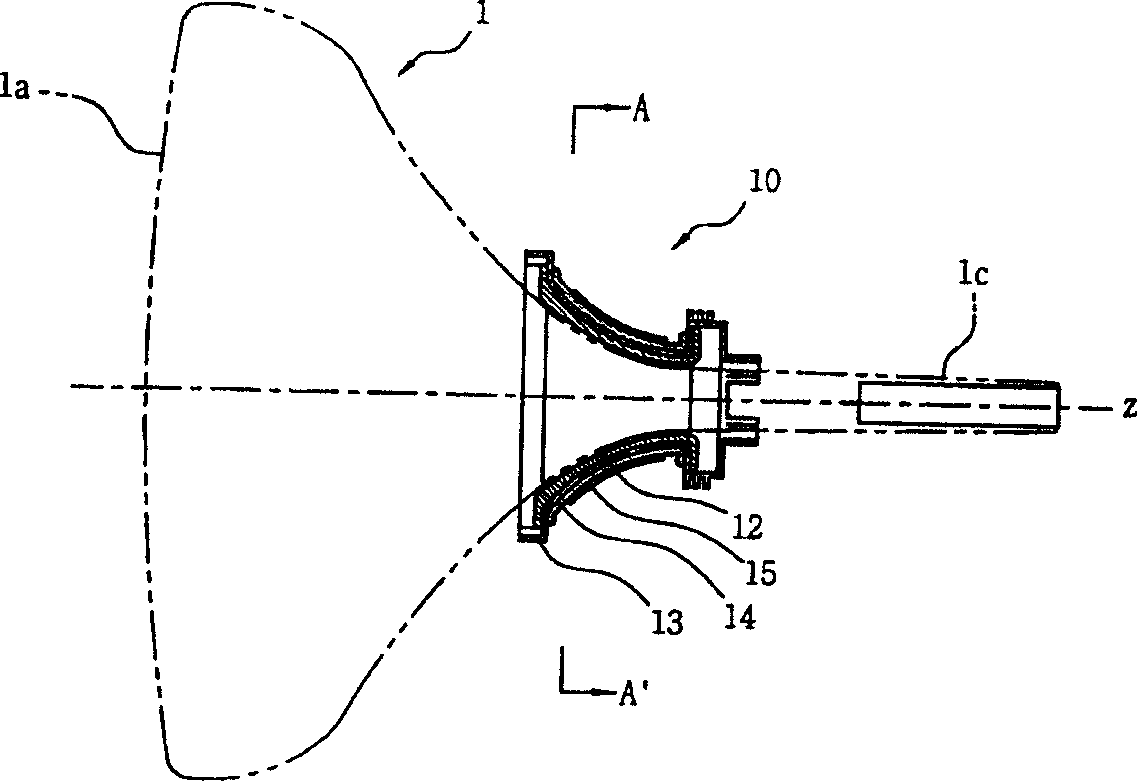

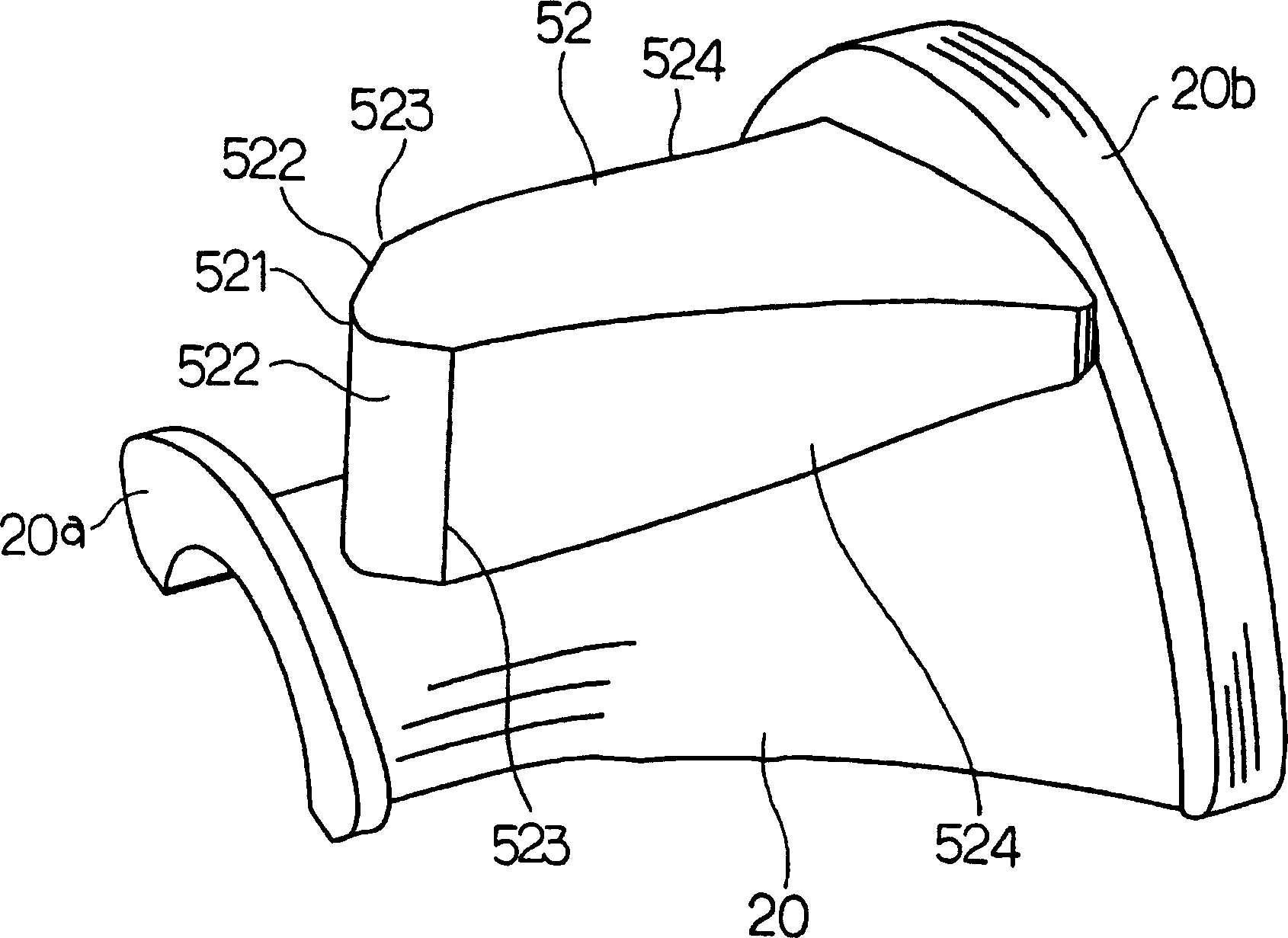

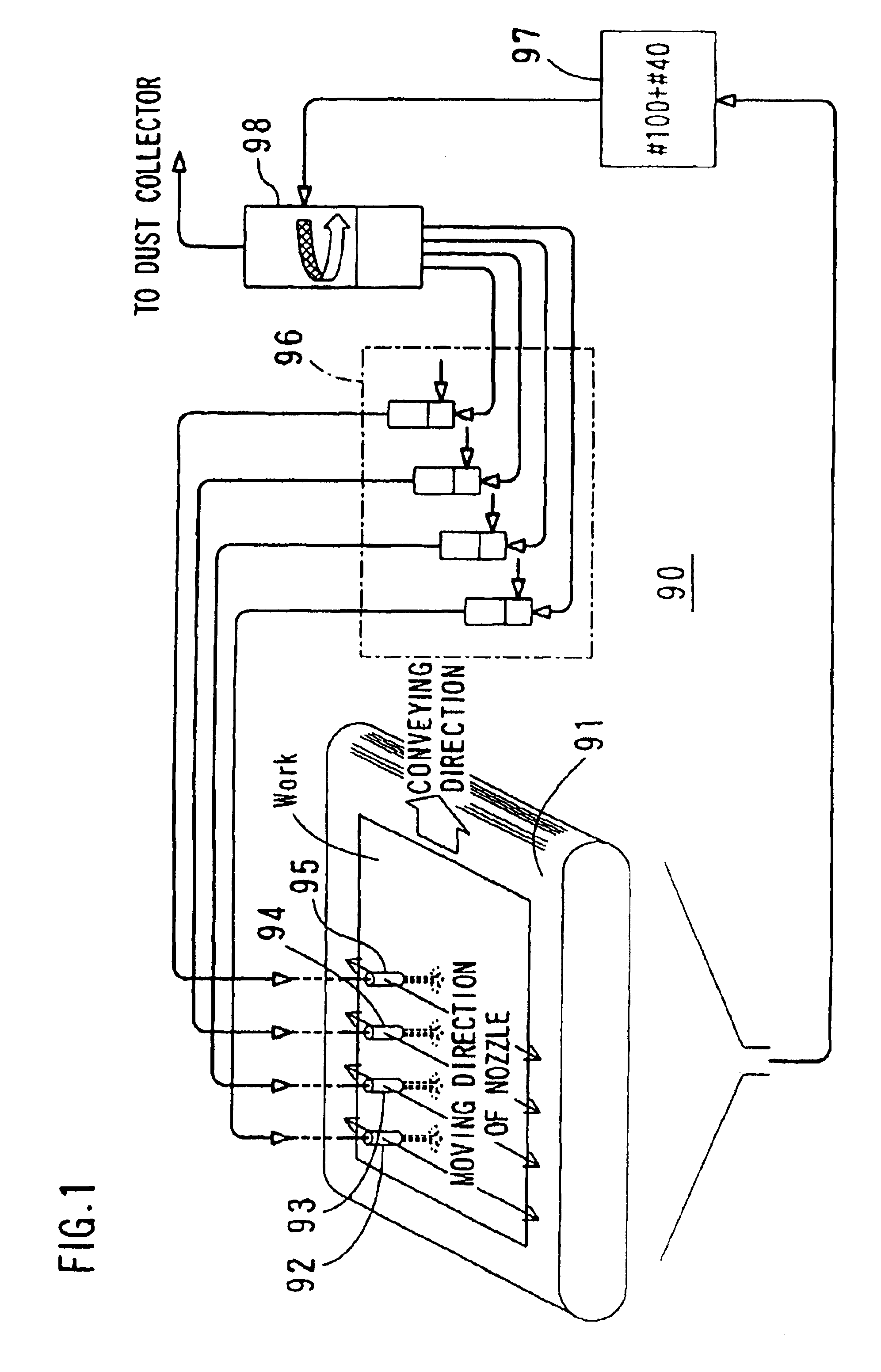

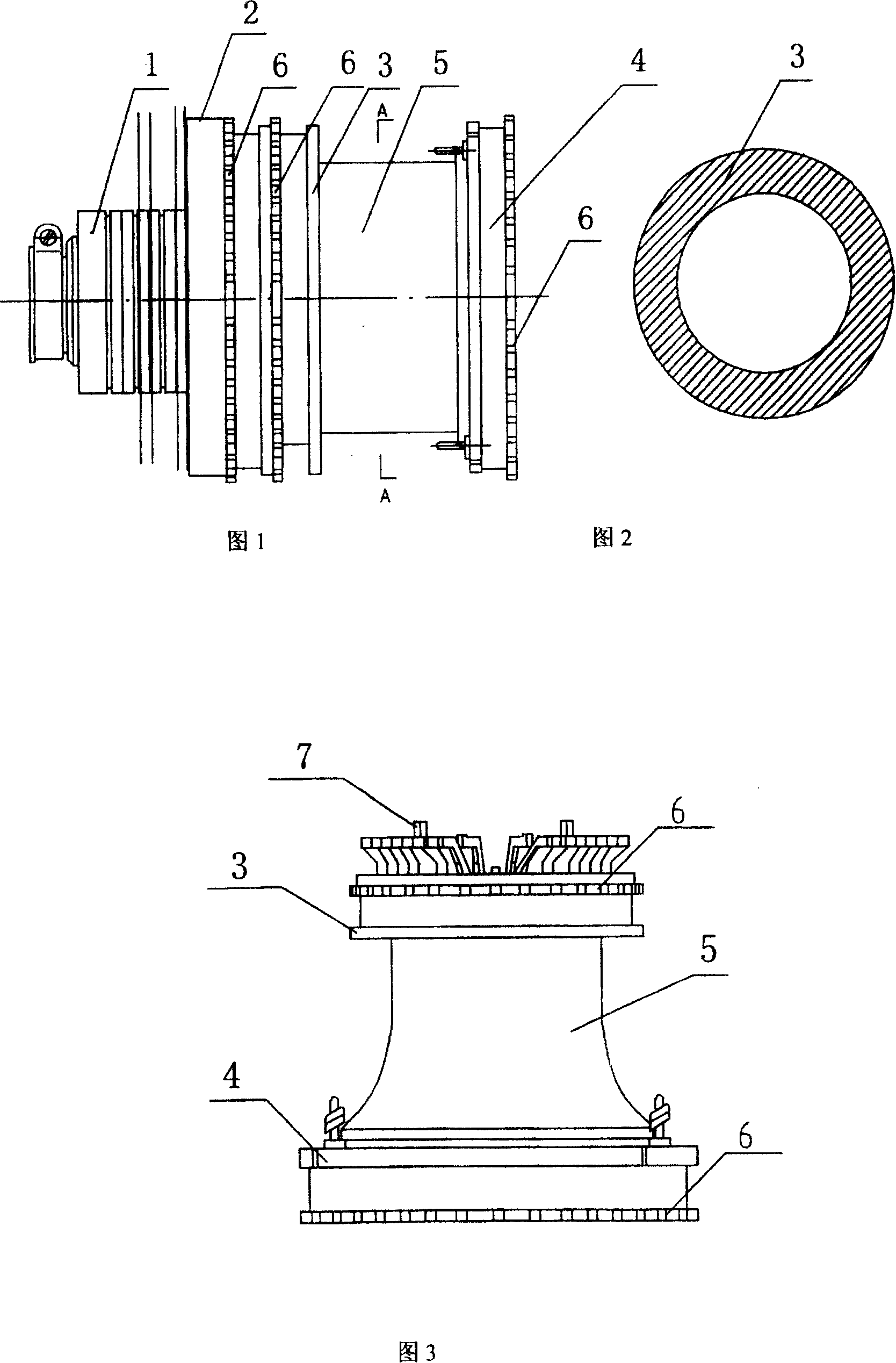

Coil winding device

InactiveCN1106022CHigh precisionReduce tensionMagnetic deflection device manufactureElectrode and associated part arrangementsTurn angleEngineering

The invention provides a winding apparatus to improve accuracy of the shape and characteristics of a coil (a deflection yoke) by accurately guide a wire to the specified winding position of a spool. A nozzle supporting part for supporting a nozzle is rotatably pin-connected to the tip of a wire supplying device capable of being freely moved in the three dimensional direction by a moving device, an engaging member to be freely turned in the normal state and to be engaged with a gear provided on the base end of the nozzle supporting part is provided, and the turning angle of the nozzle supporting part can be fixed. In winding work near a small-diameter opening part of a spool, plate members are rotatably turned to be entered into both sides of a hook of a lower hook device on which a wire is to be hooked and guided, and the wire is pushed out by the plate members to be turned, when the wire is released from the hook.

Owner:NITTOKU ENG CO LTD

Wirewound device

InactiveCN1516218AHigh precisionPrecise windingMagnetic deflection device manufactureElectrode and associated part arrangementsTurn angleEngineering

To improve accuracy of the shape and characteristics of a coil (a deflection yoke) by accurately guide a wire to the specified winding position of a spool. A nozzle supporting part for supporting a nozzle is rotatably pin-connected to the tip of a wire supplying device capable of being freely moved in the three dimensional direction by a moving device, an engaging member to be freely turned in the normal state and to be engaged with a gear provided on the base end of the nozzle supporting part is provided, and the turning angle of the nozzle supporting part can be fixed. In winding work near a small-diameter opening part of a spool, plate members are rotatably turned to be entered into both sides of a hook of a lower hook device on which a wire is to be hooked and guided, and the wire is pushed out by the plate members to be turned, when the wire is released from the hook.

Owner:NITTOKU ENG CO LTD

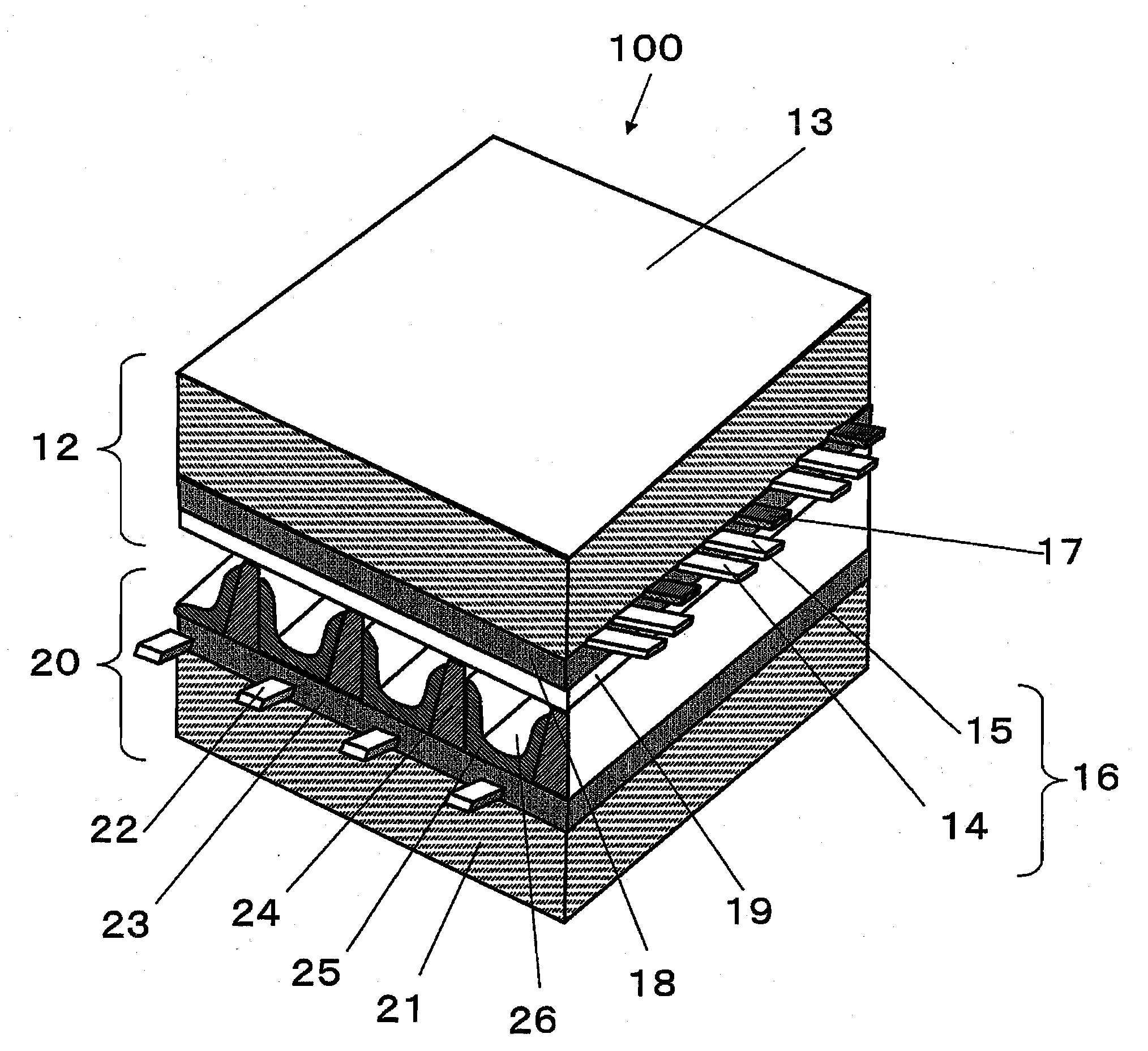

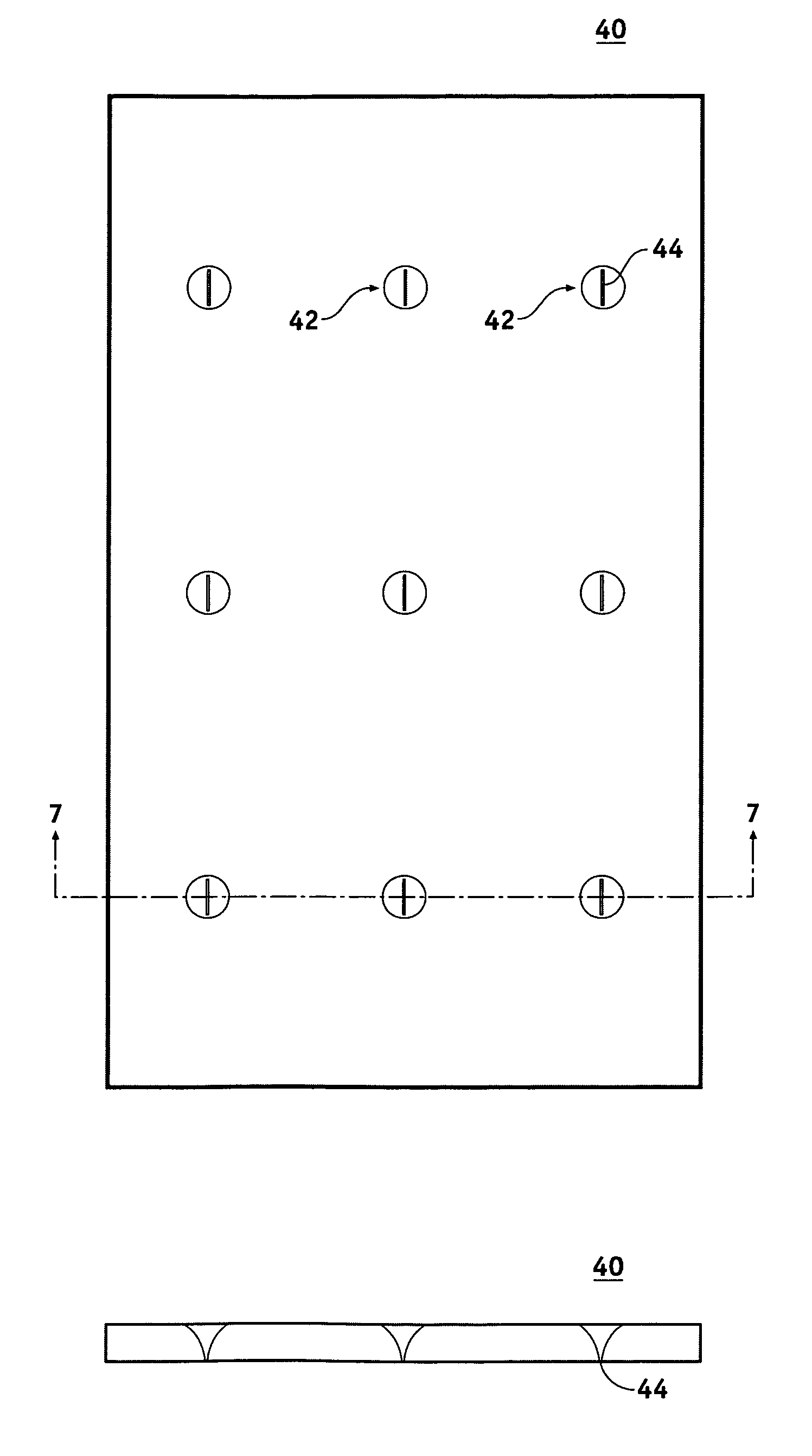

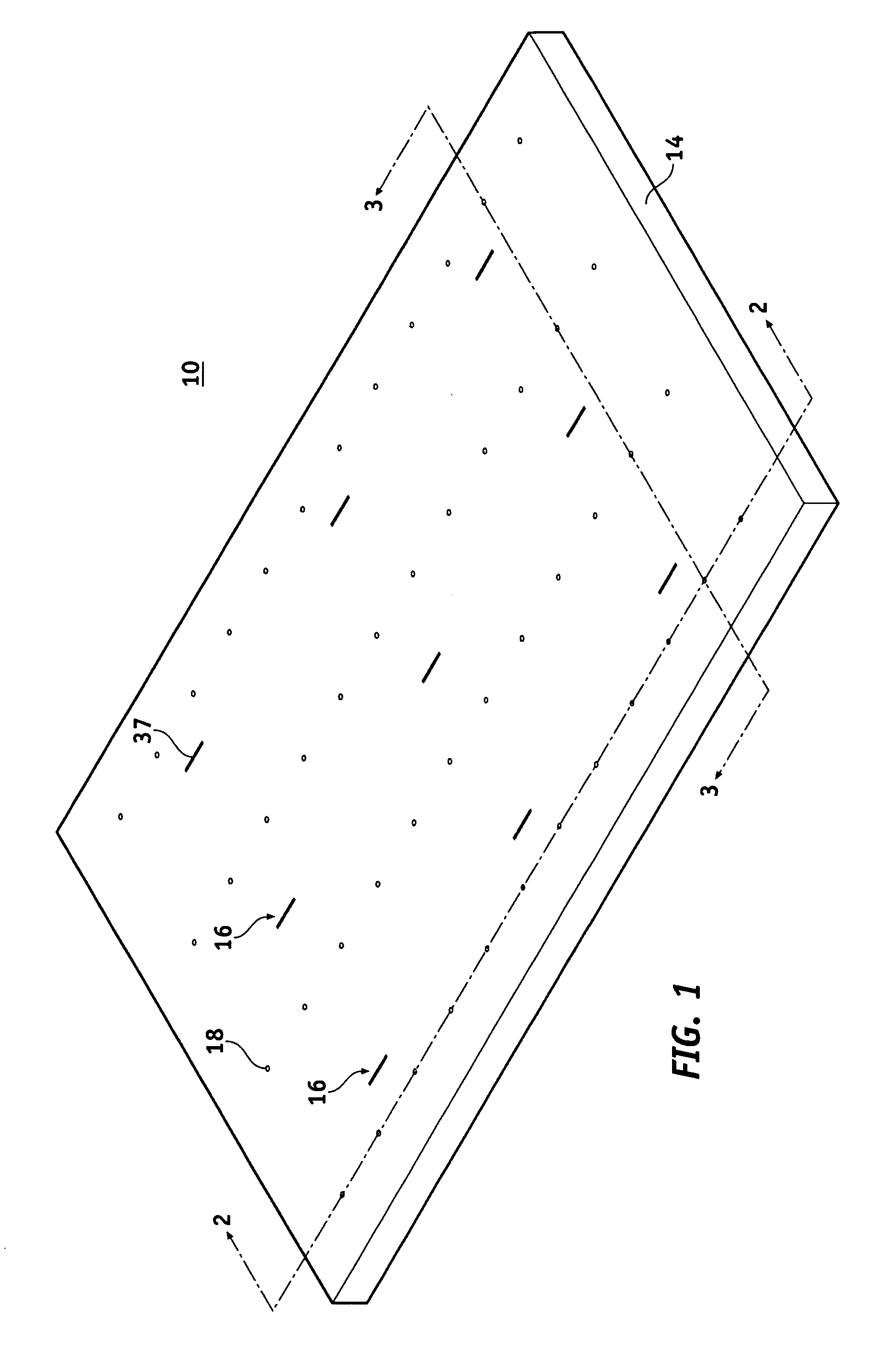

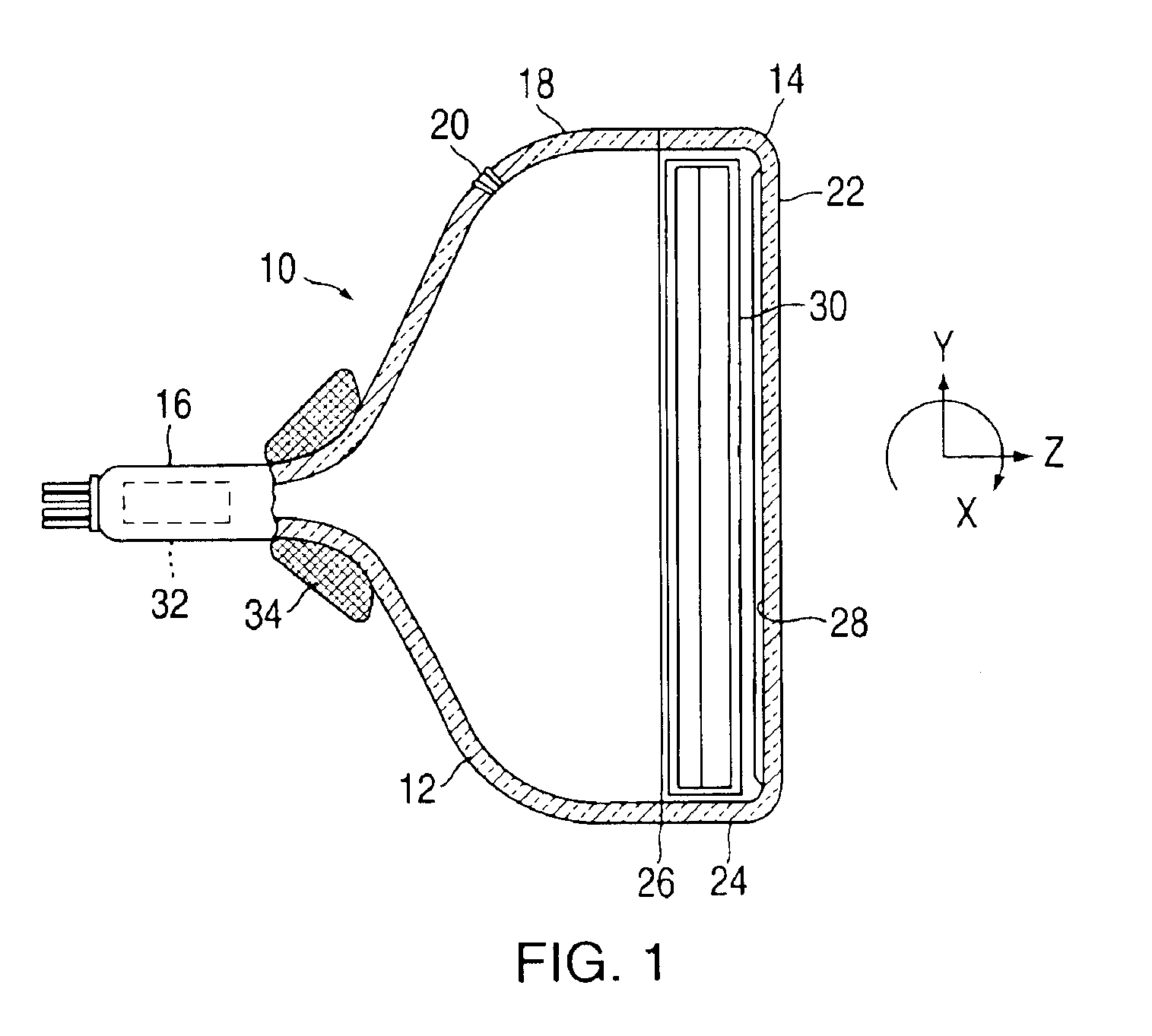

Apparatus and method for placing spacers in an emissive display

InactiveUS7169004B2Magnetic deflection device manufactureVessels or leading-in conductors manufactureDisplay deviceEngineering

An apparatus (10) for, and method of, placing a plurality of spacers (12) between a parallel opposed anode and cathode (20) of an emissive display includes temporarily securing, by applying a vacuum for example, a first side of one of the anode or cathode to a base (14) having a plurality of electromagnets (16) positioned therein. The electromagnets (16) attract a first side of each of the plurality of spacers (12), thereby positioning each of the spacers (12) in a desired location on a second side of the one of the anode or cathode (20). The spacers (12) may be provided from a shuffling tray (40) having a plurality of openings (42), each opening (42) approximately aligned with one of the electromagnets (16) and shaped so as to present the first side to the electromagnet (16) to the one of the anode or cathode (20).

Owner:MOTOROLA INC

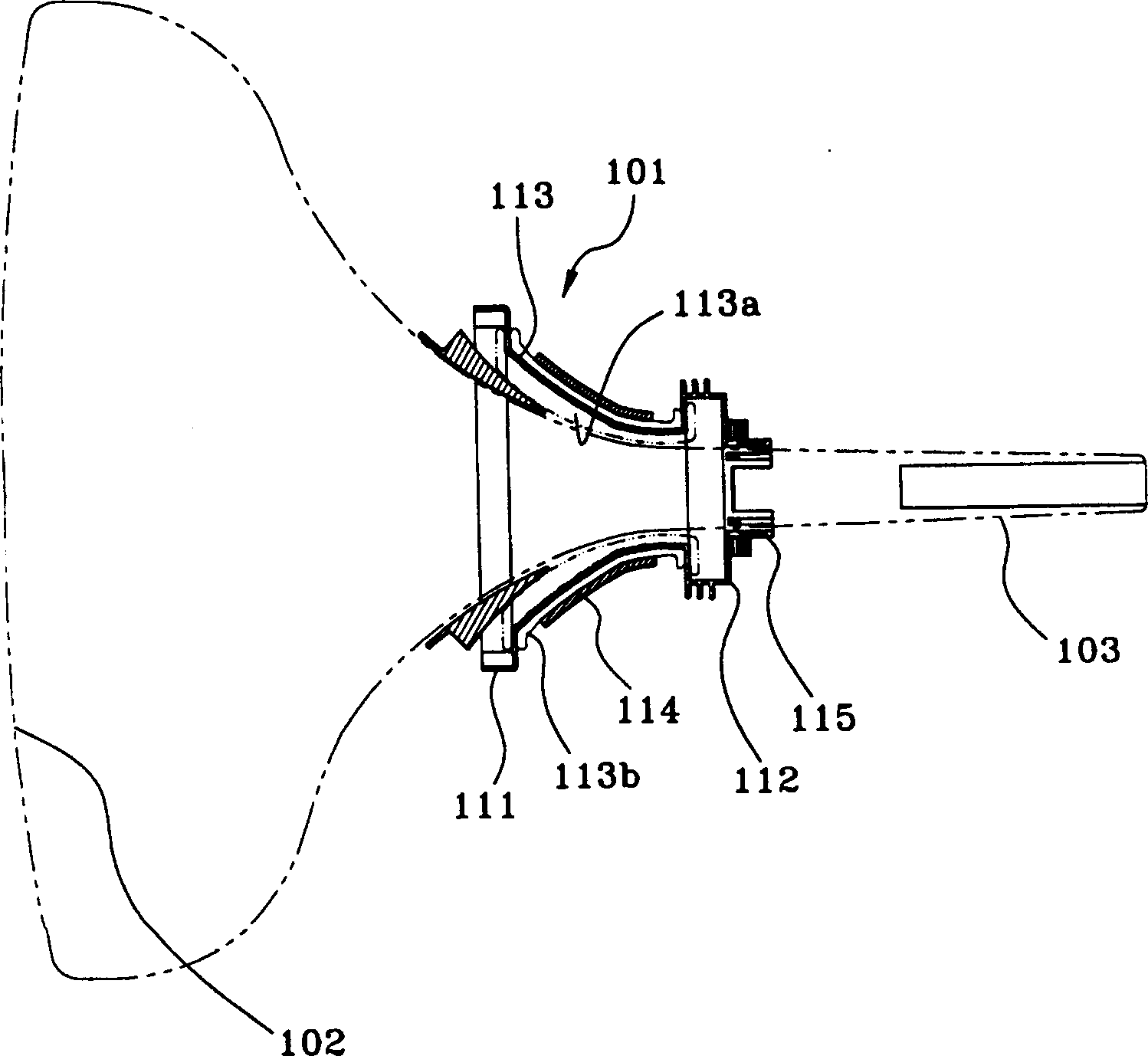

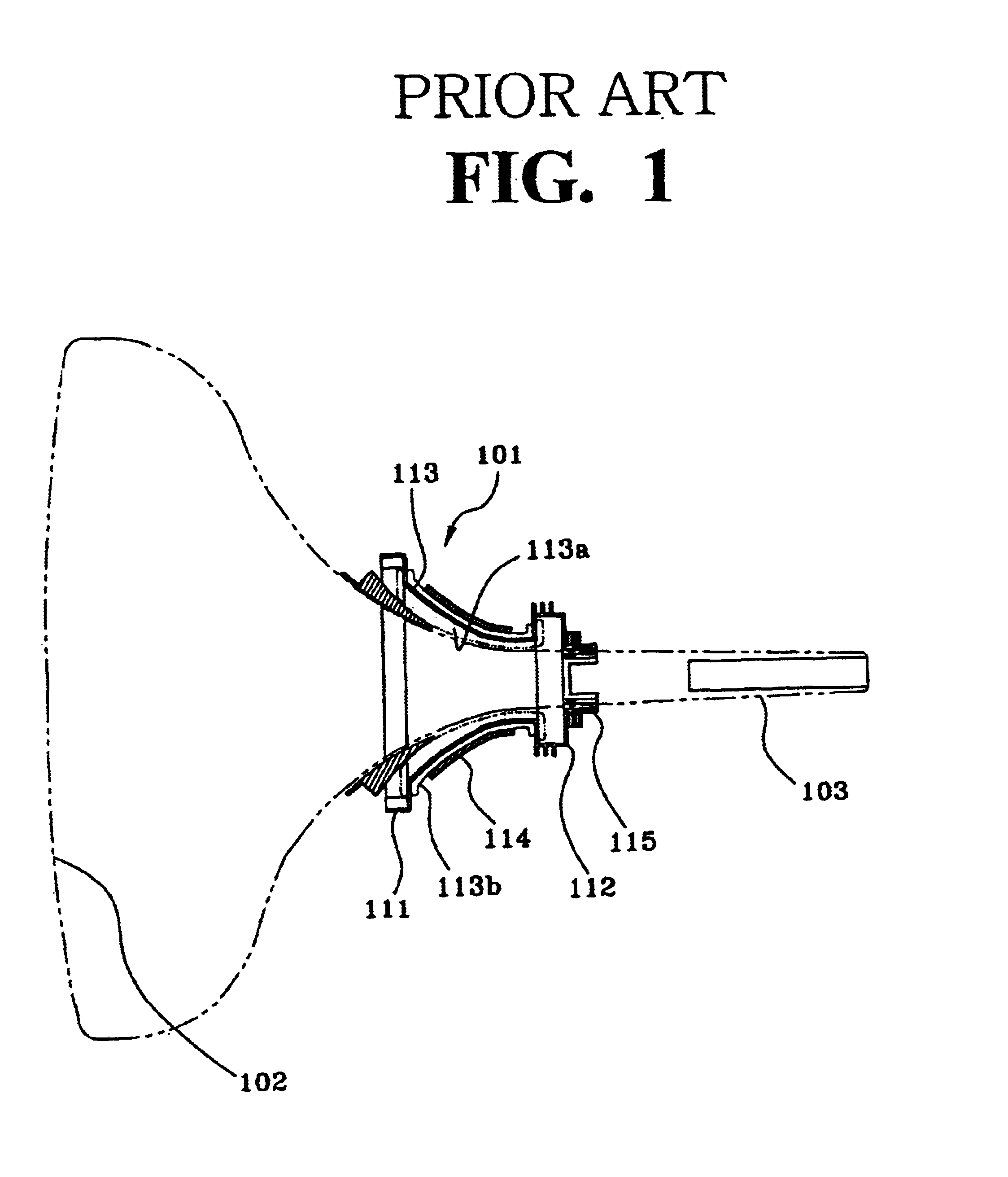

Deflectnig system of Braun tube

InactiveCN1169184CEasy CalibrationEasy to correct screen misconvergenceMagnetic deflection device manufactureElectrode and associated part arrangementsEngineeringHorizontal and vertical

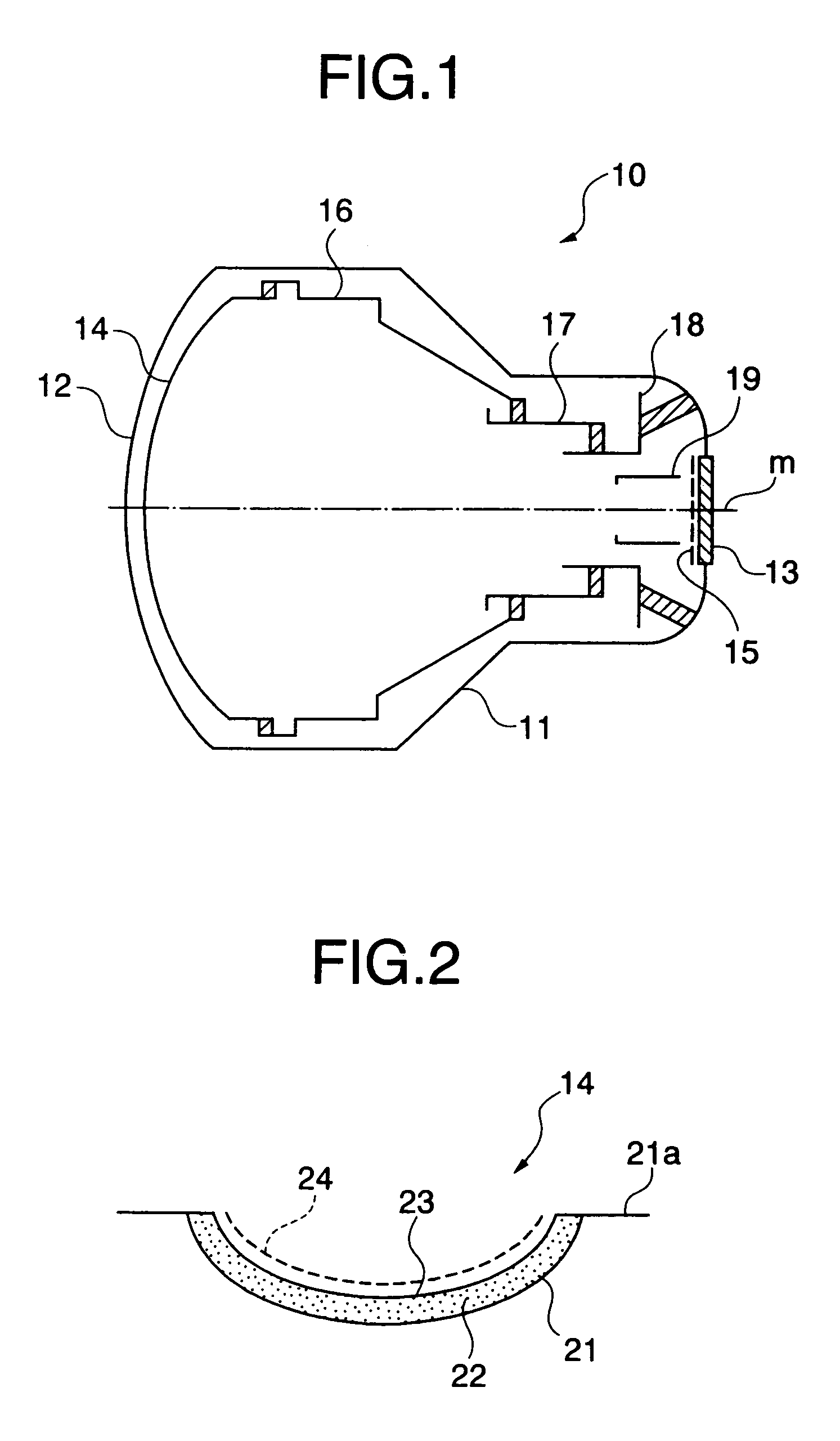

A deflection yoke for a Braun tube includes a primary 4-pole convergence yoke adapted to be positioned at a neck portion of a funnel of a Braun tube and a secondary 4-pole convergence yoke positioned in the vicinity of the funnel where horizontal and vertical deflection coils and a ferrite core are installed, for correcting a misconvergence generated due to the primary 4-pole convergence yoke, wherein at least one of the vertical and the horizontal deflection coils is wound at a first holder, and the secondary 4-pole convergence yoke is installed as an auxiliary coil wound on at least one side of the inner side or the outer side of the first holder.

Owner:MERIDIAN SOLAR & DISPLAY

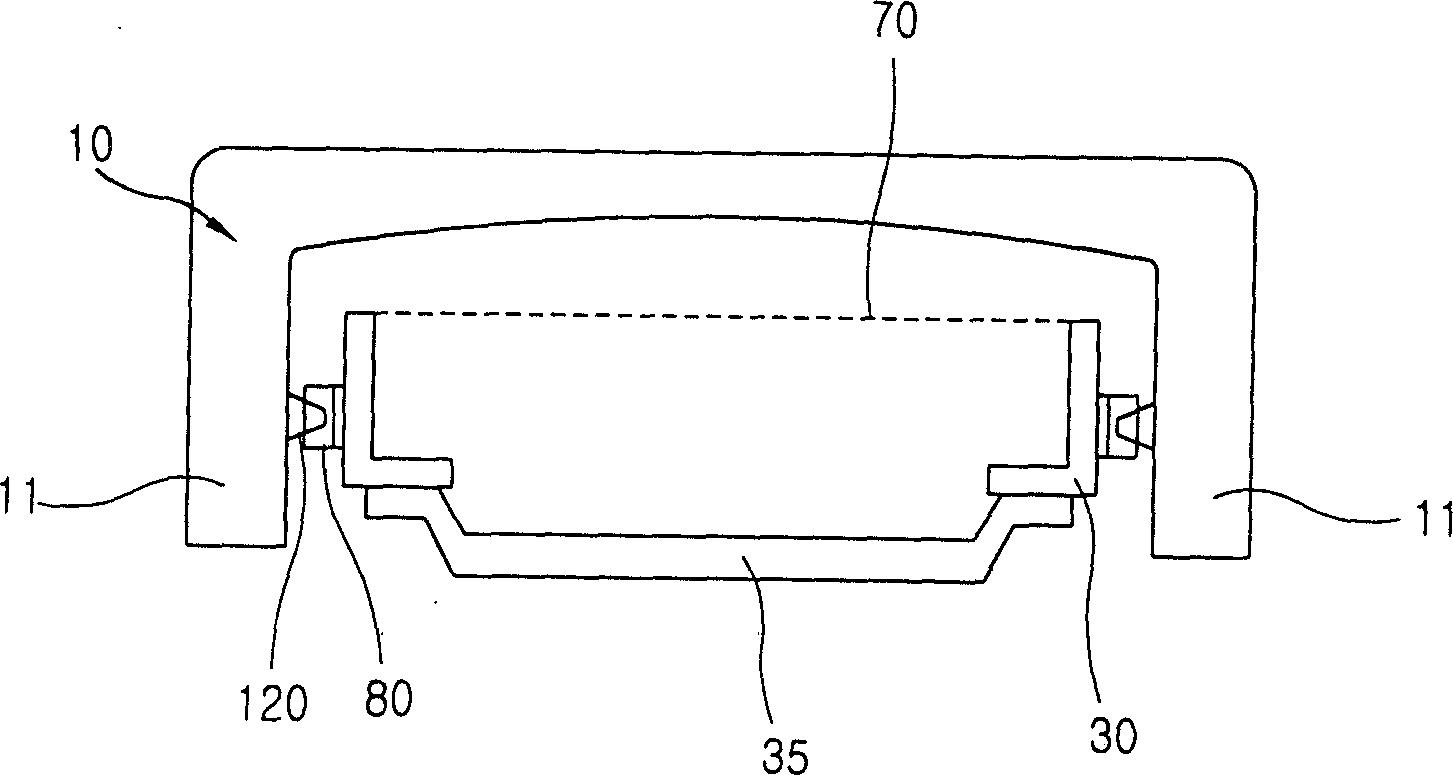

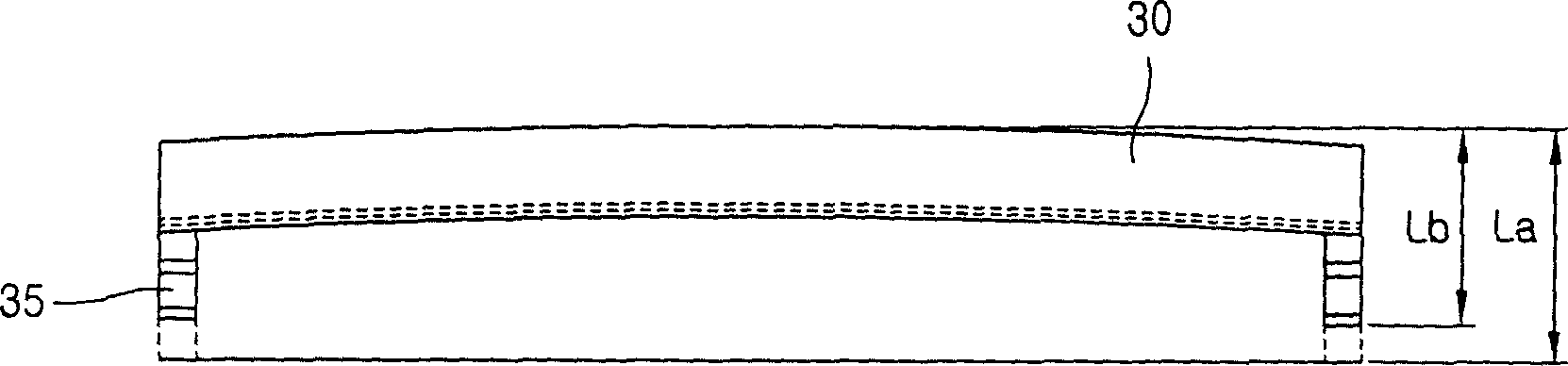

Cathode-ray tube

InactiveCN1222008CStop vibrationPrevent creepMagnetic deflection device manufactureElectrode and associated part arrangementsWrinkle skinEngineering

A Cathode Ray Tube (hereinafter, CRT), includes a mask assembly which is composed of a main frame for supporting the shadow mask and a sub frame for supporting the main frame. When the minimum distance between the flat surface extended from the upper surface of the main frame and the flat surface extended from the lower surface of the sub frame is Lb, the height of the sub frame is Ls and the minimum distance between the flat surface extended from the upper surface of the main frame and the flat surface extended from the lower surface of the sub frame, in case the mask is attached to the mask assembly, is La, the following equation, 0.40<=Ls / Lb<=0.55 or 0.45<=(Ls-Lm) / Lb<=0.59 is satisfied and after compression, the following equation, 0.08<=(La-Lb) / (Lb-Lm)<=0.17 is satisfied. Therefore, the creep phenomenon, causing tension degradation and wrinkles at the corner portion of the shadow mask after the heat processing, can be prevented and the howling phenomenon, which can cause serious degradation of quality of screens by vibration of the CRT, can be prevented, considering the instrumental formality with a panel at the same time.

Owner:LG PHILIPS DISPLAY KOREA CO LTD

Damper wire spring for a cathode ray tube

InactiveUS6879093B2Reduce vibrationConstant tensionMagnetic deflection device manufactureElectrode and associated part arrangementsSnubberEngineering

An apparatus and method for retaining a damper wire used in a cathode ray tube to reduce vibration in the grill type mask assembly of a cathode ray tube. The damper wire is retained across a grill type mask by a bimetal damper spring having a first end and an opposing second end. The second end is coupled to the frame of the grill type mask assembly. A tab located proximate the first end of the damper spring is adapted to accept the damper wire that traverses the mask.

Owner:THOMSON LICENSING SA

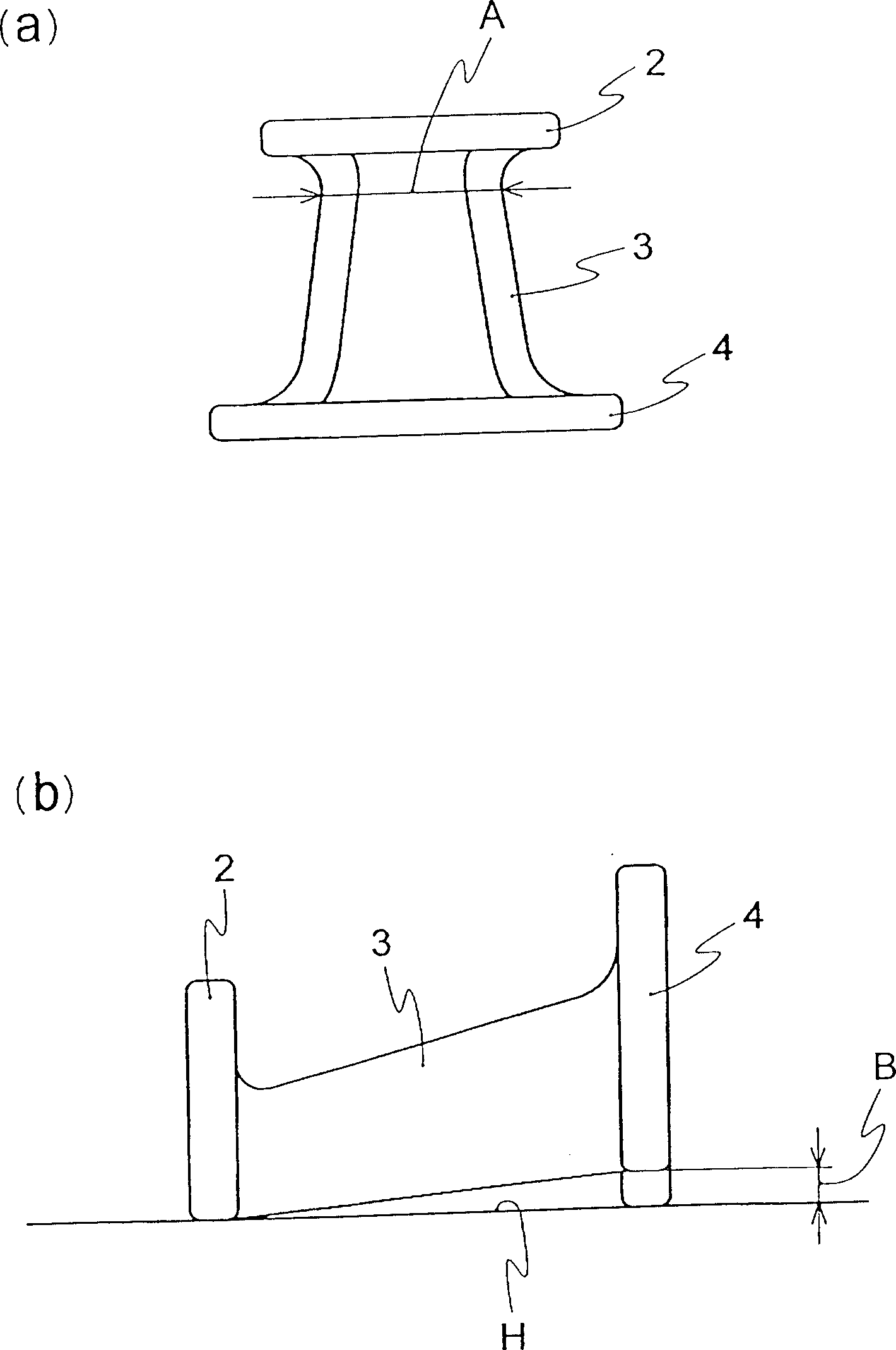

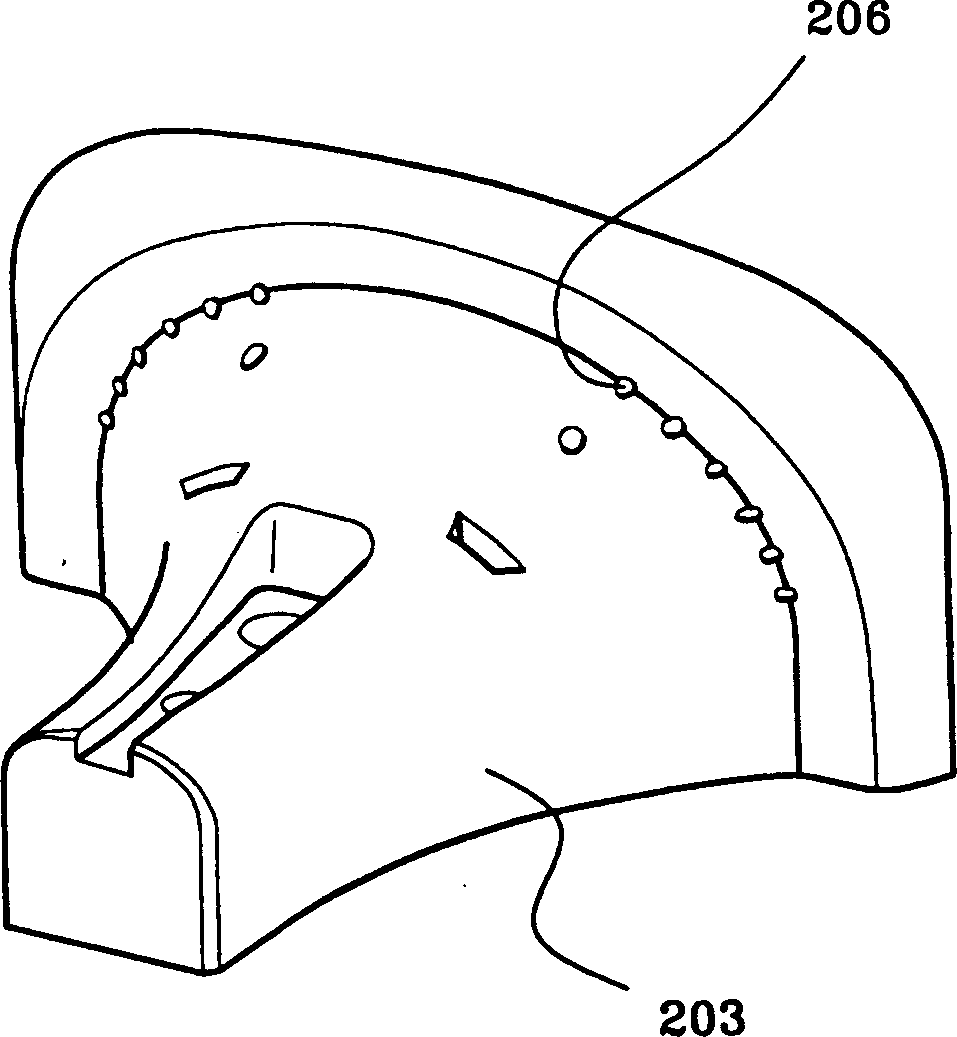

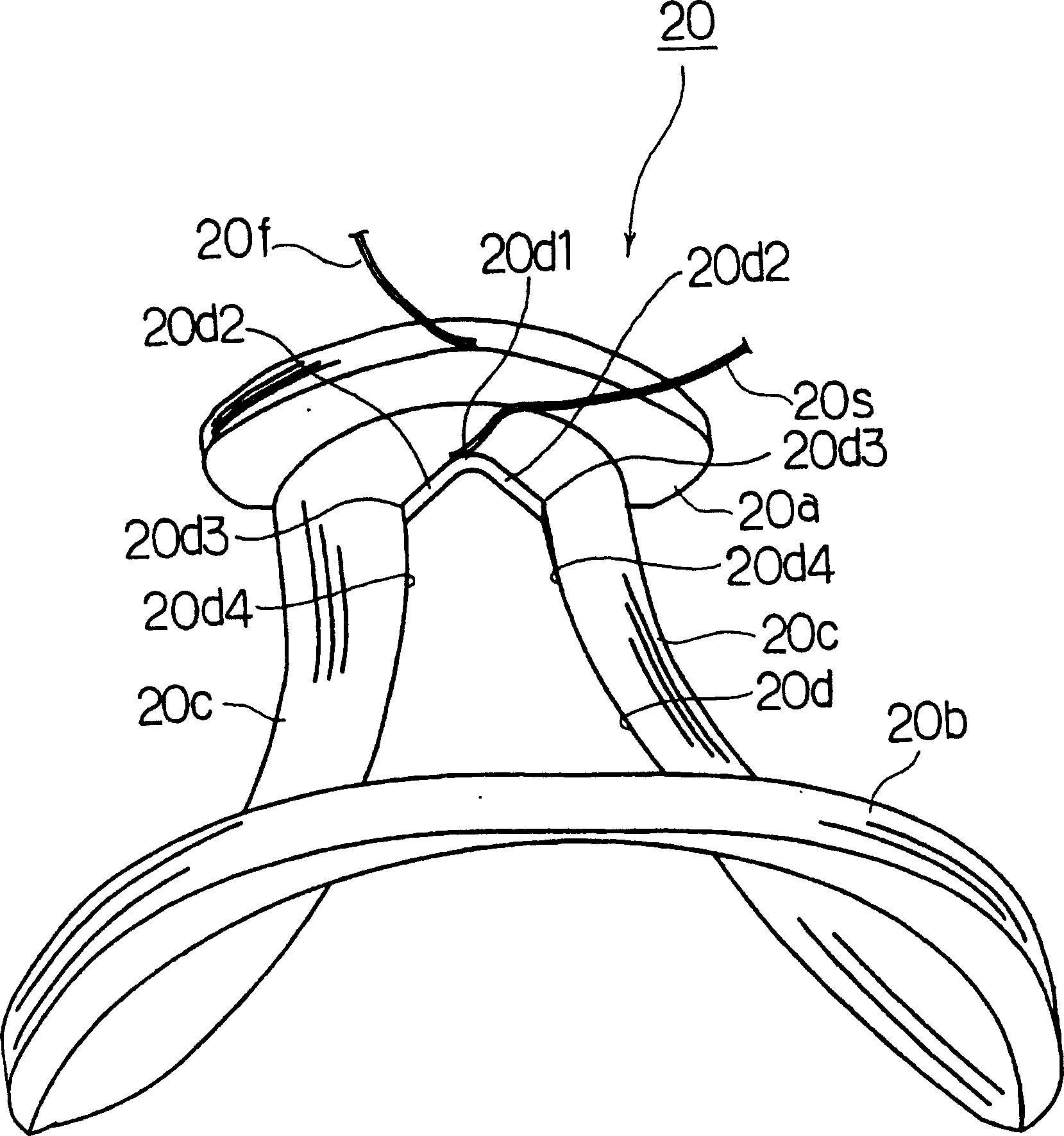

Winding mould and deflection coil

InactiveCN1428810AImprove Distortion ConvergenceImprove the winding surface structureMagnetic deflection device manufactureElectrode and associated part arrangementsConductor CoilElectric field

Disclosed is a deflection yoke for improve a screen quality, including a coiling density adjustment groove formed along a vertical direction of a coil by way of increasing the coiling density at an arbitrary portion of the electric field at the internal side of the deflection coil. To this end, a winding frame for winding coil around the deflection yoke, having a curvature of a designated shape at the center is provided, in which the winding frame includes a wire position guide that is projected as much as a designated width to a vertical direction of a coil to be wounded around an arbitrary portion of the internal electric field for increasing a coiling density.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

A method for adjusting the horizontal coil of deflection yoke

InactiveCN101582362BReduce usageImprove convergence qualityMagnetic deflection device manufactureElectrode and associated part arrangementsVisual field lossFile comparison

Owner:CAIHONG GRP ELECTRONICS CO LTD

Horizontal deflection coil

InactiveCN1700399AMagnetic deflection device manufactureElectrode and associated part arrangementsEngineering

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

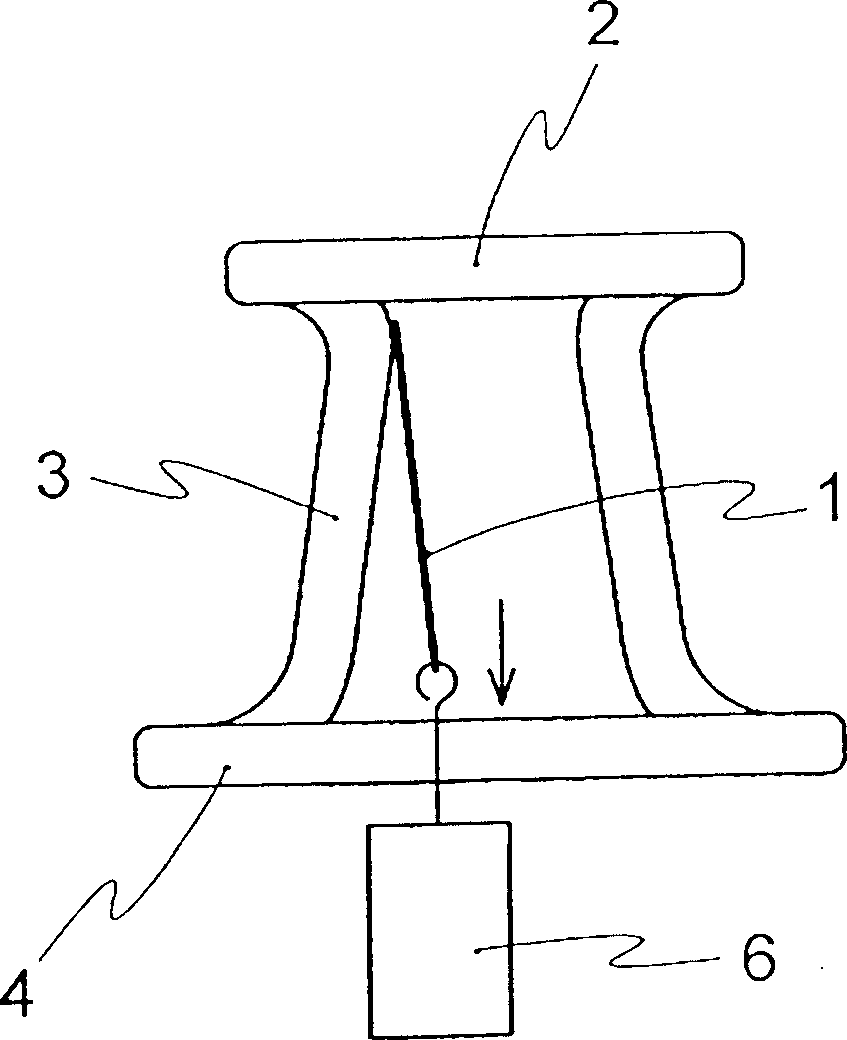

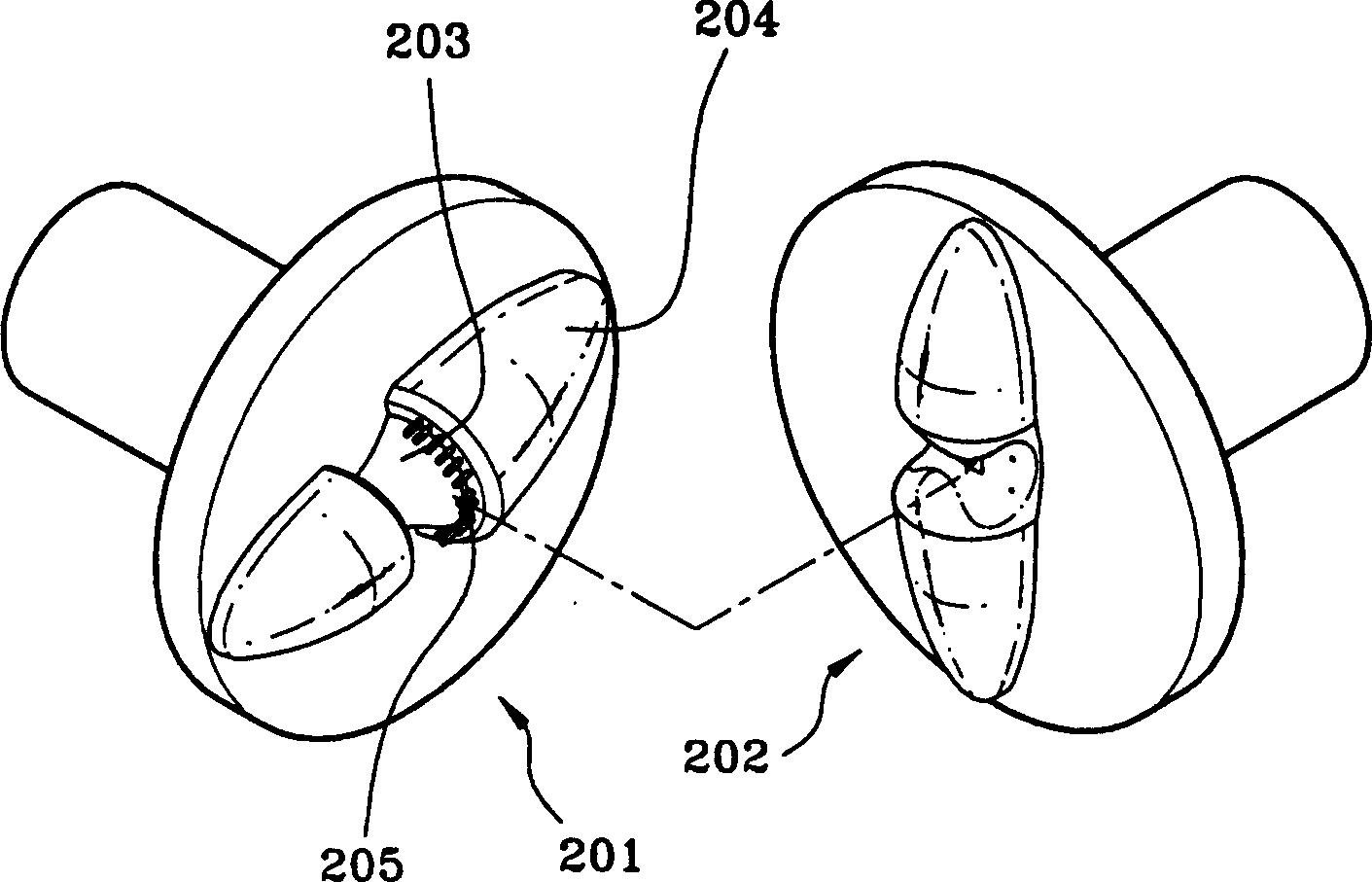

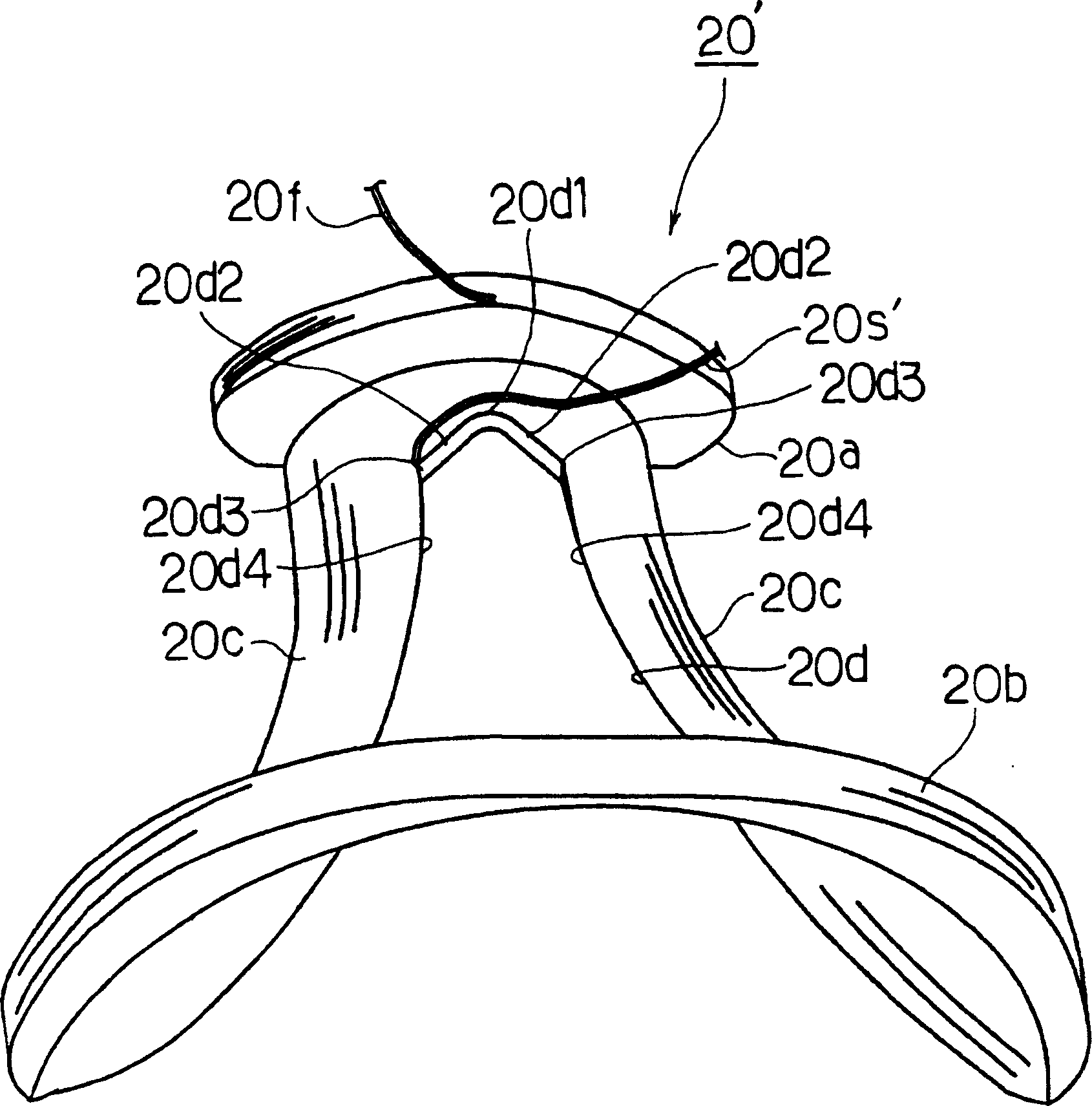

Deflection coil and its making method

InactiveCN1190819CMagnetic deflection device manufactureElectrode and associated part arrangementsMechanical engineering

Provided is a deflection yoke with a lead-out wire which is not pinched between insulation ribs, easy to assemble, enabled to restrain the generation of defect. A horizontal deflection coil 20' is composed of a small diameter part 20a, a large diameter part 20b, two side parts 20c, and a window part 20d surrounded by the above parts. A wind start wire 20s' is led out from the side part 20c, and a wind finish wire 20f is led out from the small diameter part 20a. The wind start wire 20s' is located at the position extending from a small diameter side end part 20d1 of the window part 20d at the side parts 20c to the large diameter side which is distant from other parts, and led out from a curved part 20d3.

Owner:VICTOR CO OF JAPAN LTD

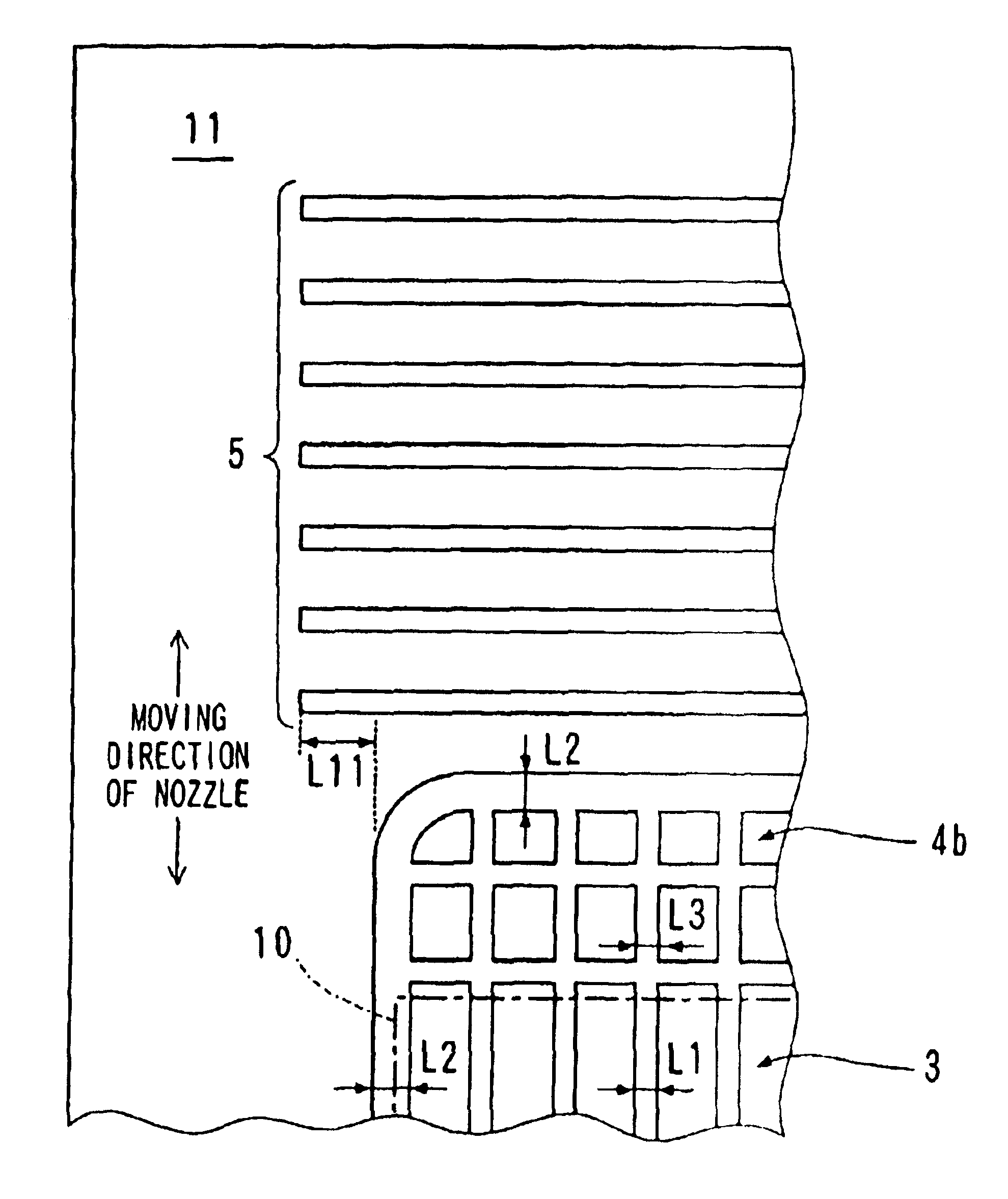

Method for forming partitions of plasma display panel by using sandblasting process

InactiveUSRE41312E1Reduce depthReduce stress concentrationMagnetic deflection device manufactureGas discharge electrodesPlasma displayElectrical and Electronics engineering

A partition is formed by the process including a step for providing a sheet-like partition material that covers a display area and outside thereof on the surface of the substrate, a step for providing a mask for patterning that covers the display area and the outside thereof, so that a pattern of the portion arranged outside of the display area of the mask is a grid-like pattern, a step for patterning the partition material covered partially with the mask by a sandblasting process, and a step for baking the partition material after the patterning.

Owner:MAXELL HLDG LTD

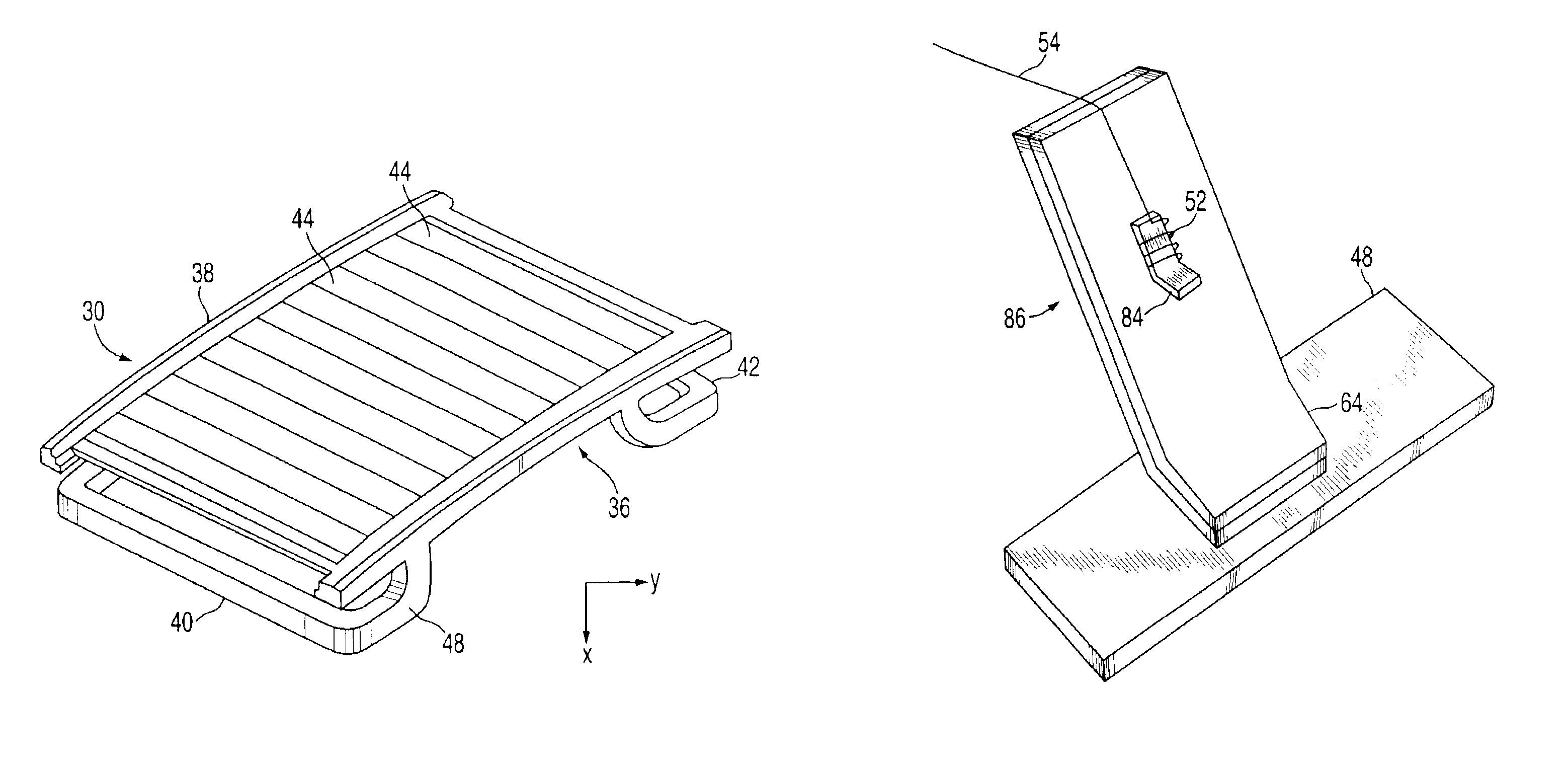

Winding frame and deflection yoke

InactiveUS6911885B2Enhance physical fitnessChange densityMagnetic deflection device manufactureElectrode and associated part arrangementsEngineeringConductor Coil

Disclosed is a deflection yoke to improve screen quality, including a coiling density adjustment groove formed along a vertical direction of a coil by way of increasing the coiling density at an arbitrary portion of the electric field at the internal side of the deflection coil. To this end, a winding frame is provided for winding coil around the deflection yoke, having a curvature of a designated shape at the center, in which the winding frame includes a wire position guide that projects as much as a designated width to a vertical direction of a coil to be wound around an arbitrary portion of the internal electric field for increasing a coiling density.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Deflecting coil for cathode ray tube and its manufacture method

InactiveCN100386840CImprove linearityLow loss levelMagnetic deflection device manufactureElectrode and associated part arrangementsAlloyEngineering

Owner:中航华东光电有限公司

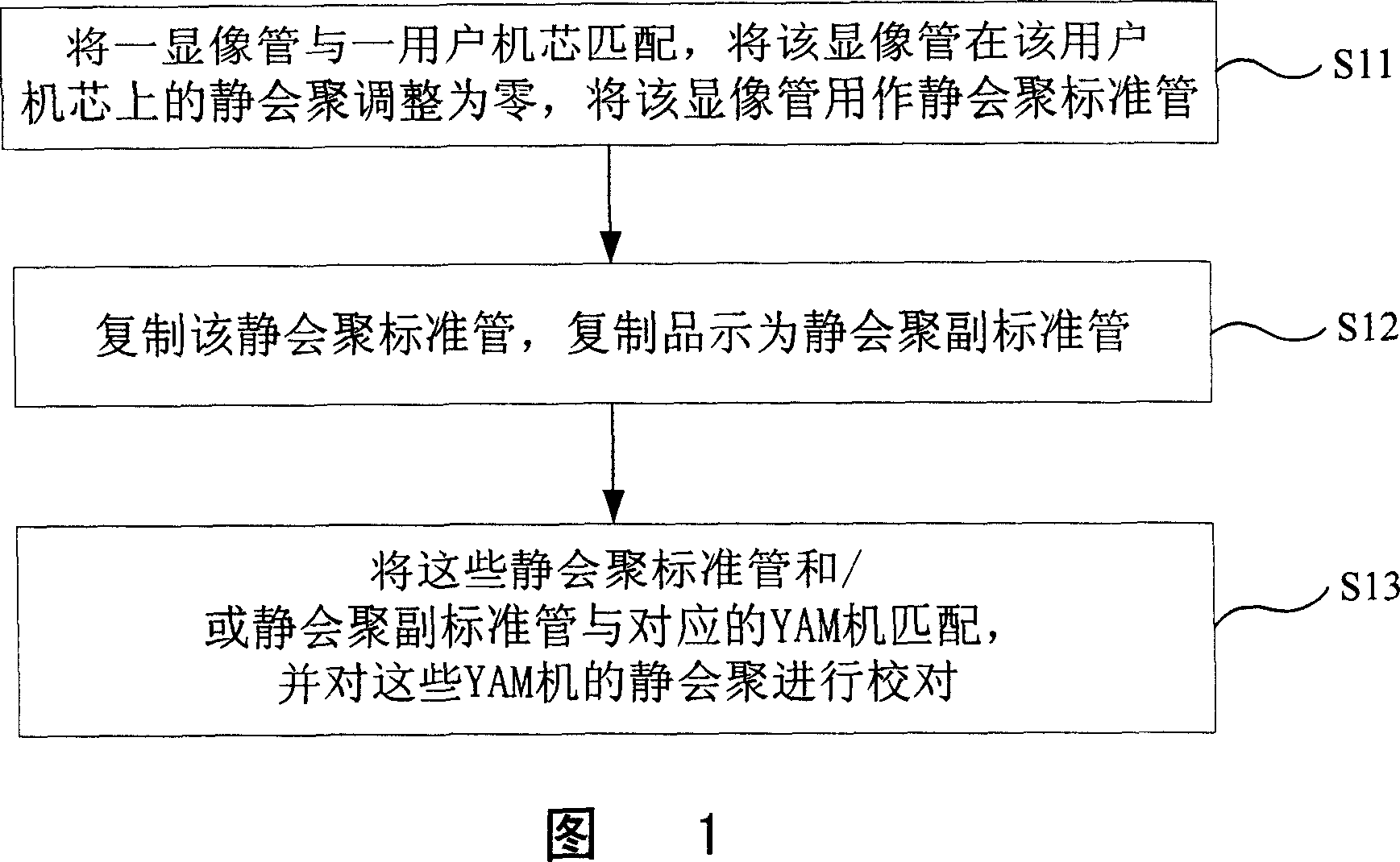

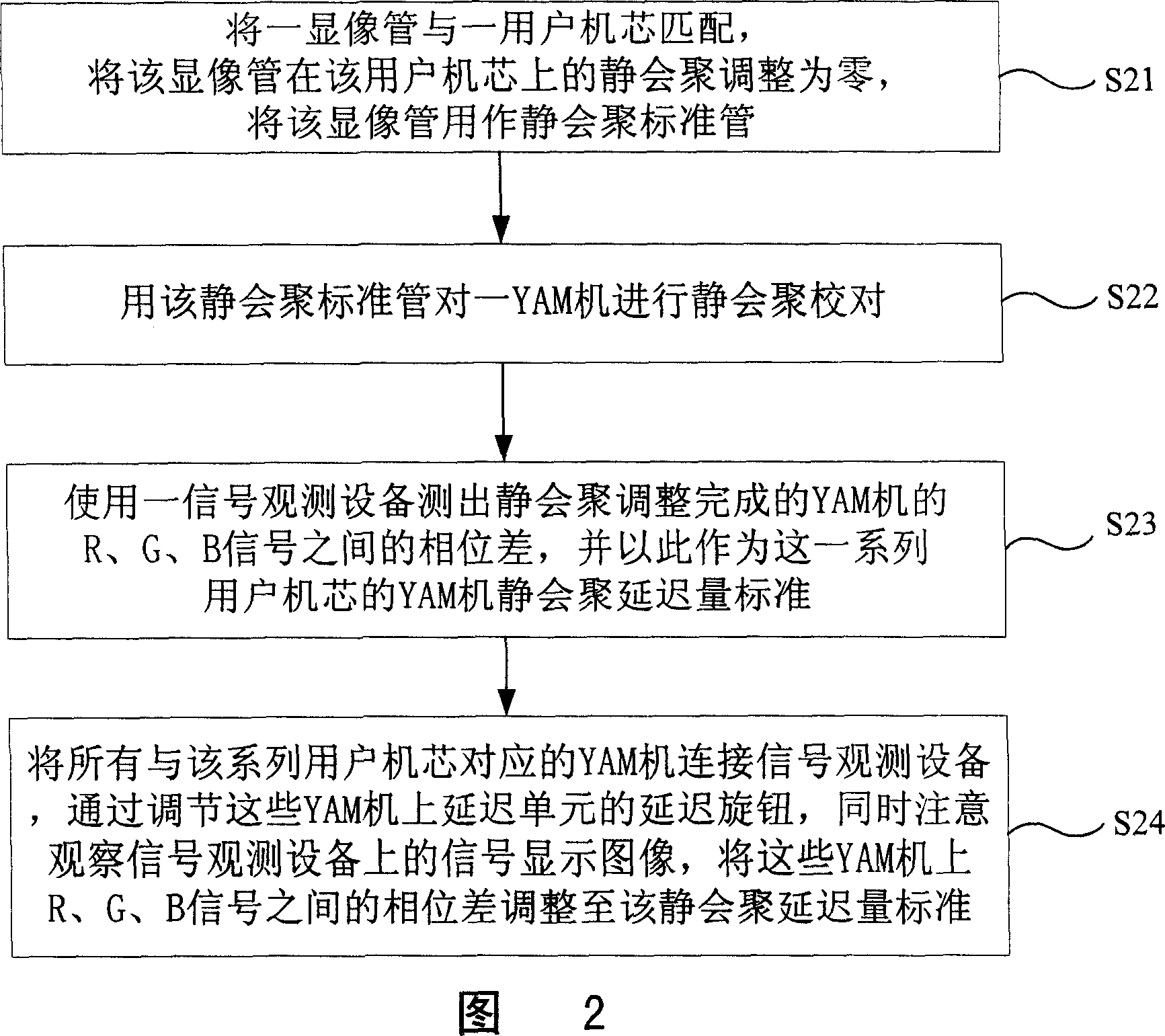

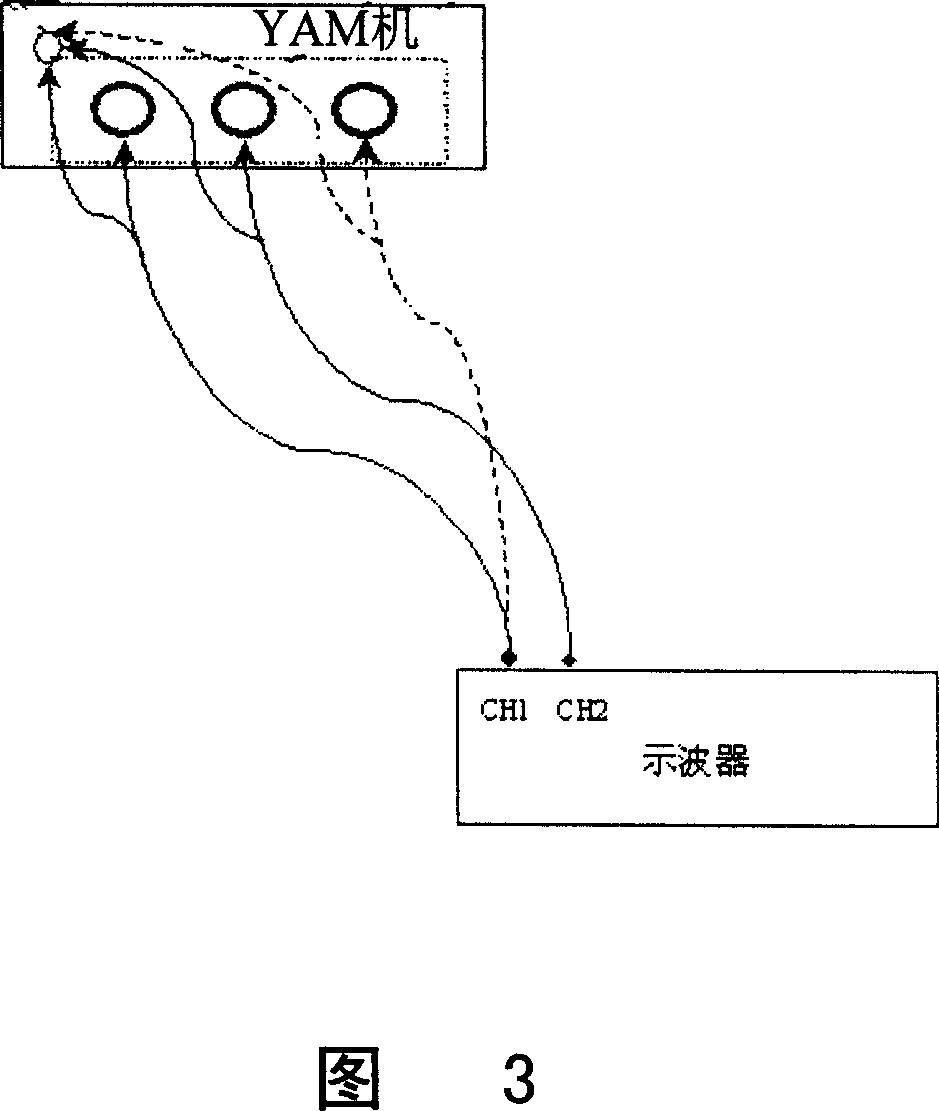

Method for checking static convergence retardation of deflecting coil adjusting machine

InactiveCN101064230AImprove stabilityImprove accuracyMagnetic deflection device manufactureTube/lamp factory adjustmentPhase differenceSignal on

The invention discloses an inspection method for static convergence delay of YAM machine, and it improves the stability and the accuracy of YAM machine, and reduces the production cost. The technical scheme is: (1) kinescope matches with user caliber, and the kinescope static convergence is adjusted as zero, that is to say the standard tube of static convergence of user caliber; (2) proofreads the YAM machine using the static convergence standard tube in step (1), the static convergence of standard tube on YAM machine can be adjusted as zero by adjusting the delay button on YAM machine; (3) detects the phase difference of R,G,B signal on YAM machine in step(2), and acts as the delay criterion of YAM machine of user caliber in step (1); (4) all YAM machines are connected with a detecting device for signal, and the phase difference of R,G,B signal on YAM machine is adjusted as the delay criterion in step (3) by adjusting the delay button. The invention can be applied in the proofreading field of static convergence of relative devices in production of kinescope.

Owner:SHANGHAI NOVEL COLOR PICTURE TUBE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com