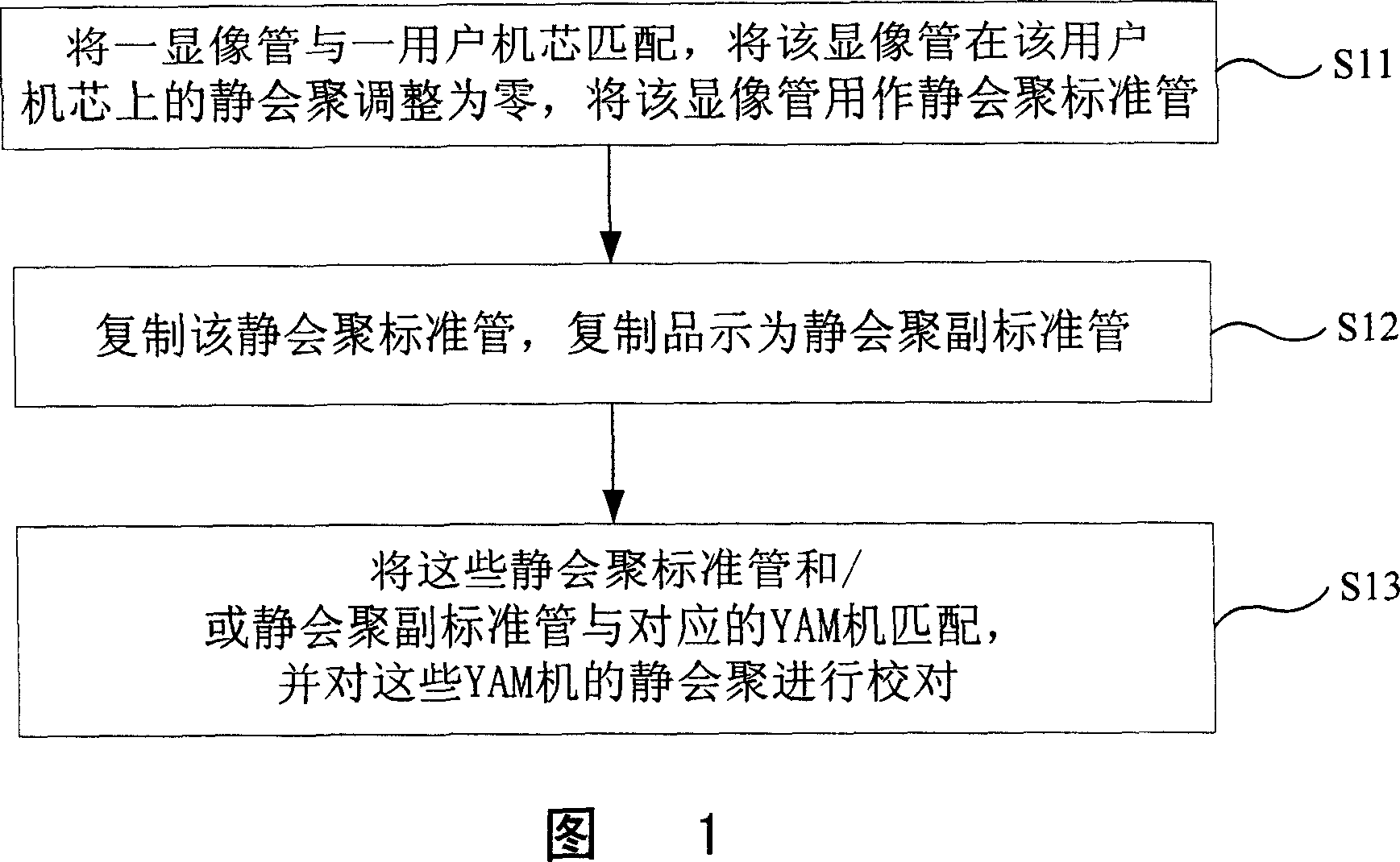

Method for checking static convergence retardation of deflecting coil adjusting machine

A technology of deflection coils and adjustment machines, which is applied in the manufacture of magnetic deflection devices, factory adjustment of electric tubes/lamps, and measurement/testing during the manufacturing process. problems, to achieve the effect of improving stability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

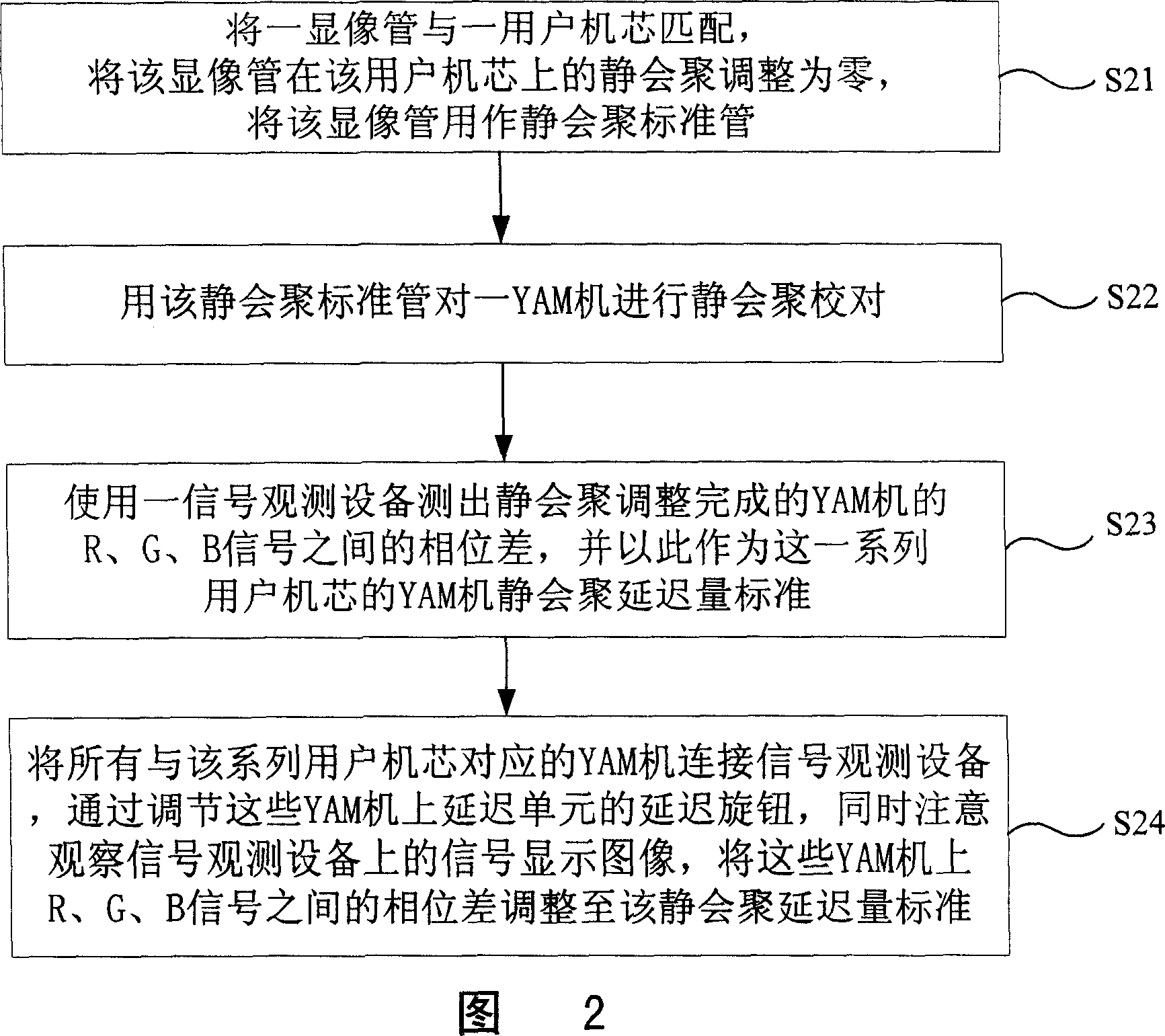

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0028] Please refer to FIG. 2 , which shows the flow of the method for correcting the YAM static convergence delay in the present invention. The process of the present invention will be described in detail below in conjunction with FIG. 2 .

[0029] S21: matching a picture tube with a user core, adjusting the static convergence of the picture tube on the user core to zero, and then using the picture tube as a static convergence standard tube for subsequent steps. Because the static convergence of different series of user movements is different, there are different static convergence standard tubes corresponding to each series of user movements. The method of static convergence adjustment is a prior art and has been explained in the background art section, and will not be described again here.

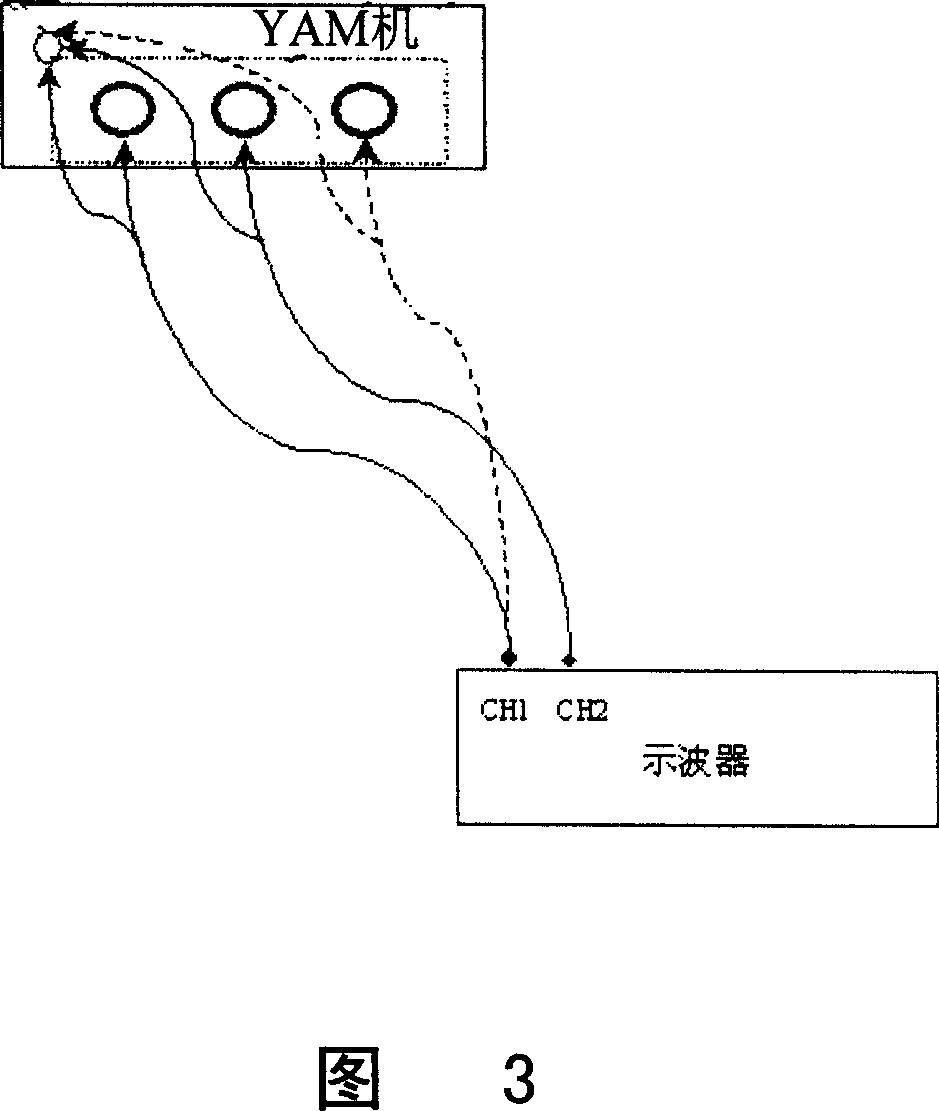

[0030] S22: Use the static convergence standard tube in S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com