Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

381results about "Manufacture testing/measurements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

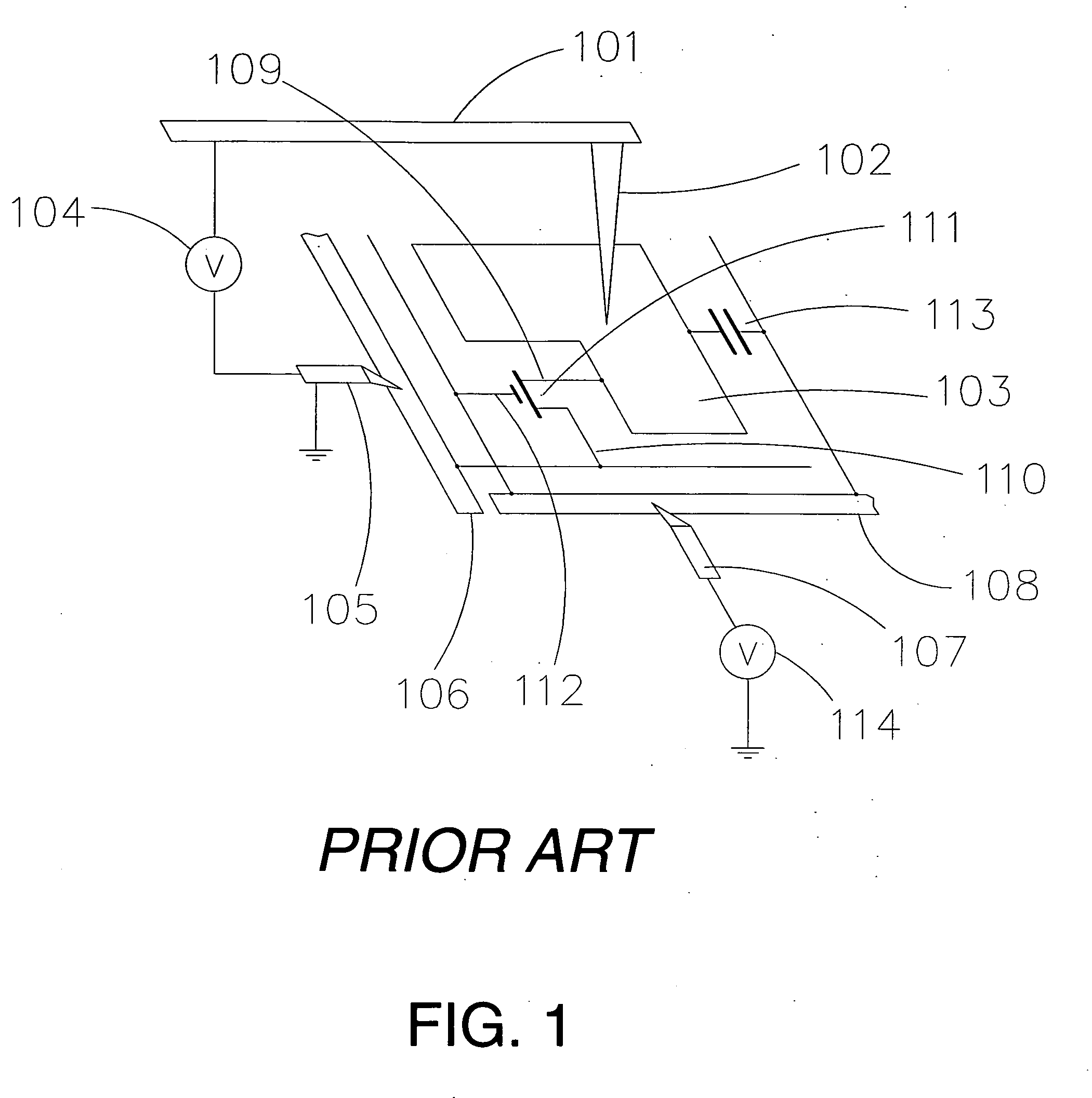

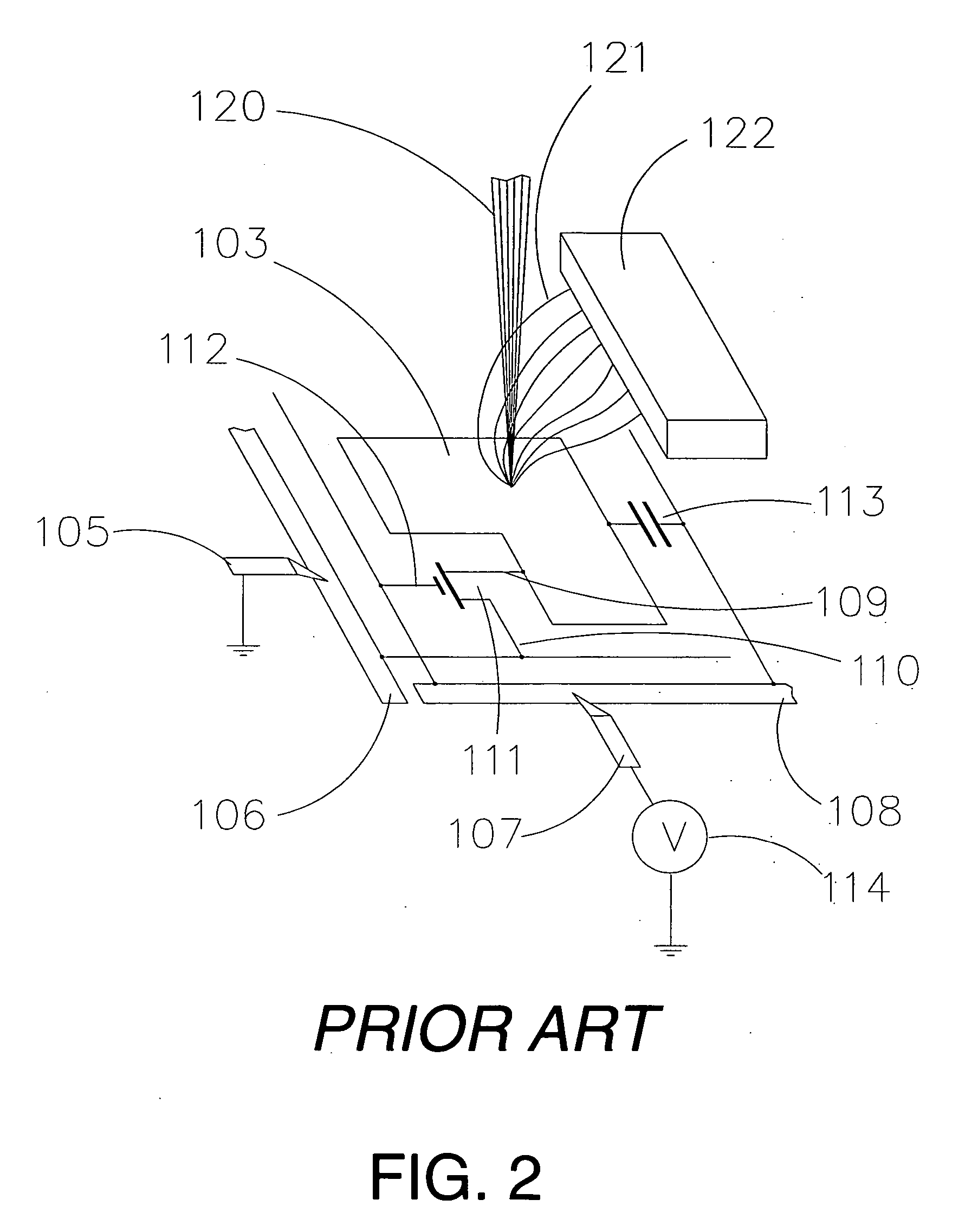

Method for testing a light-emitting panel and the components therein

InactiveUS6620012B1Sufficient resolutionManufactured very thinSparking plugsStatic indicating devicesEngineeringIonization

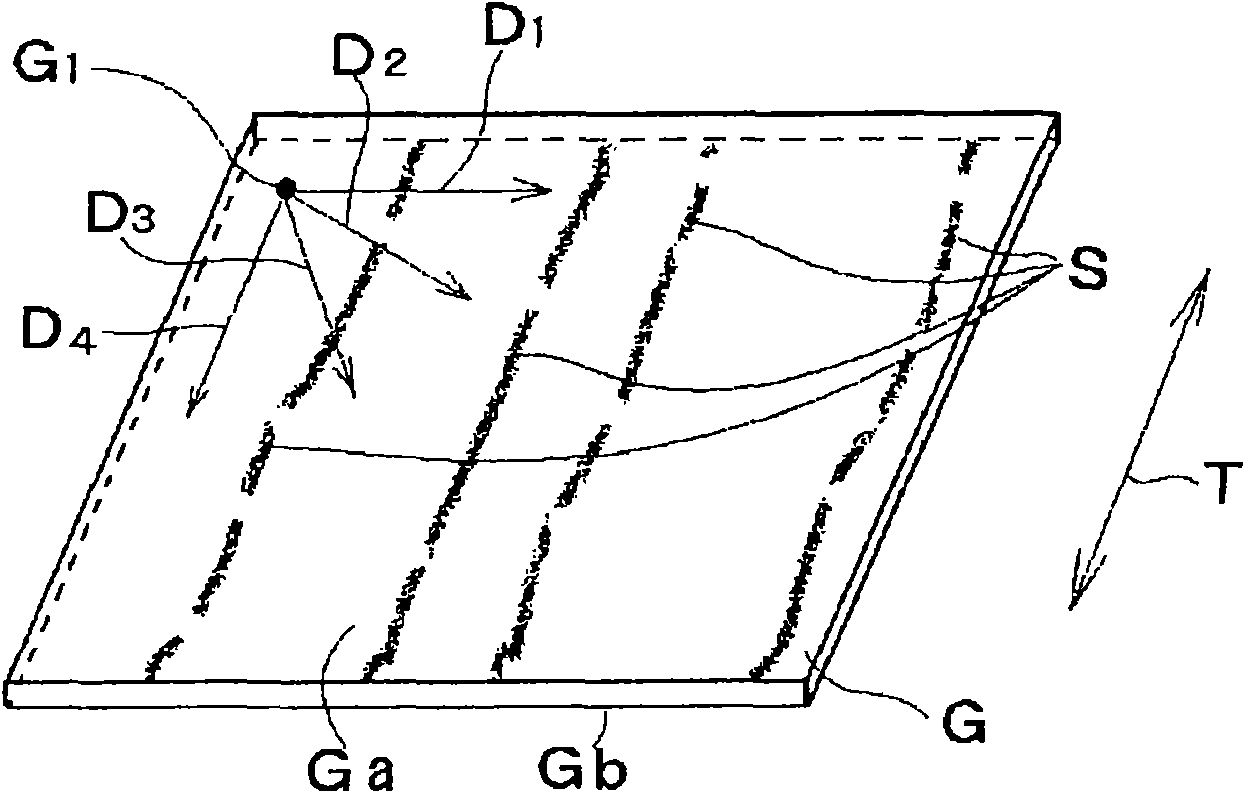

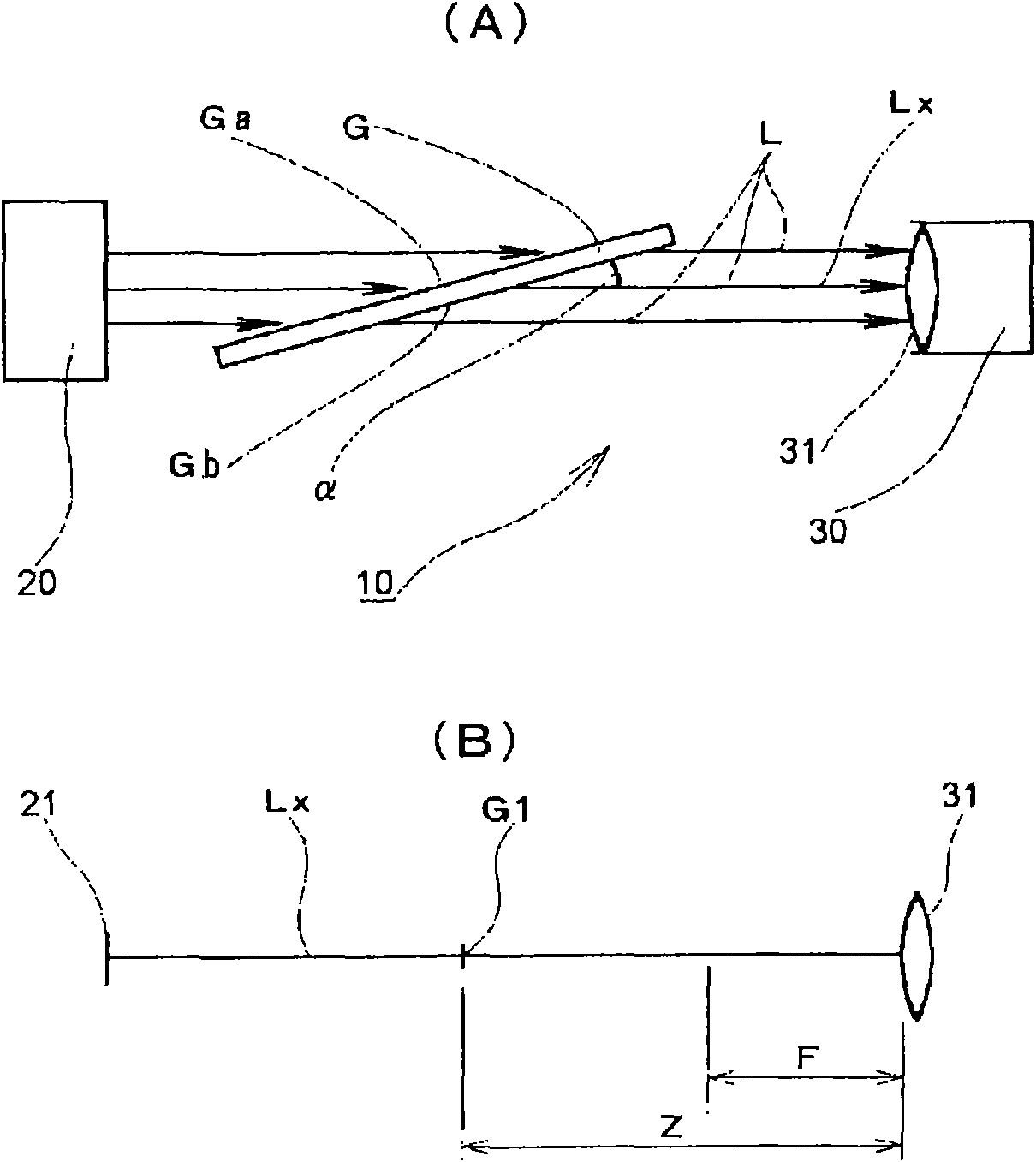

An improved light-emitting panel having a plurality of micro-components sandwiched between two substrates is disclosed. Each micro-component contains a gas or gas-mixture capable of ionization when a sufficiently large voltage is supplied across the micro-component via at least two electrodes. A method of testing a light-emitting panel and the component parts therein is also disclosed, which uses a web fabrication process to manufacturing light-emitting panels combined with inline testing after the various process steps of the manufacturing process to produce result which are used to adjust the various process steps and component parts.

Owner:LEIDOS

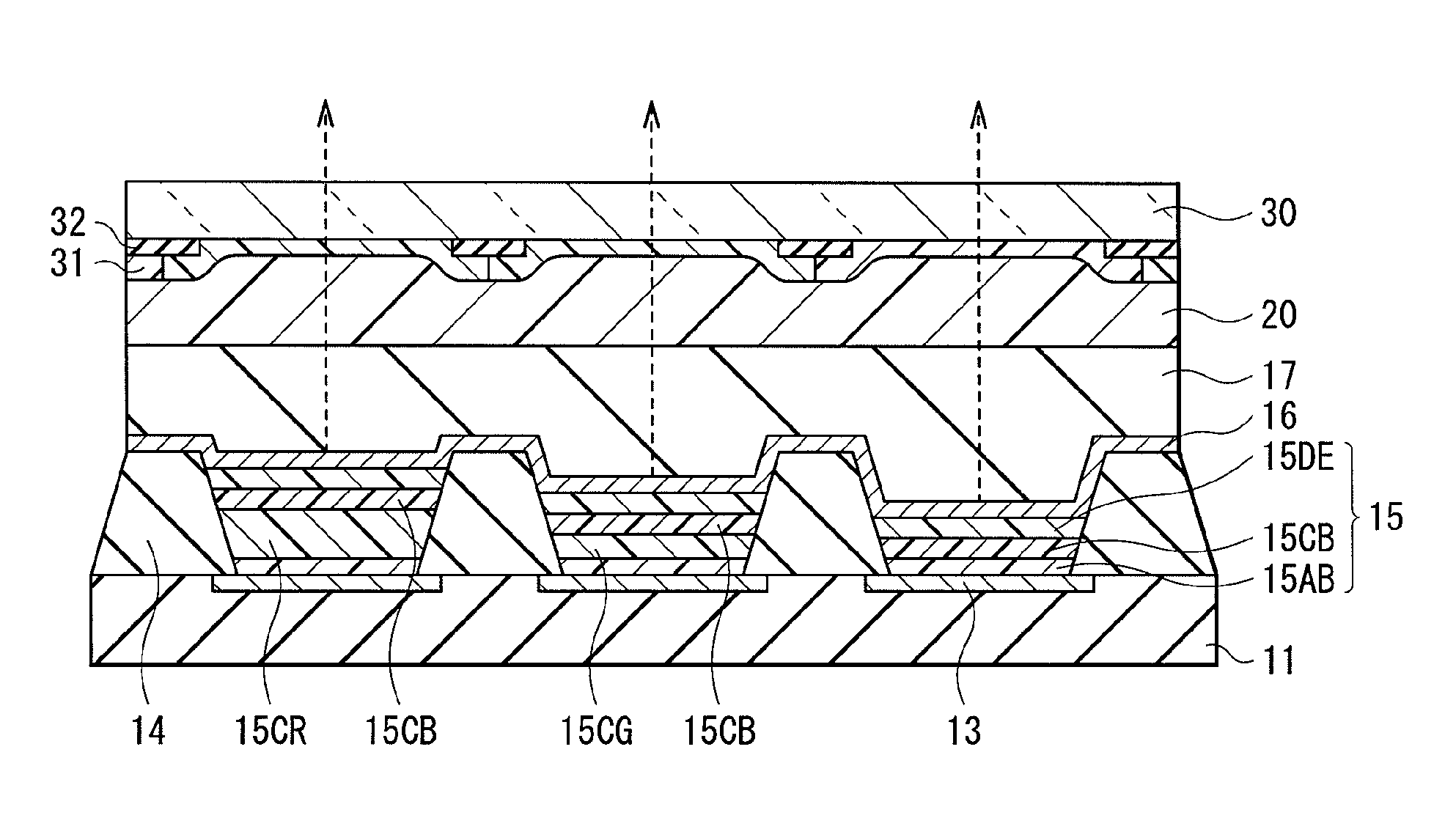

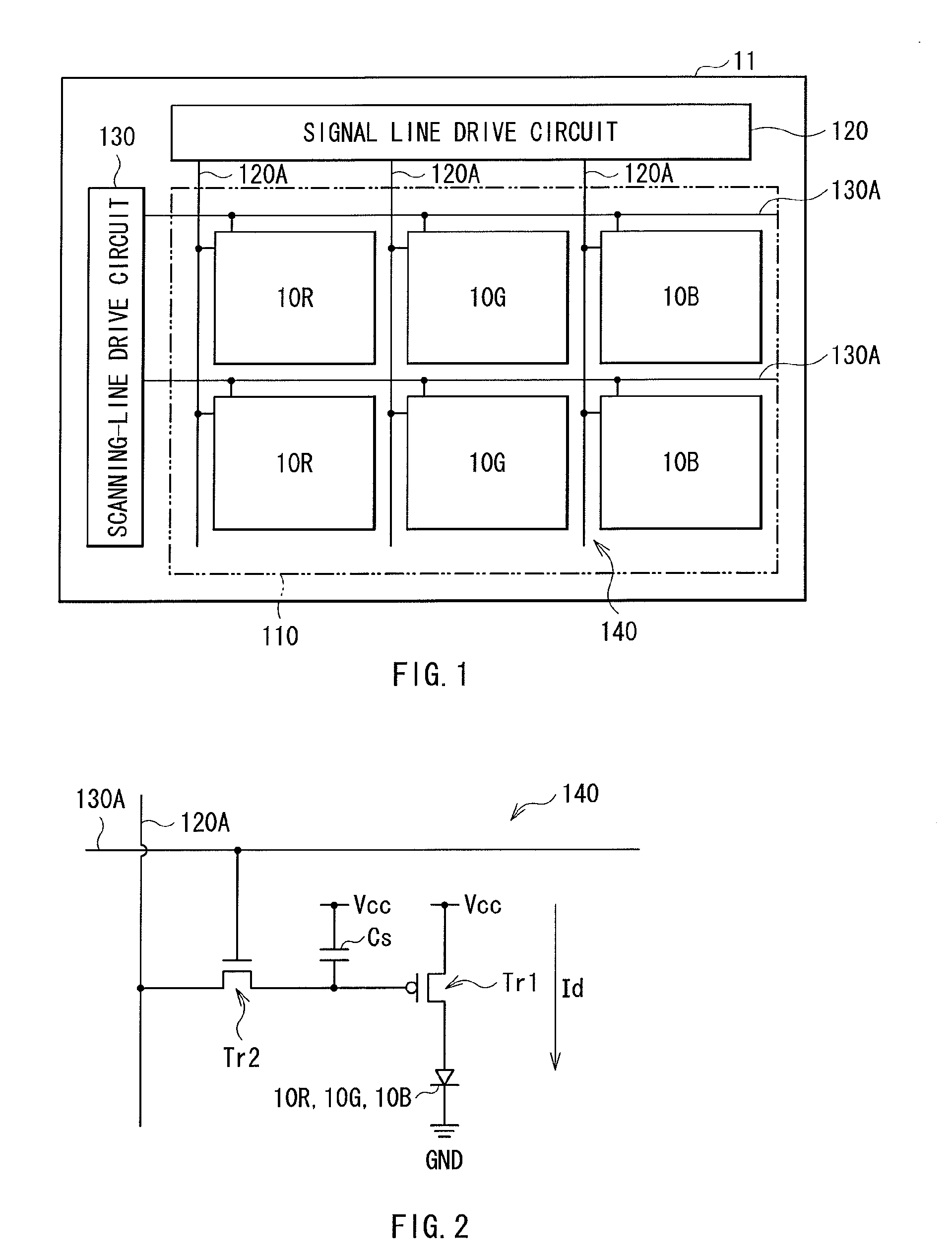

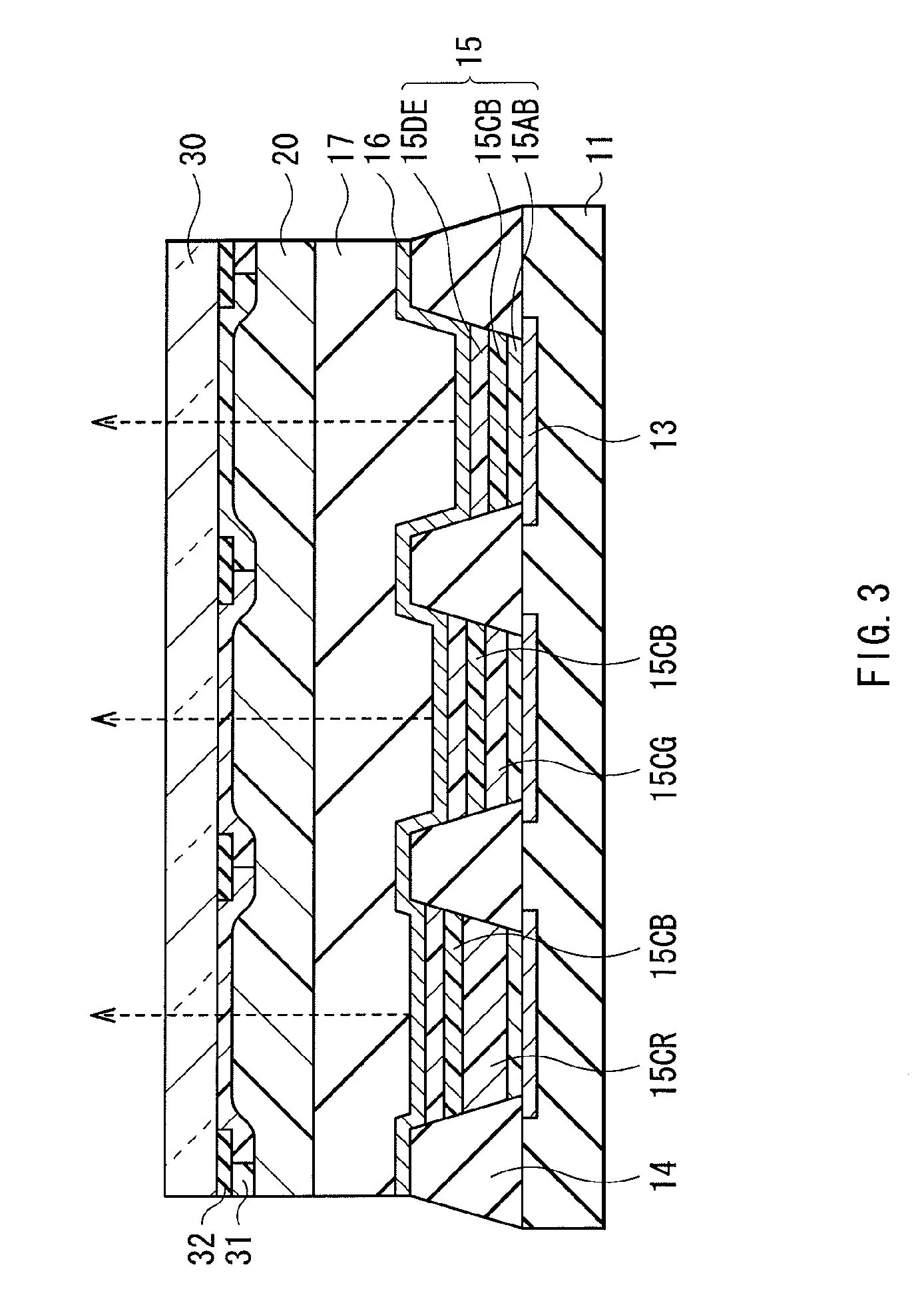

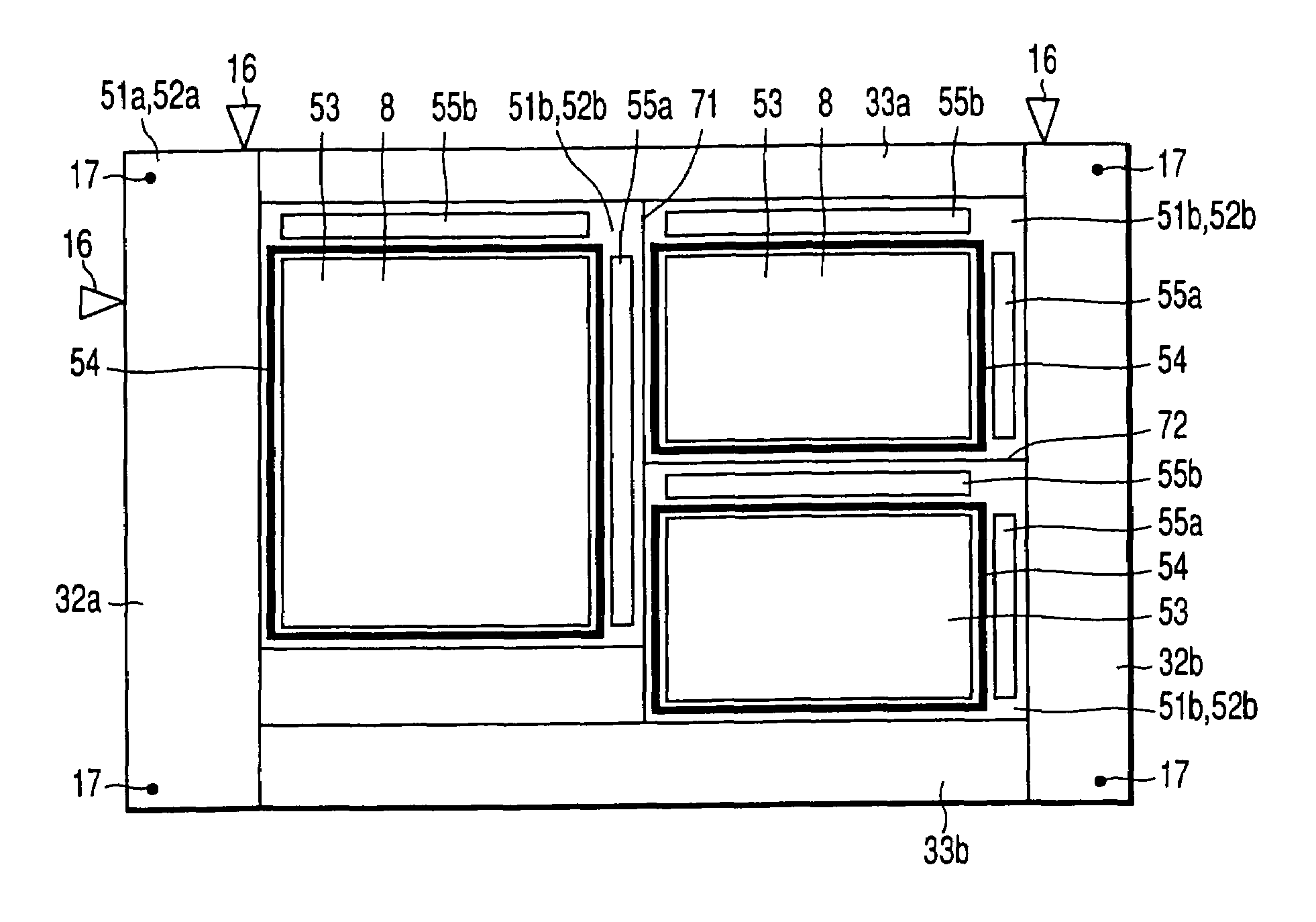

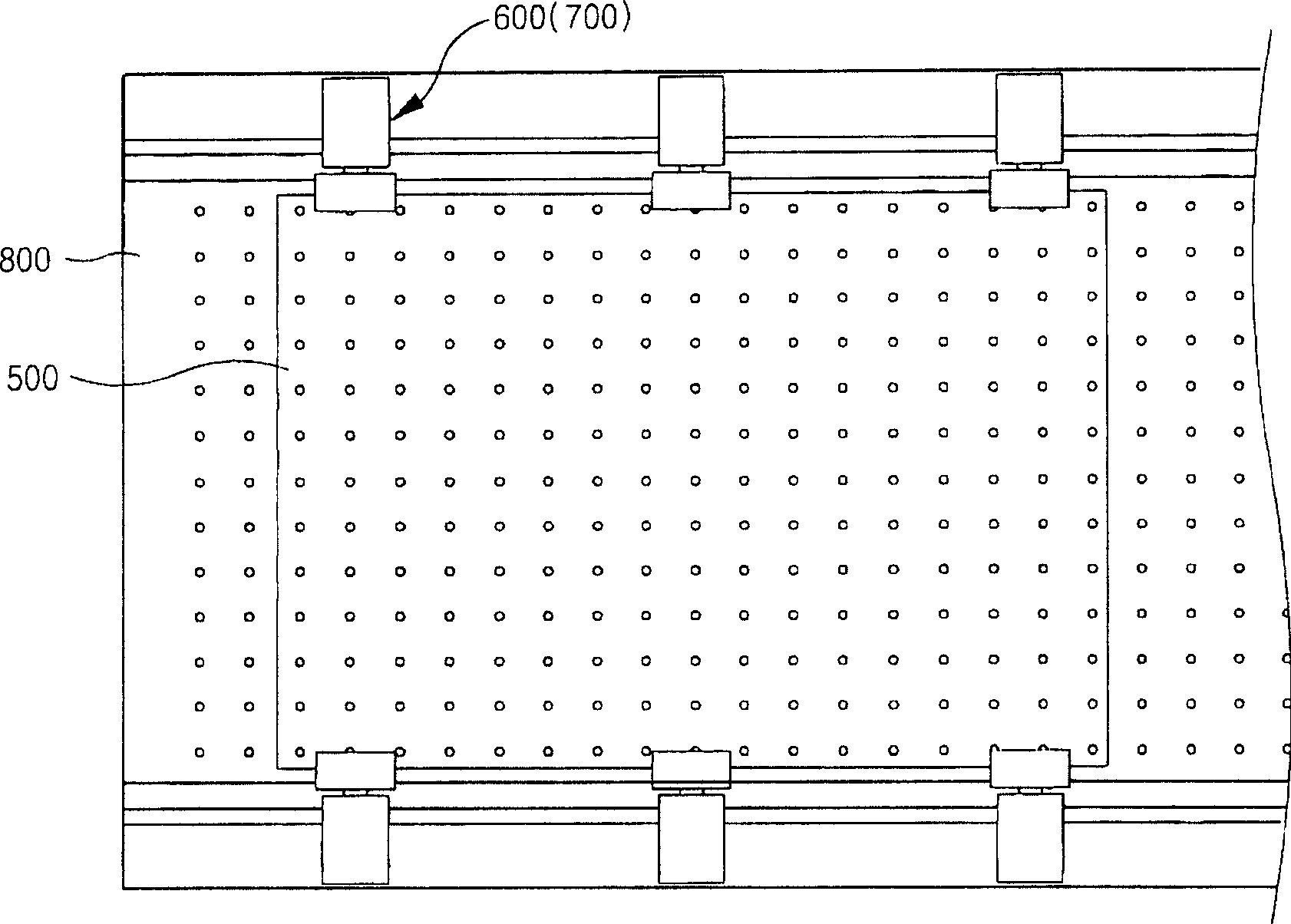

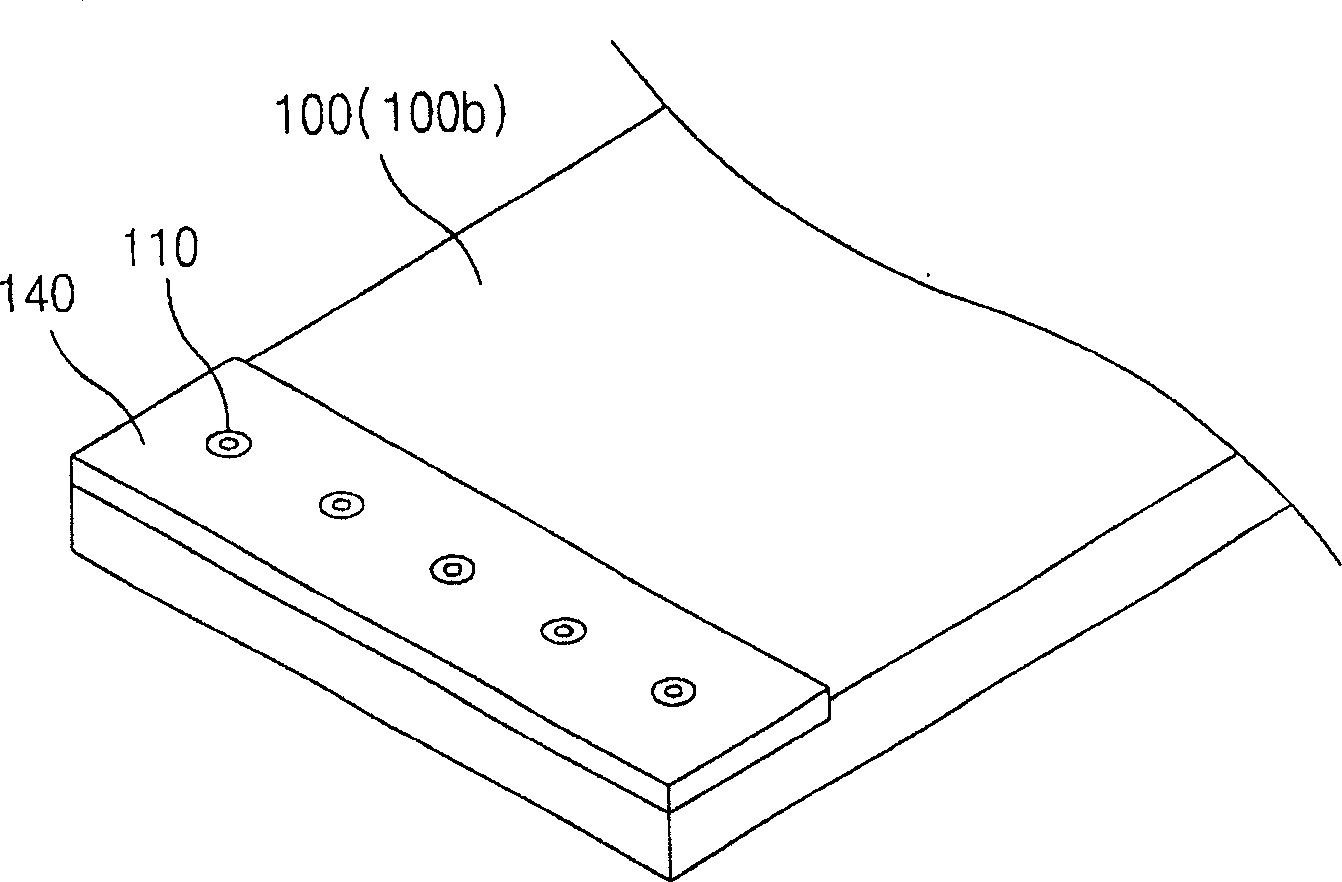

Display device and method of manufacturing same

ActiveUS20110133636A1Discharge tube luminescnet screensElectroluminescent light sourcesColor targetDisplay device

A display device capable of early finding a sign such as misregistration or width variation of an emission layer formed by a layer transfer method, and a manufacturing method of the same are provided. In an inspection region 150 outside of an effective region 110, inspection pixels Px2 made up of organic light-emitting elements 10R, 10G and 10B are provided, and a distance W2 between the inspection pixels Px2 on both sides of a color targeted for inspection is shorter than a distance W1 between display pixels Px1 on both sides of the color targeted for inspection. Based on a change in a chromaticity or a spectrum shape of EL or PL light emission of the inspection pixel Px2, a sign such as misregistration of a red-light emission layer 15CR, a green-light emission layer 15CG, is found at an early stage.

Owner:JOLED INC

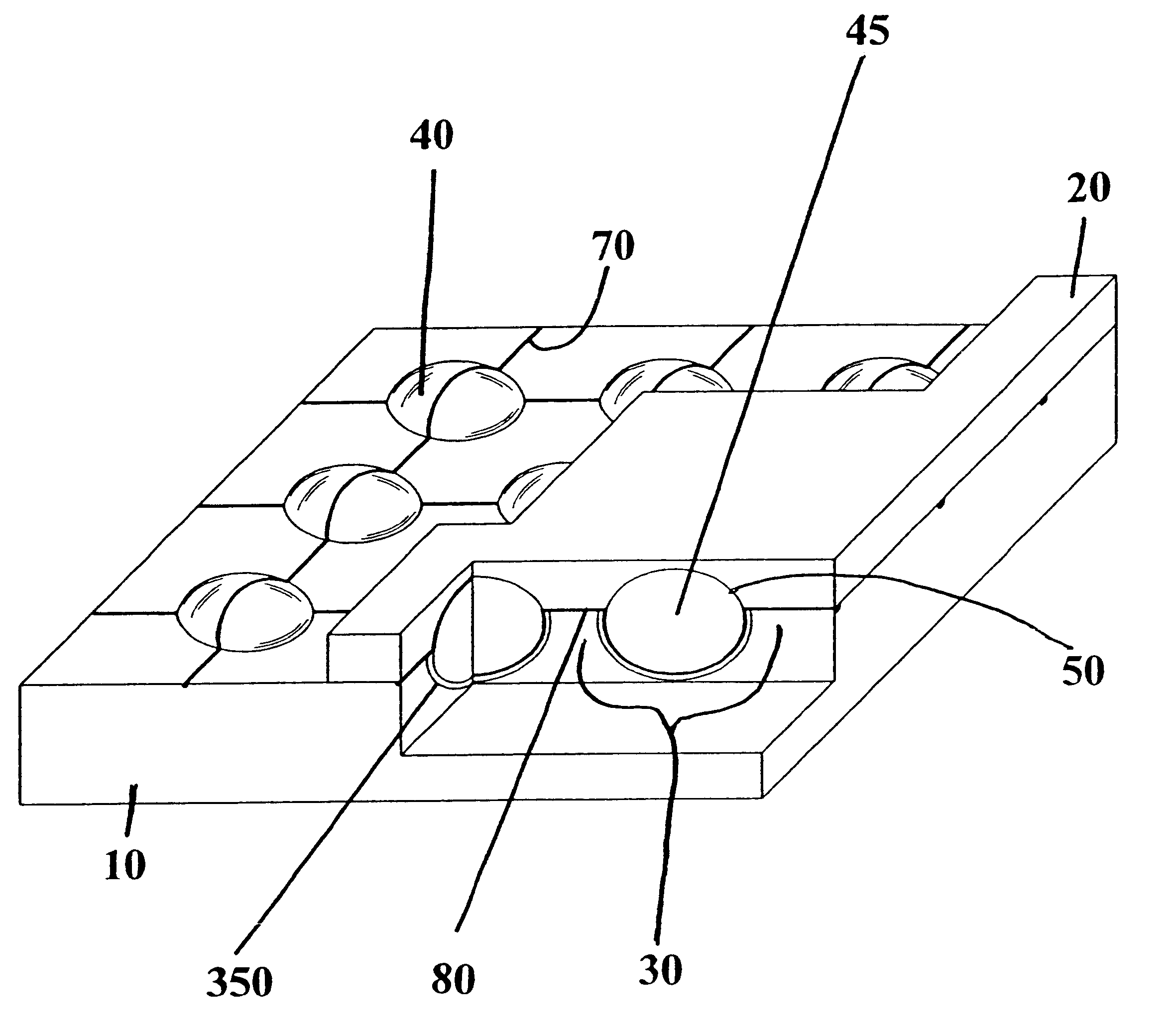

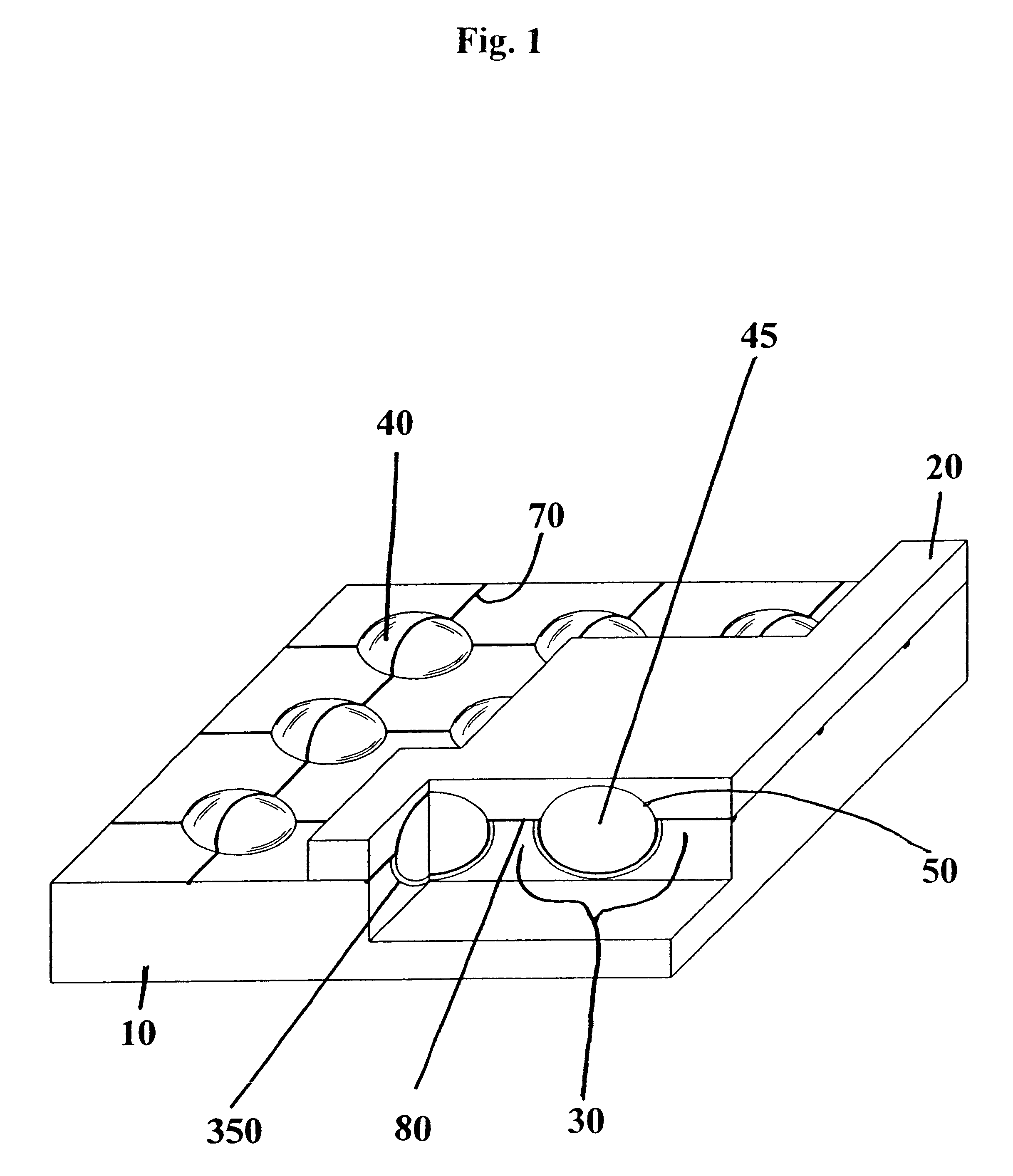

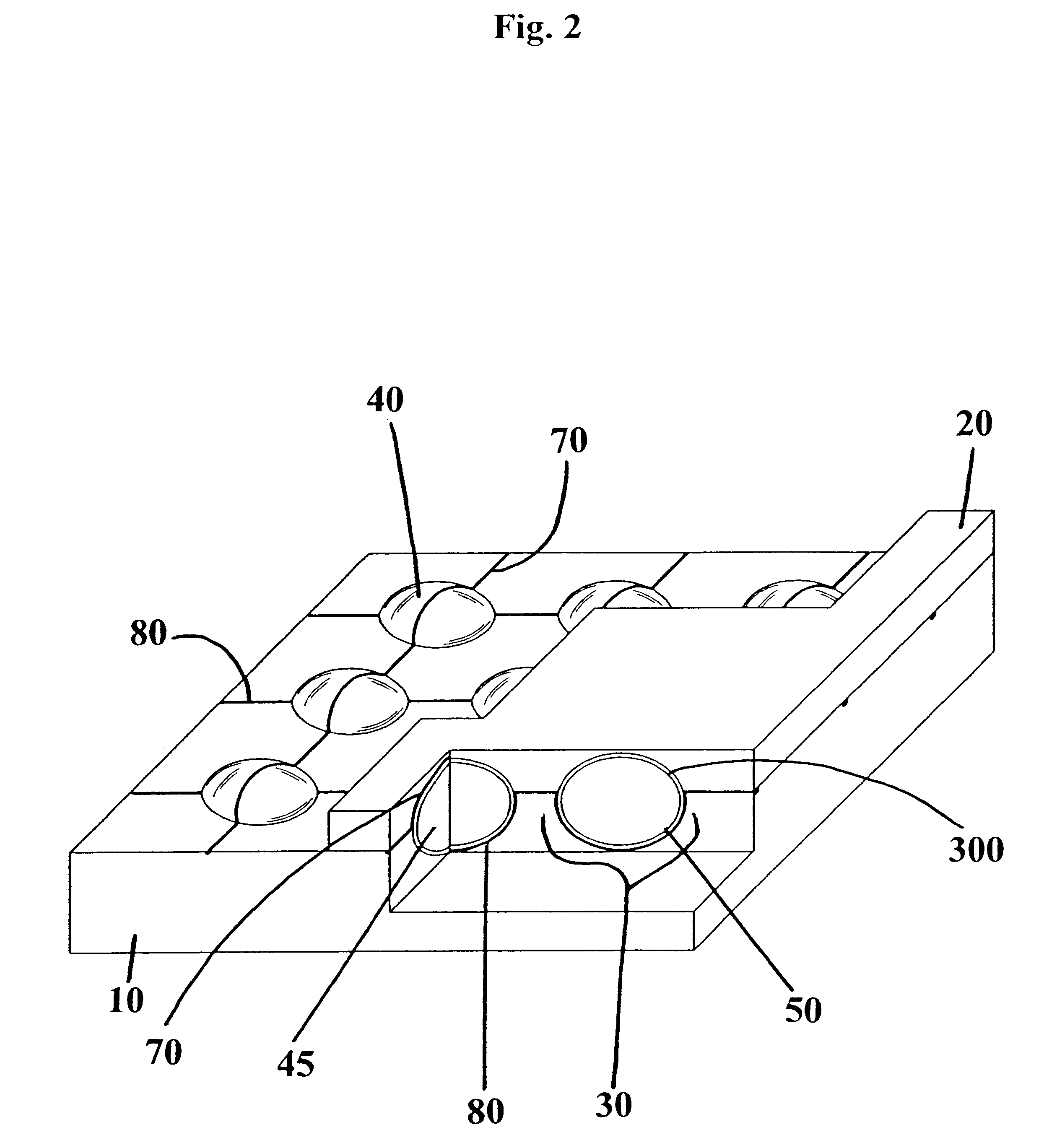

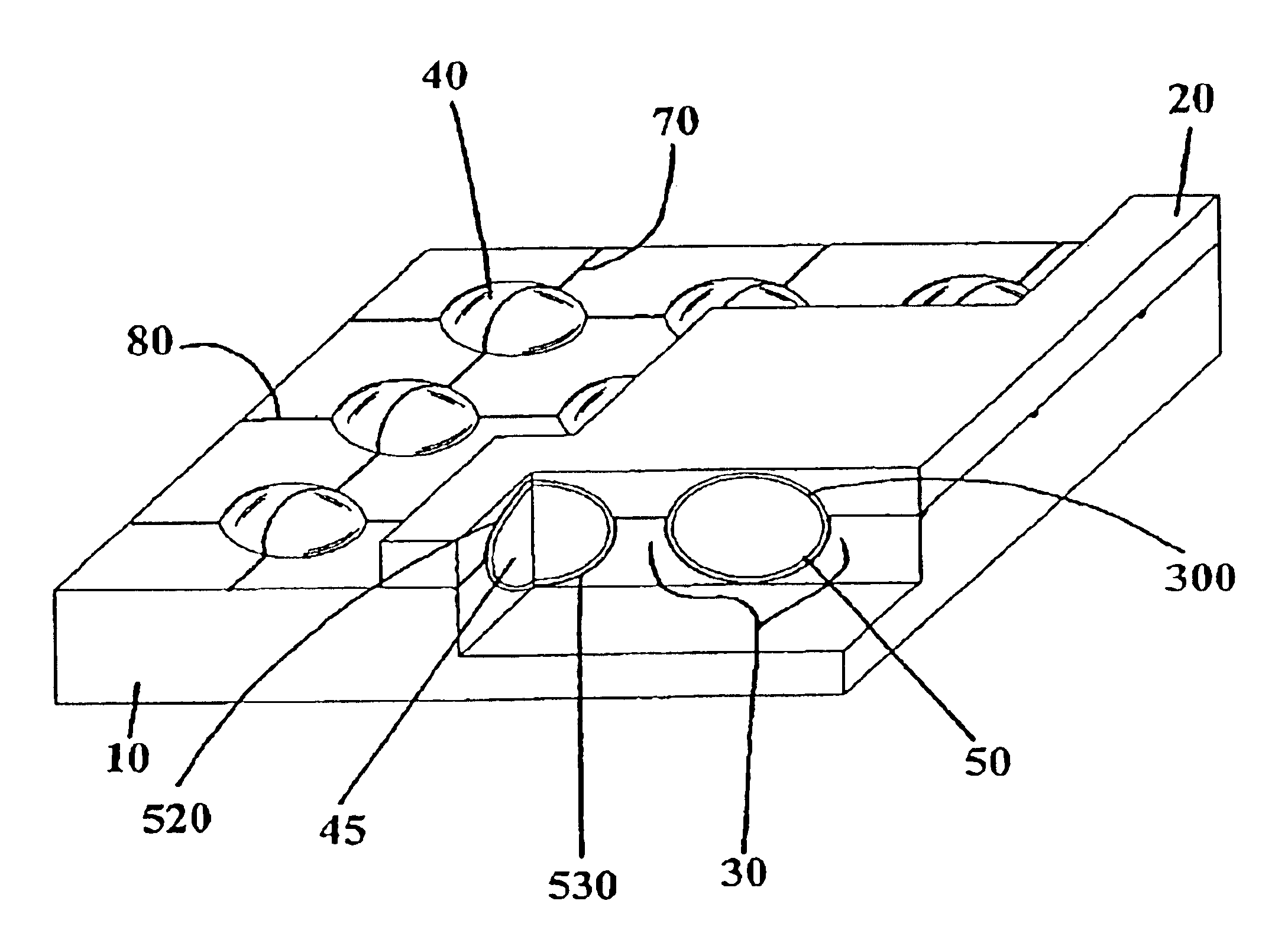

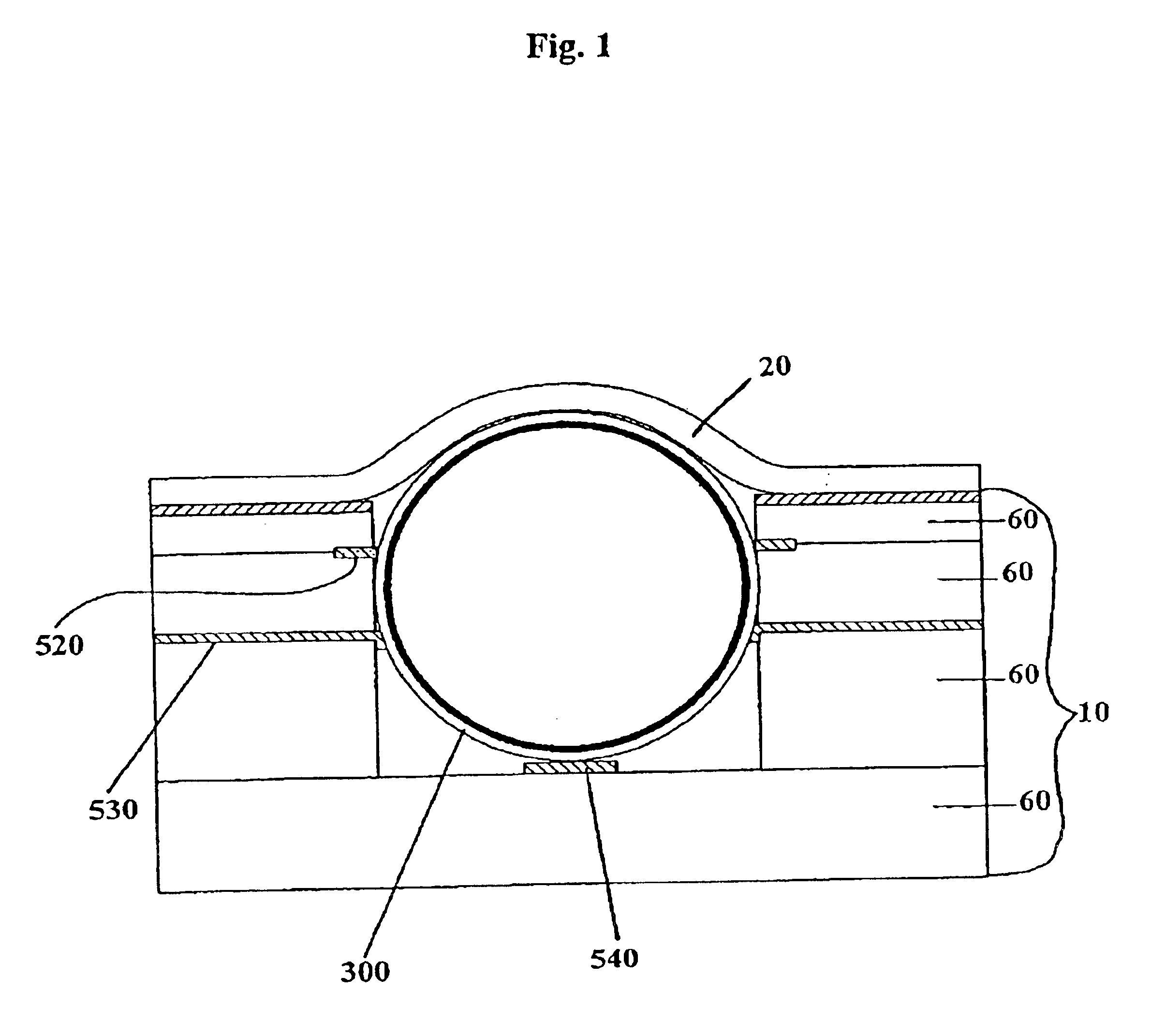

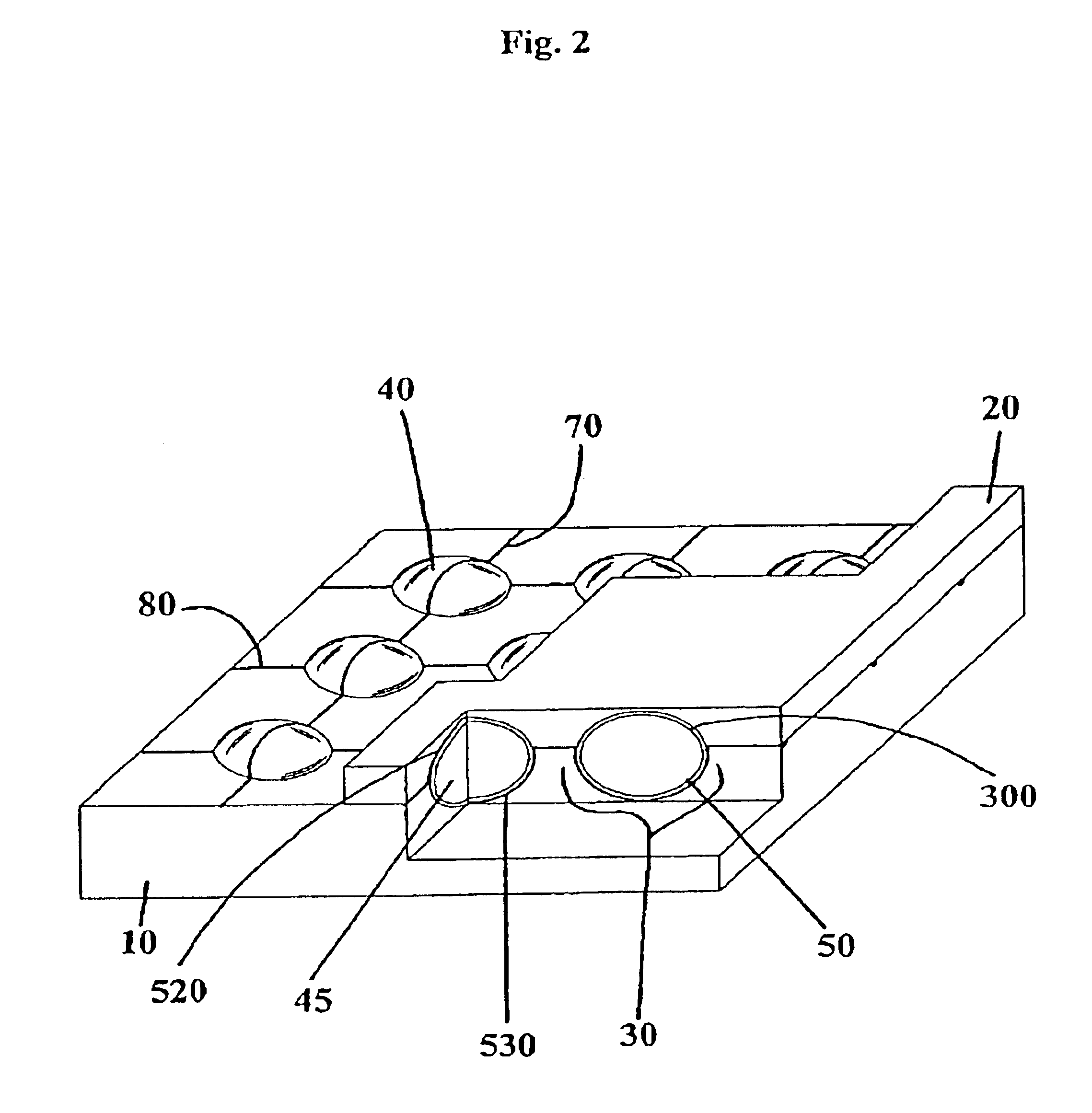

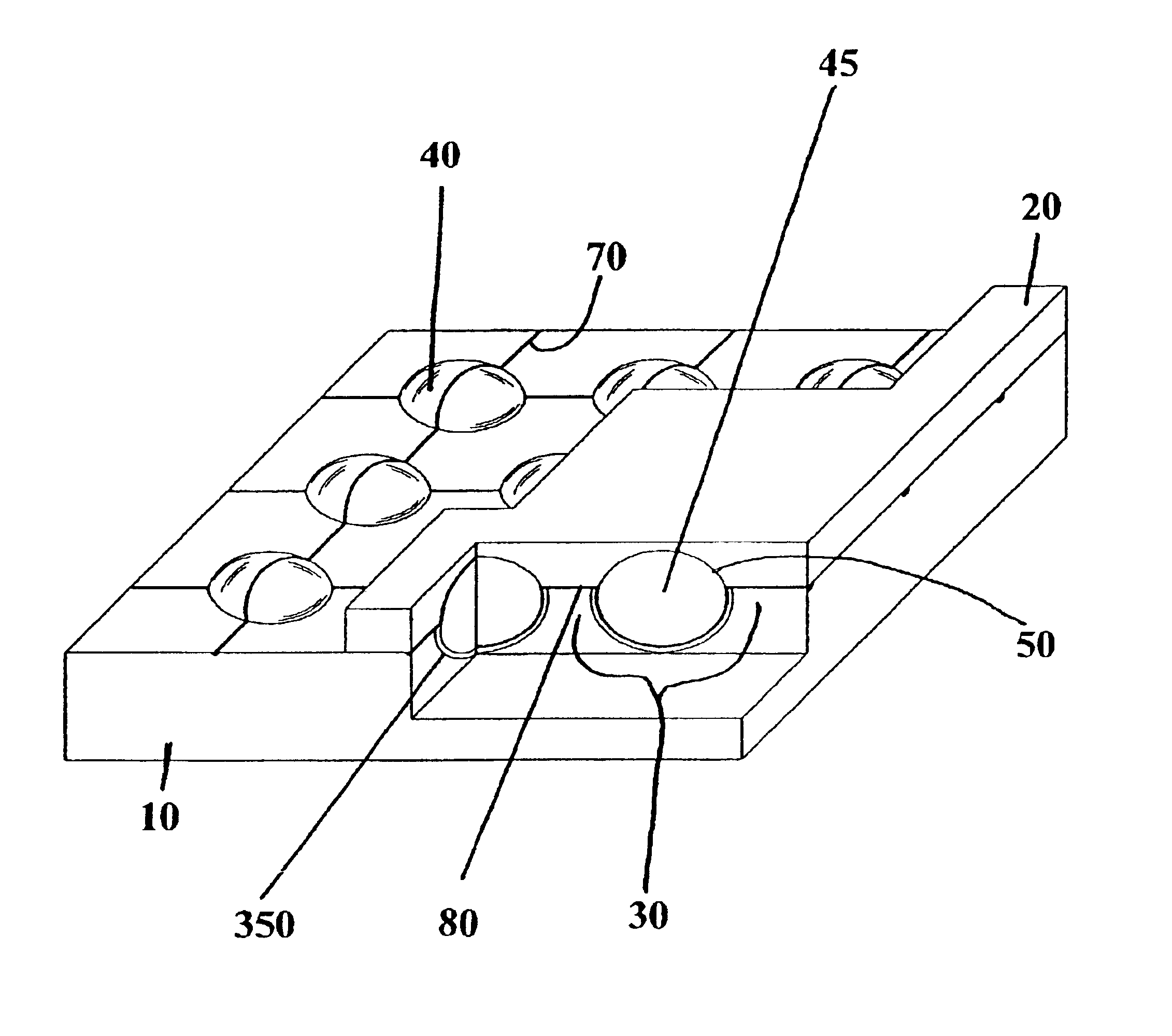

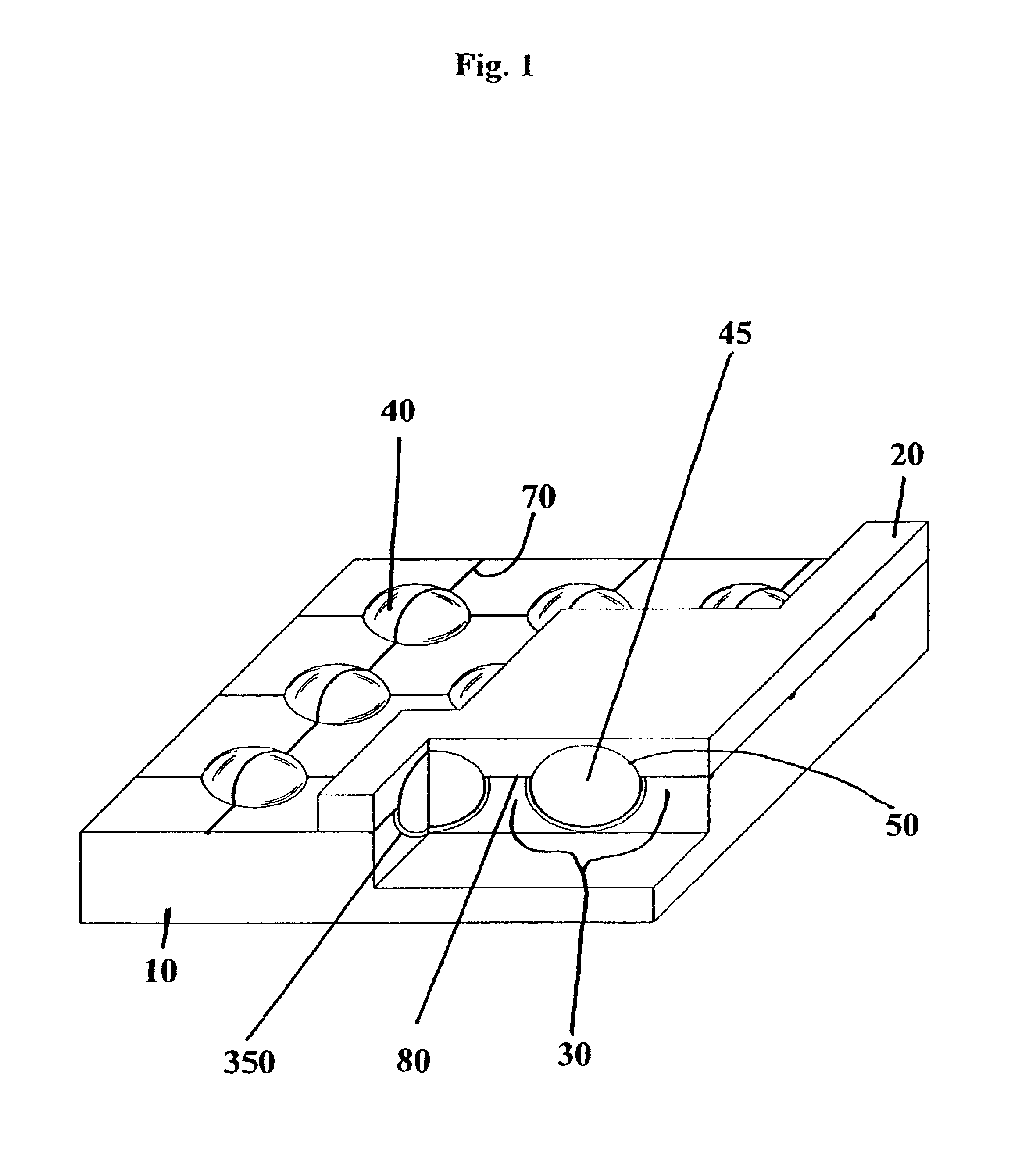

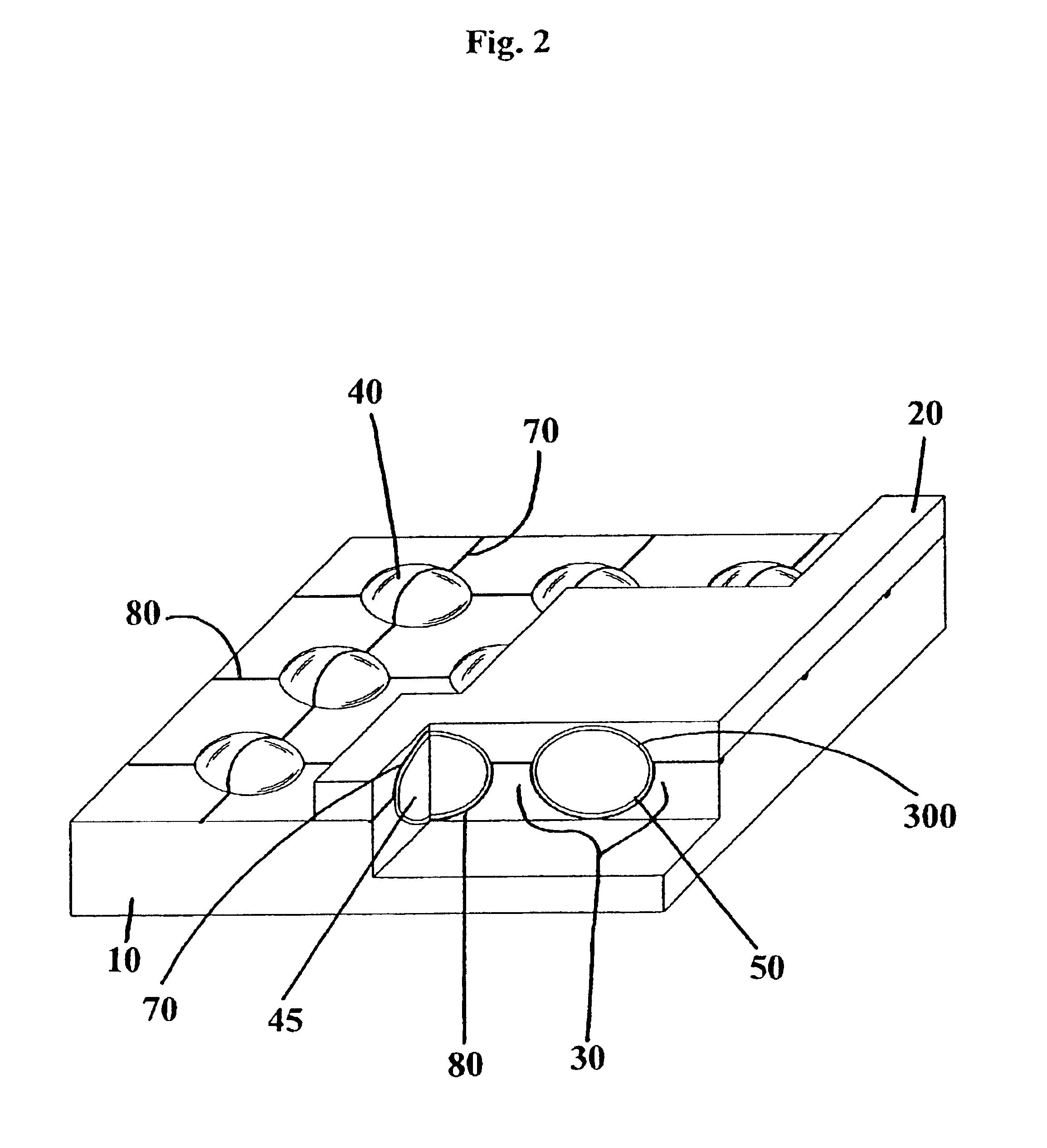

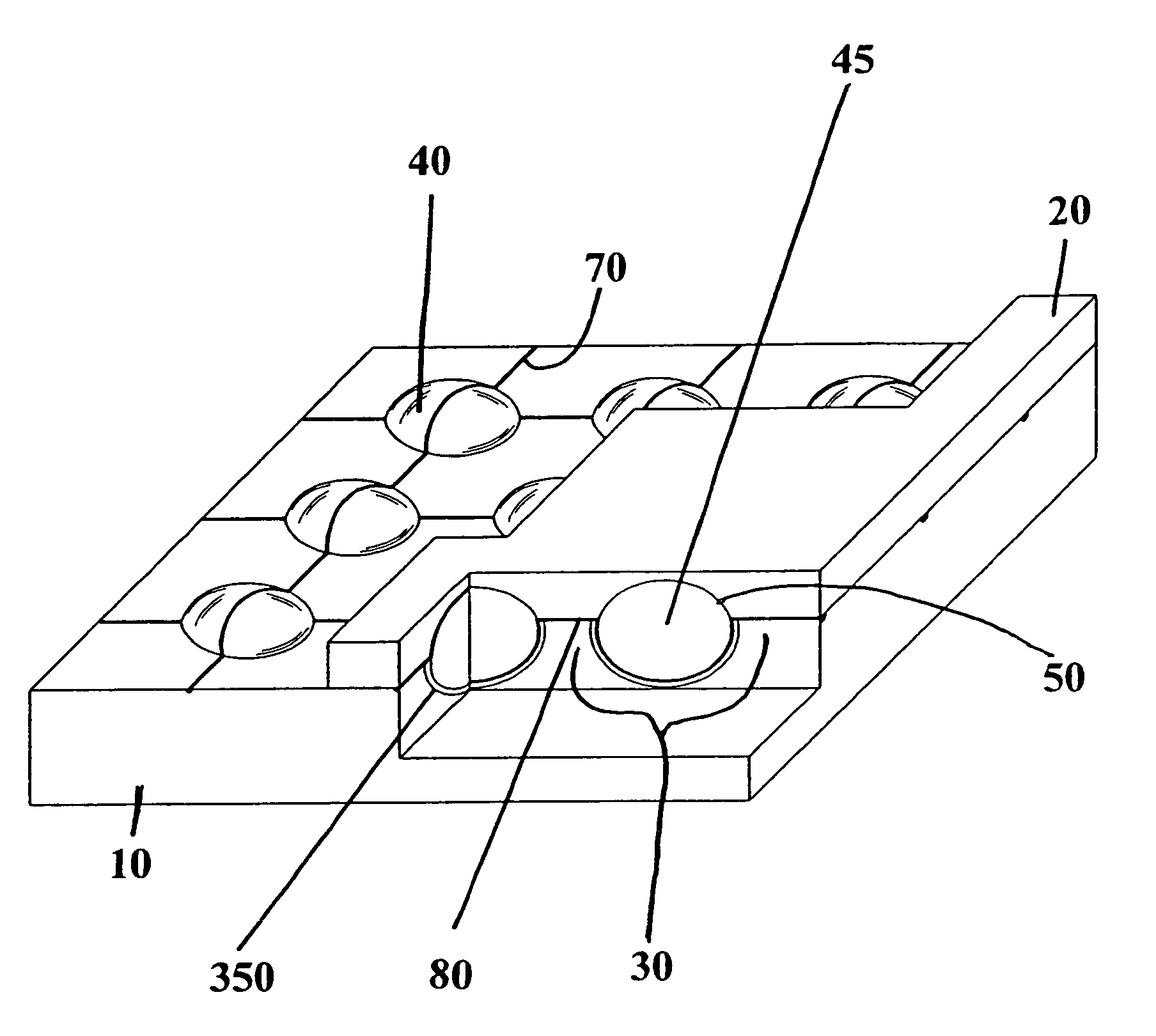

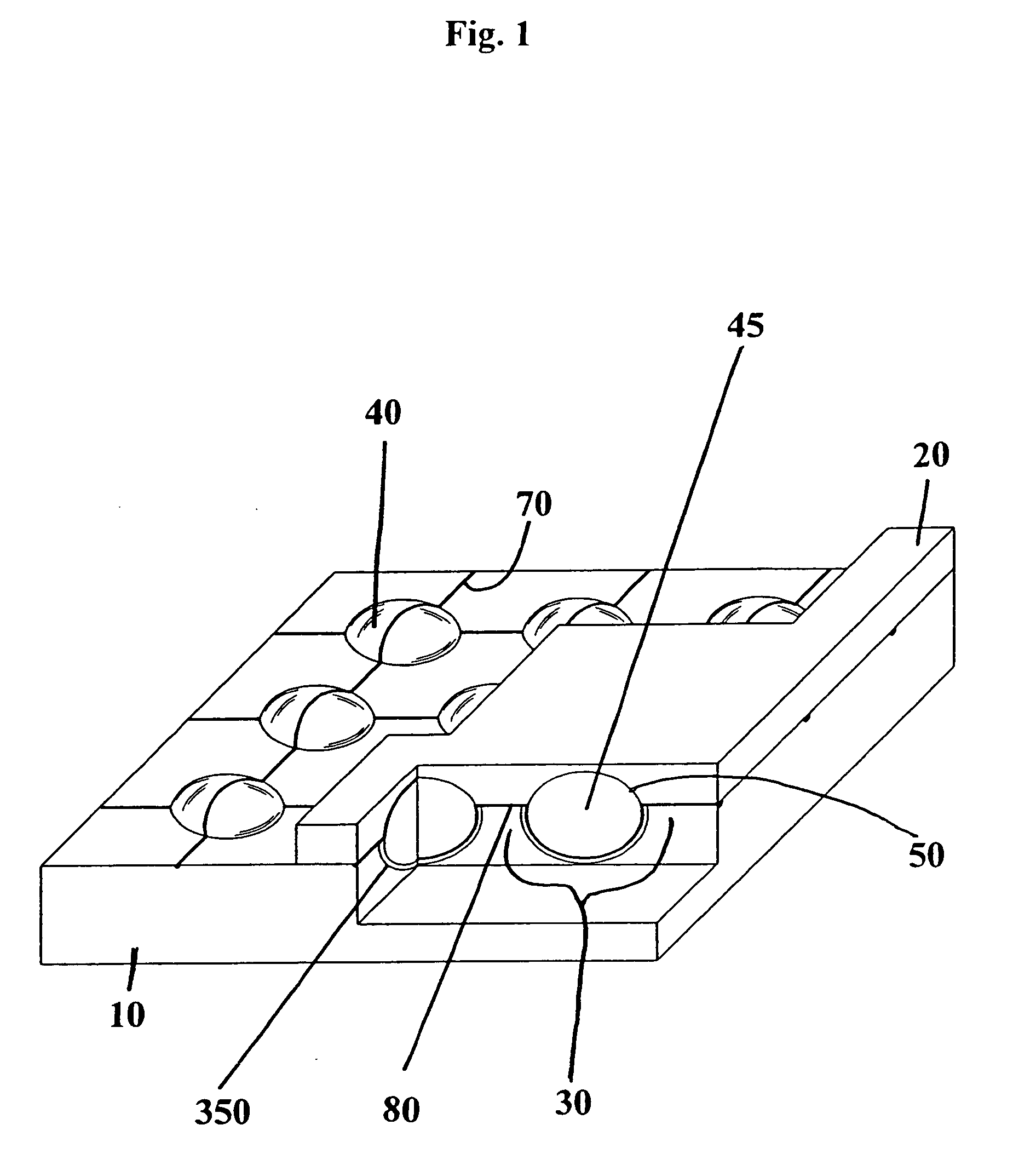

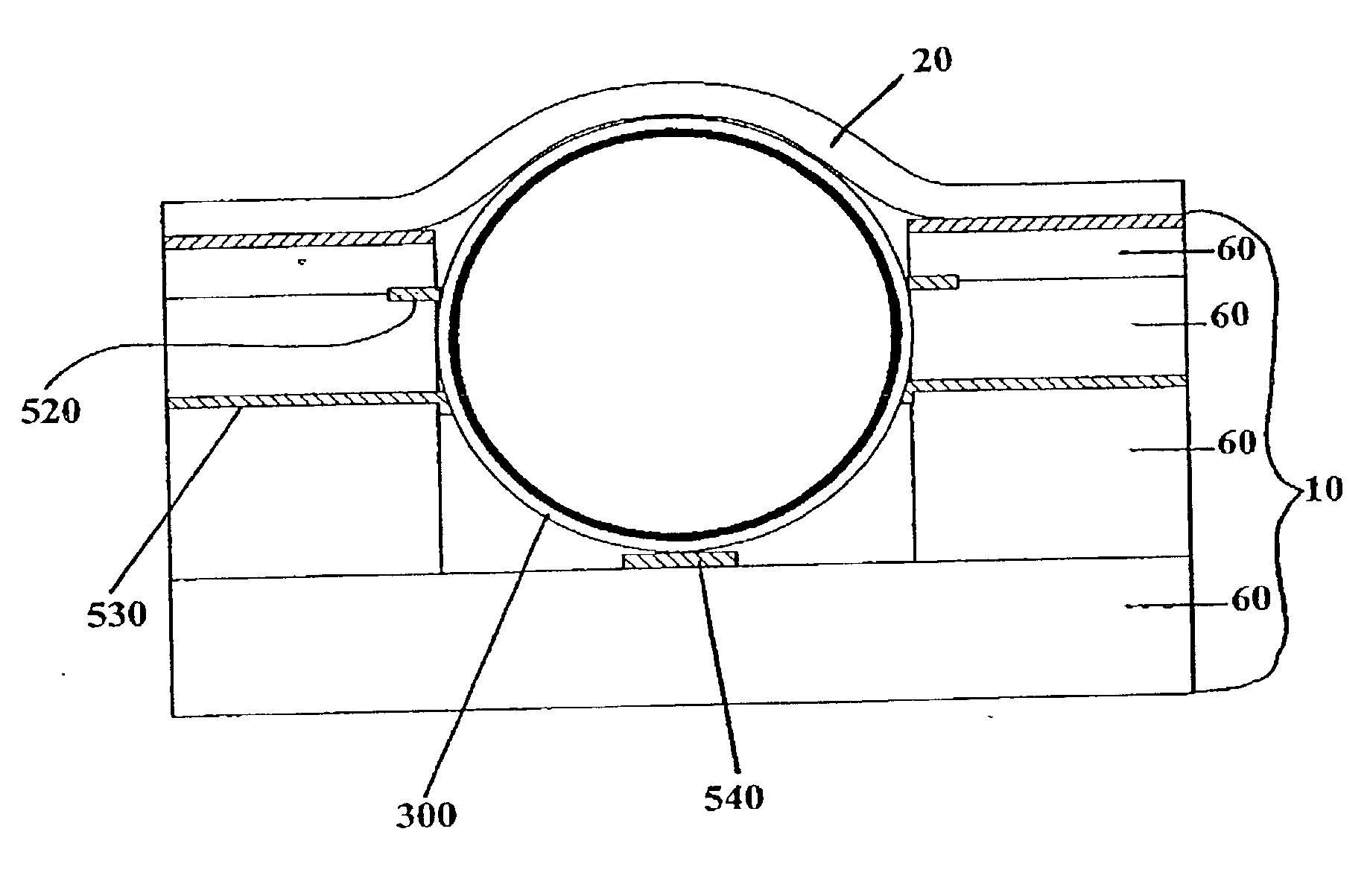

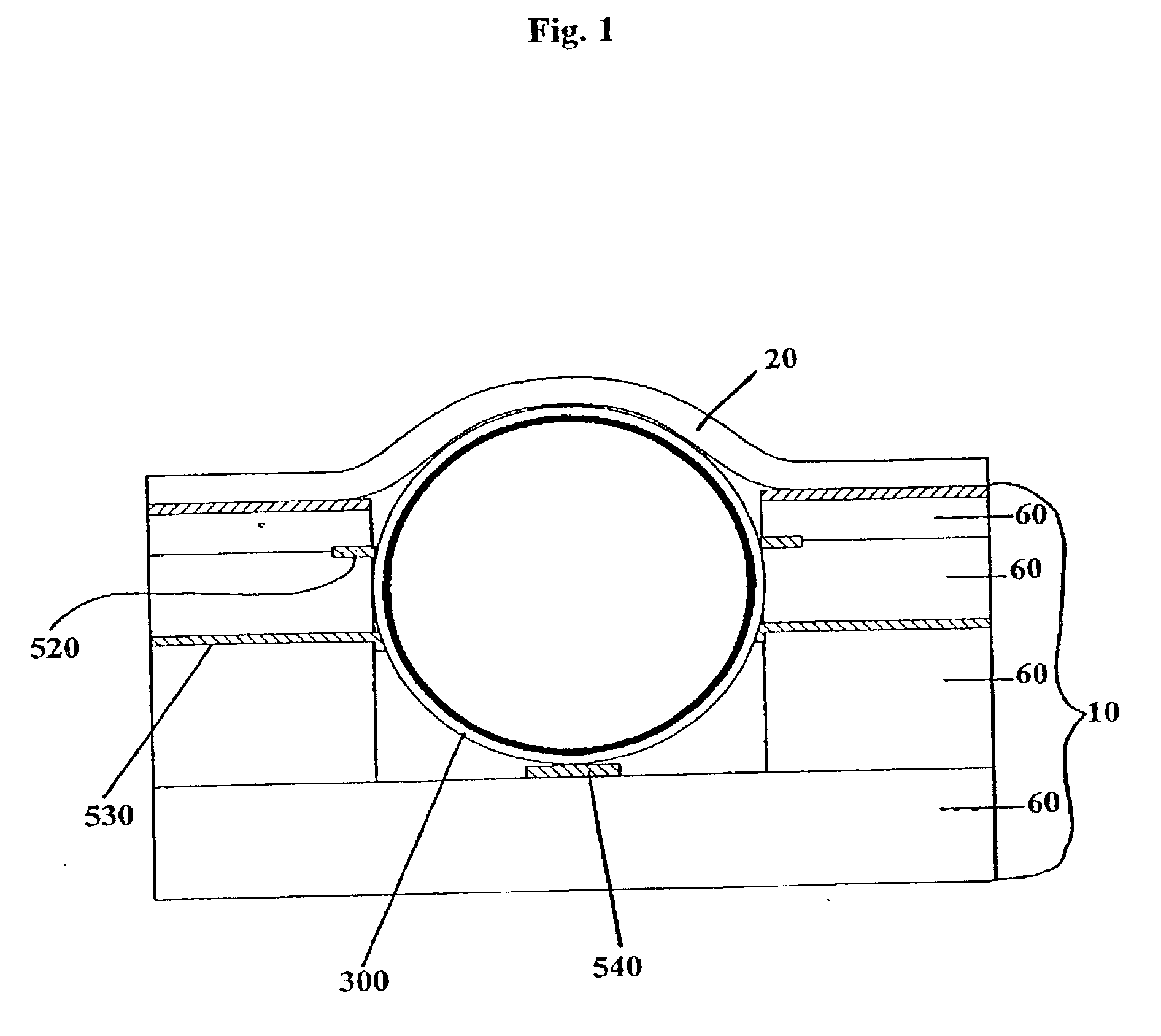

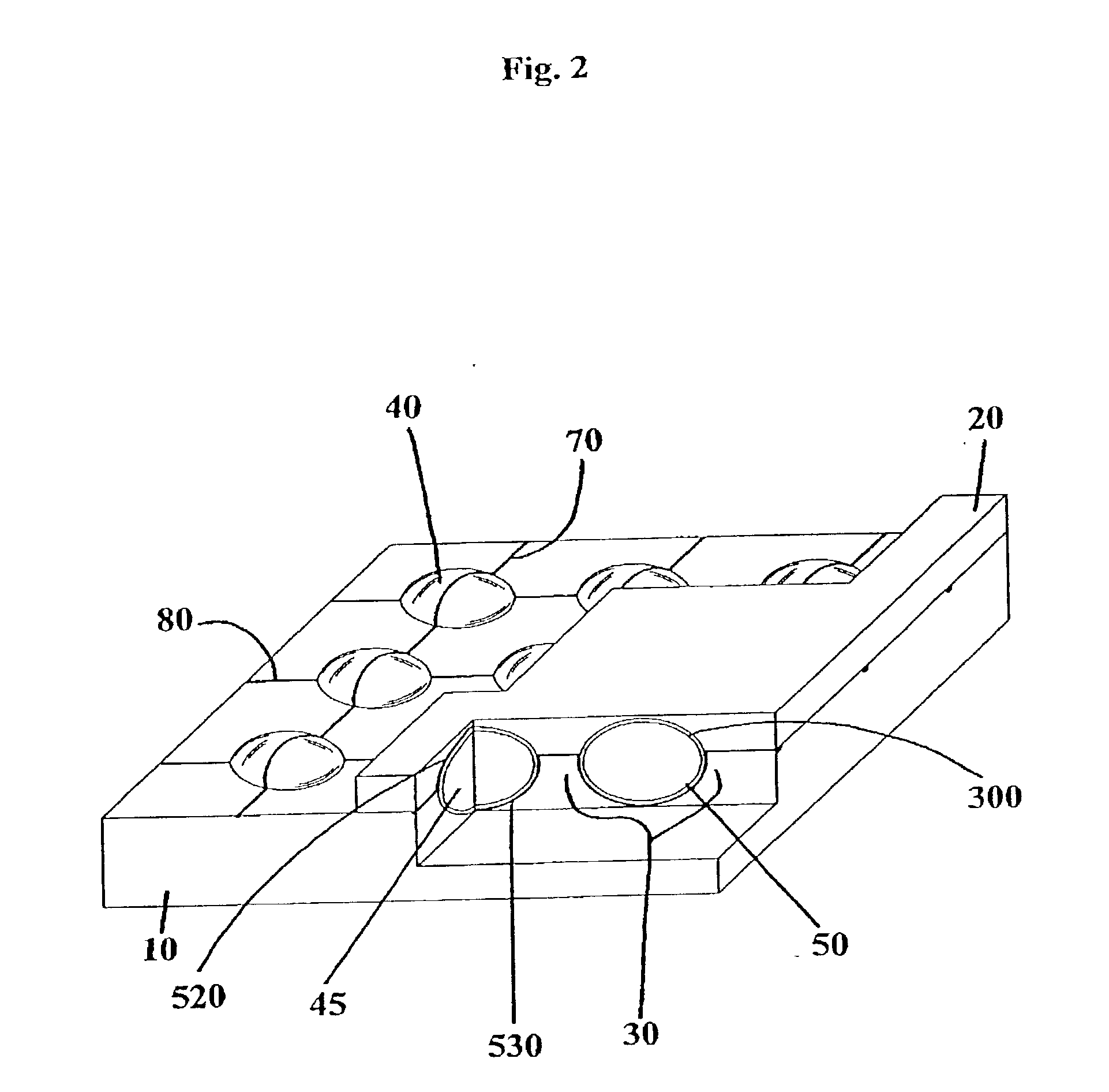

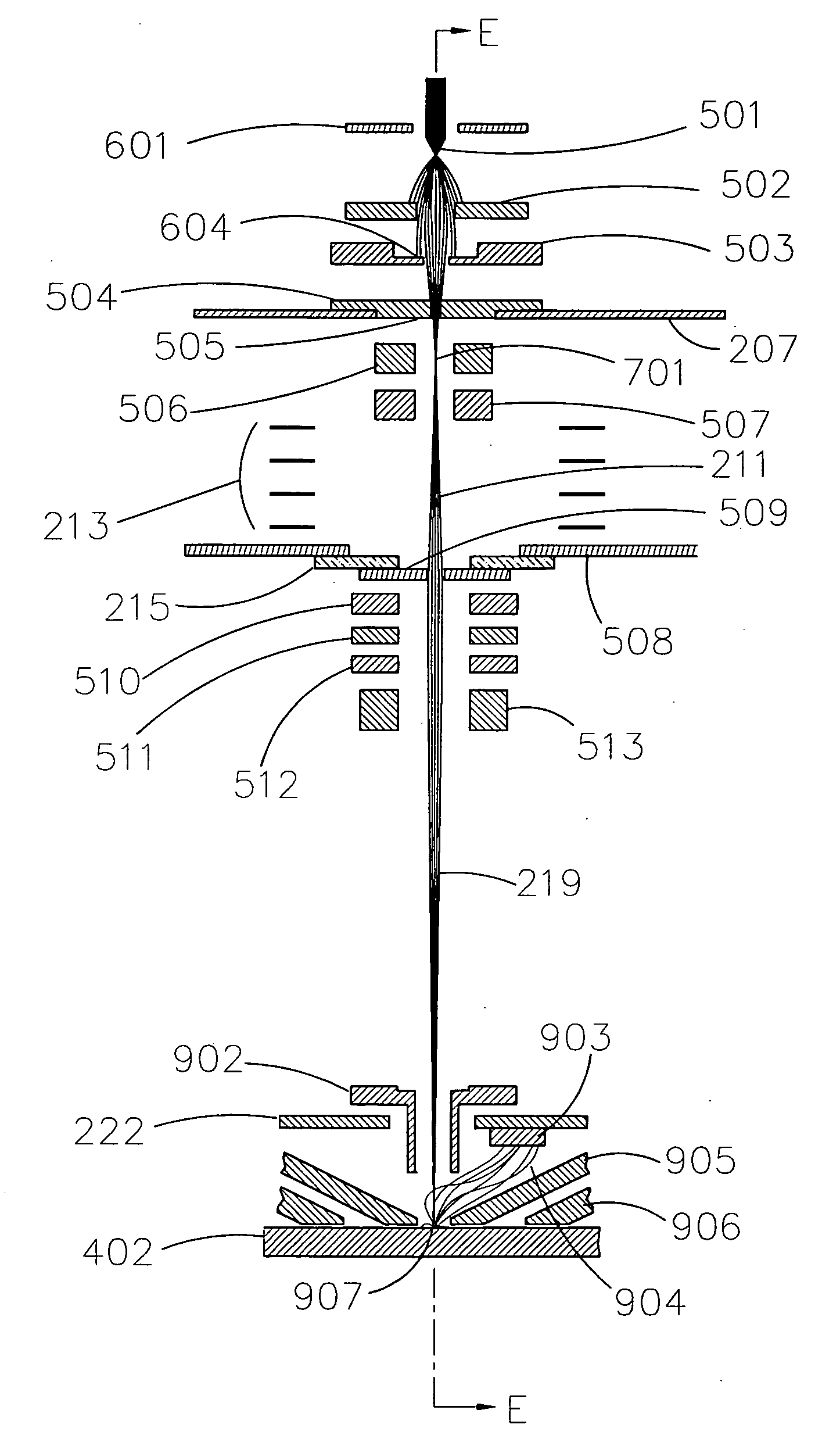

Design, fabrication, testing, and conditioning of micro-components for use in a light-emitting panel

InactiveUS6822626B2Sufficient resolutionManufactured very thinFixed microstructural devicesVolume/mass flow measurementEngineeringPre testing

Owner:LEIDOS

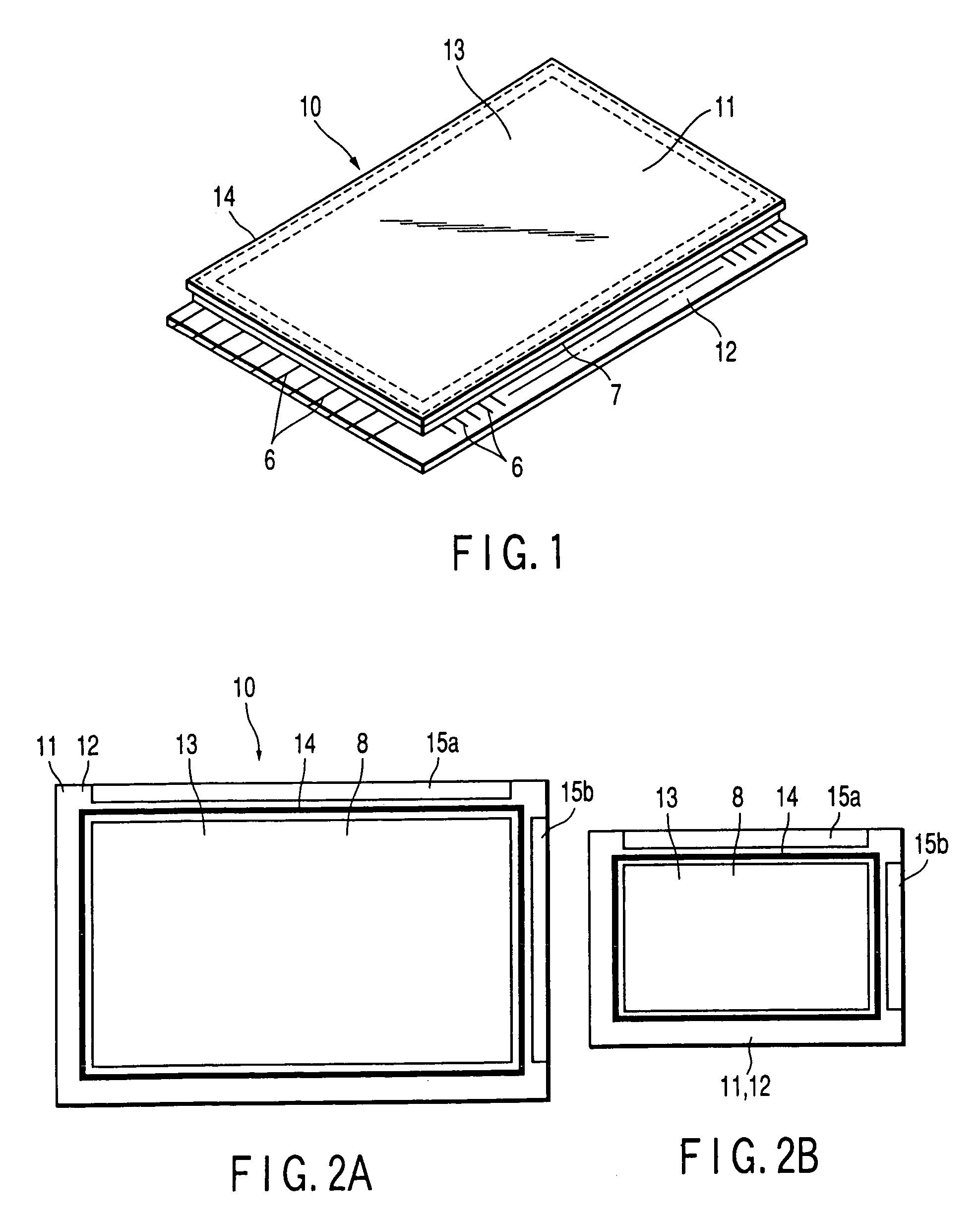

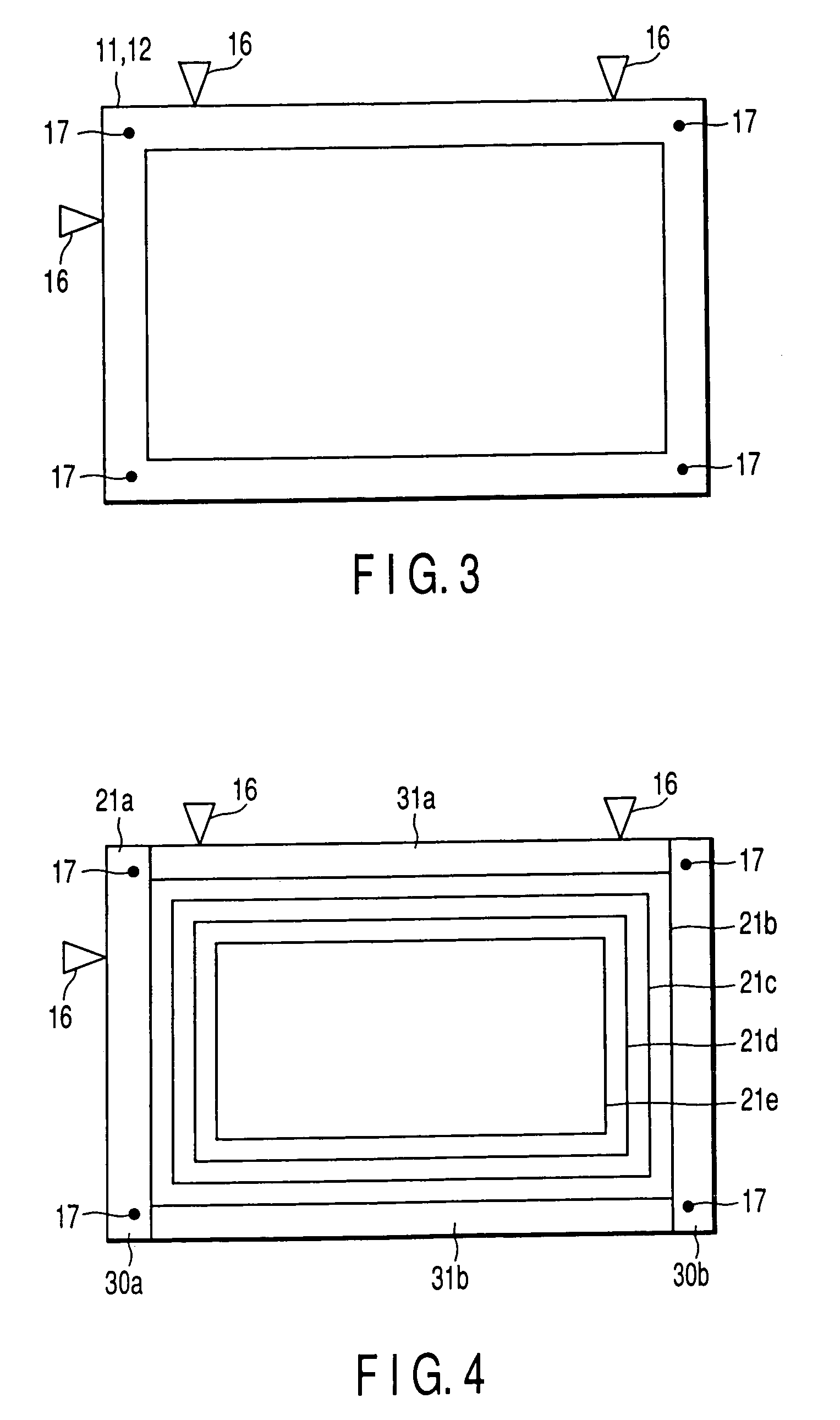

Method of manufacturing flat display panels of different sizes from a common base substrate

InactiveUS7273403B2Lower manufacturing requirementsNarrow widthSparking plugsStatic indicating devicesCommon baseDisplay device

In a method of a manufacturing flat display apparatuses by working flat substrates, a flat substrate is prepared having a first region which is used as a flat display apparatus and a second region outside the first region. After the first region is worked as desired, the second region is cut and separated from the flat substrate.

Owner:KK TOSHIBA

Method for on-line testing of a light emitting panel

InactiveUS6935913B2Sufficient resolutionManufactured very thinSparking plugsStatic indicating devicesEngineeringLight-emitting diode

Owner:LEIDOS

Method for testing a light-emitting panel and the components therein

InactiveUS20040063373A1Sufficient resolutionManufactured very thinStatic indicating devicesAlternating current plasma display panelsIonizationVoltage

An improved light-emitting panel having a plurality of micro-components sandwiched between two substrates is disclosed. Each micro-component contains a gas or gas-mixture capable of ionization when a sufficiently large voltage is supplied across the micro-component via at least two electrodes. A method of testing a light-emitting panel and the component parts therein is also disclosed, which uses a web fabrication process to manufacturing light-emitting panels combined with inline testing after the various process steps of the manufacturing process to produce result which are used to adjust the various process steps and component parts.

Owner:SCI APPL INT CORP

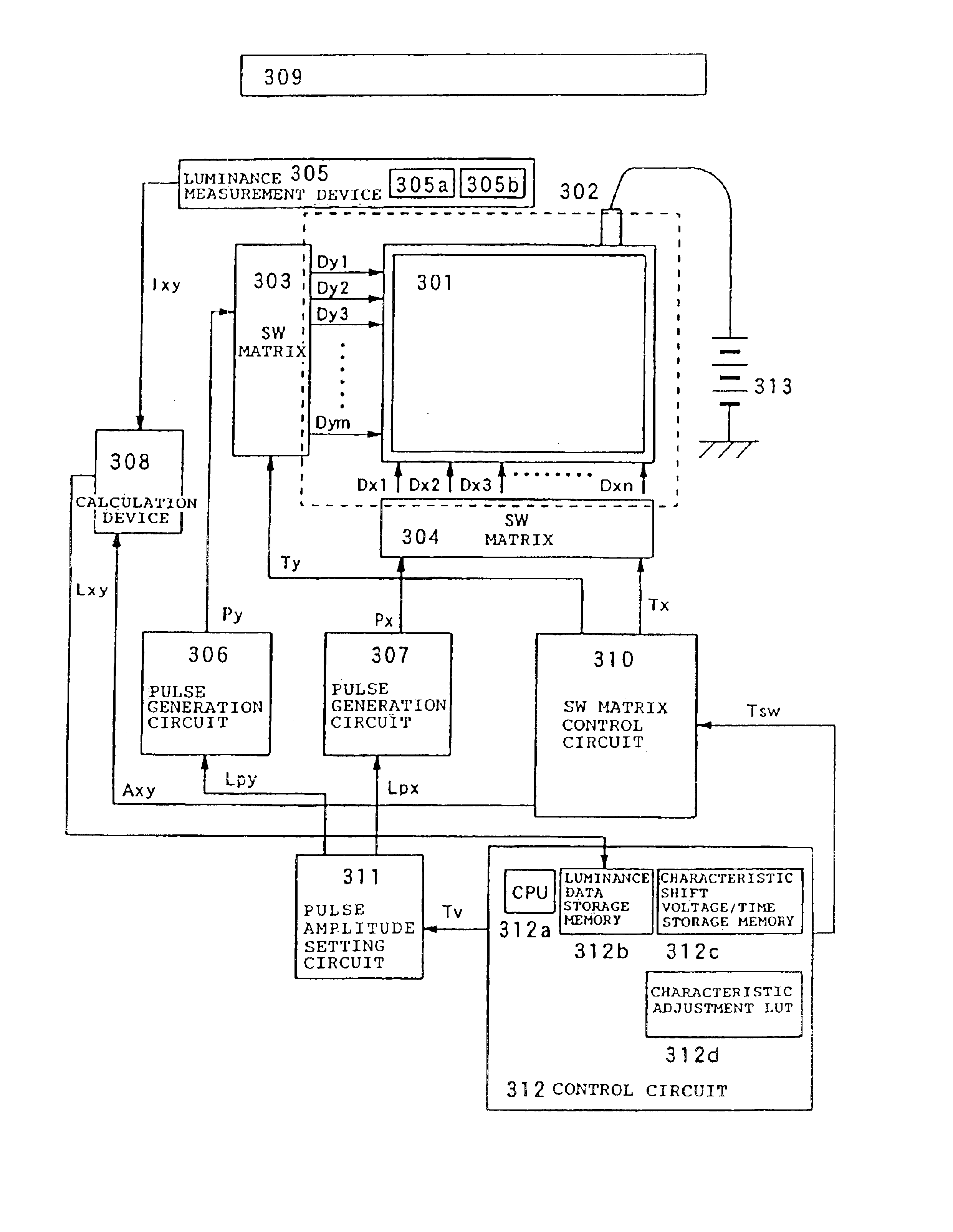

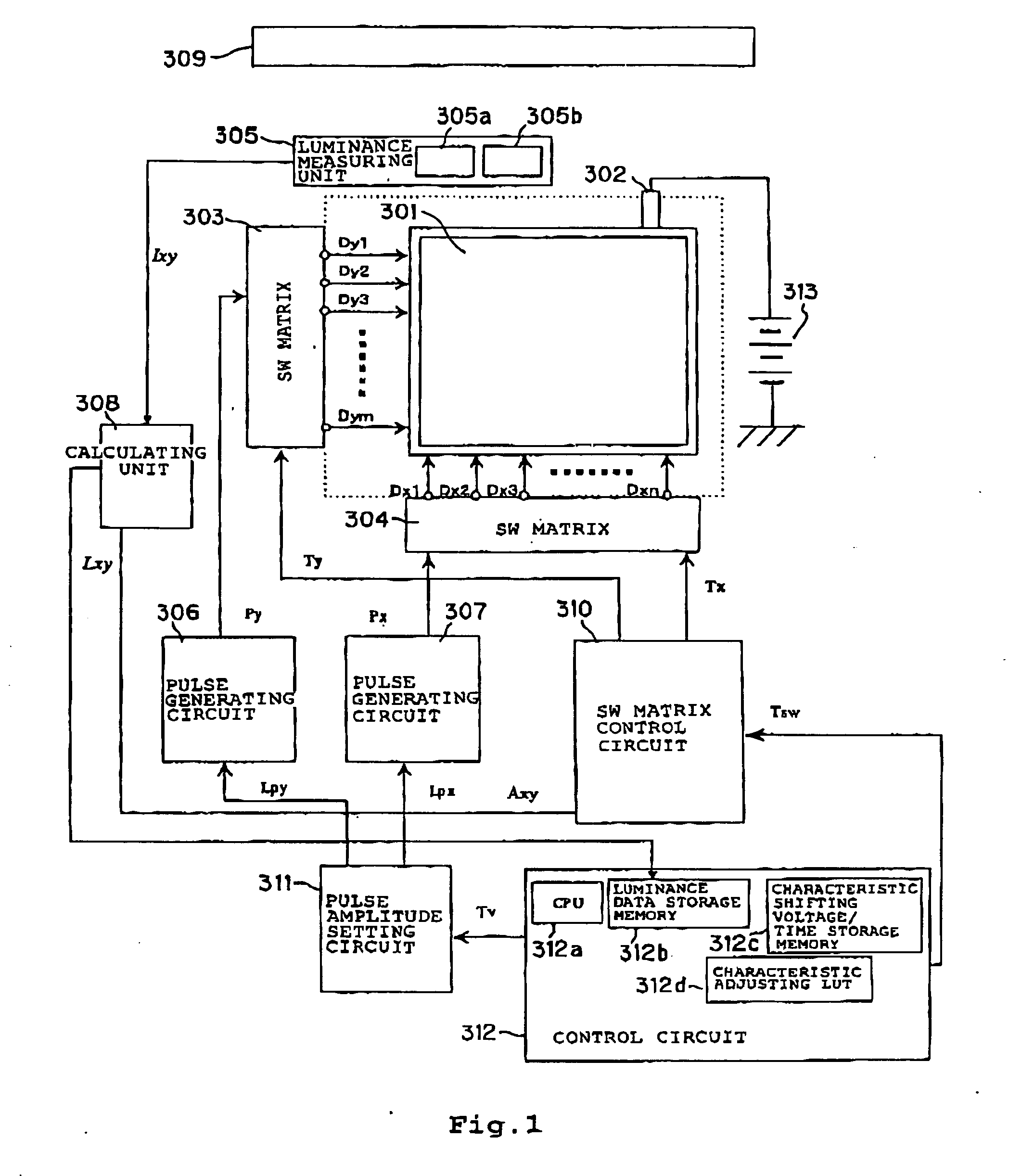

Method of manufacturing image forming apparatus

InactiveUS6822397B2Variation in timeReduce processing timeSparking plugsDigital variable displayImage formationLightness

The present invention relates to the adjustment of luminance. The present invention is a method of manufacturing image forming apparatus including a step of applying characteristic shift voltage comprising a plurality of pulses in which the amplitude of the pulse obtained from the look-up table has two or more values, to the emitter, the look-up table storing the amplitude of the pulse and the number of the pulse for shifting characteristic of emitters to a predetermined luminance target value on the basis of the measurement result of the luminance. Moreover, the present invention is a method of manufacturing image forming apparatus comprising a step of applying the second pulses of characteristic shift voltage having the amplitude which was determined in response to the measurement result of the luminance after the first characteristic shift voltage had been applied to the emitter.

Owner:CANON KK

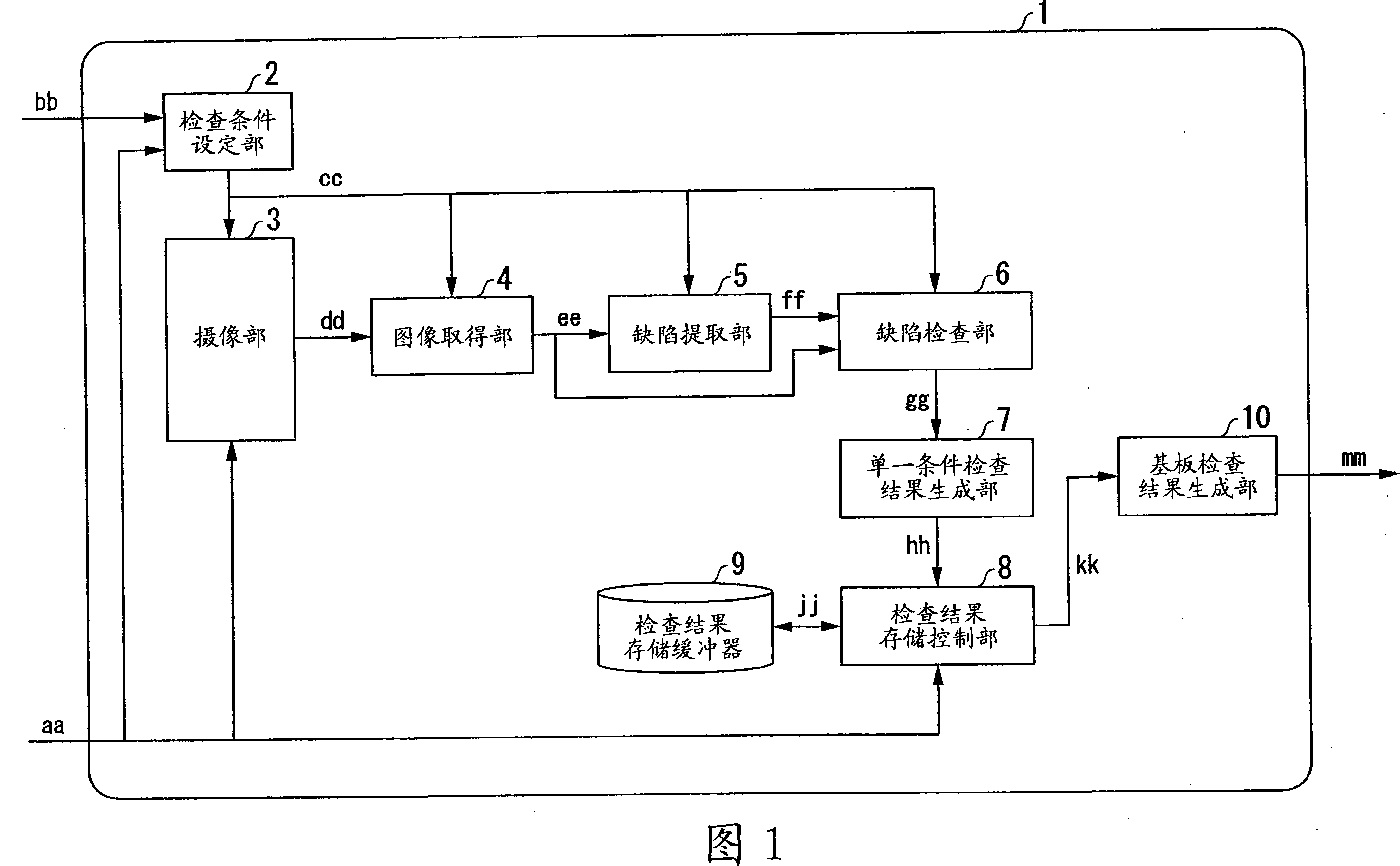

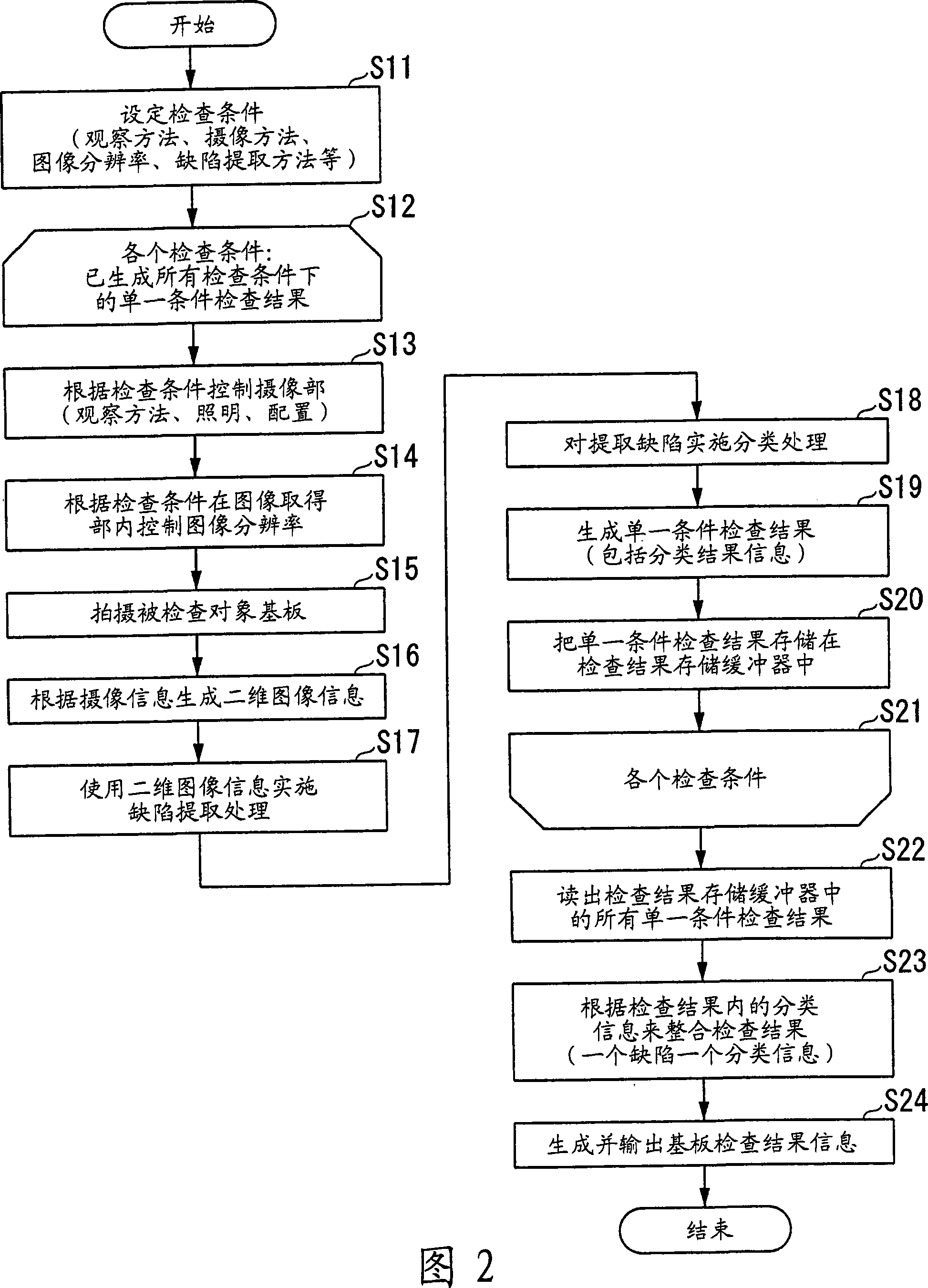

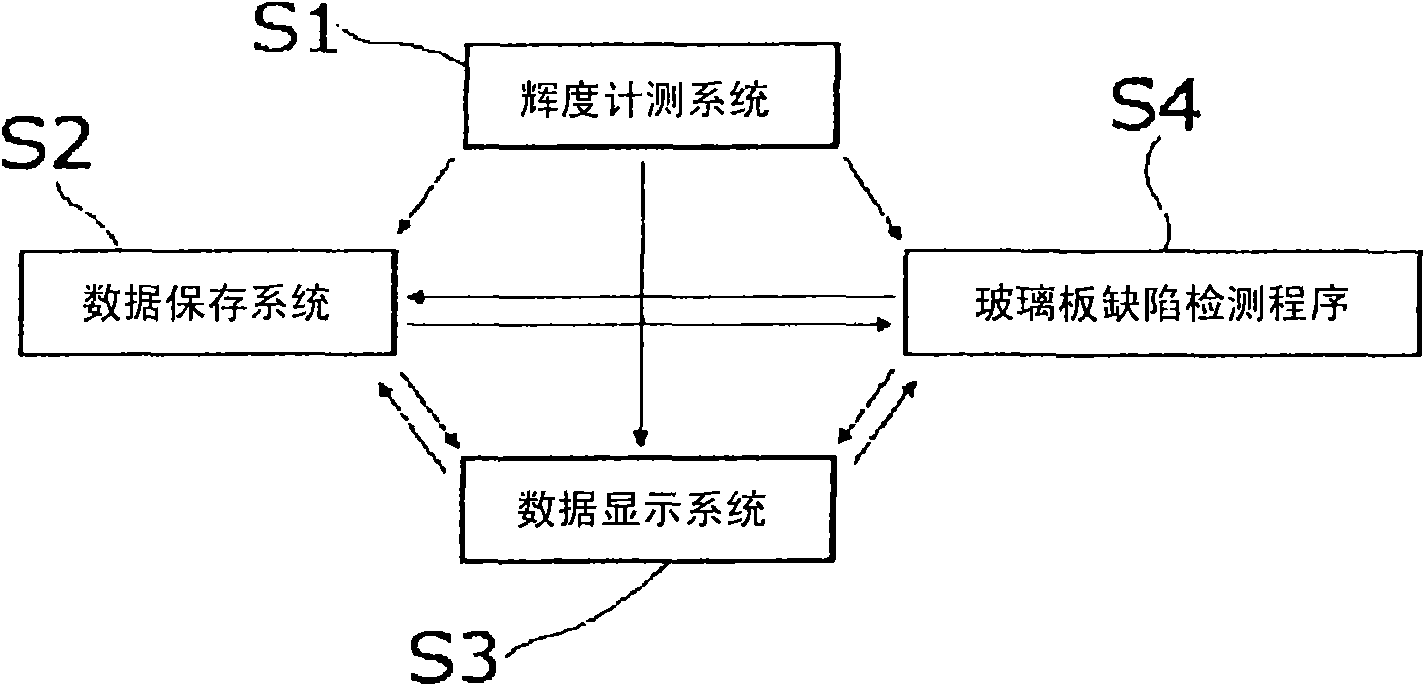

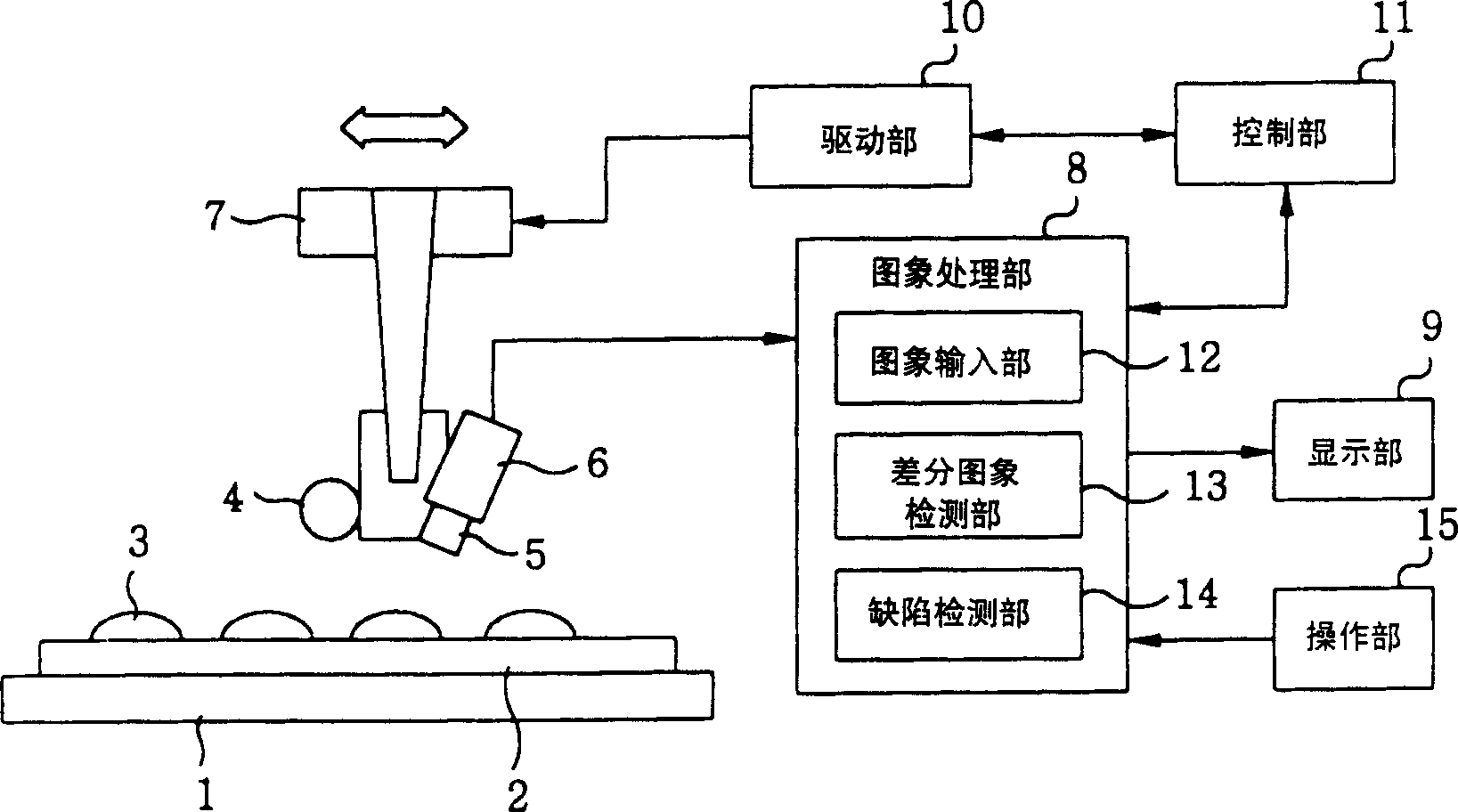

Defect testing device and method

InactiveCN101197301AImprove productivityImage enhancementImage analysisPattern recognitionProduction rate

The invention provides a defect inspection device and a defect inspection method. An imaging unit (3) images an object to be inspected to generate imaging information. An image generating unit (4) generates an image of an object to be inspected based on imaging information. A defect extraction unit (5) extracts defects on the object to be inspected using the generated image. A defect inspection unit (6) inspects the extracted defects and generates inspection results for each inspection condition. The inspection result generation unit (10) weights the inspection results under each inspection condition according to the defect-related information, and integrates the inspection results under each inspection condition on this basis. Accordingly, it is possible to provide a defect inspection device and a defect inspection method capable of improving the productivity of the entire manufacturing process by facilitating the pass / fail judgment of the substrate.

Owner:OLYMPUS CORP

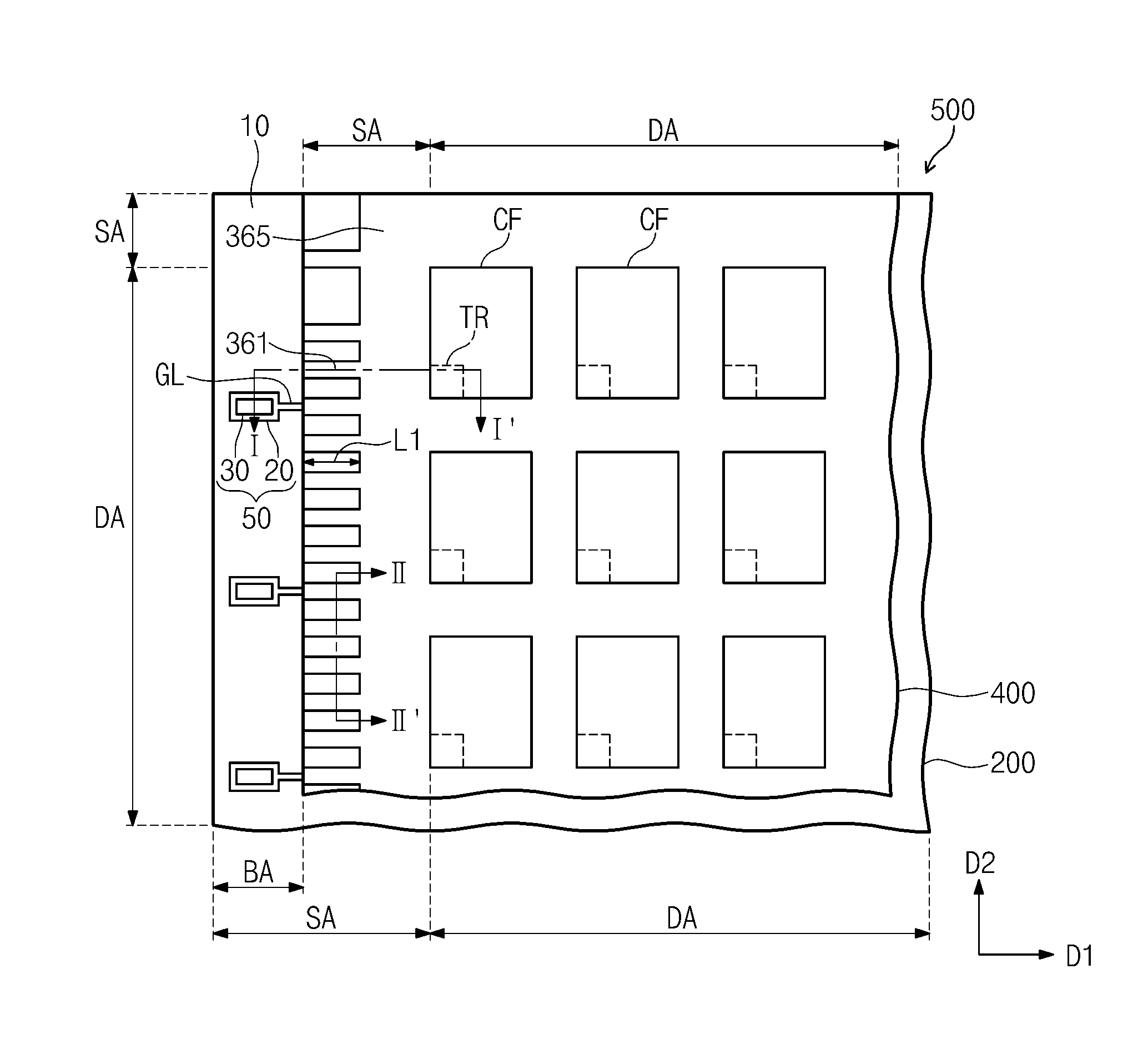

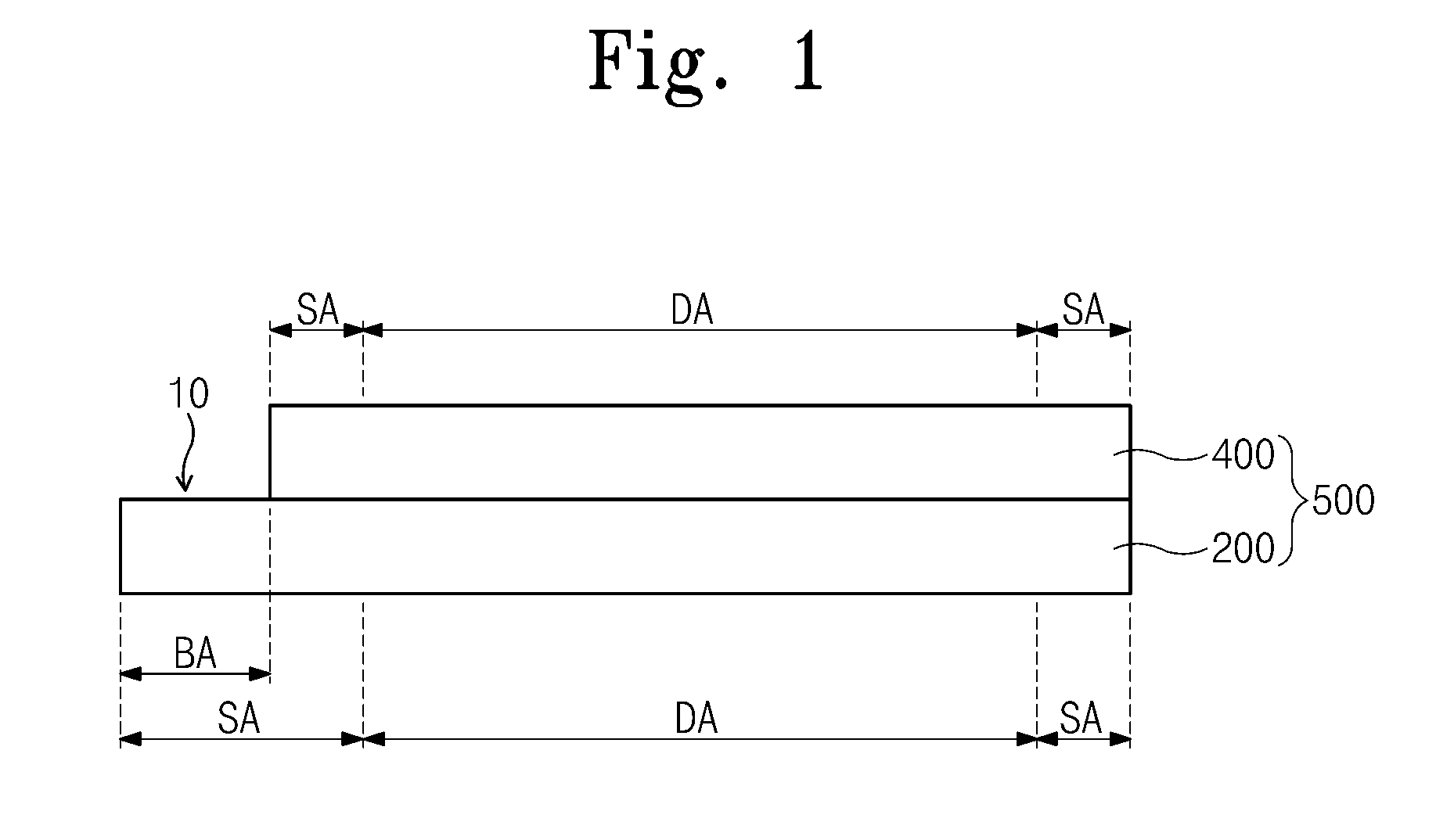

Display apparatus and method of manufacturing the same

InactiveUS20100195039A1Reducing and effectively preventing defectTube/lamp screens manufactureVessels or leading-in conductors manufactureEngineering

In a method of manufacturing a display apparatus, an opposite substrate on which a conductive pattern is formed is coupled with a display substrate to face the display substrate, and the opposite substrate is cut to partially expose the display substrate. Since the conductive pattern is cut with the opposite substrate during the cutting of the opposite substrate, an electric resistance of the conductive pattern is changed. The change in electric resistance of the conductive pattern is detected to determine whether the opposite substrate is cut or not.

Owner:SAMSUNG ELECTRONICS CO LTD

Design, fabrication, testing, and conditioning of micro-components for use in a light-emitting panel

InactiveUS20040175854A1Sufficient resolutionManufactured very thinFixed microstructural devicesVolume/mass flow measurementEngineeringPre testing

Owner:LEIDOS

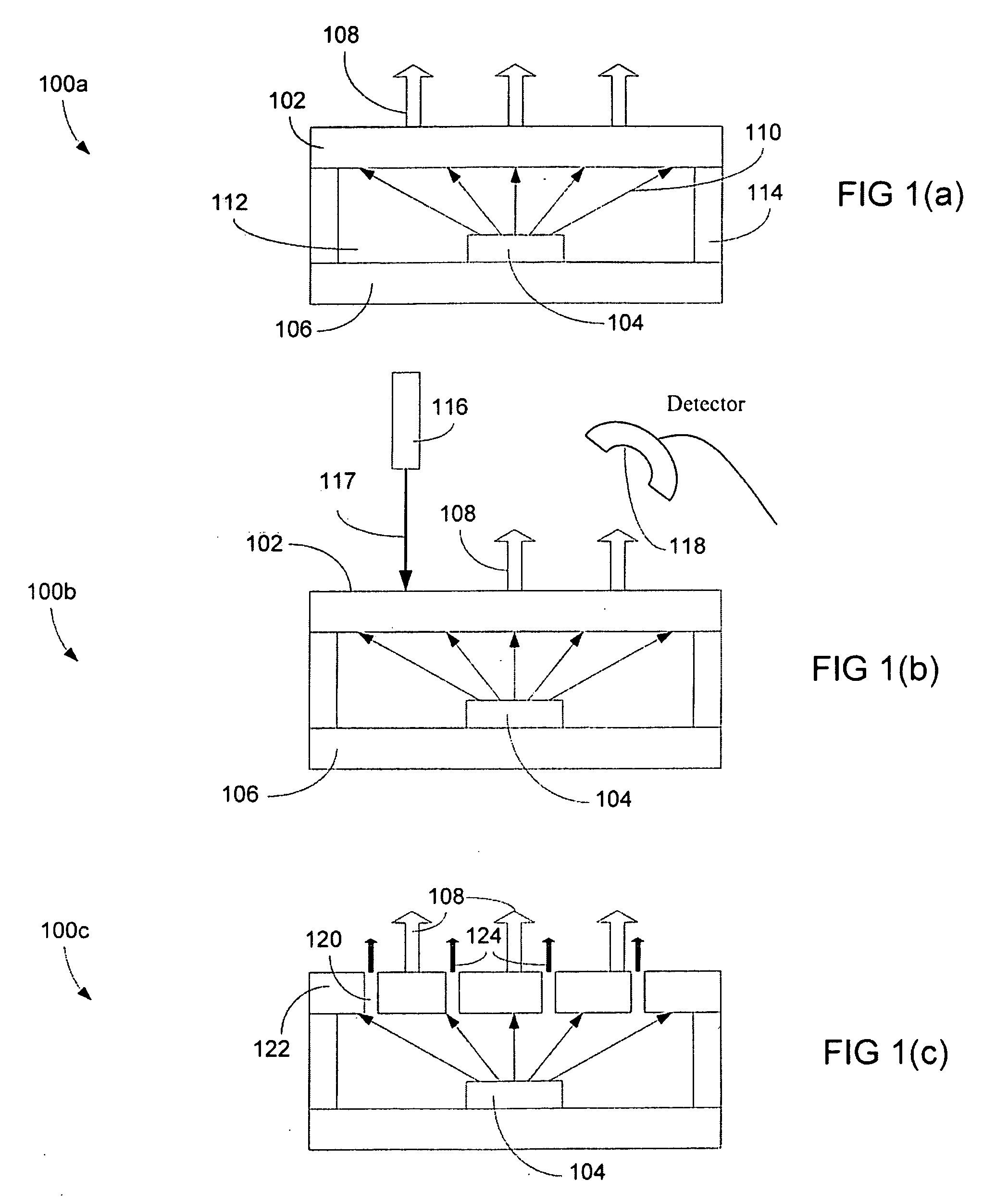

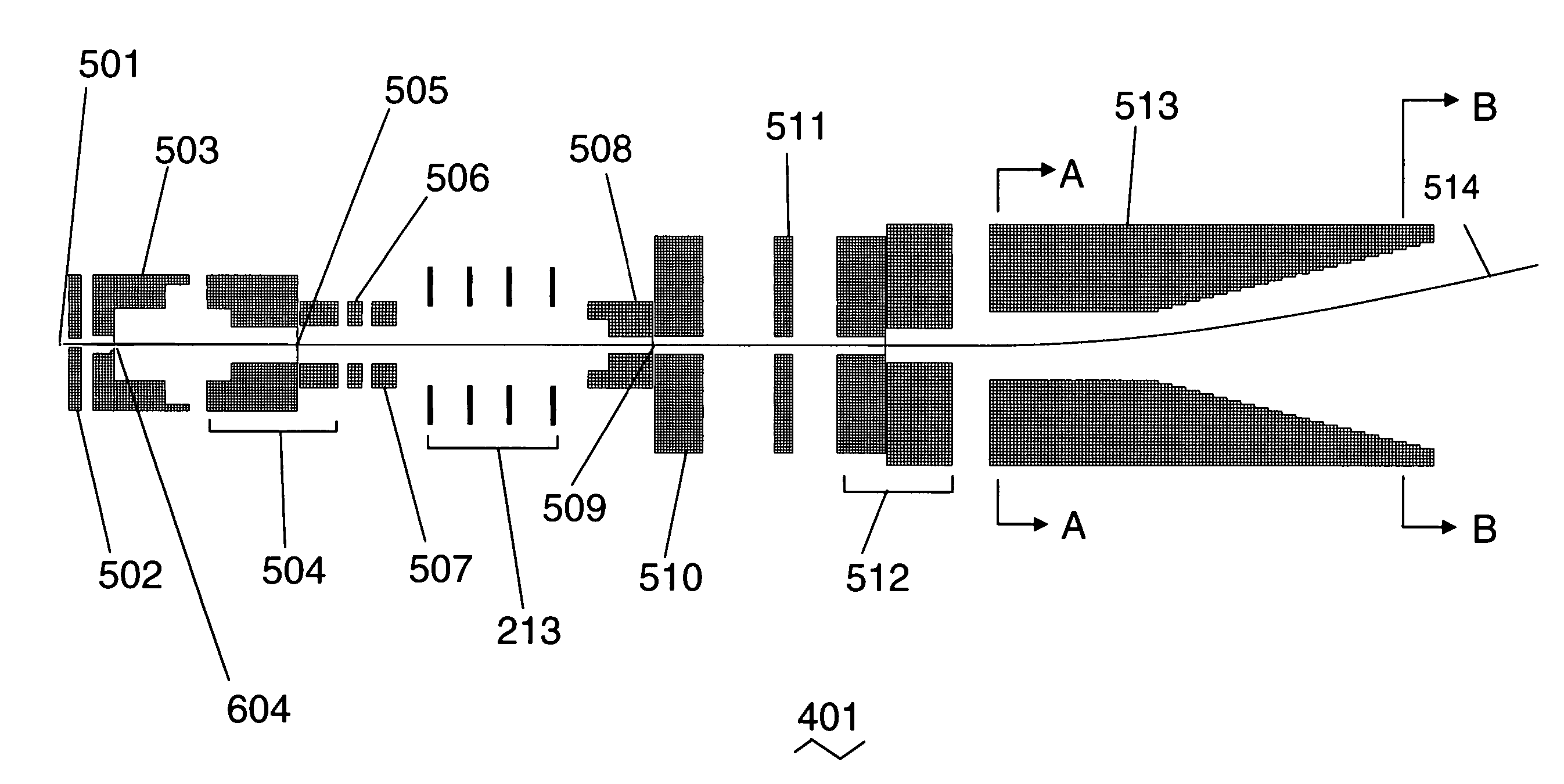

Apparatus and method for inspection and testing of flat panel display substrates

ActiveUS20060145087A1Increase vacuumReduce transmittanceThermometer detailsStability-of-path spectrometersParallel plateDisplay device

A charged particle optical system for testing, imaging or inspecting substrates comprises: a charged particle optical assembly configured to produce a line of charged particle beams equally spaced along a main scan axis, each beam being deflectable through a large angle along the main scan axis; and linear detector optics aligned along the main scan axis. The detector optics includes a linear secondary electron detector, a field free tube, voltage contrast plates and a linear backscattered electron detector. The large beam deflection is achieved using an electrostatic deflector for which the exit aperture is larger than the entrance aperture. One embodiment of the deflector includes: two parallel plates with chamfered inner surfaces disposed perpendicularly to the main scan axis; and a multiplicity of electrodes positioned peripherally in the gap between the plates, the electrodes being configured to maintain a uniform electric field transverse to the main scan axis.

Owner:MULTIBEAM CORP

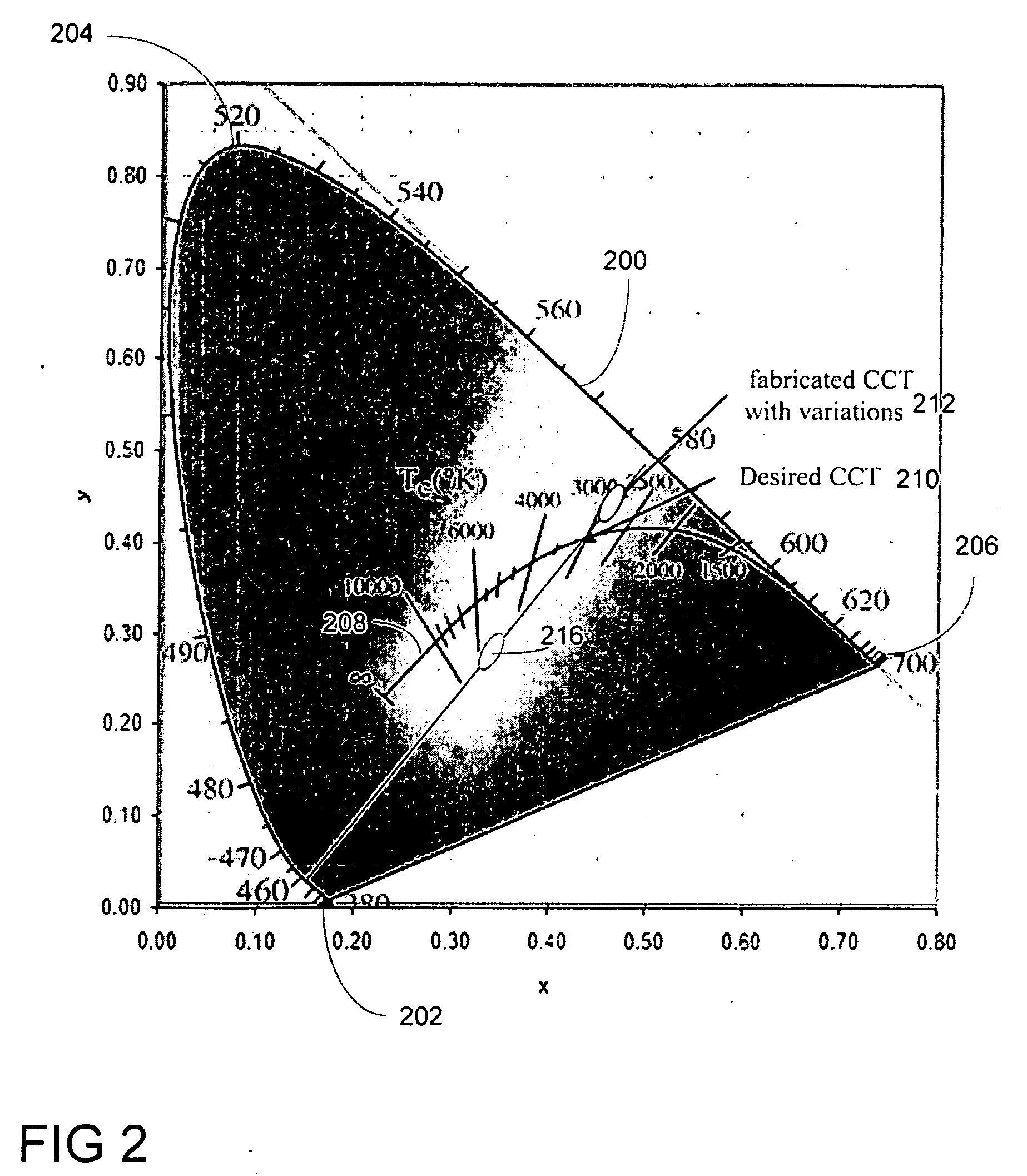

Method and Apparatus for Providing LED Package with Controlled Color Temperature

InactiveUS20100127289A1Sparking plugsDischarge tube luminescnet screensFluorescenceLight-emitting diode

An optical device capable of illuminating visual light with adjusting color temperature after fabrication is disclosed. The optical device includes a solid state light emitter and a phosphor layer, which is formed over the solid state light emitter. The solid state light emitter, which can be a light emitter diode (“LED”), converts electrical energy to blue light. The phosphor layer subsequently converts first light with a first wavelength to second light with a second wavelength. In one example, the first light is blue light while the second light is white light. A portion of the phosphor layer is adjusted after the phosphor layer is formed for adjusting color of the white light in accordance with color quality of the light detected by a light detector.

Owner:BRIDGELUX INC

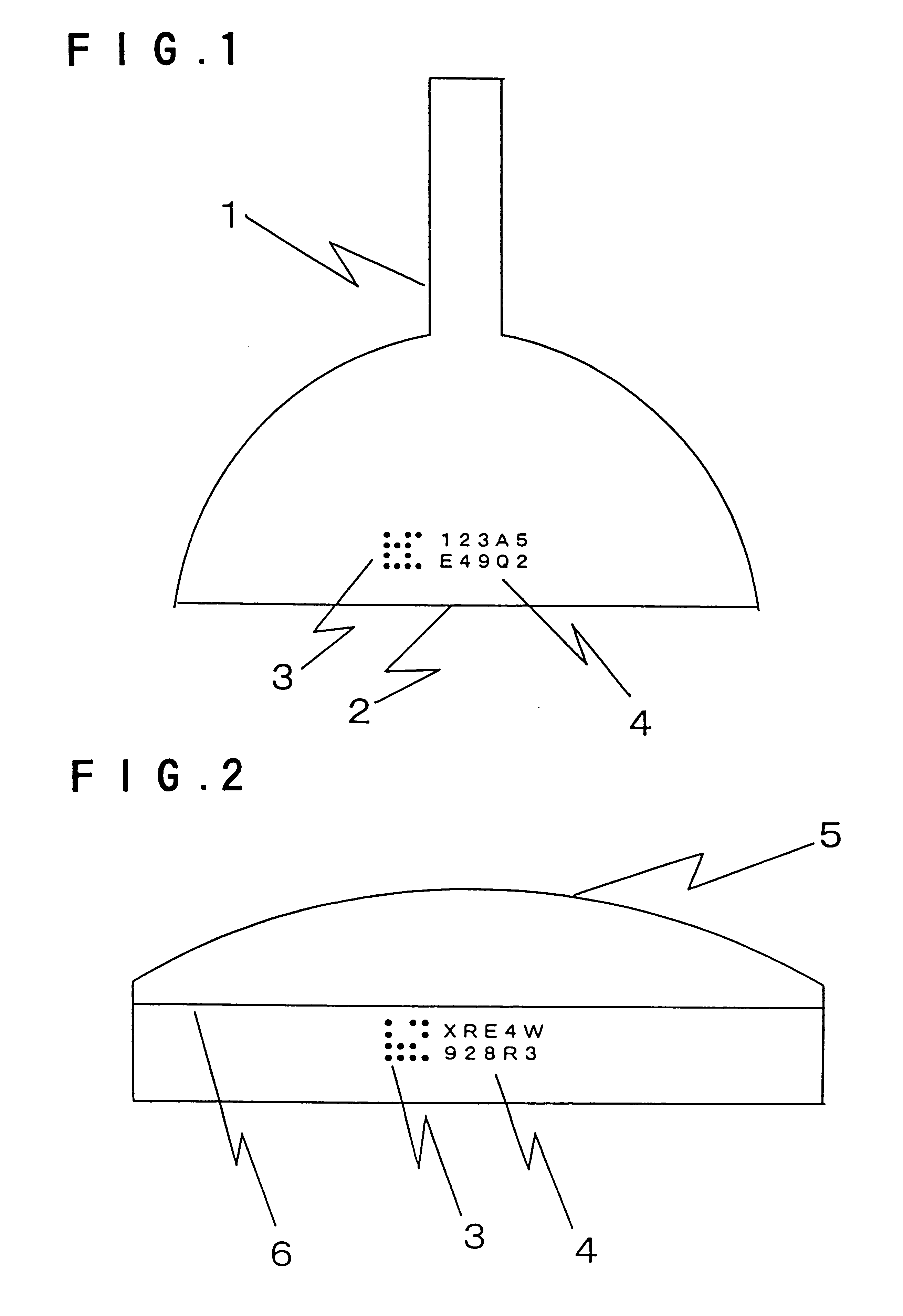

Glass bulb for a cathode ray tube and a method for producing a cathode ray tube

InactiveUS6227394B1Tube/lamp screens manufactureCathode-ray/electron-beam tube vessels/containersEngineeringCathode ray

Manufacturing steps for a cathode ray tube or a glass bulb for the cathode ray tube are controlled in such a manner that a two-dimensional matrix code 3 comprised of a plurality of dots is marked by laser in an outer side surface of a glass bulb 1, 5, the two-dimensional matrix code 3 containing the information which can identify individually glass bulbs, and the manufacturing steps are conducted by using a computer and the particulars specified by the serial information.

Owner:ASAHI GLASS CO LTD

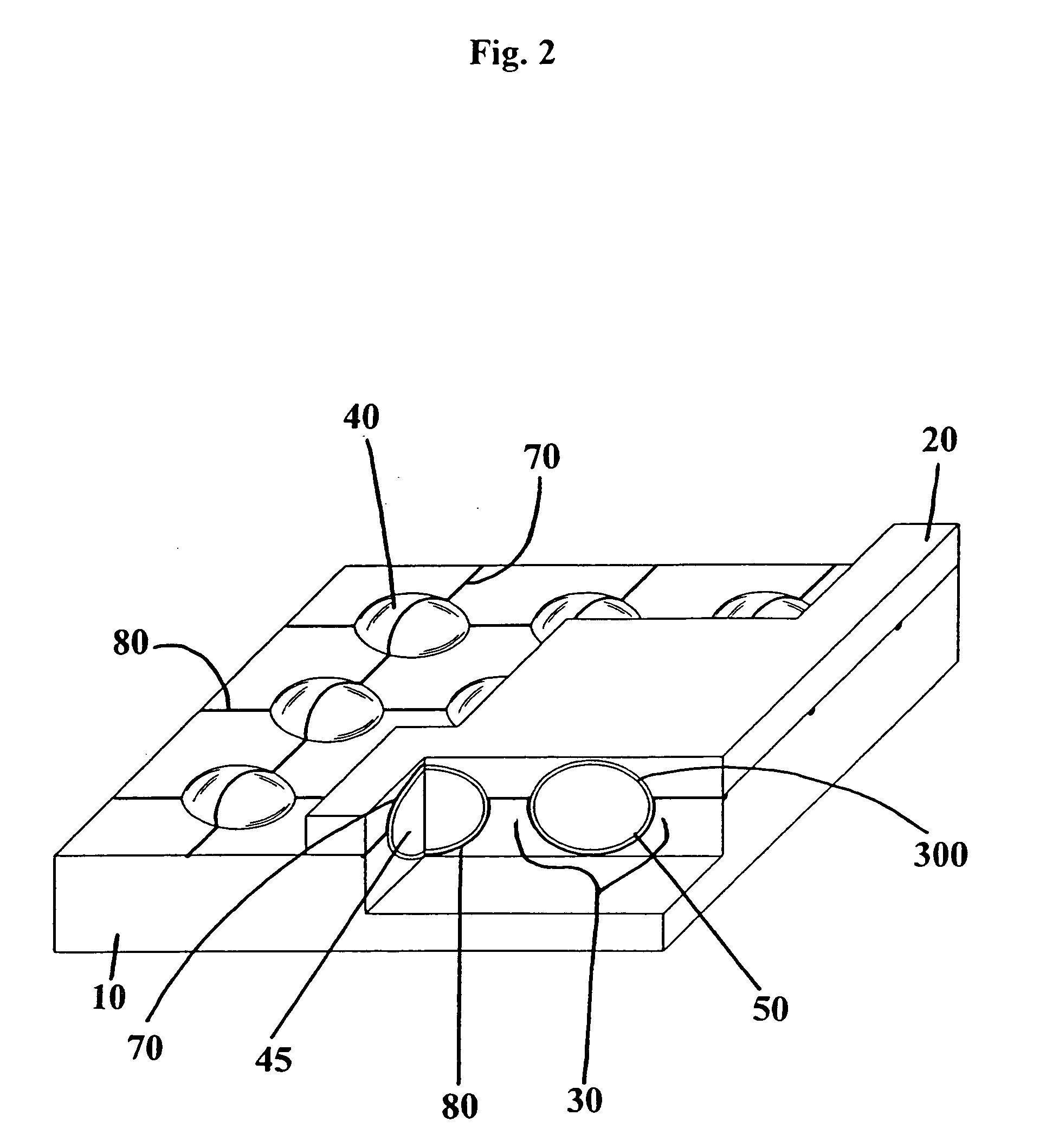

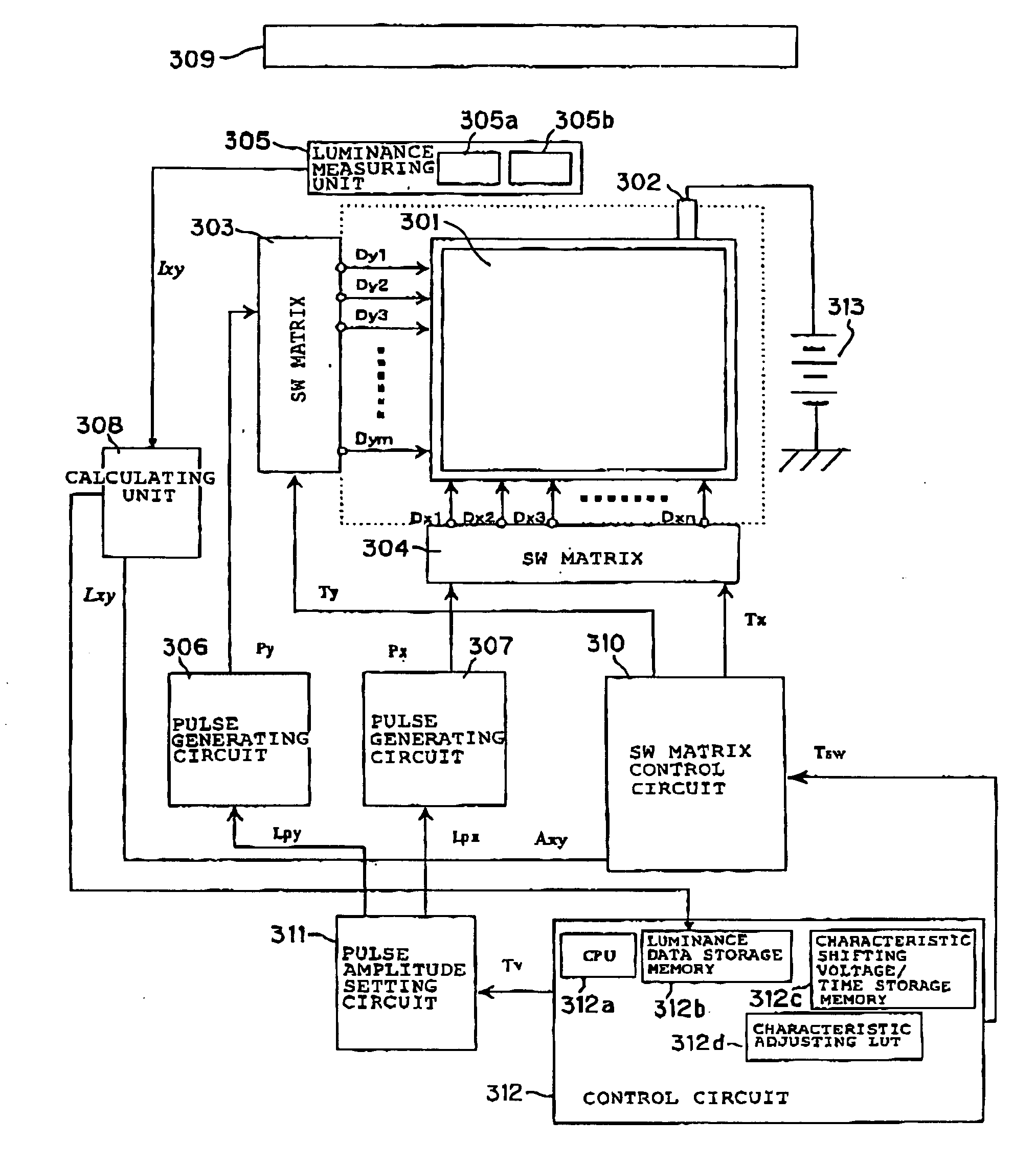

Characteristics adjustment method of image forming apparatus, manufacturing method of image forming apparatus and characteristics adjustment apparatus of image forming apparatus

InactiveUS6888519B2Simple processStatic indicating devicesImage/pattern display tubesElectron sourceFluorescence

There is provided a characteristic adjustment method for an image forming apparatus that is provided with a multi-electron source in which a plurality of electron-emitting devices are electrically connected by wiring and arranged on a substrate and a fluorescent member for emitting light by irradiation of an electron beam, the method including: a measurement step of dividing a display portion of the image forming apparatus into a plurality of areas and measuring light emitting characteristics of at least one or more of the electron-emitting devices in the respective divided areas, and a shifting step of shifting the light emitting characteristics of the electron-emitting devices in the divided areas to individual characteristic target values by applying a characteristic shift voltage to the electron-emitting devices.

Owner:CANON KK

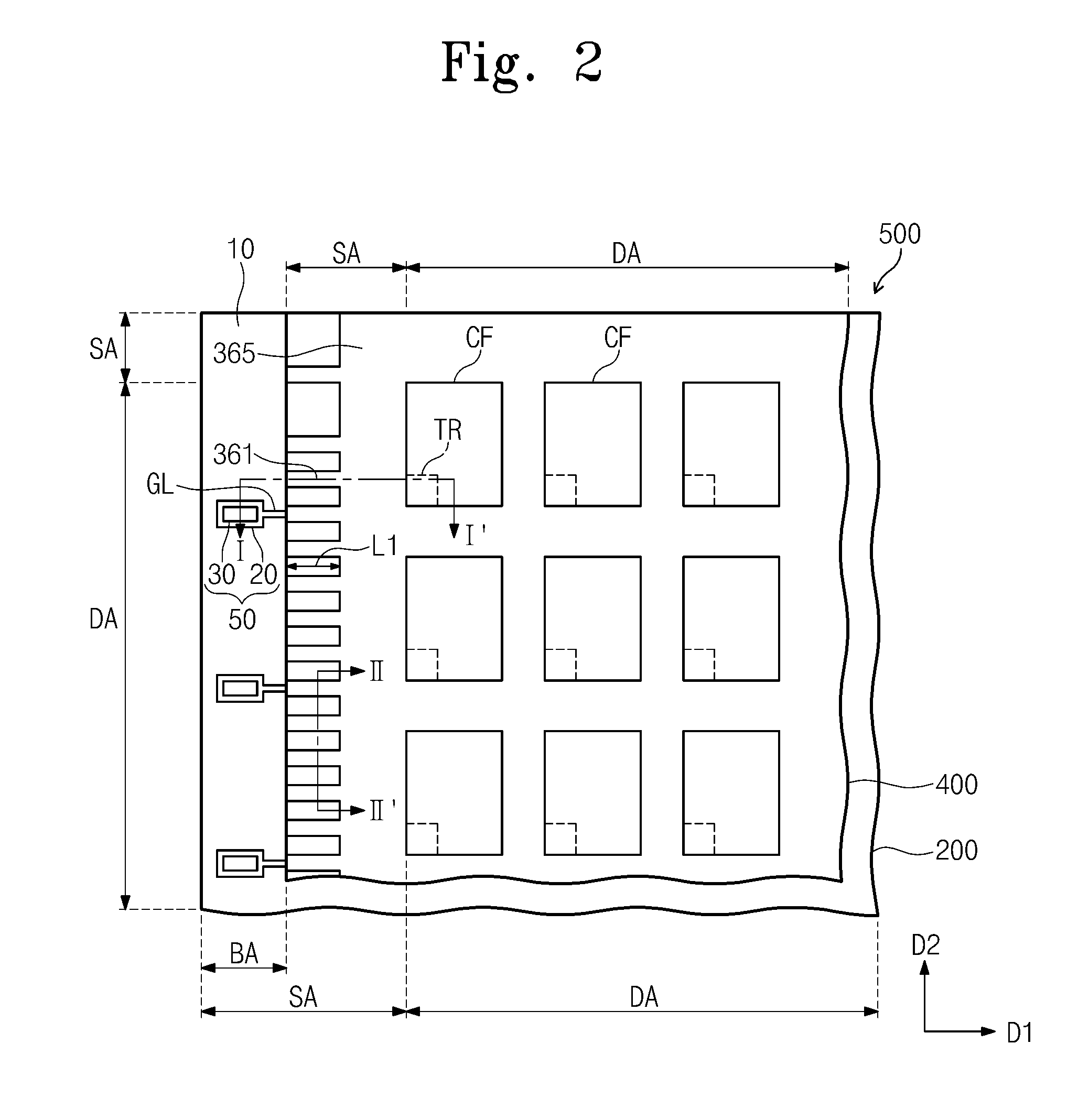

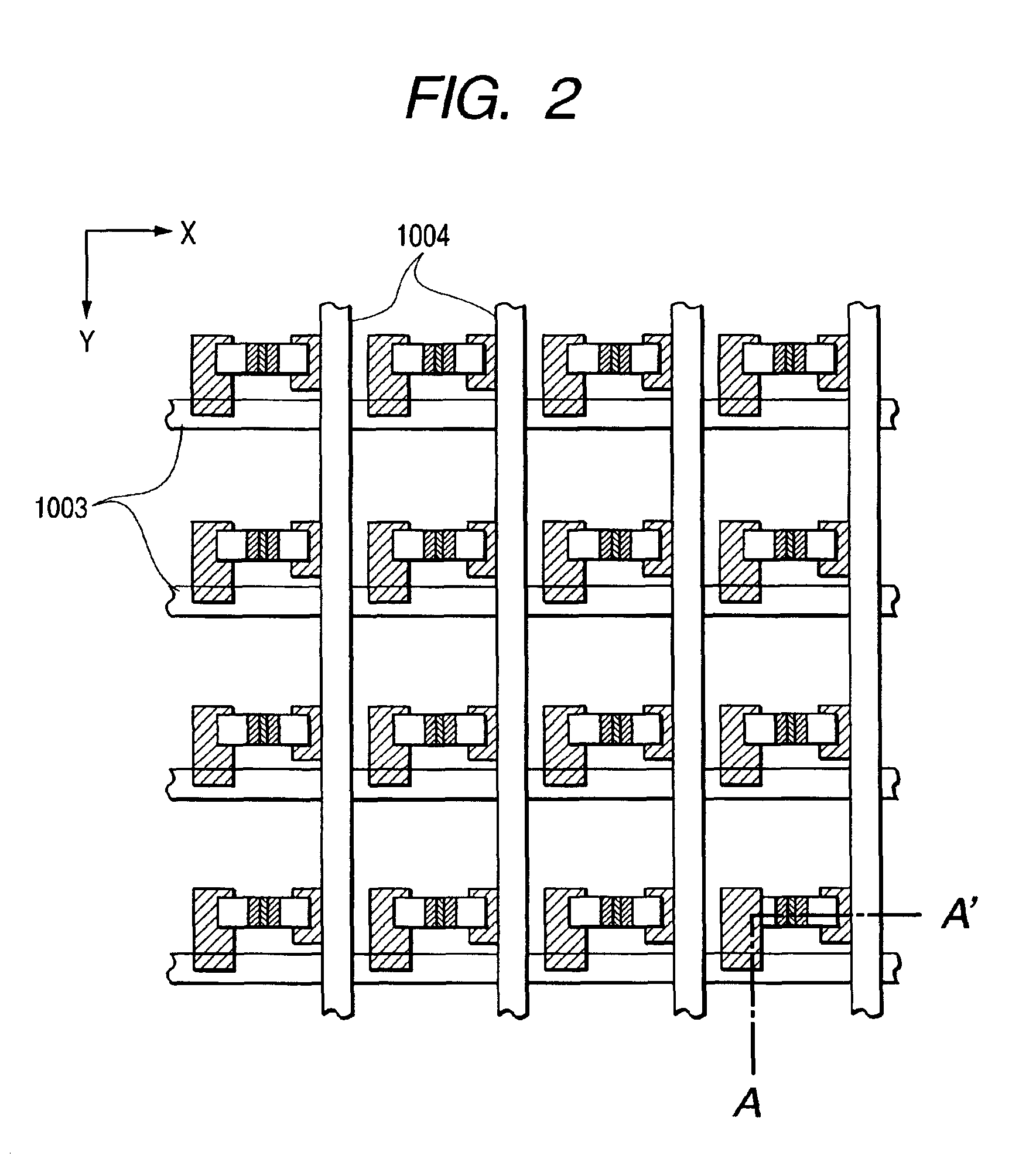

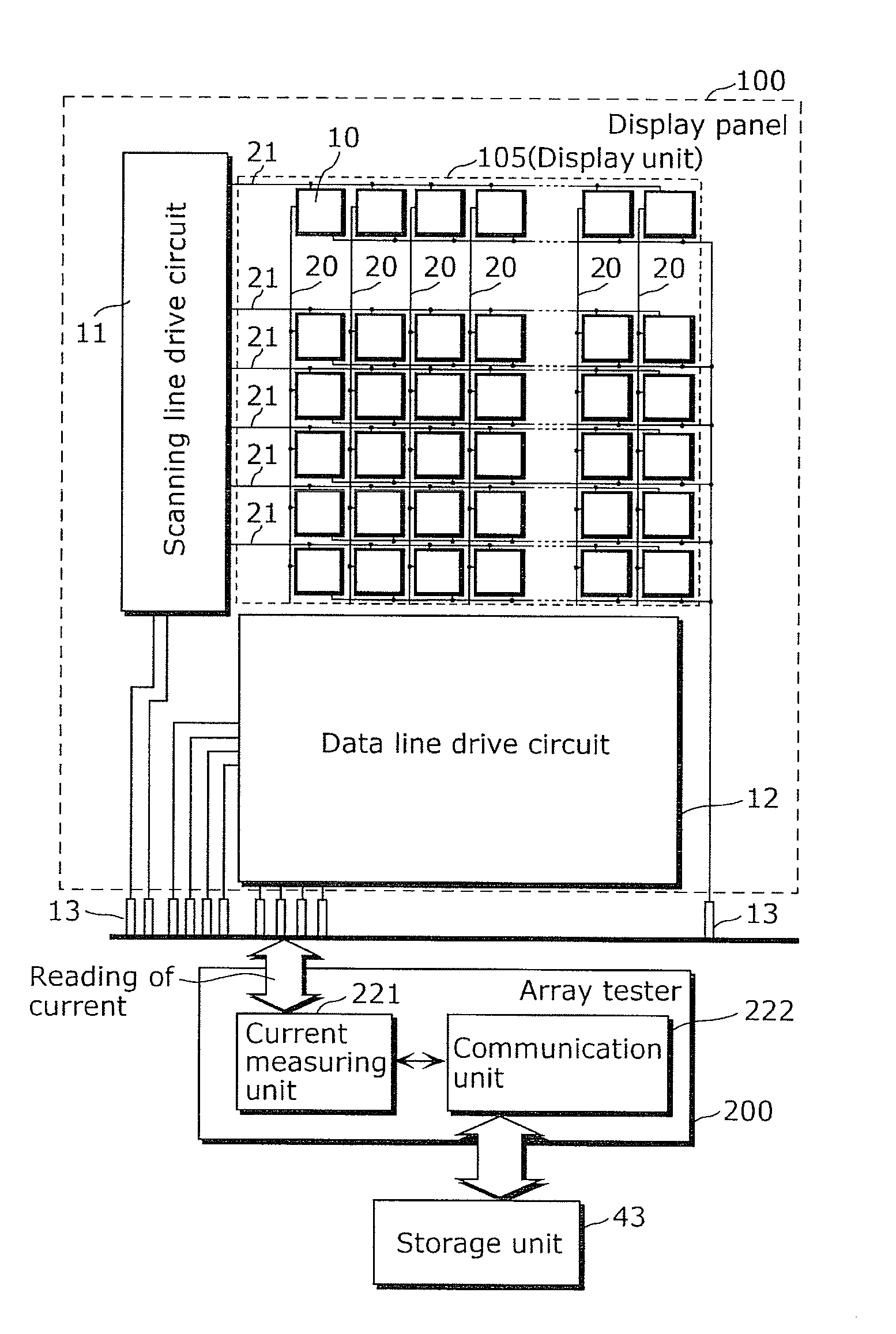

Display apparatus and fabrication method and fabrication apparatus for the same

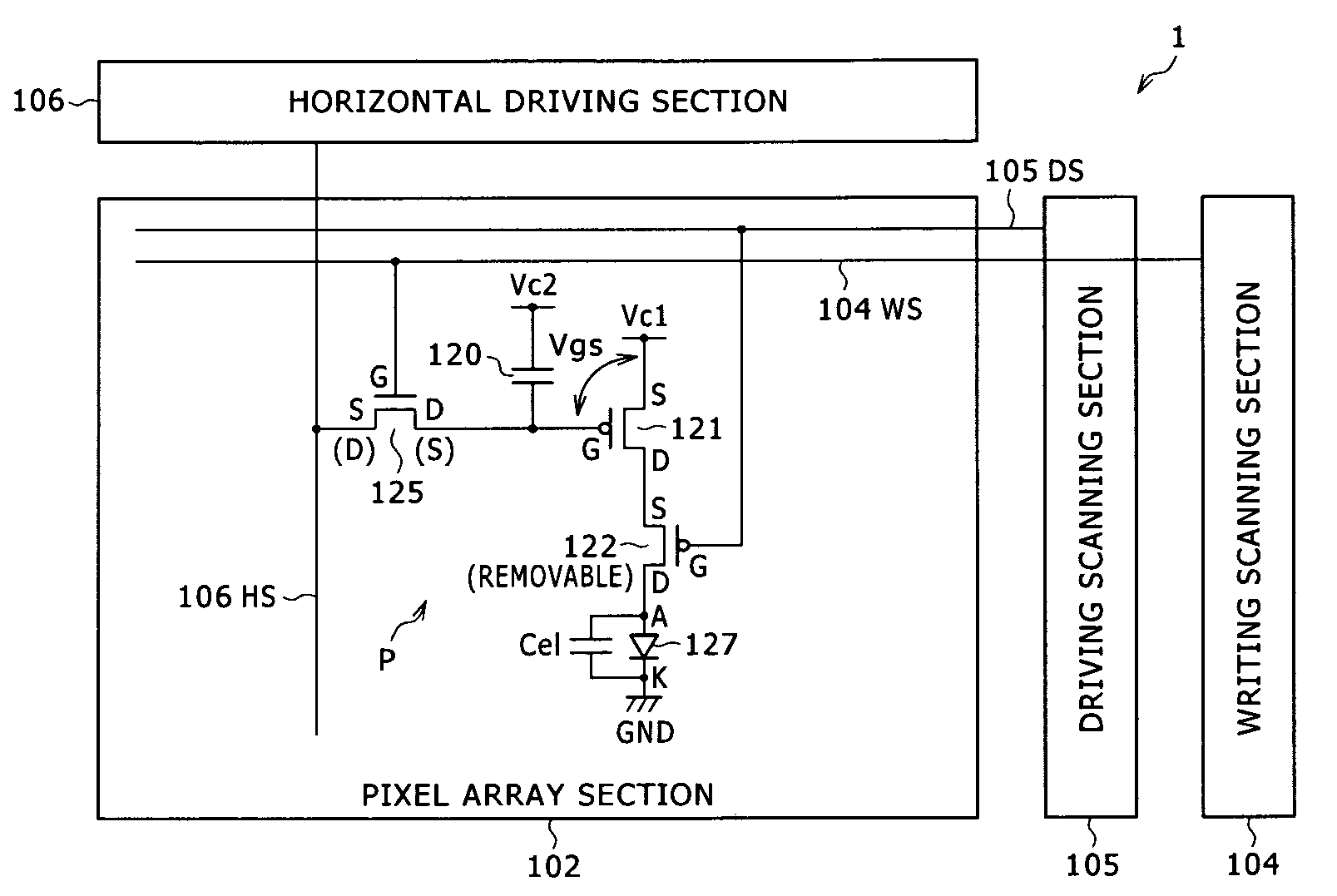

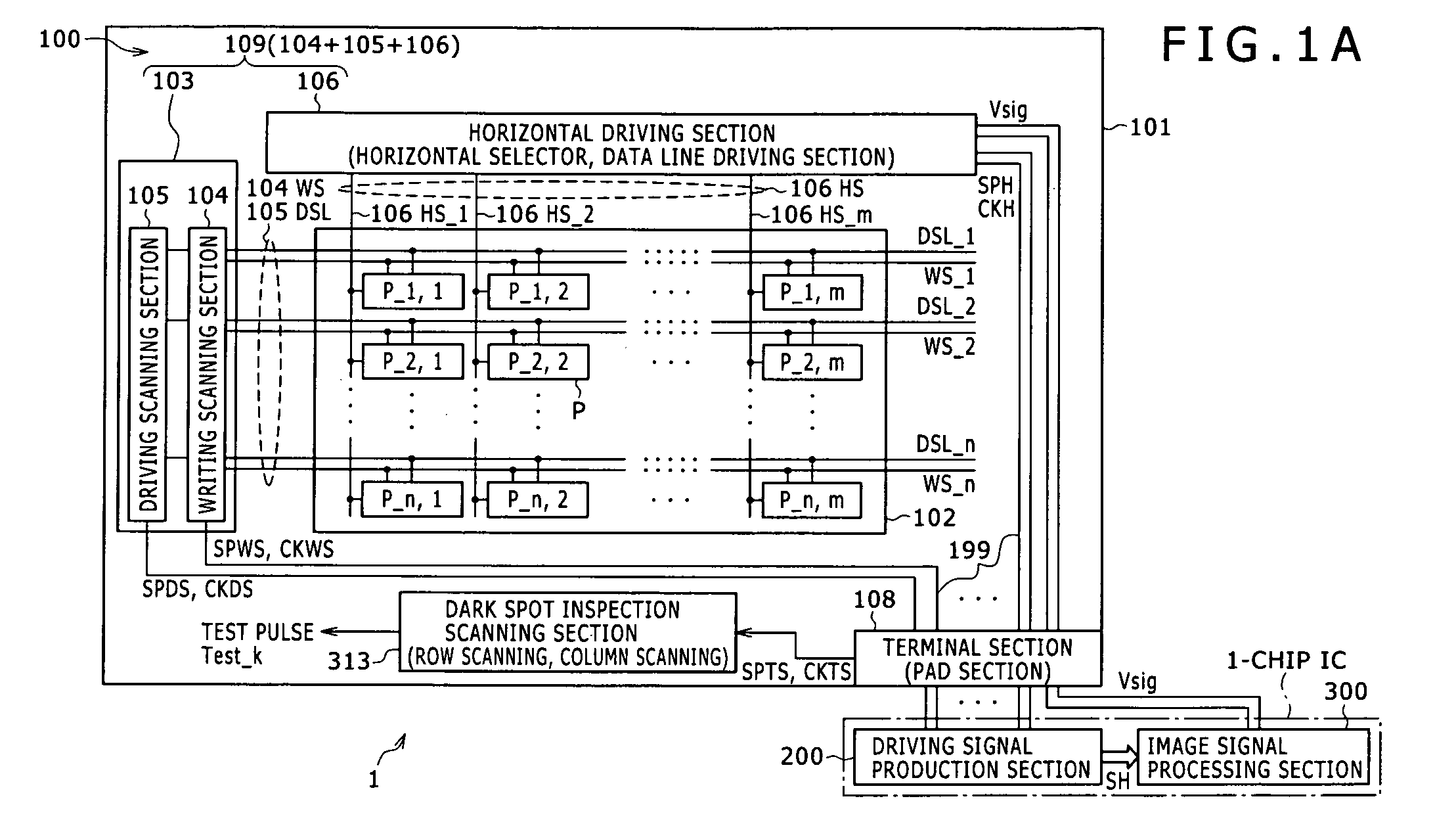

ActiveUS20090135166A1Reduce yieldImprovement of efficiency percentageSparking plugsCathode-ray tube indicatorsDark spotEngineering

A pixel array section includes a plurality of pixel circuits disposed in a matrix and each including a driving transistor, a storage capacitor, an electro-optical element, and a sampling transistor. Each pixel circuit includes a pixel divided into a plurality of divisional pixels for each of which an electro-optical element is provided, and a test transistor provided between the driving transistor and the electro-optical elements for carrying out on / off operations for specifying whether or not the electro-optical element is a dark spot element so that the electro-optical element of the dark spot can be specified. The number of the test transistors is smaller than the number of the divisional elements of the original one pixel.

Owner:JOLED INC

Glass sheet defect detection device, glass sheet manufacturing method, glass sheet, glass sheet quality judging device, and glass sheet inspection method

ActiveCN101558292ADetection defect informationReduce noiseMaterial analysis by optical meansUsing optical meansOptical axisEngineering

Owner:NIPPON ELECTRIC GLASS CO LTD

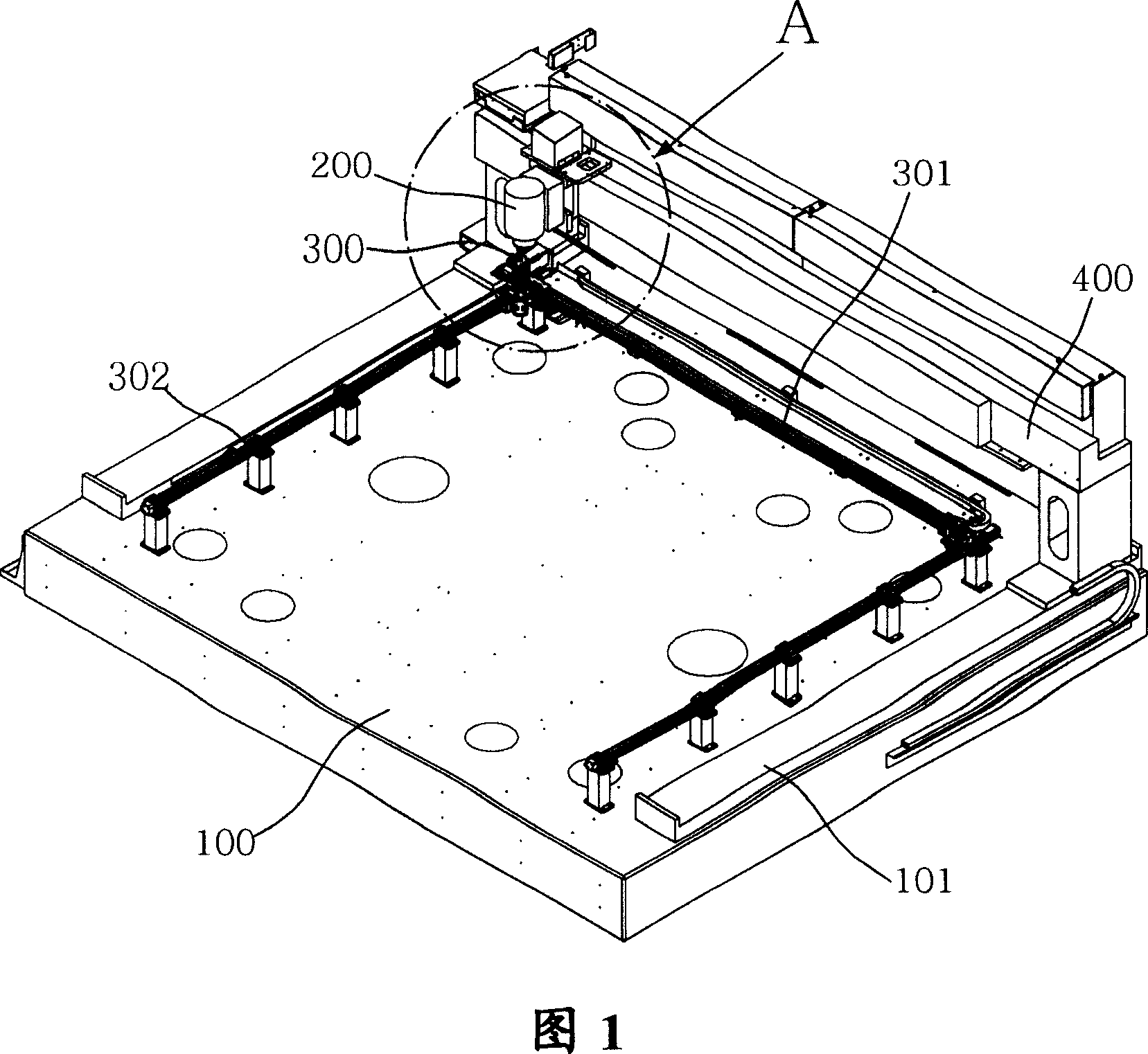

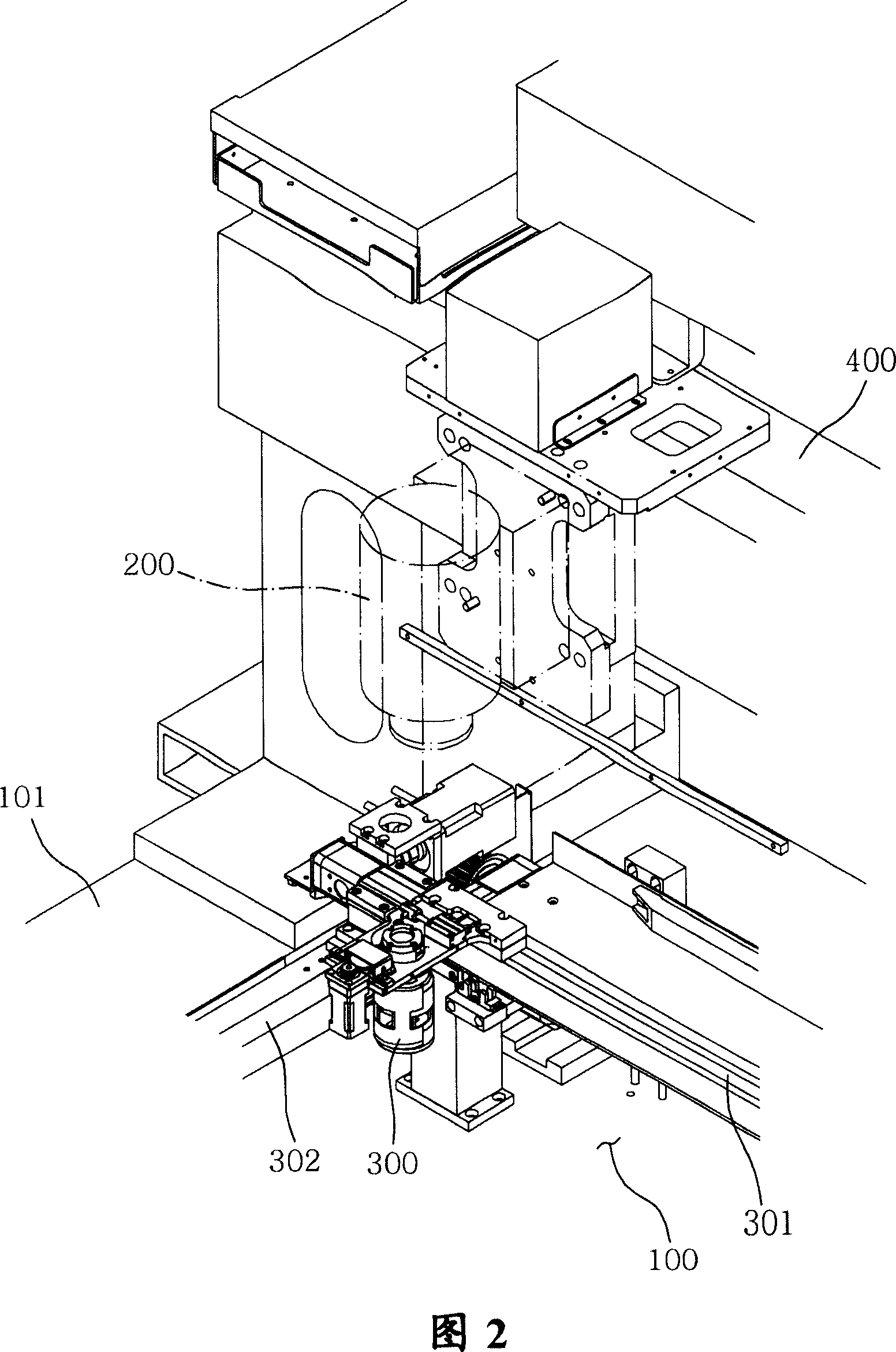

Microcosmic checking device for glass panel

InactiveCN1924513ALess dark spotsStable supportElectric discharge tubesMaterial analysis by optical meansLiquid-crystal displayMicroscopic scale

Disclosed is a microcosmic checking device for detecting the glass panel used in FPD such as LCD and PDP. The microcosmic checking device comprises: a worktable, wherein a glass panel is fixed; a microscope and a light source lamp above and below the work table for detecting the defects of the glass panel; and a driving unit for moving the microscope and light along X axis and Y axis. The driving unit comprises: a bridge, wherein the microscope and the light source lamp are mounted apart on the top or bottom, the bridge is movably connected to the surface table track formed along the relative sides of the surface table, which constitutes the main body of the microcosmic checking device; a forwards and backwards driving unit for moving the bridge along the surface table track; and leftwards and rightwards driving unit for moving the microscope and light source lamp simultaneously along the left axis and the right axis.

Owner:DE&T

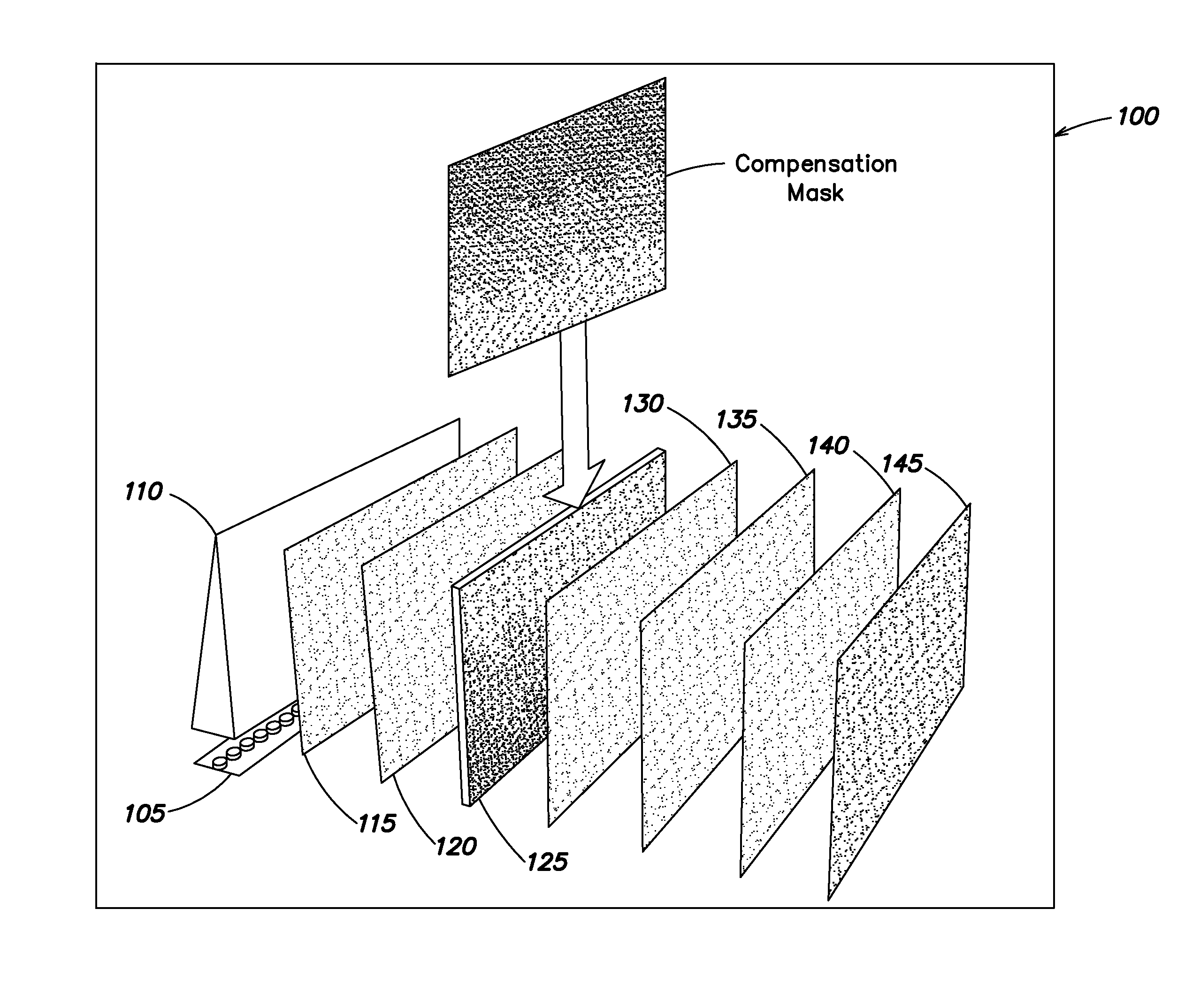

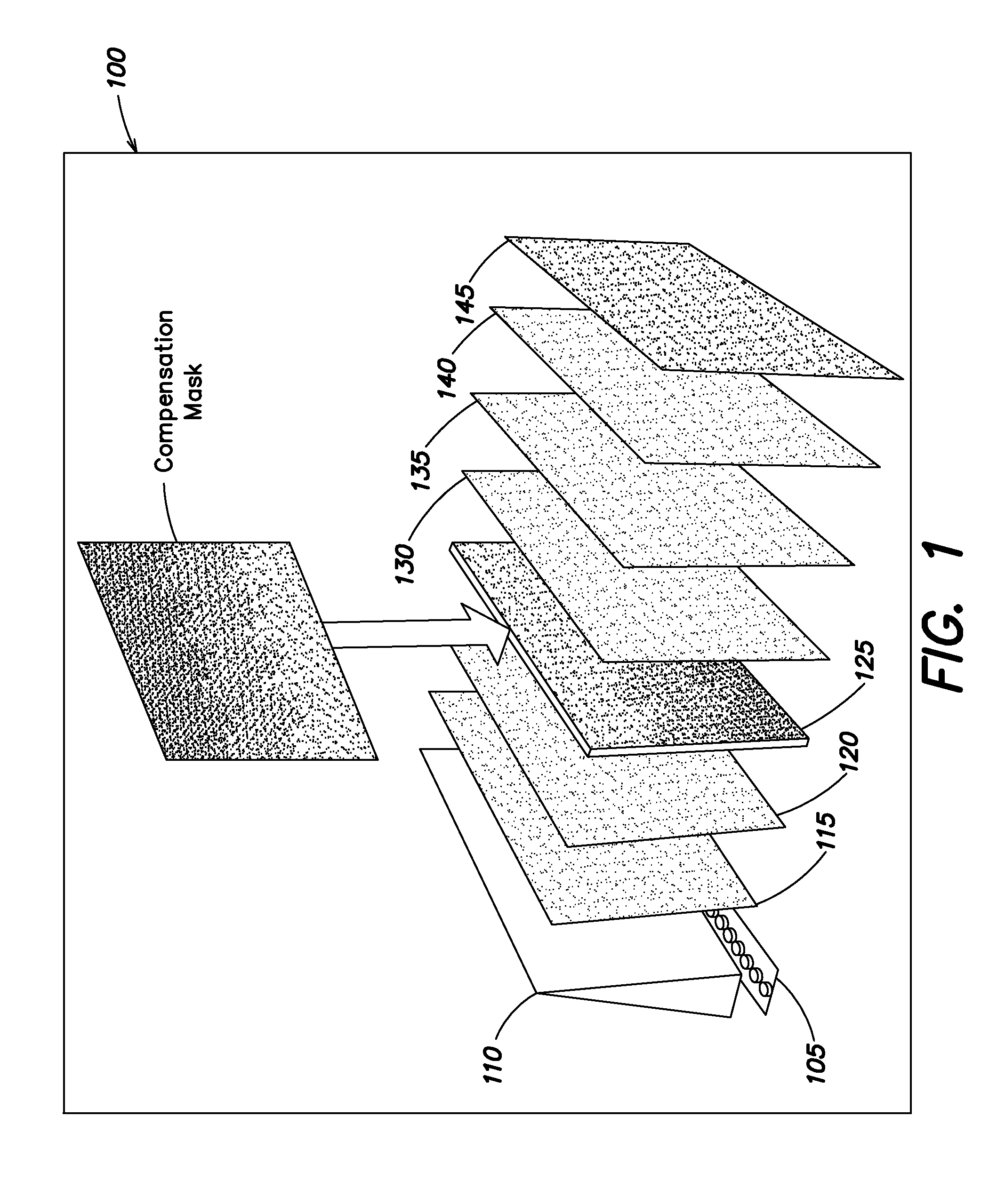

Systems and methods for display device backlight compensation

InactiveUS20100207865A1Limit on characteristicSparking plugsStatic indicating devicesComputer graphics (images)Display device

Systems and methods of controlling illumination of a display device are disclosed. These systems and methods can detect a plurality of luminance values in a digital image of the display device that correspond to a plurality of pixel positions of the display device. A first plurality of luminance values of the plurality of luminance values can be mapped to a first pixel position of the plurality of pixel positions of the display device, and a compensation mask value for the first pixel position can be determined based upon the first plurality of luminance values. The compensation mask value can correspond to an adjustment of a luminance value of the first pixel position. The compensation mask value can be provided to a display controller of the display device to permit the display controller to adjust a luminance value of the first pixel position to correspond more closely with luminance values associated with other pixel positions of the plurality of pixel positions of the display device based upon the compensation mask value.

Owner:CSR TECH INC

Apparatus and method for inspection and testing of flat panel display substrates

ActiveUS7435956B2Increase vacuumReduce transmittanceThermometer detailsMaterial analysis using wave/particle radiationParallel plateDisplay device

Owner:MULTIBEAM CORP

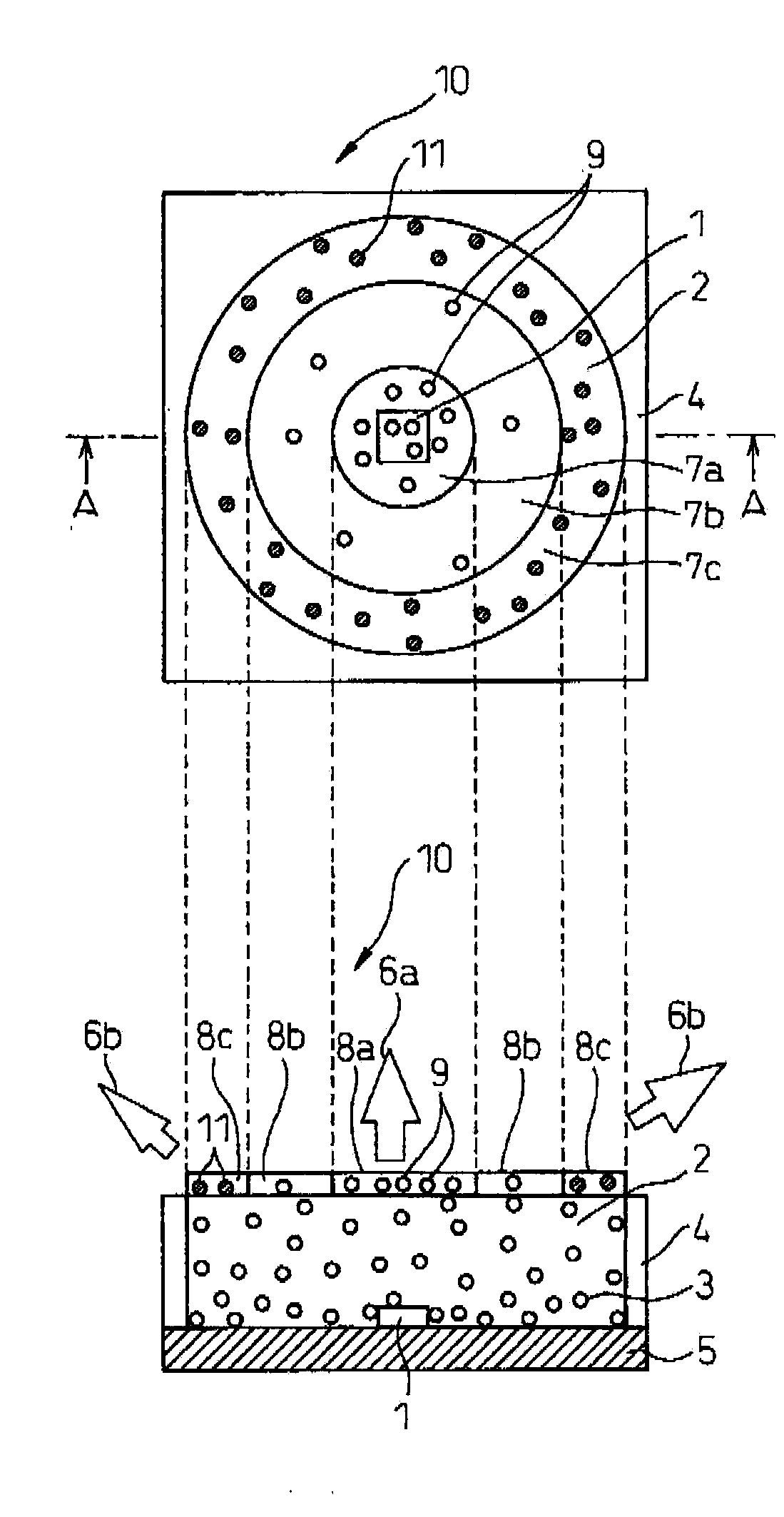

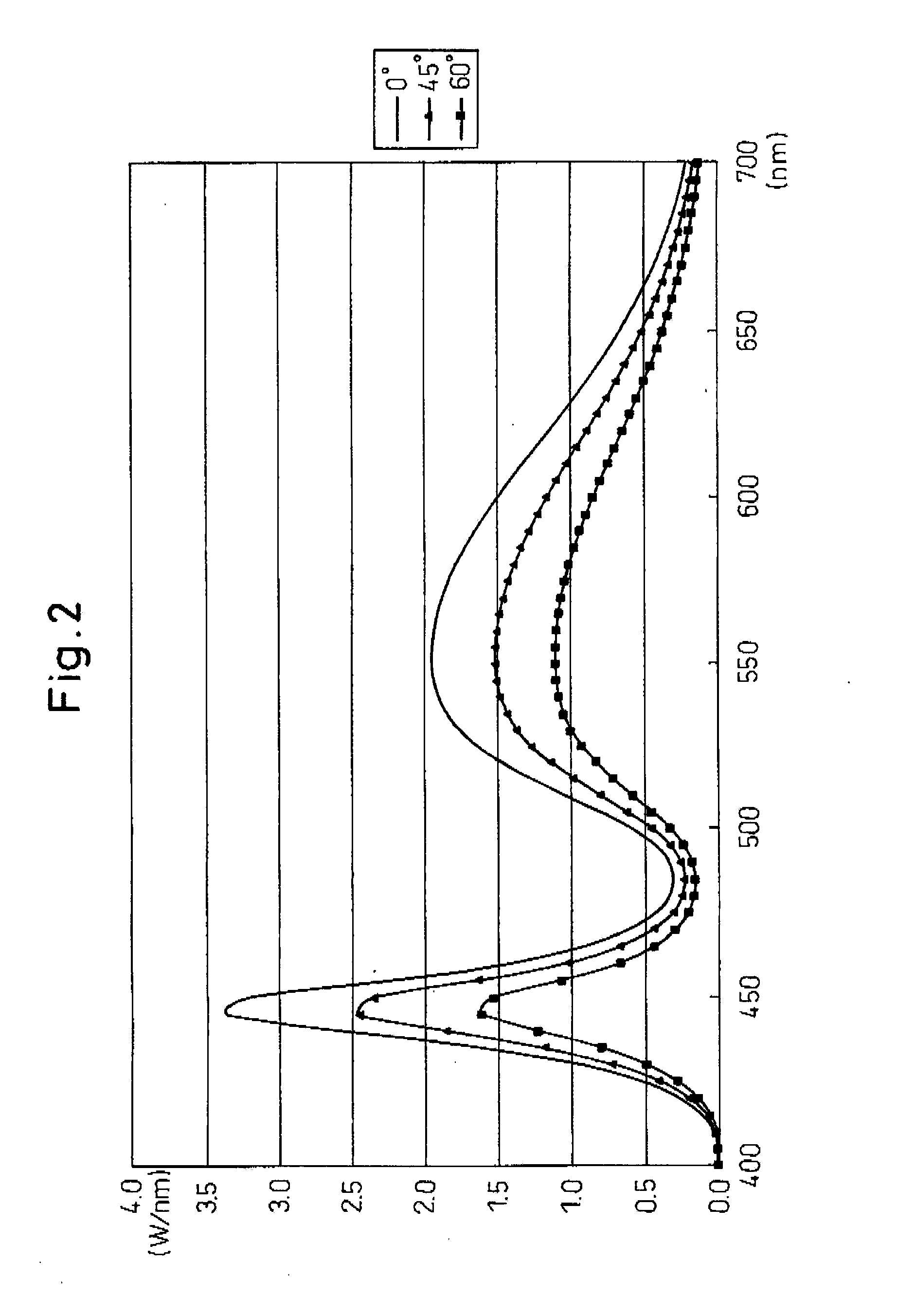

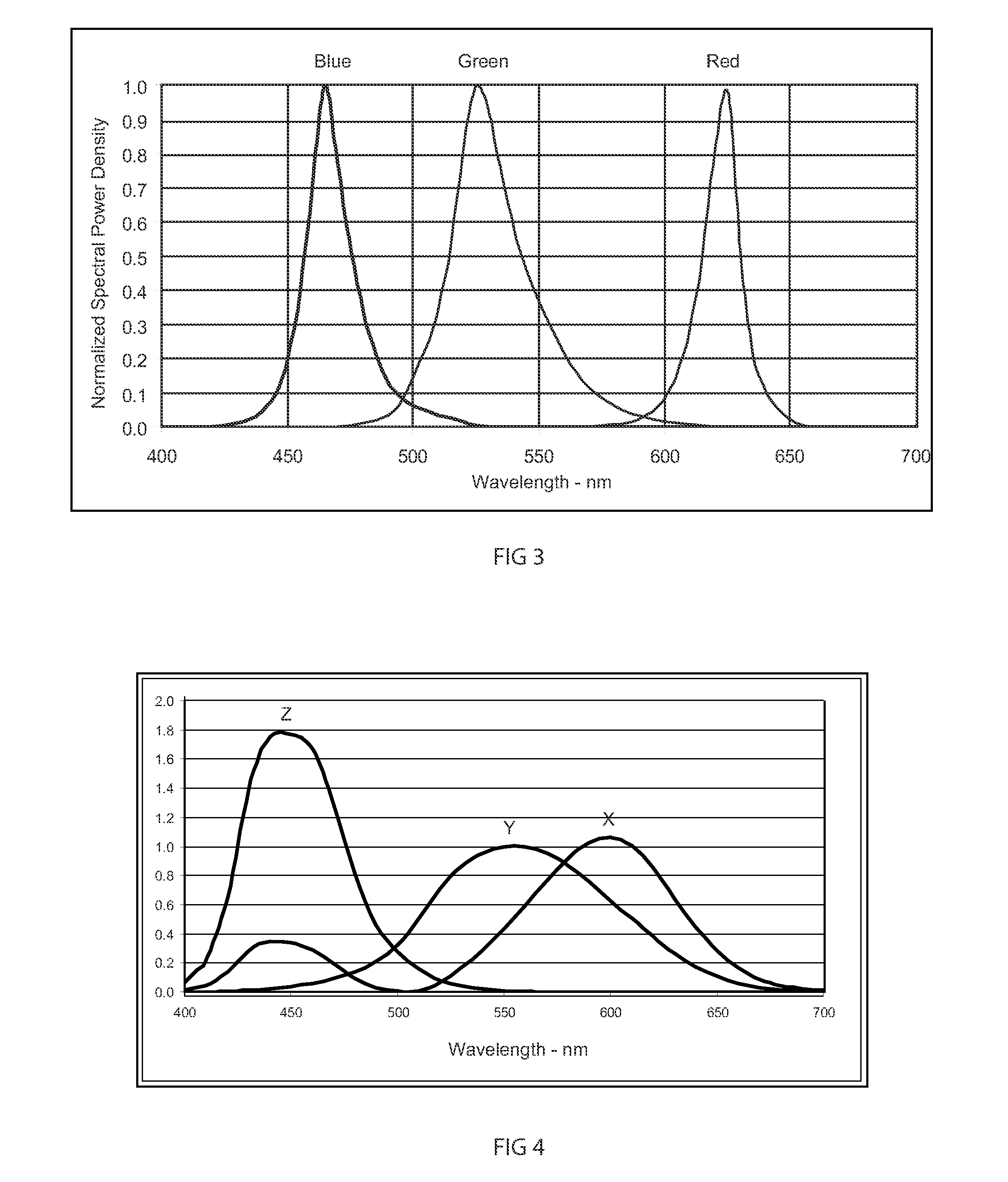

LED light source and method for adjusting chromaticity of LED light source

ActiveUS20090236967A1Easily adjusts its chromaticityEasy to doSparking plugsDischarge tube luminescnet screensPhosphorWavelength conversion

The present invention is directed to the provision of an LED light source that can easily adjust its chromaticity and a chromaticity adjustment method for such an LED light source. More specifically, the invention provides a chromaticity adjustment method for an LED light source having an LED device, a phosphor which absorbs a portion of light emitted from the LED device and emits light by wavelength conversion, and a resin material containing the phosphor and disposed so as to enclose the LED device, wherein an ink coating layer is disposed on a surface of the resin material in order to adjust chromaticity; the invention also provides an LED light source adjusted in such a manner.

Owner:CITIZEN WATCH CO LTD

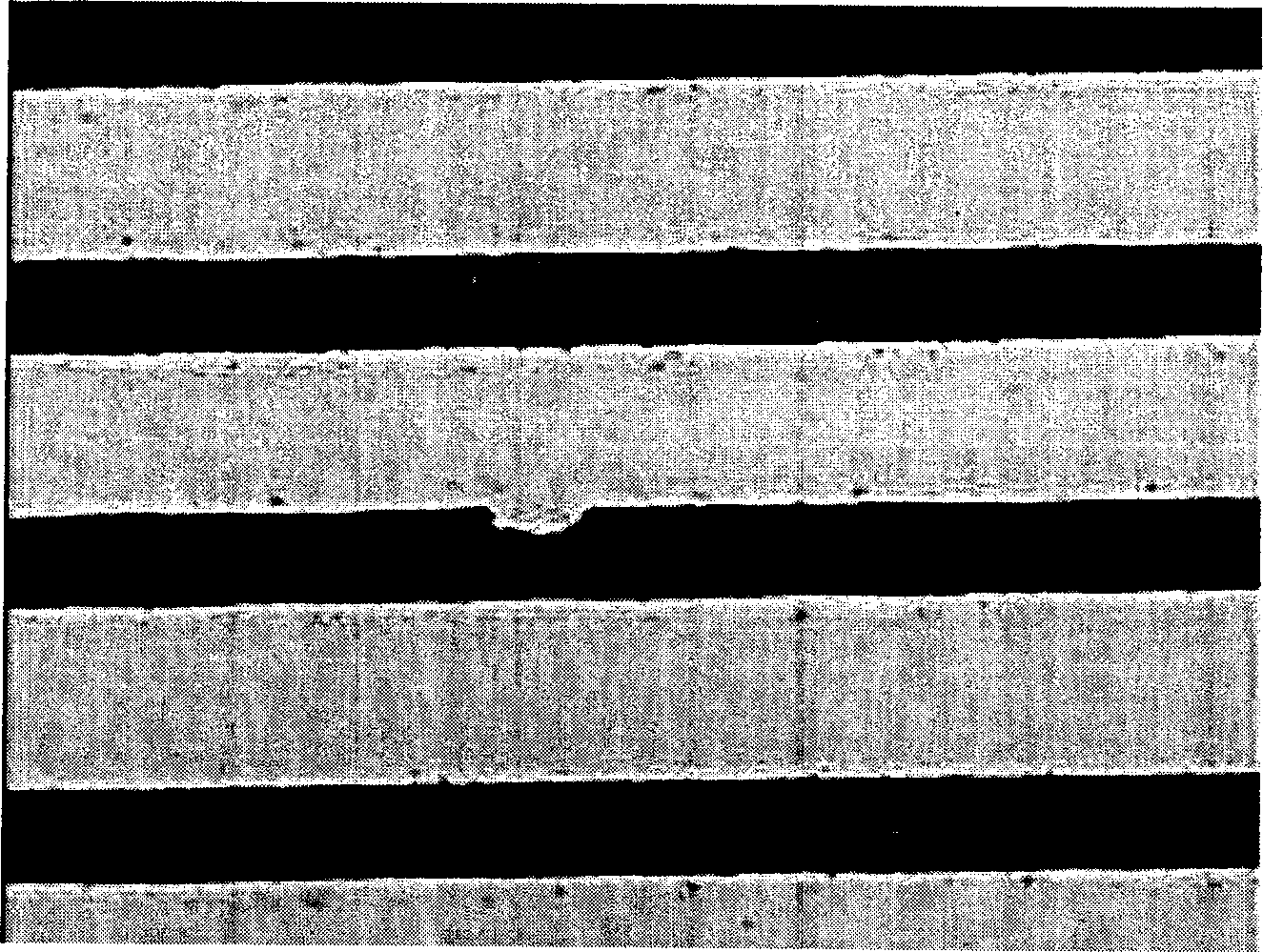

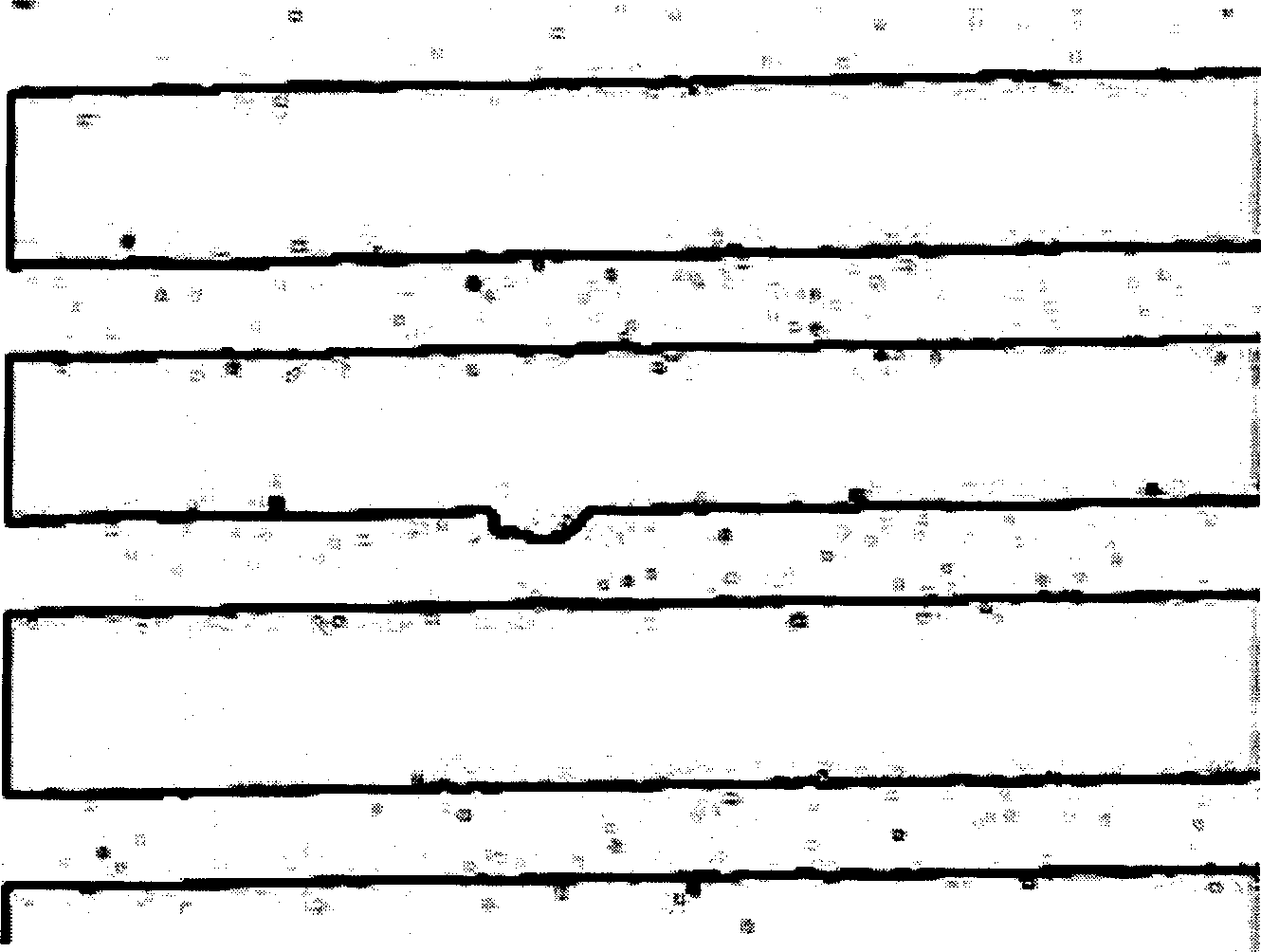

Apparatus and method for inspecting pattern defect

InactiveCN1493870ASemiconductor/solid-state device testing/measurementOptically investigating flaws/contaminationGraphicsBand pattern

Method and apparatus for inspecting pattern defect can inspect printing defects of fluorescent substances formed on a glass substrate such as a plasma display panel and the like automatically and rapidly without being affected by a coating pattern of the fluorescent substances, and can be installed easily in manufacturing process of the plasma display panel to thereby achieve a low cost and high speed detection. In case of inspecting the pattern defect, stripe-form pattern of the fluorescent substances formed on the glass substrate are scanned, and then a direction of the stripe-form pattern of the fluorescent substances are detected from picture signals obtained by the scanning, and then the pattern defect is inspected by comparing at least two picture data with each other, the picture data being related to the direction of the stripe-form pattern.

Owner:KOKUSA ELECTRIC CO LTD

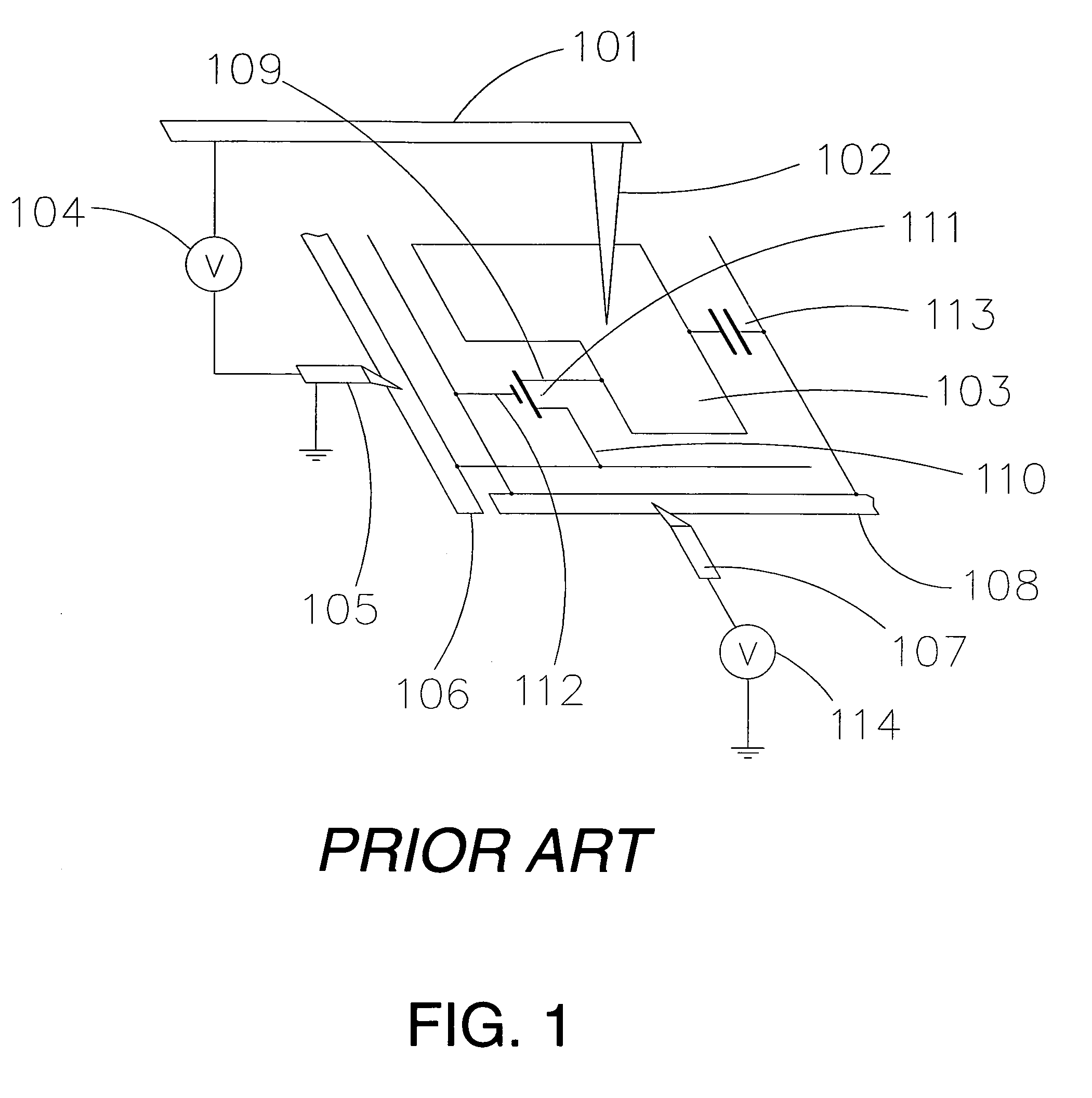

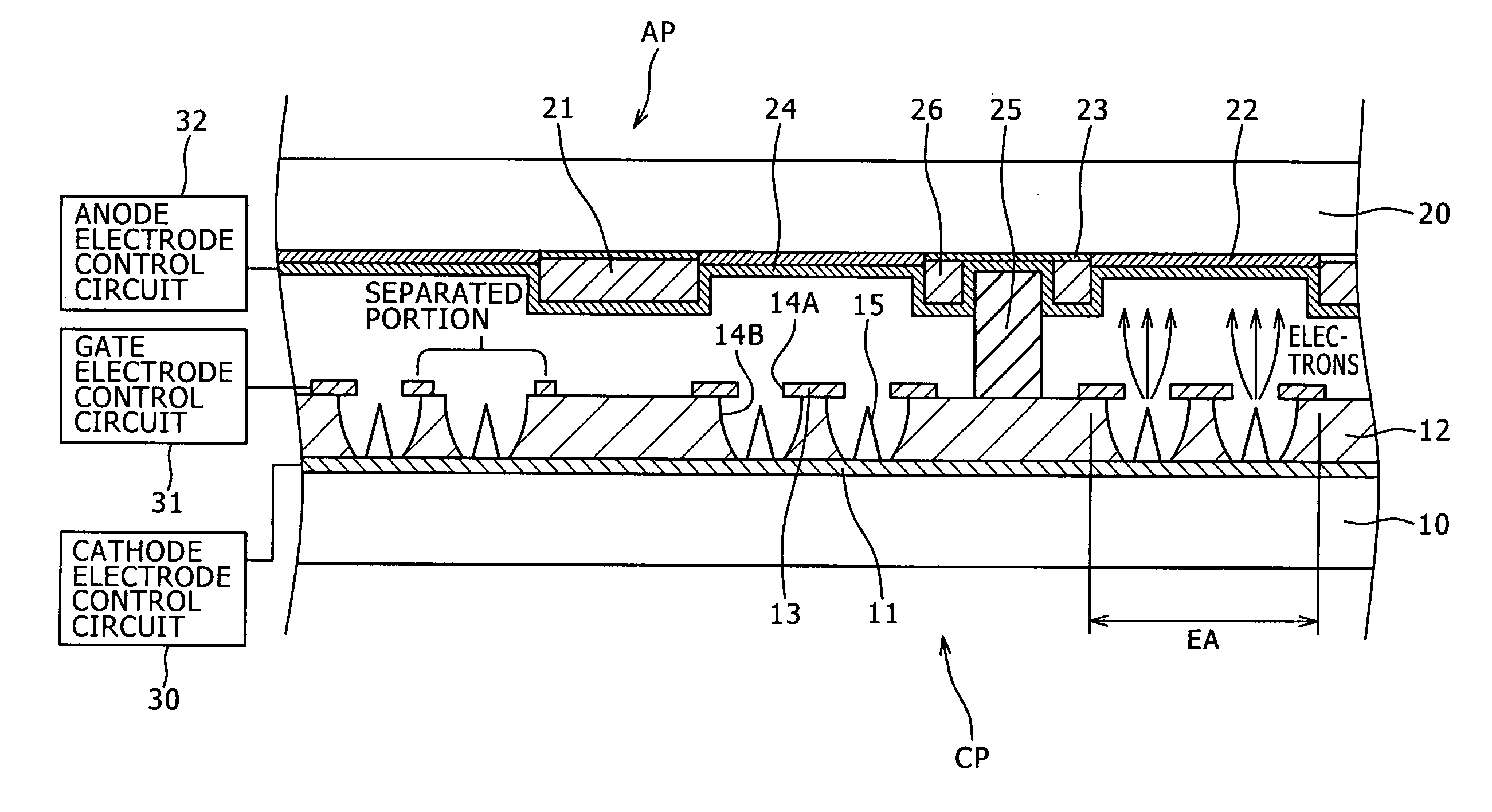

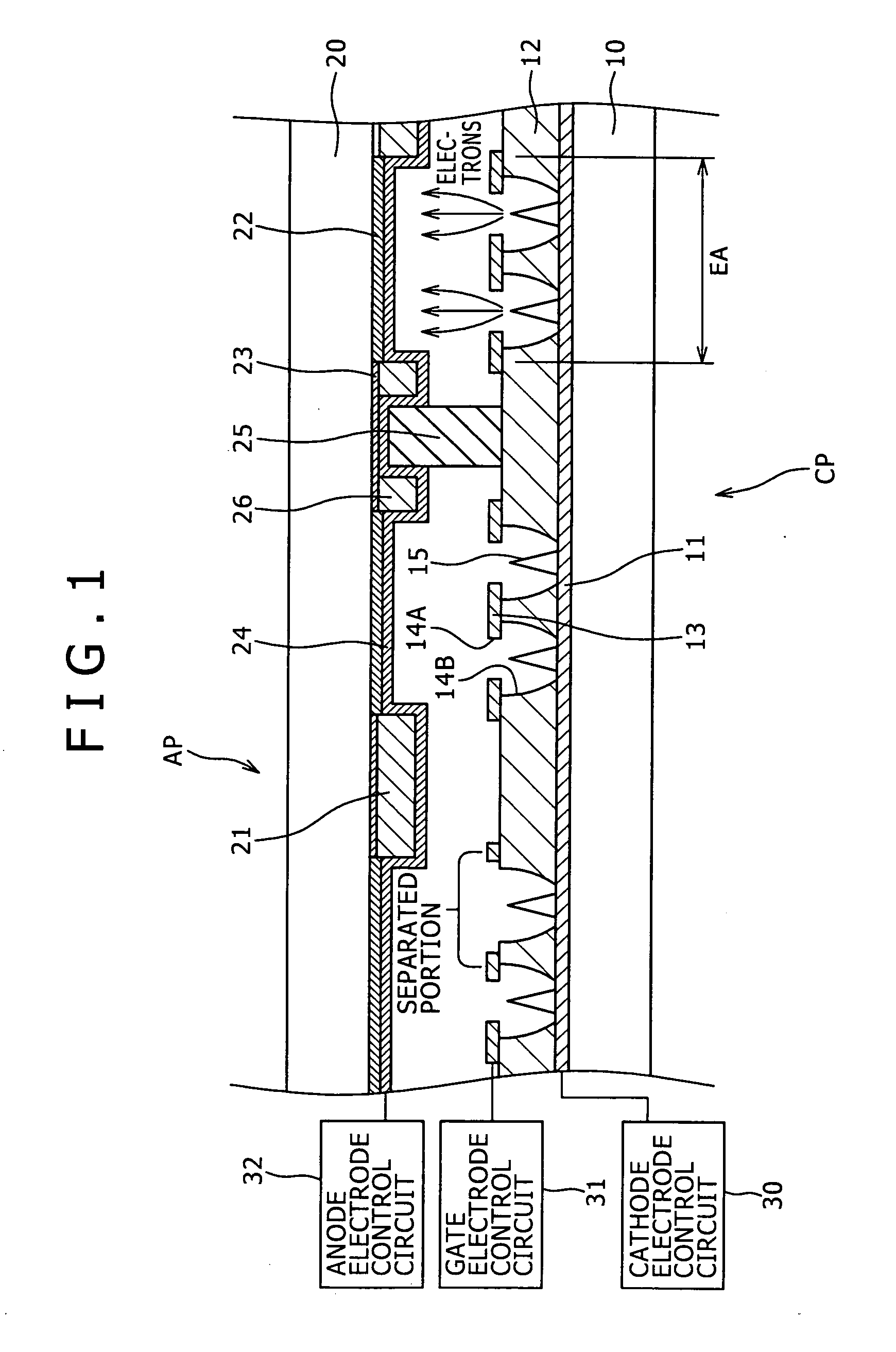

Method for Treating a Cathode Panel, Cold Cathode Field Emission Display Device, and Method for Producing the Same

InactiveUS20080012467A1Uniformity in displaying imagePrevent optical cross talkSparking plugsDischarge tube luminescnet screensInternal pressureCold cathode

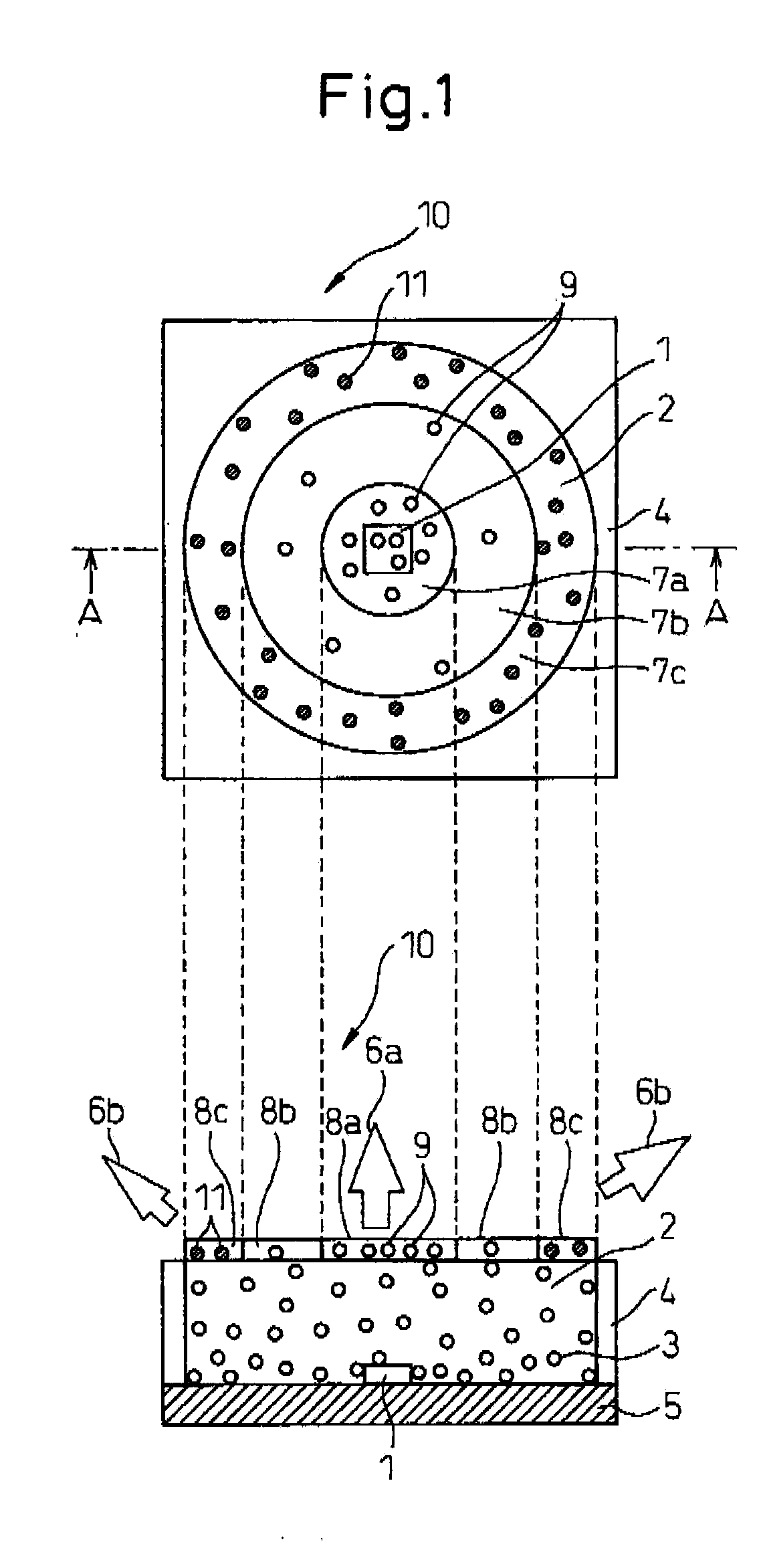

A method for treating a cathode panel, which is used for obtaining a cathode panel free of an electron emitter area recognized as a luminescent spot when the cold cathode field emission display device collectively makes the darkest display. A method for treating a cathode panel (CP) having a plurality of electron emitter areas arrayed in a two-dimensional matrix form for use in producing a cold cathode field emission display device having a predetermined internal pressure P0, wherein the method includes: (A) placing the cathode panel (CP) in a treatment chamber (100) having a predetermined internal pressure P1 (where P1>P0, preferably P1>>P0); and then (B) applying an inspection voltage (VINS) to each electron emitter area such that each electron emitter area emits electrons, causing discharge in an electron emitter area having an electron emission amount larger than that of another electron emitter area.

Owner:SONY CORP

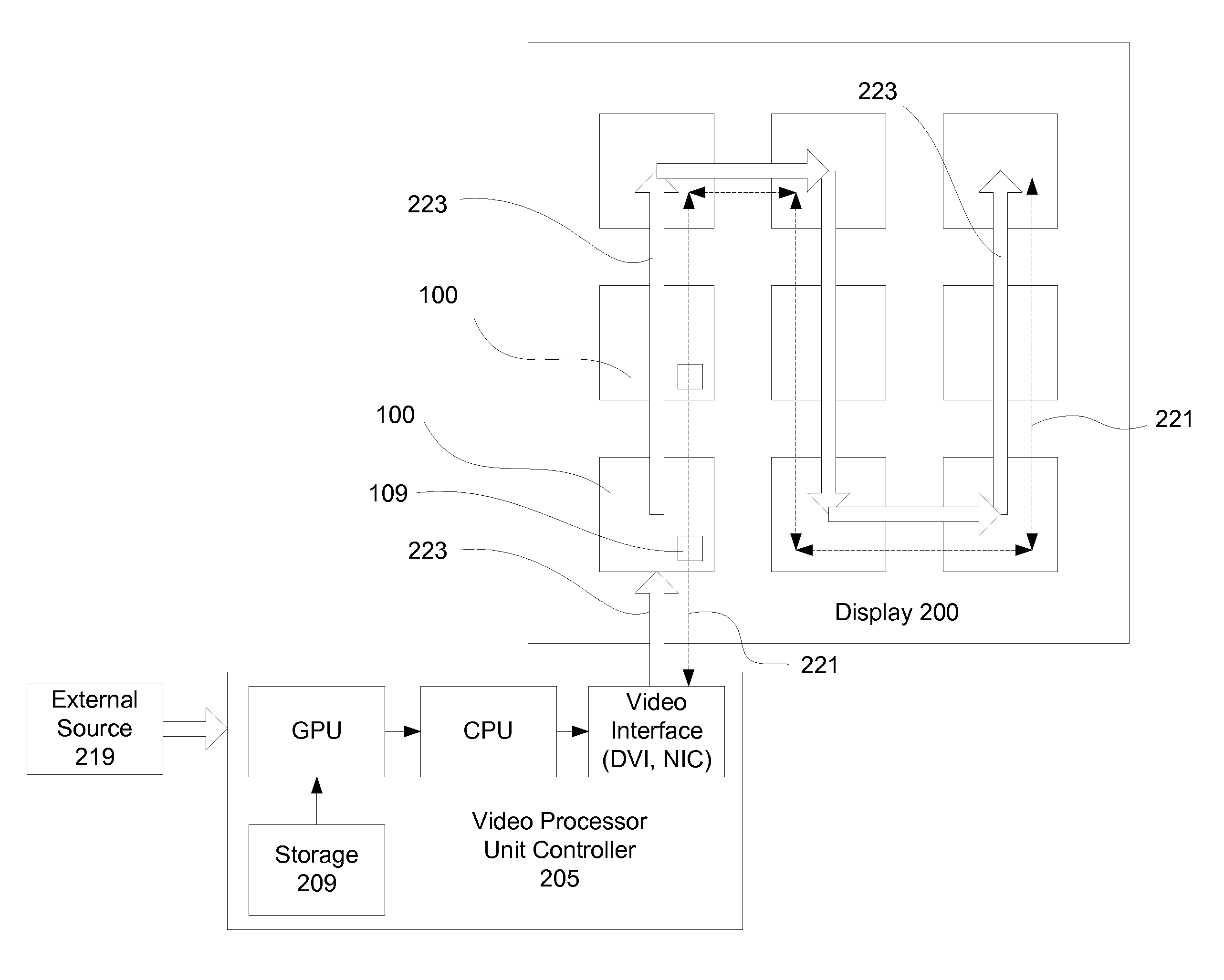

Color Calibration System for a Video Display

Large digital displays for entertainment, architectural and advertising displays have interconnected display panels with pluralities of light emitting elements. To solve calibration problems, each of the display panels stores measured luminance and chromaticity data for each of the light emitting elements of the panel. The luminance data is independent of the chromaticity data. A central controller can then perform calibration procedures so that the light emitting elements are matched across the entire display.

Owner:BARCO INC

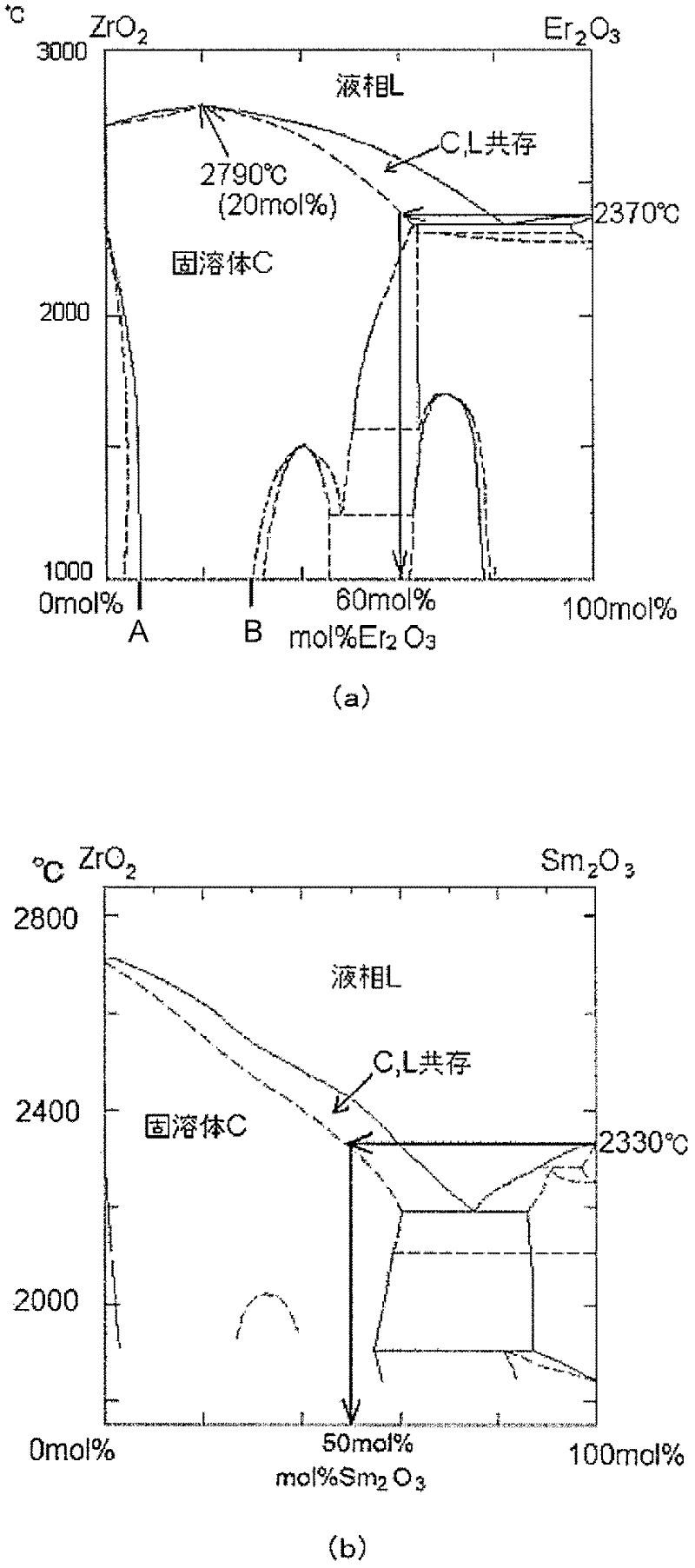

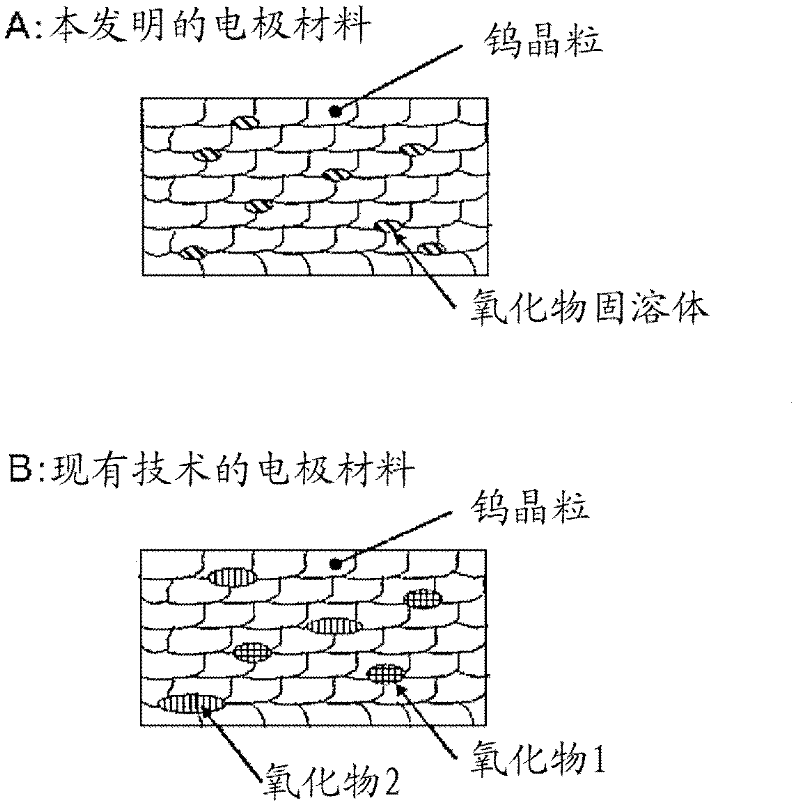

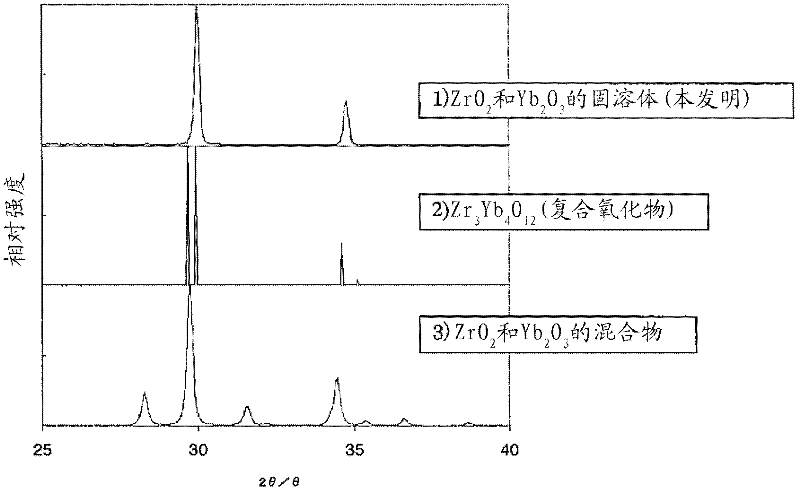

Tungsten electrode material and thermal electron emission current measurement device

InactiveCN102246260ALong electrode lifeAccurate evaluation of electrode characteristicsOxide conductorsDischarge tube/lamp detailsMeasurement devicePower flow

Provided is a tungsten electrode material which uses a material to replace thorium oxide so as to improve the electrode service life as compared to the conventional technique. The tungsten electrode material has a tungsten base and oxide particles dispersed in the tungsten base. The oxide particles are prepared as an oxide solid solution containing in a solid solved state: a Zr oxide and / or a Hf oxide and an oxide of at least one rare earth selected from a group consisting of Sc, Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu.

Owner:ALLIED MATERIAL

Clamping device, substrate transmitting device, and on-line fpd automatic optical detection device

InactiveCN1909203APrevent floatingConveyorsSemiconductor/solid-state device testing/measurementEngineeringNozzle

The present invention discloses a substrate clamping device and substrate transmitting device, used for mechanically fixing one side of the substrate and transferring the substrate through vac sorb. The substrate clamping device includes: a upper chuck; a lower chuck, wherein the structure is to put in and clamp the substrate between the upper chuck and the lower chuck; and a vacuum nozzle, to construct to adsorb and fixing the substrate on at least one of the upper chuck and the lower chuck opposite each other, so the substrate fixed by the substrate clamping device is separated during the transport process or scratched on the contact surface are prevented. When the substrate clamped by the substrate clamping device transmits rapidly, the invention prevents the substrate and the substrate clamping device separate and so assure the reliability of the substrate transmitting and advances the productivity of the product.

Owner:优视株式会社

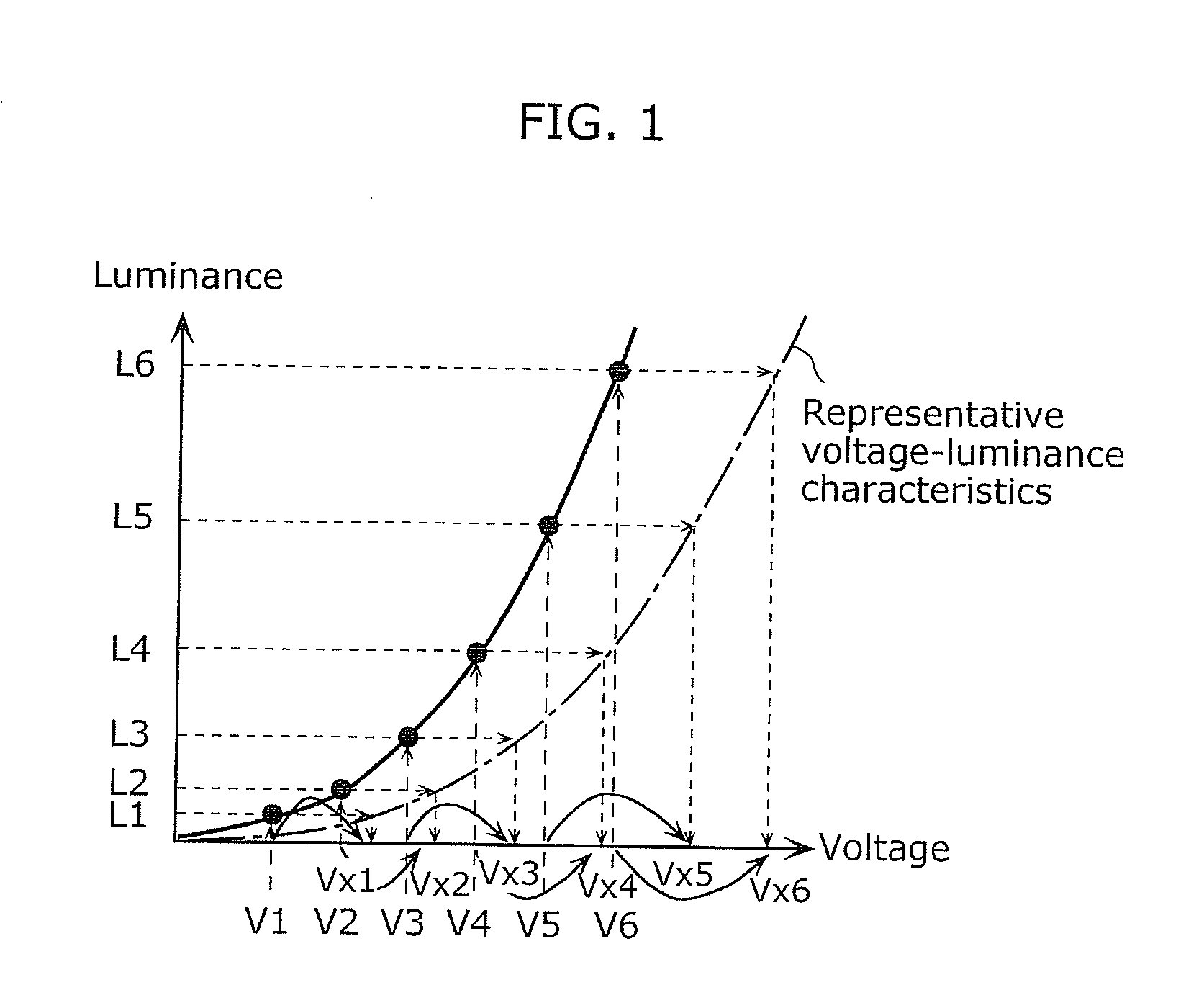

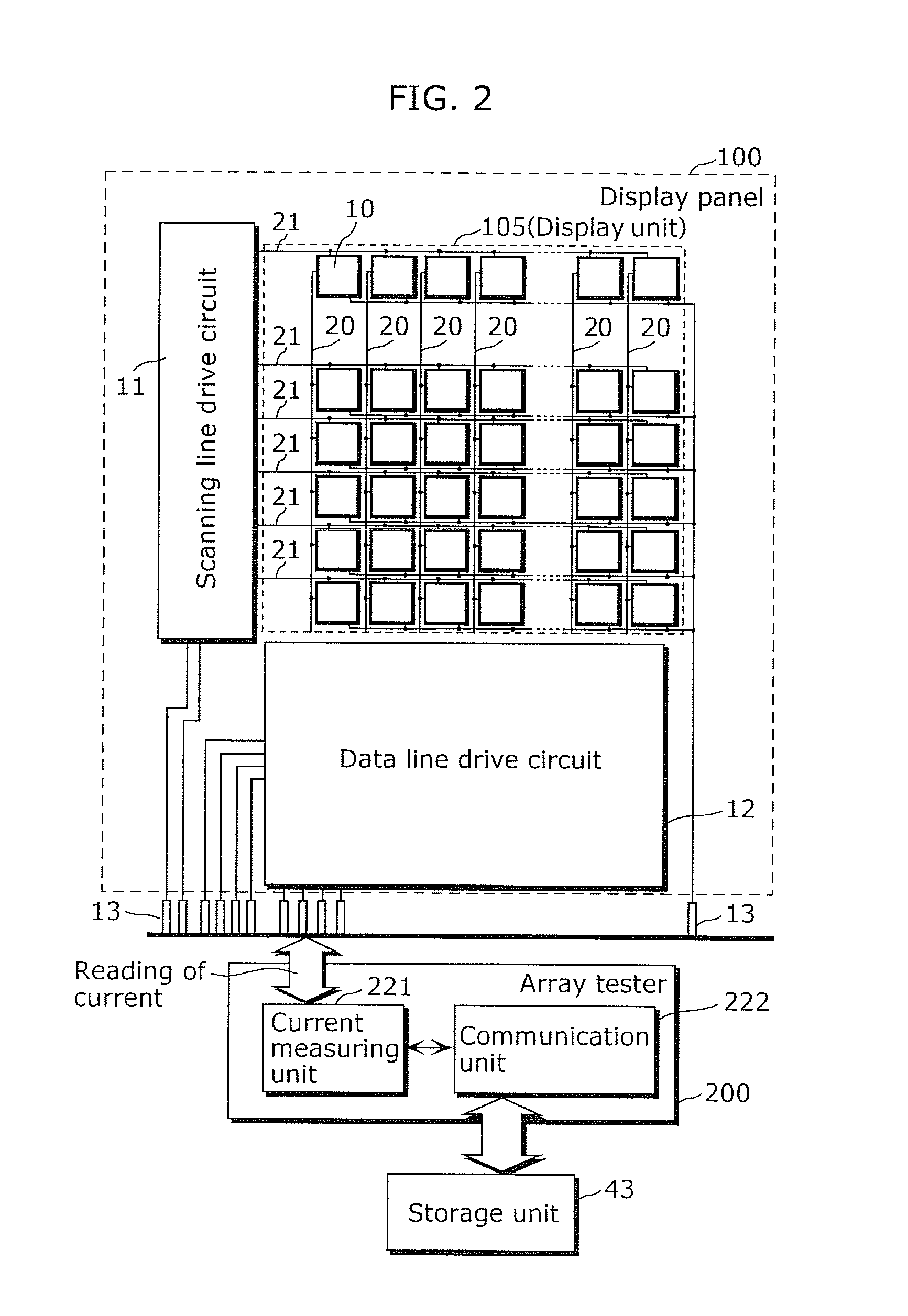

Organic electroluminescence display device manufacturing method and organic electroluminescence display device

InactiveUS20120147070A1Shorten measuring tactReduce measurementSparking plugsCathode-ray tube indicatorsDisplay deviceEngineering

A method of manufacturing an organic electroluminescence display includes preparing a substrate including pixels. The pixels each include a drive transistor and a capacitor. The capacitor of a subject pixel is caused to hold a voltage which corresponds to a threshold voltage of the drive transistor, and the voltage is read. A first signal voltage is obtained by adding a first correction parameter of the subject pixel to a second signal voltage corresponding to a single gradation level belonging to an intermediate gradation region or a high gradation region of representative voltage-luminance characteristics. The first signal voltage is applied to the driver of the subject pixel, and a luminance emitted by the subject pixel is measured. A second correction parameter with which the luminance emitted by the subject pixel becomes a standard luminance is calculated.

Owner:JOLED INC

Method of measuring luminance of image display apparatus, method of manufacturing the same, method and apparatus for adjusting characteristics of the same

InactiveUS20040174323A1Reduce measurementHigh measurement accuracyCathode-ray tube indicatorsTube/lamp factory adjustmentComputer scienceLightness

A method of measuring luminance of an image display apparatus, a method of manufacturing the same, and a method and an apparatus for adjusting characteristics of the same, in which accuracy of measurement is improved while reducing time for measuring luminance of a pixel are provided. A plurality of devices that are not adjacent to each other (for example the devices of the same color out of R, G, and B) are selected and illuminated simultaneously, and luminance is measured for each of them. Based on measured luminance, the electron-emitting characteristics of the respective electron-emitting device as are adjusted based on measured luminance.

Owner:CANON KK

Plasma display screen fault checking method

InactiveCN1801433AQuickly detect pattern defectsManufacture testing/measurementsGraphicsComputer vision

The method to detect plasma display screen defect comprises: obtaining the screen surface image with high-resolution camera for threshold treatment; taking differential minus treatment to the treated image with preset standard image; detecting defect point according to detection condition. This invention needs no repeated calculation, and also fit to nonperiodic image.

Owner:四川世纪双虹显示器件份有限公司

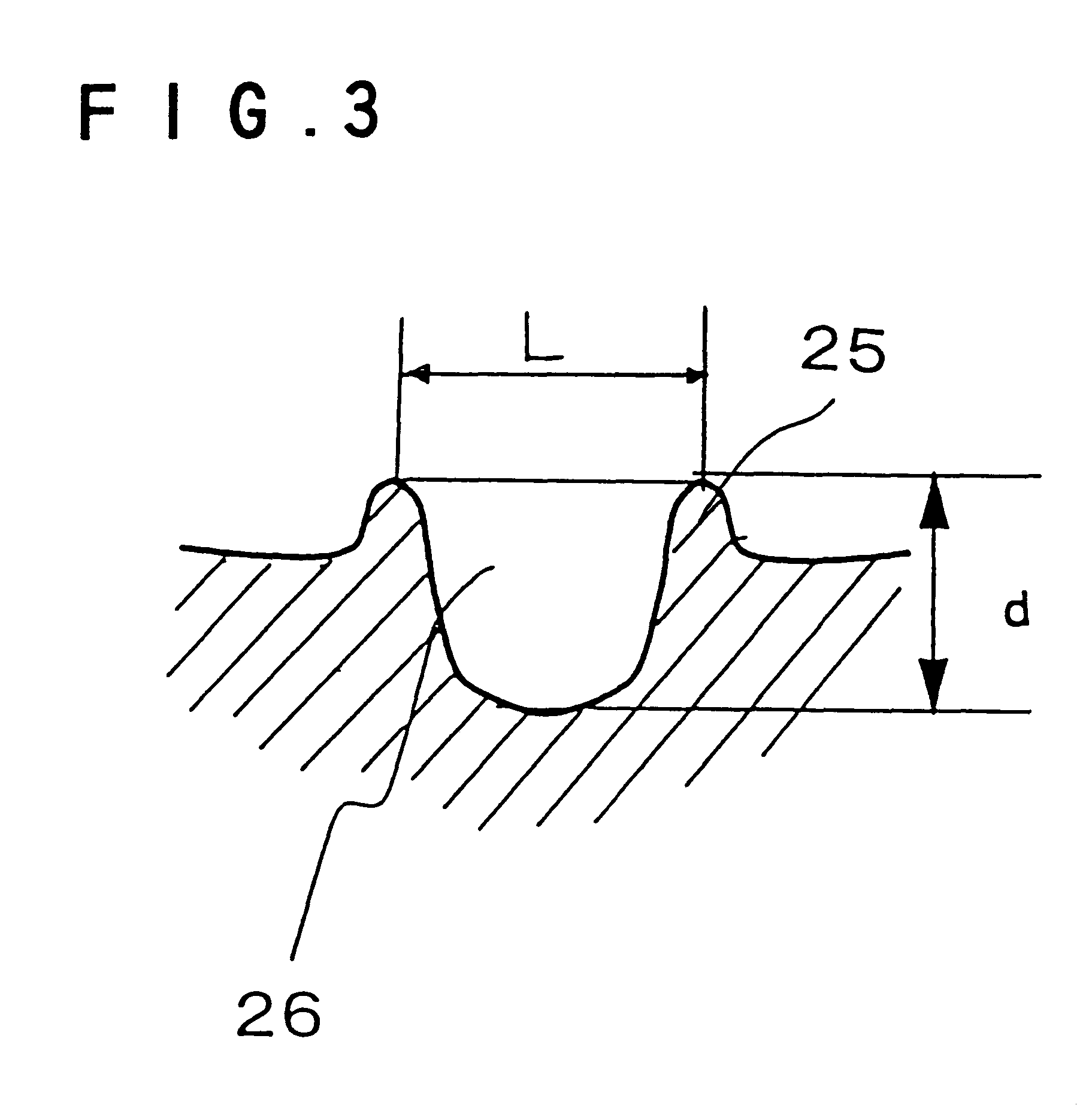

Planar light source, display device and method for manufacturing the same

InactiveUS20090168406A1Prevent uneven colorDistanceSparking plugsMultiple discharge path lampsDisplay deviceOptoelectronics

Light-emitting elements are divided into chromaticity groups on the basis of their chromaticity. In a planar light source, light-emitting elements selected from two of the chromaticity groups are alternately provided in a longitudinal direction and in a transverse direction, respectively. The two chromaticity groups are substantially equally away from a target chromaticity in directions reverse to each other. Further, pairs of two of the light-emitting elements belonging to the two chromaticity groups which are separated from each other, are provided so that distances d2 at which two of the light-emitting elements in each of the pairs are provided are less than distances d1 at which the pairs are provided.

Owner:SHARP KK

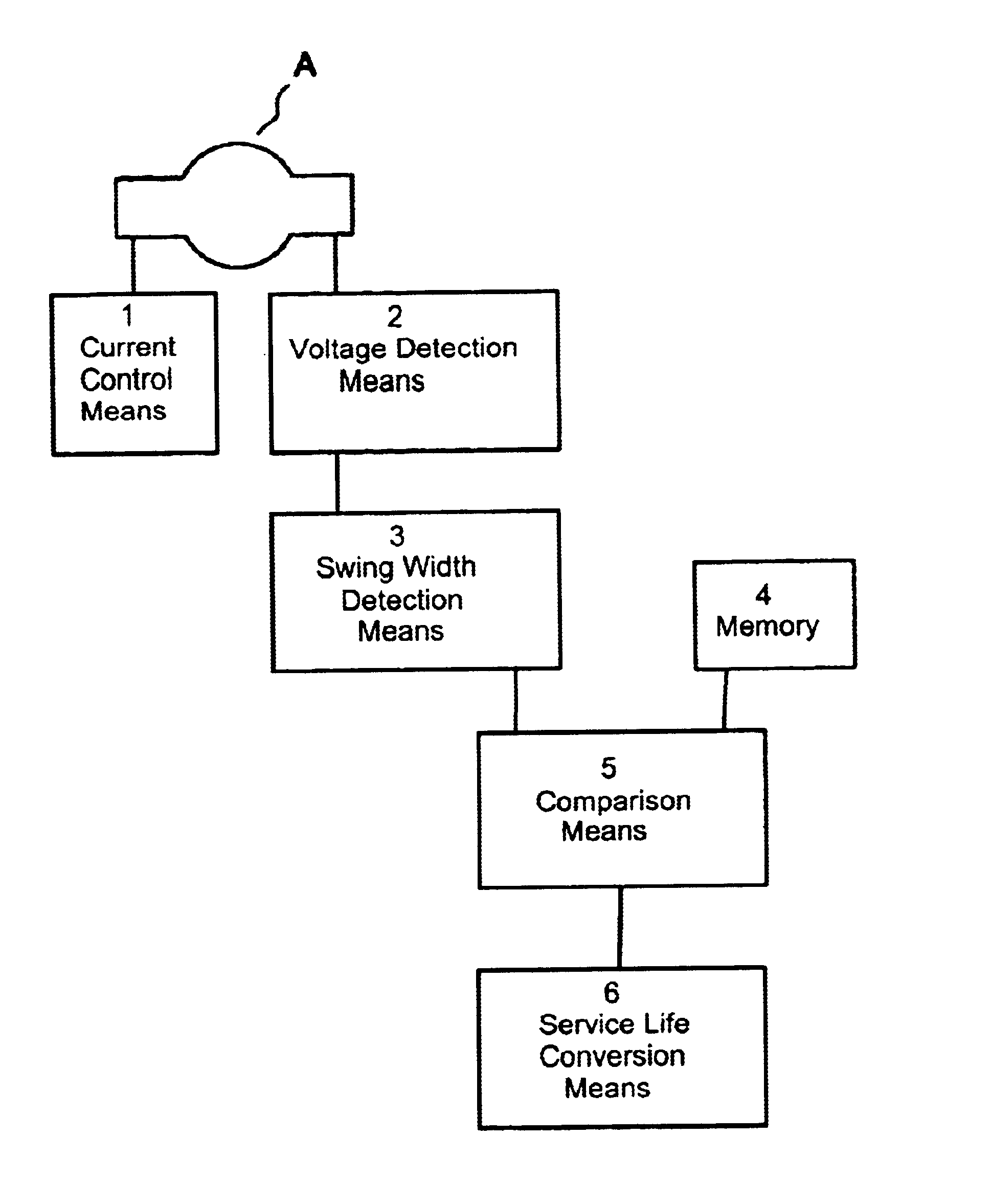

Process for anticipating the service life of a rare gas discharge lamp and a system for anticipating the service life of rare gas discharge lamp

InactiveUS6864685B2Reliably anticipate service lifeEliminate disadvantagesPlug gaugesElectrical testingGas-discharge lampNoble gas

The rare gas discharge lamp is supplied with a current, which is lower than the rated current, the voltage of the rare gas discharge lamp is determined at this instant and the swing width of this voltage is measured. A comparator for comparing measured values of the swing width of the voltage of the rare gas discharge lamp when the current control supplies a reduced current, which is lower than the rated current. A service life converter for converting the difference value output by the comparison means into an indication of the service life of the rare gas discharge lamp.

Owner:USHIO DENKI KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com