Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

244results about "Spark gaps adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

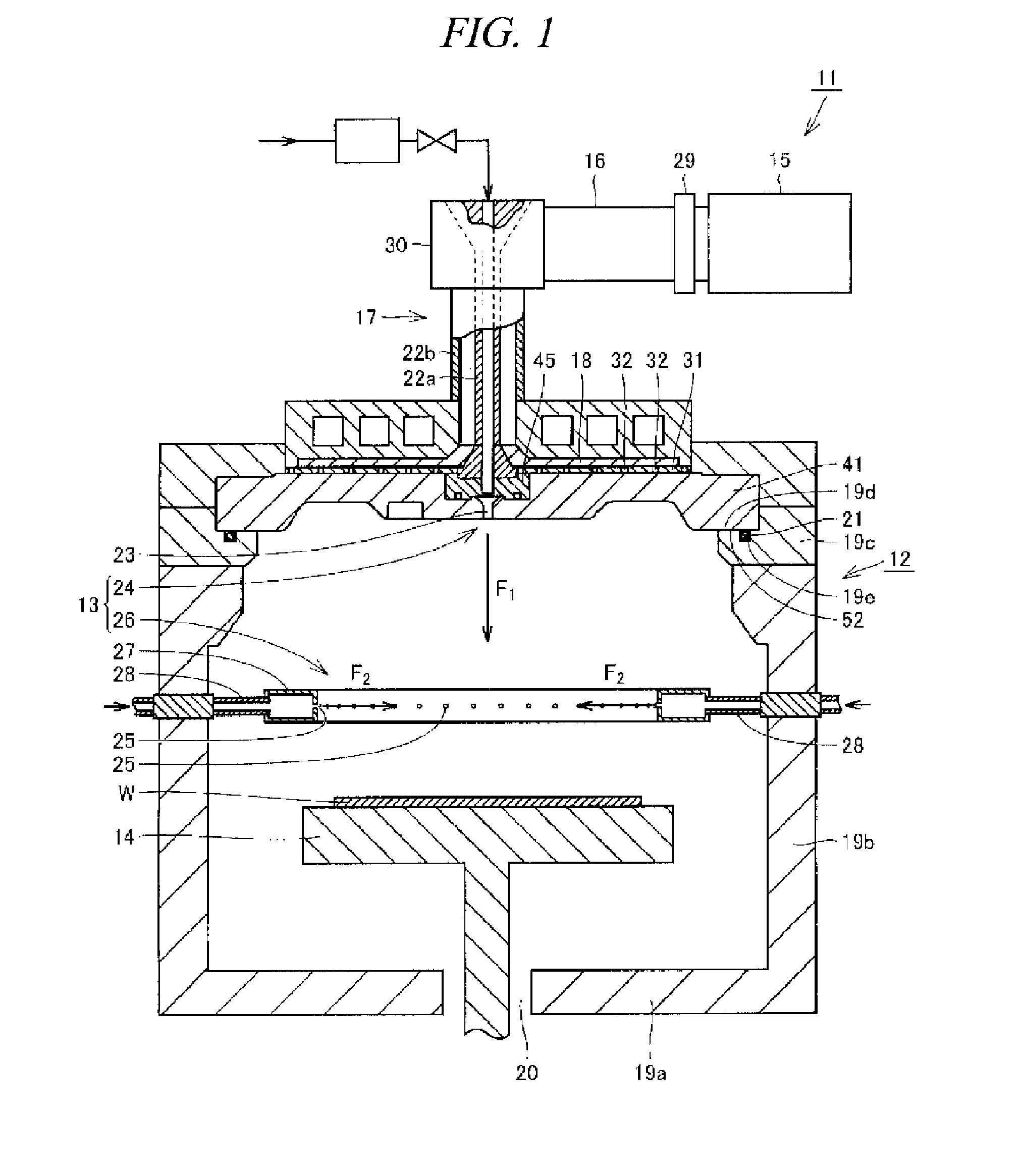

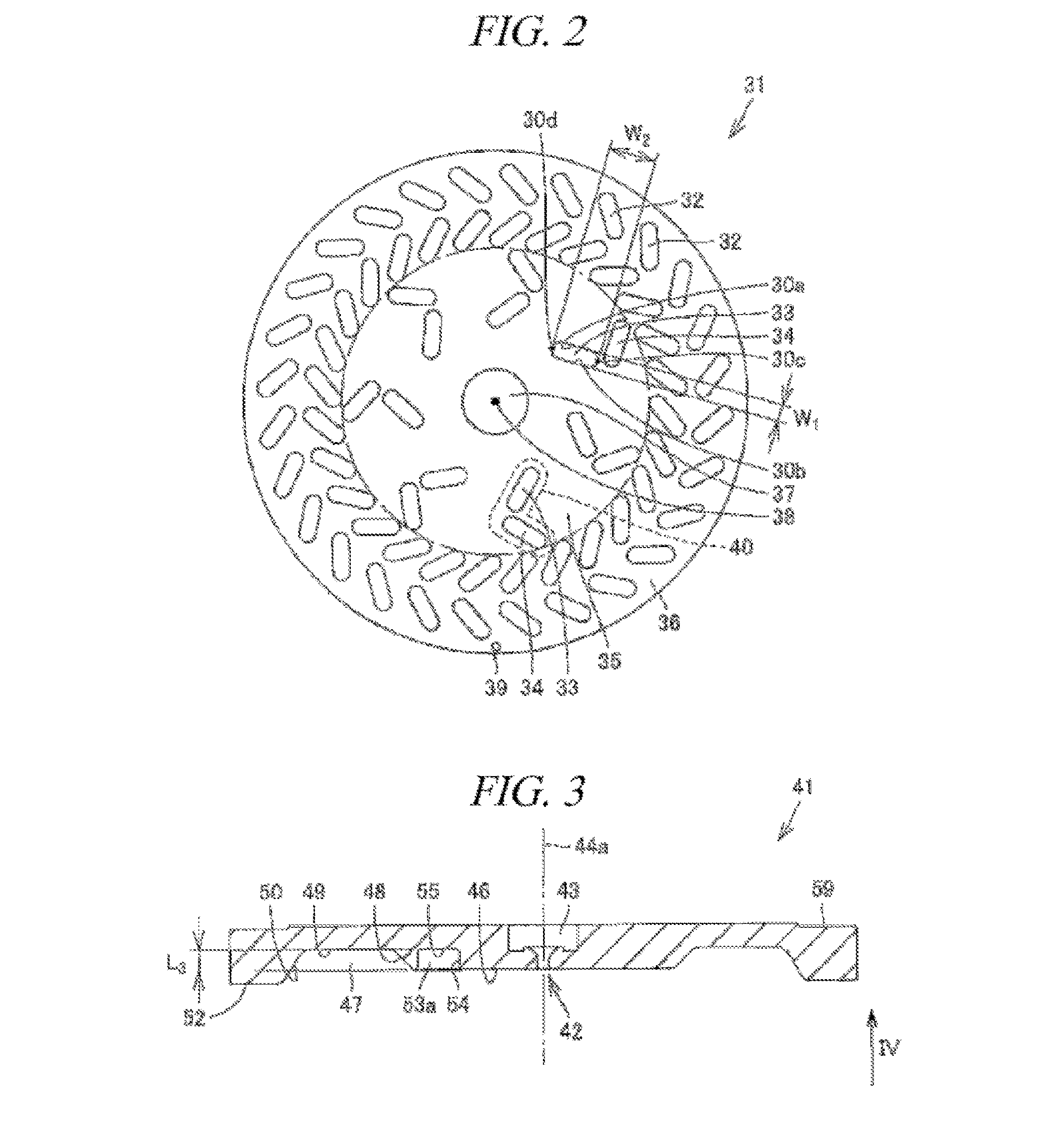

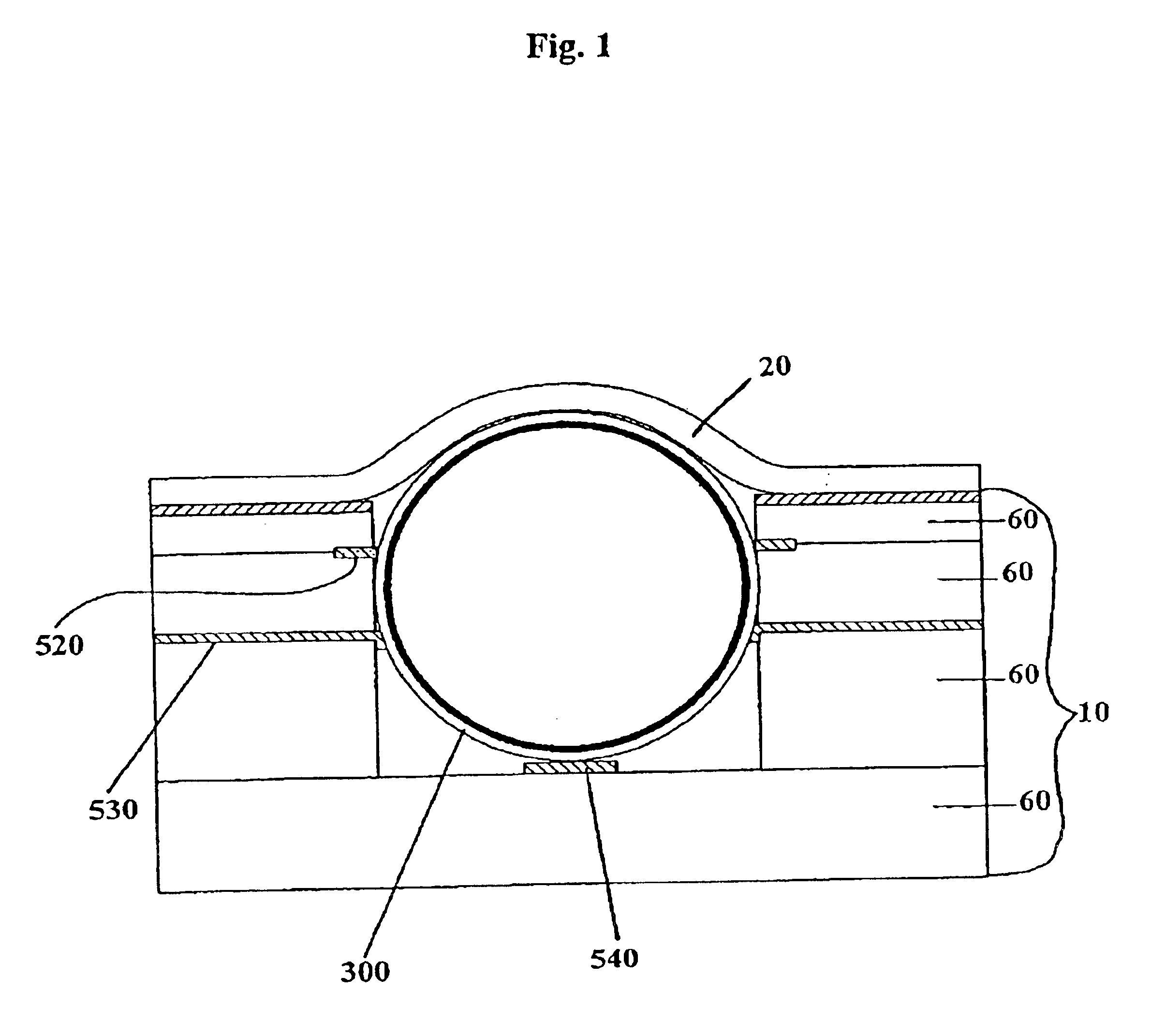

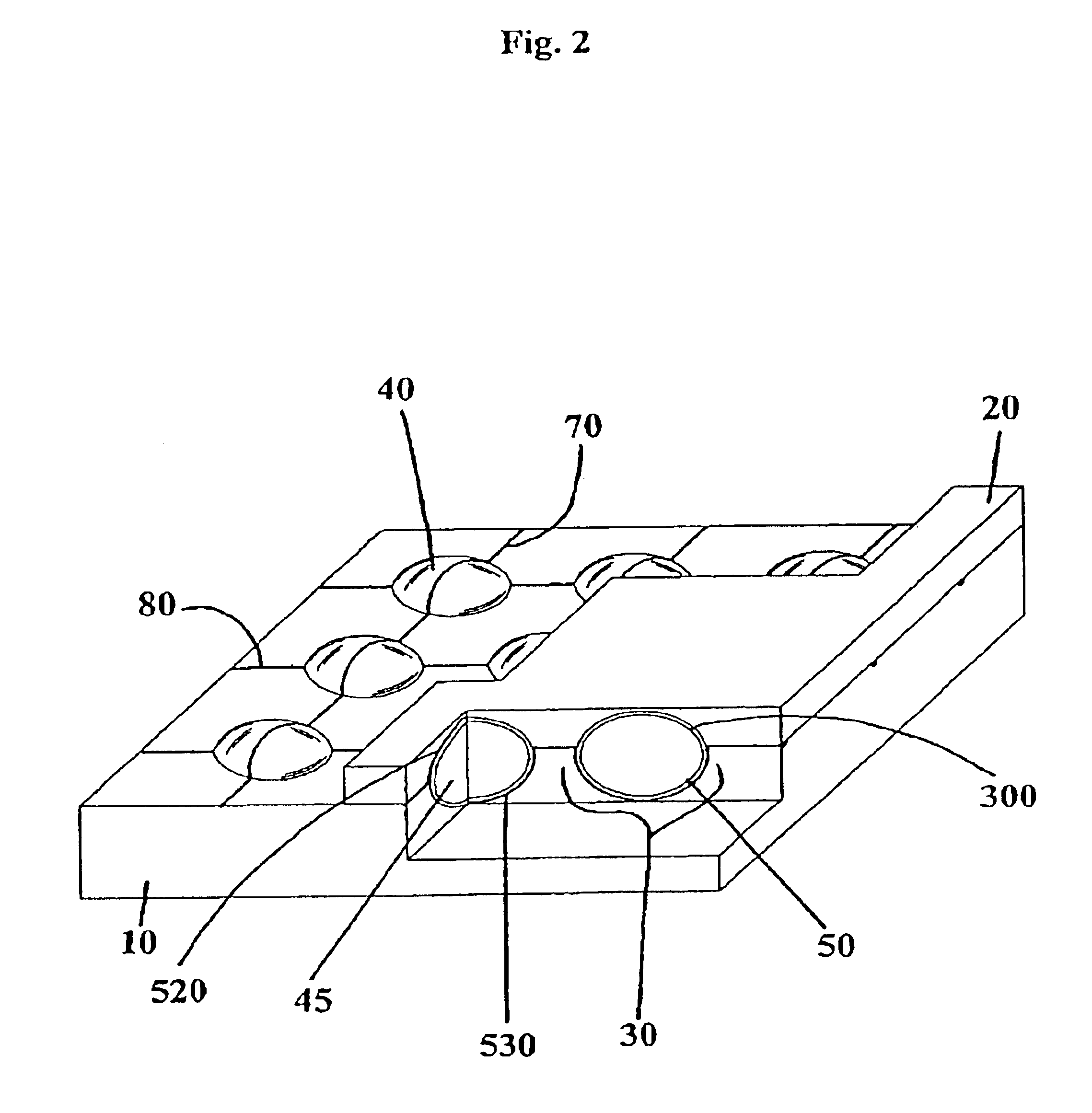

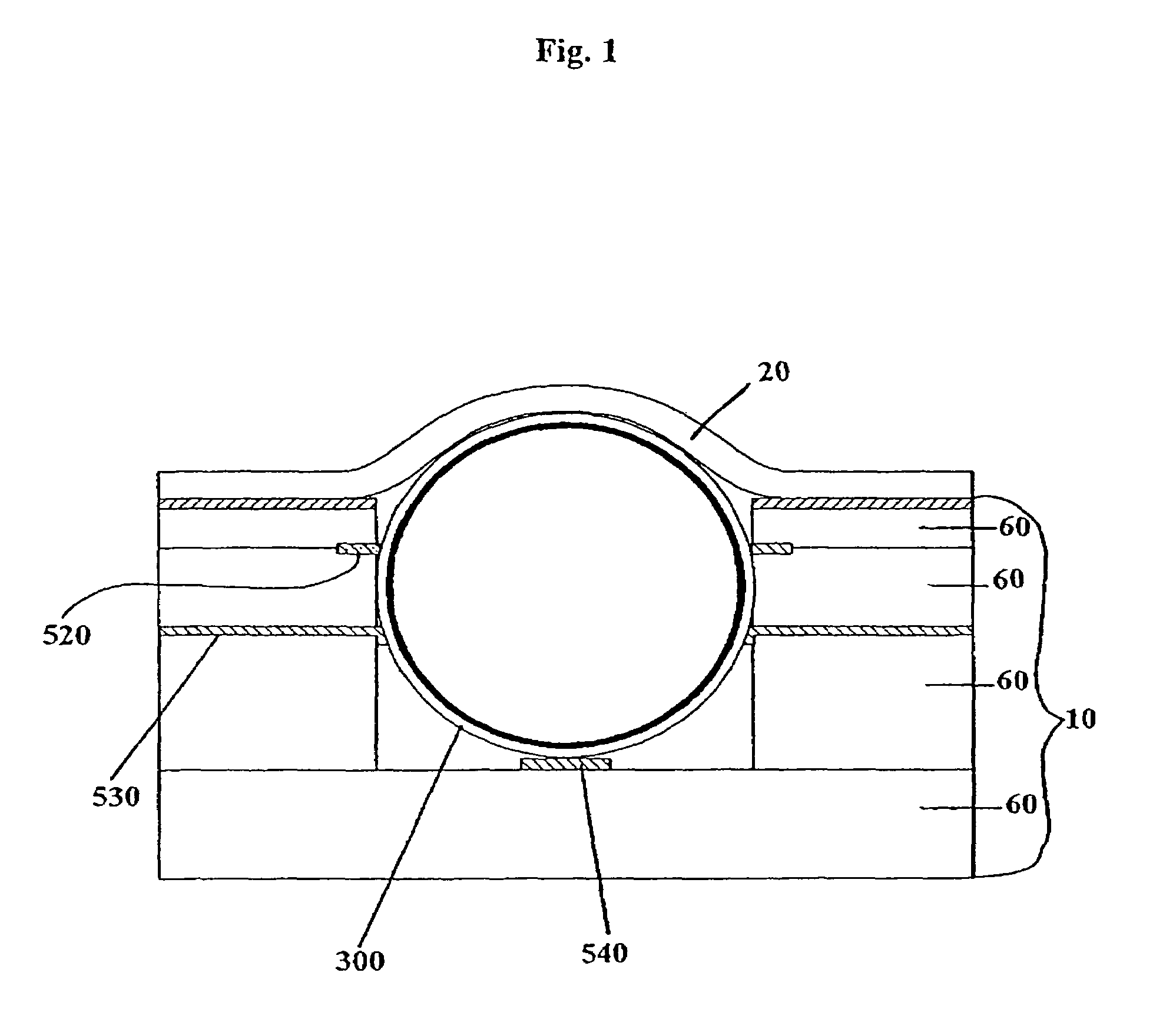

Dielectric window for plasma processing apparatus, plasma processing apparatus and method for mounting dielectric window for plasma processing apparatus

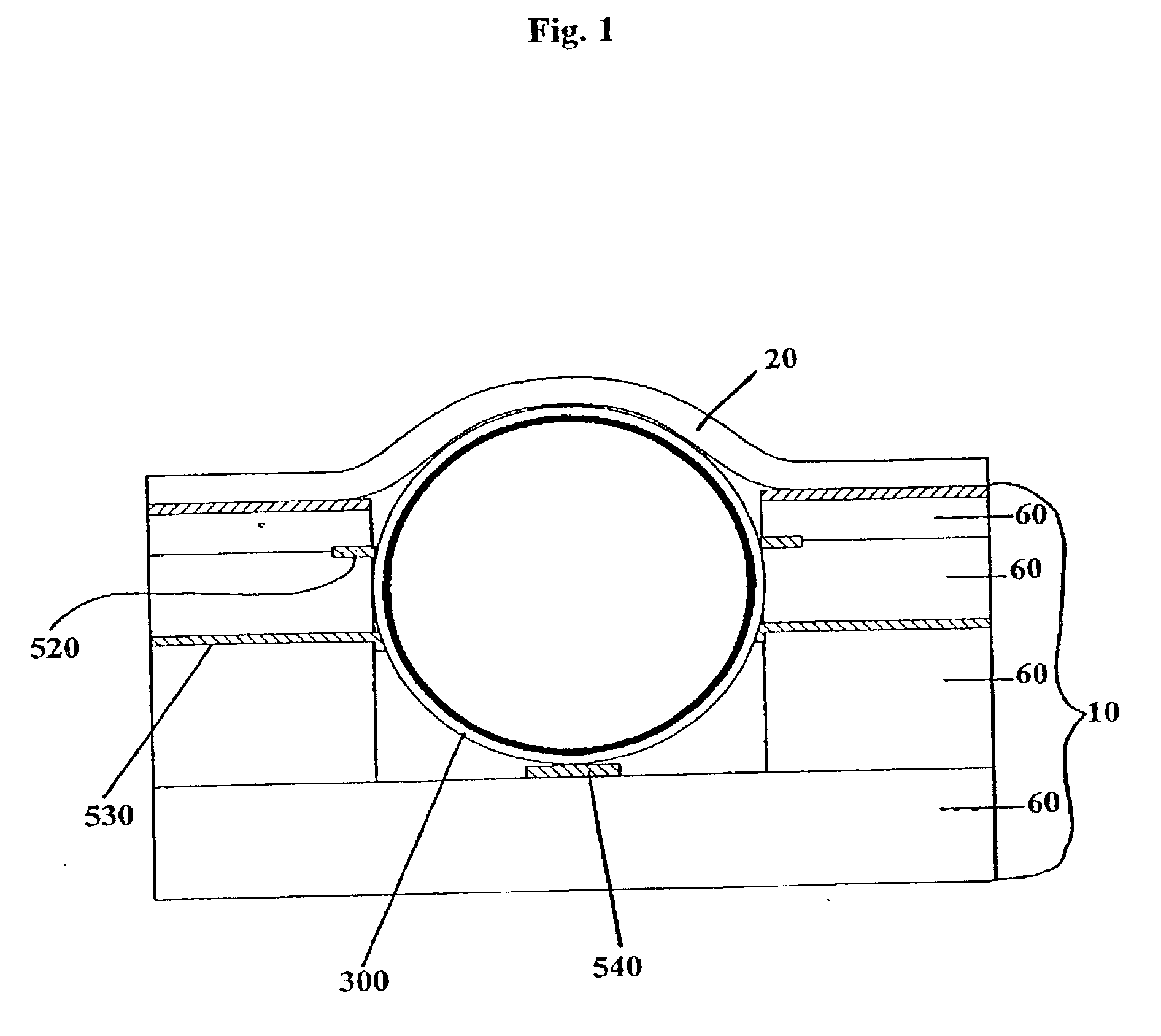

ActiveUS20130093321A1High plasma stabilityAppropriate thicknessSparking plugsSemiconductor/solid-state device manufacturingDielectricPlasma processing

In a dielectric window 41 for a plasma processing apparatus, a first dielectric window recess 47 is formed on an outer region of a surface of the dielectric window 41 in a diametrical direction of the dielectric window 41 at a side where plasma is generated, and the first dielectric window recess 47 is extended in a ring shape and has a tapered shape inwardly in a thickness direction of the dielectric window 41. A multiple number of second dielectric window recesses 53a to 53g are formed between the center of the dielectric window 41 and the first dielectric window recess 47, and each of the second dielectric window recesses 53a to 53g is recessed inwardly in the thickness direction of the dielectric window 41 from the surface of the dielectric window 41.

Owner:TOKYO ELECTRON LTD

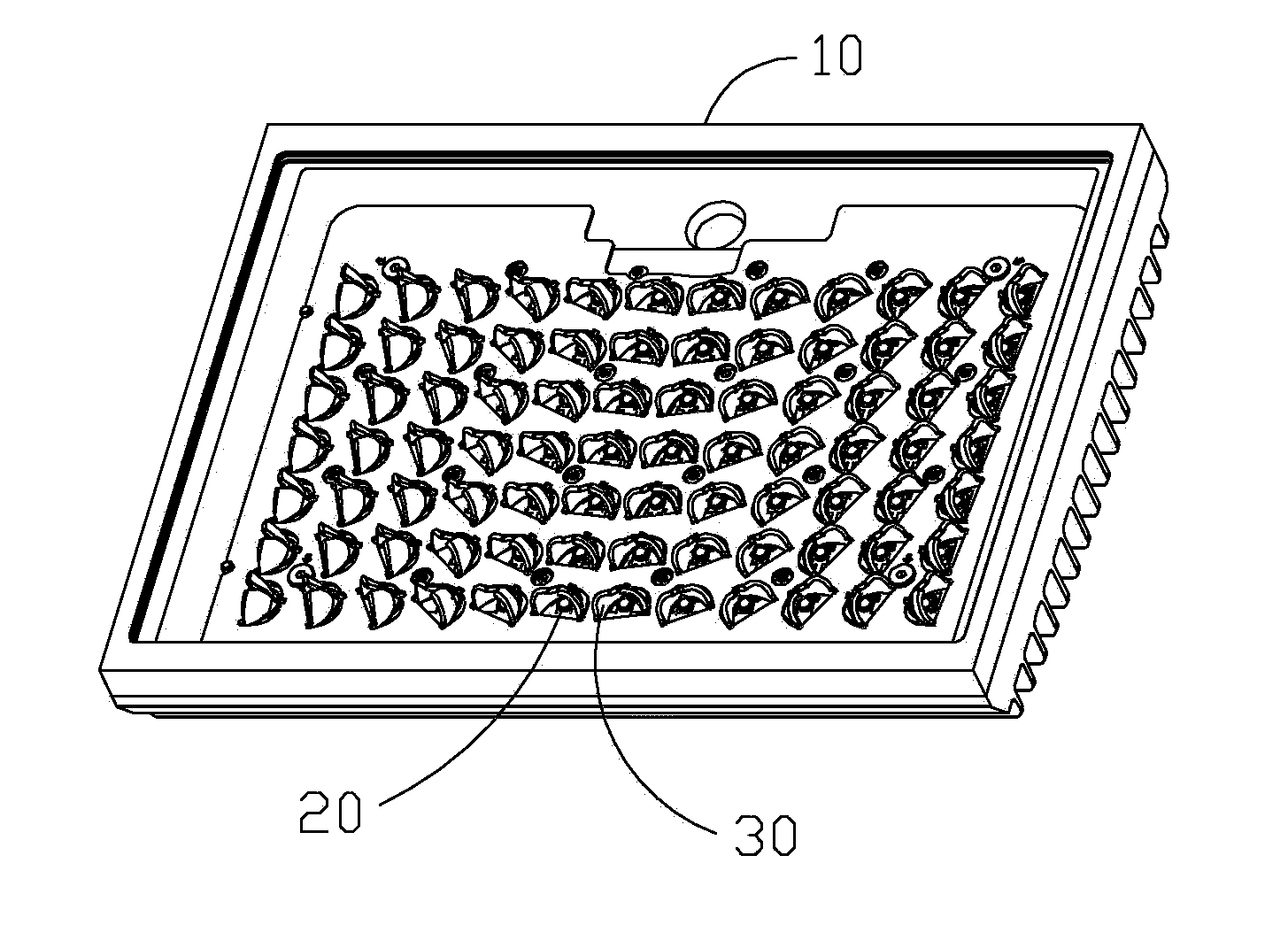

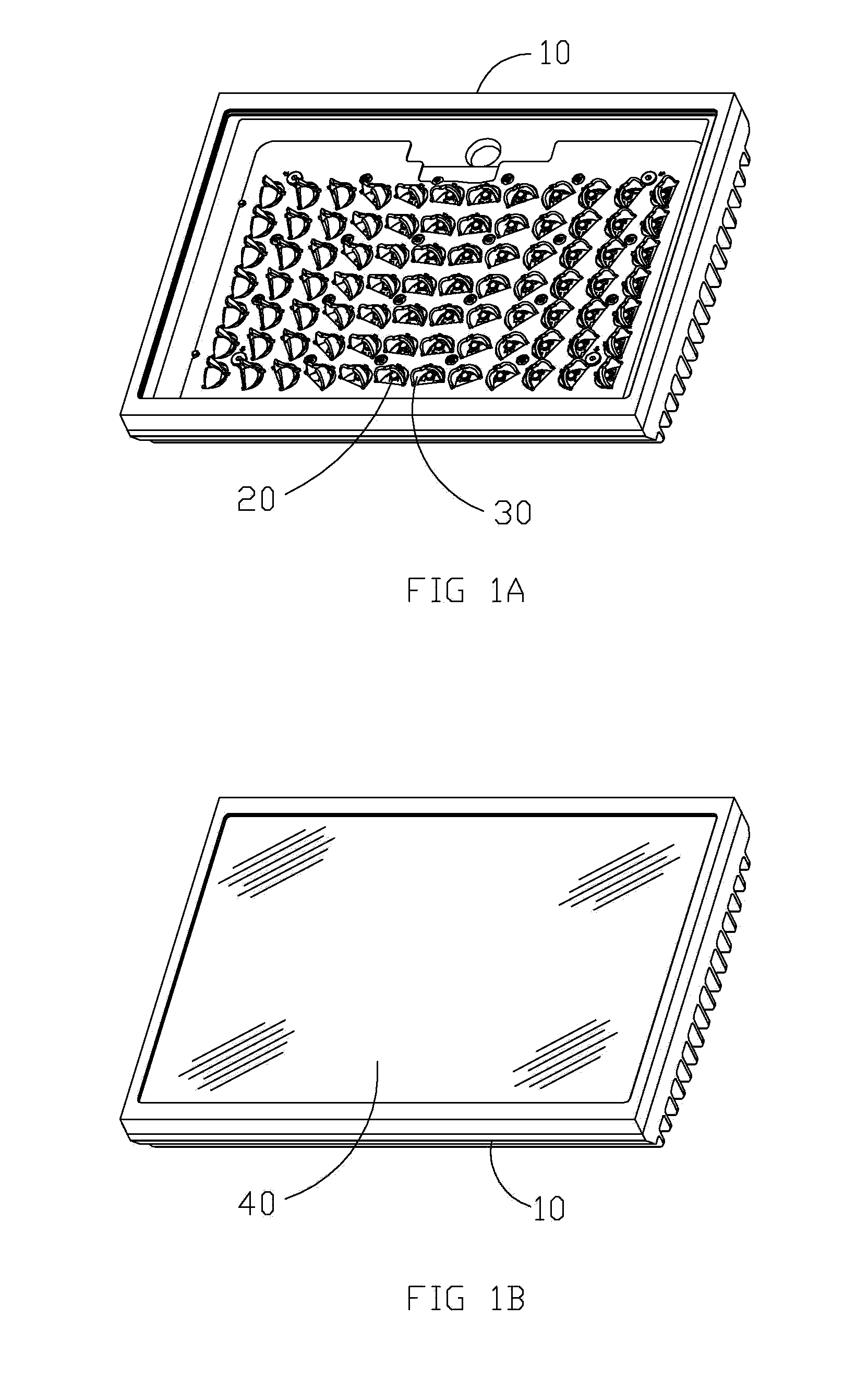

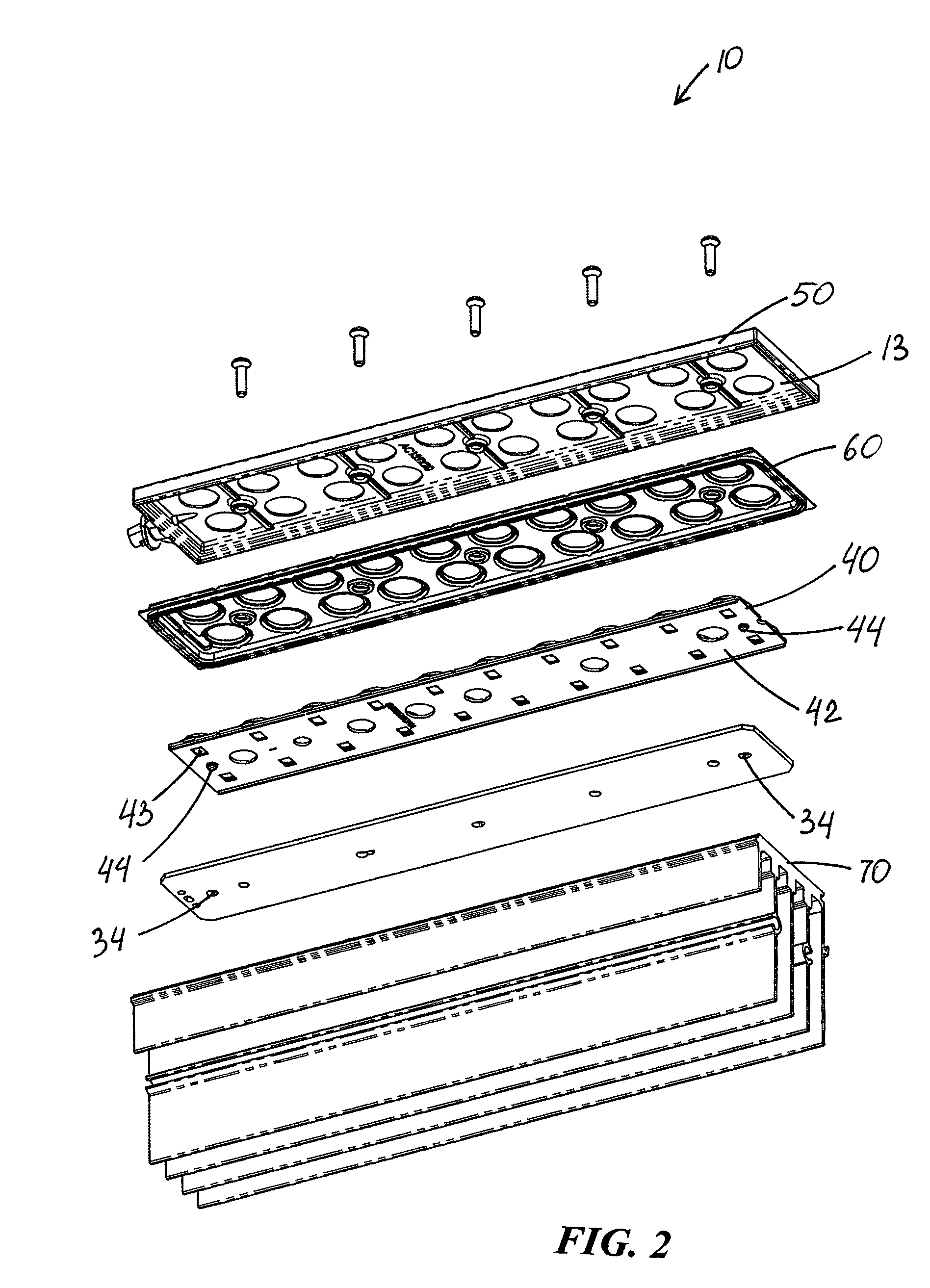

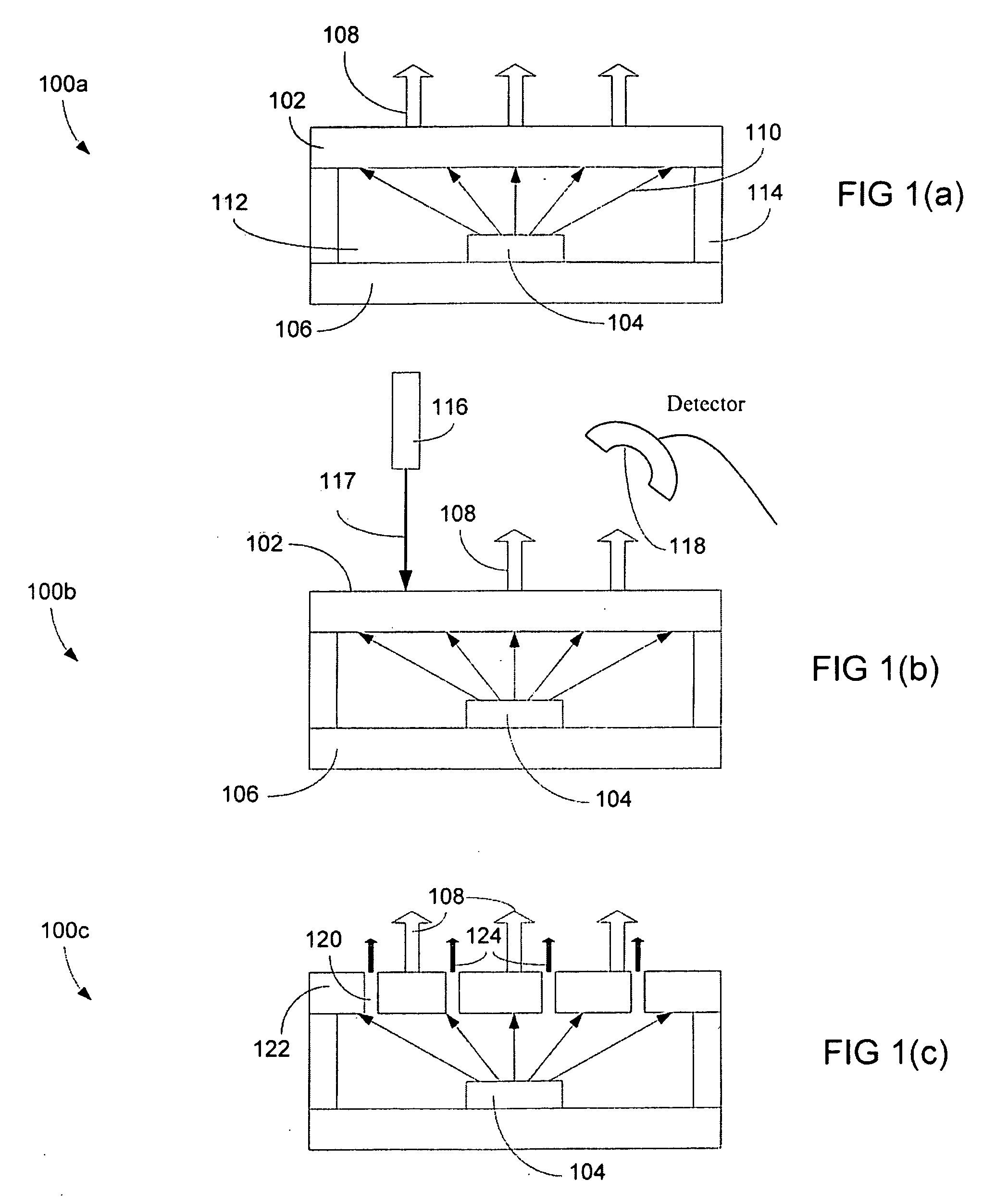

Method, system and apparatus for highly controlled light distribution from light fixture using multiple light sources (led's)

ActiveUS20090323330A1Easily pre-aimedAccurately establishedPlanar light sourcesMechanical apparatusLight equipmentBeam pattern

An apparatus, method, or system of lighting units comprising a plurality of lighting elements, such as one or more LEDs, each element having an associated optic which is individually positionable. In embodiments of the present invention, one or more optics are developed using optimization techniques that allow for lighting different target areas in an effective manner by rotating or otherwise positioning the reflectors, refractive lenses, TIR lenses, or other lens types to create a composite beam. The apparatus, method, or system of lighting herein makes it possible to widely vary the types of beams from an available fixture using a small number of inventoried optics and fixtures. In some cases, by using a combination of individual beam patterns, a small set of individual optics would be sufficient to create a majority of the typical and specialized composite beams needed to meet the needs of most lighting projects and target areas.

Owner:MUSCO

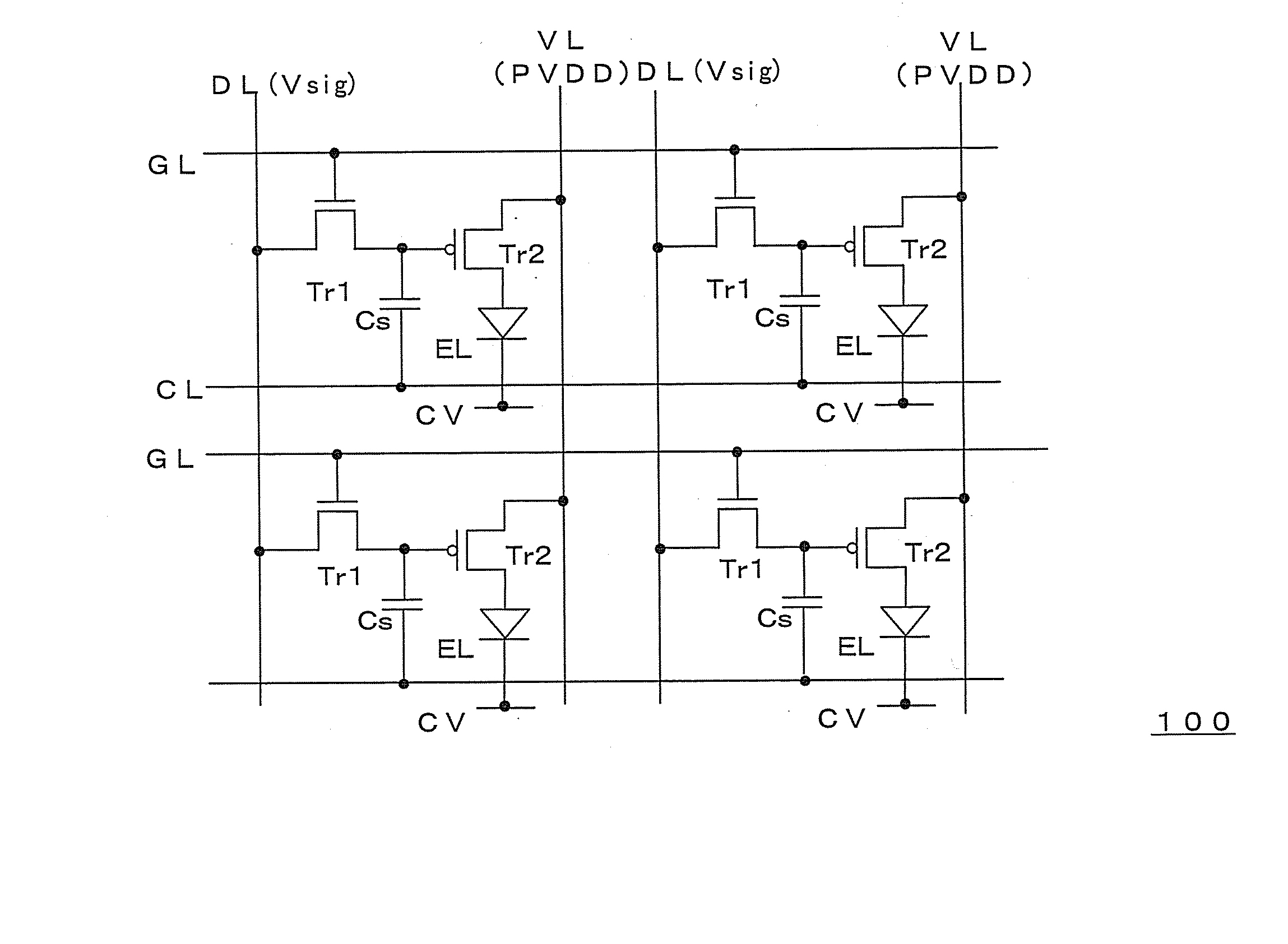

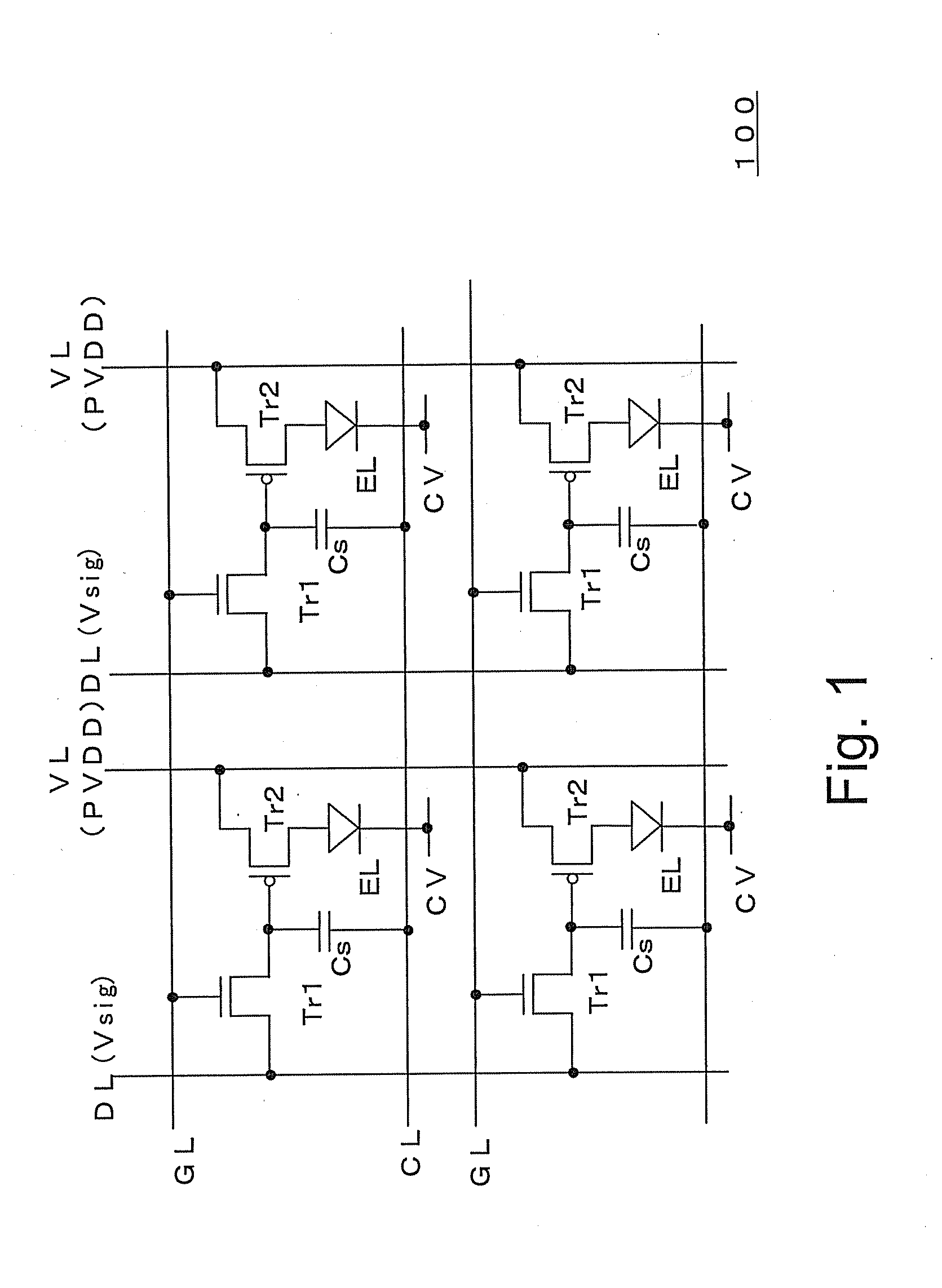

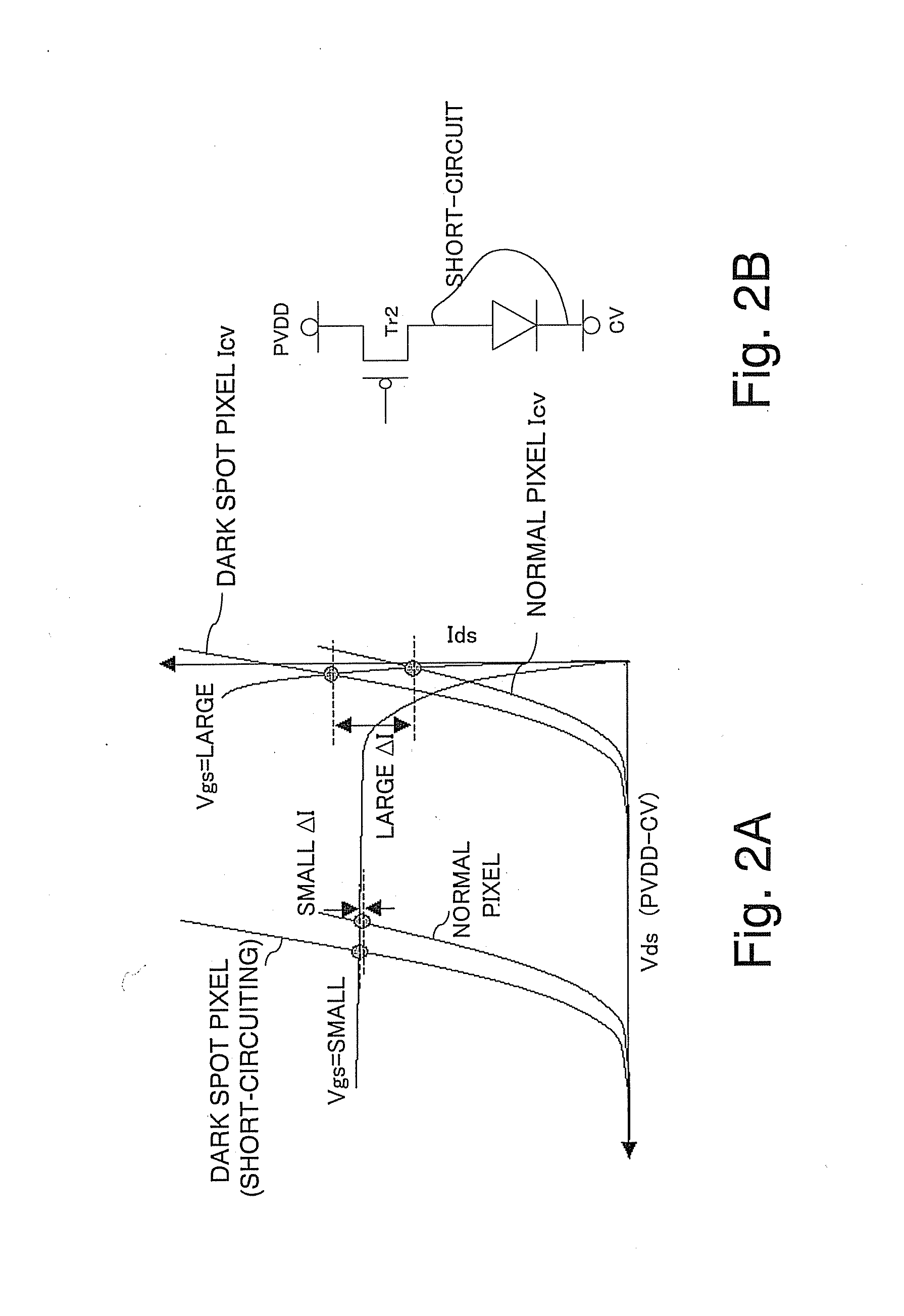

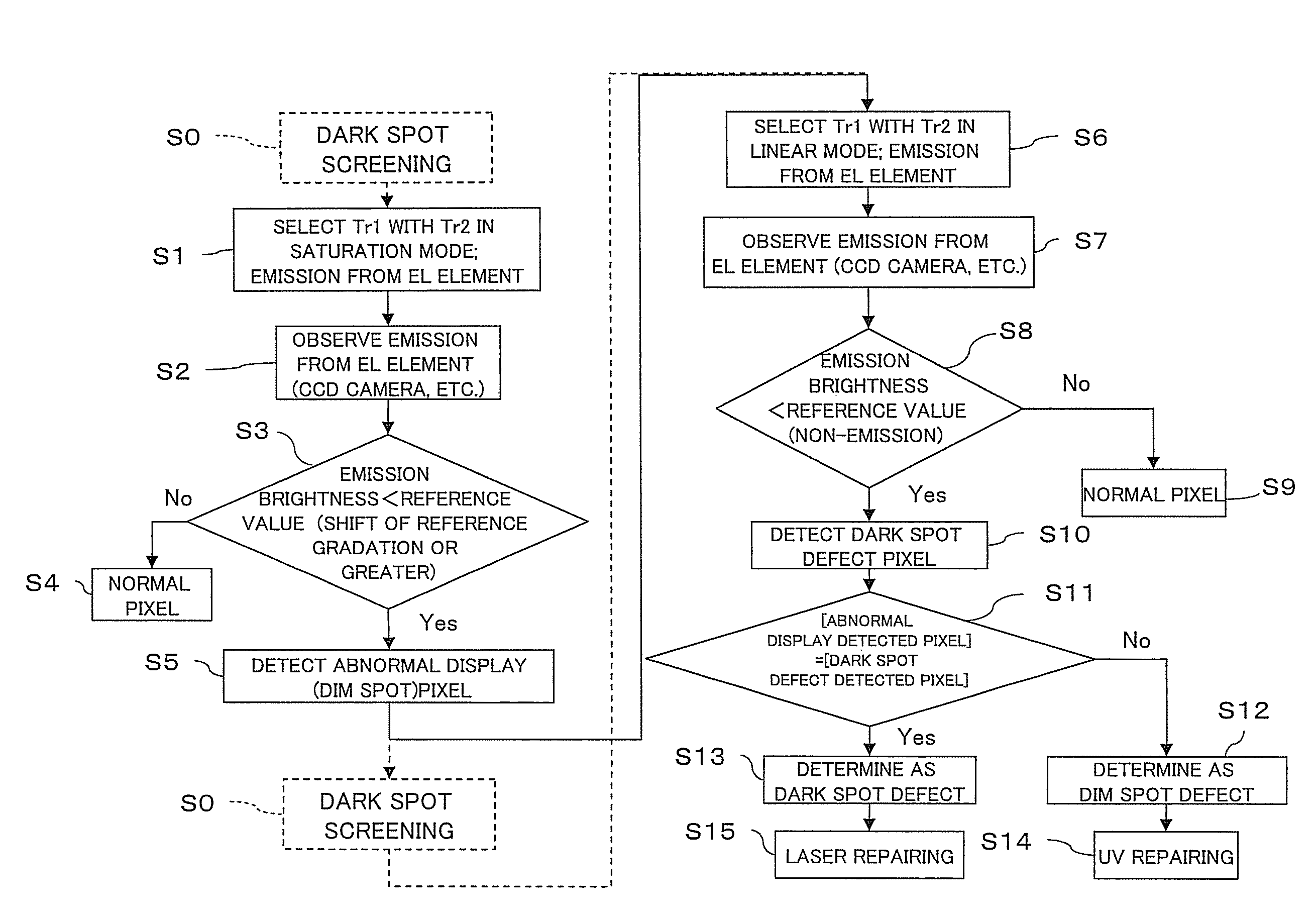

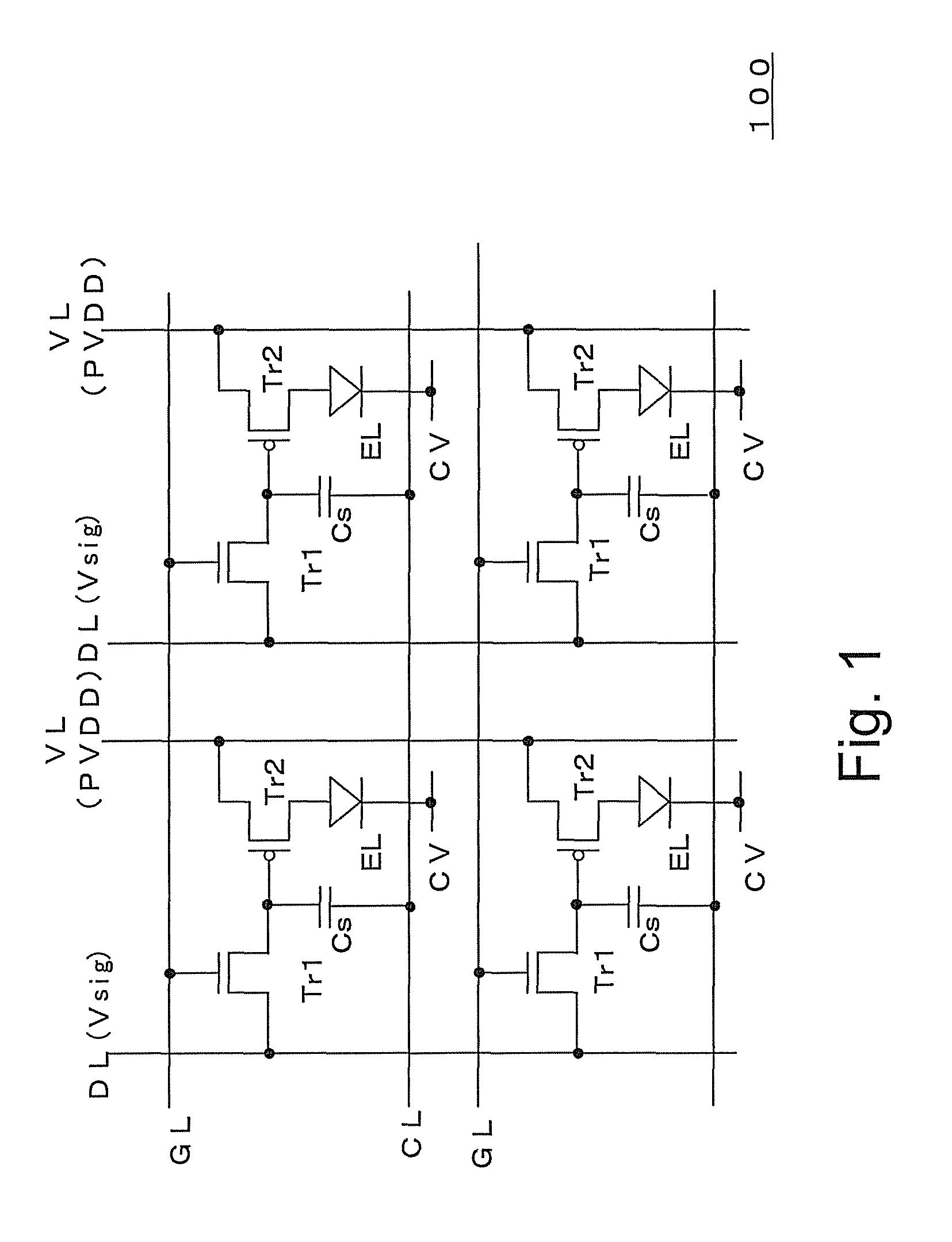

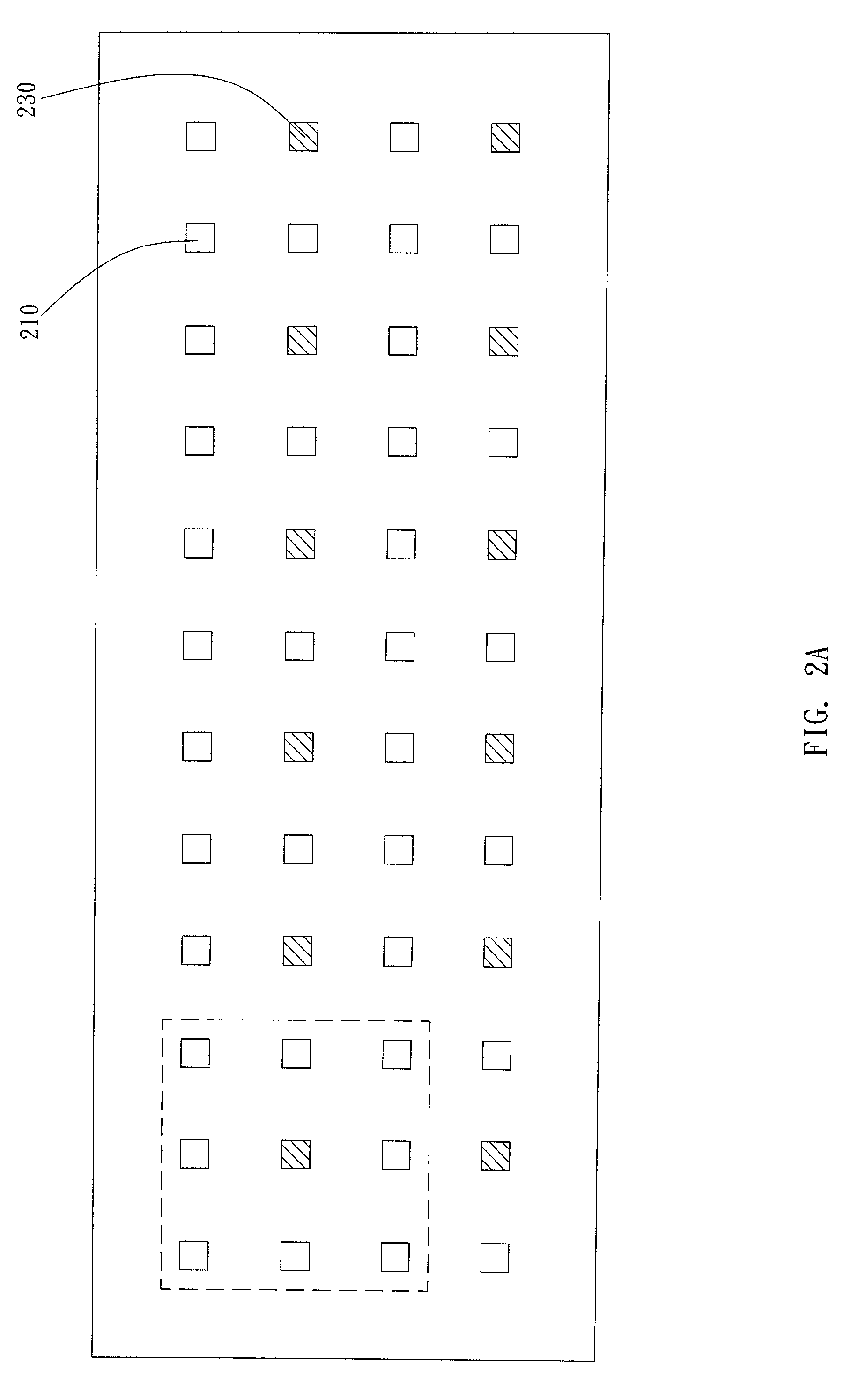

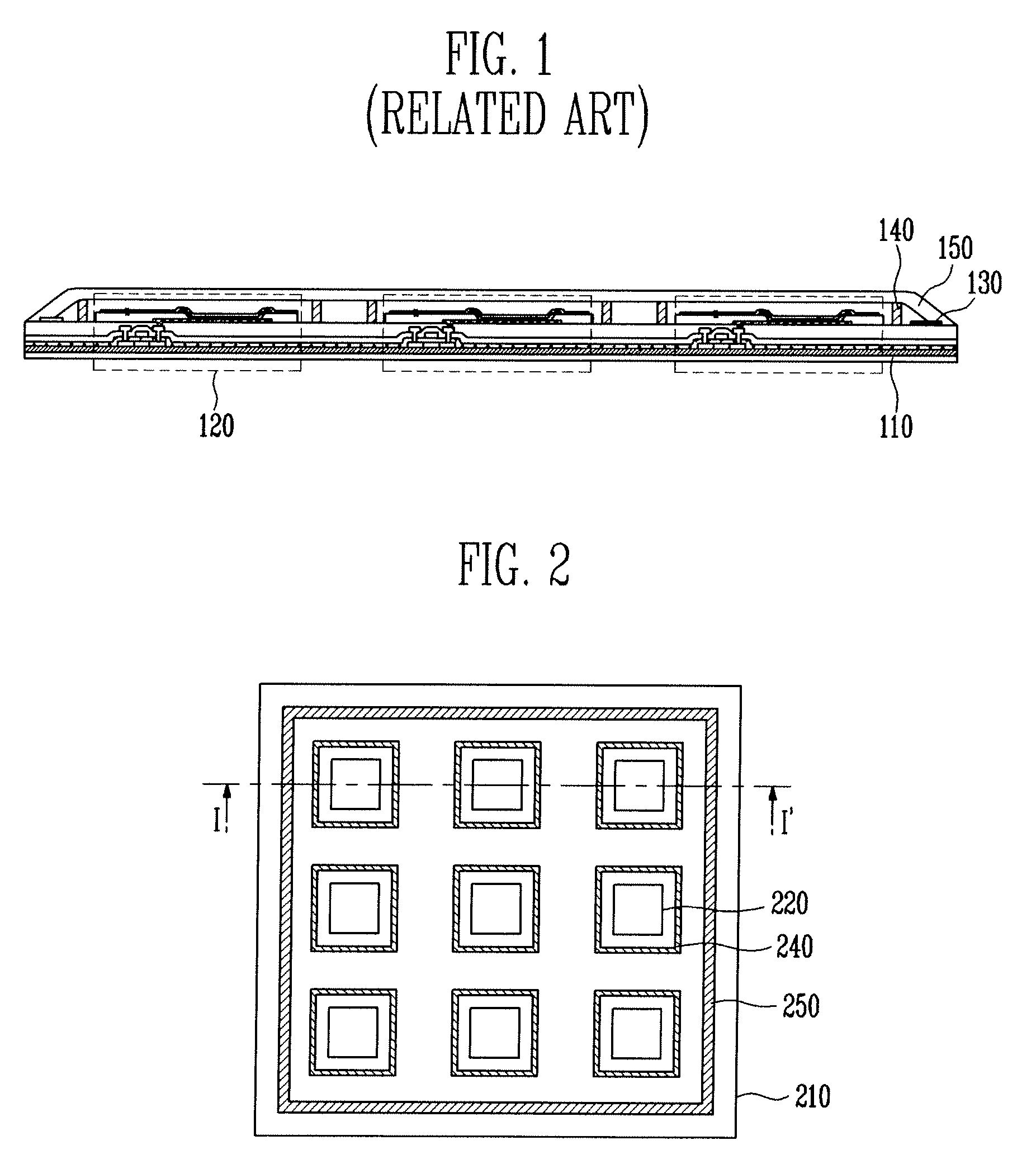

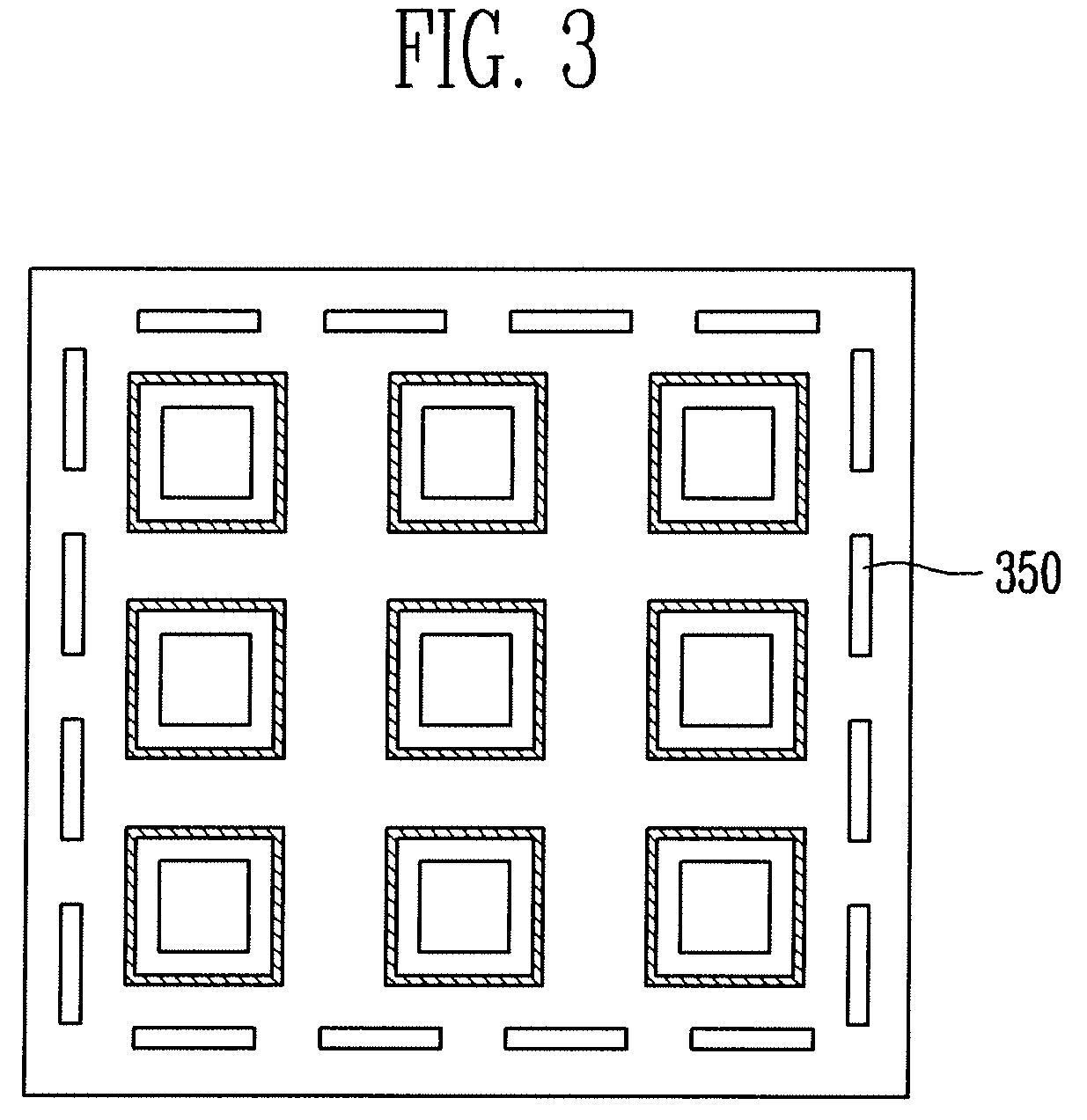

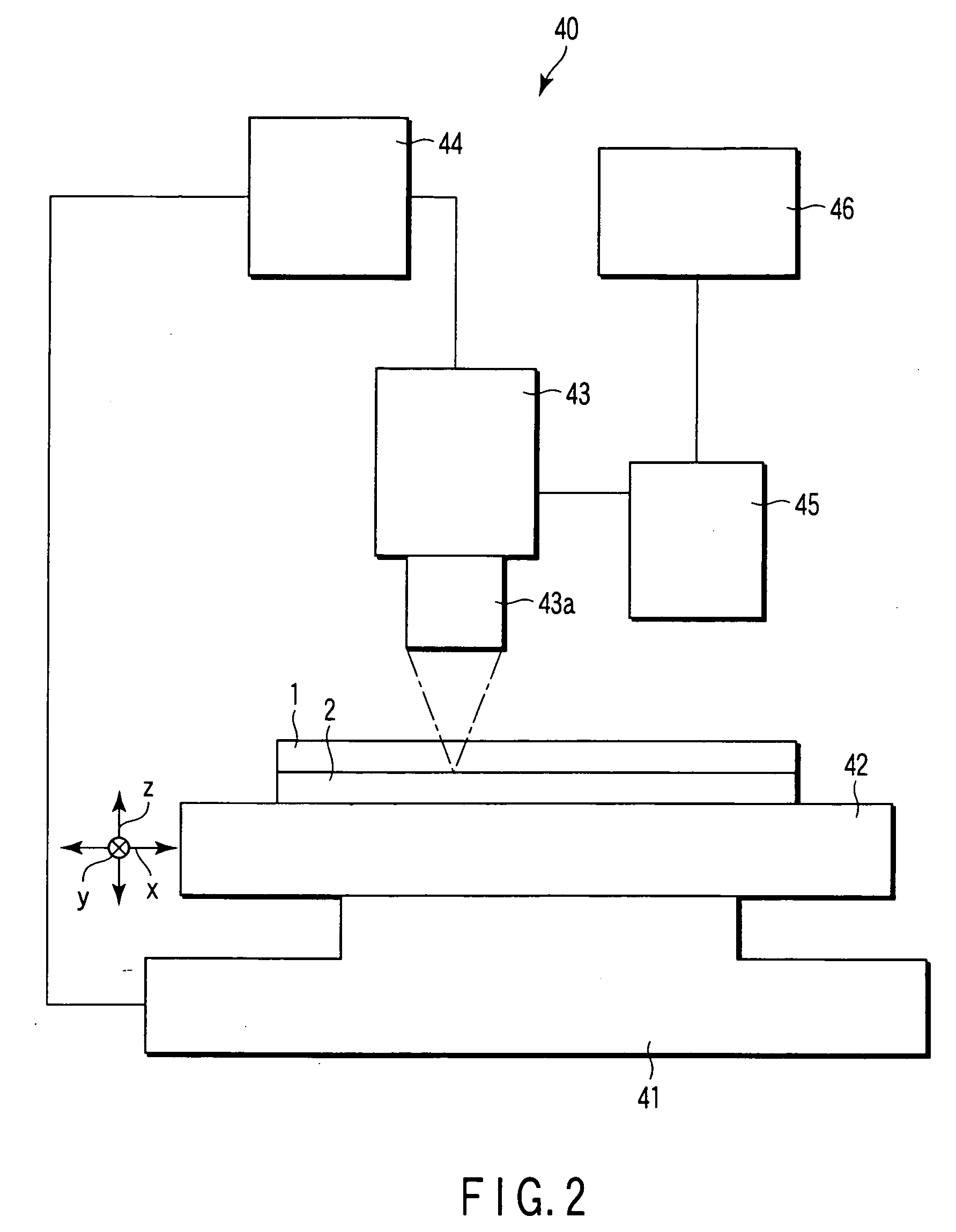

Method of inspecting defect for electroluminescence display apparatus, defect inspection apparatus, and method of manufacturing electroluminescence display apparatus using defect inspection method and apparatus

A dark spot defect caused by short-circuiting of an EL element is detected based on an emission brightness or a current flowing through the EL element when an element driving transistor which controls a drive current to be supplied to the EL element is operated in its linear operating region and the EL element is set to an emission level. A dim spot defect caused by a characteristic variation of the element driving transistor can be detected based on a current flowing through the EL element when the element driving transistor is operated in its saturation operating region and the EL element is set to the emission level. When an abnormal display pixel is detected based on an emission brightness, a pixel which is determined as an abnormal display pixel and which is not determined as a dark spot defect during a dark spot inspection is determined, and the pixel is detected as a dim spot defect caused by the characteristic variation of the element driving transistor.

Owner:SEMICON COMPONENTS IND LLC

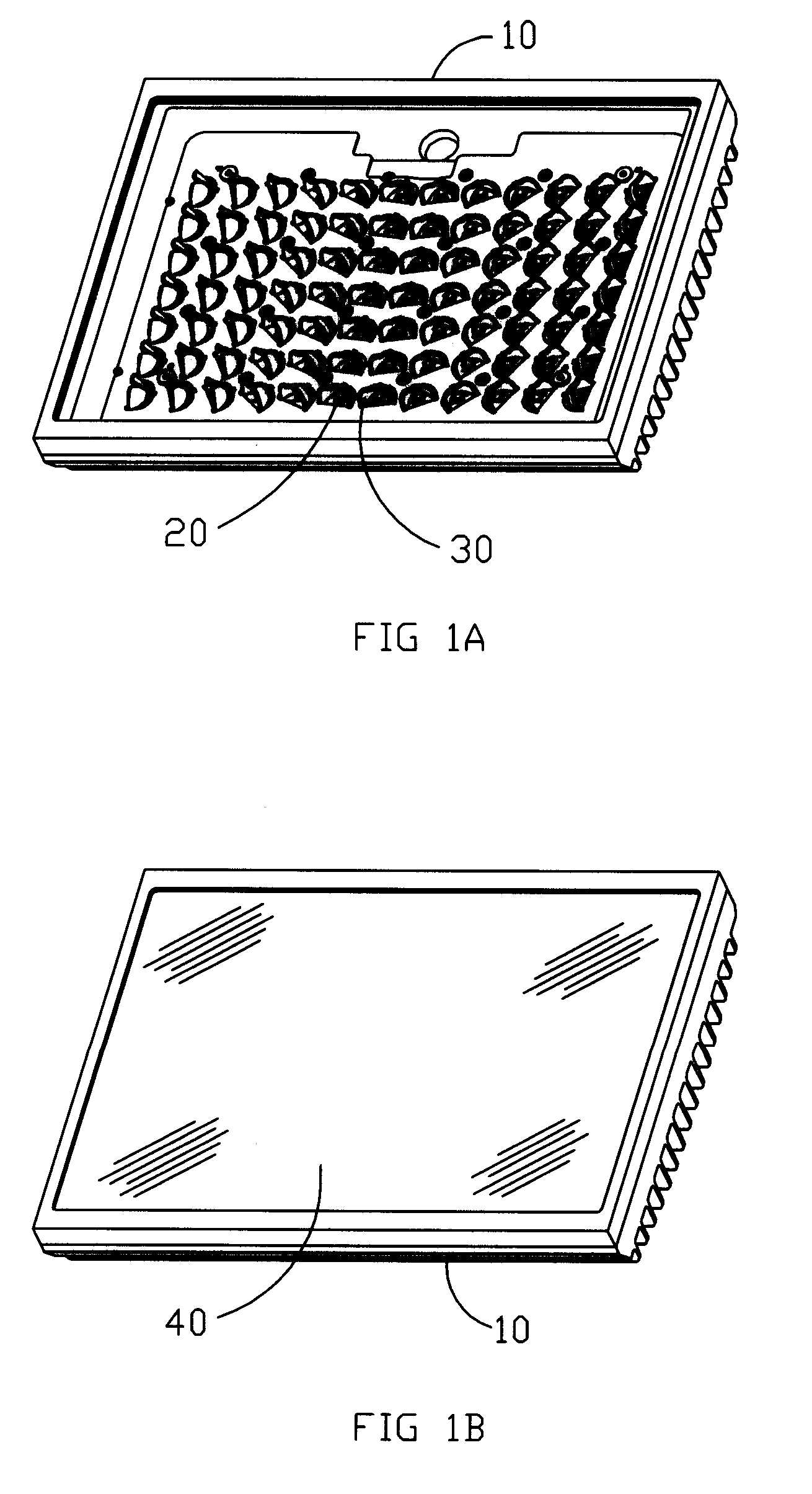

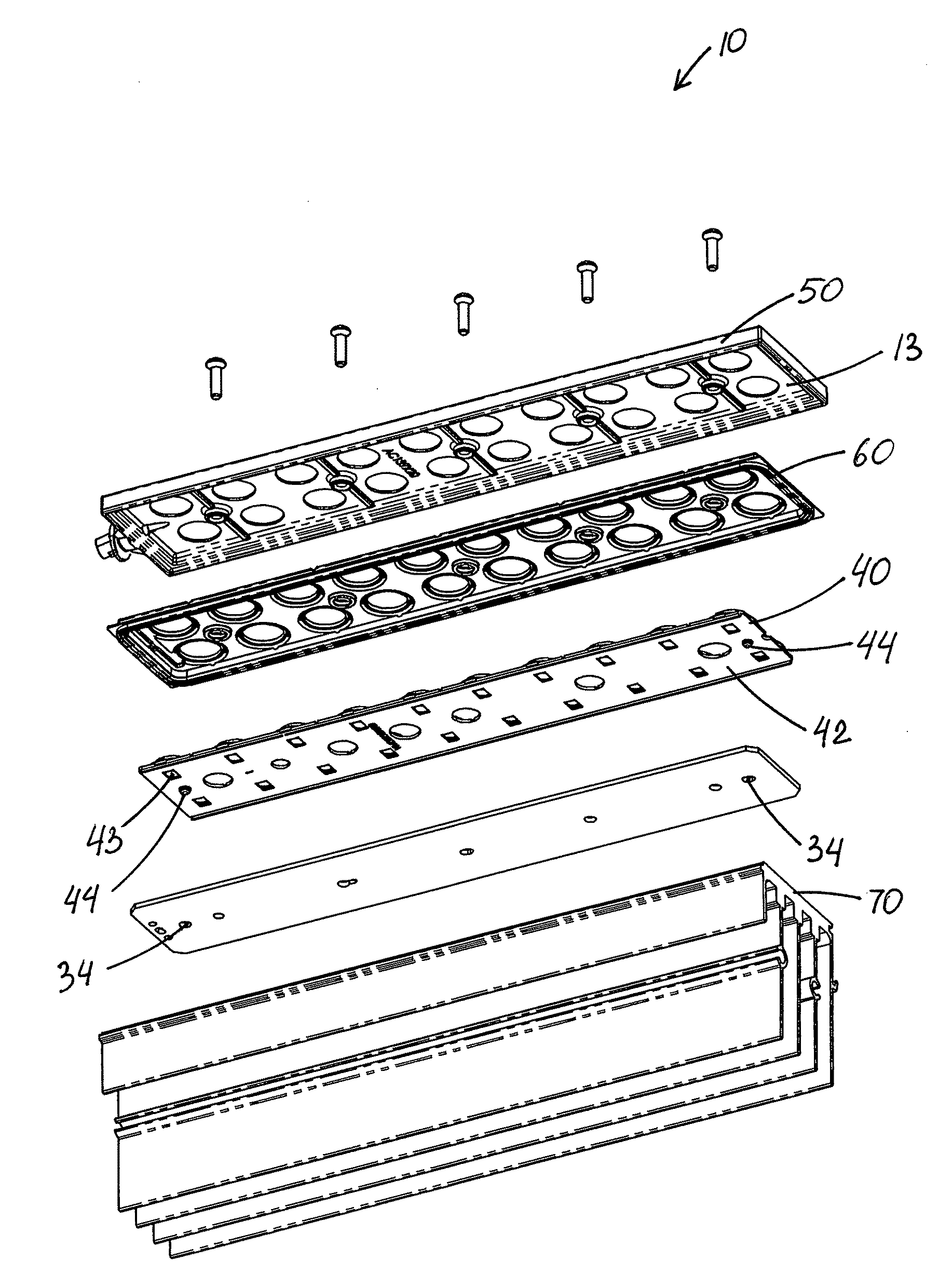

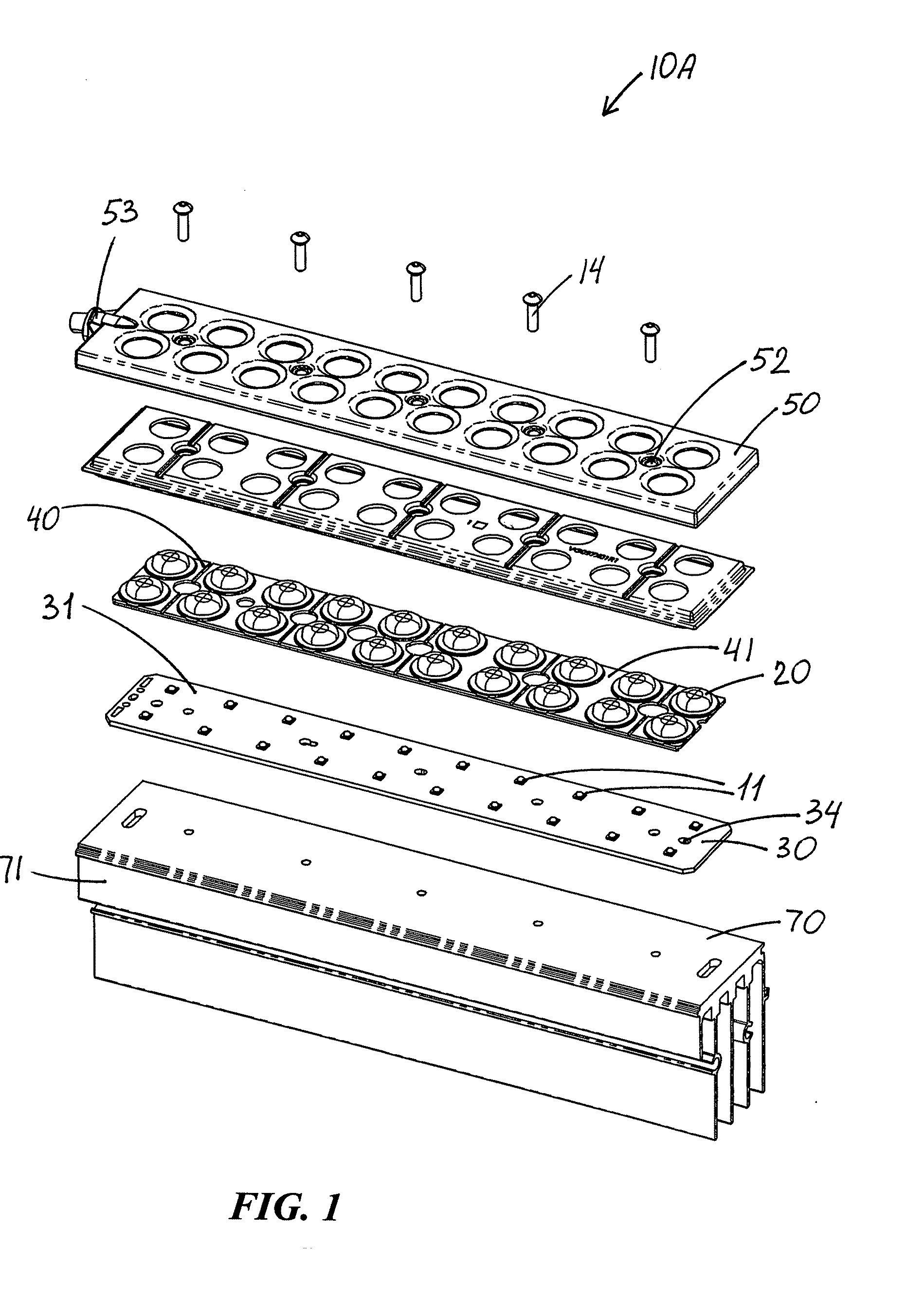

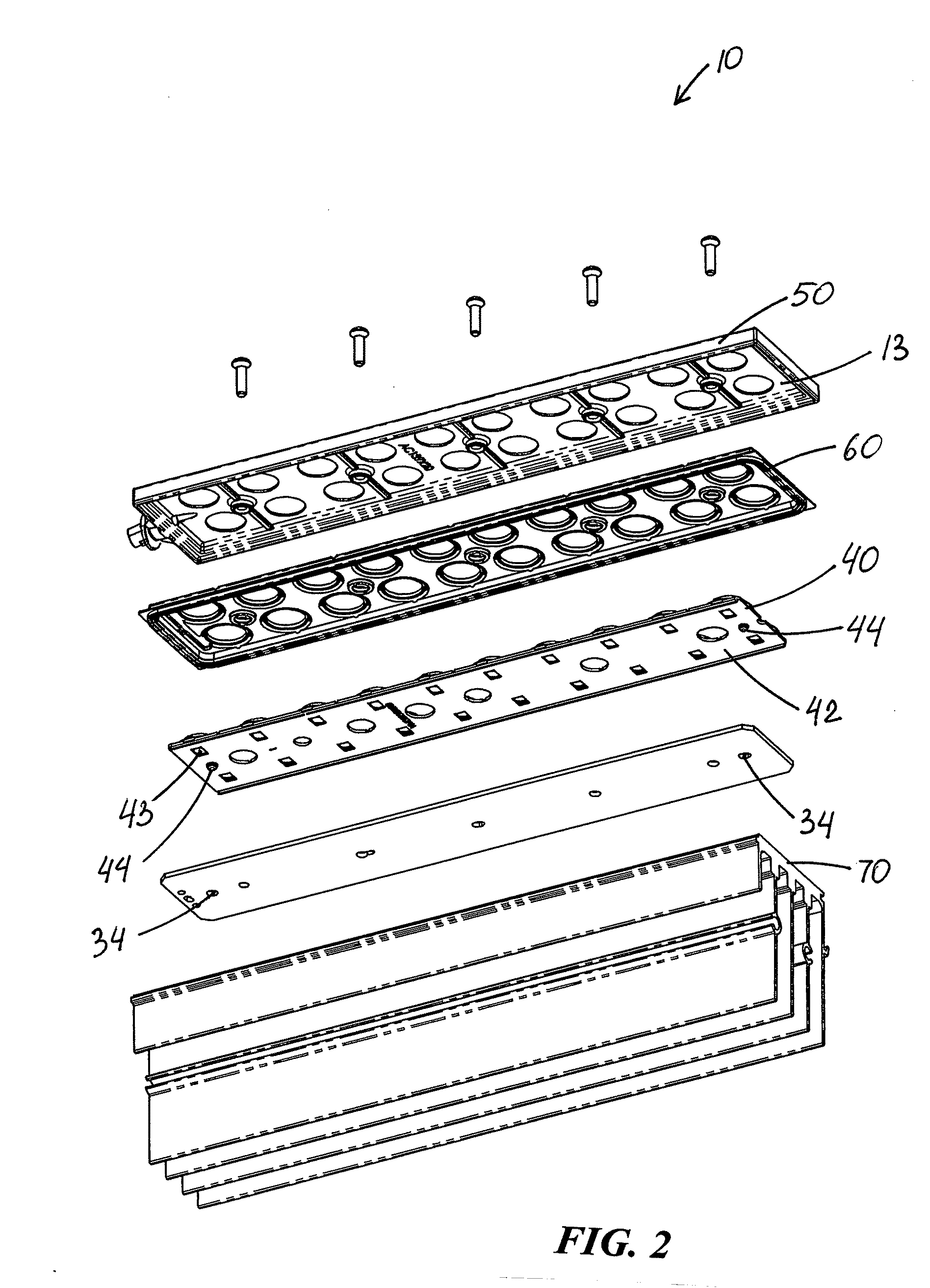

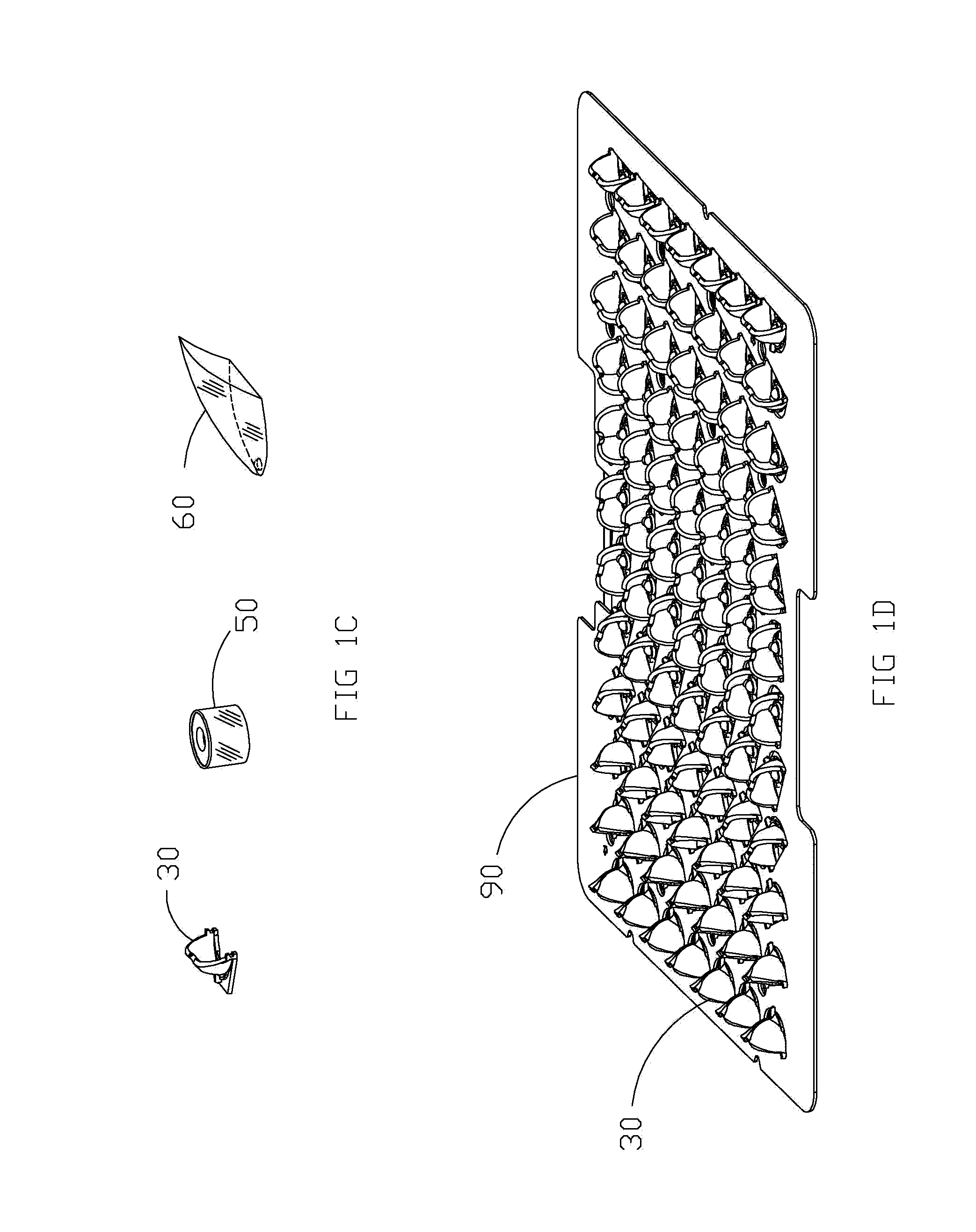

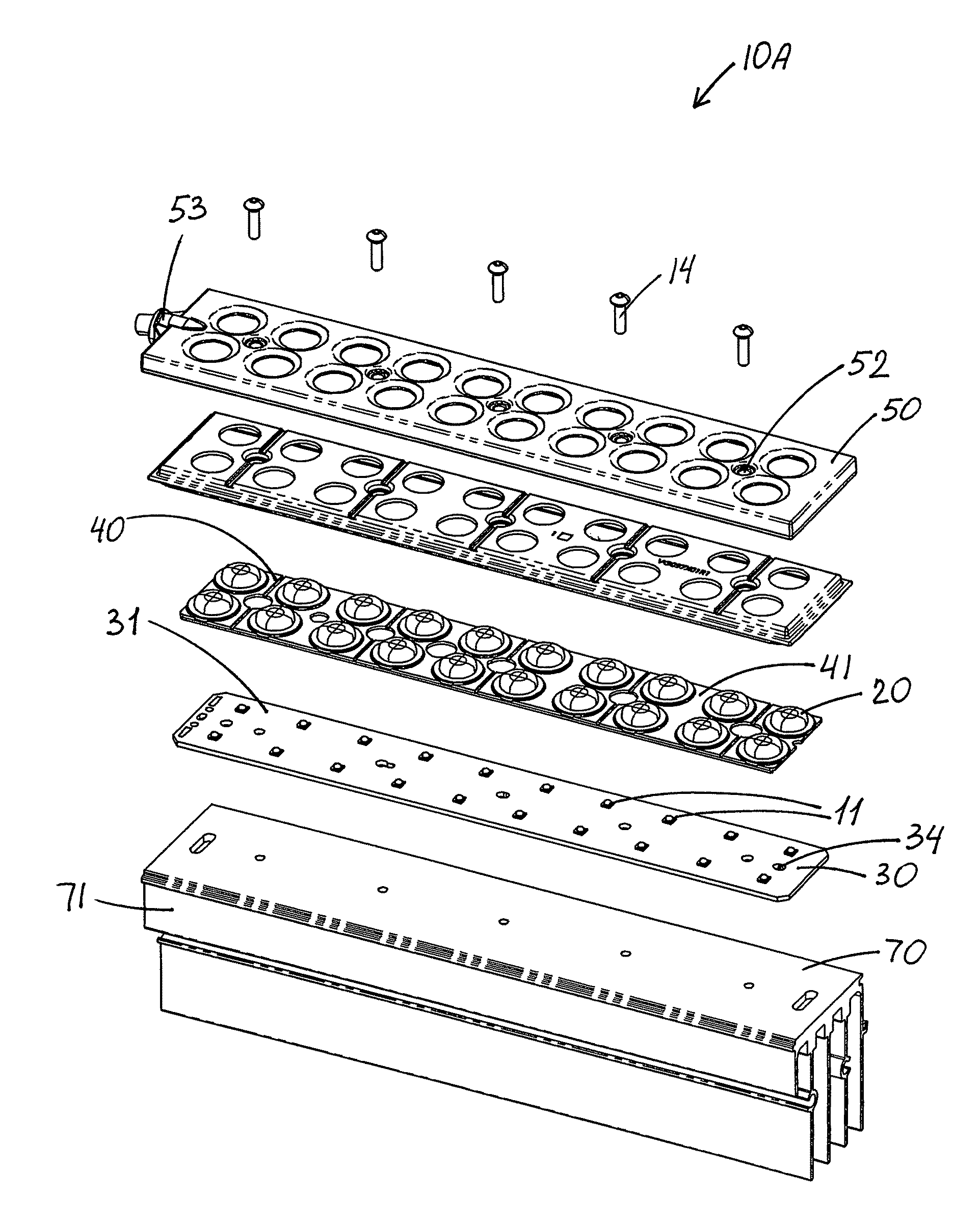

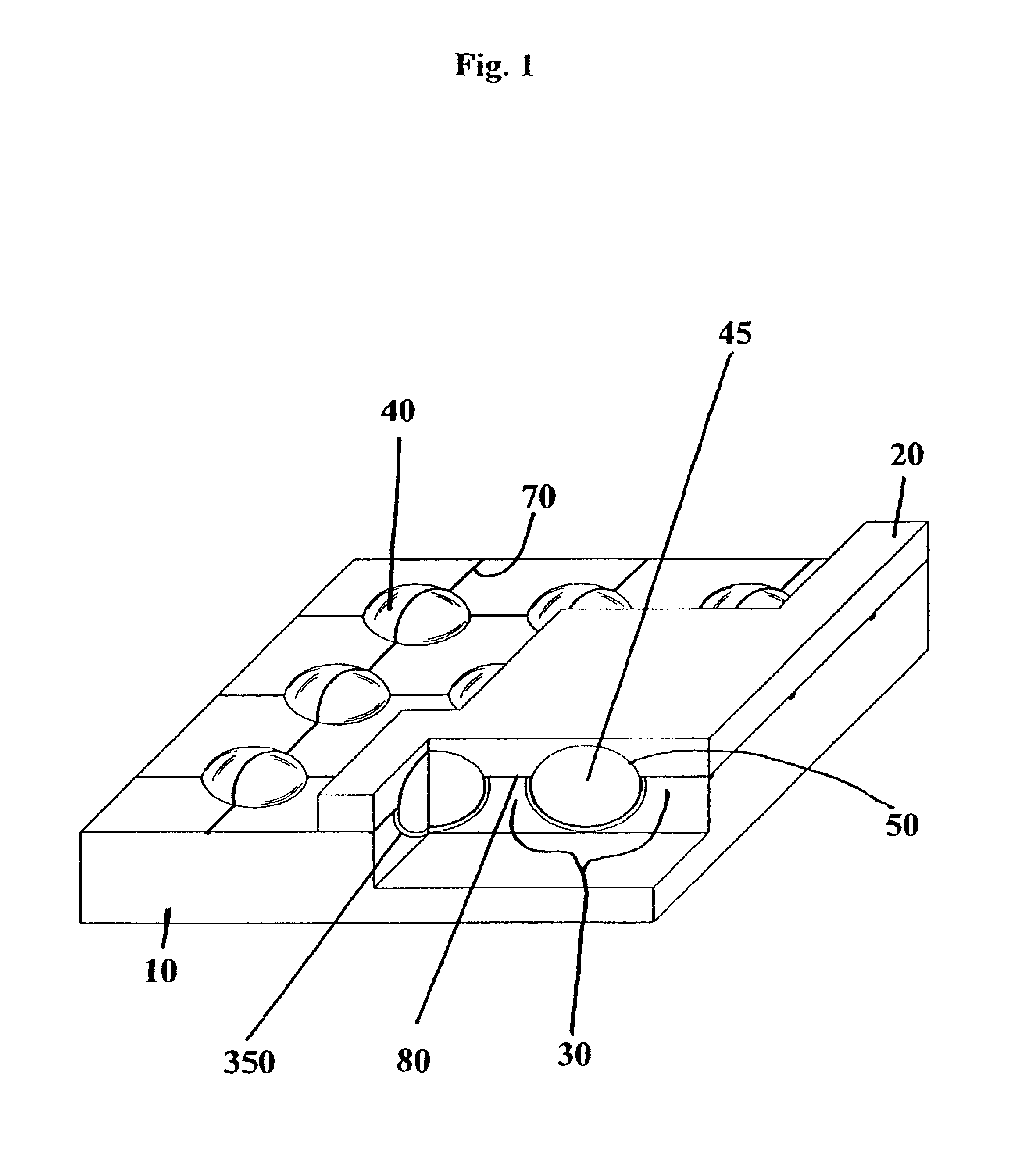

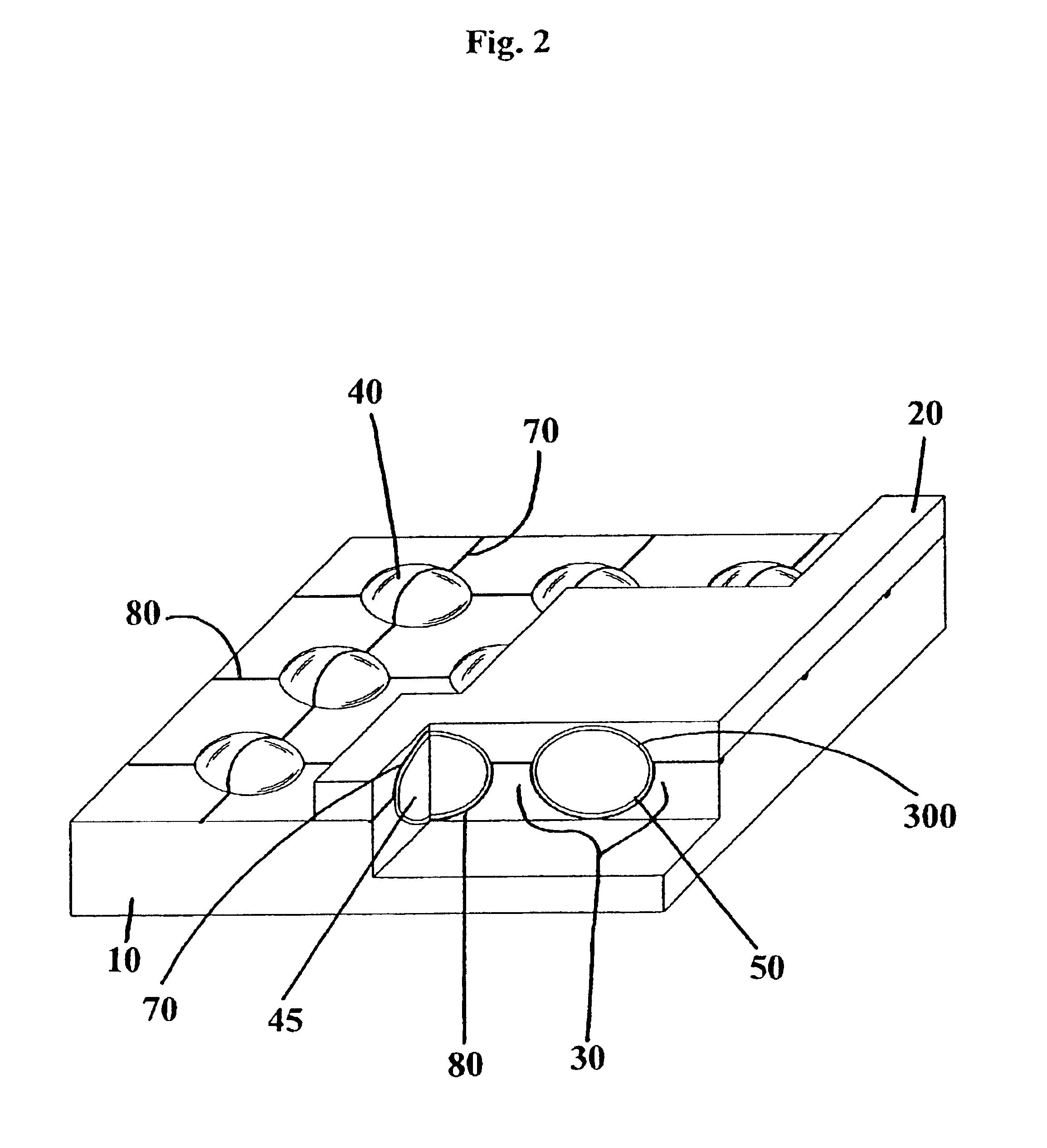

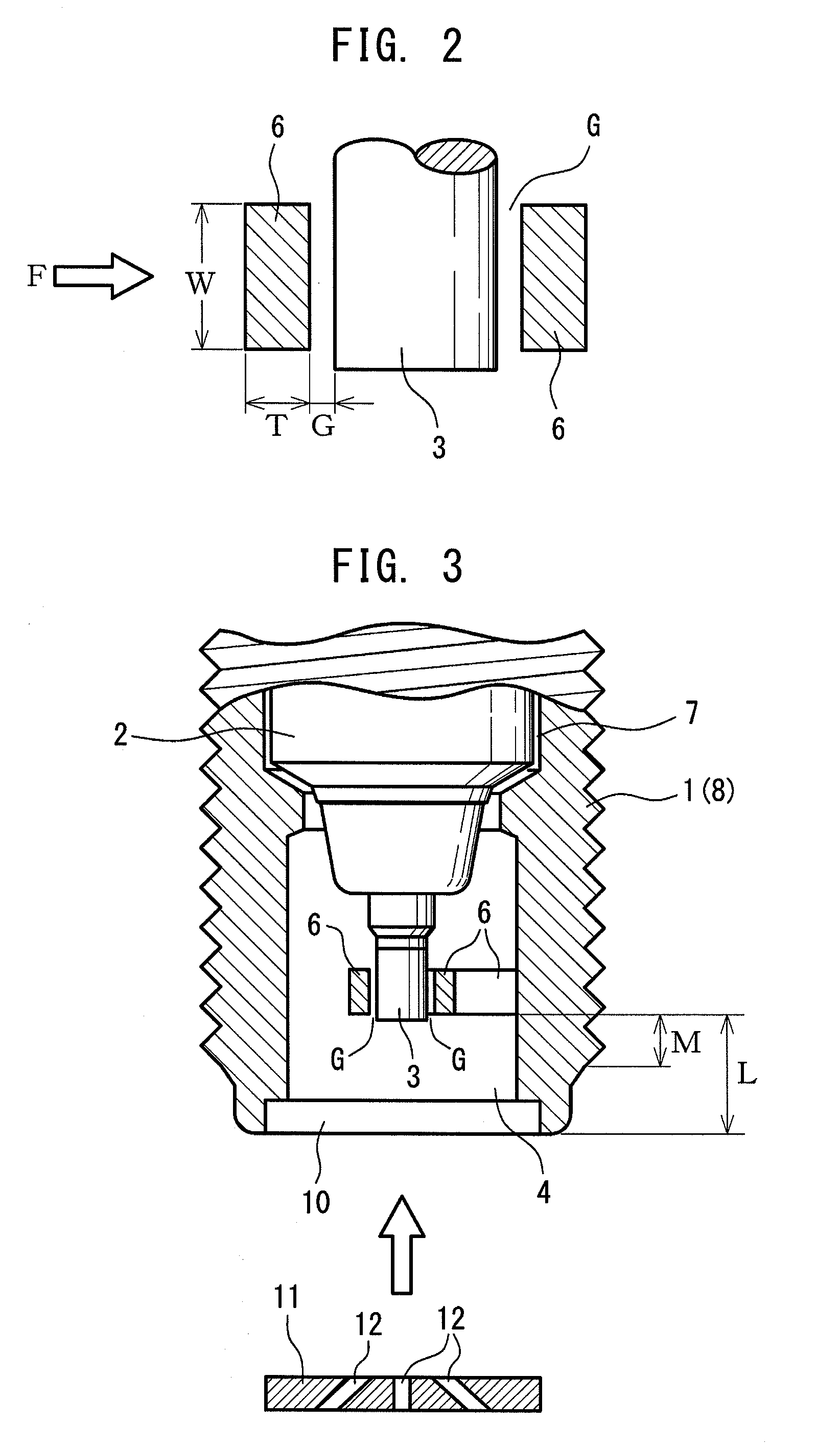

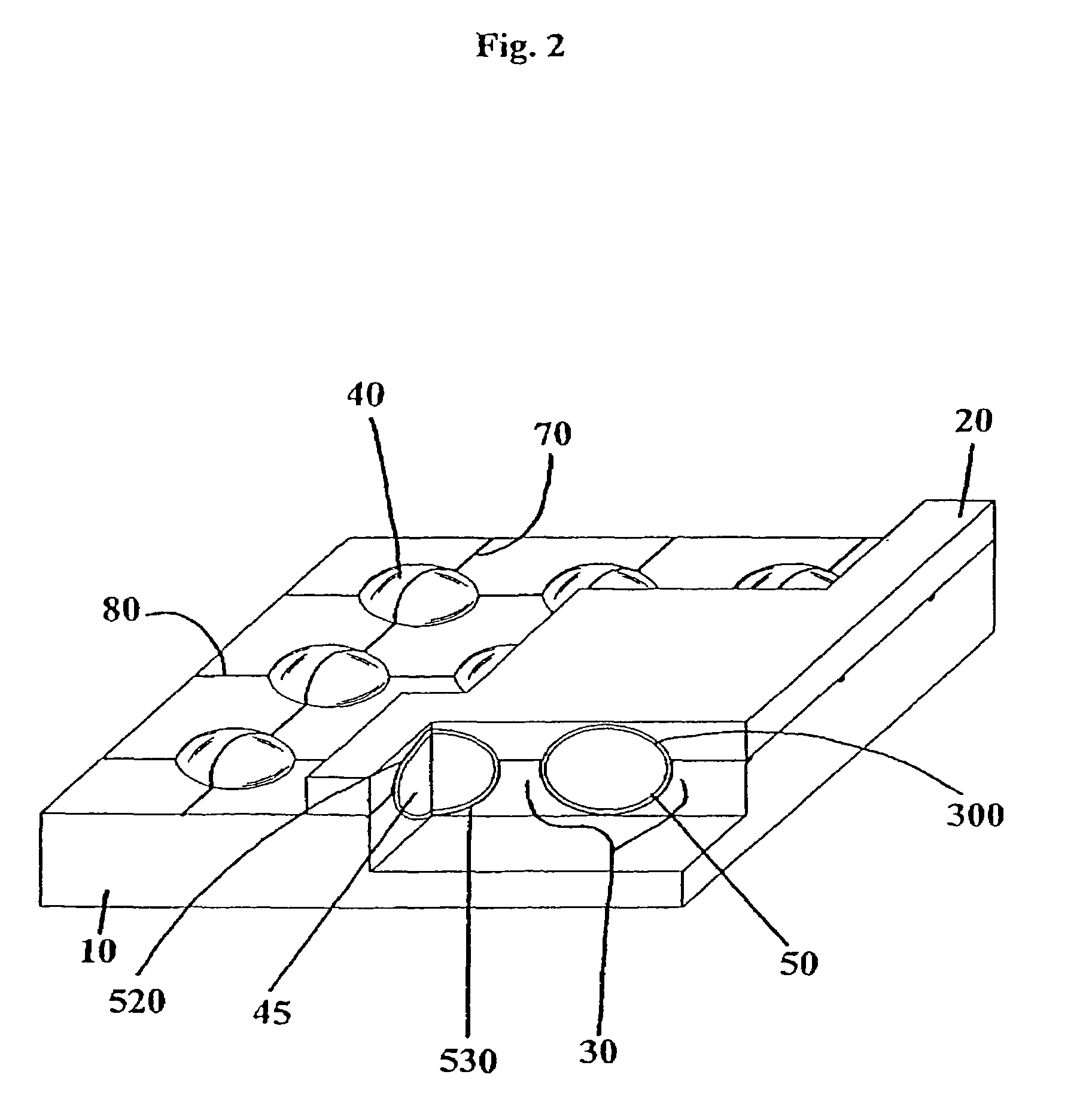

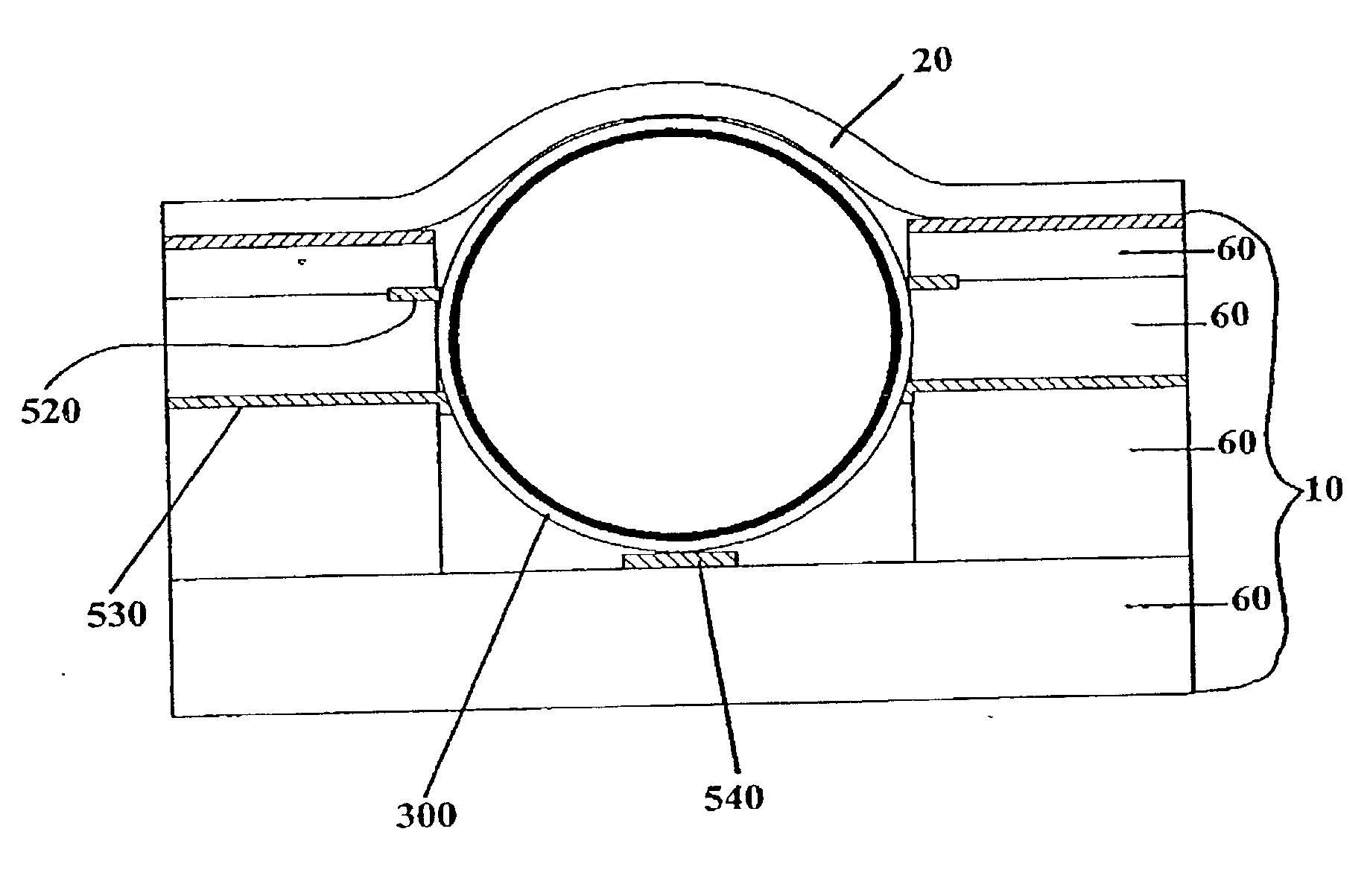

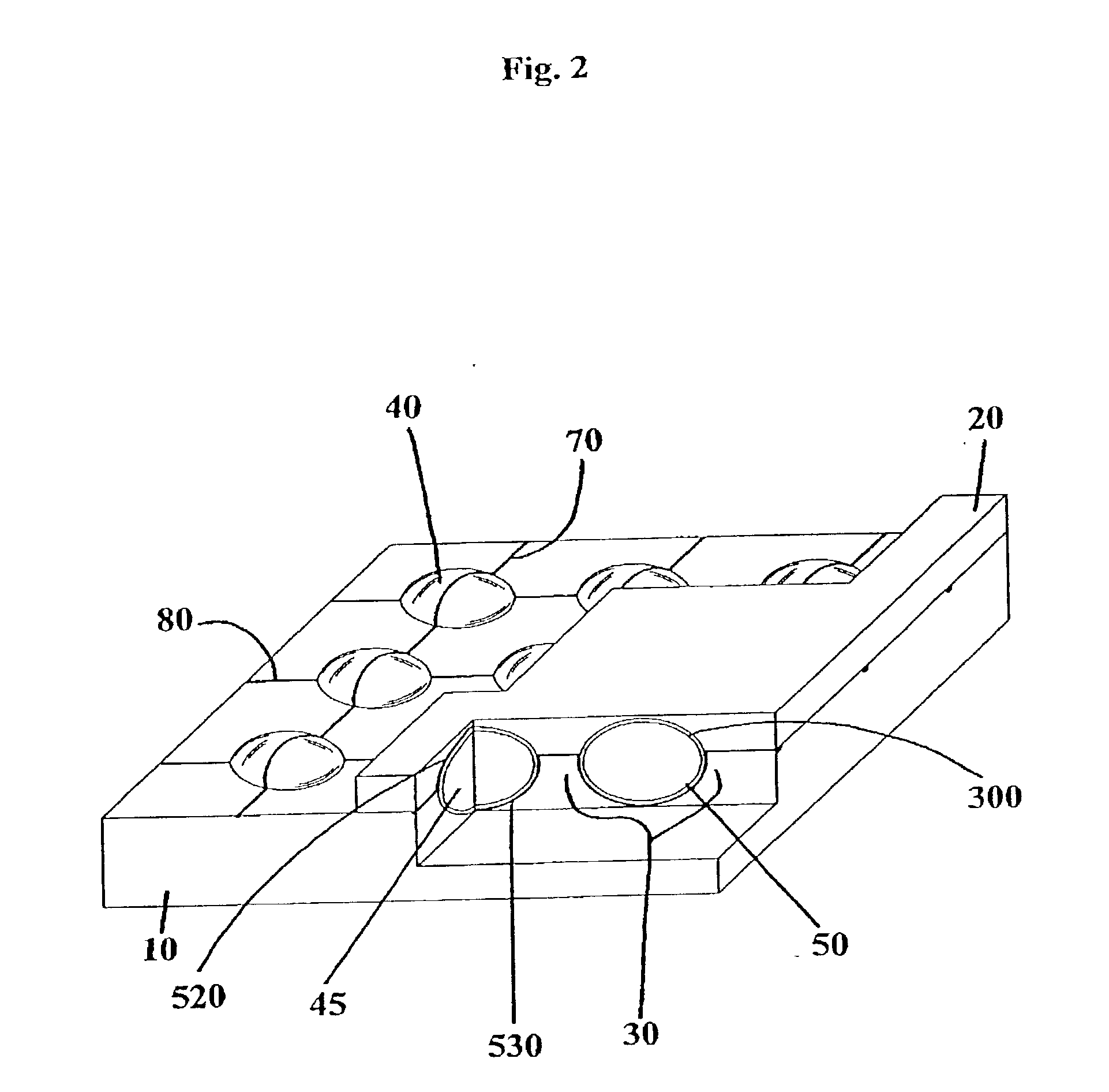

LED apparatus and method for accurate lens alignment

ActiveUS20110103051A1Accurate shapeLoss efficiency of distributionPlanar light sourcesMechanical apparatusLed arrayEngineering

An LED apparatus of the type including (a) a mounting board having an LED-supporting surface with an LED device thereon and (b) a lens member over the LED device establishing a light path therebetween. The inventive LED apparatus includes a lens-aligning member having front and back surfaces and defining an aperture receiving the LED device therethrough such that the LED device protrudes beyond the front surface. The lens member includes a lens portion and a flange thereabout, the flange being attached to the front surface of the lens-aligning member such that the lens portion substantially surrounds the protruding LED device. The lens-aligning member has a first mating feature which is positioned and arranged for mating engagement with a second mating feature of the mounting board, thereby accurately aligning the lens member over the LED device by accurately aligning the lens-alignment member with the mounting board. Other aspects of the invention is a method for LED-apparatus assembly and a method for manufacturing custom high-efficiency LED lensing for LED-array modules.

Owner:IDEAL IND LIGHTING LLC

Method of inspecting defect for electroluminescence display apparatus, defect inspection apparatus, and method of manufacturing electroluminescence display apparatus using defect inspection method and apparatus

ActiveUS8493296B2Sparking plugsSemiconductor/solid-state device testing/measurementDriving currentElectricity

A dark spot defect of an EL element is detected based on an emission brightness or a current flowing through the EL element when an element driving transistor which controls a drive current to be supplied to the EL element is operated in its linear operating region and the EL element is set to an emission level. A dim spot defect caused can be detected based on a current flowing through the EL element when the element driving transistor is operated in its saturation operating region and the EL element is set to the emission level. When an abnormal display pixel is detected based on an emission brightness, a pixel which is determined as an abnormal display pixel and which is not determined as a dark spot defect is determined, and the pixel is detected as a dim spot defect caused by the characteristic variation of the element driving transistor.

Owner:SEMICON COMPONENTS IND LLC

Method for testing a light-emitting panel and the components therein

InactiveUS6620012B1Sufficient resolutionManufactured very thinSparking plugsStatic indicating devicesEngineeringIonization

An improved light-emitting panel having a plurality of micro-components sandwiched between two substrates is disclosed. Each micro-component contains a gas or gas-mixture capable of ionization when a sufficiently large voltage is supplied across the micro-component via at least two electrodes. A method of testing a light-emitting panel and the component parts therein is also disclosed, which uses a web fabrication process to manufacturing light-emitting panels combined with inline testing after the various process steps of the manufacturing process to produce result which are used to adjust the various process steps and component parts.

Owner:LEIDOS

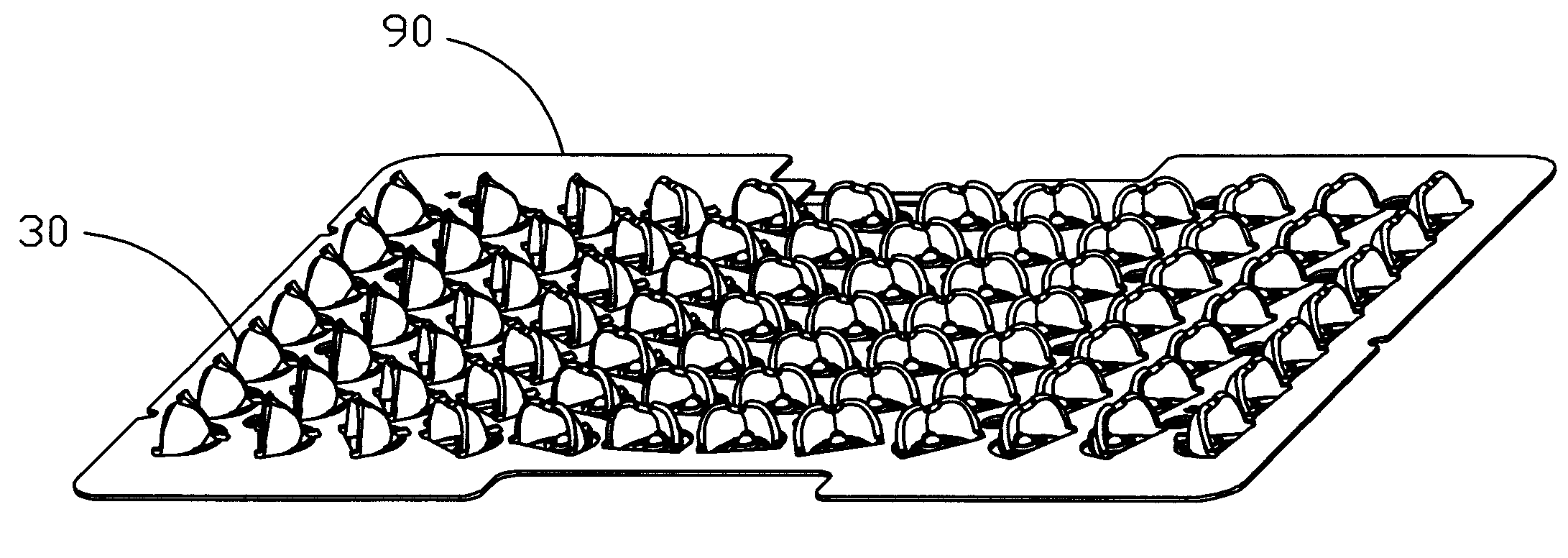

Method, system, and apparatus for highly controlled light distribution from light fixture using multiple light sources (LEDS)

InactiveUS20100110671A1High strengthHigh producedPlanar light sourcesMechanical apparatusLight beamEffect light

Disclosed herein are apparatus, methods, and systems for deriving composite beams from a plurality of light sources such as LEDs. Optical units comprising a plurality of light sources, each source having an associated optic which is individually positionable, are developed using optimization techniques that allow for lighting different target areas in an effective manner by rotating or otherwise positioning the reflectors, refractive lenses, TIR lenses, or other lens types to create a composite beam. The apparatus, methods, and systems of lighting herein make it possible to widely vary the types of beams from an available fixture using a small number of optics and fixtures. In some cases, by using a combination of individual beam patterns from the same or different types of light sources, a small set of individual optics may be sufficient to create a majority of the typical and specialized composite beams needed to meet the needs of most lighting projects and target areas.

Owner:MUSCO

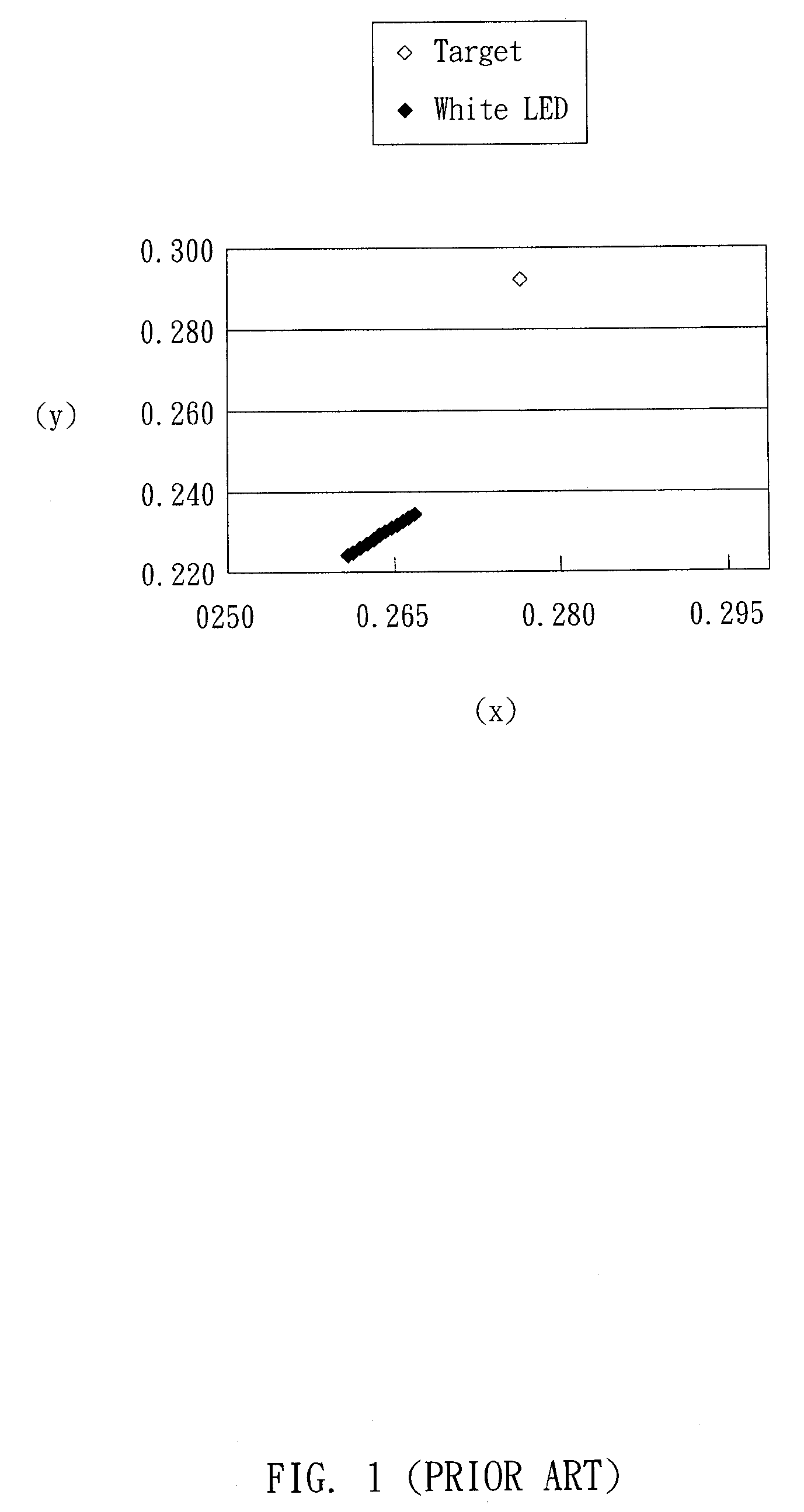

Illuminant system using high color temperature light emitting diode and manufacture method thereof

ActiveUS8109650B2High color temperatureSparking plugsDischarge tube luminescnet screensHigh colorGreen-light

A light emitting diode (LED) illuminant system, a manufacture method thereof, and a backlight module using the same are provided. The LED illuminant system includes a plurality of white light illuminants and at least one green light illuminant mixed in the white light illuminants. A light power ratio of the green light illuminant to the white light illuminants is in between ⅕ to 1 / 20. The color temperature of the whole illuminant system will be enhanced to a certain extent by mixing the green light illuminant and the white light illuminants. The manufacture method includes the following steps: obtaining a transmission spectrum of the white light illuminants; analyzing the transmission spectrum to determine n supplemental amount of a green light; and disposing at least one green illuminant in accordance with the supplemental amount of the green light.

Owner:OPTRONIC SCI LLC

LED apparatus and method for accurate lens alignment

ActiveUS8348461B2Improve efficiencyReduce manufacturing costPlanar light sourcesMechanical apparatusLed arrayEngineering

An LED apparatus of the type including (a) a mounting board having an LED-supporting surface with an LED device thereon and (b) a lens member over the LED device establishing a light path therebetween. The inventive LED apparatus includes a lens-aligning member having front and back surfaces and defining an aperture receiving the LED device therethrough such that the LED device protrudes beyond the front surface. The lens member includes a lens portion and a flange thereabout, the flange being attached to the front surface of the lens-aligning member such that the lens portion substantially surrounds the protruding LED device. The lens-aligning member has a first mating feature which is positioned and arranged for mating engagement with a second mating feature of the mounting board, thereby accurately aligning the lens member over the LED device by accurately aligning the lens-alignment member with the mounting board. Other aspects of the invention is a method for LED-apparatus assembly and a method for manufacturing custom high-efficiency LED lensing for LED-array modules.

Owner:IDEAL IND LIGHTING LLC

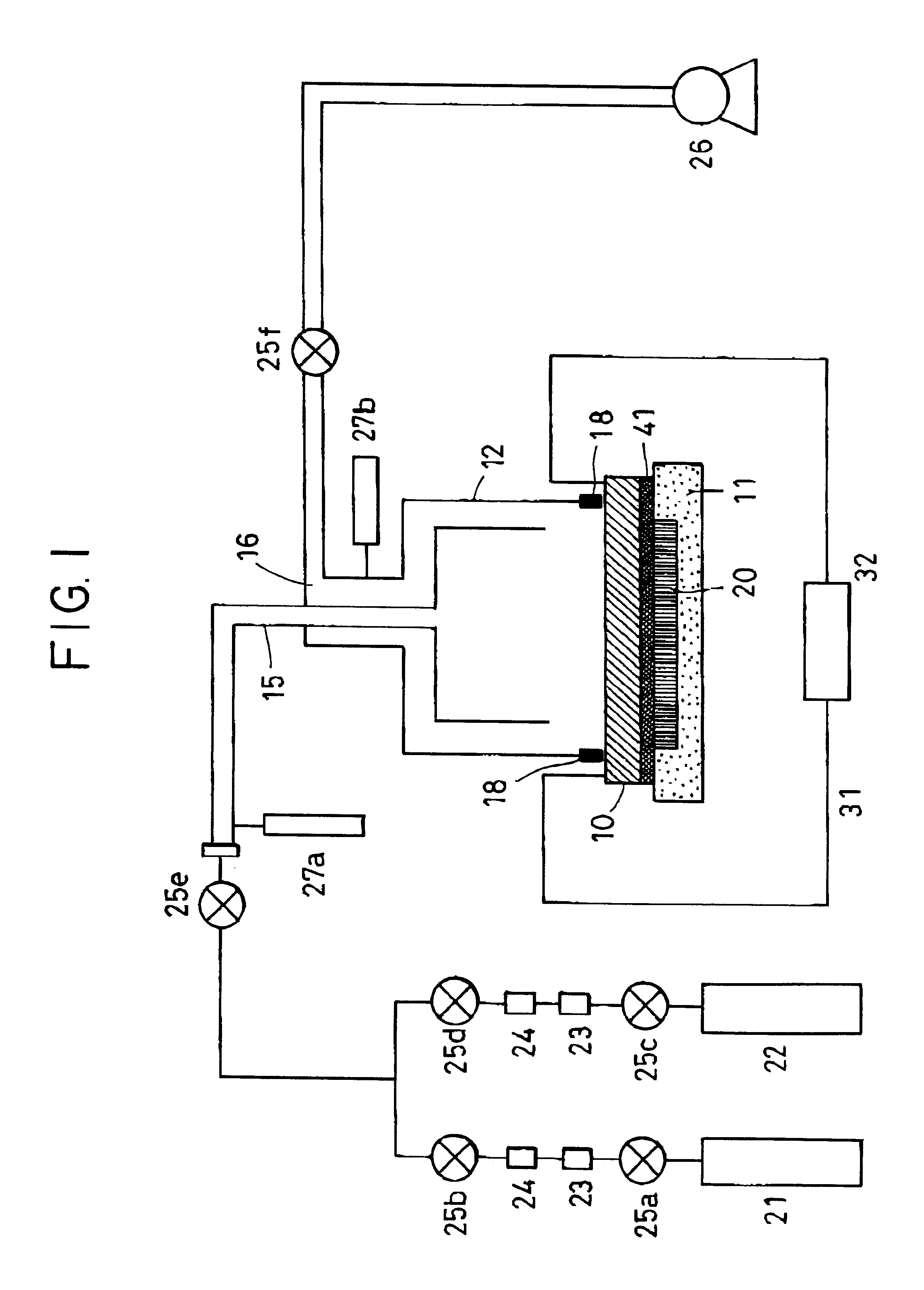

Apparatus for manufacturing electron source, method for manufacturing electron source, and method for manufacturing image-forming apparatus

InactiveUS6626718B2Sparking plugsVessels or leading-in conductors manufactureCarbon filmElectron source

A method for manufacturing an electron source includes the steps of covering a substrate provided with a first electrode and a second electrode by a container, introducing a gas composed of a carbon compound into the container, and forming a carbon film by applying a voltage between the first electrode and the second electrode. The relationship 1 / (4 / Cx-1 / Cz)>=Sout>=4Sact-Cin is satisfied, where Cin is the conductance from the gas inlet to the position of the substrate nearest to the gas inlet, Cx is the conductance from the position of the substrate nearest to the gas inlet to the position of the substrate nearest to the gas outlet, Sout is the effective exhaust rate, Sact is the consumption rate of the gas, and Cz is the conductance from the substrate to the gas outlet. An apparatus for manufacturing an electron source and a method for manufacturing an image-forming apparatus are also disclosed.

Owner:CANON KK

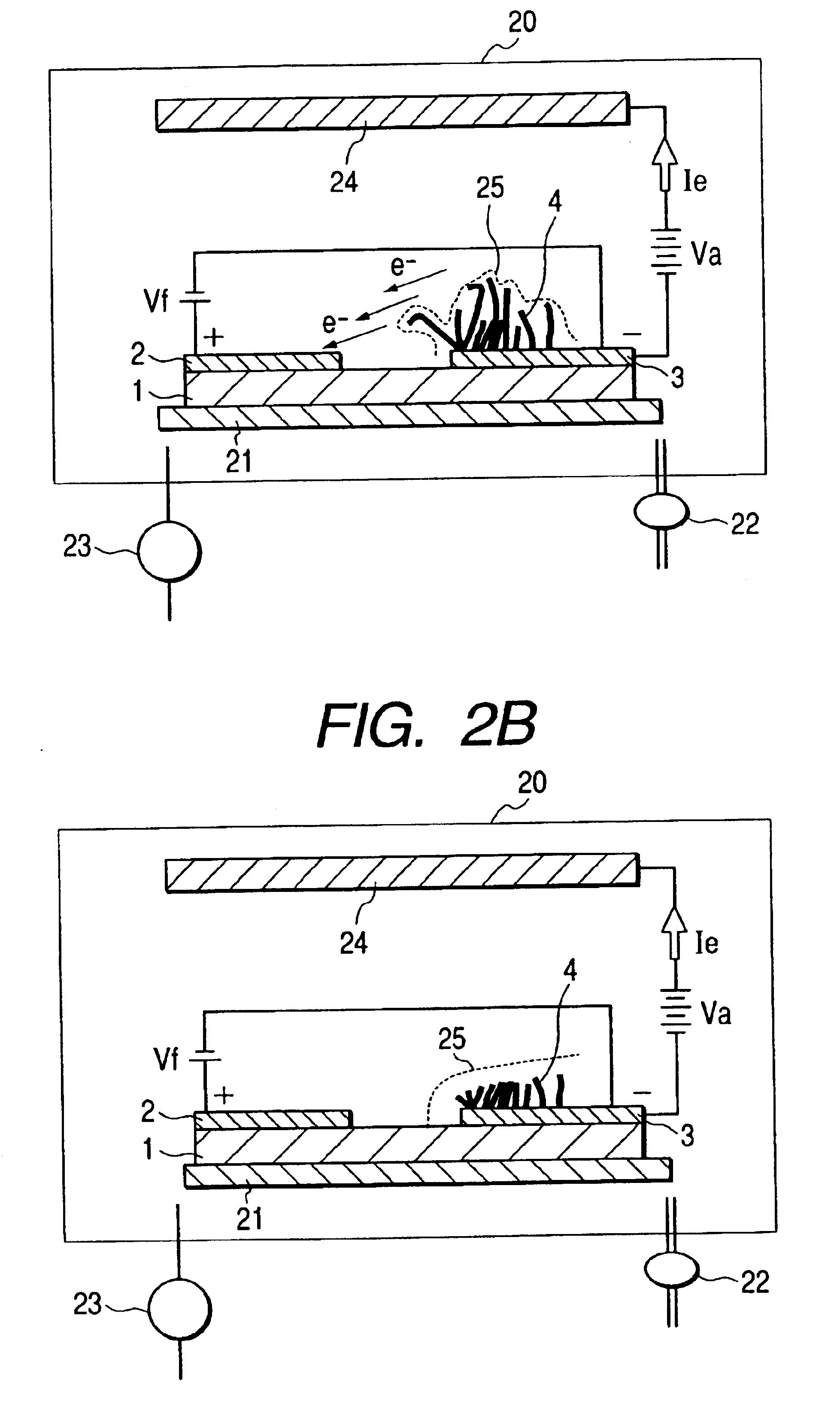

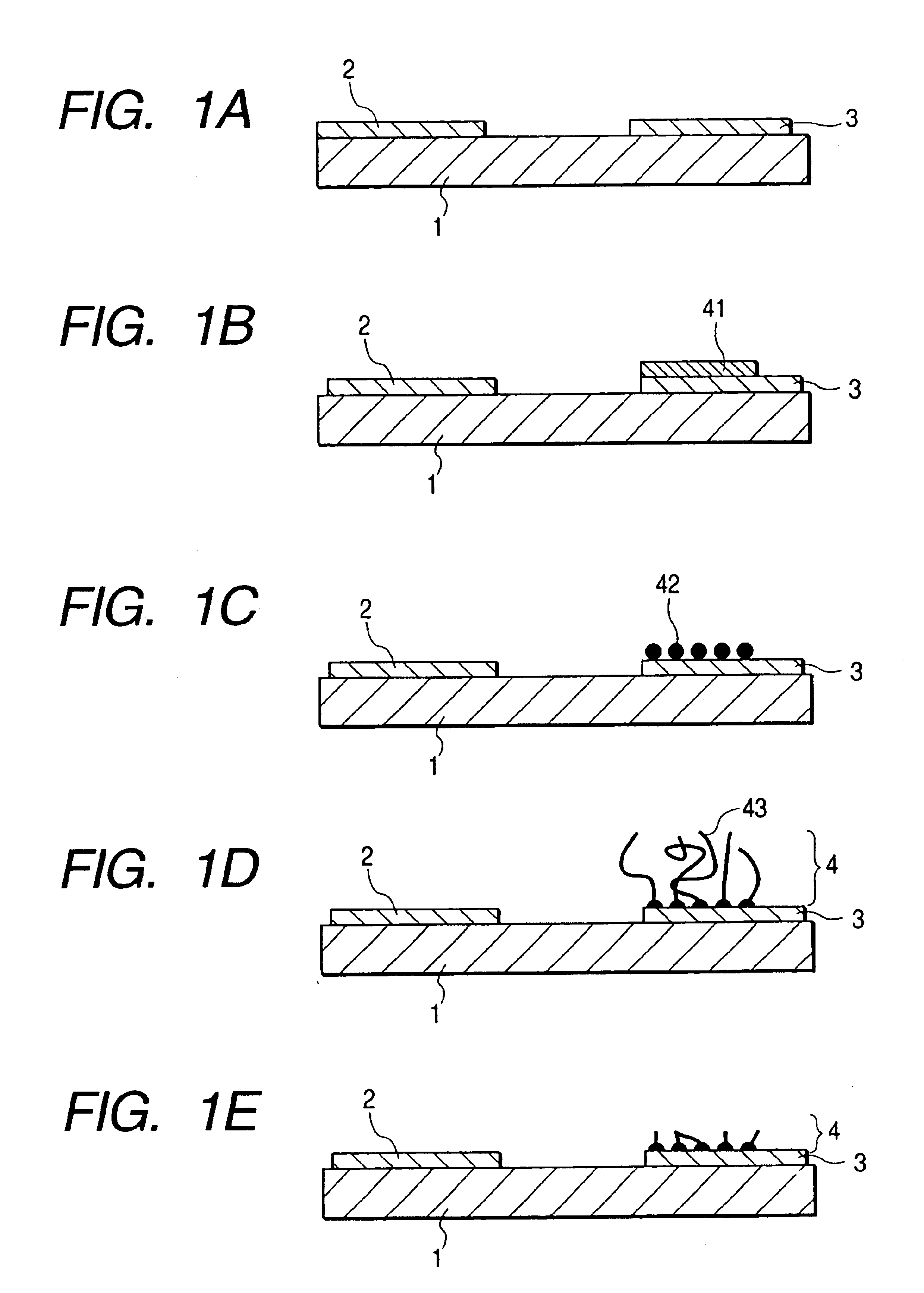

Electron-emitting device, electron source, image-forming apparatus, and method for producing electron-emitting device and image forming apparatus

InactiveUS6848962B2Reduce the differenceUniform and stableSparking plugsCathode ray tubes/electron beam tubesFiberElectron source

A method for producing a durable electron-emitting device having a uniform electron emission characteristic, an electron source, and an image-forming apparatus having a uniform display characteristic for a long period are provided. The method for producing an electron-emitting device according to the present invention includes the steps of: disposing a cathode electrode on a surface of a substrate; providing an electrode opposite the cathode electrode; disposing plural pieces of fiber containing carbon as a main component on the cathode electrode; and applying potential higher than potential applied to the cathode electrode under depressurized condition to an electrode opposite the cathode electrode.

Owner:CANON KK

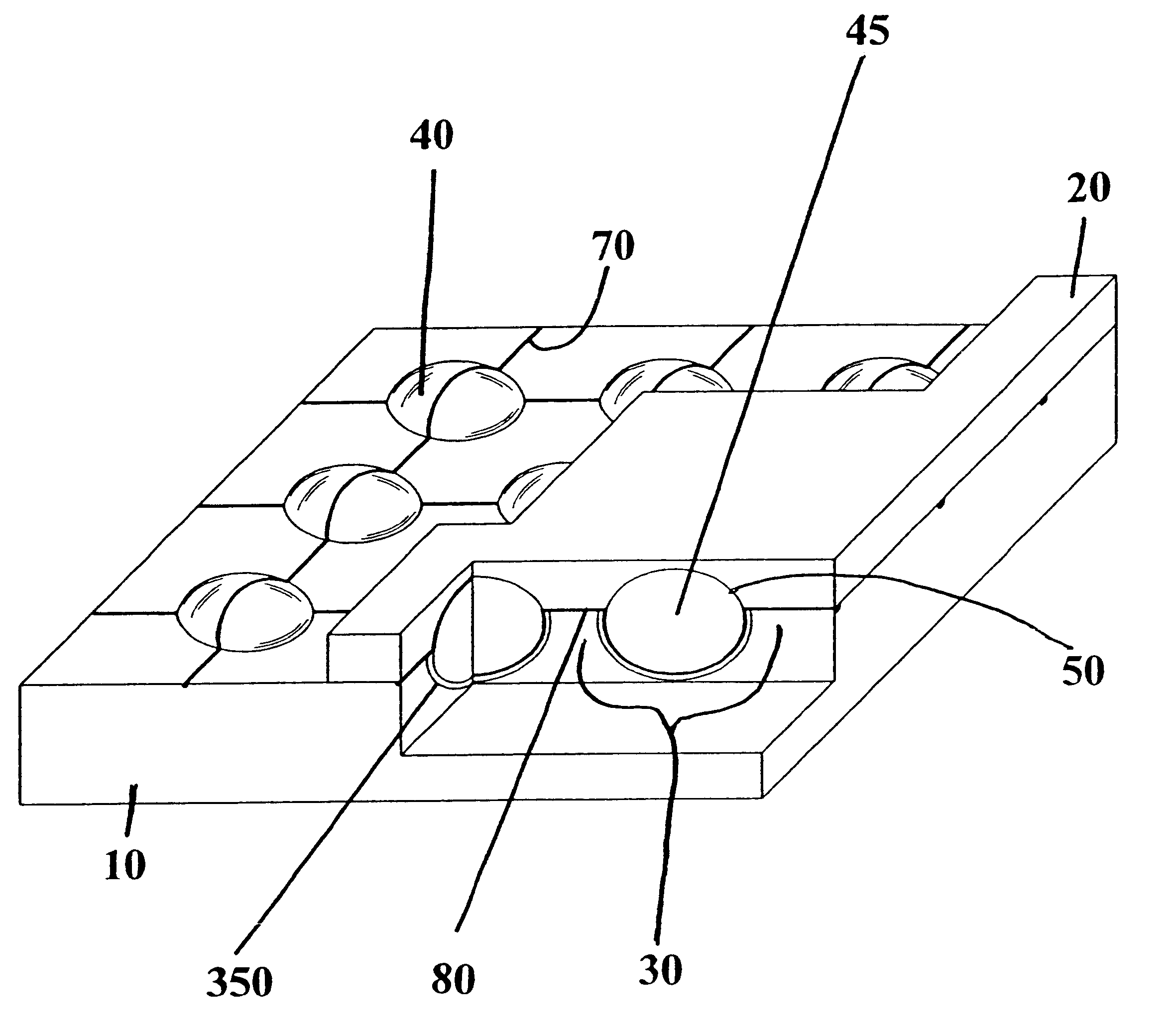

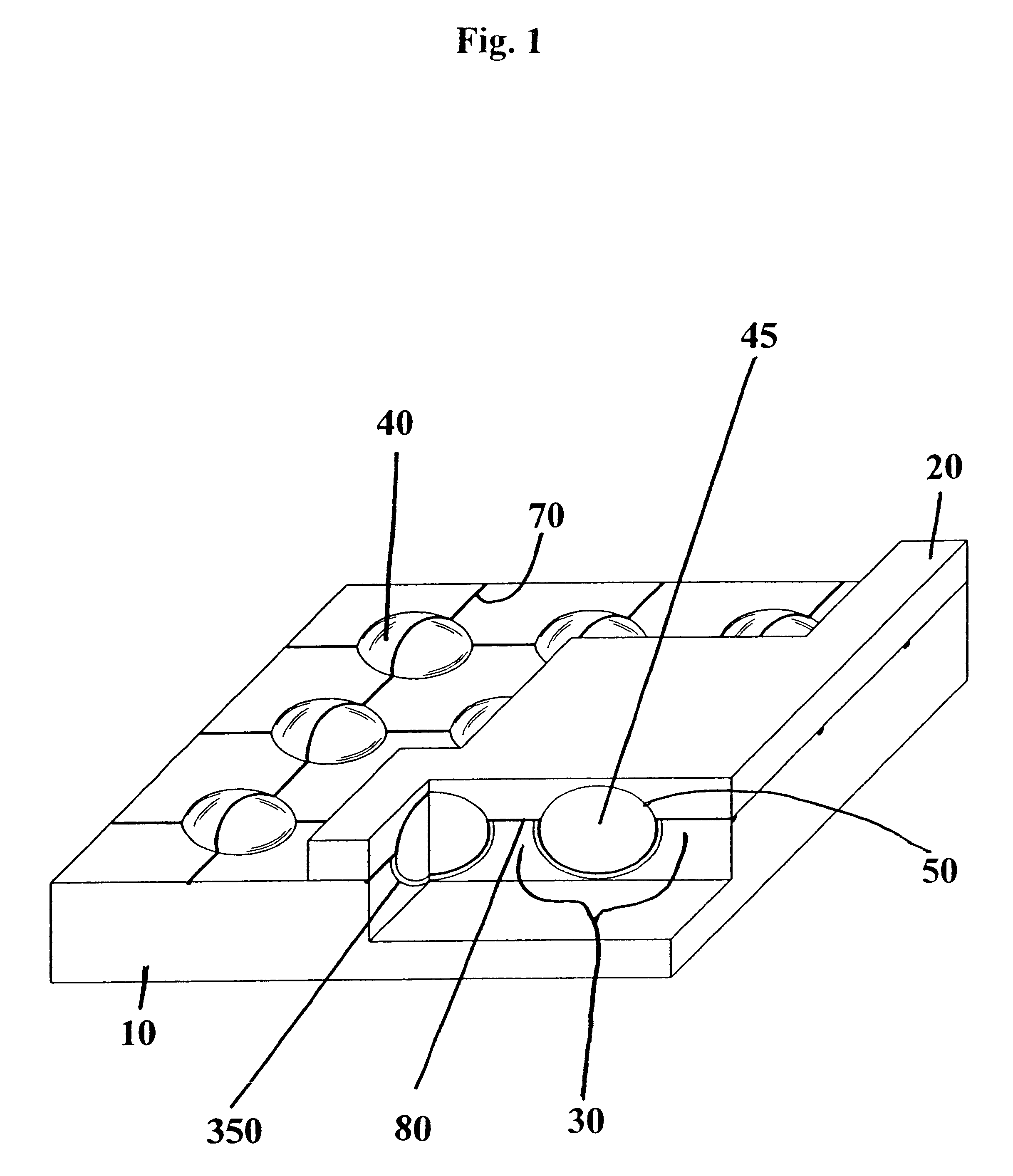

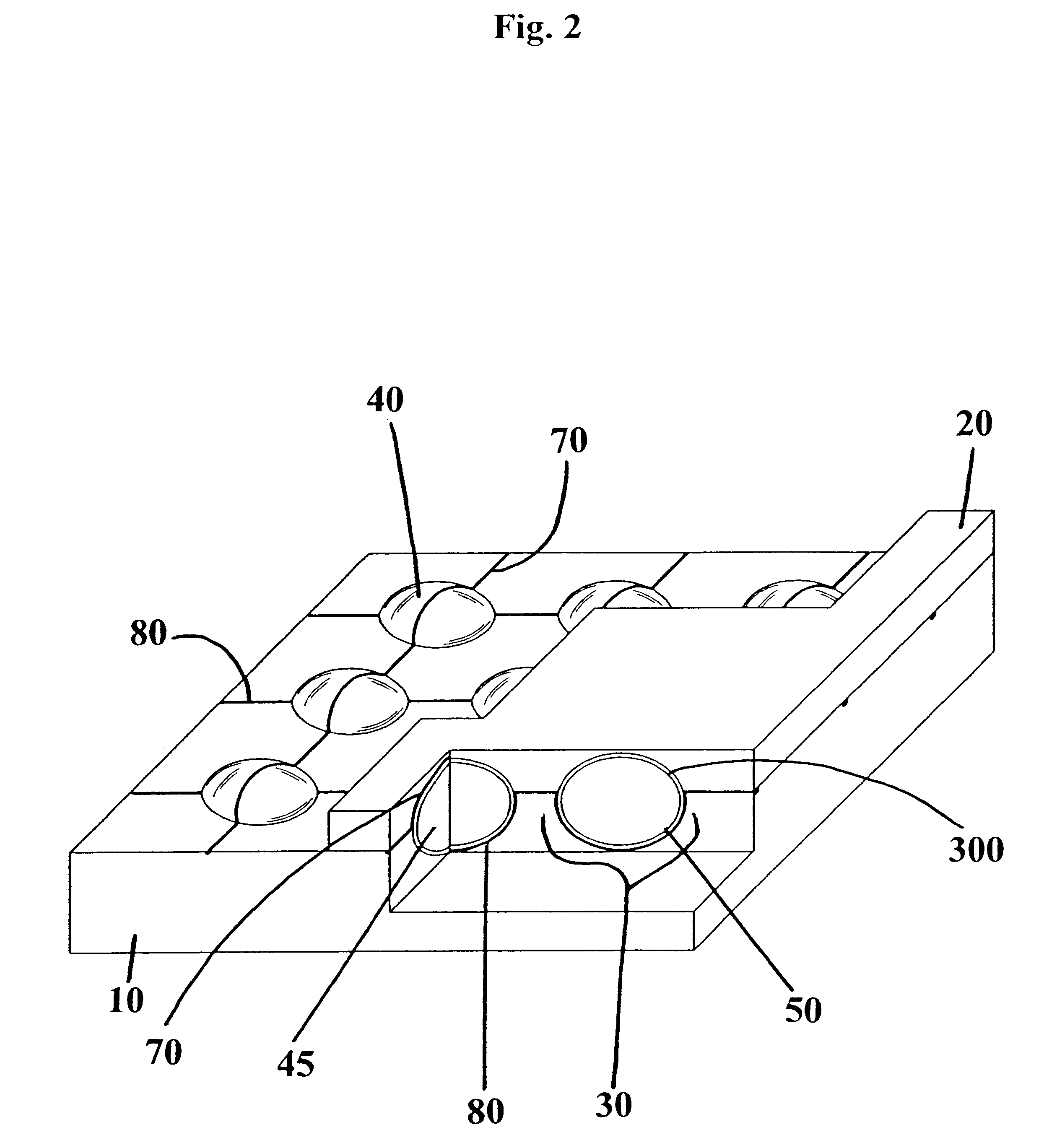

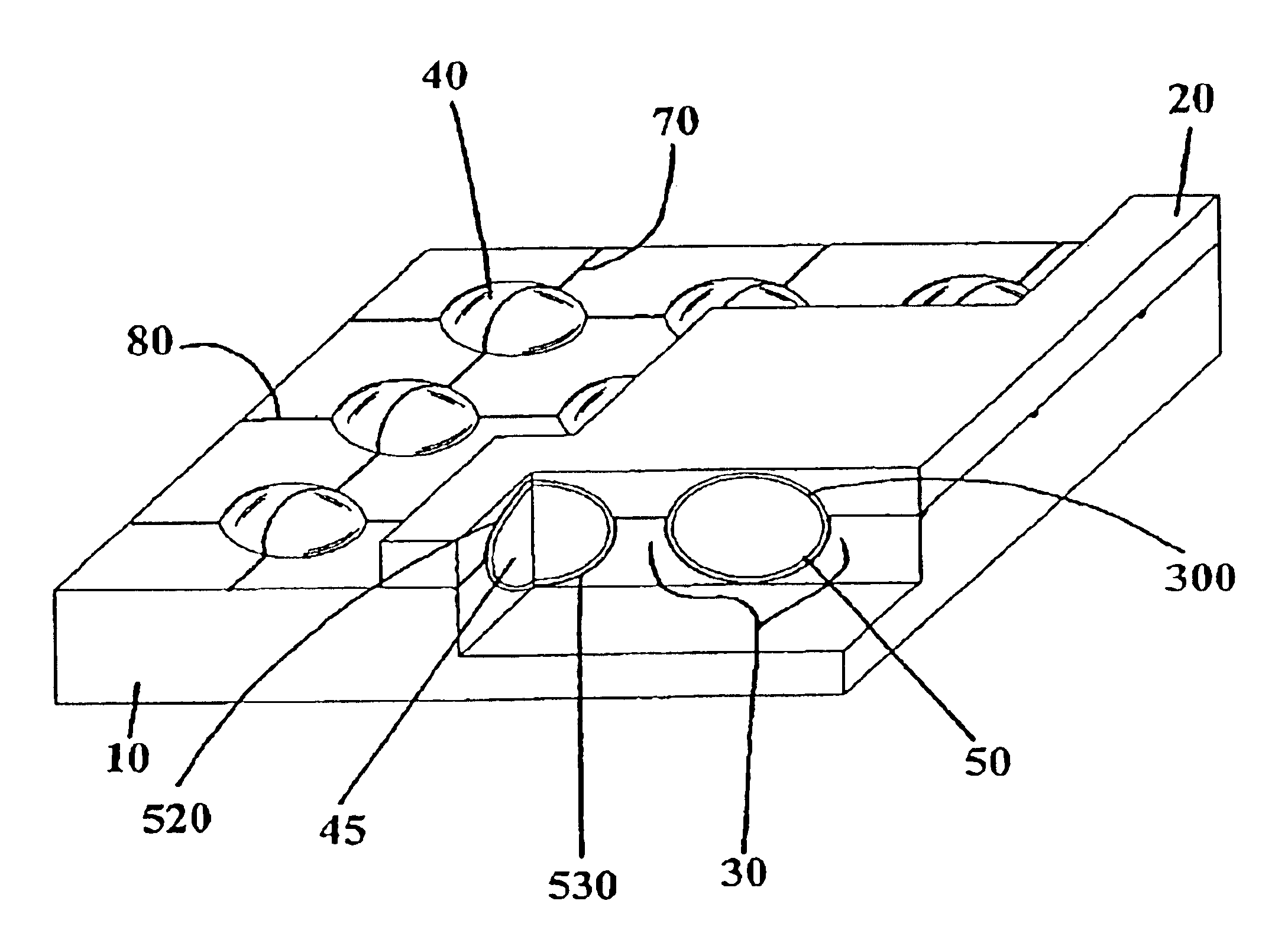

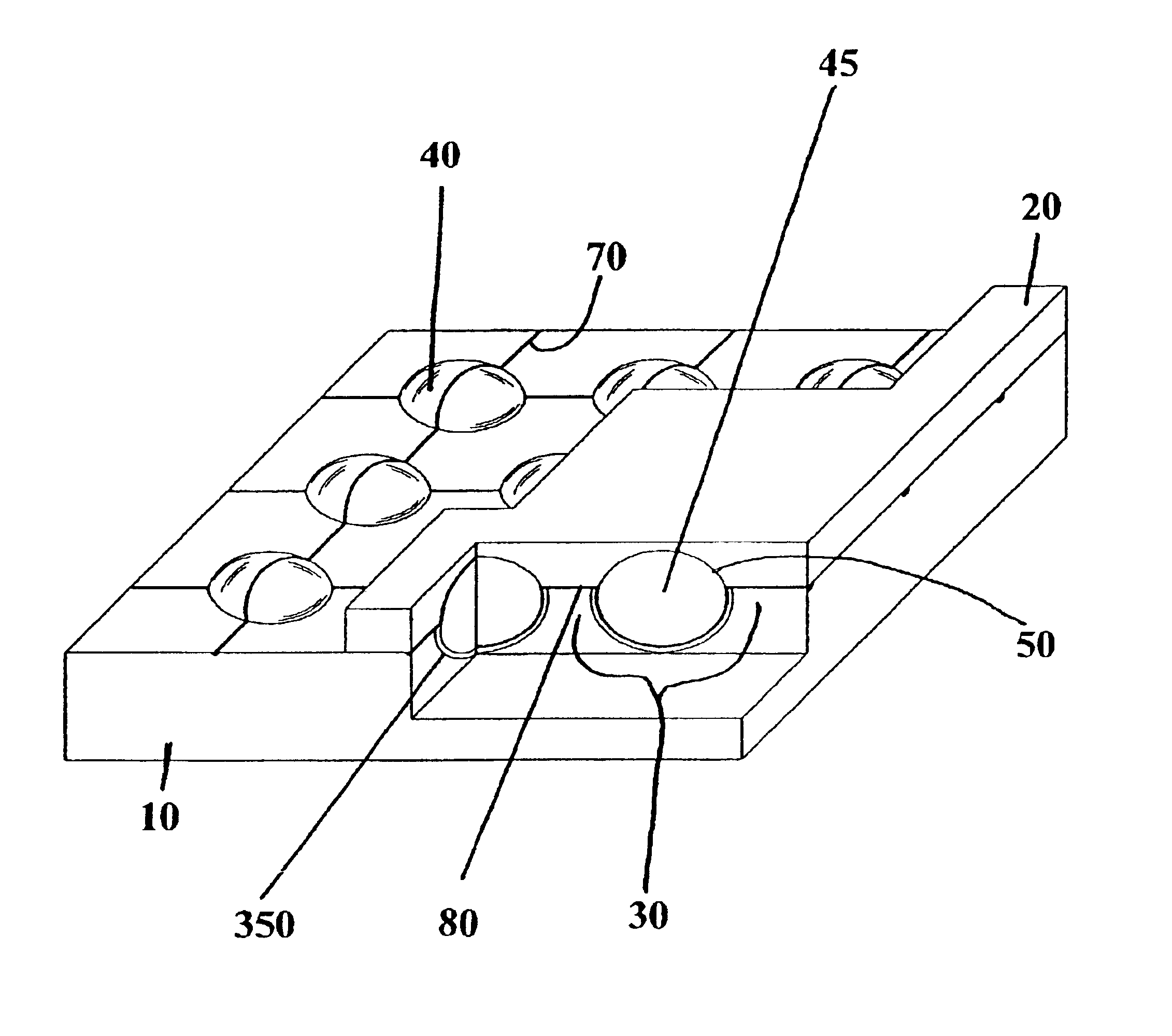

Design, fabrication, testing, and conditioning of micro-components for use in a light-emitting panel

InactiveUS6822626B2Sufficient resolutionManufactured very thinFixed microstructural devicesVolume/mass flow measurementEngineeringPre testing

Owner:LEIDOS

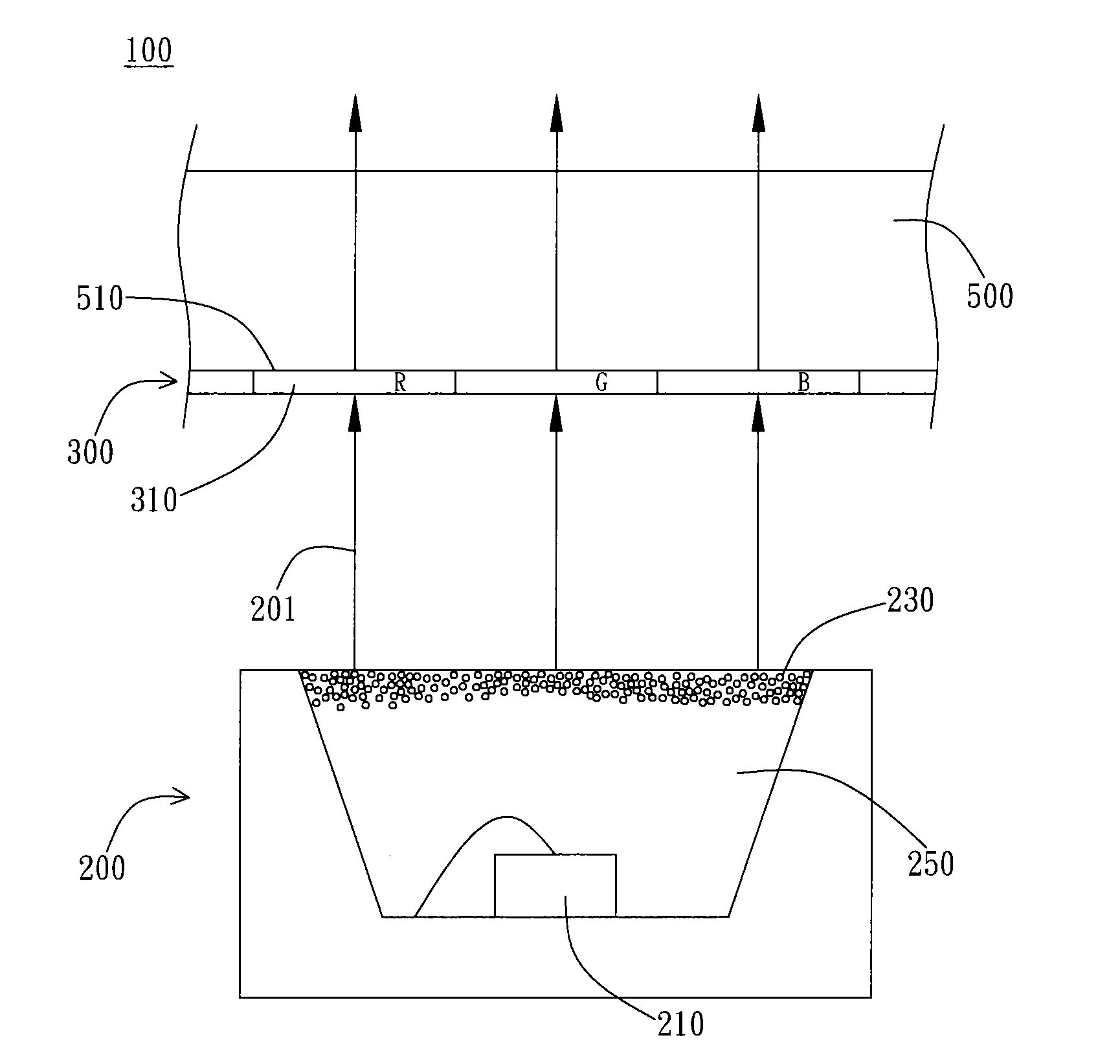

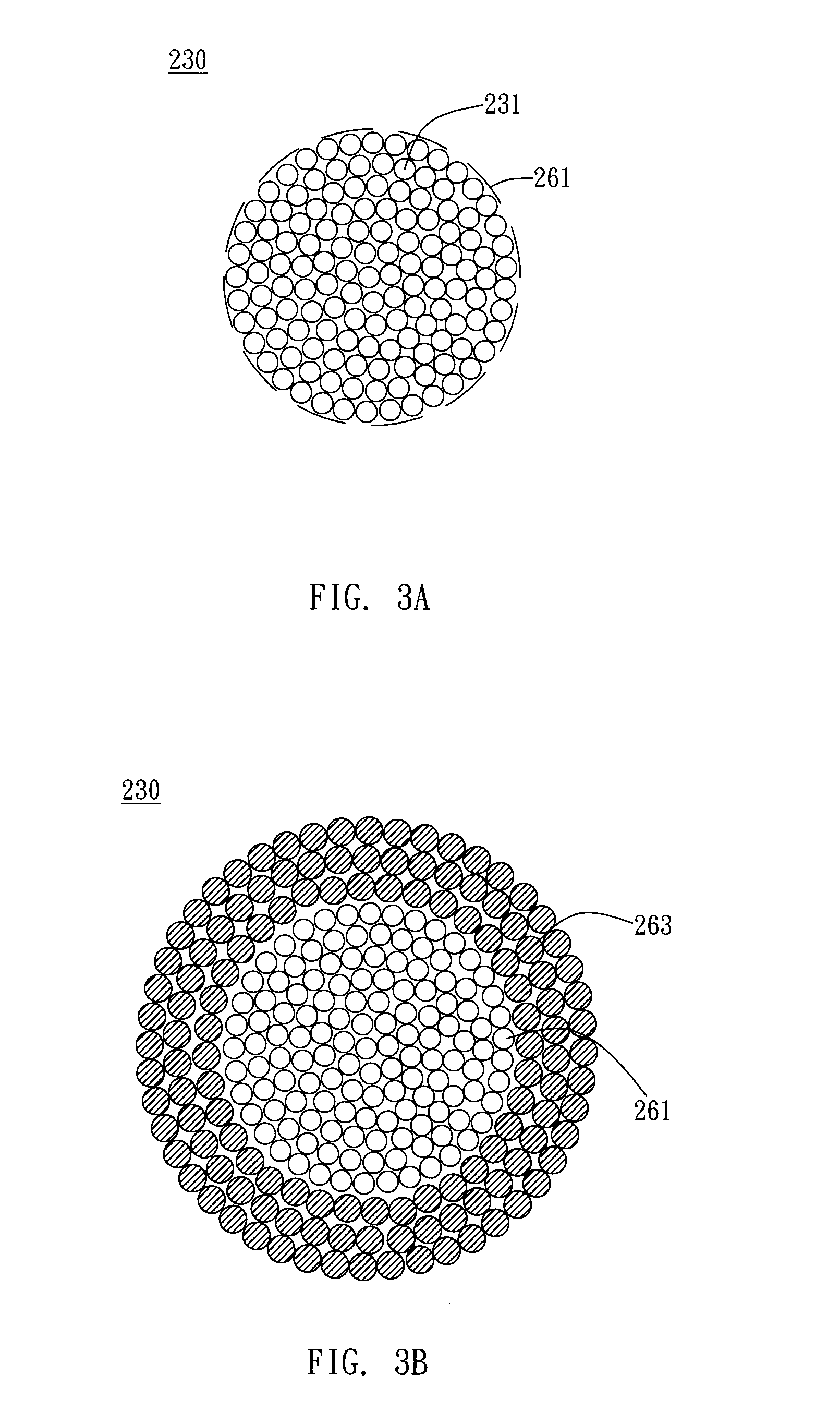

Display Device with Quantum Dot Phosphor and Manufacturing Method Thereof

ActiveUS20110156575A1Improve coloring performanceMaterial nanotechnologyVessels or leading-in conductors manufacturePhosphorDisplay device

A display device and a method of manufacturing the same are provided. The display device includes an illuminate unit and a color filter. The illuminate unit has a light-emitting chip and a plurality of quantum dot phosphors for generating a color light which has an optical spectrum including the first blue peak wavelength, a first green peak wavelength, and a first red peak wavelength. The color filter is disposed in the light path of the color light, wherein the color filter has a transmittance spectrum having a second blue peak wavelength, a second green peak wavelength, and a second red peak wavelength. The first blue peak wavelength, the first green peak wavelength, and the first red peak wavelength respectively match the second blue peak wavelength, the second green peak wavelength, and the second red peak wavelength in order to enhance the color performance of the display device.

Owner:AU OPTRONICS CORP

Method of manufacturing flat display panels of different sizes from a common base substrate

InactiveUS7273403B2Lower manufacturing requirementsNarrow widthSparking plugsStatic indicating devicesCommon baseDisplay device

In a method of a manufacturing flat display apparatuses by working flat substrates, a flat substrate is prepared having a first region which is used as a flat display apparatus and a second region outside the first region. After the first region is worked as desired, the second region is cut and separated from the flat substrate.

Owner:KK TOSHIBA

Method for on-line testing of a light emitting panel

InactiveUS6935913B2Sufficient resolutionManufactured very thinSparking plugsStatic indicating devicesEngineeringLight-emitting diode

Owner:LEIDOS

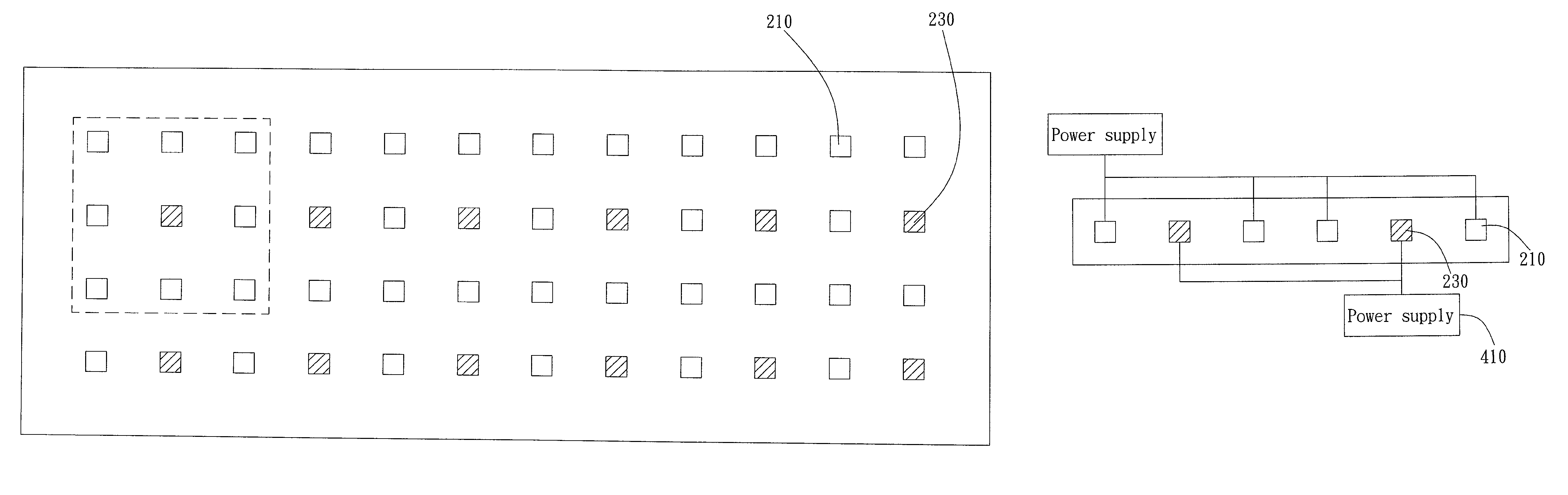

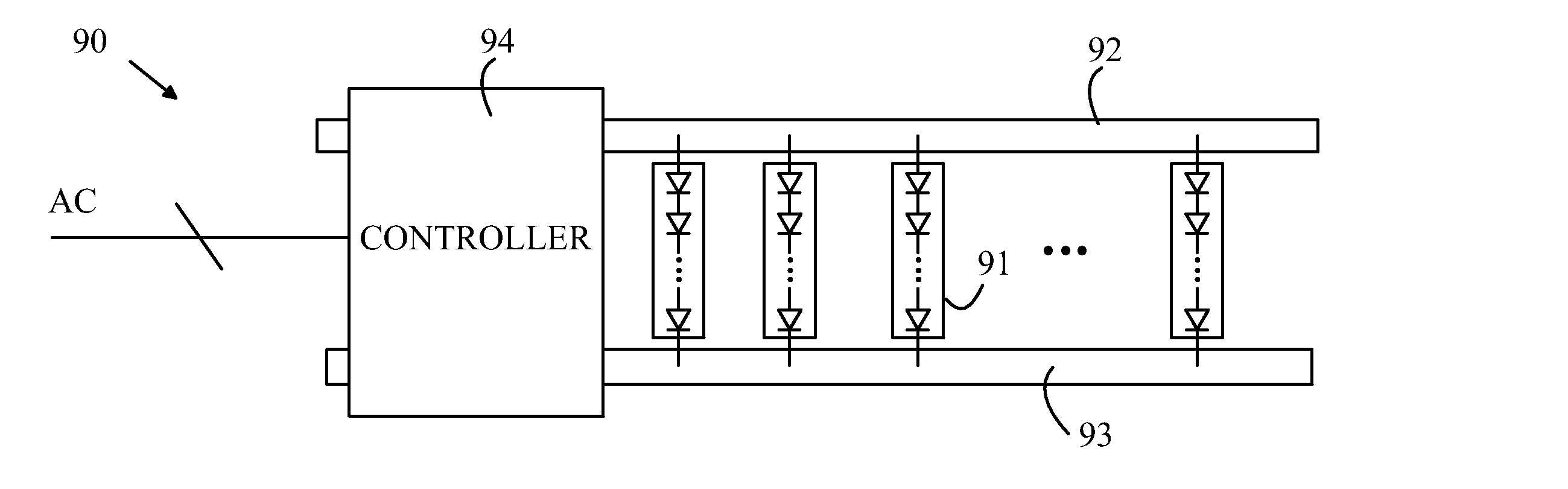

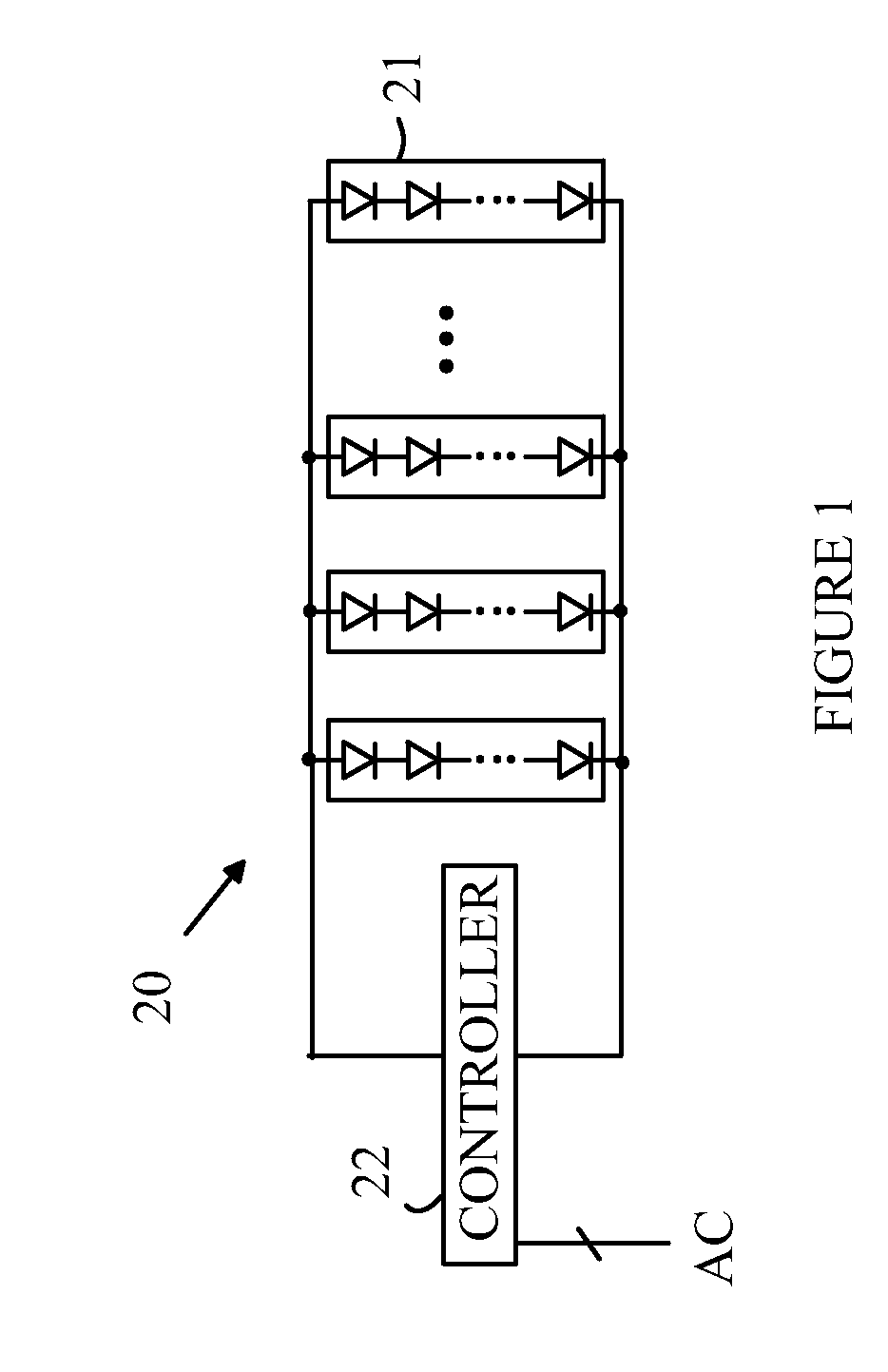

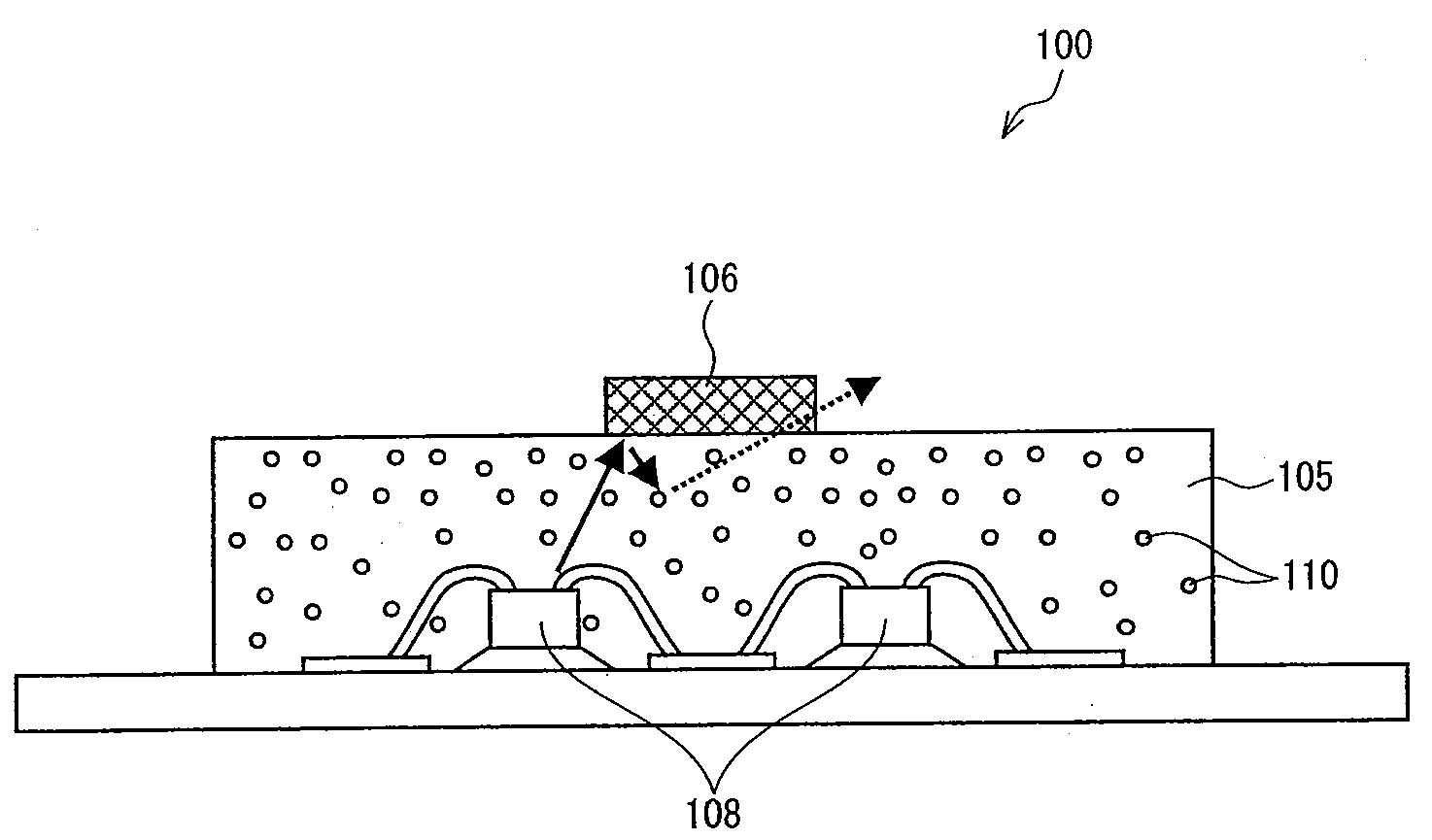

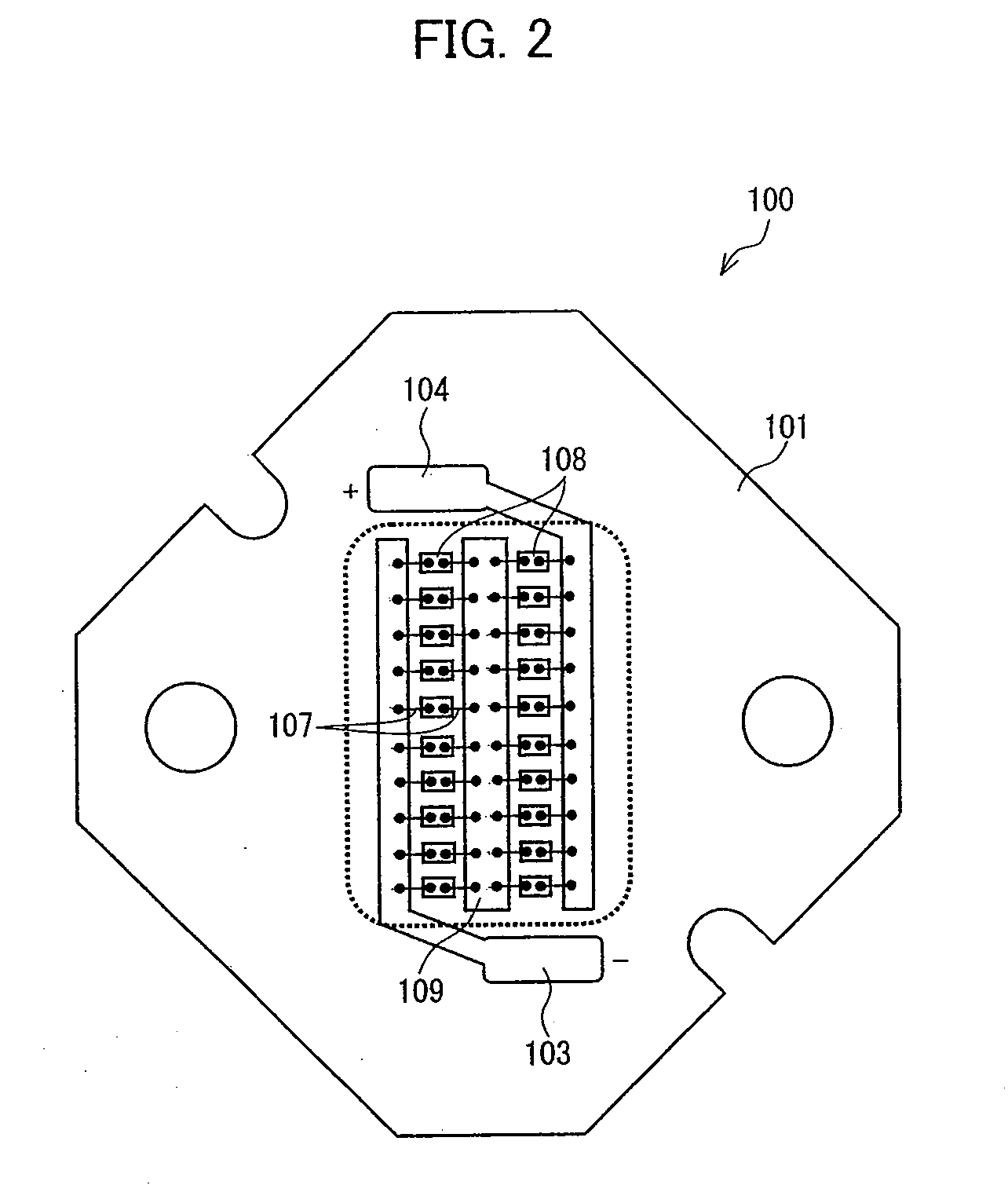

Light Sources Utilizing Segmented LEDs to Compensate for Manufacturing Variations in the Light Output of Individual Segmented LEDs

InactiveUS20100141175A1Easy to understandSparking plugsElectroluminescent light sourcesSignal onEngineering

A light source and method for making the same are disclosed. The light source includes a plurality of Segmented LEDs connected in parallel to a power bus and a controller. The power bus accepts a variable number of Segmented LEDs. The controller receives AC power and provides a power signal on the power bus. Each Segmented LED is characterized by a driving voltage that is greater than 3 times the driving voltage of a conventional LED fabricated in the same material system as the Segmented LED. The number of Segmented LEDs in the light source is chosen to compensate for variations in the light output of individual Segmented LEDs introduced by the manufacturing process. In another aspect of the invention, the number of Segmented LEDs connected to the power bus can be altered after the light source is assembled.

Owner:BX LED LLC

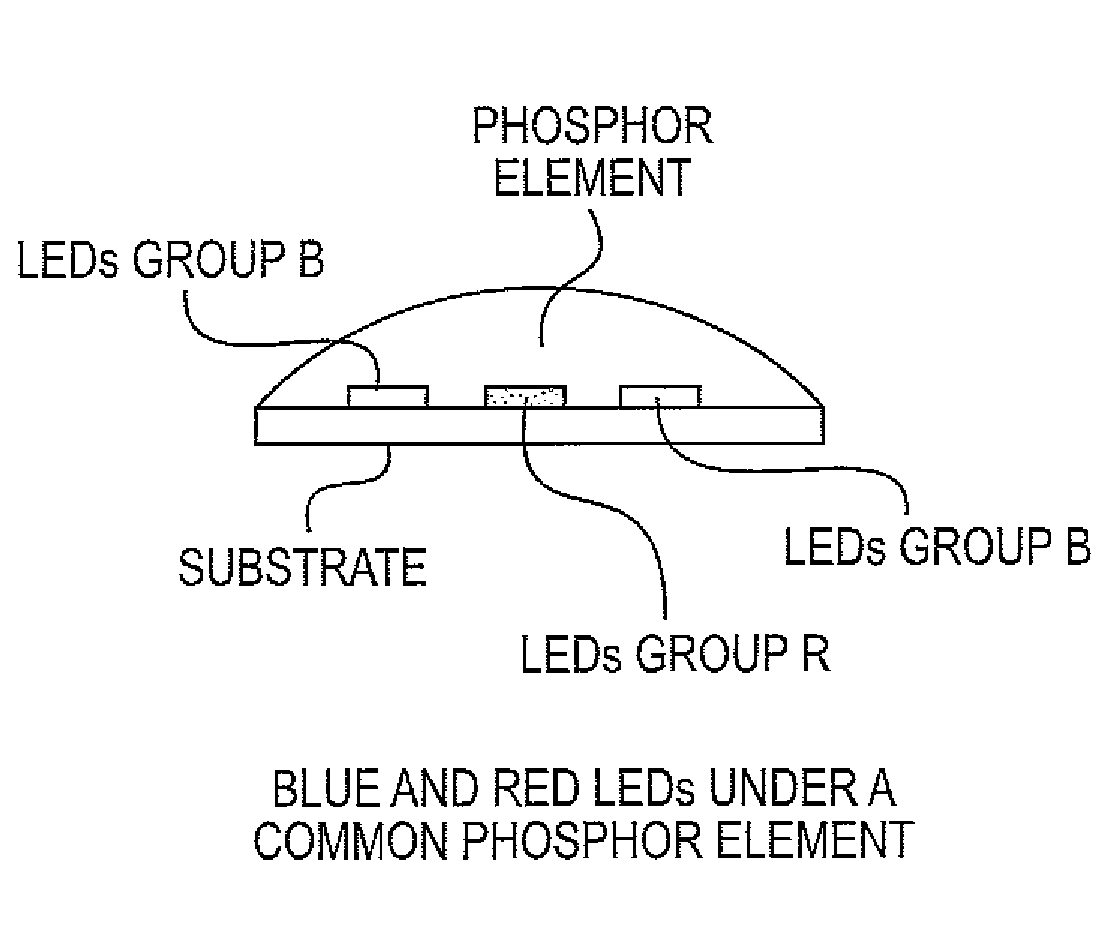

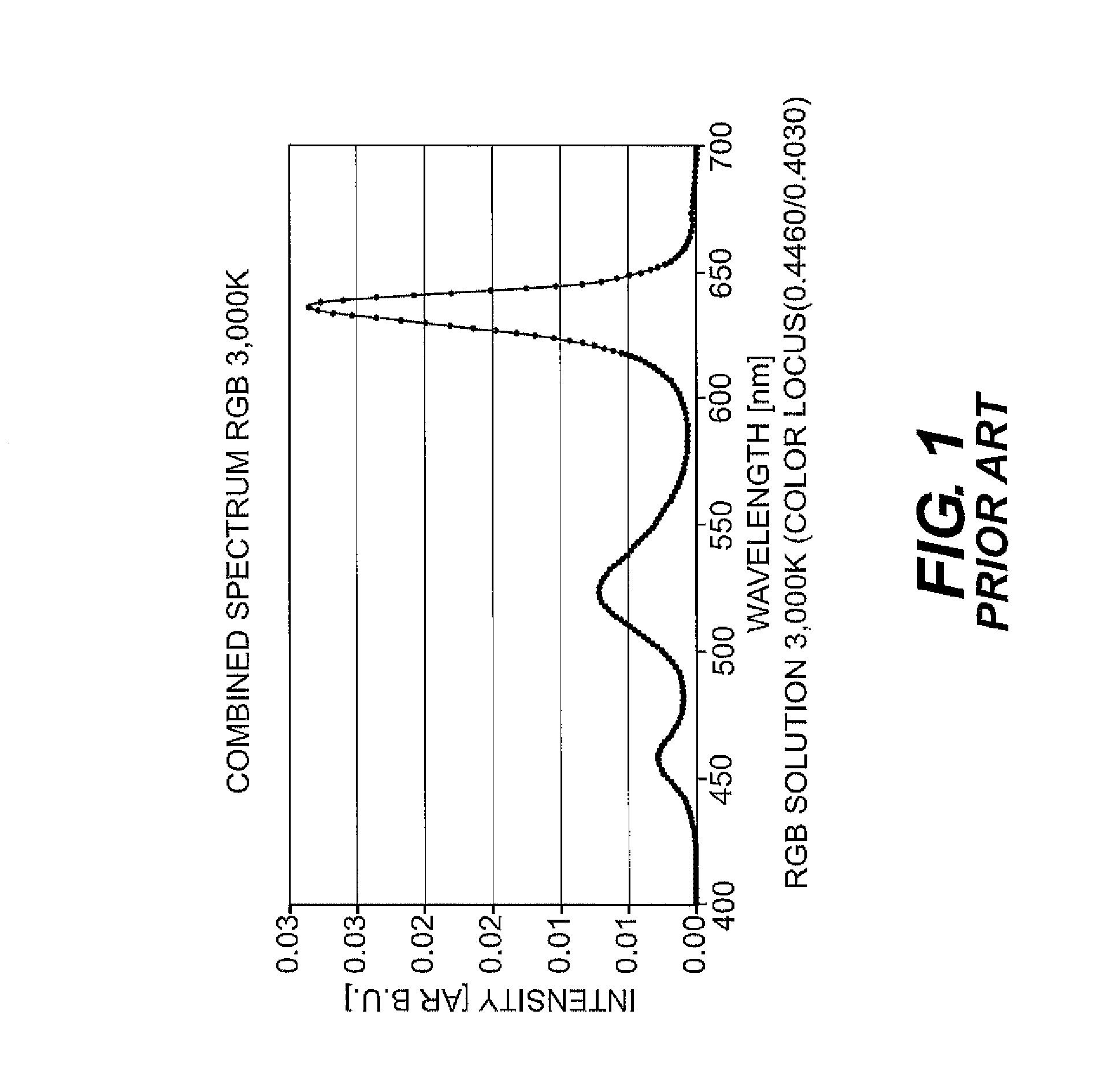

LED module, LED illumination means, and LED lamp for the energy-efficient reproduction of white light

ActiveUS20100237766A1Improve efficiencyGood colorSparking plugsLight source combinationsPhosphorLuminosity

An LED module, selectively comprising at least zero, one, or a plurality of LEDs from Group B and / or Group G and / or Group R and at least one or more LEDs from Group P. The concentration of phosphors / phosphor mixtures of the LEDs in Group P is selected such that the photometric efficiency (lm / W) thereof is at or near the maximum as a function of the CIE x-coordinates.

Owner:LUMITECH INTPROP LLC

Spark plug and method of manufacturing spark plug

ActiveUS20120299459A1Easy to adjustReliable preventionSpark gaps adjustmentSparking plugs manufactureEngineeringGrounding electrodes

An ignition plug having a metallic shell with a through hole extending therethrough in an axial direction, an insulator fitted into the through hole of the metallic shell and having an axial hole extending in the axial direction, and a center electrode fitted into the axial hole of the insulator. The ignition plug further includes a cap member which covers a front end opening of the metallic shell, provided on a front end side thereof where the center electrode is disposed, to thereby form an ignition chamber at the front end portion of the metallic shell, and a ground electrode disposed within the ignition chamber and facing a circumferential surface of the center electrode directly or indirectly.

Owner:NGK SPARK PLUG CO LTD

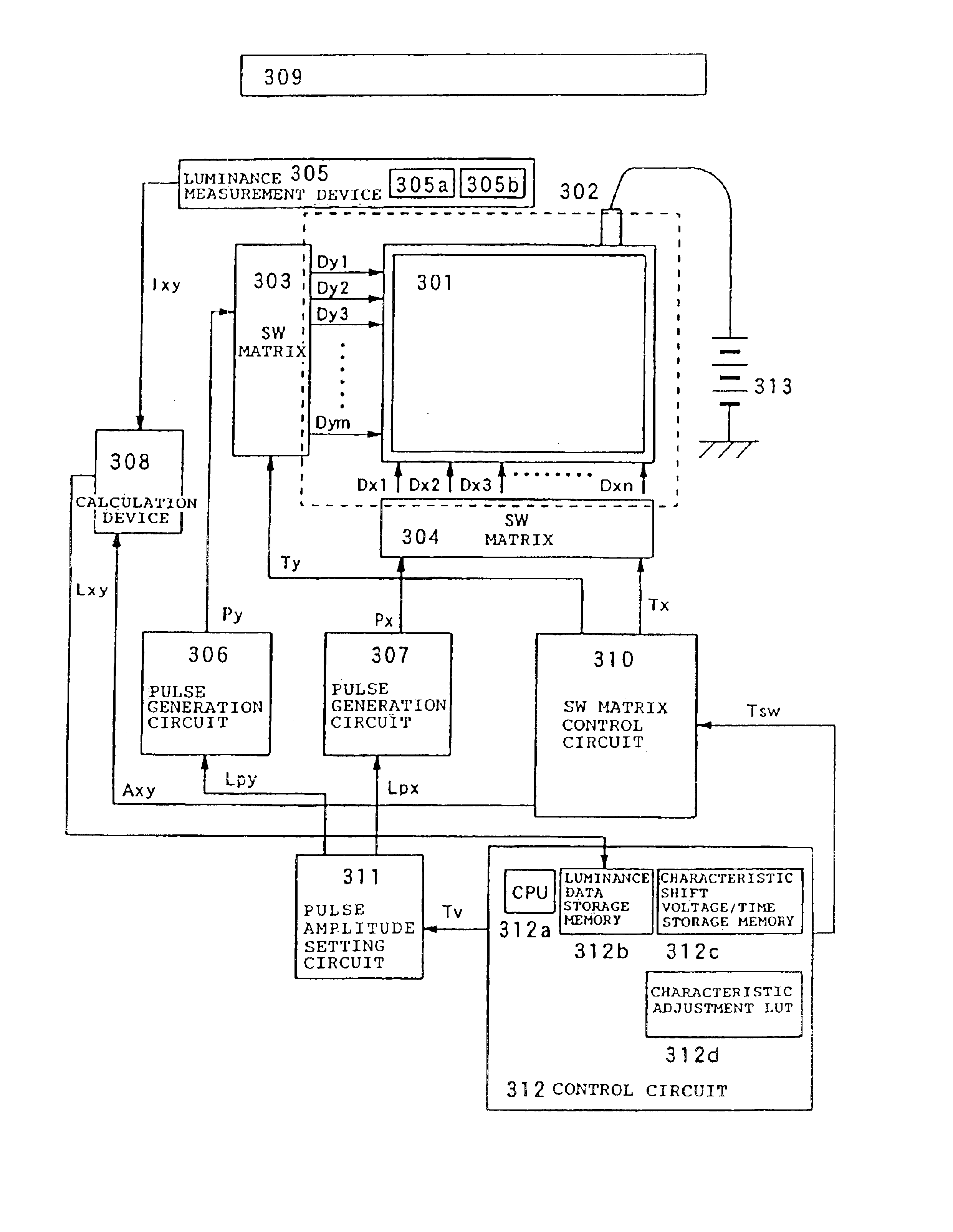

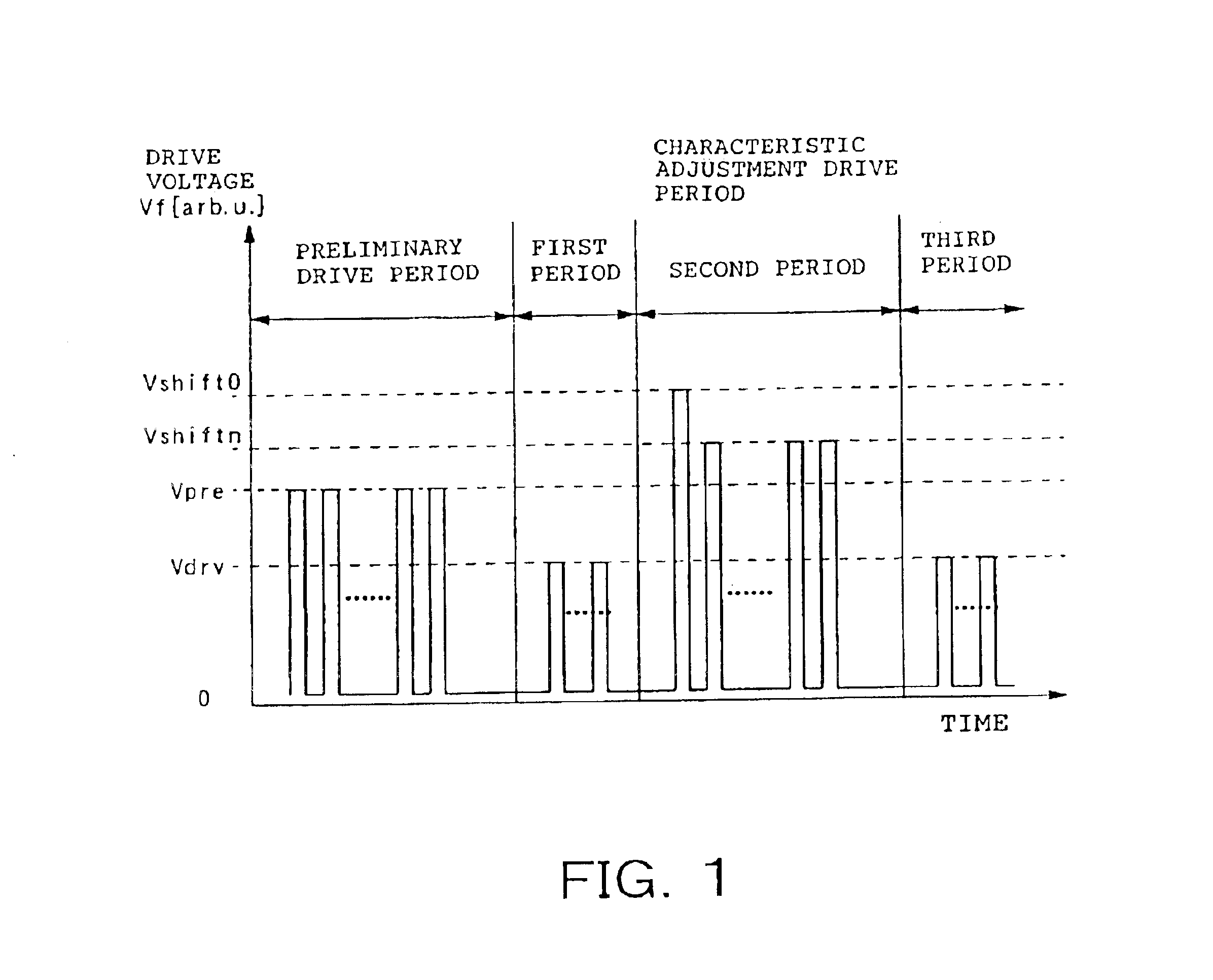

Method of manufacturing image forming apparatus

InactiveUS6822397B2Variation in timeReduce processing timeSparking plugsDigital variable displayImage formationLightness

The present invention relates to the adjustment of luminance. The present invention is a method of manufacturing image forming apparatus including a step of applying characteristic shift voltage comprising a plurality of pulses in which the amplitude of the pulse obtained from the look-up table has two or more values, to the emitter, the look-up table storing the amplitude of the pulse and the number of the pulse for shifting characteristic of emitters to a predetermined luminance target value on the basis of the measurement result of the luminance. Moreover, the present invention is a method of manufacturing image forming apparatus comprising a step of applying the second pulses of characteristic shift voltage having the amplitude which was determined in response to the measurement result of the luminance after the first characteristic shift voltage had been applied to the emitter.

Owner:CANON KK

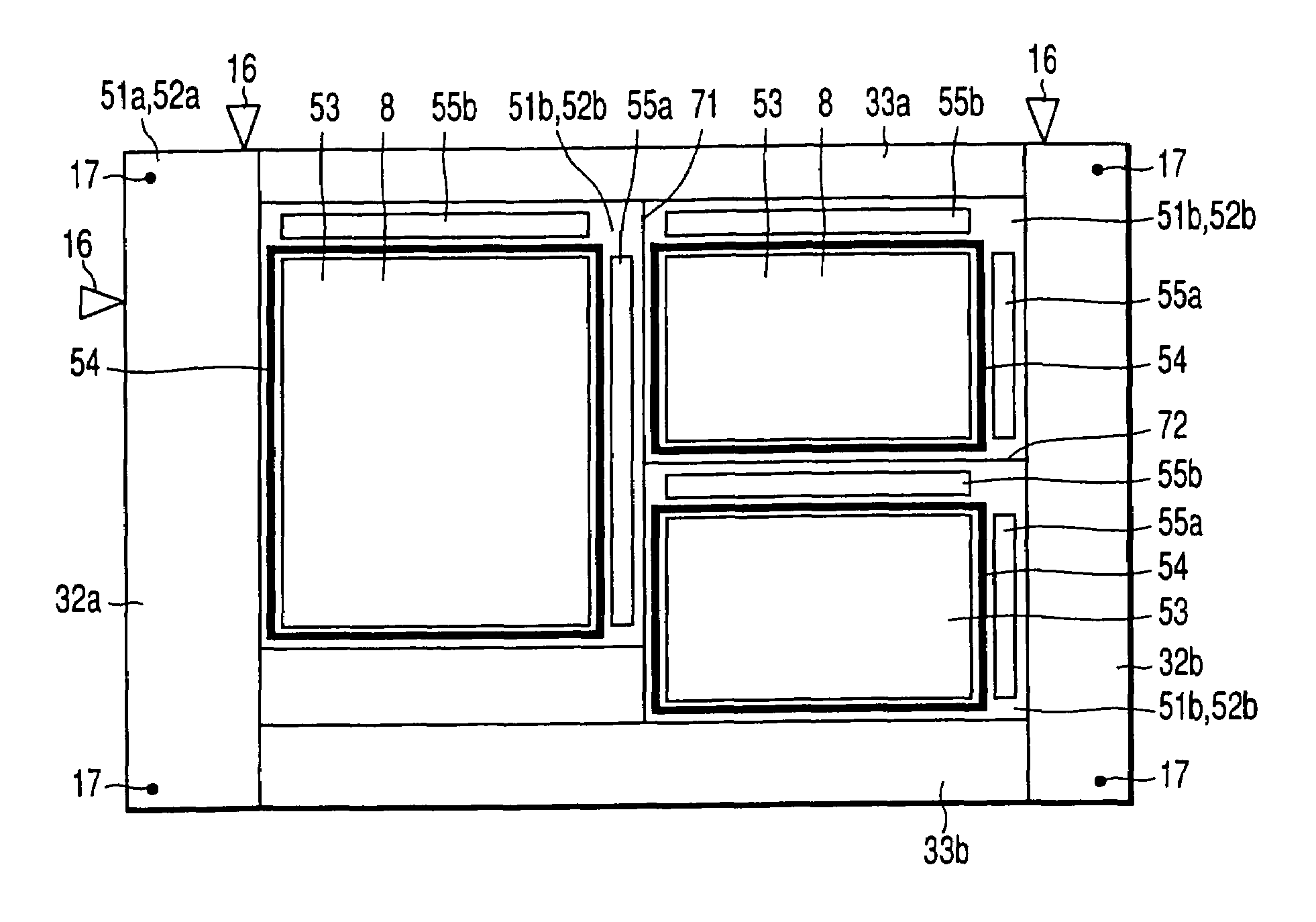

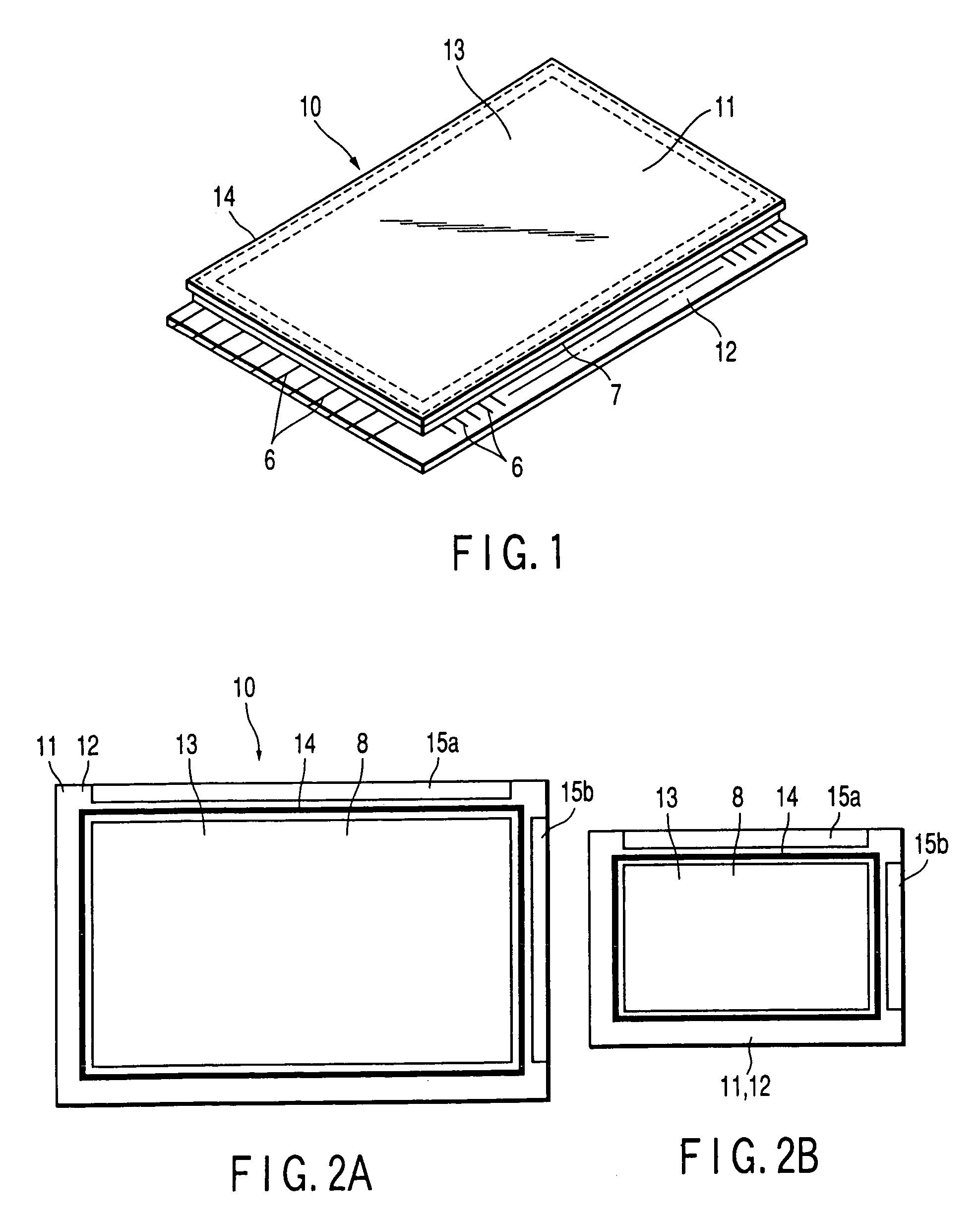

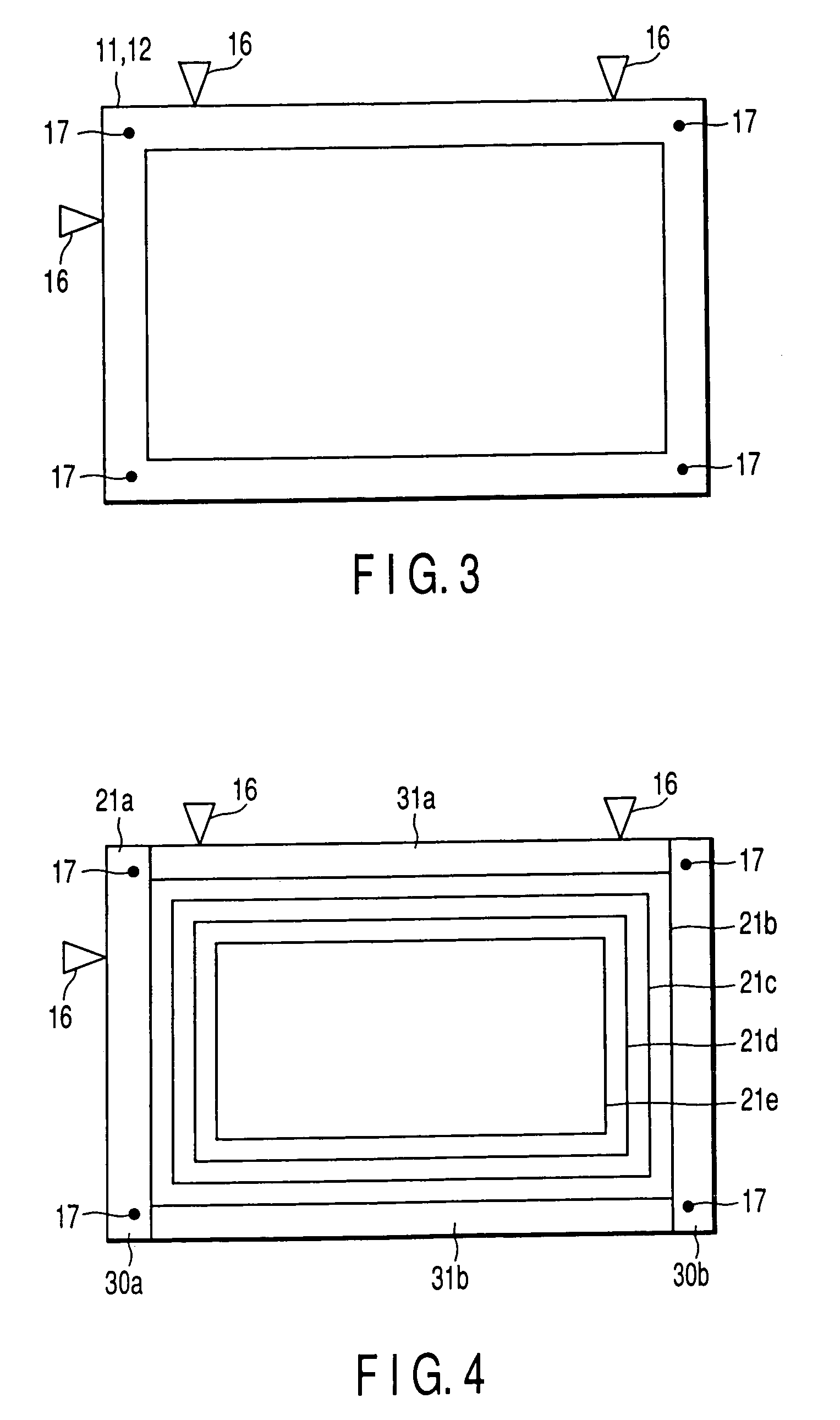

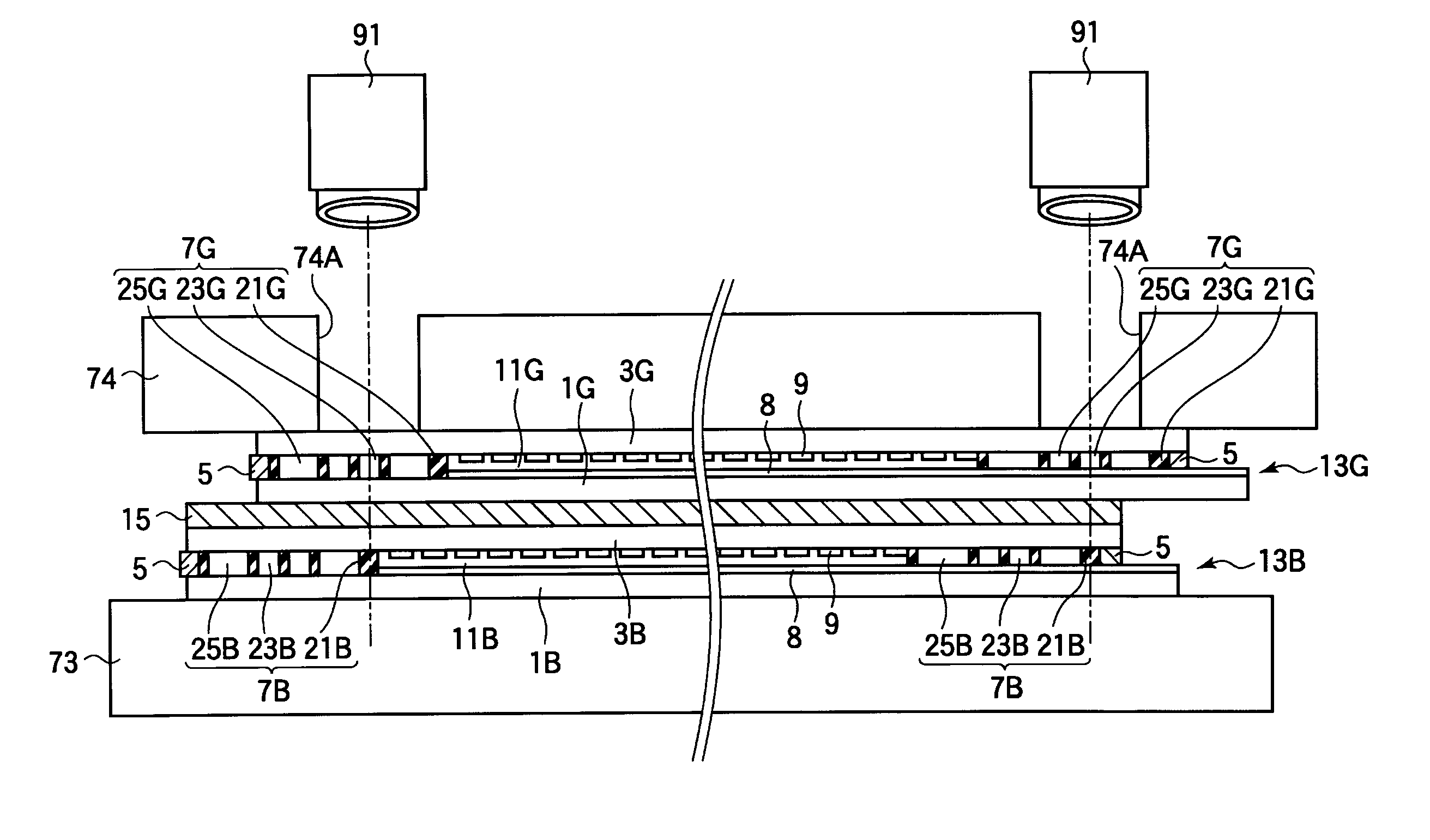

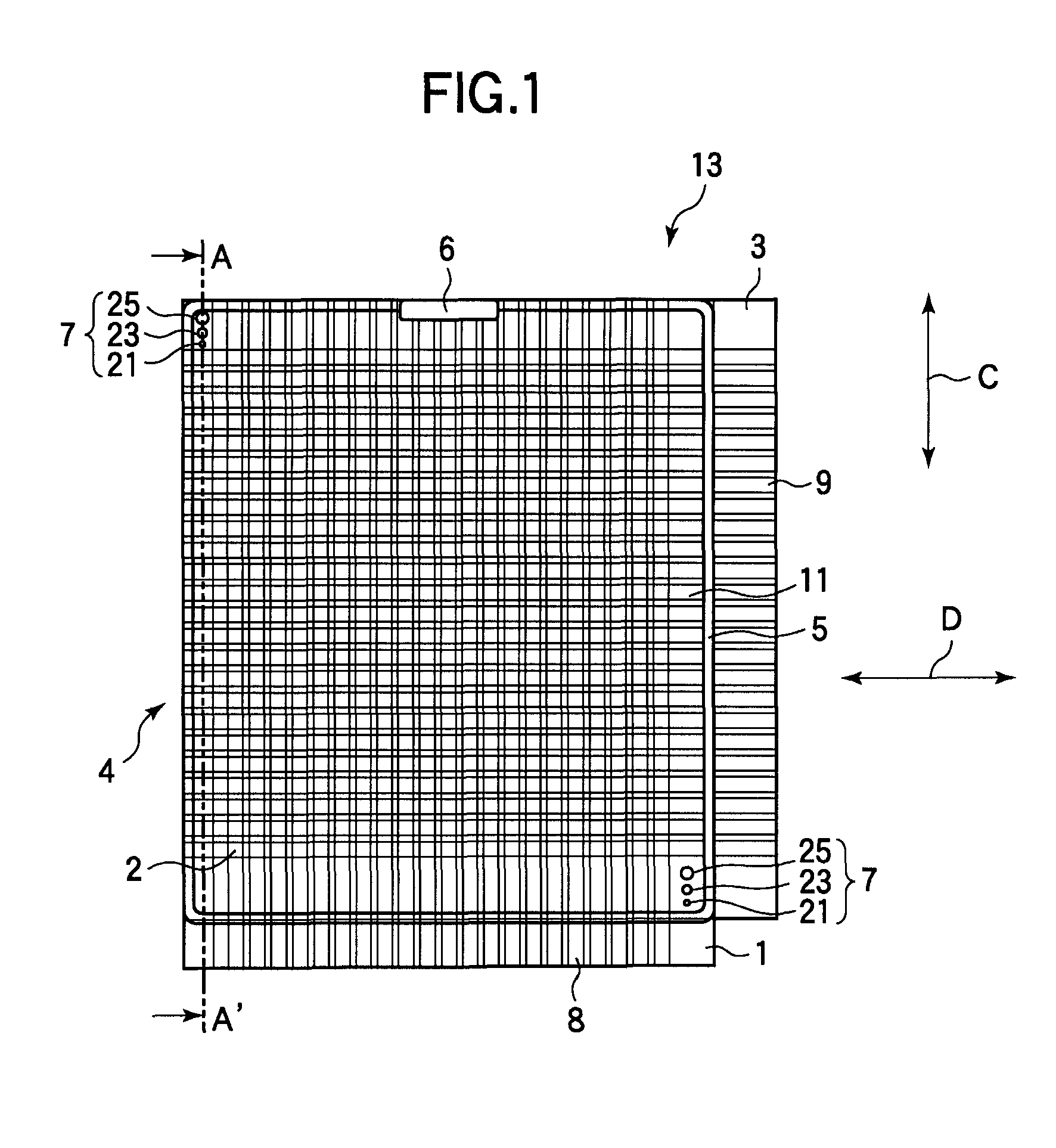

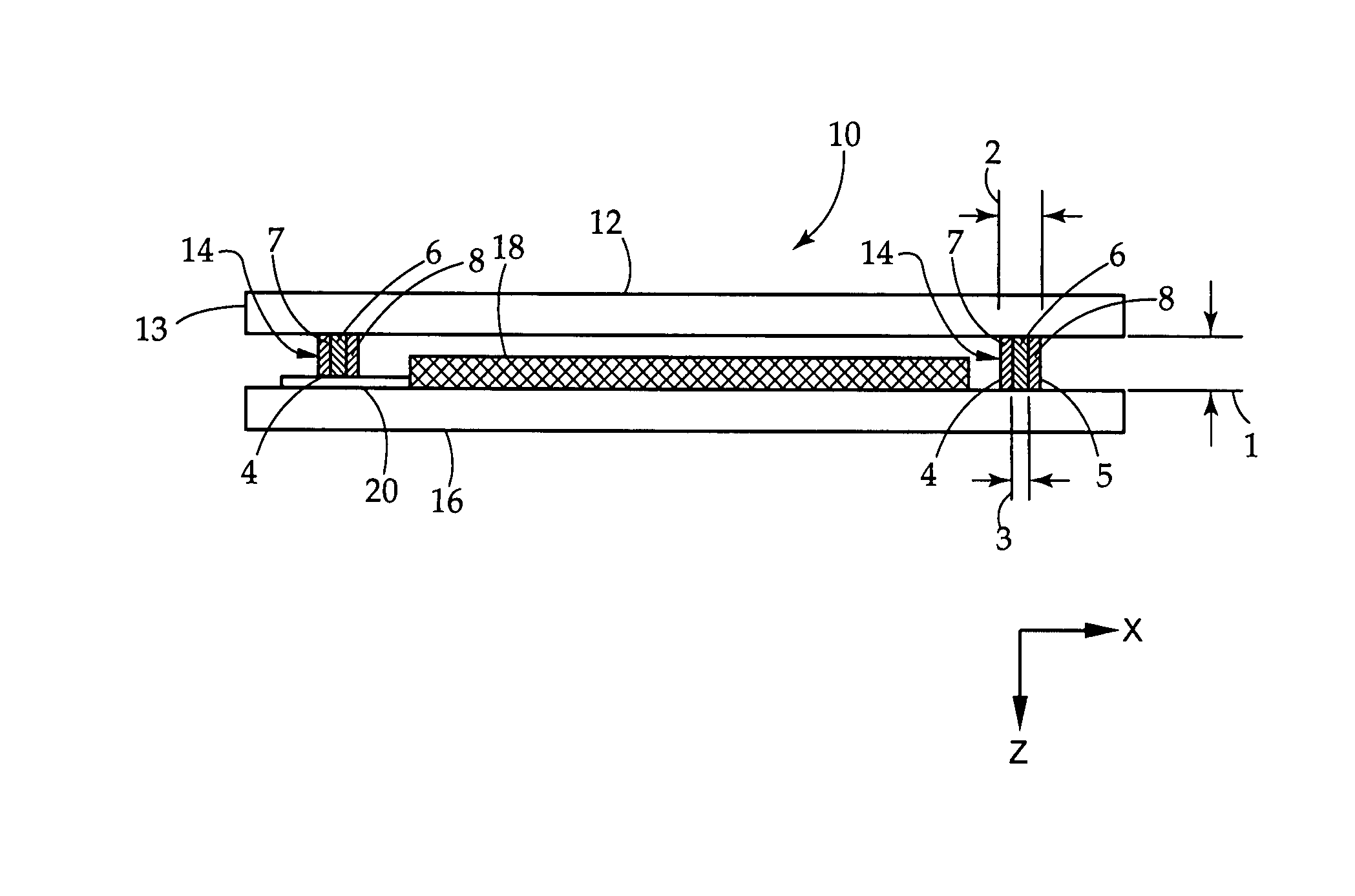

Display panel, multi-layer display element, and method of fabricating the same

InactiveUS20100002183A1Easy alignmentSparking plugsTube/lamp screens manufactureEngineeringSubstrate surface

The present invention is to provide a display panel, a multi-layer display element, and a method of fabricating same, which can readily align alignment positions of individual display panels with each other even though common alignment marks are provided on each of display panels. A display panel includes a pair of substrates faced to each other as a display material layer is sandwiched between the substrates, a plurality of pixels provided in a plane almost in parallel with a substrate surface between the substrates, and a plurality of alignment marks formed in different shapes and linearly arranged on at least one of the pair of the substrates at a predetermined interval for alignment in placing the display panels in layers.

Owner:FUJITSU LTD

Design, fabrication, testing, and conditioning of micro-components for use in a light-emitting panel

InactiveUS7288014B1Solve the lack of resolutionManufactured very thinMechanical apparatusAlternating current plasma display panelsEngineeringPre testing

Owner:LEIDOS

Light emitting element and method for producing the same

InactiveUS20090134415A1Adjust chromaticity variationSparking plugsDischarge tube luminescnet screensFluorescenceLight-emitting diode

A light scattering section is formed on at least part of a surface of a sealing resin section including fluorescent bodies and covering light emitting diode chips. Light from the light emitting diode chips is scattered by the light scattering section, and then is returned to the sealing resin section so as to excite the fluorescent bodies so that fluorescence is generated. Part of the light to be emitted outside a light emitting element from the light emitting diode chips returns to the sealing resin section so that chromaticity of the light is converted by the fluorescent bodies, thereby adjusting a chromaticity variation among the light emitting elements. In this way, the chromaticity variation among the light emitting elements can be adjusted.

Owner:SHARP KK

Display apparatus and method of manufacturing the same

InactiveUS20100195039A1Reducing and effectively preventing defectTube/lamp screens manufactureVessels or leading-in conductors manufactureEngineering

In a method of manufacturing a display apparatus, an opposite substrate on which a conductive pattern is formed is coupled with a display substrate to face the display substrate, and the opposite substrate is cut to partially expose the display substrate. Since the conductive pattern is cut with the opposite substrate during the cutting of the opposite substrate, an electric resistance of the conductive pattern is changed. The change in electric resistance of the conductive pattern is detected to determine whether the opposite substrate is cut or not.

Owner:SAMSUNG ELECTRONICS CO LTD

Design, fabrication, testing, and conditioning of micro-components for use in a light-emitting panel

InactiveUS20040175854A1Sufficient resolutionManufactured very thinFixed microstructural devicesVolume/mass flow measurementEngineeringPre testing

Owner:LEIDOS

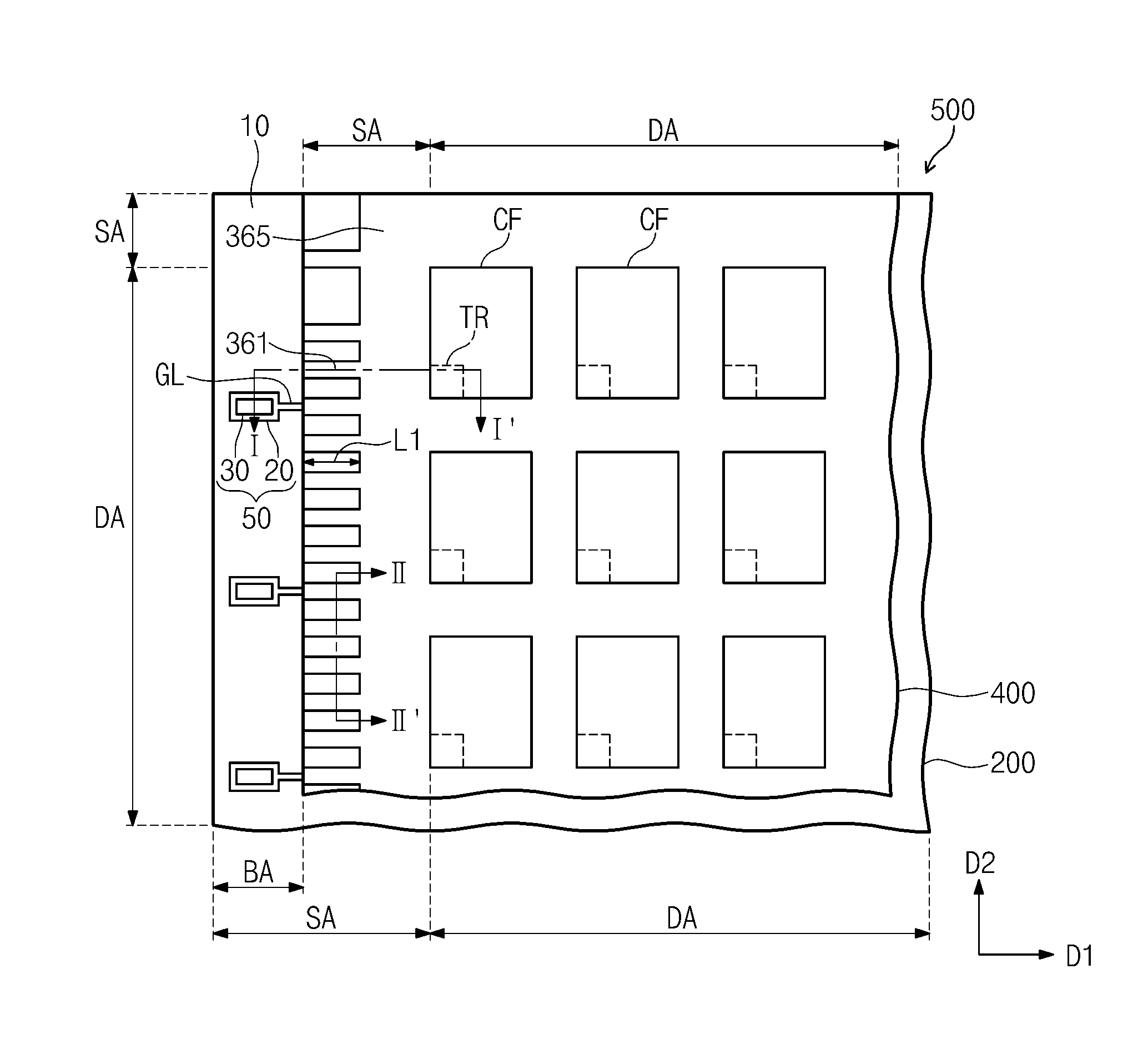

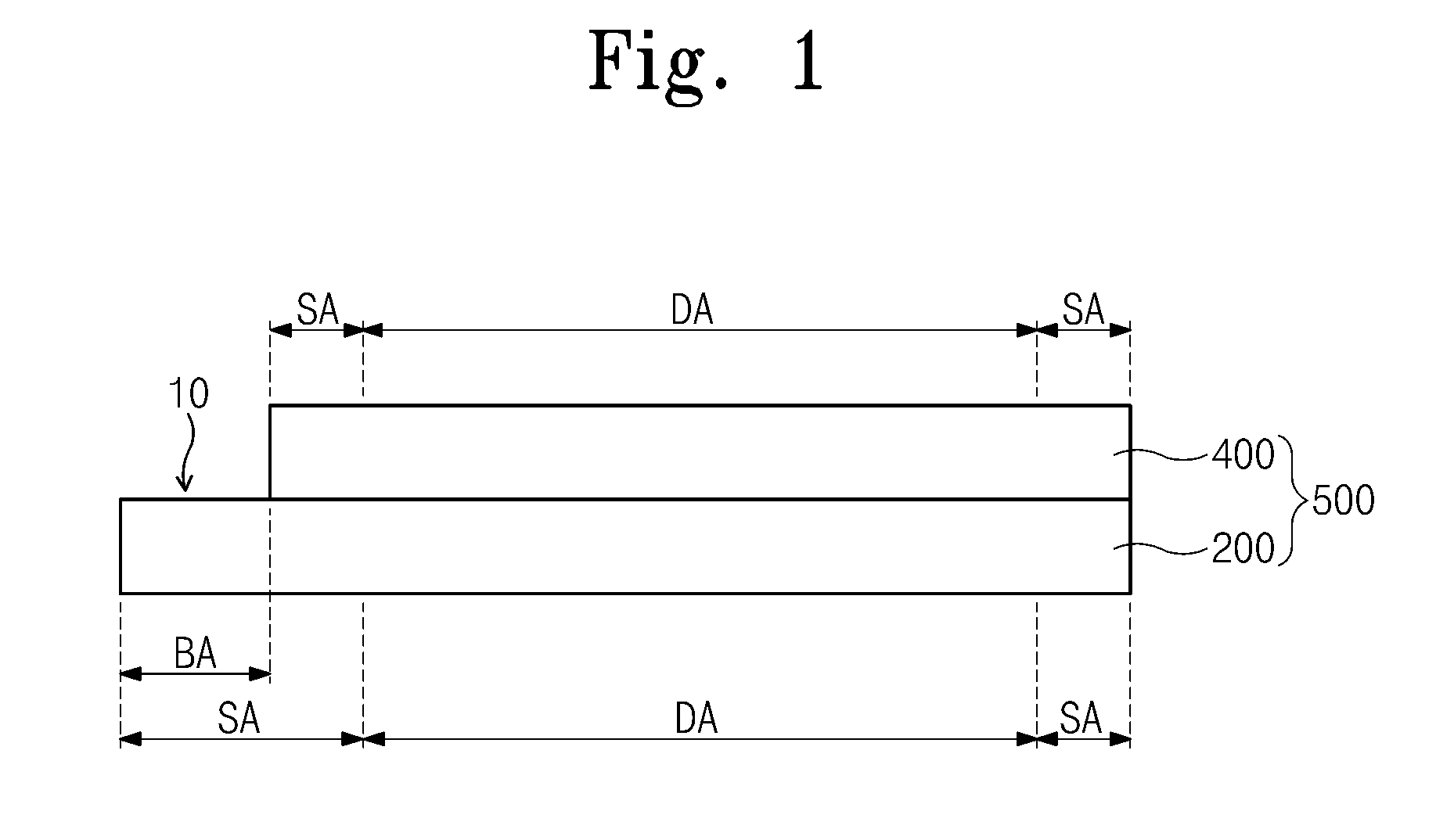

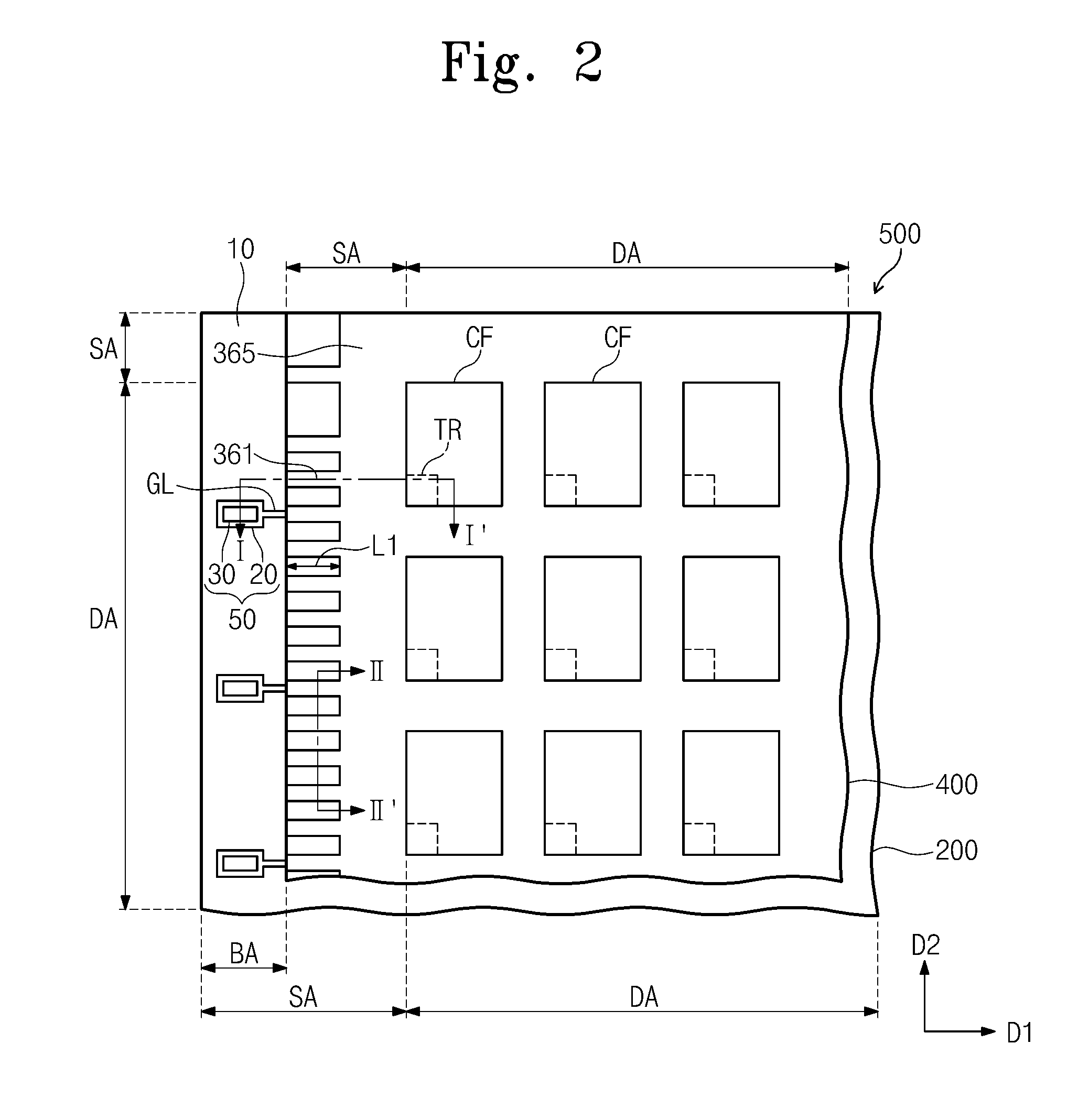

Method for manufacturing organic light emitting display

A method for manufacturing an organic light emitting display. Pixel portions are formed on a mother substrate. A test wiring for testing pixel portions is formed at a peripheral portion of the mother substrate. A sealing material is formed at one surface of a sealing substrate to enclose the pixel portions, the sealing substrate being sealed to be spaced apart from the mother substrate. A spacer is formed at a side region of the one surface of the sealing substrate on which the sealing material is formed. The mother substrate and the sealing substrate are adhered to each other by the sealing material to seal the pixel portions within an enclosure formed by the mother substrate, sealing surface, and sealing material. A part of the sealing substrate is scribed and removed to expose the test wiring, the part of sealing substrate being arranged over a portion of the test wiring.

Owner:SAMSUNG DISPLAY CO LTD

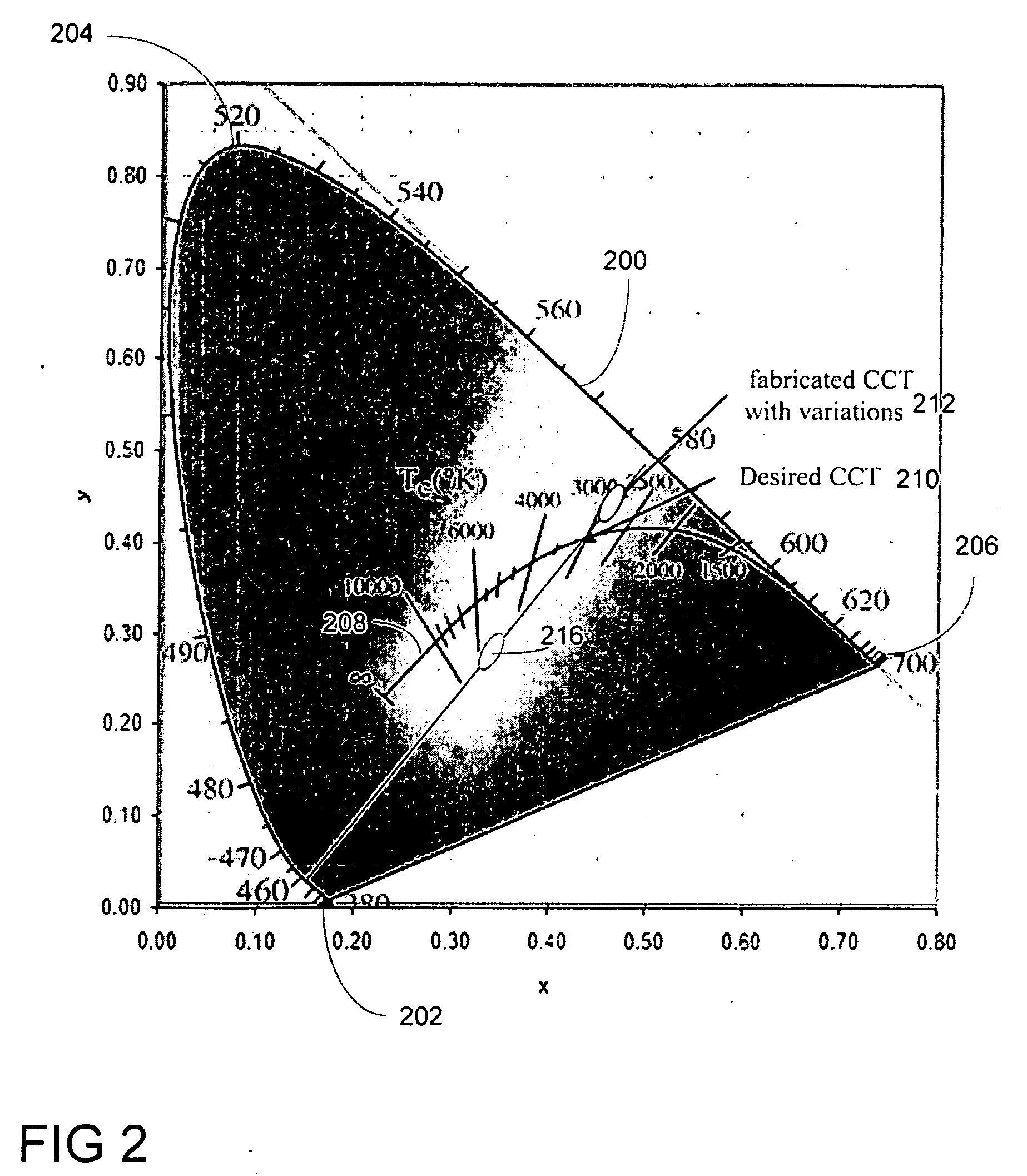

Method and Apparatus for Providing LED Package with Controlled Color Temperature

InactiveUS20100127289A1Sparking plugsDischarge tube luminescnet screensFluorescenceLight-emitting diode

An optical device capable of illuminating visual light with adjusting color temperature after fabrication is disclosed. The optical device includes a solid state light emitter and a phosphor layer, which is formed over the solid state light emitter. The solid state light emitter, which can be a light emitter diode (“LED”), converts electrical energy to blue light. The phosphor layer subsequently converts first light with a first wavelength to second light with a second wavelength. In one example, the first light is blue light while the second light is white light. A portion of the phosphor layer is adjusted after the phosphor layer is formed for adjusting color of the white light in accordance with color quality of the light detected by a light detector.

Owner:BRIDGELUX INC

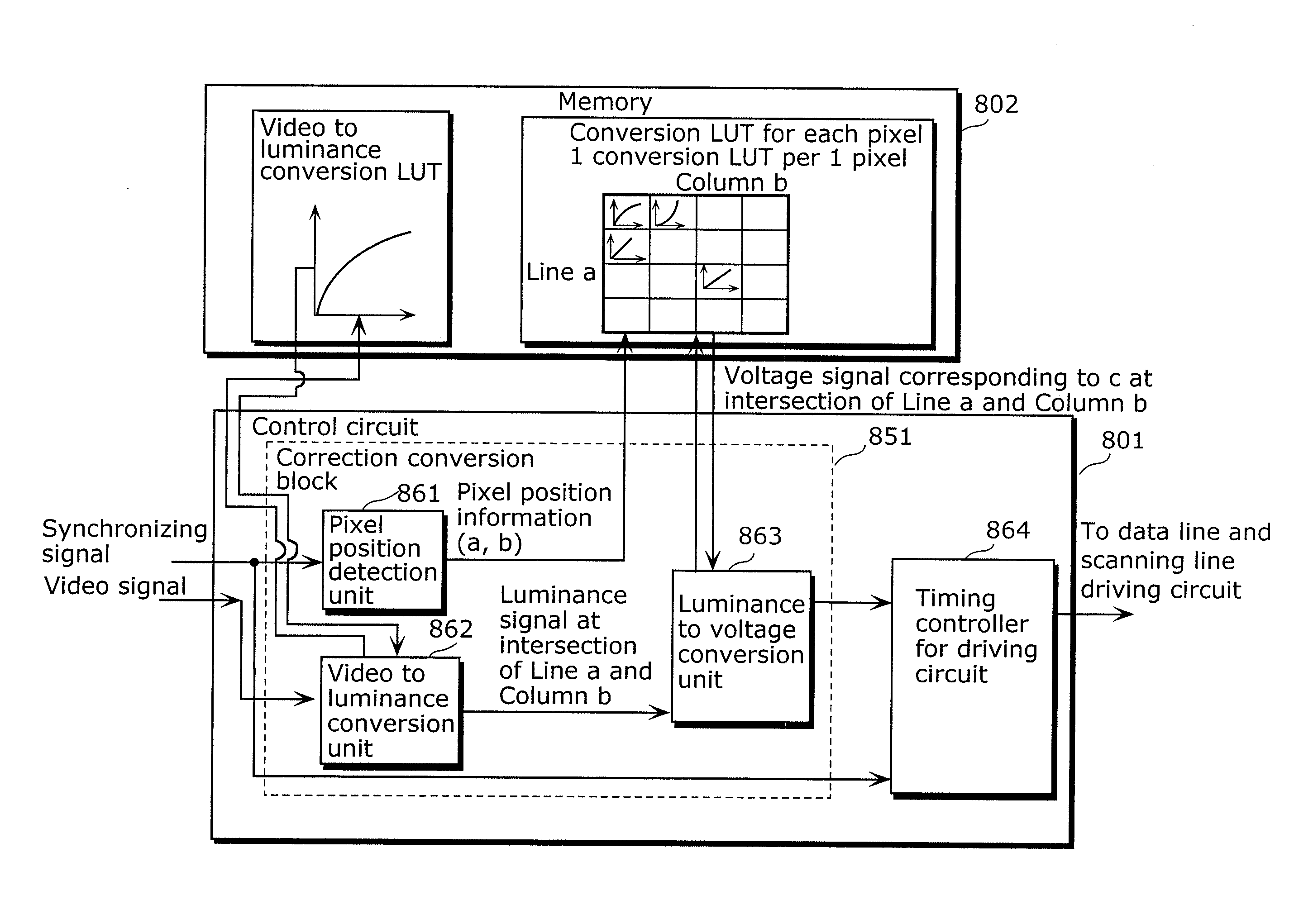

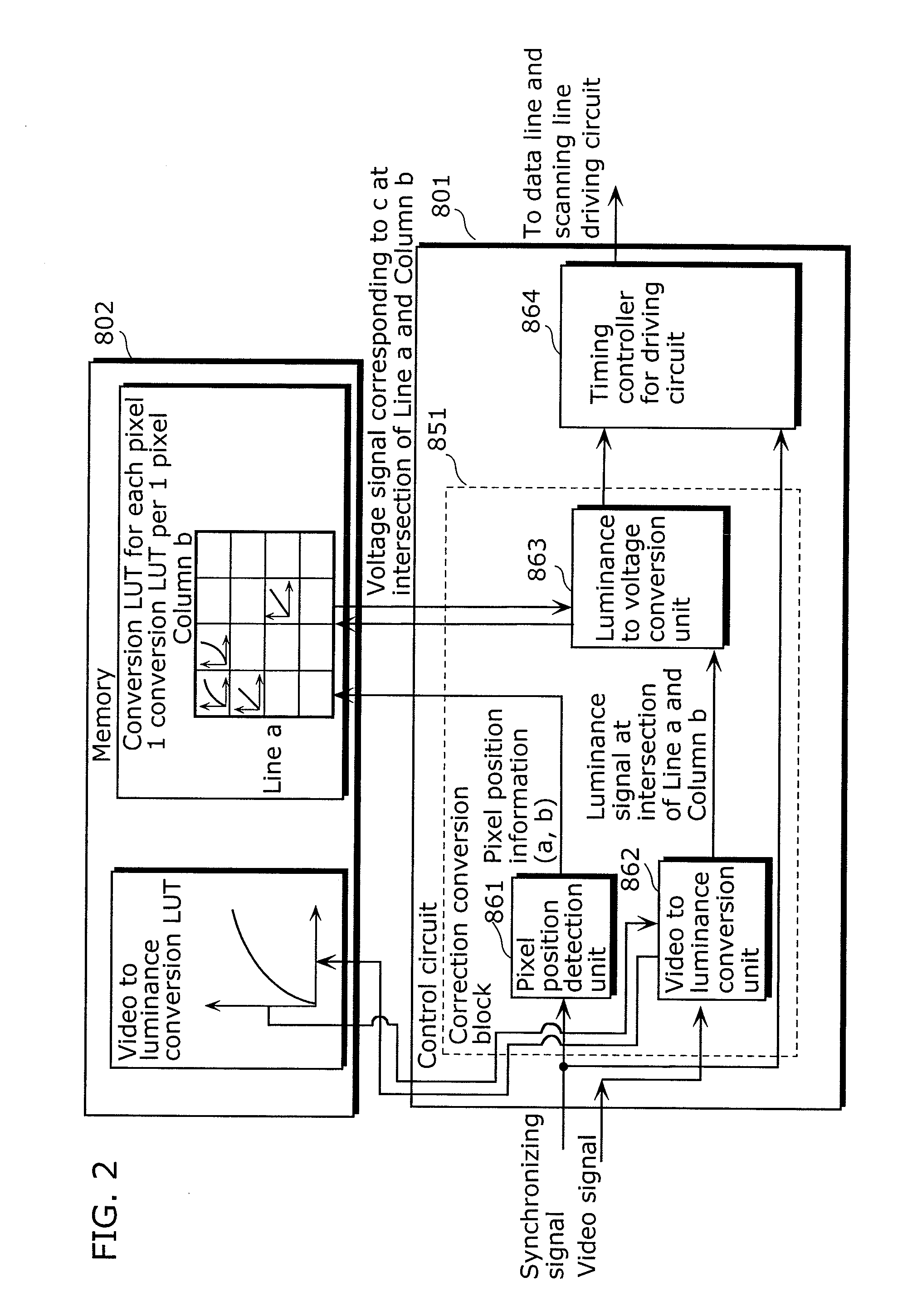

Display device, and methods for manufacturing and controlling the display device

ActiveUS20100253715A1Reduce the amount requiredThe display screen is uniformSparking plugsCathode-ray tube indicatorsDisplay deviceLine driver

A display device corrects uneven luminance due to uneven element characteristics by simple measurement and correction with a low cost. The display device includes pixels that each include a light emitter and a driver. Data lines supply a voltage signal to the driver of each pixel. A data line driver supplies the voltage signal to each data line. A first memory stores, for each pixel, a luminance gain for adjusting a luminance corresponding to a video signal to a standard luminance. A second memory stores conversion curve information representing a representative conversion curve common to the pixels. A corrector converts, for each pixel, the luminance into a corresponding standard luminance value based on a corresponding luminance gain stored in the first memory, while a converter converts, for each pixel, the corresponding standard luminance into a corresponding voltage signal based on the conversion information stored in the second memory.

Owner:JOLED INC

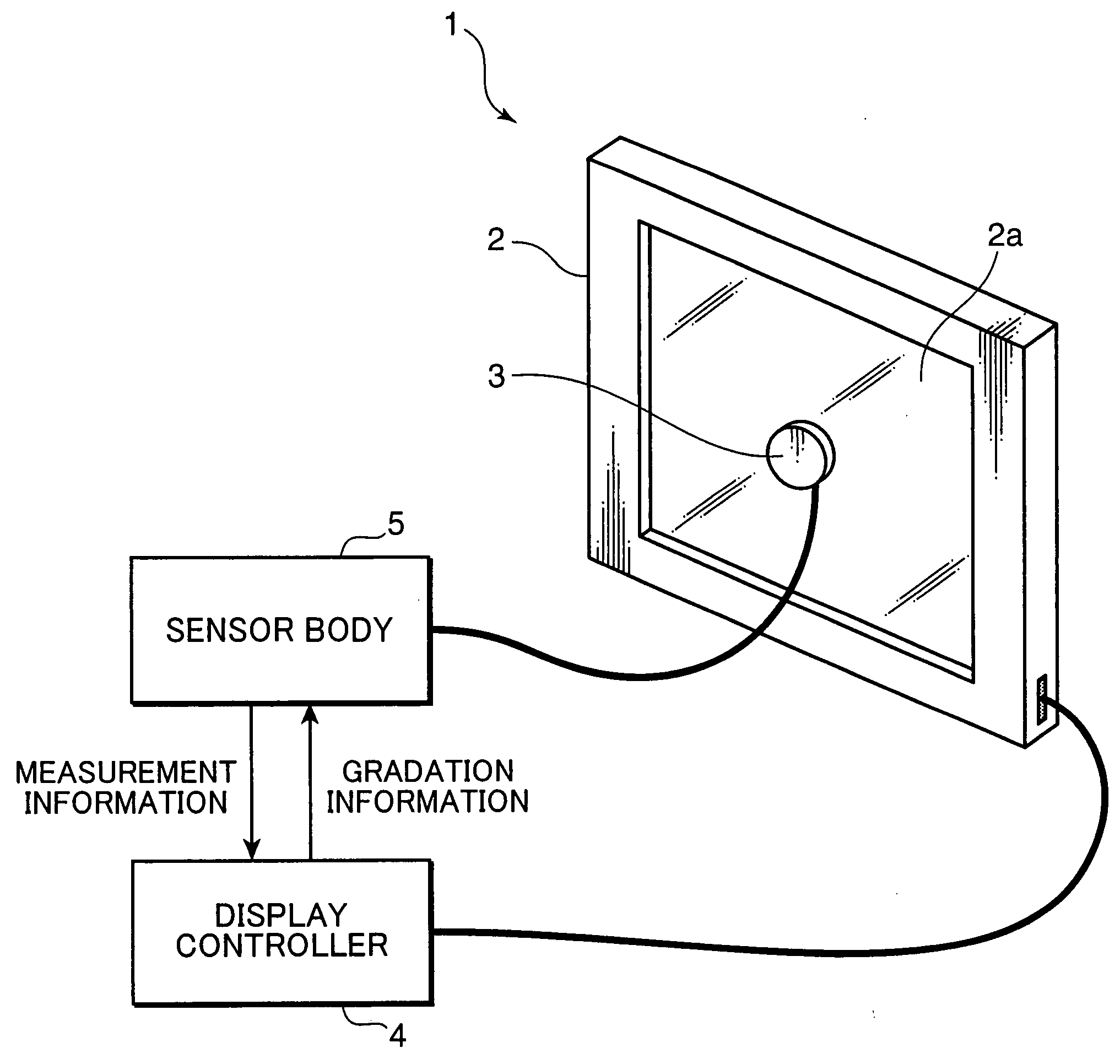

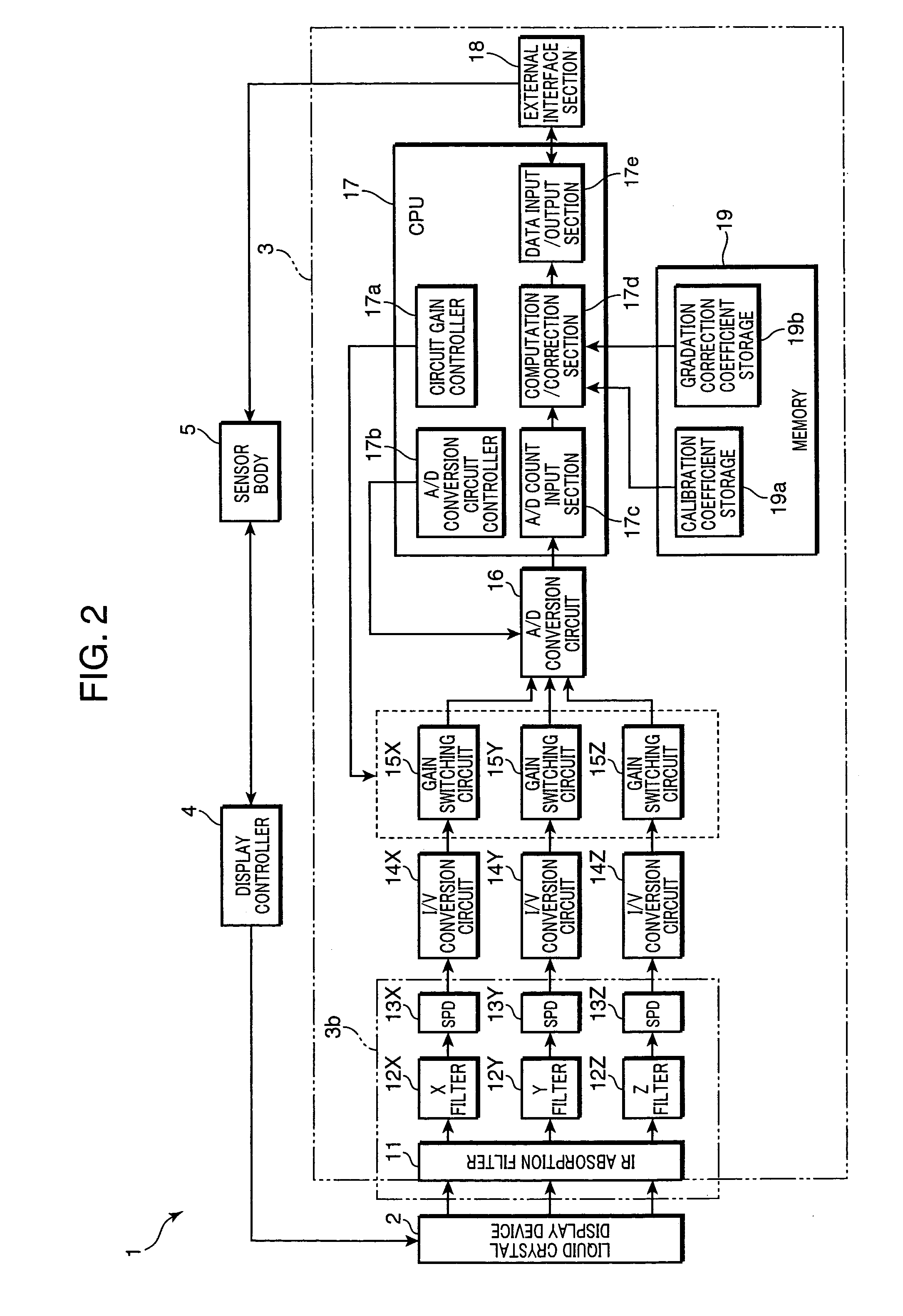

Color sensor unit for use in display device, color measuring device for use in display device, display system incorporated with color sensor unit, and display calibration method

InactiveUS20090179881A1Accurately chromaticityAccurate valueSparking plugsPhotometryMeasurement deviceDisplay device

In a color sensor unit for use in a display device, a color measuring device for use in a display device, a display system and a display calibration method of the invention, a CPU is operable to calculate a luminance value or a chromaticity value substantially equivalent to that to be obtained by a measuring device having a light receiving angle smaller than a light receiving angle of a sensor, by correcting a luminance value or a chromaticity value measured by the sensor based on gradation information from the display device.

Owner:KONICA MINOLTA SENSING INC

Method of manufacturing array substrate and method of manufacturing organic EL display device

The size of a foreign substance which is present between a cathode and an anode and which contributes to a short circuit therebetween is measured. On the basis of the measured size, the wavelength of a laser beam with which the foreign substance is irradiated is set, as is the number of times of irradiation. The foreign substance is irradiated with the laser beam to eliminate at least part of the foreign substance.

Owner:TOSHIBA MATSUSHITA DISPLAY TECH

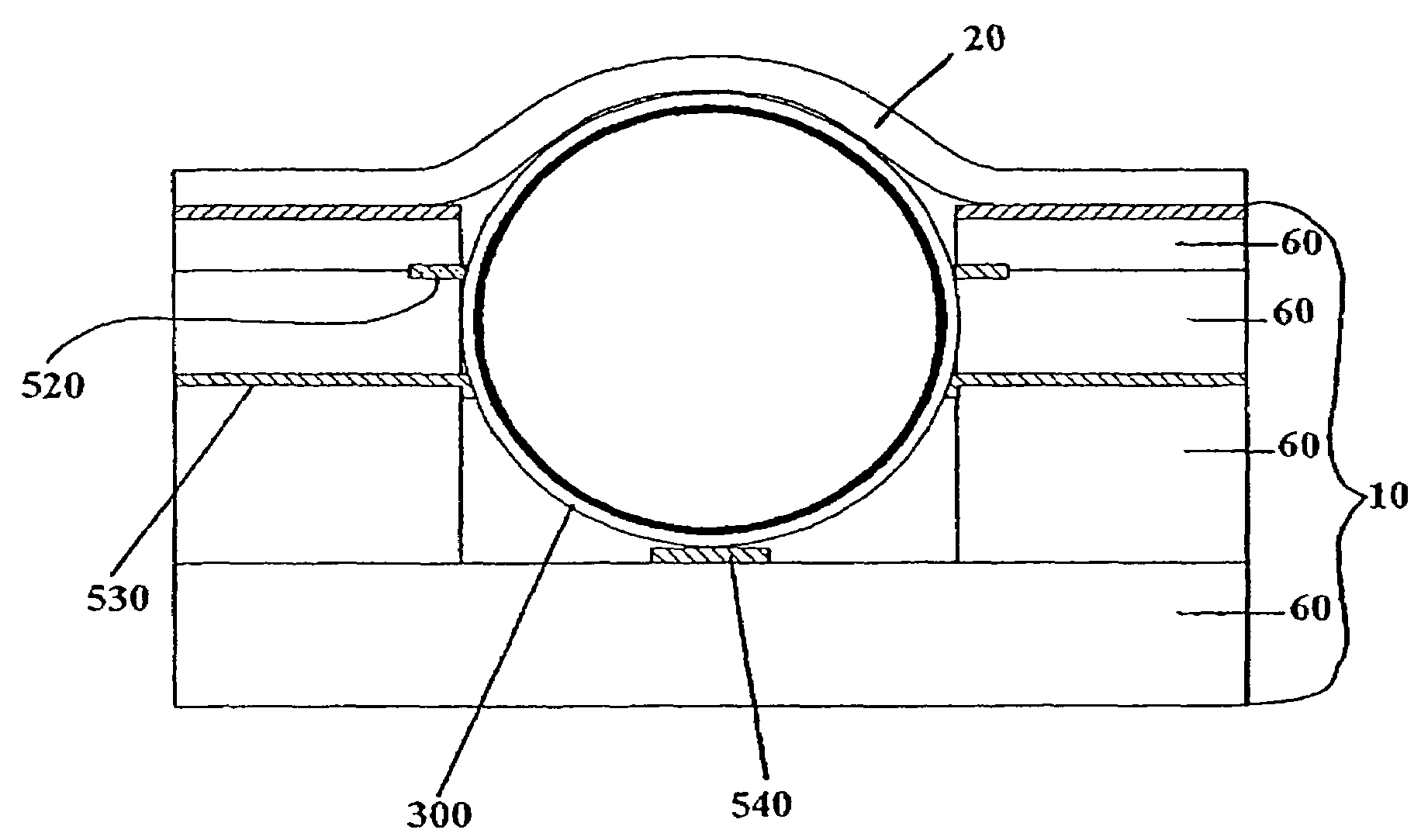

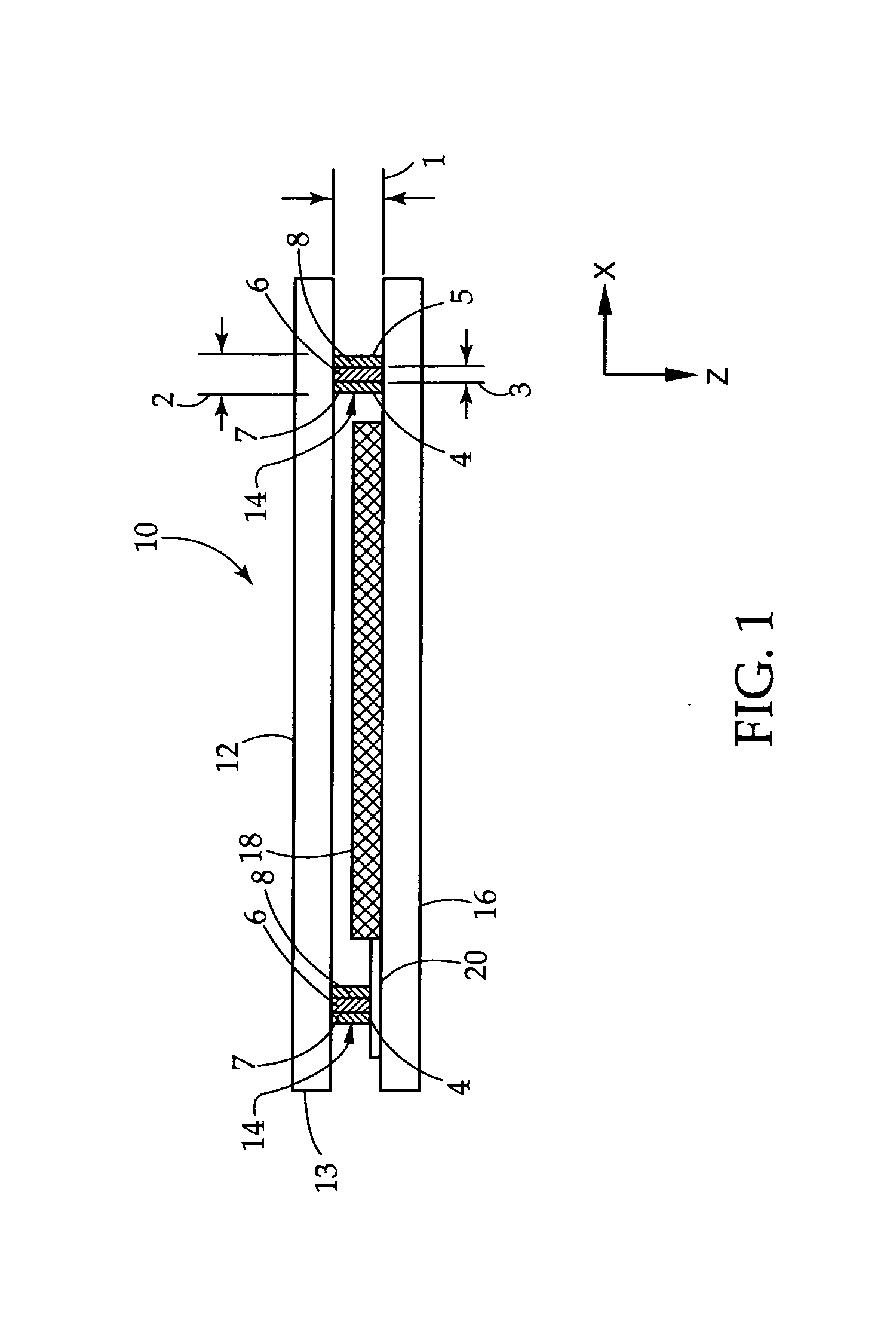

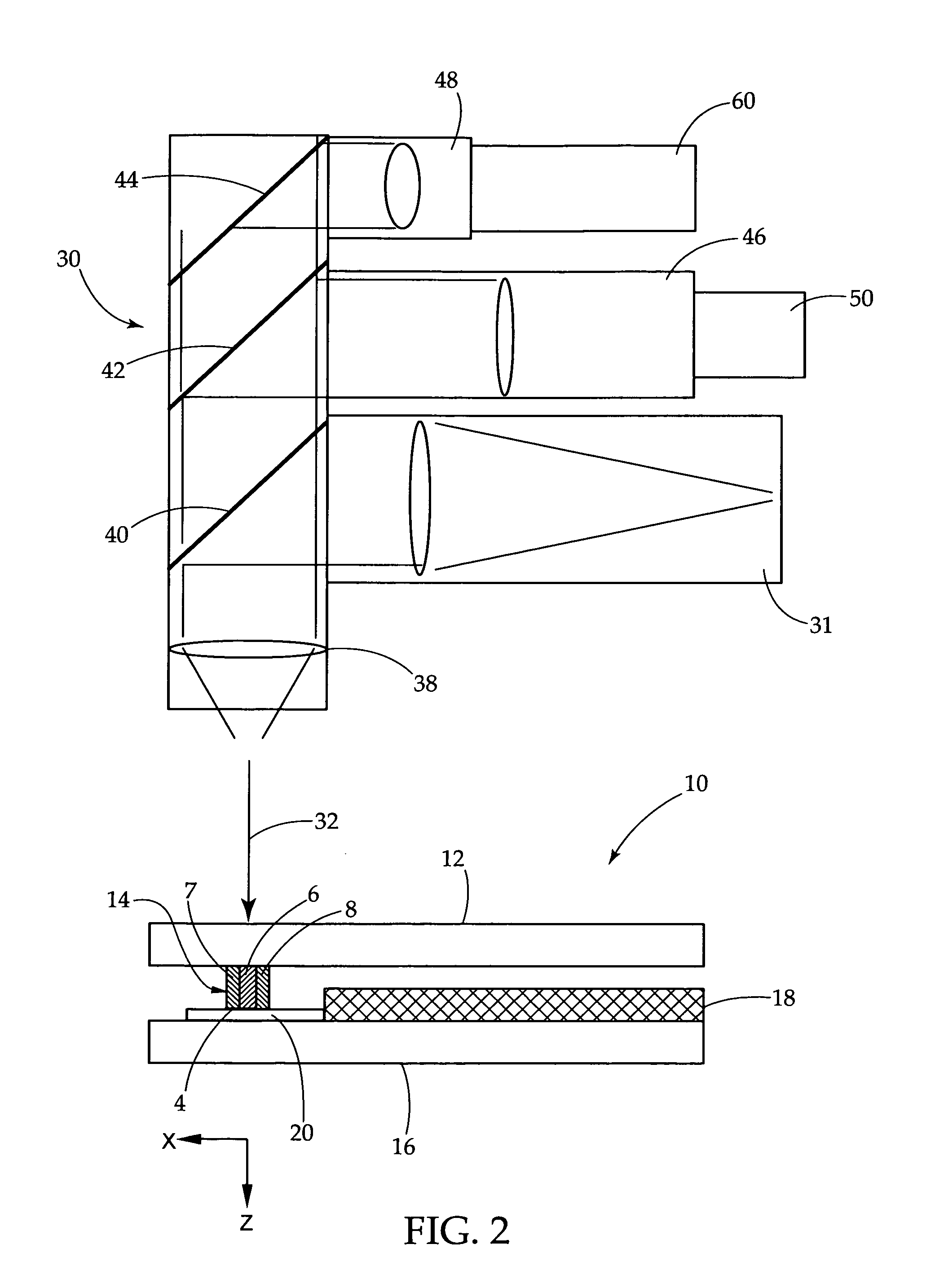

Glass packages and methods of controlling laser beam characteristics for sealing them

InactiveUS20090295277A1Less sensitiveAvoid excessive changesSparking plugsDischarge tube luminescnet screensHermetic sealDisplay device

A display device (10) including a first substrate (12), a second substrate (16), an OLED element (18), and a wall (14) that contains glass. A sealed portion (6) is formed in the wall and between the first substrate and the second substrate so as to produce a hermetic seal. The sealed portion is disposed in the wall so that unsealed portions (7,8) are disposed on opposite sides of the sealed portion. A width (3) of the sealed portion is from about 35% to about 77.3% of a width (2) of the wall. The sealed portion may be formed by heating the wall with a laser beam (32) so that a thickness (1) of the wall lies within the depth of focus (34) of the laser beam. Further, the width (36) of the laser beam can be less than or equal to the width of the wall.

Owner:CORNING INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com