Defect testing device and method

A defect inspection and defect technology, applied in measurement devices, image enhancement, instruments, etc., to achieve the effect of improving productivity and making it easier to judge whether it is qualified or not.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

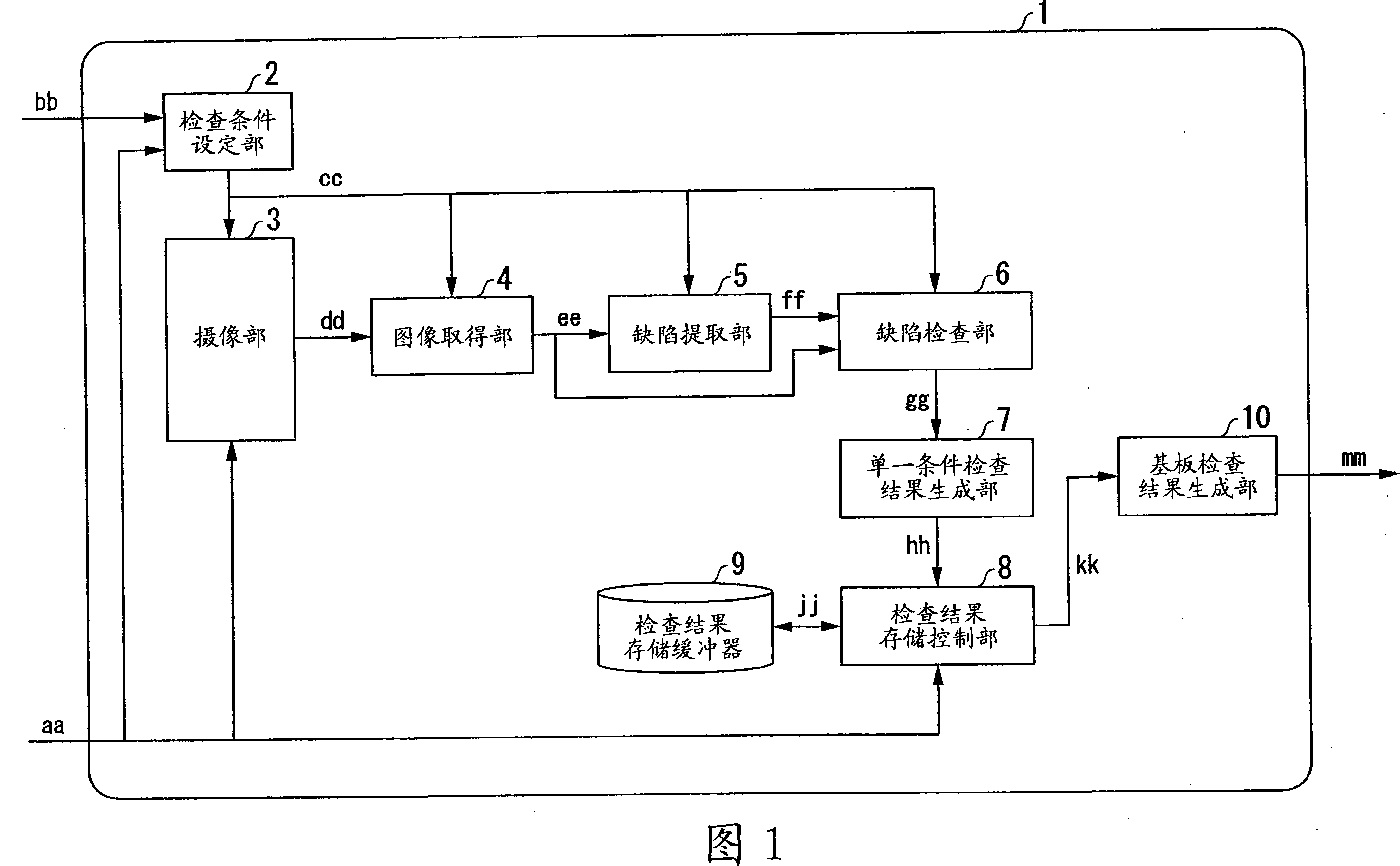

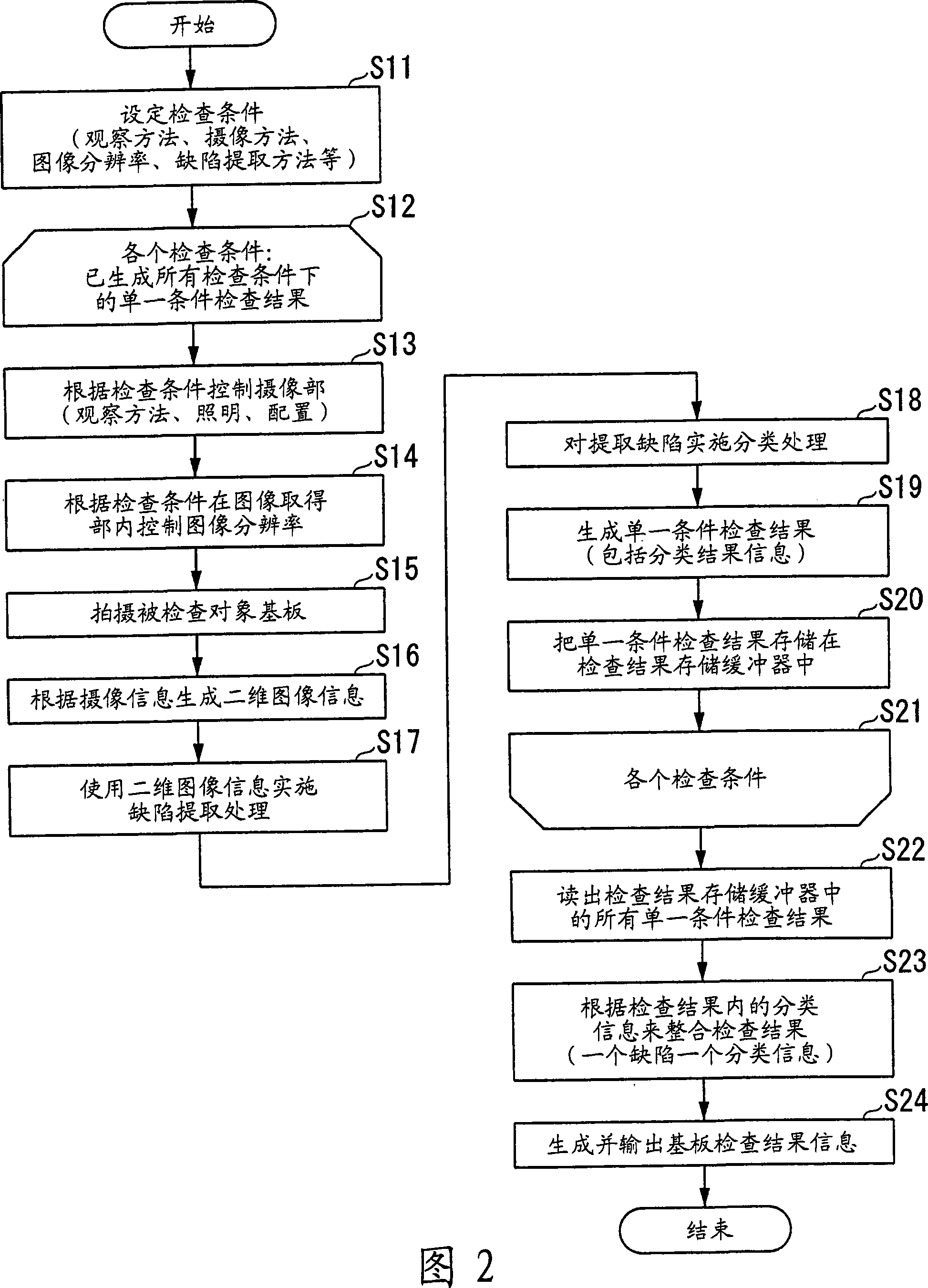

[0027] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In this embodiment mode, the present invention is applied to an inspection device for macroscopic inspection of a semiconductor wafer. FIG. 1 shows the configuration of an inspection device according to this embodiment. The inspection device 1 receives the control information aa for the control device, and related information indicating the substrate to be inspected (object to be inspected) (indicating the model number, process of the substrate, and the size and position of the chip and the exposure shot area (shot). The board information bb of design information, etc.) is used as input information from the outside. On the other hand, the inspection apparatus 1 outputs inspection result information mm related to an inspection target substrate as output information to the outside.

[0028] The control information aa and substrate information bb input into the inspection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com