Apparatus and method for inspecting pattern defect

A defect inspection and graphics technology, applied in the direction of measuring devices, optical testing flaws/defects, image communication, etc., can solve difficult and low-cost problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

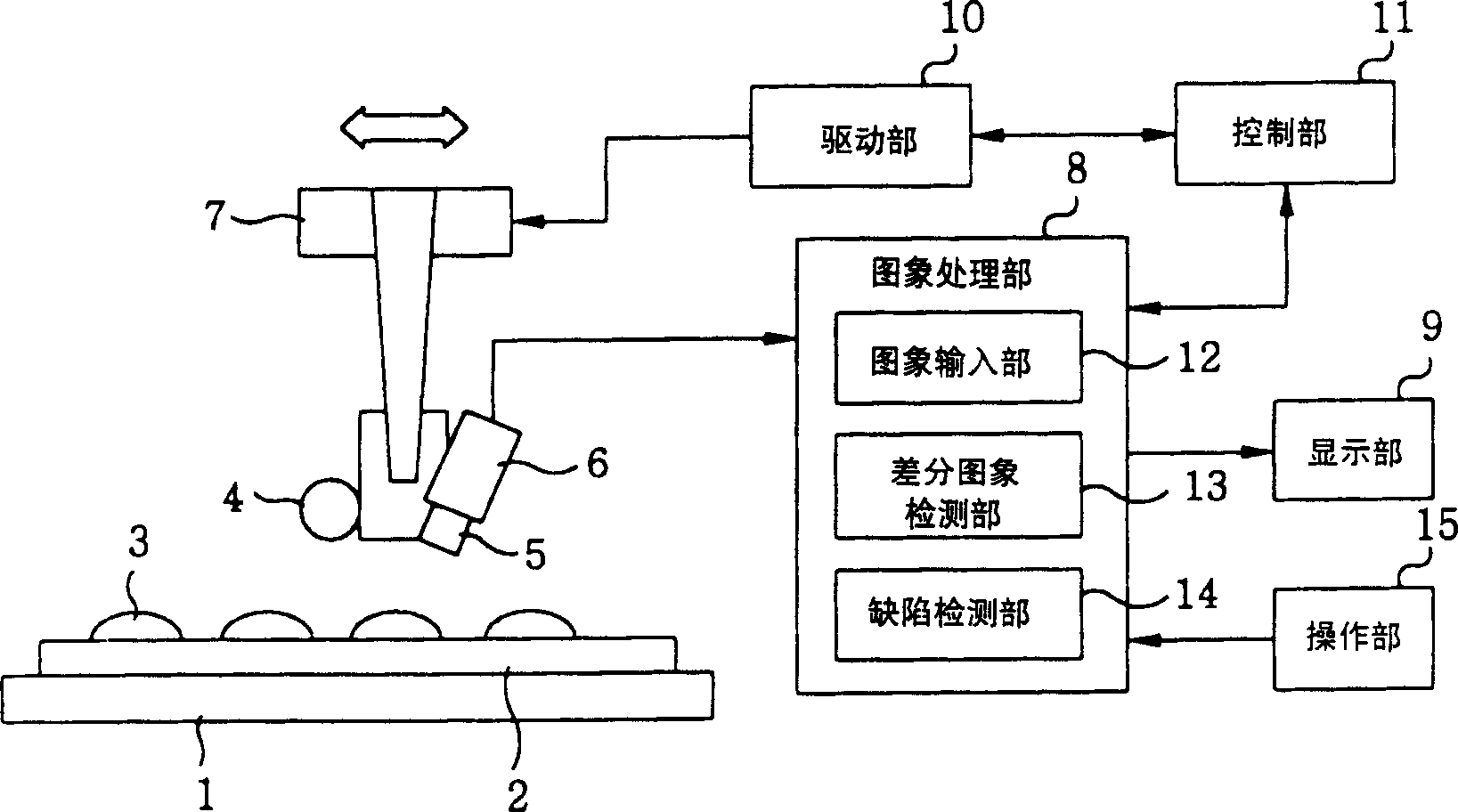

[0028] figure 1 is a diagram showing an embodiment of the pattern defect inspection device of the present invention. exist figure 1 Among them, 1 is a mounting platform for a glass substrate such as a plasma display, 2 is a glass substrate such as a plasma display, 3 is a phosphor (phosphor coating film) of R, G, and B, and 4 is for making the phosphor 3 emit light. 5 is an optical system equipped with lenses and color filters of R, G, and B, 6 is an imaging unit such as a line sensor camera for imaging, and 7 is an imaging unit 6 that makes the light source 4 The moving mechanism used to move and scan the upper surface of the glass substrate 2, 8 is an image processing part for detecting defects such as pinholes, 9 is a display part such as a color monitor or a printer for displaying inspection results or printing, and 10 is a drive A driving unit for the moving mechanism unit 7, 11 is a control unit for controlling the image processing unit 8 and the driving unit 10, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com