Clamping device, substrate transmitting device, and on-line fpd automatic optical detection device

A technology of clamping device and transmission device, which is applied in the direction of nonlinear optics, optics, measuring devices, etc., and can solve problems such as substrate scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0045] The upper and lower chucks capable of suctioning the substrate with vacuum will be explained in more detail below.

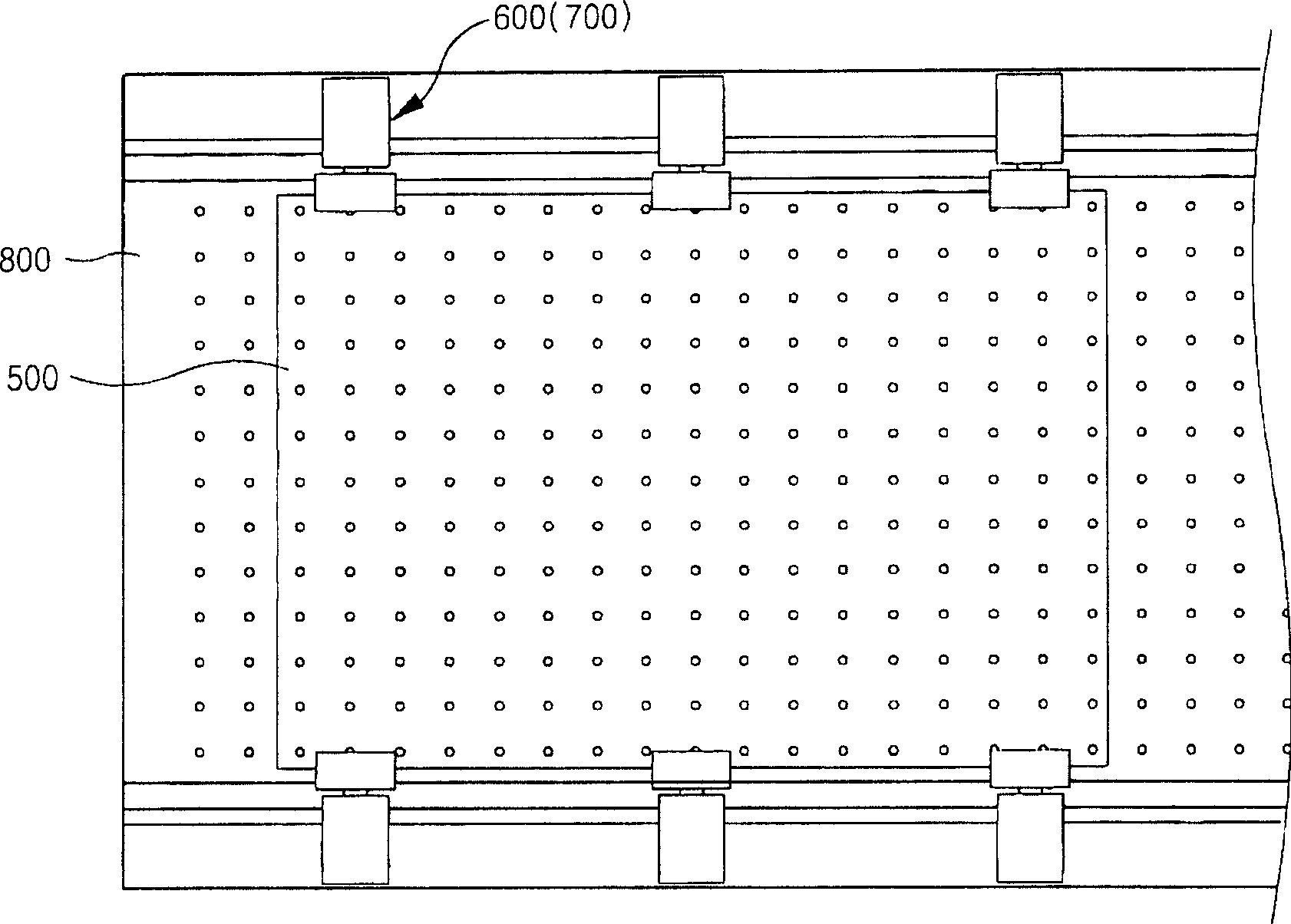

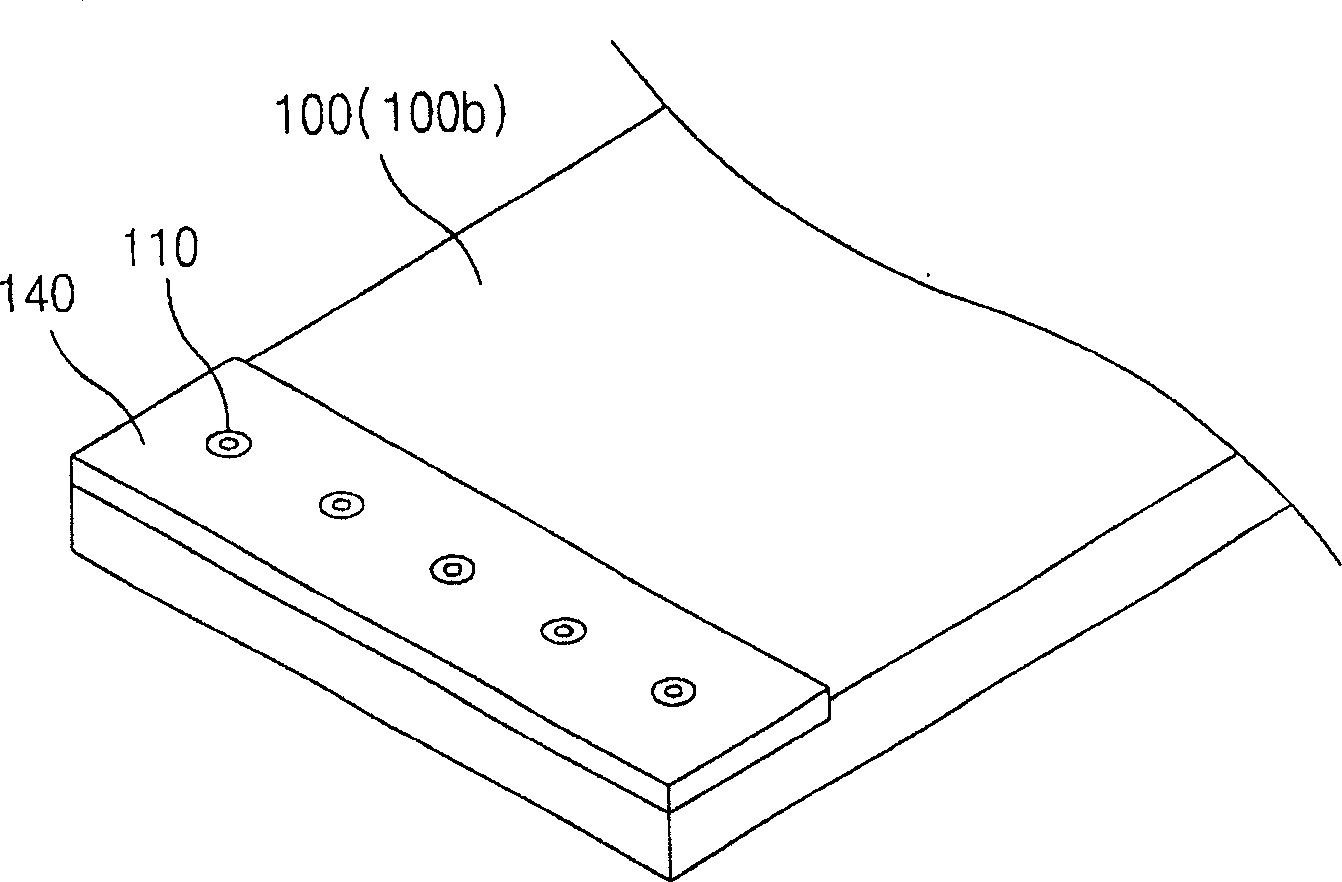

[0046] Such as Figures 3a to 5 As shown, the fixing unit 100 for fixing a substrate includes an upper chuck 100a and a lower chuck 100b. A suction nozzle 110 for sucking and fixing the substrate 500 is formed on at least one of opposing surfaces of the upper chuck 100 a and the lower chuck 100 b facing each other. In other words, at least one of the opposite surfaces is provided with a through hole 150 passing through the upper chuck 100a and the lower chuck 100b. The suction nozzle 110 is disposed in the through hole 150 . At this time, the suction nozzle 110 may be formed on one or both opposing surfaces of the upper chuck 100a and the lower chuck 100b. If the suction nozzles 110 are formed on two opposite su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com