Winding mould and deflection coil

A deflecting coil and winding technology, which is applied in the field of deflection coils and line product rate adjustment slots, can solve problems such as changes in line product rate and unimproved picture quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

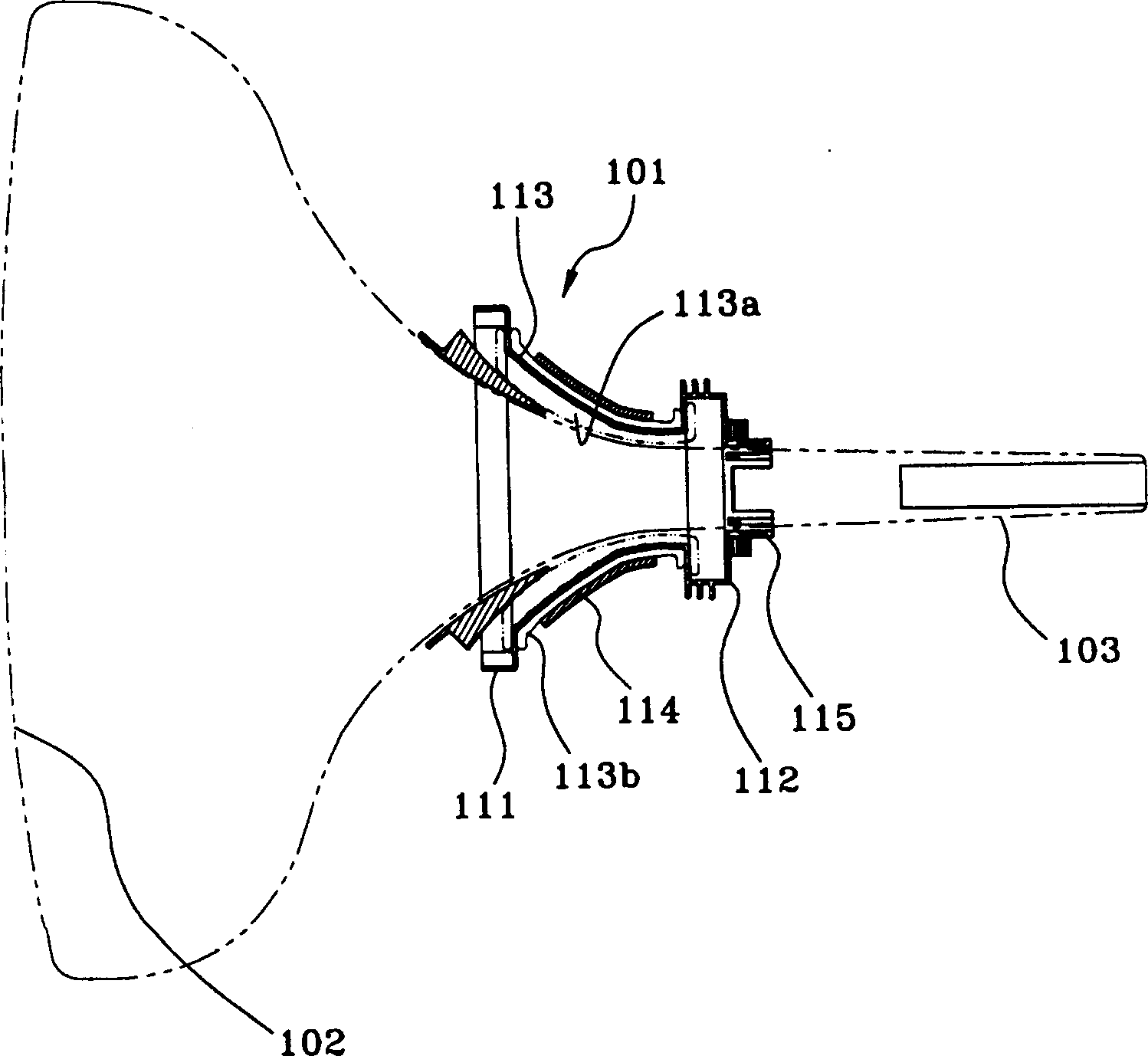

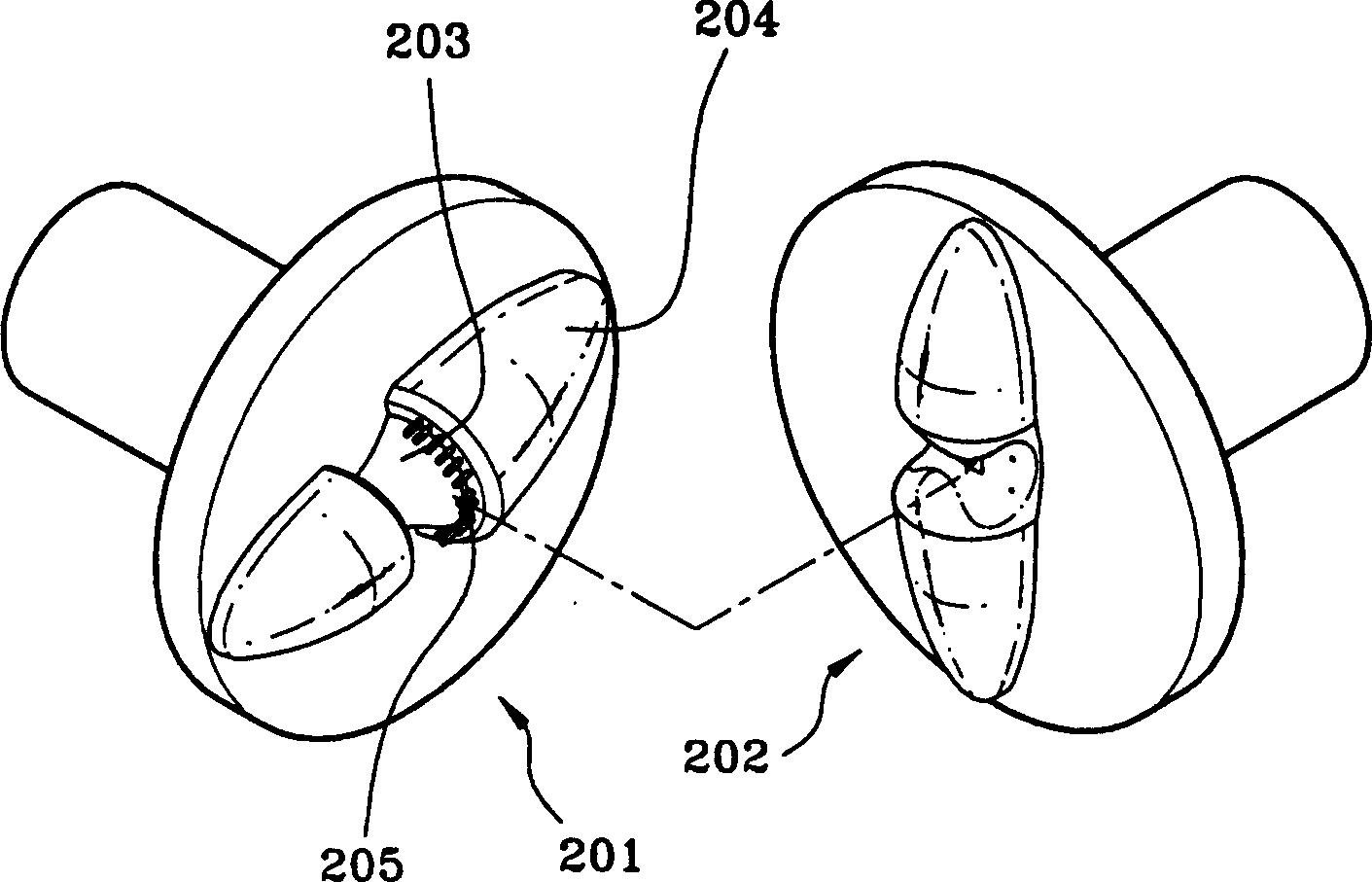

[0048] Hereinafter, a correct example of the winding die of the present invention and a deflection yoke produced therefrom will be described in detail with reference to the drawings. The same symbols are used for the same elements in different drawings. Furthermore, the invention is not limited to the examples described.

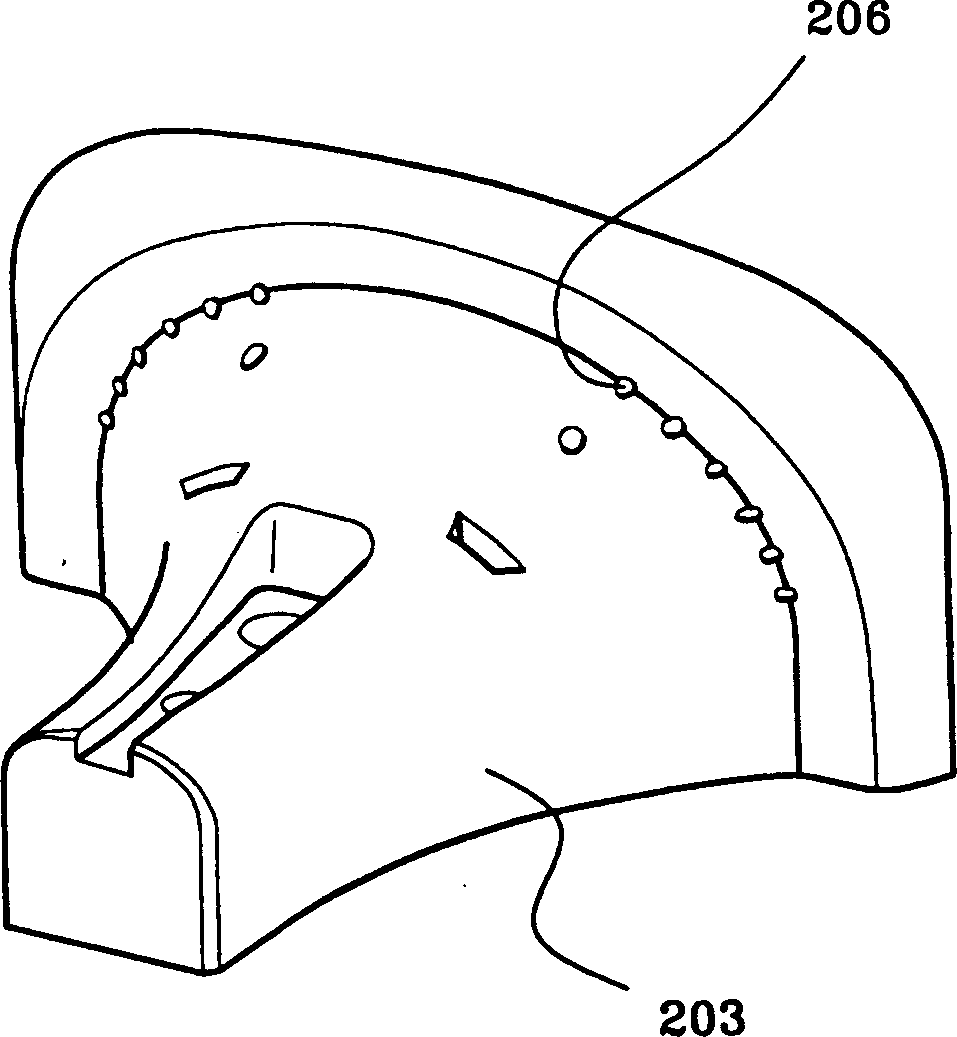

[0049] Figure 8 is an oblique view illustrating a correct example of an A-type wire winding die according to the present invention. In the center of the above-mentioned wire winding mold, there is a wire winding surface 3 with a certain degree of curvature. In the above-mentioned wire winding surface 3, in order to increase the line area ratio of the winding lines, any part of the overall surface has a certain degree of protrusion according to the vertical direction of the winding lines. The lead groove 7.

[0050] In addition, guide surfaces 4 having curved surfaces and inclinations are formed on both sides of the winding surface 3 . In the inner side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com