Deflecting coil for cathode ray tube and its manufacture method

A cathode ray tube and deflection yoke technology, applied in the field of deflection yoke, can solve the problems of reducing the deflecting coil's ability to resist external environmental interference, defects in volume, weight, display speed and accuracy, and the inability to fully meet the deflecting coil requirements, and improve the The ability to resist external environmental interference, superior performance, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

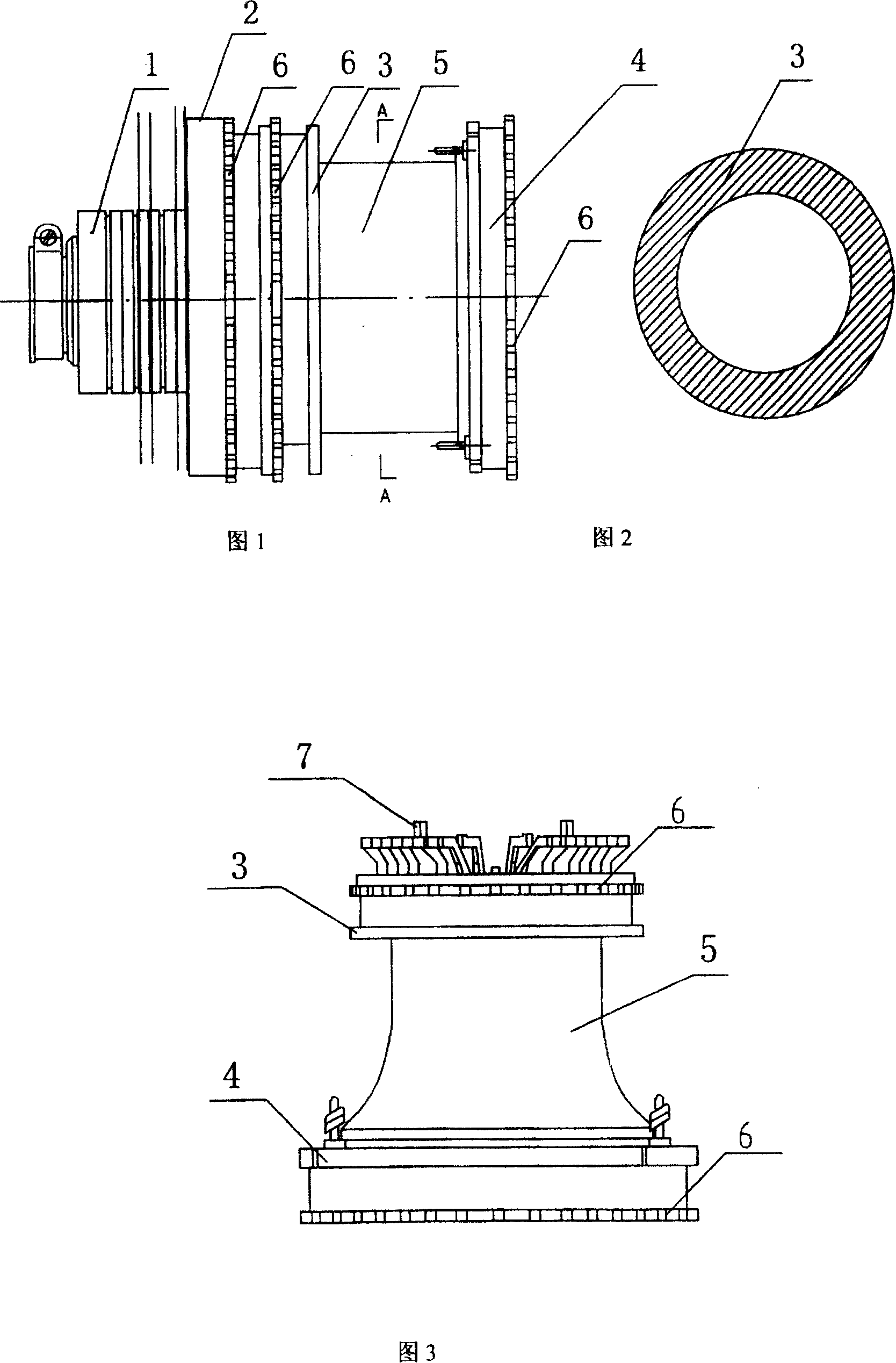

[0023] As shown in FIG. 1 , the deflection yoke includes a magnetic core 5 , a convergence correction component 1 , and insulators 2 , 3 , 4 made of epoxy resin. The magnetic core shown in Figure 2 is a hollow cylinder made of ferrite amorphous alloy strip. The performance parameters of ferrite materials are: initial permeability μ=15000; maximum permeability μm=70000; resistivity ρ(μΩ / cm)=80; Curie temperature T c (℃)=570; Saturation magnetic induction B s (T) = 1.2; residual magnetic induction B r (T)=0.35; coercive force Hc (A / m)=4.

[0024] The magnetic core 5 serves as the loop of the magnetic force line and is also the main supporting part of the deflection coil, and insulating rings are fixed at both ends of the magnetic core. The insulating ring includes an upper ring 4, a middle ring 3, and a bottom ring 2, and the upper ring 4 and the middle ring 3 are fixed on the two ends of the magnetic core 5, and the bottom ring 2 is fixed on the middle ring 3 by connecting t...

Embodiment 2

[0027] As shown in Figure 3, the amorphous alloy used in Example 1 is used to make a combination with a cylindrical shape at one end and a trumpet shape at the other end. After heat treatment, it will be used as the magnetic core 5, and then an insulating ring, epoxy The resin ring includes an upper ring 4, a middle ring 3, and a bottom ring. The upper ring 4 and the middle ring 3 are fixed on both ends of the magnetic core 5. The bottom ring is provided with tooth holes, and the middle ring 3 is provided with matching connecting teeth 7. The bottom ring It is fixed on the middle ring 3 through the connecting teeth 7 on the middle ring 3 . The upper ring 4 of the insulating ring is installed on the horn end of the magnetic core 5 , and the tooth-shaped epoxy resin ring 6 as described in Embodiment 1 is set on the upper ring 4 and the middle ring 3 . The line coil is wound on the upper ring and the middle ring, and the field coil is wound on the upper ring and the bottom ring; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com