Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

540results about "Gas discharge electrodes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

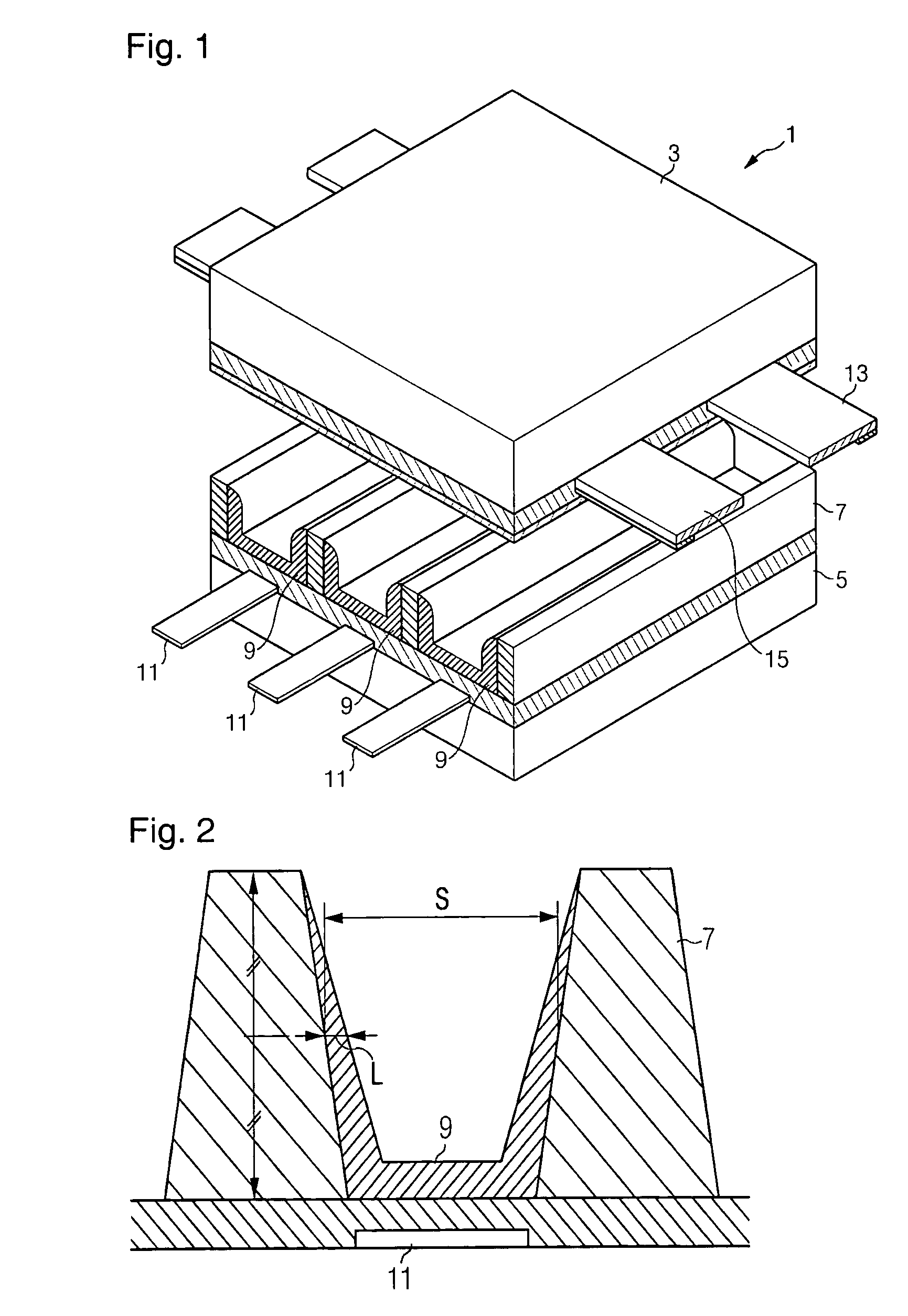

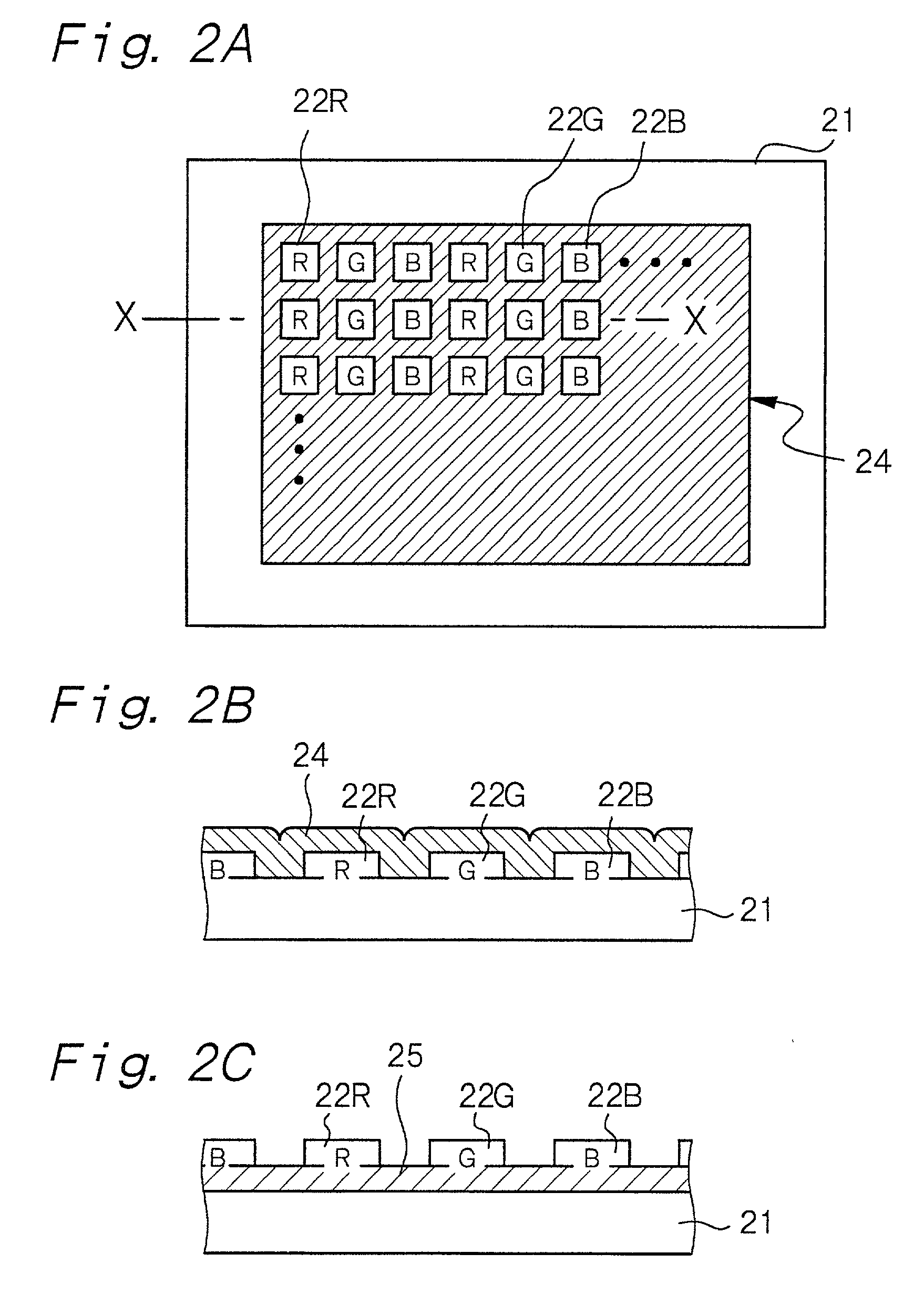

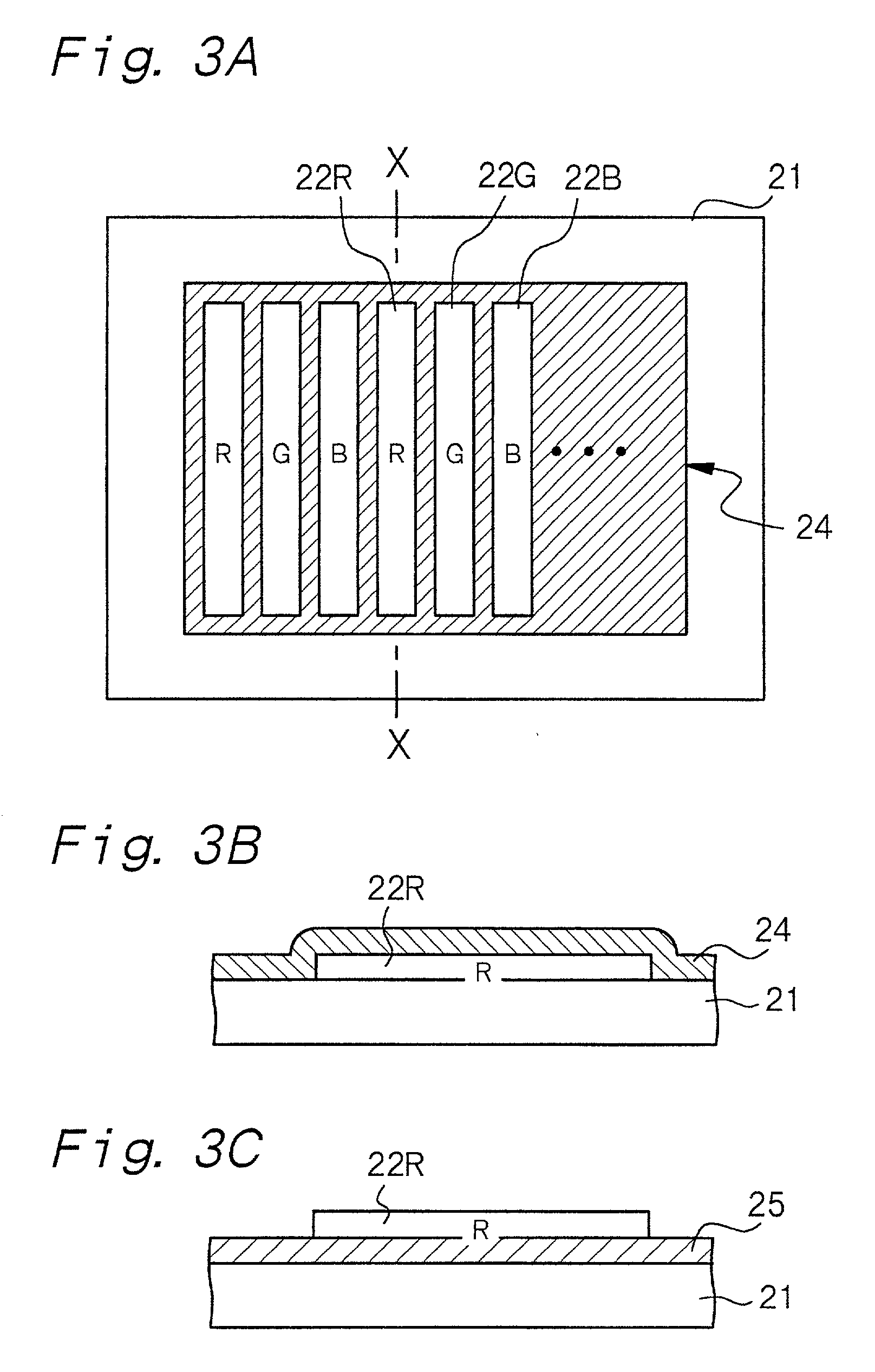

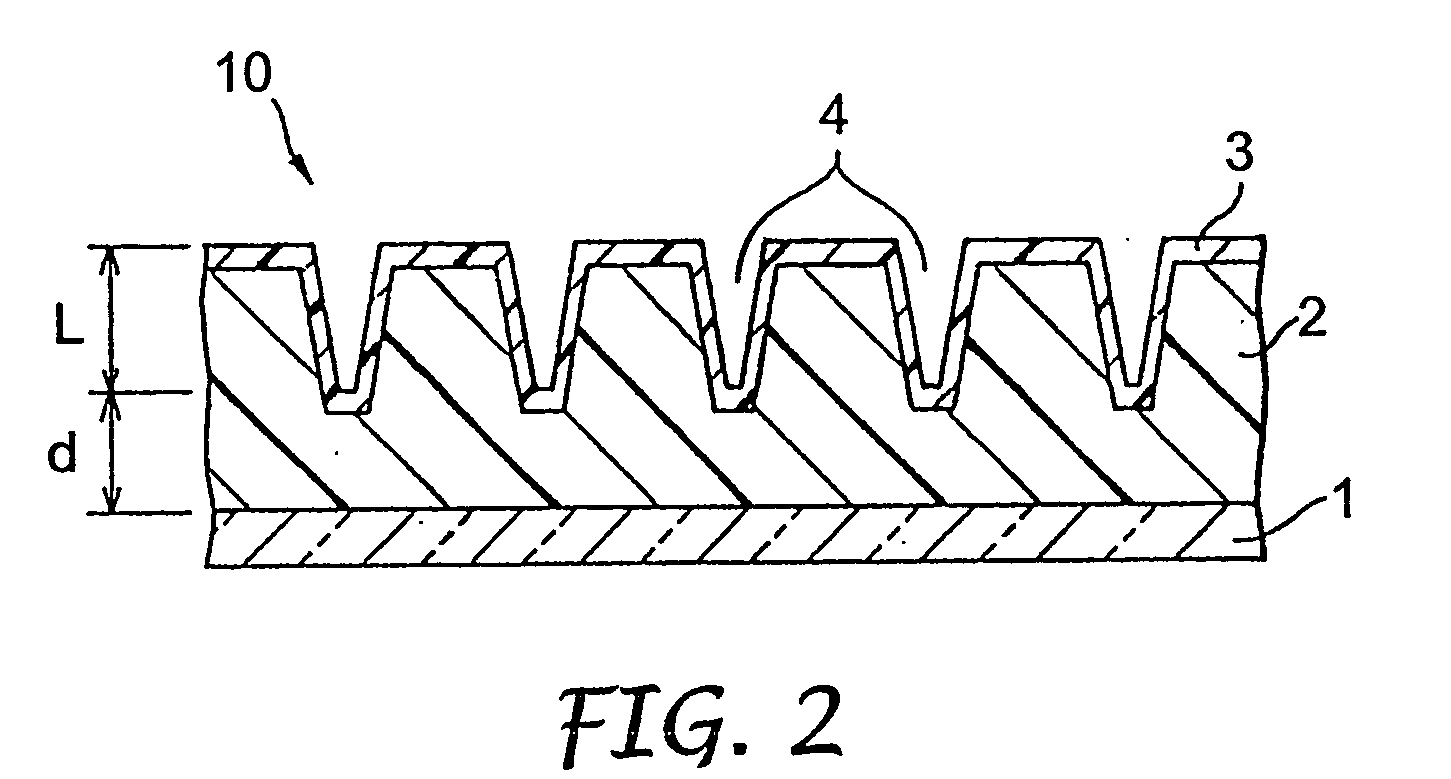

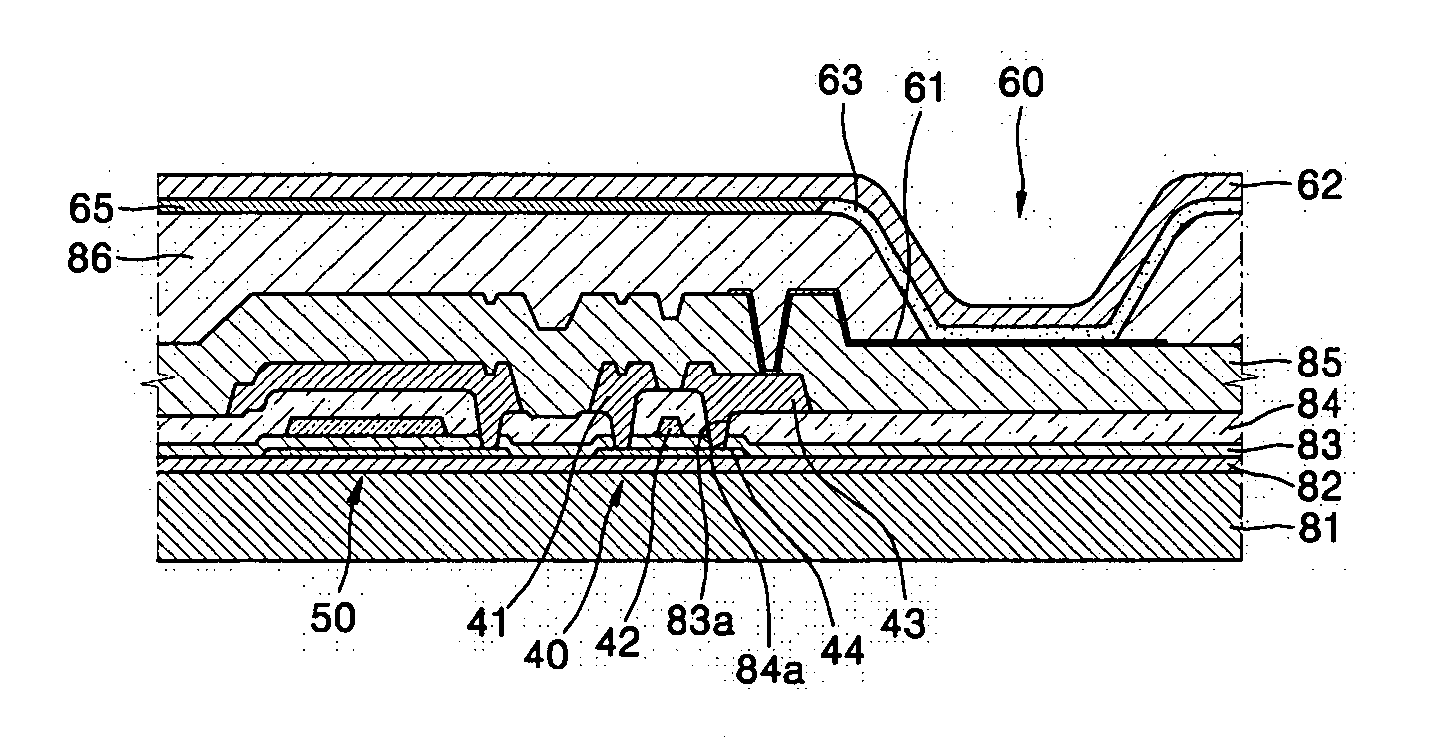

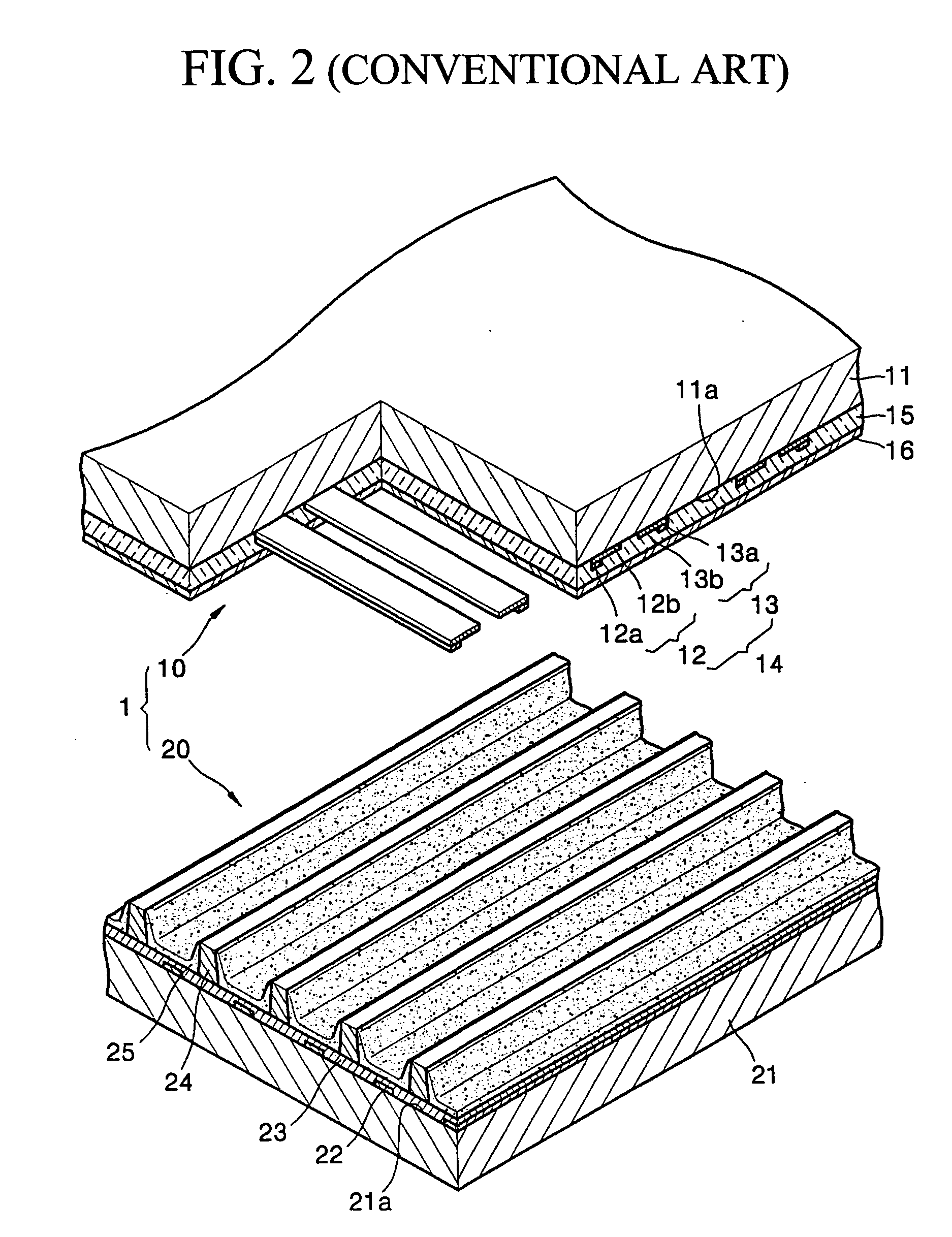

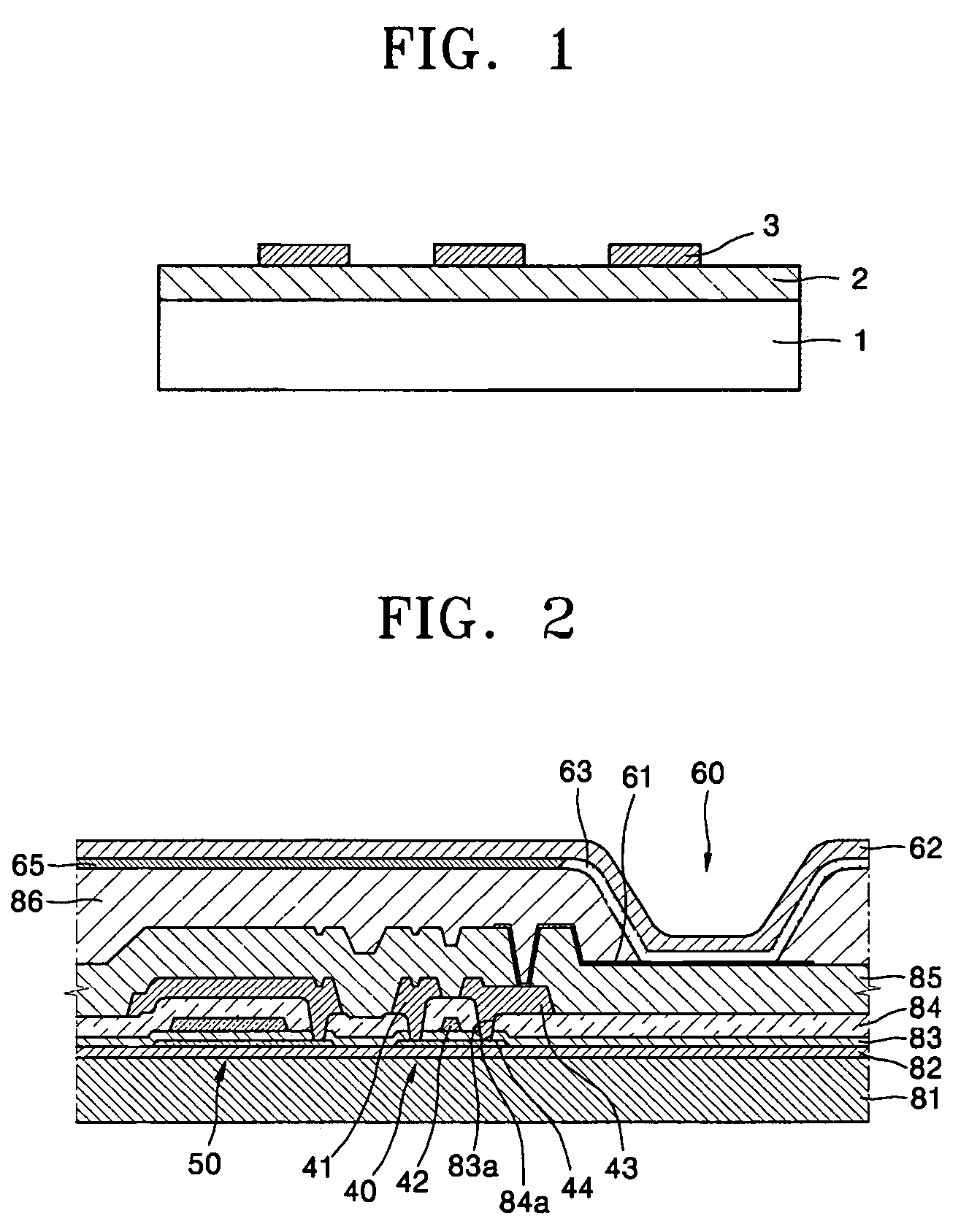

Plasma display panel with defined phosphor layer thicknesses

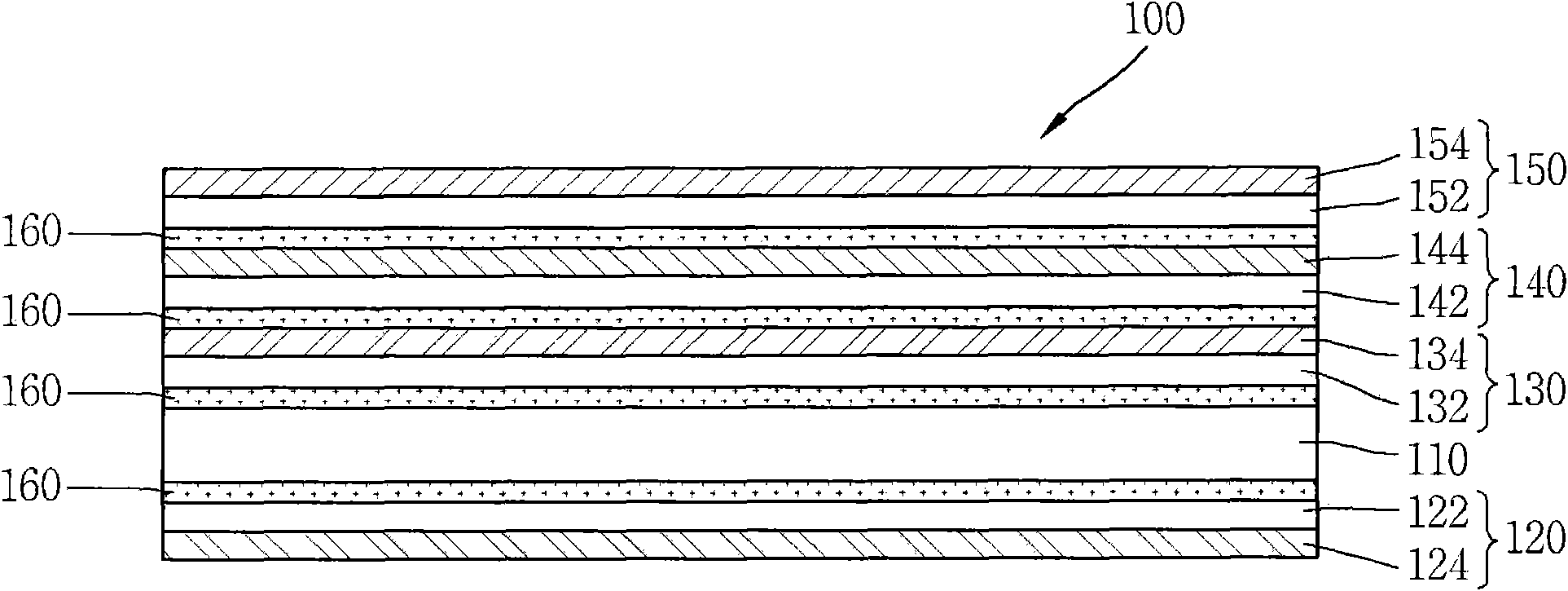

InactiveUS7164231B2Increase brightnessGood colorDischarge tube luminescnet screensGas discharge electrodesPhosphorOptoelectronics

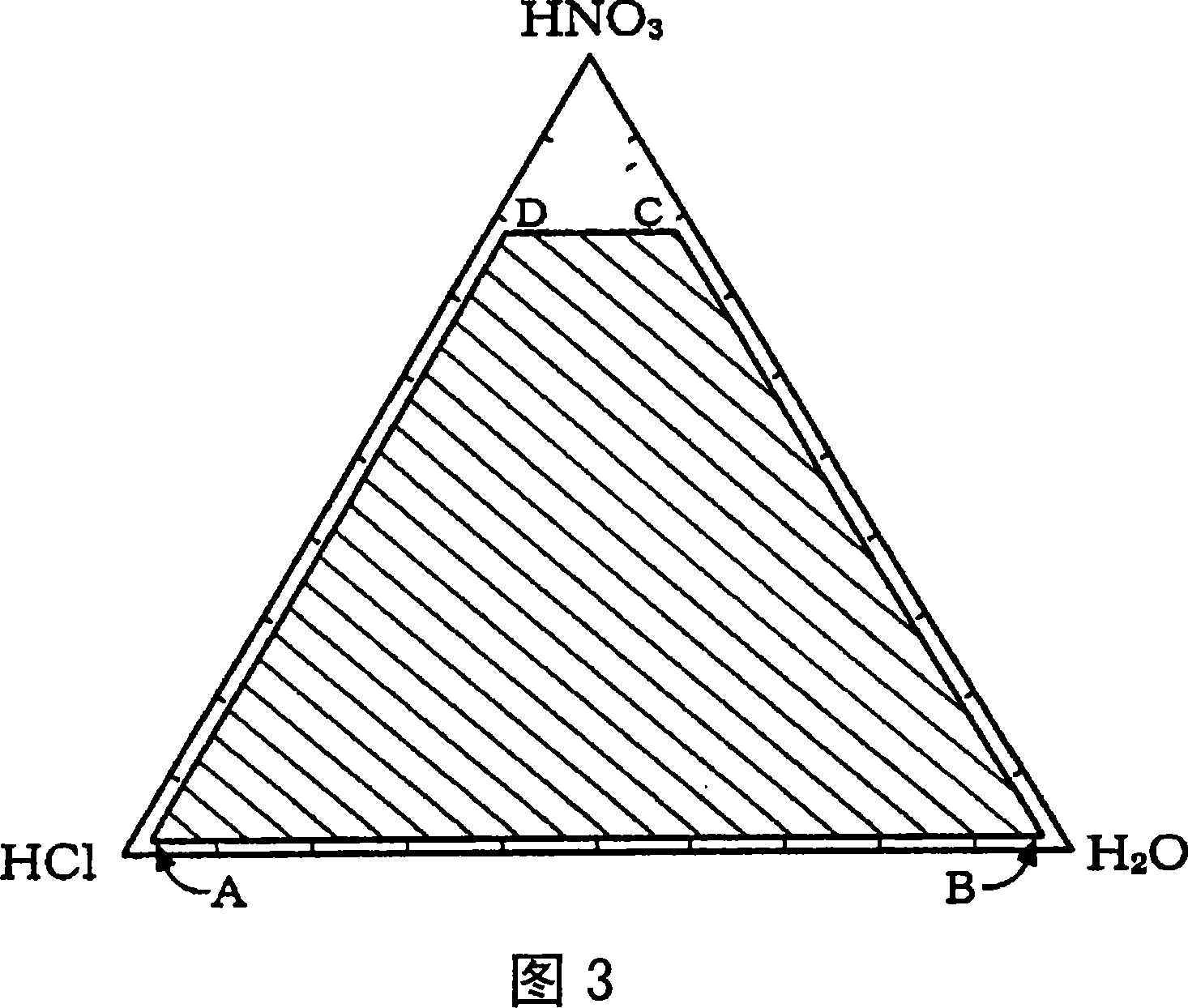

A plasma display panel includes a red phosphor layer, a green phosphor layer, and a blue phosphor layer. The thickness of the phosphor layer is satisfied by the following condition: when D is (S−2L) / S, D≧0.64, S being a distance between barrier ribs at half the height of the barrier ribs, and L being a side thickness of the phosphor layer coated on the barrier ribs at half the height thereof.

Owner:SAMSUNG SDI CO LTD

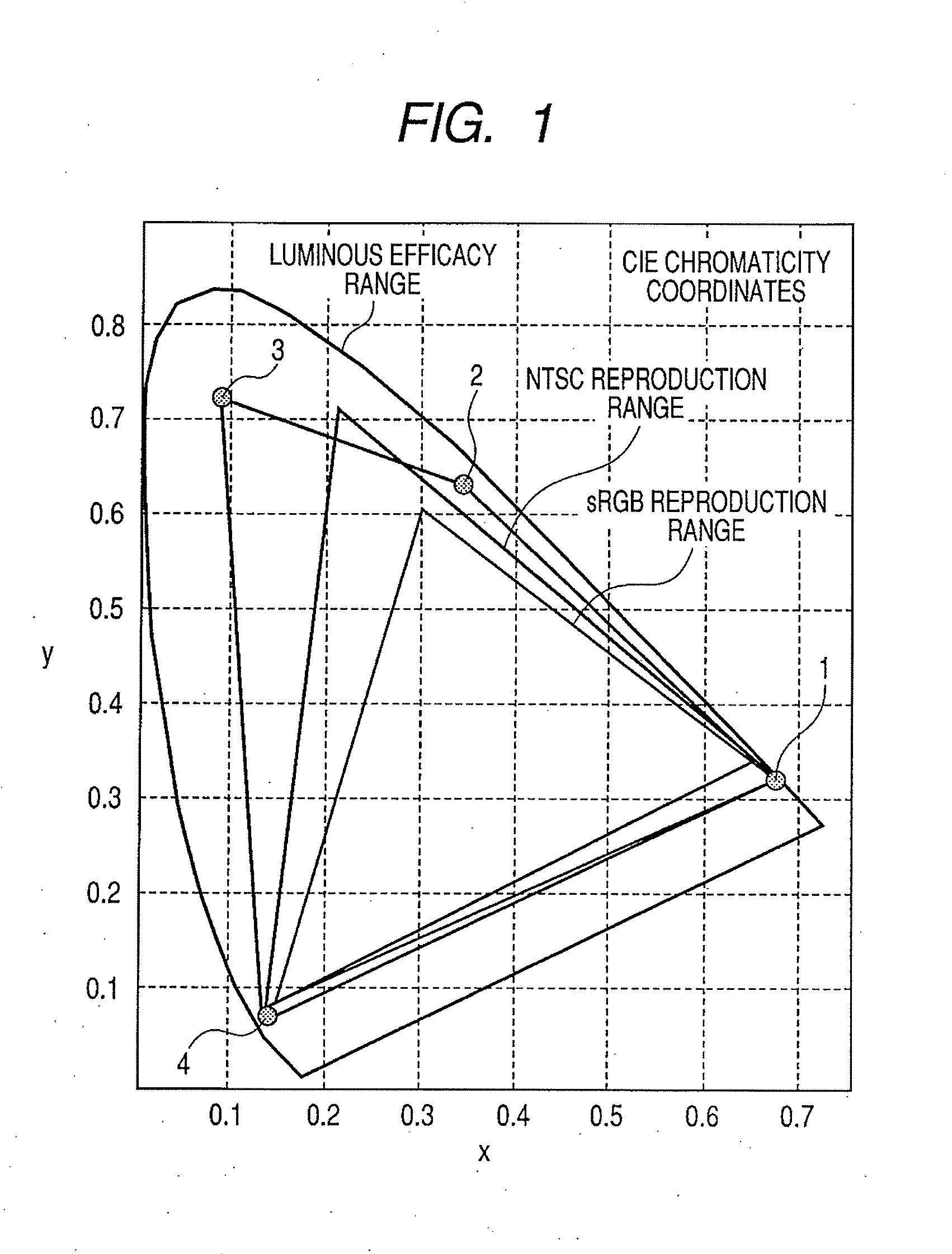

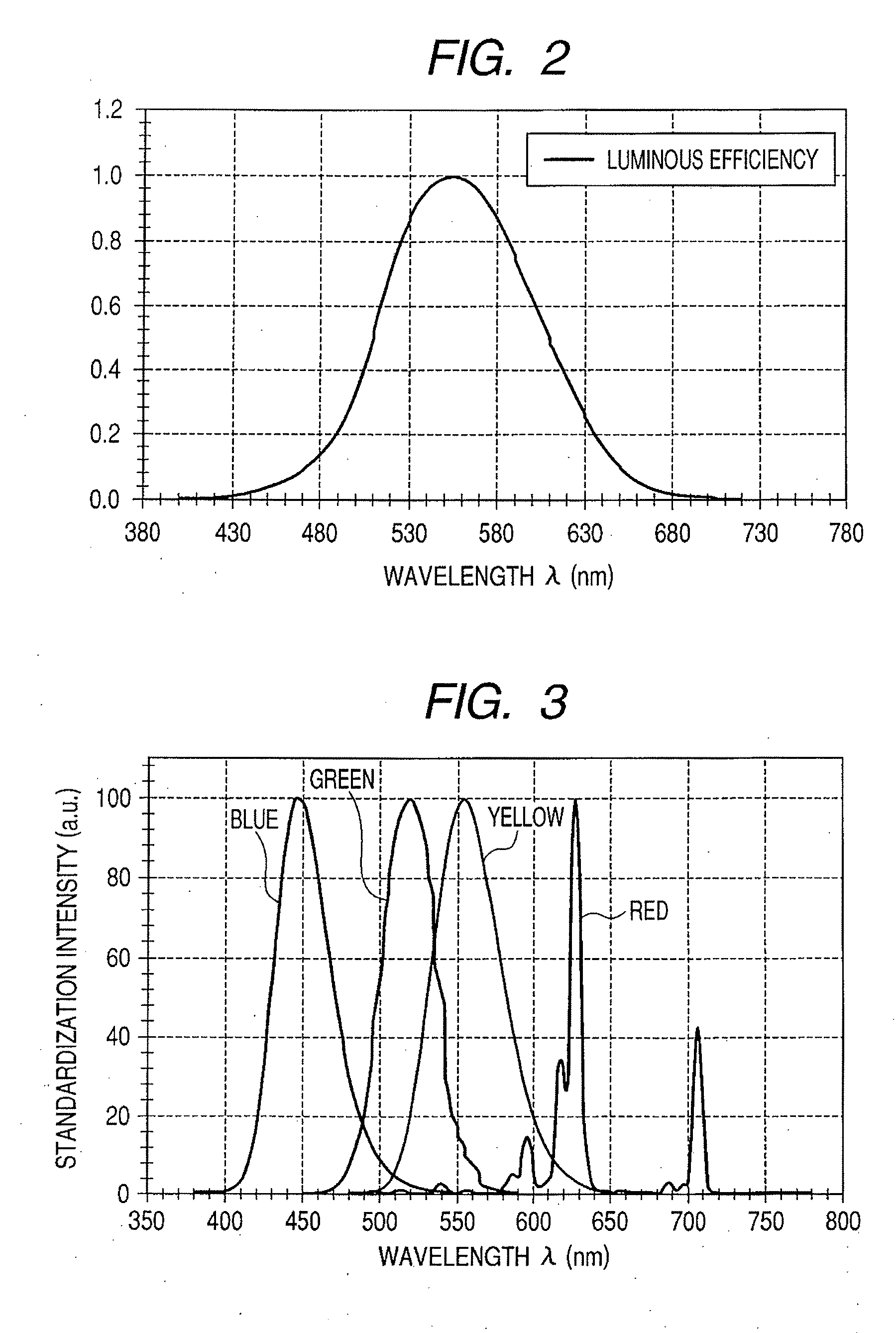

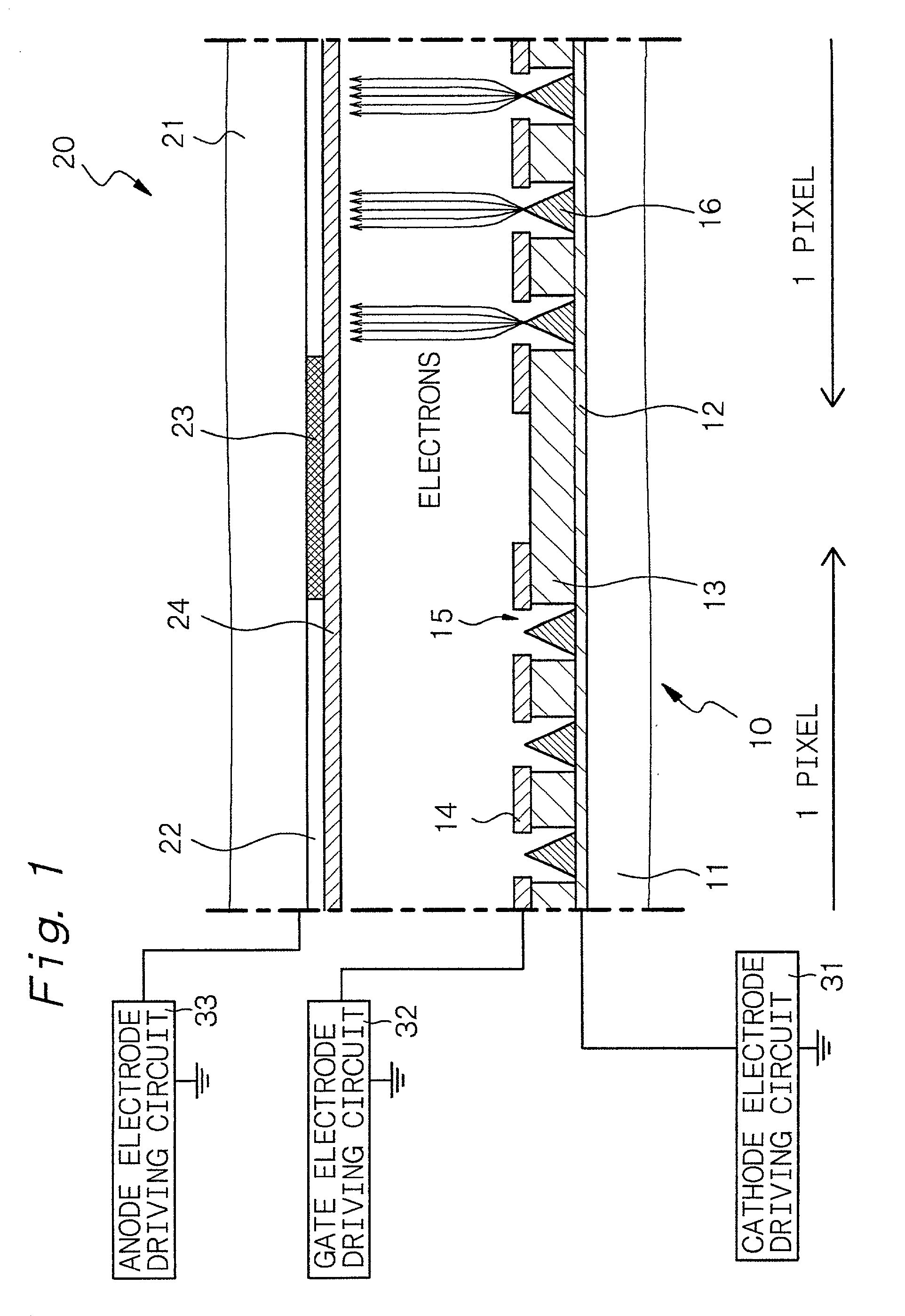

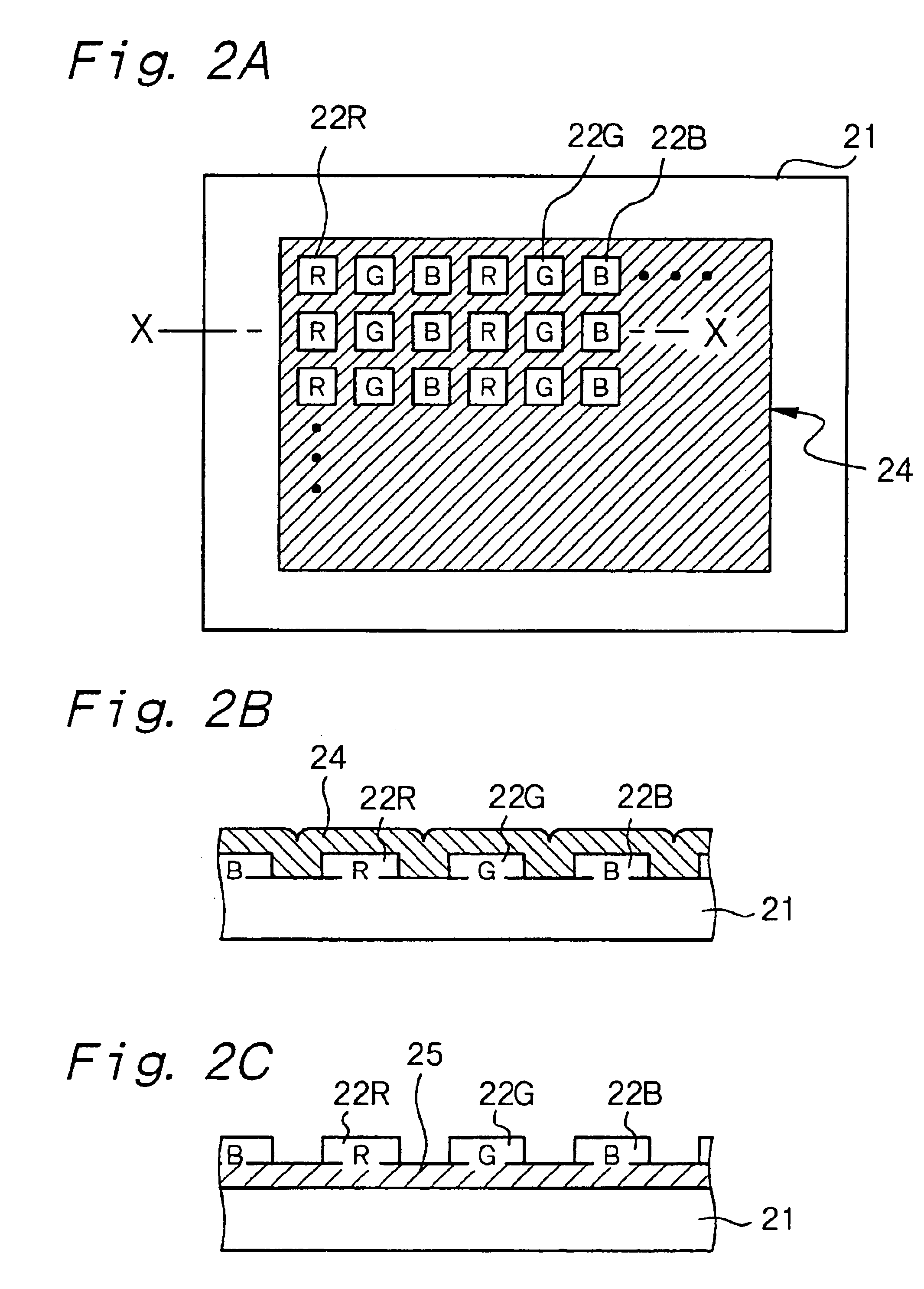

Multiprimary color display

InactiveUS20070268205A1Wide color reproduction rangeIncrease brightnessGas discharge electrodesStatic indicating devicesColor imageDisplay device

A display displays a color image by using a light source of at least four or more primary colors, and at least one color of the light source is yellow. Thus, it is possible to provide a flat panel display that can acquire a wider color reproduction range without sacrificing luminance.

Owner:CANON KK

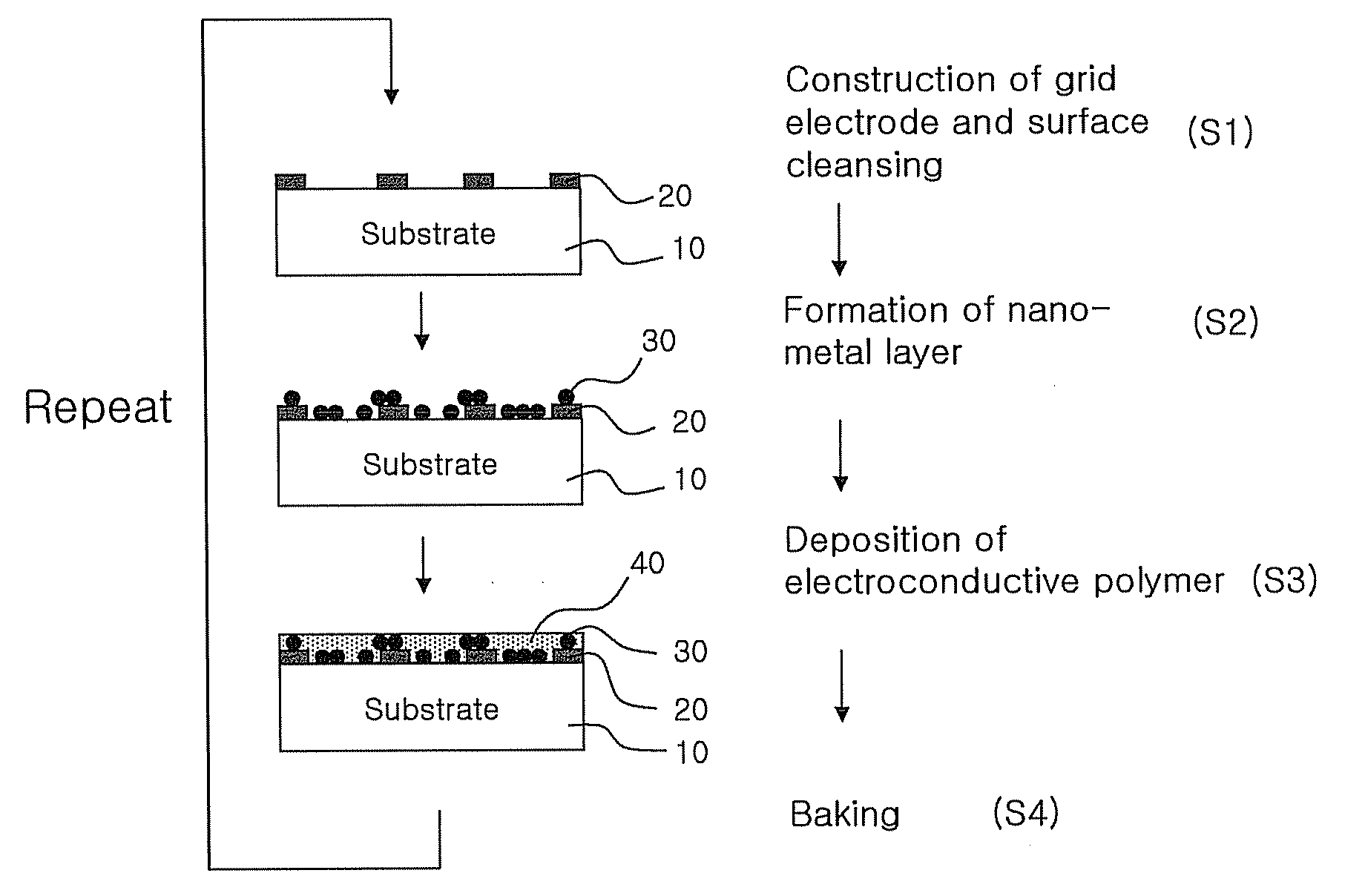

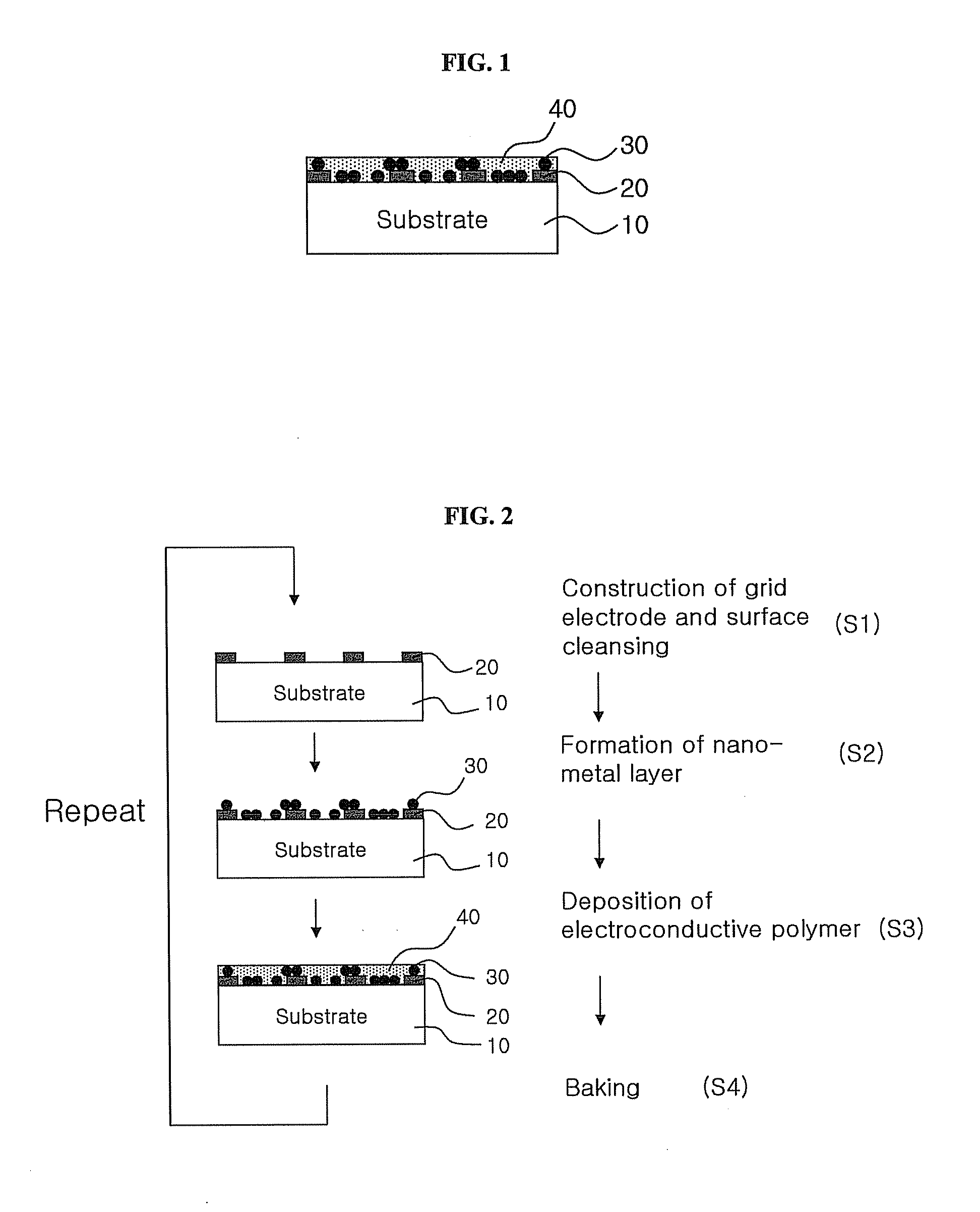

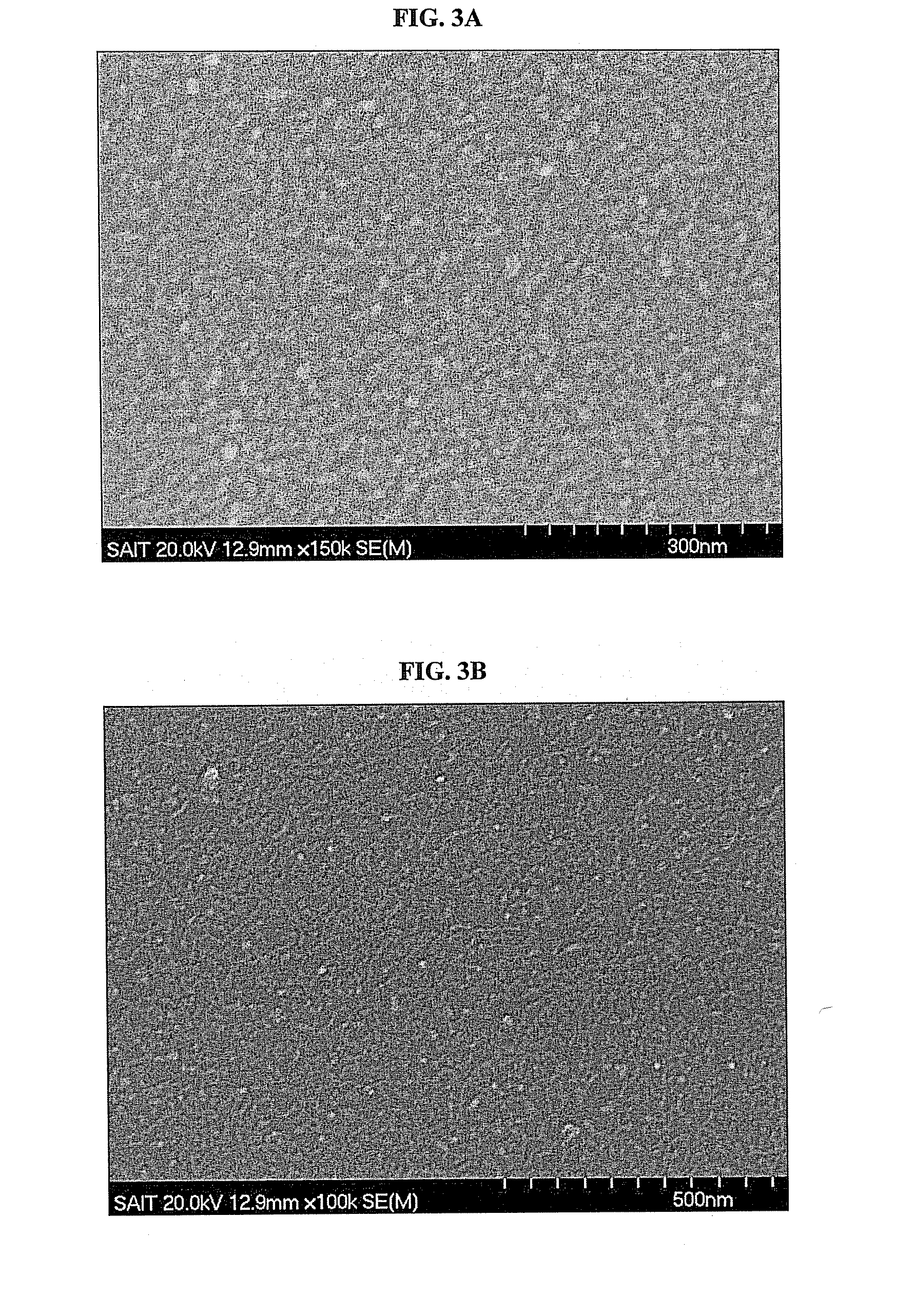

Transparent electrode and preparation method thereof

ActiveUS20070181878A1High light transmittanceLower resistanceControl electrodesGas discharge electrodesProduction rateConductive polymer

Disclosed herein is a transparent electrode featuring the interposition of a nano-metal layer between a grid electrode on a transparent substrate and an electroconductive polymer layer, and a preparation method thereof. The transparent electrode can be produced in a continuous process at high productivity and low cost and can be applied to various display devices.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

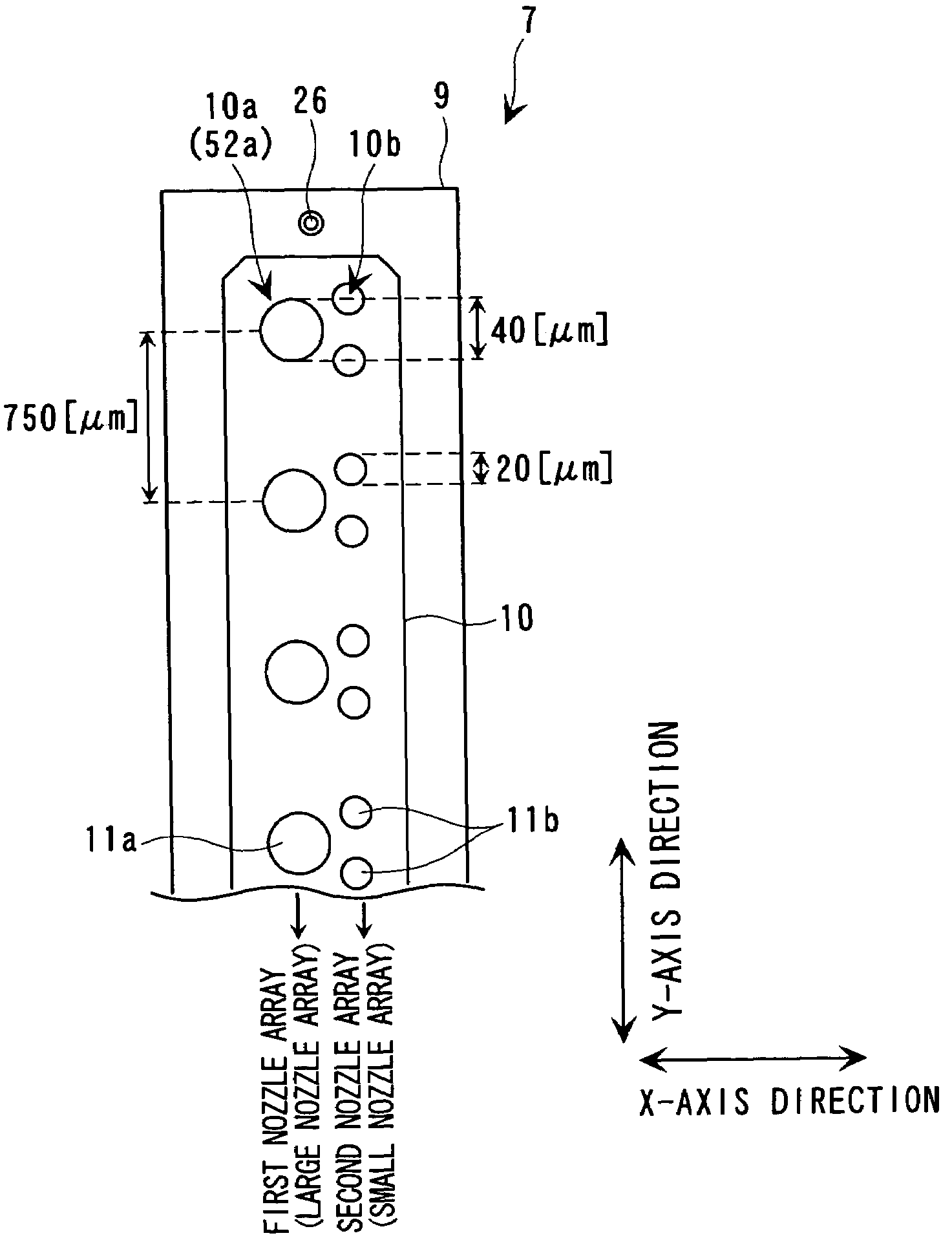

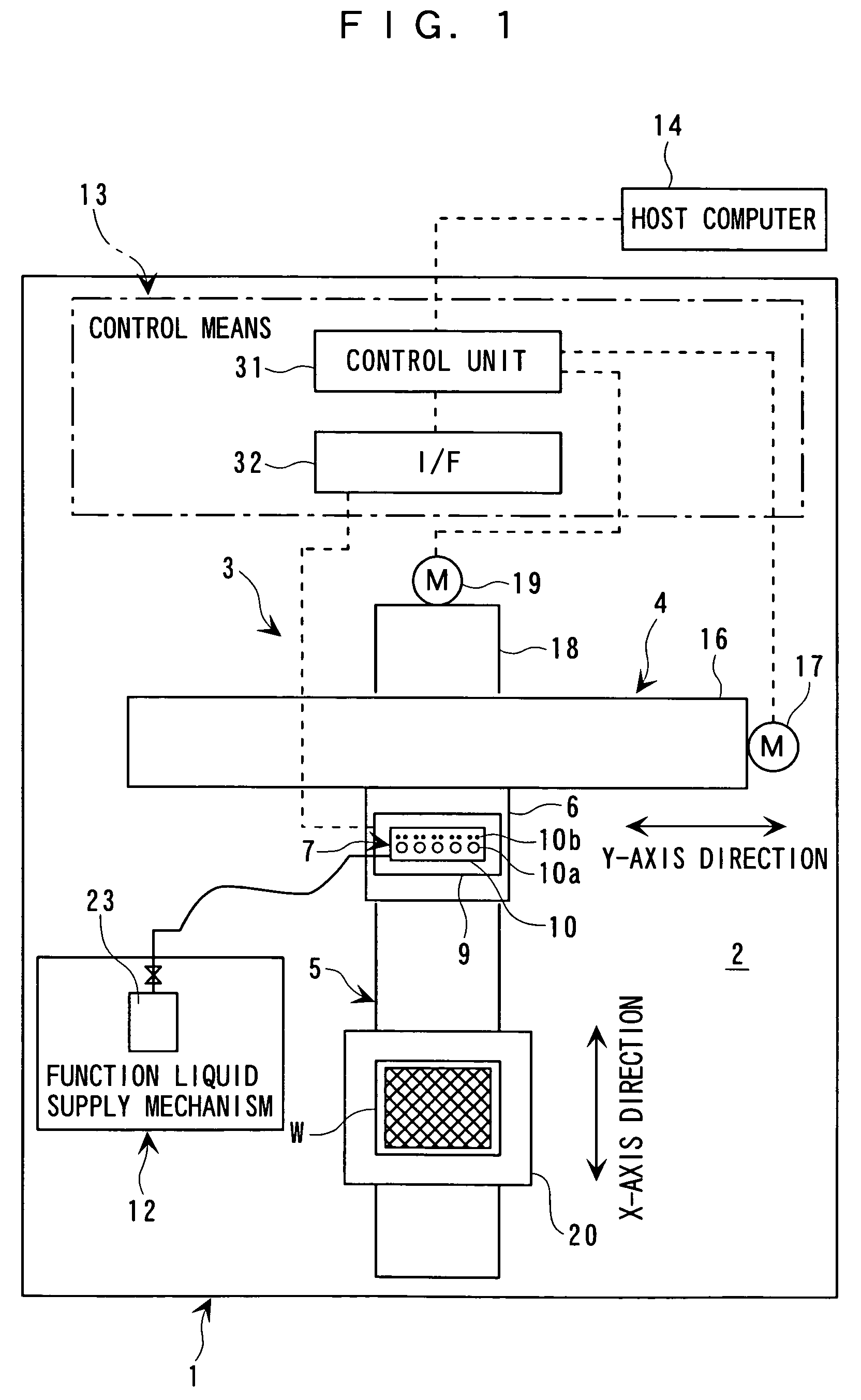

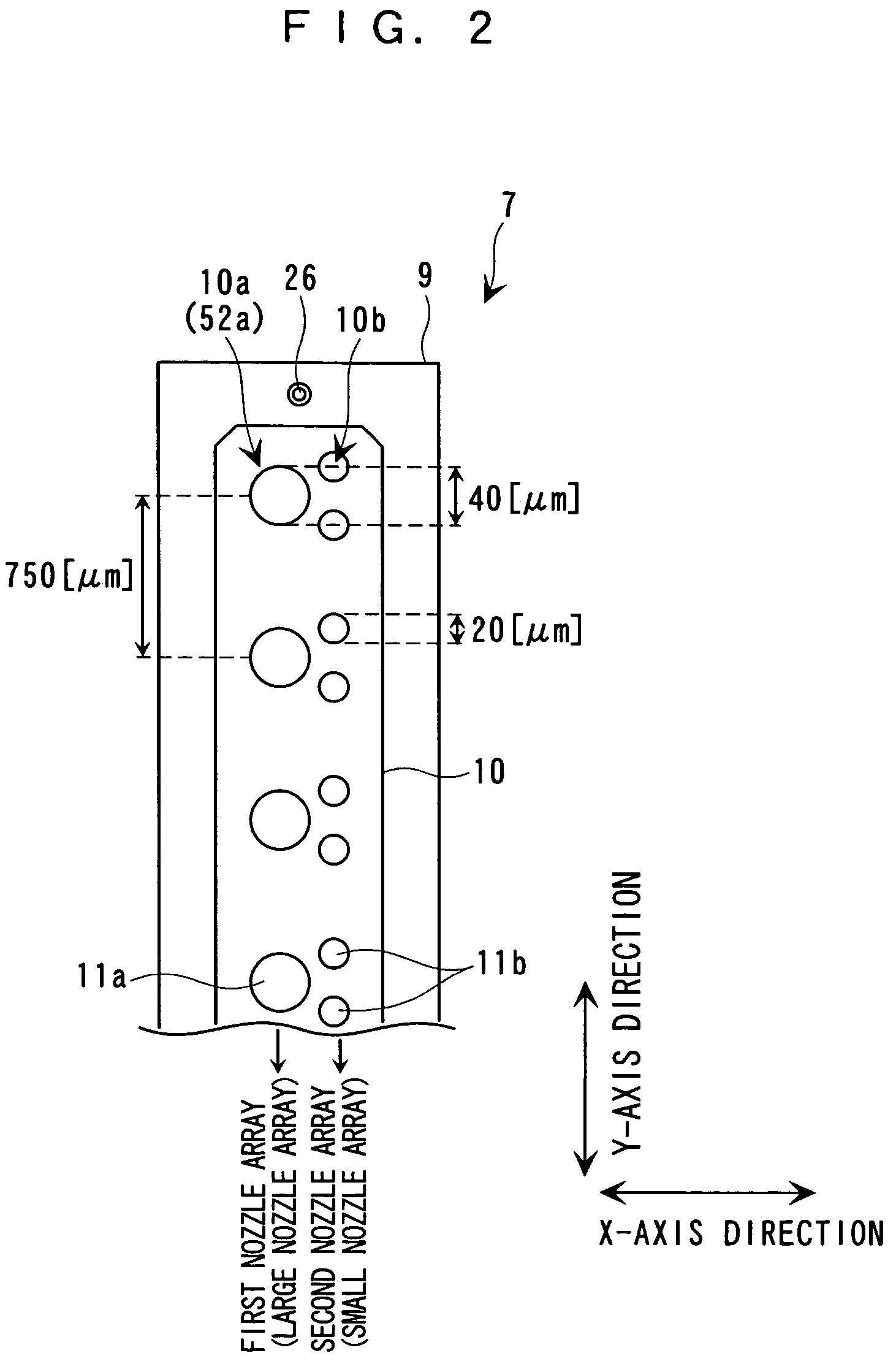

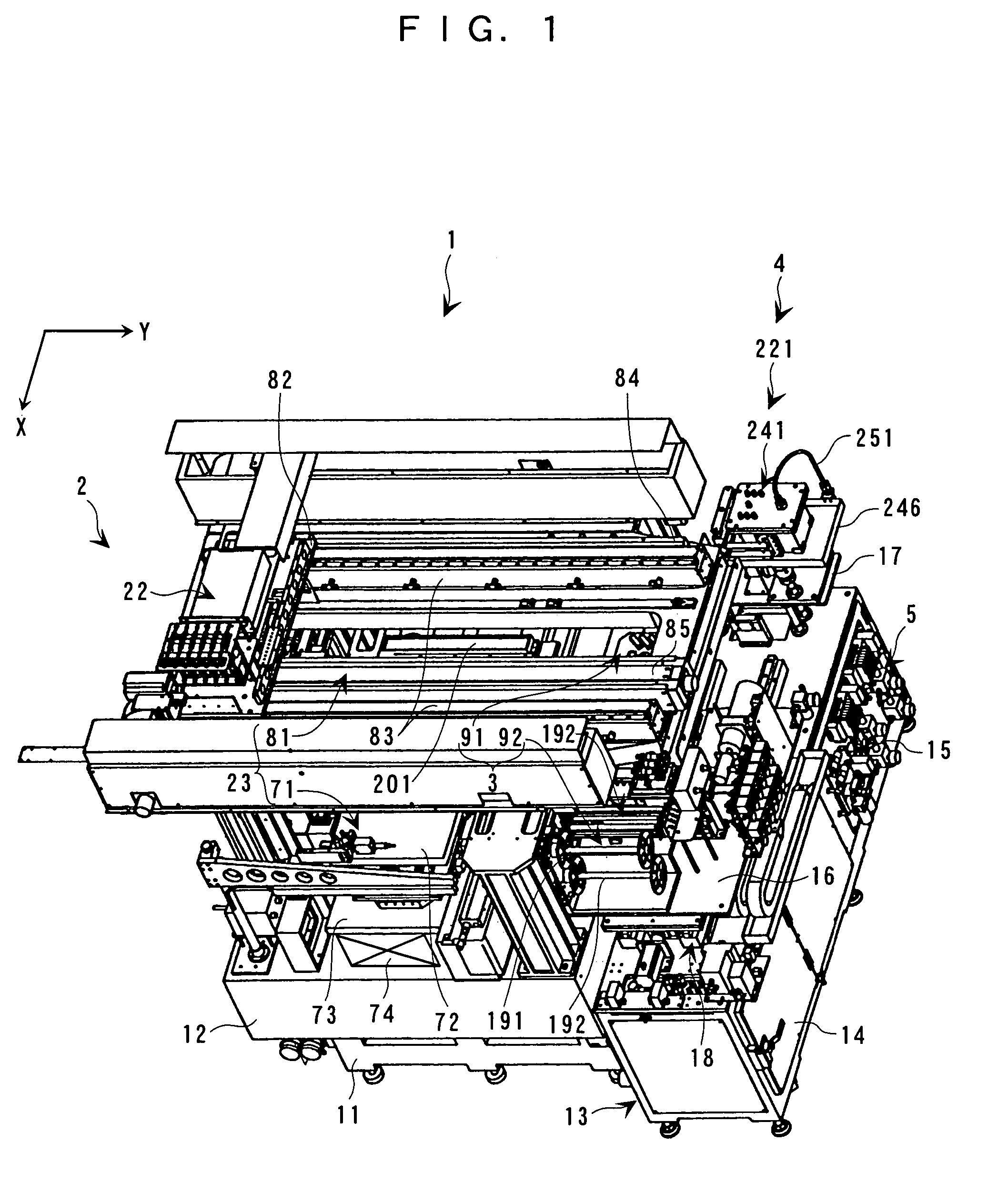

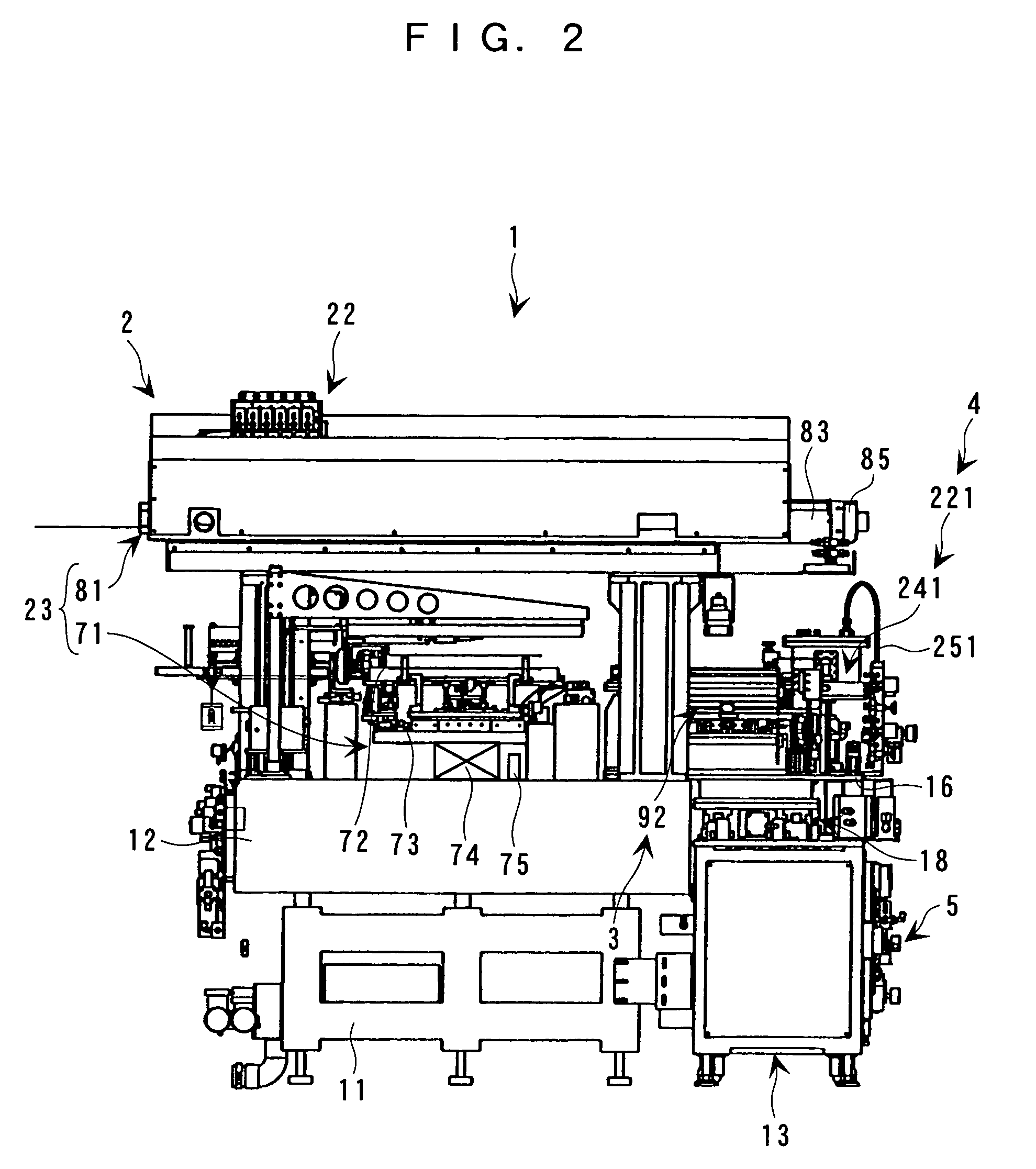

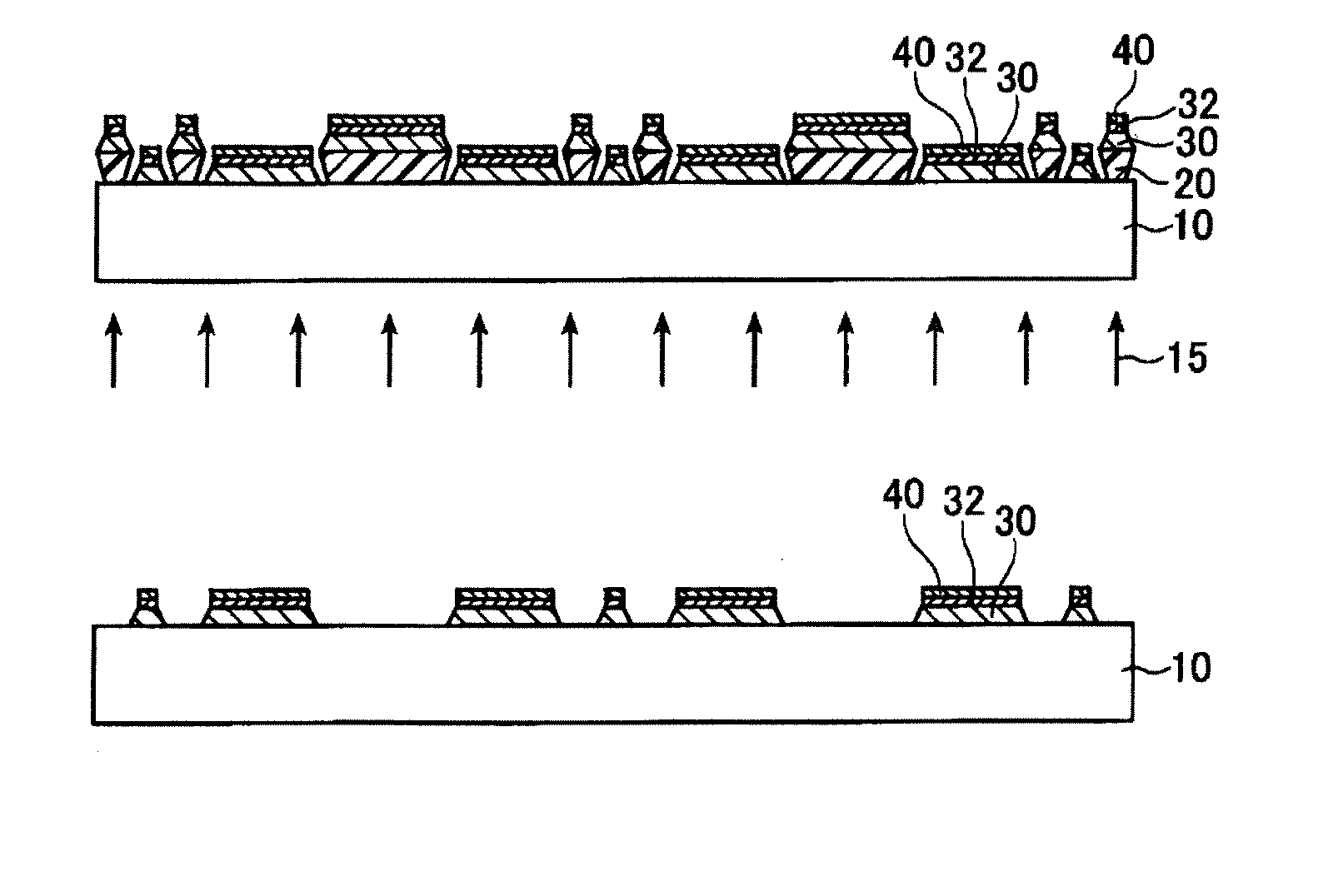

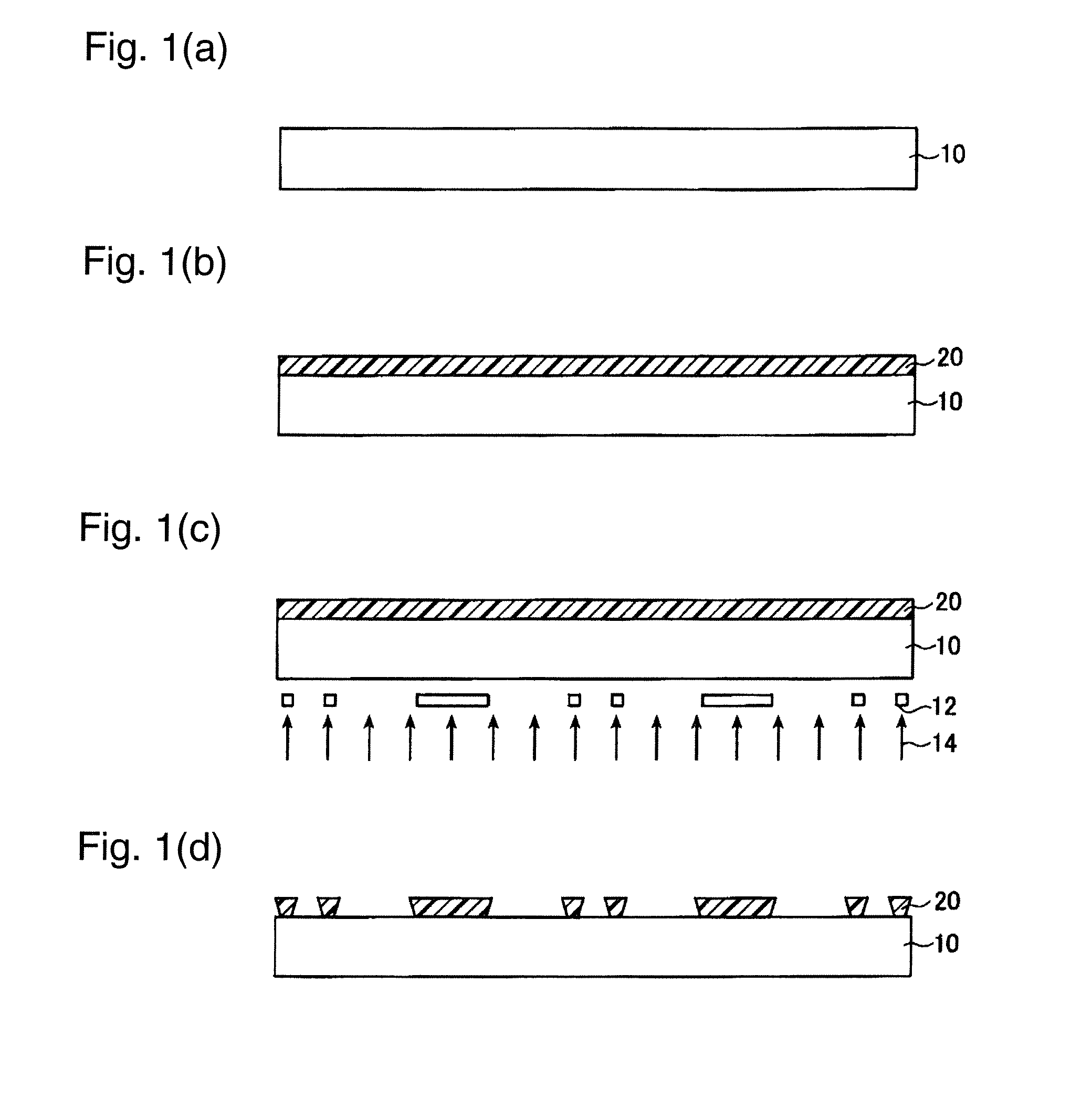

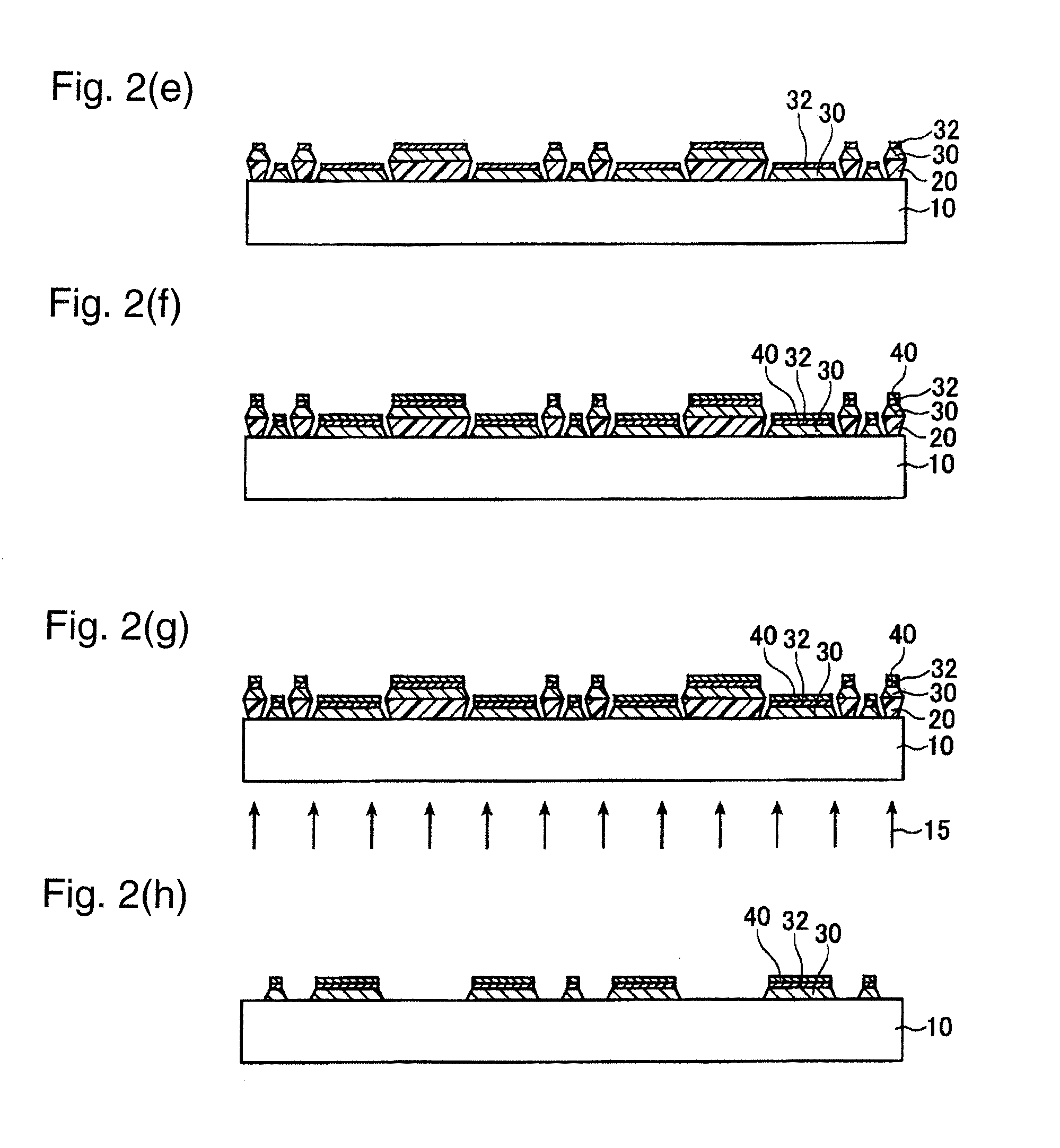

Method of controlling drive of function liquid droplet ejection head; function liquid droplet ejection apparatus; electro-optic device; method of manufacturing LCD device, organic EL device, electron emission device, PDP device, electrophoretic display device, color filter, organic EL; method of forming spacer, metallic wiring, lens, resist, and light diffusion body

ActiveUS7258408B2Easy to controlReduce throughputLiquid surface applicatorsInking apparatusDisplay deviceEngineering

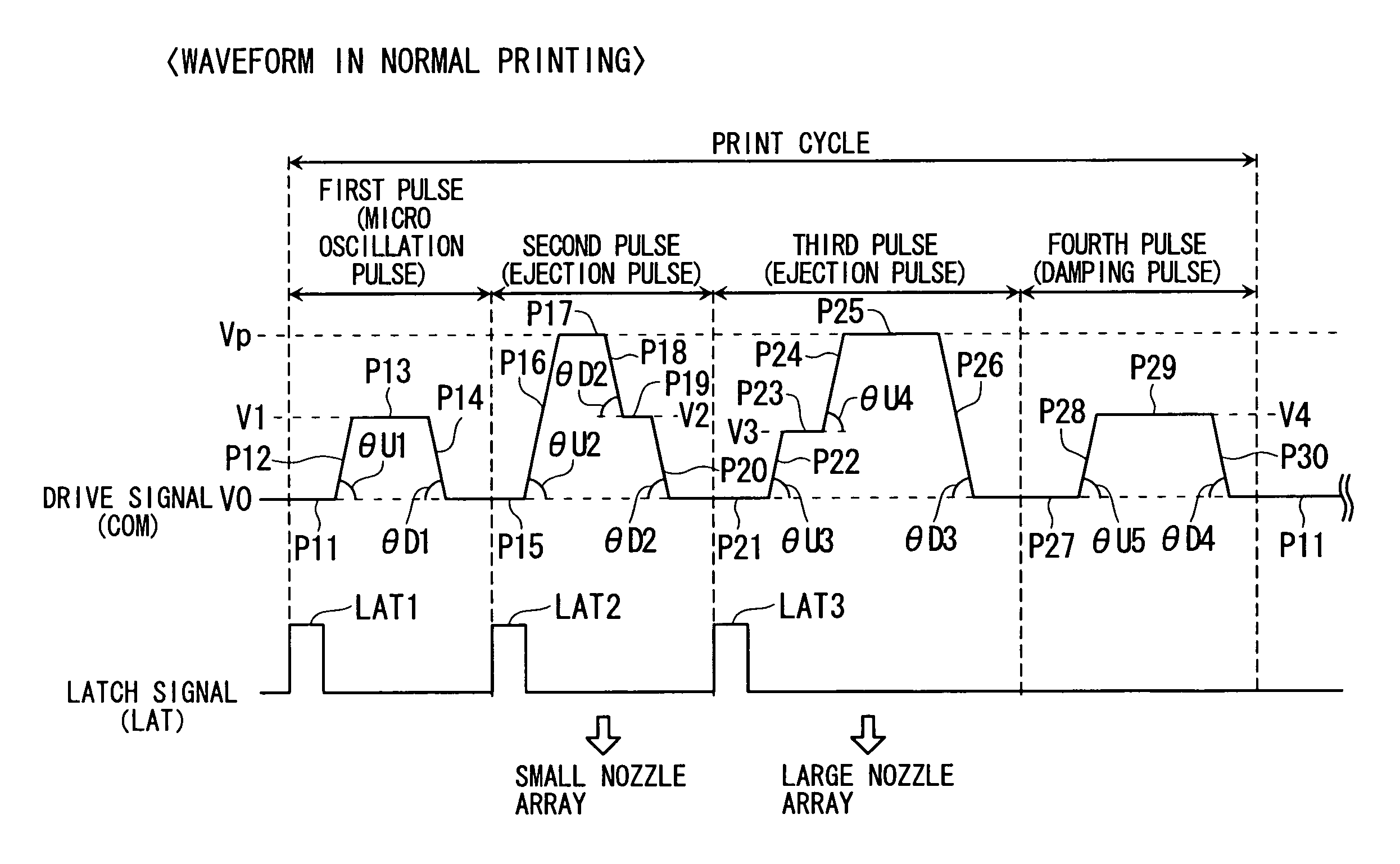

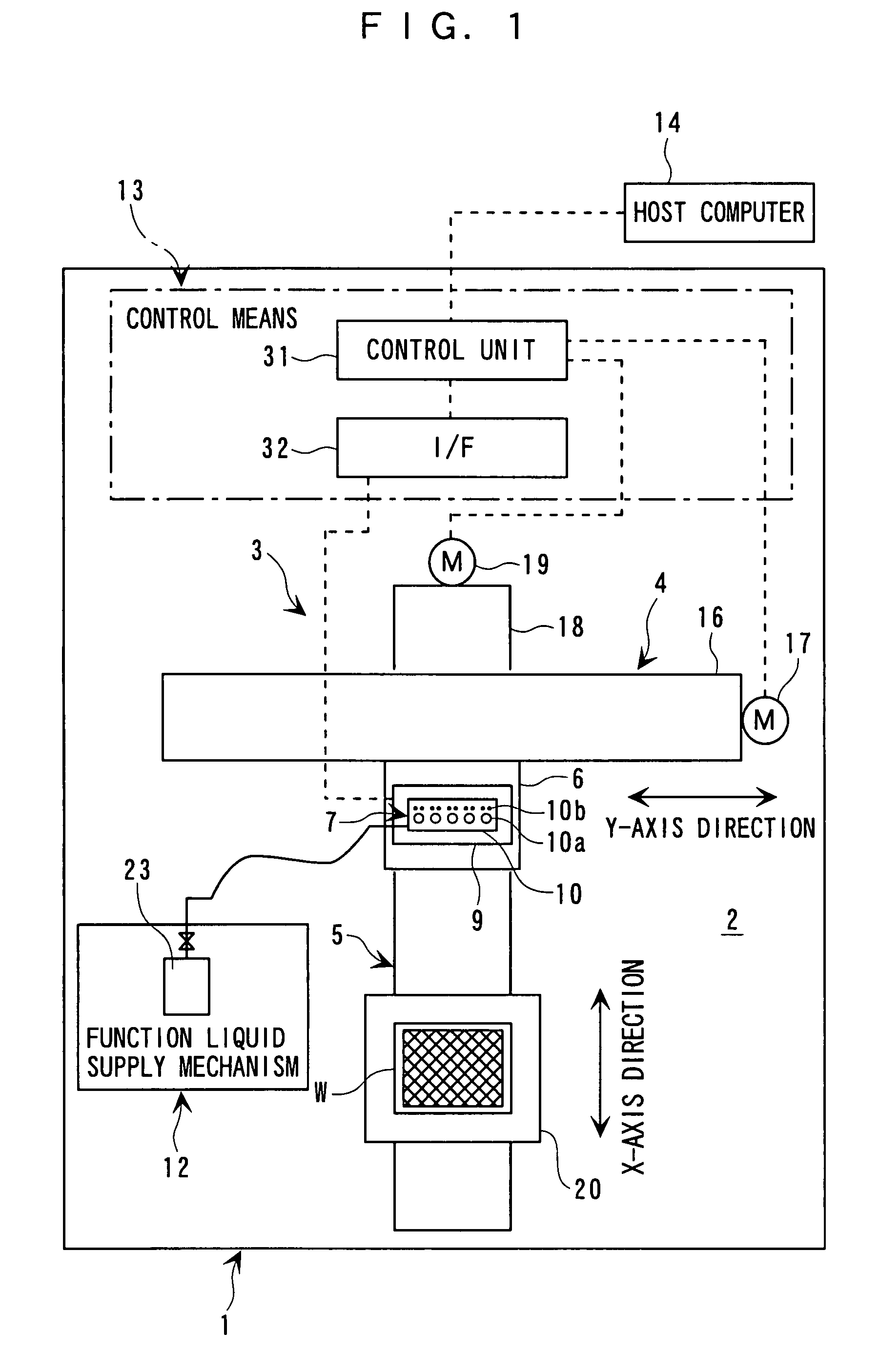

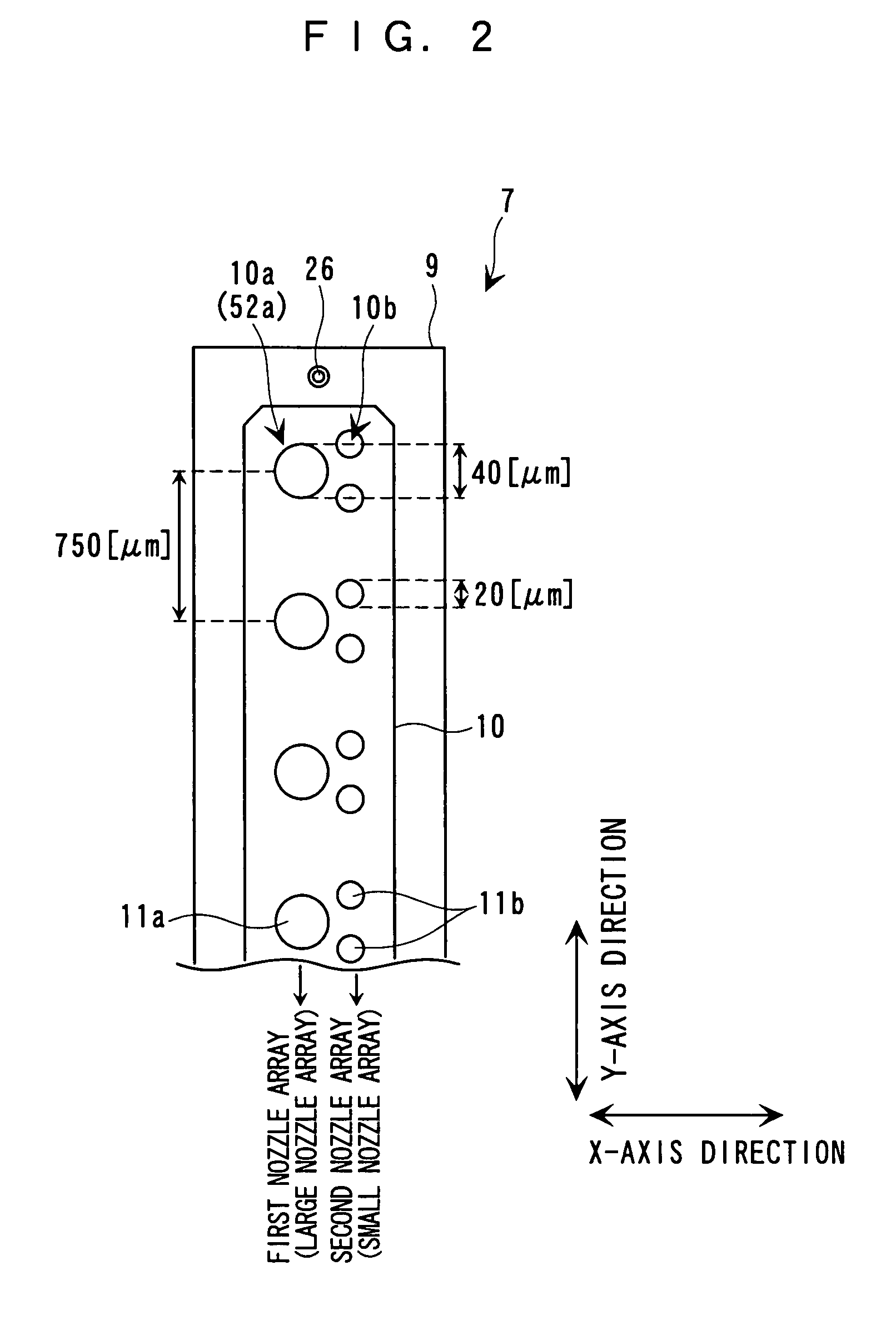

In a method of controlling drive of a function liquid droplet ejection head in which a plurality of nozzle arrays are arranged, the nozzle arrays have function liquid droplet ejection amounts which are different from each other per unit nozzle. The drive of the plurality of nozzle arrays is controlled by using a single drive signal having a plurality of ejection pulses corresponding to the plurality of nozzle arrays in one print cycle. Thus, even if a plurality of nozzle arrays having function liquid droplet ejection amounts which are different from each other per unit nozzle are disposed in one function liquid droplet ejection head, easy drive control is possible without lowering printing throughput.

Owner:KATEEVA

Luminescence crystal particle, luminescence crystal particle composition, display panel and flat-panel display

InactiveUS20010024084A1Uniform electron-emitting propertyImprove adhesionDischarge tube luminescnet screensGas discharge electrodesDisplay deviceVolumetric Mass Density

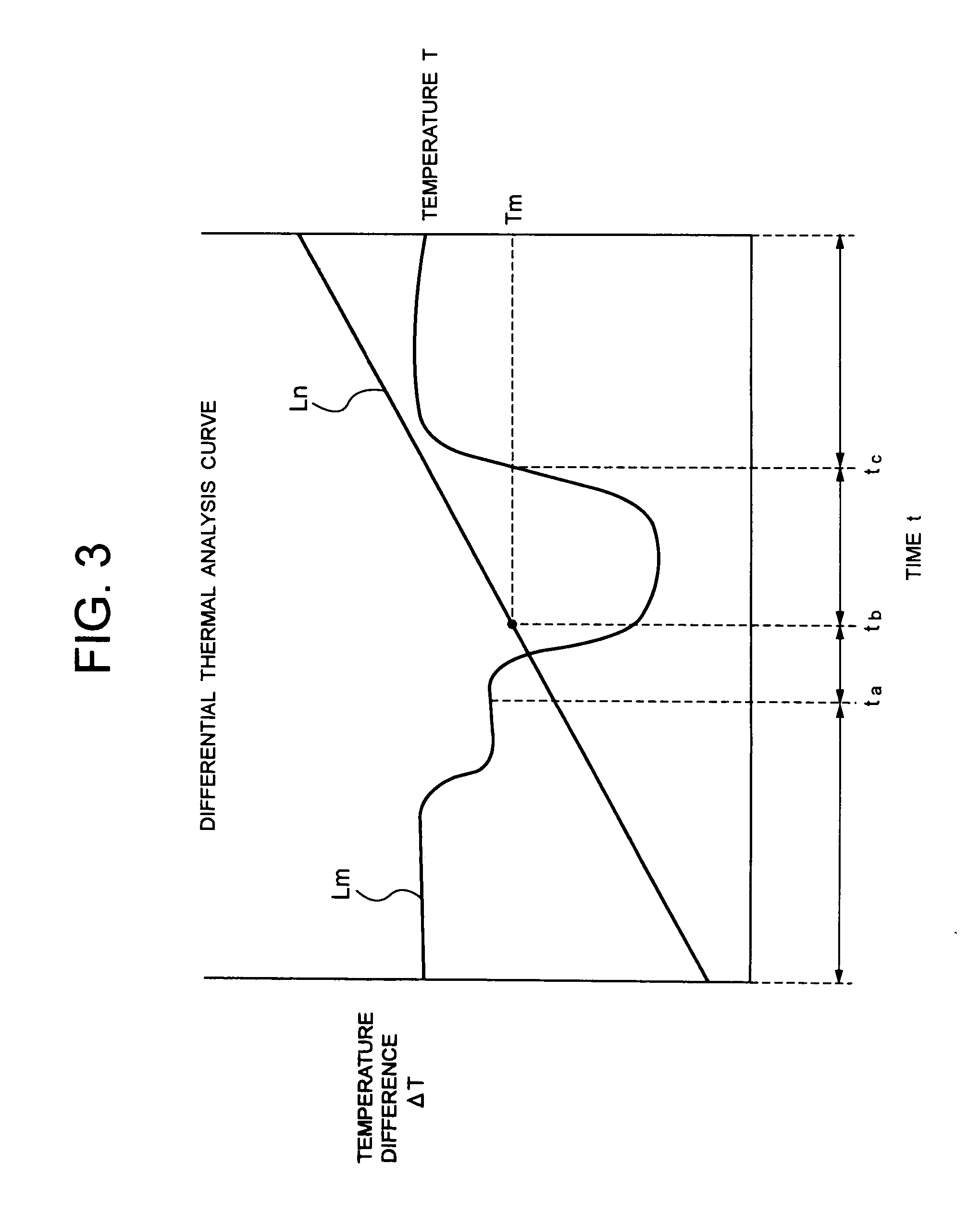

A luminescence crystal particle which emits light upon irradiation with an energy beam and which has a crystal defect density of 5x107 defects / cm2 or less in a region located from the surface of the luminescence crystal particle to a portion as deep as the energy beam reaches.

Owner:SONY CORP

Luminescence crystal particle, luminescence crystal particle composition, display panel and flat-panel display

InactiveUS6819041B2Improve adhesionImprove propertiesDischarge tube luminescnet screensGas discharge electrodesDisplay deviceVolumetric Mass Density

Owner:SONY CORP

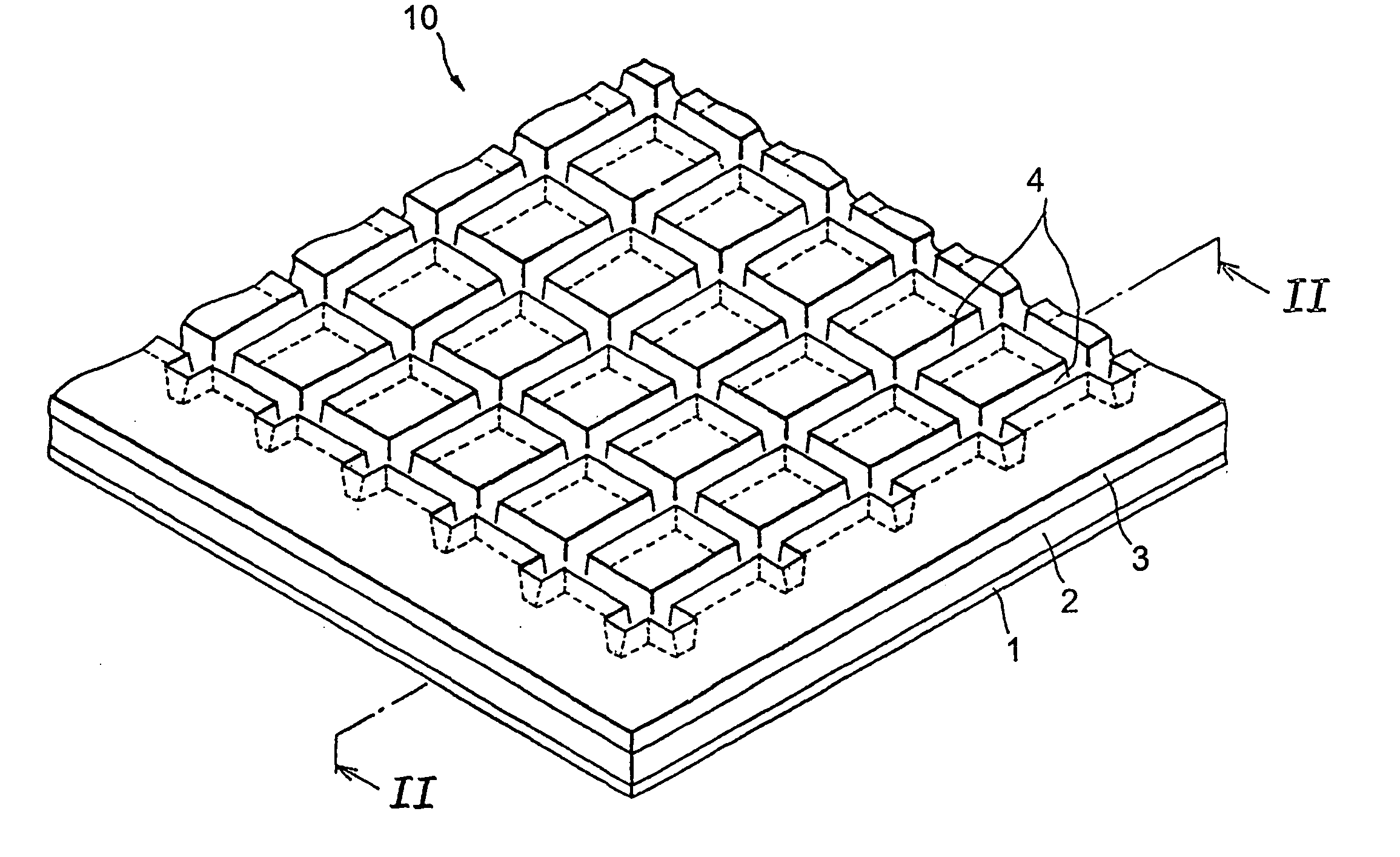

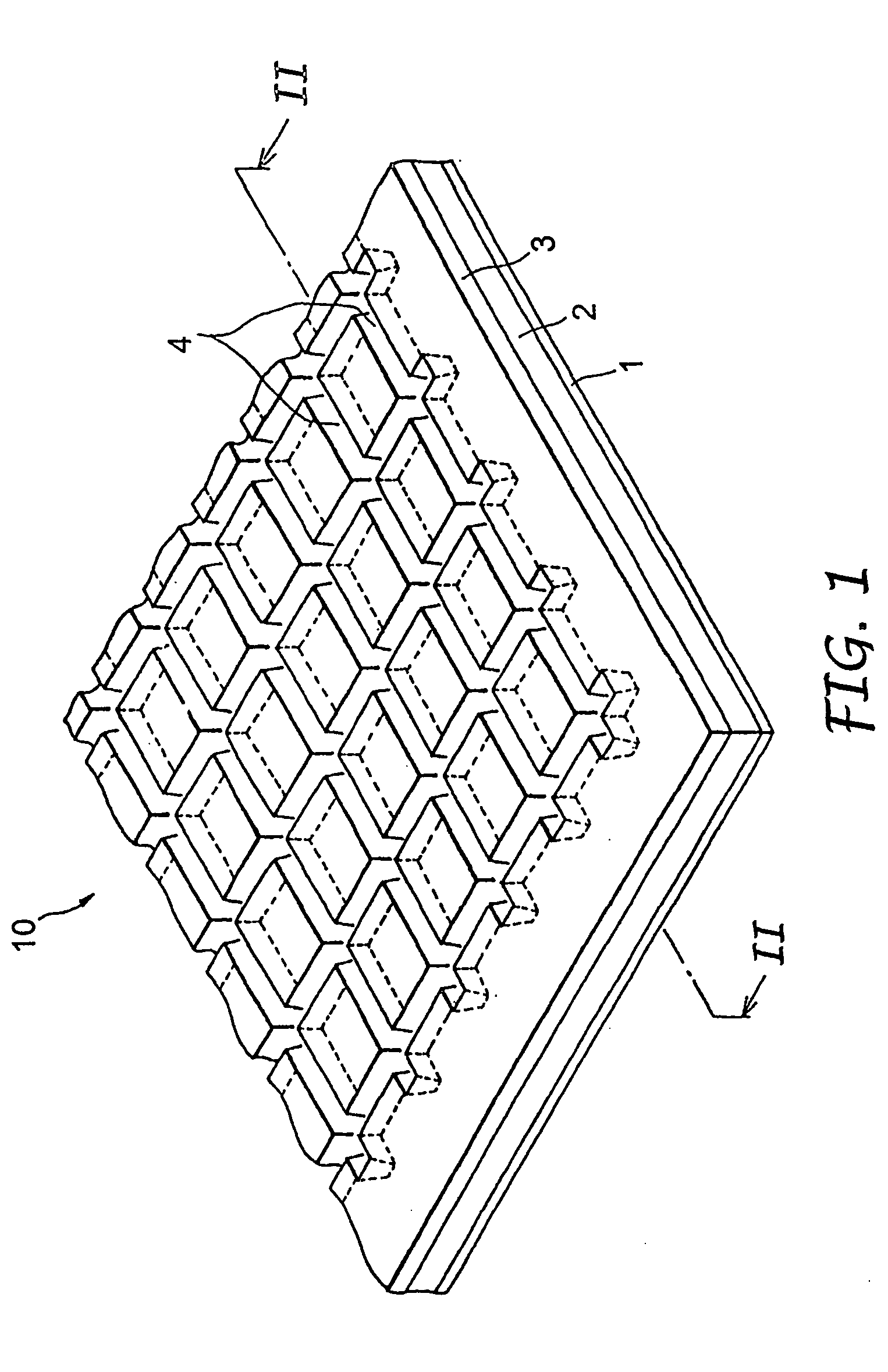

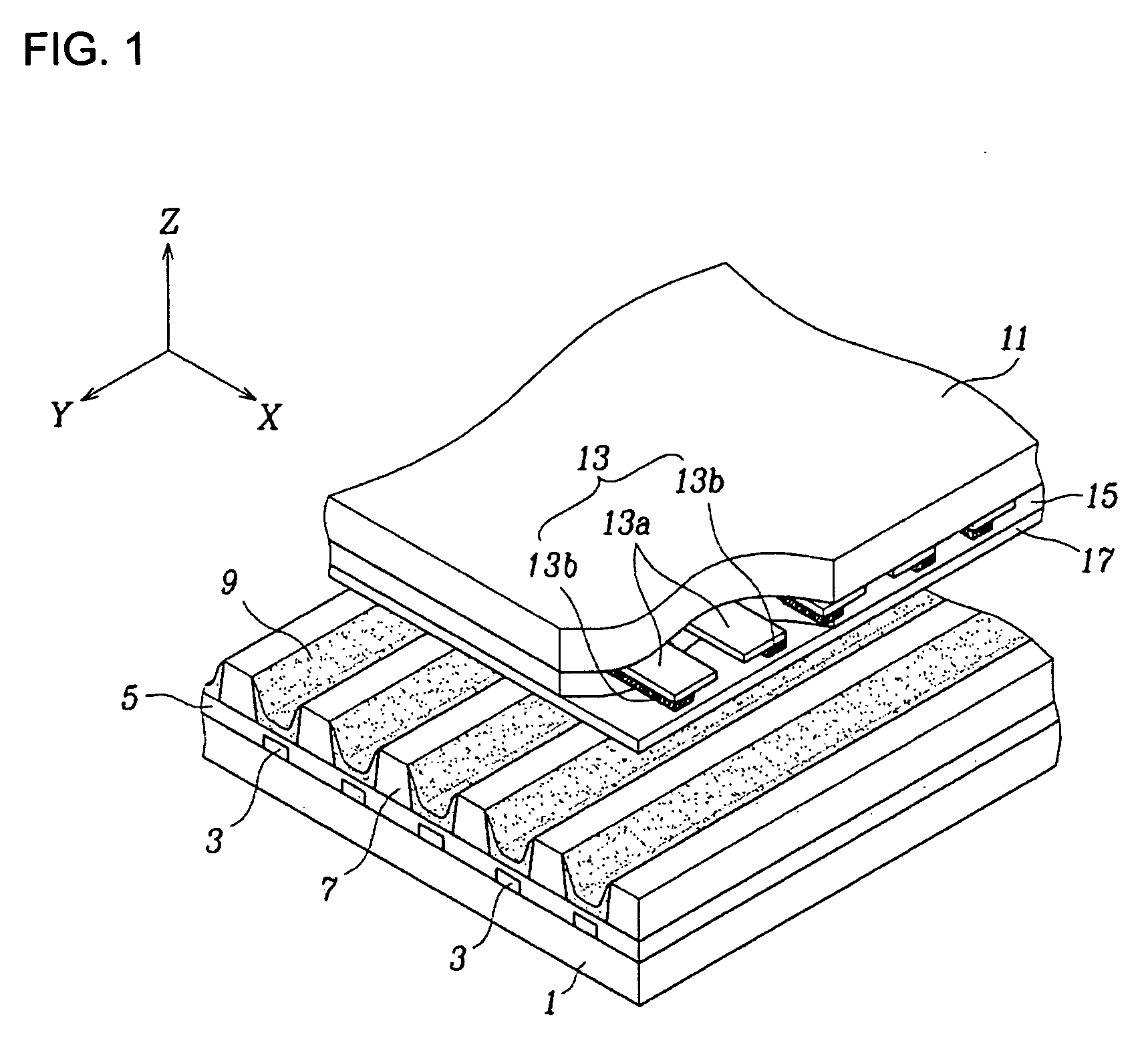

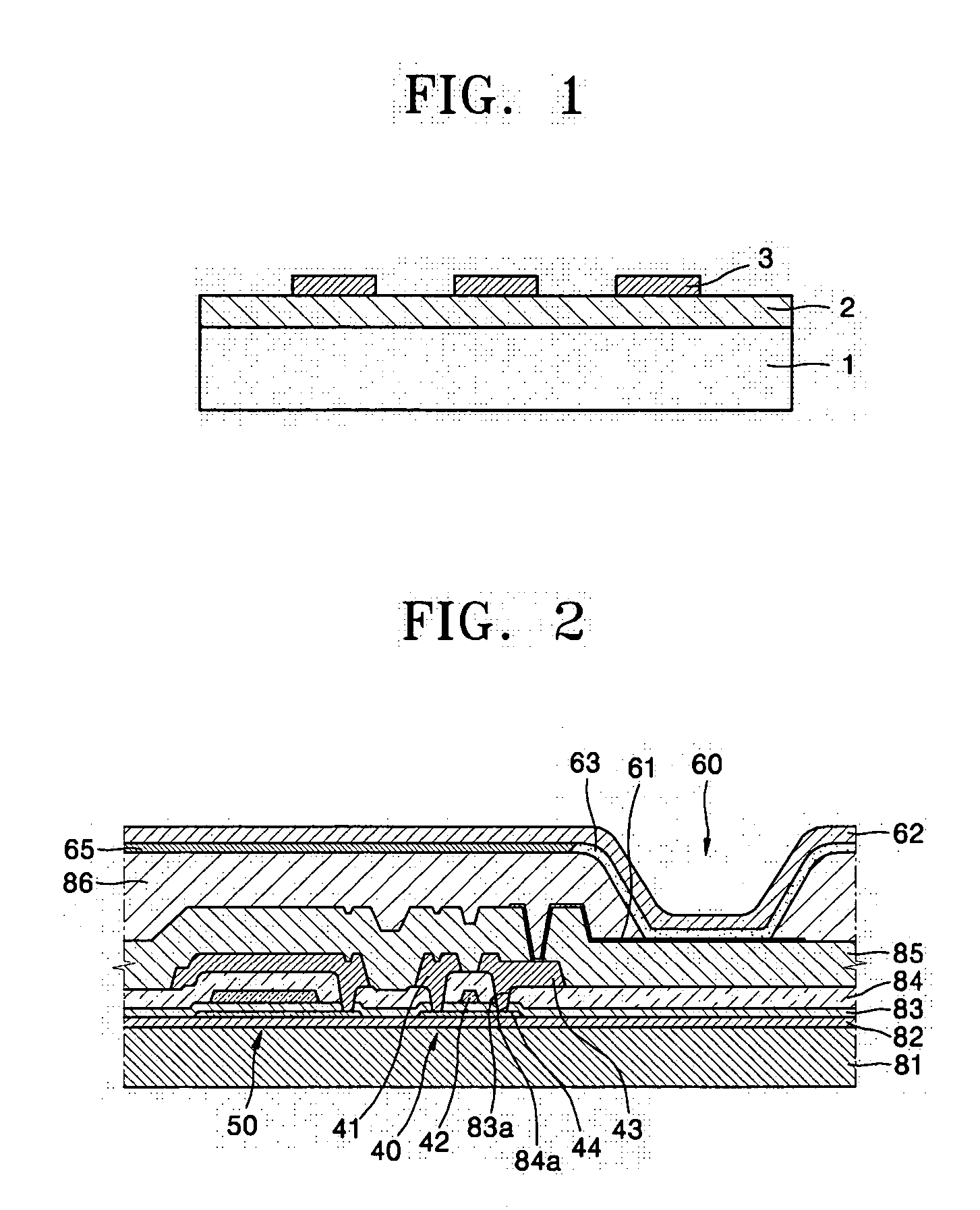

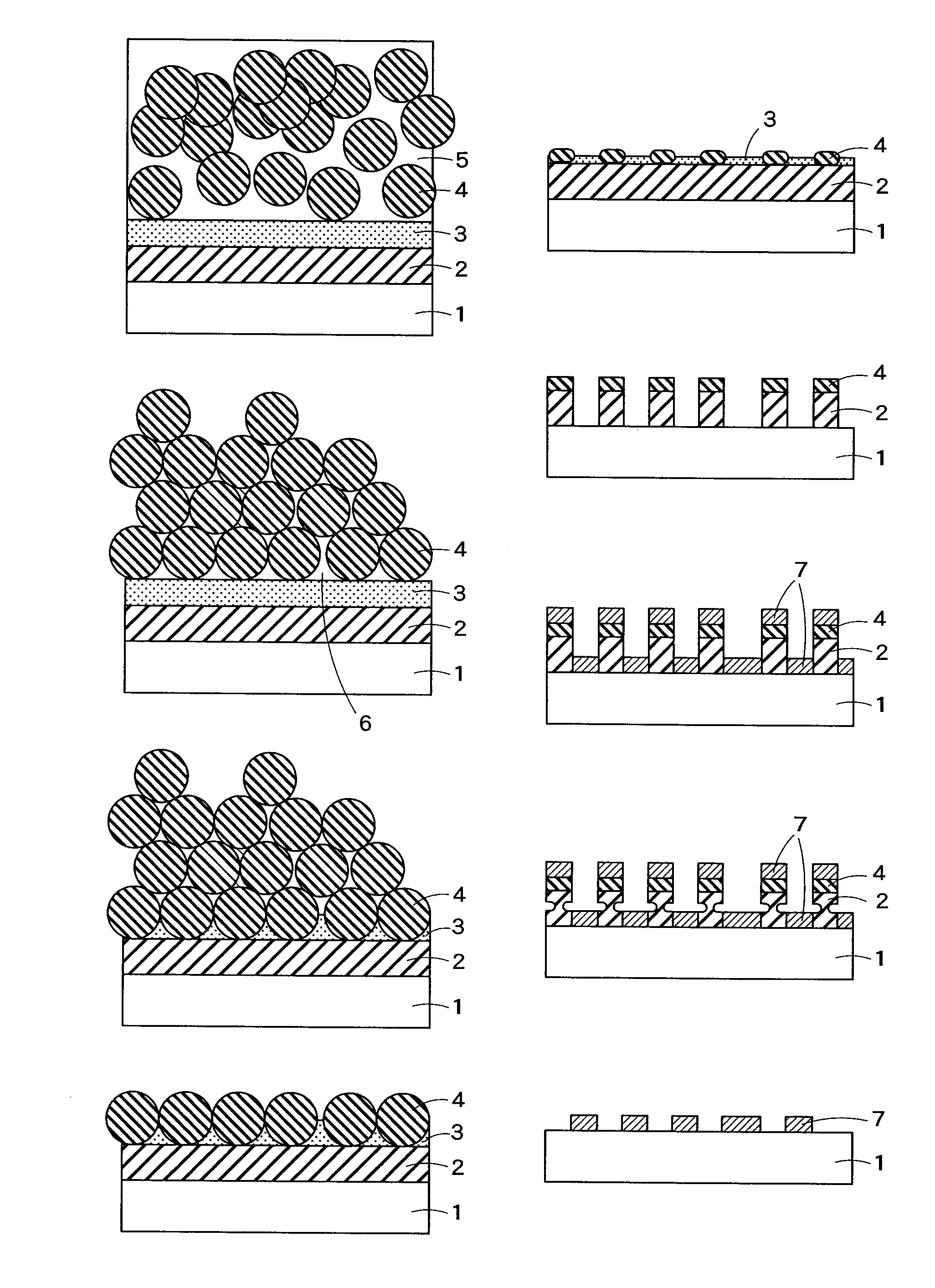

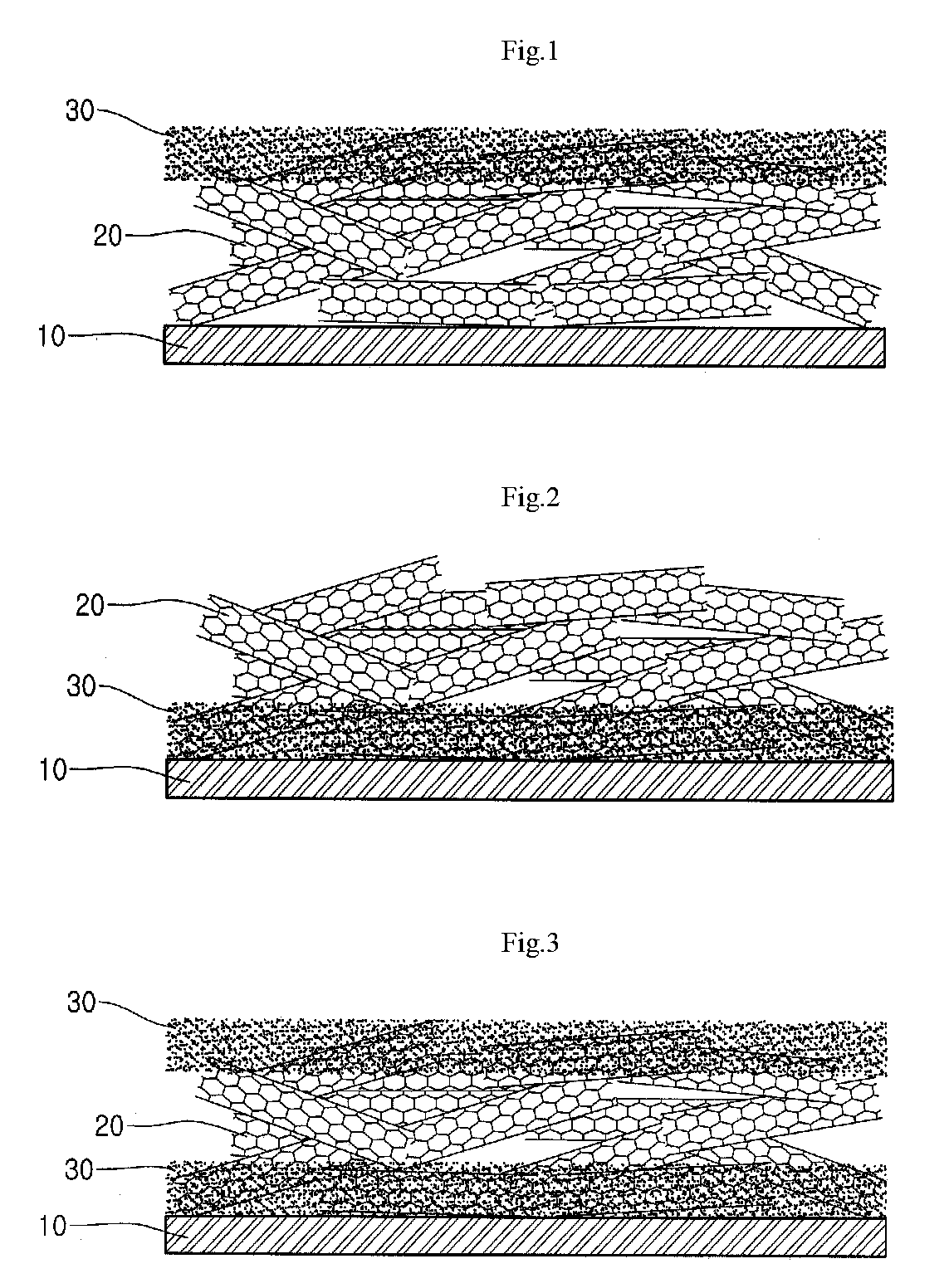

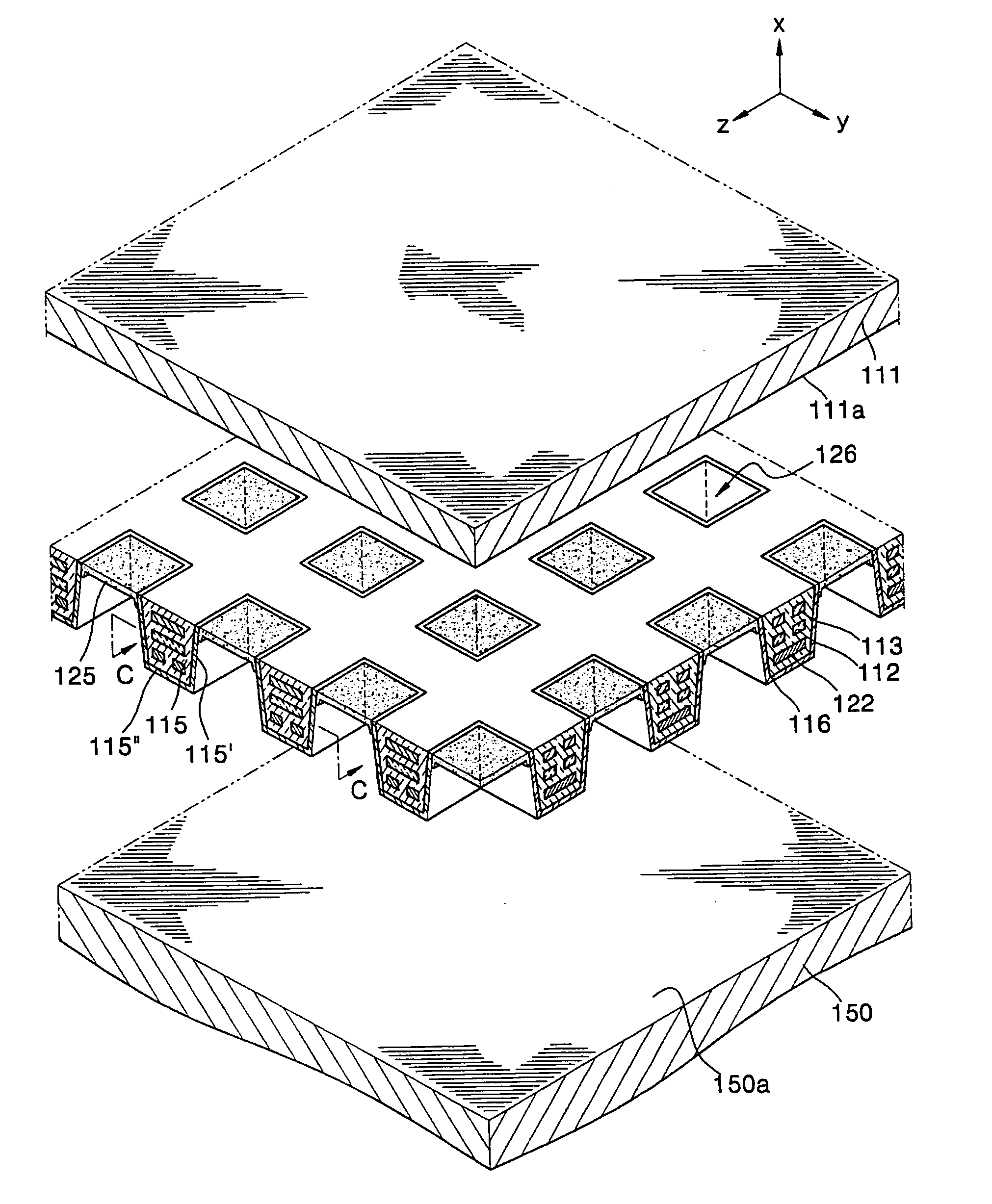

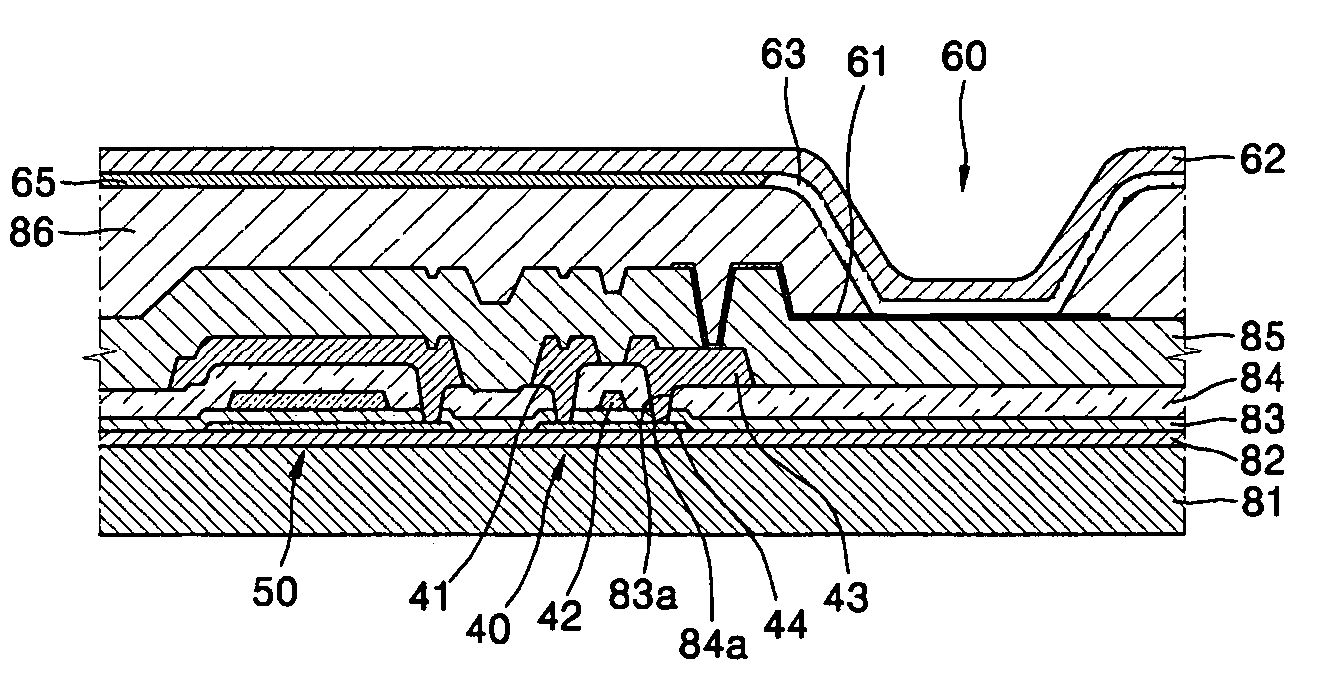

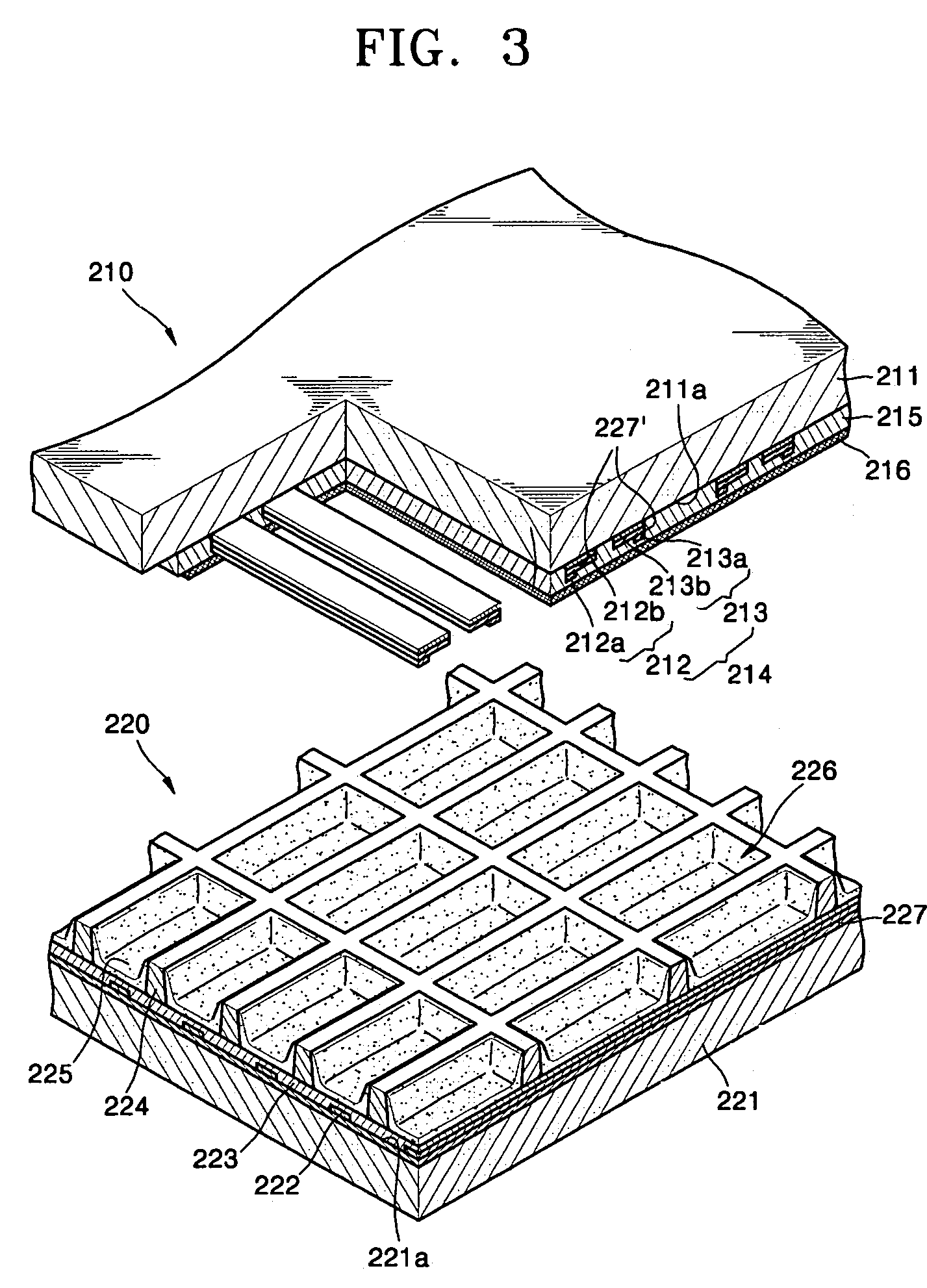

Flexible mold and method of manufacturing microstructure using the same

InactiveUS20050253290A1Simple structureLighting and heating apparatusGas discharge electrodesViscosityPolymer chemistry

To provide a flexible mold (10) useful for manufacturing a PDP rib having a lattice pattern and other microstructures, and capable of highly precisely manufacturing the microstructures without involving defects such as occurrence of bubbles and pattern deformation. A flexible mold (10) comprises a base layer (2) made of a first curable material having a viscosity of 3,000 to 100,000 cps at 10 to 80° C. and a coating layer (3) coating a surface of the base layer (2) and made of a second curable material having a viscosity of 200 cps or below at 10 to 80° C.

Owner:3M INNOVATIVE PROPERTIES CO

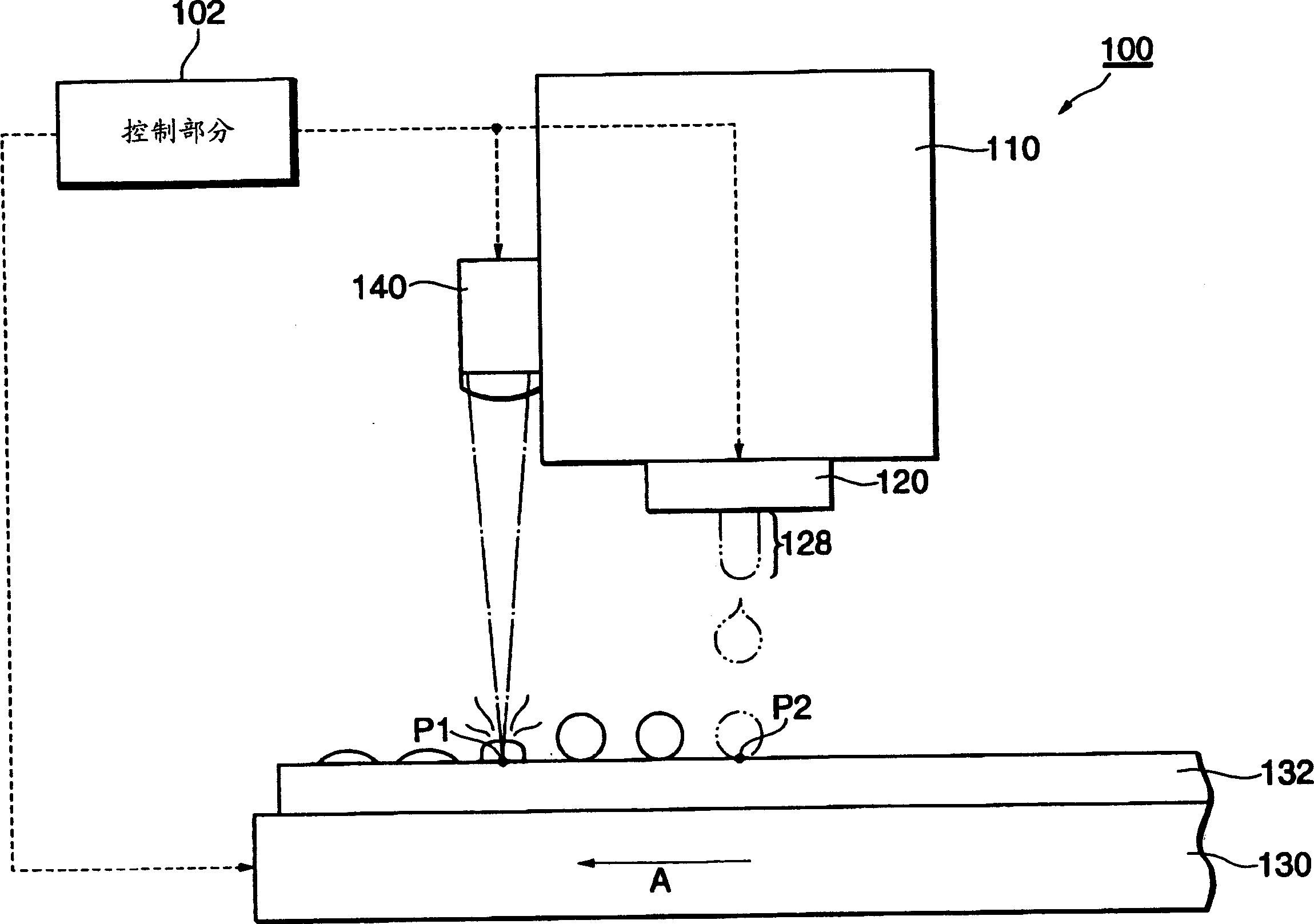

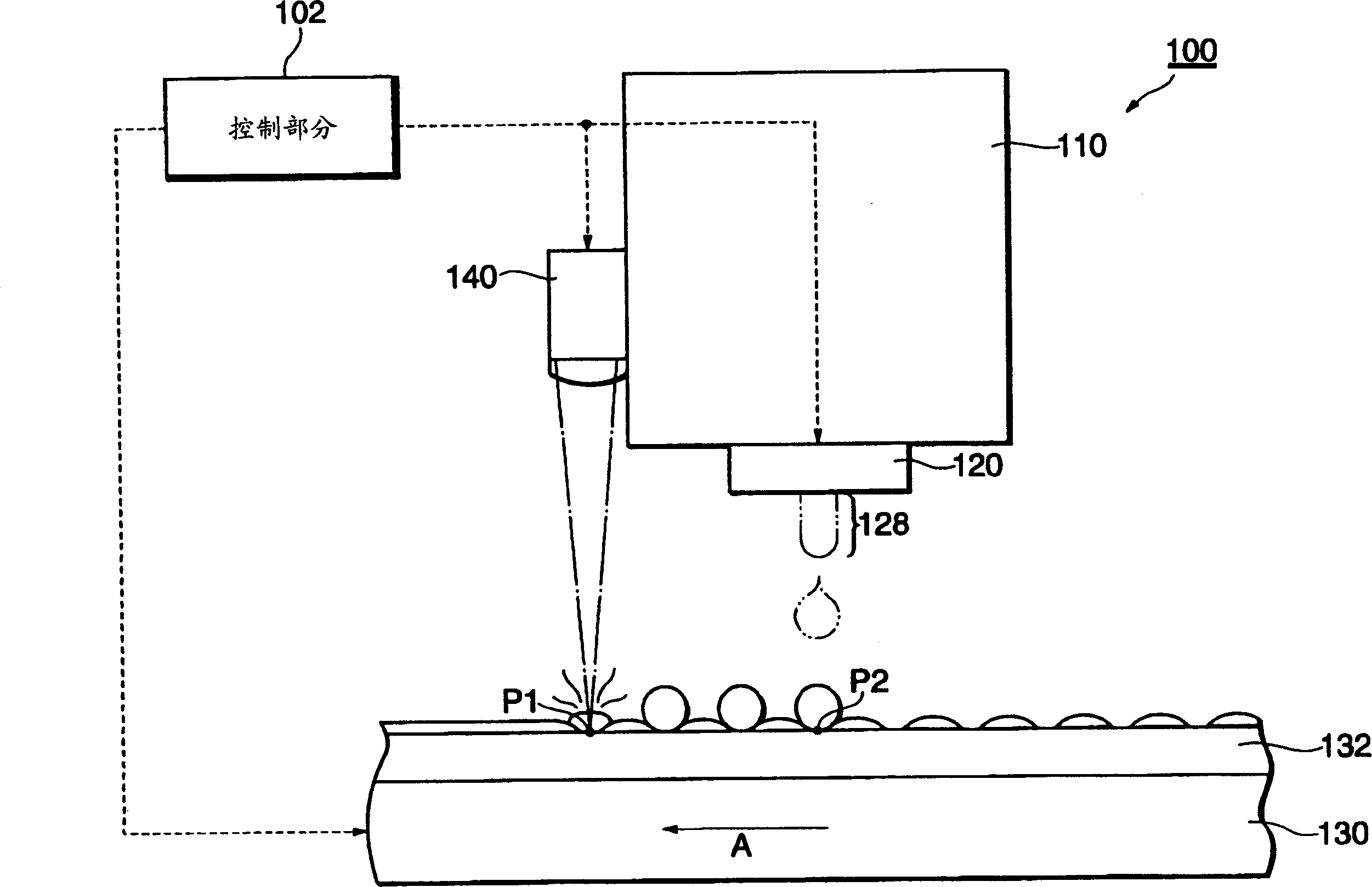

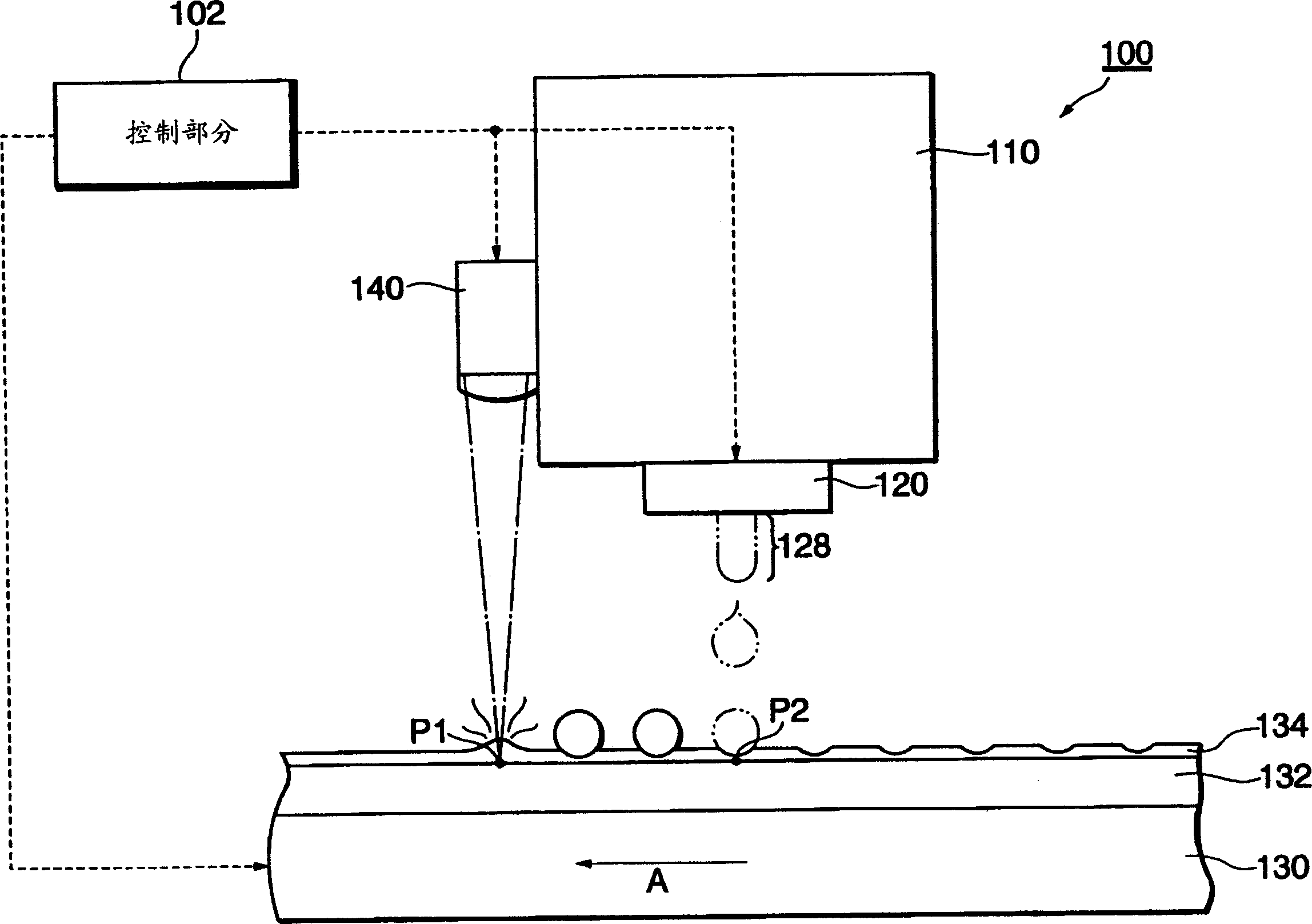

Functional material fixing method and functional material fixing device

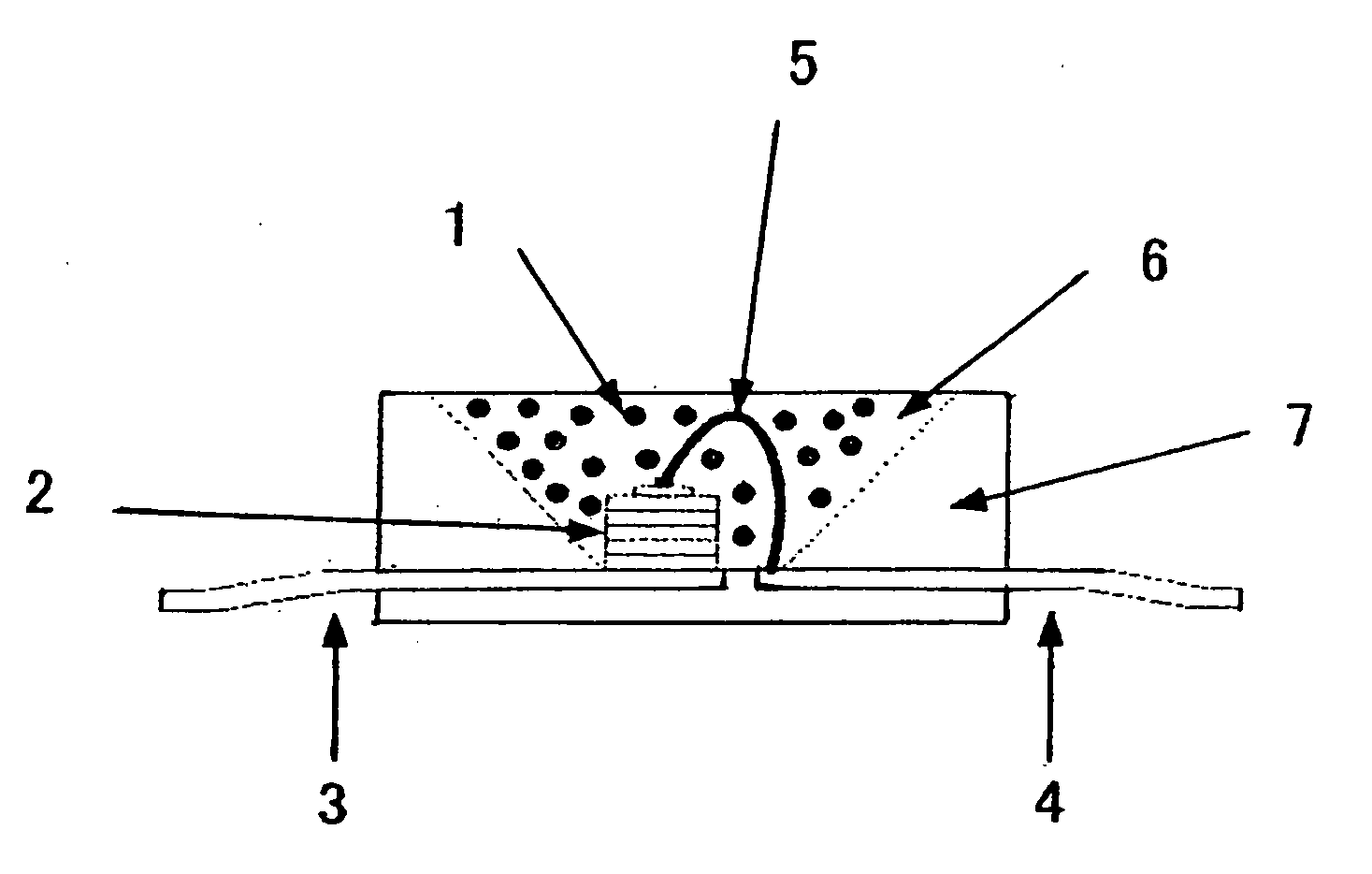

It is an object of the present invention to provide a method for fixing a functional material with good accuracy in a prescribed position on a fixing surface. In order to attain this object, the present invention provides a method for fixing a functional material, comprising a droplet ejection step of ejecting a droplet of a functional material dispersed in a solvent onto a fixing surface, and a drying step of locally heating the droplet ejected on the fixing surface and gasifying part of the droplet by irradiating the droplet with a laser beam. According to this method, the droplet can be dried rapidly, heating of the entire substrate is suppressed, and loss of alignment or breakage of wiring or the like caused by the expansion of substrate can be avoided.

Owner:SEIKO EPSON CORP

Method of controlling drive of function liquid droplet ejection head; function liquid droplet ejection apparatus; electro-optic device; method of manufacturing LCD device, organic EL device, electron emission device, PDP device, electrophoretic display device, color filter, organic EL; method of forming spacer, metallic wiring, lens, resist, and light diffusion body

ActiveUS7850267B2Easy to controlReduce throughputInking apparatusLiquid surface applicatorsDisplay deviceElectron

In a method of controlling drive of a function liquid droplet ejection head in which a plurality of nozzle arrays are arranged, the nozzle arrays have function liquid droplet ejection amounts which are different from each other per unit nozzle. The drive of the plurality of nozzle arrays is controlled by using a single drive signal having a plurality of ejection pulses corresponding to the plurality of nozzle arrays in one print cycle. Thus, even if a plurality of nozzle arrays having function liquid droplet ejection amounts which are different from each other per unit nozzle are disposed in one function liquid droplet ejection head, easy drive control is possible without lowering printing throughput.

Owner:KATEEVA

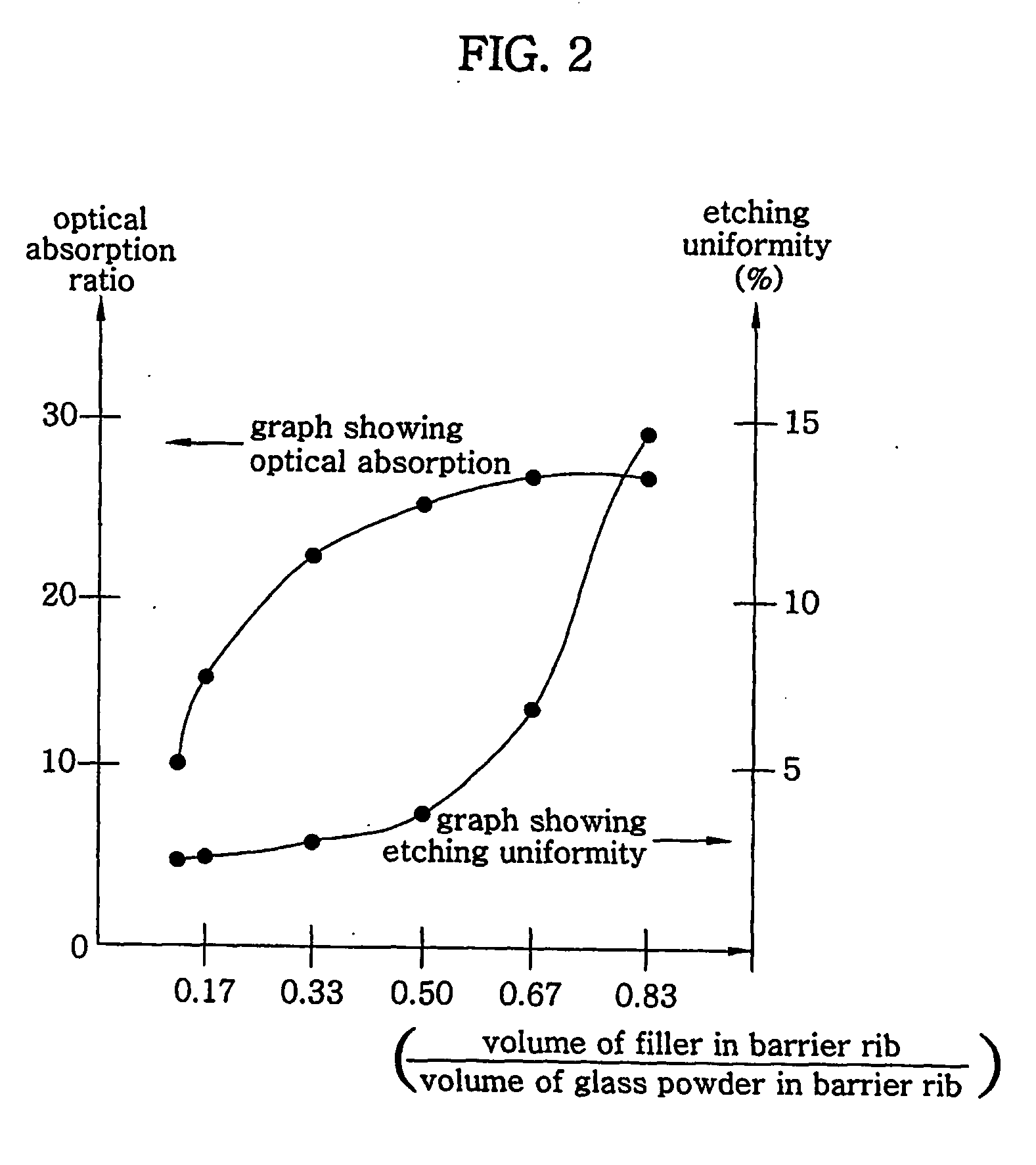

Pb-free glass composition for barrier ribs of plasma display panel, and plasma display panel comprising the Pb-free glass barrier ribs prepared therefrom

InactiveUS20060019814A1Fast etch rateHigh densityGas discharge electrodesGas discharge vessels/containersCopper oxidePolymer chemistry

Disclosed is a Pb-free glass composition for barrier ribs of a PDP, which includes from 20 to 70 wt % of ZnO; from 10 to 50 wt % of BaO; from 10 to 40 wt % of B2O3; from 0 to 20 wt % of P2O5; from 0 to 20 Wt % of SiO2; from 0 to 20 wt % of Bi2O3; from 0 to 30 wt % of V2O5; from 0 to 10 wt % of one or more oxides selected from the group consisting of Na2O, Li2O, and K2O; from 0 to 10 wt % of CaO; from 0 to 10 wt % of MgO; from 0 to 30 wt % of SrO; from 0 to 20 wt % of MoO3; from 0 to 10 wt % of Al2O3; from 0 to 10 wt % of one or more oxides selected from the group consisting of Sb2O3, CuO, Cr2O3, As2O3, CoO, and NiO; and from 0 to 10 wt % of TiO2, and a plasma display panel comprising the Pb-free glass barrier ribs prepared therefrom.

Owner:SAMSUNG SDI CO LTD +1

Display and method for manufacturing the same

ActiveUS20060022219A1High bonding strengthHigh resolutionGas discharge electrodesSemiconductor/solid-state device detailsElectrical conductorDisplay device

The present invention provides a display including a substrate and an electrode layer including a plurality of conductors, wherein a silane derivative layer is interposed between the substrate and the electrode layer to increase the bond strength between the substrate and the electrode layer. The invention also provides a method of manufacturing the device.

Owner:SAMSUNG DISPLAY CO LTD

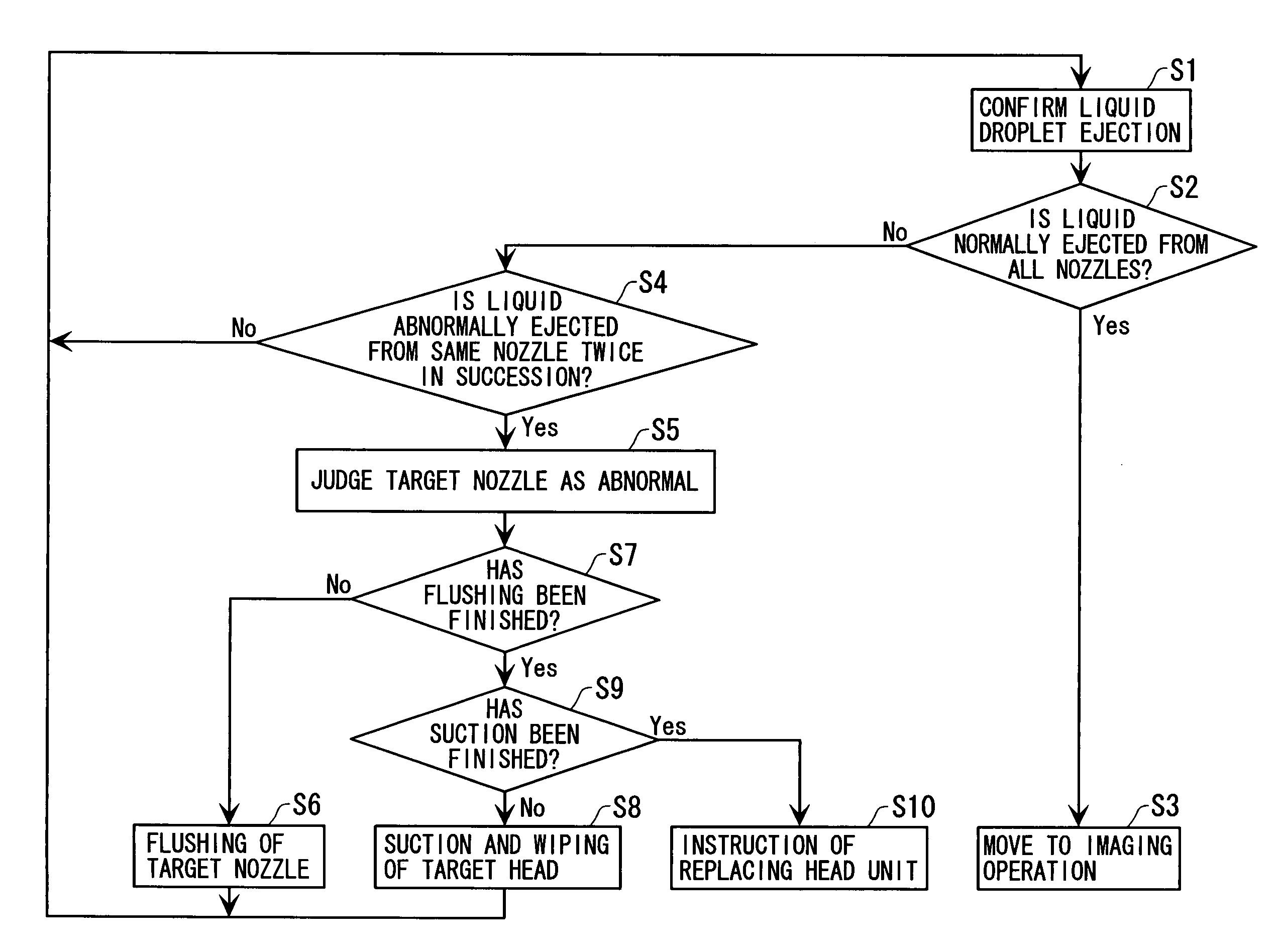

Method of determining abnormality of nozzles in imaging apparatus; imaging apparatus; electrooptic device; method of manufacturing electrooptic device; and electronic equipment

ActiveUS7101013B2Avoid misjudgmentEasy to operateInking apparatusGas discharge electrodesEngineeringImaging equipment

In an imaging apparatus having a head unit mounting thereon liquid droplet ejection heads with a plurality of ejection nozzles, a confirmation is made before starting an imaging operation as to whether or not liquid droplets are normally ejected from the respective ejection nozzles. This confirmation is made by using optical liquid droplet detectors having a light emitting element and a light receiving element. When ejection of liquid droplets from any of the ejection nozzles of liquid droplet ejection heads is determined to be abnormal in an ejection confirming operation, the ejection confirming operation is performed again. When the ejection of the liquid droplets from the same ejection nozzle is determined to be abnormal also in this ejection confirming operation, this ejection nozzle is judged to be abnormal.

Owner:KATEEVA

Light-transmitting metal electrode and process for production thereof

ActiveUS20090211783A1Easy to produceConductive layers on insulating-supportsGas discharge electrodesIn planeMaterials science

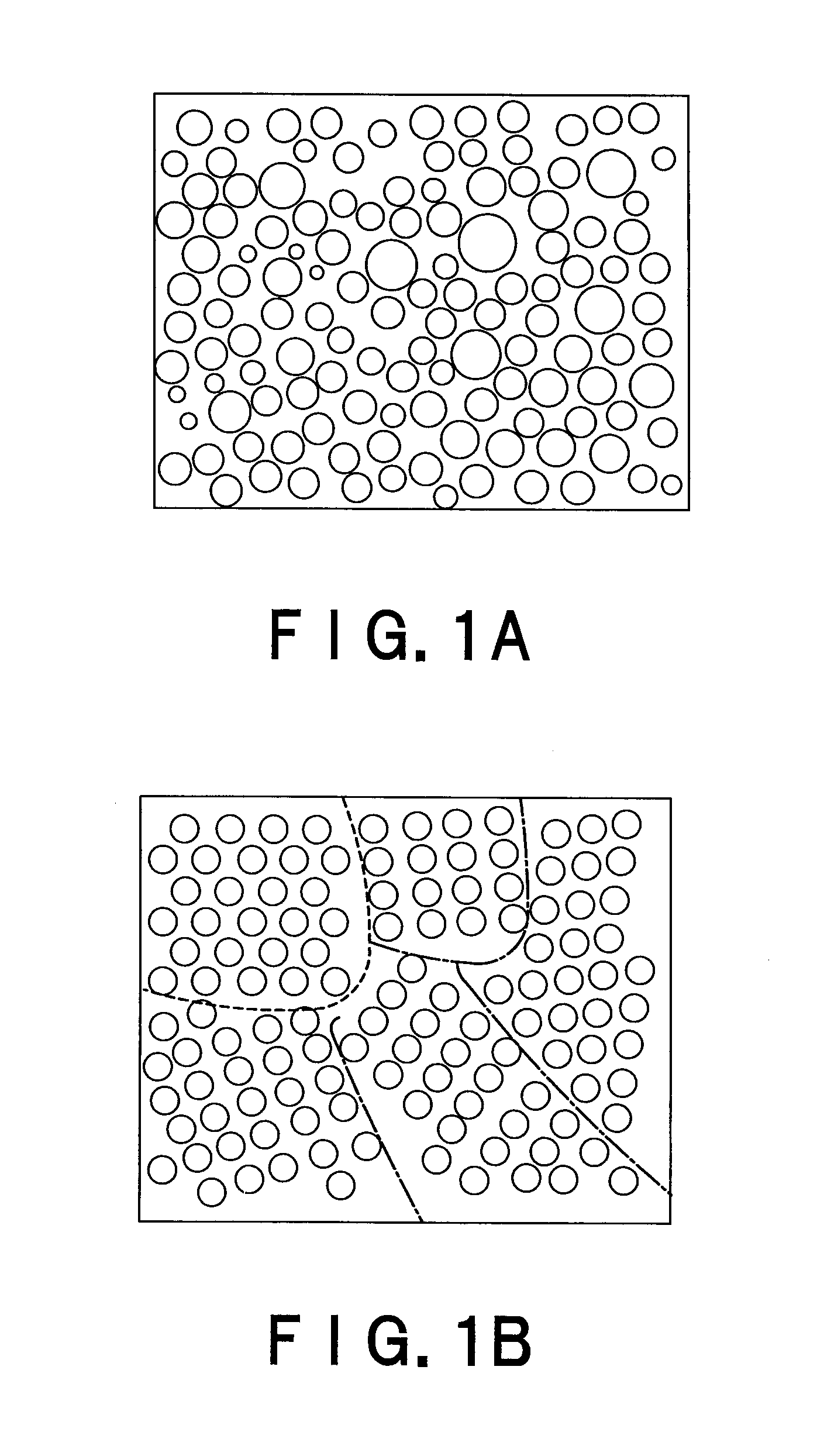

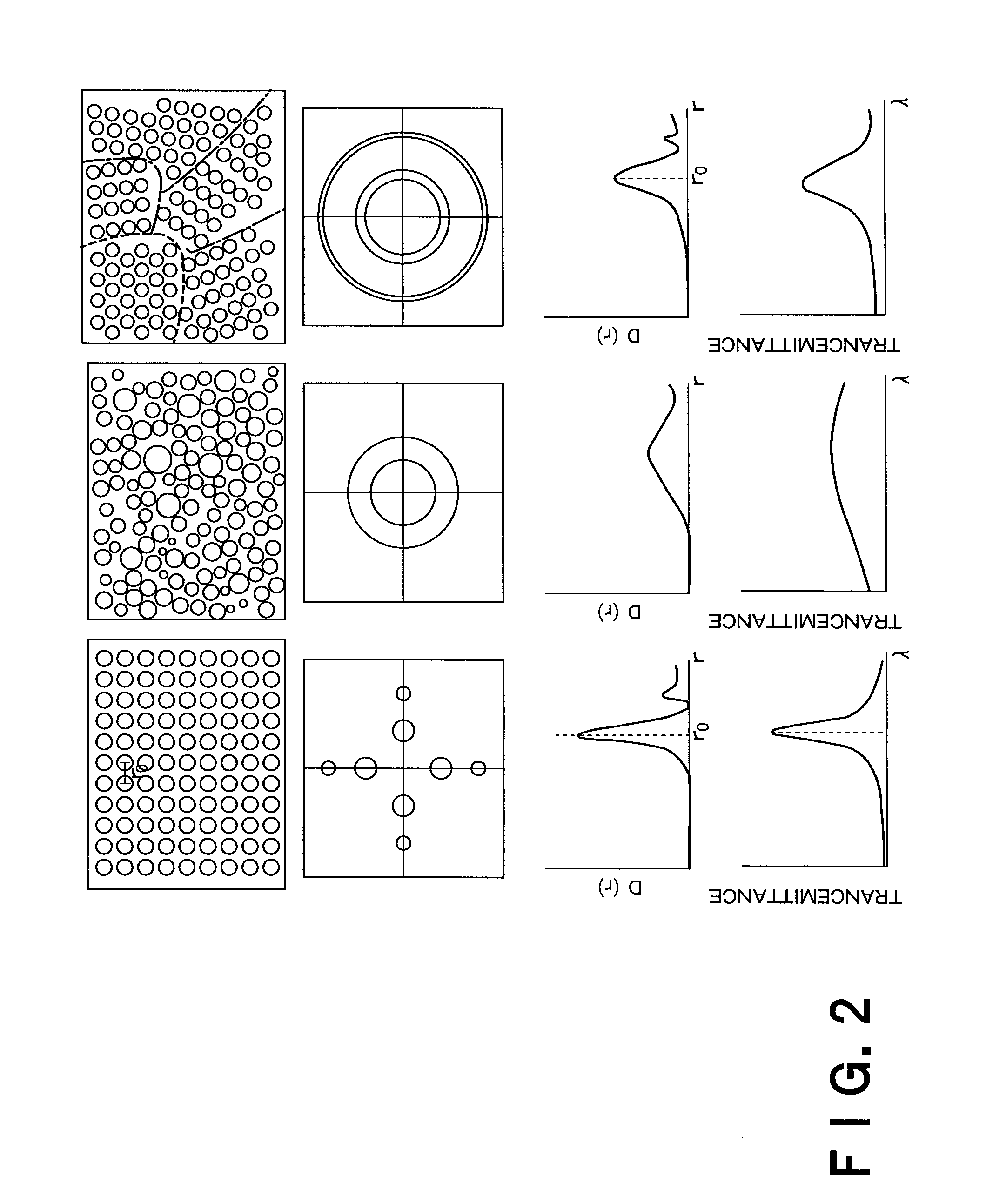

The present invention provides a light-transmitting metal electrode including a substrate and a metal electrode layer having plural openings. The metal electrode layer also has such a continuous metal part that any pair of point-positions in the part is continuously connected without breaks. The openings in the metal electrode layer are periodically arranged to form plural microdomains. The plural microdomains are so placed that the in-plane arranging directions thereof are oriented independently of each other. The thickness of the metal electrode layer is in the range of 10 to 200 nm.

Owner:KK TOSHIBA

Method of manufacturing plasma display panel and method of manufacturing plasma display apparatus

InactiveUS20050130547A1Shorten the timeReduce manufacturing costGas discharge electrodesAlternating current plasma display panelsSilver pasteFrit

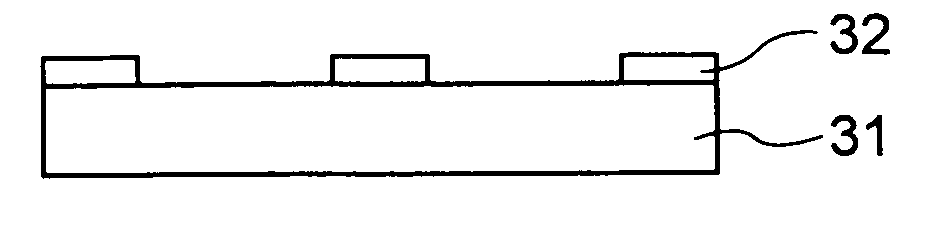

Address electrode patterns are formed on a rear surface glass substrate using a silver paste for forming address electrodes, and these patterns are dried. The average particle size of the silver powder in the silver paste is approximately 10 nm, and the softening point of the glass frit is approximately 420° C. The content ratio of the glass frit in the silver paste is set to 5 wt %. Then, a dielectric layer pattern is formed by using glass paste for forming a white dielectric layer so as to cover the address electrode patterns, and this dielectric layer pattern is dried. The glass frit in the glass paste has a softening point of approximately 540° C. Then, the address electrode patterns and the dielectric layer patterns are baked at a temperature of 540° C. Thus, the resin components in the address electrode patterns and the dielectric layer pattern are burnt away, and the glass frit components are softened so as to be fixed onto the rear surface glass substrate.

Owner:PANASONIC CORP

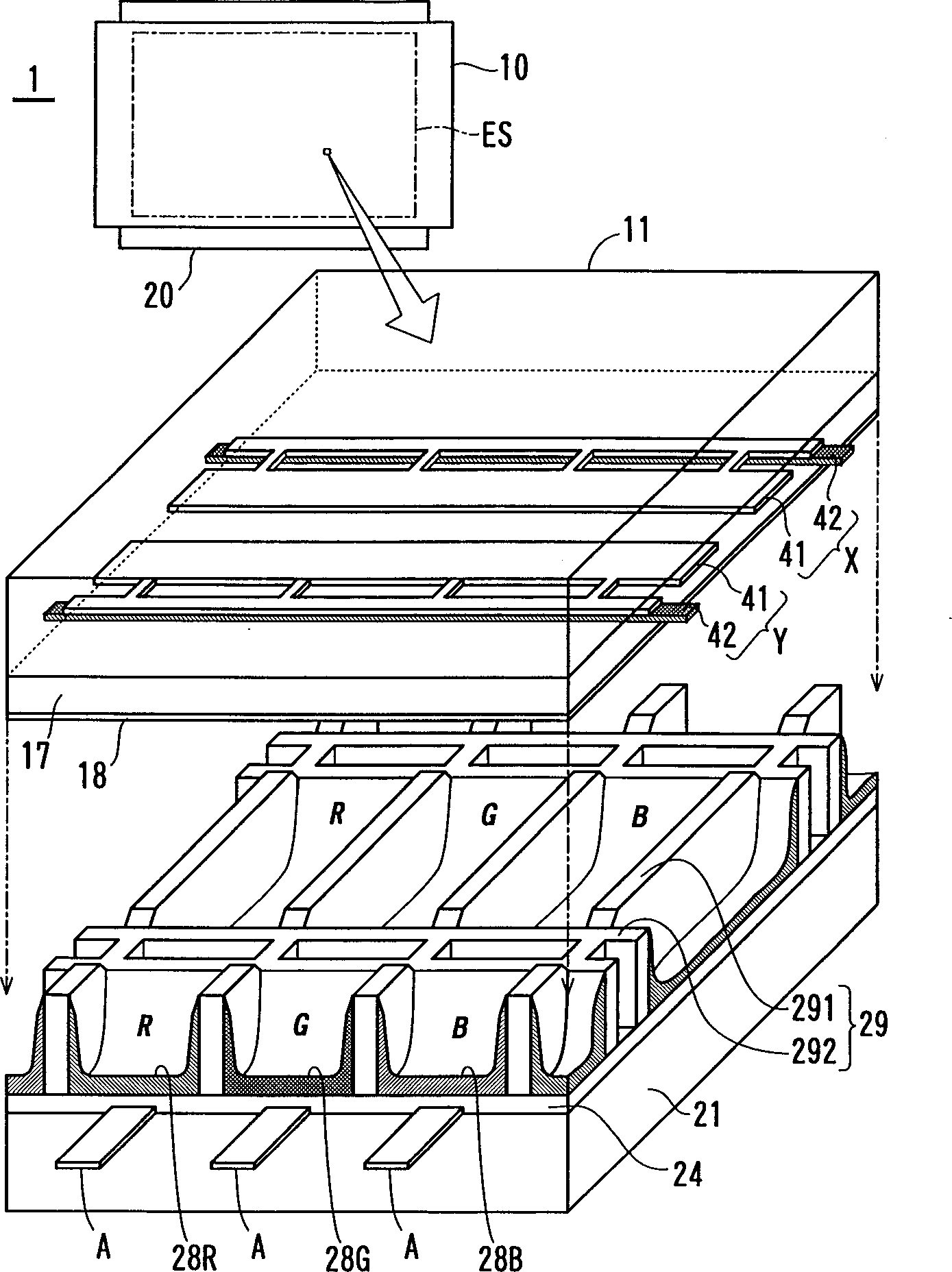

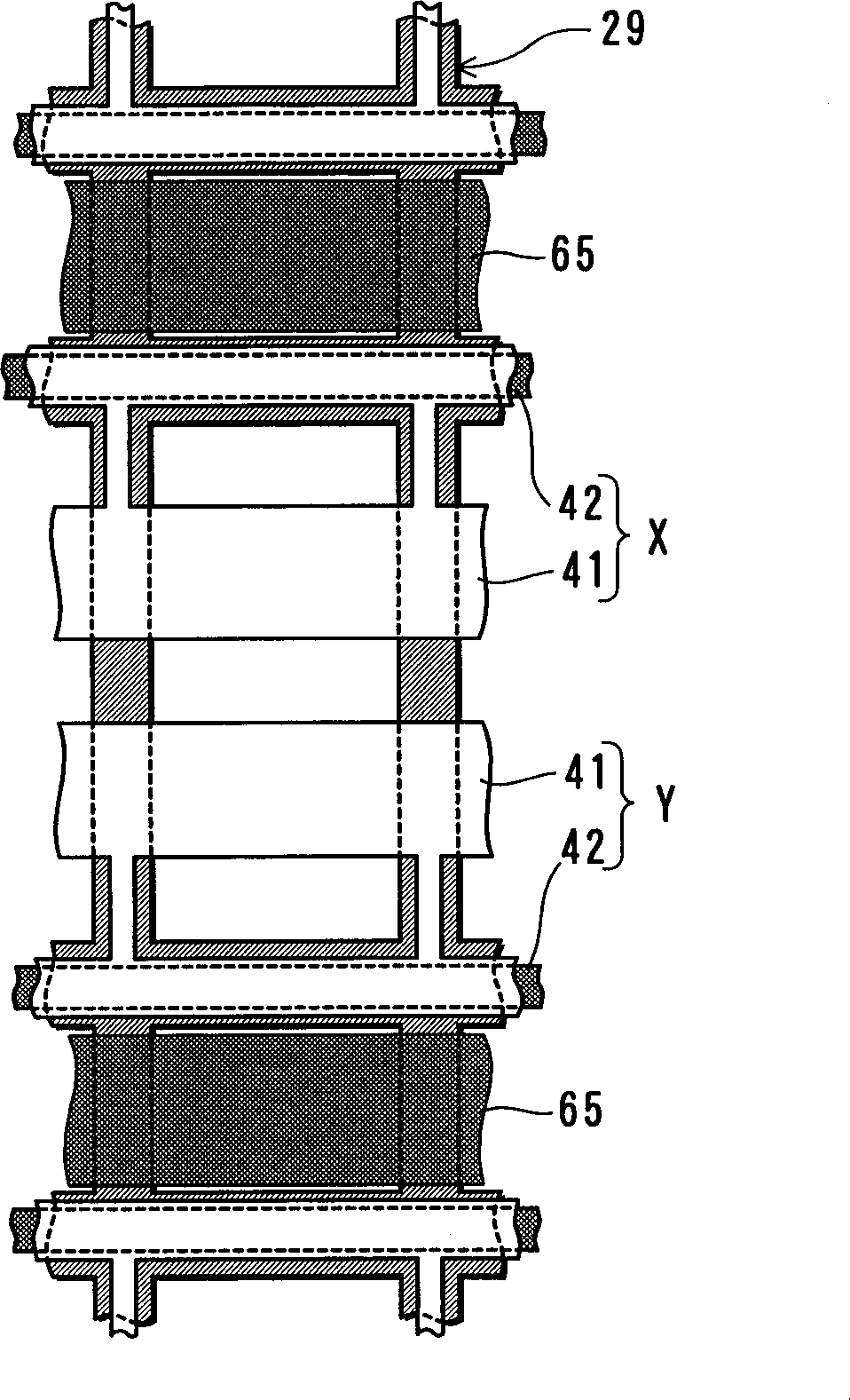

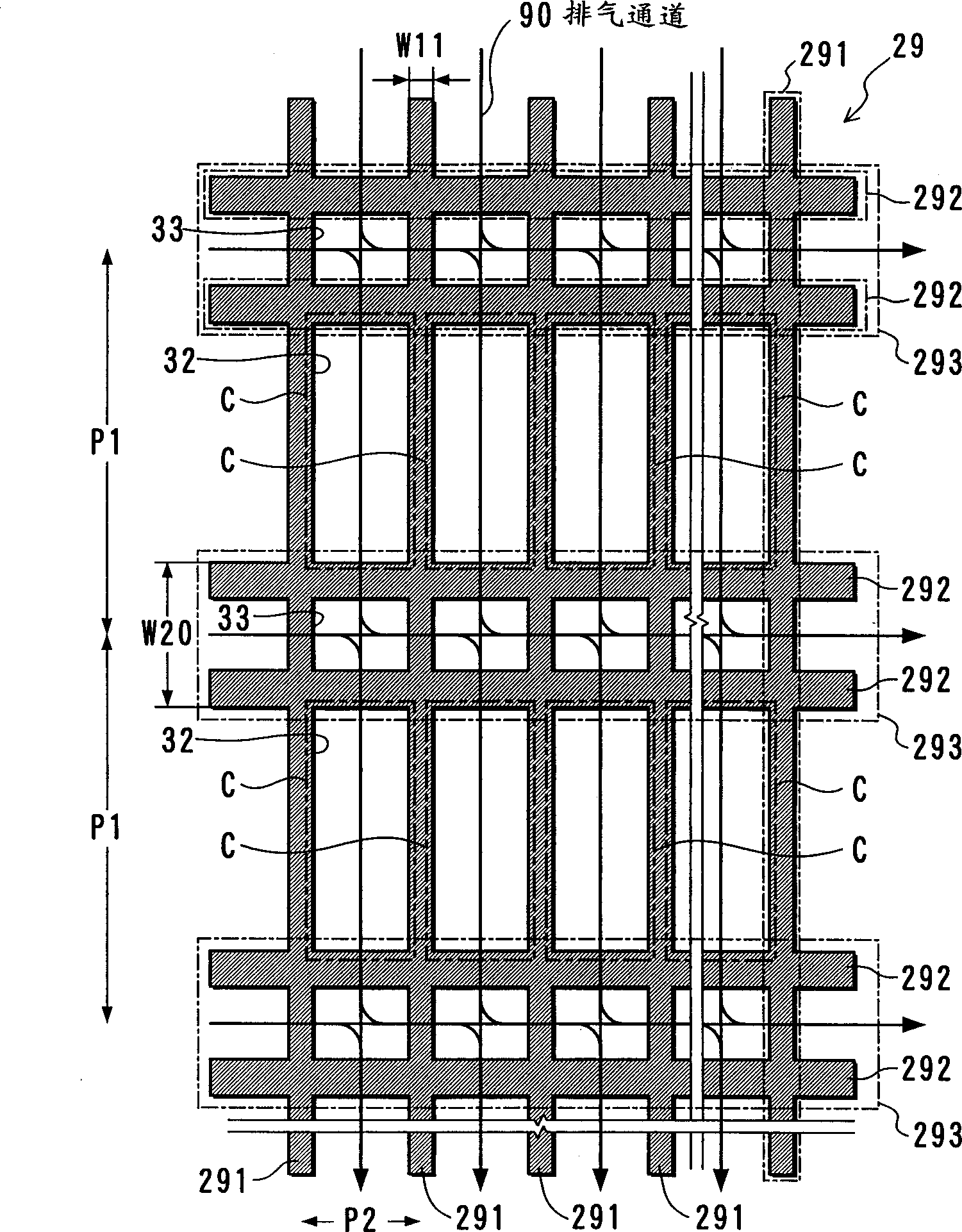

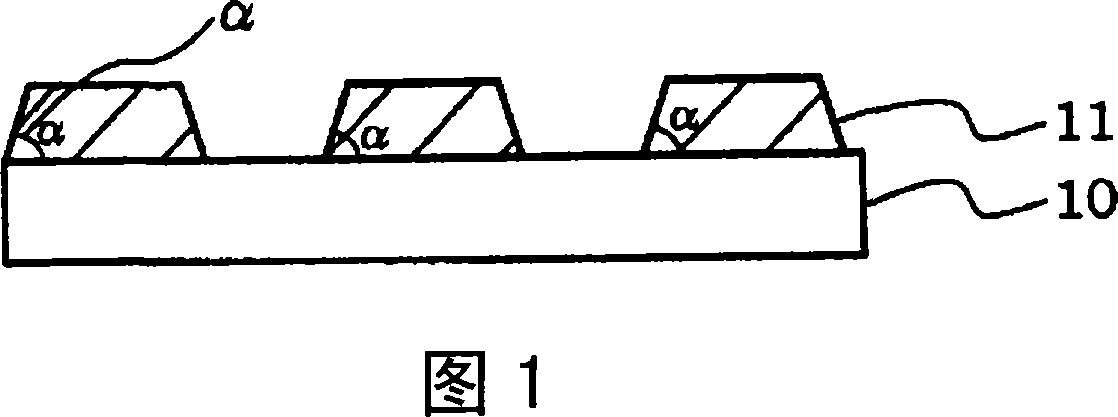

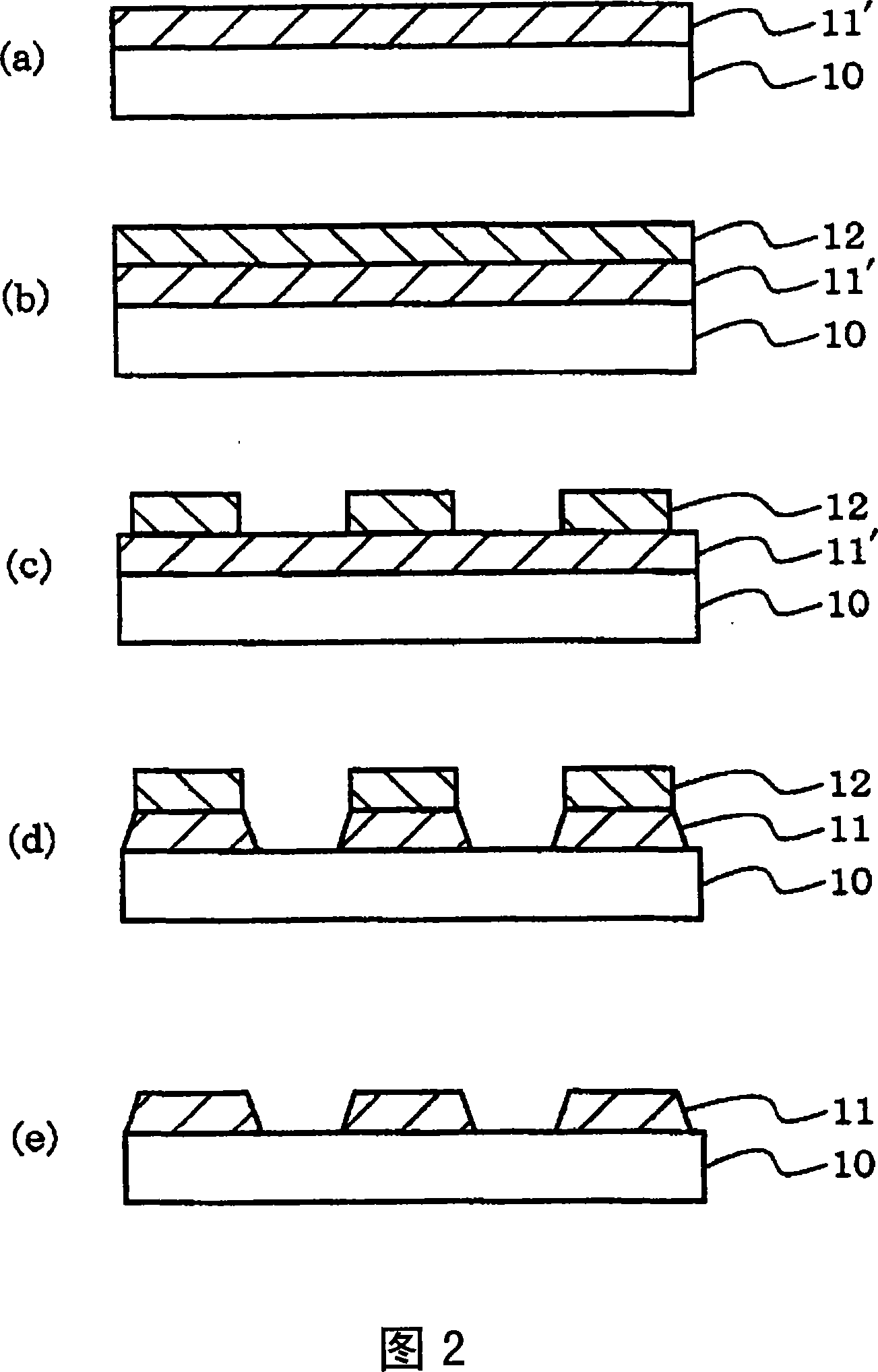

Plasma displaying panel and mfg. method thereof

InactiveCN1344005AIncrease productionShort discharge processGas discharge electrodesGas discharge vessels/containersEngineeringMechanical engineering

Owner:HITACHI CONSUMER ELECTRONICS CORP

Method for forming electrodes and/or black stripes for plasma display substrate

InactiveUS20070190886A1Lower resistanceNot vulnerable to erosionTube/lamp screens manufactureGas discharge electrodesDielectricLow load

To provide a method for forming electrodes and / or black stripes for a plasma display substrate, wherein display electrodes, bus electrodes and optionally black stripes for a plasma display panel are formed of the same material by the same dry step, whereby a clear image having reflection prevented, can be displayed on a PDP display device with a low load on the environment, at low costs, with low resistance, without erosion by a dielectric. A method for forming electrodes and / or black stripes for a plasma display substrate, which comprises applying a laser beam to a mask layer formed on a transparent substrate to form openings at areas corresponding to the respective patterns of display electrodes, bus electrodes and optionally black stripes, then continuously forming an antireflection layer to provide an antireflection effect over the entire surface and an electrode layer, and applying again a laser beam to peel off the mask layer and at the same time to remove an unnecessary thin film layer.

Owner:ASAHI GLASS CO LTD

Transparent electrode and its manufacturing method

InactiveCN101076869ALow priceGood alkali resistanceConductive layers on insulating-supportsGas discharge electrodesIndiumHeat stability

Disclosed is an indium-free transparent electrode which is excellent in alkali resistance, wet heat stability and etching properties. Specifically disclosed is a transparent electrode mainly containing zinc oxide and tin oxide wherein the taper angle at the edge portion of the electrode is 30-89 DEG . The ratio of zinc atoms to the total of zinc atoms and tin atoms in the transparent electrode (Zn / (Zn + Sn) atomic ratio) is preferably within the range of 0.5-0.9.

Owner:IDEMITSU KOSAN CO LTD

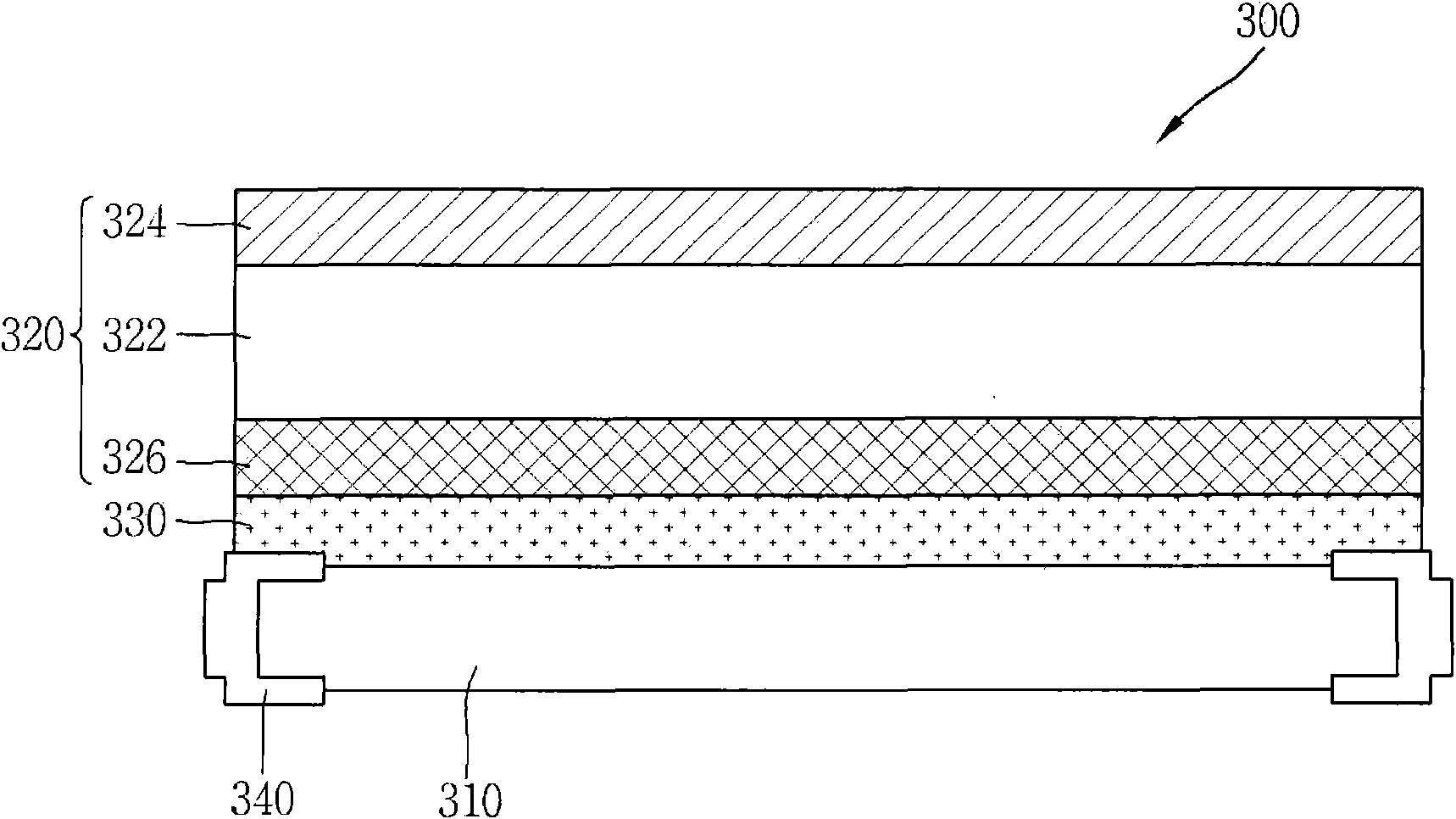

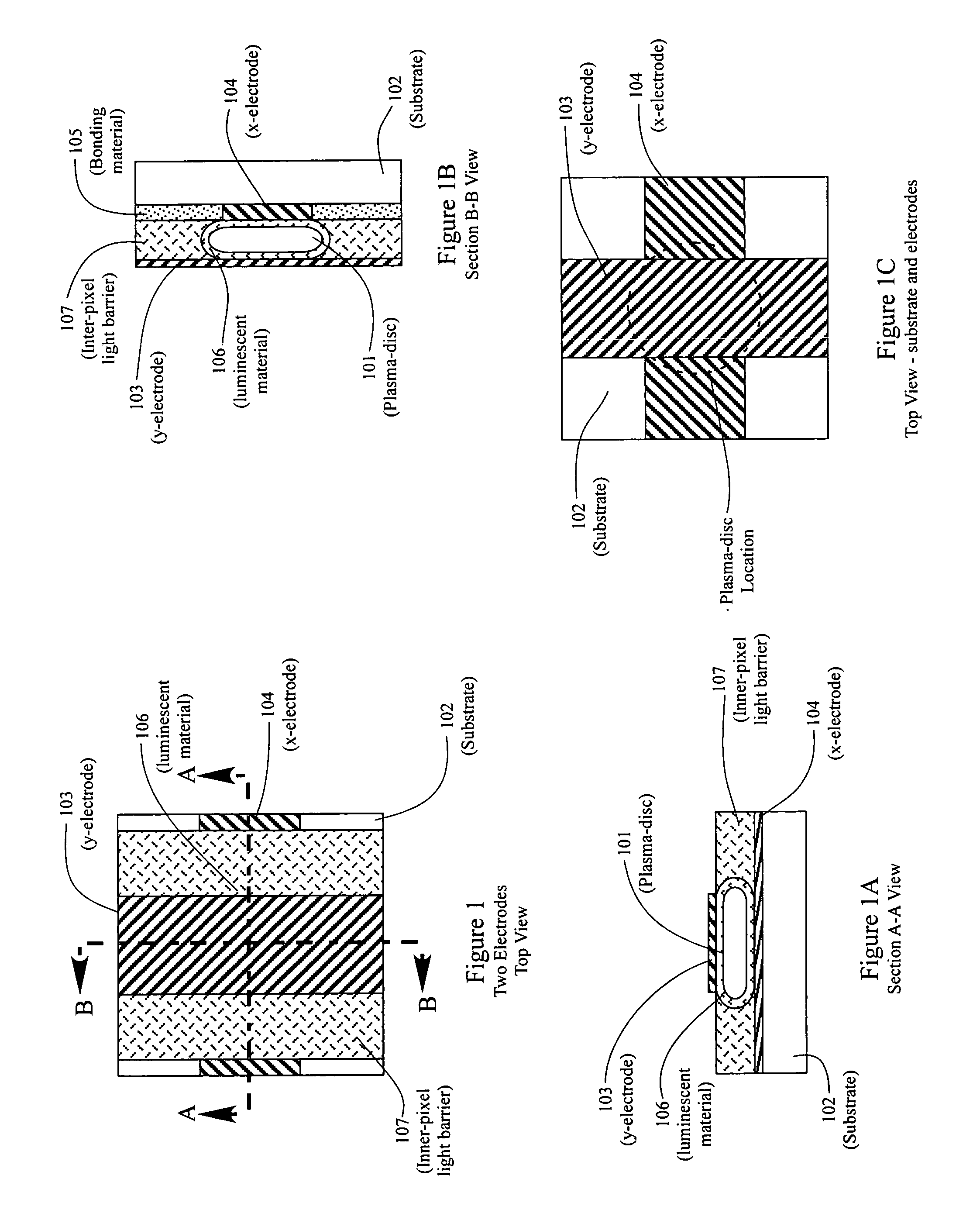

Tubular plasma display

InactiveUS20070132387A1Improve Bright Room ContrastIncrease brightnessGas discharge electrodesAlternating current plasma display panelsDisplay deviceEngineering

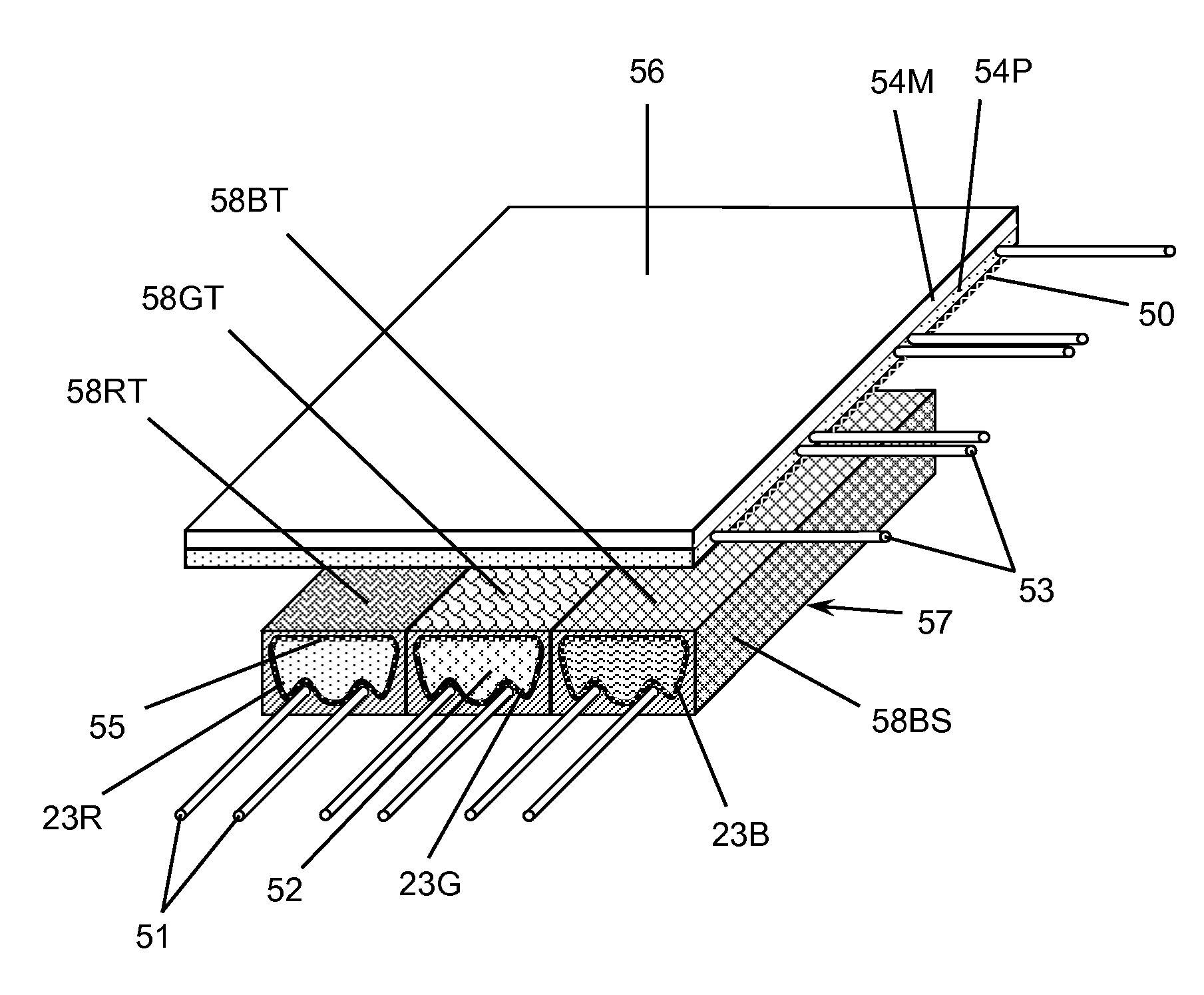

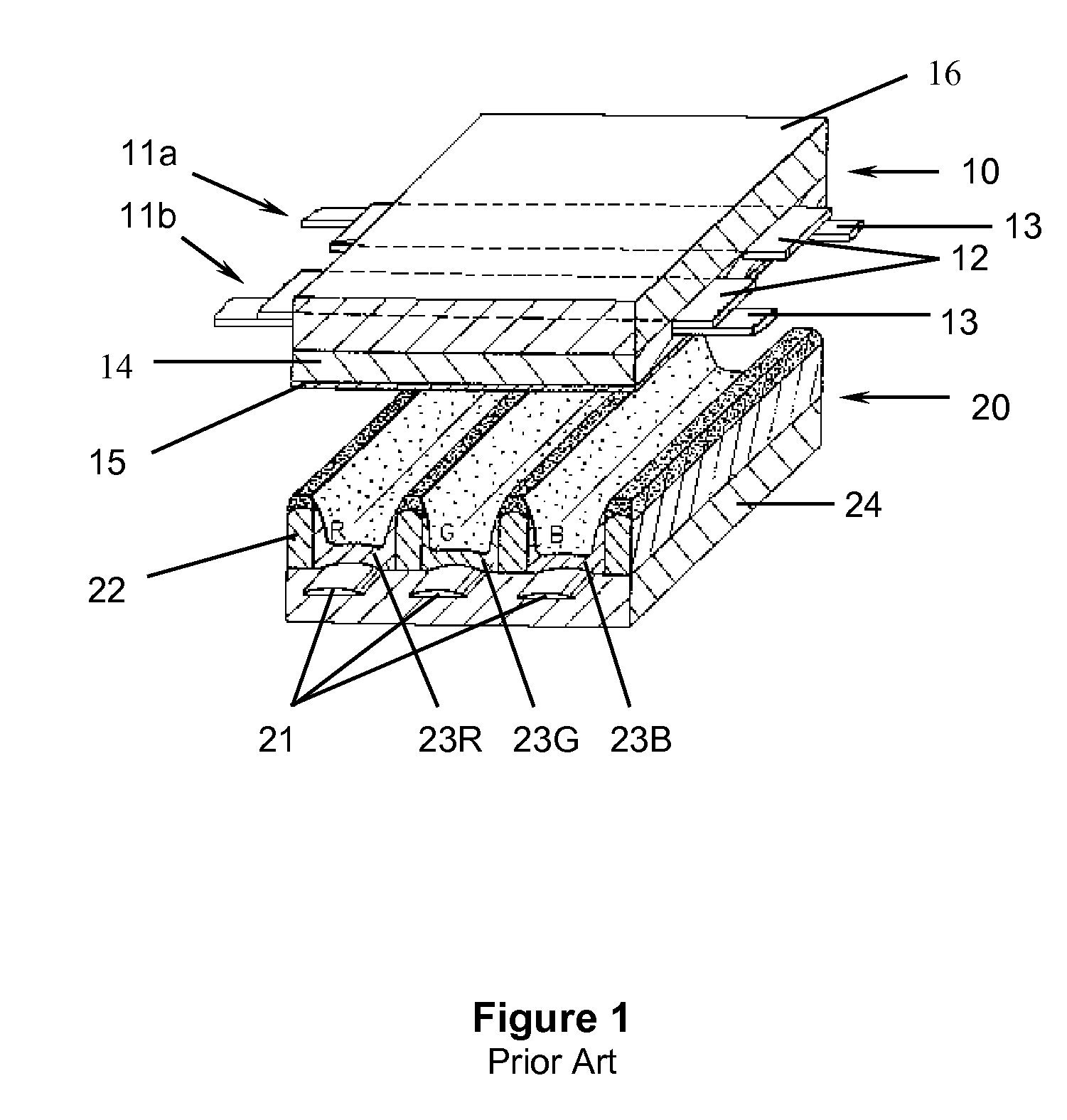

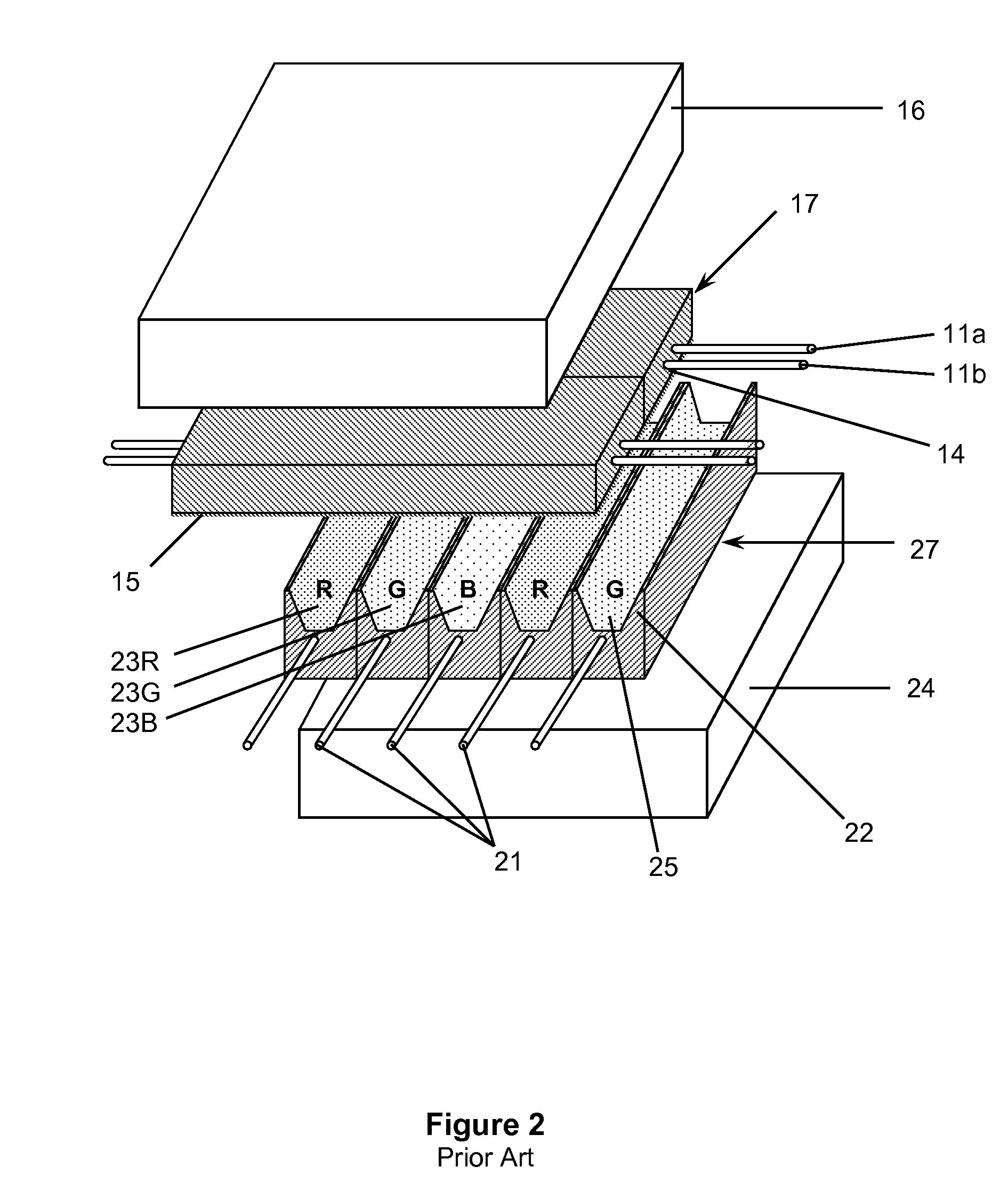

A tubular plasma display (TPD) is composed of an electroded sheet (electroded sheet) attached to an array of plasma tubes. Both the electrode sheet and the plasma tube array contain wire electrodes, which create very electrically conductive lines and the ability to address very large displays. The electroded sheet is composed of a thin flexible polymer substrate with embedded wire sustain electrodes. Each plasma tube is individually sealed and contains a wire address electrode, a hard emissive coating, a color phosphor and a Xenon based plasma gas. Polymer-based color filter coatings may also be applied to the surface of the plasma tubes after they are gas processed and sealed to drastically increase the bright room contrast, brightness, and color purity of the display.

Owner:MOORE CHAD B

Illuminator with fluorescent substance

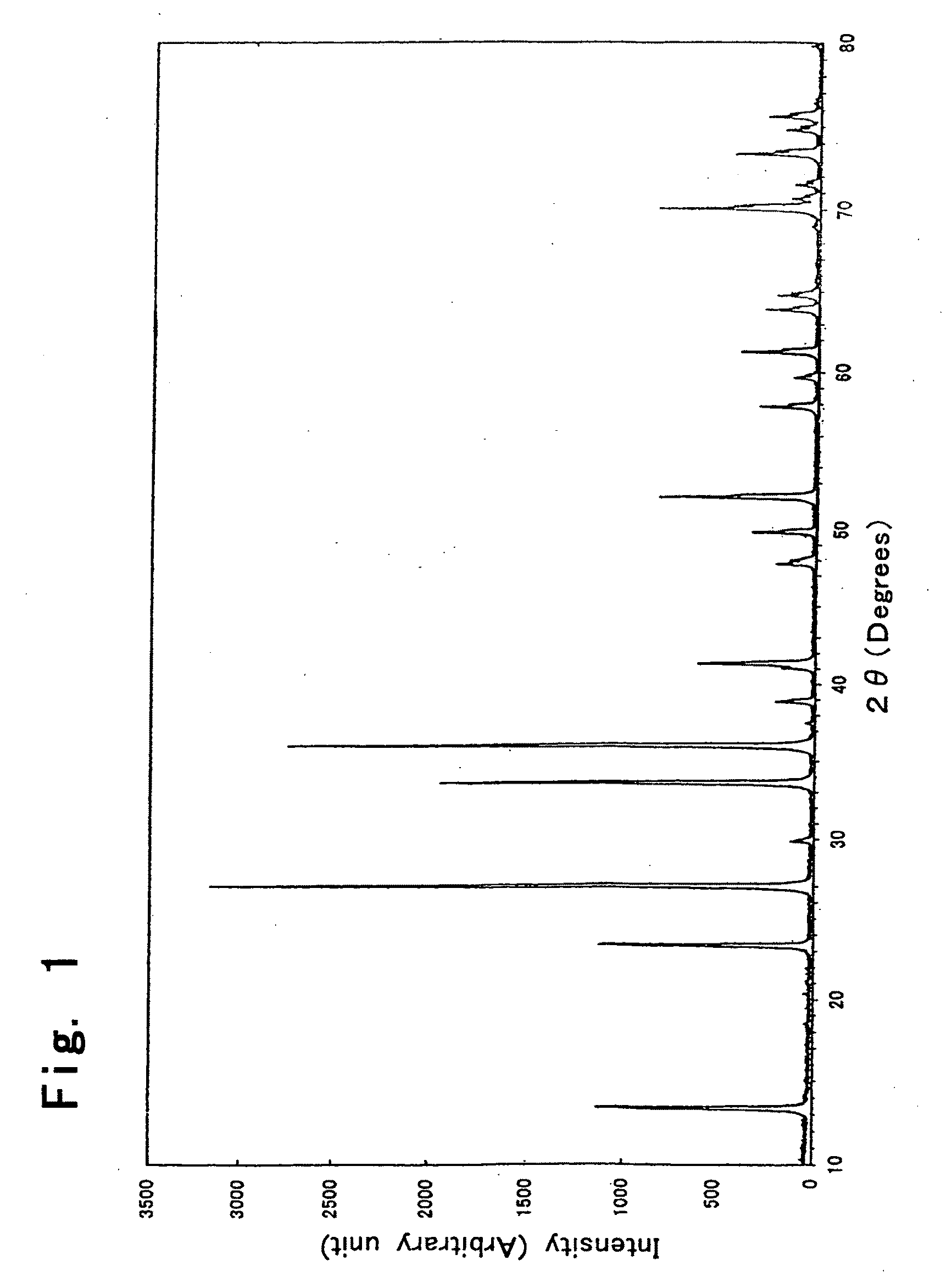

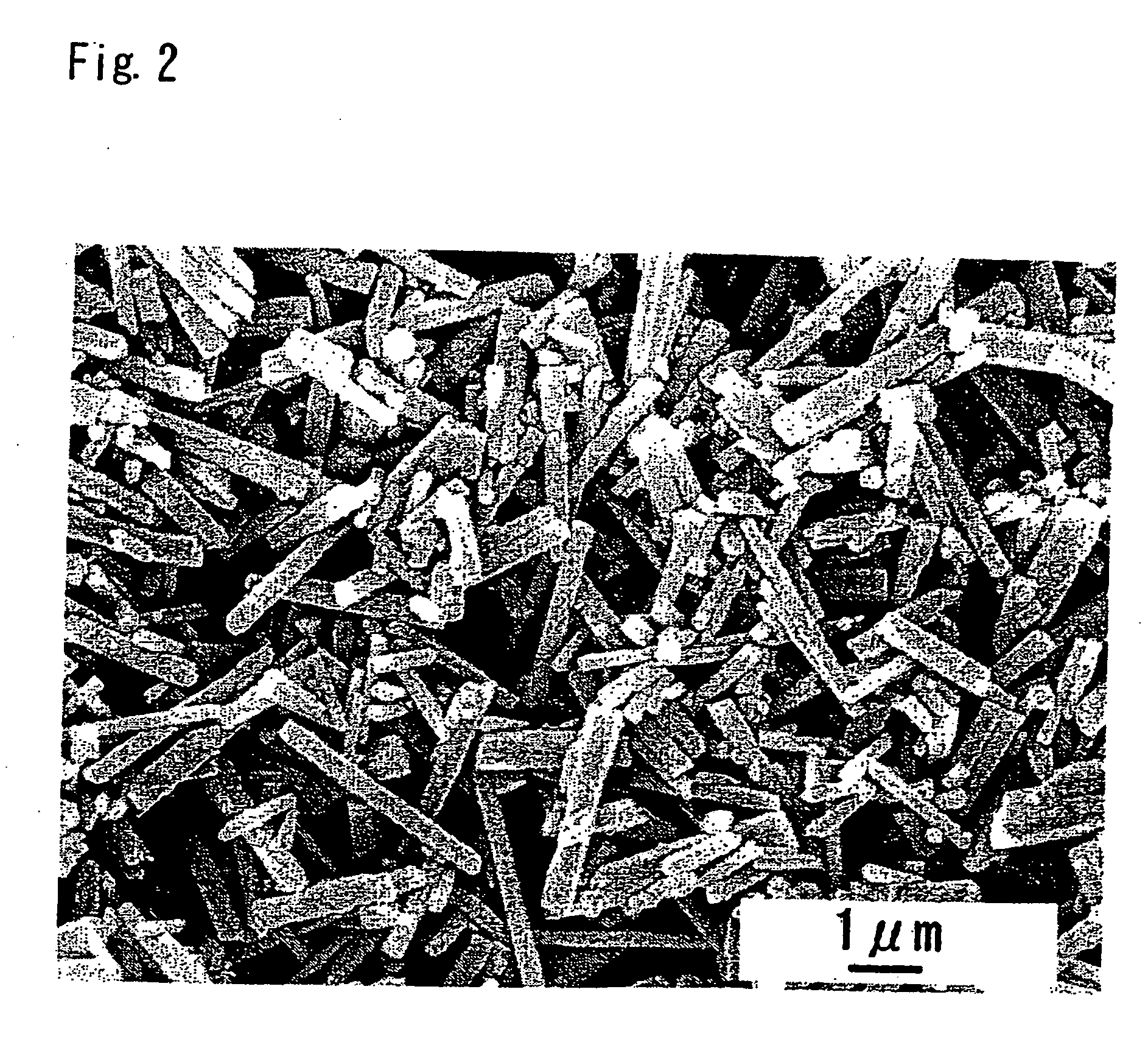

ActiveUS20090129052A1Reduced in luminanceIncrease light intensityDischarge tube luminescnet screensCathode ray tubes/electron beam tubesCrystal structureLength wave

An illuminator includes a light emitting light source and a fluorescent substance. The fluorescent substance includes a crystal of nitride or oxy-nitride having a β-type Si3N4 crystal structure having Eu+2 solid-dissolved into it and emitting a fluorescent light having a peak within a range of 500 nm to 600 nm in wavelength by being irradiated with an exciting light.

Owner:NAT INST FOR MATERIALS SCI

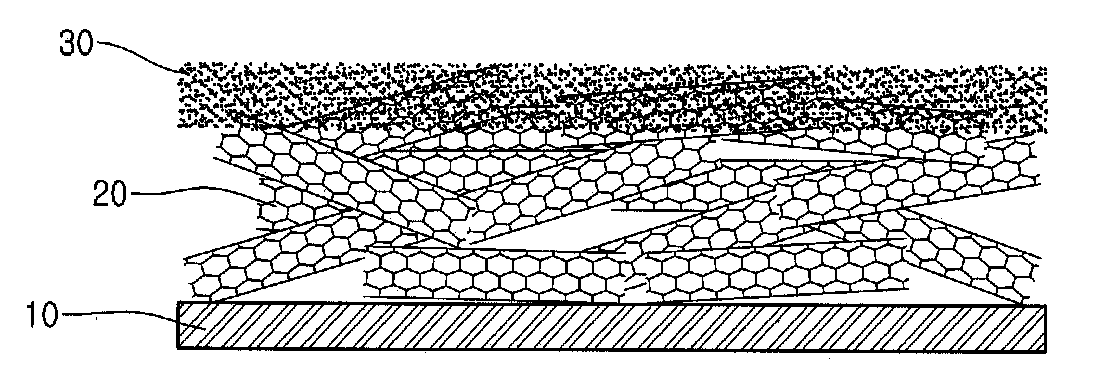

Carbon nanotube transparent electrode and method of manufacturing the same

InactiveUS20090252967A1Improve conductivityReduce electrical conductivityNanostructure manufactureGas discharge electrodesCarbon nanotubeSurface roughness

A CNT transparent electrode may have a CNT layer consisting essentially of CNT only, together with a cover layer that may include conductive particles and a polymer. The cover layer may cover an upper and / or a lower portion of the CNT layer. The CNT transparent electrode including the CNT layer which essentially consists of CNT only and does not contain other materials such as a binder or a dispersing agent can exhibit excellent conductivity. When the CNT layer is covered by the cover layer, surface roughness, film uniformity, adhesion between the CNT transparent electrode and the substrate and stability in the process of applying the CNT transparent electrode to devices can be enhanced, compared to the case where only the CNT layer is used.

Owner:SAMSUNG ELECTRONICS CO LTD +1

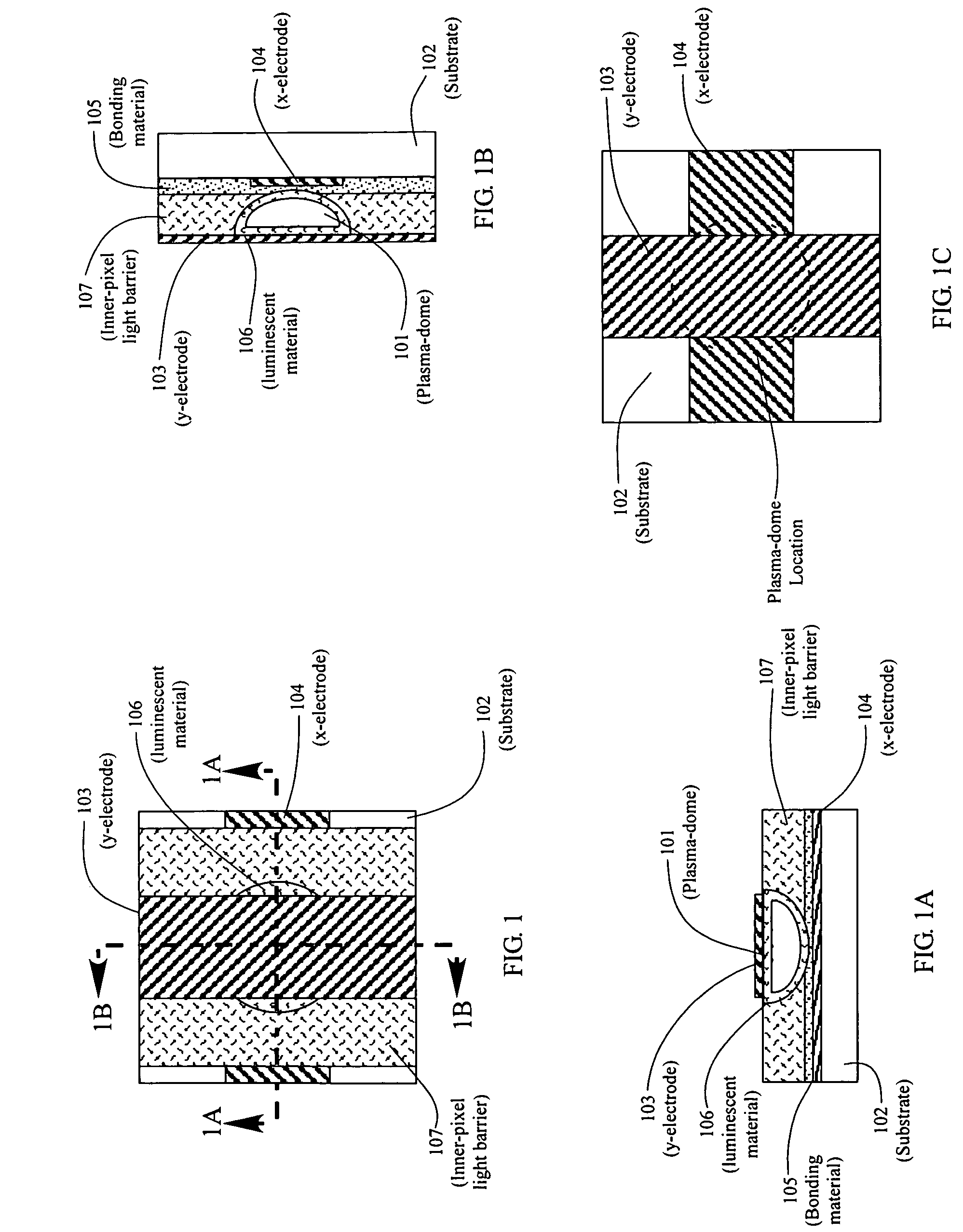

Plasma-dome PDP

InactiveUS7622866B1Gas discharge electrodesAlternating current plasma display panelsEngineeringUp conversion

There is disclosed a plasma display panel (PDP) device having one or more substrates and a multiplicity of pixels or sub-pixels. Each pixel or sub-pixel is defined by a hollow Plasma-dome™ filled with an ionizable gas. The Plasma-dome has a flat side and an opposing domed side such as a flat bottom and a domed top or a flat rear and domed front. One or more other sides or edges may also be flat. Two or more addressing electrodes are in electrical contact with each Plasma-dome. A flat base side or domed side of the Plasma-dome shell is in contact with a substrate. The PDP may also include inorganic and organic luminescent materials that are excited by the gas discharge within each Plasma-dome. The luminescent material may be located on an exterior and / or interior surface of the Plasma-dome or incorporated into the shell of the Plasma-dome. Up-conversion and down-conversion materials may be used. The substrate may be rigid or flexible with a flat, curved, or irregular surface.

Owner:IMAGING SYST TECH

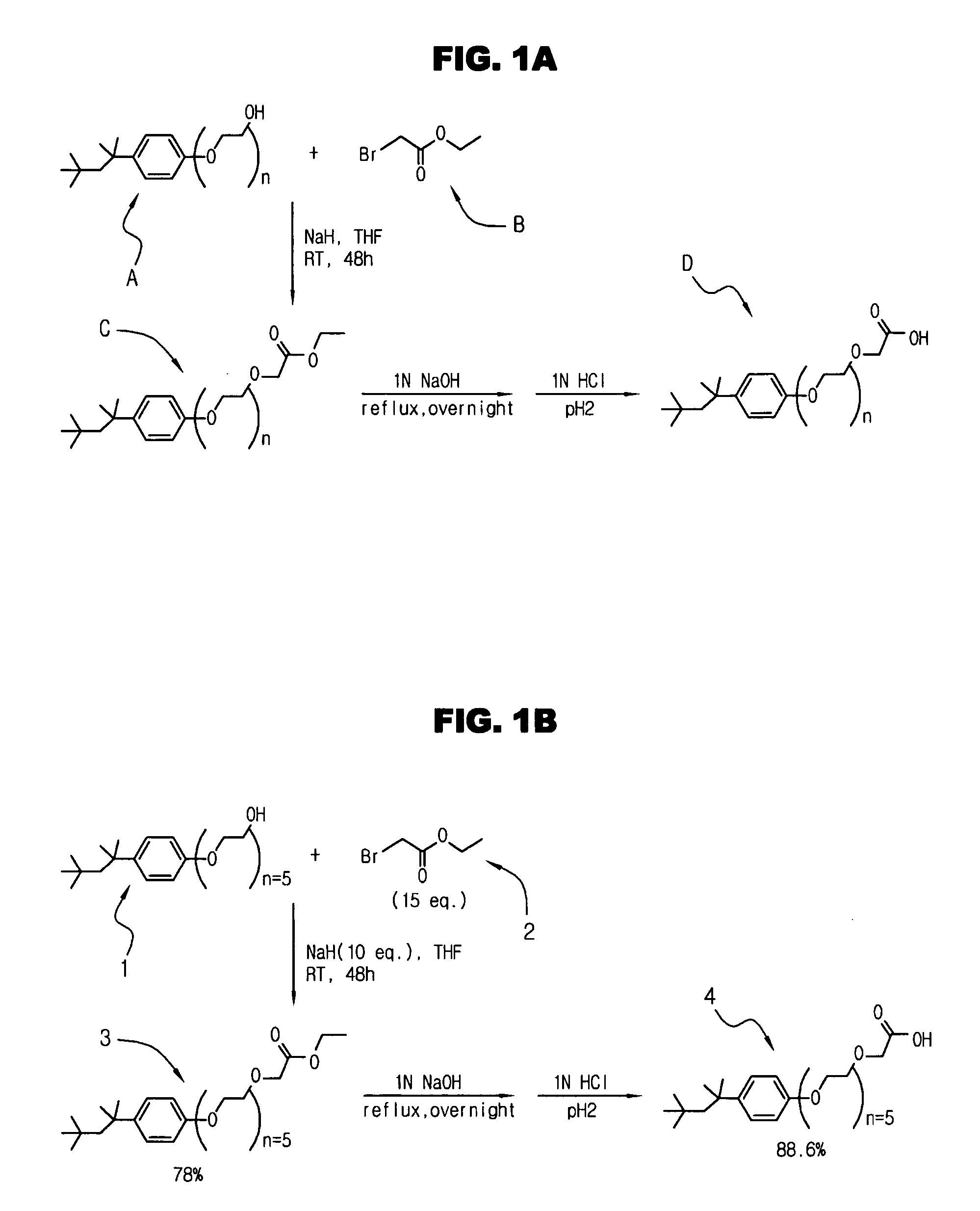

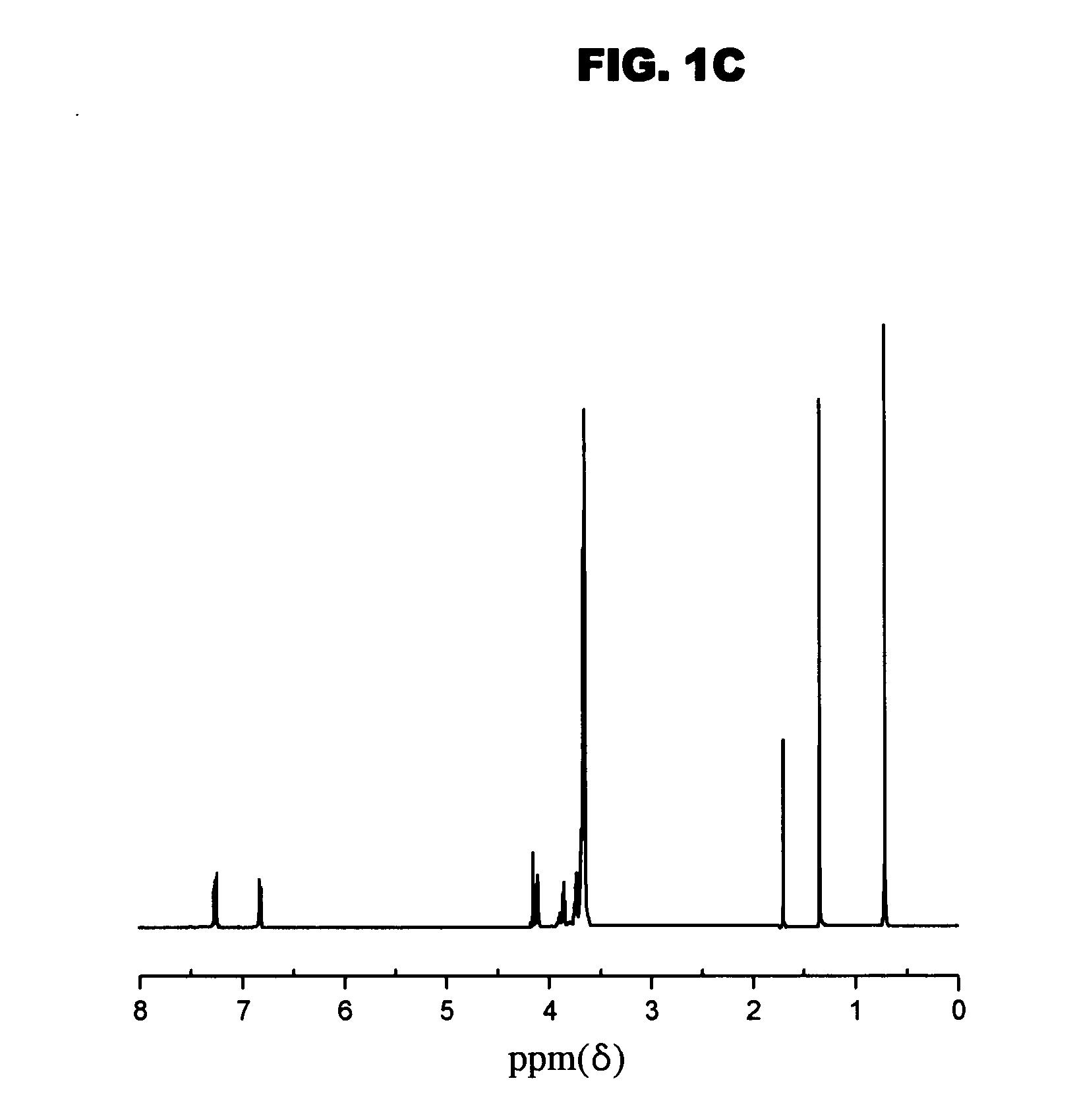

Carboxylic ester dispersant and sulfide phosphor paste composition having same

InactiveUS20070072969A1Good dispersionPrevent oxidationOrganic chemistryGas discharge electrodesPolymer scienceFluorescence

Disclosed herein is a carboxylic ester dispersant shown in the following Formula 1 and a sulfide phosphor paste composition containing the dispersant. The dispersant improves the dispersibility of the sulfide phosphor paste composition and prevents oxidation by a solvent, thus improving processability and the luminescent properties of a phosphor film made from the paste and of a display produced using the film. In Formula 1, n is 1-20.

Owner:SAMSUNG ELECTRONICS CO LTD

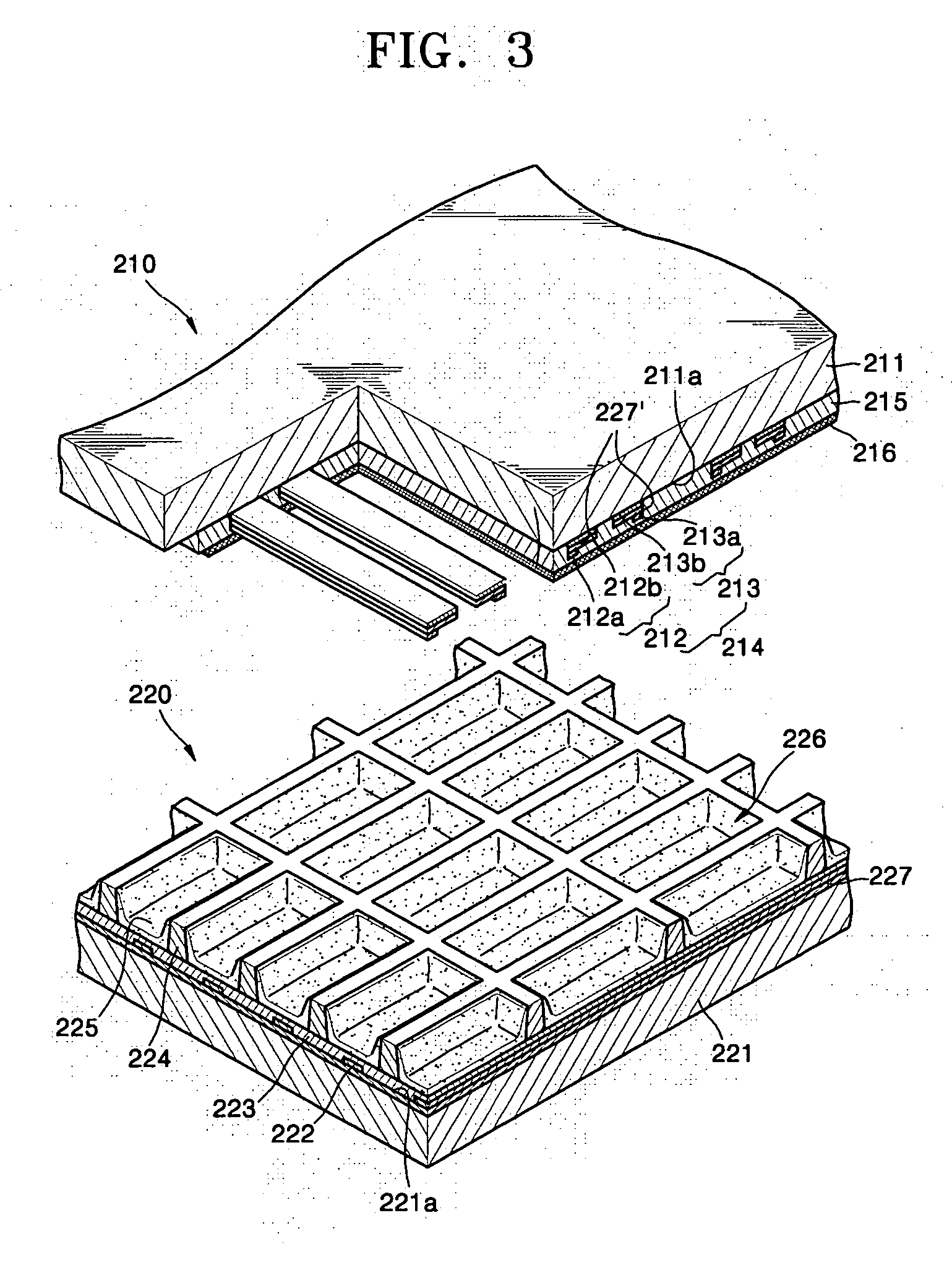

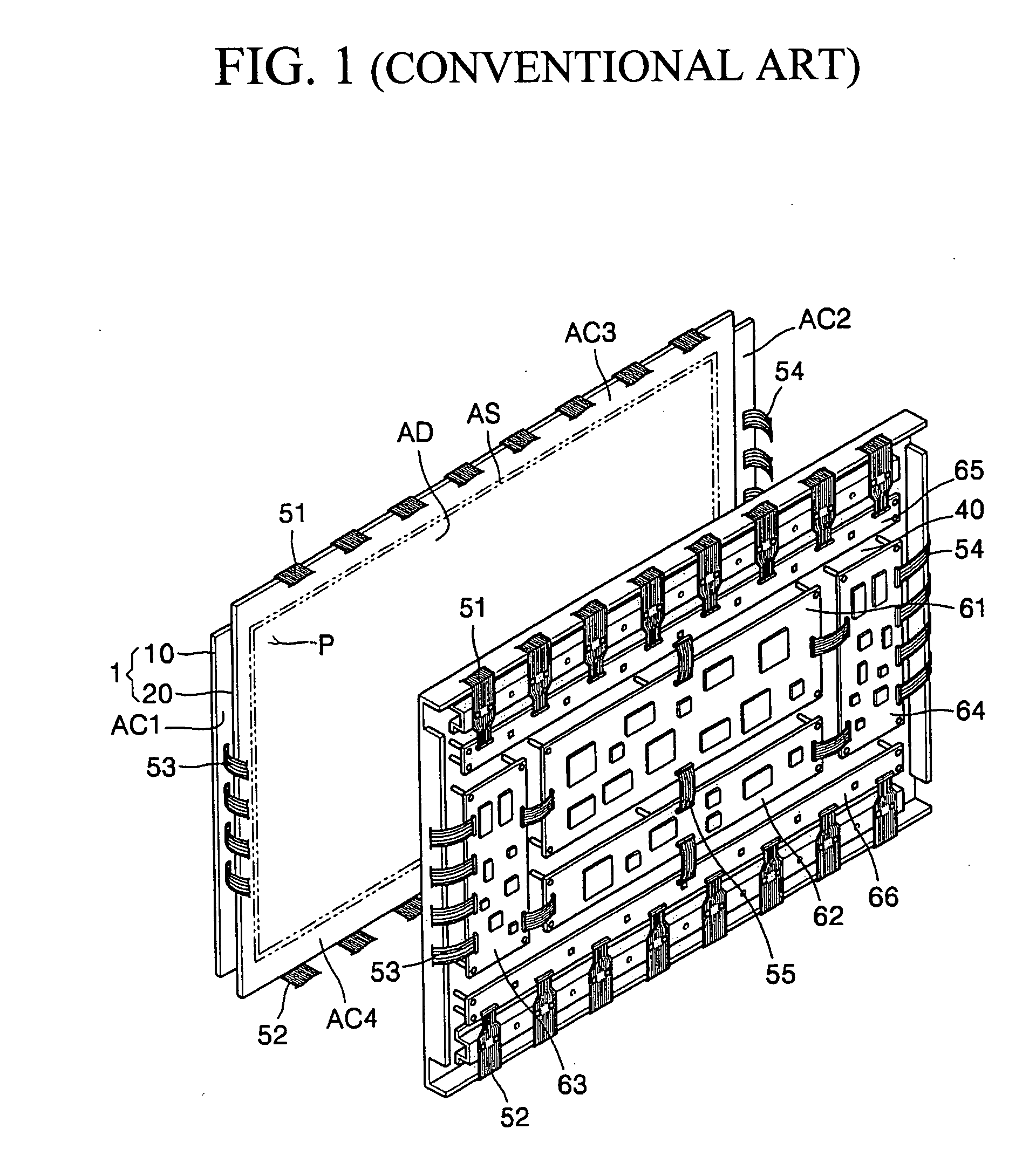

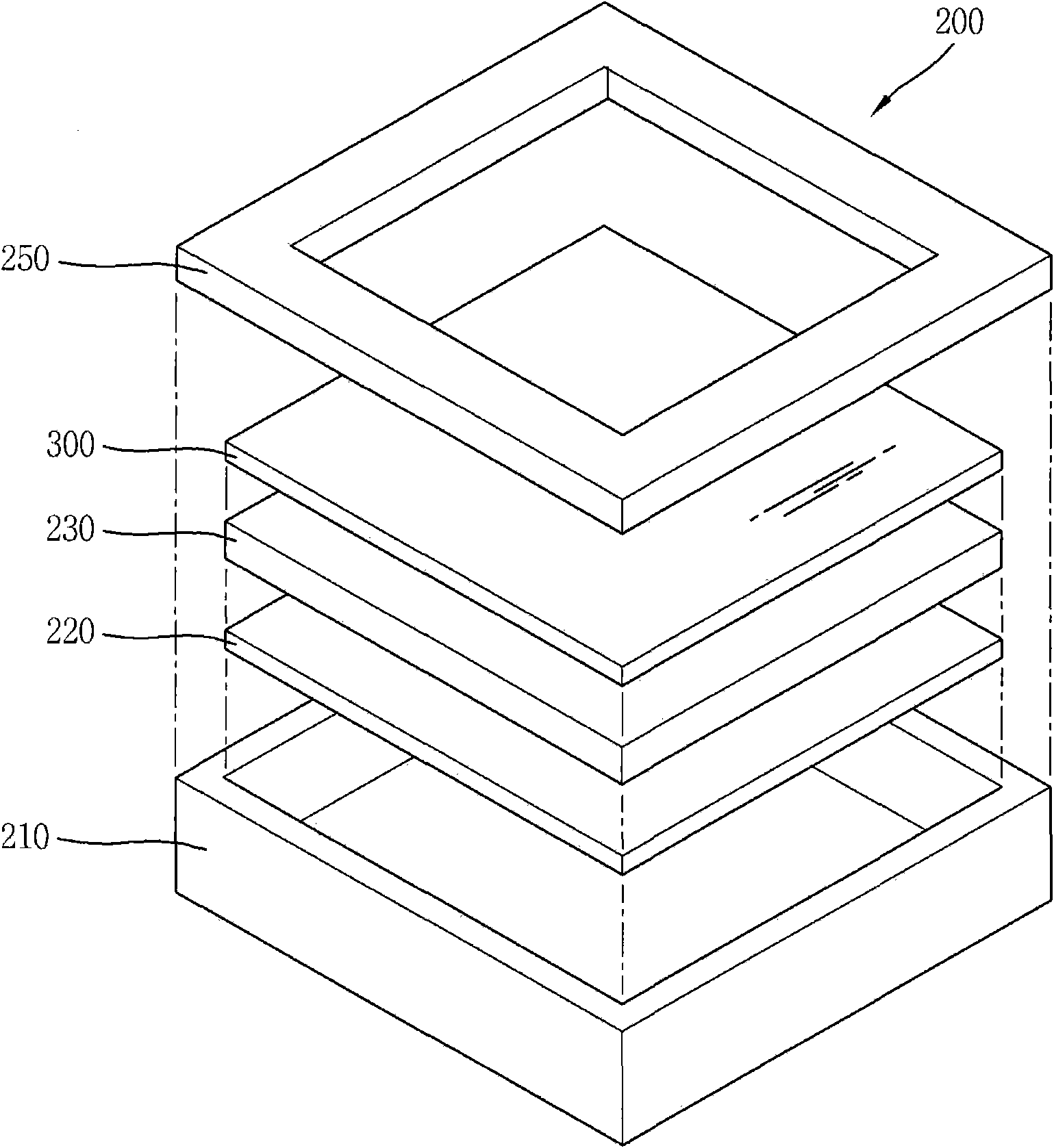

Plasma display module and method of manufacturing the same

InactiveUS20050264198A1Improve emission efficiencyQuick buildGas discharge electrodesGas discharge connecting/feedingFailure rateEngineering

A plasma display module that can improve the emission efficiency of light, generate a discharge quickly, reduce an address voltage, and be manufactured at lower costs and failure rates, includes a substrate formed of a transparent insulator, a chassis base disposed on a rear side of the substrate, a plurality of barrier ribs formed of a dielectric disposed between the substrate and the chassis base and define discharge cells together with the substrate and the chassis base, a plurality of front discharge electrodes formed in the barrier ribs that surround the discharge cell, a plurality of rear discharge electrodes spaced apart from the front discharge electrodes and formed in the barrier ribs to surround the discharge cell, a fluorescent layer disposed in the discharge cell, a discharge gas filled in the discharge cell, and a plurality of circuit substrates that apply electrical signals to the electrodes by disposing on a rear side of the chassis base.

Owner:SAMSUNG SDI CO LTD

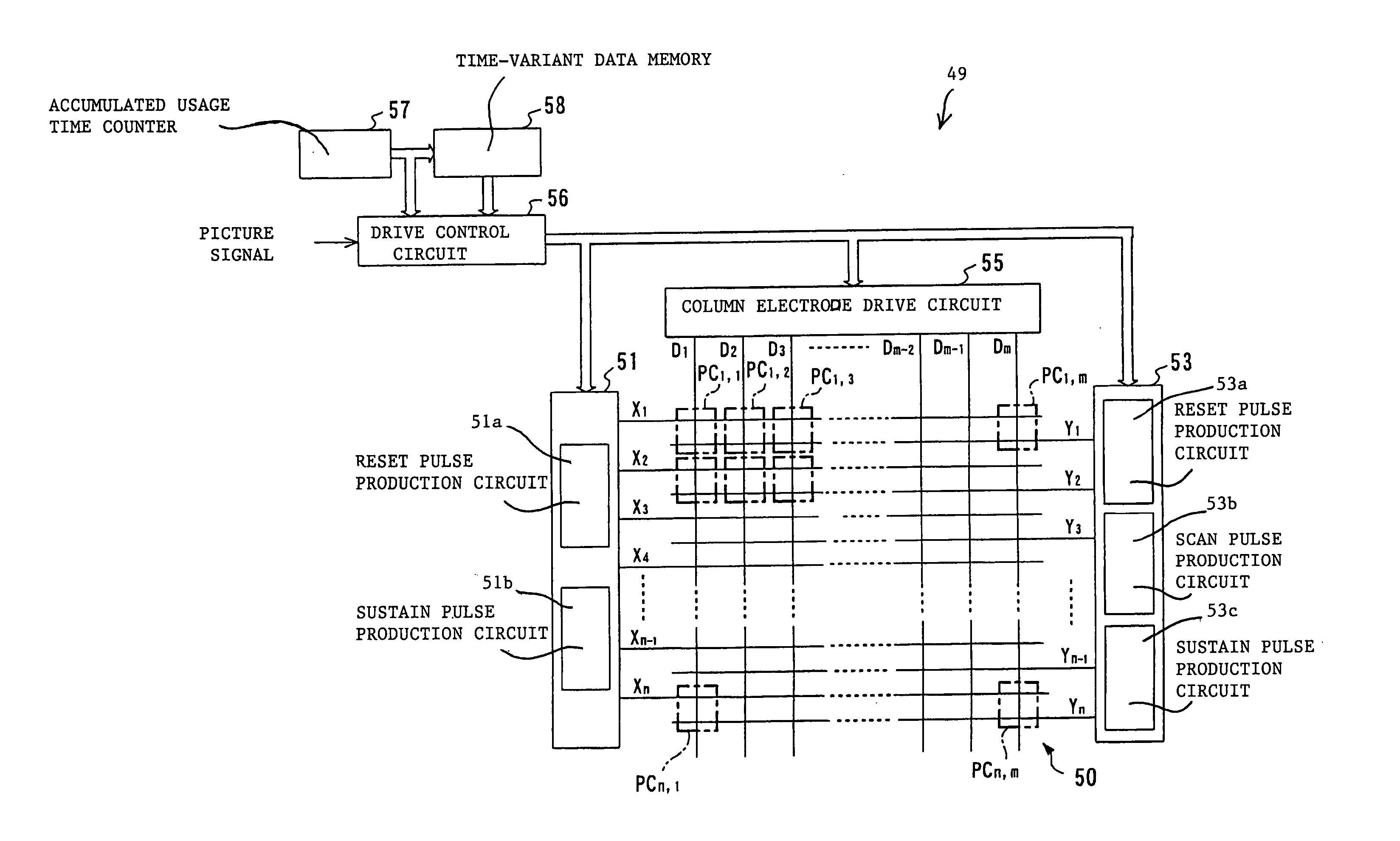

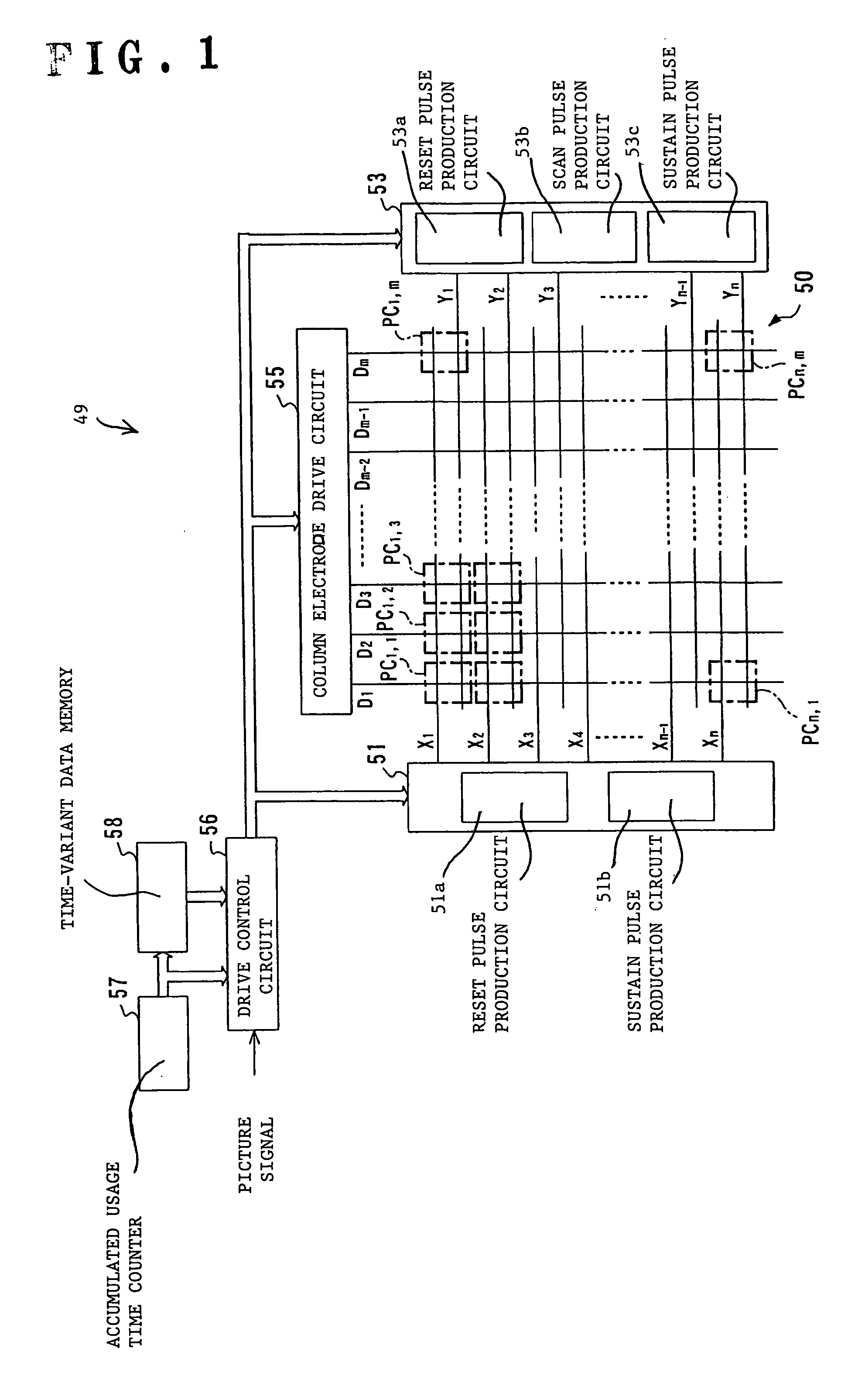

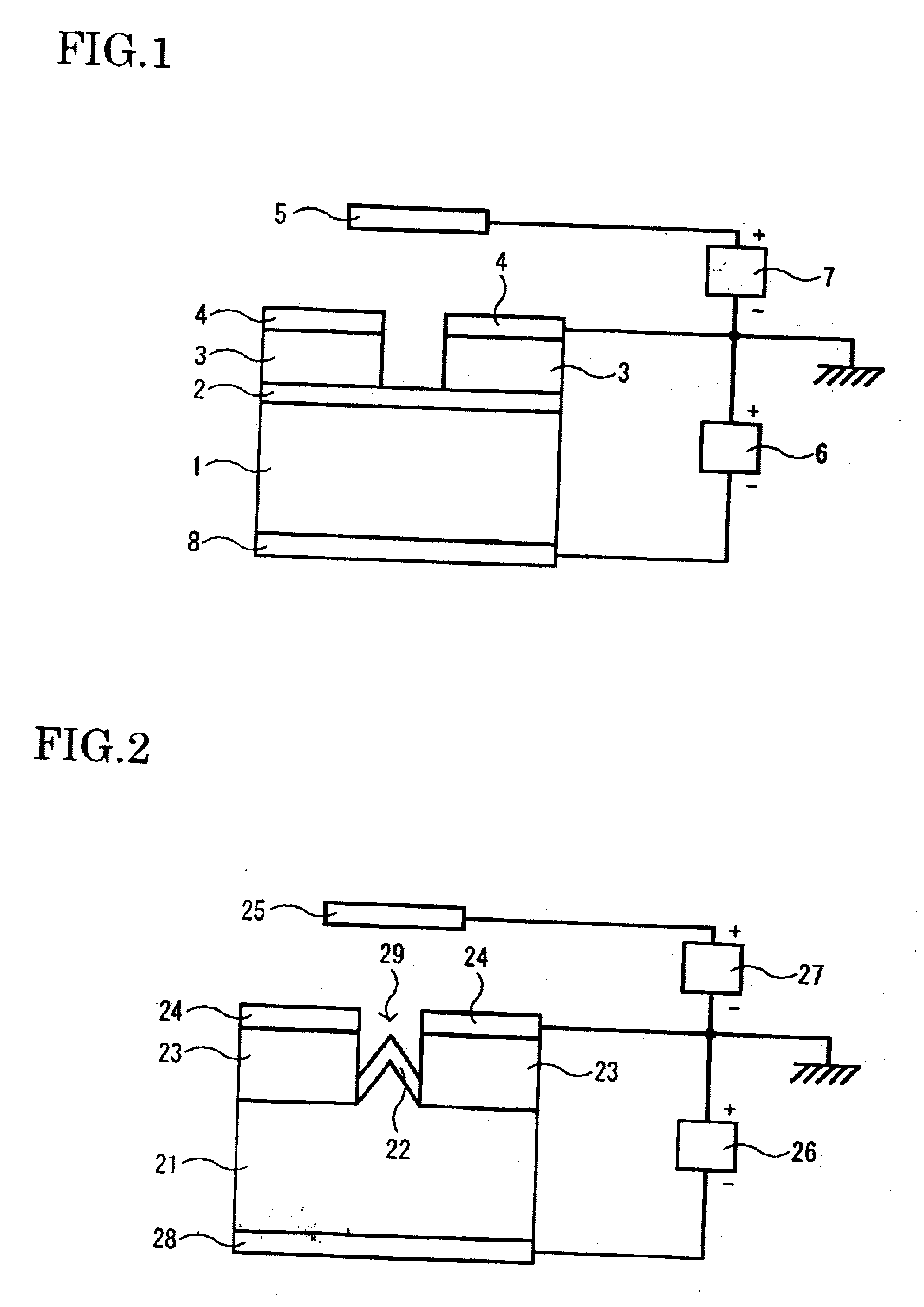

Plasma display apparatus

InactiveUS20060066519A1Suppress image degradationImprove image qualityGas discharge electrodesStatic indicating devicesPulse voltagePlasma display

A plasma display apparatus includes a plasma display panel. Pulse voltage values and / or pulse widths of a variety of drive pulses that are applied to the plasma display panel are adjusted in accordance with the accumulated usage time of the plasma display panel.

Owner:PANASONIC CORP

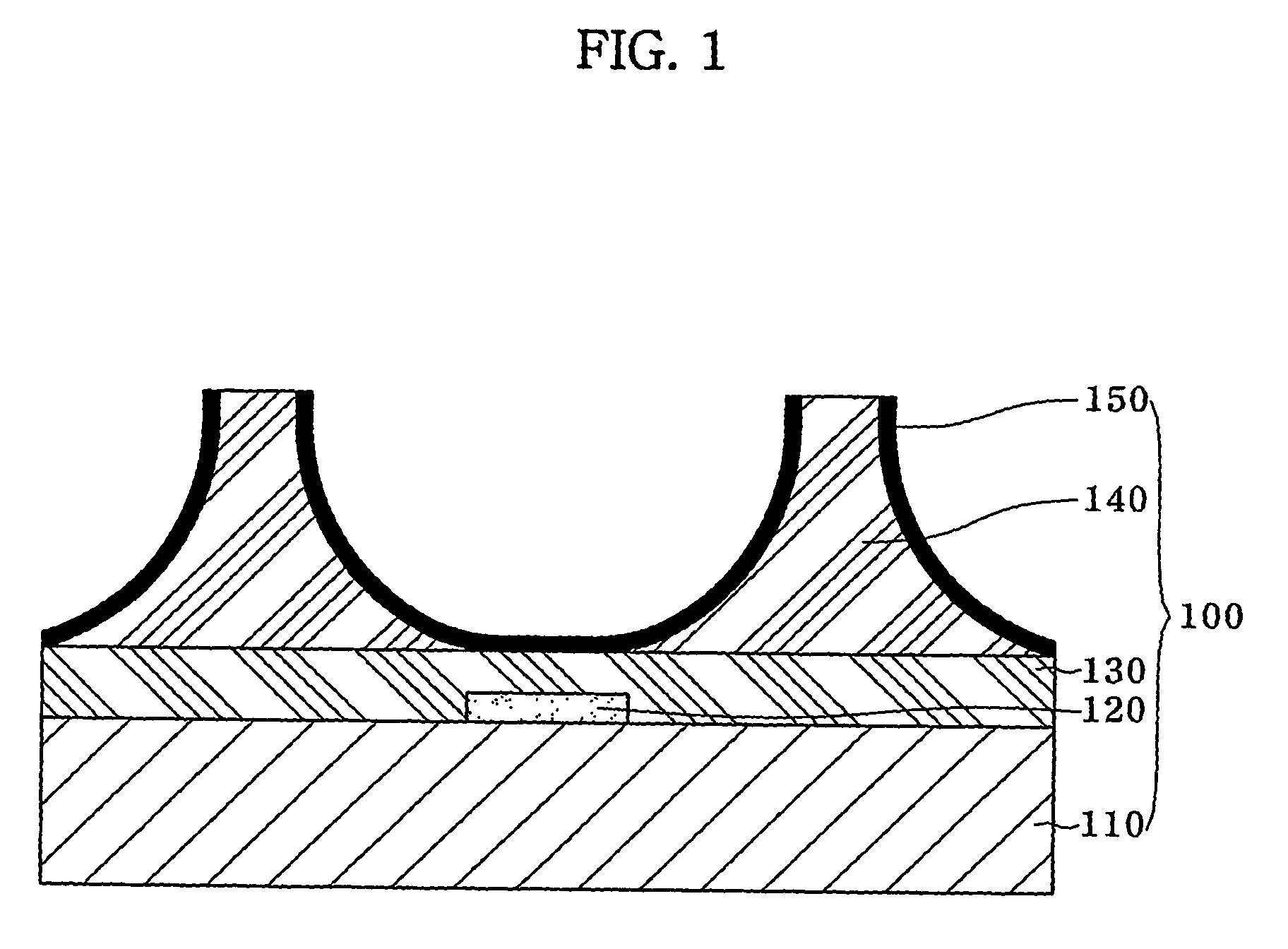

Rear plate for plasma display panel

InactiveUS20060119265A1Improve reliabilityGas discharge electrodesAlternating current plasma display panelsContrast ratioElectric efficiency

Disclosed is a rear plate of a plasma display panel. In the rear plate, barrier ribs are formed through etching after backing, and thus the completed barrier ribs are not deformed. Therefore, each electrode can be exactly located on a central portion between barrier ribs. When a PDP having front and rear plates attached to each other has been completed, optical characteristics of the PDP such as white brightness, color temperature, and contrast, and electric characteristics of the PDP such as voltage margin, power consumption, and electric efficiency, are improved, so that the reliability is improved.

Owner:LG MICRON

Filter and display device having the same

InactiveCN101604039ALimit turbidityImprove visibilityCathode ray tubes/electron beam tubesGas discharge electrodesProduction rateManufacturing cost reduction

The invention relates to filter and display device having the same. The filter for a display device includes a base substrate, a shielding film formed based on a single transparent base layer, and an adhesive layer adhering the shielding film onto the base substrate. The shielding film which realizes diverse shielding functions in a single sheet is adhered onto the base substrate through a single process, which serves to improve productivity, reduce manufacturing cost, restrain the occurrence of Haze and improve visibility.

Owner:SAMSUNG CORNING CO LTD

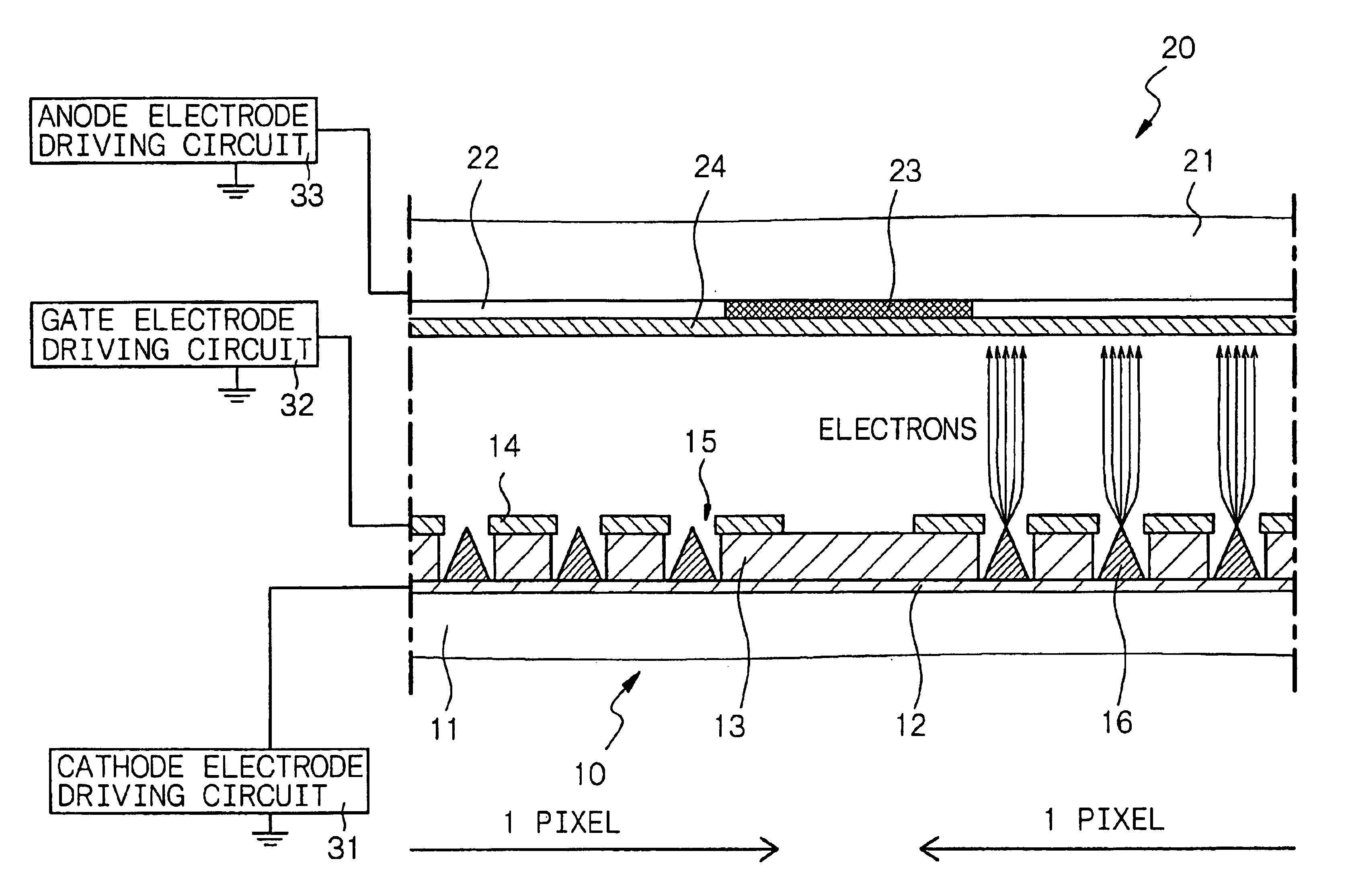

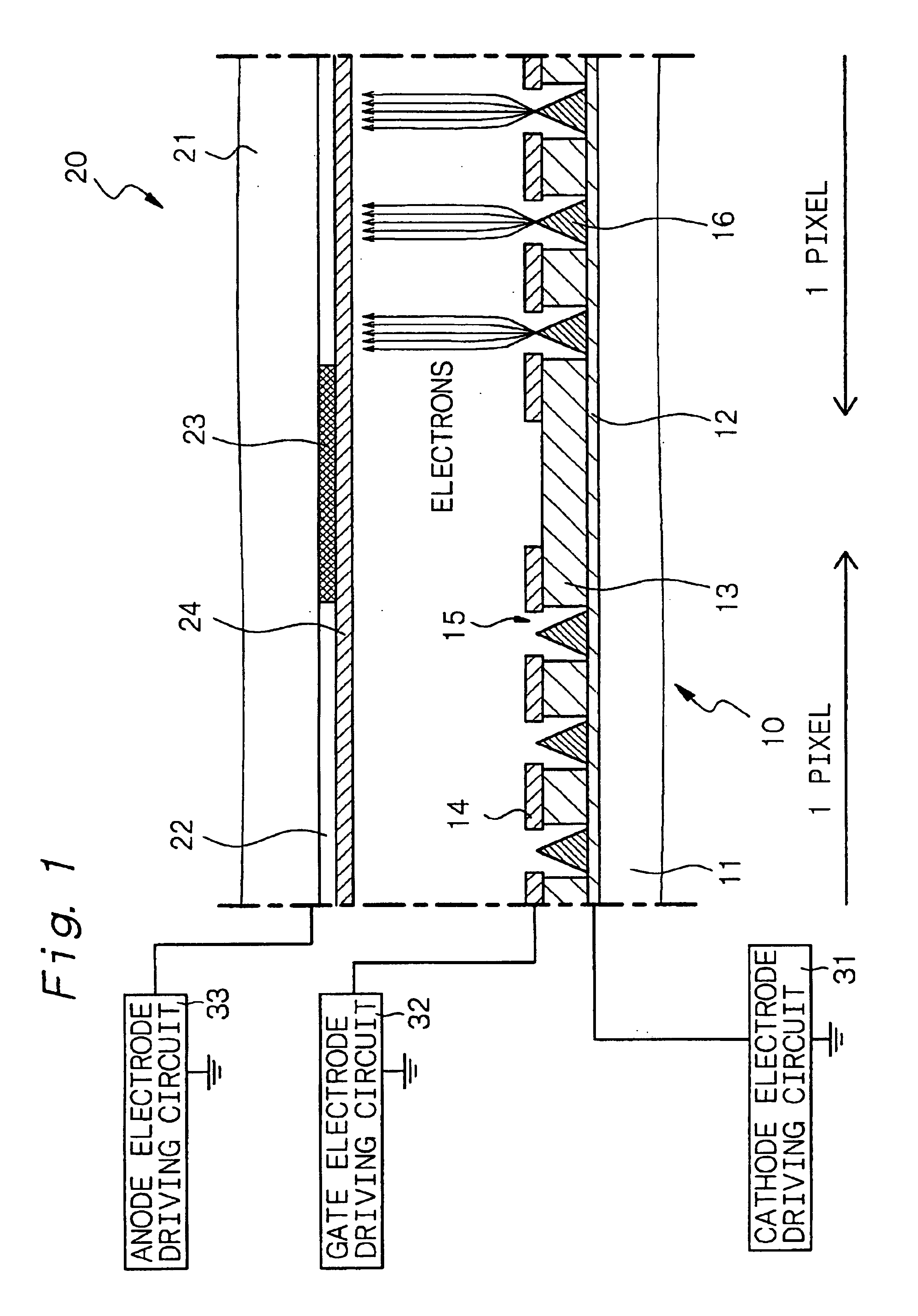

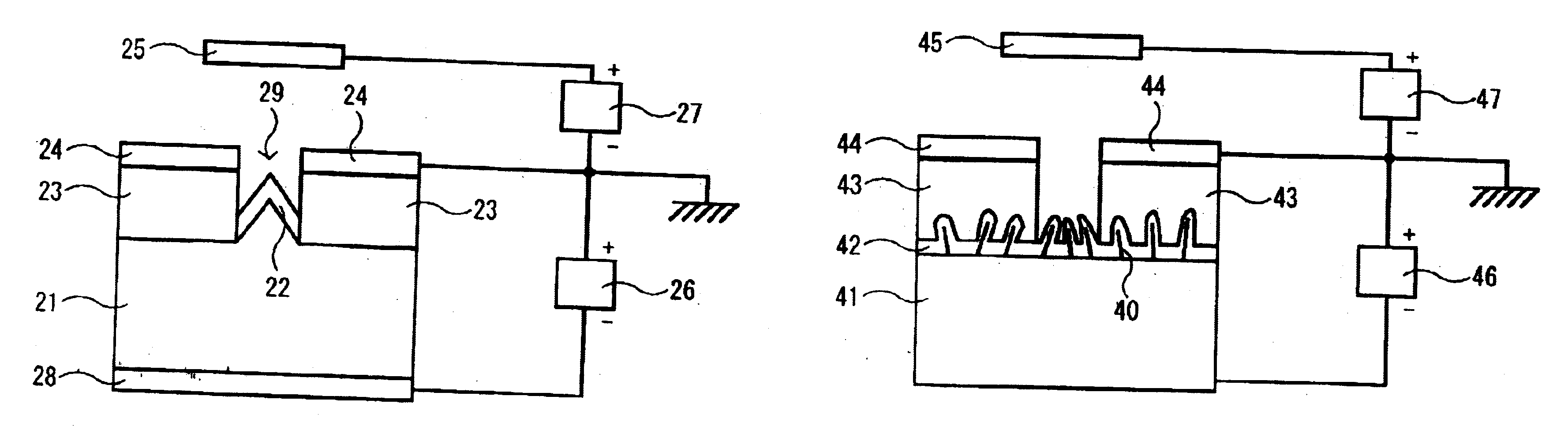

Electrode and device using the same

InactiveUS20040041508A1High resolutionImprove throughputGas discharge electrodesGas discharge vessels/containersFiberDisplay device

A high-efficiency electron-emitting device that can emit electron with higher luminance at a voltage lower than conventional electron-emitting devices, as a key device of a flat panel display, image pickup device, electron beam device, microwave traveling-wave tube is provided to improve the carrier injection efficiency and enhance luminance of an organic light-emitting device. A film having space charge with a thickness of 50 nm or less is formed on a surface of a conductive material on which irregularities, amorphous or fibrous materials are formed. The film includes compounds of group 3 atoms such as aluminum nitride, boron nitride, aluminum nitride boron, aluminum nitride gallium, boron nitride gallium and nitrogen atoms, and nitride, carbon, silicon, oxygen and boron such as oxides including nitrogen boron carbon, boron carbide, carbon nitride, boron.

Owner:SUGINO TAKASHI +1

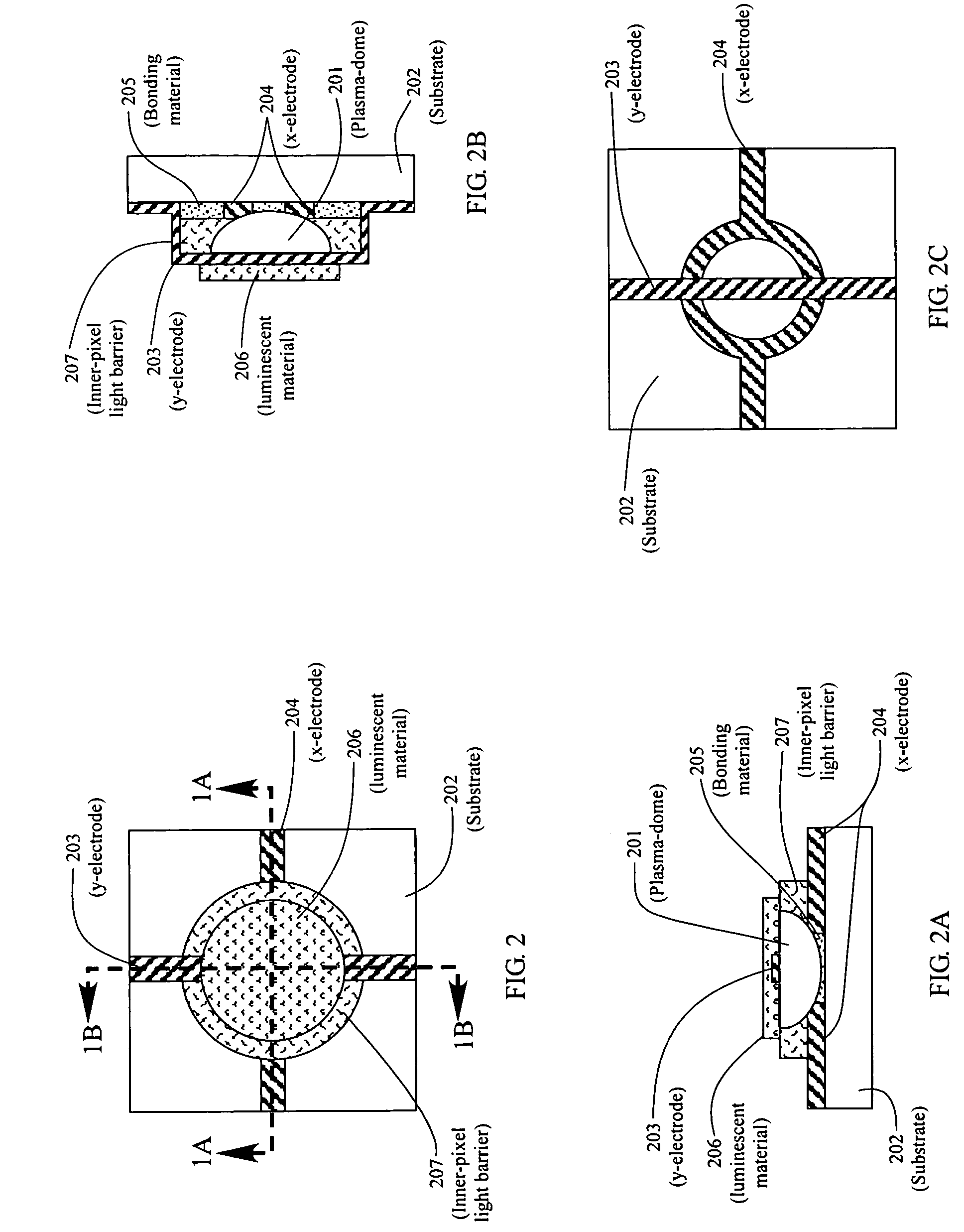

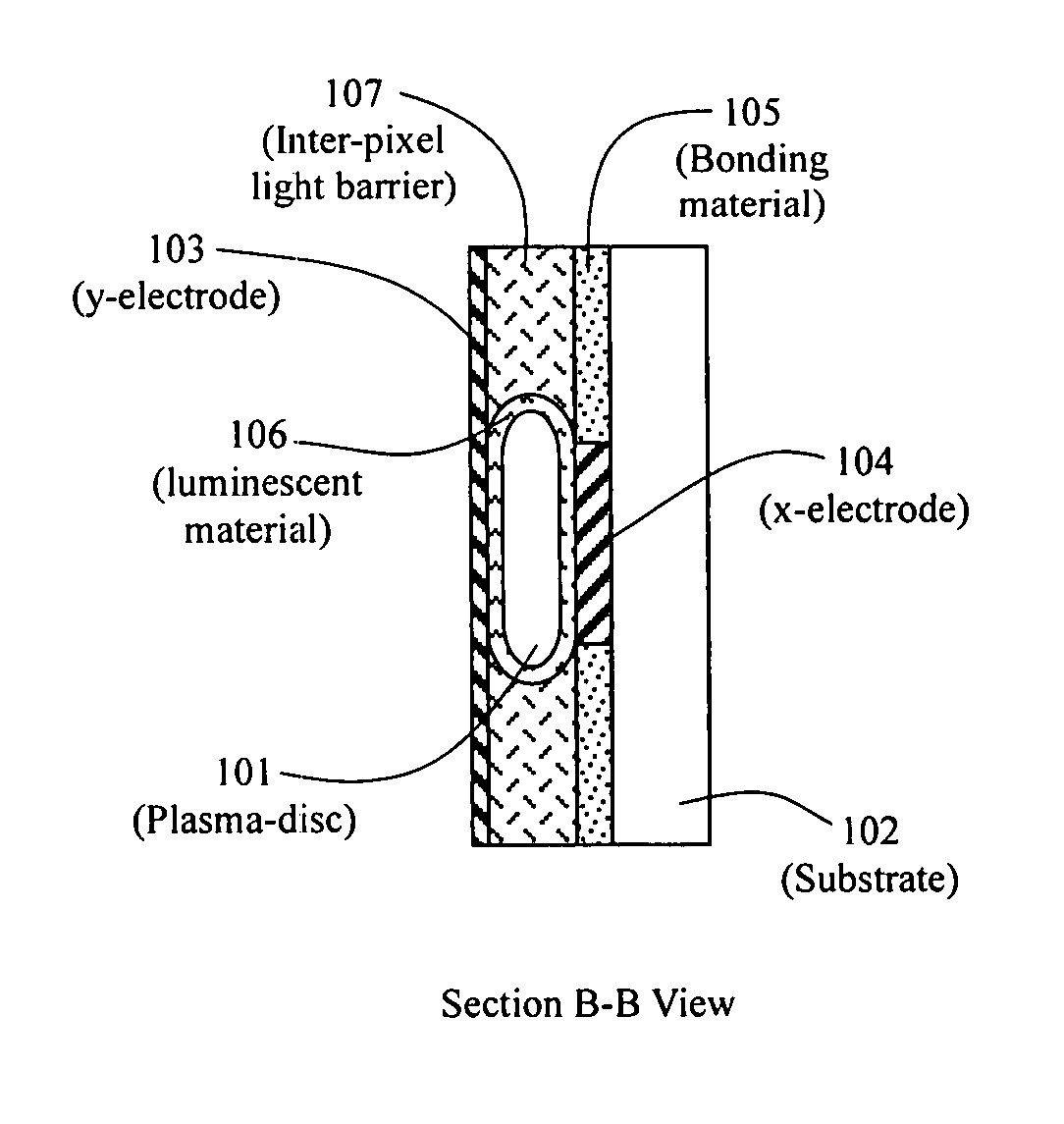

Plasma-disc article of manufacture

InactiveUS7638943B1Discharge tube luminescnet screensGas discharge electrodesEngineeringUp conversion

There is disclosed an article of manufacture comprising a Plasma-Disc™ for use in a plasma display panel (PDP) device having one or more substrates and a multiplicity of pixels or sub-pixels. Each pixel or sub-pixel is defined by a hollow Plasma-Disc™ filled with an ionizable gas. The Plasma-disc has at least two opposing flat sides such as a flat top and flat bottom or a flat rear and flat front. One or more other sides or edges may also be flat. Two or more electrodes are in electrical contact with each Plasma-disc. A flat base side of the Plasma-disc shell is in contact with a substrate and each electrode is in electrical contact with a flat side of the Plasma-disc. The PDP may also include inorganic and organic luminescent materials that are excited by the gas discharge within each Plasma-disc. The luminescent material may be located on an exterior and / or interior surface of the Plasma-disc or incorporated into the shell of the Plasma-disc. Up-conversion and down-conversion materials may be used. The substrate may be rigid or flexible with a flat, curved, or irregular surface.

Owner:IMAGING SYST TECH

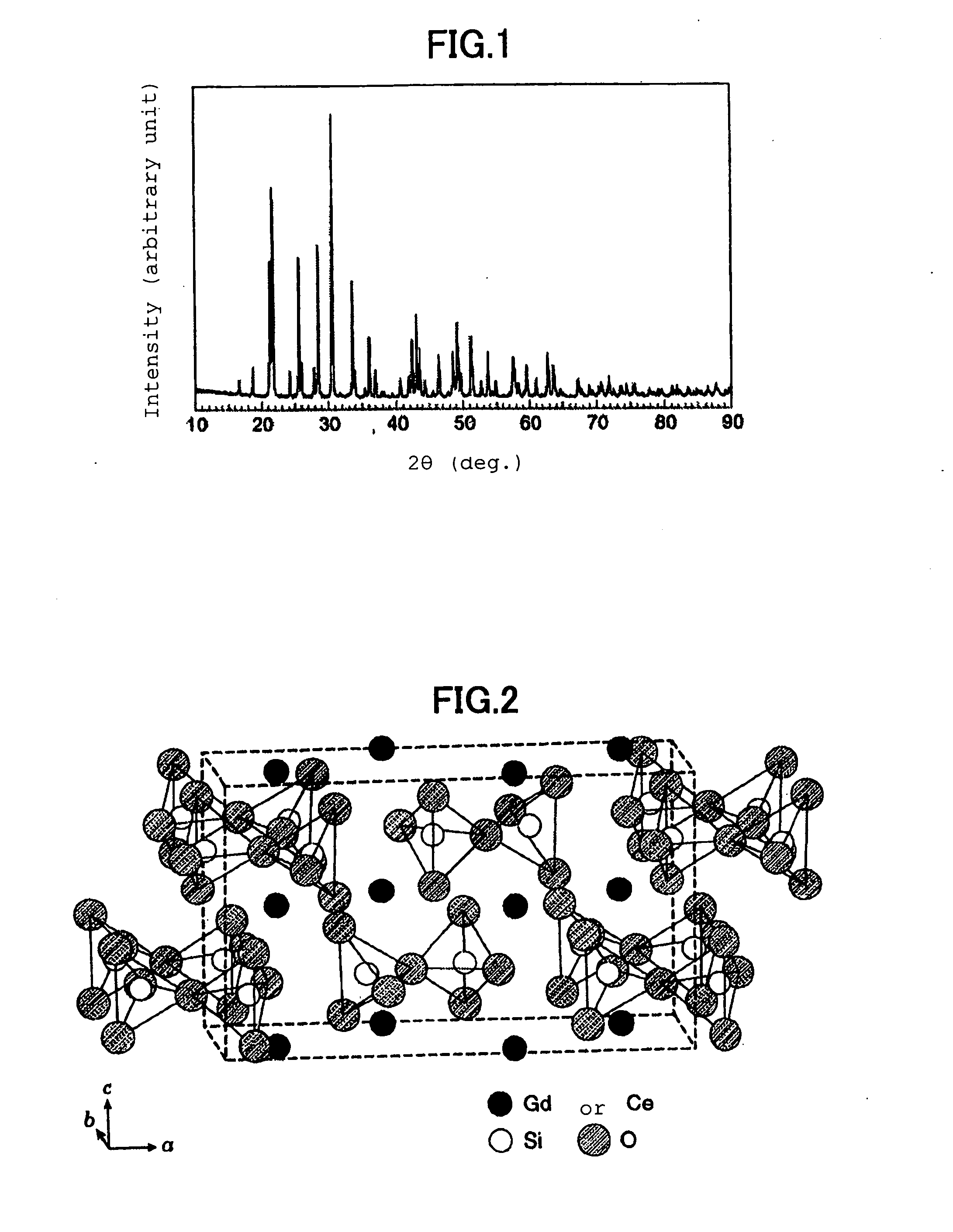

Fluorescent substance and fluorescent composition containing the same

InactiveUS20050040366A1Increase luminous powerEasy to processGas discharge electrodesMaterial analysis by optical meansRare-earth elementLength wave

The present invention provides a fluorescent substance represented by the following general formula: (A1-xBx)2Si2O7, wherein A is at least one member selected from the group consisting of Gd, Y, Lu and La, B is at least one member selected from the group consisting of rare earth elements other than A and x is a numerical value specified by the formula: 0<x≦0.2 and which can emit light rays having a wavelength falling within the range of ultraviolet, visible and infrared regions in response to, for instance, optical stimuli, electron beam stimuli, electric field stimuli, stress stimuli and radiation stimuli; a fluorescent composition comprising such a fluorescent substance dispersed in a silica glass matrix; and a scintillator obtained using the foregoing substance or composition. These fluorescent substance, fluorescent composition, scintillator material and fluorescent material have high luminous outputs and are excellent in the processability.

Owner:OXIDE

Display and method for manufacturing the same

ActiveUS7557369B2High bonding strengthHigh resolutionGas discharge electrodesSolid-state devicesElectrical conductorDisplay device

The present invention provides a display including a substrate and an electrode layer including a plurality of conductors, wherein a silane derivative layer is interposed between the substrate and the electrode layer to increase the bond strength between the substrate and the electrode layer. The invention also provides a method of manufacturing the device.

Owner:SAMSUNG DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com