Self-melting adhered insulating wire and self-melting adhered twisted wire using same

An insulated wire, self-adhesive technology, applied in the direction of insulated cables, insulated conductors, electrode devices and related components, etc., can solve problems such as insufficient strength of the adhesive film, reduction of the amount of solvent in the adhesive layer, and unclear resin components. , to achieve the effect of reducing odor and problems in the working environment, excellent heat resistance, and reducing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107] A crystalline copolyamide resin A (ε-caprolactam, ω-laurolactam, dodecanoic acid salt of hexamethylenediamine 3 Components, copolymers copolymerized at the above ratio) were dissolved in a mixed solvent of cresol and aromatic (C9) naphtha at a weight ratio of 70:30 to obtain an adhesive paint with a film component concentration of 19%. The viscosity of the obtained adhesive paint was 20 dPa·s at 30°C.

[0108] The obtained adhesive paint was repeatedly coated (coated by die drawing method) and baked (furnace length 3.0m, Oven temperature 300° C., wire speed 60 m / min), to obtain a self-adhesive insulated wire with an adhesive film thickness of 10 μm.

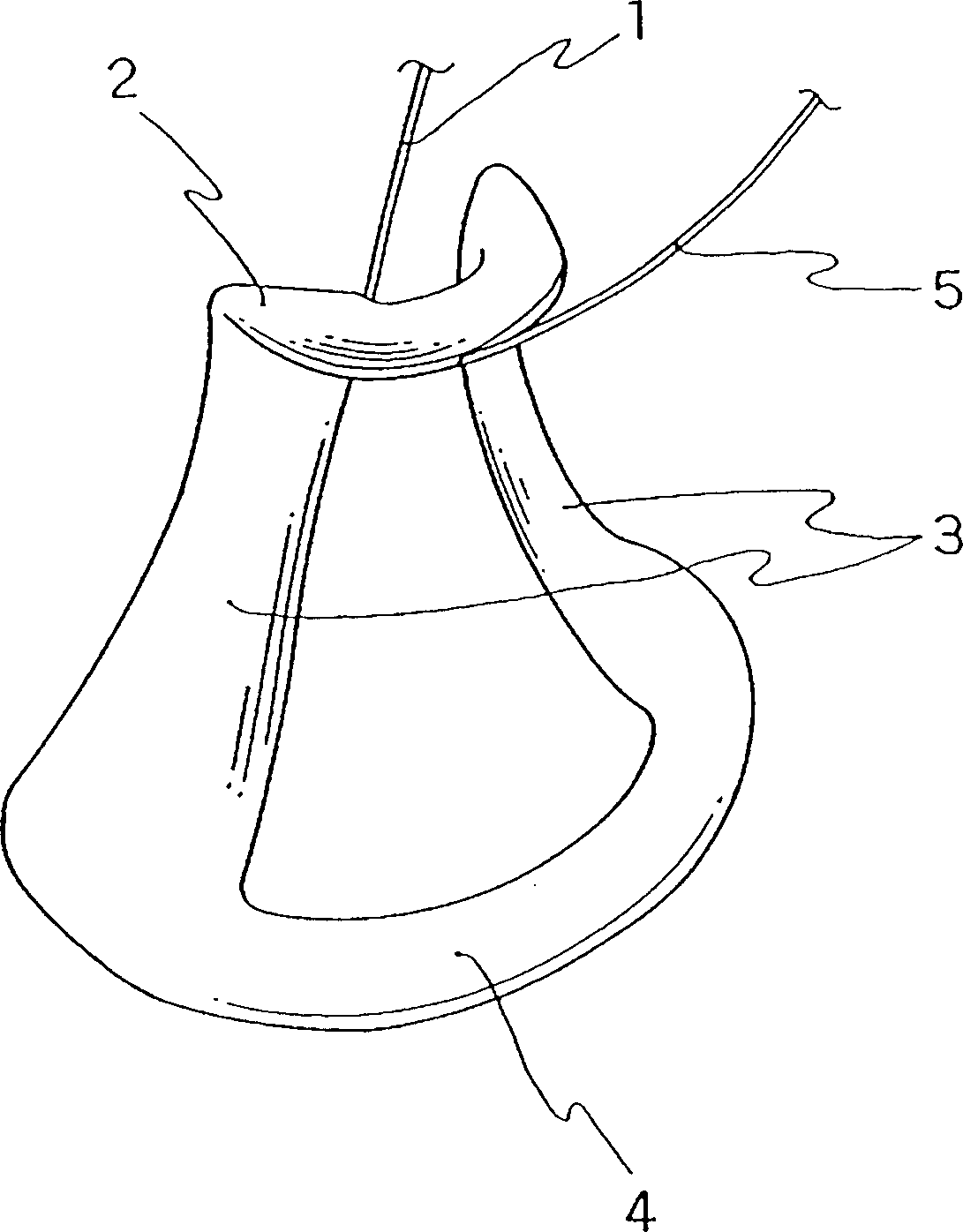

[0109]Twist 10 self-adhesive insulated wires obtained together to form a self-adhesive twisted wire, and then use the forming conditions to set 55 turns x 2 main coils, energize current 55A, energize time 1.5 seconds, cooling pressure machine for 15 seconds, and a metal mold temperature of 40°C, the self-adhesive twisted...

Embodiment 2

[0113] In addition to changing the crystalline copolyamide resin to a crystalline copolyamide resin with a melting point of 130°C, a relative viscosity of 1.42, and a crystallization energy of 44.8J / g B (ε-caprolactam, ω-laurolactam, hexamethylenediamine) Dodecanoic acid salt 3 kinds of components are copolymerized with the above-mentioned ratio), others are carried out in the same way as Example 1, and the results are shown in Table 2.

Embodiment 3

[0115] In addition to changing the crystalline copolyamide resin to crystalline copolyamide resin C (ε-caprolactam, ω-laurolactam, hexamethylenediamine) with a melting point of 130°C, a relative viscosity of 1.47, and a crystallization energy of 47.7J / g Dodecanoic acid salt 3 kinds of components are carried out in the same manner as Example 1 except that the copolymer is copolymerized at the above-mentioned ratio). The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Relative viscosity | aaaaa | aaaaa |

| Relative viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com