Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Prevent thermal deterioration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

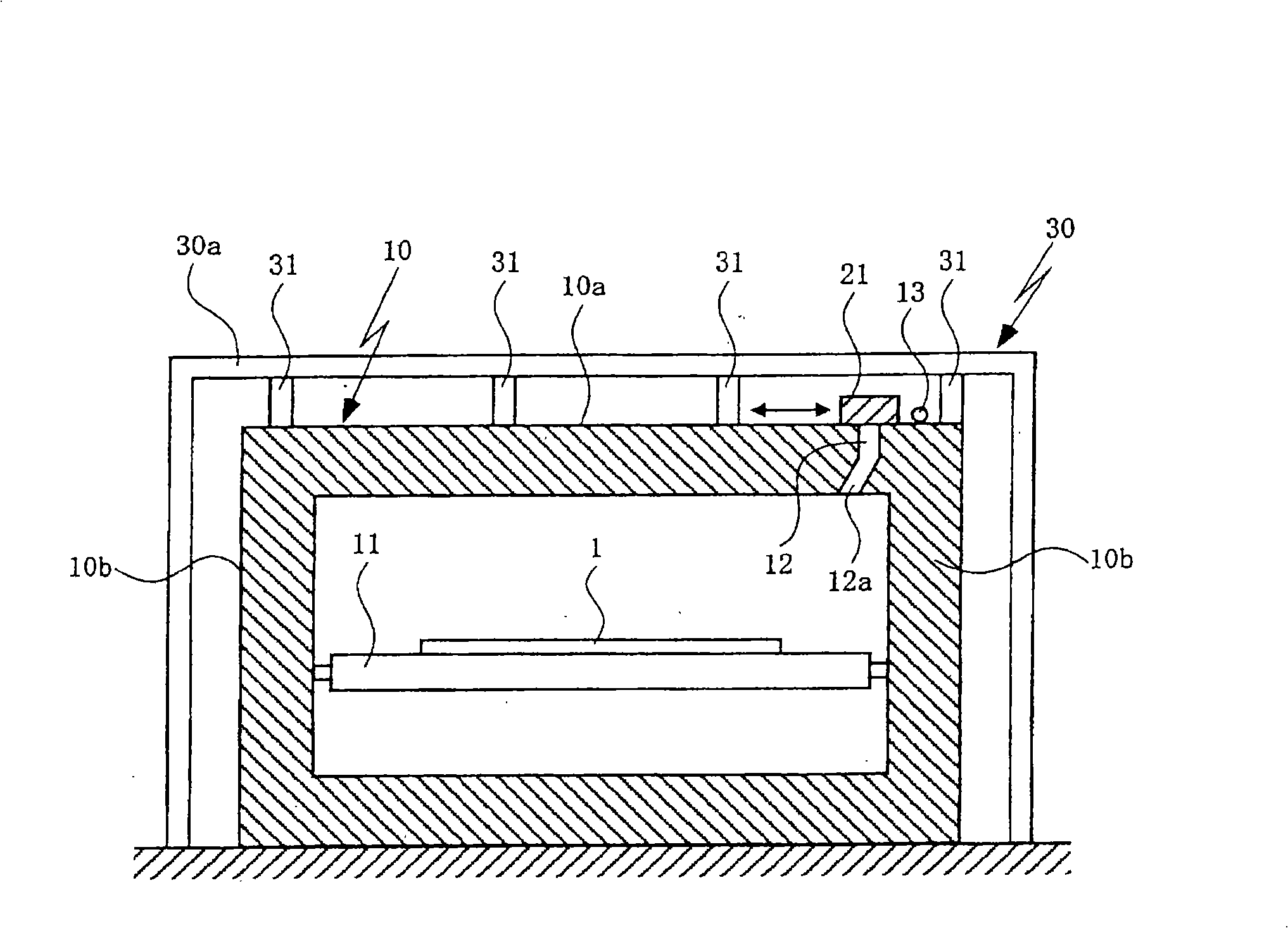

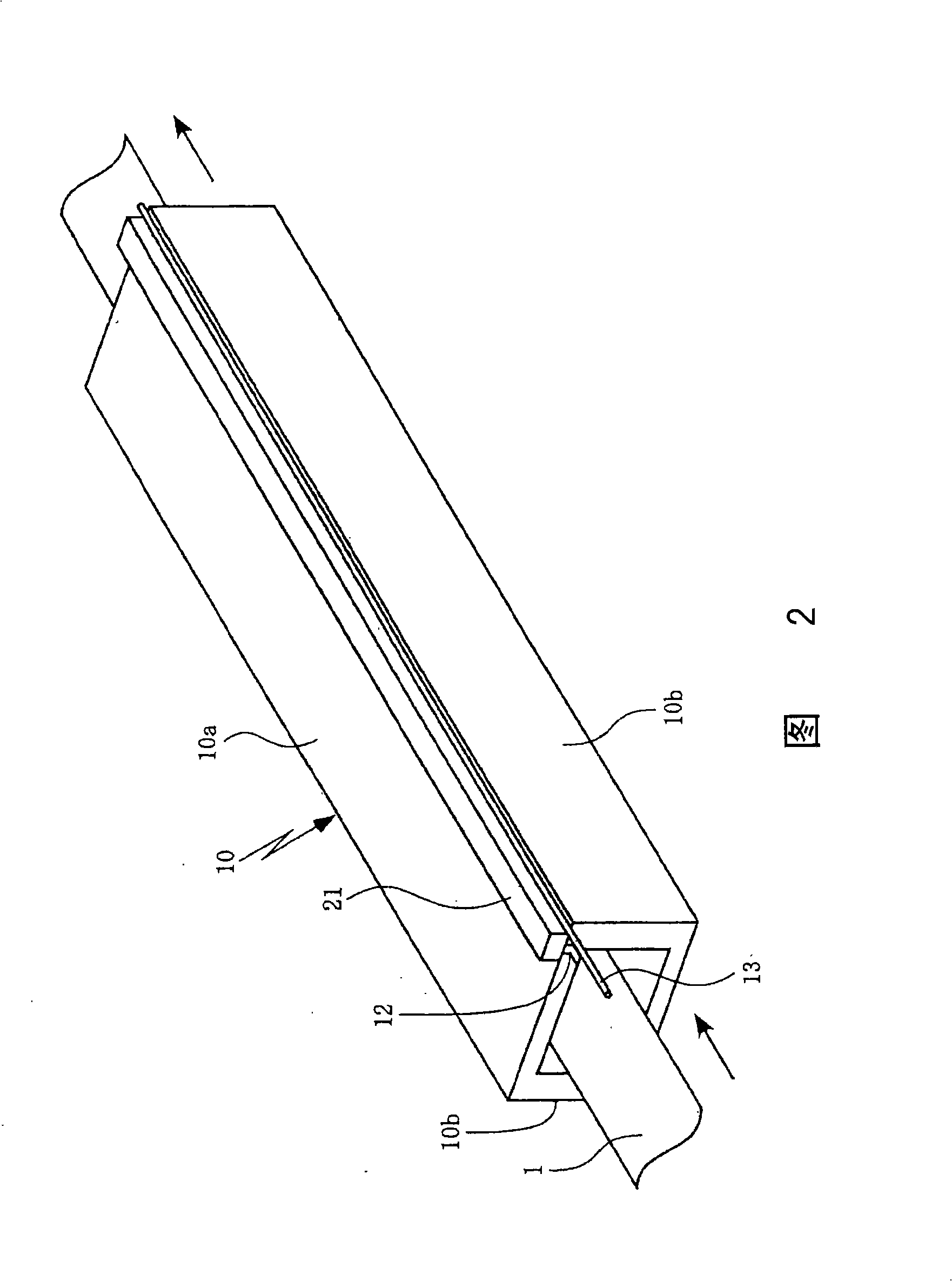

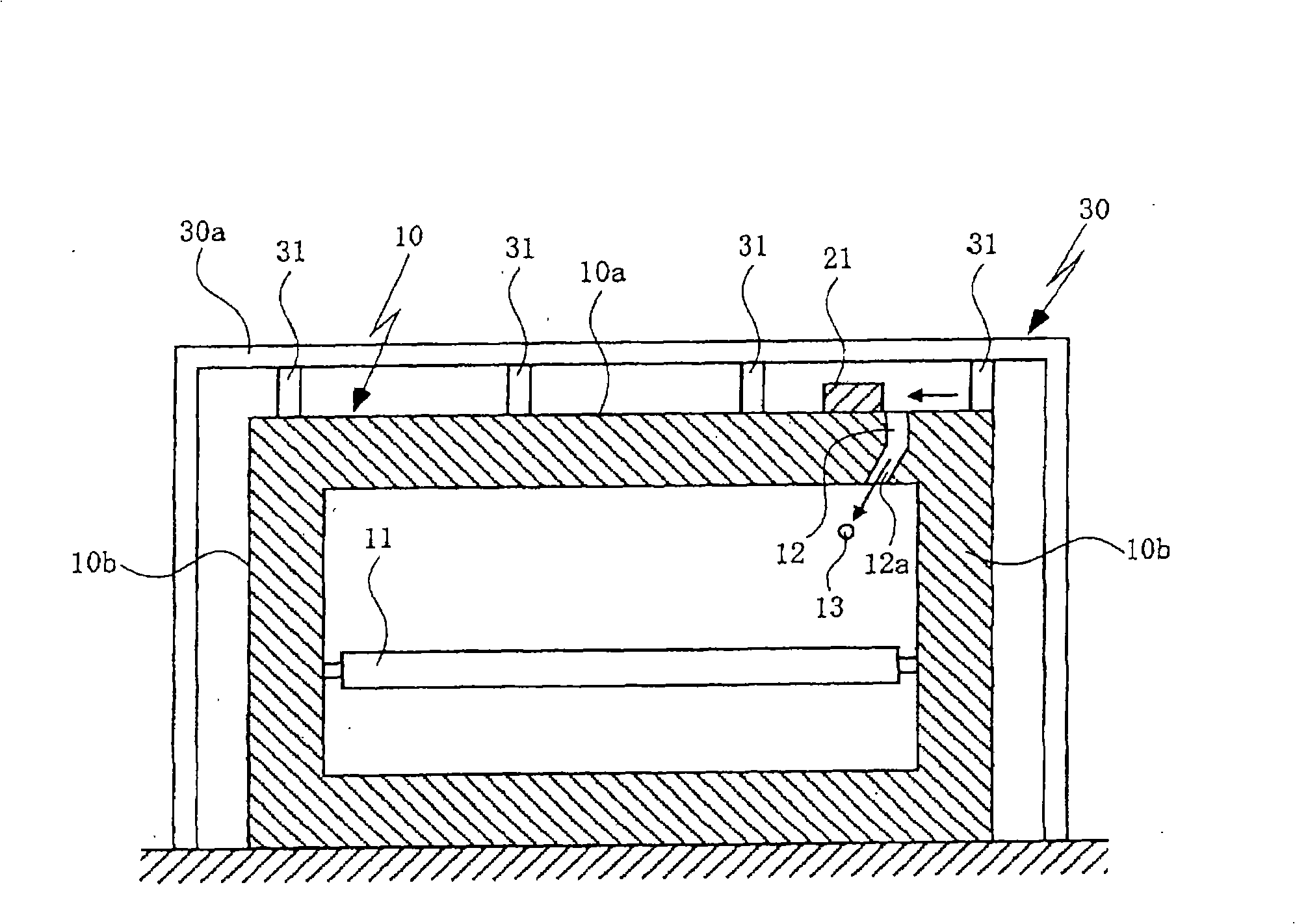

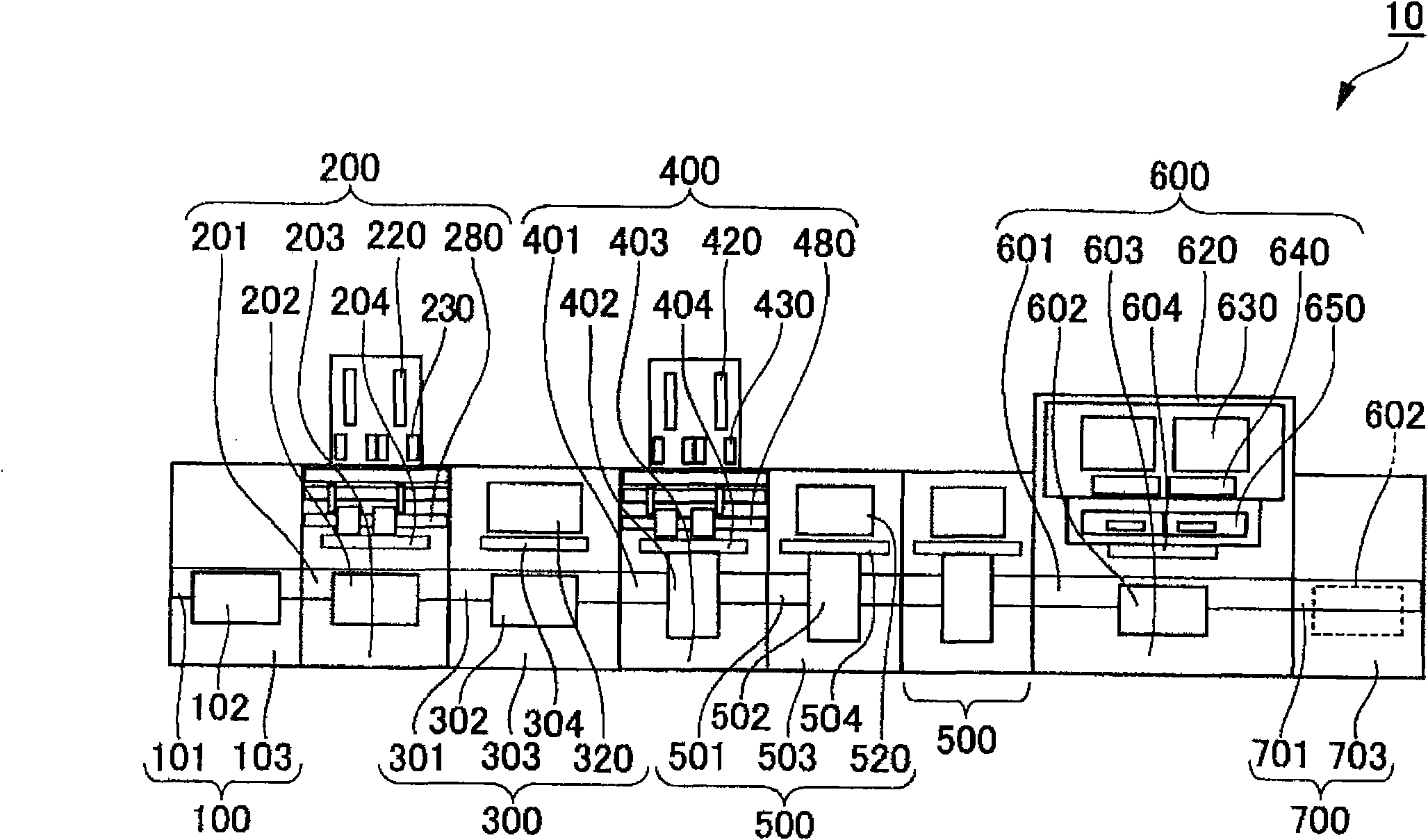

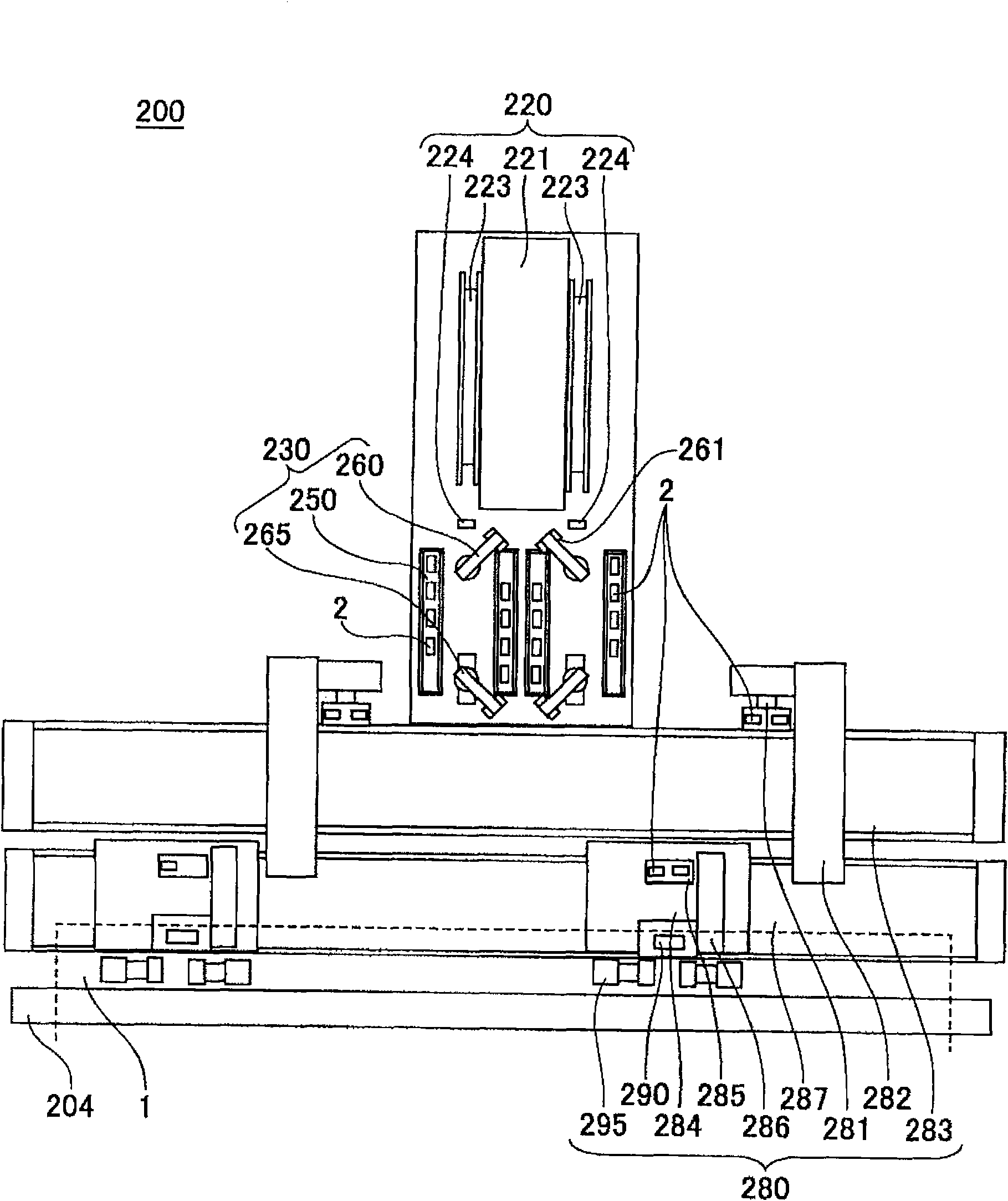

Optical device and projector

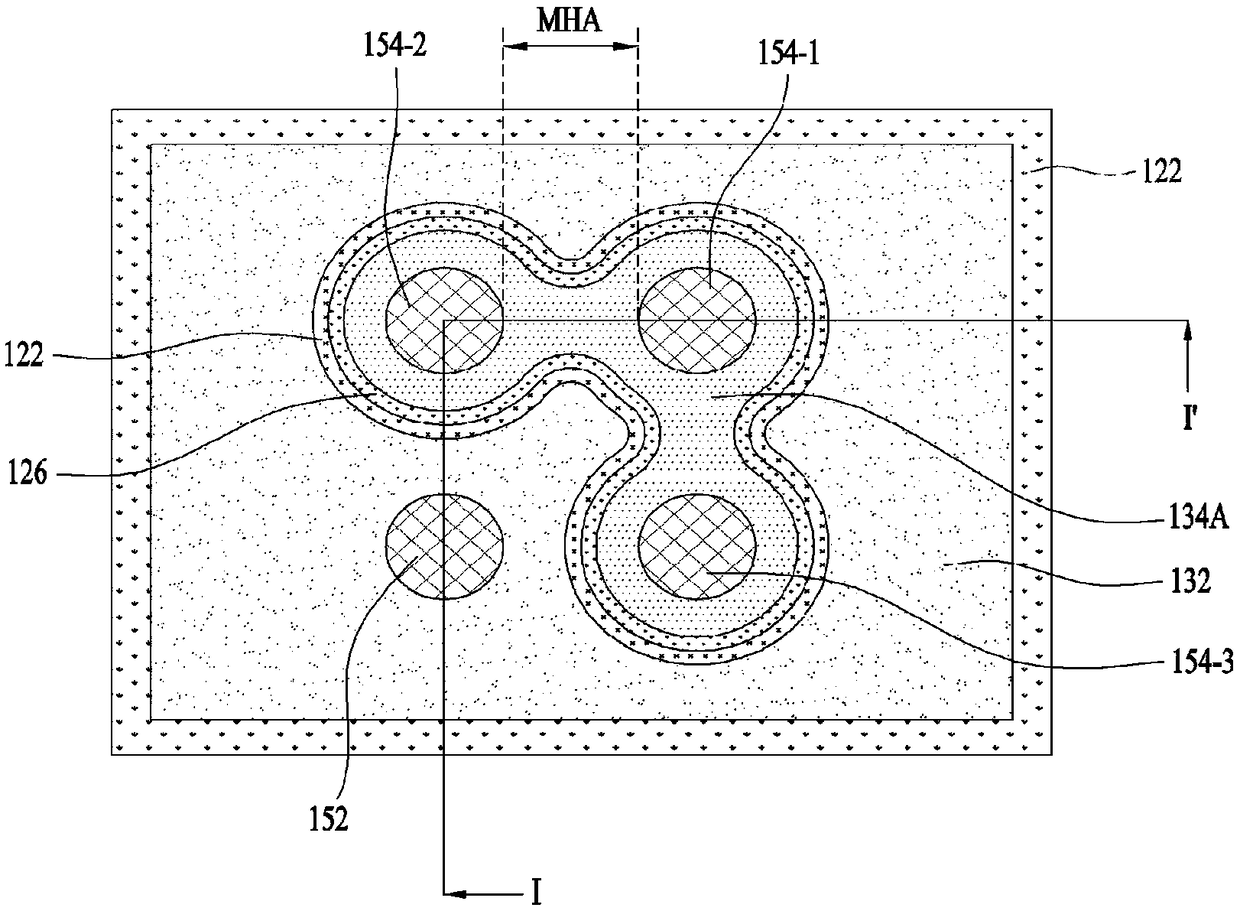

InactiveUS7270418B2Improve cooling effectPromote circulationProjectorsPicture reproducers using projection devicesCooling chamberEngineering

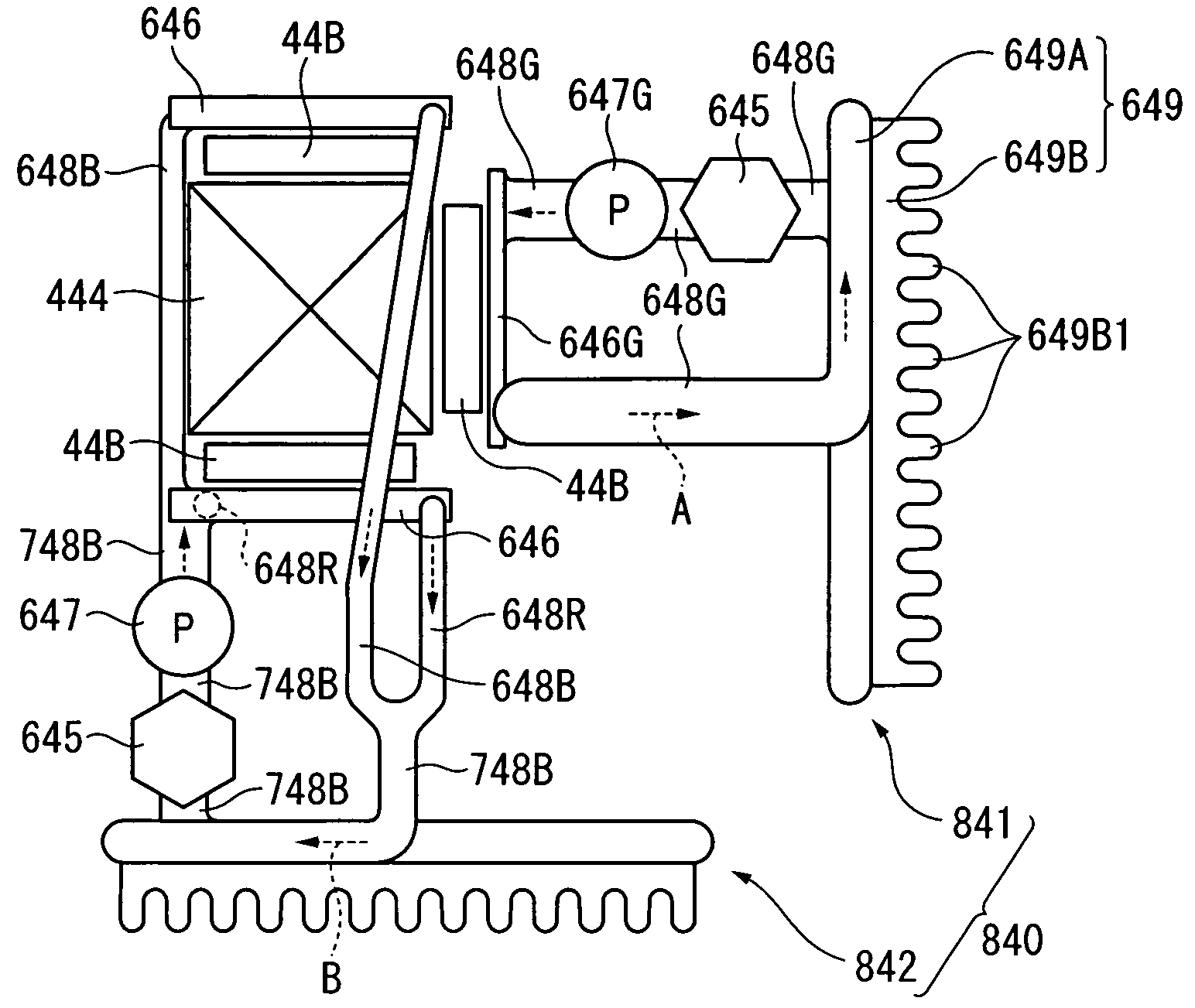

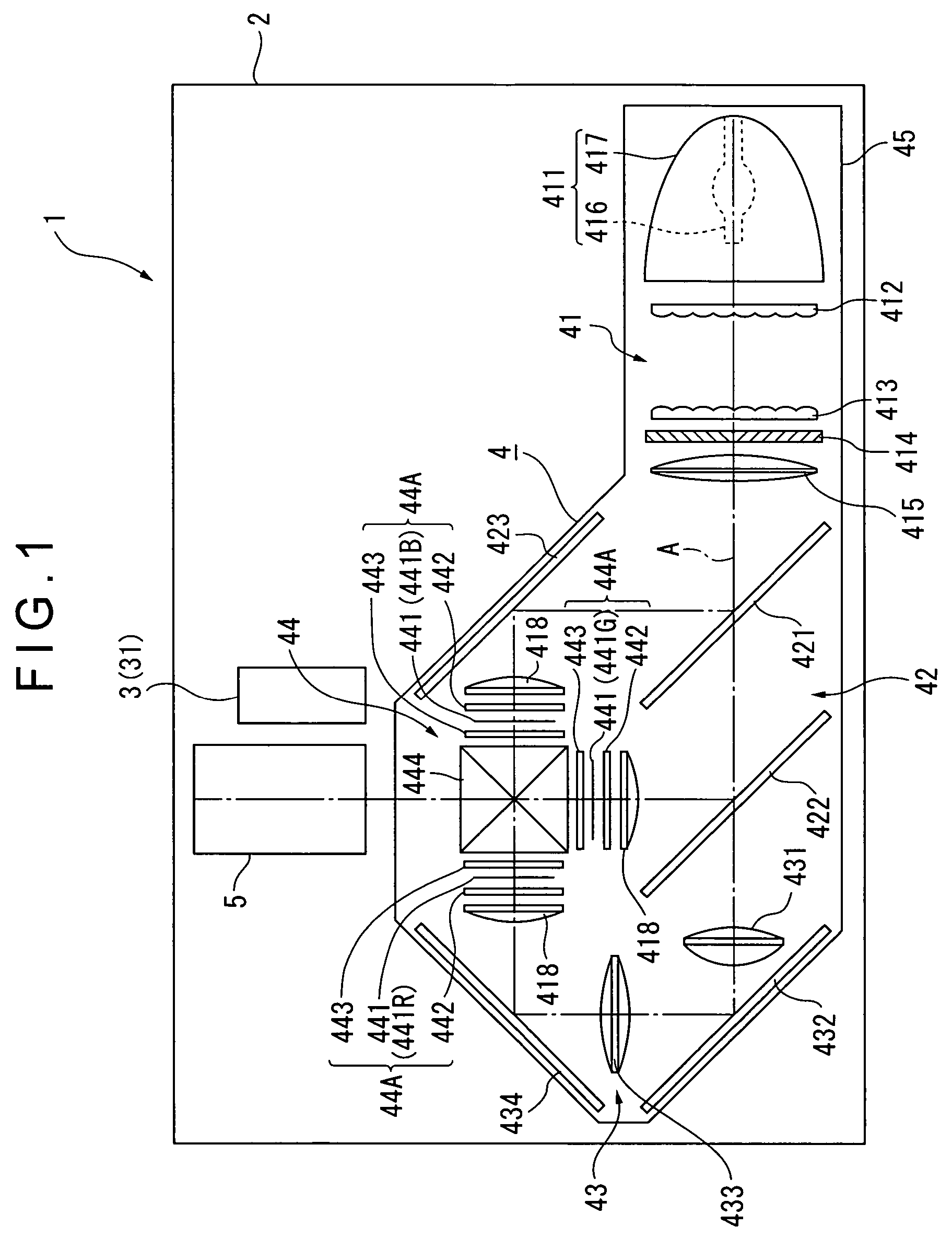

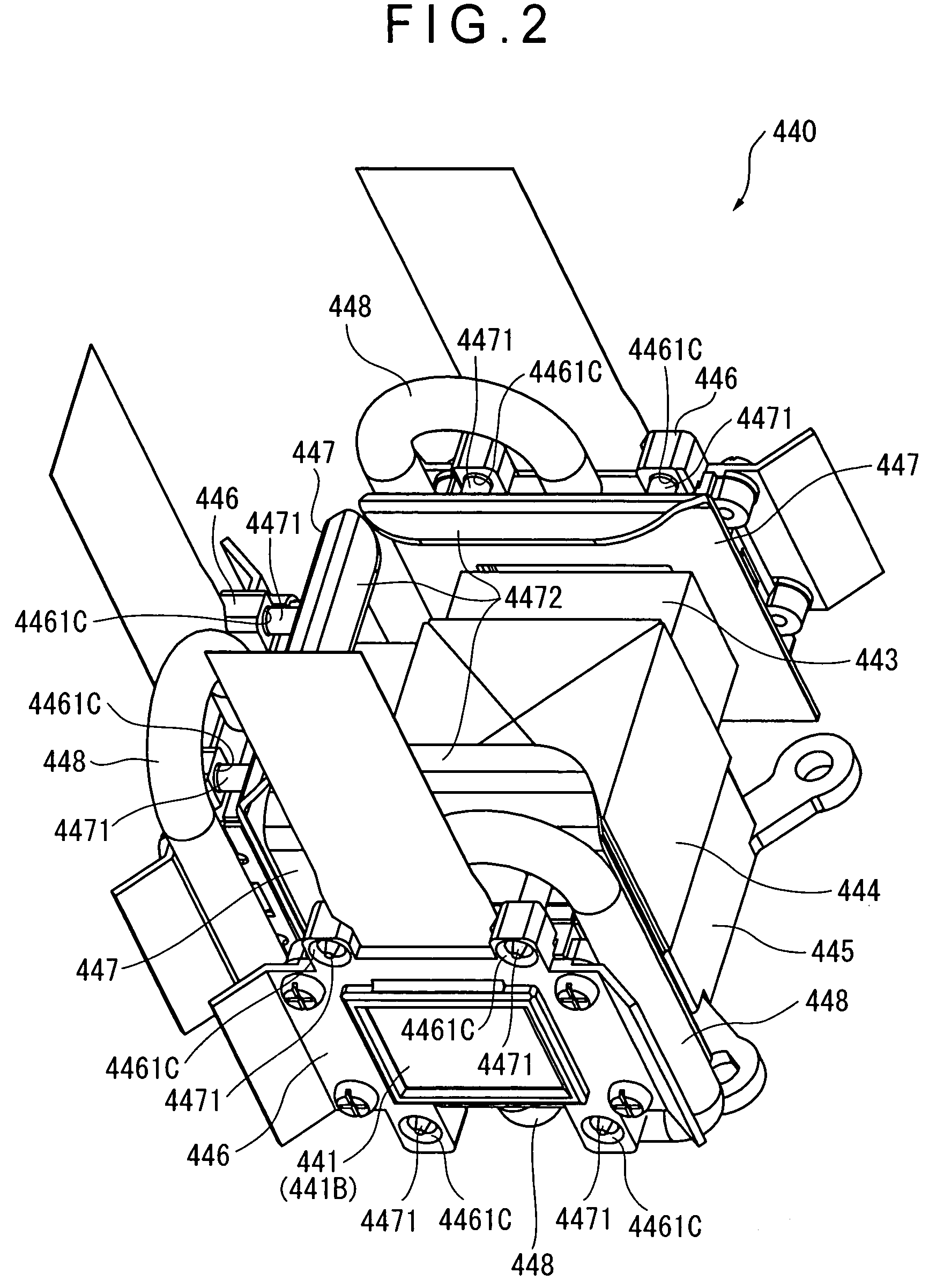

An optical device body (440) includes: three optical modulator holders (446) respectively holding three liquid crystal panels (441) and having cooling chambers with cooling fluid sealed therein to respectively cool the three liquid crystal panels (441) with the cooling fluid in the respective cooling chambers; a plurality of fluid circulators (448) intercommunicated with the three optical modulator holders (446) to guide the cooling fluid to the outside of the respective cooling chambers and re-introduce the cooling fluid into the respective cooling chambers; and a flow volume changer (449) disposed in a flow path of the cooling fluid and capable of changing flow volumes of the cooling fluid flown into the respective optical modulator holders (446) in accordance with heat values of the three liquid crystal panels (441).

Owner:SEIKO EPSON CORP

Optical device and projector

InactiveUS20050185142A1High calorific valueImprove cooling effectProjectorsPicture reproducers using projection devicesCooling chamberEngineering

An optical device body (440) includes: three optical modulator holders (446) respectively holding three liquid crystal panels (441) and having cooling chambers with cooling fluid sealed therein to respectively cool the three liquid crystal panels (441) with the cooling fluid in the respective cooling chambers; a plurality of fluid circulators (448) intercommunicated with the three optical modulator holders (446) to guide the cooling fluid to the outside of the respective cooling chambers and re-introduce the cooling fluid into the respective cooling chambers; and a flow volume changer (449) disposed in a flow path of the cooling fluid and capable of changing flow volumes of the cooling fluid flown into the respective optical modulator holders (446) in accordance with heat values of the three liquid crystal panels (441).

Owner:SEIKO EPSON CORP

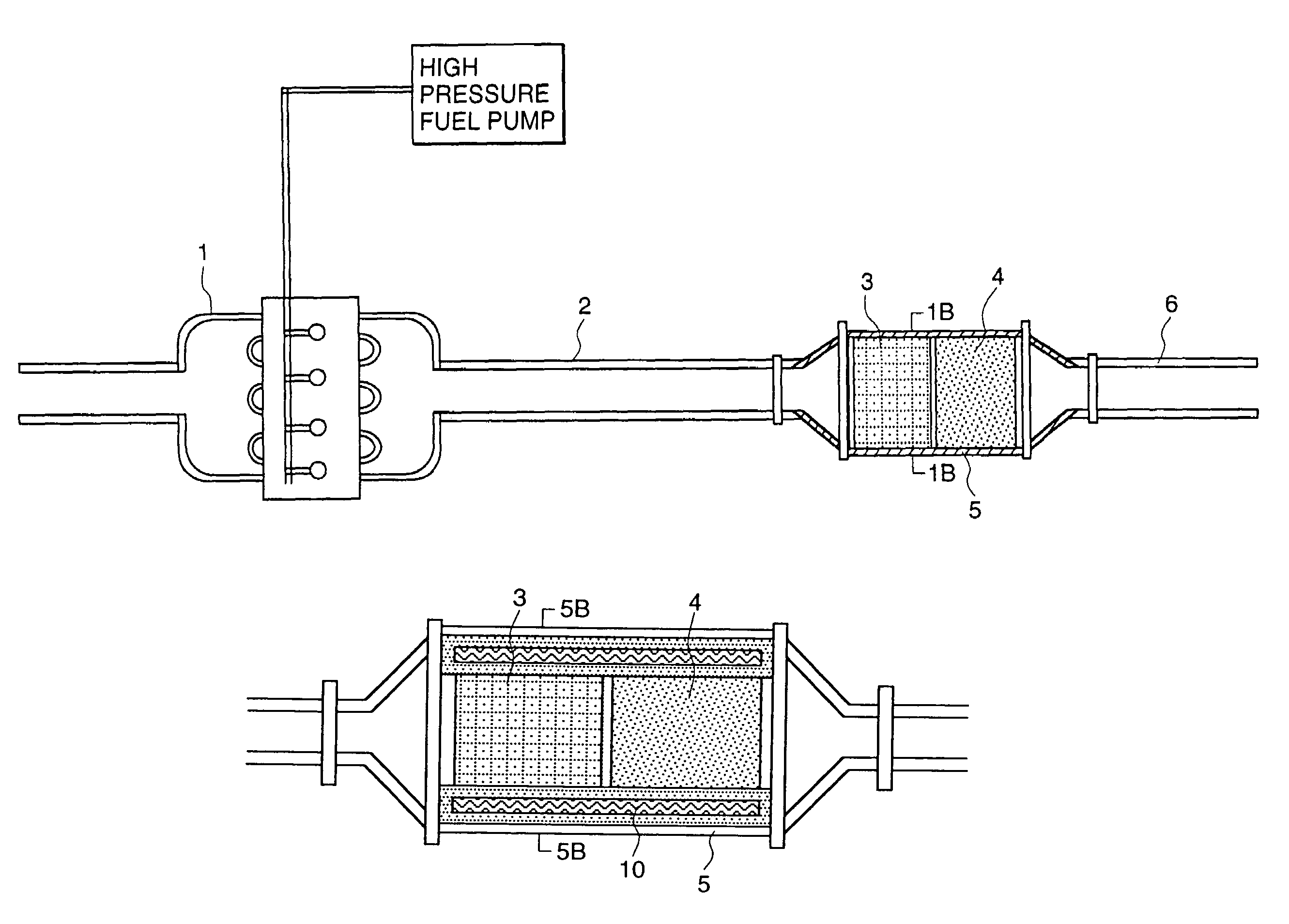

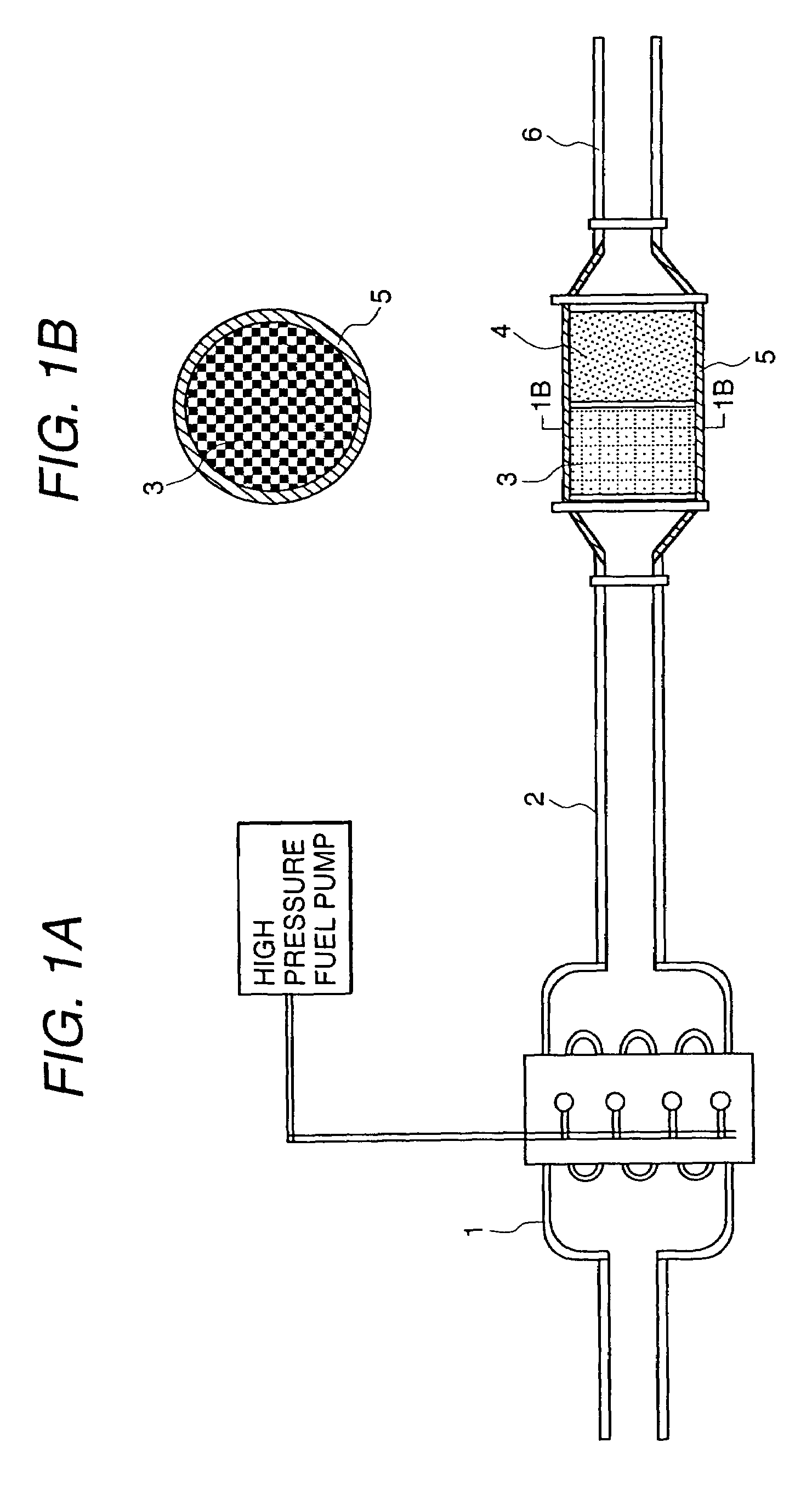

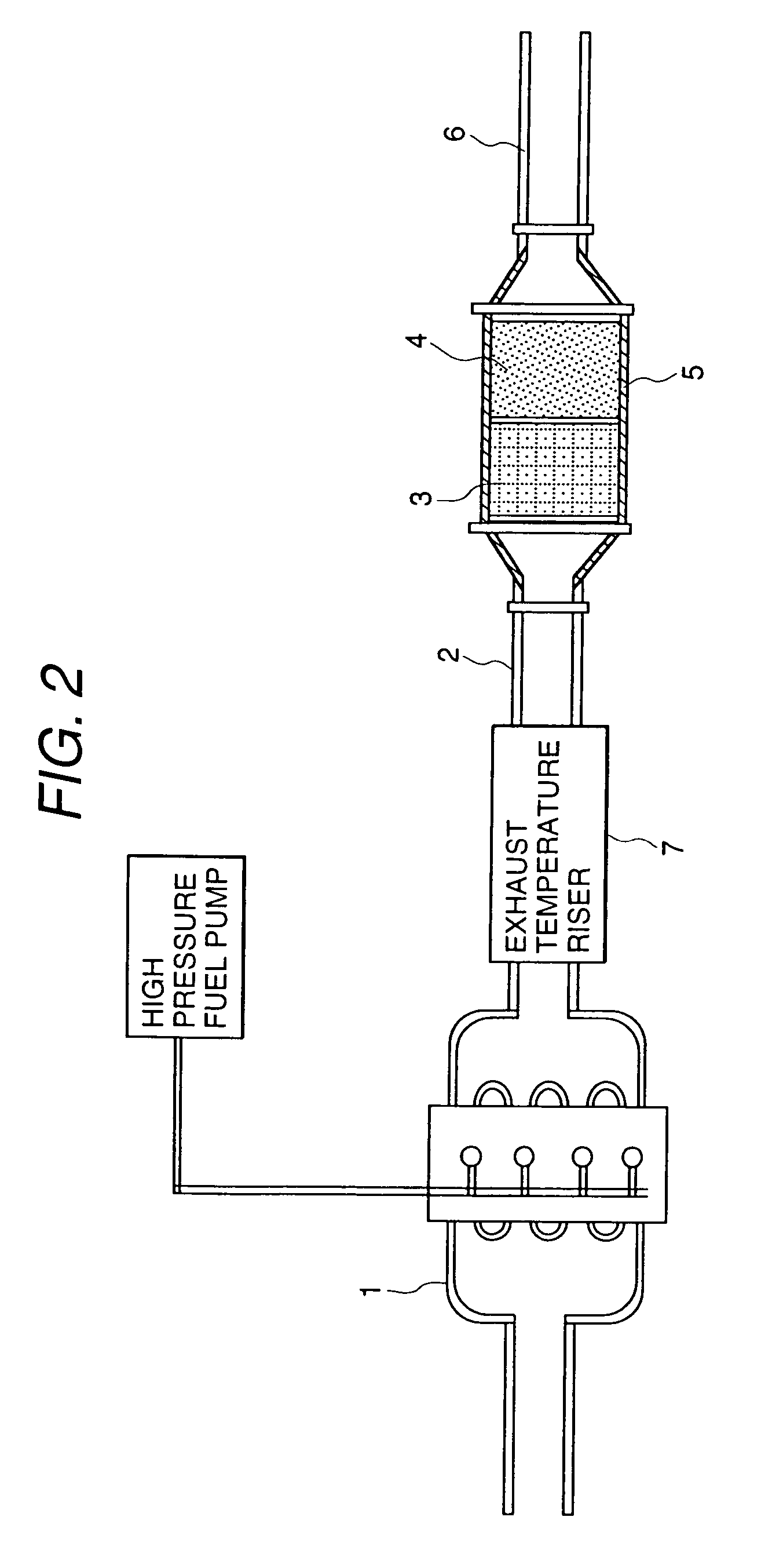

Exhaust gas purification apparatus

InactiveUS7010910B2Prevent thermal deteriorationInternal combustion piston enginesExhaust apparatusParticulatesHazardous substance

An exhaust gas purification apparatus for purifying exhaust gas exhausted from a diesel internal combustion engine and containing therein harmful substances including particulates, NOx, HC and CO, at least, comprises a removal part for trapping and removing particulates in the exhaust gas, a purification part for purifying NOx, HC and CO through contact, and a heat transfer part for transferring heat generated in the removal part to the purification part.

Owner:HITACHI LTD

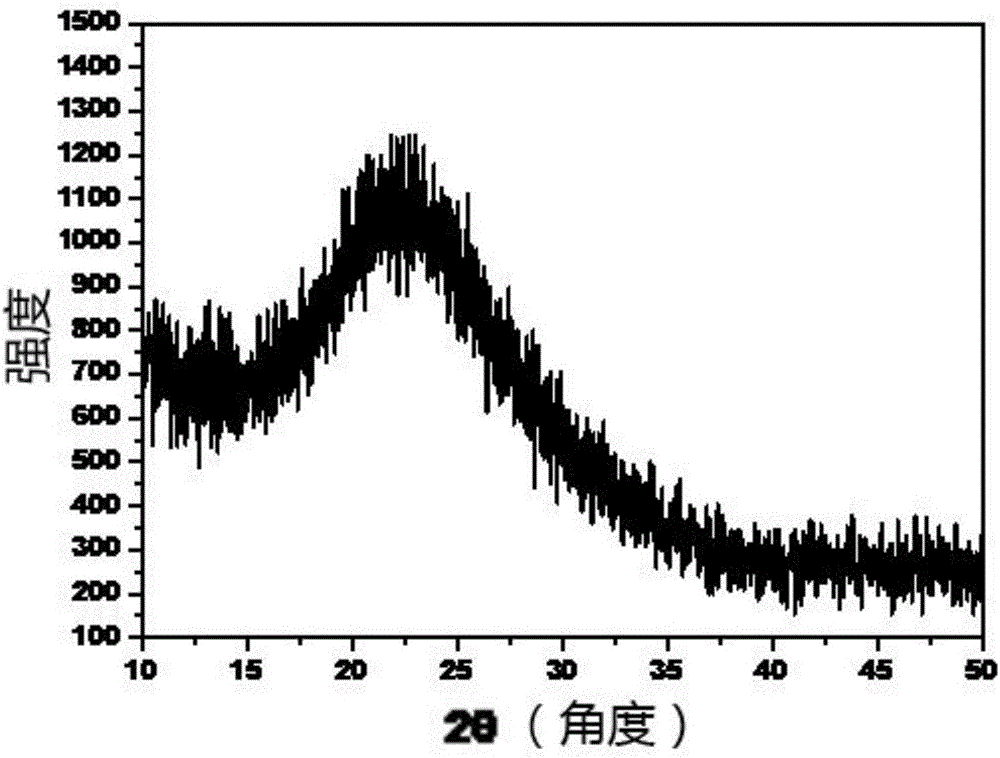

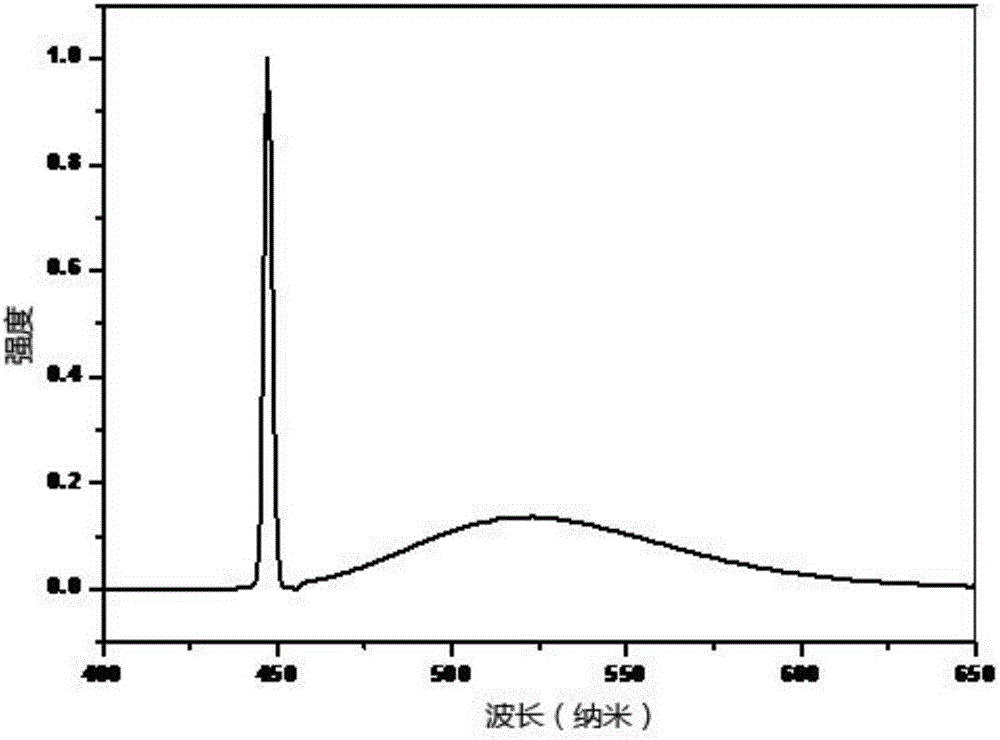

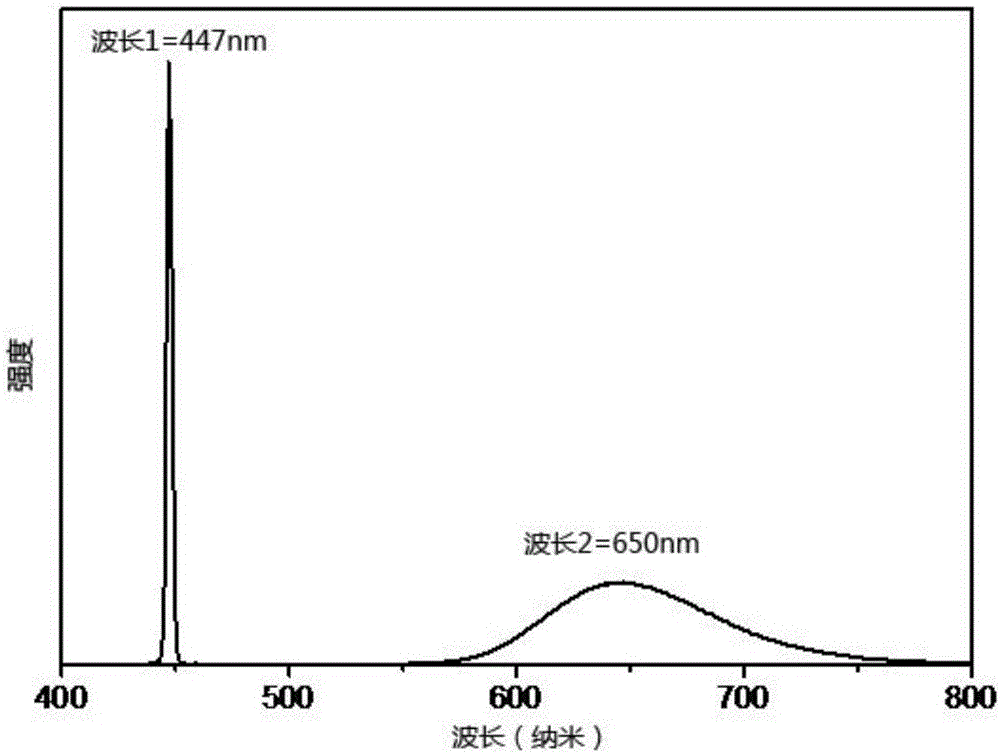

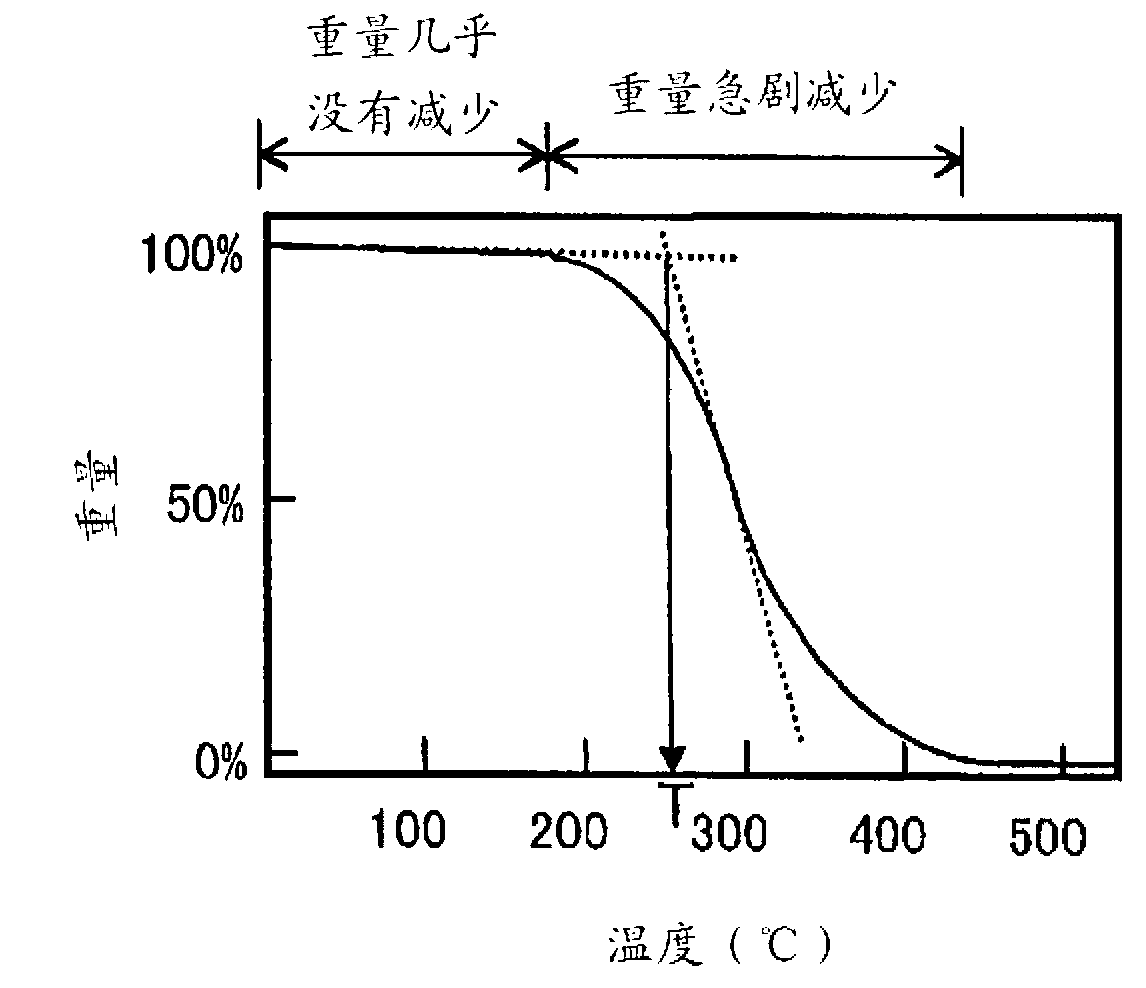

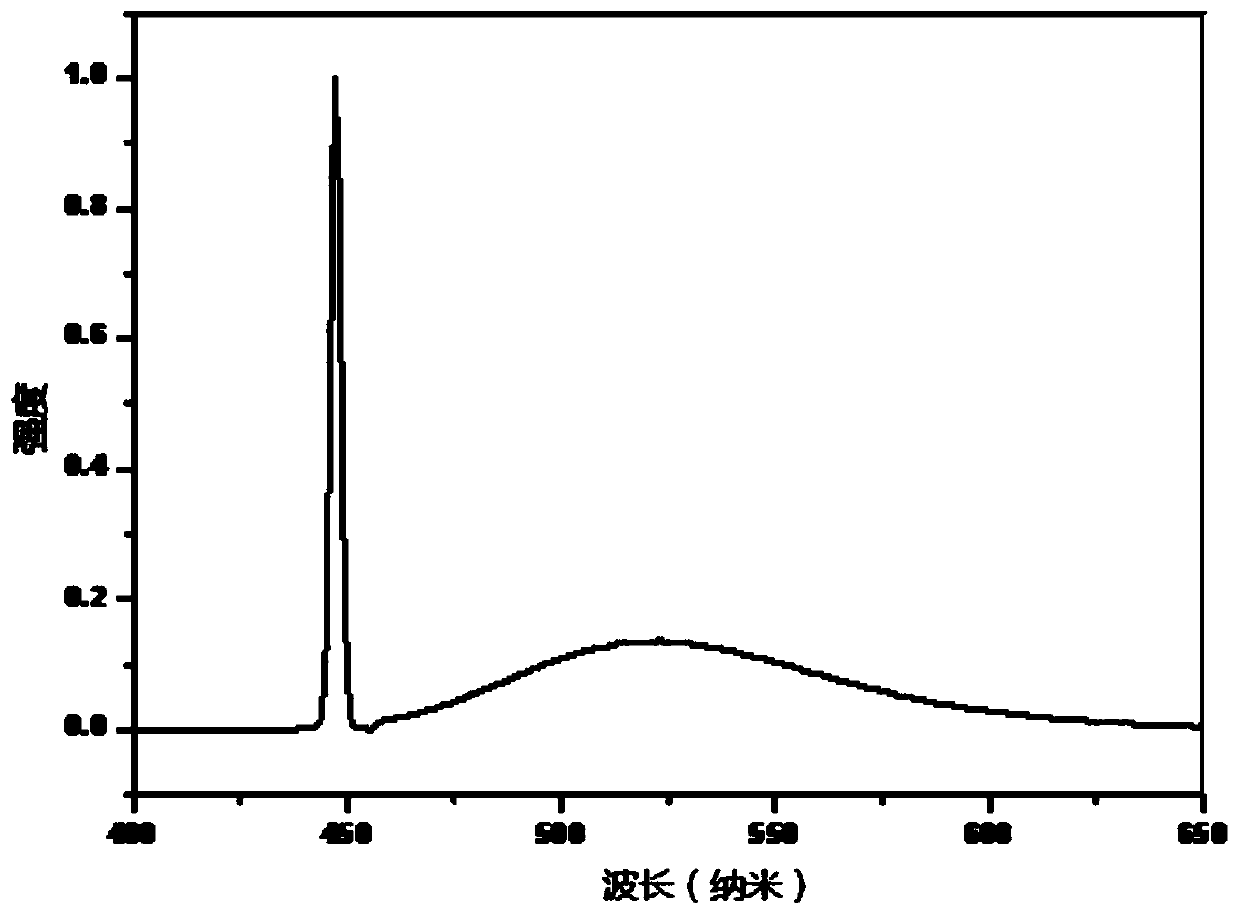

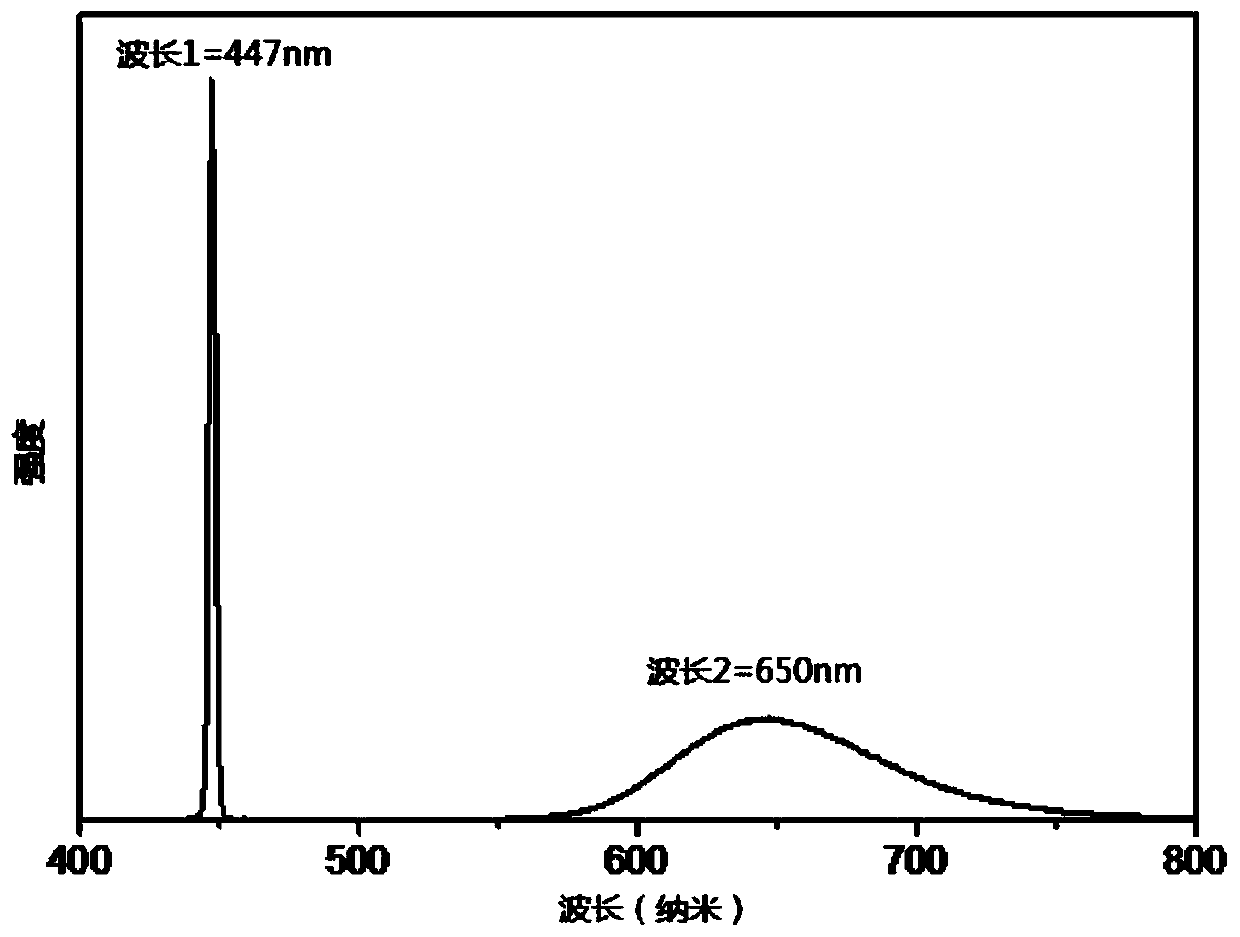

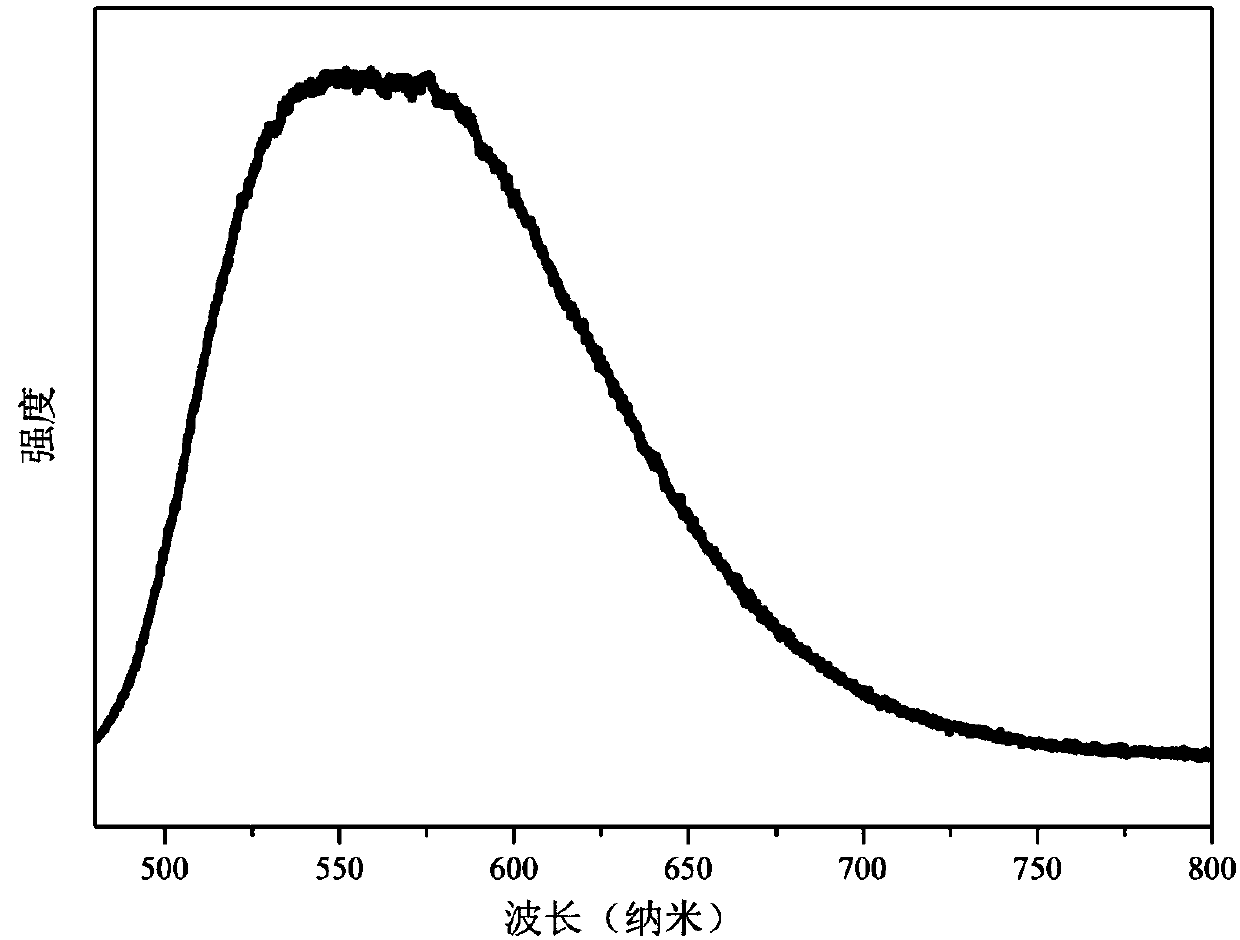

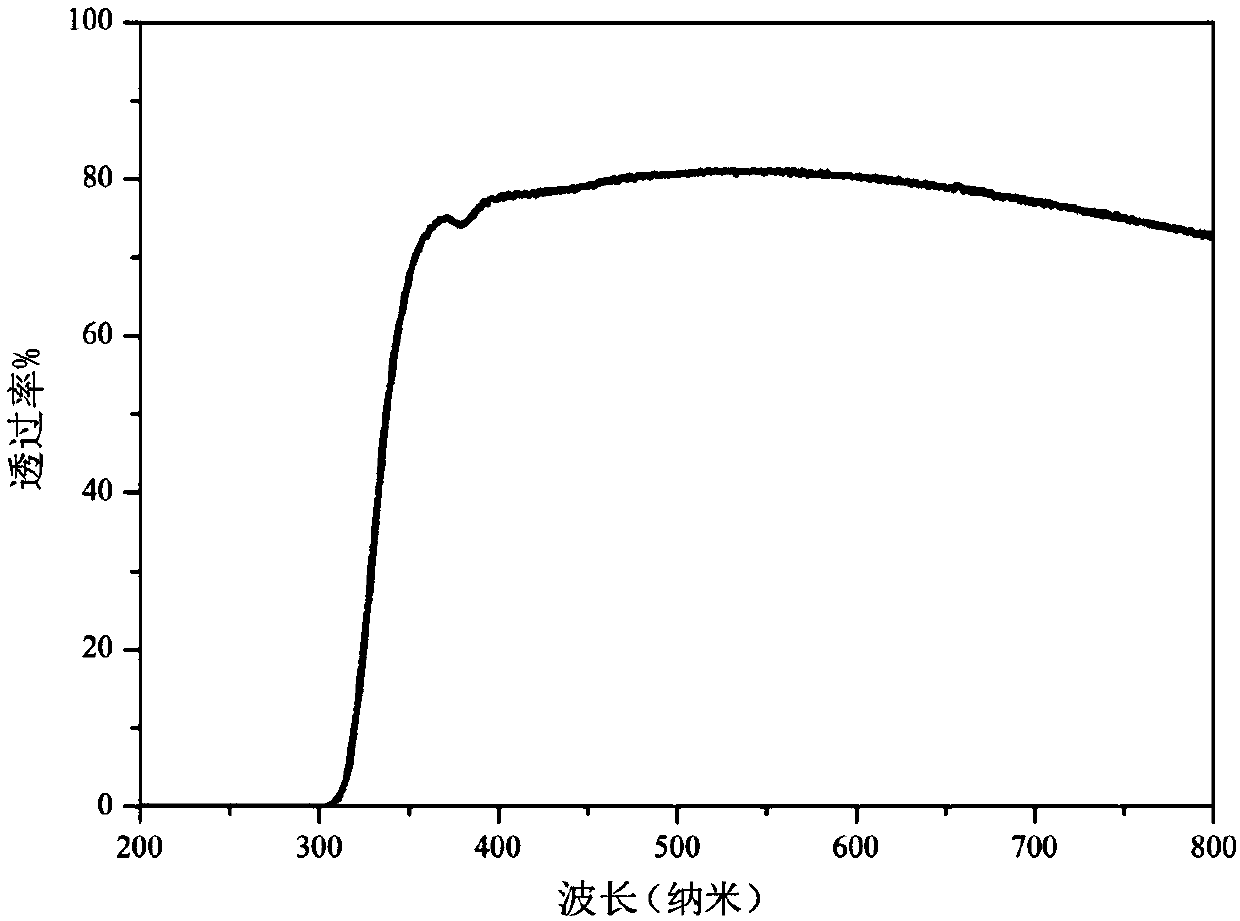

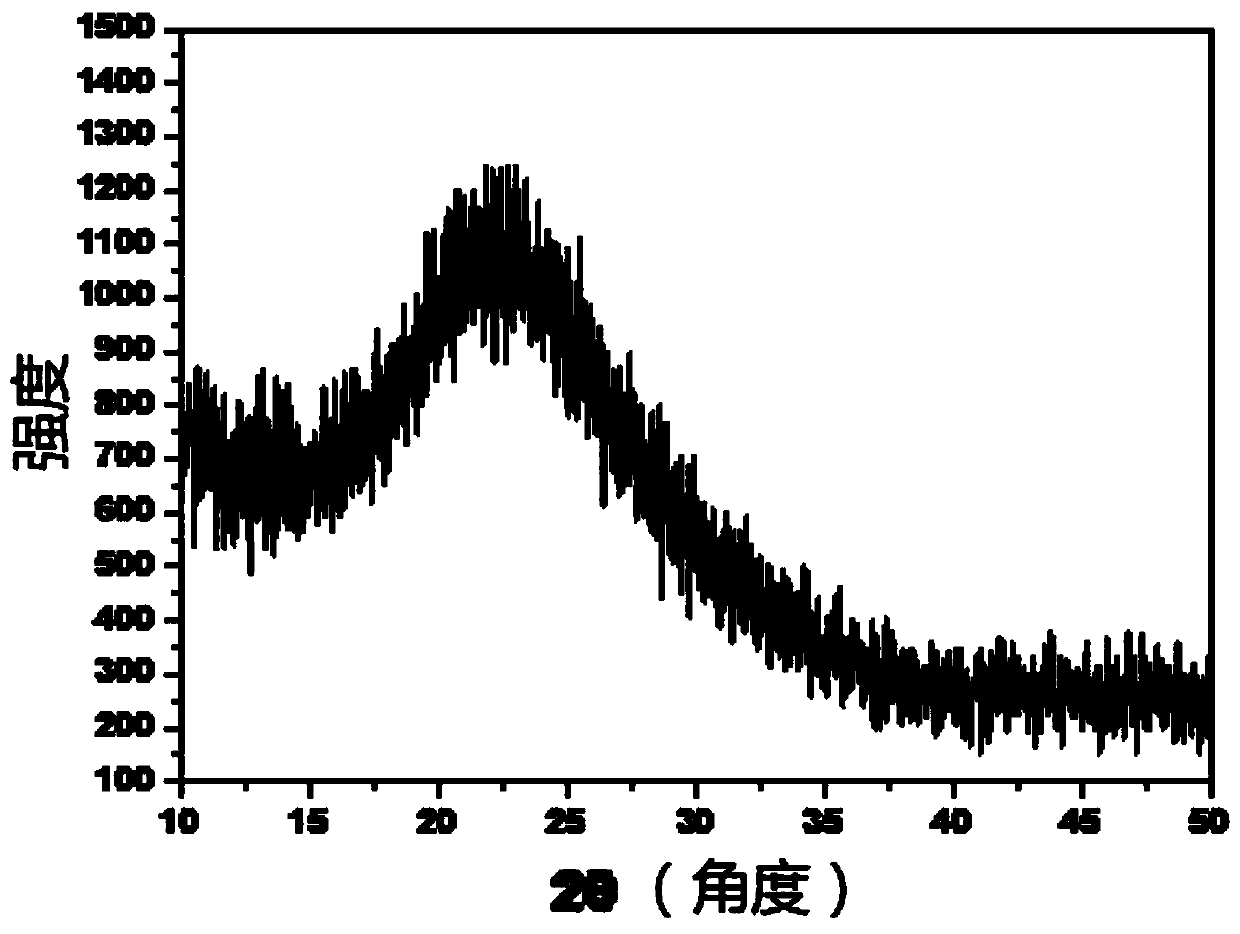

Low-melting-point glass powder and laser-illumination glass ceramic made from low-melting-point glass powder

ActiveCN106587641ALower glass transition temperaturePrevent thermal deteriorationLight fasteningsSemiconductor devices for light sourcesBall millTransition temperature

The invention discloses a low-melting-point glass powder and laser-illumination glass ceramic made from the low-melting-point glass powder. A preparing method for the low-melting-point glass powder includes the steps that raw material chemicals are mixed to be even, the mixture is melted for 15 minutes to 90 minutes at the temperature of 300 DEG C to 700 DEG C, and glass liquid is obtained; the glass liquid at the temperature of 300 DEG C to 700 DEG C is quenched and naturally cooled to be at the room temperature, and blocky glass is obtained; the blocky glass is smashed, the smashed glass is put into a ball milling machine and subjected to ball milling, and the low-melting-point glass powder is obtained. The low-melting-point glass powder has the lower glass phase inversion temperature, the glass phase inversion temperature can be adjusted within the temperature range of 200 DEG C to 500 DEG C, the low-melting-point glass powder is suitable for making seal glass and vacuum components and parts and sealing LED, and particularly suitable for making the illumination glass ceramic with a fluorescent powder material, and the illumination glass ceramic is particularly suitable for laser illumination. The glass ceramic is formed and sintered at the low temperature, thermal degradation of fluorescent powder at the high temperature can be effectively avoided, and the laser-illumination glass ceramic has the important application value in the field of laser illumination.

Owner:BINHAI IND RES INST OF TIANJIN UNIV CO LTD

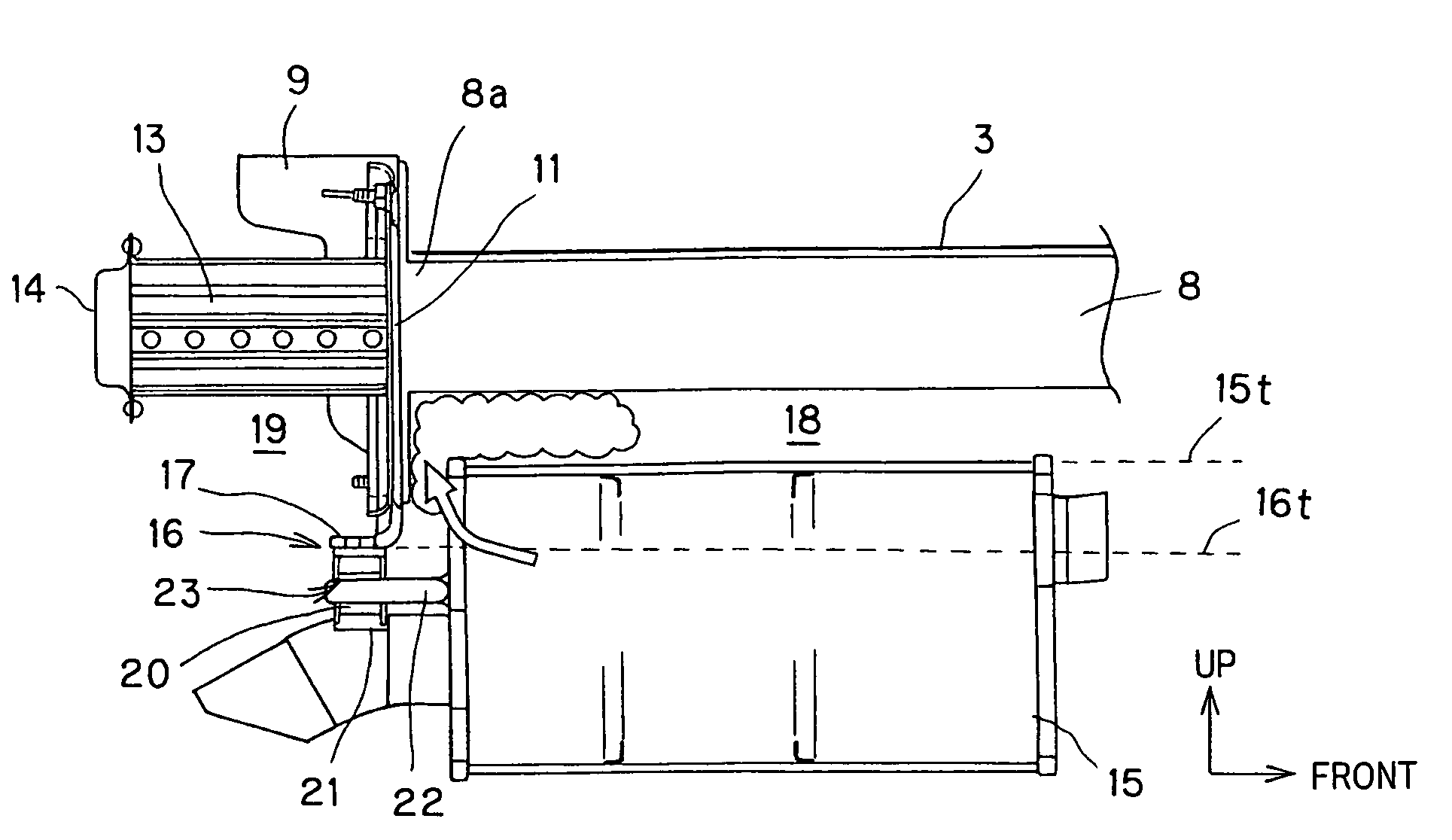

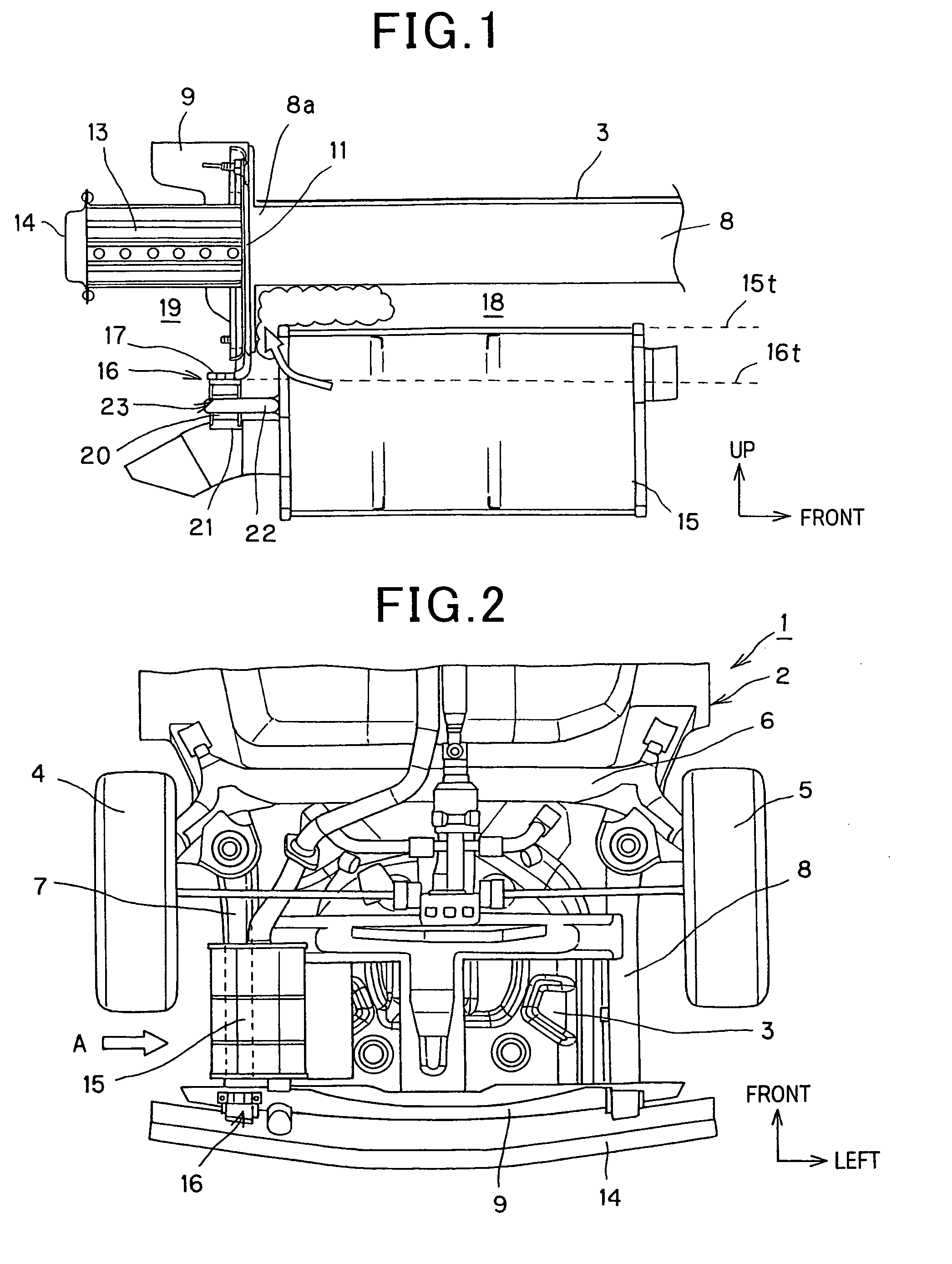

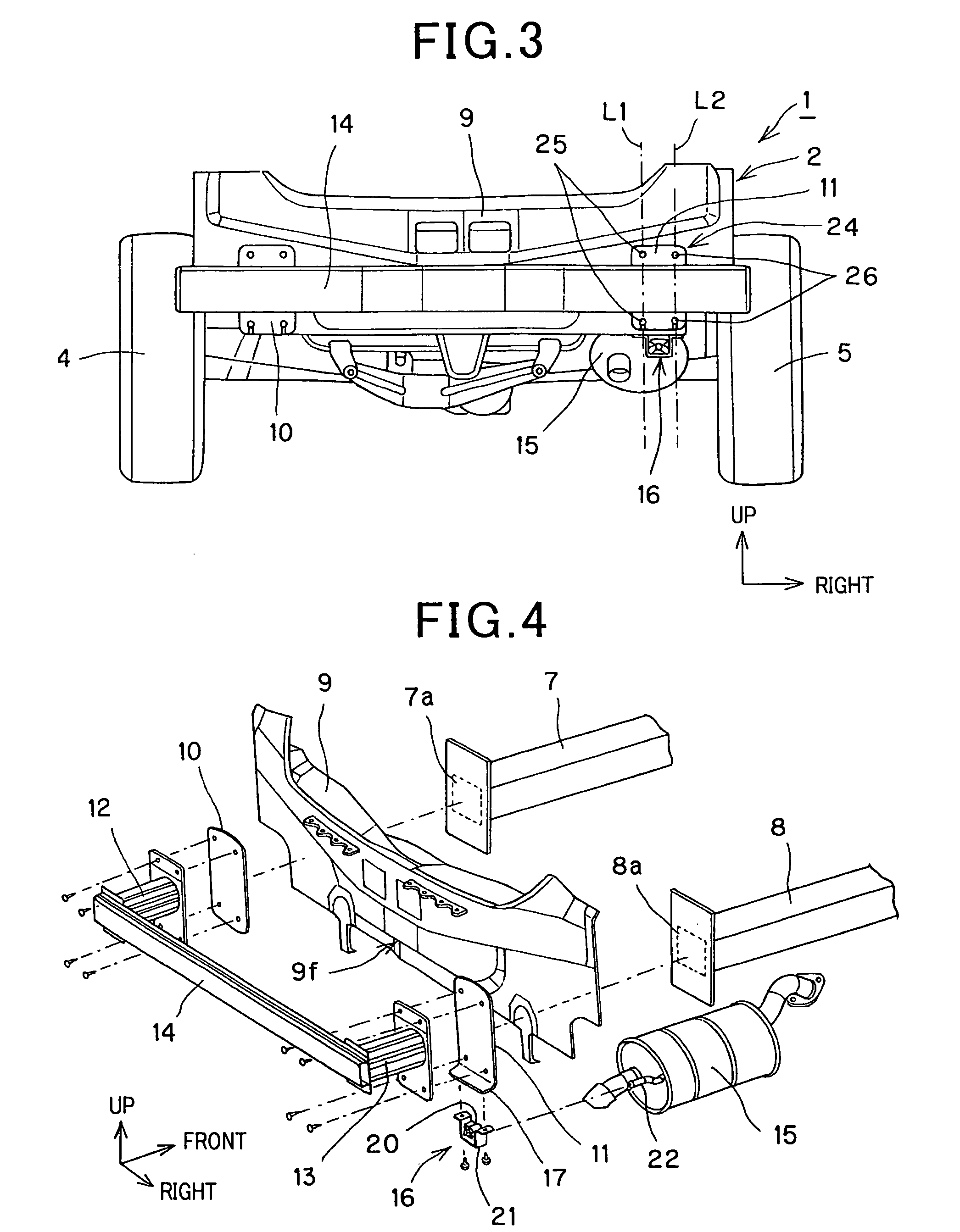

Support structure for exhaust pipe

InactiveUS7931119B2Decrease their propagationPrevent thermal deteriorationPipe supportsMining devicesExhaust pipeMuffler

A support structure for an exhaust pipe includes left and right side frames disposed on a lower side of a rear floor and a back panel extending downward from the rear floor joined to rear end portions of the side frames. Reinforcing plates join the back panel on a vehicle rear side in positions facing the rear of the side frames. Stays extending in a rearward direction mount to the respective reinforcing plates and support a bumper member. A muffler disposed below the rear floor and on a front side of the back panel or an exhaust pipe connected thereto, is supported on a vehicle body by a hanger rubber. A flange portion that is formed with a reinforcing plate extends rearwardly and perpendicularly therefrom. A hanger rubber mounts to the flange portion to support the muffler or exhaust pipe.

Owner:SUZUKI MOTOR CORP

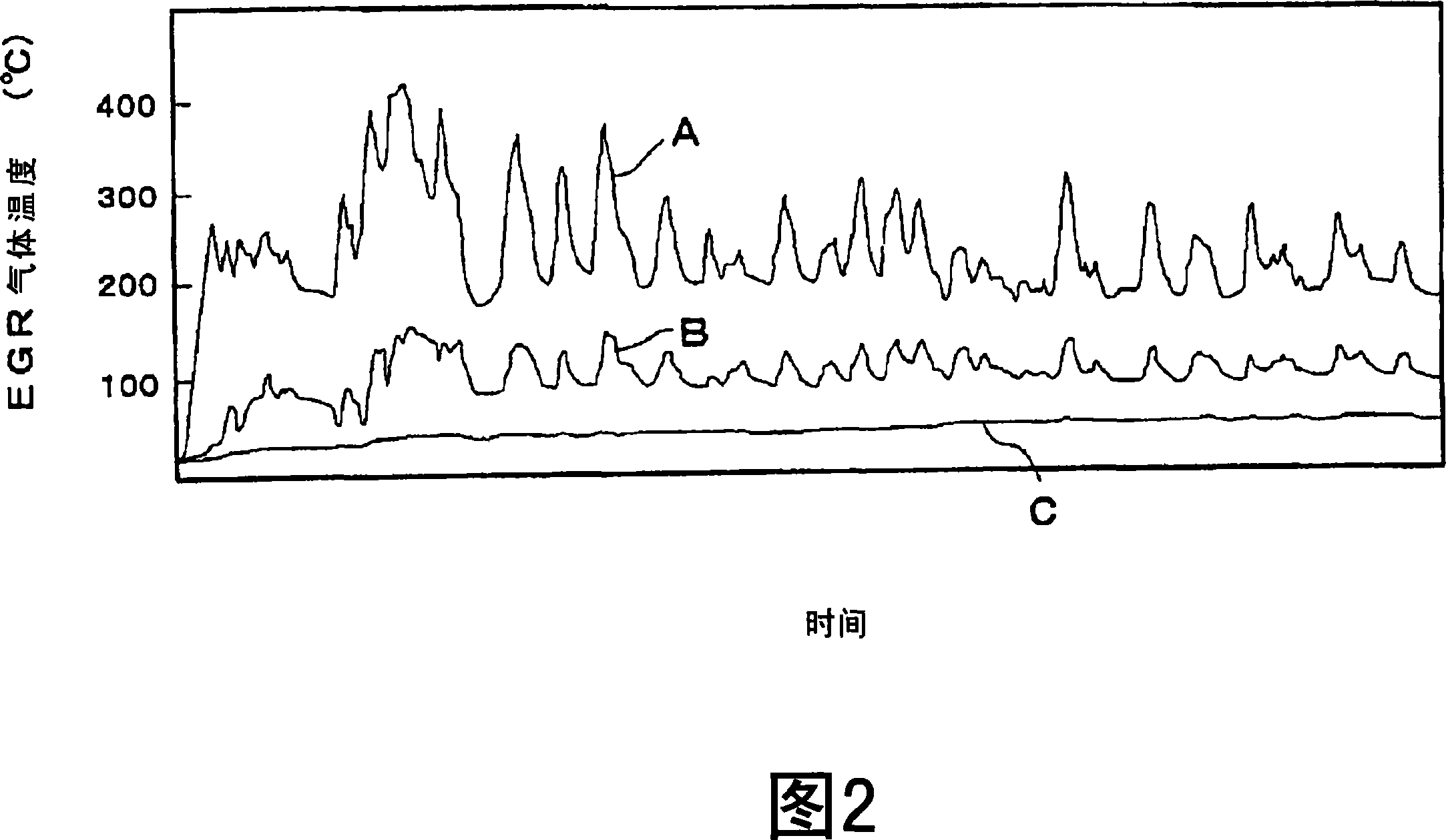

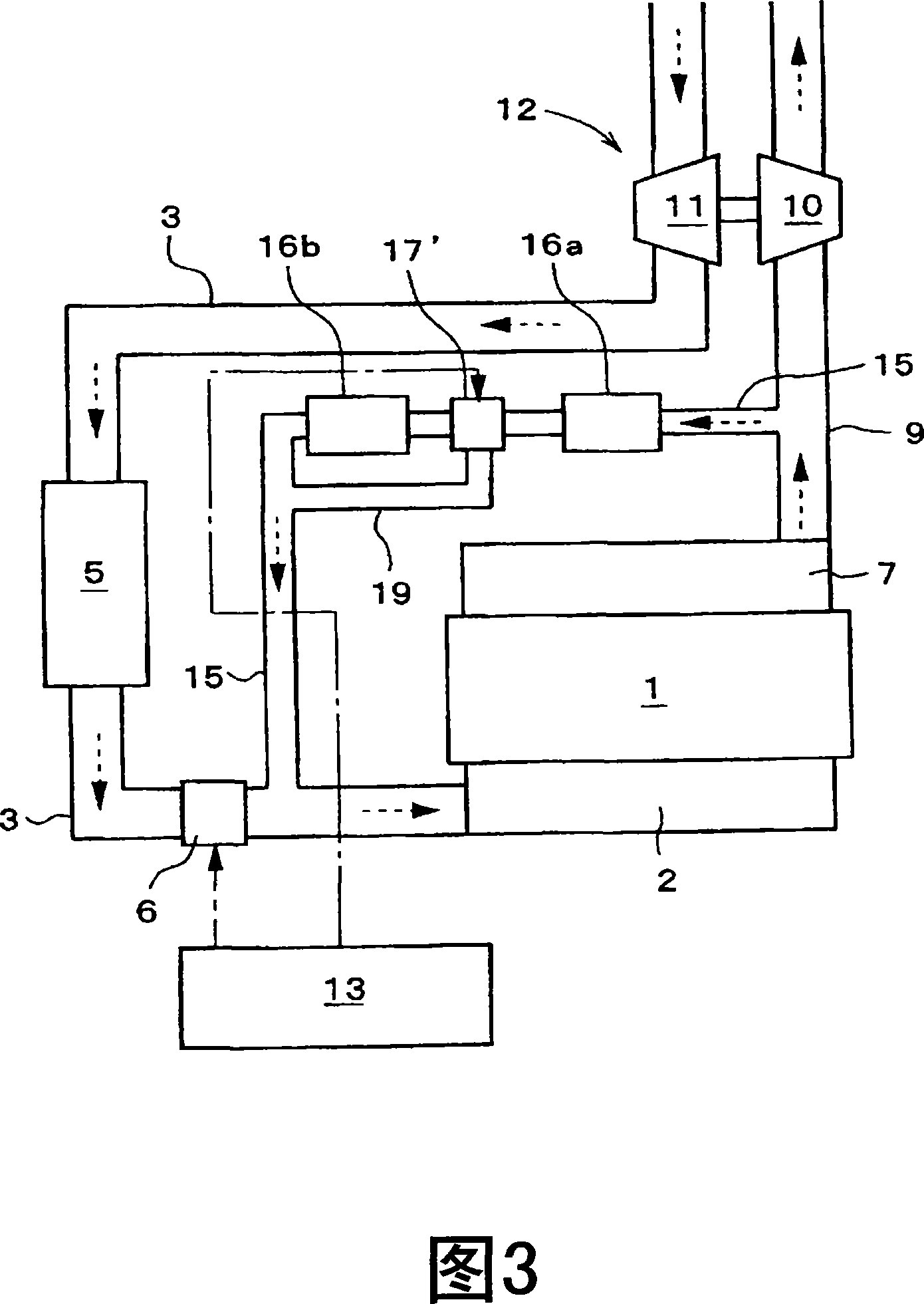

EGR device

InactiveCN101103195APrevent thermal deteriorationInternal combustion piston enginesNon-fuel substance addition to fuelEngineeringMechanical engineering

An EGR device, comprising an EGR passage (15) allowing an exhaust passage (9) to communicate with an intake passage (3) to supply a part of exhaust gas flowing in the exhaust passage (9) of an engine (1) to the intake passage (3), EGR coolers (16a) and (16b) installed in the EGR passage (15) and cooling the exhaust gas flowing in the EGR passage (15), and an EGR valve (17) installed in the EGR passage (15) and regulating the flow of the exhaust gas supplied from the EGR passage (15) to the intake passage (3). The plurality of EGR coolers (16a) and (16b) are installed in the EGR passage (15), and the EGR valve (17) is disposed between any adjacent two EGR coolers (16a) and (16b) among the plurality of EGR coolers (16a) and (16b).

Owner:ISUZU MOTORS LTD

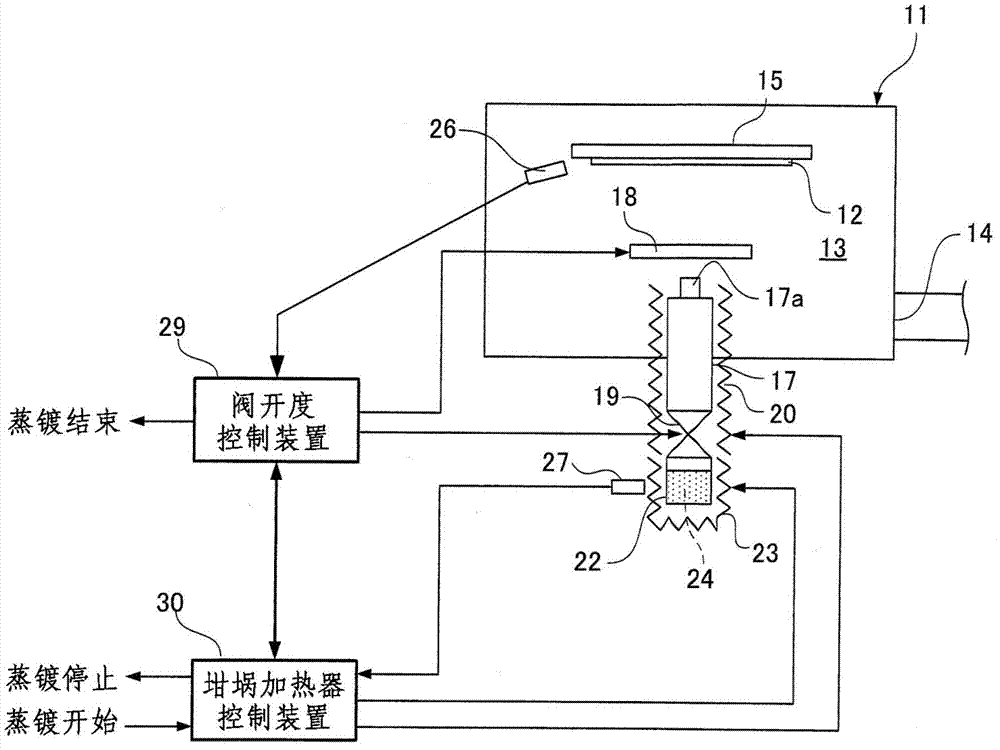

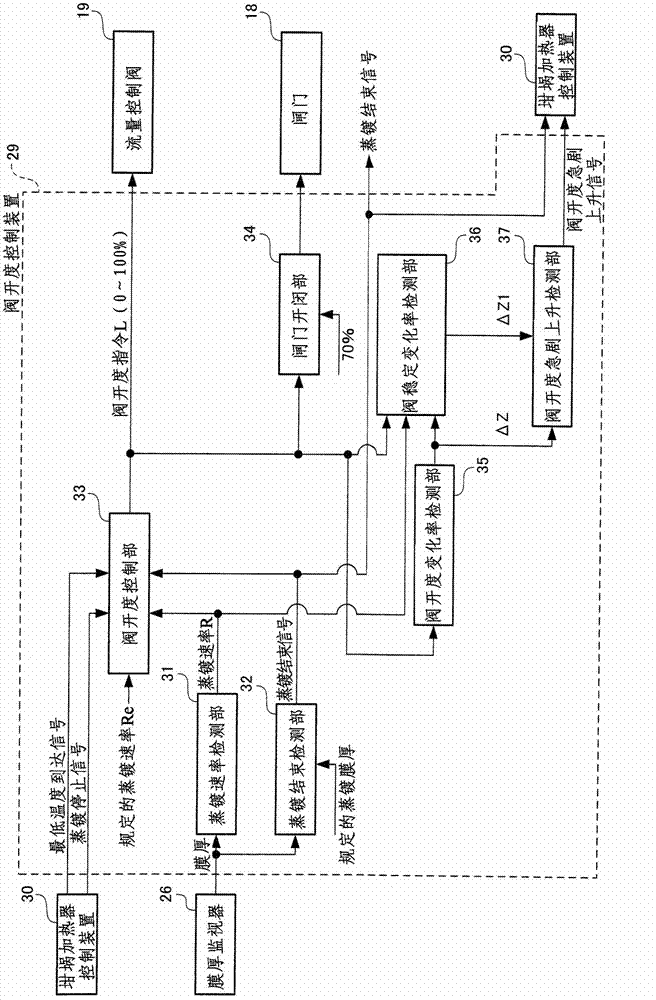

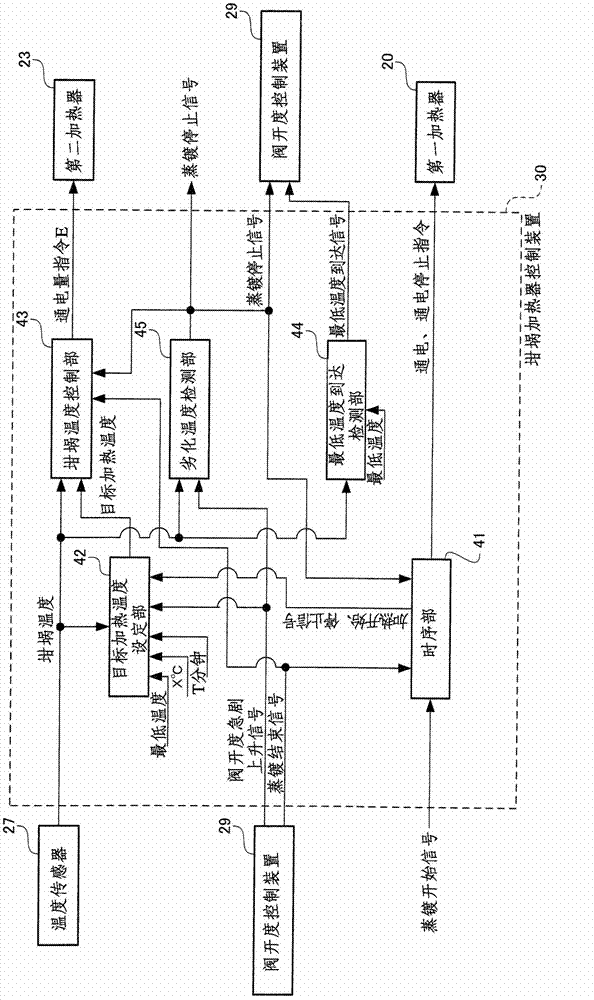

Evaporation device

ActiveCN103361608APrevent thermal deteriorationAccelerate evaporationVacuum evaporation coatingSputtering coatingEngineeringCrucible

The invention provides an evaporation device. Evaporation is performed under minimum limit temperature of a crucible necessary for a specified evaporation rate, when evaporation material (24) in the crucible (22) reduces and the evaporation amount (formation of evaporation particles supplied from the crucible (22)) of the evaporation material (24) from the crucible reduces and thereby leading to reduction of the evaporation rate, and to maintain the specified evaporation rate and in the circumstance that the aperture of a flow control valve (19) is largened sharply, a target heating temperature of the crucible rises with an incremental quantity. The result is that the evaporation amount of the evaporation material (24) form the crucible (22) increases, and the specified evaporation rate is maintained. By enabling the target temperature to rise with an incremental quantity successively, not only thermal degradation of the evaporation material (24) can be prevented and the evaporation material (24) can be used to the end, but can also reduce residues of the evaporation material (24) to a minimum value.

Owner:HITACHI ZOSEN CORP

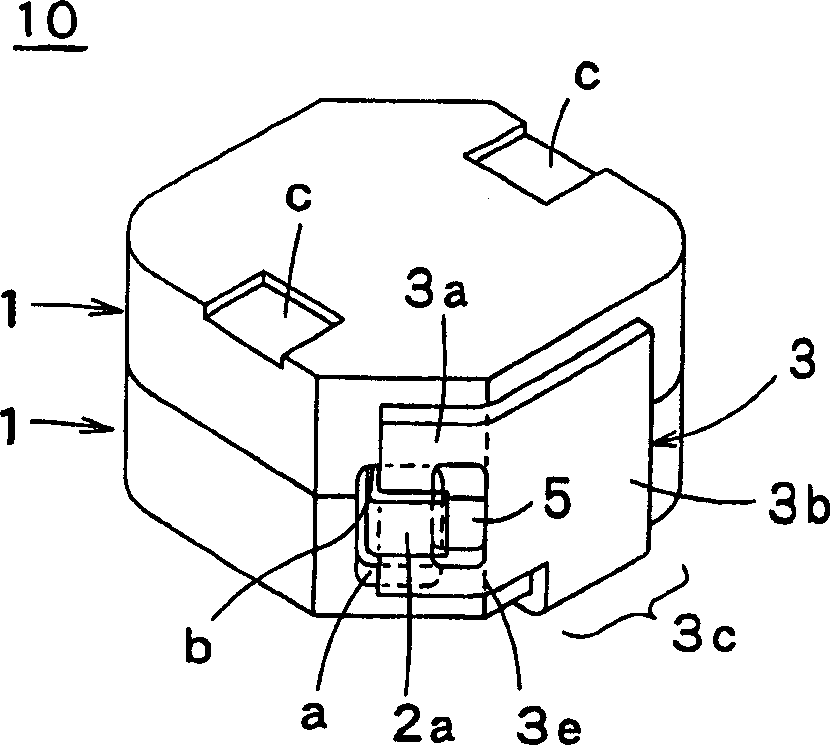

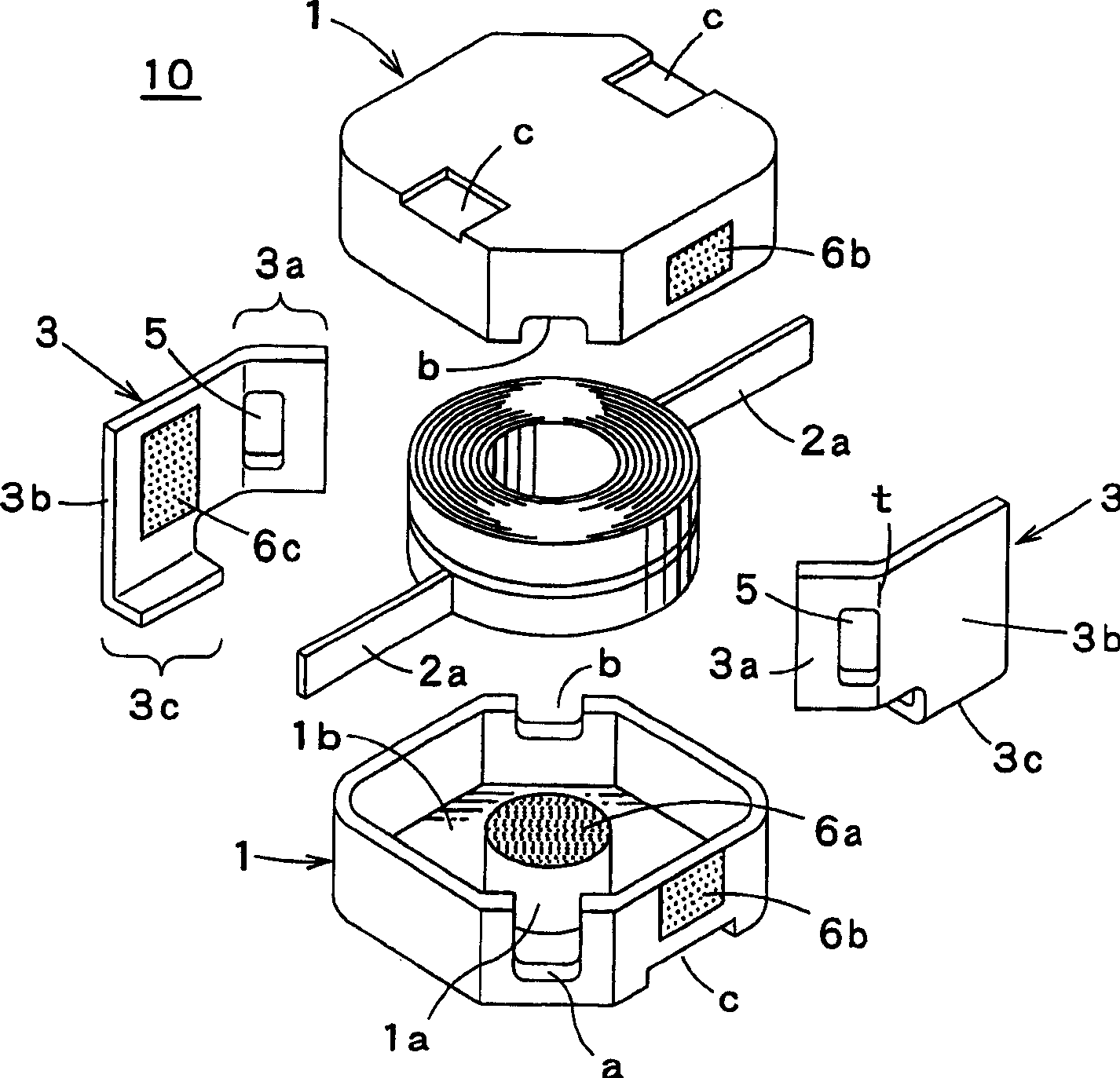

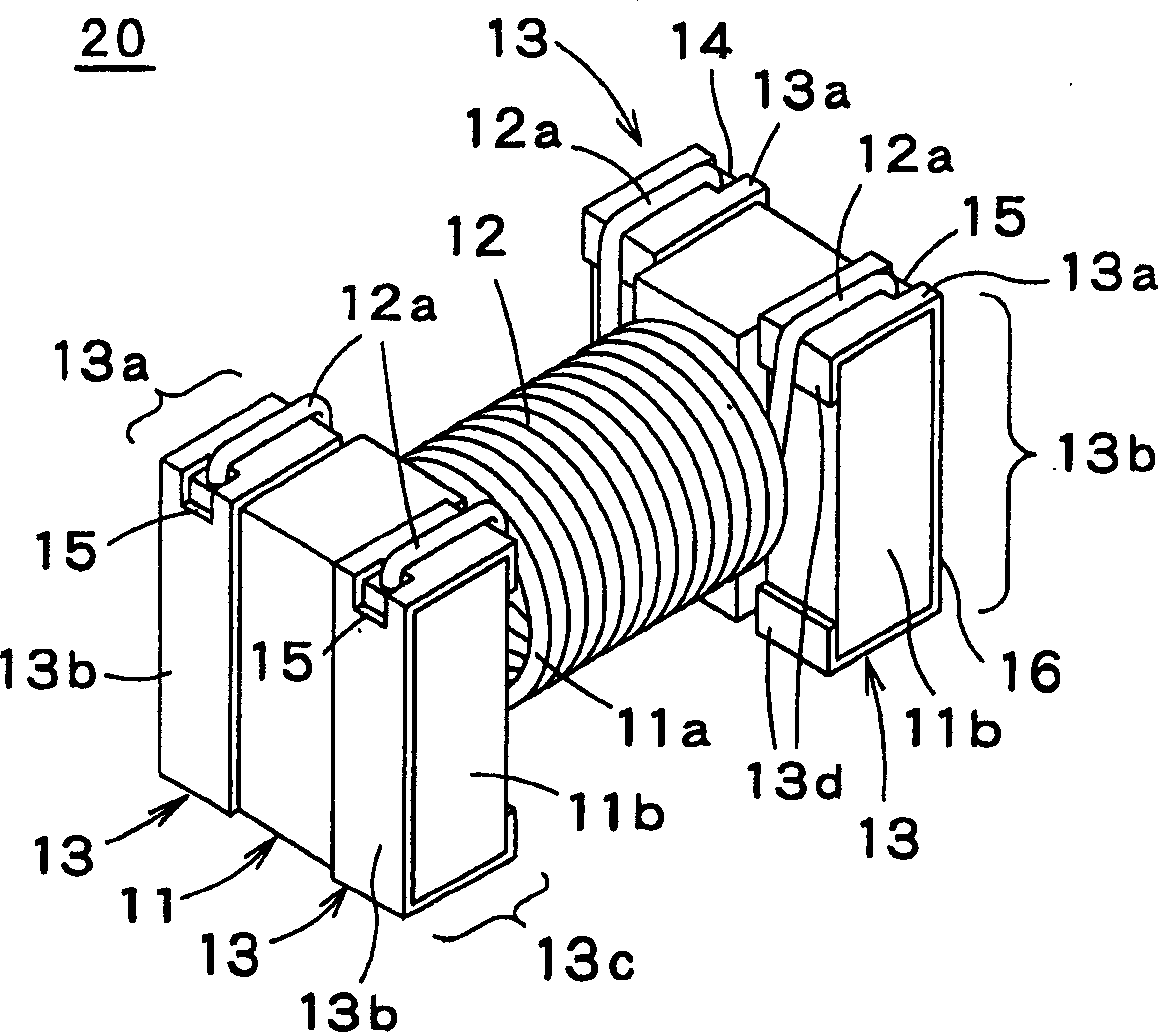

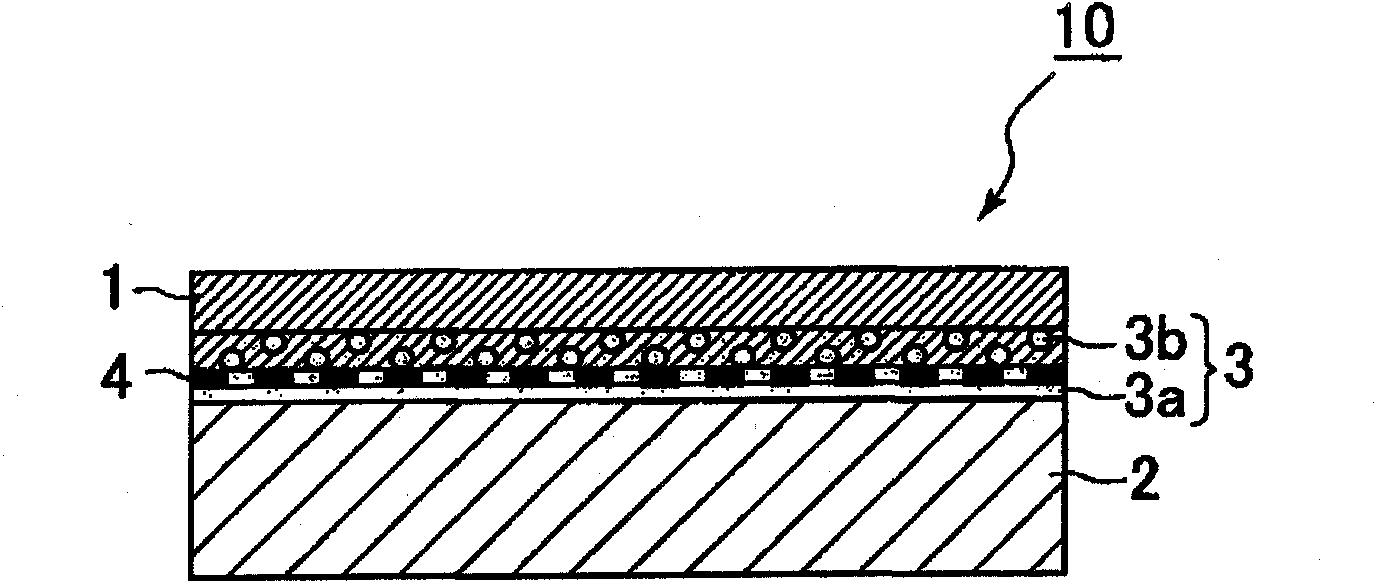

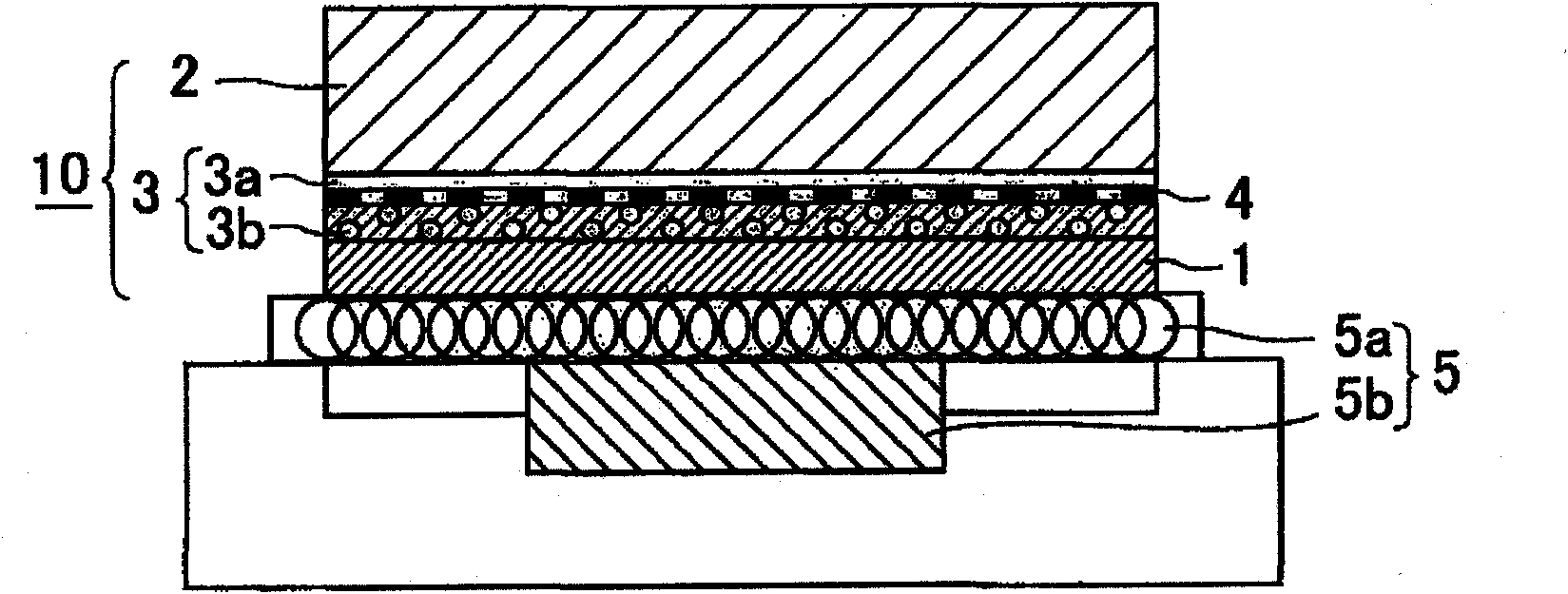

Surface mount coil component

InactiveCN1728299AHeating temperature does not runDoes not shorten lifespanTransformers/inductances coils/windings/connectionsCoils manufactureSurface mountingEngineering

An object is to provide a highly reliable surface mount coil component quickly and reliably forming thermo-compression bonding on an occasion of thermo-compression bonding by a heater chip, and reliably fixing the metal plate terminal, in a surface mount coil component having thermo-compression bonding of a winding wire and a metal plate terminal. In a surface mount coil component including a winding wire 2, a core 1 and a metal plate terminal 3, the metal plate terminal 3 integrally includes a fixing part 3 b which is bonded and fixed to the core 1, a joint part 3 a to which an end of the winding wire is bonded by thermo-compression bonding, and a mount part 3 c which is connected to an external circuit, the fixing part 3 c is integrally included between the joint part 3 a and the mount part 3 b, and a sectional reduced portion 5 is formed between the joint part 3 a and the fixing part 3 b.

Owner:TOKO KABUSHIKI KAISHA

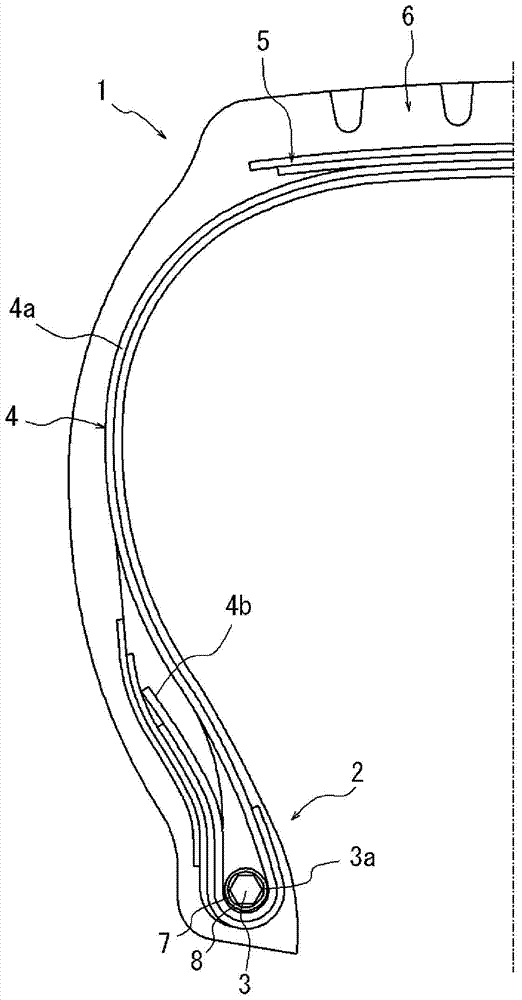

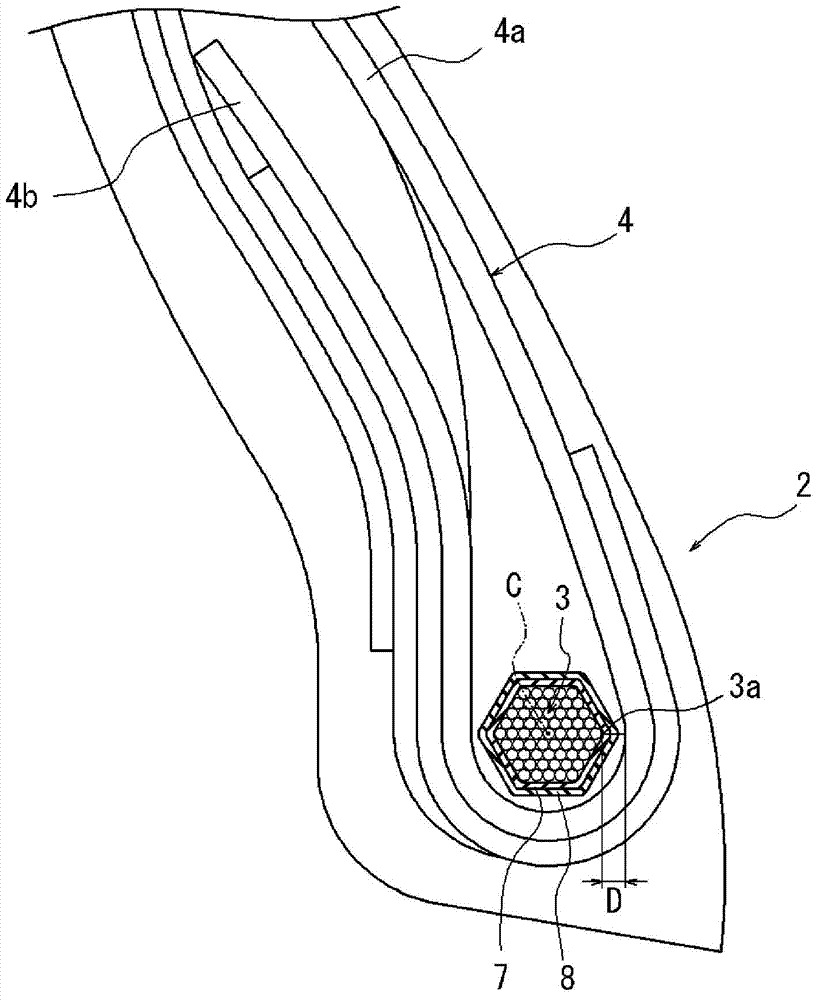

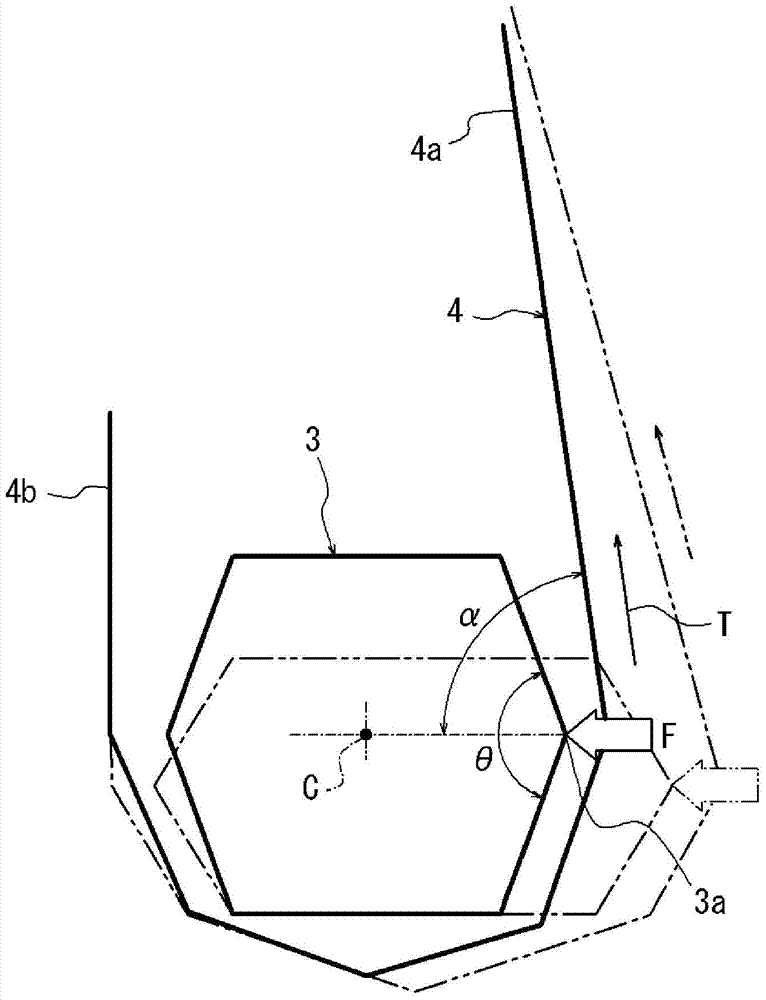

Pneumatic tire and method for producing pneumatic tire

InactiveCN103717415APrevent the risk of durability deteriorationReduce stress concentrationTyresTyre beadsTire beadFiber

This pneumatic tire is equipped with: a pair of annular bead cores embedded and disposed at a bead section; a carcass comprising a main body section extending toroidally between the pair of bead cores, and at least one carcass ply having a fold-back section that, continuously with the main body section, results from folding back around the bead core; and a tread rubber installed at the outer perimeter of the crown region of the carcass. The cross sectional shape in the widthwise direction of the tire of the bead cores is polygonal having at least one corner at the main body side of the carcass ply. At the periphery of the bead cores, at least a two-layered stack of organic fiber reinforcing layers is provided resulting from helically winding at least one rubber-covered organic fiber cord inclined with respect to the center line of the transverse plane of the bead cores; the respective organic fiber cords of organic fiber reinforcing layers that are adjacent in the inner / outer direction are caused to extend in mutually intersecting orientations with respect to the center line of the transverse plane of the bead cores, and of the organic fiber reinforcing layers that are adjacent in the inner / outer direction, in the inner organic fiber reinforcing layer, the rubber-covered organic fiber cord is wound leaving a gap in the peripheral direction of the tire at at least a portion thereof without overlapping in the peripheral direction of the tire, and the outer organic fiber reinforcing layer is providing in a manner so as to cover at least a portion of the gap.

Owner:BRIDGESTONE CORP

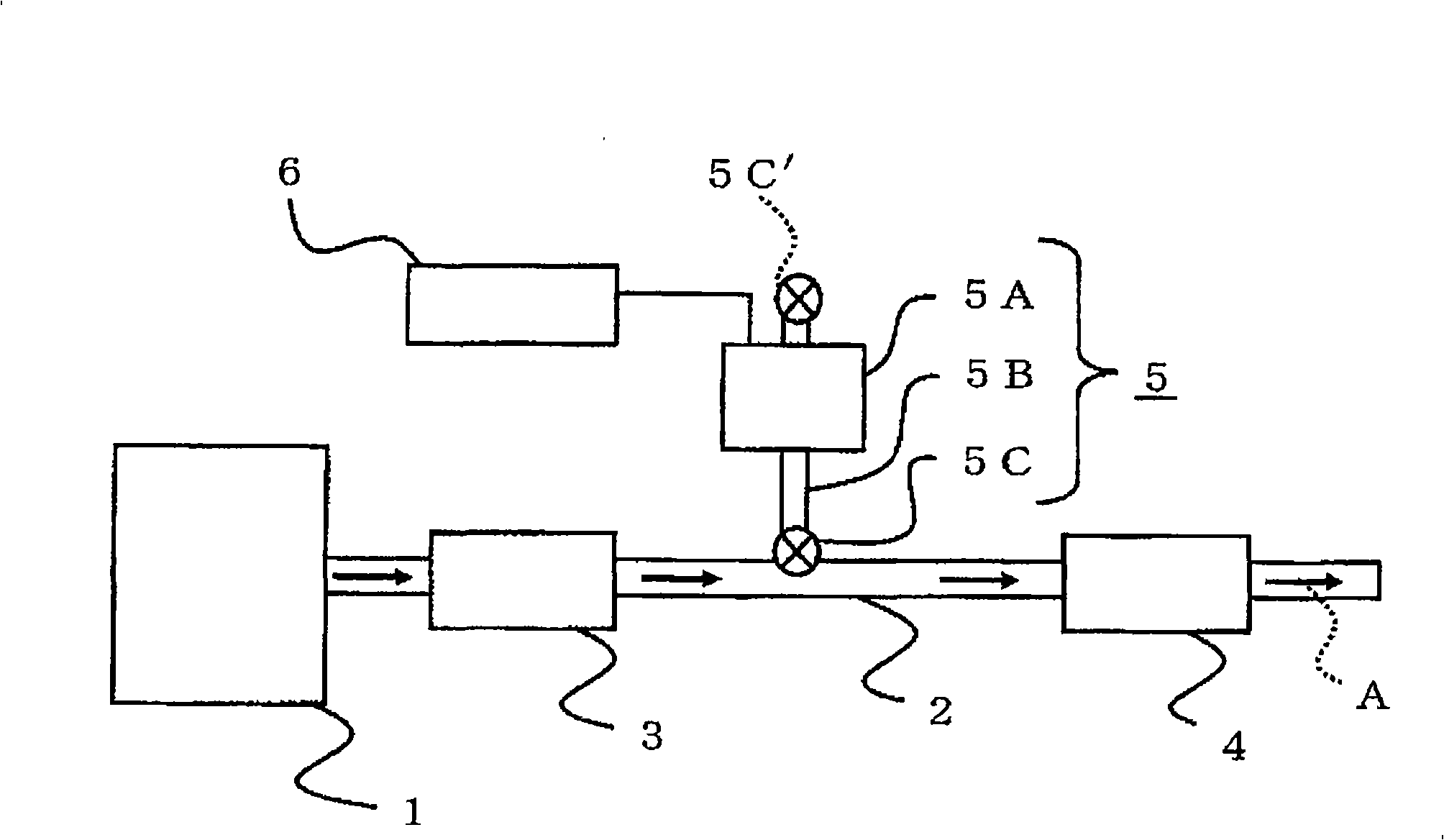

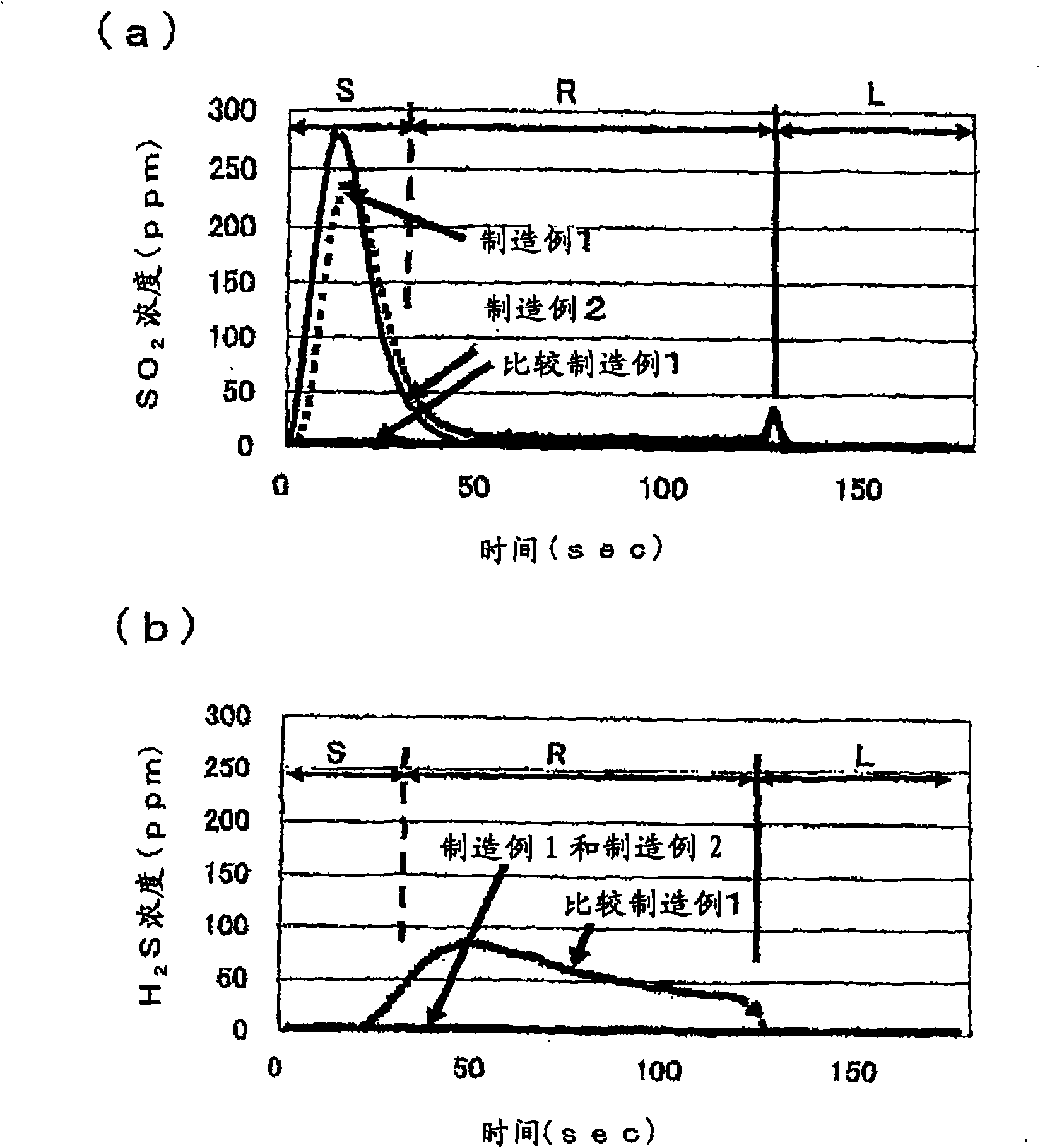

Exhaust gas purifying apparatus and exhaust gas purifying method using the same

InactiveCN101351630APrevent sulfur poisoningPrevent thermal deteriorationInternal combustion piston enginesExhaust apparatusExternal combustion engineEnvironmental engineering

Disclosed is an exhaust gas purifying apparatus comprising an exhaust gas pipe (2) connected to an internal combustion engine (1), an upstream catalyst (3) arranged on the upstream side of the exhaust gas passage in the exhaust gas pipe (2), a downstream catalyst (4) arranged on the downstream side of the exhaust gas passage in the exhaust gas pipe (2) and loaded with nickel and / or iron, and an oxidizing gas supply means (5) connected between the upstream catalyst (3) and the downstream catalyst (4) in the exhaust gas pipe (2) for supplying an oxidizing gas into the exhaust gas pipe (2).

Owner:TOYOTA JIDOSHA KK

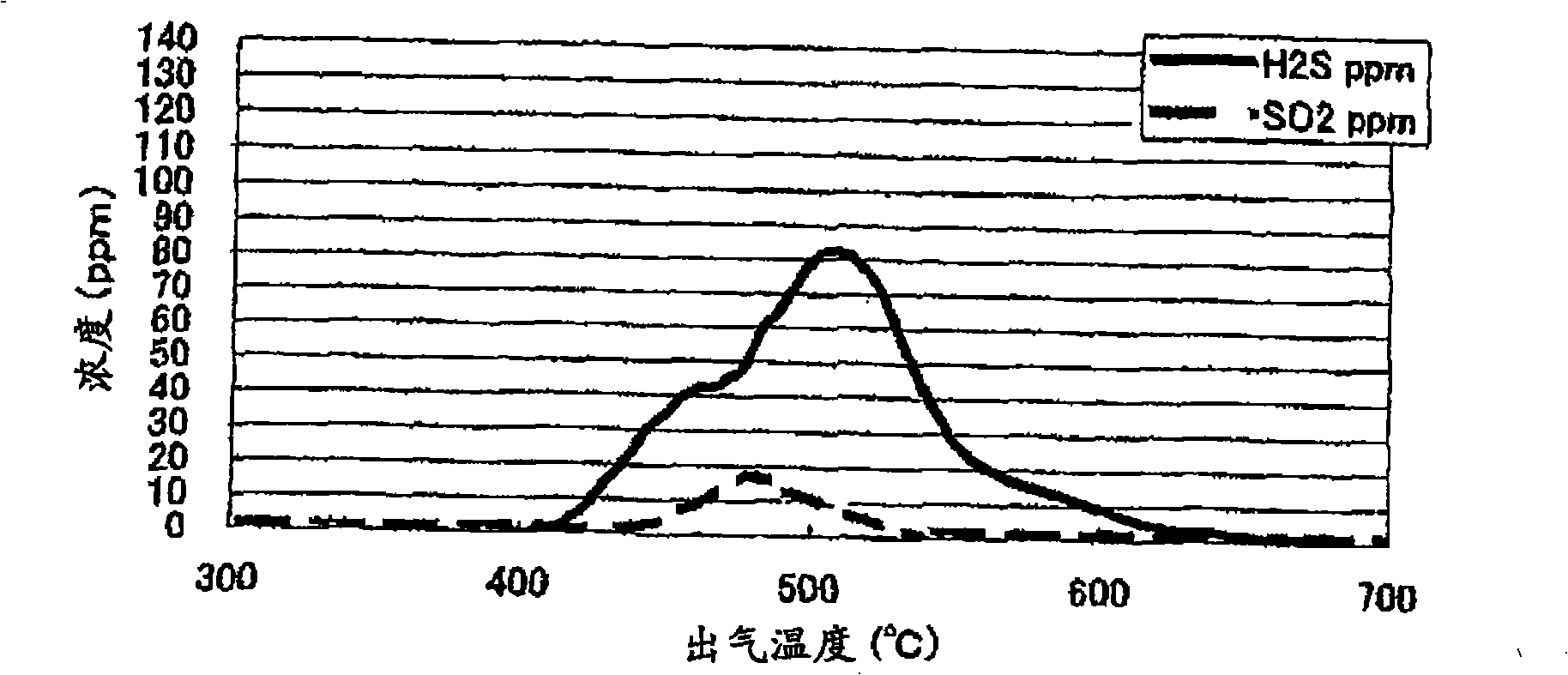

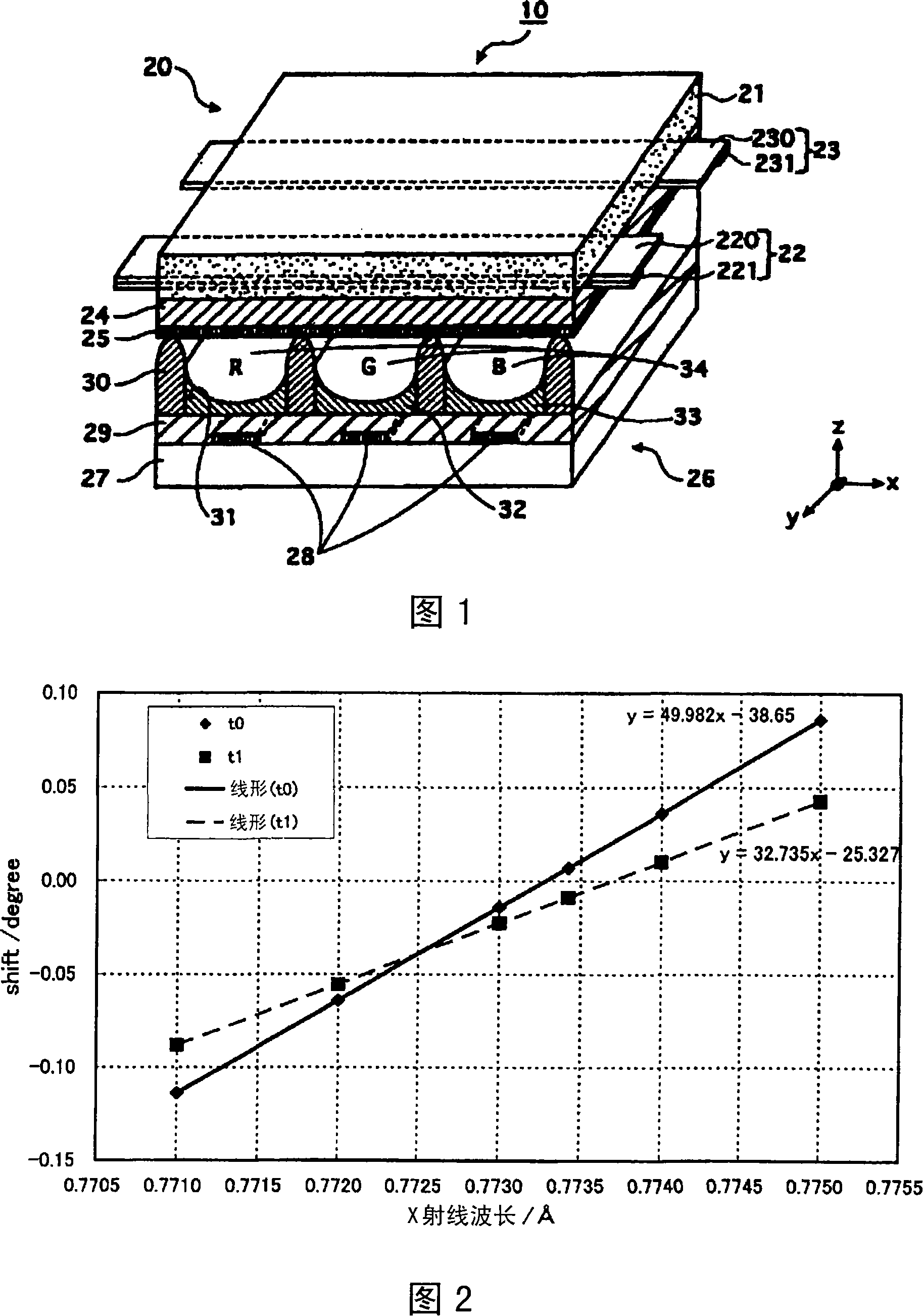

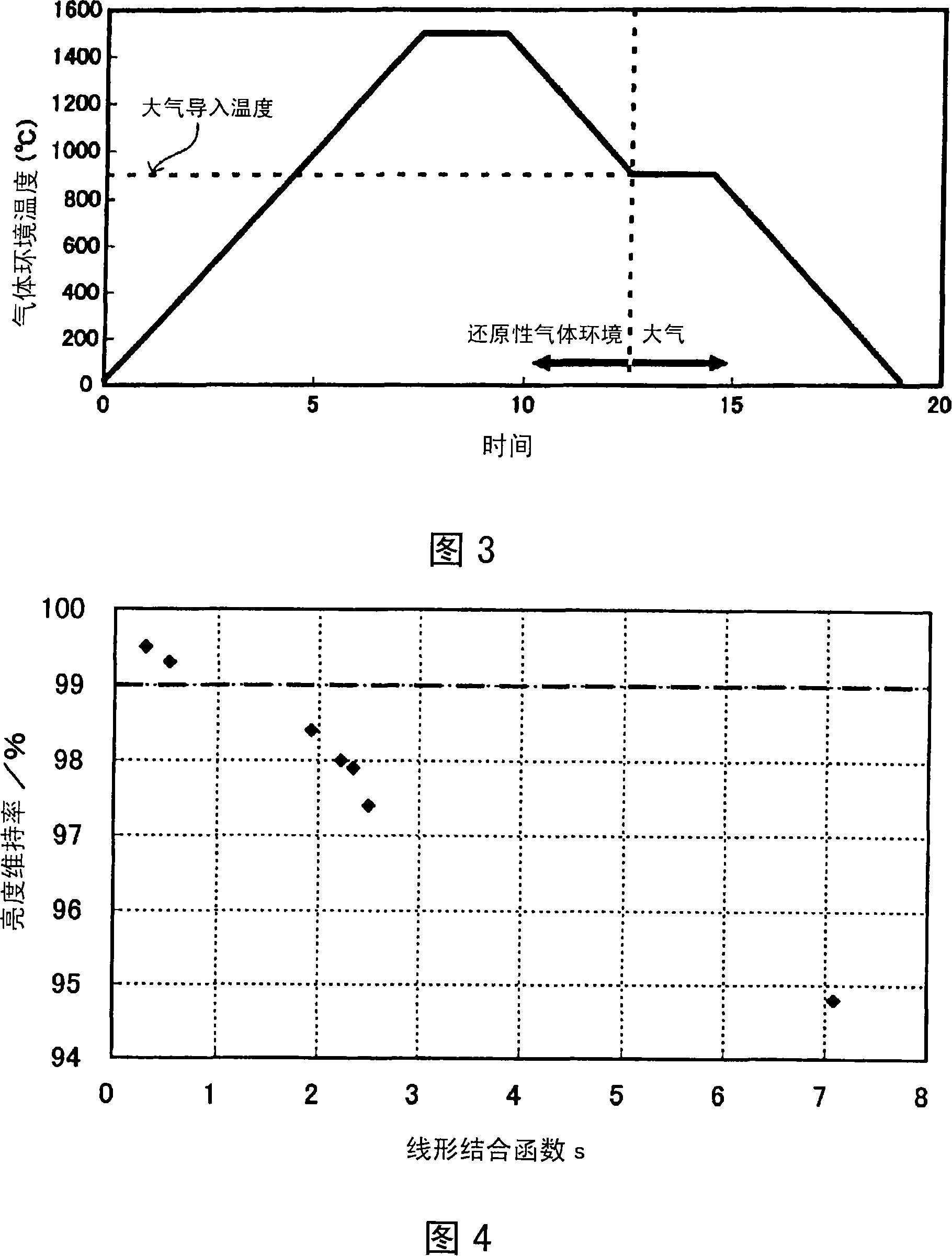

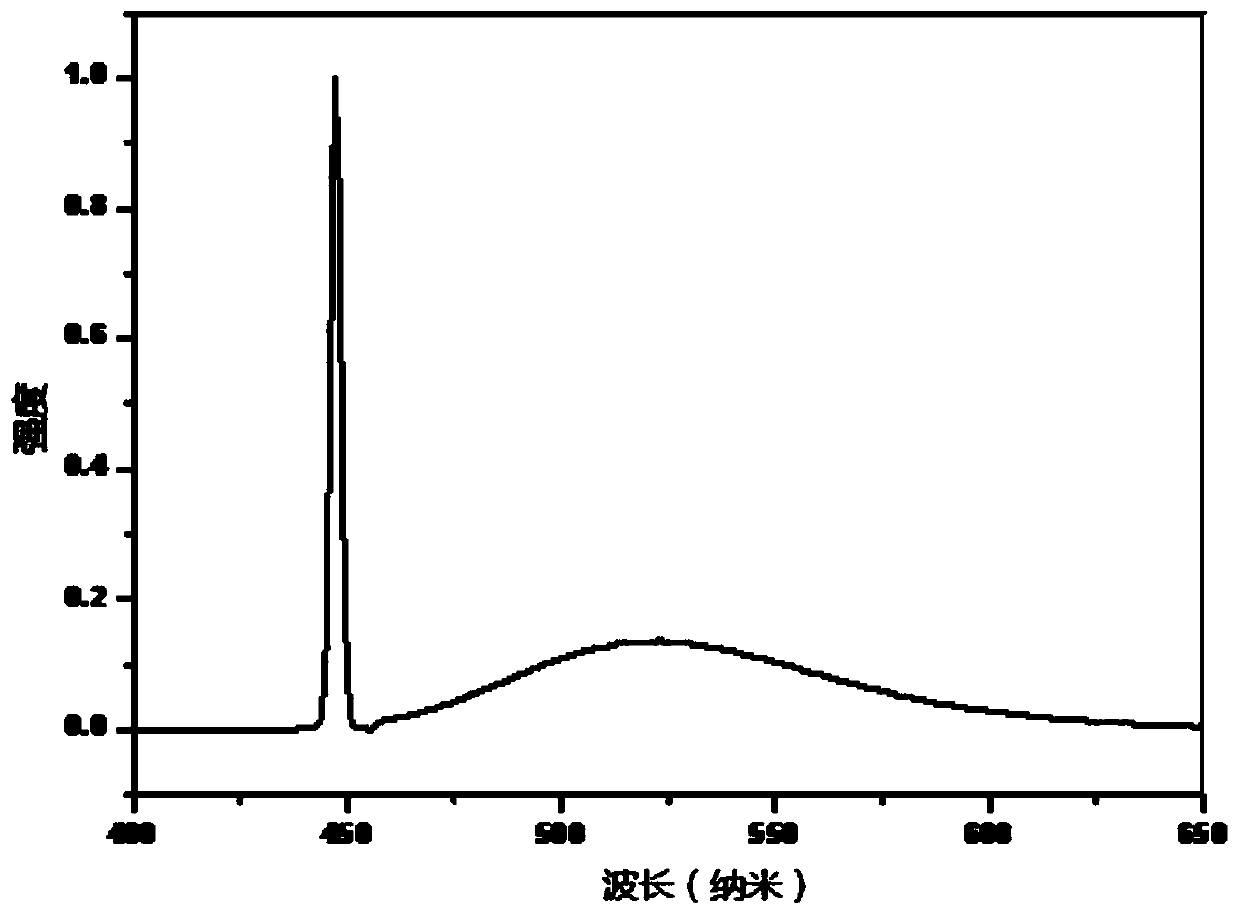

Luminescent device

InactiveCN101151347AInhibition of thermal deteriorationPrevent thermal deteriorationGas-filled discharge tubesLuminescent compositionsSpace groupFluorescence

This invention provides a luminescent device comprising a blue fluorescent substance-containing fluorescent substance layer. The fluorescent substance layer comprises, as a blue fluorescent substance, an aluminate fluorescent substance comprising Ba, Sr, Eu, Mg, Al and O as constituent elements at an atomic ratio of Ba : Sr : Eu : Mg : Al : O = p : q : r : 1 : w : 17, wherein 0.70 = p = 0.95, 0 = q = 0.15, 0.05 = r = 0.20, p + q + r = 1, and 9.8 = w = 10.5. When the aluminate fluorescent substance is subjected to X-ray crystal structure analysis on the assumption that the aluminate fluorescent substance belongs to a space group P63 / mmc, the aluminate fluorescent substance has a linear bond function s of not more than 1 as calculated by s = -11622 + 2043.07La + 199.24L1 - 116.91L2 wherein La represents a lattice constant, AA; L1 represents atomic distance between Al(2) and O(5), AA; and L2 represents atomic distance between Al(1) and O(4), AA.

Owner:PANASONIC CORP

Exhaust gas purifying device

InactiveCN102046932APrevent thermal deteriorationExtend your lifeGas treatmentInternal combustion piston enginesParticulatesElectrical and Electronics engineering

The invention relates to an exhaust gas purifying device. A support member (40) is provided to a tubular member (23) of an upstream tube body (22). The support member (40) has mounted thereto a connector section (34C) of a first temperature detector (34) for detecting the temperature of exhaust gas flowing into an oxidation catalyst (25), a connector section (35C) of a second temperature detector(35) for detecting the temperature of exhaust gas flowing into a particulate matter removing filter (31), and a sensor section (39A) of a pressure detector (39) for detecting pressures across the particulate matter removing filter (31). Accordingly, the support member (40) can support at one place in a concentrated manner the connector sections (34C, 35C) of the temperature detectors (34, 35) andthe sensor section (39A) of the pressure detector (39), and harnesses on the controller side can be easily connected to the connector sections and the sensor section.

Owner:HITACHI CONSTRUCTION MACHINERY CO LTD

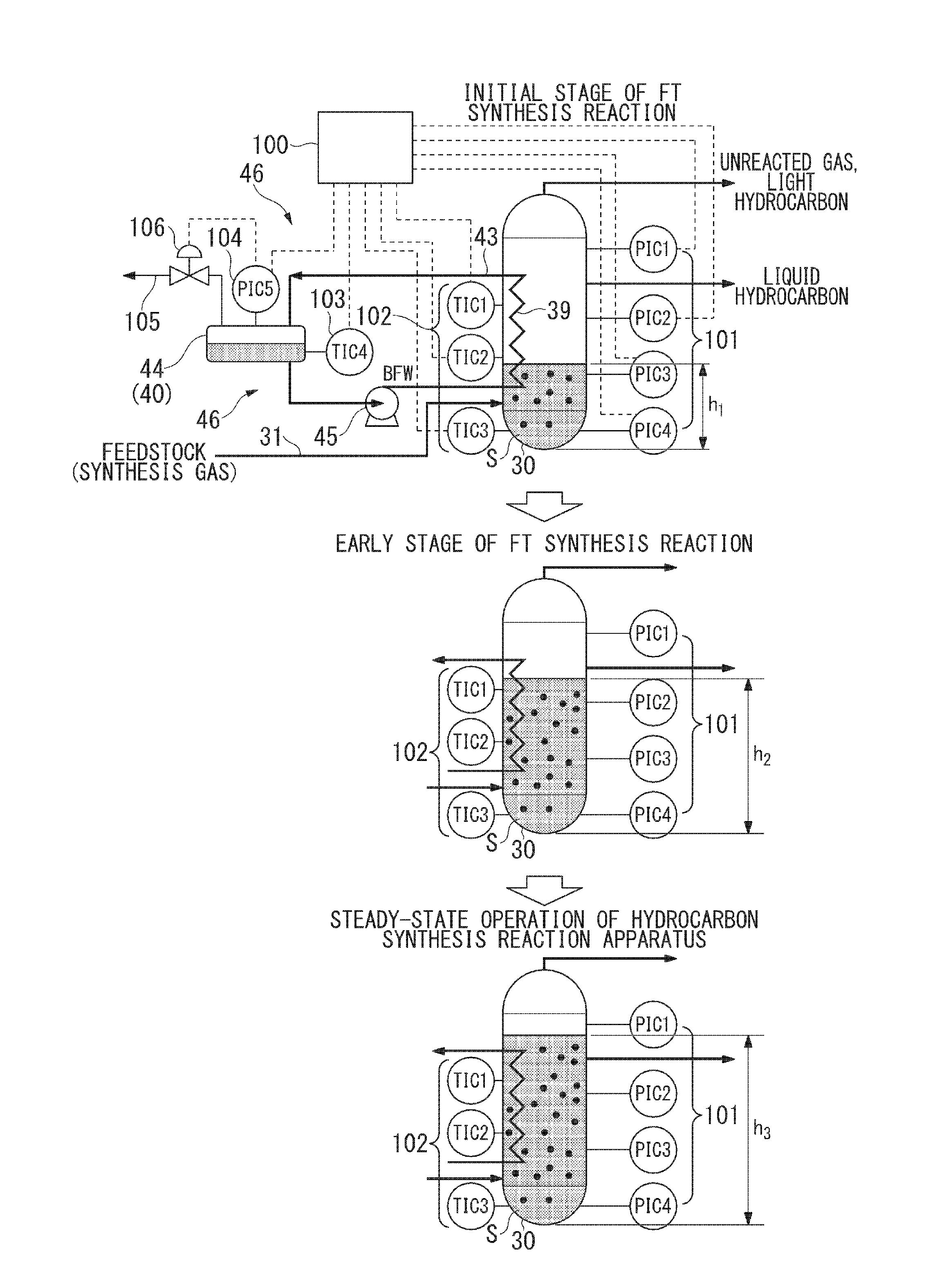

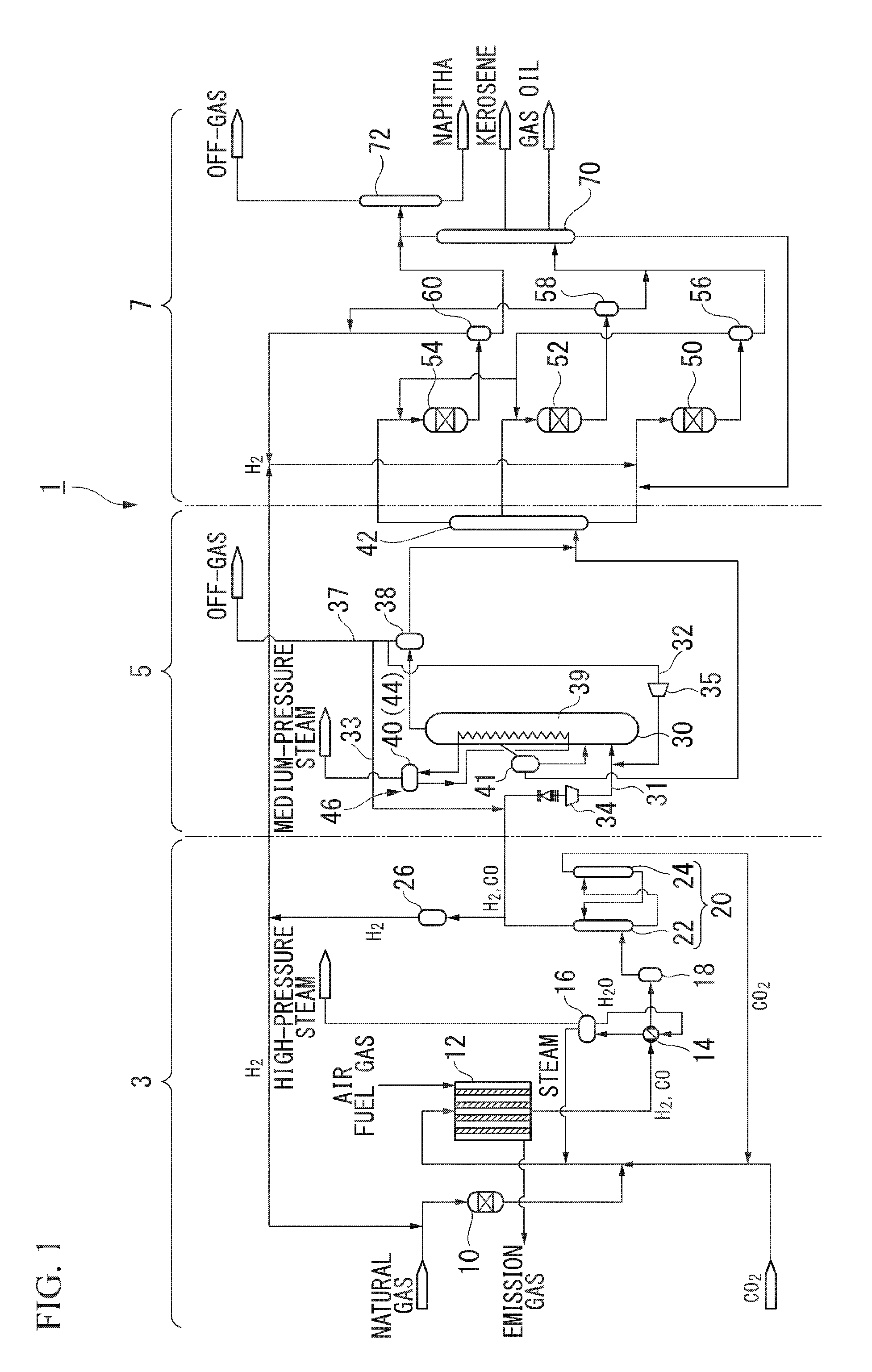

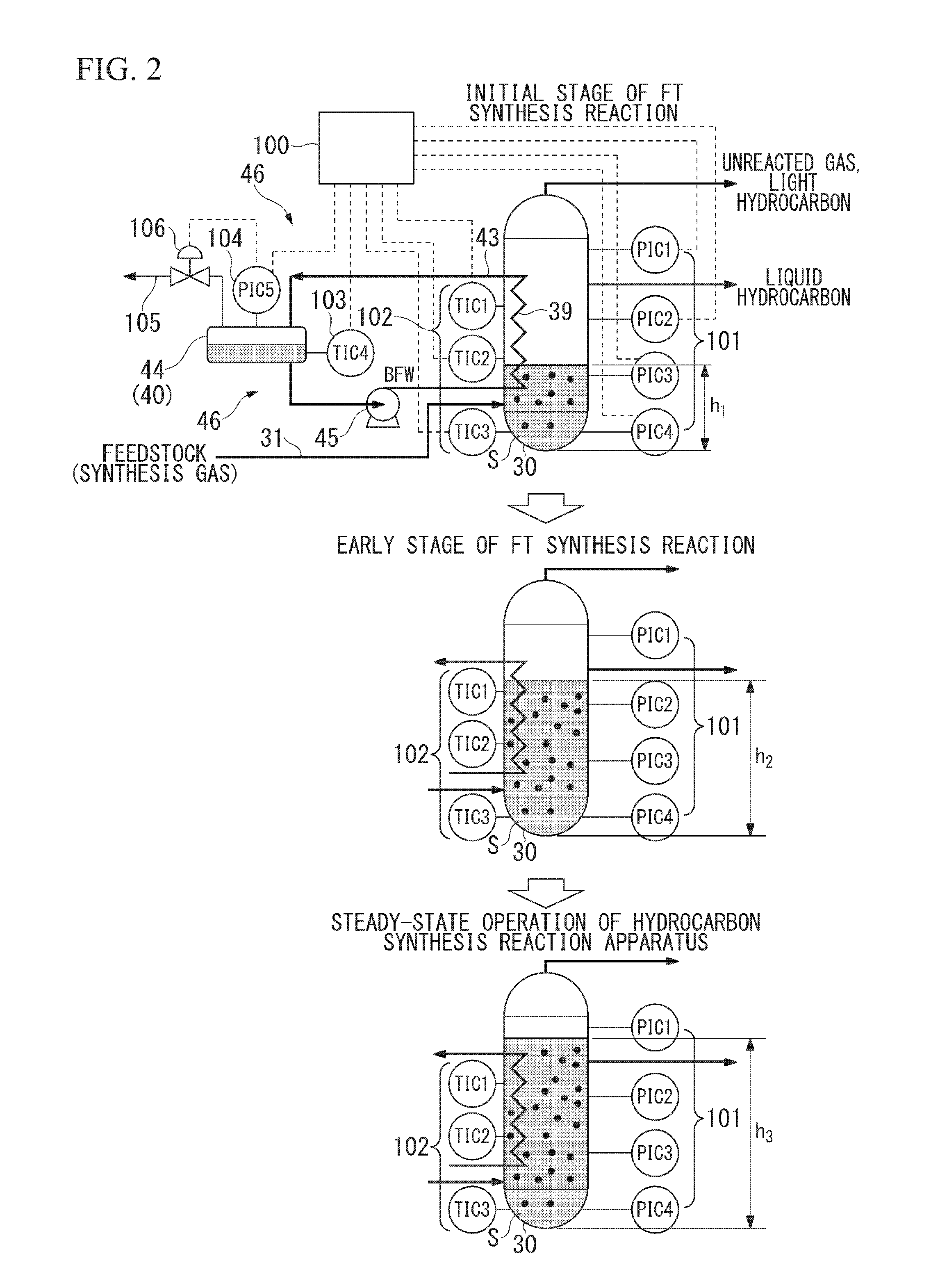

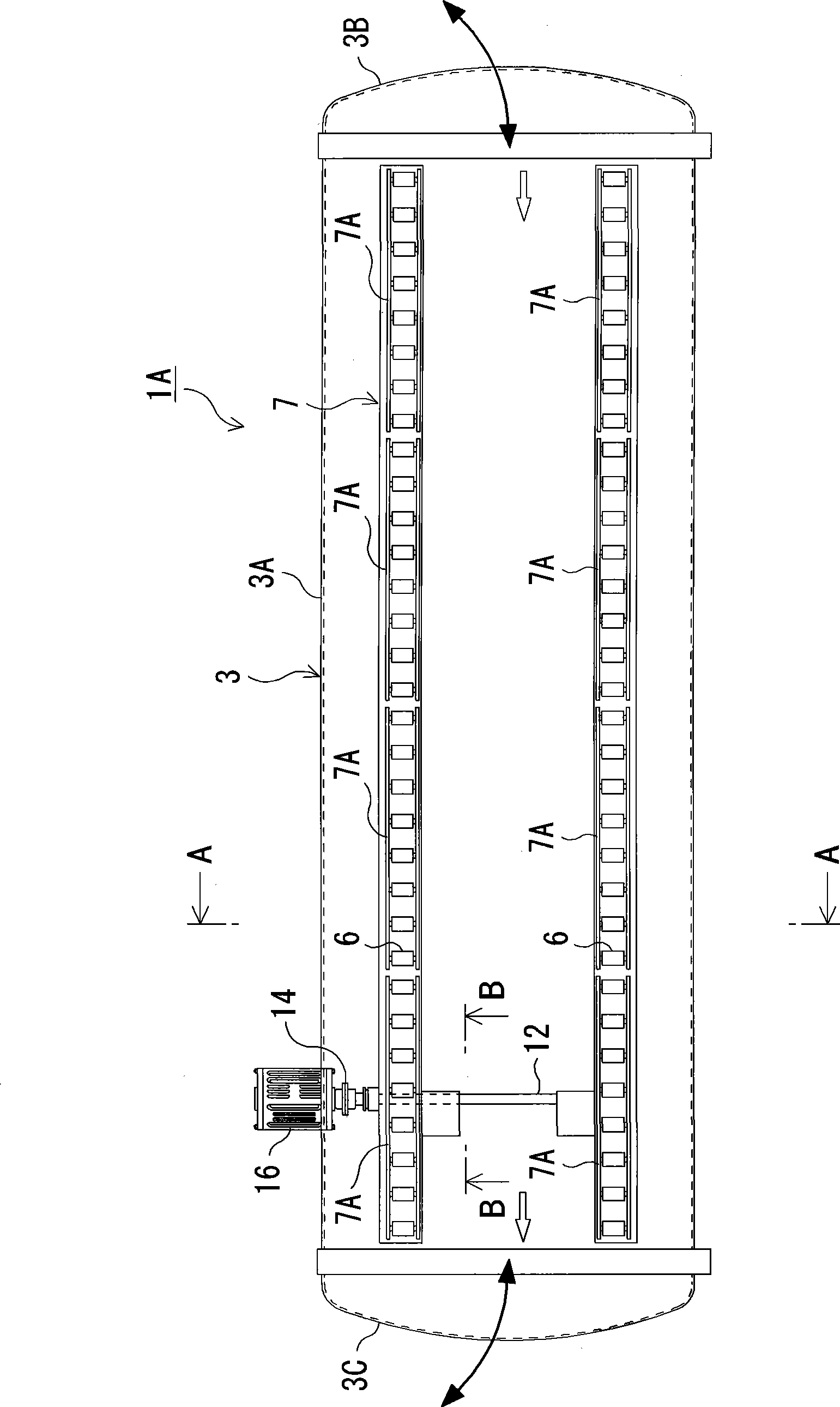

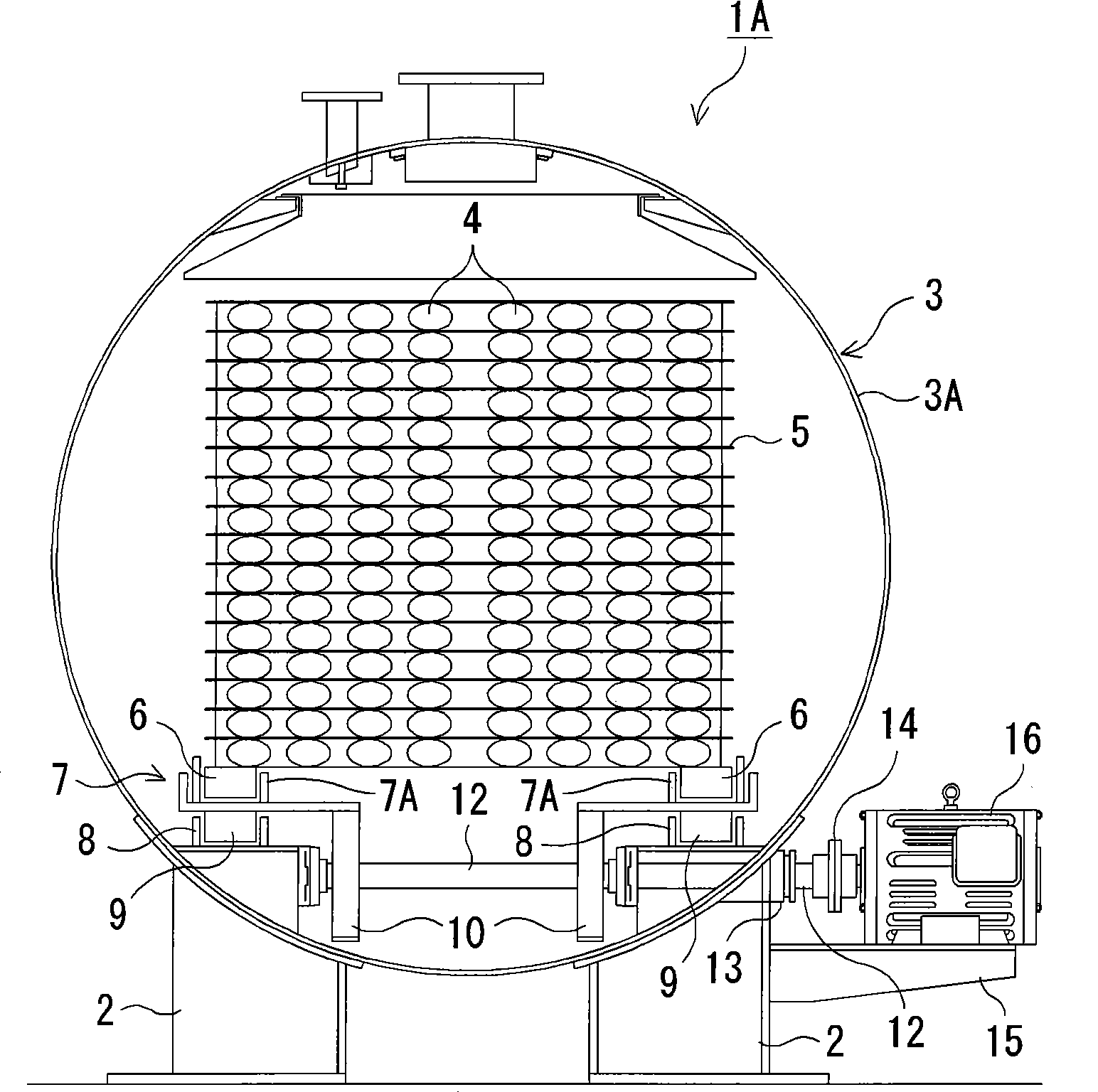

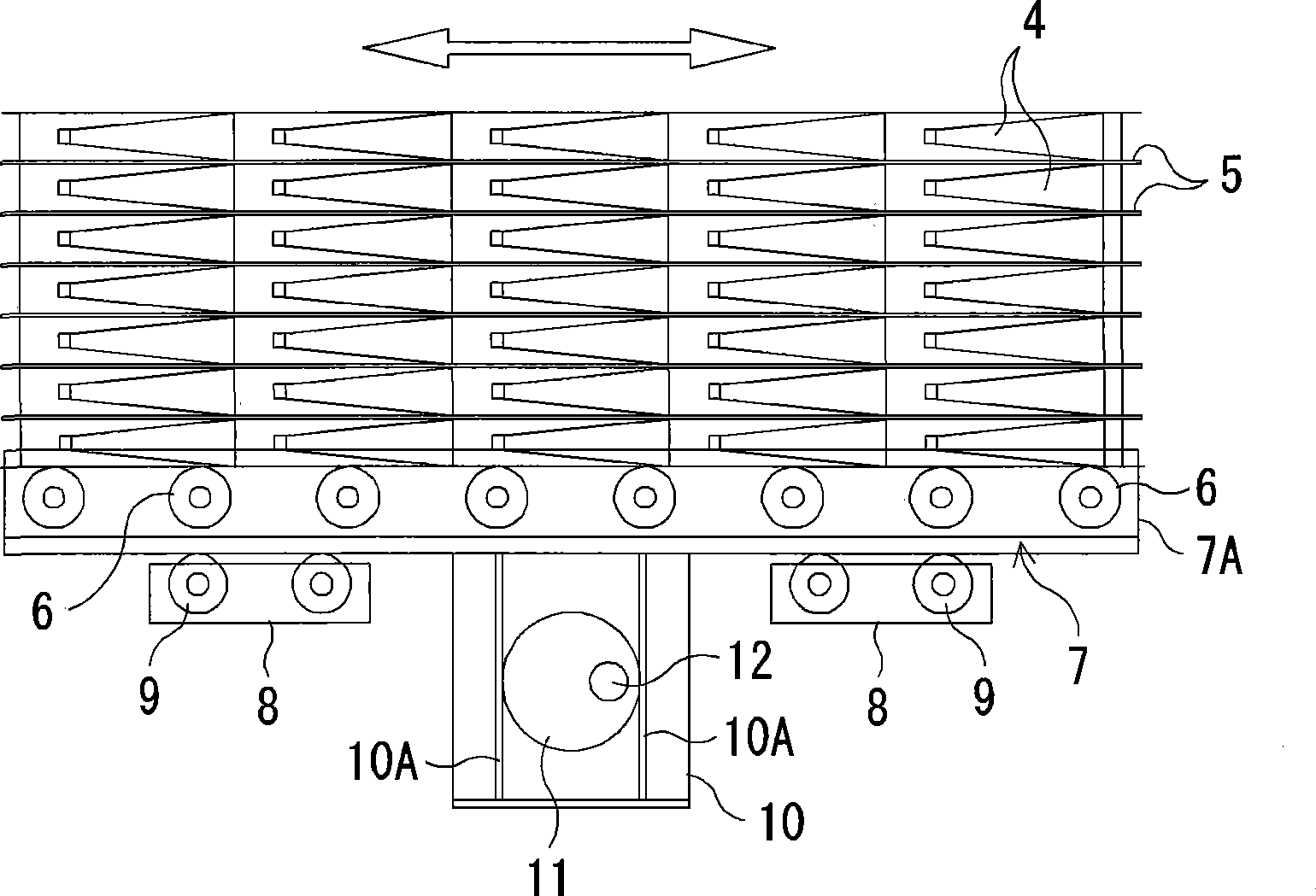

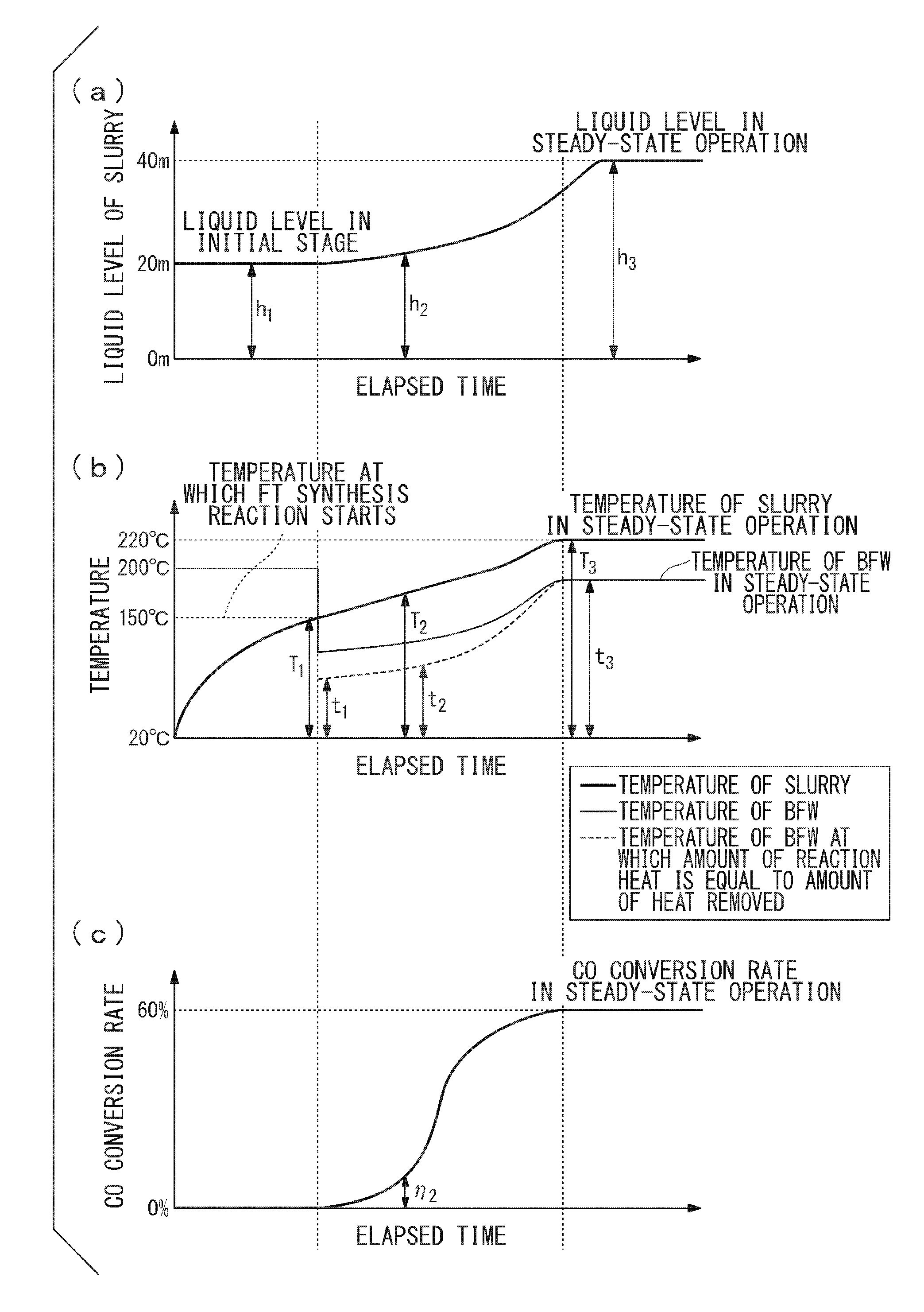

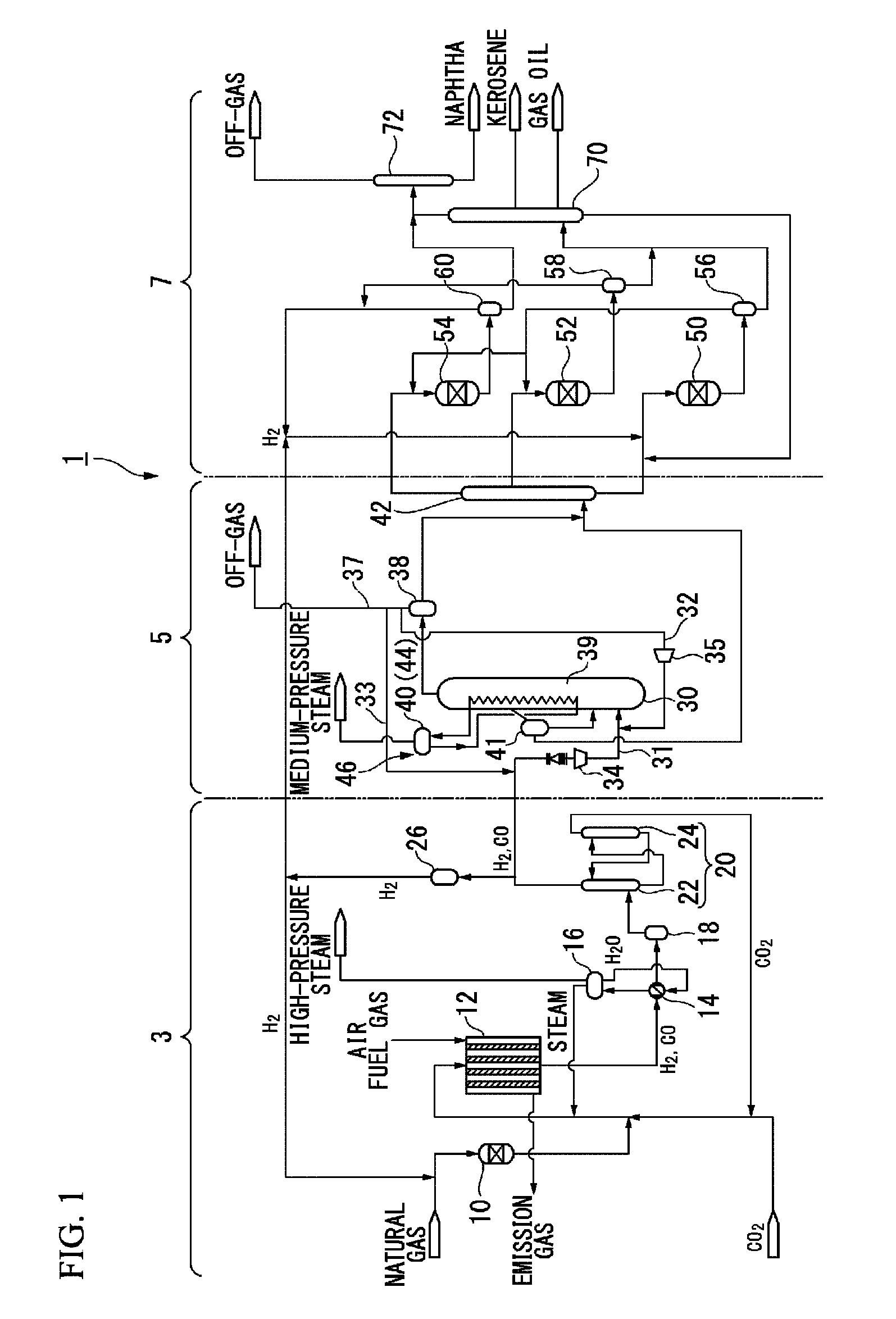

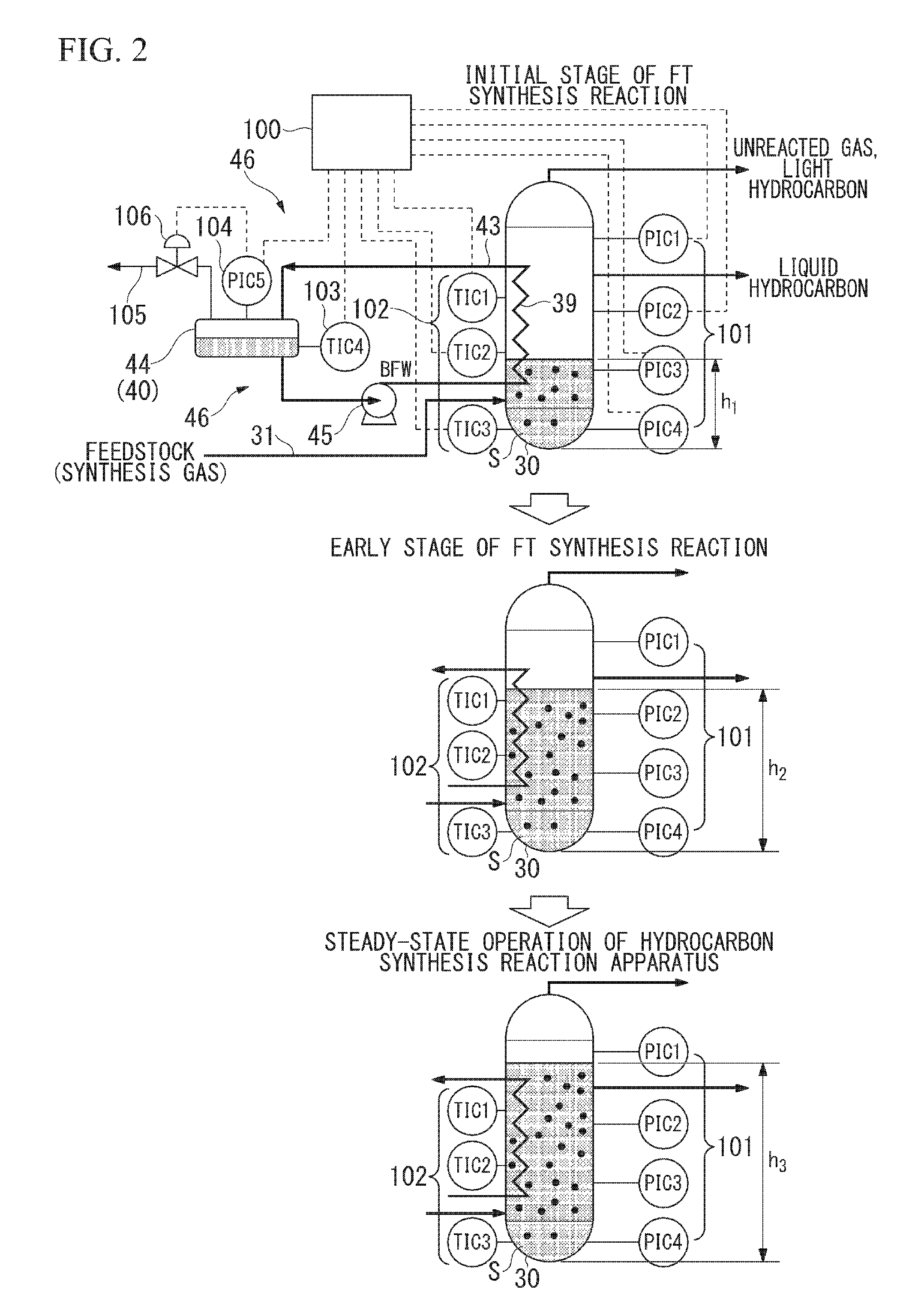

Start-up method of hydrocarbon synthesis reaction apparatus

ActiveUS20150267123A1Reduce startup timeReduce lossesOrganic compound preparationOxygen compounds preparation by reductionSlurryStart up

A start-up method for a hydrocarbon synthesis reaction apparatus, comprising: an initial slurry-loading step in which the slurry is loaded into the reactor at the initial stage of the Fischer-Tropsch synthesis reaction at a lower loading rate than that applied to the reactor in a steady-state operation; and a CO conversion ratio-increasing step in which the liquid level of the slurry in the reactor is raised by adding to the slurry the hydrocarbons synthesized at the early stage of the Fischer-Tropsch synthesis reaction so that the CO conversion ratio is increased in proportion to a rise in the liquid level of the slurry in the reactor.

Owner:JAPAN OIL GAS & METALS NAT CORP +5

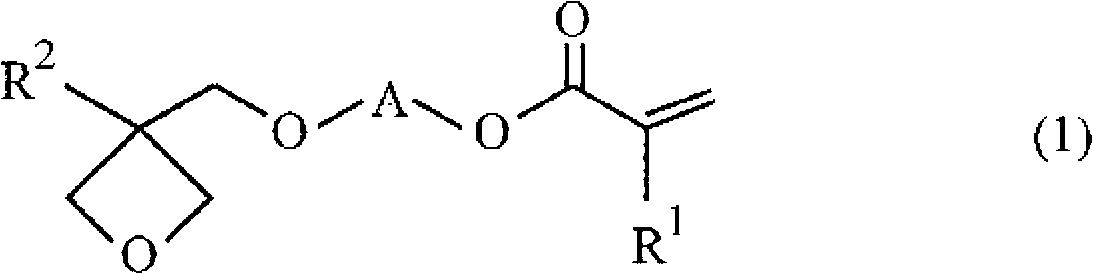

Radical polymerizable resin, radical polymerizable resin composition, and cured product thereof

Provided is a radical polymerizable resin which has a low viscosity, has excellent workability, rapidly cures by exposure to heat and / or light, and forms a cured product having excellent pliability and heat resistance. A radical polymerizable resin composition is obtained by cation polymerization of an oxetane ring-containing (meth)acrylic acid ester compound represented by formula (1) (where R1 is a hydrogen atom or a methyl group, R2 is a hydrogen atom or an alkyl group, and A is a C4-20 straight-chain or branched-chain alkylene group) alone or together with another compound having cation polymerizability.

Owner:DAICEL CHEM IND LTD

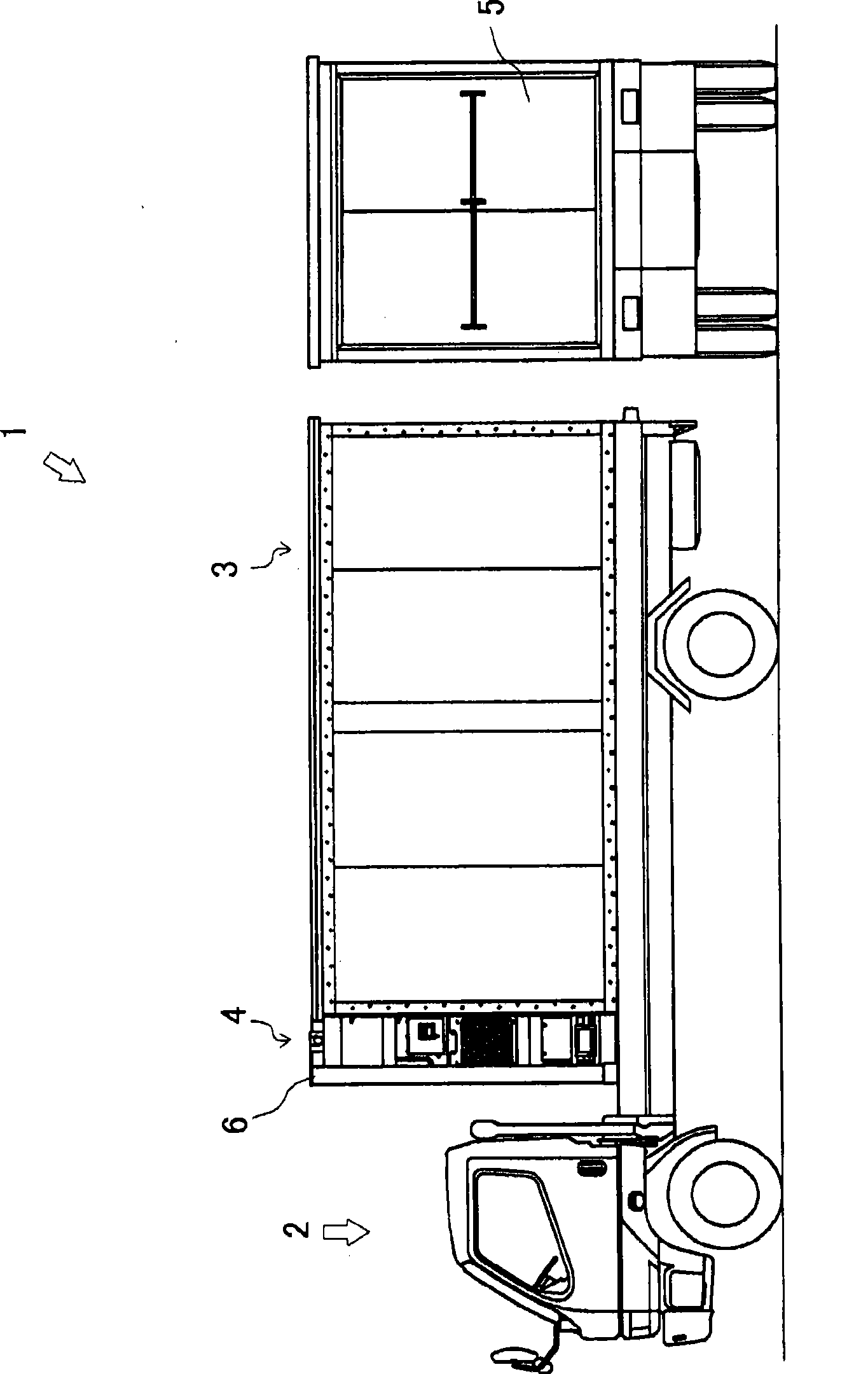

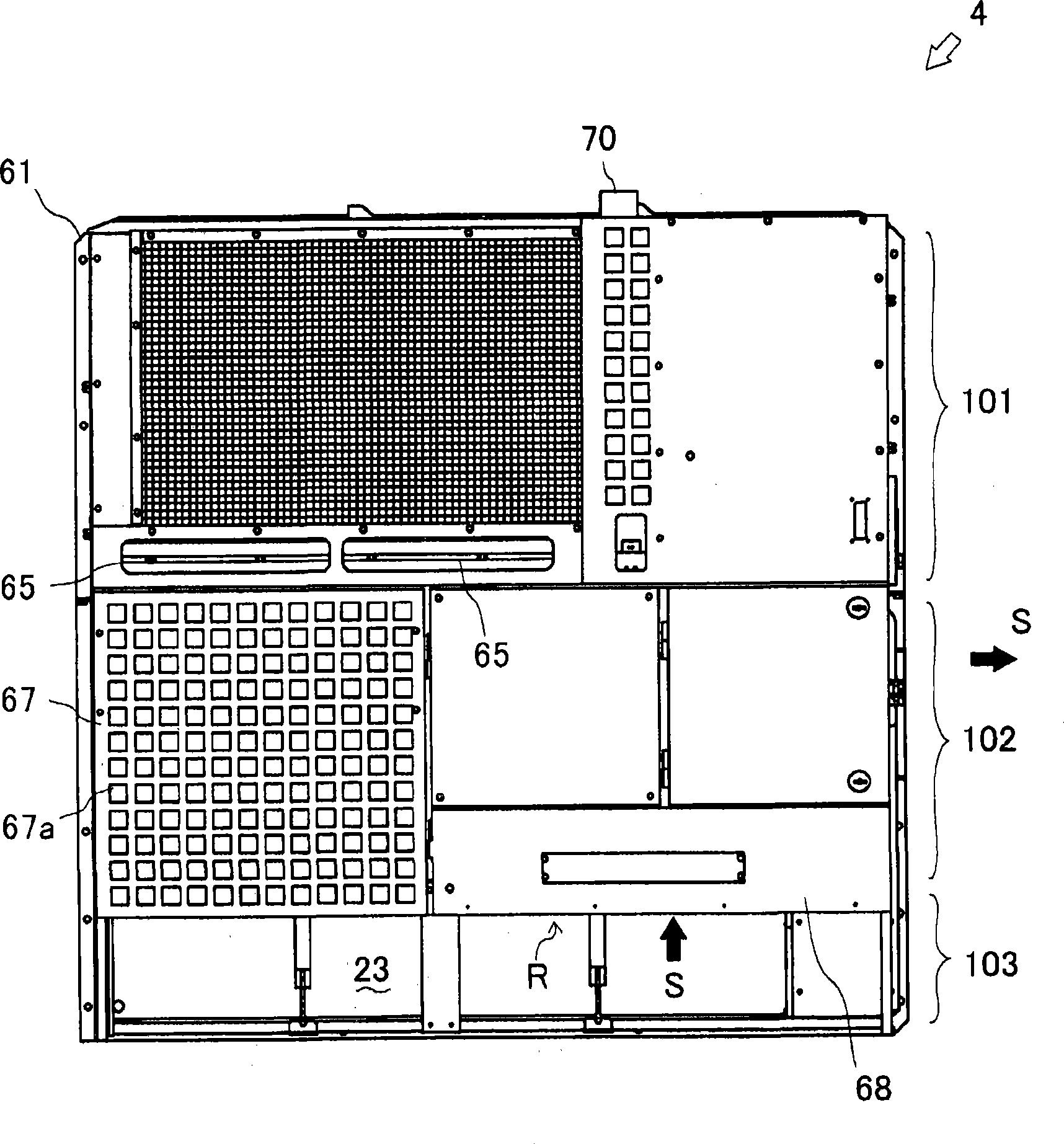

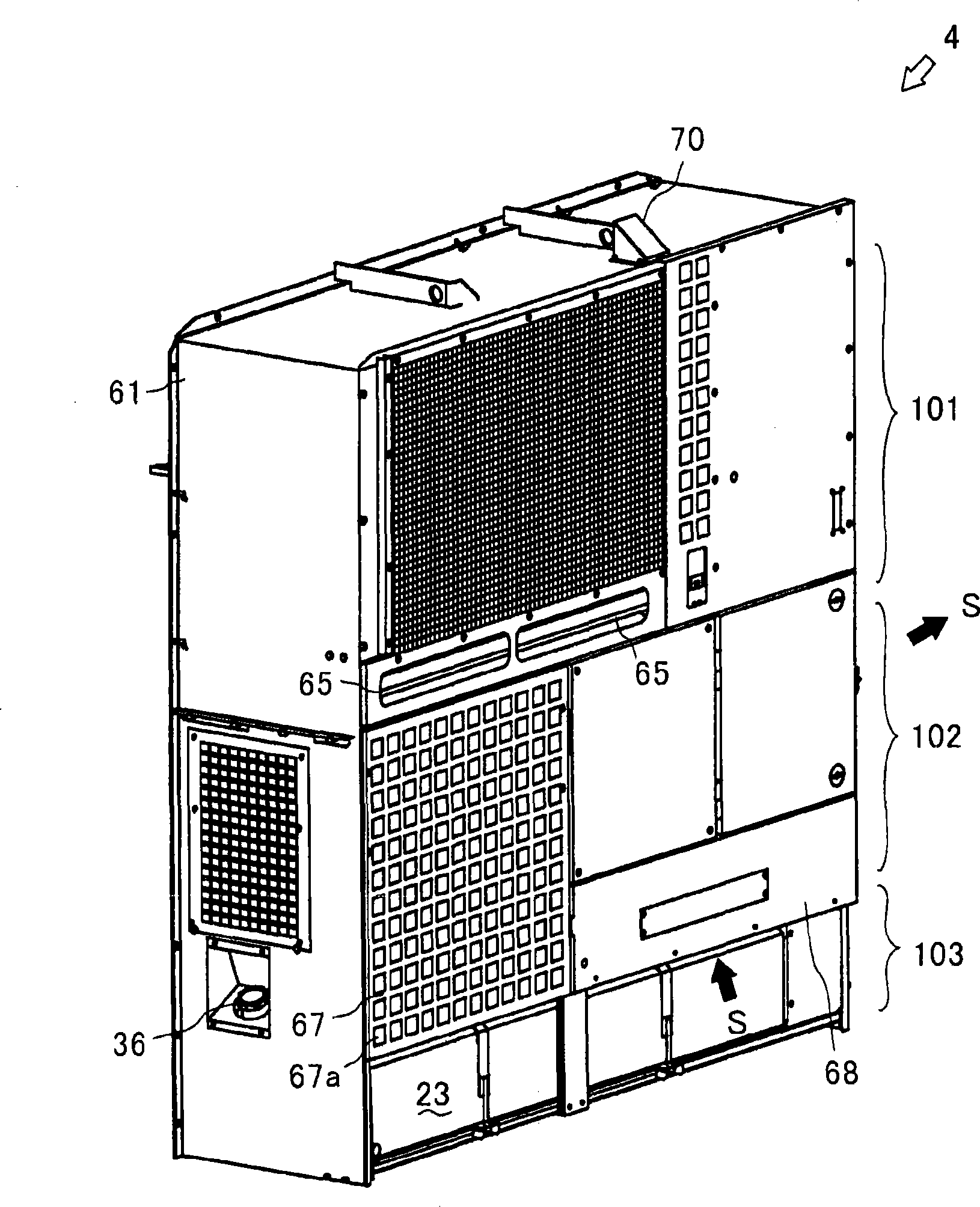

Refrigerating container

InactiveCN101501424AInhibition heightRestrain encroachmentDomestic refrigeratorsRefrigeration machinesFuel tankEngineering

A refrigerating container (1) in which the temperature in a container (3) is controlled by a refrigerating unit (4) in which a refrigerant is circulated by a compressor (11). One of the drive sources of the refrigerating unit (4) is an engine (22). To install a fuel tank (23) for the engine (22) into the refrigeration unit, the refrigerating unit (4) is divided into three parts arranged in the height direction. Heat exchangers of the refrigerating unit (4) and fans for them are disposed at the upper part (101), the engine (22) and a refrigerant device of the refrigerant unit (4) are disposed at the center part (102), and the fuel tank (23) is disposed at the lower part (103). Consequently, the entire devices including the engine and the fuel tank are efficiently arranged to realize efficient oil supply and maximized fuel tank capacity.

Owner:YANMAR CO LTD

Method for preparation of luminescent glass ceramic with low-melting point glass powder

ActiveCN109721250ALower glass transition temperaturePrevent thermal deteriorationGlass shaping apparatusLight fasteningsPhosphorFree cooling

The invention discloses a method for preparation of luminescent glass ceramic with low-melting point glass powder. The method includes: mixing bulk drugs evenly, and performing melting at 300-700DEG Cfor 15-90min to obtain molten glass; subjecting the molten glass at 300-700DEG C to quenching, and performing natural cooling to room temperature to obtain bulk glass; crushing the bulk glass, and putting the product into a ball mill for ball milling to obtain low-melting point glass powder. The low-melting point glass powder obtained by the method provided by the invention has low glass phase transition temperature, which is adjustable in the range of 200-500DEG C, is suitable for making of seal glass and vacuum components and packaging of LED, and is especially suitable for making of luminescent glass ceramic with phosphor powder material. The luminescent glass ceramic is especially suitable for laser illumination. Glass ceramic molds and sinters at a low temperature, can effectively avoid the thermal degradation of phosphor powder at high temperature, and has important application value in the field of laser lighting.

Owner:BINHAI IND RES INST OF TIANJIN UNIV CO LTD

Continuous annealing device

InactiveCN101407856APrevent thermal deteriorationLow costFurnace typesHeat treatment furnacesContinuous annealingSteel belt

A continuous annealing apparatus moves the steel belt in the annealing furnace from the entrance side of the annealing furnace to the outlet side to process continuous annealing to the steel belt, a guide component is provided outside the annealing furnace along the entrance side of the annealing furnace to the outlet side for guiding the steel belt to insert through the inner side of the annealing furnace, a guide gap is provided along the entrance side to the outlet side the of the annealing furnace for leading the guide component in the annealing furnace, and a sealing arrangement is provided for sealing the guide gap.

Owner:CHUGAI RO CO LTD

Sterilizing method and sterilizing apparatus for retorted product

InactiveCN101489423ASuppress slip frequencyIncreased freedom of choiceFood preservationHeatReciprocating motionEngineering

Provided is a sterilizing apparatus for retorted products, which can transfer the retorted products unidirectionally to and from a retort and which can heat and sterilize the retorted products homogeneously for a short time, while sliding a carriage carrying the retorted products reciprocally in the retort. The rotating motions of a rotating drive source (16) disposed on the outside portion of the retort (3) are transmitted through a shaft sealing mechanism (13) to a cam mechanism in the retort, and are converted into reciprocal motions by the cam mechanism and transmitted to the carriage (7) carrying the retorted products (4), so that the retorted products can be heated and sterilized while the carriage (7) being slid forward and backward or rightward and leftward of the retort.

Owner:TOYO SEIKAN KAISHA LTD

Sliding element, method of manufacturing the sliding element, and bearing device using the sliding element

ActiveCN102046992AEnables internal induction heatingLow costShaftsBearing componentsEngineeringMechanical engineering

A sliding element comprises a sliding surface member, a base made of a material different from that of the sliding surface member, a joining material layer which is disposed between the sliding surface member and the base and joins the sliding surface member and the base to each other, and a sheet member made of an electromagnetic induction heating material. The sliding surface member and the base are joined to each other by heating and melting the joining material layer by means of electromagnetic induction heating of the sheet member.

Owner:KK TOSHIBA

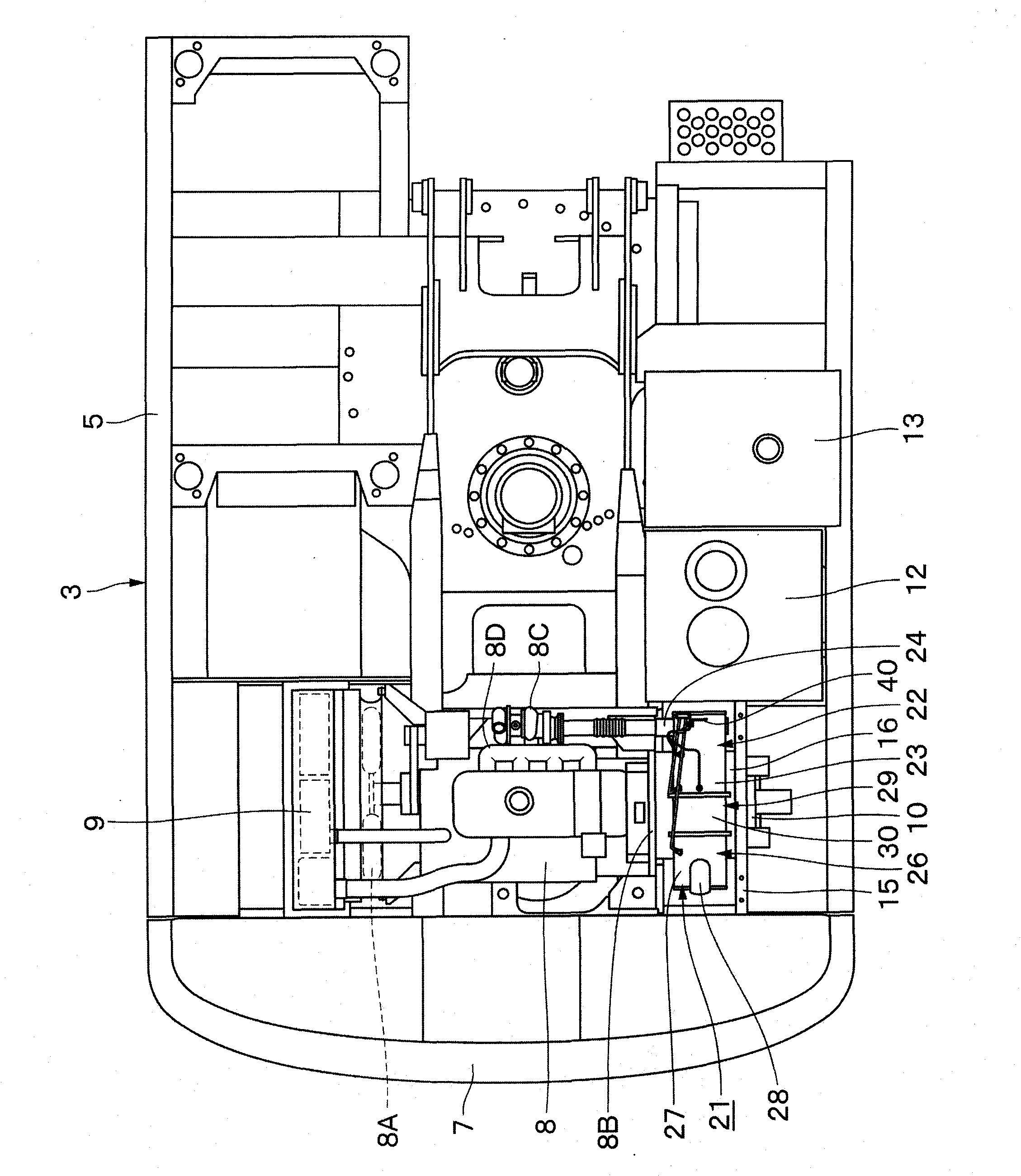

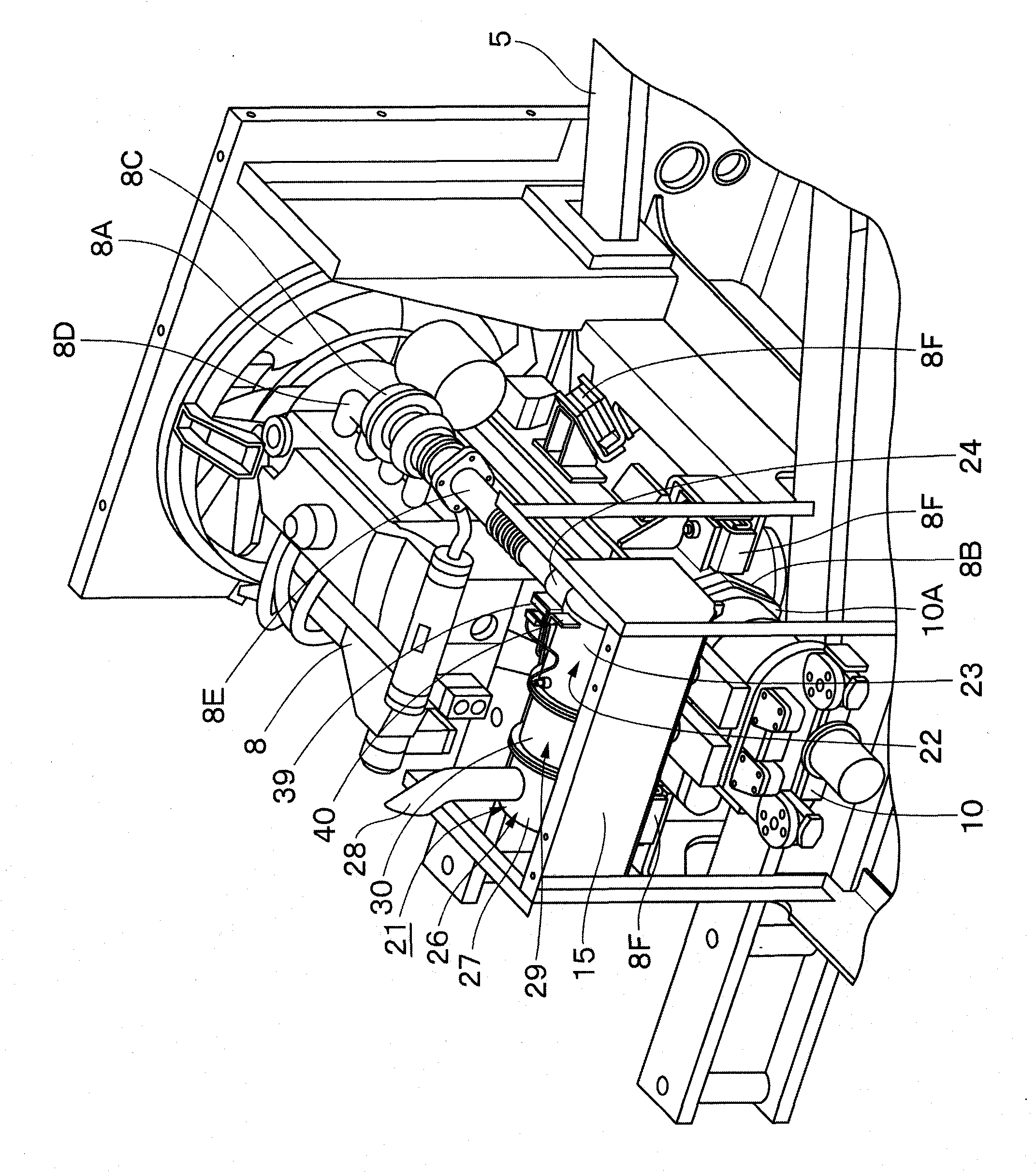

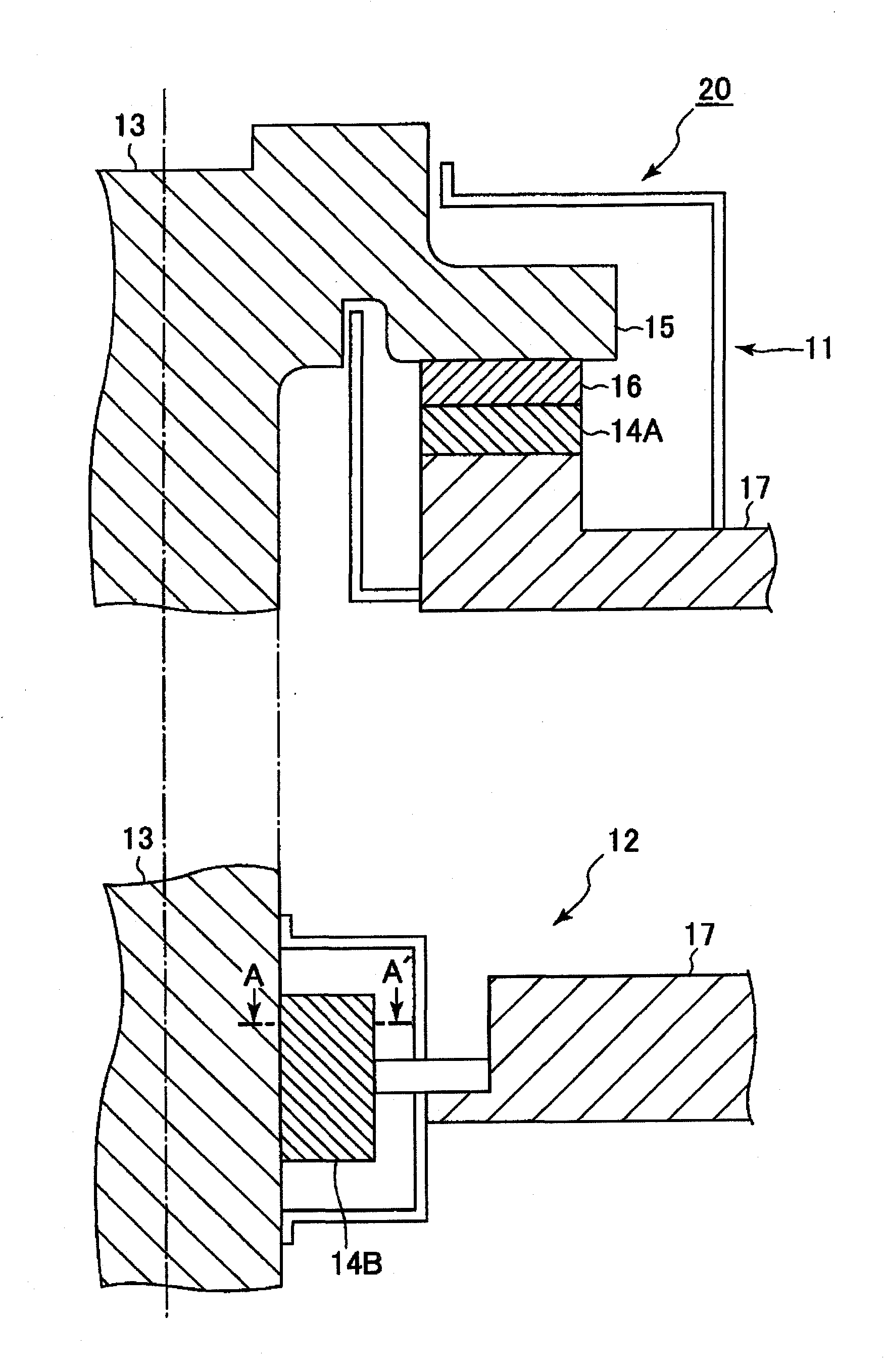

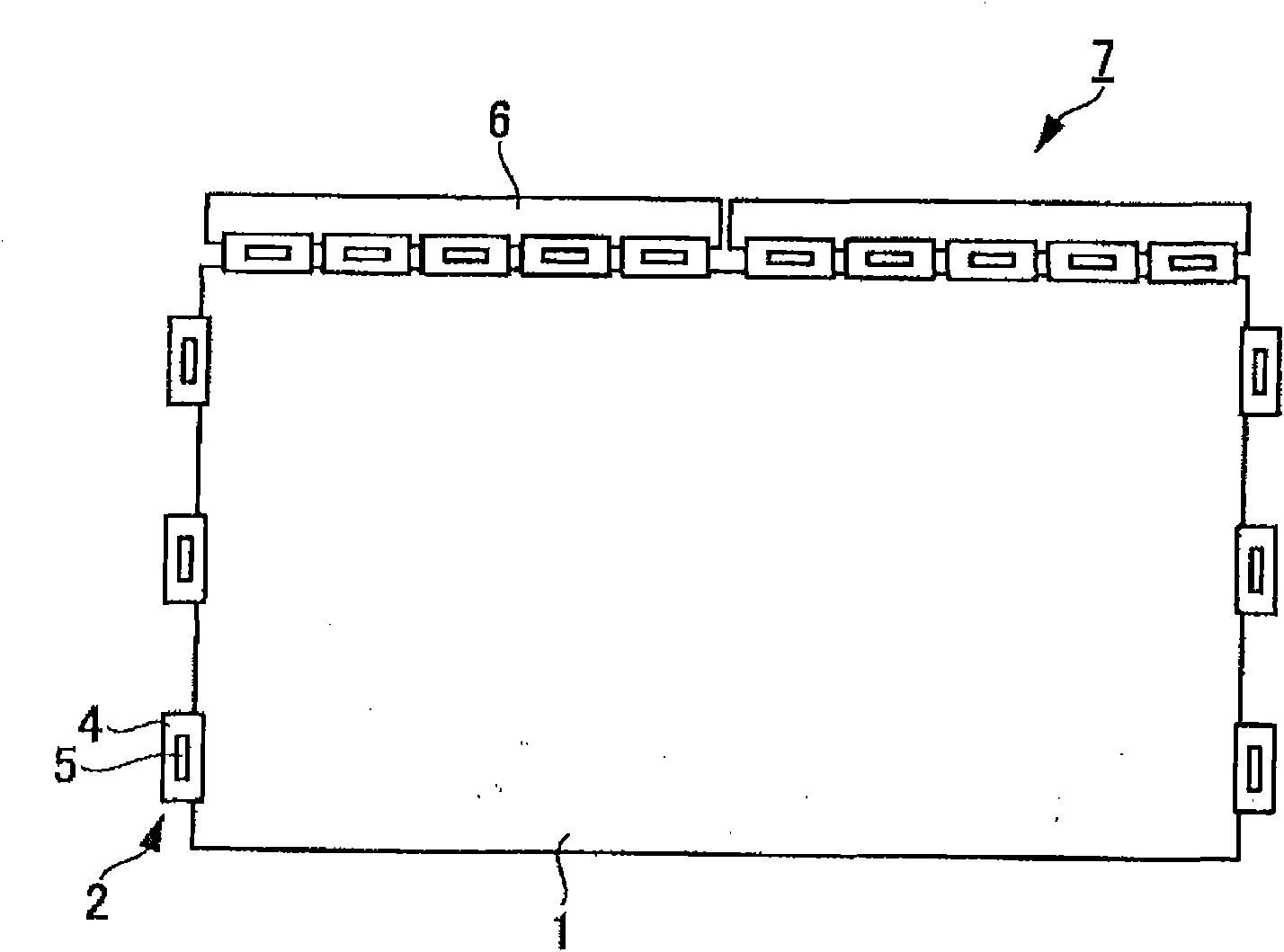

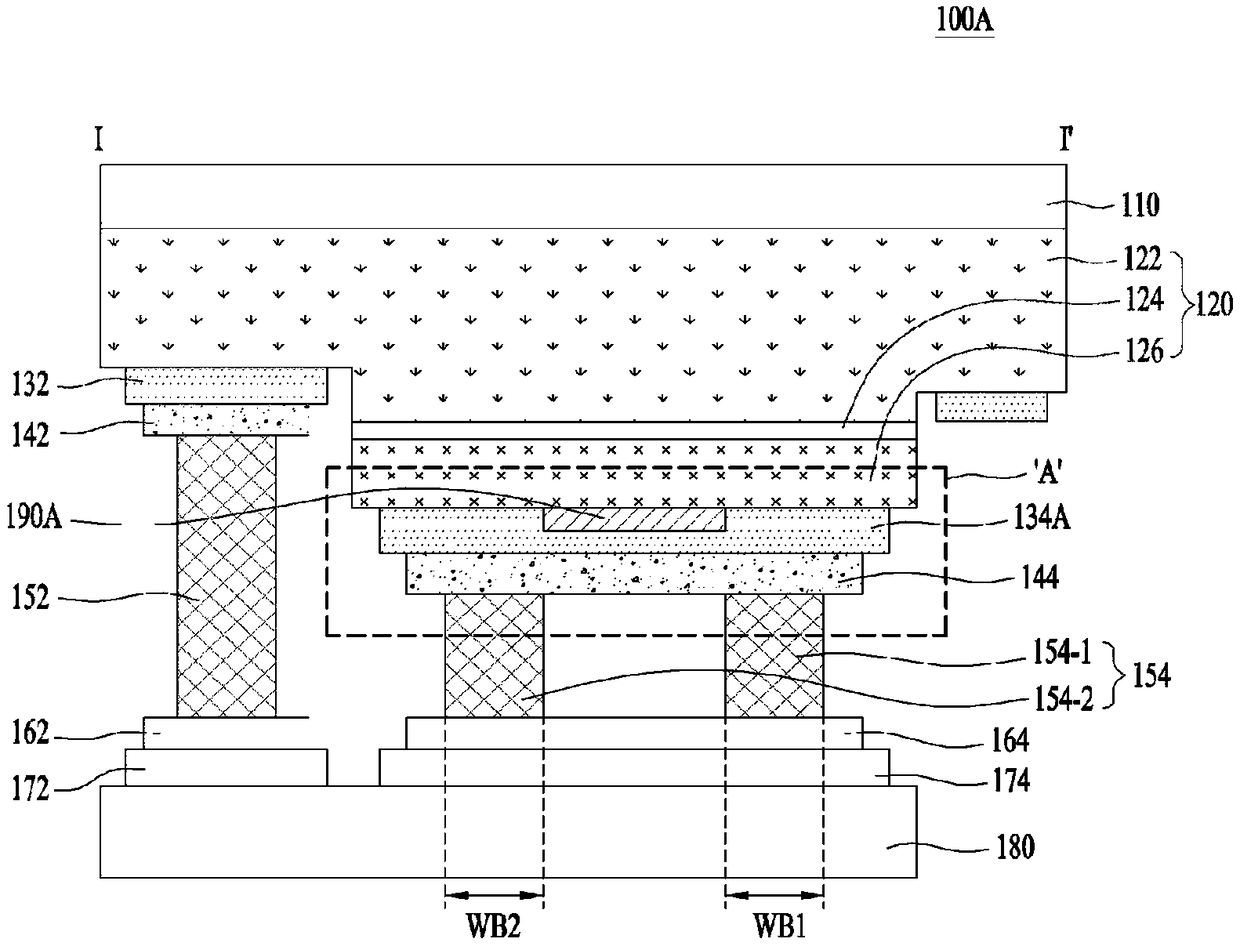

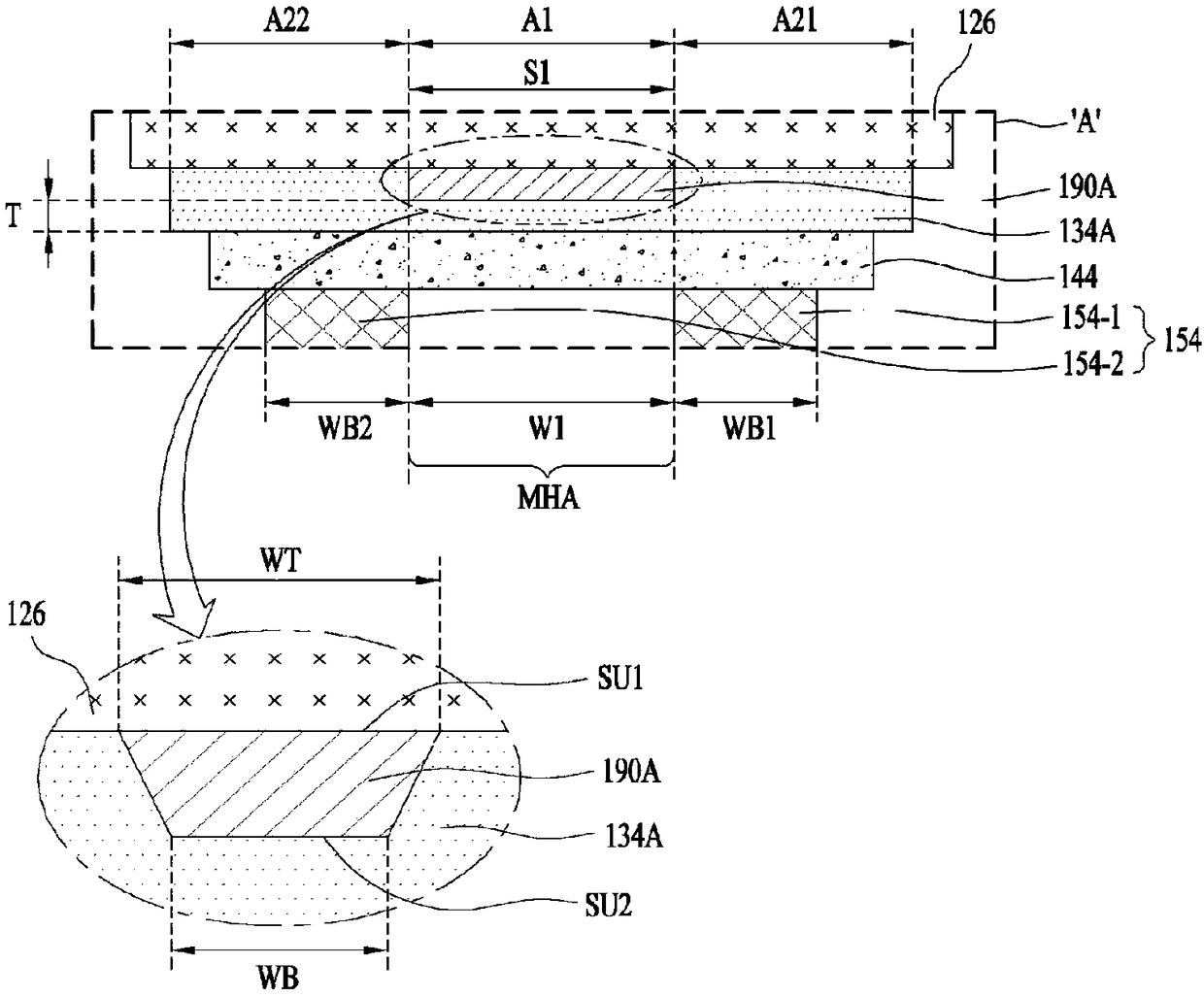

Assembling device and assembling method of FPD component

InactiveCN102142208AProtection from heatNot affected by heatIdentification meansAssembly lineElectrical and Electronics engineering

The invention provides an assembling device and an assembling method of a FPD component, wherein even if an ACF is pre-pasted on two sides of a TAB in the length direction, the hardening of an ACF on the other side can be prevented when one side is formally pressed. The assembly line for the FPD component comprises: an ACF pasting part, a pressing head (330), and a TAB-side heat insulating mechanism (340A). The ACF pasting part pastes a first ACF layer (3a1) on one side of the TAB (2) in the length direction, and pastes a second ACF layer (3a2) on the other side of the TAB (2) in the length direction. The pressing head (330) thermally presses the TAB (2) on a display substrate (1) with an interval of the first ACF layer (3a1). The TAB-side heat insulating mechanism (340A) protects the second ACF layer (3a2) of the TAB (2) from being affected by heat when the TAB (2) is thermally pressed on the display substrate (1).

Owner:HITACHI HIGH-TECH CORP

Zero-opening light-tight polymer composite sun-shading fabric and preparation process thereof

PendingCN110735214AUV resistantImprove self-cleaningProtective fabricsHeating/cooling textile fabricsPolymer sciencePolyvinyl chloride

The invention relates to the technical field of sun-shading fabrics, in particular to a zero-opening light-tight polymer composite sun-shading fabric and a preparation process thereof. The zero-opening light-tight polymer composite sun-shading fabric comprises warp yarns and weft yarns used for weaving a fabric with a compact void-free structure, wherein the warp yarns comprise warp cores and warpelastic coating layer coating the warp cores; the weft yarns comprise weft cores and weft elastic coating layers coating the weft cores; the density of the weft yarns is 16-23 yarns / cm; and the warpelastic coating layers and the weft elastic coating layers both comprise polyvinyl chloride resin powder with a polymerization degree of 1000-1100, extinction polyvinyl chloride resin powder, an ultraviolet absorbent, a toner and the rest of auxiliary agents. The zero-opening light-tight polymer composite sun-shading fabric has better toughness, enables the warp yarns and weft yarns to be tighterin the weaving process to form a zero-opening structure, is not easy to deform after long-term use, is still tight between the warp yarns and the weft yarns due to external force breakage, has extremely high structural stability and opaque function, is durable, and does not have multiple defects of coatings, so that the fabric has a wide application prospect.

Owner:温多利遮阳材料(德州)股份有限公司

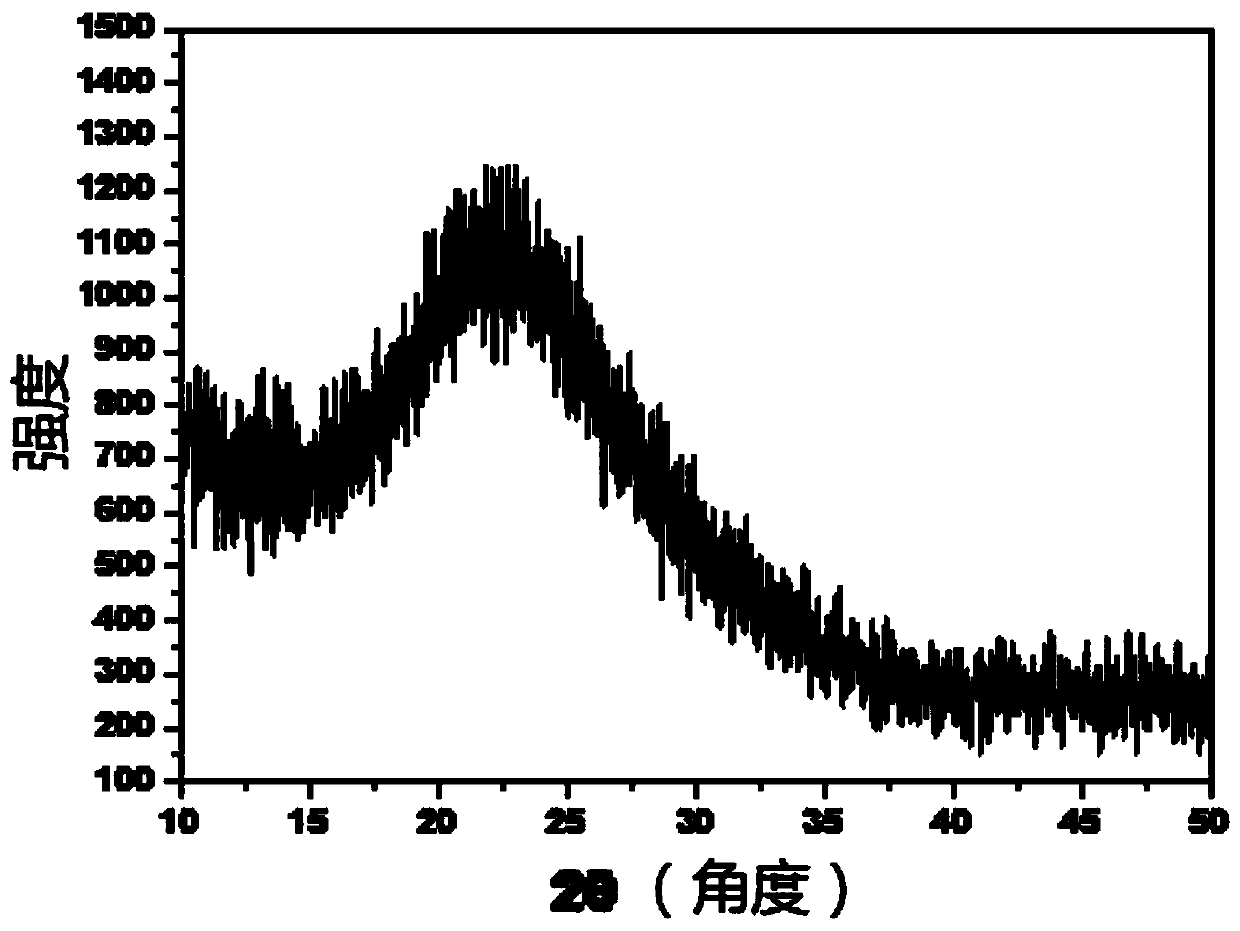

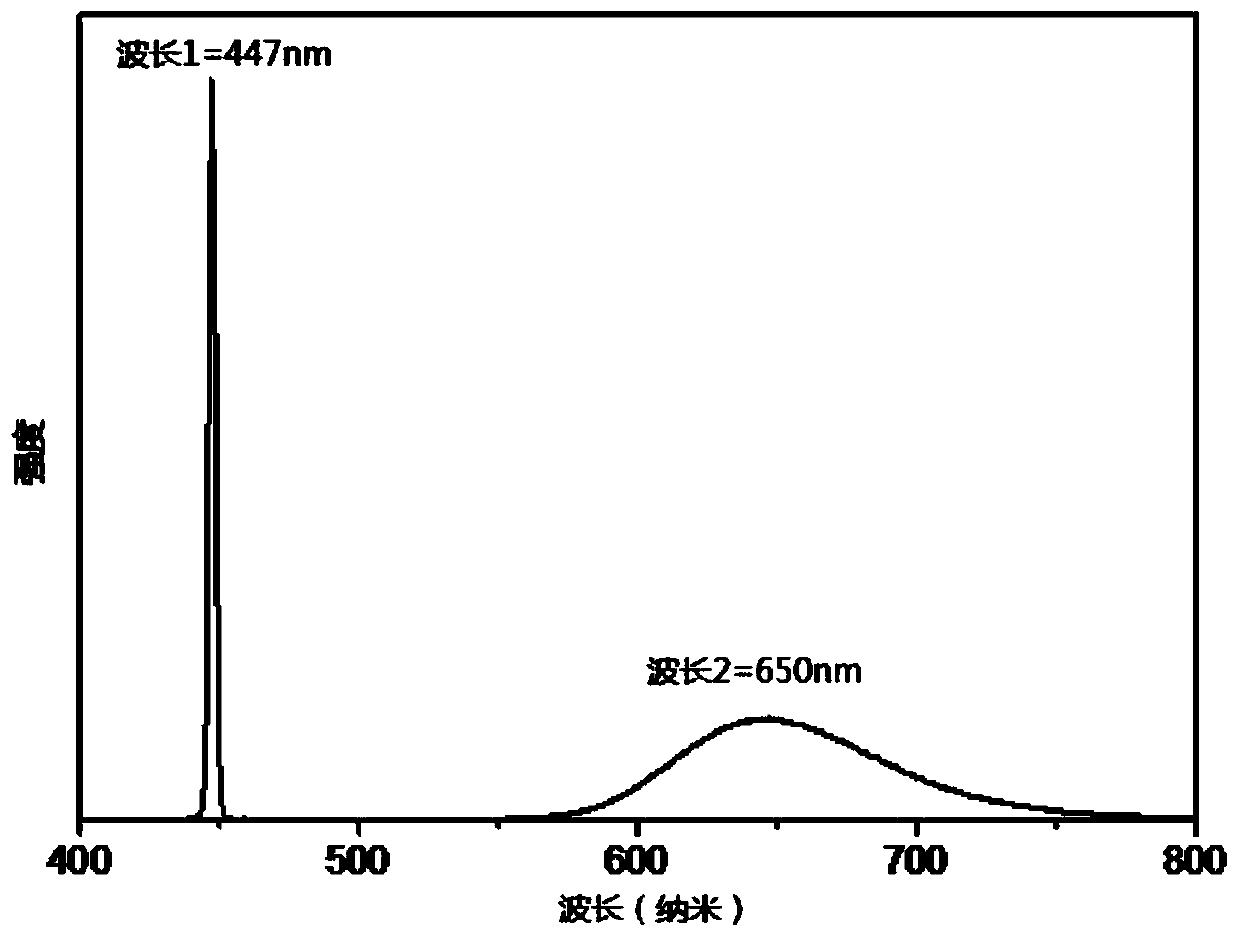

Fluorescent glass ceramic based on low-melting-point glass powder and preparation method thereof

The invention discloses a fluorescent glass ceramic based on low-melting-point glass powder and a preparation method thereof. The method includes the steps of: mixing SnCl2, P2O5, Na2O, a glass structure and a phase change adjustment component evenly, then performing melting at 300-800DEG C for 30-90min to obtain molten glass, placing the molten glass in a die for annealing to obtain transparent glass, crushing the transparent glass and conducting ball-milling to obtain the low-melting-point glass powder. The low-melting-point glass powder provided by the invention has a phase transition temperature of 270-500DEG C and a lower glass phase transition temperature. The low-melting-point glass powder not only has good structural stability and chemical stability, but also has a refractive indexmatching that of phosphor powder, and reduces light scattering loss.

Owner:BINHAI IND RES INST OF TIANJIN UNIV CO LTD

Process technique for high-rotational speed injection made gear

The invention relates to the gear processing field, in particular to a processing technology of a high-speed injection gear, sensing devices are arranged in a gear die and a gear forming machine, various data indications in the gear processing procedure are measured and counted in time, and the gear processing procedure is controlled according to the data indications, thereby producing the high-speed injection gear with high precision, low cost, and long service life.

Owner:TOHKATSU PLASTIC TIANJIN

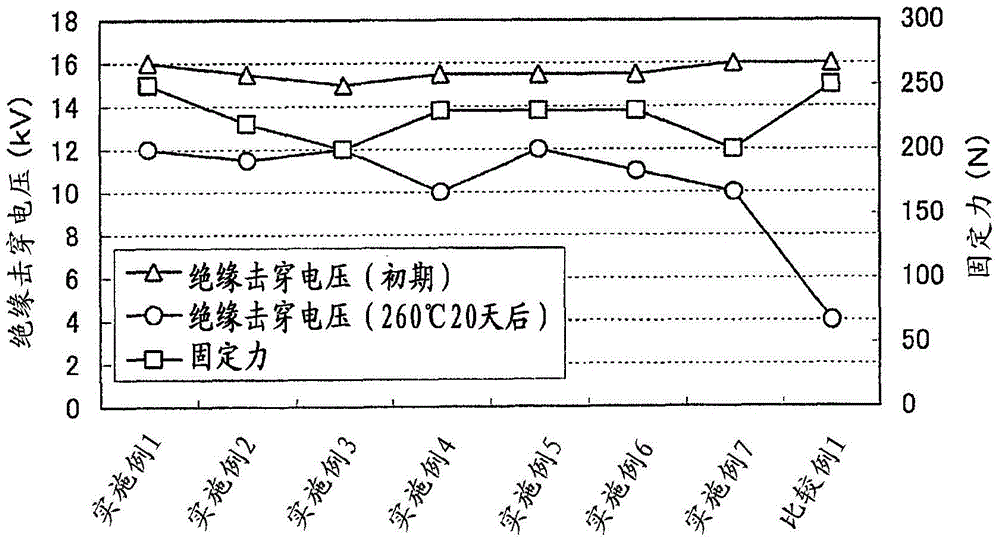

Stator coil for rotating electric machine, method for manufacturing said stator coil, and rotating electrical machine

InactiveCN104995822AEasy to fixPrevent thermal deteriorationWindings insulation materialWindings insulation shape/form/constructionElectric machineStator coil

The present invention provides a stator coil for a rotating electrical machine comprising a stator core and a coil formed by winding an enamel wire in a slot of the stator core, wherein the stator coil is characterized in that the enamel wire is coated with a cured substance of a first insulation wax containing a polyester resin, and the coil is coated with a cured substance of a second insulation wax containing epoxy acrylate resin. The stator coil for a rotating electrical machine has a high fixing strength of an insulating layer, is capable of preventing thermal deterioration of the enamel wire, and has favorable pressure resistance over a long period of time.

Owner:MITSUBISHI ELECTRIC CORP

Magnetic rubber composition for encoder

InactiveUS20050004286A1Improve bonding propertiesPrevent thermal deteriorationSpecial tyresMixingMetalMagnetic characteristic

A magnetic rubber composition for encoder having a magnetic characteristic in sufficient application range, used as encoder after magnetization as well as heat resistance, water resistance and oil resistance required for use as encoder, and excellent processing property, and capable of being bonded by vulcanization with a metal, is provided. Furthermore, a magnetic rubber composition for encoder capable of obtaining sufficient magnetic force required for encoder on a circumference of the molded encoder as well as capable of effectively restraining variation of the level of magnetic force, is provided. It is provided by comprising 300 to 1,800 parts of strontium-ferrite, or 300 to 1,800 parts of barium-ferrite, or 300 to 1,800 parts of a mixture of strontium-ferrite and barium-ferrite, 0.5 to 2 parts of silane coupling agent, and 1 to 10 parts of lubricating agent, per 100 parts of a hydrogenated nitrile butadiene rubber with 15 to 50% of acrylonitrile amount and 80 to 99% of hydrogenation ratio.

Owner:YAMAGUCHI YOSHIHIKO

Light emitting diode

ActiveCN108701739AImprove reliabilityPrevent thermal deteriorationSolid-state devicesSemiconductor devicesActive layerLight-emitting diode

A light emitting diode of embodiments comprises: a substrate; a light emitting structure disposed below the substrate and including a first conductive semiconductor layer, an active layer, and a second conductive semiconductor layer; a sub mount disposed opposite to the substrate; a first and second metal pad disposed apart from each other over the sub mount; a first bump disposed over the first metal pad; a plurality of second bumps disposed apart from each other over the second metal pad; a first ohmic layer disposed between the first conductive semiconductor layer and the first bump; a second ohmic layer disposed between the second conductive semiconductor layer and the plurality of second bumps; a first spread layer disposed between the first ohmic layer and the first bump; a second spread layer disposed between the second ohmic layer and the plurality of second bumps; and a current blocking layer disposed at the maximum heat emitting portion of the second ohmic layer overlapping the space between the plurality of second bumps in the thickness direction of the light emitting structure without severing the second ohmic layer in a horizontal direction that intersects the thickness direction.

Owner:NINGBO PURPLE CORE TECH CO LTD

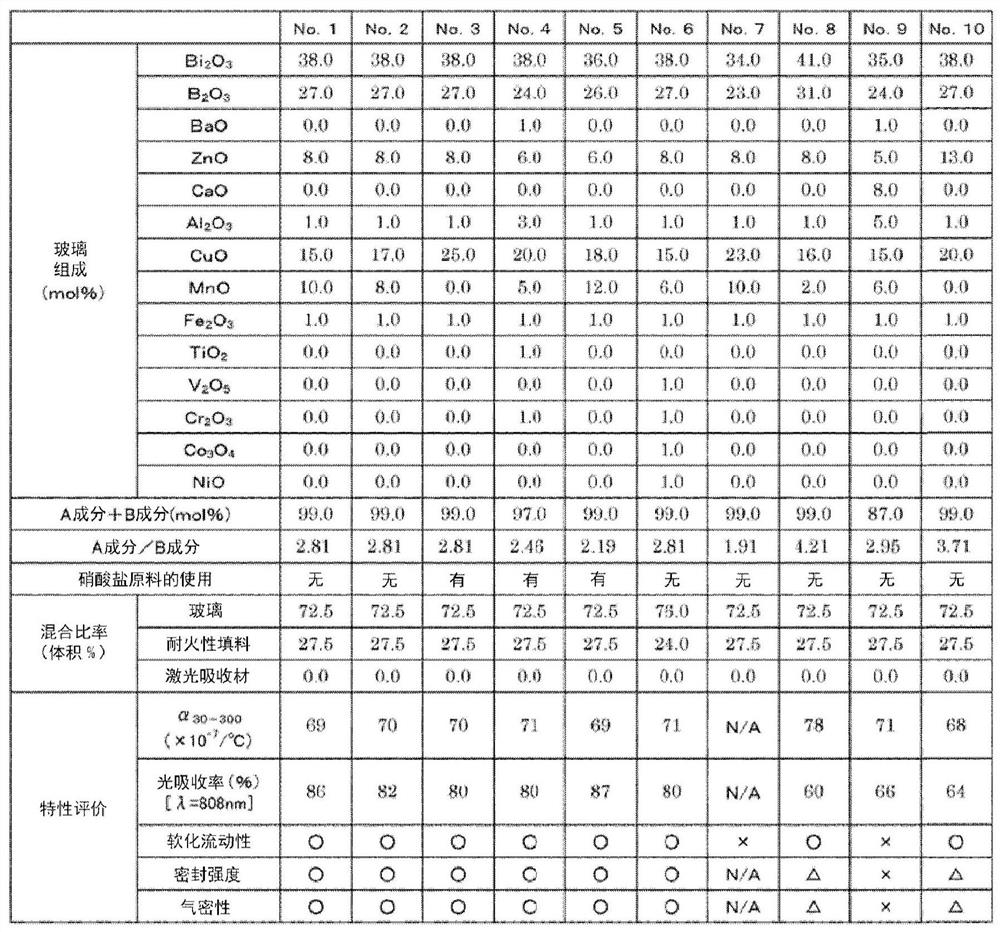

Low-melting point glass powder and glass ceramics for laser lighting made therefrom

ActiveCN106587641BLower glass transition temperaturePrevent thermal deteriorationLight fasteningsSemiconductor devices for light sourcesPhosphorRoom temperature

The invention discloses a low-melting-point glass powder and glass ceramics for laser lighting produced therefrom. The preparation method of the low-melting-point glass powder is as follows: uniformly mixing raw materials and melting at 300-700°C for 15-90 minutes to obtain molten glass ; Quenching the molten glass at 300-700°C, and naturally cooling to room temperature to obtain bulk glass; pulverizing the bulk glass and putting it into a ball mill to obtain low-melting-point glass powder. The low-melting-point glass powder of the present invention has Low glass phase transition temperature, and its glass phase transition temperature can be adjusted in the range of 200-500 ° C, suitable for the production of sealing glass and vacuum components and LED packaging, especially suitable for the production of luminous glass with phosphor materials Ceramics, the luminescent glass ceramics are especially suitable for laser lighting. Forming and sintering glass ceramics at a relatively low temperature can effectively avoid thermal degradation of phosphors at high temperatures, and has important application value in the field of laser lighting.

Owner:BINHAI IND RES INST OF TIANJIN UNIV CO LTD

Method for extracting marine nutrients by using both ultramicro grinding and supercritical carbon dioxide extraction

InactiveCN110575680AFacilitated releaseHigh extraction rateSolid solvent extractionAlcoholTert-Butylhydroquinone

The invention relates to the technical field of biological extraction, in particular to a method for extracting marine nutrients by using both ultramicro grinding and supercritical carbon dioxide extraction. The method comprises the following steps: feeding a marine product to be extracted into an ultramicro grinder for smashing to obtain marine product powder; and mixing, in parts by mass, 100 parts of the marine product powder and 0.05-0.2 part of tert-butylhydroquinone, then feeding the obtained mixture into a supercritical carbon dioxide extraction kettle, and carrying out extraction at apressure of 30-40 MPa and a temperature of 40-60 DEG C for 2-4 h under the conditions that absolute ethyl alcohol with a flow of 5-8 L / h serves as a carrying agent and the flow of carbon dioxide is 400-500 L / h. According to the method, the manner of performing ultramicro grinding at first and performing supercritical carbon dioxide extraction next is adopted, so the obtained superfine powder is infull contact with a supercritical carbon dioxide fluid, good extraction effect is obtained, other impurities are not introduced, and the thermal degradation of an extract at high temperature is avoided. Meanwhile, the nutrient substances of the marine product are wrapped and protected by tert-butylhydroquinone before extraction, so the nutrient substances are prevented from deterioration and damage during extraction, and the integrity of the nutrient substances can be guaranteed.

Owner:福建启元堂生物技术有限公司

Start-up method of hydrocarbon synthesis reaction apparatus

ActiveUS9404047B2Reduce startup timeReduce lossesOxygen-containing compound preparationOrganic compound preparationSlurryFluid level

A start-up method for a hydrocarbon synthesis reaction apparatus, comprising: an initial slurry-loading step in which the slurry is loaded into the reactor at the initial stage of the Fischer-Tropsch synthesis reaction at a lower loading rate than that applied to the reactor in a steady-state operation; and a CO conversion ratio-increasing step in which the liquid level of the slurry in the reactor is raised by adding to the slurry the hydrocarbons synthesized at the early stage of the Fischer-Tropsch synthesis reaction so that the CO conversion ratio is increased in proportion to a rise in the liquid level of the slurry in the reactor.

Owner:JAPAN OIL GAS & METALS NAT CORP +5

Bismuth-based glass, manufacturing method of bismuth-based glass, and sealing material

The bismuth-based glass of the present invention is characterized by containing Bi in terms of the following mol % in terms of oxides: 2 o 3 25-45%, B 2 o 3 20-35%, 90-100% (excluding 90%) of Bi 2 o 3 +B 2 o 3 +BaO+ZnO+CuO+MnO+Fe 2 o 3 +TiO 2 +V 2 o 5 +Cr 2 o 3 +Co 3 o 4 +NiO as glass composition, molar ratio (Bi 2 o 3 +B 2 o 3 +BaO+ZnO) / (CuO+MnO+Fe 2 o 3 +TiO 2 +V 2 o 5 +Cr 2 o 3 +Co 3 o 4 +NiO) is 2.0 to 3.5.

Owner:NIPPON ELECTRIC GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com