Exhaust gas purifying apparatus and exhaust gas purifying method using the same

An exhaust purification device and exhaust pipe technology, which is applied to the electronic control of exhaust treatment devices, exhaust devices, chemical instruments and methods, etc., can solve the problems of exhaust odor, catalyst function deterioration and change, etc. Effects of preventing sulfur poisoning, suppressing H2S production, and preventing functional degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0063] (Manufacturing example 1: Pt / CZ+Ni catalyst)

[0064] Using a carrier containing a ceria-zirconia solid solution (CZ carrier), a catalyst (Pt / CZ+Ni catalyst) in which platinum and nickel were supported on a CZ carrier was produced. That is, first, as a CZ carrier, the following carriers were used as stabilizers containing La in an amount of 3% by mass and 7% by mass, respectively. 2 o 3 and Pr 2 o 3 A solid solution (ceria content: 60% by mass, zirconia content: 40% by mass) mainly composed of ceria and zirconia, with a specific surface area of about 100m 2 / g. The CZ support and alumina sol were mixed to prepare a catalyst slurry, and the above-mentioned catalyst slurry was coated on a honeycomb substrate containing cordierite to support it, and then fired at a temperature of 500°C to obtain a support coating. Substrate. Then, the carrier-coated substrate is adsorbed and loaded with platinum, fired at a temperature of 500° C., and the nickel nitrate aqueous sol...

manufacture example 2

[0065] (Manufacturing example 2: Pt / CZ+Fe catalyst)

[0066]A catalyst (Pt / CZ+Fe catalyst) in which platinum and iron were supported on a CZ carrier was obtained in the same manner as in Production Example 1, except that an aqueous nitrate solution of iron (Fe) was used instead of an aqueous solution of nickel nitrate. . In addition, the loadings of platinum, CZ carrier, alumina sol and iron in the obtained catalyst were respectively: 0.03g of platinum per liter of catalyst, 150g of CZ carrier per liter of catalyst, and 20g of oxide oxide per liter of catalyst. Aluminum sol, 0.05mol iron per liter of catalyst.

Embodiment 1

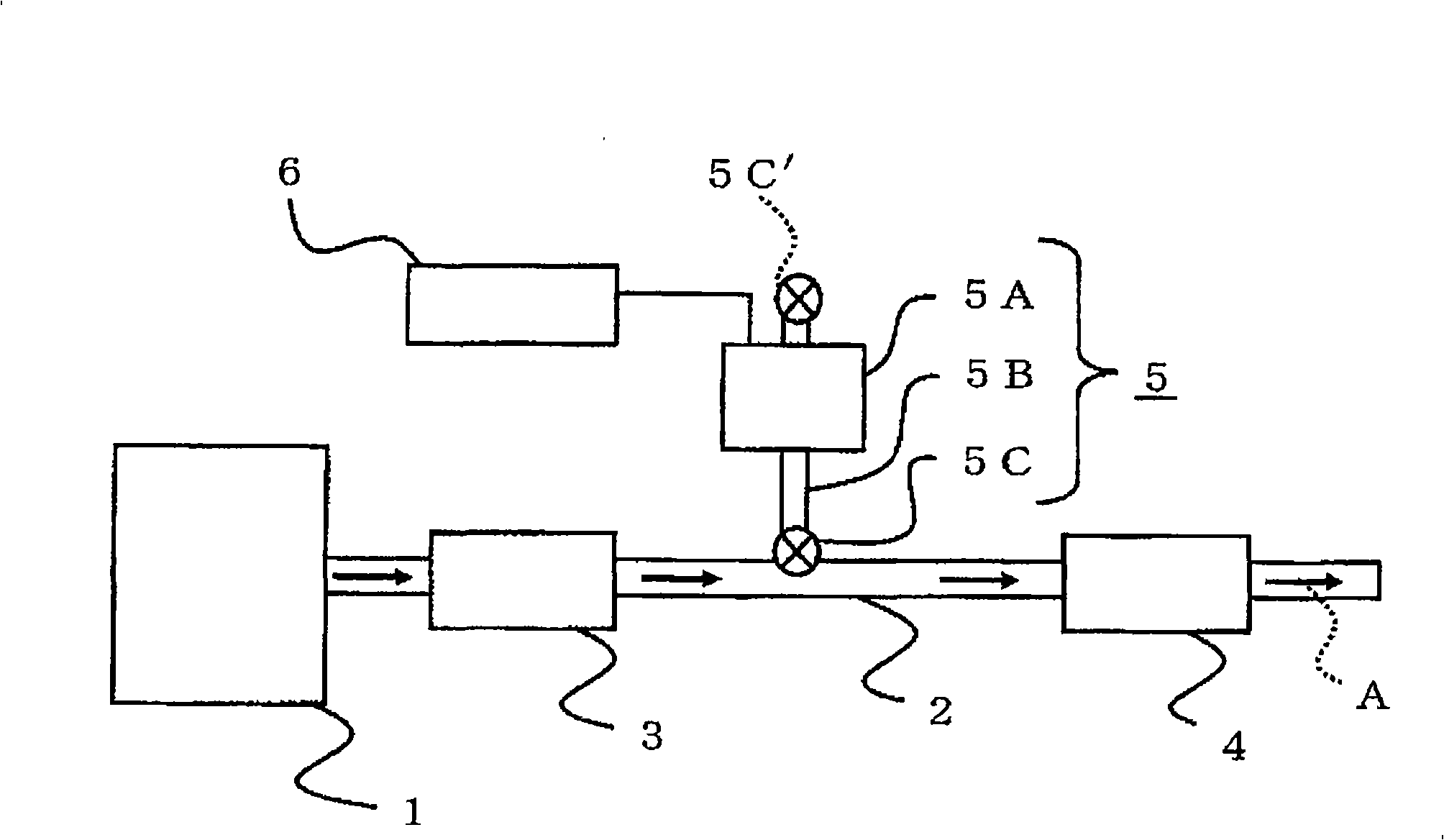

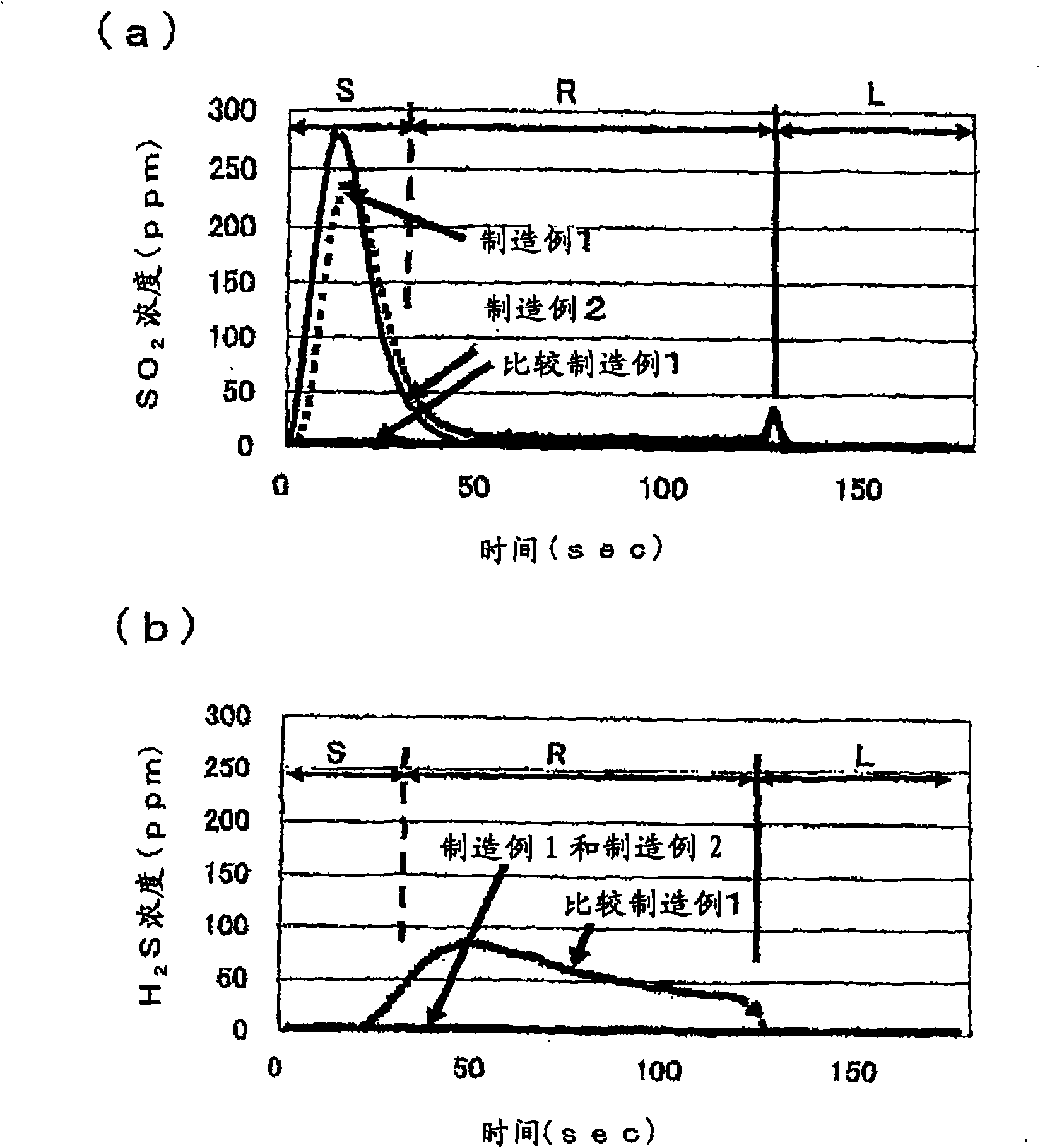

[0079] Install the exhaust purification device in the exhaust system of a car equipped with a 2.4L gasoline engine to conduct a model test and measure the H contained in the exhaust gas 2 S and SO 2 concentration. That is, it is first used as an exhaust purification device figure 1 The exhaust gas purifying device of the structure shown, wherein, as the upstream catalyst 3 has a commercially available three-way catalyst (Pt-Rh / (alumina+CZ) catalyst), as the downstream catalyst 4 has the Pt / The CZ+Fe catalyst has a small pump with a gas supply capacity of 30 L / min as the oxidizing gas supply pump 5A, a bimetal intake valve as the intake valve 5C, and an ECU as the control unit 6 . Then, the following model test was carried out, that is: the automobile in which the above-mentioned exhaust purification device was installed in the exhaust system of a 2.4L gasoline engine was driven on the chassis under the test conditions of the American model (LA#4), and then Accelerate rapi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com