Flat-plate scr denitrification catalyst for high-temperature flue gas and preparation method thereof

A denitration catalyst, high temperature flue gas technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low upper limit of catalyst temperature, poor denitration activity, etc. The effect of saving operating costs and reducing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

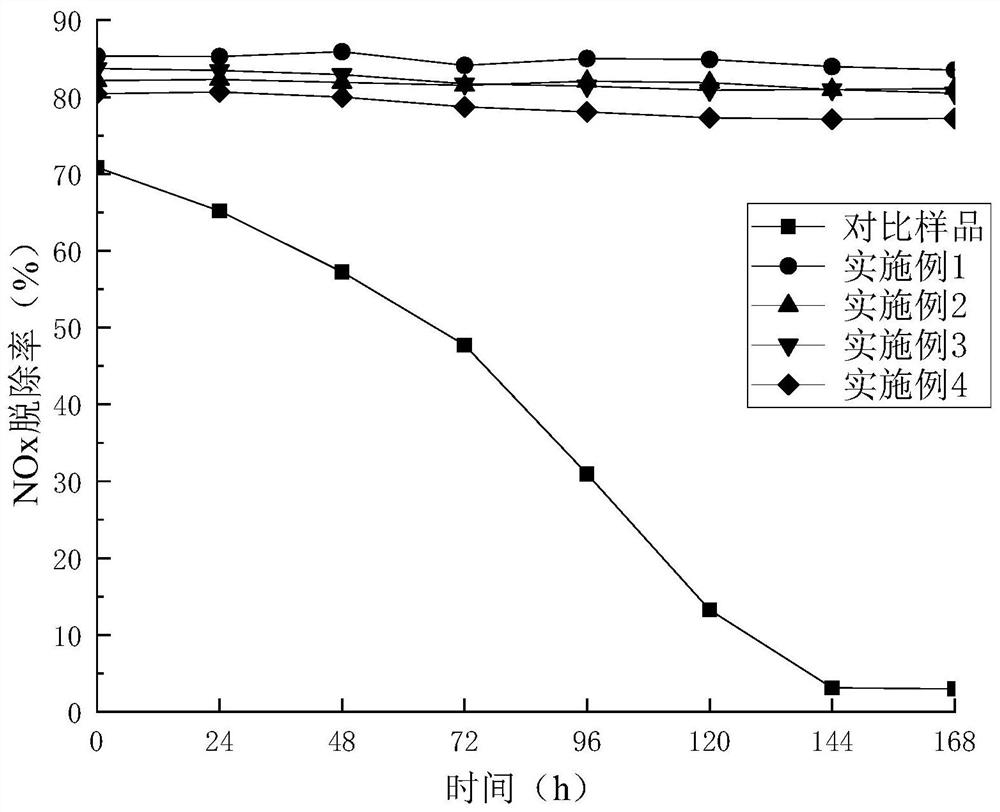

Examples

preparation example Construction

[0033] In order to better realize the above-mentioned technical scheme, the present invention also provides a preparation method of a flat-plate SCR denitration catalyst for high-temperature flue gas, and the specific steps include:

[0034] S1. TiO 2 -Y 2 o 3 -γ-Al 2 o 3 Preparation of Composite Nanocarriers

[0035] Dissolve titanium tetrachloride in water at 10°C to obtain a titanium tetrachloride solution, add monoglyceride stearate into the titanium tetrachloride solution and stir evenly, and adjust the pH value of the solution to 6.5-7.5 with ammonia water with a volume concentration of 30%. , heat the solution to 50°C to hydrolyze titanium to obtain a uniform white emulsion; add acetic acid solution of yttrium nitrate and aluminum trichloride solution to the solution in turn, stir evenly, adjust the pH value of the solution to 9-10 with ammonia water, and then Stir continuously at 85°C for 2 to 4 hours; filter to obtain the hydrolyzed precipitate, wash it with etha...

Embodiment 1

[0045] This embodiment provides a flat-plate SCR denitration catalyst for high-temperature flue gas and its preparation method. The specific steps include:

[0046] (1) TiO 2 -Y 2 o 3 -γ-Al 2 o 3 Preparation of Composite Nanocarriers

[0047] Dissolve 1896.8g titanium tetrachloride with 20L water respectively, 295mL water dissolve 169.64g yttrium nitrate hexahydrate and 0.89g acetic acid, 1.96L water dissolve 392.18g aluminum trichloride, obtain titanium solution, yttrium solution and aluminum solution; Add 38.1g of monoglyceride stearate to the solution, adjust the pH value of the solution to 6.5 with ammonia water, and then heat the solution to 50°C to hydrolyze the titanium solution to obtain a uniform white emulsion; add the yttrium solution and the aluminum solution to the emulsion in turn, Adjust the pH value of the solution to 9, heat the solution to 85°C and continue to stir for 2h; filter to obtain a hydrolyzed precipitate, wash with ethanol and deionized water, ...

Embodiment 2

[0054] Example 2 also describes a flat-plate SCR denitration catalyst for high-temperature flue gas and its preparation method. The specific steps include:

[0055] (1) TiO 2 -Y 2 o 3 -γ-Al 2 o 3 Preparation of Composite Nanocarriers

[0056] Dissolve 1896.8g titanium tetrachloride with 20L water respectively, dissolve 509.47g yttrium nitrate hexahydrate and 2.67g acetic acid with 887mL water, dissolve 130.67g aluminum trichloride with 327mL water, obtain titanium solution, yttrium solution and aluminum solution; Add 107.57g of monoglyceride stearate, adjust the pH value of the solution to 7.5 with ammonia water, and then heat the solution to 50°C to hydrolyze the titanium solution to obtain a uniform white emulsion; add the yttrium solution and aluminum solution to the emulsion in turn, adjust The pH value of the solution was 10, heated the solution to 85°C and continued to stir for 4h; filtered to obtain a hydrolyzed precipitate, washed with ethanol and deionized water,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com