Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6783results about How to "Suitable for large-scale production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

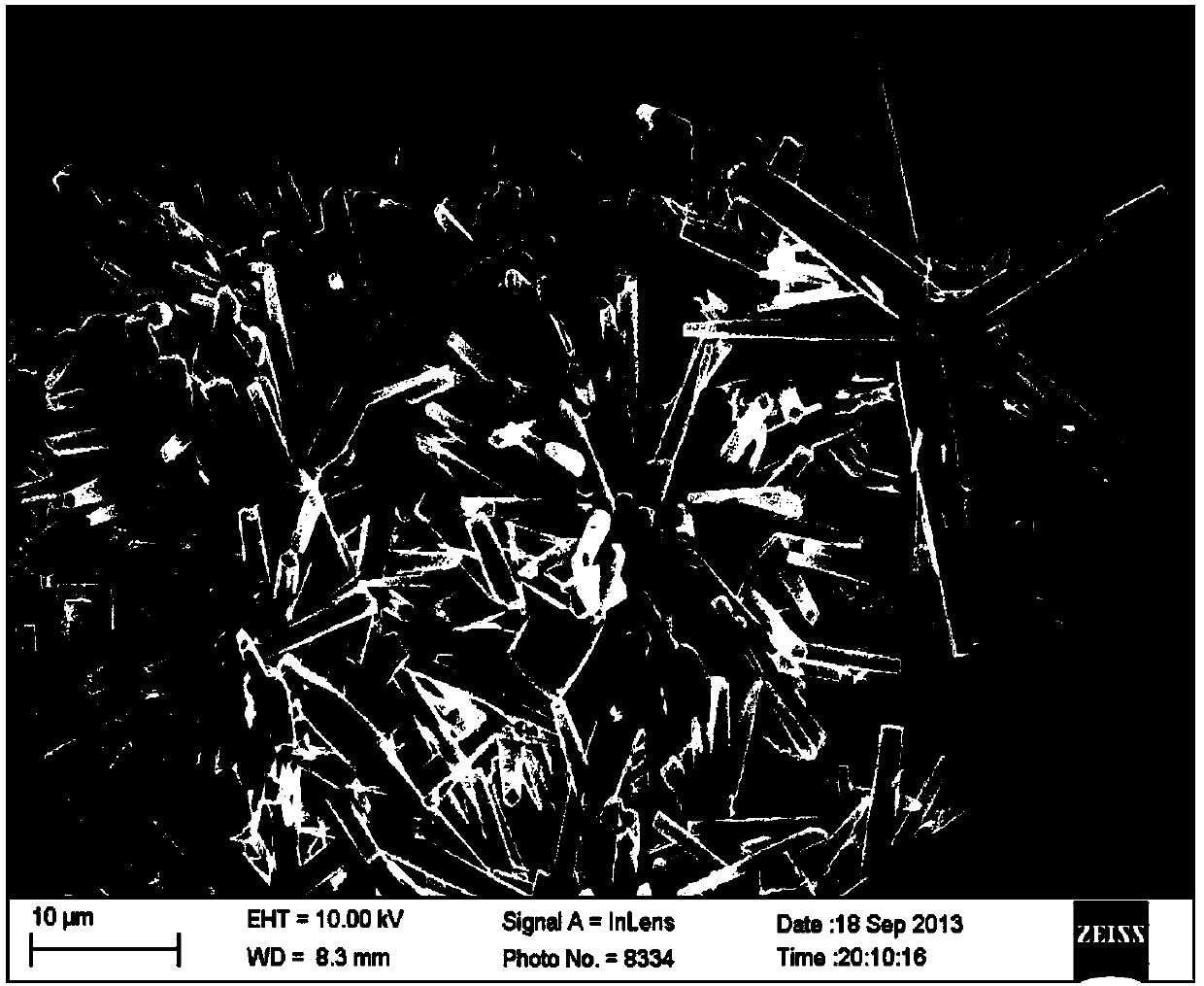

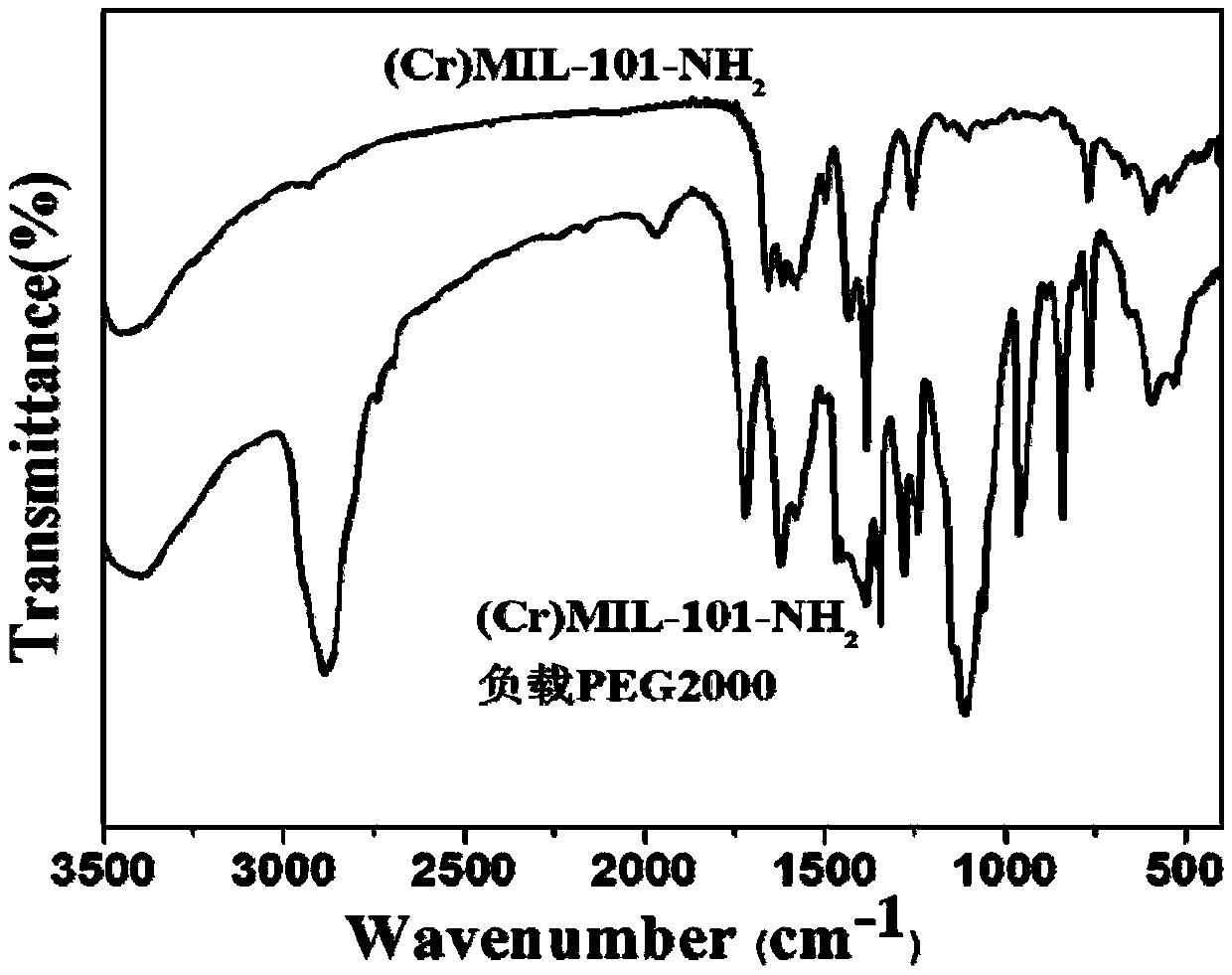

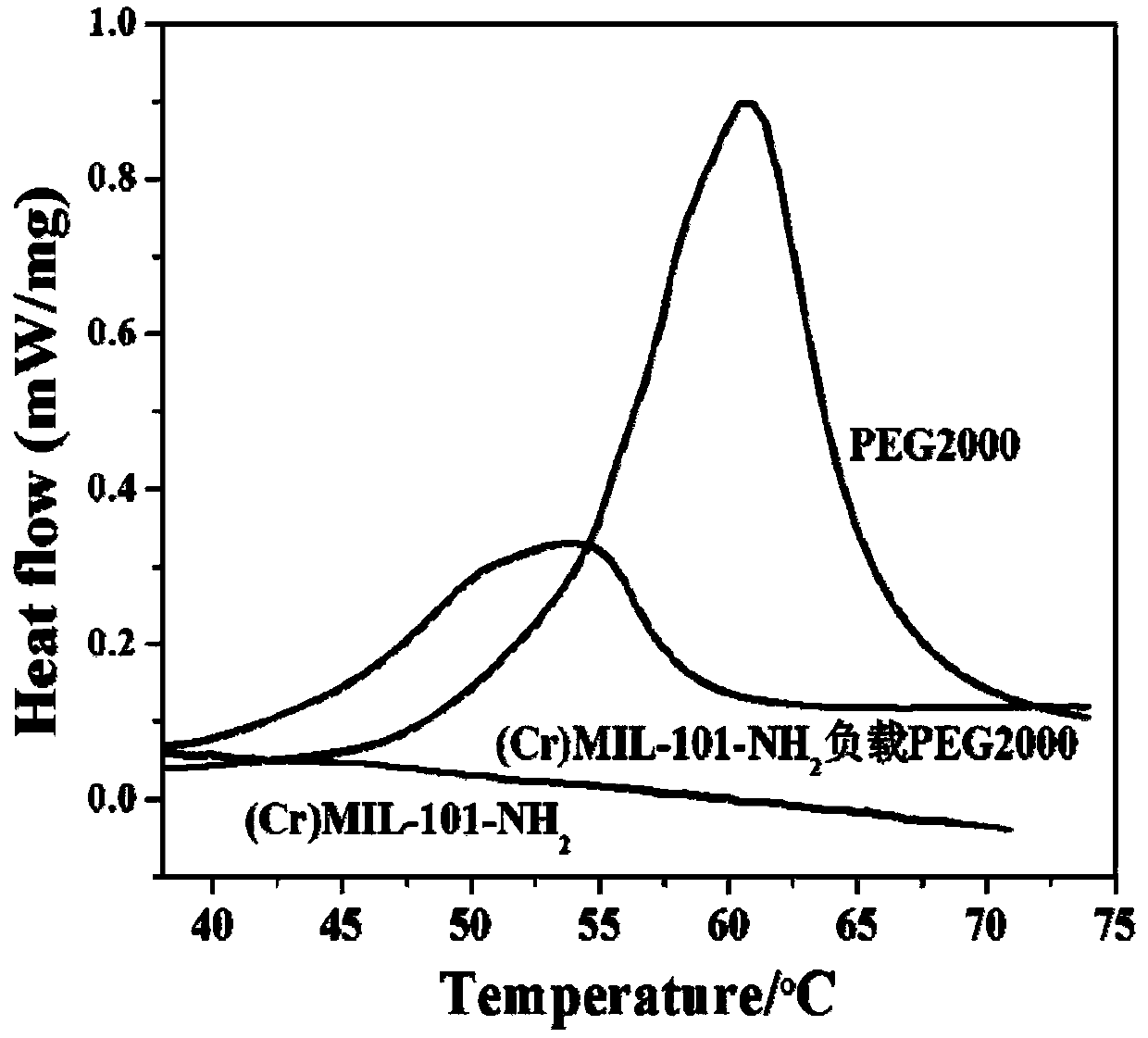

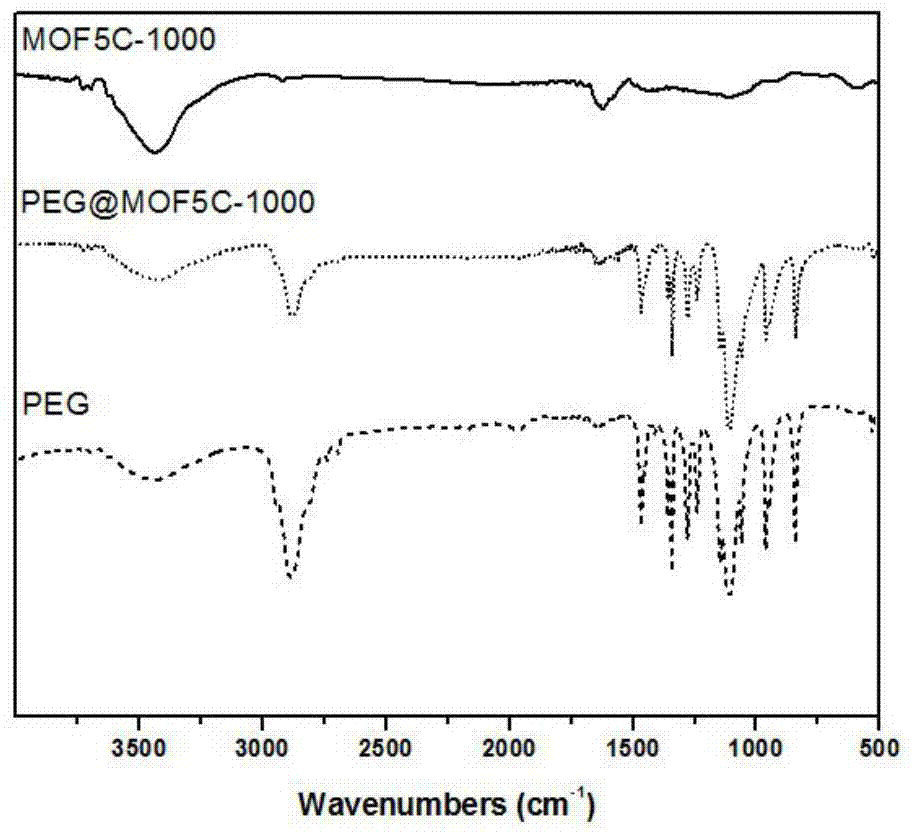

Preparation method of metal organic framework based composite phase-change material

InactiveCN103756646AWide range of choicesPrevent leakage and other issuesProductsReagentsMetal-organic frameworkElectrical polarity

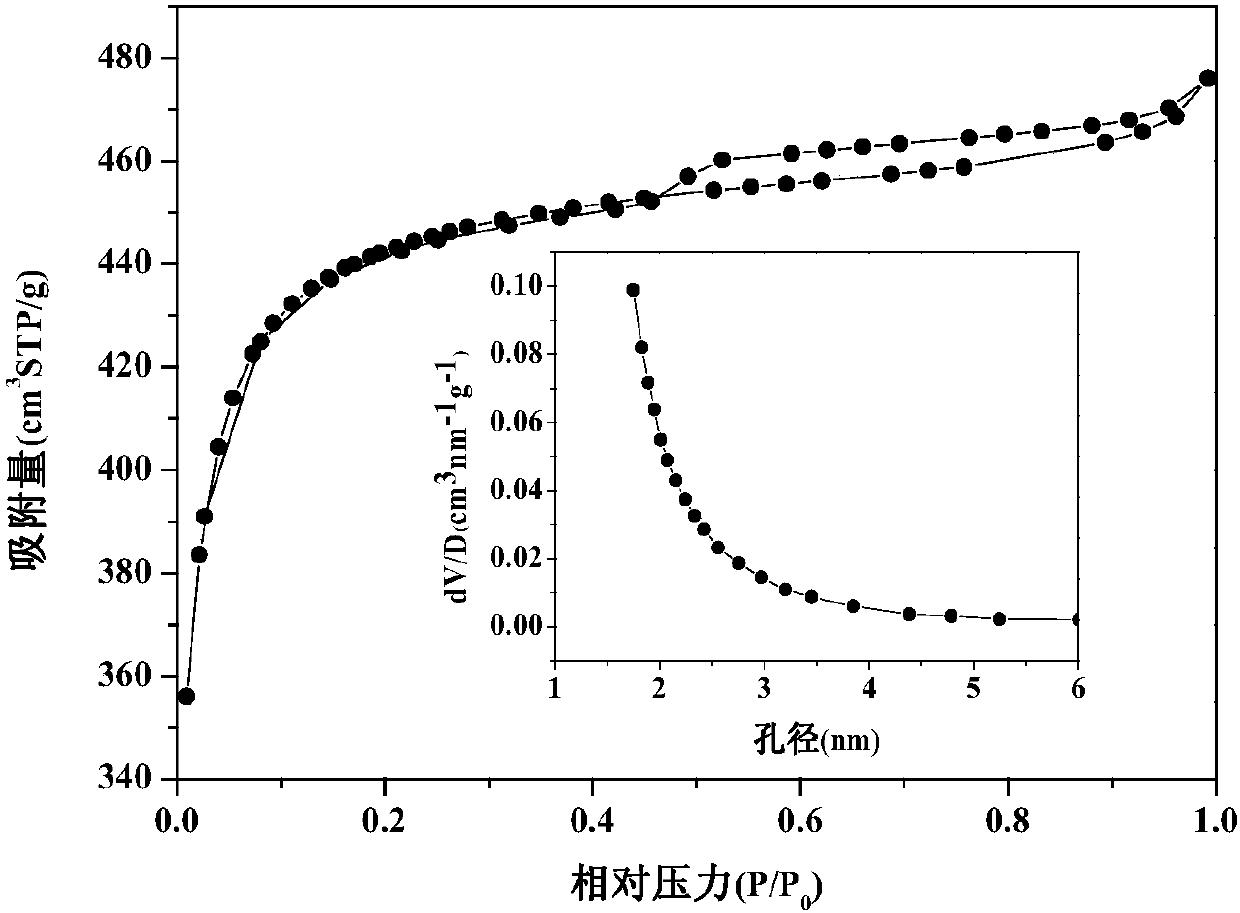

The invention relates to a preparation method of a metal organic framework based composite phase-change material. The method comprises the steps that a metal organic framework material substrate is prepared selectively; hole diameter size design and hole channel polarity regulation and control are performed on the substrate according to the size and the kind of a core material, so that a phase-change core material to be loaded is matched better; the soluble phase-change core material is prepared into a solution; a metal organic framework material is dispersed in the prepared phase-change material solution; a phase-change material is adsorbed by utilizing an extra-large specific surface area and a nano hole channel structure of the metal organic framework material; drying is performed; and then the metal organic framework composite phase-change material with a shaping effect is obtained. According to the method, a novel metal organic framework based composite phase-change material is developed; the prepared metal organic framework based composite phase-change material can effectively avoid leakage and the like, and has the advantages of adjustable nano hole structure and wide core material selection range; the method is simple in technology and mild in reaction condition, and is suitable for scale production; and a raw material is cheap and easy to obtain.

Owner:UNIV OF SCI & TECH BEIJING

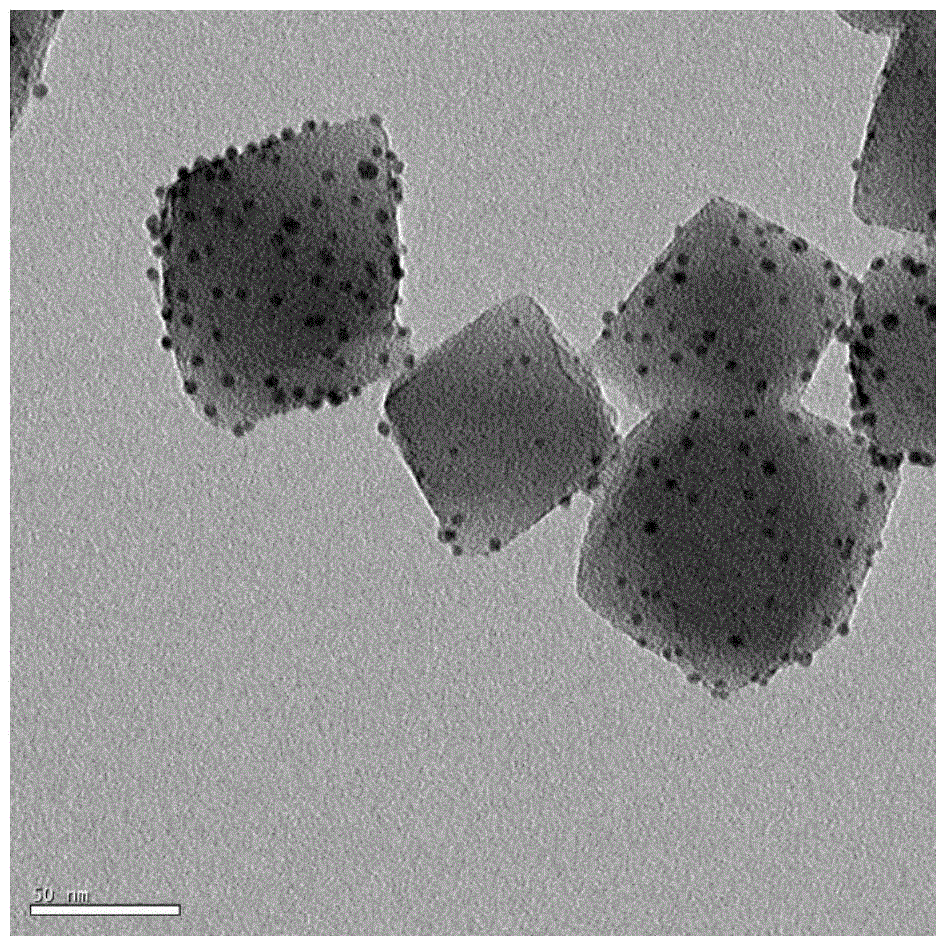

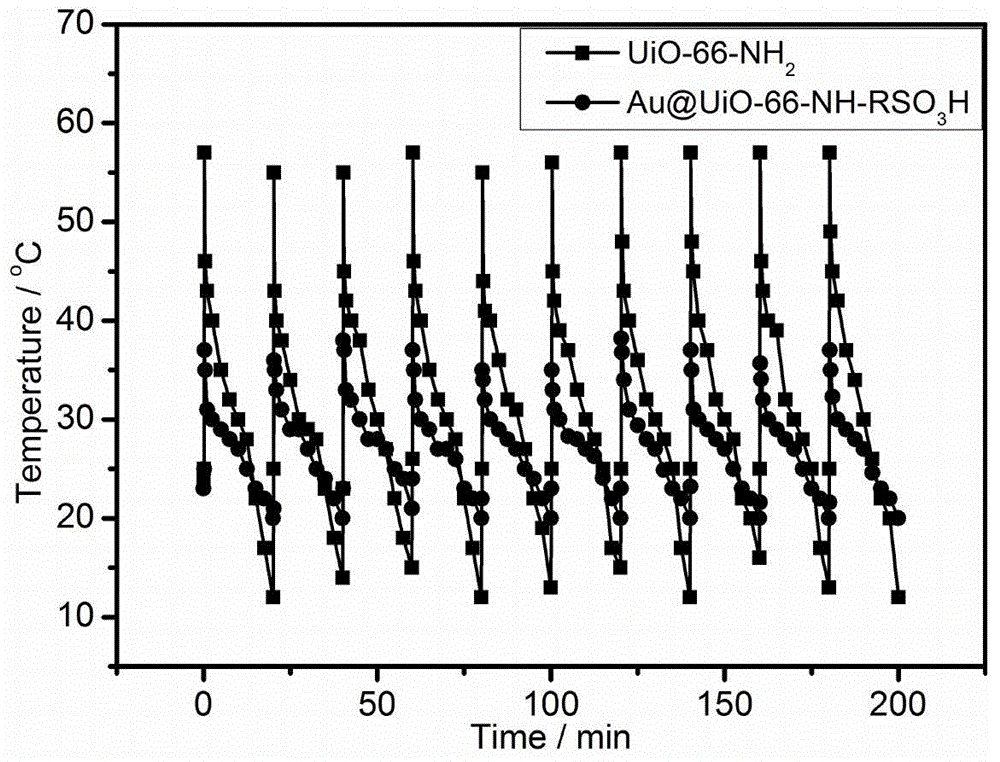

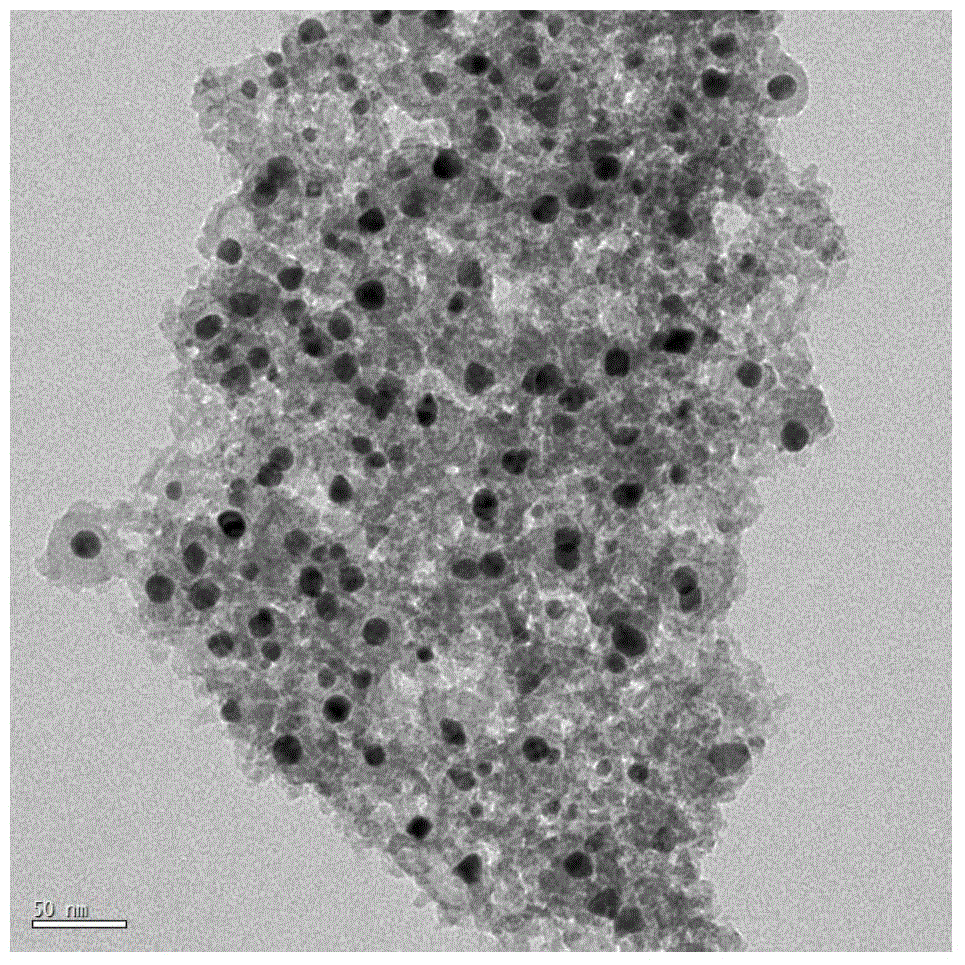

Preparation method of thermal conduction enhanced metal organic framework gas storage material

ActiveCN104624160AImprove adsorption capacityHigh thermal conductivityOther chemical processesGroup 4/14 organic compounds without C-metal linkagesIndustrial gasSorbent

The invention relates to a preparation method of a thermal conduction enhanced metal organic framework gas storage material and belongs to the field of nanocomposites. The preparation method comprises the following steps: firstly selectively preparing a metal organic framework material with a large surface area and a high micropore proportion; performing synthesis post-modification on the metal organic framework material by a 'one-pot' method, regulating the polarity and contained functional groups of pores, immobilizing metal nanoparticles inside the pores to enhance the thermal conduction property of the metal organic framework material; adsorbing industrial gas by utilizing the ultra-large specific surface area and the nano duct structure of the metal organic framework material, wherein the thermal conduction enhanced adsorption material can be used for quickly transmitting the heat generated in the adsorption and desorption process of the industrial gas. The metal organic framework industrial gas adsorber prepared by the invention can be used for efficiently adsorbing and desorbing the industrial gas and effectively improving the thermal conduction property of the adsorber, and avoiding the influence of the heat effect on the adsorption quantity in the adsorption and desorption process. The preparation method provided by the invention has the advantages of use of readily available and inexpensive raw materials, simple process, and mild reaction conditions and is suitable for large-scale production.

Owner:UNIV OF SCI & TECH BEIJING

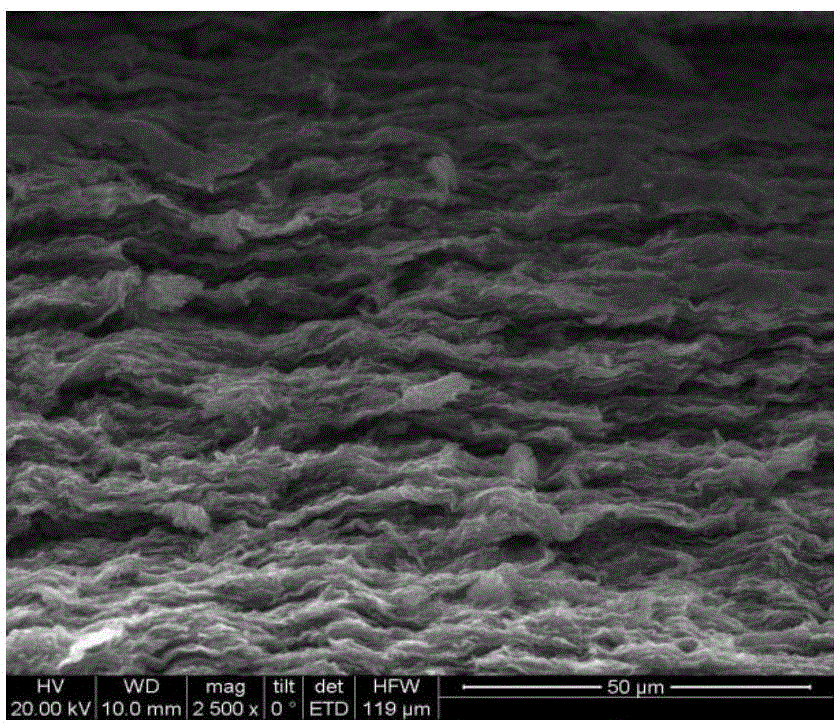

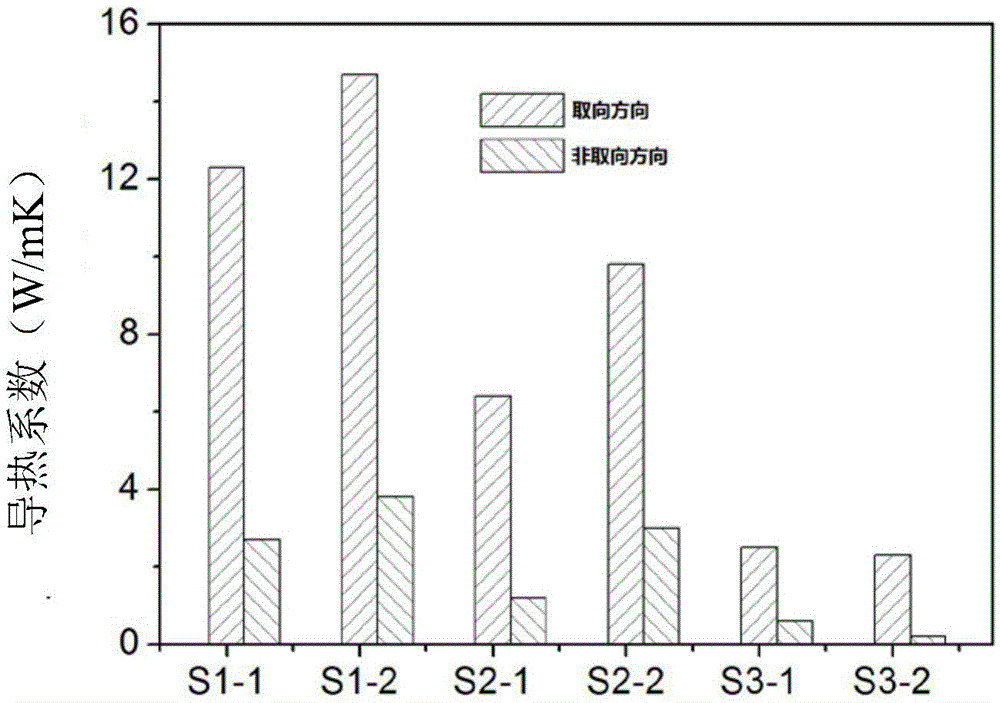

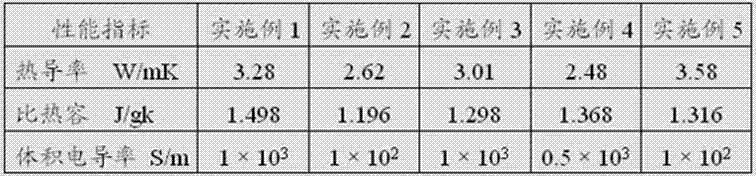

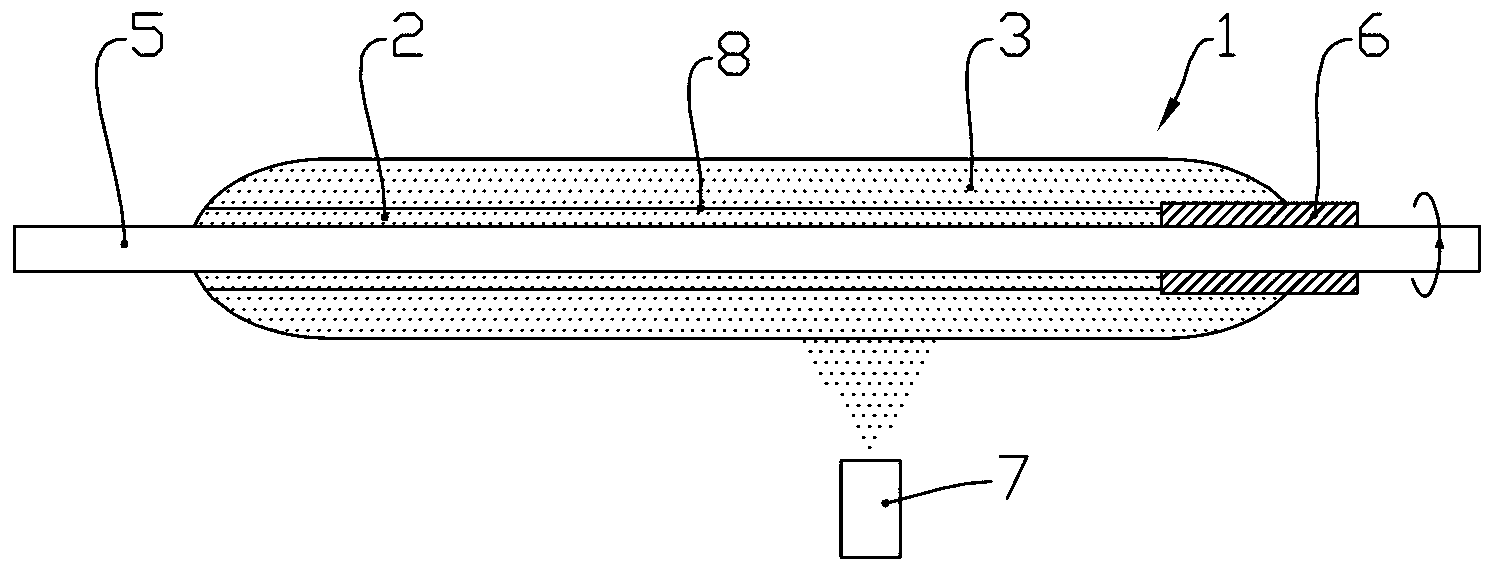

Oriented graphene/polymer composite system, and preparation method and application thereof

InactiveCN105176086AGood electrical conductivityEfficient deliveryNon-macromolecular adhesive additivesHeat-exchange elementsGraphitePolymer composites

An oriented graphene / polymer composite system, and a preparation method and an application thereof are provided. The composite system includes an oriented network component at least including graphene and a substrate component compounded with the oriented network component, wherein at least a part of graphene is arranged according to set orientation; the composite system at least has a heat conductivity coefficient in the set direction higher than heat conductivity coefficients in other directions. The preparation method includes the steps: the oriented network component is subjected to orientation treatment, at least a part of graphene is arranged according to the set orientation, and thus an oriented network is formed; and the substrate component at least containing a polymer is taken to be compounded with the oriented network component, and thus the composite system is formed. The composite system has high heat conductivity and high electrical conductive characteristic, can efficiently transfer heat in a needed direction when in use, has the characteristics of being simple, high in efficiency and the like, is suitable for scale production, and has broad application prospects in high-efficiency heat conductivity and heat dissipation.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Graphene filled polymer matrix composite material and its preparation method

ActiveCN103087404AImprove conductivityImprove thermal conductivityIn situ polymerizationMechanical property

The invention discloses a graphene filled polymer matrix composite material. The composite material is prepared through using 90-99 parts by weight of a thermoplastic resin, 0.1-10 parts by weight of a graphene microchip, 0.01-1 part of a coupling agent, and 1-10 parts of a lubricant. The invention also discloses a preparation method of the graphene filled polymer matrix composite material. Compared with other carbon system filled composite materials, the graphene filled polymer matrix composite material has the advantages of easy processing, easy forming, less filler filling amount, wide raw material source, environmental protection and the like. The composite material has the characteristics of excellent electric conductivity, excellent thermal conductivity, good mechanical properties, good dimensional stability, good weather resistance and the like; and compared with present technologies for preparing a graphene / polymer composite material through in-situ polymerization or solution polymerization, the melt blending method for preparing the graphene filled polymer matrix composite material in the invention has the advantages of continuous production, suitableness for the large-scale production, and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

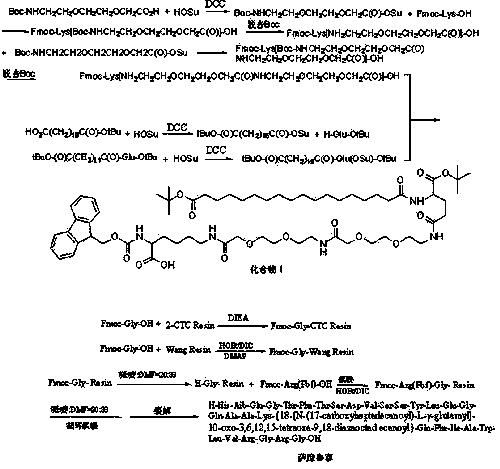

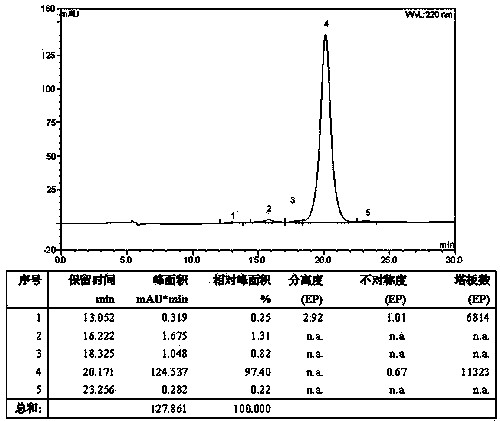

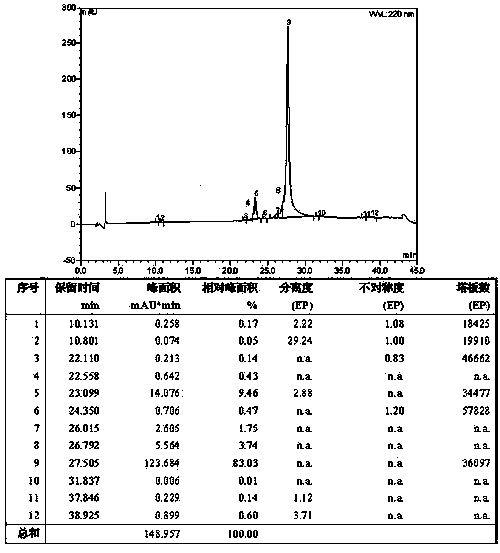

Preparation method of semaglutide

InactiveCN104356224ASynthetic cycle is longLow costPeptide preparation methodsBulk chemical productionSolid phasesSide chain

The invention relates to the technical field of polypeptide synthesis, in particular to a preparation method of semaglutide. The preparation method comprises the following specific steps: A) synthesizing a pentapeptide fragment (compound I) by a liquid phase method; B) in the presence of an activator system, coupling a solid-phase resin carrier and FmoC-Gly-OH to obtain FmoC-Gly-resin; C) by a solid-phase synthesis method, sequentially coupling amino acids with FmoC protections at N terminals and side chain protections according to a peptide sequence of a main chain of the semaglutide, wherein the lysine is the pentapeptide fragment (compound I); D) cracking, purifying and freeze-drying peptide resin to obtain the semaglutide. The invention provides a synthesis process of the semaglutide, which is short in synthesis period, low in cost and high in yield and is suitable for mass production.

Owner:ADLAI NORTYE BIOPHARMA CO LTD

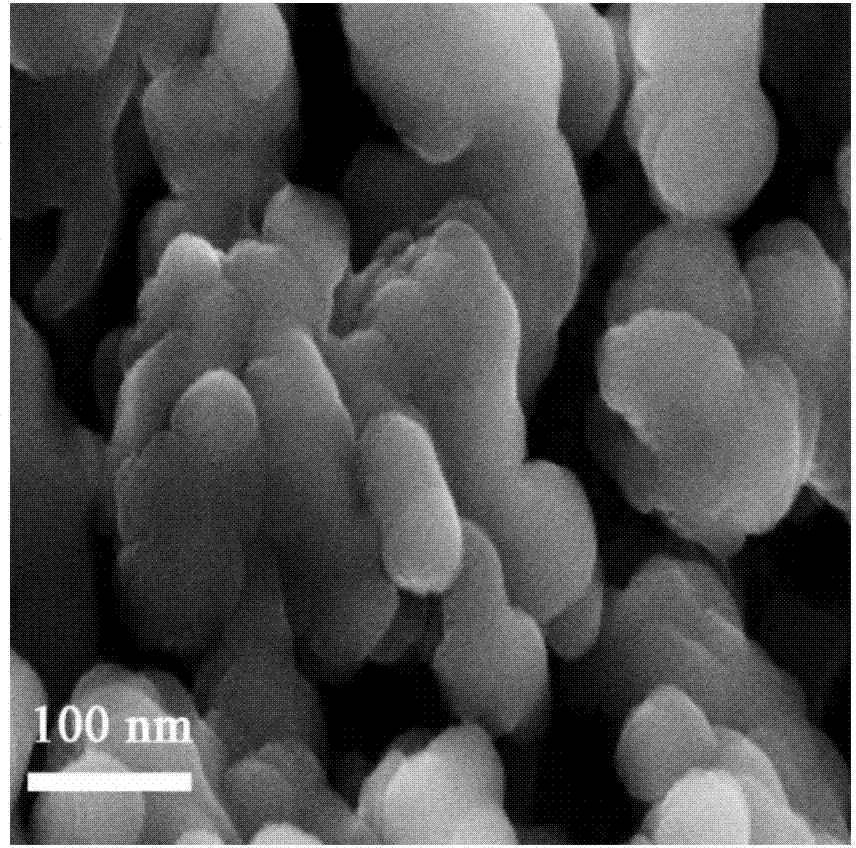

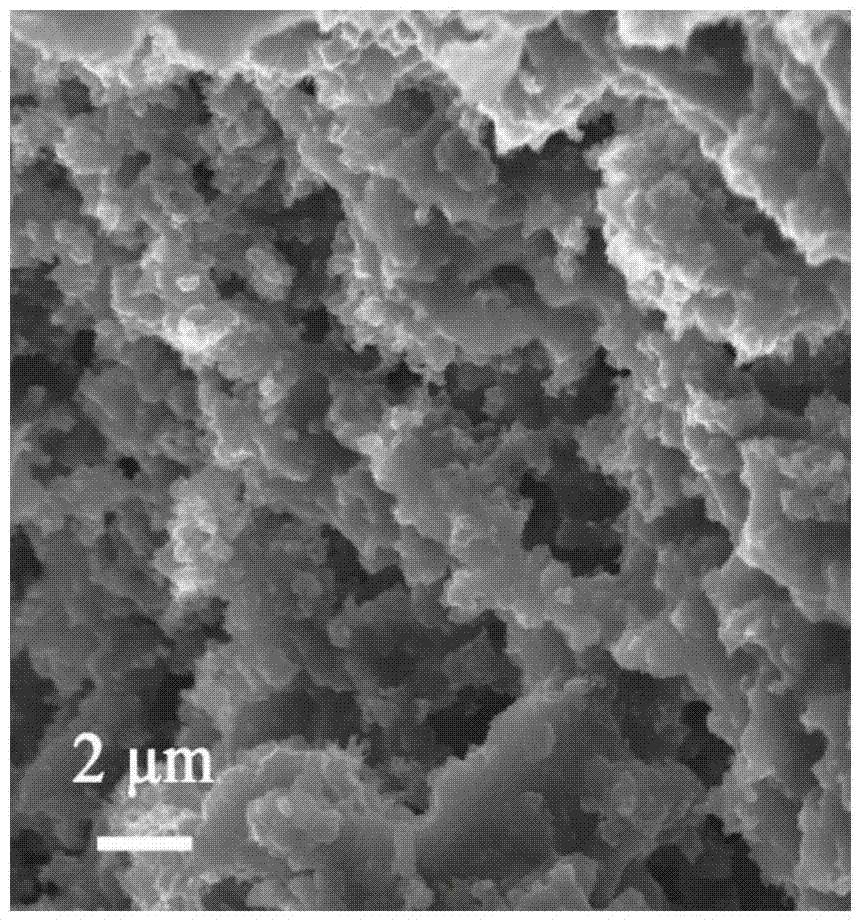

Method for preparing multilevel porous carbon base composite phase change material

InactiveCN104710965AImprove heat storage capacityLarge temperature rangeProductsReagentsPorous carbonSynthesis methods

The invention provides a method for preparing a multilevel porous carbon base composite phase change material, and belongs to the field of composite phase change materials. The method comprises the following steps: at first, preparing an organic metal skeleton material by using such methods as a solution method, a solvothermal method or a stirring synthesis method; with the organic metal skeleton material as a template, high temperature carbonizing under the protection of an inert gas, and changing the carbonizing temperature and the post treatment manner to obtain a multilevel porous carbon material with a super-large specific surface area and a super-large pore volume; selecting proper solvents according to different kinds of phase change core materials, preparing the phase change core materials to a solution, dispersing the porous carbon material into the solution, removing the solvent by such manners as heating, and meanwhile the phase change core materials are adsorbed and limited in the porous carbon material. The composite phase change material prepared by the method provided by the invention has good thermal storage property, can effectively avoid the leakage problem of the phase change core material, and has the advantages of excellent heat transfer property, good cycling stability and wide application range, and the process is simple and is suitable for large-scale production.

Owner:UNIV OF SCI & TECH BEIJING

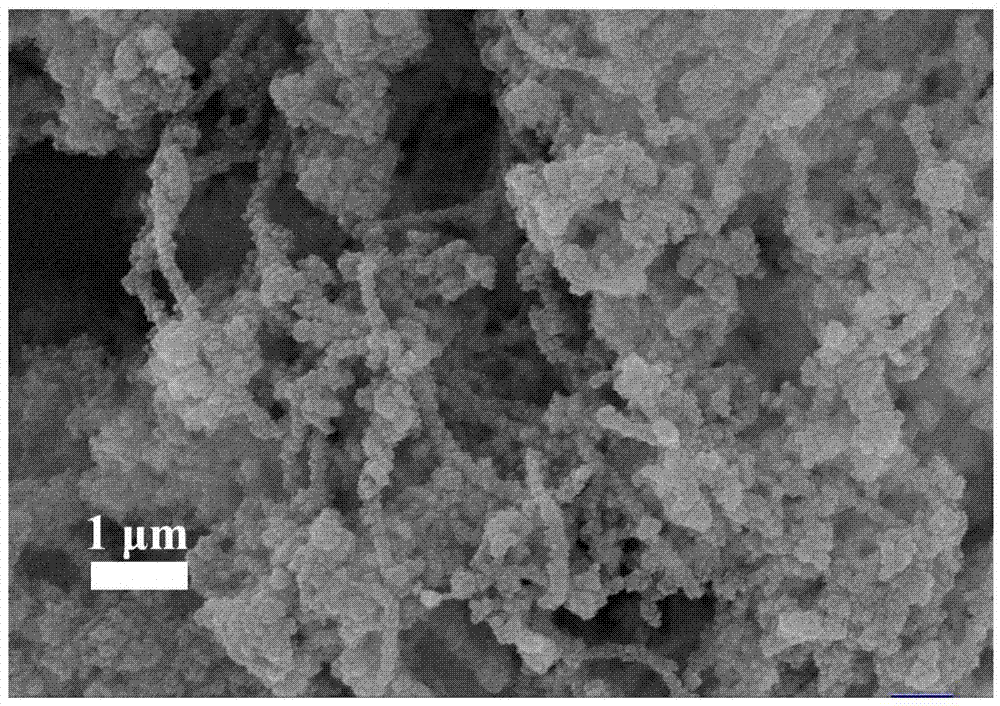

Preparation method for carbon-containing material metal organic framework-based composite phase change material

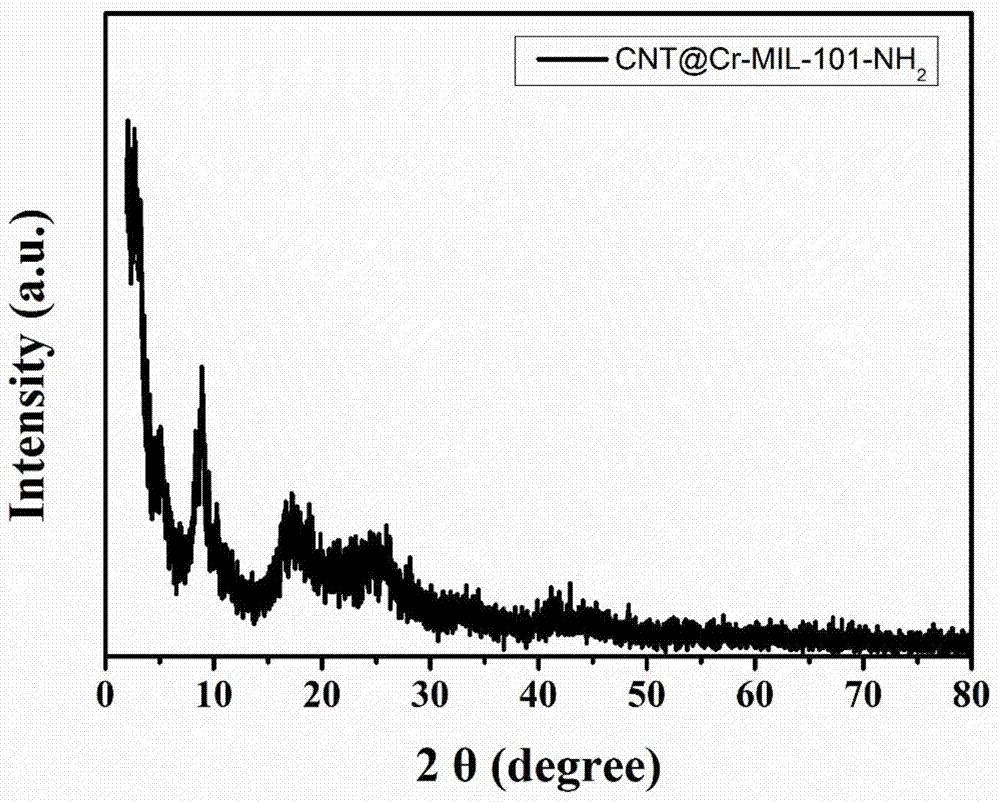

InactiveCN104745149AImprove heat transfer performanceImprove cycle stabilityHeat-exchange elementsModified carbonMetal-organic framework

The invention discloses a preparation method for a carbon-containing material metal organic framework-based composite phase change material and belongs to the field of nano composite materials and composite phase change materials. The preparation method comprises the following steps: carrying out in-situ growth of MOFs particles on a polyvinylpyrrolidone (PVP)-modified carbon material surface by adopting a hydrothermal method to prepare a carbon-containing material metal organic framework-based porous carrier material; then, dispersing a carbon material @MOFs porous carrier material into a prepared solution containing a phase change core material by adopting a solution dipping method; adsorbing a phase change core material by utilizing an oversized specific surface area of the metal organic framework material and a nao duct structure; and drying at a temperature higher than the phase change material to obtain the carbon-containing material metal organic framework-based composite phase change material. The material can be used for improving the heat transfer performances of the composite phase-change material, effectively preventing core material leakage, and has the advantages of wide core material selection range. The composite phase change material prepared by the method provided by the invention is excellent in heat transfer performance, good in circulating stability, simple in process and suitable for large-scale production.

Owner:UNIV OF SCI & TECH BEIJING

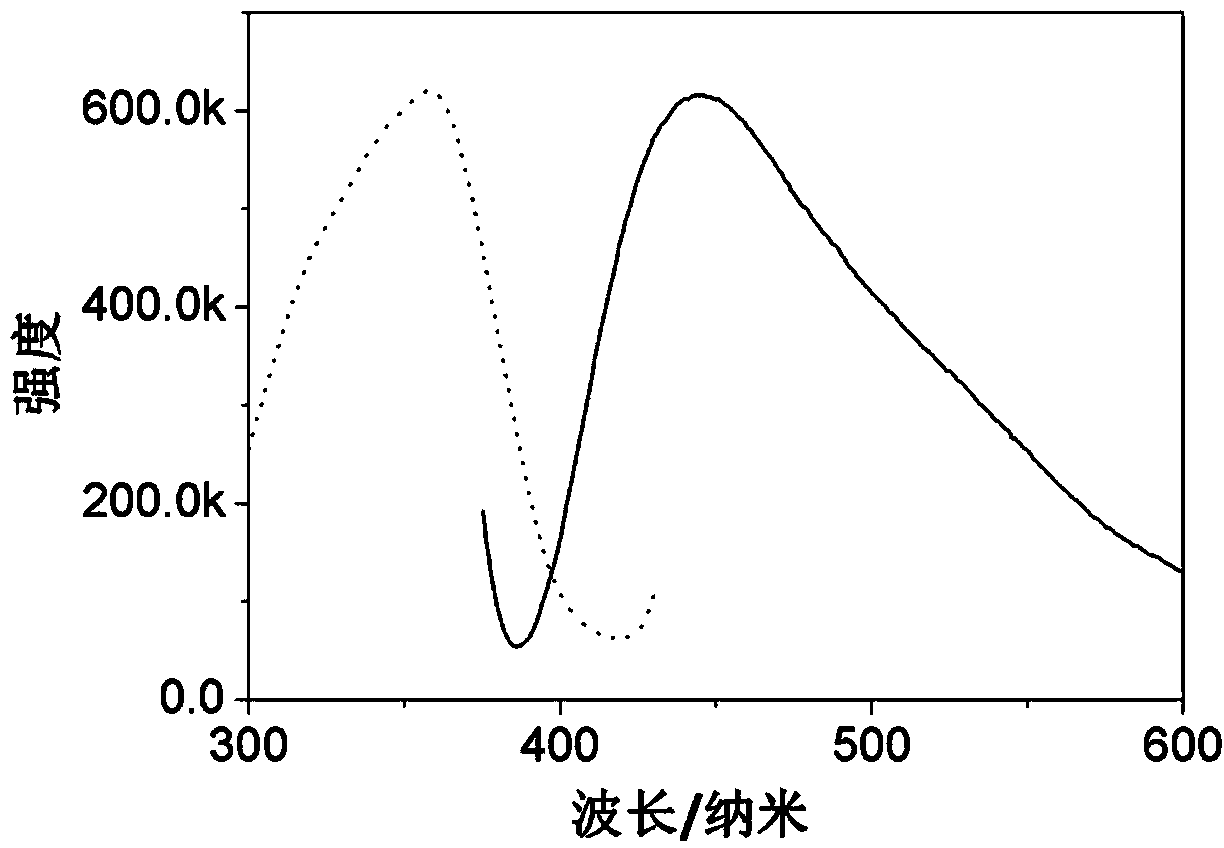

Preparation method of carbon quantum dots with adjustable fluorescence colors

InactiveCN103663412AHigh yieldImprove quantum efficiencyNano-carbonFluorescence/phosphorescenceUltraviolet lightsTumor cells

The present invention relates to a preparation method of carbon quantum dots with adjustable fluorescence colors, and belongs to the technical field of nanometer materials. According to method, citric acid or a citrate is adopted as a carbon source, a nitrogen-containing compound is adopted as a nitridation agent, hydrogen peroxide is adopted as an oxidant, a hydrothermal synthesis method is adopted to obtain an aqueous solution of carbon quantum dots emitting blue or green fluorescence under ultraviolet light excitation, reaction conditions are easily controlled, and the method is suitable for scale production. The prepared carbon quantum dots have advantages of adjustable fluorescence color, high yield, high quantum efficiency, good result reproducibility and the like, wherein the product can be directly used for tumor cell labeling and live cell imaging labeling. According to the present invention, only the one reactant is required, the raw materials are easily-available and non-toxic, the production process does not require special protection, the reaction condition is easily controlled, and the obtained carbon quantum dots have advantages of high yield, high quantum efficiency, good result reproducibility and the like; and the method has characteristics of high yield, simple preparation process, low cost, easy scale production and the like.

Owner:UNIVERSITY OF CHINESE ACADEMY OF SCIENCES

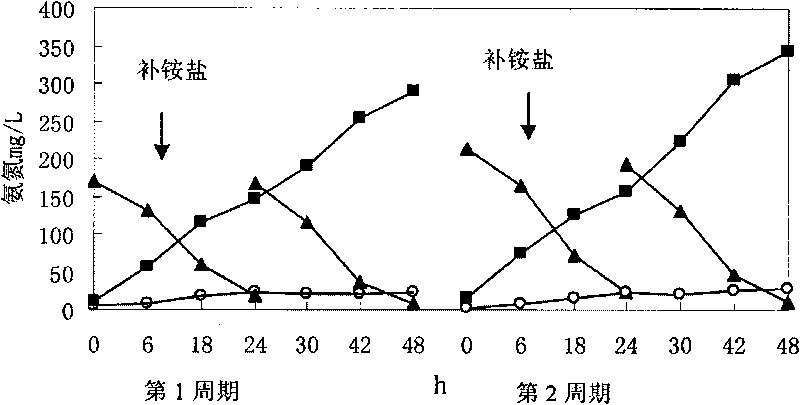

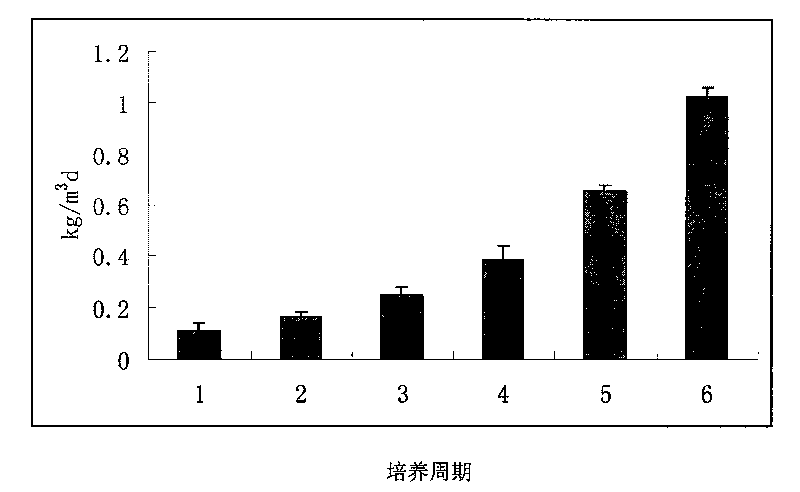

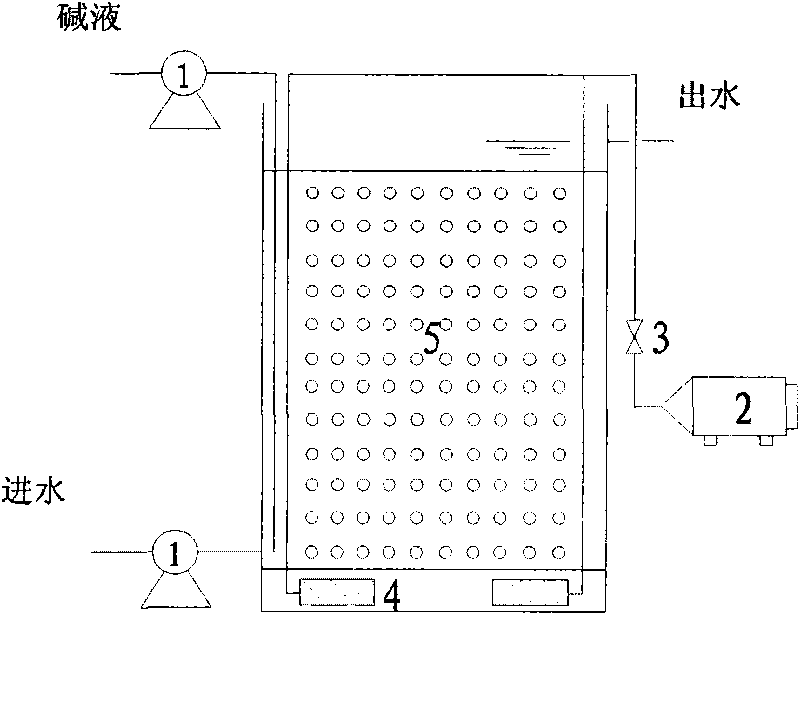

Large-scaled culture method of high-concentration nitrosobacteria and application thereof

ActiveCN101709278AIncrease concentrationHigh activityBacteriaBiological water/sewage treatmentActivated sludgeHigh concentration

The invention discloses a large-scaled culture method of high-concentration nitrosobacteria and application thereof. The method comprises the following steps of: (1) adding an enrichment culture solution with initial ammonia nitrogen mass concentration of 30-500mg / L in a reaction device with functions of stirring, heating and aeration; preparing activated sludge of a waste water treatment plant in activated sludge of 0.5-20% for primary inoculation to conduct the enrichment culture of the nitrosobacteria by 2-6d as a culture cycle, wherein extra ammonium salts and a growth promoter are added during the enrichment culture of the nitrosobacteria; (2) ending the culture when the concentration of NO2-N in the solution is accumulated to reach 70-95% of the concentration of total nitrogen; adding a flocculating agent for flocculation and sedimentation; and allowing to stand still to remove supernate, and then adding the enrichment culture solution to start the culture of the second cycle; and (3) continuously conducting 3-8 cycles of the enrichment culture to obtain the high-concentration nitrosobacteria. By adopting the nitrosobacteria to strengthen the bi-nitrification treatment of ammonia nitrogen contained waste water, the method has the advantages of high stress resistance, low cost and high efficiency and is suitable for the complicated treatment of ammonia nitrogen contained industrial waste water.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

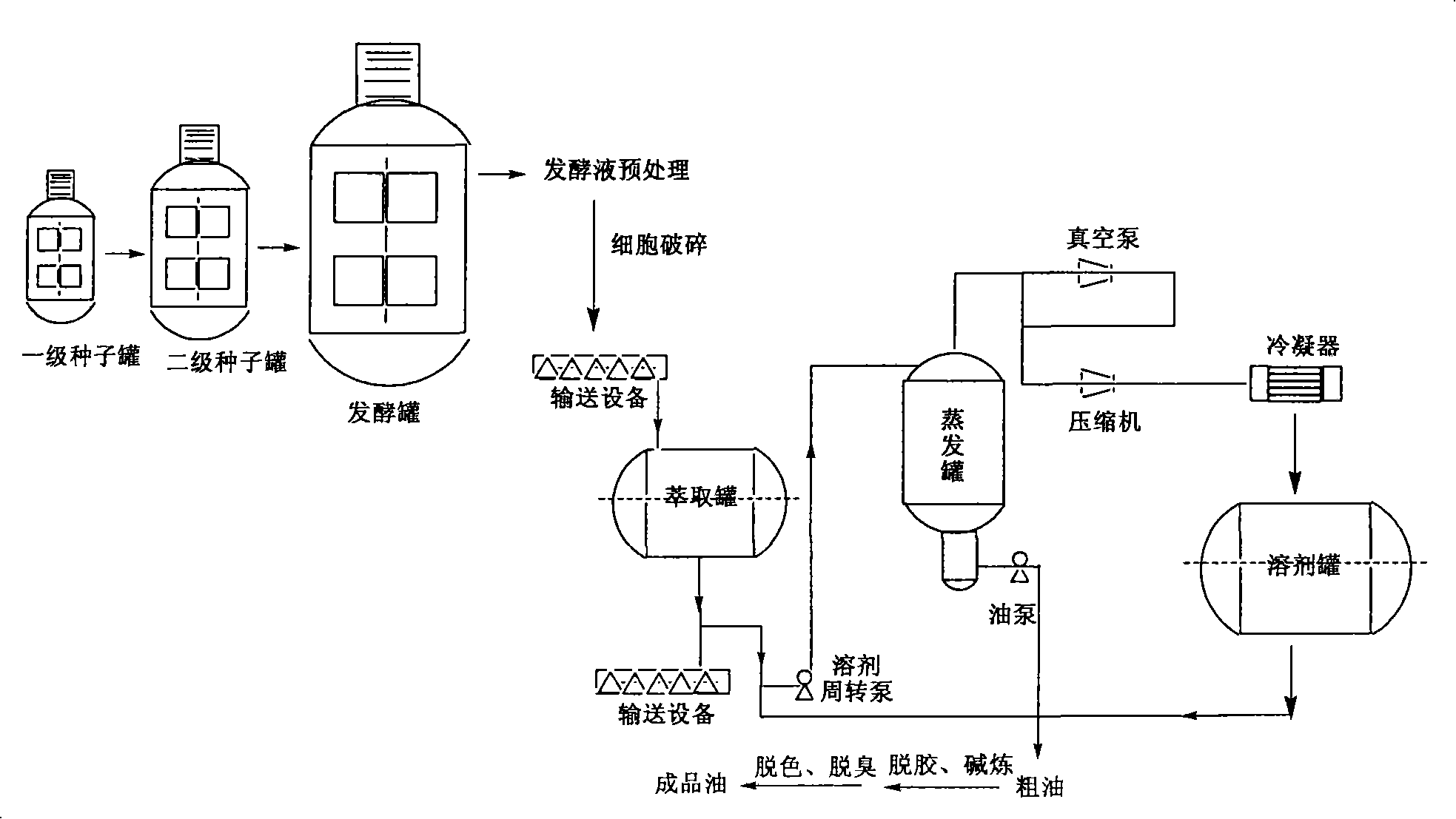

Technique for extracting and refining DHA enriched fatty acid from Crypthecodinium cohnii

ActiveCN101168501AEasy to operateReduce extraction costsCarboxylic compound separation/purificationChemistryOrganic solvent

The invention discloses a process for extracting and refining fatty acid rich in DHA from Cryptidinosa. The process first flocculates the fermentation broth of Crypthecodinium cohnii and then separates the solid from the liquid. After breaking the wall with alkali, the cells are mechanically broken, and then the broken bacteria are extracted with an organic solvent to obtain DHA crude oil; the DHA crude oil is passed through DHA essential oil is obtained after degumming, alkali refining, decolorization and deodorization. The method is simple to operate and can reduce the cost of extracting DHA oil. Only organic solvents are used in the operation process, and there is no residue in the end. After refining, the quality of DHA oil is improved. The DHA content in the extract is about 40-50%, which is suitable for DHA Large-scale production.

Owner:NANJING UNIV OF TECH

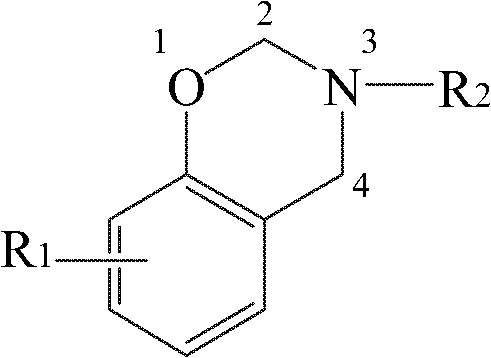

Dibenzoxazine containing oxazole ring and preparation method thereof

InactiveCN102250117ASimple preparation processLow equipment requirementsLiquid crystal compositionsOrganic chemistrySolventOrtho-aminophenol

The invention relates to a dibenzoxazine containing an oxazole ring and a preparation method thereof. The preparation method comprises the following two steps of: 1: mixing ortho-aminophenol hydrochloride and para-hydroxybenzoic acid, adding polyphosphoric acid as a solvent, reacting at 60-180 DEG C for 24-60 hours, and washing by using deionized water, filtering and drying to obtain diphenol containing an oxazole ring structure; and 2: mixing the diphenol containing the oxazole ring structure, phenylamine and paraformaldehyde, reacting at 80-110 DEG C for 40-80 minutes, then filtering and precipitating, washing 4-8 times by using alkali liquor, and then washing, filtering and drying to obtain the product. The dibenzoxazine disclosed by the invention has the advantages of very good mechanical property because the high temperature resistant oxazole ring structure is introduced to a benzoxazine molecule structure, dielectric constant of only 1.6-2.3, simple process, lower equipment requirement and suitability for large-scale production.

Owner:EAST CHINA UNIV OF SCI & TECH

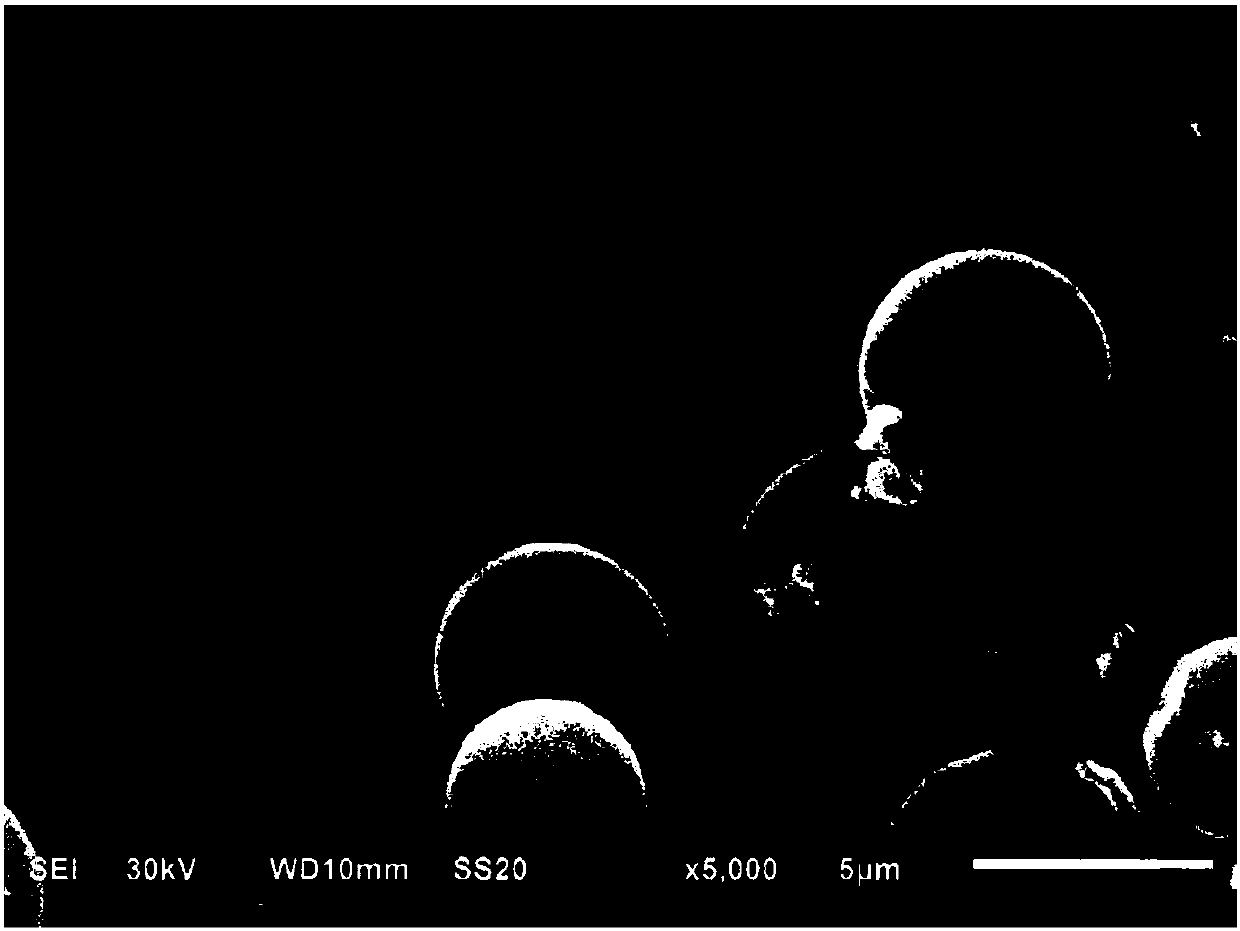

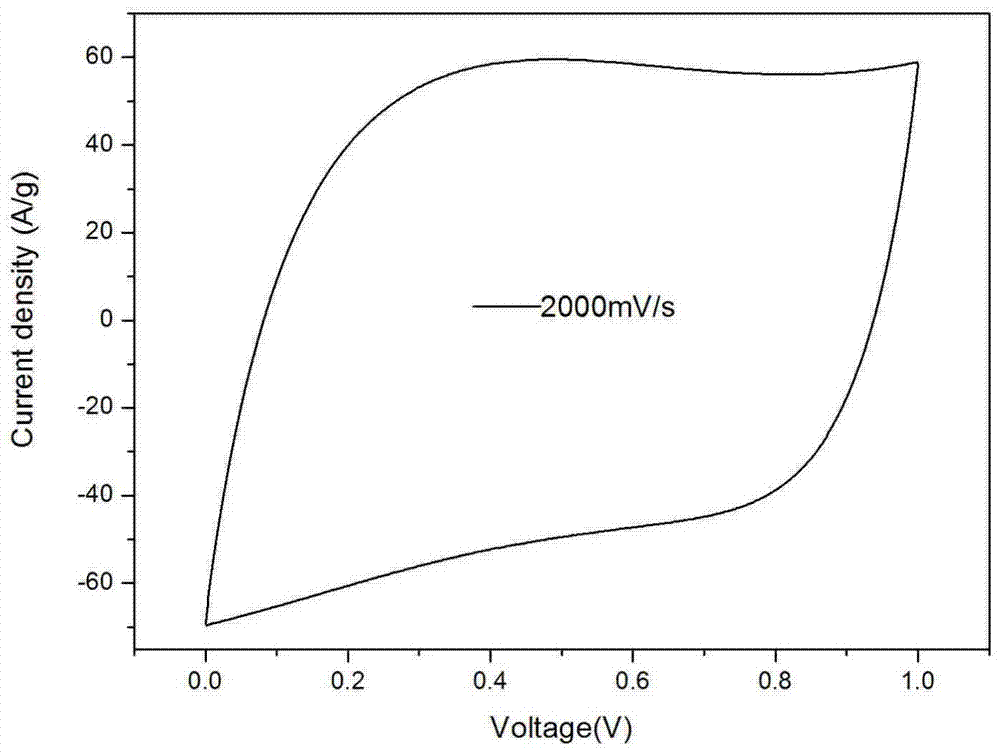

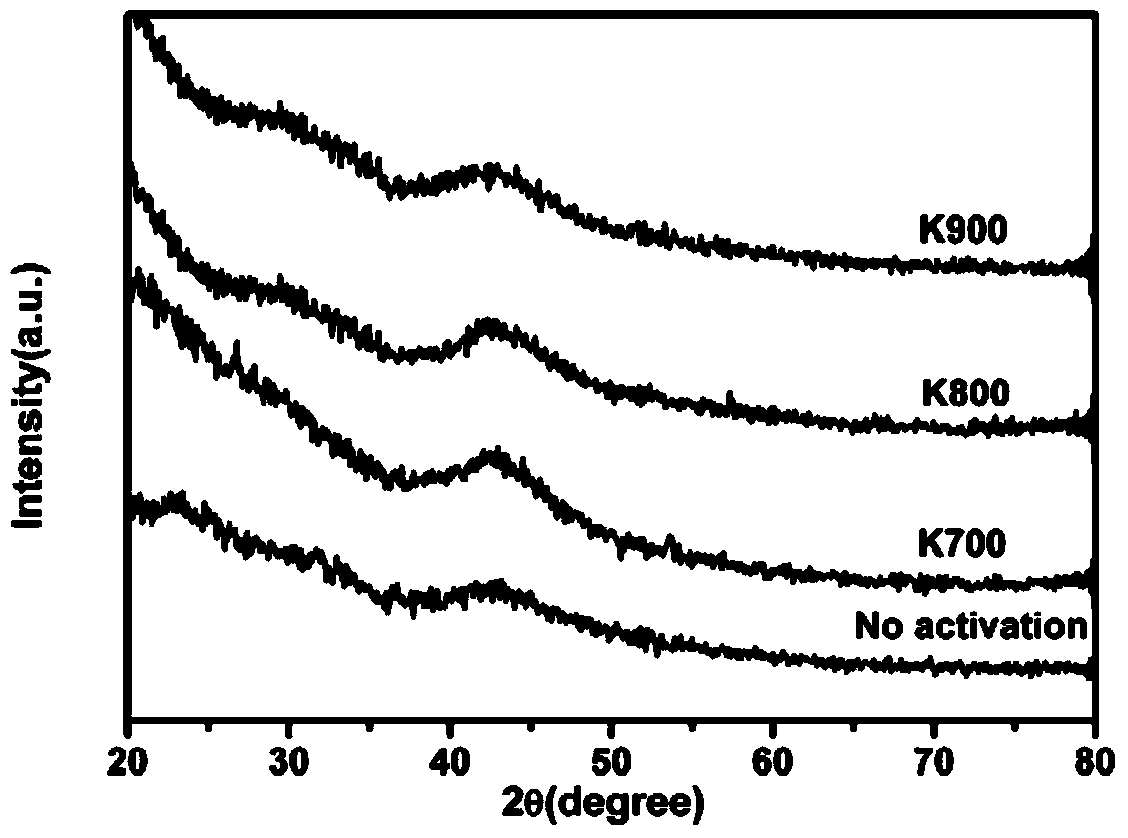

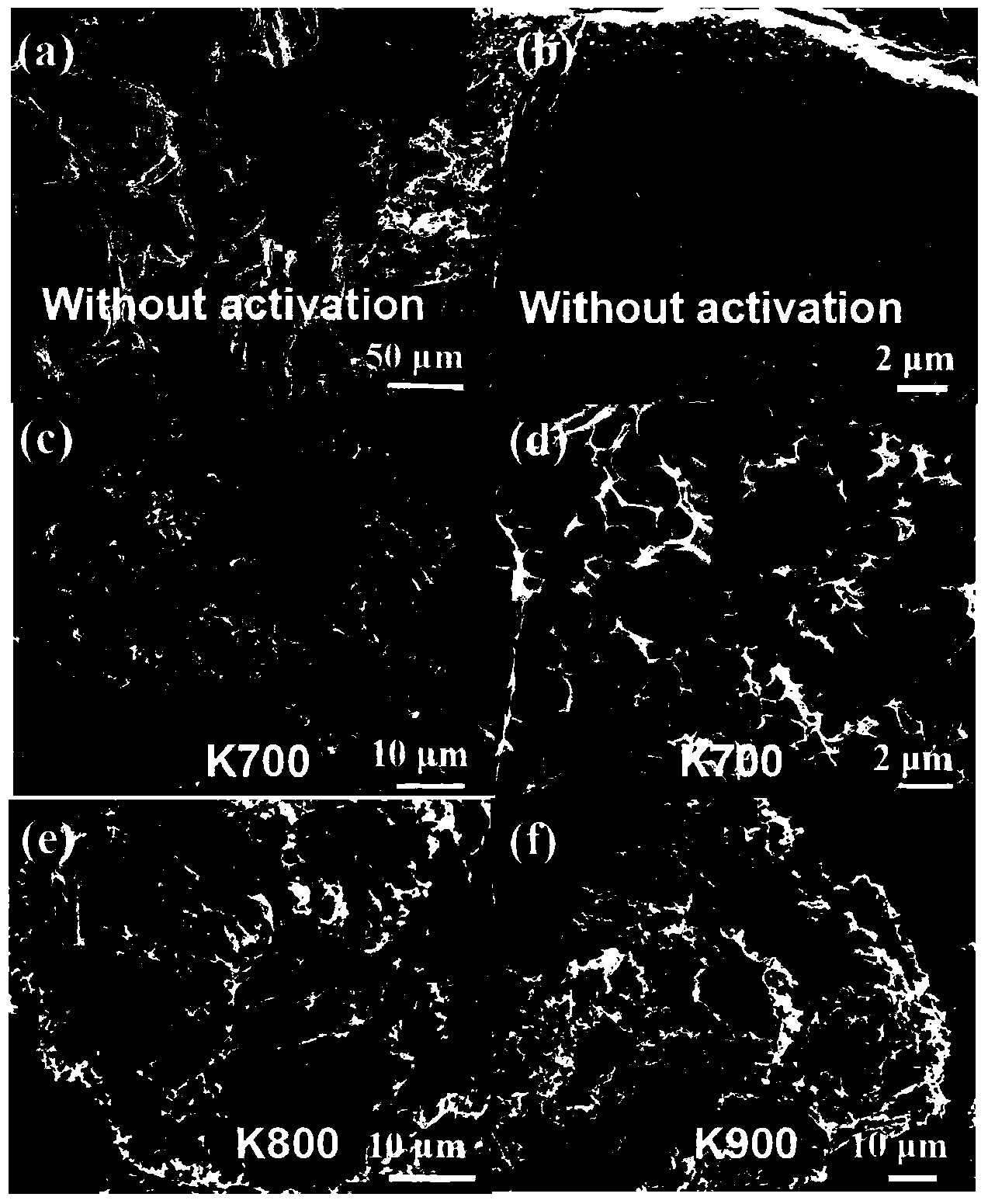

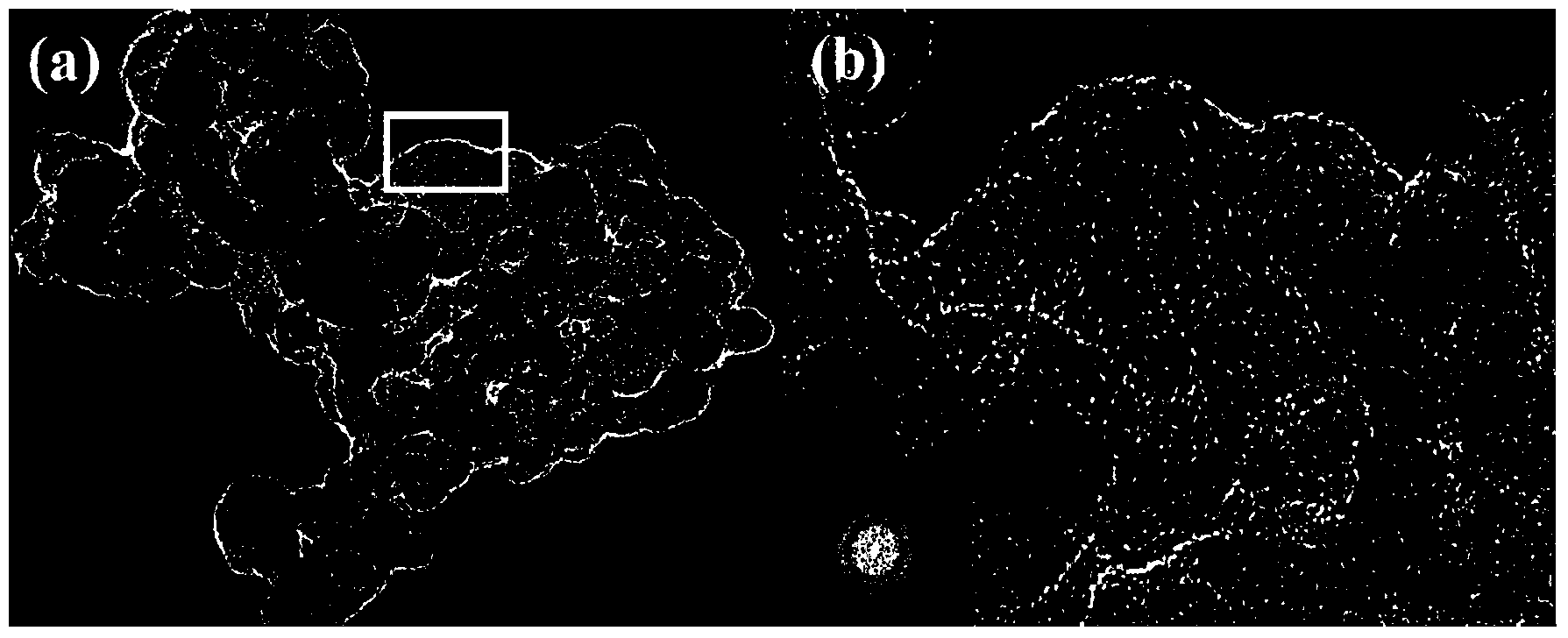

Preparation method and application of nitrogen-doped starch-based activated carbon microsphere material

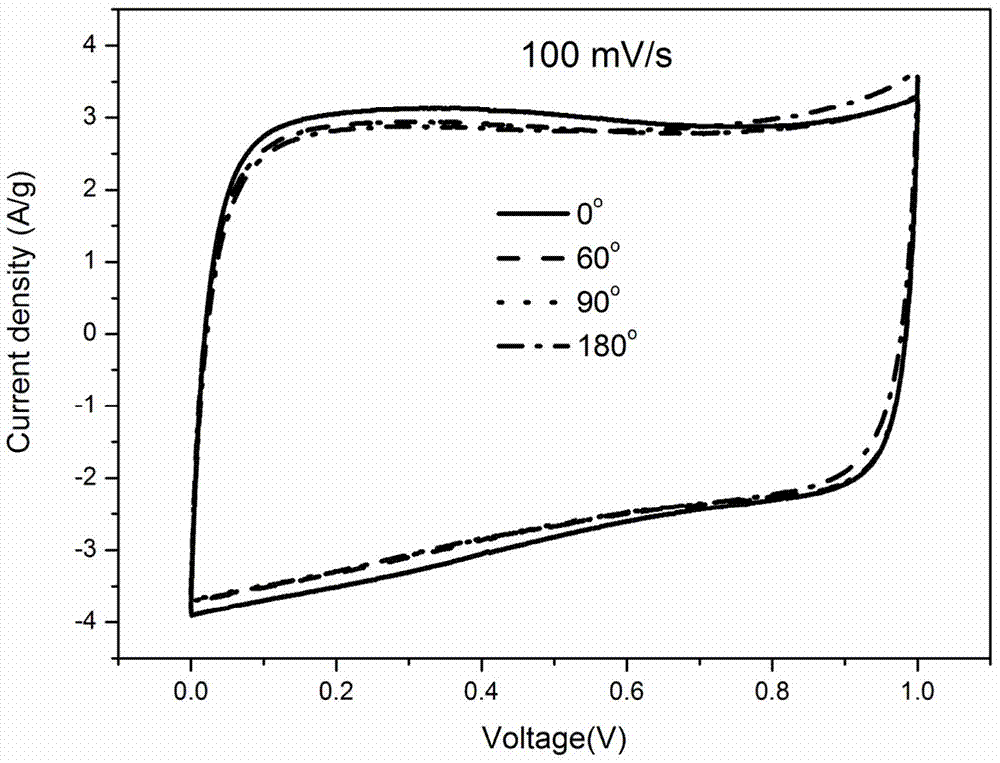

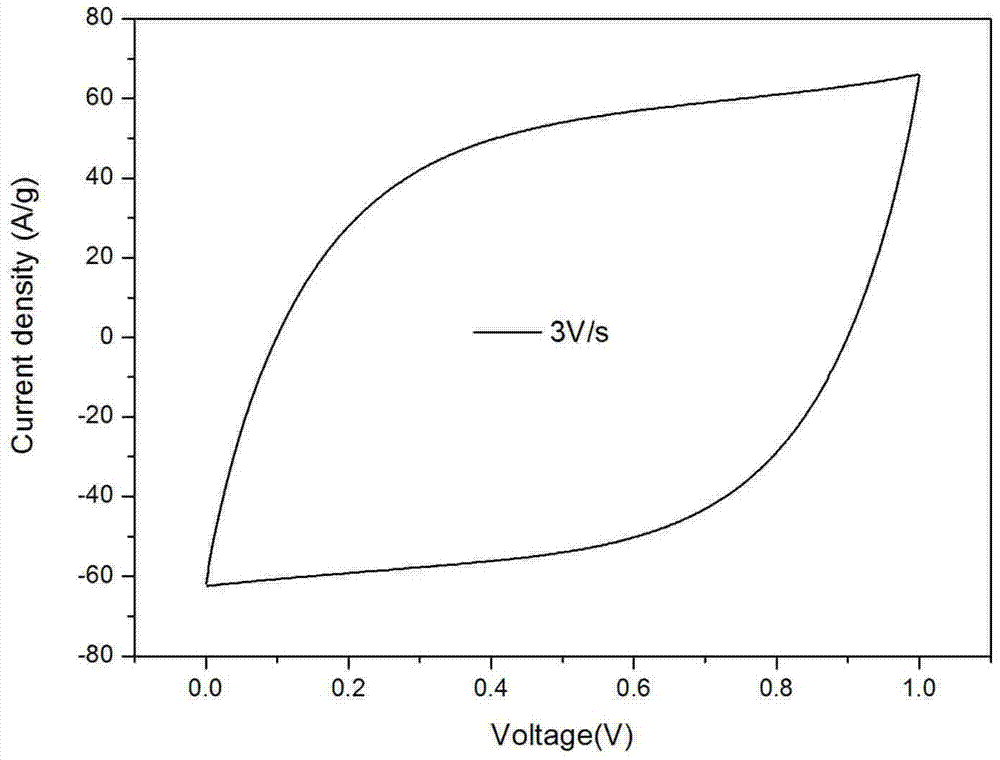

ActiveCN105948045AMicrostructure is easy to controlGood dispersionHybrid capacitor electrodesDispersityMicrosphere

The invention discloses a preparation method and application of a nitrogen-doped starch-based activated carbon microsphere material. The nitrogen-doped starch-based activated carbon microsphere material is prepared by taking starch as the carbon source and taking a nitrogen-containing compound as the nitrogen source through the steps of gelatinization, hydrothermal treatment, carbonization, activation and the like. The diameters of prepared carbon microspheres range from 0.5 micrometer to 10 micrometers, the particle size is controllable, the dispersity is good, the specific surface area ranges from 1,000 m<2> / g to 3,000 m<2> / g, and the nitrogen content ranges from 0.2% to 15%. The prepared material relates to the application fields of electrochemical energy storage, adsorption separation, catalyst carriers, drug carriers and the like and is particularly applicable to electrochemical energy storage. Green biomass is adopted as the carbon source, sources are wide, the price is low, and the preparation technology is simple, easy to control, environmentally friendly and suitable for large-scale production.

Owner:XIANGTAN UNIV

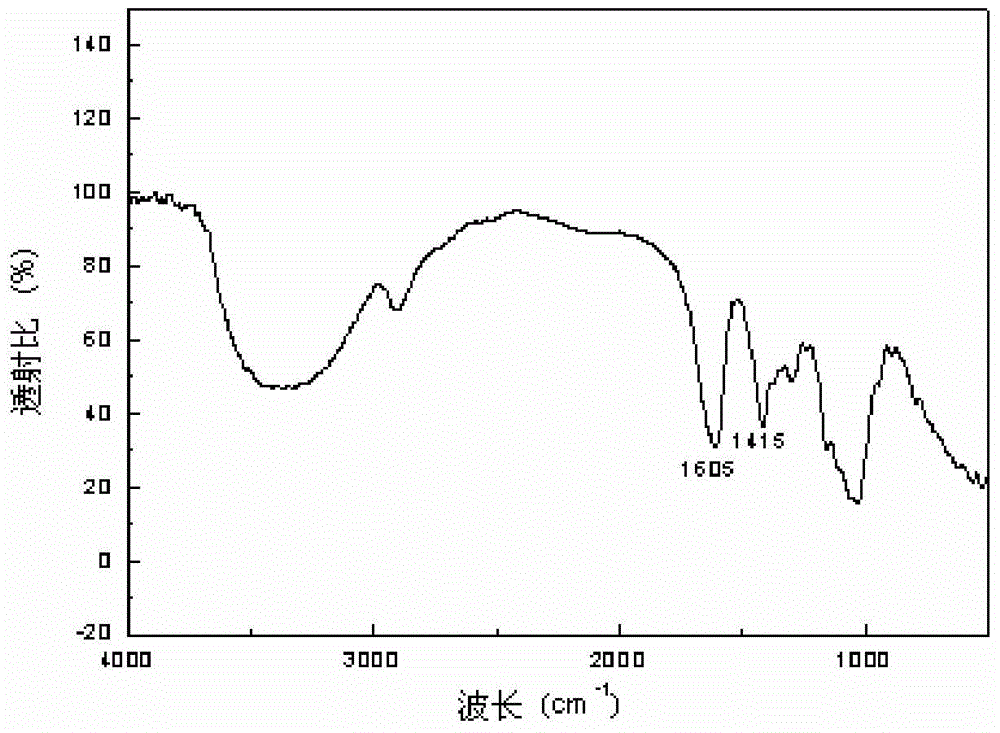

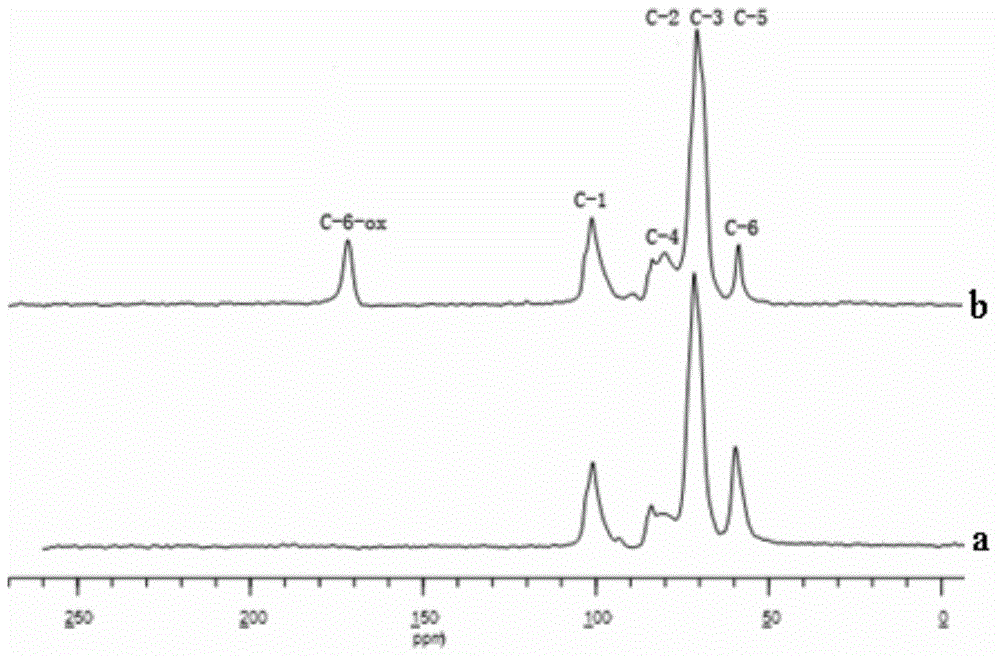

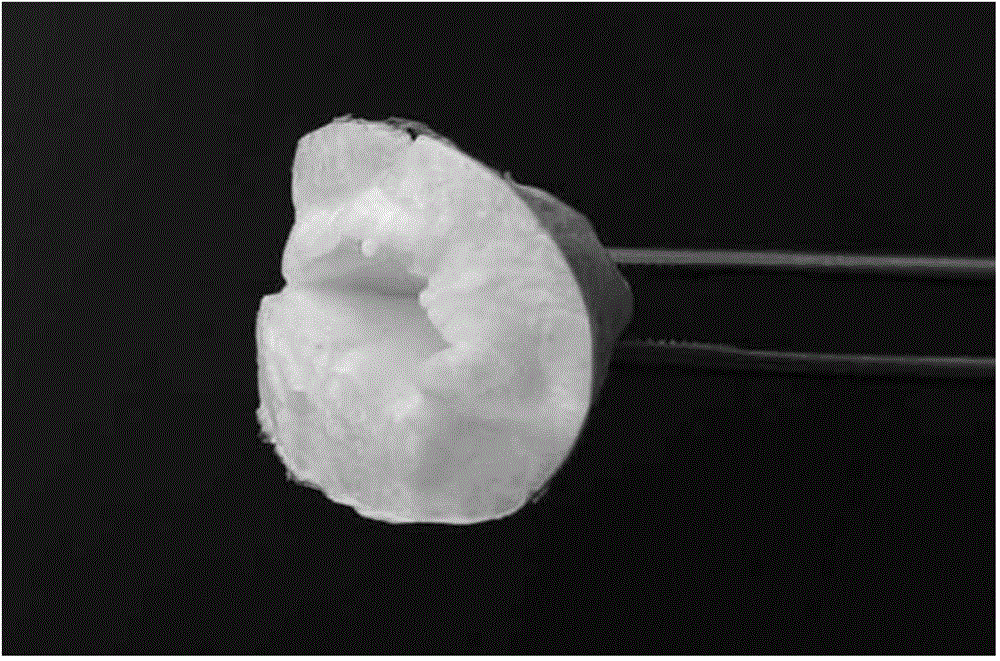

Method for preparing modified regenerated cellulose/alginate hemostatic composite material

ActiveCN104013991AImproves Structural IntegrityHigh viscosityAbsorbent padsBandagesWoven fabricRegenerated cellulose

The invention discloses a method for preparing a modified regenerated cellulose / alginate hemostatic composite material, and relates to a method for preparing a hemostatic material, belonging to the technical field of biomedical composite materials. The invention aims to solve the technical problem that an existing alginate material has an unsatisfactory hemostatic effect, poor structure integrity, and relatively low mechanical strength and stability. The method comprises a first step of modification of regenerated cellulose; a second step of preparation of an oxidized regenerated cellulose / sodium alginate water solution; a third step of molding of the hemostatic composite material; and a fourth step of cross-linking and solidification of the hemostatic composite material. According to the modified regenerated cellulose / alginate hemostatic composite material, due to the introduction of a sodium carboxylic acid structure at the C6 site of the regenerated cellulose molecule through the selective oxidization of a TEMPO-NaClO-NaBr oxidation system, the hemostatic property, structure integrity, mechanical strength and stability of the modified regenerated cellulose / alginate hemostatic composite material are improved, and the defects of poor wet strength, low mechanical integrity and easy deformation of ordinary alginate non-woven fabrics are overcome.

Owner:HARBIN INST OF TECH

Supercapacitor electrode material preparation method based on three-dimensional graphene

InactiveCN103545121AImprove performanceReduce manufacturing costHybrid/EDL manufactureMoistureHydroiodic acid

A supercapacitor electrode material preparation method based on three-dimensional graphene comprises the steps that foamed nickel with surface oxide removed is steeped in oxidized graphene dispersion liquid, the oxidized graphene is made to be deposited on the foamed nickel, and then the foamed nickel is aired to remove moisture at room temperature after being taken out. The steeping method comprises the steps that the foamed nickel is steeped in the oxidized graphene dispersion liquid with the concentration of 0.5mg / ml-10mg / ml, and is aired after ultrasonic processing is carried out for 1-30 minutes; the quality of the oxidized graphene deposited on the foamed nickel is controlled through the concentration of the oxidized graphene and steeping times, and the steeping times is 1 to 30 times. The prepared oxidized graphene / foamed nickel composite electrodes are reduced through ascorbic acid, then a part of metal nickel is etched and removed by using a chemical etching method or a part of the metal nickel is simultaneously reduced, etched and removed through hydroiodic acid to obtain graphene / foamed nickel composite electrodes. The supercapacitor electrode material preparation method based on the three-dimensional graphene is simple, easy to operate, capable of improving the performance of supercapacitors and reducing manufacturing cost, and suitable for mass production.

Owner:NANJING UNIV

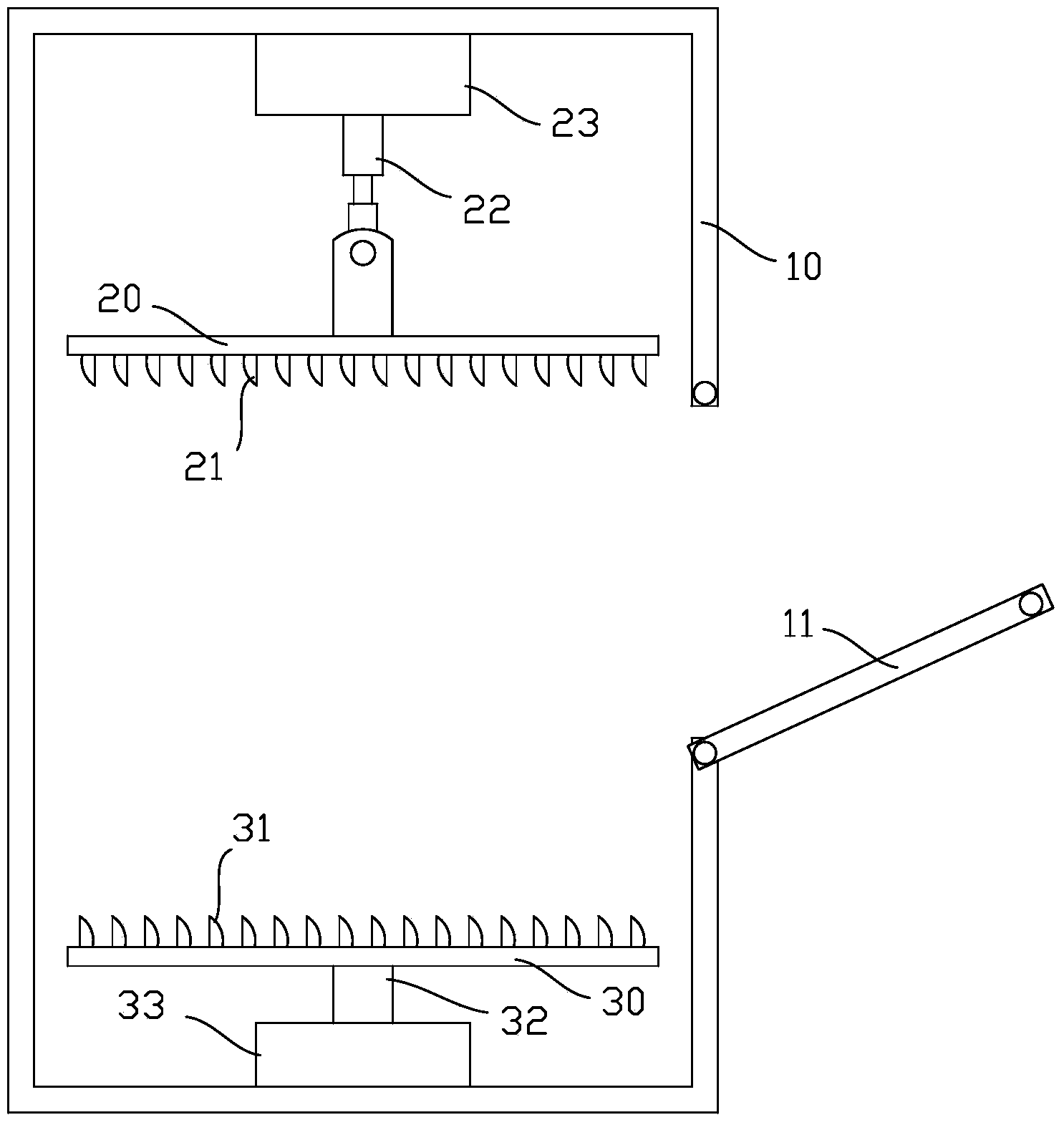

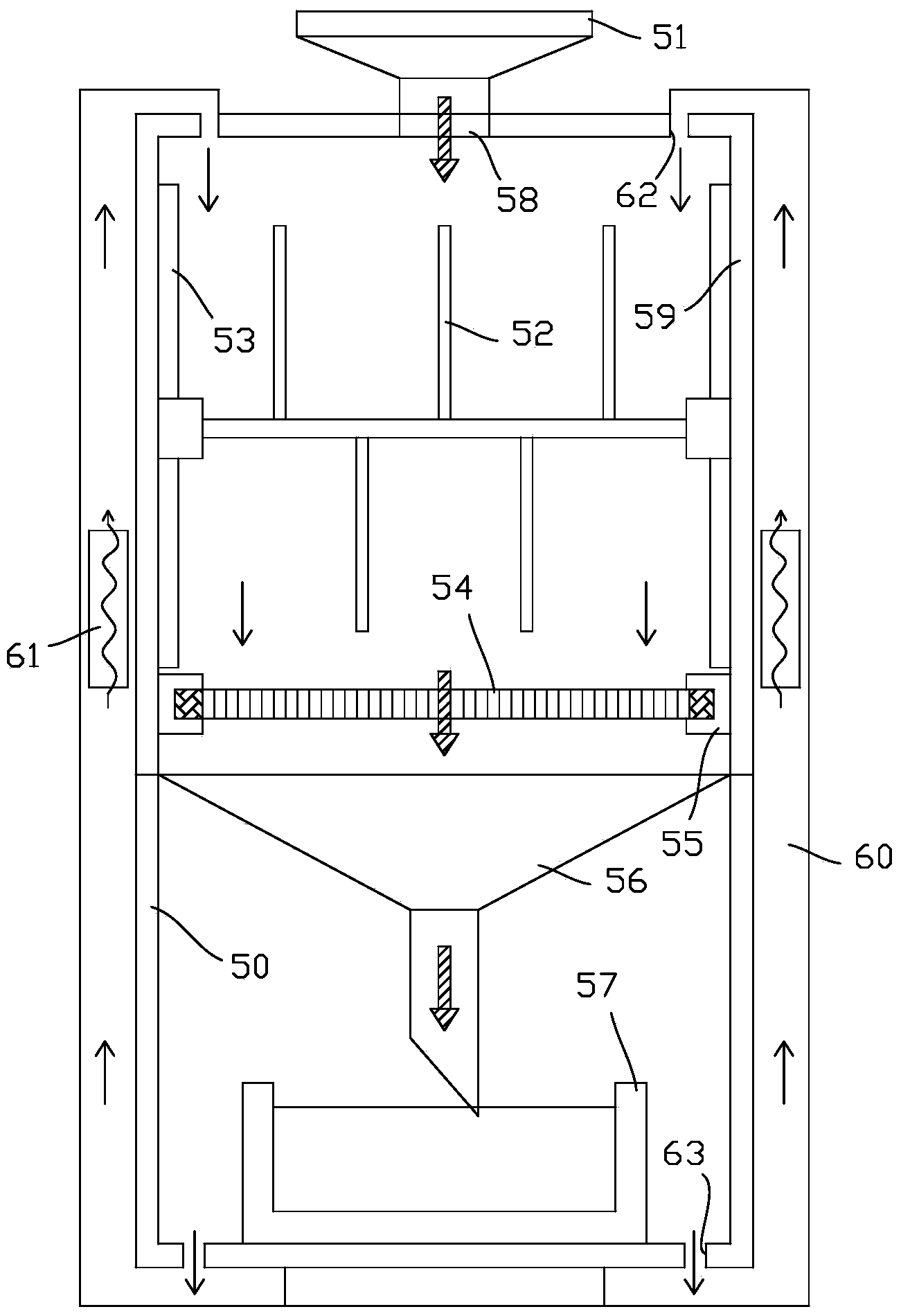

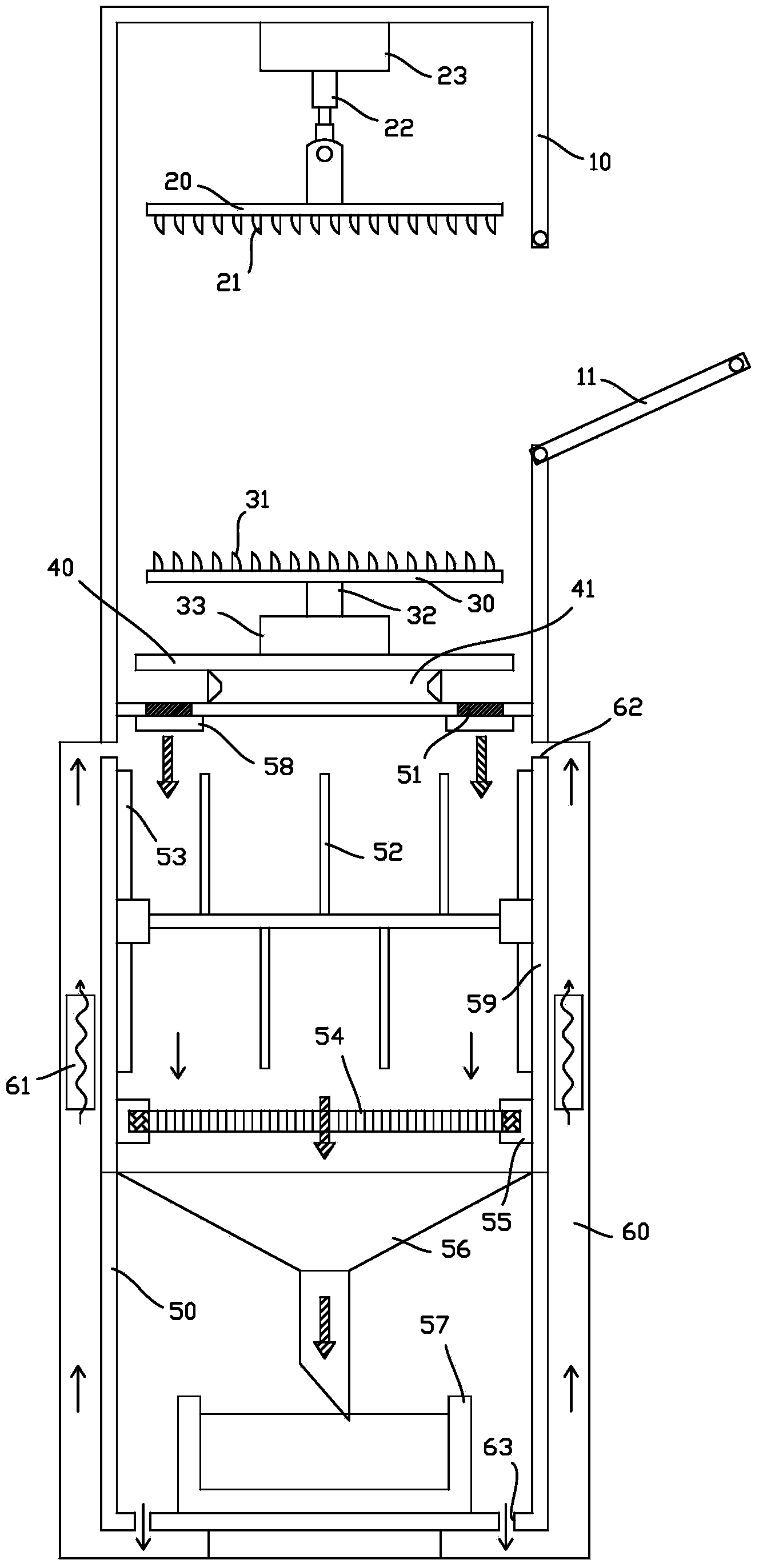

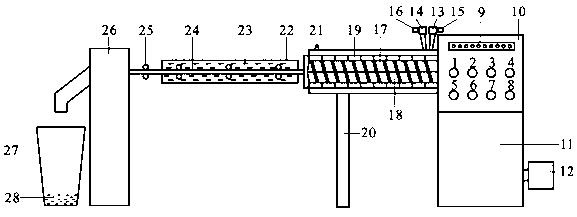

Waste and old mixed plastic recovery and separation device and method

ActiveCN103934923AEffective classificationRealize resource utilizationPlastic recyclingMechanical material recoveryPlastic forming machineMolten state

The invention discloses a waste and old mixed plastic recovery and separation device and method, and belongs to the field of resource recycling of waste and old mixed plastic. The waste and old mixed plastic recovery and separation device comprises a crushing device and a melting, sorting and recovering device, wherein a material feeding mechanism, a crushing mechanism and a material discharging mechanism are arranged in a crushing box body of the crushing device; a heating device, a screening mechanism and a plastic molding mechanism are arranged in a melting box body of the melting, sorting and recovering device; the heating mechanism is used for heating crushed granular materials to a molten state in a staged way; the screening mechanism is used for separating the materials in the molten state and un-melted granular materials; the plastic molding mechanism is placed on the bottom of the melting box body and recycling the separated materials in the molten state. The recovery and separation device can effectively classify the waste and old plastic generated in daily life and industrial production; different plastics are separated and are made into a single plastic which is relatively pure, so that the resource utilization of the waste and old plastic is realized; the post-processing process is omitted; energy resources are saved; the operation is simple; the automation degree is high; the sorting degree is high; the sorting range is wide.

Owner:ANHUI UNIV OF SCI & TECH

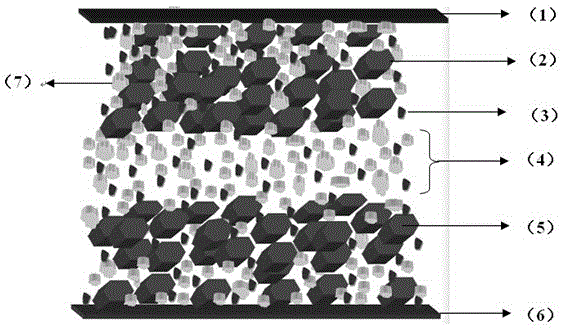

All-solid-state lithium ion battery and preparation method thereof

ActiveCN105098227AGood for deep conductionReduce interface impedanceSolid electrolytesFinal product manufactureAll solid stateInterface impedance

The invention discloses an all-solid-state lithium ion battery and a preparation method thereof. The all-solid-state lithium ion battery is prepared by an ink-jet printing technology; different components are dissolved into a solvent to prepare slurry; the slurry is put into different ink boxes; designing is carried out by computer program; electrodes and electrolyte are longitudinally printed in a stepwise gradient manner; the electrolyte longitudinally changes in electrode plates in a gradient manner; the interface impedance of an electrode active material / electrolyte can be reduced by the gradient structure distribution of the electrolyte in the electrode plates; deep conduction of lithium ions is facilitated; the capacity property of the active material is put into the greatest play; and other parts, except for a current collector, of the all-solid-state lithium ion battery structure prepared by ink-jet printing form an overall lamination structure. Various components in the lamination structure are in tight contact and regular arrangement, so that the interface impedance is much lower than that of the all-solid-state lithium ion battery which is prepared in a mechanical superposition manner; and the ink-jet printing mode is convenient, fast and suitable for large-scale production.

Owner:HARBIN INST OF TECH

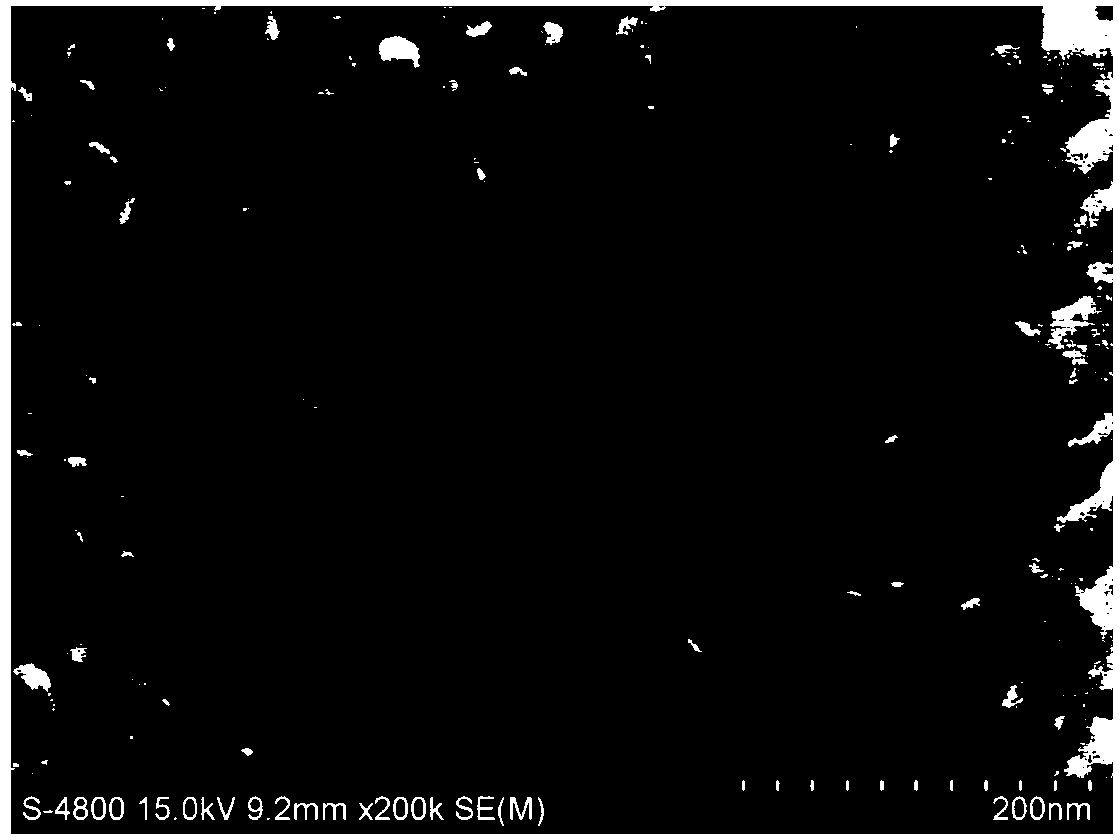

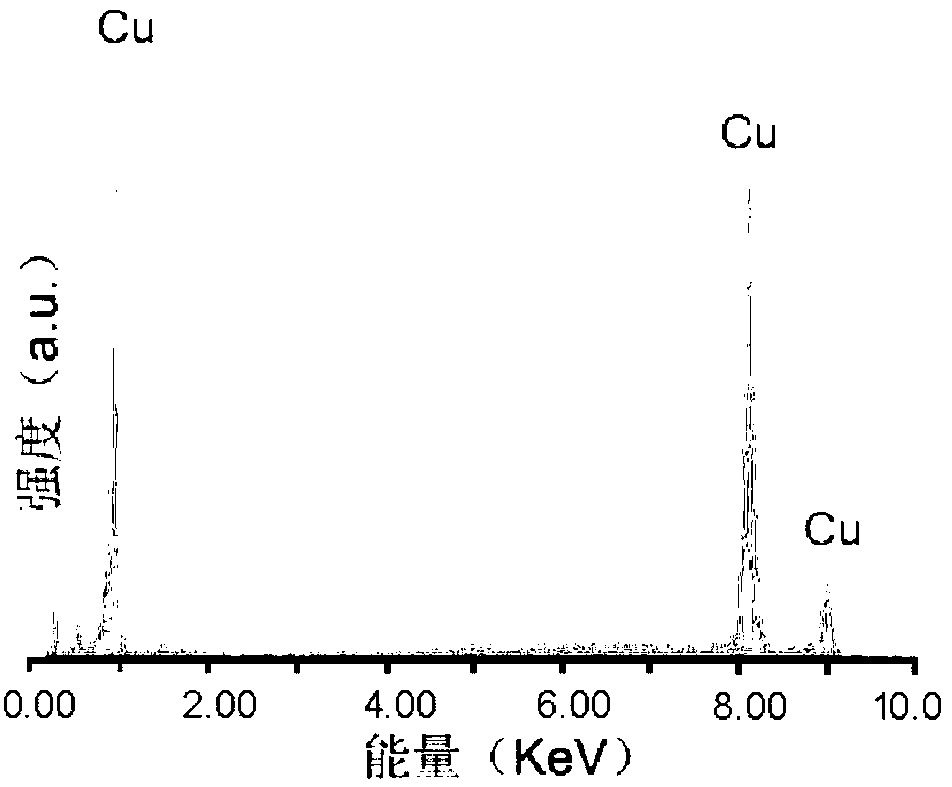

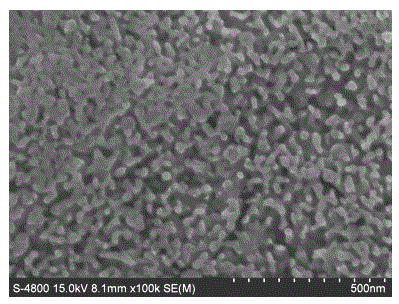

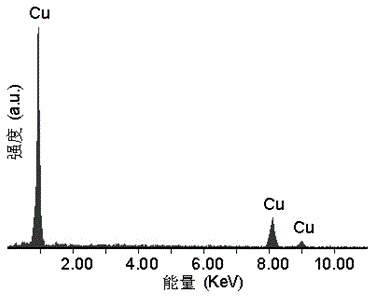

Method for preparing nano-porous copper

ActiveCN103343253AUniform and continuous nanoporous structureReduce complexityElectric arc furnaceIngot

The invention discloses a method for preparing nano-porous copper, which relates to manufacturing for metals with nanoscale porosity. The method comprises the following steps of: calculating the masses of the needed raw materials according to the atomic percent at. % of each element in a target alloy Cu (having an atomic percent of 50.00%)-Zr (having an atomic percent of 42.50-50.00%)(-Al (having the remainder atomic percent)), weighing copper sheets, zirconium grains and aluminium blocks, and mixing to obtain a mother alloy raw material; then smelting the mother alloy raw material in a vacuum arc furnace to prepare a Cu-Zr(-Al) alloy ingot; then preparing a Cu-Zr(-Al) amorphous alloy strip by smelting-spinning equipment; and then preparing a nano-porous metallic copper strip by one-step dealloying, cleaning, and then storing the cleaned nano-porous metallic copper strip in a vacuum chamber having a vacuum degree of 0.1 MPa for the later use, so as to avoid oxidation. With the adoption of the method, the defects of complex preparation process, high cost and inconvenience for industrialized large-scale production of the prior art are overcome.

Owner:HEBEI UNIV OF TECH

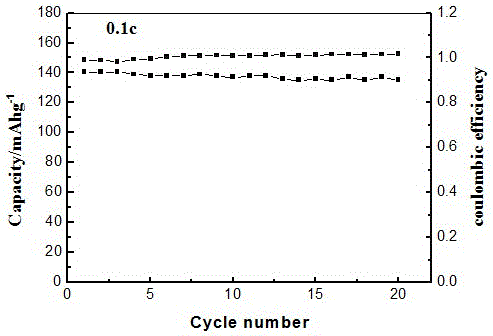

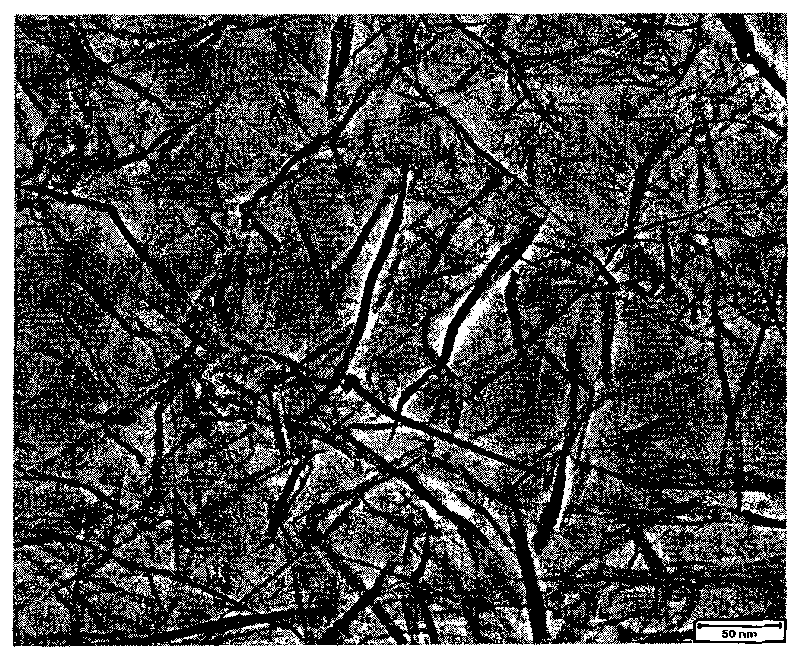

Lithium ion battery conducting material and preparation method and application thereof

InactiveCN101728535AHigh specific capacityCoulombic efficiency is highCell electrodesConductive materialsHigh conductivity

The invention relates to a lithium ion battery conducting material and a preparation method and application thereof. A graphene lithium ion battery conducting material is prepared by adopting a graphite oxide rapid heat expansion method and has high aspect ratio, which is beneficial to shortening the migration distance of lithium ions and improving the wetting quality of an electrolyte, thereby, the rate performance of an electrode is improved; the graphene lithium ion battery conducting material also has high conductivity and can ensure that an electrode active substance has higher utilization ratio and excellent cyclical stability. Compared with a common acetylene black conductive agent under the same using amount, the specific capacity of a lithium ion battery cathode constructed by the conducting material is improved by 25-40 percent, and the coulomb efficiency is improved by 10-15 percent. In addition, the method has low cost, simple process, high security and low energy consumption and is suitable for large-scale production.

Owner:BEIJING UNIV OF CHEM TECH

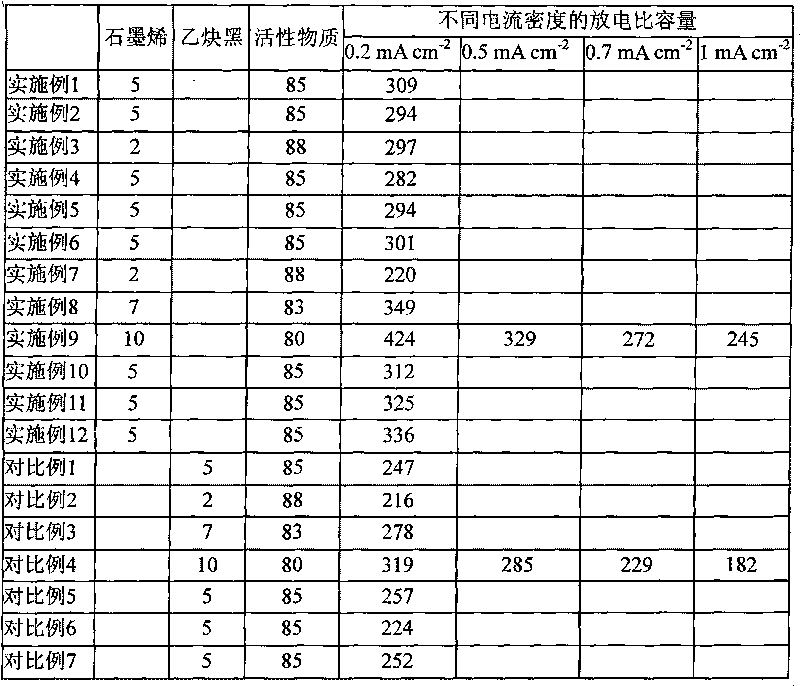

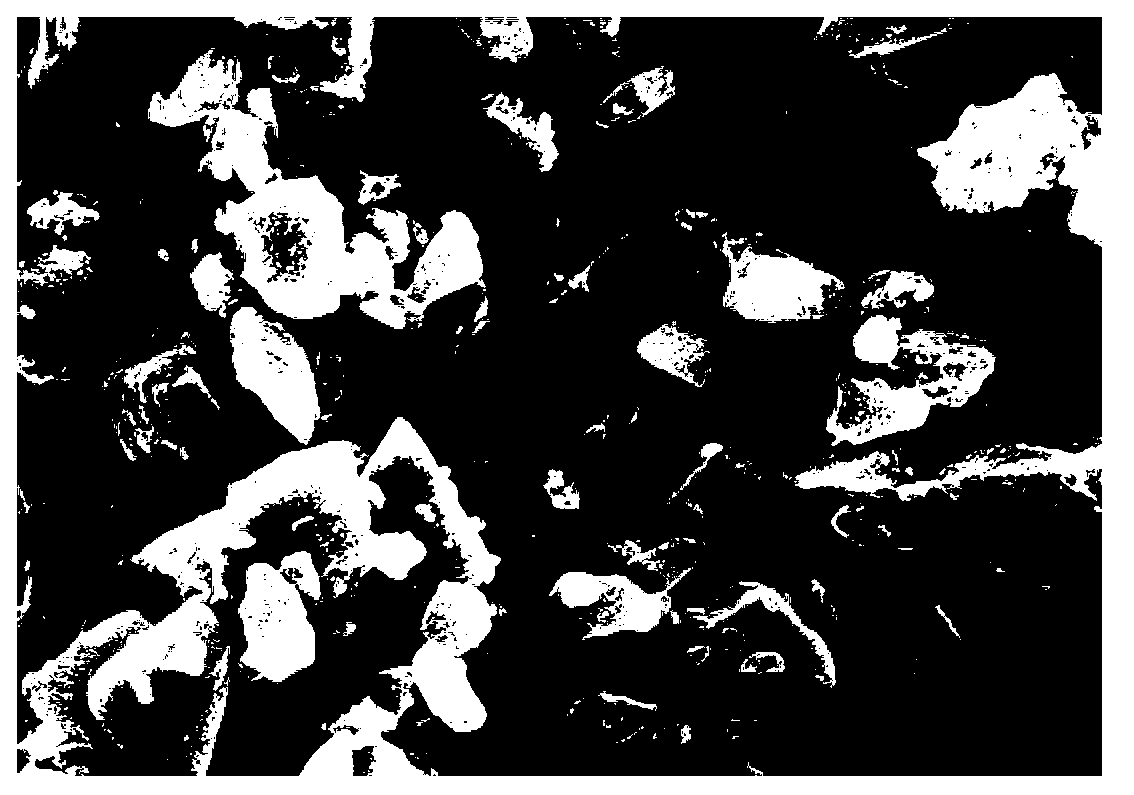

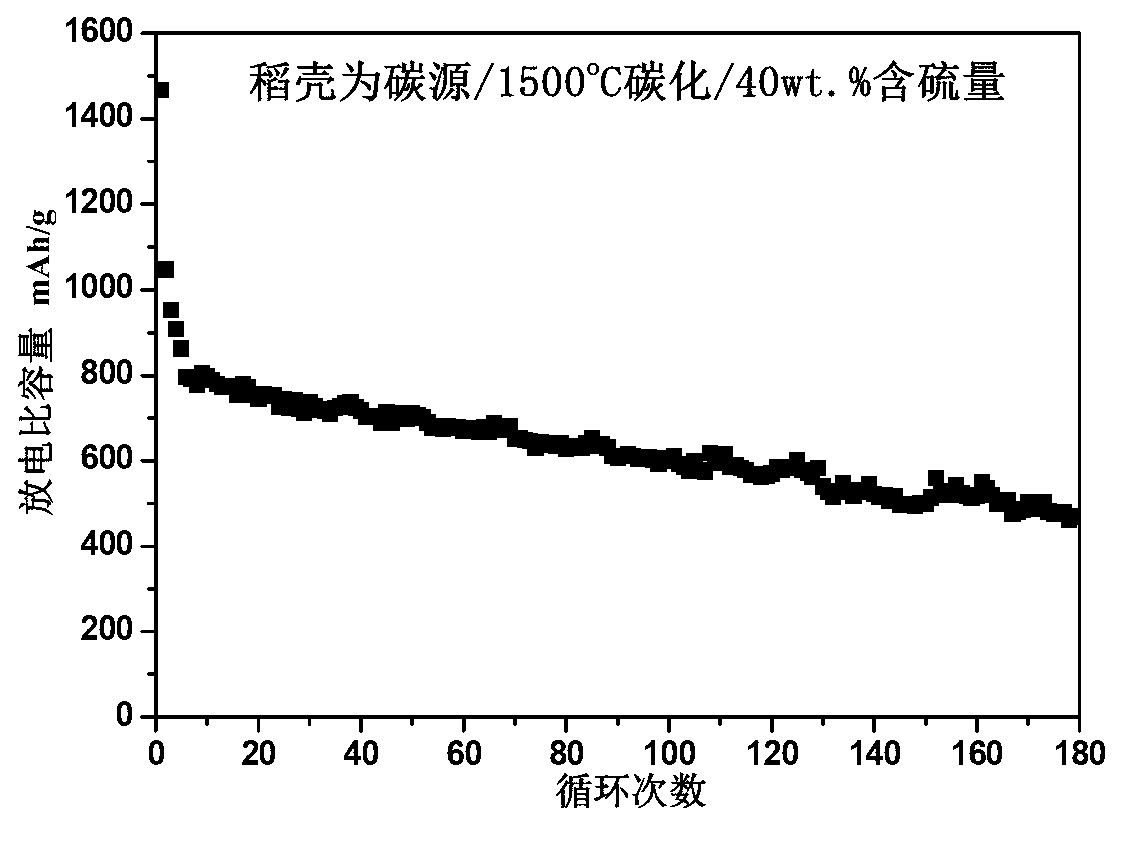

Lithium-sulfur battery sulfur/carbon composite positive electrode material, preparation method and applications thereof

ActiveCN103236560ASimple methodIncrease productivityLi-accumulatorsNon-aqueous electrolyte accumulator electrodesCarbon compositesLithium–sulfur battery

The present invention belongs to the field of lithium ion battery positive electrode materials and lithium ion batteries, and particularly relates to a lithium ion battery positive electrode material and a preparation method thereof, a positive electrode adopting the material, and a lithium ion battery adopting the positive electrode. The lithium-sulfur battery sulfur / carbon composite positive electrode material preparation method comprises: mixing sulfur and carbon through a ball milling method or a stirring method, carrying out heat preservation on the obtained mixture for 0.5-24 h at a temperature of 100-600 DEG C in vacuum, argon or nitrogen atmosphere, and cooling to obtain the sulfur / carbon composite material, wherein a carbon-containing biomass material is adopted as a carbon source, and is subjected to carbonization to obtain the used carbon, the used sulfur is elemental sulfur, and a mass ratio of the sulfur to the carbon in the composite material is (0.4-5):1. With application of the prepared sulfur / carbon composite material as the lithium ion battery positive electrode material, first discharge capacity can be 1300-1600 mAhg<-1>, and capacity after 200 cycles can be 620 mAhg<-1>.

Owner:ZHEJIANG UNIV

Preparation method of hypha/nanoparticle composite sphere material

InactiveCN104785216AHigh activityImprove stabilityOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsFiltrationFreeze-drying

The invention discloses a preparation method of a hypha / nanoparticle composite sphere material. The preparation method is characterized by comprising steps as follows: preparing a culture medium; adding 4-20 ml of a nanoparticle aqueous solution containing 1-10 mg of nanoparticles per milliliter to the sterilized liquid culture medium, evenly mixing the mixture, inoculating the mixture with strains, culturing the mixture for 48-96 h under conditions that the temperature is 15-35 DEG C and rotating oscillation is performed at the speed of 80-200 r / min to form a hypha / nanoparticle composite sphere material, performing filtration to remove a liquid, soaking solids, namely, hypha / nanoparticle composite spheres, with a sodium hydroxide aqueous solution for 12 h, washing the spheres with deionized water until the spheres are neutral, and then performing freeze-drying to prepare the hypha / nanoparticle composite sphere material. The composite sphere material prepared with the method is applicable to fields of industrial catalysis, wastewater treatment, biomedicine and the like and has the characteristics of low cost, high activity, easiness in recovery and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

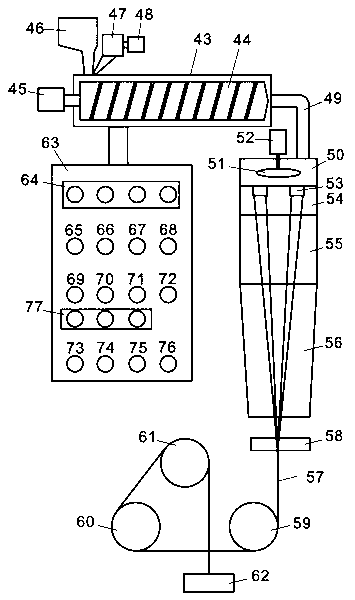

Preparation method of functional polyester fiber

ActiveCN103789868AAdequate responseHigh apparent viscosityArtificial filament heat treatmentMelt spinning methodsPolymer scienceMoisture absorption

The invention relates to a preparation method of a functional polyester fiber. The preparation method comprises the following steps: performing esterification by stages, wherein dihydric alcohols, polyhydric alcohols and functional inorganic powder are mixed according to a certain mole ratio, in the first esterification stage, acid is slightly excess to ensure that monomers with low capability of participating in esterification reaction in the polyhydric alcohols fully react and are grafted into polyester molecular chains, and in the second esterification stage, the dihydric alcohols are replenished to control the terminal carboxyl group of copolyester. The preparation method has the advantages that polyhydric functional groups can improve the apparent viscosity of a system and play a role in wrapping the introduced functional inorganic powder (such as far infrared ceramic inorganic powder, titanium dioxide powder and zinc oxide antibacterial powder), thus improving the dispersion uniformity of particles; settlement is unlikely to happen in the polymerization process and then functional polyester is prepared through condensation polymerization; the functional polyester fiber is finally prepared by carrying out melt spinning on the prepared polyester, has good moisture absorption property and flexibility and can be widely used for preparing far-infrared moisture absorbing and sweat releasing antistatic and antibacterial fabrics next to the skin.

Owner:JIANGSU HENGZE COMPOSITE MATERIALS TECH

Preparation method for heat-resisting polylactic acid fiber

InactiveCN102839443AImprove heat resistanceEnsuring environmental friendlinessSpinning head liquid feederMelt spinning methodsPolymer scienceTriethoxysilane

The invention relates to a preparation method for a heat-resisting polylactic acid fiber, which comprises the following steps: drying polylactic acid grains in a vacuum drum; modifying the surface of nanometer silicon dioxide by using a silane coupling agent, namely, gamma-aminopropyl triethoxy silane; mixing the dry polylactic acid grains with the modified nanometer silicon dioxide; preparing into polylactic acid plus silicon dioxide master batches by utilizing a double-screw extruding machine; uniformly mixing the master batches and the polylactic acid grains at weight ratio; pouring the mixture into a melt spinning machine for spinning; and drafting through two areas, thereby obtaining polylactic acid plus silicon dioxide fibers. The process of the preparation method is advanced; the data is full and accurate; the preparation method is suitable for mass production; the prepared polylactic acid filament is excellent in heat resistance and mechanical property; the problem of poor heat resistance of the polylactic acid fiber is effectively solved; and the application scope of the polylactic acid fiber is widened.

Owner:TAIYUAN UNIV OF TECH

Method for preparing black tea fungus juice beverage by using fermentation method

InactiveCN101843346ACompliance with securityGood Flavor Taste ColorFood preparationNutritive valuesFruit juice

The invention belongs to the field of light industrial food and relates to a method for preparing a black tea fungus juice beverage by using a fermentation method. The method is characterized in that the black tea fungus juice comprises the following raw materials: 100-300ml of black tea fungus mother liquor, 3-10g of tea leaf, 1,000ml of water, 15-50g of sugar and 100-200ml of fruit juice. The method comprises the following steps of: dissolving the sugar in tea water to prepare sweet tea water; then adding the fruit juice and the black tea fungus juice; and fermenting according to two different fermentation stages of early ventilating, stirring and fermenting and later standing and fermenting. The method overcomes the defects of a traditional domestic workshop type natural and single fermentation mode and the defects of unstable quality, no output guarantee, poor product taste, and the like, improves the product nutritional value, the taste and the flavor and the product quality and provides a technological base for the industrial development and the scale production of black tea funguses and the comprehensive utilization of tea resources.

Owner:FUJIAN NORMAL UNIV

Method for improving flavor and texture of plant enzyme food by utilizing fermentation of compound strains

ActiveCN104223036AStable textureShort manufacturing timeFood ingredient functionsFood preparationFiltrationSweetness

The invention discloses a method for improving the flavor and the texture of plant enzyme food by utilizing fermentation of compound strains. The method is characterized in that strains with good permeability resistance, aroma strains, plant-source preponderant strains and strains for optimizing the texture of a product are screened by sugaring digestion, fermentation of the compound strains, after-ripening, clarifying and membrane filtration treatment, reasonable and scientific combination is carried out on the strains, the preparation time of the plant enzyme food is effectively shortened by controlling the matching and the used amount of the strains, the prepared plant enzyme food is coordinated in flavor, stable in texture, safe and sanitary, and uniform in color, has strong composite fruit flavor and fermenting mellow flavor, is viscous in organization and mellow in taste, has no stimulation in eating, is coordinated in sweetness and sourness, smooth in swallowing, and sweet and lasting in residual taste. The method disclosed by the invention has the advantages that the process is simple, the fermented product can be stored at normal temperature, and the quality is still stable after 6 months, so that the method is suitable for large-scale production, and has a good market prospect.

Owner:深思来福(深圳)科技有限公司

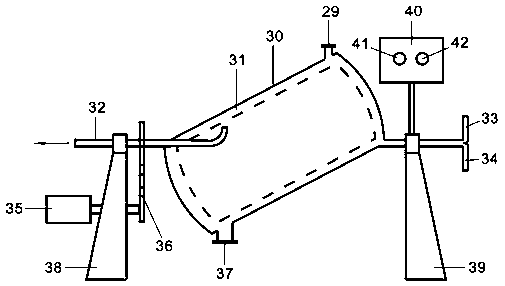

Optical fiber preform cladding fluorine doping method

ActiveCN103224325AReduce OH

<sup>-</sup>

contentSuitable for large-scale productionGlass making apparatusGlass fibre productsGlass transitionCore (optical fiber)

The present invention discloses an optical fiber preform cladding fluorine doping method, which comprises the following steps: depositing a core layer loose body on a target rod; heating the outer surface of the core layer loose body to form a dense layer, such that density of the dense layer is higher than density in the core layer loose body; depositing an inner cladding loose body outside the dense layer to form a core rod loose body comprising the core layer loose body and the inner cladding loose body; taking the target rod out to form a center hole in the center of the core rod loose body; placing the core rod loose body into a glass transition furnace, carrying out heating dewatering in a dewatering atmosphere, and introducing dewatering gas into the center hole during heating; heating the core rod loose body in a fluoride atmosphere, such that fluorine is selectively doped into the inner cladding loose body to form step refraction index distribution; and carrying out glass transition on the core rod loose body, such that the center hole is shrunk, the core layer loose body forms a core layer, and the inner cladding loose body forms an inner cladding so as to form a core rod. With the method, OH<-> content in the core layer can be effectively reduced, attenuation of optical fiber 1383 nm can be reduced, and fluorine distribution in a radial direction of the cladding is uniform.

Owner:ZHEJIANG FUTONG OPTICAL FIBER TECH +1

Method for preparing supercapacitor carbon aerogel by utilization of bagasse

ActiveCN103839699AImprove electrochemical performanceLow costHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceToxic industrial waste

The invention discloses a method for preparing supercapacitor carbon aerogel by the utilization of bagasse. The method includes the steps that the bagasse is used for preparing cellulose powder without xylogen and hemicellulose; the cellulose powder is used for preparing cellulose aerogel; the cellulose aerogel is carbonized to obtain carbon aerogel; the carbon aerogel is activated to obtain the supercapacitor carbon aerogel. According to the method, the industrial waste bagasse is used as raw materials, the requirements for sustainable development and environmental protection are met, and the cost of electrode materials is effectively lowered. The product prepared through the method is of a three-dimensional hierarchical pore structure; compared with a product obtained through a conventional method, the product prepared through the method is large in specific area and good in repeatability, and has higher specific capacitance and better cycling stability. The method is more suitable for preparing supercapacitor electrode materials and has wide development prospects.

Owner:SHANDONG UNIV

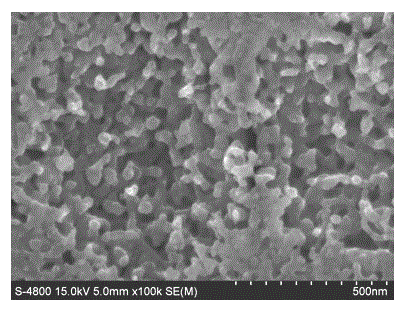

Preparation method of nano porous copper

The invention discloses a preparation method of nano porous copper, and relates to manufacture of alloy with pores, in particular to a method for preparing the nano porous copper by adopting a free dealloying technology. The preparation method comprises the following steps of: firstly according to the atomic percent of all elements in target alloy: 50.00-55.00% of Cu, 40.00-45.00% of Hf and the balance of Al, weighing copper pieces with the mass percent purity being 99.99%, hafnium particles with the mass percent purity being 99.99% and aluminium blocks with the mass percent purity being 99.99%; putting raw materials of master alloy in a vacuum electric-arc furnace, smelting to prepare Cu-Hf-Al master-alloy casting ingot; then preparing a Cu-Hf-Al amorphous alloy strip by using the master-alloy casting ingot; and finally carrying out dealloying treatment with low-concentration hydrofluoric acid solution to prepare the nano porous copper belt. The preparation method disclosed by the invention has the advantages that the defects of complex operation, high cost, long production period and inapplicability for large-scale industrial production in the prior art are overcome.

Owner:HEBEI UNIV OF TECH

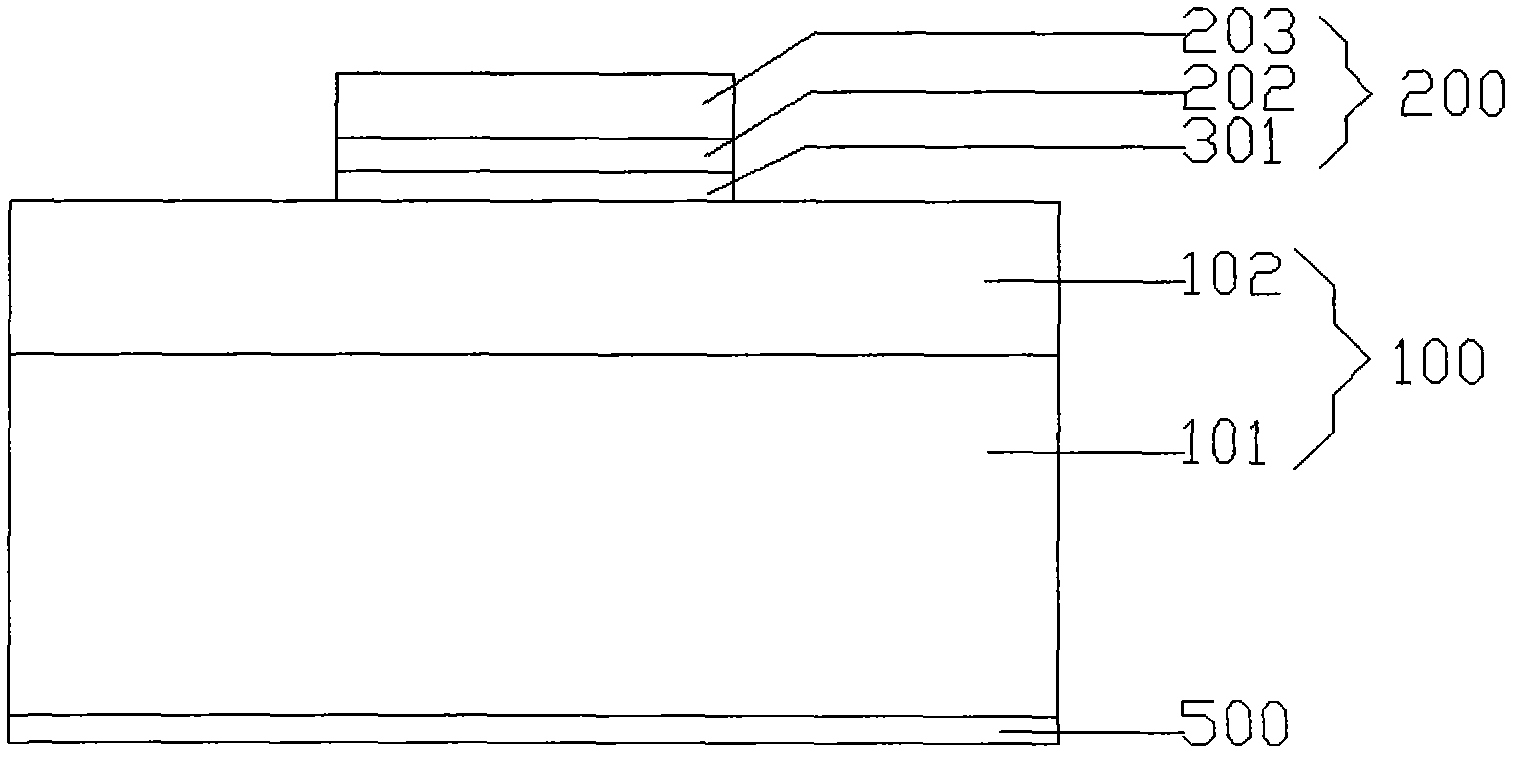

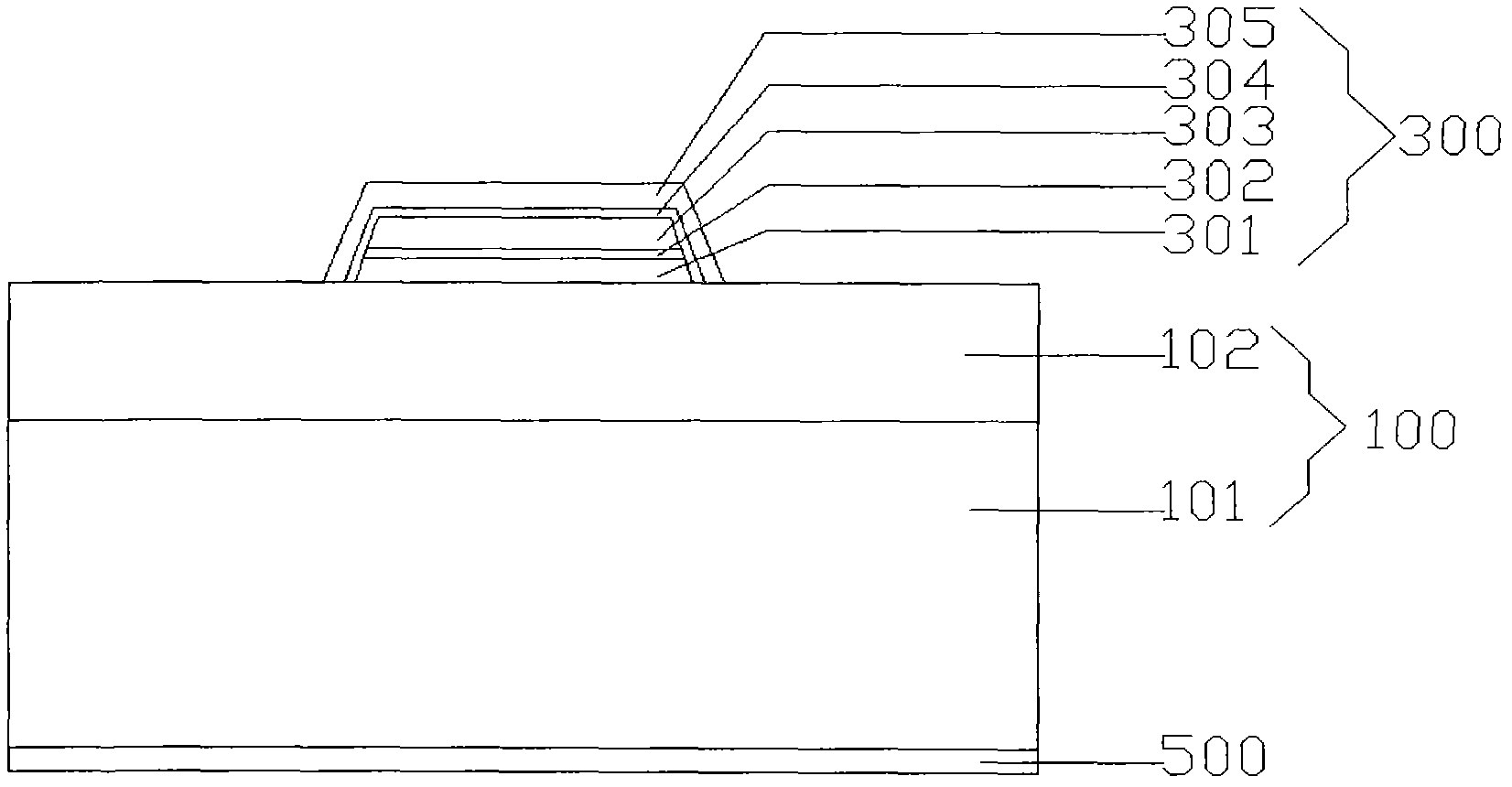

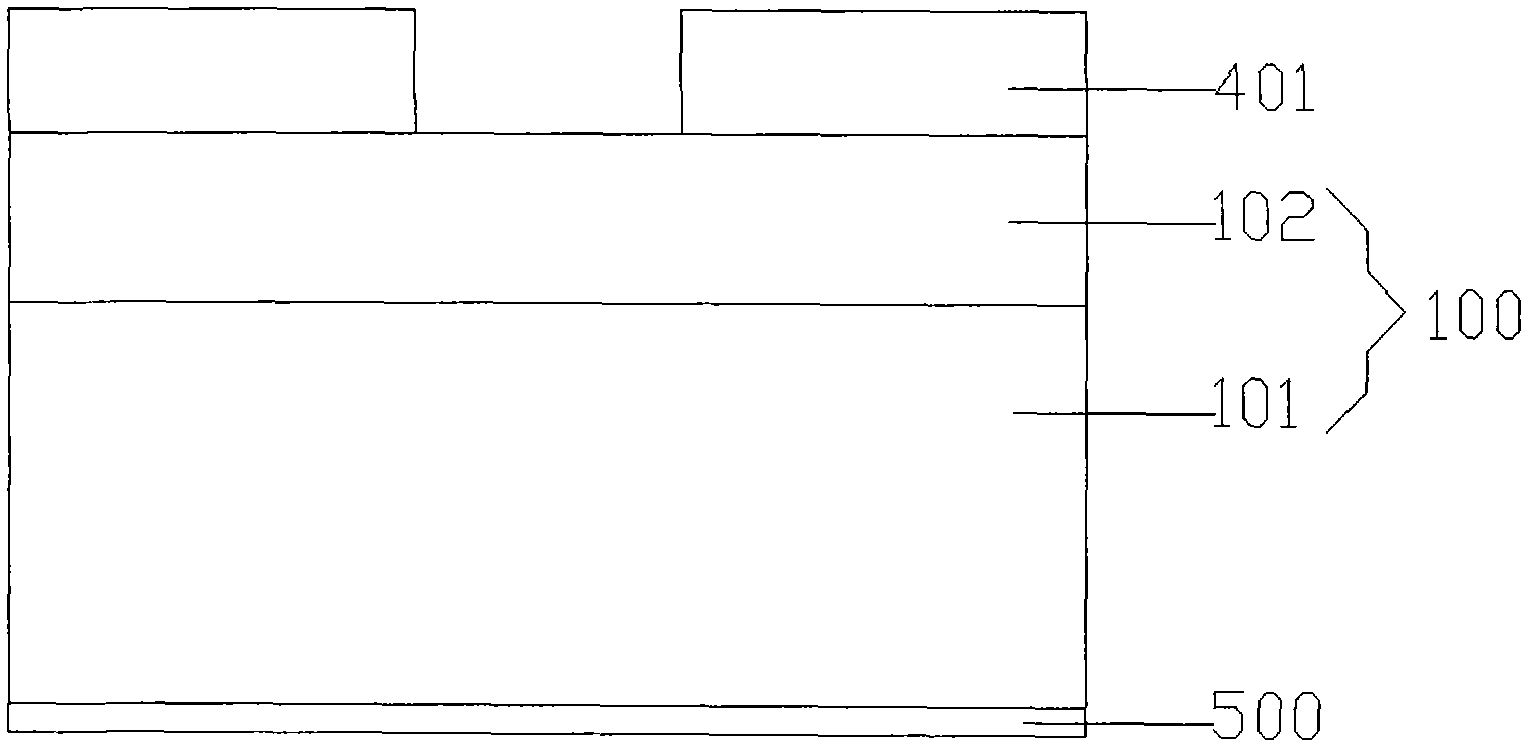

Composite electrode of light-emitting diode chip and manufacturing methods thereof

InactiveCN102130259ALow costImprove environmental adaptabilitySemiconductor devicesComposite electrodeOhmic contact

The invention belongs to the field of light-emitting semiconductors, and particularly relates to the field of light-emitting diode chips. The structure of a composite electrode of the light-emitting diode chip comprises an ohmic contact metal layer, a first isolated metal layer, a filled metal layer, a second isolated metal layer and a surface metal layer from bottom to top respectively, wherein the second isolated metal layer and the surface metal layer are covered on the upper surfaces and the side surfaces of the ohmic contact metal layer, the first isolated metal layer and the filled metal layer so as to completely wrap the three electrode layers in the electrode. The invention further comprises two manufacturing methods of the composite electrode, which are the method I and the method II respectively. The composite electrode uses Al, Ag and other active metals with low using cost to replace part of Au in the electrode, thereby reducing the cost of the electrode and having stronger ability to adapt to the environment; through multiple tests by an author, the composite electrode can be quickly effectively manufactured by the two methods, the manufacturing process is simple and feasible, the operability is high, and the large-scale production is convenient.

Owner:DALIAN MEIMING EPITAXIAL WAFER TECH

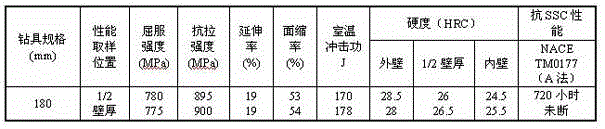

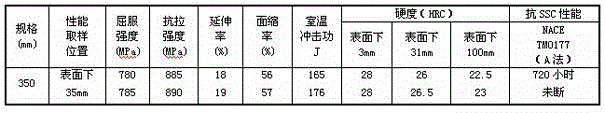

Round steel with high strength and toughness and hydrogen sulfide stress corrosion resistance for drilling tool and manufacturing method of round steel

The invention discloses a round steel with high strength and toughness and hydrogen sulfide stress corrosion resistance for a drilling tool and a manufacturing method of the round steel. The round steel comprises the following chemical components in percentage by mass: 0.20-0.30% of C, 0.15-0.40% of Si, 0.20-0.70% of Mn, less than or equal to 0.010% of P, less than or equal to 0.005% of S, 0.70-1.30% of Cr, 0.40-0.95% of Mo, less than or equal to 0.25% of Ni, 0.05-0.10% of Cu, 0.05-0.10% of Alt, less than or equal to 0.1% of V, less than or equal to 0.06% of Nb, less than or equal to 0.010% of Ti, less than or equal to 0.009% of N, 0.001-0.003% of B and the balance of Fe and inevitable impurities. By adopting the preparation method, the round steel with the maximum specification of 350mm can be manufactured, and the round steel is particularly suitable for being processed to be stress complex drilling tools with large specifications and high strength and toughness requirements such as hydrogen sulfide corrosion resistant drill rods, drill collars, and drill rod joints applied to acidic oil wells.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

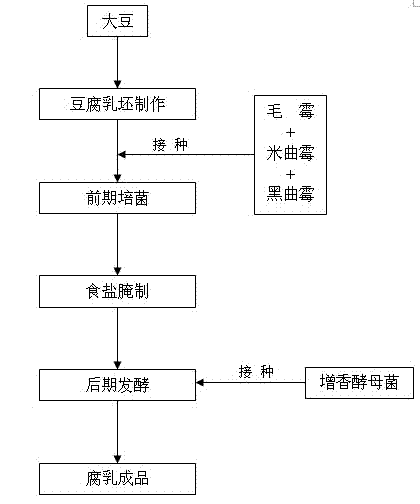

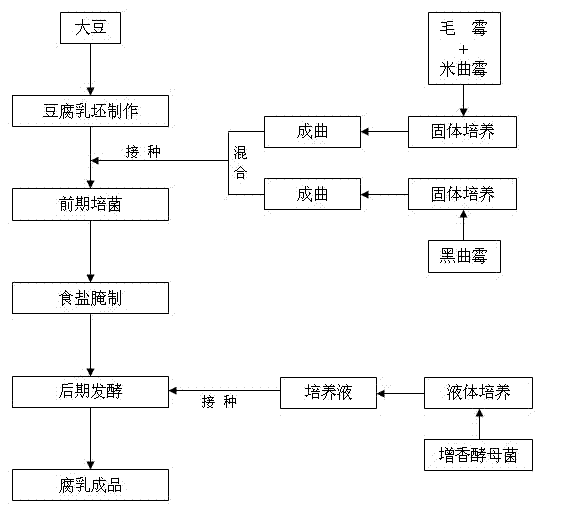

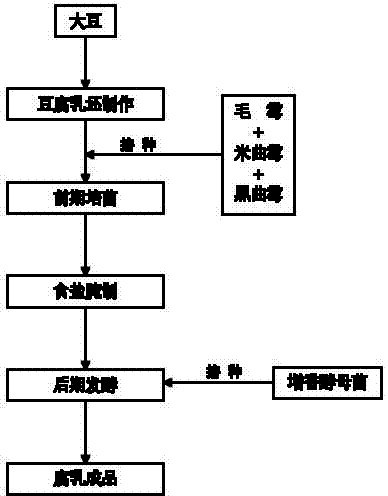

Method for producing fermented bean curd through multi-strain mixed fermentation

ActiveCN102197847APromote decompositionRich flavorCheese manufactureFood scienceYeastAspergillus oryzae

The invention discloses a method for producing fermented bean curd through multi-strain mixed fermentation. The method comprises the following steps of: (1) preparing raw fermented bean curd, namely preparing the raw fermented bean curd from soybean; (2) culturing bacteria at the early stage, namely inoculating mixed strains comprising mucor, Aspergillus oryzae and Aspergillus niger into the raw fermented bean curd to culture bacteria at the early stage to obtain the fermented bean curd blanks; (3) pickling by using salt, namely placing the fermented bean curd blanks obtained in the step (2) into a rubber box, scattering salt layer by layer, and pickling with the salt to prepare salty blanks; (4) fermenting at the later stage, namely placing the pickled fermented bean curd salty blanks into a bottle, inoculating flavor-increasing yeast into wine liquid of semifinished products, and fermenting at the later stage; and (5) obtaining the fermented bean curd. By the method, the flavor of the fermented bean curd products can be enriched and the fermenting period of the fermented bean curd is shortened.

Owner:GUANGDONG CHUBANG FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com