Optical fiber preform cladding fluorine doping method

A fiber preform and cladding technology, which is applied in glass fiber products, manufacturing tools, glass manufacturing equipment, etc., can solve the problem of ensuring the uniformity of fluorine doping in the axial and radial directions, and the difficulty of forming a step-type refractive index profile structure and other problems, to achieve the effect of reducing attenuation, uniform distribution, and reducing OH- content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

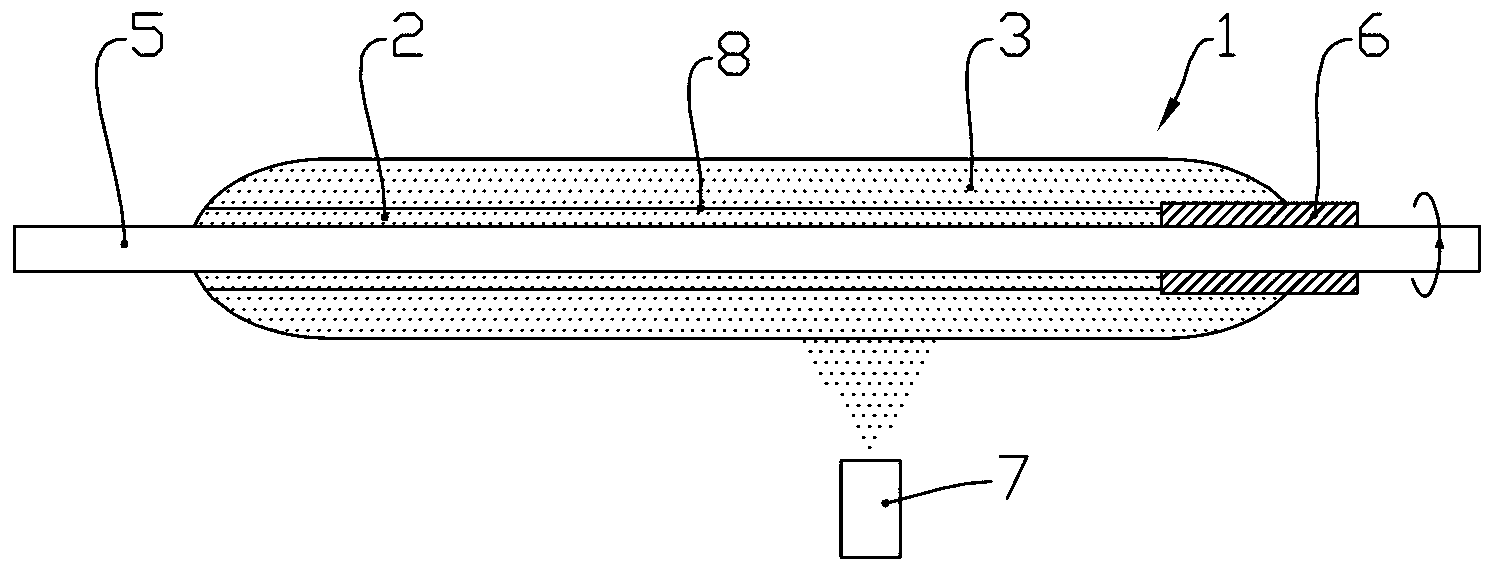

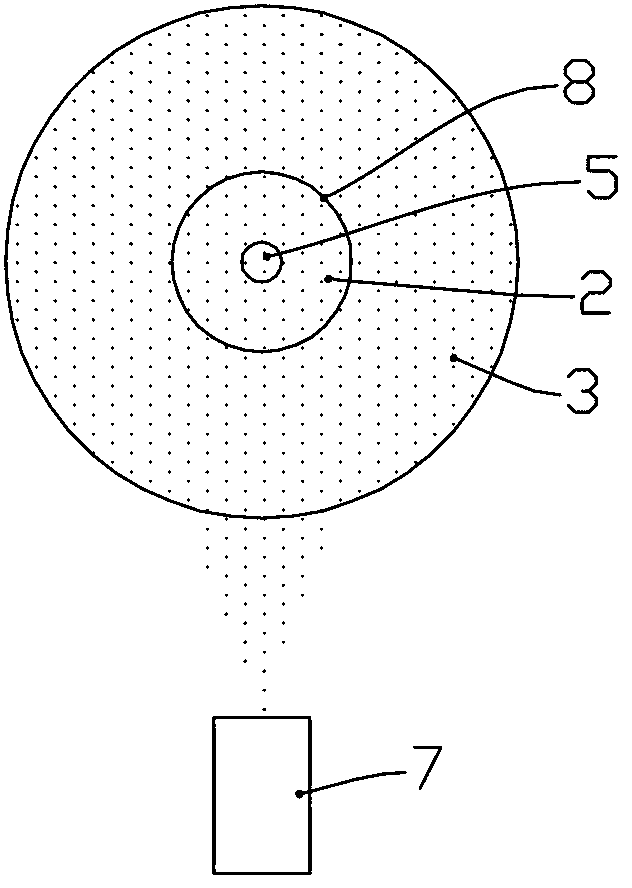

[0076] The mandrel loose body 1 is manufactured by OVD method. Insert the target rod 5 into the tubular handle 6 and install it on the lathe. Gaseous halide raw material SiCl 4 、GeCl 4 The hydrolysis reaction is carried out in an oxygen-hydrogen flame to produce a large amount of SiO 2 doped GeO 2 The particles are deposited onto the target rod 5 . As the target rod 5 moves back and forth, the SiO 2 -GeO 2 The particles are deposited layer by layer on the outer surface of the rotating mandrel loose body 1 . After the core layer loose body 2 is deposited, stop supplying the raw material SiCl in the blowtorch 7 4 and GeCl 4 , heat the outer surface of the loose core layer 2 with an oxyhydrogen flame to vitrify it to form a dense layer 8 . The flow rates of hydrogen and oxygen in the blowtorch 7 are 200 slpm and 90 slpm respectively. Next, feed the raw material SiCl in the blowtorch 7 4 , depositing the inner cladding loose body 3 on the outer surface of the dense laye...

Embodiment 2

[0079] The mandrel loose body 1 is manufactured by the OVD method as described in Example 1. The difference is that when the core layer loose body 2 is deposited, the raw material SiCl 4 The hydrolysis reaction in an oxygen-hydrogen flame produces SiO 2 The particles are deposited onto the target rod 5 to form pure SiO 2 Core loose body 2. After heating to form the dense layer 8 as described in Example 1, the inner cladding loose body 3 is continuously deposited. After the deposition is completed, the ratio of the diameter of the inner cladding loose body 2 to the diameter of the core layer loose body 2 is 5.0. The mandrel loose body 1 has an outer diameter of 100mm and a length of 1800mm.

[0080] Pull out the target rod 5, weld the tubular extension handle 9 to the tubular handle 6, then install the tubular extension handle 9 on the fixture above the vitrification furnace (not shown in the figure), and slowly lower the mandrel loose body 1 Vitrification in a vitrification...

Embodiment 3

[0082] The mandrel loose body 1 is manufactured by the OVD method as described in Example 2. The dense layer 8 at the interface between the loose body of the core layer 2 and the loose body of the inner cladding layer 3 is formed by heating in a heating furnace to obtain pure SiO 2 For the mandrel loose body 1 of the core layer, the ratio of the diameter of the inner cladding loose body 3 to the diameter of the core layer loose body 2 is 5.0. The mandrel loose body 1 has an outer diameter of 100mm and a length of 1200mm.

[0083] Pull out the target rod 5, weld the tubular extension handle 9 to the tubular handle 6, then install the tubular extension handle 9 on the fixture above the vitrification furnace (not shown in the figure), and slowly lower the mandrel loose body 1 Vitrification in a vitrification furnace. The mandrel loose body 1 rotates at a speed of 10 rpm, and gradually descends into the heating zone. First pass inert gas nitrogen purge, then pass through Cl 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com