Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1532results about How to "Guaranteed thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

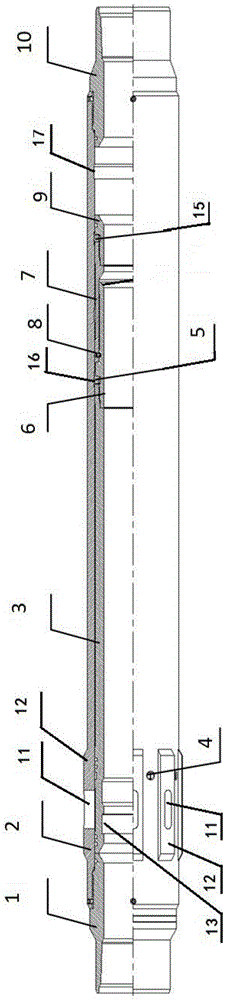

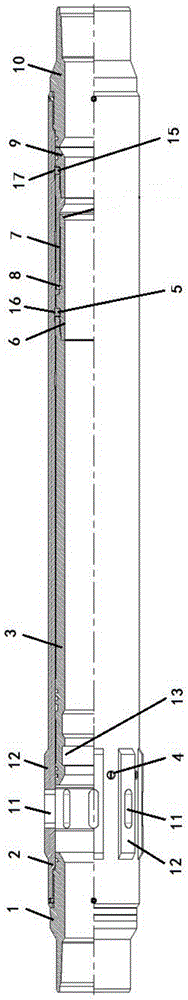

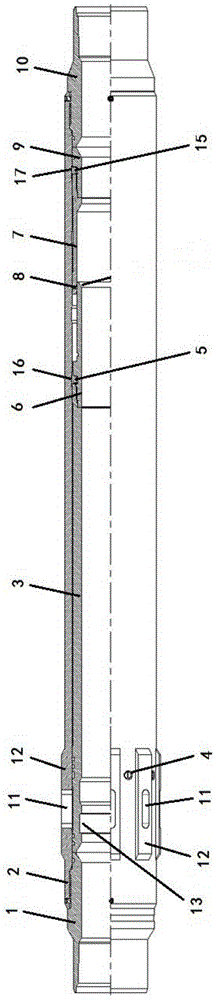

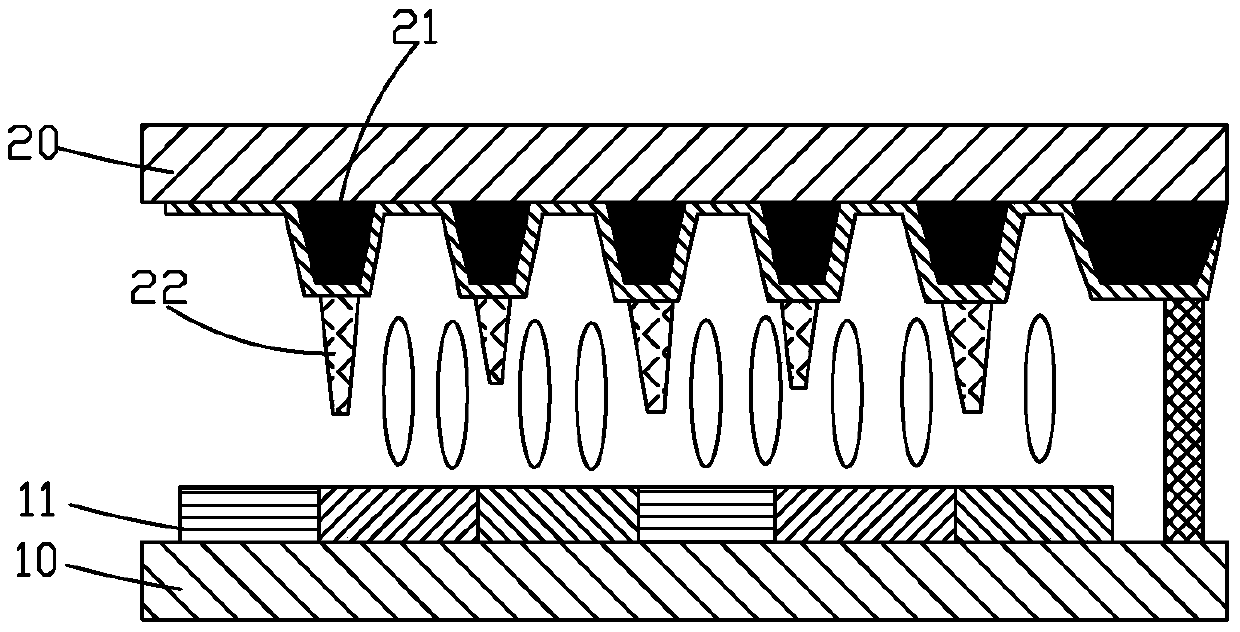

Switchable well cementation sliding sleeve based on fracturing of separate layers and construction method thereof

A switchable well cementation sliding sleeve based on fracturing of separate layers comprises an outer barrel, an upper joint and a lower joint are installed at the upper end and the lower end of the barrel respectively, a fracturing port is formed in the side wall of the upper portion of the outer barrel, and an upper center pipe, an upper connection sleeve, a lower center pipe and a lower connection sleeve are installed inside the outer barrel. The switchable well cementation sliding sleeve based on fracturing of the separate layers is not provided with a ball seat, so a full bore of the inner wall can be maintained, fracturing fluid can flow back in time, and the construction period is shortened. The well cementation sliding sleeve is set in the upper center pipe through a bottom packer, downward pushing force big enough can be generated in the process of annular or continuous tubing pressing, so the upper center pipe can overcome shearing force of corresponding shearing dowels and move downwards, and therefore the fracturing port of the well cementation sliding sleeve can be opened.

Owner:JEREH ENERGY SERVICES

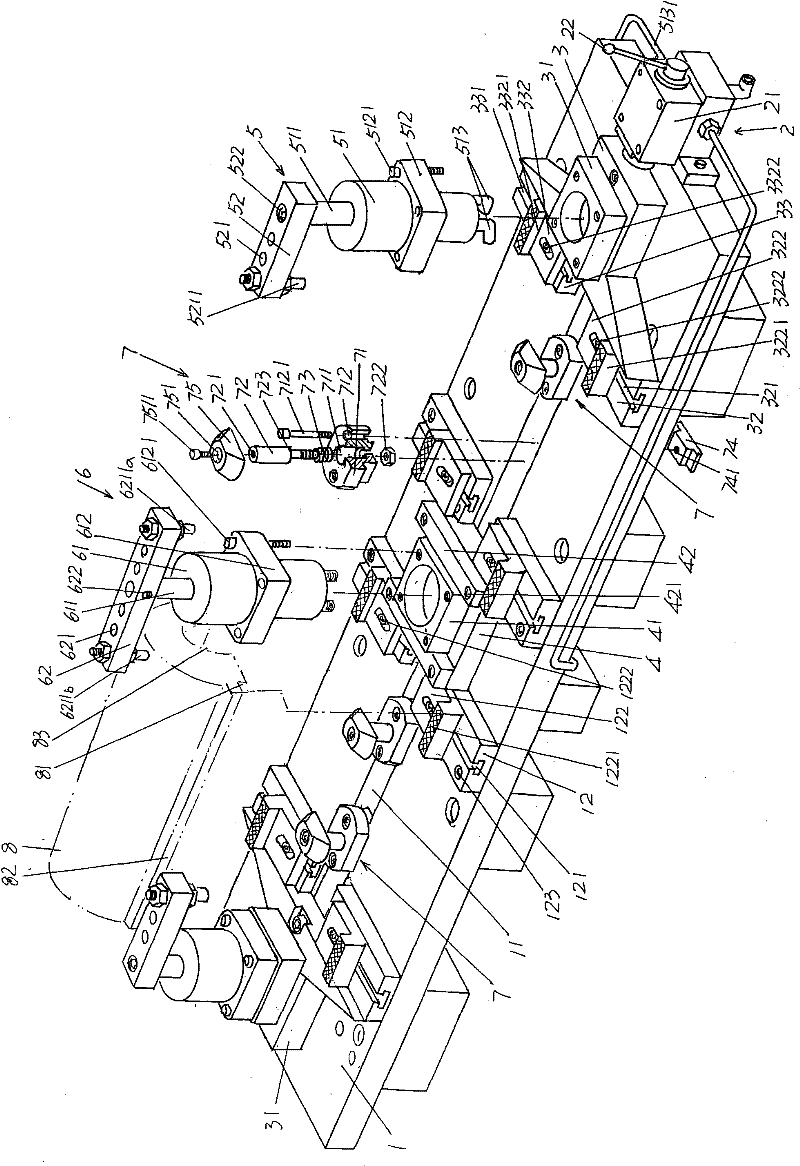

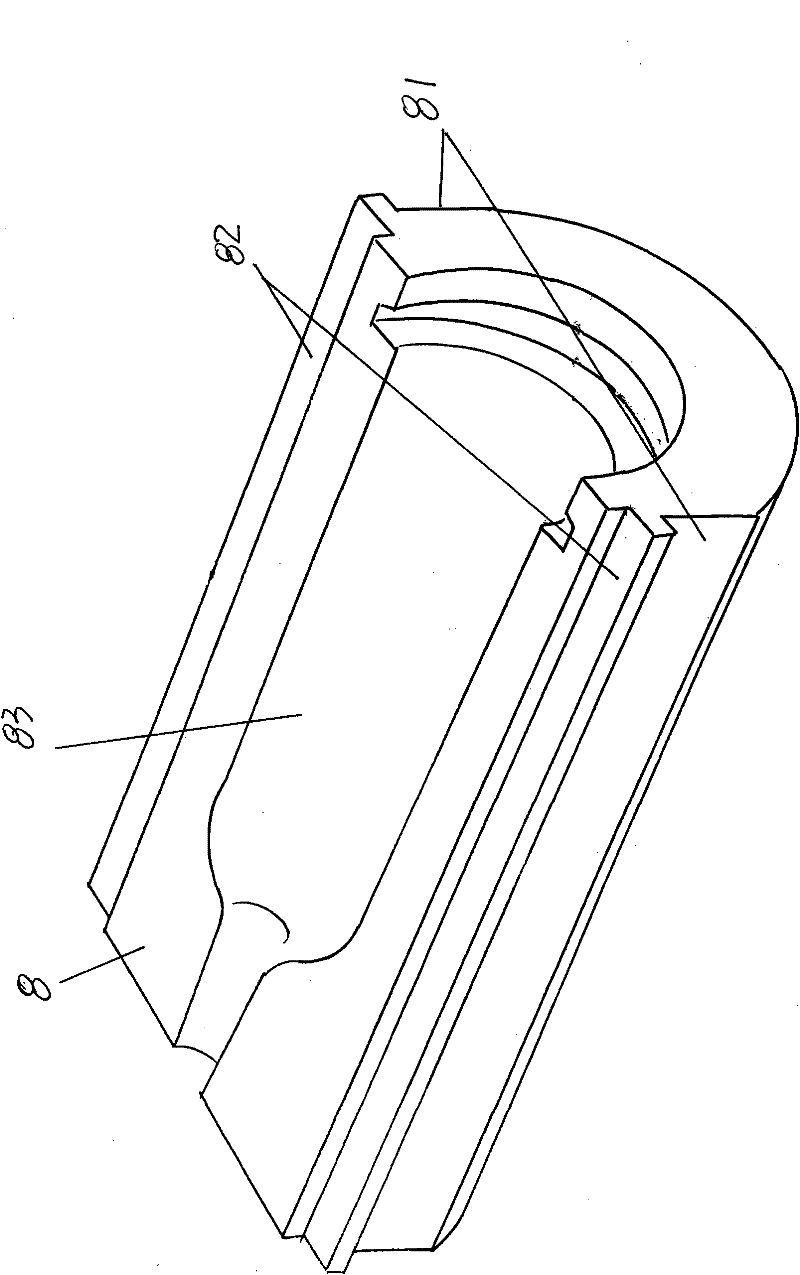

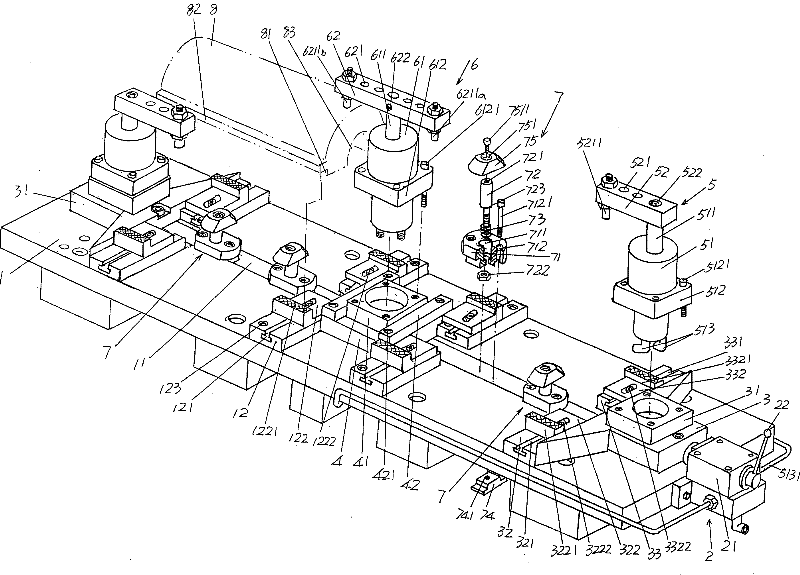

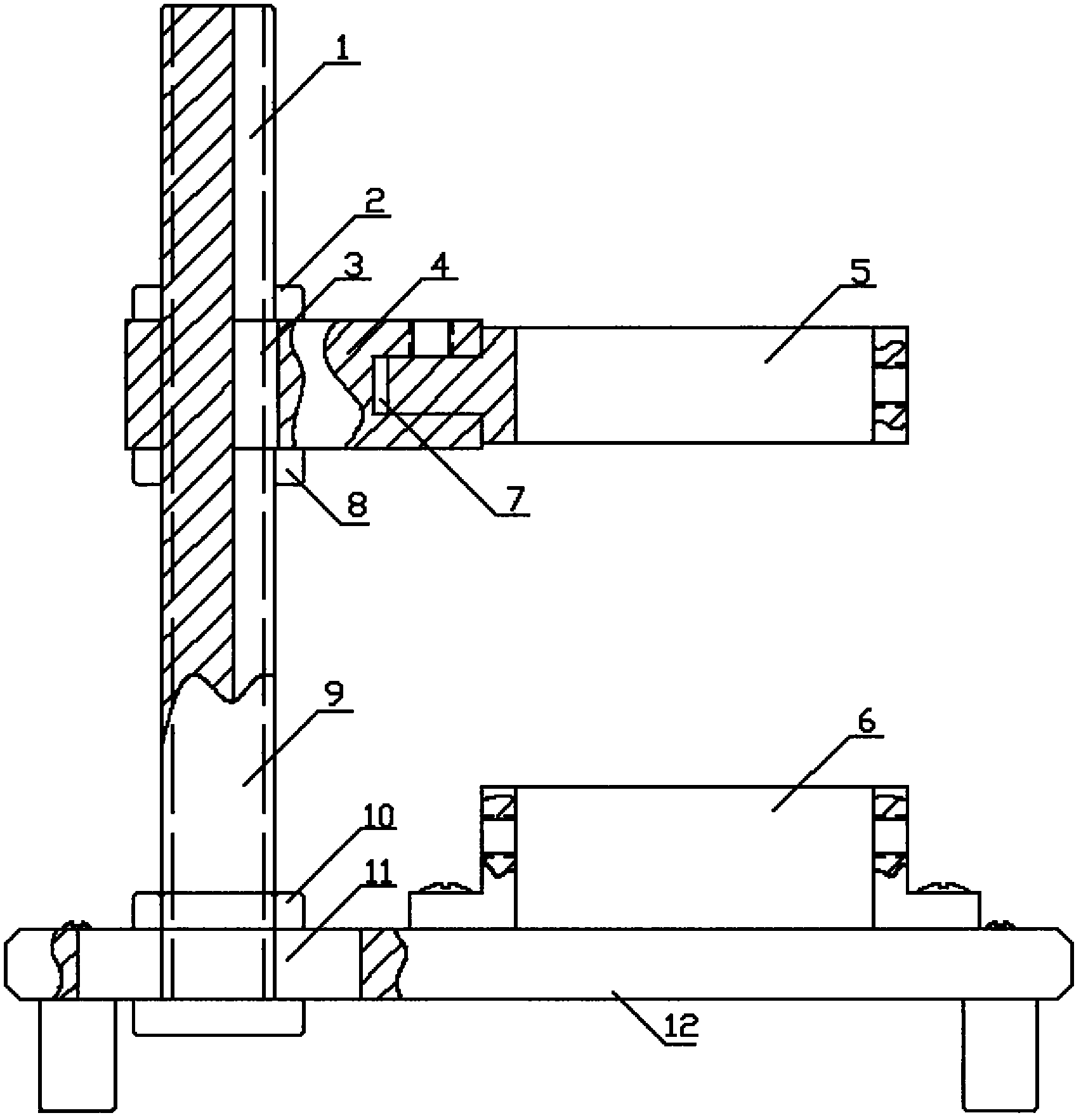

Clamp structure for milling positioning reference plane on glass die blank

ActiveCN101898311BGuaranteed thicknessAvoid damageMilling equipment detailsPositioning apparatusEngineeringMechanical engineering

The invention provides a clamp structure for milling a positioning reference plane on a glass die blank and belongs to an auxiliary facility for processing a glass die. The structure comprises a base, an acting cylinder control device, at least one adjusting seat, a fixed seat, a first die blank back side pressing device, a second die blank back side pressing device and at least one pair of die blank die cavity supporting devices, wherein a reference seat adjusting groove which is penetrated from one end to the other end is formed at a middle position in the width direction of the base; the acting cylinder control device is fixed at one end of the base; the at least one adjusting seat is arranged on the base and in sliding fit with the reference seat adjusting groove; the fixed seat is fixedly arranged on the base and corresponds to the adjusting seat; the first die blank back side pressing device is arranged on the adjusting seat and connected with the acting cylinder control device;the second die blank back side pressing device is arranged on the fixed seat and connected with the acting cylinder control device; and the at least one pair of die blank die cavity supporting devices is arranged on the reference seat adjusting groove in a sliding way and positioned between the adjusting seat and the fixed seat. The structure has the advantages of guaranteeing the accuracy of subsequent processing and ensuring the thickness of a high-quality compact layer of the die cavity.

Owner:CHANGSHU JIANHUA MOLD TECH

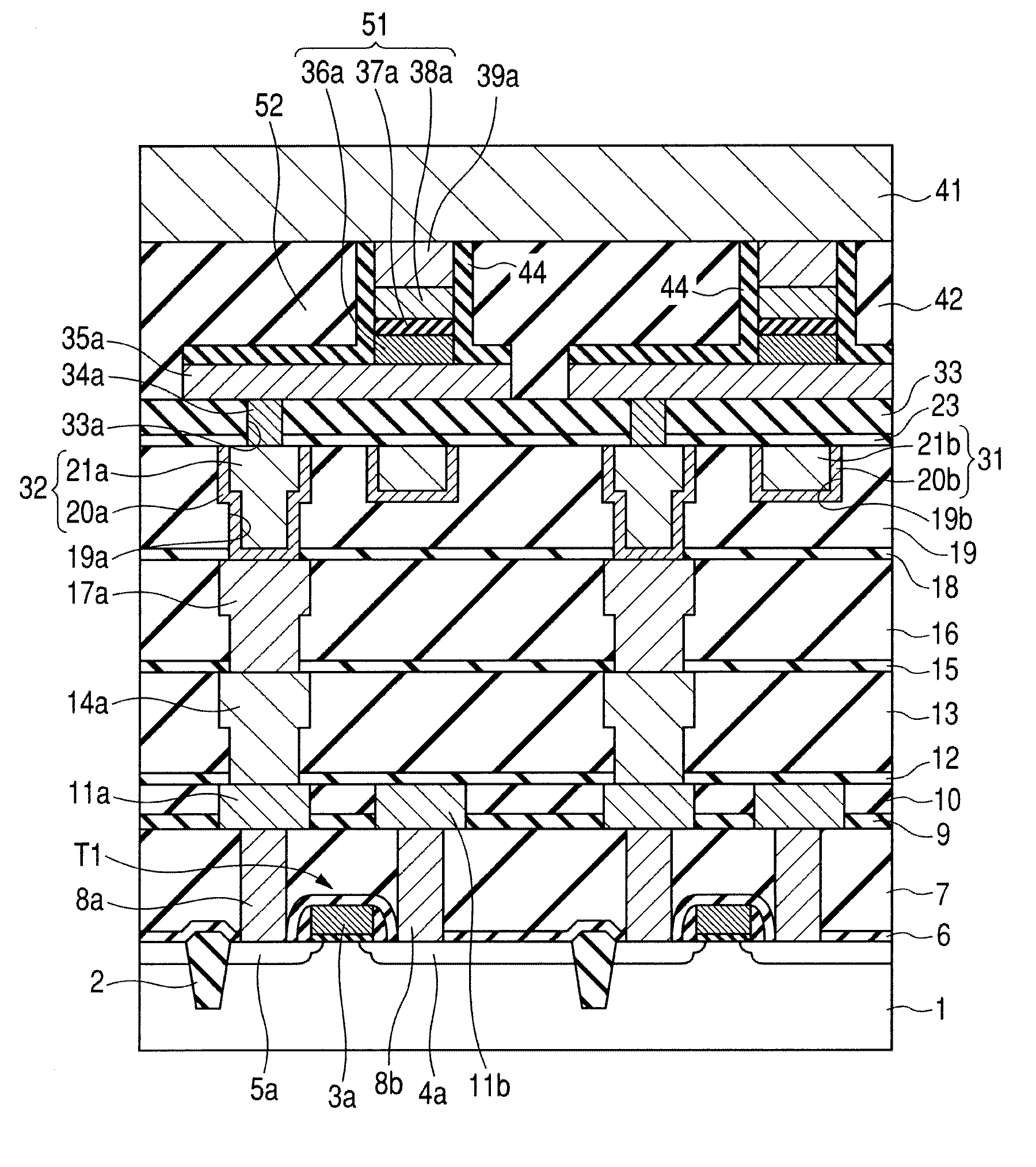

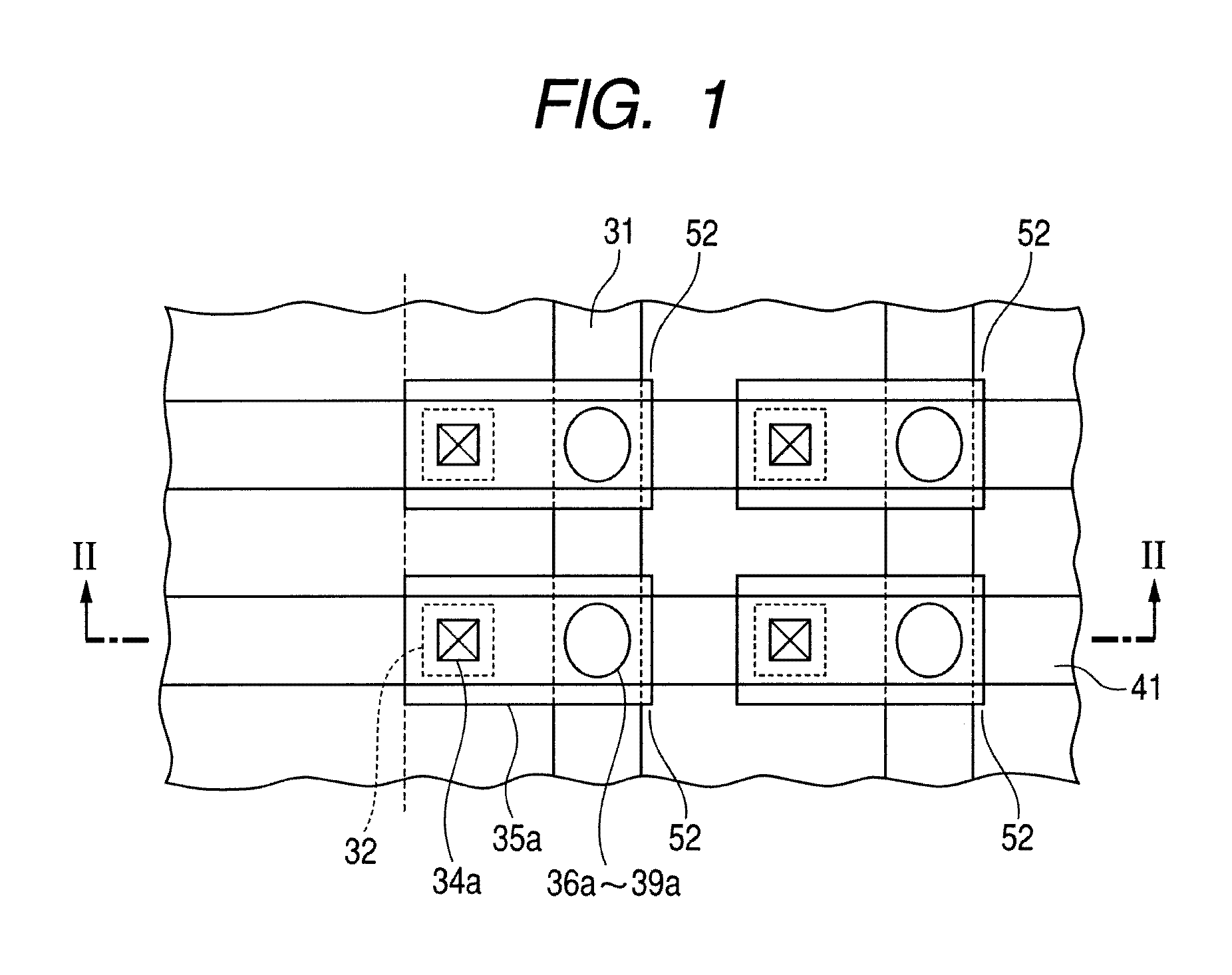

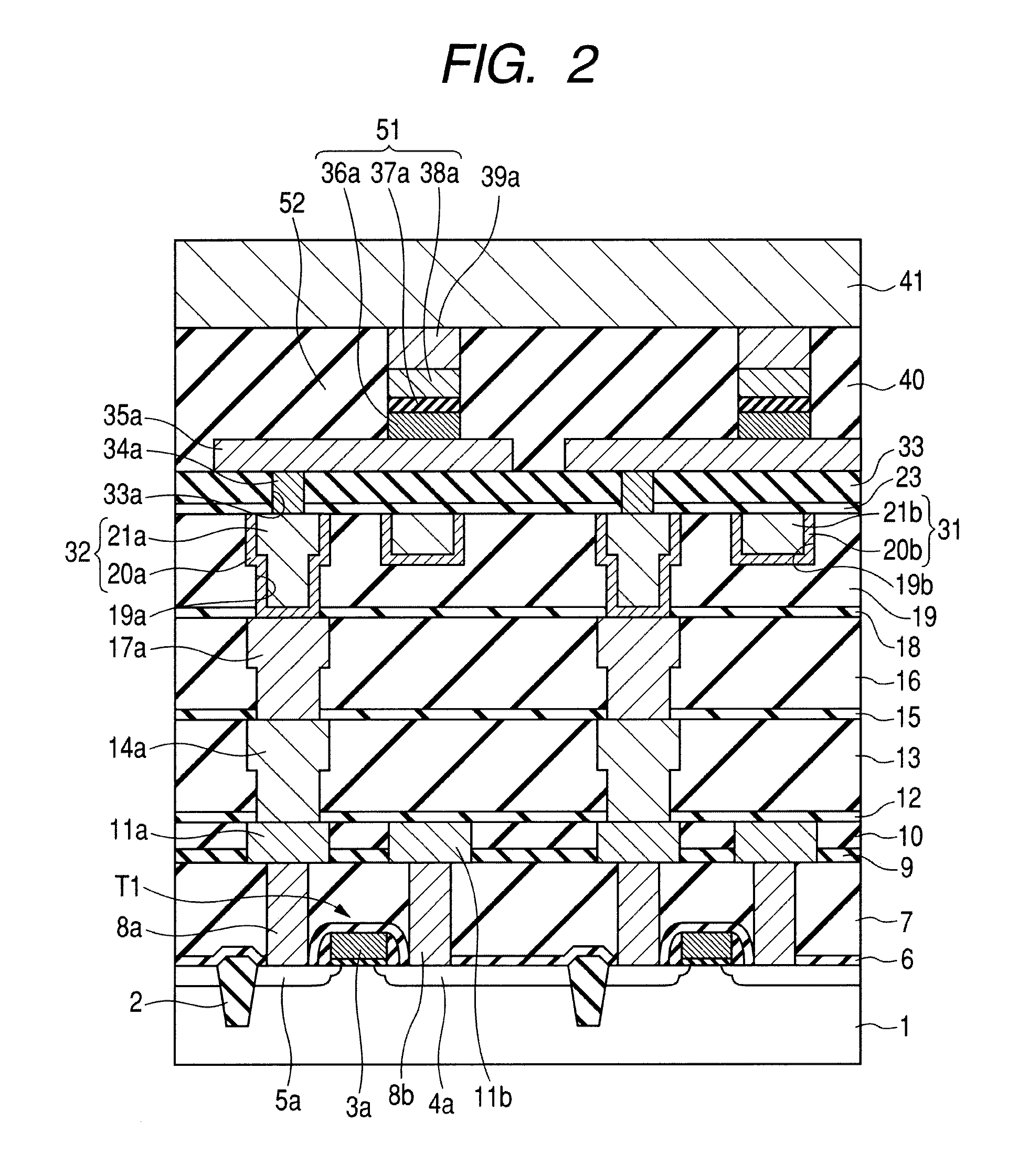

Semiconductor device and method of manufacturing the same

InactiveUS20110049657A1Reduce short circuit failureGuaranteed thicknessMagnetic-field-controlled resistorsSolid-state devicesBit lineDevice material

There are provided a semiconductor device in which short circuit failures in magnetic resistor elements and the like are reduced, and a method of manufacturing the same. An interlayer insulating film in which memory cells are formed is formed such that the upper surface of the portion of the interlayer insulating film located in a memory cell region where the magnetic resistor elements are formed is at a position lower than that of the upper surface of the portion of the interlayer insulating film located in a peripheral region. Another interlayer insulating film is formed so as to cover the magnetic resistor elements. In the another interlayer insulating film, formed are bit lines electrically coupled to the magnetic resistor elements. Immediately below the magnetic resistor elements, formed are digit lines.

Owner:RENESAS ELECTRONICS CORP

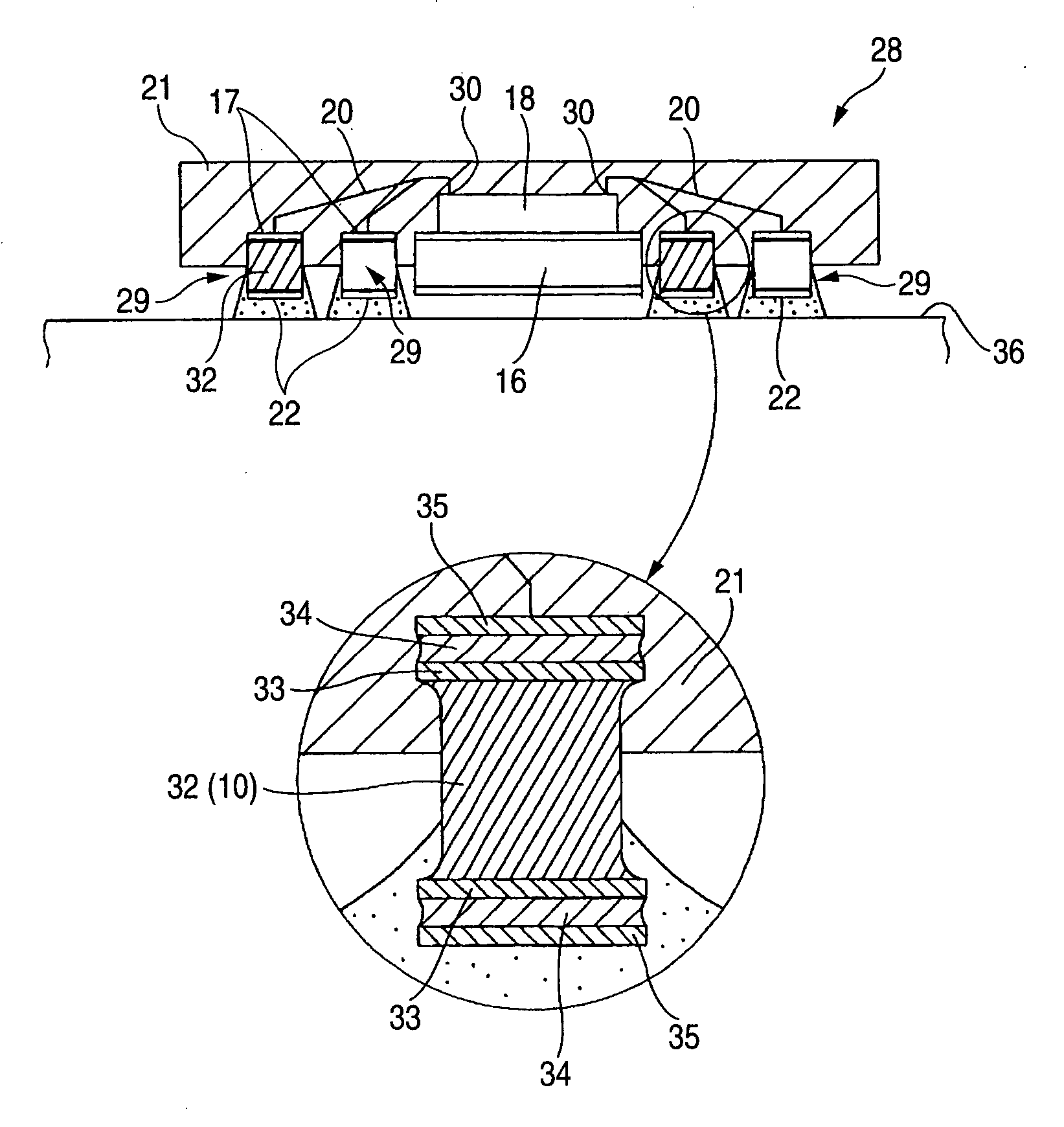

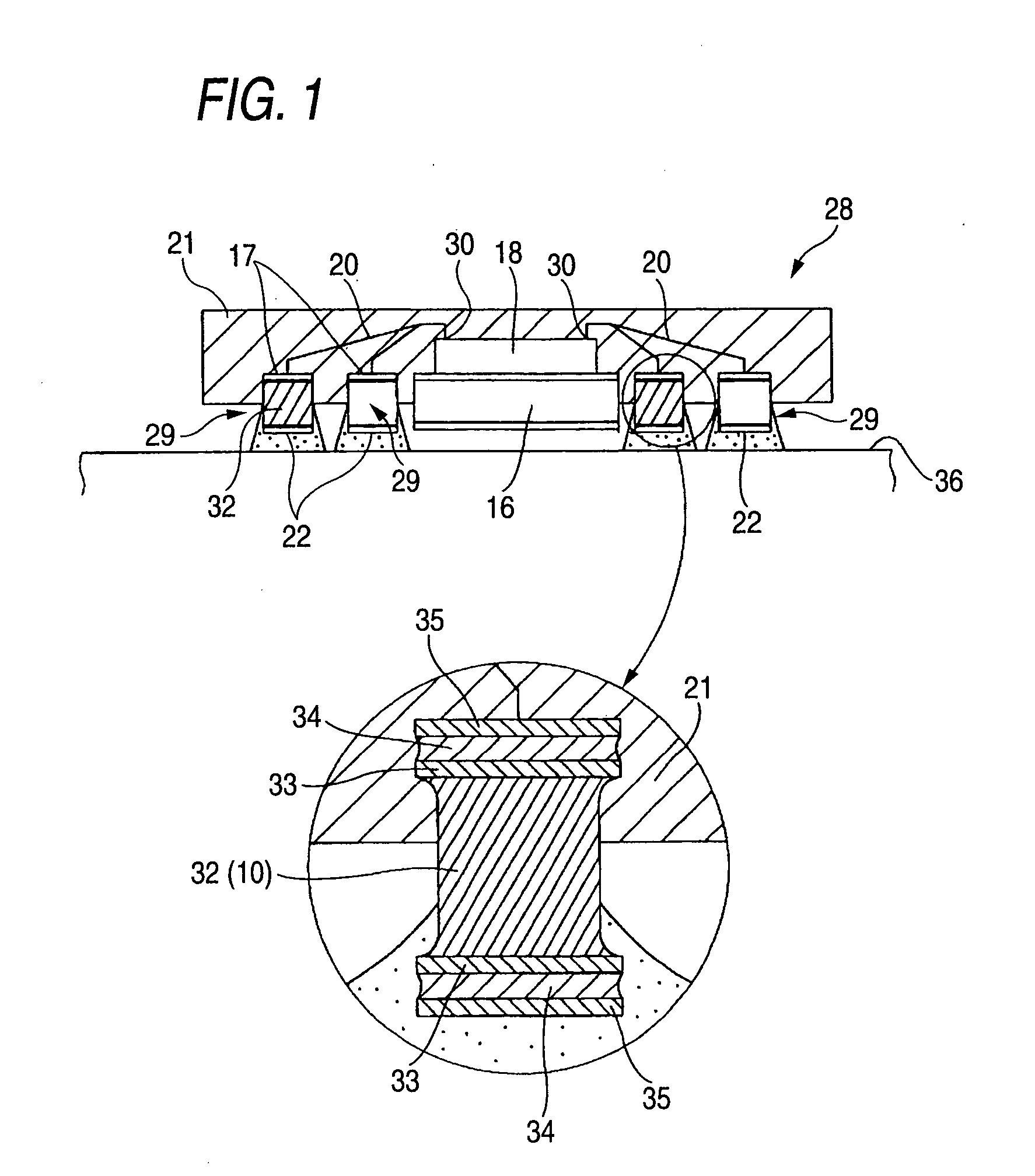

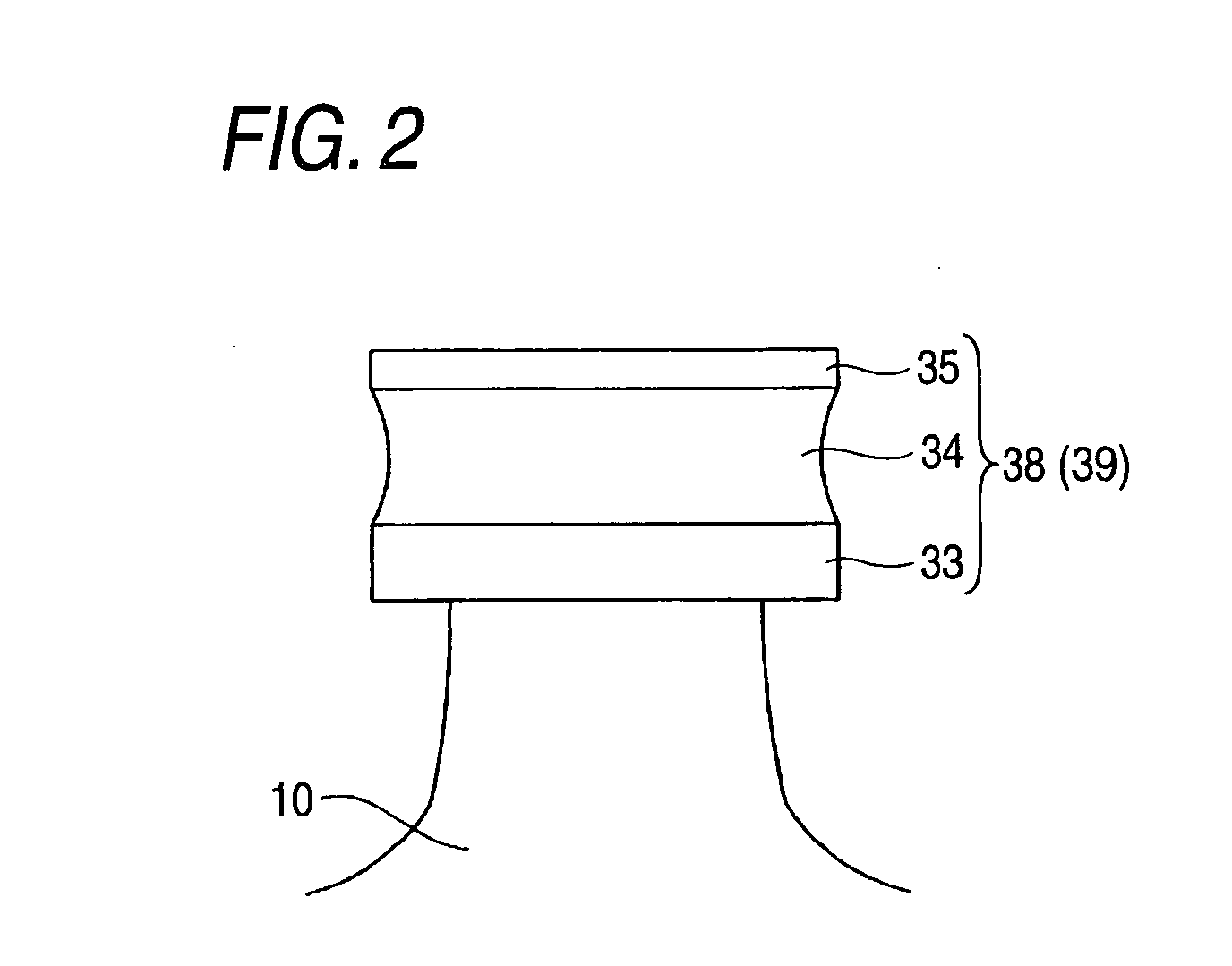

Semiconductor device and manufacturing method thereof

InactiveUS20070181983A1Suppress generationFraction defective is lowSemiconductor/solid-state device detailsSolid-state devicesResistEngineering

A method of manufacturing a semiconductor device 28 in which a plating mask 38, 39 having a noble metal plating layer 35 as an uppermost layer is formed at a predetermined portion on an obverse surface side or a reverse surface side of a leadframe material 10, and the leadframe material 10 is consecutively subjected to etching by using the plating mask 38, 39 as a resist mask, so as to form external connection terminal portions 22 which electrically communicate with a semiconductor element 18 disposed in an interior of an encapsulating resin 21, and which project downwardly. Base metal plating or noble metal plating 33 exhibiting etching solution resistance is provided as a lowermost layer of the plating mask 38, 39.

Owner:MITSUI HIGH TEC INC

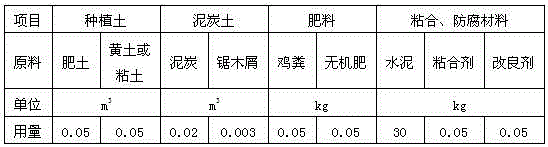

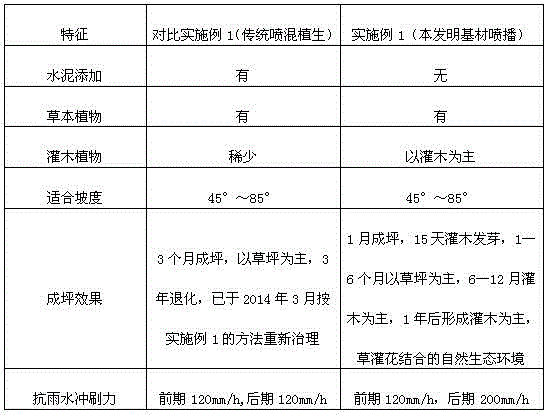

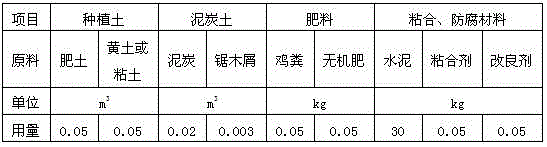

High and steep side slope ecological retrieved green spray-seeding base material and preparation method and application of base material

InactiveCN104782383AAvoid churn problemsEvenly distributedPlant cultivationCultivating equipmentsFiberCoreopsis

The invention relates to the technical field of side slope treatment, and discloses a high and steep side slope ecological retrieved green spray-seeding base material and a preparation method and application of the base material. The spray-seeding base material comprises the following raw materials in parts by weight: 330-420 parts of planting soil, 20-30 parts of peat soil, 1.5-5 parts of organic fertilizer, 1-3 parts of grass fibers, 1-3 parts of sawdust, 0.03-0.05 part of a water-retaining agent, 0.02-0.04 part of an adhesive, 0.1-0.5 part of inorganic fertilizer, 0.5-2 parts of a pH adjustment agent, 30-44 parts of hybrid seeds and 150-200 parts of water, wherein the hybrid seeds consists of the following plant seeds in parts by weight: 10-12 parts of rhizomes tall fescue, 2-4 parts of trifolium repens, 3-5 parts of alfalfa, 2-3 parts of bermuda grass, 2.5-4 parts of indigofera pseudotinctoria, 4-6 parts of magnolia multiflora, 3-5 parts of cassia corymbosa, 2-3 parts of amorpha fruticosa and 1-2 parts of coreopsis. The base material disclosed by the invention for spray-seeding can make a soil replacement base layer with the intensity higher than 0.25MPa; after 45 days when a turf is formed, the rainwash strength is higher than or equal to 120mm / h; within half a year to a year, an ecological plant colony with shrubs which grow with the rainwash strength higher than or equal to 200mm / h and serve as main plants is formed.

Owner:HUANGSHI GARDEN FLOWER & WOOD CO LTD

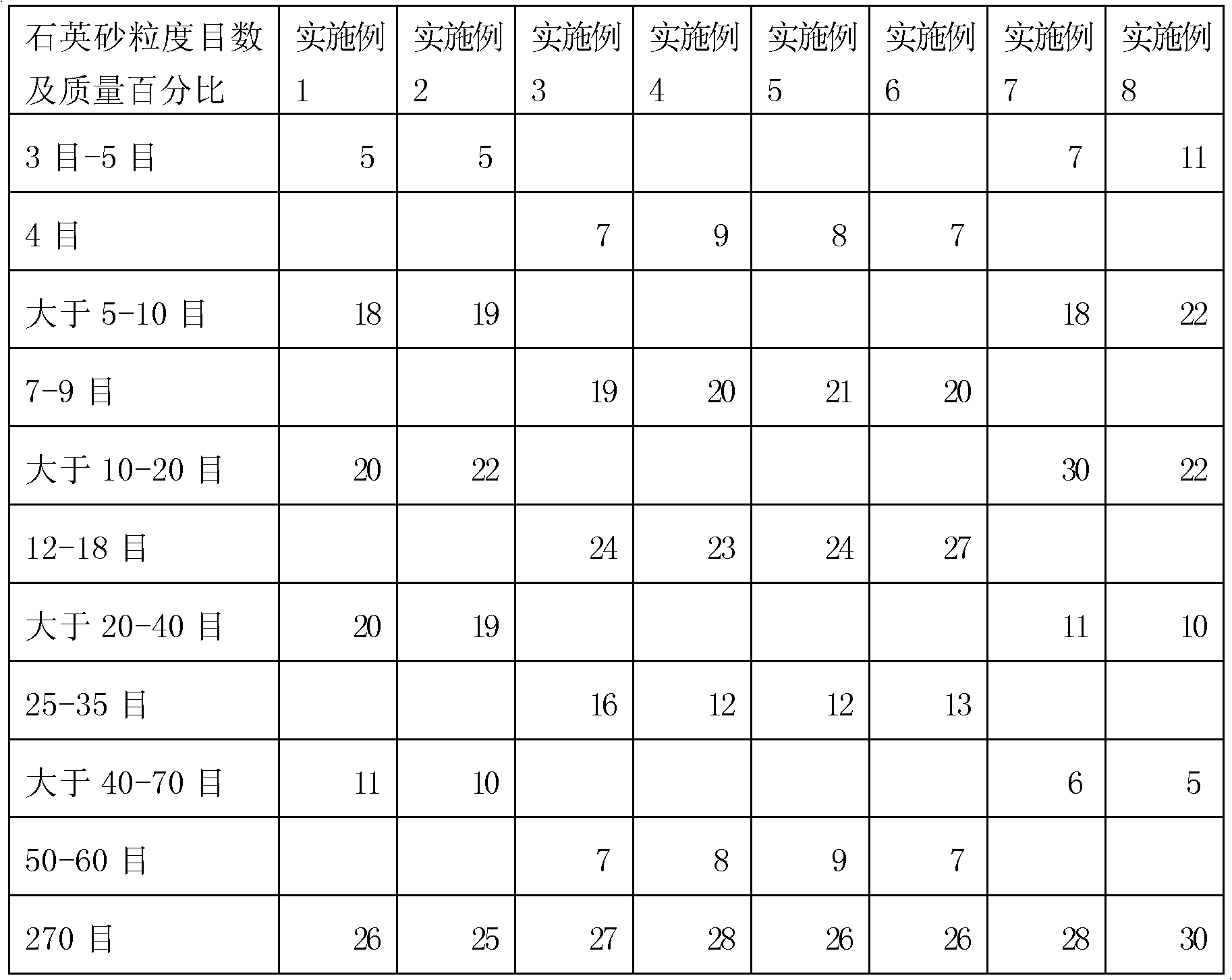

Acid lining material of medium-frequency induction furnace and furnace building method thereof

ActiveCN102617164ACounteract bad effectsCounteracts boric acid to reduce adverse effectsLinings repairCooking & bakingGranularity

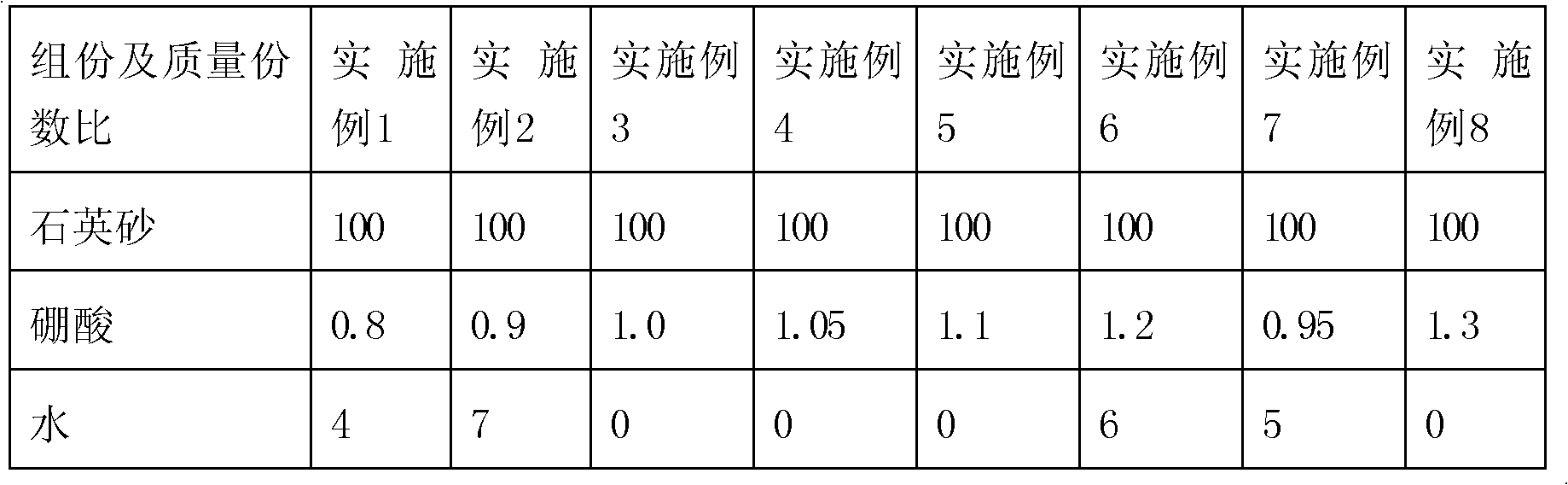

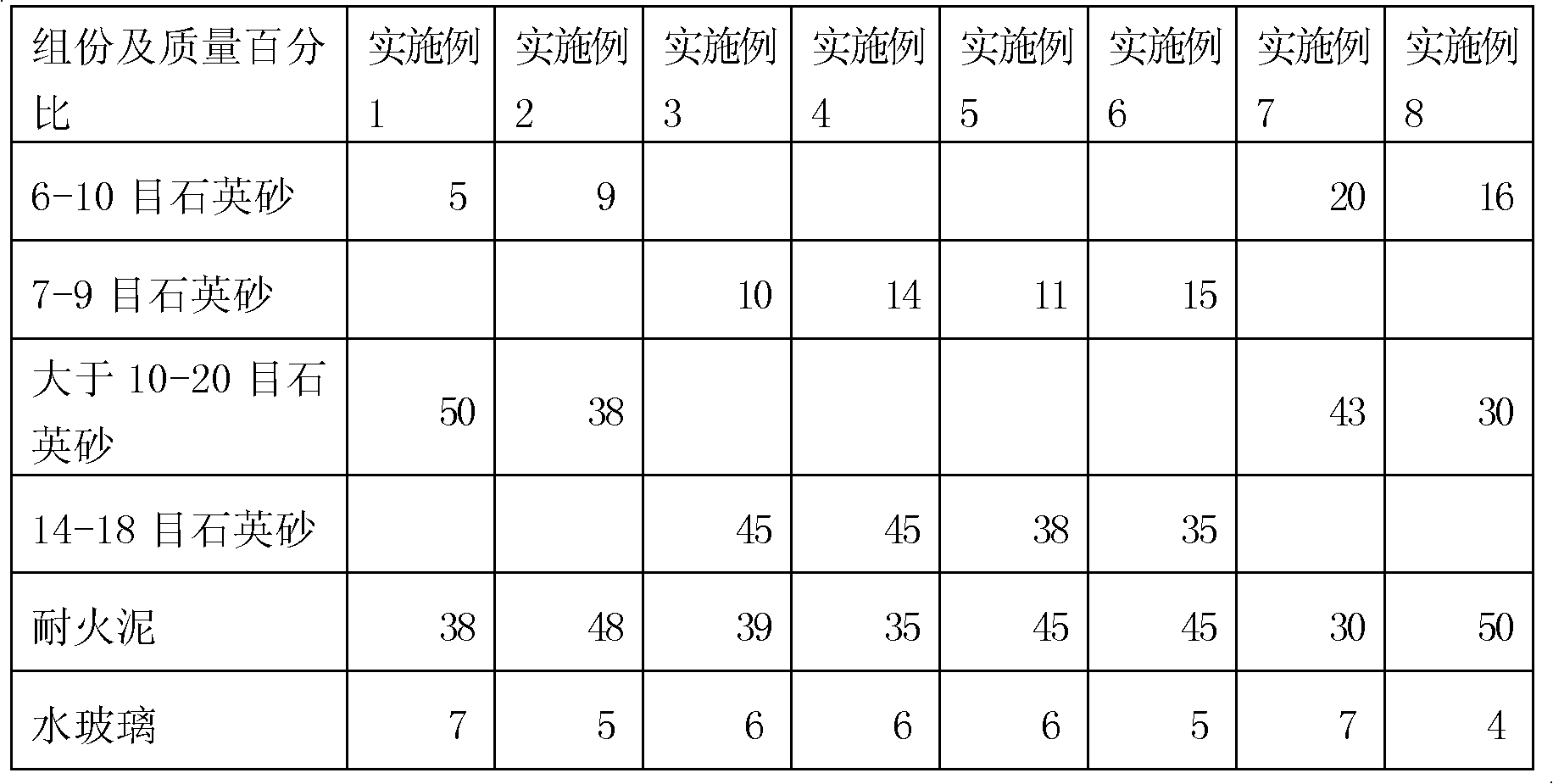

The invention relates to an acid lining material of a medium-frequency induction furnace and a furnace building method thereof. Components of a furnace body lining material comprise that proportion of quartz sand and boric acid is 100: 0.8-1.3 by mass percentage. The quartz sand comprises 5% to 11% of quartz sand with granularity of 3-5 meshes, 18% to 22% of quartz sand with granularity larger than 5-10 meshes, 20% to 30% of quartz sand with granularity larger than 10-20 meshes, 10% to 20% of quartz sand with granularity larger than 20-40 meshes, 5% to 11% of quartz sand with granularity larger than 40-70 meshes and 25% to 30% of quartz sand with granularity of 270 meshes by weight. Materials of a furnace collar and a furnace nozzle comprise 5% to 20% of quartz sand with granularity of 6-10 meshes, 30% to 50% of quartz sand with granularity larger than 10-20 meshes, 30% to 50% of fire clay and 4% to 7% of water glass. The acid lining material and the furnace building method can prolong effective service life of an acid lining and shorten furnace baking time by improving the lining material and the furnace building process.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Manufacture method for gold finger circuit board and circuit board manufactured by method

ActiveCN103153000ARealize productionGuaranteed thicknessElectrical connection printed elementsPrinted element electric connection formationFinger structureEngineering

The invention provides a manufacture method for a gold finger circuit board and the circuit board manufactured by the method. The manufacture method for the gold finger circuit board comprises the steps of offering a base board with a ladder groove, manufacturing a gold finger structure inside the ladder groove, wherein the gold finger structure comprises a gold finger figure and a lead wire connected with the gold finger figure, covering heat resisting solder resisting ink on the surface of the lead wire, coating heat resisting adhesive tape on the surface of the gold finger figure in an attached mode, offering a plurality of plates which are arranged inside the ladder groove in a stack mode, pressing the plurality of plates in a fit mode, milling a top plate corresponding to the adhesive tape in the stacked plates, taking out a sandwich plate clamped between the plate at the top of the plates and the heat resisting adhesive tape, removing the heat resisting adhesive tape covered on the surface of the gold finger figure, electroplating the gold finger figure, forming a gold finger, and obtaining the required gold finger circuit board. The manufacture method can accurately manufacturing the thickness of the required circuit board, can achieve manufacture of the gold finger inside the ladder groove, and is simple in process.

Owner:DONGGUAN SHENGYI ELECTRONICS

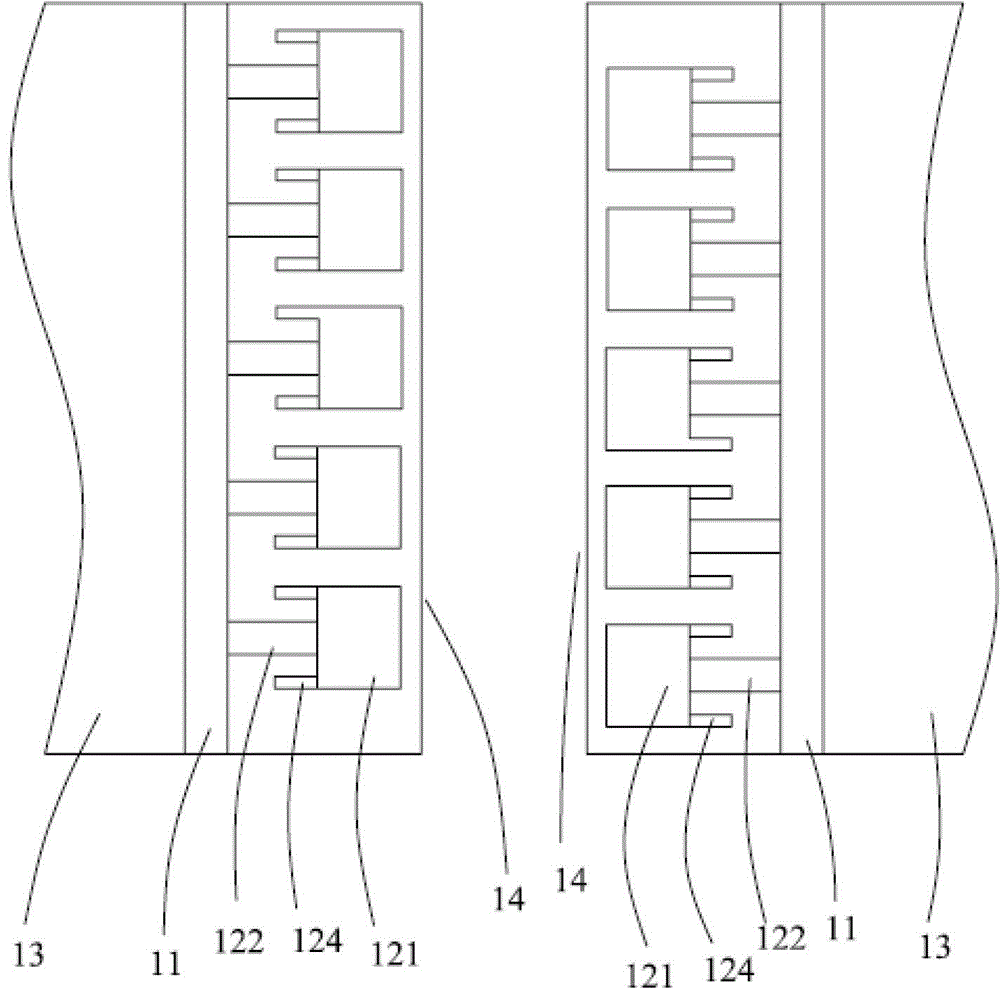

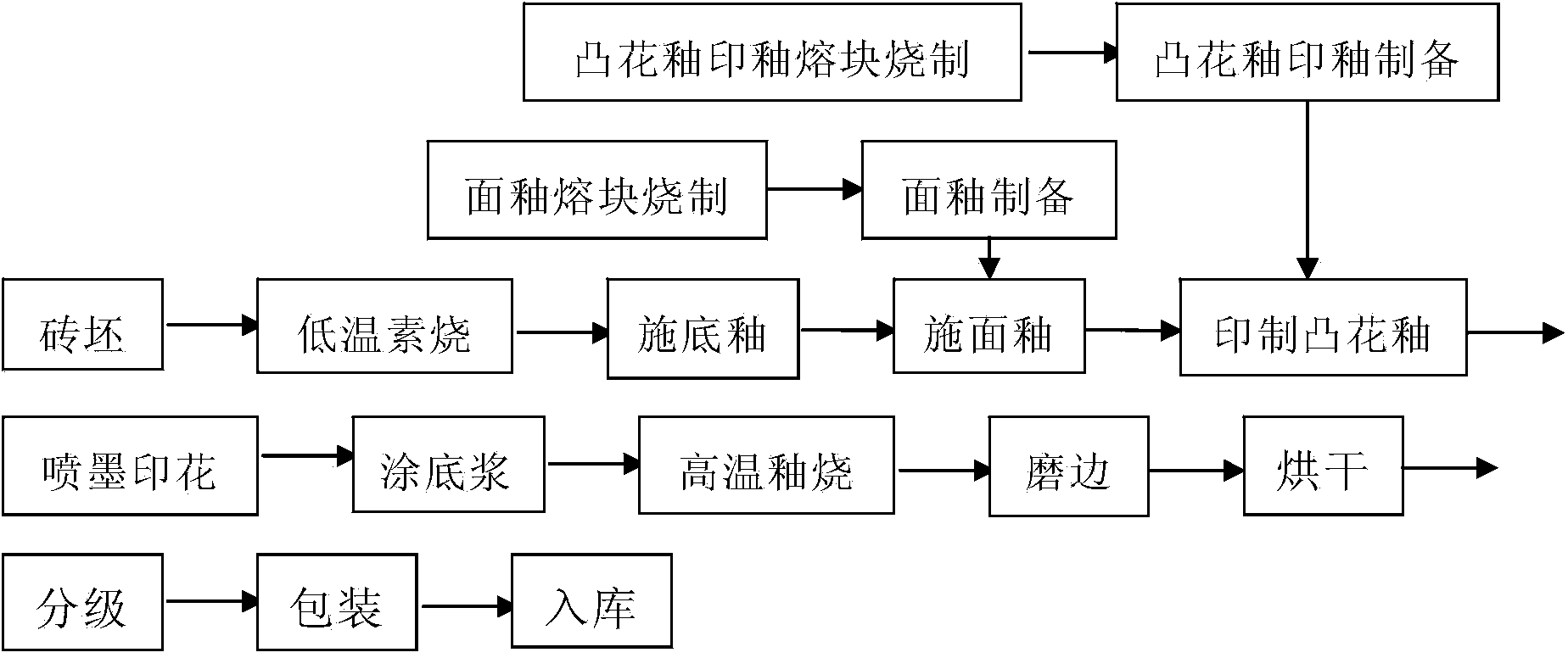

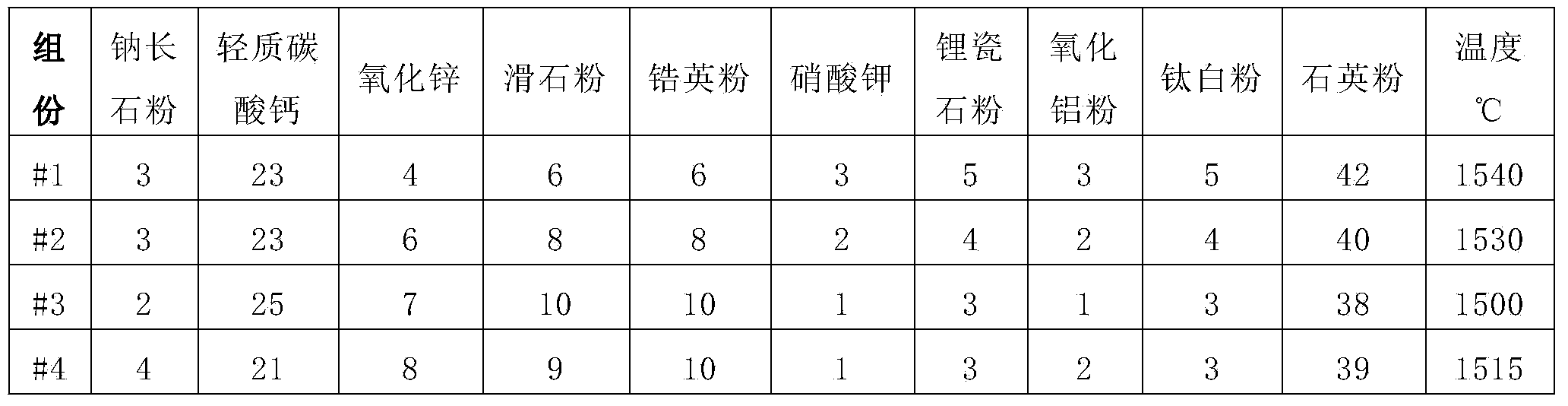

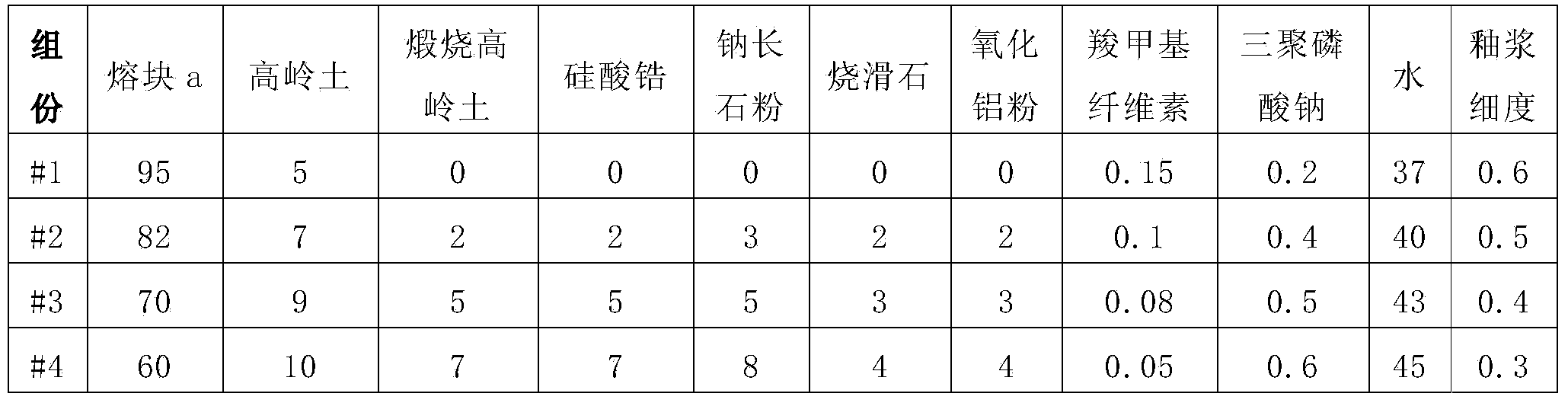

Glazed tile with wallpaper or bark-shaped surface and concave and convex effect and preparation method

The invention discloses glazed tile with wallpaper or bark-shaped surface and concave and convex effect and a preparation method. According to the invention, a product which is a glazed tile with wallpaper or bark-shaped surface and concave and convex effect is obtained by optimizing the composition of an overglaze frit and an overglaze formula, as well as the composition of a convex fancy glaze printed glaze frit and a convex fancy glaze printed glaze formula, printing the convex fancy glaze printed glaze on a green body coated with underglaze and overglaze through a special rubber roller or screen printing plate, and then enabling patterns of convex fancy glaze to keep original printing appearance after being fired at a high temperature and protrude on the surface of inkjet patterns through inkjet printing and high-temperature firing. Further, by mixing with optimized ceramic rubber roller printing ink, through the special rubber roller with optimized design or the screen printing plate with optimized mesh count, the surface gloss of the obtained glazed tile with wallpaper or bark-shaped surface and concave and convex effect is 15-40, the convex fancy glaze has good performance, the protruding height is greater than or equal to 0.8mm, and the convex fancy glaze does not adsorb pollution, so that the decorative patterns formed by inkjet printing are not damaged, and the disadvantage of single decoration style of an existing glazed tile is overcome.

Owner:GUANGDONG WINTO CERAMICS +3

Method for preparing fiber wallboard through wet process

InactiveCN101638874ALarge stockWide variety of sourcesWater-repelling agents additionPaper/cardboardFiberHigh intensity

The invention discloses a method for preparing a fiber wallboard through a wet process. The method comprises the following steps: 1) pulping: mixing non-wood type natural plant fiber pulp with gramineous plant pulp according to a dry weight ratio of 1:0-1.5 and adding water into the raw materials to dilute the pulp; 2) storing the pulp: placing the obtained mixture pulp into a pulp storage pond and adding water for dilution; 3) carrying out suction filter and formation: inputting the pulp obtained from the previous step into a die cavity for cold-pressing, dehydration and formation so as to obtain a wet blank; and 4) carrying out hot-pressing formation and drying; transferring the wet blank into a hot-pressing mould for hot pressing, removing water generated during the hot pressing, and obtaining the fiber wallboard. The fiber wallboard obtained by using the method has the characteristics of environment-friendliness and high strength.

Owner:陈集双

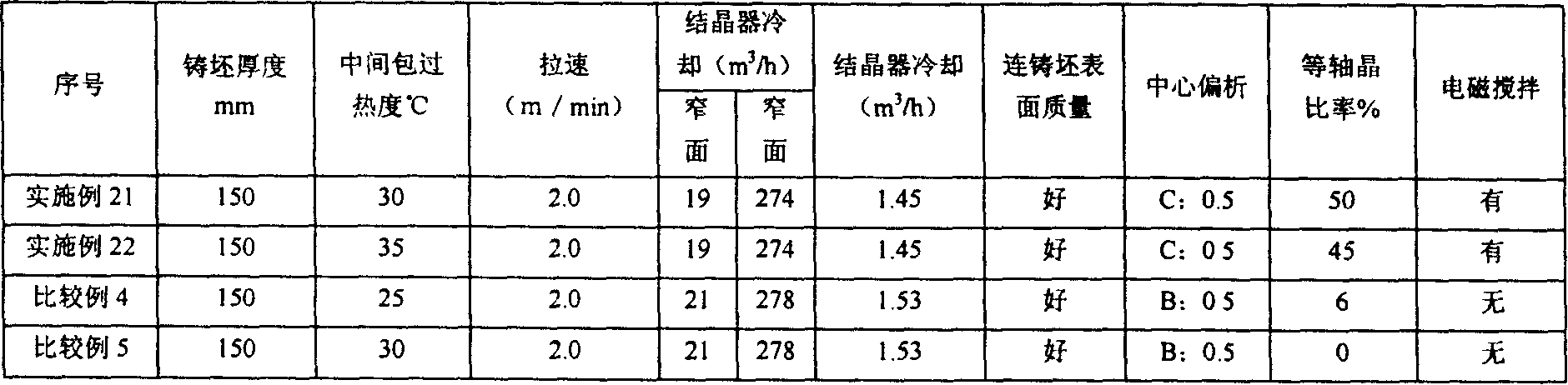

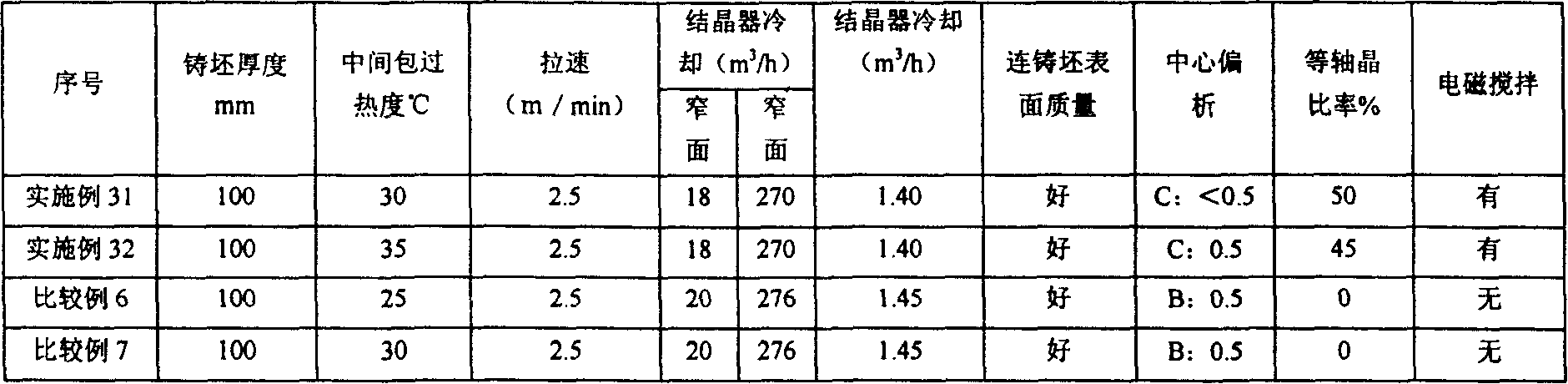

Continuous casting method for increasing equal thickness continuous casting plate billet equal axial crystal rate in non-oriented silicon steel

InactiveCN101164720AImprove mechanical propertiesImprove dynamic conditionsSiliconElectromagnetic stirring

The present invention provides a continuous casting method capable of increasing non-oriented silicon steel medium-thickness continuous cast slab equiaxial crystal rate. It is characterized by that it adopts a medium-thickness slab continuous casting machine, in the continuous casting second cooling zone it adopts a roller electromagnetic stirring equipment. The casting billet size of continuous casting machine is 100-150mmX850-1550mm, pouring speed is 1.5-3.5m / min, the cooling pattern: the narrow edge of crystallizer is 14-25m3 / h, the wide edge of crystallizer is 250-290m3 / h and second cooling intensity is 1.3-1.8L / kg. The described electromagnetic stirring equipment includes 2-4 pairs of introroller built-in traveling wave magnetic field type electromagnetic stirring devices which are assembled into two groups and mounted.

Owner:ANGANG STEEL CO LTD

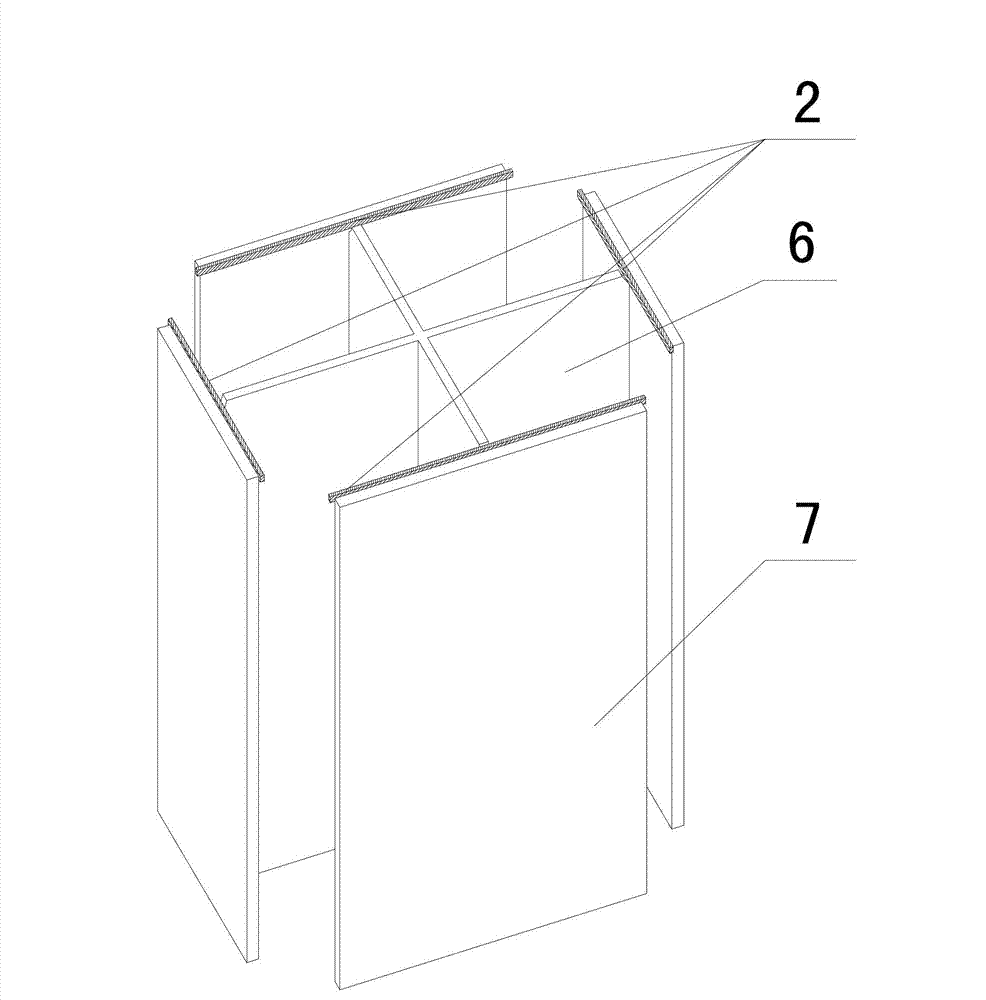

Fastening strip and fastening network framework

ActiveCN101457572AGuaranteed pouringSolve the problem of convenient and quick fixWallsForms/shuttering/falseworksFloor slabStructural element

The invention relates to a blocking strip and a blocking net framework. The blocking strip comprises at least two strip sides, at least one of which is provided with convex teeth that are provided with breaches, the breaches are internally provided with agnails or barbs. The blocking net framework can be made by applying the blocking strip, and is formed by connecting keels, the blocking strip and a steel screen in a combining way. The keels are section steel parts and are arranged in parallel according to certain spacing; the blocking strips are vertical to the keels, arranged in parallel according to certain spacing and are fixed at one side or two sides of the keels to form a steel frame; the steel screen is distributed with a longitudinal convex rib as well as fish scales holes or meshes on the surface; the steel screen is attached to the outer surface of the steel frame, and is firmly and conveniently blocked and connected with the blocking strip. The invention solves the problems of composition and construction of a steel screen concrete member as well as the reinforcement of a steel screen concrete wall body. Meanwhile, the invention realizes large-scale and mechanized production, and is suitable for various building structural elements, especially for the structures of multilayer and high residential building wall bodies and floor slabs.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV +1

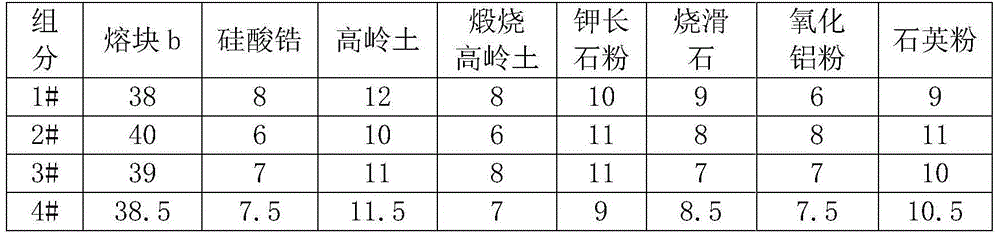

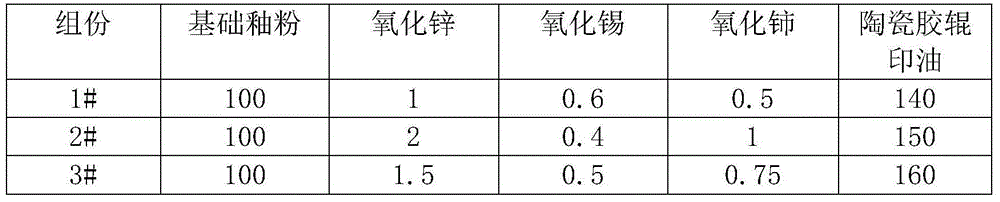

Glaze and preparation of embossment phantom glazed brick

The invention discloses a glaze and preparation of an embossment phantom glazed brick. The glaze comprises a ground glaze, a surface glaze and an embossment phantom printing glaze, wherein the ground glaze is prepared from a frit b, zirconium silicate, kaolin, calcined kaolin, potassium feldspar powder, fired talc, aluminum oxide powder, quartz powder, carboxymethyl cellulose, sodium tripolyphosphate and water; the surface glaze is prepared from a frit, the frit b, a frit c, kaolin, carboxymethyl cellulose, sodium tripolyphosphate and water; the embossment phantom printing glaze is prepared from parent glaze powder, zinc oxide, tin oxide, cerium oxide and ceramic adhesive roll-printing oil; the parent glaze powder is prepared from the frit c, kaolin, carboxymethyl cellulose, sodium tripolyphosphate and water. The preparation method comprises the following steps: sequentially applying the ground glaze and the surface glaze on a green brick, then printing the embossment phantom printing glaze, performing inkjet printing, and finally firing to obtain the embossment phantom glazed brick. The product disclosed by the invention has unique decorative effect and visual aesthetic feeling; moreover, each indicator can reach the standard requirements, so that the product has relatively strong universality, and is easily popularized in the industry.

Owner:GUANGDONG WINTO CERAMICS +3

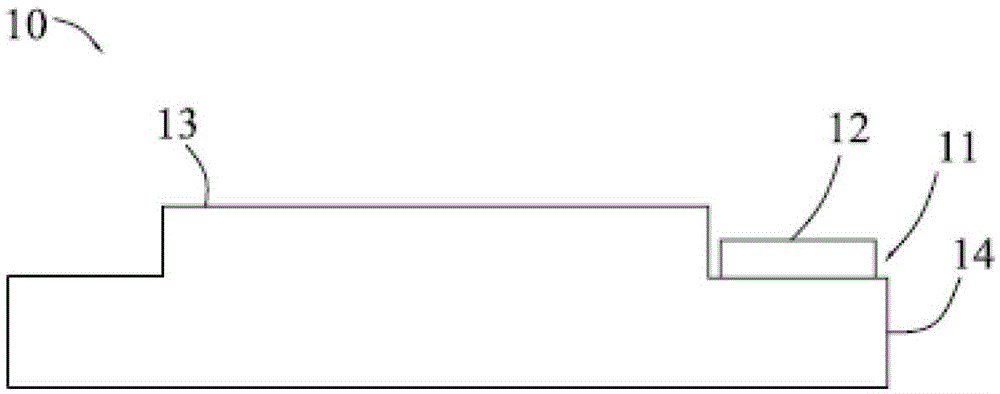

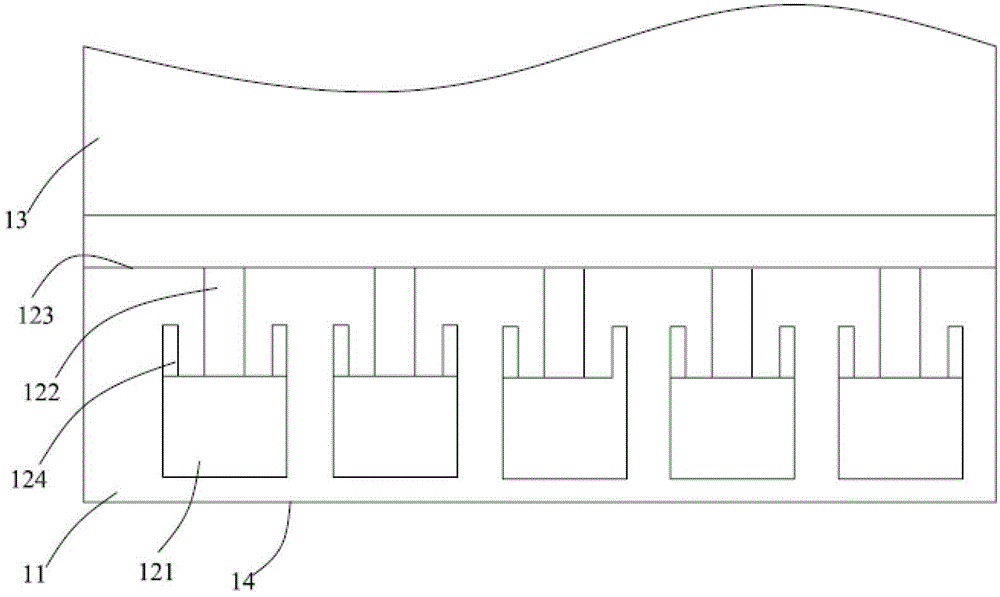

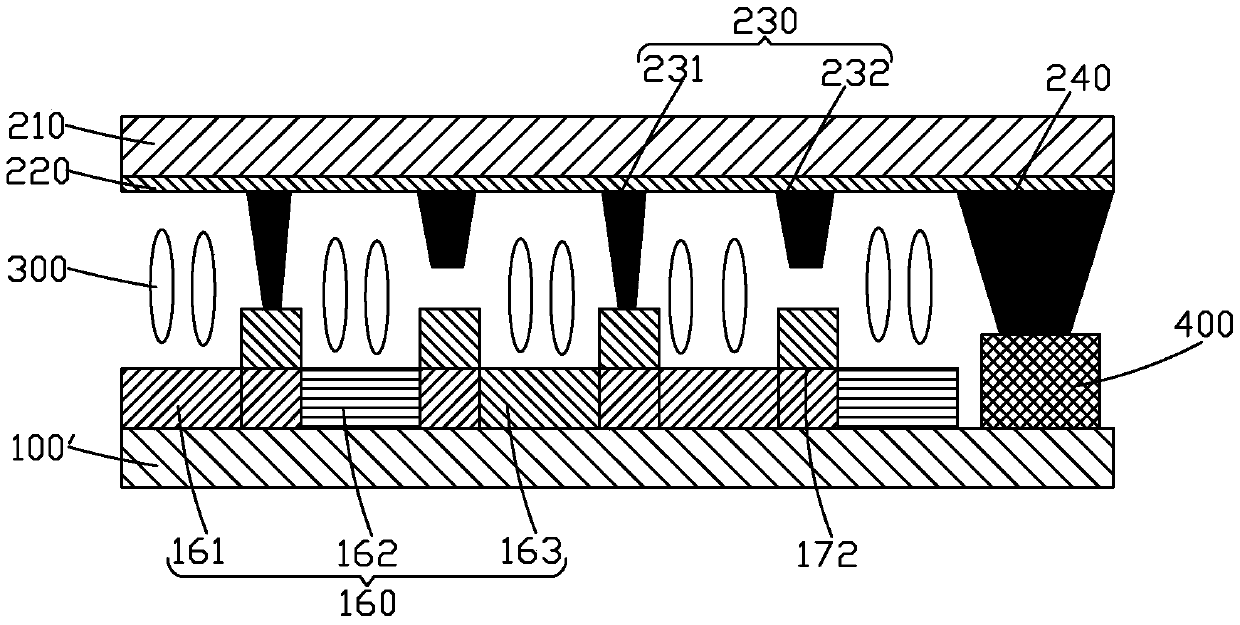

VA-type COA liquid crystal display panel

ActiveCN105511189AIncrease opening ratioSimple processNon-linear opticsLiquid-crystal displayScan line

The invention provides a VA-type COA liquid crystal display panel. A first light shielding layer made of a red color resisting material or a blue color resisting material and a common electrode are correspondingly arranged over grid scanning lines, the common electrode is arranged over the first light shielding layer and electrically communicated with a public electrode layer arranged on an upper substrate to enable the voltage difference of the upper substrate and a lower substrate at the grid scanning lines to be zero, then the panel is in a normally black state at the grid scanning lines due to the fact that liquid crystals are not driven by the voltage difference and do not rotate, and therefore light shielding on the grid scanning lines is achieved; in addition, a second light shielding layer formed by stacking two of the red color resisting material, a green color resisting material and the blue color resisting material is correspondingly arranged over the data lines, and therefore light shielding on the data lines is achieved; accordingly, on the premise of ensuring the spacer elasticity compression amount and the panel box thickness, a black matrix arranged on the upper substrate is omitted, and the panel is high in aperture ratio, simple in manufacturing process and low in production cost.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

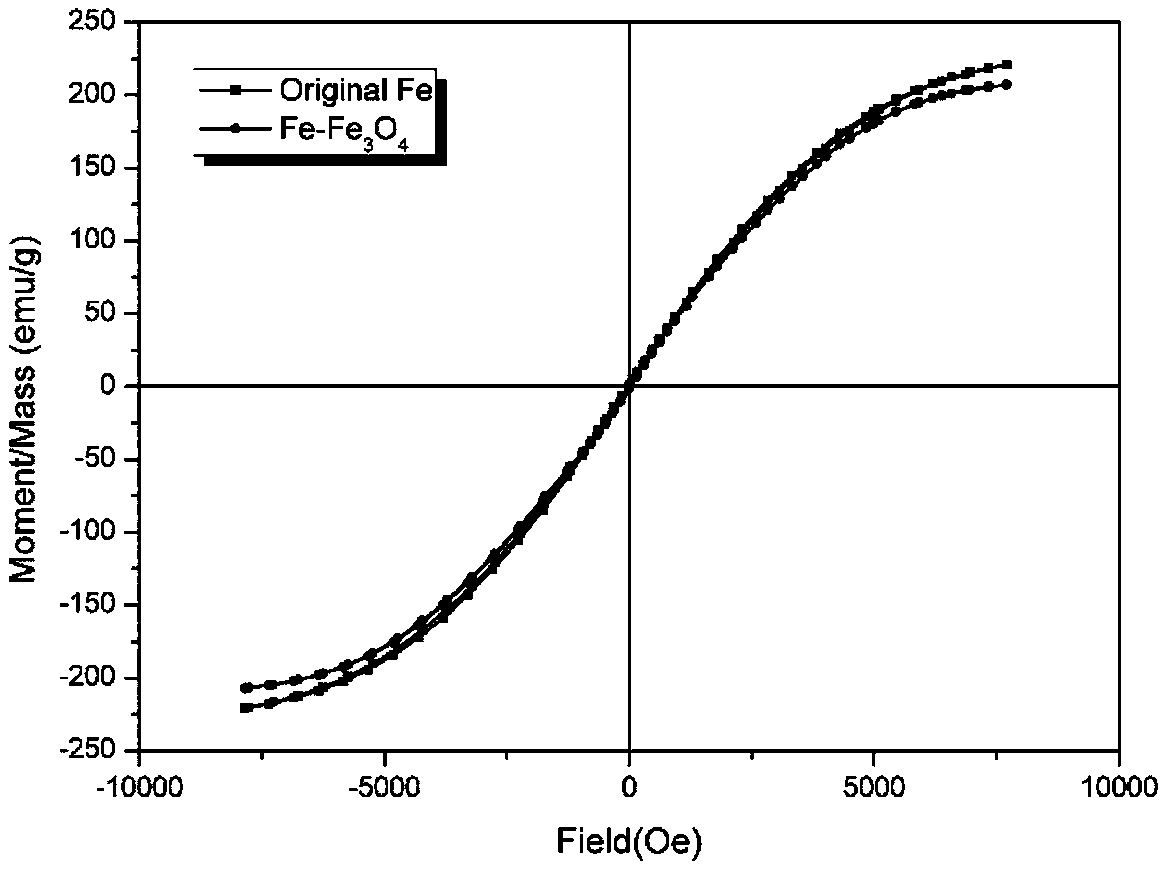

Magnetic powder core material with stable magnetic permeability and low loss and preparation method thereof

ActiveCN108335820AReduce porosityHigh permeabilityTransportation and packagingMetal-working apparatusMagnetic powderMagnetic dilution

The invention relates to a magnetic powder core material with stable magnetic permeability and low loss and a preparation method thereof. First modifying the surface of the iron powder; preparing iron / ferrite composite powder with core-shell structure by high-energy ball milling; mixing the composite powder with the modified powder and then filling the mixture into an alloy steel mold for normal temperature pressing to obtain iron / ferrite soft magnetic composite magnetic powder cores; then performing subsequent heating treatment on the magnetic powder cores. Compared with the prior art, the present invention utilizes a ball milling method to prepare iron / ferrite coated powder. The process is short in time, uniform in coating, and simple in operation. At the same time, the present inventionuses a ferrimagnetic ferrite as an insulating coating agent, which reduces the magnetic dilution phenomenon caused by a non-magnetic substance as a coating agent. The suitable heat treatment temperature avoids the reaction between iron and ferrite during heat treatment to form magnetic disadvantageous components, ensures high saturation magnetization of magnetic powder core, high magnetic permeability, reduces loss, and obtains magnetic permeability of soft magnetic composite magnetic powder core.

Owner:TONGJI UNIV

Chemical nickel-plating method on magnesium alloy surface

InactiveCN1500910AReduce pollutionUniform thicknessLiquid/solution decomposition chemical coatingFluorideAqueous solution

The present invention relates to magnesium alloy surface treating technology, and is especially chemical nickel plating process for magnesium alloy. The operation process includes the following steps: activating or finishing magnesium alloy through polishing or grinding, degreasing and acid pickling with acid fluoride bearing solution at 20-60 deg.c for 0.5-5 min; pre-treating with water solution containing fluoride bearing compound, iron bearing compound and complex at 15-45 deg.c for 5-30 min; and chemically nickel plating. The said process can make chemical nickel coating with homogeneous thickness, firm combination with substrate, high corrosion resistance and metal appearance. The process of the present invention has low cost and less environmental pollution and is suitable for industrial production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

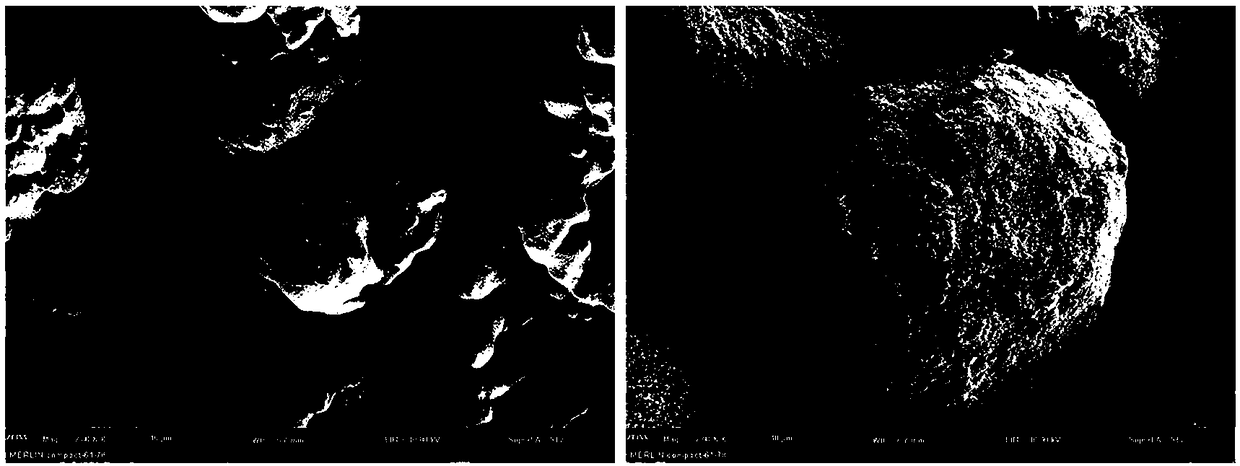

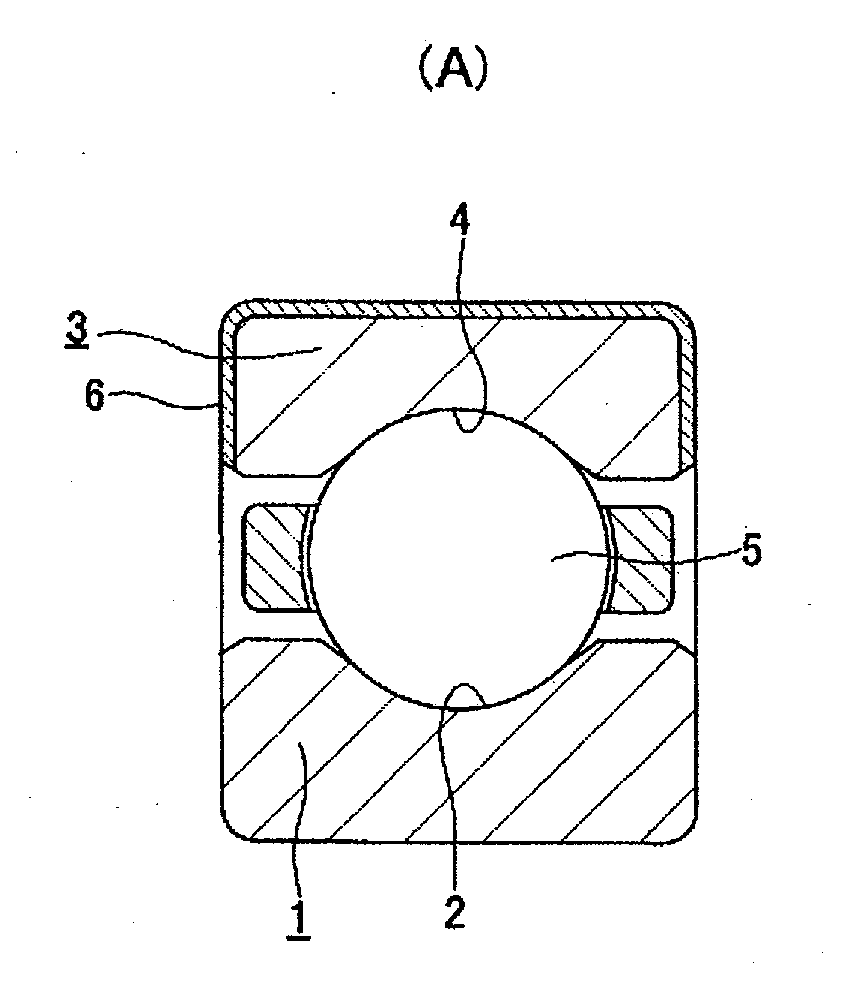

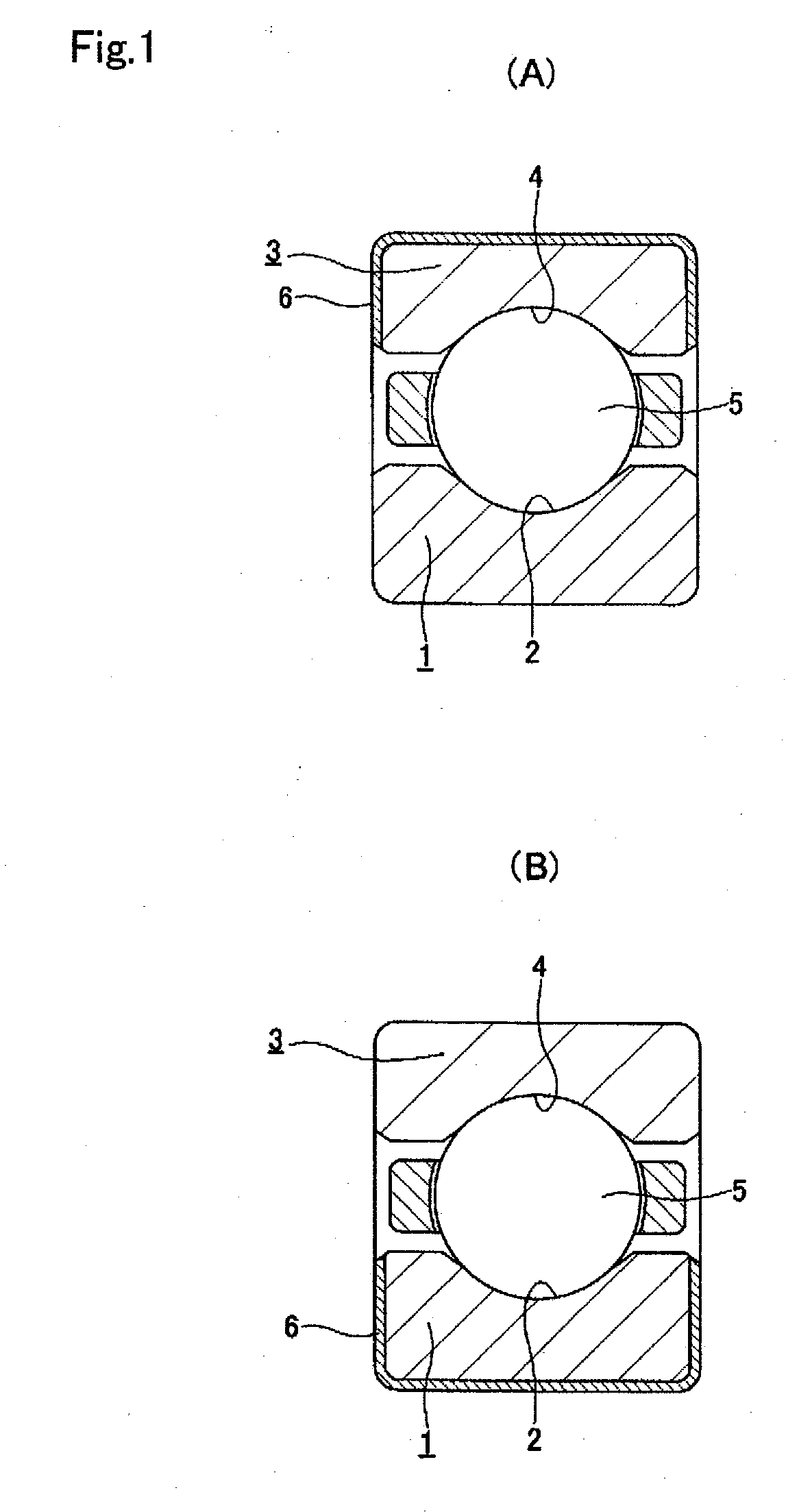

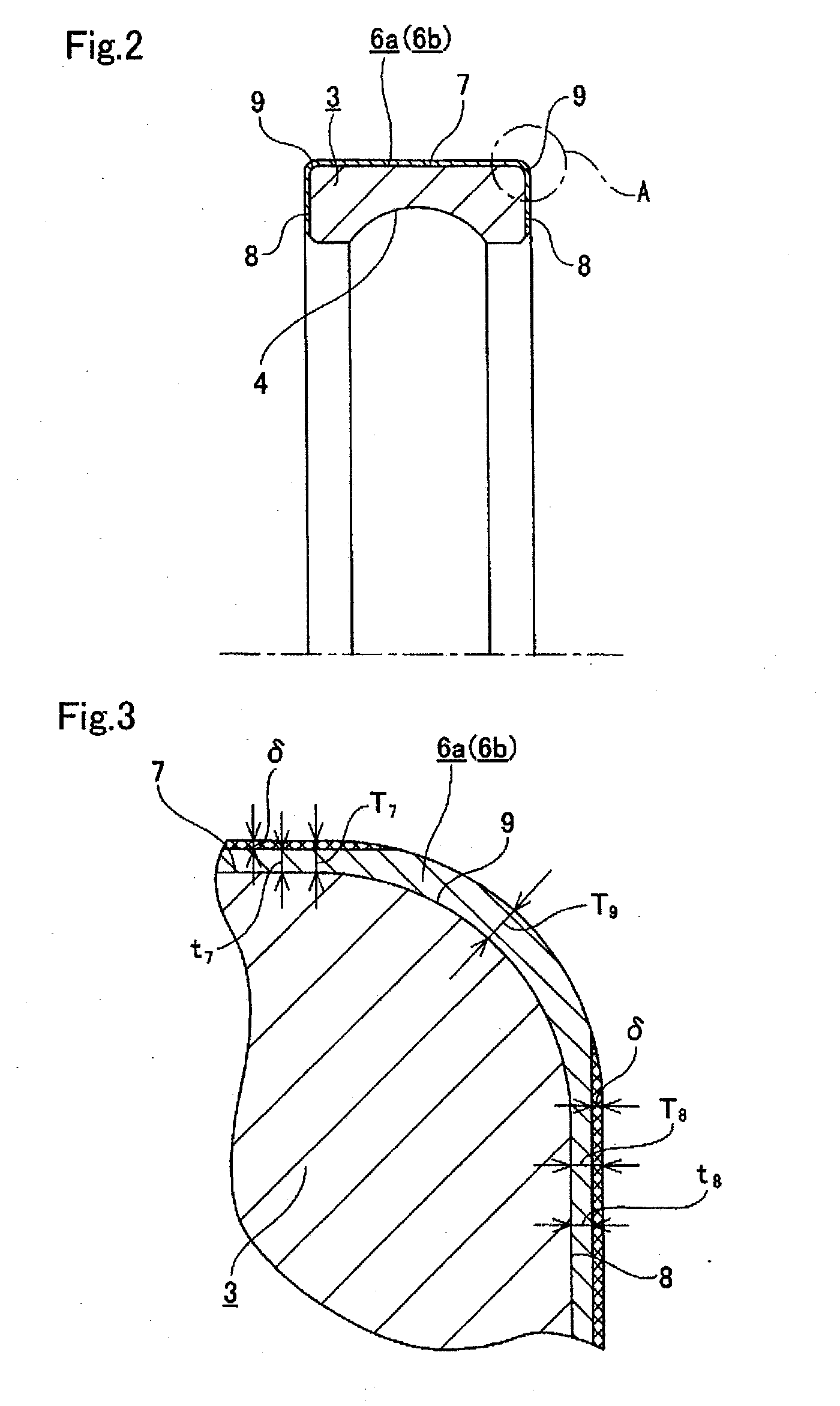

Electrolytic Erosion Preventing Insulated Rolling Bearing, Manufacturing Method Thereof, and Bearing Device

ActiveUS20090304318A1Increased durabilityHigh of insulation performanceBearing assemblyShaftsElectrolysisCeramic coating

In order to ensure high levels of insulation performance, and low cost, and have an excellent external appearance, as a ceramic constituting an insulating coating 6 being a ceramic coating layer, one with alumina as its main component, and in which the content of titanium oxide is limited to 0.01 to 0.2 percent by weight is used. Moreover, a particle size of ceramic forming the coating layer is 10 to 50 μm, and average particle size is 15 to 25 μm. By limiting the content of titanium oxide, the insulating coating 6 can be made thin, and by limiting the particle size the film thickness accuracy can be improved, thus simplifying finishing. Moreover, by mixing of titanium oxide, deterioration of the external appearance after sealing can be prevented. As a result, the above problem is solved.

Owner:NSK LTD

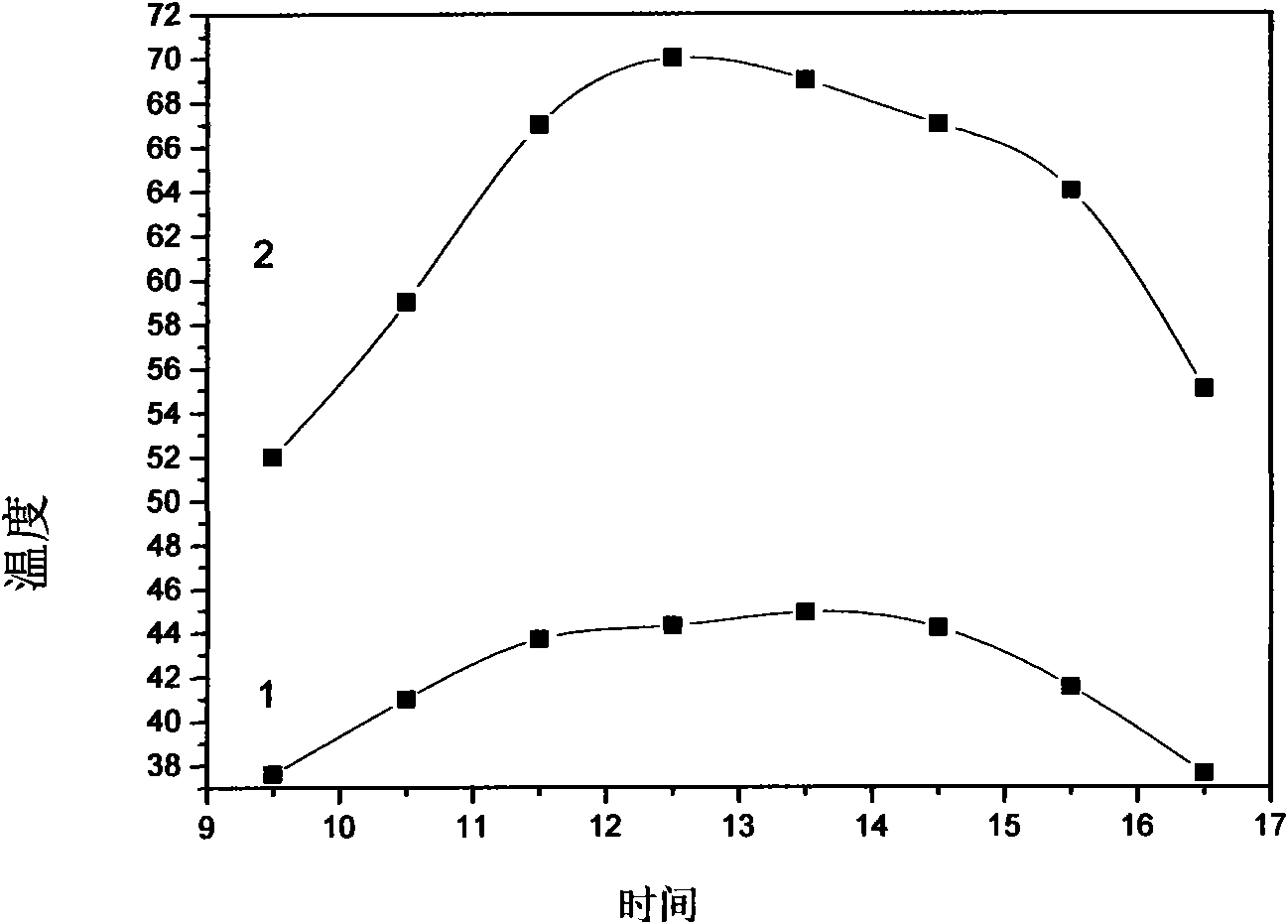

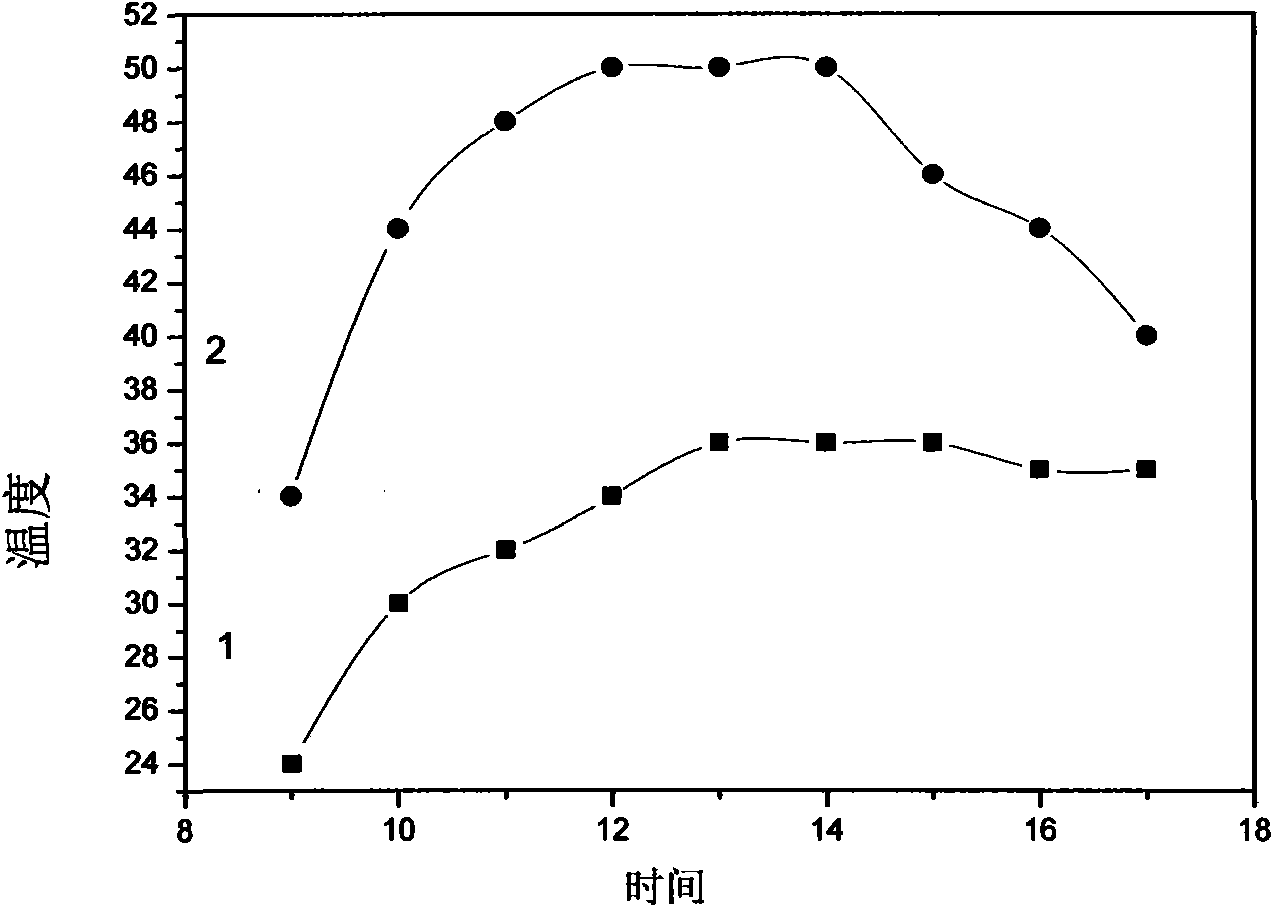

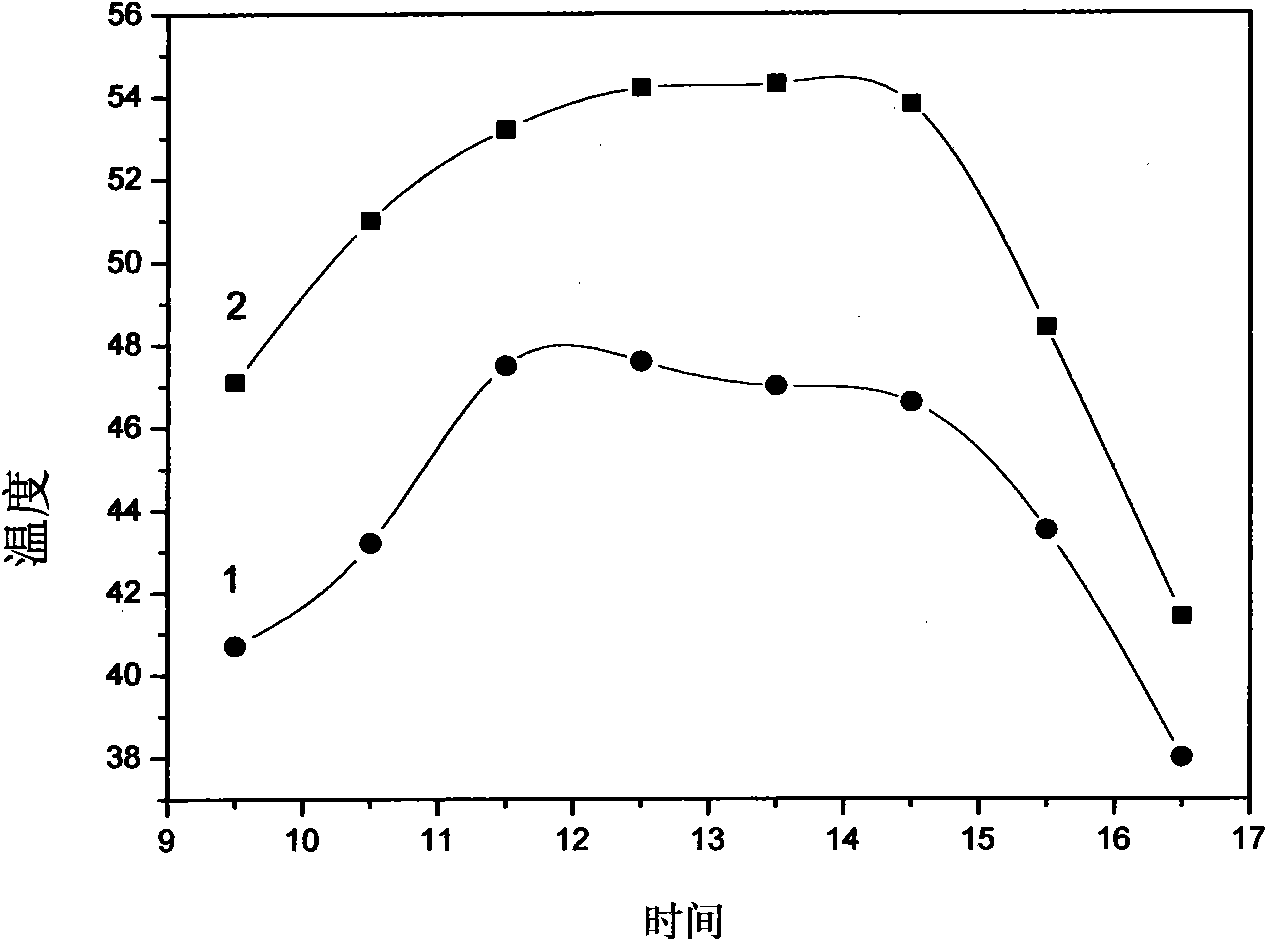

Reflecting thermal insulating paint

InactiveCN101818013AEasy constructionEffective reflectionReflecting/signal paintsWater basedEmulsion

The invention discloses a reflecting thermal insulating paint which comprises the following components in parts by mass: 70 parts to 80 parts of water, 85 parts to 100 parts of rutile type titanium dioxide, 35 parts to 40 parts of cenosphere, 10 parts to 12 parts of far infrared ceramic powder, 6 parts to 10 parts of dispersing agent and 230 parts to 250 pars of pure elasticity acrylic emulsion. The invention also provides a preparation method of the reflecting thermal insulating paint. The reflecting thermal insulating paint belongs to water-based paints, has the advantages of safety and environment protection, has the thermal insulating temperature higher than 10 DEG C, has extensibility,crack resistance and wide application.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +2

Flat vacuum glass welded by using metal welding material and provided with strip frame edge sealing, and manufacturing method thereof

InactiveCN102976592AExtend your lifeGuaranteed tightnessGlass reforming apparatusGlass productionAlloyGlass manufacturing

The present invention relates to a vacuum glass, which is characterized in that peripheries of an upper glass and a lower glass of the vacuum glass comprise edge sealing strip frames, and a metal welding material or an alloy welding material is adopted to integratedly weld the upper glass and the lower glass in a vacuum edge sealing furnace, such that vacuum glass manufacturing is simple, and a sealing effect is ensured through engagement of the upper edge sealing strip frame and the lower edge sealing strip frame. The manufacturing method has characteristics of simple process, low cost, high production efficiency, reliable sealing and good sealing effect. With the technology, large mass manufacturing of the vacuum glass with no gas exhaust port through the one-step method can be achieved. In addition, with the method, the universal vacuum glass can be manufactured, and the tempered vacuum glass can be manufactured.

Owner:戴长虹

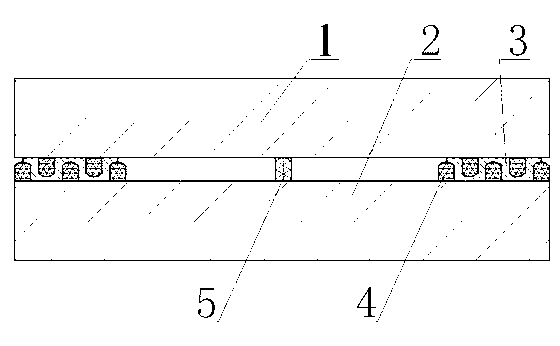

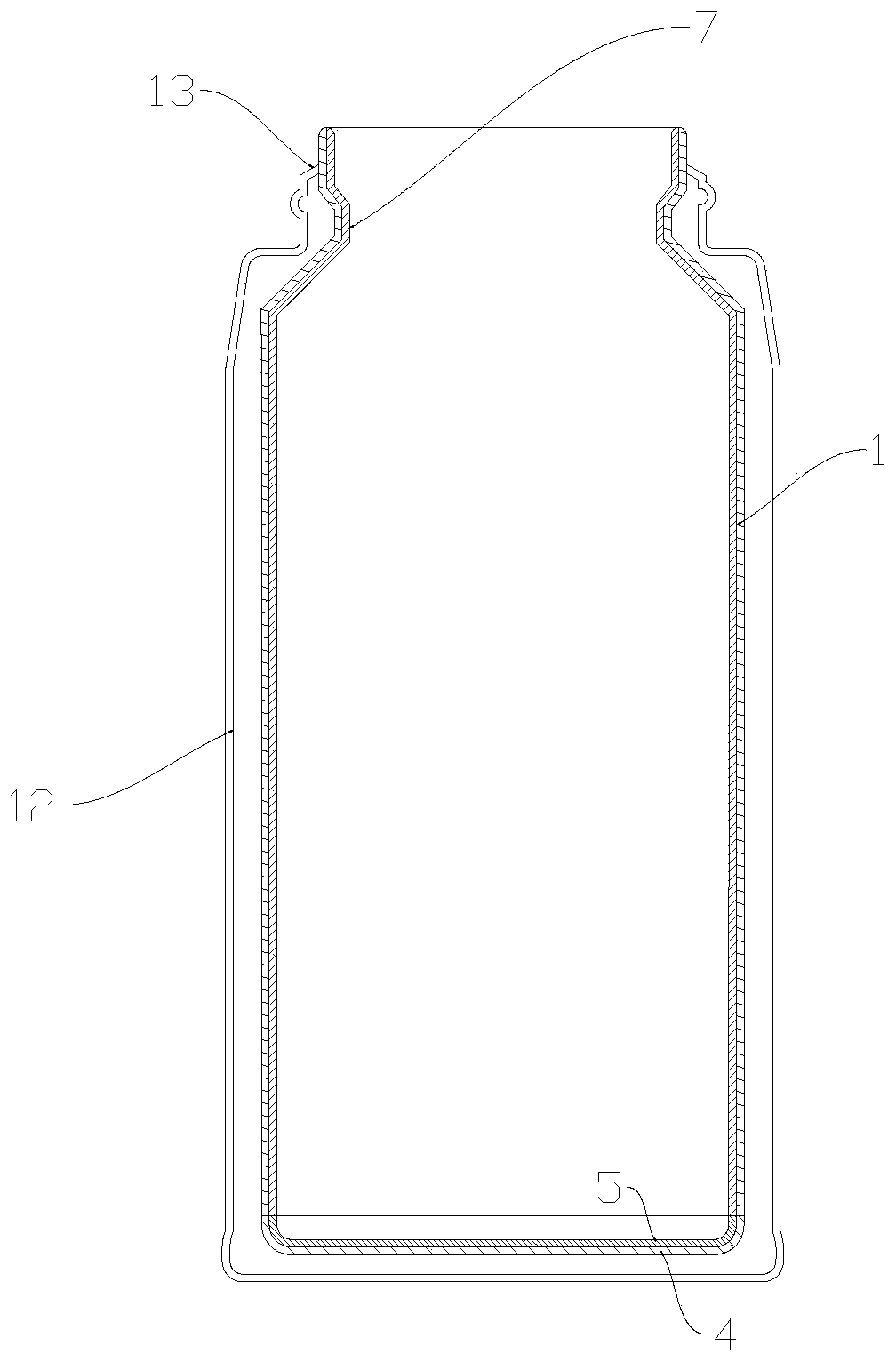

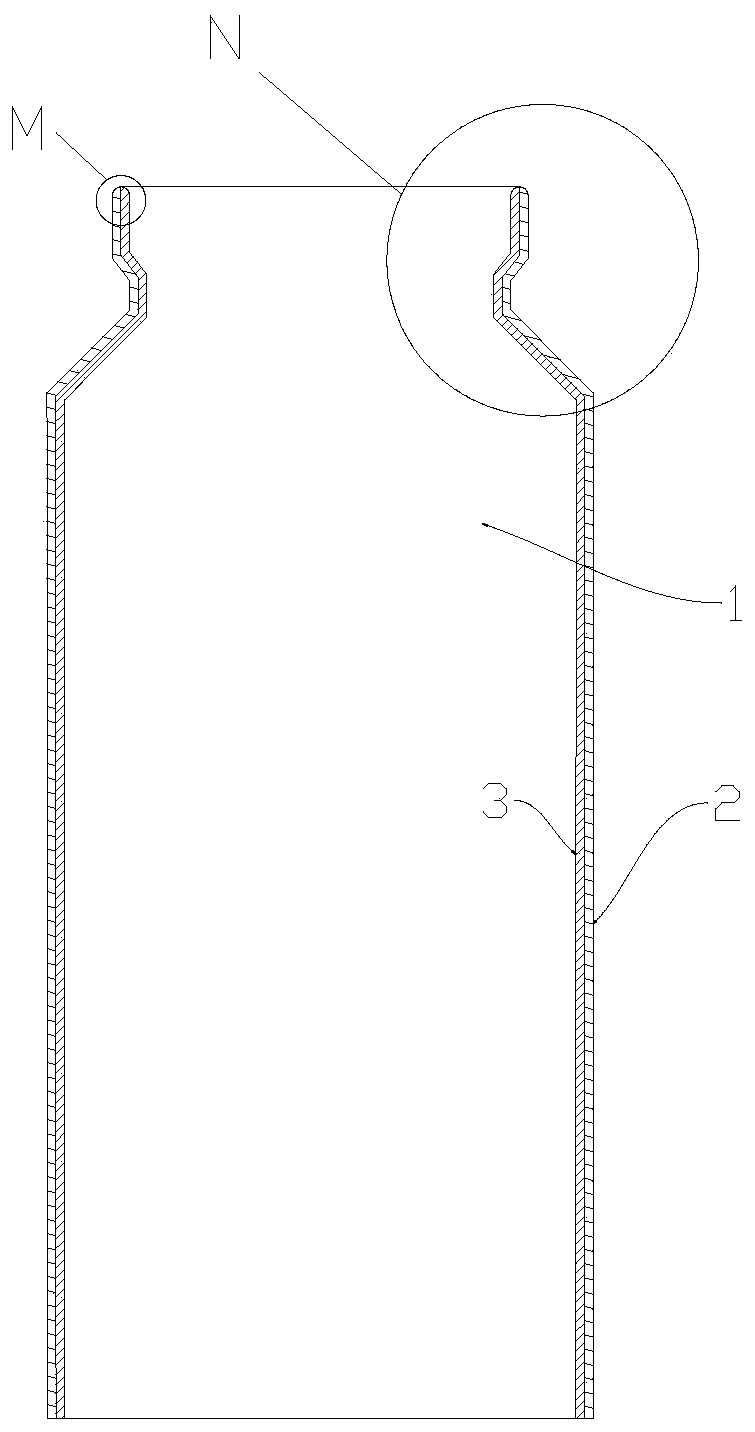

Insulation cup with titanium composite inner tank and manufacturing process thereof

ActiveCN111250620AReduce manufacturing costGuaranteed manufacturing costDwelling equipmentDrinking vesselsTitaniumStainless steel material

The invention relates to the technical field of insulation cups, and discloses an insulation cup with a titanium composite inner tank and a manufacturing process thereof. The insulation cup with the titanium composite liner includes an inner tank body (1); the inner tank body (1) includes a first inner tank layer (2) and a second inner tank layer (3); the first inner tank layer (2) and the secondinner tank layer (3) are arranged concentrically; the first inner tank layer (2) is made of a stainless steel material, a copper material, an iron material or an aluminum material; the second inner tank layer (3) is made of a titanium material; the lower end of the inner tank body (1) is provided with a first bottom layer (4) and a second bottom layer (5); the first bottom layer (4) is made of thestainless steel material; the second bottom layer (5) is made of the titanium material; the first bottom layer (4) is fixedly connected to the lower end of the first inner tank layer (2); and the second bottom layer (5) is fixedly connected to the lower end of the second inner tank layer (3). The invention reduces the consumption of the precious metal titanium material, reduces the manufacturingcost of the inner tank body, and ensures the health of the water quality.

Owner:ZHEJIANG SUNTRUE TITANIUM TECHNOLOGY CO LTD

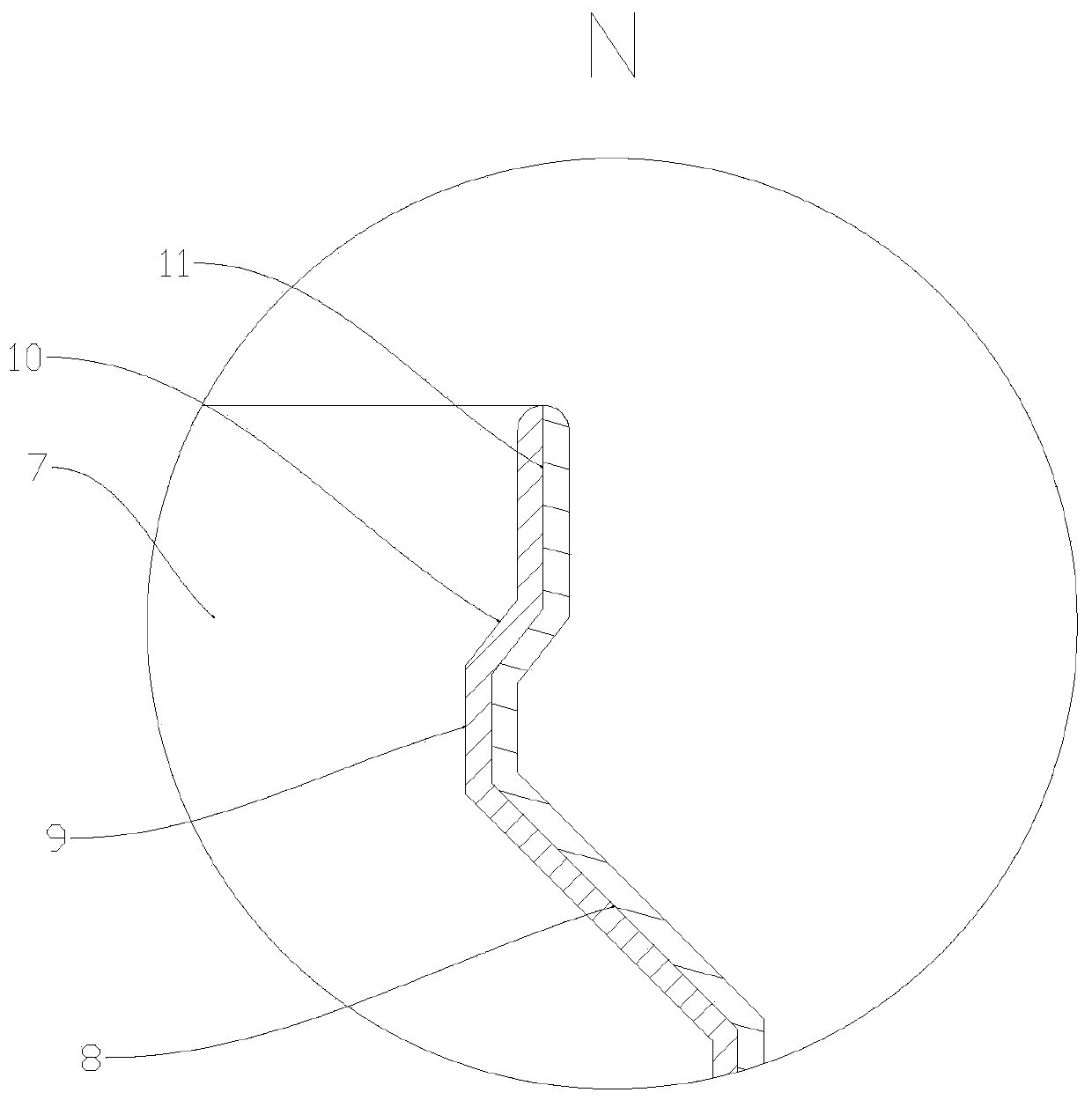

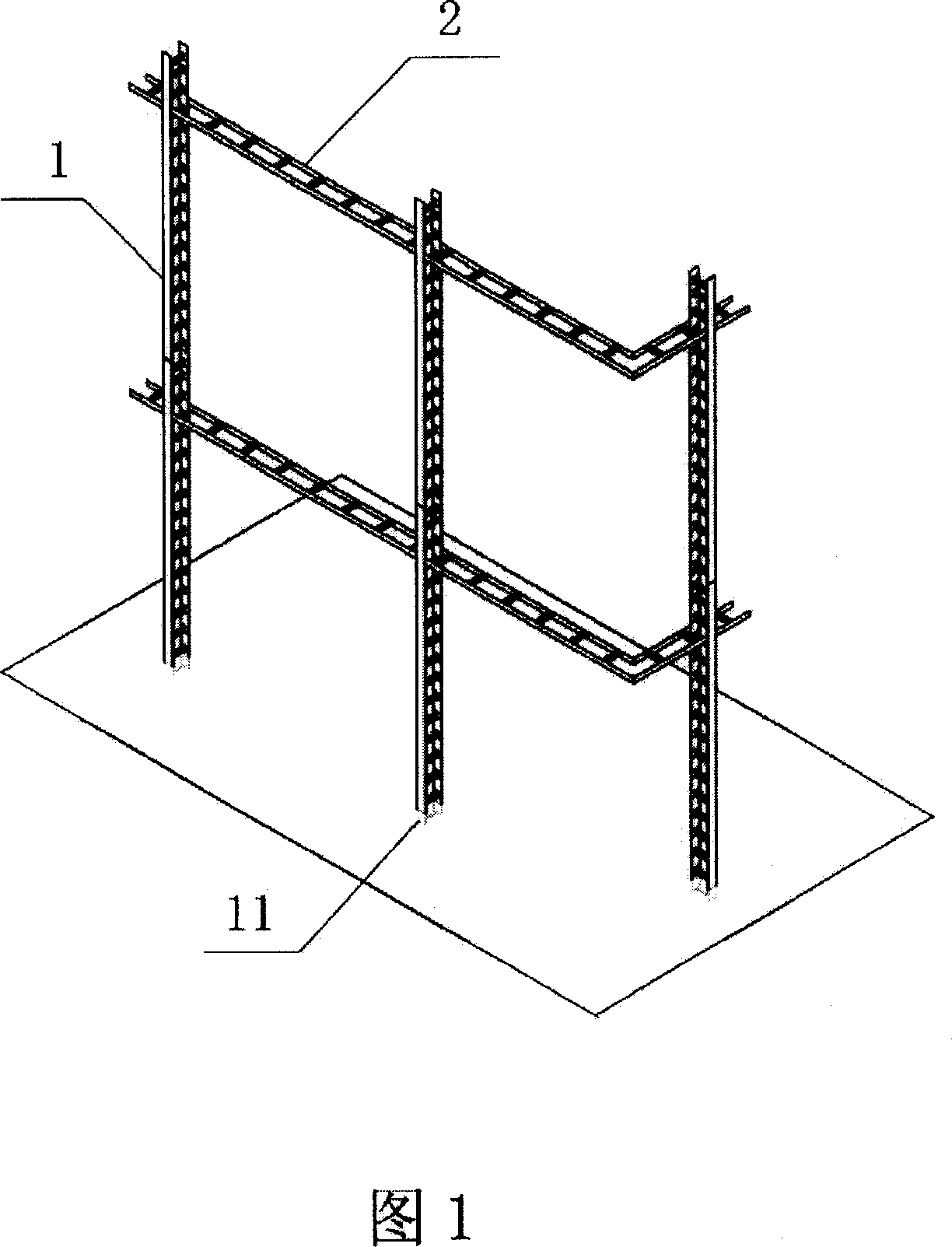

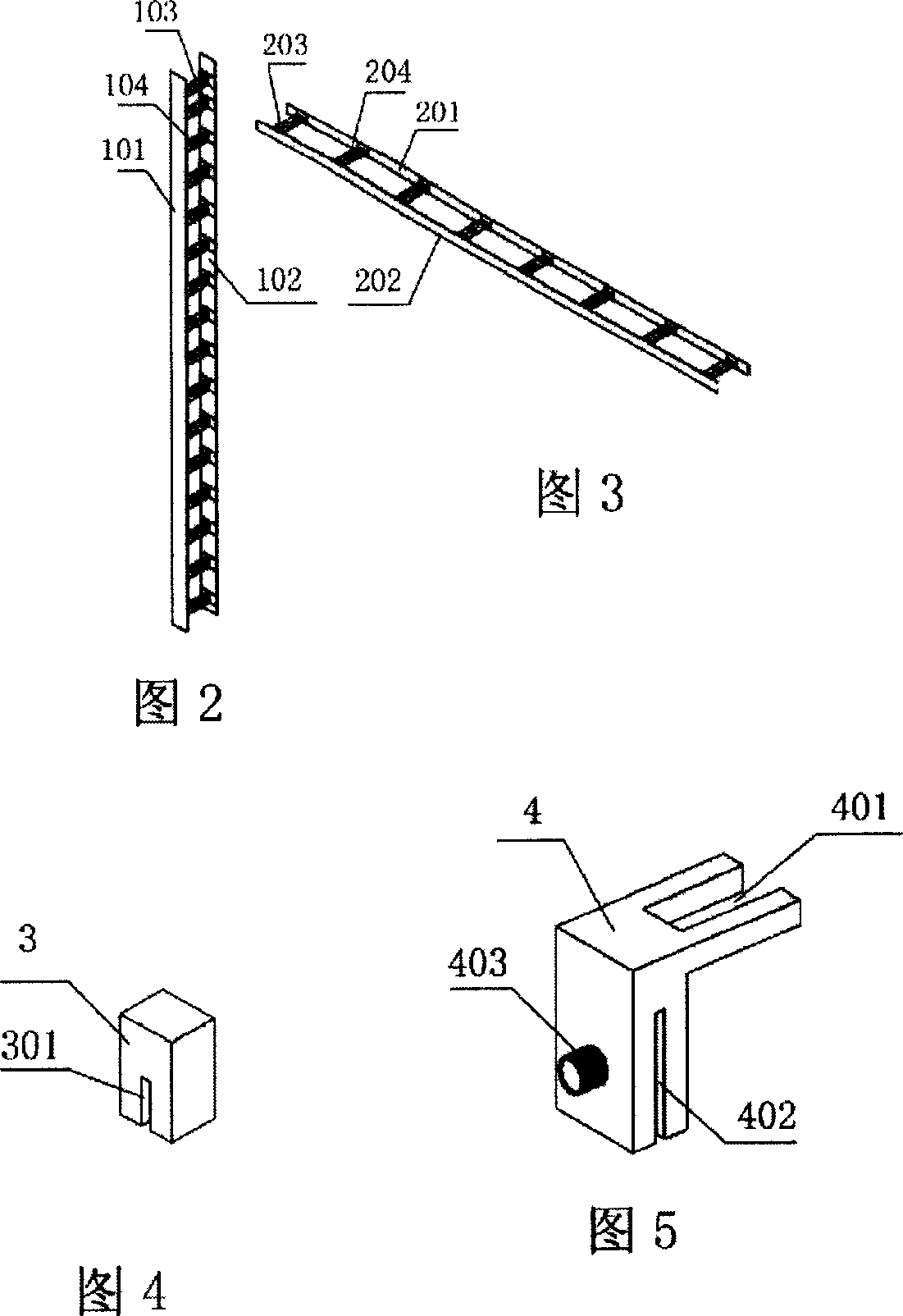

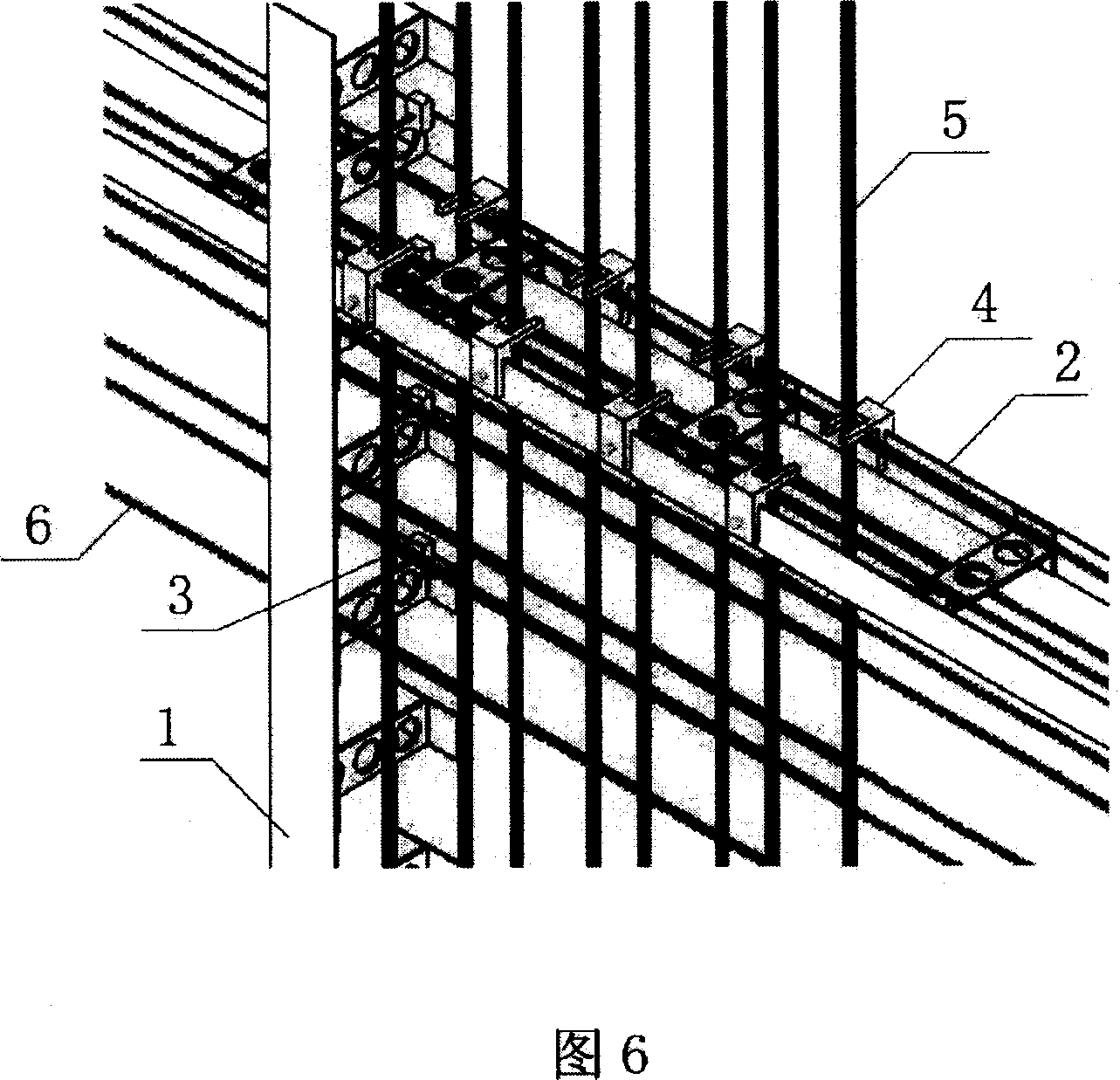

Concrete building reinforcing-bar precision positioning system and its construction method

InactiveCN1936228ANo displacementAvoid corrosionBuilding reinforcementsBuilding material handlingRebarPositioning system

The invention relates to a concrete construction reinforcing steel bar accurate locating system and the constructing method. It includes vertical localizer, horizontal positioning, vertical reinforcing steel bar locating block component, horizontal reinforcing steel bar locating block component, and pre-buried steel component. The vertical localizer is made up of inner board, external board, crosspiece fixation stairway stringer that is plumbed to vertical reinforcing steel bar and paralleled to horizontal reinforcing steel bar, and has the same thickness with wall and the same width with cavity of it. The invention could improve constructing speed and increase the constructing accuracy and entire rigidity of the reinforcing steel bar construction.

Owner:朱秦江

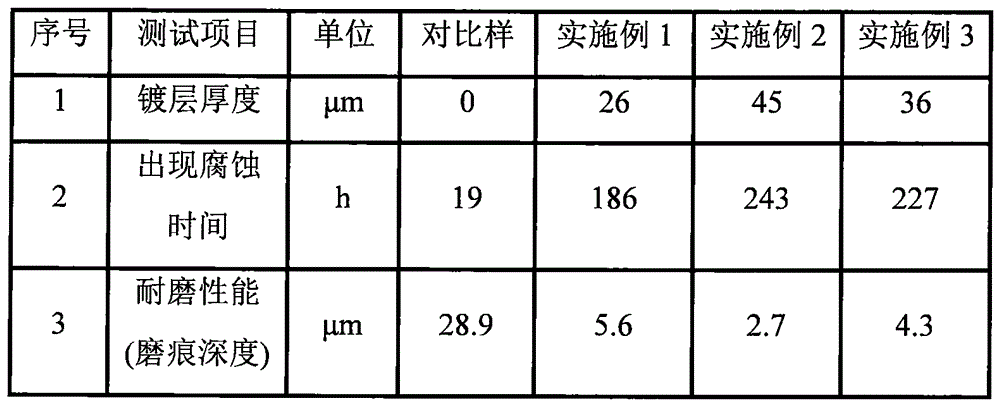

Corrosion-resistant multi-coating neodymium iron boron and preparation process

ActiveCN106710767AAccelerated corrosionImprove wear resistanceMagnetic materialsSuperimposed coating processSingle processDysprosium

The invention provides corrosion-resistant multi-coating neodymium iron boron and a preparation process. The corrosion-resistant multi-coating neodymium iron boron is composed of a neodymium iron boron permanent magnet and multiple coatings arranged on the outer surface of the neodymium iron boron permanent magnet, the multiple coatings sequentially include a nickel-plated layer, a dysprosium-plated aluminum alloy thin film layer and a nickel-chromium composite coating, thickness of the nickel-plated layer is 10-15um, thickness of the dysprosium-plated aluminum alloy thin film layer is 10-20um, and thickness of the nickel-chromium composite coating is 6-10um; modification of the multiple coatings can be realized on the surface of the permanent magnet, binding strength between the coatings and a permanent magnet base is guaranteed, the defect that the coatings are thin and poor in corrosion resistance and wear resistance caused by single process is overcome, and the corrosion-resistant multi-coating neodymium iron boron prepared by the process has high corrosion resistance and wear resistance.

Owner:宁波元辰新材料有限公司

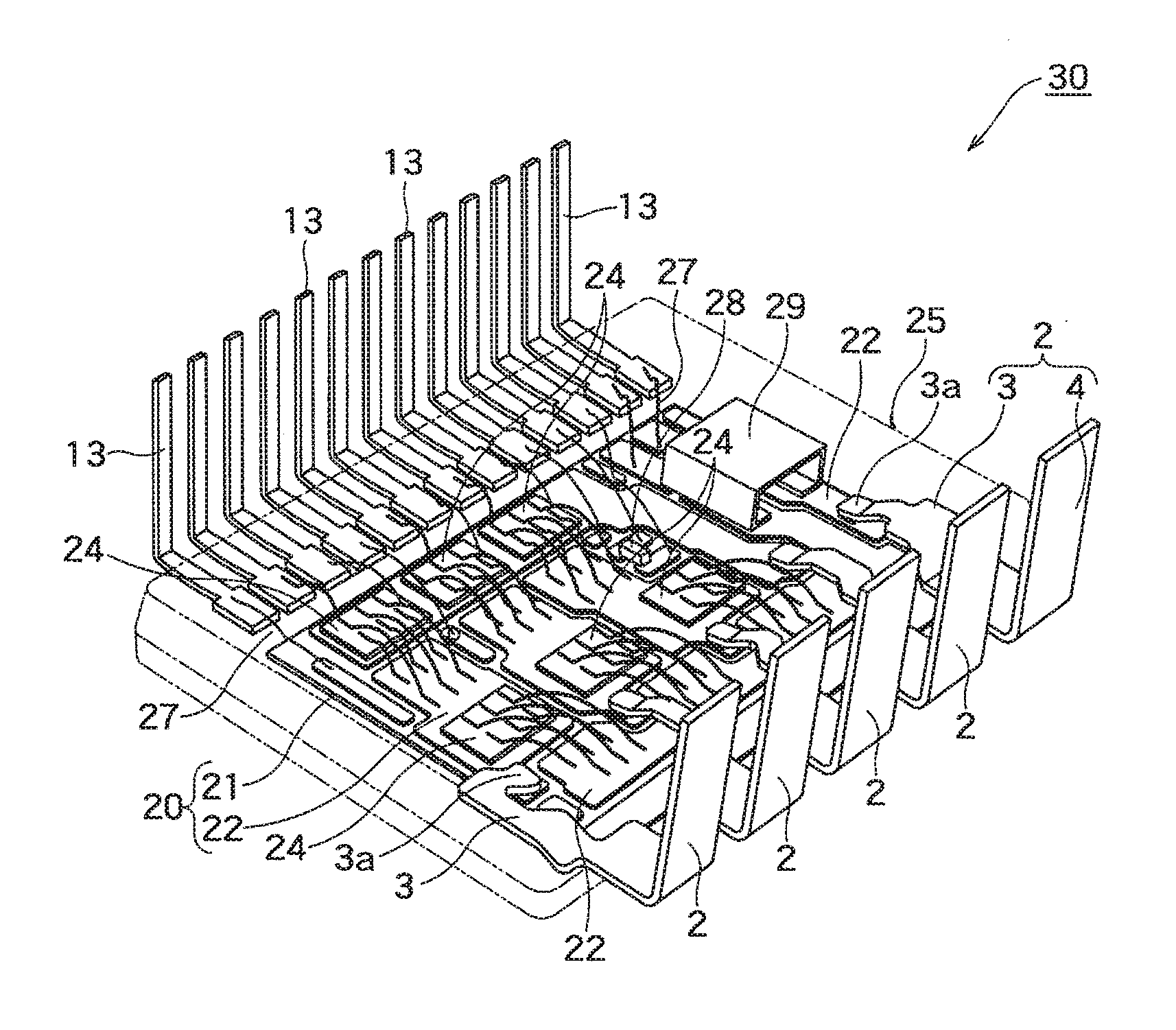

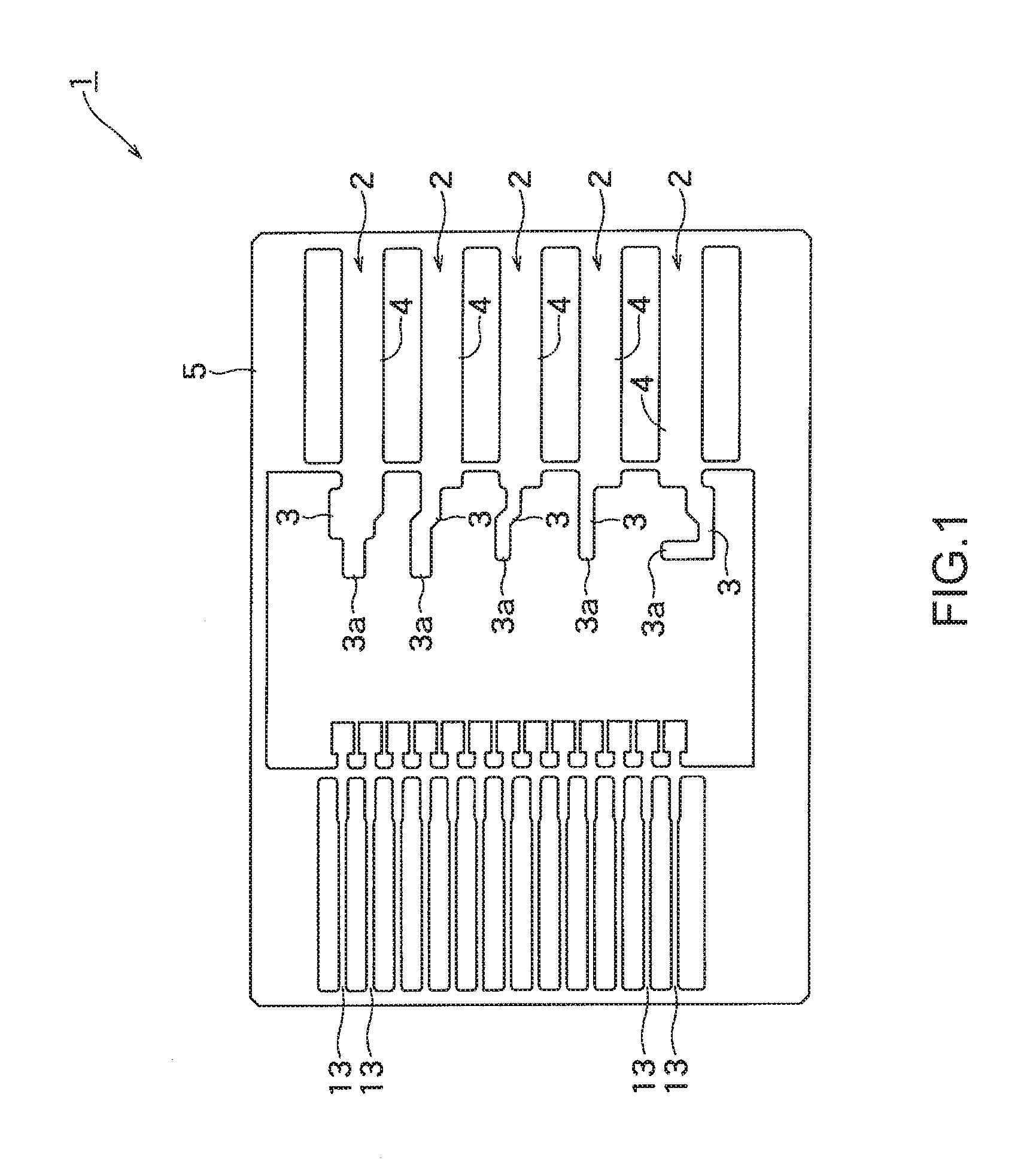

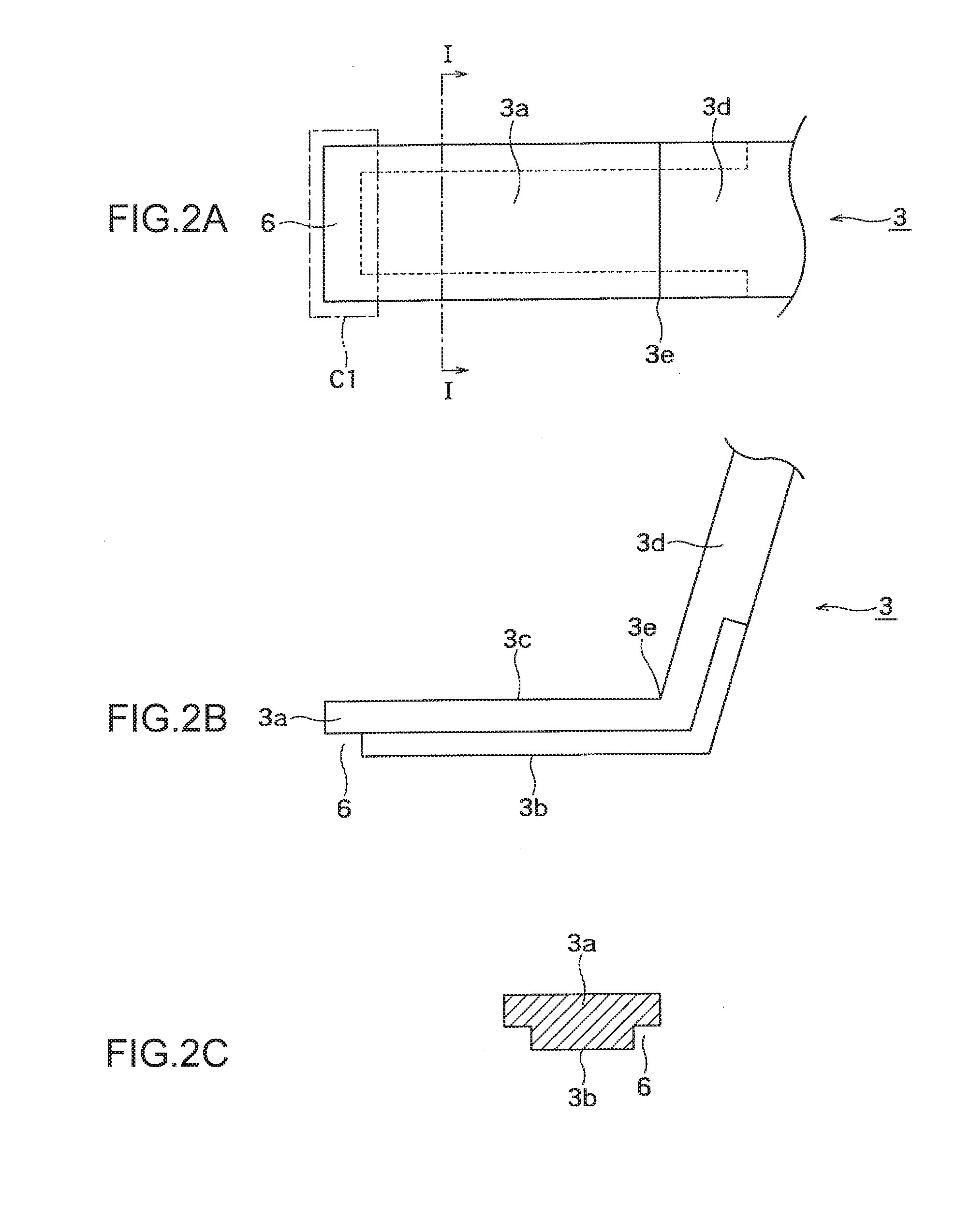

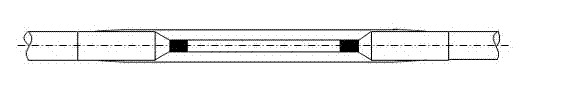

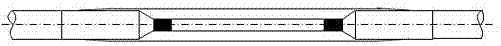

Lead frame, semiconductor device, method for manufacturing lead frame, and method for manufacturing semiconductor device

ActiveUS20170025331A1Reduce generationGuaranteed thicknessSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

A lead frame according to one embodiment includes a lead part including an inner lead and an outer lead connected to the inner lead, and a frame unit supporting the lead part. The inner lead has a terminal portion having a facing surface and a back surface in the opposite side from the facing surface. The facing surface faces a conductive pattern of a wiring board. An outer region of the terminal portion is provided with a solder thickness ensuring portion where the facing surface is depressed toward the back surfaceThe solder thickness ensuring portion is thinner than a center region of the facing surface. A center region of the back surface is flat without a depression.

Owner:SHINDENGEN ELECTRIC MFG CO LTD

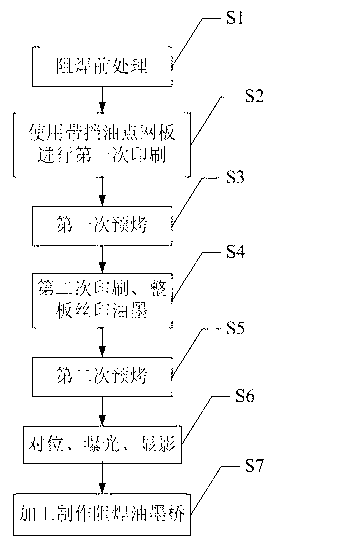

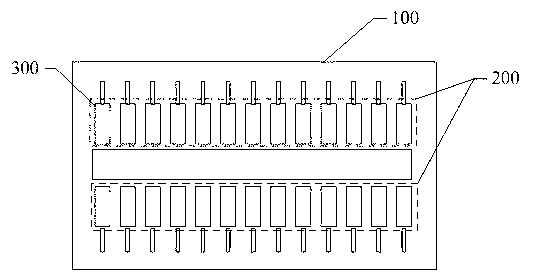

Manufacture method of thick copper plate fine solder resist bridge

InactiveCN103200777ASatisfy the thickness conditionGuaranteed thicknessPrinted circuit manufactureResistDouble-time

The invention discloses a manufacture method of a thick copper plate fine solder resist bridge. The manufacture method comprises the following steps of: baffling printing ink at the position of a fine solder resist bridge by a mesh plate with oil baffle points when first oil printing is carried out, wherein the thickness of the printing ink of a thick copper plate line can be guaranteed only by printing the printing ink at the other positions; and carrying out second printing by a normal blank mesh plate. After the method is used, under the condition that the thickness of the printing ink of the thick copper plate line is guaranteed, the thickness of the printing ink at the fine solder resist bridge is reduced, and the thickness condition of the manufactured fine solder resist bridge can be met; the conventional double-alignment, exposure and development technology is changed into one-time-alignment, exposure and development technology after the whole craft process is used; and the printing oil at the edge within an oil baffle region inwards leaks due to the liquidity of the printing ink after the first printing, so that the stepped drop can be avoided in the process of secondary silk screen, and the thick copper plate fine solder resist bridge is attractive in appearance. The stepped apparent defect caused by the double times of exposure and development can be avoided.

Owner:SHENZHEN KINWONG ELECTRONICS

Method for repairing damage of external shield of medium and high voltage cable

InactiveCN102361271ATightly boundGuaranteed shielding effectApparatus for repairing insulation/armouring cablesPolyesterSurface finishing

The invention discloses a method for repairing the damage of an external shield of a medium and high voltage cable, belongs to the technical field of wires and cables, and is used for cleanly processing the damaged external shield and the surface of an insulator. The method comprises the following steps of: completely wrapping a damage part by using a pressing sheet of an external semi-conductive material; tightly winding the exterior of the damage part by using a polyester belt or a polytetrafluoroethylene belt; putting the repaired damage part into a heating device which is pre-heated to a constant temperature of 118 to 122 DEG C; heating for 4 to 6 minutes under the pressure of 1.1 MPa to 1.3 MPa; and cooling, and then cutting a thicker part to make the appearance smooth. The method has the advantages that: the appearance of the repaired part is almost the same as that of the unrepaired part; the thickness of the external shield can be guaranteed; any influence of the external shield is avoided; the shielding effect of the external shield and the quality of finished cable products are guaranteed; and economical cost is low.

Owner:圣安电缆有限公司

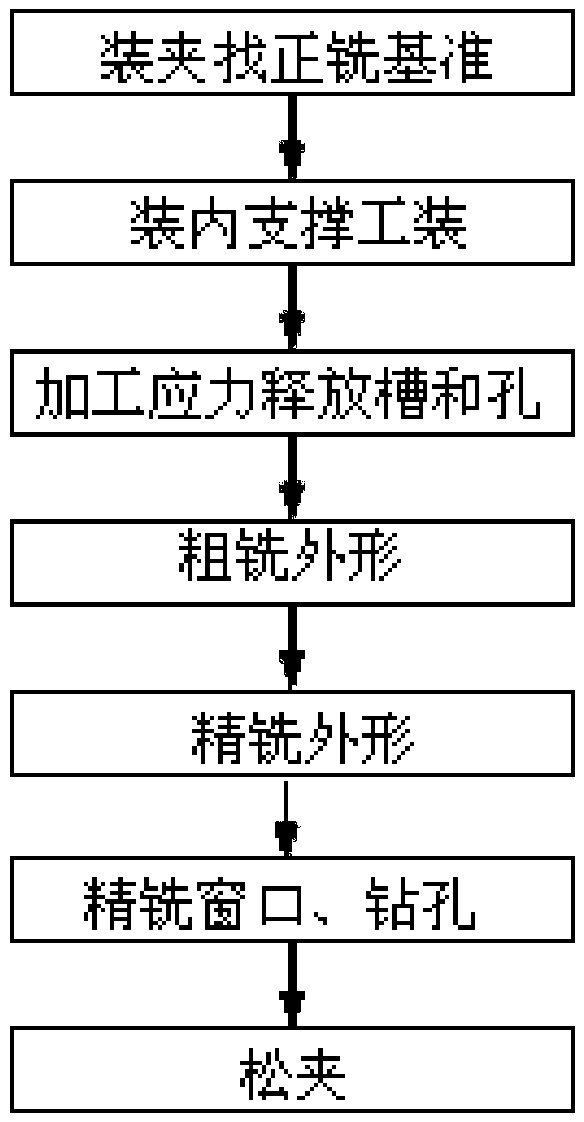

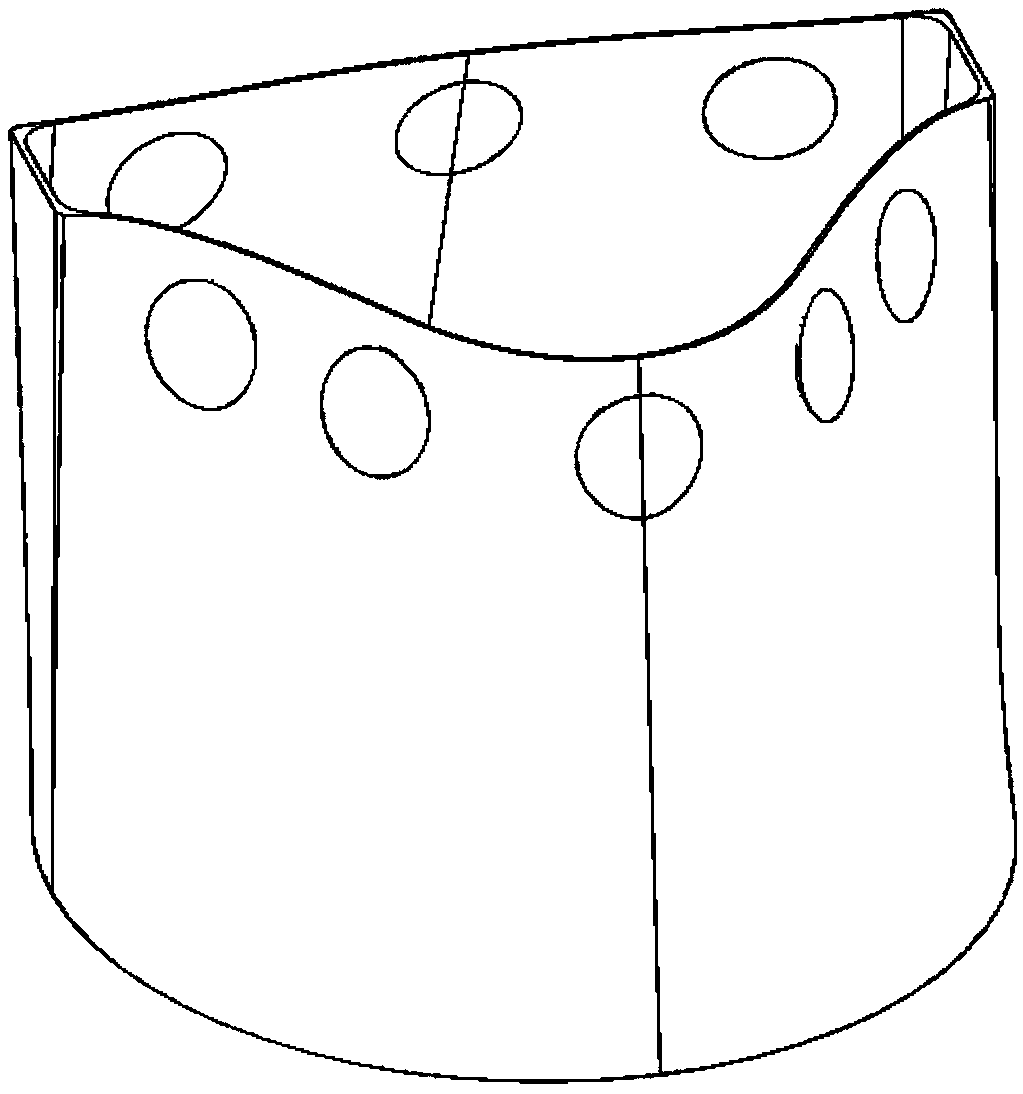

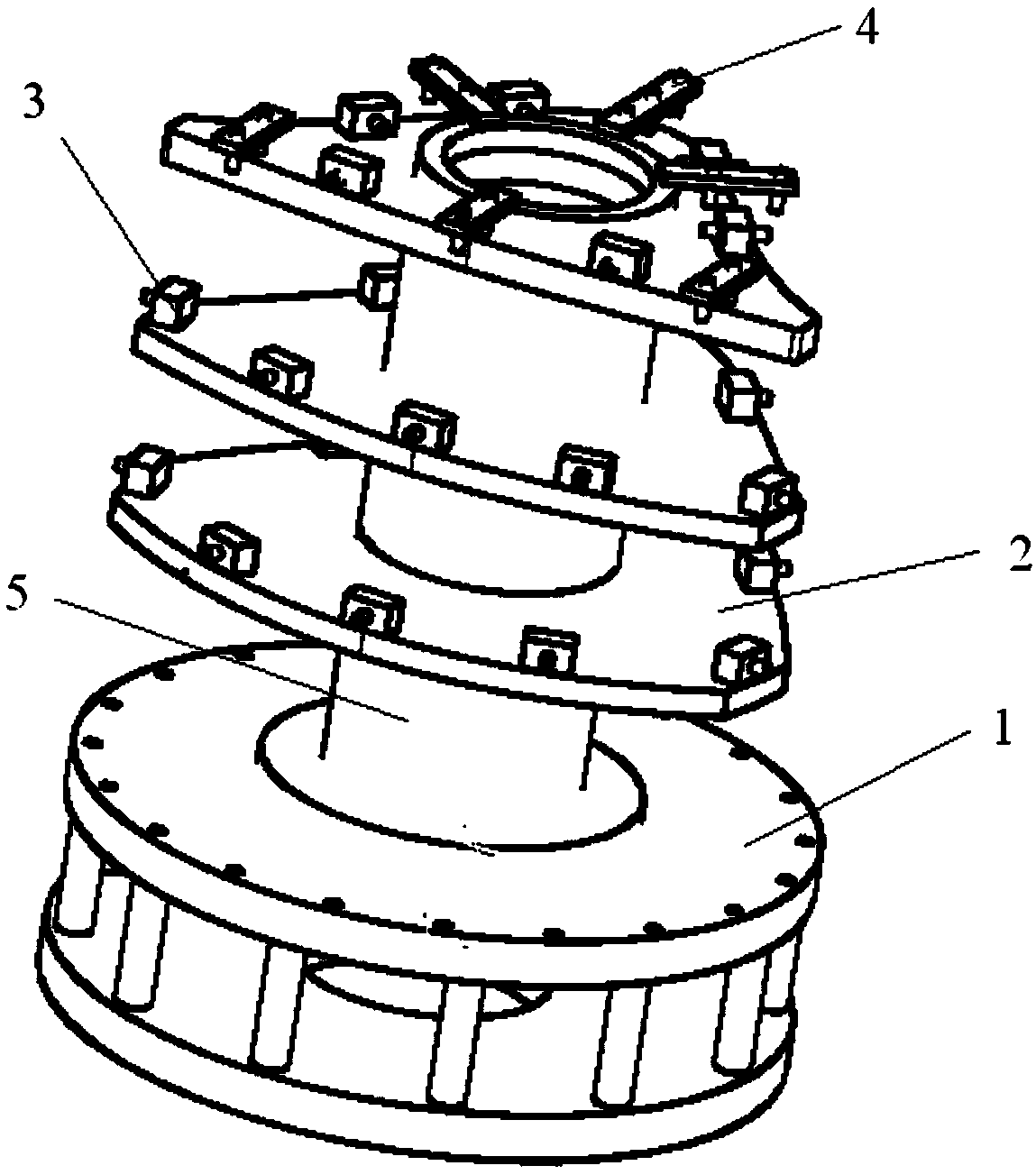

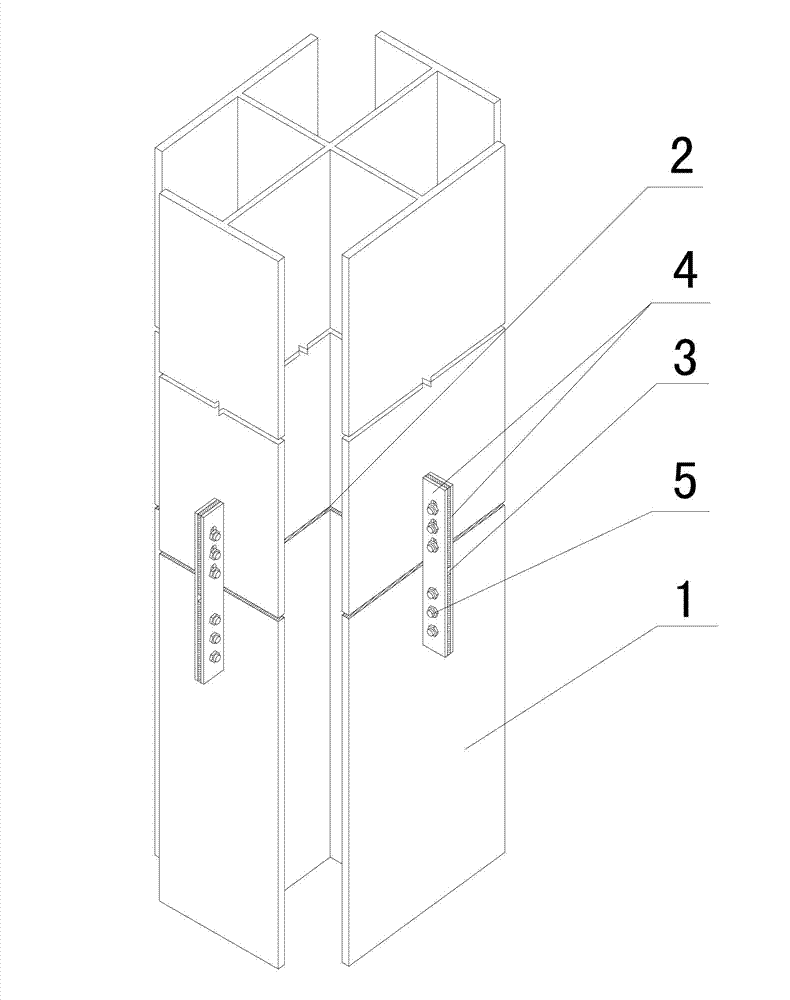

Low-deformation processing method for thin-wall large-area special-shaped composite case

ActiveCN108890225AImprove grinding efficiencyOptimizing Tool Position AlgorithmMeasurement/indication equipmentsPositioning apparatusThin walledTool path

The invention relates to a low-deformation processing method for a thin-wall large-area special-shaped composite case, provides a measuring method of the thin-wall large-area special-shaped compositecase, designs an internal supporting tool, provides a technology method that residual stress is released by using a stress segmentation groove and optimizing tool path planning, and solves the problems that the thin-wall large-area special-shaped composite case is difficult to measure and large in deformation. Through practical application and testing, it is shown that when the method is applied,low-deformation processing of the thin-wall large-area special-shaped composite case can be achieved, and fundamental research experience is provided for low-deformation processing of other similar thin-wall cases.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

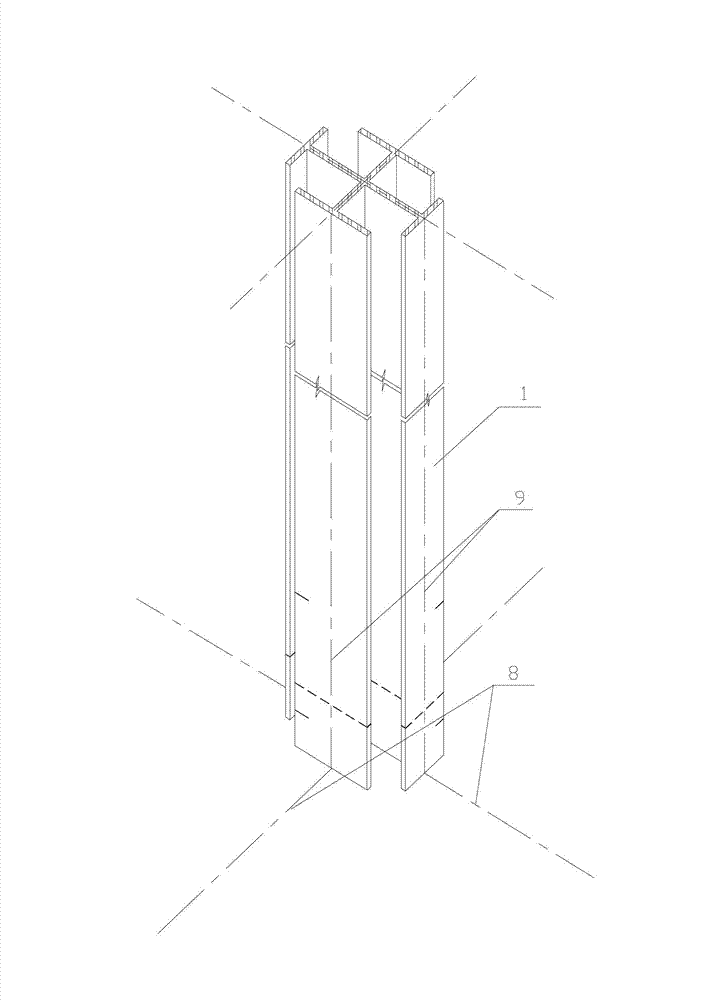

Section steel column for high-rise building section steel concrete combination structure, and construction method thereof

ActiveCN102733545AGuaranteed section sizeGuaranteed lengthStrutsBuilding material handlingConnection typeEngineering

The present invention discloses a section steel column for a high-rise building section steel concrete combination structure, and a construction method thereof. The section steel column comprises a plurality of column sections, wherein the column sections are sequentially connected from bottom to top, an interface position of two optionally adjacent column sections is provided with an inner sleeve interface, and an outer side wall of a connection position of the two adjacent column sections is provided with a buckle fixation type assembly. The construction method comprises that: the insert-connection type initial positioning of the two adjacent column sections is achieved through the inner sleeve interface; the cross extending line and the buckle fixation type assembly are combined to carry out positioning correction on the column; a scale measurement method is adopted to carry out column scale height adjustment; and the cross extending line and the buckle fixation type assembly are combined to carry out verticality correction on the full length of the column sections. With the section steel column of the present invention, the model of one construction interface in each floor of the traditional section steel column can be increased to the model of one construction interface in every two floors or three floors, such that more than half of the construction interfaces of the section steel column can be saved, the probability of deviation error due to construction interface operation can be greatly reduced, and the guarantee degree of installation quality can be improved.

Owner:广东中城建设集团有限公司 +1

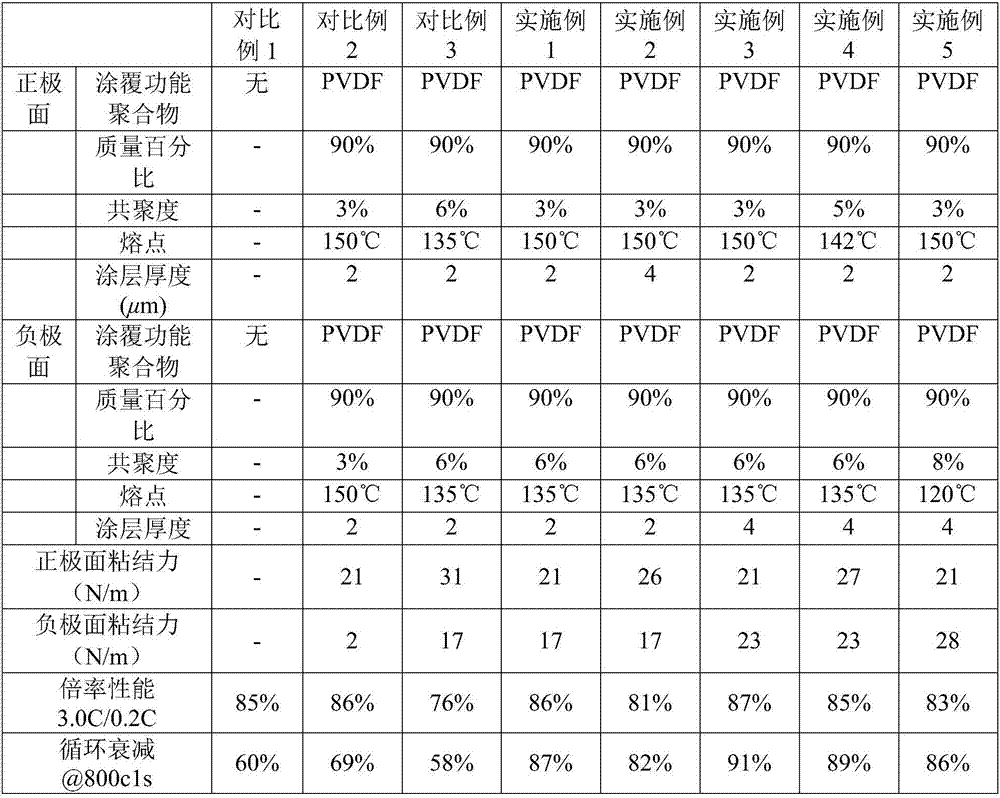

Organic functional porous isolating membrane, preparation method and lithium ion battery

ActiveCN107123767AImprove adhesionExcellent rate performanceCell seperators/membranes/diaphragms/spacersSecondary cellsSodium-ion batteryLong term cycling

The invention discloses an organic functional porous isolating membrane, a preparation method and a lithium ion battery, and aims to the solve the problem that a function of a coating layer is influenced caused by different binding effects when the surfaces of two coating layers of the same specification of an isolating membrane are laminated and glued with positive and negative plates of different physical properties of a battery. According to the main points of the technical scheme, the organic functional porous isolating membrane comprises a porous base material and organic functional coating layers attached to two surfaces of the porous base material; and each organic functional coating layer comprises organic functional polymer polyvinylidene fluoride, an aqueous polymer thickening agent, and an aqueous polymer binder. According to the different characteristics of the positive and negative electrode materials of the lithium ion battery corresponding to the two surfaces of the porous base material, the organic functional polymer polyvinylidene fluoride with different copolymerization degrees and fusing temperatures can be selected on the surfaces of the isolating membranes of the corresponding positive and negative electrodes, so that the safety performance and the long-term cycling stability of the battery can be improved.

Owner:深圳市旭然电子有限公司

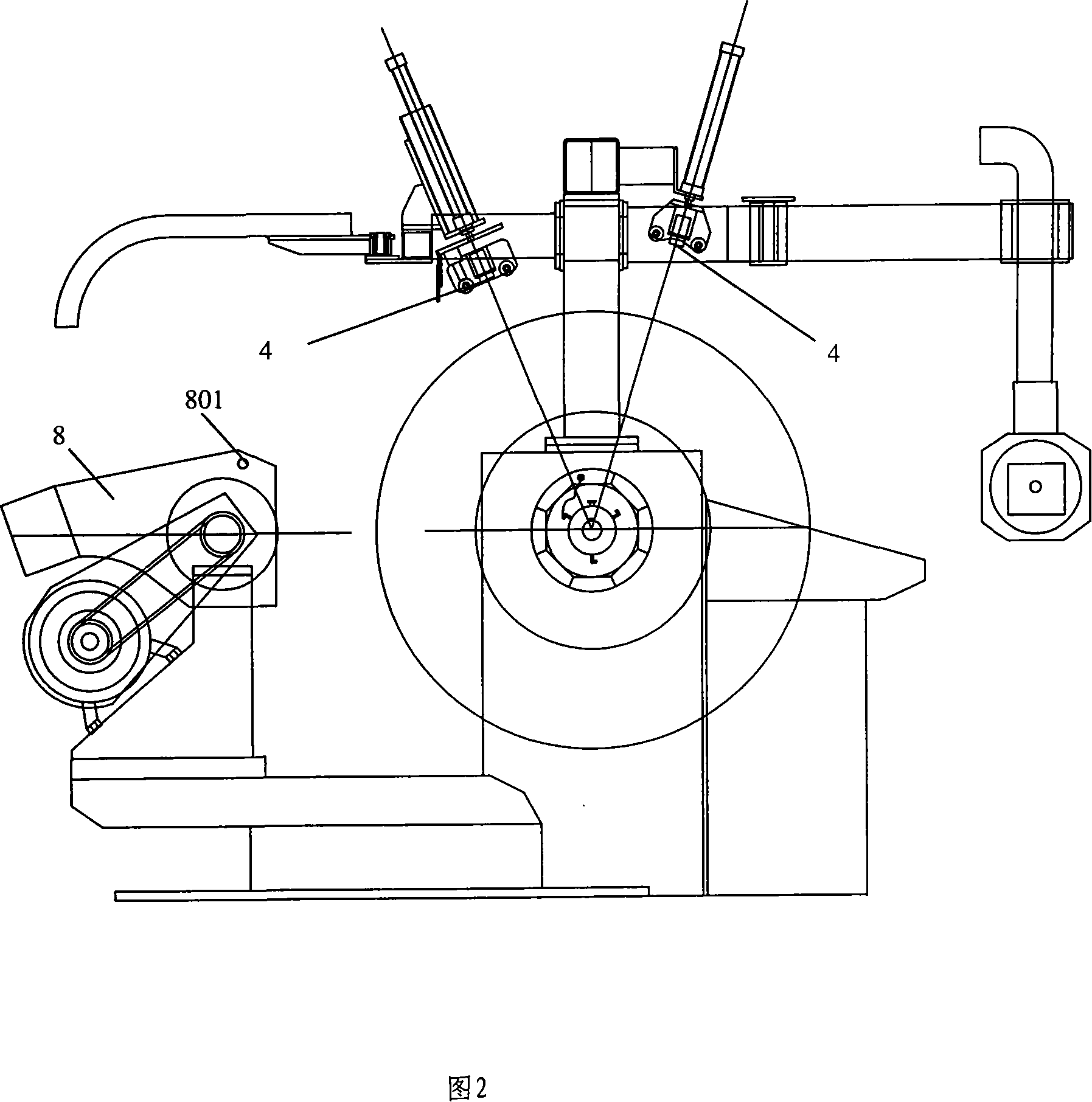

Novel tyre renovating sander

InactiveCN101148020AMeet the needs of the renovation processGuaranteed thicknessRevolution surface grinding machinesSanderAutomatic control

The grinding machine for retreading tire includes one machine body, one grinding head and one feeding mechanism, and features its automatic control system comprising one data processing device and one set of detecting heads, and one servo control device to control the grinding head based on the command from the data processing device. The grinding machine of the present invention has the features of automation and high efficiency.

Owner:BEIJING DUBELI TYRE CO LTD

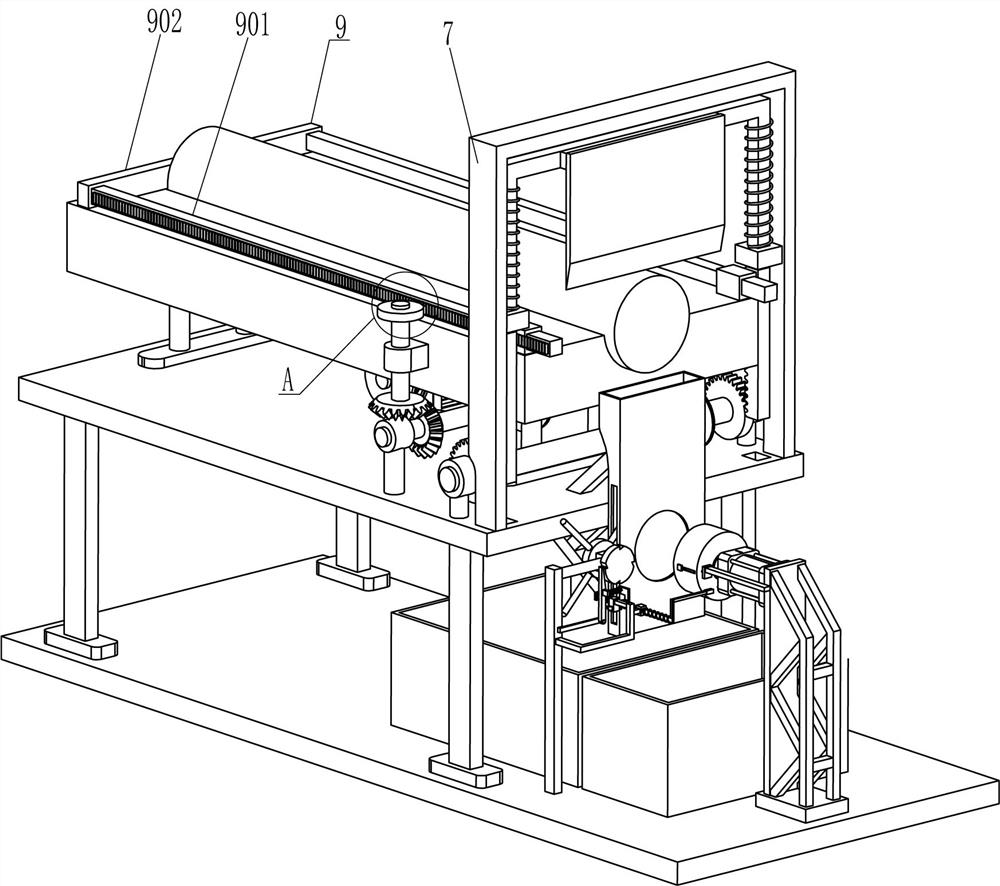

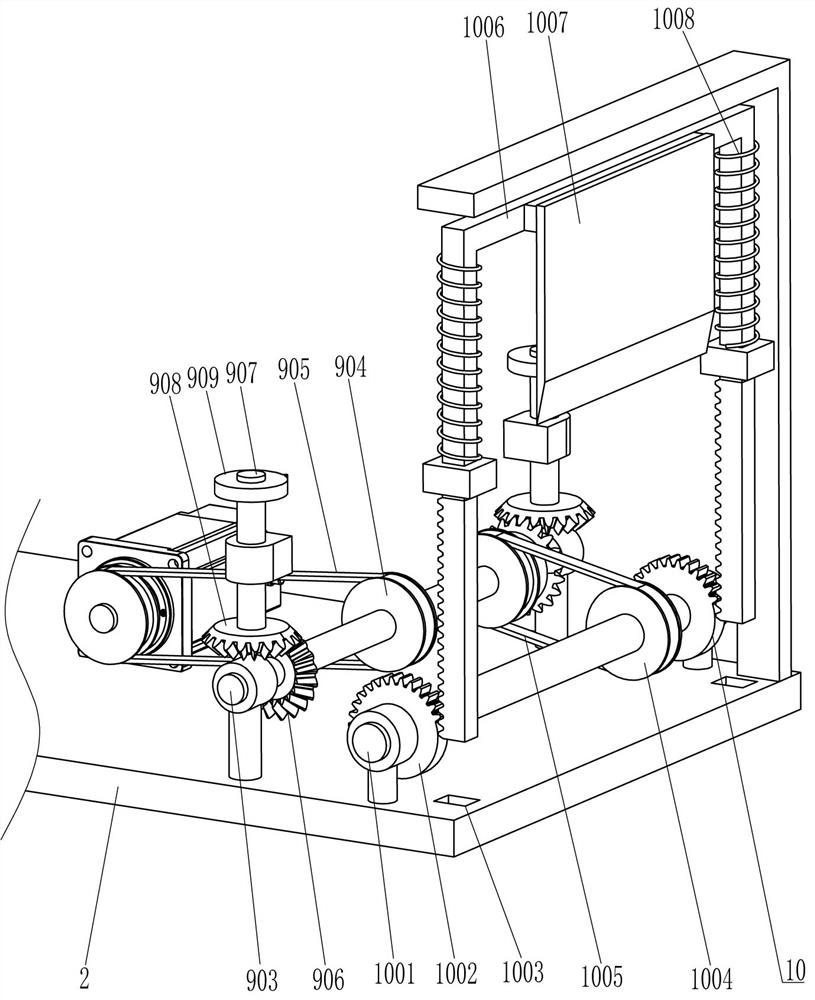

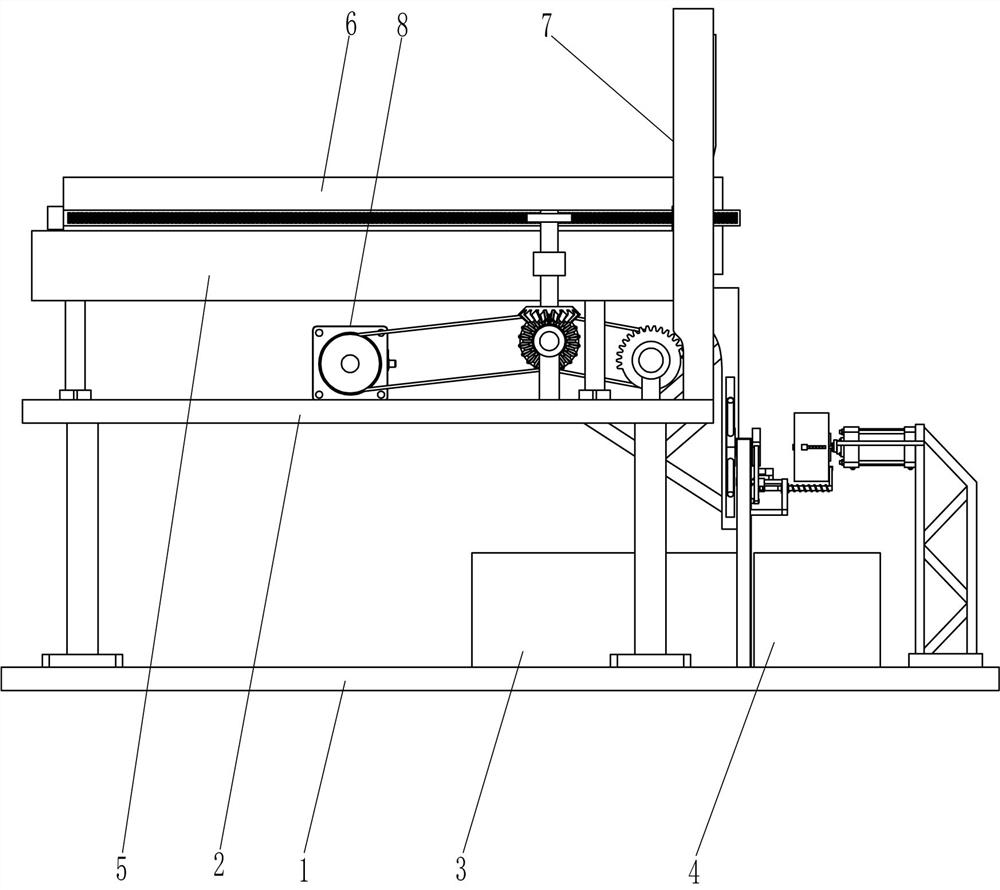

Graphite rod slicing and graphite gasket processing equipment

ActiveCN111823412AGuaranteed thicknessImprove work efficiencyWorking accessoriesStone-like material working toolsStampingEngineering

The invention relates to the field of graphite sheet processing, in particular to graphite rod slicing and graphite gasket processing equipment. The graphite rod slicing and graphite gasket processingequipment is high in working efficiency, can control the thickness of graphite sheets, and avoids defective products. According to the technical scheme, the graphite rod slicing and graphite gasket processing equipment comprises a bottom plate and a first collecting frame, wherein an objective table is bolted on the bottom plate; and the first collecting frame and a second collecting frame are placed on the bottom plate. According to the graphite rod slicing and graphite gasket processing equipment, a graphite rod can be cut through a cutting assembly, a stamping assembly can stamp the cut graphite sheets, so that cutting and stamping are carried out at the same time, and therefore the working efficiency can be improved; and the graphite rod is conveyed by a machine instead of manual work, so that the thickness of the graphite sheets can be effectively guaranteed.

Owner:内蒙古骅扬高新材料科技有限公司

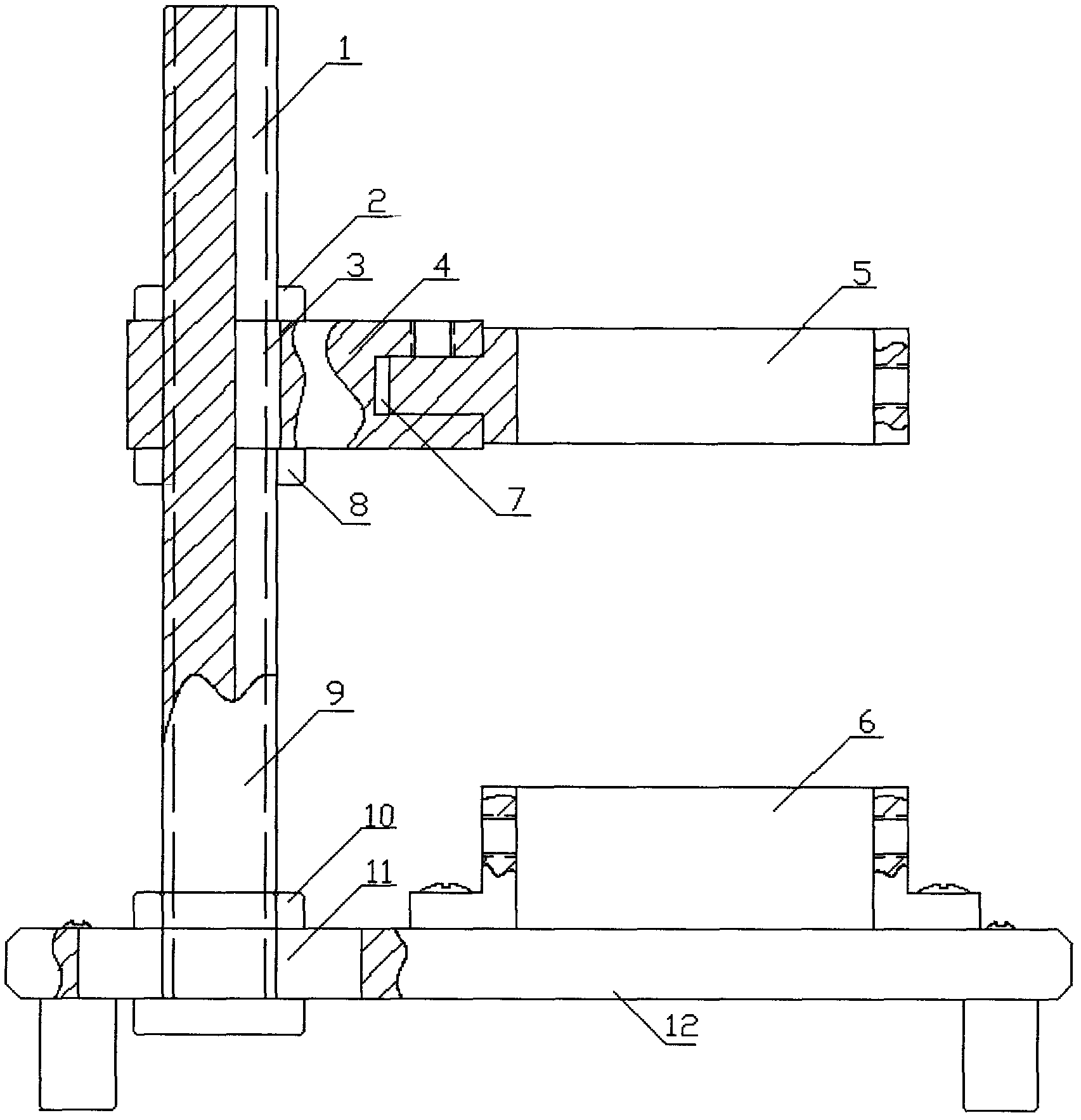

Preparation device of indoor single-cracked rock specimen

InactiveCN102435475AReasonable structureEasy to manufacturePreparing sample for investigationPetrologyButt joint

The invention relates to a preparation device of a rock cracked specimen, in particular to a preparation device of a single-cracked rock specimen filled with a binding material with a certain thickness. The preparation device comprises a base, an upper movable seat, a lower rock core fixing lantern ring, an upper rock core fixing lantern ring, a threaded spindle, an adjusting screw cap and a fastening screw cap; the concentricity of an upper rock core and a lower rock core arranged in the upper rock core fixing lantern ring and the lower rock core fixing lantern ring can be ensured through adjusting the position of the spindle relative to a through groove of the base and the position of the upper rock core fixing lantern ring relative to a horizontal through groove; the distance between the upper rock core and the lower rock core is controlled through the adjusting screw cap and the fastening screw cap; and meanwhile, the thickness of a binding layer between the upper rock core and the lower rock core is ensured so that the upper rock core and the lower rock core are coupled and butt-jointed to form a standard single-cracked rock specimen. The preparation device of the single-cracked rock specimen in the invention is easy to manufacture, simple in operation, strong in practicability and capable of being widely used for preparing single-cracked rock specimens.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com