Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

261 results about "Fire clay" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fire clay is a range of refractory clays used in the manufacture of ceramics, especially fire brick. The United States Environmental Protection Agency defines fire clay very generally as a "mineral aggregate composed of hydrous silicates of aluminium (Al₂O₃·2SiO₂·2H₂O) with or without free silica."

High-temperature far infrared paint and preparing method thereof

ActiveCN1552779AImprove adhesion strengthImprove thermal shock resistanceCellulose derivative coatingsFire clayBrown iron oxide

A refractory far infrared paint is prepared from zirconium oxide, Cr2O3, refractory clay, bentonite, TiO2 powder, brown corundum, iron oxide, silicon carbide, adhesive PA80 or water glass and carboxymethyl cellulose through proportional mixing, and nano-class superfine processing. Its advantage is high emissivity (0.93) at high temp.

Owner:山东慧敏科技开发有限公司

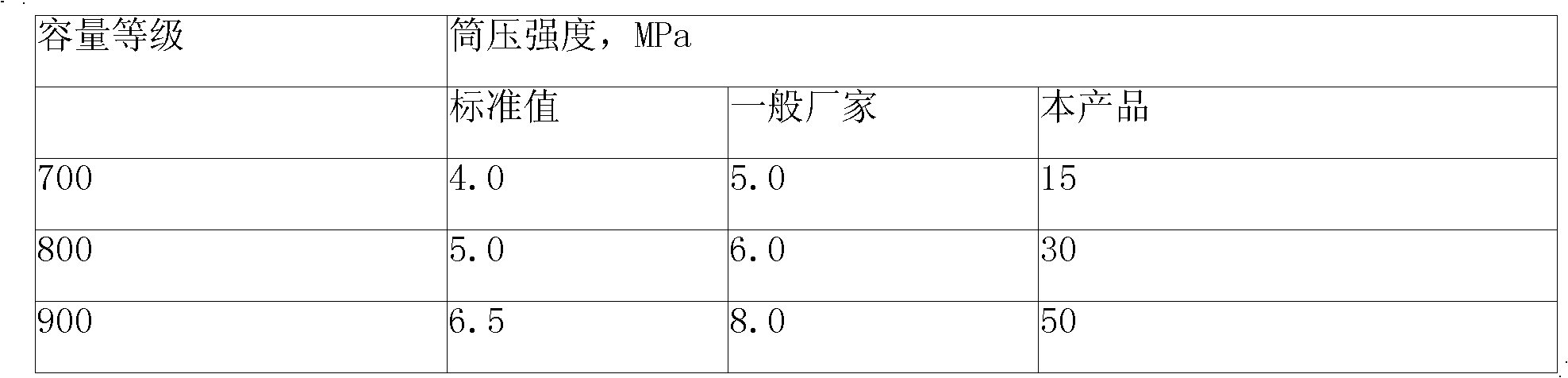

Ceramsite and production method thereof

ActiveCN101786845ARealize comprehensive utilizationHigh strengthSolid waste managementSlagExpanded clay aggregate

The invention discloses ceramsite and a production method thereof. The ceramsite comprises the following raw materials by weight percentage: 40 to 99.5 percent of high alumina fly ash or high alumina coal slag and 0.5 to 60 percent of bond, and 1 to 23 percent of auxiliary material is particularly added. The above raw materials are ground, dried and burned to form the finished product, so the strength, the fire resistance and the duration of the product are multiplied, and the ceramsite can be used for the production of particular concrete aggregate with the high strength of more than 60MPa and the heat-preserving and heat insulation materials with high fire resistant requirement. At the same time, the ceramsite can be used for proppant for oil and gas well cracks. Compared with the conventional proppant, not only the density is low, the strength is high and the performance is excellent, but also the expensive and rare alumina fire-resistant clay resource can be saved, and the comprehensive application of the resource can be realized. Compared with the prior process, the production method is more energy-saving and more environment-friendly, and favors the industrialized mass production.

Owner:四川省鑫沙矿渣微粉有限责任公司 +2

Balling method using medium- and low-grade phosphate rocks or ground phosphate rocks

ActiveCN103663396AHigh strengthHigh phosphorus contentPhosphorus compoundsPhosphoric acidCalciums magnesium

The invention relates to a balling method using medium- and low-grade phosphate rocks or ground phosphate rocks. The method comprises the following steps: S1, preparing materials, namely A, 85-100 parts of 60-120-mesh medium-grade and low-grade phosphate rocks or ground phosphate rocks, B, 1-10 parts of water or aqueous liquor of phosphoric acid, C, 2-8 parts of coke powder with the granularity of 60-120 meshes and D, 1-8 parts of one or more of phosphate fire clay, kaolin, sodium silicate, sodium carbonate, calcium carbonate and serpentine; S2, stirring, namely after uniformly mixing the raw materials, pressing the mixture into balls by use of a dry powder ball press machine, after pre-drying, delivering the mixture to a vertical calcining kiln, using purified yellow phosphorus tail gas, heating to 850-950 DEG C; starting roasting to obtain a finished product. The method is free from binders and low in cost, and the medium-grade and low-grade phosphate rocks are not hardened. The value of the medium-grade and low-grade phosphate rocks can be improved, and the ground phosphate rock of a mine can be fully utilized. The phosphate rock balls prepared are suitable for production of yellow phosphorus or calcium magnesium phosphate fertilizers.

Owner:刘静忠 +1

Torpedo tank lining gunning repairing material, preparation method and applications thereof

The invention discloses a torpedo tank lining gunning repairing material, a preparation method and applications thereof, wherein the torpedo tank lining gunning repairing material comprises, by weight, 60-67 parts of a Al2O3-containing fireproof material after-using regenerating material, 3-7 parts of fireproof clay, 2-5 parts of flaky graphite, 3-7 parts of silicon carbide, 10-15 parts of an alumina homogeneous material, 3-6 parts of kyanite, 2-5 parts of alpha-Al2O3 micro-powder, 3-11 parts of a binder, and 1.2-3.4 parts of an admixture. According to the present invention, the torpedo tank lining gunning repairing material has characteristics of low raw material cost, wide regeneration material source, convenient cold-hot state gunning repairing, excellent thermal shock stability, strong repairing layer interface bonding strength, strong slag iron corrosion resistance, high torpedo tank operation rate, long service life, and the like.

Owner:武汉钢铁有限公司

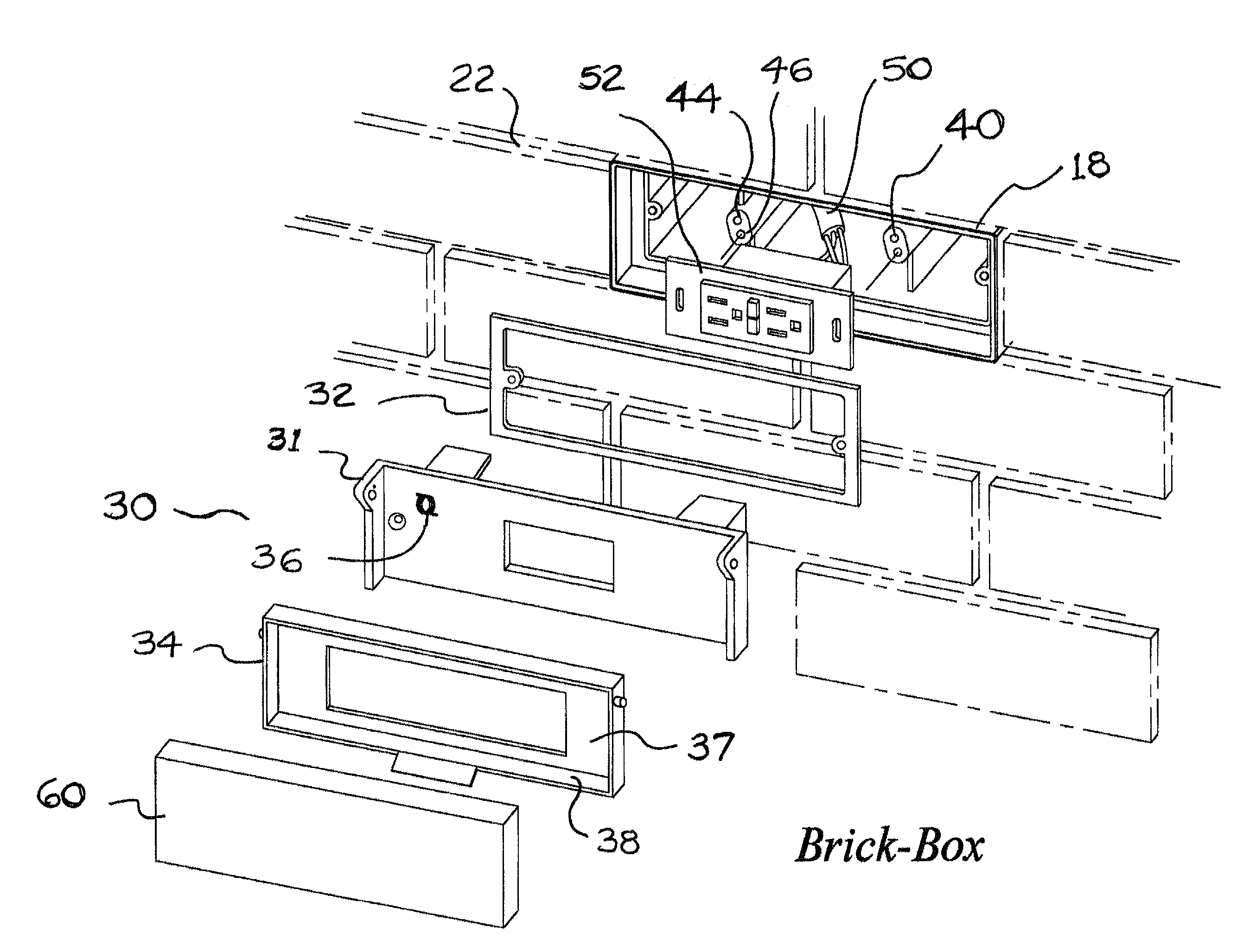

Electrical wiring box

An electrical wiring box with outer dimensions specifically sized and shaped to match a standard architectural component is disclosed. The disclosed electrical wiring box is of a minimum size corresponding to industrial standards and configured to accept standard electrical wires and fittings. The outer dimensions of the disclosed electrical wiring box are selectively larger than the standard box. The invention discloses an electrical wiring box which is the size of a standard fired clay building brick, or fraction thereof, thus simplifying installation in a wall of brick and mortar construction. The invention further discloses a cover which simulates a brick surface thus providing for improved appearance when installed in a brick wall. The electrical wiring box disclosed in this invention can take a number of different configurations and be used in different orientations to provide simplified installation and improved aesthetics.

Owner:KRUER THOMAS R

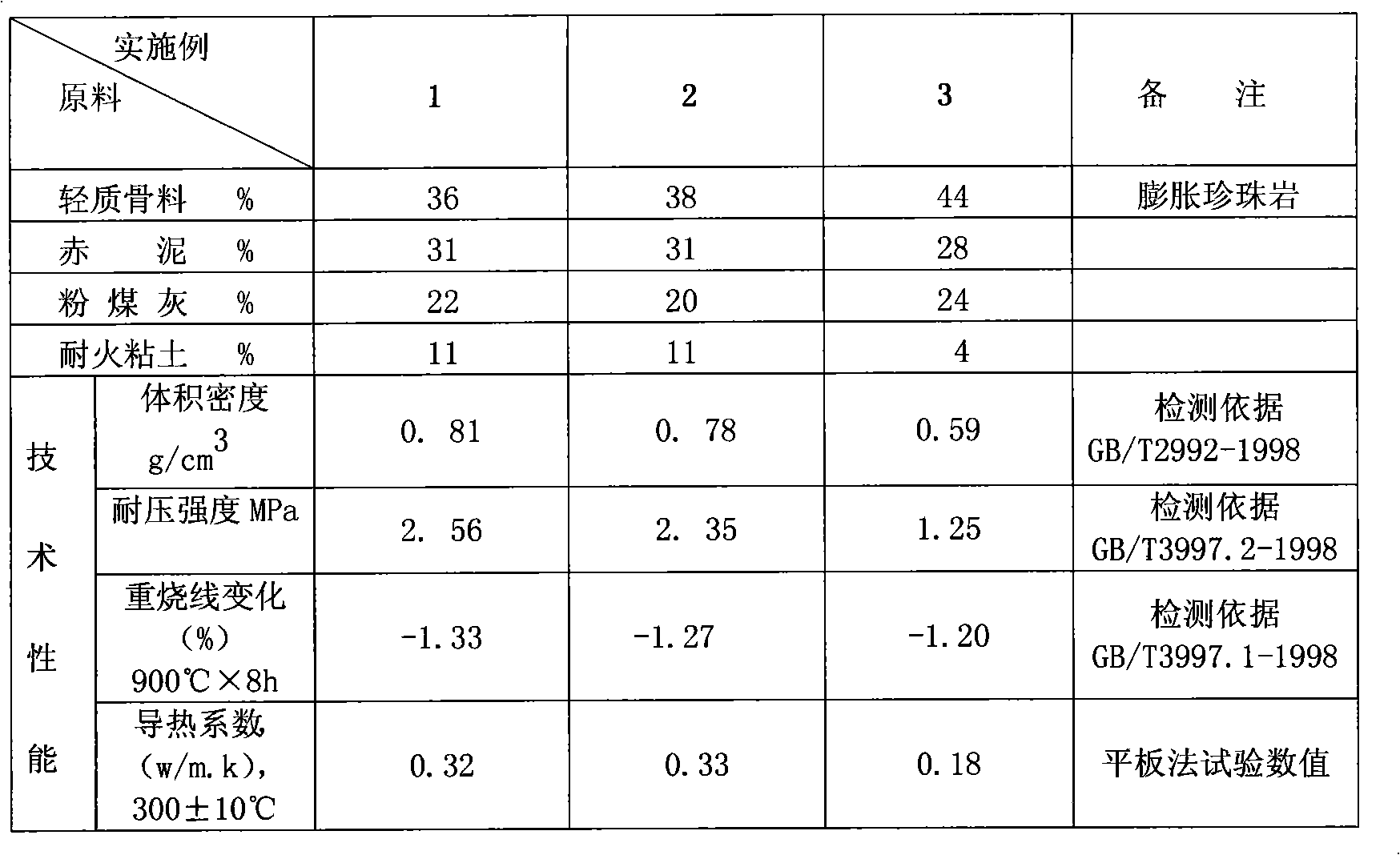

Red mud and fly ash fireproof insulation brick

InactiveCN101514110ALow thermal conductivityPlay a role in heat preservationChemical industryInsulation layer

The invention provides red mud and fly ash fireproof insulation brick which use solid waste red mud produced by alumina industry and solid waste fly ash in fuel electric plant as main raw materials and uses lightweight aggregate and fireproof clay as auxiliary materials. The weight percentage of each component is 10-60 of red mud, 10-50 of fly ash, 15-48 of lightweight aggregate, 4-18 of fireproof clay and 12-25 of water. The used lightweight aggregate is lightweight ceramsite, floating bead, vermiculite, expansion perlite or other lightweight fireproof raw material. The red mud and the fly ash fireproof insulation brick of the present invention have advantages of small volume density and low heat conduction coefficient, can be used for heat-insulation layer of industrial high temperature kiln in industries such as metallurgy, machinery, non-ferrous metal, power, chemical industry and building material, can insulate heat for thermal source, can prevent heat loss in with temperature higher than ambient temperature, and reaches purpose of utilizing industrial waste material, saving resource and energy and reducing emission.

Owner:阮克胜

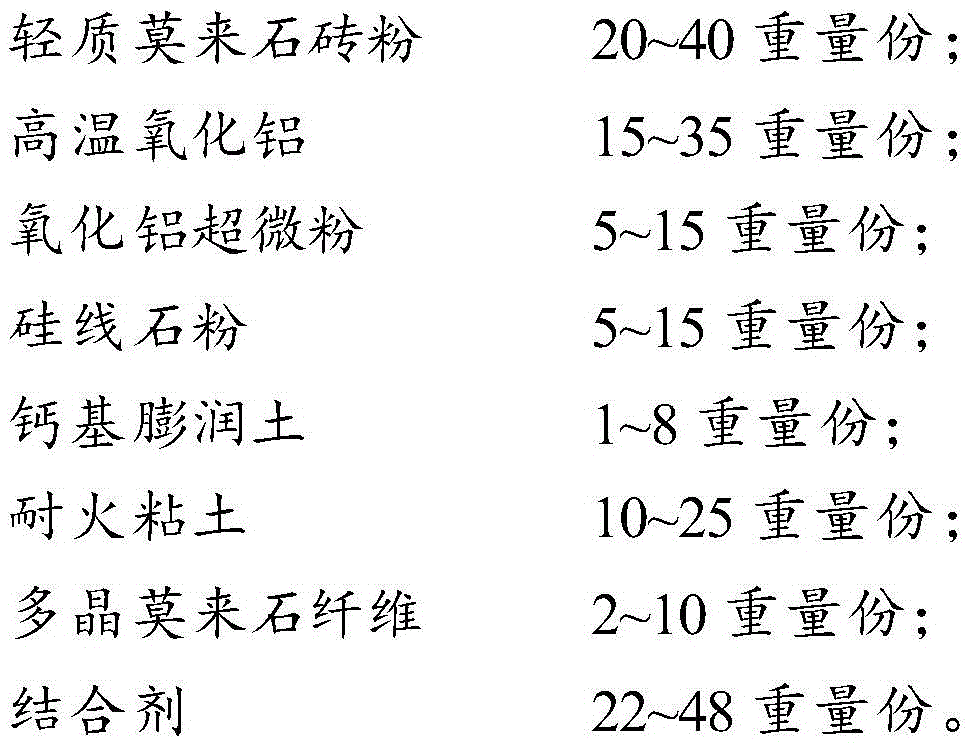

High-temperature-resistant cement and preparation method for same

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

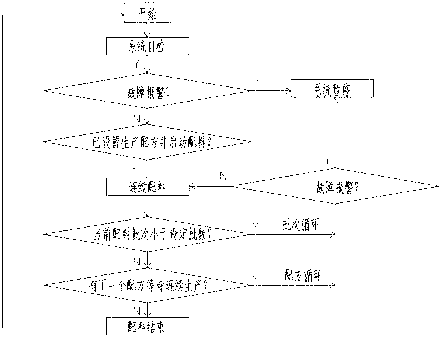

Full-digital automatic control fire clay mixing method and device

ActiveCN103009482AGuaranteed accuracy requirementsMeet speed requirementsMixing operation control apparatusDirt cleaningAutomatic controlControl system

The invention discloses a full-digital automatic control fire clay mixing method and device. The device mainly comprises a large silo group, a small silo group, electric augers, a conveying trolley and a control system, wherein the large silo group is located at a workstation and is provided with a plurality of large silos; the small silo group is located at another workstation and is provided with a plurality of small silos; during mixing, the conveying trolley stops at the two workstations in turn for receiving by a trolley hopper on the conveying trolley and weighing by a weighing sensor below the trolley hopper; the weighing sensor monitors the weight change of the trolley hopper before and after unloading; the control system controls the working state of each electric auger by reading the weight change value; after mixing is finished, the trolley hopper is moved to a transportation workstation with the conveying trolley and is hoisted by a bridge crane to be carried away after being fully loaded; and finally, a non-loaded trolley hopper is replaced to perform next mixing. The device is easy to operate, reduces the labor intensity of workers and improves the production efficiency.

Owner:武汉宝德机电股份有限公司

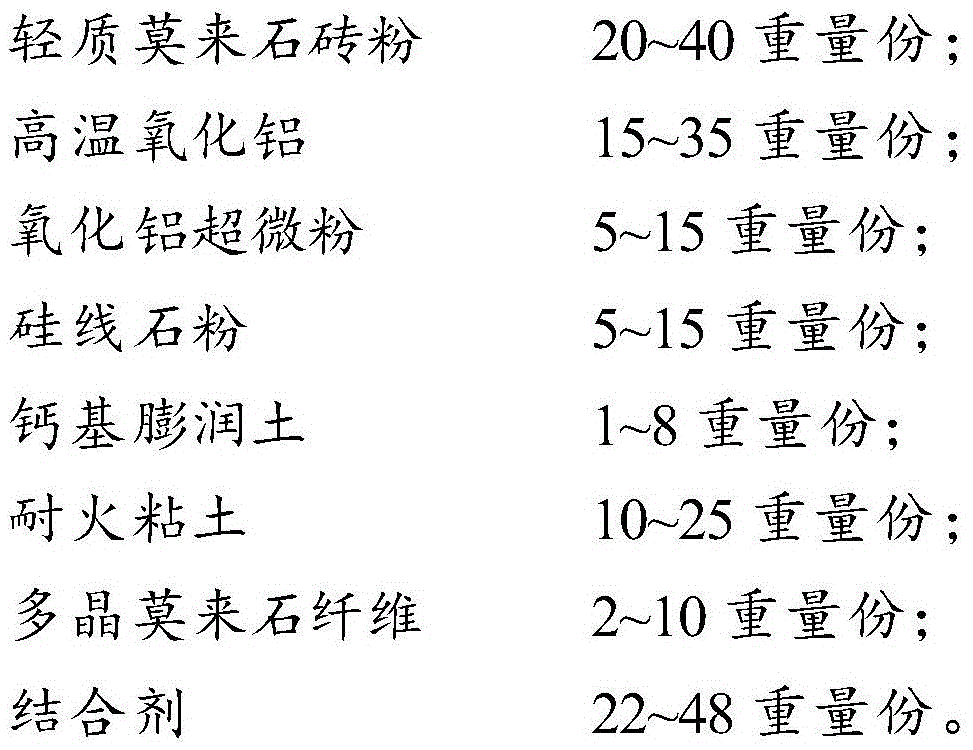

In-situ synthesized mullite whisker reinforced high-temperature ceramic roller

InactiveCN102249722AIn situ generation of composite enhancementsImprove thermal shock resistanceRefractoryWhiskers

The invention relates to an in-situ synthesized mullite whisker reinforced high-temperature ceramic roller which is prepared from natural raw mineral materials and industrial raw chemical materials. The in-situ synthesized mullite whisker reinforced high-temperature ceramic roller comprises the following compositions in percentage by weight: 15-25% of kaolin, 5-15% of refractory clay, 15-25% of alpha-Al2O3 micro-powder, 3-10% of zirconium silicate, 10-20% of zirconium-titanium mineralizer containing andalusite and 30-40% of refractory corundum; and the ceramic roller is prepared through the following steps: ball-milling, stirring, molding, drying, roasting at a temperature of 1500-1600 DEG C, carrying out heat preservation for 5-10 hours, and naturally cooling, thus obtaining a ceramic roller product (the rupture strength of the product is greater than 57.40 Mpa at a temperature of 1350 DEG C). The in-situ synthesized mullite whisker reinforced high-temperature ceramic roller provided by the invention has a wide application prospect in roasting roller kilns for products such as high-temperature and high-load domestic ceramics, building sanitary ceramics, high-grade large-sized vitrified tiles, technical ceramics and magnetic materials and the like.

Owner:JINGDEZHEN NUONAI TECH CERAMICS

Thick-type steel structure fireproof coating and preparation method thereof

The invention relates to a steel structure fireproof coating, and particularly relates to a thick-type steel structure fireproof coating and a preparation method thereof. The thick-type steel structure fireproof coating is prepared from the following raw materials by mass percent: 1 to 50 percent of cement binding materials, 1 to 20 percent of coal ash, 1 to 30 percent of fire-resistant clay, 1 to 30 percent of calcium carbonate, 1 to 20 percent of hydrophobic silicon dioxide aerosol, 1 to 20 percent of expanded perlite, 0.01 to 2 percent of air entraining agent, 0.01 to 2 percent of water retaining agent, 0.01 to 5 percent of flame retardant agent, 0.01 to 2 percent of thixotropic agent and 0.1 to 5 percent of fibers. The coating can solve the disadvantages of the existing steel structure fireproof technology, and can greatly improve the heat insulation and fireproof capacity of the steel structure fireproof coating.

Owner:山东三木建材科技有限公司

Fireproof fired clay hollow brick and preparation method thereof

InactiveCN105967696AUniform Flame RetardancyUniform fire resistanceCeramic materials productionClaywaresPolyvinyl alcoholSlag

The invention discloses a fireproof fired clay hollow brick and a preparation method thereof. The fireproof fired clay hollow brick is prepared from the following raw materials (by weight): 15-25 parts of Benshan green mud, 17-29 parts of picrite, 7-14 parts of high aluminum fine powder, 9-18 parts of fused magnesite, 13-21 parts of periclase, 10-15 parts of high boron calcium borate, 16-24 parts of petroleum coke slag, 11-19 parts of kyanite ore tailings, 5-10 parts of sodium metaantimonate, 18-26 parts of brown fused alumina slag, 14-22 parts of silica fume, 32-46 parts of attapulgite, 17-23 parts of polyvinyl alcohol, 8-14 parts of magnesium silicate, 12-18 parts of barite, 10-15 parts of chromite slag, 13-21 parts of sawdust, 19-33 parts of fly ash and a proper amount of water. The prepared fired clay hollow brick has both excellent flame retardancy and fire resistance, long-term operation temperature of the fired clay hollow brick is also greatly raised. Actual operation temperature can reach 1350 DEG C and above.

Owner:安徽宏发节能设备有限公司

Wet precoated sand

ActiveCN101934350AImprove bindingGood refinement effectFoundry mouldsFoundry coresCouplingMoisture absorption

The invention discloses wet precoated sand, which comprises raw sand, a binding agent, a curing agent, a coupling agent and a lubricating agent. The amounts of the curing agent and the coupling agent are respectively 50-70% and 0.5-1% of the amount of the binding agent; the amounts of the binding agent and the lubricating agent are respectively 3-5% and 0.2-0.8% of the amount of the raw sand; the binding agent comprises the following components in part by weight: 70-80 parts of phenolic resin, 10-20 parts of quartz powder and 5-15 parts of fire clay; the coupling agent is a silane coupling agent; and the wet precoated sand has the tensile strength not less than 4 MPa and the gas-generating amount not more than 19. The wet precoated sand not only has relatively small degree of roughness, relatively strong cohesive property, but also has relatively good density, difficult moisture absorption and difficult dryness absorption and can be stored for a long time in a daily environment.

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

Metallurgical casting mould

InactiveCN102921879ASatisfy one mold castingHigh hardnessFoundry mouldsFoundry coresGraphiteMaterials science

The invention discloses a metallurgical casting mould. The metallurgical casting mould comprises the following materials in part by weight: 40-50 parts of silica sand, 30-35 parts of zircon sand, 10-15 parts of refractory clay, 5-9 parts of graphite, 4-10 parts of auxiliary materials, and 6-18 parts of a molding sand binder. The metallurgical casting mould disclosed by the invention has the beneficial effects that because of the adding of refractory clay, graphite and other auxiliary materials, the hardness of the metallurgical casting mould is greatly increased, the metallurgical casting mould can satisfy the one-time mould-forming casting of large devices, is uneasy to collapse, and can adapt to the production needs of various devices.

Owner:WUXI ZHONGCAI NEW MATERIAL

Method for preparing ceramic water permeable brick from refractory clay tailings as raw material

InactiveCN106336201AInhibit aggregationReduce accumulationCeramic materials productionClaywaresEcological environmentHigh intensity

The invention relates to a method for preparing a ceramic water permeable brick from refractory clay tailings as a raw material. The method is characterized in that the refractory clay tailings are adopted as a main raw material. The method comprises the following steps: 1) mixing 75-90wt% of the refractory clay tailings, 1-10wt% of quartz and 5-20wt% of a solvent according to a ratio, and performing wet-method fine grinding so as to obtain a mixed mud material; 2) drying, pelleting, molding and sintering the mixed mud material so as to obtain high-strength aluminosilicate ceramic; 3) crushing, screening and grading the prepared ceramic so as to obtain ceramic aggregate; 4) uniformly stirring 85-95wt% of the ceramic aggregate with 5-15wt% of a binding agent, molding and drying, and sintering at 1100-1200 DEG C, thereby obtaining the ceramic water permeable brick. By adopting the method, direct recycling and utilization of the refractory clay tailings can be achieved, and meanwhile the ceramic water permeable brick which is high in strength and good in water permeability can be made, so that the requirements of circular economy development can be met, and a very positive effects on ecological environment protection can be achieved.

Owner:ZHENGZHOU UNIV +1

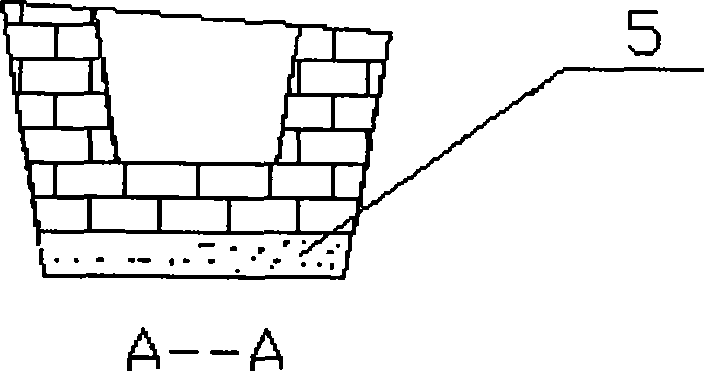

Method for maintaining and building 320-ton torpedo ladle cone working layer

A method for maintaining and building a 320-ton torpedo ladle cone working layer includes the steps of (1) cleaning the working layer and making the thickness of the left working layer not less than 80mm, (2) leveling the working layer in a painting mode after water is added into carborundum fire clay, (3) naturally drying the leveled working layer, (4) building a refractory brick layer in a conventional mode, wherein refractory bricks are identical in structure and different in size, and first special-shaped bricks, second special-shaped bricks and third special-shaped bricks are matched with one another for building of the refractory brick layer, (5) closely smearing a combination portion of the front end and a tail portion wall of a torpedo ladle with refractory castable, and roasting and preserving temperature according to phases. According to the method, safety operation of the torpedo ladle is guaranteed, the torpedo ladle can serve for 1350 times in an original process that only etched refractory materials are demolished, a maintenance working period can be shortened by at least 50%, maintenance work load is obviously reduced, the refractory materials used in maintenance is saved at least 40%, and maintenance cost is greatly reduced.

Owner:武汉钢铁有限公司

Method for producing forsterite sand-containing gunning material for steel ladles

InactiveCN101671185AImprove fire resistanceHigh bonding strengthMelt-holding vesselsSodium BentoniteRoom temperature

The invention discloses a method for producing a gunning material for steel ladles, in particular to a method for producing a forsterite sand-containing gunning material for steel ladles. The invention adopts the following technical scheme: magnesia and forsterite sand are used as main raw materials and the main raw materials are crushed and then mixed to prepare mix-grained materials; and bondingagents and accelerating agents are added into the mix-grained materials to be fully stirred to prepare the gunning material. The method is simple and easy to implement. As the forsterite sand is added in the production method, the production cost is greatly reduced. In addition, as the forsterite sand has high melting point, no crystal transformation occurs from the normal temperature to the melting point, and the crystal form is quite stable, the fire resistance of the produced gunning material is greatly improved. Besides, the added bentonite and fire clay, which are used as the bonding agents, and sodium tripolyphosphate, sodium silicate and the like enable the bonding strength of the gunning material and a lining to be greatly improved and bonding to be firm. The method solves variousproblems that the gunning materials produced by the current methods and used for steel ladle linings have low bonding strength, etc.

Owner:YINGKOU CHENXING REFRACTORY MATERIAL

Fireproof fire clay with vanadium iron slag

The invention discloses fireproof fire clay with vanadium iron slag. The fireproof fire clay contains fine aggregate and gel material formed by vanadium iron slag fine powder. The fireproof fire clay with vanadium iron slag has excellent performance; and by adopting the fireproof fire clay, the overall performance and service life of the brick lining refractory material can be increased.

Owner:PANZHIHUA IRON AND STEEL +1

High-strength refractory brick and preparation method thereof

The invention discloses a high-strength refractory brick and a preparation method thereof. The high-strength refractory brick is prepared by the following raw materials: expanded perlite, diatomite tailings, alumina micro-powder, silicon carbide micro-powder, grapheme, coal gangue, high-alumina bauxite, refractory clay, inorganic fibers, a bonding agent, a water reducing agent, a foaming agent anddeionized water. The high-strength lightweight refractory brick takes the expanded perlite, the diatomite tailings, the alumina micro-powder, the silicon carbide micro-powder, the grapheme, the coalgangue, the high-alumina bauxite, the refractory clay and the inorganic fibers as main components and is supplemented with processes such as mixing, foaming and high-temperature firing through addingthe bonding agent, the water reducing agent, the foaming agent and other auxiliary ingredients; the prepared high-strength refractory brick has higher strength, excellent fire resistance and low production cost, can meet industry requirements and has a better application prospect.

Owner:合肥金云新材料有限公司

Repair material for molten iron desulfurization stirring paddle

ActiveCN102746006AImprove sintering performanceImproved thermal shock stabilityFiberAluminum silicate

The invention discloses a repair material for a molten iron desulfurization stirring paddle, which is prepared by mixing a base material and a proper amount of additives. The base material is prepared from the following components in percentage by weight: 45-65% of common bauxite, 3-8% of flint clay, 10-20% of andalusite, 20-28% of fireclay and 1-5% of pure calcium aluminate cement. The additives are sodium tripolyphosphate or melamine, and aluminum silicate fiber crushed cotton or organic fiber; on the basis of the total weight of the base material of the repair material (100%), the sodium tripolyphosphate or melamine accounts for at most 0.5%, and the aluminum silicate fiber crushed cotton or organic fiber accounts for at most 0.5%; and the two additives are matched, and the addition amount can not be zero. In order to overcome the defects in the prior art, the invention provides a repair material for a molten iron desulfurization stirring paddle, which has the advantages of wide raw material sources, low cost and excellent properties. The repair material can repair the stirring paddle, and can prolong the average service life of the KR desulfurization stirring paddle by more than 30 times.

Owner:莱芜钢铁集团泰东实业有限公司

Automatic silver ingot casting system

InactiveCN103611923AAvoid pinch outExtend your lifeMolten metal supplying equipmentsControl systemIngot casting

The invention relates to an automatic silver ingot casting system which comprises a casting machine, an automatic mold positioning machine and a control system. The casting machine comprises an intermediate frequency furnace, a crucible in the furnace and a furnace frame. The intermediate frequency furnace is fixed on the furnace frame, the crucible is placed in the furnace, the crucible and the intermediate frequency furnace are built together through fire clay, a pair of hydraulic oil cylinders is arranged on the two sides of the furnace frame in a matched mode, the automatic mold positioning machine is arranged right ahead of the smelting furnace, and the control system is arranged in front of the automatic mold positioning machine. A traditional manual casting mode is changed, casting speed is greatly increased, labor intensity is relieved, and due to the fact that the crucible, the intermediate frequency furnace and the furnace frame are built into a whole, it is avoided that the crucible is clamped out through an iron stand when casting is performed each time, cold and hot impact and mechanical damage are reduced or avoided, service life of the crucible can be prolonged, and cost is lowered.

Owner:HUNAN JINWANG BISMUTH

Compressive and fireproof insulating brick and preparation method thereof

The invention discloses a compressive and fireproof insulating brick and a preparation method of the insulating brick. The insulating brick comprises the following raw materials: corundum mullite, quartz sand, expanded perlite, vermiculite, silicon carbide micropowder, floating beads, silica micropowder, titanium dioxide, fireproof clay, a foaming agent and water. The preparation method of the insulating brick comprises the steps of (1) grinding the raw materials, (2) adding the water, performing uniform stirring, performing heating to be 1200-1400 DEG C, and performing insulation for 3-5h, (3) performing natural cooling, adding the foaming agent, performing uniform stirring, performing pouring into a mold, and performing insulation for 1-3h at 700-800 DEG C, and (4) performing demolding, drying and heating to obtain the compressive and fireproof insulating brick. The compressive and fireproof insulating brick has the characteristics of high compressive strength, low heat conductivity coefficient, good insulating property, excellent fireproof property, good weather resistance and the like.

Owner:HEFEI FANTENG ENVIRONMENTAL PROTECTION TECH CO LTD

Preparation method of high temperature resistant dope for lost foam

InactiveCN101811172AGood suspensionIncreased one-time shedding percentageFoundry mouldsFoundry coresAcetic acidSurface finish

The invention relates to a preparation method of high temperature resistant dope for lost foam. The invention comprises the following components by weight percent: 2 to 3 fire clay, 25-50 black charcoal ash, 5 to 6 hard charcoal ash and 10 polyvinyl acetate emulsion, which are mixed to obtain a condensate. Water is added to the condensate according to the weight proportion of 1 to 5-20. The water and the condensate are mixed evenly and the dope is prepared. The invention adopts water as solvent, which is non-toxic, tasteless and has no pollution. The black charcoal ash, the hard charcoal ash, the polyvinyl acetate emulsion anti-burnt-on sand and the fire clay can resist the high temperature of more than 1500 degrees centigrade. The dope manufactured through the method has good suspension property and a compact high-strength coating can be formed on the surface of a foam plastic mould. The disposable falling off percentage of the dope layer of casting finished products is improved further, the surface is smooth and the pass percent is increased greatly. The invention has the advantages of simple brushing process, good quality and easy technology. The cost of the invention is lower than the cost of the traditional like dope on condition that the surface of the casting does not adhere to sand and the surface finish degree of the casting is ensured.

Owner:JIANGSU KAMING MOLD

Mortar used for building firewall in petroleum industry and its construction process

InactiveCN102515672AImprove early strengthGuaranteed StrengthBuilding material handlingFire proofingSide effectAdditive ingredient

The invention relates to a mortar used for building a firewall in petroleum industry, which comprises the following ingredient by mass percentage 15-25% of alumina cement, 2-5% of powdery fire clay, 15-25% of bauxite particle, 50-60 parts of dry sand and the balance of water. The mortar of the invention is capable of effectively raising the intensity of the mortar at early stage, increasing the bonding performance of the mortar and firebricks, ensuring the intensity of the mortar after high temperature calcining, and enhancing the corrosivity resistance of sulfate; and invention has the advantages that the preparation process and the construction process are convenient to operate, the construction period can not be prolonged, no other side-effect and hidden trouble can be generated, and is suitable for projects with short construction period and immediate usage, thereby the construction risk can be effectively reduced and the hidden trouble can be eliminated, compared with a traditional process, the cost of the invention is lower.

Owner:四川蜀渝石油建筑安装工程有限责任公司

Method to Produce Durable Non-Vitrified Fly Ash Bricks and Blocks

InactiveUS20070000412A1Other chemical processesWood working apparatusSmall Business Innovation ResearchMaterials science

This patent deals with a method to make durable (i.e., freeze / thaw resistant), non-vitrified (non-fired) fly ash masonry units (bricks, blocks, tiles and other construction products), that can pass contemporary standards for building bricks established by the American Society for Testing and Materials (ASTM). In contrast, existing processes for making non-vitrified fly ash masonry units cannot make products durable—passing the 50 freeze / thaw cycles required by ASTM. By using the process specified in this invention, fly ash can be made into durable bricks and other products without having to heat the green products in kilns at high temperature, thereby reducing energy consumption and costs associated with making ordinary clay bricks. The process resulted from a Small Business Innovation Research (SBIR) project sponsored by the National Science Foundation (NSF), which demonstrated that durable, non-vitrified, fly ash masonry units can be produced by using this process. Since fly ash is a material generated in large quantity at coal-fired power plants and since currently (in 2006) only about a third of the fly ash generated in the United States is used with the rest being disposed of as solid waste, use of fly ash to make bricks and other construction products not only has commercial value but also helps to reduce and to recycle wastes generated at coal-fired power plants. Furthermore, use of such non-vitrified (non-fired) fly ash products in the future reduces the use of fired clay products, which require using fossil fuel to heat the units in kilns, which in turn generates air pollution and carbon dioxide that causes greenhouse effect and global warming. Therefore, use of the fly ash brick invented here has the additional advantage of being environmentally friendly—reducing air pollution and global warming.

Owner:ECOLOGIC TECH

Coke oven low-aluminum lattice brick and production technology

The invention discloses a coke oven low-aluminum lattice brick and a production technology. The coke oven low-aluminum lattice brick is prepared from, by mass, 30% of semisoft clay, 55% of flint clay, 15% of fire-clay grog and 2% of additional organic binding agent sulphite cellulose waste liquor. The lattice brick is a low-aluminum product, the low-aluminum product is a semi-acid refractory product, the size of the product is stable under the high temperature state, the alkali atmosphere resistance is high, the load softening point is high, the high temperature using strength is improved, and the brick is suitable for being used for a coke oven chamber bottom, a heat storage chamber and a perforated strainer; due to the design, the defect that an original material coke oven lattice brick is frequently deformed and blocked is overcome, the novel material is adopted, the service life of the lattice brick can be prolonged, normal heat exchange of a coke oven is smoothly ensured, and coking production stability is effectively guaranteed and supported.

Owner:MAANSHAN IRON & STEEL CO LTD

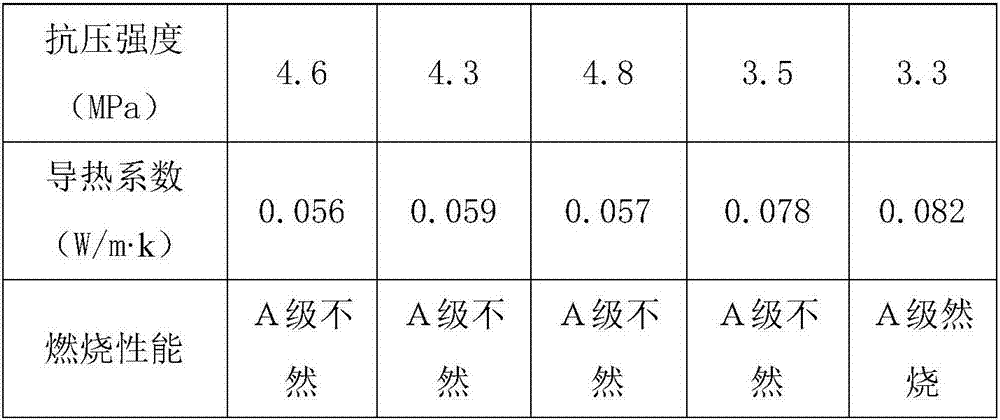

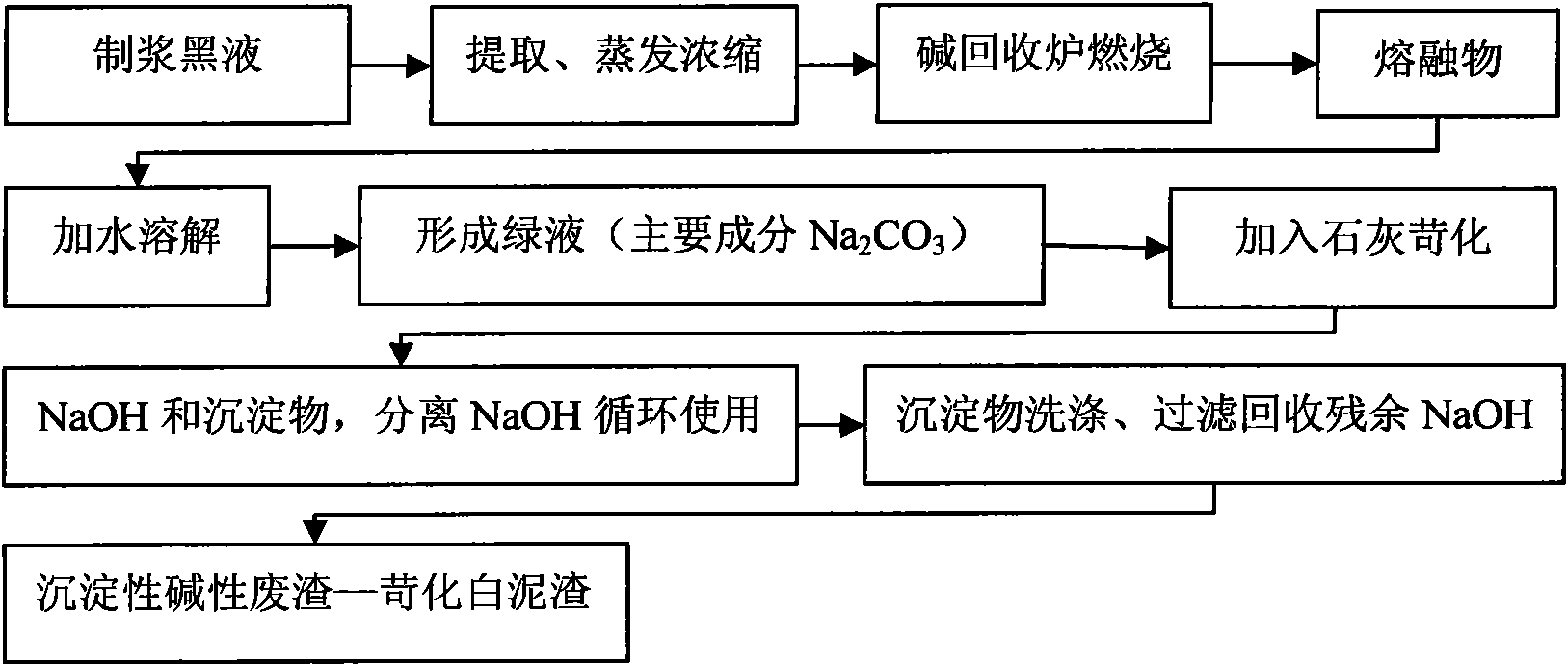

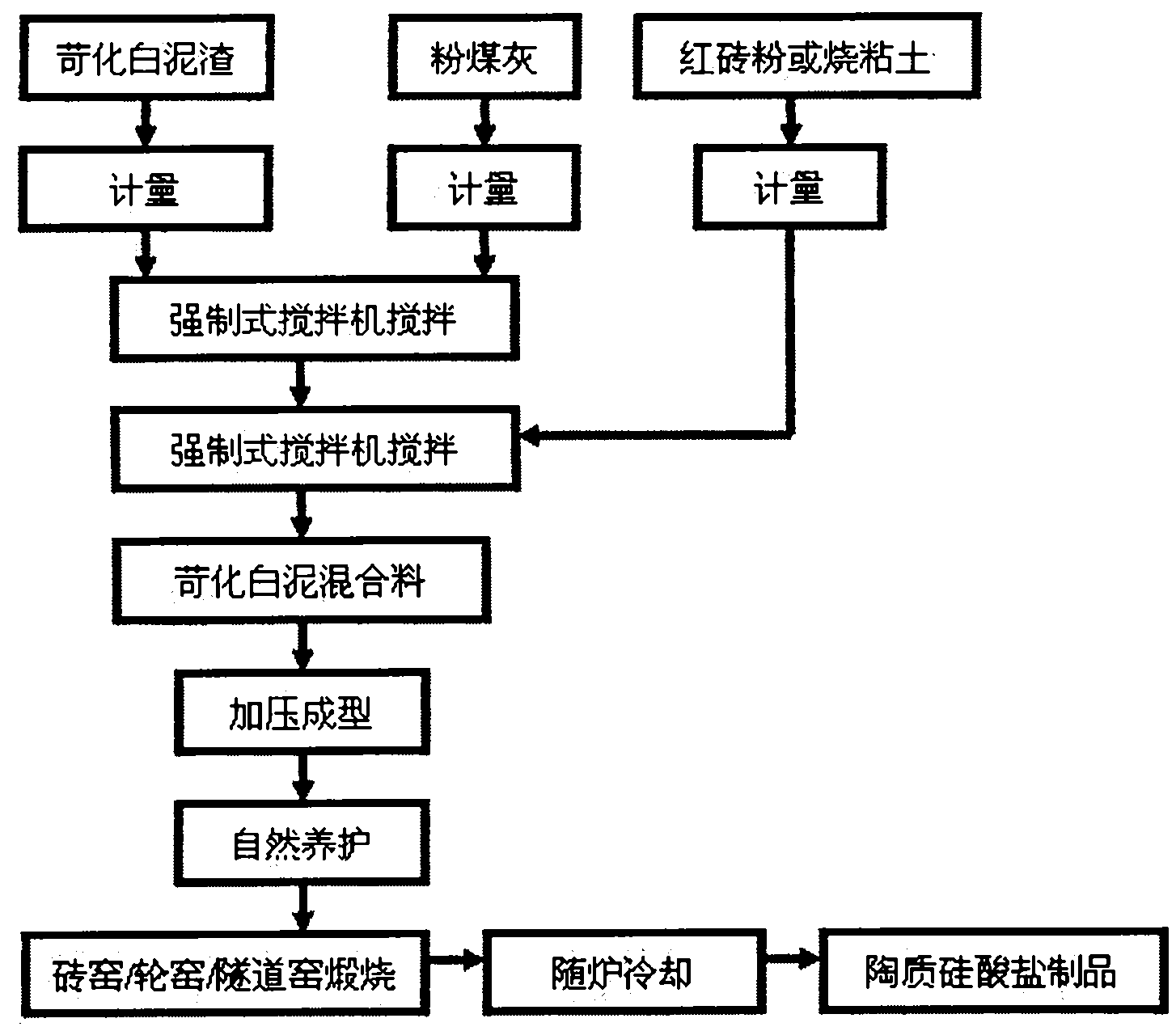

Method for preparing high-strength ceramic wall material from papermaking causticized white mud residues

InactiveCN102070322AReduce moisture contentHigh strengthCeramic materials productionClaywaresPapermakingCalcination

The invention discloses a method for preparing a high-strength ceramic wall material from papermaking causticized white mud residues. The method comprises the following steps of: (1) adding papermaking causticized white mud residues and fly ash to a forced mixer, stirring, after the papermaking causticized white mud residues and fly ash are uniformly mixed, adding red brick powder or fired clay to the forced mixer, and uniformly stirring to obtain a mixture; (2) by selecting a brick former, adding the mixture obtained in the step (1) to a former die to obtain formed brick blanks; (3) piling the formed brick blanks in a stock yard with favorable ventilation conditions for dewatering and solidification until the brick blanks have constant quality and initial compression strength over 1 MPa;and (4) and conveying the dewatered and solidified brick blanks into a brick kiln for calcining, keeping the temperature and cooling in the kiln to a room temperature so as to obtain the high-strength ceramic wall material. The method provided by the invention is favorable for greatly decreasing the water content of the causticized white mud residues before calcination and decreasing the burning heat consumption and the production cost, a formed test piece can be easily and practically calcined in a low-cost common brick kiln, and a ceramic wall material which has high higher compression strength and can substitute clay bricks can be obtained through selecting suitable parameters for the calcination process.

Owner:NANJING UNIV OF SCI & TECH

Sand glaze and preparation method thereof

The invention discloses a sand glaze and a preparation method thereof. The sand glaze comprises a bottom glaze and a surface glaze. The bottom glaze is prepared from, by weight, 15-30% of potassium feldspar, 10-20% of albite, 15-25% of quartz, 25-30% of fire clay, 10-15% of calcite and 10-15% of iron oxide red, wherein the sum of weight percentages of all components is 100%. The surface glaze is prepared from, by weight, 25-35% of potassium feldspar, 15-25% of quartz, 10-12% of calcite, 5-10% of talc, 8-10% of spodumene, 10-12% of refractory clay, 6-8% of titanium oxide and 8-12% of zinc oxide, wherein the sum of weight percentages of all components is 100%. The sand glaze is superior in hue, purity and brightness, attractive in appearance and high in ornamental value. The preparation method is simple, convenient, high in operability, easy to learn and suitable for industrial production.

Owner:HUNAN LILING CHUHUA CERAMIC INDAL

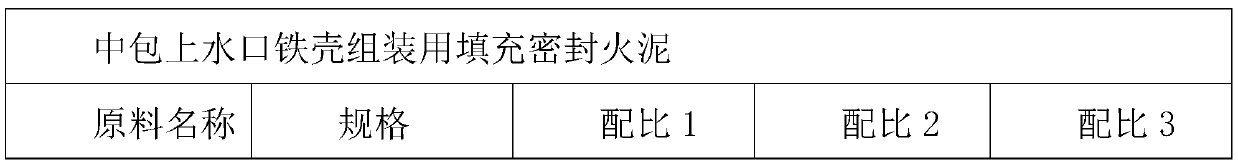

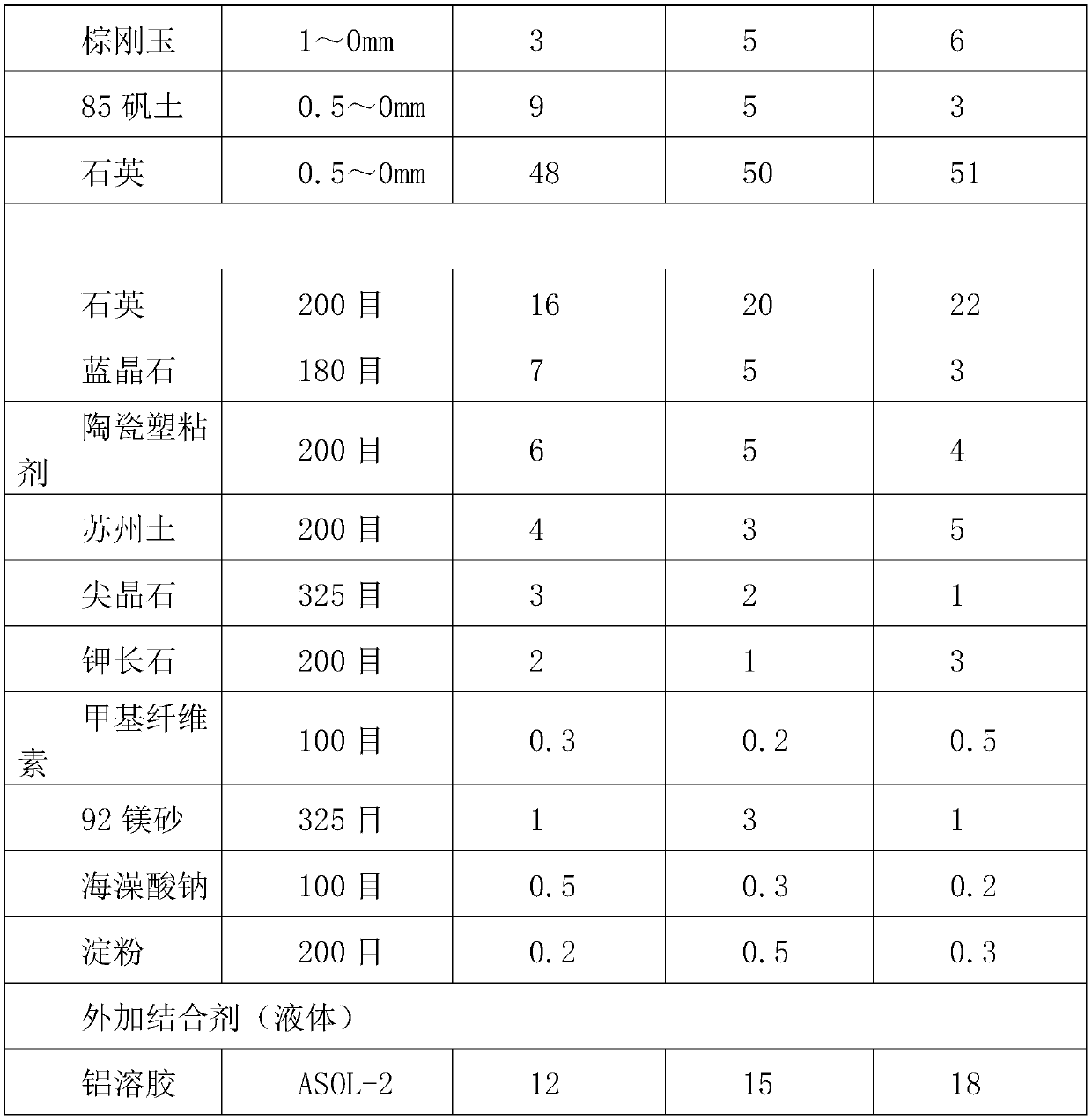

Filling fire clay for assembling tundish upper water gate iron shell and preparation method thereof

The invention discloses filling fire clay for assembling a tundish upper water gate iron shell. The filling fire clay comprises the following components: 3-7% of brown fused alumina, 3-7% of 85 alumina, 65-75% of quartz, 3-7% of kyanite, 3-7% of a ceramic plastic adhesive, 2-5% of Suzhou clay, 1-3% of spinel, 1-2% of potassium feldspar, 0.1-0.3% of methylcellulose, 2-5% of 92 magnesia, 0.2-0.5% ofsodium alginate, 0.3-0.7% of starch and 12-18% of alumina sol. The invention aims to provide the filling fire clay for assembling the tundish upper water gate iron shell of an anti-seepage steel structure, wherein the service life of tundish refractory materials is prolonged, and the steel seepage problem is fundamentally solved under a high continuous casting condition.

Owner:无锡市南方耐材有限公司

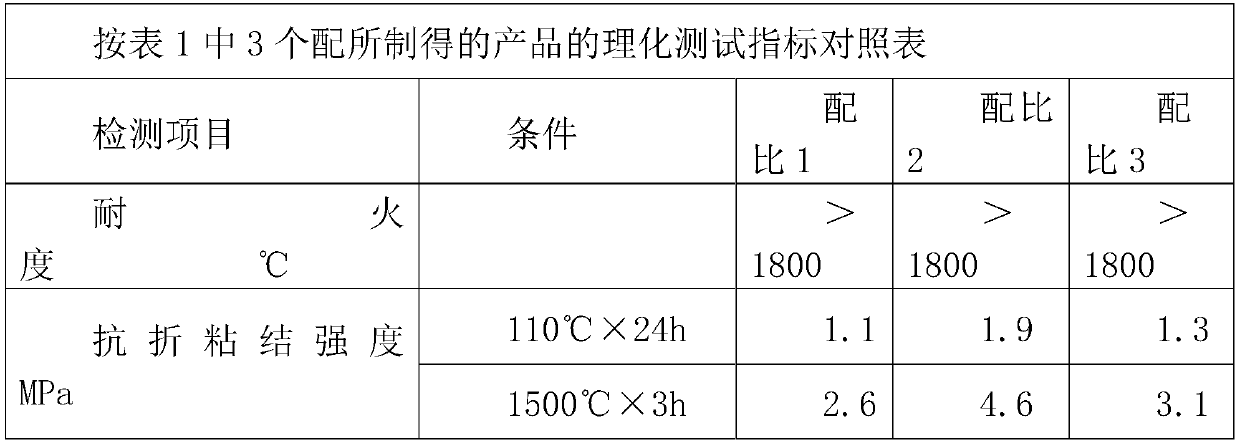

Repairing method of molten iron chute for mixer furnace

The invention relates to a method for repairing and bricking an iron charging chute of a blast furnace mixer, which comprises the following steps: 1. a chute mouth precast block is forged; the shape of the precast block is manufactured according to the shapes of a chute mouth and a chute body; 2. the bottom of the chute body is welded with a mushroom nail, is cast with a layer of a casting material as a permanent layer; 3. after finishing casting, the permanent layer and the precast block are kept stand for 12 to 24 hours and are roasted for 24 to 48 hours by small fire; 4. after the permanent layer on the bottom of the chute body is dried, the upper layer is subjected to one-layer bricking; and a brick joint is filled with fire clay; 5. the surface of the chute body towards iron is bricked; 6. the iron charging surface and the residual surface of the iron charging chute are bricked; and 7. impurities on the surface of the iron charging chute are cleaned; and the iron charging chute is kept stand for 12 to 15 hours, is fully solidified, is positioned under a roasting rack and is roasted for 24 to 48 hours and can be brought into production. The method has the advantages of adopting the casting of the permanent layer, increasing and improving the chute mouth precast block, increasing the service life of the iron charging chute, reducing labor intensity, shortening the repairingand bricking time, improving the working efficiency and reducing the cost.

Owner:SHANDONG TAISHAN STEEL GROUP

Quartz sand/fire clay composite alcohol group casting coating and preparation method thereof

InactiveCN104014720AGood suspensionLow gas productionFoundry mouldsFoundry coresFire resistanceMaterials science

The invention discloses a quartz sand / fire clay composite alcohol group casting coating. The quartz sand / fire clay composite alcohol group casting coating is characterized by comprising following raw materials in part by weight: 40-60 of quartz sand, 30-40 of fire clay, 3-4 of rosin, 1-2 of kieselguhr, 0.2-0.4 of zinc borate, 0.1-0.3 of calcium stearate, 0.4-0.8 of magnesium chloride, 1-4 of waste foam plastic particles, 1.2-3.2 of ammonium sulfate, 1.1-2.4 of abietate, 4-7 of traditional Chinese medicine dregs, 0.3-0.6 of dichloromethane, 40-50 of ethyl alcohol, and 3-6 of an adjuvant. The coating provided by the invention has the advantages that the coating is not easy to settle, the suspension property is good, air sending volume is small, high temperature is resisted, the fire resistance is good, the coating property is good, the traditional Chinese medicine dregs after processing are added into the raw materials, the coating has an anti-mould effect, the suspension effect of the coating is improved, and thus the coating is suitable for different castings.

Owner:方学军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com